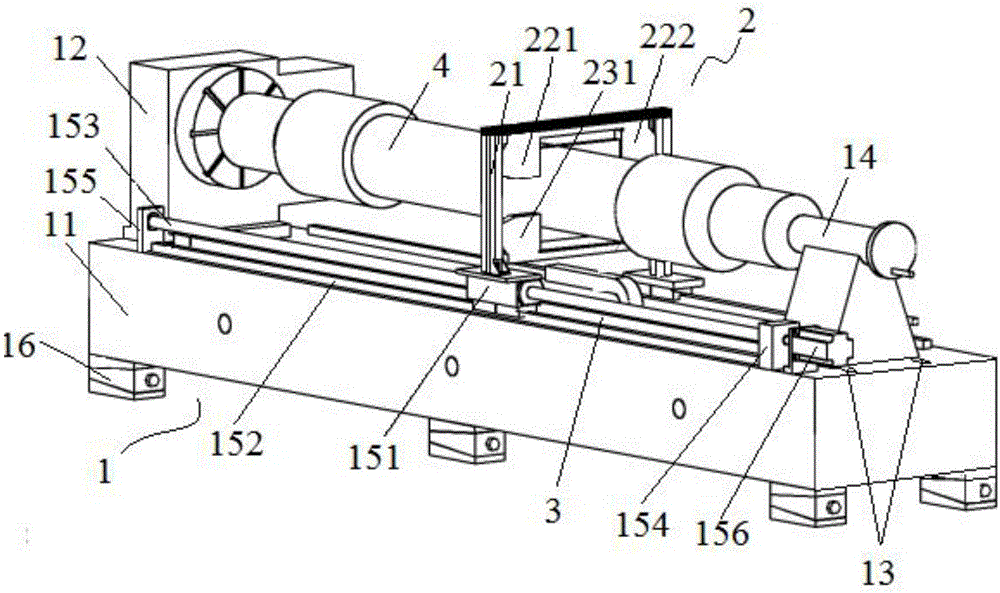

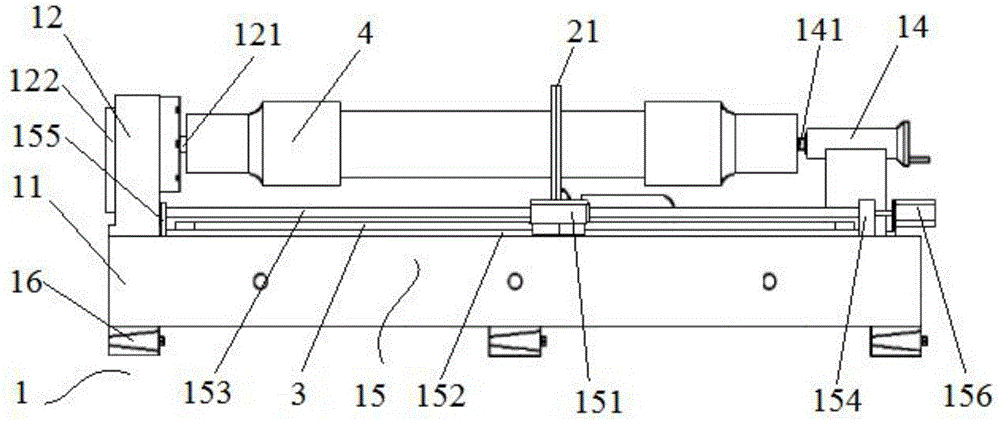

Device and method for detecting large-size shaft part

A technology for shaft parts and detection devices, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of inability to assemble, small measurement range, and inability to accurately judge whether shaft parts meet the design requirements, etc., to eliminate installation Error, the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

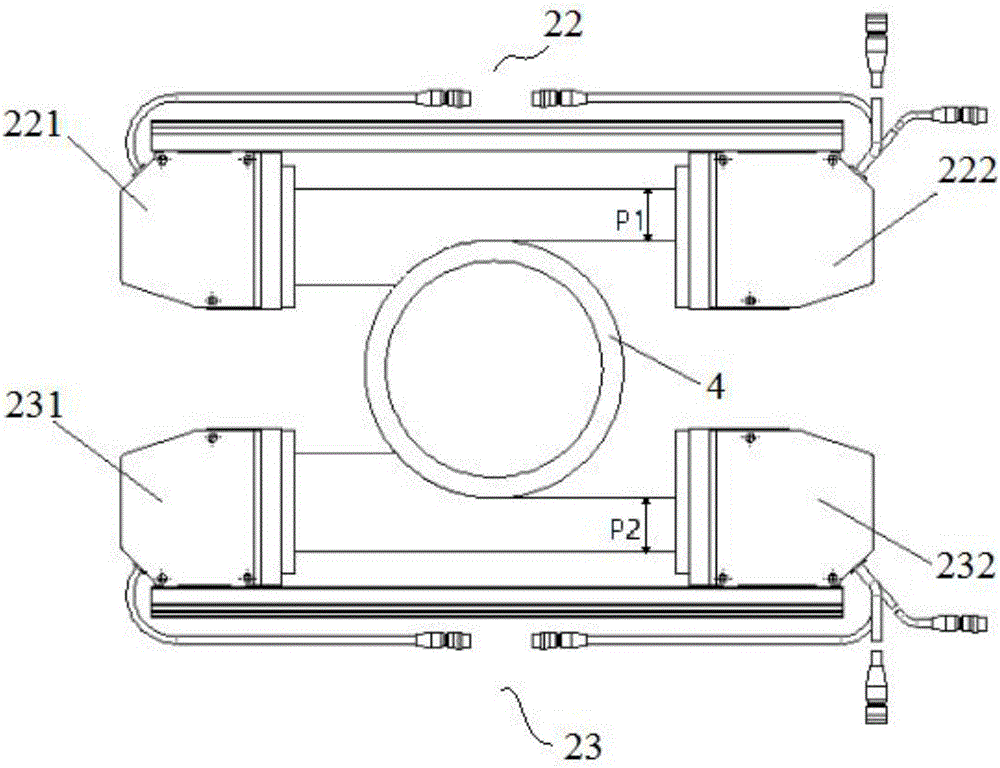

[0070] As an optional implementation manner, the method for obtaining the calibration parameter A specifically includes:

[0071] Obtain the position coordinates P*3 of the standard axis detected by the head of the grating ruler, and construct a position coordinate array P*3[n];

[0072] At the same time, obtain the upper light curtain length P*1 and the lower light curtain length P*2 corresponding to the position coordinate P*3 of the standard axis detected by the light transmission sensor group;

[0073] Carry out linear fitting to described upper light curtain length P * 1 and described lower light curtain length P * 2 respectively, obtain the straight line J corresponding to described upper light curtain length P1 1 x+K 1 y+L 1 =0 and the straight line J corresponding to the length P2 of the lower light curtain 2 x+K 2 y+L 2 = 0;

[0074] According to the straight line J 1 x+K 1 y+L 1 = 0 and J 2 x+K 2 y+L 2 =0 Calibration parameter A:

[0075] Where x is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com