Patents

Literature

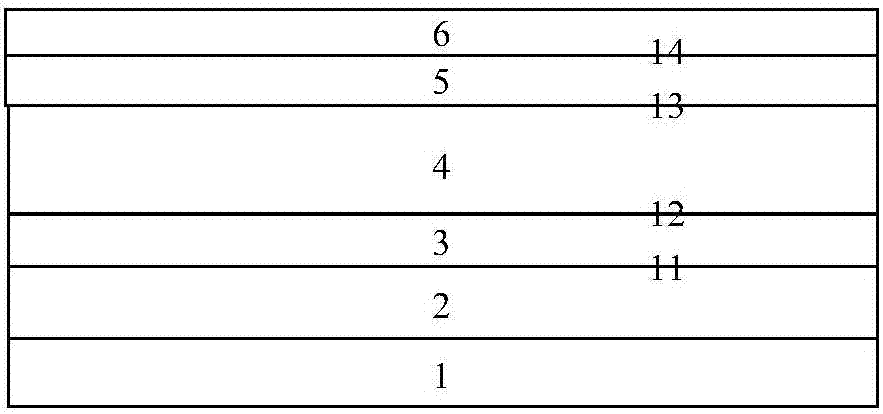

95 results about "Radio frequency magnetron" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

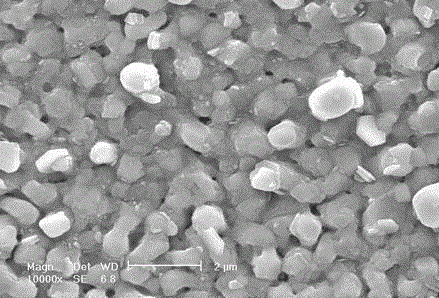

Radio frequency magnetron sputtering, also called RF magnetron sputtering is a process that is used to make thin film, especially when using materials that are non-conductive. In this process, a thin film is grown on a substrate that is placed in a vacuum chamber.

Solid oxide fuel cell cerium-oxide-based electrolyte barrier layer and preparation method thereof

ActiveCN103390739AImprove long-term stabilityImprove long-term reliabilityFinal product manufactureCell component detailsChemical reactionFuel cells

The invention discloses a solid oxide fuel cell cerium-oxide-based electrolyte barrier layer comprising a compact layer and a loose layer. The compact layer can effectively inhibit harmful chemical reactions and element diffusion between cobalt cathode and a zirconia-based electrolyte. The loose layer can improve the contact performance of a cathode / electrolyte interface. The barrier layer is prepared with a radio frequency magnetron reactive sputtering method under a lower temperature, such that the production of cerium-zirconium oxide solid solution produced through the reaction with the zirconia-based electrolyte is avoided. With the barrier layer, cell performance is effectively improved, and long-time stability and reliability of the solid oxide fuel cell are improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Thin-film getter with high gas absorption performance and preparation method thereof

ActiveCN103182297AImprove adhesionInhibition of poisoningOther chemical processesDispersed particle separationAbsorption capacityRadio frequency magnetron sputtering

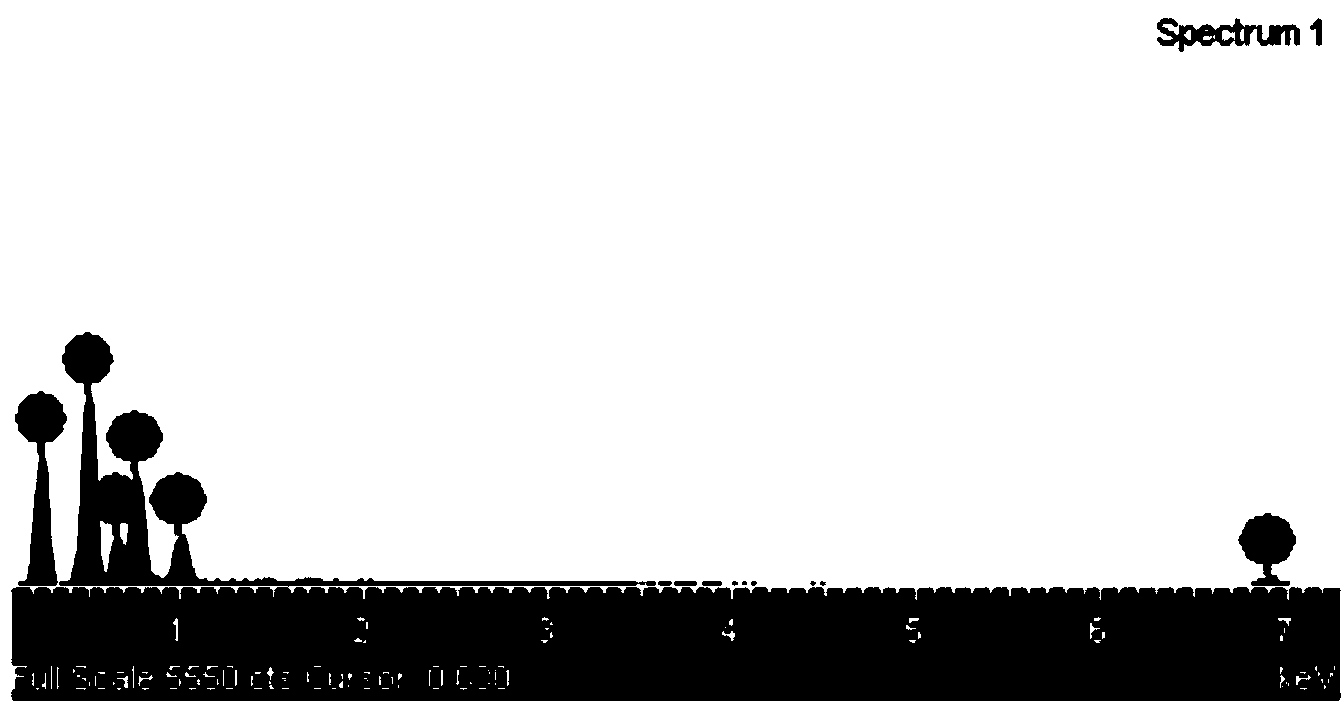

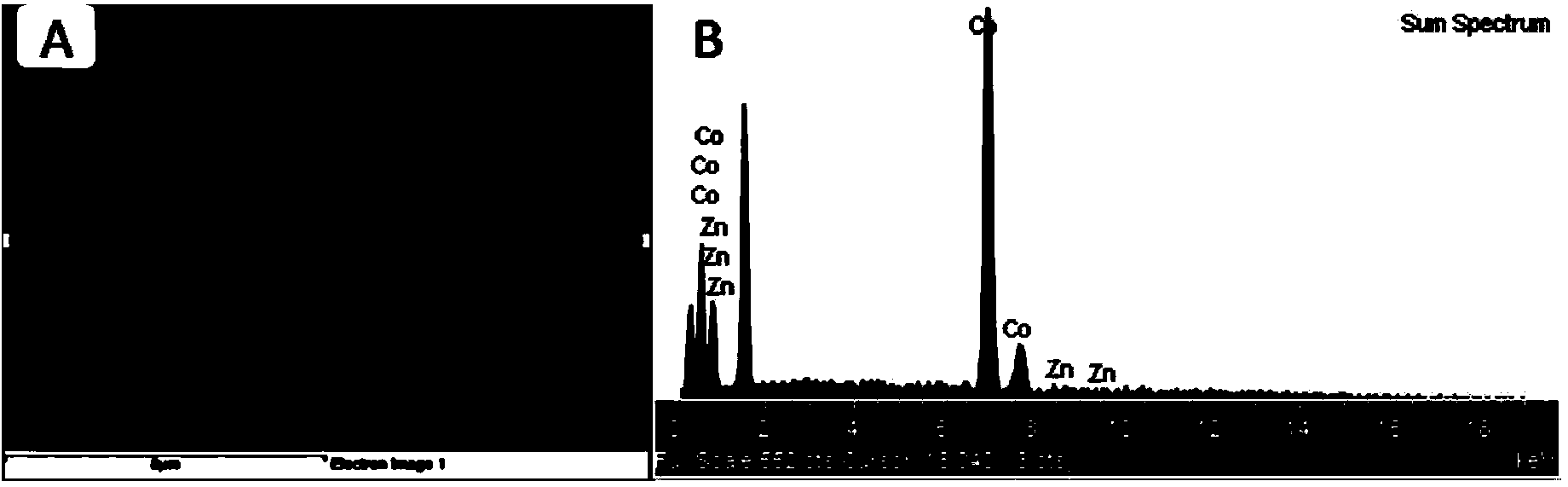

The invention provides a thin-film getter with high gas absorption performance and a preparation method thereof. The thin-film getter is formed by depositing a gas absorbing layer on a metal, silicon, ceramic or glass substrate or on the inner wall of a sealed device or is a film with two-layer structure composed by the gas absorbing layer and an adjusting layer, wherein the gas absorbing layer is multi-component alloy formed by Zr, Co and at least one material selected from the group consisting of Y, La, Ce, Pr and Nd, and the adjusting layer is one or alloy of more selected from the group consisting of Ti, Zr, Y, Hf, Mn, Cu, Cr, Al, Fe, Pt and Ru. The preparation method employs radio frequency magnetron sputtering for deposition of films of the gas absorbing layer and the adjusting layer. The thin-film getter provided by the invention is activated at a temperature in a range of 250 to 350 DEG C, has a high gas absorption rate and high gas absorption capacity, overcomes the problems of poor adhesion, low preparation efficiency and easy poisoning during activation of conventional thin-film getters and can meet design requirements for a vacuum working environment needed for realizing high reliability and a long service life of micro-electromechanical systems (MEMS), flat-panel displays (OLED / FED / LCD), solar heat-insulating boards and hydrogen-sensitive microelectronic devices.

Owner:GRIMAT ENG INST CO LTD

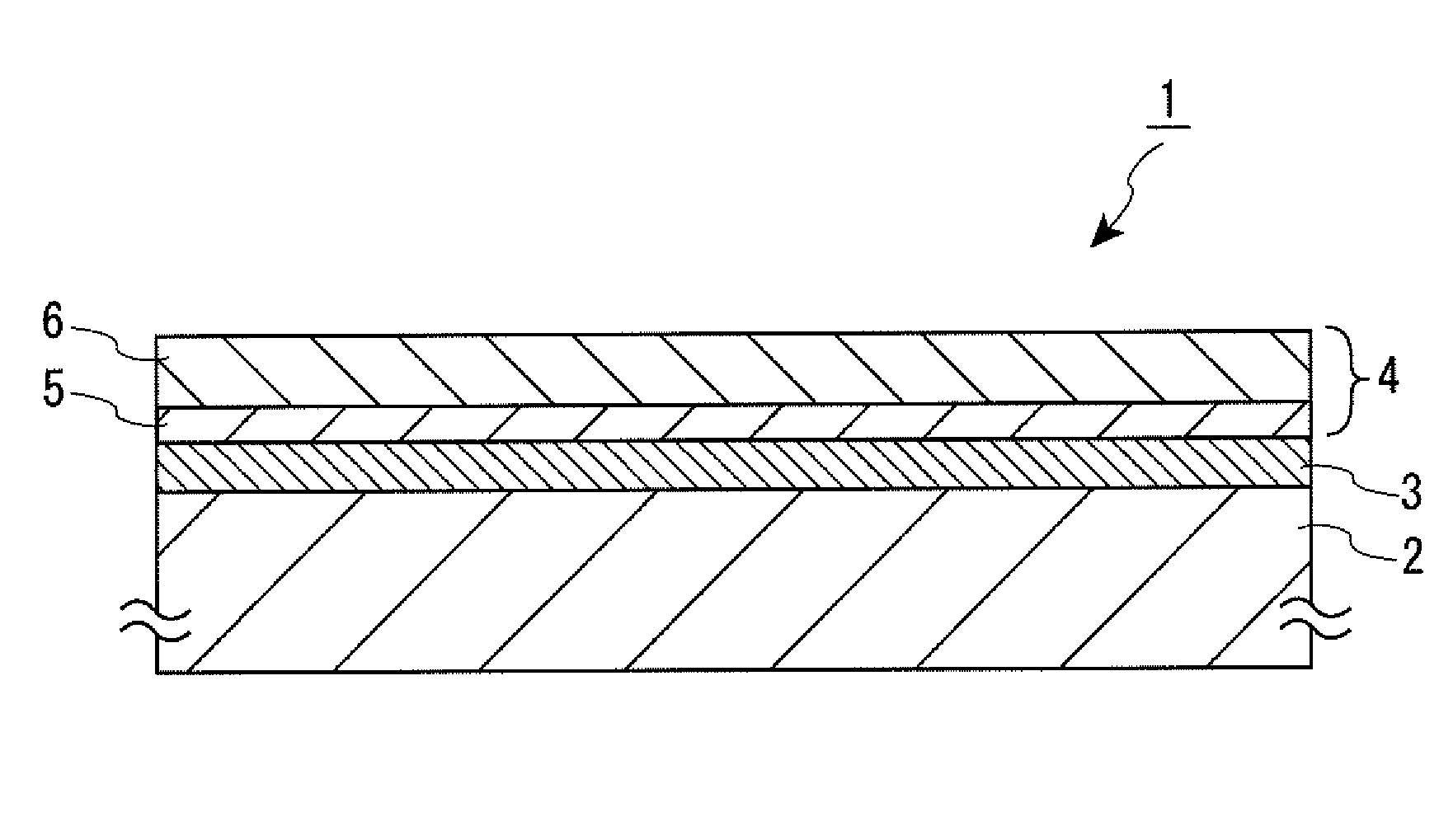

Display Substrate Having a Transparent Conductive Layer Made of Zinc Oxide and Manufacturing Method Thereof

InactiveUS20090242887A1Improve adhesionLower resistanceConductive layers on insulating-supportsVacuum evaporation coatingLiquid-crystal displayRadio frequency magnetron sputtering

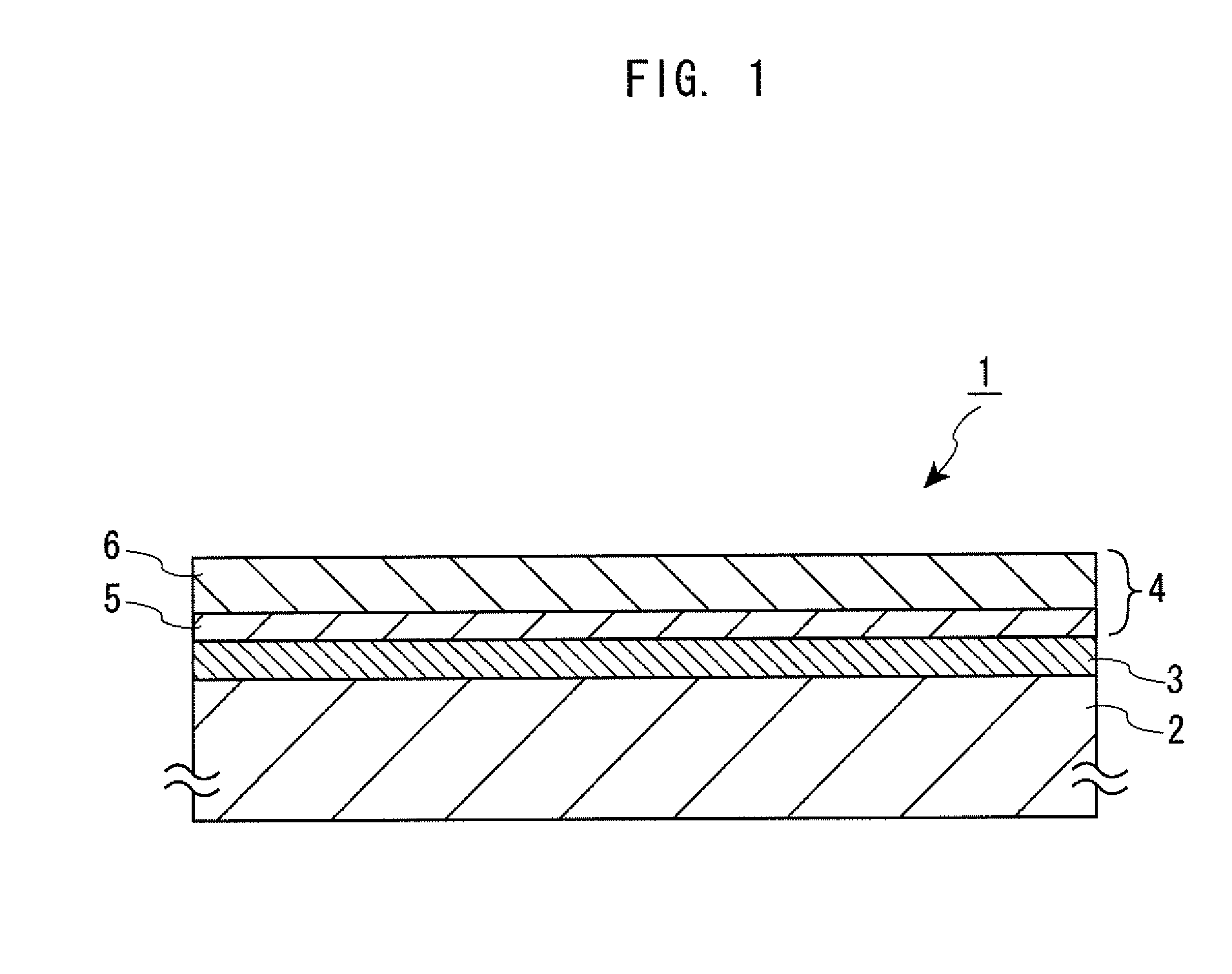

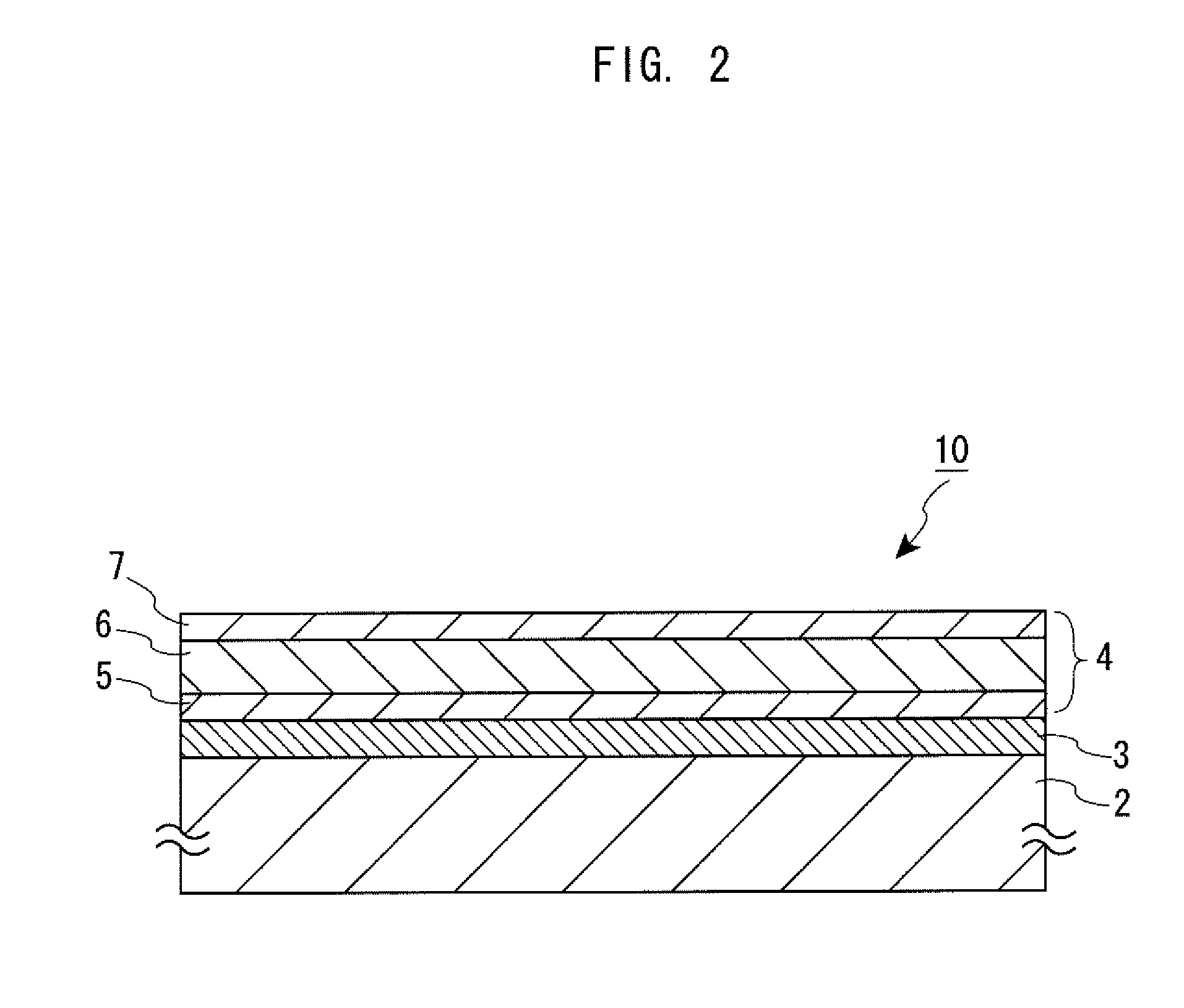

A display substrate is disclosed comprising: a supporting substrate; an organic resin layer formed on the supporting substrate; and a transparent electrode formed on the organic resin layer, wherein the transparent electrode includes: a first layer containing a zinc oxide and formed in close contact with the organic resin layer; and a second layer containing a zinc oxide and which has a thickness thicker than a thickness of the first layer and is formed on the first layer, wherein the first layer is deposited by either one of a DC sputtering and a DC magnetron sputtering, and the second layer is deposited by any one of a radio frequency sputtering, a radio frequency magnetron sputtering, a radio frequency superimposing a DC sputtering, and a radio frequency superimposing a DC magnetron sputtering, and the display substrate is available, for example, as the substrate having a transparent electrode for counter electrode of liquid crystal display device.

Owner:CASIO COMPUTER CO LTD +1

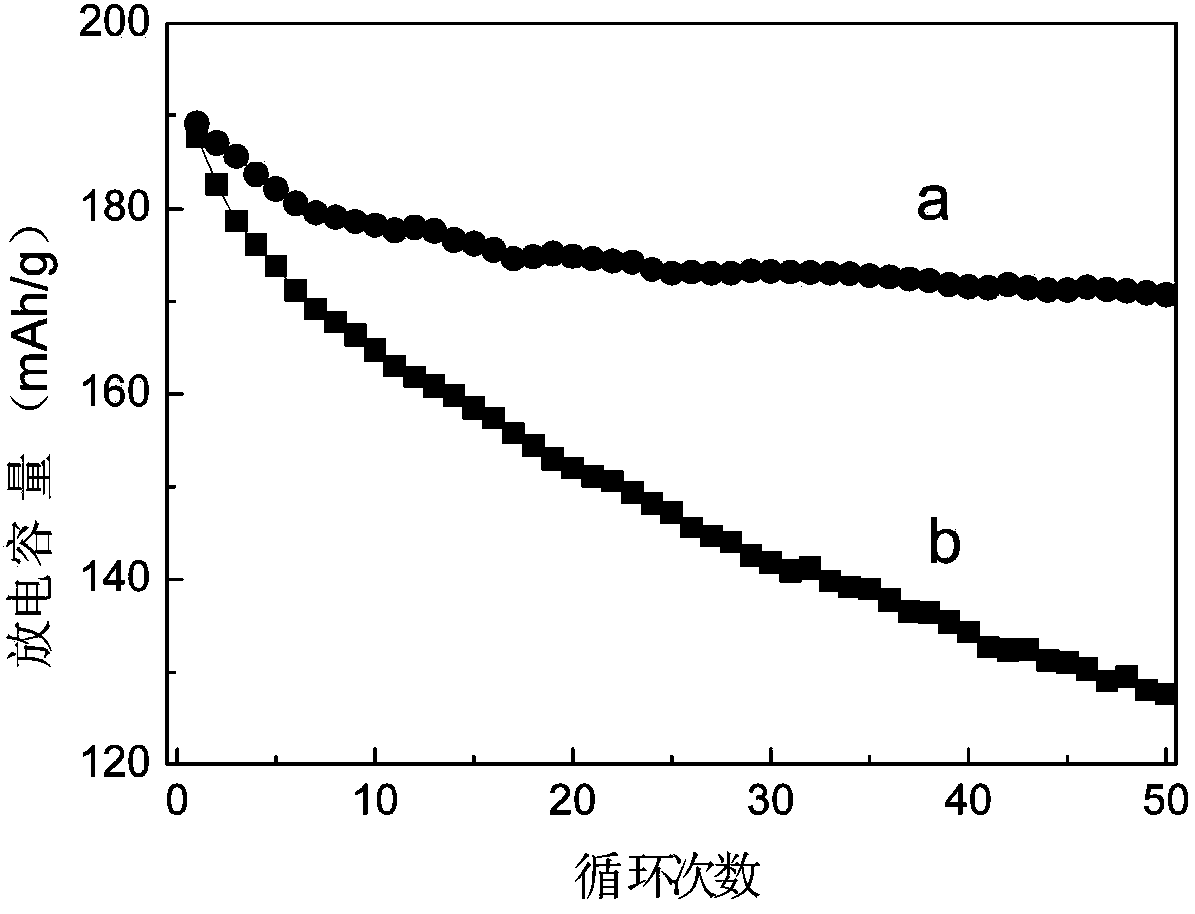

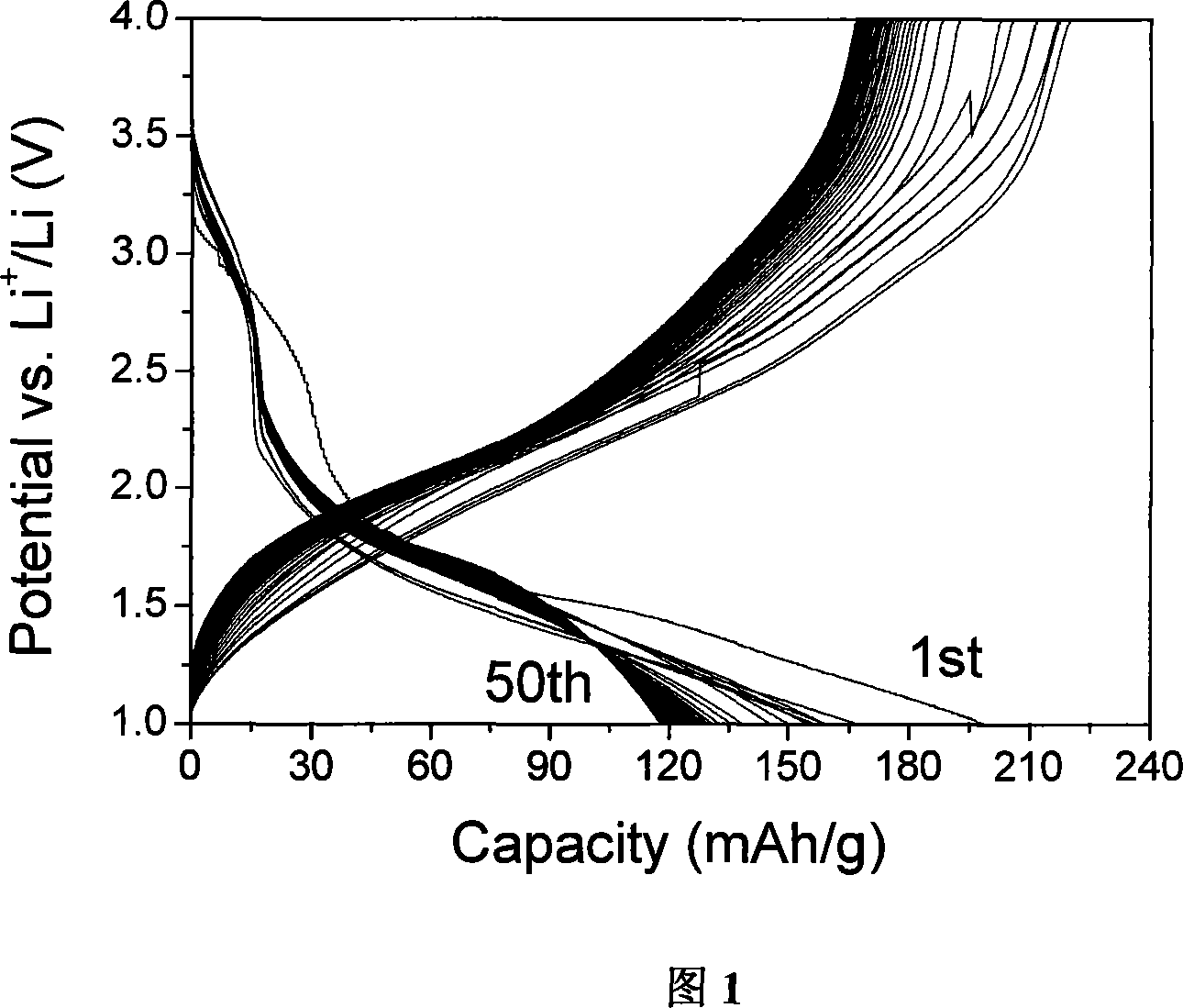

Making method of zinc oxide or aluminum-doped zinc oxide coated lithium cobaltate electrode

InactiveCN103594684AAvoid affecting transport performanceInhibition of dissolutionCell electrodesAluminum doped zinc oxideRadio frequency magnetron sputtering

A making method of a zinc oxide or aluminum-doped zinc oxide coated lithium cobaltate electrode belongs to the technical field of batteries. In the invention, zinc oxide or aluminum-doped zinc oxide deposited on a routine lithium cobaltate electrode through a radio frequency magnetron sputtering technology as a coating material to obtain the coated and modified lithium cobaltate electrode. The method concretely comprises the following steps: mixing lithium cobaltate powder with a conductive additive, a binder and a solvent, grinding to prepare a slurry, coating a current collector with the slurry, drying the coated current collector to make the routine sheet lithium cobaltate electrode, and depositing the coating layer of zinc oxide or aluminum-doped zinc oxide by adopting the radio frequency magnetron sputtering technology to realize the coating modification of the lithium cobaltate electrode. The method improves the electrode interface situation, effectively inhibit the secondary reactions on the high-potential interval electrode surface, reduces the capacity loss and improves the structural stability of an active material, so the working voltages of the batteries are widened, and the energy density, the power density and the cycle performance of the batteries are improved.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

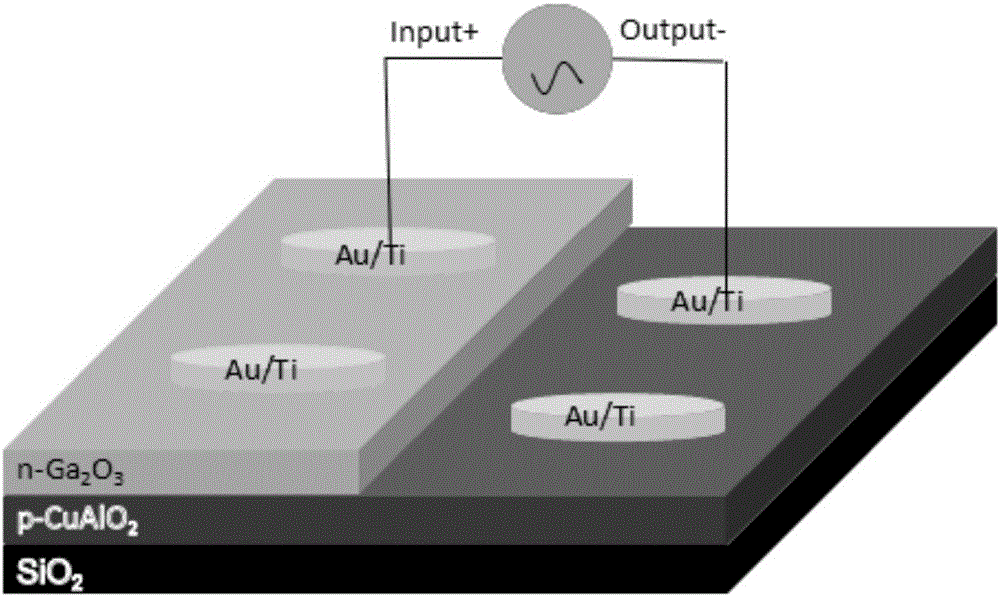

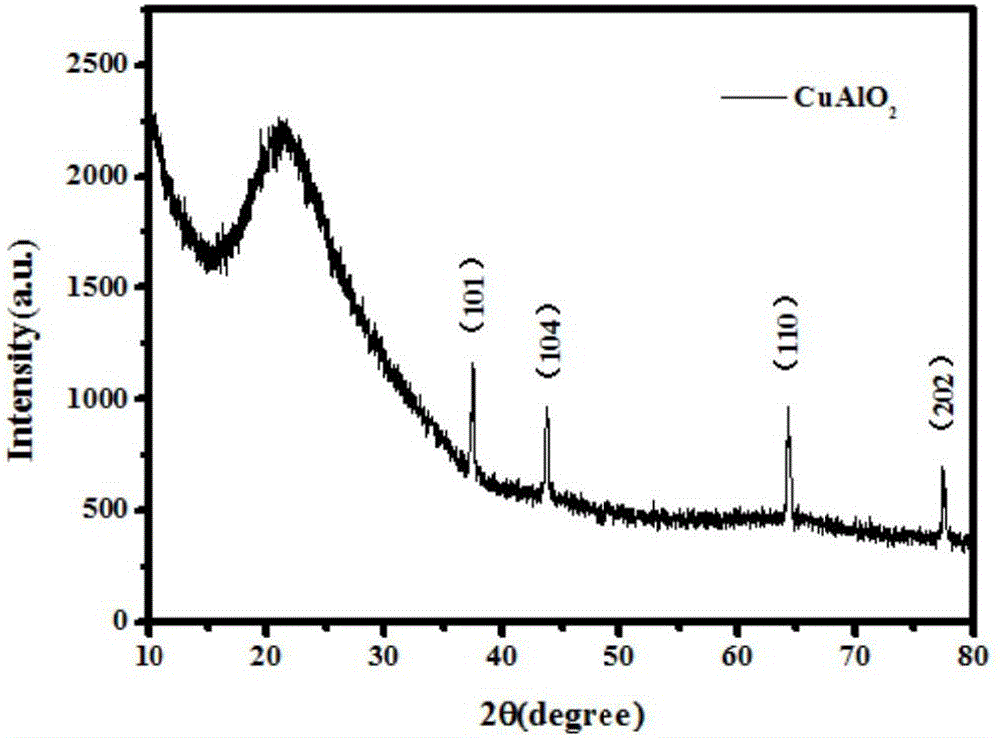

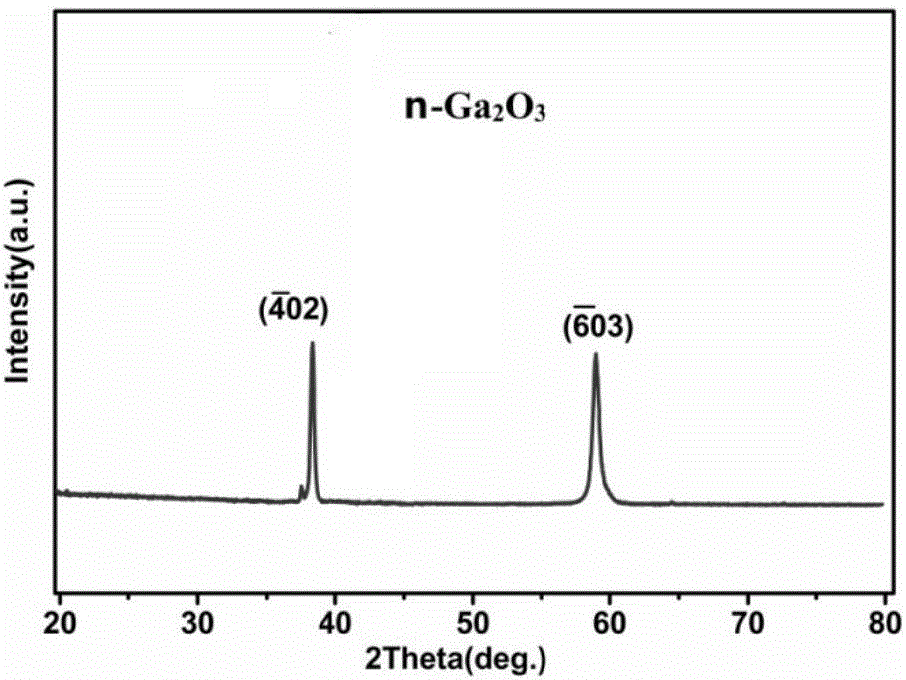

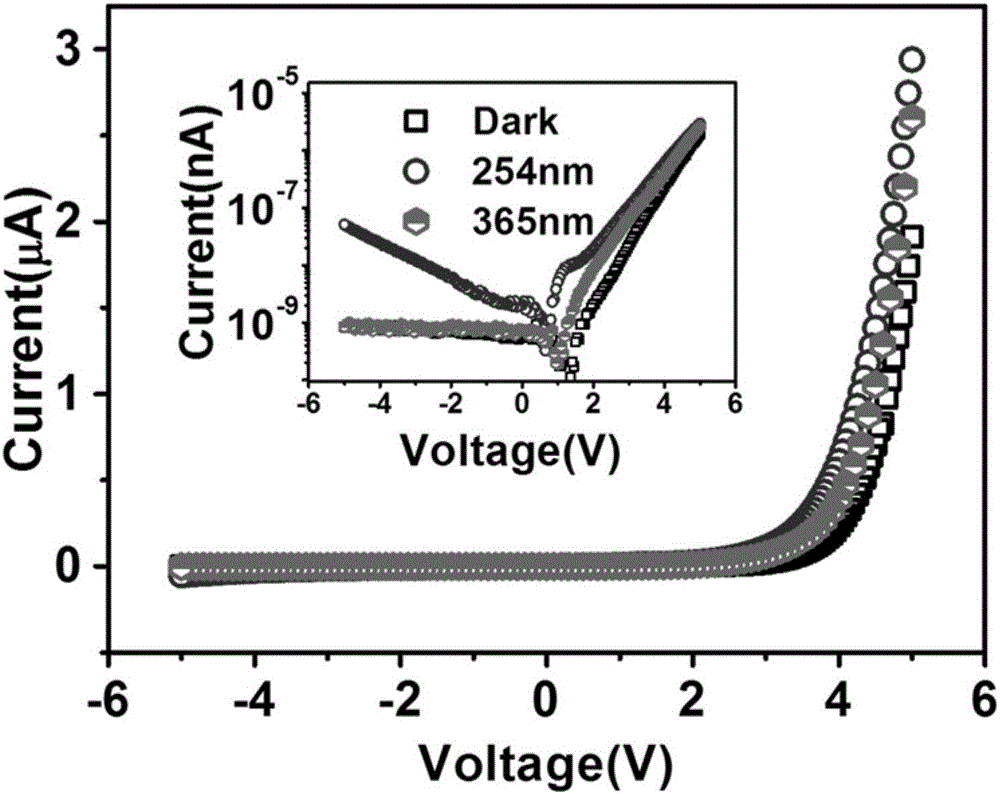

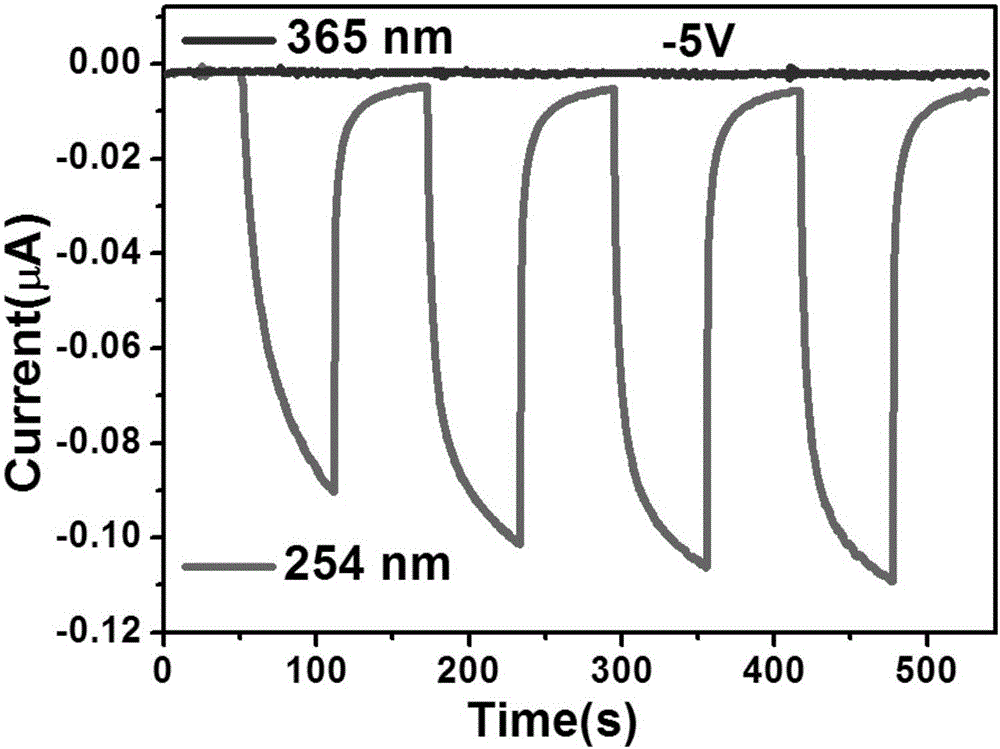

Preparation method of solar blind type ultraviolet detector based on Ga2O3/CuAlO2 heterojunction

ActiveCN106449889AImprove photoelectric propertiesHigh rectification ratioFinal product manufactureSemiconductor devicesHeterojunctionUltraviolet detectors

The invention relates to a preparation method of a solar blind type ultraviolet detector based on Ga2O3 / CuAlO2 heterojunction. The method is characterized in that a layer of p-CuAlO2 thin film is deposited on a quartz (SiO2) substrate through a radio frequency magnetron sputtering technology; then, a layer of n-Ga2O3 thin film is deposited on the p-CuAlO2 thin film by using a mask plate through the radio frequency magnetron sputtering technology; the area of the n-Ga2O3 thin film is half of the area of the p-CuAlO2 thin film; finally, a layer of Ti / Au thin film is deposited on the p-CuAlO2 and n-Ga2O3 thin films by the radio frequency magnetron sputtering technology and is used as an electrode. The preparation method has the advantages that the prepared solar blind type ultraviolet detector has stable performance, sensitive response, small dark current and wide application range; in addition, the preparation method has the characteristics of high process controllability, simple operation, good universality, recoverability during repeated test and the like; great application prospects are realized.

Owner:北京镓创科技有限公司

Anti strong light and strong heat radiative composite coating and preparation method thereof

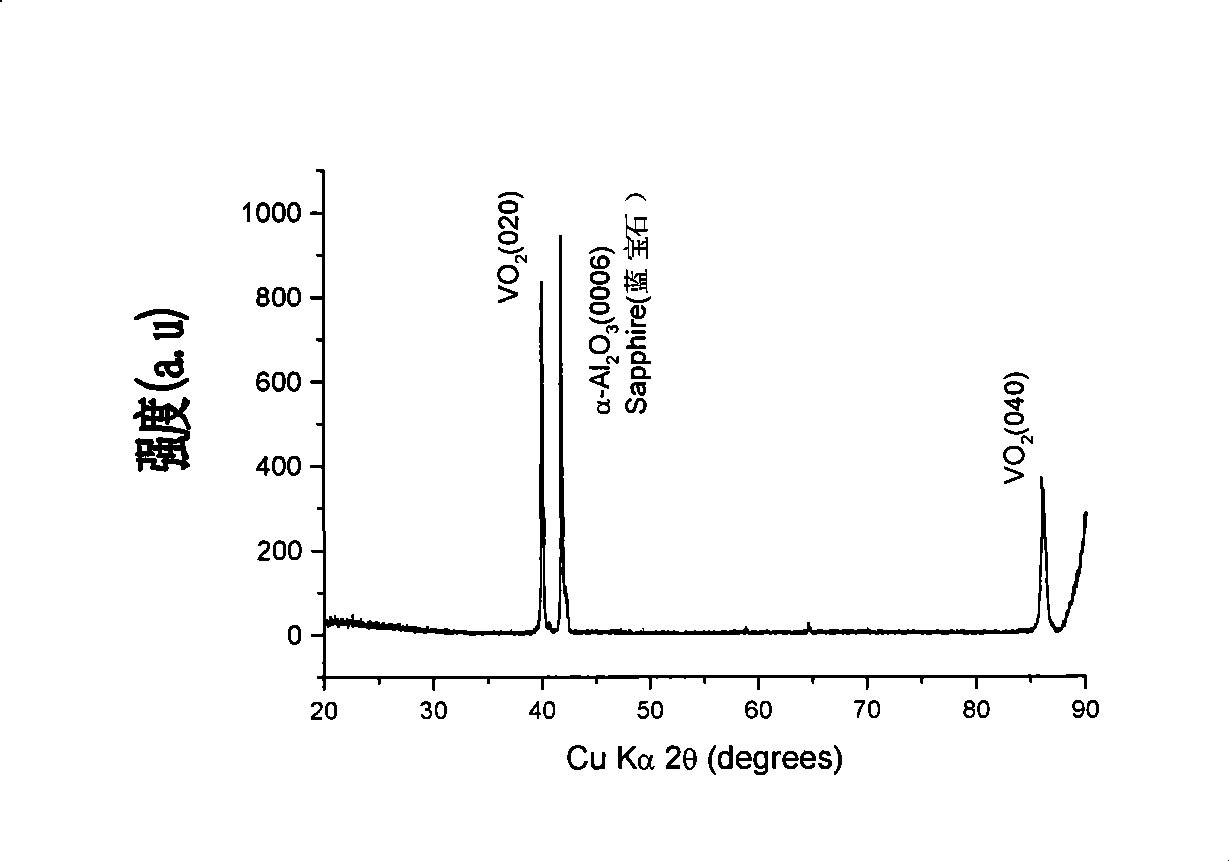

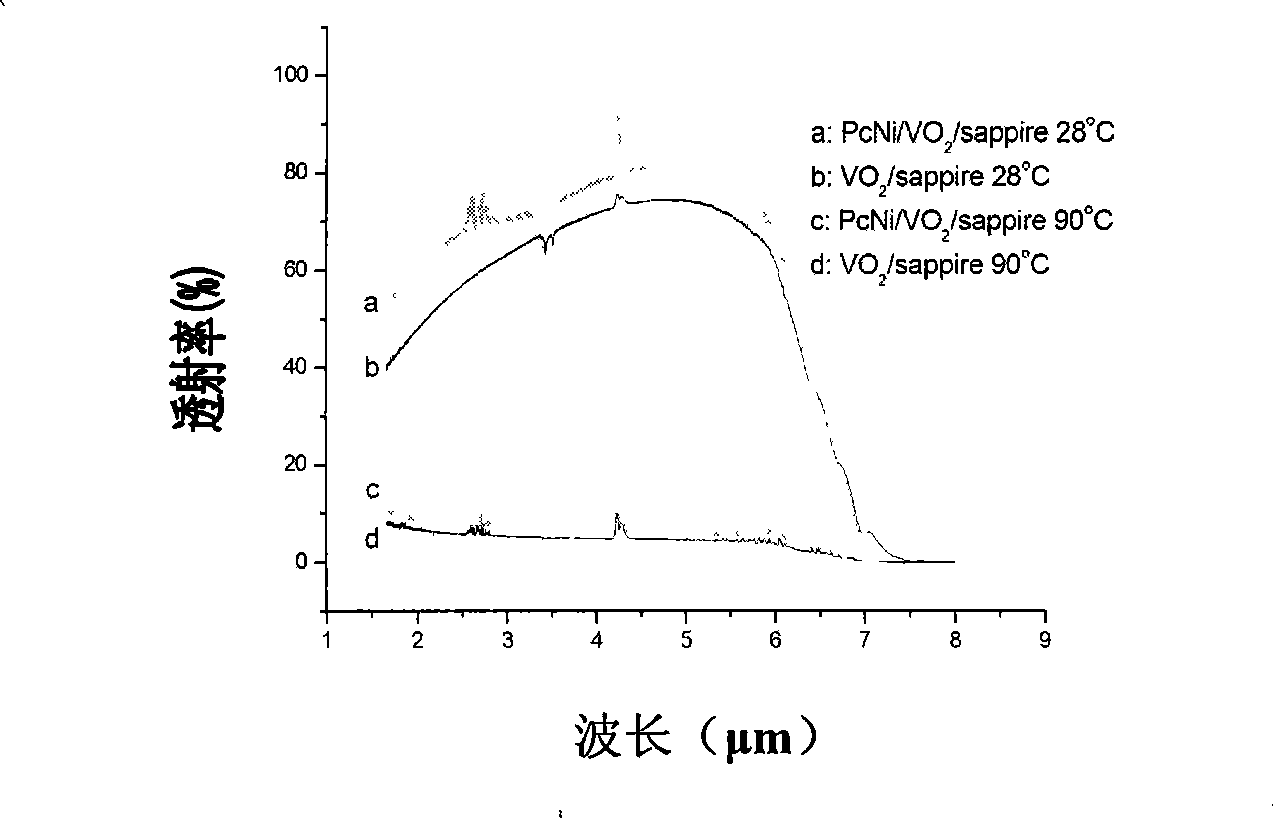

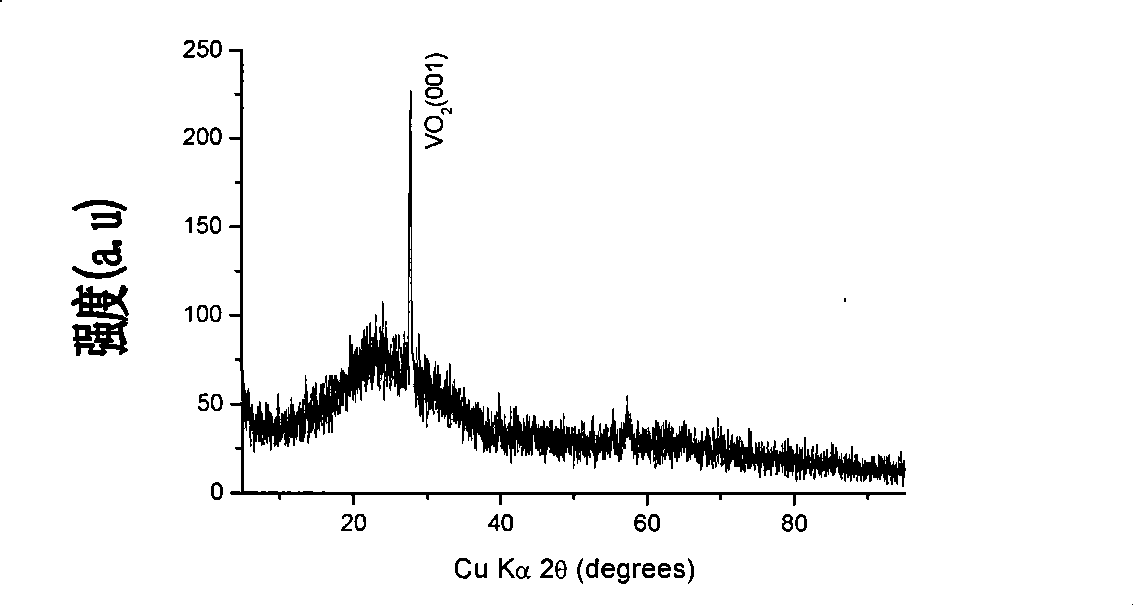

InactiveCN101362631AImprove performancePromote environmental protectionLiquid surface applicatorsVacuum evaporation coatingThermal radiationRadio frequency magnetron

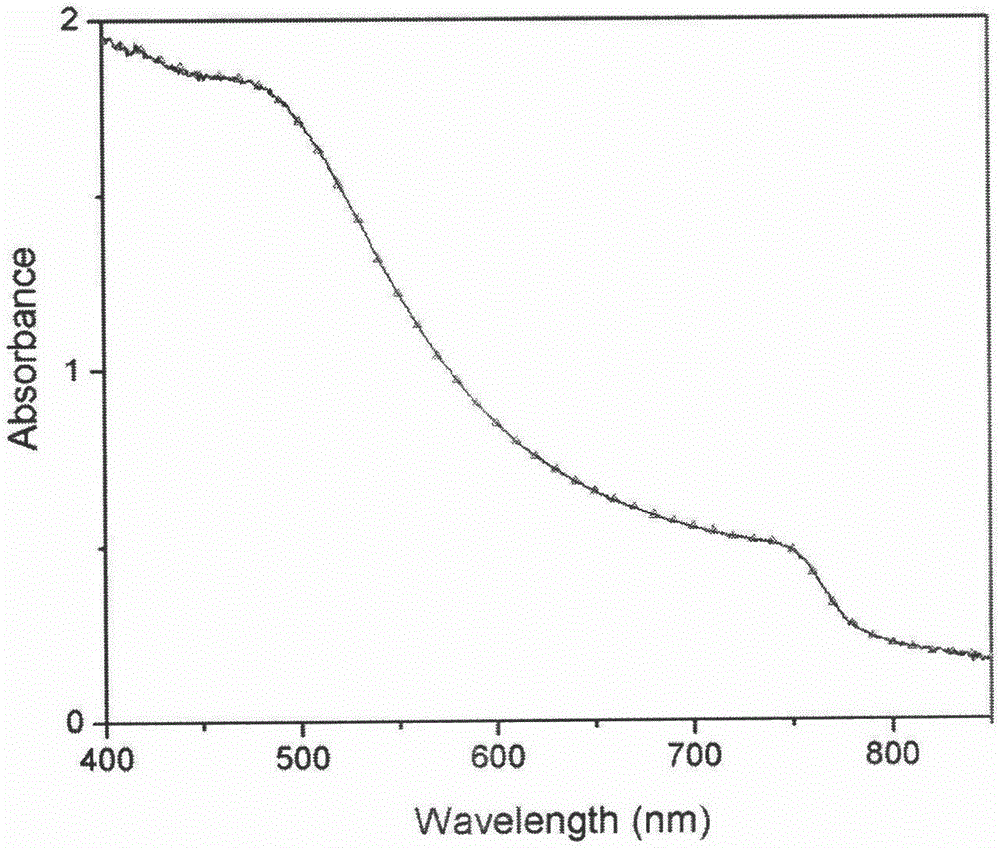

The invention provides a compound coating for preventing strong light and strong thermal radiation, the coating sequentially comprises: an infrared intelligent layer which is arranged on a glass, ceramic or metal matrix and a light amplitude limiting layer which is covered outside the infrared intelligent layer; the thickness of the infrared intelligent layer is 50 to 500nm; and the thickness of the light amplitude limiting layer is 100 to 1000nm. The invention further provides a method for preparing the compound coating layer for preventing the strong light and the strong thermal radiation on the glass, ceramic or metal matrix, the method firstly adopts the radio frequency magnetron sputtering technology to form the infrared intelligent layer on the glass, ceramic or metal matrix by sputtering; then the method adopts the Spin-coating method or the vacuum evaporation method to form the light amplitude limiting layer on the infrared intelligent layer. The compound coating increases the light amplitude limiting layer on the infrared intelligent layer, thereby improving the performance of the existing VO2 thin film, being conductive to the environmental protection and being capable of preventing the strong light and the strong thermal radiation.

Owner:BEIJING SHANGCHAO NEW ENERGY TECH

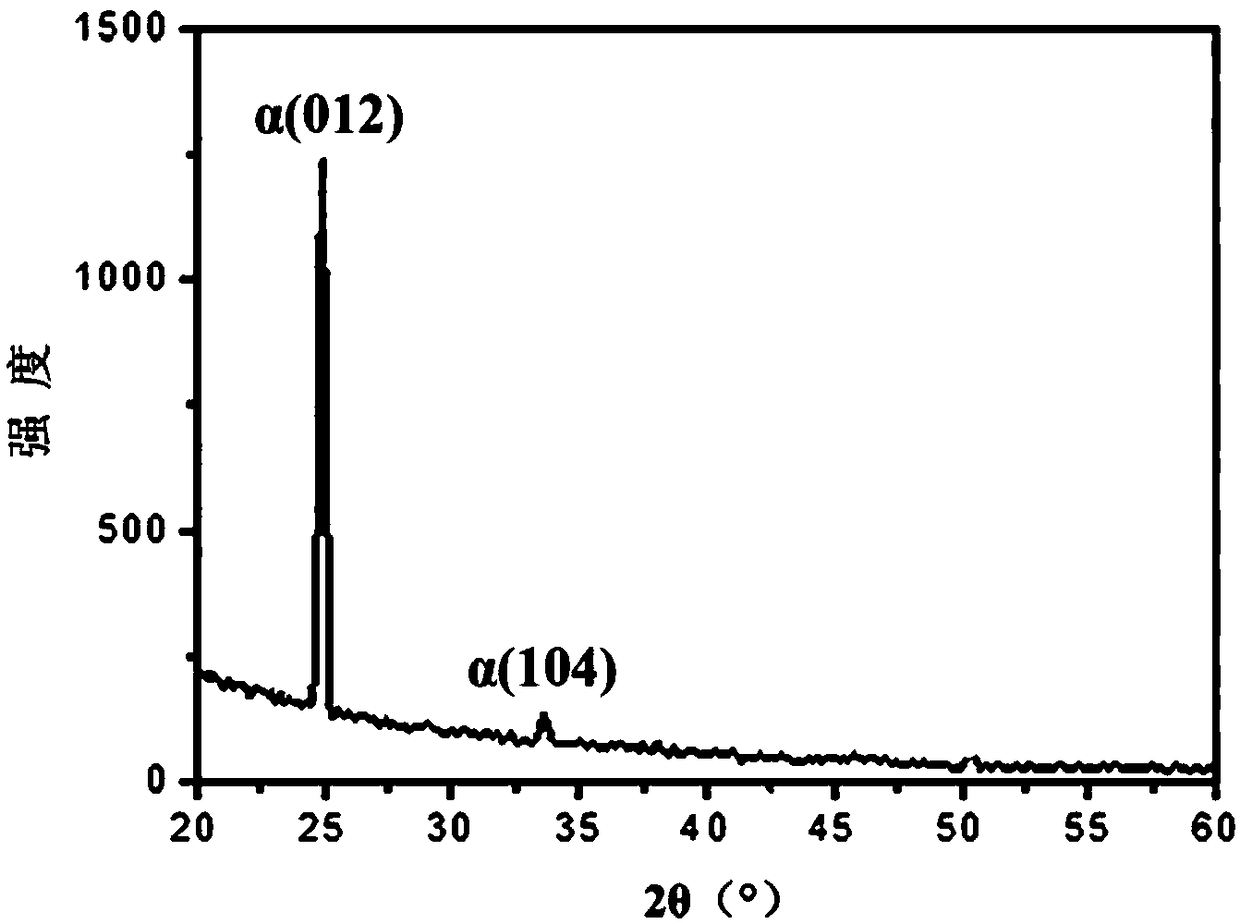

Three-layer film structure coating layer and fabrication method thereof

ActiveCN109082641AReduce stressPrevents Diffusion Adhesive WearVacuum evaporation coatingSputtering coatingRadio frequency magnetron sputteringSuperalloy

The invention belongs to the technical field of fabrication of a metal coating layer, and discloses a three-layer film structure coating layer and a fabrication method thereof. The three-layer film structure coating layer comprises a dual-phase Cr+Alpha-(Al, Cr)2O3 matrix pasting layer, a single phase Alpha-(Al, Cr)2O3 support layer and a single-phase nanometer Alpha-Al2O3 surface layer. The fabrication method comprises the steps of sequentially depositing the Cr+Alpha-(Al, Cr)2O3 matrix pasting layer and the Alpha-(Al, Cr)2O3 support layer by DC magnetron sputtering and by a CrAl alloy target; and obtaining the single-phase nanometer Alpha-Al2O3 surface layer by radio-frequency magnetron sputtering by an Al+Alpha-Al2O3 compost target. The surface working layer of the obtained coating layer is of a single-phase nanometer Alpha-Al2O3 structure, the coating layer is high in hardness, good in toughness, high in high-temperature thermal stability, low in friction coefficient during friction with a metal matrix and is firmly combined with a matrix such as high-speed steel, a hot work die steel and high-temperature alloy.

Owner:SOUTH CHINA UNIV OF TECH

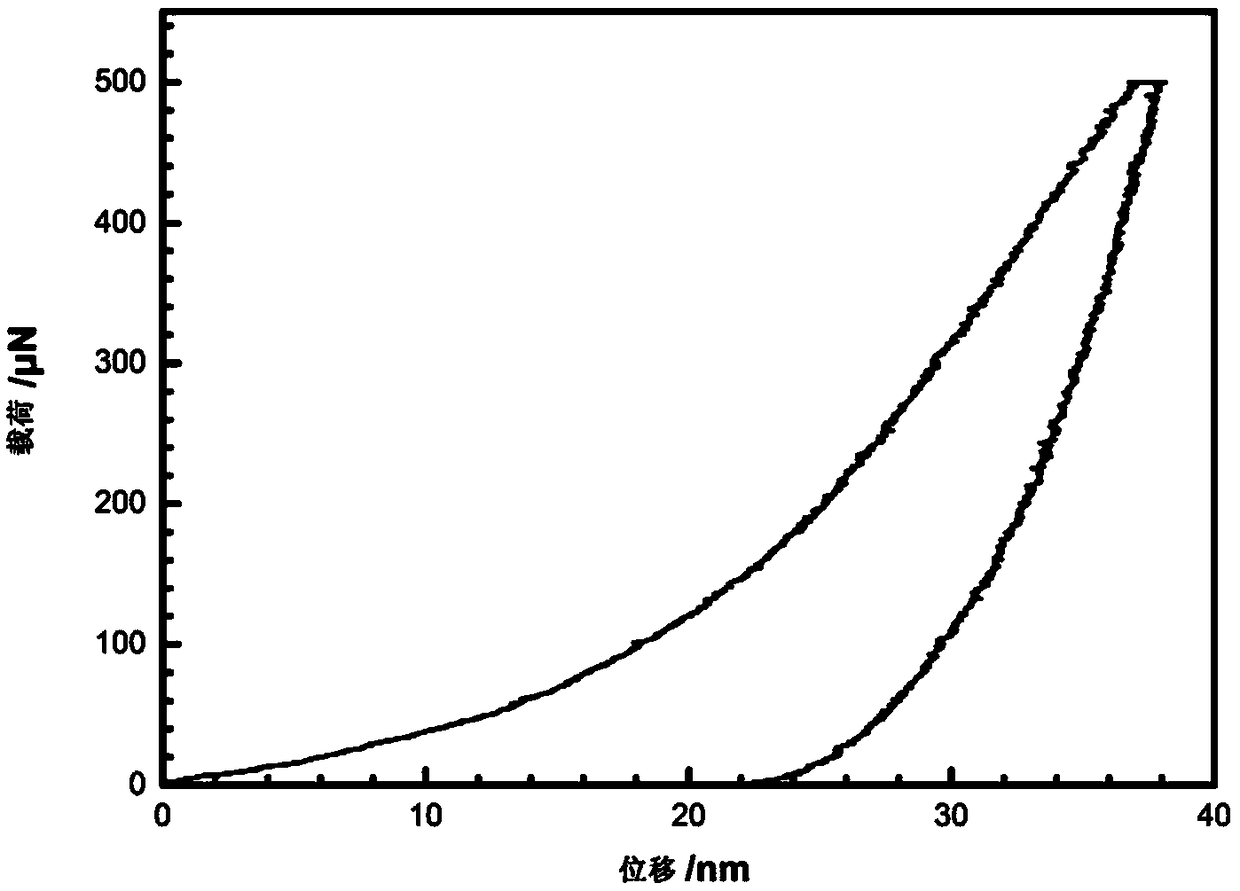

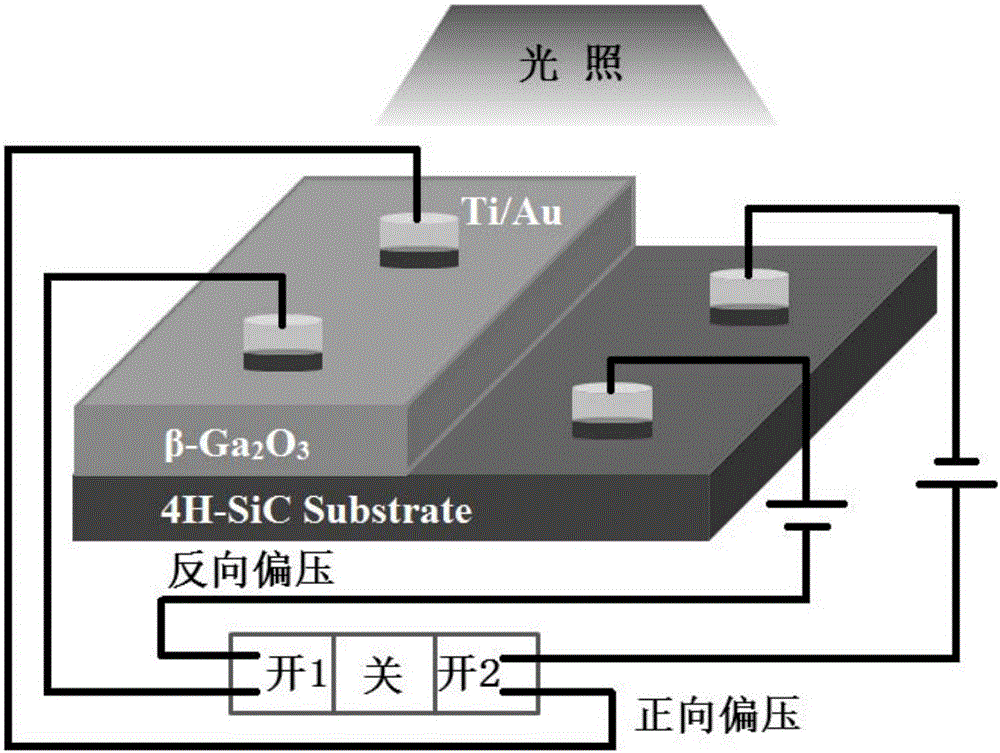

Monolithically-integrated multi-functional ultraviolet/solar blind ultraviolet two-color detector and fabrication method thereof

ActiveCN105870225AStrong process controllabilityEasy to operateFinal product manufacturePhotometry for measuring UV lightRadio frequency magnetron sputteringHigh pressure

The invention relates to an ultraviolet / solar blind ultraviolet two-color detector, in particular to a monolithically-integrated multi-functional ultraviolet / solar blind ultraviolet two-color detector and a fabrication method thereof. A layer of gallium oxide thin film is deposited on a silicon carbide substrate by a laser molecular beam epitaxial technology, and then a layer of titanium / gold thin film is deposited on the silicon carbide substrate and the gallium oxide thin film by a mask plate through a radio frequency magnetron sputtering technology to be used as an electrode. The monolithically-integrated multi-functional two-color ultraviolet detector fabricated according to the method has the advantages of reaction sensitivity, performance stability and low dark current, the functions of ultraviolet flame detection and ultraviolet intensity detection of a solar blind region can be separately achieved in different voltage modes, and the monolithically-integrated multi-functional two-color ultraviolet detector can be used for detecting fire alarm, high-voltage line corona and solar ultraviolet intensity; and moreover, the fabrication method has the characteristics of high process controllability, high universality, restorability of repeated tests and great application prospect, and is simple to operate.

Owner:东港智科产业园有限公司

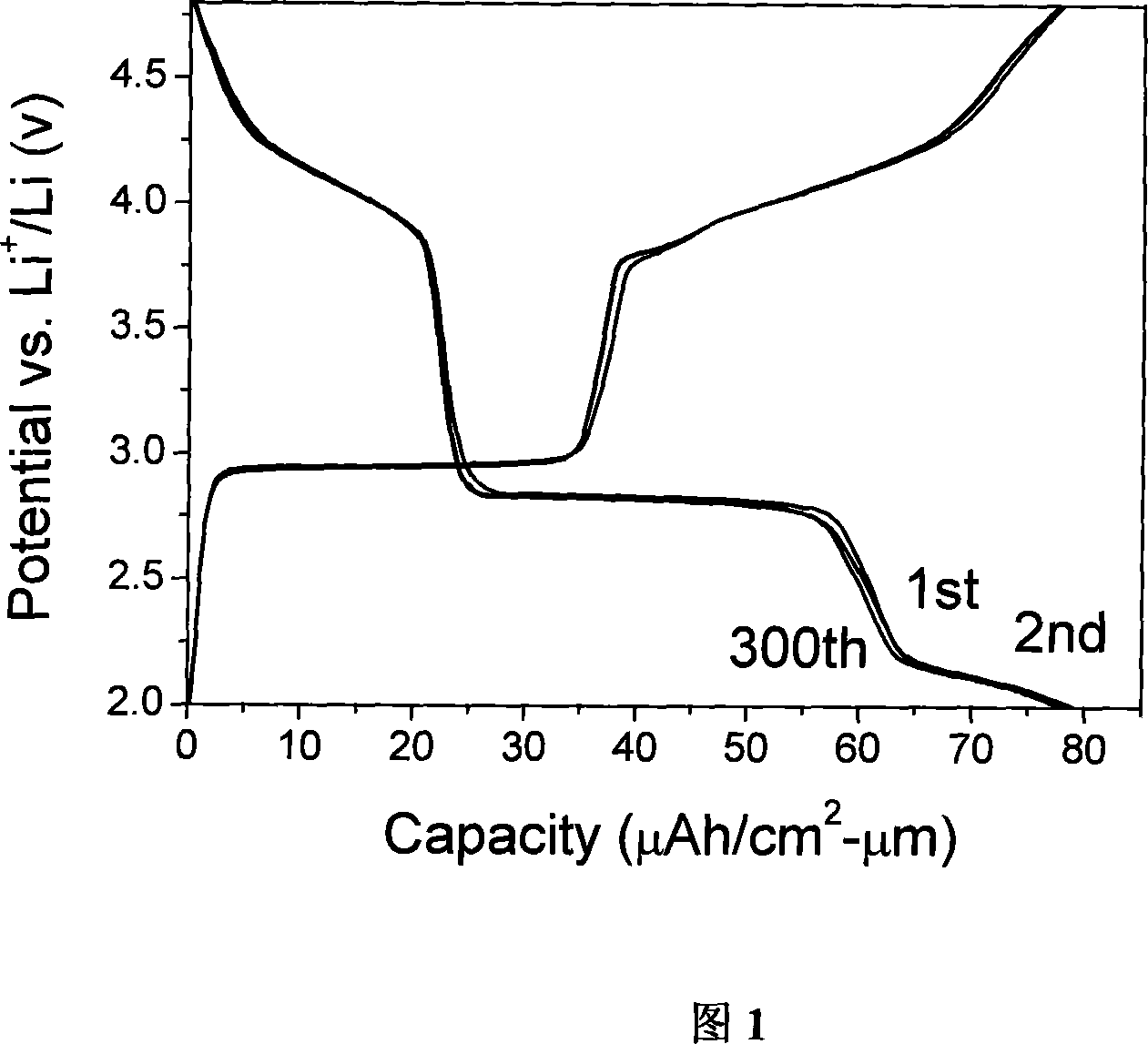

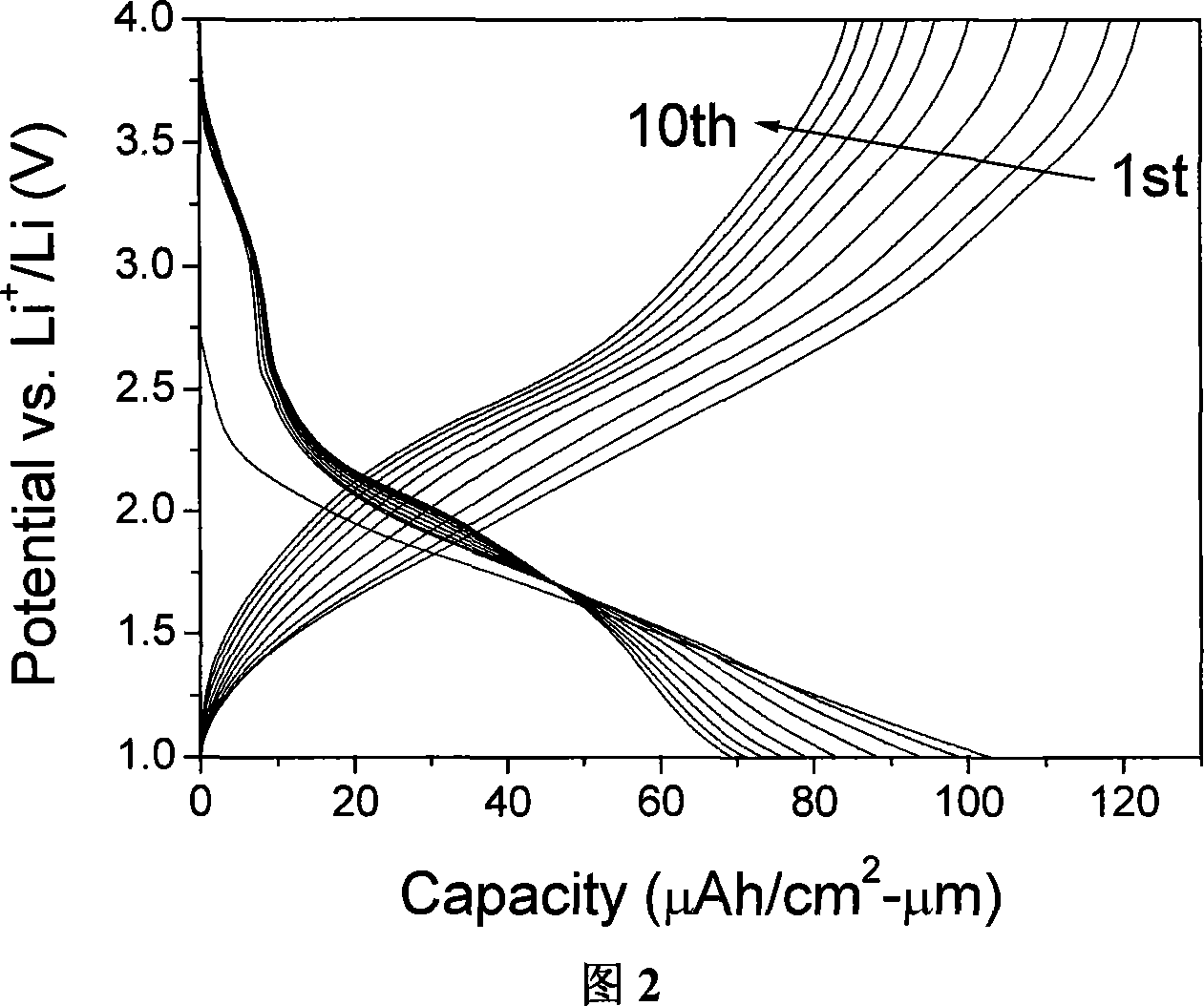

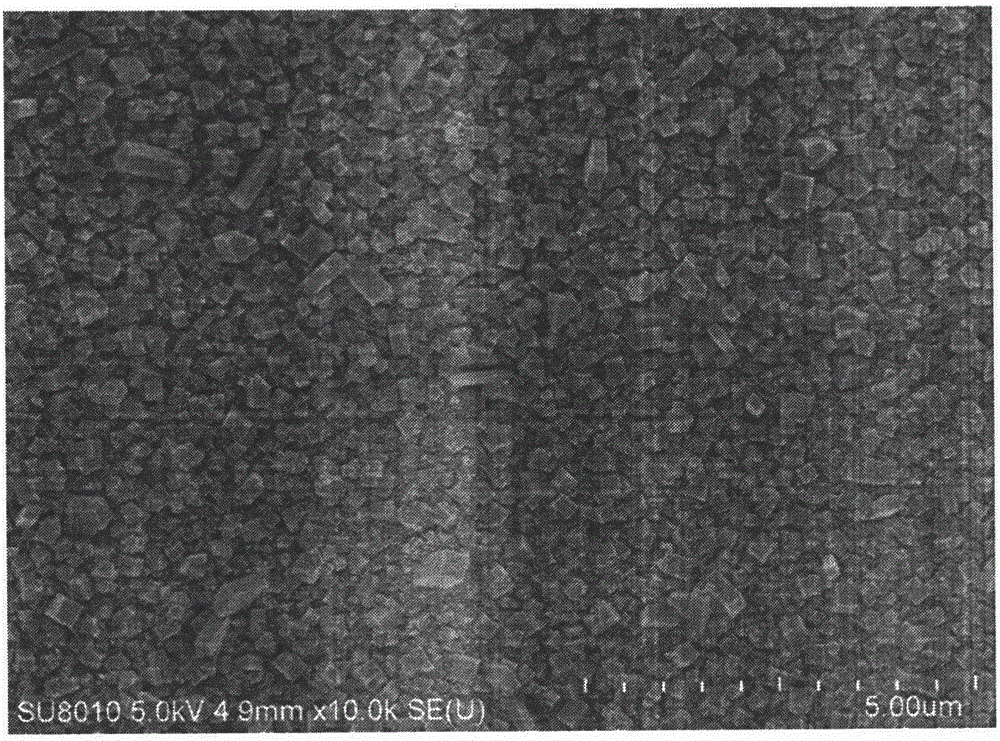

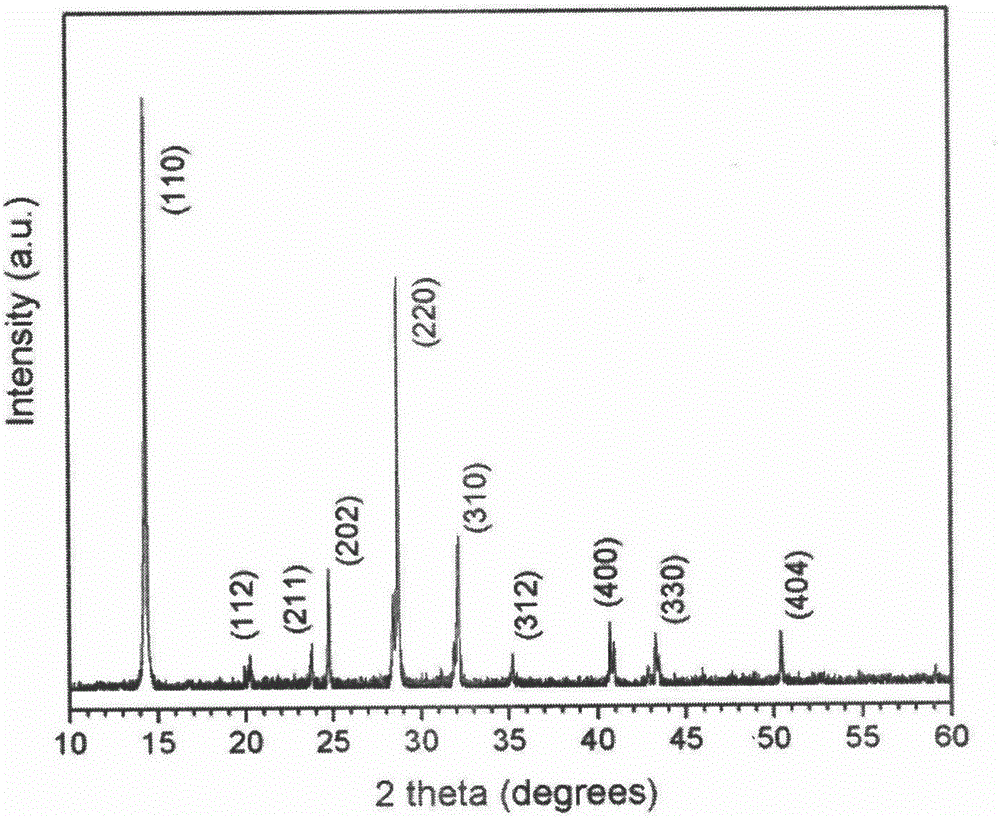

Zirconium adulterated lithium manganate anode film material and its making method

InactiveCN101034741AImprove conductivitySimple preparation conditionsElectrode manufacturing processesVacuum evaporation coatingSolid state electrolyteElectrical battery

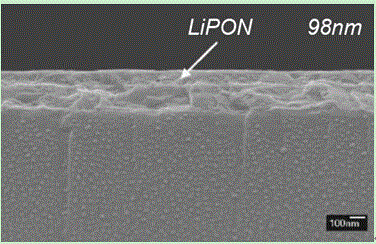

The invention belongs to the lithium ion film battery technology area, specifically relates to a positive electrode material mix with the zirconium lithium manganate film (LMZO) which applies to the entire solid film lithium battery and its preparation method, the invention uses the radio frequency magnetron sputtering sedimentation method prepare the mix zirconium lithium manganate film. Combined the lithium phosphorus oxygen nitrogen (LiPON) solidstate electrolyte film by radio frequency magnetron sputtering preparation and the metal lithium negative film by the vacuum hotly evaporate preparation, composing the solid state film lithium battery. The battery specific capacity can reach 53mAh / cm2-u m; the cycle-index can reach 300 times. These results indicated that, the radio frequency magnetron sputtering method prepare LMZO positive electrodes films, can apply to the entire solid state film lithium battery.

Owner:FUDAN UNIV

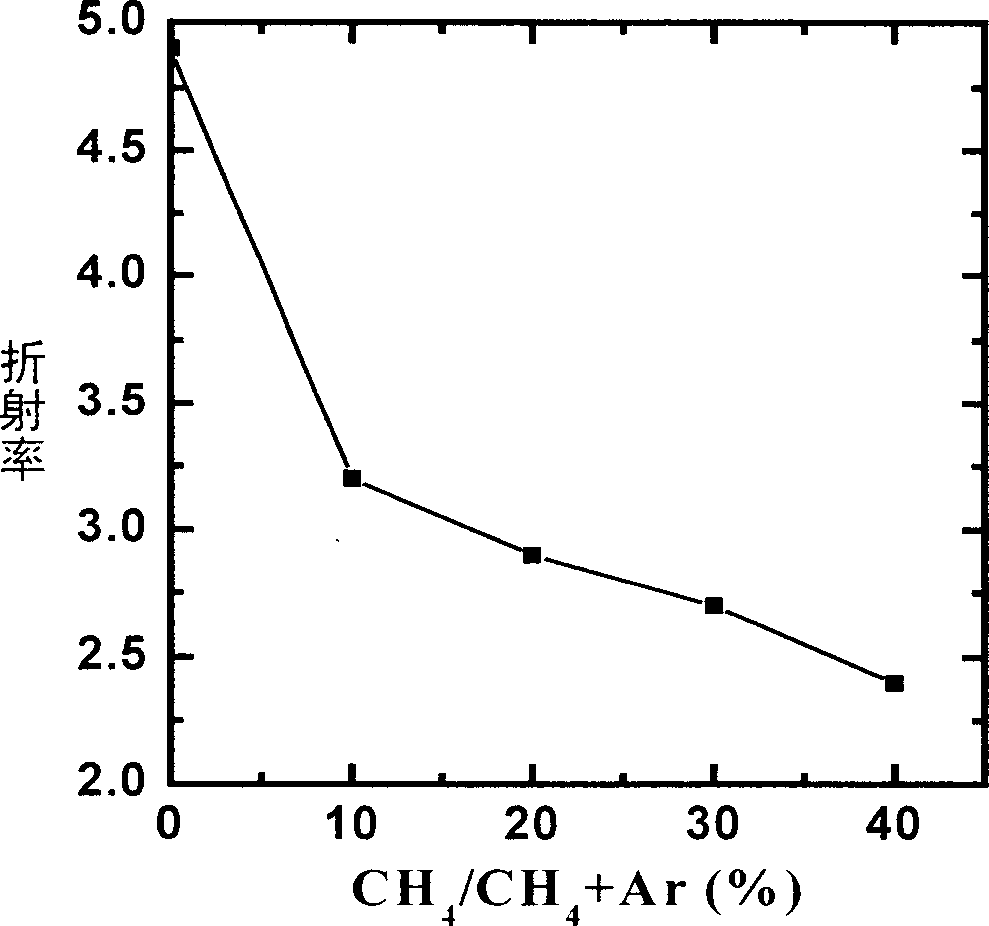

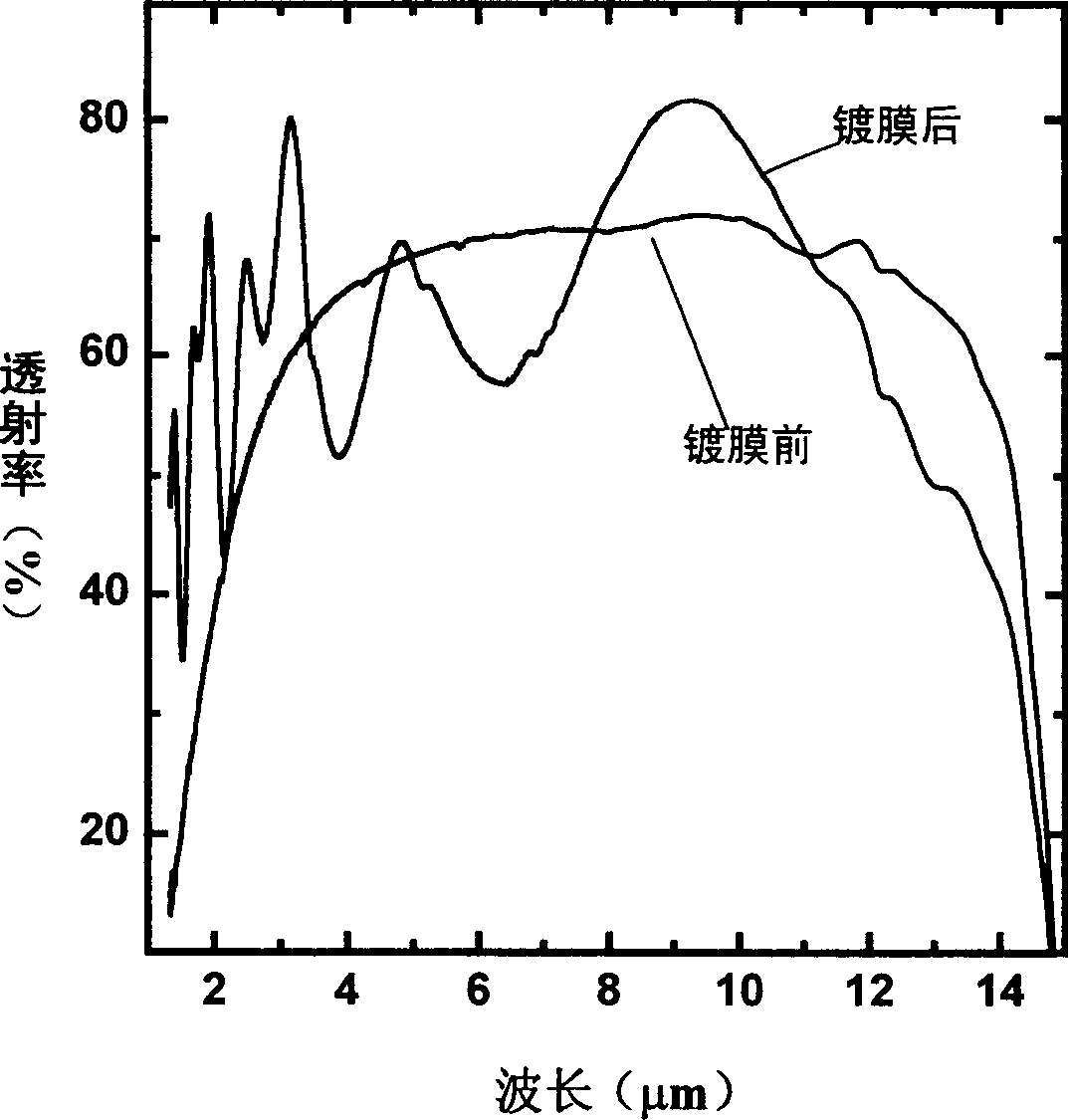

ZnS infrared window transparent increasing protective film and its preparing method

InactiveCN1687807AAvoid the index of refractionAvoid thicknessOptical elementsTectorial membraneRadio frequency magnetron sputtering

This invention is about a kind of ZnS infrared window reflection reducing and protecting coating and its producing method, belonging to the field of coating technology. We choose 9.2micron as the central wavelength lambda 0. On Base 1 of the ZnS material we make lambda 0 / 4 - lambda 0 / 4 double-layer reflection reducing and protecting coating series. The refractive index of the high refractive index coating 2 is 3.2 -4.0 and the optical thickness is 2-3micron. Meanwhile, the refractive index of the low refractive index coating 3 is 2.3 -3.0 and the optical thickness is 2-3micron. The producing method is the radio-frequency magnetron sputter method, choosing Ge as the target source and CH4 / Ar as the electric discharge gas. Then deposit Ge1-xCx reflection reducing and protecting coating on the base of ZnS, and by changing the depositing time we can make each coating's optical thickness is lambda 0 / 4. This invention is easy, economic, efficient and has satisfying effect of reflection reducing.

Owner:JILIN UNIV

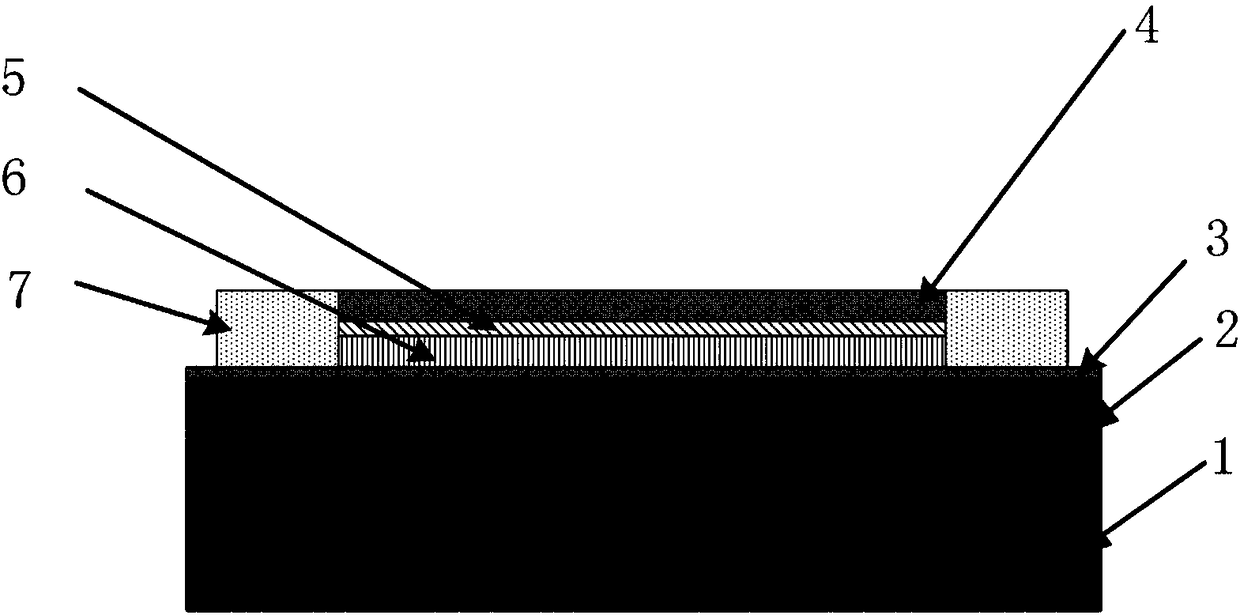

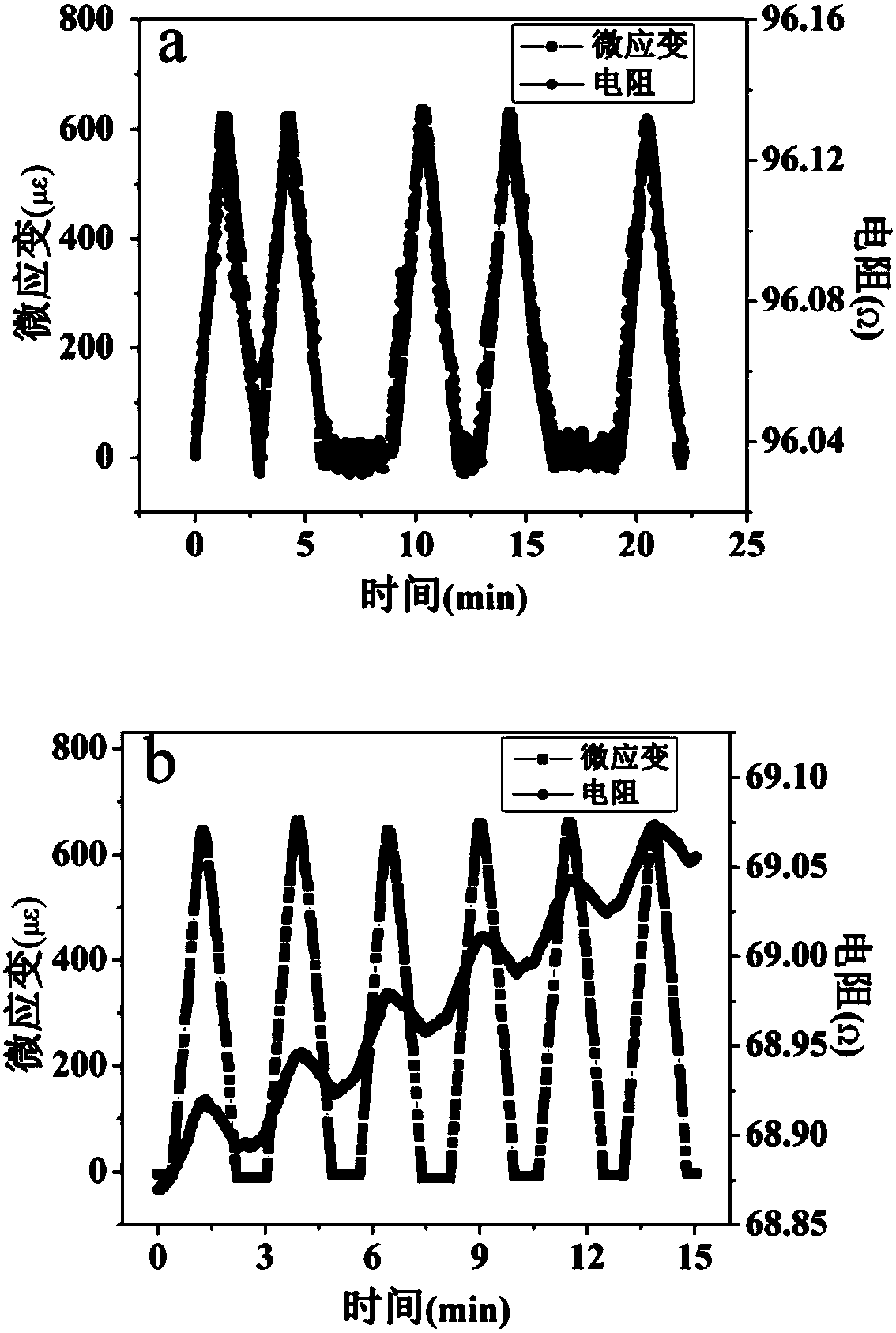

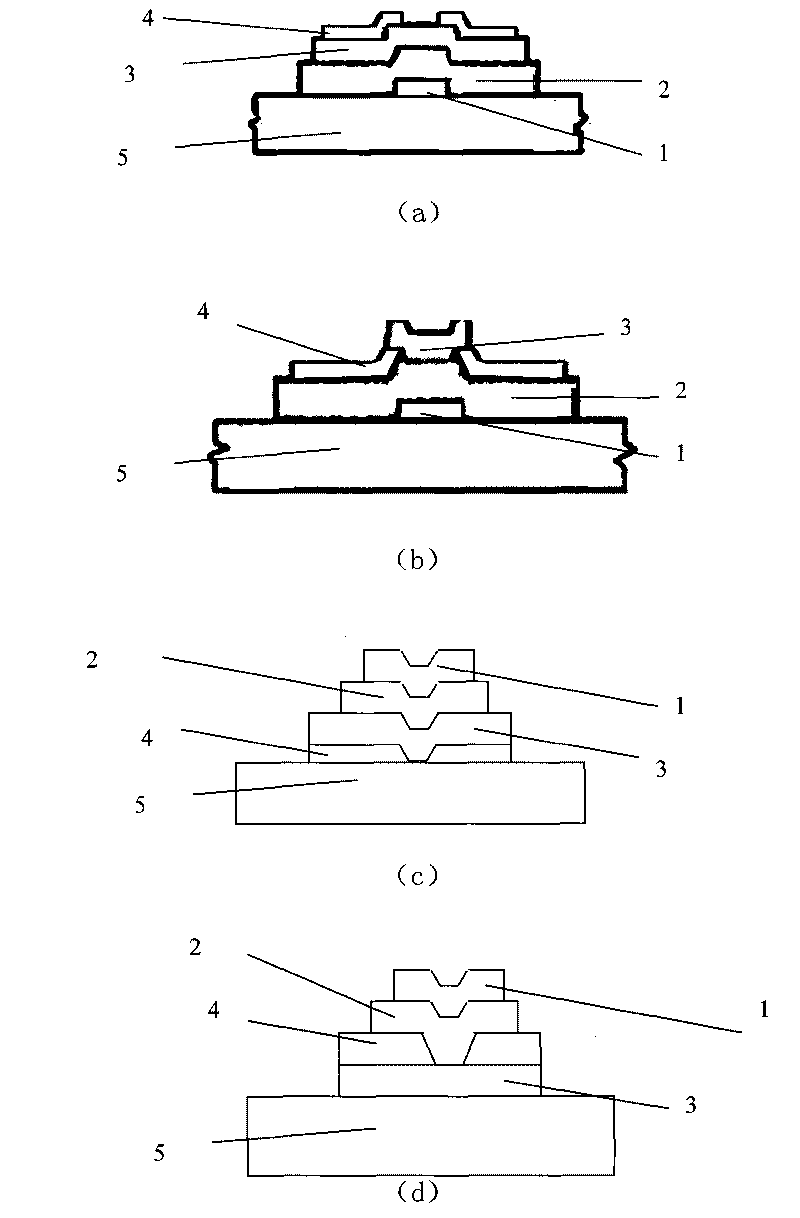

High-temperature thin film strain meter of composite protection layer and preparation method thereof

ActiveCN108088610AImprove protectionImprove high temperature stabilityDecorative surface effectsFluid pressure measurement using ohmic-resistance variationRadio frequency magnetron sputteringOxidation resistant

The invention relates to a high-temperature thin film strain meter of a composite protection layer and a preparation method thereof. The strain meter comprises a high-temperature alloy component substrate, an alloy transition layer, an aluminum oxide insulating layer, an aluminum oxide protection layer, an aluminum intermediate layer, a PdCr strain layer and a Pt electrode. the strain meter takesa high-temperature alloy component as a substrate, a transition layer alloy is firstly subjected to magnetron sputtering on the substrate and is subjected to high-temperature oxidation to generate a thin-layer aluminum oxide film, the aluminum oxide insulating film is deposited by double ion beam sputtering, and a PdCr strain layer is subjected to radio frequency magnetron sputtering on the insulating film, and the ion beams sputter AL intermediate layer and an AL2O3 protective layer. The strain meter is suitable for the real-time measurement of the strain of a component in the high-temperature working process, a universal MEMS patterning process is adopted, and the PDCR is sputtered to serve as a strain layer, the ion beams sputter to prepare Al and Al2O3 to obtain a composite protectionlayer by heat treatment, so that the oxidation of the PdCr thin film is prevented, and the oxidation resistance and the stability of the strain meter are improved.

Owner:SHANGHAI JIAO TONG UNIV

Preparation methods of ZnO base powder target and thin film transistor active layer

InactiveCN101748362AReduce difficultyShort manufacturing cycleVacuum evaporation coatingSputtering coatingRadio frequency magnetron sputteringActive layer

The invention discloses a powder target which comprises ZnO or multiple metal oxide powders of InwGaxSnyZnzOu mainly comprising the ZnO. The invention also discloses a preparation method of the powder target and also discloses a preparation method of a thin film transistor active layer. The preparation method of the thin film transistor active layer comprises the steps of: preparing the powder target, wherein the powder target comprises the ZnO or multiple metal oxides mainly comprising the ZnO; arranging a filling groove on a high heat conduction metal base, arranging a powder block body which is tightly combined with the filling groove and has high compactness in the filling groove; and then depositing the thin film transistor active layer by adopting a radio frequency magnetron sputter plating method. The preparation method of the ZnO base powder target has simple operation and low use and maintenance cost. The high-quality thin film transistor active layer is deposited to be used as a sputtering target, and the prepared thin film transistor has excellent performance.

Owner:INESA ELECTRON

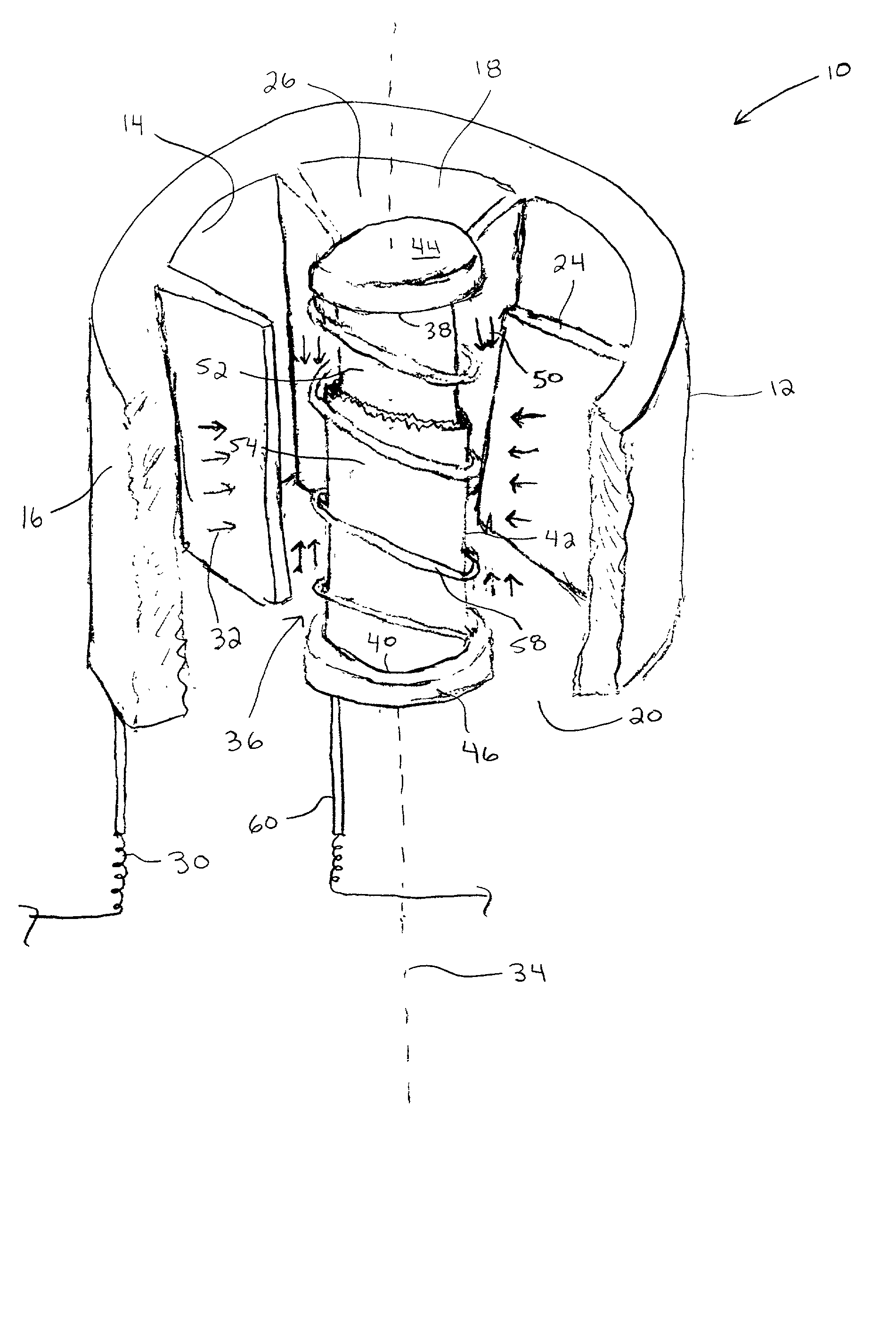

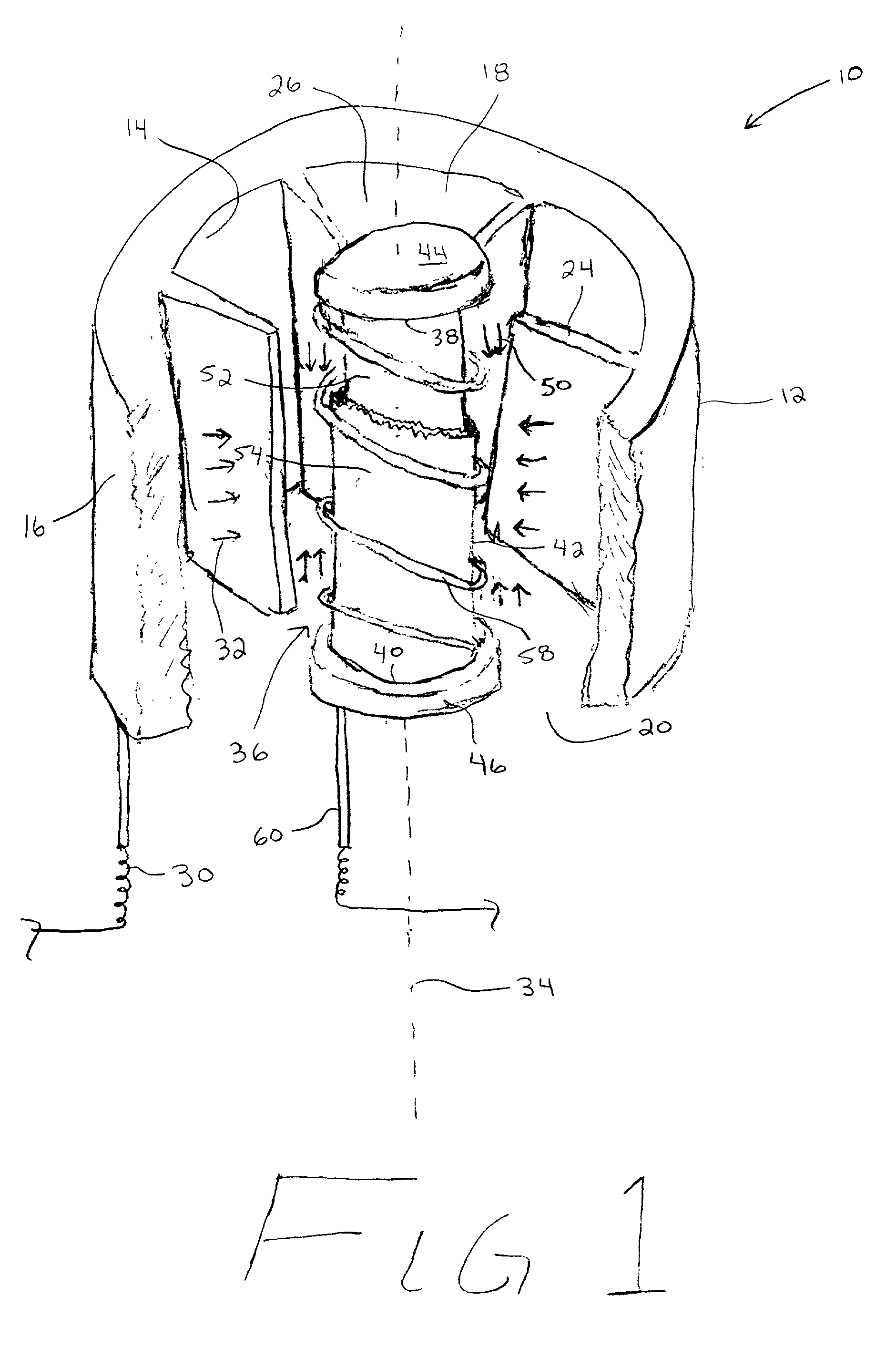

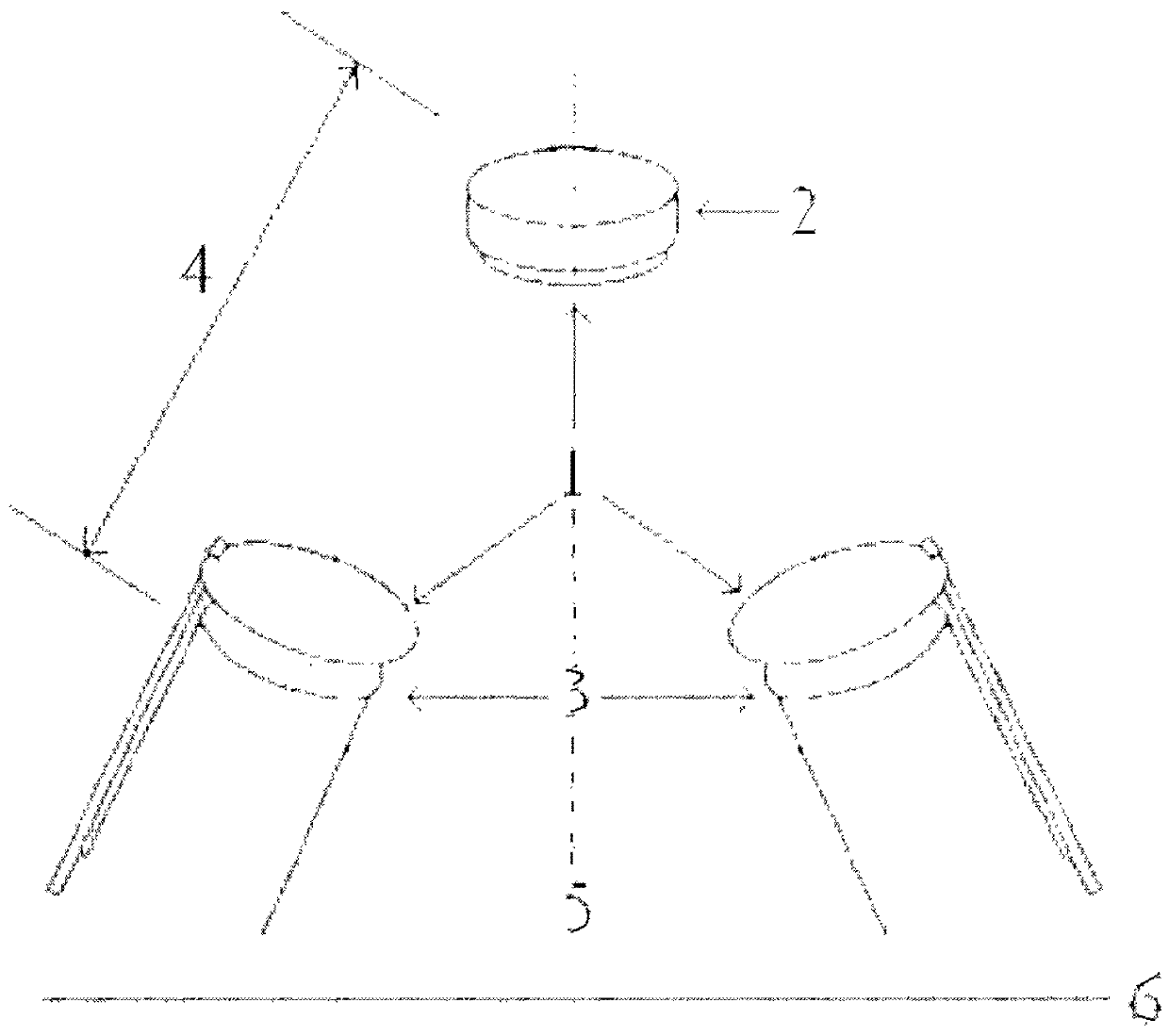

Magnetron with diamond coated cathode

InactiveUS20020125827A1Reduce operating costsMinimizes electronic noiseTransit-tube electron/ion gunsTransit-tube cathodesSecondary electronsPole piece

A radio frequency magnetron device for generating radio frequency power includes a cathode at least partially formed from a diamond material. An anode is disposed concentrically around the cathode. An electron field is provided radially between the anode and the cathode. First and second oppositely charged pole pieces are operatively connected to the cathode for producing a magnetic field in a direction perpendicular to the electric field. A filament is provided within the electron tube which when heated produces primary electrons. Alternatively, a voltage is applied to the anode which causes primary electrons to emit from the diamond coated cathode. A portion of the primary electrons travel in a circular path and induce radio frequency power. Another portion of the primary electrons spiral back and collide with the cathode causing the emission of secondary electrons. The secondary electron emission sustains operation of the magnetron device once the device has been started.

Owner:TERAPHYSICS CORP

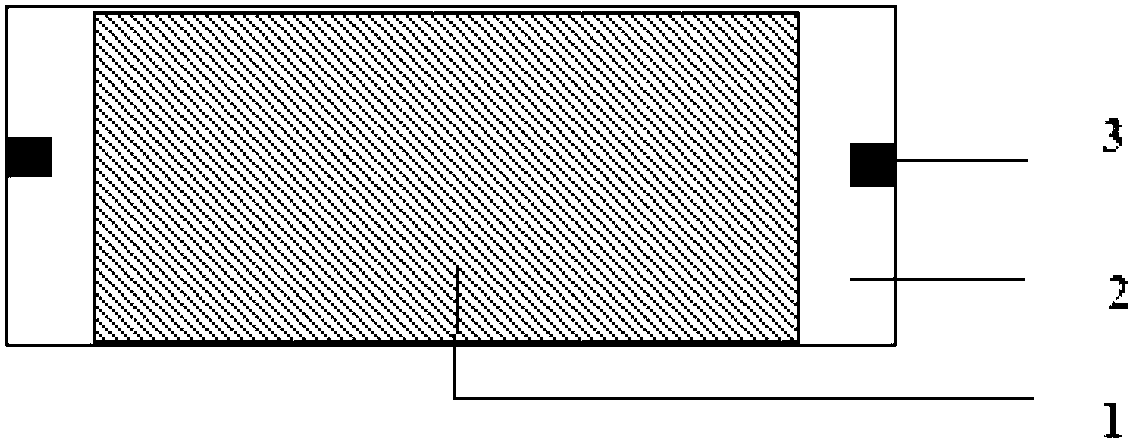

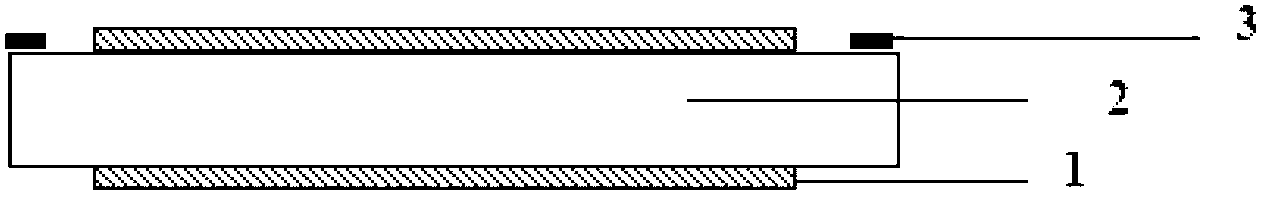

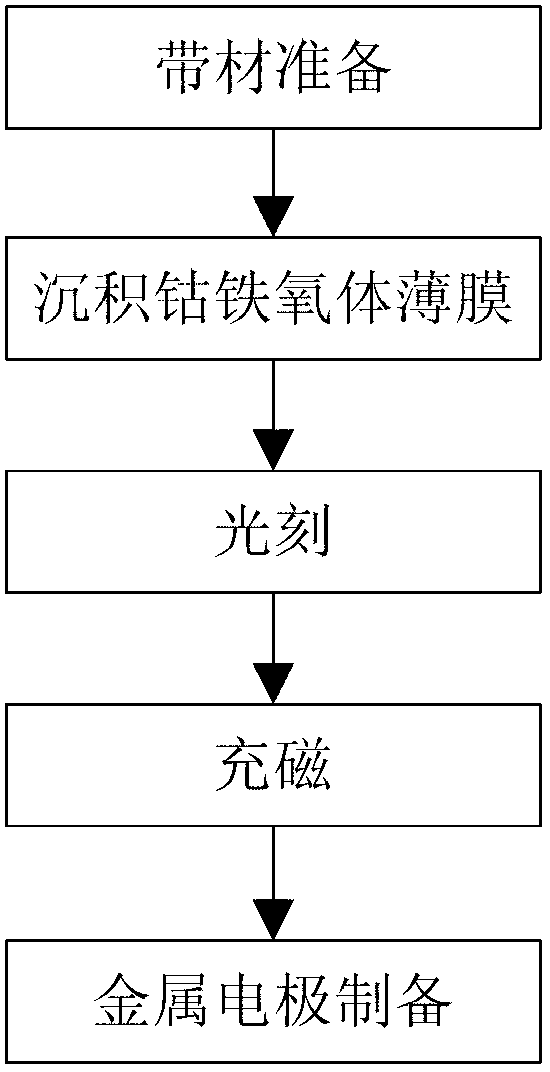

Self-biased giant magneto-impedance sensor probe and preparation method thereof

InactiveCN102707247APlay a protective effectImprove job stabilityMagnetic measurementsManufacture of electrical instrumentsMagnetic phaseRadio frequency magnetron sputtering

A self-biased giant magneto-impedance sensor probe and a preparation method thereof belong to the technical field of information functional devices. The probe comprises an amorphous strap-shaped magnetic material and metal counter electrodes positioned at two ends of the surface of the amorphous strap-shaped magnetic material, wherein two vectolite films are respectively deposited on two sides of the amorphous strap-shaped magnetic material between the metal counter electrodes; and the upper and the lower vectolite films have consistent hard magnetic phase characteristic in the length direction of the amorphous strap-shaped magnetic material. During preparation of the probe, the key process is that the vectolite films are deposited on the amorphous strap-shaped magnetic material through the radio-frequency magnetron sputtering technology and are magnetized through a magnetizer to present hard magnetic phase. The self-biased giant magneto-impedance sensor probe provided by the invention has the characteristics of small size, easiness in integration and no extra power consumption; the product is simple to prepare, the process is controllable and the stability is high; and a wider linear working space can be obtained and the sensitivity is greatly improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

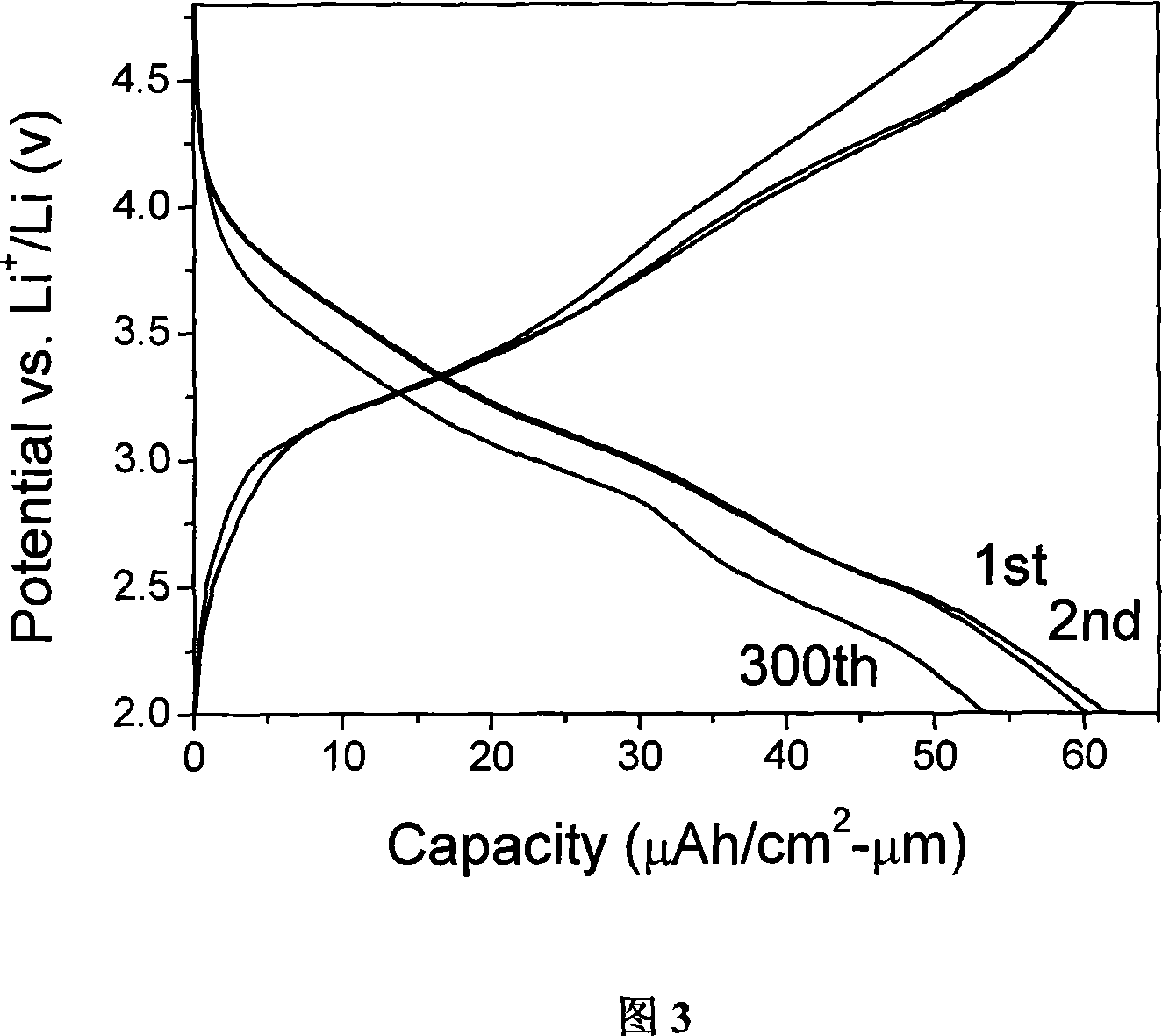

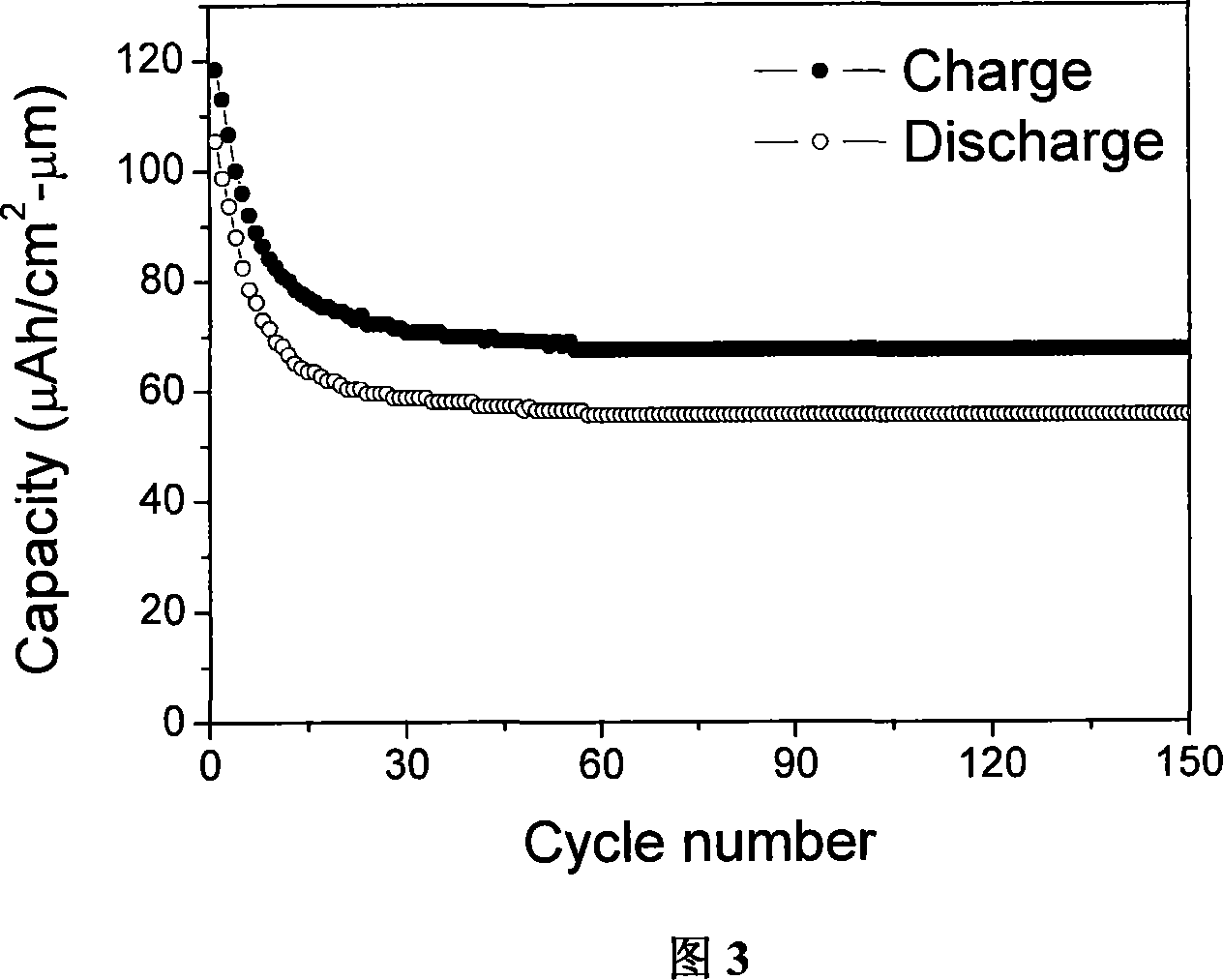

FeLiWO4 anode film material and its making method

InactiveCN101034740AImprove charge and discharge performanceElectrode manufacturing processesVacuum evaporation coatingSolid state electrolyteTungstate

The invention belongs to the lithium ion film battery technology area, specifically relates to a positive electrode material tungstate ferric lithium film (LiFe (WO4) 2) which applies to the entire solid film lithium battery and its preparation method, the invention uses the radio frequency magnetron sputtering sedimentation method prepare amorphous material tungstenic acid ferric lithium film. Combined the lithium phosphorus oxygen nitrogen (LiPON) solidstate electrolyte film by radio frequency magnetron sputtering preparation and the metal lithium negative film by the vacuum hotly evaporate preparation, composing the solid state film lithium battery. The battery specific capacity can reach 104 mAh / cm2-u m; the cycle-index can reach 150 times. These results indicated that, the radio frequency magnetron sputtering method prepare LiFe (WO4) 2 positive electrodes films, can apply to the entire solid state film lithium battery.

Owner:FUDAN UNIV

Method of preparing perovskite film using radio-frequency magnetron sputtering technology

InactiveCN105914296AImprove uniformityGood surface coverageFinal product manufactureSolid-state devicesChemical reactionRadio frequency magnetron sputtering

A method of preparing a perovskite film using a radio-frequency magnetron sputtering technology of the invention relates to the technical filed of functional film preparation. The method comprises the following steps: (1) cleaning a substrate; (2) growing a PbO film on the substrate using the radio-frequency magnetron sputtering technology to prepare a PbO film sample; (3) soaking the PbO film sample in isopropyl alcohol solution of methyl halide amine, and generating an organic metal halide perovskite film in situ through chemical reaction; and (4) annealing the perovskite film sample. The perovskite film prepared by the method is of high uniformity and coverage and good crystallization quality, and has the advantages of low cost, simple and controllable process, easy mass-production, and the like.

Owner:HEXI UNIV

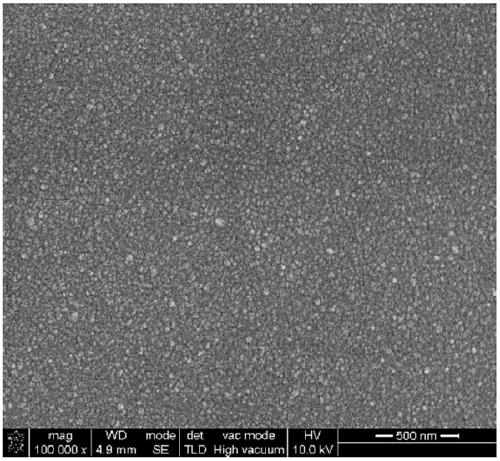

Nano pitch templet and preparation method thereof

InactiveCN1884964ASmall nominal pitchMaterial analysis using wave/particle radiationSurface/boundary effectEpoxyRadio frequency magnetron sputtering

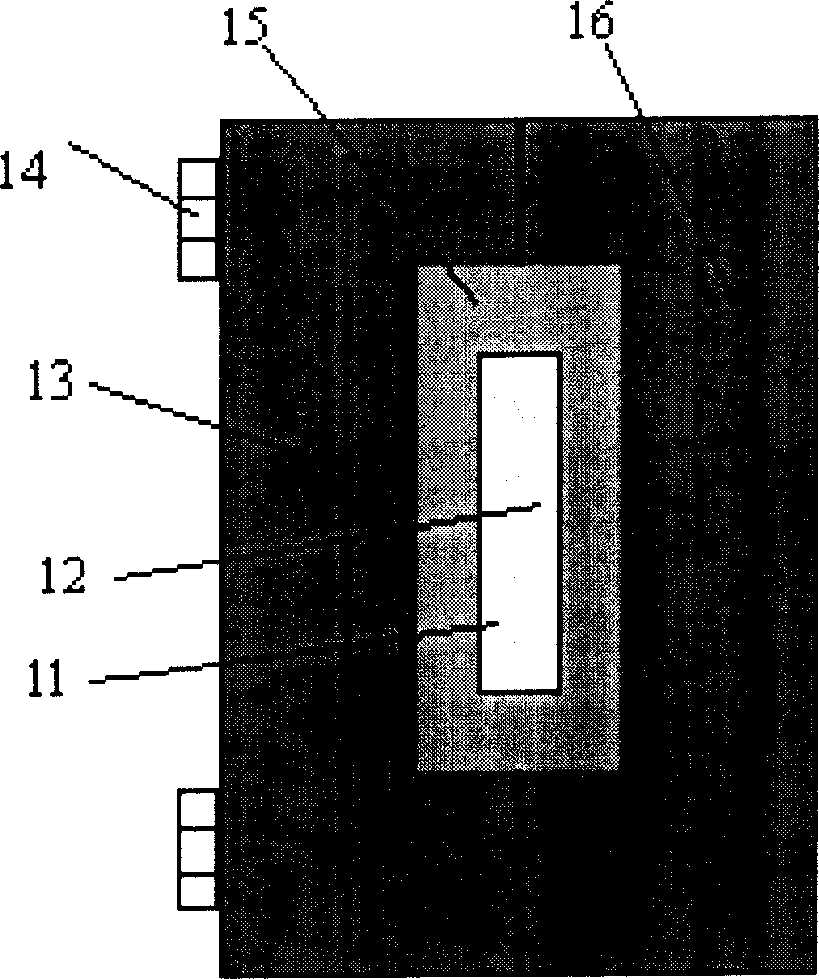

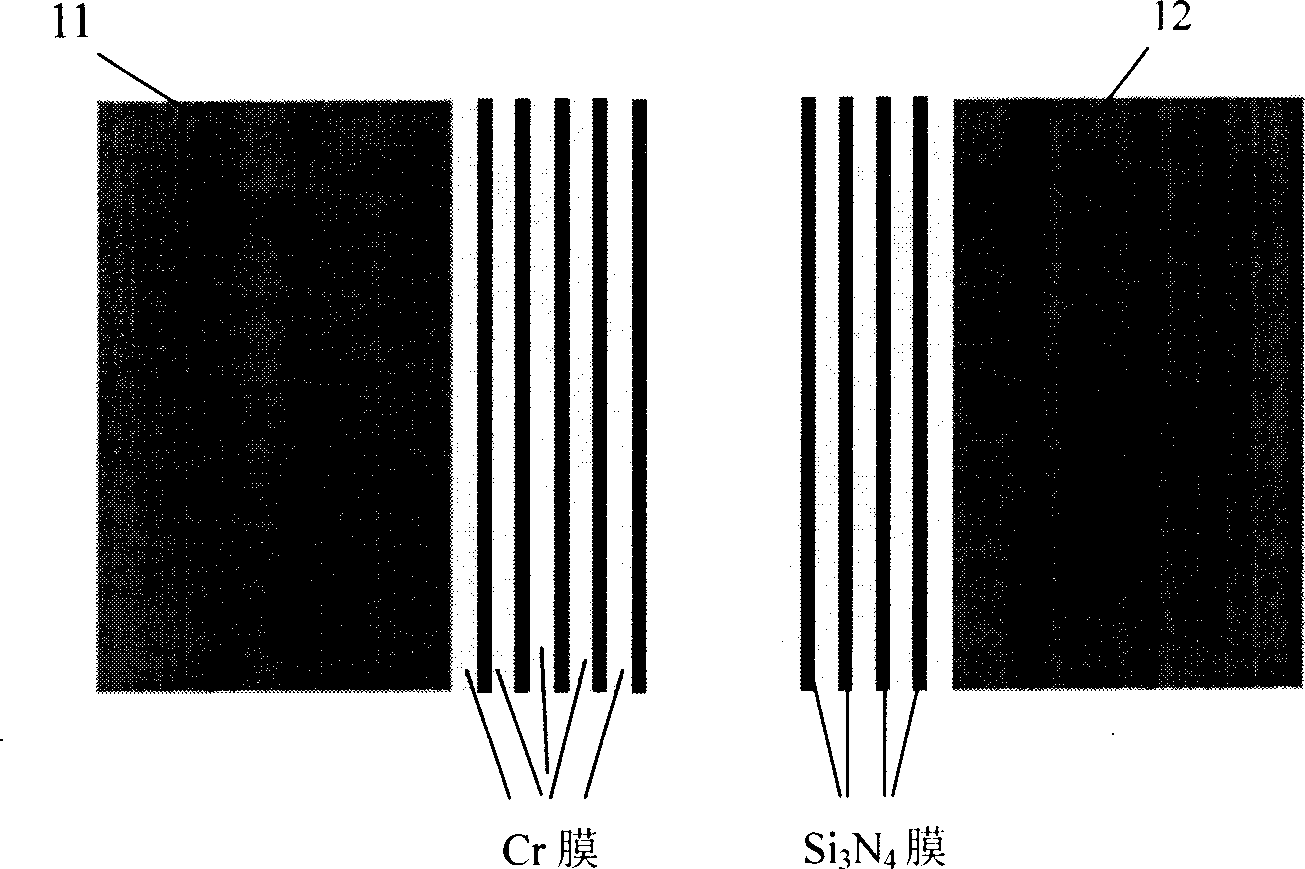

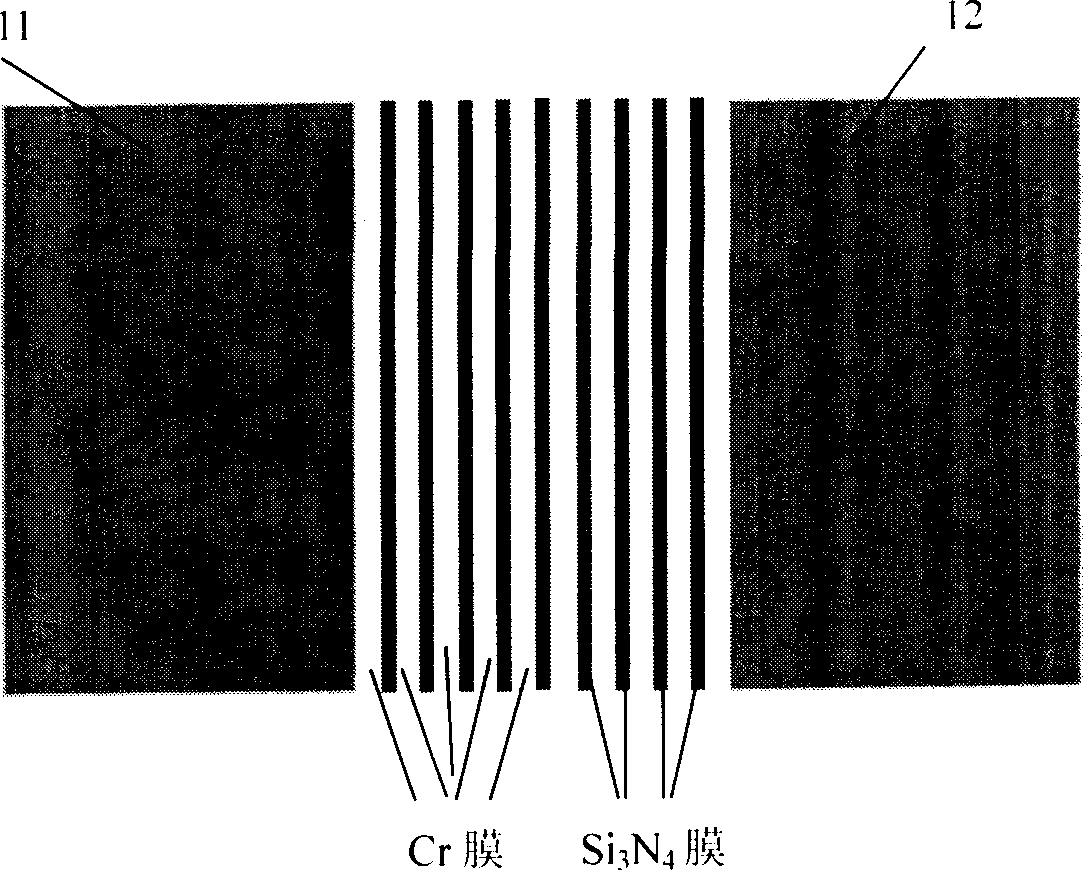

The invention relates to a nanometer pitch copy and relative preparing method. First, the plasma enhancing chemical vapor deposition (CVD) craft and the radio-frequency magnetron sputtering craft alternating deposit multiple Si3N4 film and Cr film on the silicon chip; second, scribing the silicon chip and jointing their surfaces that deposited with multi-ply film face-to-face; third, clamping the silicon chips by right and left grip blocks, to make the sections of silicon chips with multiple films as the surface of nanometer pitch copy; then, injecting epoxies resin into the groove formed by right and left grip blocks and solidifying it; at last, using metallographic paper and alumina suspension to sand, buffer, and clean said sections in turn to form a nanometer pitch copy surface to obtain the nanometer pitch copy with required nominal value.

Owner:XI AN JIAOTONG UNIV

Method for preparing cobalt titanate film by dual-target magnetron sputtering method

InactiveCN102041476AStrong adhesionIncreased durabilityPolycrystalline material growthVacuum evaporation coatingRadio frequency magnetron sputteringRadio frequency

The invention discloses a method for preparing a cobalt titanate film by a dual-target magnetron sputtering method. The method comprises the following steps: granulating TiO2 and Co2O3 respectively, and pre-sintering to prepare TiO2 target and Co2O3 target; placing the TiO2 target and Co2O3 target in two radio frequency targets of a magnetron sputtering device respectively; putting a substrate in the mixture solution of acetone and ethanol, and carrying out ultrasonic cleaning for later use; placing the processed substrate on a film coating sample table of the magnetron sputtering device; vacuumizing a film coating chamber and a sample chamber; setting the substrate heating temperature between 100 and 600 DEG C; introducing Ar gas into the film coating chamber to back-sputters the surface of the substrate; upon the back-sputtering, applying radio frequency sputtering power and starting to coat a film on the substrate; and after finishing the film coating, closing the vacuum system and the main power to obtain the product cobalt titanate film when the temperature in the film coating chamber is reduced to the room temperature. In the invention, two targets are made from oxides of titanium and cobalt respectively, and the CoTiO3 film is synthesized by radio frequency magnetron sputtering in the condition of heating the substrate. The method has the advantages of readily available raw materials and high reaction efficiency; and the prepared film has the advantages of strong adhesion and high durability and stability.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing super-hard, high efficacy heat conduction and low-absorption AlxSiyN film by double-target radio frequency magnetron co-sputtering

The invention discloses a method for preparing a super-hard, high efficacy heat conduction and low-absorption AlxSiyN film by double-target radio frequency magnetron co-sputtering, which belongs to the technical field of thin films. The known thin films of the same type in the field have the defects of low hardness, poor heat conductivity and high light absorption and are limited to be applied in related fields. The method for preparing the super-hard, high efficacy heat conduction and low-absorption AlxSiyN film by the double-target radio frequency magnetron co-sputtering comprises the following steps of: co-sputtering a silicon target and an aluminum target in a proper proportion of nitrogen gas to argon gas under the condition with certain sputtering power ratio between the double targets to form the AlxSiyN film by using a principle of the double-target radio frequency magnetron co-sputtering; and adjusting the gas proportion, the sputtering chamber pressure and the power ratio between the double targets to realize a proper proportion of x to y so as to prepare the super-hard and high efficacy heat conduction antireflection film. The method is of great significance to the promotion of the development in related fields.

Owner:CHANGCHUN UNIV OF SCI & TECH

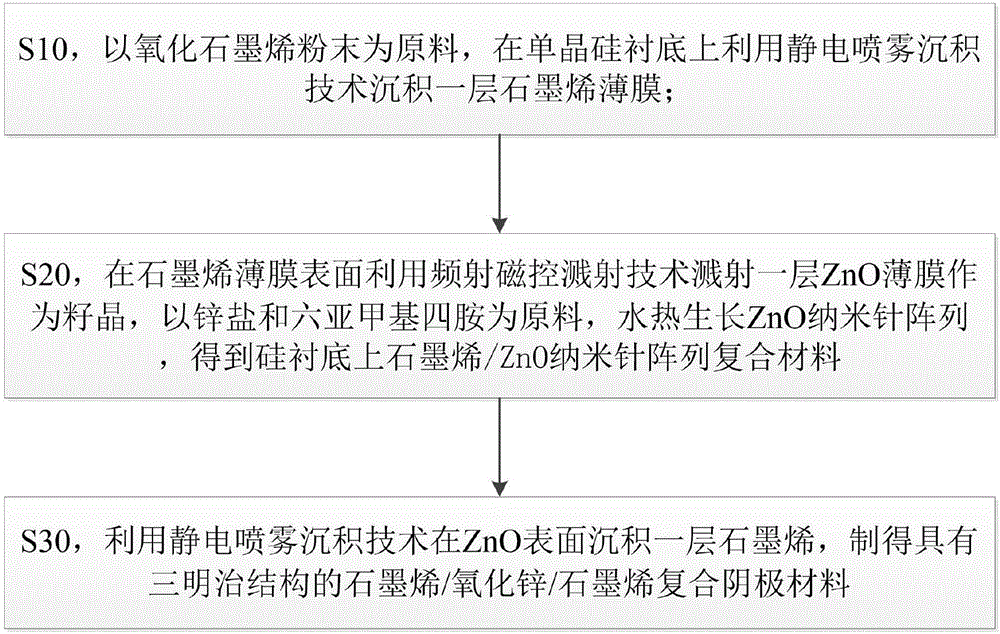

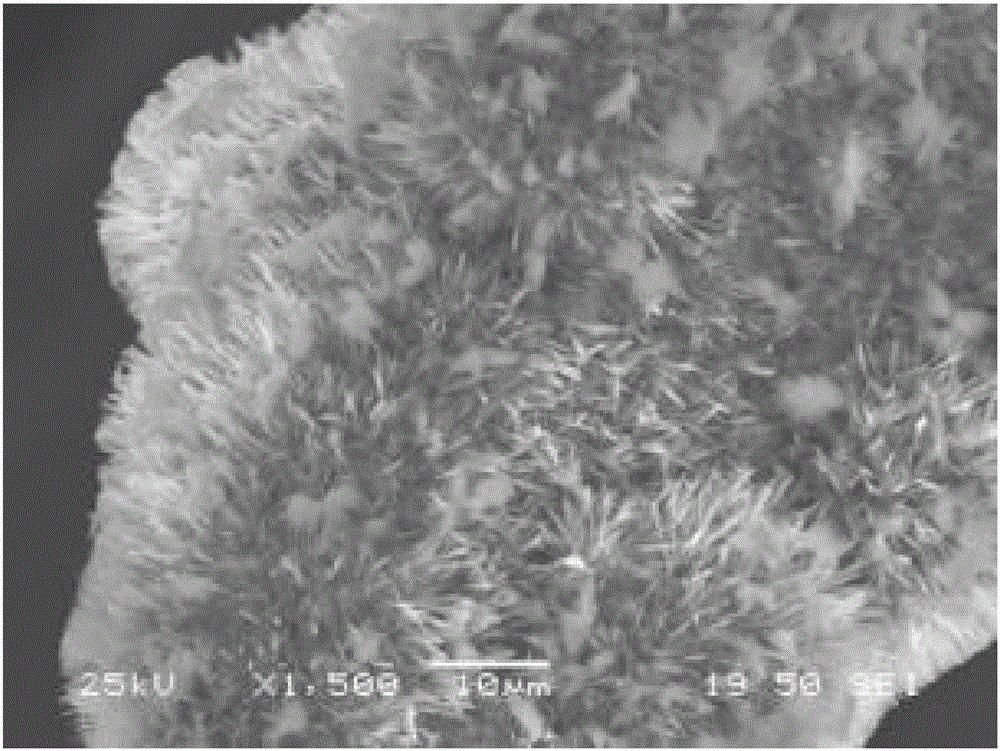

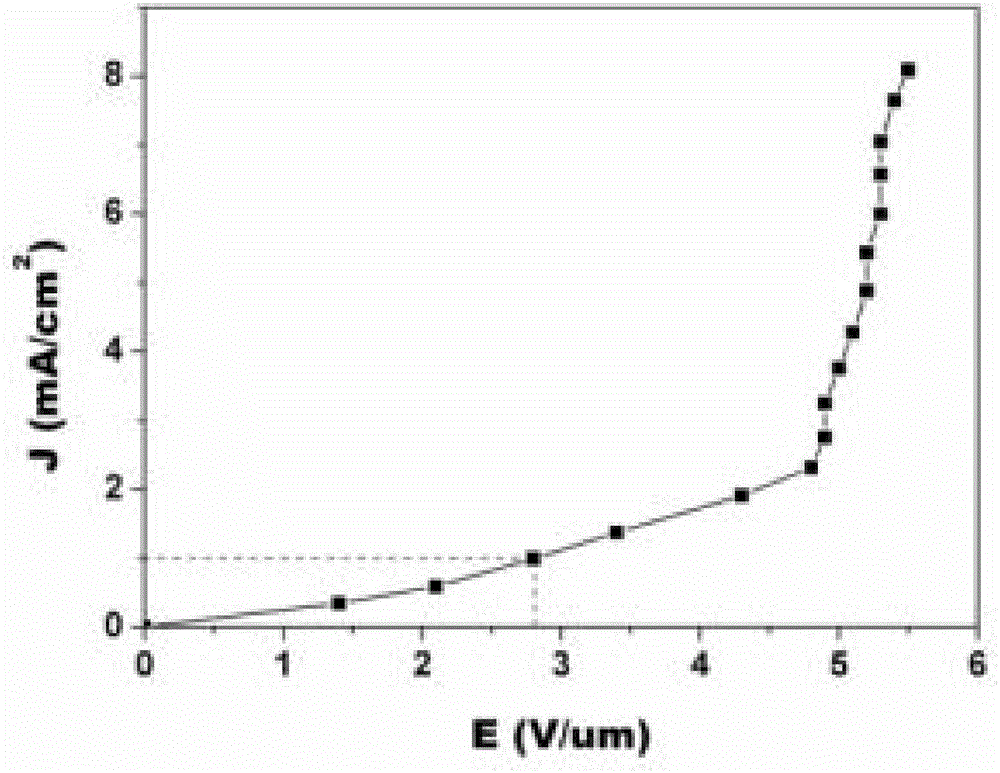

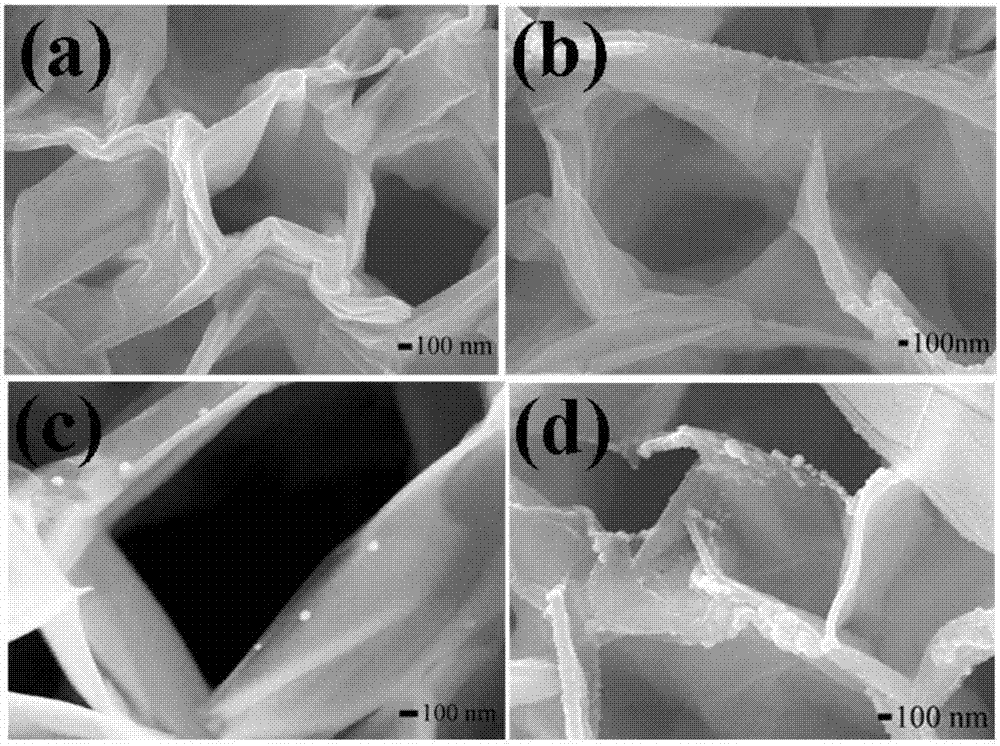

Preparation method for grapheme/zinc oxide/grapheme sandwich structure composite cathode materials for field emission

ActiveCN106847648AStrong Field Launch FieldImprove launch performanceMaterial nanotechnologyCold cathode manufactureRadio frequency magnetron sputteringSeed crystal

The present invention belongs to the vacuum microelectronics and display technology field, and especially relates to a preparation method for grapheme / zinc oxide / grapheme sandwich structure composite cathode materials for field emission. The method comprises the following steps: S10, taking graphene oxide powder as raw materials, employing an electrostatic spraying deposition technology to deposit a layer of grapheme film on a monocrystalline silicon substrate; S20, employing a radio-frequency magnetron sputtering technology to sputter a layer of ZnO film as seed crystal at the surface of the grapheme film, taking zinc salt and hexamine as raw materials, performing hydrothermal growth of a ZnO nanoneedle array, and obtaining grapheme / ZnO nanoneedle array composite materials on the silicon substrate; and S30, employing the electrostatic spraying deposition technology to deposit a layer of grapheme at the ZnO surface, and making grapheme / zinc oxide / grapheme composite cathode materials with a sandwich structure. The preparation technology is high in operationality, is not high in device requirement and low in cost, can perform large-scale rapid preparation, and is helpful to be compatible with the large-scale production technology, and therefore the obtained grapheme / zinc oxide / grapheme sandwich structure composite cathode materials are low in field emission opening field intensity and stable in emission performance.

Owner:深圳前海石墨烯产业有限公司

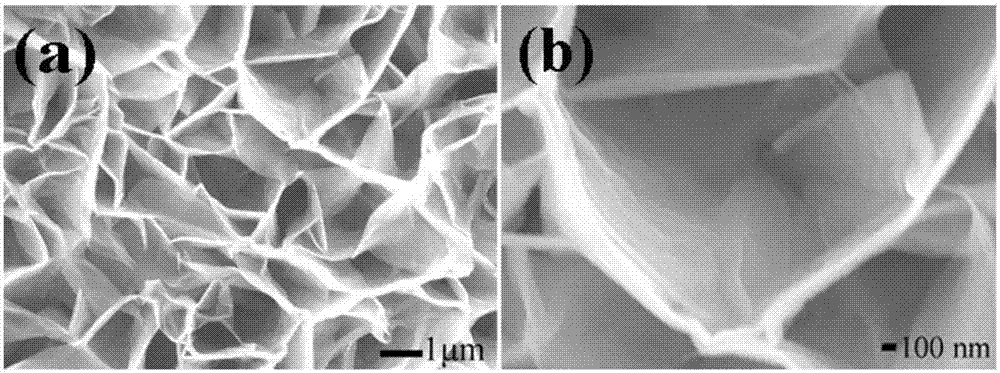

Preparation method of honeycomb-shaped zinc oxide nanowall array

InactiveCN107321347AHigh porosityEasy to apply in many fieldsMaterial nanotechnologyWater/sewage treatment by irradiationMethyl orangePhotocatalytic degradation

The invention discloses a preparation method of a honeycomb-shaped zinc oxide nanowall array. The preparation method comprises steps as follows: (1), an aluminum foil substrate is cleaned; (2), a seed layer is subjected to sputtering with a radio frequency magnetron method; (3), a product obtained in the step (2) is subjected to a hydrothermal reaction, and the honeycomb-shaped zinc oxide nanowall array is obtained; (4), a product obtained in the step (3) is subjected to direct current sputtering for silver plating; (5), a product obtained in the step (4) is subjected to annealing treatment. After 90 min, 93% of a methyl orange solution can be degraded by a photocatalytic material at the room temperature, and the degradation rate is in accordance with a first-order constant and reaches 0.02952 min<-1>. The prepared zinc oxide photocatalytic material does not require a template, is low in cost, good in recoverability, excellent in photocatalytic performance and good in stability and facilitates large-scale production, thereby being capable of applying to photocatalytic degradation for dye organic pollutants.

Owner:TSINGHUA UNIV

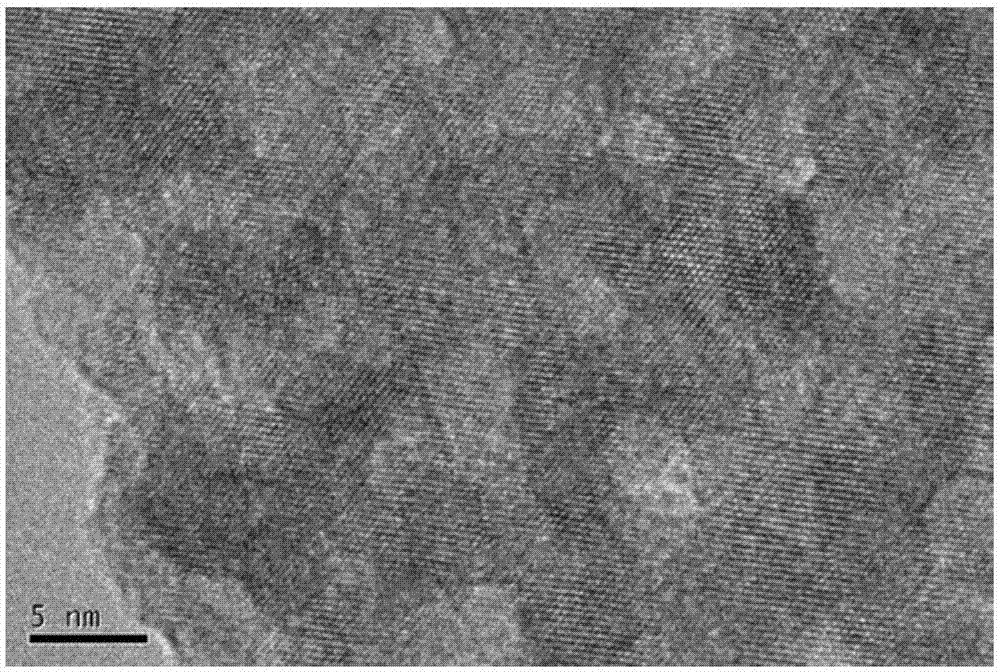

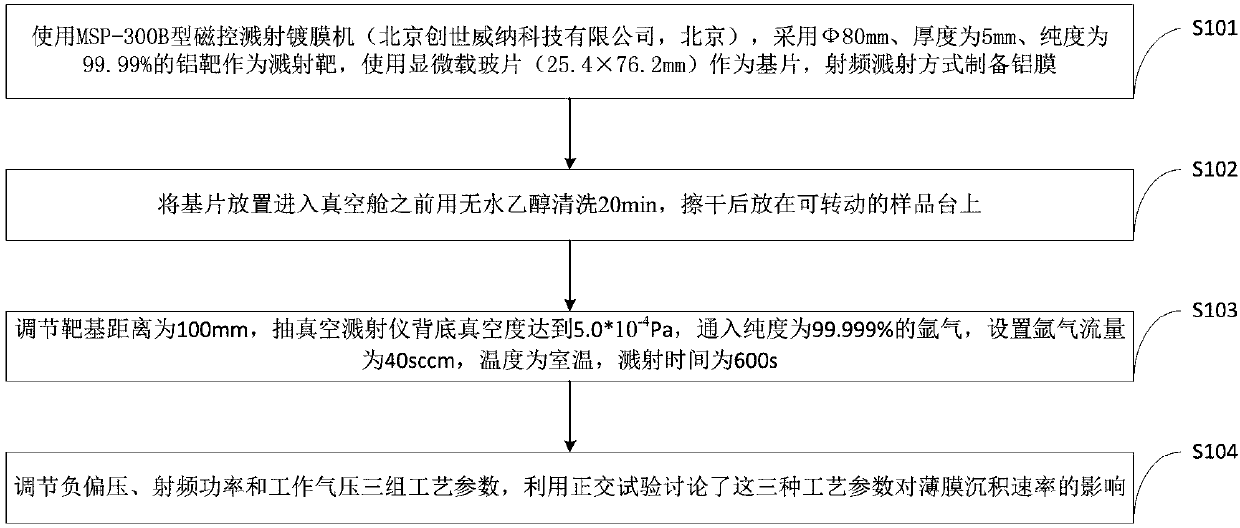

Method for preparing nano aluminum film by radio frequency magnetron sputtering

InactiveCN107779834AIncrease deposition rateQuality improvementVacuum evaporation coatingSputtering coatingRadio frequency magnetron sputteringRadio frequency

The invention belongs to the technical field of aluminum film preparation and discloses a method for preparing nano aluminum film by radio frequency magnetron sputtering. The method comprises the following steps: preparing an aluminum film by adopting a way of radio frequency sputtering by using a magnetron sputtering coating machine by taking an aluminum target as a sputtering target and a microscopic glass slide as a substrate; putting the substrate which is washed for 20min with absolute ethyl alcohol into a vacuum cabin, and erasing the substrate dry and putting the same onto a sample table capable of rotating; adjusting the target-substrate distance to 100mm, carrying out vacuumizing, wherein the back bottom vacuum degree of a sputtering apparatus reaches 5.0*10<-4>Pa, introducing argon, the purity of which is 99.99%, setting the argon flow at 40sccm and the temperature at the room temperature and the sputtering time at 600s; and adjusting three process parameters: negative bias,radio-frequency power and working air pressure, and discussing influence of the three process parameters on the depositing rate of the film by means of an orthogonal test. By selecting the process parameters, the aluminum film which is relatively high in depositing rate, good in film quality, relatively great in thickness and fine in grain size is designed.

Owner:CHONGQING JIAOTONG UNIVERSITY

Method for preparing nitrogen aluminum co-doping p type zinc oxide thin film

ActiveCN104818452ALow resistivityOptimizing Process ParametersVacuum evaporation coatingSputtering coatingZinc nitrideNitrogen gas

The invention provides a method for preparing a nitrogen aluminum co-doping p type zinc oxide thin film. The method comprises the following steps that S1, high-purity zinc serves as a target material, a high-purity aluminum piece is placed on the target face, a substrate is placed above the target material, the distance between the substrate and the target material is adjustable, high-purity nitrogen gas is led to carry out radio frequency magnetron reactive sputtering, and the aluminum-contained zinc nitride thin film obtained through preparation serves as a precursor; S2, after the precursor is prepared, vacuumizing is carried out, high-purity oxygen is led to carry out in-situ low-pressure oxidization on a precursor thin film, and the nitrogen aluminum co-doping p type zinc oxide thin film is obtained through preparation. According to the method, on the premise that the performance of the precursor is optimized, the content of active nitrogen in the thin film is improved, and therefore the concentration and the migration rate of a hole carrier are increased, the resistance rate of the zinc oxide thin film is reduced, the resistance rate of the obtained zinc oxide thin film is reduced to 10.84W*cm, the concentration of the carrier reaches +4.65*1018cm-3, an optical band gap is 3.27 eV, and the crystalline state and the optical property of the thin film are good.

Owner:LINGNAN NORMAL UNIV

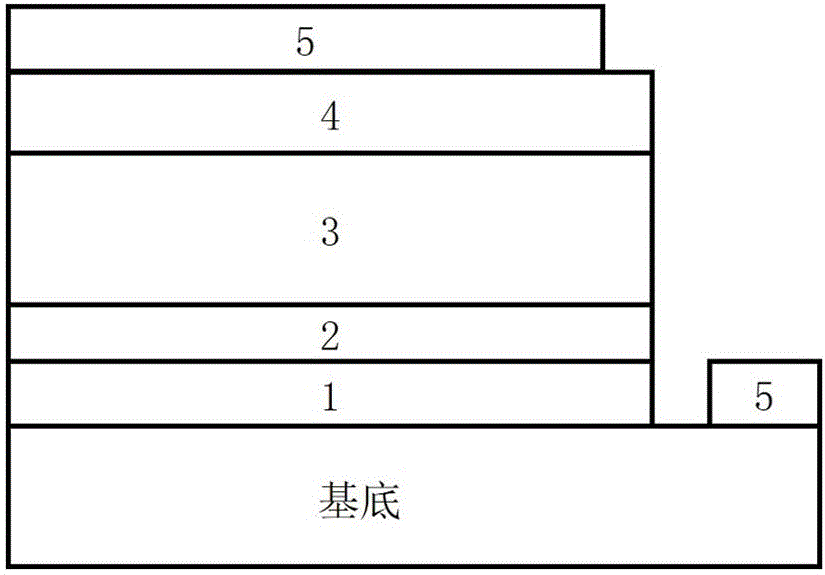

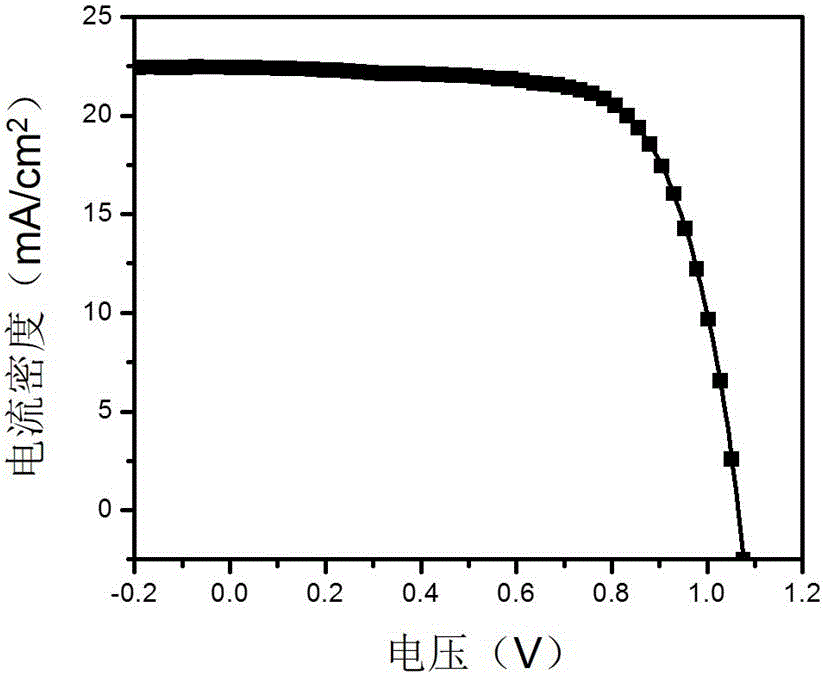

Perovskite solar cell with high performance transparent conductive electrode and electron transfer layer and preparation method thereof

ActiveCN107394044AGood repeatabilityImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingTransport layerPerovskite solar cell

The invention discloses a perovskite solar cell with a high performance transparent conductive electrode and an electron transfer layer and a preparation method thereof. The perovskite solar cell comprises a glass substrate, and a transparent conductive oxide electrode, a metal oxide electron transport layer, a perovskite light absorption layer, a hole transport layer and a metal electrode, which are orderly arranged on the glass substrate in a stacking way; and the transparent conductive oxide electrode and the metal oxide electron transport layer are deposited by using a radio frequency magnetron co-sputtering method. The perovskite solar cell provided by the invention is simple in process, good in uniformity, good in repeatability and high in efficiency of the perovskite solar cell.

Owner:SHAANXI NORMAL UNIV

Preparation method of electrolyte thin film for all-solid-state thin-film lithium ion battery

InactiveCN105762407ASmall production volumeIncrease energy densityVacuum evaporation coatingSputtering coatingRadio frequency magnetron sputteringHigh energy

The invention relates to a preparation method of an electrolyte thin film for an all-solid-state thin-film lithium ion battery.The electrolyte thin film is an amorphous lithium phosphorus oxynitride thin film.The preparation method adopts a radio frequency magnetron sputtering process.The LiPON thin film prepared according to the method is amorphous, larger than 2*10<-6>S / cm in ionic conductivity and excellent in electrochemical performances such as high thermodynamic stability and large electrochemical window width, thereby being an ideal solid electrolyte material and especially suitable for production of the all-solid-state thin-film lithium ion battery small in size, high in energy density and long in service life.

Owner:惠州市佰特瑞科技有限公司

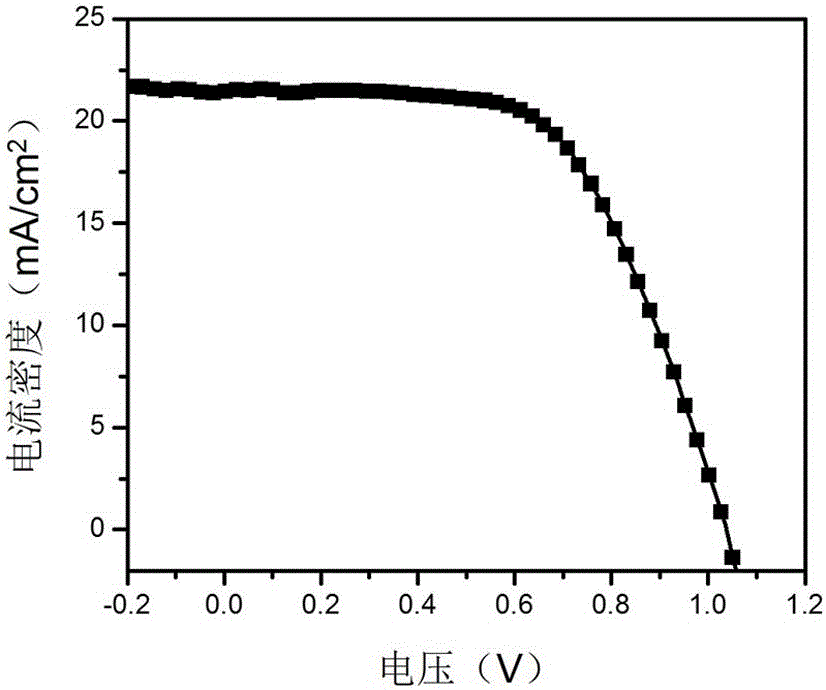

Perovskite solar battery and preparation method thereof

ActiveCN106449989AImprove uniformityGood repeatabilityFinal product manufactureSolid-state devicesPerovskite solar cellRadio frequency magnetron sputtering

The invention discloses a perovskite solar battery and a preparation method thereof. The preparation method comprises the following steps: on a cathode substrate, preparing a niobium oxide film through radio frequency magnetron sputtering at room temperature so as to form an electron transmission layer for transmitting electrons; preparing a perovskite light absorption layer on the electron transmission layer, and furthermore sequentially preparing a hole transmission layer for transmitting holes and an anode for collecting the holes to obtain the perovskite solar battery. The preparation method for preparing a niobium oxide electron transmission layer under the room temperature condition has the characteristics of being simple and controllable in process, and good in uniformity and repeatability of the prepared niobium oxide film, and large-scale production can be achieved; meanwhile, as the electron transmission layer, the niobium oxide film prepared by using a radio frequency magnetron sputtering method under the room temperature condition does not need high-temperature calcinations, so that the whole production process of the perovskite solar battery can be implemented at low temperature (less than or equal to 100 DEG C), and is particularly applicable to a flexible substrate.

Owner:SUZHOU UNIV

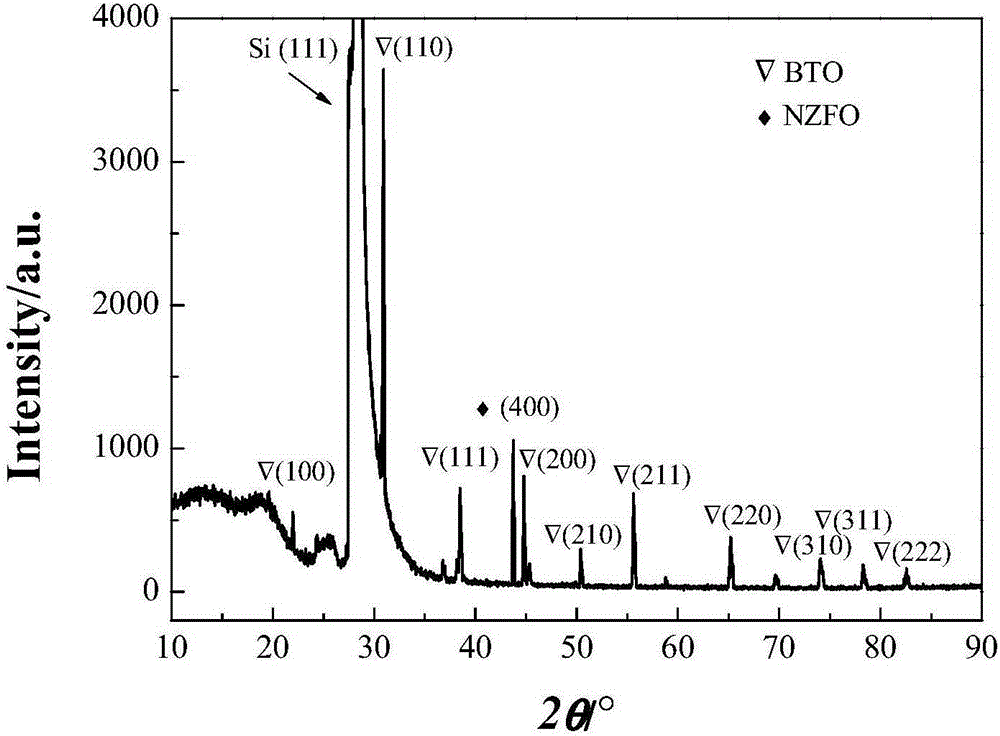

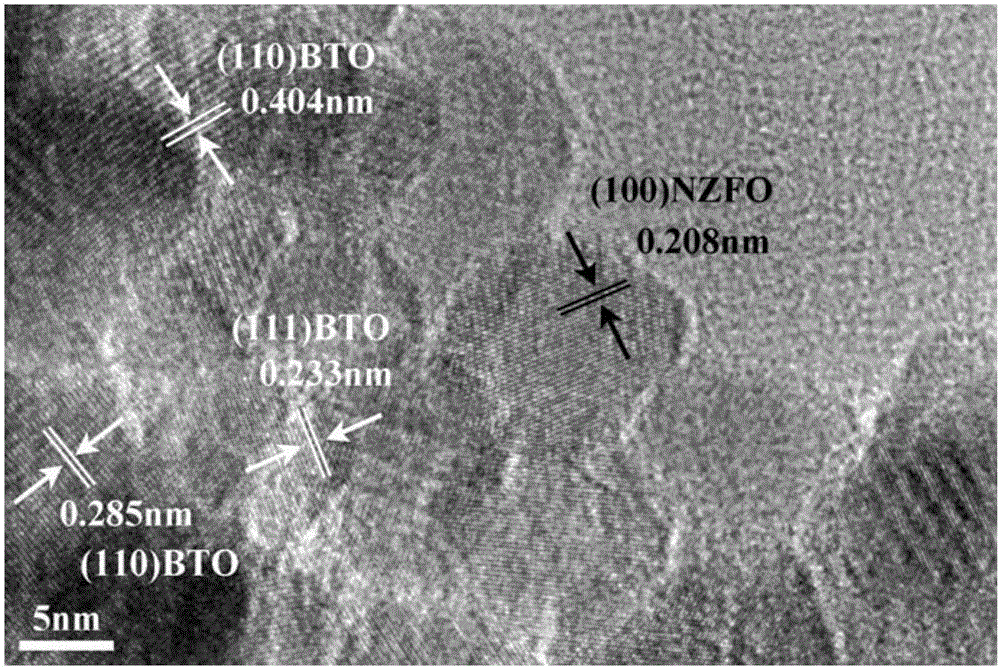

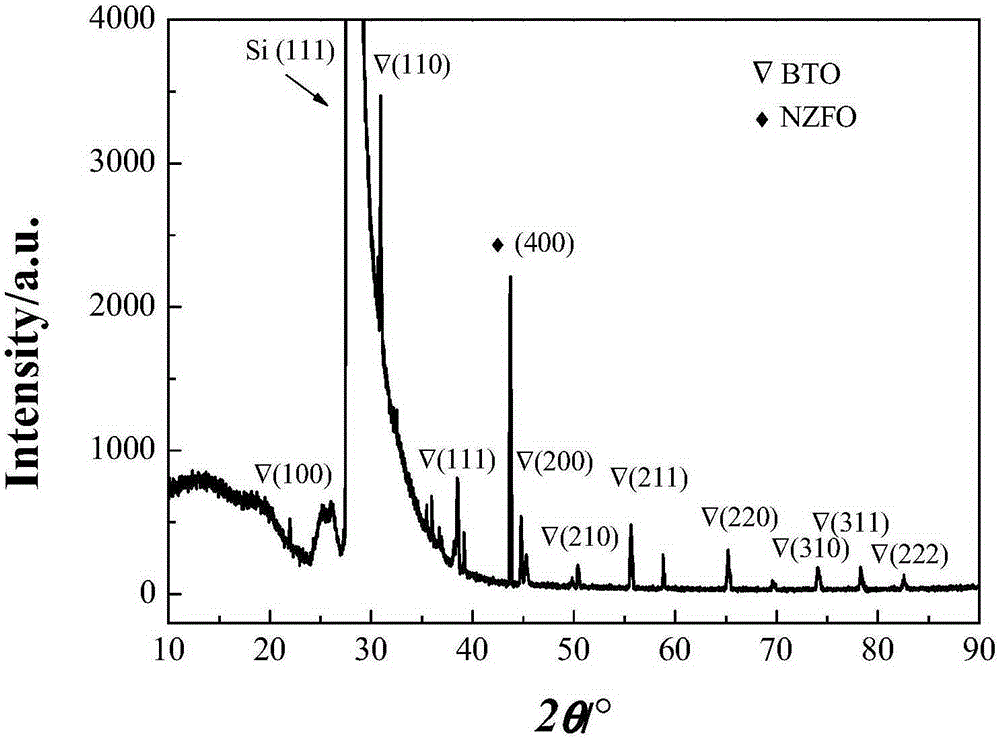

Magnetic-phase-oriented barium titanate/Ni-Zn ferrite nanocrystalline complex-phase thin film and preparation method thereof

The invention discloses a ferromagnetic-phase-oriented growth barium titanate / Ni-Zn ferrite nanocrystalline complex-phase thin film material and a preparation method thereof. A barium titanate crystal phase in a complex-phase thin film grows randomly, crystalline-phase-oriented growth is carried out on a Ni-Zn ferrite, and two-phase disorder distribution is achieved. The thin film is prepared through the method combining radio frequency magnetron sputtering with heat treatment. The material has electric and magnetic double percolation thresholds, has low dielectric loss, high dielectric constant and high magnetic conductivity, and has a good phase-to-phase stress transfer effect and a coupling effect. The multiferroic complex-phase thin film material is simple in preparation technology, low in cost and capable of being used in multi-state memories and heterogeneous read-write capacitors, and can be widely used in the field of electromagnetic devices.

Owner:ZHEJIANG UNIV

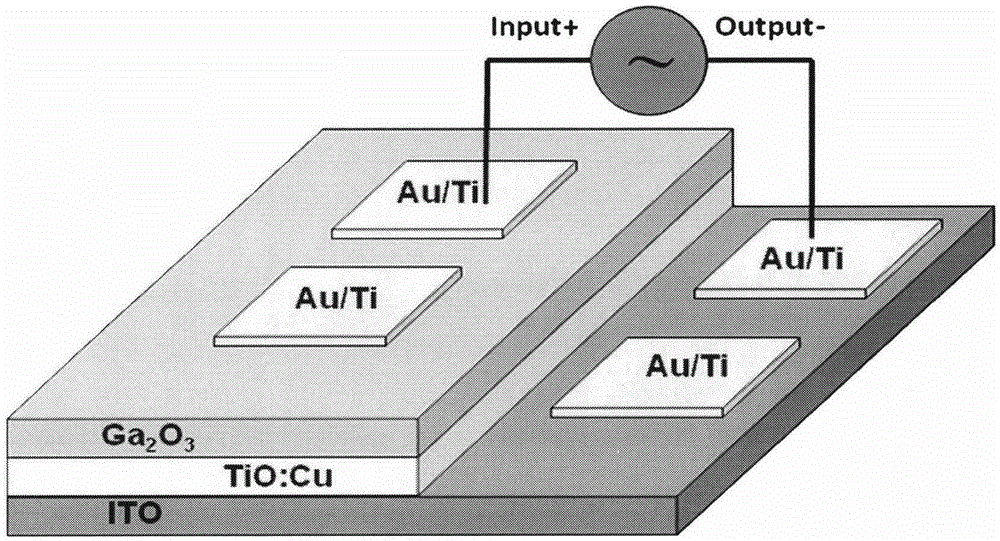

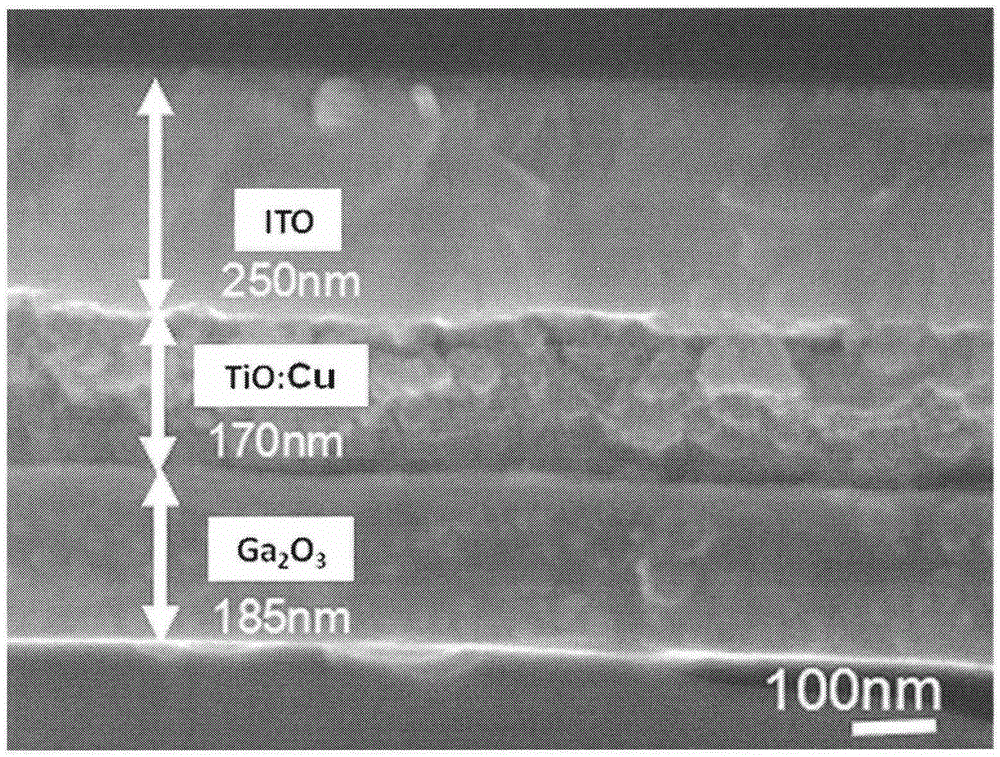

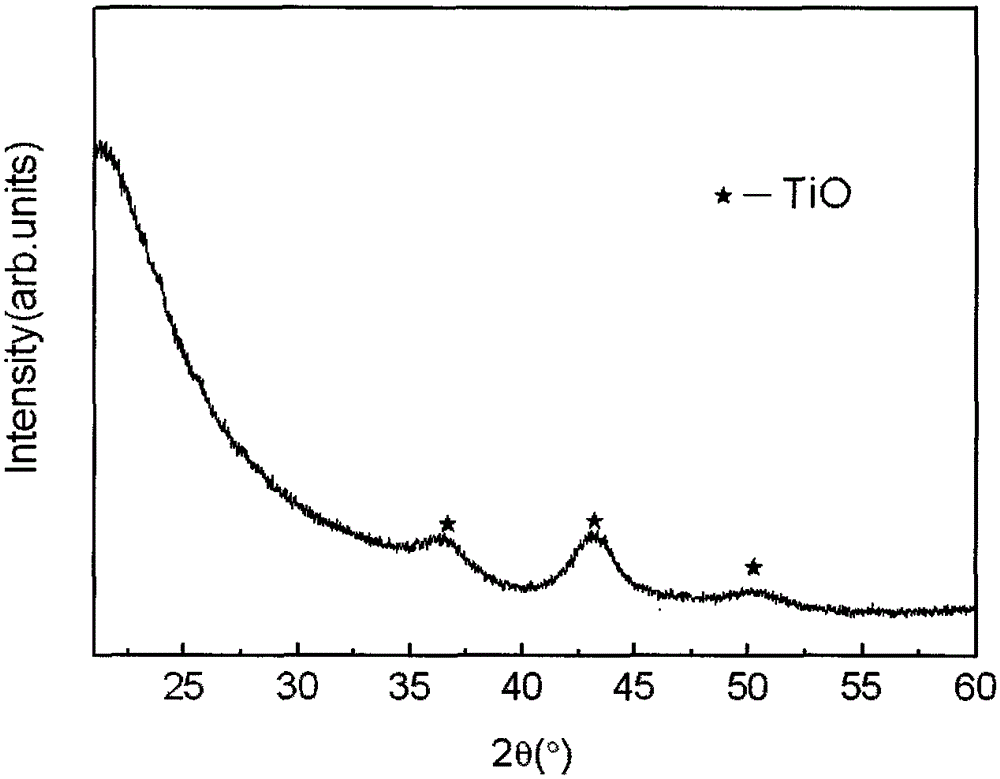

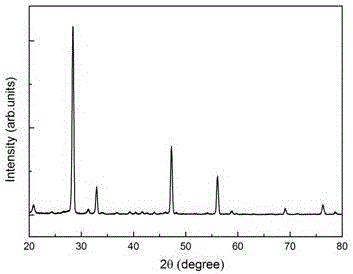

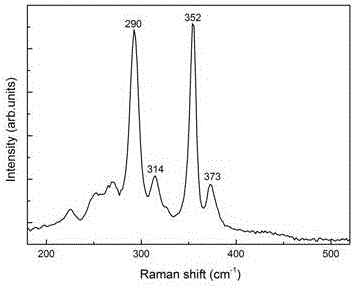

Multi-resistance-state double-layer film resistance random access memory and manufacturing method therefor

ActiveCN105185904AStable and uniform dense thicknessStable characteristicsSemiconductor/solid-state device manufacturingFilm resistanceHeterojunction

The invention discloses a multi-resistance-state double-layer film resistance random access memory and a manufacturing method therefor. The resistance random access memory has stable maintaining property and multi-value storage performance; and particularly, Ti / Au is taken as an upper electrode, ITO is taken as a substrate and a lower electrode, an ITO substrate is successively coated with TiO:Cu and Ga2O3 films by utilizing a radio-frequency magnetron deposition technology to form a resistance change layer, and then Ti and Au films are sputtered on the ITO substrate and the film coated with Ga2O3, so that a memory device with an ITO / TiO:Cu / Ga2O3 / Ti / Au structure is manufactured, and a multi-value storage function is realized. The multi-resistance-state double-layer film resistance random access memory has the superiorities that single-pole or double-pole resistance change is generated through motion of defects at a heterojunction interface, the manufactured resistance random access memory device has stable maintaining property, cycle property and multi-resistance-state resistance random access memory performance, the memory capacity of the memory device is expanded, and the service life of the memory device is prolonged.

Owner:江苏惠沣环保科技有限公司

Method sputtering tin target and copper sulfide target to prepare copper-tin-sulfur film and battery

ActiveCN106449812AImprove crystal qualityControl concentrationFinal product manufactureVacuum evaporation coatingVulcanizationRadio frequency magnetron sputtering

The invention discloses a method using radio frequency magnetron tin (Sn) target sputtering and radio frequency magnetron copper sulfide (CuS) target sputtering to prepare a copper-tin-sulfur (Cu2SnS3, CTS) film. The method is characterized in that mixed sputtering of a single-metal tin target and a compound copper sulfide target is used to prepare a copper-tin-sulfur film prefabricated layer, and soft annealing and high-temperature vulcanization are performed on the prefabricated layer to obtain the copper-tin-sulfur film. The method has the advantages that compared with a traditional method sputtering a single-metal copper target and a tin target, the method can well control the carrier concentration in the film; compared with a method sputtering a copper sulfide target and a tin sulfide target, the method can solve the problem that the film easily falls off from a substrate and generates holes due to high-temperature vulcanization; the copper-tin-sulfur film even, compact, and good in photo-electric property is prepared after the prefabricated layer prepared by the sputtering is subjected to the soft annealing and high-temperature vulcanization, and photoelectric conversion efficiency of 1.32% is obtained when the copper-tin-sulfur film is used to prepare a copper-tin-sulfur film battery; a preparation method for preparing the copper-tin-sulfur film battery with a good absorption layer is provided.

Owner:YUNNAN NORMAL UNIV

Method for low-temperature preparation of hafnium oxide-based ferroelectric film through ion beam assisted magnetron sputtering deposition

PendingCN113025959AThe composition of the film is uniformUniform compositionVacuum evaporation coatingSputtering coatingRadio frequency magnetron sputteringFerroelectric thin films

The invention discloses a method for low-temperature preparation of a hafnium oxide-based ferroelectric film through ion beam assisted magnetron sputtering deposition. The method comprises the following steps of (1) cleaning a substrate; (2) blow-drying the substrate, and feeding the substrate into a sputtering chamber; (3) pumping the sputtering chamber to high vacuum by using a vacuum pump, and then introducing high-purity argon to pre-sputter a hafnium oxide target material and an oxide target material of a to-be-doped element; (4) starting an ion beam auxiliary source and a radio frequency magnetron sputtering system, and carrying out auxiliary sputtering deposition on the surface of the substrate for a certain time under the condition that the substrate is not heated so as to obtain a hafnium oxide-based ferroelectric film; and (5) turning off the ion beam auxiliary source and the radio frequency magnetron sputtering system, turning on a sputtering power supply of an upper electrode target material, and preparing an upper electrode on the surface of the hafnium oxide-based ferroelectric film, thereby forming a capacitor with a semiconductor / metal-HfO2-based ferroelectric film-semiconductor / metal structure. According to the method, the hafnium oxide-based ferroelectric film with the smooth and compact surface, low electric leakage and high remanent polarization can be obtained.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com