Patents

Literature

60 results about "Secondary tooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Comparison between primary and secondary teeth. Primary teeth are often called deciduous teeth, and other common names for them are milk teeth, baby teeth, or temporary teeth. They exist during childhood. Primary dentition consists of 20 primary teeth, 5 in each quadrant: 2 incisors, 1 canine and 2 molars but there is no premolars.

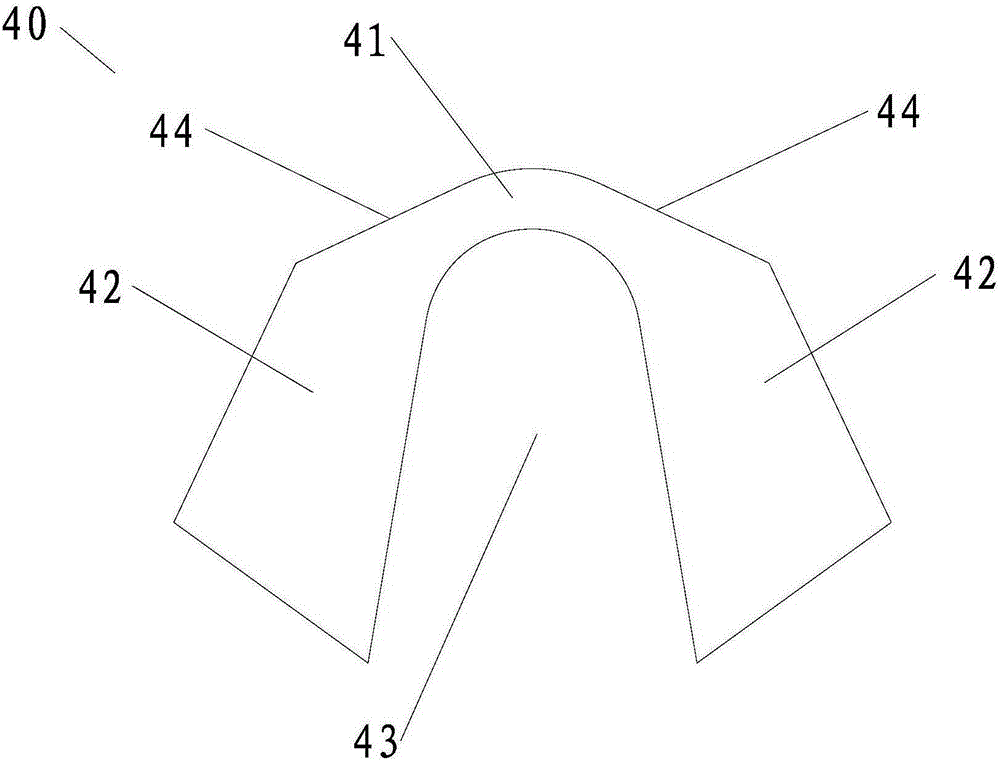

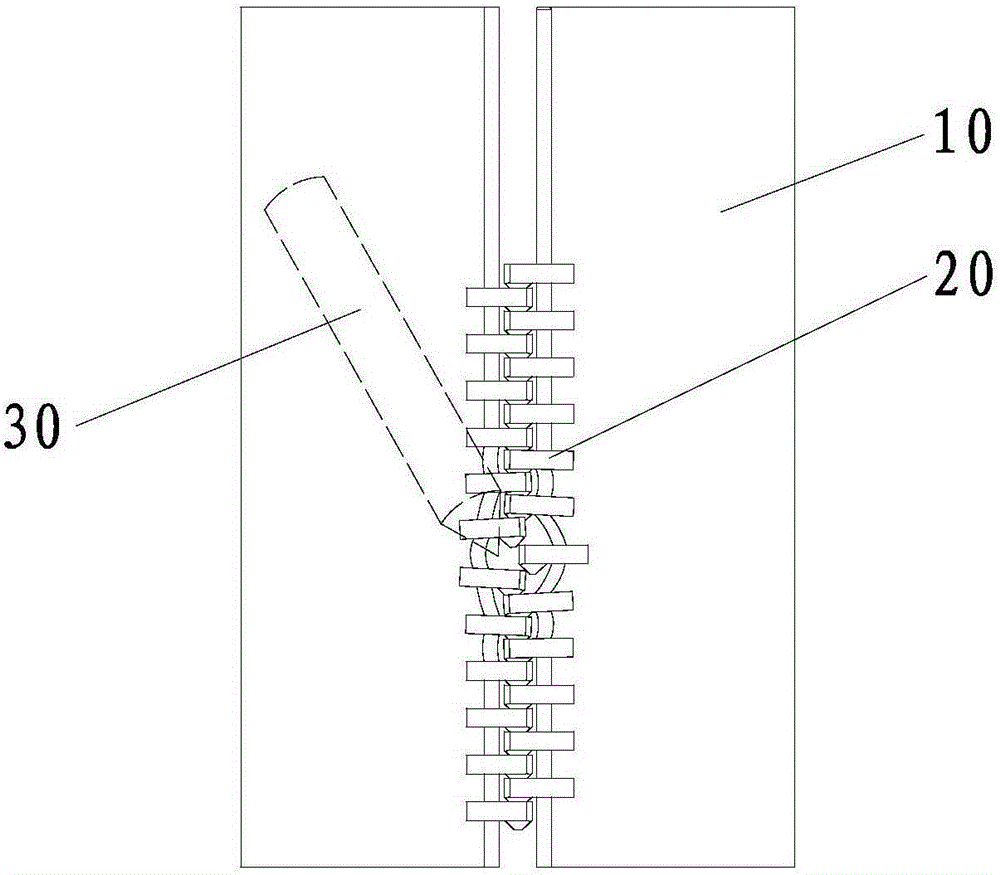

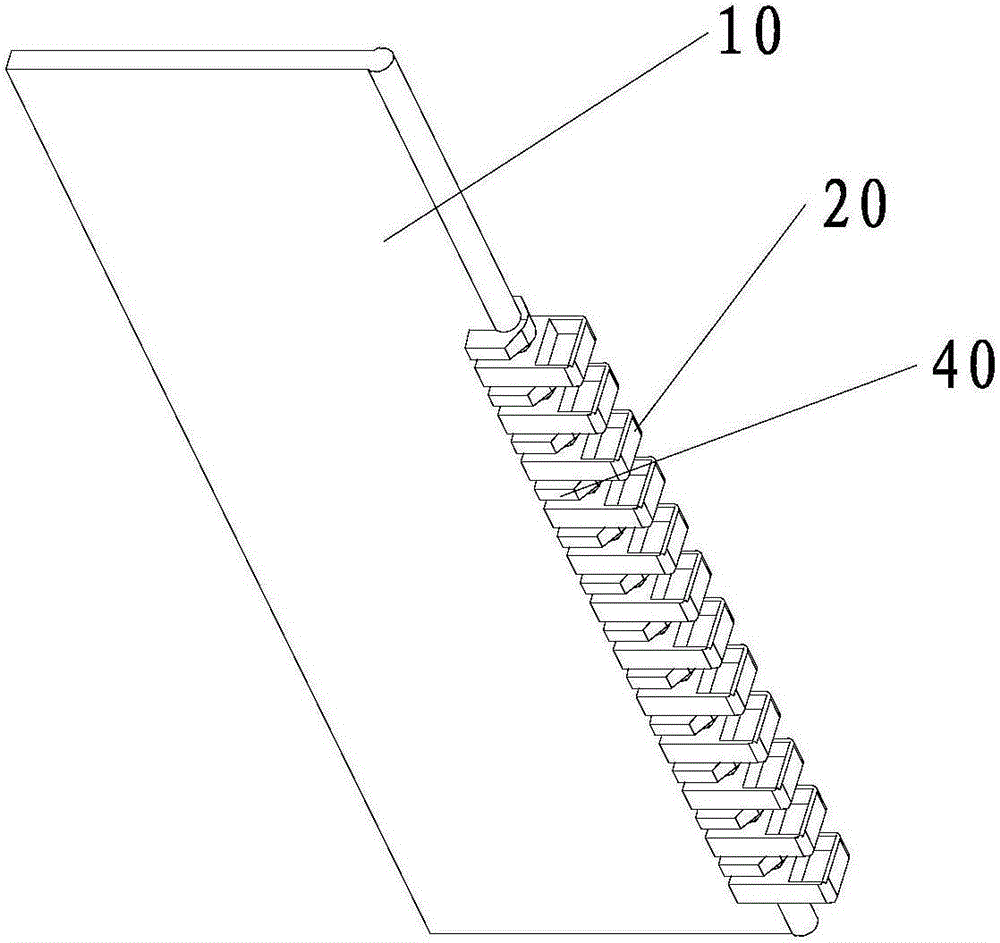

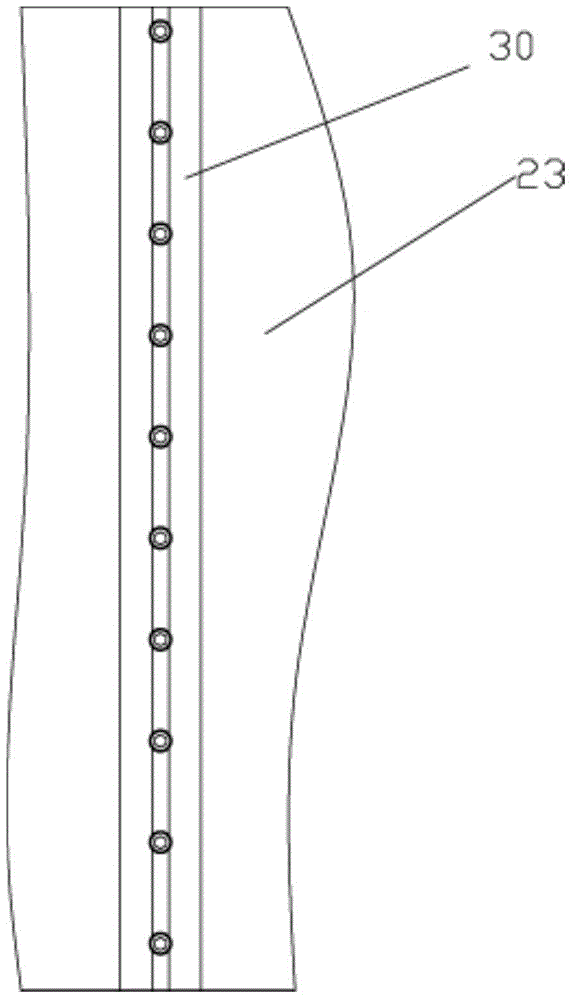

Metal wire and zipper using same

The invention provides a metal wire and a zipper using the same. The metal wire is in a shape of a straight line, and comprises a head part and two leg parts which are connected with the head part and arranged symmetrically, wherein the ends, not connected with the head part, of the two leg parts stretch in opposite directions, a U-shaped groove is formed between the head part and each leg part, mutually symmetric diagonal planes are arranged on two sides, corresponding to the leg parts, of the head part respectively, and the leg parts has sharp corners in the positions of the opening parts of the U-shaped grooves. The zipper comprises a ribbon and zipper teeth arranged on the ribbon in a snap-in manner, and one secondary tooth is arranged between every two chain teeth and is obtained by cutting the metal wire. One secondary tooth is arranged between every two chain teeth, and the distance between two adjacent chain teeth is reduced, so that a sharp object cannot easily pierce the distance or cannot easily take up the ribbon after piercing, the zipper can be prevented from being opened by the sharp object, and the safety is relatively higher.

Owner:DET IND DESIGN

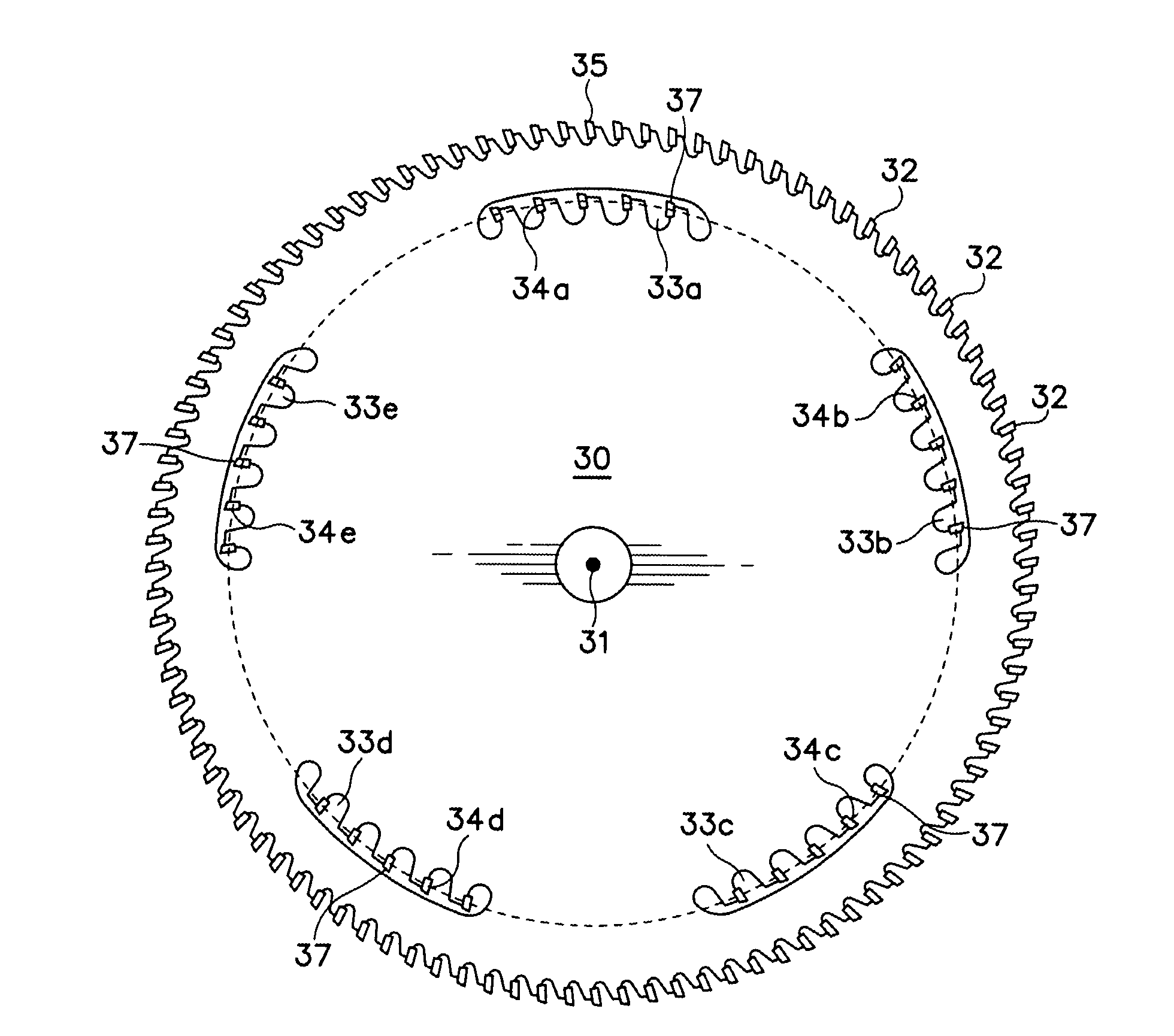

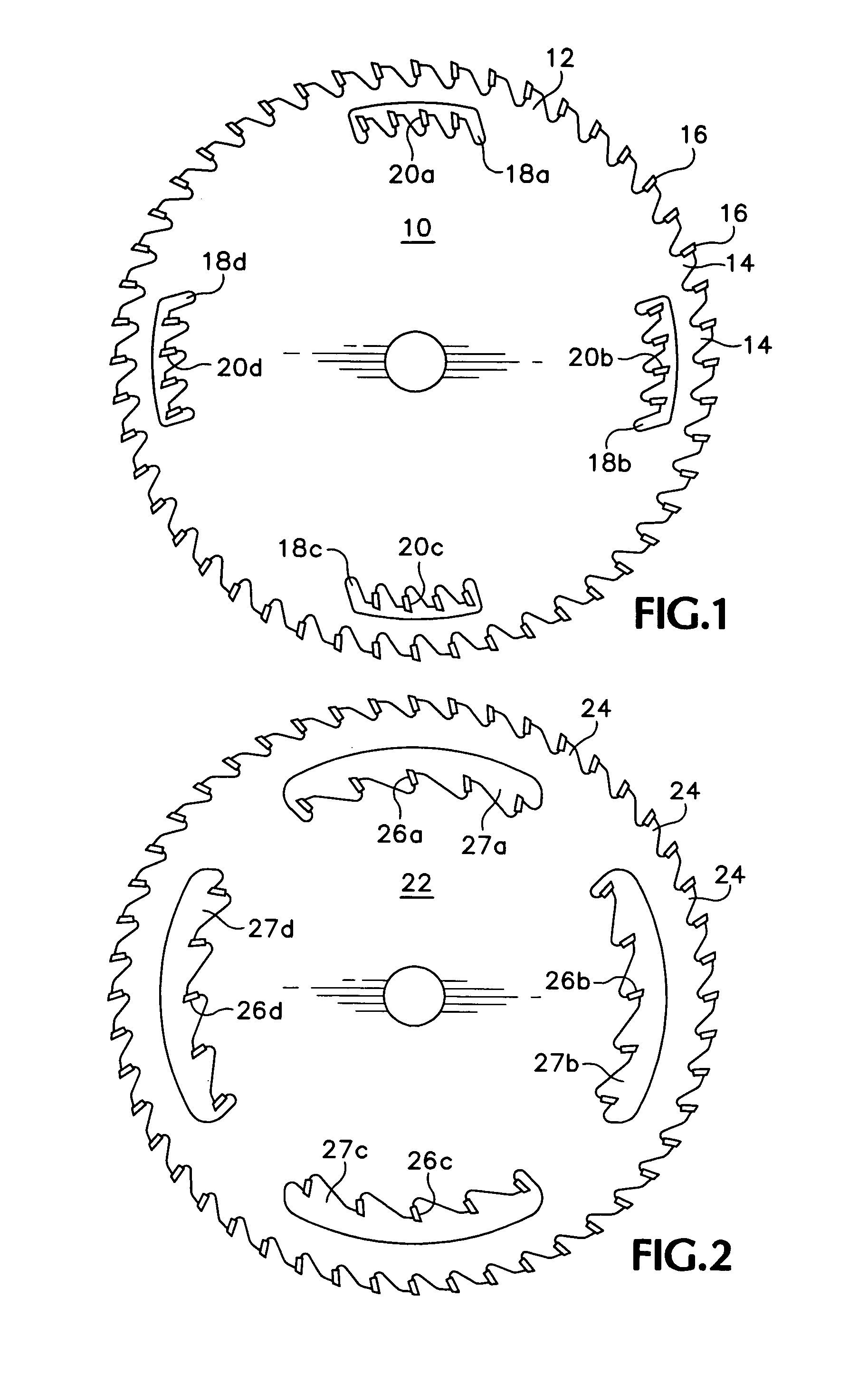

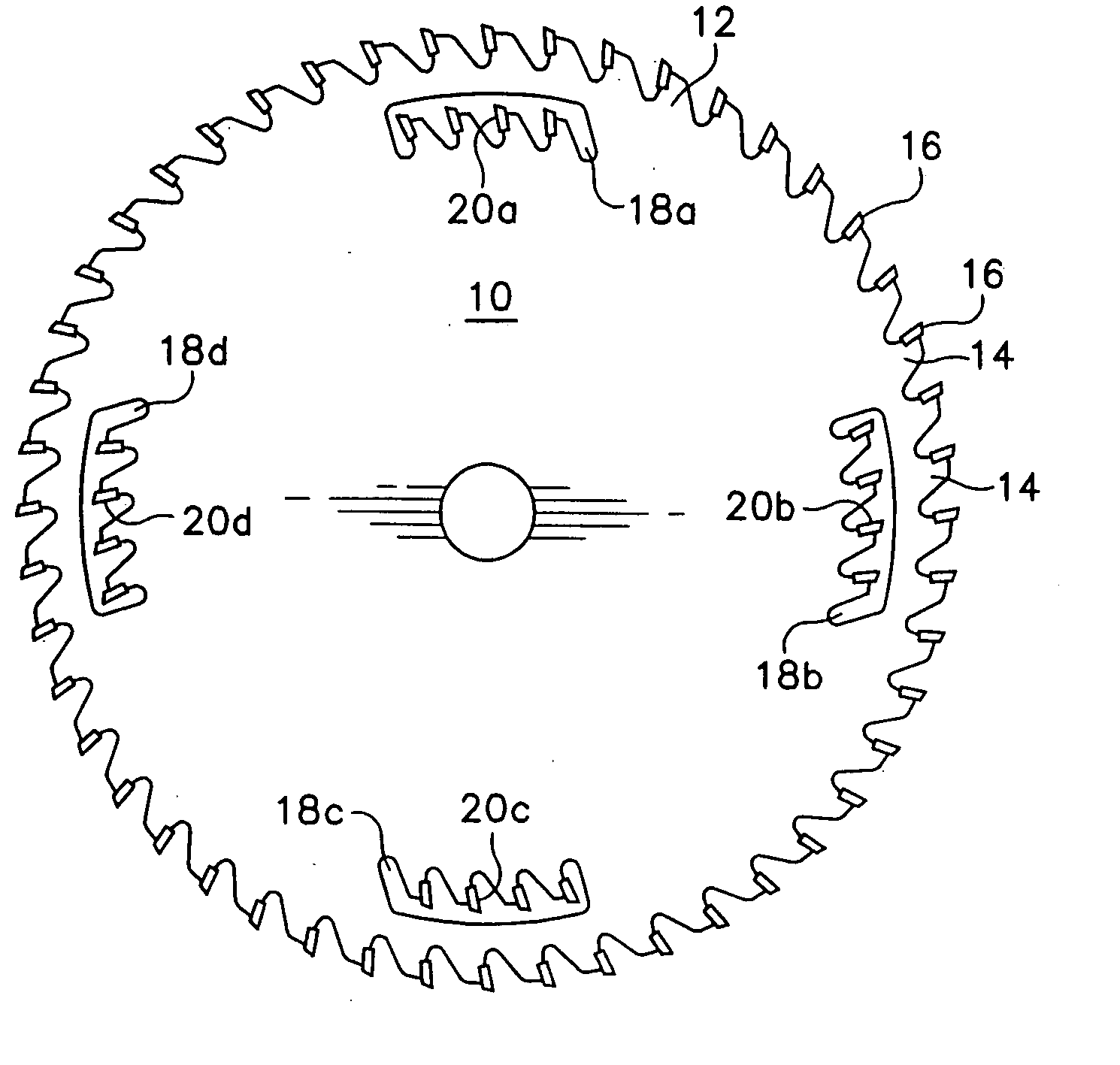

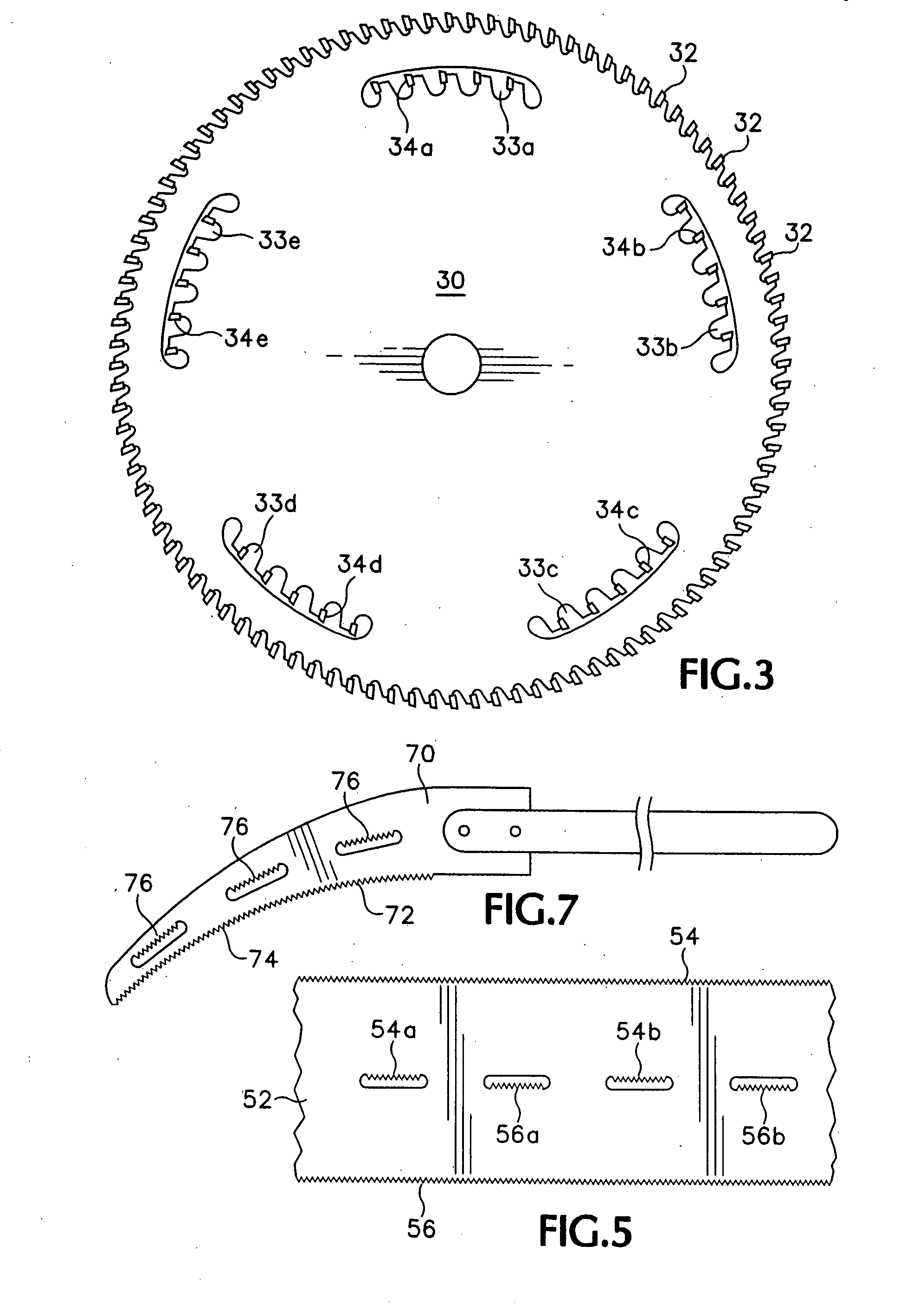

Saw blade with secondary teeth

A saw comprising a planar body includes at least one cutting edge with serrated teeth. The planar body has cutout portions displaced from the outer cutting edges which include sets of secondary teeth which are aligned generally parallel to or in an arc concentric with the outer cutting edge or edges.

Owner:EUGENE CARBIDE SAW SERVICE

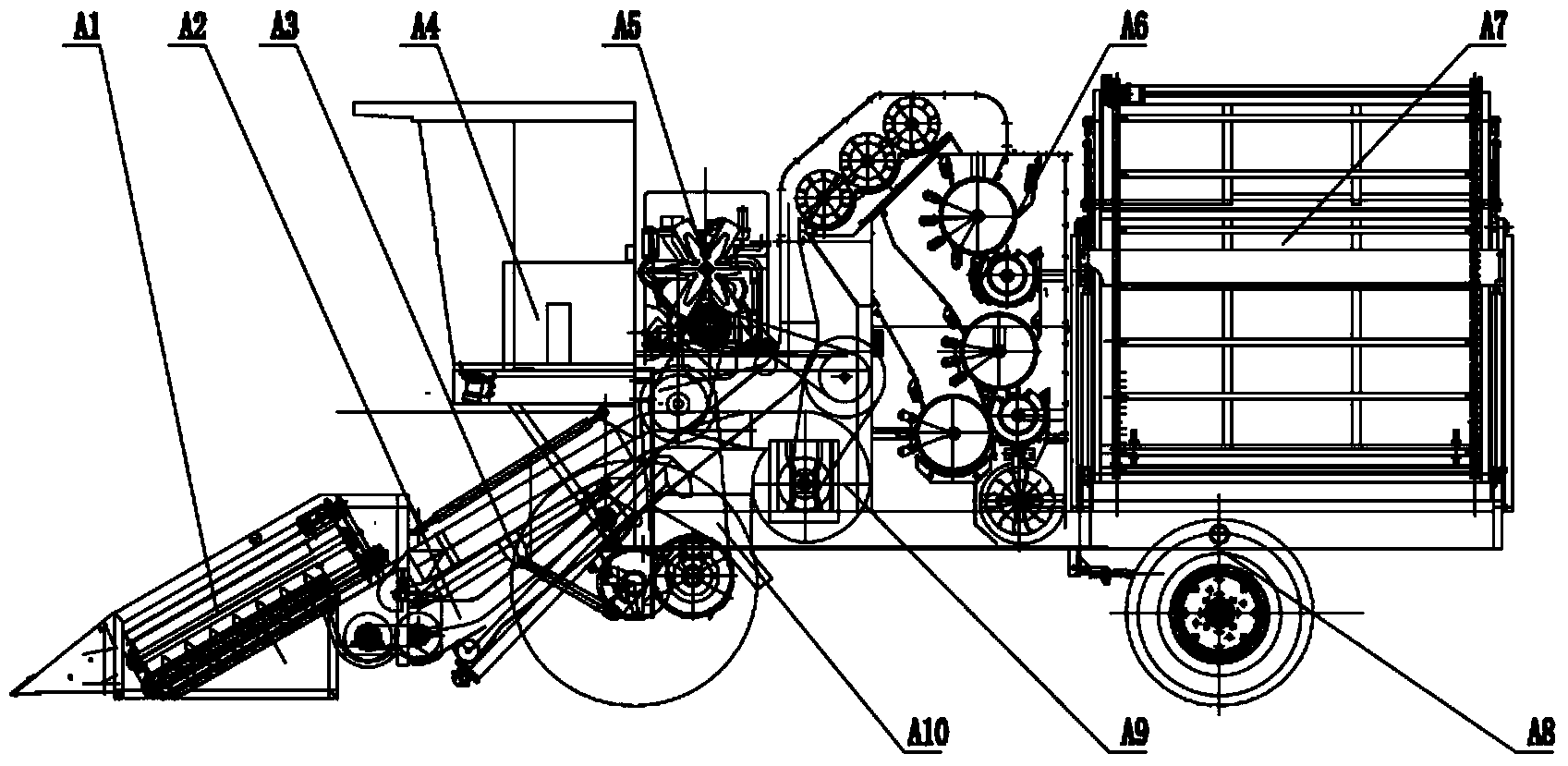

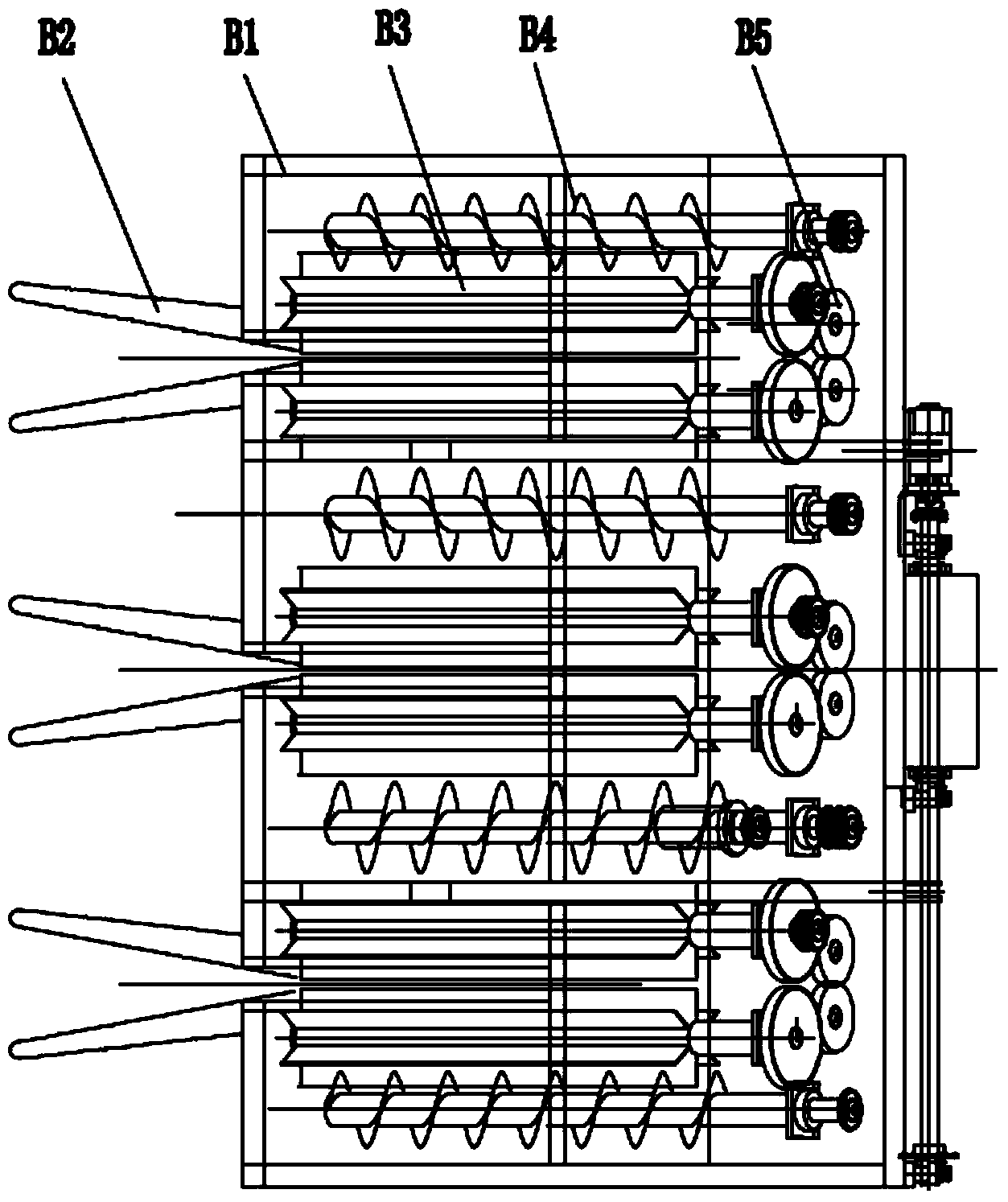

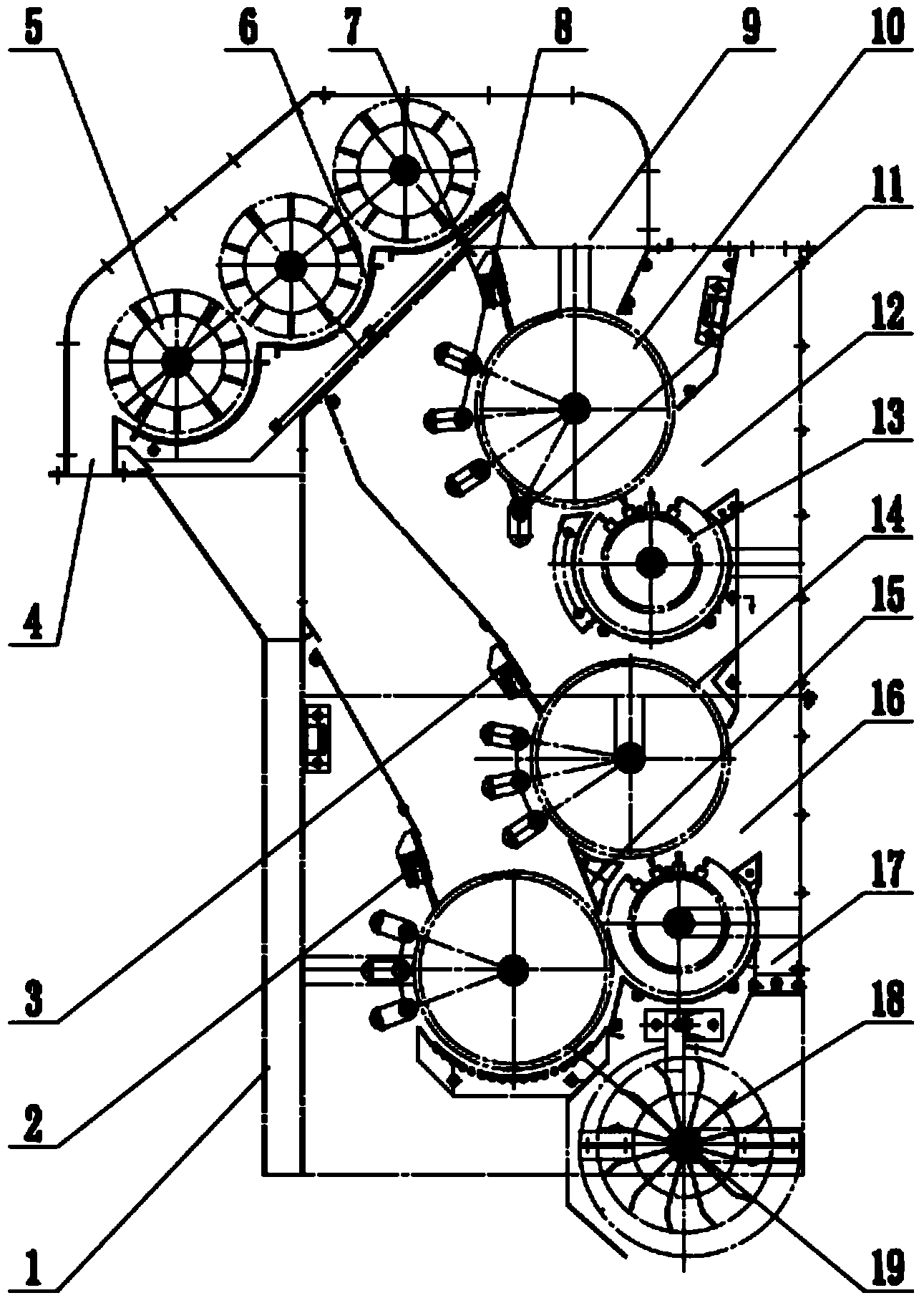

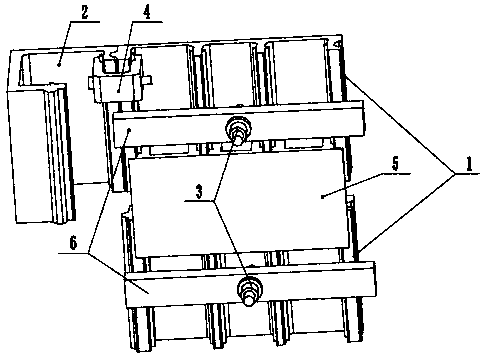

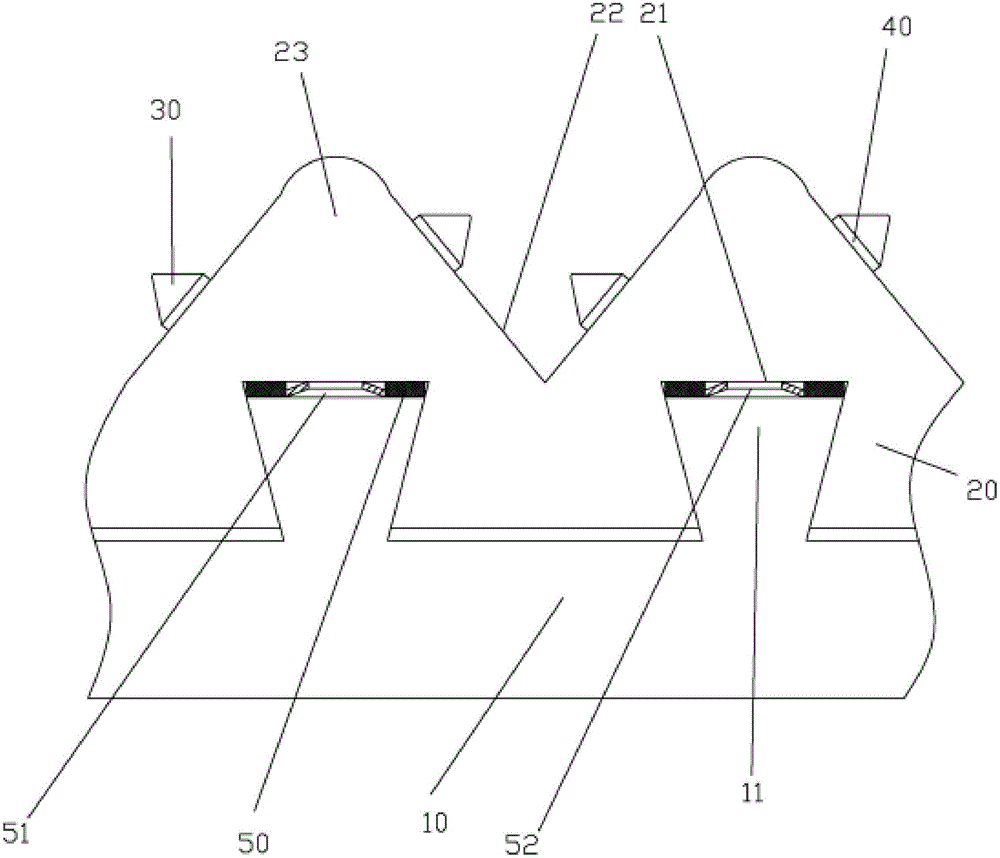

Brush roll cotton picker

The invention relates to a brush roll cotton picker and belongs to the technical field of agricultural machinery. The brush roll cotton picker comprises a picking table, an air conveying device, a cotton boll separating device, an impurity cleaning device and a cotton collecting box which are arranged on a self-walking chassis, the impurity cleaning device comprises primary, secondary and tertiary tooth rollers, one side of the primary tooth roller is provided with an upper brush, one side of the secondary tooth roller is provided with a middle brush, one side of the tertiary tooth roller is provided with a lower brush, sides of the primary, secondary and tertiary tooth rollers are provided with interval arranged beating rods respectively, an upper brush roller is arranged below the primary tooth roller, a lower brush roller with bristles which simultaneously contact with outer circles of the secondary and tertiary tooth rollers is arranged below the secondary tooth roller, an arc barrier is mounted on the lower side of the tertiary tooth roller, one side in a casing, which is far from the beating rods, is provided with a cotton collecting flow channel which conveys air flow from bottom to top, and the cotton collecting flow channel is provided with upper and lower flow suction openings. The bottom of the cotton collecting flow channel is connected with an air outlet of a cotton conveying fan. By means of the brush roll cotton picker, cotton fiber damages can be remarkably reduced, the impurity cleaning effect is improved, the impurity content rate is lower than 10%, meanwhile, the recycling effect is enhanced, and the unginned cotton loss can be greatly reduced.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

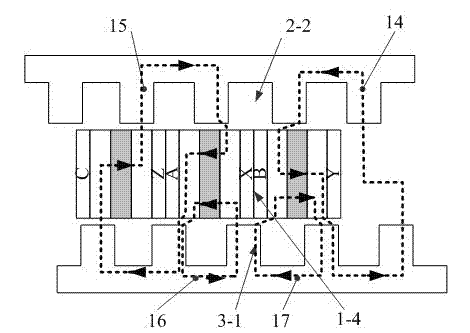

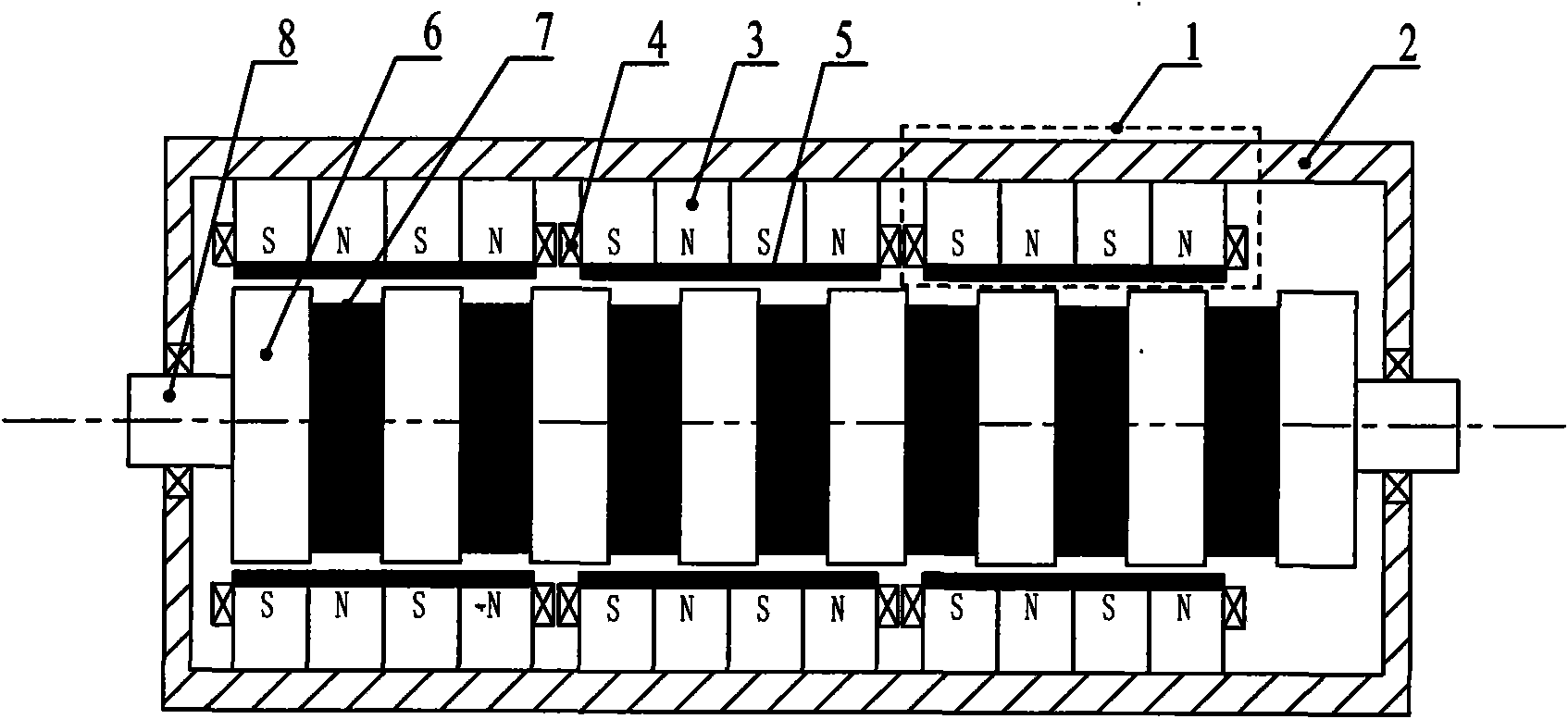

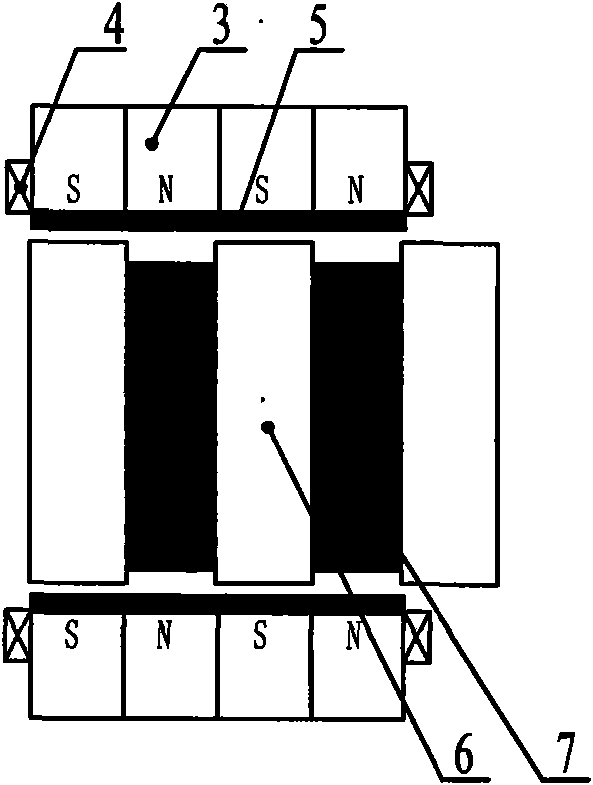

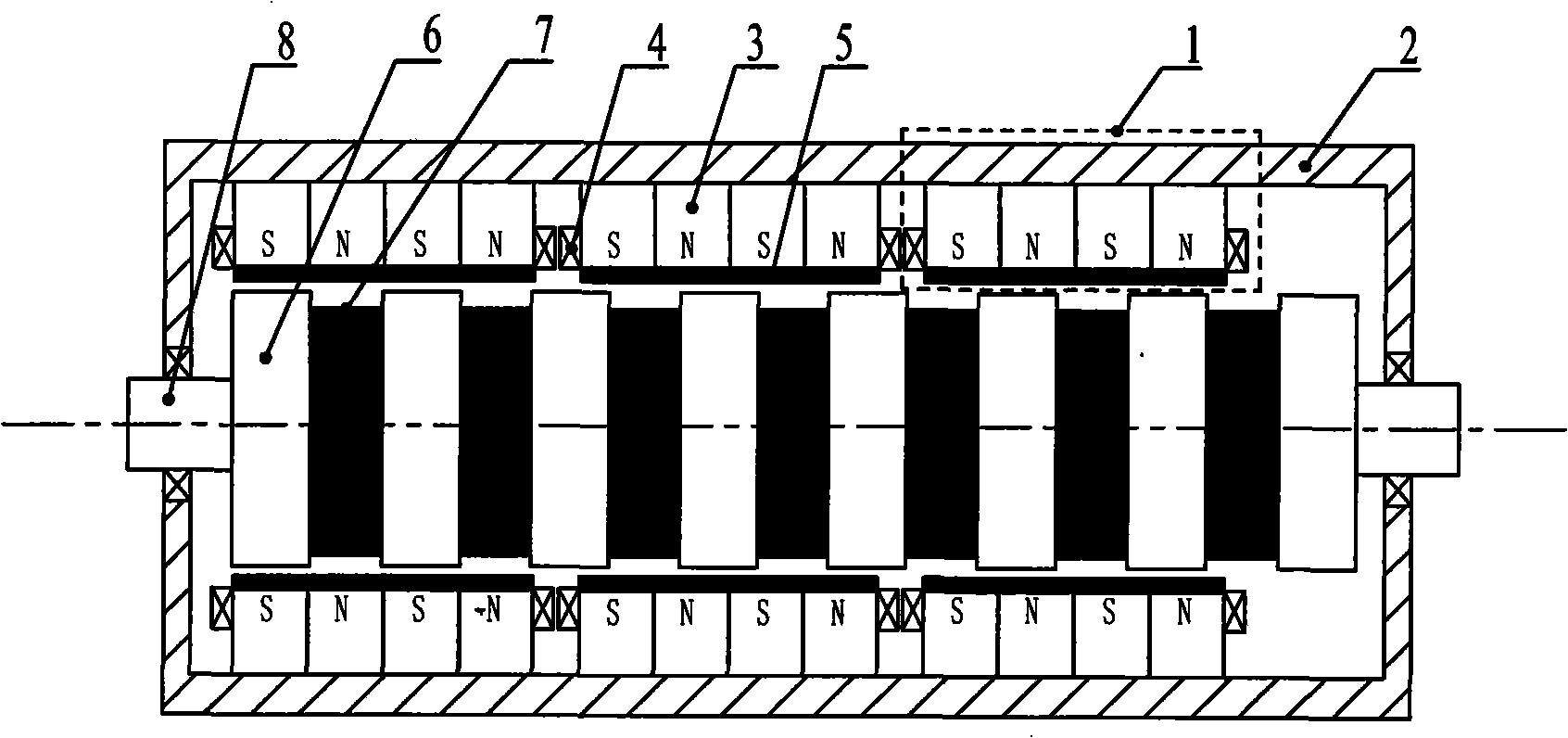

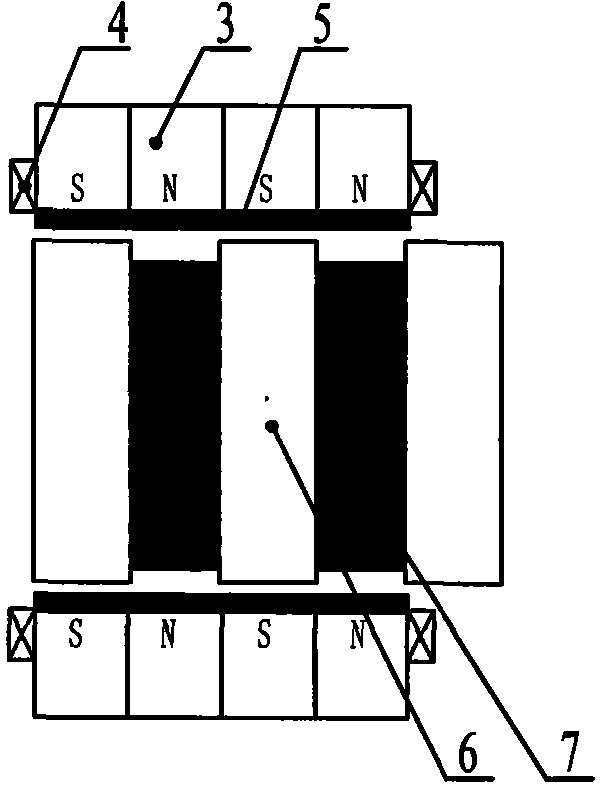

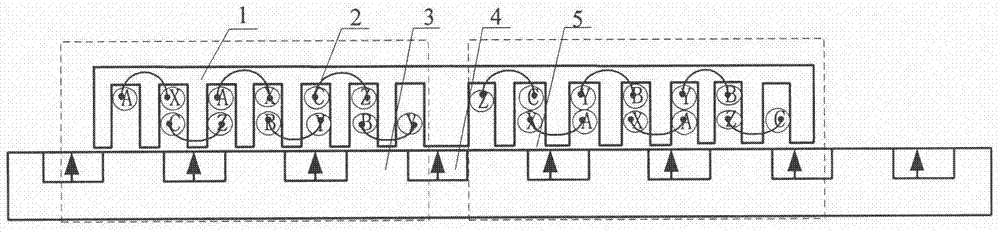

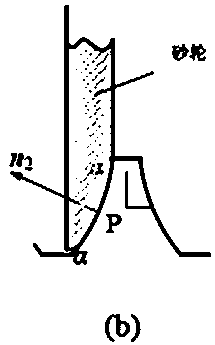

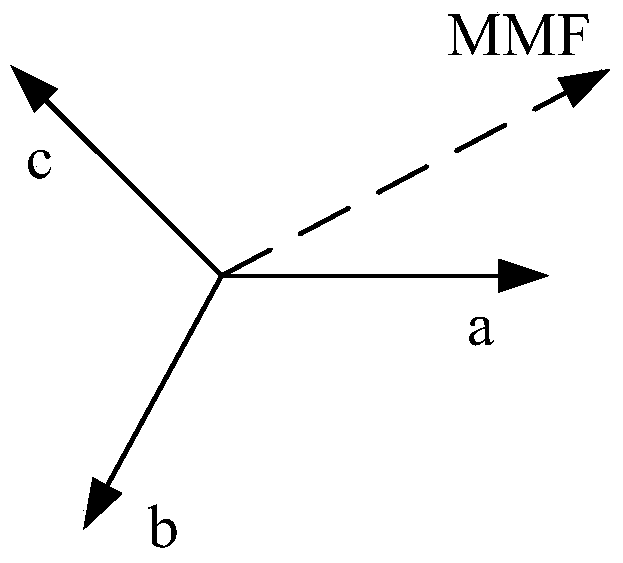

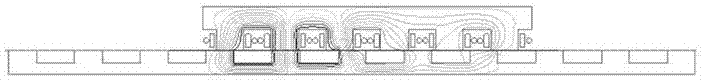

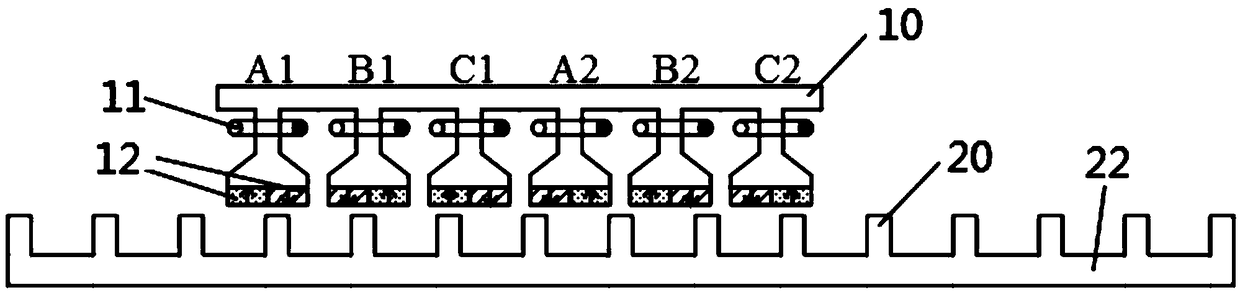

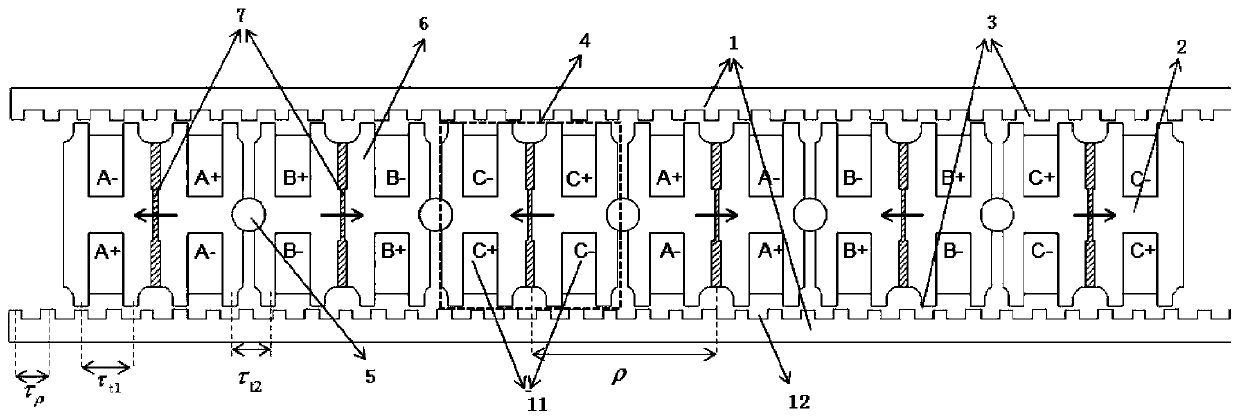

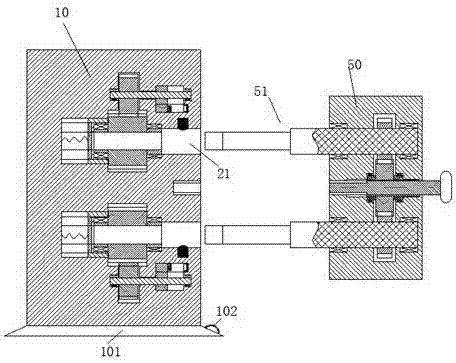

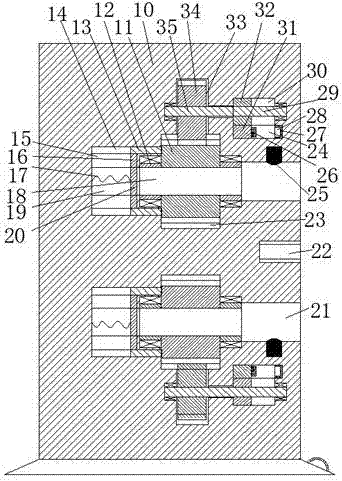

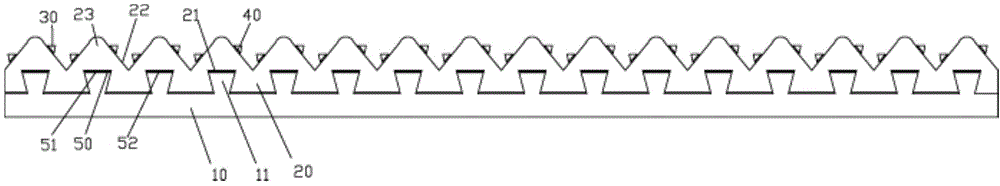

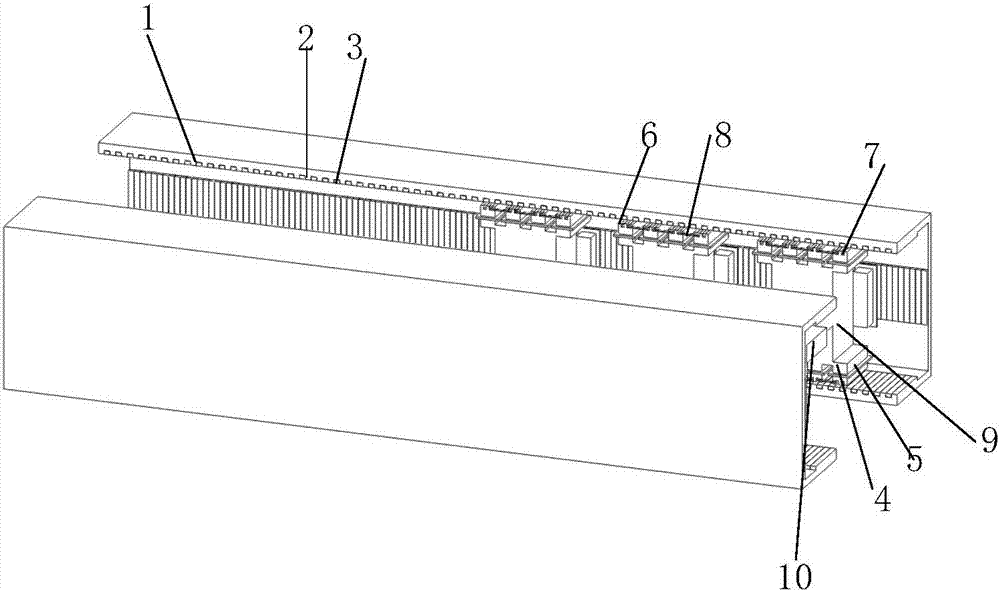

Double-edge staggered teeth flat type flux switching permanent magnet linear motor

InactiveCN103296857AIncrease thrust densityIncrease profitReciprocating/oscillating/vibrating magnetic circuit partsMagnetic circuit stationary partsSecondary toothMagnet

The invention provides a double-edge staggered teeth flat type flux switching permanent magnet linear motor and belongs to the technical field of motors. The double-edge staggered teeth flat type flux switching permanent magnet linear motor comprises a primary part and two secondary parts. In the primary part, a permanent magnet body is arranged between two magnet guiding primary iron core teeth to form a sandwich structure, magnetizing directions of the permanent magnet bodies on two adjacent sandwich structures are opposite, through grooves are formed between the sandwich structures, and armature windings are arranged in the through grooves. The two secondary parts are arranged on two sides of the primary part and are both magnet guiding iron cores of tooth socket structures. Secondary teeth on one side of the primary part and opposite secondary teeth on the other side of the primary part are staggered in position to form a structure with teeth of one secondary part corresponding to grooves of the other secondary part. During work of the double-edge staggered teeth flat type flux switching permanent magnet linear motor, along with changing of the relative positions of the primary part and the secondary parts on two sides, a flux changes the path, and the maximum flux with a winding turn chain in each groove is generated by three adjacent permanent magnets. The double-edge staggered teeth flat type flux switching permanent magnet linear motor can improve utilization rate of the permanent magnet bodies, improves thrust density and removes one-side magnetic pull.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

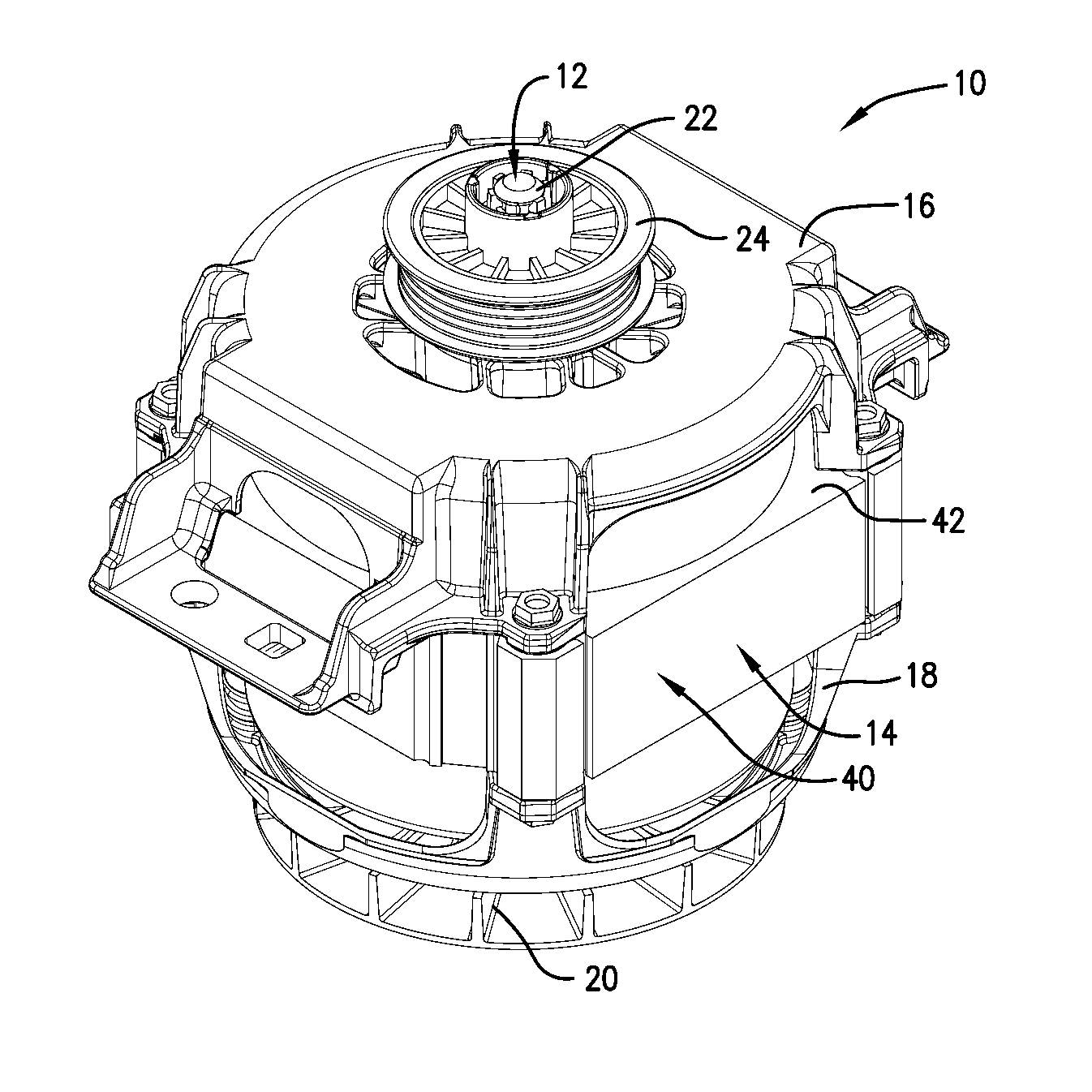

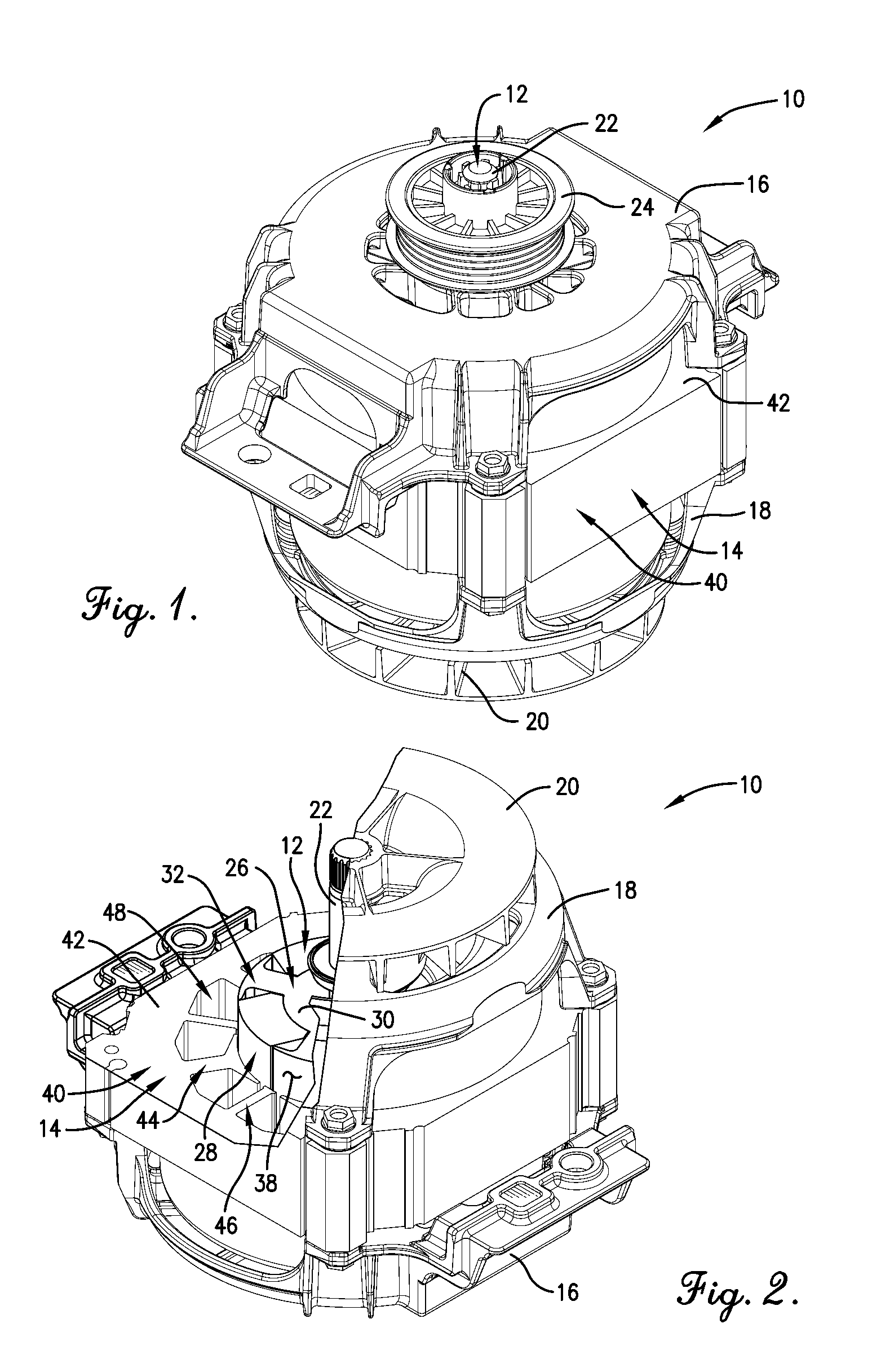

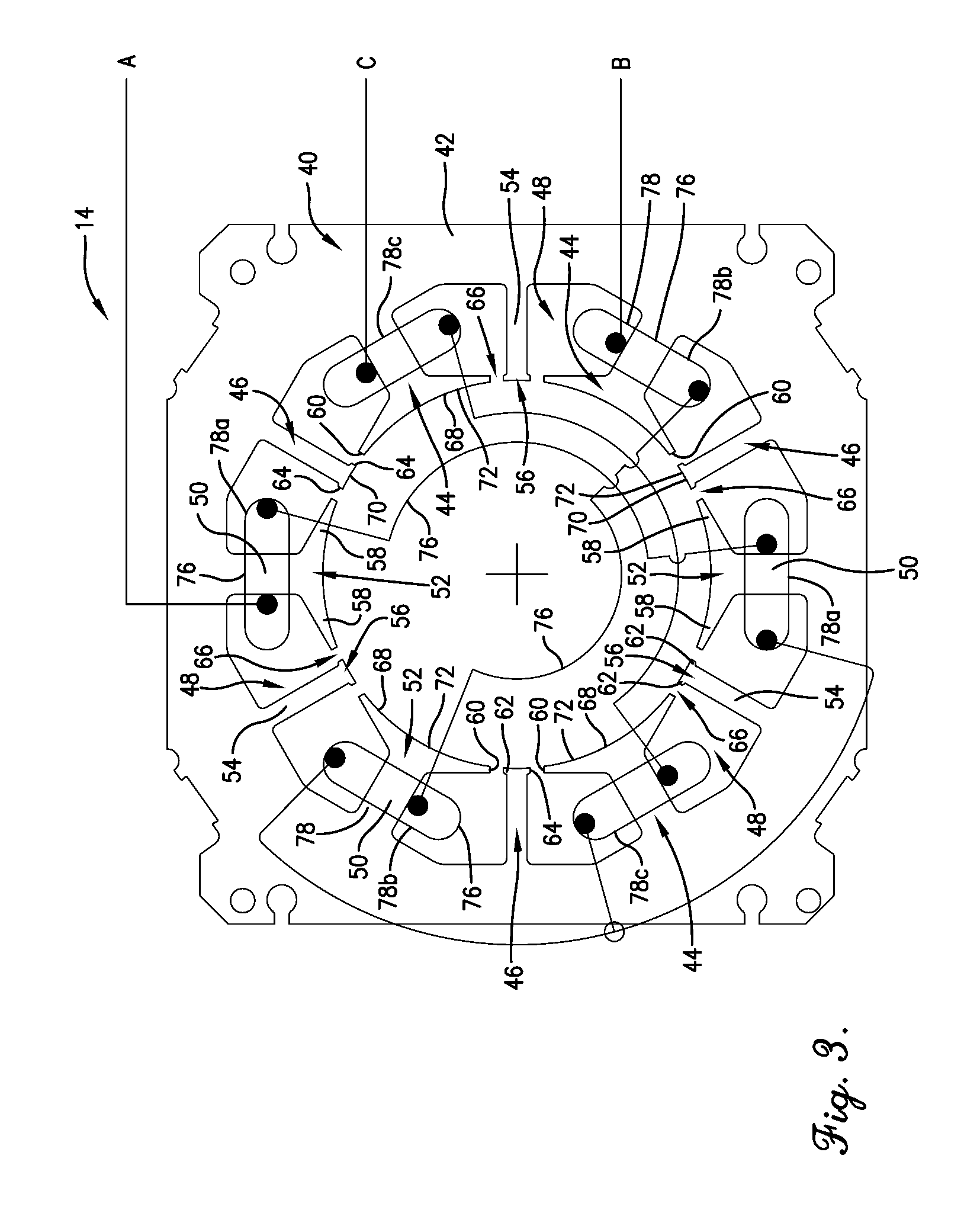

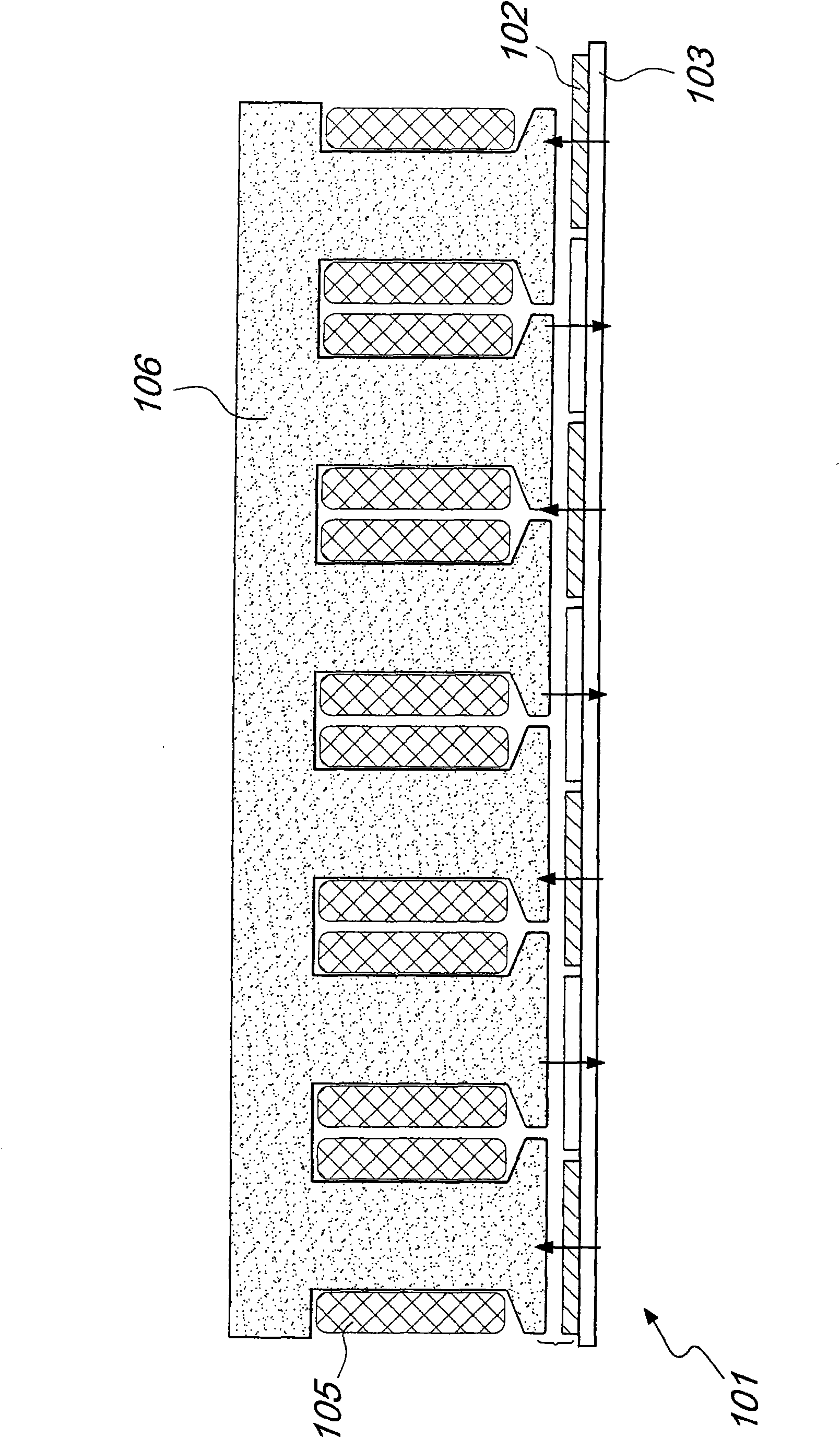

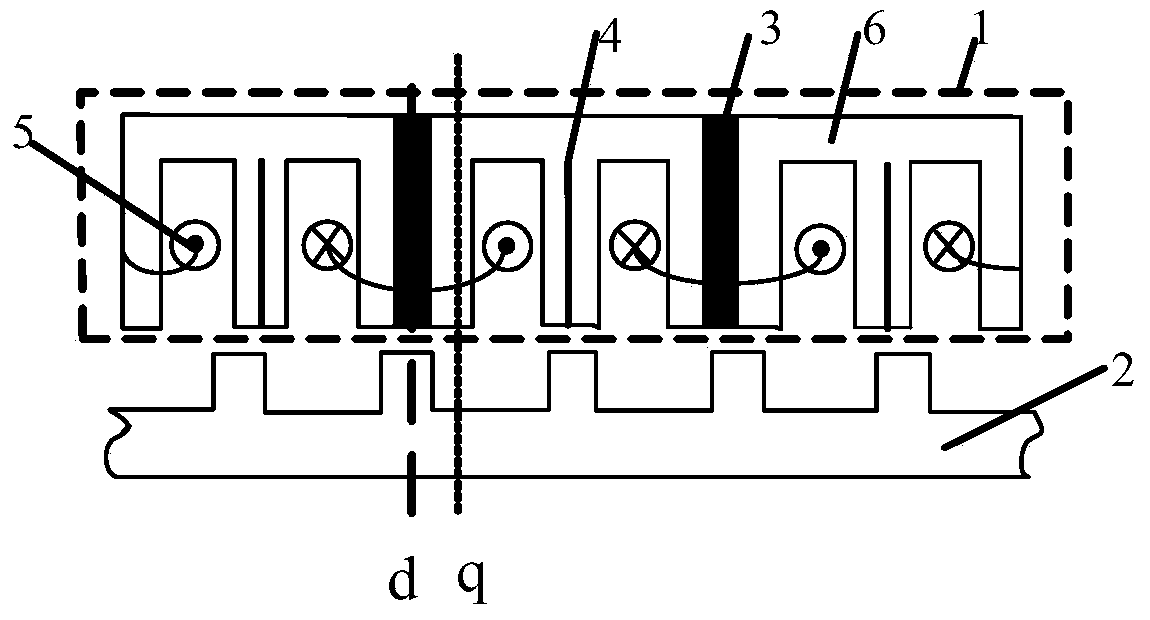

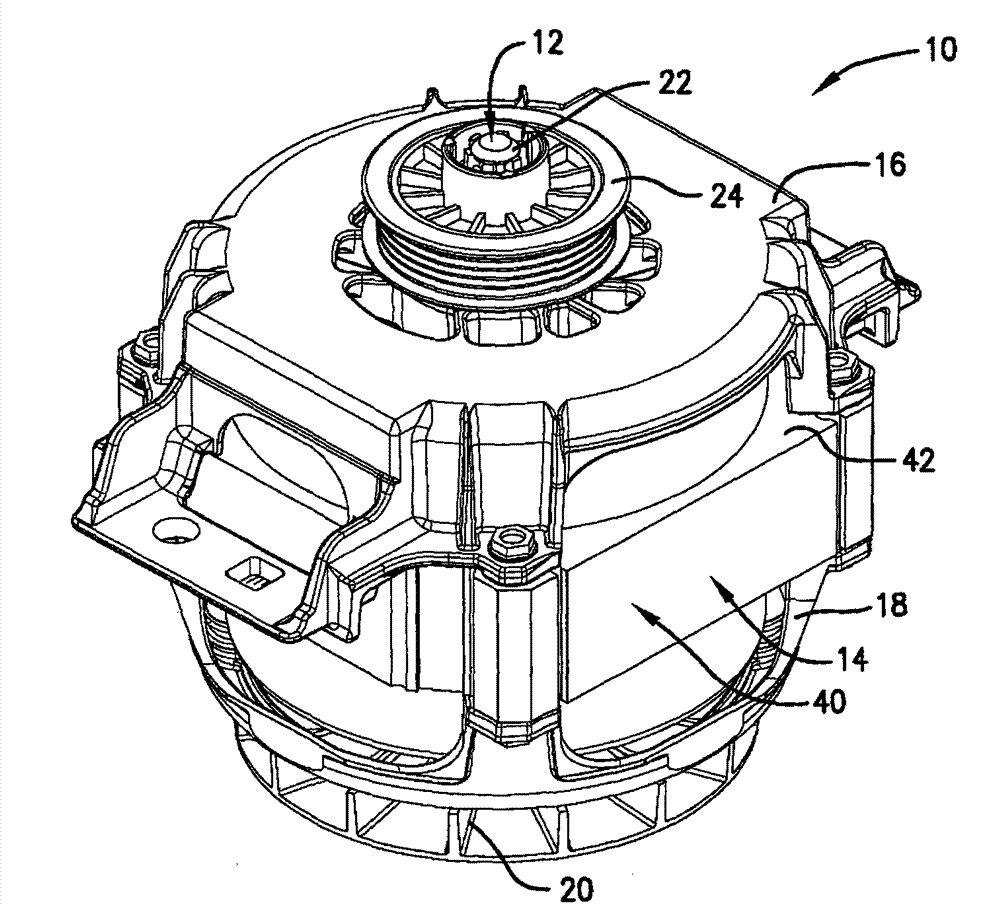

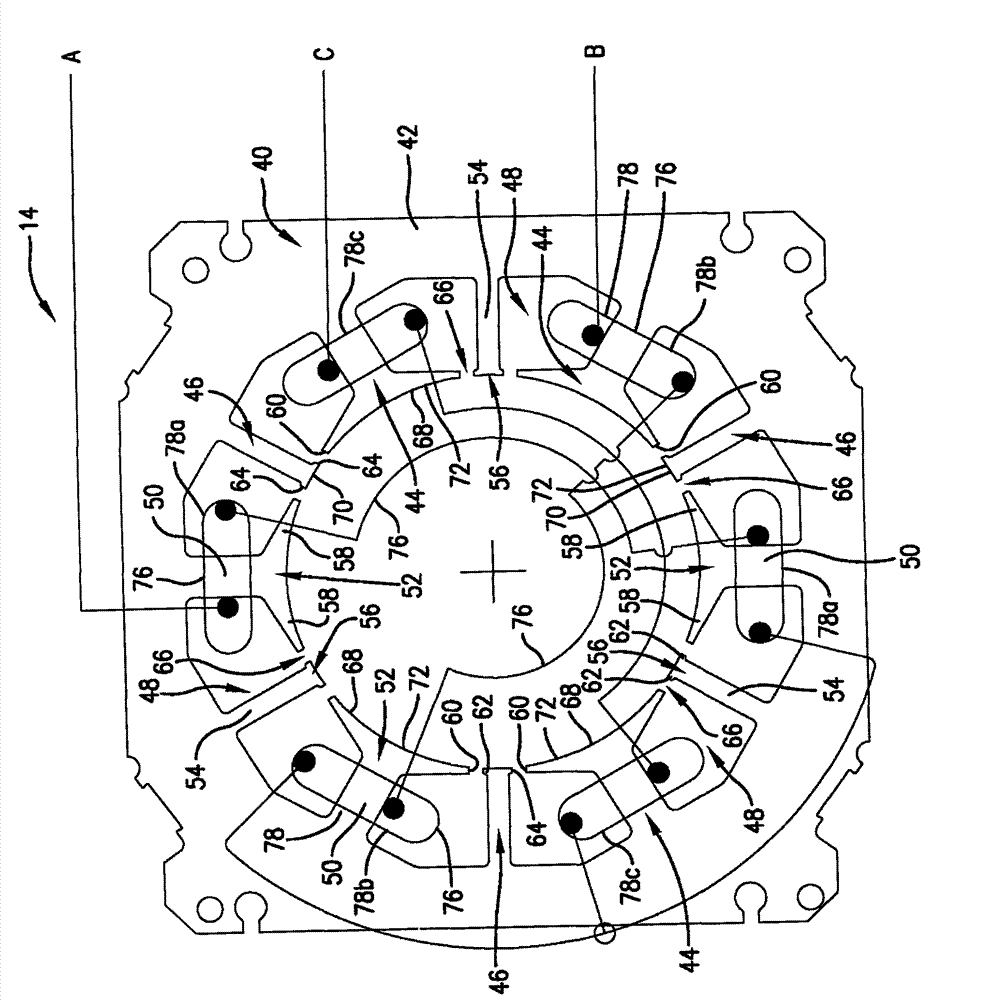

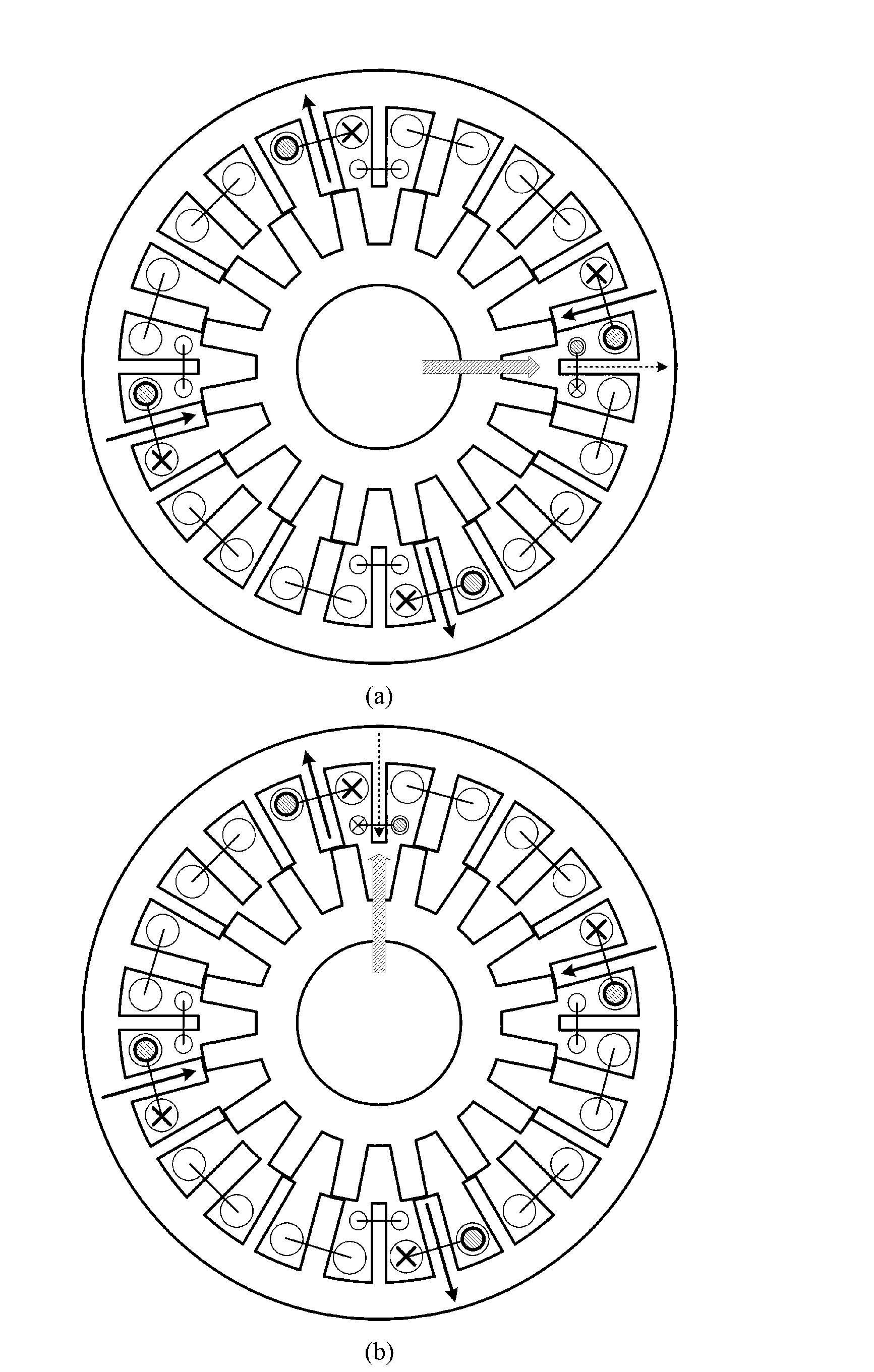

3-phase permanent magnet motor or generator having variable stator teeth

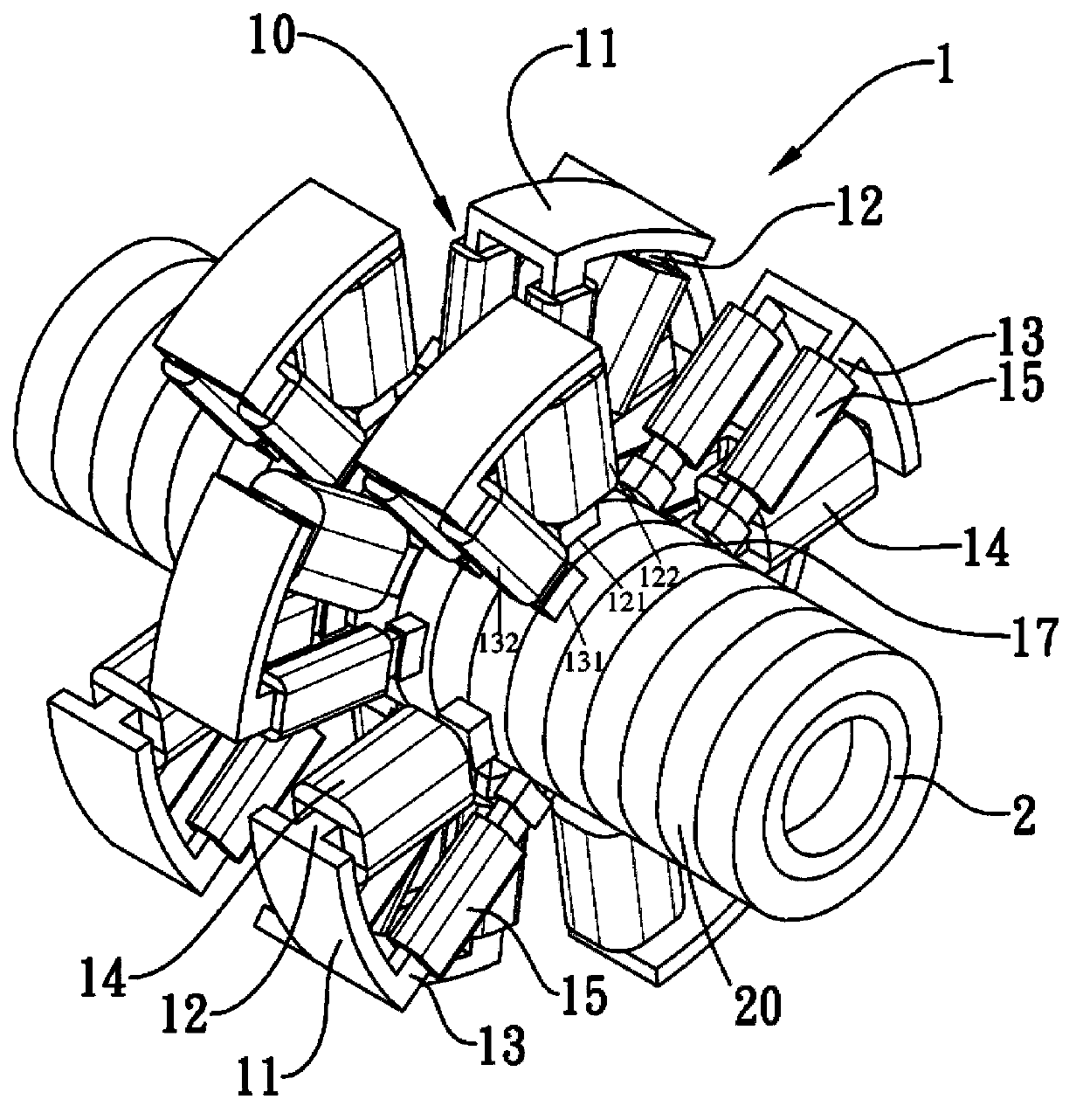

InactiveUS20140125189A1Well formedMagnetic circuitSynchronous machinesPermanent magnet motorControl theory

An electric motor or generator machine is provided. The machine includes a rotor rotatable about an axis, as well as a stator. The stator includes a stator core and wiring wound around the stator core. The stator core includes a plurality of arcuately spaced apart alternating primary teeth and secondary teeth, such that each secondary tooth is spaced between a corresponding pair of primary teeth. The wiring is wound about the primary teeth to form a plurality of coils. The plurality of coils includes an A-phase coil, a B-phase coil, and a C-phase coil. Each of the primary teeth includes a generally radially extending primary arm and a generally arcuately extending primary crown. Each of the primary crowns spans one hundred sixty (160) to two hundred (200) electrical degrees.

Owner:NIDEC MOTOR CORP

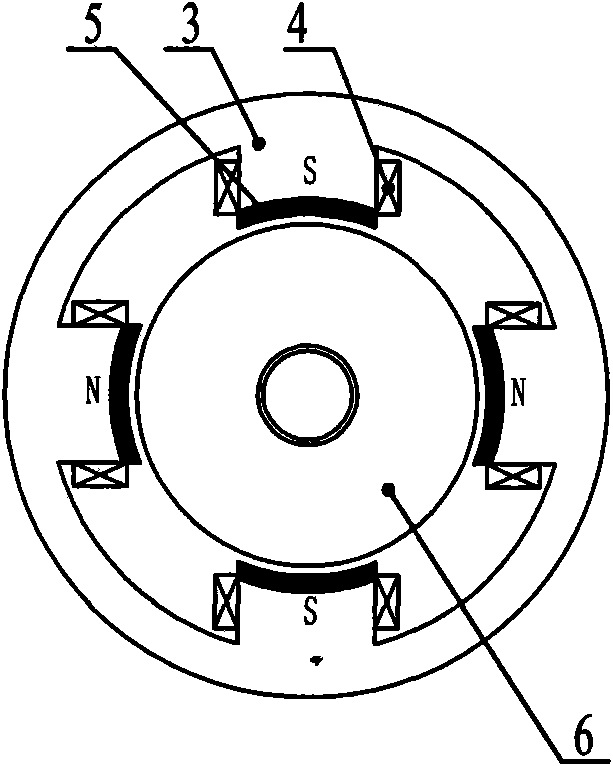

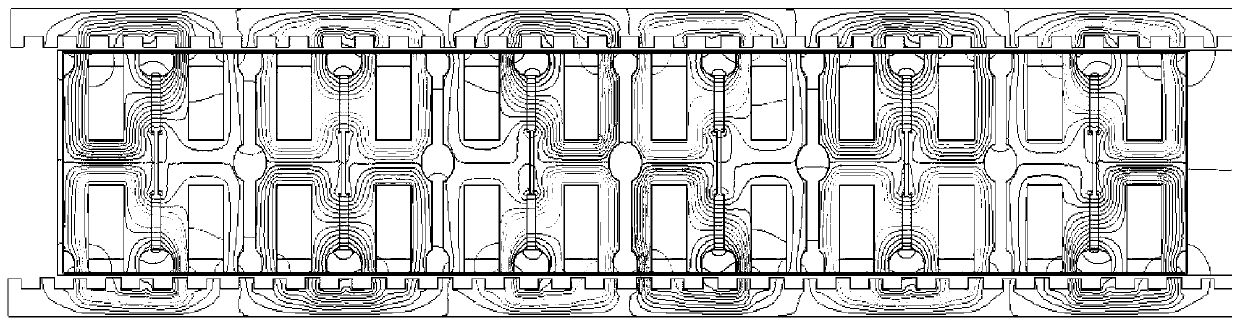

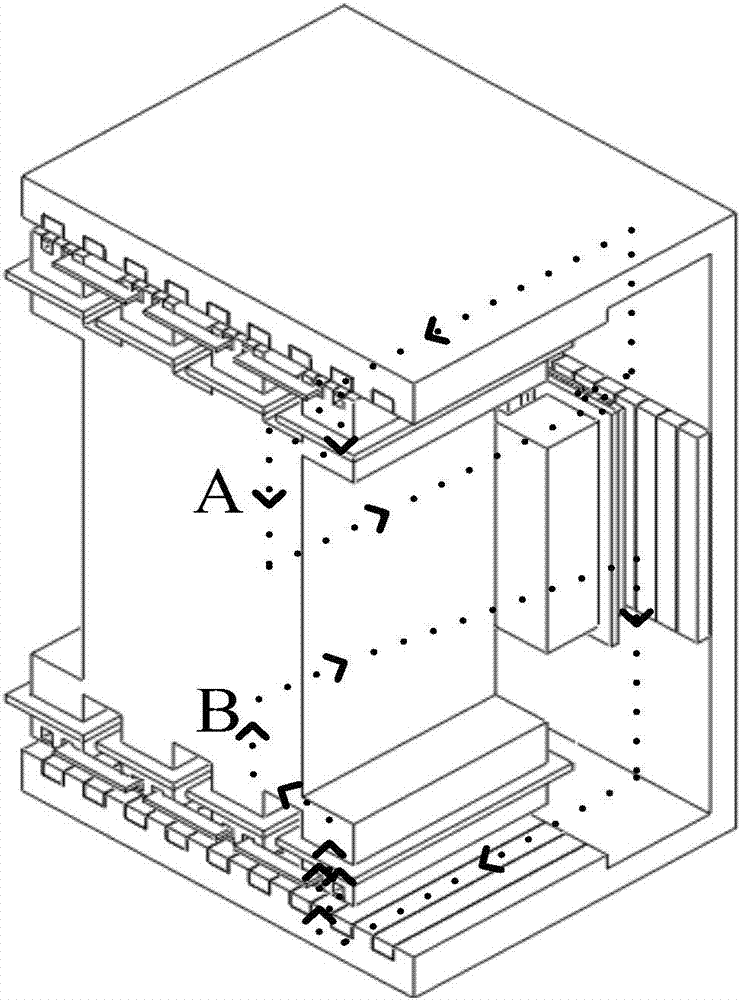

Cylinder type flux-reversal linear machine

InactiveCN101552535ASimple structureIncrease thrust densityPropulsion systemsElectric machineEddy current

The present invention relates to a cylinder type flux-reversal linear machine. The invention relates to the field of electric machine and settles the problems of low efficiency, large eddy current loss, complex technique and effect to control precision and dynamic characteristic in prior linear machine. The armature core of phase unit according to the nveition is an annular core which is uniformly installed with 2n teeth on the inner circumstance, wherein n is a natural number. The armature winding of phase unit is a concentrated winding. Each coil is corresponding winded on each tooth of armature core of phase unit. The winding directions of coils on adjacent teeth are opposite. All coils on the teeth of armature core of same phase unit are connected in series to a same phase unit armature winding. The phase unit armature windings are connected in series or in parallel to each phase armature winding. A permanent magnet is adhibited on the teeth of armature core of phase unit. The phase unit armature core center distance taut between two adjacent phase armature units in axial direction and the tooth pitch taup of secondary teeth along the axial direction satisfy a relationship: taut=ktaup+ / -(1 / m)taup, wherein k and m are natural numbers, and m is a phase number and is larger than or equal to 3. The cylinder type flux-reversal linear machine not only can be used as a motor, but also can be used as a generator.

Owner:HARBIN INST OF TECH

Cylinder type flux-reversal linear machine

InactiveCN101552535BSimple structureIncrease thrust densityPropulsion systemsElectric machineLinear machine

Owner:HARBIN INST OF TECH

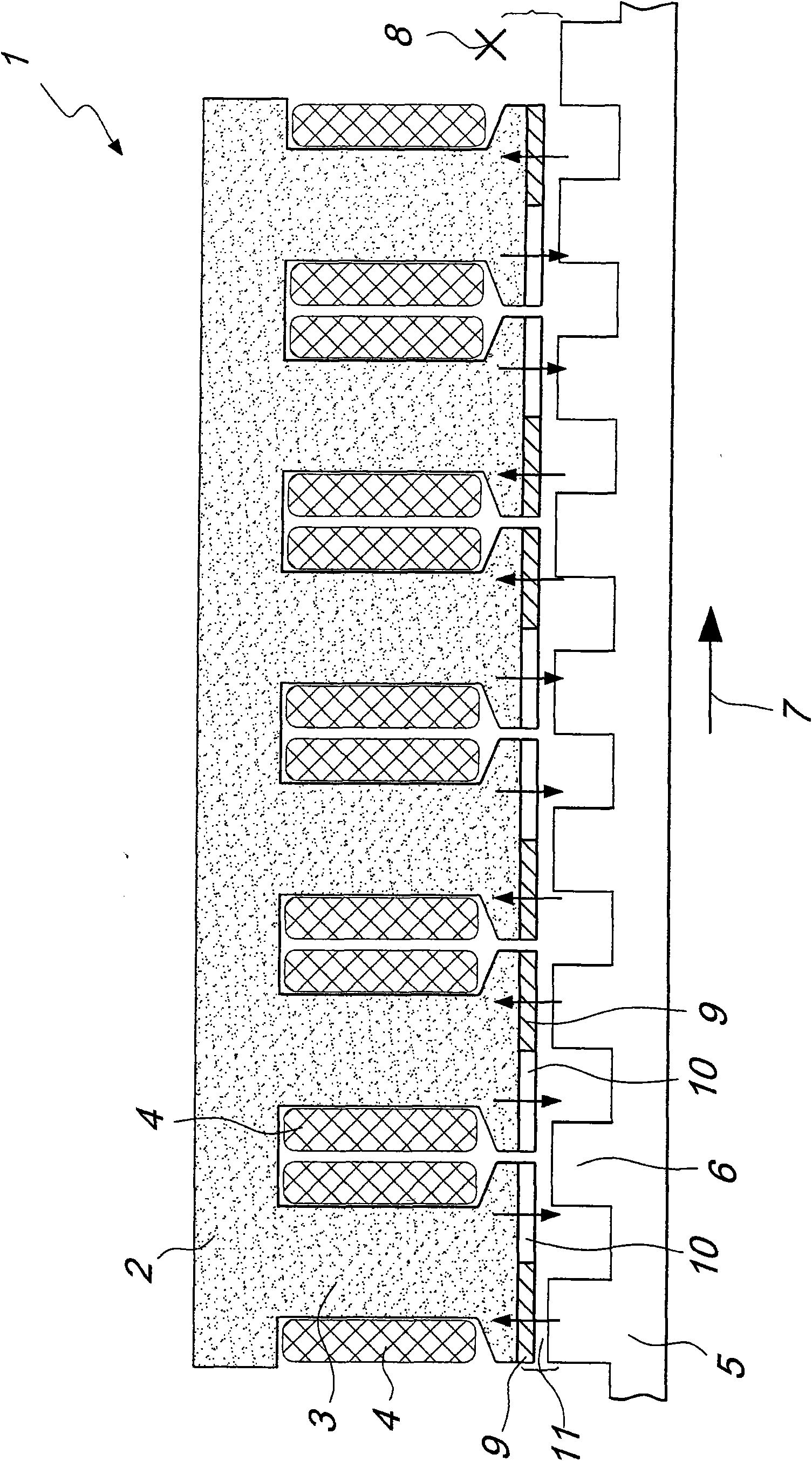

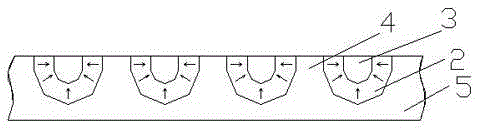

Magnetic flux reverse linear motor

InactiveCN101572473AImprove performanceImprove efficiencyPropulsion systemsLinear motorMagnetic flux

The invention relates to a magnetic flux reverse linear motor (1) which comprises a primary element (2) and a toothed secondary element (5), wherein the primary element (2) is provided with at least one primary tooth (3), and a corresponding coil (4) which is suitable for conducting changeable current is arranged around the primary tooth (3). The magnetic flux reverse linear motor is characterized in that a toothed secondary element (5) facing the primary tooth (3) is arranged and comprises a plurality of secondary teeth (6) made of ferromagnetic material, the secondary teeth (6) are protruded towards the primary tooth to determine an air gap (11) of the motor; at a primary tooth end (31) which is guided towards the air gap of the motor, each primary tooth comprises a pair of magnetic bodies (9, 10); and the magnetic bodies are installed towards the air gap in a mode of guiding reverse polarities with each other.

Owner:XI TELE MA

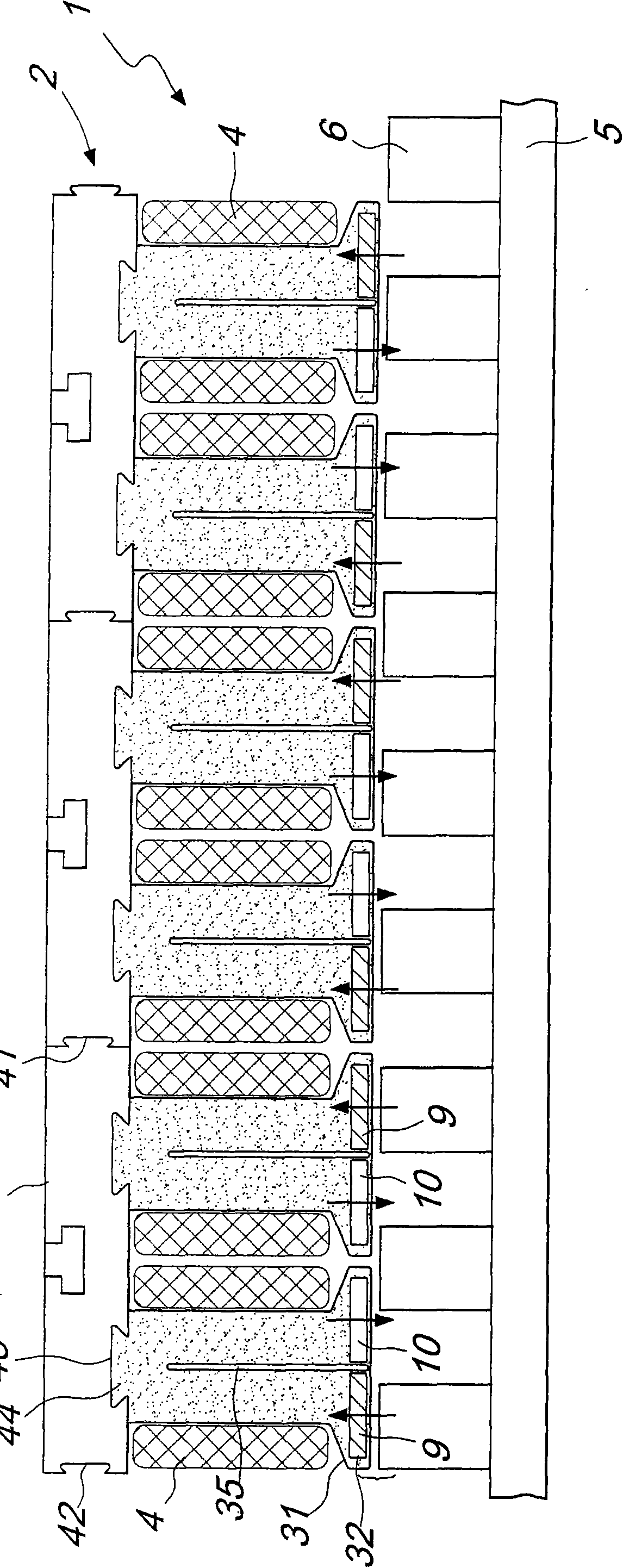

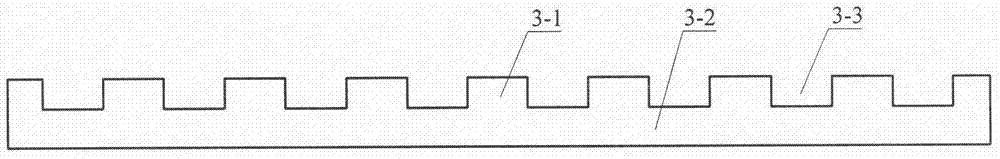

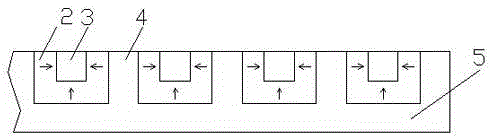

Low-thrust-fluctuation continuous pole permanent magnet synchronous linear motor

The invention provides a low-thrust-fluctuation continuous pole permanent magnet synchronous linear motor, which belongs to the technical field of motors. The low-thrust-fluctuation continuous pole permanent magnet synchronous linear motor comprises a primary assembly and a secondary assembly, wherein the primary assembly is composed of an armature winding and a primary iron core, a groove is formed in the primary iron core, the armature winding is arranged in the groove, phase positions of unit motors are staggered by 180 degrees by means of the structural design of the primary iron core, and winding directions of in-phase windings on the adjacent unit motors are opposite; and the secondary assembly is composed of permanent magnets and a secondary iron core, magnetizing directions of the permanent magnets are the same, and the secondary iron core is composed of secondary teeth and secondary back yokes between the permanent magnets.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

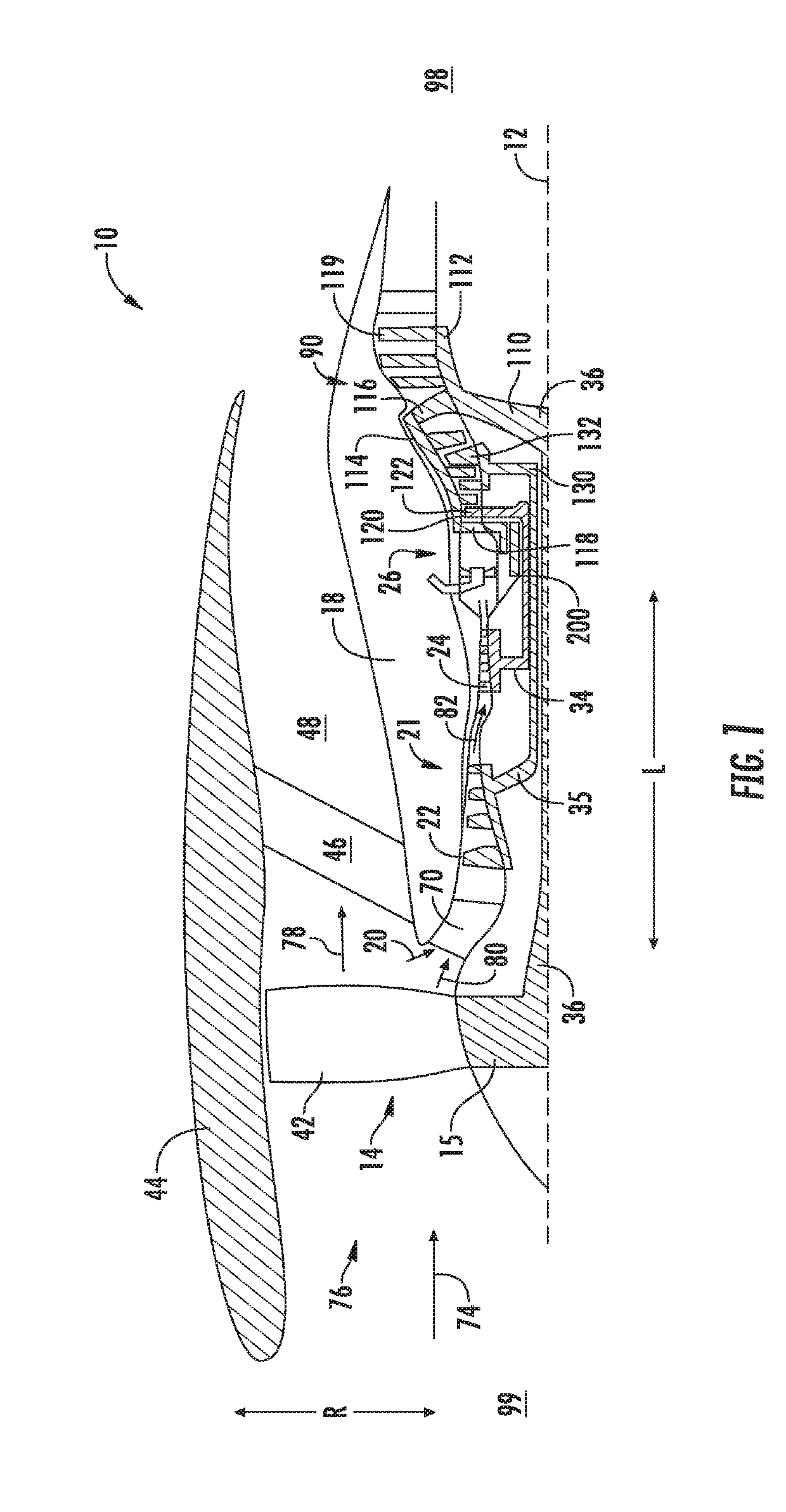

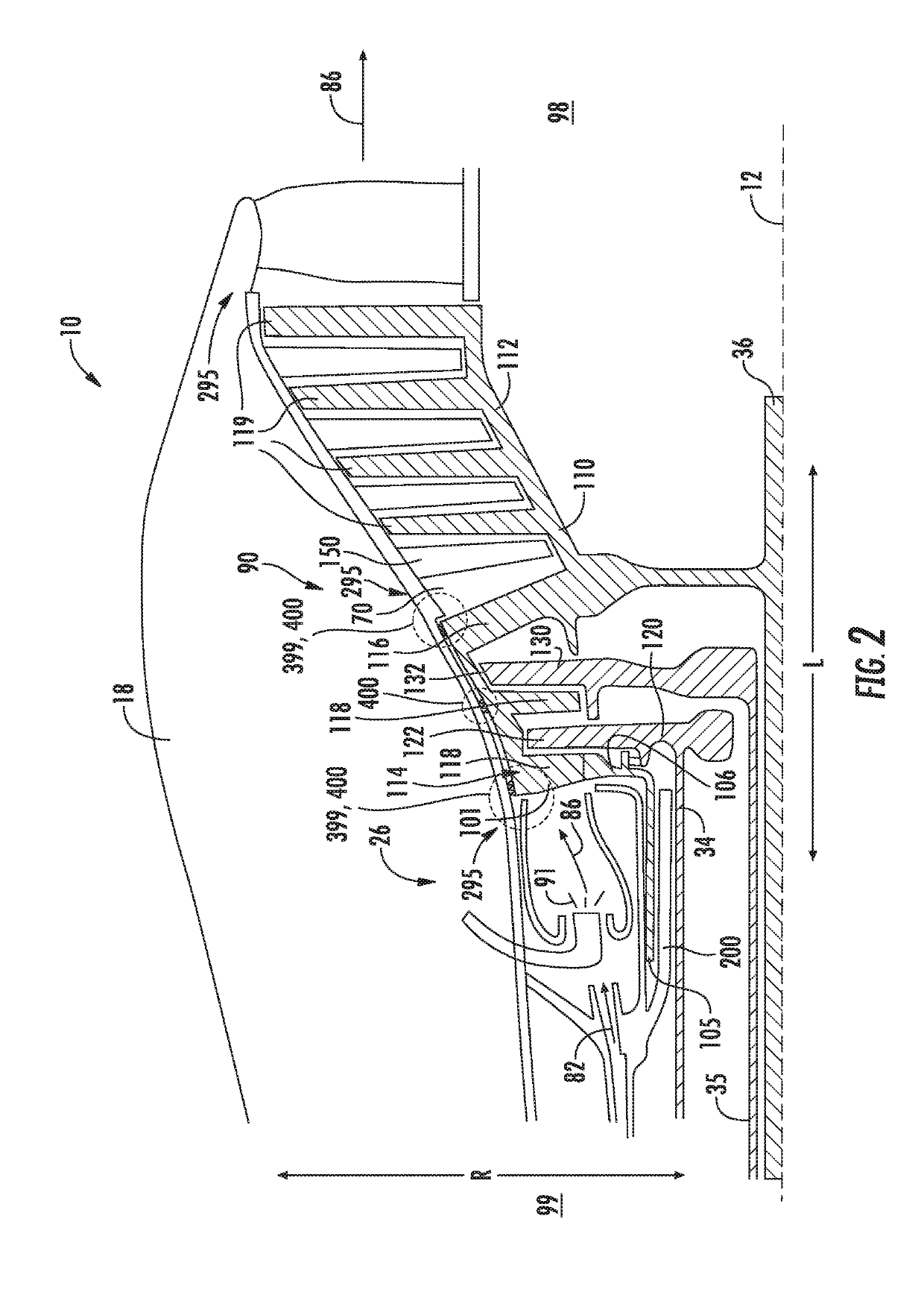

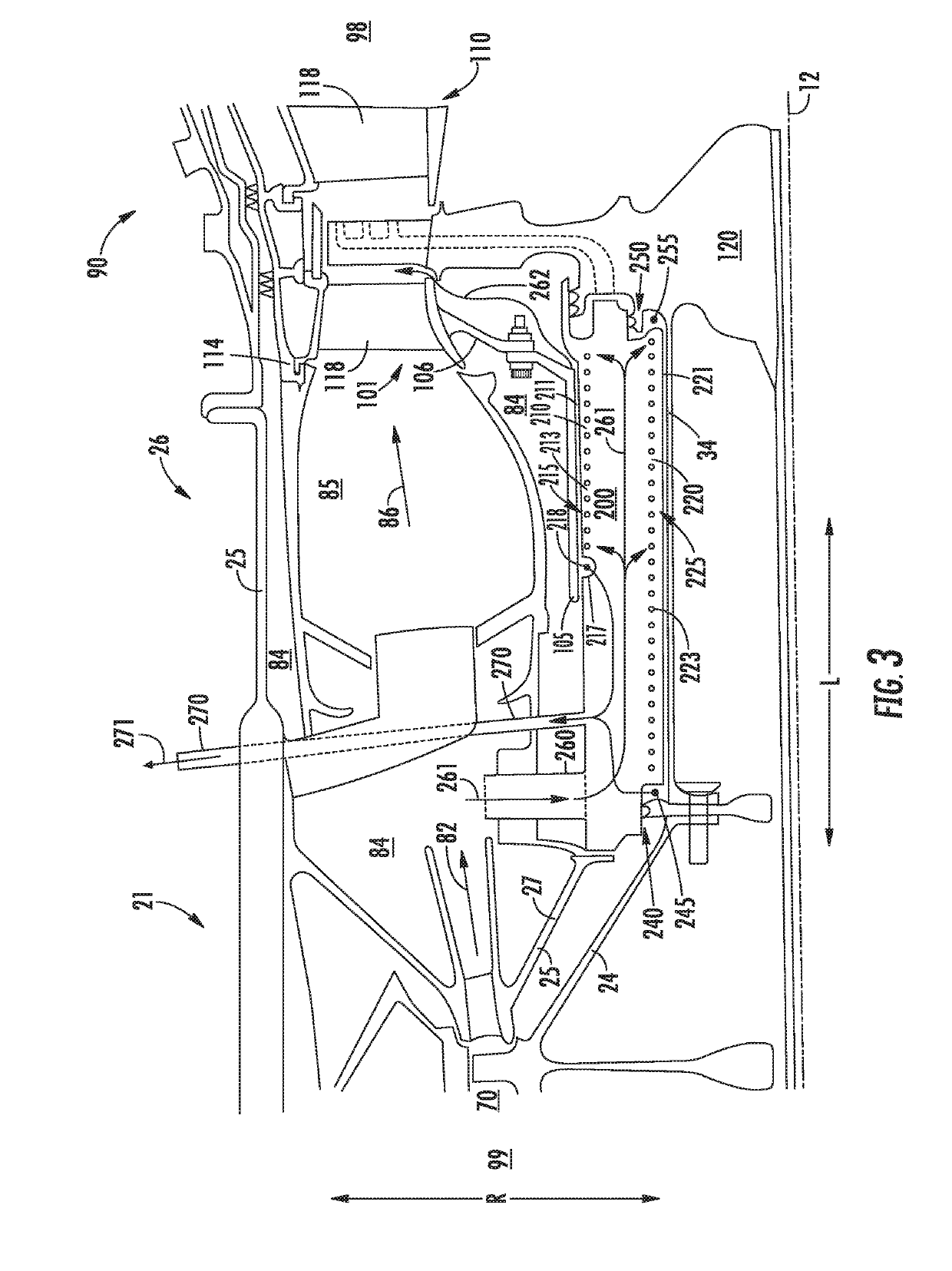

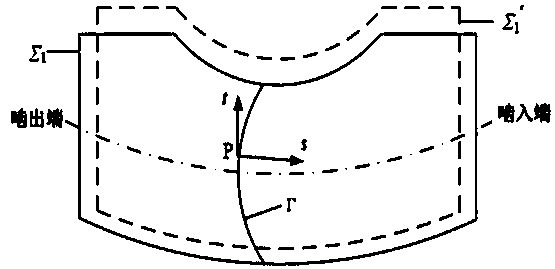

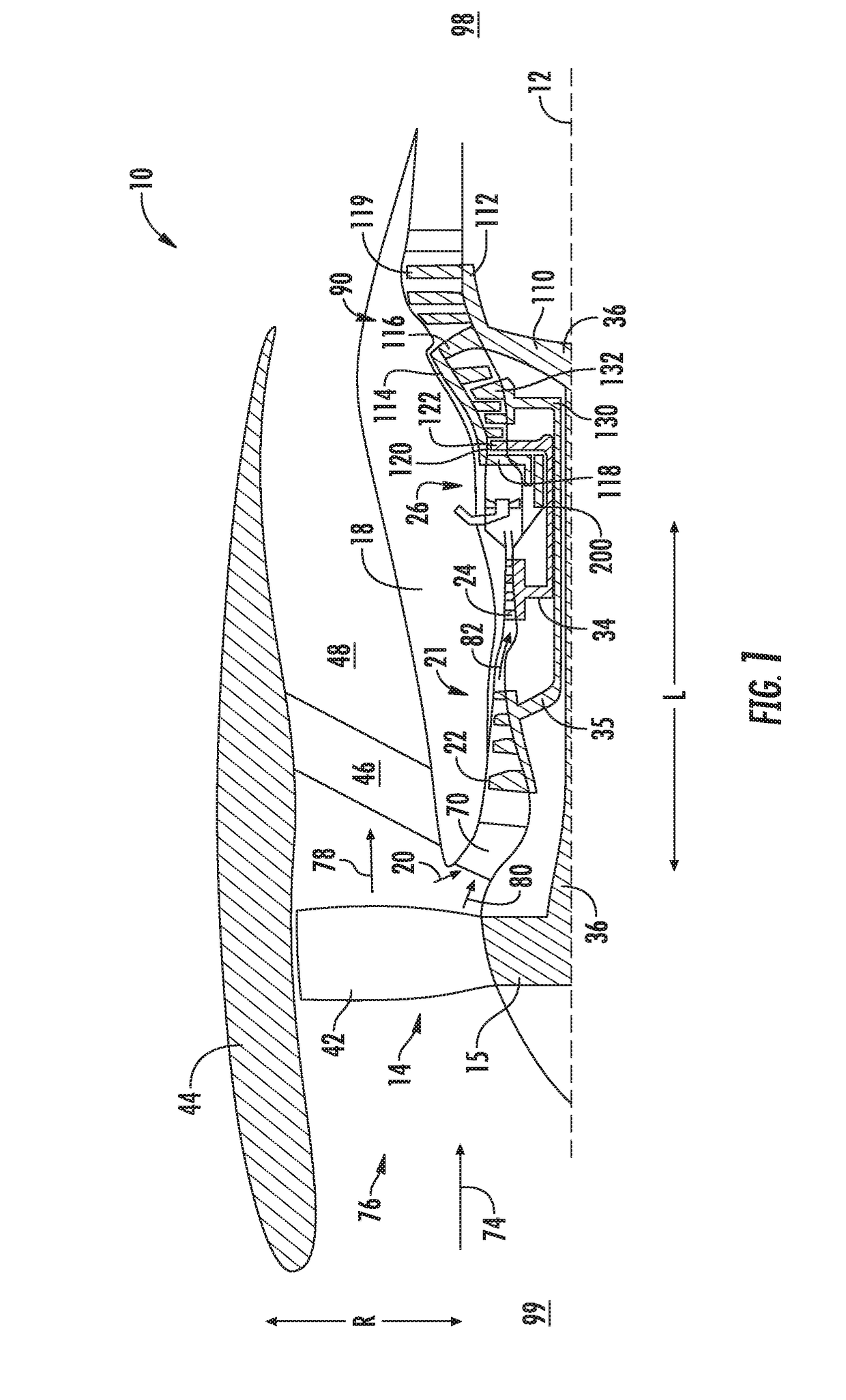

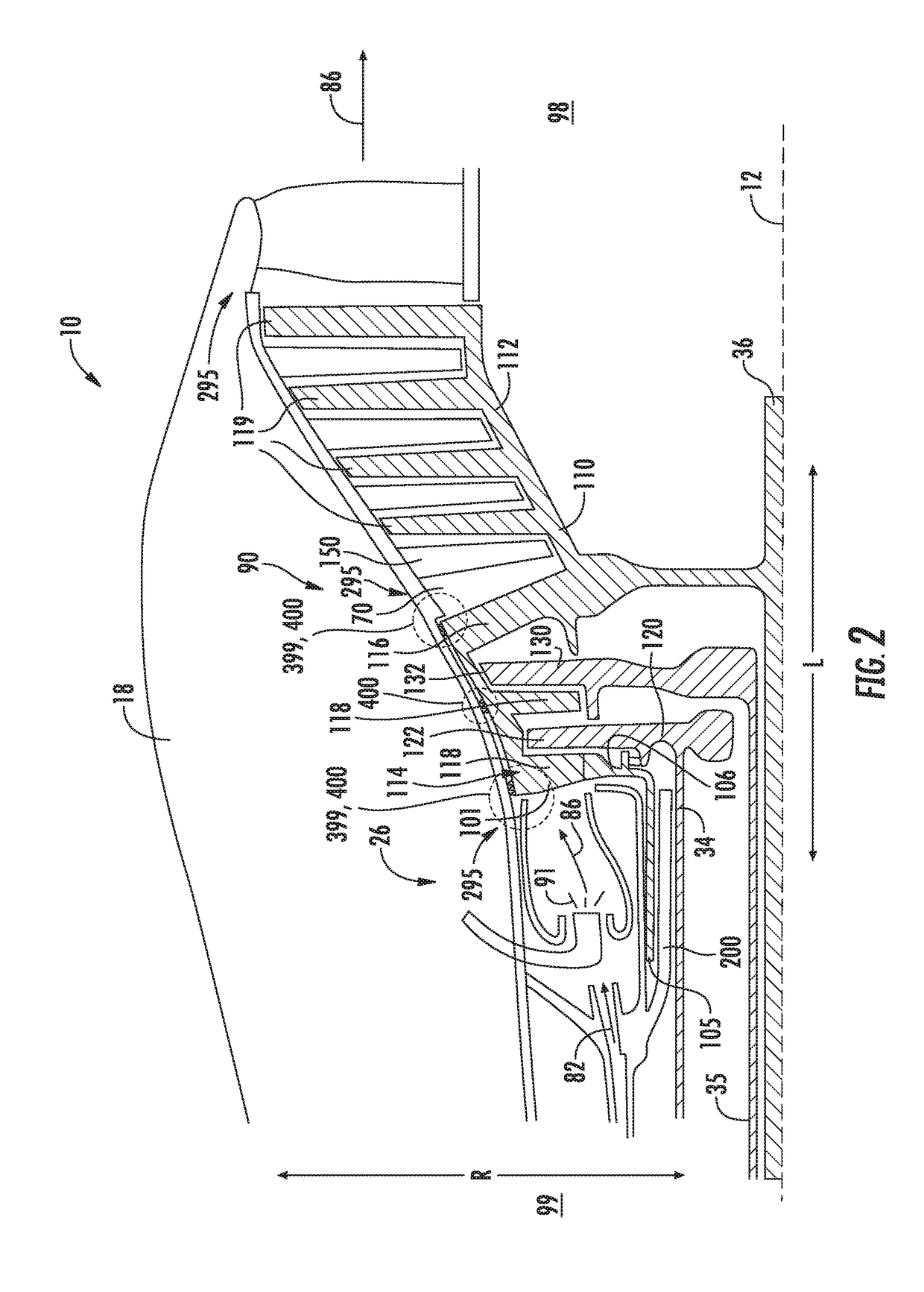

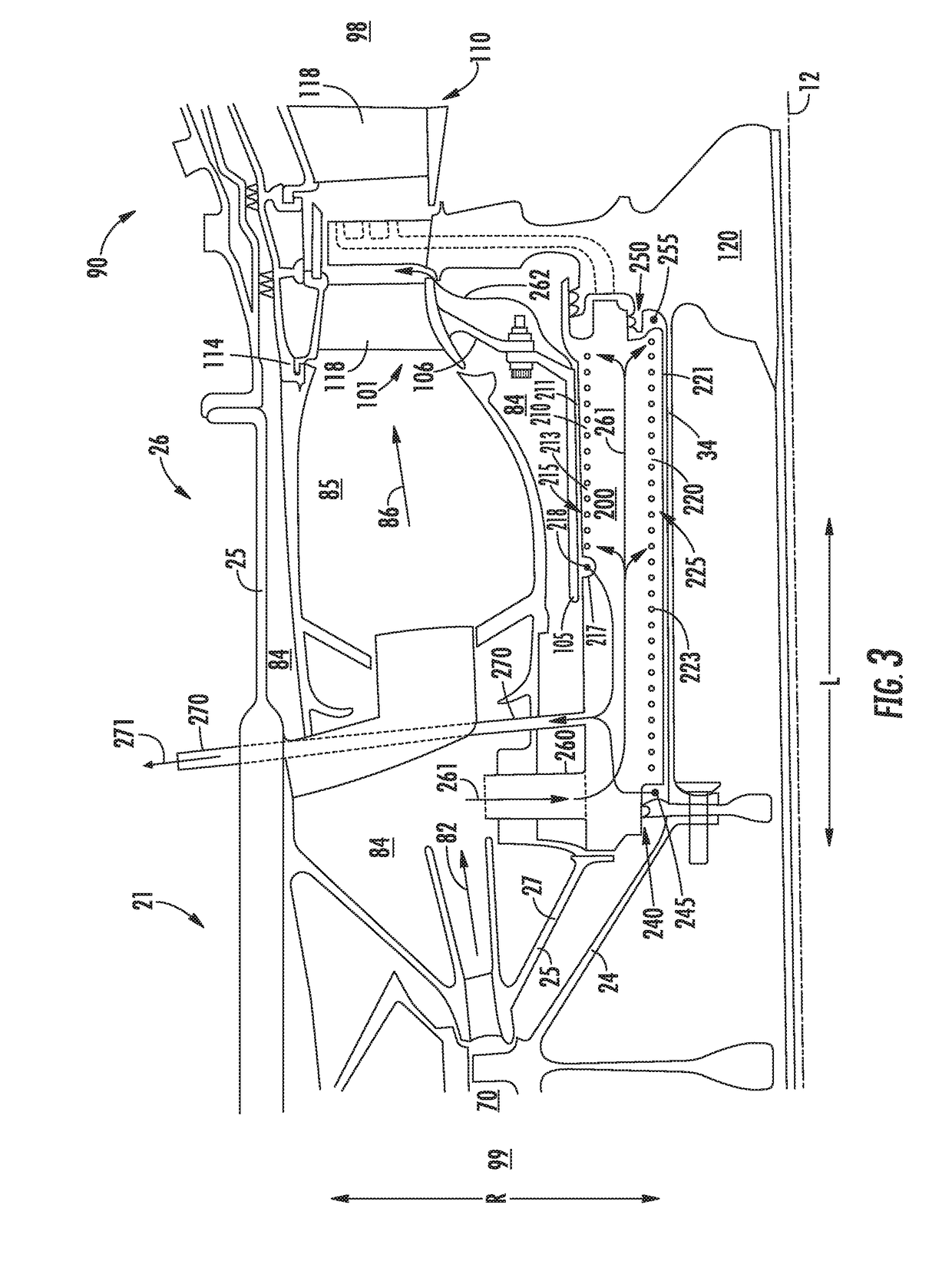

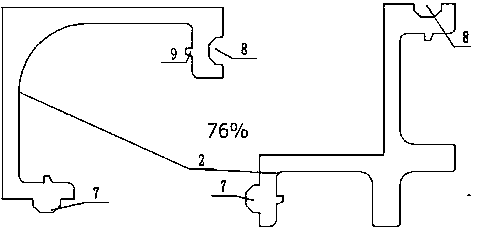

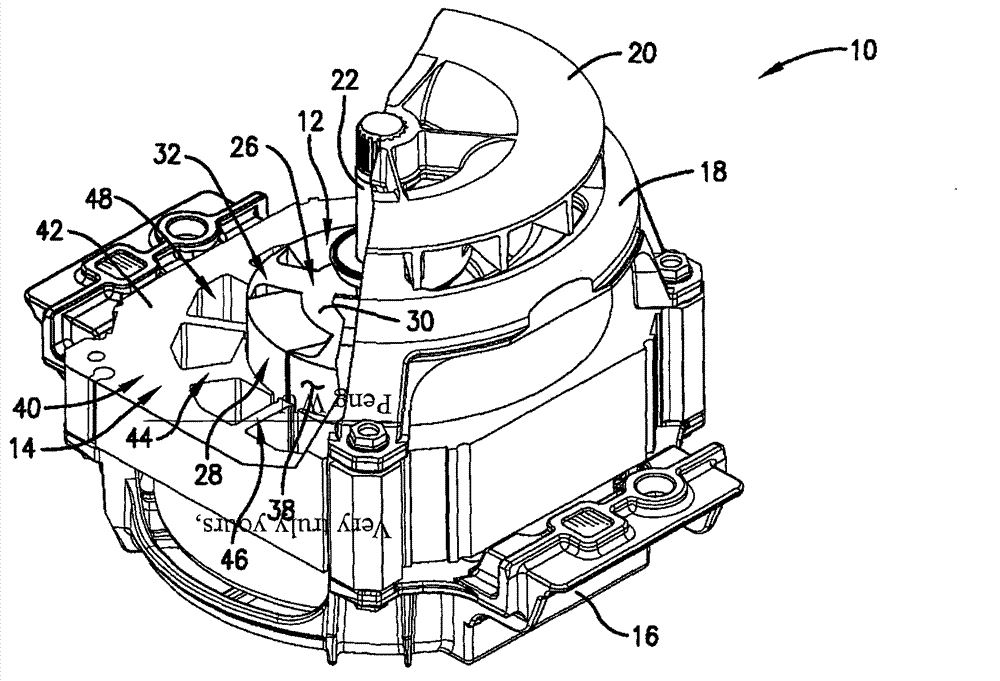

Seal assembly for counter rotating turbine assembly

The present disclosure is directed to a gas turbine engine including a turbine rotor, a turbine frame at least partially surrounding the turbine rotor, and an outer diameter seal assembly. The turbine rotor includes an inner shroud, an outer shroud, and at least one connecting airfoil coupling the inner shroud and the outer shroud. The outer shroud includes a plurality of outer shroud airfoils extended inward along a radial direction. The outer diameter seal assembly includes a sliding portion disposed between the turbine frame and the outer shroud of the turbine rotor. The outer diameter seal assembly defines a secondary tooth at the outer shroud radially inward of a longitudinal face of the sliding portion, and a primary tooth defined axially adjacent to a radial face of the sliding portion.

Owner:GENERAL ELECTRIC CO

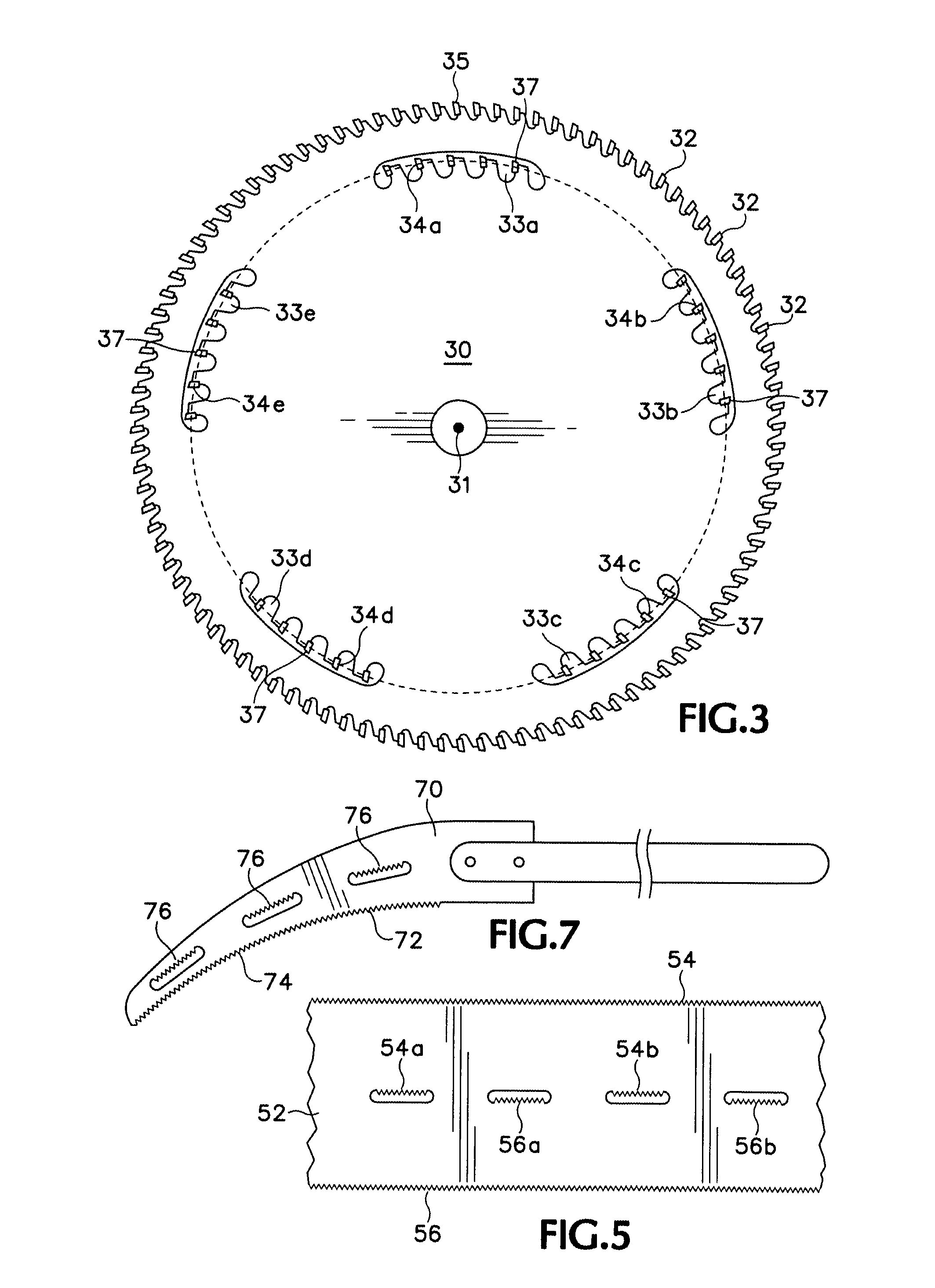

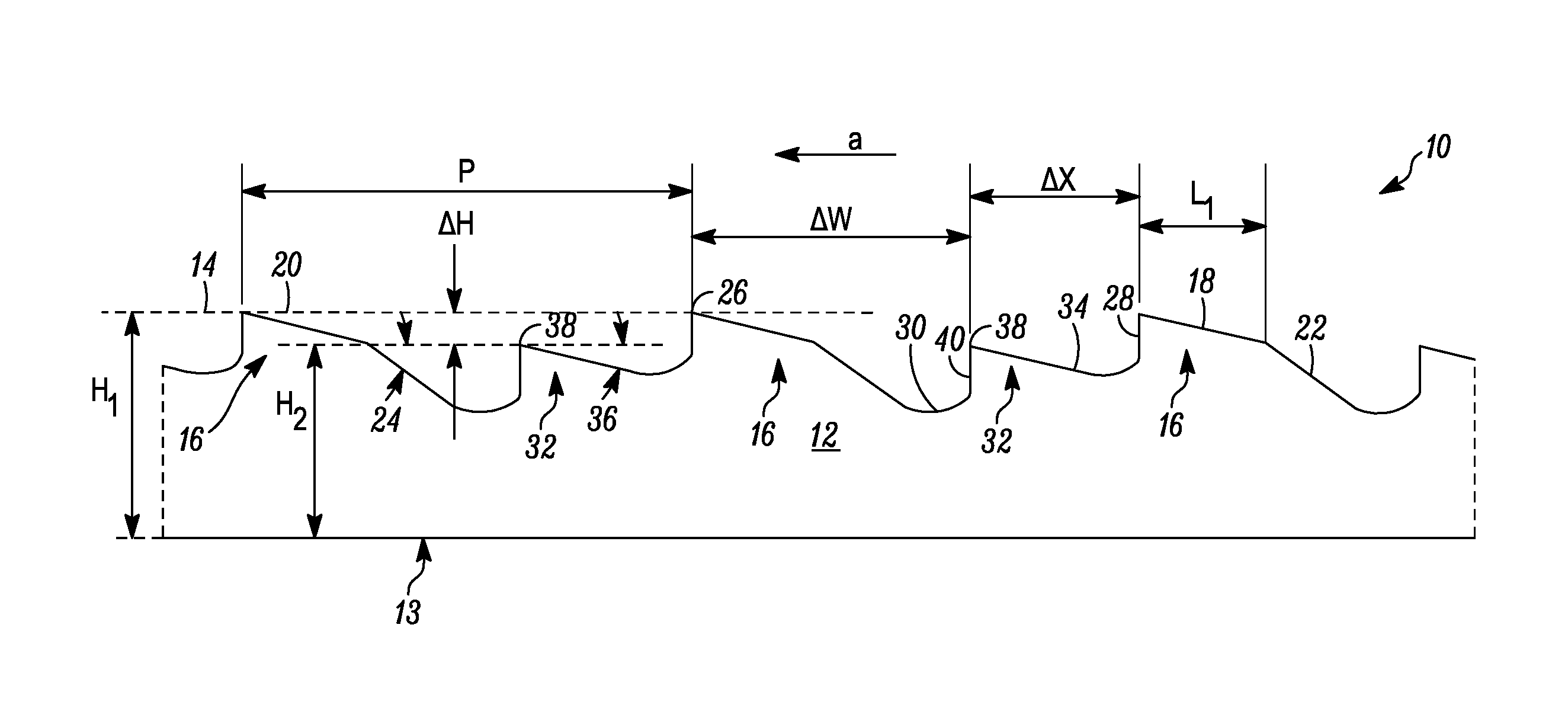

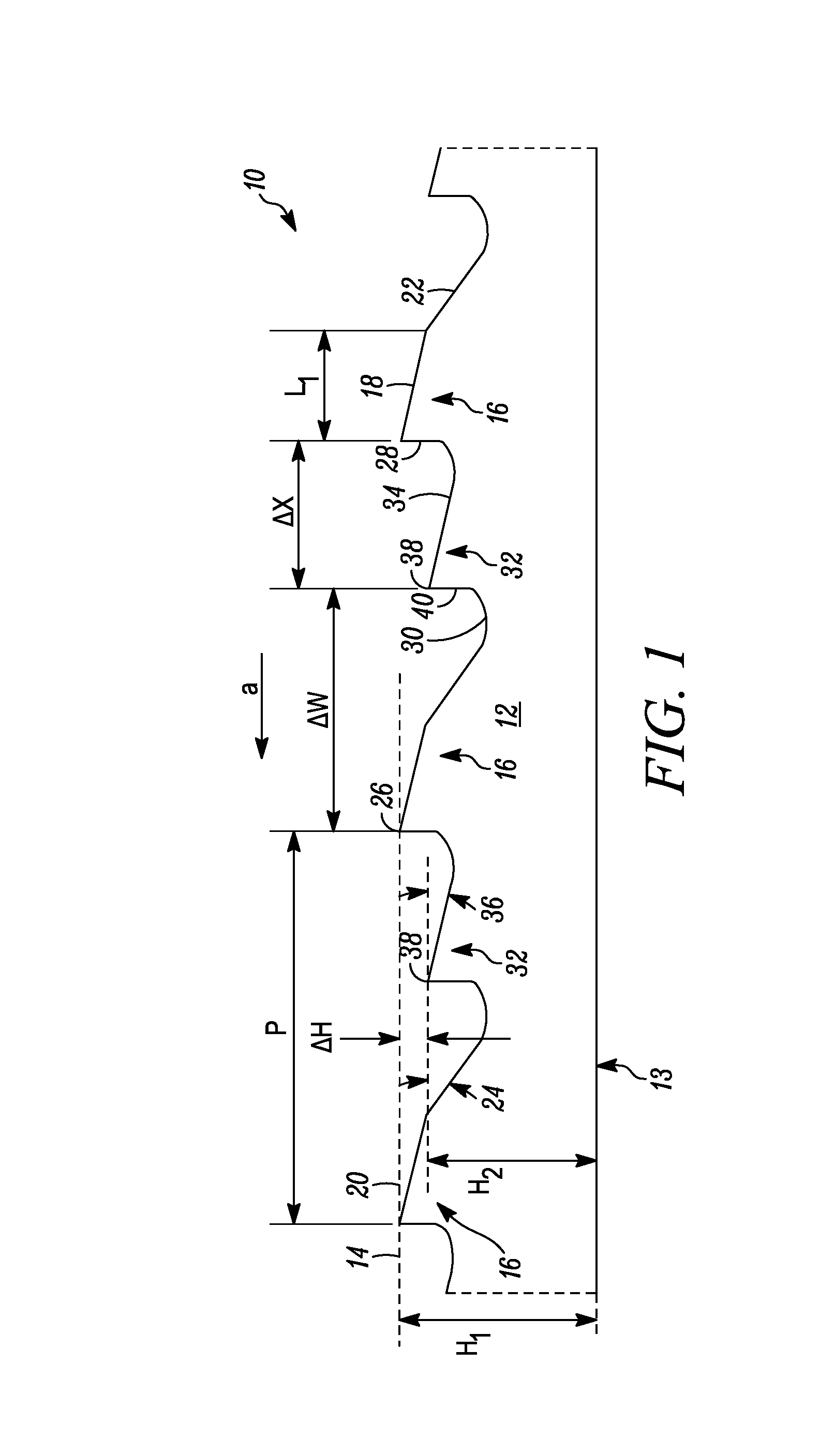

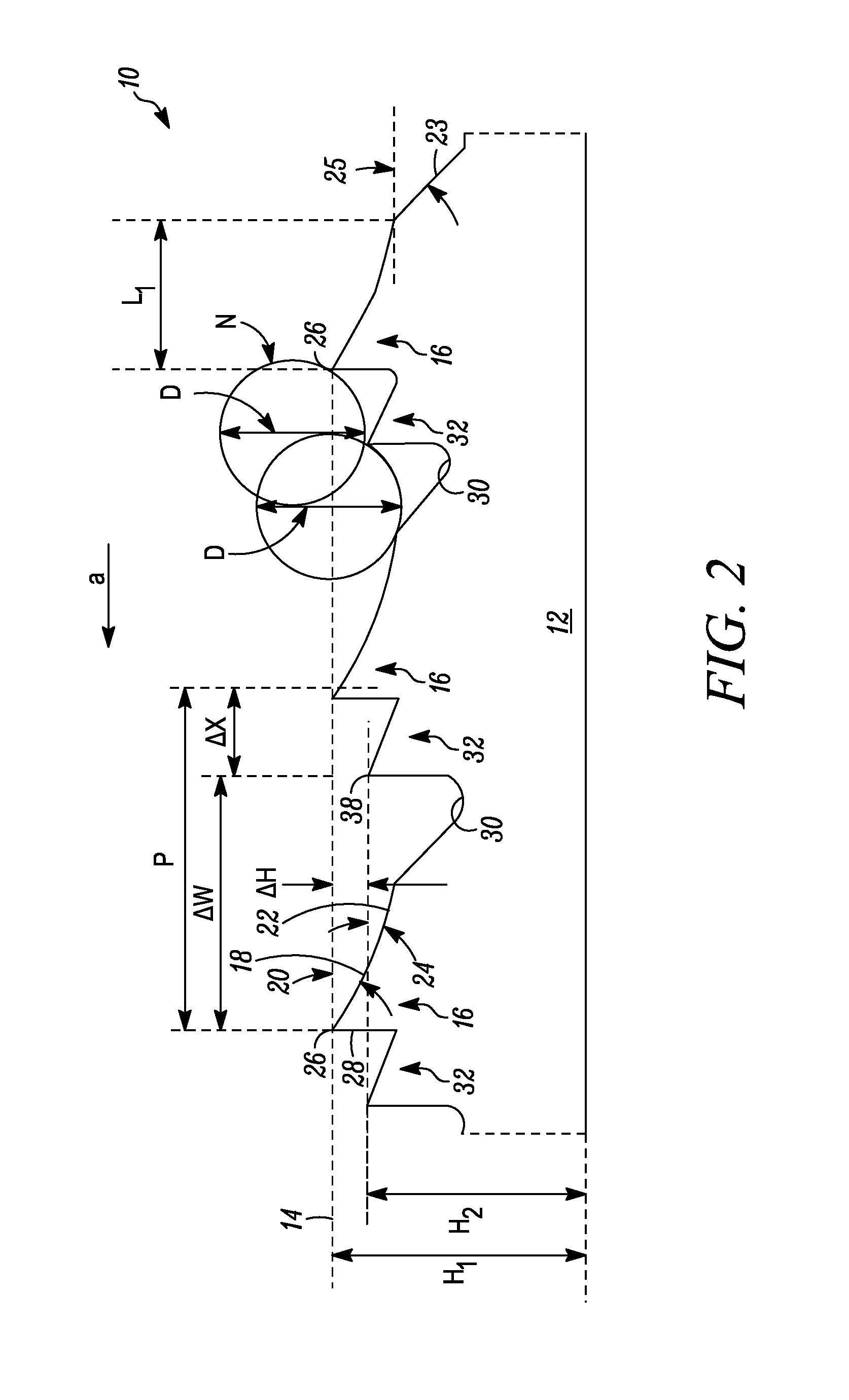

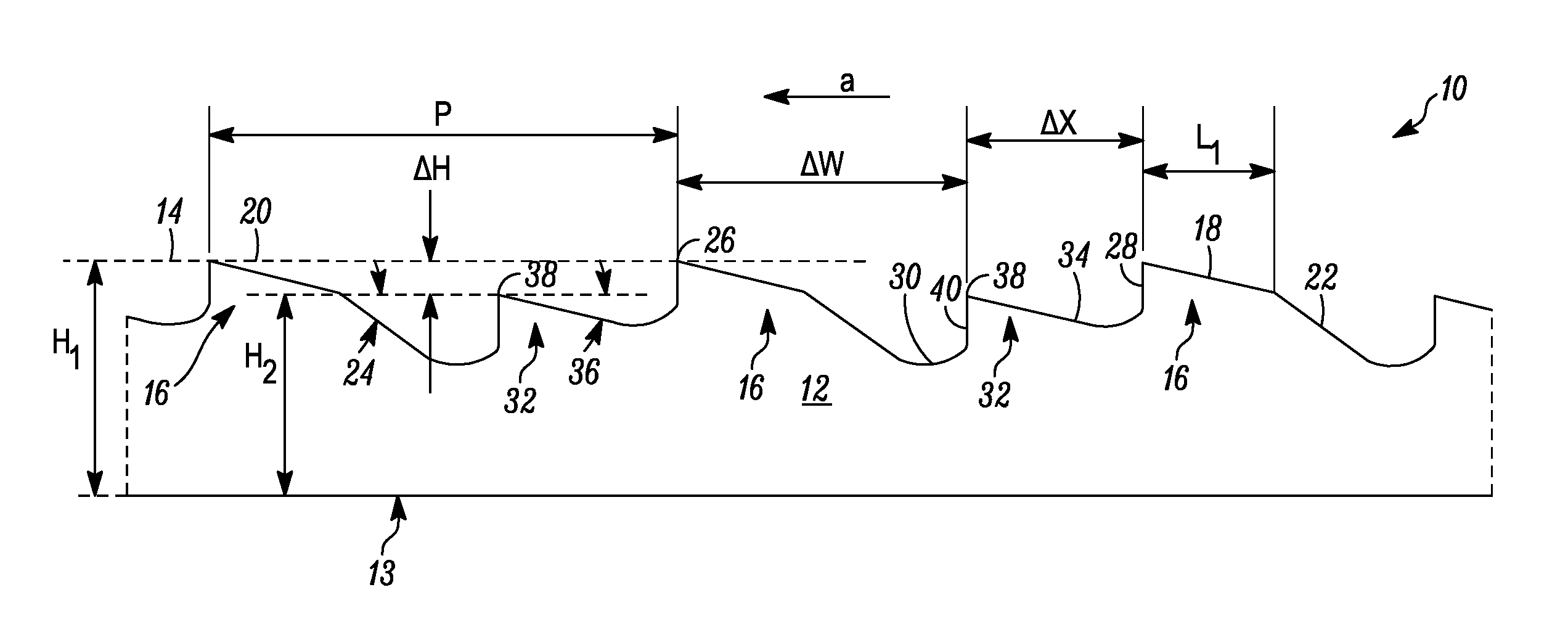

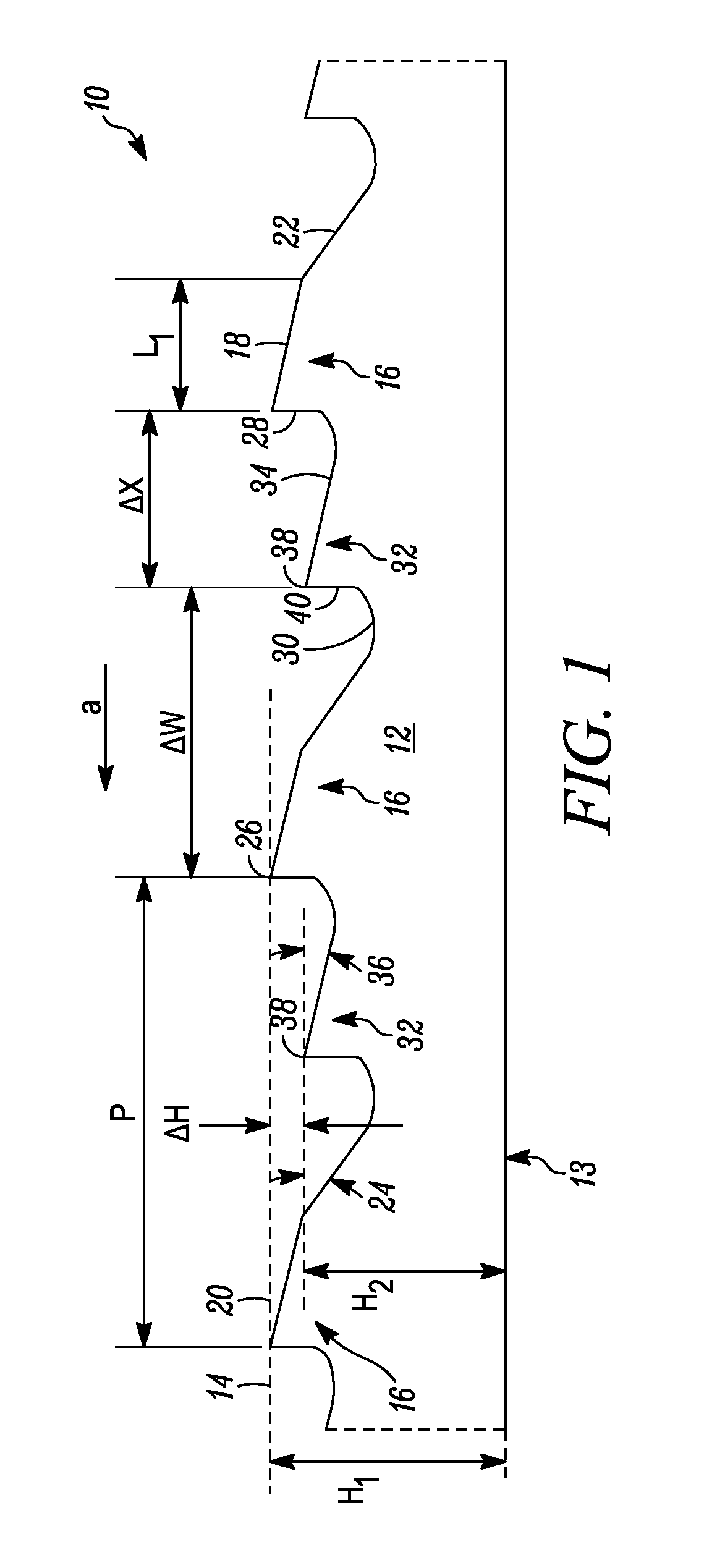

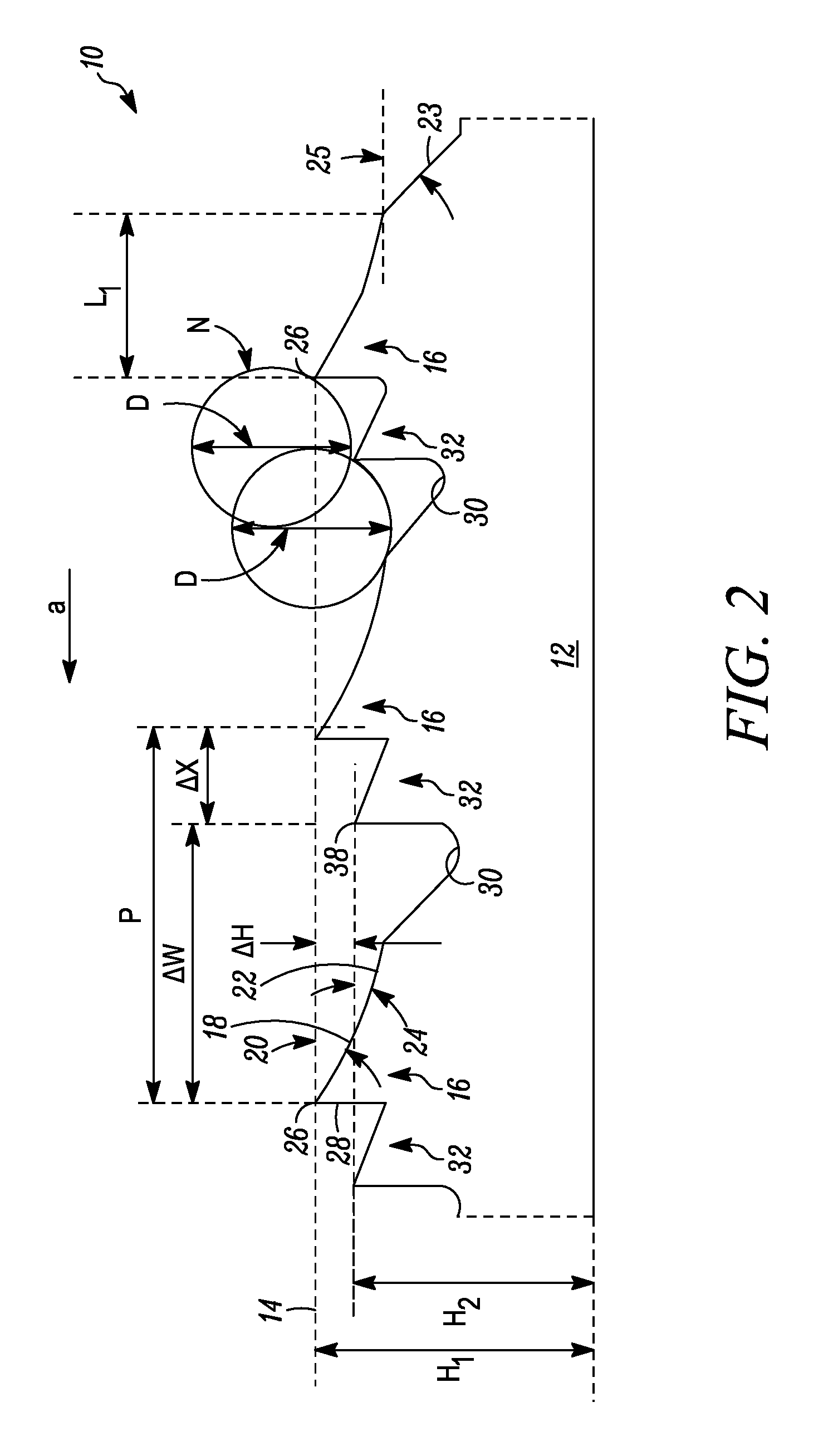

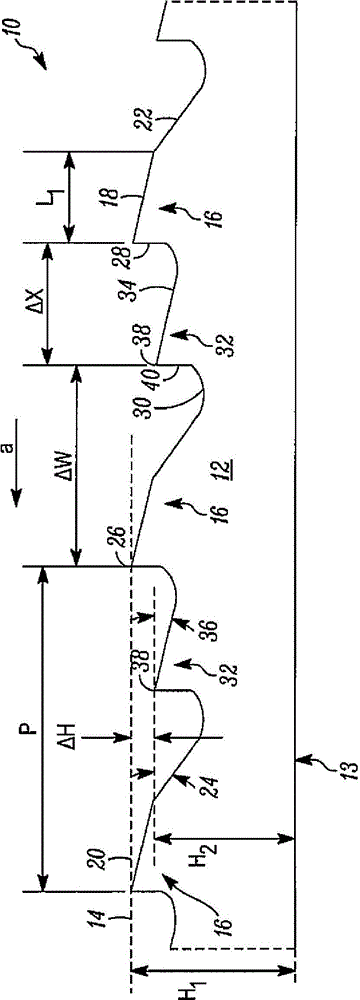

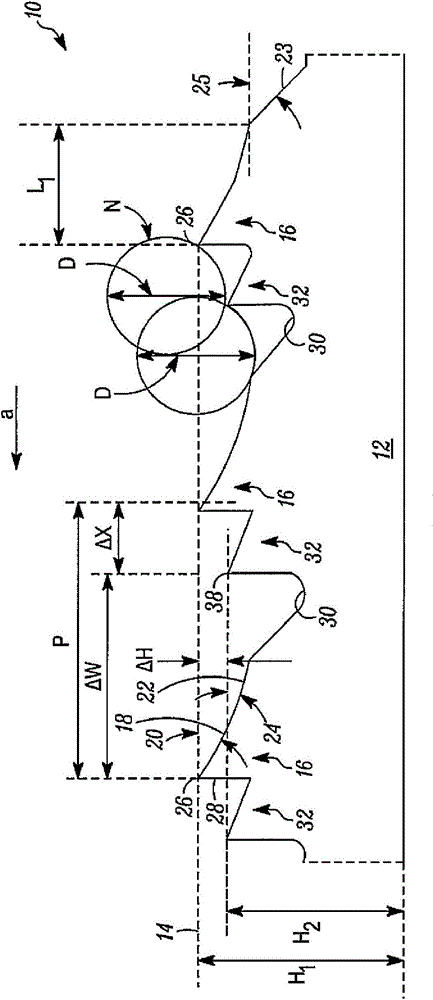

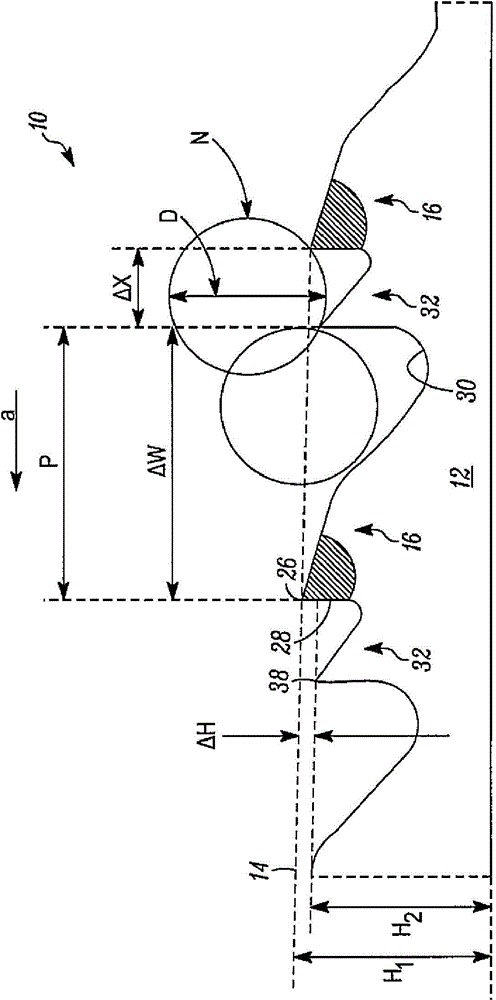

Saw blade with feed limiter

ActiveUS20140260882A1Cutting efficiencyMetal sawing devicesMetal sawing toolsEngineeringSecondary tooth

A saw blade comprising cutting teeth, having at least one of chip-limiters protruding from the teeth or secondary teeth in the gullets of the cutting teeth configured to mitigate the blade from over-feeding. The chip limiters and / or secondary teeth provide that only a limited portion of an object that the saw blade encounters during cutting falls below the cutting tips of the cutting teeth. The chip limiters and / or secondary teeth also assist the cutting teeth in cutting.

Owner:BLACK & DECKER INC

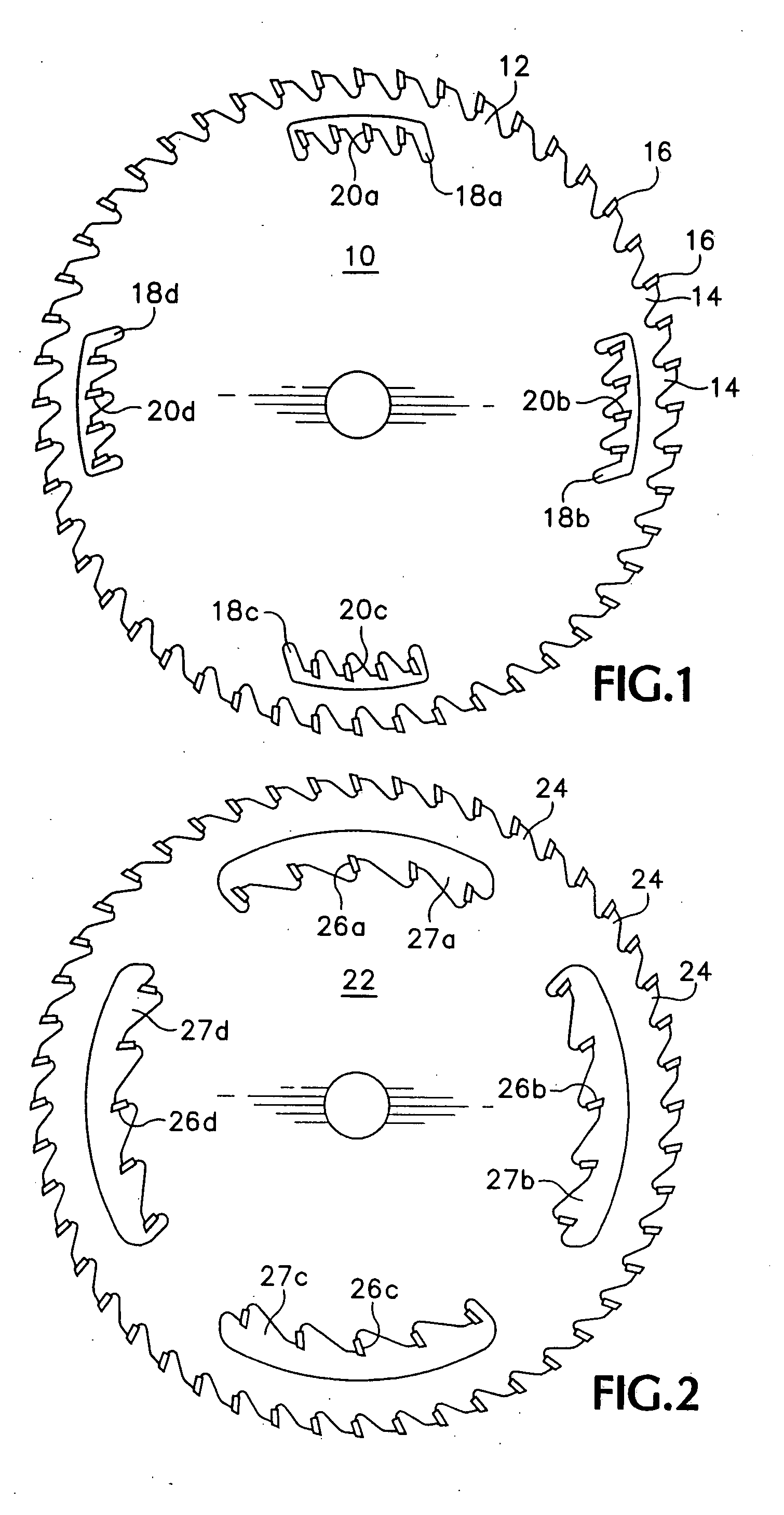

Saw blade with multiple interior secondary saw teeth

A saw comprising a planar body includes at least one cutting edge with serrated teeth. The planar body has cutout portions displaced from the outer cutting edges that include first and second sets of secondary teeth, which are positioned along first and second arcs concentric with the outer cutting edge or edges, at first and second radial distances from the center of the saw blade.

Owner:EUGENE CARBIDE SAW SERVICE

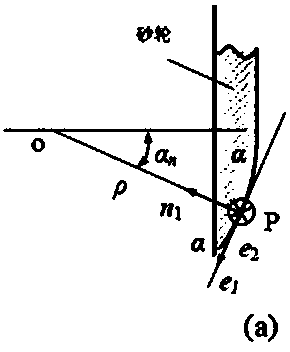

Controllable profile modification method of tooth surface of arc-tooth cylindrical worm

InactiveCN108204441AIncrease contact areaImprove the lubrication effectPortable liftingGearing elementsMathematical modelEngineering

The invention provides a controllable profile modification method of a tooth surface of an arc-tooth cylindrical worm, and belongs to the technical field of self-adaptive heavy-load conveying and driving equipment. The method is characterized in that the curvature of the tooth surface of the arc-tooth worm is corrected to realize consistent change of the tooth surface profile modifying rules and the normal curvature radius in opposite moving direction of secondary tooth surfaces of the worm; the main curvature of a worm grinding wheel is analyzed and a mathematic model for profile modifying isbuilt based on the worm pair engaging theory and the induced curvature concept; then the induced curvature and the geodesic torsion of a contact point of the tooth surface of the worm are solved, andthe microscopic shape of the tooth surface of the worm is analyzed; and finally a curvature correction equation and a tooth surface profile modifying equation are solved based on the analyzing result, thus realizing the curvature based profile modification of the tooth surface of the worm; after the worm is subjected to tooth surface curvature correction, the tooth surface engaging is replaced byarc-surface contact, thus the mounting error can be removed, and the normal direction of the tooth surface of the worm pair is vertical to the relative speed direction of the tooth surfaces of a wormgear and the worm, and as a result, the worm gear and the worm which are engaged with each other can be lubricated.

Owner:HAIAN COUNTY SHENLING ELECTRICAL APPLIANCE MFG +1

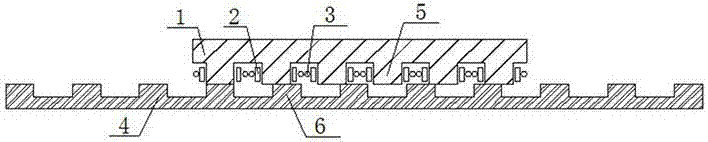

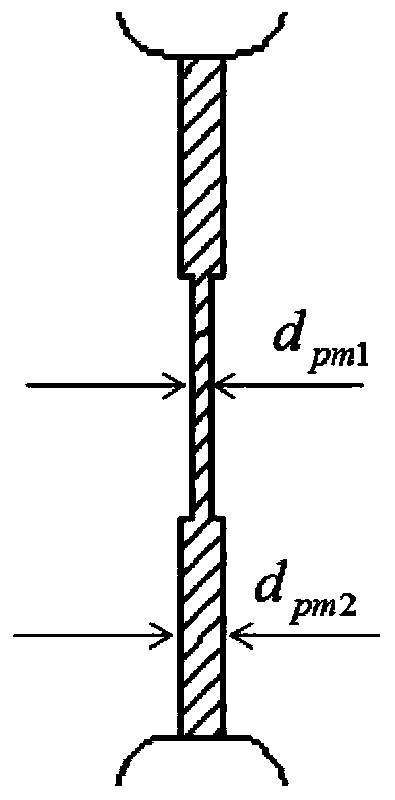

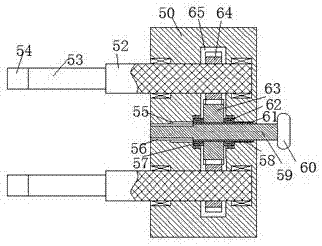

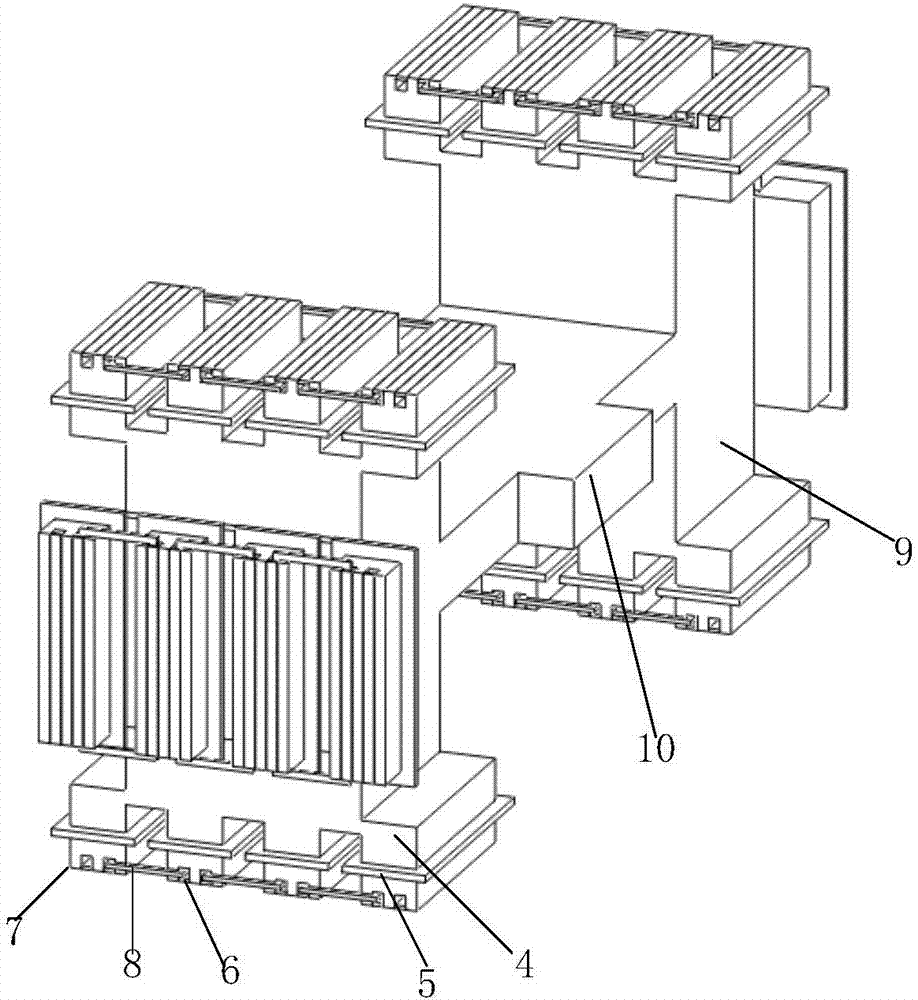

Modularized fault-tolerant magnetic flow switching permanent magnet linear motor and control method thereof

ActiveCN103441640ASimple structureIncrease powerElectronic commutation motor controlVector control systemsElectric machinePermanent magnet linear motor

The invention discloses a modularized fault-tolerant magnetic flow switching permanent magnet linear motor and a control method thereof. The motor comprises a primary tooth and secondary tooth. The primary tooth and the secondary tooth are all of a salient pole structure. The primary tooth comprises permanent magnet bodies, armature windings and fault-tolerant type III-shaped magnetism conducting modules. Each III-shaped magnetism conducting module comprises fault-tolerant teeth and magnetism conducting iron cores which are transversely arrayed side by side. The fault-tolerant teeth are arranged in the magnetism conducting iron cores. The permanent magnets magnetize in a tangential alternating mode. Each permanent magnet is embedded between two adjacent III-shaped magnetism conducting modules. The each-phase armature windings are in a centralized winding mode, are arranged in grooves of III-shaped magnetism conducting modules, transversely penetrate through the permanent magnets, and are wound on the primary tooth. The fault-tolerant teeth are arranged between the each-phase armature windings to space the each-phase armature windings. The invention further provides a fault-tolerant control strategy which comprises a fault-tolerant control method and a fault-tolerant topology structure. The modularized fault-tolerant magnetic flow switching permanent magnet linear motor has the advantages of being simple in structure, high in power, low in cost, strong in ability of operating with failures, and the like.

Owner:JIANGSU UNIV

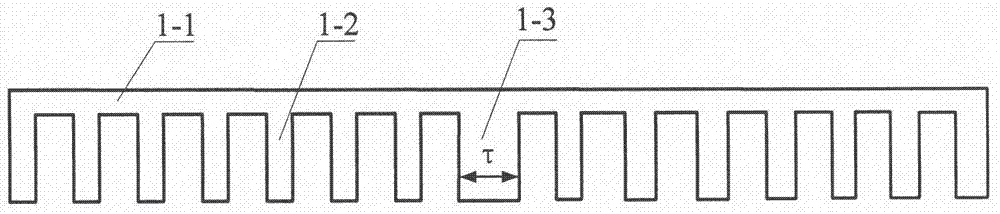

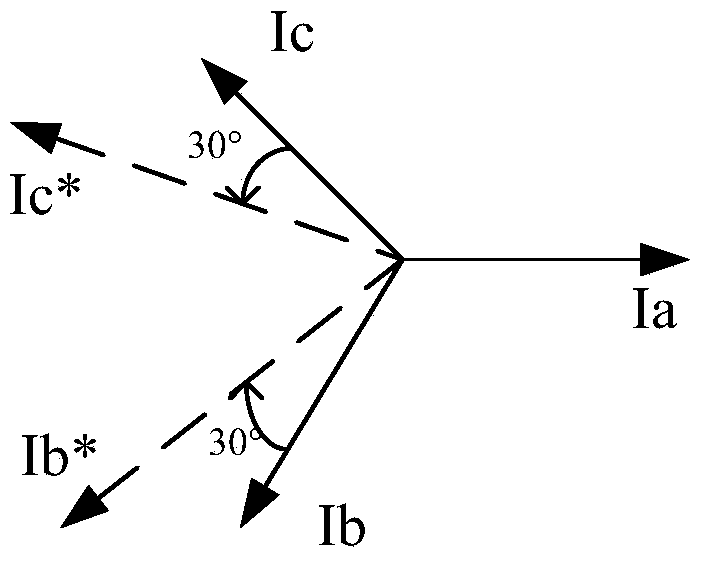

Electro-magnetic doubly-salient linear motor

InactiveCN107465327AReduce output thrust pulsationPropulsion systemsWindings conductor shape/form/constructionThree-phaseLinear motor

The invention discloses an electro-magnetic doubly-salient linear motor. The electro-magnetic doubly-salient linear motor comprises primary teeth, secondary teeth and air gaps between the primary teeth and the secondary teeth, wherein the primary teeth are rotors, the secondary teeth are stators, the primary teeth and the secondary teeth adopt salient pole structures respectively, a direct-current exciting winding and a three-phase armature winding are wound on each primary tooth, and the proportion of primary pole pitch tau p to secondary pole pitch tau s is that tau s / tau p is equal to 5 / 6, the primary pole pitch is twice of the tooth pitch of the primary teeth, and the tooth pitch of the secondary pole pitch is equal to or slightly greater than the tooth pitch of the primary teeth; due to the fact that the exciting windings are wound on each primary tooth respectively, the paths of each phase of flux are the same, and three-phase flux linkages and counter potential waveforms are relatively symmetrical; complementary characteristics exist between the m-th phase of winding and the (m+3)-th phase of winding, one phase is formed after inverted series connection of m phase, and the flux linkage and no-load counter potentital symmetry of the phase are improved. When the electro-magnetic doubly-salient linear motor works, the output thrust pulse can be effectively reduced, the electro-magnetic doubly-salient linear motor is novel in structure, reliable in performance and simple in control, and the electro-magnetic doubly-salient linear motor is applicable for medium-and-low-power power generation or electric occasions for relatively high output requirements.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

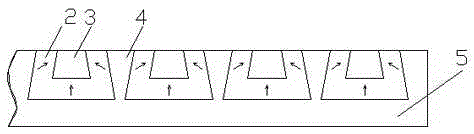

Tooth-slot salient permanent magnet composite array linear motor

The invention belongs to the electric appliance fields of an electromagnetic apparatus and a motor, and specifically relates to a tooth-slot salient permanent magnet composite array linear motor. A secondary tooth-slot salient permanent magnet array comprises a slot part convex iron 3, a magnet array 2 and a tooth part convex iron 4; the tooth part convex iron 4 is formed by iron core teeth with a yoke part 5; the magnet array 2 is formed by slot peripheral magnets pasted along the inner wall of the iron core slot; the slot part convex iron 3 is positioned on the other surface, tightly adhered to the magnet array 2, in the iron core slot. By adoption of the tooth-slot salient permanent magnet composite array linear motor, the secondary internal flux leakage can be greatly suppressed or even eliminated; under the condition of a same volume and a same manufacturing cost, the power and output of the motor can be greatly improved; or under a condition of the same power, the volume and the manufacturing and use cost of the motor can be dramatically reduced; and therefore, the tooth-slot salient permanent magnet composite array linear motor is particularly suitable for engineering application occasions of high power permanent magnet linear motors.

Owner:HENAN POLYTECHNIC UNIV

A double-sided alternating-pole permanent magnet linear motor with secondary yokeless section

ActiveCN109245483AIncrease thrustIncrease thrust densityPropulsion systemsPermanent magnet linear motorEngineering

The invention discloses a double-side alternating-pole permanent magnet linear motor with a secondary yokeless section, which comprises double primary winding, secondary winding and armature winding.The double primary winding is symmetrically arranged on both sides of the secondary winding, and an air gap is arranged between the primary winding and the secondary winding. The secondary winding comprises N2 'uniformly spaced secondary core blocks; Each primary winding has N1 'primary teeth, the top surface of each primary tooth faces the secondary tooth, the top surface of each primary tooth isprovided with n permanent magnet grooves, and the top surface between two adjacent permanent magnet grooves is formed as an iron core salient pole; A permanent magnet is nested in each permanent magnet slot, where n=1, 2, 3, 4 or 5; The magnetizing direction of permanent magnets on each primary tooth is the same; N1 primary teeth and N2 secondary salient poles constitute the basic unit of the motor, where N2=N1 x n + / - i, where i=1 or 2; N1 '>= N1, N2' >= N2. The invention is suitable for long-distance application, can further improve thrust density and utilization ratio of permanent magnet,and reduce cost.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Seal assembly for counter rotating turbine assembly

The present disclosure is directed to a gas turbine engine including a turbine rotor, a turbine frame at least partially surrounding the turbine rotor, and an outer diameter seal assembly. The turbine rotor includes an inner shroud, an outer shroud, and at least one connecting airfoil coupling the inner shroud and the outer shroud. The outer shroud includes a plurality of outer shroud airfoils extended inward along a radial direction. The outer diameter seal assembly includes a sliding portion disposed between the turbine frame and the outer shroud of the turbine rotor. The outer diameter seal assembly defines a secondary tooth at the outer shroud radially inward of a longitudinal face of the sliding portion, and a primary tooth defined axially adjacent to a radial face of the sliding portion.

Owner:GENERAL ELECTRIC CO

Saw blade with feed limiter

A saw blade including cutting teeth, having at least one of chip-limiters protruding from the teeth or secondary teeth in the gullets of the cutting teeth configured to mitigate the blade from over-feeding. The chip limiters and / or secondary teeth provide that only a limited portion of an object that the saw blade encounters during cutting falls below the cutting tips of the cutting teeth. The chip limiters and / or secondary teeth also assist the cutting teeth in cutting.

Owner:BLACK & DECKER INC

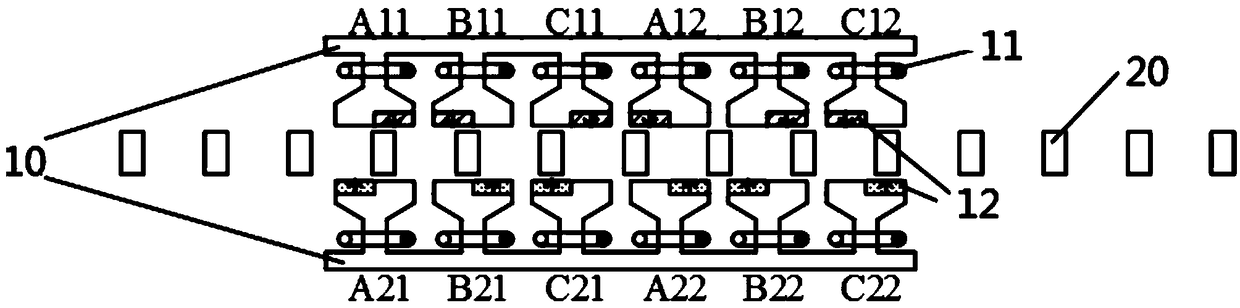

Low-positioning-force bilateral flux switching permanent magnet linear motor

ActiveCN111509946AReduce dosageReduce the magnetoresistance effectMagnetic circuitPropulsion systemsPermanent magnet linear motorElectric machinery

The invention discloses a low-positioning-force bilateral flux switching permanent magnet linear motor, and relates to the technical field of linear motors. The motor comprises double-side secondary stators and a primary rotor arranged between the stators. A plurality of secondary teeth are formed on each single-side secondary stator at intervals; secondary tooth grooves are formed between the secondary teeth; a yoke part is formed at the bottom of the secondary tooth groove; the secondary teeth comprise first secondary teeth and second secondary teeth; the first secondary teeth and the secondsecondary teeth are arranged at intervals, the polar distances of the secondary teeth between the first secondary teeth and the second secondary teeth are the same, and the widths and the heights ofthe first secondary teeth are different from those of the second secondary teeth, so that the linear motor effectively reduces the positioning force and increases the thrust of the motor.

Owner:SHIJIAZHUANG TIEDAO UNIV

Dust collector equipment

InactiveCN107579372AImprove the safety of useGuaranteed uptimeLive contact access preventionElectricityEngineering

The invention discloses dust collector equipment. The dust collector equipment comprises a power transmission base and a power transmission head connected with a dust collector. Inserting bars are vertically and oppositely arranged in the power transmission head, and comprise powering-on bars, clamping bars and pushing bars, wherein the powering-on bars, the clamping bars and the pushing bars areconnected from right to left; first rotatable holes with leftward hole openings are vertically and oppositely formed in the power transmission head, first installing holes which vertically extend andare connected with the first rotatable holes in series are also formed in the power transmission head, the right ends of the powering-on bars are rotatably installed in the first rotatable holes, first secondary tooth gears fixedly connected with the powering-on bars are installed in the first installing holes, a first rotatable cylinder and a second rotatable cylinder are rotatably installed in the left end wall and the right end wall in the centers of the installing holes respectively, a first primary tooth gear matched with the first secondary tooth gears is fixedly connected between the first rotatable cylinder and the second rotatable cylinder, a center groove connected left and right is formed in the center of the power transmission head, and a spline hole extending left and right isformed in the center of the first primary tooth gear, the first rotatable cylinder and the second rotatable cylinder.

Owner:陈志桂

Saw blade with feed limiter

A saw blade comprises cutting teeth, and the saw blade is further provided with at least one of cutting limiters which protrude from teeth or secondary teeth in grooves of the cutting teeth and are used for relieving too much feeding of a blade after configuration. It is required by the cutting limiters and / or the secondary teeth that in the cutting period, only a limited part of an object met by the saw blade falls under the cutting tip ends of the cutting teeth. The cutting limiters and / or the secondary teeth further assist the cutting teeth in cutting.

Owner:IRWIN IND TOOL CO

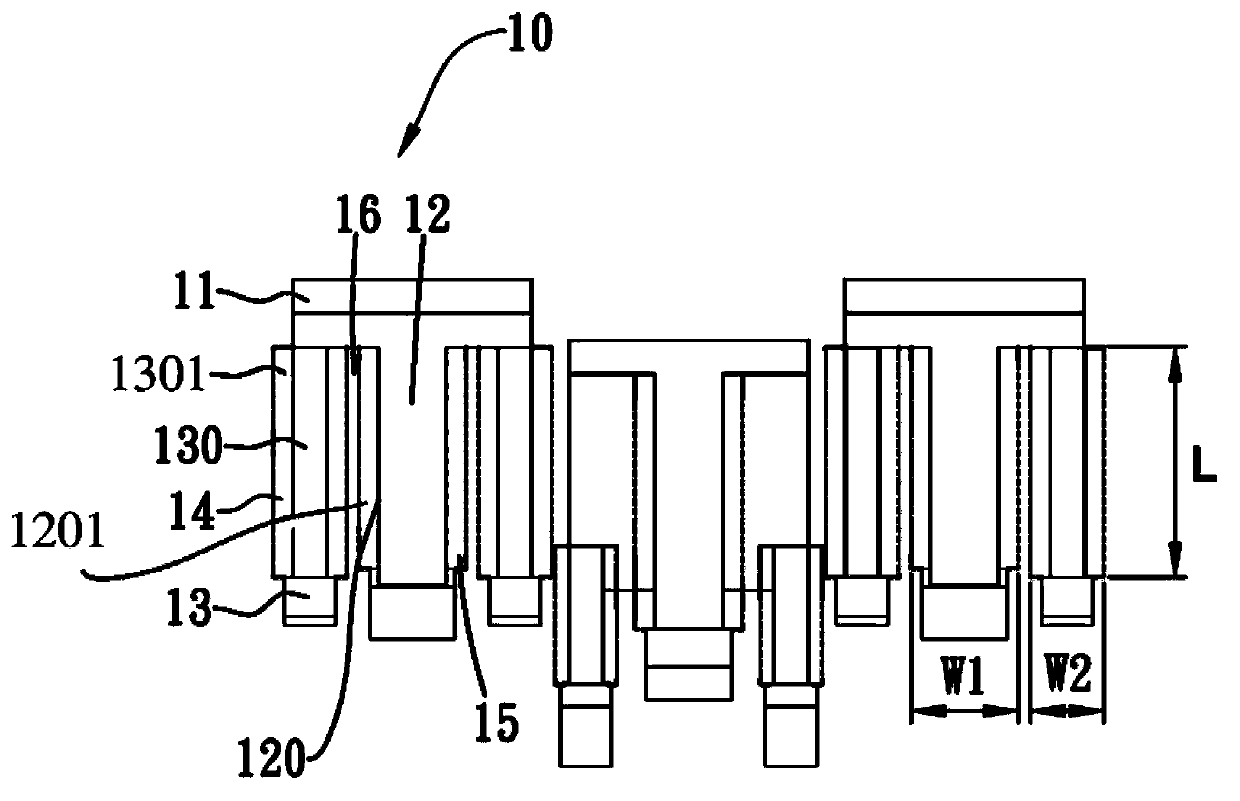

Stator structure

InactiveCN103872802AMagnetic circuit stationary partsSynchronous machines with stationary armatures and rotating magnetsMultiple frameEngineering

A stator structure includes a main body having multiple frames each having an arc panel, a main tooth, at least one secondary tooth, at least one main coil and at least one secondary coil. The main tooth and the secondary tooth are disposed at one face of the arc panel. The main coil is installed at the main tooth, and the secondary coil is installed at the secondary coil. A rotor is penetrated through the stator structure. The frames are in a multi-layer circular arrangement at the rotor, and a dislocation angle exists between the frame at any layer and the frame at the neighboring layer.

Owner:IND TECH RES INST

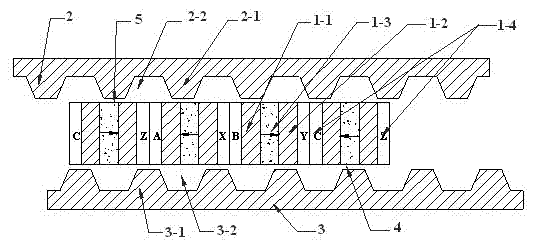

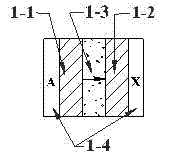

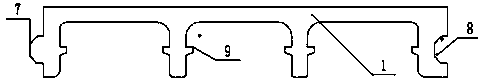

Composite building formwork system

InactiveCN103452308AAchieve standardizationSystematizeAuxillary members of forms/shuttering/falseworksForming/stuttering elementsButt jointJoint (building)

The invention relates to a composite building formwork system comprising standard formworks, special-shaped formworks, butt joint clamps, formwork clamps, a connecting insertion plate and key keels. The standard formworks are in butt joint transversely through secondary teeth, primary teeth, secondary fasteners and primary fasteners. The connecting insertion plate is inserted into the joint of the upper transverse formwork and the lower transverse formwork in a row. The butt joint clamps are supported between the two opposite formworks, and accordingly the thickness of a wall can be ensured to reach the standard size. The formwork clamps are clamped at the joints of the primary teeth, the secondary teeth, the primary fasteners and the secondary fasteners of the two frameworks. The key keels are supported on the outer side of a connected formwork module. According to the seamless building formwork joint system, the two formworks are lapped in a flat seam and staggered manner and in butt joint through the secondary teeth, the primary teeth, the secondary fasteners and the primary fasteners to enable contact seams to be tightly jointed and the two formworks to be lapped in a planar manner, so that mud leakage is prevented, and further the lapped seams are tight to enable a building side to be seamless. An insertion connection mode of the special connecting insertion plate is adopted for vertical connection of the formworks; since each formwork is provided with a clamp fixing groove, the special connecting insertion plate can be connected with the vertically connected formworks in an inserted manner flexibly, firmly and reliably, and the seams are tight. Meanwhile, the problems of variable size and deformation in the design scheme can be flexibly solved. The special-shaped formworks are used for solving the problem of internal-external corners and other different design requirement schemes.

Owner:山东华鑫机械设备股份有限公司

Jaw crusher toothed plate with buffering mechanism

The invention discloses a jaw crusher toothed plate with a buffering mechanism. The jaw crusher toothed plate comprises a main connection plate, wherein raised stripes are arranged on the main connection plate; grooves are formed in the back surface of a collision plate; the raised stripes are inserted in the grooves in a sleeving manner; the collision plate presses the main connection plate; a tooth-shaped raised surface is formed on the front surface of the collision plate; a plurality of tooth-shaped raised stripes are uniformly distributed on the tooth-shaped raised surface; secondary tooth-shaped raised stripes are fixedly arranged at two sides of the tooth-shaped raised stripes; an elastic block is fixedly arranged on the top surfaces of the raised stripes; an elongated groove is formed in the middle of the elastic block; a plurality of springs are inserted in the elongated groove in a sleeving manner; the elastic block and the springs are clamped between the top surfaces of the raised stripes and the top surfaces of the grooves. By using the jaw crusher toothed plate, the crushing capacity is improved; simultaneously, the secondary tooth-shaped raised stripes are fixedly arranged at the two sides of the tooth-shaped raised stripes, so that the crushing effect is greatly improved; the elastic block and the springs play a buffering role, so that the damage to the collision plate during crushing can be reduced.

Owner:芜湖银海机械制造有限公司

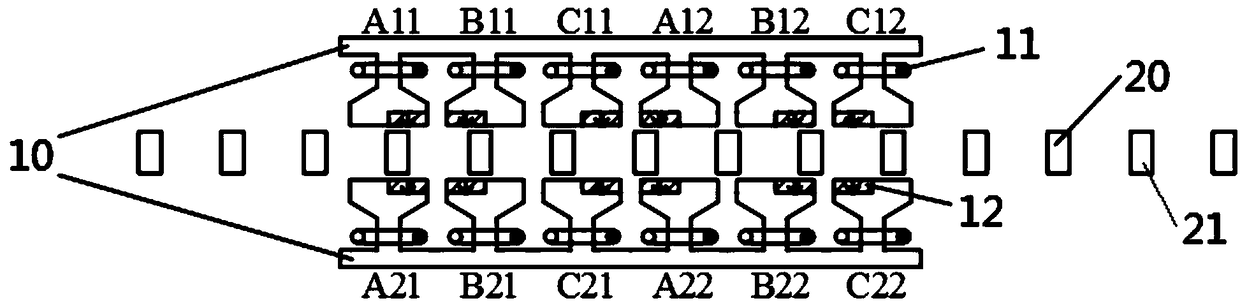

3-phase permanent magnet motor or generator having variable stator teeth

InactiveCN103812240AMagnetic circuit rotating partsSynchronous machinesPermanent magnet motorControl theory

An electric motor or generator machine is provided. The machine includes a rotor rotatable about an axis, as well as a stator. The stator includes a stator core and wiring wound around the stator core. The stator core includes a plurality of arcuately spaced apart alternating primary teeth and secondary teeth, such that each secondary tooth is spaced between a corresponding pair of primary teeth. The wiring is wound about the primary teeth to form a plurality of coils. The plurality of coils includes an A-phase coil, a B-phase coil, and a C-phase coil. Each of the primary teeth includes a generally radially extending primary arm and a generally arcuately extending primary crown. Each of the primary crowns spans one hundred sixty (160) to two hundred (200) electrical degrees.

Owner:NIDEC MOTOR CORP

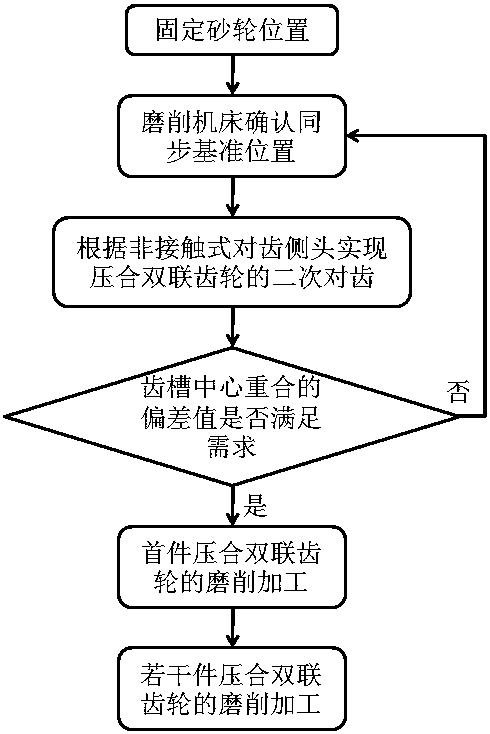

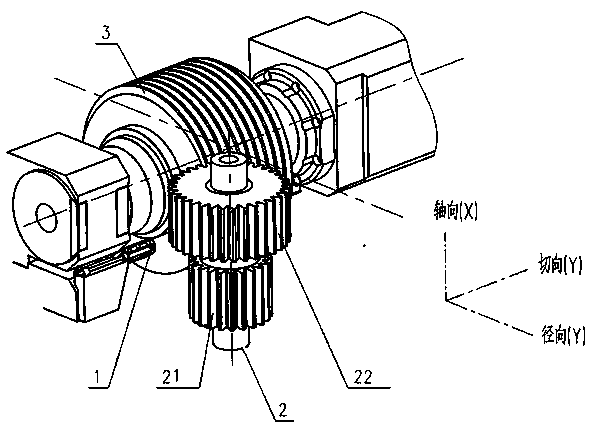

Pressing duplex gear tooth groove centering grinding method

ActiveCN111215707AReduced precision requirementsReduce the precision requirements before grindingGear teethGear wheelGrinding wheel

The invention discloses a pressing duplex gear tooth groove centering grinding method. The method comprises the steps that the position of a grinding wheel is fixed according to a clamping groove marked during pressing; a grinding machine tool takes the position of the grinding wheel and the position of a pressing duplex gear as synchronous reference positions, and grinds disk gears in the pressing duplex gear according to the reference positions; secondary tooth alignment of the pressing duplex gear is realized according to a non-contact tooth alignment side head, and grinding of the first pressing duplex gear is completed; and subsequent grinding of a plurality of pressing duplex gears is completed according to the grinding machining of the first pressing duplex gear. Secondary tooth alignment of the pressing duplex gear is realized through the non-contact tooth alignment side head, the requirement for pre-grinding precision of the disk gears and the requirement for the precision ofdirect tooth groove coincidence of the disk gears and a shaft gear during pressing are lowered, and the production cost is reduced while the product qualification rate is improved.

Owner:南京二机齿轮机床有限公司

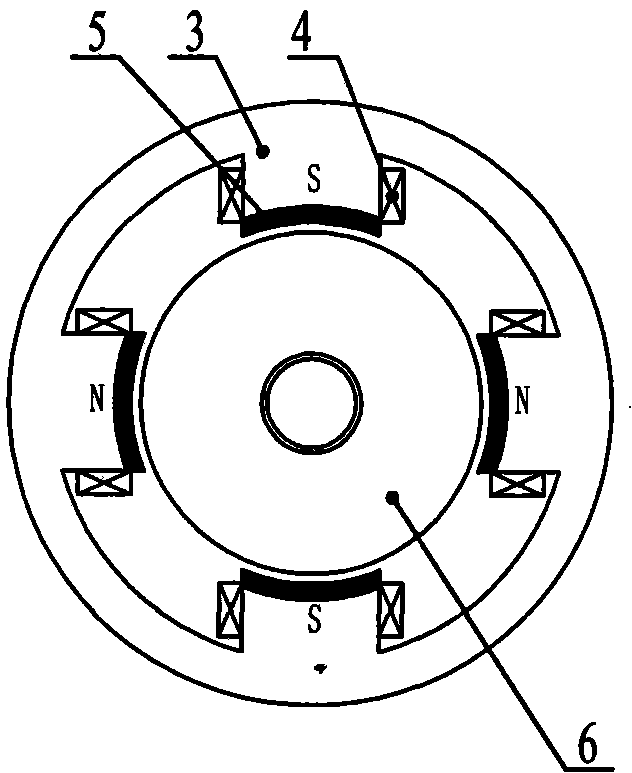

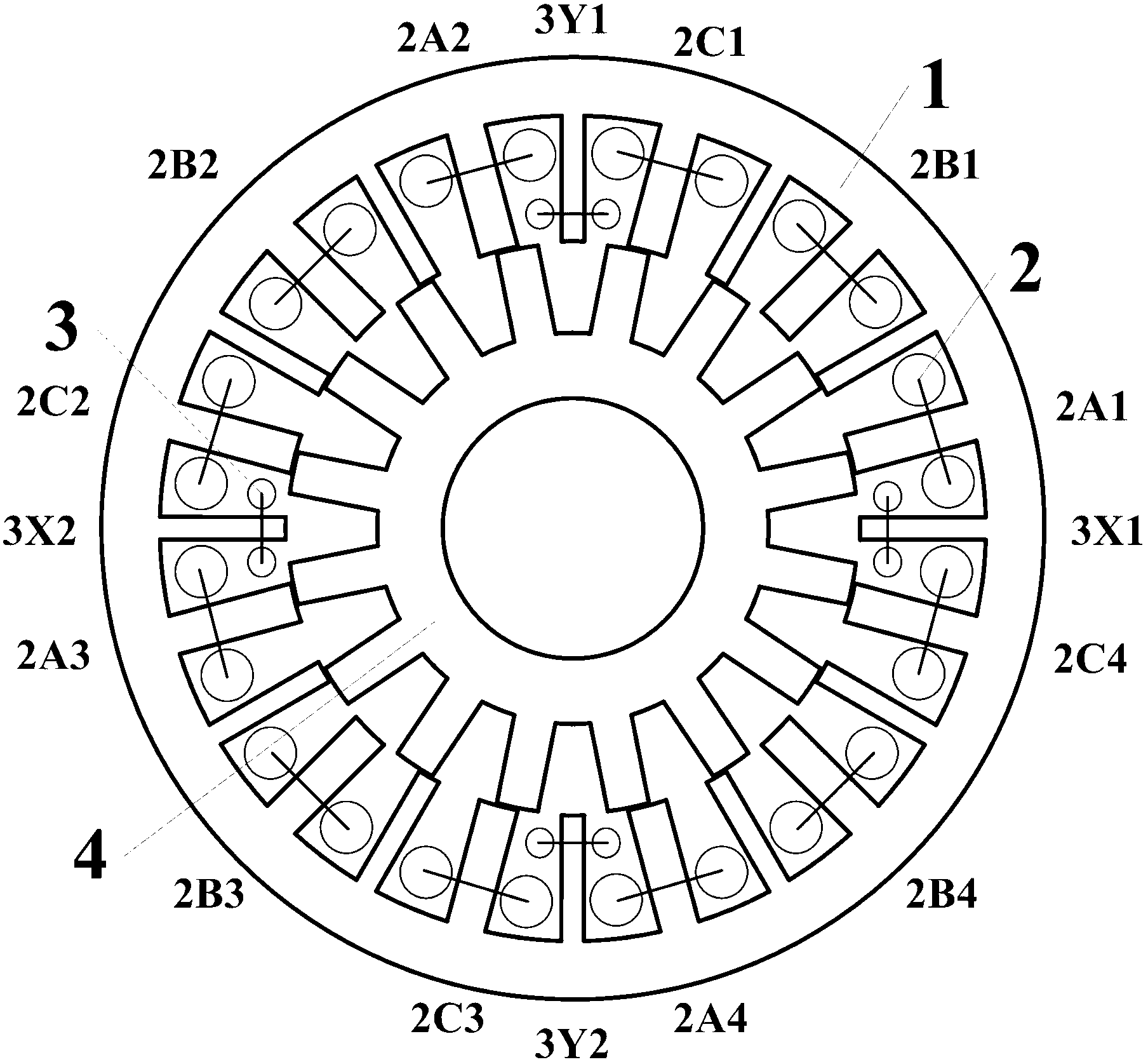

Four-pole bearingless switched reluctance motor

ActiveCN103236806AChange the winding methodDifferent number of turnsMagnetic holding devicesFault toleranceUltra high speed

The invention discloses a four-pole bearingless switched reluctance motor. An even number of salient pole teeth are arranged on a stator and can be divided into main teeth and secondary teeth according to different functions; two kinds of different windings are nested on the stator teeth; torque windings are used for outputting mechanical torque and are sequentially nested on all the main teeth of the motor; and four phases of levitation force windings are available and are nested on four secondary teeth at vertical orthogonal positions of the motor for controlling the displacements of the motor rotor in the horizontal X axis direction and the vertical Y axis direction respectively. According to the motor, the advantage of simple and firm structure of the switched reluctance motor is kept, the full rate of each motor winding slot is high, and the reliability is good; each motor torque winding is of a half-tooth winding structure, and different phases of windings are not placed in the same stator slot, so that the electric, magnetic and thermal coupling among the phases are obviously weakened, and the fault tolerance is improved; and meanwhile, bearingless operation of the switched reluctance motor is realized through skillful change of the winding mode, so that the switched reluctance motor can bring the advantage of suitability for high speed and ultra-high speed work into play.

Owner:SOUTHEAST UNIV

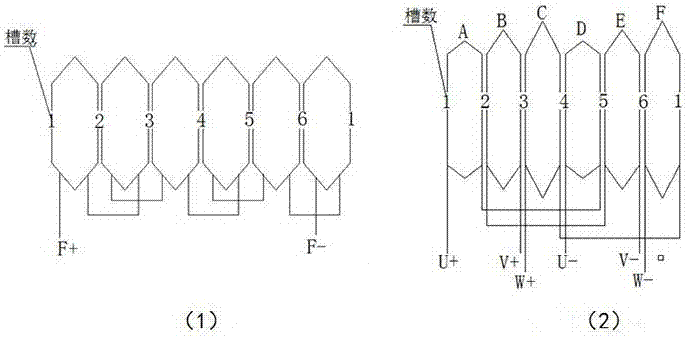

Transverse flux magnetic field modulation type linear motor

ActiveCN106961203AImprove space utilizationSimple structurePropulsion systemsTransverse fluxPower flow

The invention discloses a transverse flux magnetic field modulation type linear motor. The linear motor comprises primary bodies and secondary bodies. The two secondary bodies are in a C-shaped, mirror image arrangement, and three air gaps are arranged among the primary body and the secondary bodies. The inner sides of the secondary bodies are provided with a plurality of secondary grooves and a plurality of secondary teeth at equal intervals, and secondary permanent magnets are disposed in the secondary grooves. Each of the primary bodies comprises two same primary iron cores and a connecting beam used for connecting the two primary iron cores. The upper surfaces and the lower surfaces of the primary iron cores and the surfaces of the primary iron cores back to the connecting beams are provided with salient pole teeth, which are arranged at equal intervals, and are the same. The salient pole teeth are provided with salient armature windings in a coiled manner, and are provided with virtual teeth, and virtual grooves are arranged among adjacent virtual teeth, and in addition, virtual groove permanent magnets are disposed in the virtual grooves. Virtual groove armature windings are disposed in the virtual grooves. The three phases of the primary bodies are provided with three phases of armature windings. The armature winding of the same primary body is used to form one phase, and the armature windings of the three primary bodies are used to form three phases, and a difference among currents flowing through the three phases is 120degrees. The transverse flux magnetic field modulation type linear motor adopts modularization design, and has advantages of simple structure, and ability of improving fault-tolerant performance.

Owner:湖南天友精密技术有限公司

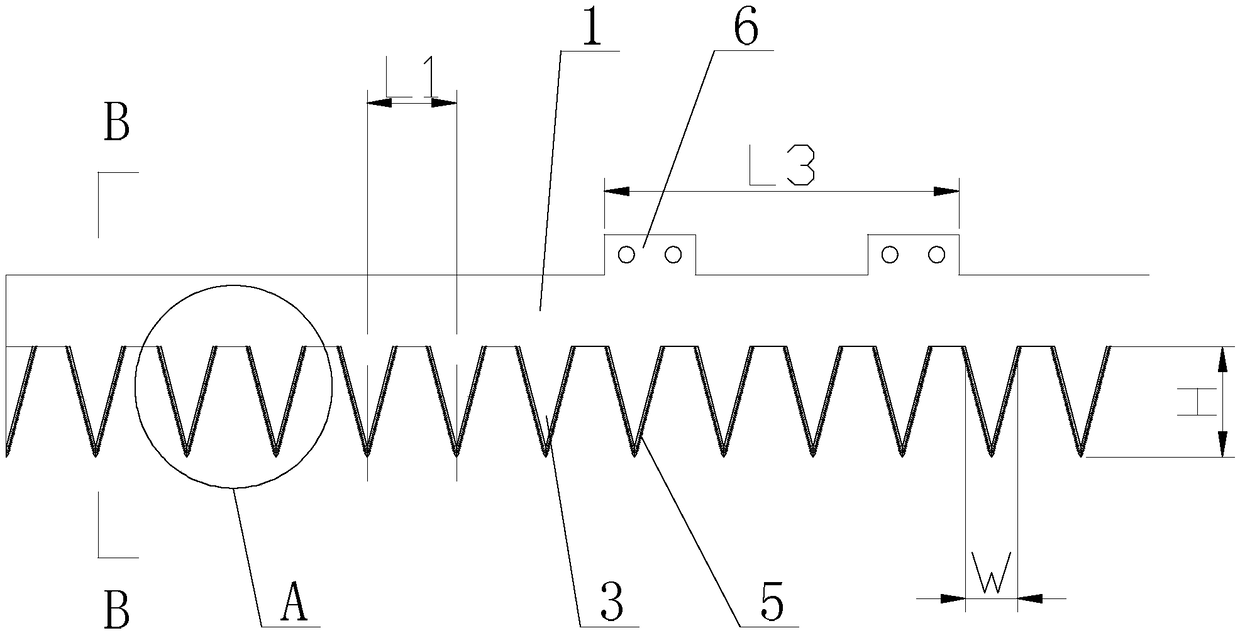

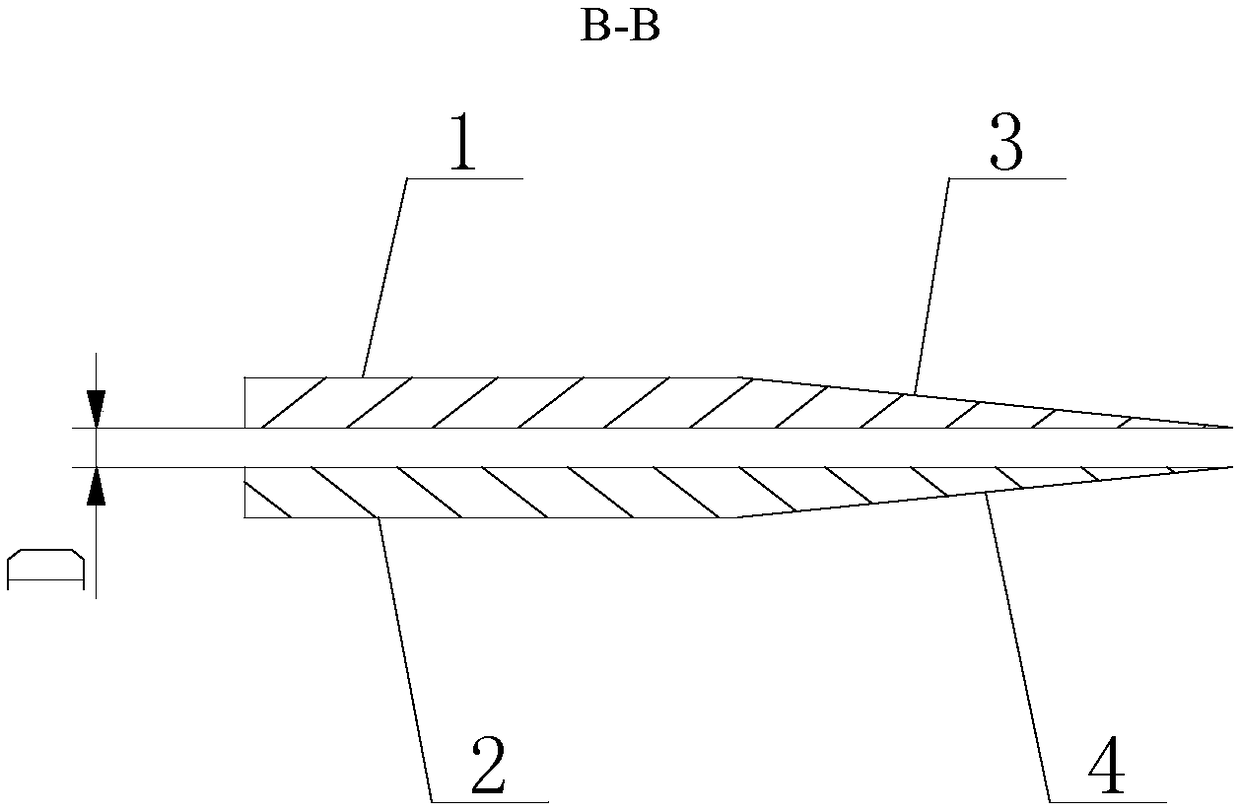

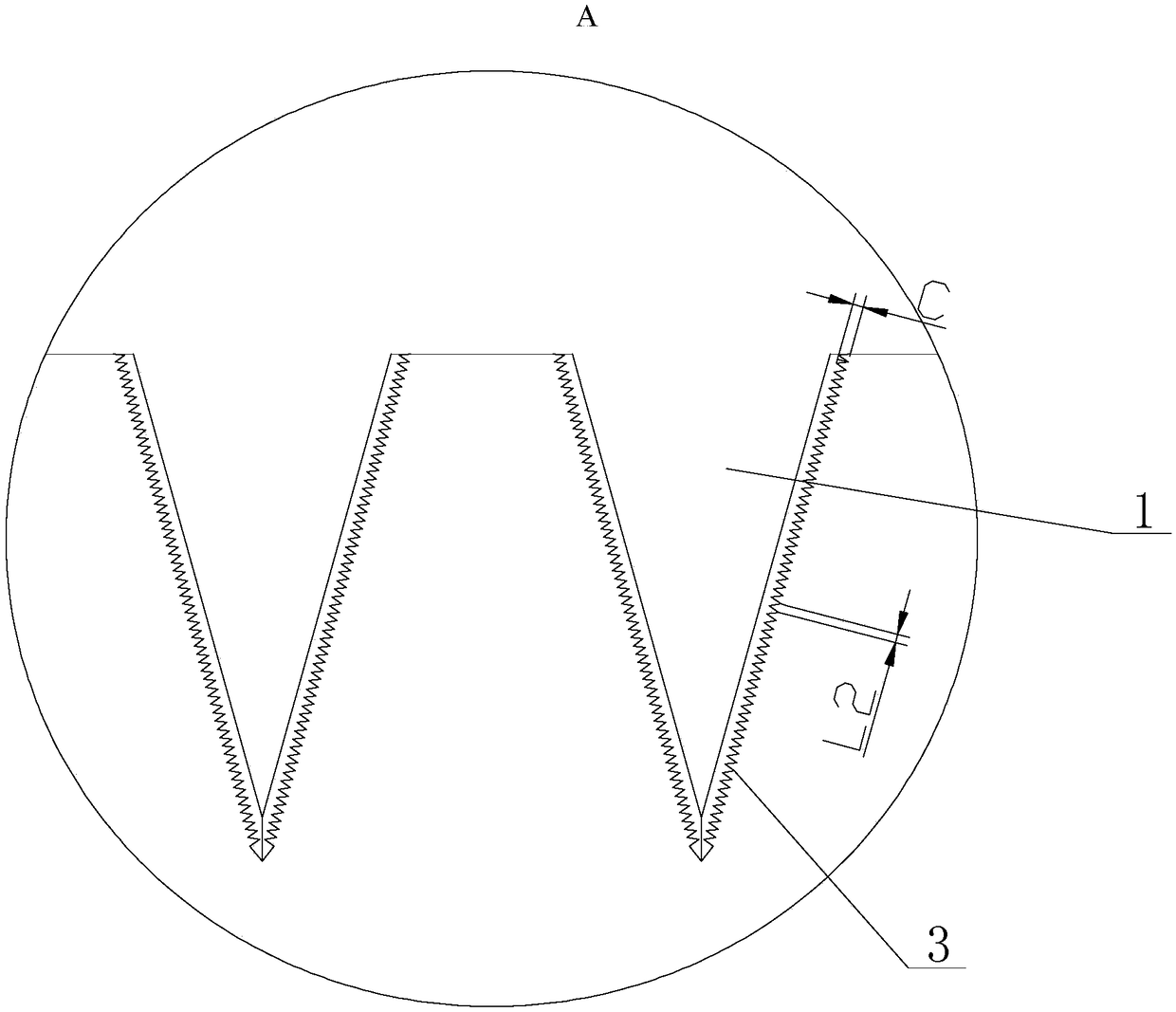

Secondary tooth reciprocating scissors

InactiveCN108849000APrevent slippageImprove pruning efficiencySecateursMechanical engineeringSecondary tooth

The invention provides secondary tooth reciprocating scissors, relates to reciprocating scissors, in particular to the secondary tooth reciprocating scissors. In order to solve the problem that in theprocess of trimming grape side shoots, hedges, lawns and the like, cut branches or strips often slip off from shearing blades, which causes cutting leakage phenomenon of the trimmed hedges, the lawnsand the like. The scissors comprise an upper blade body, a lower blade body, a plurality of upper cutting blades and a plurality of lower cutting blades, the upper blade body and the lower blade bodyare superposed from top to bottom, one side of the upper blade body is provided with the upper cutting blades in the length direction, each upper cutting blade is integrally connected with one side of the upper blade body, one side of the lower blade body is provided with the lower cutting blades in the length direction, each lower cutting blade is integrally connected with one side of the lowerblade body, and the edges of the upper cutting blades and the lower cutting blades are provided with a plurality of secondary teeth. The scissors belong to the field of forestry machinery.

Owner:HARBIN RES INST OF FORESTRY MACHINERY CHINA MIN OF FORESTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com