Epitaxial structure of gallium nitride series compound semiconductor and mfg. method

An epitaxial structure, gallium nitride-based technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem of difficult control of production pass rate, reduction of electronic activity, and difficulty of controlling the uniformity of silicon nitride micromasks and density issues, to achieve the effect of improving efficiency and service life, and low crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

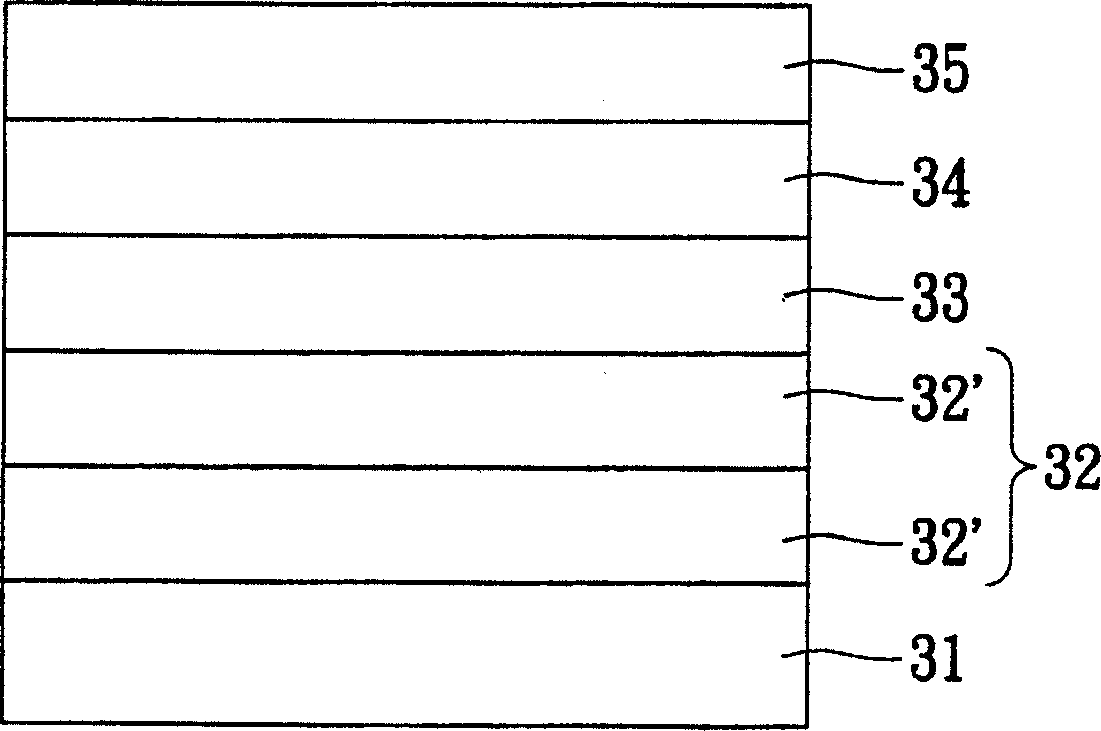

[0027] In view of the shortcomings of common techniques, the present invention proposes an epitaxial structure of GaN-based compound semiconductors. see image 3 , the epitaxial structure 30 of the present invention includes a substrate 31 , a first GaN buffer layer 32 , a second InGaN buffer layer 33 and a GaN epitaxial layer 34 . In the epitaxial structure 30, the substrate 31 is made of one of sapphire, SiC, ZnO and Si, and the first gallium nitride buffer layer 32 further includes a low-temperature gallium nitride buffer layer 32' from bottom to top and a high-temperature GaN buffer layer 32 ″. In addition, the epitaxial structure 30 may further include a GaN-based epitaxial layer 35 on the GaN epitaxial layer 34 .

[0028] see Figure 4 , which illustrates a flow chart of a method of fabricating the epitaxial structure of the present invention. Firstly, a substrate 31 is provided, and the surface of the substrate 31 is thermally cleaned (step 41); then the low-temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com