Making method of zinc oxide or aluminum-doped zinc oxide coated lithium cobaltate electrode

A technology of aluminum-doped zinc oxide and coated lithium cobalt oxide, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as coating and modification of difficult lithium cobalt oxide electrodes, and improve battery cycle performance. The method is simple and The effect of mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

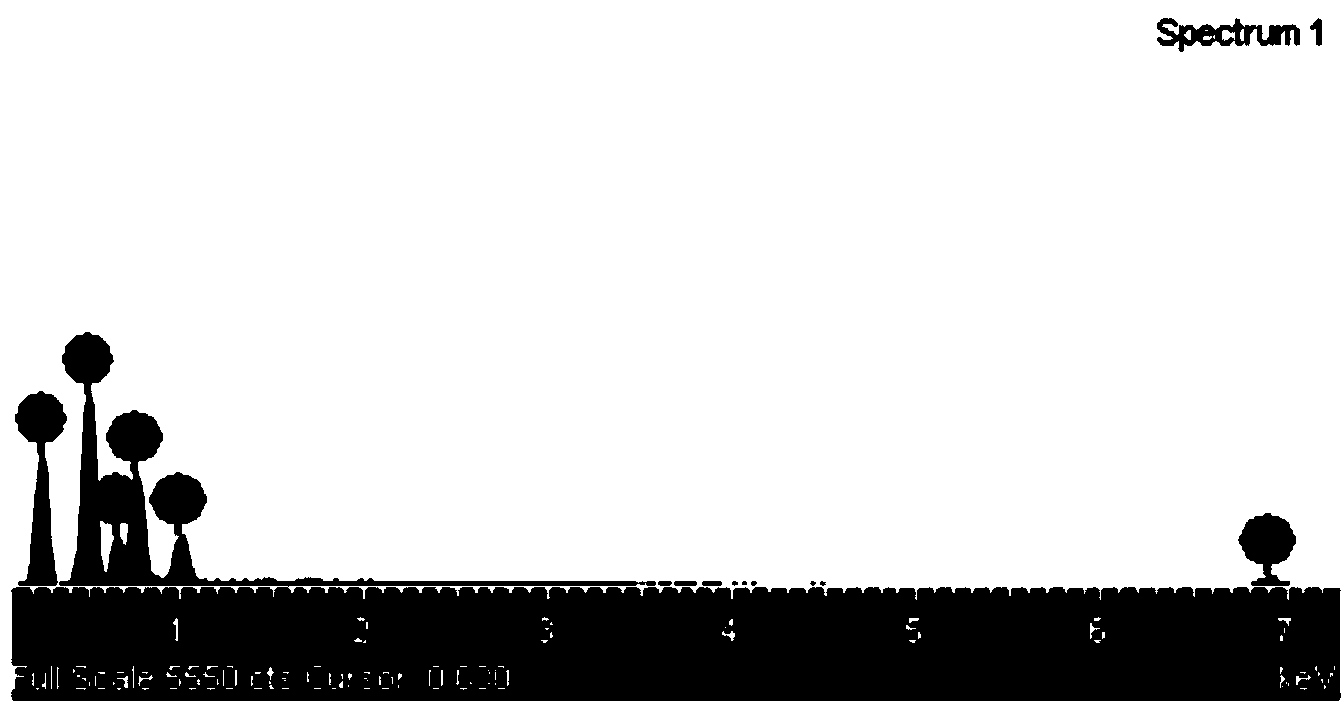

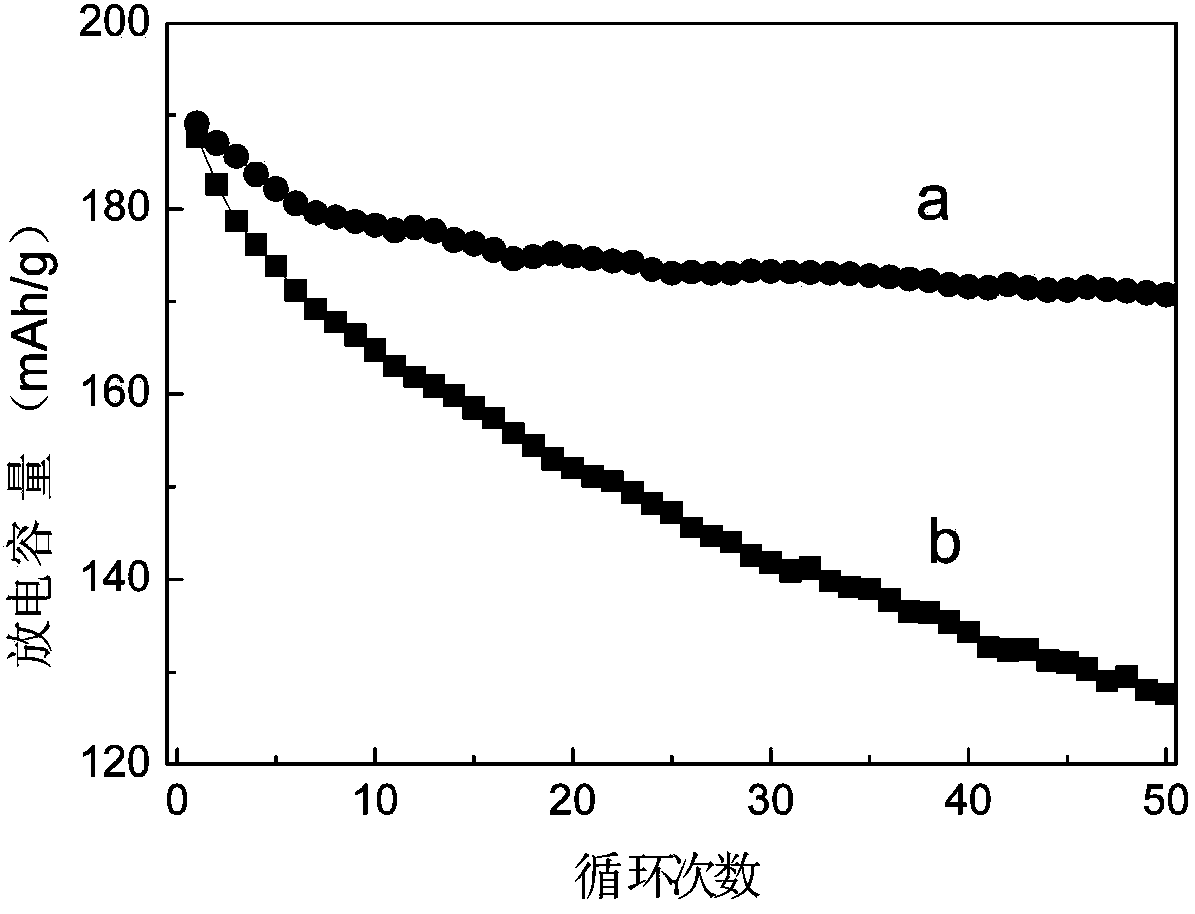

Embodiment 1

[0028] This example is used to illustrate the preparation method of lithium cobaltate electrode and the method of coating and modifying it by radio frequency magnetron sputtering. The specific steps are as follows:

[0029] A. Preparation of conventional lithium cobalt oxide electrode

[0030] Weigh 80 parts by weight of lithium cobaltate, 10 parts by weight of acetylene black and mix evenly, then add 10 parts by weight of polyvinylidene fluoride (PVDF) with N-methylpyrrolidone (NMP) as solvent, mix and grind to make a slurry and uniform Coated on aluminum foil and dried at 110°C to make a conventional lithium cobalt oxide electrode.

[0031] B. Install the target

[0032] Install the zinc oxide (ZnO) target in the magnetron sputtering chamber

[0033] C. Install the substrate

[0034] The prepared conventional lithium cobalt oxide electrode is installed in the magnetron sputtering chamber as a substrate;

[0035] D. Working gas

[0036] Vacuumize the magnetron sputtering c...

Embodiment 2

[0045] This example is used to illustrate the preparation method of lithium cobaltate electrode and the method of coating and modifying it by radio frequency magnetron sputtering. The specific steps are as follows:

[0046] A. Preparation of conventional lithium cobalt oxide electrode

[0047] Weigh 80 parts by weight of lithium cobaltate, 10 parts by weight of acetylene black and mix evenly, then add 10 parts by weight of polyvinylidene fluoride (PVDF) with N-methylpyrrolidone (NMP) as solvent, mix and grind to make a slurry and uniform Coated on aluminum foil and dried at 110°C to make a conventional lithium cobalt oxide electrode.

[0048] B. Install the target

[0049] Install the zinc oxide (ZnO) target in the magnetron sputtering chamber

[0050] C. Install the substrate

[0051] The prepared conventional lithium cobalt oxide electrode is installed in the magnetron sputtering chamber as a substrate;

[0052] D. Working gas

[0053] Vacuumize the magnetron sputtering...

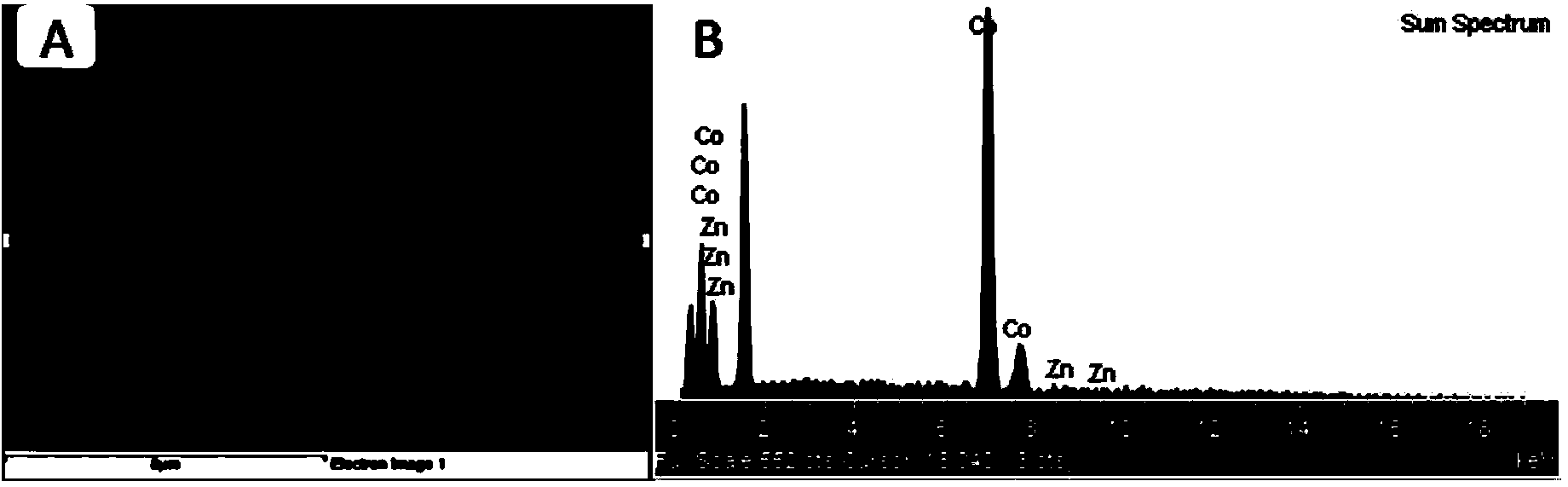

Embodiment 3

[0059] This example is used to illustrate the preparation method of lithium cobaltate electrode and the method of coating and modifying it by radio frequency magnetron sputtering. The specific steps are as follows:

[0060] A. Preparation of conventional lithium cobalt oxide electrode

[0061]Weigh 80 parts by weight of lithium cobaltate, 10 parts by weight of acetylene black and mix evenly, then add 10 parts by weight of polyvinylidene fluoride (PVDF) with N-methylpyrrolidone (NMP) as solvent, mix and grind to make a slurry and uniform Coated on aluminum foil and dried at 110°C to make a conventional lithium cobalt oxide electrode.

[0062] B. Install the target

[0063] Install the aluminum-doped zinc oxide target in the magnetron sputtering chamber (the target contains Al 2 o 3 5.0wt.%);

[0064] C. Install the substrate

[0065] The prepared conventional lithium cobalt oxide electrode is installed in the magnetron sputtering chamber as a substrate;

[0066] D. Workin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com