Controllable profile modification method of tooth surface of arc-tooth cylindrical worm

A worm tooth surface and arc-shaped tooth technology, which is applied to components with teeth, belts/chains/gears, portable lifting devices, etc., can solve the problem of increasing the transmission noise of arc-shaped cylindrical worm pairs, affecting transmission accuracy, and affecting The bearing capacity and service life of the arc-shaped cylindrical worm pair transmission can eliminate installation errors, expand the contact area, and achieve the effects of good lubrication performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

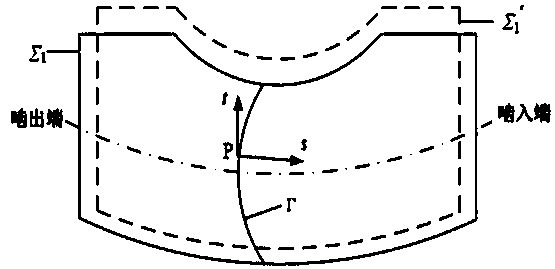

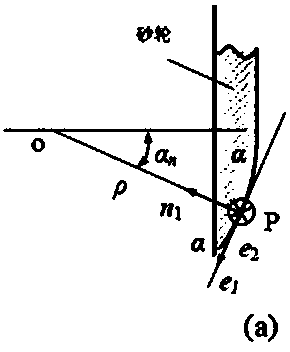

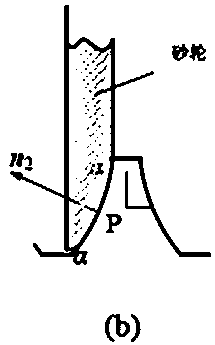

[0028] like figure 1 As shown in the schematic diagram of curvature correction of the tooth surface, the tooth surface of the arc-shaped cylindrical worm and the tooth surface of the worm gear are recorded as Σ 1 and Σ 2. According to the principle of meshing, in order to achieve the requirement of continuous transmission of the worm pair, the normal direction of the two tooth surfaces of the worm pair must coincide at the contact surface, and the normal direction and the direction of the relative speed are perpendicular to each other. The tooth surface of the worm is Σ 1, order P The point is a controllable contact point on any surface Γ, and the surface Γ exist P The tangent to the point is τ. at the point of contact P opposite to the tooth surface of the worm Σ 1 along the surface Γ exist P Point arc length direction (tooth length direction) s and surfaces Γ exist P Tangent direction of point (tooth height direction) t Make curvature correction and get a ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com