Brush roll cotton picker

A cotton picker and brush roller type technology, which is applied to picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of secondary pollution of seed cotton, poor removal of cotton stalks and branches, and damage to cotton fibers. Low net rate, solve the effect of easy pulling up of cotton stalks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

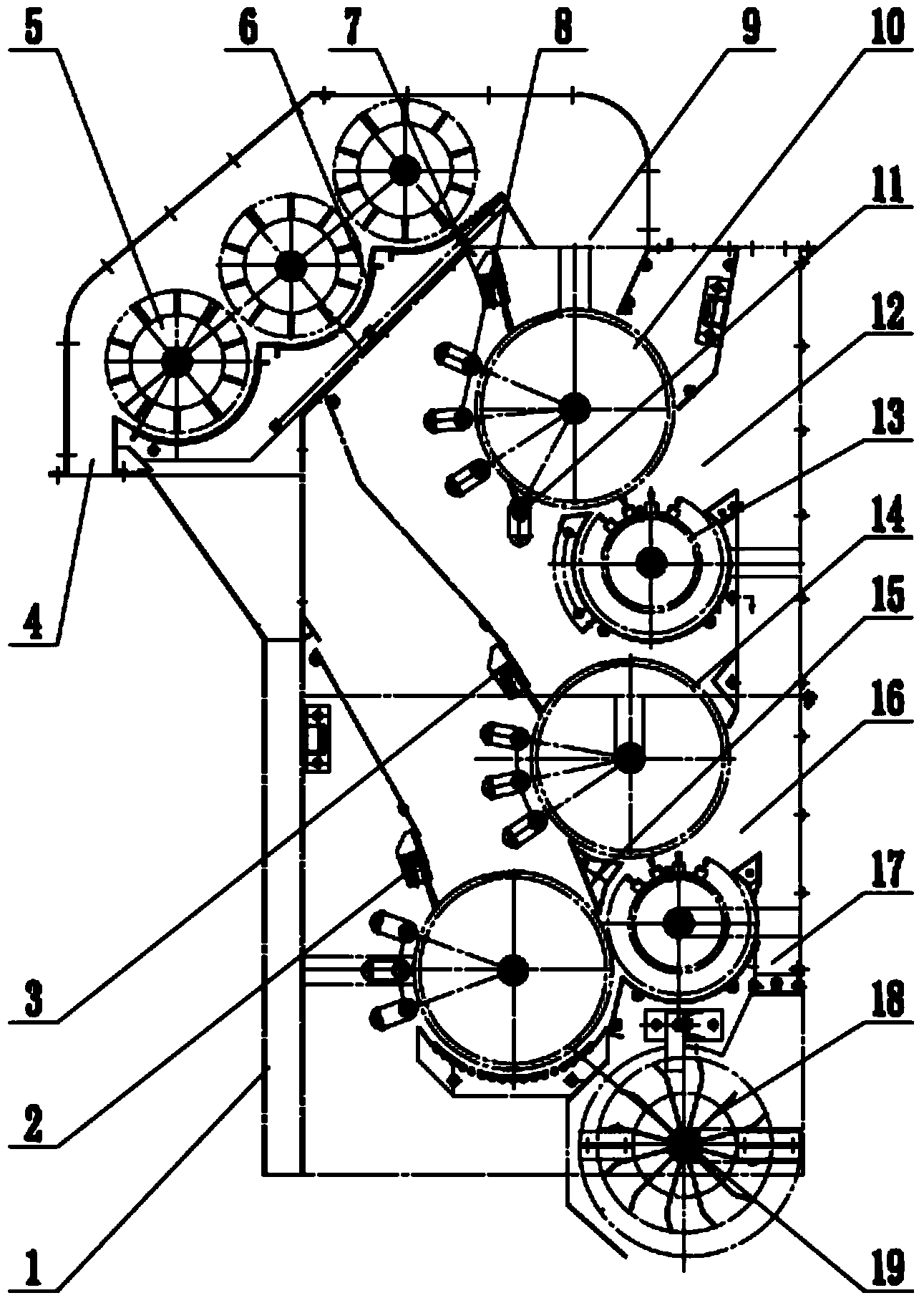

[0026]Due to the unique geographical environment in the Yangtze River cotton area, there is more rain, and the air and soil humidity are high. The cotton opening period is relatively long, the opening rate is relatively low and the opening is not smooth. There are many stiff flowers and semi-twisted flocks, which are not easy to be entangled and easy to fall. The use of spindle picking cotton pickers generally has the problems of low picking rate and high loss rate, and picking is very difficult. On the other hand, most of the Yangtze River cotton area adopts ridge planting, and drainage ditches are usually opened for drainage. Due to the high soil humidity, cotton is easy to pull up, which has become a difficult problem for picking with double-finger cotton pickers. As far as the applicant knows, the brush-roll cotton picker implemented in this application is the only model suitable for use in this area so far.

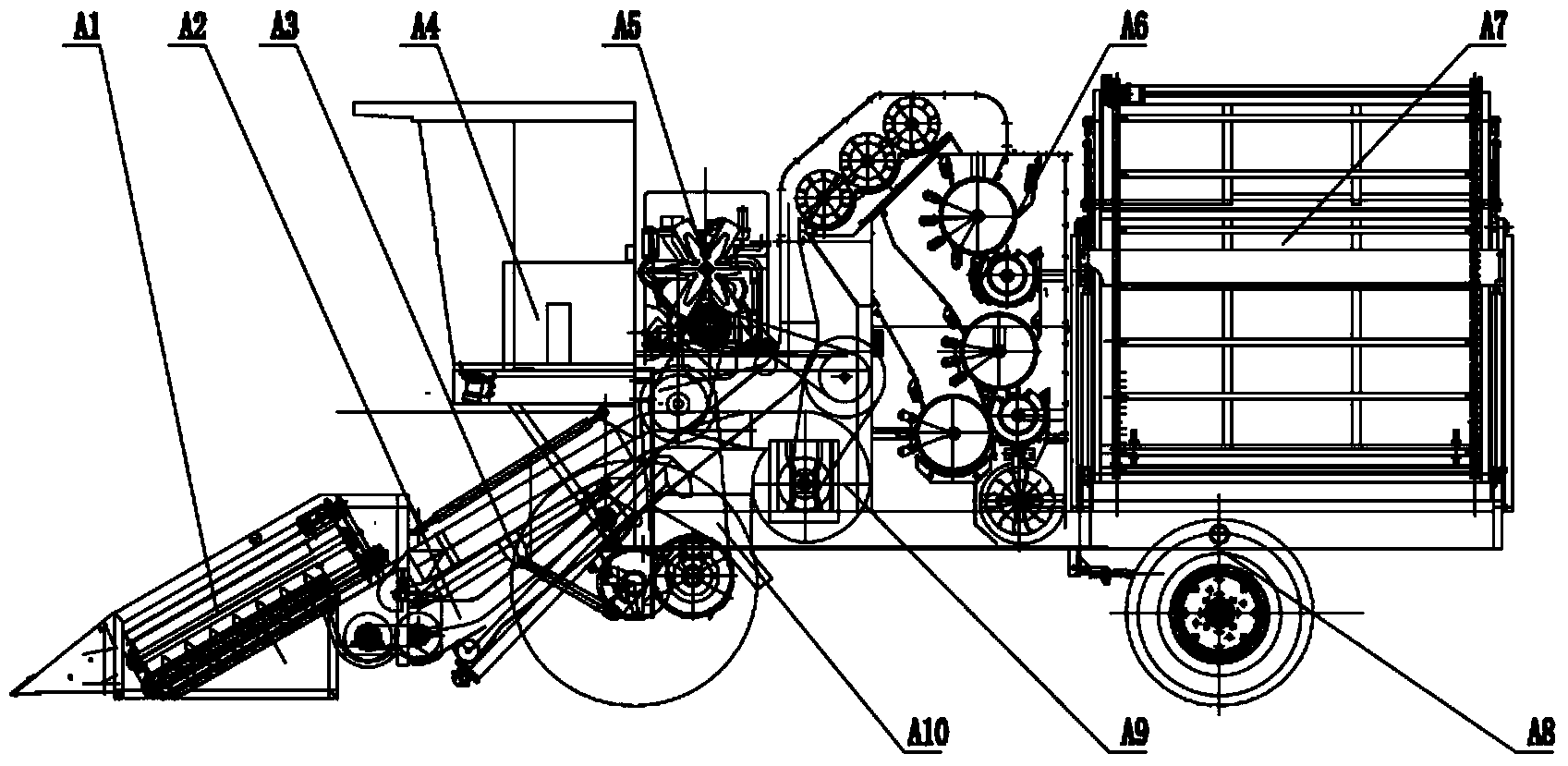

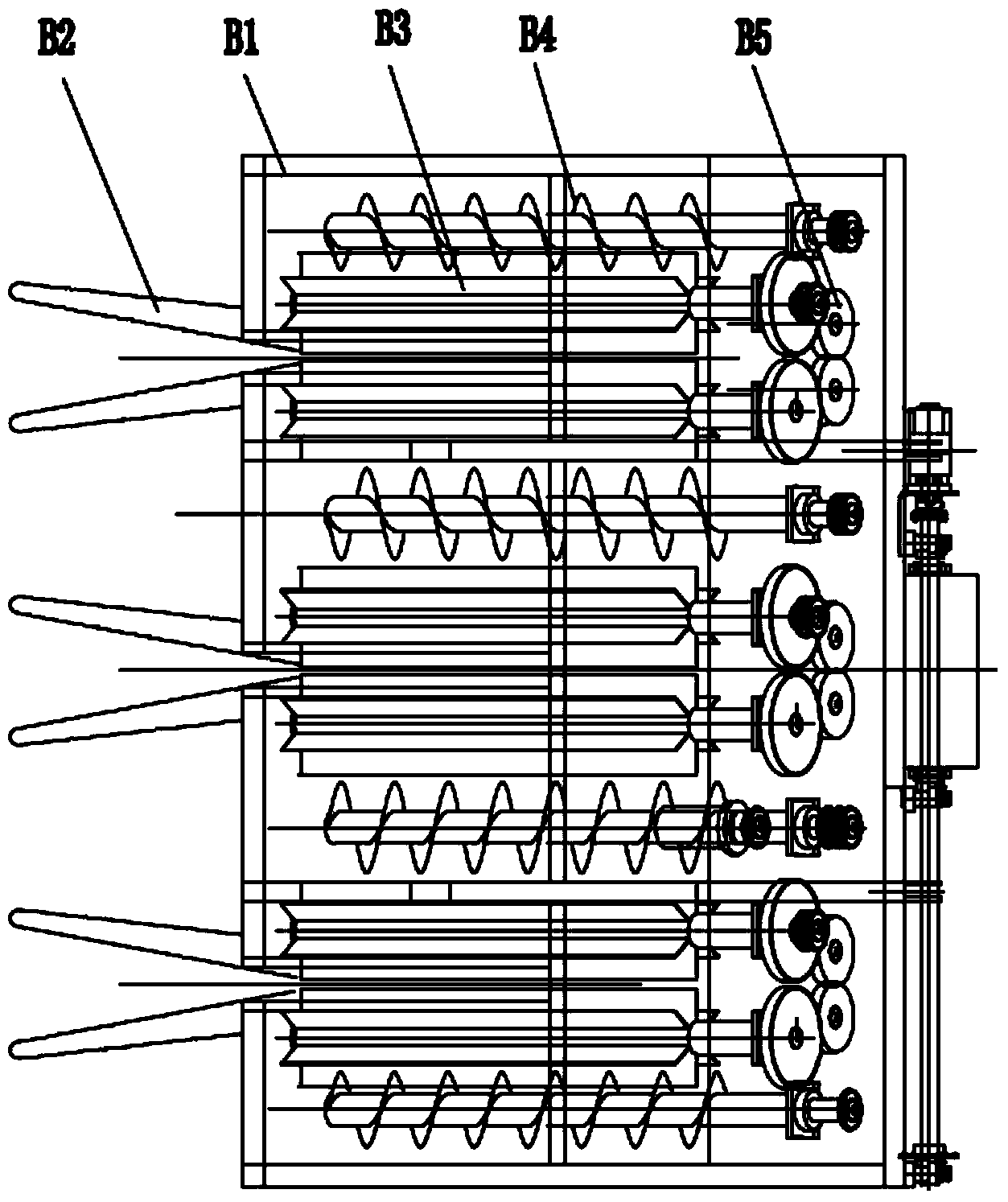

[0027] The brush roller type cotton picker of this implementati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com