Patents

Literature

181 results about "Indium nitride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

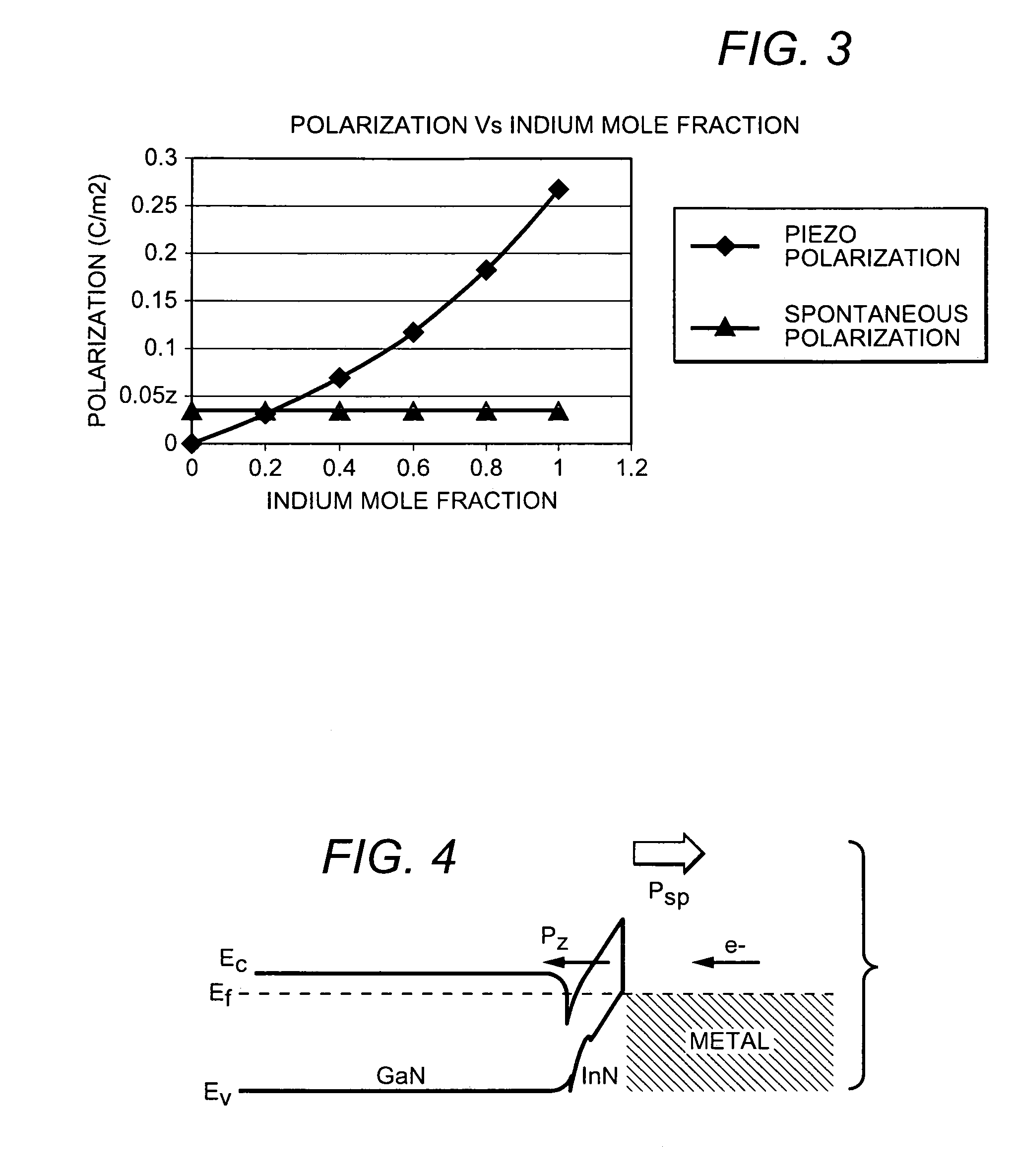

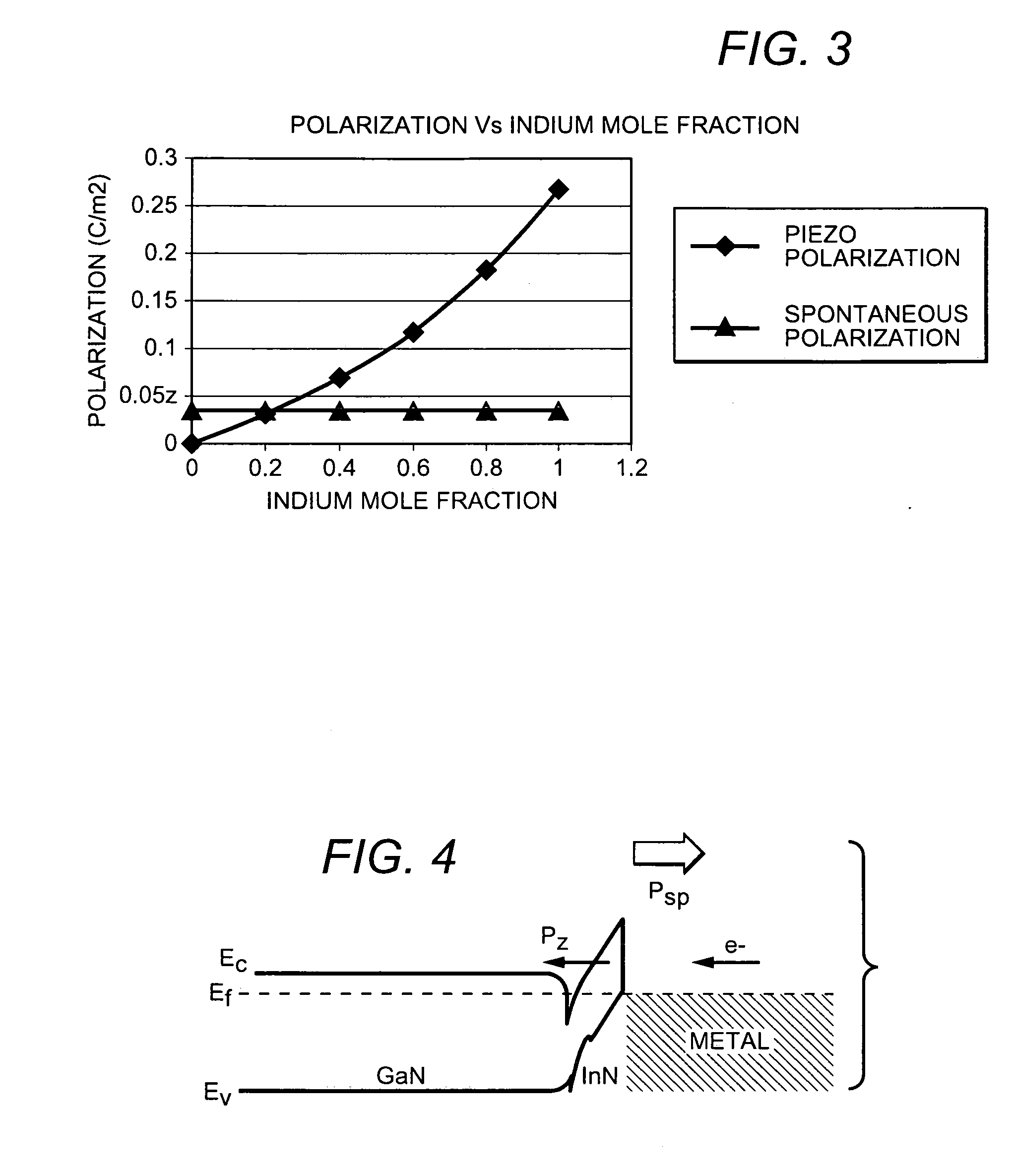

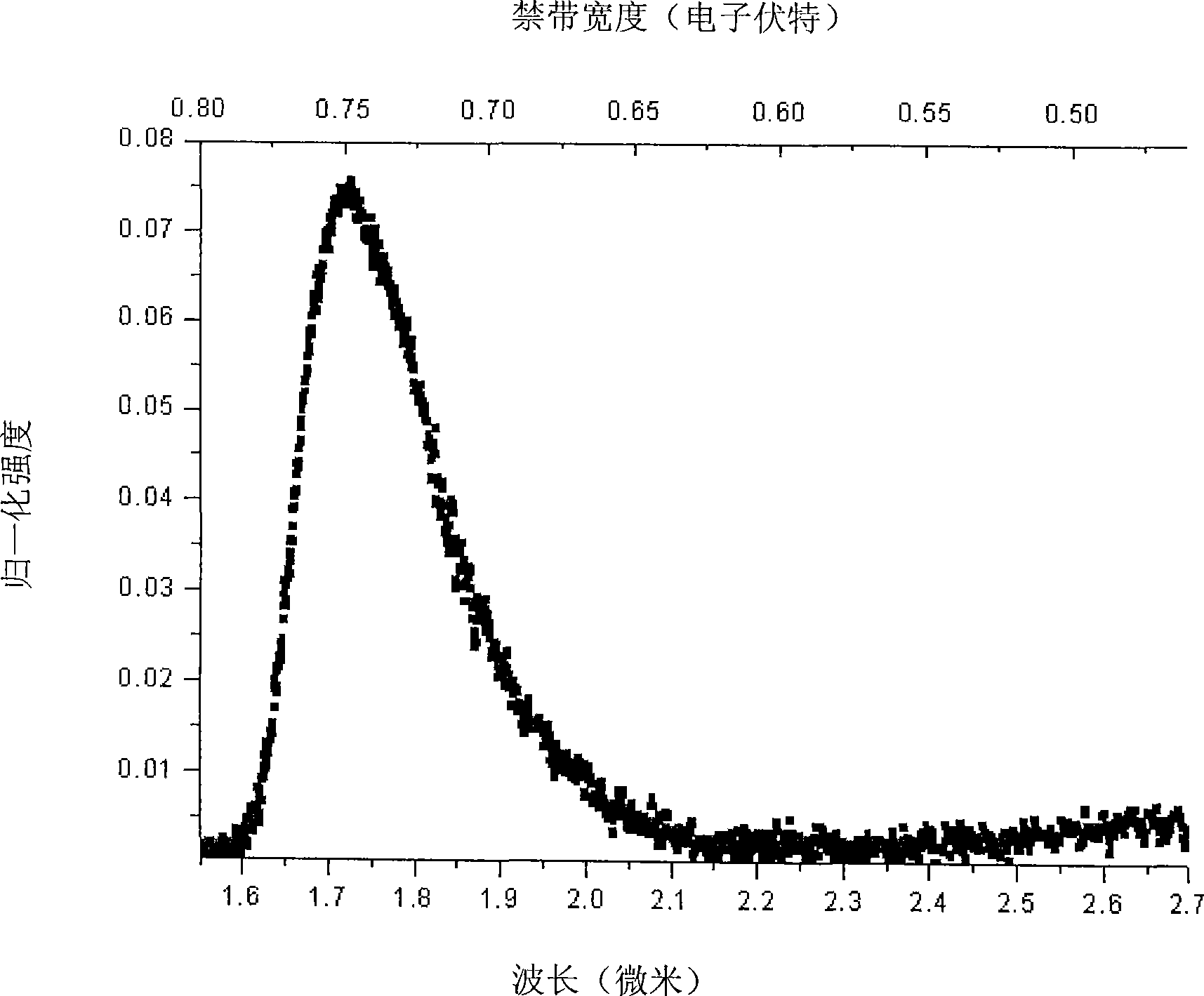

Indium nitride (InN) is a small bandgap semiconductor material which has potential application in solar cells and high speed electronics. The bandgap of InN has now been established as ~0.7 eV depending on temperature (the obsolete value is 1.97 eV). The effective electron mass has been recently determined by high magnetic field measurements, m*=0.055 m₀.

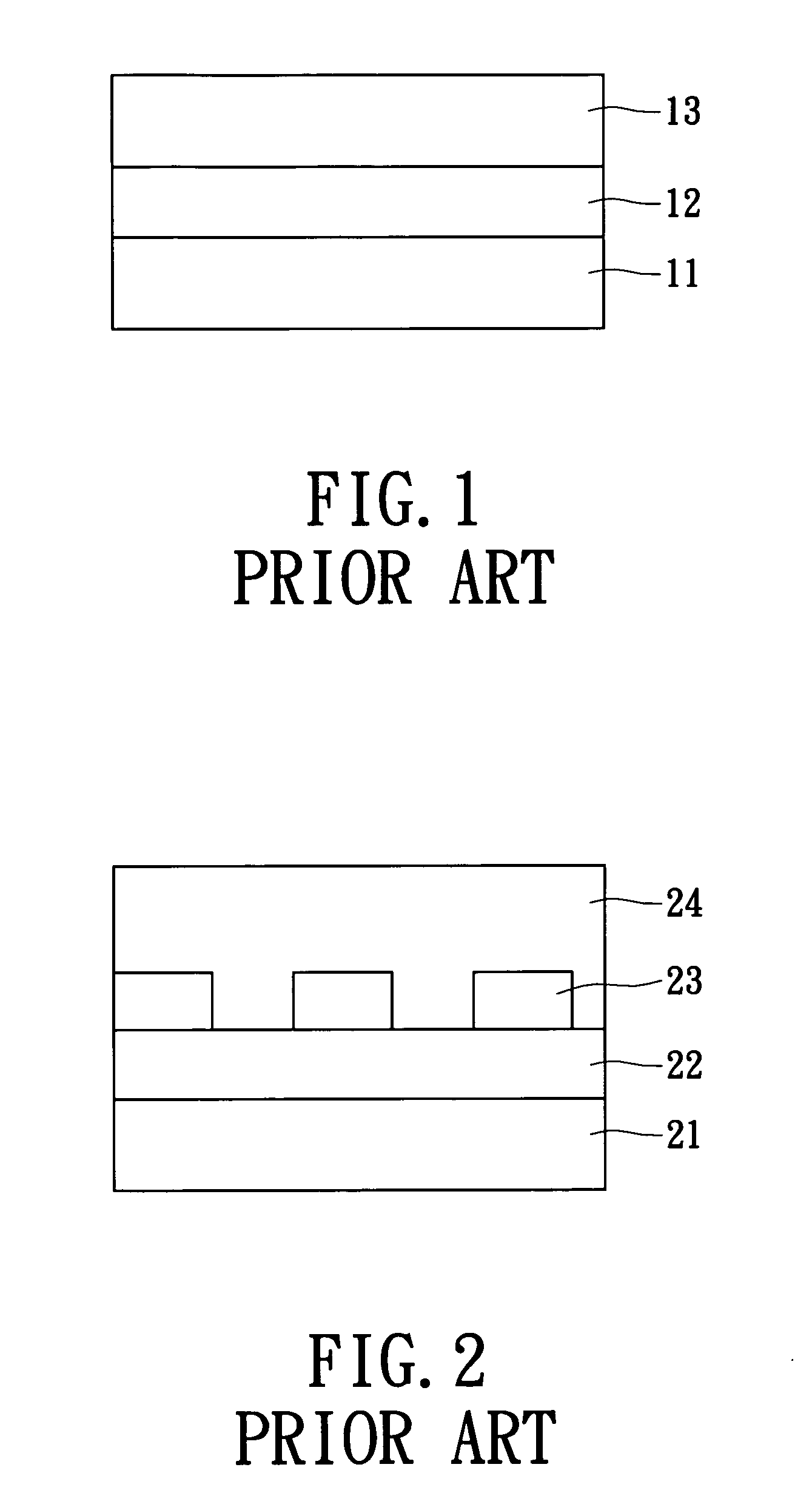

Solar cell assembly

InactiveUS20050211291A1PV power plantsSemiconductor/solid-state device manufacturingConductive coatingGallium alloy

A multi-junction solar cell assembly includes a transparent substrate and a transparent conductive coating formed on the transparent substrate. The transparent conductive coating includes gallium nitride. The solar cell assembly also includes a plurality of gallium indium nitride junction layers formed successively on the transparent conductive coating, and a metallization layer formed on the plurality of gallium indium nitride junction layers.

Owner:THE BOEING CO

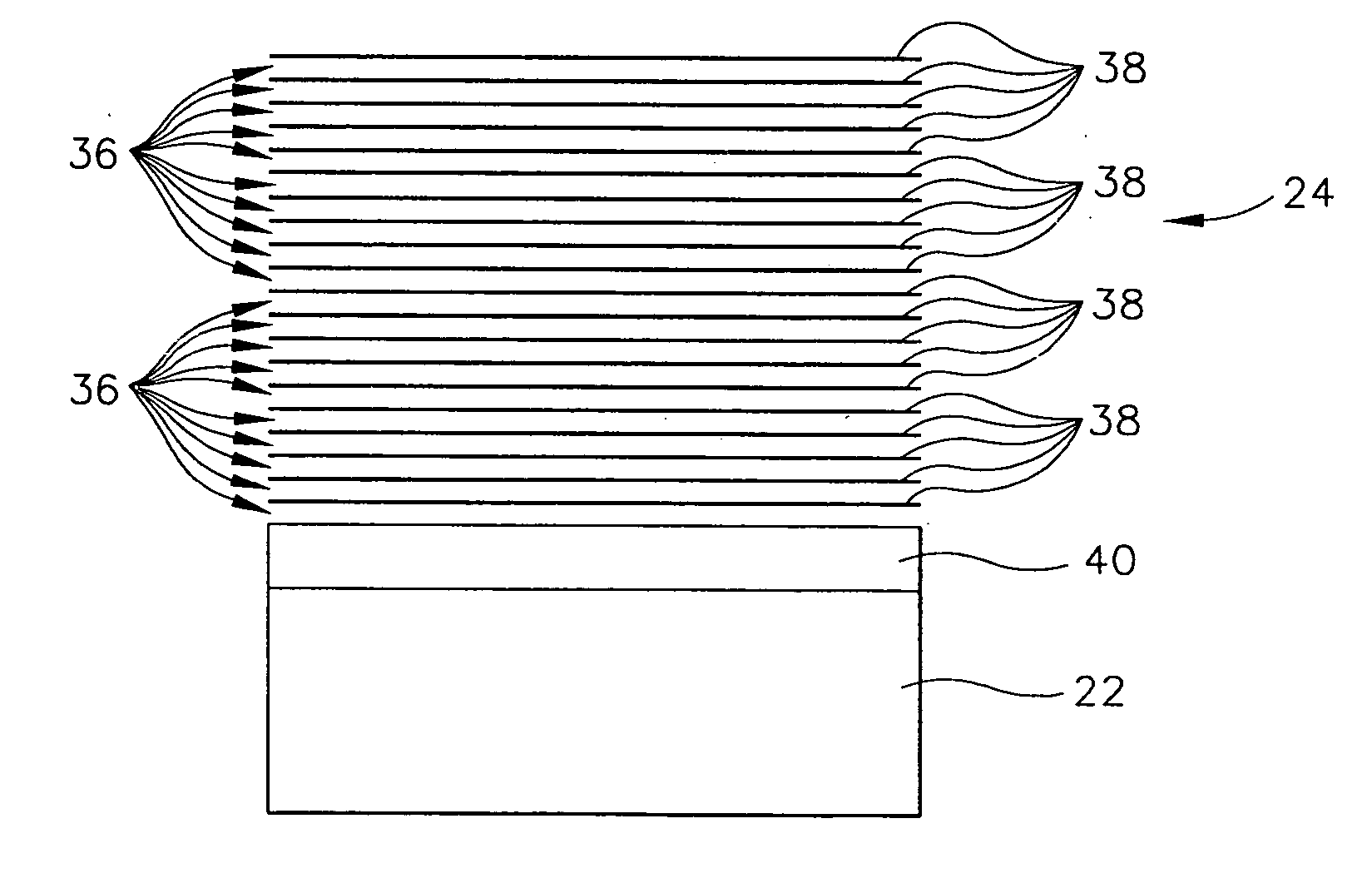

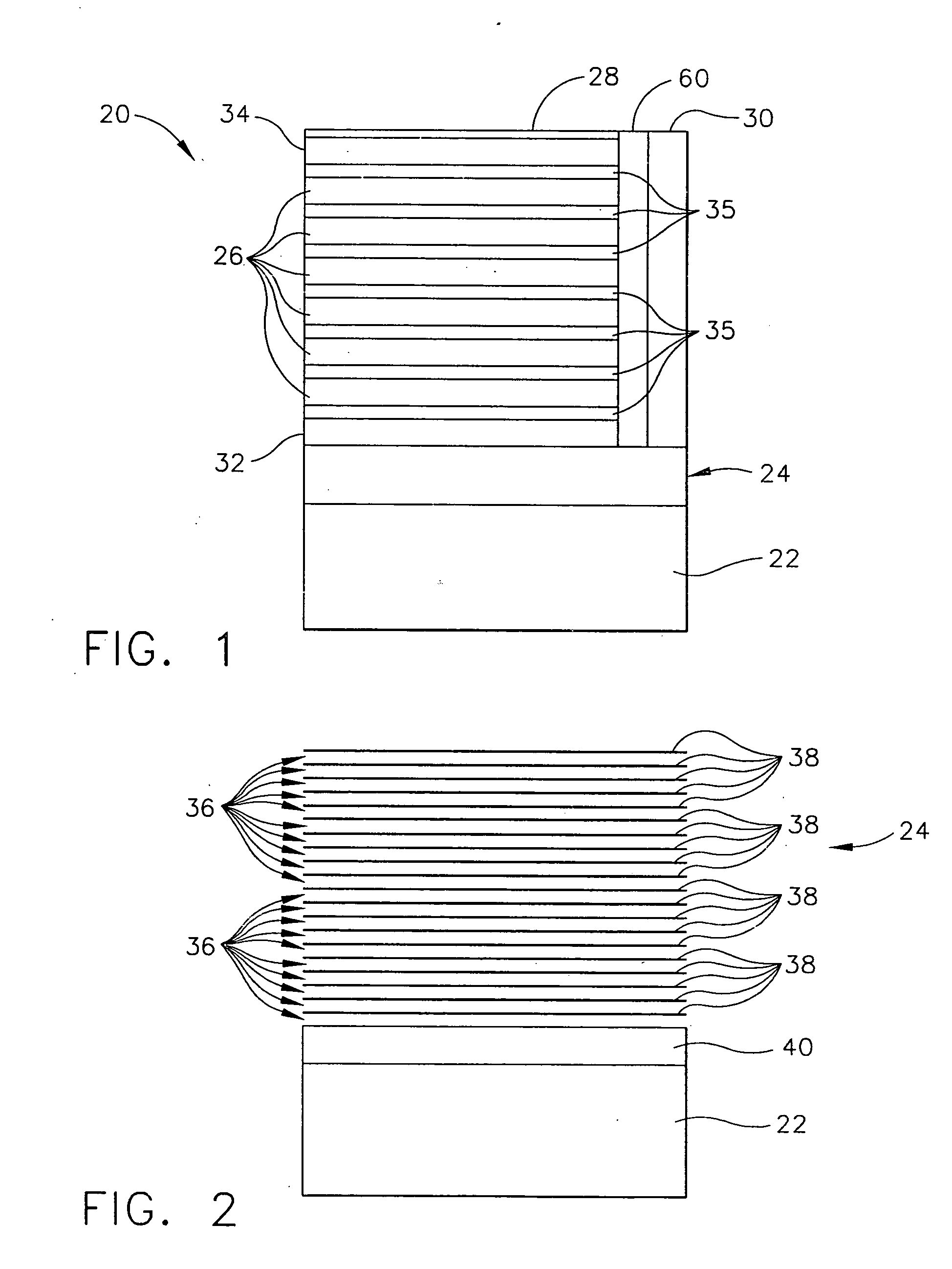

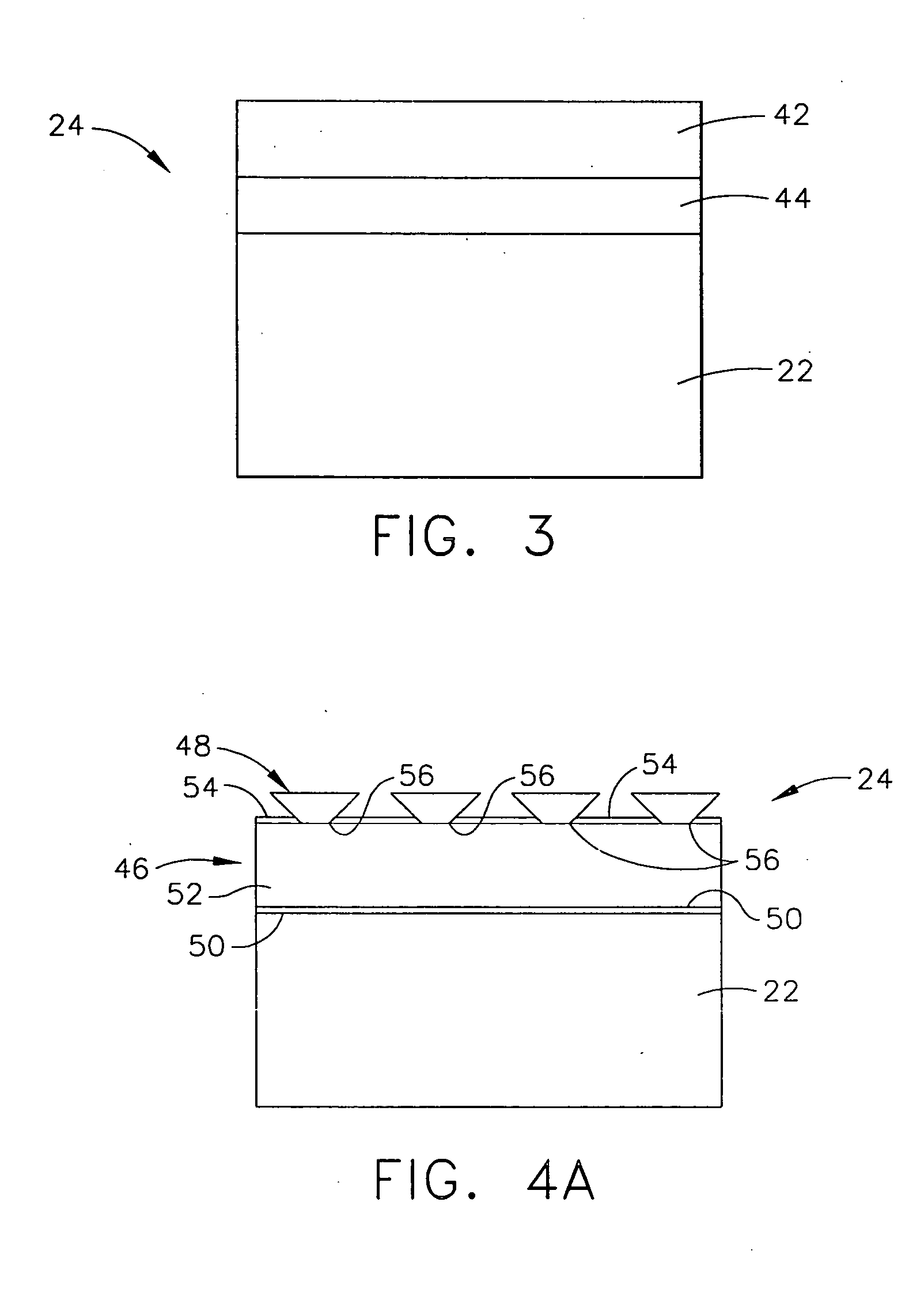

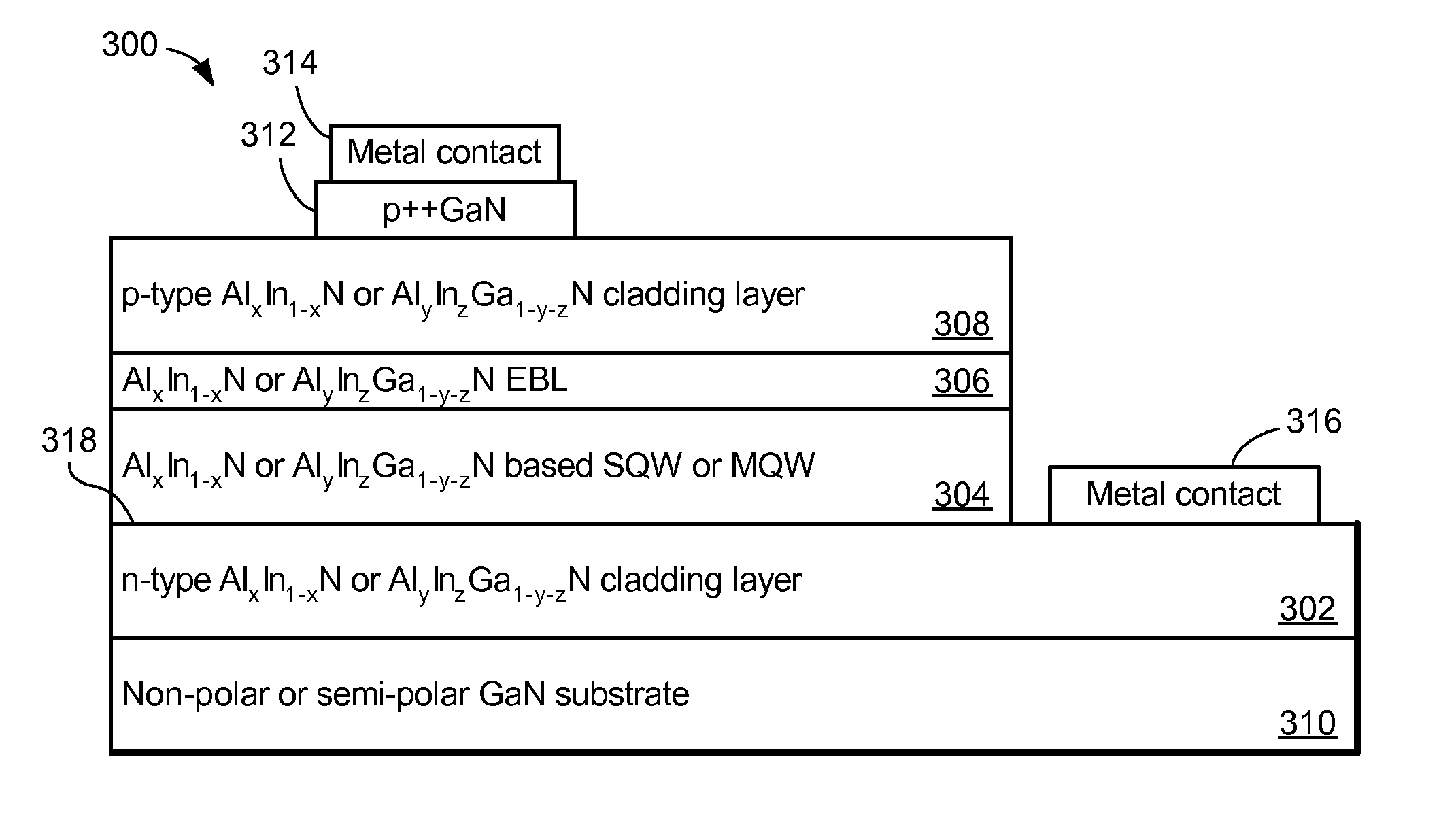

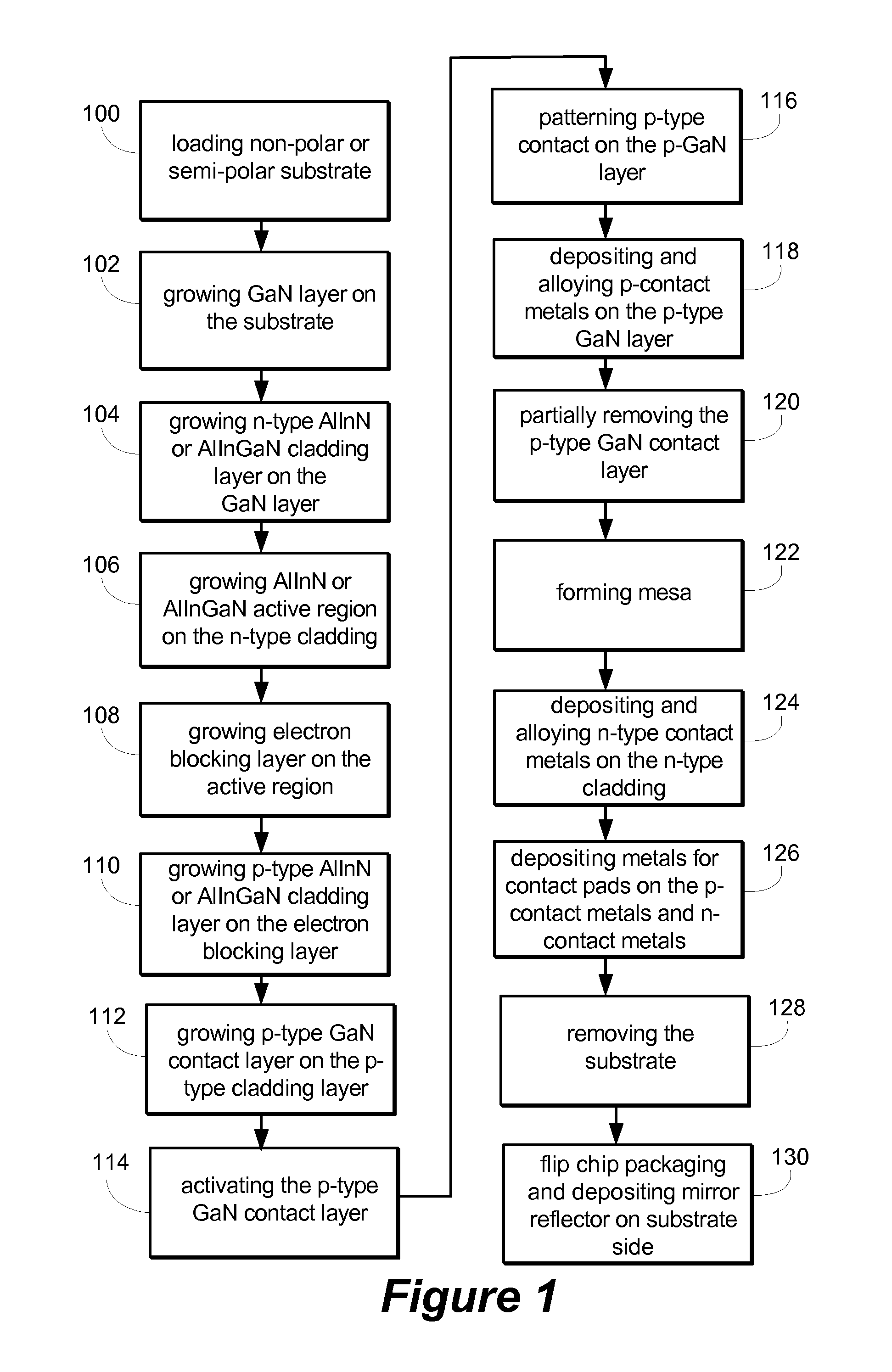

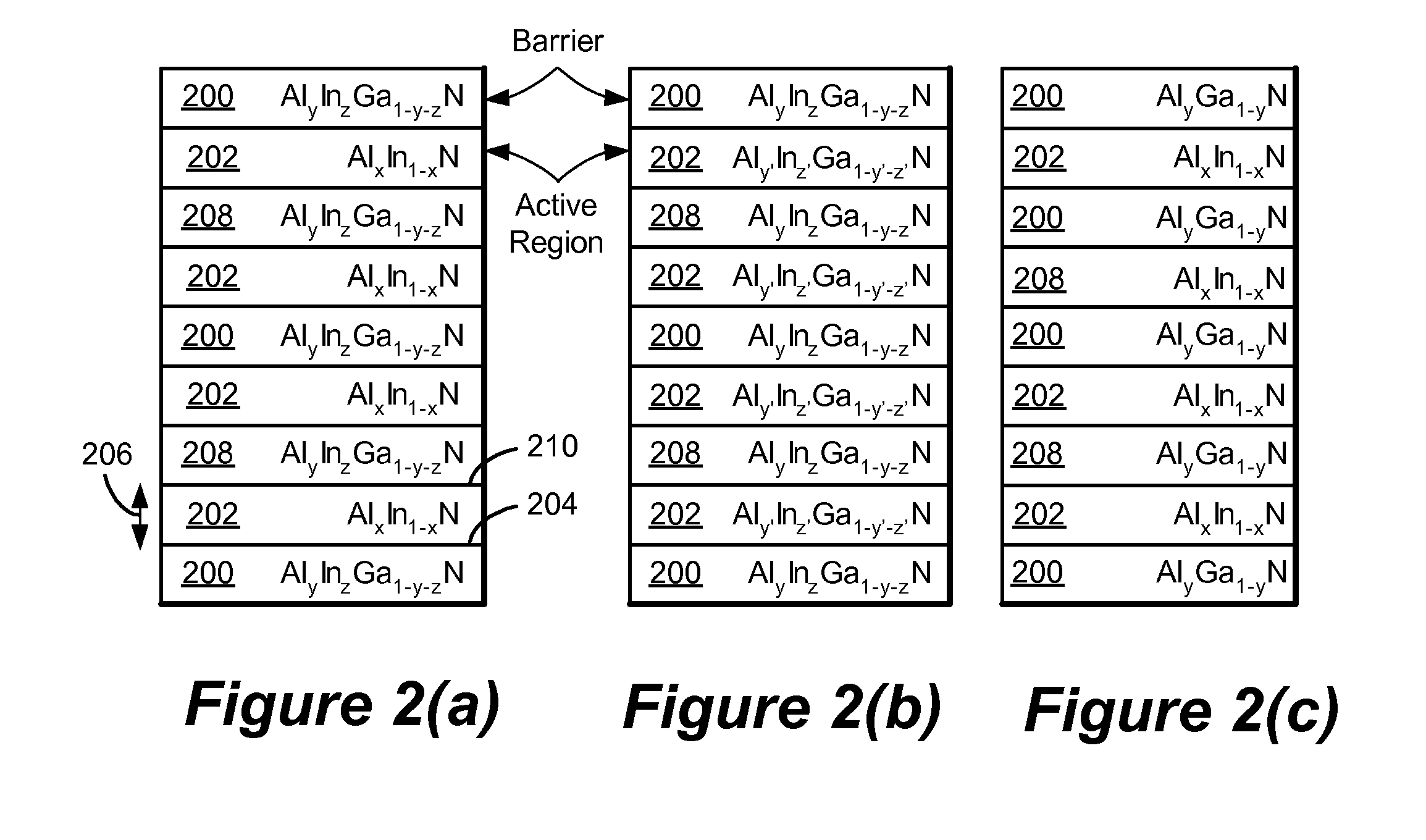

Optoelectronic device based on non-polar and semi-polar aluminum indium nitride and aluminum indium gallium nitride alloys

ActiveUS20100108985A1Low quantum efficiencySemiconductor/solid-state device manufacturingNanoopticsAlloyLength wave

A high-power and high-efficiency light emitting device with emission wavelength (λpeak) ranging from 280 nm to 360 nm is fabricated. The new device structure uses non-polar or semi-polar AlInN and AlInGaN alloys grown on a non-polar or semi-polar bulk GaN substrate.

Owner:RGT UNIV OF CALIFORNIA

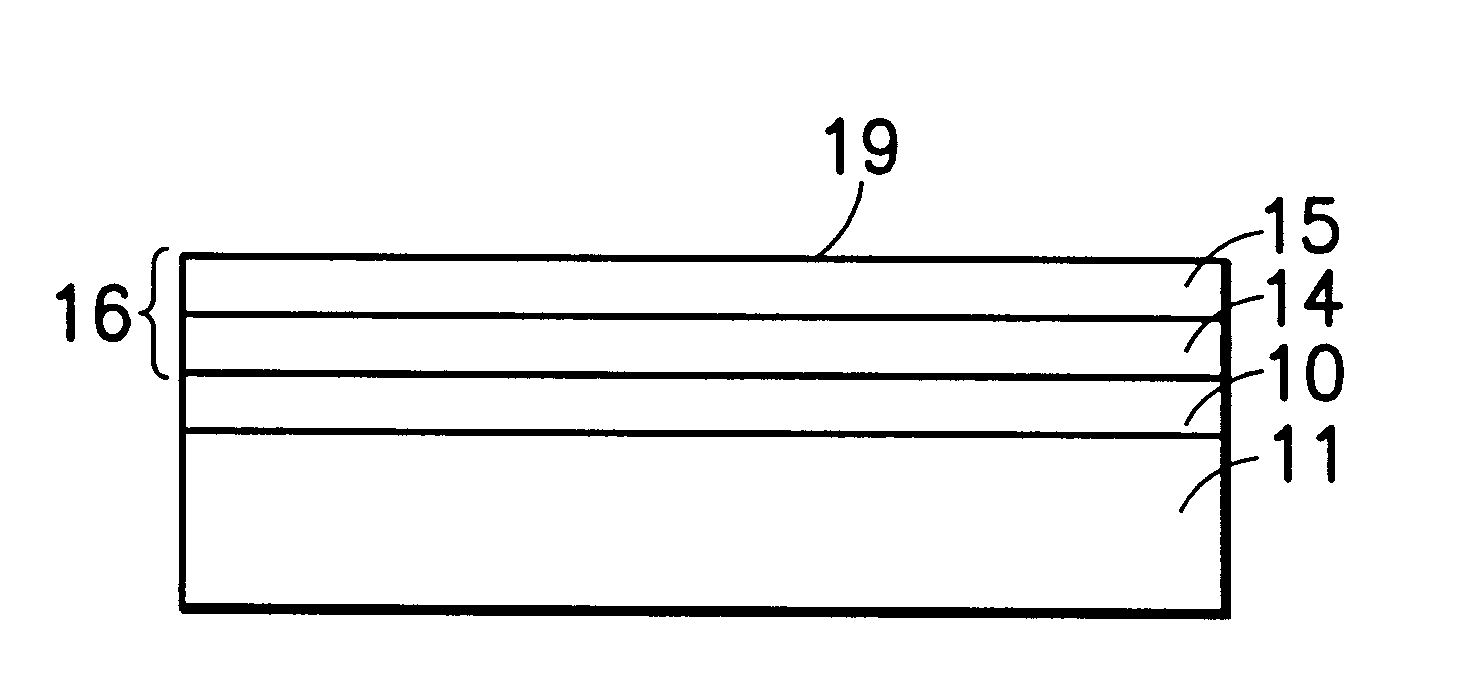

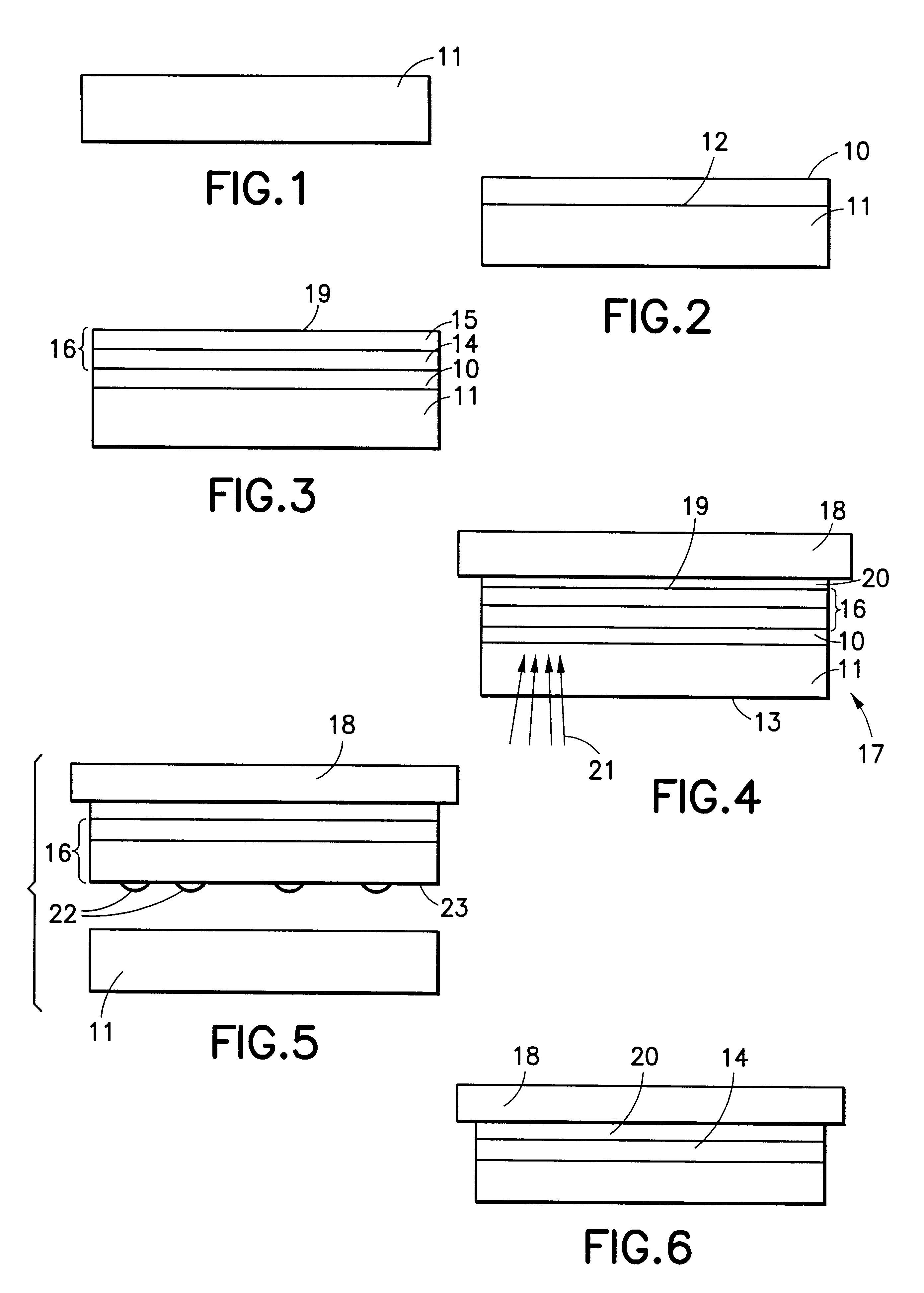

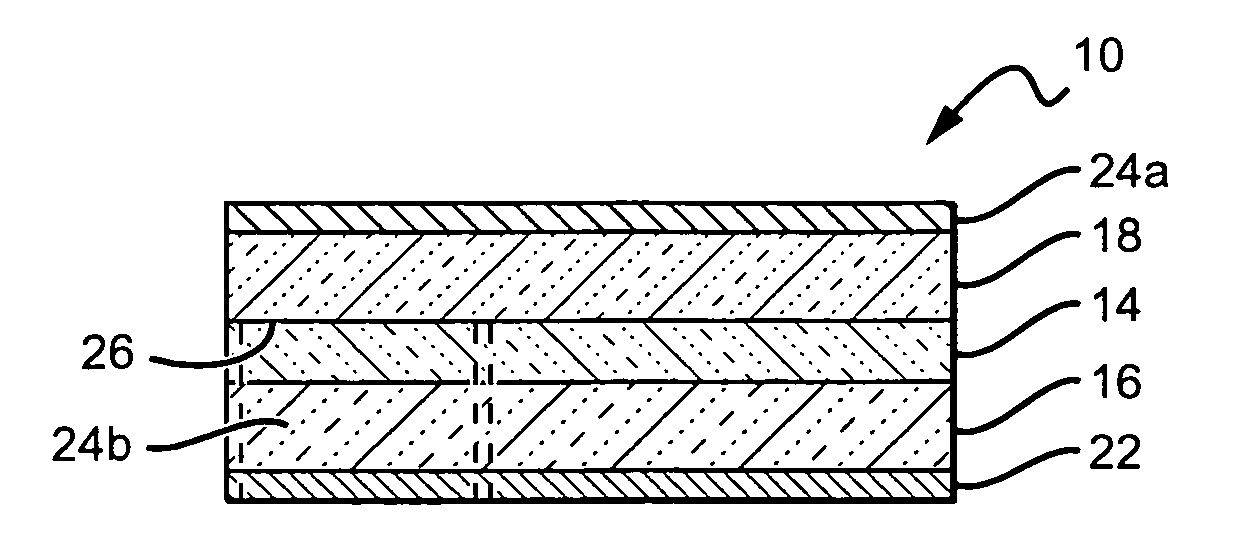

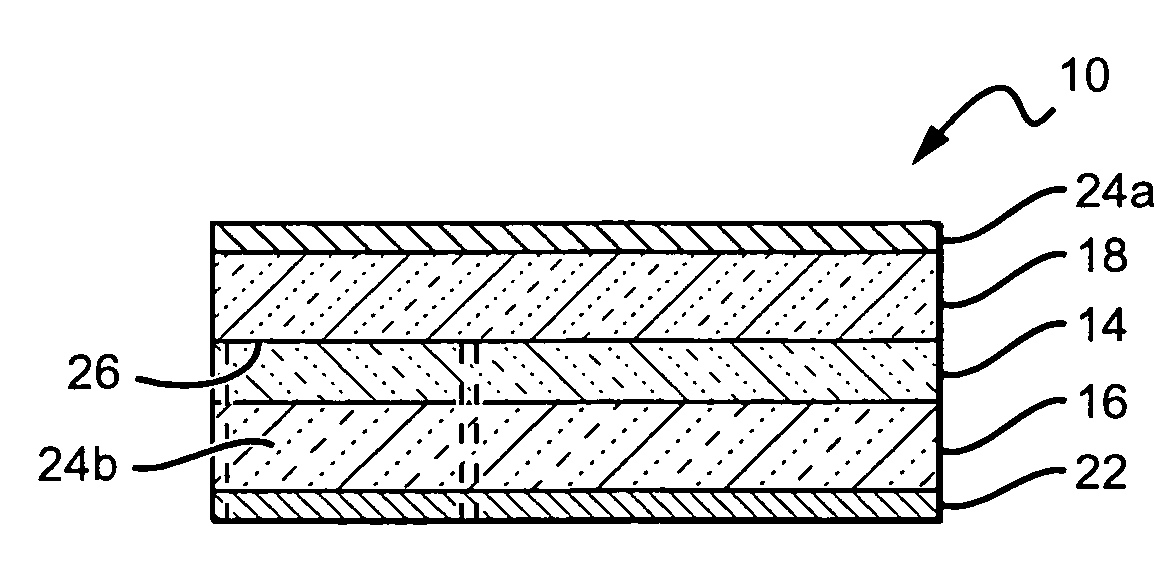

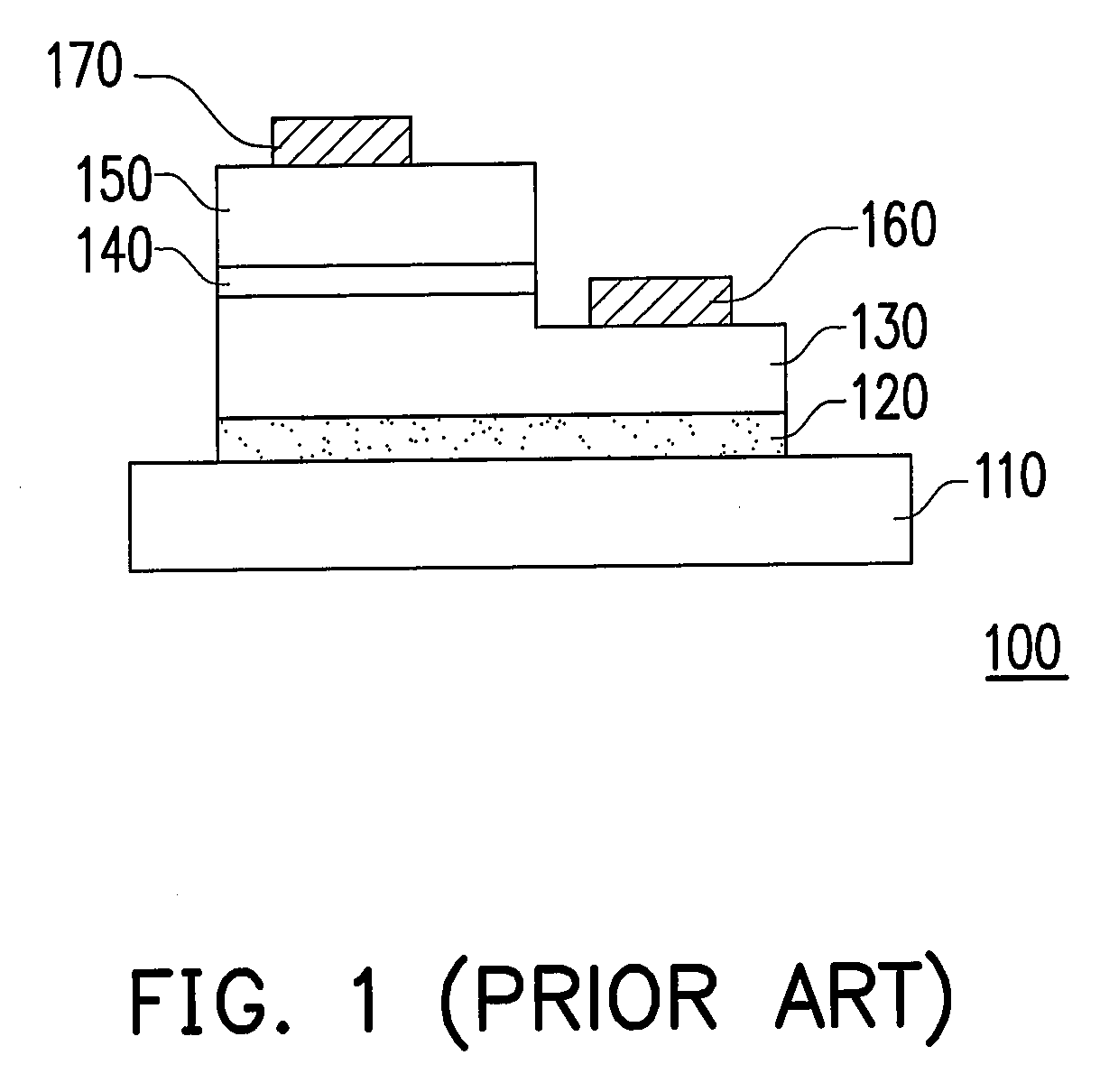

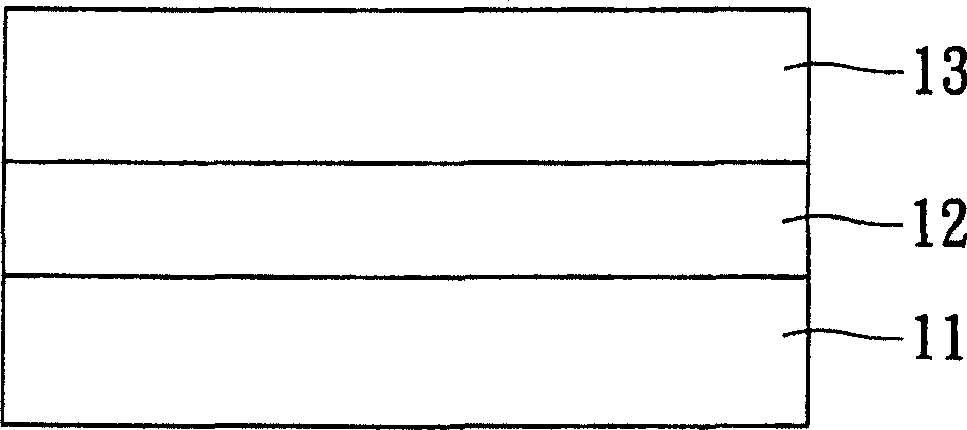

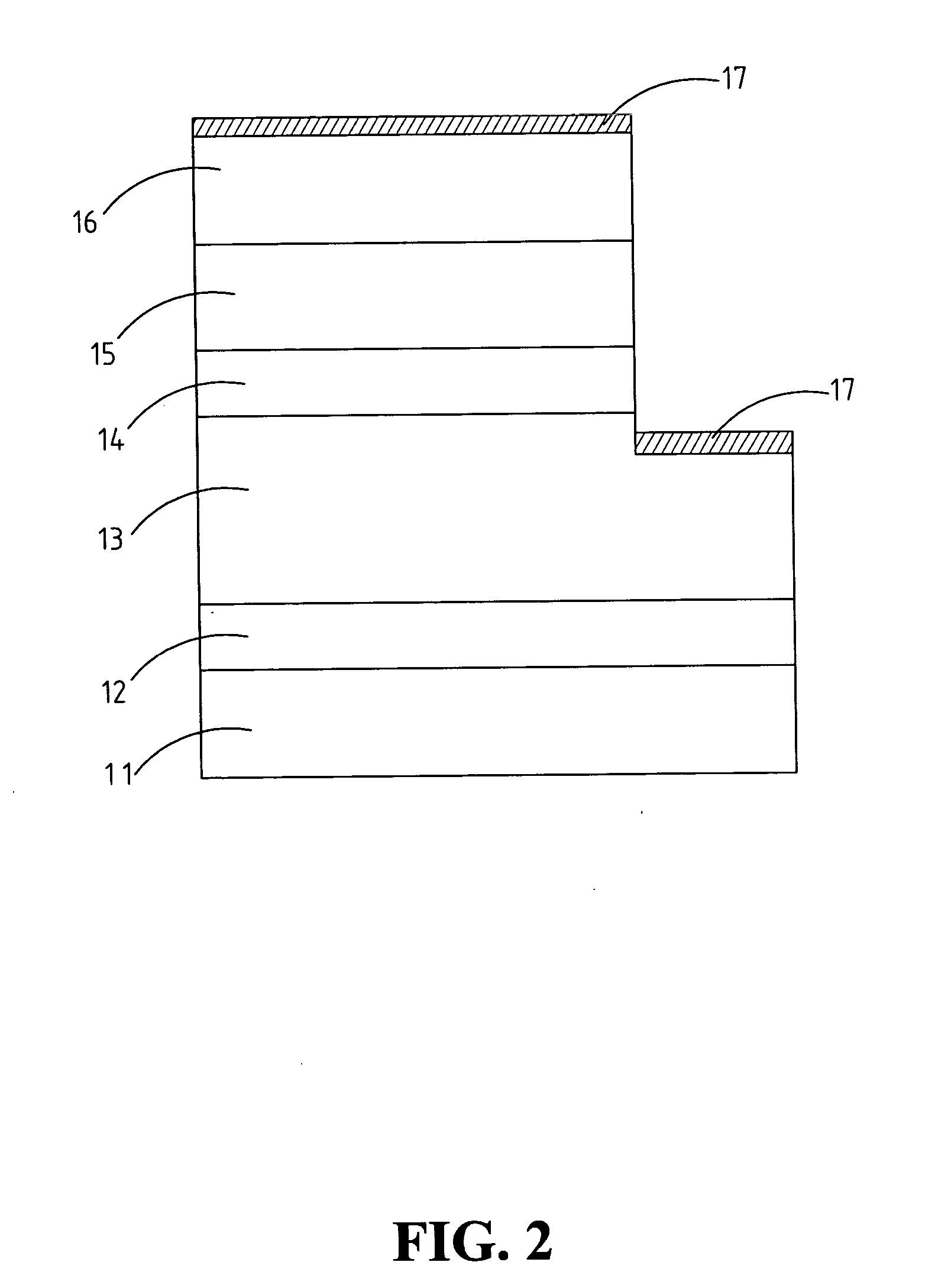

Product and process for forming a semiconductor structure on a host substrate

InactiveUS6210479B1Polycrystalline material growthSemiconductor/solid-state device manufacturingSemiconductor structureNitrogen

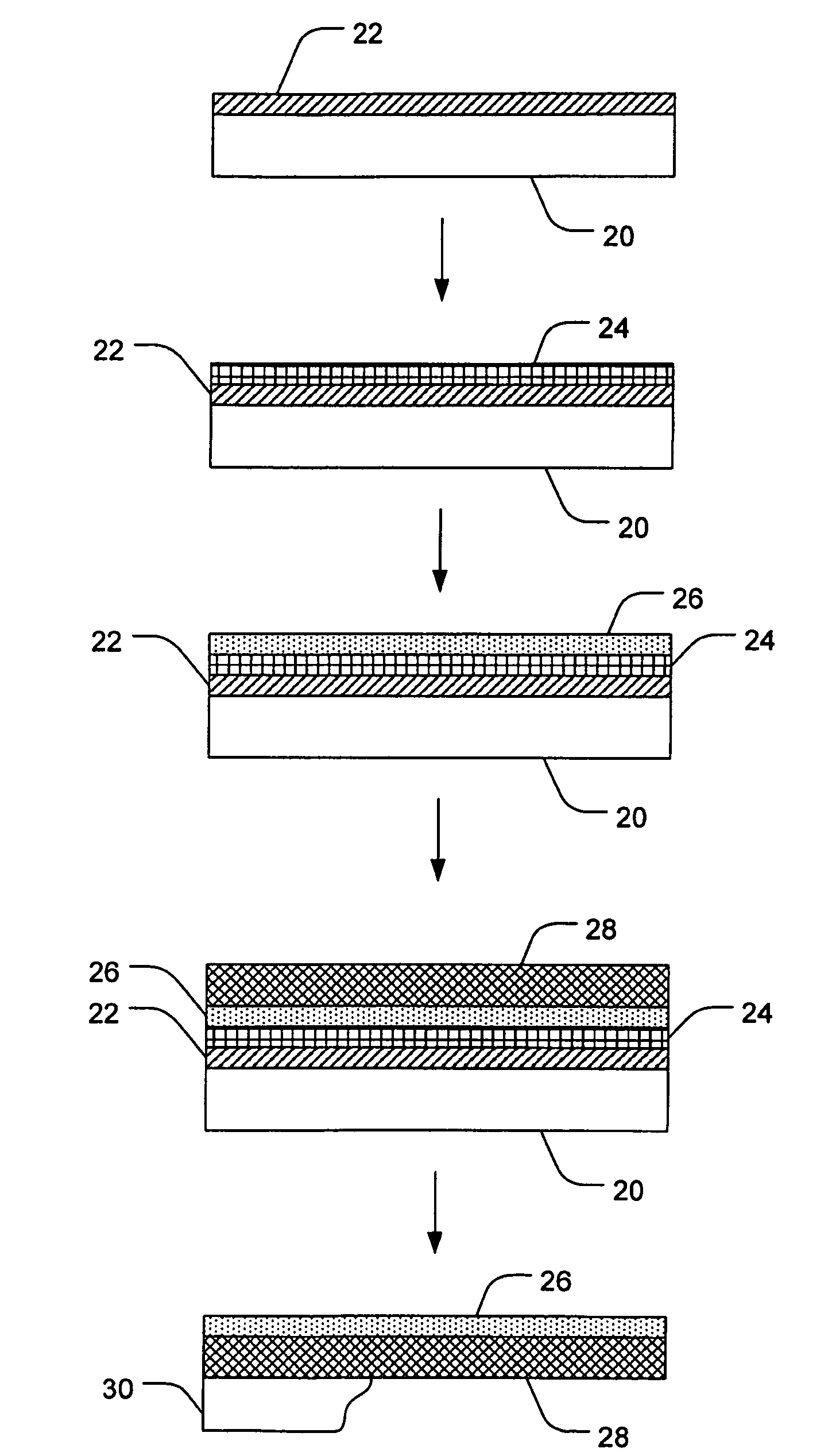

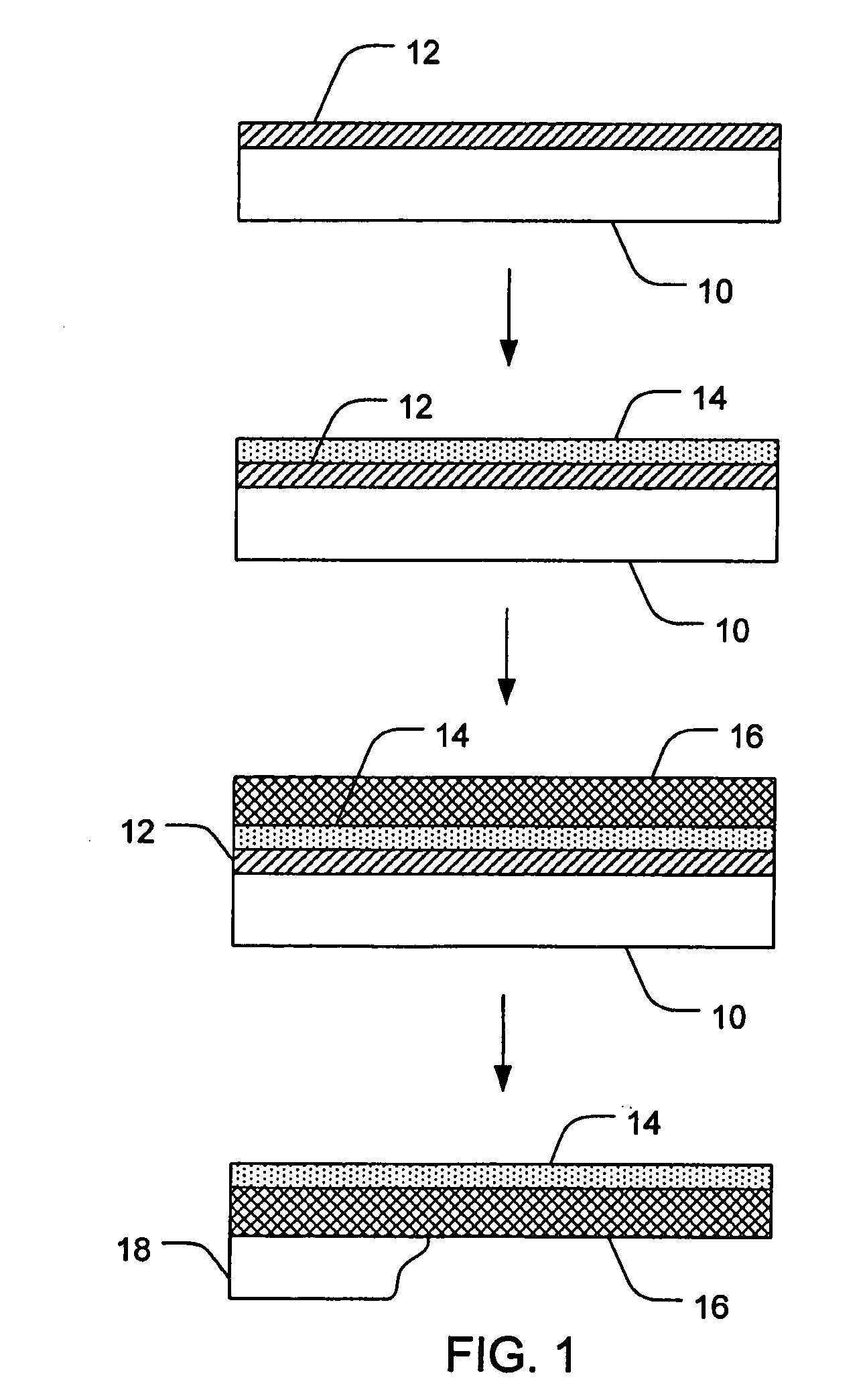

A process for cheaply fabricating a substantially single crystal or a polycrystalline semiconductor structure on a host substrate. The process begins by depositing a layer of wide band gap nitride material 10, such as gallium nitride, aluminum nitride and / or indium nitride, on a sapphire substrate 11. The semiconductor structure 14 is then grown on the nitride layer. Next, the host substrate 15 is attached with a bonding agent to an exposed surface area of the semiconductor structure 14. The sapphire substrate is lifted off by irradiation in which nitrogen is dissociated from the nitride layer.

Owner:IBM CORP

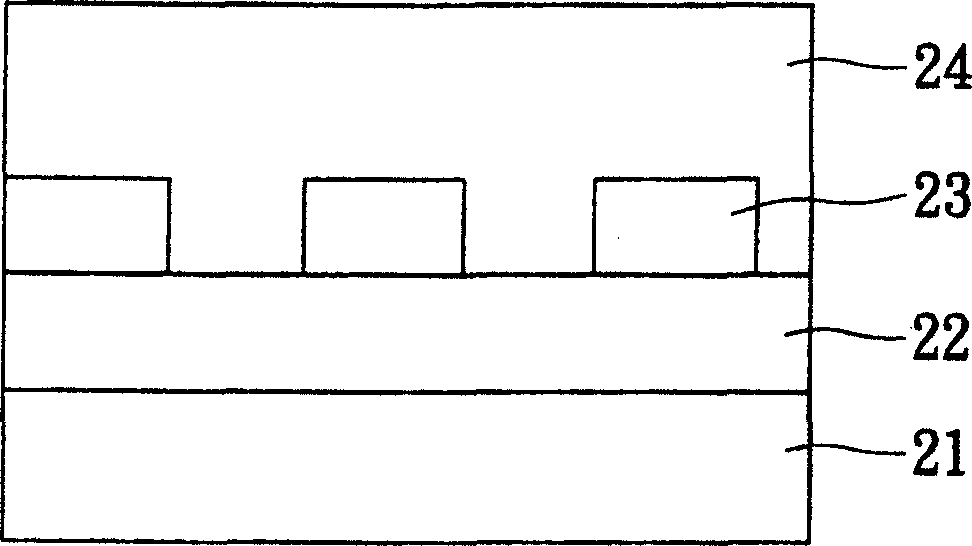

Substrate for thin film formation, thin film substrate, and light-emitting device

InactiveUS20060163605A1Easy to manufactureSmall transmission lossPolycrystalline material growthSemiconductor/solid-state device detailsSingle crystalLight emitting device

A substrate for forming a thin film composed mainly of gallium nitride, indium nitride or aluminum nitride, the substrate consisting of a sintered compact composed mainly of a ceramic material; and a thin-film substrate furnished with the thin film. The use of the sintered compact composed mainly of a ceramic material, especially translucent sintered compact, as the substrate enables formation thereon of a highly crystalline single-crystal thin film composed mainly of at least one member selected from among gallium nitride, indium nitride and aluminum nitride. Thus, there is provided a thin-film substrate furnished with a highly crystalline single-crystal thin film. Further, the use of the sintered compact composed mainly of a ceramic material enables providing of a light emitting element excelling in luminous efficiency.

Owner:MIYAHARA KENICHIRO

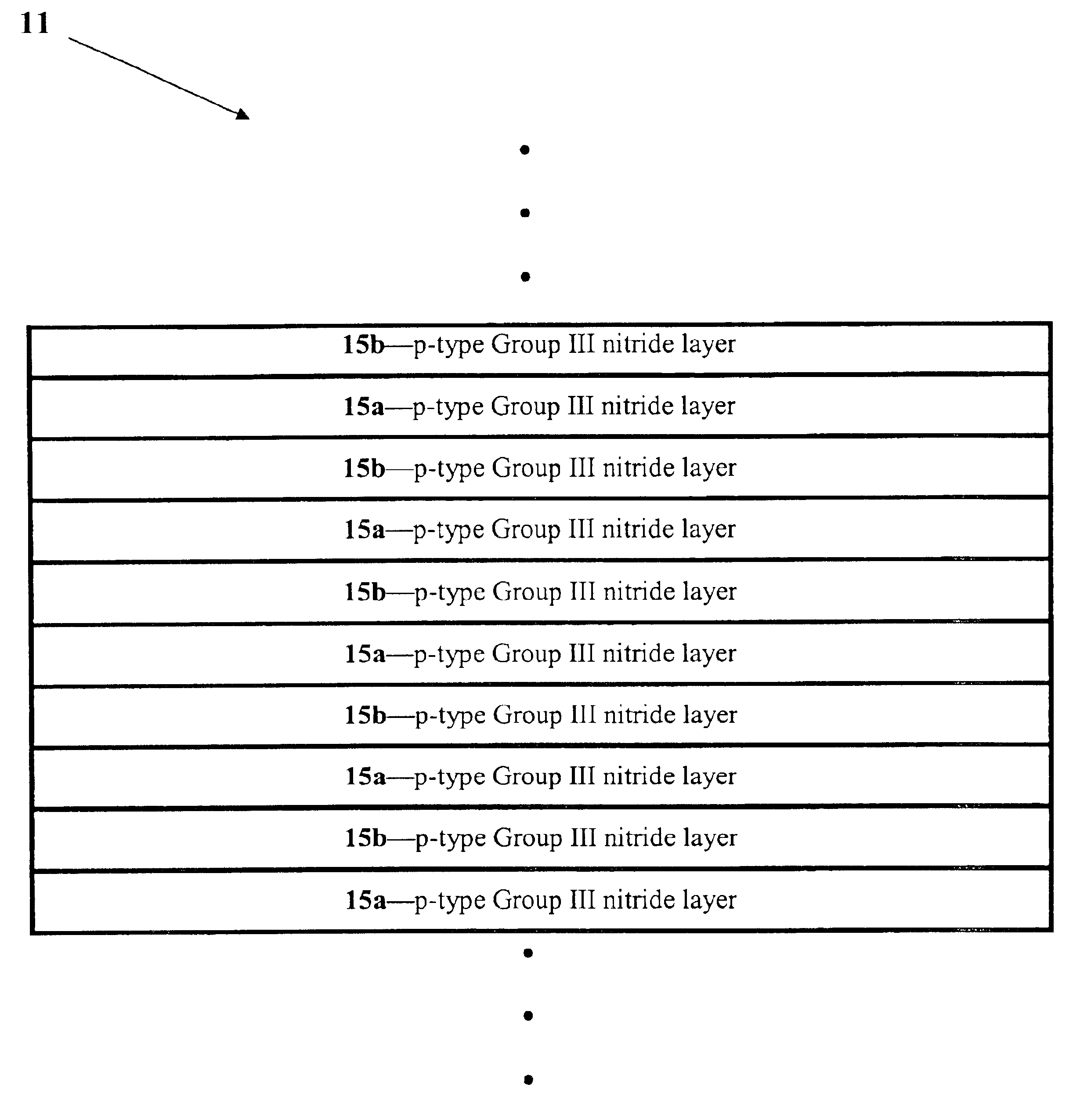

Ohmic contacts to nitrogen polarity GaN

ActiveUS8021904B2Solid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsOhmic contact

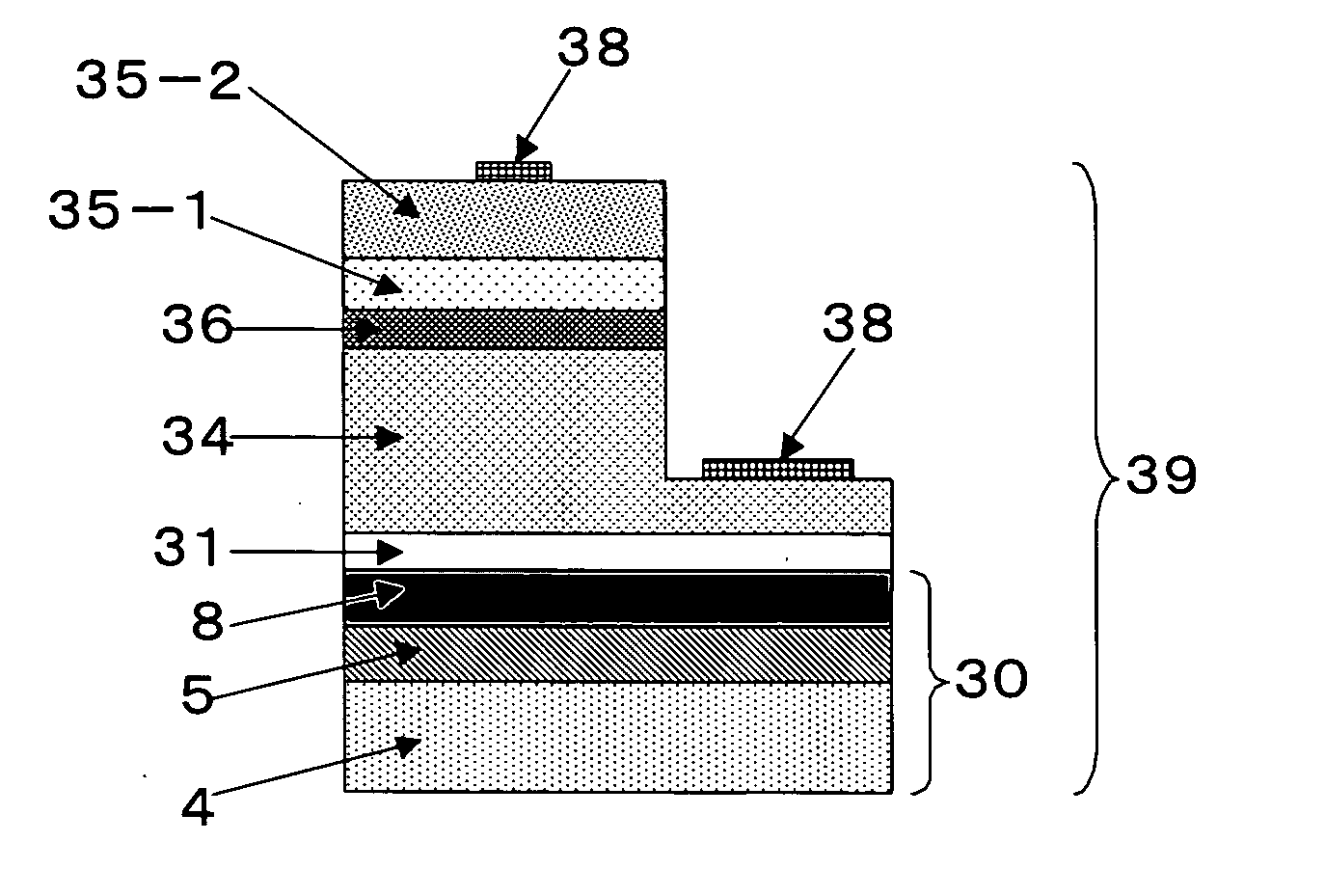

Contacting materials and methods for forming ohmic contact to the N-face polarity surfaces of Group-III nitride based semiconductor materials, and devices fabricated using the methods. One embodiment of a light emitting diode (LED) a Group-III nitride active epitaxial region between two Group-III nitride oppositely doped epitaxial layers. The oppositely doped layers have alternating face polarities from the Group III and nitrogen (N) materials, and at least one of the oppositely doped layers has an exposed surface with an N-face polarity. A first contact layer is included on and forms an ohmic contact with the exposed N-face polarity surface. In one embodiment, the first contact layer comprises indium nitride.

Owner:CREELED INC

Ohmic contacts to nitrogen polarity GaN

ActiveUS20080185608A1Solid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsOhmic contact

Contacting materials and methods for forming ohmic contact to the N-face polarity surfaces of Group-III nitride based semiconductor materials, and devices fabricated using the methods. One embodiment of a light emitting diode (LED) a Group-III nitride active epitaxial region between two Group-III nitride oppositely doped epitaxial layers. The oppositely doped layers have alternating face polarities from the Group III and nitrogen (N) materials, and at least one of the oppositely doped layers has an exposed surface with an N-face polarity. A first contact layer is included on and forms an ohmic contact with the exposed N-face polarity surface. In one embodiment, the first contact layer comprises indium nitride.

Owner:CREELED INC

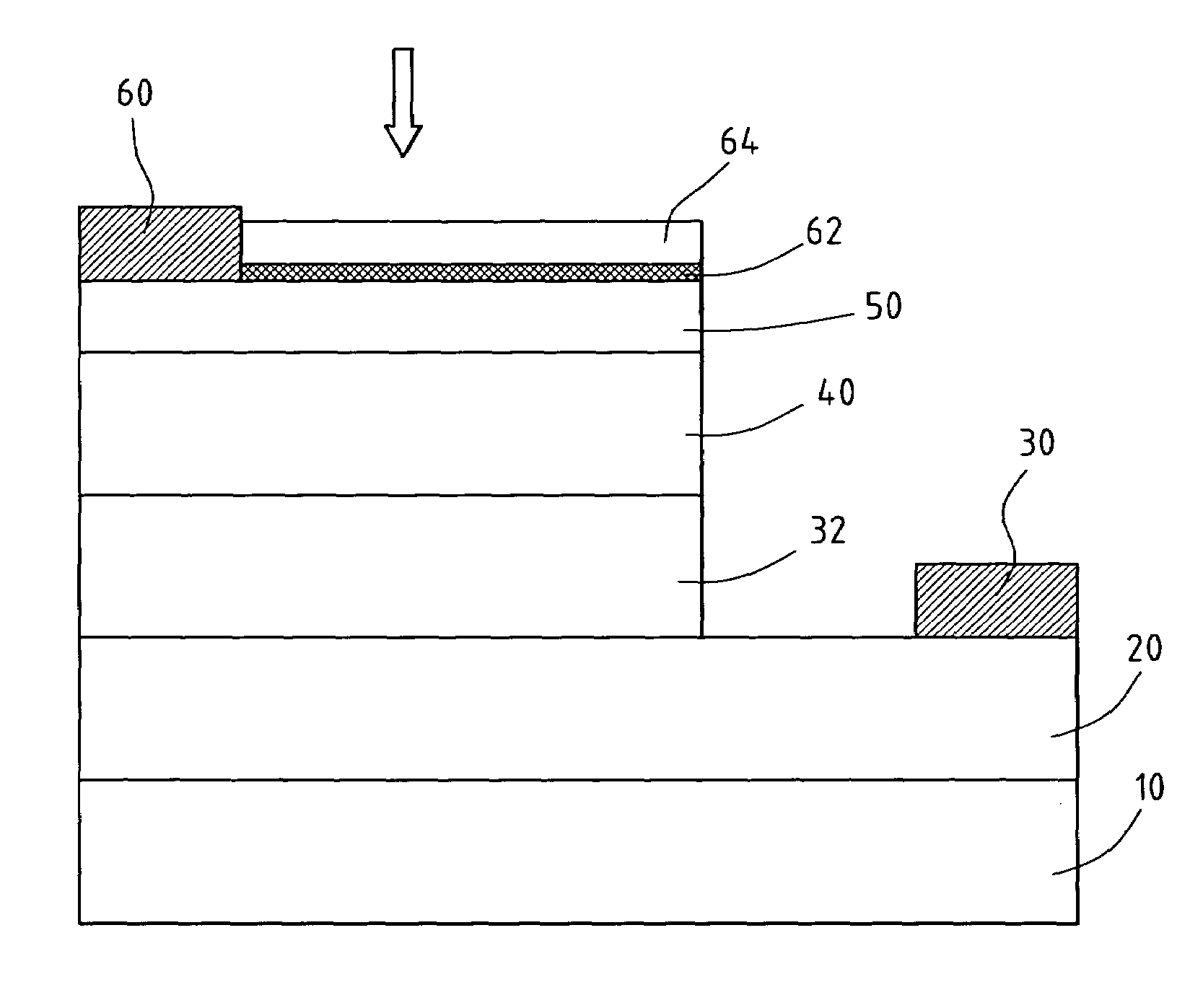

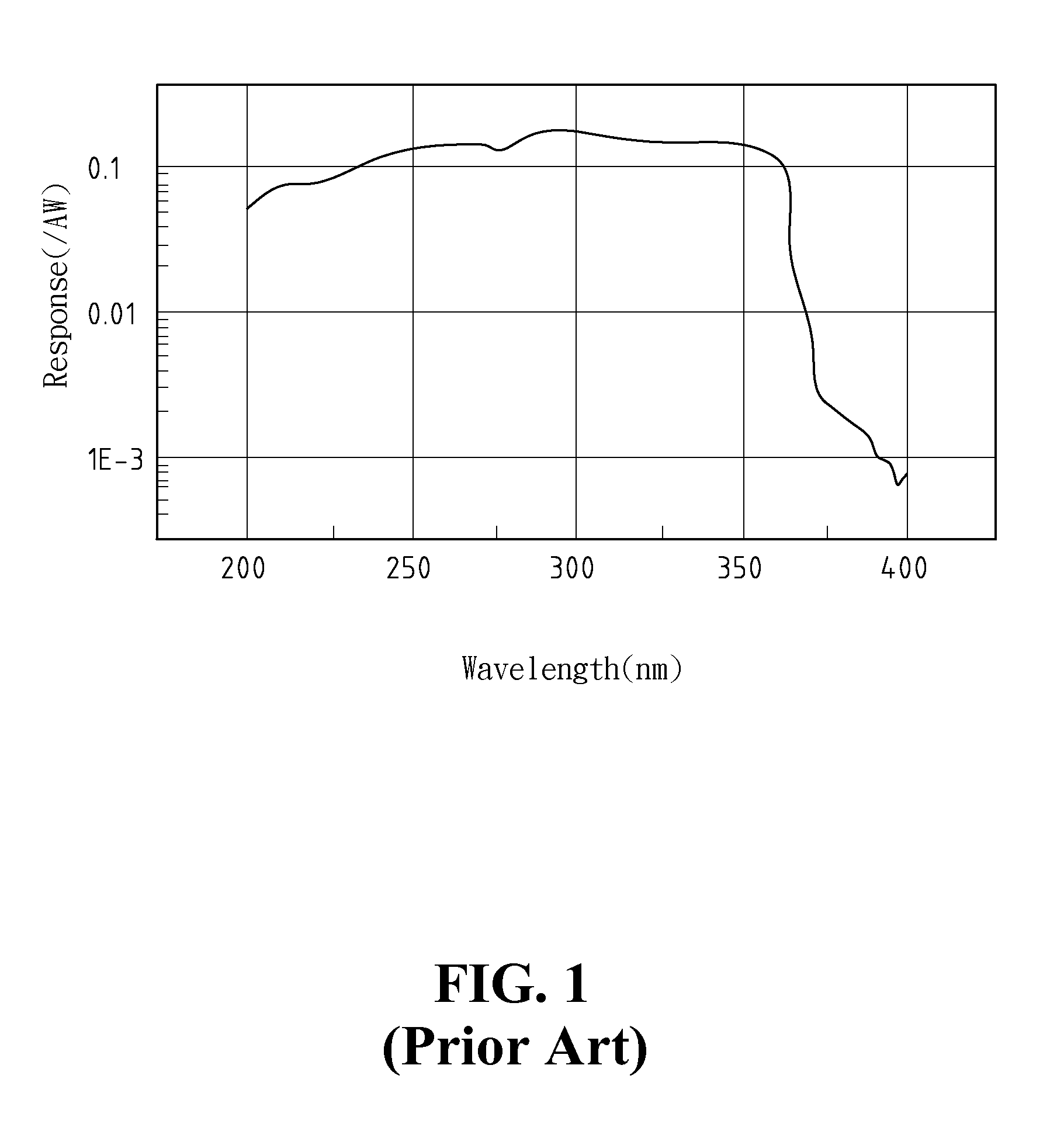

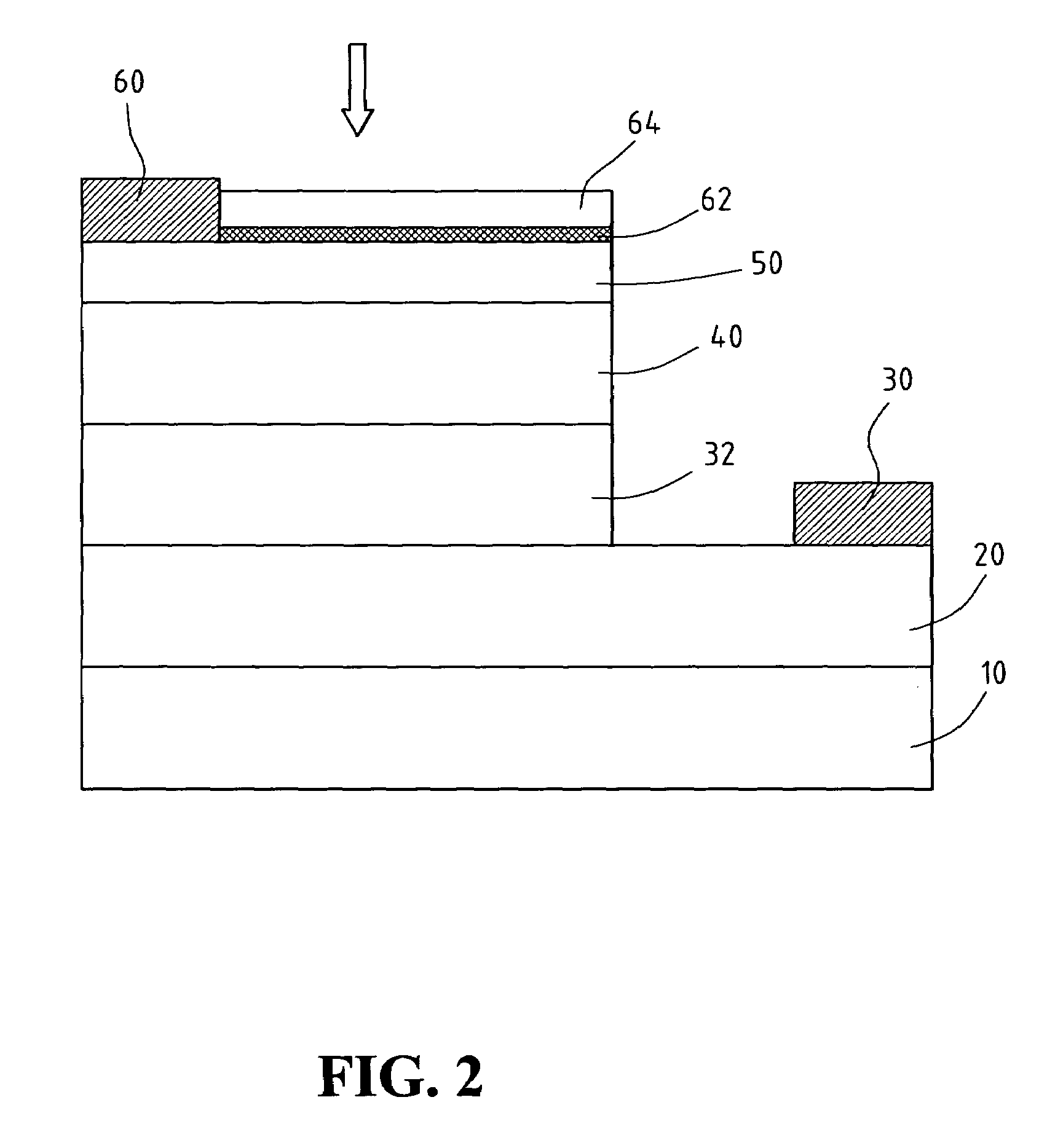

Gallium-nitride based ultraviolet photo detector

ActiveUS7307291B2Avoid development and accumulationSimple structureSolid-state devicesNanoopticsAnti-reflective coatingIndium

A structure for a gallium-nitride (GaN) based ultraviolet photo detector is provided. The structure contains an n-type contact layer, a light absorption layer, a light penetration layer, and a p-type contact layer, sequentially stacked on a substrate from bottom to top in this order. The layers are all made of aluminum-gallium-indium-nitride (AlGaInN) compound semiconductors. By varying the composition of aluminum, gallium, and indium, the layers, on one hand, can achieve the desired band gaps so that the photo detector is highly responsive to ultraviolet lights having specific wavelengths. On the other hand, the layers have compatible lattice constants so that problems associated with excessive stress are avoided and high-quality epitaxial structure is obtained. The structure further contains a positive electrode, a light penetration contact layer, and an anti-reflective coating layer on top of the p-type contact layer, and a negative electrode on the n-type contact layer.

Owner:FORMOSA EPITAXY INCORPORATION +1

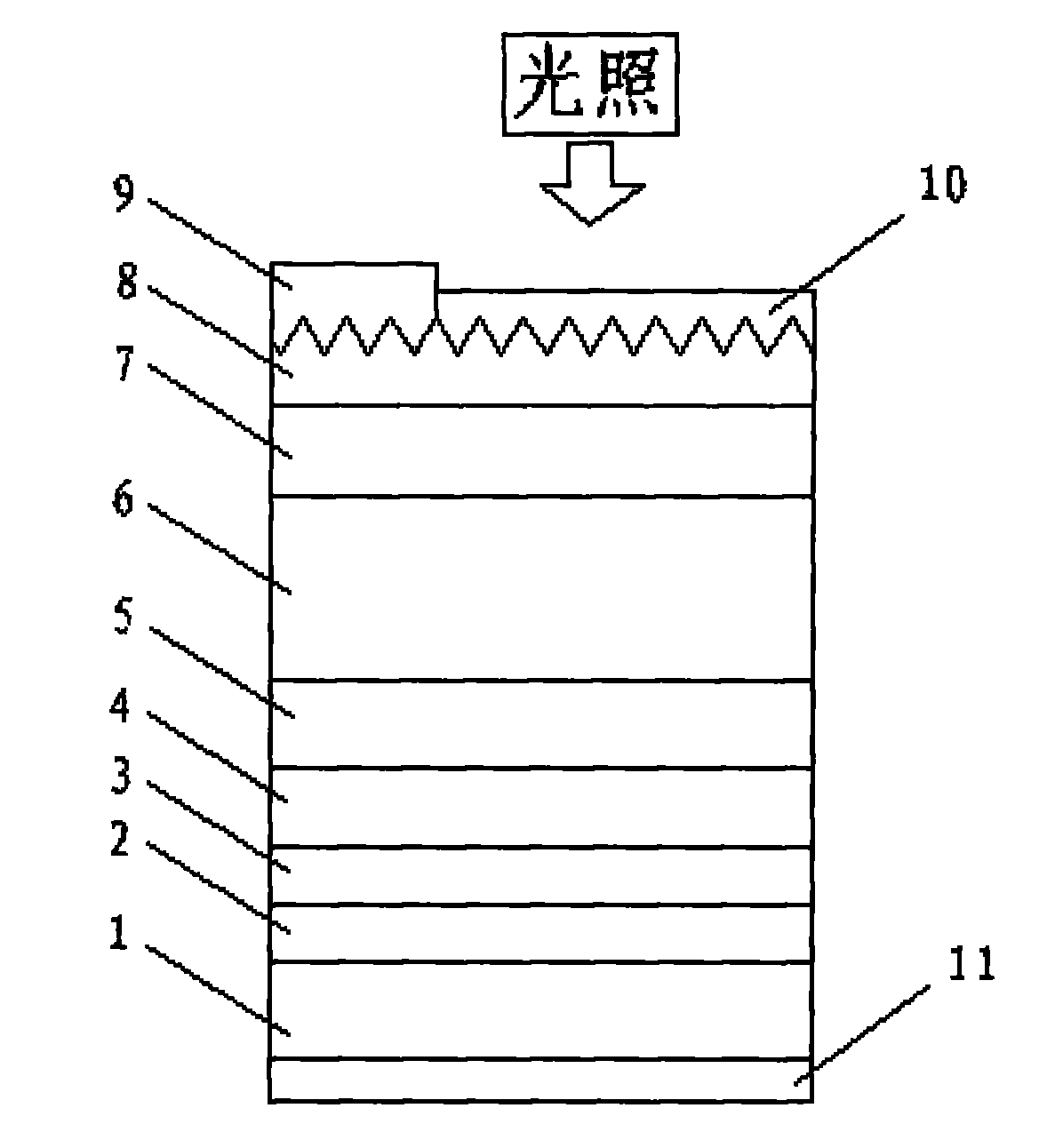

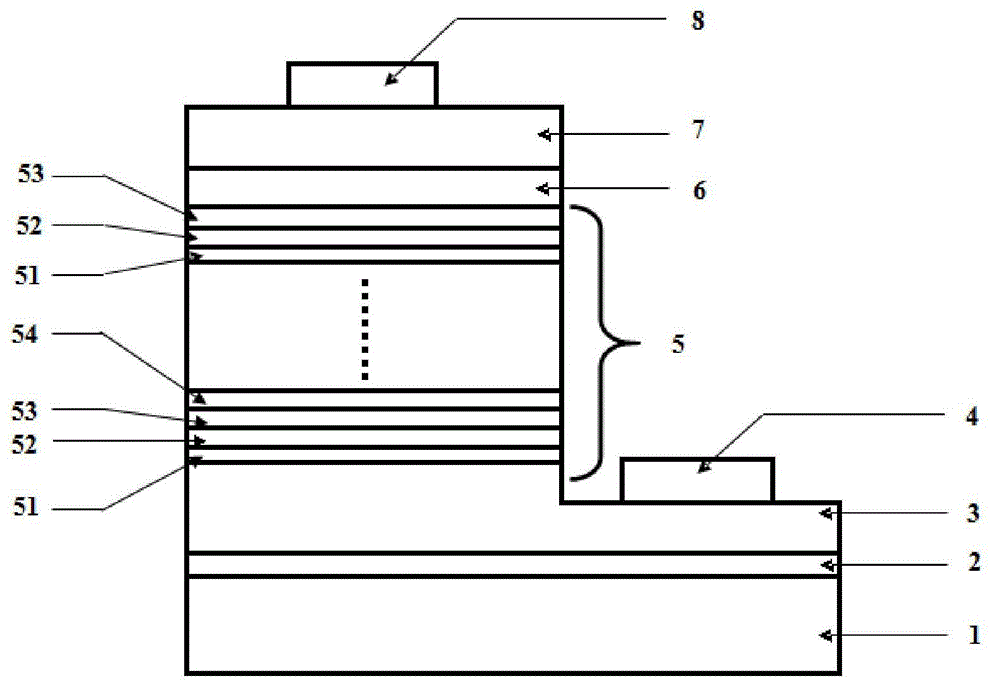

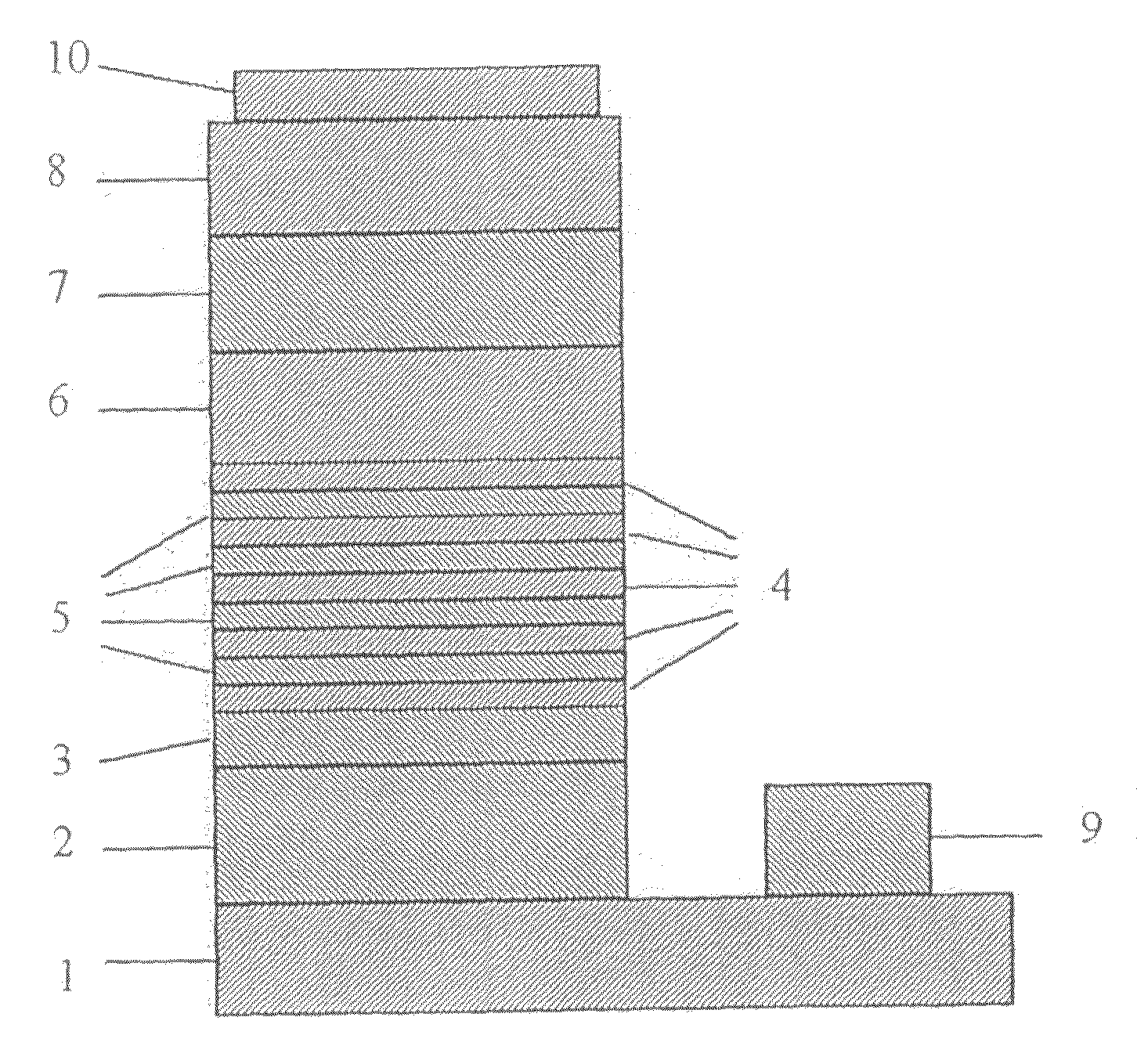

Solar cell

InactiveCN101866967AReduce manufacturing costImprove conductivityFinal product manufacturePhotovoltaic energy generationThermal expansionSolar cell

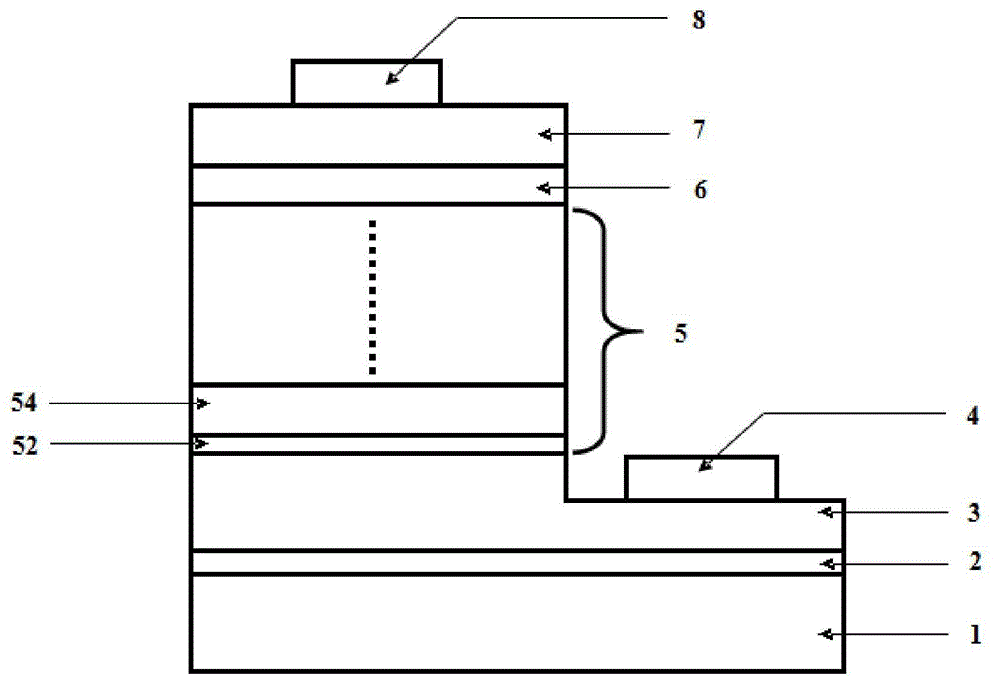

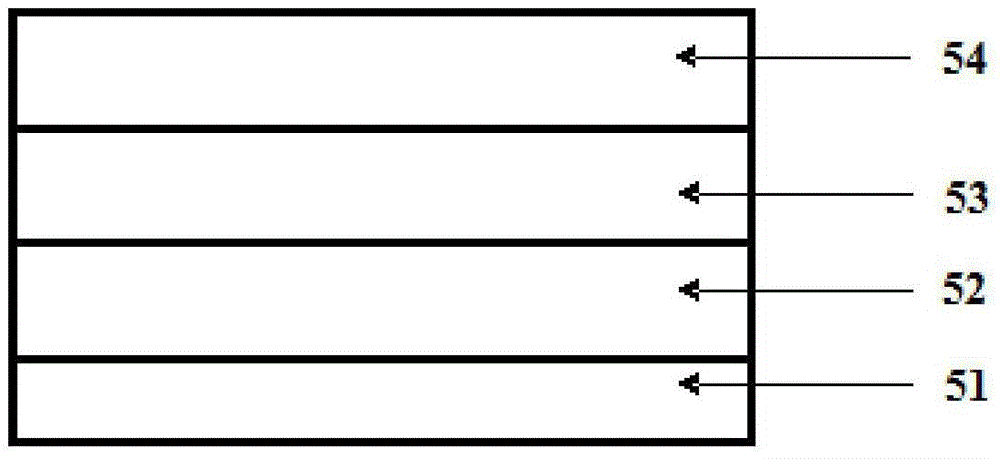

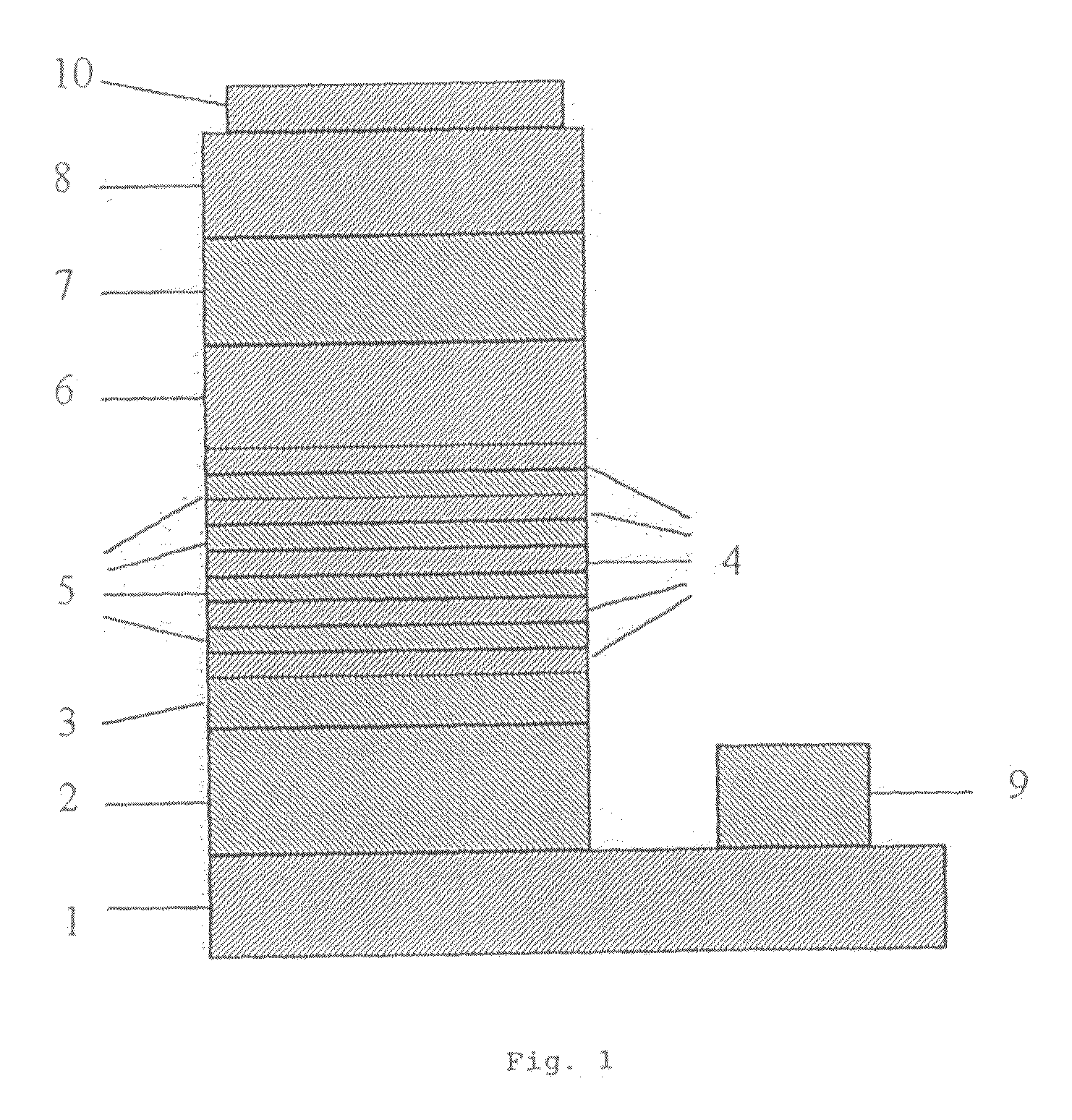

The invention relates to a silicon-based single-junction gallium indium nitride solar cell which comprises a back electrode (11), a silicon substrate (1), a seed crystal layer (2), a buffer layer (3), an n-type doped GaN buffer layer (4), an InaGal-aN layer (5), an unintentional doped InbGal-bN layer (6), a p-type doped IncGal-cN layer (7), a window layer (8), a positive electrode (9) and an anti-reflection conductive film (10) which are arranged from bottom to top, wherein the silicon substrate and the InaGal-aN layer is are an n-type doped structure, the seed crystal layer and the buffer layer are made of ZnO material, the window layer is made of p-type heavily doped GaN, and the anti-reflection conductive film covers areas of the window layer other than the positive electrode. The solar cell can quite effectively solve the problems of lattice matching, thermal expansion coefficient matching and the like encountered when a GaN film extends from the silicon substrate, and has the advantages of low manufacturing cost, high sunlight absorbability and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

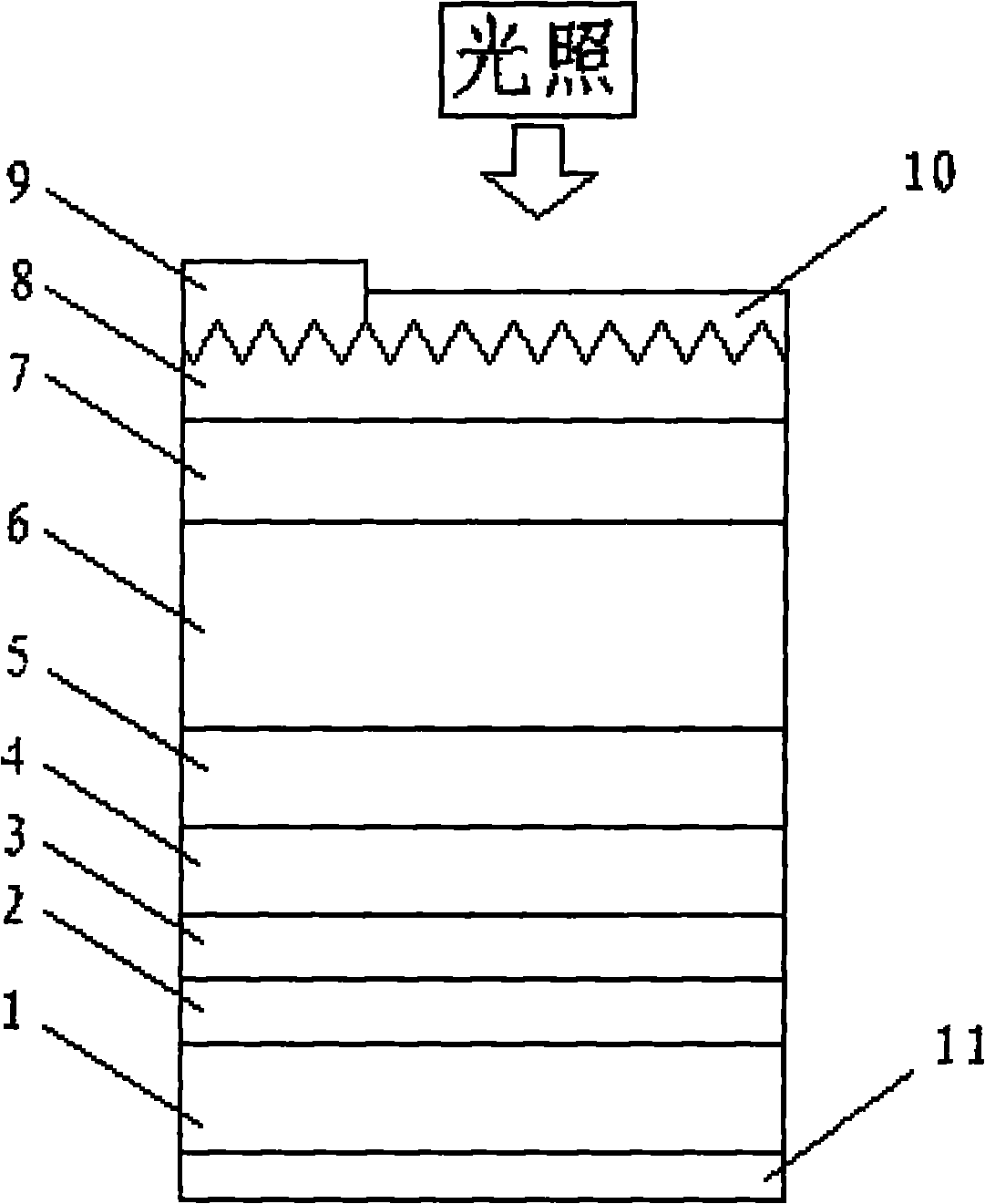

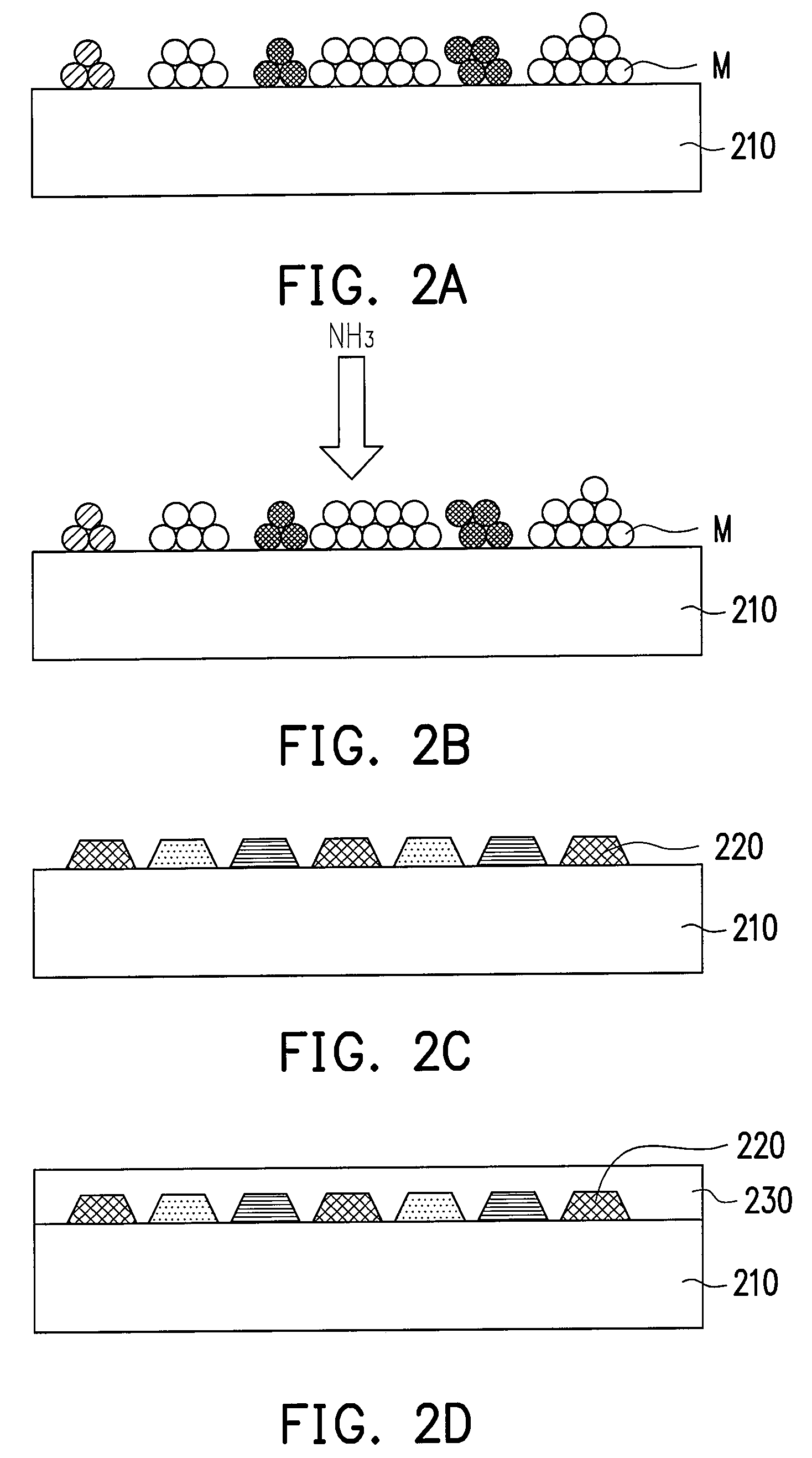

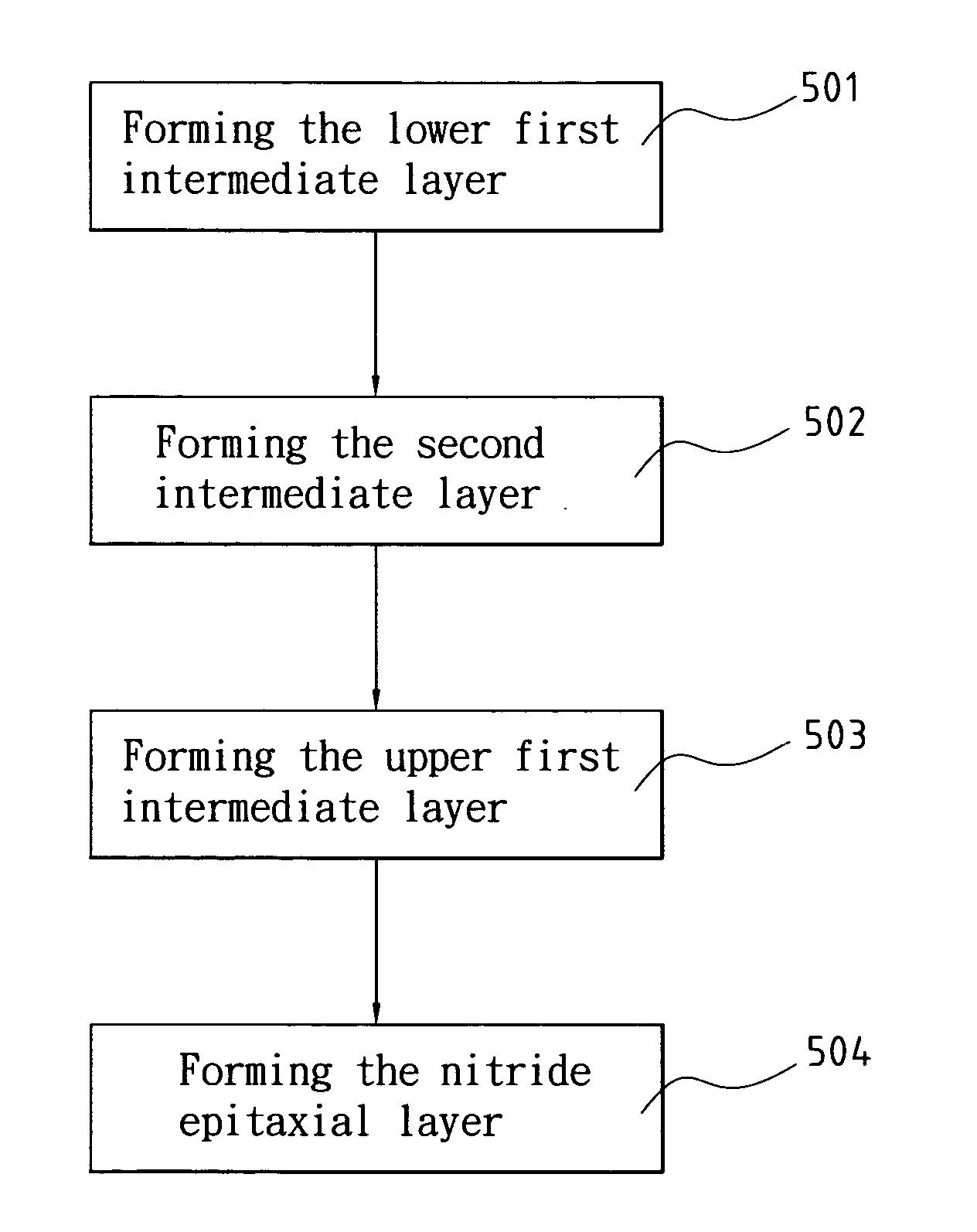

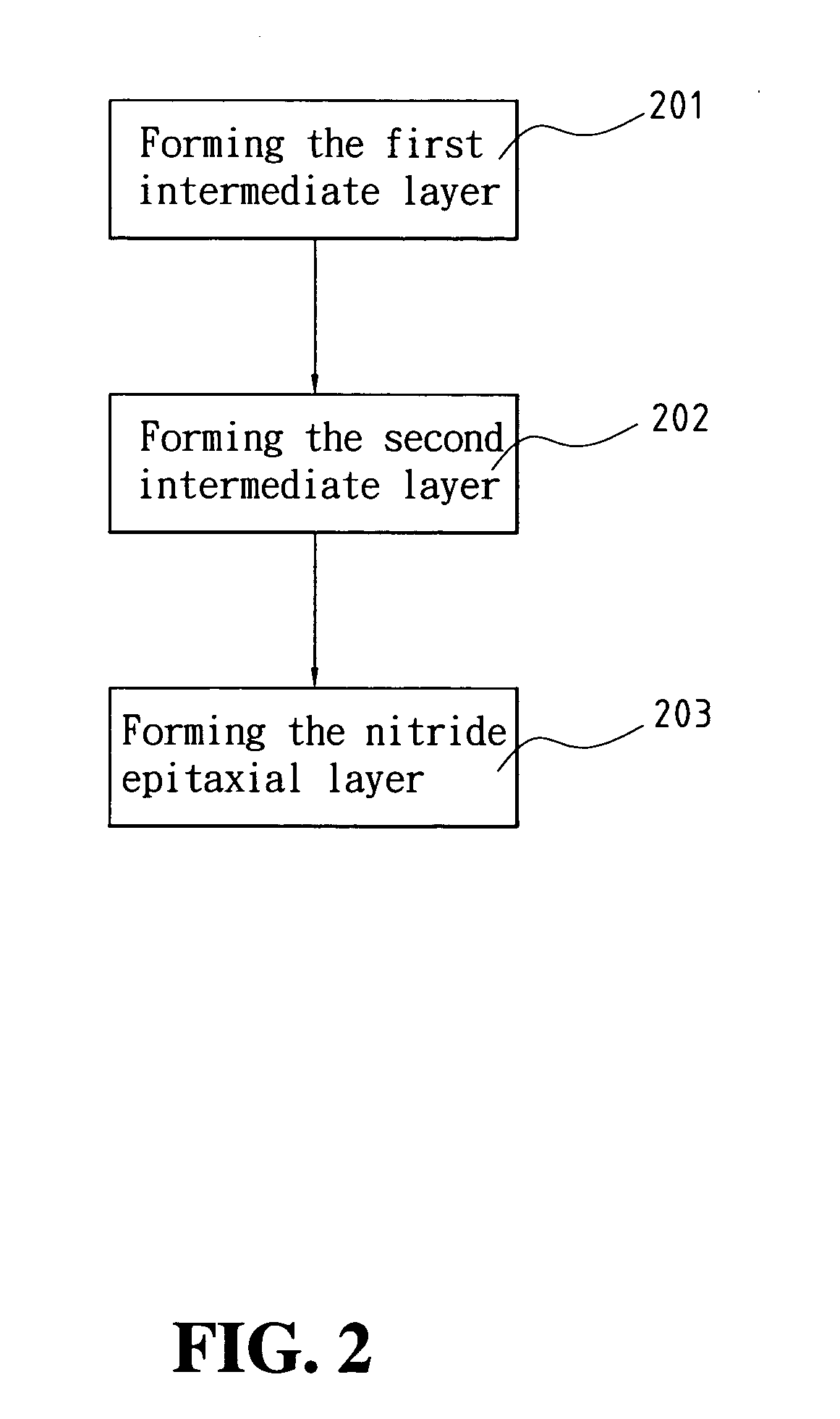

Method of Growing Nitride Semiconductor material

InactiveUS20090162999A1Improve flatnessLow densitySemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsQuantum well

A method of growing nitride semiconductor material and particularly a method of growing Indium nitride is disclosed can increase surface flatness of a nitride semiconductor material and decrease density of V-defects therein. Further, the method can increase light emission efficiency of a quantum well or quantum dots of the produced LED as well as greatly increase yield. The method is also applicable to the fabrications of electronic devices made of nitride semiconductor material and diodes of high breakdown voltage for rectification. The method can greatly increase surface flatness of semiconductor material for HBT, thereby increasing quality of the produced semiconductor devices.

Owner:NAT CENT UNIV

Semiconductor-on-diamond devices and associated methods

ActiveUS20070269964A1Improve lattice matchingSemiconductor/solid-state device detailsSolid-state devicesBoron arsenideSingle crystal

Semiconductor-on-diamond (SOD) substrates and methods for making such substrates are provided. In one aspect, a method of making an SOD substrate may include depositing a base layer onto a lattice-orienting silicon (Si) substrate such that the base layer lattice is substantially oriented by the Si substrate, depositing a semiconductor layer onto the base layer such that the semiconductor layer lattice is substantially oriented with respect to the base layer lattice, and disposing a layer of diamond onto the semiconductor layer. The base layer may include numerous materials, including, without limitation, aluminum phosphide (AlP), boron arsenide (BAs), gallium nitride (GaN), indium nitride (InN), and combinations thereof. Additionally, the method may further include removing the lattice-orienting Si substrate and the base layer from the semiconductor layer. In one aspect, the Si substrate may be of a single crystal orientation.

Owner:SUNG CHIEN MIN

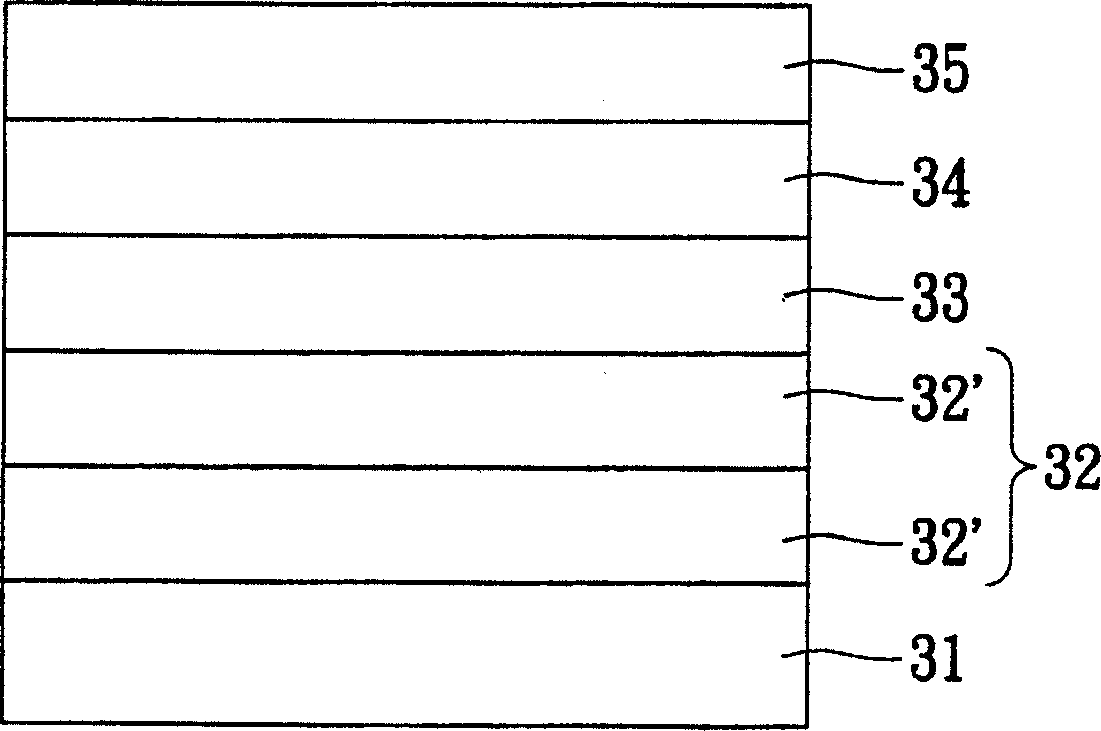

Light emitting diode having indium nitride

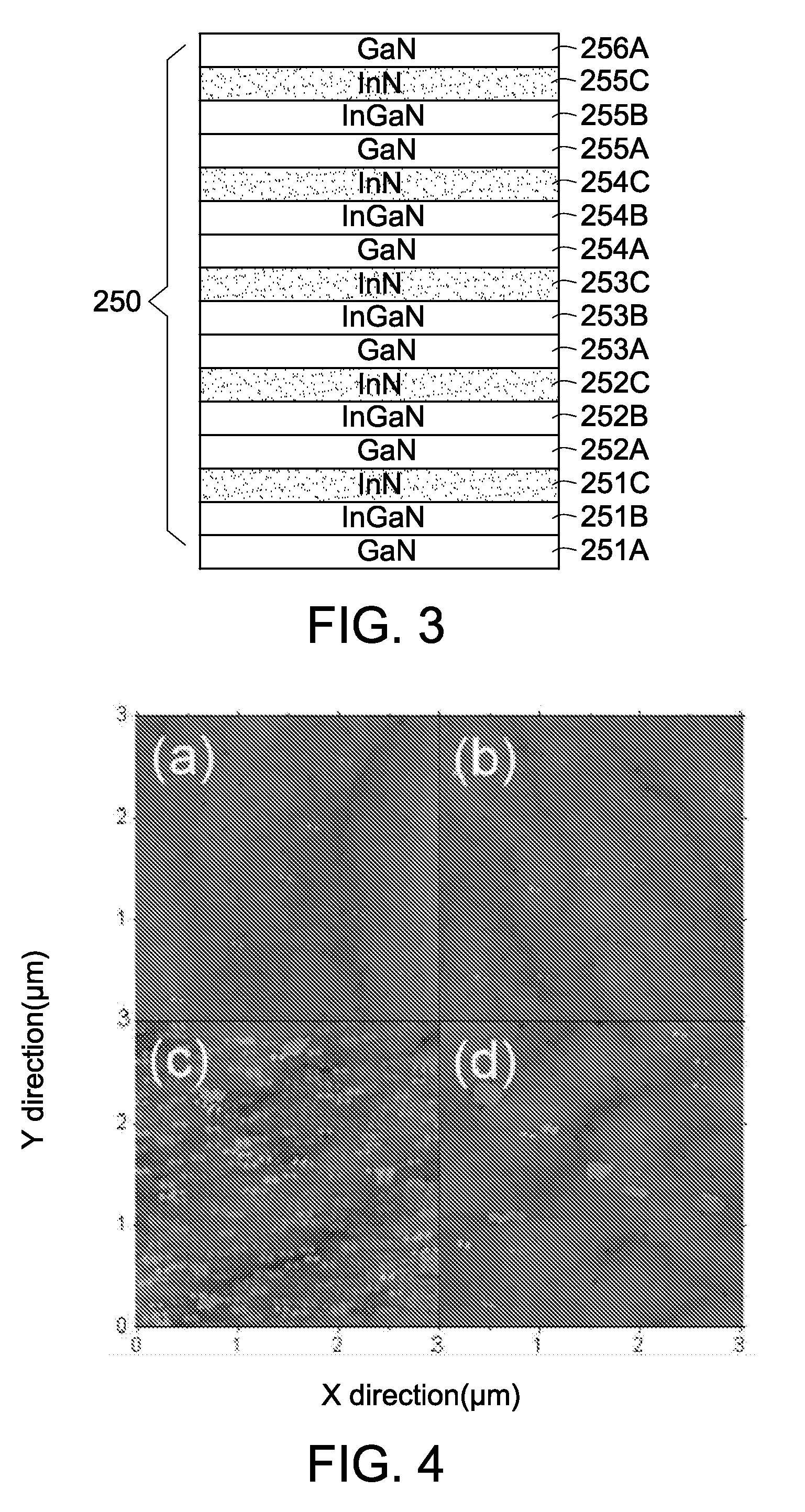

The present invention relates to a light emitting diode (LED) including an n-type nitride semiconductor layer, a p-type nitride semiconductor layer, and an active region interposed between the n-type nitride semiconductor layer and the p-type nitride semiconductor layer. The active region may include an InGaN quantum well layer. The LED may further include a super lattice layer interposed between the n-type nitride semiconductor layer and the active region. The super lattice layer may be a structure wherein InN layers and InxGa1-xN (0≦x<1) layers are alternately stacked. The active layer may be formed on the InGaN / InxGa1-xN super lattice layer, so that strain can be relieved in the active region and so that crystallinity of the quantum well can be improved to increase an electron-hole recombination rate.

Owner:SEOUL OPTO DEVICE CO LTD

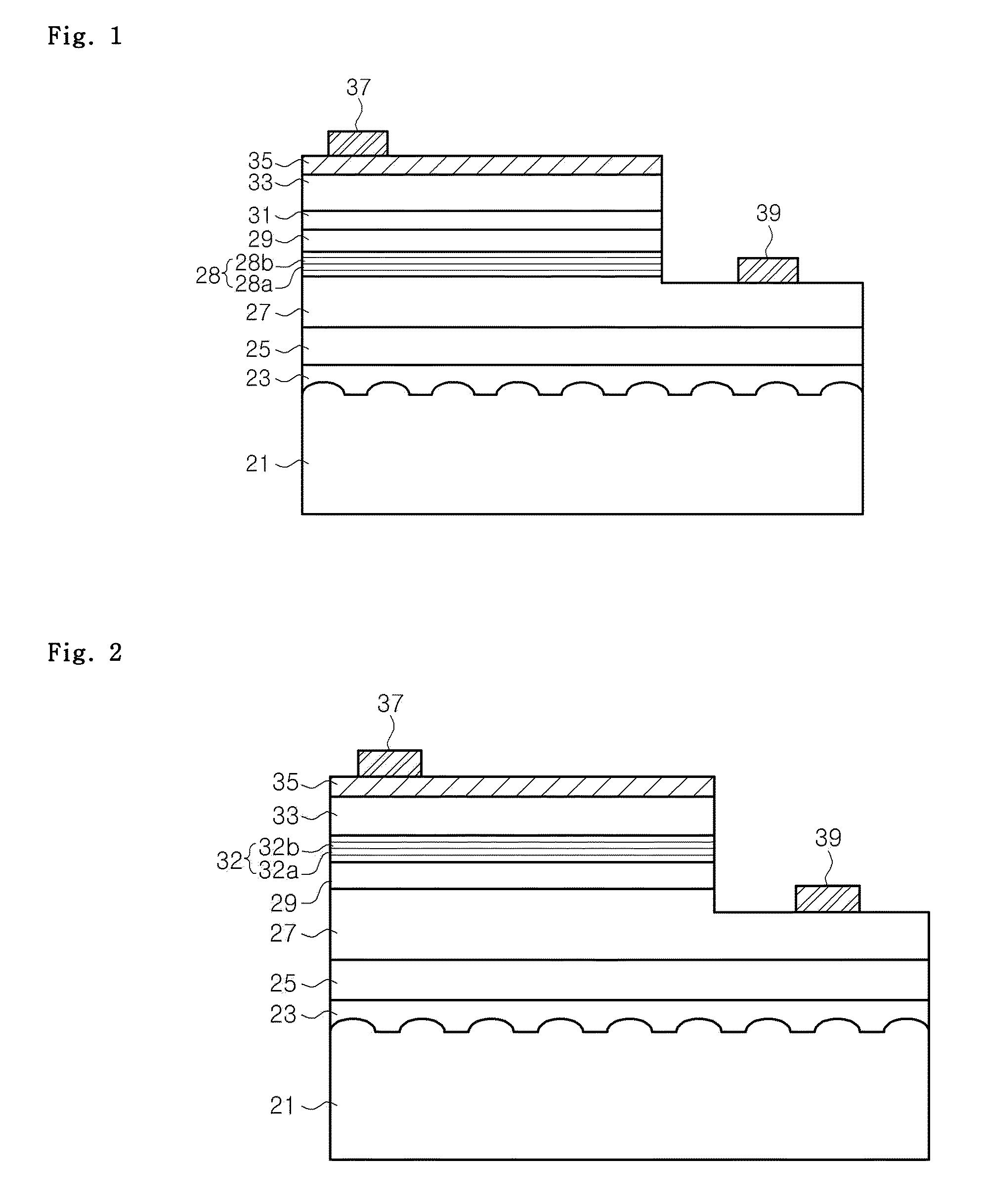

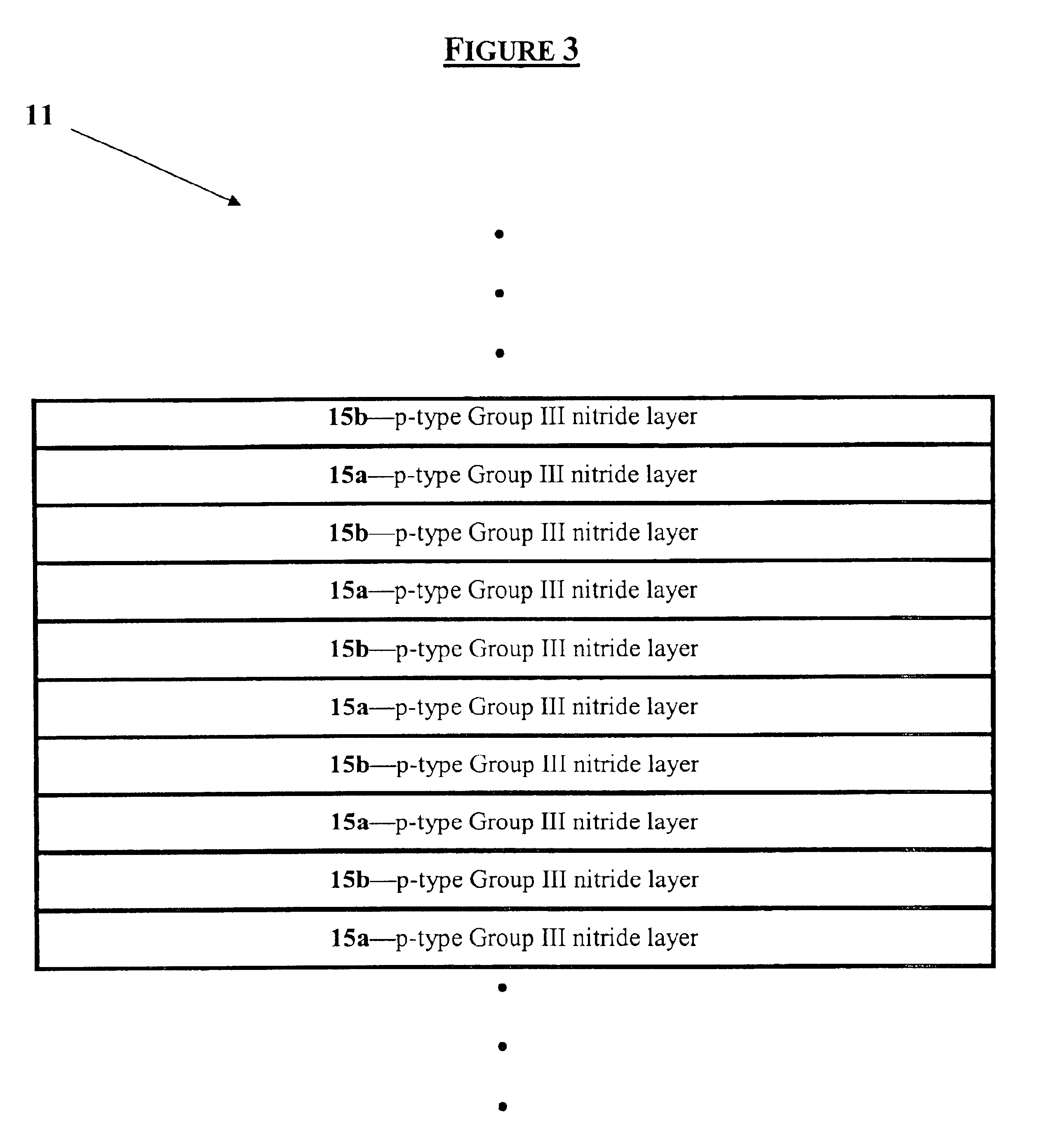

Group III nitride contact structures for light emitting devices

A superlattice contact structure for light emitting devices includes a plurality of contiguous p-type Group III nitride layers. The contact structure may be formed of p-type indium nitride, aluminum indium nitride, or indium gallium nitride. Also disclosed is a light emitting device that incorporates the disclosed contact structures.

Owner:CREELED INC

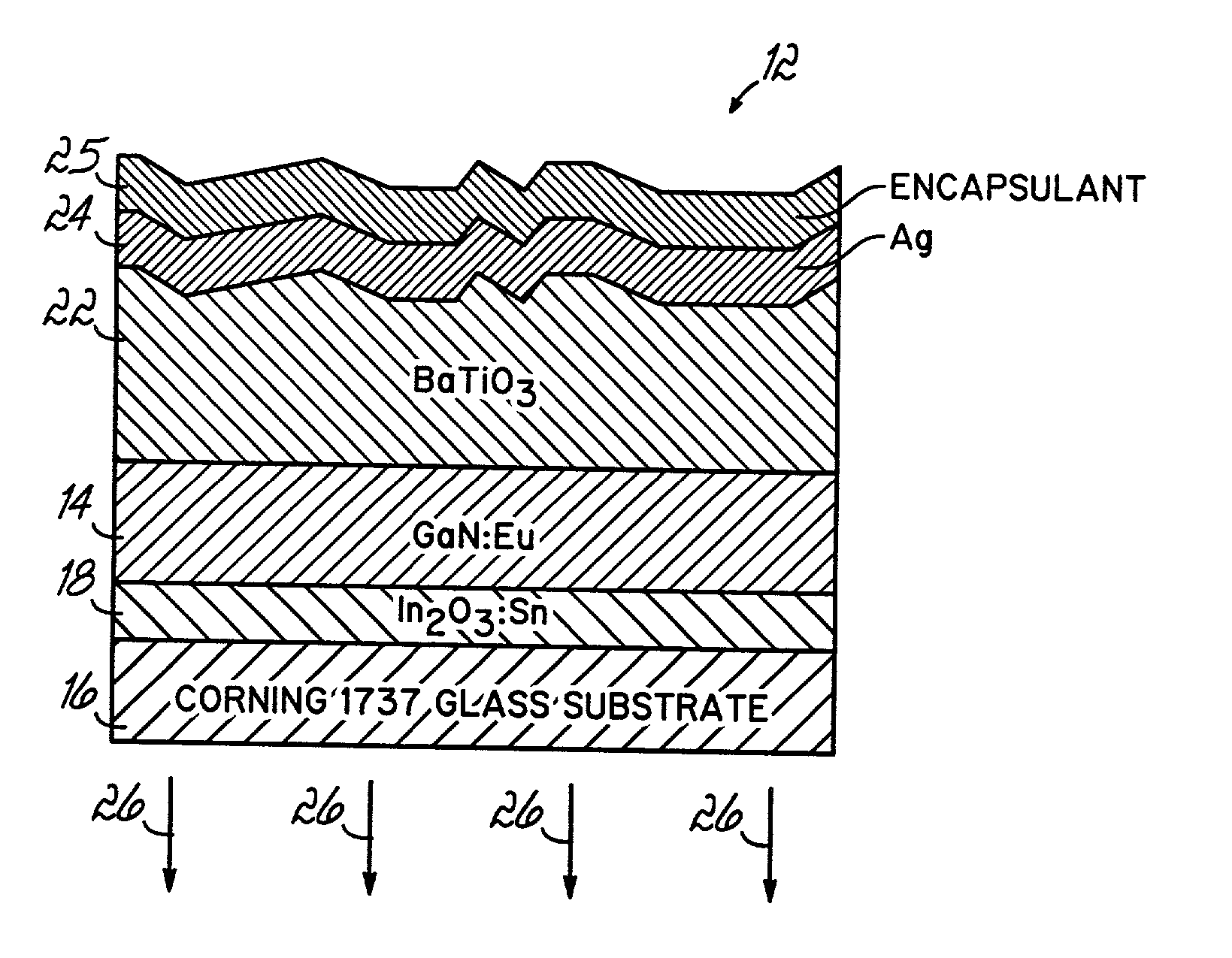

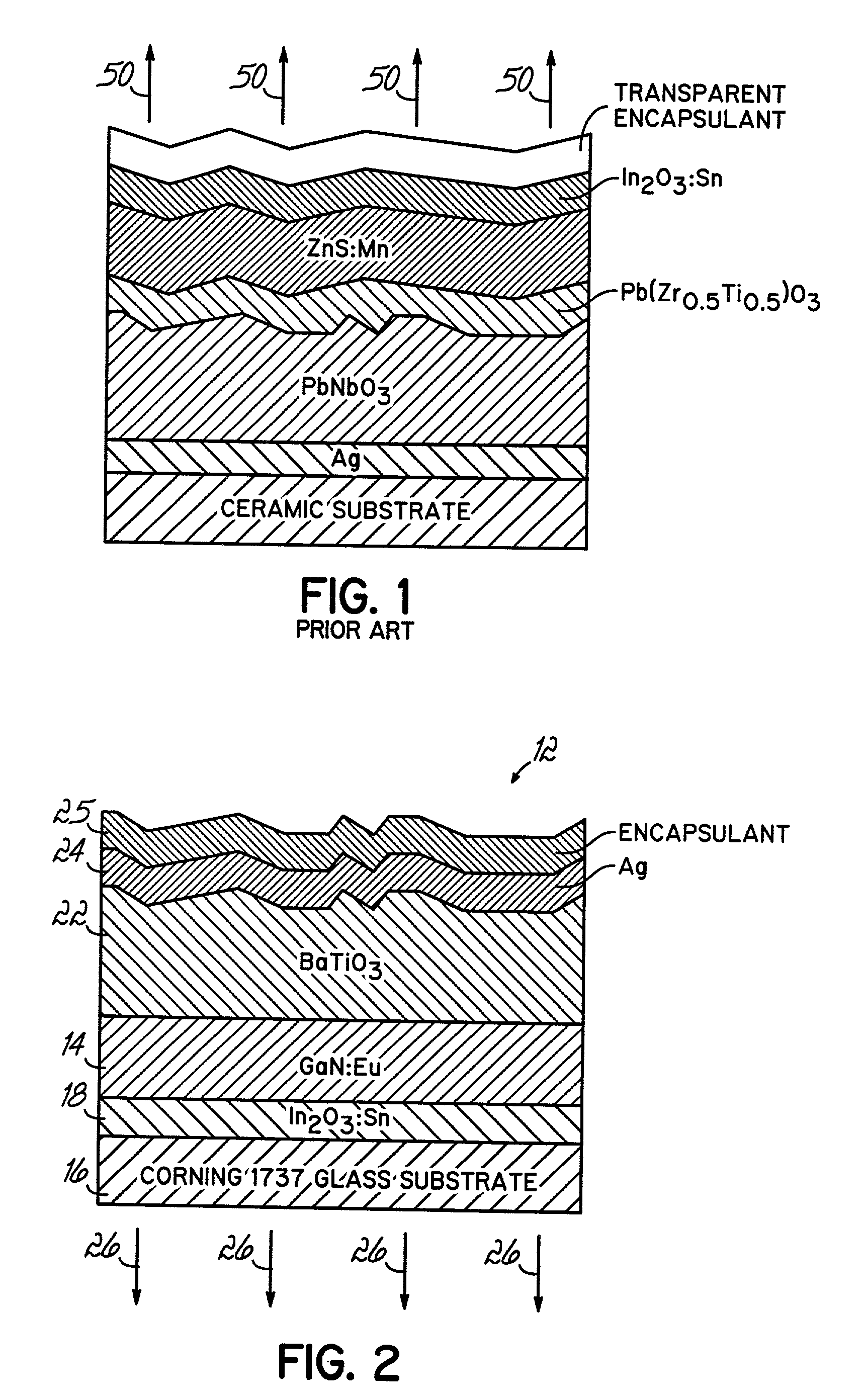

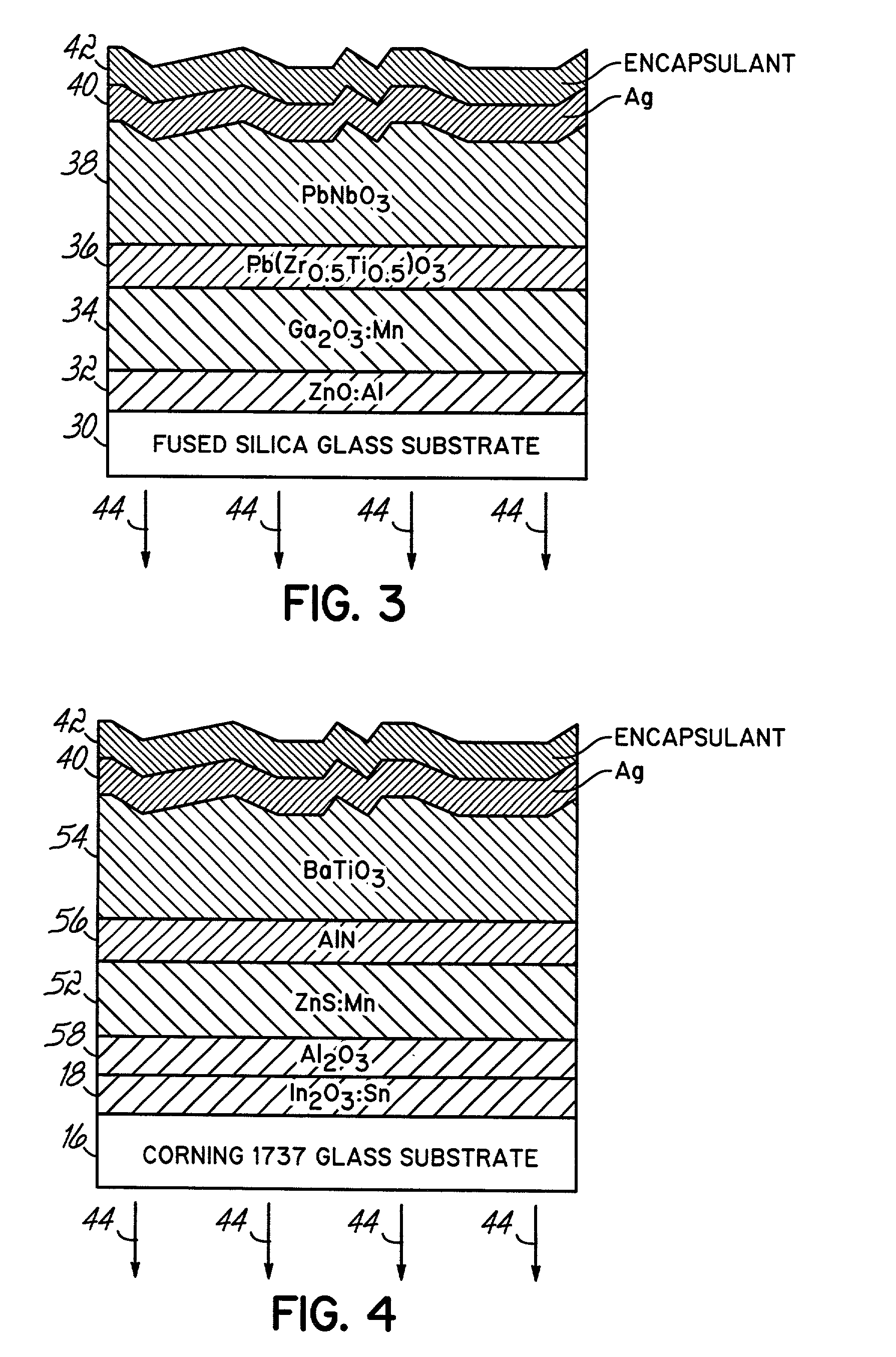

Electroluminescent display formed on glass with a thick film dielectric layer

InactiveUS20020125821A1Choose accuratelyPromote economic technologyDischarge tube luminescnet screensElectroluminescent light sourcesSemiconductor materialsRare earth

Wide band gap semiconductor materials doped with rare earth form alternating current electroluminescent devices. The semiconductors are preferably gallium nitride, indium nitride or aluminum nitride and the electric luminescent device may have an upper and lower thin coat of a dielectric material in turn connected to alternating current electrodes. In a preferred embodiment, the electroluminescent device is formed on a glass substrate coated with a thick film of dielectric. The dielectric can be applied as a gel and heat treated after coating the semiconductor material to form a light emitting device.

Owner:UNIVERSITY OF CINCINNATI

Process for preparing nitride ultromicro powder and nitride crystal wunder hydrothermal condition

InactiveCN1364728AImprove protectionEasy to monitorNitrogen-metal/silicon/boron binary compoundsIndiumTitanium nitride

The present invention relates to the field of nano material and crystal growth technology. The present ivnention features that crystal and superfine powder of boron nitride, gallium nitride, aluminium nitride and indium nitride are prepared through dissolving boron, gallium, aluminium and indium in deionized water, adding metal nitride or ammonia while stirring; adding P, Zn and other reductant; heating at 100-800 deg.c for 10-120 hr and by means of reaction coupling. The present inventino has the advantages of no need of large and expensive instrument and equipment, no need of oxygen-free and water-free condition and capability of obtaining large crystal. The process is low in nitride preparing cost and suitable for large-scale production.

Owner:SHANDONG UNIV

Gallium nitride base light-emitting diode with composite potential barrier

ActiveCN103151435AReduce the built-in electric fieldEliminate mismatchSemiconductor devicesPotential wellIndium

The invention discloses a gallium nitride base light-emitting diode with a composite potential barrier. The gallium nitride base light-emitting diode comprises a sapphire substrate, a buffering layer, an n-type gallium nitride epitaxial layer, a multiple quantum well active area, a p-type algan epitaxial layer and a p-type gallium nitride epitaxial layer, wherein the sapphire substrate, the buffering layer, the n-type gallium nitride epitaxial layer, the multiple quantum well active area, the p-type algan epitaxial layer and the p-type gallium nitride epitaxial layer are arranged sequentially from bottom to top. A p-type metal electrode is arranged on the upper surface of the p-type gallium nitride epitaxial layer. An n-type electrode is arranged on a lower platform surface of the n-type gallium nitride epitaxial layer. The multiple quantum well active area comprises 5-20 indium gallium nitride potential well layers which are arranged at intervals from bottom to top. A first kind composite potential barrier layer is arranged between every two indium gallium nitride potential barrier layers. A second kind composite potential well layer is arranged on the upper surface of an indium gallium nitride potential well layer at the top layer. According to the composite potential barrier, at the contact position of an aluminum, gallium and indium nitride layer and an InGaN potential well layer, a built-in electric field which is produced due to a polarization effect can be decreased through adjustment of aluminum (Al) and indium (In). On a contact interface between an AlInGaN layer and a GaN layer, a ratio between the Al and the In is adjusted to be 0.83:0.17, and lattices of the Al and the In are enabled to be matched.

Owner:SOUTHEAST UNIV

Gallium-nitride based light-emitting diode epitaxial structure

ActiveUS6979835B1Improve external quantum efficiencyLow working voltageSemiconductor/solid-state device manufacturingNanoopticsOhmic contactEngineering

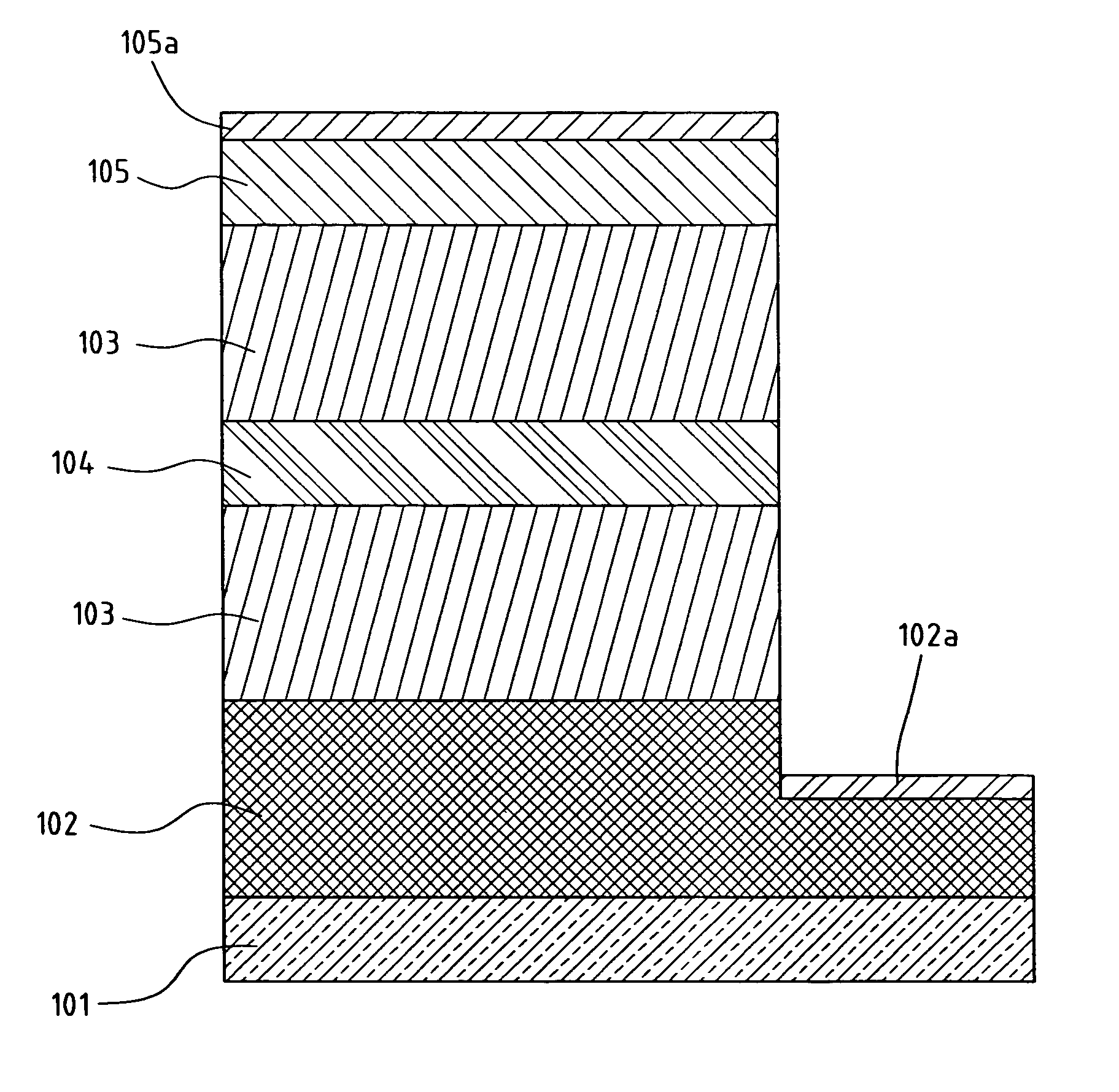

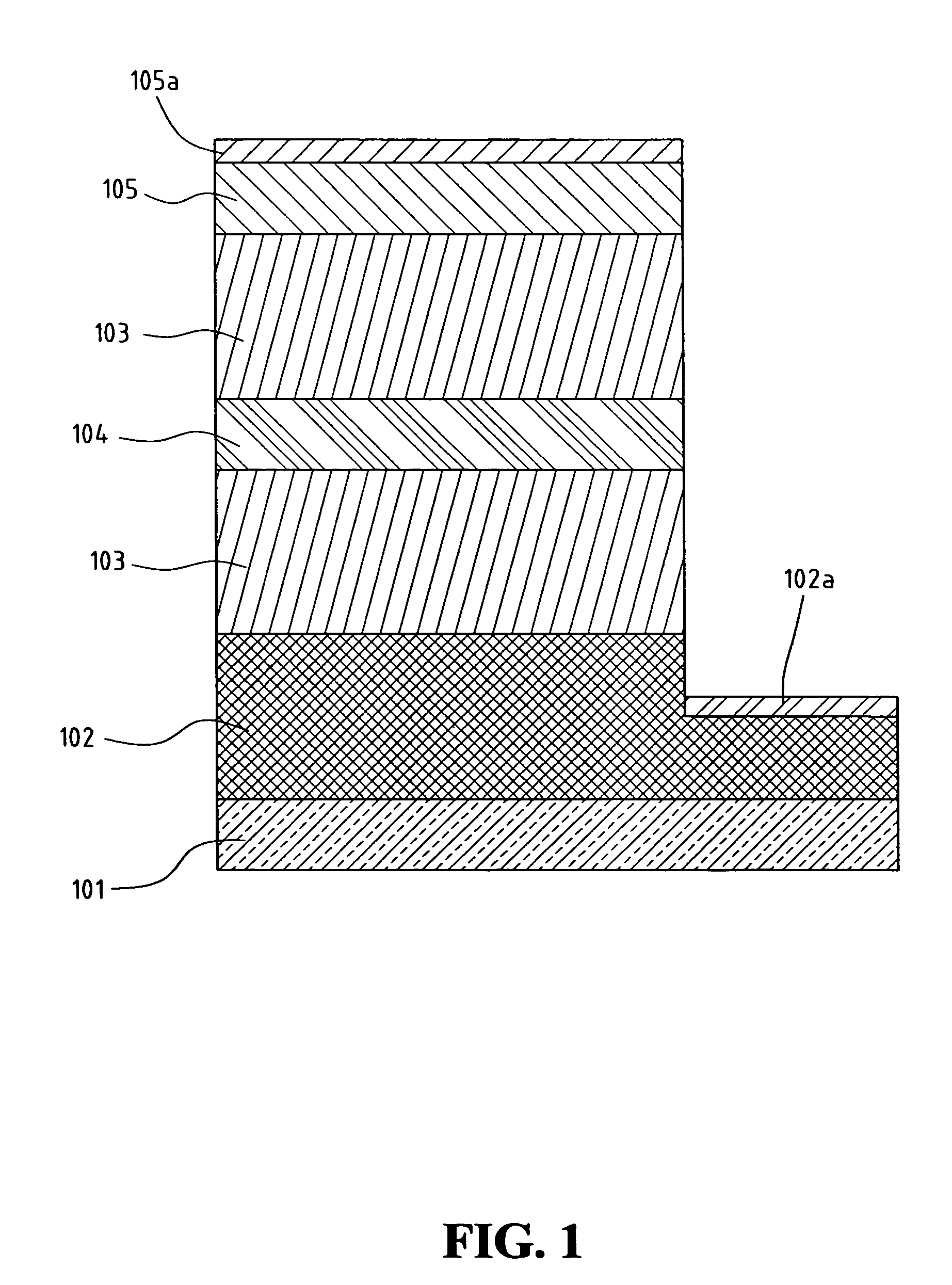

An epitaxial structure for the GaN-based LED is provided. The GaN-based LED uses a substrate usually made of sapphire or silicon-carbide (SiC). On top of the substrate, the GaN-based LED contains an n-type contact layer made of an n-type GaN-based material. On top of the n-type contact layer, the GaN-based LED further contains a lower barrier layer covering part of the surface of the n-type contact layer. A negative electrode is also on top of and has an ohmic contact with the n-type contact layer in an area not covered by the lower barrier layer. On top of the lower barrier layer, the GaN-based LED then further contains an active layer made of aluminum-gallium-indium-nitride, an upper barrier layer, a p-type contact layer made of a magnesium (Mg)-doped GaN material, and a positive electrode having an ohmic contact with the p-type contact layer, sequentially stacked in this order from bottom to top. Within this structure, each of the barrier layers further contains, from bottom to top, a first AlGaInN layer, a SiN layer, and a second AlGaInN layer.

Owner:FORMOSA EPITAXY INCORPORATION +1

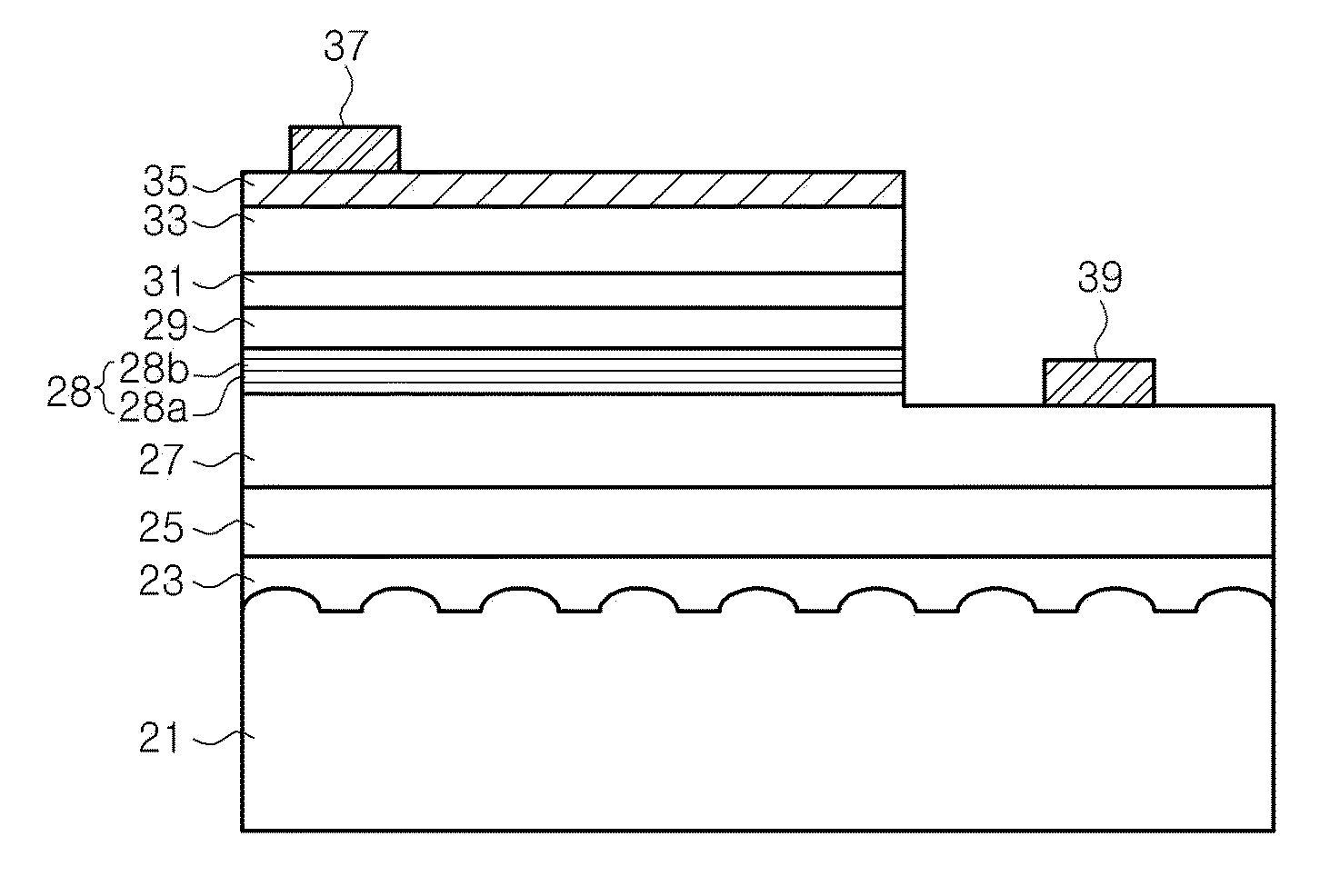

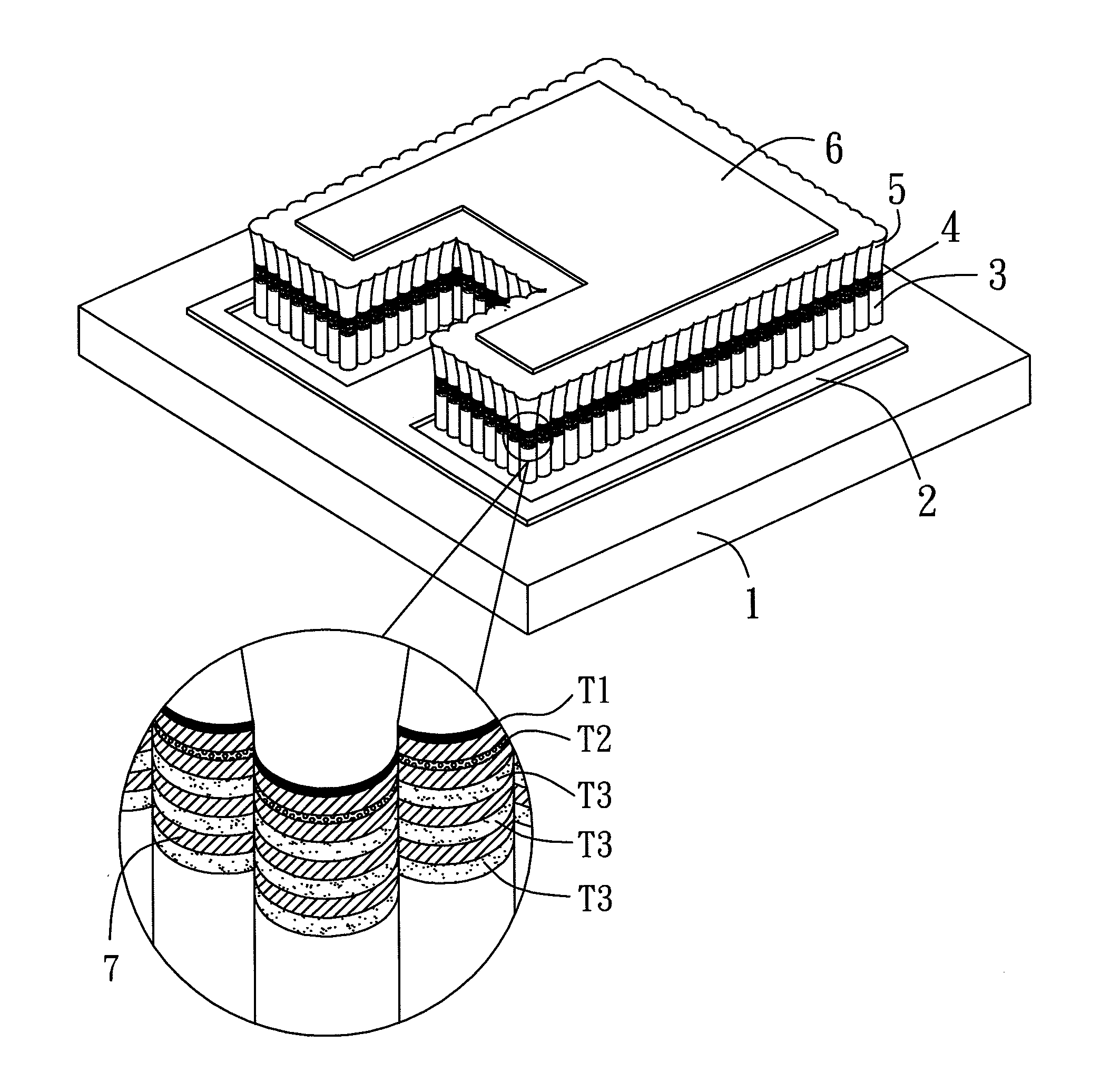

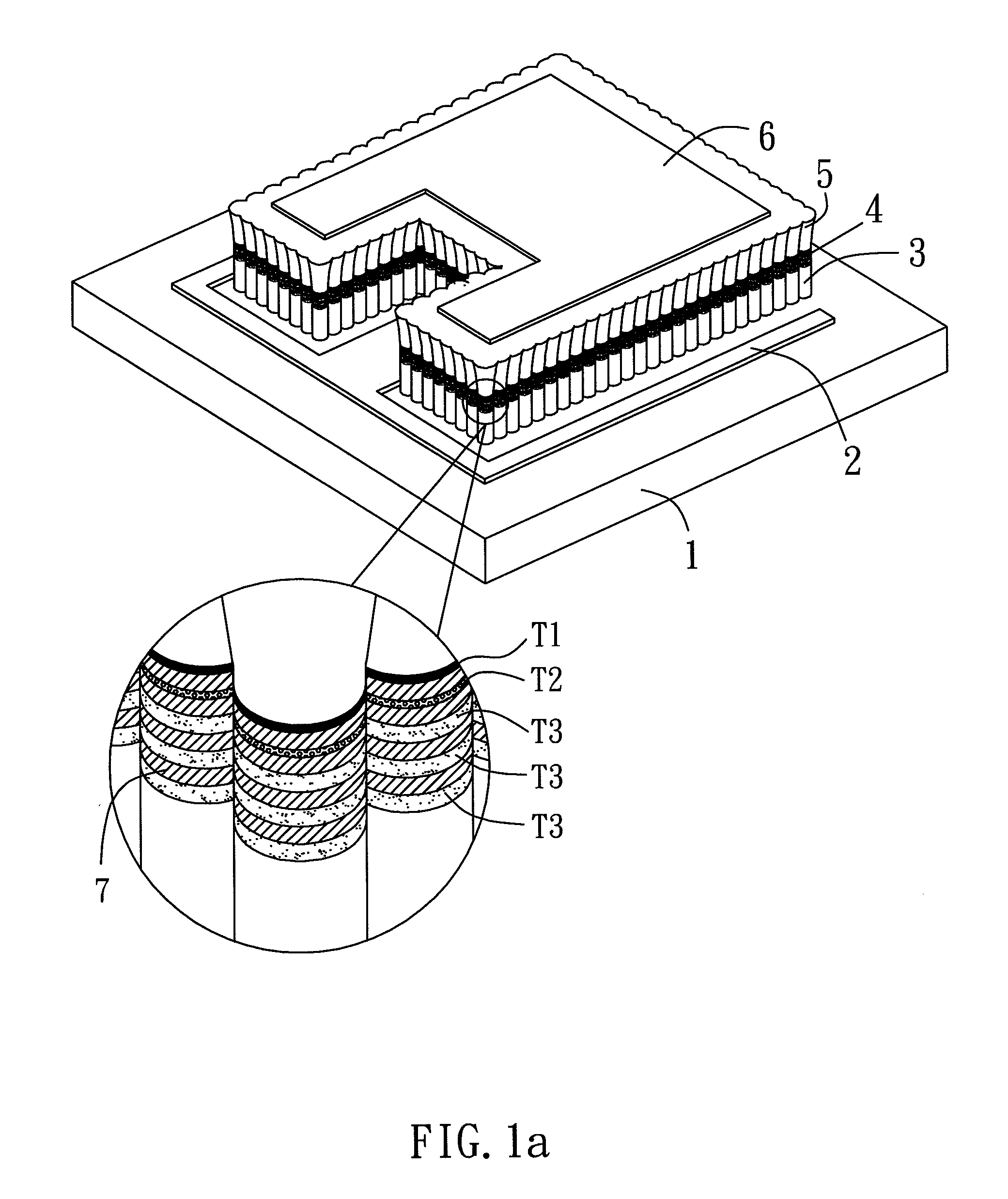

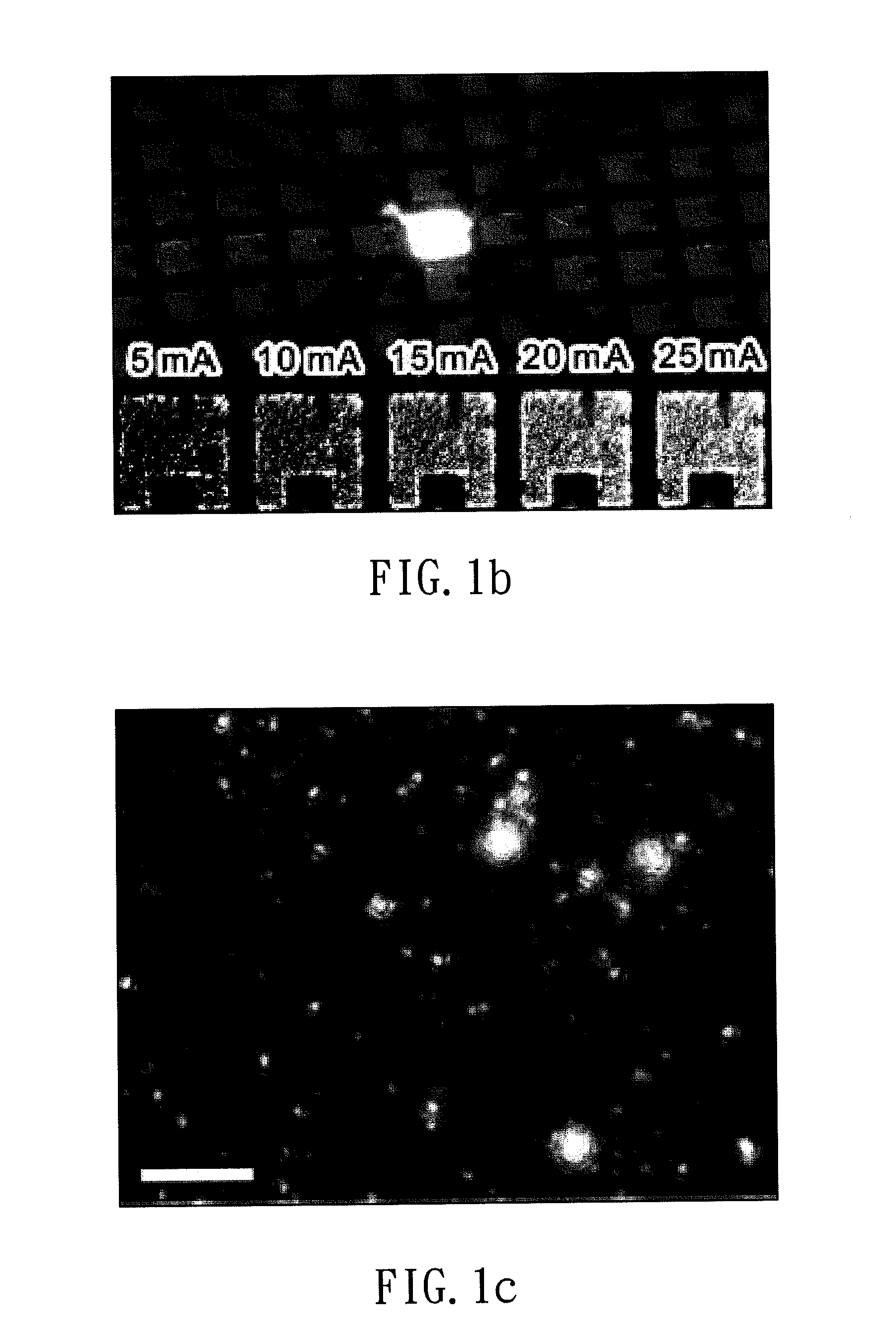

Iii-nitride light-emitting diode and method of producing the same

ActiveUS20120025232A1Improve performanceMaintain good propertiesSemiconductor/solid-state device manufacturingSemiconductor devicesOhmic contactLight-emitting diode

Embodiments of the present invention provides III-nitride light-emitting diodes, which primarily include a first electrode, a n-type gallium nitride (GaN) nanorod array consisted of one or more n-type GaN nanorods ohmic contacting with the first electrode, one or more indium gallium nitride (InGaN) nanodisks disposed on each of the n-type GaN nanorods, a p-type GaN nanorod array consisted of one or more p-type GaN nanorods, where one p-type GaN nanorod is disposed on top of the one ore more InGaN nanodisks disposed on each of the n-type GaN nanorods, and a second electrode ohmic contacts with the p-type GaN nanorod array.

Owner:NATIONAL TSING HUA UNIVERSITY

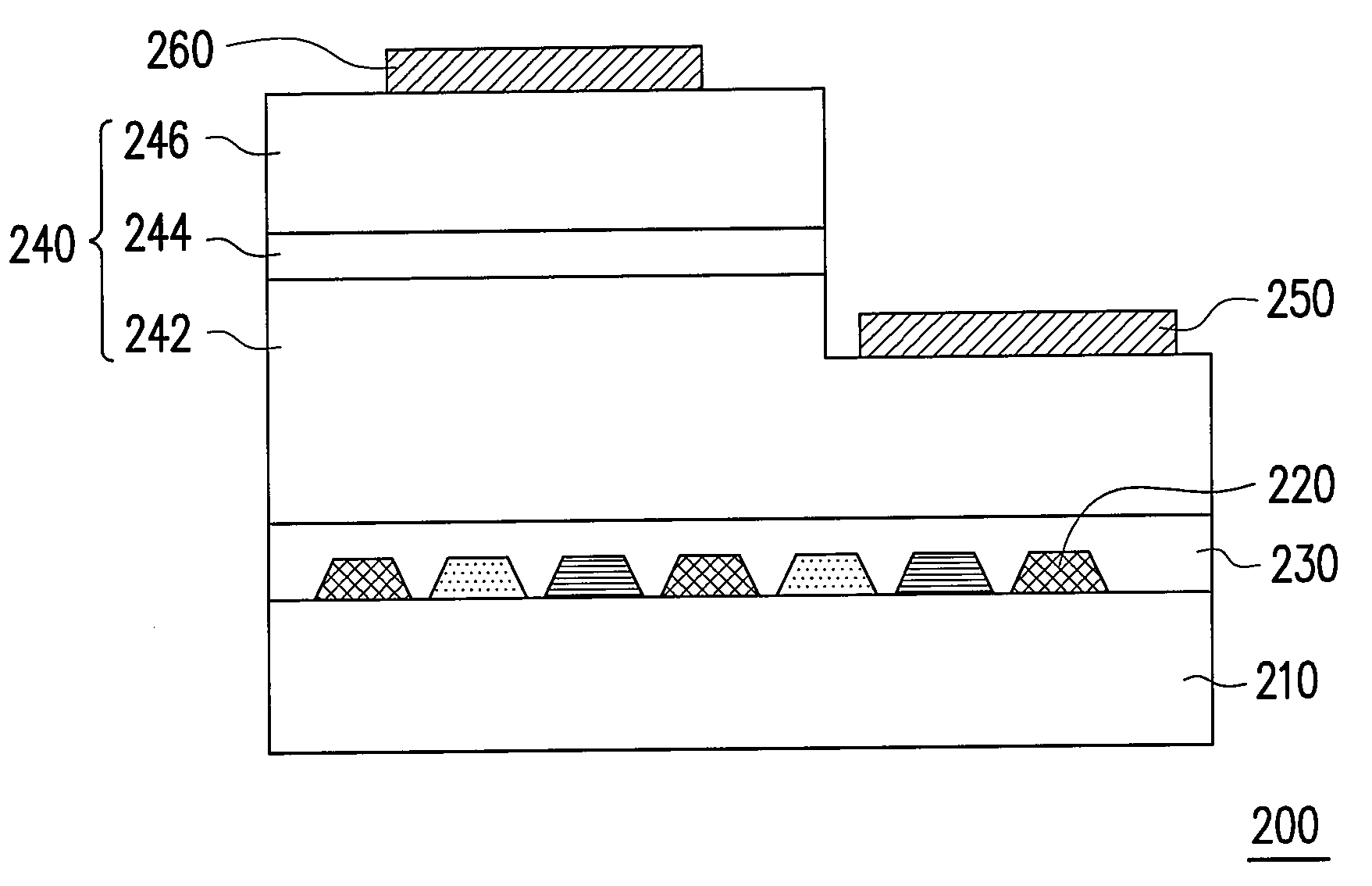

Light emitting diode, optoelectronic device and method of fabricating the same

InactiveUS20080315226A1Structural strainReduce dislocation densitySemiconductor/solid-state device manufacturingSemiconductor devicesOpto electronicLight-emitting diode

A light emitting diode structure including a substrate, a strain-reducing seed layer, an epitaxial layer, a first electrode and a second electrode is provided. The strain-reducing seed layer having a plurality of clusters is disposed on the substrate, and the material of the clusters is selected from a group consisting of aluminum nitride, magnesium nitride and indium nitride. The epitaxial layer includes a first type doped semiconductor layer, a light emitting layer and a second type doped semiconductor layer. The first electrode is disposed on the exposed first type doped semiconductor layer and electrically connected thereto. The second electrode is disposed on the second type doped semiconductor layer and electrically connected thereto.

Owner:NAT CENT UNIV

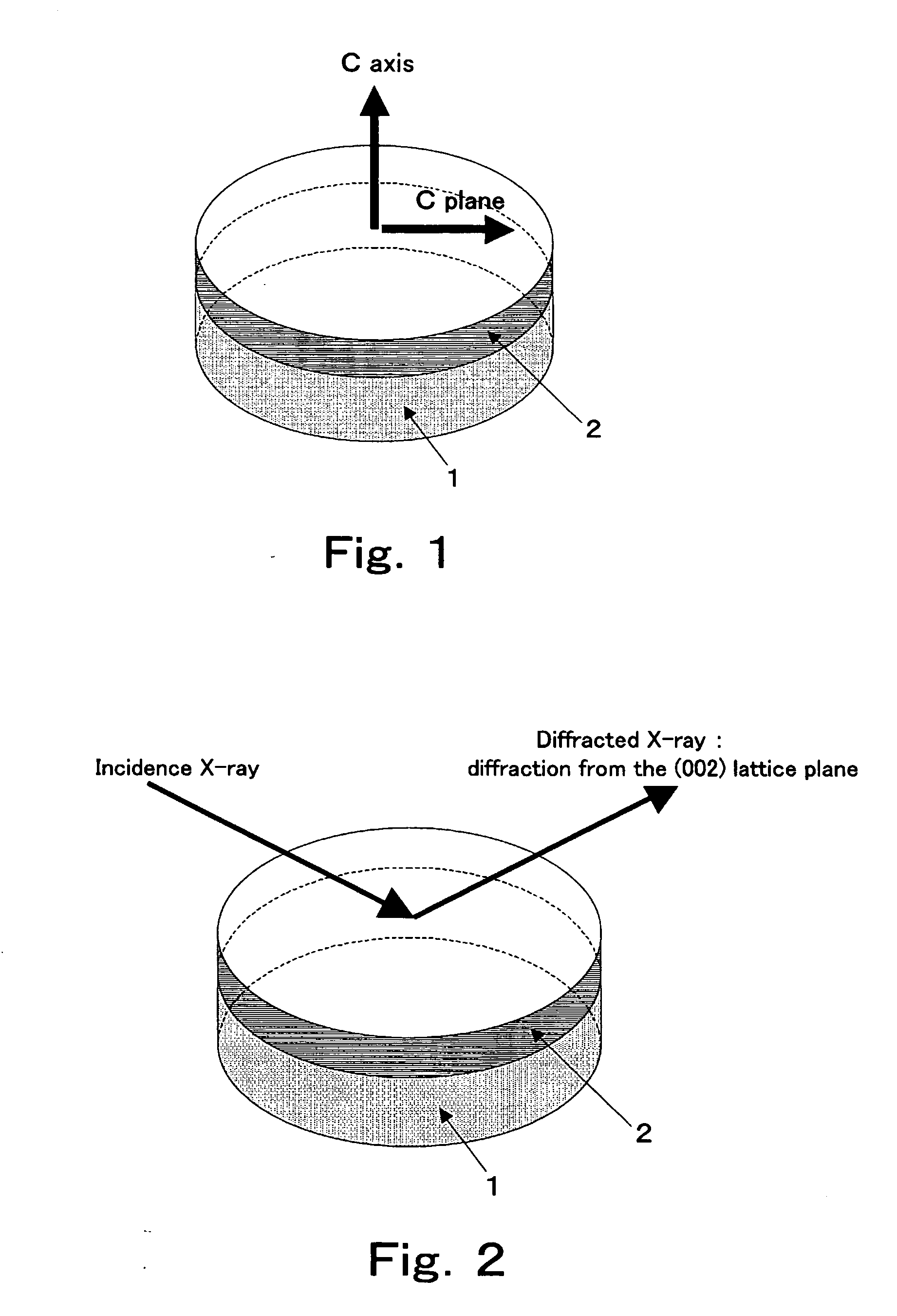

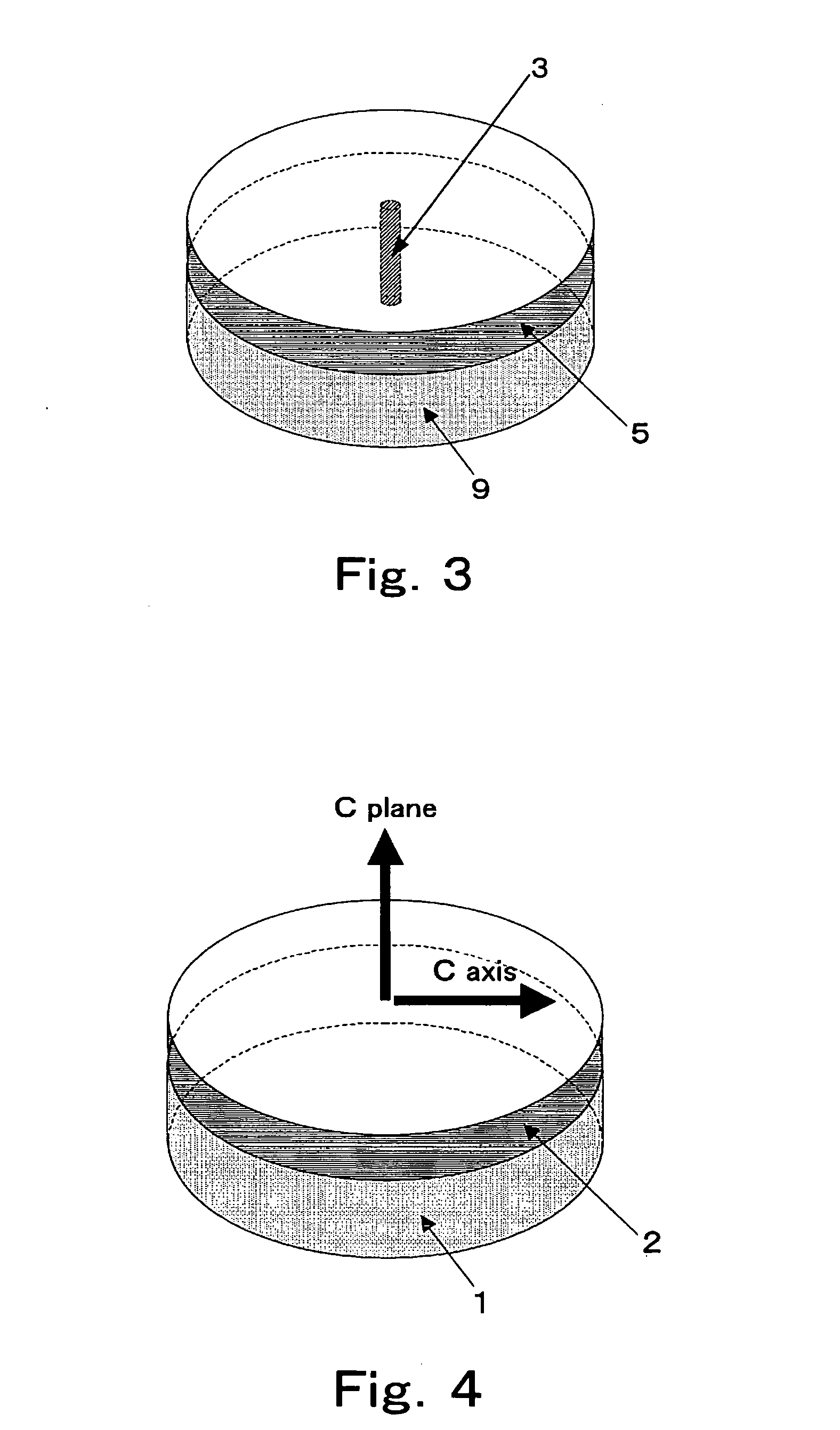

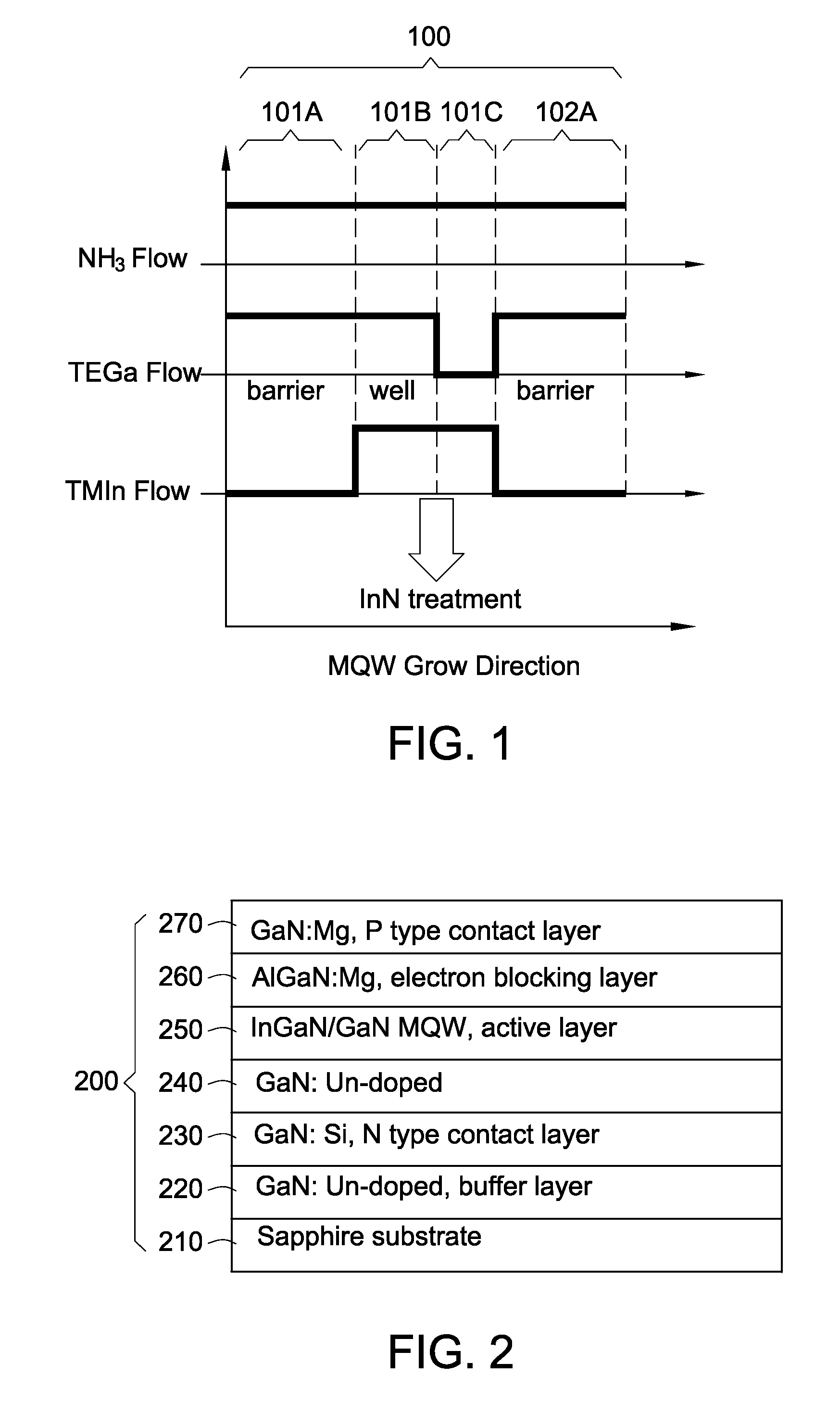

Group lll-V compound semiconductor and a method for producing the same

InactiveUS20090200538A1Increase brightnessSemiconductor/solid-state device manufacturingNanoopticsX-rayLength wave

A Group III-V compound semiconductor includes an n-type layer, a p-type layer, a p-type layer represented by a formula InaGabAlcN, having a thickness of not less than 300 nm, and a multiple quantum well structure which exists between the n-type layer and the p-type layer, has at least two quantum well structures including two barrier layers and a quantum well layer represented by a formula InxGayAlzN between the barrier layers; and a ratio of R / α of not more than 42.5%, wherein R is an average mole fraction of indium nitride in the quantum well layer, which is measured by X-ray diffraction, and α is a mole fraction of indium nitride calculated from a wavelength of light emitted from the group III-V compound semiconductor due to current injection.

Owner:SUMITOMO CHEM CO LTD

Titanium nitride based metamaterial

ActiveUS20150285953A1Good dispersionImprove efficiencyRadiation/particle handlingElectrode and associated part arrangementsSharp interfaceTantalum nitride

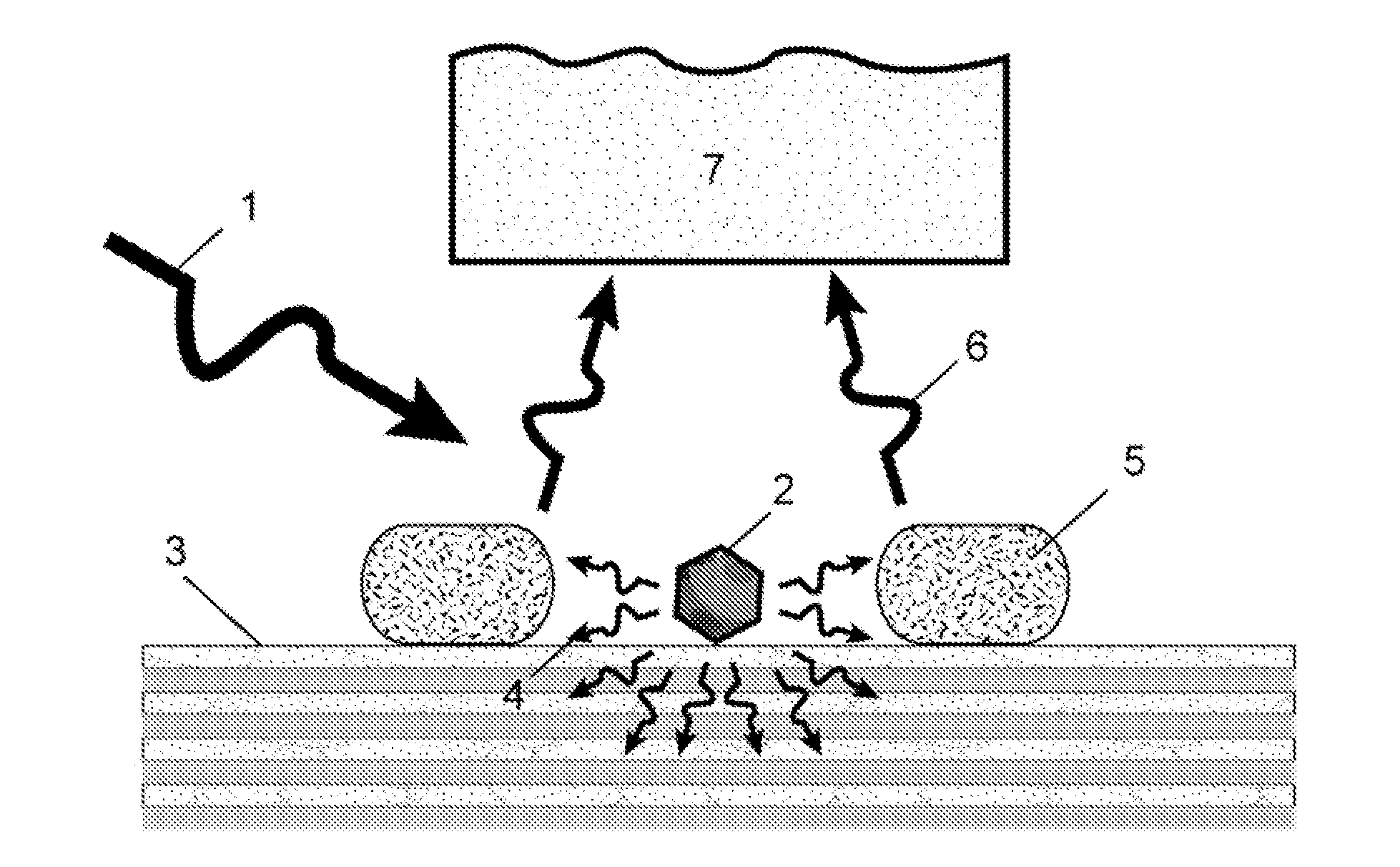

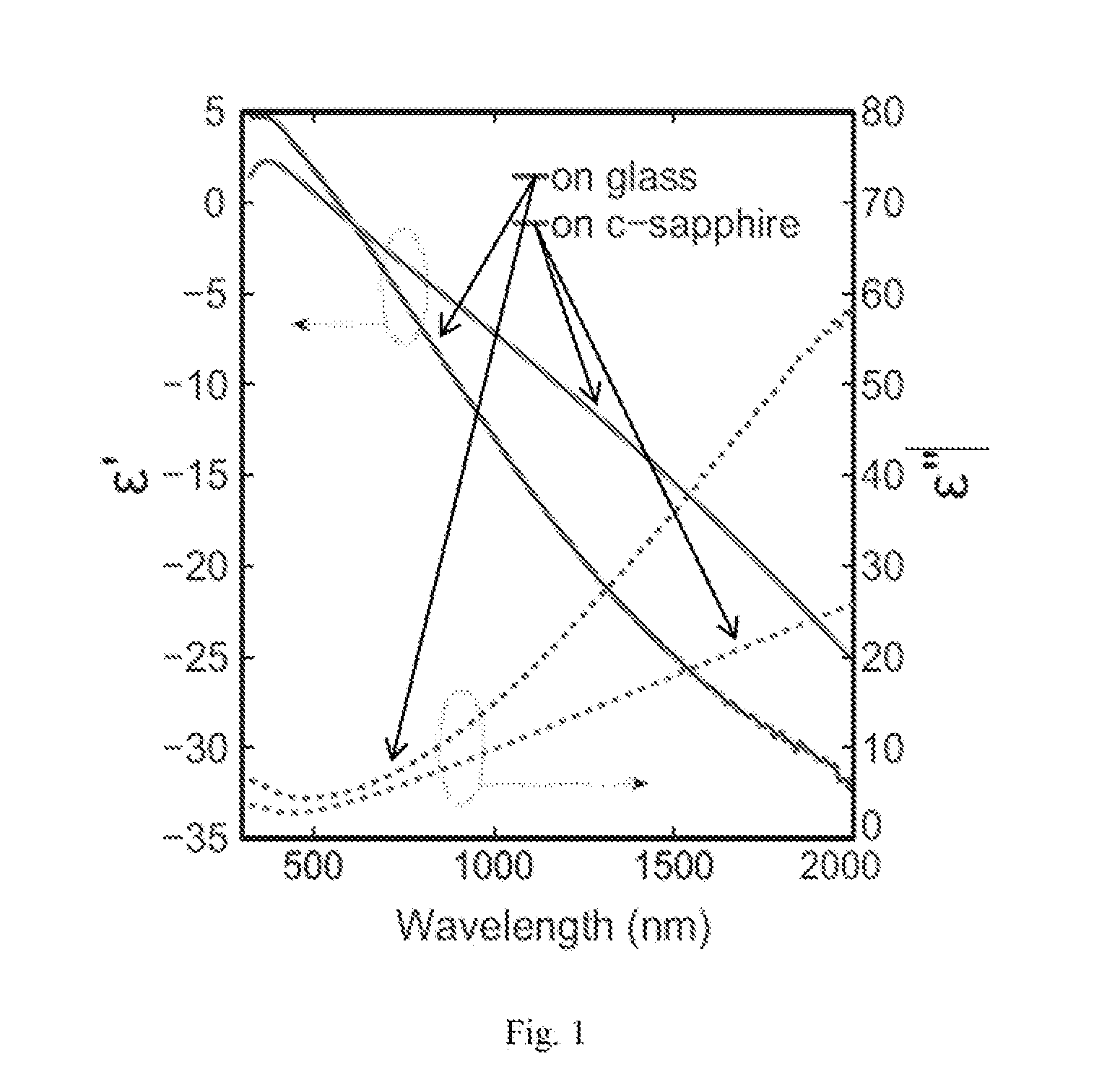

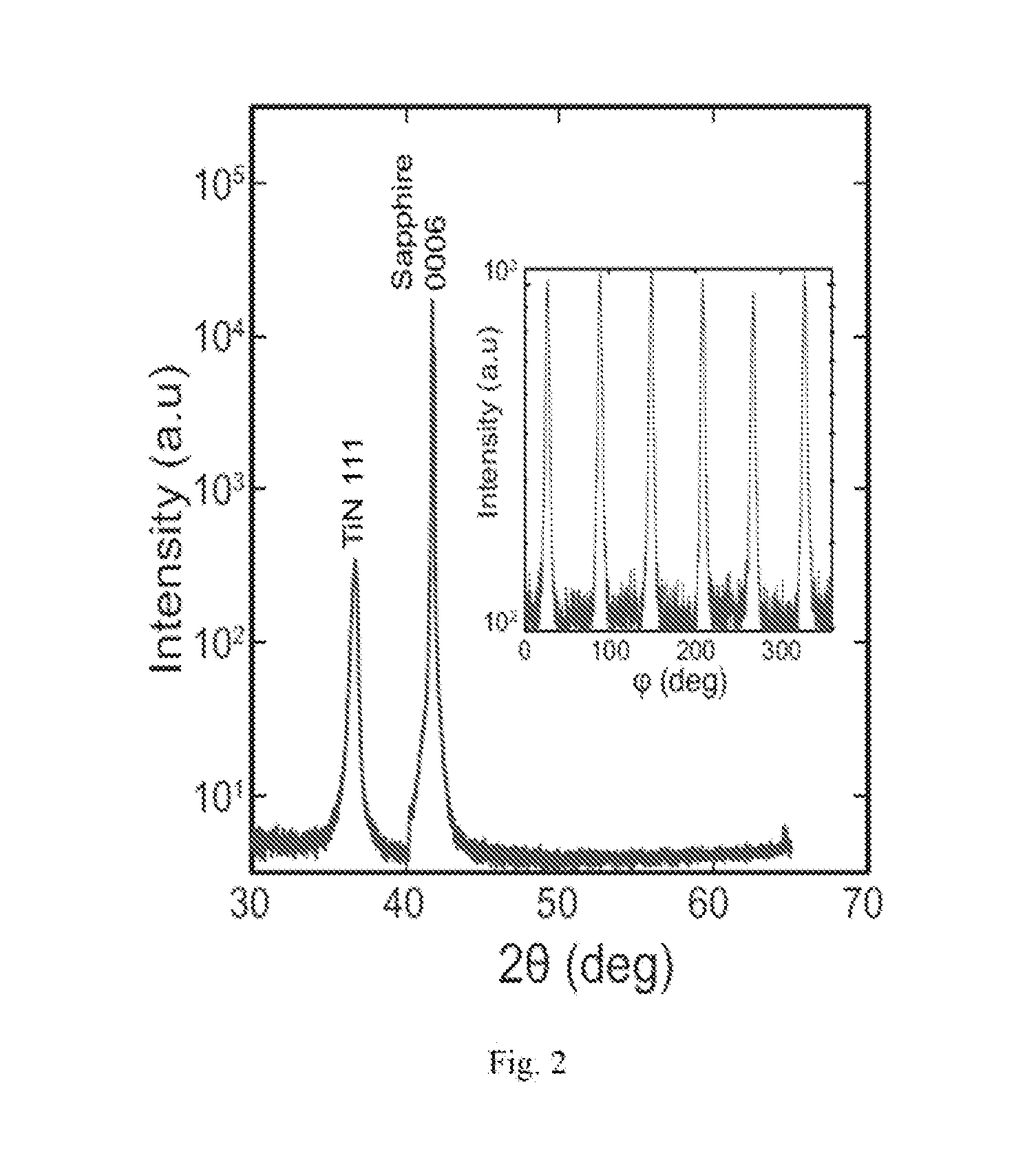

A titanium nitride-based metamaterial, and method for producing the same, is disclosed, consisting of ultrathin, smooth, and alternating layers of a plasmonic titanium nitride (TiN) material and a dielectric material, grown on a substrate to form a superlattice. The dielectric material is made of A1-xScxN, where ‘x’ ranges in value from 0.2 to 0.4. The layers of alternating material have sharp interfaces, and each layer can range from 1-20 nanometers in thickness. Metamaterials based on titanium TiN, a novel plasmonic building block, have many applications including, but not ‘limited to emission enhancers, computer security, etc. The use of nitrogen vacancy centers in diamond, and light emitting diode (LED) efficiency enhancement is of particular interest.

Owner:PURDUE RES FOUND INC

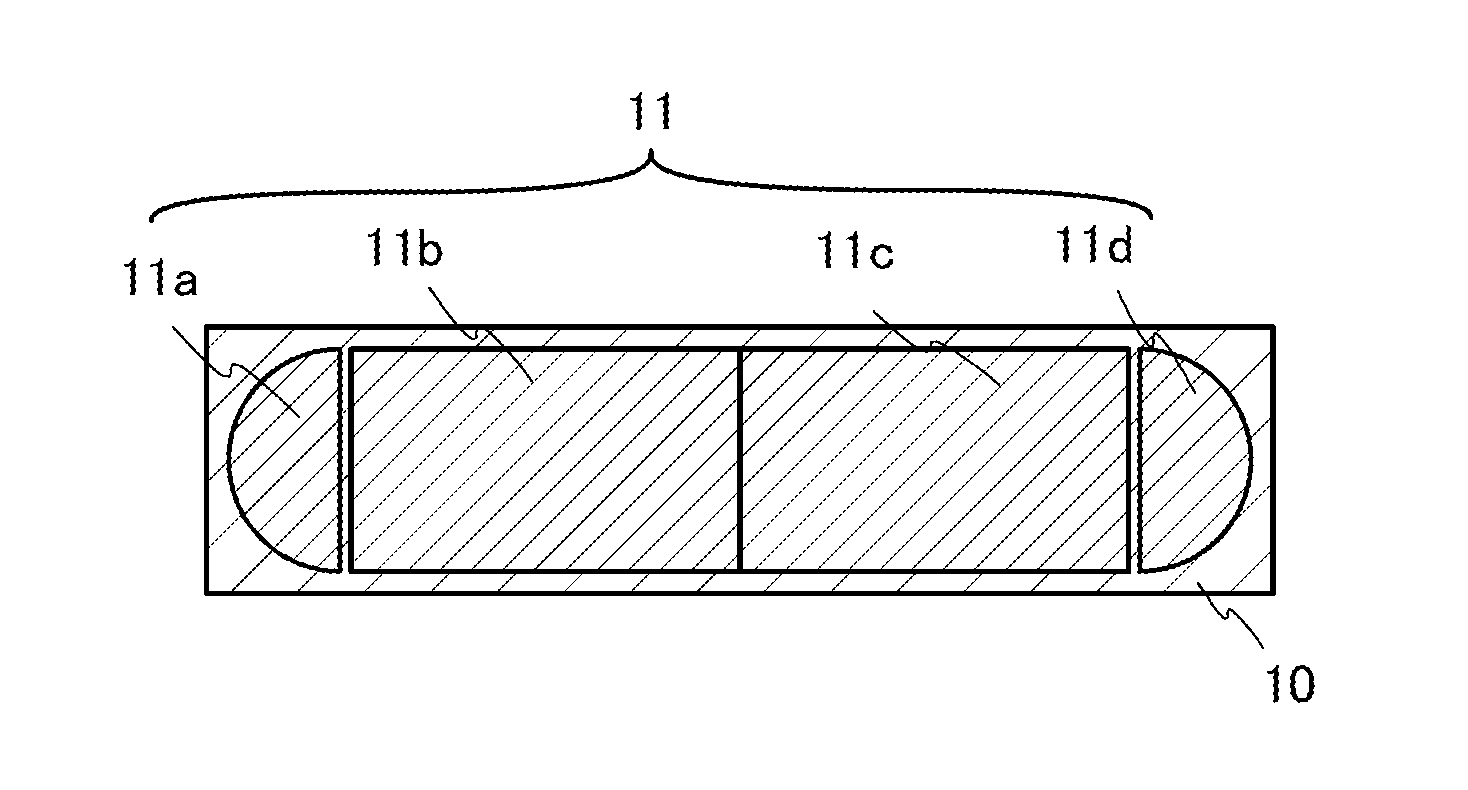

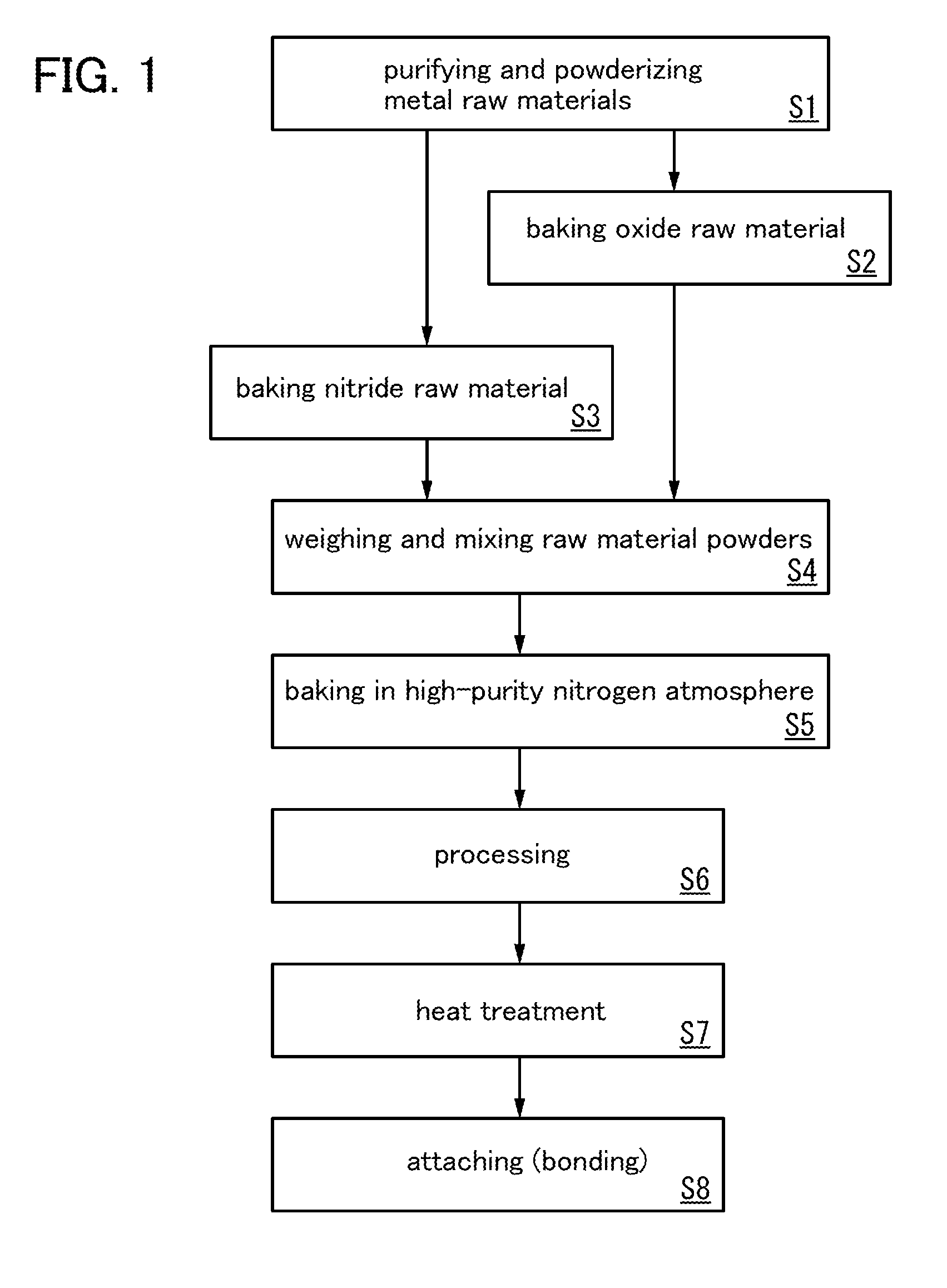

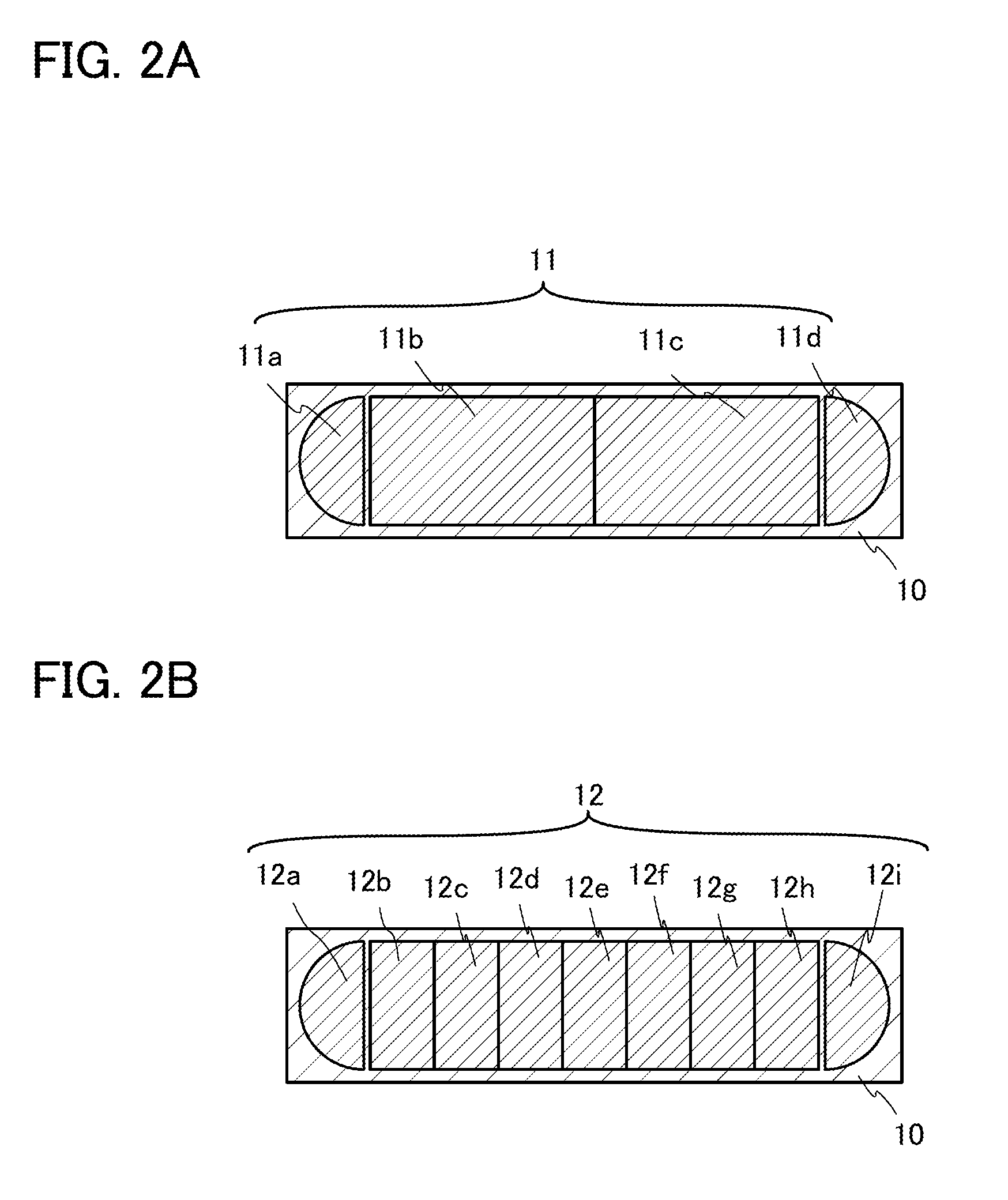

Sputtering target, method for manufacturing the same, and method for manufacturing semiconductor device

InactiveUS20120152728A1Reduce concentrationRaise the ratioCellsVacuum evaporation coatingZinc nitrideIndium

A deposition technique for forming an oxynitride film is provided. A highly reliable semiconductor element is manufactured with the use of the oxynitride film. The oxynitride film is formed with the use of a sputtering target including an oxynitride containing indium, gallium, and zinc, which is obtained by sintering a mixture of at least one of indium nitride, gallium nitride, and zinc nitride as a raw material and at least one of indium oxide, gallium oxide, and zinc oxide in a nitrogen atmosphere. In this manner, the oxynitride film can contain nitrogen at a necessary concentration. The oxynitride film can be used for a gate, a source electrode, a drain electrode, or the like of a transistor.

Owner:SEMICON ENERGY LAB CO LTD

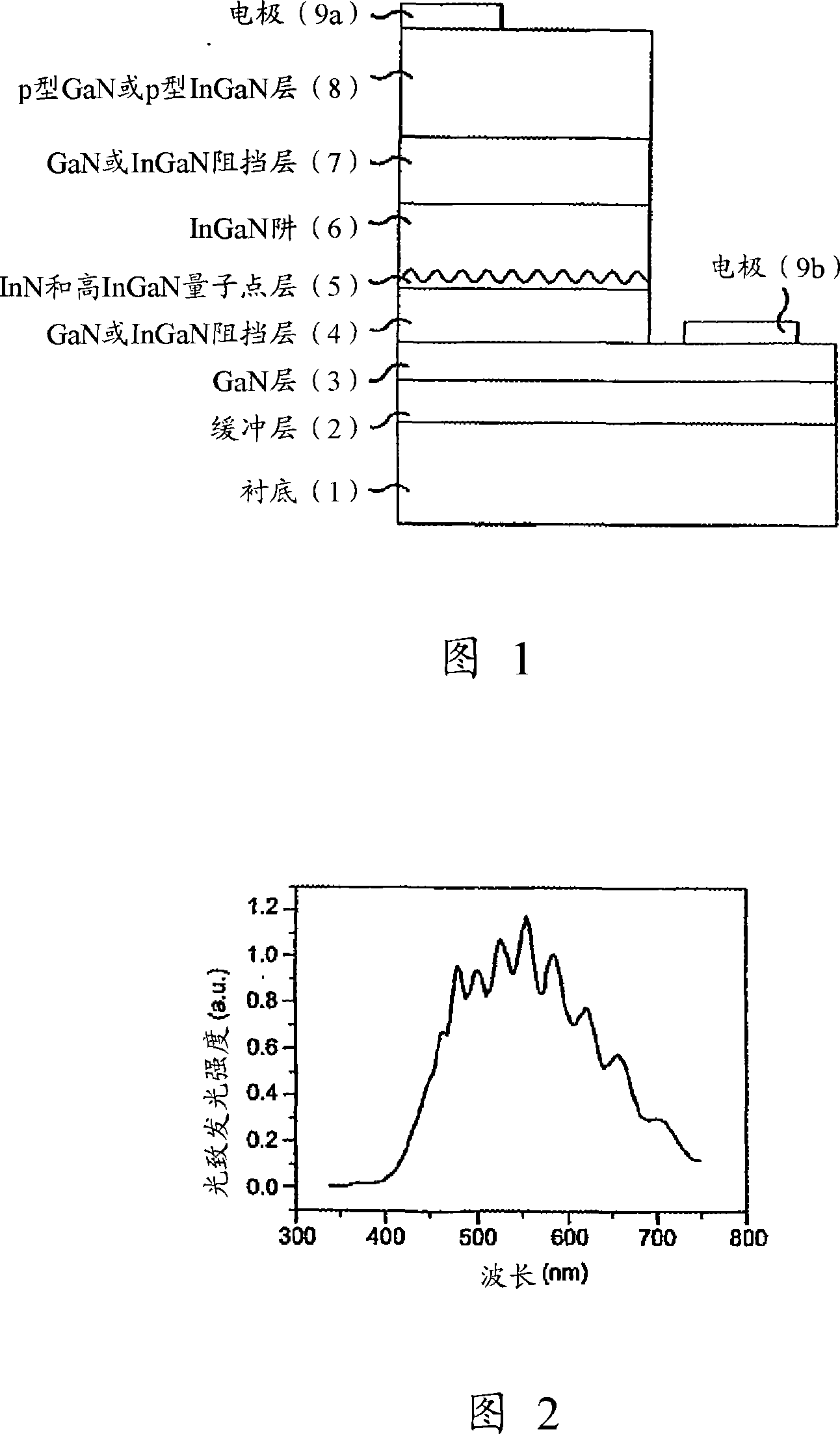

III nitride white light LED

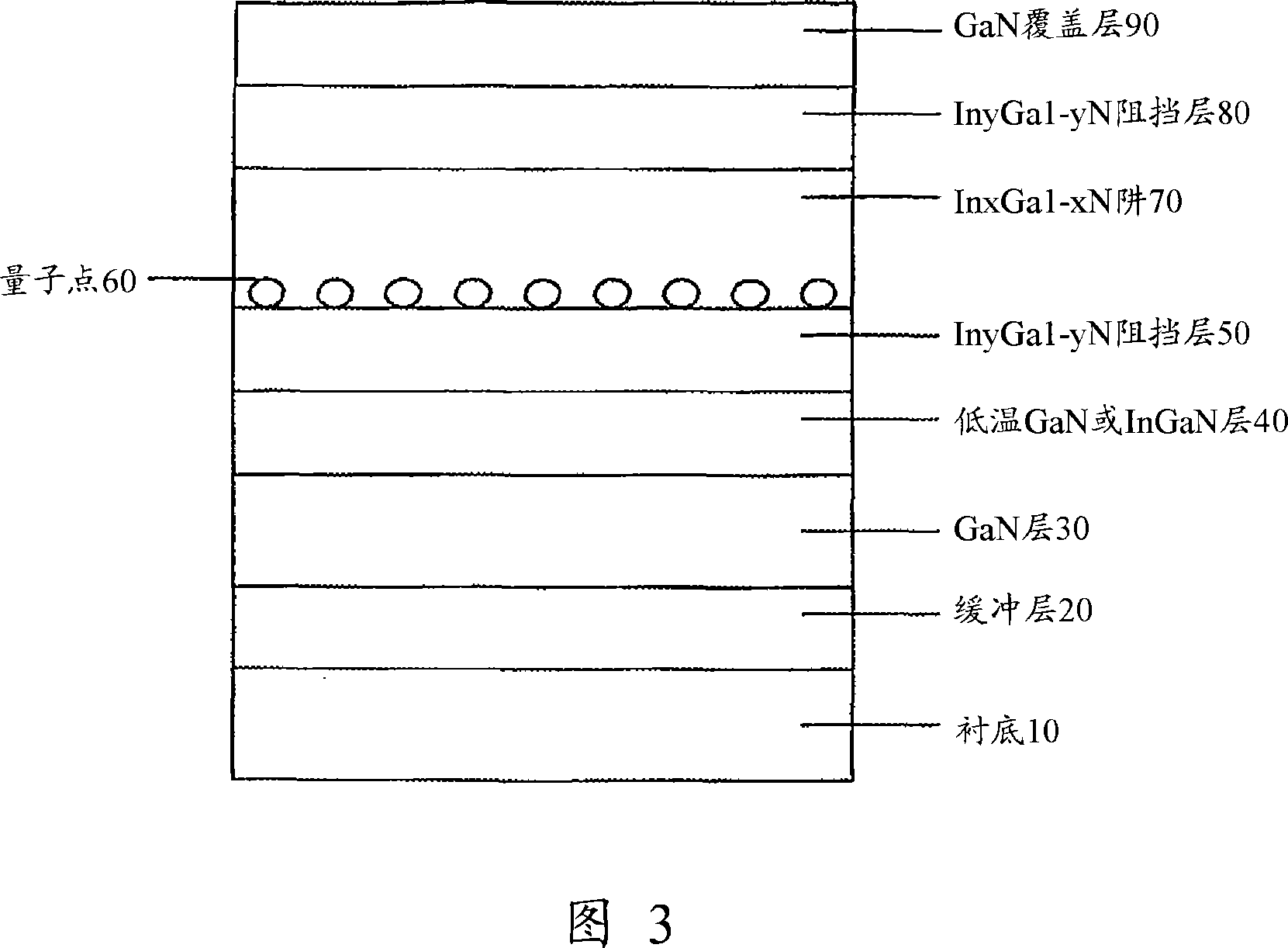

InactiveCN101208810ANanoinformaticsSemiconductor/solid-state device manufacturingIndiumLight-emitting diode

A white light-emitting diode prepared by metal-organic chemical vapor deposition (MOCVD), which can cover indium nitride (InN) quantum dots (QD) and Indium-rich indium gallium nitride (InGaN) quantum dots produce broadband emission covering the entire visible spectral region by introducing trimethylindium (TMIn) as nuclei for growing QDs within the QW, The release of at least one of triethylindium (TEIn) and ethyldimethylindium (EDMIn) is achieved. Therefore, the diode can emit white light in the range of 400nm to 750nm by adjusting the In release parameters.

Owner:AGENCY FOR SCI TECH & RES +1

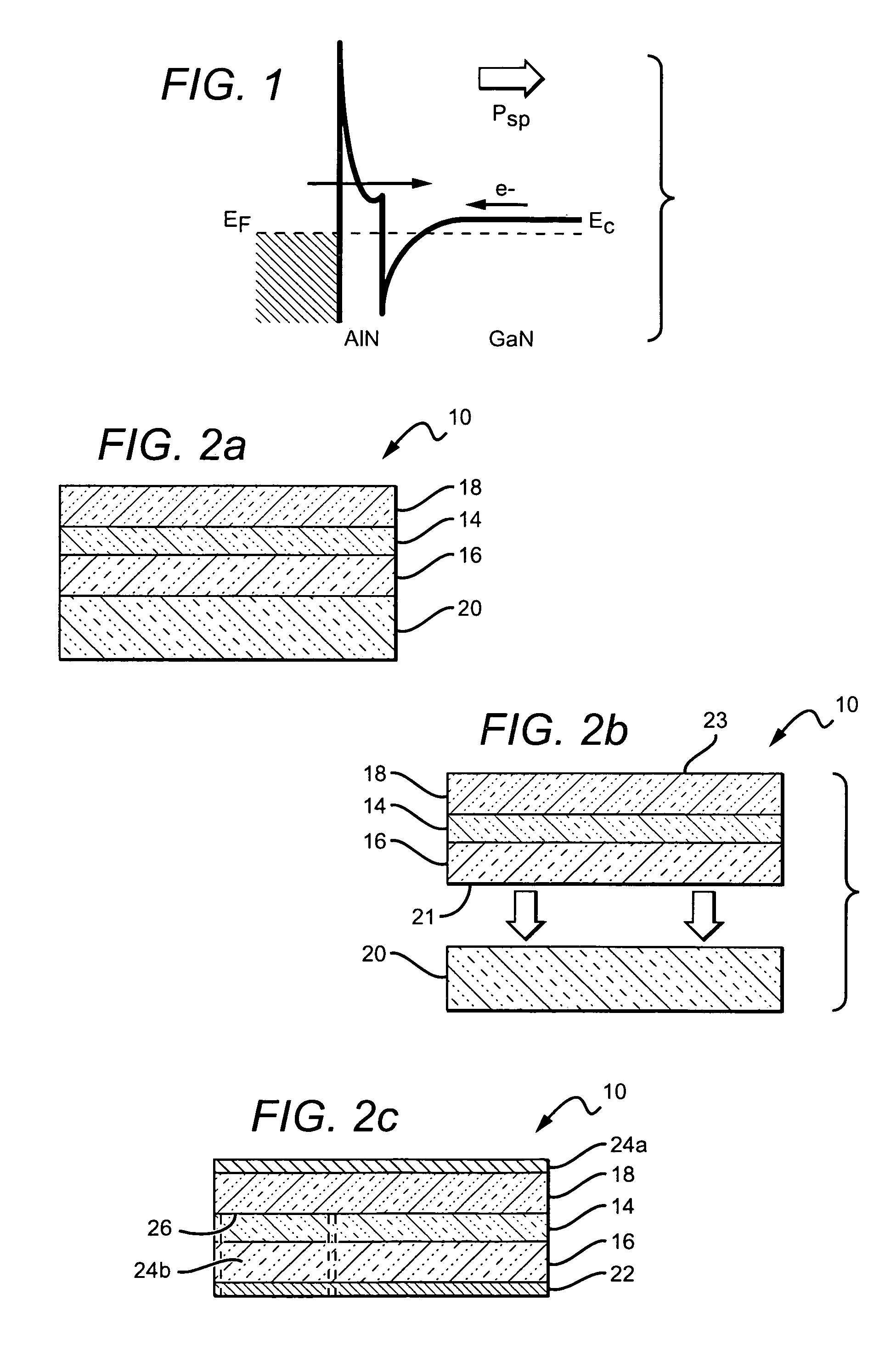

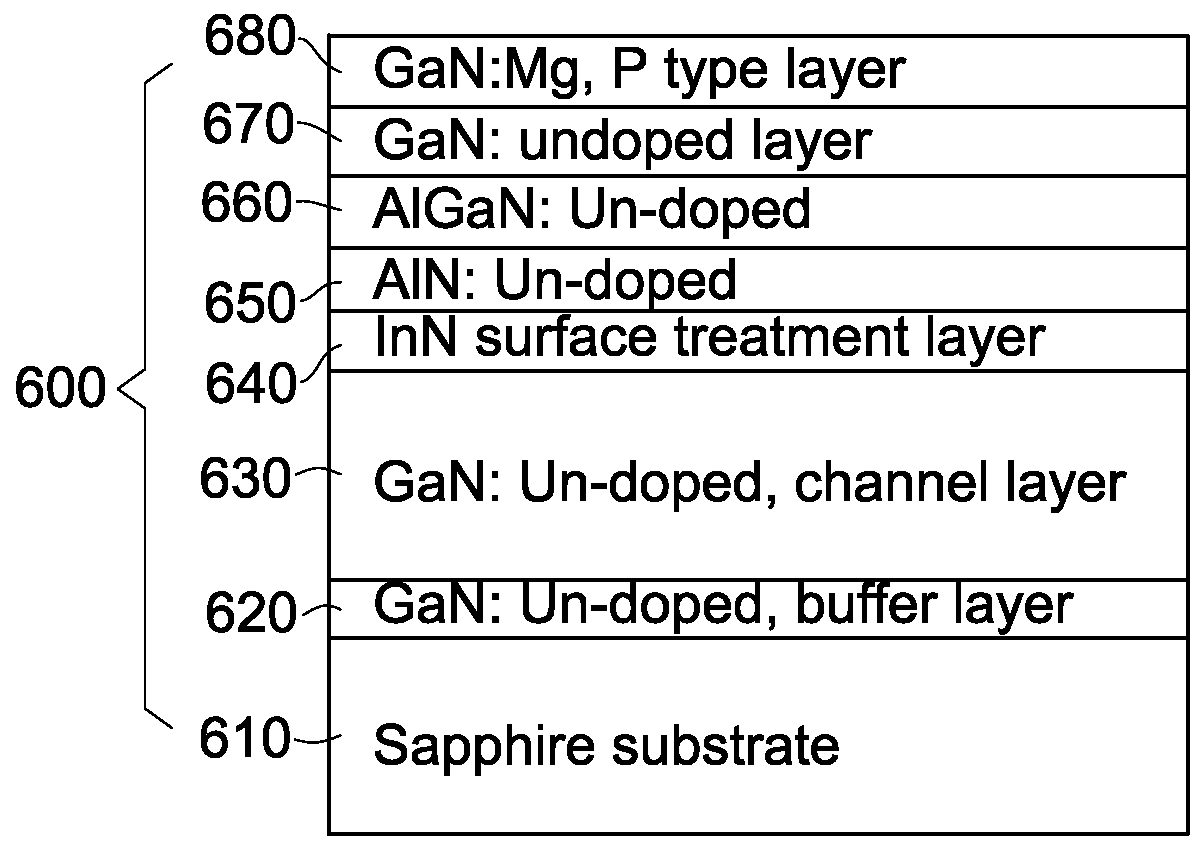

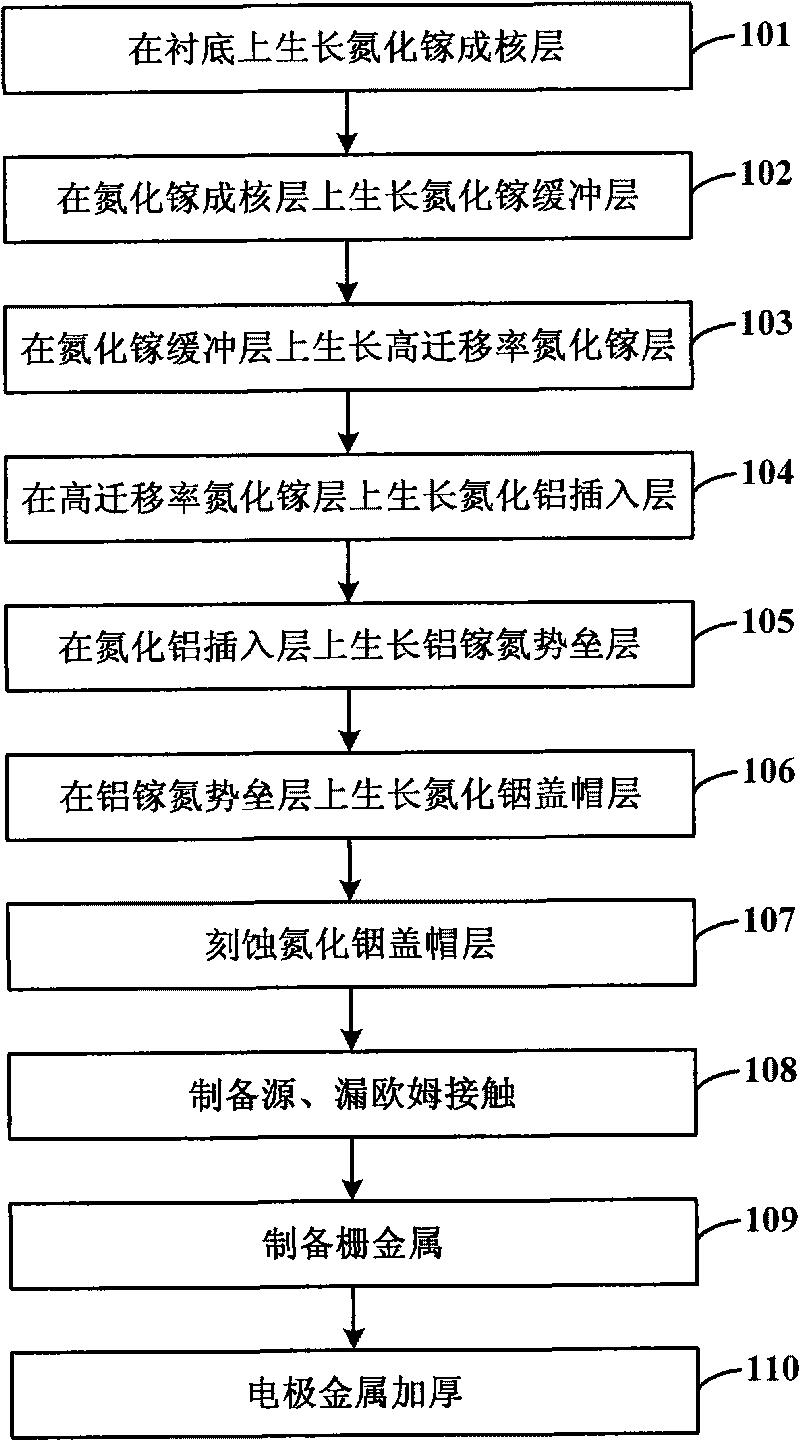

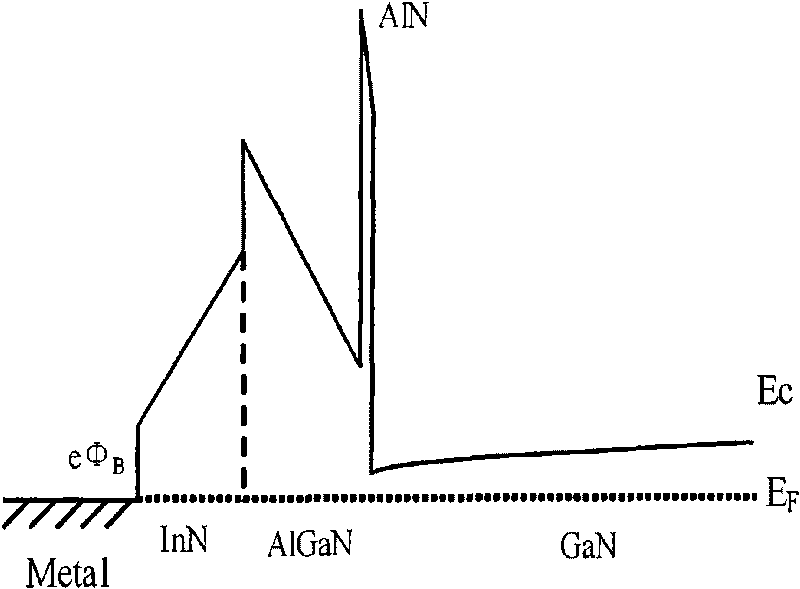

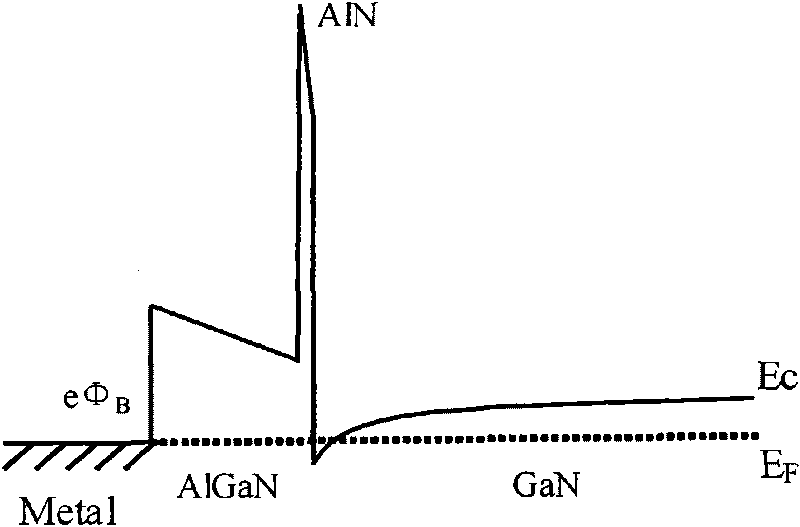

Method for preparing enhanced aluminum-gallium-nitrogen/gallium nitride transistor with high electron mobility

InactiveCN101740384ALower on-state resistanceHigh on-state resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesOhmic contactNitrogen

The invention discloses a method for preparing enhanced aluminum-gallium-nitrogen / gallium nitride transistor with high electron mobility. The method comprises the following steps: growing a gallium nitride nucleation layer on a substrate; growing a gallium nitride buffer layer on the gallium nitride nucleation layer; growing a high-mobility gallium nitride layer on the gallium nitride buffer layer; growing an aluminum nitride insertion layer on the high-mobility gallium nitride layer; growing an aluminum-gallium-nitrogen barrier layer on the aluminum nitride insertion layer; growing an indium nitride capping layer on the aluminum-gallium-nitrogen barrier layer; etching the indium nitride capping layer; preparing source-drain ohmic contact; preparing gate metal; and thickening electrode metal. The method has the advantages of reducing preparation cost, simplifying preparation process and improving process reliability.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

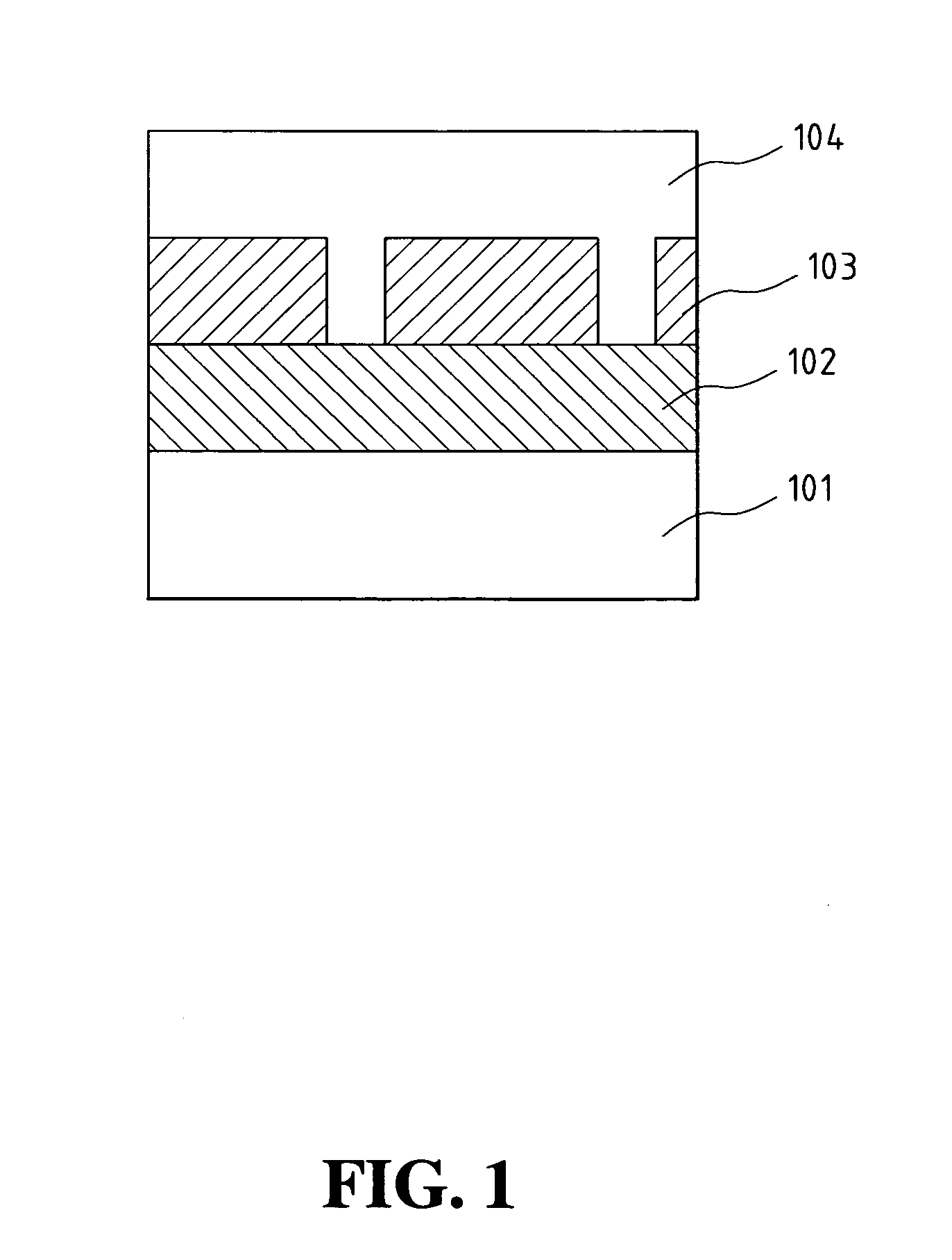

Epitaxial structure of gallium nitrIde series semiconductor device and process of manufacturing the same

InactiveUS20050247942A1Prolong lifeImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorSemiconductor device

An epitaxial structure of a gallium nitride series semiconductor device and a process of forming the same are described. A first buffer layer of gallium nitride is epitaxially formed on a substrate at a first temperature. A second buffer layer of indium gallium nitride is formed on the first buffer layer at a second temperature. The second temperature increases up to a third temperature, during which precursors including In(CH3)3 and NH3 are used for surface treatment. A high-temperature gallium nitride is formed at the third temperature. The buffer layer and the way to form such a buffer layer allow improved crystal configuration and lowered defect density, thereby increasing the performance and service life of a semiconductor device.

Owner:SEMILEDS OPTOELECTRONICS CO LTD

Epitaxial structure of gallium nitride series compound semiconductor and mfg. method

InactiveCN1677697AImprove efficiencyExtended service lifeSemiconductor/solid-state device manufacturingSemiconductor devicesCrystal structureLow density

The epitaxial structure comprises following parts: a substrate; a first buffer layer of gallium nitride formed on the substrate; a second buffer layer of gallium indium nitride formed on the first buffer layer; and a epitaxial layer of gallium nitride formed on the second buffer layer. Steps for preparing the structure are as following: forming the first buffer layer of gallium nitride on the substrate at first temperature through epitaxy; forming second buffer layer of gallium indium nitride on the first buffer layer at second temperature; in procedure of raising temperature to third temperature, carrying out surface treatment by maintaining predecessor of trimethyl aluminum and ammonia on second buffer layer; finally, epitaxial layer of gallium nitride is developed at third high temperature. Advantages are: perfective crystal structure and lower density of defects increase efficiency and lifetime of subassembly.

Owner:SUPERNOVA OPTOELECTRONICS

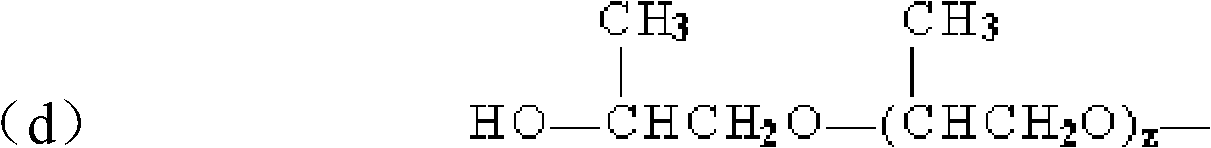

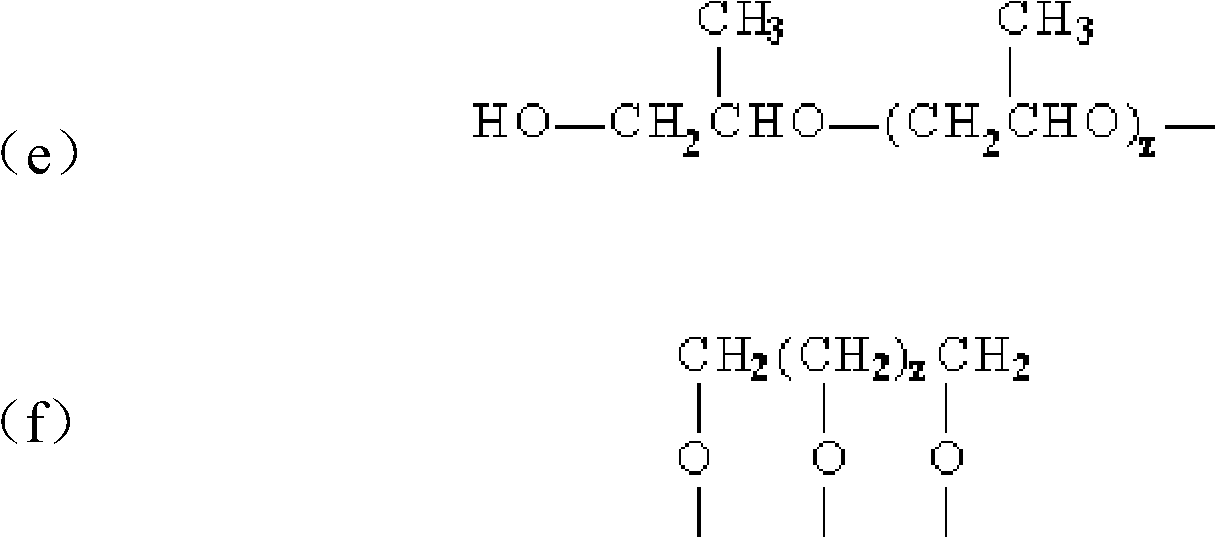

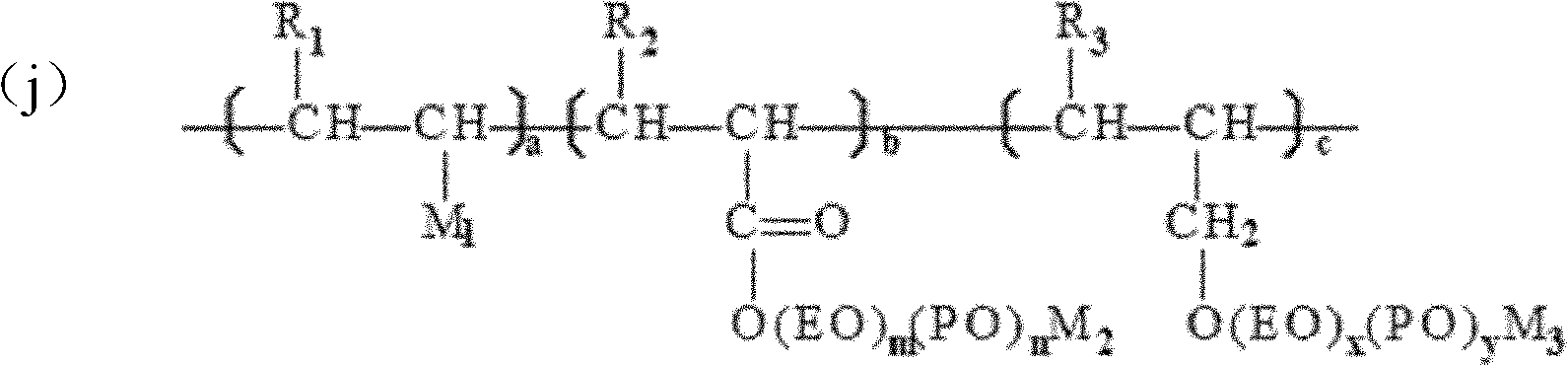

Water-base cutting liquid for hard and brittle materials and preparation method and application thereof

ActiveCN101935579ANo pollution in the processFree from harmLubricant compositionWater basedMetal impurities

The invention provides a water-base cutting liquid for hard and brittle materials. The liquid is characterized by comprising the following components in percentage by weight: 70 to 95 percent of poly-alkoxy compound, 0 to 5 percent of extreme-pressure resistant chelating agent, 0.001 to 5 percent of anti-settling re-dispersing agent and 4 to 20 percent of deionized water. The cutting liquid of the invention has the characteristics of no pollution and low metal impurity content; at the same time, the stability of a motar formed by mixing the cutting liquid and grinding material carborundum is high and grinding material carborundum re-dispersing capacity is high; and the cut product has the advantages of high yield, high qualification rate, high surface cleanliness, easy cleaning and the like. The invention also relates to the application of the cutting liquid to processing monocrystalline silicon, polycrystalline silicon, germanium, gallium arsenide, quartz, gallium indium nitride or precious stones.

Owner:LIAONING OXIRANCHEM INC

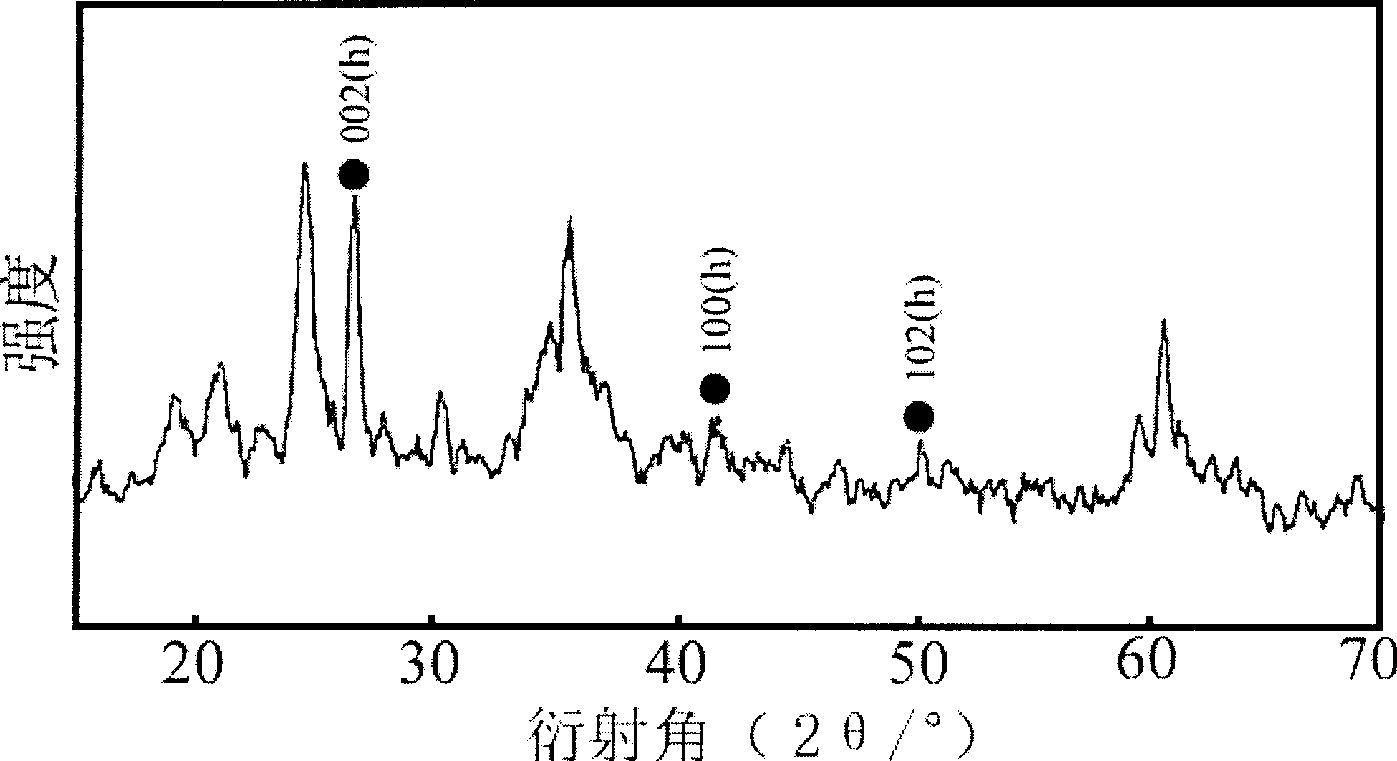

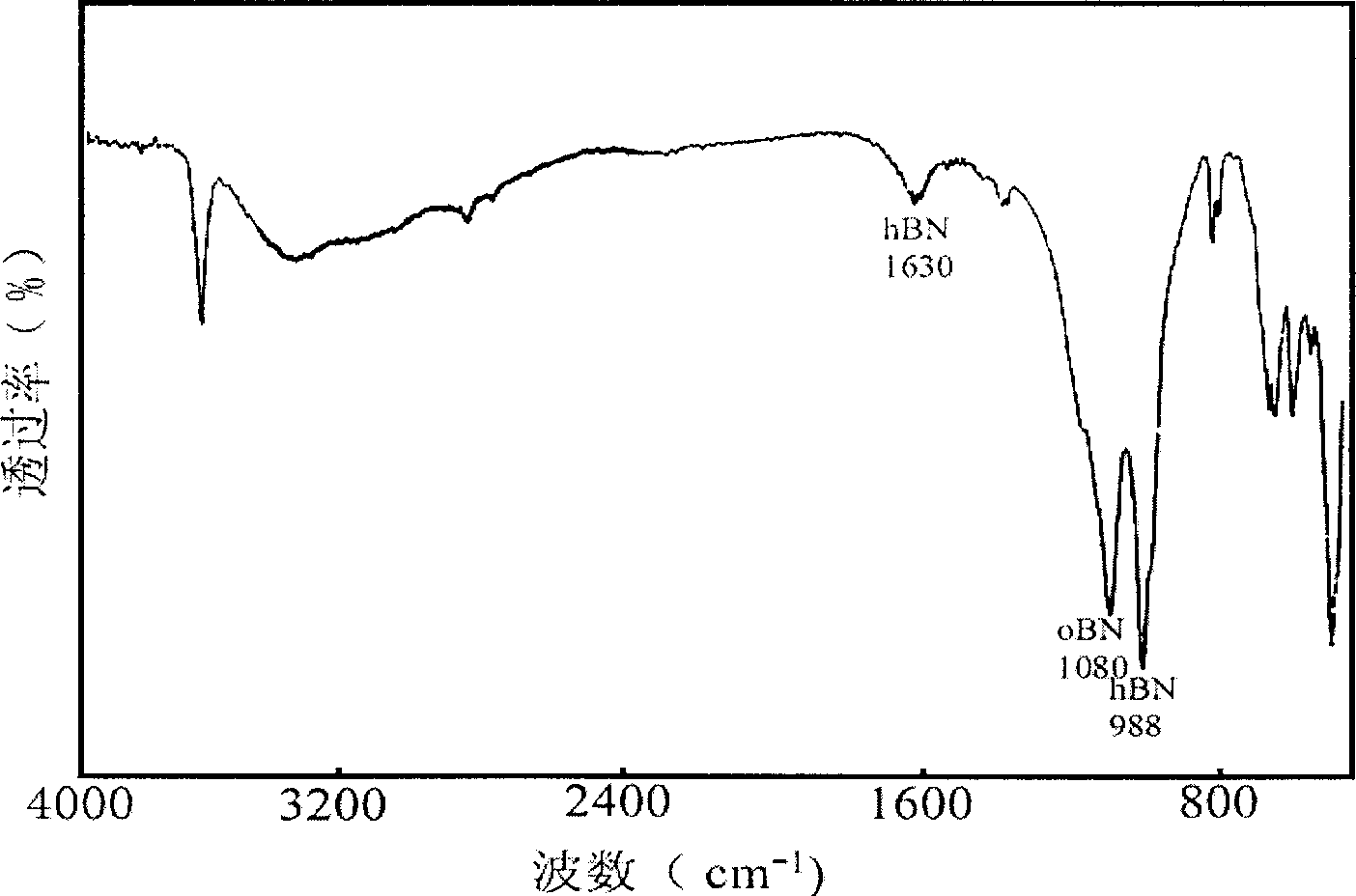

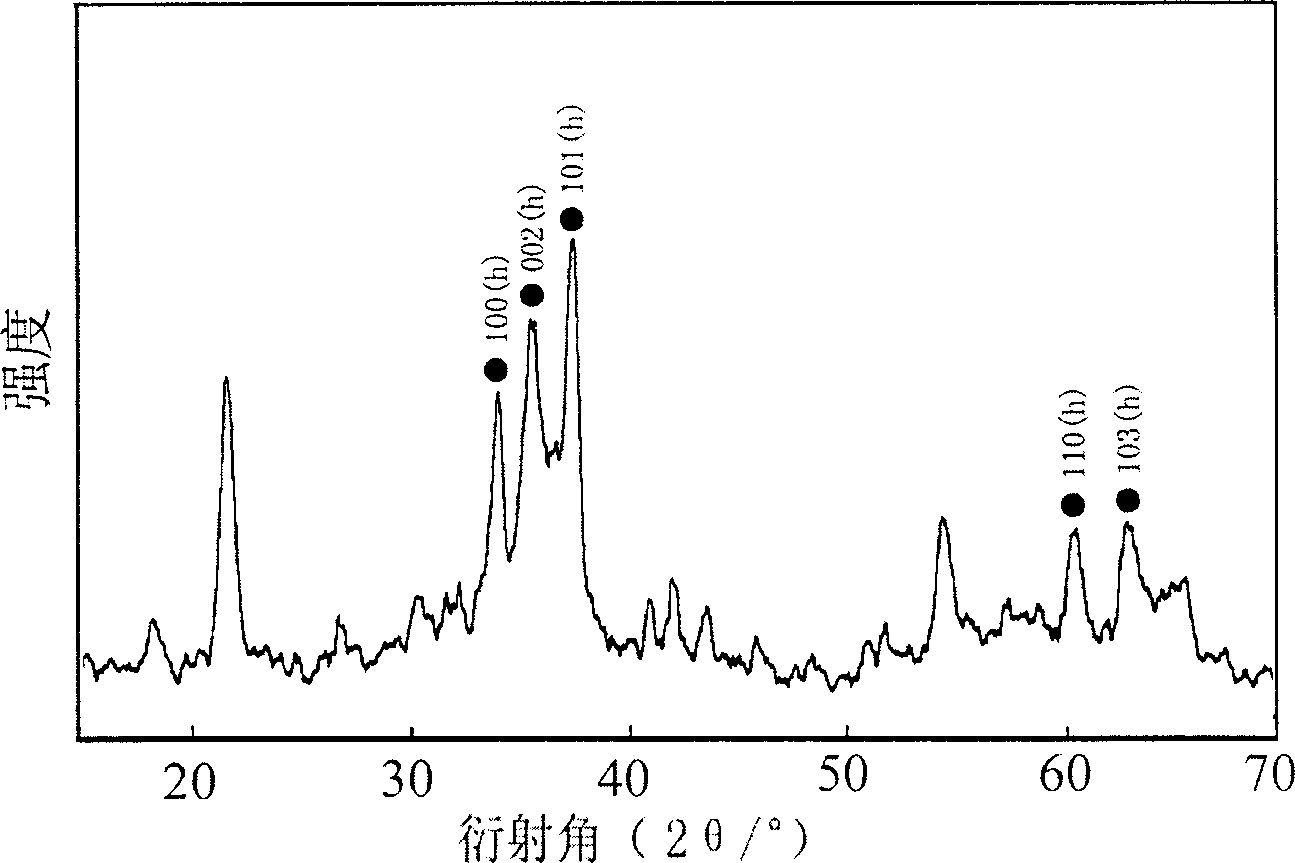

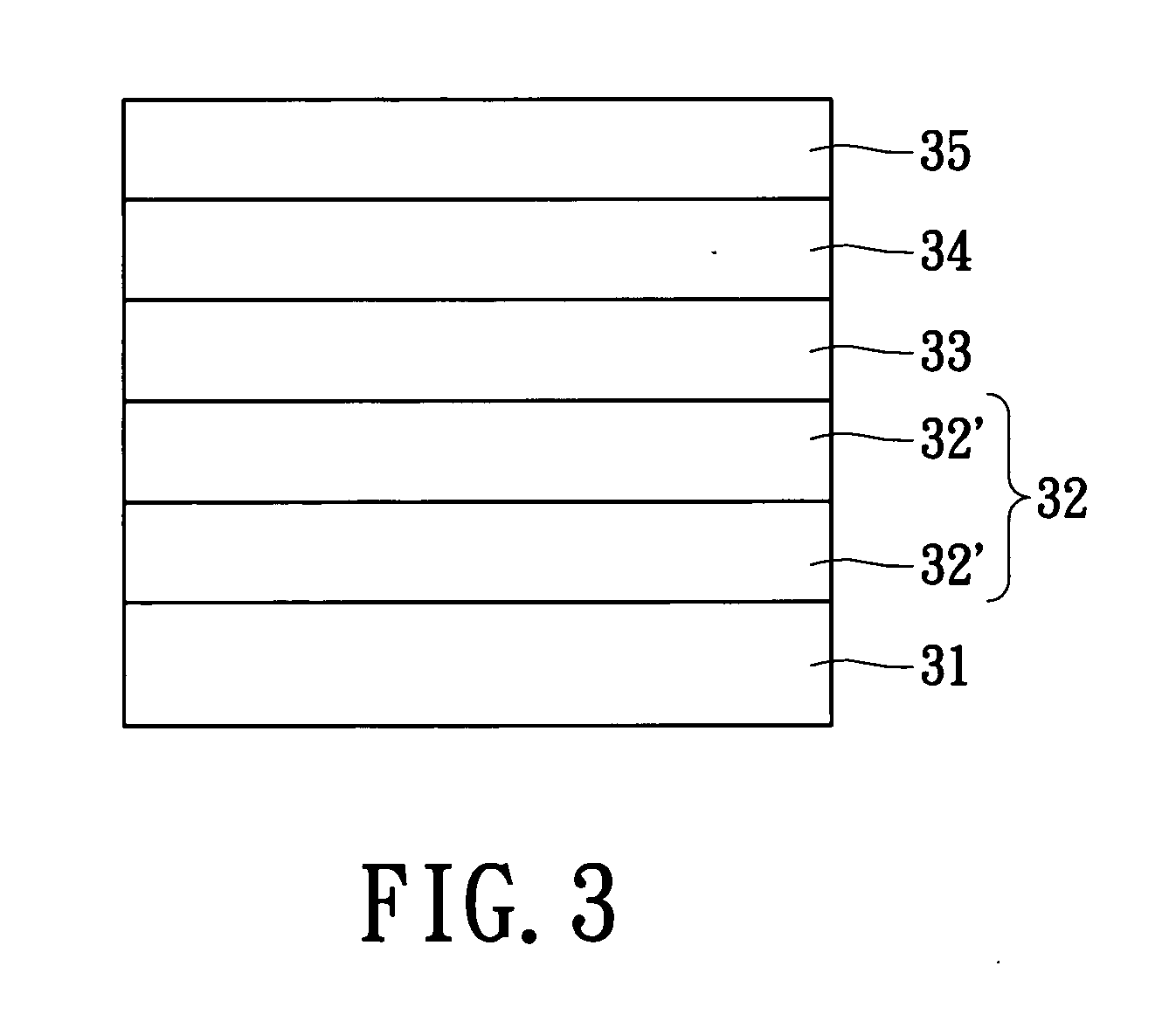

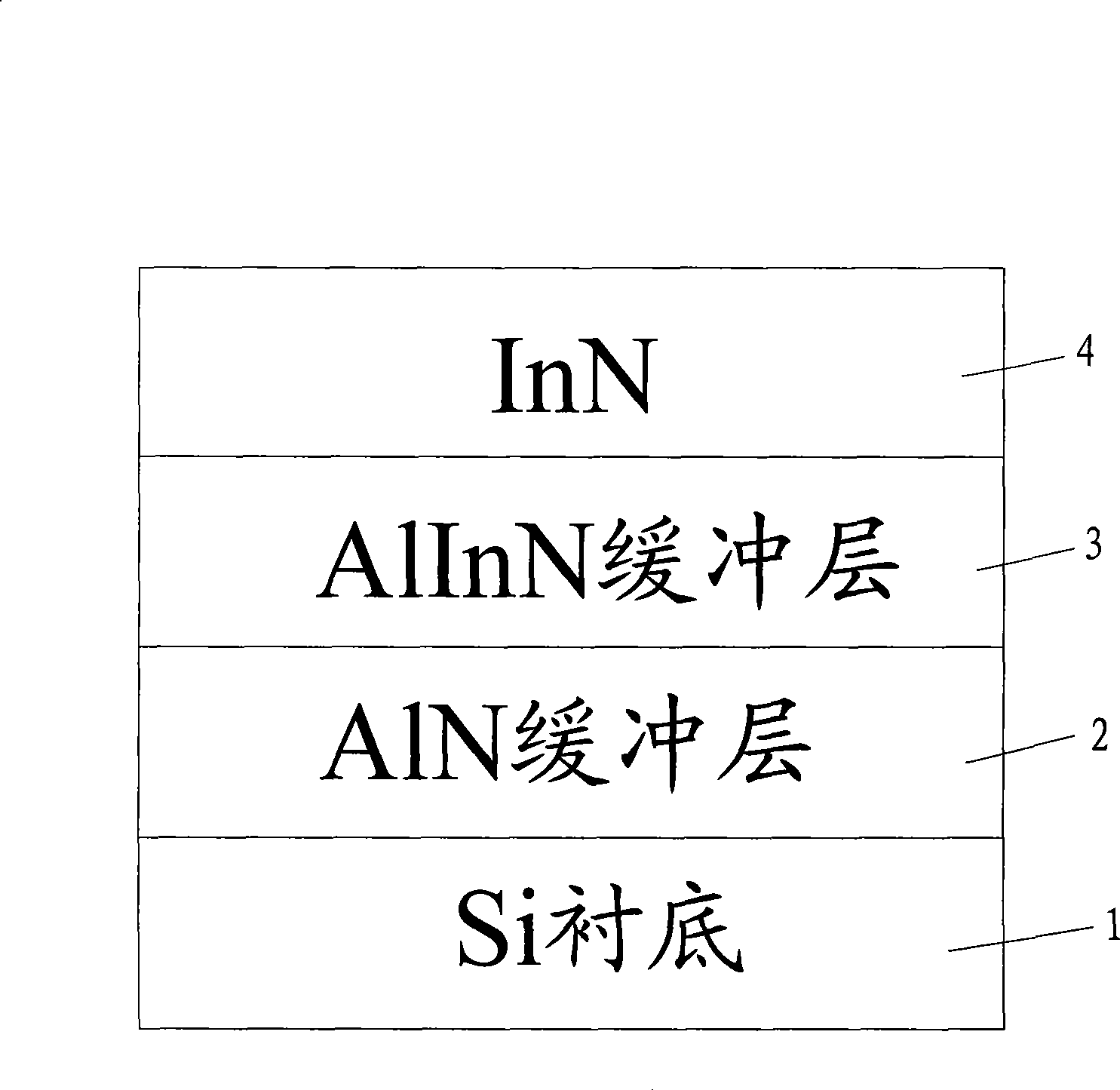

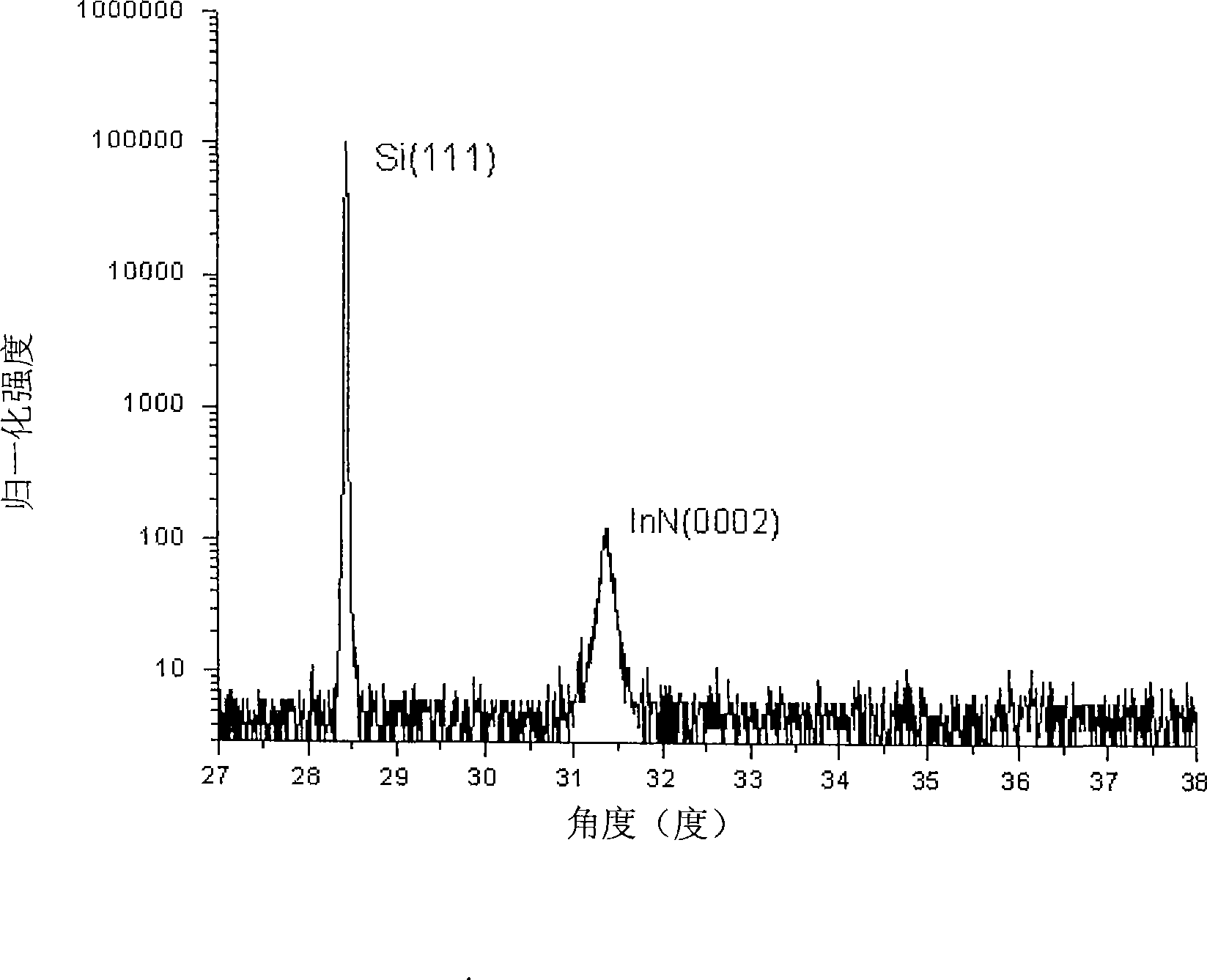

Process for growing high-quality monocrystal indium nitride thin-film having double buffering layers

InactiveCN101388337AReduce spreadReduce mismatchSemiconductor/solid-state device manufacturingIndiumSingle crystal

The invention discloses a process for growing single-crystal nitriding indium films with high quality and double buffer layers, which comprises growing an AlN buffer layer on a silicon substrate through utilizing the MOCVD technology, continuously growing an AlInN buffer layer on the AlN buffer layer, finally growing InN single-crystal epitaxy, wherein the AlInN buffer layer can be an AlInN buffer layer with single component or an AlInN buffer layer with gradually varied components, wherein In component is gradually increased in a linear change, or be a multi-layer AlInN buffer layer with different components, wherein In component in each layer is gradually increased in a linear change. The process can increase the crystal quality of the InN single-crystal exiptaxy.

Owner:XIAMEN CHANGELIGHT CO LTD

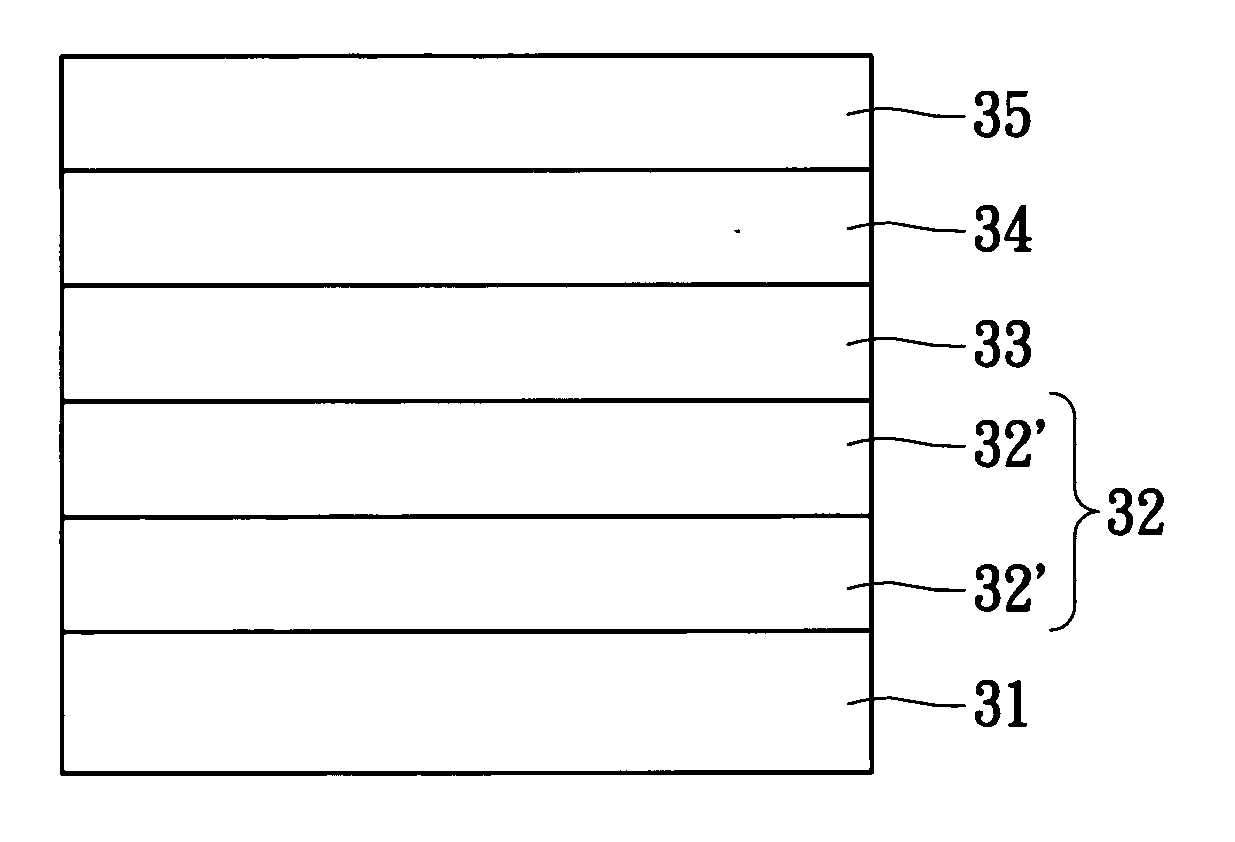

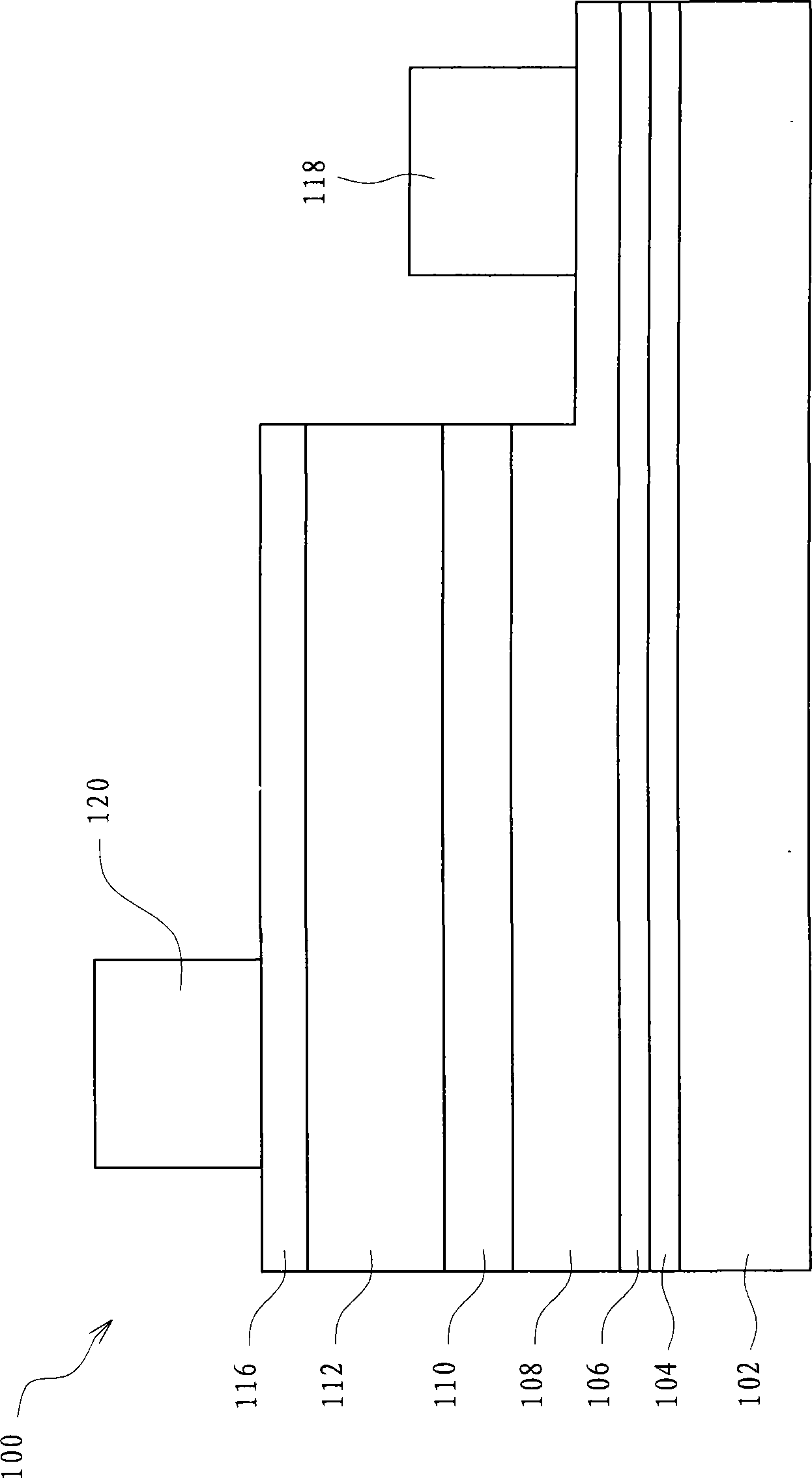

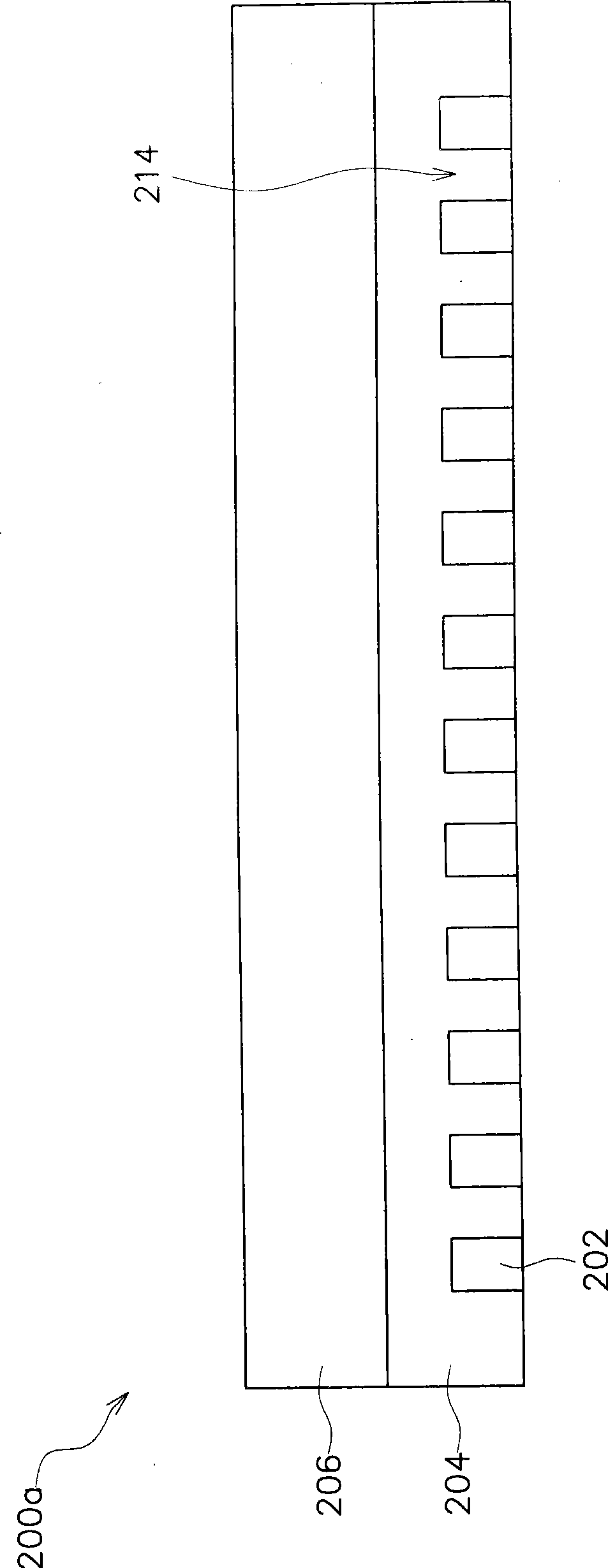

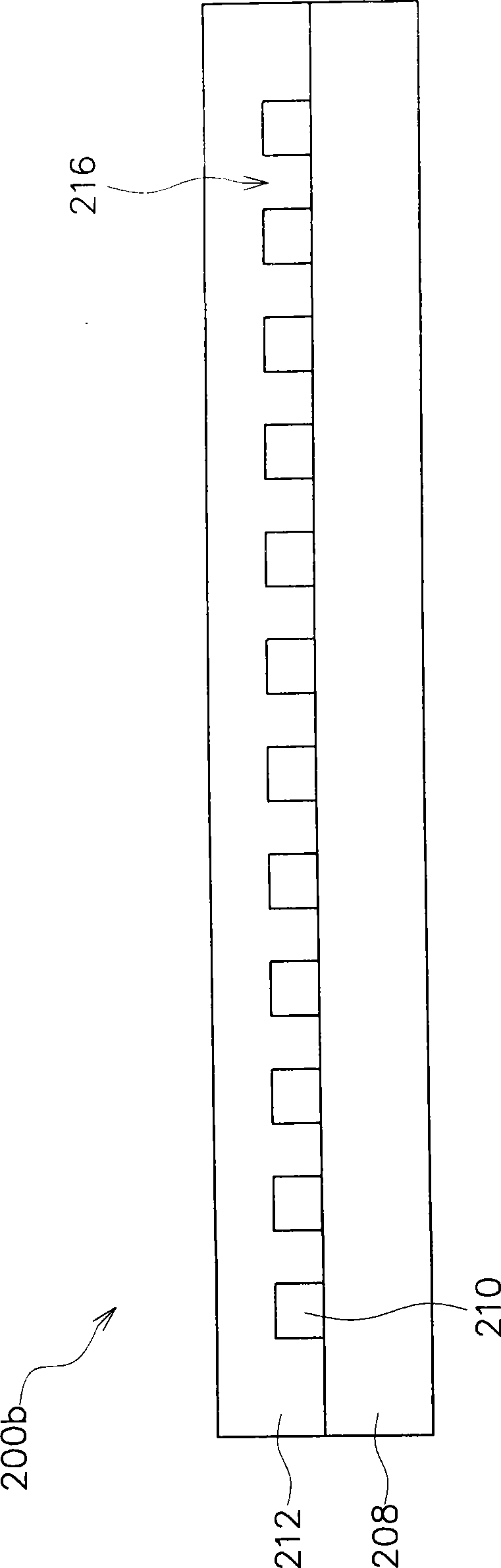

Epitaxial structure and fabrication method of nitride semiconductor device

InactiveUS20060049418A1Semiconductor/solid-state device manufacturingSemiconductor devicesInter layerLattice constant

Owner:FORMOSA EPITAXY INCORPORATION

LED device

InactiveCN101510578AImprove light extraction efficiencyReduce the phenomenon of total reflection critical angle lossSemiconductor devicesCurrent distributionLight reflection

The invention relates to a light-emitting diode device which at least comprises a buffering layer, a non-InAlGaN-doped layer, a first conductive InAlGaN layer, an active layer, a second conductive InAlGaN layer and a light transmission nitrogen-oxide structure which are stacked on a substrate in sequence; the light transmission nitrogen-oxide structure is provided with a first surface and a second surface which are opposite, wherein the first surface faces and is joined with the surface of the second conductive InAlGaN layer; and the light transmission nitrogen-oxide structure is a structure with graded refraction coefficients which decrease from the first surface direction to the second surface direction. The light-emitting diode device can reduce the light reflection effect between interfaces of different materials, the loss of the critical angle of total reflection and the like, increase the light extraction efficiency of the light-emitting diode, achieve the optimal current distribution result through controlling the current distribution by the light transmission layers, and prevent the injected current from flowing through the active layer below the metal electrode, thereby further increasing the light emitting efficiency.

Owner:CHI MEI LIGHTING TECH

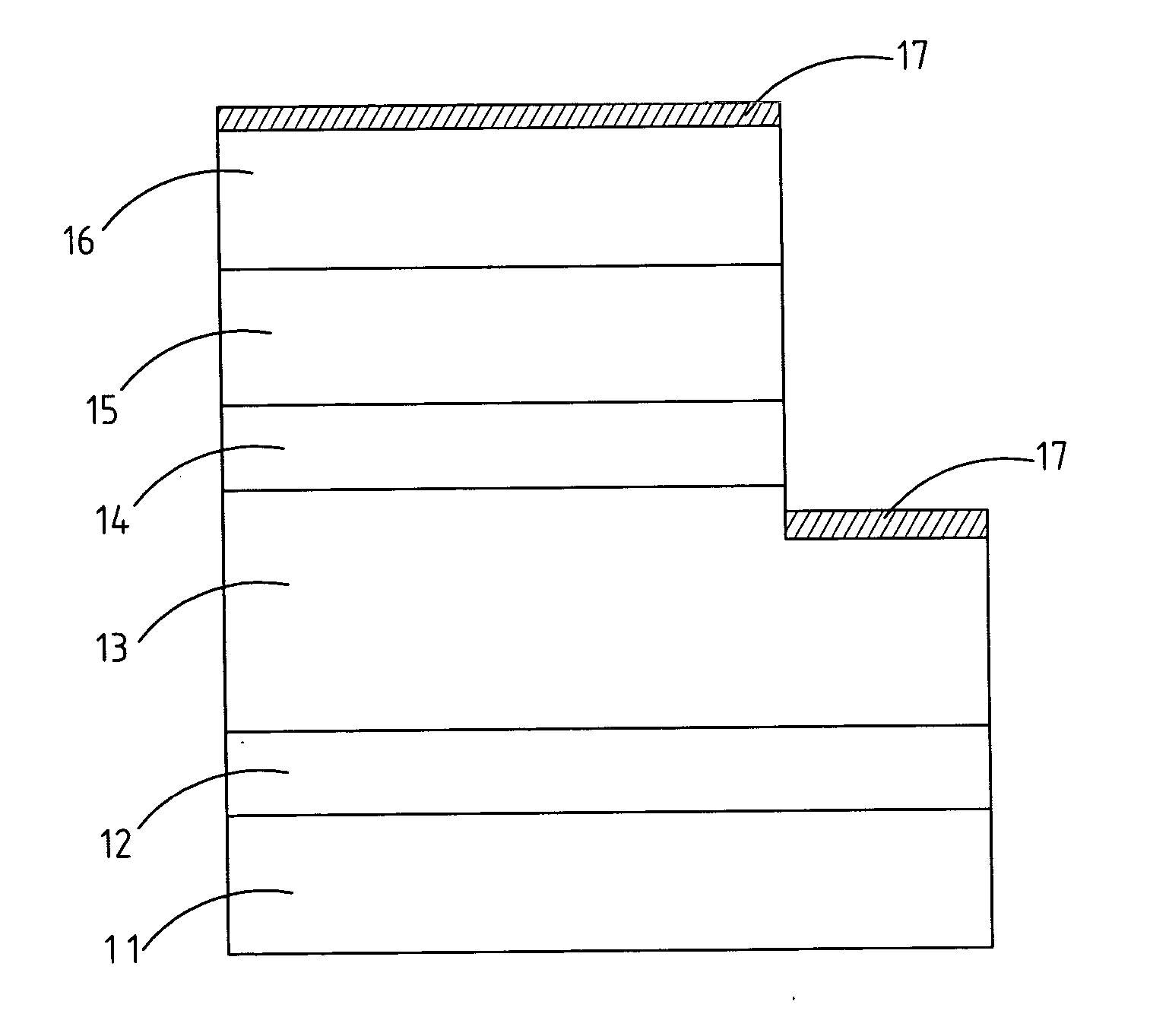

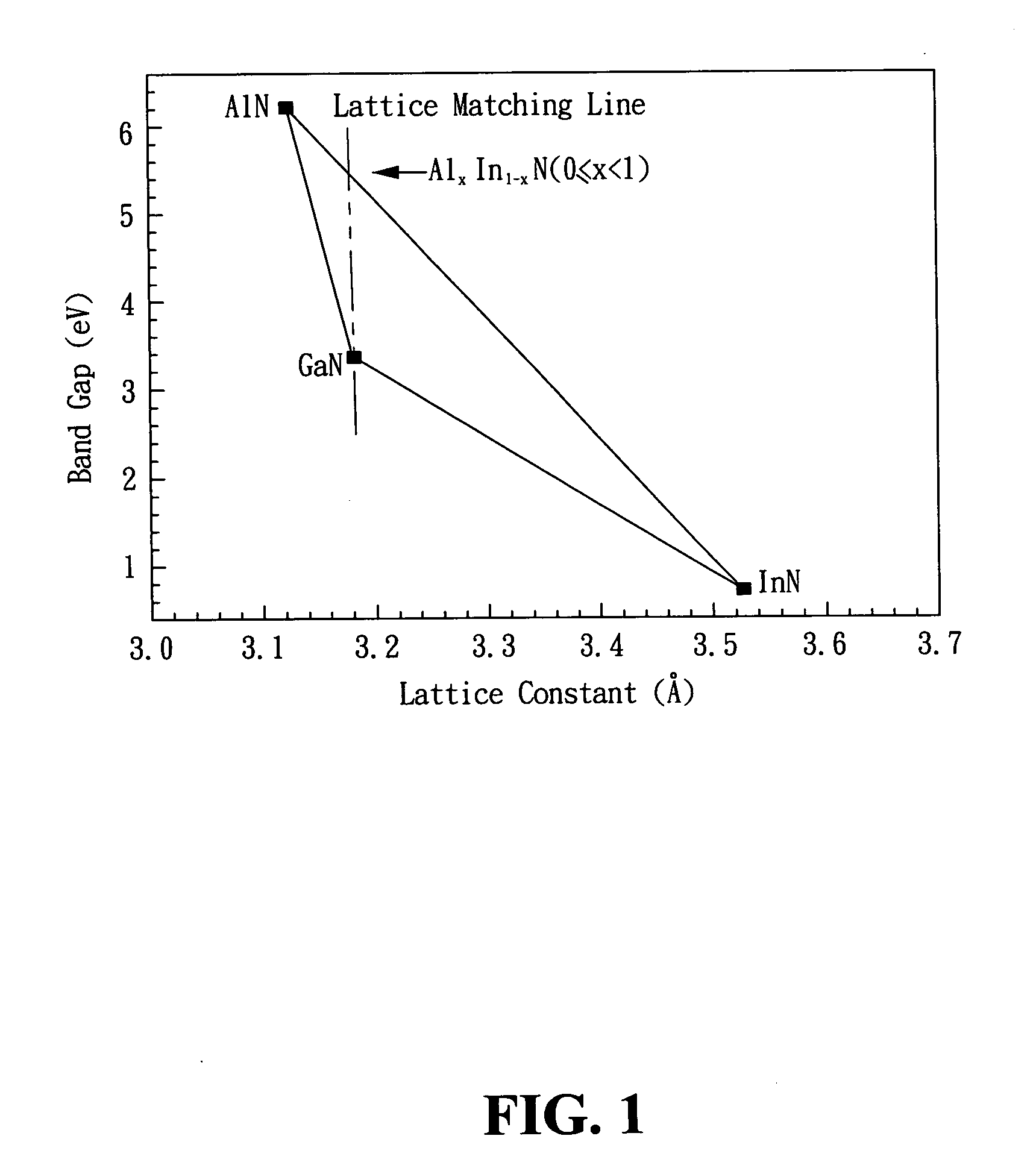

Gallium-nitride based light emitting diode structure

InactiveUS20060043394A1Reduce the overall heightImprove lighting efficiencySemiconductor devicesElectron holeQuantum well

A gallium-nitride(GaN) based light emitting diode (LED) structure utilizing materials having compatible lattice constant is provided. When aluminum-indium-nitride (AlxIn1-xN, 0<x<1) is used to make the p-type cladding layer within the GaN-based LED structure, the cladding layer has a lattice constant compatible with that of GaN. The active layer's multi-quantum well (MQW) structure, therefore, would not be damaged from the excessive stress resulted from the incompatible lattice constant during the GaN-based LED's epitaxial growth. In addition, AlxIn1-xN (0<x<1) has a wider band gap than that of GaN, which can prevent electrons from overflowing from the MQW active layer. This, in turn, will increase the possibility of forming electron-hole pairs within the MQW active layer. Also due to its wider band gap, AlxIn1-xN (0<x<1) has an effective confinement effect on the photons, which again will increase the GaN-based LED's lighting efficiency. Besides, AlxIn1-xN (0<x<1) has a lower growing temperature so that the MQW active layer would remain intact during the low-temperature growth of the cladding layer, which, again, would increase the GaN-based LED's lighting efficiency.

Owner:FORMOSA EPITAXY INCORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com