Patents

Literature

48 results about "Primary Tooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

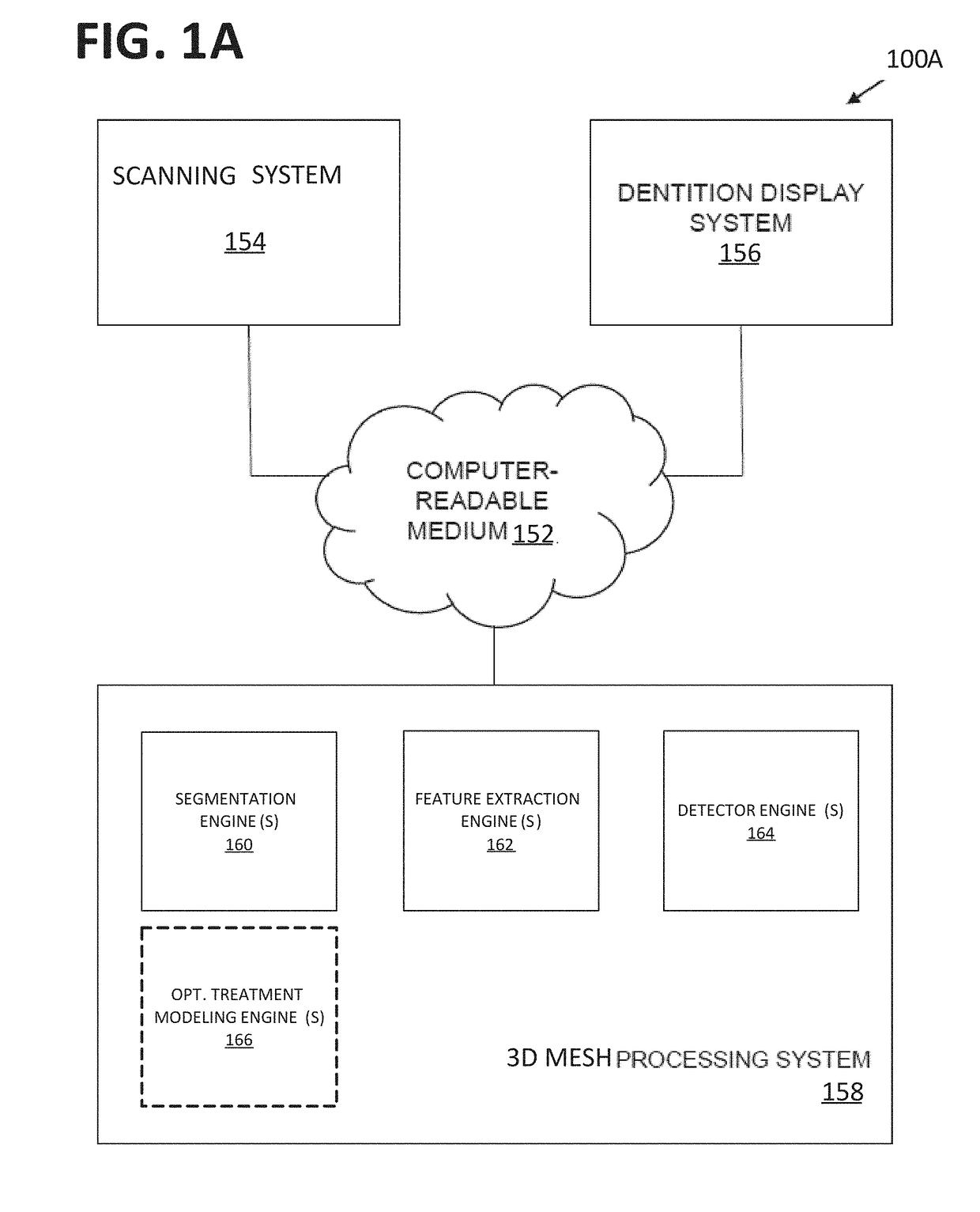

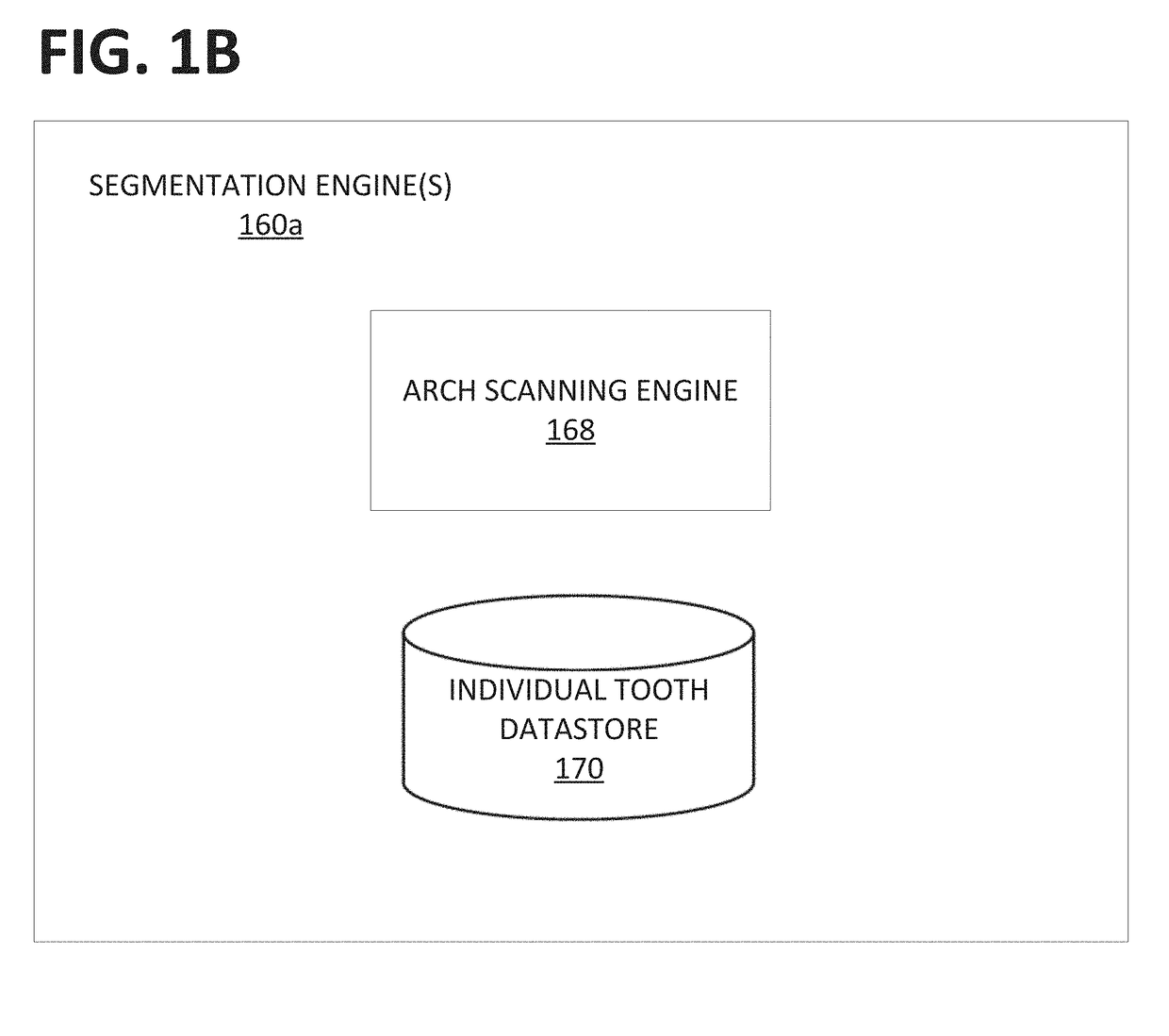

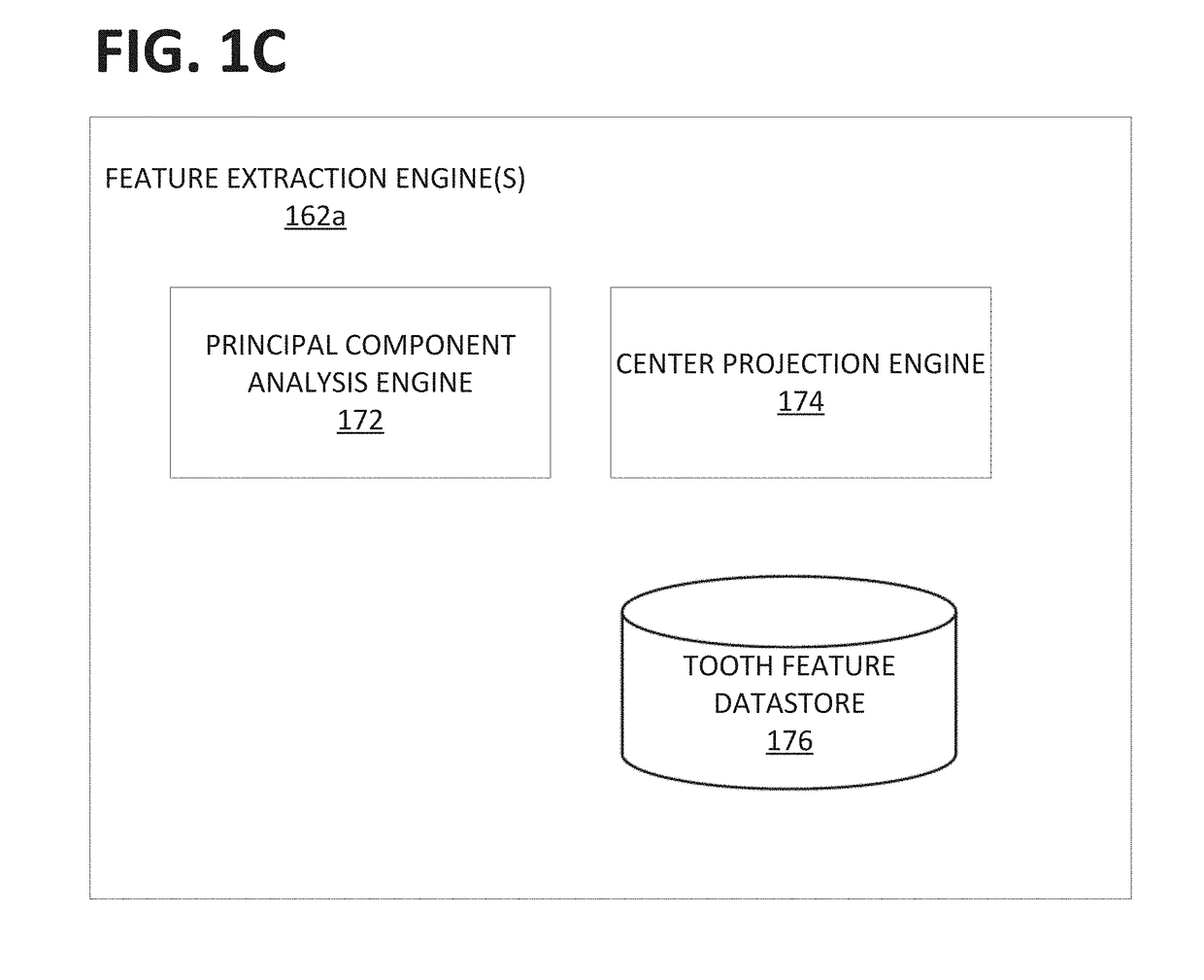

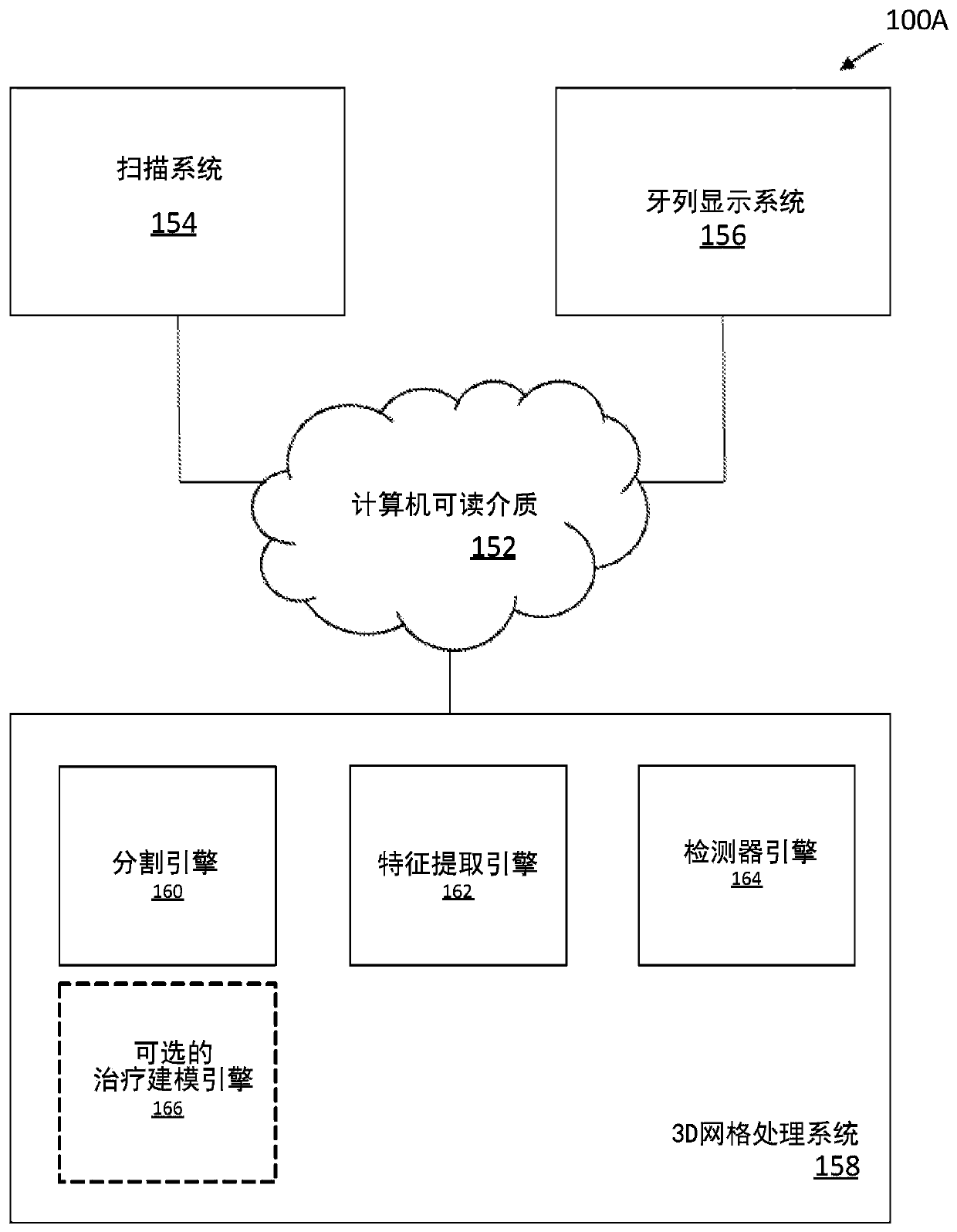

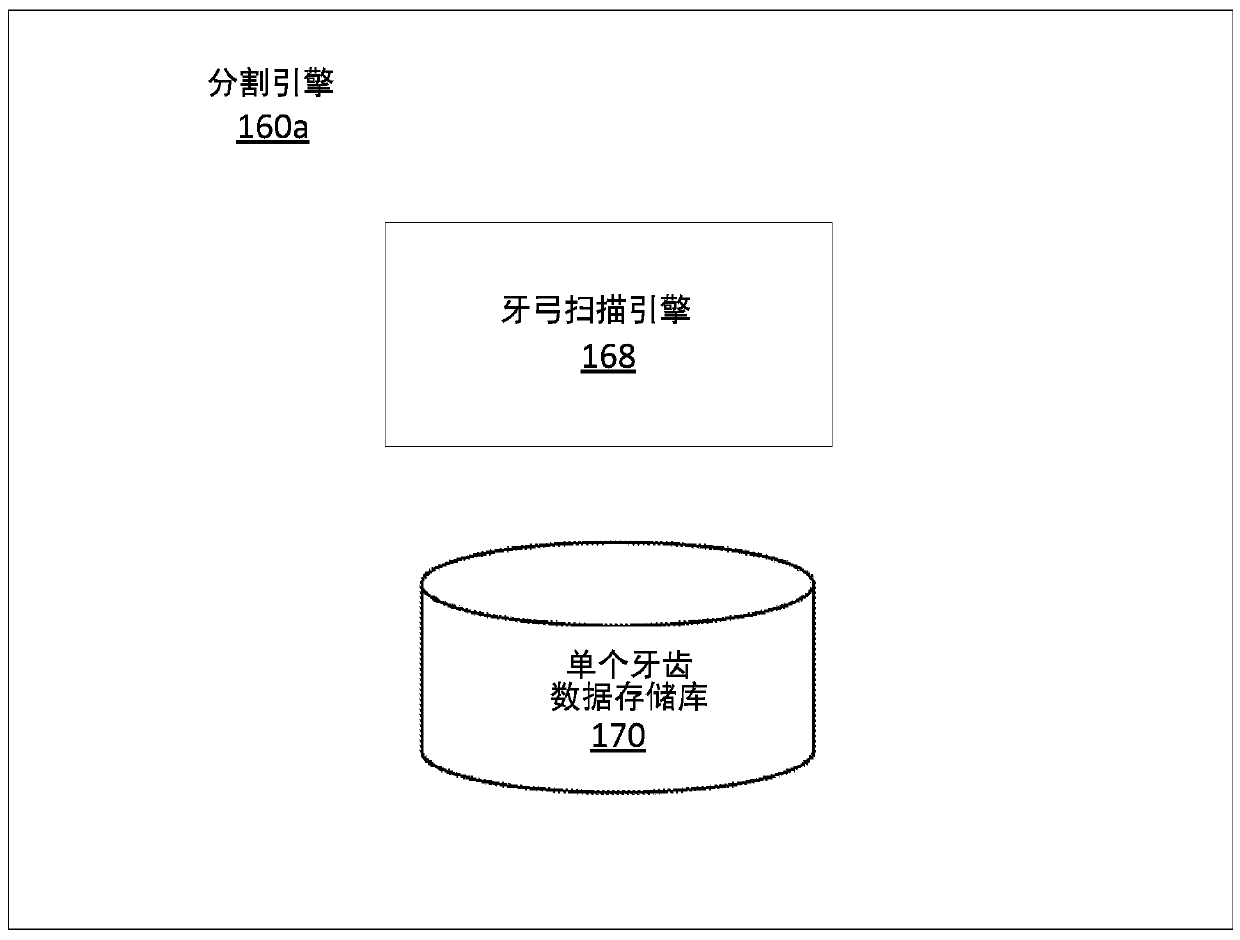

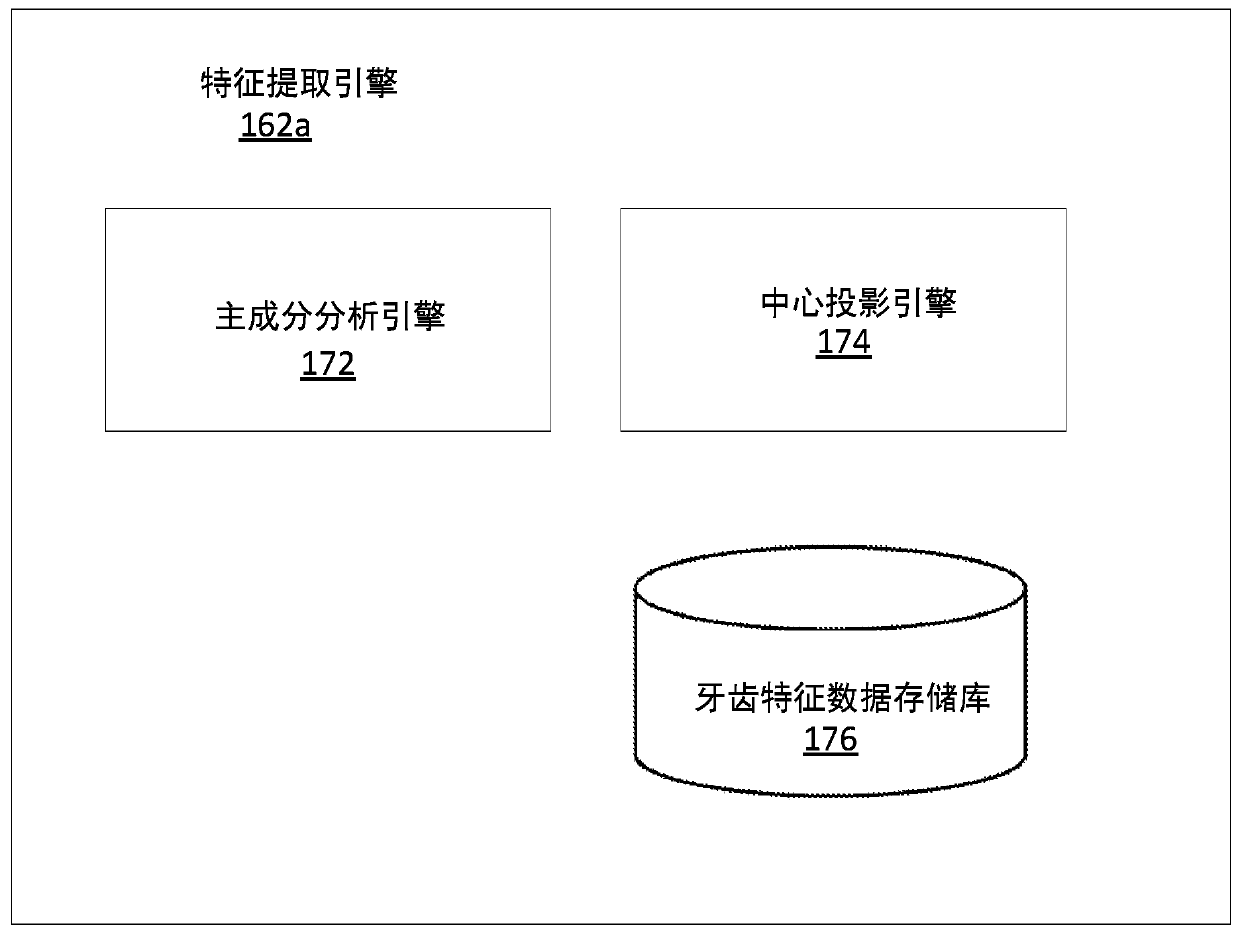

Automatic detection of tooth type and eruption status

Provided herein are systems and methods for detecting the eruption state (e.g., tooth type and / or eruption status) of a target tooth. A patient's dentition may be scanned and / or segmented. A target tooth may be identified. Dental features, principal component analysis (PCA) features, and / or other features may be extracted and compared to those of other teeth, such as those obtained through automated machine learning systems. A detector can identify and / or output the eruption state of the target tooth, such as whether the target tooth is a fully erupted primary tooth, a permanent partially erupted / un-erupted tooth, or a fully erupted permanent tooth.

Owner:ALIGN TECH

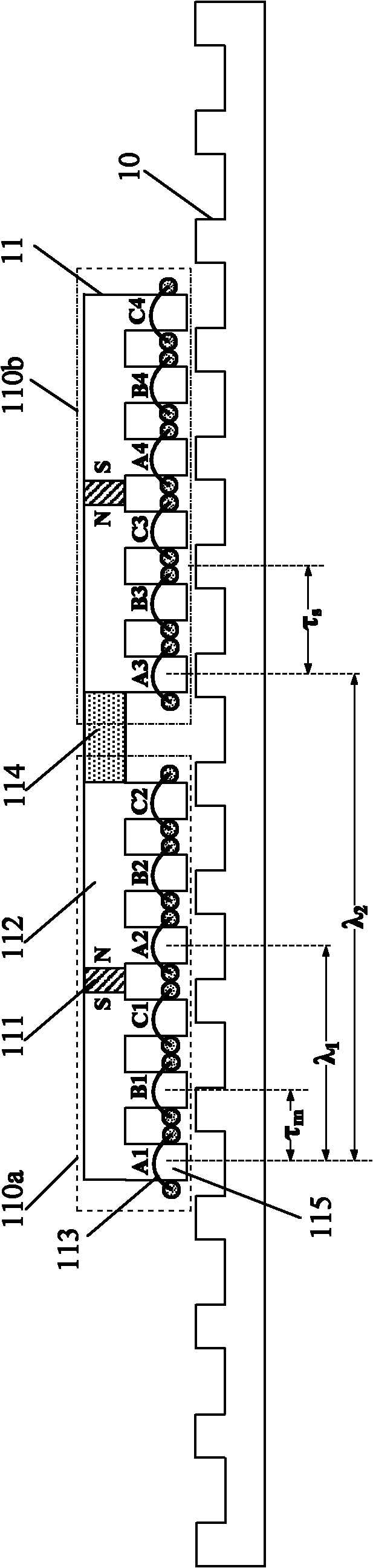

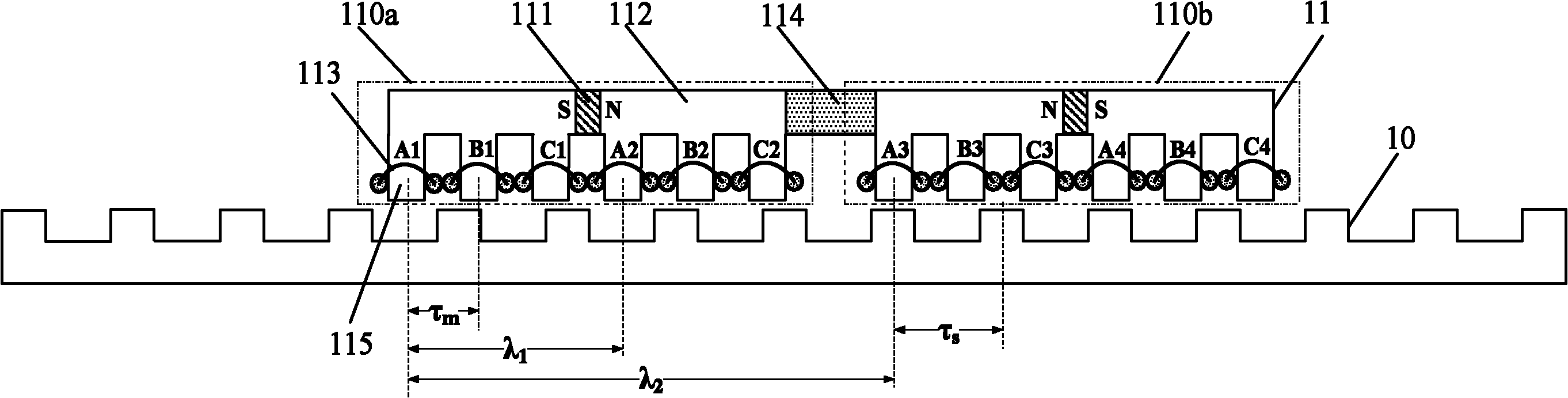

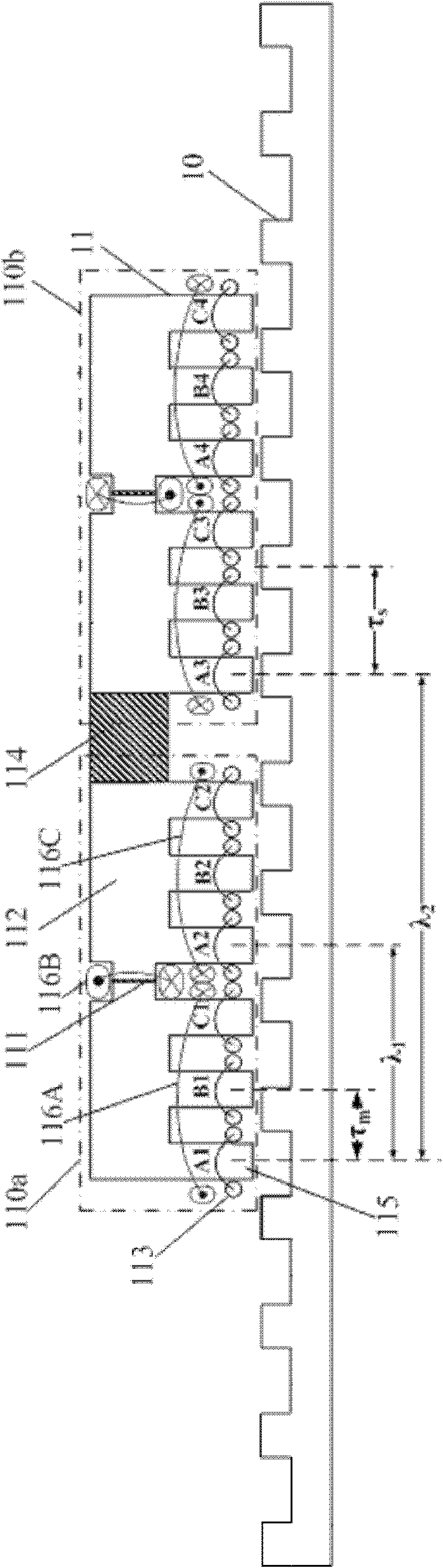

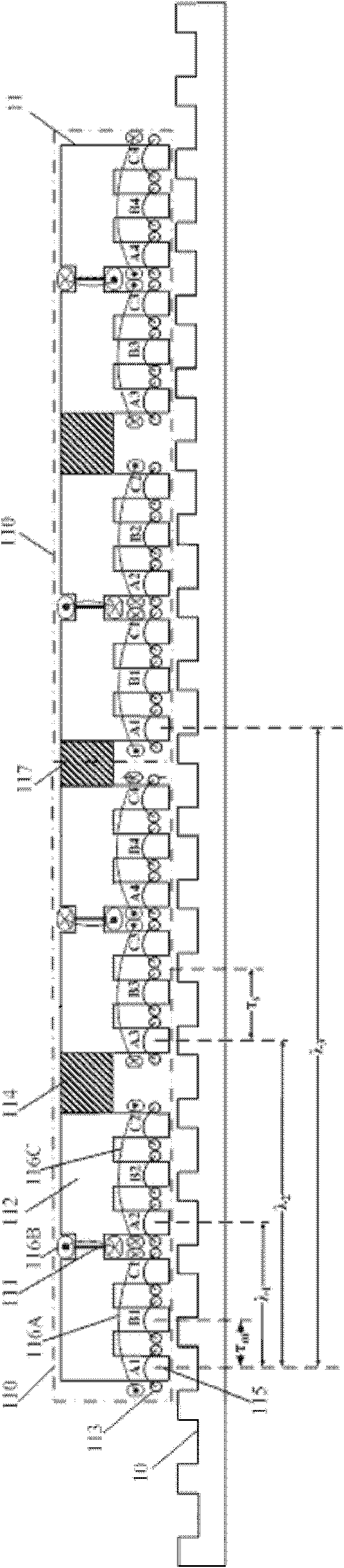

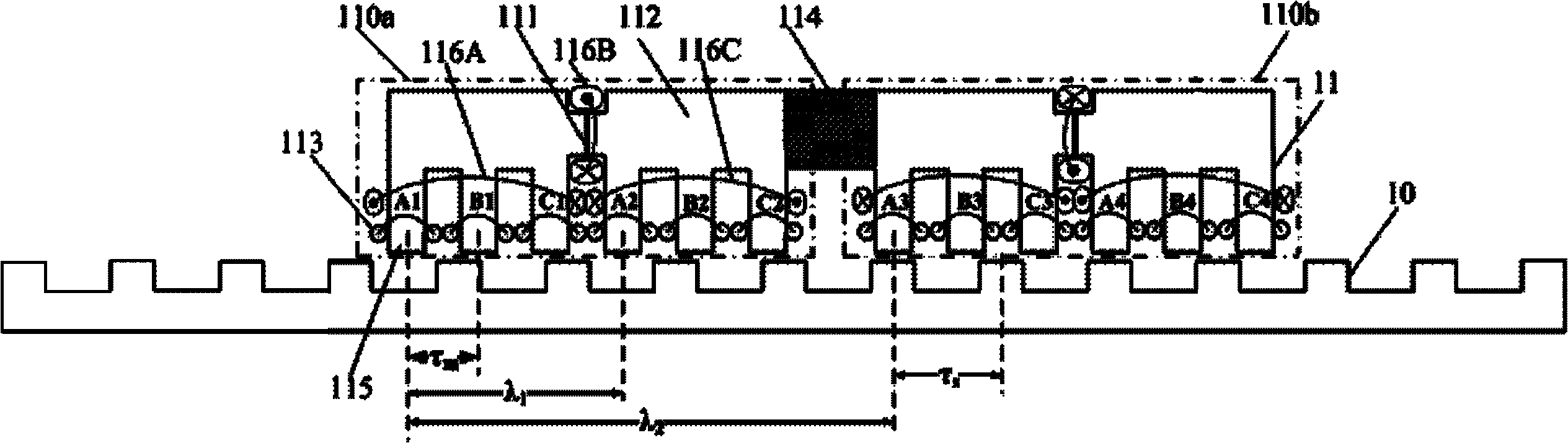

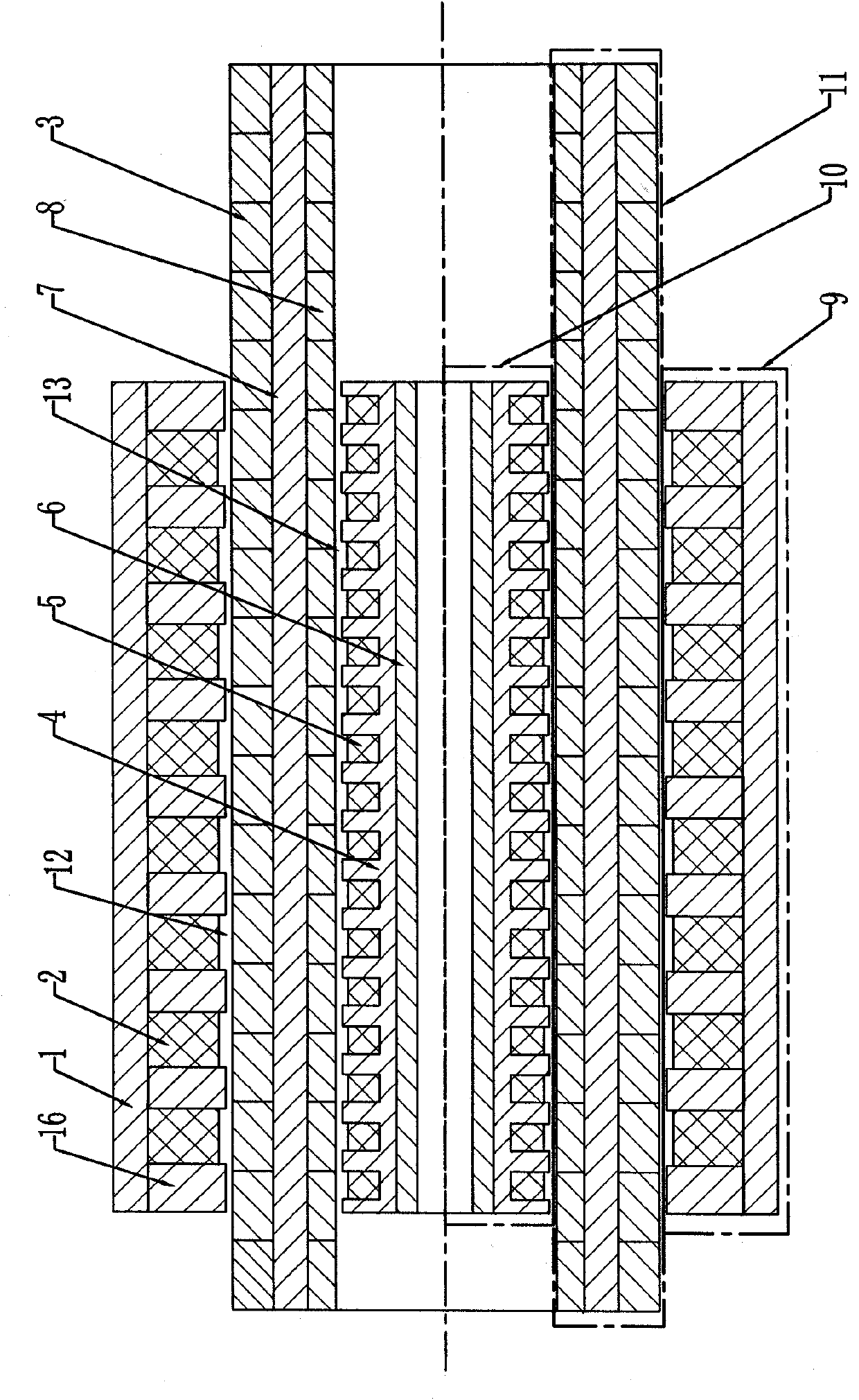

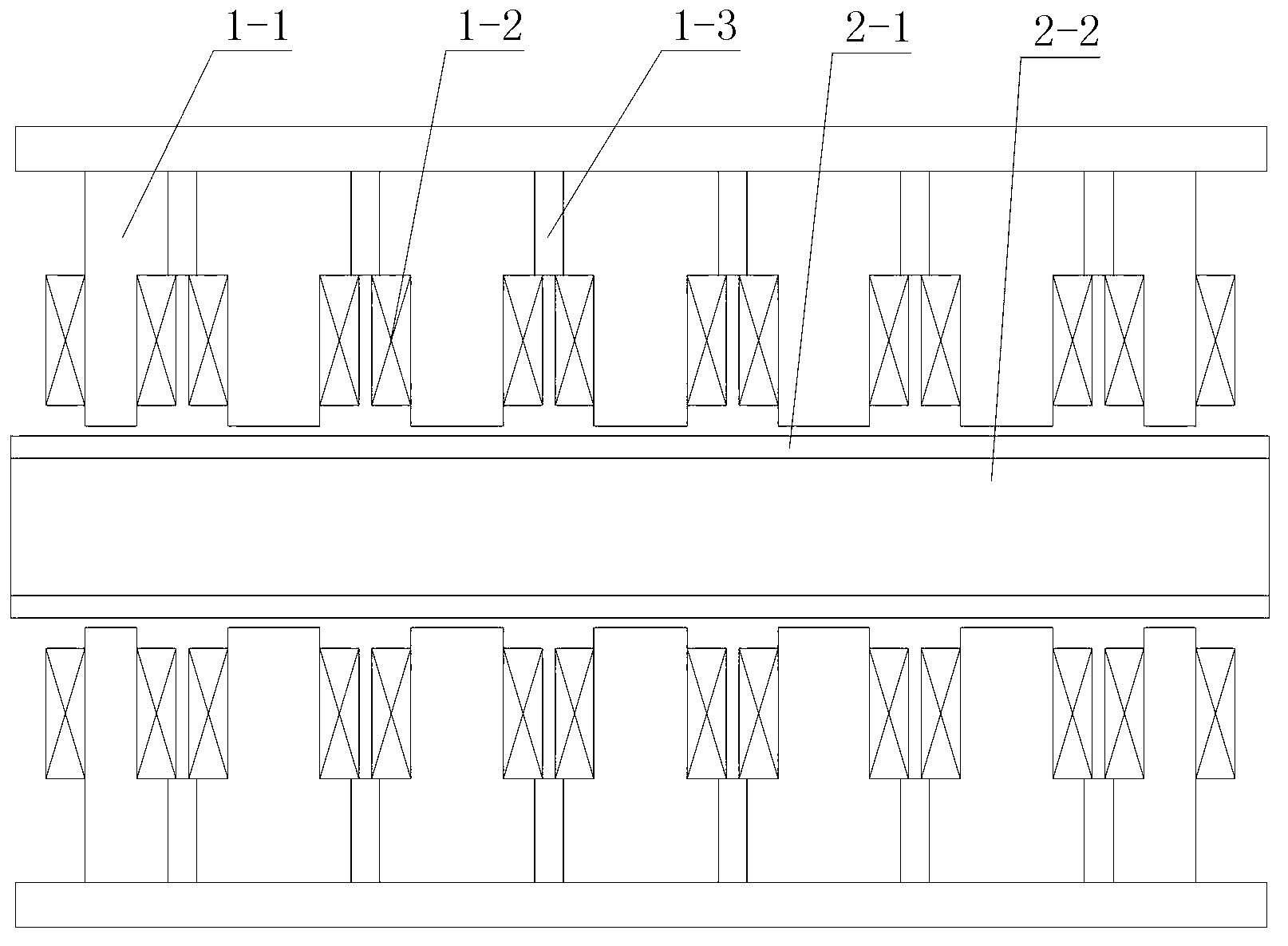

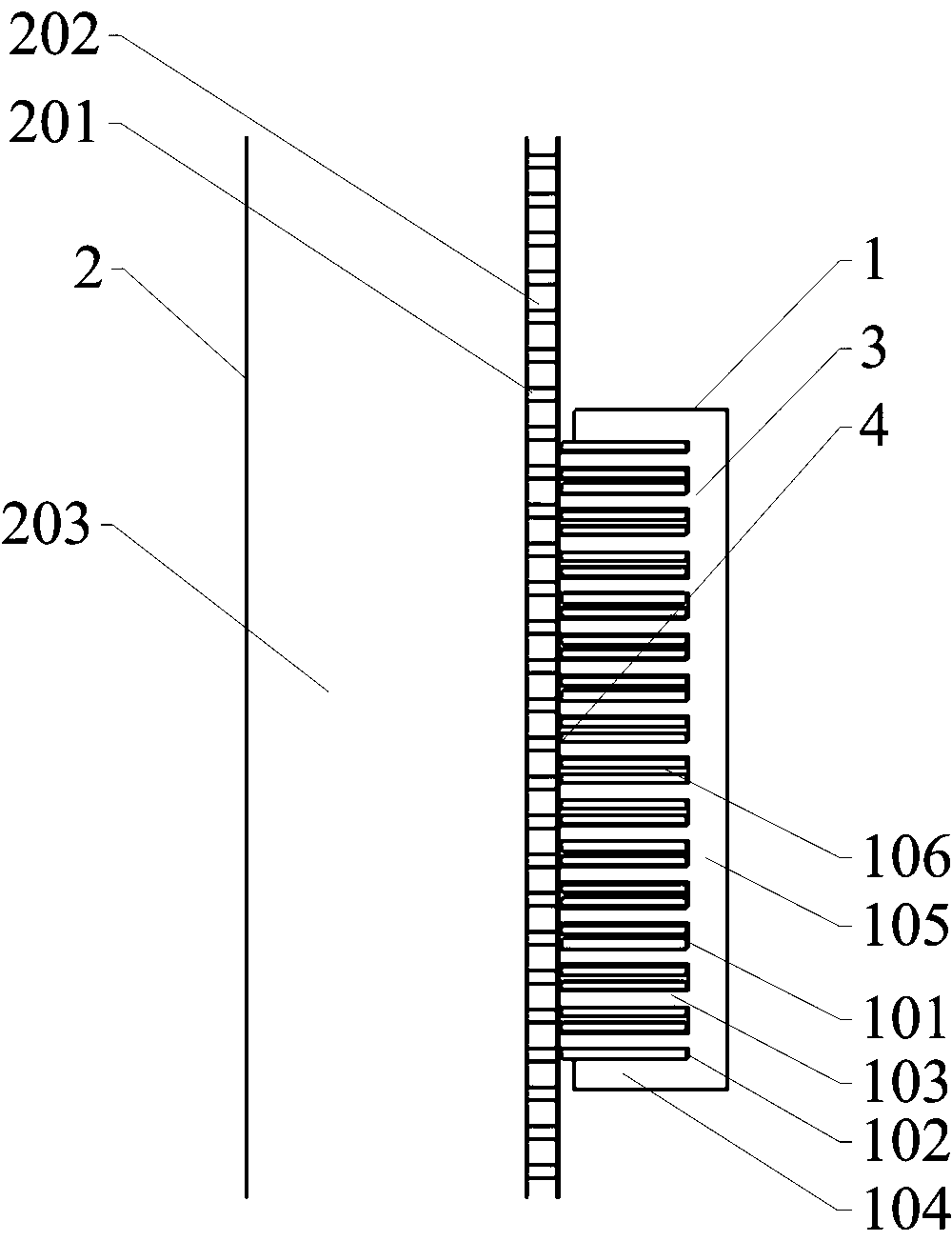

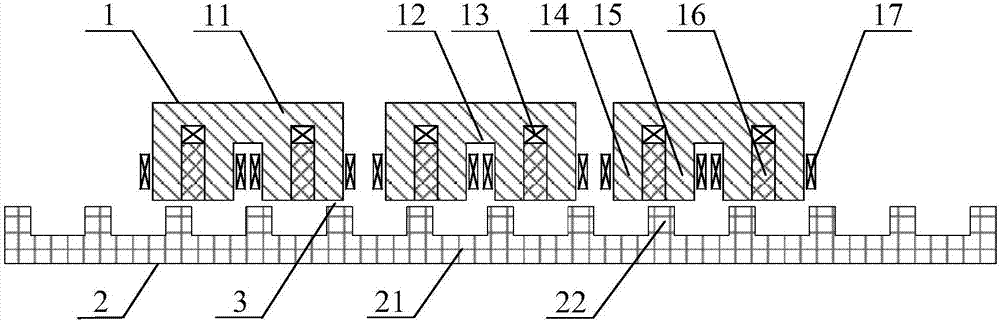

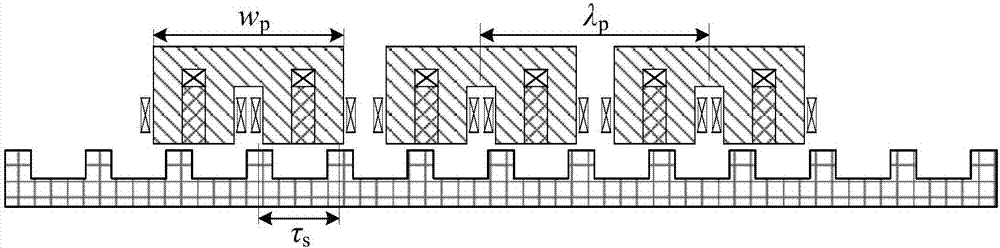

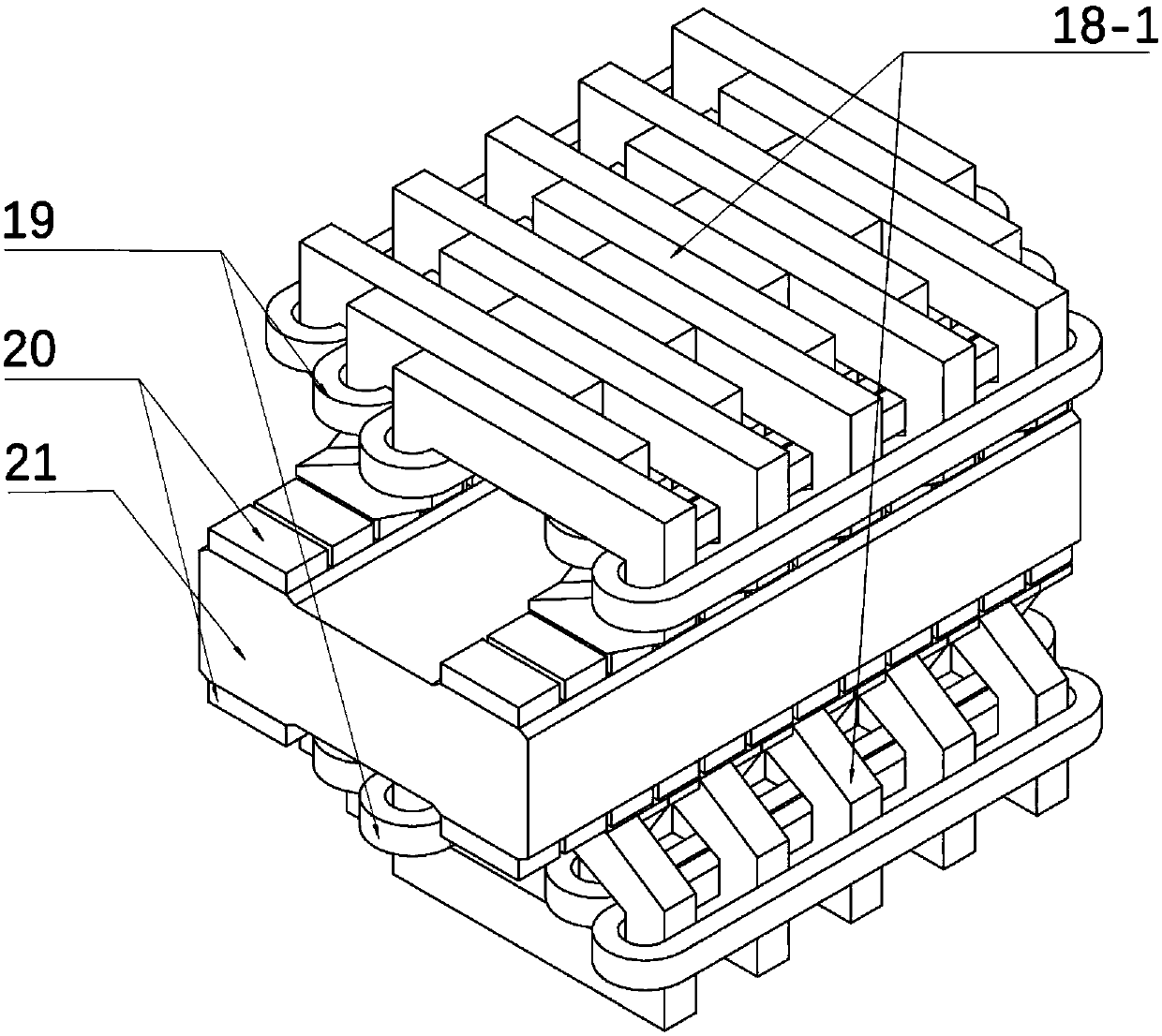

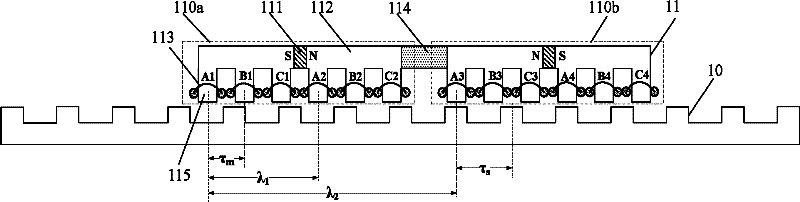

Modular complementary type primary permanent magnet linear motor and motor module formed thereby

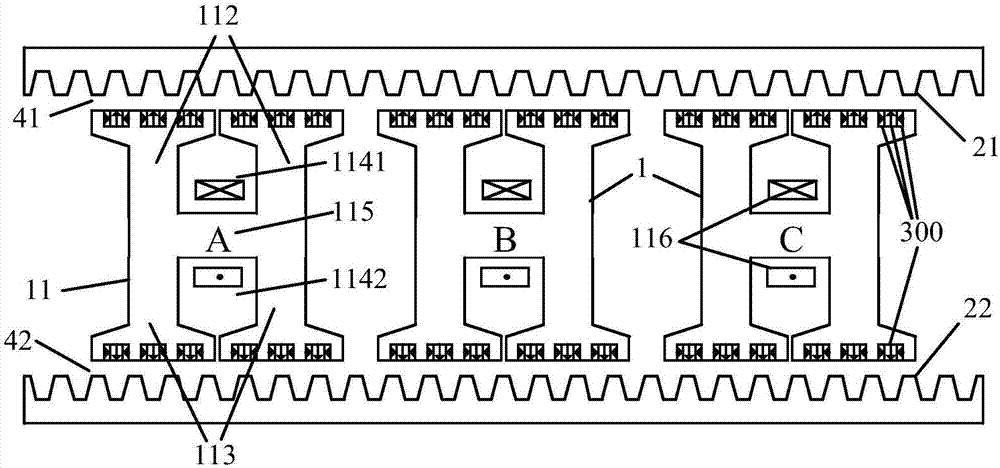

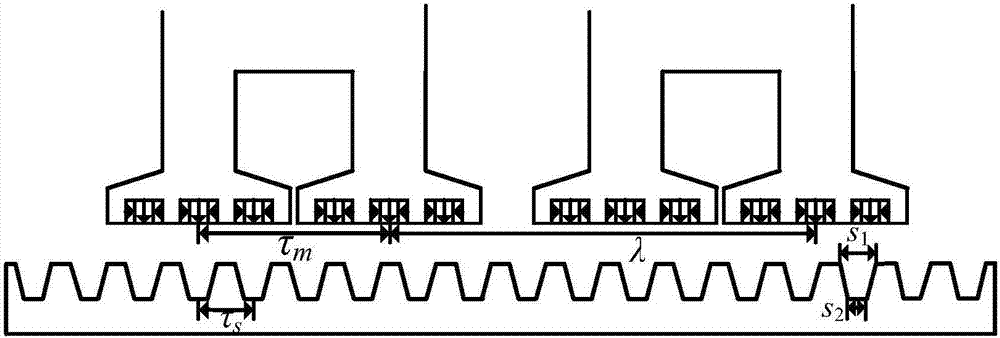

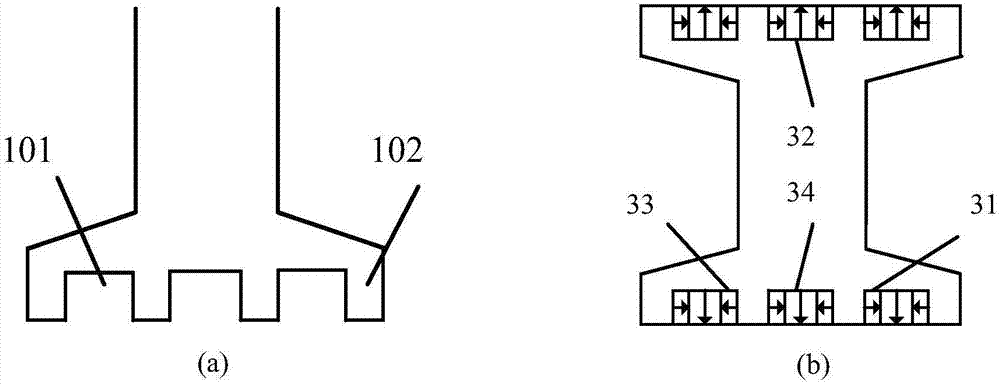

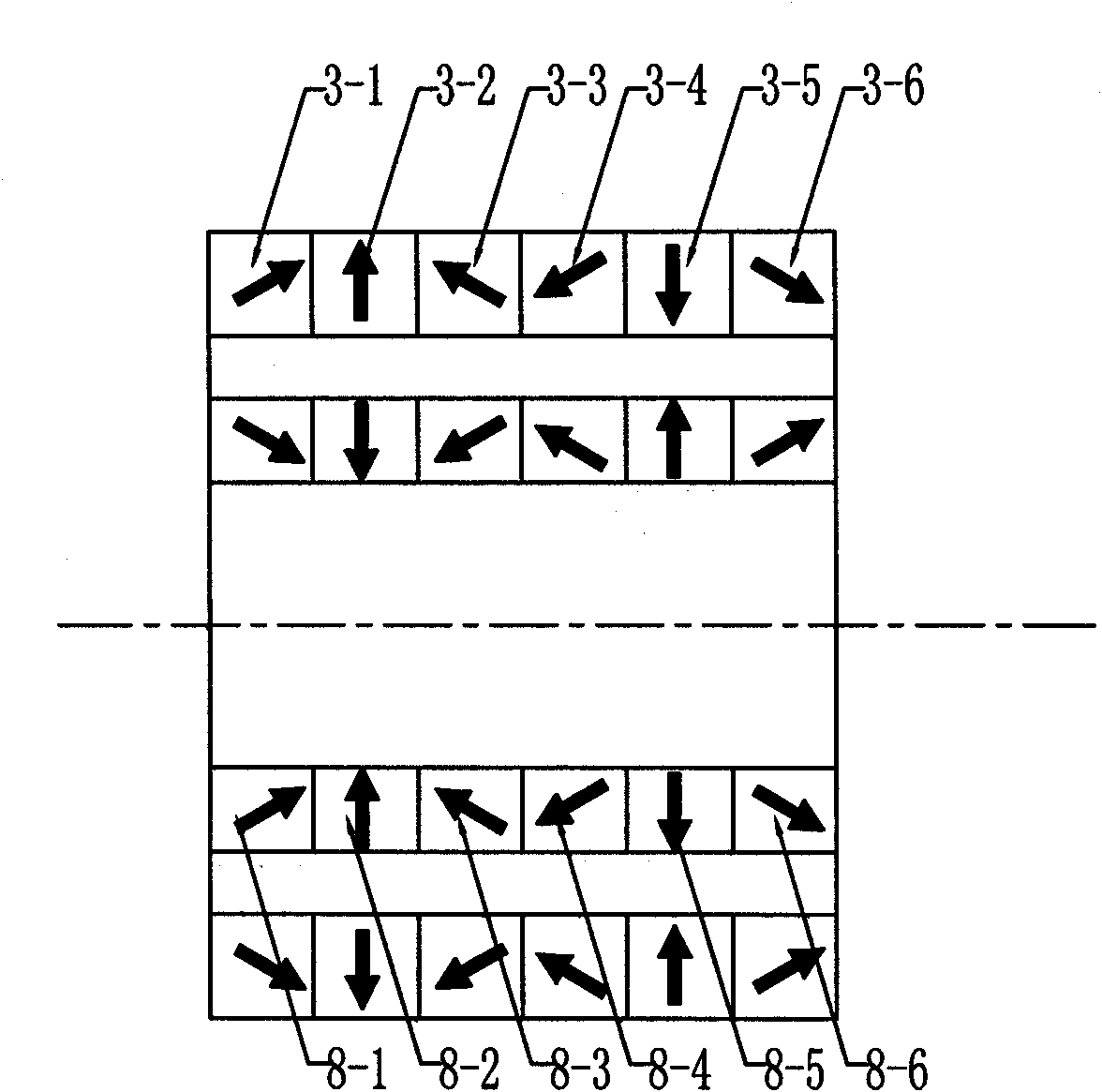

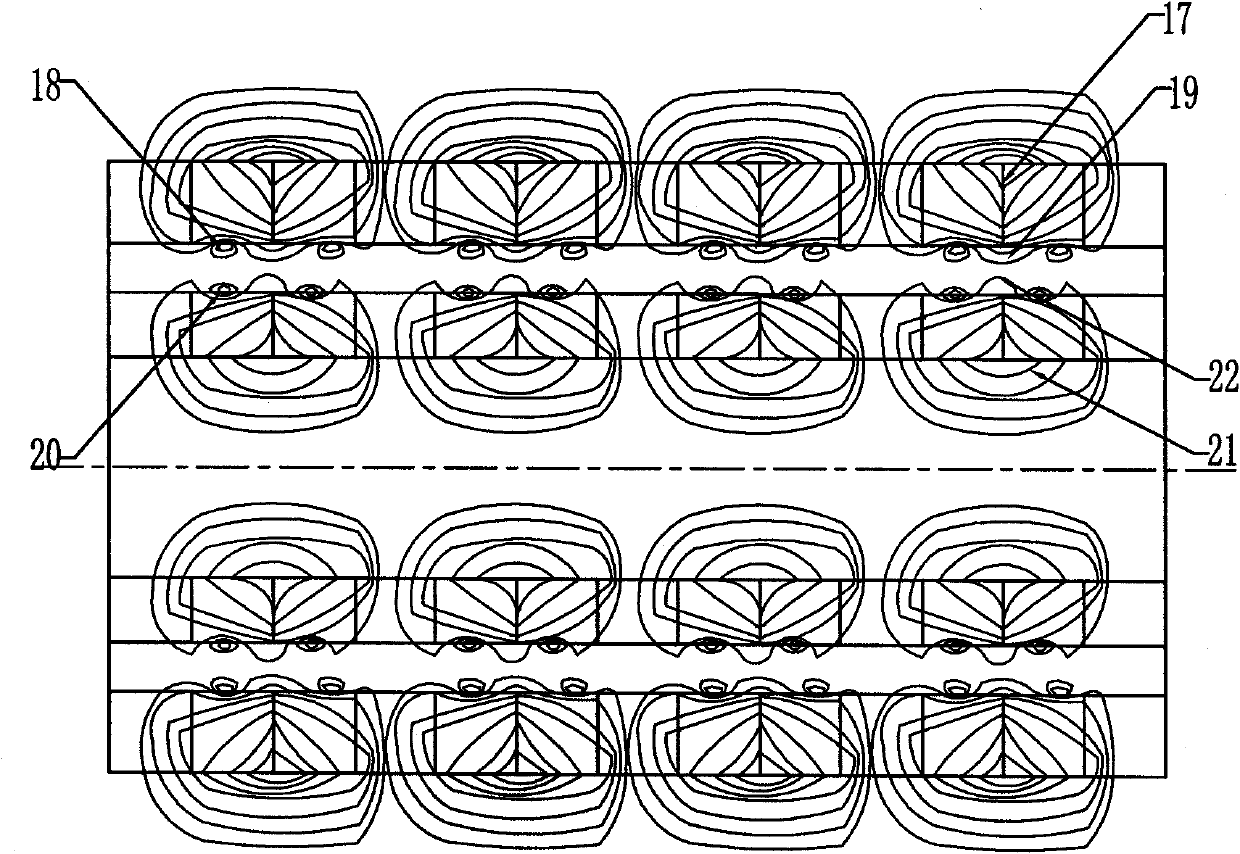

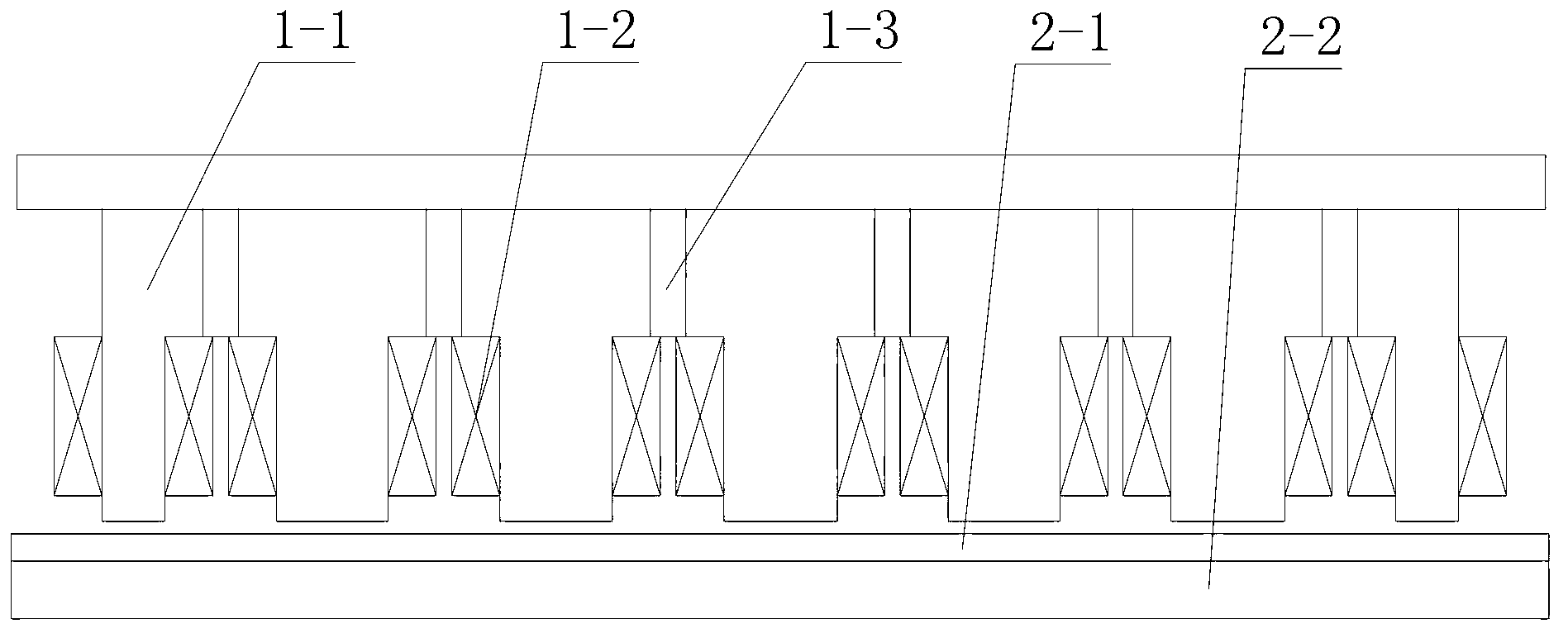

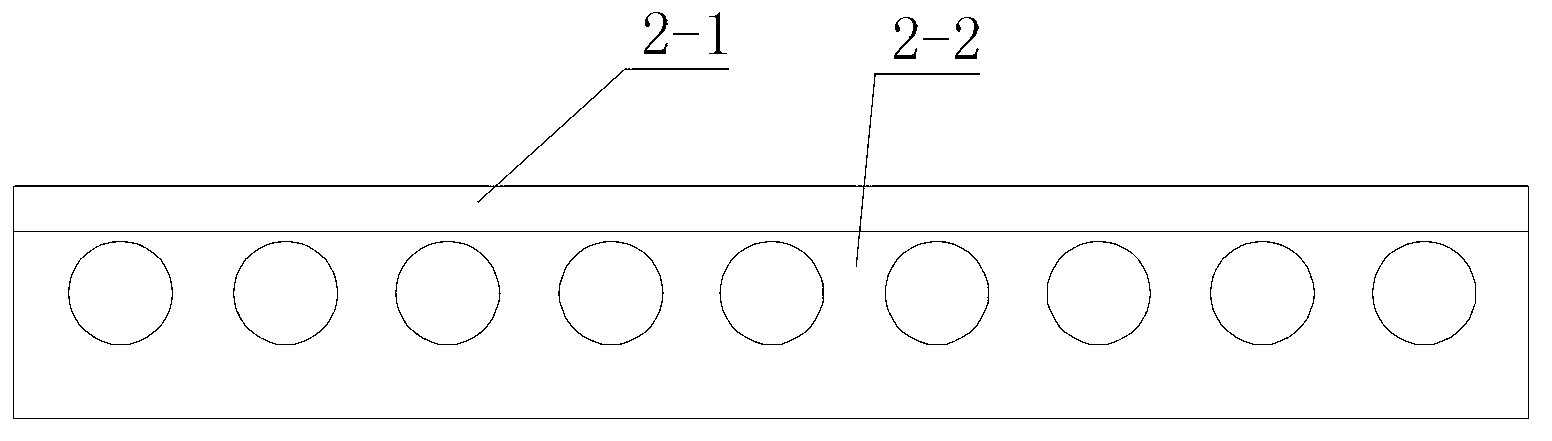

The invention discloses a modular complementary type primary permanent magnet linear motor and a motor module formed thereby. The primary permanent magnet linear motor comprises a primary level and a secondary level; the primary level and the secondary level are respectively in a salient-pole structure, and an air gap is formed between the two levels; the primary level comprises a rotor module which comprises a first module and a second module; a first non-magnetic material is arranged between the first module and the second module; the first module and the second module both comprise two salient-pole magnetic materials and a permanent magnet arranged between the two salient-pole magnetic materials; the salient-pole magnetic material is provided with m numbered primary teeth, and a central armature winding is arranged on the primary teeth; the relative displacement between the first module and the second module is calculated as follows: lambda2=(k+ / -0.5) tau s; the relative displacement between the adjacent two salient-pole magnetic materials is calculated as follows: lambda1=m*tau m; and the ratio of the primary polar distance to the secondary polar distance is as follows: tau m: tau s=(m+ / -1):m. The invention has the advantages of symmetric back electromotive force, relatively small positioning force, low thrust fluctuation and the like and is applicable to the application occasion of a linear motor with a long-stator structure.

Owner:SOUTHEAST UNIV

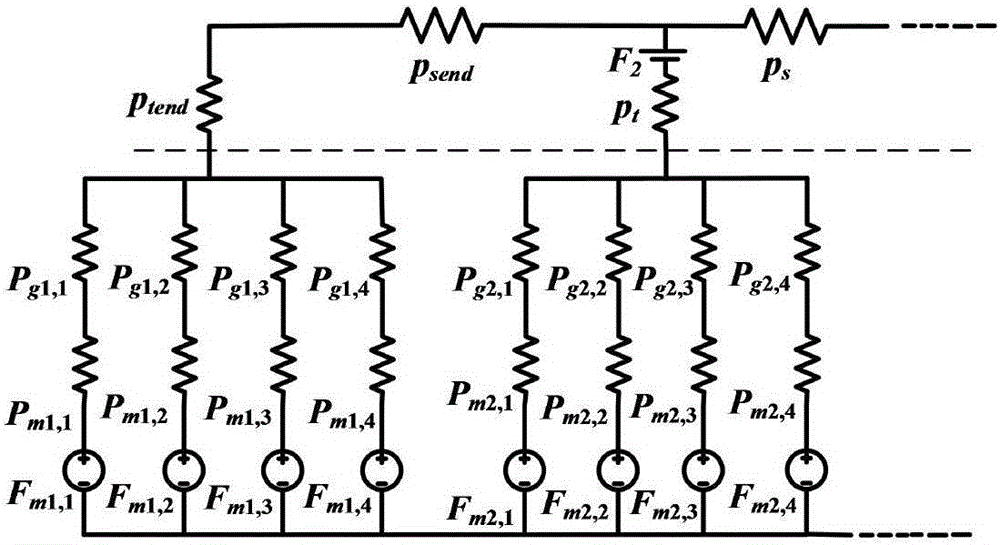

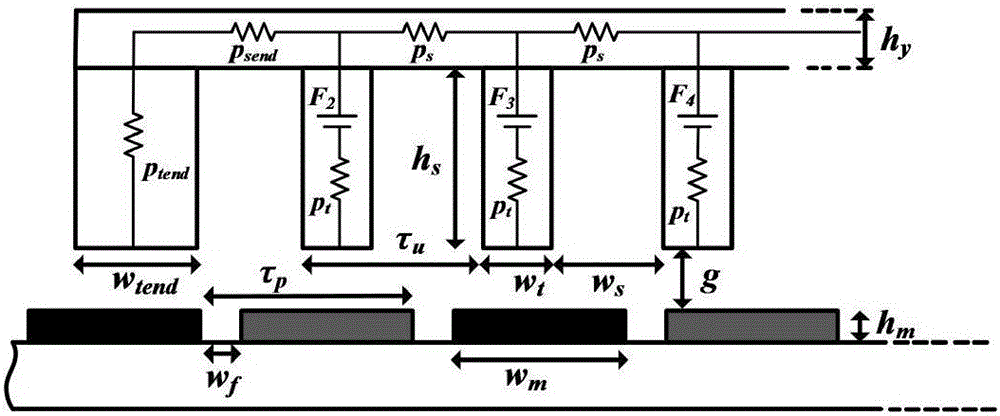

Permanent magnet synchronous linear motor modeling and characteristic analyzing method based on equivalent magnetic circuit method

InactiveCN105787158AGuaranteed accuracyGeometric CADSpecial data processing applicationsPermanent magnet synchronous motorConductor Coil

The invention relates to a permanent magnet synchronous linear motor modeling and characteristic analyzing method based on an equivalent magnetic circuit method. The method comprises following steps of dividing a permanent magnet synchronous linear motor equivalent magnetic circuit method analyzing model into two parts, wherein a linear motor primary forms a first part, and an air gap and a motor secondary form a second part; ignoring the saturation of an iron core, solving the permeance of the first part and magnetomotive force parameters generated by an armature winding; equally dividing the magnetic circuit in each space width entering into each primary tooth into four branches except the end part of the motor; obtaining the distribution of the air gap flux density of the motor at any moment; and solving the magnetic linkage of the motor, the counter electromotive force of an armature and the magnetic resistance of the motor. According to the method, under the premise of ensuring the model precision, the model is simple and practicable.

Owner:TIANJIN UNIV

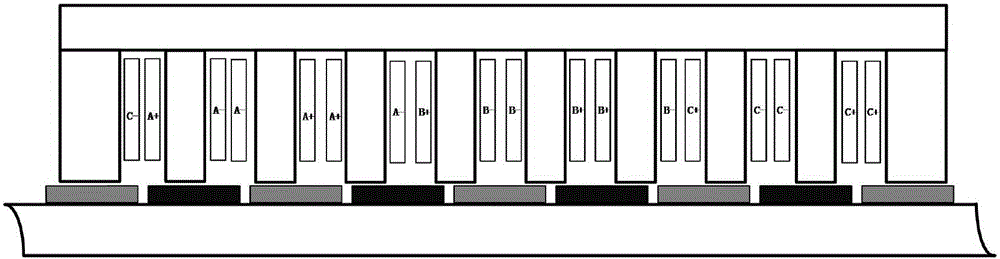

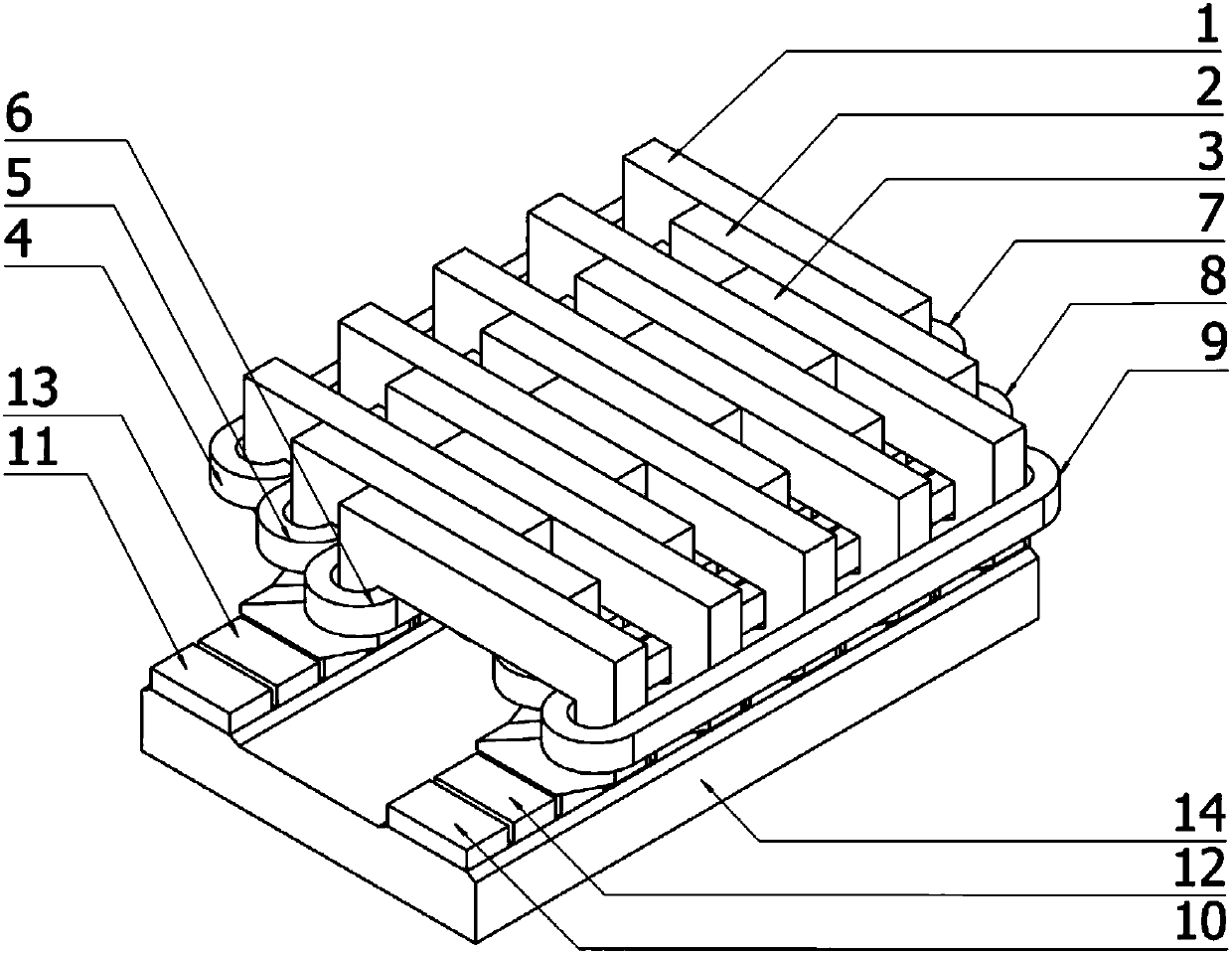

Modularized complementary type primary double-fed brushless direct-current linear motor and motor module composed by same

ActiveCN102142763ABroaden the range of constant power speed regulationMagnetic circuit rotating partsMagnetic circuit stationary partsDrive motorEngineering

The invention discloses a modularized complementary type primary double-fed brushless direct-current linear motor and a motor module composed by same. The modularized complementary type primary double-fed brushless direct-current linear motor comprises a primary part and a secondary part, wherein the primary part comprises a rotor module, and the rotor module comprises a first module, a second module and a first non-magnetic-conducting material arranged between the first module and the second module; the first module and the second module respectively comprise two salient pole magnetic-conducting materials which are provided with m primary teeth; each primary tooth is provided with an concentrated armature winding, and a connection part of every two salient pole magnetic-conducting materials and the corresponding m primary teeth are respectively provided with a concentrated exciting winding; and m is the number of phases of the motor. When being used as a driving motor, the modularized complementary type primary double-fed brushless direct-current linear motor is particularly suitable for application occasions of linear motors with long stator structures, such as urban railway transit linear motors and electromagnetic catapults or application occasions needing a wide speed regulation range. The modularized complementary type primary double-fed brushless direct-current linear motor disclosed by the invention can also be used as a power generator and used for occasions of seawave power generation and the like and can achieve the characteristics of variable-speed constant-voltage output and constant-speed variable-voltage output through regulating the magnitude of exciting current.

Owner:SOUTHEAST UNIV

Magnetic field modulation permanent magnet linear motor capable of improving winding utilization rate and optimum design method thereof

ActiveCN106992655AImprove fault toleranceImprove stabilityPropulsion systemsEngineeringPerformance index

The invention discloses a magnetic field modulation permanent magnet linear motor capable of improving winding utilization rate and an optimization design method thereof, and belongs to the field of a permanent magnetism motor. The permanent magnet linear motor comprises a single primary side and double secondary sides. An air gap is arranged between the single primary side and each of the double secondary sides. The single primary side is formed by three unit modules. Each unit module is slotted in the sides close to the air gaps to form four primary teeth and two primary slots. The tooth end of each primary tooth is provided with a plurality of virtual slots and virtual teeth in the motor motion direction, wherein the number of the virtual teeth is larger by one than that of the virtual slots, and each virtual slot is embedded by a magnetic concentrating unit formed by three permanent magnets. Three phases of windings in the primary slots are wounded on yoke portions of the three primary unit modules respectively; and each phase of winding can cut magnetic force lines generated by the permanent magnets on the four primary teeth in the corresponding module simultaneously. The permanent magnet linear motor improves winding utilization rate, reduces half of the winding use amount and reduces copper consumption under the condition of ensuring that performance indexes of no-load counter potential, thrust output, permanent magnet use amount and fault-tolerant capability and the like are not influenced.

Owner:常熟市董浜科技创业投资发展有限公司

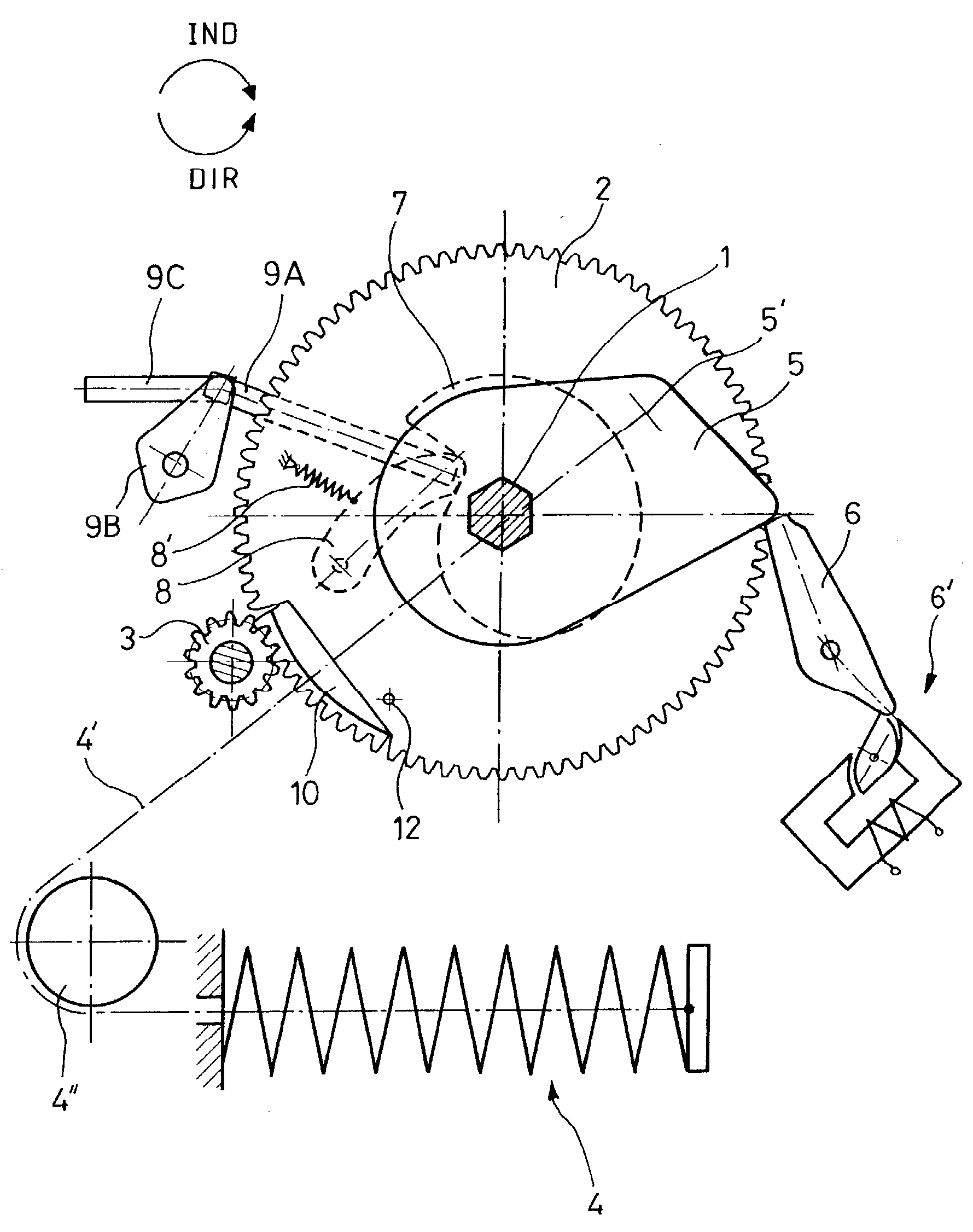

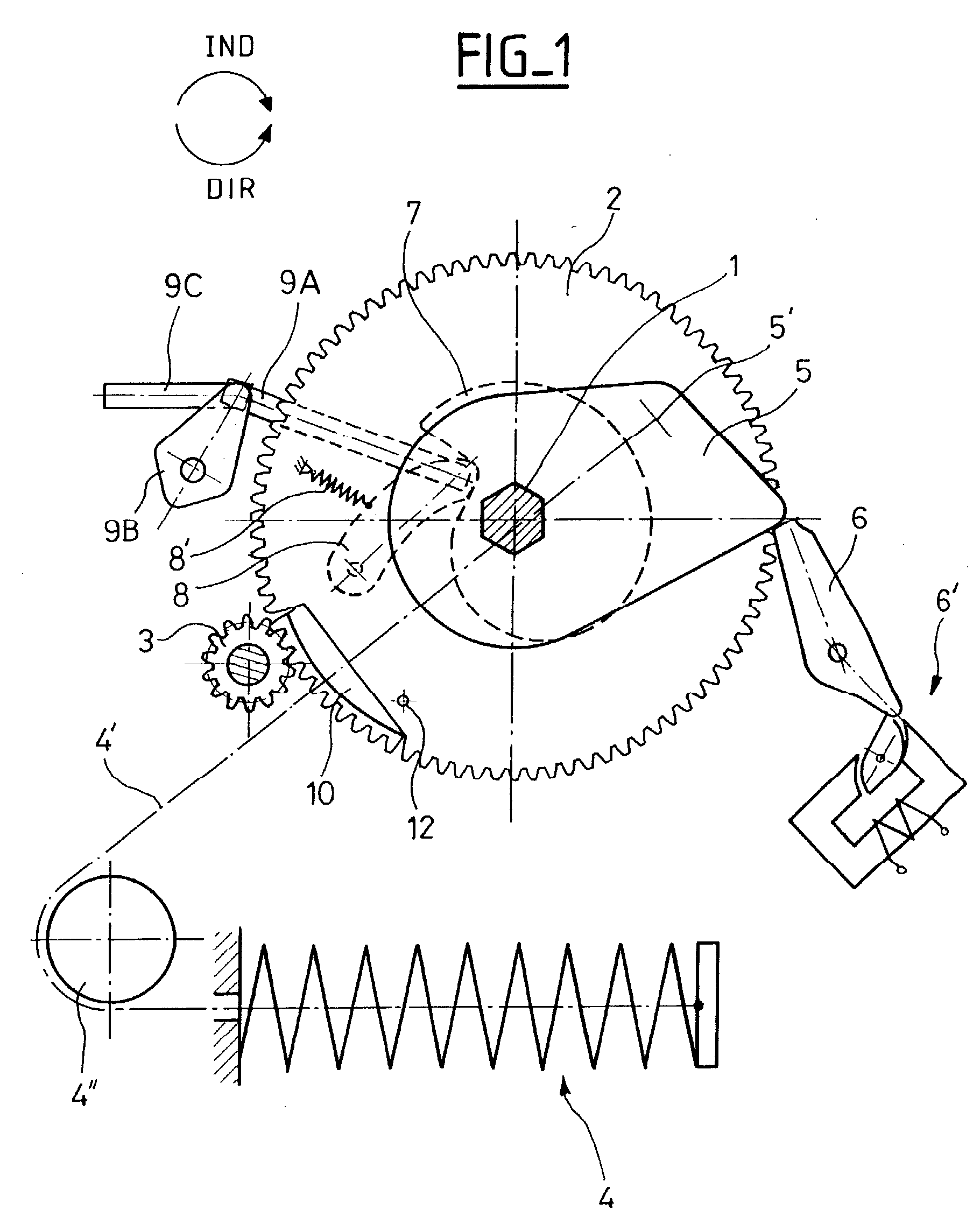

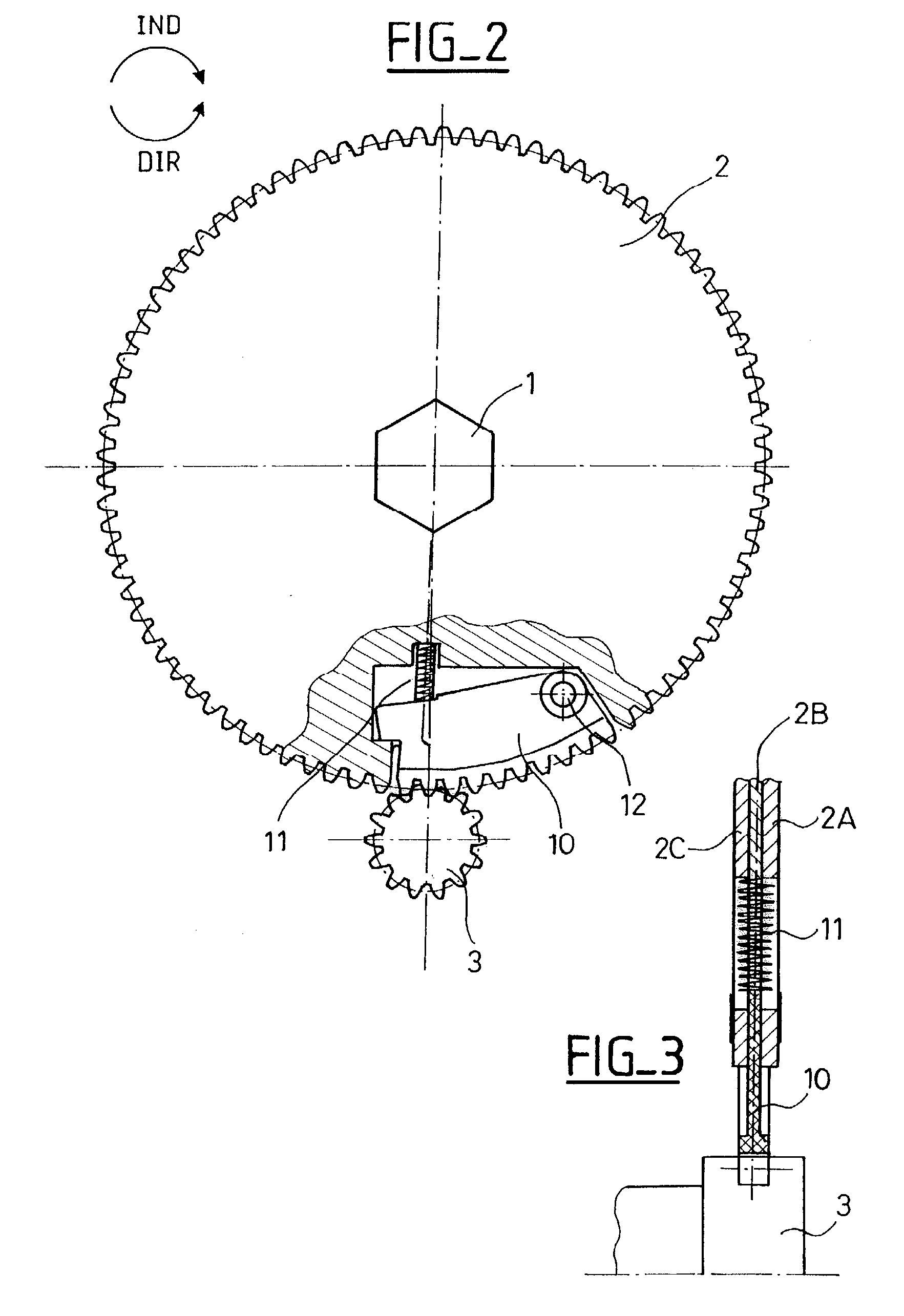

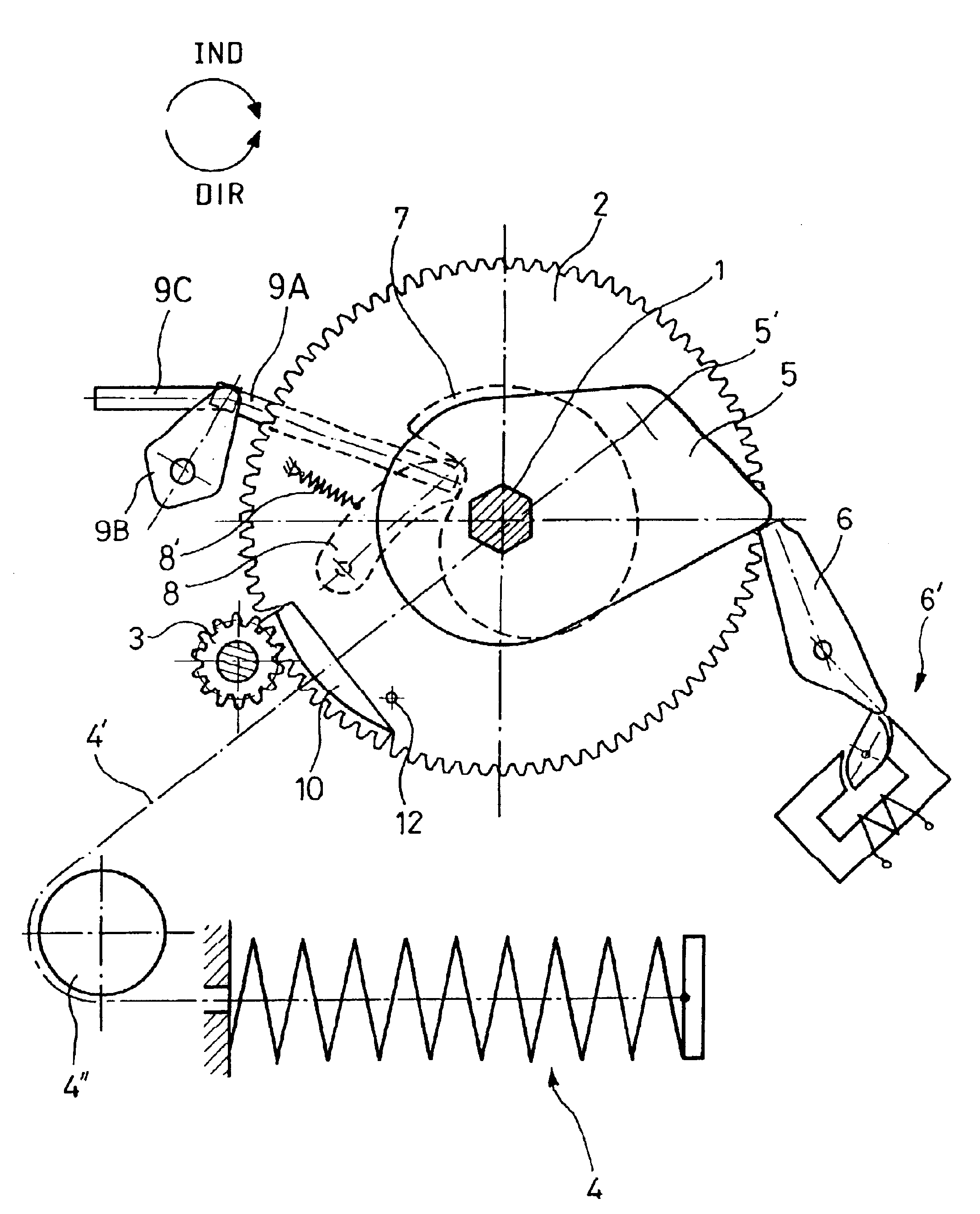

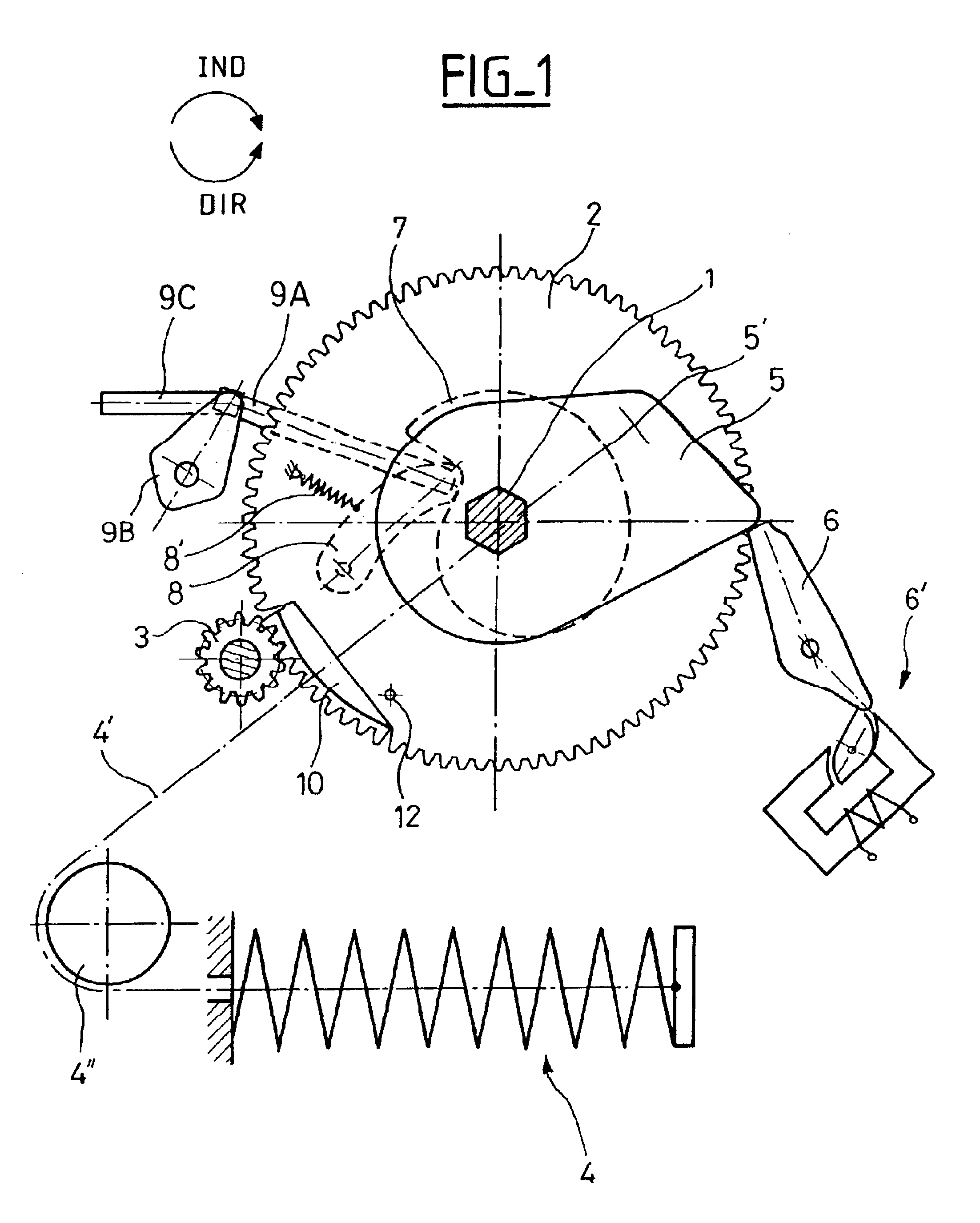

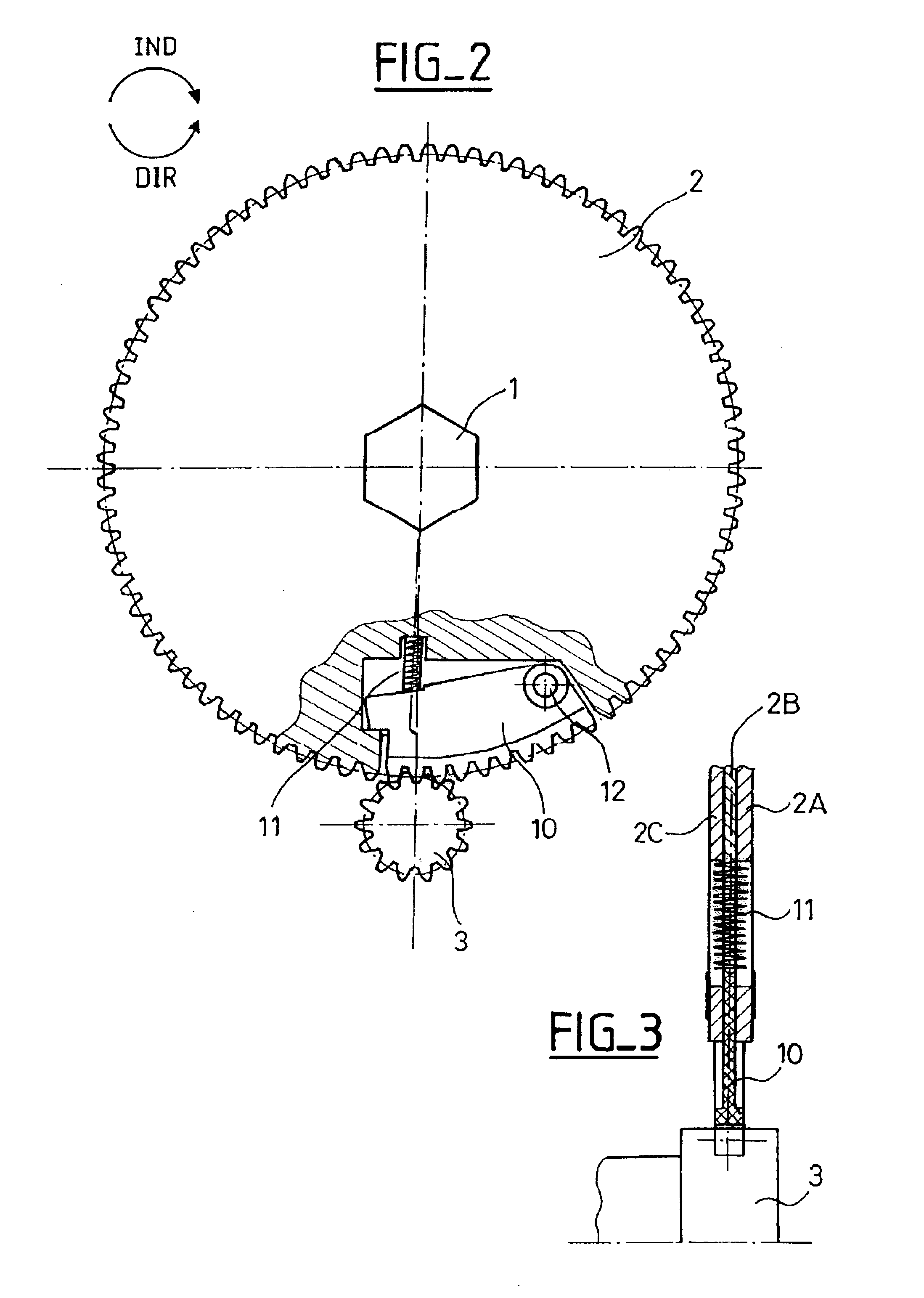

Spring-loaded mechanical control mechanism for a high-voltage or medium-voltage circuit-breaker, the control mechanism comprising a toothed wheel co-operating with a cog wheel

InactiveUS20040003989A1Reduce manufacturing costMore reliableContact driving mechanismsSwitch power arrangementsPrimary ToothPower grid

The spring-loaded mechanical control mechanism for a circuit-breaker in a high-voltage or medium-voltage grid comprises a toothed wheel turned by a spring from a first angular position to a second angular position, and a cog wheel co-operating with the toothed wheel to displace it from the second angular position to the first angular position so as to tension said spring. Said toothed wheel has a peripheral set of teeth including a retractable segment on which at least four teeth are spaced apart from one another at a constant pitch identical to the pitch of the primary teeth.

Owner:ALSTOM TECH LTD

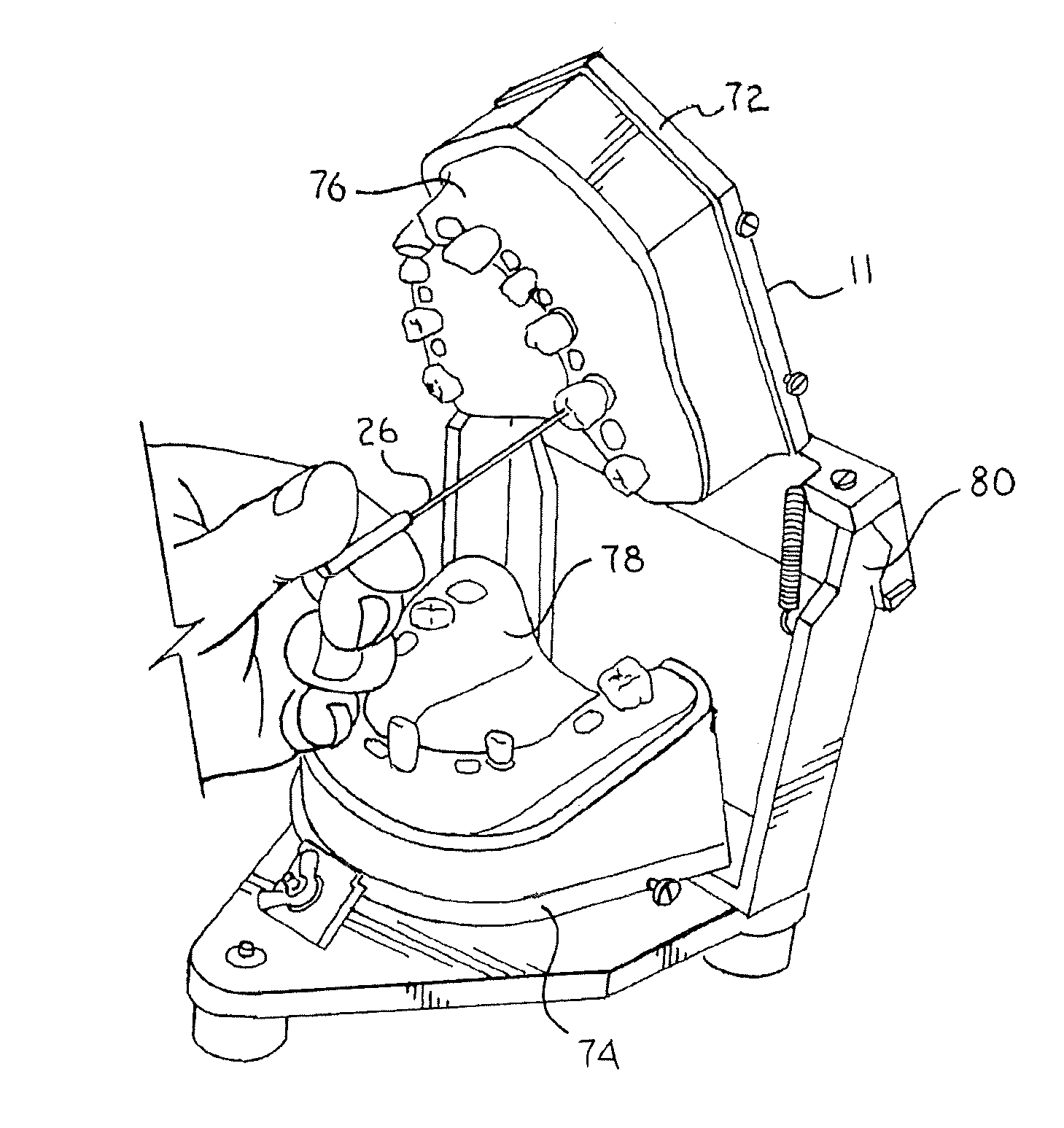

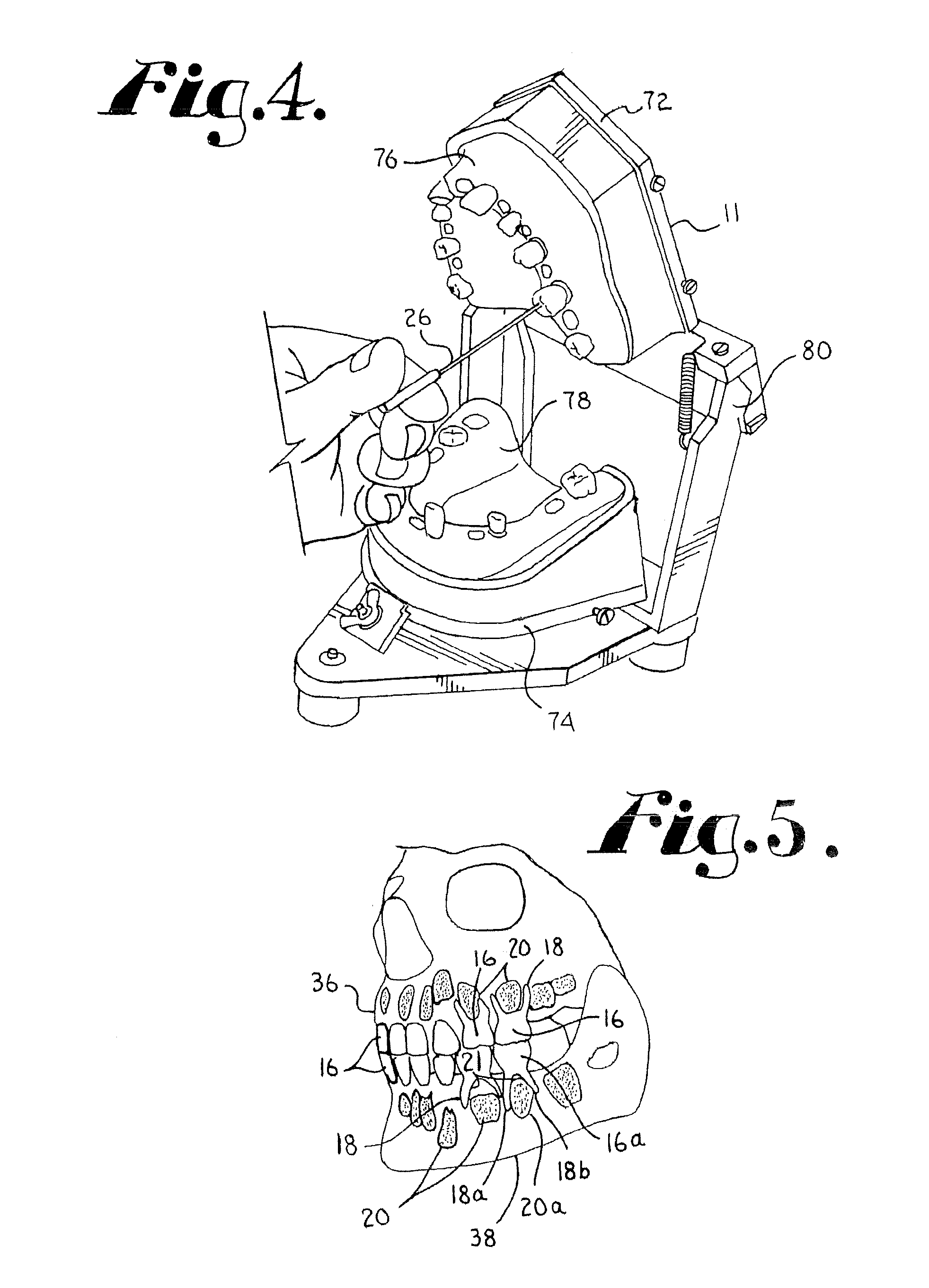

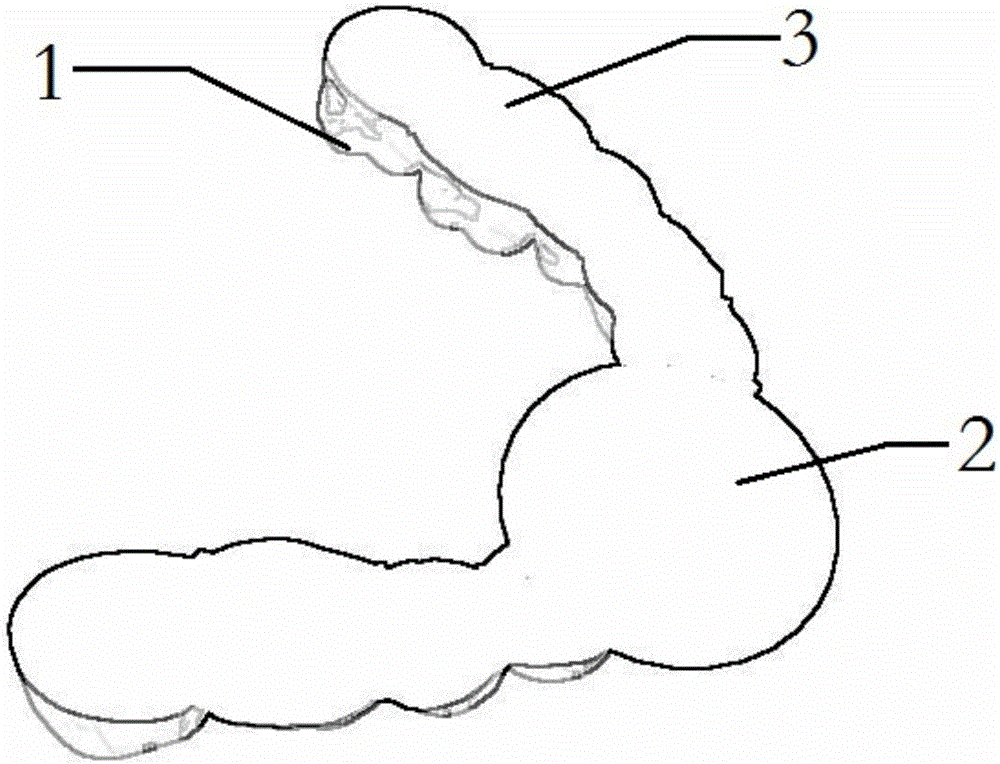

Dental training device

ActiveUS20160365008A1Fixed securityNot to damageEducational modelsTeeth cappingPrimary ToothGingival tissue

A manikin assists a student in learning to perform root canal therapy on a primary tooth of a child without damaging the underlying adult tooth bud. The manikin includes one or more inserts including a model of an upper primary tooth with roots and a lower adult tooth bud. The manikin includes a jaw portion that is receivable into a hinged dental training aid, so as to simulate the mandible or maxilla of the child. The jaw includes bony portions with a plurality of insert-receiving sockets. The bony portions are covered by an elastic simulated gum tissue that engages the primary tooth of an installed insert.

Owner:LEE CHARLES Q

Spring loaded mechanical control mechanism for a circuit breaker comprising a toothed wheel cooperating with a cog wheel

InactiveUS6809279B2More reliableReduce manufacturing costContact driving mechanismsSwitch power arrangementsPrimary ToothGear wheel

The spring-loaded mechanical control mechanism for a circuit-breaker in a high-voltage or medium-voltage grid comprises a toothed wheel turned by a spring from a first angular position to a second angular position, and a cog wheel co-operating with the toothed wheel to displace it from the second angular position to the first angular position so as to tension said spring. The toothed wheel has a peripheral set of teeth including a retractable segment on which at least four teeth are spaced apart from one another at a constant pitch identical to the pitch of the primary teeth.

Owner:ALSTOM TECH LTD

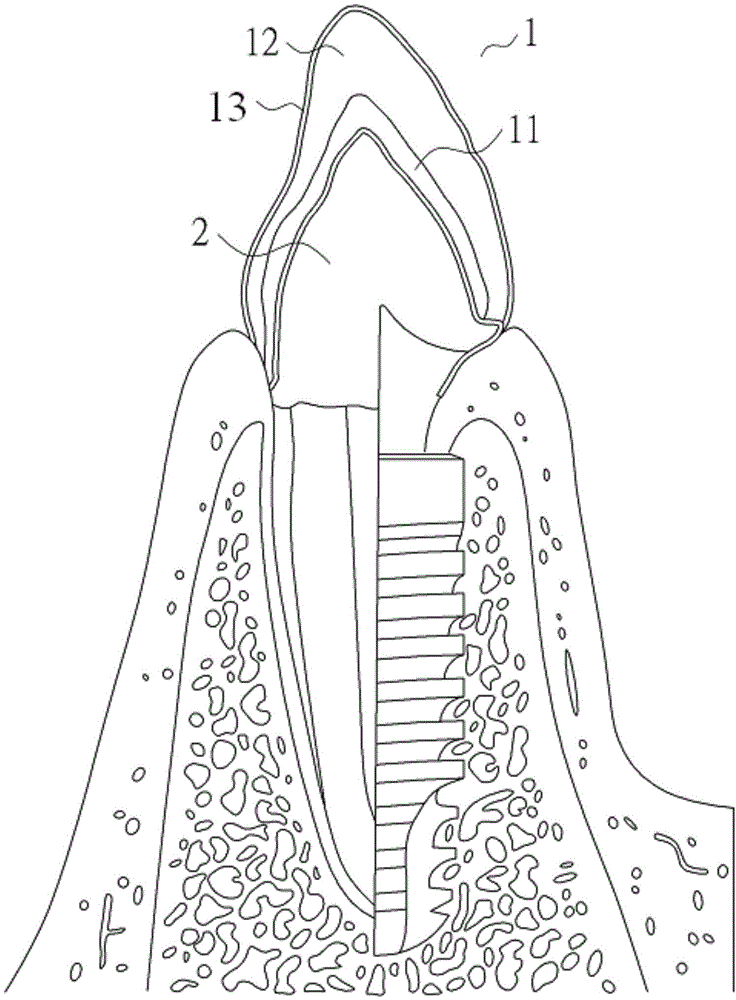

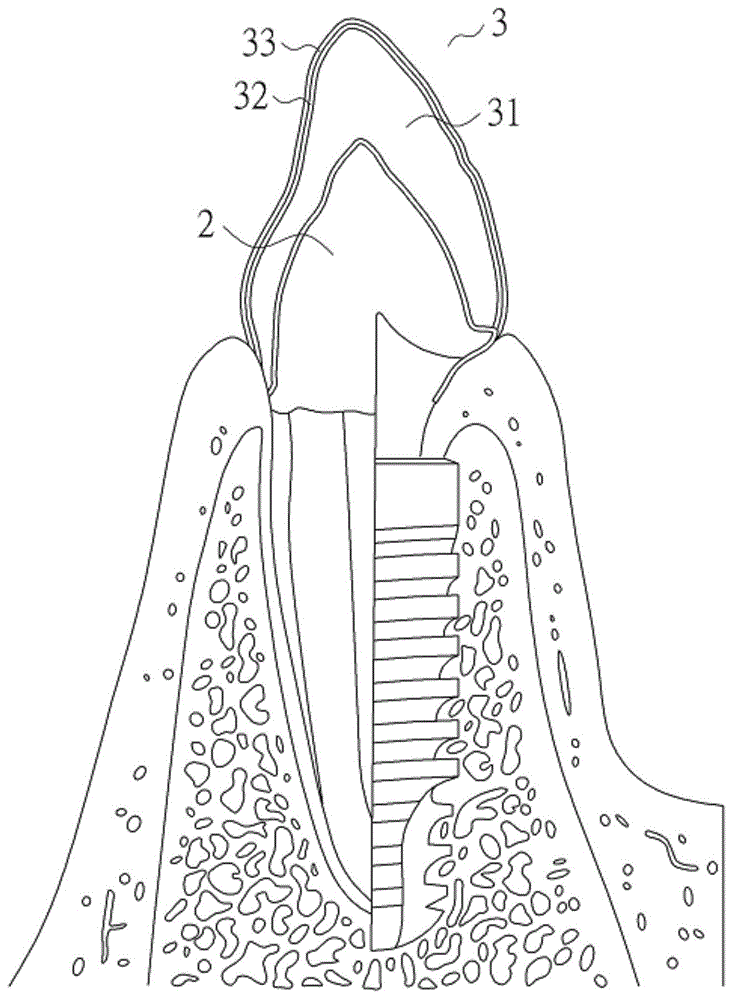

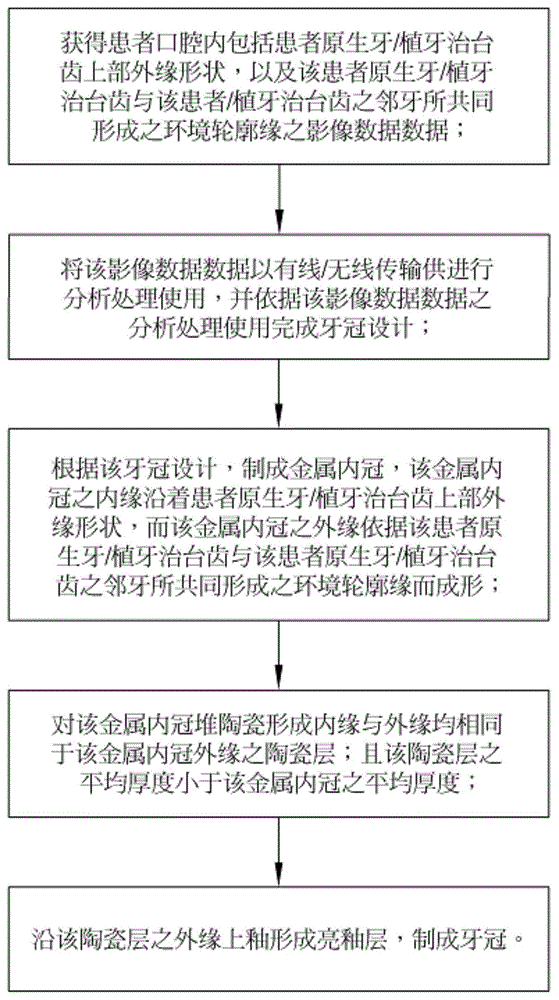

Dental crown and manufacturing method thereof

InactiveCN105266904AFast deliveryRapid productivityTooth crownsTeeth cappingPrimary ToothSelective laser melting

The invention provides a dental crown and a manufacturing method thereof. The manufacturing method mainly comprises the steps: carrying out mold impression in an oral cavity of a patient or scanning in the oral cavity, to obtain patient oral cavity internal image data comprising an upper outer edge shape of a patient primary tooth / tooth implantation abutment, and an environment contour edge together formed by the patient primary tooth / tooth implantation abutment and adjacent teeth of the patient primary tooth / tooth implantation abutment; according to the image data, designing the dental crown, then carrying out selective laser melting (SLM) with a metal powder as a material to form a metal inner crown, and next piling ceramics and glazing; and consistently, fast and accurately manufacturing to complete the dental crown. The dental crown completed by using the method is more careful in protection of the patient primary tooth / tooth implantation abutment, more comfortable in use and durable in use.

Owner:台湾创新生医股份有限公司

Cylindrical linear motor with double-layer air gaps

InactiveCN101771326ALarge thrustIncrease thrust to volume ratioPropulsion systemsPrimary ToothEngineering

The invention provides a cylindrical linear motor with double-layer air gaps, which relates to the field of motors and improves the volume space and the winding availability of the existing motor. Outer primary yokes are cylindrical magnetic conduction iron cores, outer primary teeth are annular magnetic conduction iron cores, and the teeth and outer windings are sequentially arranged on the inner walls of the yokes at intervals along the moving direction of a motor rotor; an inner primary non-magnetic conduction shaft is in a cylindrical shape, a plurality of annular grooves are sequentially formed on the outer surface of an inner primary magnetic conduction iron core at intervals along the moving direction of the motor rotor, inner primary windings are wound in the annular grooves, and the inner magnetic conduction iron core is sleeved on the non-magnetic conduction shaft; a middle secondary magnetic conduction iron core is in a cylindrical shape, and middle secondary outer and inner Halbach permanent magnet arrays are respectively pasted on the outer surface and the inner surface of the middle magnetic conduction iron core; and outer air gaps are formed between the outer primary magnetic conduction iron core and the middle secondary magnetic conduction iron core, and inner air gaps are formed between the inner primary magnetic conduction iron core and the middle secondary magnetic conduction iron core. The cylindrical linear motor is provided with the double-layer air gaps.

Owner:HARBIN INST OF TECH

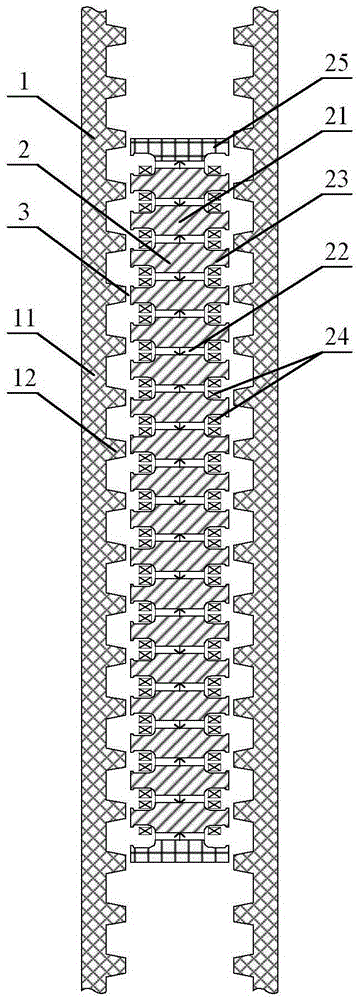

Linear electromagnetic damper with serially-connected magnetic circuit structure

The invention relates to a linear electromagnetic damper with a serially-connected magnetic circuit structure, belongs to the technical field of motors and aims to solve the problems that prior thrust loading testing devices of linear motors can only load thrust on motors in a single direction, and loaded thrust cannot be changed continuously. The linear electromagnetic damper comprises a primary component and a secondary component, and air space is formed between the primary component and the secondary component; the primary component is composed of a primary iron core, an exciting winding and (2n-1) primary permanent magnets. (2n-1) winding grooves are evenly opened on the surface of the air space side of the primary iron core along the relative moving direction of the primary component and the secondary component, so that a primary tooth and winding groove alternating structure is formed on the primary iron core. Grooving directions of the winding grooves are perpendicular to the relative moving direction of the primary component and the secondary component. A coil is wound on each primary tooth, and coils on all the primary teeth are connected in series to form the exciting winding. A primary permanent magnet is embedded in each permanent magnet groove on the yoke portion of the primary iron core.

Owner:HARBIN INST OF TECH

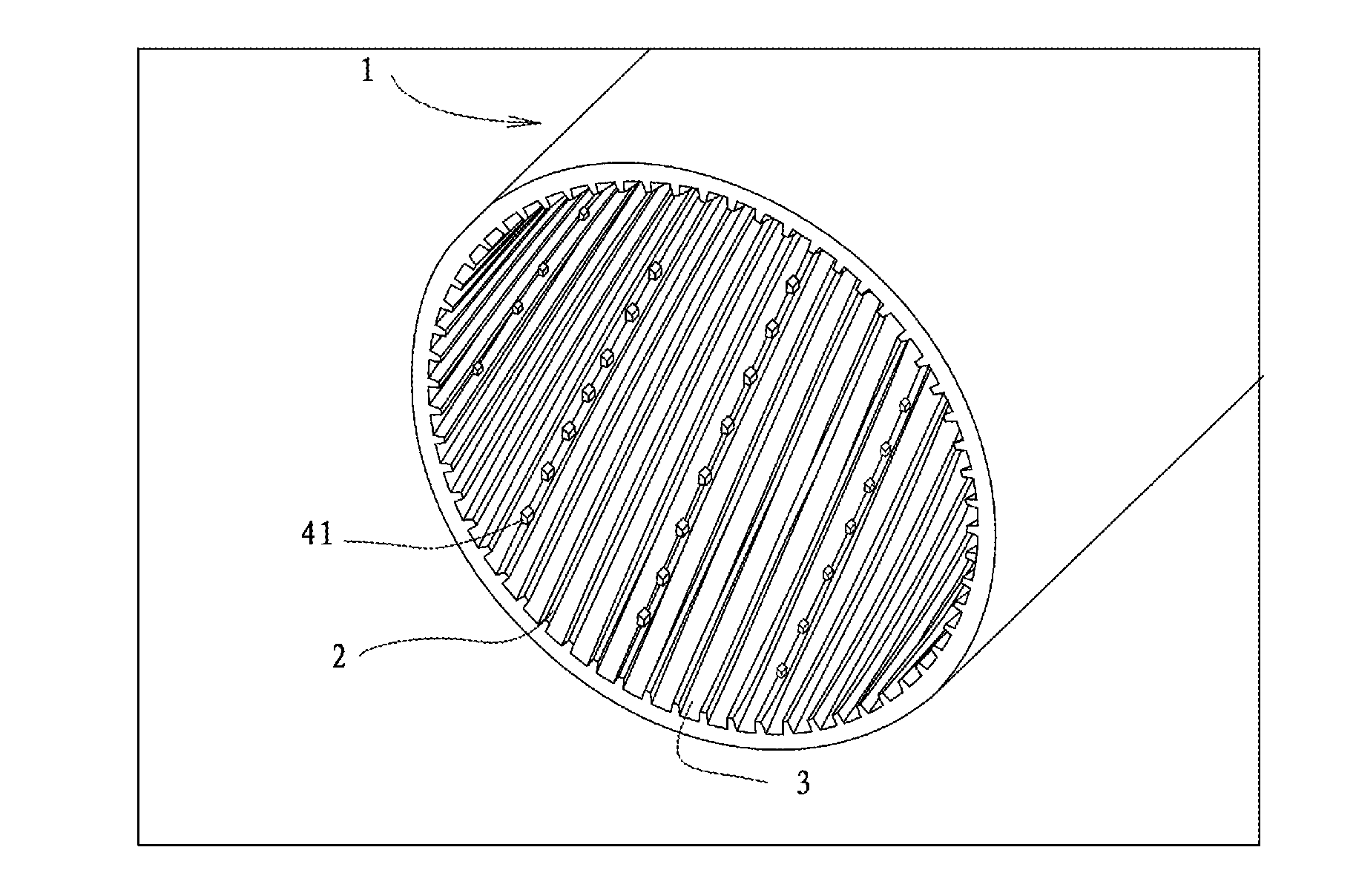

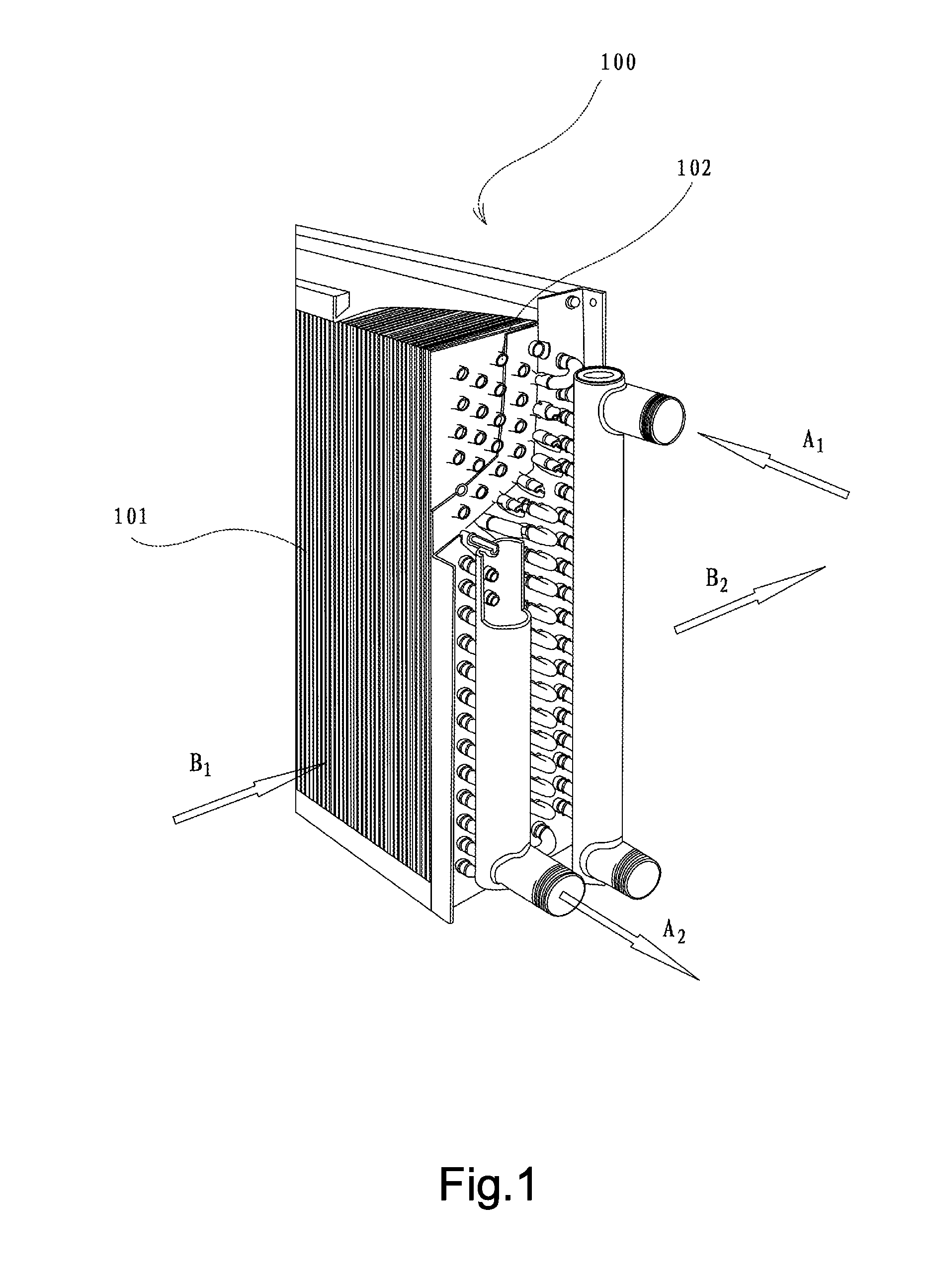

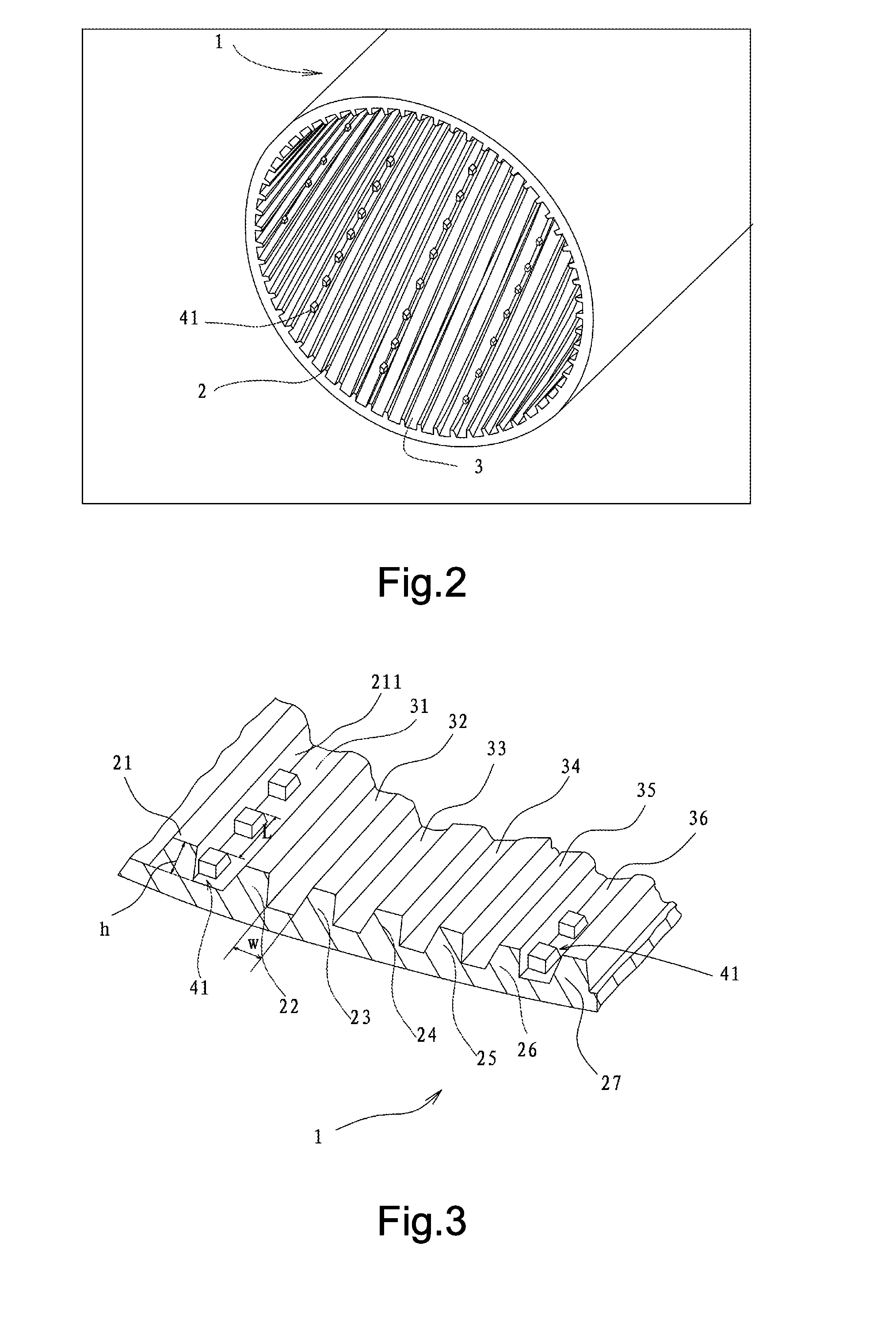

Heat transfer pipe for heat exchanger

InactiveUS20140083668A1Lower transfer resistanceSimple structureFluid dynamicsHeat transfer modificationPrimary ToothEngineering

The invention provides a heat transfer pipe for heat exchanger, an inner surface of the heat transfer pipe being provided alternately with a plurality of helical primary teeth (21, 22, 23, 24, 25, 26, 27) and a plurality of grooves (31, 32, 33, 34, 35, 36), each groove being disposed between adjacent primary teeth, wherein a protrusion set is provided in at least one groove (31, 36), the protrusion set comprises a plurality of protrusions (41) sequentially and intermittently disposed in an extending direction of the primary teeth, and each protrusion (41) has a radial height lower than those of the primary teeth, and wherein at least one groove having no protrusion set (32, 33, 34, 35) is provided between the adjacent ones (31, 36) of the grooves each having a protrusion set. In this way, the above heat transfer pipe suppresses significantly increasing flow resistance of a fluid, and is easy to manufacture with low manufacturing cost, at the same time of improving the efficiency of heat exchange.

Owner:LUVATA ALLTOP ZHONGSHAN LTD

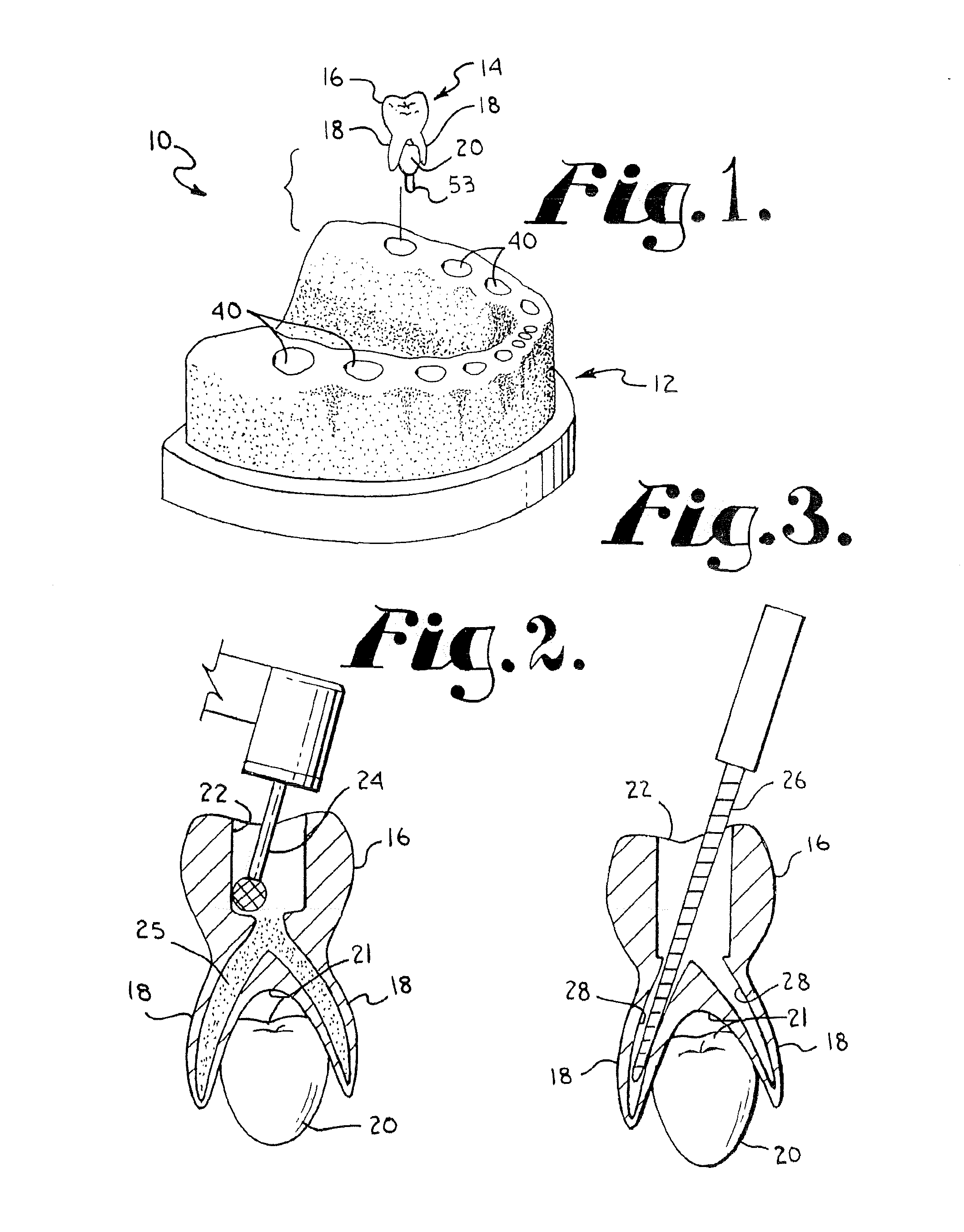

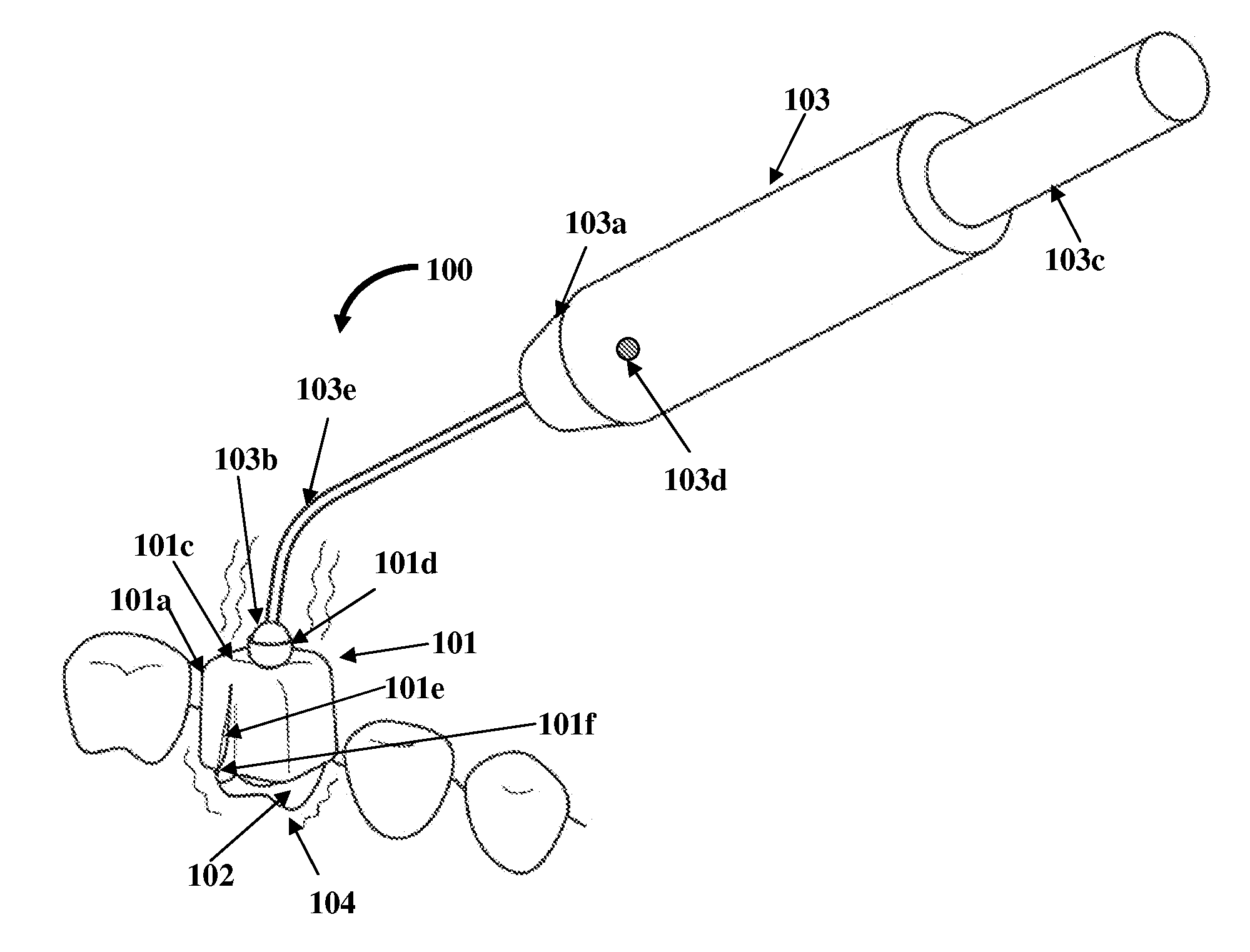

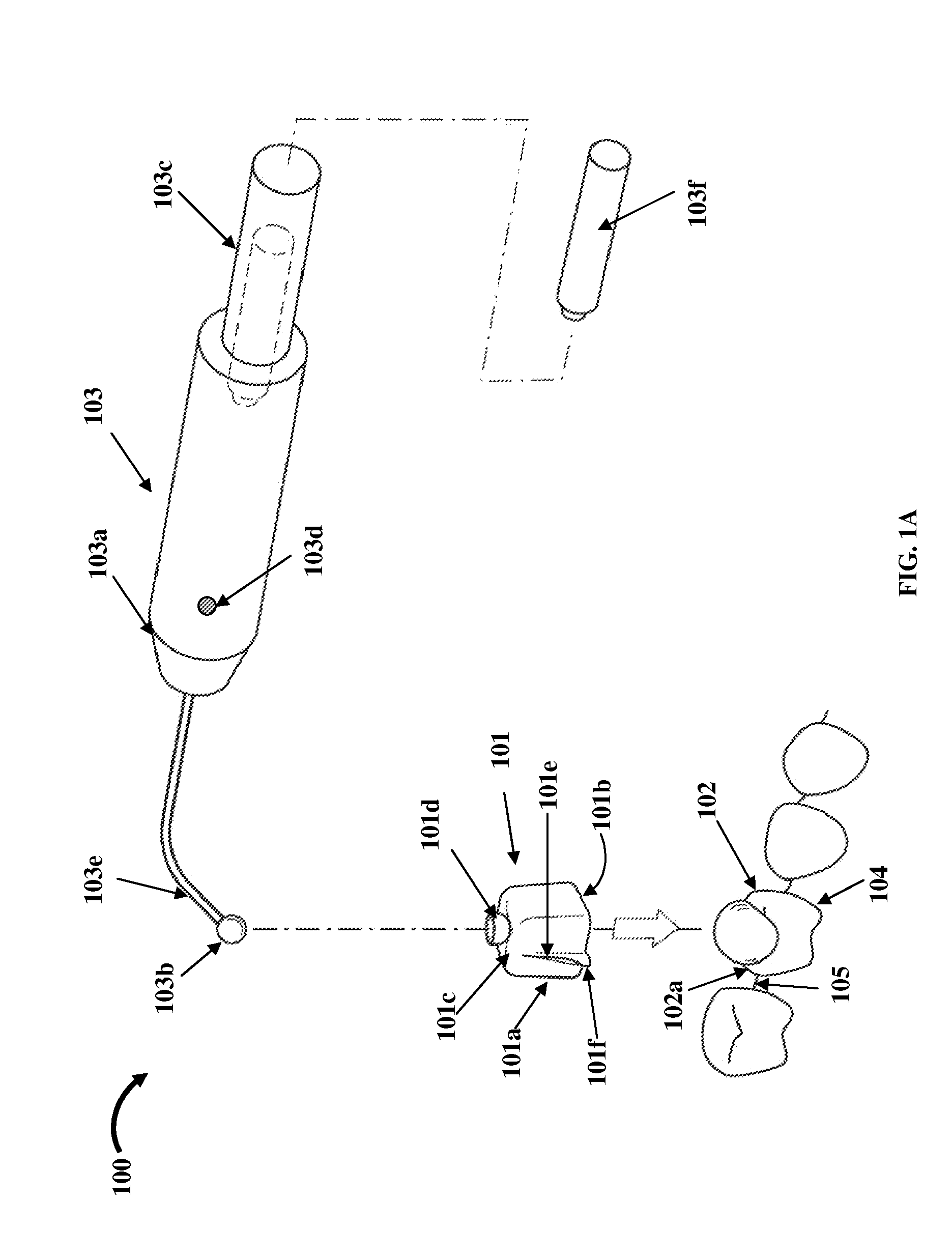

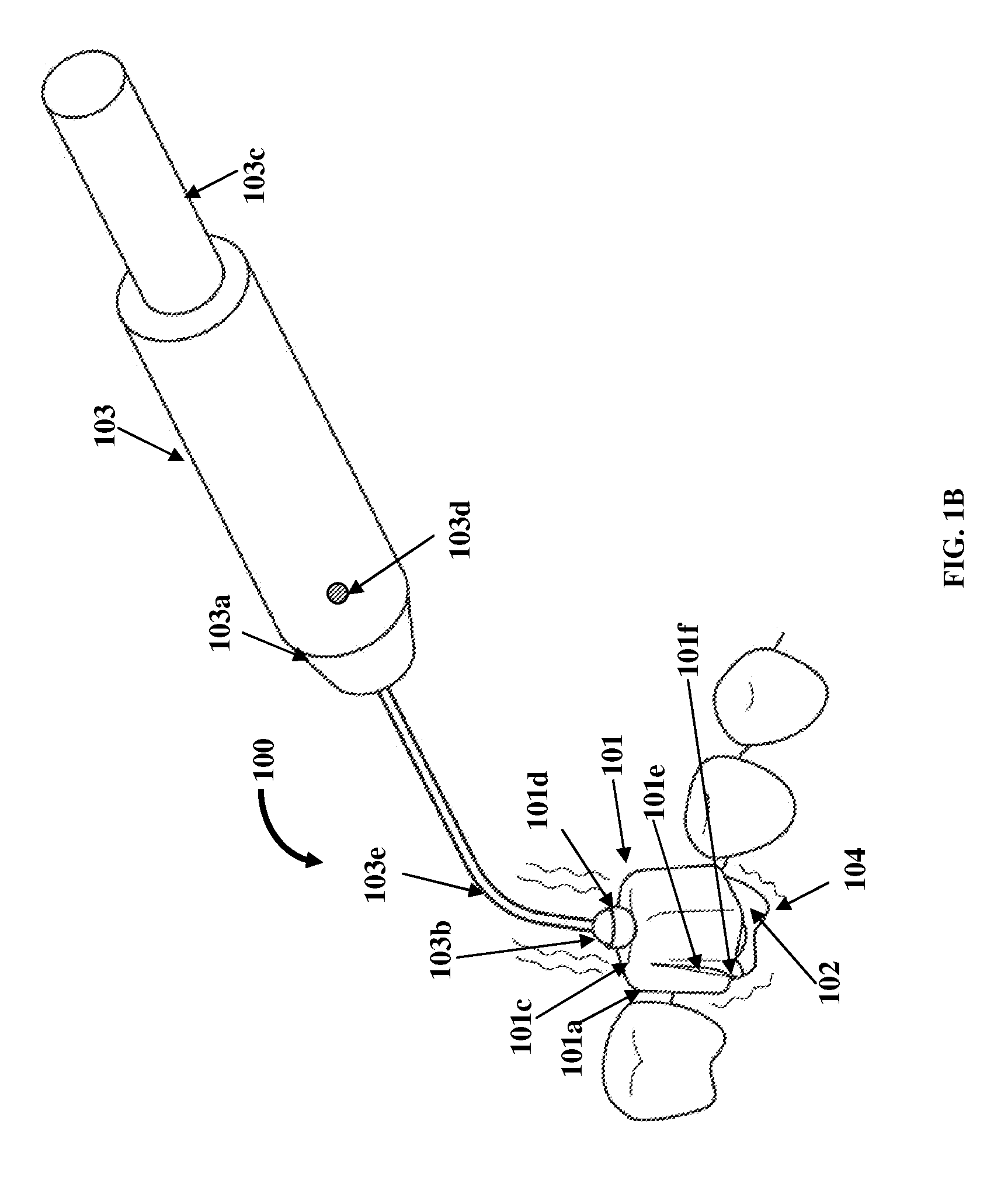

Removing Primary Teeth And Loosening Permanent Teeth

InactiveUS20130040262A1Minimal pain and discomfortEasy to disassembleDentist forcepsTooth pluggers/hammersPrimary ToothTransducer

A method and apparatus for rupturing connective tissues that attach a tooth to a patient's alveolar bone socket are provided. The apparatus includes a metal cap removably attached to the tooth using a cementing agent, and a transducer assembly having a transducer head and a ball projection. The metal cap includes a body section having a hollow space defined by its coronal surface and contiguous vertical surfaces for enclosing the tooth. The body section has a slit terminating with an apical strip and loop arrangement. The metal cap further includes a ball socket extending from the coronal surface of the body section. The transducer head generates vibrational and tapping movements in the ball projection. The ball projection operatively engages the ball socket to transfer the vibrational and tapping movements to the metal cap and thereby to the tooth, which ruptures the connective tissues of the tooth.

Owner:HANKOOKIN

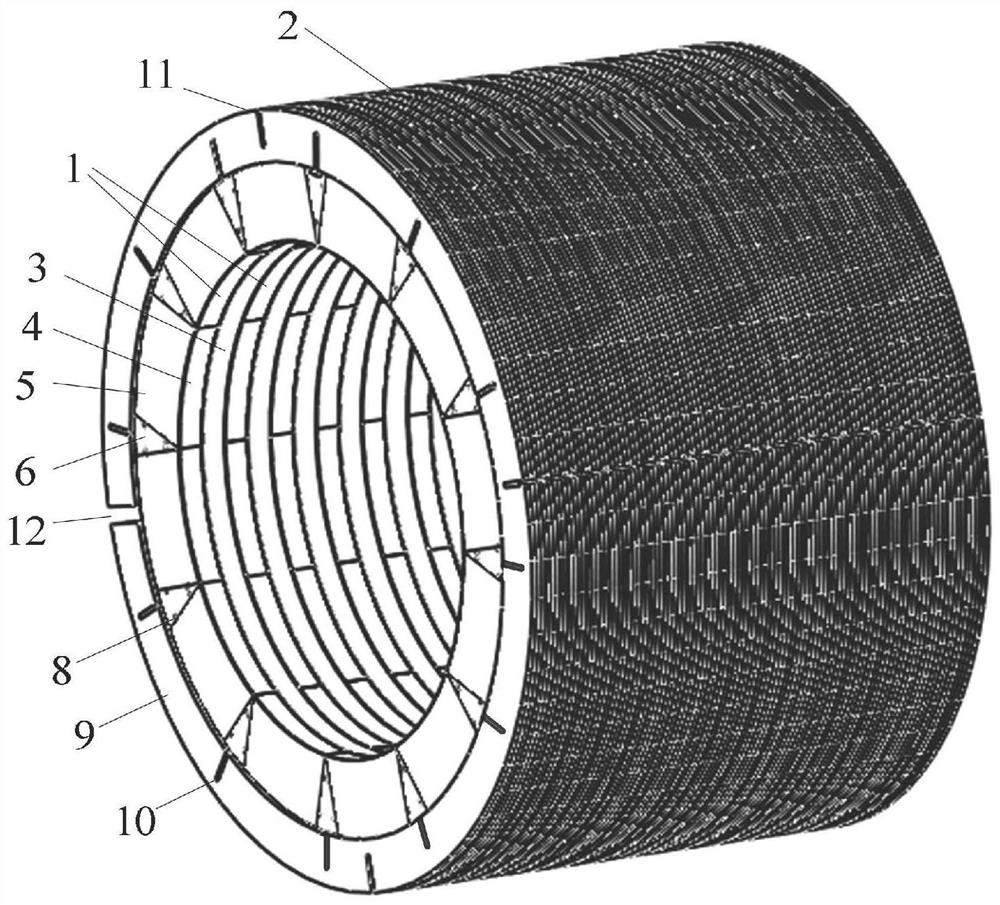

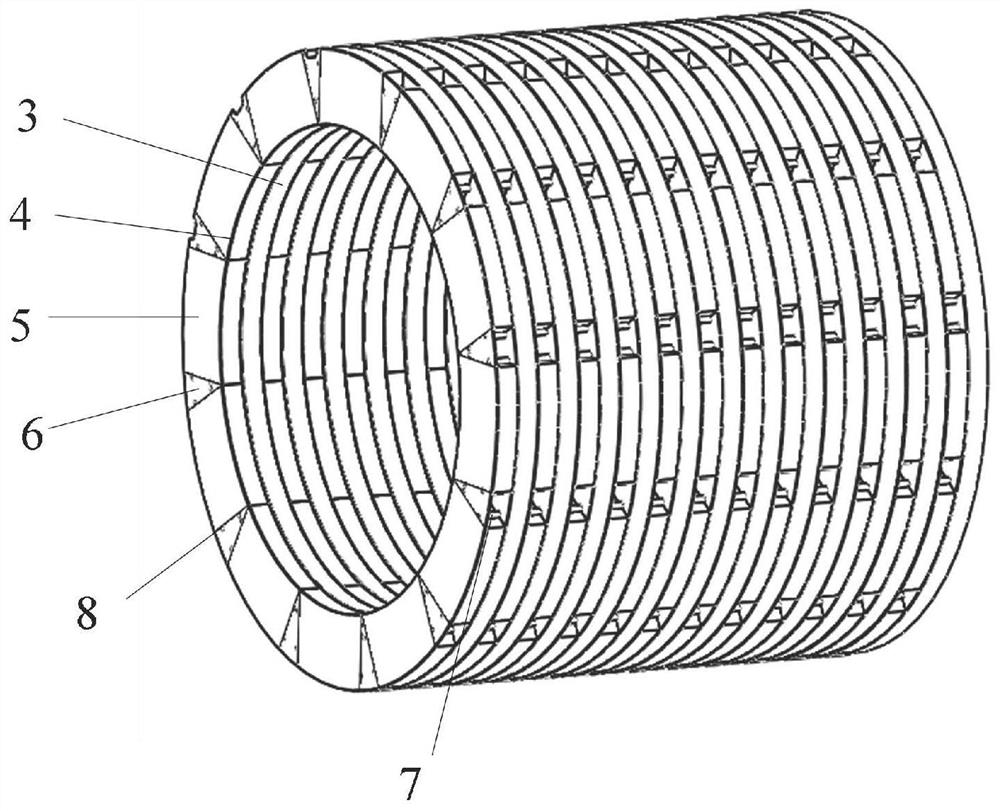

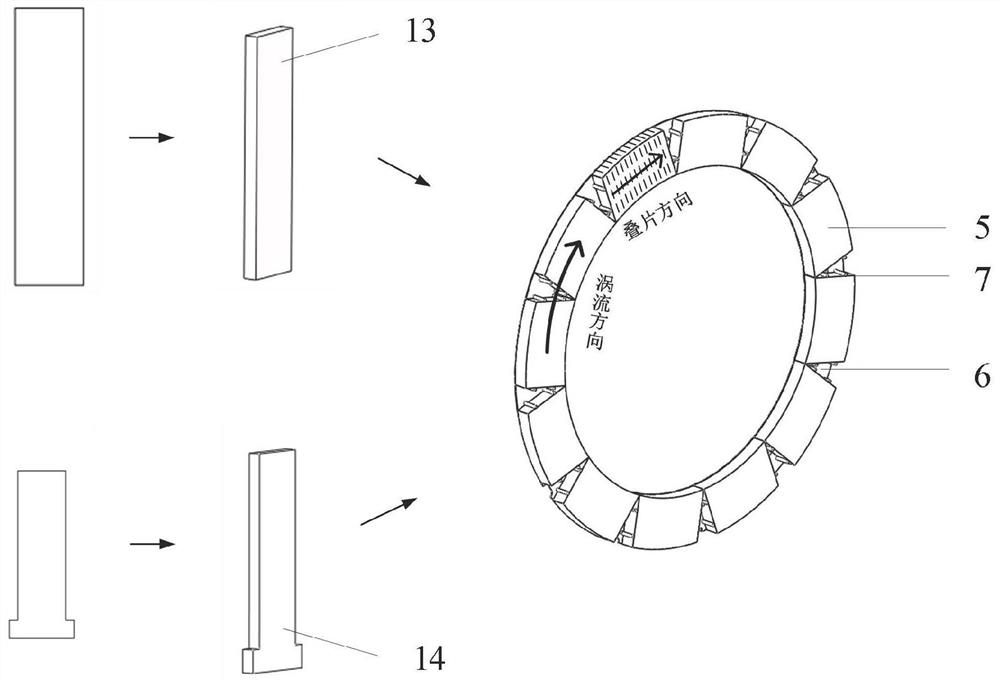

Low-eddy-current-loss primary structure of tooth groove type cylindrical linear motor

The invention discloses a low-eddy-current-loss primary structure of a tooth groove type cylindrical linear motor. The low-eddy-current-loss primary structure comprises primary teeth, a primary yoke and a plurality of ring windings; the primary teeth and the primary yoke are separated components and are tightly sleeved together to form a primary iron core; one or more circular ring windings are embedded between every two primary tooth components; each annular primary tooth component is formed by arranging a plurality of tooth iron core blocks of the same specification in an array mode along the side length of an equilateral polygon, and each iron core block is formed by laminating silicon steel sheets in the circumferential direction; and the primary yoke component is formed by laminating silicon steel sheets along the motion direction of the motor, and each lamination is uniformly provided with a plurality of yoke shallow slots along the circumferential direction so as to block an eddy current path along the direction. According to the low-eddy-current-loss primary structure of the tooth groove type cylindrical linear motor of the invention, the primary iron core is combined by adopting a mode of tooth and yoke separation and lamination in different directions, so that the eddy current loss of the tooth groove type cylindrical linear motor can be effectively reduced, the efficiency of the motor is improved, and meanwhile, the motor can maintain relatively high thrust density.

Owner:HEFEI UNIV OF TECH

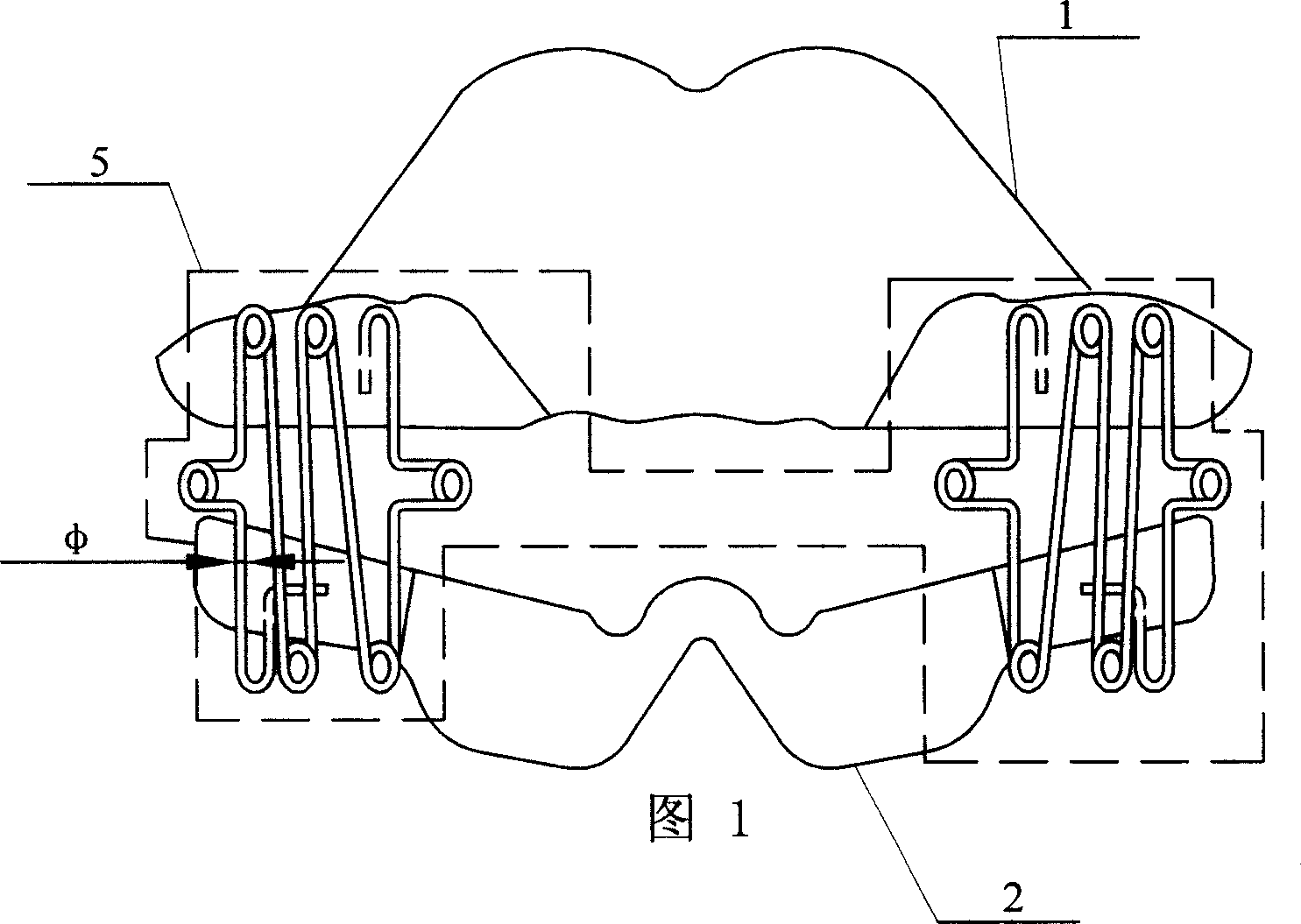

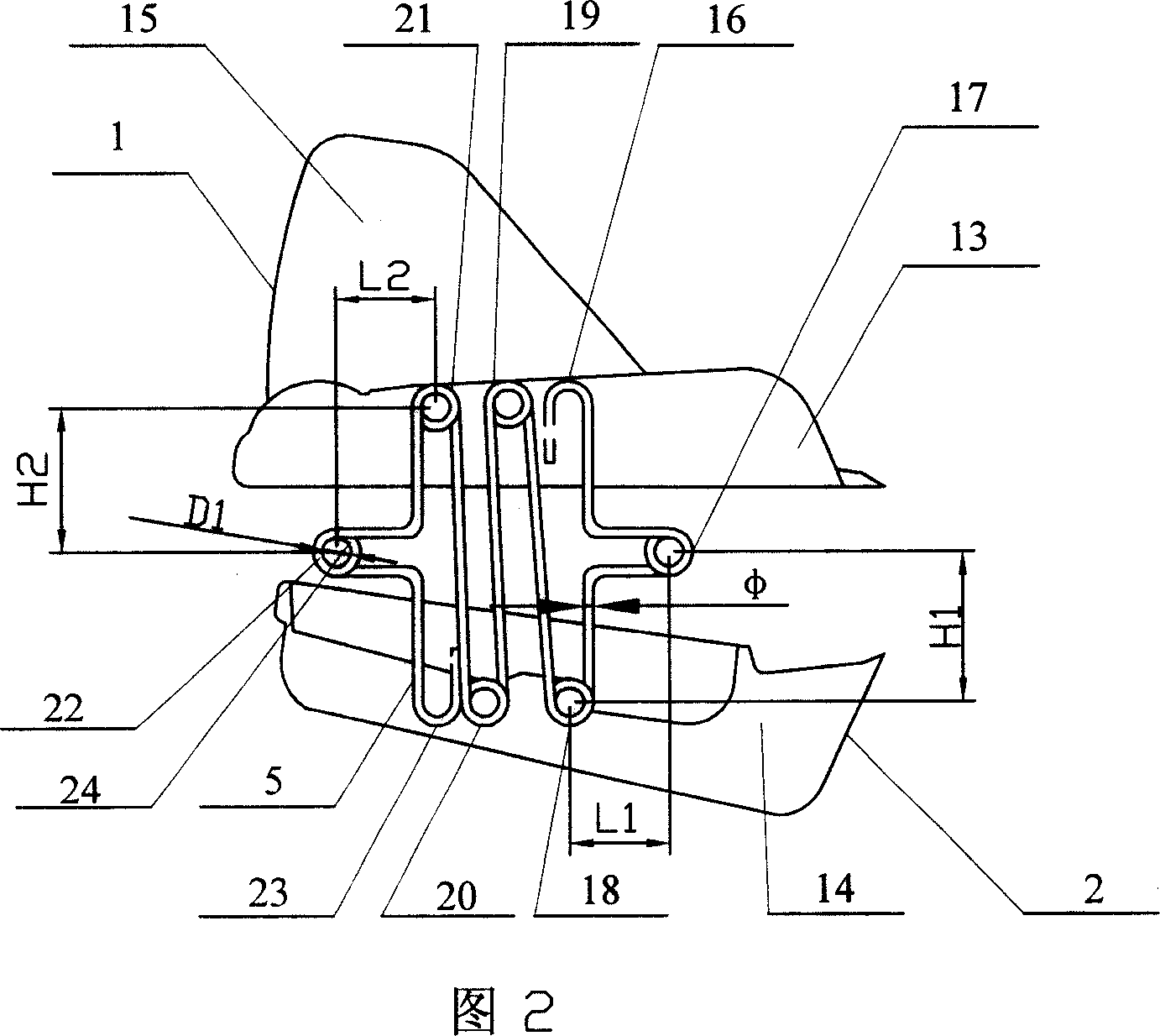

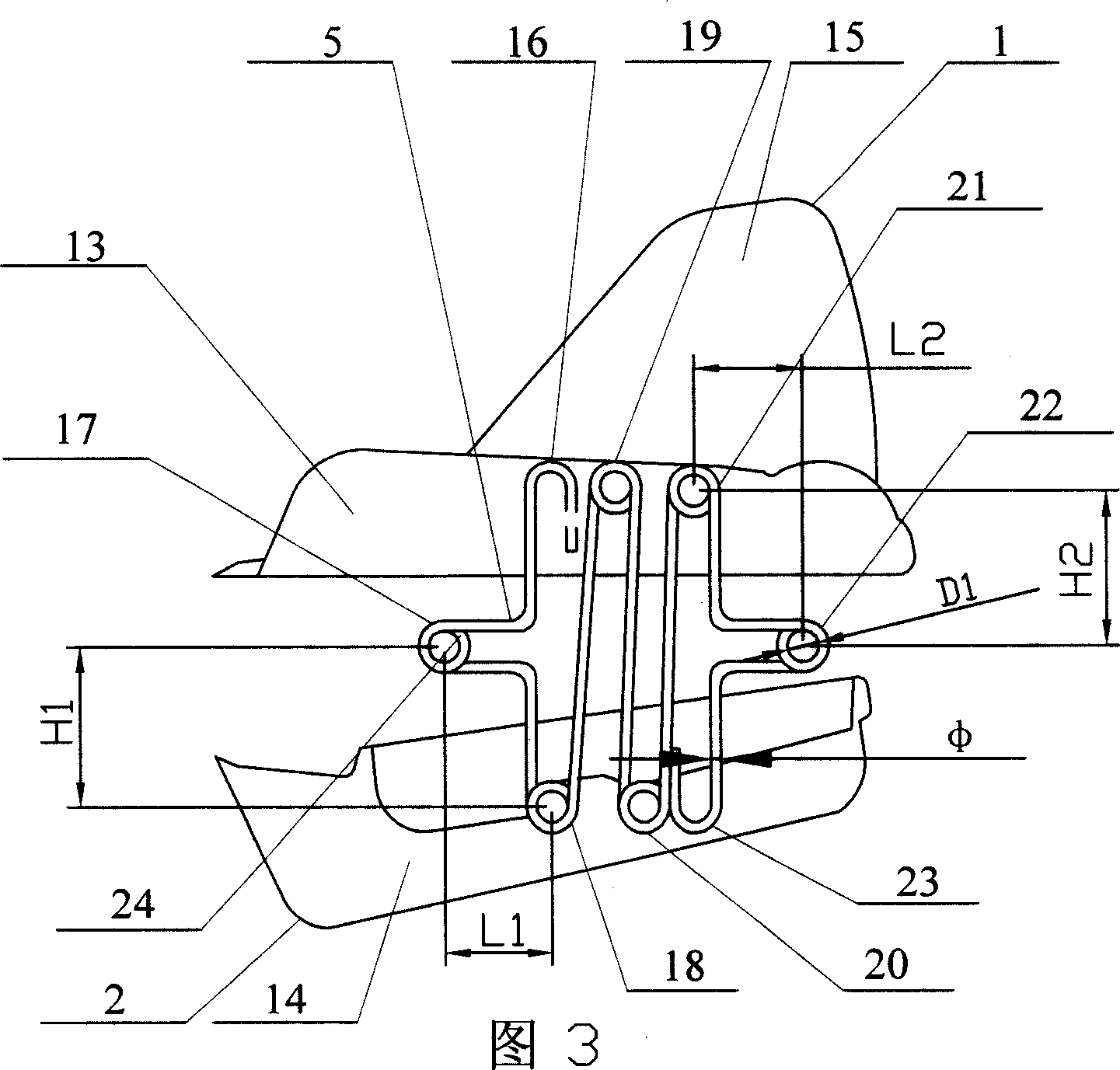

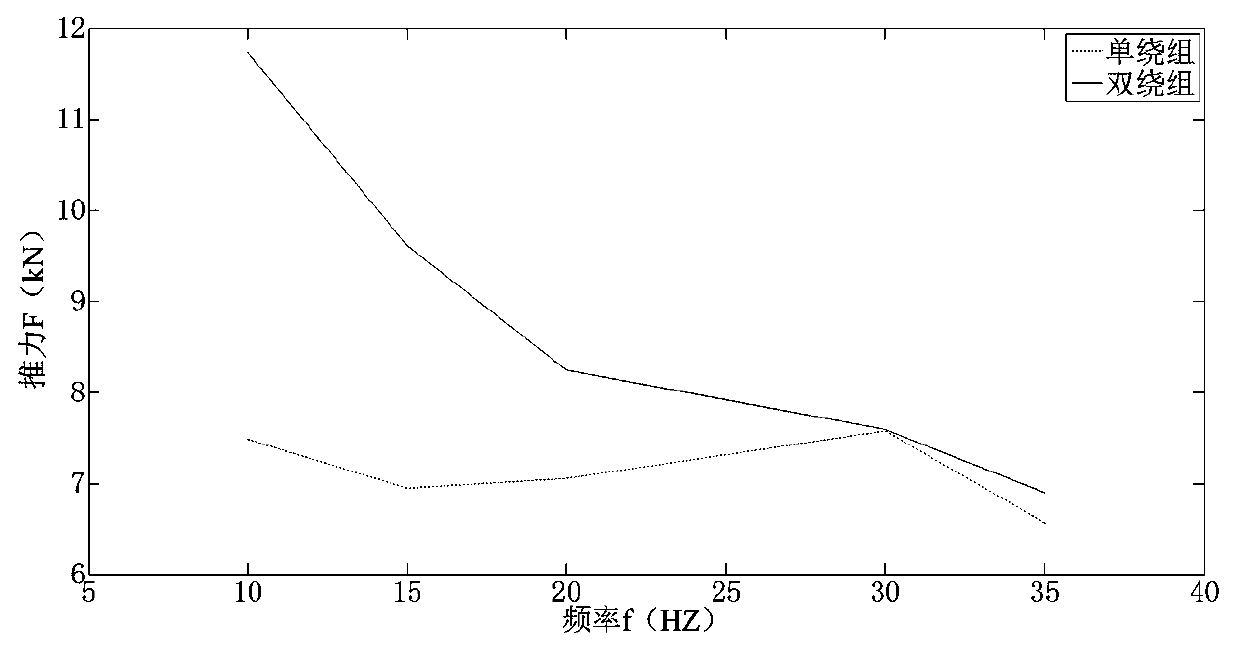

Buccal side multiple curve spring correction device and buccal side multiple curve spring mould

An appliance is presented. In said inventive appliance, the free end of the upward bend upper jaw of the side cheek with much crooked spring is buried within the upper jaw support, the free end of downward bend lower jaw is buried within the lower jaw support; in another appliance, the free end of the upward bend upper jaw of the side cheek with much crooked spring is buried within splitting upper jaw support, the free end of downward bend lower jaw is buried within the lower jaw support; 12 guide pins are installed within the placenta of side cheek with much crooked spring positioner.

Owner:侯录

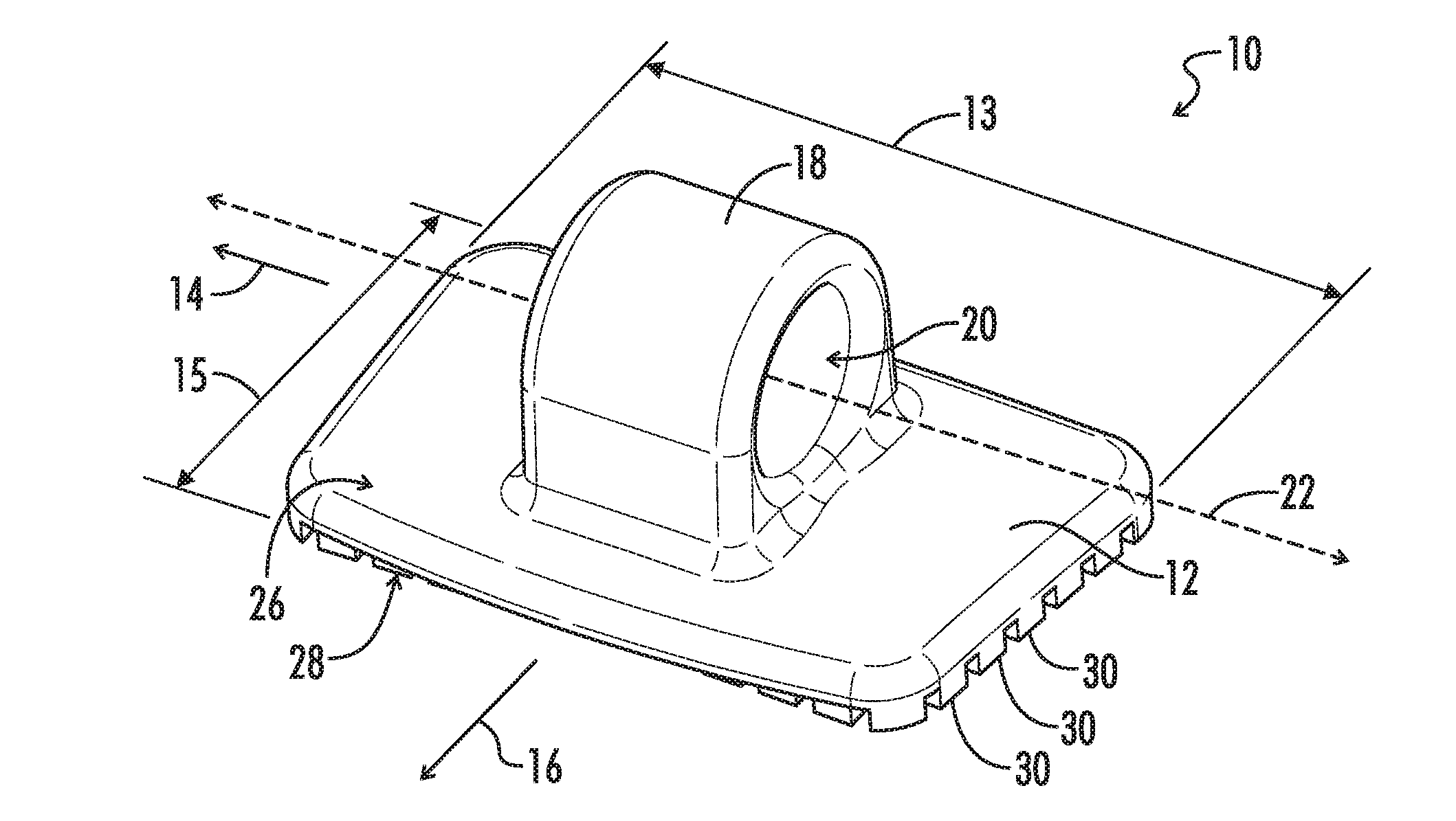

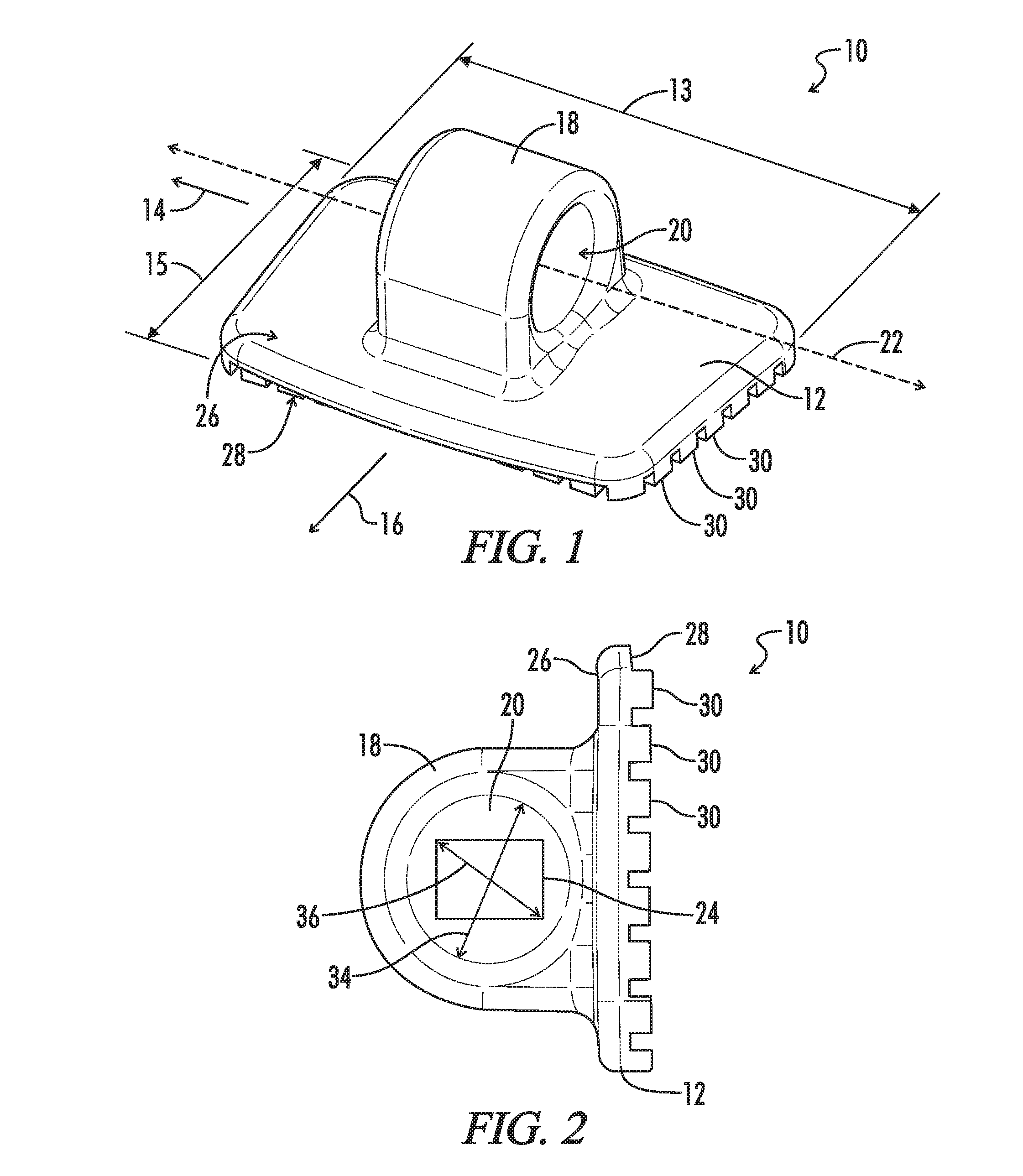

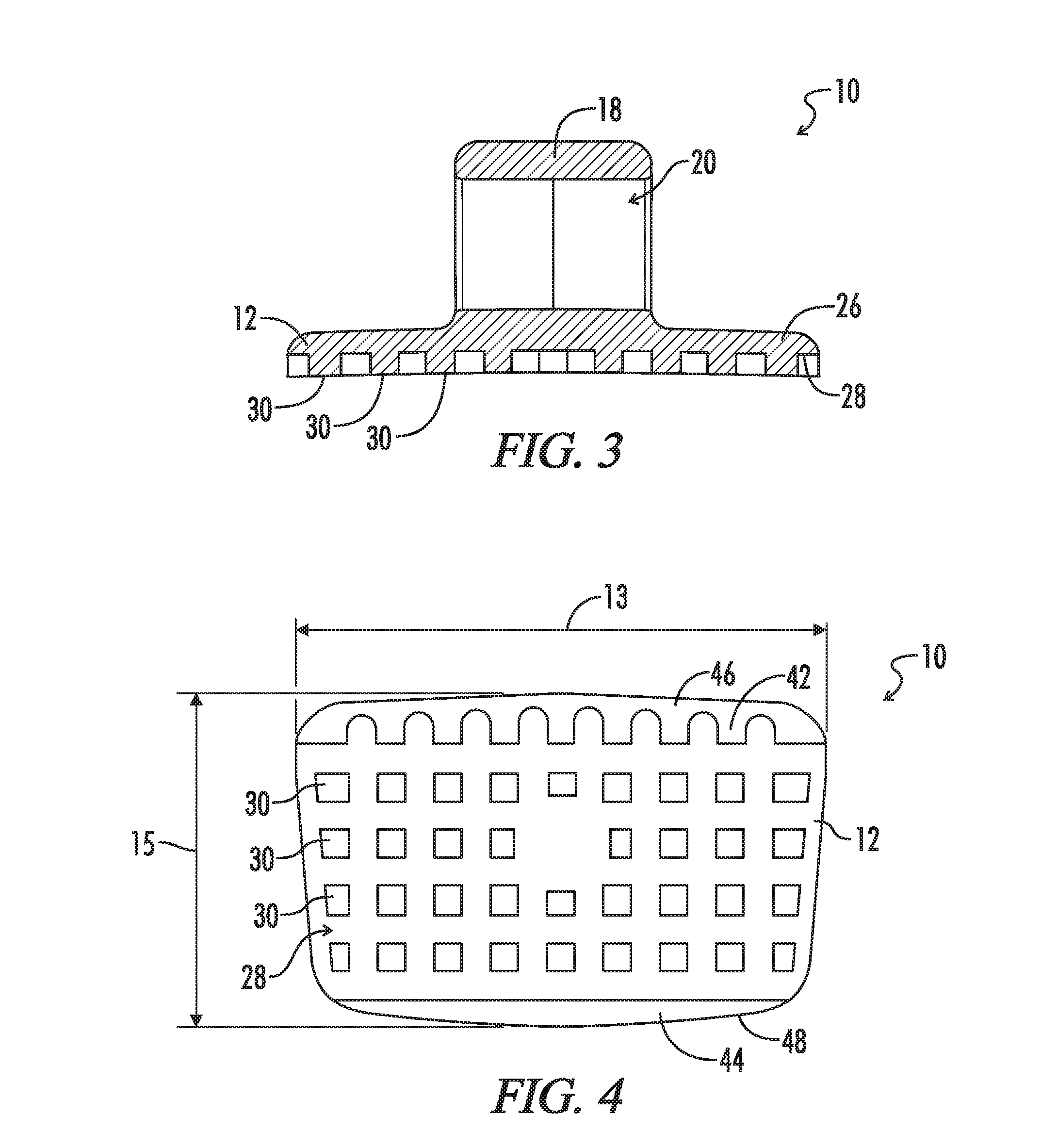

Orthodontic bracket for primary teeth

ActiveUS20160287356A1Torque force is reducedEasily and more comfortably removedArch wiresBracketsPrimary ToothArch wires

Owner:BERNSTEIN RAEL

Dental implant

A dental implant is provided to solve the problems where it is difficult to shorten the period of time of treatment for the conventional dental implant and it will inevitably damage the alveolus in acertain degree. The dental implant of the invention includes an implant having a head and a tail, and an abutment integrally formed with the head of the implant. A primary tooth portion is located between the head and the tail.

Owner:METAL INDS RES & DEV CENT

Dual-long-secondary and primary permanent magnetic field modulation linear motor for oil pumping unit

ActiveCN105429423ASimple structureImprove reliabilityPropulsion systemsPrimary ToothPrimary permanent

The invention discloses a dual-long-secondary and primary permanent magnetic field modulation linear motor for an oil pumping unit. The motor comprises two long secondary stators arranged symmetrically and oppositely, a short primary rotor arranged between the two long secondary stators, and air gaps formed between the short primary rotor and the long secondary stators, wherein the short primary rotor comprises primary iron cores arranged at equal intervals in a motion direction, and primary permanent magnets embedded between the adjacent primary iron cores; the primary iron cores are wider than the primary permanent magnets, so that primary teeth are formed on two sides of each primary iron core in the width direction; and armature windings are nested on the primary teeth. According to the motor, the armature windings and the permanent magnets are all arranged in the short primary rotor; the long secondary stators only adopt salient pole flat plate structures composed of magnetic materials; a primary magnetic field is modulated by air gap permeance changes caused by secondary salient poles to realize electromechanical energy conversion; and the motor has the characteristics of simple structure, high reliability, low cost and high thrust density.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

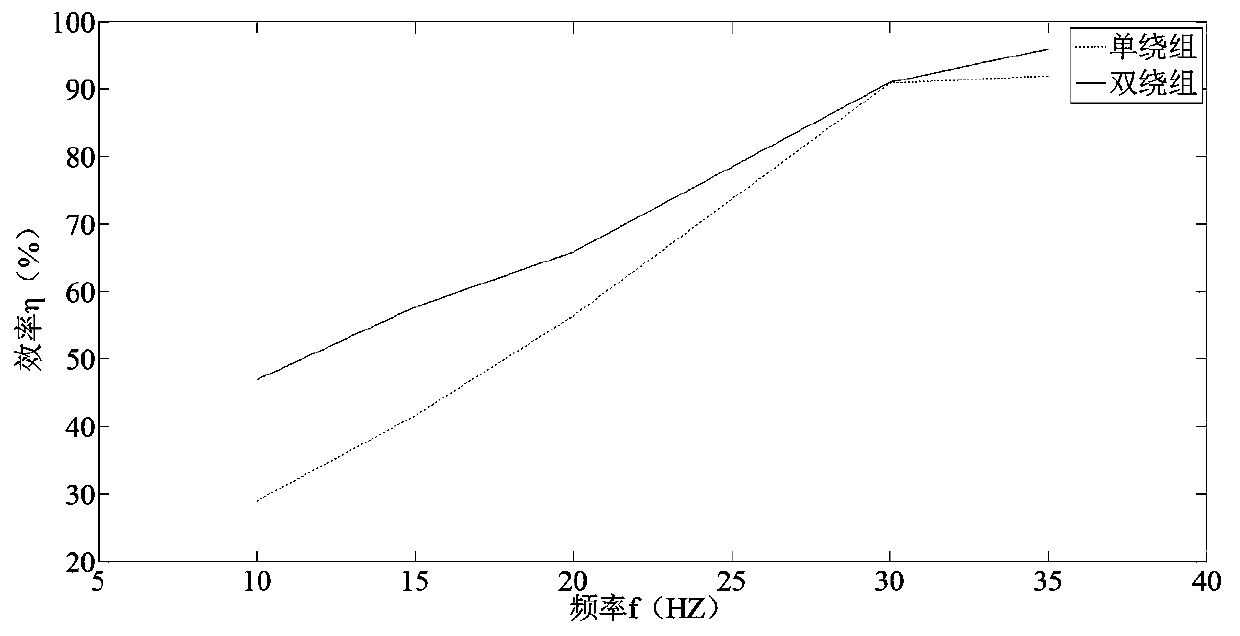

Low-speed high-thrust-density double-layer fractional slot winding cylindrical linear motor

InactiveCN108683319AReduce cogging forceSuppression of thrust fluctuationsPropulsion systemsWindings conductor shape/form/constructionPrimary ToothLow speed

The invention provides a low-speed high-thrust-density double-layer fractional slot winding cylindrical linear motor which belongs to the technical field of a linear motor. The low-speed high-thrust-density double-layer fractional slot winding cylindrical linear motor comprises a motor primary stage, a motor secondary stage, a primary iron core, an air gap, a primary wire duct, a primary half wireduct, primary teeth, primary edge teeth, a primary yoke, a cake-shaped winding, a permanent magnet, a magnet guiding ring, etc. A double-layer factional slot winding structure is utilized. A motor polar distance is reduced, and working frequency is effectively increased, thereby improving motor efficiency, and realizing a certain speed adjusting range of the motor. The width of an edge trough isset to one half of that of a normal primary trough, and the thickness of the primary edge trough is smaller than that of the primary tooth. Furthermore the effective length of the motor primary pole is equal with (n+1 / 2)*tau, and a remarkable inhibition effect is performed on motor thrust force fluctuation. A motor fixing force is reduced so that higher stability and higher reliability are realized in motor operation. The low-speed high-thrust-density double-layer fractional slot winding cylindrical linear motor has advantages of simple structure, relatively low cost, high efficiency, relatively large speed adjusting range, high thrust force density, high operation stability, high operation reliability, etc. The low-speed high-thrust-density double-layer fractional slot winding cylindricallinear motor is suitable for a low-speed large-thrust-force occasion.

Owner:HARBIN UNIV OF SCI & TECH +2

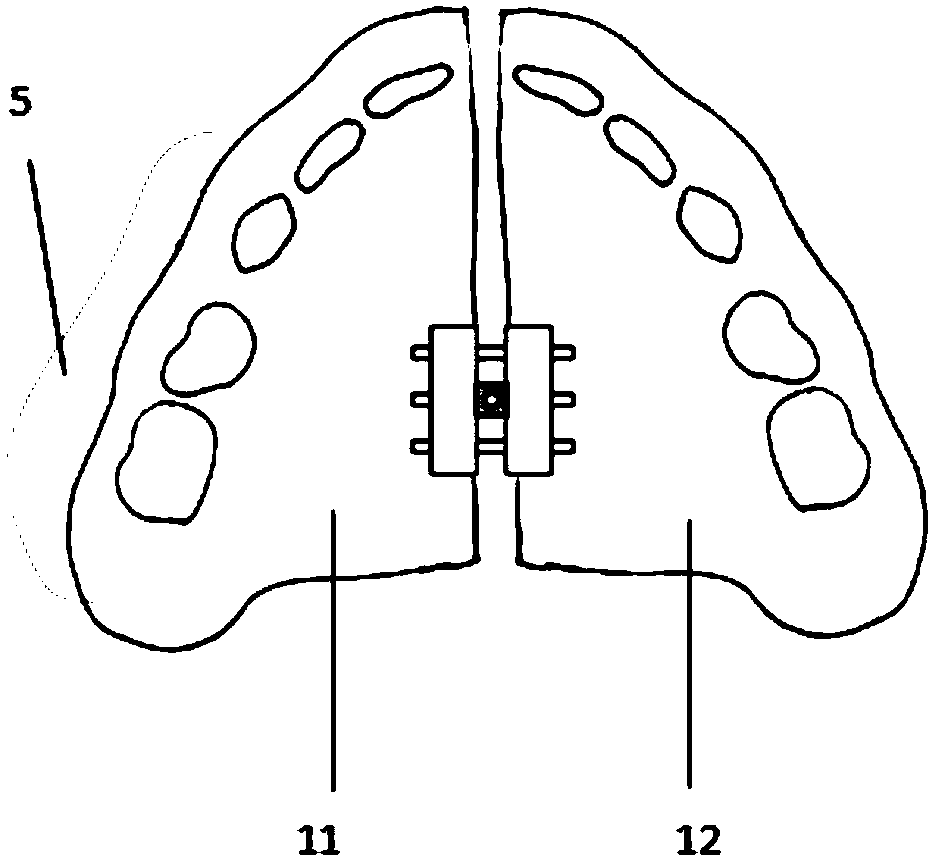

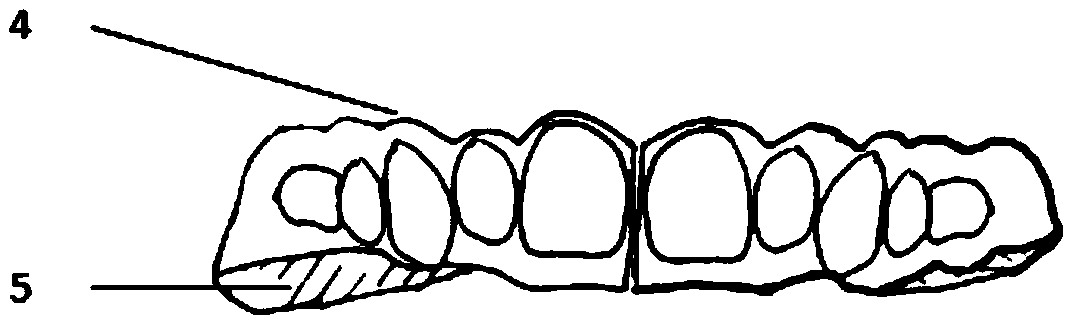

Maxillary expansion type occlusal pad

PendingCN108371561AIncrease widthPromote lateral developmentOthrodonticsFunction recoveryCanine fossa

The invention discloses a maxillary expansion type occlusal pad used for mixed dentition condylar fracture. The maxillary expansion type occlusal pad comprises a base bracket, function surfaces, tissue surfaces, and a maxillary expansion device; the base bracket is used for coating upper dentition; the tissue surfaces on the upper part of the base bracket are fixedly arranged on oral cavity upperdental crowns of patients via bonding; the base bracket is divided into two parts, including an affected side base bracket and a healthy side bracket, at the center; the affected side base bracket andthe healthy side bracket are connected through the maxillary expansion device; the function surfaces on the lower part of the base bracket are designed to match mandibular teeth. The maxillary expansion type occlusal pad is used for correcting discordant maxilla and mandible width of children condylar fracture, and posterior crossbite, reducing the pressure of affected side condylar process zones, is excellent in matching relationship with canine fossa of antagonist teeth, and is capable of achieving preferable occlusion function recovery. The maxillary expansion type occlusal pad is reasonable in design, is convenient to use, is suitable for patients at deciduous dentition and / or mixed dentition, and especially suitable for patients at deciduous dentition.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

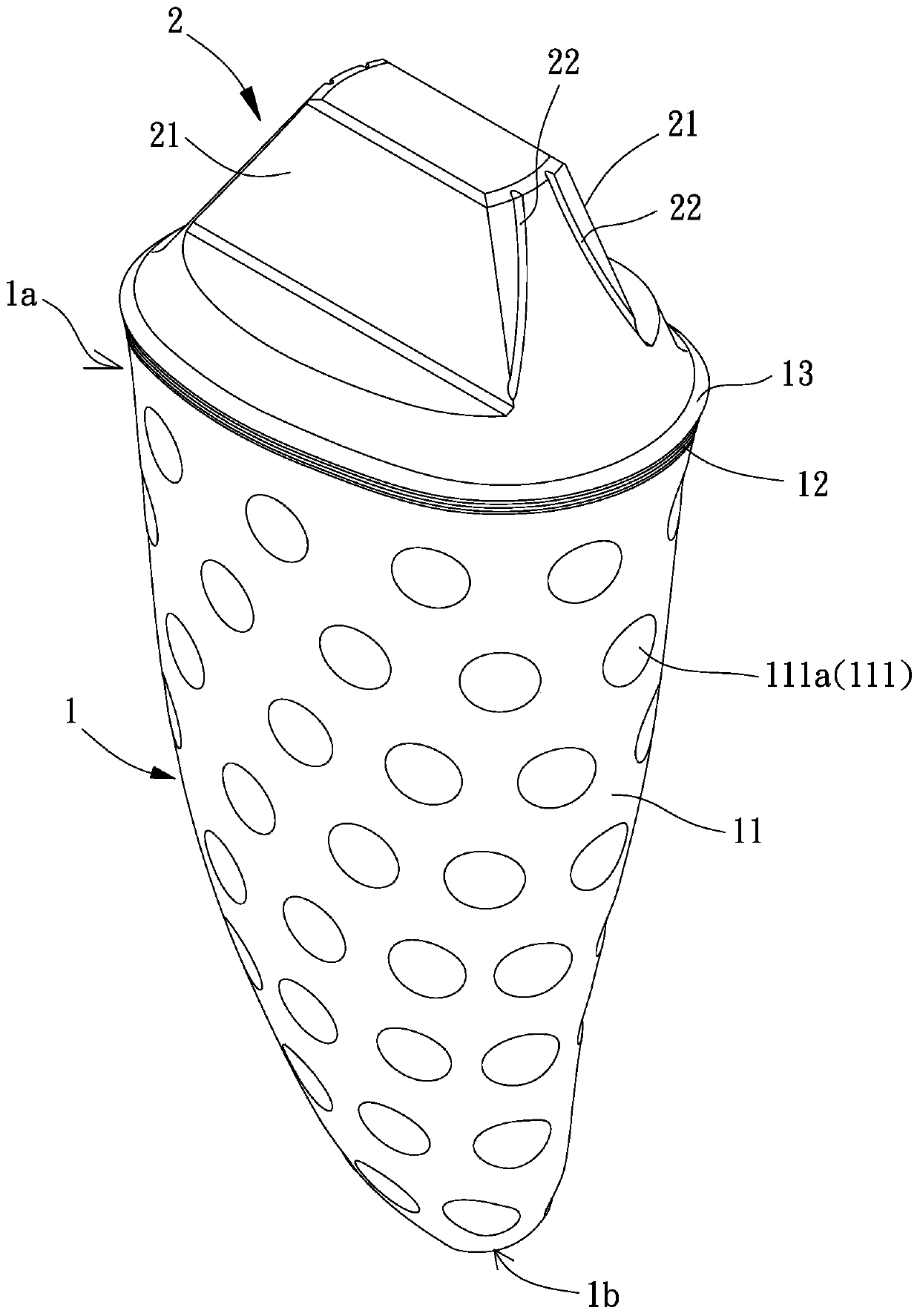

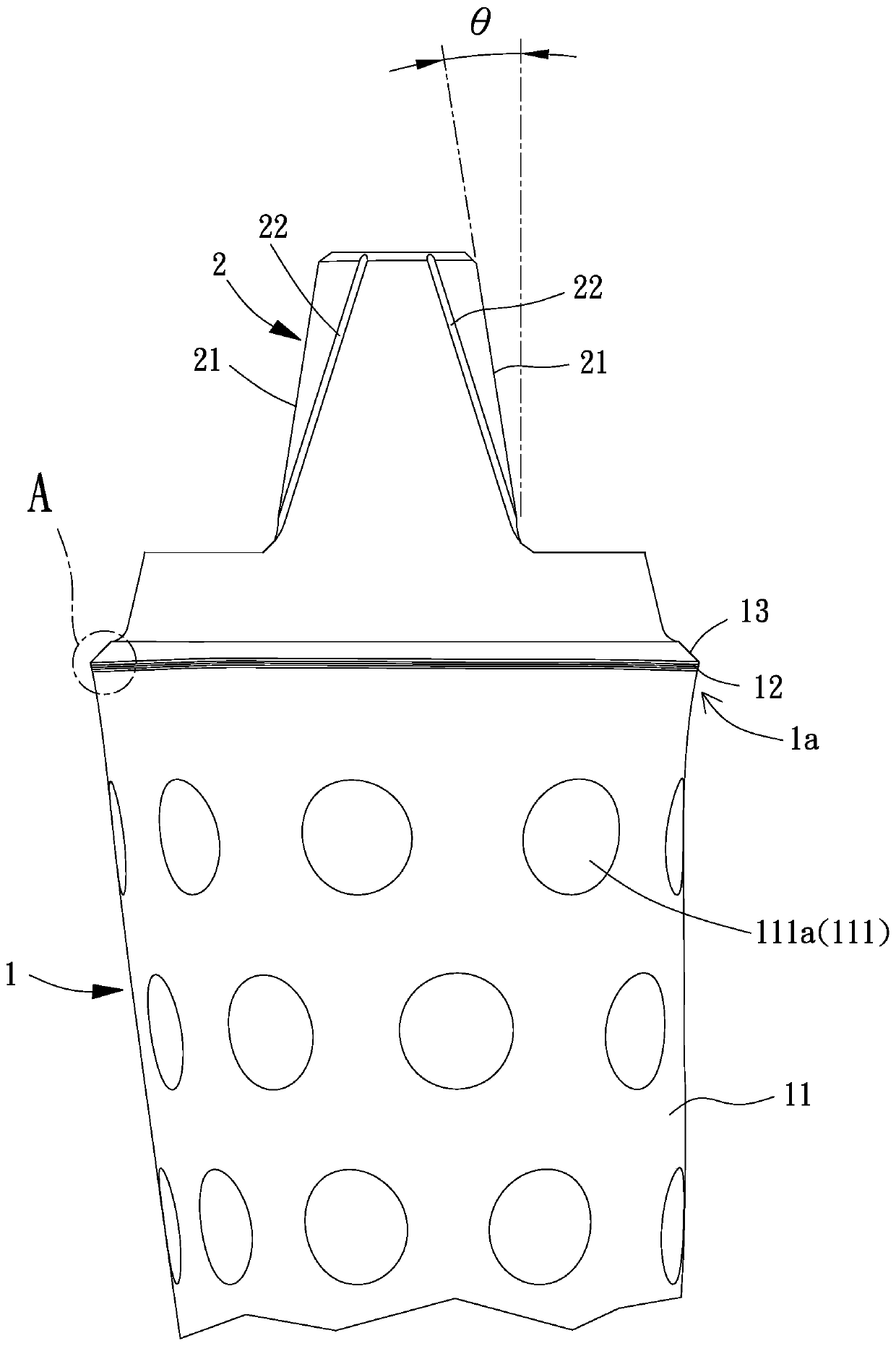

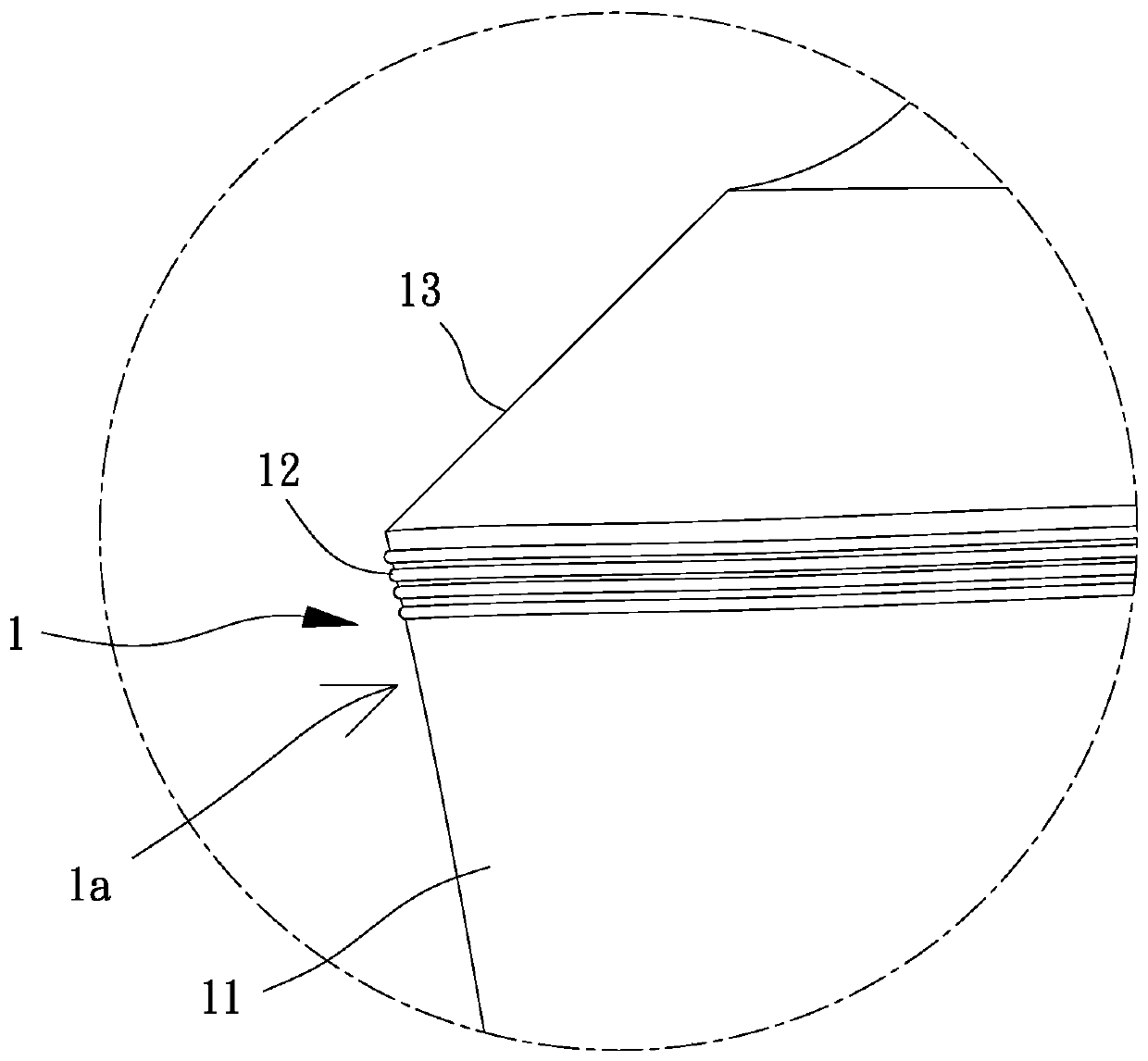

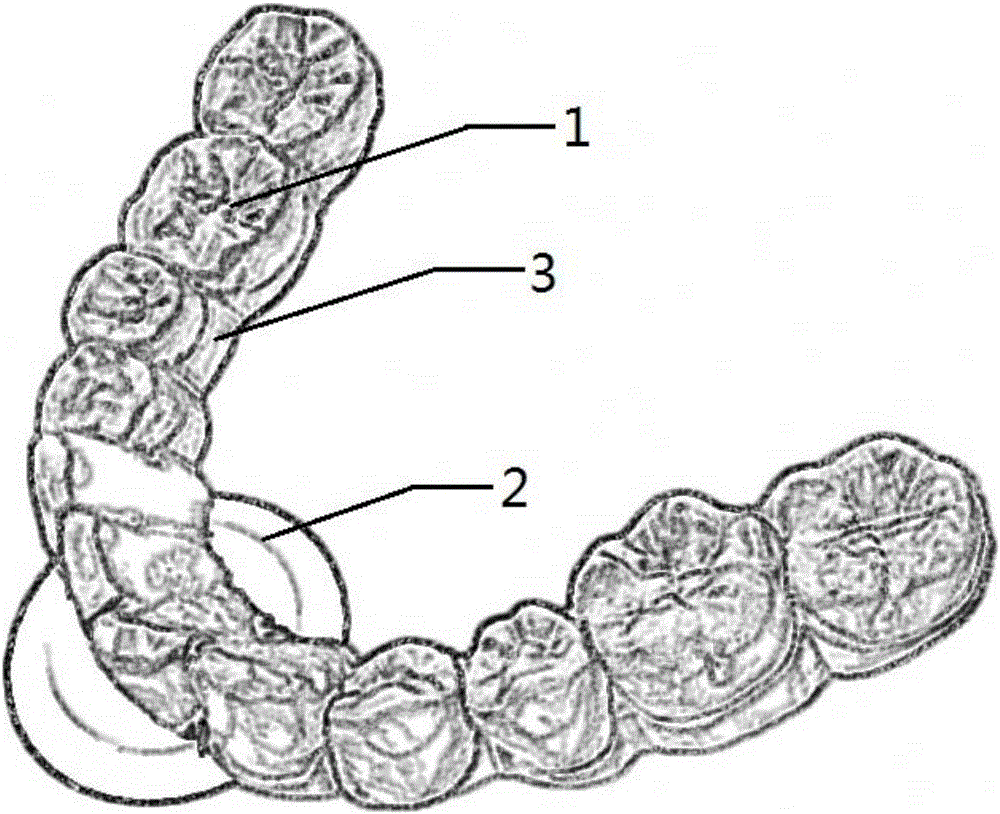

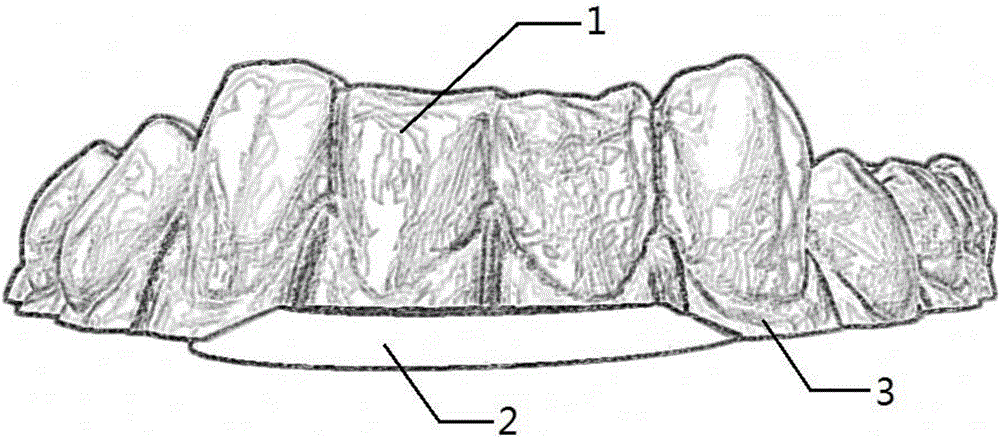

Teeth model and method for preparing concealed correcting device by utilizing model

InactiveCN106109028AAvoid difficultiesReduce the chance of damageOthrodonticsPrimary ToothEngineering

The invention relates to a teeth model. The teeth model comprises an upper dental crown part and a lower gingival part, wherein a truncated cone sheet is arranged below the gingival part, the upper bottom area of the truncated cone sheet is smaller than the lower bottom area, the diameter of the upper bottom is greater than the width of the gingival part, and the lower bottom is leveled to the bottom of the gingival part. A method for preparing a concealed correcting device by utilizing the teeth model comprises the following steps: (1) obtaining the teeth model with the truncated cone sheet on the bottom by virtue of three-dimensional modeling and three-dimensional printing; (2) placing the teeth model on a metal plate of a film pressing machine, and carrying out the film pressing; (3) after the film pressing is ended, separating a diaphragm from the teeth model, slightly bending the hot-pressed diaphragm part, enabling the truncated cone sheet to be warped, holding, by a hand, the truncated cone sheet, and vigorously turning upwards the diaphragm, thus obtaining a primary tooth socket template; and (4) further processing to obtain the concealed correcting device. The method is simple and practical, the operation speed is high, the efficiency is improved, the cost is reduced, and the damage probability of the macromolecular diaphragm when in demolding can also be maximally reduced.

Owner:QINGDAO LANXIN MEDICAL TECH CO LTD

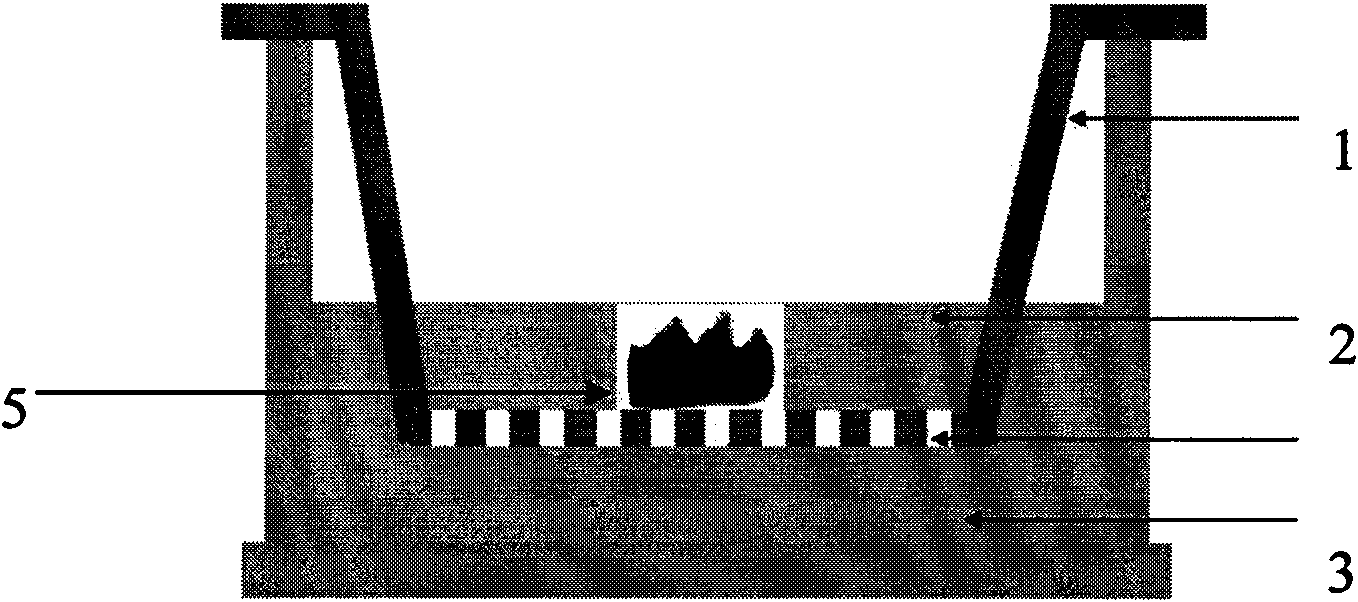

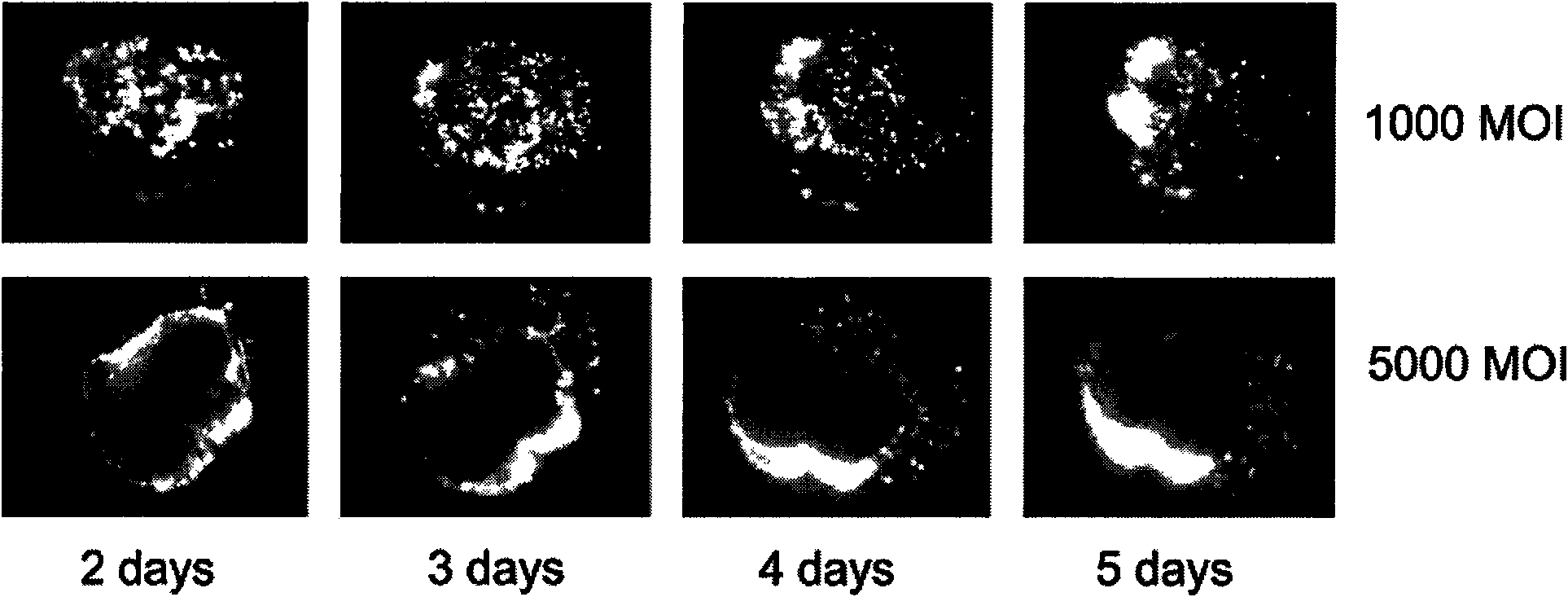

Adenovirus vector-mediated gene transfection method for stereoscopic-state tooth germ ameloblasts

InactiveCN101586121APromote growthGrowth continuesGenetic engineeringFermentationPrimary ToothSurface layer

The invention discloses an adenovirus vector-mediated gene transfection method for stereoscopic-state tooth germ ameloblasts. The method comprises the following steps that: a separated primary tooth germ with an upward cusp is placed on a microporous filter membrane of a Transwell built-in cabinet and is cultured in a culture medium containing the tooth germ; infectious viral particles containing an AAV-GFP gene are used to infect the cultured tooth germ; green fluorescence appears on a surface layer of the tooth germ 24 hours after infection; in combination with the immunostaining of amelogenin, recombinant tooth germ ameloblasts co-expressed by GFP and the amelogenin are positioned on the tooth germ. The ameloblasts of the Transwell-system in vitro cultured tooth germ maintain a stereoscopic state and have interaction with surrounding matrixes and related cells, and the gene transfection success of the ameloblasts in the mode is favorable for researching the gene function of the ameloblasts in the tooth germ from a three-dimensional perspective.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Primary high-temperature super-conducting excitation linear motor with easy phase expansion

The invention discloses a primary high-temperature super-conducting excitation linear motor with easy phase expansion. The motor adopts a structure with a short primary rotor and a long secondary stator; an air gap is formed between the primary part and the secondary part; the short primary rotor consists of multiple phase units arranged at intervals at equal spacings in the movement direction; each phase unit comprises a flat plate type primary iron core, a primary salient pole which is positioned at the middle position of the surface of the iron core and protrudes towards the secondary side, a high-temperature super-conducting excitation winding wound around the primary salient pole, primary teeth which protrude from the respective two end surfaces of the primary iron core and the primary salient pole towards the secondary side respectively, and a primary armature winding embedded on the primary teeth in a sleeving manner; and the long secondary stator comprises a flat plate type secondary iron core, and a plurality of secondary salient poles which protrude from the surface of the secondary iron core at equal distances towards the primary side. By adoption of high-temperature super-conducting excitation, strong magnetic field design can be realized and thrust density can be improved, so that the linear motor is suitable for the high-power application occasion; and the short primary rotor adopts the phase unit modular design, so that multiple-phase expansion can be realized easily, and high fault-tolerant performance is achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

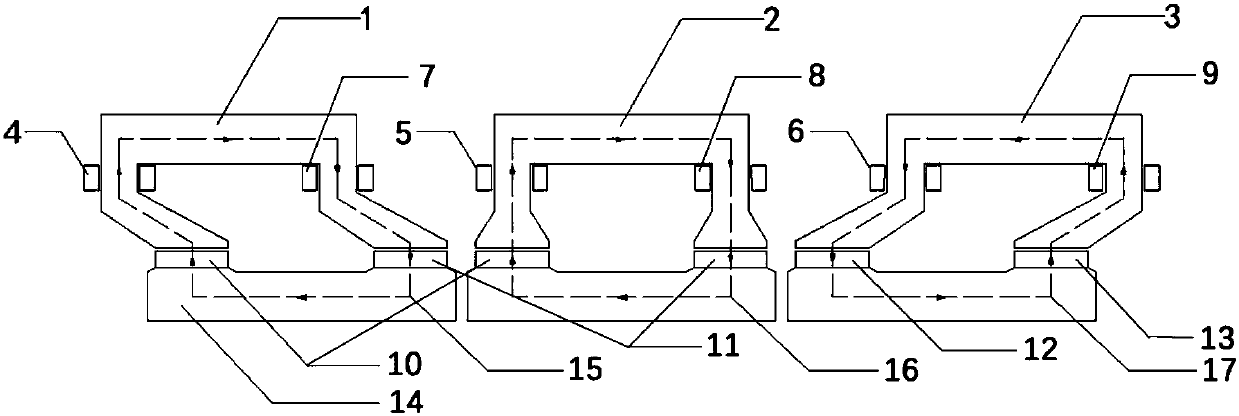

Flat-plate-type transverse flux permanent magnet synchronous linear generator

ActiveCN107742969AReduce lossImprove space utilizationPropulsion systemsTransverse fluxPrimary Tooth

Provided is a flat-plate-type transverse flux permanent magnet synchronous linear generator. The generator comprises flat-plate-type transverse flux primary pole iron cores, a flat-plate-type transverse flux secondary pole iron core, secondary pole magnetic steel and a racetrack winding; the secondary magnetic steel is flatly laid and arrayed on the surface of the flat-plate-type transverse flux secondary pole iron core in the z axis direction that a motor moves by adopting a surface-mount mode. A flat-plate-type transverse flux primary pole is mounted parallel to and opposite to the secondarymagnetic steel, and air gaps are formed between flat-plate-type transverse flux primary tooth pole shoes and the secondary magnetic steel; the racetrack winding winds around pole bodies of flat-plate-type transverse flux primary pole iron core tooth poles. The flat-plate-type transverse flux permanent magnet synchronous linear generator can be applied to direct-driving-type wave energy generationsystems.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Automatic detection of tooth type and eruption status

Provided herein are systems and methods for detecting the eruption state (e.g., tooth type and / or eruption status) of a target tooth. A patient's dentition may be scanned and / or segmented. A target tooth may be identified. Dental features, principal component analysis (PCA) features, and / or other features may be extracted and compared to those of other teeth, such as those obtained through automated machine learning systems. A detector can identify and / or output the eruption state of the target tooth, such as whether the target tooth is a fully erupted primary tooth, a permanent partially erupted / un-erupted tooth, or a fully erupted permanent tooth.

Owner:ALIGN TECH

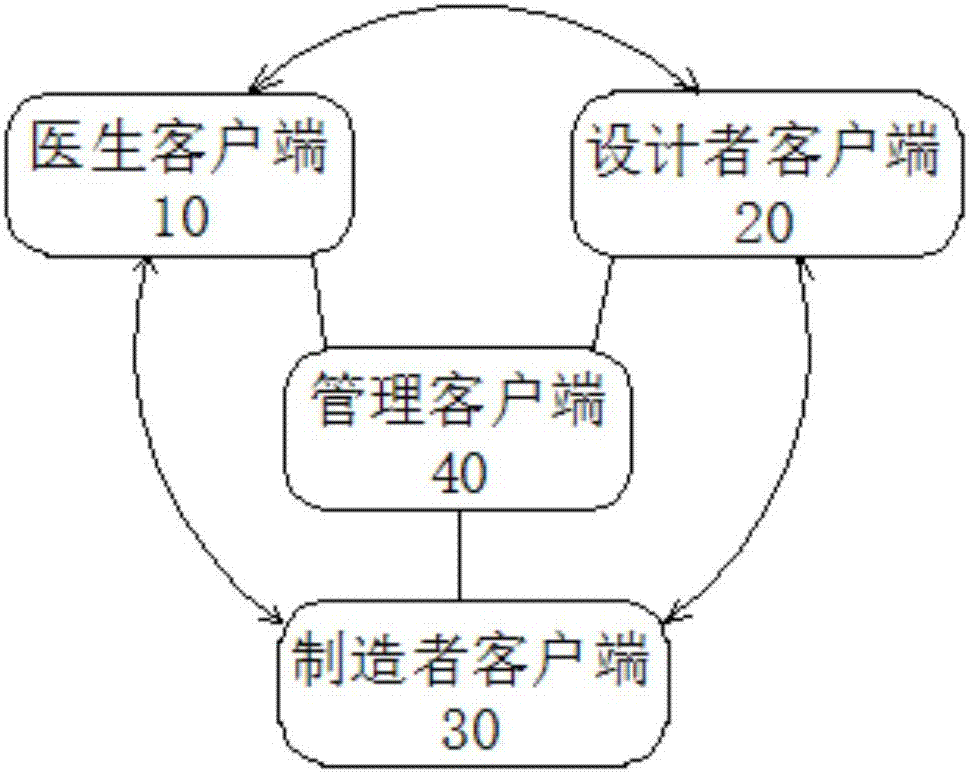

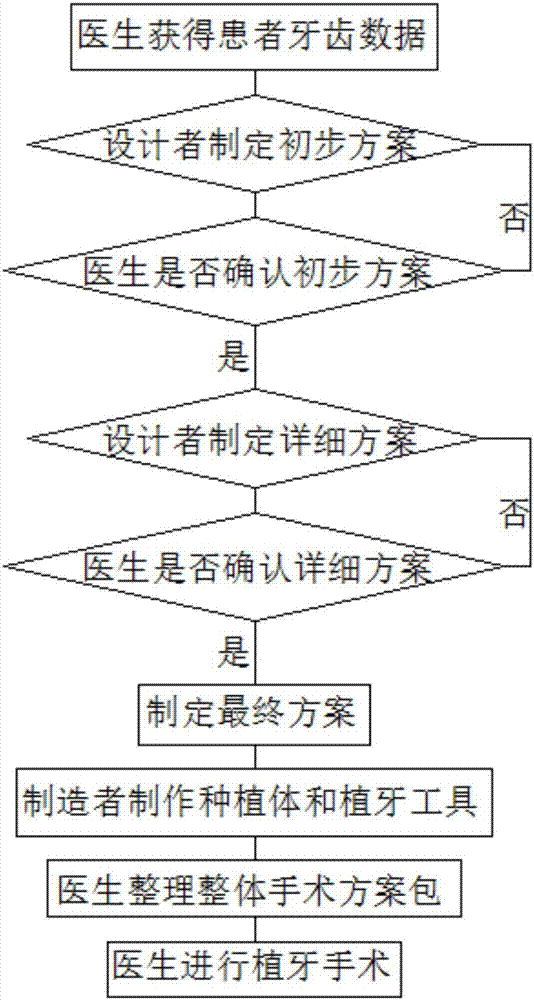

Remote digital tooth implantation method

InactiveCN106901851AGuaranteed accurate implementationReduce dependenceDental implantsSpecial data processing applicationsPrimary ToothIntegrated operations

The invention discloses a remote digital tooth implantation method. The method comprises the following steps: obtaining scanning data of teeth of a patient; uploading the scanned data of the teeth of the patient to a design side through a client side; designing a primary tooth implantation operation plan through the design side according to the patient data, and submitting the primary plan to the client side through network; determining the primary plan by the client side, and designing a detailed plan through the design side; designing the detailed plan through the design side, and submitting the designed detailed plan to the client side; observing and examining the detailed plan by the client side; giving specific suggestion; communicating with the design side, and modifying to obtain a final plan; manufacturing an implant and a dental implantation tool; packing whole implantation operation plan and the implant and the tooth implantation tool required for implementing the plan into an integrated operation plan pack; then finishing the clinic tooth implantation operation according to the whole operation plan pack.

Owner:JIANGSU MEILUN IMAGING SYST

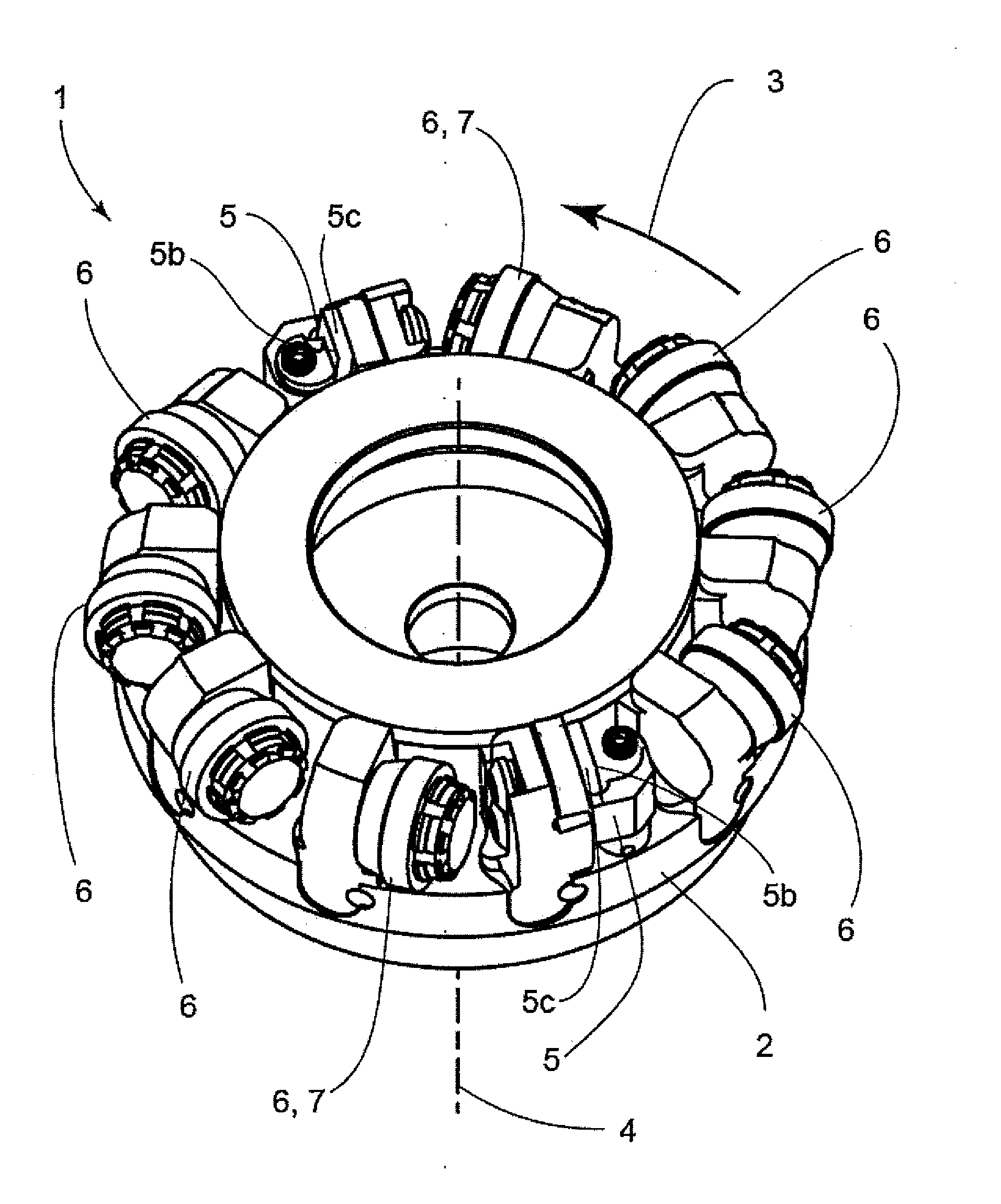

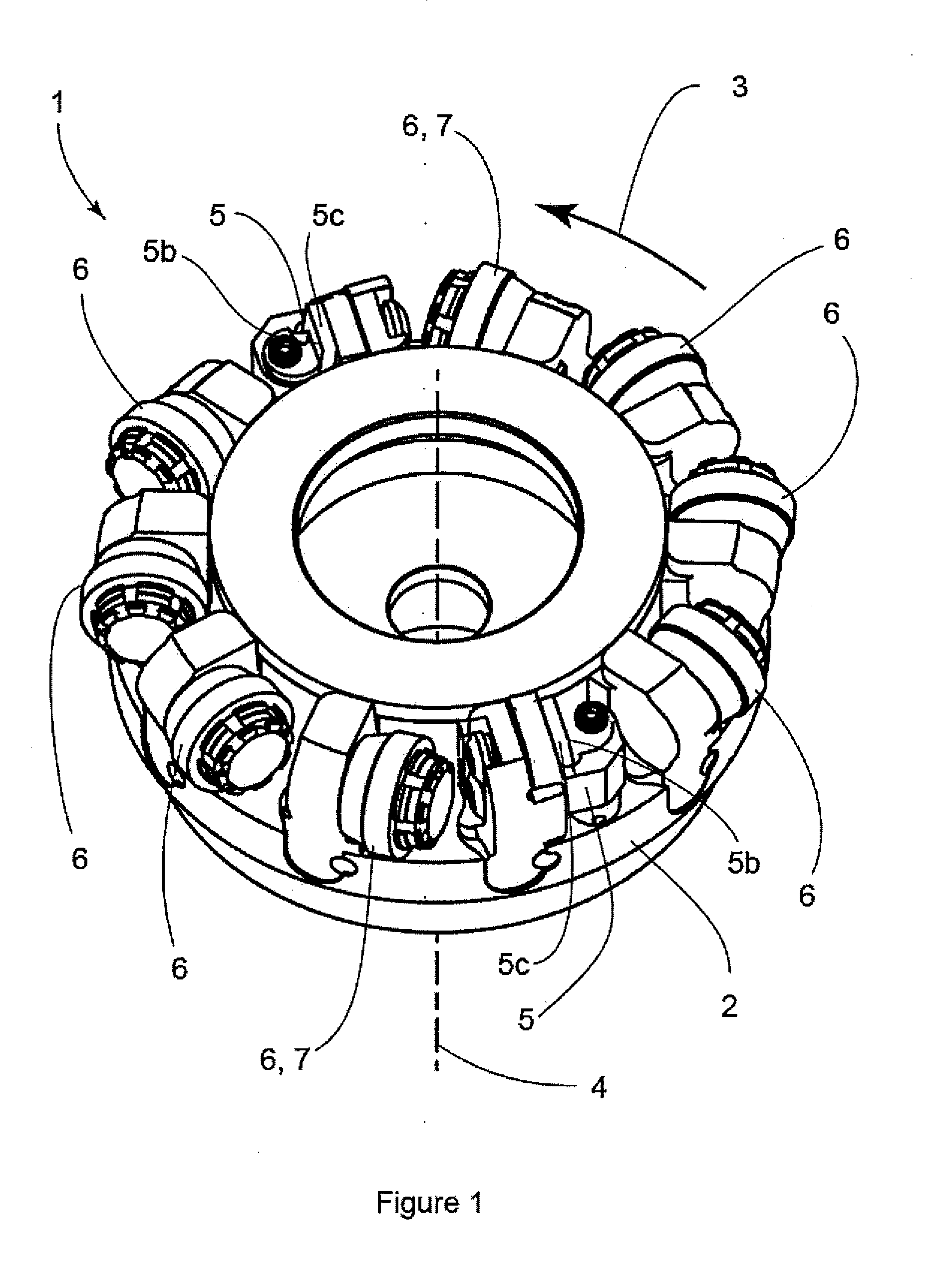

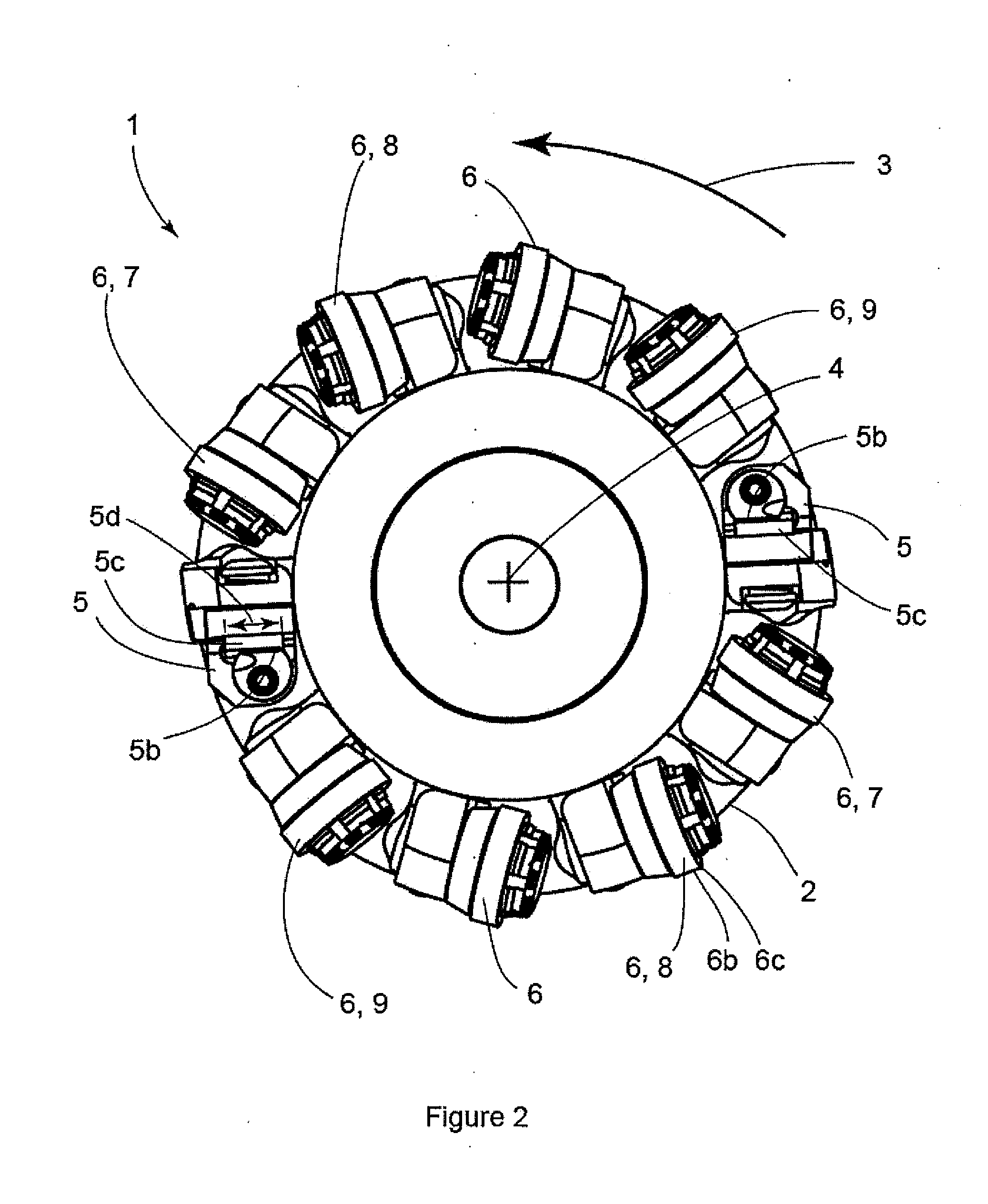

Finishing face mill with reduced chip load variation and method of obtaining the same

A face milling tool includes a body which is rotatable about an axis, at least one wiper tooth, and at least two primary cutting teeth mounted on the body having a cutting edge for cutting about the axis. The primary cutting teeth are staggered radially relative to each other by a radial shift so that a chip load variation during operation is less than 0.7 times a mean primary-tooth chip load. A method for determining the primary cutting tooth radial positions on a face milling tool body is provided such that a chip load variation during operation is less than 0.7 times a mean primary-tooth chip load.

Owner:EIP HLDG

Modular complementary type primary permanent magnet linear motor and motor module formed thereby

ActiveCN102013786BImprove fault toleranceLow costPropulsion systemsPrimary permanentElectromotive force

The invention discloses a modular complementary type primary permanent magnet linear motor and a motor module formed thereby. The primary permanent magnet linear motor comprises a primary level and a secondary level; the primary level and the secondary level are respectively in a salient-pole structure, and an air gap is formed between the two levels; the primary level comprises a rotor module which comprises a first module and a second module; a first non-magnetic material is arranged between the first module and the second module; the first module and the second module both comprise two salient-pole magnetic materials and a permanent magnet arranged between the two salient-pole magnetic materials; the salient-pole magnetic material is provided with m numbered primary teeth, and a central armature winding is arranged on the primary teeth; the relative displacement between the first module and the second module is calculated as follows: lambda2=(k+ / -0.5) tau s; the relative displacement between the adjacent two salient-pole magnetic materials is calculated as follows: lambda1=m*tau m; and the ratio of the primary polar distance to the secondary polar distance is as follows: tau m:tau s=(m+ / -1):m. The invention has the advantages of symmetric back electromotive force, relatively small positioning force, low thrust fluctuation and the like and is applicable to the application occasion of a linear motor with a long-stator structure.

Owner:SOUTHEAST UNIV

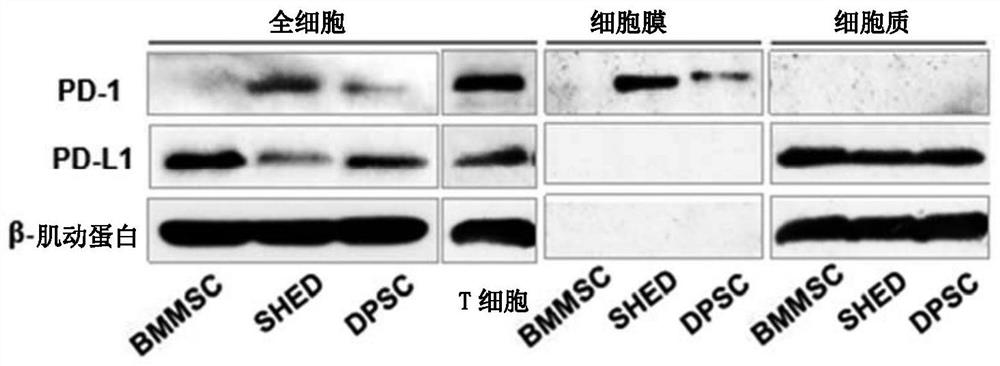

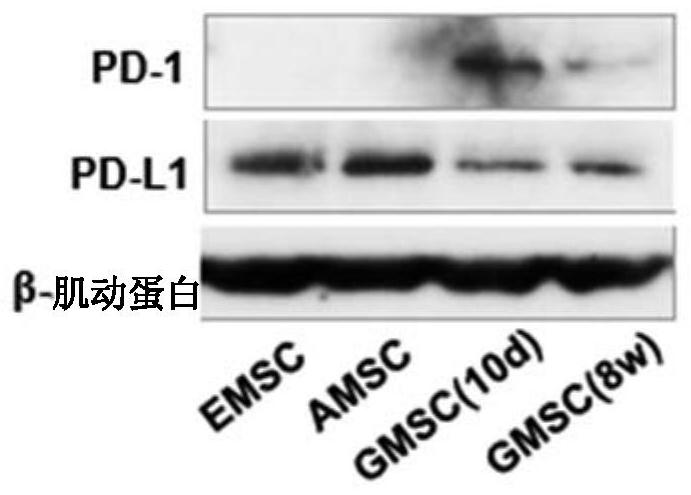

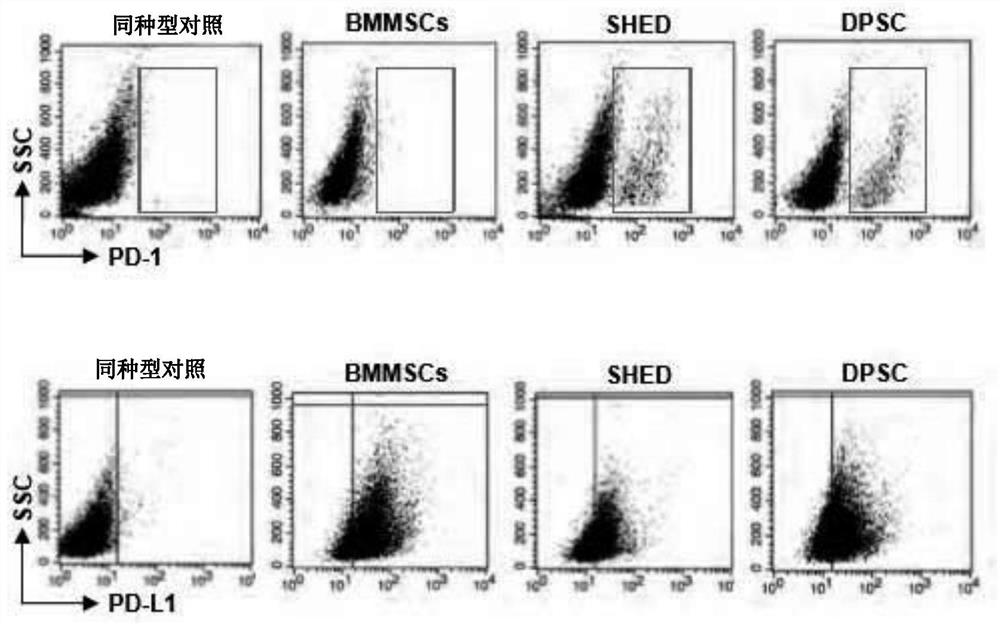

Stem cells specifically expressing PD-1, their identification and isolation methods and uses

The invention discloses a stem cell specifically expressing programmed death receptor 1 (PD‑1), especially stem cells derived from the oral cavity, including but not limited to dental pulp stem cells, gingival stem cells (GMSCs), periodontal ligament stem cells (PDLSCs) ), dental papilla stem cells (SCAPs) and dental follicle stem cells (DFSCs) or any combination thereof, preferably including primary tooth pulp mesenchymal stem cells (SHED) and / or permanent tooth pulp mesenchymal stem cells (DPSC); Mesenchymal stem cells from other tissues that express PD-1 but have been modified by CRISPR to express PD-1, such as CRISPR-modified PD-1 + Bone marrow mesenchymal stem cells (BMMSCs). The invention also discloses a method for identifying and isolating stem cells specifically expressing programmed death receptor 1 (PD-1), and preparing CRISPR-modified PD-1 + The method of mesenchymal stem cells and the use of the mesenchymal stem cells expressing PD-1 of the present invention in tissue regeneration, pain relief, treatment of chronic pain and treatment of a series of diseases.

Owner:北京泰盛生物科技有限公司

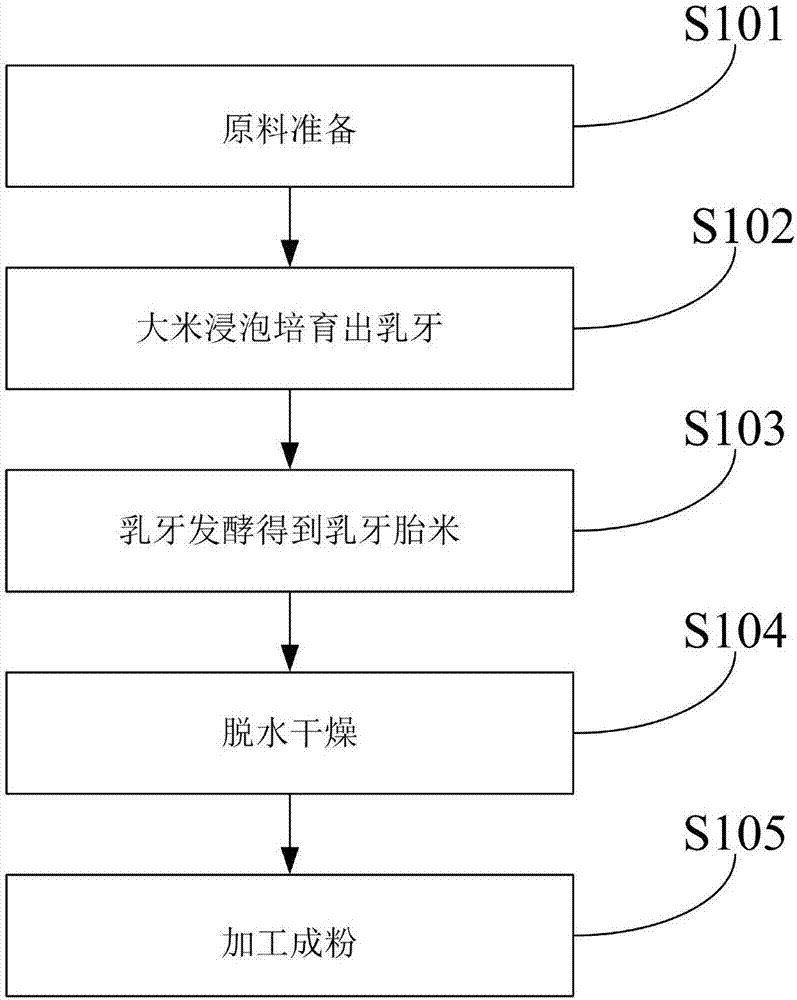

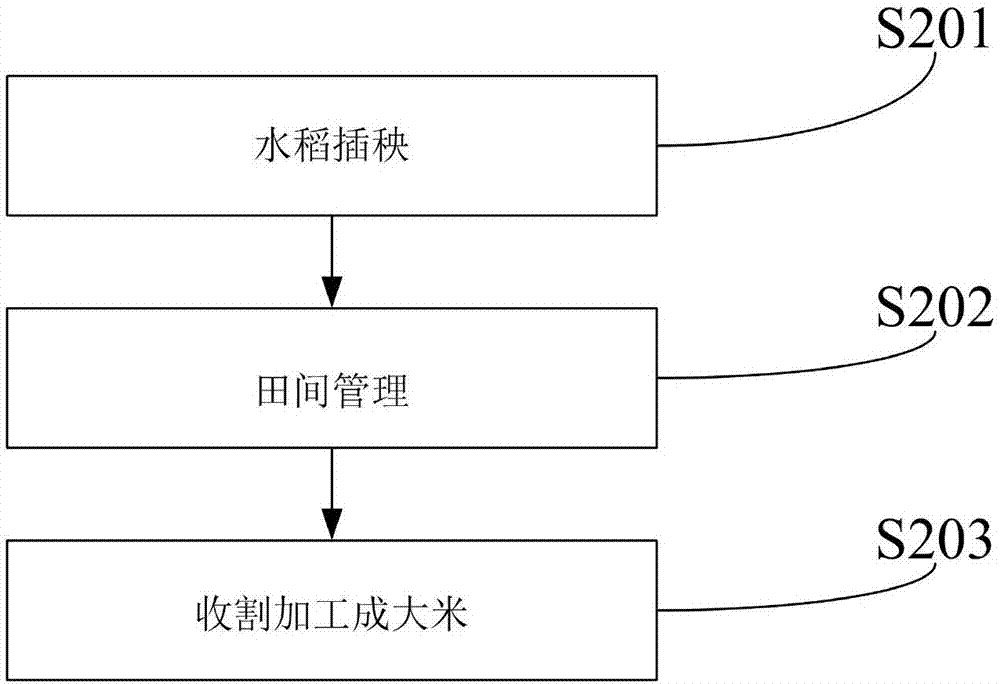

Primary tooth fetal rice fermentation technology

The invention provides a primary tooth fetal rice fermentation technology which solves the problems of a simple fermentation technology, and poor nutrition and health-care effects of products in the prior art. The primary tooth fetal rice fermentation technology comprises the steps: raw material preparation, rice soaking for cultivation of primary teeth, primary tooth fermentation to form primary tooth fetal rice, dewatering, drying, and processing into powder, wherein the raw material preparation comprises the steps: rice transplanting, field management, harvesting and processing into rice. Raw material selection adopts a full ecological mechanism and an ecological process no chemical agent is added; and a product obtained by using the technology contains selenium, SOD, ferment and the like, is nutritional and healthy to eat, prevents and resists cancers, resists oxidation, prevents senescence and is convenient to popularize and use.

Owner:伍宝年

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com