Triaxial heat convection acceleration sensor

A technology of acceleration sensor and temperature sensor, which is used in acceleration measurement using inertial force, navigation through speed/acceleration measurement, instruments, etc., can solve the problem of unpublished three-axis thermal convection acceleration sensor, and achieve low cost and small size. , the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

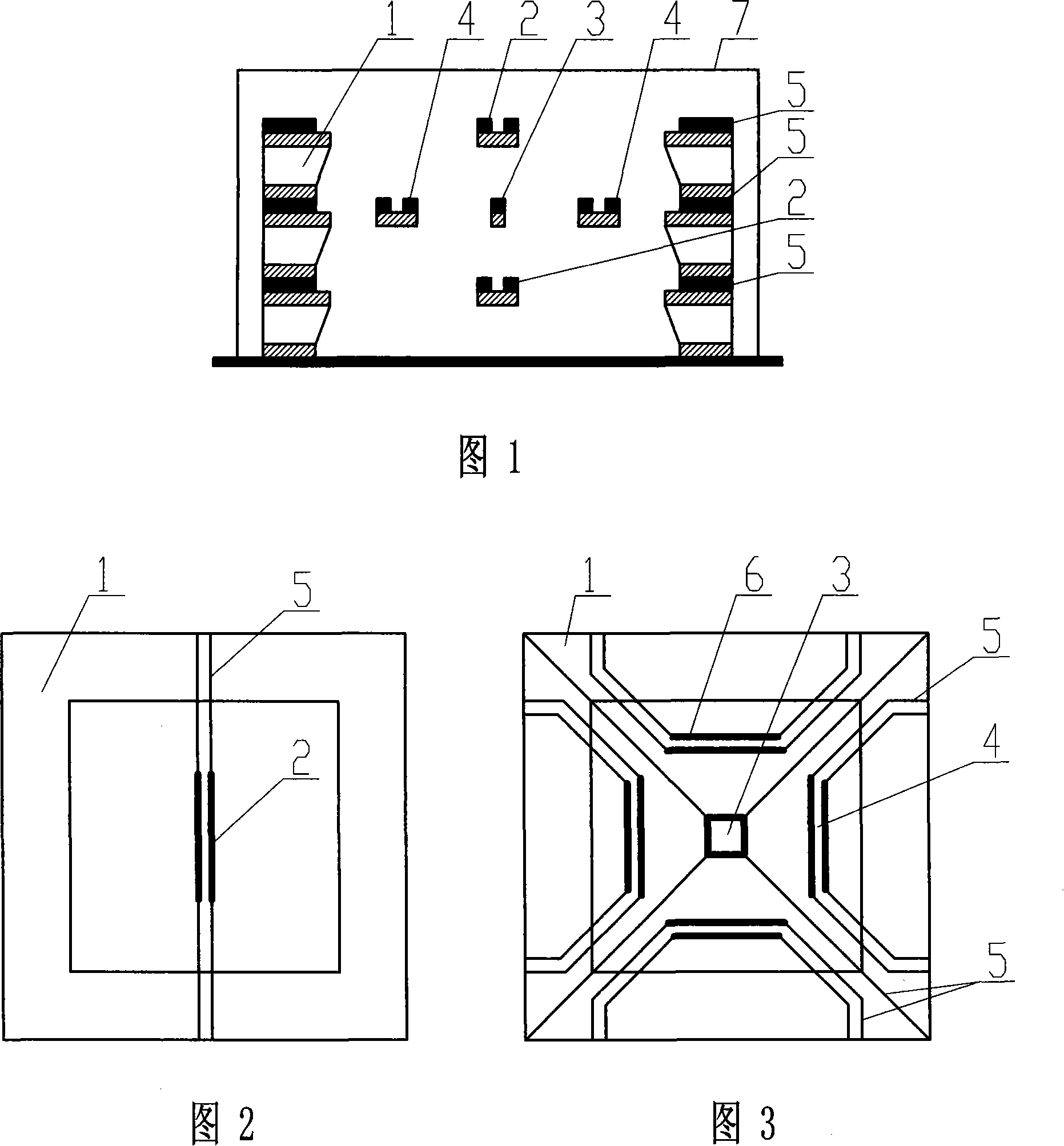

[0022] As shown in Figure 1, Figure 2, and Figure 3. The three-axis thermal convection acceleration sensor of the present invention includes a closed cavity 7, a heater 3, and a temperature sensor that are provided with sensitive elements inside. Inside cavity 7. The substrate structure of the triaxial thermal convection acceleration sensor of the present invention is composed of a silicon substrate 1, and the acceleration sensor is composed of three layers, which are bonded together by bonding technology after they are manufactured respectively. The first and third layers are respectively two pairs of Z-axis thermistors 2; the front and back of the second layer are two pairs of Y-axis thermistors 6, and the left and right are two pairs of X-axis thermistors 4. The heater is the heating resistor 3, which is located at the center of the second layer and also the center of the closed cavity 7; the temperature sensors on the three axes of X, Y, and Z are equidistant and symmetri...

Embodiment 2

[0025] The difference between this embodiment and Embodiment 1 is that the temperature sensors in the X, Y, and Z axes are respectively a pair of thermopiles, and the thermopiles are connected to the external temperature detection circuit through lead wires.

Embodiment 3

[0027] The difference between this embodiment and Embodiment 1 is that the heating resistor is circular, and the lead wires of the heating resistor are arranged in the diameter direction of the circle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com