A filter wall for upstream tailings pond

A technology for filter walls and tailings ponds, applied in soil protection, filling, construction, etc., can solve problems such as the rise of the infiltration line of the lower reservoir, reduce the seepage effect, and construction difficulties, so as to achieve the safety and stability of the dam body and improve the Good effect of seepage drainage and interception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

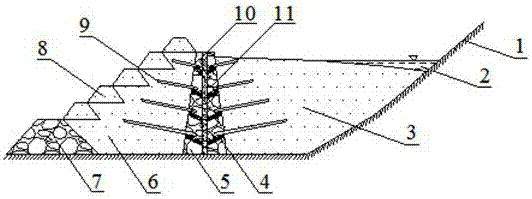

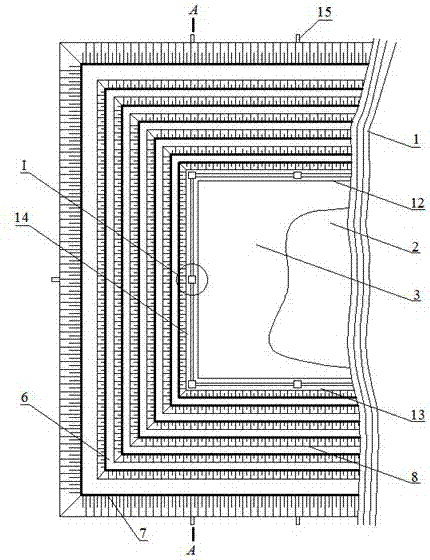

[0036] A filter wall for an upstream tailings pond. Such as figure 1 and figure 2 As shown, the filter wall is surrounded by a first filter wall 12 , a second filter wall 13 and a third filter wall 14 . The first water filter wall 12 and the second water filter wall 13 extend outwards from both sides of the hillside 1 and are respectively connected to the two ends of the third water filter wall 14. The first water filter wall 12 is connected to the third water filter The included angle between the walls 14 is 90°, and the included angle between the second filter water wall 13 and the third filter water wall 14 is 90°.

[0037] Such as figure 1 and figure 2 As shown, the filter wall and the hillside 1 form the inner reservoir 3, and the filter wall, the sub-dams 8 at various levels and the initial dam 7 constitute the outer reservoir 6.

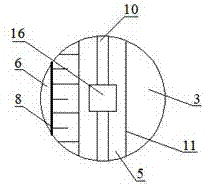

[0038] Such as figure 1As shown, the wall cross sections of the first filter wall 12 , the second filter wall 13 and the third filter...

Embodiment 2

[0048] A filter wall for an upstream tailings pond. Except following technical parameter, all the other are with embodiment 1:

[0049] The angle between the first filter wall 12 and the third filter wall 14 is 90-120°, and the angle between the second filter wall 13 and the third filter wall 14 is 90-120°.

[0050] The base angle of the isosceles trapezoid is 70-80°, the top edge of the isosceles trapezoid is 4-8m, and the height of the isosceles trapezoid is 20-100m; the thickness of the concrete interlayer 10 is 0.5-1m.

[0051] The spacing of the water collection wells 16 is 20-100m.

[0052] Both sides of the concrete interlayer 10 are symmetrically provided with 5 to 10 layers of water collecting plates 4 , and the interlayer spacing of each layer of water collecting plates 4 is 5 to 10 m.

[0053] The distance between the water filter pipes 9 in the same row is 5-15m.

[0054] The lengths of the first water filter wall 12 , the second water filter wall 13 and the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com