Flexible organic thin film transistor and fabrication method thereof

An organic thin film and transistor technology, applied in the field of high mobility flexible organic thin film transistors and their preparation, can solve problems such as difficult preparation methods, and achieve the effects of optimized spin coating process, good flexibility, and low operating voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

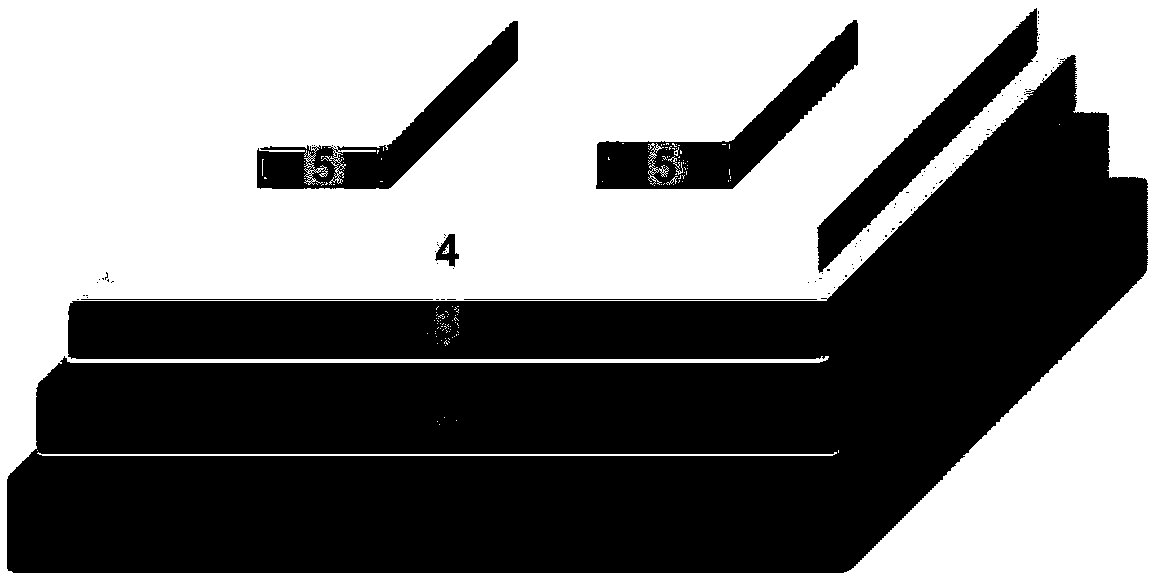

[0043] In this embodiment, the device structure of the flexible organic thin film transistor is as follows figure 1 As shown, it mainly includes a substrate 1 , a gate electrode 2 , an insulating layer 3 , a semiconductor layer 4 and a source-drain electrode 5 . The gate electrode 2 is located on the upper surface of the substrate 1 , the insulating layer 3 is located on the upper surface of the gate electrode 2 , the semiconductor layer 4 is located on the upper surface of the insulating layer 3 , and the source and drain electrodes 5 are located on the upper surface of the semiconductor layer 4 . Among them, the substrate 1 is polyethylene terephthalate (PET), the gate electrode 2 is a conductive ITO film, the insulating layer 3 is a PVP-HDA cross-linked product, and the semiconductor layer 4 is a C8-BTBT:PS film. Pole 5 is metal gold.

[0044] The preparation method of the flexible organic thin film transistor mainly includes the following steps:

[0045] (1) Stir and dis...

Embodiment 2

[0050] In this embodiment, the basic structure refers to Embodiment 1, the substrate 1 is polyethylene terephthalate (PET), the gate electrode 2 is a conductive Ag NWs film, the insulating layer 3 is a PVP-HDA cross-linked product, and the semiconductor layer 4 is a C8-BTBT:PS thin film, and the source and drain electrodes 5 are metal gold or silver. The preparation method of the flexible organic photodetector mainly includes the following steps:

[0051] Refer to the steps (1), (2), and (3) of Example 1. Ag NWs are dispersed in ethanol solution, and then coated on the substrate PET and then thermally annealed and dried to form a very thin staggered stack of Ag NWs conductive film. The Ag NWs / PET substrate prepared by a similar process can be purchased by self-preparation or through merchants. It should be noted that before depositing the insulating layer PVP-HDA film, the gate electrode film ITO in Example 1 can be treated with ultraviolet ozone for 20 minutes to increase t...

Embodiment 3

[0054] In this embodiment, the basic structure refers to embodiment 1, the substrate 1 is polyethylene terephthalate (PET), the gate electrode 2 is a conductive Ag NWs-PEDOT:PSS film, and the insulating layer 3 is PVP-HDA cross-linked material, the semiconductor layer 4 is a C8-BTBT:PS thin film, and the source and drain electrodes 5 are metal gold or silver.

[0055] The preparation method of the flexible organic thin film transistor mainly includes the following steps:

[0056] (1) Add 5% volume of DMSO in the total mixed solution to PEDOT:PSS, and stir at room temperature for 30 min. The blended solution was scraped and deposited on the Ag NWs / PET substrate, and then annealed in the air at 130 °C for 30 min. After annealing, the substrate was placed in N 2 Or store in an argon glove box.

[0057] (2) Referring to the steps (1), (2) and (3) of Example 1, the device preparation can be completed.

[0058] It has been determined that the flexible organic thin film transistor...

PUM

| Property | Measurement | Unit |

|---|---|---|

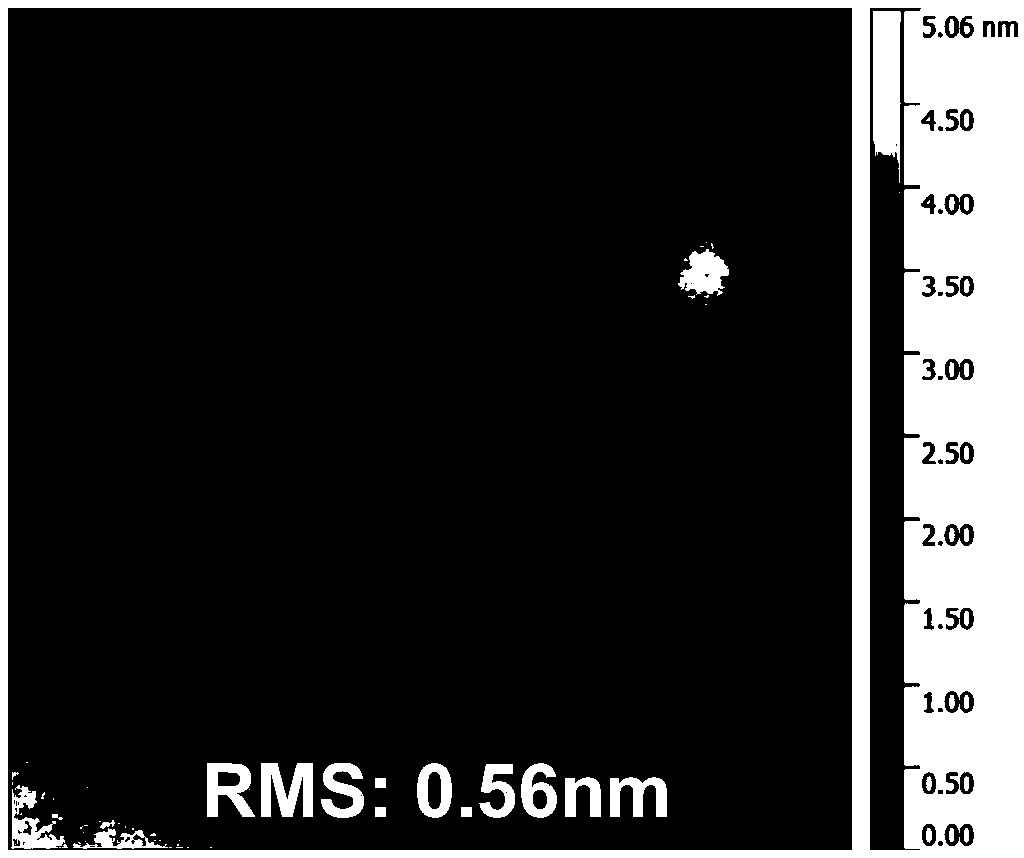

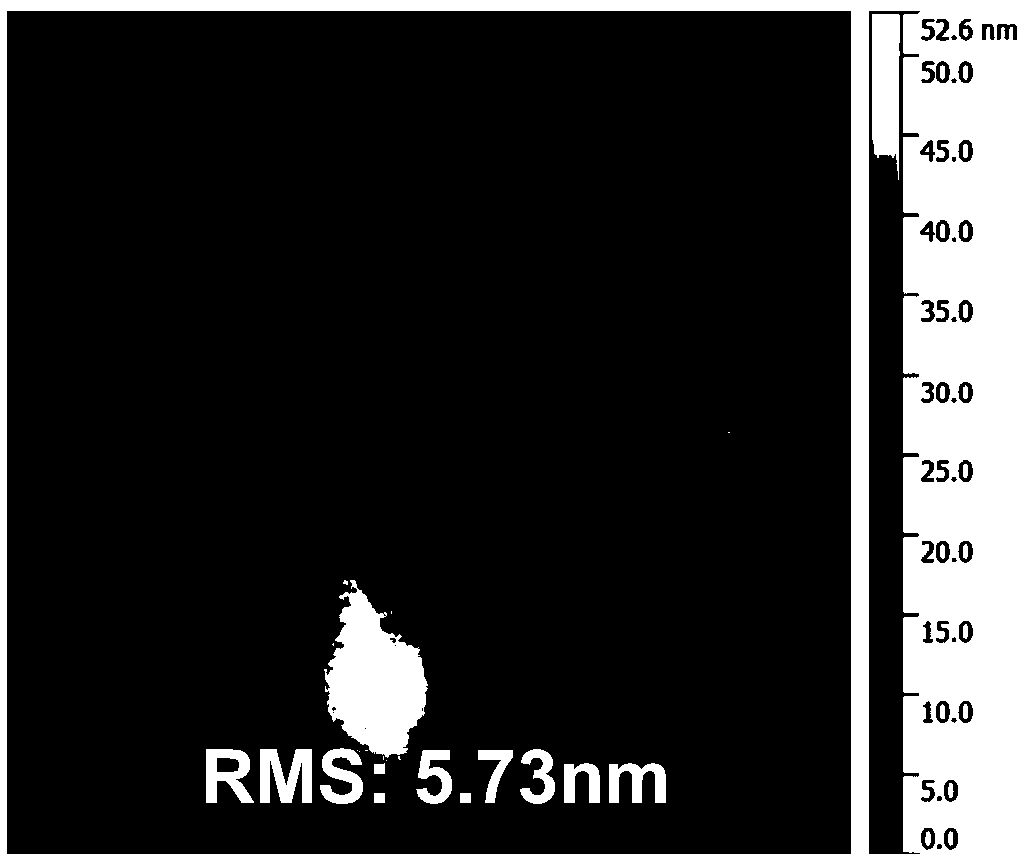

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com