Patents

Literature

171results about How to "Eliminate installation errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

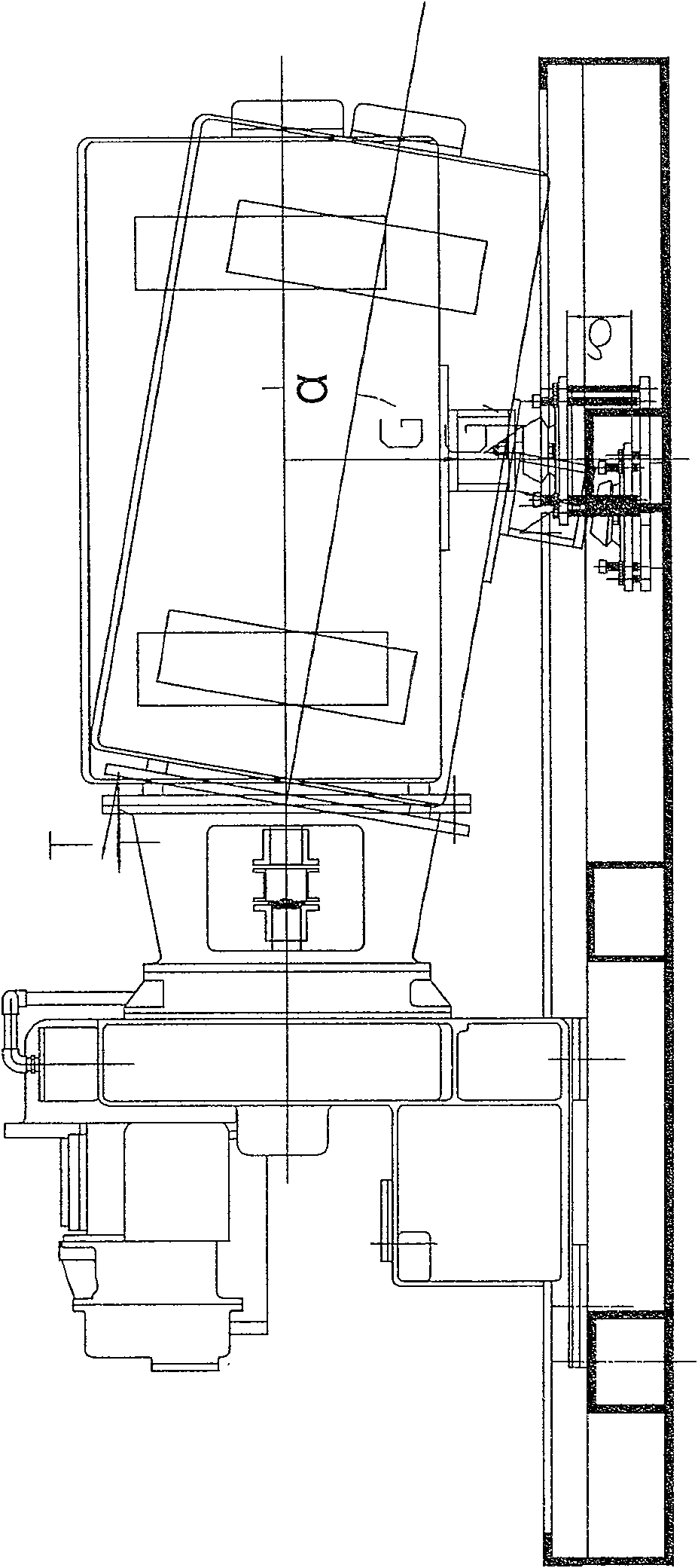

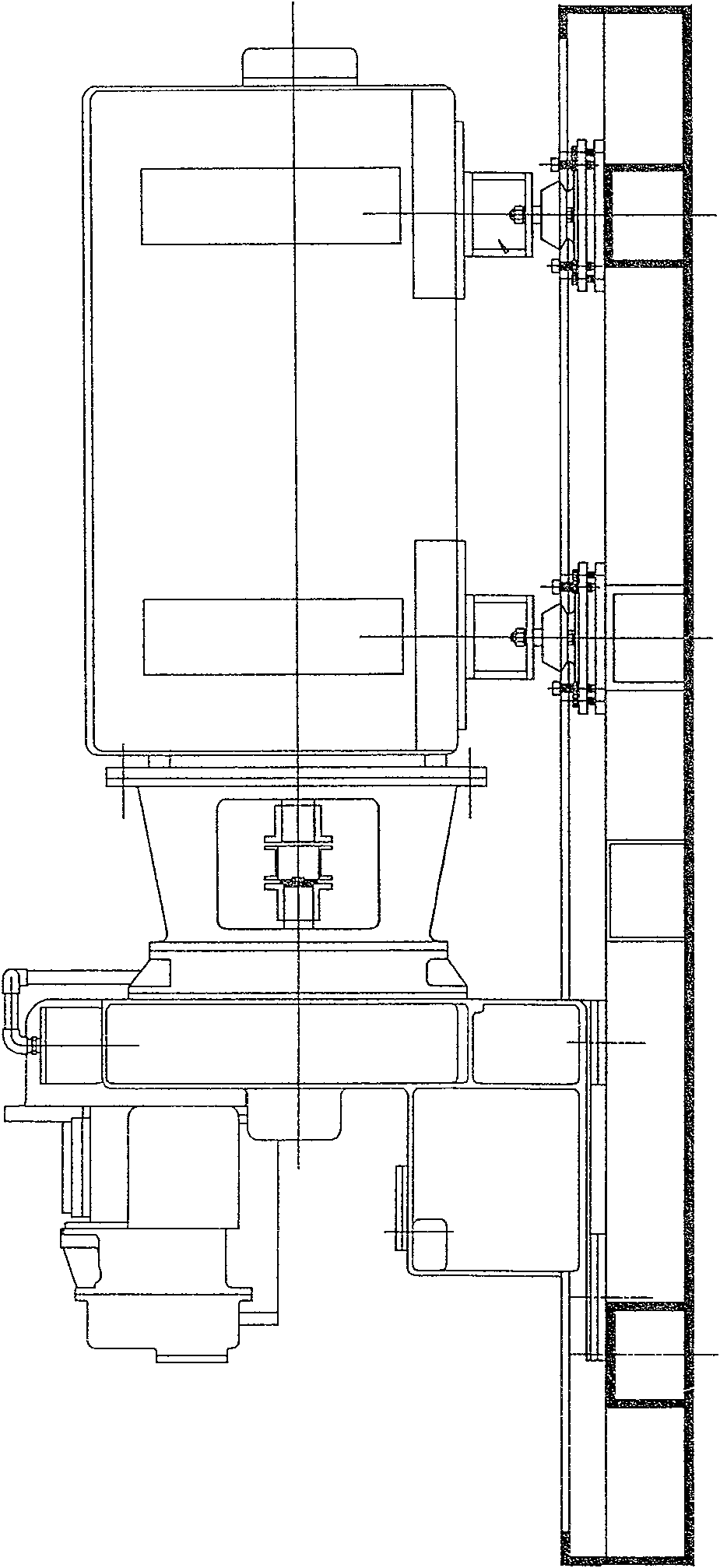

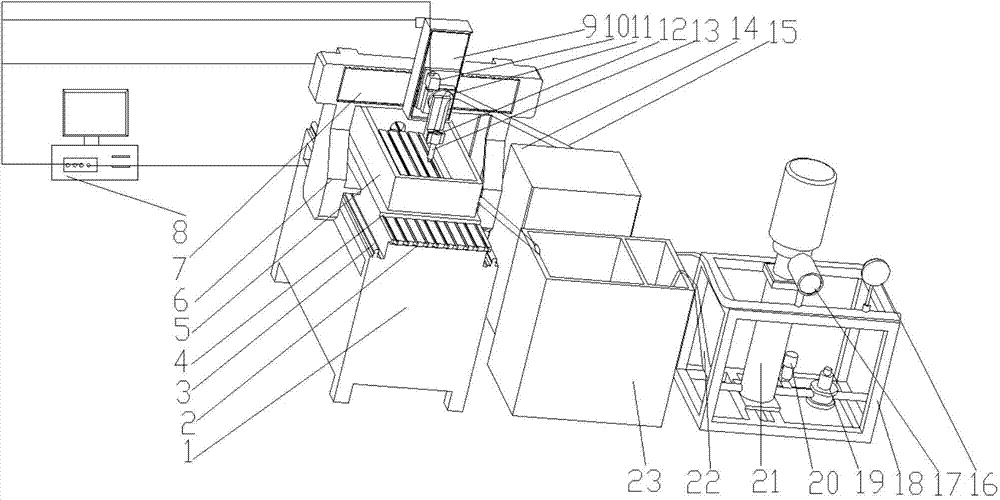

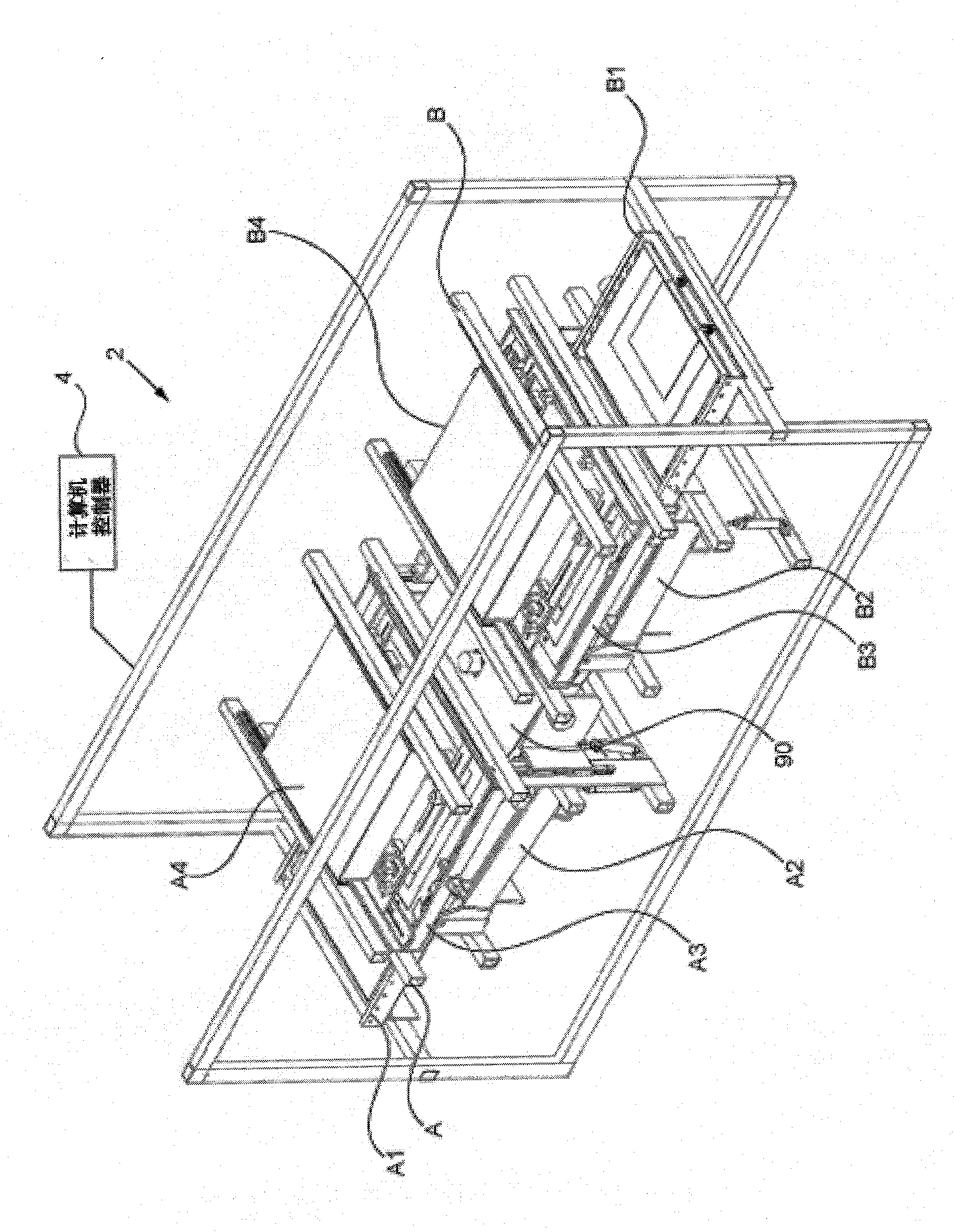

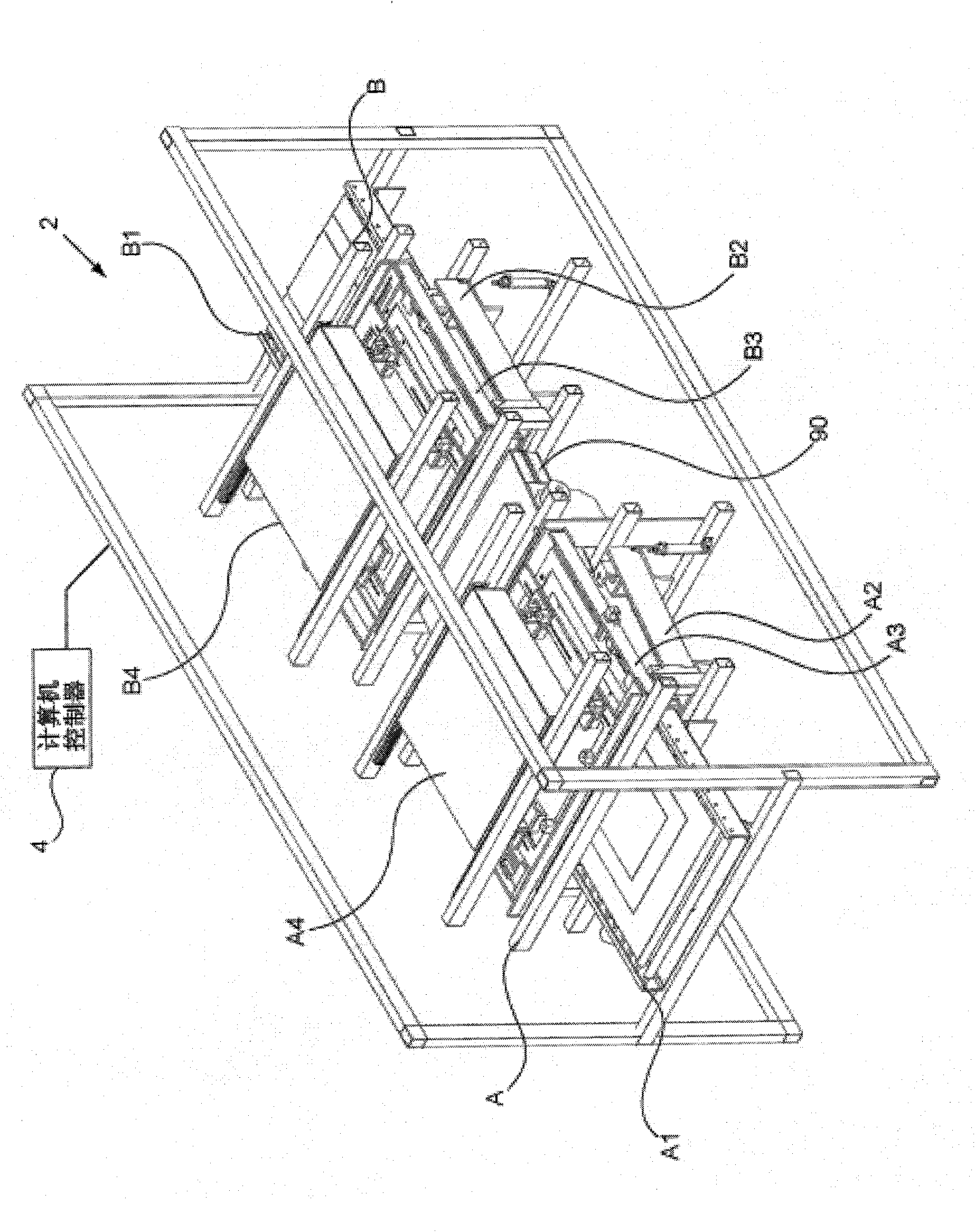

Numerical control electrolyze mechanical compound processing machine tool

InactiveCN101249578AEliminate installation errorsImprove machining accuracyFeeding apparatusElectric circuitsElectric machineryComposite cathode

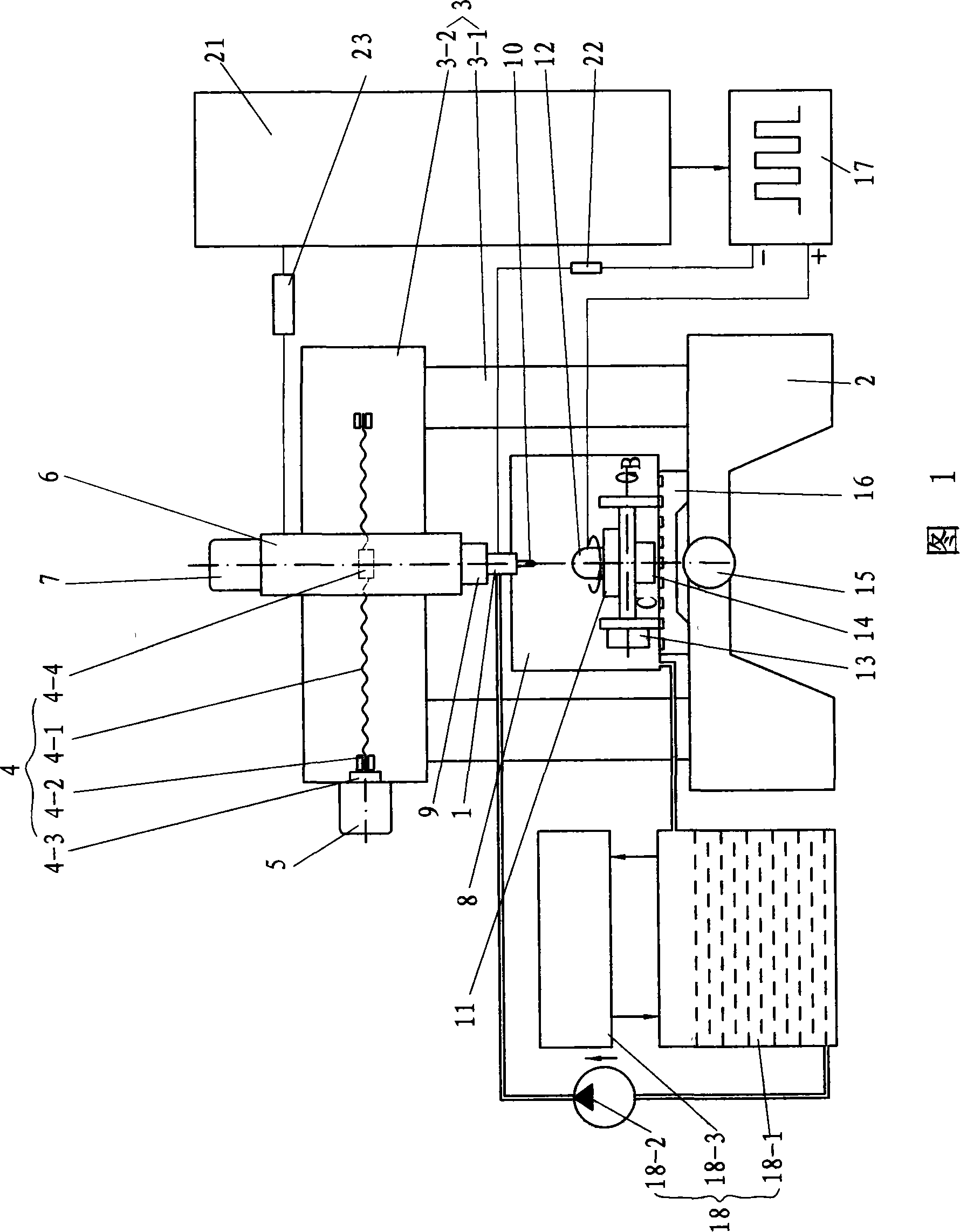

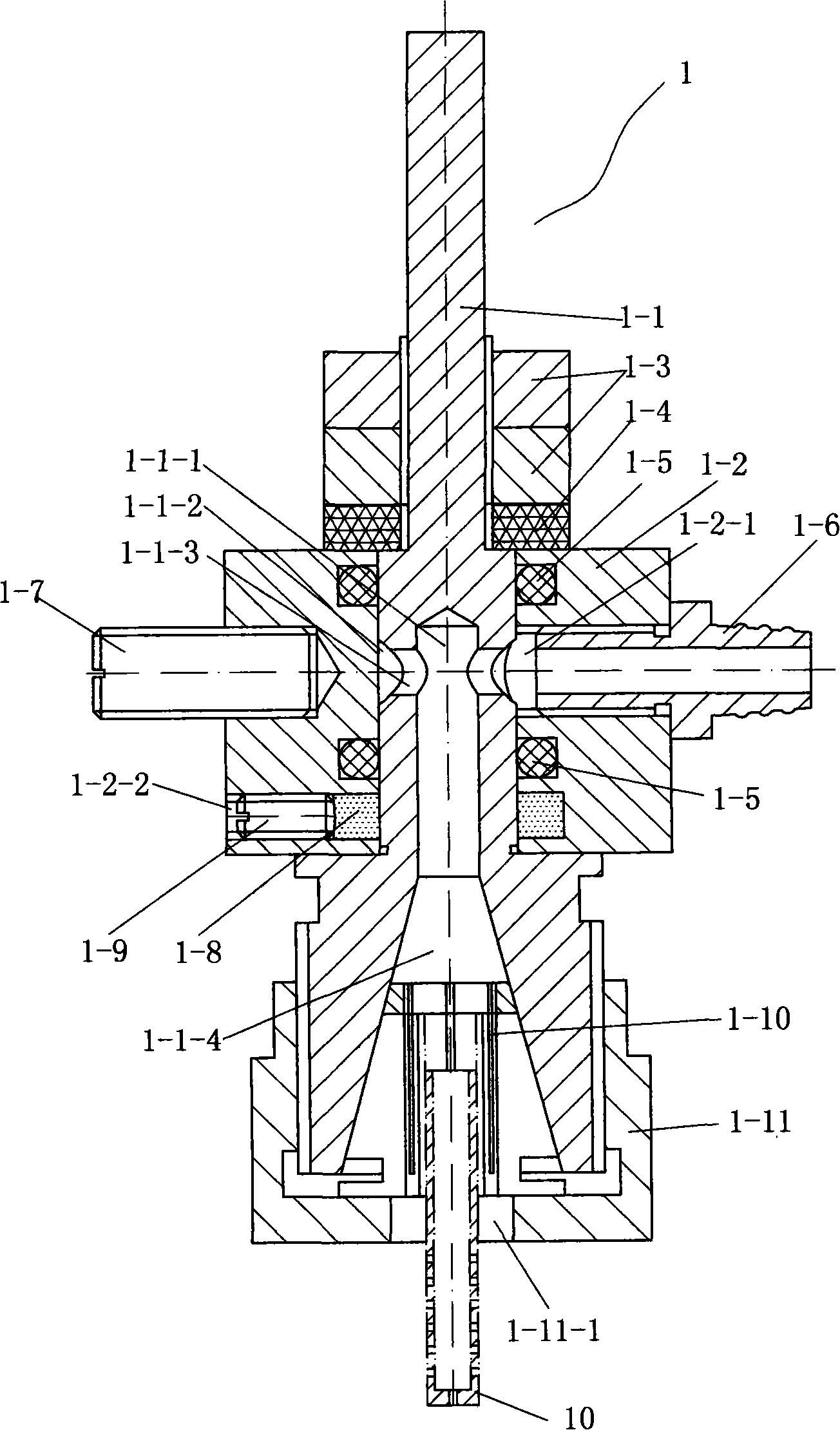

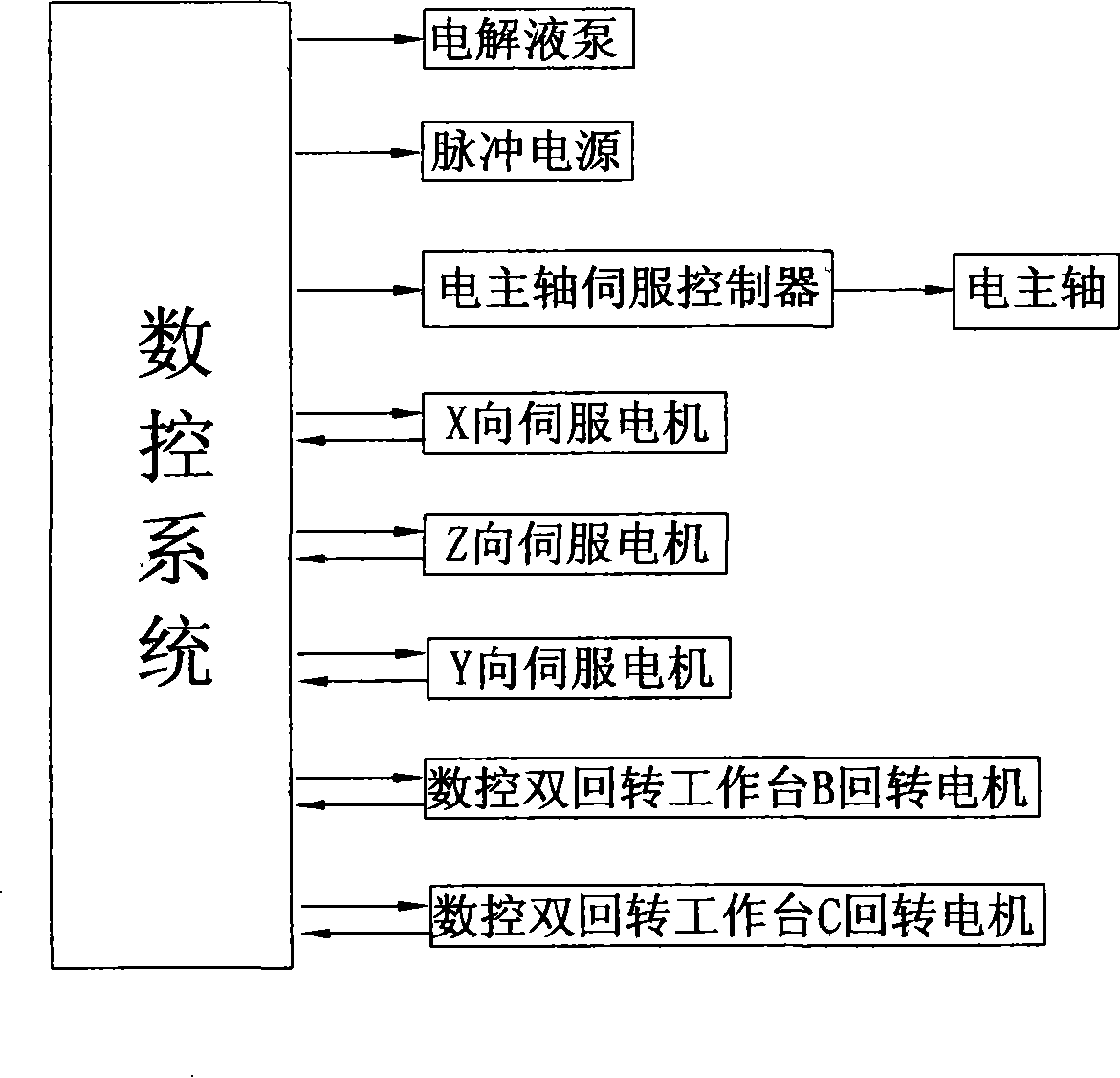

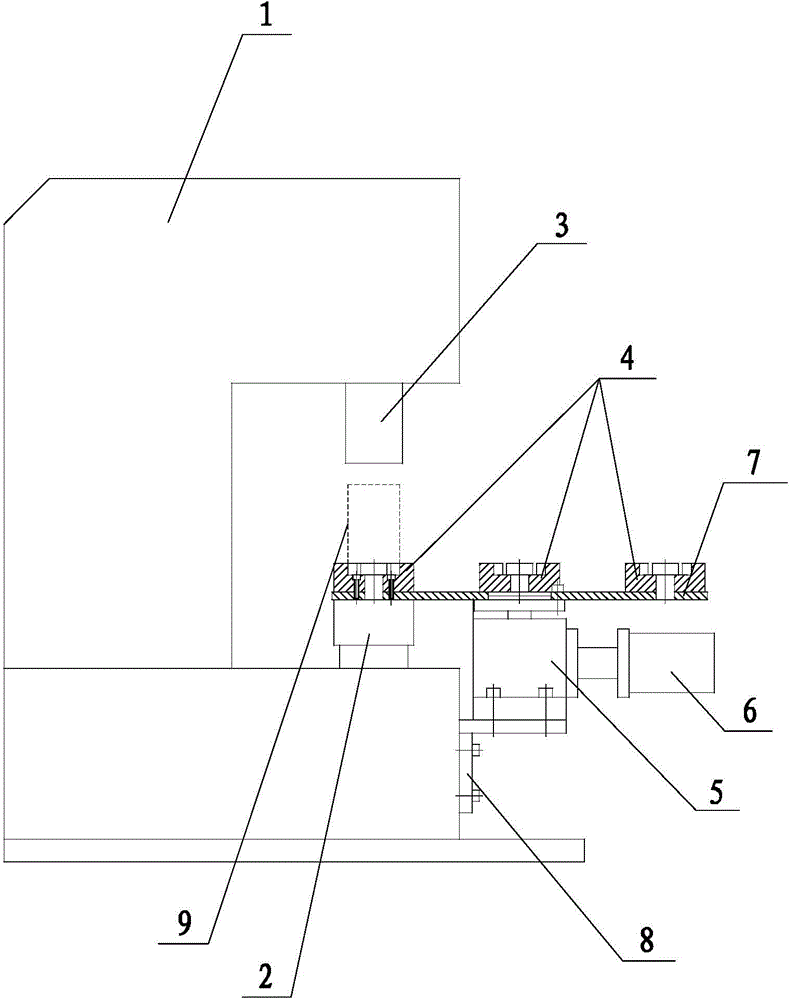

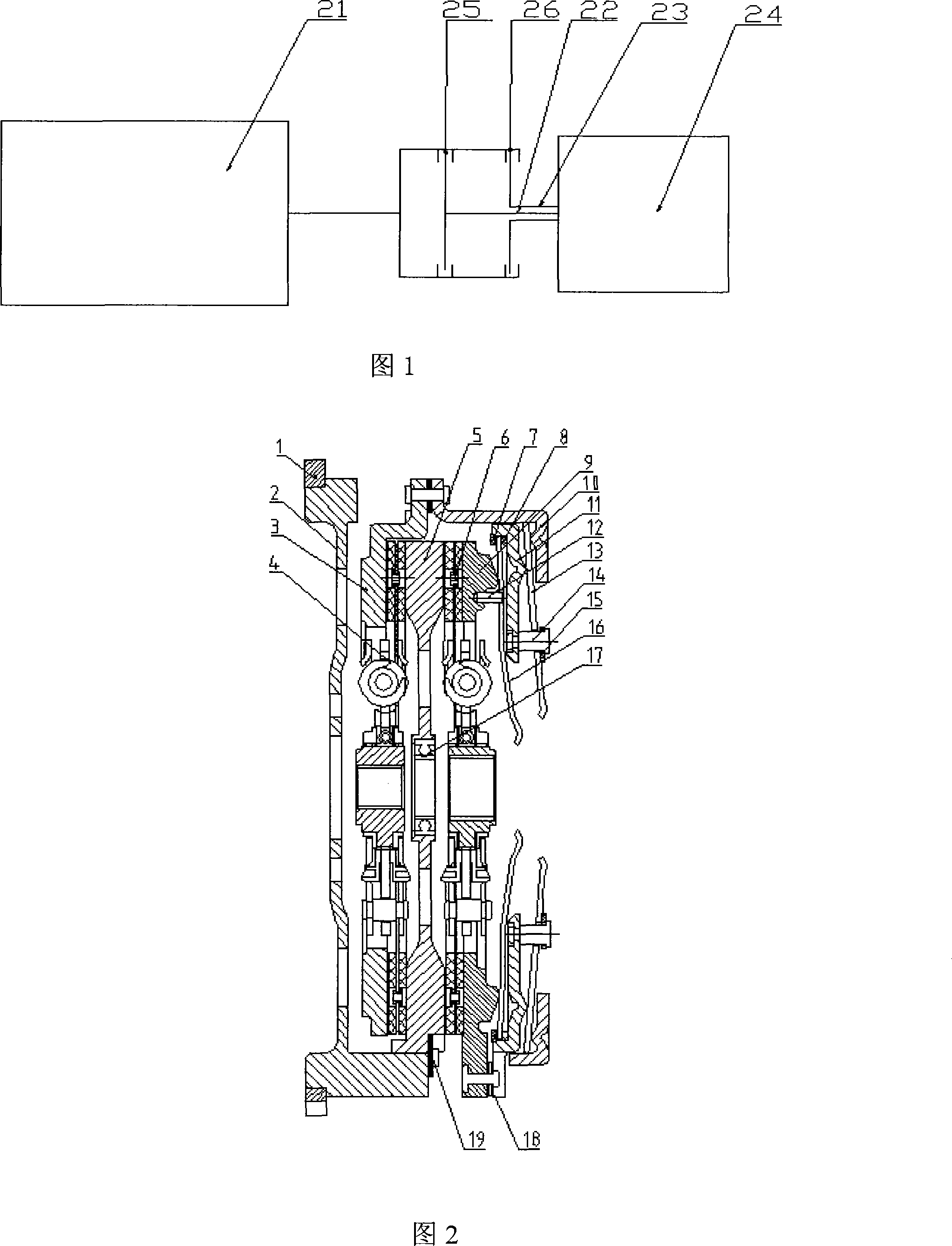

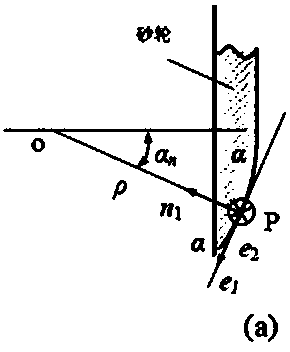

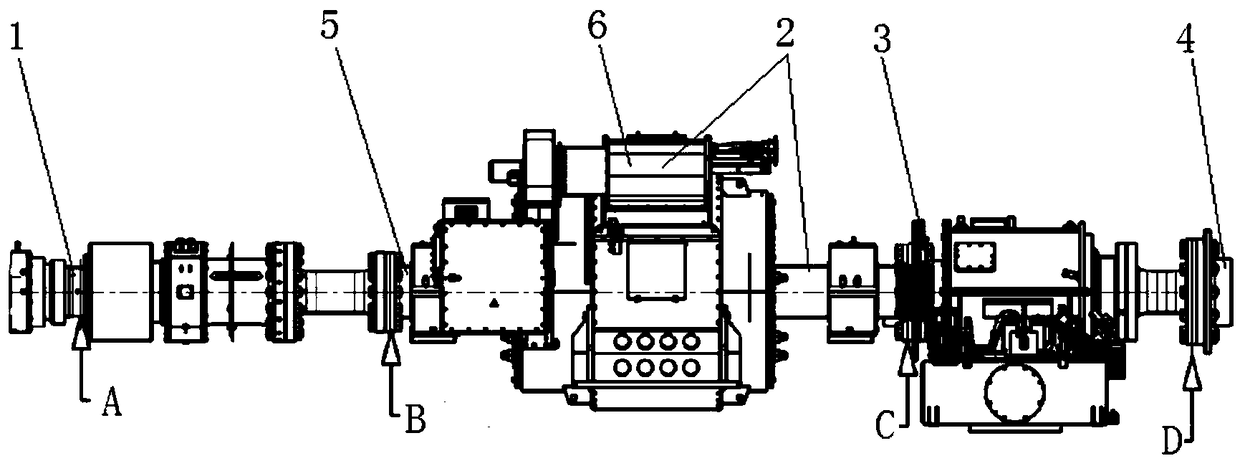

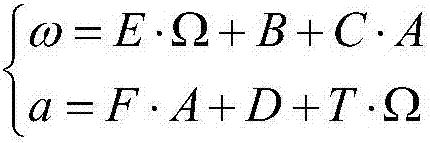

A numerical control electrolytic-mechanical composite machine tool comprises a machine body, a frame, a horizontal work bench, a numerical control double-revolving work bench, a protection box, a spindle head, an electrical spindle, a numerical control system, a pulse power supply, an electrolyte circulating device, and an X-direction transmission mechanism, a Z-direction transmission mechanism as well as a Y-direction transmission mechanism, wherein the electrical spindle, the pulse power supply, an electrolyte pump of the electrolyte circulating device, an X-direction servo motor, a Z-direction servo motor, a Y-direction servo motor, and a B revolving motor and a C revolving motor of the numerical control double-revolving motor are all controlled by the numerical control system. By controlling the relative movement of a composite cathode and an anode workpiece, the machine tool can process mold cavities and mold surfaces for complex workpieces, thus processing workpieces of different shapes. By changing different composite cathodes and adjusting different processing parameters, rough processing, finish processing and surface smoothing of one part can be achieved by one machine tool in different processing manners such as drilling, milling, cutting, grinding and polishing, thus eliminating installation error caused by repeated installation of workpieces.

Owner:CHANGZHOU INST OF TECH

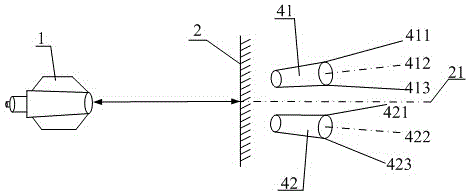

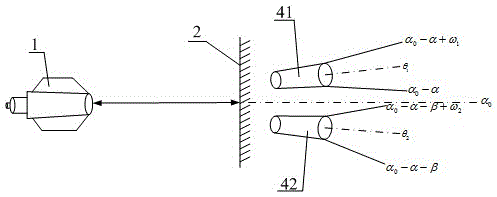

Device for calibrating parallelism of optical axis of multi-axis optical system, and calibration method thereof

InactiveCN105091792AEliminate installation errorsReduce the difficulty of production and installationUsing optical meansTesting optical propertiesInstallation ErrorTheodolite

The invention discloses a device for calibrating parallelism of optical axes of a multi-axis optical system, and a calibration method thereof. The device comprises a high precision autocollimation theodolite, a planar mirror, a to-be-calibrated multi-axis optical system, a pedestal, a cross target plate and a rotary platform. The multi-axis optical system and the planar mirror are both disposed on the pedestal. The pedestal is placed on the rotary platform. The cross target plate is fixed in a position 1000 times of the longest lens focal length away from the front end of the optical system. The autocollimation theodolite is disposed behind the planar mirror and is used for aiming. Through rotation of the rotary platform many times, the direction values of the planar mirror, which are measured by aiming of the autocollimation theodolite, are obtained. The directions of optical axes can be known by calculating the direction values measured many times. The difficulties in manufacturing and installing detection equipment can be reduced, less requirements of places are needed, the measuring operation is convenient, high applicability is exhibited, and installation errors of the planar mirror are eliminated. The device is suitable for measuring or calibrating parallelism of optical axes of a multi-axis optical system and a multispectral multi-axis optical system.

Owner:XIAN UNIV OF POSTS & TELECOMM

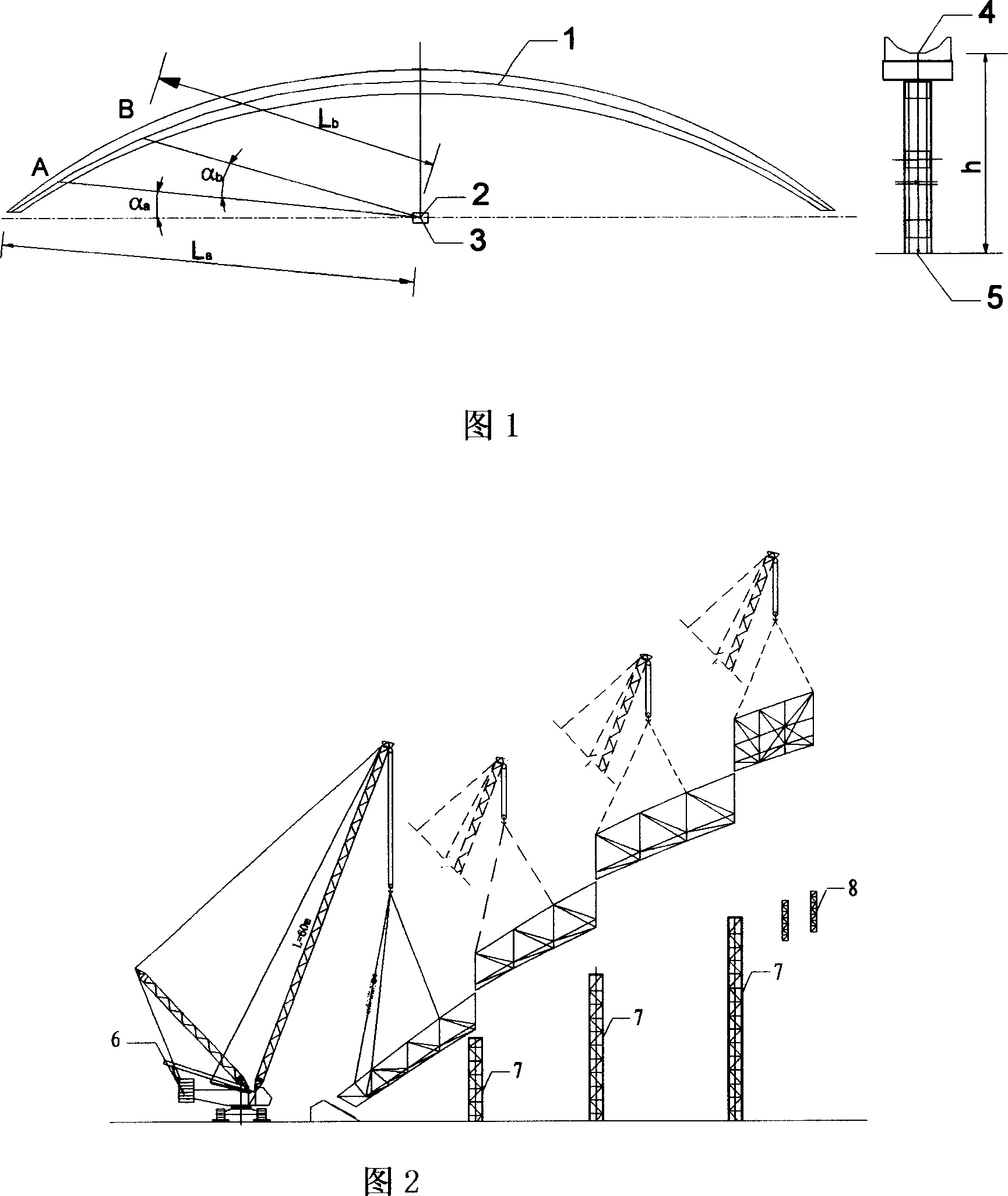

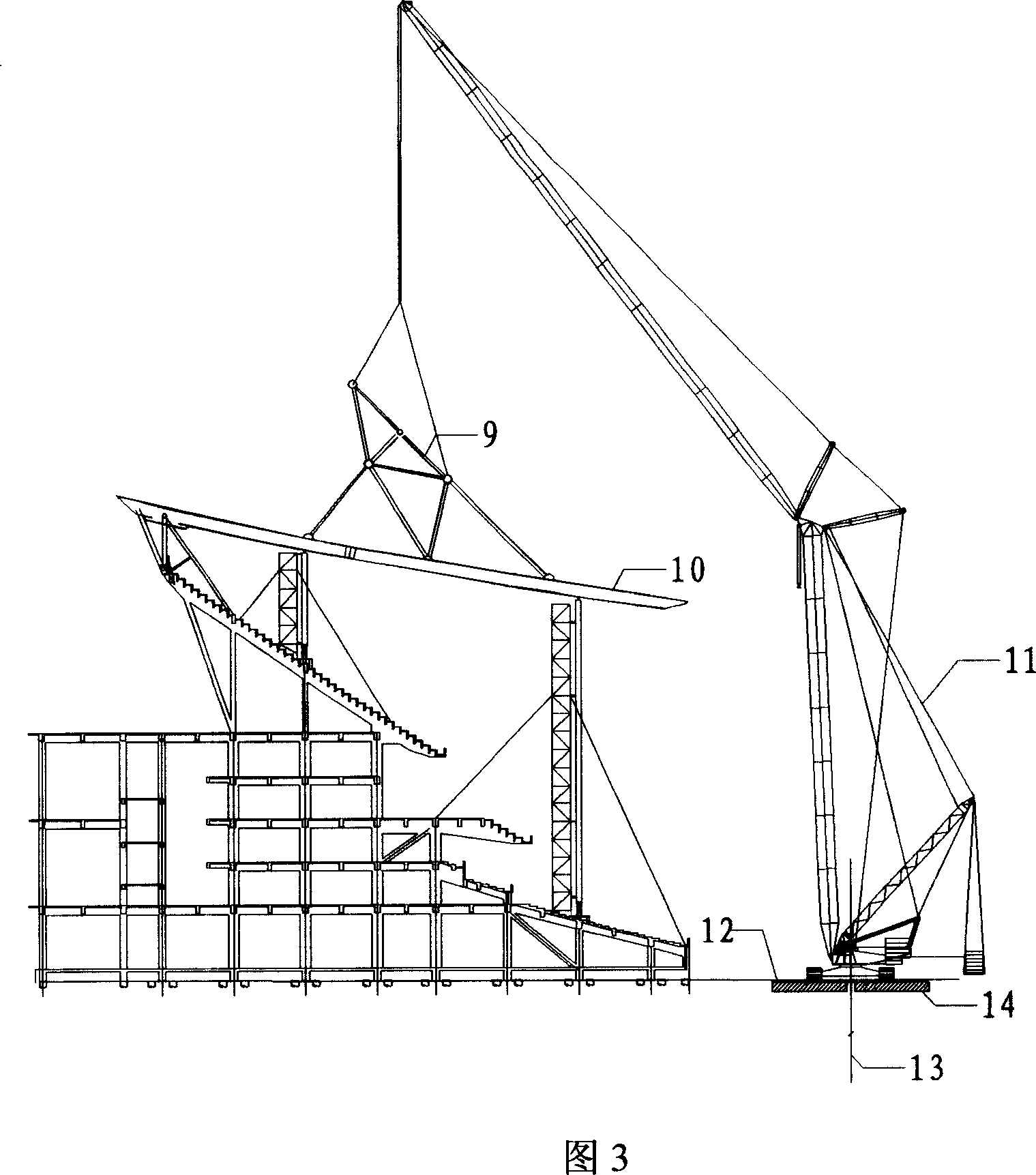

Super-span steel skew arch construction method

ActiveCN1978801AAvoid WeldingAvoid Welding StressArched structuresVaulted structuresArchitectural engineeringTotal station

The invention discloses super span steel skew arch construction method. Its feature is that it adopts molding bed support sectionalizing installation method which includes the following steps: dividing the super span steel skew arch into twenty one construction units; assembling each of them by horizontal type assembling method; laying off and locating supporting molding bed by total stations instrument; installing supporting molding bed; orderly installing the 1-4, 18-21 sections steel skew arch in roof covering, the 5-10, 12-17 sections out roof covering, the eleventh healing section in roof covering; removing the supporting molding bed. The invention can eliminate installing accumulative error, increase insurance coefficient for whole project to ensure steel skew arch healing successful at a time. The method can be used in large scale hall super span steel skew arch construction.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

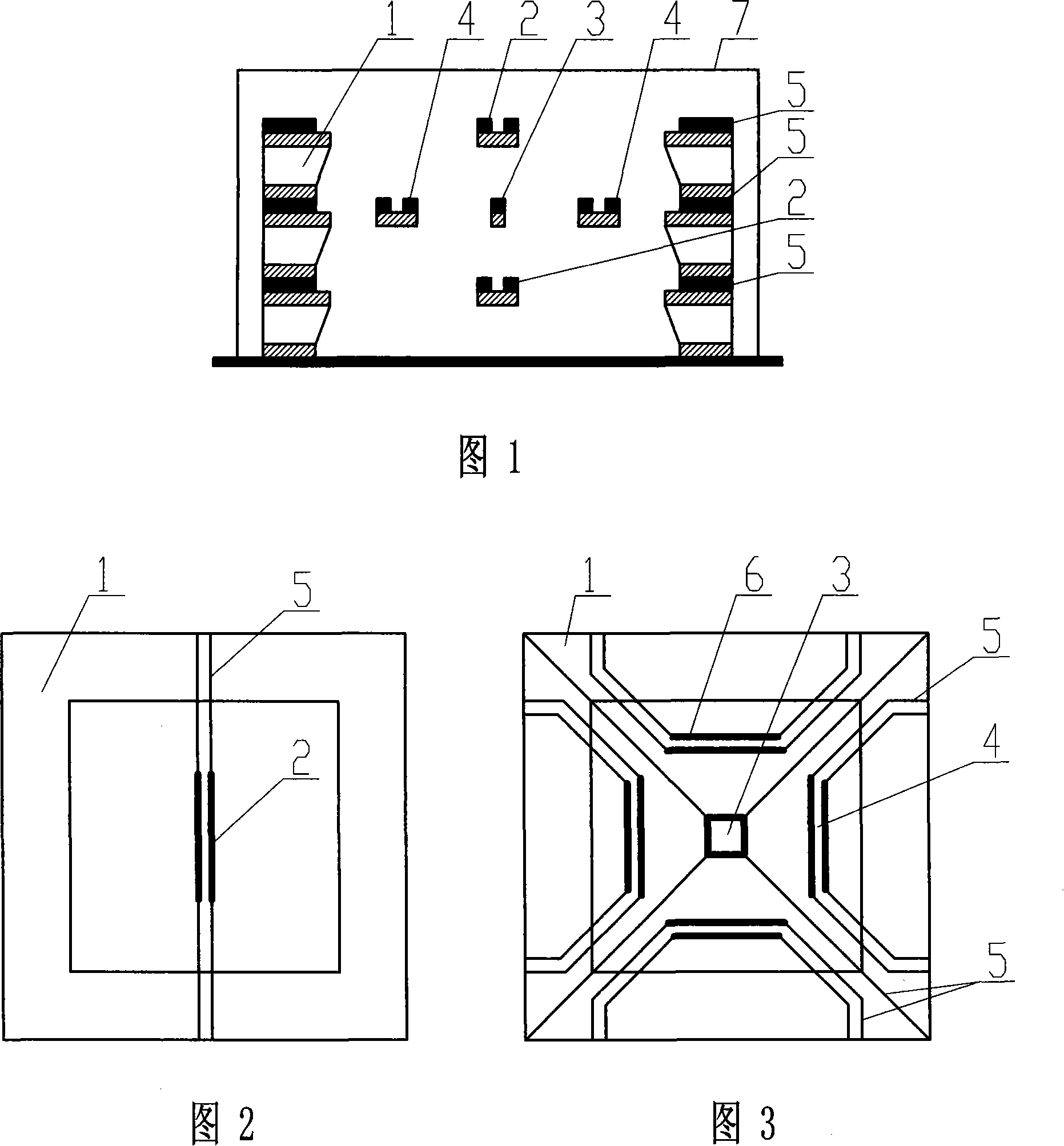

Press fitting tool for fitting electromagnetic ferromagnetic yoke on bottom plate in pressing mode

ActiveCN104440039AEasy to operateAvoid Work InjuryWork holdersMetal working apparatusEngineeringMachine tool

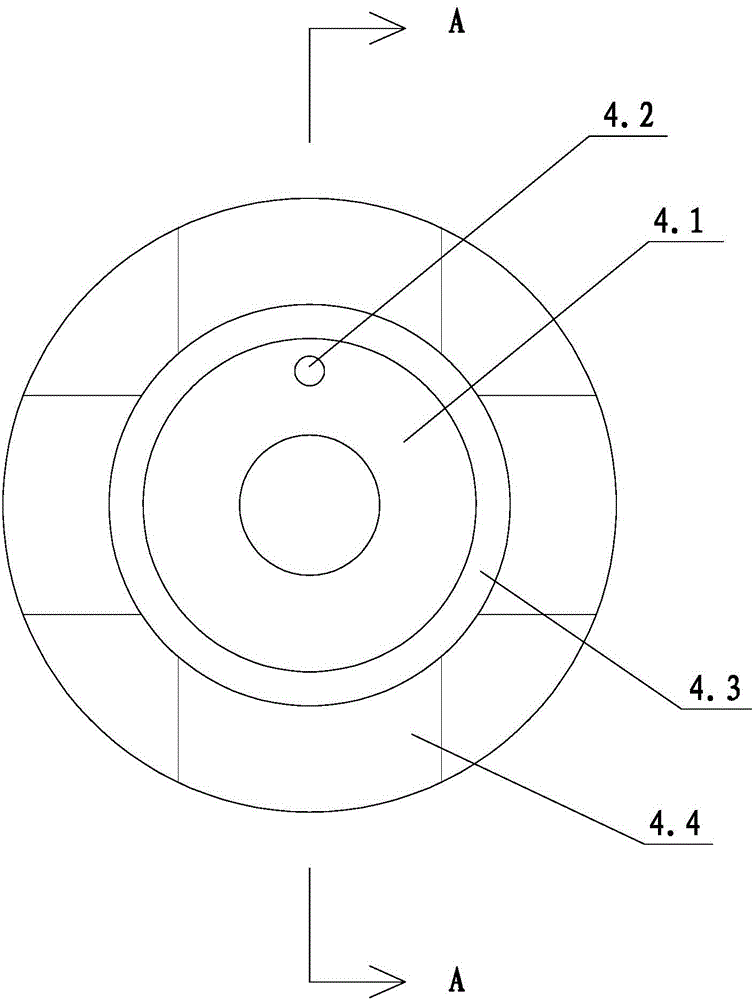

The invention discloses a press fitting tool for fitting an electromagnetic ferromagnetic yoke on a bottom plate in a pressing mode. The press fitting tool comprises a hydraulic machine tool (1). A base (2) and a movable pressing head (3) are arranged on the hydraulic machine tool (1). The base (2) is arranged under the movable pressing head (3). The press fitting tool further comprises a rotary part locating device. The rotary part locating device comprises multiple locating seats (4) used for carrying out locating on the electromagnetic ferromagnetic yoke and the bottom plate and can rotate to alternately feed the multiple locating seats (4) into the space between the movable pressing head (3) and the base (2). The press fitting tool is quite safe to operate and high in press fitting efficiency.

Owner:宁波市鄞州通力液压电器厂

Multi-line laser radar system and horizontal mounting angle correction method thereof

ActiveCN107247268AAchieve correctionEliminate installation errorsElectromagnetic wave reradiationRadar systemsCorrection method

The invention relates to a multi-line laser radar system and a horizontal mounting angle correction method thereof. The method comprises steps that the standard calibration environment is set; a multi-line laser radar is arranged in the standard calibration environment, and the standard calibration environment is scanned; angle-distance data generated when each laser line scans the standard calibration environment is acquired; one laser line is taken as a reference channel, other laser lines are taken as correction channels, and cross correlation operation of distance data D1 of the reference channel and distance data Di of each to-be-corrected channel is respectively carried out to acquire a cross correlation curve; an abscissa corresponding to the largest ordinate value of the cross correlation curve is taken as a horizontal offset angle corresponding to the to-be-corrected channel; the horizontal offset angle is utilized to correct a horizontal mounting angle of the corresponding laser. The system is internally provided with a program capable of realizing horizontal angle offset calculation. The system and the method are advantaged in that single parameter correction can be realized, and the system and the method are easy to implement.

Owner:SUTENG INNOVATION TECH CO LTD

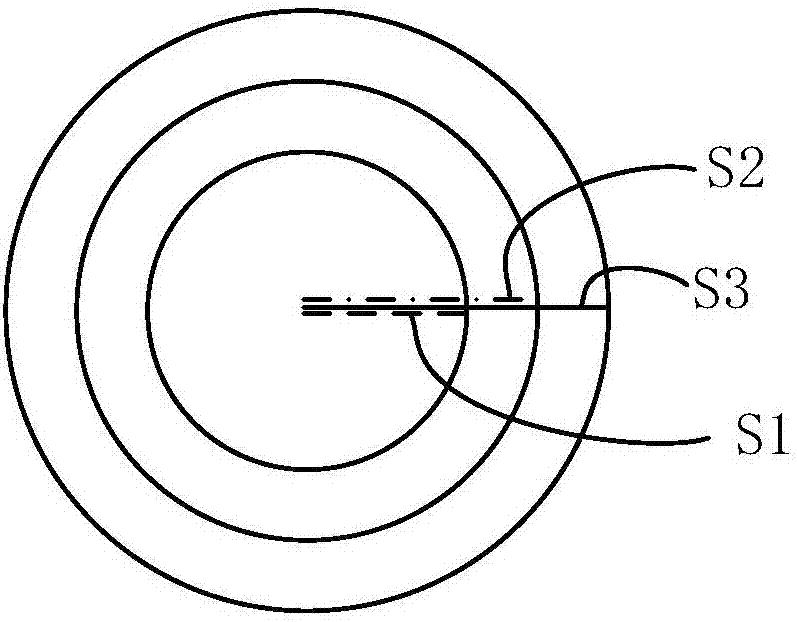

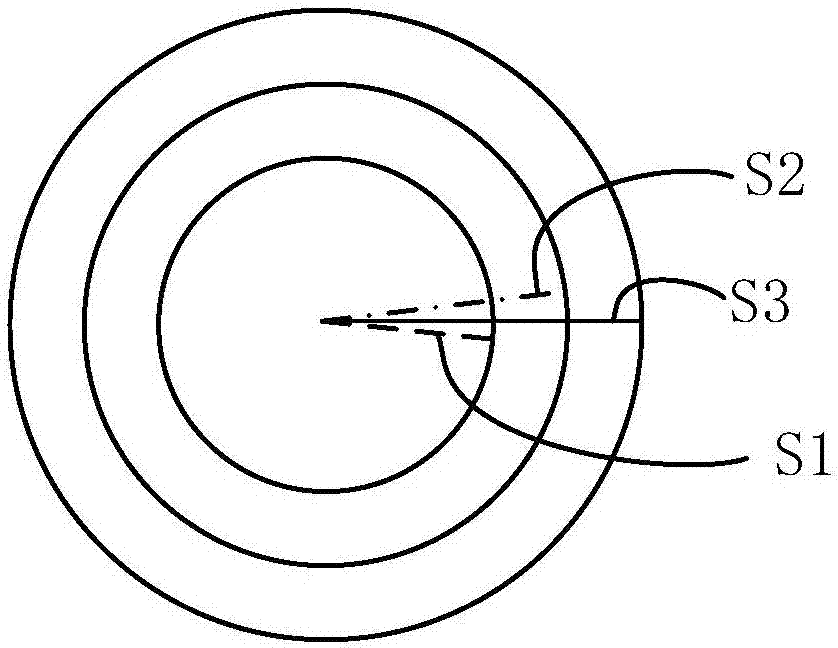

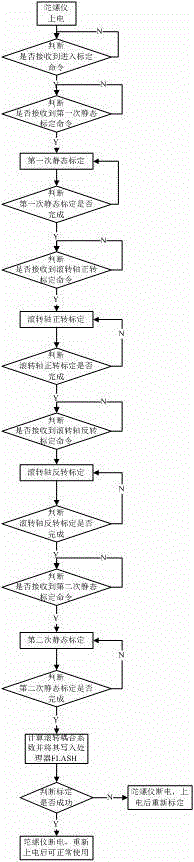

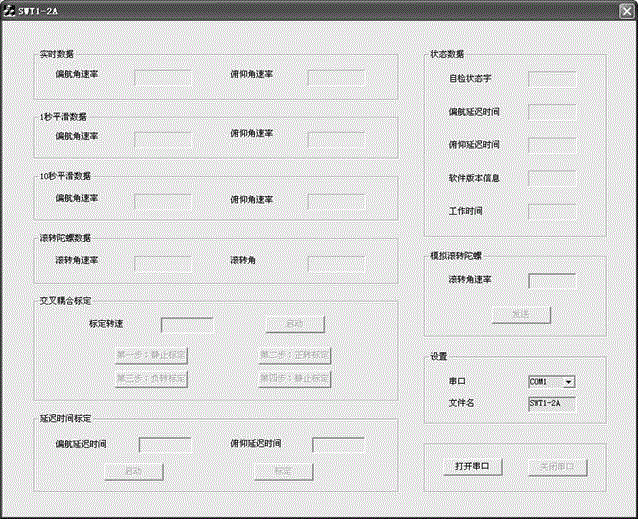

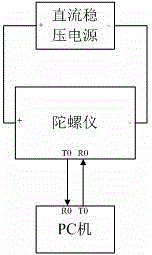

Gyroscope dynamic calibration method for measuring rotary carrier transversal posture

ActiveCN104101363AHigh measurement accuracyEliminate double installation errorsMeasurement devicesCode writingGyroscope

The invention discloses a gyroscope dynamic calibration method for measuring rotary carrier transversal posture. The method comprises the following steps: mounting a gyroscope in a rotary carrier, mounting the rotary carrier on a high-speed rotary table, then adopting a velocity testing method to identify installation error of tops of the gyroscope in all directions corresponding to the rolling directions by a gyroscope error model so as to obtain a compensation factor, writing the compensation factor into a processor FLASH on line, and finally judging the calibration result, when the calibration result is in the set calibration result range, the calibration is effective, or calibration needs to be conducted again until the requirements are met. According to the gyroscope dynamic calibration method, not only is the installation error caused by secondary mounting eliminated, but also the primary installation error of the tops in the gyroscope is eliminated, and the gyroscope measuring accuracy is obviously improved. In calibration, the compensation factor is written into the processor FLASH inside the gyroscope on line, not only is the experiment data saved, but also the secondary code writing is avoided, and the calibration workload is greatly relieved.

Owner:CHINA ELECTRONICS TECH GRP NO 26 RES INST

Adjustable elastic support structure

InactiveCN100555806CEliminate manufacturing errorsEliminate installation errorsSupports/enclosures/casingsCouplingEngineering

The invention relates to an adjustable elastic support structure, specifically for the support connection between rotary machines (screw compressors, motors, etc.) and machine bases, and belongs to the technical field of support devices. It mainly adopts the shock absorber to be connected with the bottom plate and the bracket respectively, the motor is connected with the bracket, the chassis is supported by the top screw, the nut locks the top screw, and the bottom plate and the chassis are connected by the connecting bolt. The invention has a simple, compact and reasonable structure; the elastic support can eliminate and reduce the transmission of motor vibration; the adjustable support can eliminate the manufacturing error and installation error of each component, so that each support point can obtain ideal support force and reduce additional vibration and noise ; It can reduce the additional bending moment on the connecting cylinder and the additional force of the connecting bolts, so as to ensure the smooth operation of the machine.

Owner:WUXI COMPRESSOR CO LTD

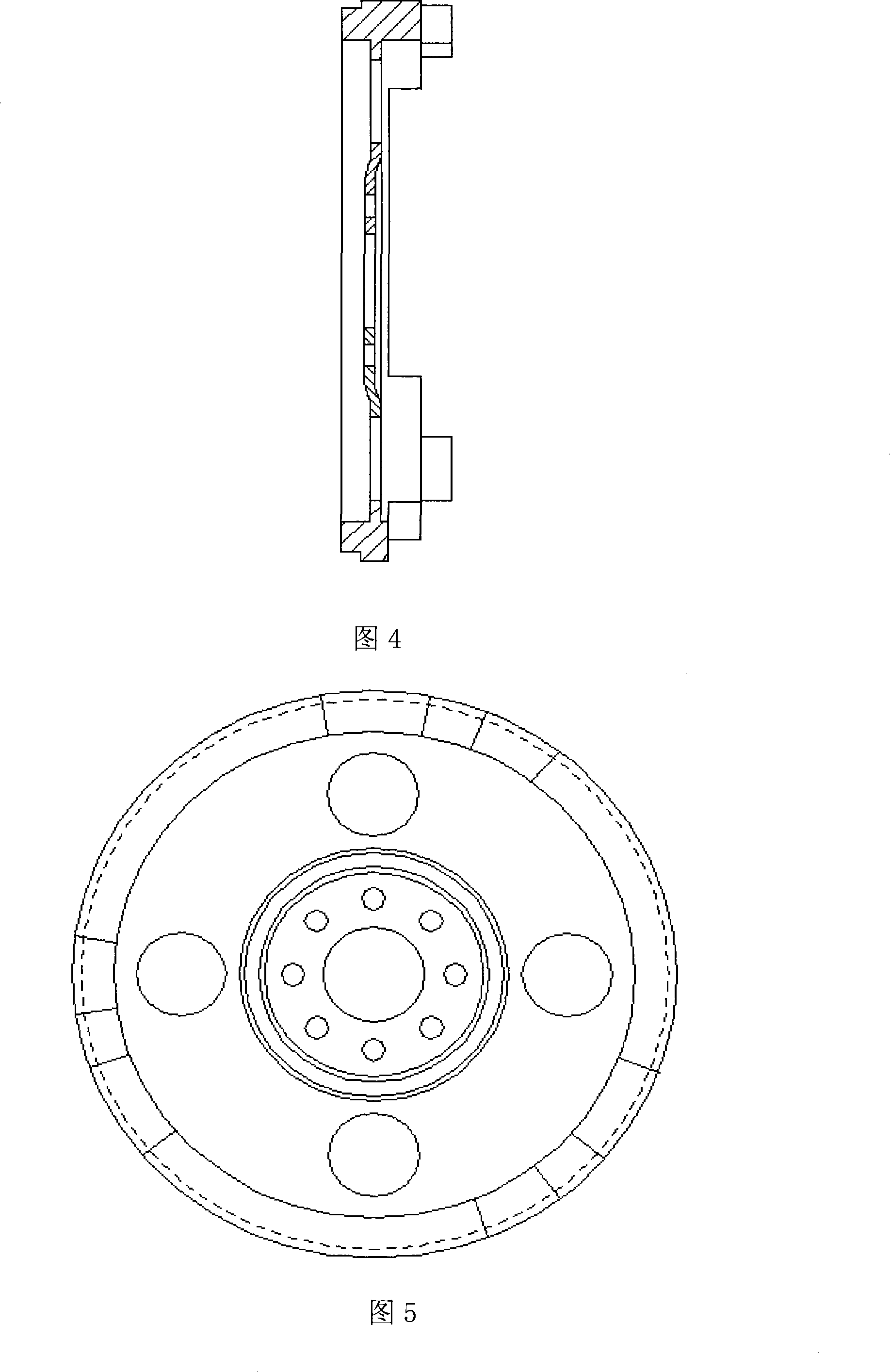

Two flywheels for dry type dual clutch

InactiveCN101225867AAvoid non-adjustable disadvantagesEliminate installation inconvenienceRoad transportFriction clutchesIsosceles trapezoidEngineering

The invention discloses two flywheels applied on a dry dual clutch, aiming to overcome the problem of difficult assembly of the dual clutch, which is characterized in that: a flywheel (2) and an intermediate flywheel (5) both are round disks each comprising a wheel rim, a plurality of wheel spokes, and a wheel hub; a plurality of engaging teeth (28) are radially machined on the right end face of the wheel rim of the flywheel (2) for mesh-connecting with the intermediate flywheel. A plurality of through engaging tooth spaces (30) are machined on the circumference of the wheel rim of the intermediate flywheel (5) for mesh-connecting with the engaging teeth (28) of the flywheel (2); the cross sections of the engaging teeth (28) and engaging tooth spaces are in the shapes of isosceles trapezoids or rectangles, and are evenly distributed on the wheel rims. A flange through hole and a bearing hole are respectively arranged on the centers of the wheel hubs of the flywheel (2) and the intermediate flywheel (5), and a flywheel snap ring is arranged on the left end of the bearing hole for restraining the intermediate flywheel (5) from moving along the axial direction. The invention also discloses the dry dual clutch using the two flywheels.

Owner:JILIN UNIV

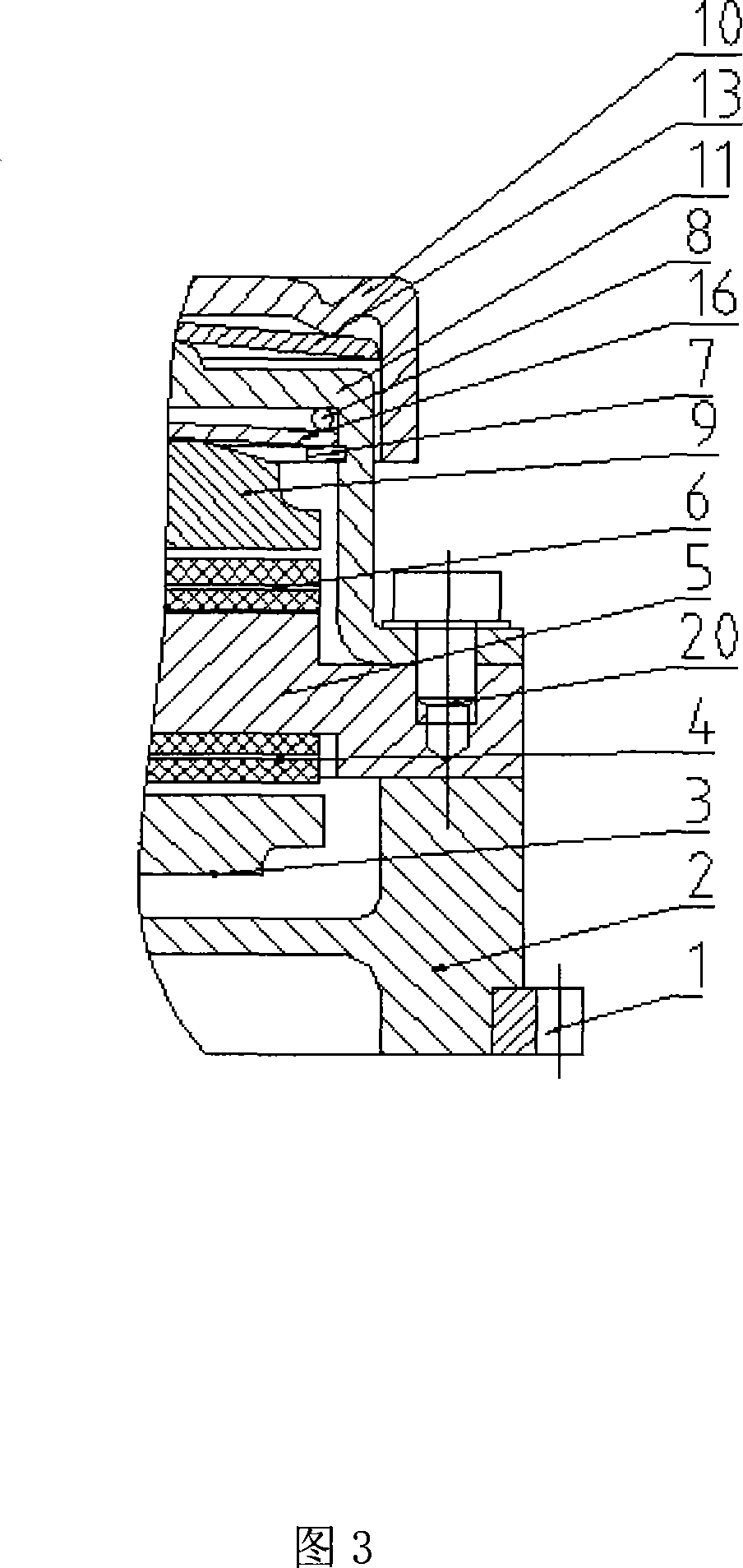

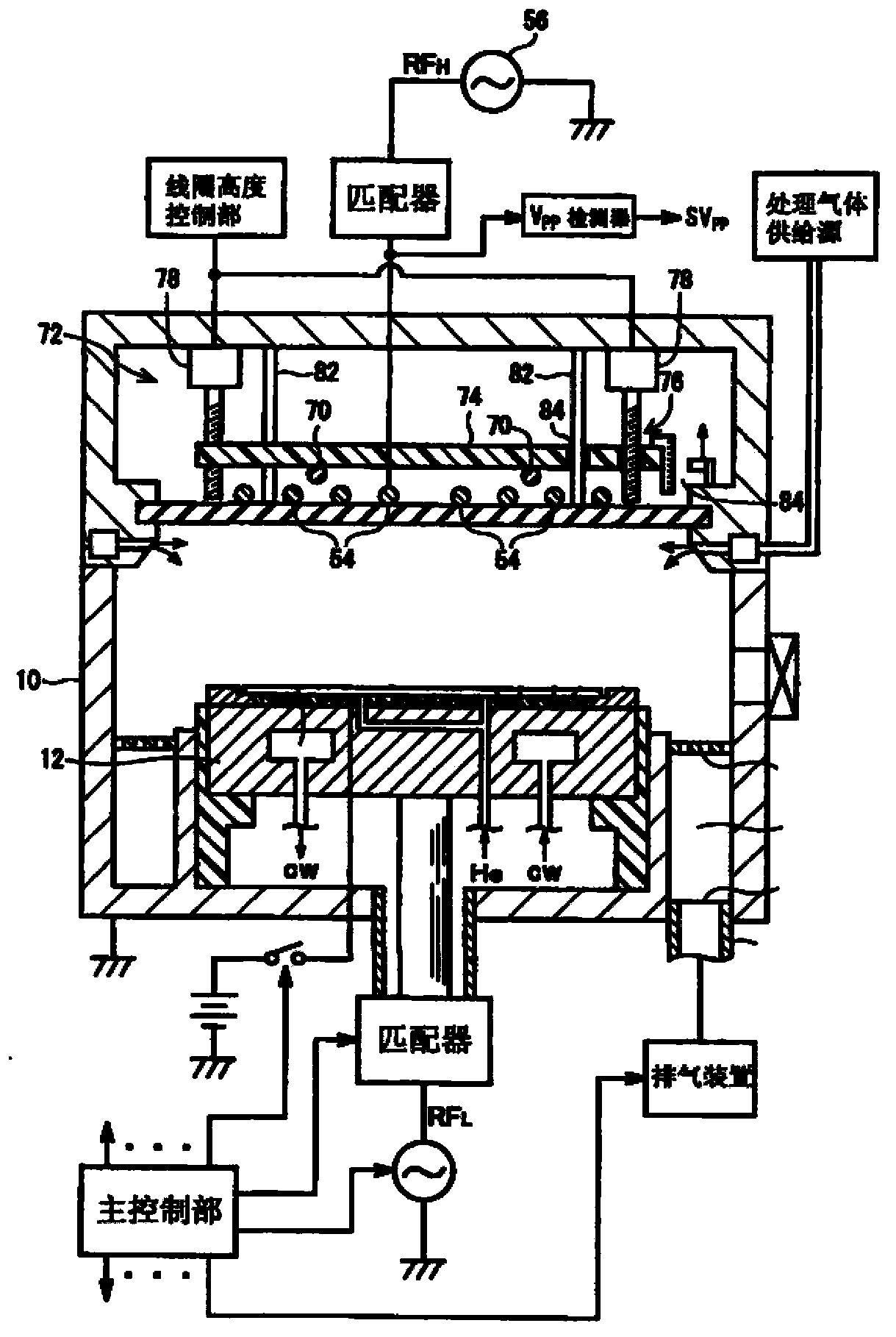

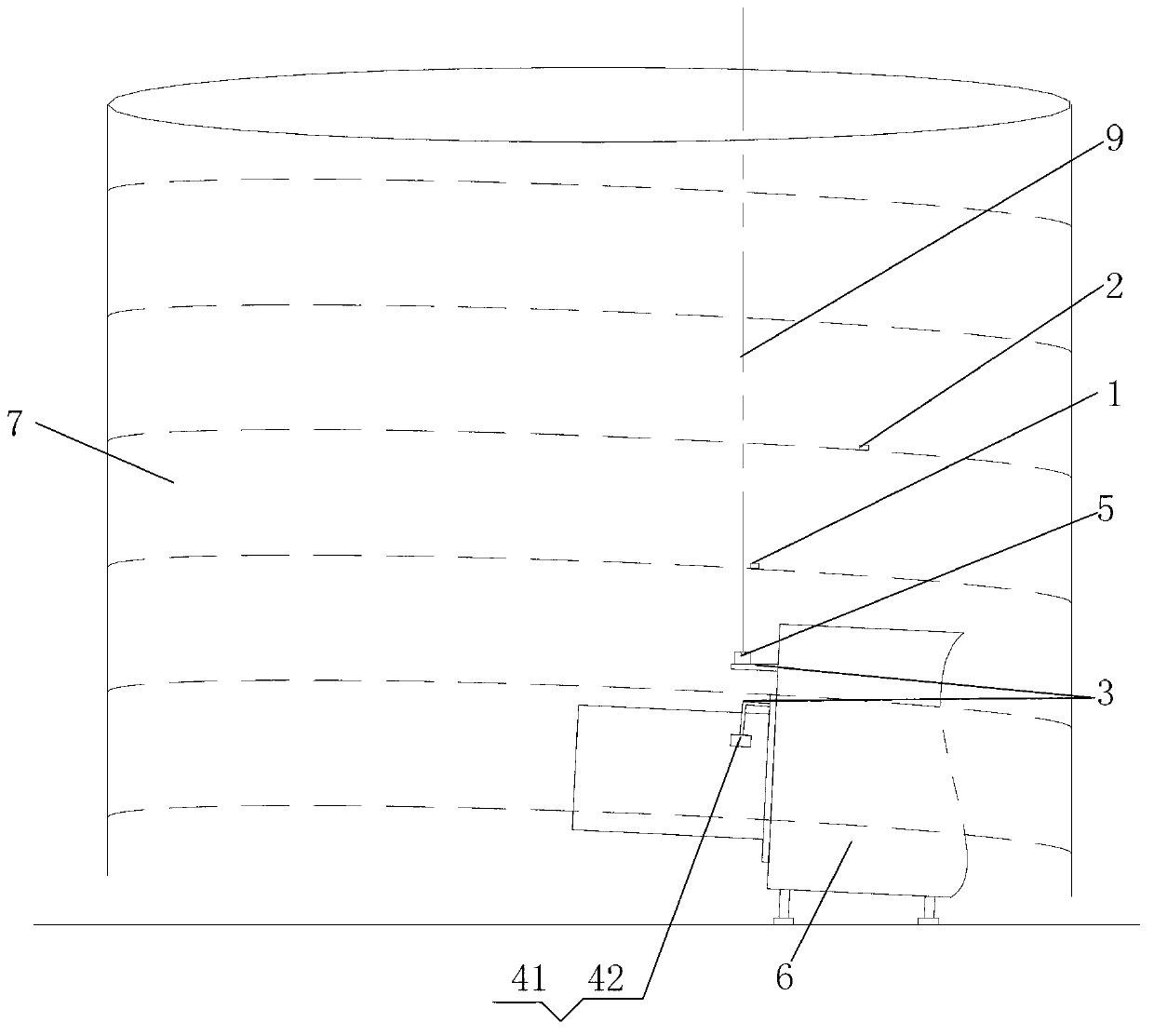

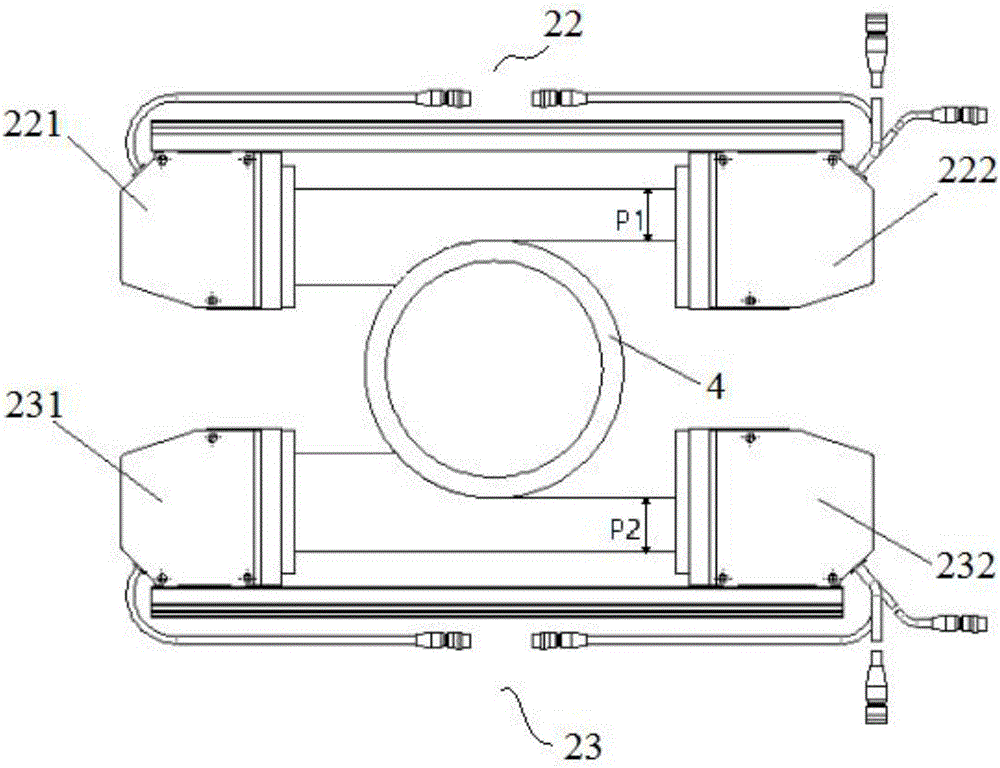

Coil supporting device and plasma processing equipment

ActiveCN104299870AEliminate installation errorsEliminate machining errorsElectric discharge tubesRadio frequencyPlasma processing

The invention relates to a coil supporting device and plasma processing equipment. The coil supporting device is used for supporting a coil arranged above the top part of a reaction chamber. The coil supporting device comprises a shielding cover, a coil support and an elevating driving mechanism. The shielding cover is fixed at the top part of the reaction chamber. The coil and the coil support used for fixing the coil are arranged in the internal part of the shielding cover. The elevating driving mechanism is fixed above the top part of the shielding cover and used for driving the coil support and the coil fixedly connected with the coil support to move in an elevating way relative to the reaction chamber. According to the coil supporting device, height of the coil relative to the reaction chamber can be adjusted by driving the coil to move in the elevating way so that possible installing error and processing error of the coil can be eliminated, distribution of a radio frequency magnetic field in the reaction chamber can also be flexibly and accurately adjusted, and thus uniformity of the technology can be enhanced.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

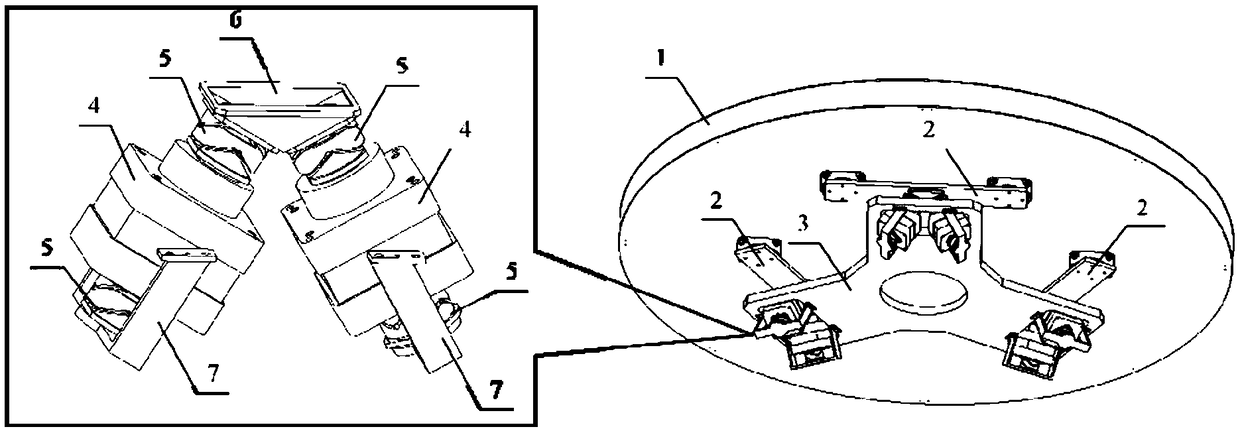

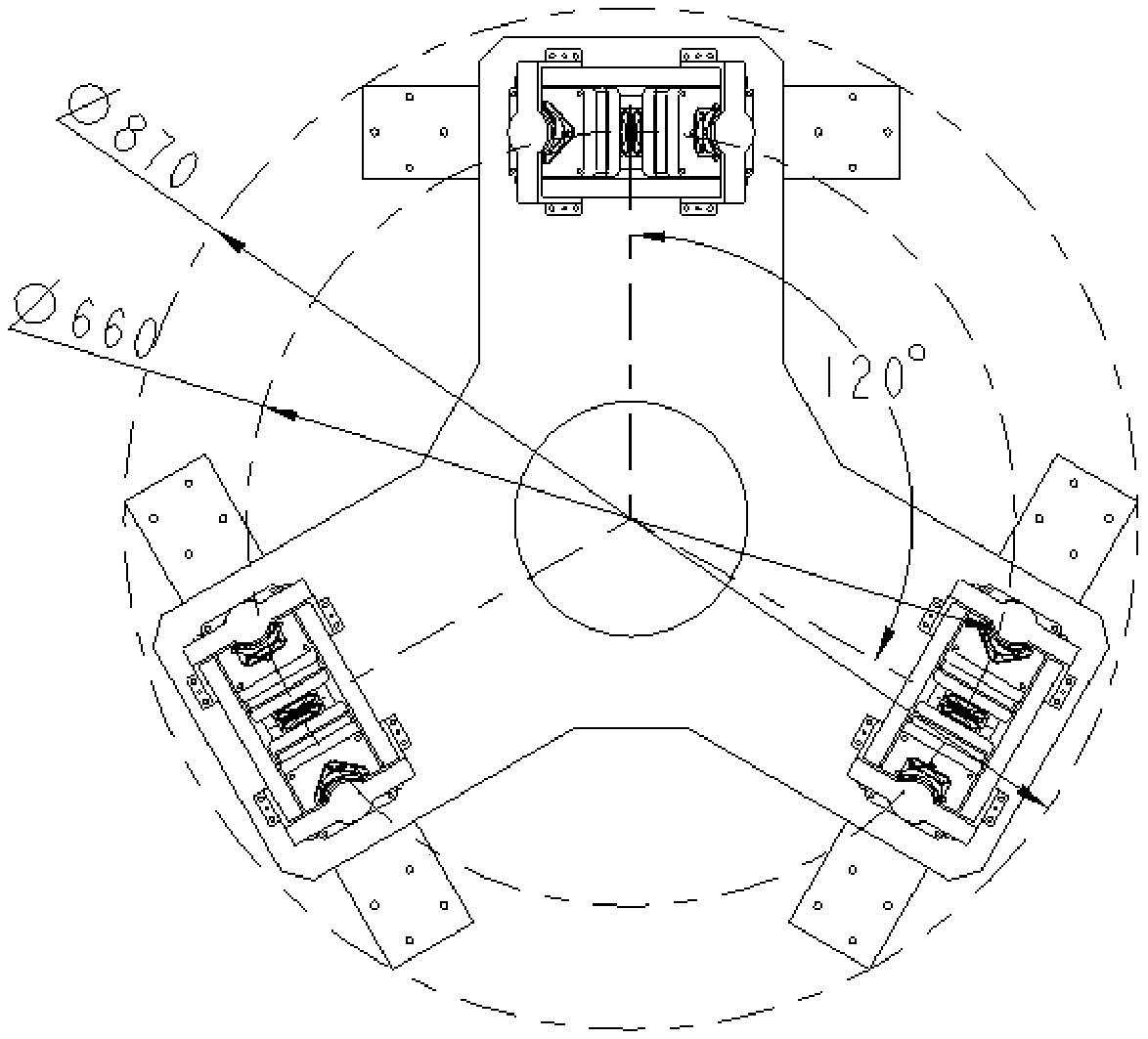

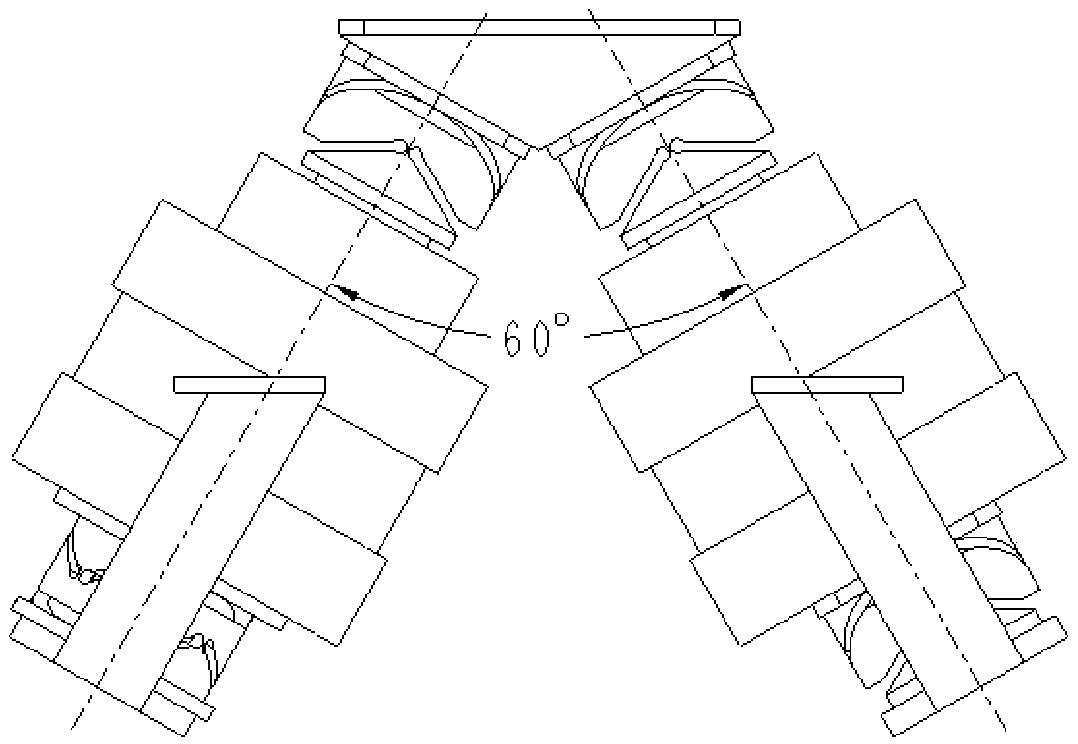

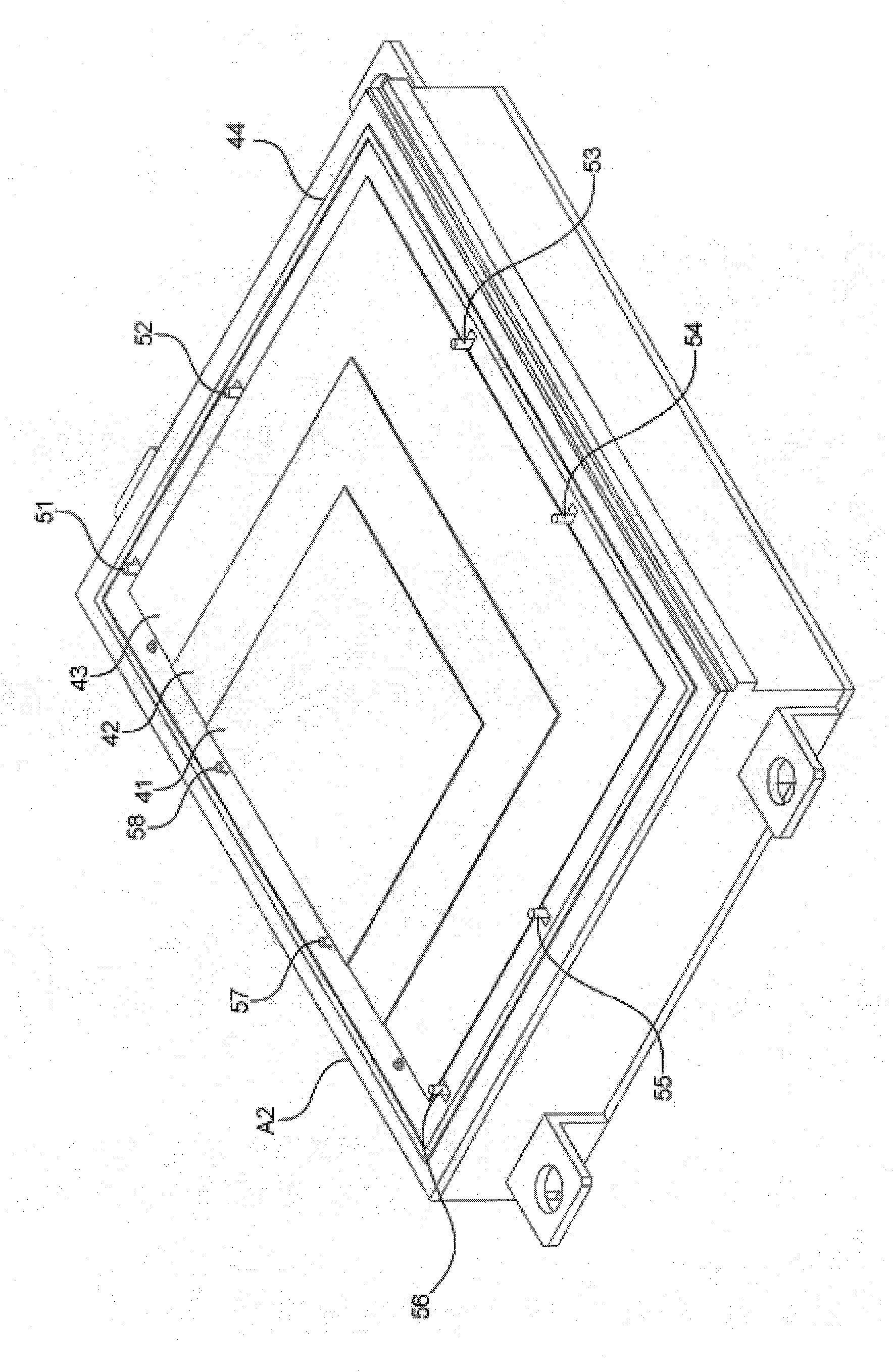

A six-degree-of-freedom posture adjusting device for satellite antenna

InactiveCN109004361AImprove on-orbit work efficiencyEliminate installation errorsAntennasDegrees of freedomActuator

A six-degree-of-freedom position and posture adjusting device for satellite antenna includes three sets of antenna mounted actuating assemblies mounted on the base, The three sets of actuator assemblies are evenly distributed on the pitch circle; Each set of actuator assembly comprises two actuators, the driving axes of the two actuators are at an included angle of 60 DEG, the upper ends of the two actuators are connected to the same adapter bracket A, and the lower ends of the two actuators are respectively connected to corresponding adapter brackets B; And the upper and lower ends of each actuator are respectively provided with flexible hinges. The invention can realize the six-degree-of-freedom posture adjustment of the satellite-borne antenna and compensate the position and posture deviation of the antenna on the orbit. The invention is applicable to satellite-borne antenna systems which require high position and attitude accuracy such as reflector antenna, measurement and controlantenna and data transmission antenna.

Owner:SHANGHAI SATELLITE ENG INST

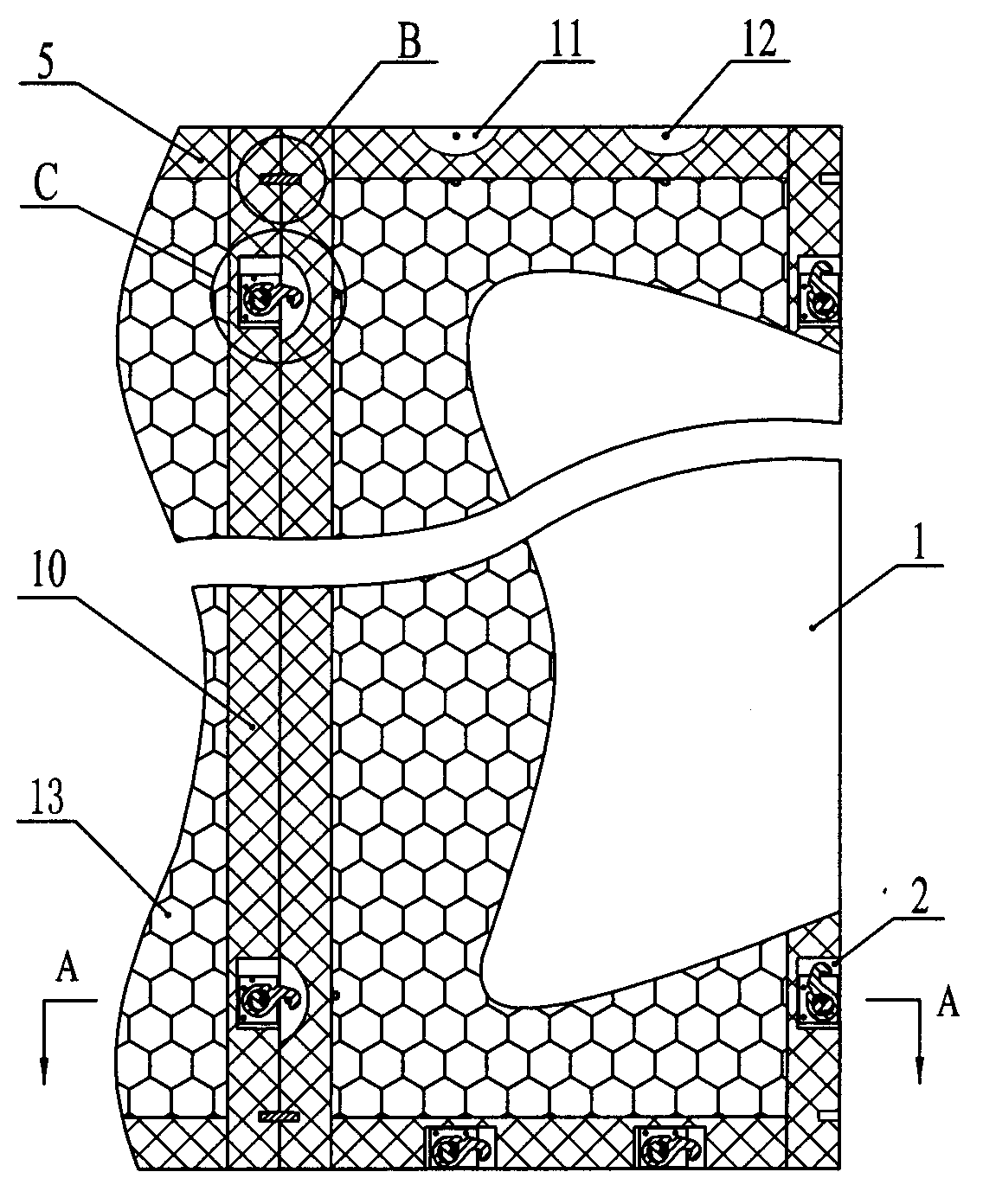

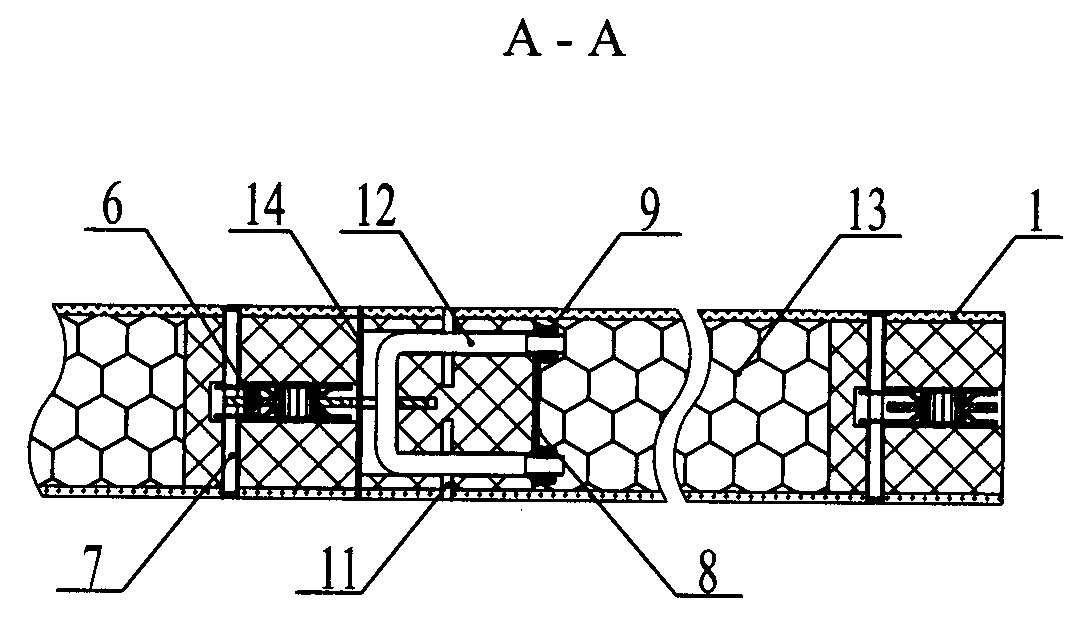

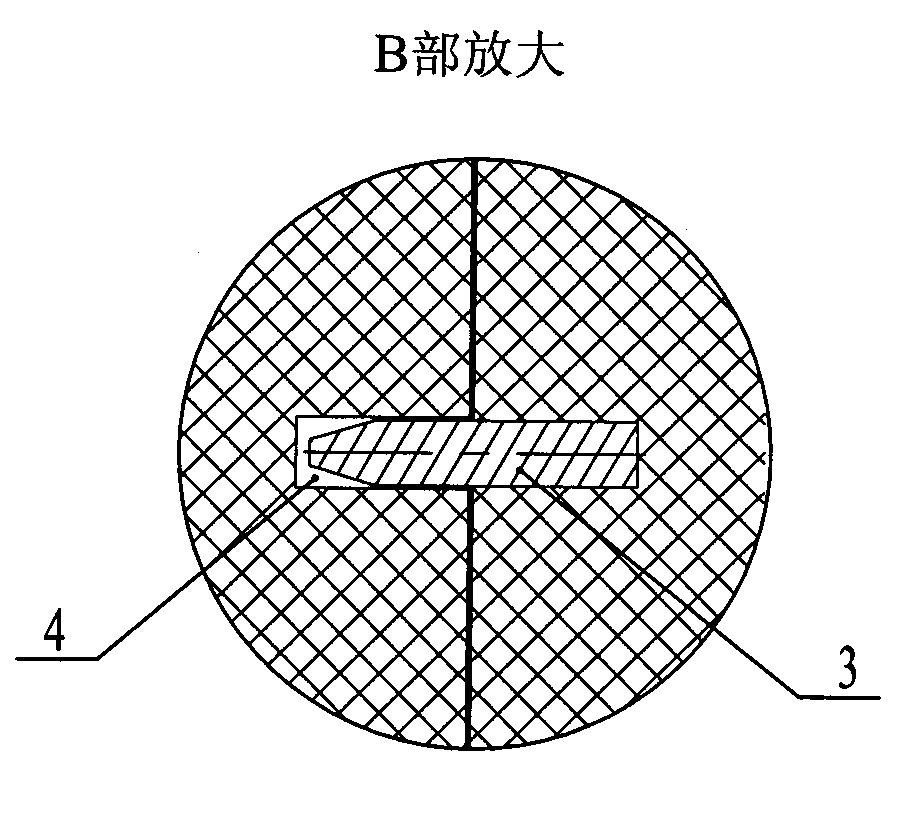

Self-positioning construction unit plate

InactiveCN103233548ANo step differenceEasy to processSheet joiningHeat proofingThermal insulationEngineering

The invention relates to a self-positioning construction unit plate, and solves problems such as complicated processing and difficult adjustment of existing spliced plates. The plate comprises a surface material and assembly components used for assembling adjacent surface materials. The invention has the technical points that: the surface material adopts a construction-use filling-type thermal-insulation load-bearing composite plate material; the assembly components comprise hitch devices composed of eccentric hook assemblies arranged in supporting frame blind hole hook slots of the surface material and U-shaped bolts arranged in supporting frame arc slots of an adjacent surface material, and self-positioning devices composed of positioning pins fixed on the surface material supporting frame and positioning holes provided on the supporting frame of an adjacent surface material; and with the hitching of the movable hooks and the U-shaped bolts of the hitch device, and with the cooperation of the positioning pins and the positioning holes of the self-positioning device, adjacent surface materials can be accurately spliced. The plate provided by the invention has reasonable structural design, and assists in realizing standardized production. Plate assembly and positioning are simple and fast, and self-positioning connection can be realized. Adjustment, transportation, and moving are convenient, such that construction quality and working efficiency are substantially improved.

Owner:SHENYANG THRIVE INDALIZED HOUSING

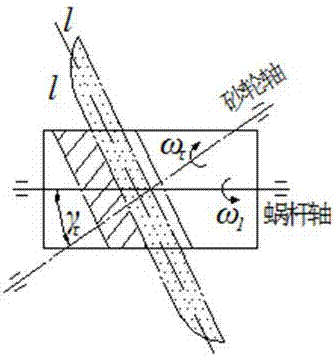

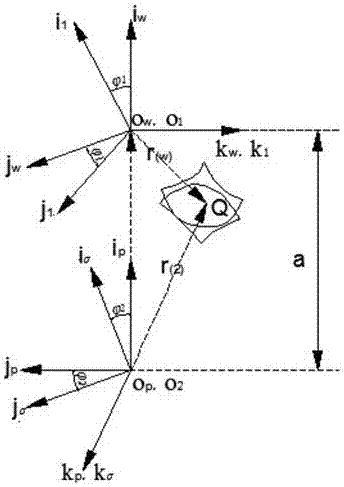

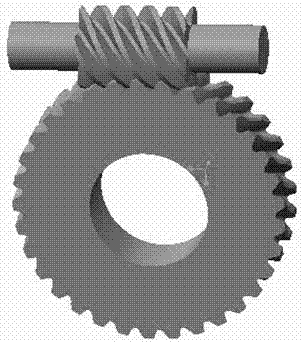

Arc-shaped face contact worm wheel and worm transmission power device

InactiveCN107965550AOvercoming difficult-to-manufacture problemsOptimized dynamic meshing performancePortable liftingToothed gearingsReducerEngineering

The invention discloses an arc-shaped face contact worm wheel and worm transmission power device and belongs to the field of escalator speed reducers. According to arc-shaped face contact worm wheel and worm transmission, a multi-head arc-shaped cylindrical worm is adopted; a optimized mathematical model of a worm wheel and the worm is established based on an evolutionary fish swarm algorithm, andparameter optimization is conducted on a worm pair so that engagement performance of tooth faces can be obtained; tooth face curvature correction is conducted on the worm based on grinding machining,so that the tooth faces are engaged into arc-shaped face contact, and the instant contact line of the worm wheel and the worm is changed gradually and stably and distributed uniformly; and the instant contact line of the tooth faces is perpendicular to the relative movement direction of the tooth faces of the worm wheel and the worm. After optimization design is conducted on the worm wheel and the worm which are engaged with each other through the device, tooth face curvature correction is conducted on the worm, so that the tooth faces are engaged into arc-shaped face contact; mounting errorsare eliminated; and the normal direction of the tooth faces of the worm pair is perpendicular to the relative speed direction of the tooth faces of the worm wheel and the worm so that the worm wheeland the worm which are engaged with each other can have good lubricating performance.

Owner:HAIAN COUNTY SHENLING ELECTRICAL APPLIANCE MFG +1

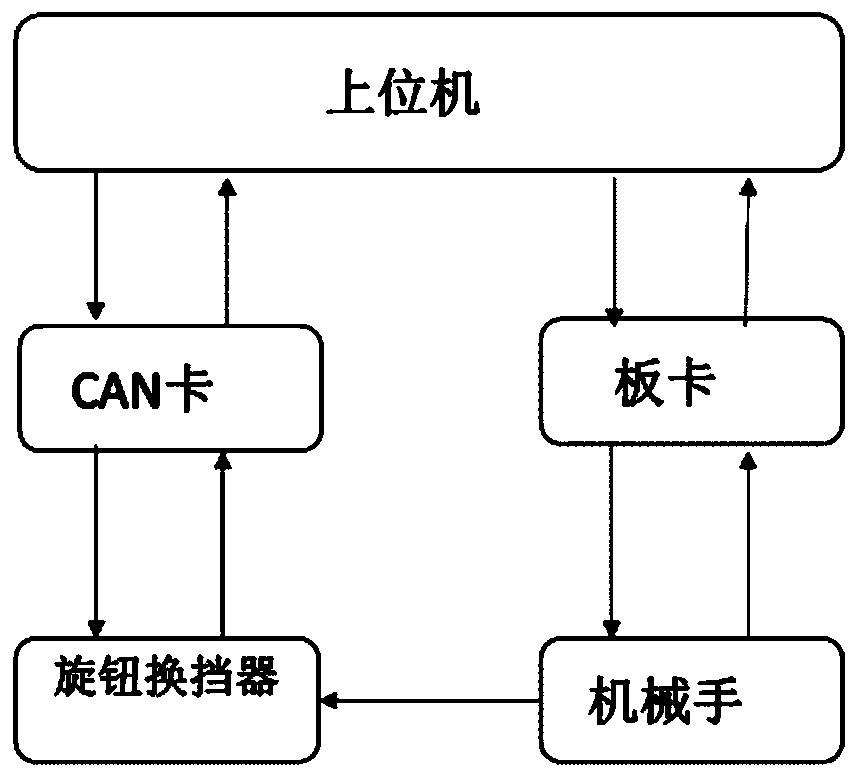

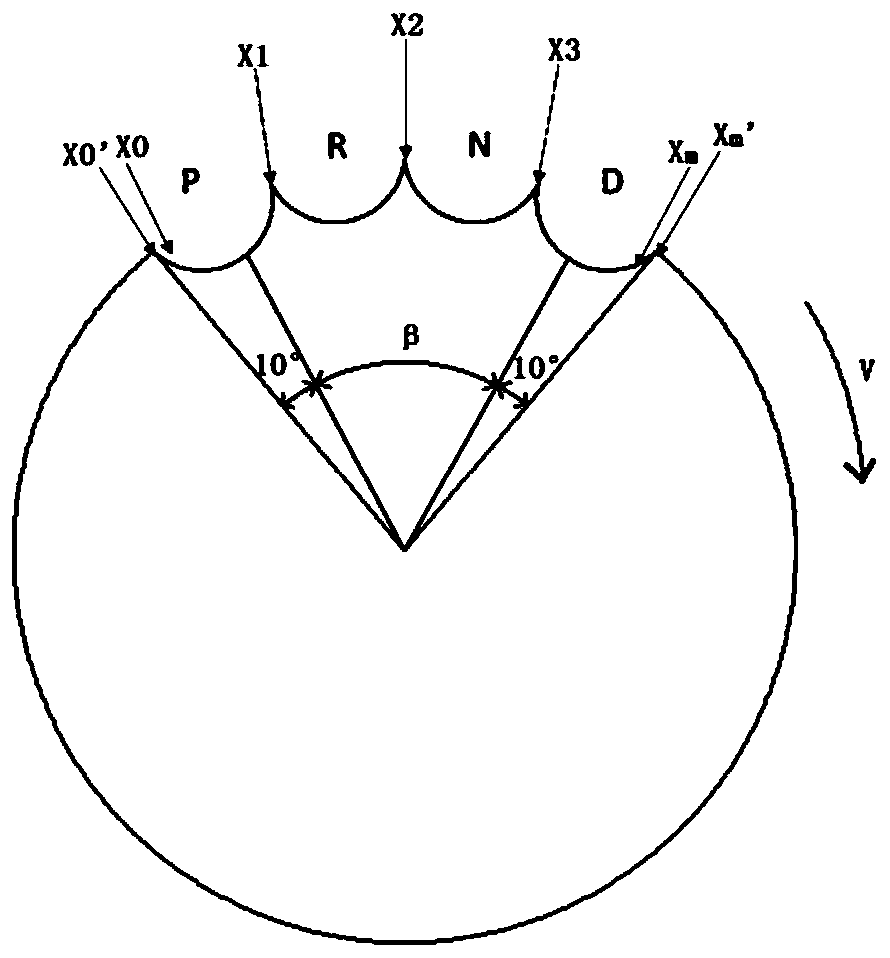

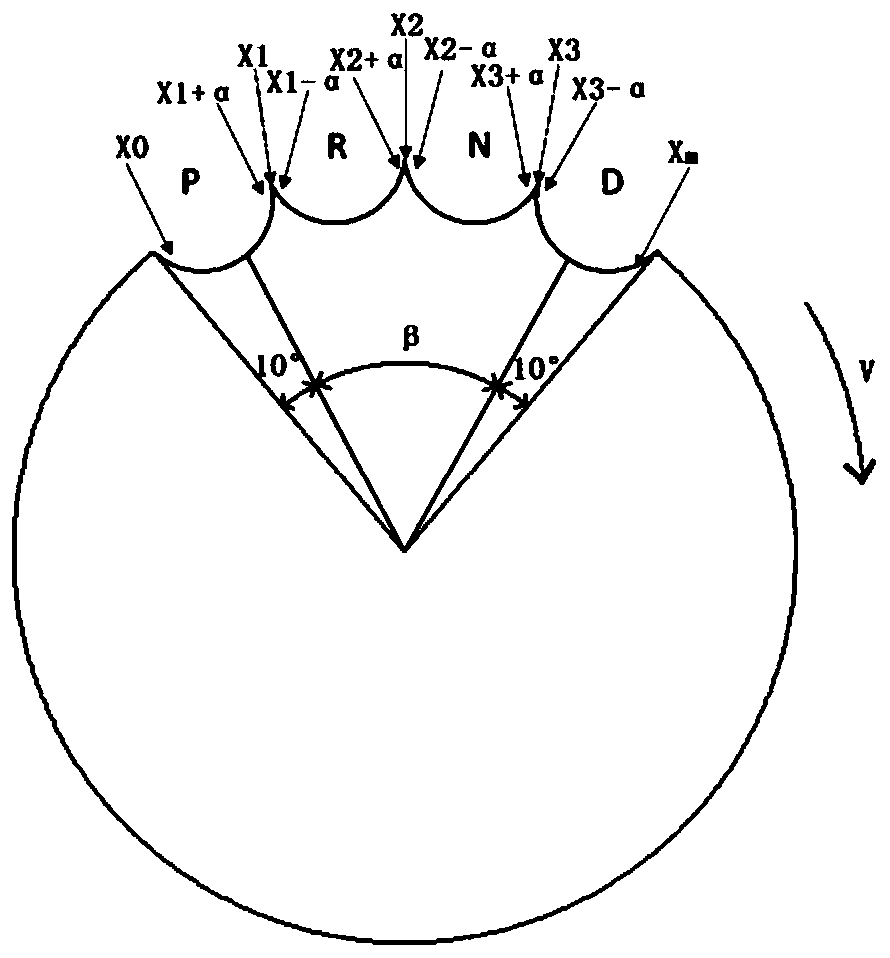

Gear self-learning method of knob shifter

ActiveCN110056643AEliminate installation errorsEliminate errorsGearing controlEngineeringStudy methods

The invention discloses a gear self-learning method of a knob shifter. a left dead center position and a right dead center position of the knob shifter are detected, taking the measured left stoppingpoint angle value X0 and the right stopping point angle value Xm as reference, the gear angle range of each gear of the knob shifter is calculated through self-learning, the installation error of theknob shifter and the error of the hall sensor can be eliminated to the maximum degree, so that the accuracy of the gear angle range obtained by self-learning is improved, so that the accuracy of the gear position recognition and judgment of the knob shifter is improved, and the driving safety is guaranteed; moreover, whether the left stopping point angle value X0 and the right stopping point anglevalue Xm of the knob shifter can be measured through the step S1, whether the limiting pins of the knob shifter at the left stopping point and the right stopping point are correctly installed or notis judged so as to prevent the workers from being misloaded and neglected.

Owner:GAC COMPONENT CO LTD

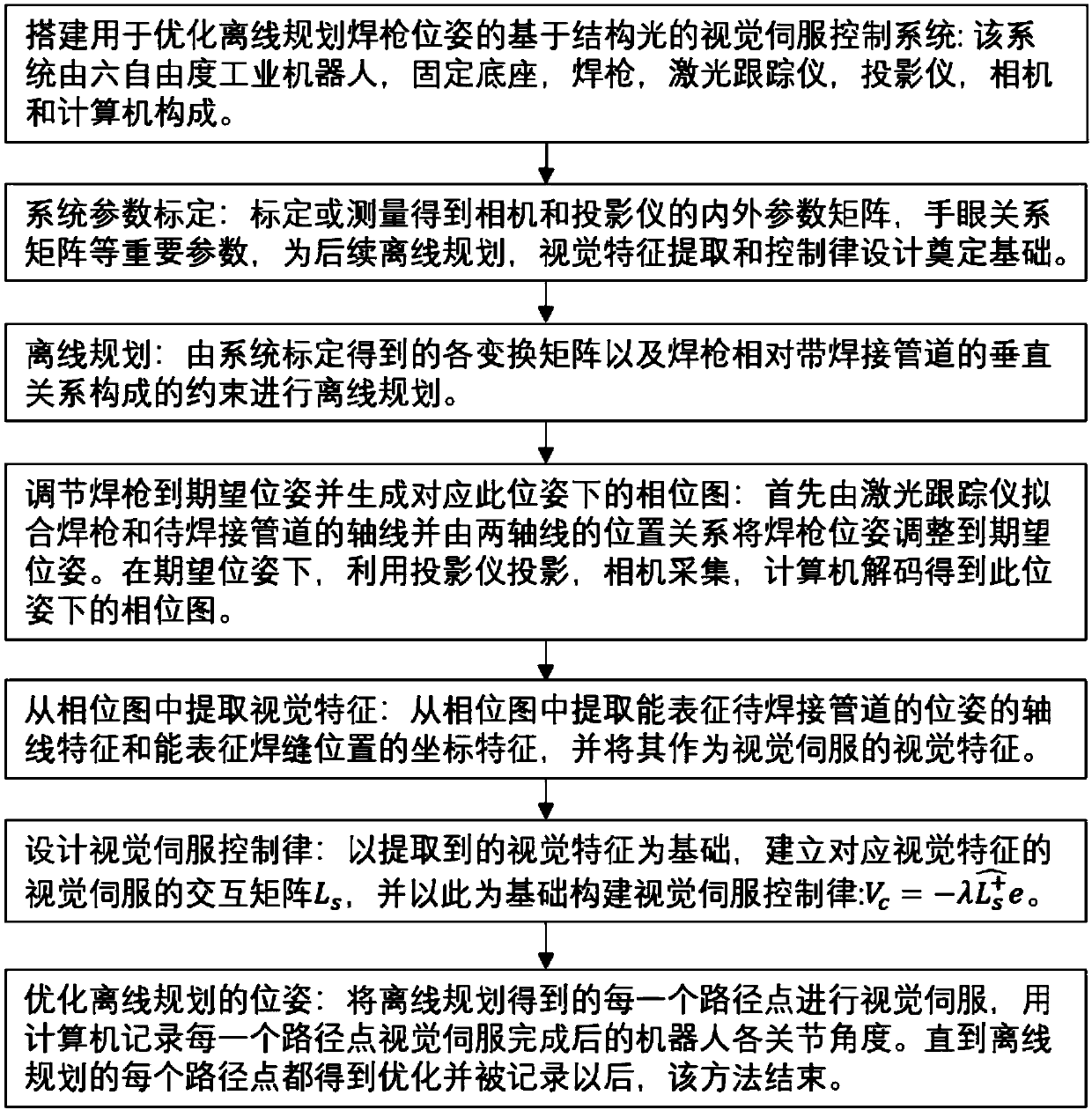

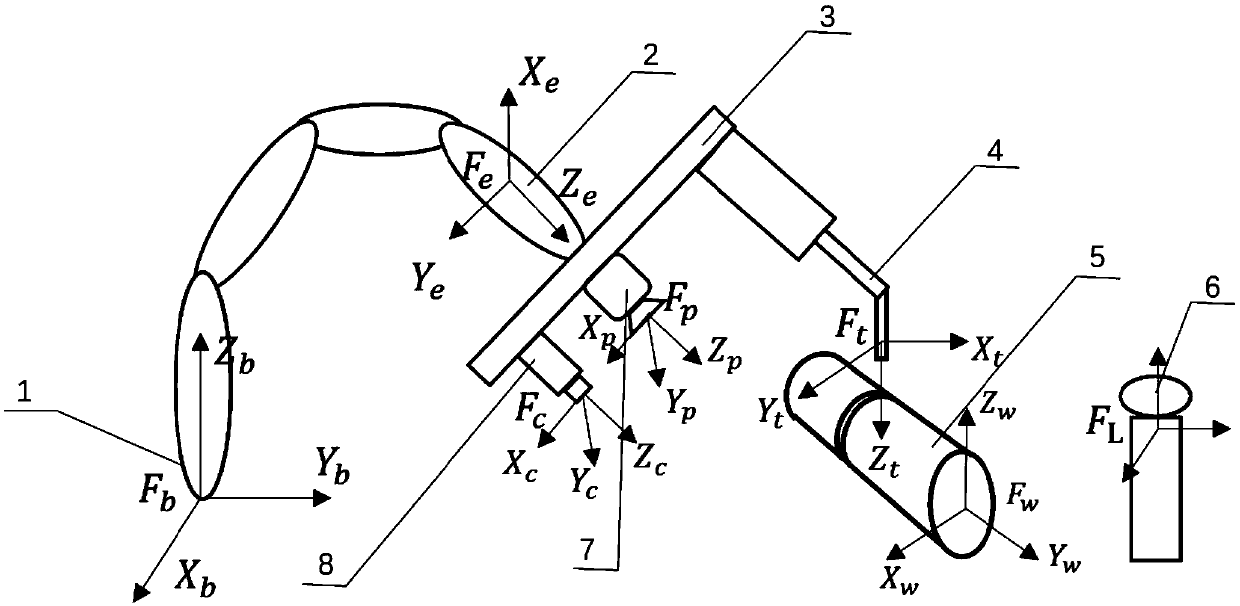

Method for optimizing off-line planned welding gun pose in robot pipeline welding

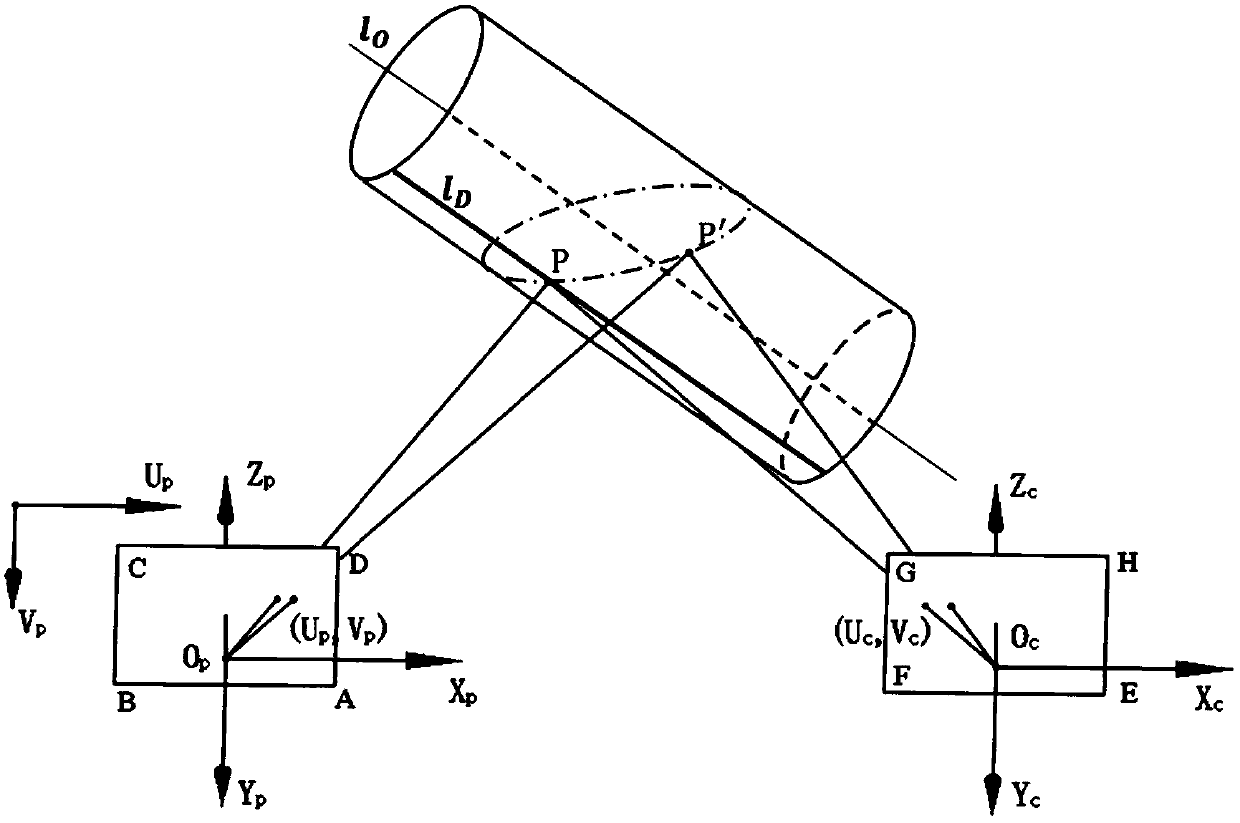

ActiveCN109623206AEliminate installation errorsEliminate modeling errorsWelding/cutting auxillary devicesAuxillary welding devicesVisual perceptionPipe welding

The invention provides a method for optimizing off-line planned welding gun pose in robot pipeline welding, and belongs to the field of welding gun pose optimizing and adjusting in pipeline welding. According to the method, firstly, a structured light measurement system for off-line planned welding gun pose optimization is built, and system parameters are calibrated; then, pipeline welding path points are off-line planned; a welding gun is adjusted to a desired pose, a phase diagram corresponding to the pose is generated, visual features of visual servo are extracted from the phase diagram, and a visual servo control law is designed; and at each off-line planned path point, the pose of each path point is optimized based on the visual servo control law, and corresponding angles of robot joints are recorded. According to the method, the advantages that structured light measurement is high in precision and visual servo control is high in precision are combined, and the advantage that a robot is high in repeated positioning precision is fully utilized, so that the pose of the welding gun in the actual welding process can be effectively optimized.

Owner:TSINGHUA UNIV

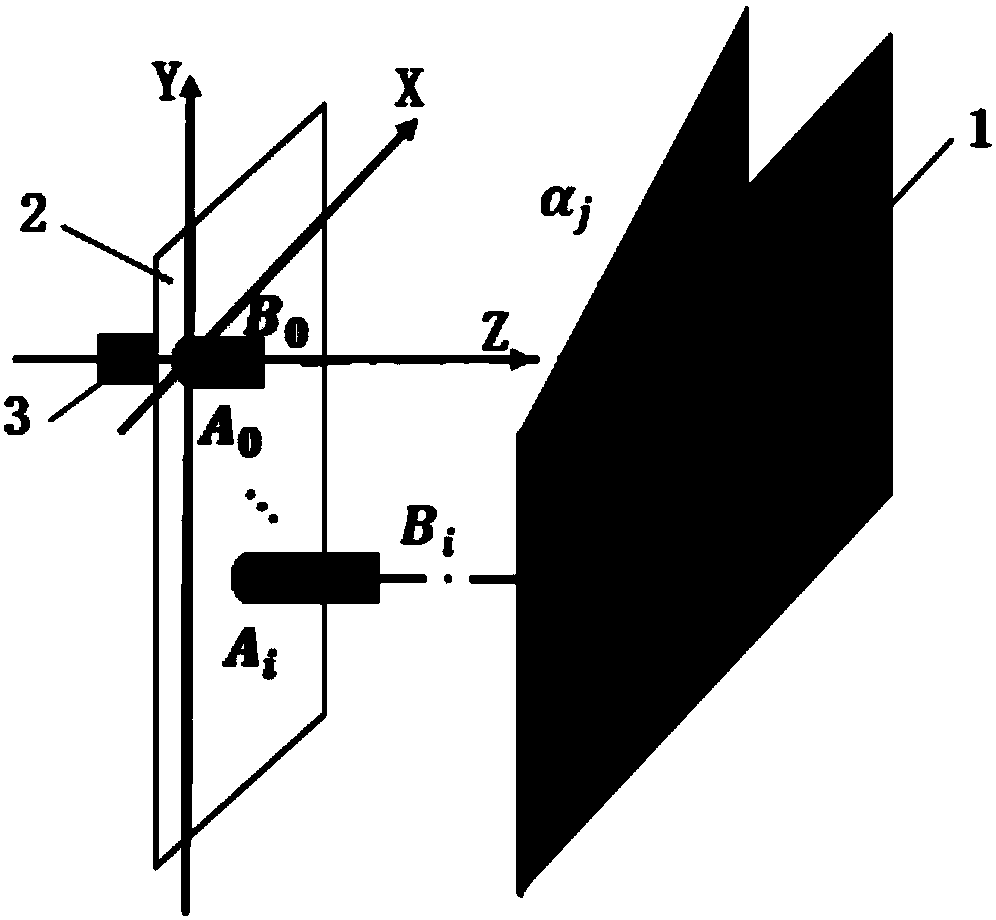

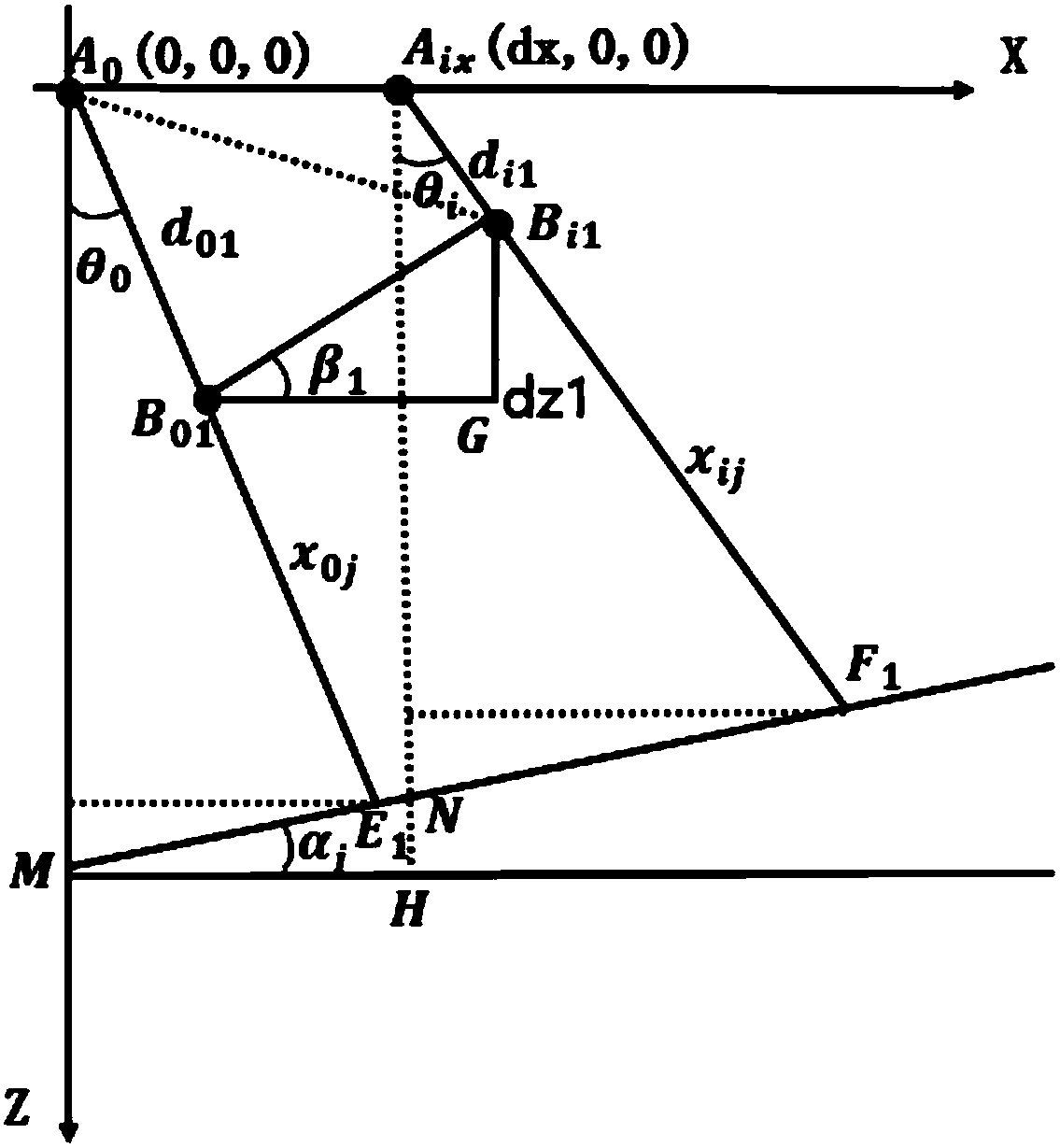

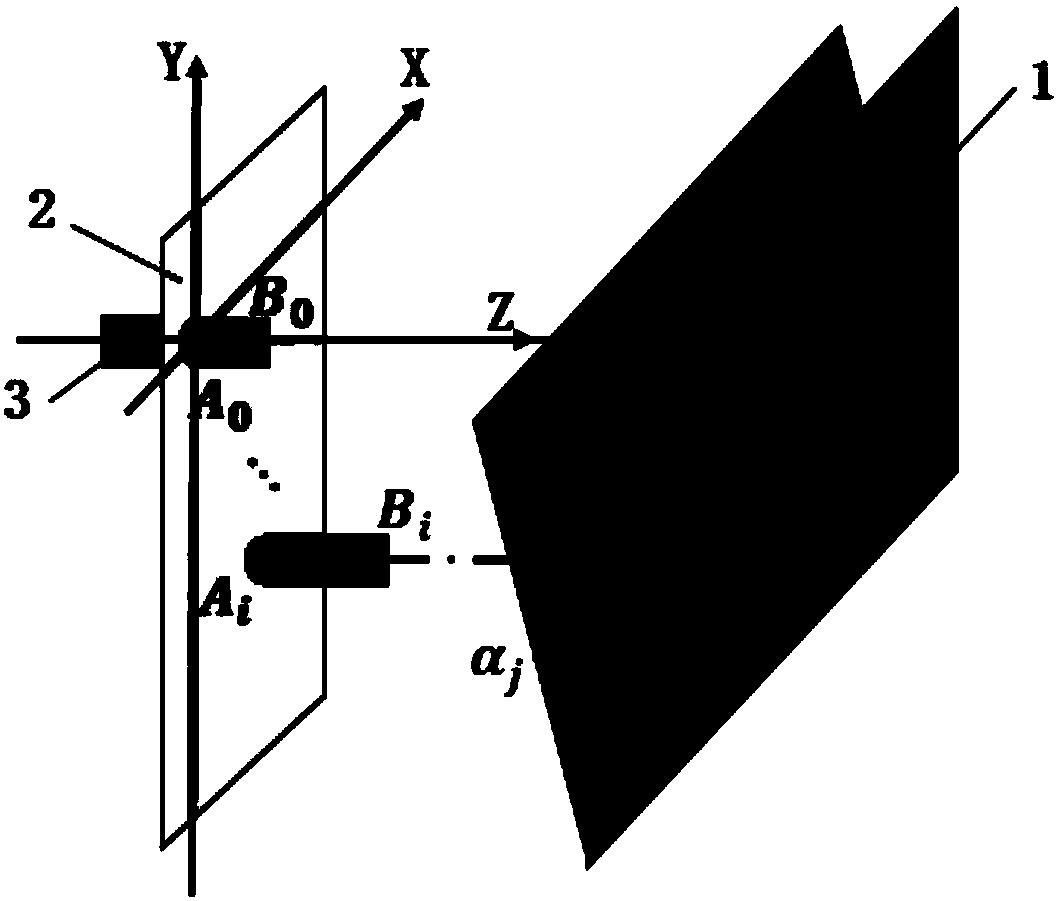

Eddy current displacement sensor array space geometry calibration method

ActiveCN107621220AAchieving Spatial Geometry CalibrationEliminate installation errorsUsing electrical meansSensor arrayEddy current

The invention belongs to the detection technical field and relates to a space geometry calibration method for any eddy current displacement sensor array by utilizing a common plane calibration board.The method is characterized by, to begin with, through rotation of the plane calibration board along one edge, realizing space geometry calibration in two directions between any two probes in an eddycurrent displacement sensor array; then, through rotation of the plane calibration board along the other edge, realizing space geometry calibration in the third direction of the any two probes; and finally, realizing space geometry calibration of the eddy current displacement sensor array, and obtaining space three-dimensional information of any probe in the array. The method realizes overall space geometry calibration of the eddy current displacement sensor array through two-axis rotation of the calibration board, thereby eliminating installation and processing errors, and improving calibration precision effectively; and the method is high in universality.

Owner:DALIAN UNIV OF TECH

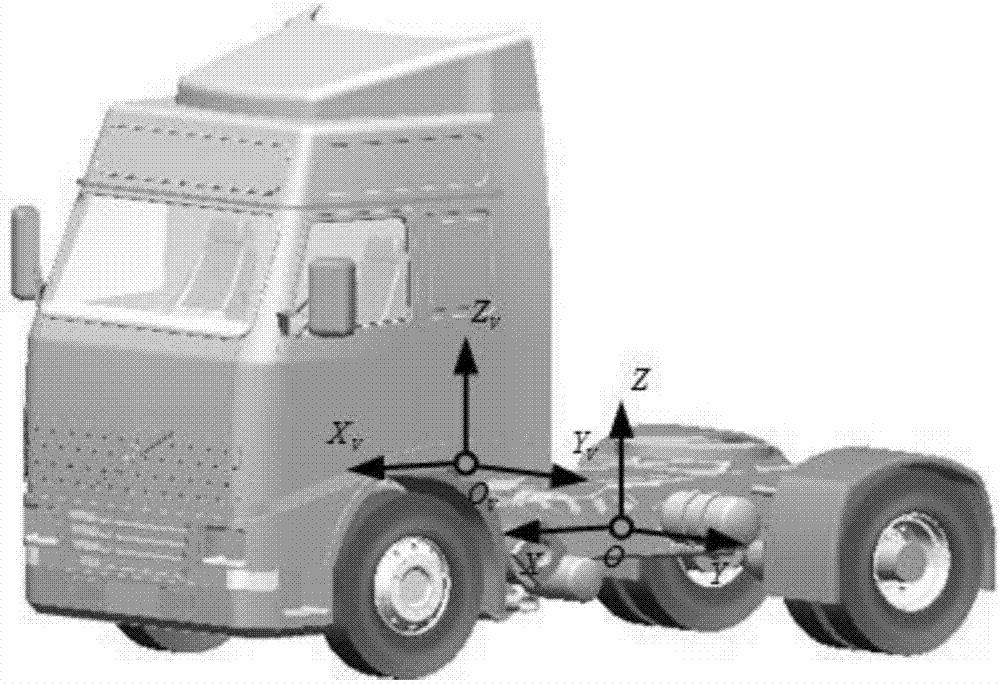

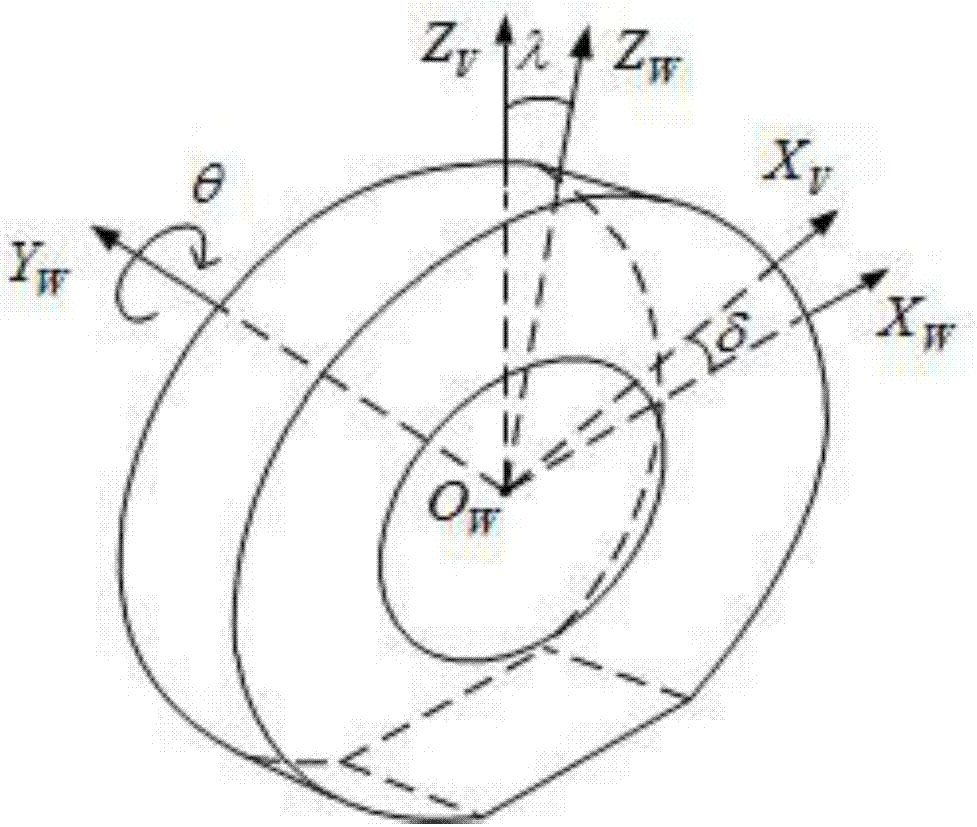

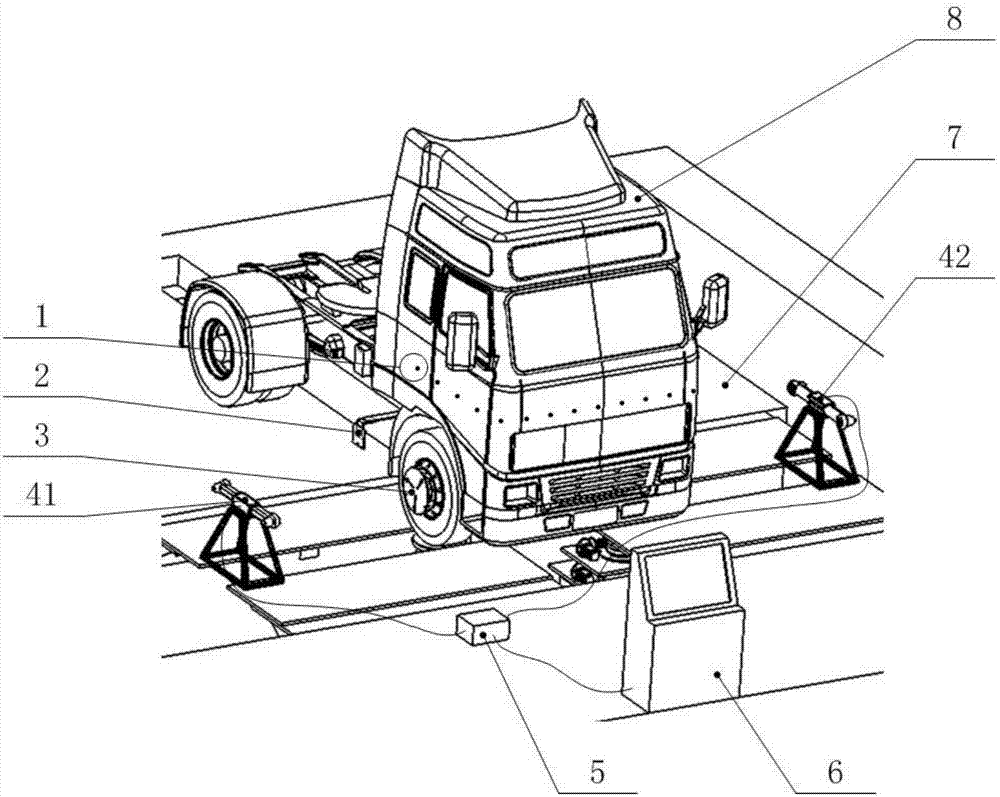

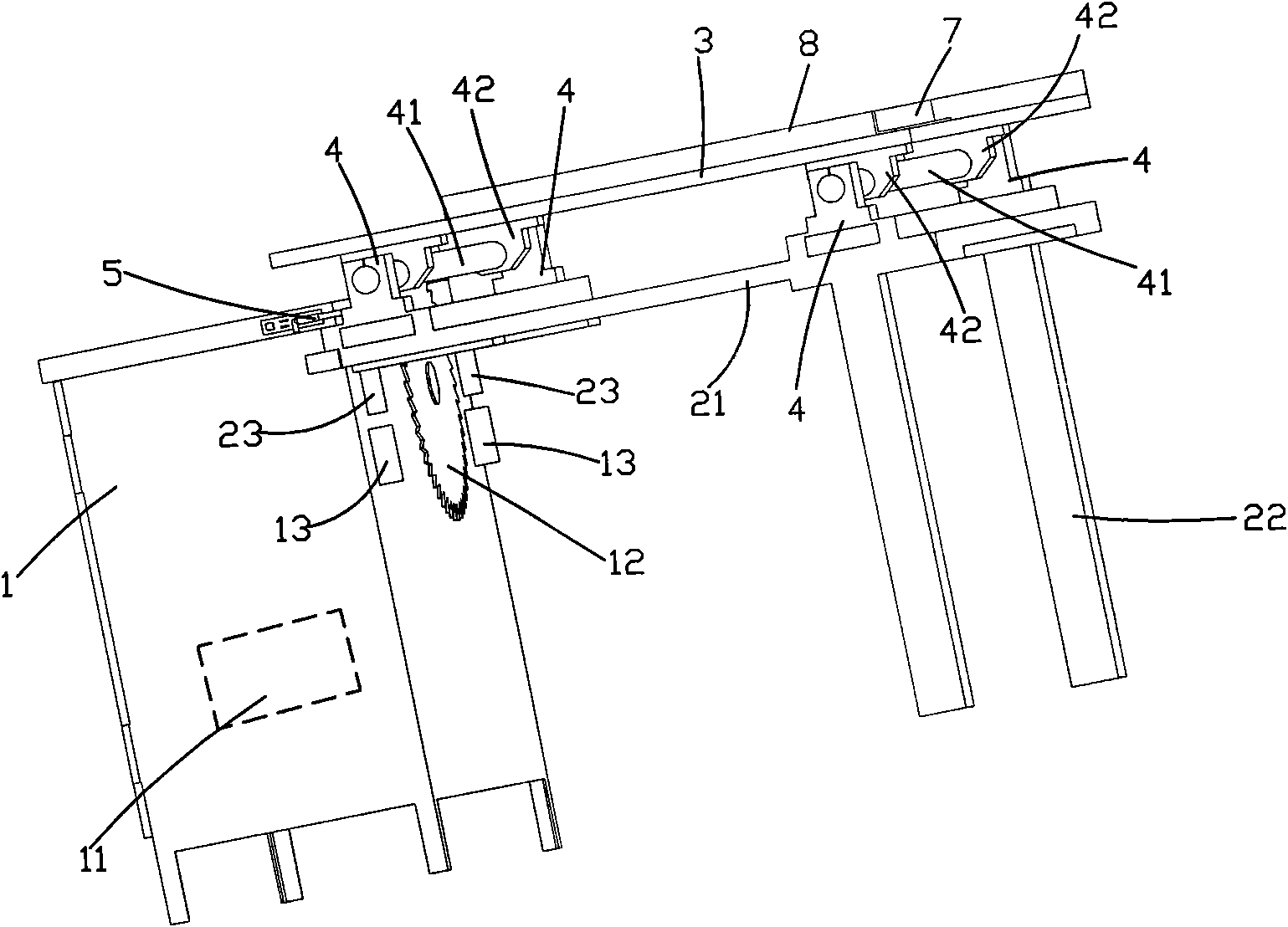

Suspension characteristic test vehicle wheel six-degree-of-freedom displacement measurement device and method

PendingCN107192343AEasy to measureOptimize layoutUsing optical meansSustainable transportationCoordinate changeVehicle frame

The invention discloses a suspension characteristic test vehicle wheel six-degree-of-freedom displacement measurement device and method. The device mainly comprises a first binocular vision measuring instrument (41), a second binocular vision measuring instrument (42), optical targets, a data exchange device (5), an upper computer (6), a vehicle wheel positioning fixture (3) and a reference fixture (2); a measured vehicle (8) is fixed on a test bench (7); the vehicle wheel positioning fixture and the reference fixture are respectively installed on a vehicle wheel and a frame; the optical targets are distributed on the measuring planes of the fixtures and a vehicle body; and the upper computer is connected with the binocular vision measuring instruments through the data exchange device, controls the binocular vision measuring instruments to measure the spatial coordinate change of the optical targets, calculates the six-degree-of-freedom displacement of the vehicle wheel under a vehicle coordinate system. According to the suspension characteristic test vehicle wheel six-degree-of-freedom displacement measurement device and method of the invention, the six-degree-of-freedom displacement of the vehicle wheel under the vehicle coordinate system is solved according to the spatial coordinate change of the optical targets, and accurate non-contact measurement can be realized. The measurement device and method of the invention have the advantages of convenient and flexible measurement, wide test range, high precision and bright application prospect.

Owner:HUAZHONG UNIV OF SCI & TECH

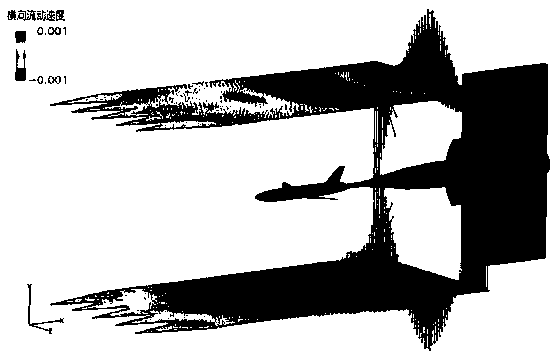

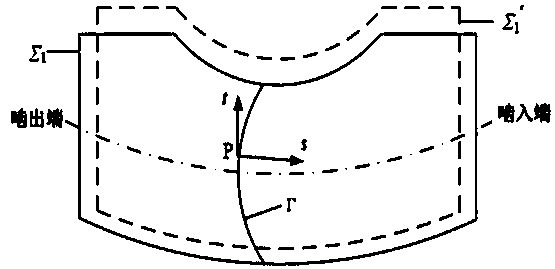

Test method for obtaining Darcy coefficient of hole wall, and application thereof

ActiveCN109883644AEliminate installation errorsEliminate zero driftAerodynamic testingSpecific modelEngineering

The invention discloses a test method for obtaining the Darcy coefficient of a hole wall, and application thereof, and aims to solve the problems as follows: the Darcy coefficient of the hole wall isobtained mainly through a comparative measurement method of a test model at home and abroad currently; but, only the Darcy coefficient in the forms of a specific model and a single wall plate can be obtained through the method; hole wall boundary layer change influence due to model blockage change cannot be evaluated; furthermore, a measurement result includes deviation due to different trains andmodels; and the result accuracy is relatively low. The invention provides the test method for conventional transonic wind tunnel hole wall Darcy coefficient measurement, and application thereof in asubsonic and transonic open-hole wind tunnel. Darcy coefficients different in Mach number and model attack angle state can be obtained in the invention; furthermore, influence of hole wall boundary layer characteristics, test running Reynolds numbers and the like can be included in the relation of the Darcy coefficient and a model lift coefficient; the method is suitable for a subsonic and transonic running range, the Mach number of which is less than 0.95; and a limiting condition is that large-area flow separation does not occur on a model lift surface.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

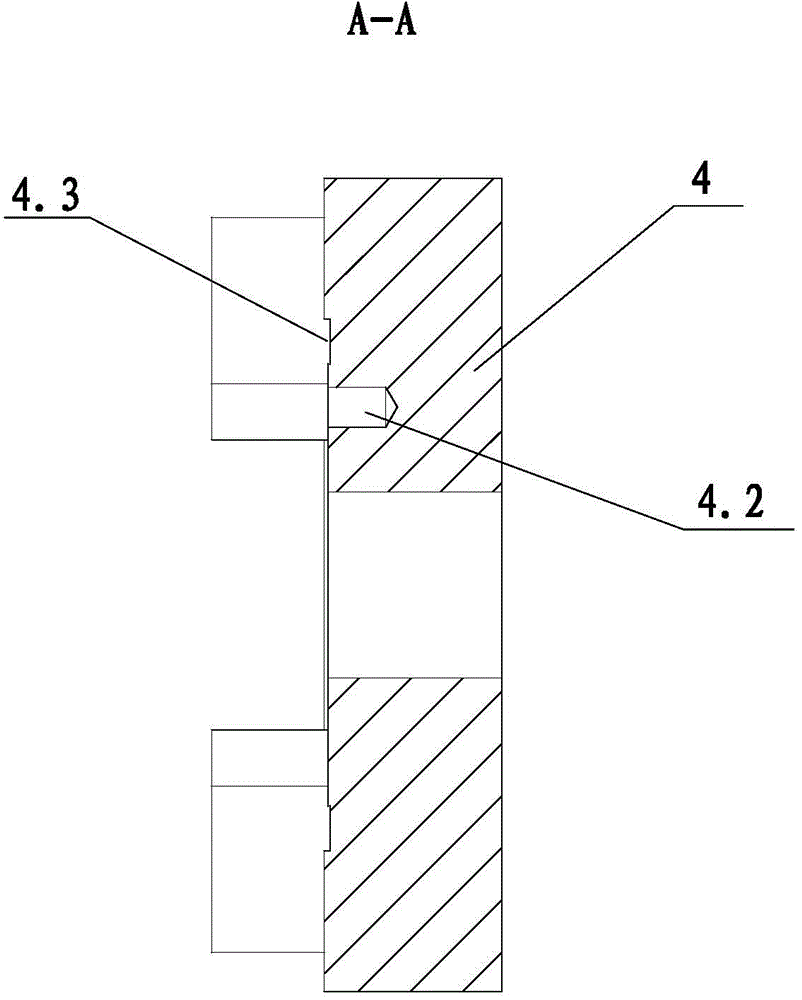

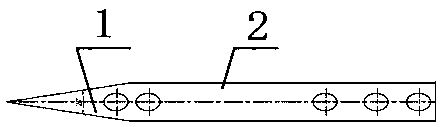

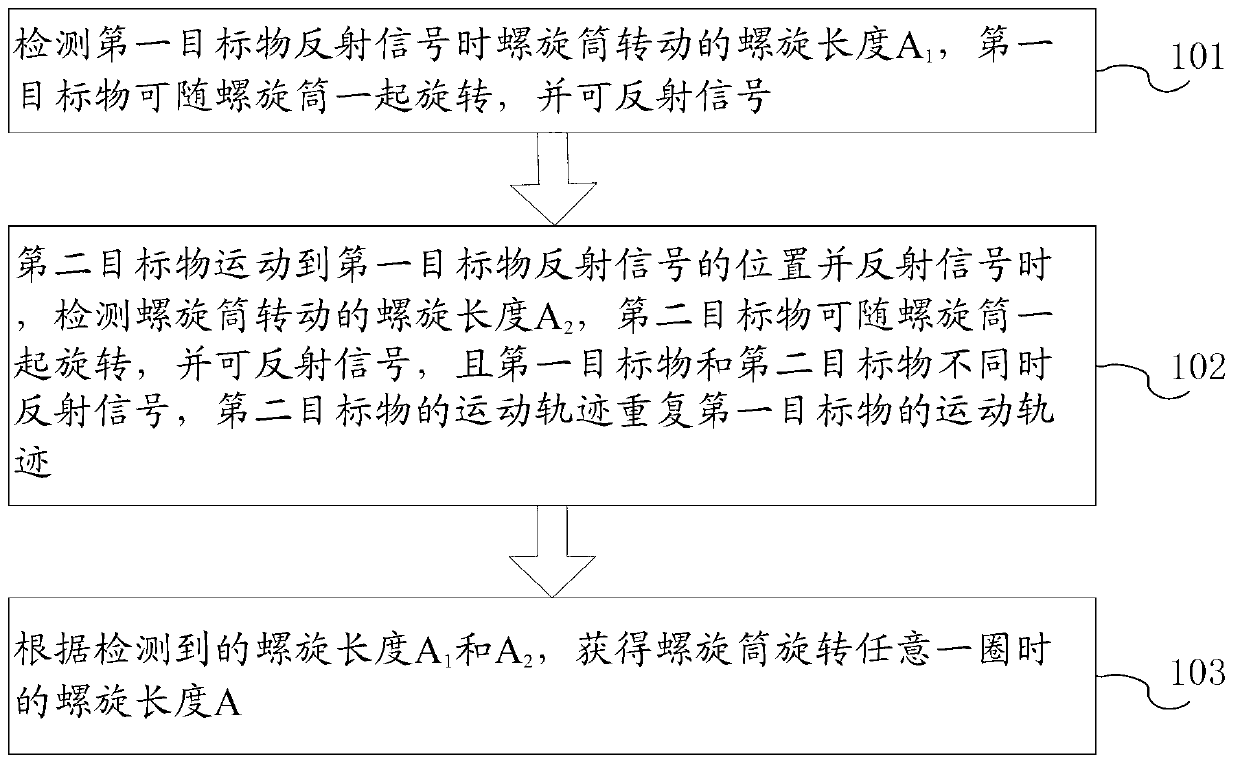

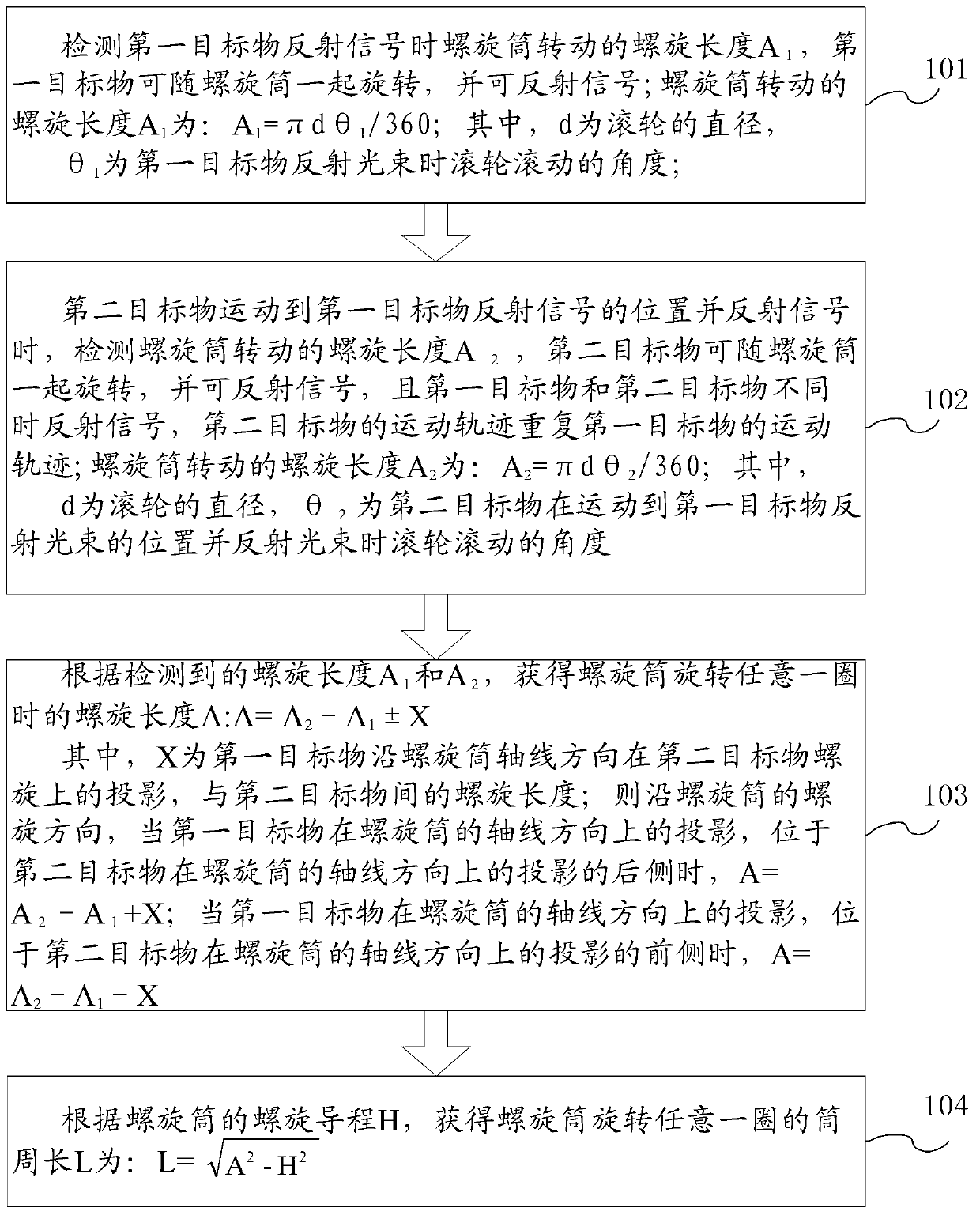

Circumference measurement method and device of spiral tube

ActiveCN102997851AMeasuring DynamicsAccurate measurementUsing optical meansMeasurement deviceEngineering

The invention provides a circumference measurement method and device of a spiral tube. The circumference measurement device comprises a detection device, a signal transmission device, a first target object, a second target object and a controller. The detection device can detect the spiral length of the spiral tube during rotation and is connected with the controller. The signal transmission device can transmit a signal. The first target object and the second target object are arranged on the wall of the spiral tube, can rotate along with the spiral tube, and respectively reflect the signal. The controller can obtain the spiral length and the tube circumference of the spiral tube rotating for any circle according to the spiral length of the spiral tube detected by the detection device when the first target object and the second target object respectively reflect the signal. By means of the technical scheme, circumference parameters such as the circumference, the diameter and the circumference error of the spiral tube can be measured accurately in a real-time and online mode, so that timely adjustment can be performed on a manufacture device of the spiral tube, installation errors can be eliminated, and manufacture accuracy of the spiral tube can be improved.

Owner:CHINA POWER IND INTERNET CO LTD

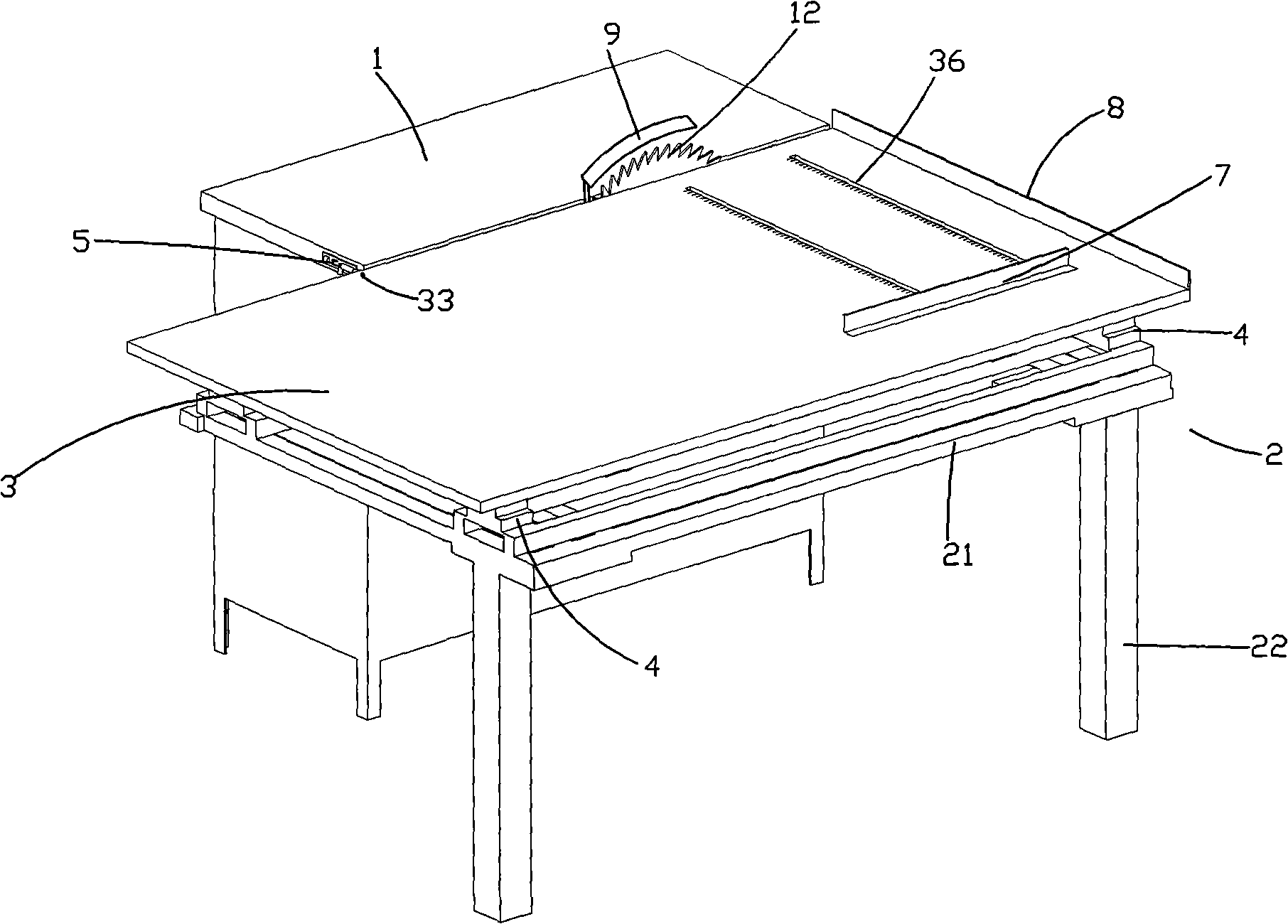

Carpenter saw

InactiveCN101524852AEliminate installation errorsReduce vibrationCircular sawsBark-zones/chip/dust/waste removalEngineeringWoodworking

The invention relates to a carpenter saw which comprises a power supply box, a bracket and a working platform, wherein, the power supply box is internally provided with a motor, the right end of the power supply box is provided with a saw bit driven by the motor, one end of the bracket is connected with the right end of the power supply box in an inserting way, the upper end of the bracket is provided with at least two sliding rods which are arranged in parallel along the longitudinal direction by a support seat, each of the sliding rods is sheathed and connected with at least two sliding linear bearings, and the working platform is fixedly installed on the linear bearings; when the working platform slides, the linear bearings move along with the working platform in real time, so that the good matching between the linear bearings and the sliding rods can be ensured when in sliding, the vibration can be effectively reduced, and the processing quality of wood can be improved; in addition, the linear bearings can be directly used for limiting the movement of the working platform along the vertical direction and need not to be in virtue of other structures. Therefore, the carpenter saw is very simple in structure and convenient in installation and maintenance.

Owner:张俊华

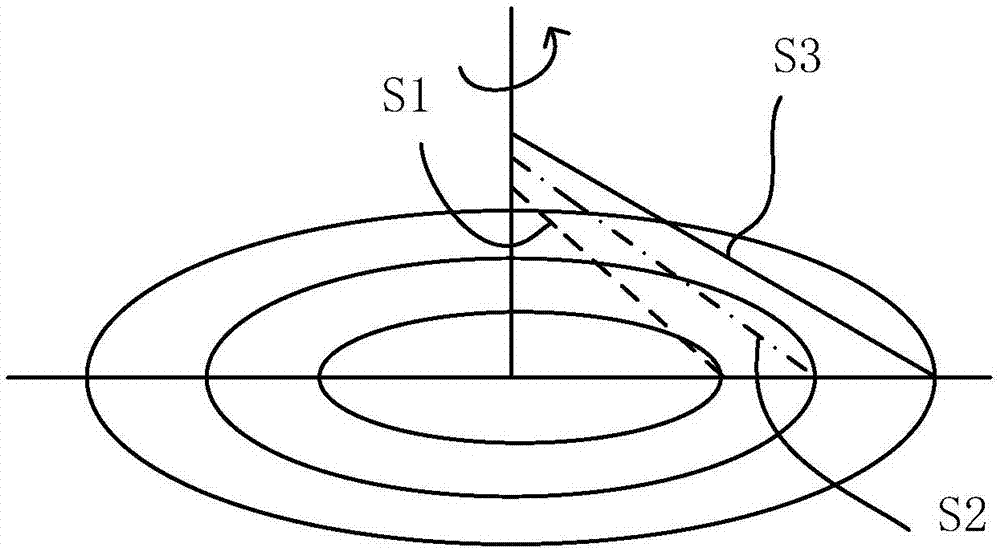

Controllable profile modification method of tooth surface of arc-tooth cylindrical worm

InactiveCN108204441AIncrease contact areaImprove the lubrication effectPortable liftingGearing elementsMathematical modelEngineering

The invention provides a controllable profile modification method of a tooth surface of an arc-tooth cylindrical worm, and belongs to the technical field of self-adaptive heavy-load conveying and driving equipment. The method is characterized in that the curvature of the tooth surface of the arc-tooth worm is corrected to realize consistent change of the tooth surface profile modifying rules and the normal curvature radius in opposite moving direction of secondary tooth surfaces of the worm; the main curvature of a worm grinding wheel is analyzed and a mathematic model for profile modifying isbuilt based on the worm pair engaging theory and the induced curvature concept; then the induced curvature and the geodesic torsion of a contact point of the tooth surface of the worm are solved, andthe microscopic shape of the tooth surface of the worm is analyzed; and finally a curvature correction equation and a tooth surface profile modifying equation are solved based on the analyzing result, thus realizing the curvature based profile modification of the tooth surface of the worm; after the worm is subjected to tooth surface curvature correction, the tooth surface engaging is replaced byarc-surface contact, thus the mounting error can be removed, and the normal direction of the tooth surface of the worm pair is vertical to the relative speed direction of the tooth surfaces of a wormgear and the worm, and as a result, the worm gear and the worm which are engaged with each other can be lubricated.

Owner:HAIAN COUNTY SHENLING ELECTRICAL APPLIANCE MFG +1

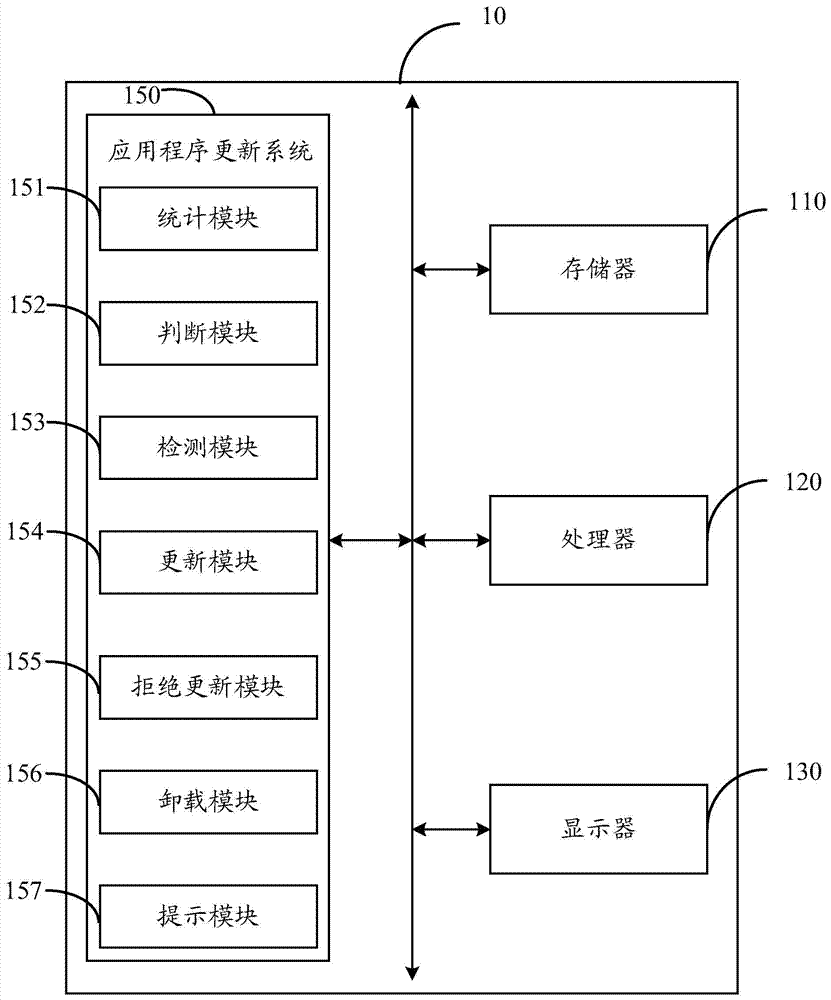

Application program update method and application program update system

InactiveCN104778058AAvoid inconvenienceEliminate installation errorsProgram loading/initiatingTime rangeApplication software

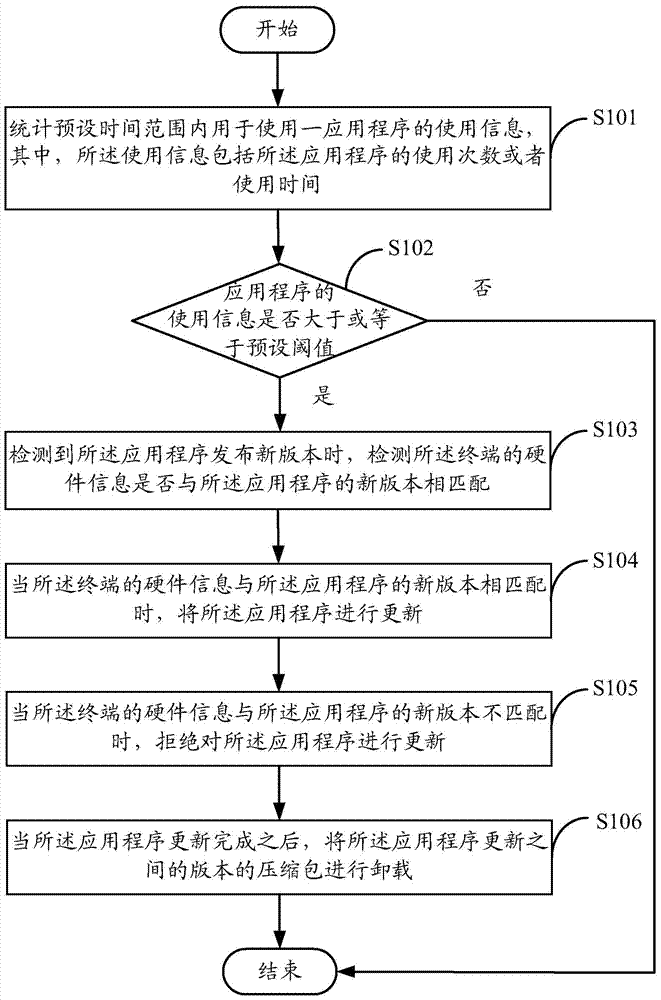

The invention provides an application program update method and an application program update system. The application program update method comprises the steps of collecting use information of an application program by a user within a preset time range, wherein the use information includes use frequency or use time of the application program; determining whether the use information of the application program is greater than or equal to a preset threshold value; determining whether hardware information of a terminal is matched with a new version of the application program or not upon determination that the user information of the application program is greater than or equal to the preset threshold value and that the new version of the application program is issued; and updating the application program when the hardware information of the terminal is matched with the new version of the application program.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

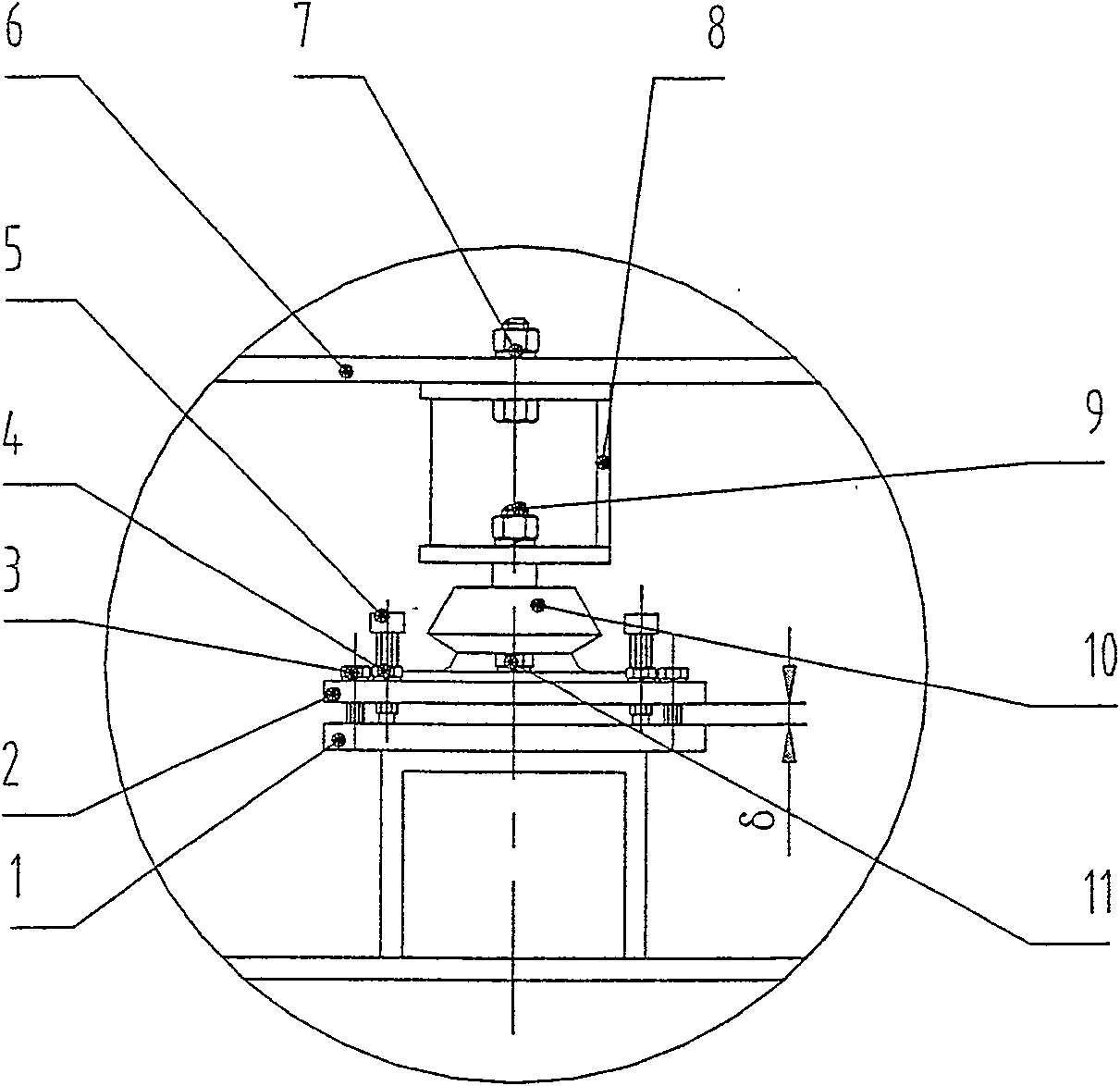

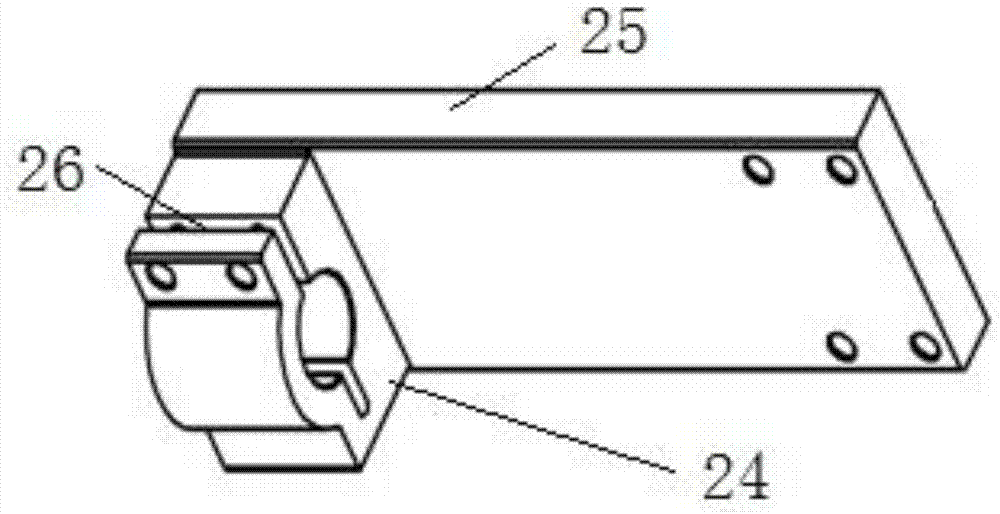

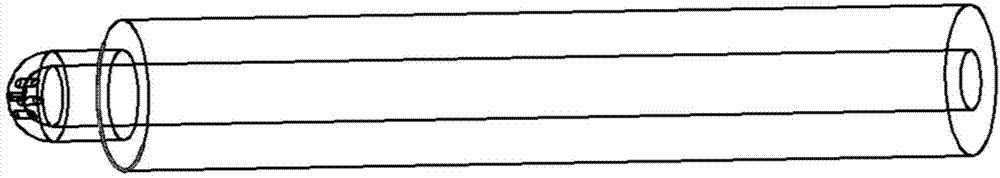

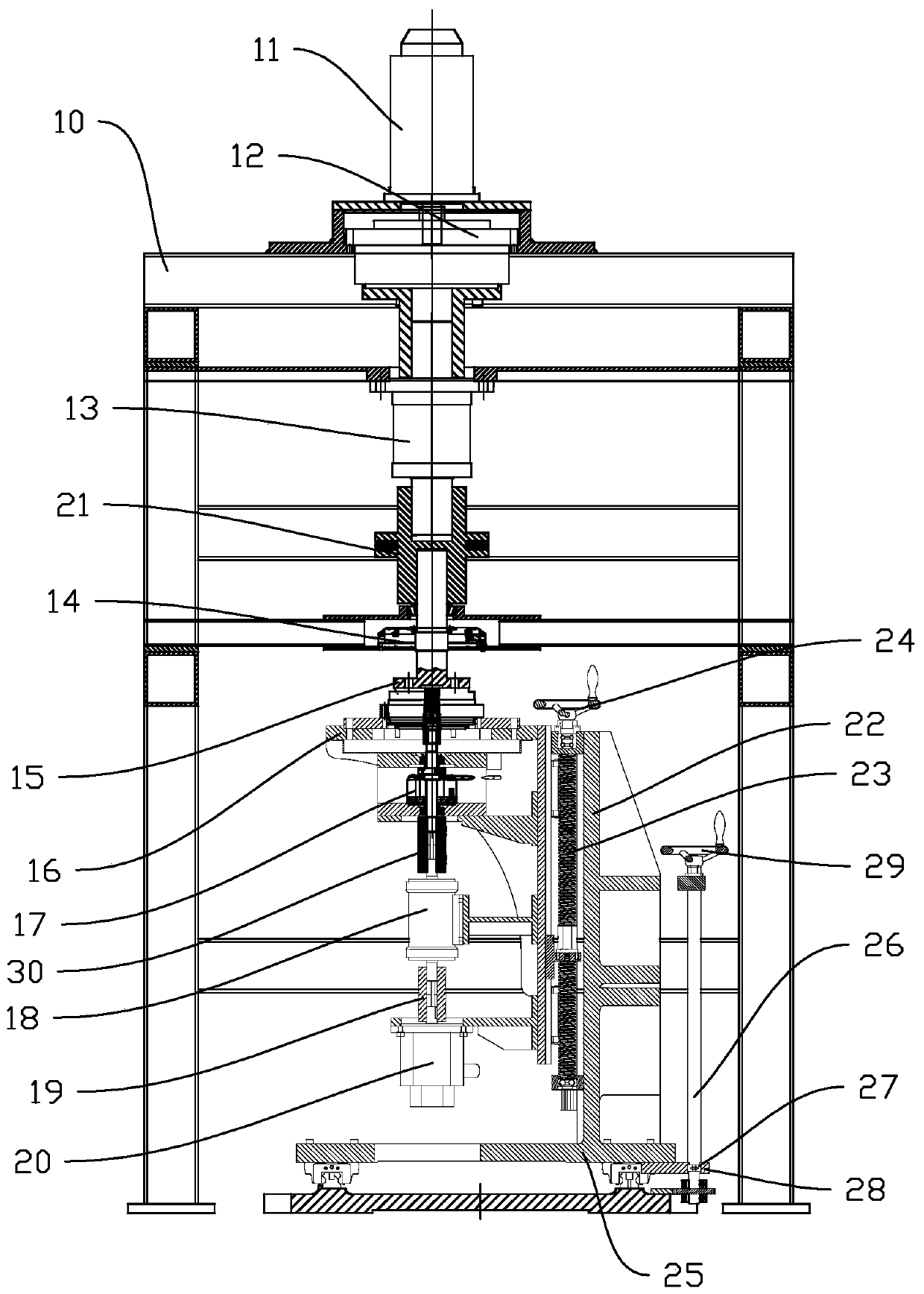

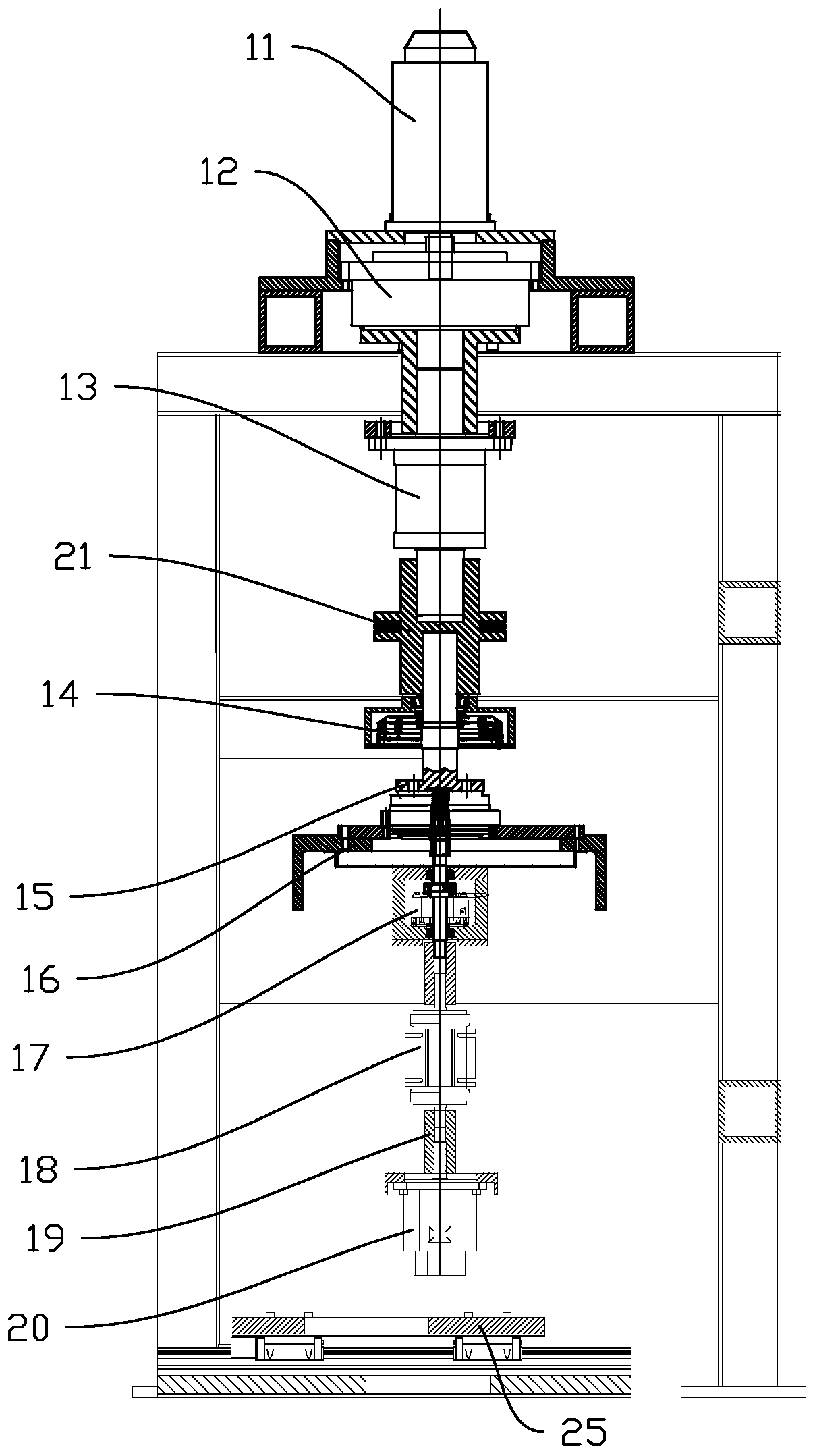

Spherical cathode numerical control electrochemical machining machine tool

InactiveCN104741712AAvoid designAvoid makingMachining electrodesMachining working media supply/regenerationNumerical controlElectrolysis

The invention relates to a spherical cathode numerical control electrochemical machining machine tool which comprises a machine tool body. The machine tool body is provided with a linear circular rail. The machine tool body is provided with a workbench. The workbench is provided with an insulating plate. The insulating plate is connected with a machining box in a closed mode. The linear circular rail is provided with a three-axis movement mechanism. A Z-direction movement mechanism and a C-direction rotating mechanism in the three-axis movement mechanism are fixedly connected. The C-direction rotating mechanism is provided with a spherical cathode through a fixture in a clamped mode. The spherical cathode is of a round-rod-shaped structure with a spherical head. The spherical head end of the spherical cathode is provided with a plurality of small holes. The spherical cathode is internally provided with through holes communicated with the small holes. One side of the machine tool body is provided with an electrolyte storage mechanism and a pumping mechanism. The pumping mechanism pumps the electrolyte in the electrolyte storage mechanism to the through holes in the spherical cathode, and then the electrolyte flows out of the small holes. In the flowing out process of the electrolyte, the spherical cathode is driven by the three-axis movement mechanism and the C-direction rotating mechanism to finish machining of workpieces.

Owner:SHANDONG UNIV

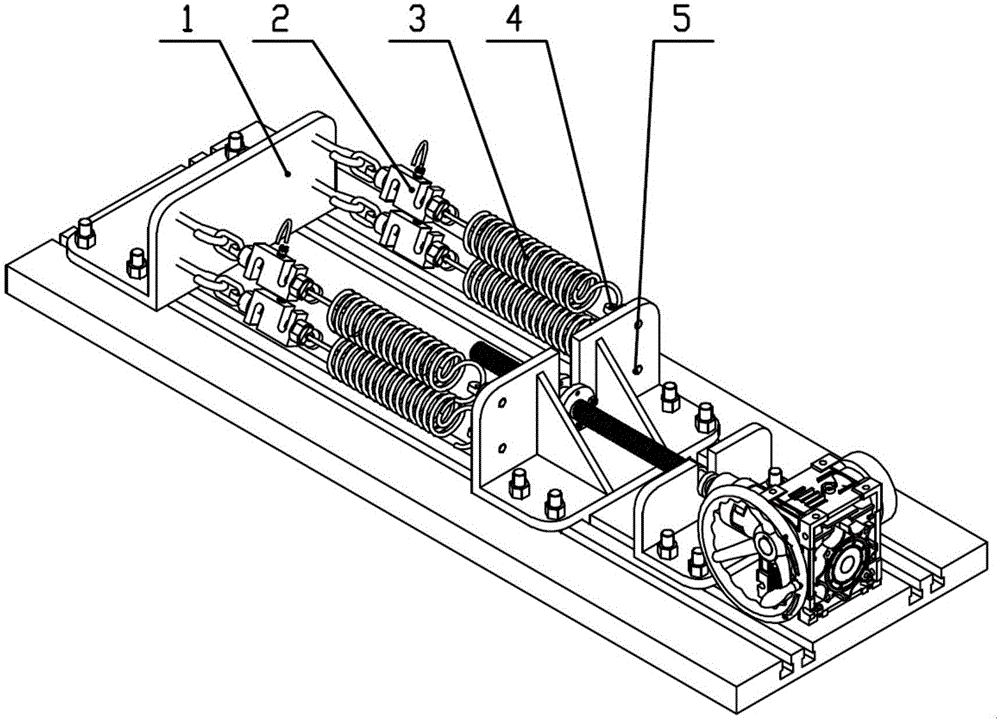

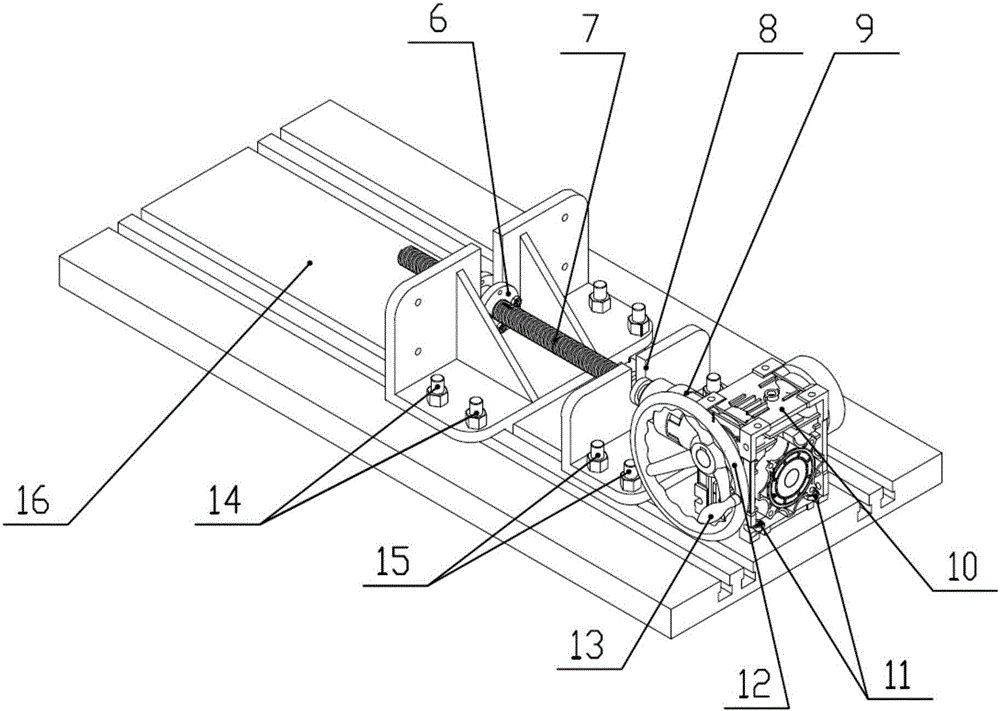

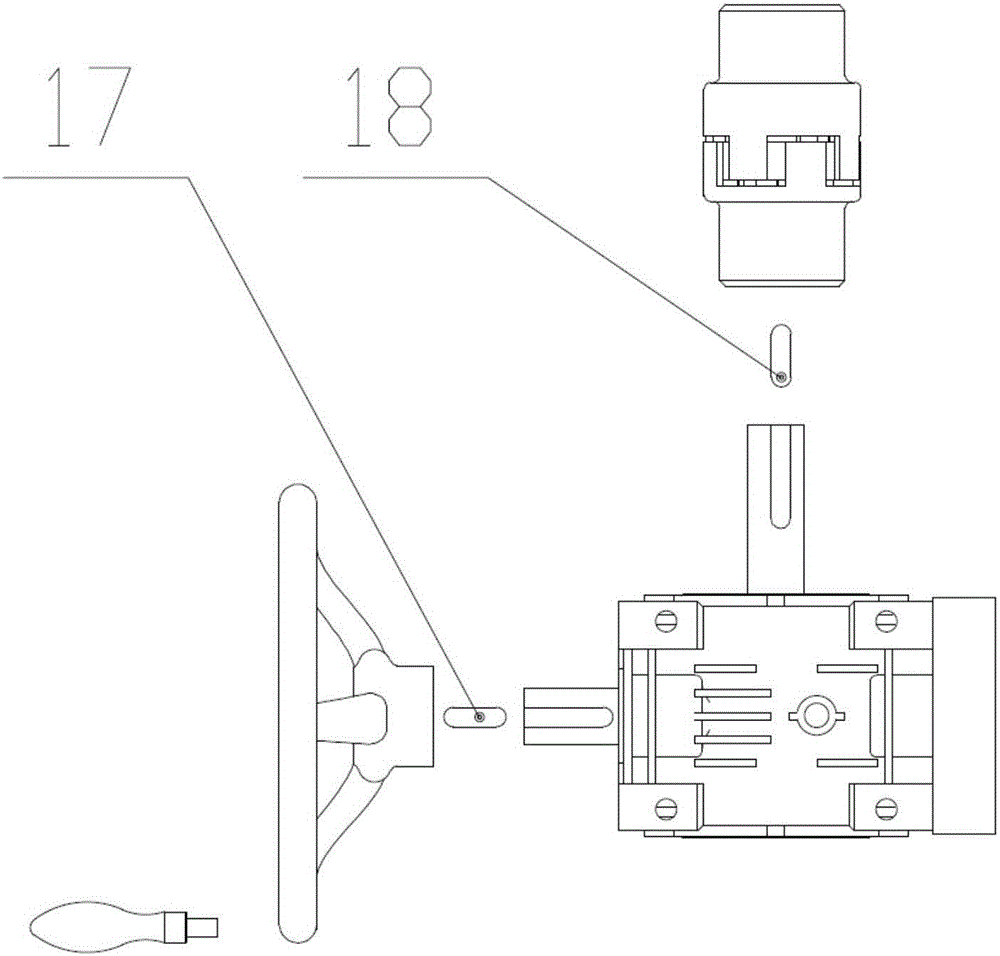

Testing table for detecting the relaxation of high voltage breaker closing spring stress

ActiveCN106370402ATest for stress relaxationQuantitative description of stress relaxationMachine part testingPull forceEngineering

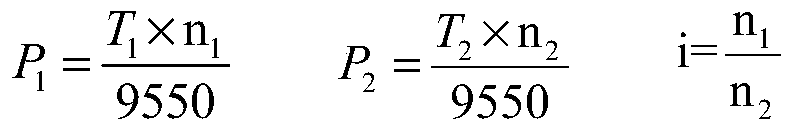

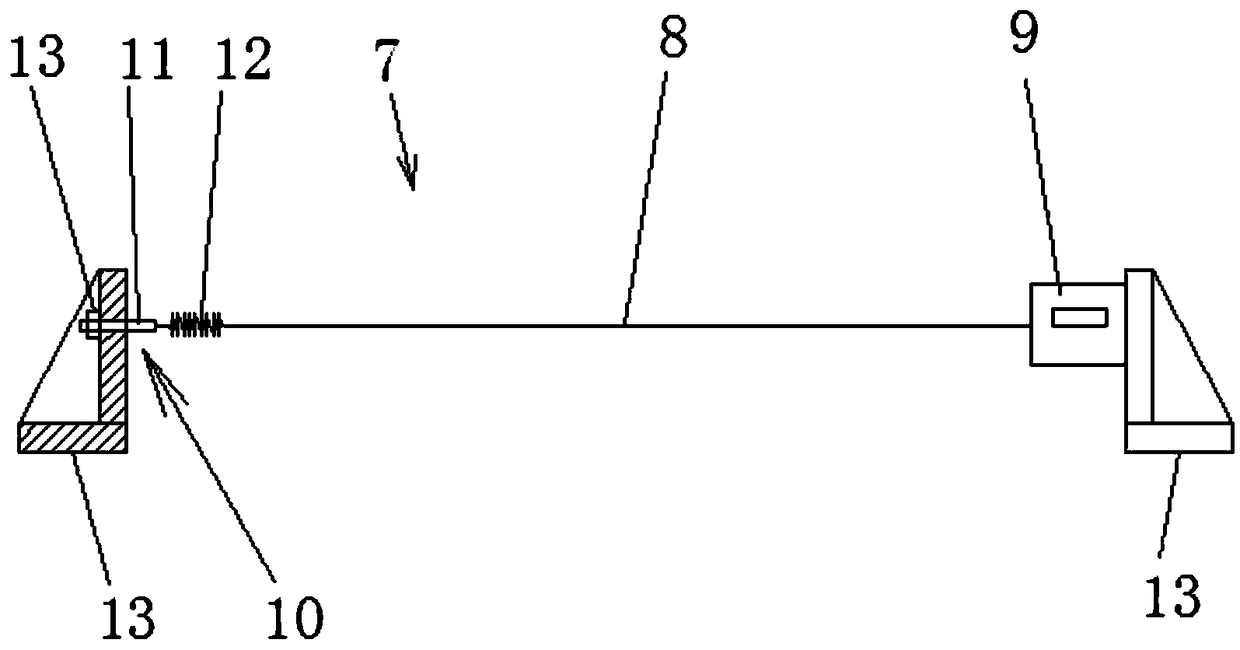

The invention discloses a testing table for detecting the relaxation of high voltage breaker closing spring stress, which comprises a substrate, a spring fixing plate, a spring moving platform, a screw rod fixing plate, a hand wheel and a speed reducer. The spring fixing plate and the screw rod fixing plate are fixedly arranged on the substrate; the spring moving platform is capable of sliding in the track of the T shaped groove arranged on the substrate through a T shaped sliding block. The spring fixing plate is provided with a plurality of pressure pulling sensors. The spring moving platform is provided with corresponding suspension ring screw nails. The to-be-tested springs are placed between the suspension ring screw nails and the pressure pulling sensors. The spring moving platform is connected with the screw rod fixing plate through a leading screw and nut mechanism; the screw rod fixing plate is provided with a clamping groove. The transmission screw rod of the leading screw and nut mechanism is provided with a clamping ring cooperating with the clamping groove. The hand wheel is connected to the end part of the transmission screw rod through the speed reducer. Through the hand wheel and the speed reducer, great torque is provided to the transmission screw rod so that the leading screw and nut mechanism can provide strong pulling force to the spring moving platform and that a plurality of the to-be-tested springs are tested at the same time.

Owner:WUHAN UNIV

Operating platform and method of automatically installing shims

InactiveCN101794077AAvoid breakingIncrease productivityWork holdersPhotomechanical exposure apparatusEngineeringWorkbench

Owner:WKK DISTRIBUTION

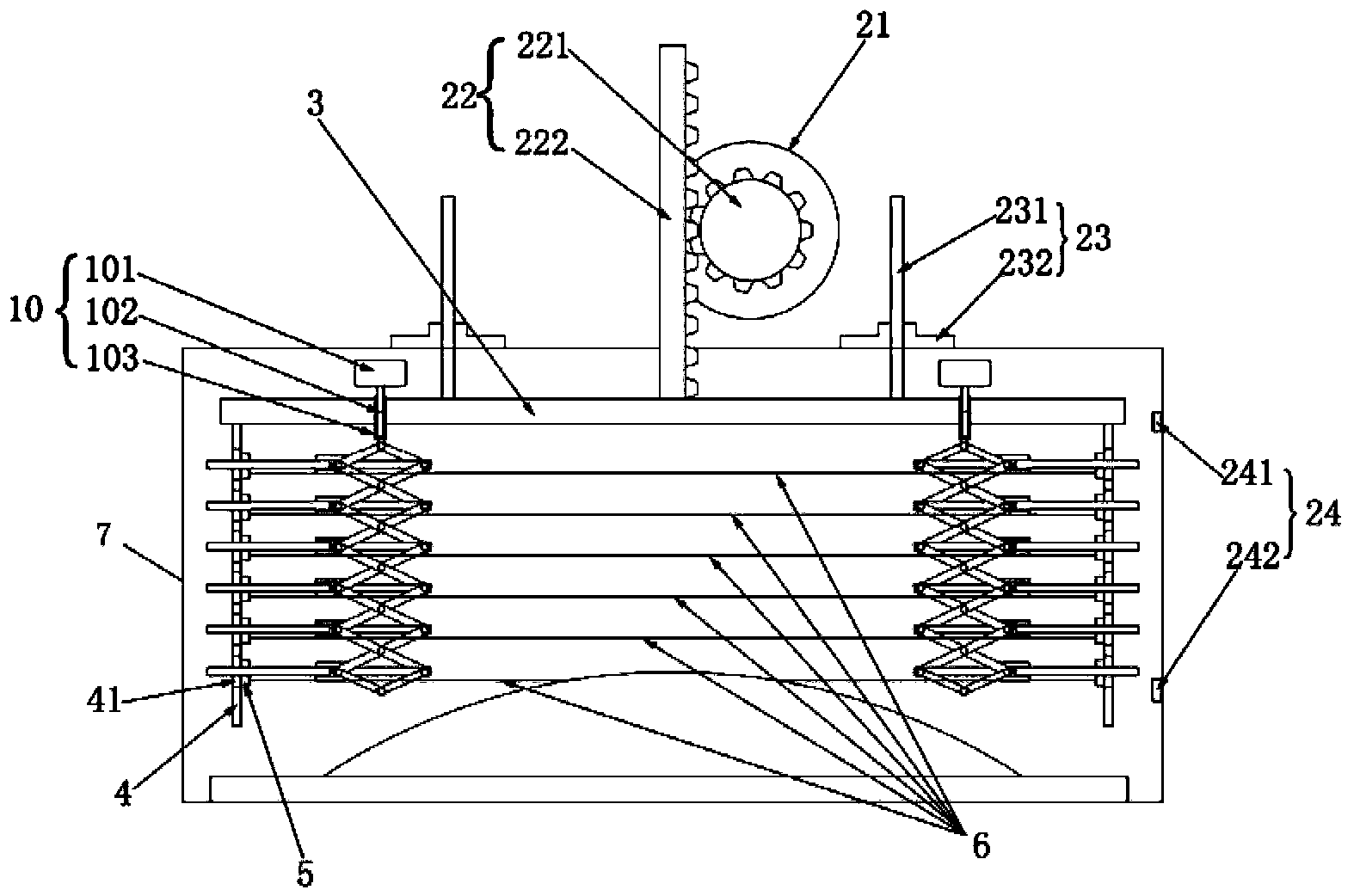

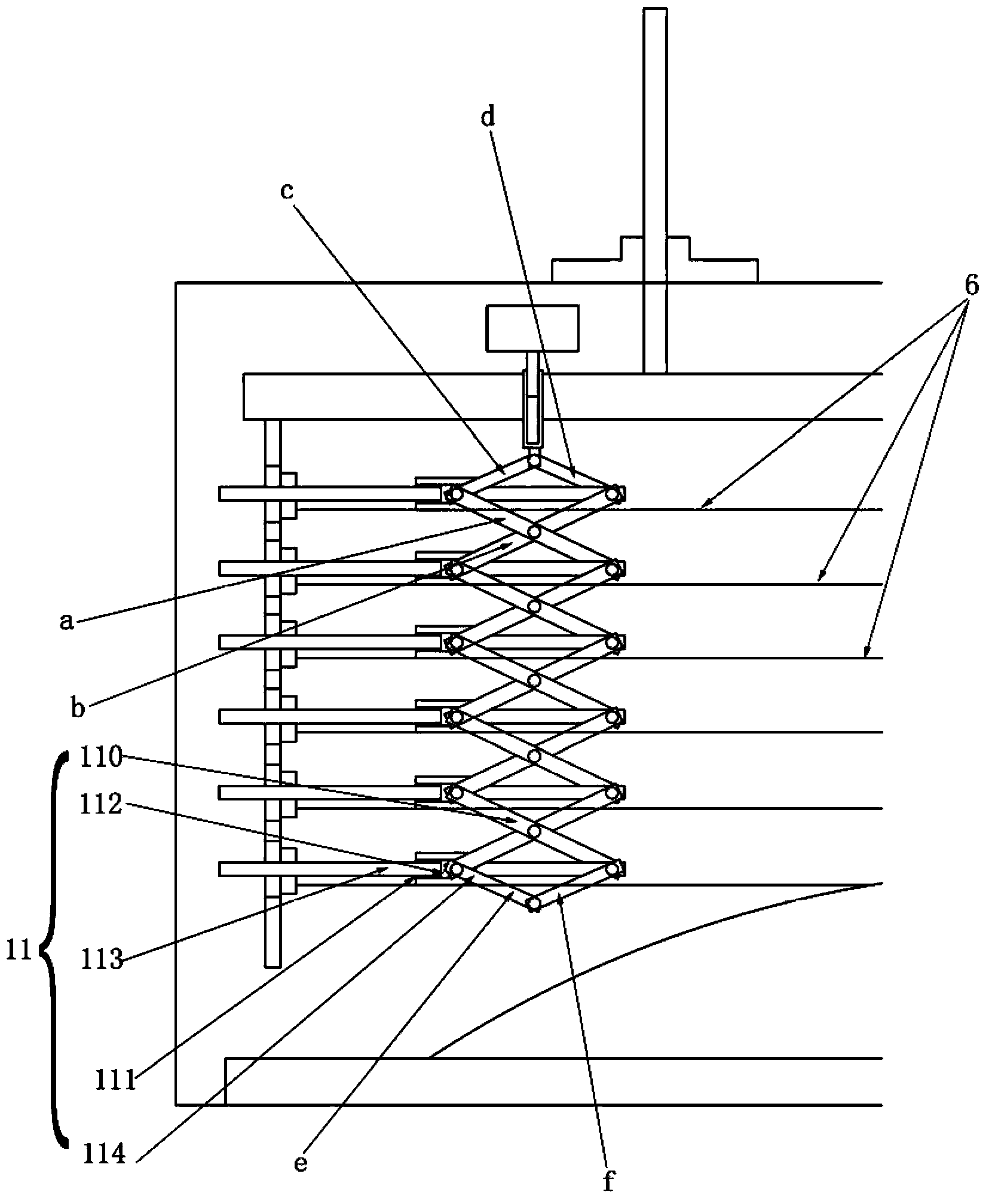

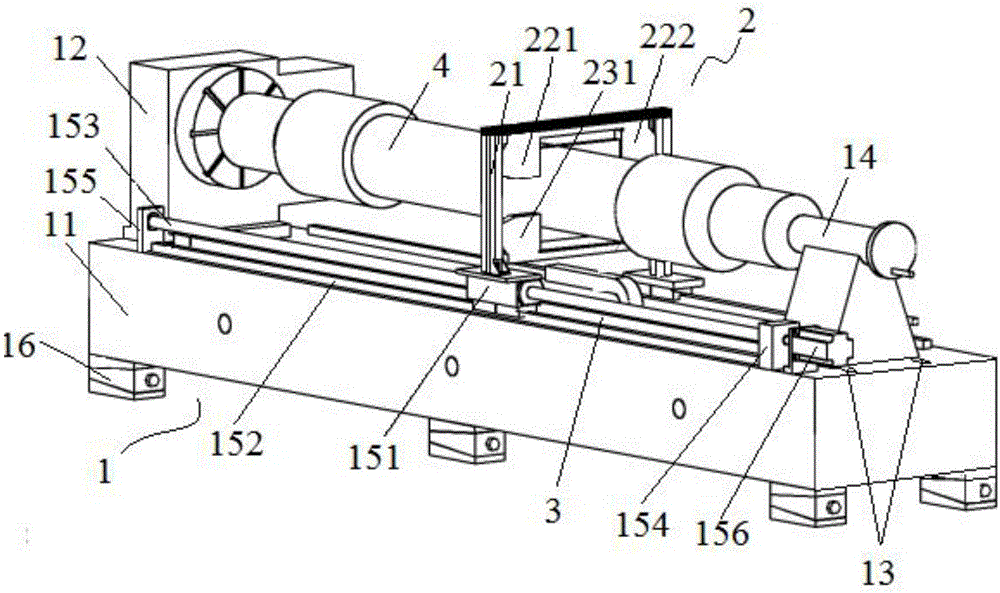

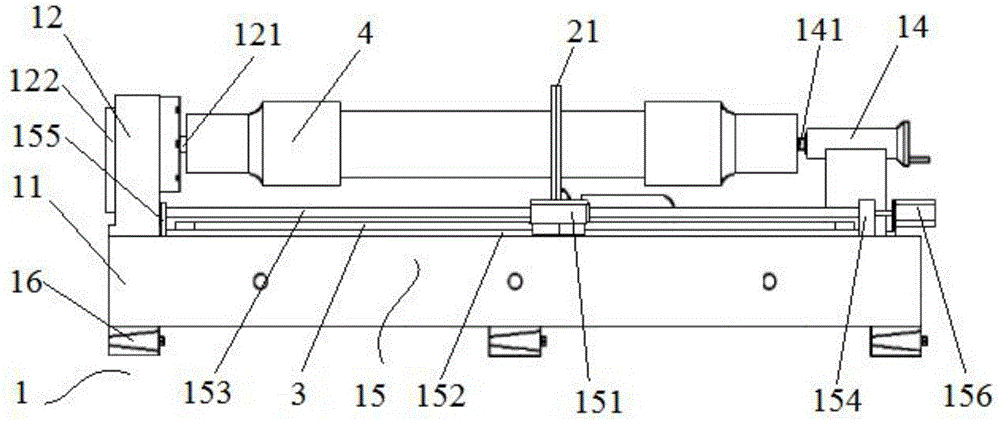

Special machine for testing comprehensive performance parameters of RV speed reducer

PendingCN110441052AConvenience to workGuaranteed accuracySubsonic/sonic/ultrasonic wave measurementMachine gearing/transmission testingCouplingOutput coupler

The invention discloses a special machine for testing comprehensive performance parameters of an RV speed reducer, and the special machine comprises a rack, wherein the rack is provided with a torqueloading servo motor, a test bed positioned below the torque loading servo motor and an input servo motor positioned below the test bed, the upper end surface of the test bed is provided with a placingarea for placing the speed reducer to be tested, the output end of the torque loading servo motor faces the test bed, the output end of the torque loading servo motor is provided with an output torque rotating speed sensor, an output coupler, an output angle encoder and an output connecting flange, the output end of the input servo motor faces the test bed, and the output end of the input servo motor is provided with an input torque rotating speed sensor, an input coupler and an input angle encoder. The torque loading servo motor, the test bed and the input servo motor are arranged along thevertical direction, namely, a vertical platform is adopted, so that the test bed is convenient for testers to work, the mounting accuracy can be ensured, and the occupied area is small.

Owner:清远敏实汽车零部件有限公司

Triaxial heat convection acceleration sensor

ActiveCN101105502AImprove impact resistanceImprove reliabilityAcceleration measurement using interia forcesThermometers using electric/magnetic elementsEngineeringSensor field

The invention discloses a triaxial heat convection accelerated speed sensor which belongs to the micromechanical sensor field; the triaxial heat convection accelerated speed sensor comprises a closed cavity equipped with a sensing element in the internal part, a heater and a temperature sensor; the heater and the temperature sensors in the three axial directions are equipped in the closed cavity; the sensing element is a gas limited in the closed cavity; the heater is positioned in the center of the closed cavity; three temperature sensors with the same characteristic value are symmetrically provided in the X axial direction, the Y axial direction and the Z axial direction; a single gas is used as the sensing element which can sense the accelerated speeds in the three axial directions. The accelerated speed sensor in the invention can be used in a plurality of occasions to sense the accelerated speed in any direction in a space; the invention has the advantages of simple, convenience, small volume, low cost, and big reliability.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

Device and method for detecting large-size shaft part

ActiveCN106152955AEliminate installation errorsHigh measurement accuracyUsing optical meansGratingLarge size

The invention discloses a device for detecting a large-size shaft part. The device comprises a to-be-detected shaft support mechanism, a light transmission sensor group and a grating ruler, the to-be-detected shaft support mechanism comprises a support platform, a rotary platform, a free slideway, a tailstock and a guiderail, the rotary platform is provided with a first shifting top tip, the tailstock is provided with a second shifting top tip, the first shifting top tip and the second shifting top tip are used for fixing a to-be-detected shaft, the light transmission sensor group comprises an upper sensor and a lower sensor of an installation frame, the bottom part of the installation frame is connected with the guiderail through a slide block movably, the grating ruler and the guiderail are fixed on the support platform in a parallel manner, and a header of the grating ruler is arranged on the slide block. The device corrects the assembly error of the sensor, data of shaft diameter and shaft length of various segment positions of the to-be-detected shaft are measured, points not meeting the specifications on the to-be-detected shaft are marked, and the purposes of accurate measurement and wide scope of measurement are fulfilled.

Owner:JILIN UNIV

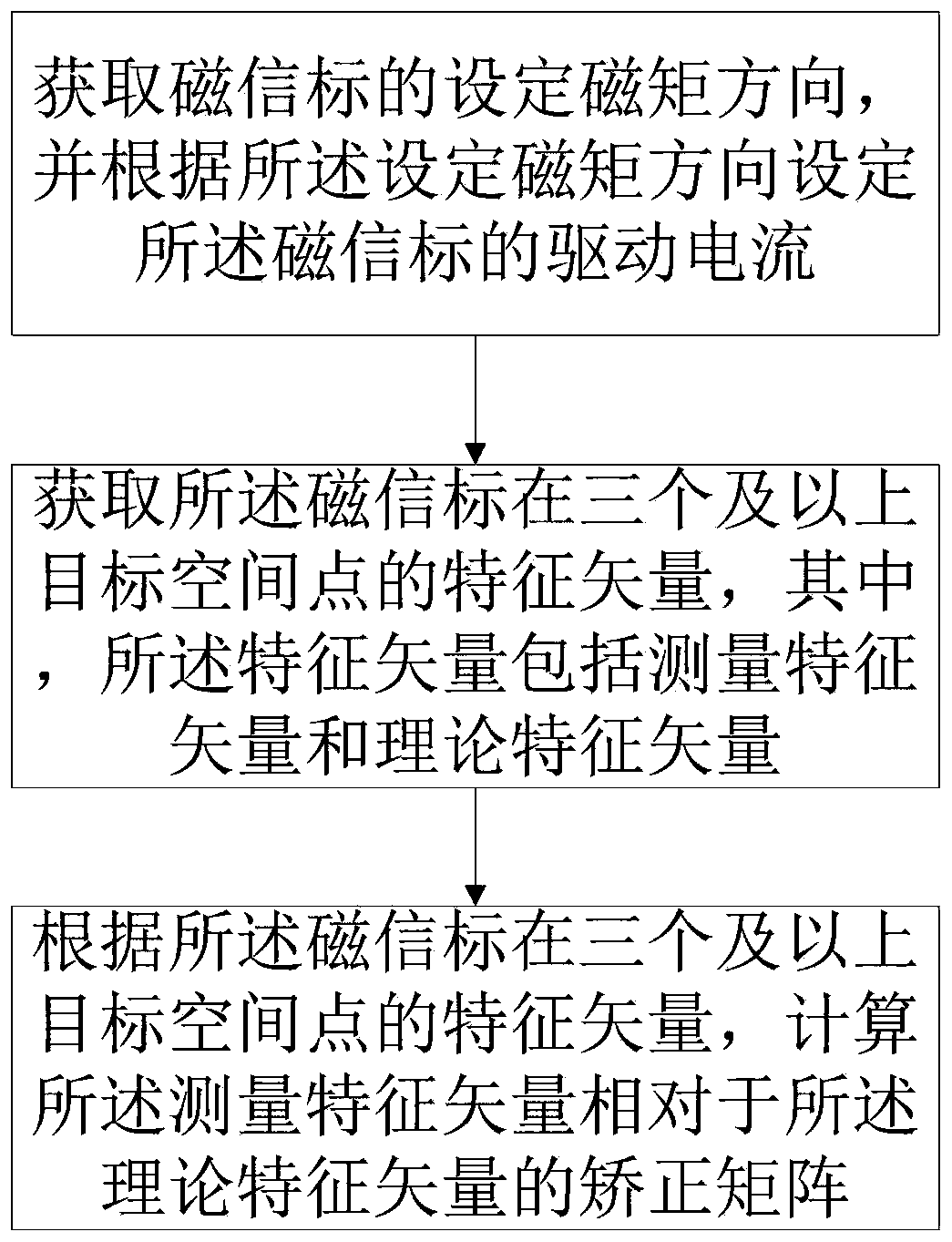

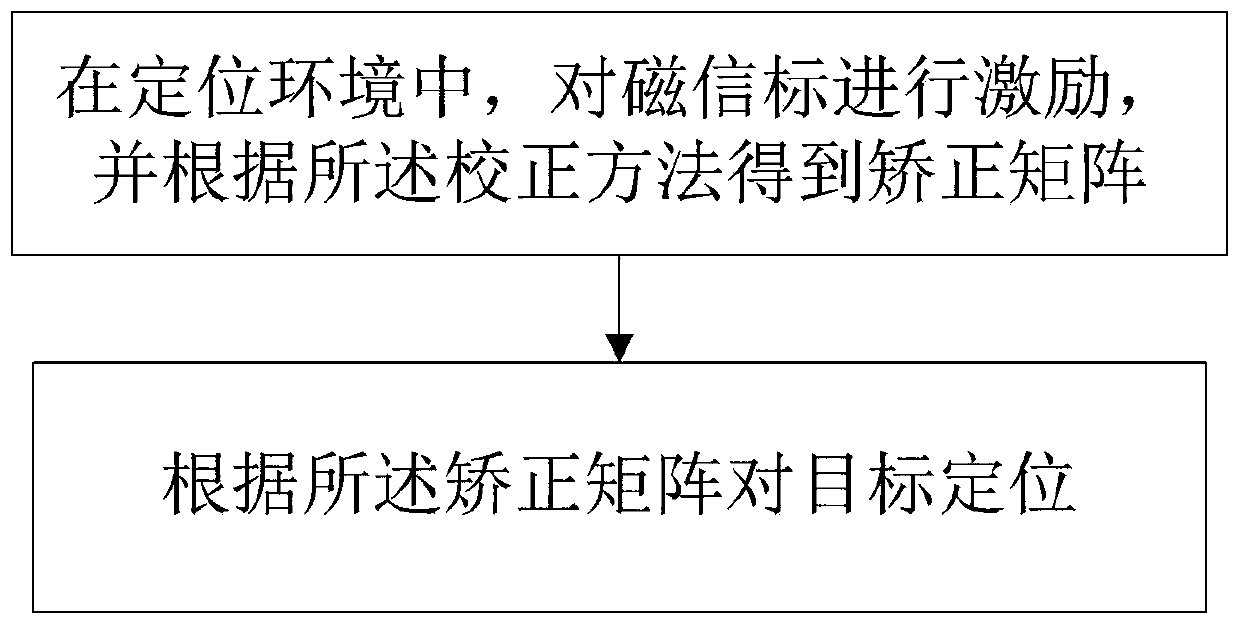

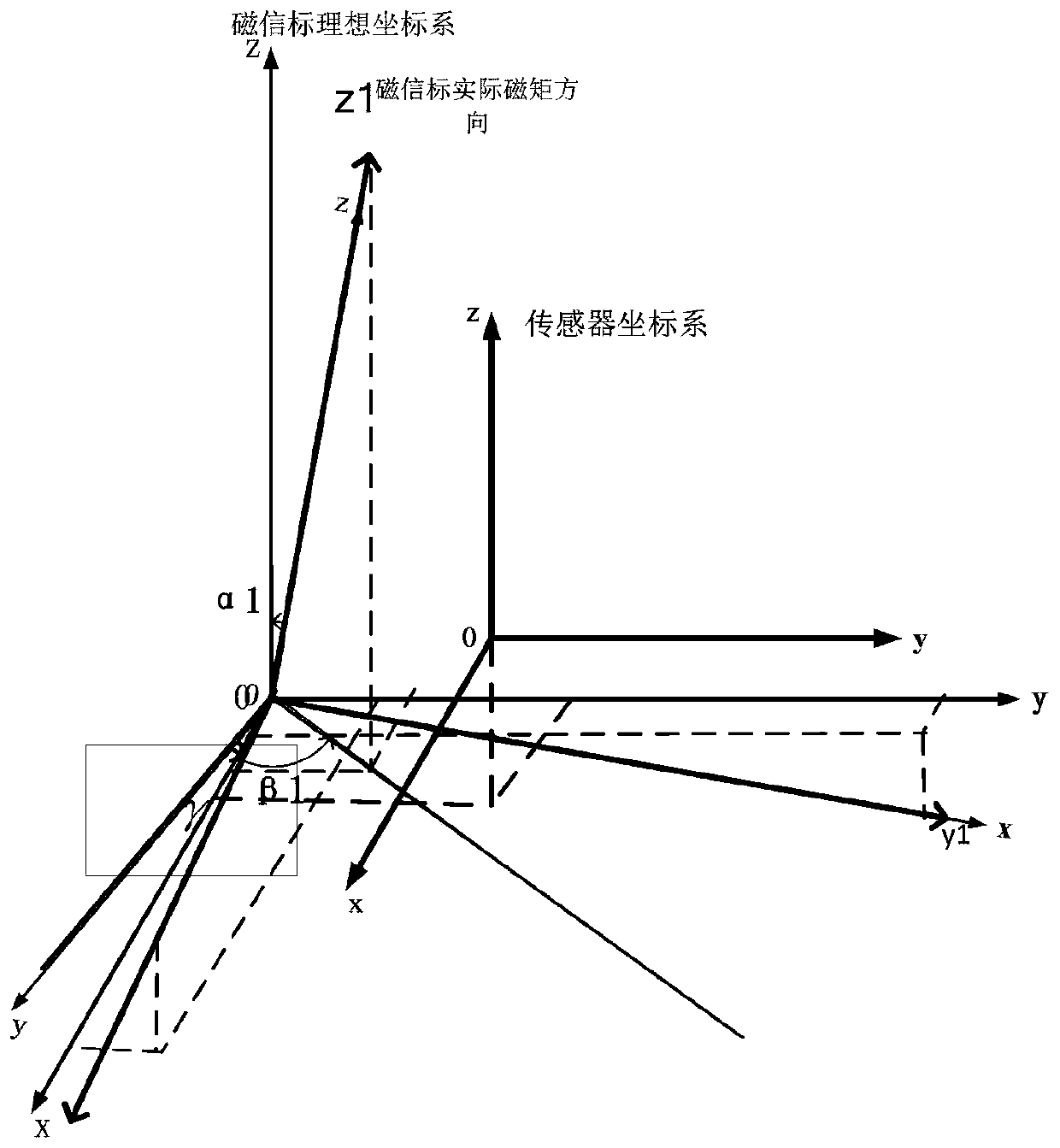

Magnetic beacon correction method and positioning method based on rotating magnetic dipole

ActiveCN111561924AEliminate installation errorsImprove navigation accuracyNavigation instrumentsNuclear physicsNuclear magnetic resonance

The invention provides a magnetic beacon correction method and a positioning method based on a rotating magnetic dipole, and relates to the technical field of signal positioning. The magnetic beacon correction method comprises the following steps of: acquiring a set magnetic moment direction of a magnetic beacon, and setting a driving current of the magnetic beacon according to the set magnetic moment direction; acquiring feature vectors of the magnetic beacon at three or more target space points, wherein the feature vectors comprise a measurement feature vector and a theoretical feature vector; and calculating a correction matrix of the measurement feature vector relative to the theoretical feature vector according to the feature vectors of the magnetic beacon at three or more target space points. According to the technical scheme, the correction matrix is determined through the measurement feature vector and the theoretical feature vector and is applied to correction of the measurement feature vector of an unknown point, so that the installation error of the magnetic beacon is eliminated, and the navigation precision of the magnetic beacon is improved.

Owner:HARBIN INST OF TECH

Installation and alignment technology of a ship shafting

ActiveCN109131734AEliminate installation errorsImprove pre-installation accuracyVessel designingEpoxyManufacturing technology

The invention relates to the technical field of shipbuilding, the invention discloses an installation and alignment process of a ship shafting, including the pre-installation of the ship's shafting, centering alignment of coupling flanges of propeller shaft and countershaft, the alignment of intermediate shaft and clutch flange, the alignment of clutch flange and diesel engine, the pouring of epoxy gasket under the base of diesel engine, the adjustment and installation of rotor coupling on shaft belt generator, the alignment of shaft belt generator and intermediate shaft, and the measurement of bearing load; at the pouring step of the epoxy gasket under the base of the diesel engine main engine, according to the drying shrinkage amount of the epoxy gasket, the mounting height of the dieselengine main engine is corrected to be the sum of the theoretical mounting height and the dry shrinkage amount; the amount of drying shrinkage of the epoxy gasket is obtained by drying shrinkage testdata of the epoxy gasket material. The invention improves the installation precision of the ship shafting, and improves the operation reliability of the ship shafting equipment.

Owner:CHENGXI SHIPYARD

MEMS inertial measurement unit with crossing axis coupling error compensation

ActiveCN107270902AEliminate shafting non-orthogonal errorsImprove output accuracyNavigation by speed/acceleration measurementsData conversionDigital conversion

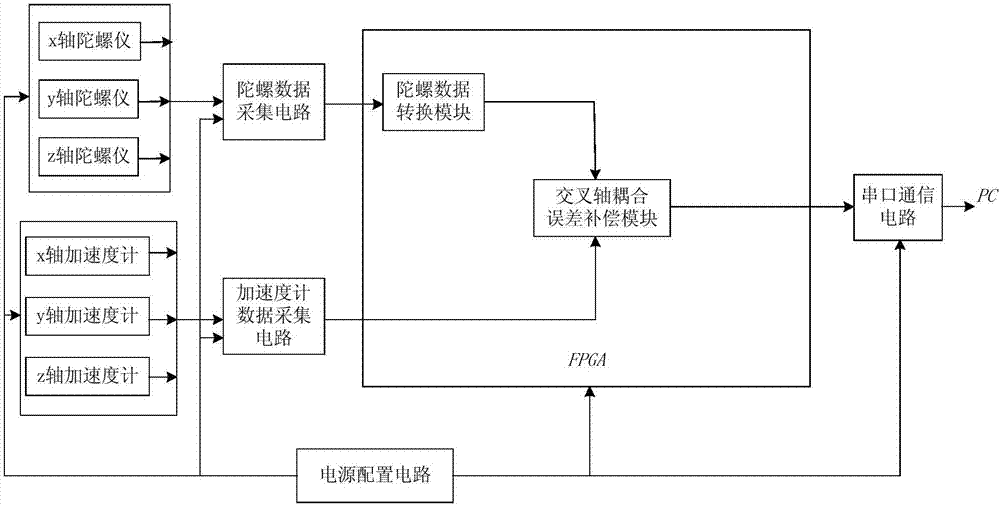

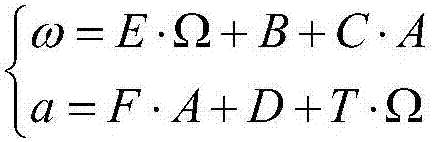

The invention discloses an MEMS inertial measurement unit with crossing axis coupling error compensation. The MEMS inertial measurement unit comprises three axial MEMS analog output gyroscopes and signal collecting circuits thereof, three axial MEMS digital output accelerometers and signal collecting circuits thereof, a gyroscope data conversion module, a crossing axis coupling error compensation module, a serial port communication circuit and a power supply configuration circuit, wherein the three axial MEMS analog output gyroscopes and the signal collecting circuits thereof are used for realizing the collection of gyroscope signals; the three axial MEMS digital output accelerometers and signal collecting circuits thereof are used for realizing the collection of accelerometer output signals; the gyroscope data conversion module is used for realizing the analog-digital conversion of the gyroscope data; the crossing axis coupling error compensation module is used for realizing the data treatment for the analog output gyroscopes and the digital output accelerometers; the serial port communication circuit is used for realizing the communication with an upper computer; the power supply configuration circuit is used for supplying various power supplies to the whole measurement unit. The MEMS inertial measurement unit not only can realize the collection of the carrier six-axis position information but also can eliminate the crossing axis coupling error caused by processing and mounting.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com