Teeth model and method for preparing concealed correcting device by utilizing model

A tooth model and gingiva technology, applied in the field of orthodontics, can solve the problems of raising the production cost of invisible aligners, prolonging the production time of tooth models, and prolonging the cycle of a single aligner, so as to save cost and price, save printing time, and methods Simple and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

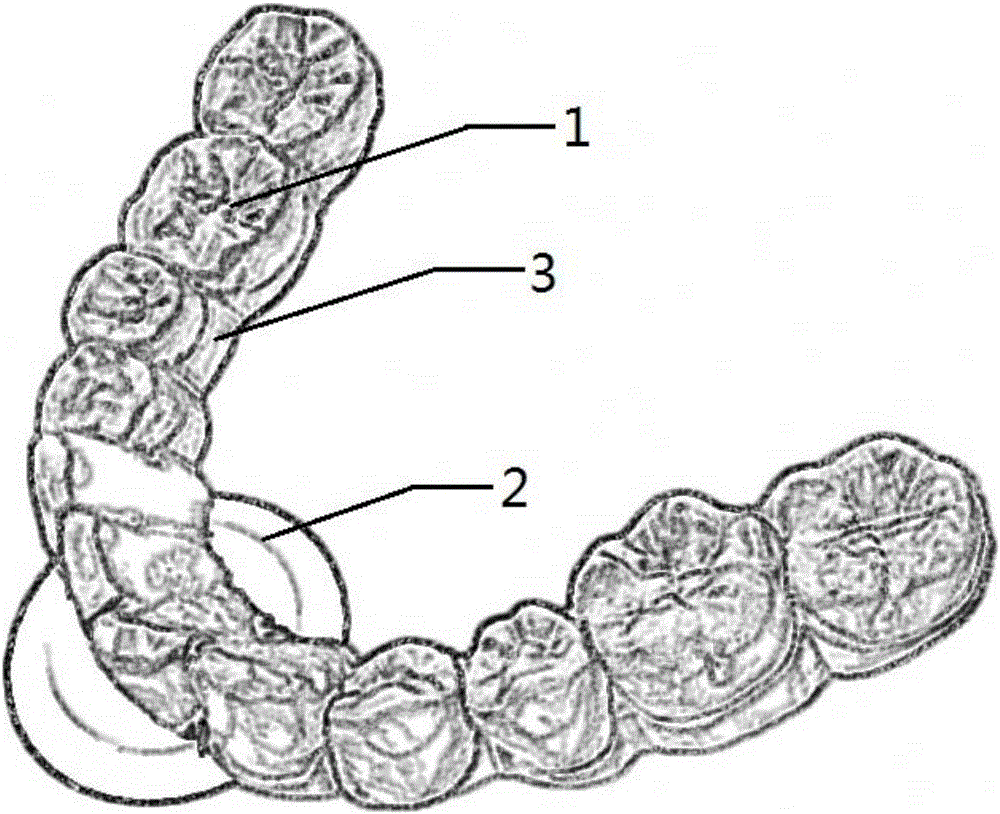

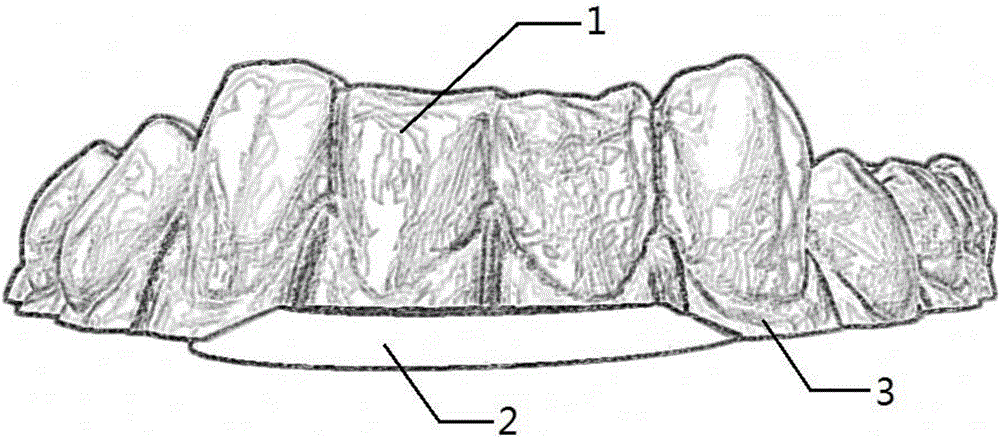

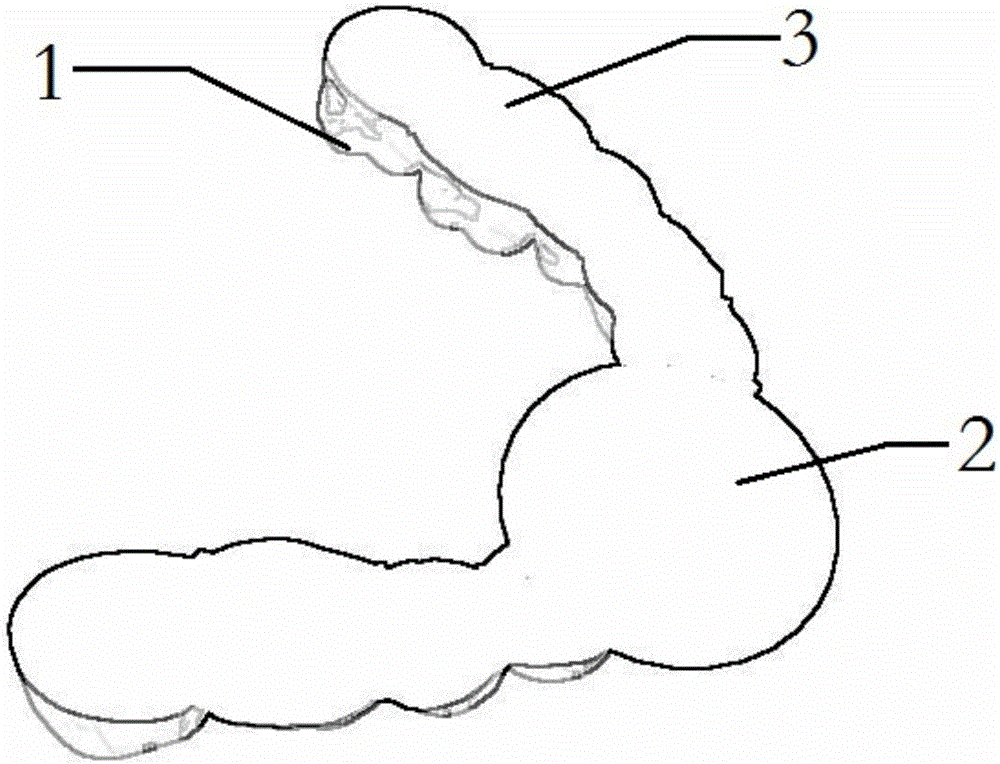

[0029] Such as Figure 1-3 The tooth model shown includes the crown part 1 of the upper part and the gingival part 3 of the lower part, and the truncated cone sheet 2 is arranged below the gingival part 3, and the upper bottom surface area of the truncated pyramid sheet 2 is smaller than the lower bottom surface area, and The diameter is greater than the width of the gingival part 3, and the bottom surface is flush with the bottom surface of the gingival part, such as image 3 shown.

[0030] Such as Figure 4 As shown, the truncated cone sheet 2 is a truncated cone, the height of the truncated cone sheet 2 is 1.5mm, the base angle is 40°, and the upper bottom surface area is about 153.86mm 2 , the bottom surface area is about 314mm 2 . The frustum piece 2 is located in the middle of the dental arch. When the diaphragm is separated from the tooth model, the two symmetrical parts in the middle of the dental arch bear basically the same force, which is conducive to separa...

Embodiment 2

[0035] Such as Figure 6 As shown, the frustum sheet 2 is a truncated polyhedron, the height of the frustum sheet 2 is 1.8mm, the base angle is 50°, and the upper bottom surface area is about 145.32mm 2 , the bottom surface area is about 330mm 2 .

[0036] All the other are with embodiment 1.

[0037]When the above tooth model was produced, the base was not printed, and only the crown 1, the gingiva 3 and the frustum 2 were printed, which saved 26% of the printing time compared to printing the 8mm thick base. At the same time, the consumption of expensive printing consumables is also saved, and the production cost of each appliance can be reduced by 20% to 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Base angle | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com