Magnetic field modulation permanent magnet linear motor capable of improving winding utilization rate and optimum design method thereof

A permanent magnet linear motor, magnetic field modulation technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of reducing the thrust density of the motor, poor fault tolerance of the motor, loss of magnetism of the permanent magnet, etc., to improve the thrust output characteristics, The effect of reducing the magnetic flux leakage at the tooth end and reducing the thrust fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

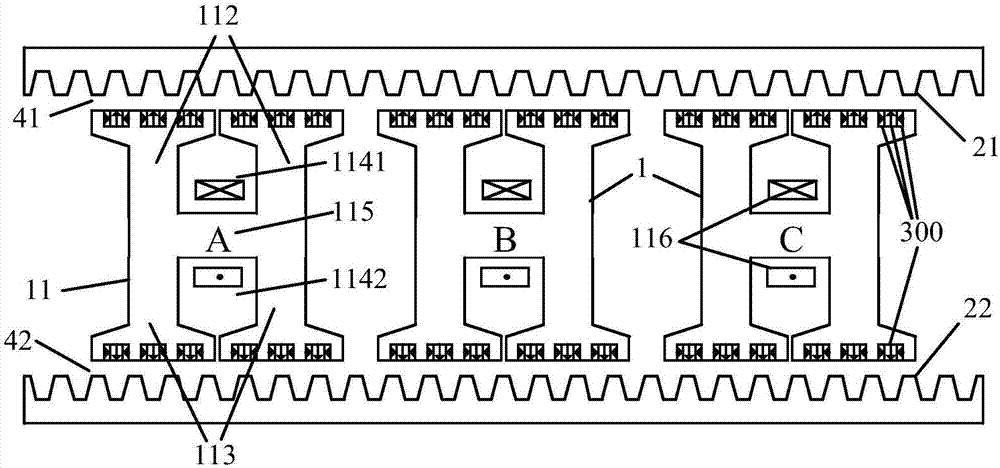

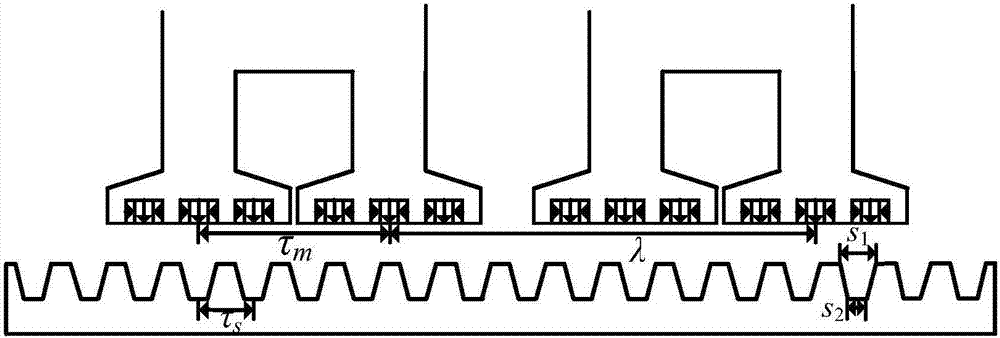

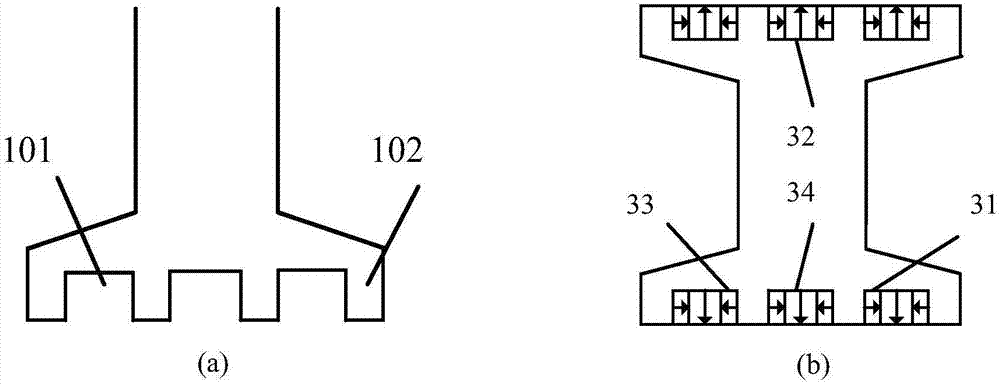

[0047] see figure 1 The structure of the magnetic field modulation permanent magnet linear motor with improved winding utilization in the present invention includes three parts: the primary 1, the first secondary 21 and the second secondary 22, the primary 1 and the first secondary 21, the second secondary There is a first air gap 41 and a second air gap 42 between 22 respectively, and the thickness of the air gap is selected according to the power requirements of the motor and the working environment. Both the primary and the secondary are made of laminated silicon steel sheet materials. The secondary 21 and secondary 22 are grooved on the side close to the air gap 41 and 42 respectively to form a trapezoidal groove structure. The primary 1 is opened on the side close to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com