Laser etching method of three-dimensional curved surface

A laser etching method, a technology of three-dimensional curved surfaces, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of inability to obtain accurate texture patterns, angle changes, etc., to solve the angle change, improve accuracy, flexibility high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing and specific embodiment the content of the present invention is described in further detail:

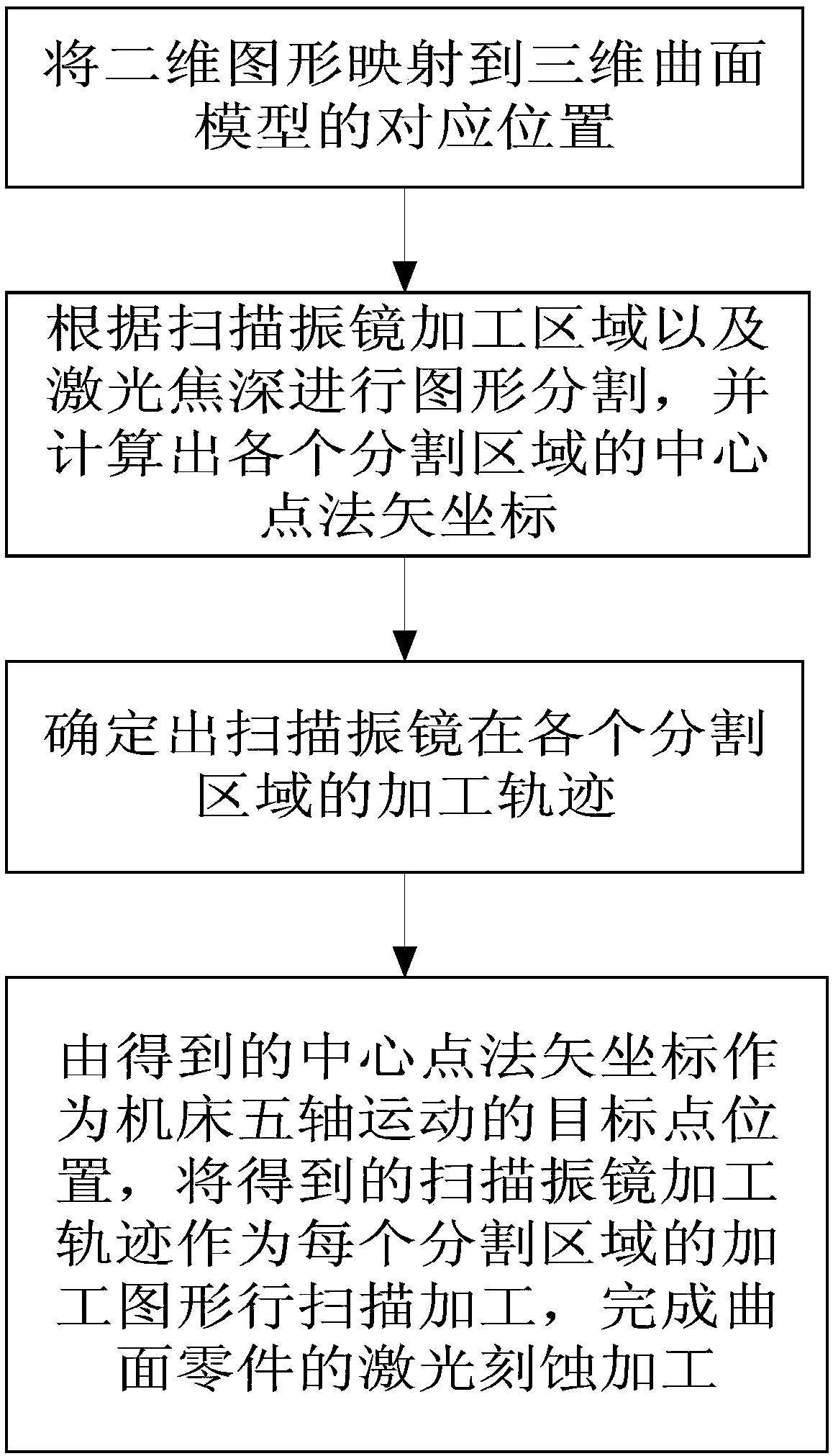

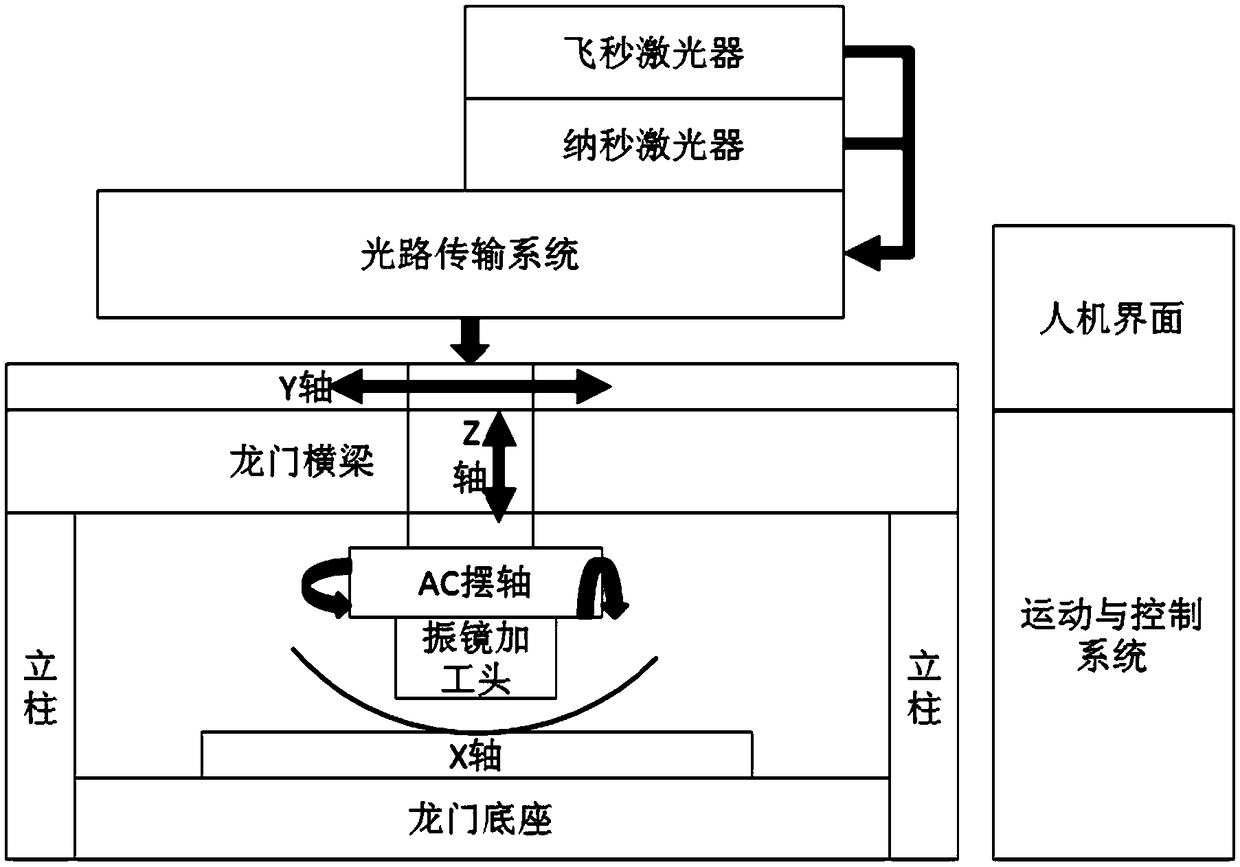

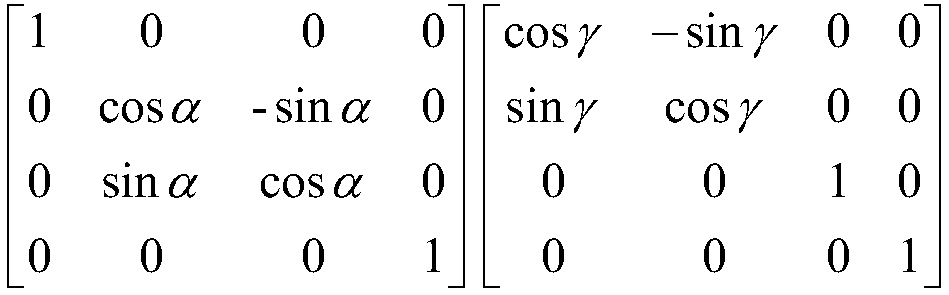

[0042] The equipment of the present invention is an existing laser processing equipment, mainly composed of a laser, a two-dimensional scanning vibrating mirror, an XYZAC five-axis linkage numerical control machine tool and other components. This method uses the five-axis movement of the XYZAC axis to enable the two-dimensional scanning galvanometer to locate various positions and angles on the processed part before processing, and then turn on the laser to complete the scanning and etching of the processing area. Due to the limited processing area of the scanning galvanometer, if the part to be processed is large, the scanning galvanometer can only process part of the part at a time. Therefore, for the processing of large curved parts, the scanning galvanometer needs to be positioned and scanned sequentially according to the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com