Single and double-wall combined steel cofferdam construction method and its single and double-wall combined steel cofferdam

A construction method, steel cofferdam technology, applied in the direction of infrastructure engineering, construction, etc., can solve problems such as waste of materials, unfavorable insertion and fixing of steel sheet piles, and failure to seal the bottom, so as to achieve low cost investment, low construction difficulty, and project progress fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail below in conjunction with embodiment.

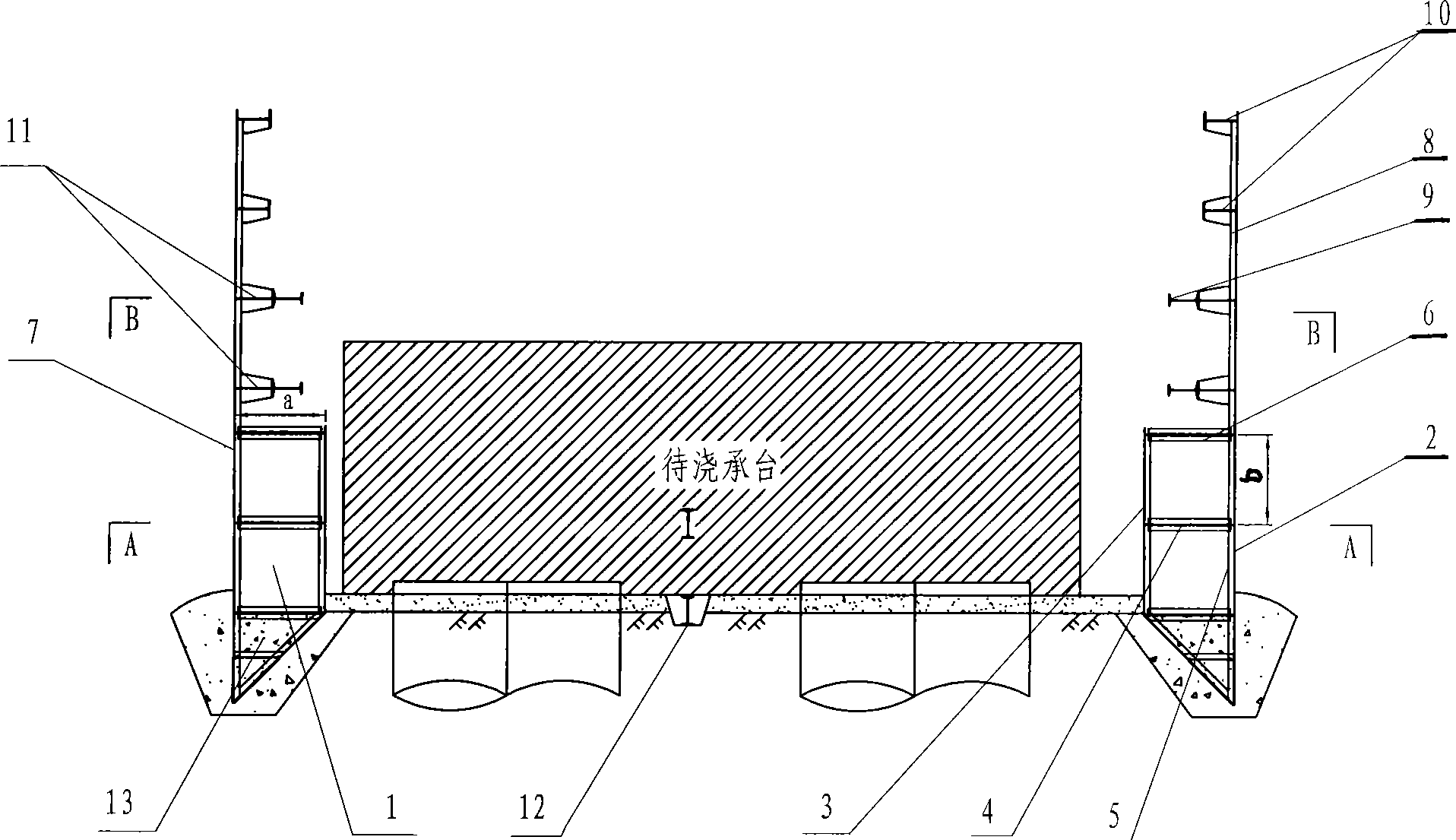

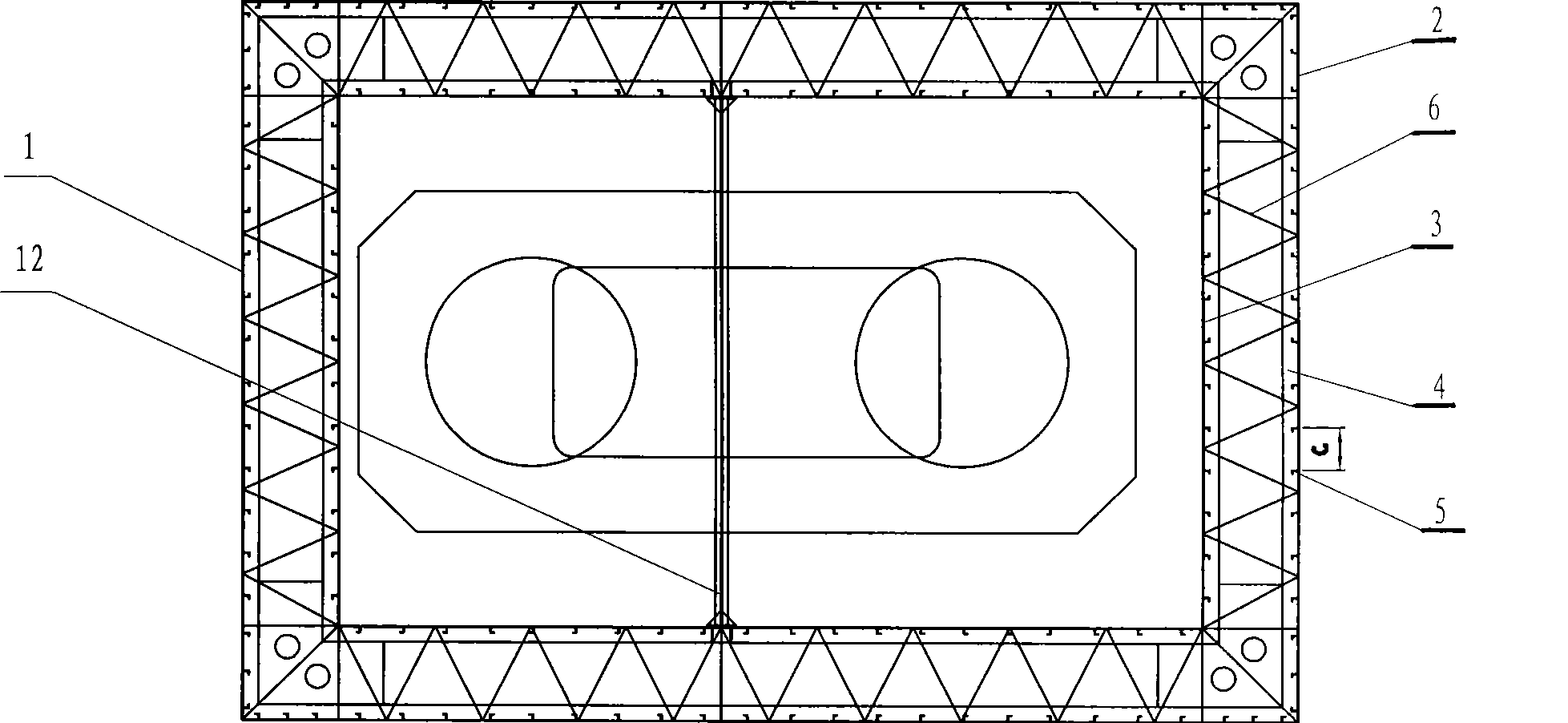

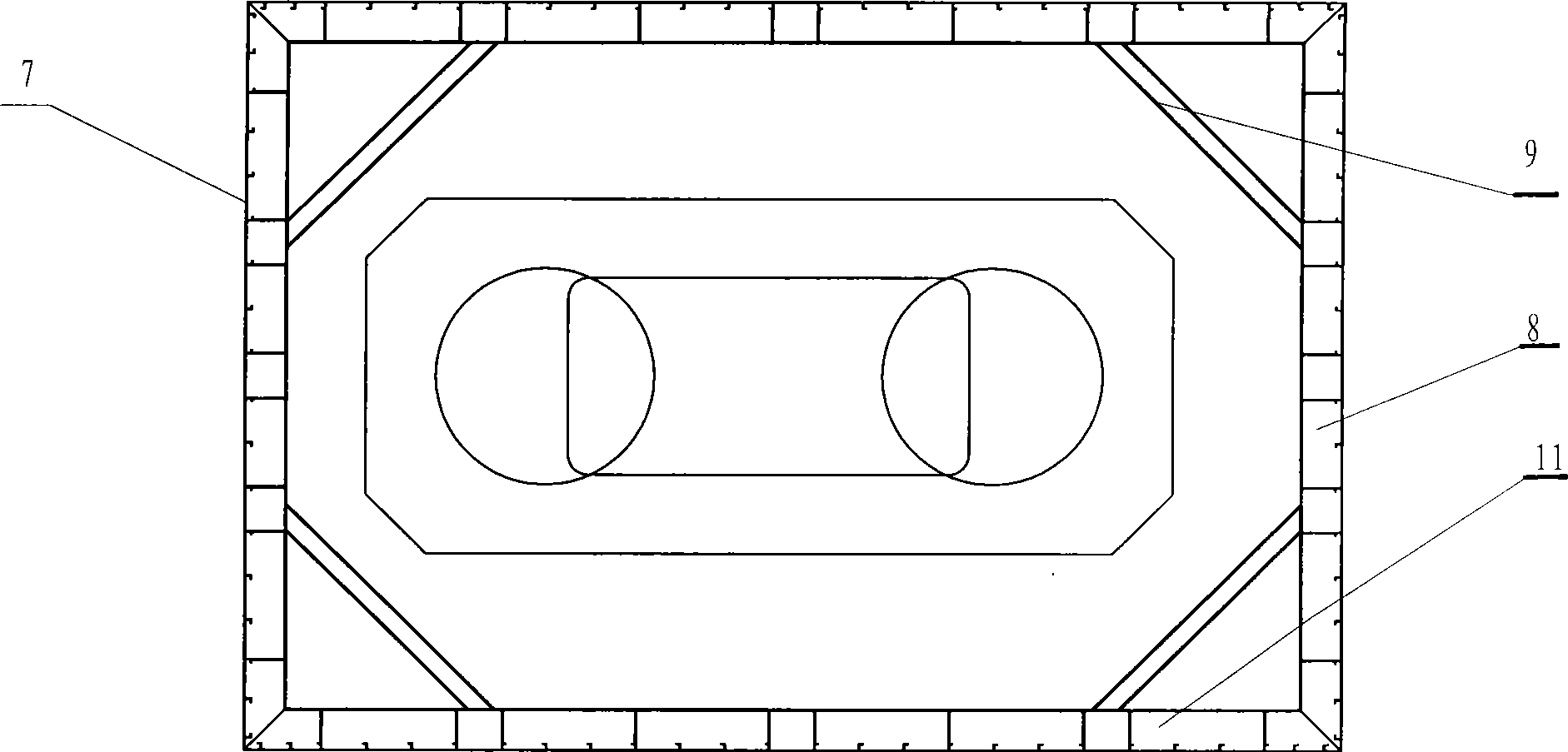

[0026] A construction method of single and double wall combined steel cofferdam:

[0027] A. After the individual parts of the single- and double-wall combined steel cofferdam are manufactured in blocks, they are transported to the flat assembly site on the shore and beach through the river access road to assemble part 1 of the bottom section side plate cofferdam, and the bottom section side The location of the assembly site for the slab cofferdam 1 should consider the requirements for the bottom section and side slab cofferdam 1 to go down the river. When floating (the ground elevation of the site is below 25.5m so that the cofferdam can be floated out of the assembly site when the water level is 27.0m), when assembling the bottom section side plate cofferdam 1, use the blocking dam to isolate it from the river, and the bottom section side plate enclosure After the weir 1 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com