Preparation method of titanium alloy thin-wall honeycomb structure

A honeycomb structure and titanium alloy technology, which is applied in the field of preparation of titanium alloy thin-walled honeycomb structure, can solve the problem of low flexibility, affecting the high-temperature performance of the honeycomb structure, limiting the geometric shape diversity of the honeycomb structure and further optimizing the structure of parts, etc. problems, to achieve a high degree of flexibility, excellent mechanical properties and corrosion resistance, and reduce the effect of stress accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

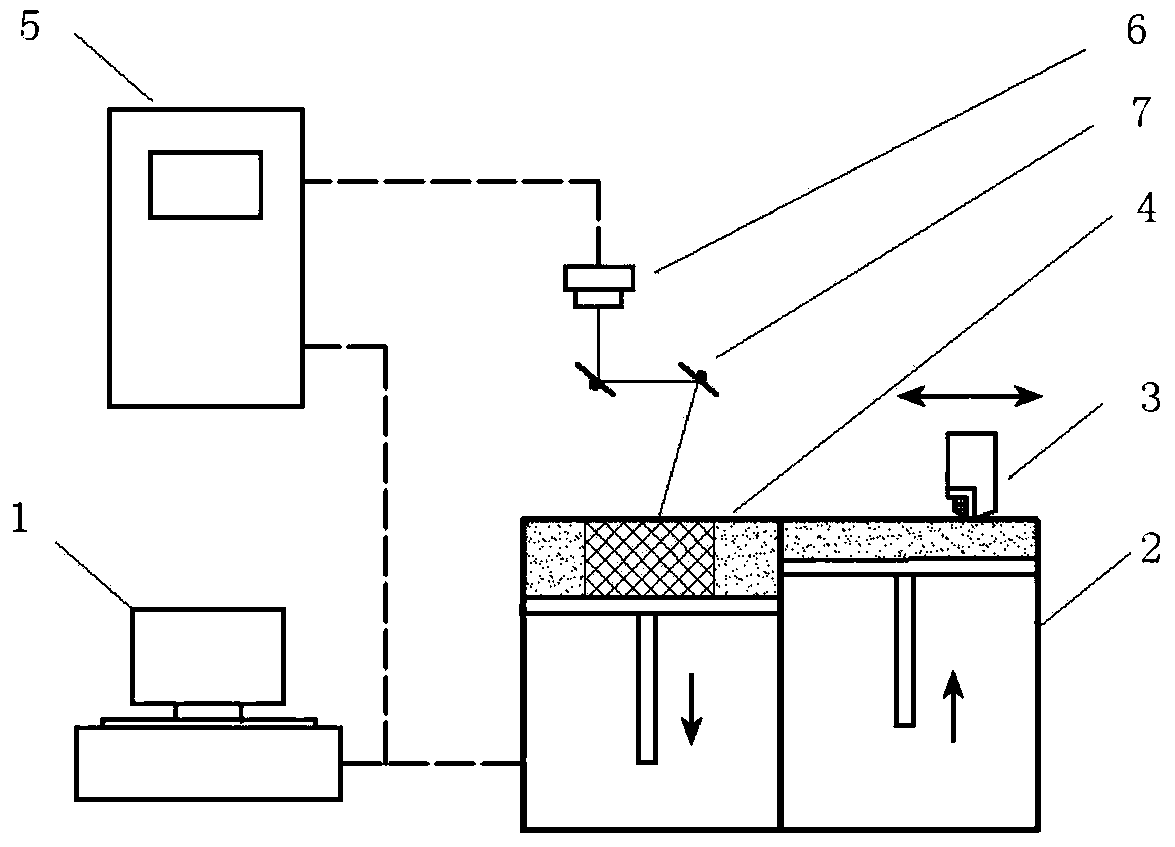

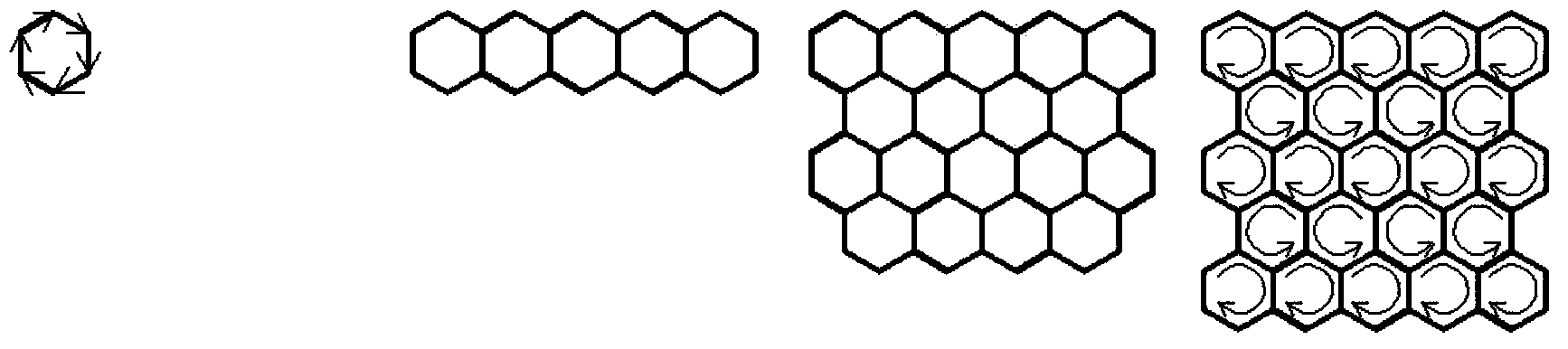

[0022] The preparation method of the thin-walled titanium alloy honeycomb structure of the present invention adopts the selective laser melting forming method to prepare the thin-walled titanium alloy honeycomb structure. The selective laser melting forming technology is based on the basic idea of rapid prototyping, that is, the way of layer-by-layer cladding / incremental manufacturing.

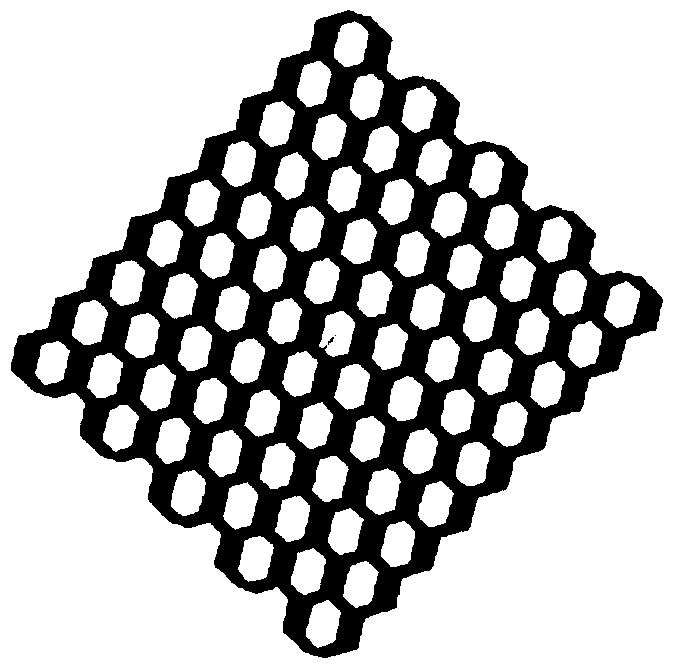

[0023] like figure 1 As shown, taking a titanium alloy thin-walled six-deformation honeycomb structure as an example, the size: 100mm × 100mm × 50mm, the wall thickness is 0.5mm, and the preparation method of a titanium alloy thin-walled honeycomb structure according to the present invention is used for processing. The steps are as follows, such as figure 2 Shown:

[0024] (a) First, establish a three-dimensional CAD model of the titanium alloy thin-walled honeycomb structure in the computer 1, and slice and layer the titanium alloy thin-walled honeycomb structure model according to the t...

Embodiment 2

[0033] like figure 1 As shown, taking a titanium alloy thin-walled six-deformation honeycomb structure as an example, the size: 100mm×60mm×30mm, the wall thickness is 0.15mm, and the preparation method of a titanium alloy thin-walled honeycomb structure according to the present invention is used for processing. The steps are as follows, such as figure 2 Shown:

[0034] (a) First, a three-dimensional CAD model of a titanium alloy thin-walled honeycomb structure is established in computer 1, and the titanium alloy thin-walled honeycomb structure model is sliced and layered according to a layer thickness of 20 μm (specifically divided into 1500 layers), so that according to the thickness of each layer of titanium alloy The wall honeycomb structure is processed layer by layer;

[0035] (b) Convert the three-dimensional shape data of the titanium alloy thin-walled honeycomb structure of each layer into a series of two-dimensional profile data, and then determine the trajectory...

Embodiment 3

[0043] Taking a titanium alloy thin-walled six-deformation honeycomb structure as an example, the size: 100mm×40mm×60mm, the wall thickness is 0.8mm, and the specific steps of processing are as follows by using the preparation method of a titanium alloy thin-walled honeycomb structure according to the present invention. Such as figure 2 Shown:

[0044] (a) First, a three-dimensional CAD model of a titanium alloy thin-walled honeycomb structure is established in computer 1, and the titanium alloy thin-walled honeycomb structure model is sliced and layered according to a thickness of 30 μm (specifically divided into 2000 layers), so that the titanium alloy thin-walled honeycomb structure model is sliced and layered according to the thickness of each layer of titanium alloy. The wall honeycomb structure is processed layer by layer;

[0045] (b) Convert the three-dimensional shape data of the titanium alloy thin-walled honeycomb structure of each layer into a series of two-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com