Patents

Literature

59 results about "Zinc nitride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

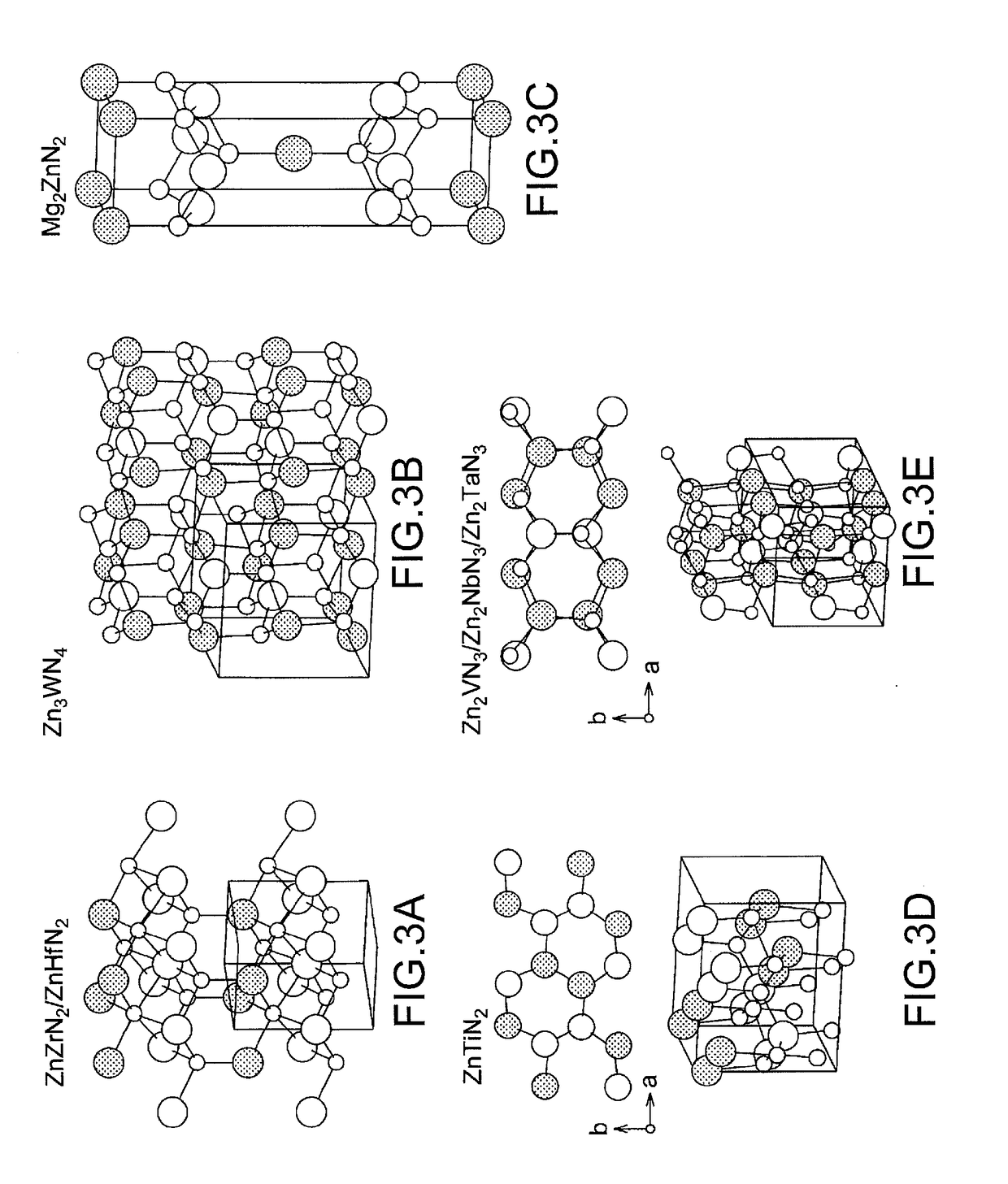

Zinc nitride (Zn₃N₂) is an inorganic compound of zinc and nitrogen, usually obtained as (blue)grey crystals. It is a semiconductor. In pure form, it has the anti-bixbyite structure.

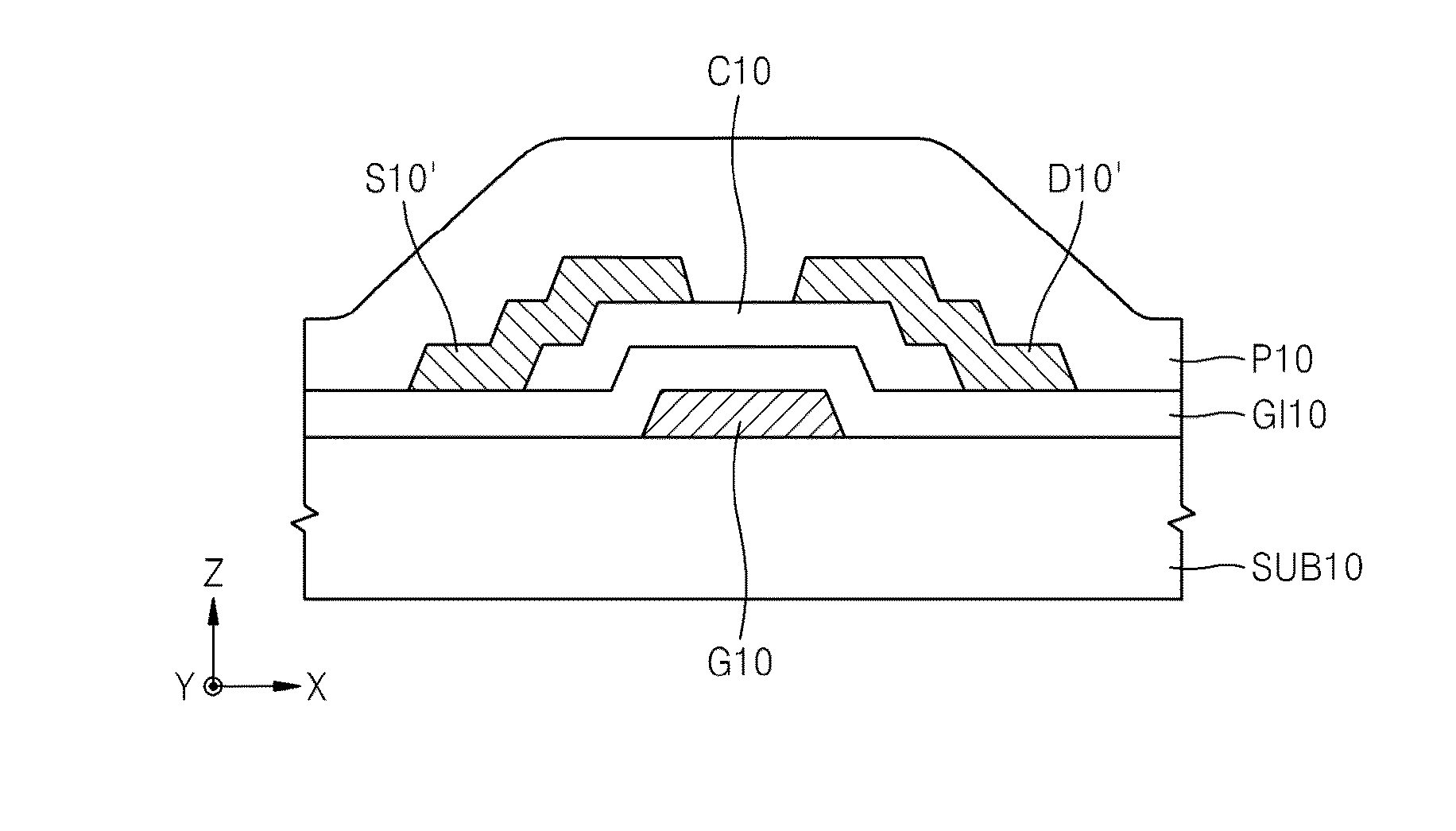

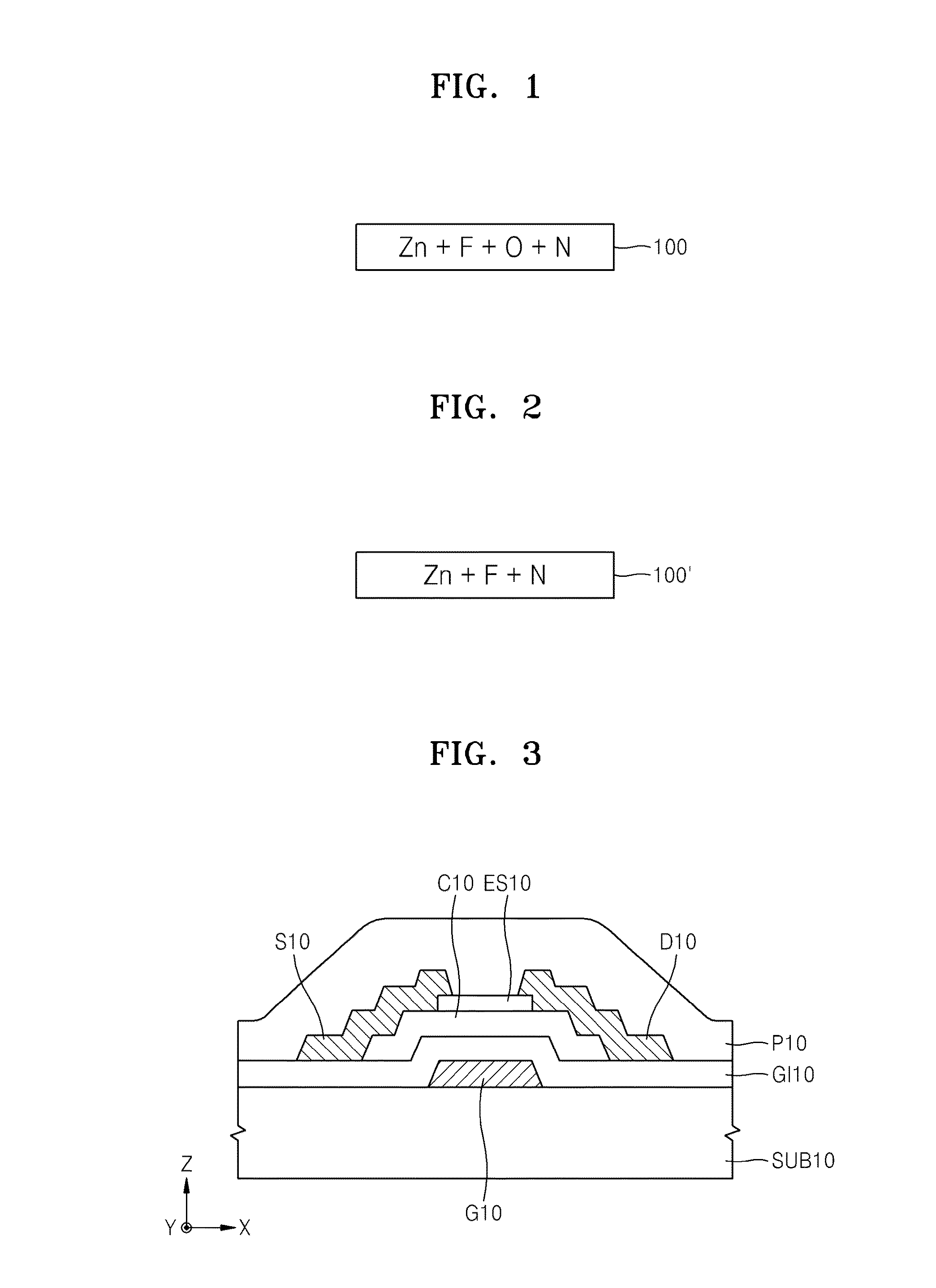

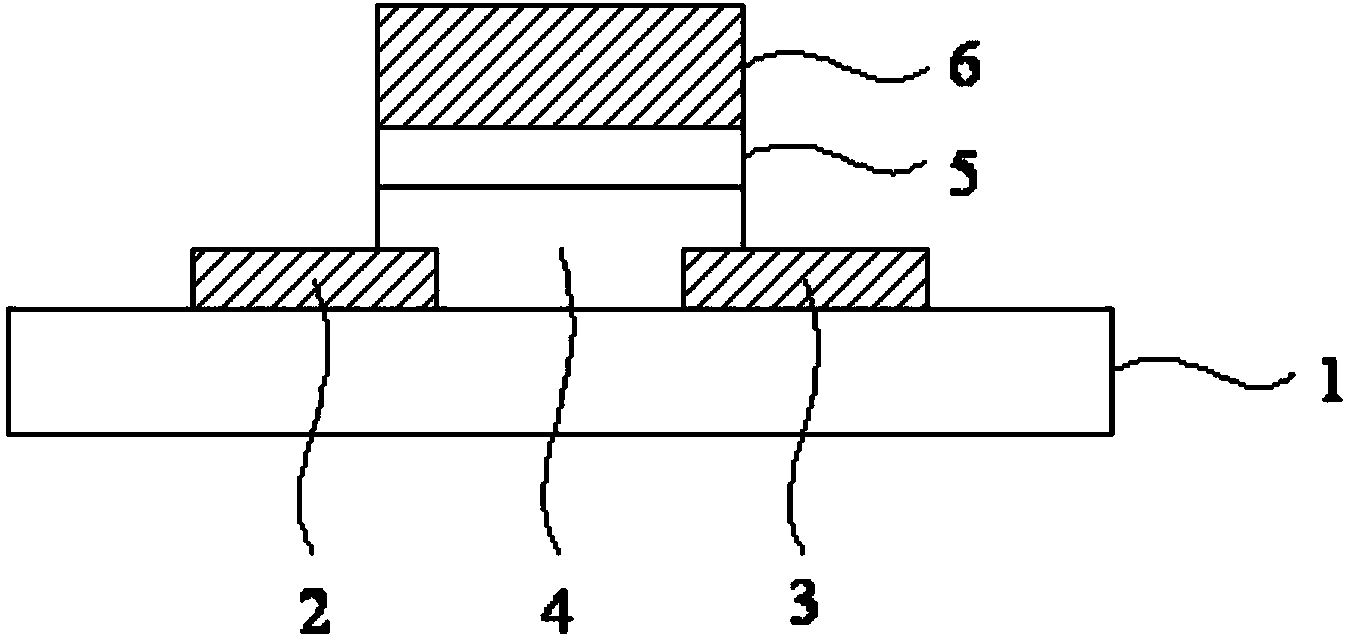

Semiconductor materials, transistors including the same, and electronic devices including transistors

ActiveUS20140152936A1Improve mobilityImprove switching characteristicsTransistorNitrogen compoundsZinc nitrideSemiconductor materials

According to example embodiments, a semiconductor material may include zinc, nitrogen, and fluorine. The semiconductor material may further include oxygen. The semiconductor material may include a compound. For example, the semiconductor material may include zinc fluorooxynitride. The semiconductor material may include zinc oxynitride containing fluorine. The semiconductor material may include zinc fluoronitride. The semiconductor material may be applied as a channel material of a thin film transistor (TFT).

Owner:SAMSUNG ELECTRONICS CO LTD +1

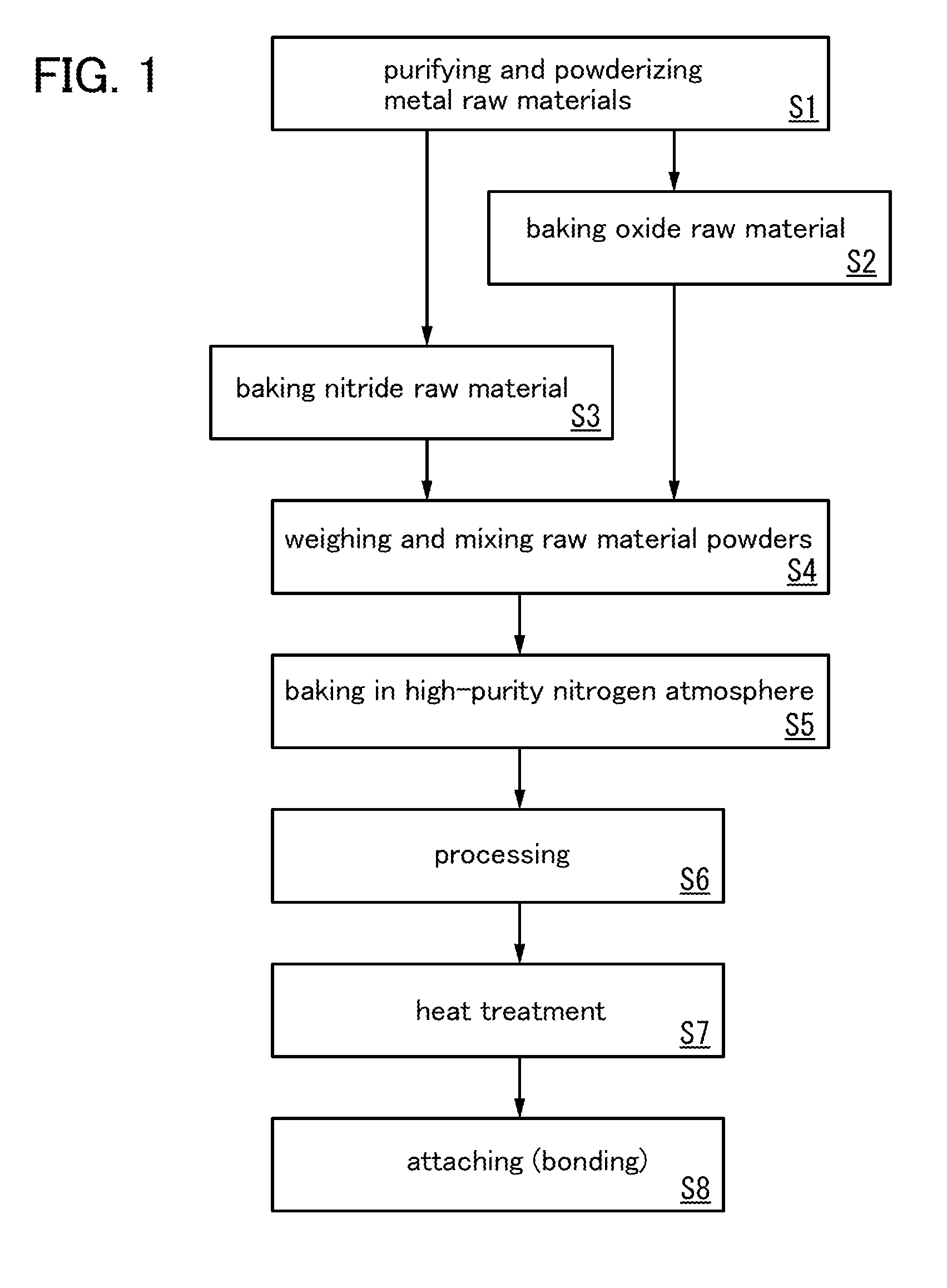

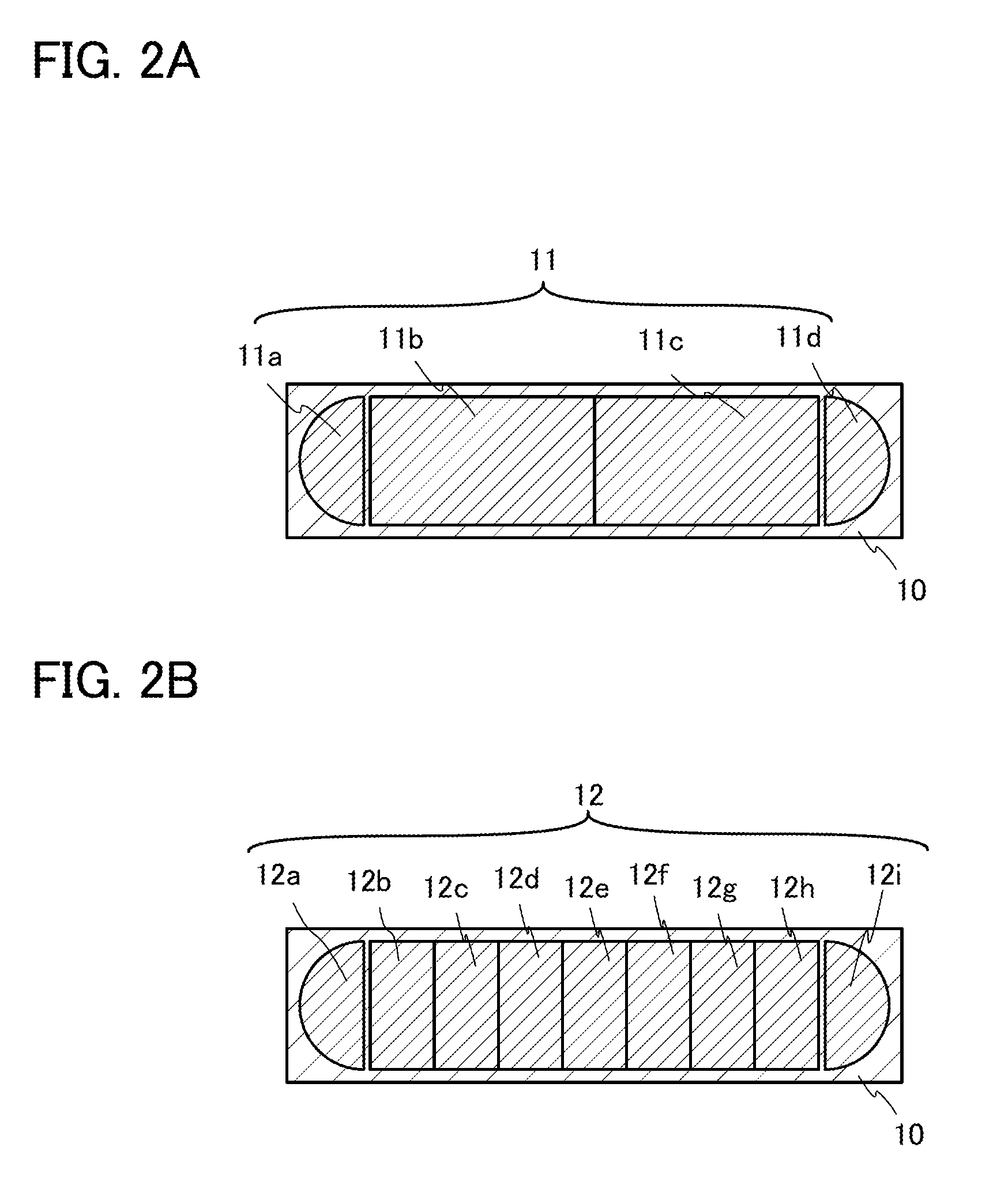

Sputtering target, method for manufacturing the same, and method for manufacturing semiconductor device

InactiveUS20120152728A1Reduce concentrationRaise the ratioCellsVacuum evaporation coatingZinc nitrideIndium

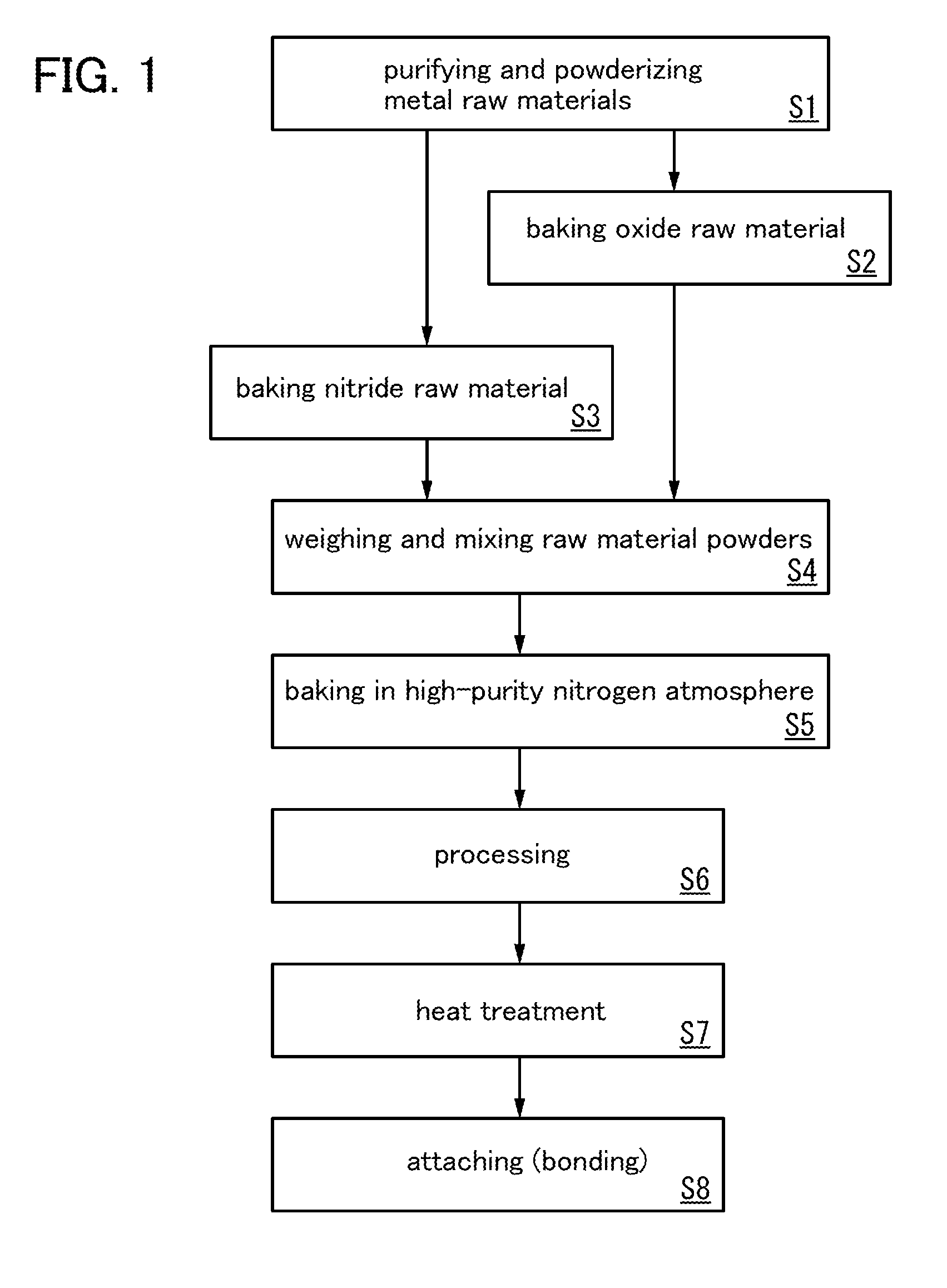

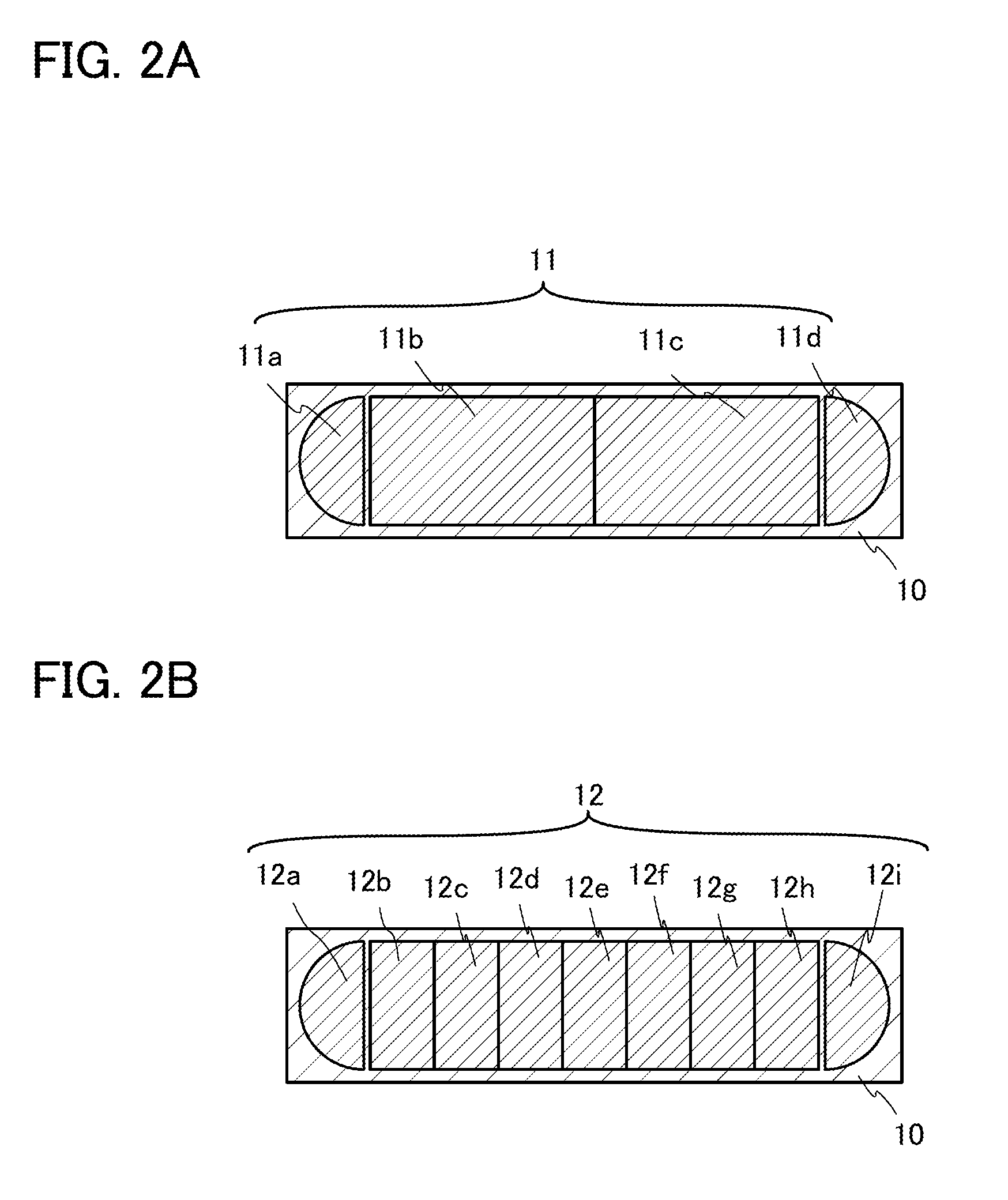

A deposition technique for forming an oxynitride film is provided. A highly reliable semiconductor element is manufactured with the use of the oxynitride film. The oxynitride film is formed with the use of a sputtering target including an oxynitride containing indium, gallium, and zinc, which is obtained by sintering a mixture of at least one of indium nitride, gallium nitride, and zinc nitride as a raw material and at least one of indium oxide, gallium oxide, and zinc oxide in a nitrogen atmosphere. In this manner, the oxynitride film can contain nitrogen at a necessary concentration. The oxynitride film can be used for a gate, a source electrode, a drain electrode, or the like of a transistor.

Owner:SEMICON ENERGY LAB CO LTD

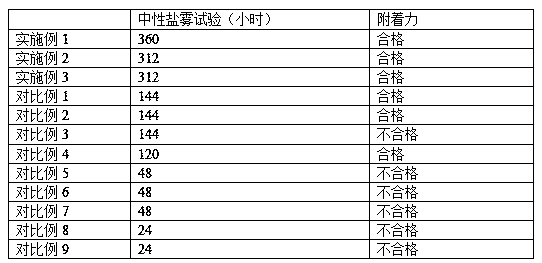

Metal surface treatment passivation liquid

ActiveCN108546942AAccelerated corrosionImprove adhesionMetallic material coating processesZinc nitrideMesoporous material

The invention relates to a metal surface treatment passivation liquid which comprises 1-20g / L zinc nitride, 5-40g / L inorganic acid, a 5-50g / L dispersant and a 1-10g / L modified mesoporous nano material. The modified mesoporous nano material is a polybasic acid grafted mesoporous nano material, and the percent grafting of polybasic acid is 1-5wt%. A film with extremely good corrosion resistance andadhesive force is obtained on the metal surface treated by the passivation liquid.

Owner:湖州富美材料科技有限公司

Sputtering target, method for manufacturing the same, manufacturing semiconductor device

InactiveUS8894825B2Reduce concentrationRaise the ratioCellsVacuum evaporation coatingZinc nitrideIndium

A deposition technique for forming an oxynitride film is provided. A highly reliable semiconductor element is manufactured with the use of the oxynitride film. The oxynitride film is formed with the use of a sputtering target including an oxynitride containing indium, gallium, and zinc, which is obtained by sintering a mixture of at least one of indium nitride, gallium nitride, and zinc nitride as a raw material and at least one of indium oxide, gallium oxide, and zinc oxide in a nitrogen atmosphere. In this manner, the oxynitride film can contain nitrogen at a necessary concentration. The oxynitride film can be used for a gate, a source electrode, a drain electrode, or the like of a transistor.

Owner:SEMICON ENERGY LAB CO LTD

Method for preparing P-type zinc oxide film from in situ low-pressure oxidized aluminum-doped zinc nitride

InactiveCN101798672ACompact structureNot easy to spreadVacuum evaporation coatingSputtering coatingZinc nitrideUltra-high vacuum

The invention discloses a method for preparing a P-type zinc oxide film from in situ low-pressure oxidized aluminum-doped zinc nitride; an ultra-high vacuum magnetron sputtering system is adopted to prepare an aluminum-doped zinc nitride film on a quartz substrate as a precursor, wherein the select purity of a target is 99.999 percent high-purity zinc; and a high-purity aluminum sheet is put on the surface of the target to control the aluminum content in a sample. After the precursor is prepared, the background of a reaction chamber is vacuumized to be 10 to 4Pa, and 99.999 percent high-purity oxygen is fed in to oxidize the precursor at low pressure. The method improves the active nitrogen content in the zinc oxide with nitrogen and aluminum doping, improves the concentration and the mobility of a hole carrier, and reduces the resistivity of the zinc oxide film. When the oxidation temperature is 550DEG C, the resistivity is low to 19.8(ohm.cm), the concentration of the carrier reaches +4.6E1018cm-3. An optical band gap is 3.27Ev, and the film has excellent crystalline state and optical properties.

Owner:ZHANJIANG NORMAL UNIV

Method for preparing nitrogen aluminum co-doping p type zinc oxide thin film

ActiveCN104818452ALow resistivityOptimizing Process ParametersVacuum evaporation coatingSputtering coatingZinc nitrideNitrogen gas

The invention provides a method for preparing a nitrogen aluminum co-doping p type zinc oxide thin film. The method comprises the following steps that S1, high-purity zinc serves as a target material, a high-purity aluminum piece is placed on the target face, a substrate is placed above the target material, the distance between the substrate and the target material is adjustable, high-purity nitrogen gas is led to carry out radio frequency magnetron reactive sputtering, and the aluminum-contained zinc nitride thin film obtained through preparation serves as a precursor; S2, after the precursor is prepared, vacuumizing is carried out, high-purity oxygen is led to carry out in-situ low-pressure oxidization on a precursor thin film, and the nitrogen aluminum co-doping p type zinc oxide thin film is obtained through preparation. According to the method, on the premise that the performance of the precursor is optimized, the content of active nitrogen in the thin film is improved, and therefore the concentration and the migration rate of a hole carrier are increased, the resistance rate of the zinc oxide thin film is reduced, the resistance rate of the obtained zinc oxide thin film is reduced to 10.84W*cm, the concentration of the carrier reaches +4.65*1018cm-3, an optical band gap is 3.27 eV, and the crystalline state and the optical property of the thin film are good.

Owner:LINGNAN NORMAL UNIV

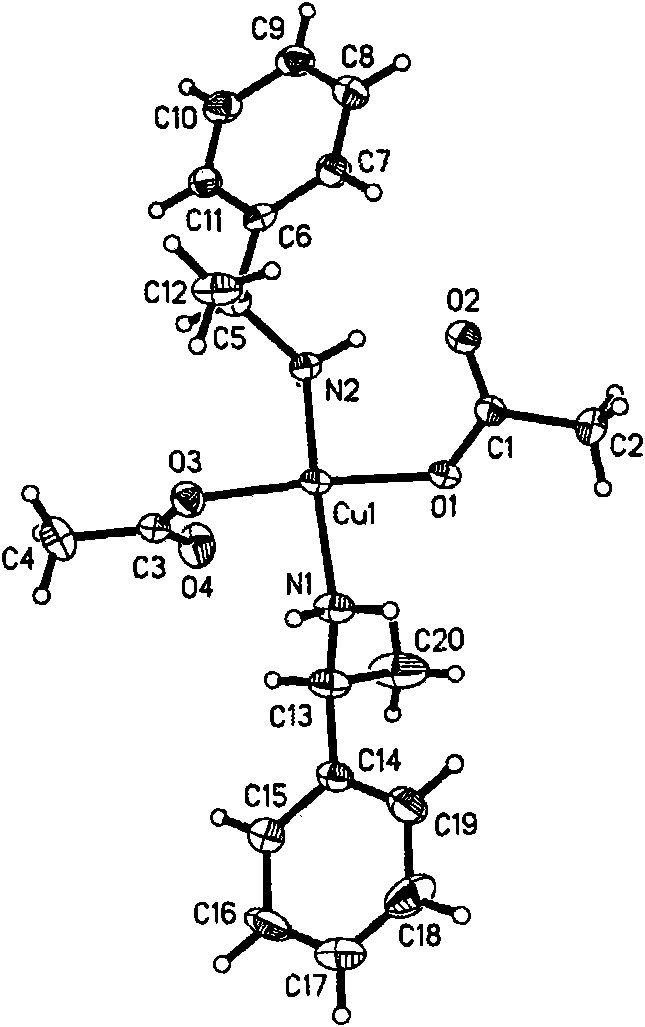

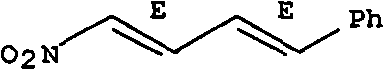

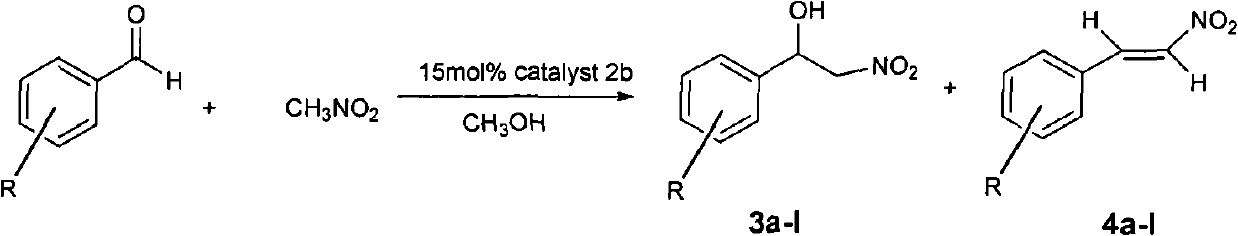

Zinc nitride and copper nitride compound of chiral alpha-phenylethylamine and use thereof

InactiveCN101830919AAmino preparation from aminesOrganic-compounds/hydrides/coordination-complexes catalystsZinc nitrideCopper chloride

The invention discloses a zinc nitride and copper nitride compound of chiral alpha-phenylethylamine, which comprises a (S) alpha-phenylethylamine zinc nitride and copper nitride compound and a (R) alpha-phenylethylamine zinc nitride and copper nitride compound, which are prepared from the alpha-phenylethylamine, zinc acetate dihydrate, copper acetate monohydrate and copper chloride dihydrate and have the following formulas. In the formulas, ML is Zn(OOCCH3)2, Cu(OOCCH3)2 or CuCl2. The compound serves as a chiral catalyst in a Henry reaction.

Owner:HEFEI UNIV OF TECH

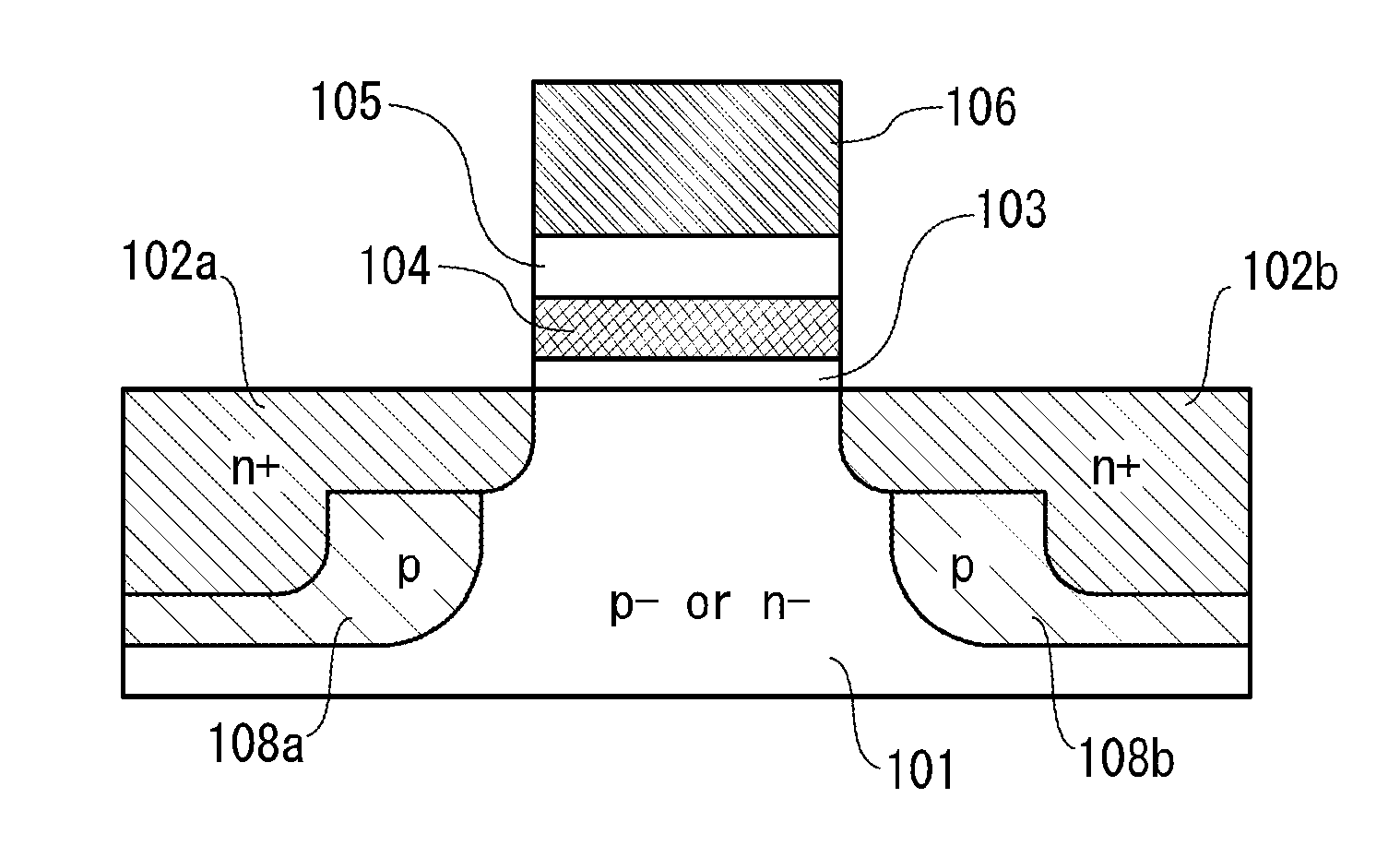

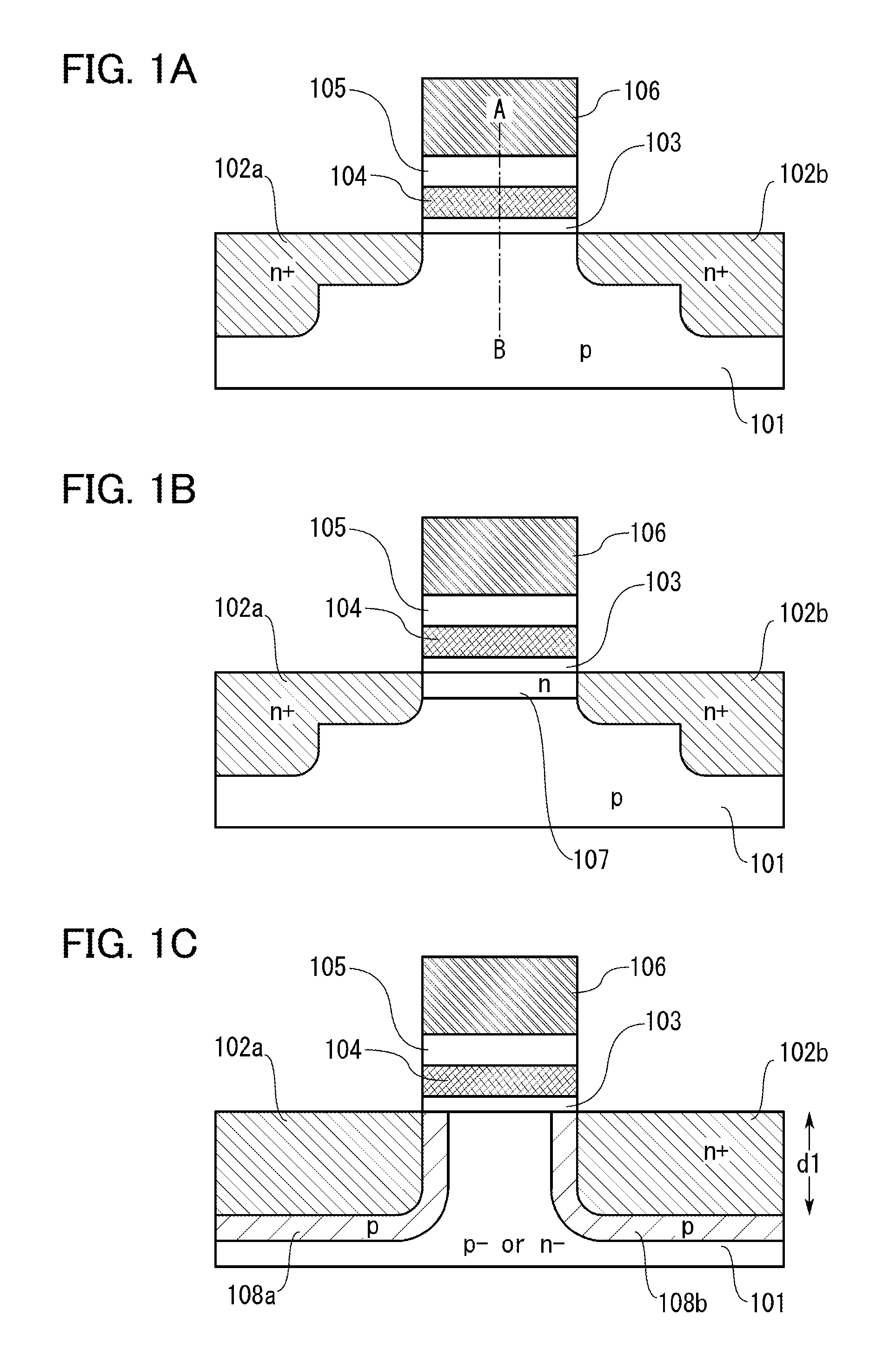

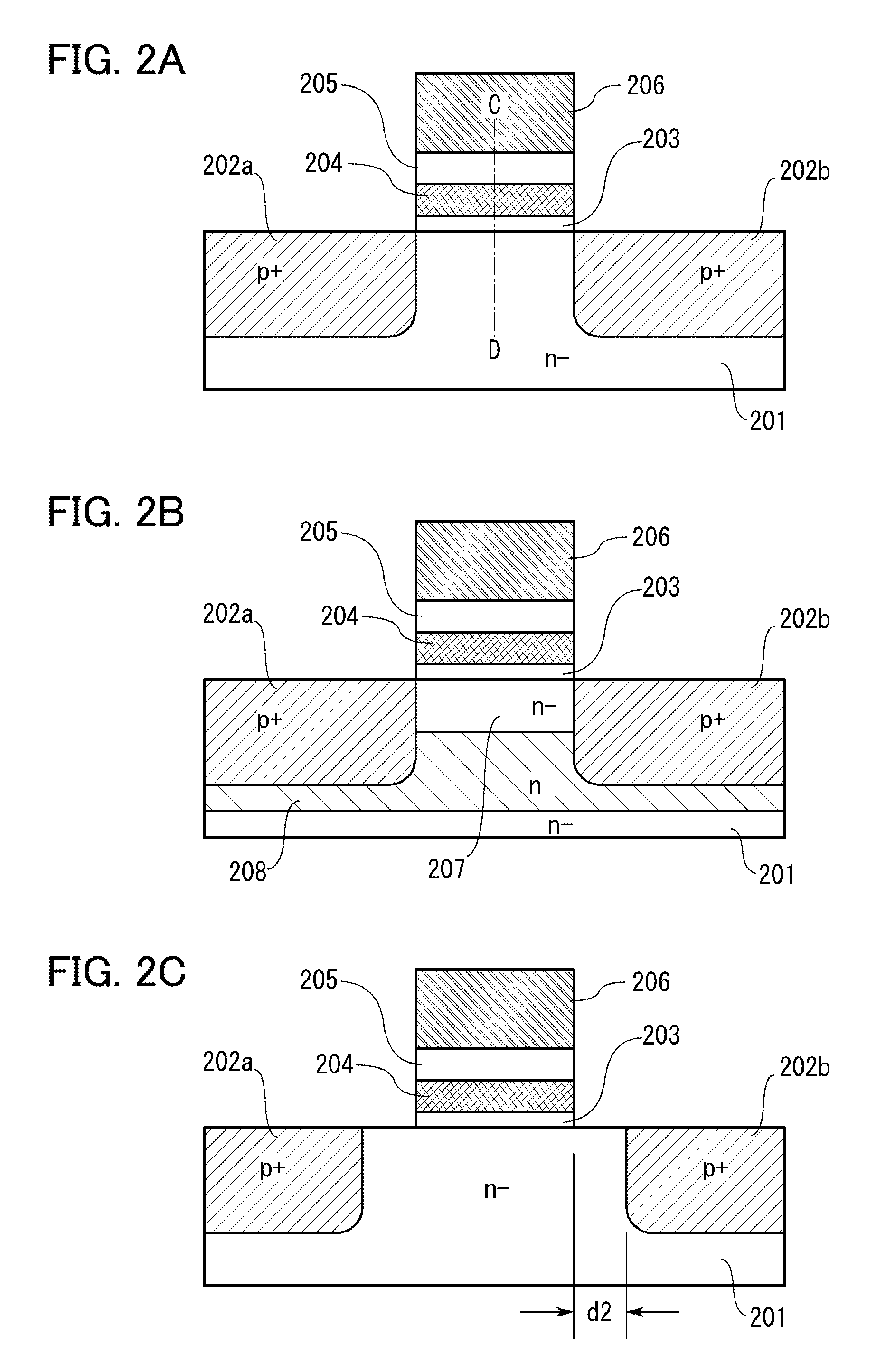

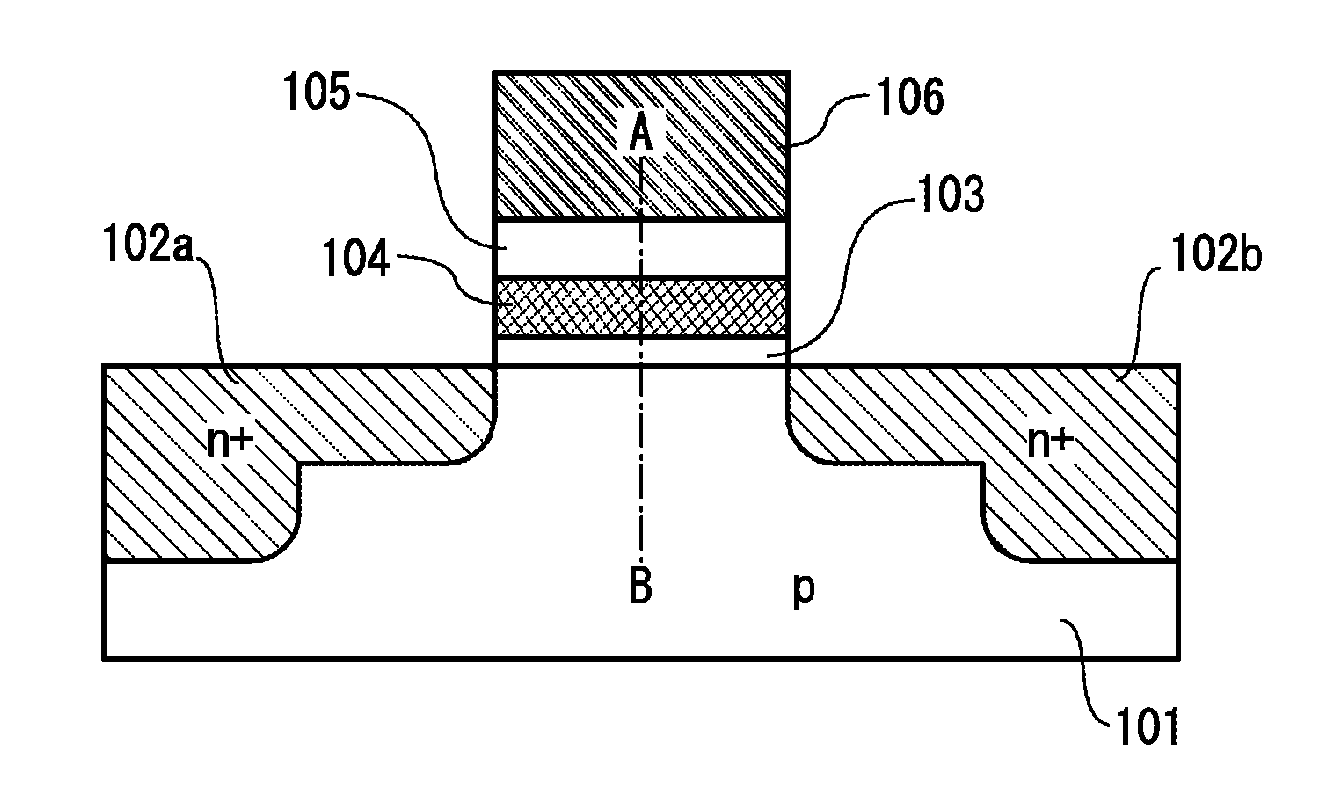

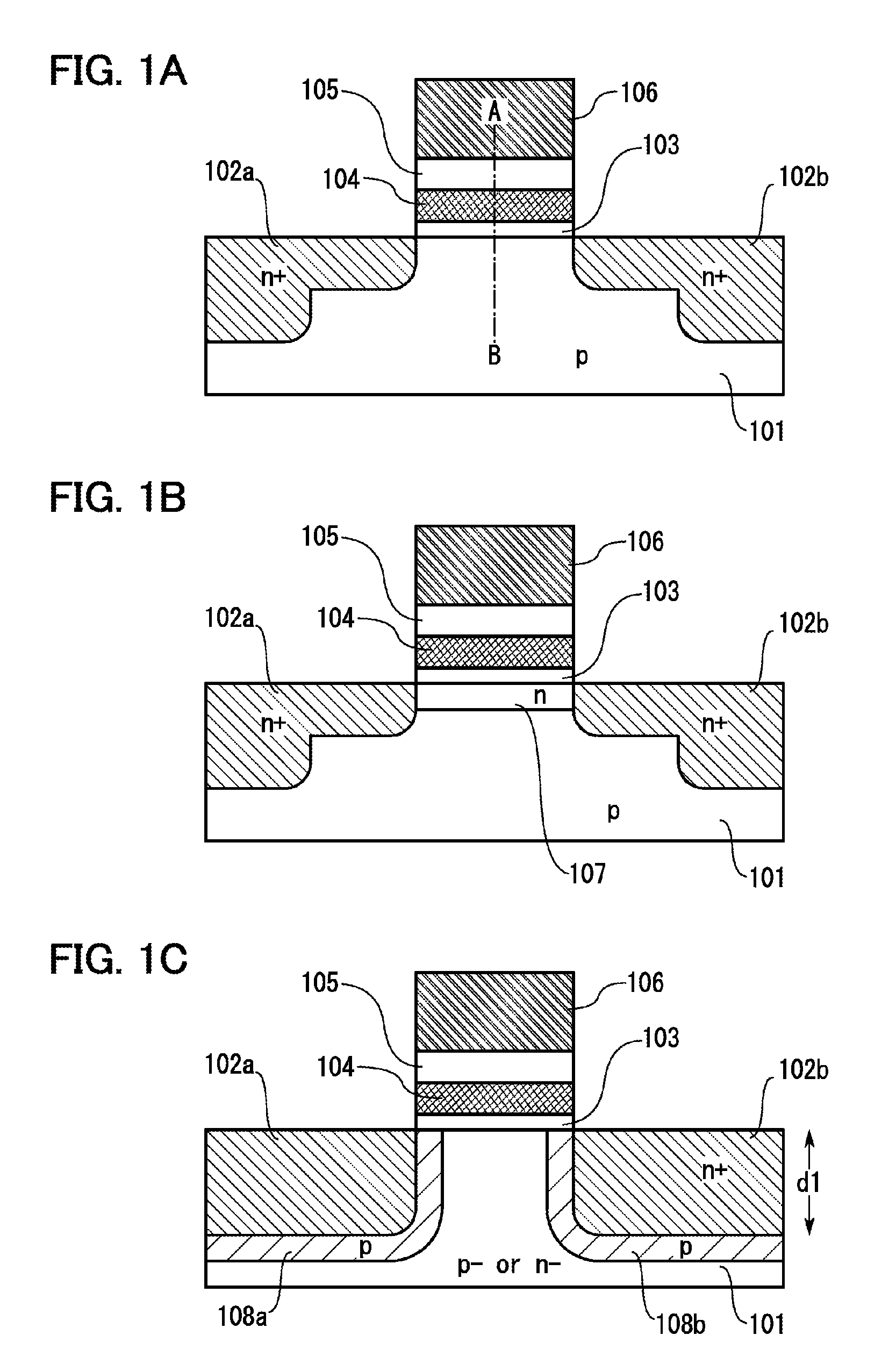

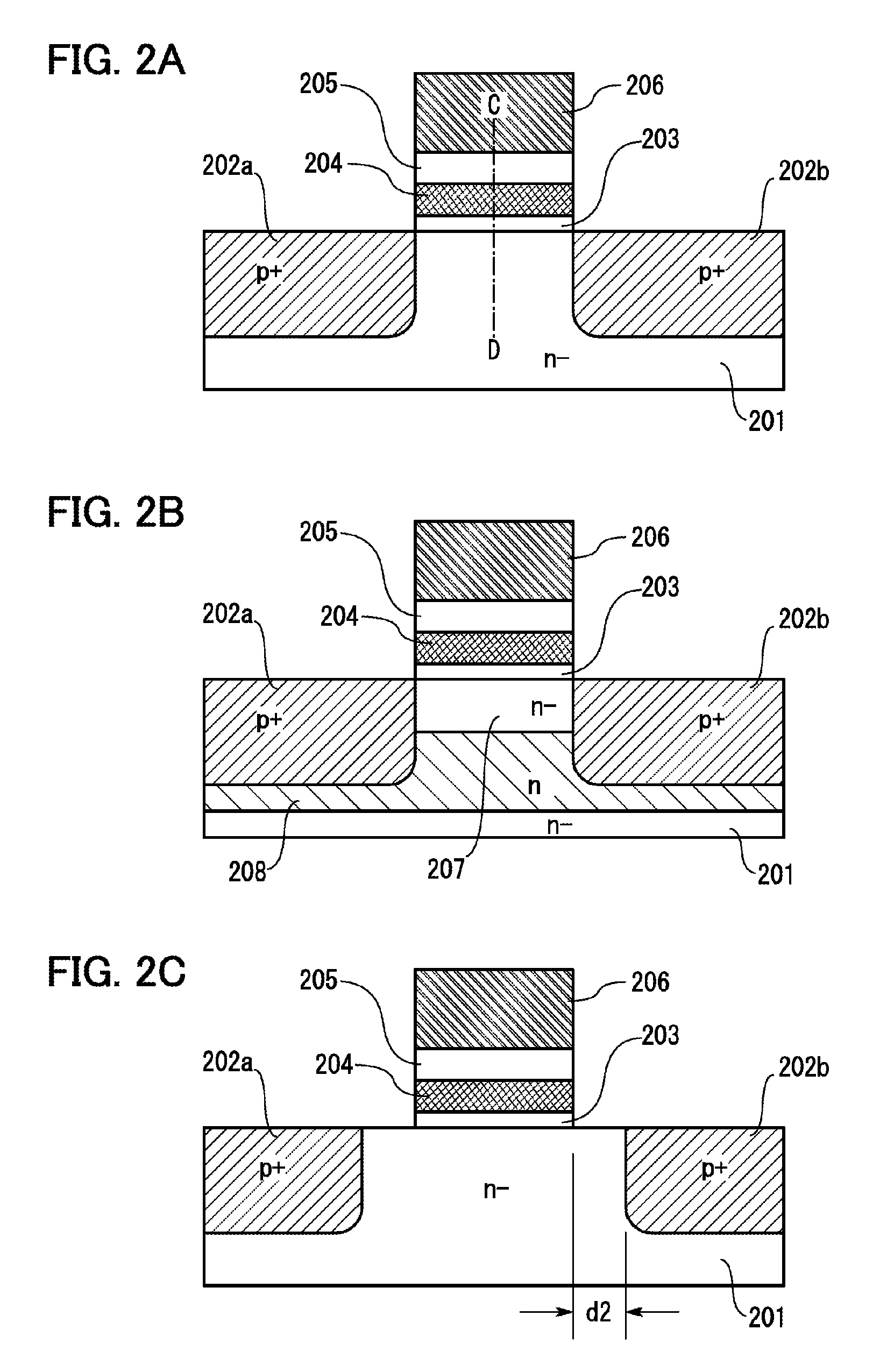

Semiconductor memory device

ActiveUS20120181597A1Small channel lengthLeak of electric chargeTransistorRead-only memoriesZinc nitrideWork function

To provide a semiconductor memory device having a floating gate which operates with a short channel. A high-work-function compound semiconductor having a work function of greater than or equal to 5.5 eV, such as indium nitride or zinc nitride, is used for the floating gate. Accordingly, the potential barrier of the floating gate insulating film between the substrate and the floating gate is higher than that of a conventional one, so that leakage of electric charge due to a tunnel effect can be reduced even if the thickness of the floating gate insulating film is made small. Since the thickness of the floating gate insulating film can be made small, the channel can be further shortened.

Owner:SEMICON ENERGY LAB CO LTD

Method for preparing nitrogen oxygen zinc thin film

ActiveCN103474356AImprove mobilityLow resistivitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingZinc nitrideRadio frequency magnetron sputtering

The invention discloses a method for preparing a nitrogen oxygen zinc thin film. Radio frequency magnetron sputtering is used, a zinc nitride target which is 99.9-99.999% in volume percentage is taken as sputtering target materials, and the distance between the target materials and a substrate is 20-150mm; under certain radio frequency, argon which is 99.9-99.999% in volume percentage is taken as sputtering gas, sputtering is carried out at the substrate temperature of 25-150DEG C and at power density of 0.5-5W / cm2, and the background vacuum of a sputtering room is smaller than 1*10-7torr; pre-sputtering is carried out for a period of time through the argon, and then oxygen which is 99.9-99.999% in volume percentage is taken as reaction gas to obtain the nitrogen zinc oxide thin film with oxygen flow of 0.1-60sccm and argon flow of 5-100sccm and at sputtering pressure of 0.1-10.0Pa, wherein the atomic number of Zn accounts for 51-66%, and N:O=1:3-2:1. The method for preparing the nitrogen zinc oxide thin film solves the problem that the nitrogen is low in solid solubility in zinc oxide, and the prepared n-type nitrogen zinc oxide thin film is high in carrier mobility and low in specific resistance.

Owner:SHENZHEN DANBANG INVESTMENT GROUP

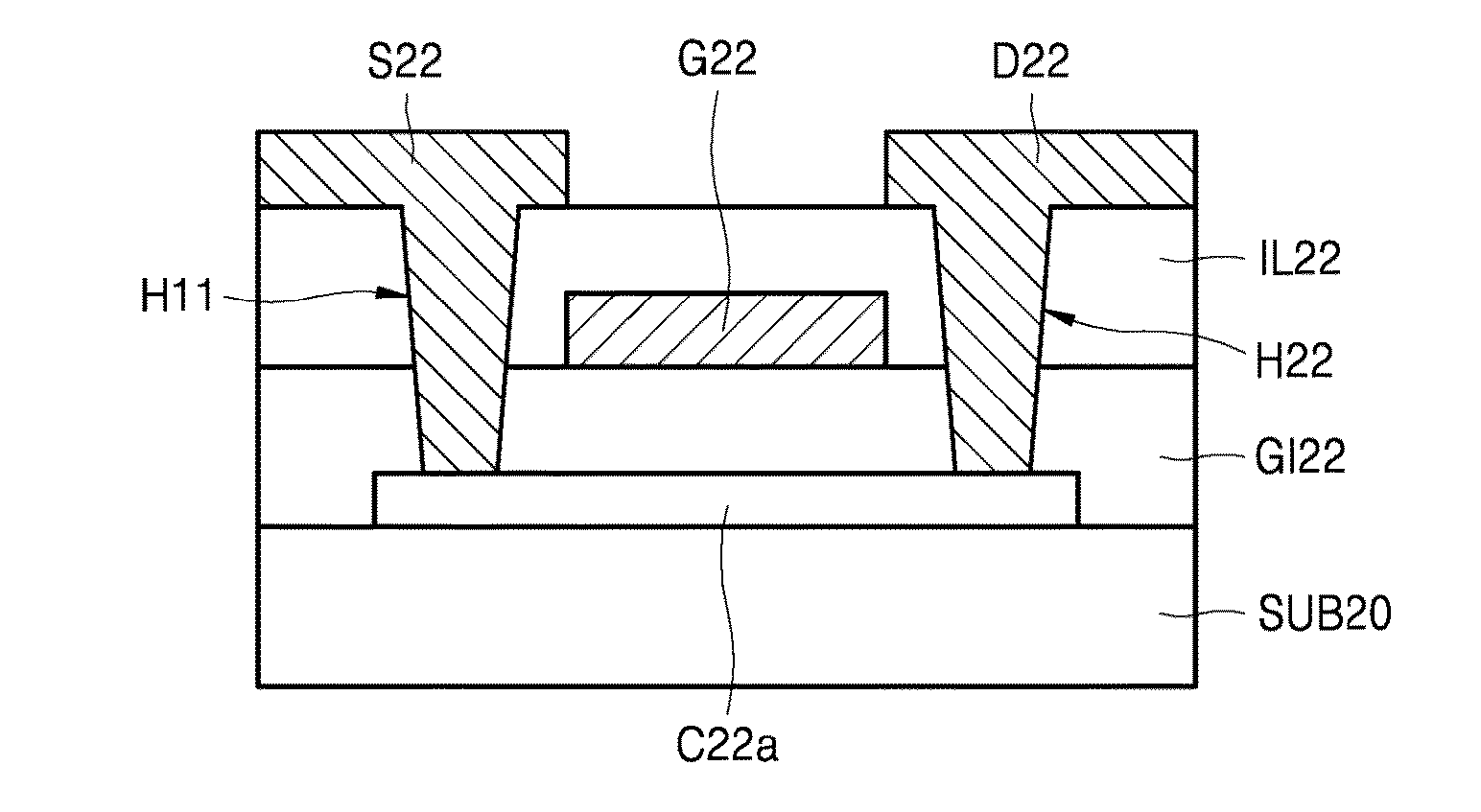

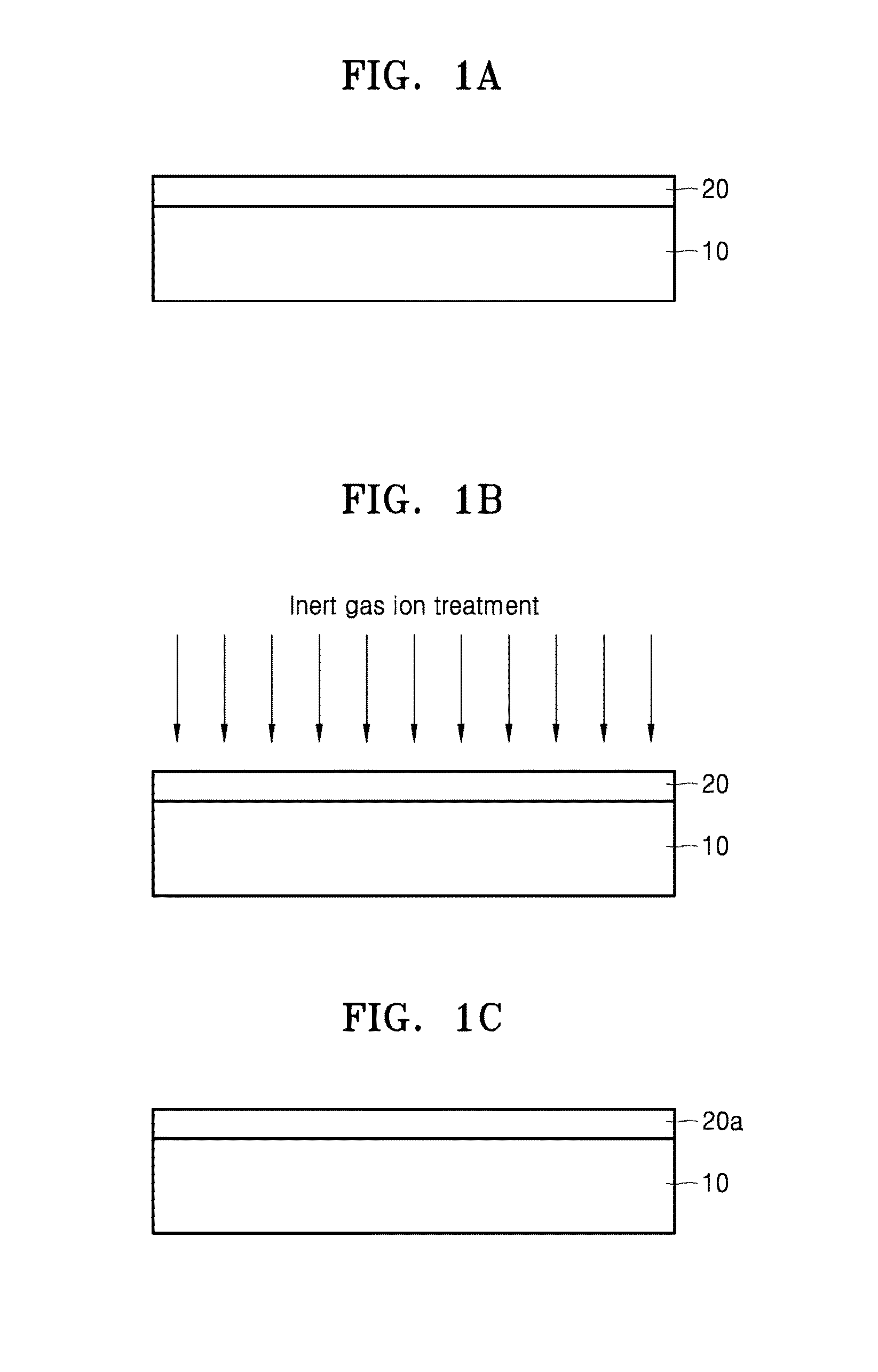

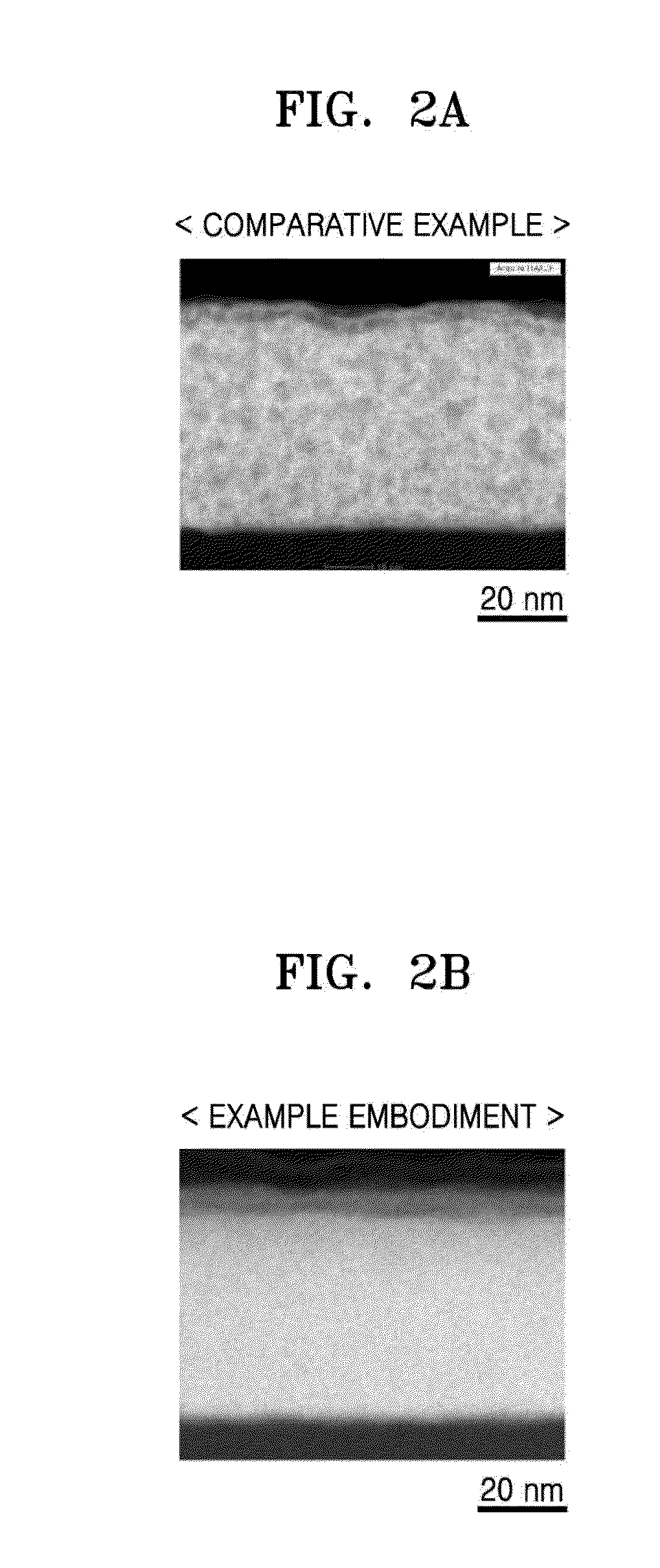

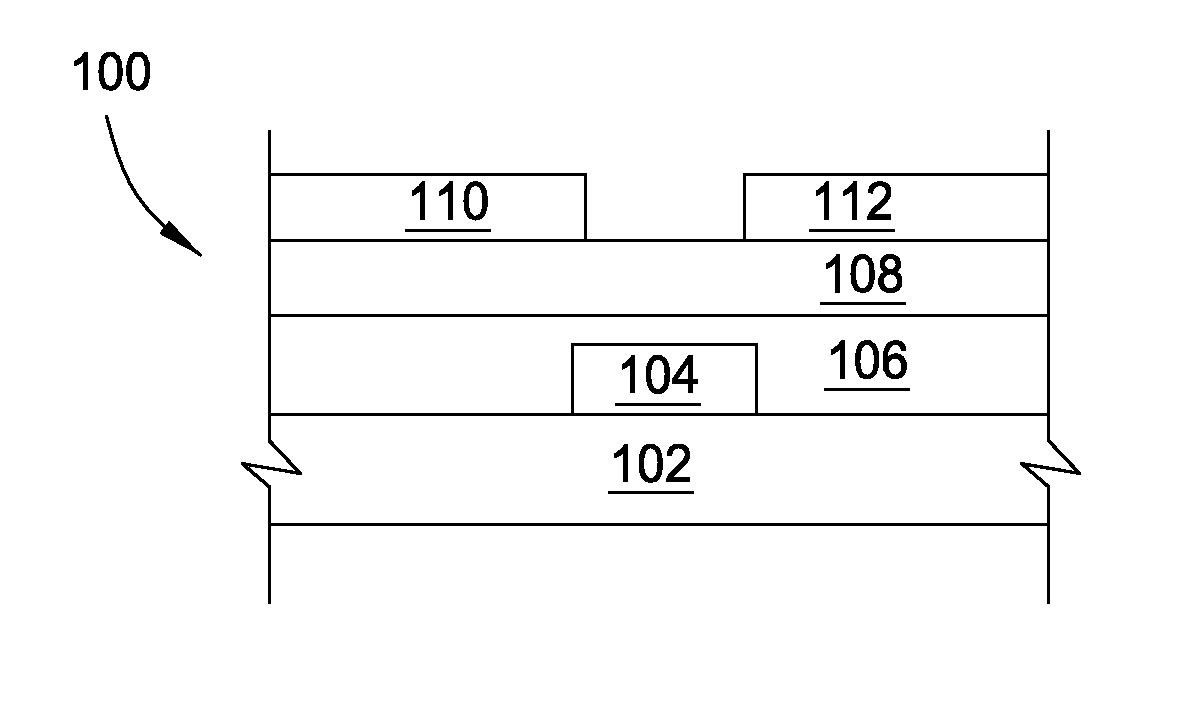

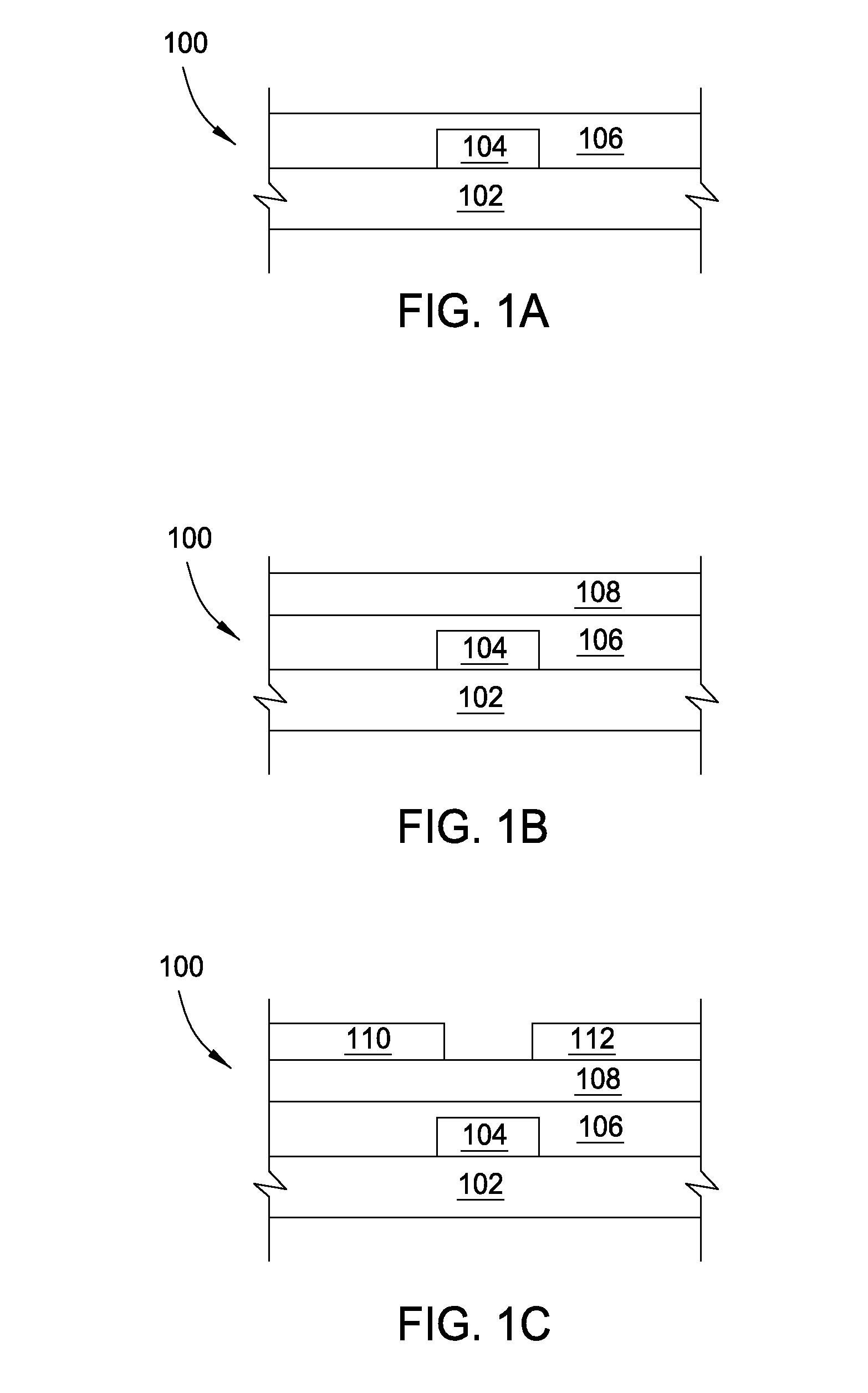

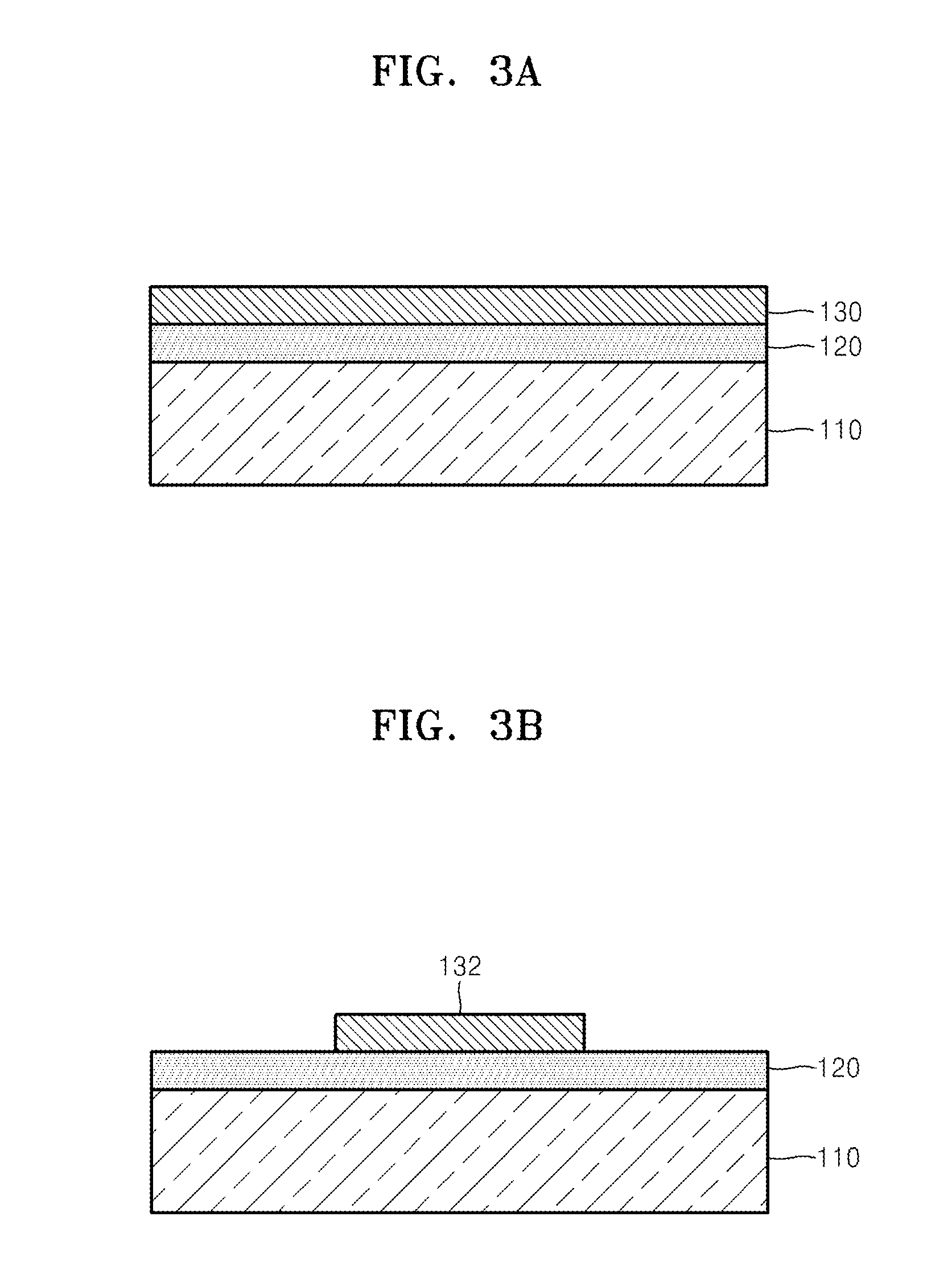

Thin film, method of forming thin film, semiconductor device including thin film, and method of manufacturing semiconductor device

ActiveUS20140225106A1Improve performanceImprove reliabilityTransistorSemiconductor/solid-state device manufacturingDevice materialZinc

A thin film, a method of forming the thin film, a semiconductor device including the thin film, and a method of manufacturing the semiconductor device include forming a thin film including a metal oxynitride, and treating the thin film with inert gas ions so as to stabilize properties of the thin film. The metal oxynitride may include zinc oxynitride (ZnOxNy). The inert gas ions may include at least one of Ar ions and Ne ions. The treating of the thin film with the inert gas ions may be performed by a sputtering process, a plasma treatment process, or the like.

Owner:SAMSUNG ELECTRONICS CO LTD

Thin film semiconductors made through low temperature process

ActiveUS20140363934A1Semiconductor/solid-state device manufacturingSemiconductor devicesZinc nitrideDeposition temperature

Owner:APPLIED MATERIALS INC

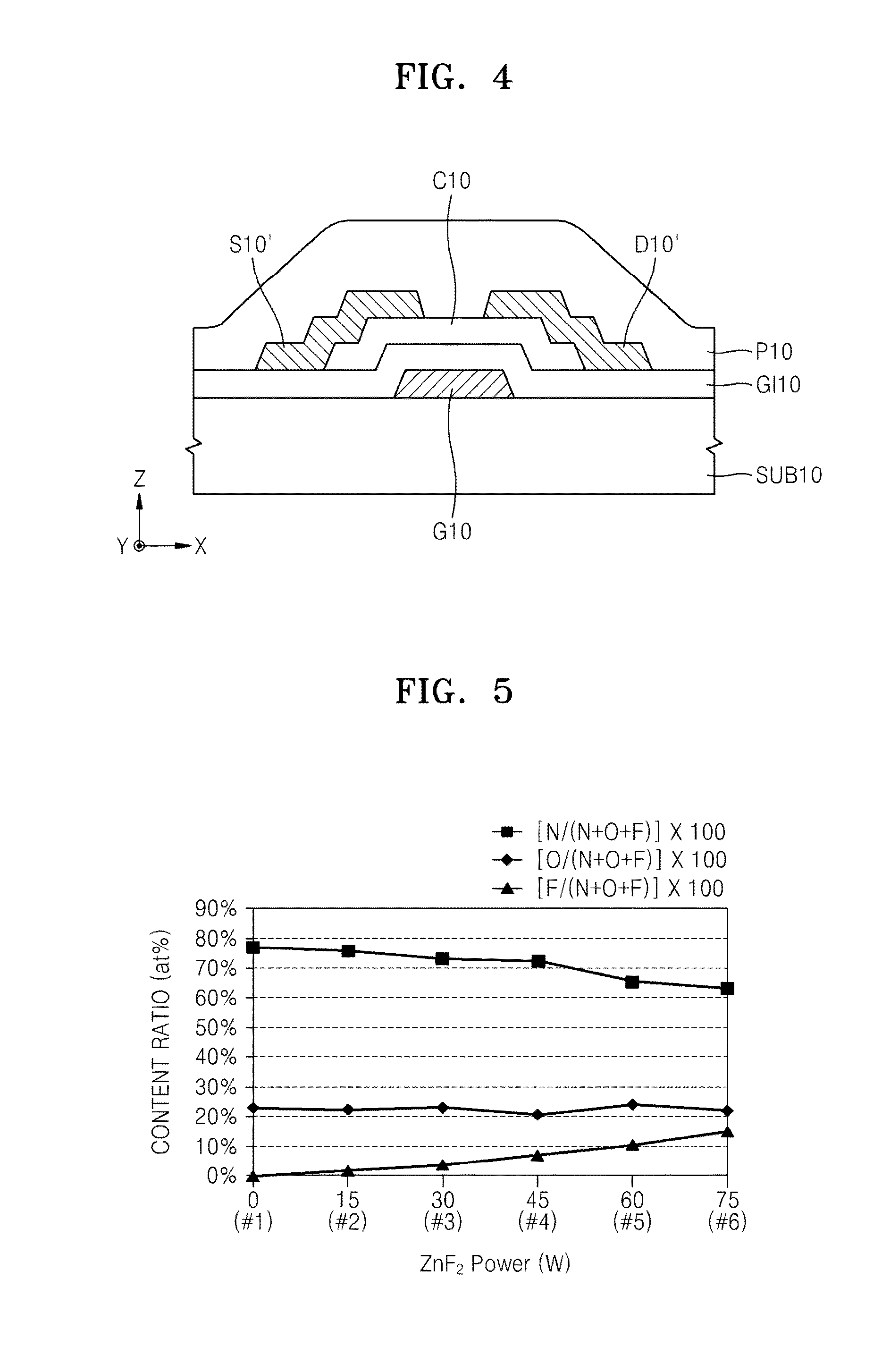

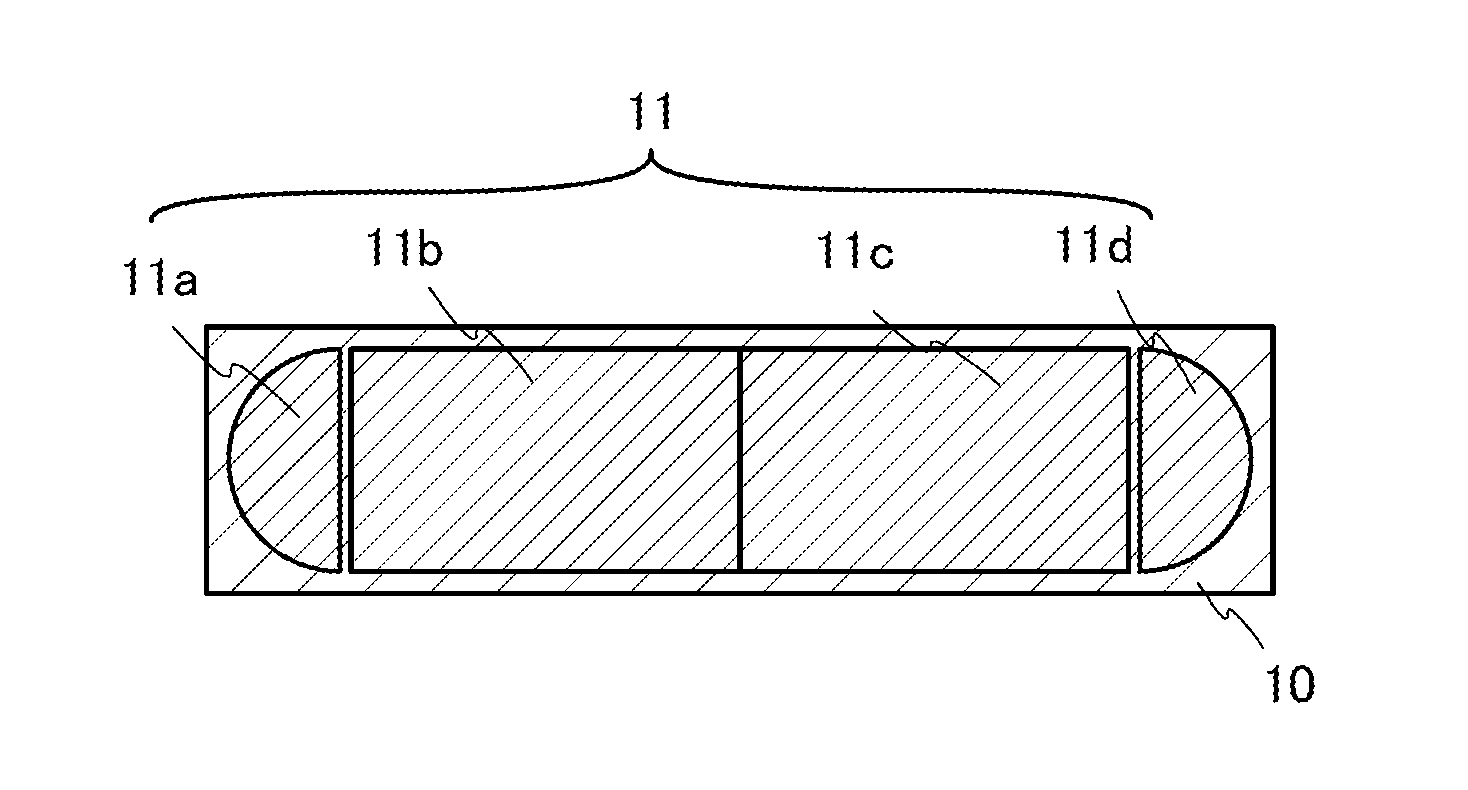

Zinc target including fluorine, method of fabricating zinc nitride thin film by using the same, and method of fabricating thin film transistor by using the same

Provided are fluorine-containing zinc targets, methods of fabricating a zinc oxynitride thin film by using the zinc targets, and methods of fabricating a thin film transistor by using the zinc oxynitride thin film. The methods include mounting a fluorine-containing zinc target and a substrate in a sputtering chamber, supplying nitrogen gas and inert gas into the sputtering chamber, and forming a fluorine-containing zinc oxynitride thin film on the substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

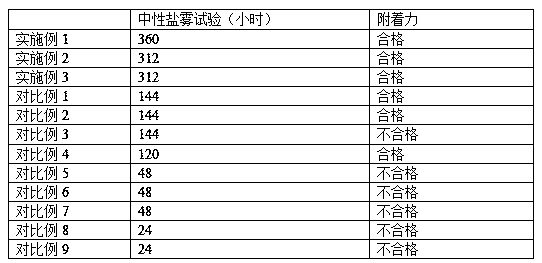

Surface anticorrosion method for neodymium iron boron ferrite

InactiveCN106756859AImprove corrosion resistanceWon't fall offVacuum evaporation coatingSputtering coatingZinc nitrideMetallurgy

Owner:俞虹

Method for preparing zinc nitride film

InactiveCN101463469AImprove transmittanceImprove mobilityVacuum evaporation coatingSputtering coatingZinc nitrideNitrogen gas

The invention relates to a method for preparing a zinc nitride film, which is characterized in that the mixed gas of nitrogen and argon is pumped into a sputtering combination plant when sputtering zinc, and stabler zinc nitride is prepared on a quartz substrate. The method comprises the steps: first, the quartz substrate is cleaned by alcohol, acetone and deionized water in ultrasonic wave, a zinc target is put into a magnetron sputtering chamber, and the quartz substrate is also placed in the sputtering chamber; the sputtering chamber is vacuumized below the high vacuum until the background vacuum is 10<-4>-10<-5>Pa; a flowmeter is turned on, the air in the gas circuit is firstly pumped, and nitrogen is started to be filled when the flow rate is reduced to be zero; when the flow rate is 60-80sccm, the gas is continuously pumped in the process; when being heated to 200 DEG C, the pressure intensity of the sputtering chamber is slightly increased, and then build-up of luminance is carried out; the reaction starts after half hour of pre-sputtering, and the reaction lasts for about two hours; when the reaction stops and the temperature of the sputtering chamber reduces to about 50 DEG C, the machine can be stopped, and the substrate is taken out. The film obtained by the method has low electric resistivity, high migration rate and transmittance, good stability, etc.

Owner:闫金承

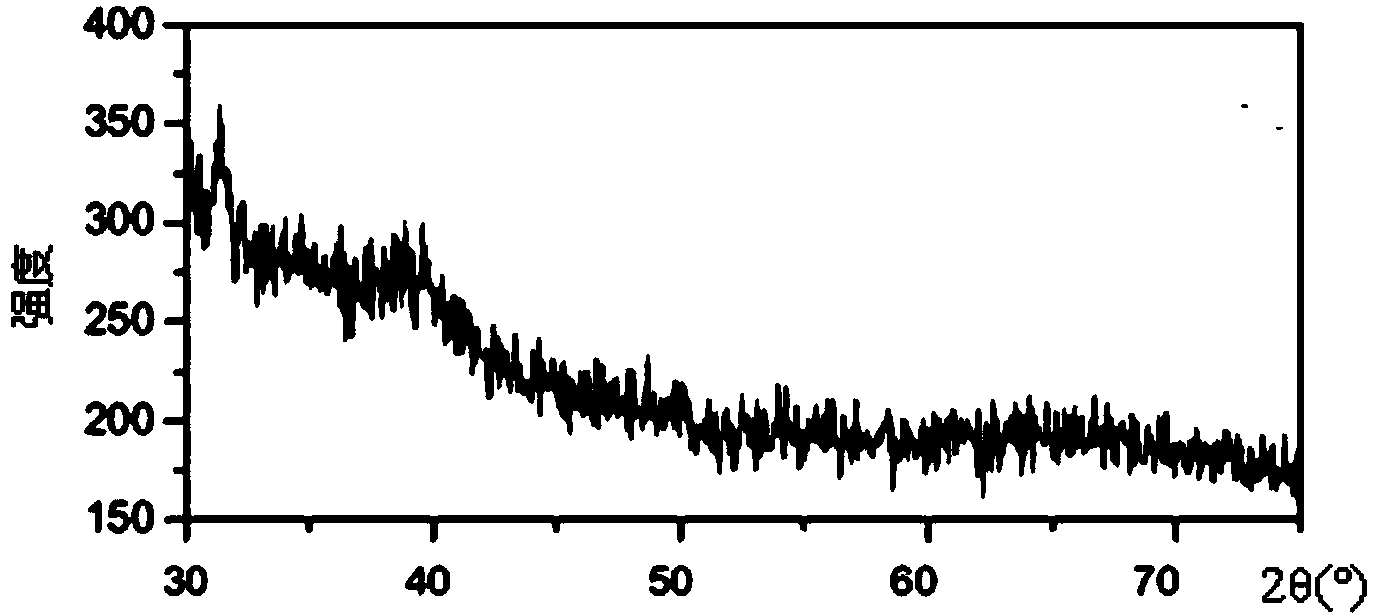

Preparation method of polycrystalline zinc nitride film

InactiveCN102392215AGood effectLow costVacuum evaporation coatingSputtering coatingZinc nitrideRadio frequency magnetron sputtering

The invention discloses a preparation method of a polycrystalline zinc nitride film, belonging to the technical field of electronic materials, characterized in that: a polycrystalline Zn3N2 film is prepared at room temperature by reactive radio-frequency magnetron sputtering on a quartz substrate, the sputtering target is a pure metal Zn target, the distance between the sputtering target and the substrate is 50-80 mm, the basic vacuum of a sputtering chamber is less than 1.0*10<-3> Pa, the sputtering gas is argon, the reactive gas is ammonia, the flow range of the ammonia is 1-5 sccm, the flow range of the argon is 15-19 sccm, and the total flow of the argon and the ammonia is 20 sccm; the pressure intensity of the argon-ammonia mixed gas in the sputtering chamber is 0.5-2.5 Pa, the radio-frequency sputtering power is 30-200 w, and the temperature of the substrate is room temperature. The invention has the advantages of low cost, convenient preparation of target material, recycle target material, and no need of heating the substrate, and the prepared polycrystalline zinc nitride film has large optical band gap.

Owner:LUDONG UNIVERSITY

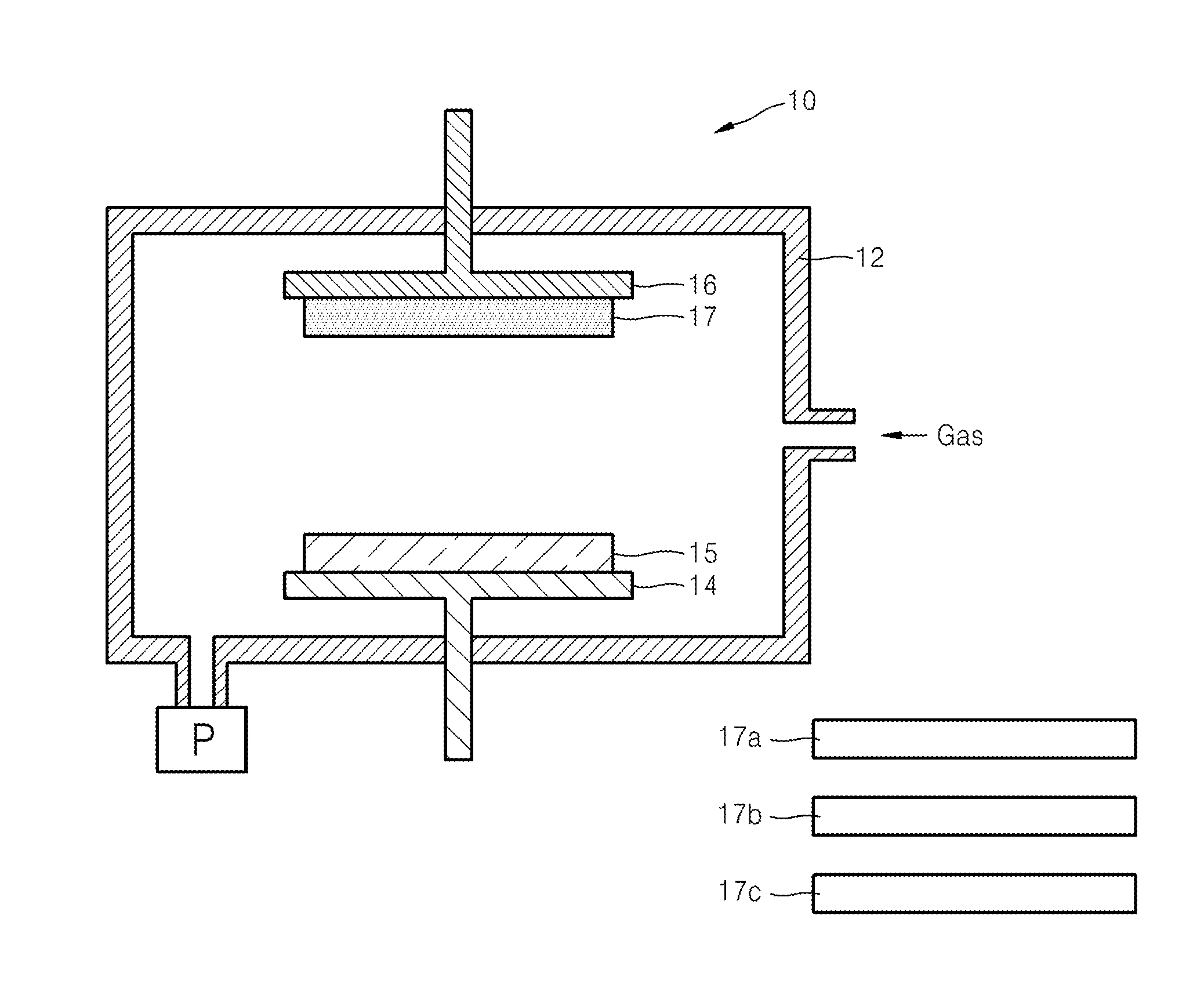

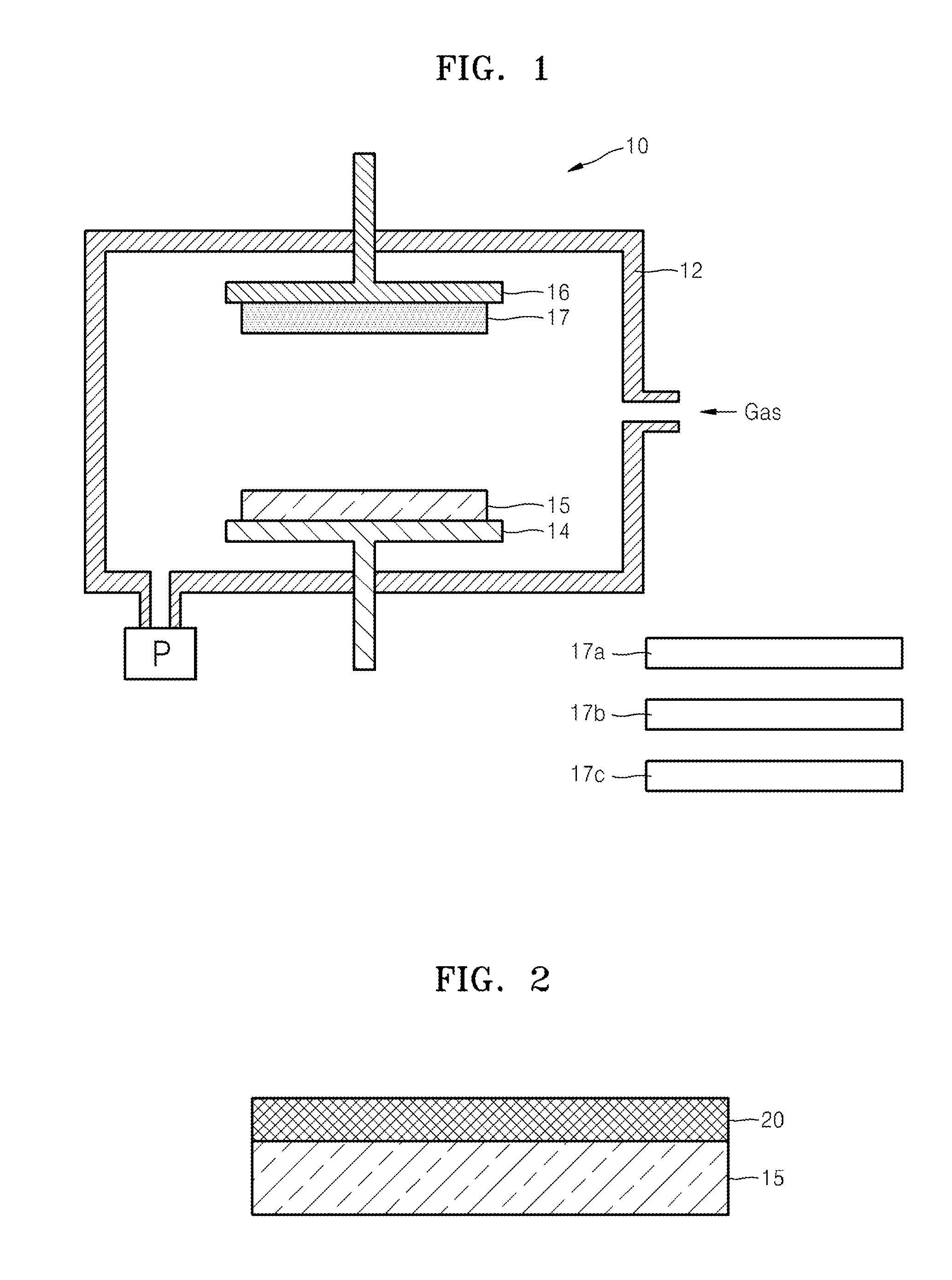

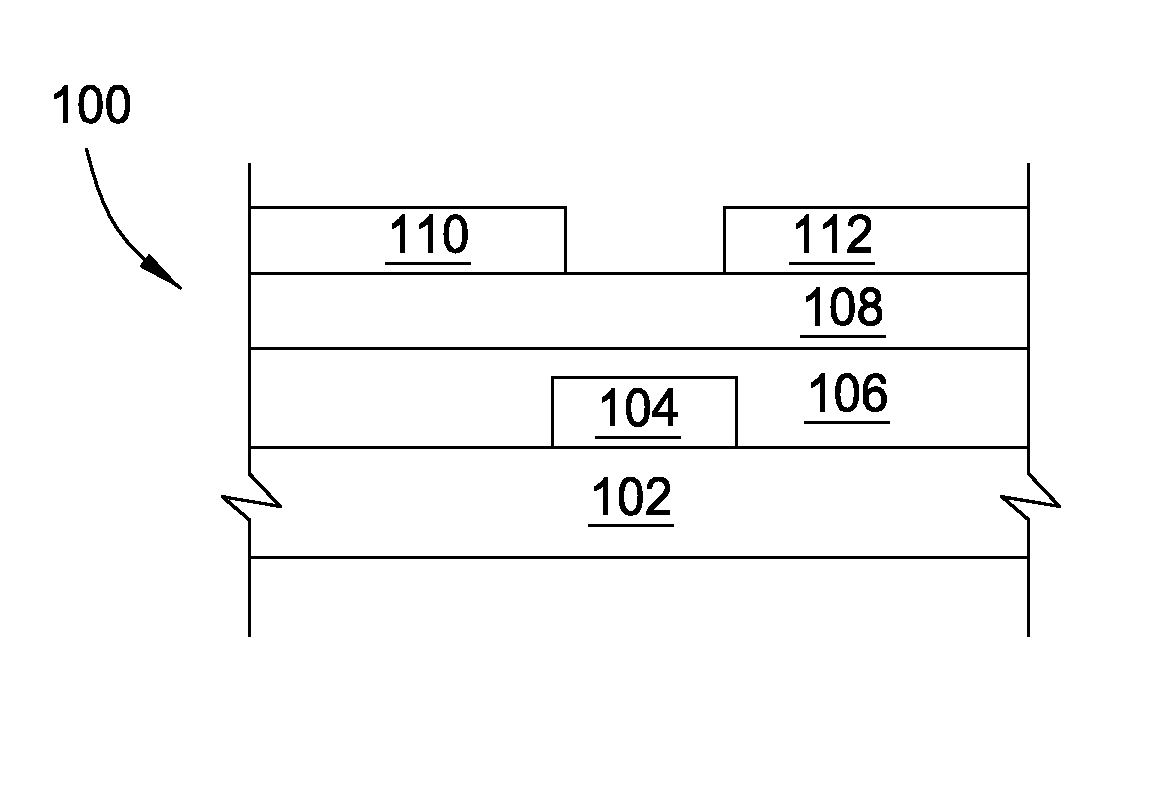

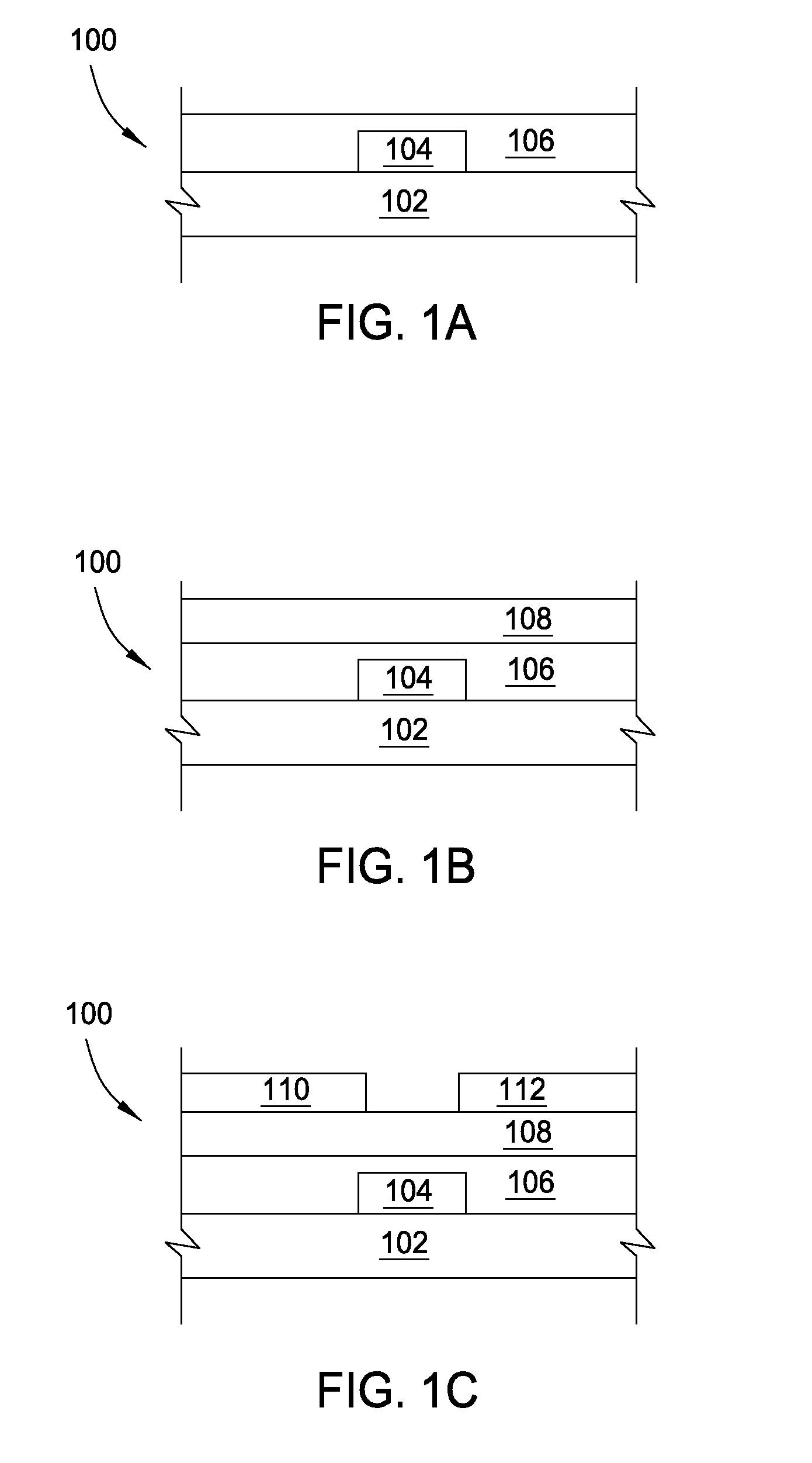

Thin film semiconductors made through low temperature process

ActiveUS9396940B2TransistorSemiconductor/solid-state device manufacturingZinc nitrideDeposition temperature

Embodiments disclosed herein relate to a TFT and methods for manufacture thereof. Specifically, the embodiments herein relate to methods for forming a semiconductor layer at a low temperature for use in a TFT. The semiconductor layer may be formed by depositing a nitride or oxynitride layer, such as zinc nitride or oxynitride, and then converting the nitride layer into an oxynitride layer with a different oxygen content. The oxynitride layer is formed by exposing the deposited nitride layer to a wet atmosphere at a temperature between about 85 degrees Celsius and about 150 degrees Celsius. The exposure temperature is lower than the typical deposition temperature used for forming the oxynitride layer directly or annealing, which may be performed at temperatures of about 400 degrees Celsius.

Owner:APPLIED MATERIALS INC

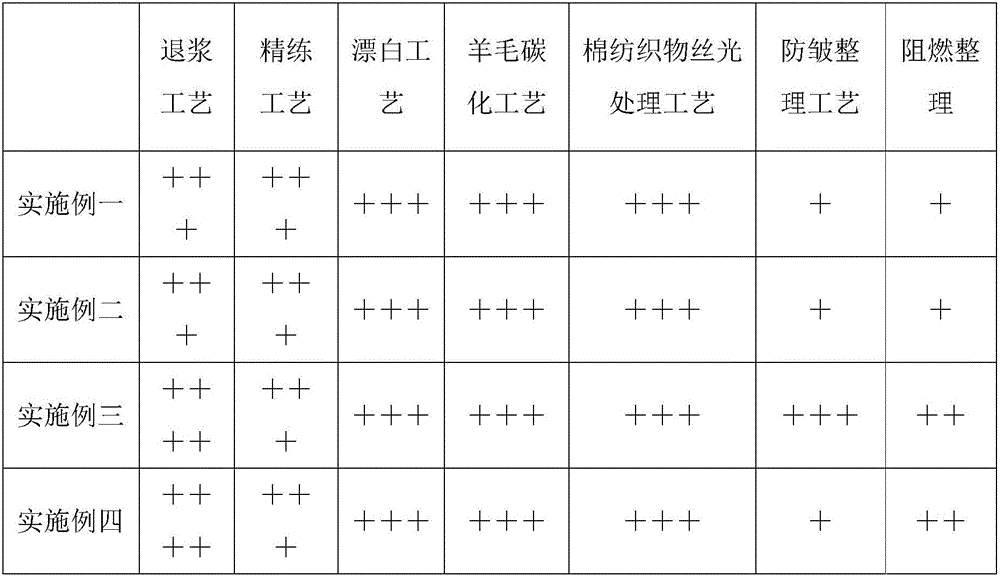

Wetting agent as well as preparation method and application of wetting agent

InactiveCN106758196AImprove permeabilityGood penetration performanceHeat resistant fibresDry-cleaning apparatus for textilesZinc nitridePolyethylene glycol

The invention belongs to the technical field of textile auxiliary agents and discloses a wetting agent as well as a preparation method and application of the wetting agent. The wetting agent is prepared from the following components in parts by weight: 1 to 1.2 parts of trans-4-[(2-amino-3,5-dibromobenzyl)amino]cyclohexanol, 3 to 5 parts of citric acid triamine, 0.1 to 0.5 part of methyl orange, 12 to 14 parts of sodium sulfate, 0.5 to 0.7 part of zinc nitride, 3 to 4 parts of sodium dimethylbenzenesulfonate, 0.6 to 0.9 part of methylisothiazolinone, 100 to 120 parts of polyethylene glycol and 300 to 350 parts of de-ionized water. The invention also discloses the preparation method of the wetting agent. The wetting agent disclosed by the invention can be widely applied to a plurality of processes of sizing, bleaching, desizing, refining, dyeing, after-finishing textiles and the like, can be used for mercerization treatment on pure cotton textiles and carbonization treatment on wool textiles, and has a wide application prospect.

Owner:FOSHAN XUNTUOAO TECH CO LTD

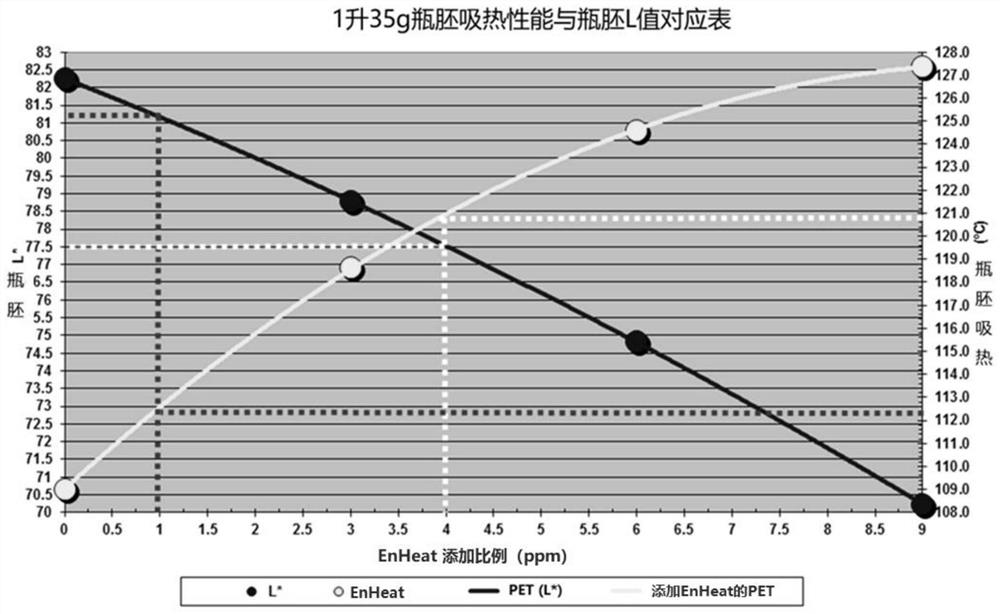

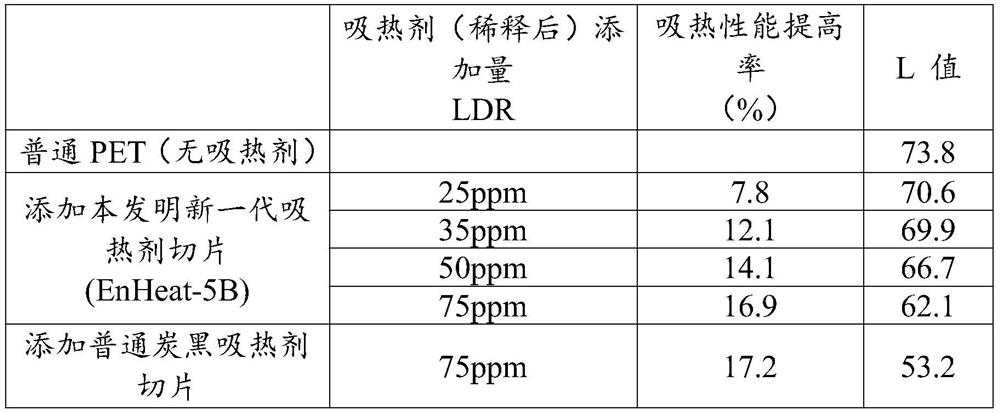

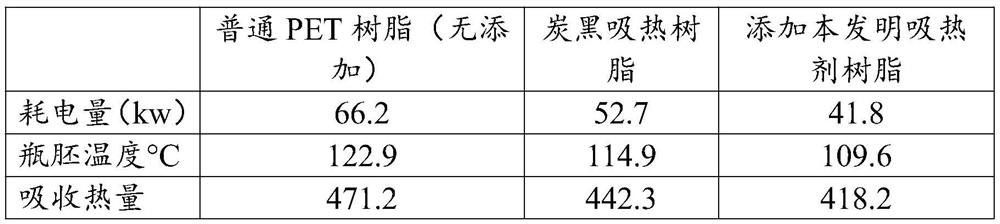

Assistant for improving heat absorption performance of PET polyester chip and production method of PET bottle

The invention provides an assistant for improving the heat absorption performance of a PET polyester chip and a production method of a PET bottle. According to the assistant for improving the heat absorption performance of the PET polyester chip and the production method of the PET bottle, titanium nitride or zinc nitride is added into the assistant to form a mixed assistant, so the heat absorption performance of the PET polyester chip is more uniform; in addition, the color of titanium nitride / zinc nitride is more close to light blue compared with a traditional carbon black heat absorber, so compared with a traditional carbon black heat absorption additive chip, the chip of the invention has the advantages of higher L value, lower b value, higher transparency and higher degree of fineness; and comprehensive cost is lower, and 30%-50% of raw material cost is saved for manufacturers.

Owner:上海翰晖新材料有限公司

Anticorrosive coating for LED lamps

InactiveCN108285704AGood weather resistanceGood acid and alkali resistanceAnti-corrosive paintsZinc nitrideGas phase

The invention discloses anticorrosive coating for LED lamps. The anticorrosive coating comprises the following raw materials in parts by mass: 20-30 parts of waterborne acrylic resin, 10-20 parts of fluorosiloxane, 5-15 parts of zinc nitride, 1-2.5 parts of glass fiber, 5-12 parts of kaolin, 10-15 parts of far infrared ceramic nanoparticles, 1-5 parts of gaseous titanium dioxide, 10-30 parts of asolvent, 0.5-1.5 parts of a wetting and dispersing agent, 2-3 parts of an MOK-2015 leveling agent and 15-25 parts of a curing agent, wherein the solvent is a mixture of glycerol, coconut oil and ethylformate; the wetting and dispersing agent is the MOK-2030 dispersing agent; the curing agent is a waterborne isocyanate curing agent; the glass fiber is sodium calcium glass fiber with the particle size of 50-150 nm; and the sizes of the far infrared ceramic nanoparticles are 100-150 nm. Coating formed by the anticorrosive coating has excellent mechanical properties and a protective function, andalso has good waterproof and anticorrosive characteristics while radiating temperature reduction is achieved; and the anticorrosive coating is simple and convenient in production process and convenient to use.

Owner:FOSHAN YINNUOWEI BIOTECH CO LTD

Semiconductor memory device with floating gate

ActiveUS8575678B2Improve performanceConsumes less powerTransistorRead-only memoriesZinc nitrideWork function

To provide a semiconductor memory device having a floating gate which operates with a short channel. A high-work-function compound semiconductor having a work function of greater than or equal to 5.5 eV, such as indium nitride or zinc nitride, is used for the floating gate. Accordingly, the potential barrier of the floating gate insulating film between the substrate and the floating gate is higher than that of a conventional one, so that leakage of electric charge due to a tunnel effect can be reduced even if the thickness of the floating gate insulating film is made small. Since the thickness of the floating gate insulating film can be made small, the channel can be further shortened.

Owner:SEMICON ENERGY LAB CO LTD

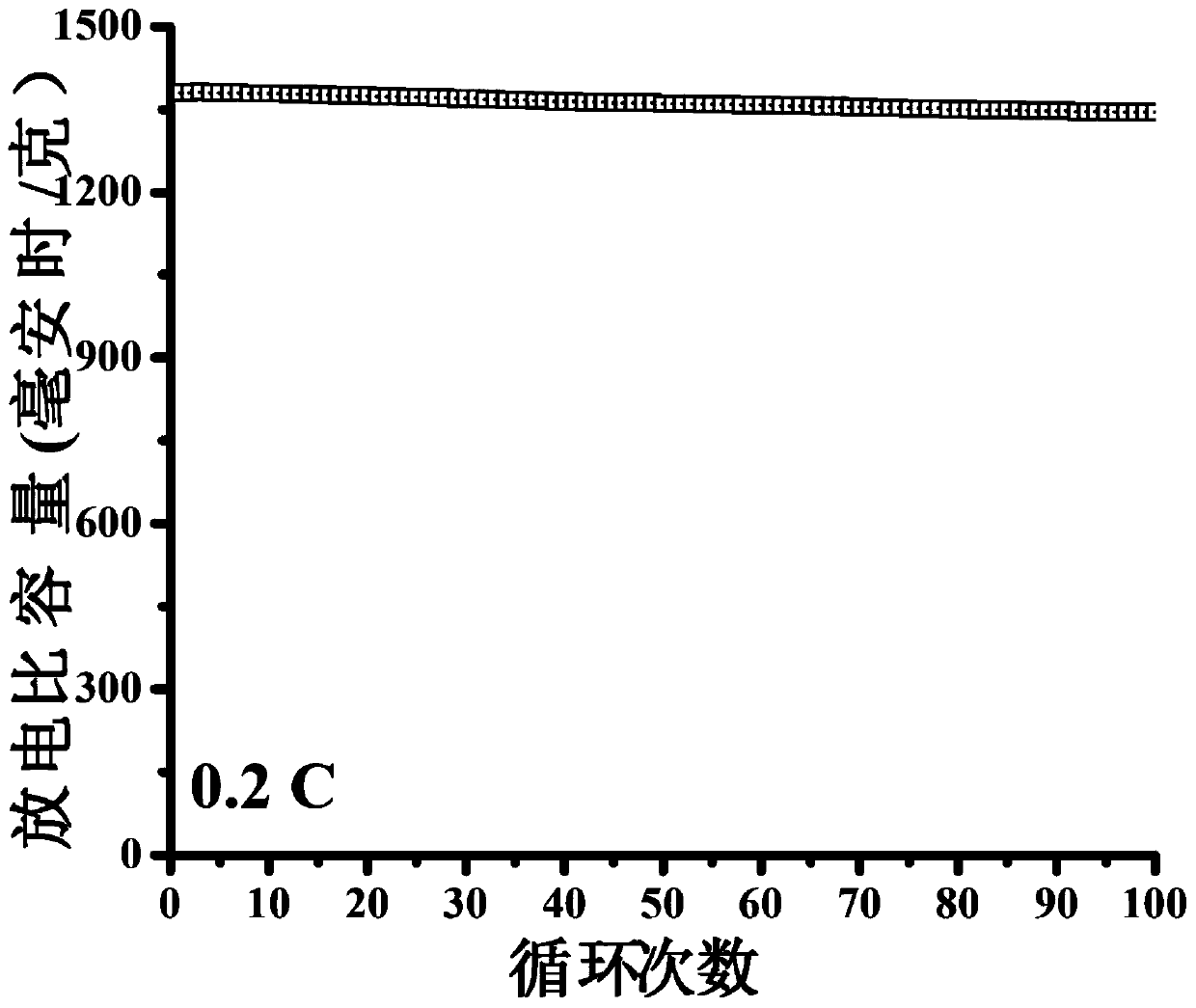

Preparation method of functional interlayer of lithium-sulfur battery

ActiveCN111341973ALarge specific surface areaEffective chemisorptionLi-accumulatorsCell component detailsZinc nitrideLithium–sulfur battery

The invention relates to a preparation method of a functional interlayer of a lithium-sulfur battery. The method comprises the following steps: firstly, preparing MXene, growing a layer of zinc oxidefilm on the surface of the MXene, and then coating the surface of the zinc oxide film with a layer of zinc nitride as a functional interlayer coating material of the lithium-sulfur battery. Accordingto the method, the shuttle effect of polysulfide in the lithium-sulfur battery prepared in the prior art is effectively relieved, the utilization rate of active substances in the positive electrode material is increased, and the problem that the cycle performance of the lithium-sulfur battery is unstable is solved.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

Method for preparing acceptor zinc oxide film material by using thermal-oxidative zinc nitride

InactiveCN1153304CSimple methodExperimental conditions are easy to controlSemiconductor/solid-state device manufacturingSemiconductor devicesZinc nitrideSingle crystal

This invention relates to a preparation method of film materials of acceptor Zn oxide obtaining P-type Zn oxide material by high temperature thermal-oxidating Zn nitride single crystal film to control the acceptor impurity concentration of type-P Zn oxide material by controlling oxidation temperature and thermal-oxidative time. Nitride in cubic antiferro Mn ore is easy to be substituted by oxygen under high temperature and form hexagonal P-type Zn oxide, realizing nitride doped substitution to from P-type Zn oxide and process its film materials with the accepter concentration of 6X10 to the power 16 - 4X10 to the power 18 cm to the power -3 and hexagonal P-type Zn oxide film material, realizing control of Zn oxide electricity performance and carrier concentration which Satifies the needs of preparing P-N material of Zn oxide and photo electronic apparatus.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Preparation method of biomass quick burning bricks and device

The invention discloses a preparation method and device for biomass fast-burning bricks. The preparation method is to add sodium bicarbonate, potassium permanganate, zeolite powder, sodium silicate and fatty alcohol polyoxygen after drying the biomass to remove impurities. Sodium vinyl ether sulphate, mixed evenly, the intermediate product is obtained through two heating reactions, then add water, zinc nitrate, calcium oxide, bentonite, epoxy resin, gum arabic and xanthan gum, mix evenly, heat up and extrude , to obtain biomass fast-burning bricks. The device provided by the invention comprises a drying unit, a mixing unit, a reaction unit, a pulverizing unit and an extruding unit connected in sequence, and the connection between the units is through a conveyor belt. The biomass quick-combustible brick obtained by the preparation method provided by the invention is easy to ignite when used, has a fast burning speed and is fully burned, and does not emit dust and other pollutants to the surroundings. The preparation process of the device provided by the invention can be fully automated and controlled, and the preparation efficiency is high.

Owner:江苏恒茂再生能源有限公司

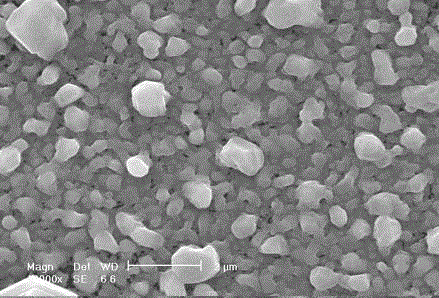

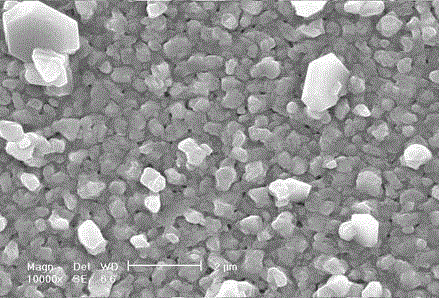

Preparation of high-purity zinc nitride powder material

PendingCN112794294ALow purityHigh purityNitrogen-metal/silicon/boron binary compoundsZinc nitrideZinc

The invention provides preparation of a high-purity zinc nitride powder material, and relates to the field of zinc nitride. The preparation method of the high-purity zinc nitride powder material comprises the following steps: preparing 5N high-purity zinc, obtaining high-purity zinc particles, drying the high-purity zinc particles, preparing Zn3N2 and sieving the Zn3N2. According to the present invention, the high-purity zinc nitride is obtained by obtaining the high-purity zinc and the high-purity zinc particles, introducing the high-purity ammonia gas and well controlling the flow of the high-purity ammonia gas through finding the suitable technical conditions, and the traditional method is to obtain the zinc nitride through the precipitation of a large amount of chemical materials, but the process is complex, and the purity is difficult to ensure.

Owner:段文轩

A metal surface treatment passivation solution

ActiveCN108546942BAccelerated corrosionImprove adhesionMetallic material coating processesZinc nitrideMesoporous material

The invention relates to a metal surface treatment passivation liquid which comprises 1-20g / L zinc nitride, 5-40g / L inorganic acid, a 5-50g / L dispersant and a 1-10g / L modified mesoporous nano material. The modified mesoporous nano material is a polybasic acid grafted mesoporous nano material, and the percent grafting of polybasic acid is 1-5wt%. A film with extremely good corrosion resistance andadhesive force is obtained on the metal surface treated by the passivation liquid.

Owner:湖州富美材料科技有限公司

Corrosion-resistant metal ceramic material and preparation method thereof

InactiveCN106756387AImprove corrosion resistanceShorten the production cycleZinc nitrideMethacrylate

The invention discloses a corrosion-resistant metal ceramic material and a preparation method thereof. The corrosion-resistant metal ceramic material comprises, by weight, 18-25 parts of copper oxide, 15-20 parts of silicon dioxide, 10-20 parts of graphite, 10-15 parts of zinc nitride, 5-10 parts of nickel, 5-10 parts of molybdenum oxide, 5-10 parts of teflon, 3-5 parts of sodium tripolyphosphate and 0.1-1 part of tributyl tin methacrylate. The corrosion-resistant metal ceramic material has strong corrosion resistance, raw materials are easy to obtain, and the cost of the raw materials is low; the production process is simple, and the production cost is reduced; and in addition, the corrosion-resistant metal ceramic material has the advantages of being short in production cycle and good in high temperature resistance.

Owner:HENAN SHUIJINGTOU CULTURAL MEDIA CO LTD

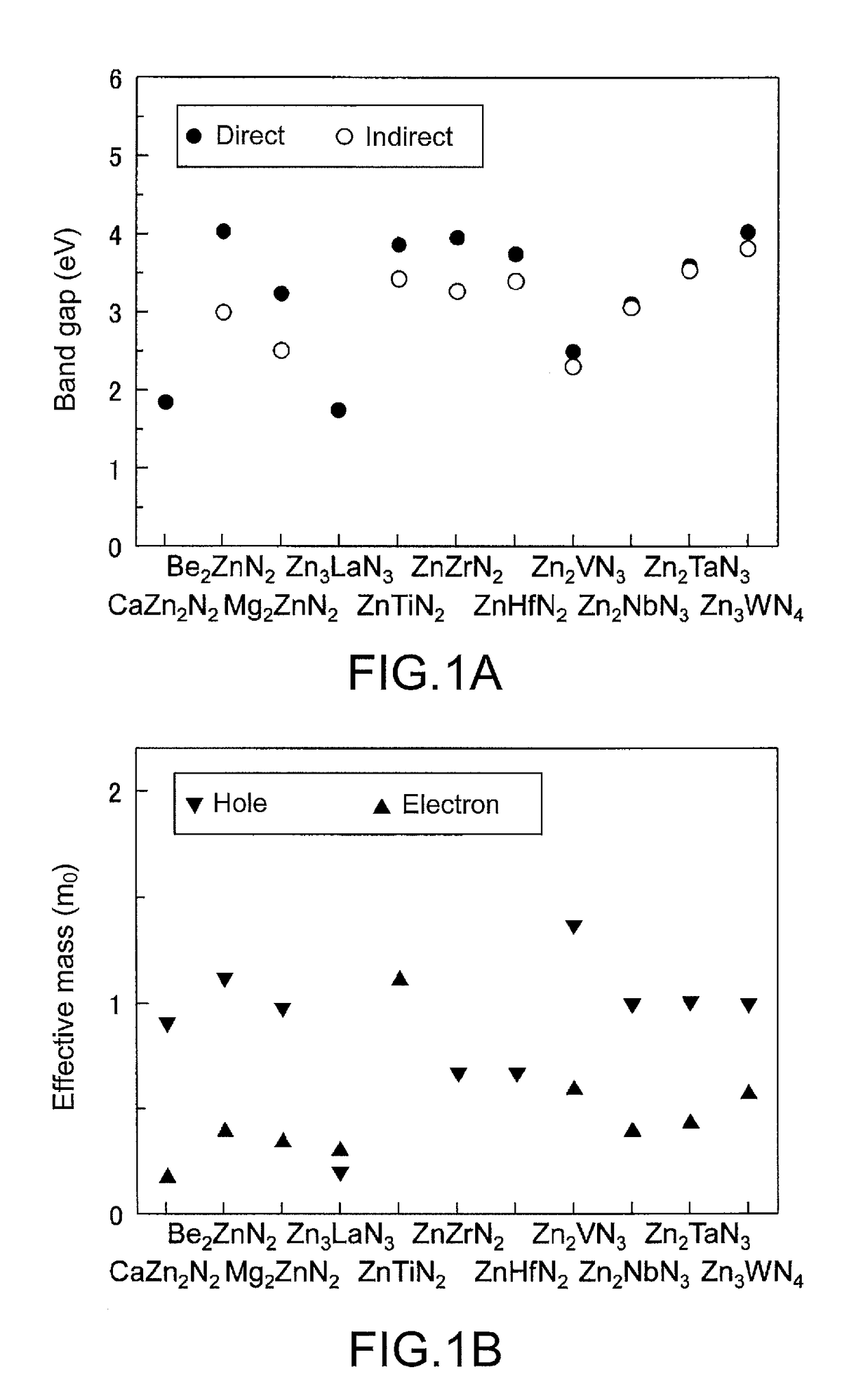

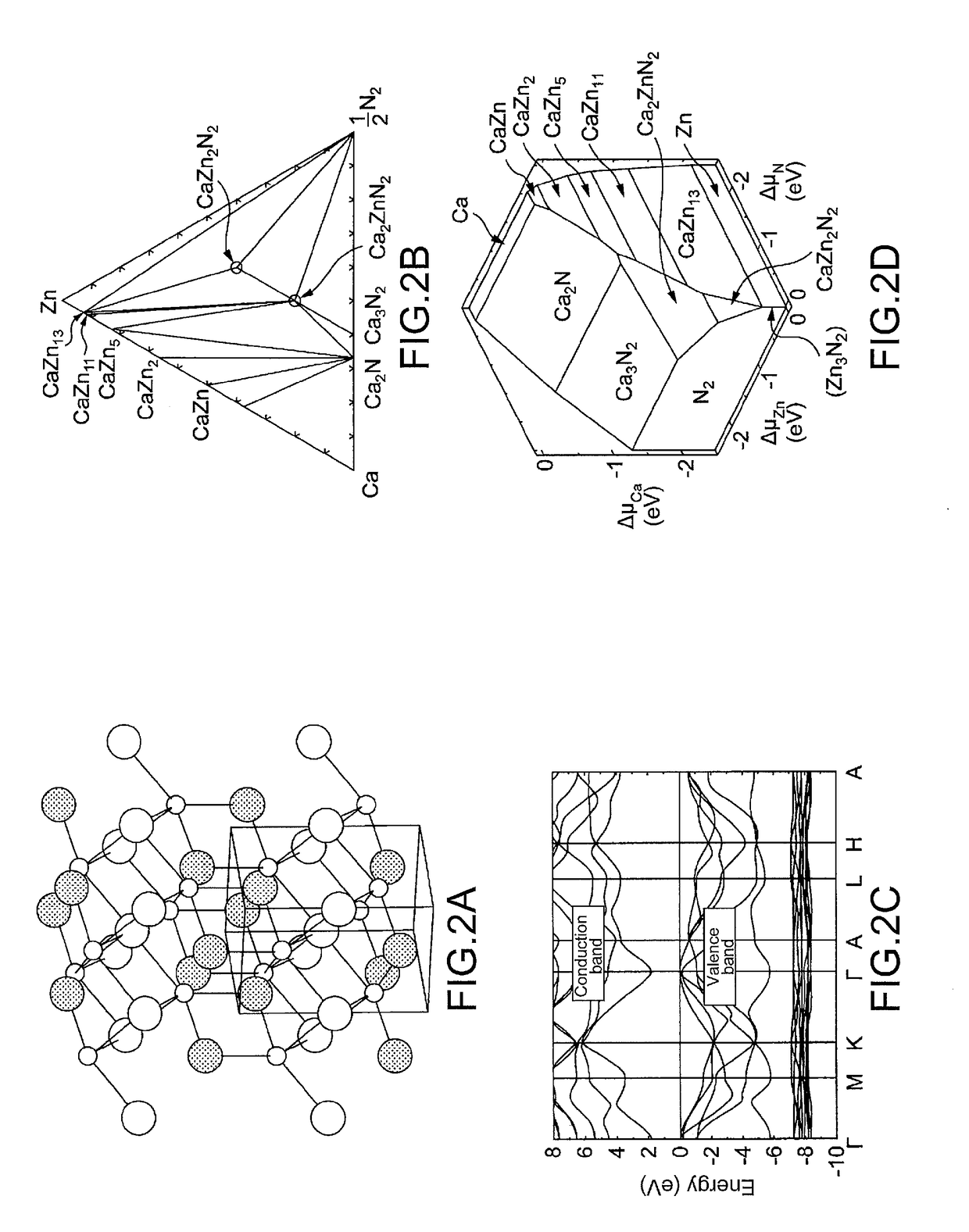

Zinc nitride compound and method for producing same

ActiveUS20180354791A1Final product manufactureNitrogen-metal/silicon/boron binary compoundsZinc nitrideSolar cell

The present invention provides a zinc nitride compound suitable for electronic devices such as high-speed transistors, high-efficiency visible light-emitting devices, high-efficiency solar cells, and high-sensitivity visible light sensors. The zinc nitride compound is represented, for example, by the chemical formula CaZn2N2 or the chemical formula X12ZnN2 wherein X1 is Be or Mg. The zinc nitride compound is preferably synthesized at a high pressure of 1 GPa or more.

Owner:PANASONIC CORP

Casting method capable of preventing deformation of complex motor case

InactiveCN107470560AAvoid local sinking problemsExtend curing timeFoundry mouldsFoundry coresZinc nitrideSlag

The invention belongs to the technical field of complex motor cases, in particular to a casting method capable of preventing deformation of a complex motor case. The casting method capable of preventing deformation of the complex motor case comprises processes of melt processing, re-casting and step-by-step cooling of motor case materials. Compared with the prior art, the casting method capable of preventing deformation of the complex motor case has the following advantages that chromium carbide, zinc nitride and sulfur powder are added in the high temperature nitrogen protection atmosphere so that air entrapment can be avoided during melt casting, and excessive gas volume is avoided, the sand-type curing time can be prolonged, sand dropping or sand crushing in the casting process is avoided, and after columnar mold stripping, cooling is conducted first, then heating is conducted, the cooling speed is controlled, so that the problem of local shrinkage of the complex motor case can be avoided, the finish degree of the surface of a formed part is improved, and defects of blowholes, slag holes and sand holes are prevented; the product yield reaches 97%, wherein the problems of blowholes, sand holes and shrinkage accounts for about 25% of the scrap rate, and deformation of the complex motor case can be reduced effectively.

Owner:安徽省含山县潮林铸管厂(普通合伙)

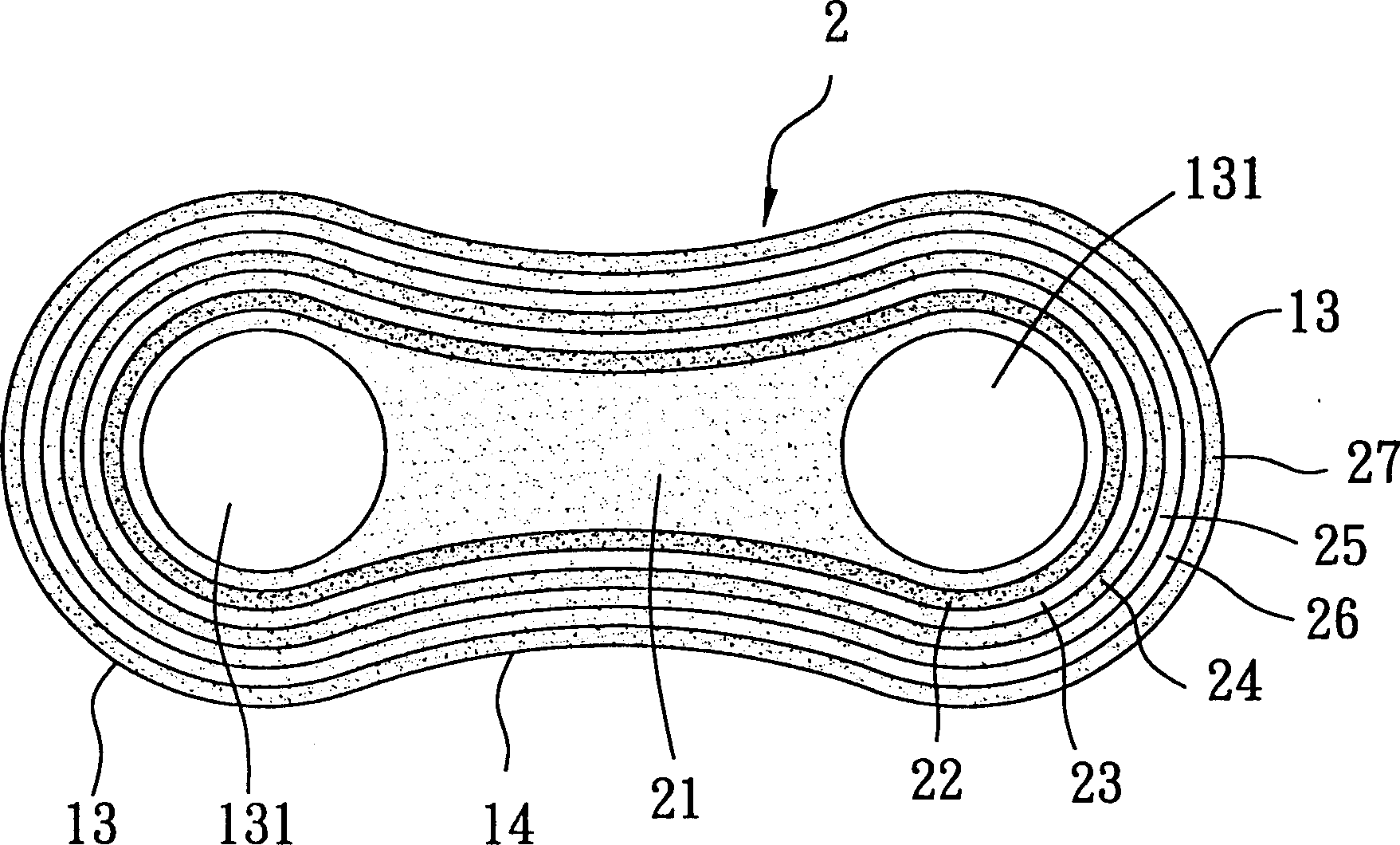

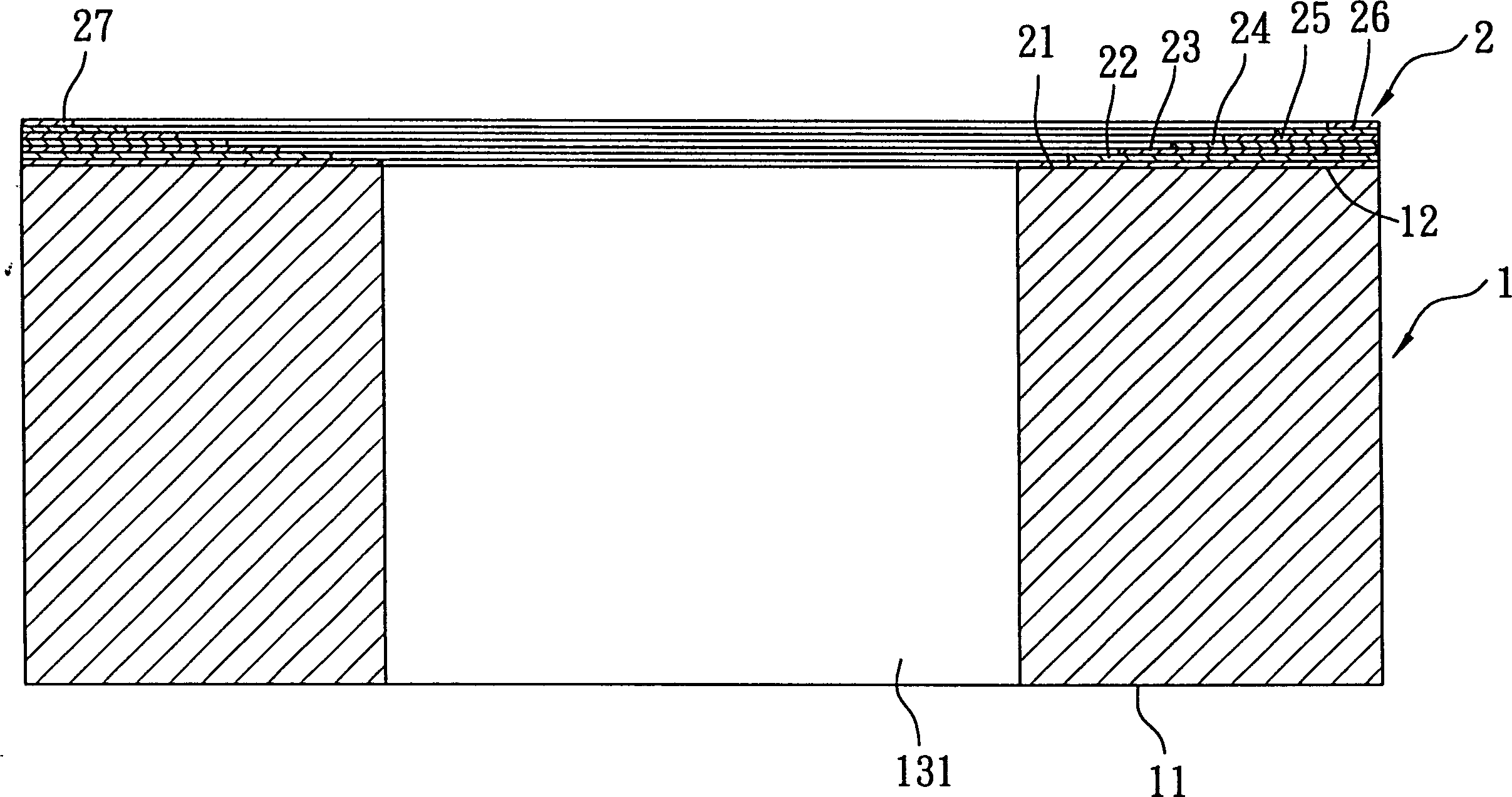

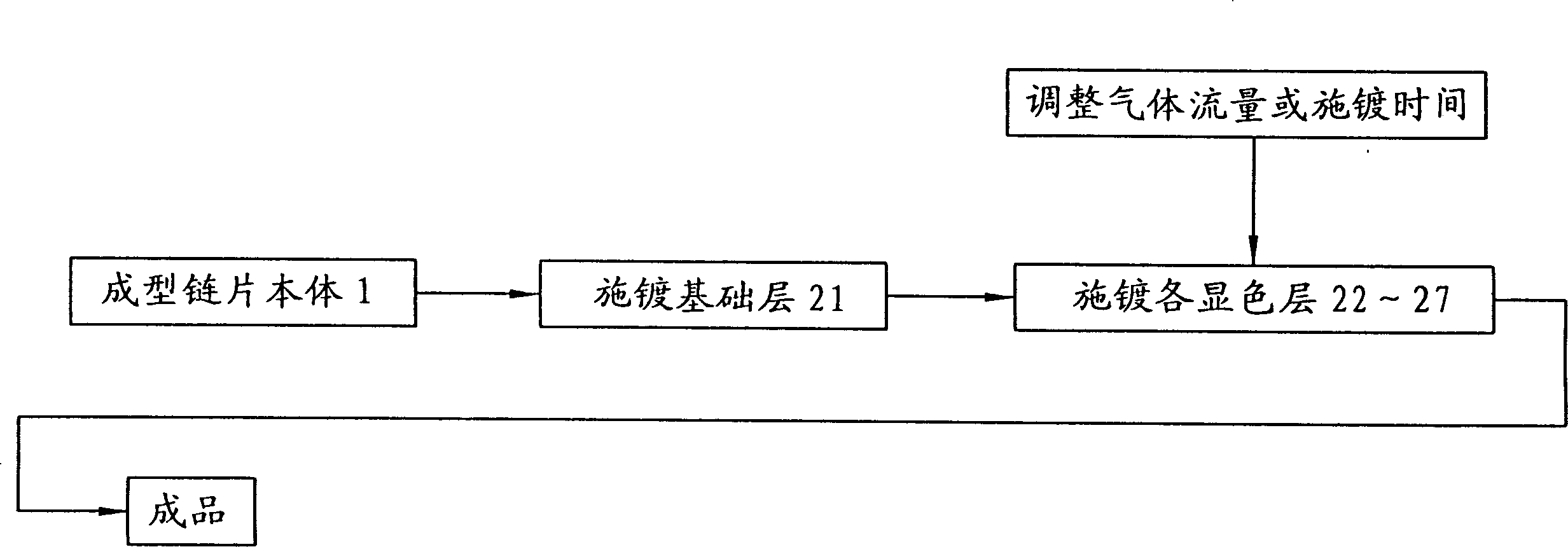

Chain piece with gorgeous color surface and mfg mehtod thereof

InactiveCN1270845CWith anti-counterfeiting identification functionImprove wear resistanceMetal chainsZinc nitrideEngineering

Owner:KMC CHAIN INDUSTRIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com