Patents

Literature

295 results about "Aluminum doped zinc oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

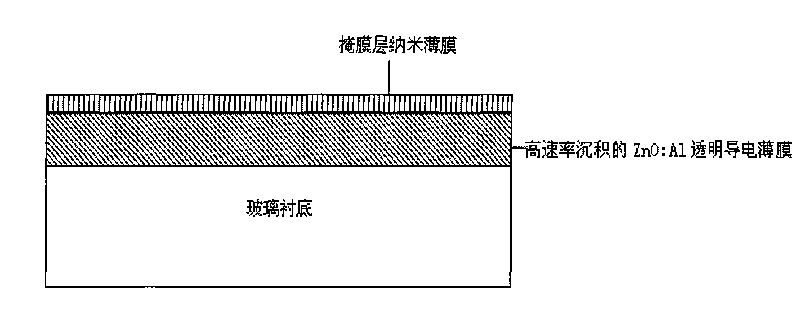

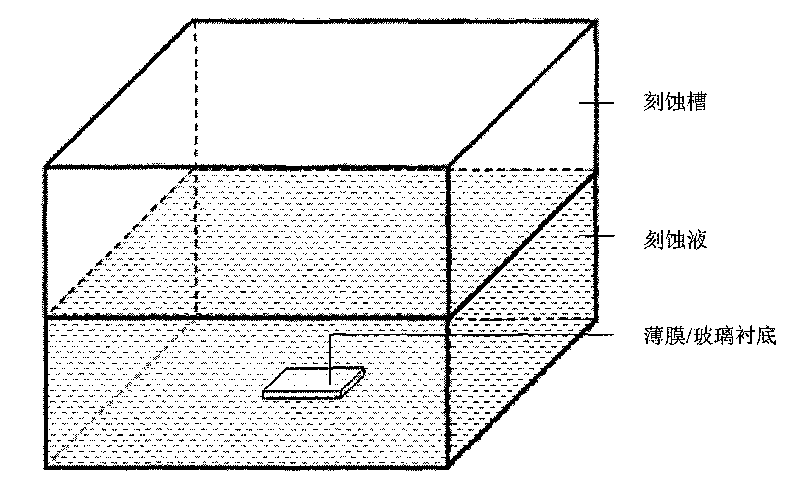

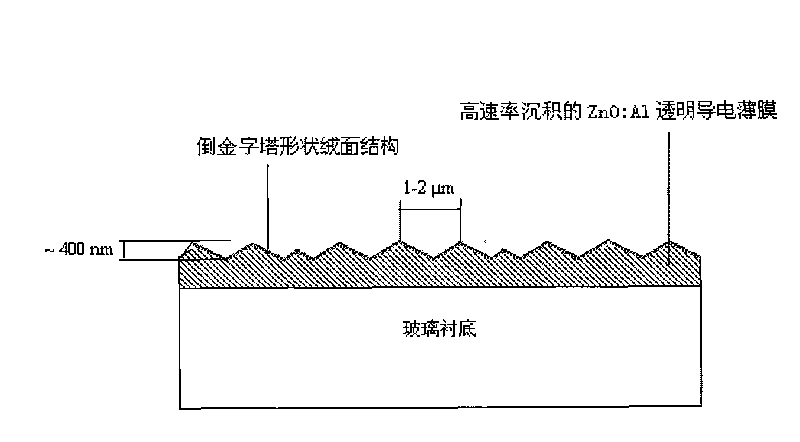

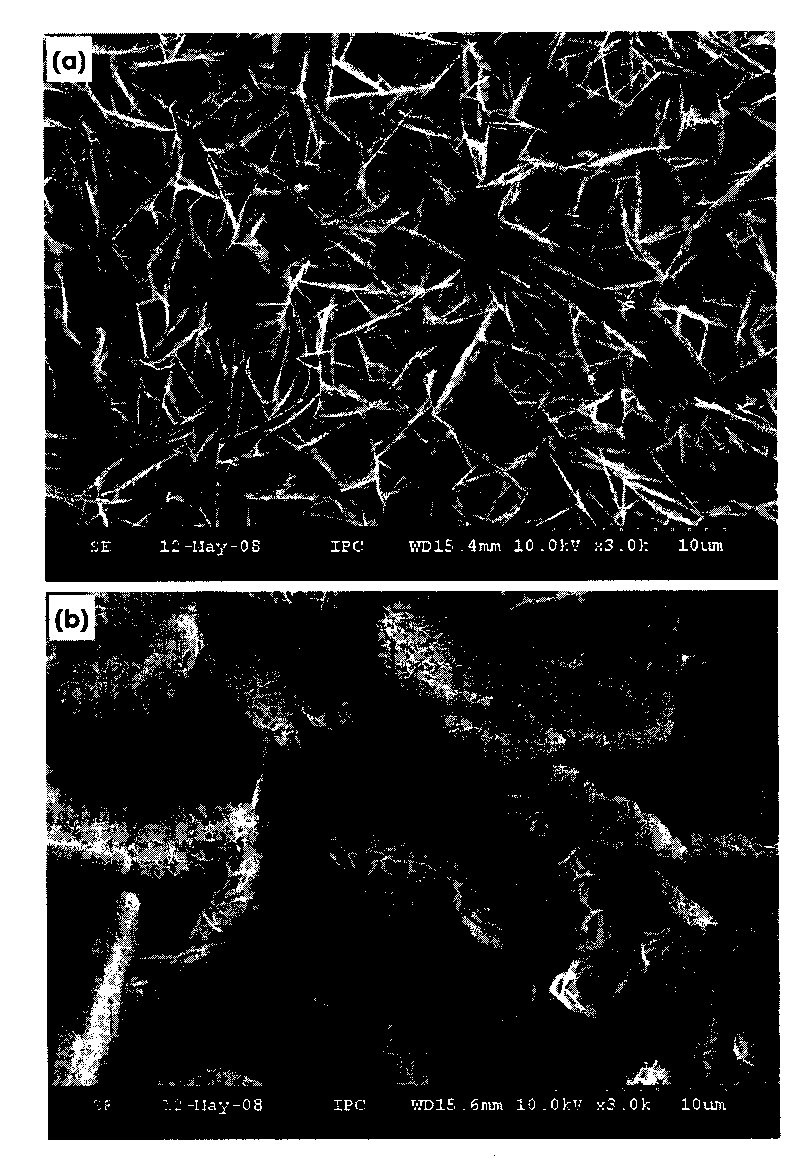

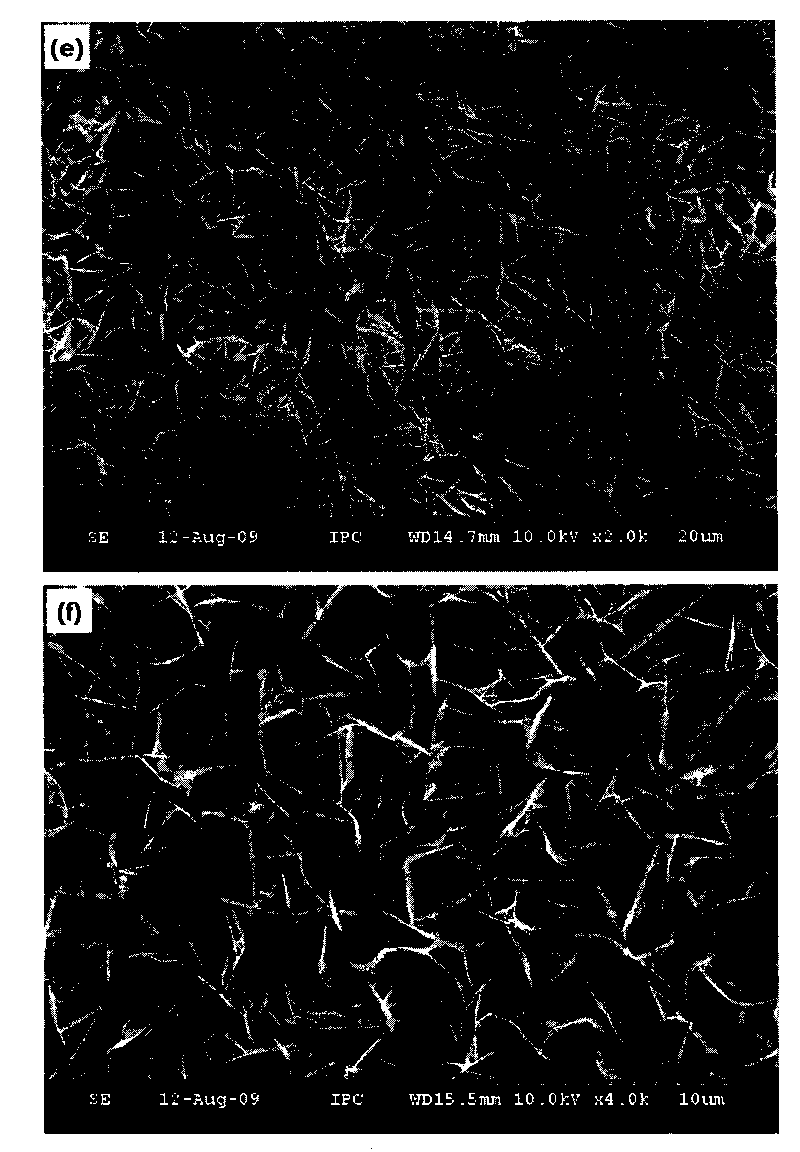

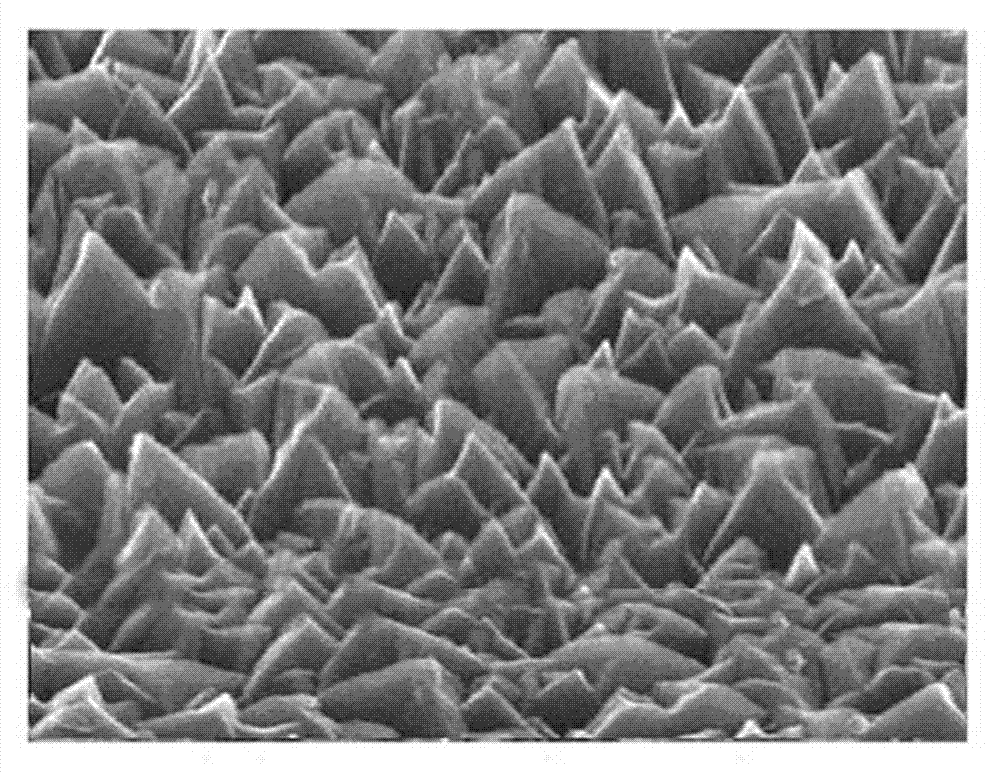

Method for preparing pile face doped zinc oxide transparent conductive film

InactiveCN101692357AImprove trapping effectImprove photoelectric conversion efficiencyConductive layers on insulating-supportsFinal product manufactureAluminum doped zinc oxideTrapping

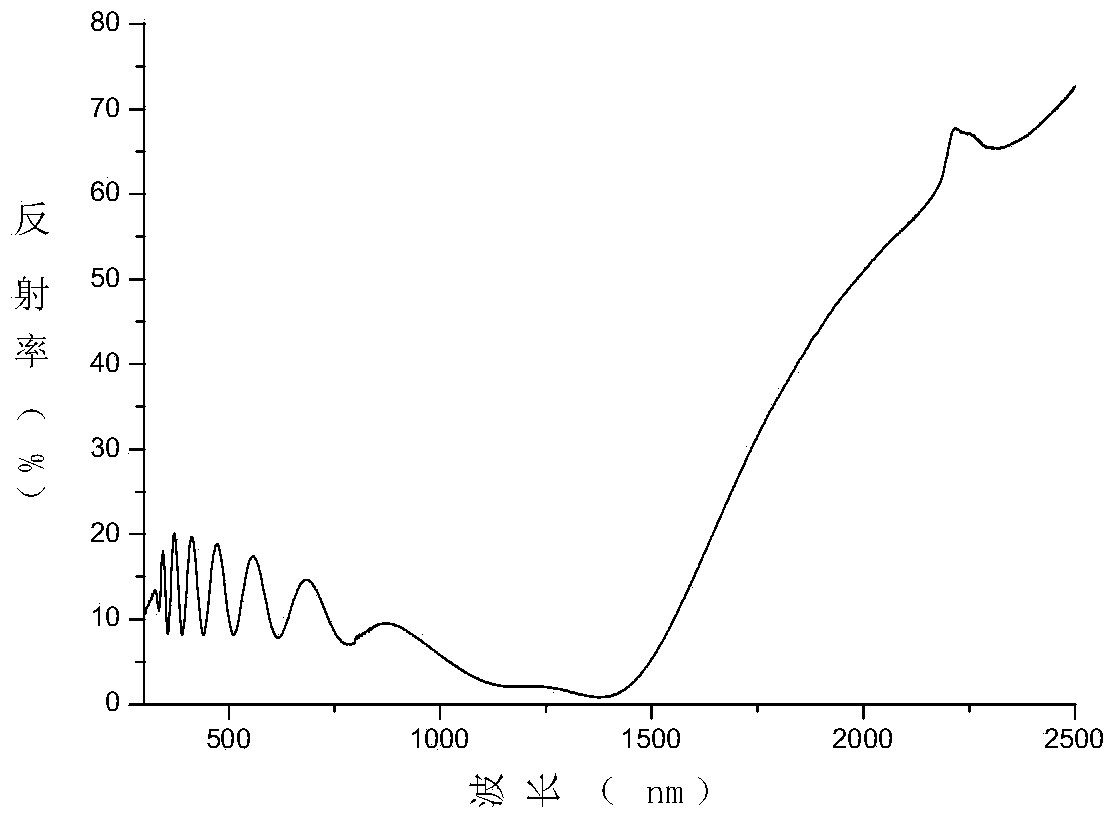

The invention discloses a method for preparing a pile face doped zinc oxide transparent conductive film. The method comprises magnetic control sputtering growth of an aluminum doped zinc oxide(ZnO:Al) transparent conductive film, preparation of a masking layer nanometer film and formation of a pile face structure by the wet method chemical etching treatment of the deposited transparent conductive film at a later stage. The ZnO:Al transparent conductive film is prepared by the non-reaction magnetic control sputtering deposition, and the target materials used in the magnetic control sputtering are ZnO:Al203 ceramic target materials at doping concentrations; and the pyramid-inversed pile face ZnO:Al transparent conductive film is prepared by designing a masking layer for the ZnO:Al transparent conductive film and adopting the wet method chemical etching. The method has the advantages that: the process is simplified; the cost is reduced; and the conductive film prepared by the method has good light trapping effect and can be widely used in various highly efficient photoelectric devices, flat panel displayers and film solar cells to improve efficiency of the devices, in particular in the preparation of the silicon film solar cells to improve the photoelectric conversion efficiency of the solar cells.

Owner:EAST CHINA NORMAL UNIV

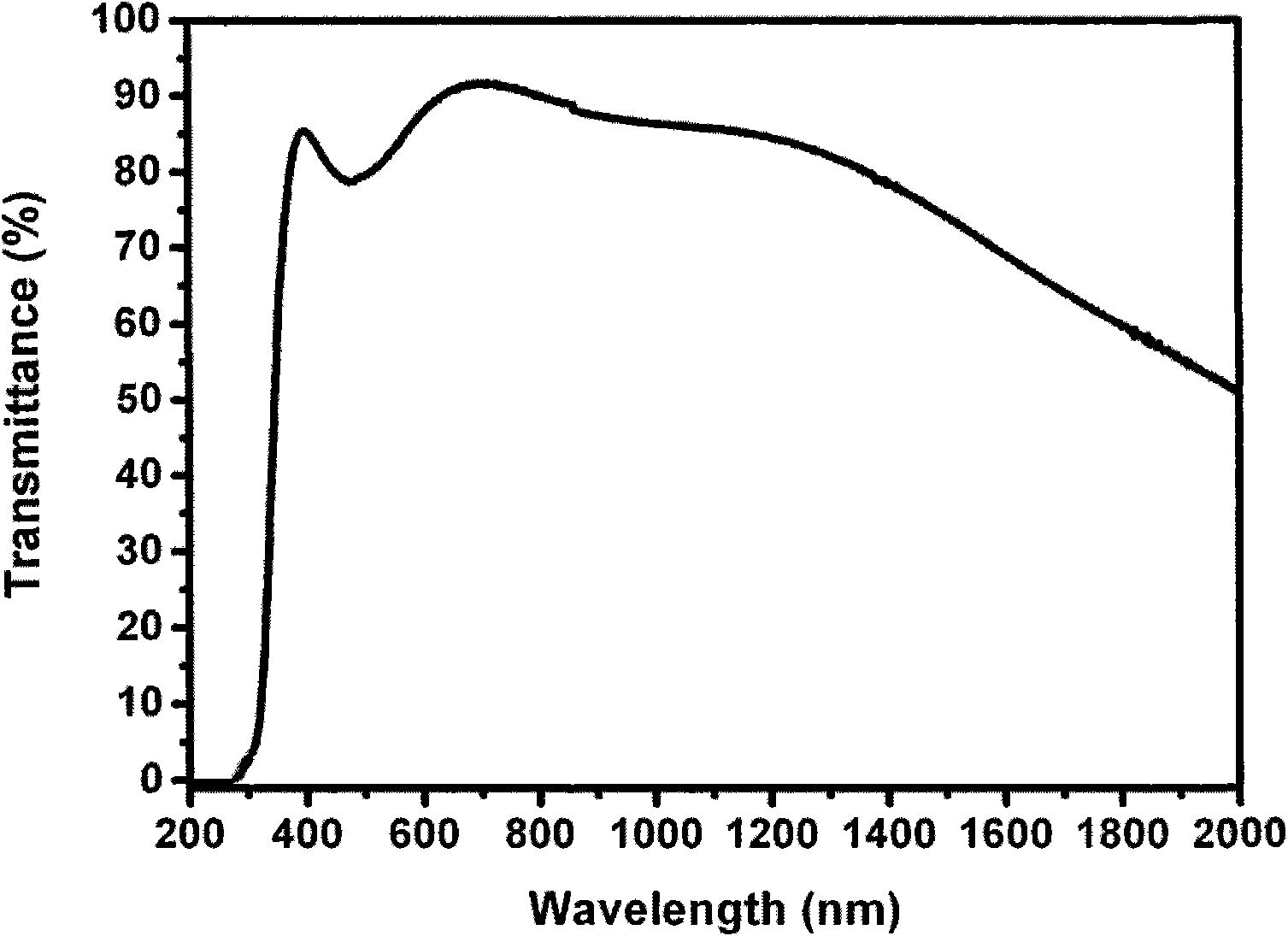

Water-based transparent heat-insulating paint used for energy-saving doors and windows and preparation method thereof

ActiveCN103351757AReduce usageRich varietyPolyurea/polyurethane coatingsWater basedAluminum doped zinc oxide

The invention discloses a water-based transparent heat-insulating paint used for energy-saving doors and windows. The paint comprises the following components by weight: 50 to 60% of an aqueous base latex, 20 to 30% of aqueous nanometer heat-insulating slurry, 0.5 to 1% of a defoaming agents, 1 to 5% of a thickening agent, 0.5 to 1% of a film forming auxiliary agent and 0.5 to 1% of a leveling agent, with the balance being deionized water, wherein the aqueous base latex is an aqueous acrylic resin emulsion with solid content of 30 to 60 wt% or an aqueous polyurethane resin emulsion with solid content of 30 to 60 wt%, and the aqueous nanometer heat-insulating slurry contains the two functional particles consisting of fluorine-doped tin oxide and aluminum-doped zinc oxide. The invention further discloses a preparation method for the paint. The paint prepared in the invention can be coated on the surface of door and window glass to form a transparent film; and the film can absorb the vast majority of ultraviolet light and obstruct more than 60% of infrared light and has average transmittance of more than 70% in a visible light area.

Owner:ZHEJIANG UNIV

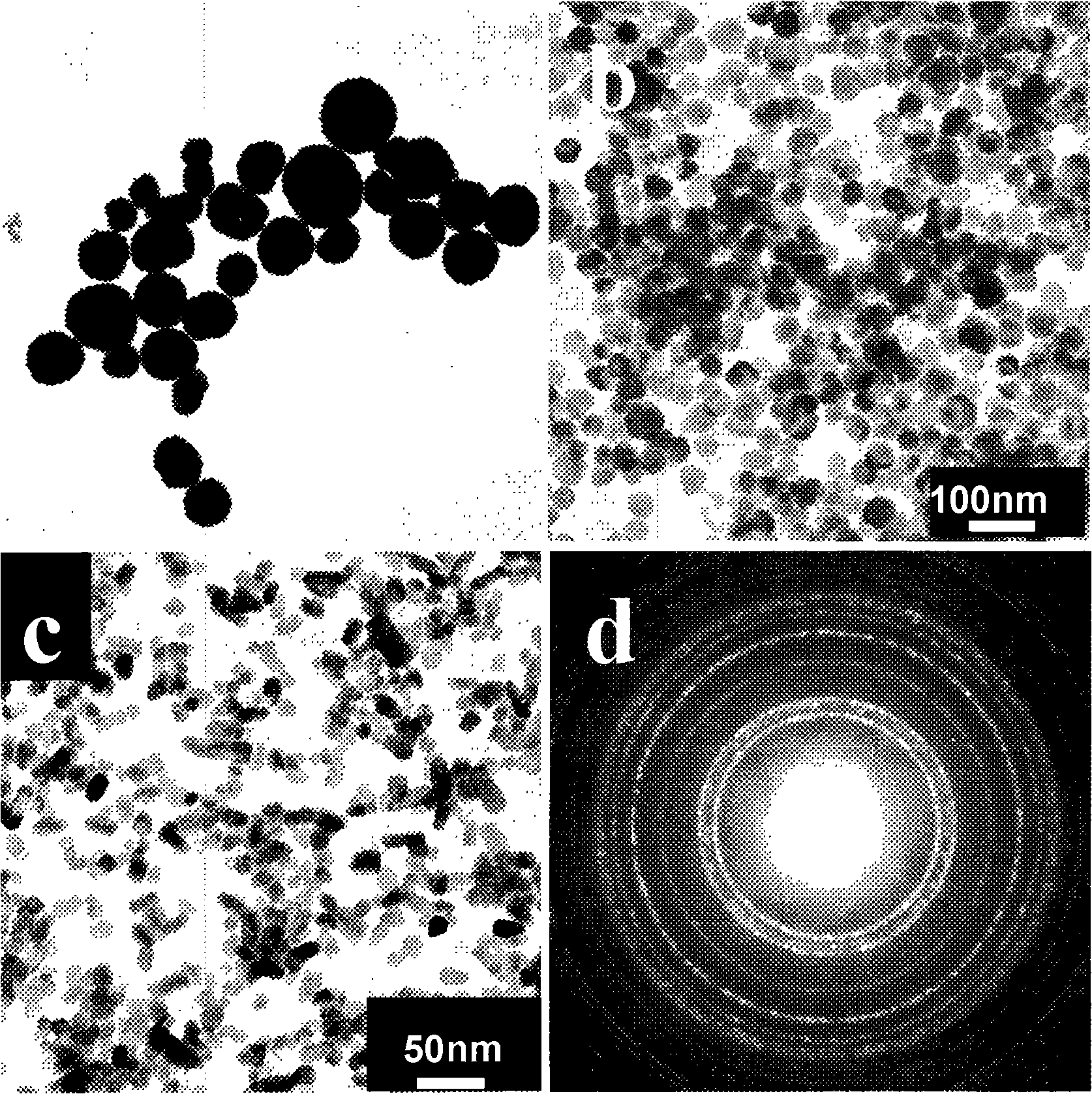

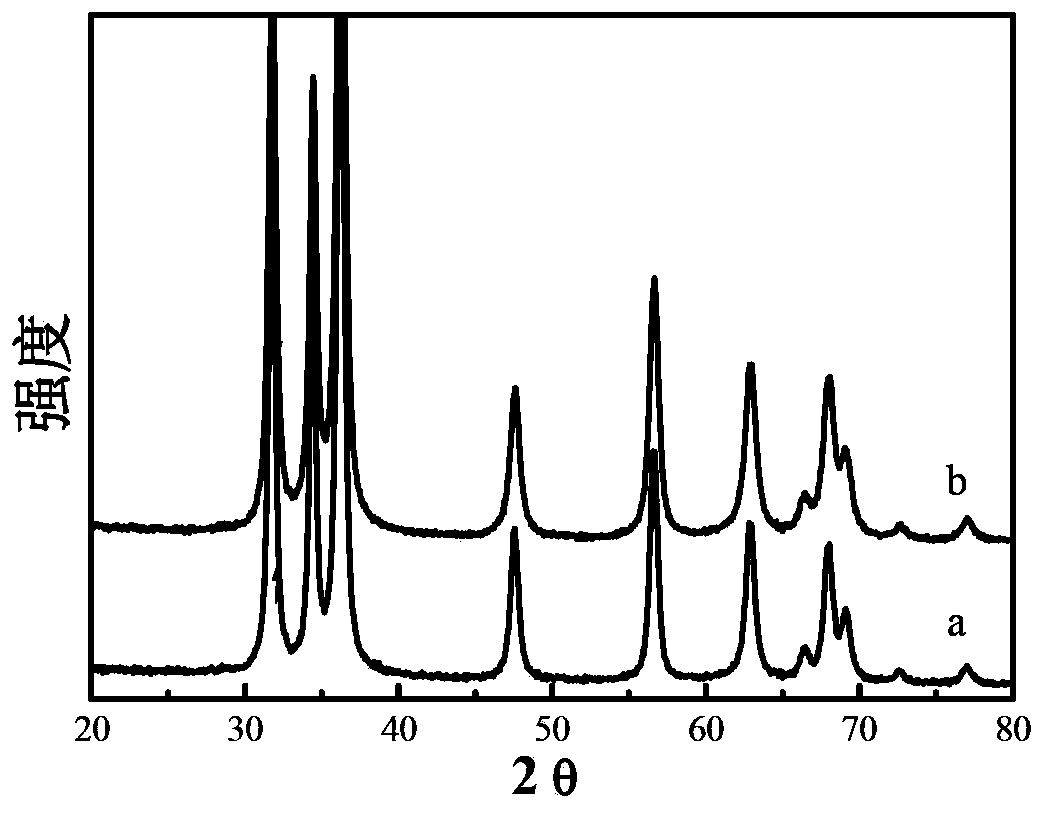

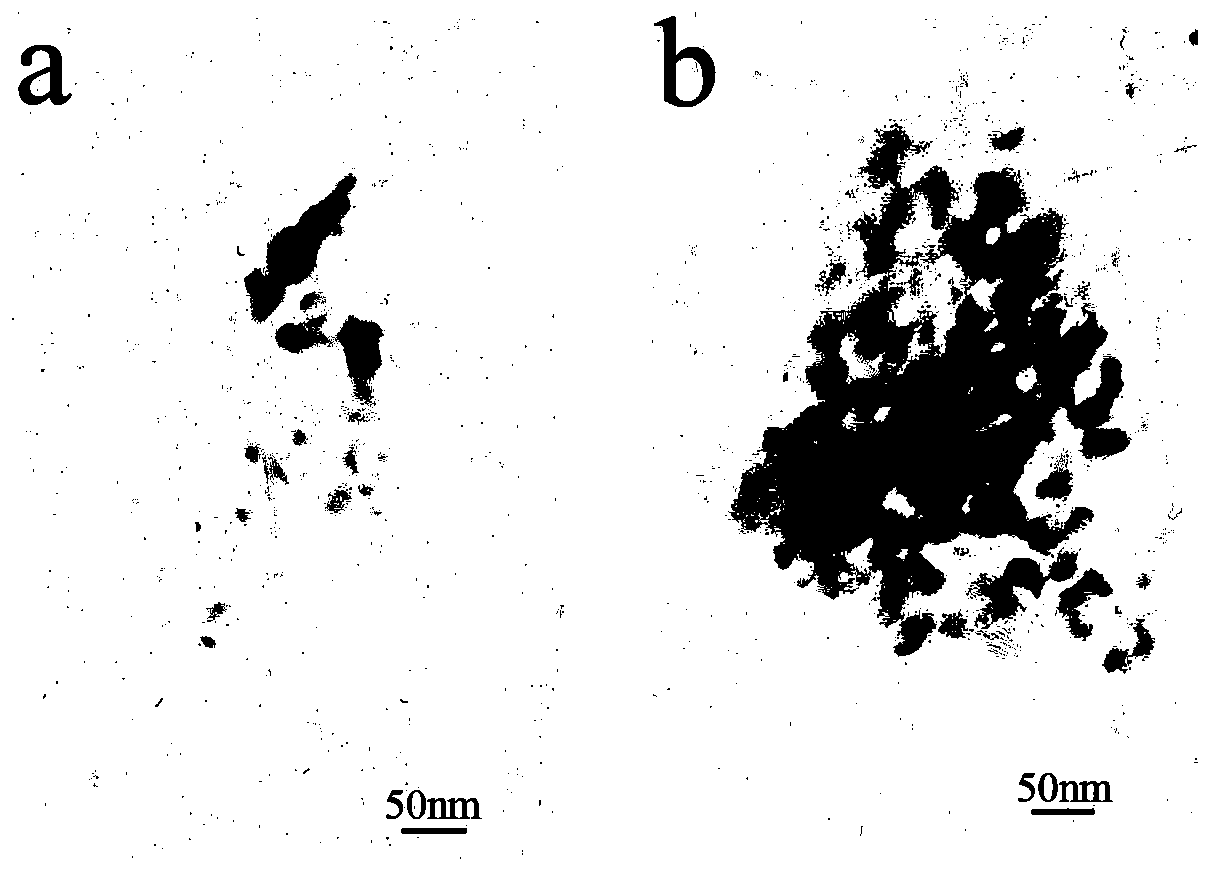

High-conductivity aluminum-doping zinc oxide nanometer noodles powder and preparation thereof

InactiveCN101274775AShape is easy to controlHigh crystallinityNanostructure manufactureZinc oxides/hydroxidesFiberDispersity

The invention provides high-conductivity aluminum-doped nano-zinc oxide powder and a preparation method thereof. The method of the invention comprises the steps that aluminum-doped zinc oxide nanocrystals are first prepared by solvothermal reaction and then sintered in the atmosphere of hydrogen to obtain nanometer-degree quasi-spherical conductive powder. The conductive powder is white and slightly gray and is non-toxic, light in weight and environment-friendly and also has less conglobation, good dispersity and repeatability and uniform size distribution; in addition, the particle size of the powder synthesized in different solvents is different and the minimum resistivity of the powder can reach 15 Omega cm and can be suitable for the various demands of products. The preparation method of the invention is simple in operation, short in period and low in cost, needs no surface active agents and templates and can be applied to mass production. The nanometer-degree conductive powder obtained by utilizing the method can be taken as conductive filler to be widely applied to fields such as paints, rubber, plastics and fibers, etc., for carrying out electrostatic prevention and electromagnetic shielding.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

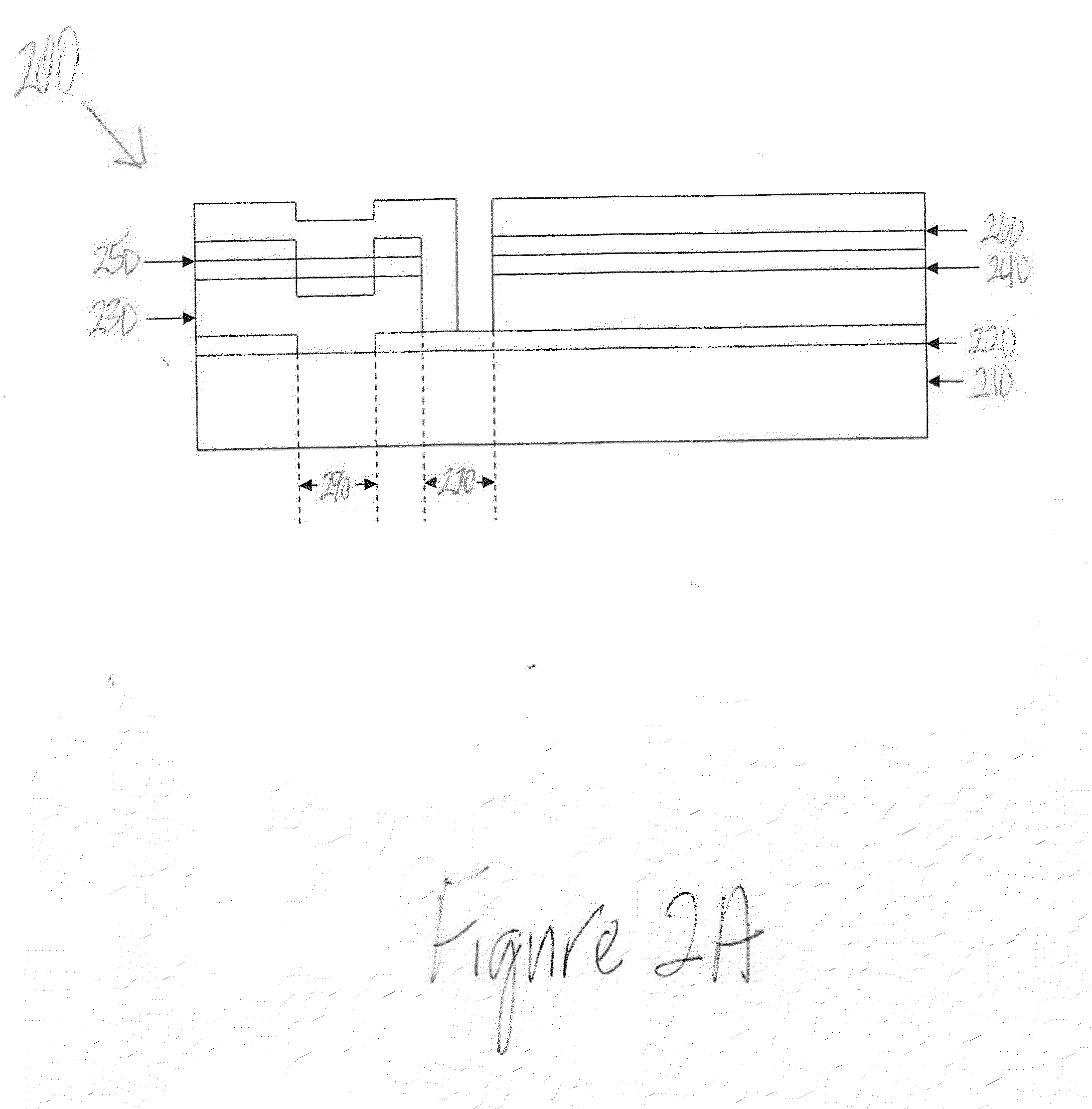

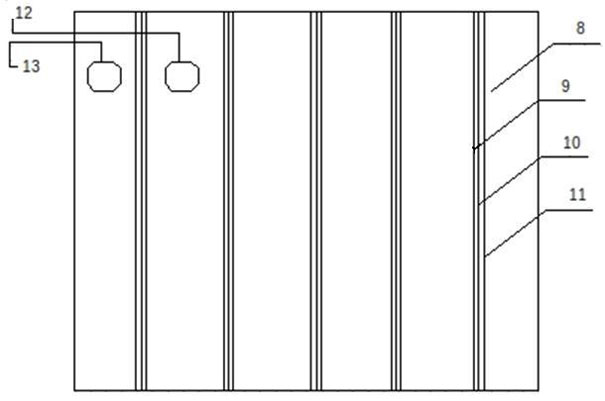

Full-laser grooving and scribing method of large-area copper indium gallium selenide (CIGS) thin-film solar cell assembly

ActiveCN104993013AIncrease component powerReduce dead areaFinal product manufactureSemiconductor/solid-state device manufacturingIndiumAluminum doped zinc oxide

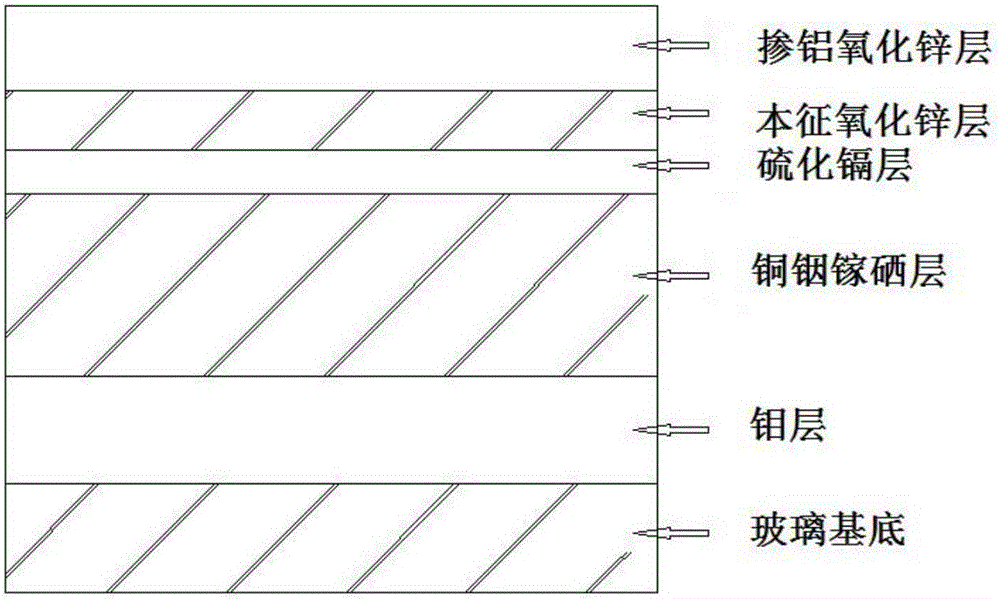

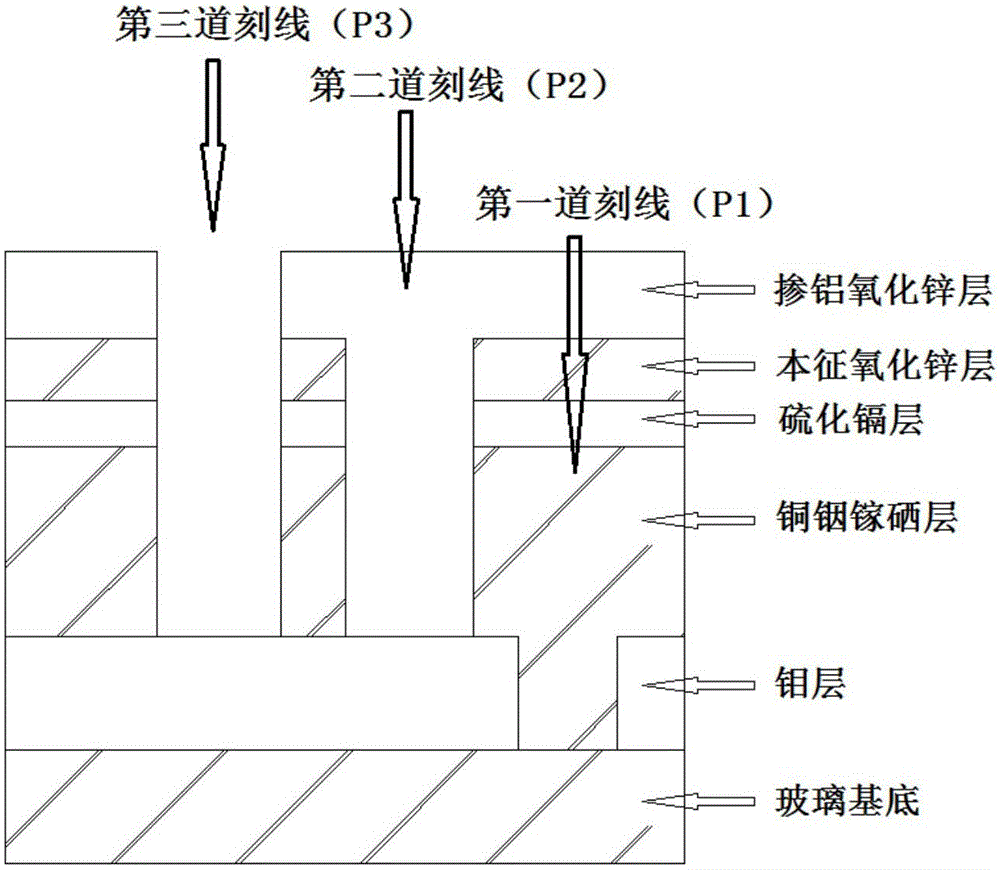

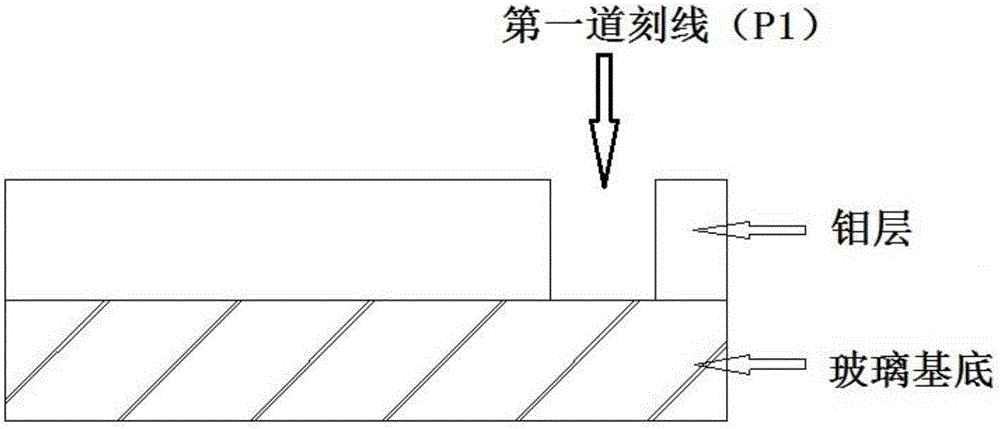

The invention provides a full-laser grooving and scribing method of a large-area copper indium gallium selenide (CIGS) thin-film solar cell assembly. The method comprises steps of using a laser to groove and scribe a molybdenum thin film prepared on soda-lime glass so as to form a first scribed line (P1); successively preparing a CIGS layer, a cadmium sulfide layer and an intrinsic zinc oxide layer on the molybdenum layer where the P1 has been grooved and scribed; after finishing the above film layer preparation, using a laser to perform grooving and scribing so as to form a second scribed line (P2) which is parallel to the P1; and after preparing an aluminum-doped zinc oxide layer on the intrinsic zinc oxide layer where the P2 has been grooved and scribed, using a laser to perform grooving and scribing so as to form a third scribed line (P3) which is parallel to the P1. According to the invention, inner join is performed for the CIGS thin-film solar cell assembly by the laser grooving and scribing method, so defects of large area of dead zones and frequency change of machinery needles in traditional machinery grooving and scribing technology can be overcome, thereby increasing efficiency of the assembly, improving stability of the grooving and scribing device and achieving objectives to reduce production cost and improve production efficiency.

Owner:BEIJING SIFANG JIBAO AUTOMATION

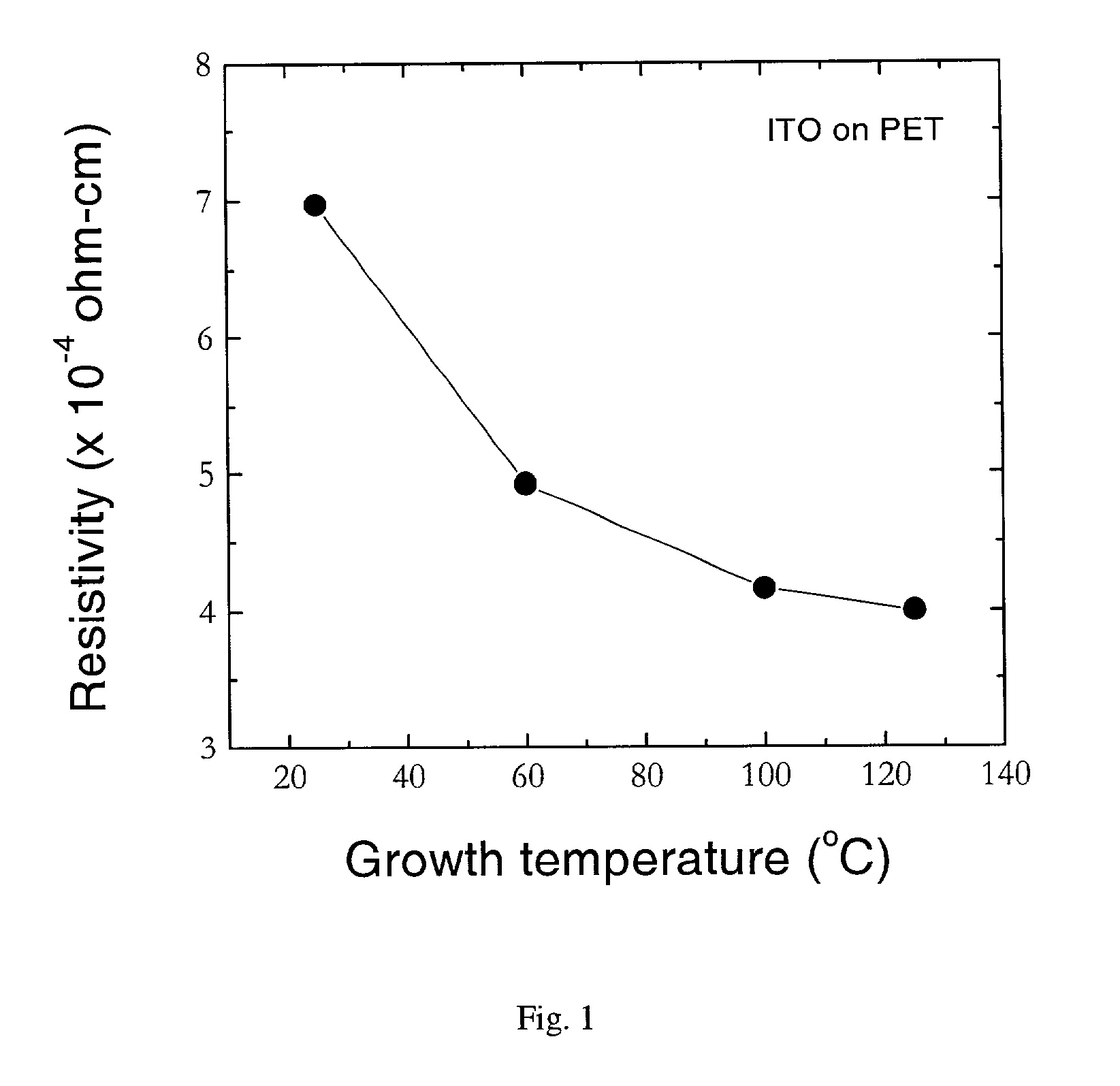

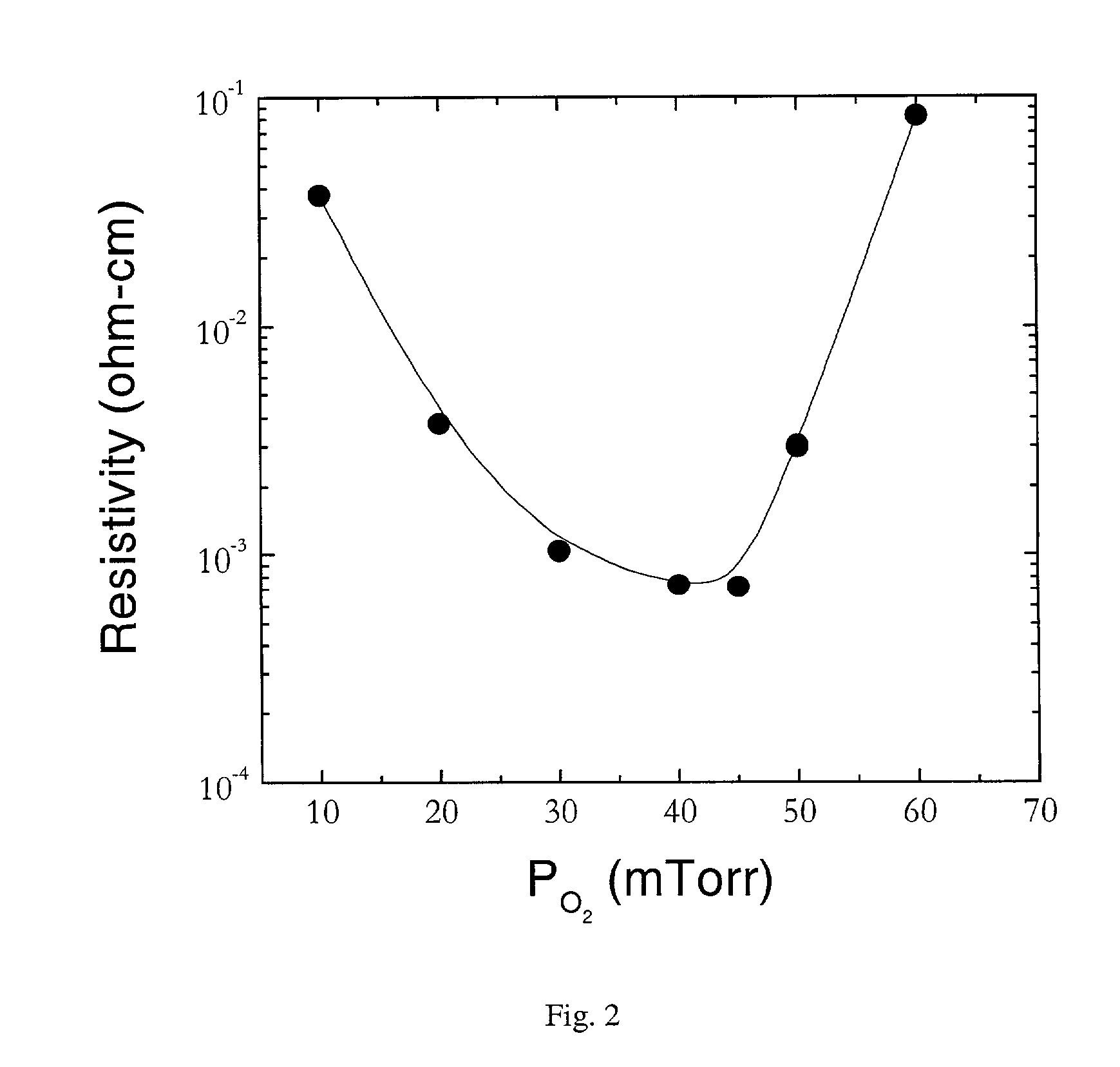

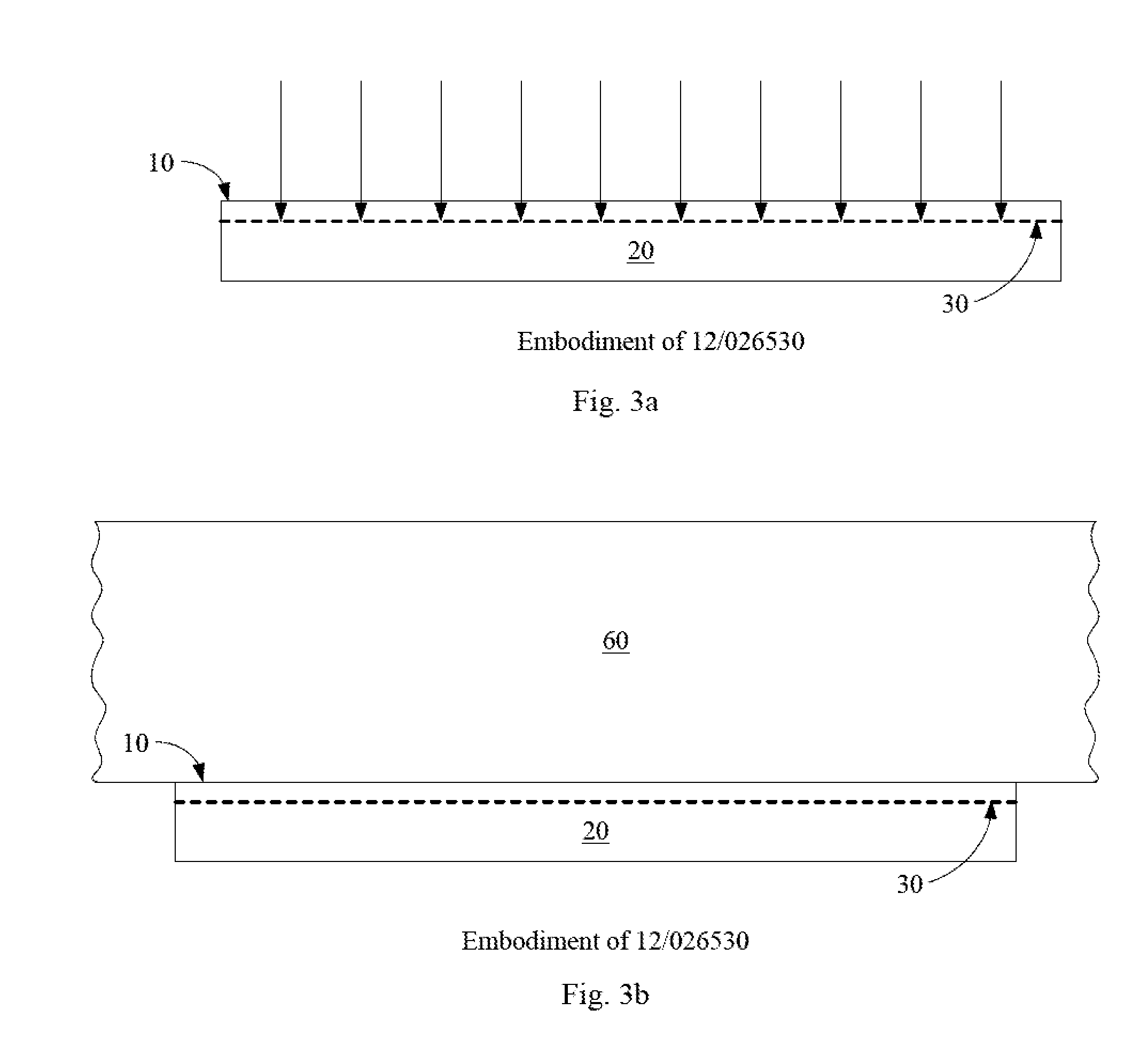

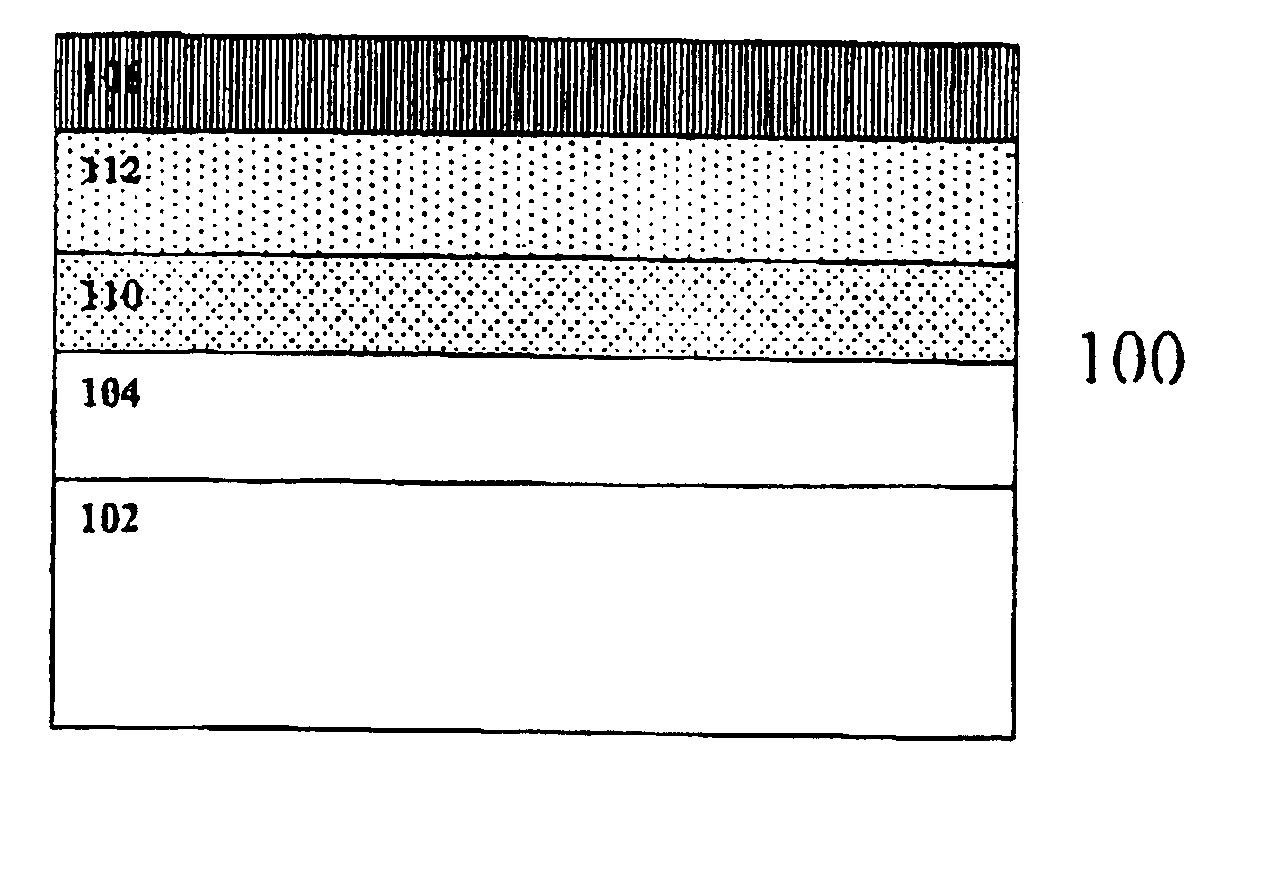

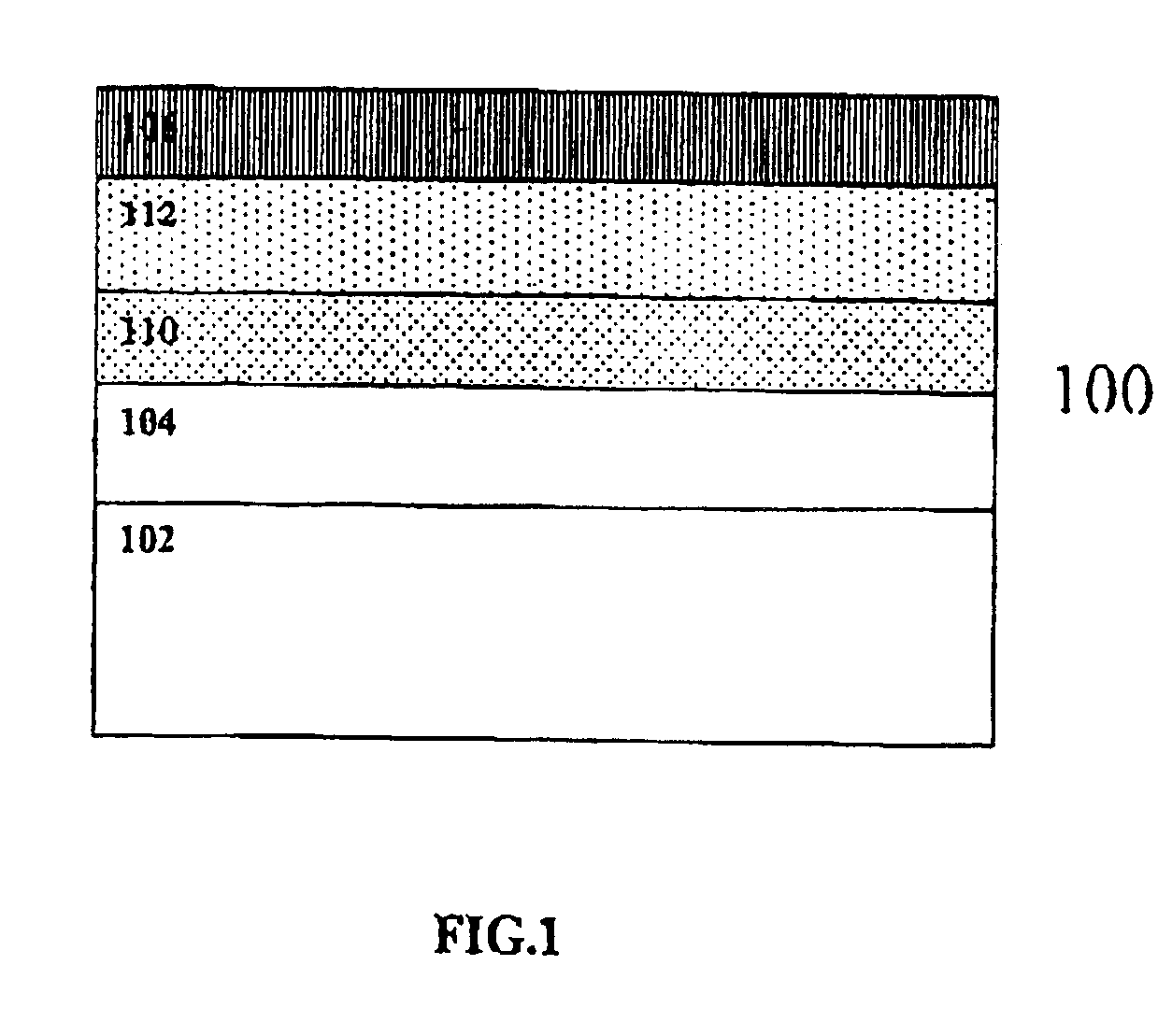

Pulsed laser deposition of transparent conducting thin films on flexible substrates

InactiveUS20020098668A1Flat surfaceGood light transmissionSolid-state devicesSemiconductor/solid-state device manufacturingIndiumAluminum doped zinc oxide

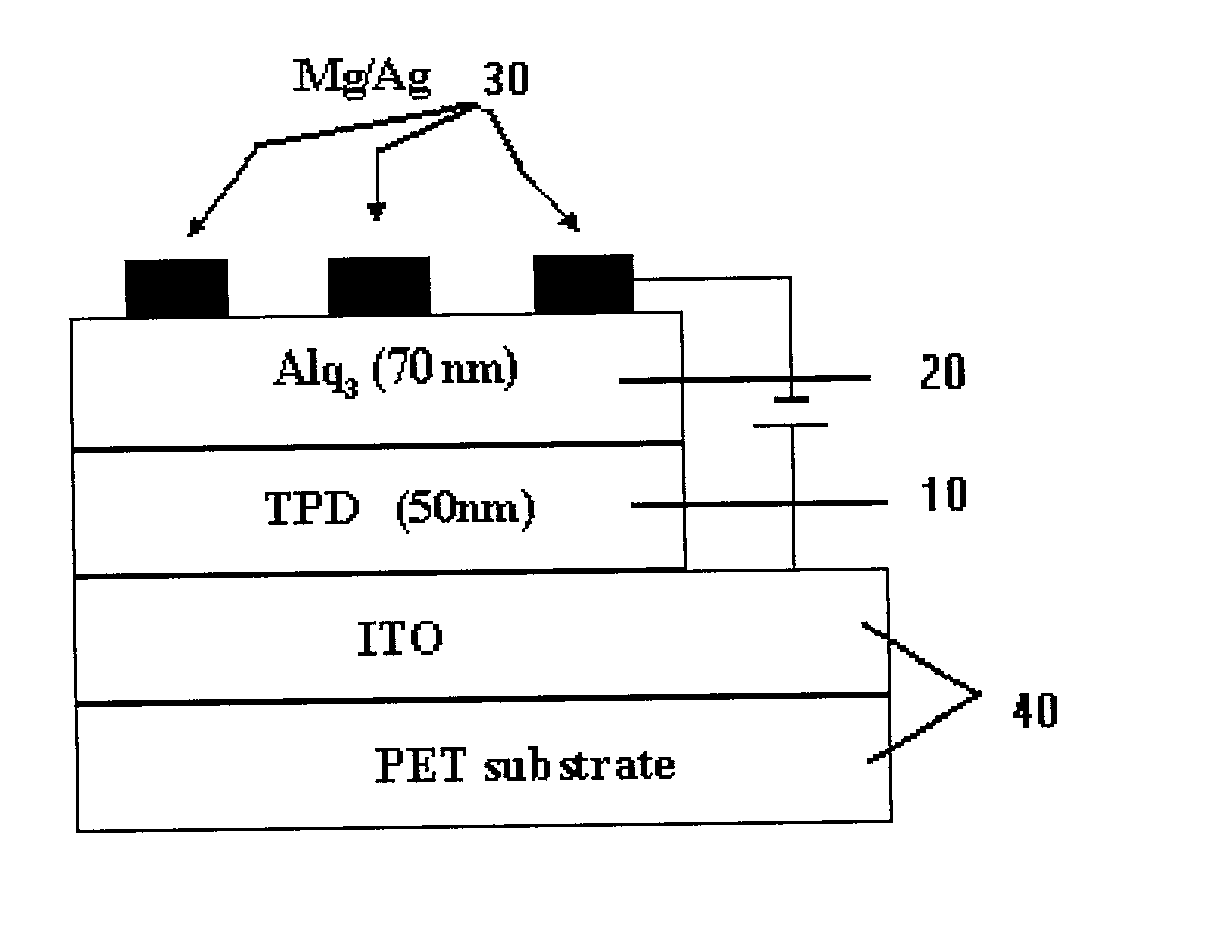

The invention relates to the deposition of transparent conducting thin films, such as transparent conducting oxides (TCO) such as tin doped indium oxide (ITO) and aluminum doped zinc oxide (AZO) on flexible substrates by pulsed laser deposition. The coated substrates are used to construct low cost, lightweight, flexible displays based on organic light emitting diodes (OLEDs).

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

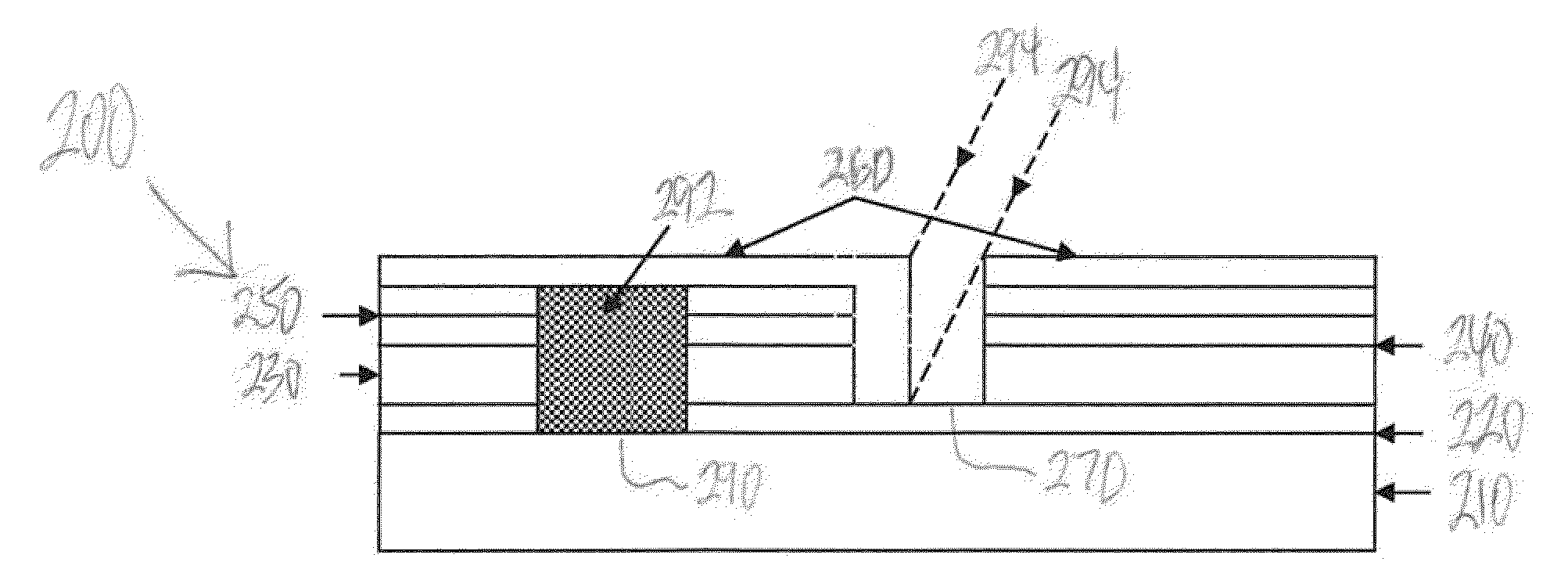

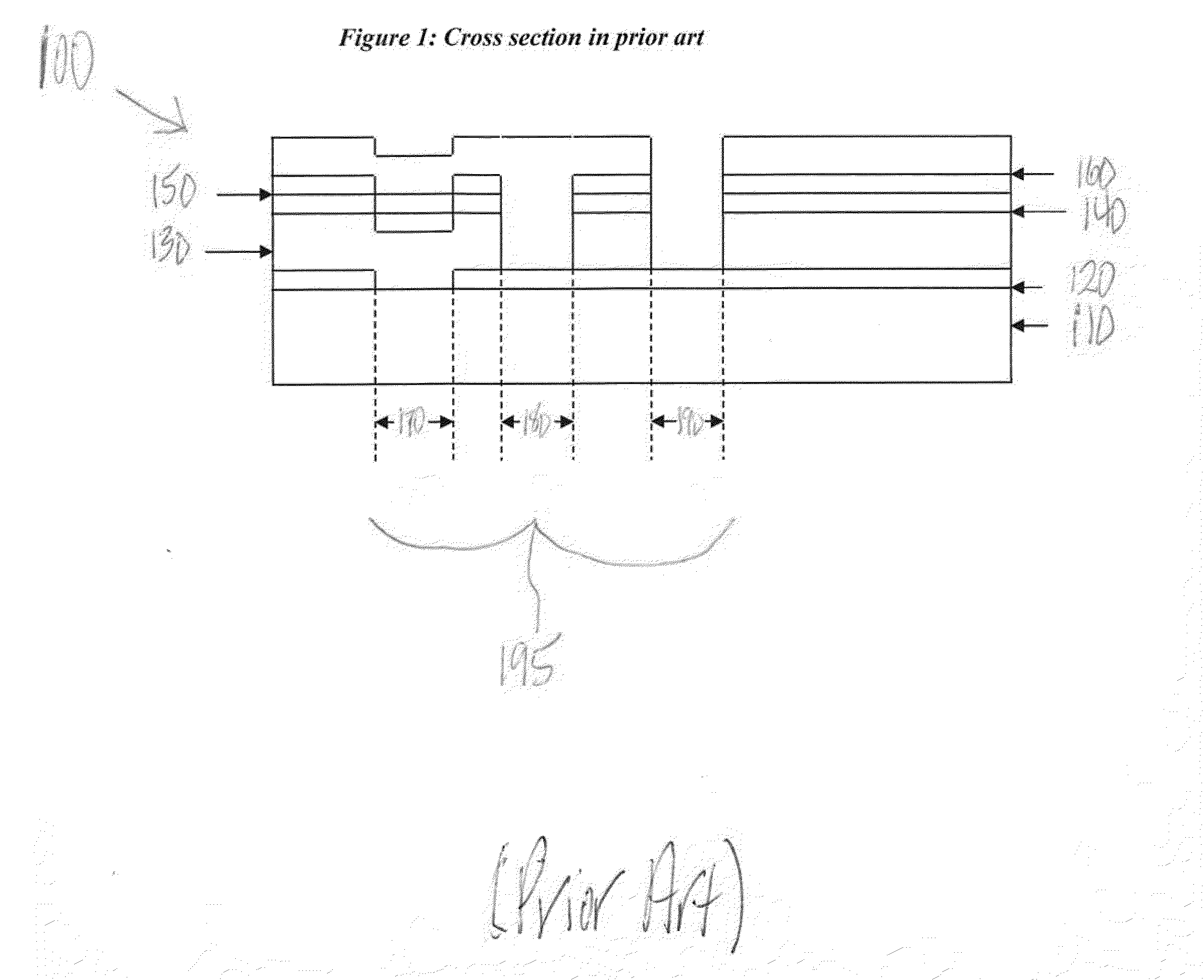

Method and device for scribing a thin film photovoltaic cell

InactiveUS20110240118A1Increase productionIncrease powerVacuum evaporation coatingSputtering coatingIndiumAluminum doped zinc oxide

The present invention is a method for scribing a thin film solar cell that includes a soda lime glass substrate, a film of molybdenum (Mo), a film of copper indium gallium diselenide (GIGS), a buffering layer, a layer of zinc oxide (i-ZnO), a layer of aluminum doped zinc oxide (n-ZnO:Al or AZO), a first scribe, a conductive link and a second scribe. The method steps include producing the first scribe on the Mo film, depositing the CICS film, the buffering layer and the zinc oxide layer onto the Mo film, producing the second scribe on the CICS film, the zinc oxide layer and the buffering layer above the Mo film, depositing and filling a first insulating material into the first scribe. and depositing a second insulating material that covers the solar cell while filling the first scribe forming a conduction layer.

Owner:BEATTY PAUL HANLON JAMES

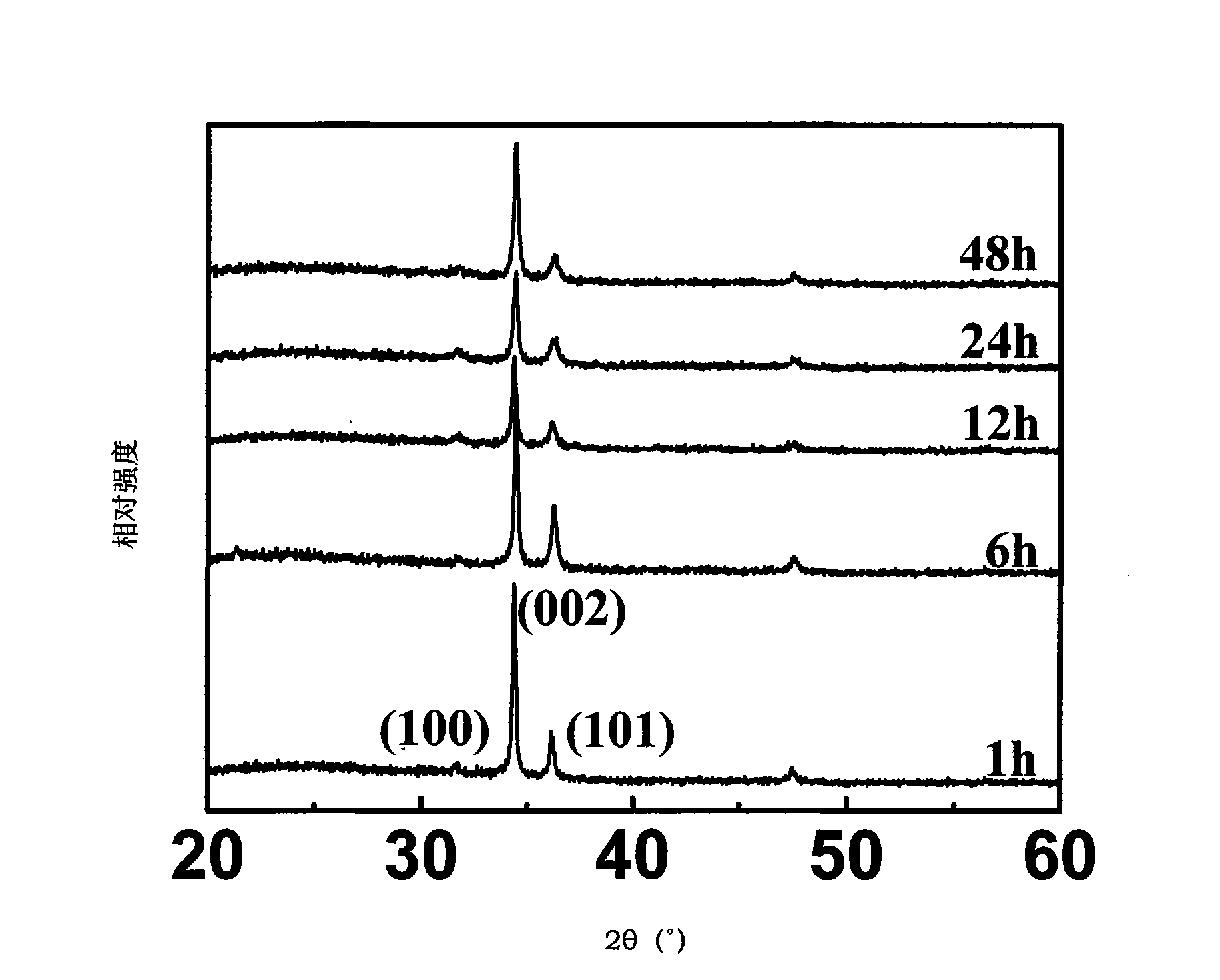

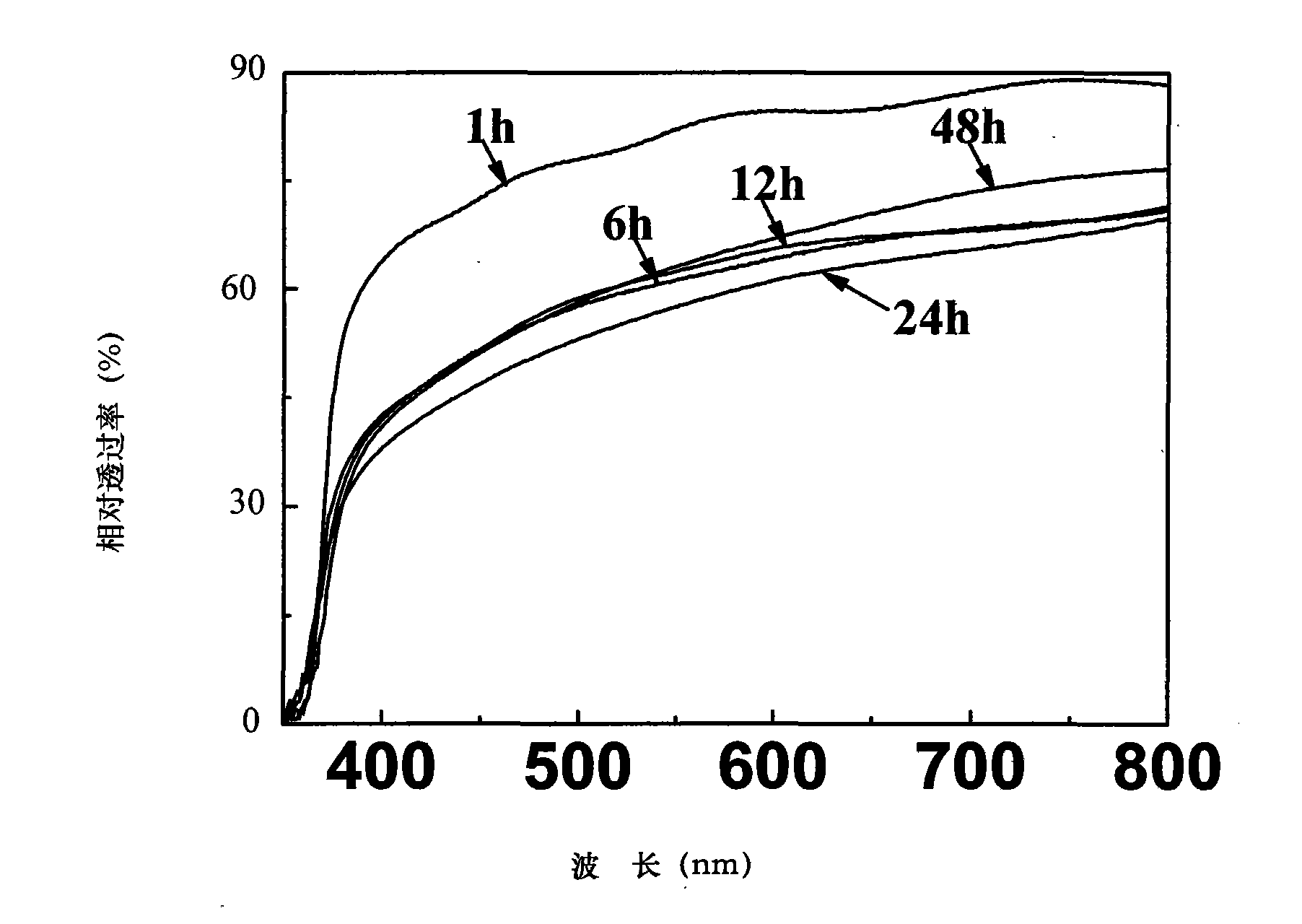

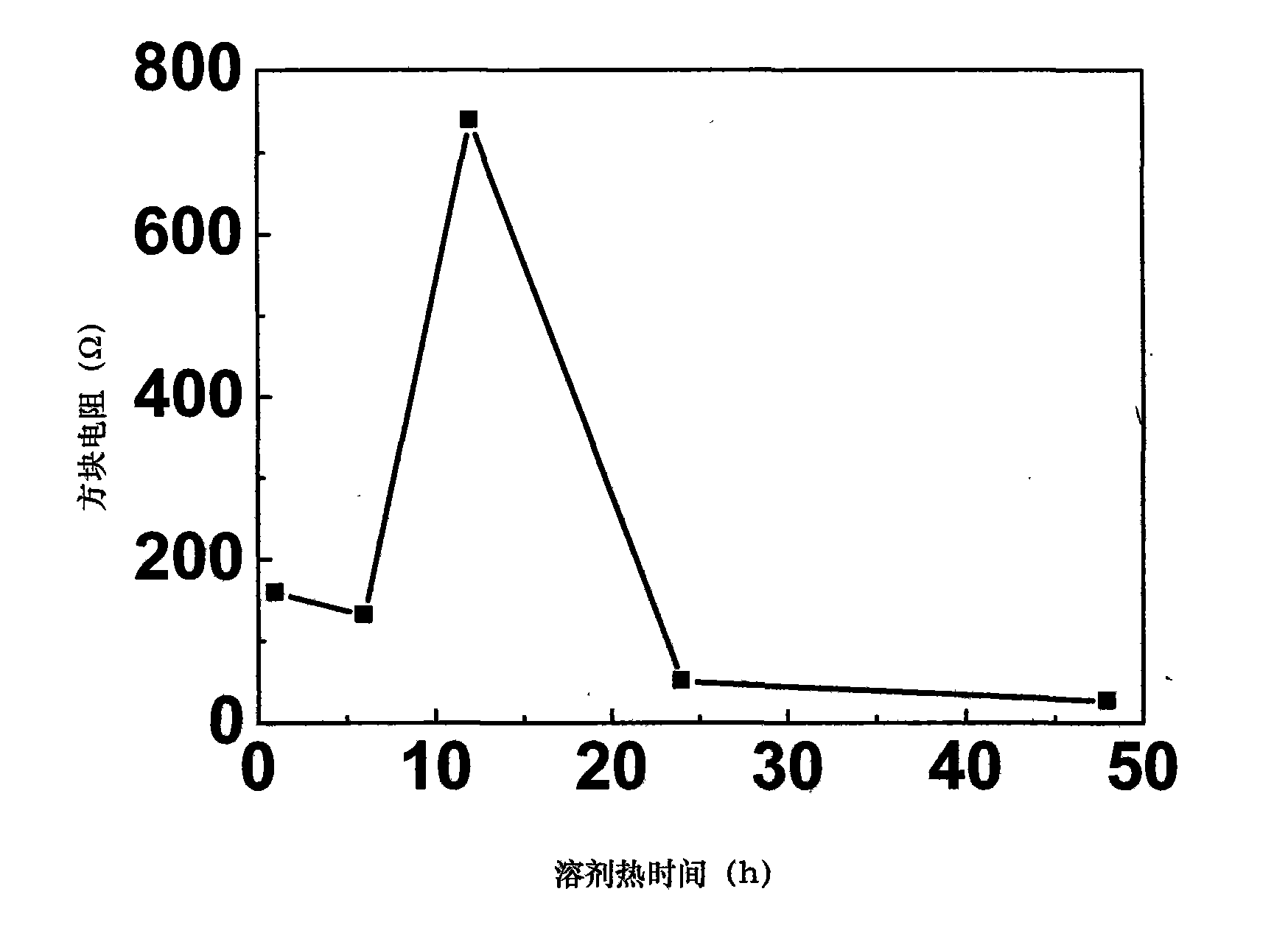

Method for preparing aluminium-doped zinc oxide transparent conductive film by solvent thermal process

InactiveCN101629284AAchieve preparationQuality improvementLiquid/solution decomposition chemical coatingAluminum doped zinc oxideSolvent

The invention discloses a method for preparing an aluminium-doped zinc oxide transparent conductive film by solvent thermal process; soluble organic slat and inorganic slat of zinc are taken as precursors, and the aluminium-doped zinc oxide transparent conductive film is deposited on a substrate by the solvent thermal process. By controlling the concentration of reactant precursor liquid, the aluminium ion doping quantity, the thermal reaction temperature of solvent, the thermal reaction time of the solvent, the cooling way of a reaction kettle and the filling amount of the reaction kettle, the technique can deposit the aluminium-doped zinc oxide transparent conductive film on the substrate at the temperature of below 200 DEG C; furthermore, the visible light transmission of the film can reach 80%, and the square resistance is less than 760 omega.

Owner:BEIHANG UNIV

Laminated diffractive optical element and resin composition therefor

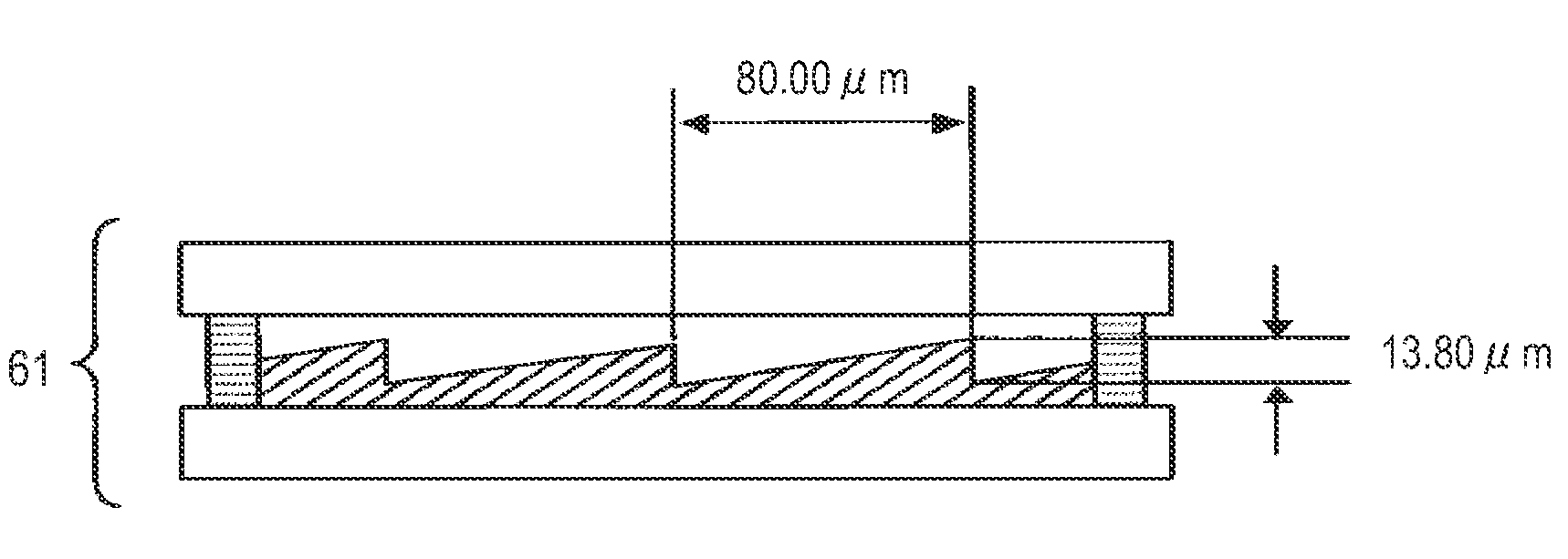

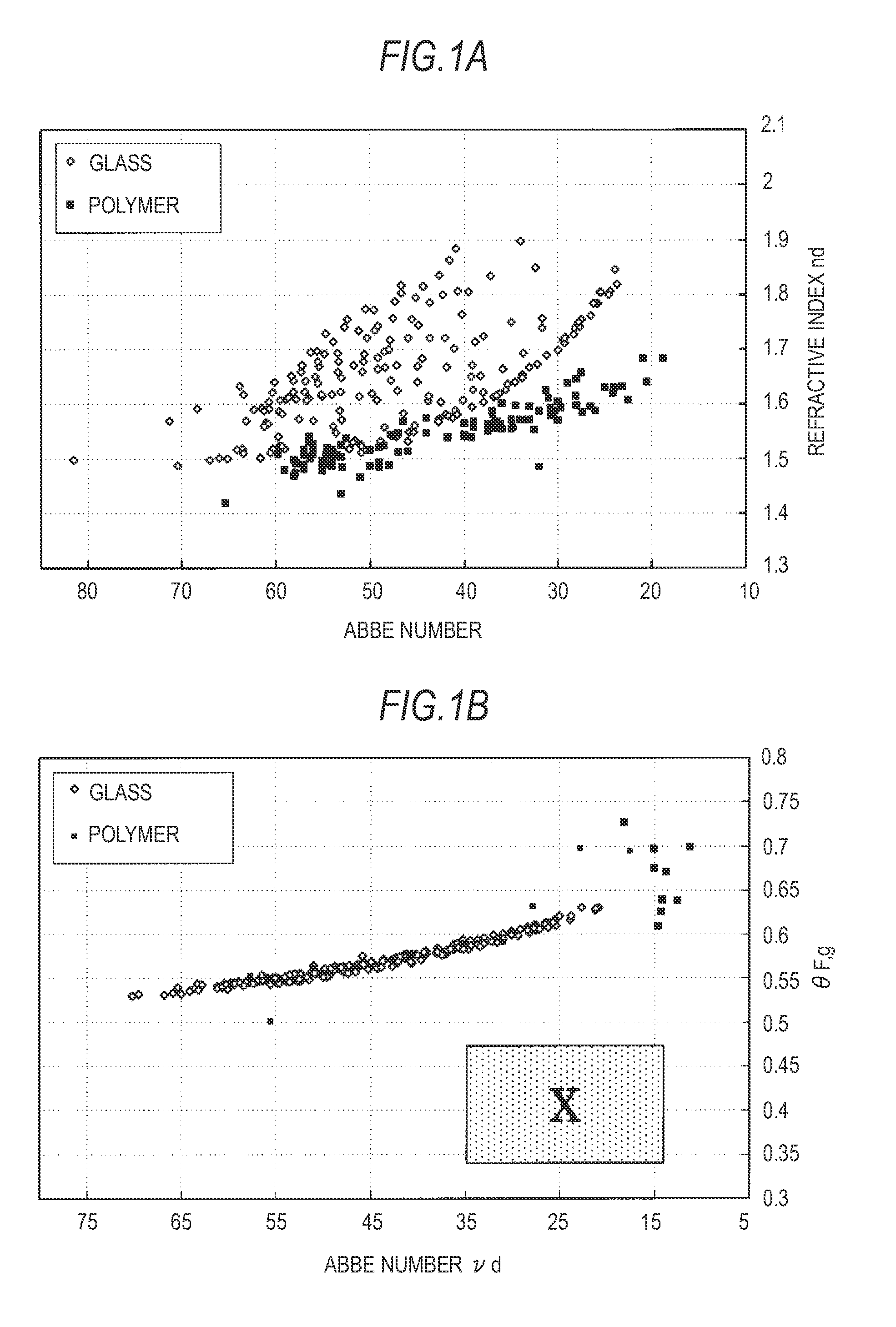

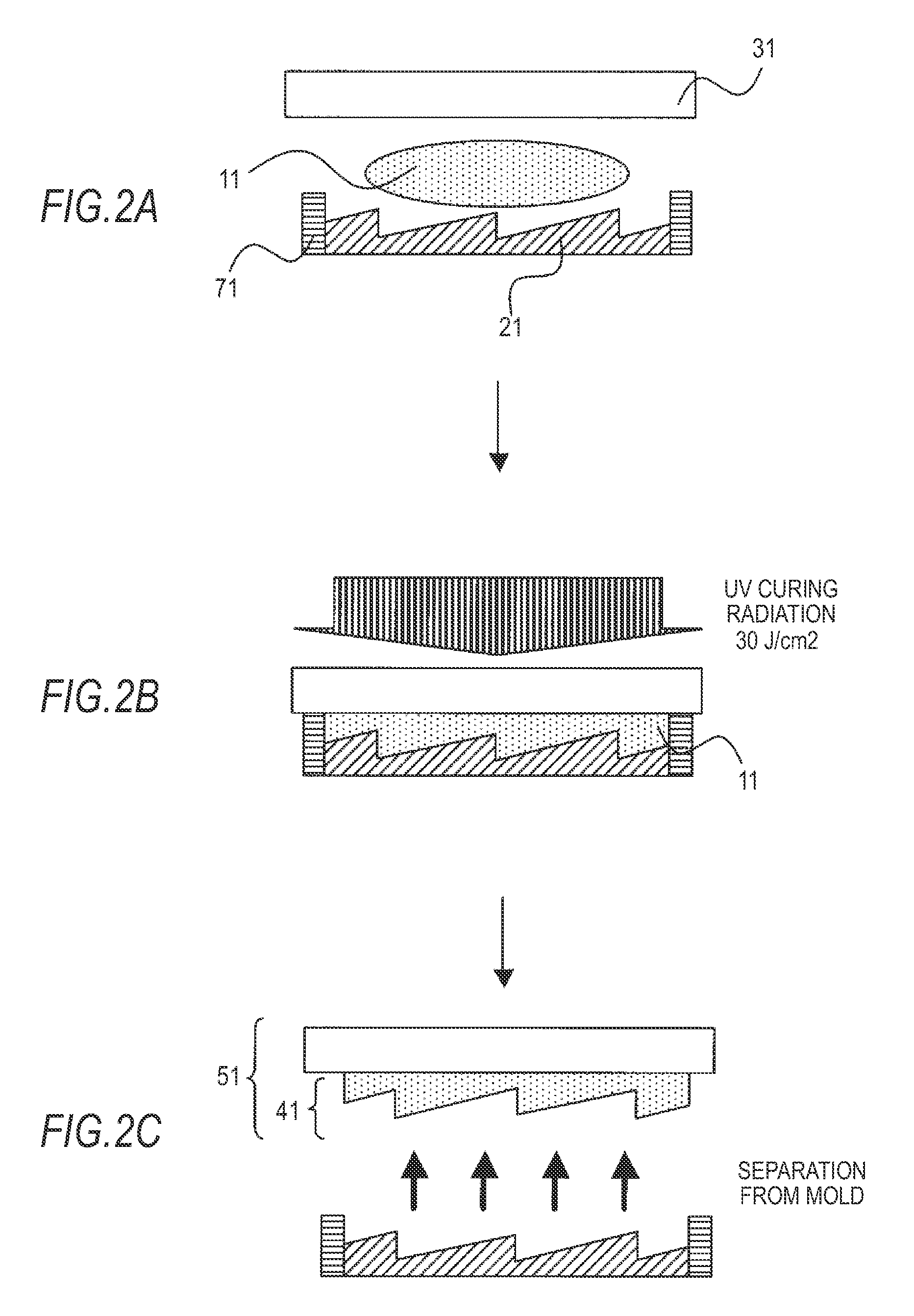

InactiveUS20090190224A1Eliminate the effects ofReliable environmentPhotomechanical apparatusOptical articlesTin dioxideAluminum doped zinc oxide

A resin composition includes a binder component having at least one of a monomer and an oligomer of one or more of a fluorine system and a silicone system having a polymerizable functional group in a molecule. The resin composition also includes fine metal oxide particles, and a polymerization initiator. The fine metal oxide particles include particles selected from the group of zinc oxide, indium oxide, tin oxide, antimony oxide, tin-doped indium oxide (ITO), antimony-doped tin oxide (ATO), zinc-doped indium oxide (IZO), aluminum-doped zinc oxide (AZO), and fluorine-doped tin oxide (FTO).

Owner:CANON KK

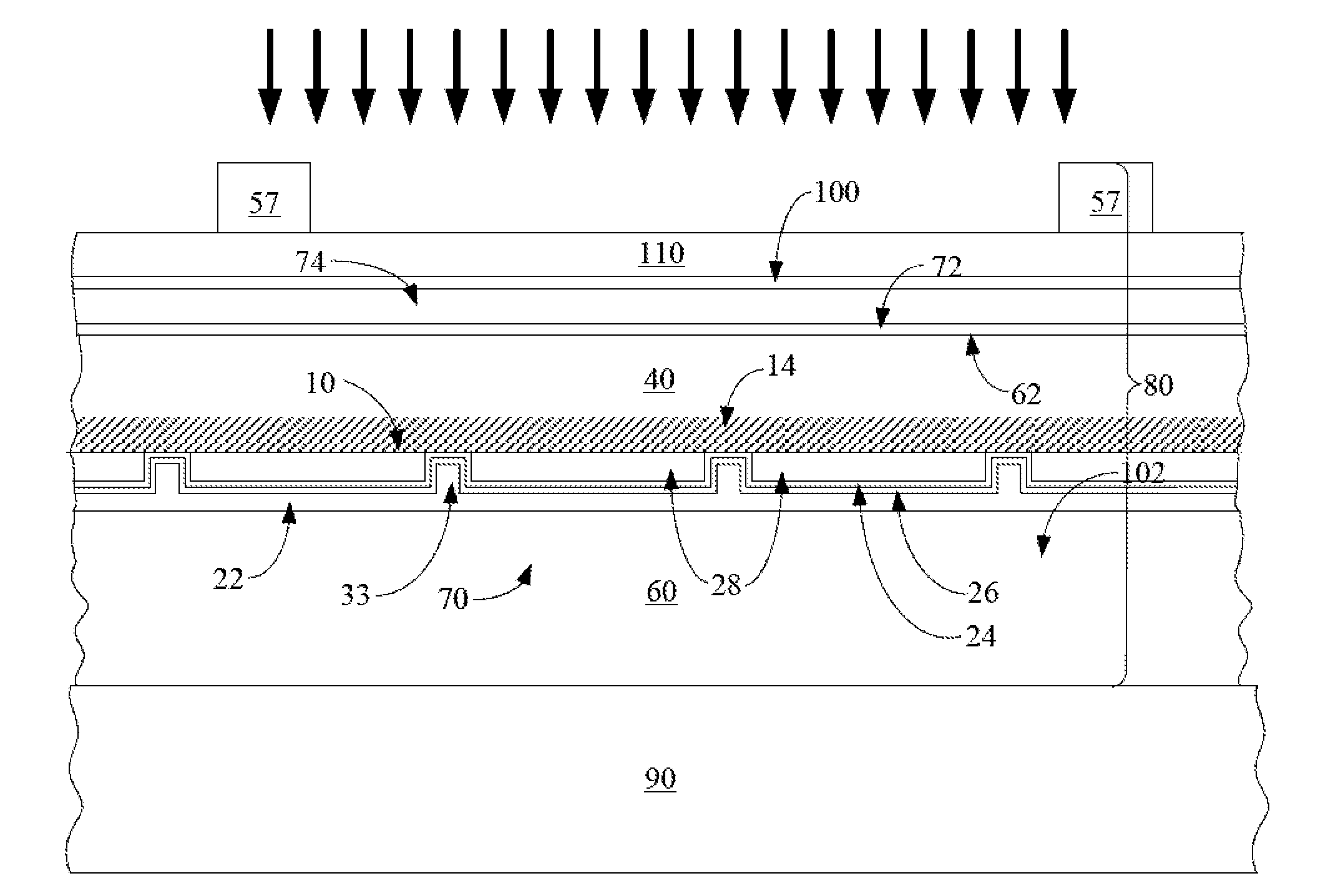

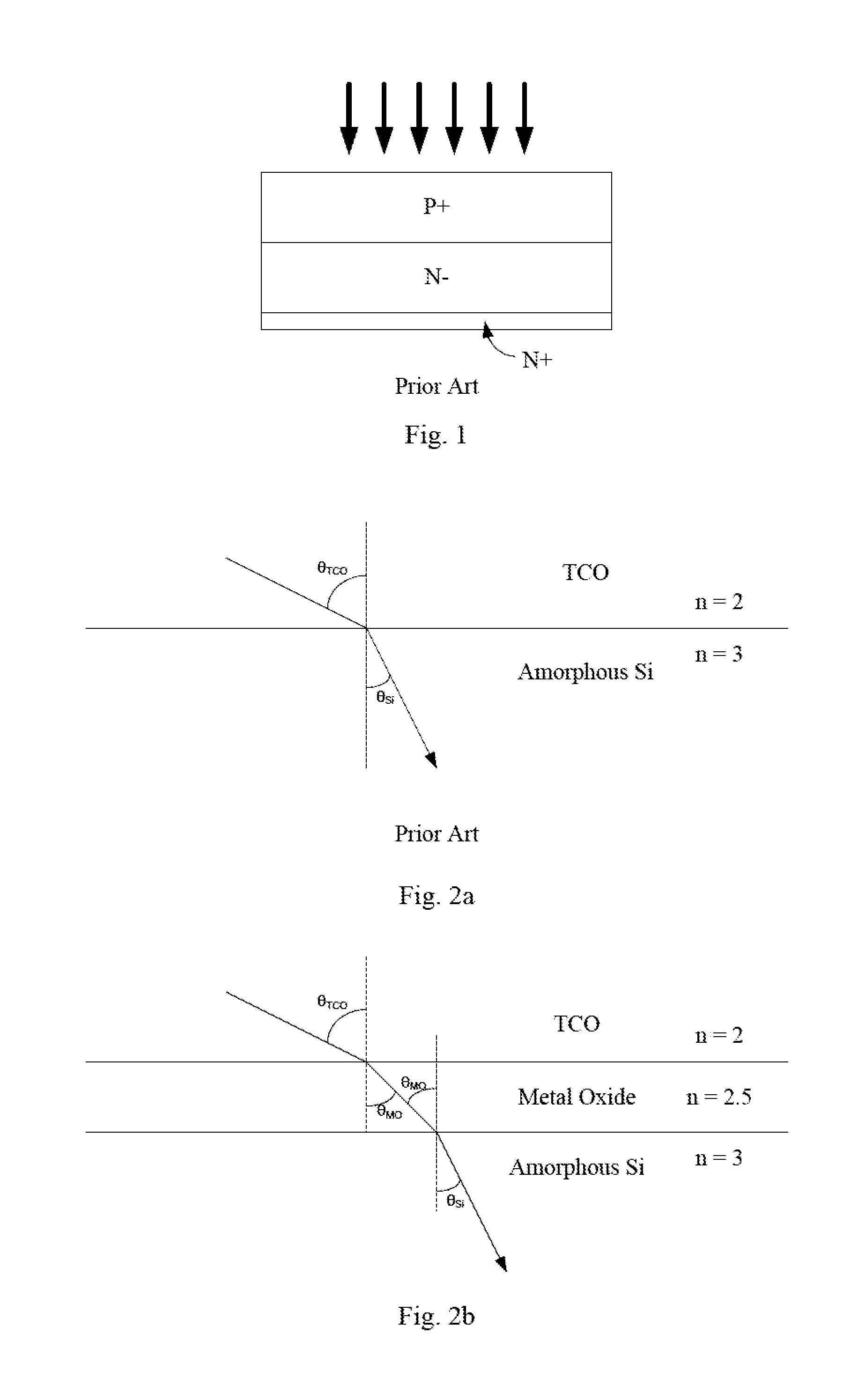

Semiconductor assembly with a metal oxide layer having intermediate refractive index

InactiveUS20120080083A1Reduce light reflectionFinal product manufactureSemiconductor/solid-state device manufacturingThin metalAluminum doped zinc oxide

A semiconductor assembly is described with a thin metal oxide layer interposed between a transparent conductive oxide and an amorphous silicon layer, along with methods for making this structure. The metal oxide layer has a refractive index or range of refractive indices intermediate between that of the transparent conductive oxide and the amorphous silicon layer, and thus tends to reduce reflection at the interface. Such a layer can be used at the light-facing surface of a light-sensitive device such as a photovoltaic cell to maximize the amount of incident light entering the cell. Titanium oxide is a suitable metal oxide, and has a refractive index between those of silicon and of both indium tin oxide and aluminum-doped zinc oxide, two common transparent conductive oxides.

Owner:GTAT CORPORATION

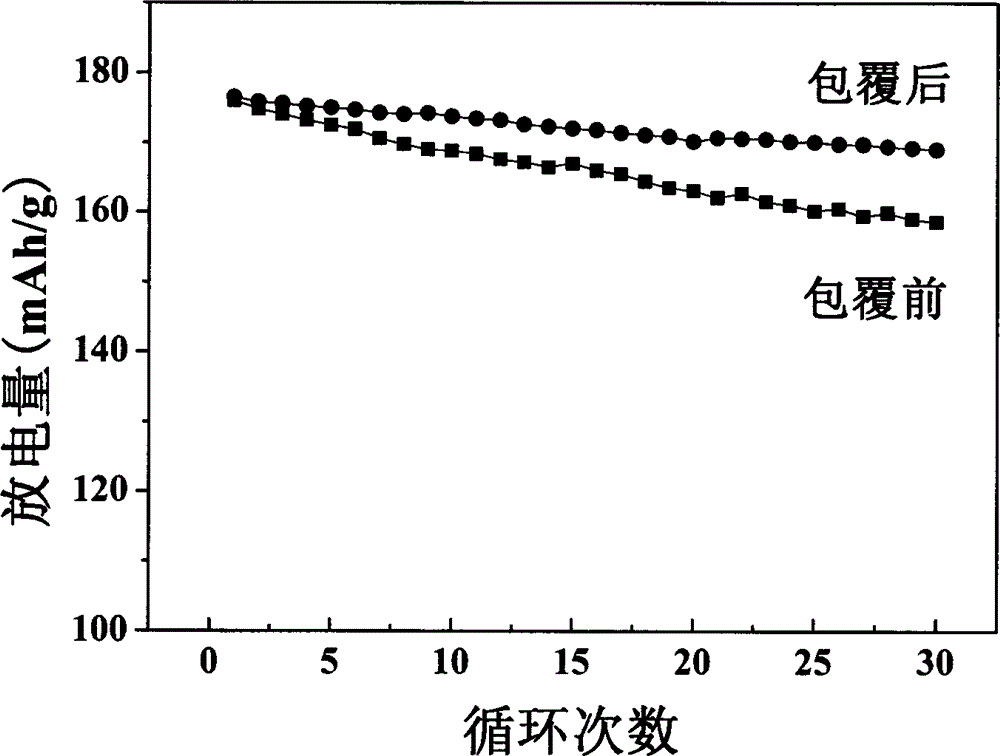

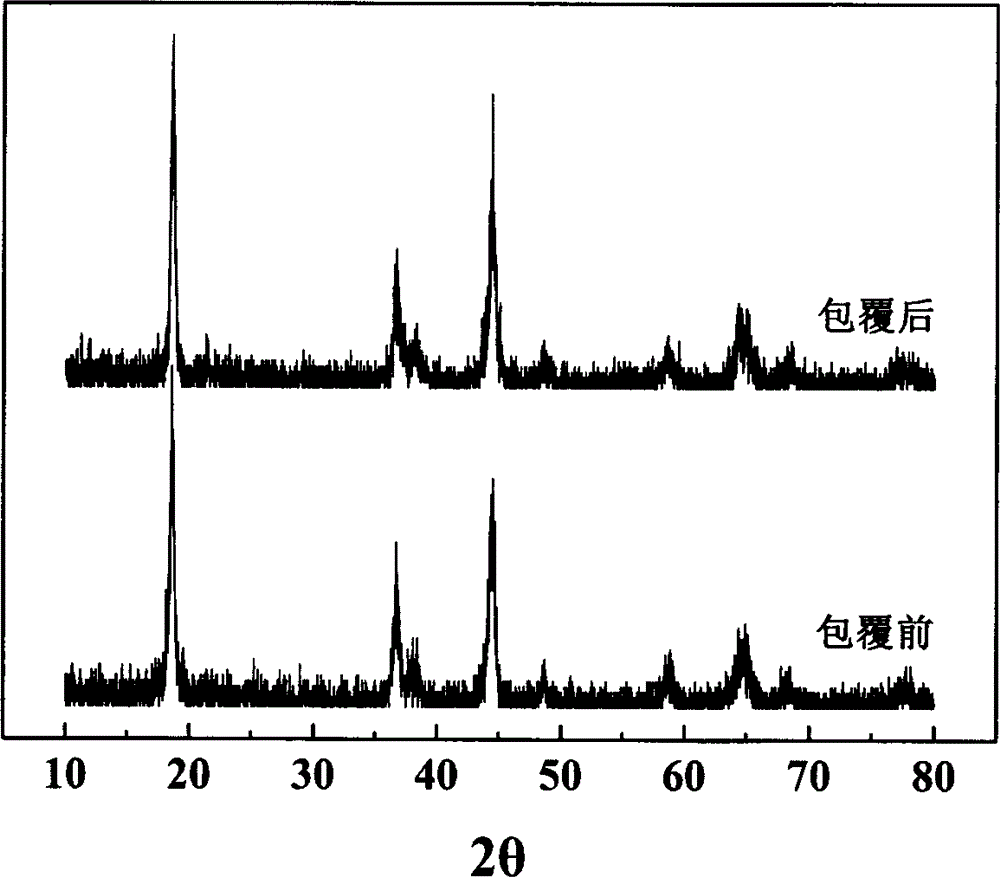

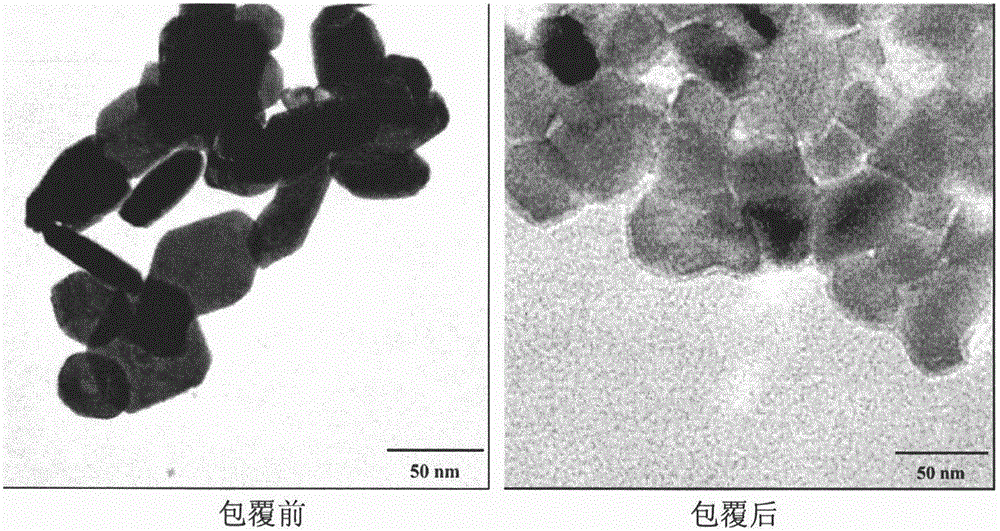

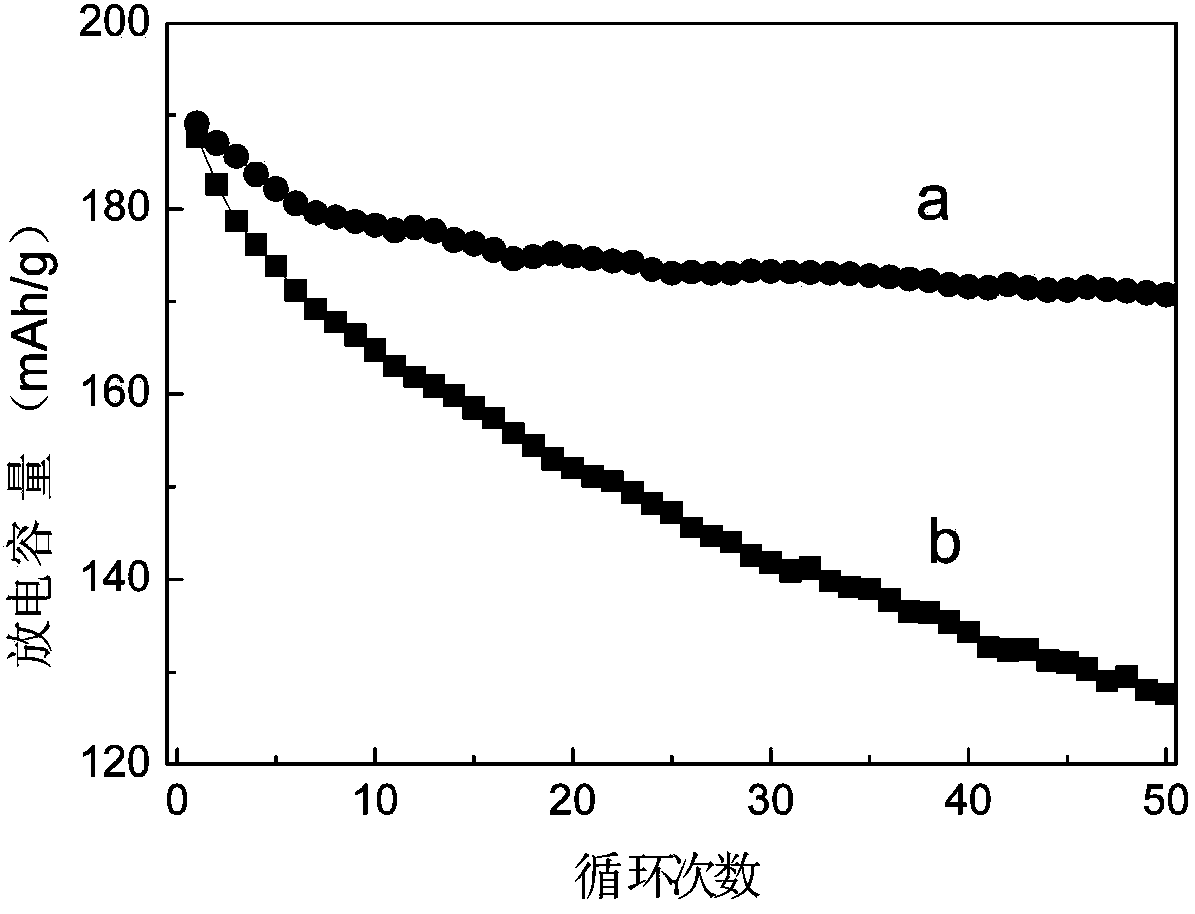

Method for preparing aluminum-doped zinc oxide coated lithium-ion battery positive-pole material

InactiveCN103151528AImprove cycle performanceExcellent rate performanceCell electrodesAir atmosphereAluminum doped zinc oxide

The invention discloses a method for preparing an aluminum-doped zinc oxide coated lithium-ion battery positive-pole material and belongs to the technical field of lithium-ion battery pole materials and preparation thereof. The method has the following steps of: preparing aluminum-doped zinc sol by adopting a sol-gel method, adding a positive pole material into the aluminum-doped zinc sol, stirring until a solvent in the sol is completely evaporated so as to obtain a black positive pole material of which the surface is coated with a hydrolysis product, and then carrying out high-temperature calcination treatment in an air atmosphere, thereby obtaining the lithium-ion battery positive-pole material of which the surface is coated with aluminum-doped zinc oxide. The preparation method disclosed by the invention is simple in process, convenient to operate, low in cost and little in pollution; and the prepared positive-pole material of which the surface is coated with aluminum-doped zinc oxide has good cycle performance, power multiplying performance, overcharge resistance and thermal stability, and meanwhile, the initial discharge capacity of the positive-pole material is not lowered.

Owner:TIANJIN POLYTECHNIC UNIV

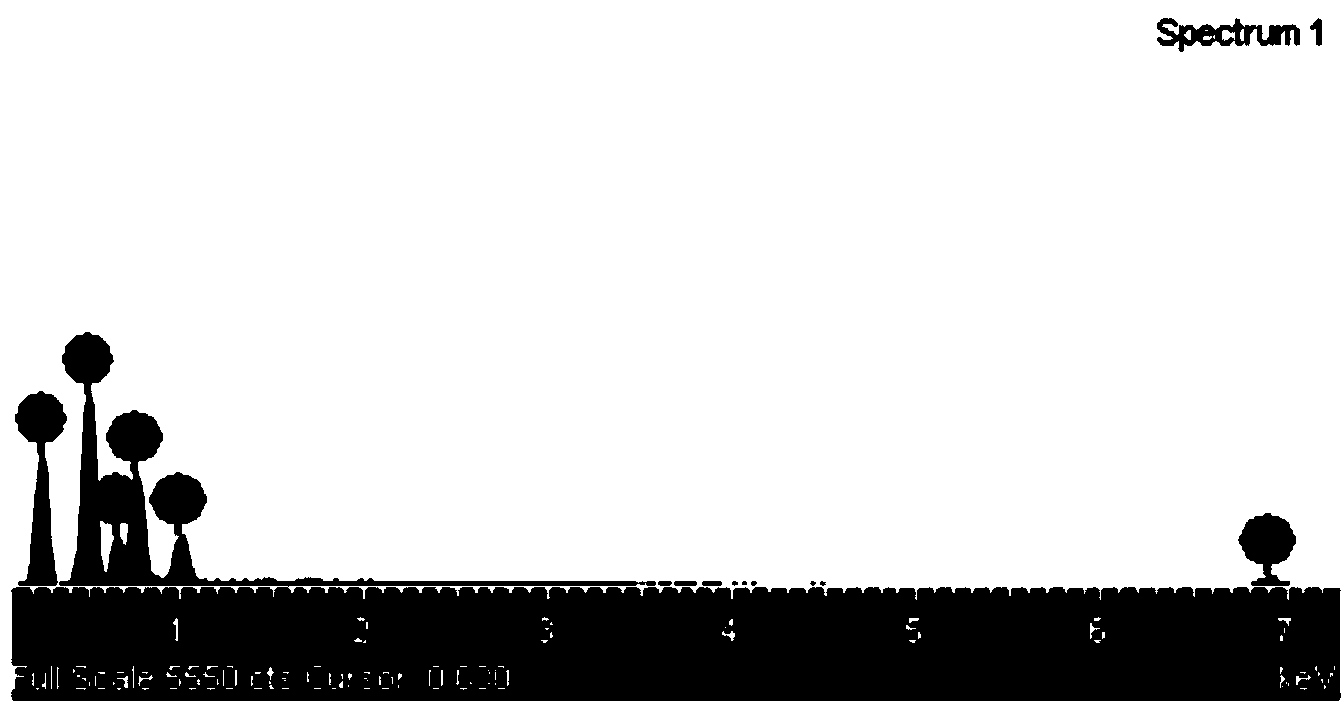

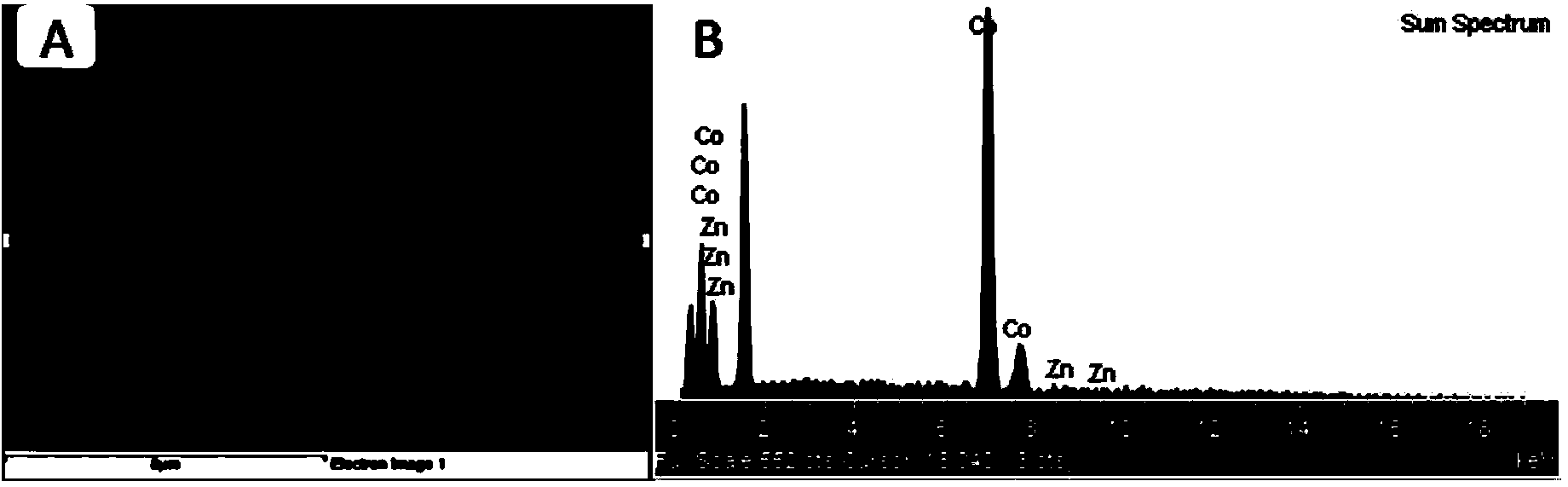

Making method of zinc oxide or aluminum-doped zinc oxide coated lithium cobaltate electrode

InactiveCN103594684AAvoid affecting transport performanceInhibition of dissolutionCell electrodesAluminum doped zinc oxideRadio frequency magnetron sputtering

A making method of a zinc oxide or aluminum-doped zinc oxide coated lithium cobaltate electrode belongs to the technical field of batteries. In the invention, zinc oxide or aluminum-doped zinc oxide deposited on a routine lithium cobaltate electrode through a radio frequency magnetron sputtering technology as a coating material to obtain the coated and modified lithium cobaltate electrode. The method concretely comprises the following steps: mixing lithium cobaltate powder with a conductive additive, a binder and a solvent, grinding to prepare a slurry, coating a current collector with the slurry, drying the coated current collector to make the routine sheet lithium cobaltate electrode, and depositing the coating layer of zinc oxide or aluminum-doped zinc oxide by adopting the radio frequency magnetron sputtering technology to realize the coating modification of the lithium cobaltate electrode. The method improves the electrode interface situation, effectively inhibit the secondary reactions on the high-potential interval electrode surface, reduces the capacity loss and improves the structural stability of an active material, so the working voltages of the batteries are widened, and the energy density, the power density and the cycle performance of the batteries are improved.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

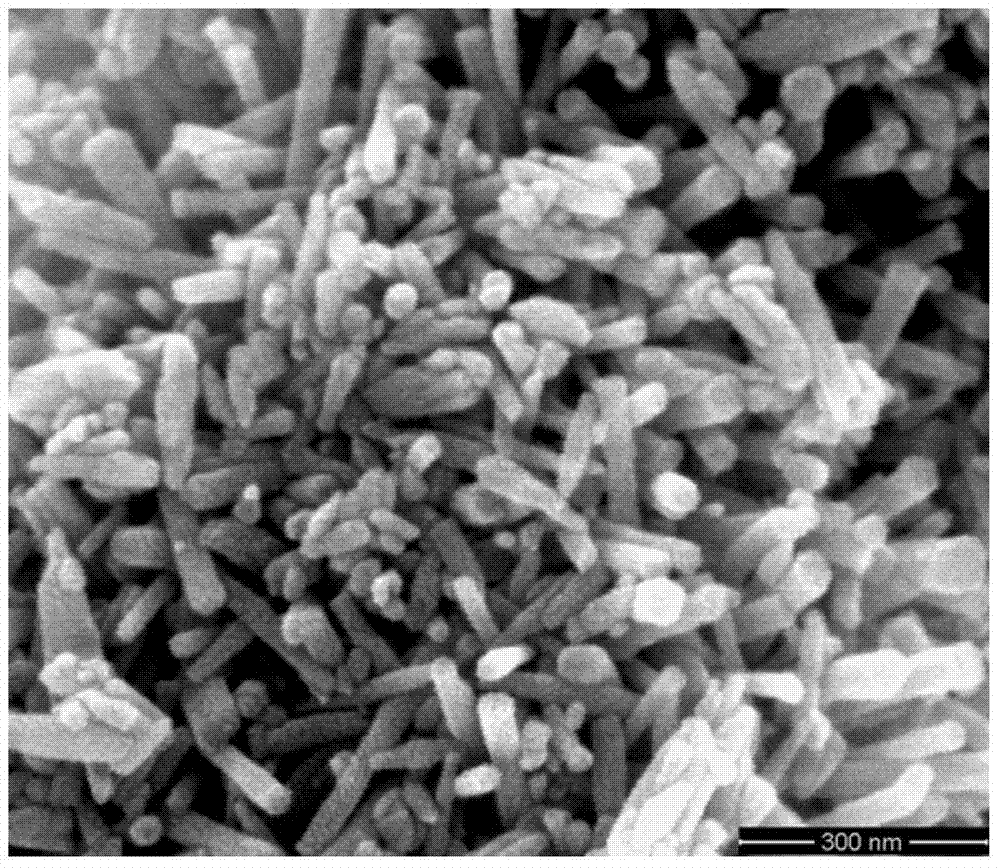

Graphene-rod-like aluminum-doped zinc oxide antistatic coating and preparation method thereof

ActiveCN103937350AAdd lessImprove conductivityElectrically-conductive paintsEmulsionAluminum doped zinc oxide

The invention belongs to the technical field of production of antistatic coating and in particular relates to a graphene-rod-like aluminum-doped zinc oxide antistatic coating and a preparation method thereof. The antistatic coating comprises the following components in parts by weight: 60-85 parts of waterborne acrylic emulsion, 0.5-1.0 part of antifoaming agent, 1-2.5 parts of flatting agent, 1-3.5 parts of thickening agent, 2-3 parts of graphene, 7.15-31.25 parts of rod-like aluminum-doped zinc oxide dispersion and 0.5-30 parts of deionized water. Flake graphene and the rod-like aluminum-doped zinc oxide can form a three-dimensional conductive network in a coating system, so that the conductive performance of the coating can be enhanced, and compared with a coating formed by singly graphene or aluminum-doped zinc oxide, the graphene-rod-like aluminum-doped zinc oxide antistatic coating has the advantages that the same conductive effect is achieved, and the addition amount is obviously reduced. Moreover, due to a special structure, the mechanical property of the coating can be obviously enhanced.

Owner:CHANGZHOU UNIV

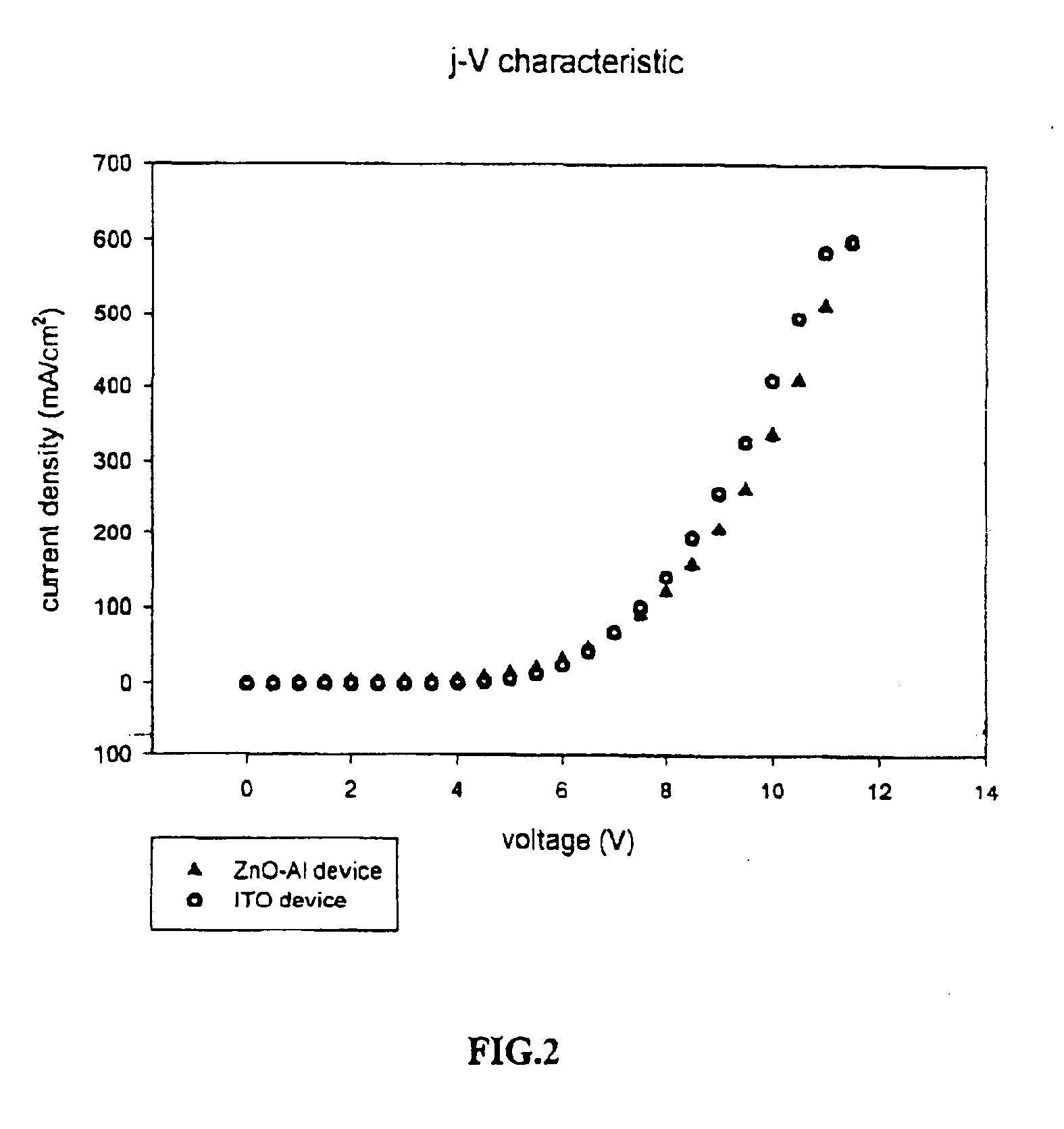

High-qualty aluminum-doped zinc oxide layer as transparent conductive electrode for organic light-emitting devices

InactiveUS6917158B2Improve performanceLong-term stable and high performanceDischarge tube luminescnet screensElectroluminescent light sourcesAluminum doped zinc oxideIntermediate frequency

An organic light-emitting diode is described in which the anode comprises midfrequency magnetron sputtered aluminum-doped zinc oxide to increase the device stability and to decrease the material cost. Due the novel deposition technique, ZnO:Al film with ITO-like electrical conductivity can be deposited and improved device performance, especially the long-term stability can be obtained which are attributed to the modification of the ZnO:Al conductivity and surface chemistry.

Owner:INTELLECTUAL VENTURES II

Preparation method of aluminum doped zinc oxide nano powder

InactiveCN103395826AHigh purityGood dispersionMaterial nanotechnologyZinc oxides/hydroxidesPolyvinyl alcoholAluminum doped zinc oxide

The invention discloses a preparation method of aluminum doped zinc oxide nano powder. A technological process of the preparation method is shown as follows: first synthesizing a zinc nitrate-urea white sol microemulsion, standing, then filtering, adding aluminum nitrate into a filtering liquid to form a zinc nitrate aluminum mixed solution; preparing a sodium carbonate solution, dropping both the sodium carbonate solution and the zinc nitrate aluminum mixed solution into a polyvinyl alcohol aqueous solution to synthesize a white precipitate precursor; standing and filtering, and thus obtaining the aluminum doped zinc oxide nano powder through deionized water leaching, drying, grinding, sieving and calcining of a filter cake. The aluminum doped zinc oxide nano powder obtained by the method has good dispersibility and less agglomeration, the powder particle size is between 5 and 30 nm, the particle size distribution range is narrow, and the morphology is spherical or quasi spherical. The method has the advantages of simple process, low cost, short reaction period, high yield, and easy control of the reaction processes, and is suitable for mass production; and compared with traditional methods, the powder produced by the method contains no chlorine ion which can influence the performance of the powder, and the method needs no ethanol for washing, and no alkali for neutralization.

Owner:DALIAN JIAOTONG UNIVERSITY

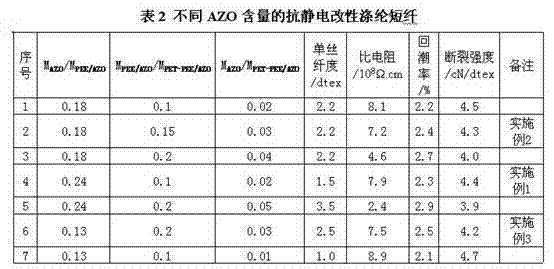

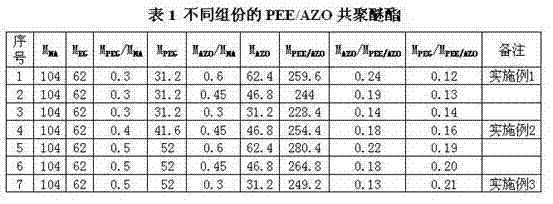

Anti-static modified polyester staple fiber and preparation method thereof

ActiveCN103361765AHas permanent antistatic propertiesImprove antistatic performanceElectroconductive/antistatic filament manufactureArtificial filament heat treatmentFiberPolymer science

The invention belongs to the field of processing of a high polymer material, and particularly relates to a different polyester staple fiber with an anti-static function, and a preparation method thereof. The method comprises the following steps of: a, preparing polyether ester fiber / aluminium-doped zinc oxide (PEE / AZO) composite polyether ester, namely adding the surface-modified aluminium-doped zinc oxide (AZO) to an ethylene glycol (EG) solution to carry out disperse treatment, esterifying together with malonic acid (MA) and polyether (PEG) to generate the PEE / AZO composite polyether ester; b, preparing PET-PEE / AZO copolyester, namely carrying out esterification on purified terephthalic acid (PTA) and EG, adding the PEE / AZO composite polyether ester to carry out copolycondensation after esterification is finished, and generating the PET-PEE / AZO copolyester with the anti-static property; and c, melting and spinning, namely preparing into the anti-static modified polyester staple fiber from the PET-PEE / AZO copolyester by melting and spinning. By adopting the preparation method, various problems caused by large static electricity in the processes of spinning, weaving and taking the polyester staple fiber are solved.

Owner:宿迁逸达新材料有限公司

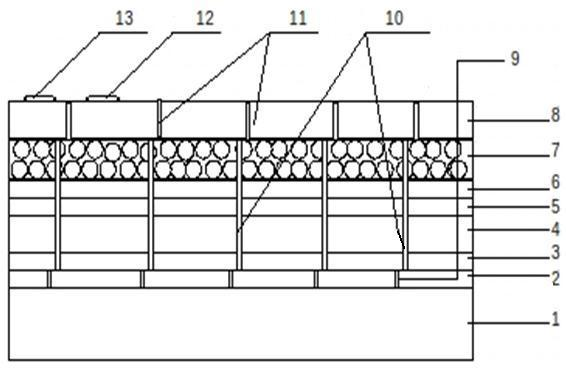

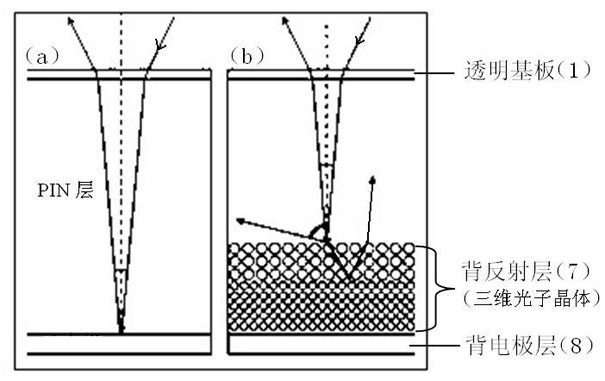

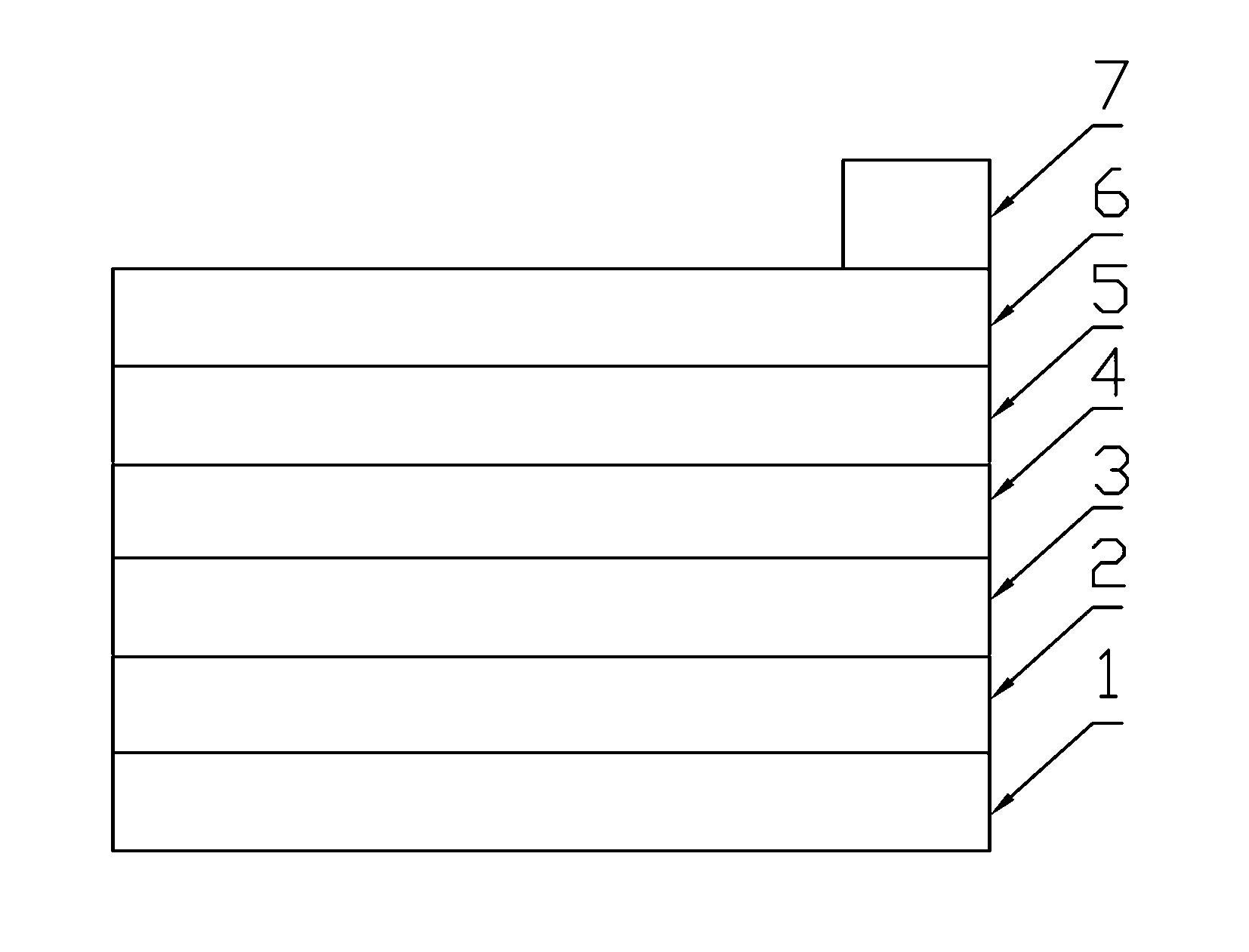

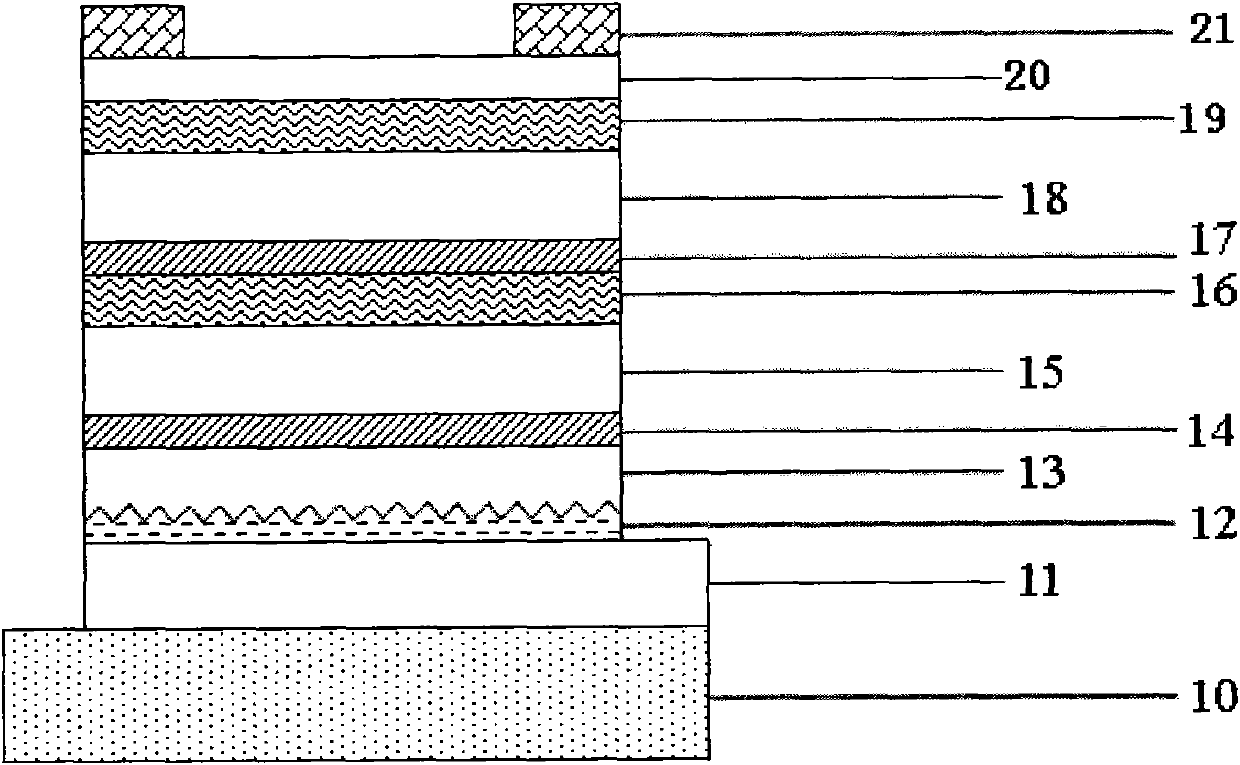

Amorphous silicon solar cell with three-dimensional photonic crystal serving as back reflecting layer and manufacturing method thereof

InactiveCN101807613AImprove utilization efficiencyIncreasing the thicknessFinal product manufacturePhotovoltaic energy generationGas phaseAluminum doped zinc oxide

The invention discloses an amorphous silicon solar cell with a three-dimensional photonic crystal serving as a back reflecting layer and a manufacturing method thereof, relates to the method for manufacturing the amorphous silicon solar cell and solves the problem of low efficiency of the solar cell caused by low reflectivity of the traditional A1 back reflecting layer. The back reflecting layer of the amorphous silicon solar cell is a three-dimensional macroporous sequential aluminum-doped zinc oxide photonic crystal. The manufacturing method comprises the following steps: depositing a front electrode layer by low-pressure chemical vapor deposition, depositing a P-I-N layer by PECVD, preparing an ITO transparent conductive film by magnetron sputtering, preparing a colloidal crystal template by a vertical deposition process or spin-coating process, performing electrodeposition to obtain the back reflecting layer, and performing vacuum evaporation on a back electrode layer to obtain the back reflecting layer. The AZO has high transmissivity for visual light and can realize over 80 percent transmissivity for 600 to 1,000nm visual optical band when combined with the bandgap effect of the three-dimensional photonic crystal. The three-dimensional photonic crystal has big reflecting angle, so transmission optical path of optical waves in an absorbing layer is increased; the utilization rate of photons is improved; and photocurrent density and photoelectric conversion efficiency are increased.

Owner:HARBIN INST OF TECH

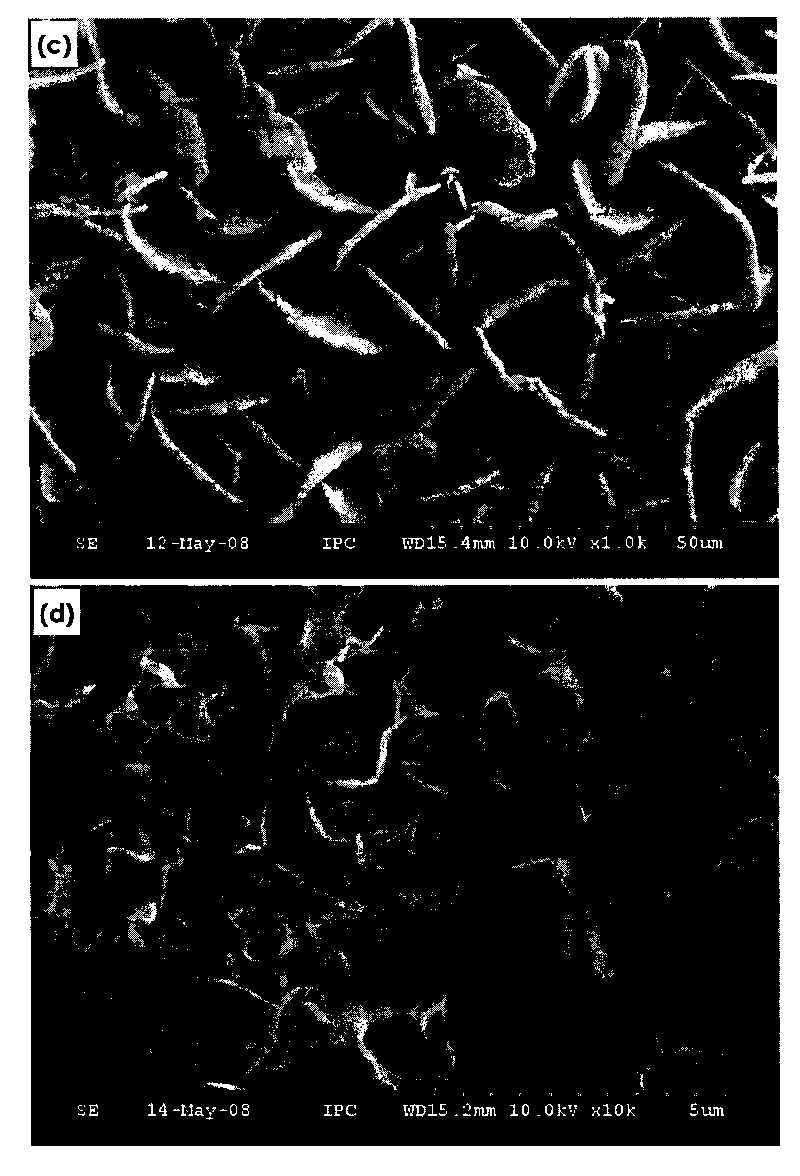

Method for preparing aluminum-doping zinc oxide nanometer sheet with photo-catalysis function

InactiveCN101717070AGood photocatalytic degradation effectPlay a role in environmental governanceNanostructure manufactureAluminum doped zinc oxidePhotocatalytic degradation

The invention belongs to the preparing technical field of nanometer material, in particular relates to a method for preparing aluminum-doping zinc oxide nanometer sheet with photo-catalysis function by electrochemical deposition. The invention uses water solution of zinc salt and aluminum salt as electrolyte solution; the electrochemical deposition process is carried out in a standard three-electrode system; electrolyte solution is poured in an electrolytic cell; platinum sheet is used as counter electrode, saturated calomel electrode is used as reference electrode, and an electric conductive base is used as work electrode; the electrolytic cell is heated with water; electrolyte solution in the electrolytic cell is kept at the temperature of 70-90 DEG C; the work electrode is applied with electric potential being -0.8 to -1.6 V relative to the reference electrode; after reaction, aluminum-doping zinc oxide nanometer sheet is obtained on the electric conductive base. The aluminum-doping zinc oxide nanometer sheet shows obvious photo-catalysis degradation effect upon methyl orange, and has great application foreground in the field of environmental improvement.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

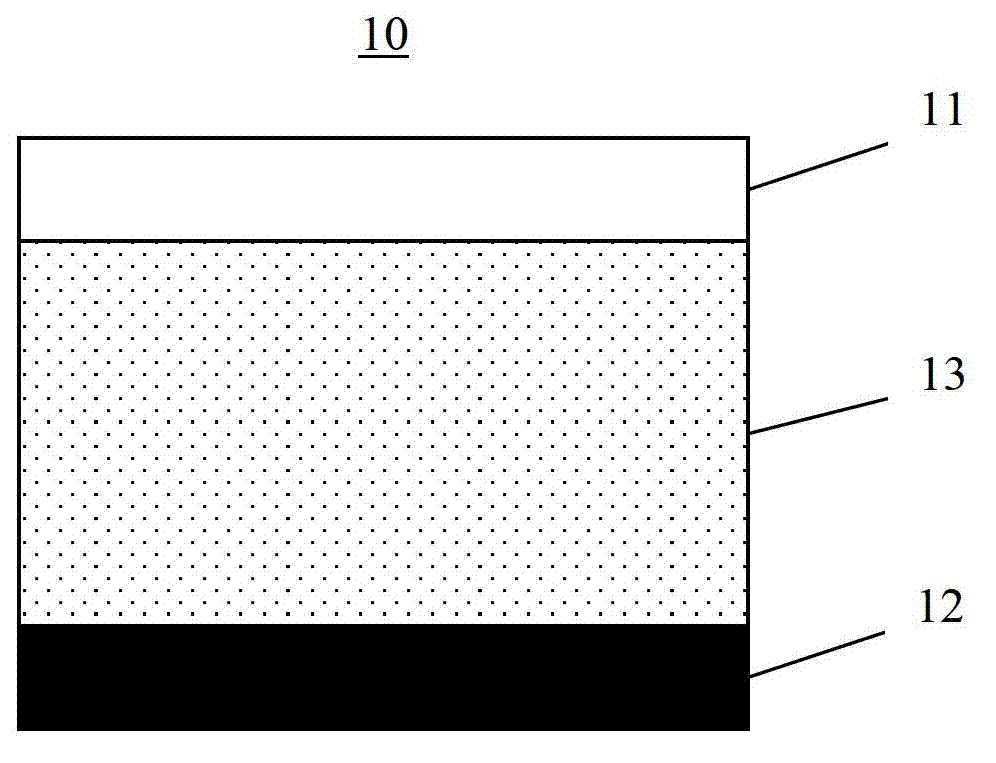

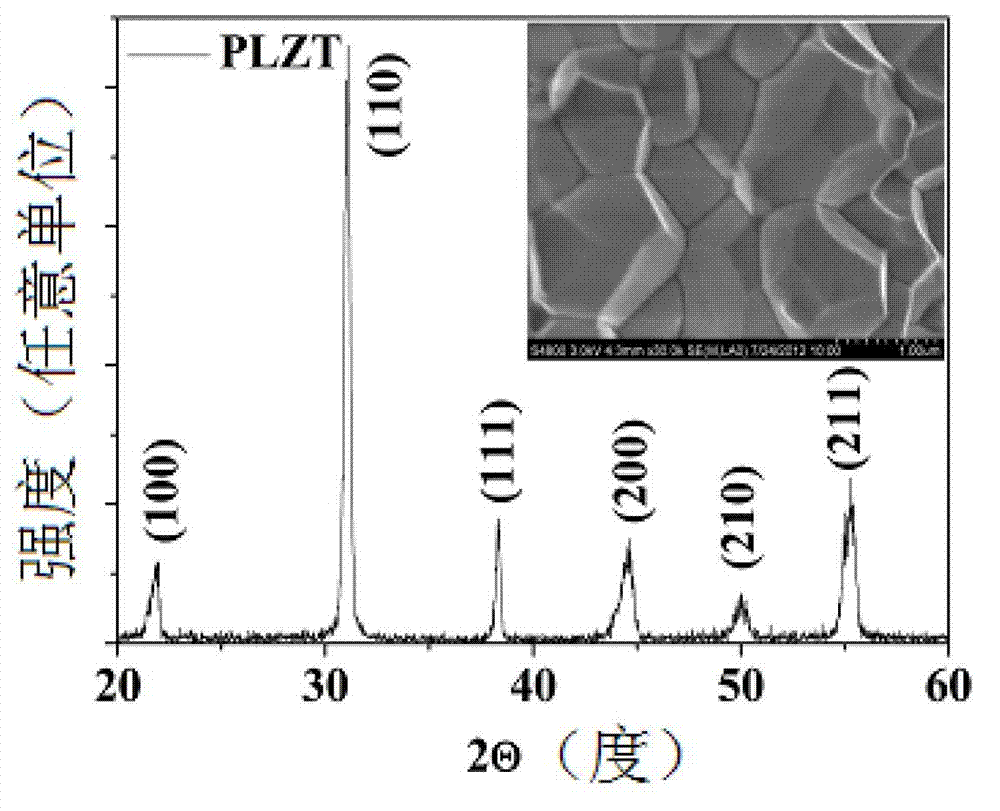

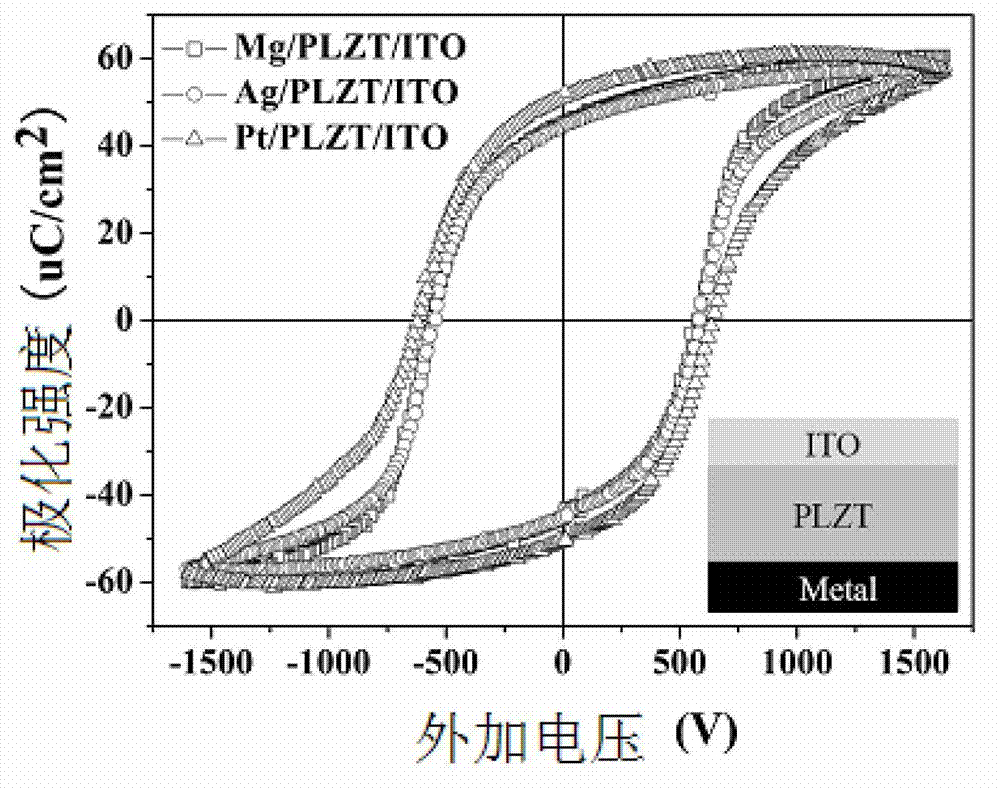

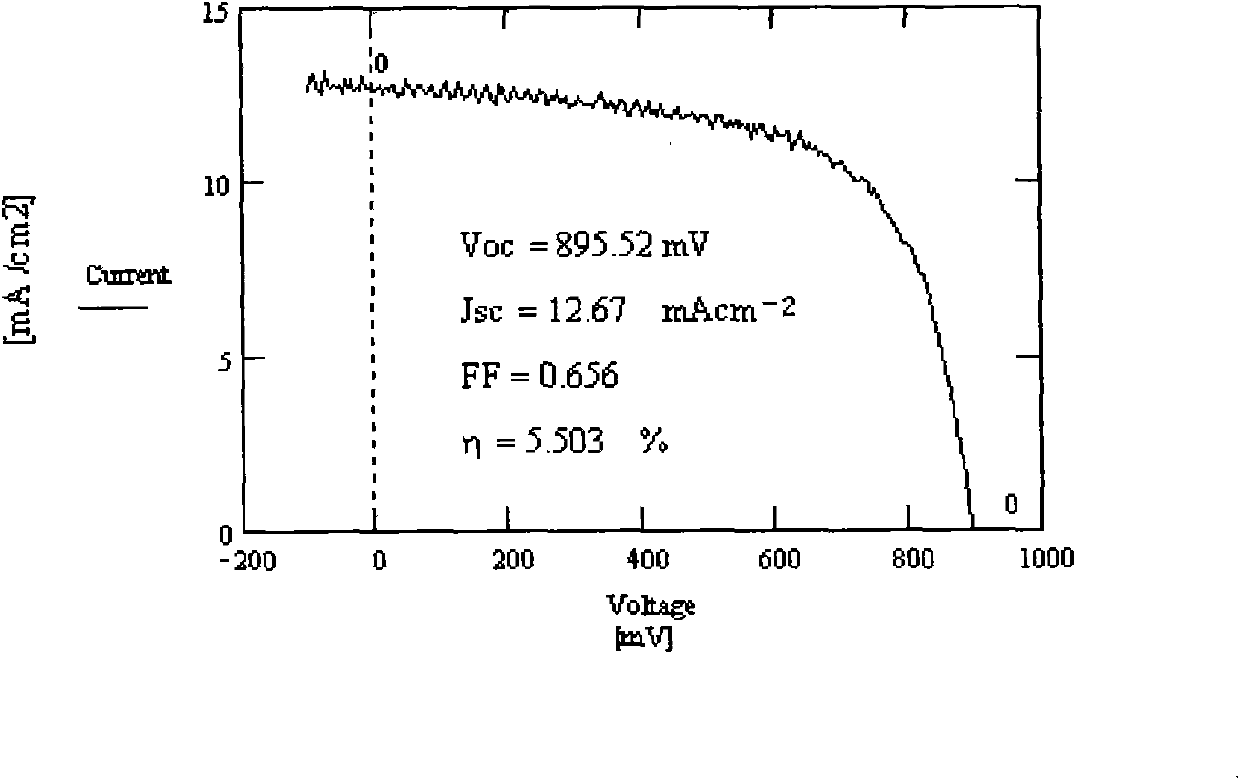

Ferroelectric photovoltaic device and preparation method of ferroelectric photovoltaic device

InactiveCN102832266AImprove performanceLower Schottky Barrier HeightFinal product manufacturePhotovoltaic energy generationLead zirconate titanateUltraviolet lights

The invention discloses a ferroelectric photovoltaic device which comprises an upper electrode, a lower metal electrode and a ferroelectric material between the two electrodes. The ferroelectric material is lead lanthanum zirconate titanate (PLZT), lead zirconate titanate (PZT), barium titanate (BTO) or bismuth ferrite oxide (BFO), etc., the upper electrode is made of a transparent electrode material such as indium tin oxide (ITO) or aluminum doped zinc oxide (AZO), and the lower metal electrode is made of the metal with a low work unction such as Ag, Al or Mg. The invention also discloses a preparation method of the ferroelectric photovoltaic device. According to the invention, the photovoltaic characteristic of this kind of ferroelectric photovoltaic device can be improved through material design and energy band engineering based on the photoelectric effect of the metal with the low work function and the photovoltaic effect of the ferroelectric material; the light response wavelength of the traditional broad-band gap ferroelectric photovoltaic device can be extended from the range of ultraviolet light to the range of visible light; and the application field of the ferroelectric photovoltaic device can be enlarged.

Owner:SUZHOU UNIV

Method for preparing copper-indium-gallium-selenide (CIGS) solar photovoltaic cell

InactiveCN102386283AIncrease profitImprove photoelectric conversion efficiencyFinal product manufactureSemiconductor devicesVulcanizationIndium

The invention discloses a method for preparing a copper-indium-gallium-selenide (CIGS) solar photovoltaic cell. The method for preparing the photovoltaic cell comprises the following steps of: cleaning a glass substrate, sputtering a molybdenum metal, sputtering a copper-indium-gallium alloy, performing selenylation (vulcanization), depositing zinc sulfide in a chemical bath, sputtering zinc oxide and sputtering aluminum-doped zinc oxide. The method is high in utilization rate of raw materials, uniform in components of cell compounds, high in photoelectric conversion efficiency and good in repeatability.

Owner:陈群

Preparation method of textured AZO (aluminum-doped zinc oxide) transparent conductive film

ActiveCN102863156AAvoid wastingReduce manufacturing costFinal product manufacturePhotovoltaic energy generationAcid etchingAluminum doped zinc oxide

The invention relates to a preparation method of a textured AZO (aluminum-doped zinc oxide) transparent conductive film. A high-alkali aluminosilicate glass substrate is subjected to texturing treatment to form a textured structure on the glass surface so as to provide foundation for the subsequent direct growth of the AZO film and the final formation of the textured surface, thereby implementing the textured structure of the directly growing AZO transparent conductive film on the glass surface, overcoming the defects of overhigh requirement for the thickness of the AZO transparent conductive film and waste of etching in the conventional technique of film formation before acid etching, and effectively lowering the production cost. The haze of the AZO transparent conductive film prepared by the method is 10-30%, the visible light transmittance is greater than or equal to 85%, and the square resistance is 8-15 ohm per square.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

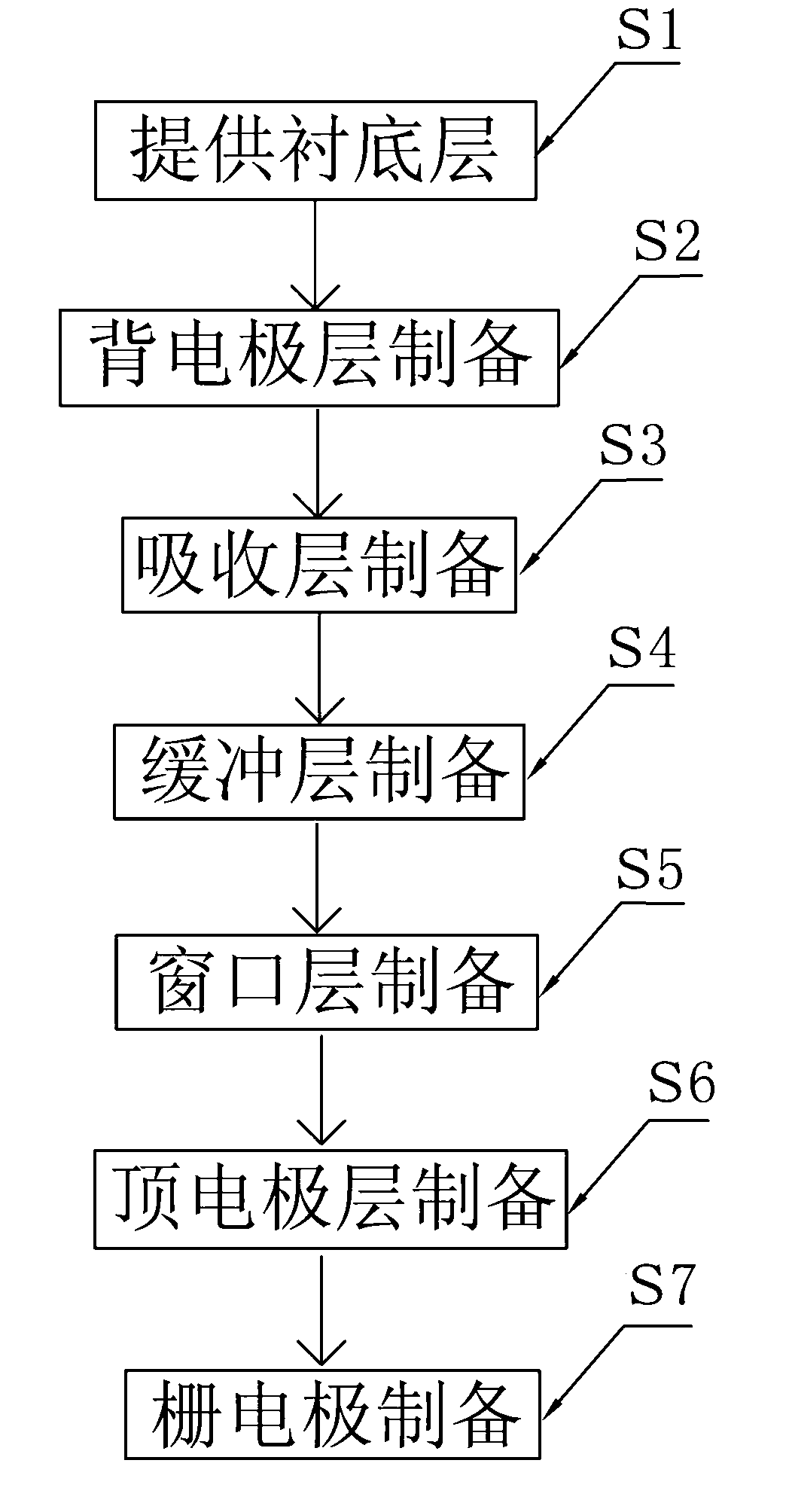

Full-non-vacuum process preparation method of copper-zinc-tin-sulfur thin film solar cell

ActiveCN103078010AReduce processing costsSuitable for mass productionRenewable energy productsSemiconductor devicesVulcanizationAluminum doped zinc oxide

The invention provides a full-non-vacuum process preparation method of a copper-zinc-tin-sulfur thin film solar cell and belongs to the technical field of a photoelectric material new energy source. The full-non-vacuum process preparation method is low in cost and is suitable for large-scale and large-batch production of the solar cell. The full-non-vacuum process preparation method comprises the following steps of: a, providing a substrate layer; b, preparing a rear electrode layer: preparing one layer of molybdenum or silver thin film; c, preparing an absorption layer: preparing a copper-zinc-tin metal precursor and carrying out vulcanization heat treatment to obtain a copper-zinc-tin-sulfur thin film; d, preparing a buffering layer: preparing a cadmium sulfide or zinc sulfide thin film; e, preparing a window layer: preparing an intrinsic zinc oxide window layer thin film; f, preparing a top electrode layer: preparing an aluminum-doped zinc oxide top electrode layer thin film; and g, preparing a grid electrode: adopting a reflow soldering lamination compound process to prepare a grid electrode. The full-non-vacuum process preparation method of the copper-zinc-tin-sulfur thin film solar cell disclosed by the invention has the advantages of low process cost and suitableness for large-scale production, so that the full-non-vacuum process preparation method has very good popularization and utilization values.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

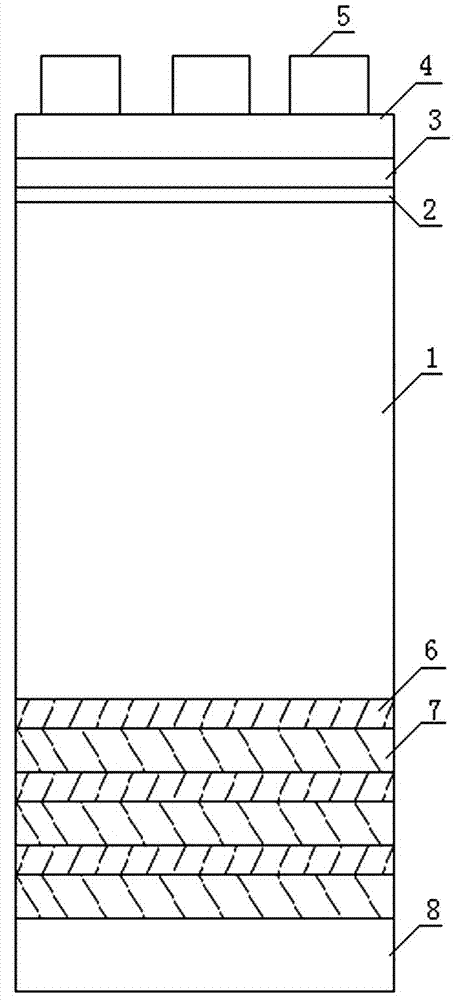

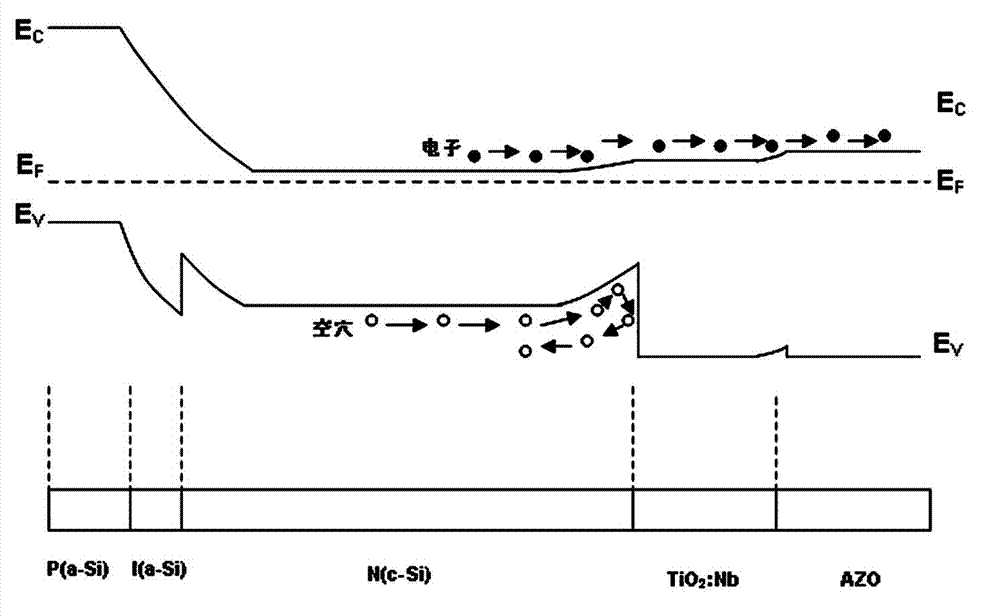

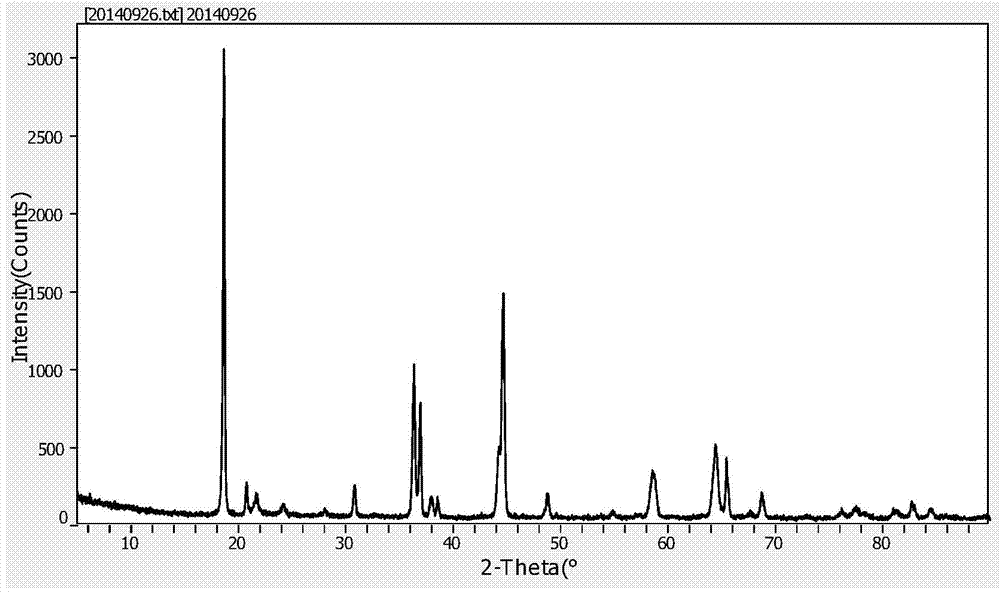

Silicon-based heterojunction solar cell and preparation method thereof

ActiveCN102931267ACombination of good conductivityImprove photoelectric conversion efficiencyFinal product manufacturePhotovoltaic energy generationHeterojunctionNiobium

The invention discloses a silicon-based heterojunction solar cell which comprises grid electrodes, a transparent conductive film, a boron-doped amorphous silicon, an intrinsic amorphous silicon, an N-type monocrystalline and a back electrode in sequence, wherein the back electrode is formed by a distributed Bragg reflector and an aluminum thin film, the distributed Bragg reflector is formed by arranging niobium-doped titanium dioxide thin films and aluminum-doped zinc oxide thin films at intervals, and the aluminum thin film is arranged on the surface layer of the aluminum-doped zinc oxide thin film on the outermost layer of the distributed Bragg reflector. The distributed Bragg reflector used as the back electrode consists of two transparent conductive films with different refraction indexes, so that the resistance of the cell device connected in series is reduced, the collection of current carriers is facilitated, and the photoelectric conversion efficiency of the cell is high; and by adopting the back-reflecting electrode formed by combining the distributed Bragg reflector and the aluminum anode, the long wave band of the near infrared part with characteristic wavelength can be reflected to the inside of the crystalline silicon wafer to be reabsorbed through the two layers of conductive films with different refractive indexes, so that both the current and the photoelectric conversion efficiency of the cell are improved.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

Method for preparing aluminum-doped zinc oxide coated lithium manganese material

InactiveCN104241635AEffective isolationImprove transmission performanceCell electrodesSecondary cellsLithiumAluminum doped zinc oxide

The invention discloses a method for preparing an aluminum-doped zinc oxide coated lithium manganese material. The method includes the steps of preparing a precursor of a lithium manganese positive electrode material and calcining the precursor of the lithium manganese positive electrode material in a muffle furnace for obtaining the lithium manganese positive electrode material; dissolving soluble aluminum salt and soluble zinc salt in an aqueous solution, adding polyvinylpyrrolidone and the lithium manganese positive electrode material sequentially, and stirring at constant temperature for obtaining a precursor solution; drying the precursor solution at constant temperature in air and calcining the dried precursor in air for obtaining the aluminum-doped zinc oxide coated lithium manganese material. The method for preparing the aluminum-doped zinc oxide coated lithium manganese material is simple and easy to implement, low in requirement on equipment and pollution-free in the reaction and has a good prospect on industrial application.

Owner:西安中科新能源科技有限公司

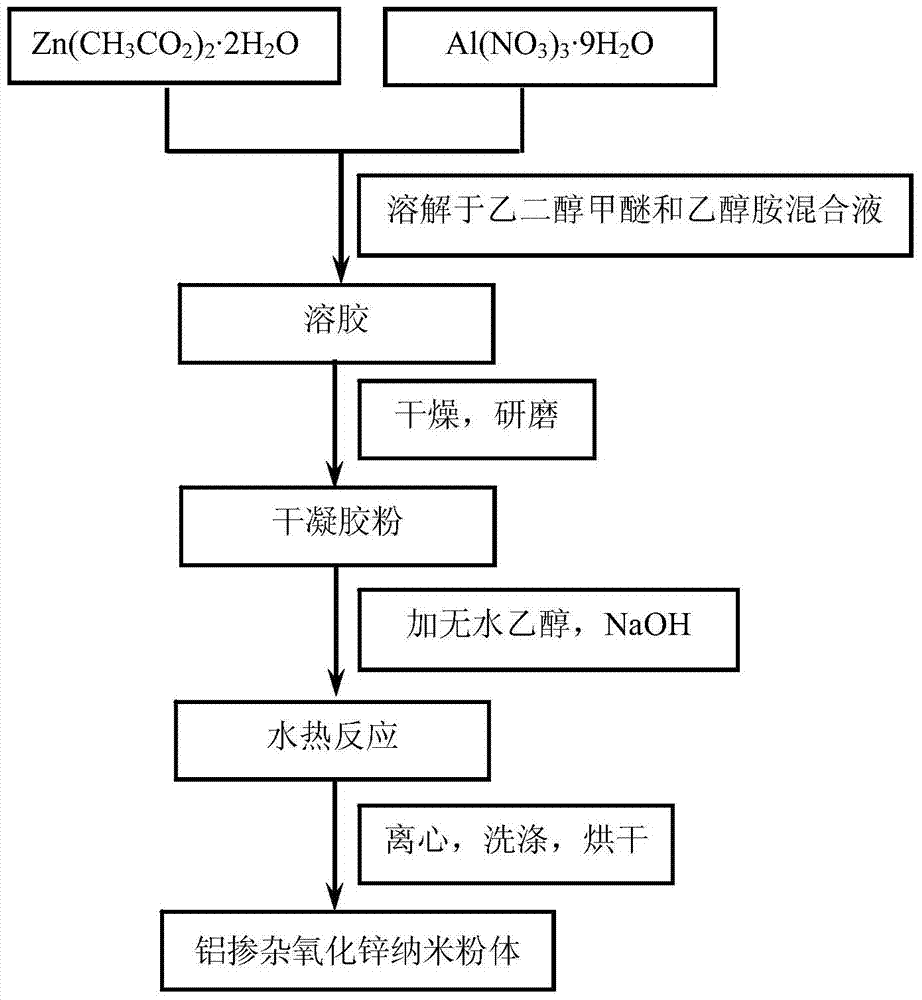

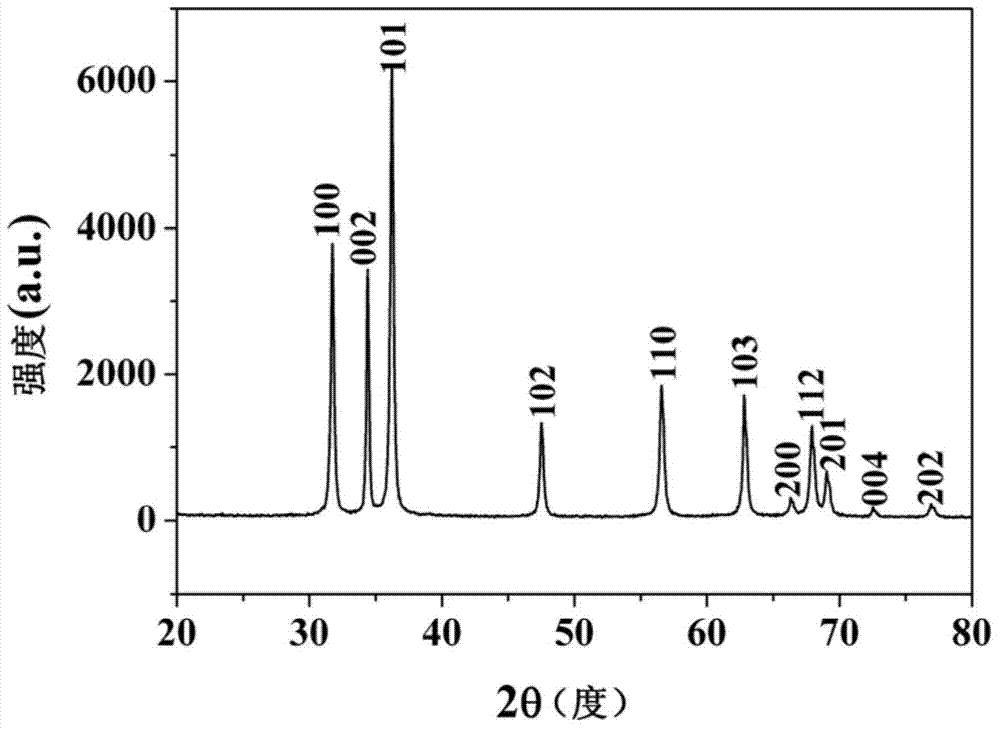

Preparation method of high-conductivity aluminum-doped zinc oxide nano powder

ActiveCN103496732ALow resistivityReduce the temperatureMaterial nanotechnologyZinc oxides/hydroxidesAlcoholAluminum doped zinc oxide

The invention discloses a preparation method of high-conductivity aluminum-doped zinc oxide nano powder. The preparation method comprises the steps of adding zinc acetate and aluminum nitrate which are taken as raw materials to a beaker, adding a mixed solution of ethylene glycol monomethyl ether and ethanol amine, and magnetically stirring to obtain uniform sol; drying the generated sol in an oven to obtain dry gel, and grinding the dry gel to obtain dry gel powder, namely a hydrothermal reaction precursor; adding the prepared hydrothermal reaction precursor to a hydrothermal kettle, and adding absolute ethyl alcohol as a solvent and NaOH as a mineralizing agent; sealing the reaction kettle, placing the reaction kettle in the oven at 120-180 DEG C, taking out a product after reaction, and filtering the product to obtain precipitate; washing and drying the precipitate to obtain the aluminum-doped zinc oxide powder. The preparation method prepares high-conductivity aluminum-doped zinc oxide nano powder at low temperature without a catalyst, and is simple in process control and synthesis-required instrument and is low in cost.

Owner:SOUTH CHINA UNIV OF TECH

Composite back reflection metal electrode for thin film solar cell, as well as preparation method and application of composite back reflective metal electrode

InactiveCN102569433AImprove performanceImprove yieldFinal product manufactureSemiconductor devicesAluminum doped zinc oxideTrapping

The invention discloses a composite back reflection metal electrode for a thin film solar cell; the composite back reflective metal electrode is a composite multi-layer film, and a transition layer metal, a silver film and aluminum-doped zinc oxide are sequentially deposited on a substrate. The invention further discloses a preparation method of the composite back reflective metal electrode. According to the composite back reflective metal electrode disclosed by the invention, as the transition layer metal has excellent adhesion with the flexible substrate, all layers of the deposited thin films are less prone to shed from the substrate; simultaneously, the silver film has obvious texture, and a light trapping structure is formed, so that the reflection of incident light is enhanced, the absorption of the incident light in an absorption layer of the cell is fuller, and the performances of the cell can be improved; and the aluminum-doped zinc oxide has appropriate thickness, so that the aluminum-doped zinc oxide can not only prevent silver from being diffused and entering into the cell during the preparation process of the cell, but also have the effects of covering a peak on the surface of the silver film and enhancing reflected light. Therefore, the composite back reflective metal electrode disclosed by the invention can improve the bonding force between the thin films and the substrate, and significantly improve the performances of the cell and the uniformity.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

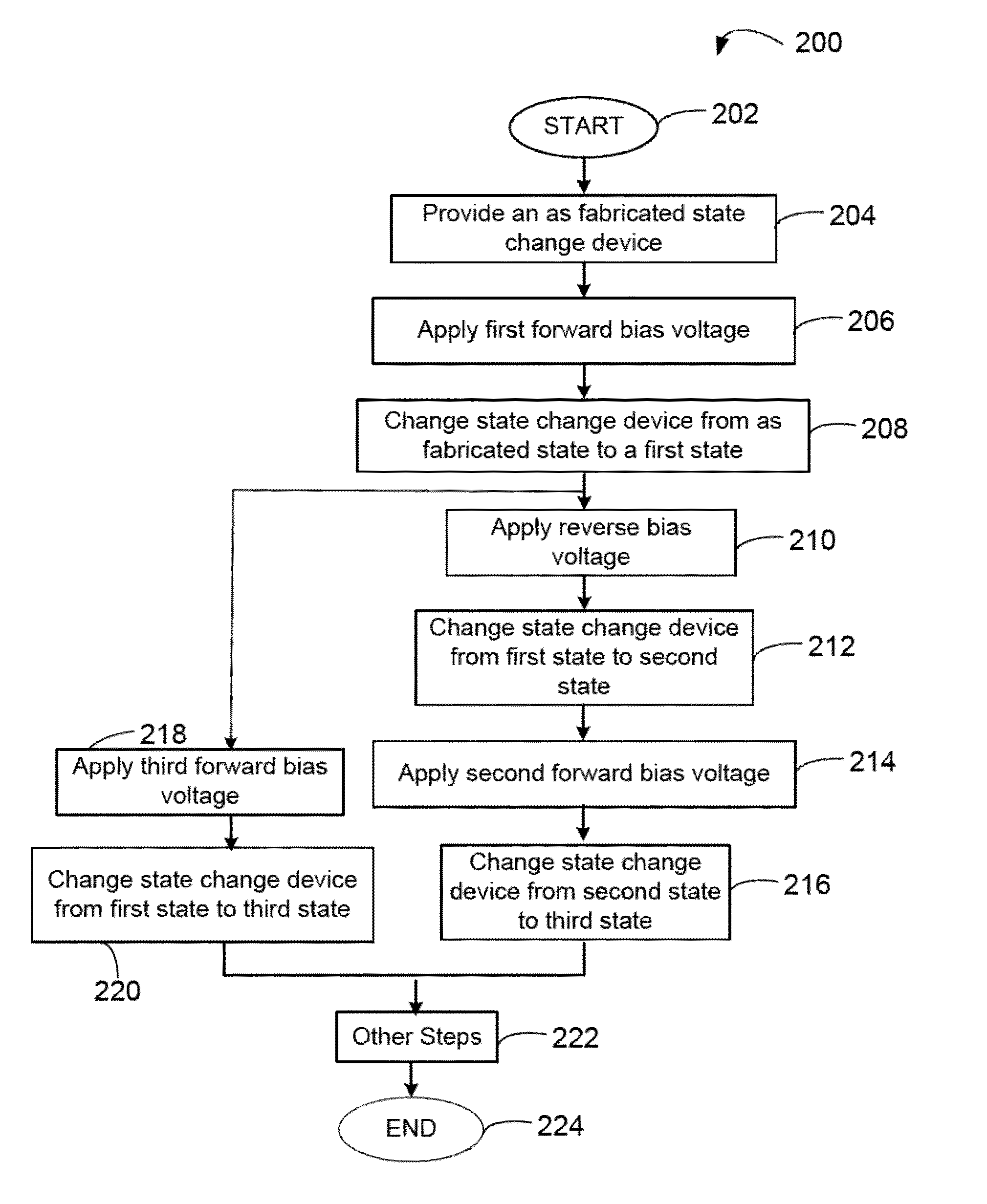

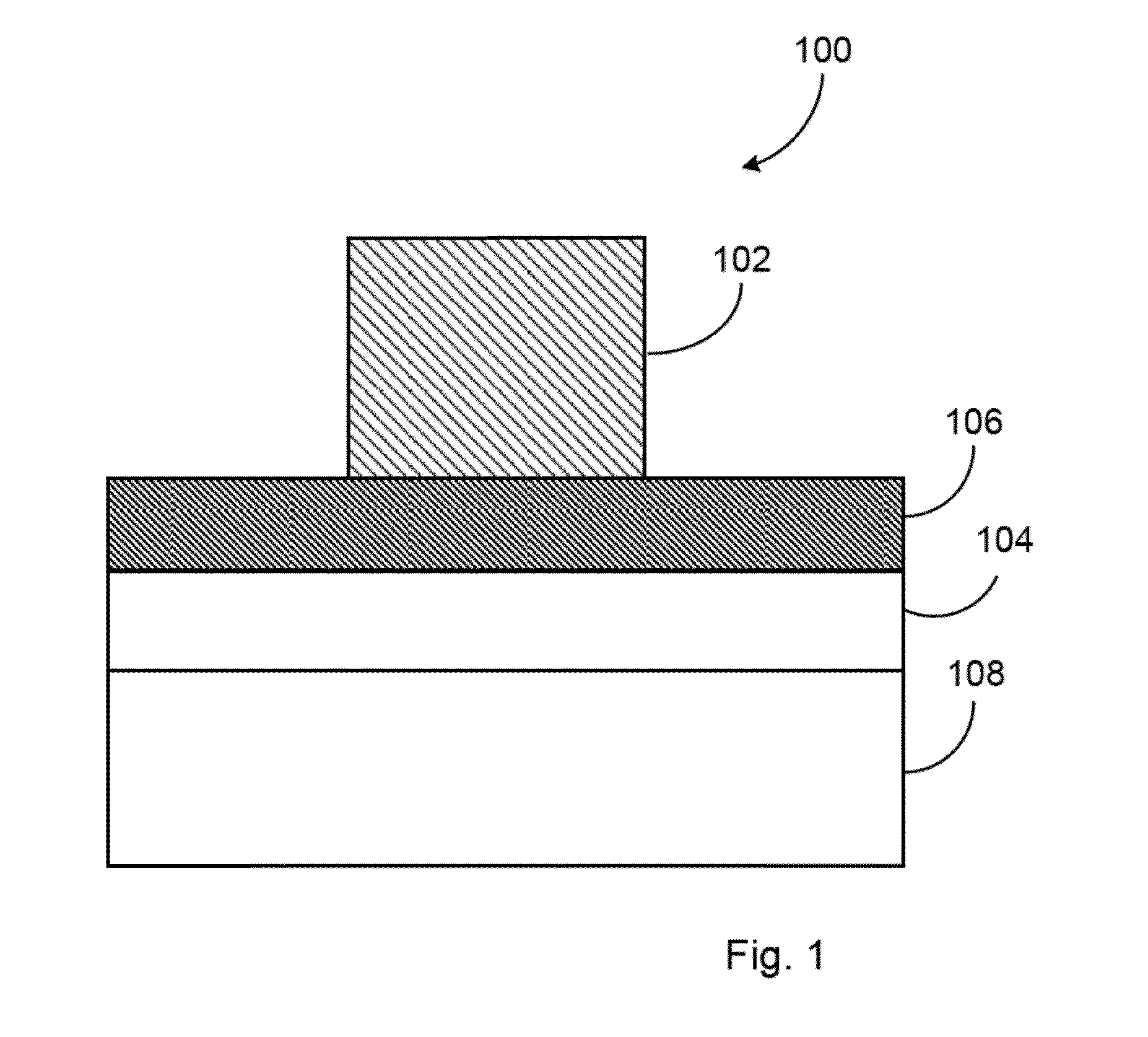

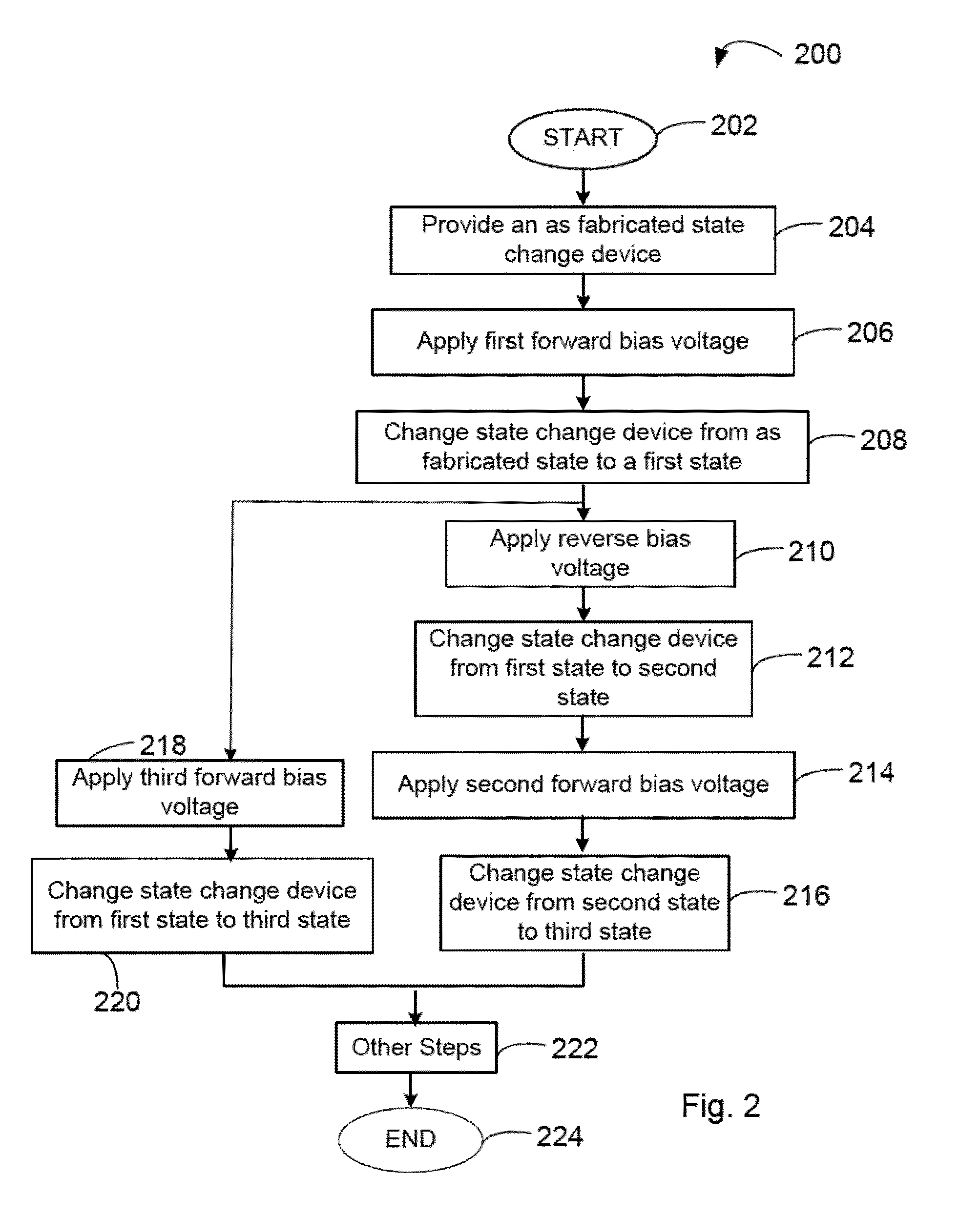

Multi-level cell operation using zinc oxide switching material in non-volatile memory device

A method for programming a non-volatile memory device includes providing an as-fabricated state-change device having an aluminum doped zinc oxide material first electrode, a p++ polysilicon material second electrode, and a zinc oxide (ZnO) material state-change material there between. A first amplitude bias voltage is applied to the first electrode of the as-fabricated state-change device causing the ZnO material to change form an as-fabricated state to a first state. A second amplitude bias voltage having an opposite polarity having an amplitude similar to the first amplitude is applied to cause the ZnO to change from the first state to a second state substantially similar as the as-fabricated state. A third amplitude bias voltage having a same polarity to the first bias voltage and having an amplitude dissimilar to the first bias voltage is applied to cause the ZnO to change from the second state to a third state.

Owner:CROSSBAR INC

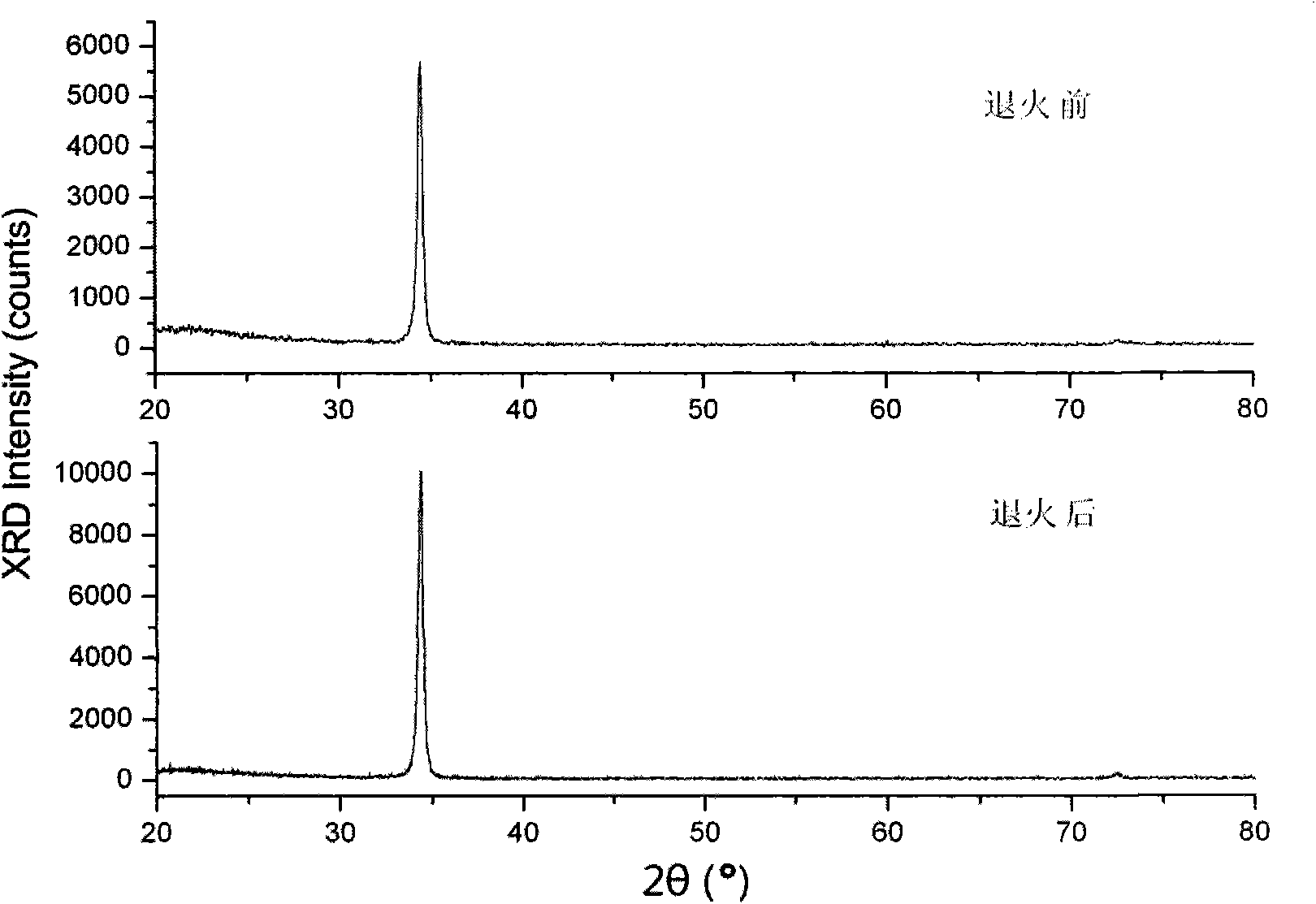

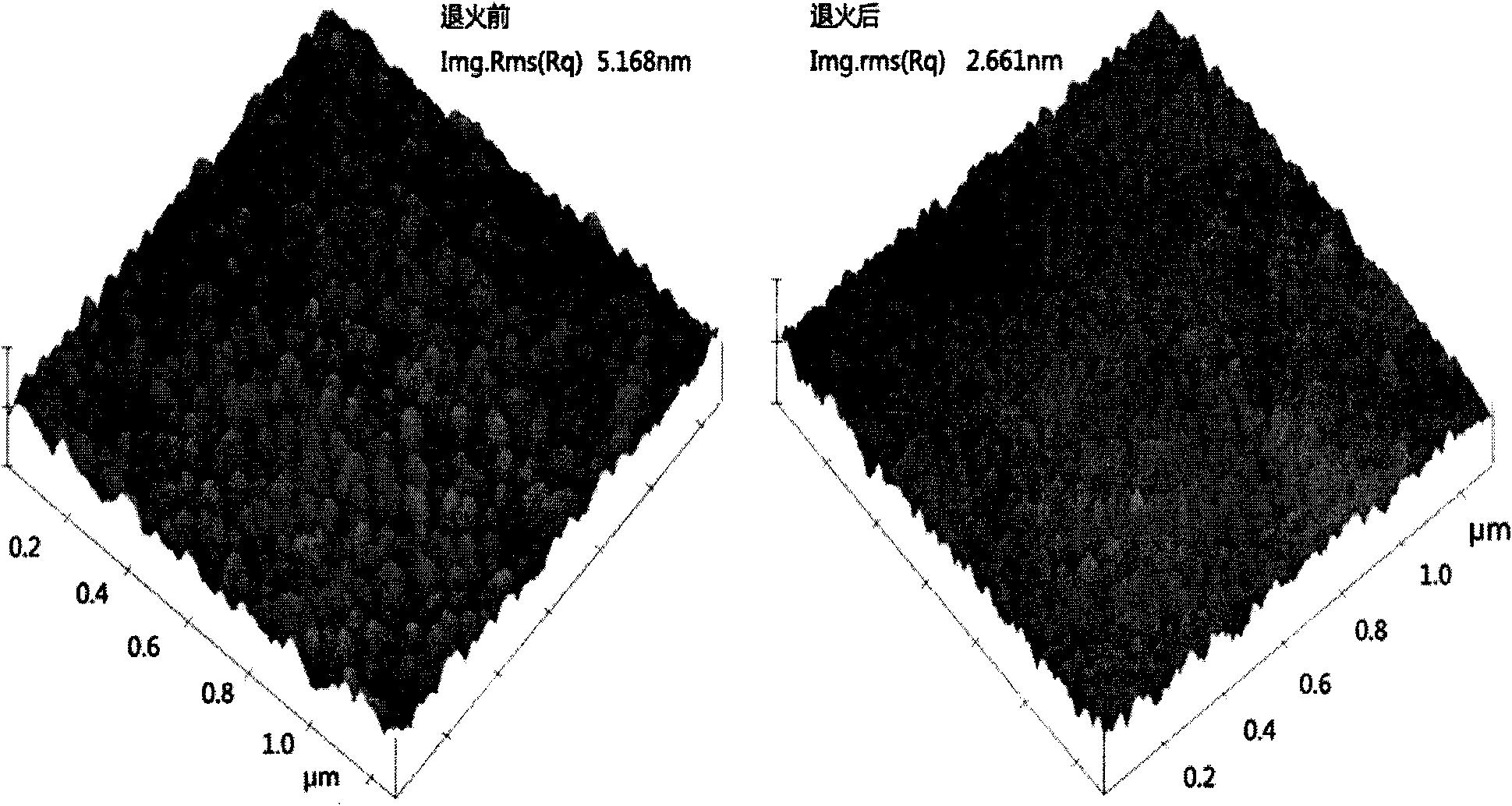

Method for annealing aluminum-doped zinc oxide transparent conductive thin film

InactiveCN101985740AImprove mobilityIncrease the carrier concentrationVacuum evaporation coatingSputtering coatingHydrogenAluminum doped zinc oxide

The invention relates to a method for annealing an aluminum-doped zinc oxide (AZO) transparent conductive thin film. In the method, the AZO transparent conductive film is annealed by introducing a certain amount of inert gas (such as nitrogen gas, argon gas and the like), reducing gas (hydrogen gas, methane and the like) or mixed gas of the inert gas and the reducing gas into an annealing furnace under vacuum. By annealing, the mobility and the carrier concentration are obviously improved, so that the resistivity of the thin film is reduced; and the crystallization of the annealed thin film is improved, and a good C-axis preferred orientation structure is kept. By the method, the AZO transparent conductive thin film rapidly grows in a magnetron sputtering coating machine at a low temperature and then is annealed in the annealing furnace in batches, so that the performance of the AZO transparent conductive thin film is improved, and the production efficiency of the AZO transparent conductive thin film is greatly improved.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

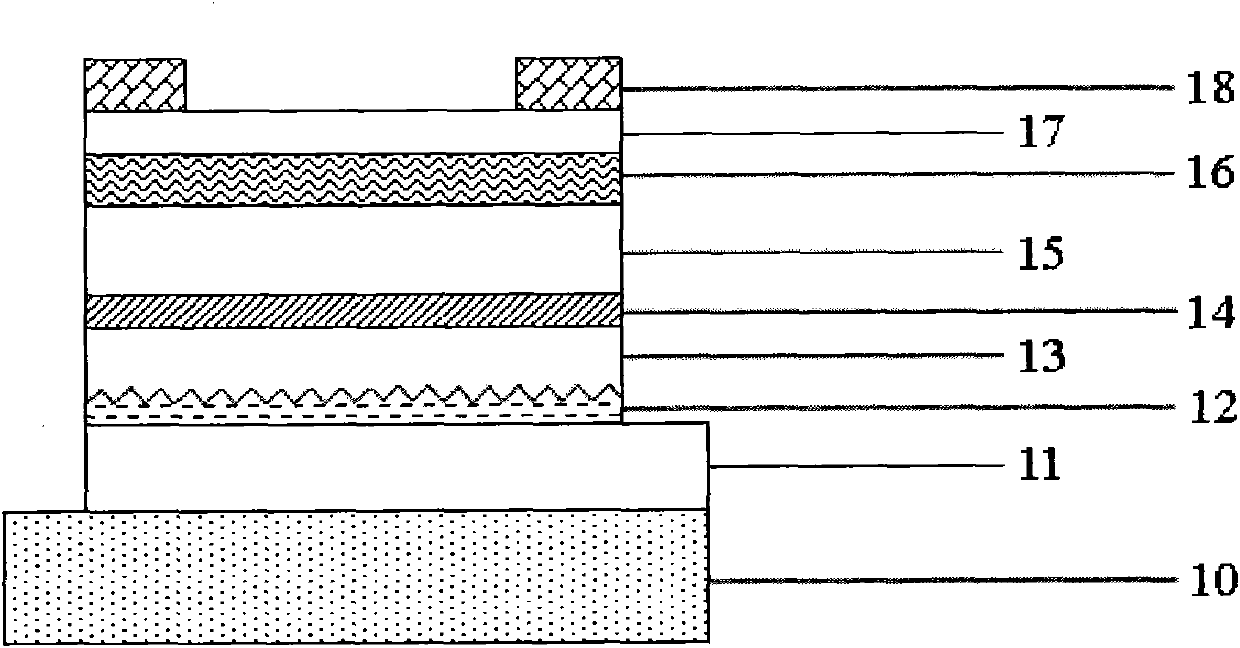

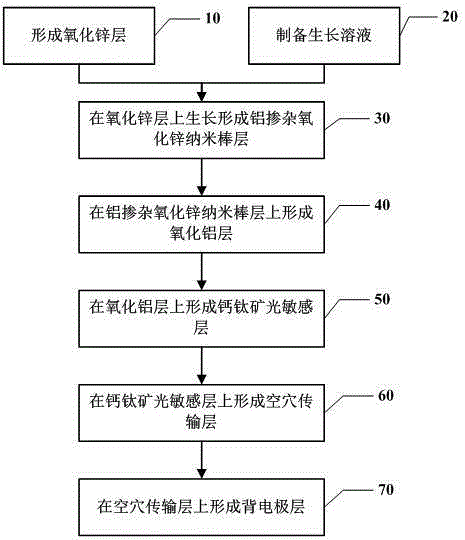

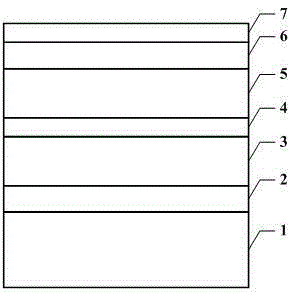

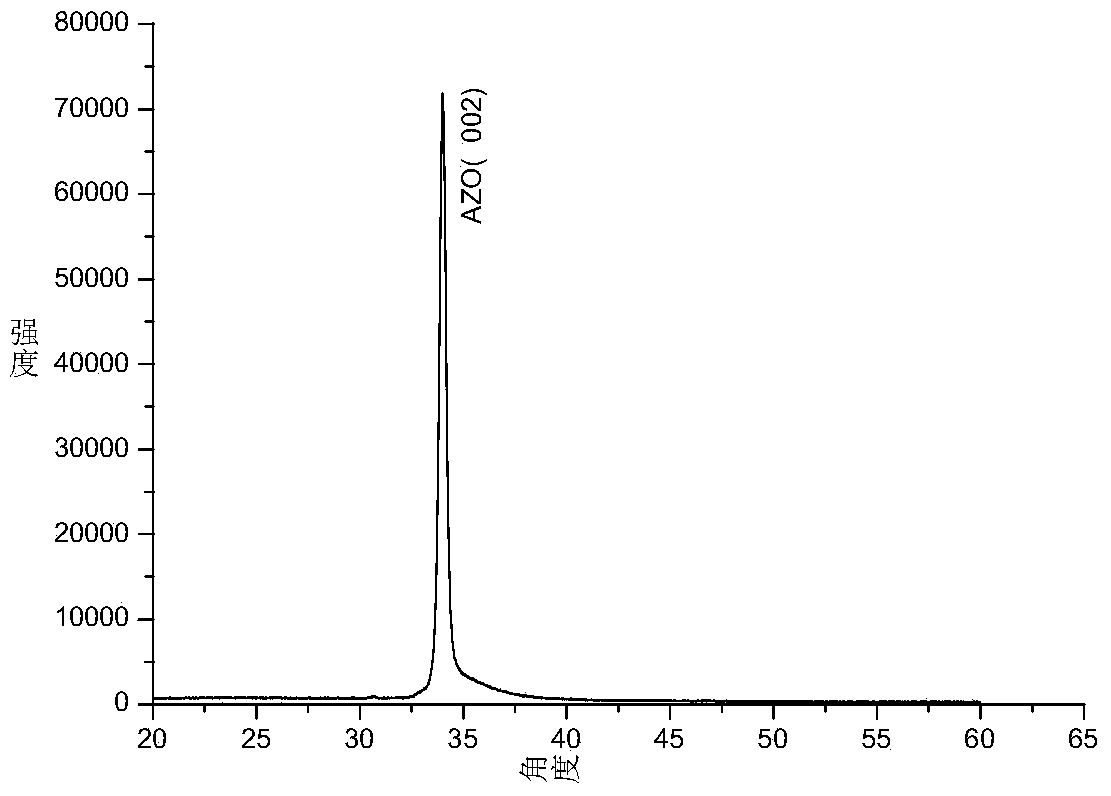

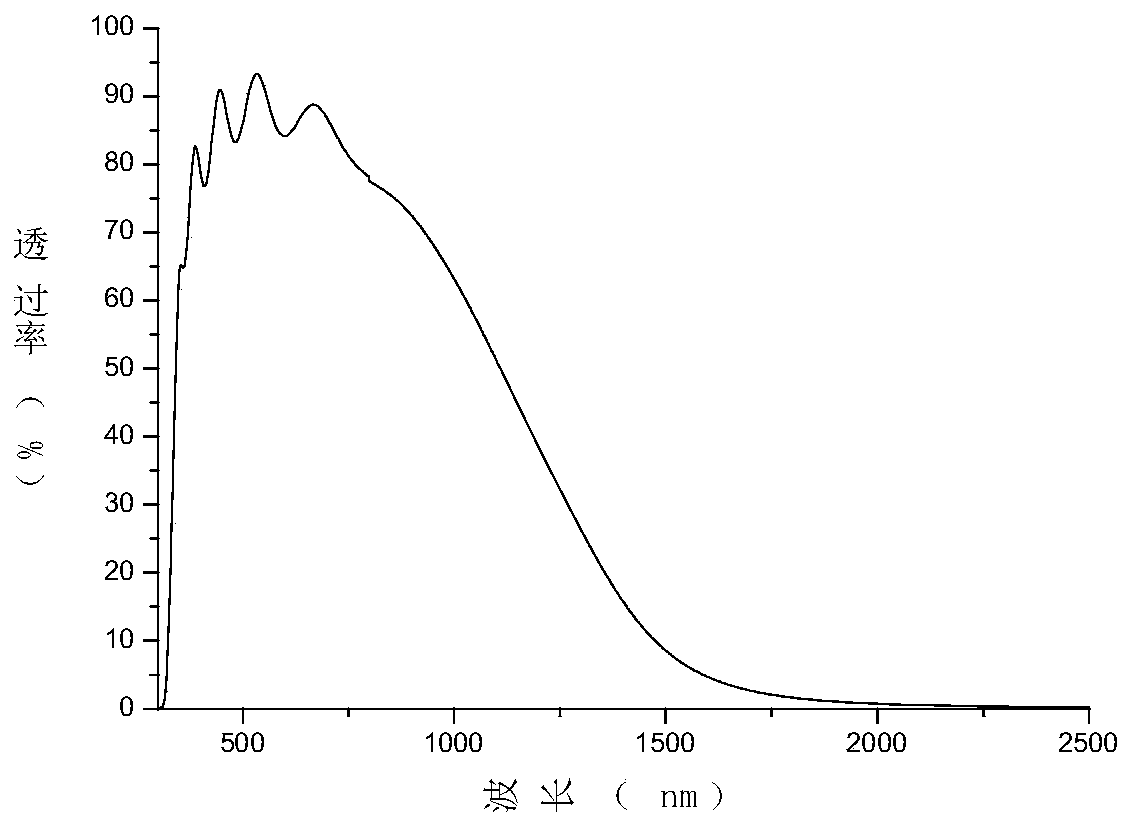

Perovskite solar cell and manufacturing method thereof

InactiveCN105244439AImprove photoelectric conversion efficiencyImprove defectsSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellAluminum doped zinc oxide

The embodiment of the invention discloses a perovskite solar cell and a manufacturing method thereof. The method comprises steps: a zinc oxide layer is formed on a transparent substrate; the substrate with the zinc oxide layer formed is placed in a growth solution for reaction, and an aluminum-doped zinc oxide nanorod layer grows and is formed on the zinc oxide layer; an aluminium oxide layer is formed on the aluminum-doped zinc oxide nanorod layer; a perovskite light sensitive layer is formed on the aluminium oxide layer; a hole transport layer is formed on the perovskite light sensitive layer; and a back electrode layer is formed on the hole transport layer. in the embodiment of the invention, the aluminum-doped zinc oxide nanorod layer serves as an electron transport layer, and a large surface area and a good electron transport ability are provided; the aluminium oxide layer is formed on the aluminum-doped zinc oxide nanorod layer to serve as a modified barrier layer, and defects of the zinc oxide nanorod can be improved; and thus, the photoelectric conversion efficiency of the perovskite solar cell based on the aluminum-doped zinc oxide nanorod can be improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Preparation method of aluminum-doped zinc oxide (AZO) transparent conducting film

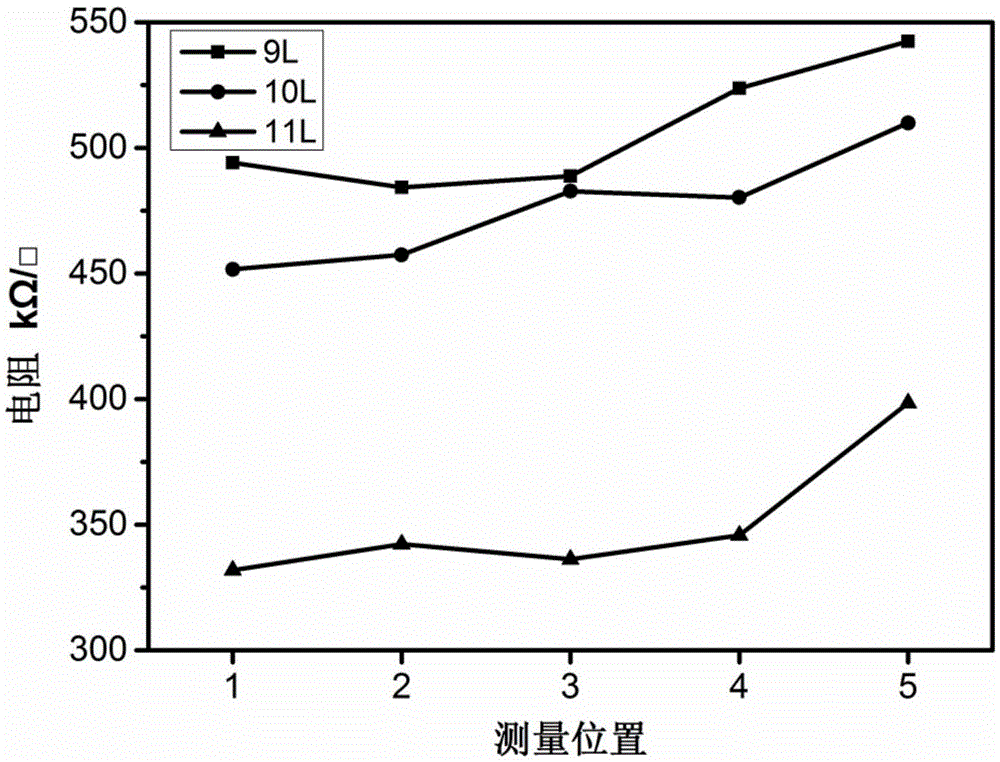

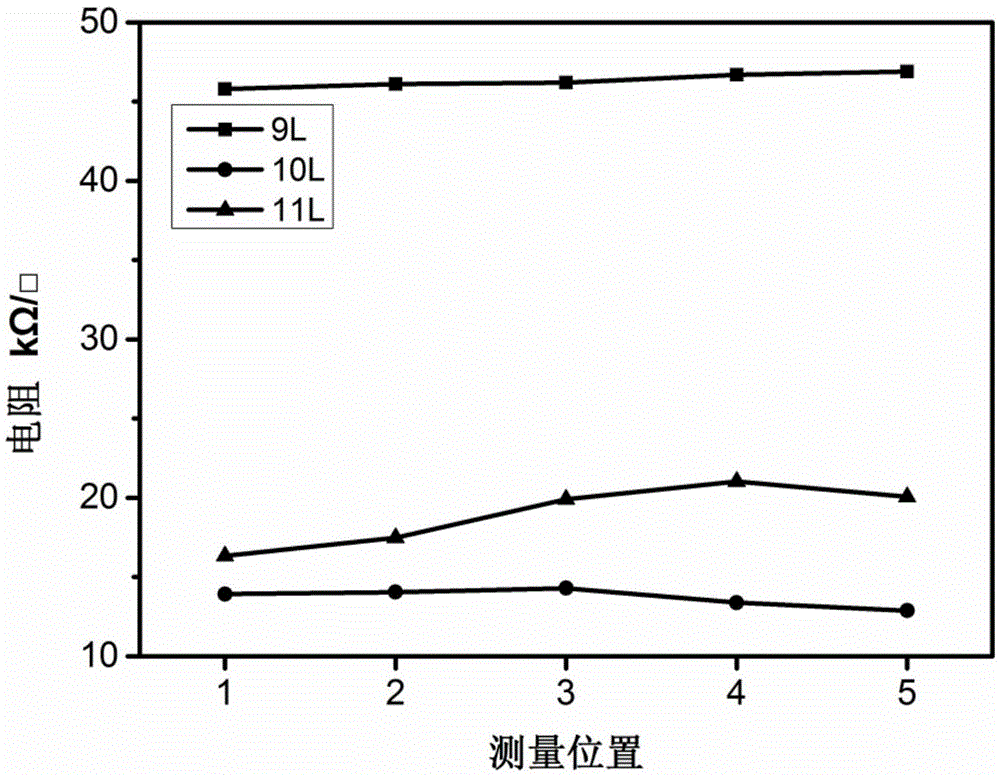

InactiveCN103526169AImprove uniformityImprove processing stabilityVacuum evaporation coatingSputtering coatingDeposition temperatureHydrogen

The invention relates to a preparation method of an aluminum-doped zinc oxide (AZO) transparent conducting film. The AZO film is prepared through an AZO ceramic target direct-current magnetron sputtering process in an argon-hydrogen mixed atmosphere at room temperature. The process parameters are as follows: the vacuum degree is 0.08-0.4Pa, the flow ratio of hydrogen gas to argon gas is (40:0.5)-(40:8)(SCCM), the sputtering power is 180W, the target-substrate distance is 160mm, and the deposition temperature is room temperature.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Method of directly preparing flexible and transparent conductive film through sol-gel process

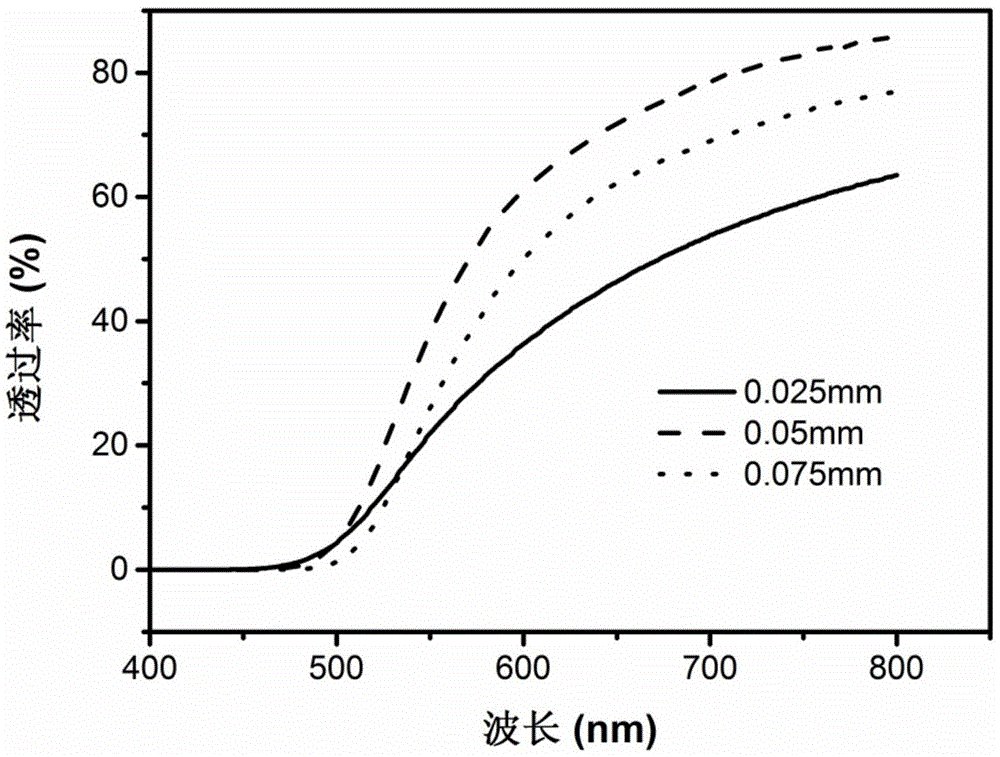

InactiveCN105575551AGuaranteed smoothReduce bending deformationApparatus for heat treatmentAluminum doped zinc oxideHYDROSOL

The invention provides a method of directly preparing a flexible and transparent conductive film through a sol-gel process, mainly relating to the film preparation field. The method employs a sol-gel process to directly prepare an aluminum-doped zinc oxide flexible conductive film, guarantees the transmittance of a flexible transparent conductive film, meanwhile realizes low temperature preparation of the flexible transparent conductive film, and regulates the electrical property of the flexible transparent conductive film through low temperature annealing treatment. The method optimizes the electrical property of the flexible transparent conductive film through selecting different substrate thickness and annealing conditions, realizes the direct preparation of the flexible transparent conductive film with higher transmittance and electrical properties by employing a sol-gel process, effectively optimizes the conductive performance of the film through different annealing treatments, controllably regulates the electrical property of the flexible transparent conductive film, and realizes flexible transparent conductive film production under industrialization and low cost conditions.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com