Wetting agent as well as preparation method and application of wetting agent

A wetting agent and amino technology, applied in the application field of textile auxiliaries, can solve the problems of few research reports, difficult testing and evaluation, and achieve the effects of good permeability, less foam, and improved compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

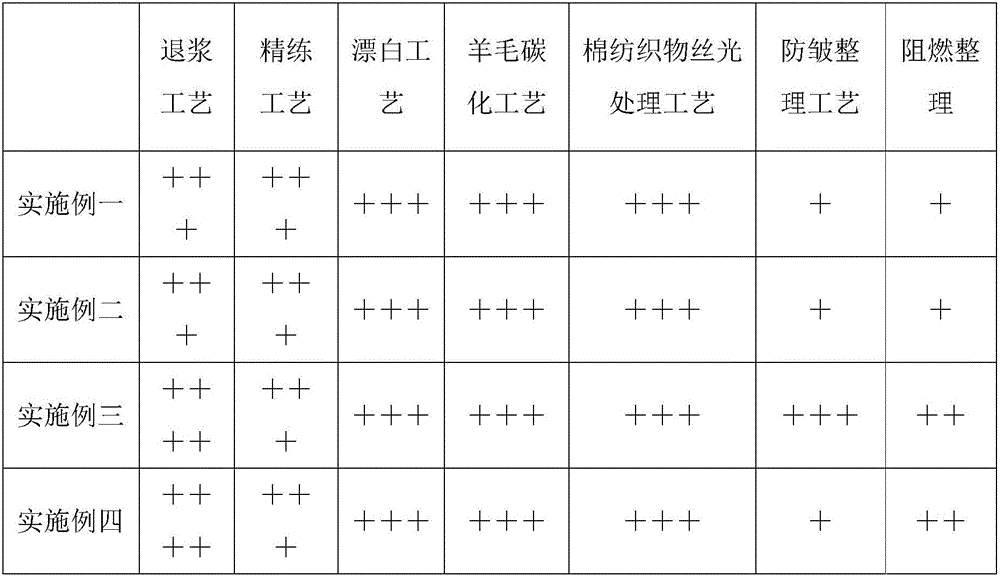

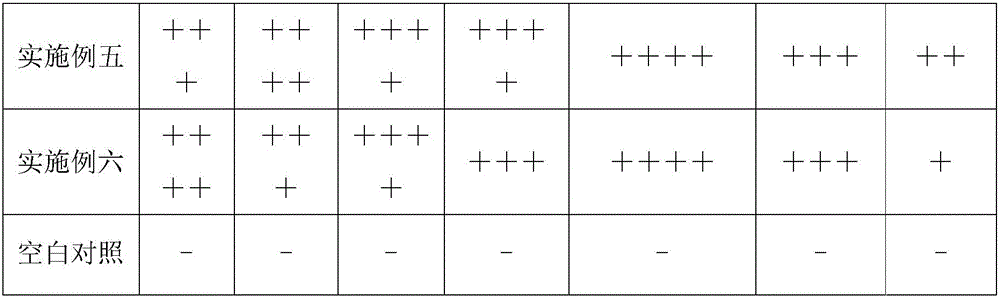

Examples

Embodiment 1

[0033] A wetting agent containing trans-4-[(2-amino-3,5-dibromobenzyl)amino]cyclohexanol, comprising the following components in parts by weight:

[0034] 1 part of trans-4-[(2-amino-3,5-dibromobenzyl)amino]cyclohexanol, 3 parts of triamine citrate, 0.1 part of methyl orange, 12 parts of sodium sulfate, 0.5 part of zinc nitrate , 3 parts of sodium xylene sulfonate, 0.6 parts of methylisothiazolinone, 100 parts of polyethylene glycol, and 300 parts of deionized water.

[0035] The polyethylene glycol is polyethylene glycol 400.

[0036] Its preparation method is:

[0037] Mix triamine citrate, sodium sulfate, zinc nitrate, sodium xylene sulfonate and methylisothiazolinone according to parts by weight, then irradiate with ultraviolet light for 100 minutes, add methyl orange solution and part of deionized water and stir Evenly, add polyethylene glycol solution to seal and heat at a low speed of 10 rpm for 1 hour, then add the remaining deionized water and shake for 30 minutes A...

Embodiment 2

[0039] A wetting agent containing trans-4-[(2-amino-3,5-dibromobenzyl)amino]cyclohexanol, comprising the following components in parts by weight:

[0040] Trans-4-[(2-amino-3,5-dibromobenzyl)amino]cyclohexanol 1.2 parts, triamine citrate 5 parts, methyl orange 0.5 parts, sodium sulfate 14 parts, zinc nitrate 0.7 parts , 4 parts of sodium xylene sulfonate, 0.9 parts of methylisothiazolinone, 120 parts of polyethylene glycol, and 350 parts of deionized water.

[0041] The polyethylene glycol is polyethylene glycol 400.

[0042] Its preparation method is:

[0043] Mix triamine citrate, sodium sulfate, zinc nitrate, sodium xylene sulfonate and methylisothiazolinone according to parts by weight, then irradiate with ultraviolet light for 200 minutes, add methyl orange solution and part of deionized water and stir Uniform, add polyethylene glycol solution to seal, stir at a low speed of 15rpm and heat for 1 hour, then add the remaining deionized water and shake for 40 minutes Add t...

Embodiment 3

[0045] A wetting agent containing trans-4-[(2-amino-3,5-dibromobenzyl)amino]cyclohexanol, comprising the following components in parts by weight:

[0046]Trans-4-[(2-amino-3,5-dibromobenzyl)amino]cyclohexanol 1 part, triamine citrate 4.5 parts, methyl orange 0.1 part, sodium sulfate 12 parts, zinc nitrate 0.5 part , 3.6 parts of sodium xylene sulfonate, 0.6 parts of methylisothiazolinone, 100 parts of polyethylene glycol, and 340 parts of deionized water.

[0047] The polyethylene glycol is polyethylene glycol 400.

[0048] Its preparation method is:

[0049] Mix triamine citrate, sodium sulfate, zinc nitrate, sodium xylene sulfonate and methylisothiazolinone according to parts by weight, then irradiate with ultraviolet light for 200 minutes, add methyl orange solution and part of deionized water and stir Uniform, add polyethylene glycol solution to seal, stir and heat at a low speed of 15rpm for 3 hours, then add the remaining deionized water and shake for 40 minutes Add tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com