Self-locking installation components for non-destructive assembly and disassembly of dense panels

A technology of installing components and close-fitting, which is applied in the fields of construction engineering, decoration engineering, and installation engineering, can solve the problems of inconvenient installation and disassembly, and cannot be disassembled separately, and achieve the effect of eliminating installation errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to enable those skilled in the art to better understand the technical solution, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

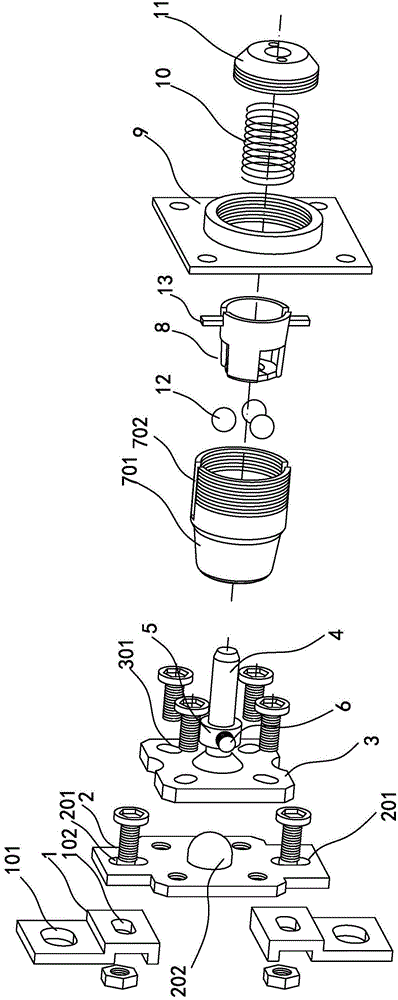

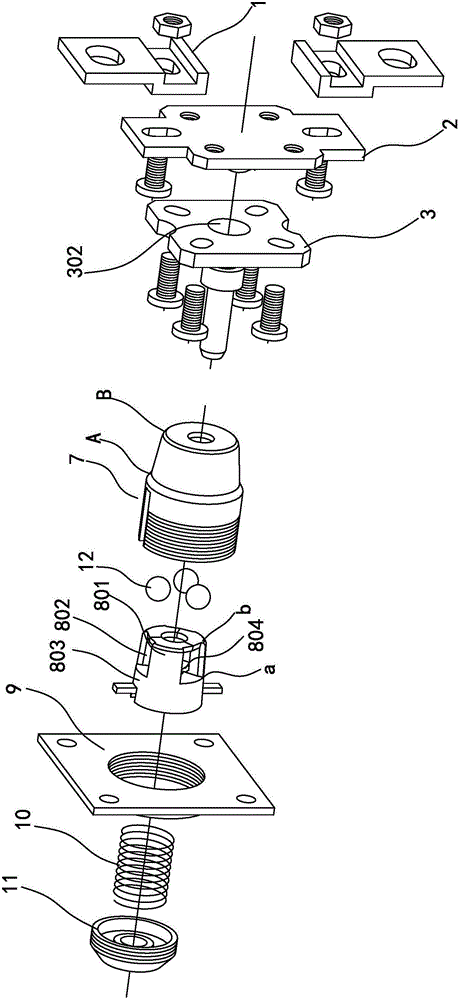

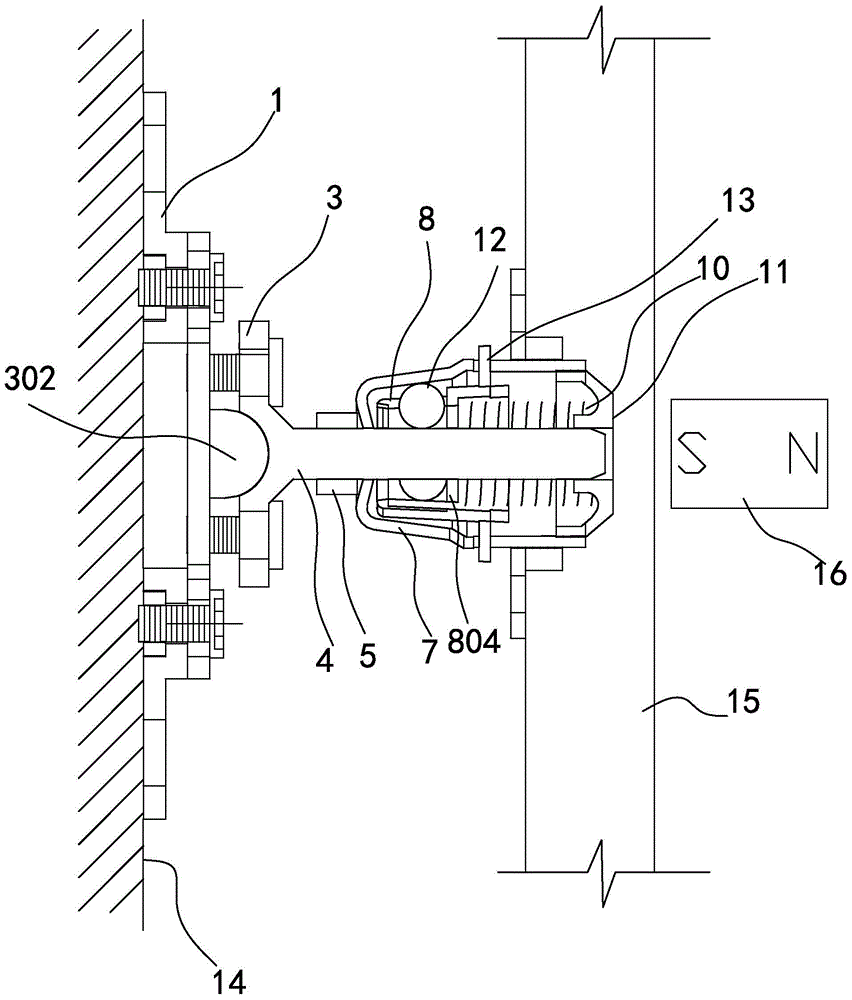

[0015] Such as Figure 1-2 As shown, the self-locking installation member that the plates are assembled and disassembled without damage includes a separably connected base and a movable lock sleeve; the base includes: two fixed plates 1 with mounting holes 101 and fixing holes 102, with adjustment The calibration plate 2 of the hole 201, the calibration plate 3 with four calibration holes 301, the lock cylinder 4, the positioning nut 5, the adjustment part 6; the movable lock sleeve includes: the shell 7, the lock core 8, the lock plate 9, the spring 10. Back cover 11, steel ball 12; lock column 4, adjustment member 6, shell 7, and back cover 11 are made of antimagnetic materials, and lock core 8, lock plate 9, spring 10, and steel ball 12 are made of soft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com