Patents

Literature

233 results about "Indium gallium nitride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

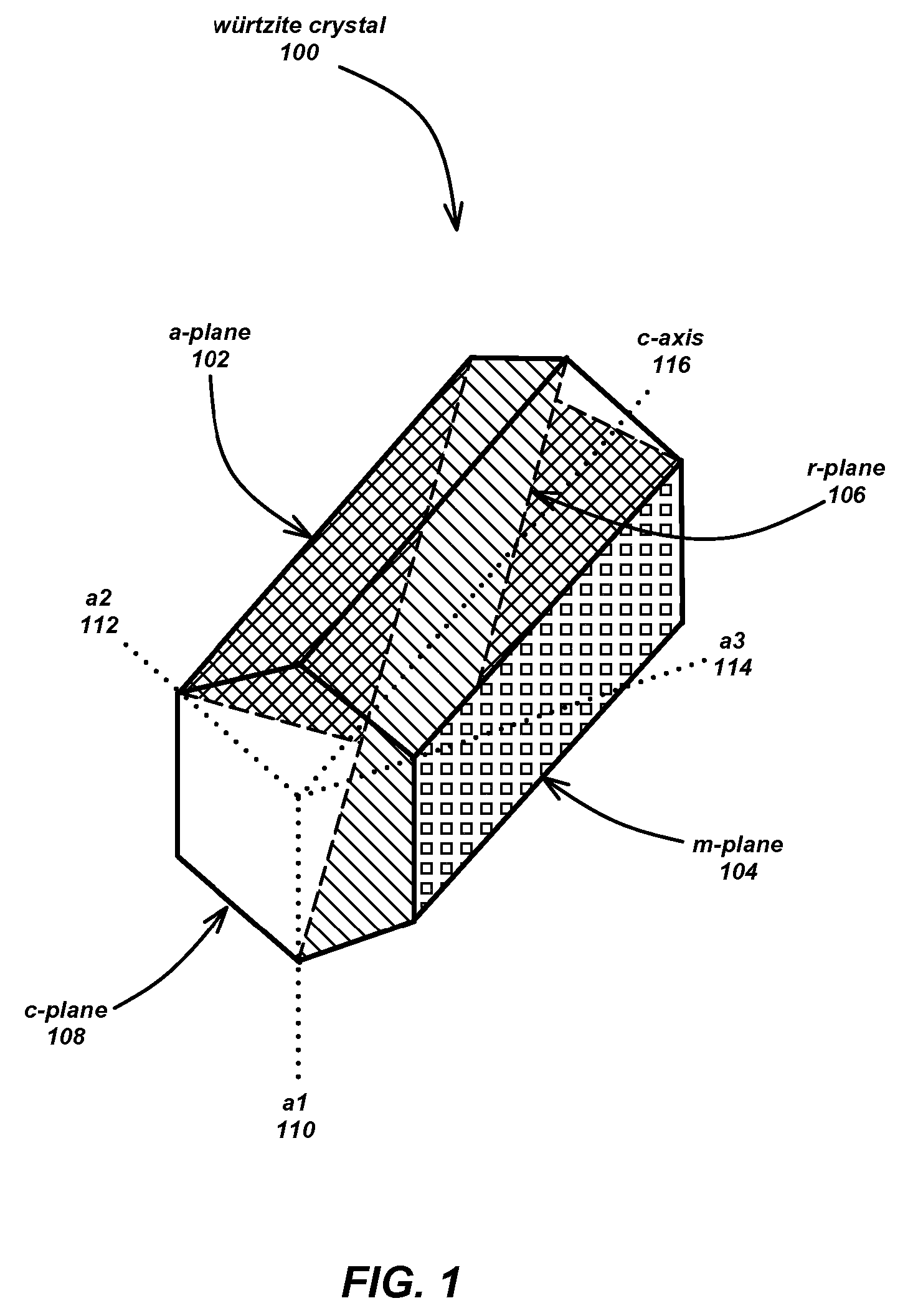

Indium gallium nitride (InGaN, InₓGa₁₋ₓN) is a semiconductor material made of a mix of gallium nitride (GaN) and indium nitride (InN). It is a ternary group III/group V direct bandgap semiconductor. Its bandgap can be tuned by varying the amount of indium in the alloy. InₓGa₁₋ₓN has a direct bandgap span from the infrared (0.69 eV) for InN to the ultraviolet (3.4 eV) of GaN. The ratio of In/Ga is usually between 0.02/0.98 and 0.3/0.7.

Group III nitride photonic devices on silicon carbide substrates with conductive buffer interlay structure

InactiveUS6201262B1Avoid crackingEasy to manufactureSemiconductor/solid-state device manufacturingSemiconductor devicesStress inducedStress relieving

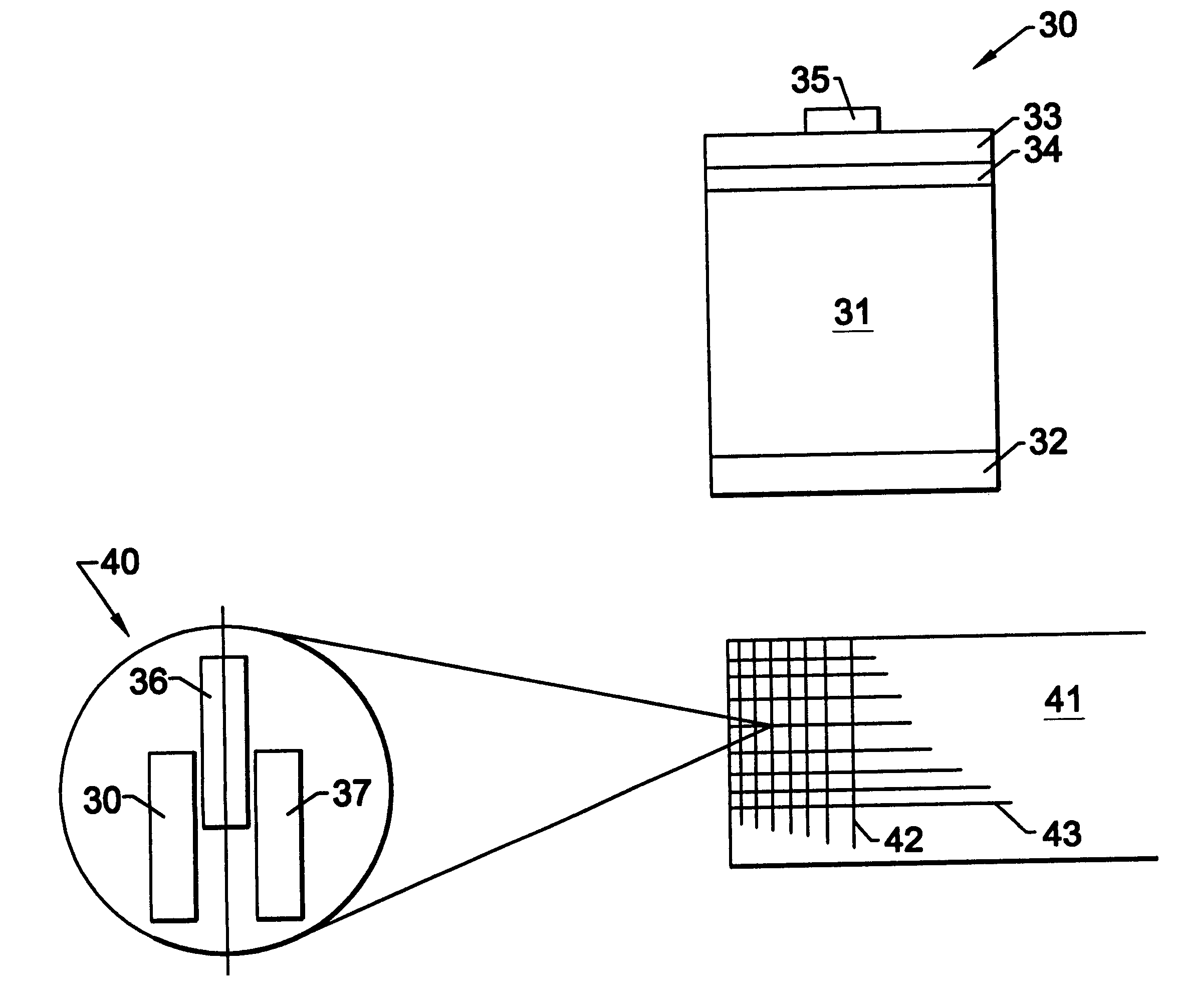

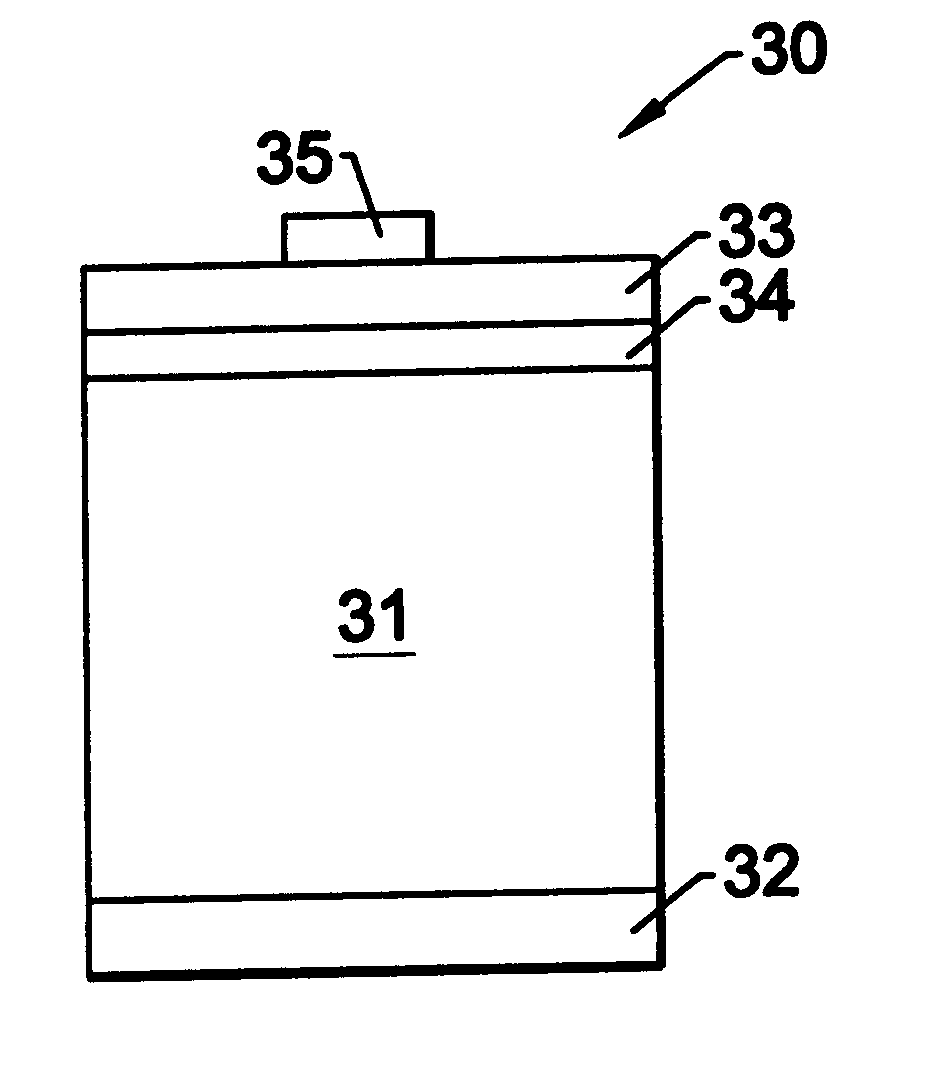

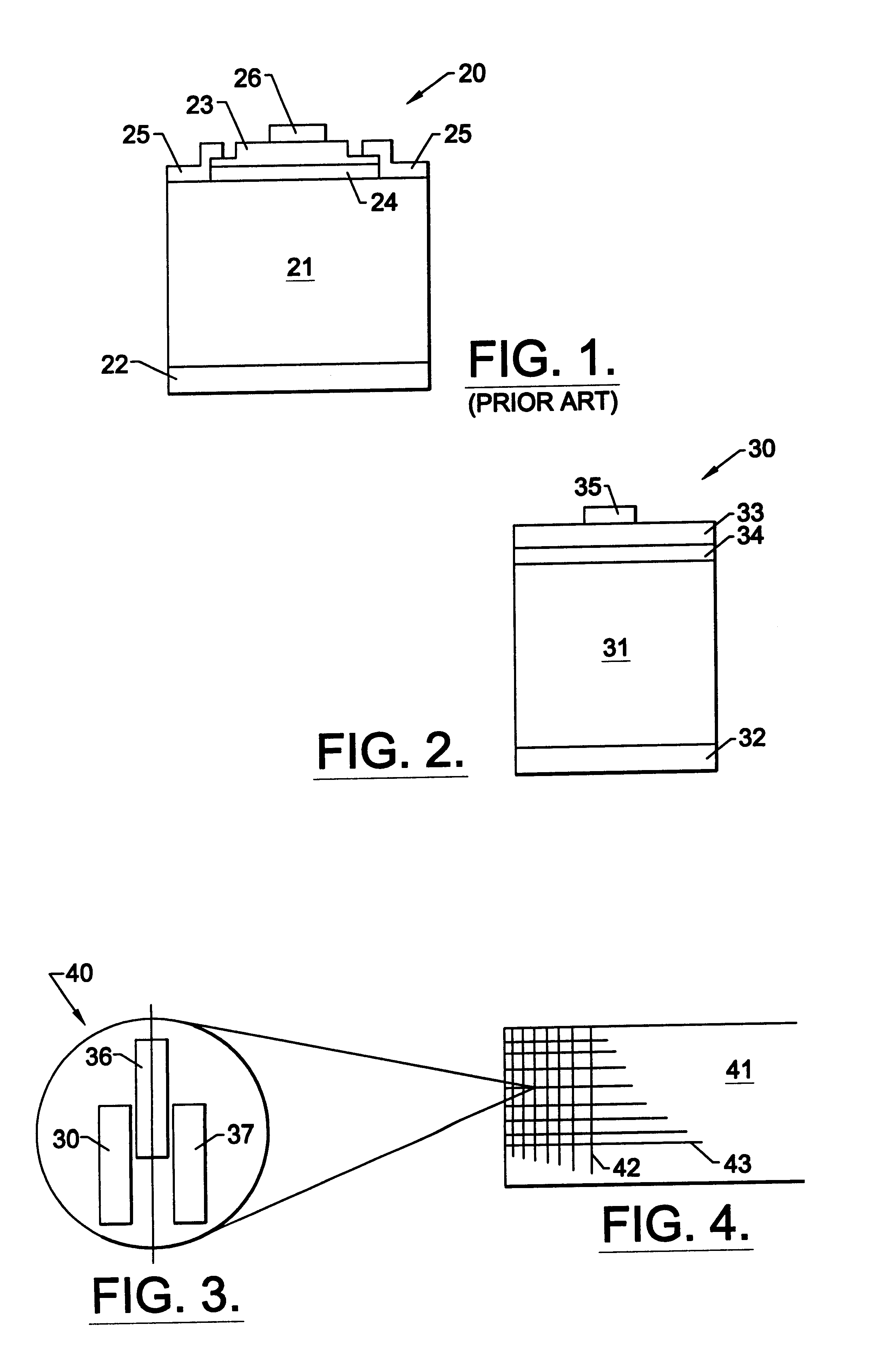

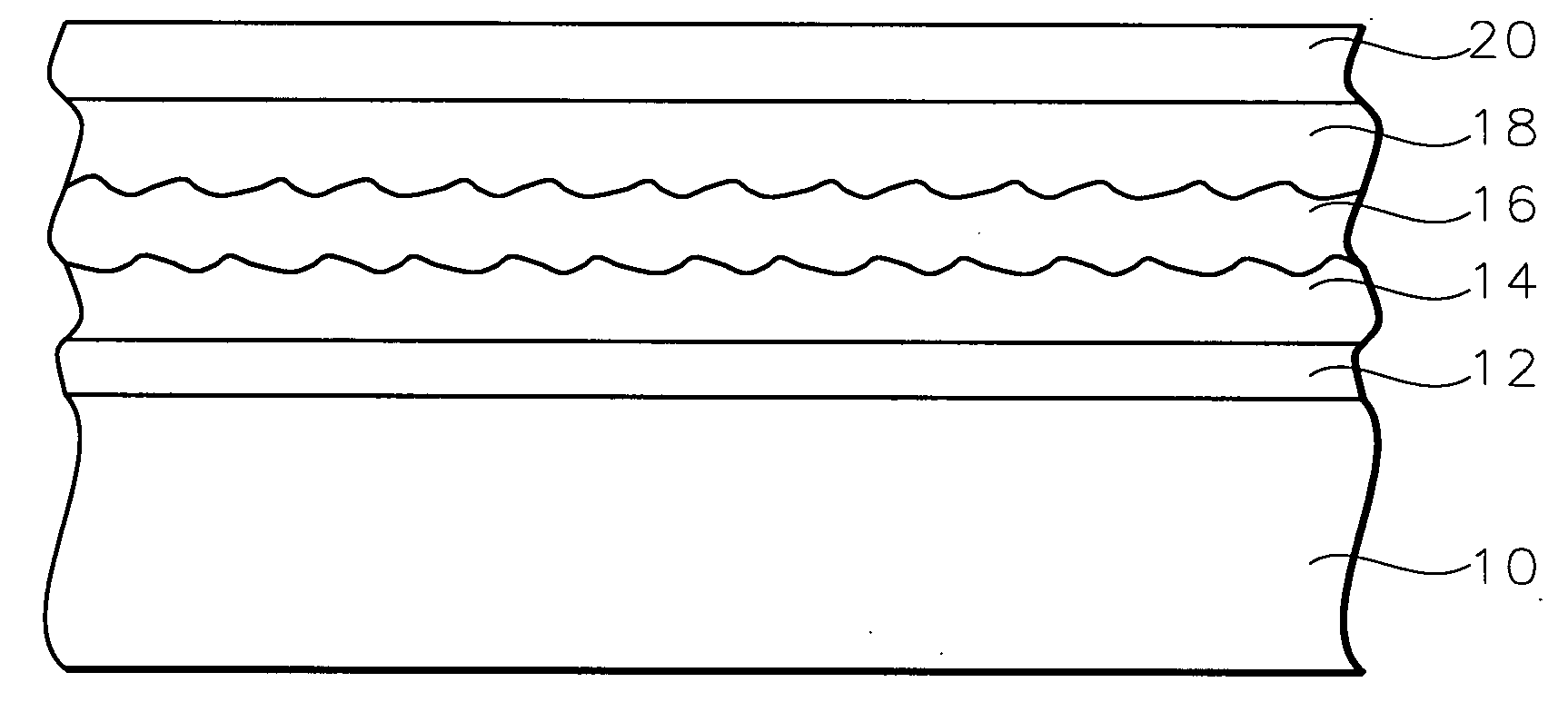

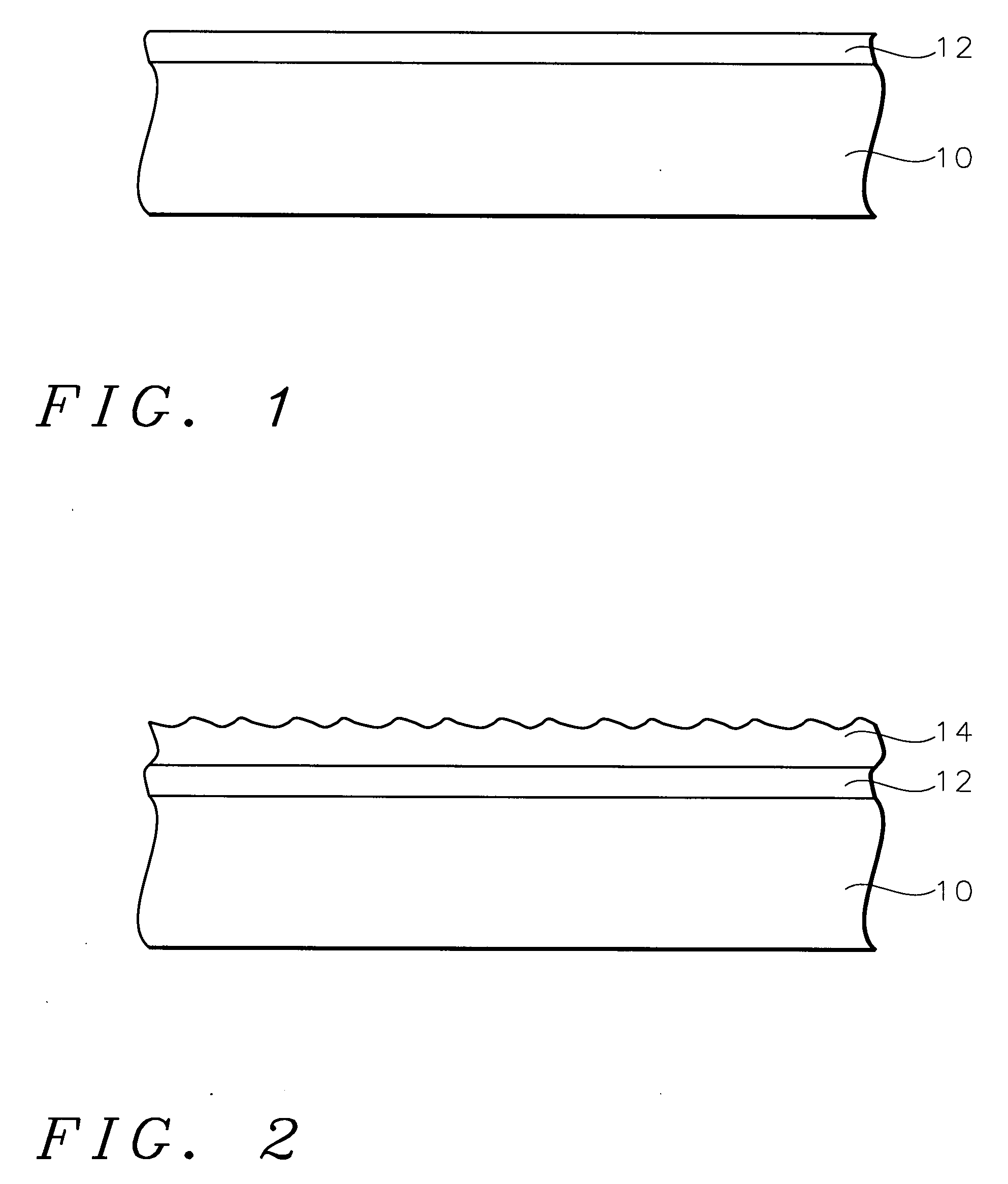

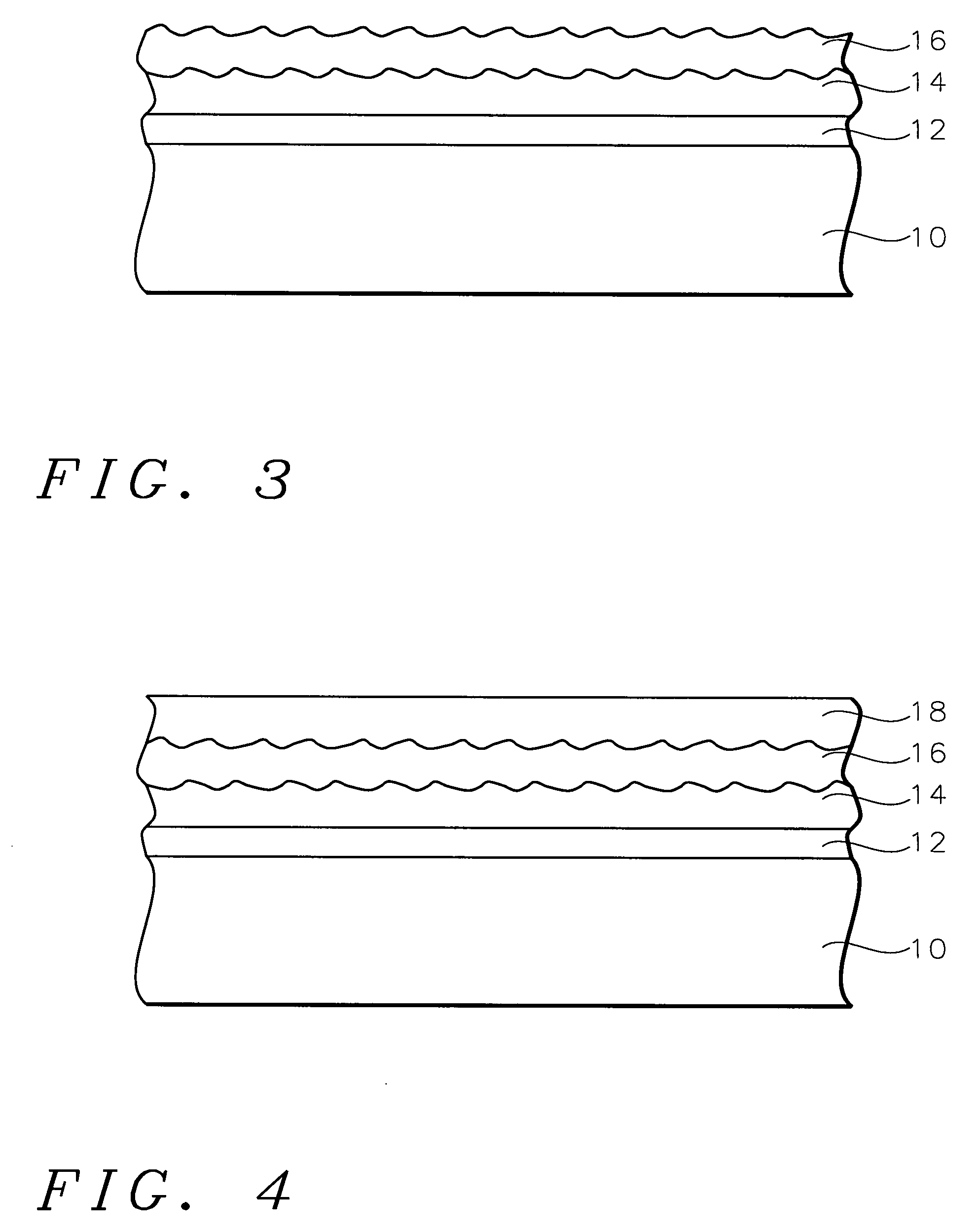

An optoelectronic device with a Group III Nitride active layer is disclosed that comprises a silicon carbide substrate; an optoelectronic diode with a Group III nitride active layer; a buffer structure selected from the group consisting of gallium nitride and indium gallium nitride between the silicon carbide substrate and the optoelectronic diode; and a stress-absorbing structure comprising a plurality of predetermined stress-relieving areas within the crystal structure of the buffer structure, so that stress-induced cracking that occurs in the buffer structure occurs at predetermined areas rather than elsewhere in the buffer structure.

Owner:CREE INC

Group III nitride photonic devices on silicon carbide substrates with conductive buffer interlayer structure

InactiveUS6187606B1Avoid crackingMinimize and eliminate heterobarrierSemiconductor/solid-state device manufacturingSemiconductor devicesStress inducedStress relieving

An optoelectronic device with a Group III Nitride active layer is disclosed that comprises a silicon carbide substrate; an optoelectronic diode with a Group III nitride active layer; a buffer structure selected from the group consisting of gallium nitride and indium gallium nitride between the silicon carbide substrate and the optoelectronic diode; and a stress-absorbing structure comprising a plurality of predetermined stress-relieving areas within the crystal structure of the buffer structure, so that stress-induced cracking that occurs in the buffer structure occurs at predetermined areas rather than elsewhere in the buffer structure.

Owner:CREE INC

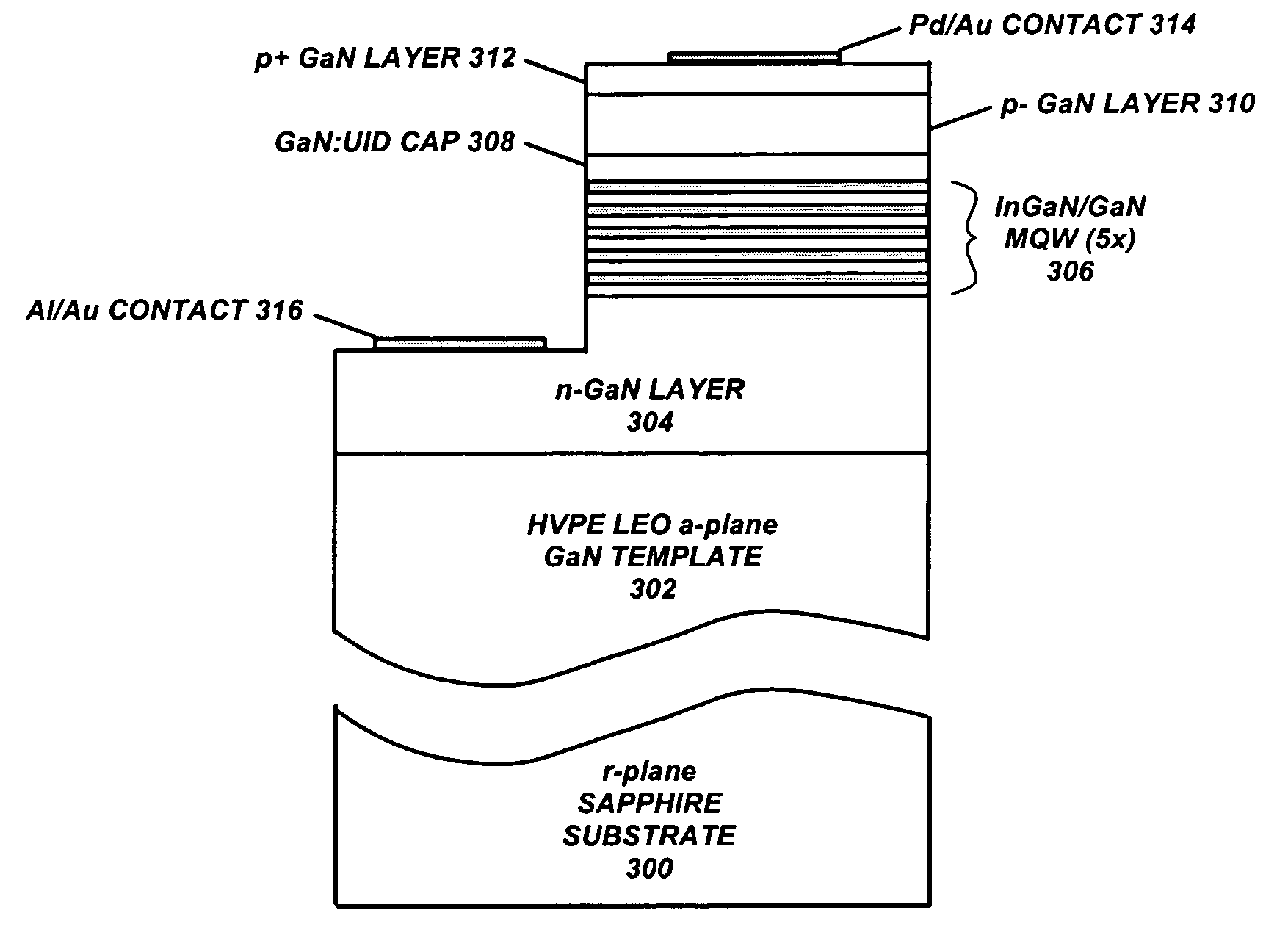

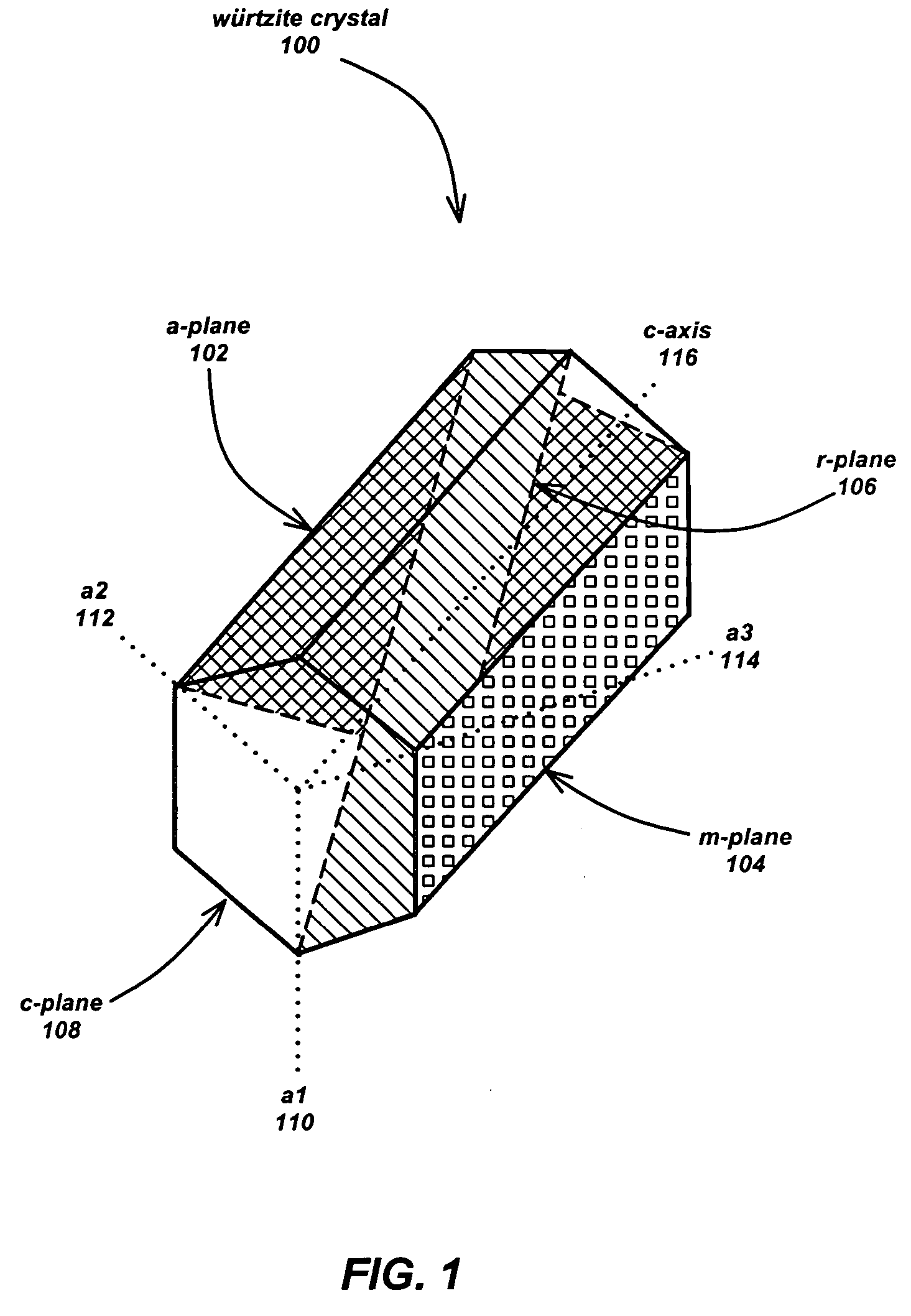

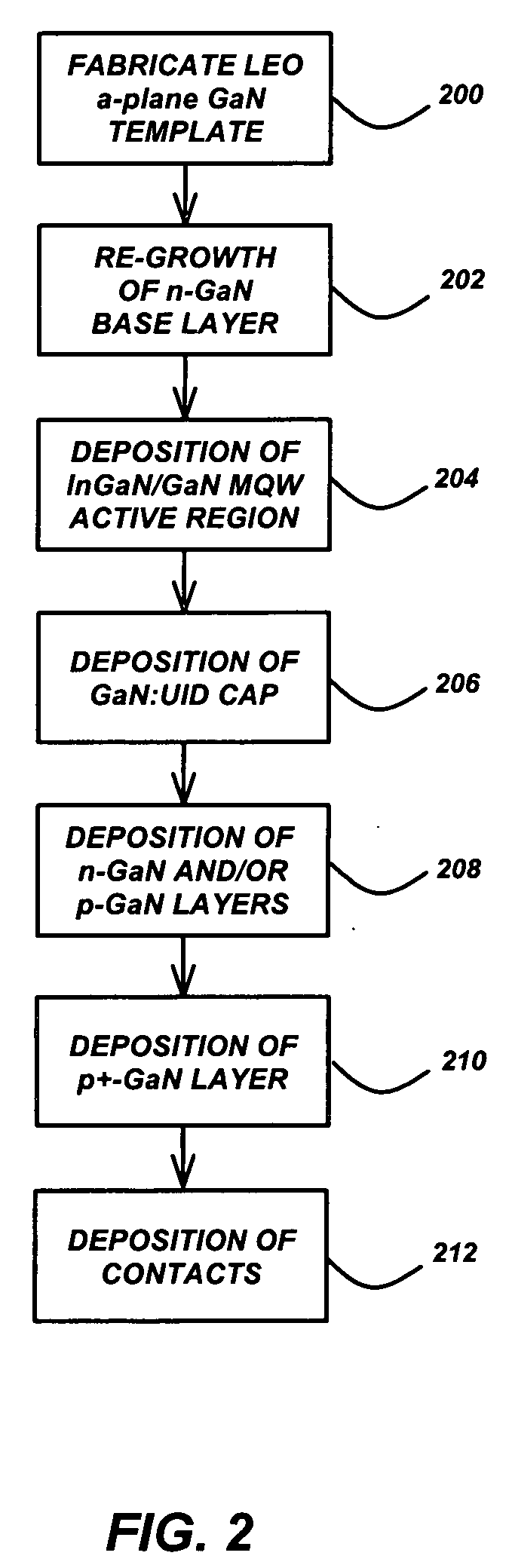

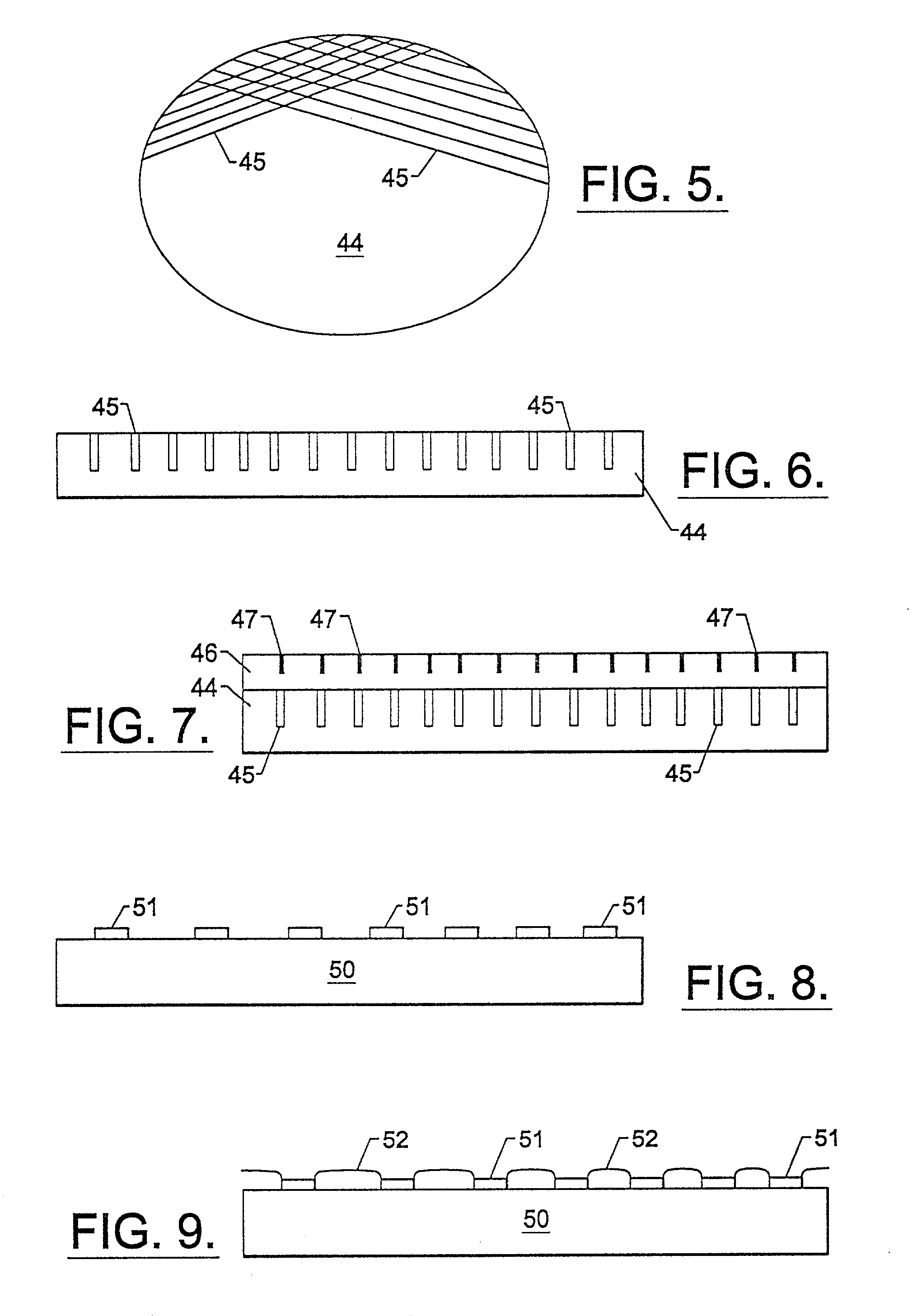

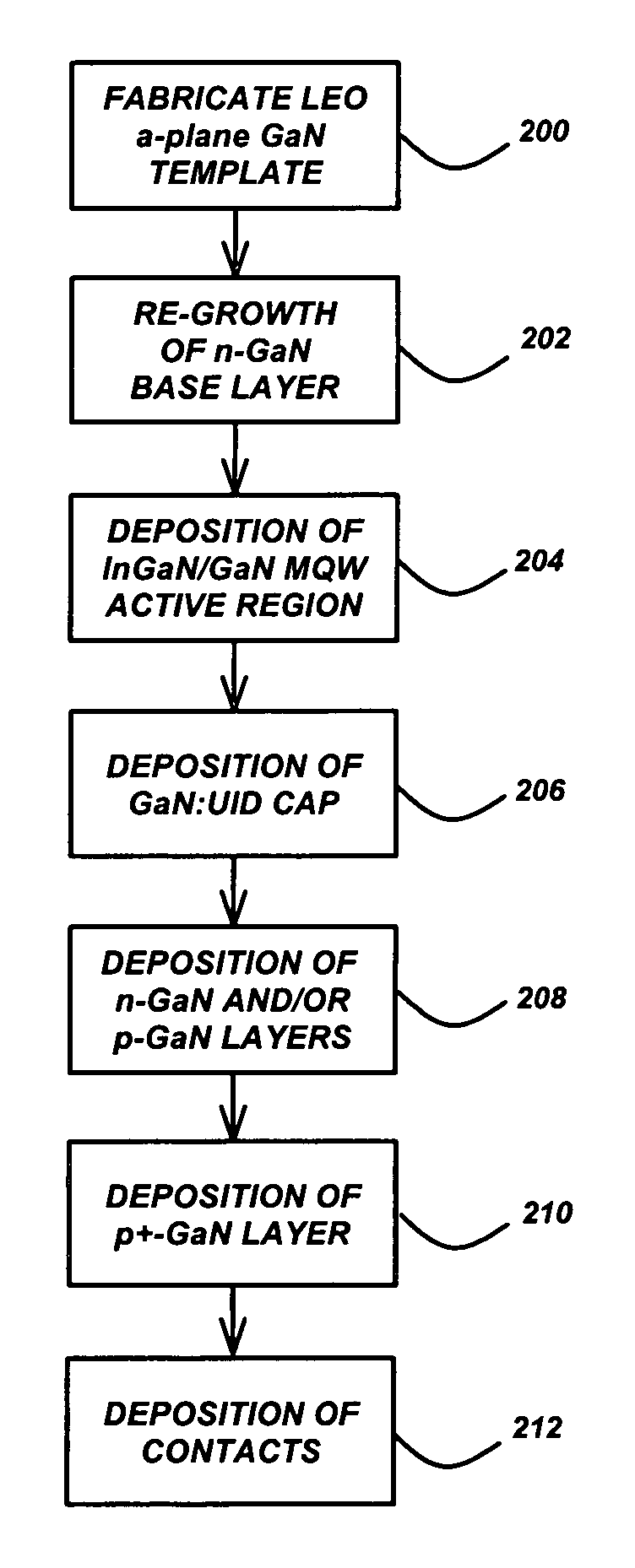

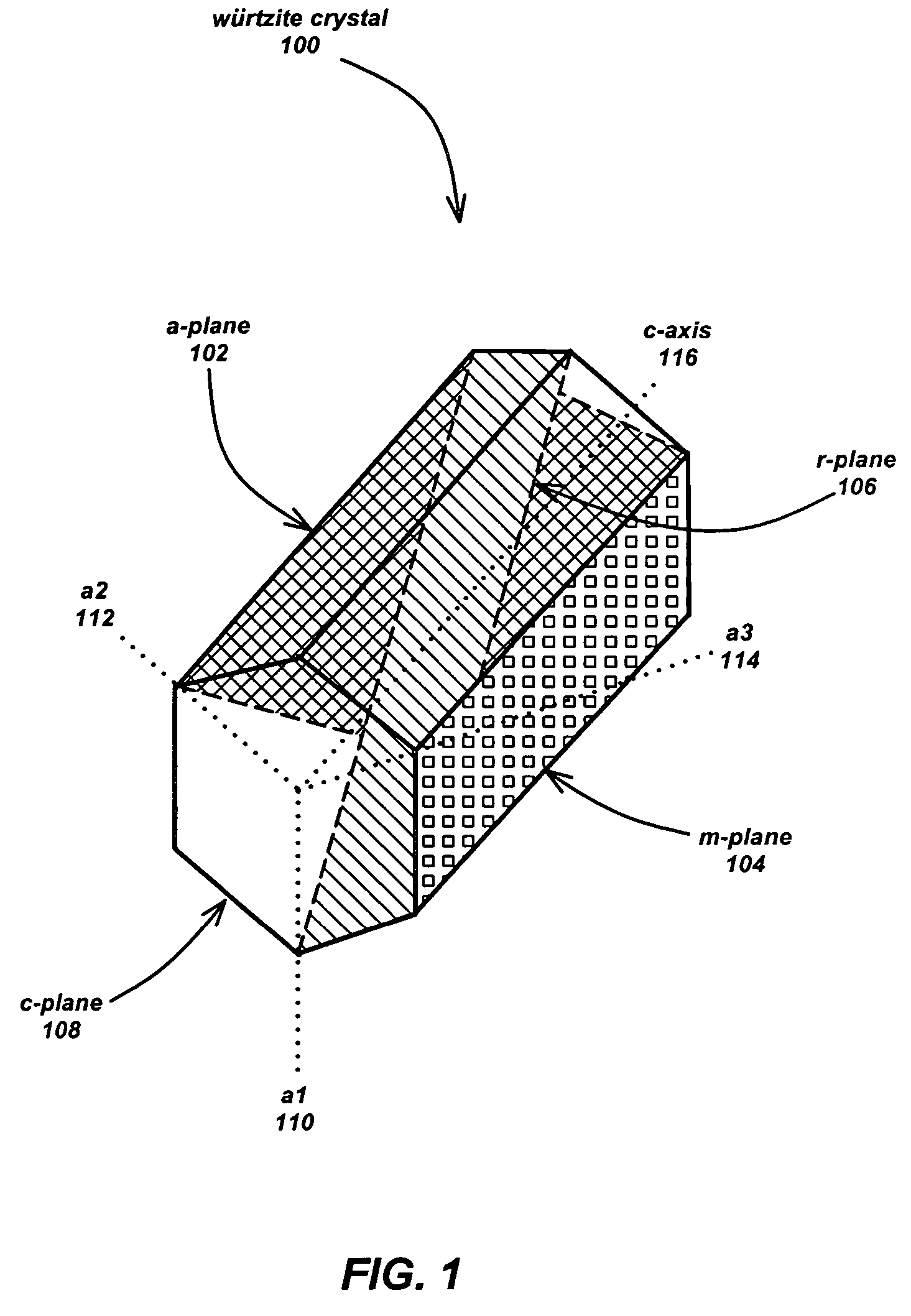

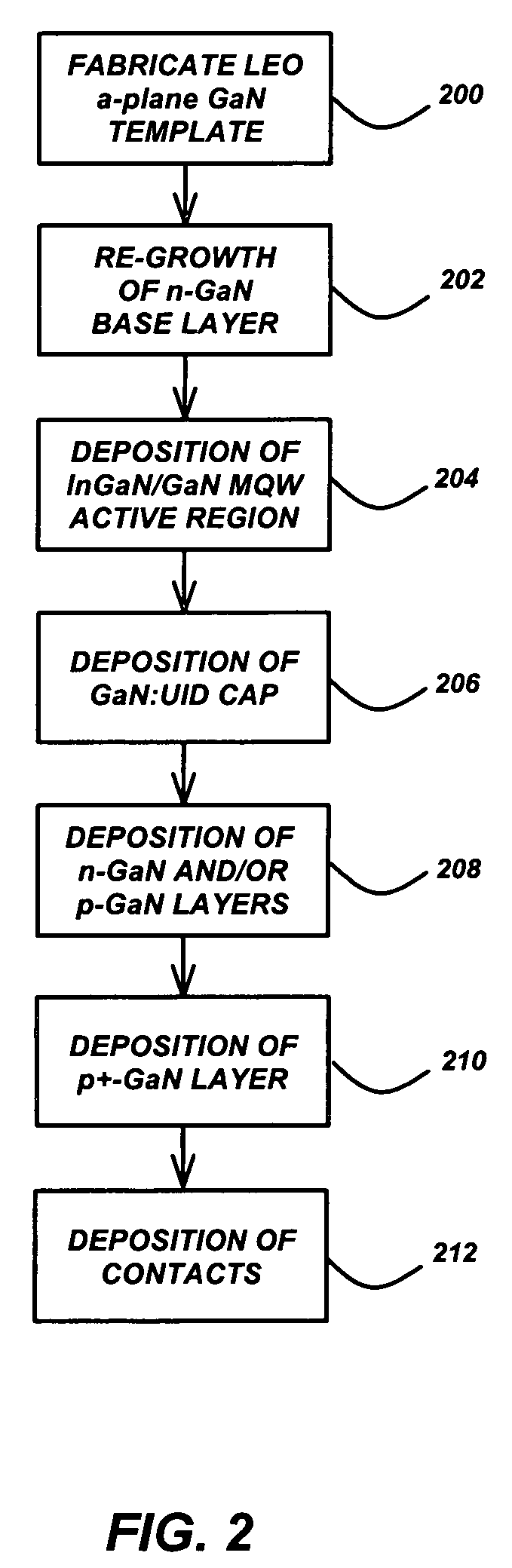

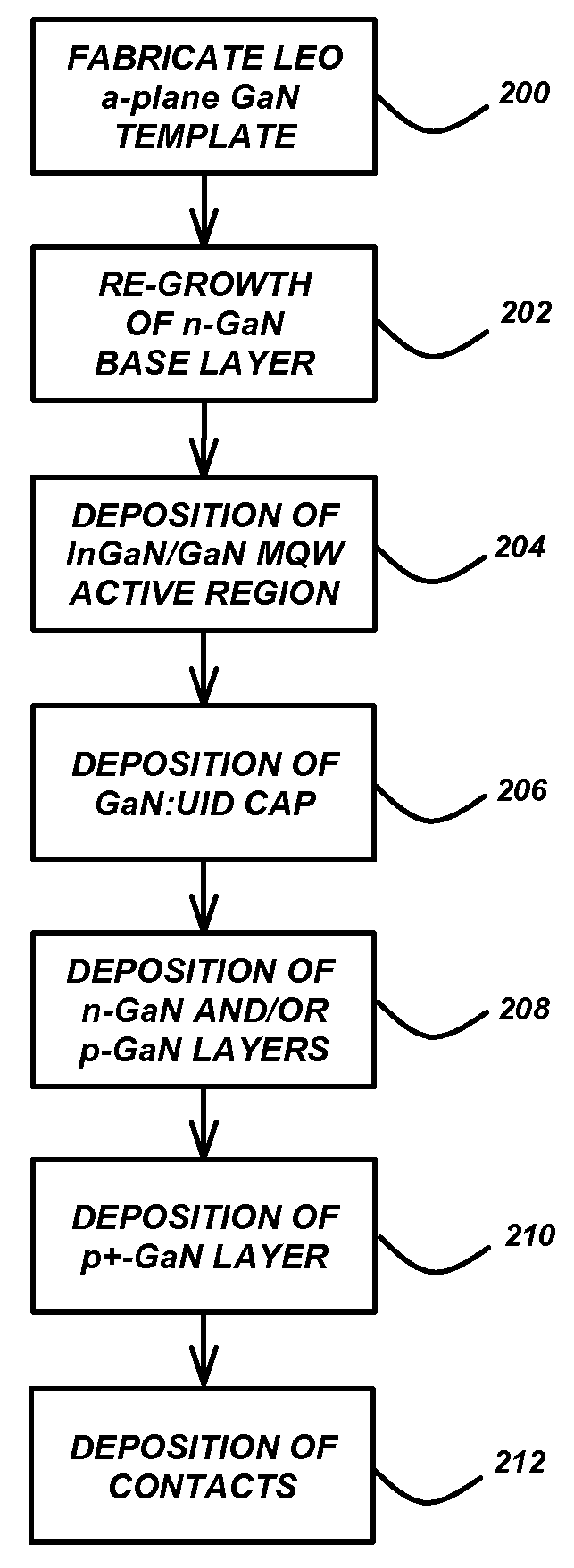

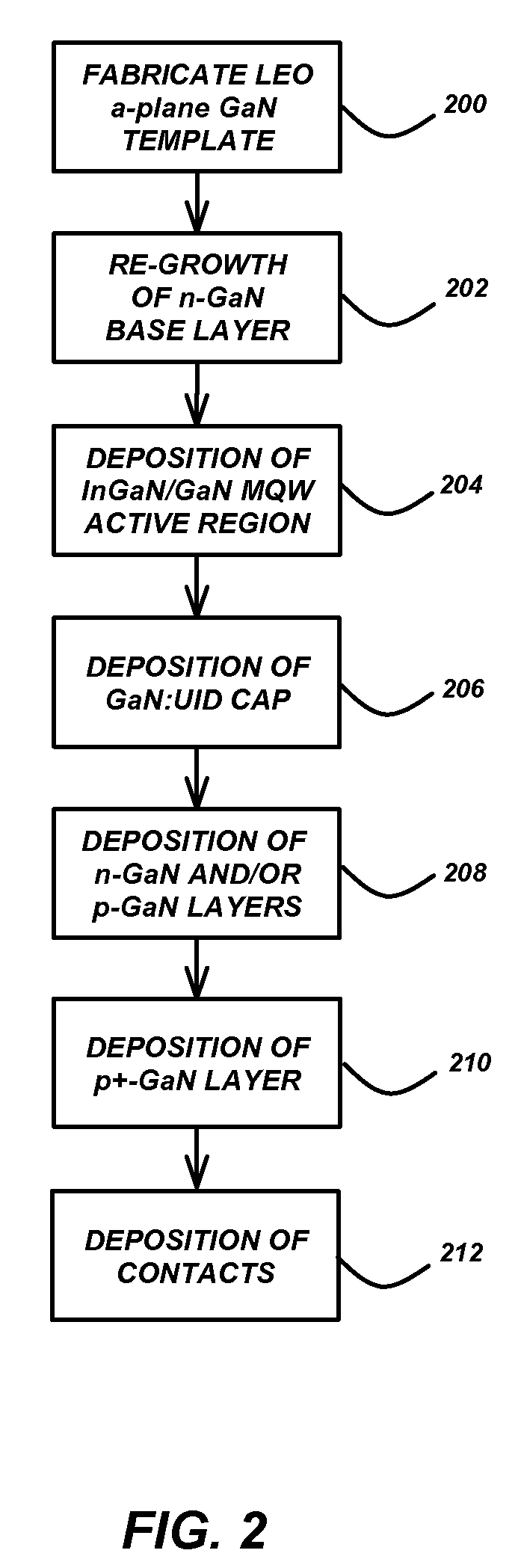

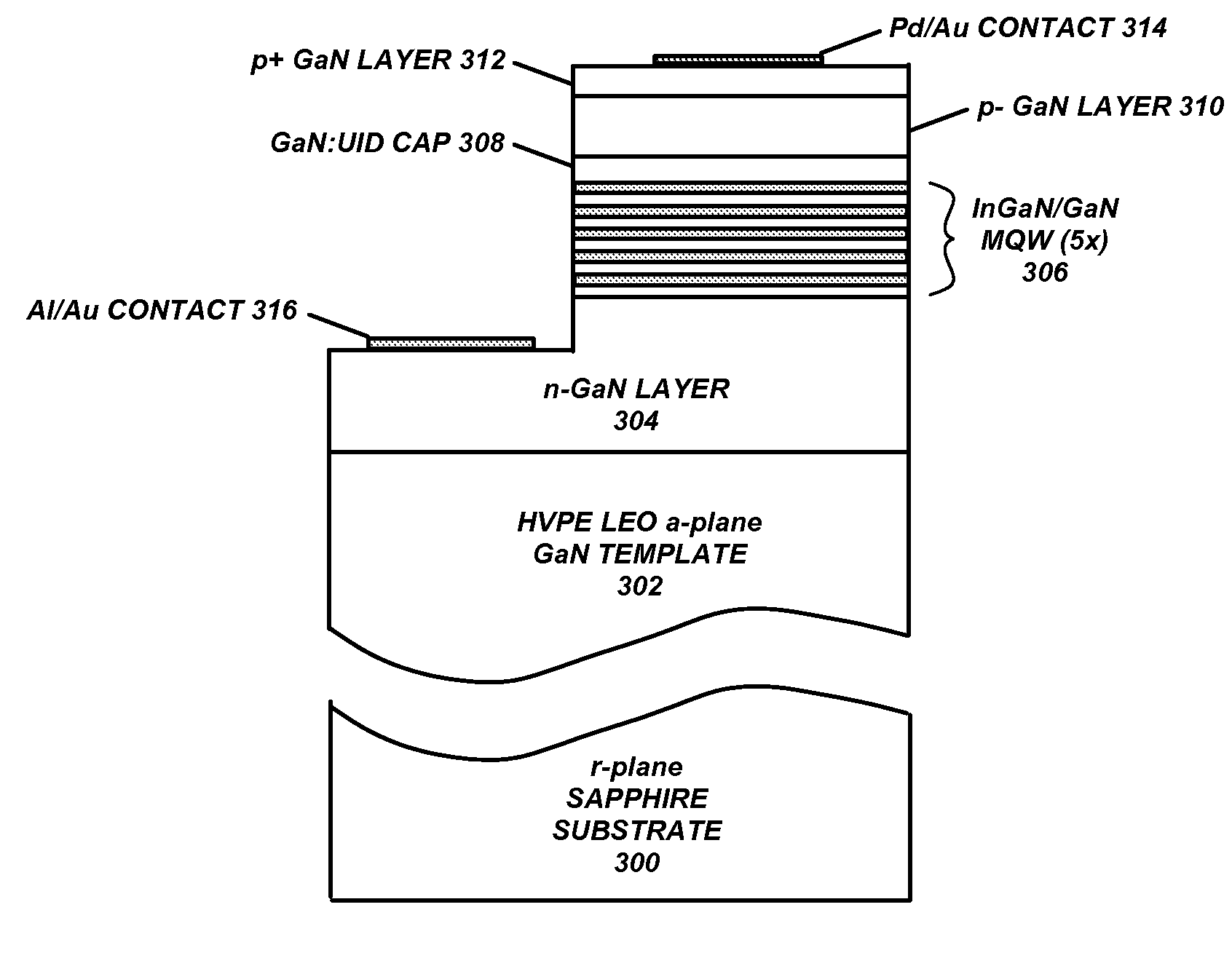

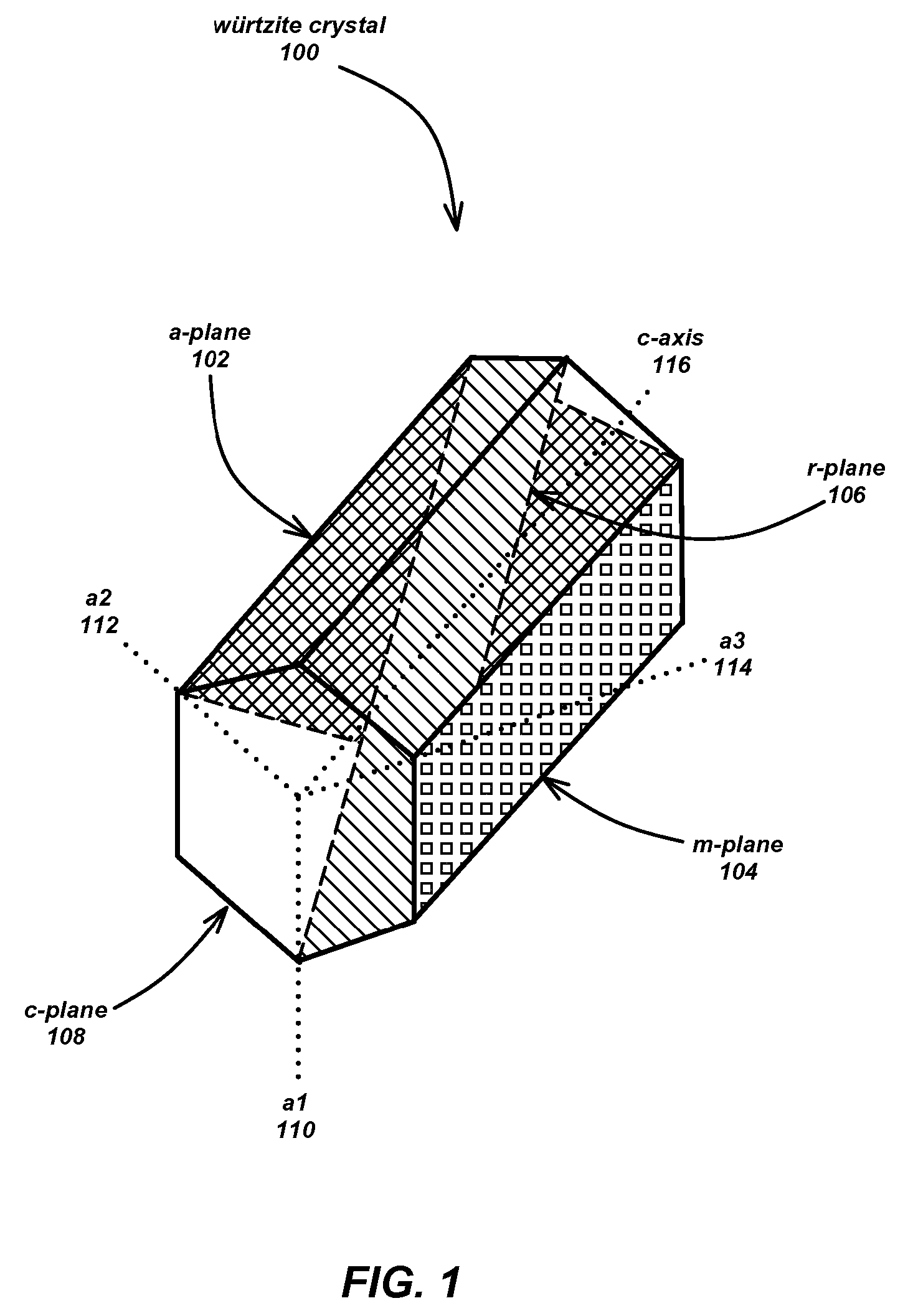

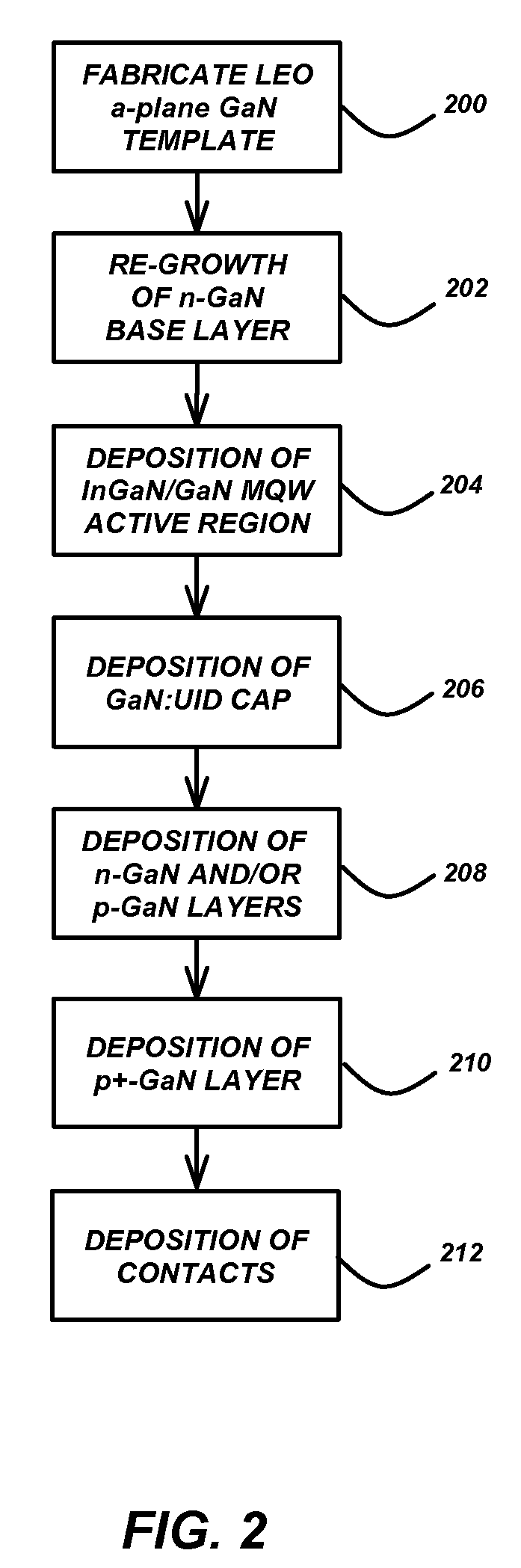

Fabrication of nonpolar indium gallium nitride thin films, heterostructures and devices by metalorganic chemical vapor deposition

ActiveUS20050214992A1Semiconductor/solid-state device manufacturingSemiconductor devicesGas phaseNear ultraviolet

A method for the fabrication of nonpolar indium gallium nitride (InGaN) films as well as nonpolar InGaN-containing device structures using metalorganic chemical vapor deposition (MOVCD). The method is used to fabricate nonpolar InGaN / GaN violet and near-ultraviolet light emitting diodes and laser diodes.

Owner:JAPAN SCI & TECH CORP

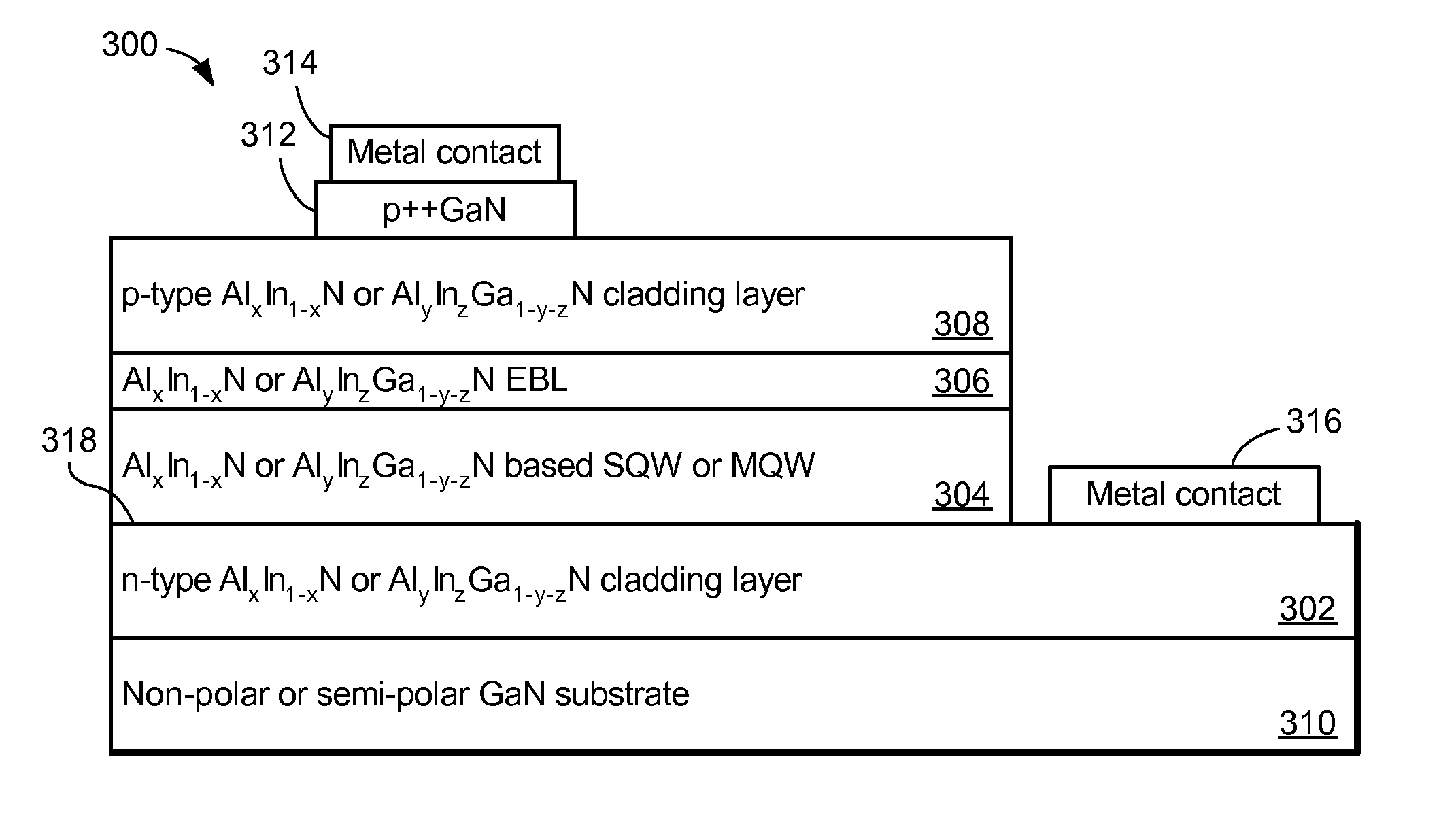

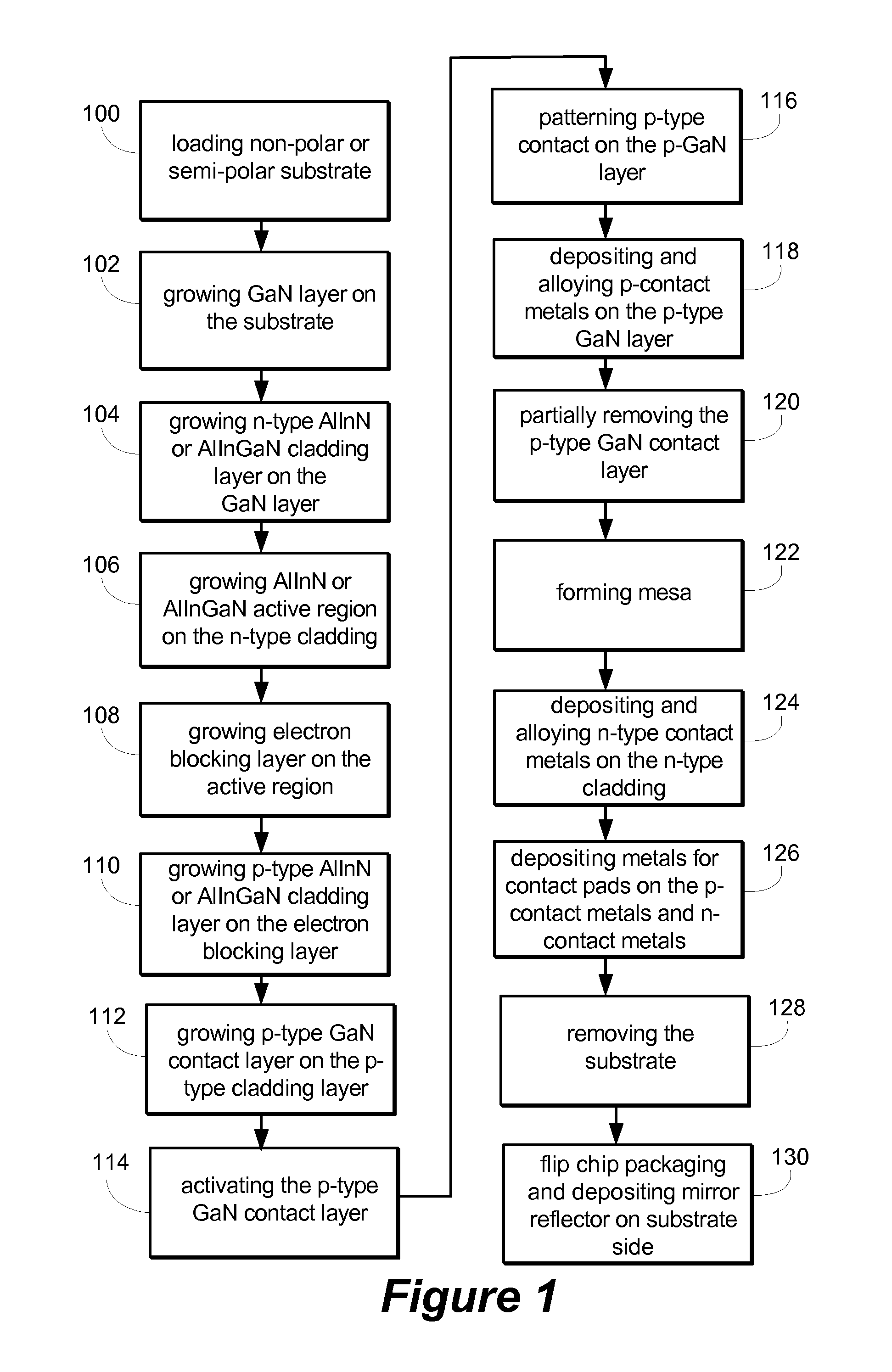

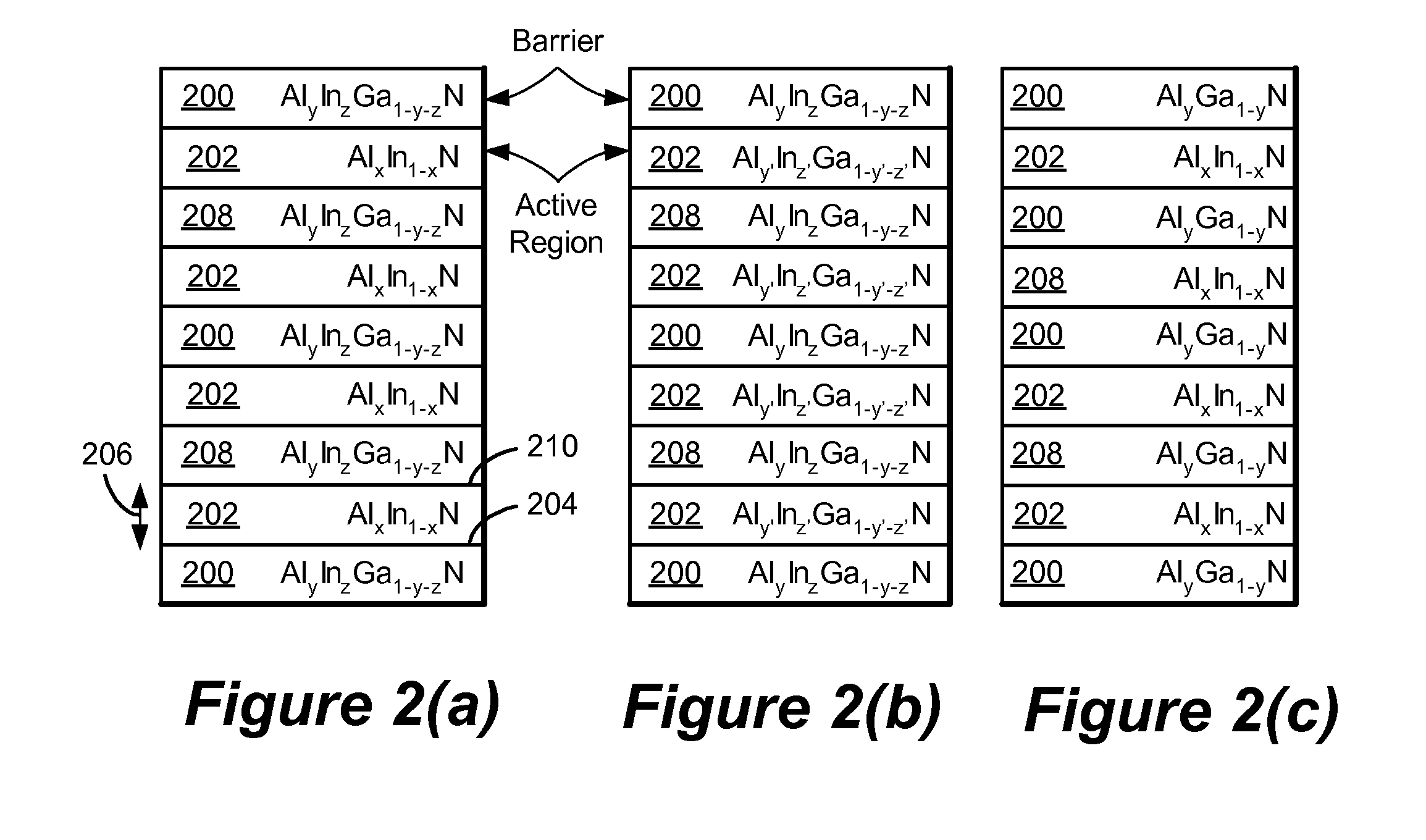

Optoelectronic device based on non-polar and semi-polar aluminum indium nitride and aluminum indium gallium nitride alloys

ActiveUS20100108985A1Low quantum efficiencySemiconductor/solid-state device manufacturingNanoopticsAlloyLength wave

A high-power and high-efficiency light emitting device with emission wavelength (λpeak) ranging from 280 nm to 360 nm is fabricated. The new device structure uses non-polar or semi-polar AlInN and AlInGaN alloys grown on a non-polar or semi-polar bulk GaN substrate.

Owner:RGT UNIV OF CALIFORNIA

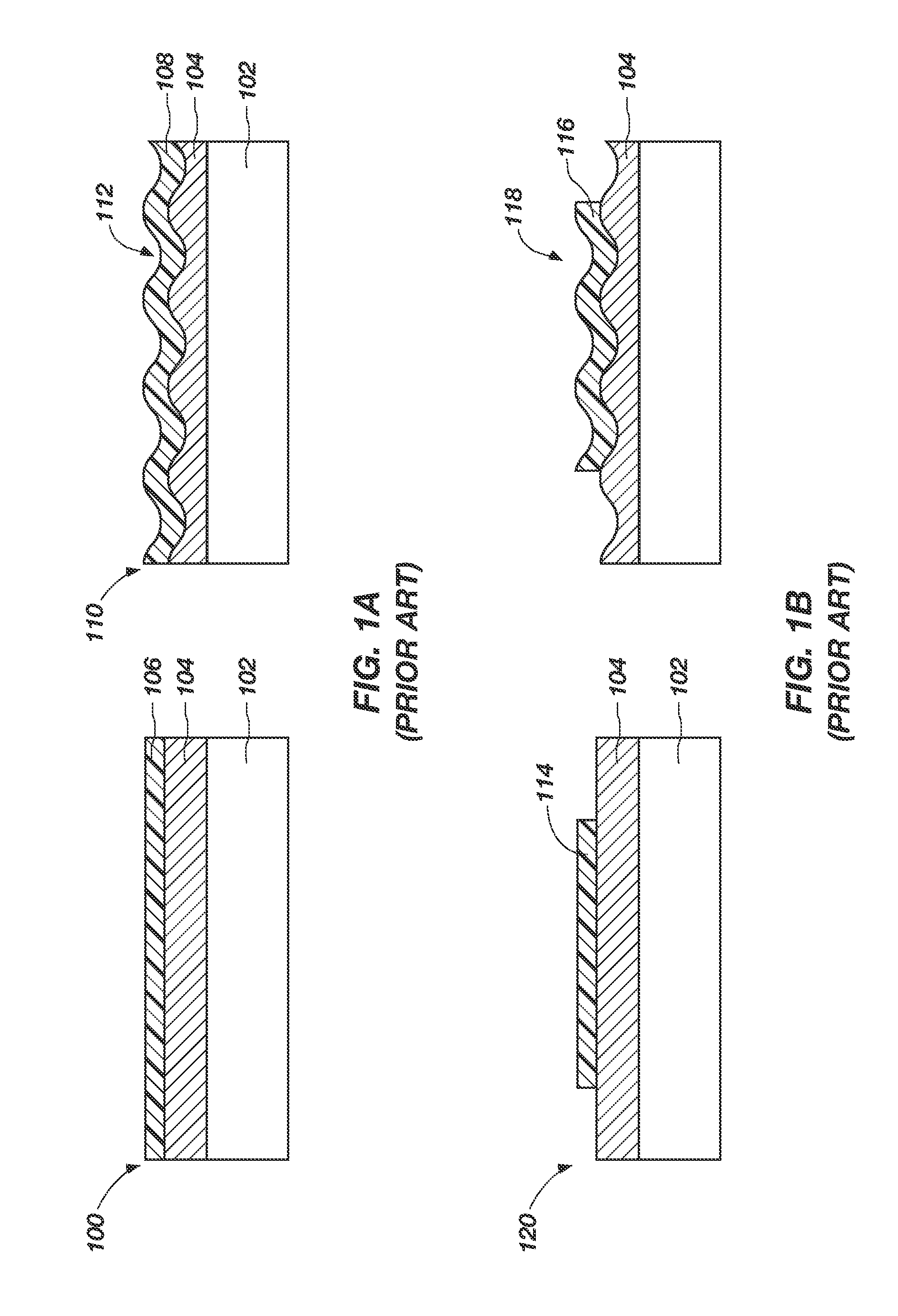

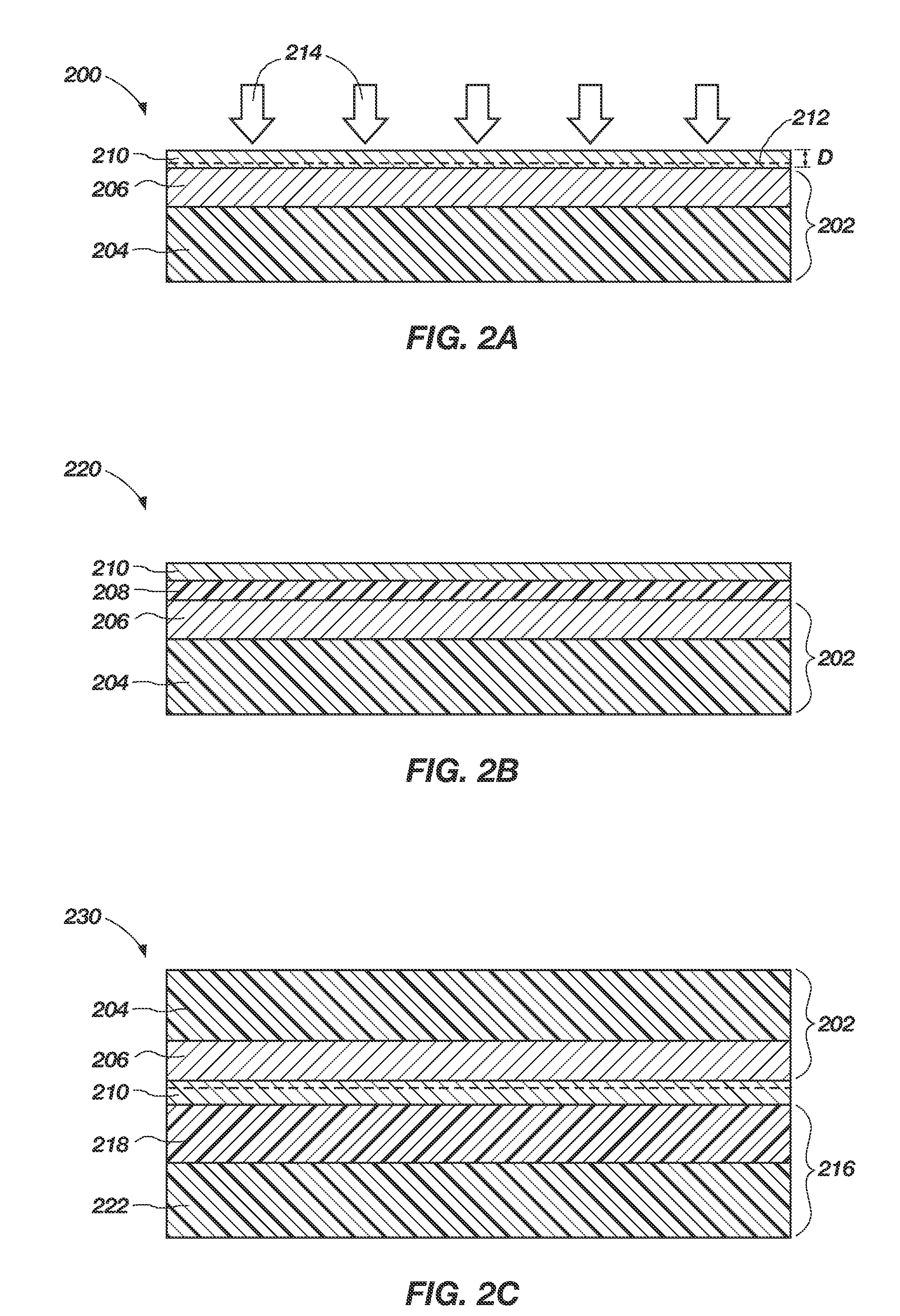

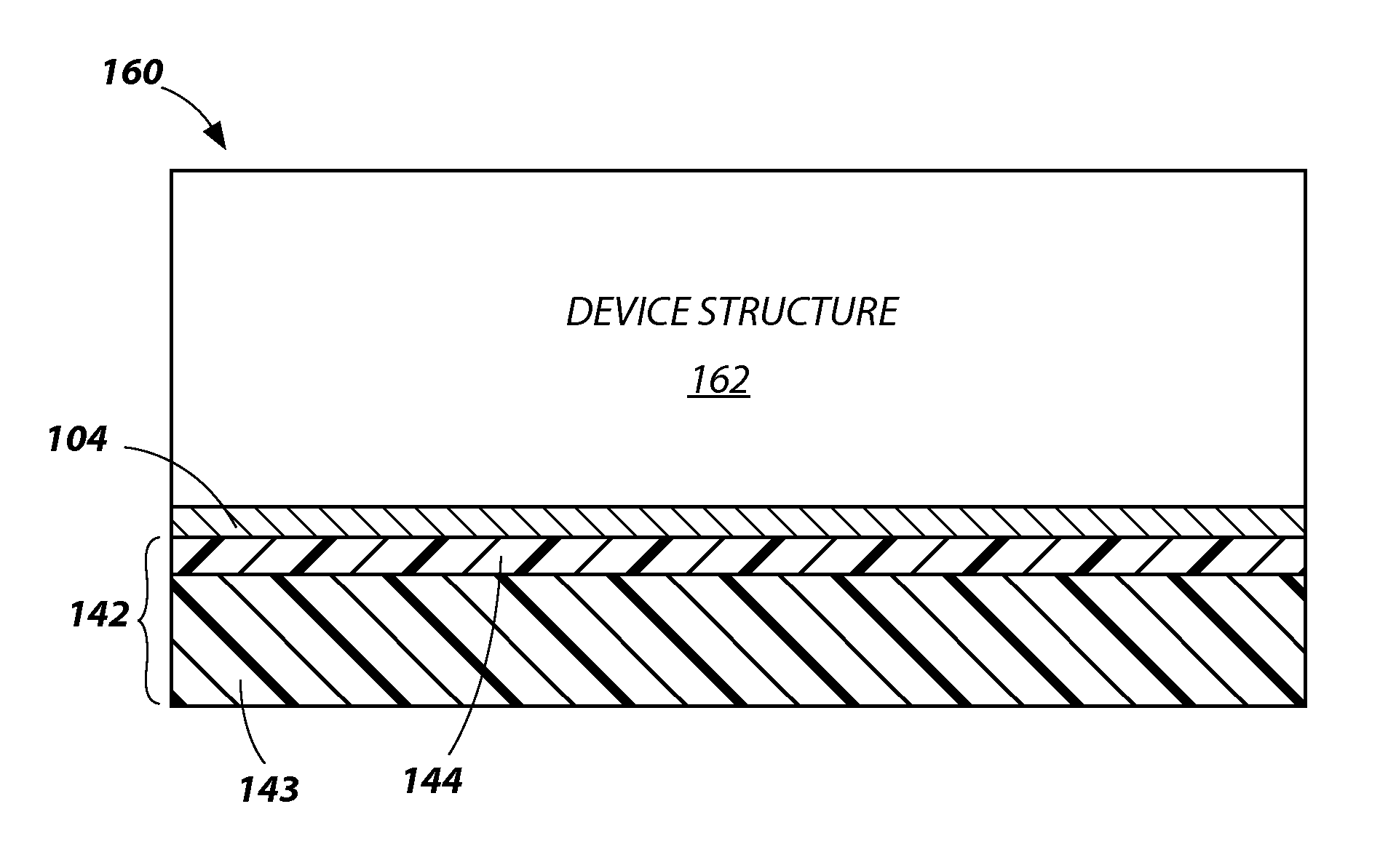

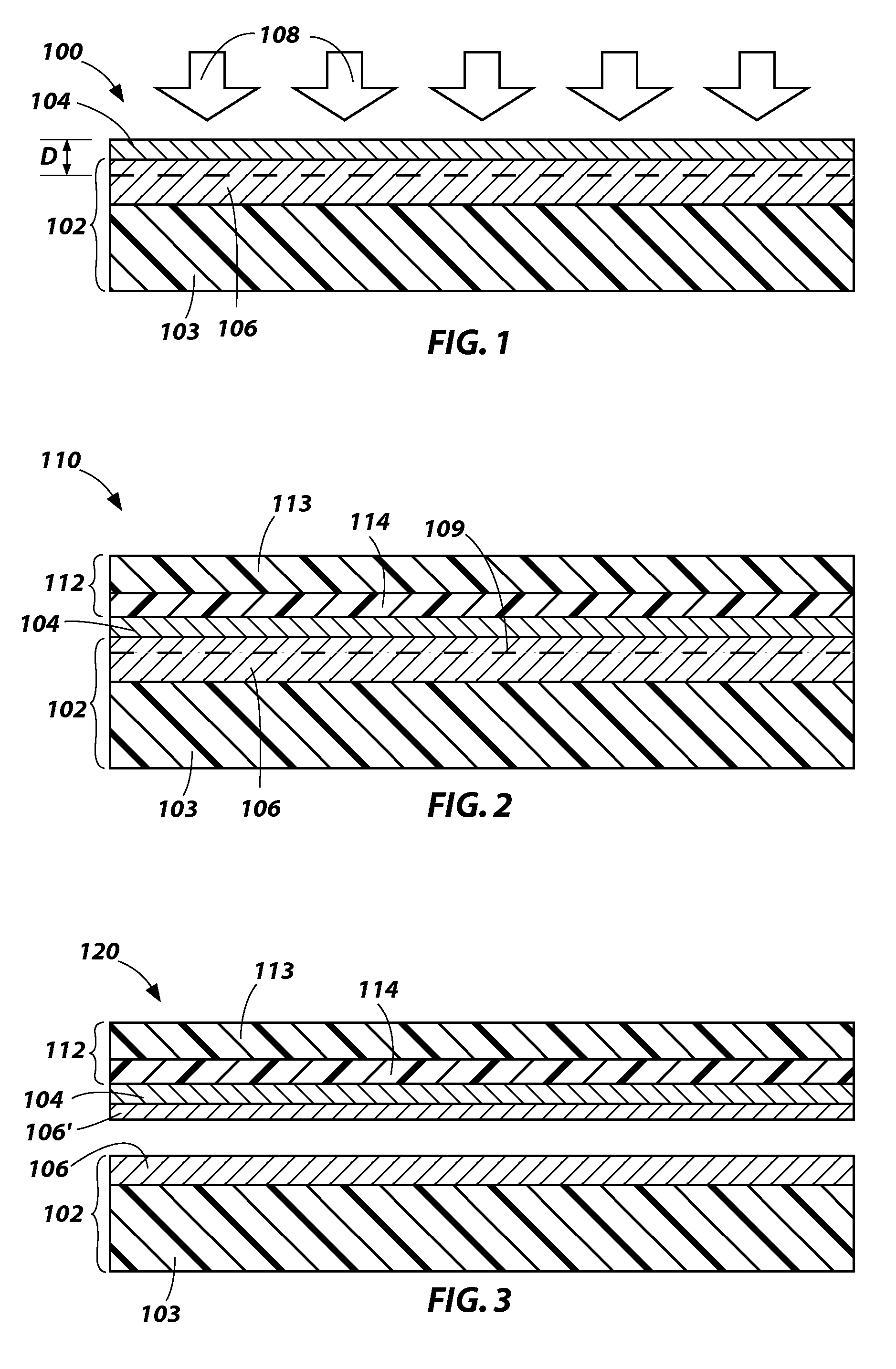

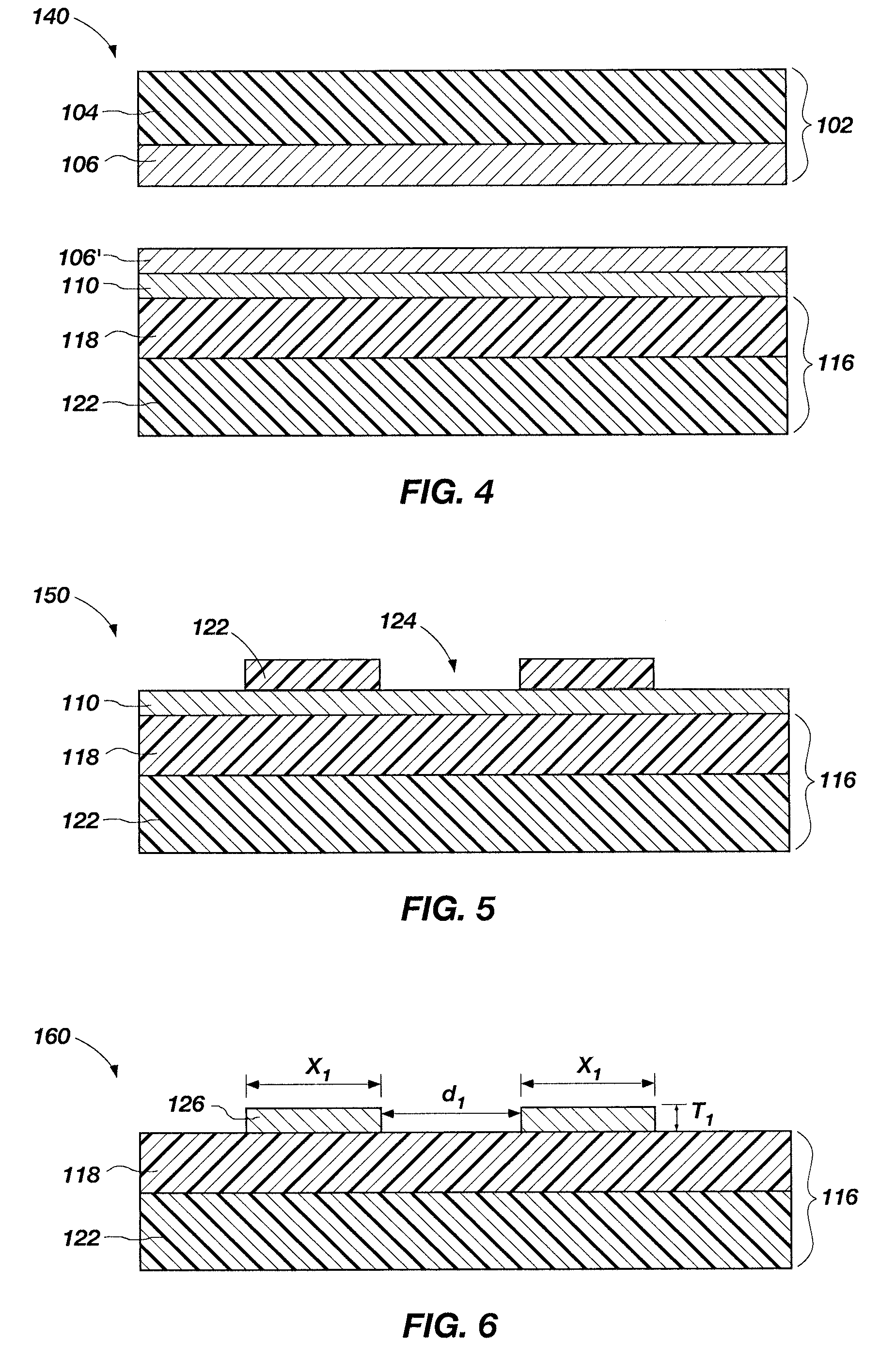

Methods of forming layers of semiconductor material having reduced lattice strain, semiconductor structures, devices and engineered substrates including same

ActiveUS20100109126A1Low viscositySemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsSemiconductor structure

Methods of fabricating semiconductor devices or structures include forming structures of a semiconductor material overlying a layer of a compliant material, subsequently changing the viscosity of the compliant material to relax the semiconductor material structures, and utilizing the relaxed semiconductor material structures as a seed layer in forming a continuous layer of relaxed semiconductor material. In some embodiments, the layer of semiconductor material may comprise a III-V type semiconductor material, such as, for example, indium gallium nitride. Novel intermediate structures are formed during such methods. Engineered substrates include a continuous layer of semiconductor material having a relaxed lattice structure.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

Group III nitride photonic devices on silicon carbide substrates with conductive buffer interlayer structure

InactiveUS20020008241A1Avoid crackingEasy to manufactureTransistorSolid-state devicesStress inducedStress relieving

An optoelectronic device with a Group III Nitride active layer is disclosed that comprises a silicon carbide substrate; an optoelectronic diode with a Group III nitride active layer; a buffer structure selected from the group consisting of gallium nitride and indium gallium nitride between the silicon carbide substrate and the optoelectronic diode; and a stress-absorbing structure comprising a plurality of predetermined stress-relieving areas within the crystal structure of the buffer structure, so that stress-induced cracking that occurs in the buffer structure occurs at predetermined areas rather than elsewhere in the buffer structure.

Owner:CREE INC

Fabrication of nonpolar indium gallium nitride thin films, heterostructures and devices by metalorganic chemical vapor deposition

ActiveUS7186302B2Semiconductor/solid-state device manufacturingSemiconductor devicesGas phaseChemical vapor deposition

A method for the fabrication of nonpolar indium gallium nitride (InGaN) films as well as nonpolar InGaN-containing device structures using metalorganic chemical vapor deposition (MOVCD). The method is used to fabricate nonpolar InGaN / GaN violet and near-ultraviolet light emitting diodes and laser diodes.

Owner:JAPAN SCI & TECH CORP

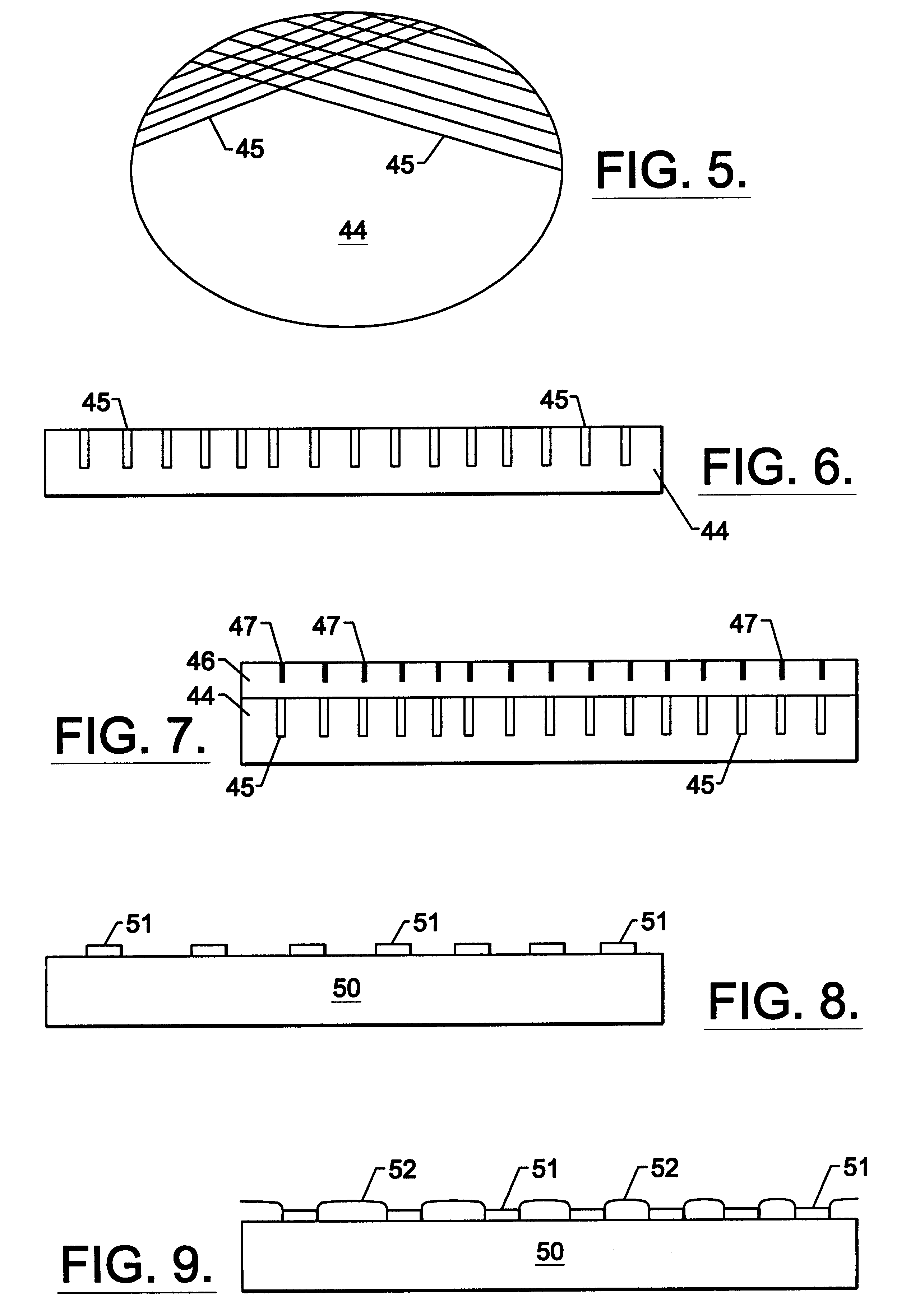

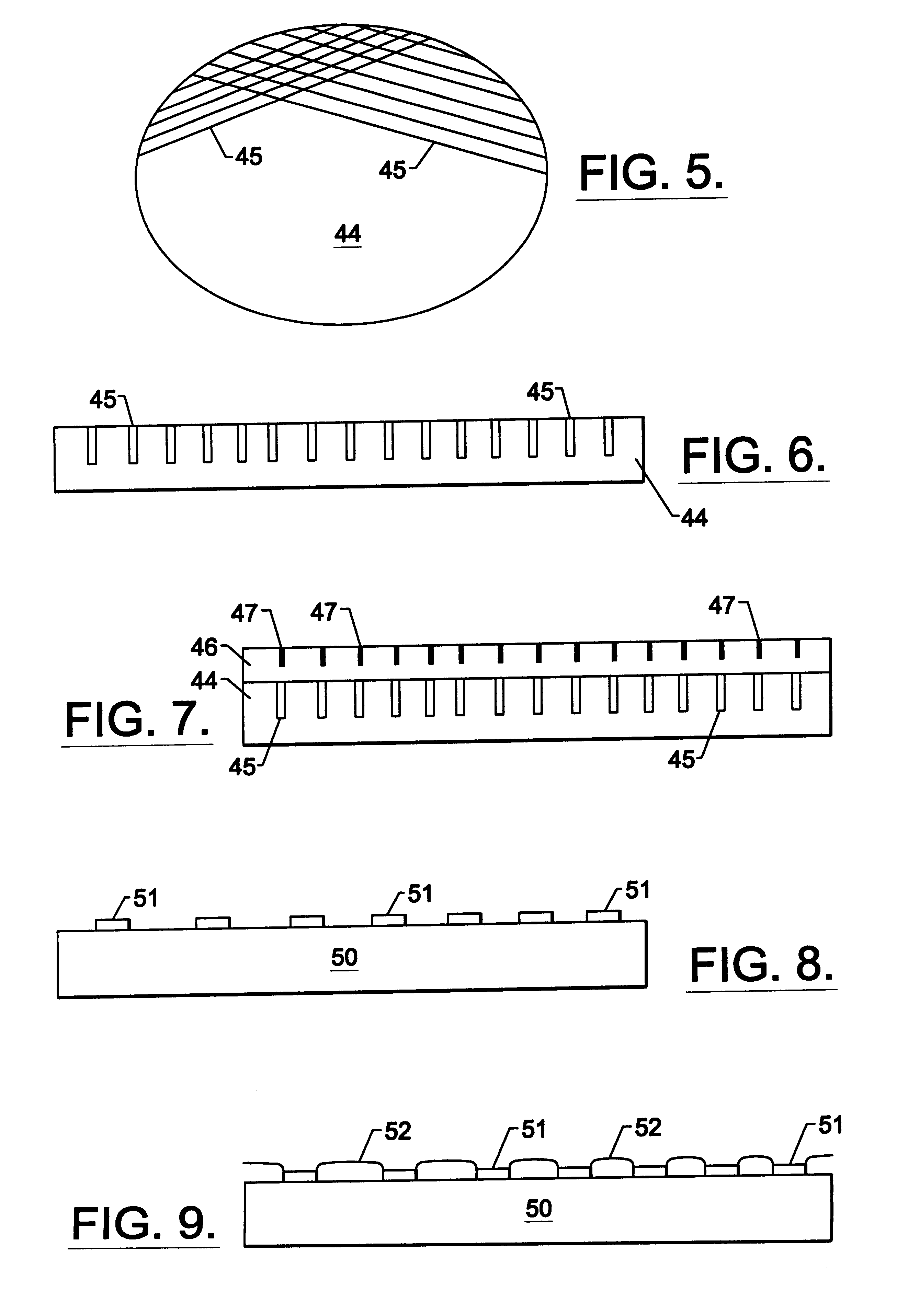

Growth of indium gallium nitride (InGaN) on porous gallium nitride (GaN) template by metal-organic chemical vapor deposition (MOCVD)

InactiveUS20090001416A1Increase indium incorporationLarge emissionsPolycrystalline material growthSemiconductor/solid-state device manufacturingIndiumGallium nitride

Si-doped porous GaN is fabricated by UV-enhanced Pt-assisted electrochemical etching and together with a low-temperature grown buffer layer are utilized as the template for InGaN growth. The porous network in GaN shows nanostructures formed on the surface. Subsequent growth of InGaN shows that it is relaxed on these nanostructures as the area on which the growth takes place is very small. The strain relaxation favors higher indium incorporation. Besides, this porous network creates a relatively rough surface of GaN to modify the surface energy which can enhance the nucleation of impinging indium atoms thereby increasing indium incorporation. It shifts the luminescence from 445 nm for a conventionally grown InGaN structure to 575 nm and enhances the intensity by more than two-fold for the growth technique in the present invention under the same growth conditions. There is also a spectral broadening of the output extending from 480 nm to 720 nm.

Owner:NAT UNIV OF SINGAPORE

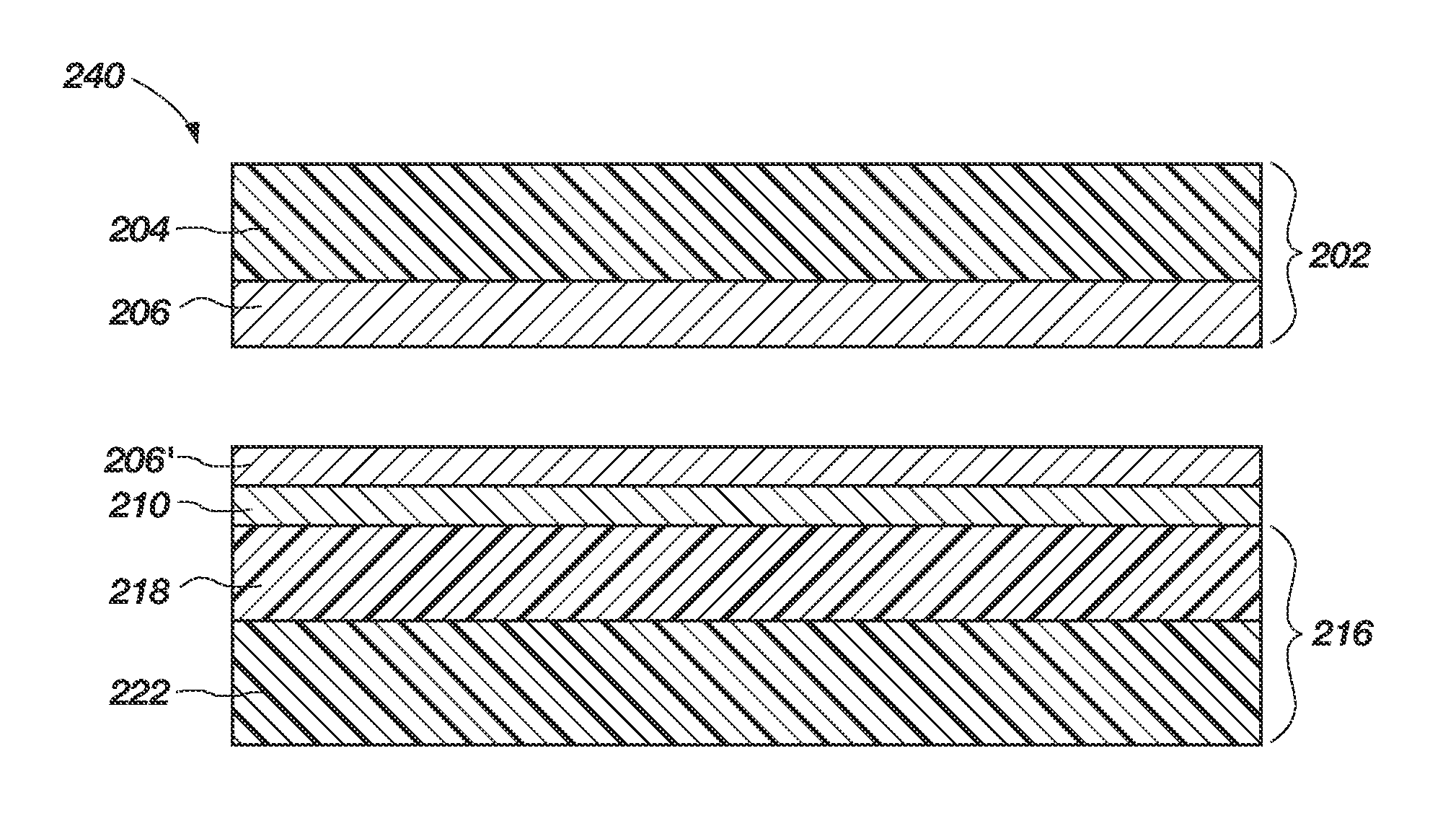

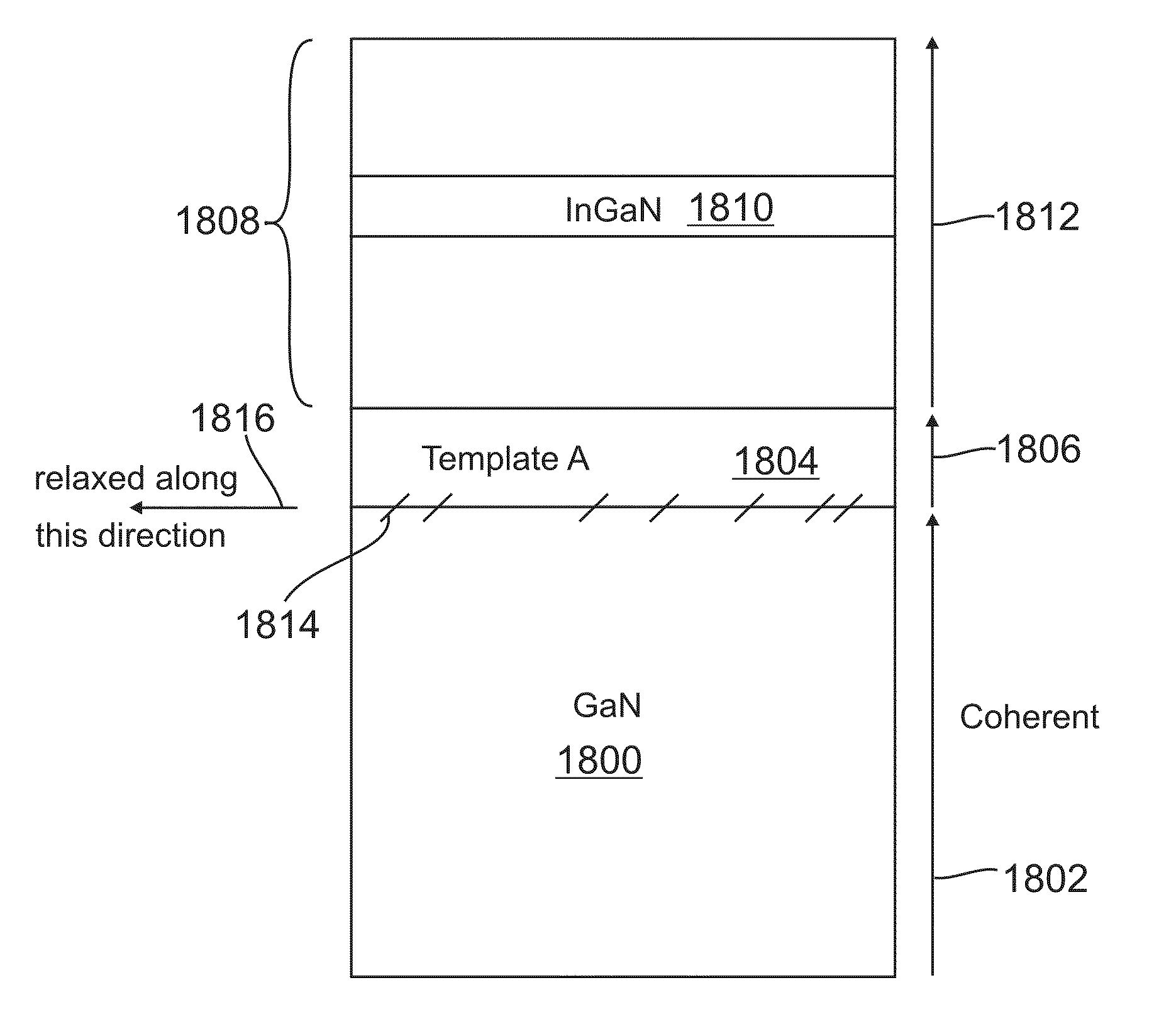

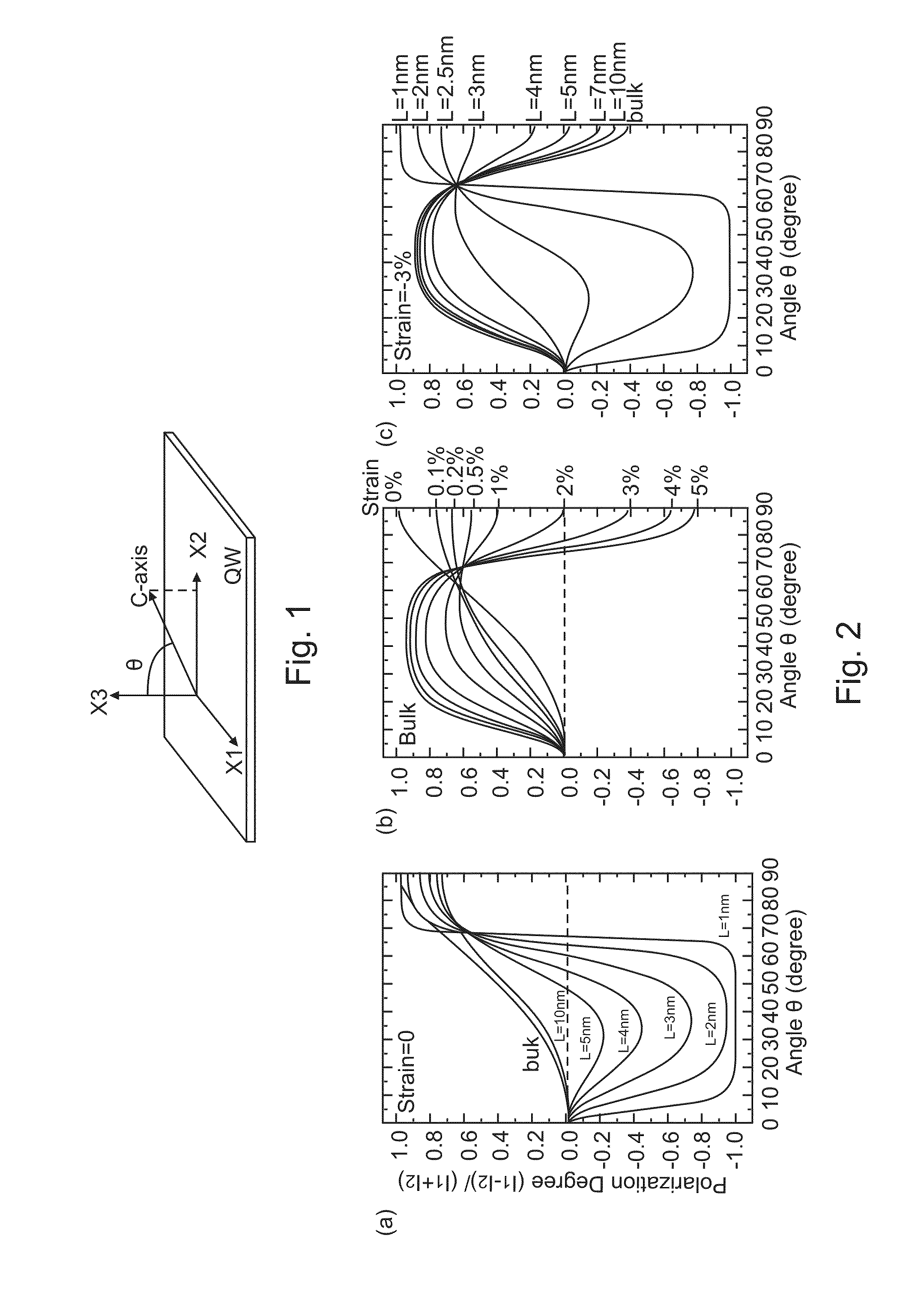

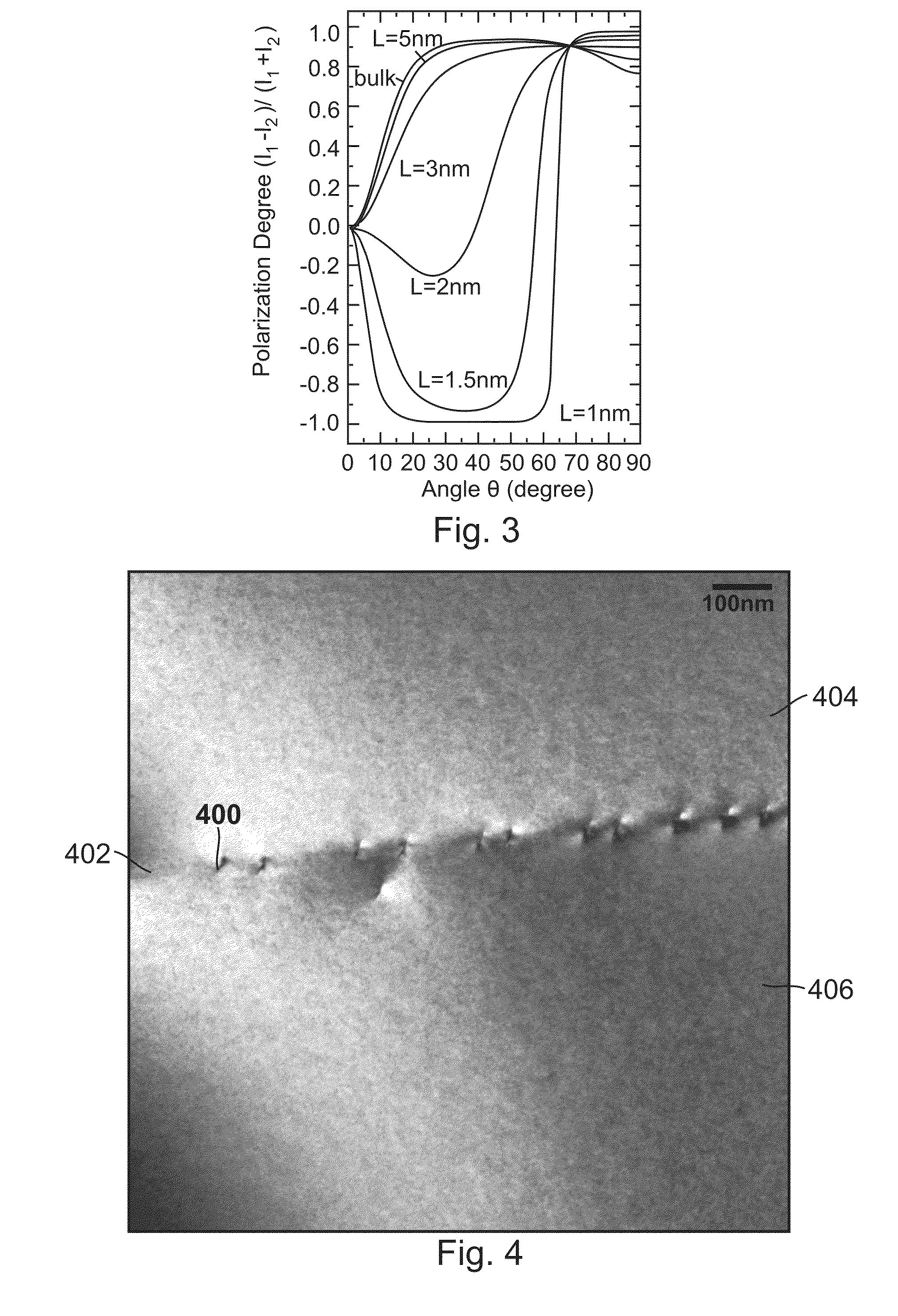

Anisotropic strain control in semipolar nitride quantum wells by partially or fully relaxed aluminum indium gallium nitride layers with misfit dislocations

ActiveUS20110062415A1High device performance/efficiencyPoor device performanceLaser detailsLaser active region structureAnisotropic strainLattice constant

An epitaxial structure for a III-Nitride based optical device, comprising an active layer with anisotropic strain on an underlying layer, where a lattice constant and strain in the underlying layer are partially or fully relaxed in at least one direction due to a presence of misfit dislocations, so that the anisotropic strain in the active layer is modulated by the underlying layer.

Owner:RGT UNIV OF CALIFORNIA

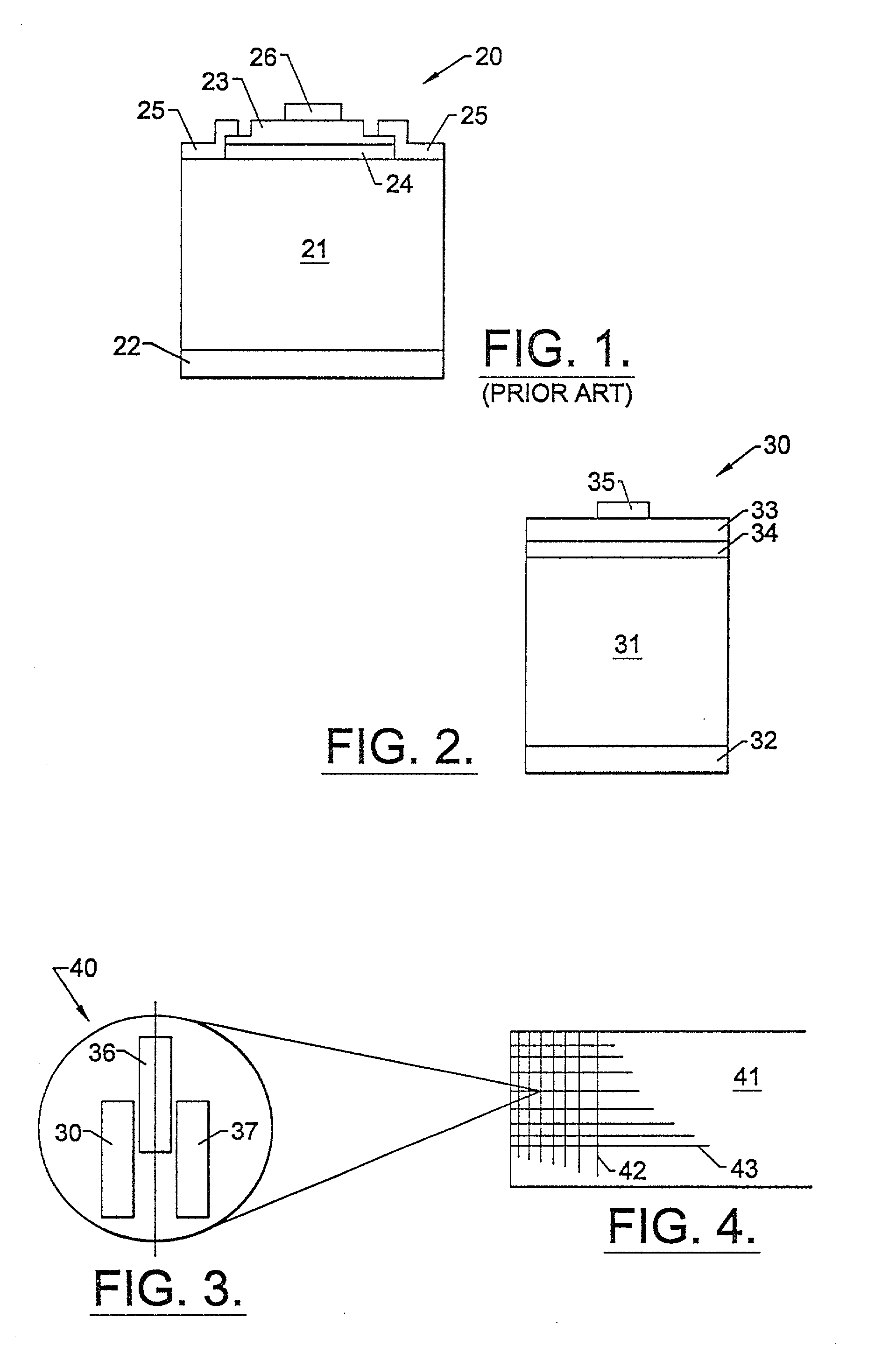

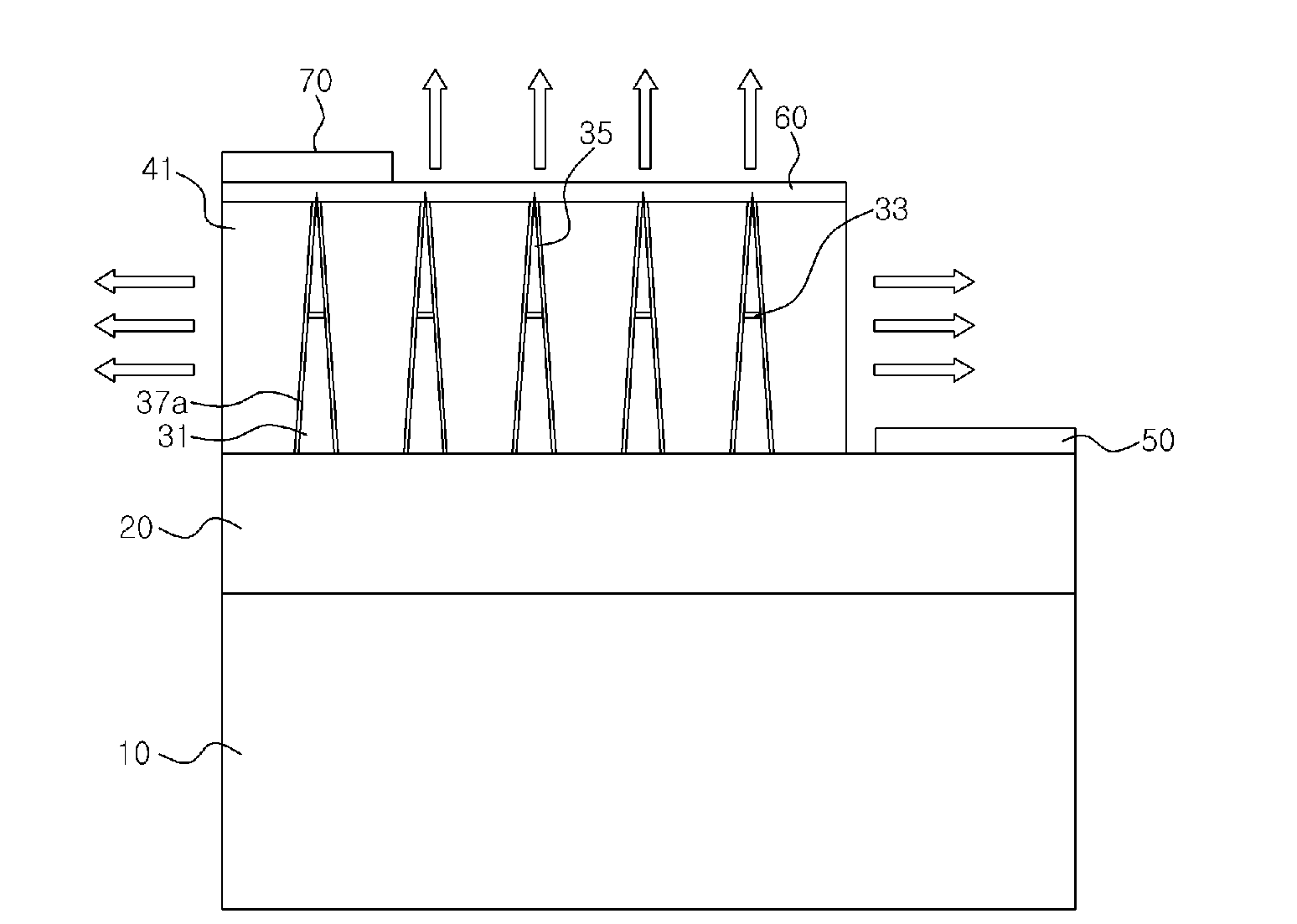

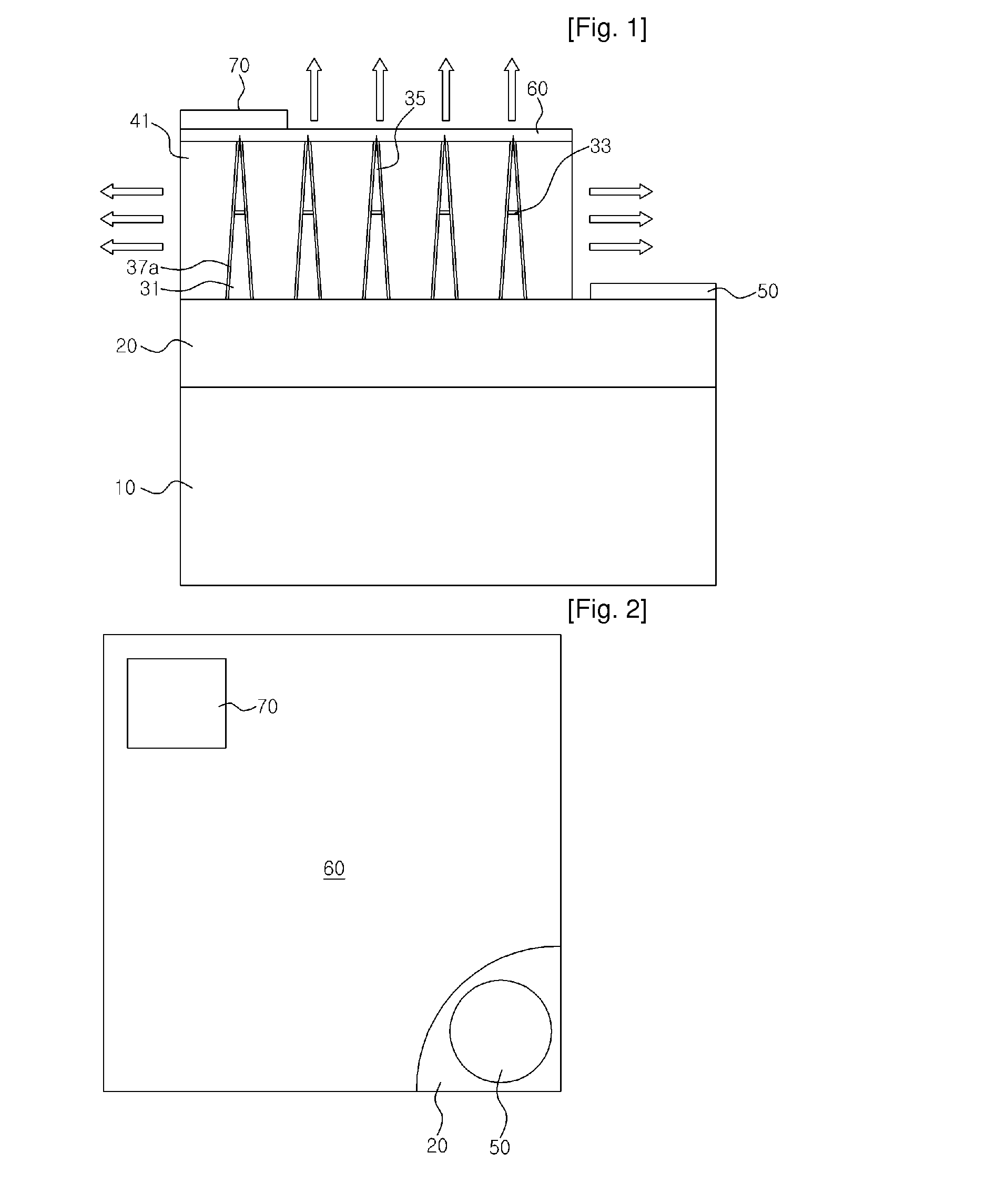

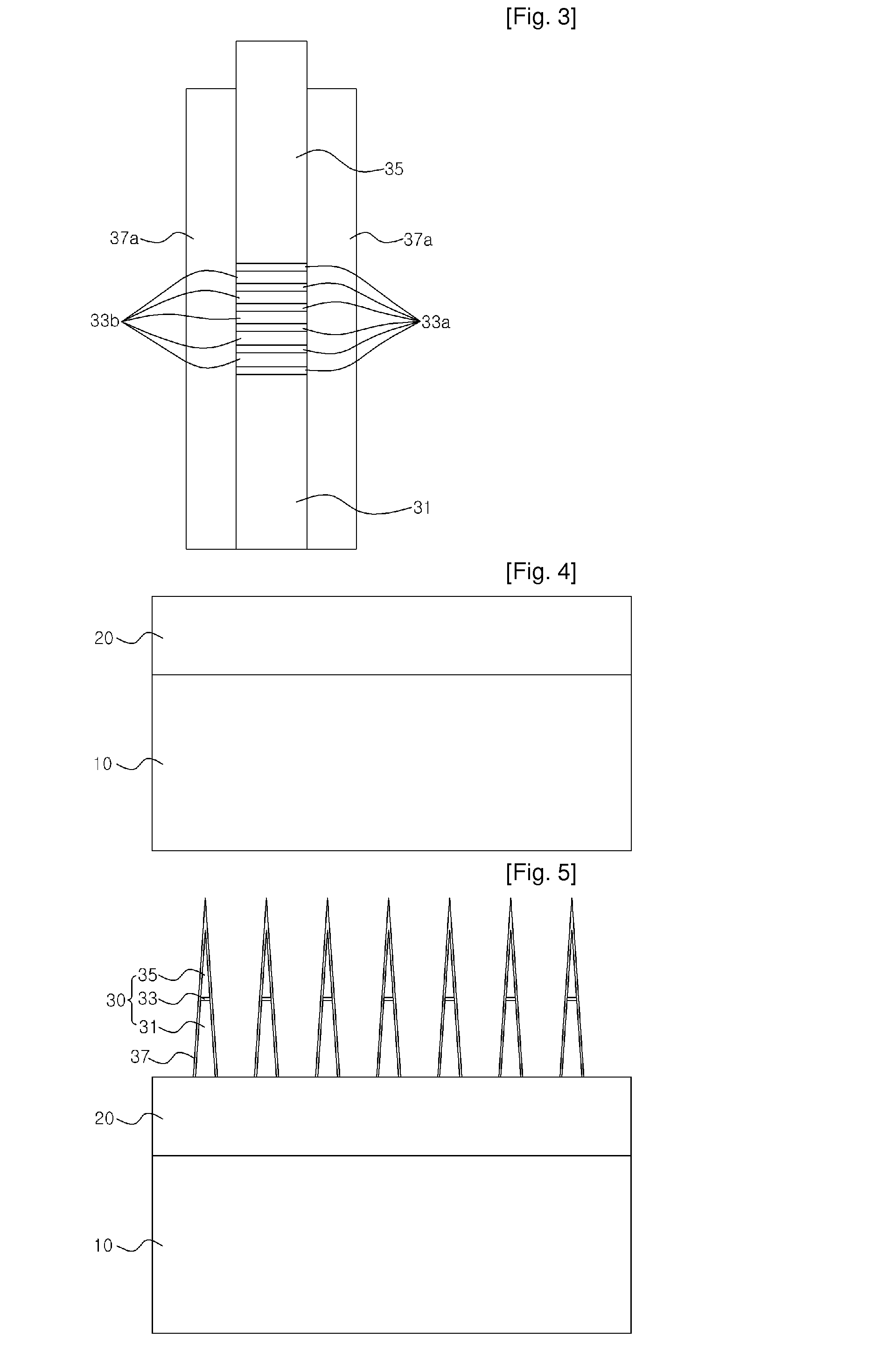

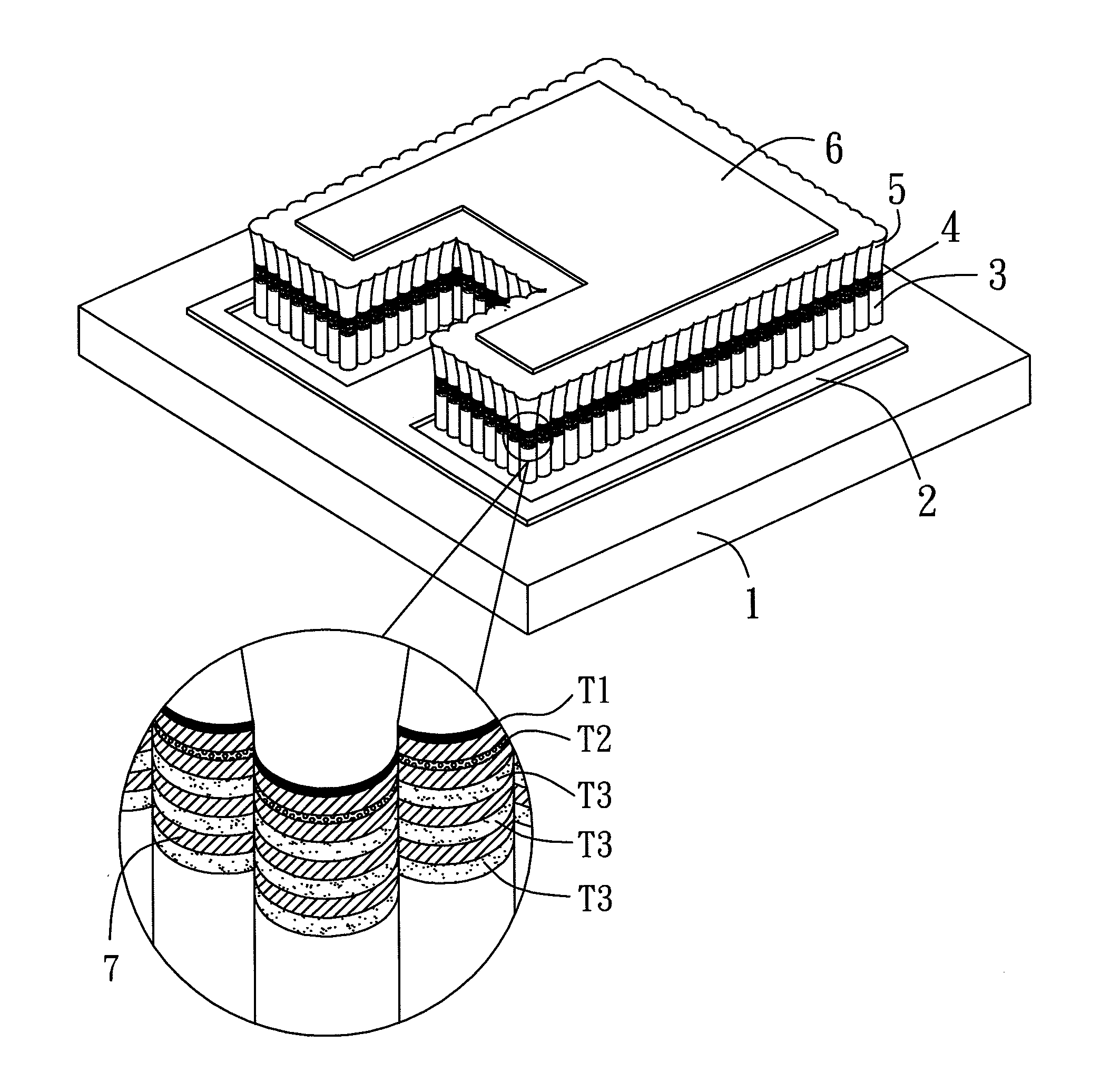

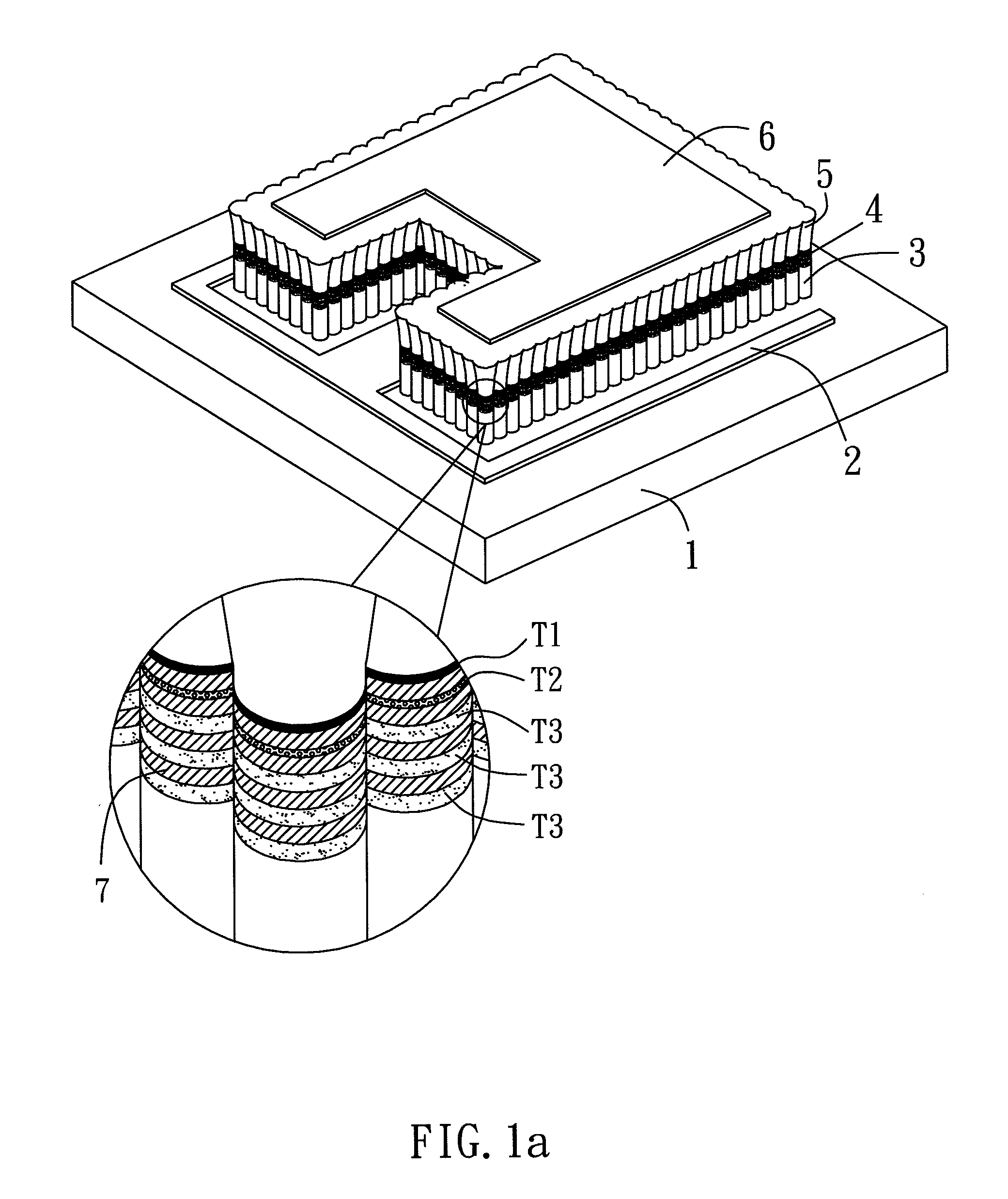

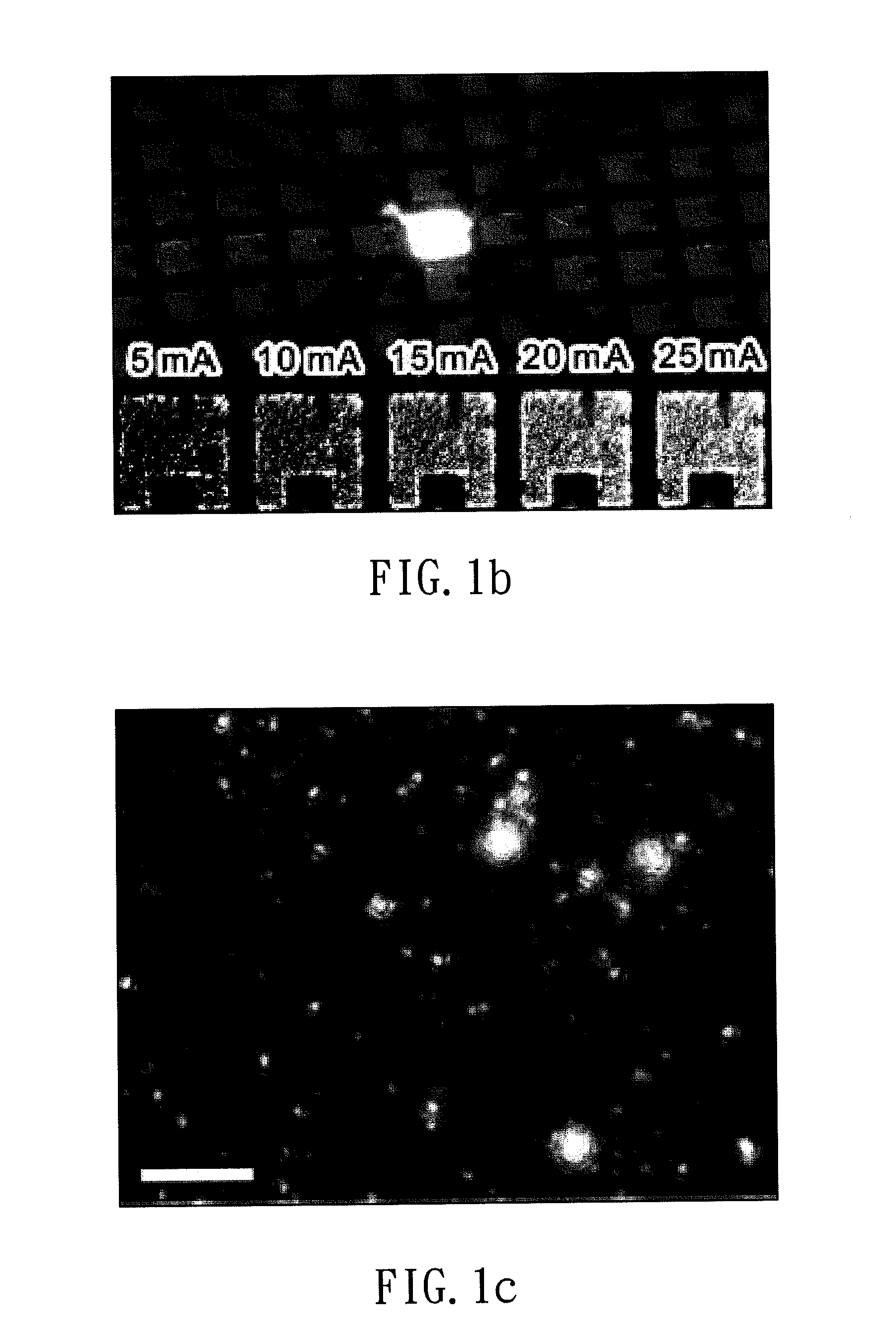

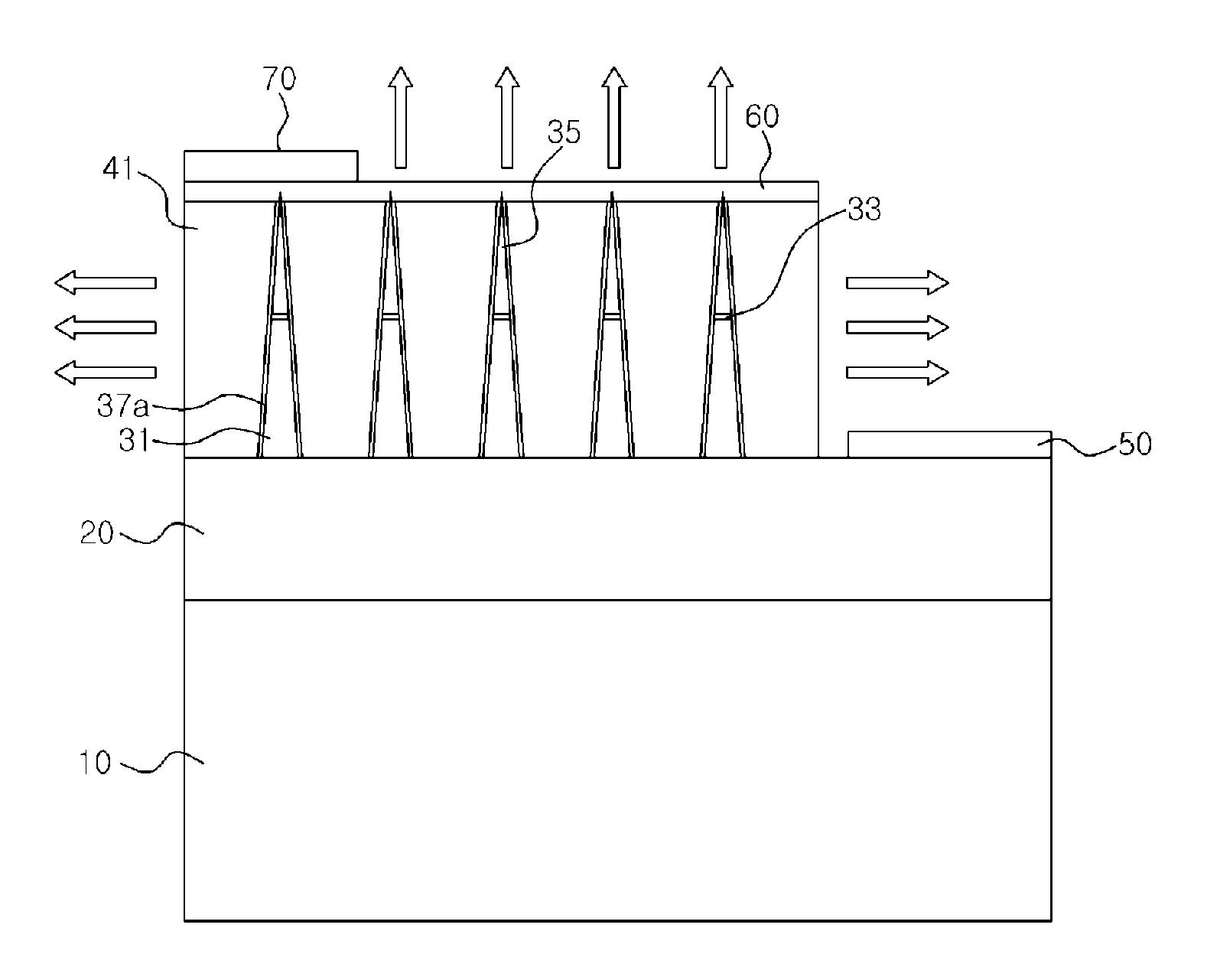

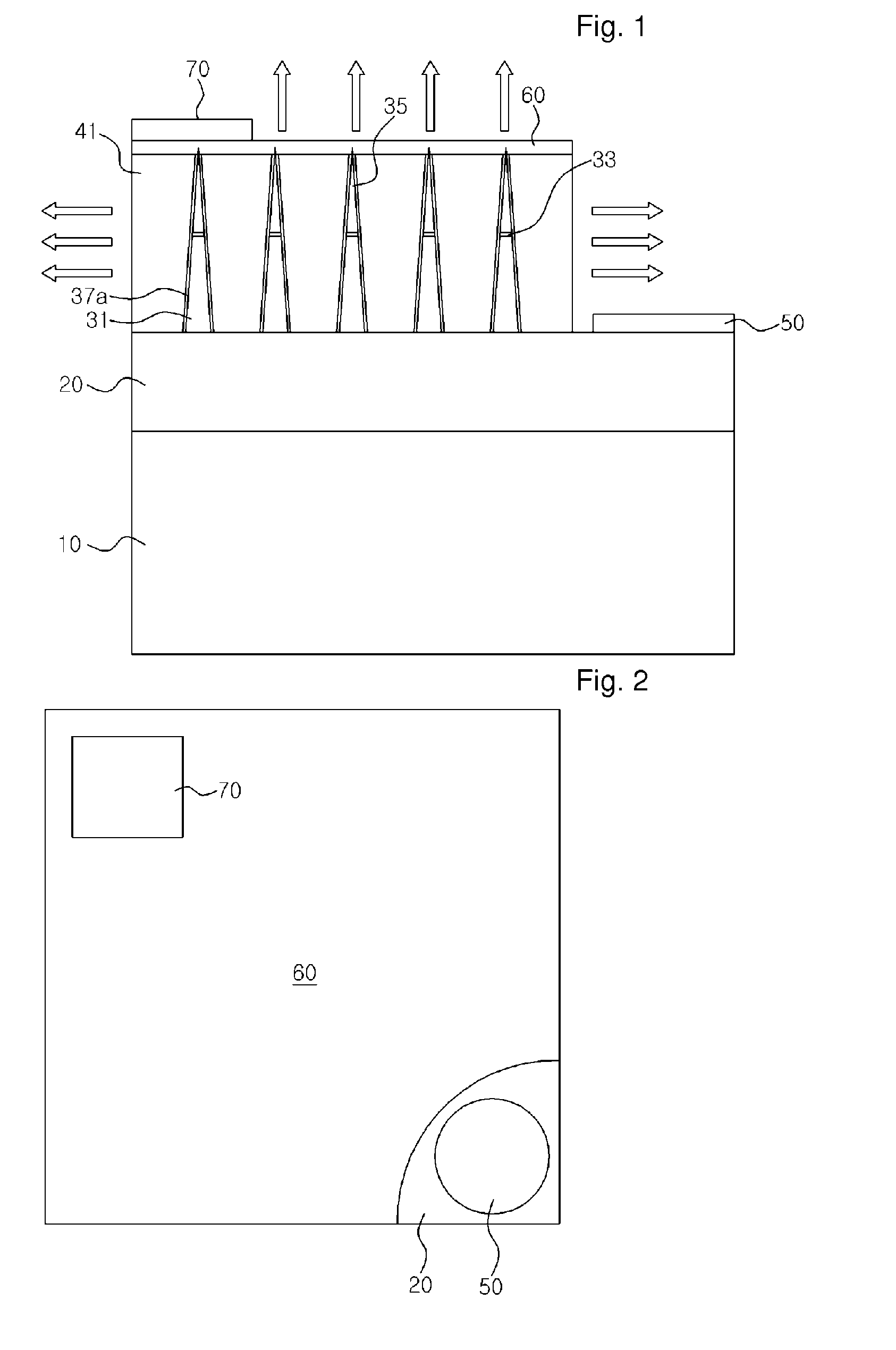

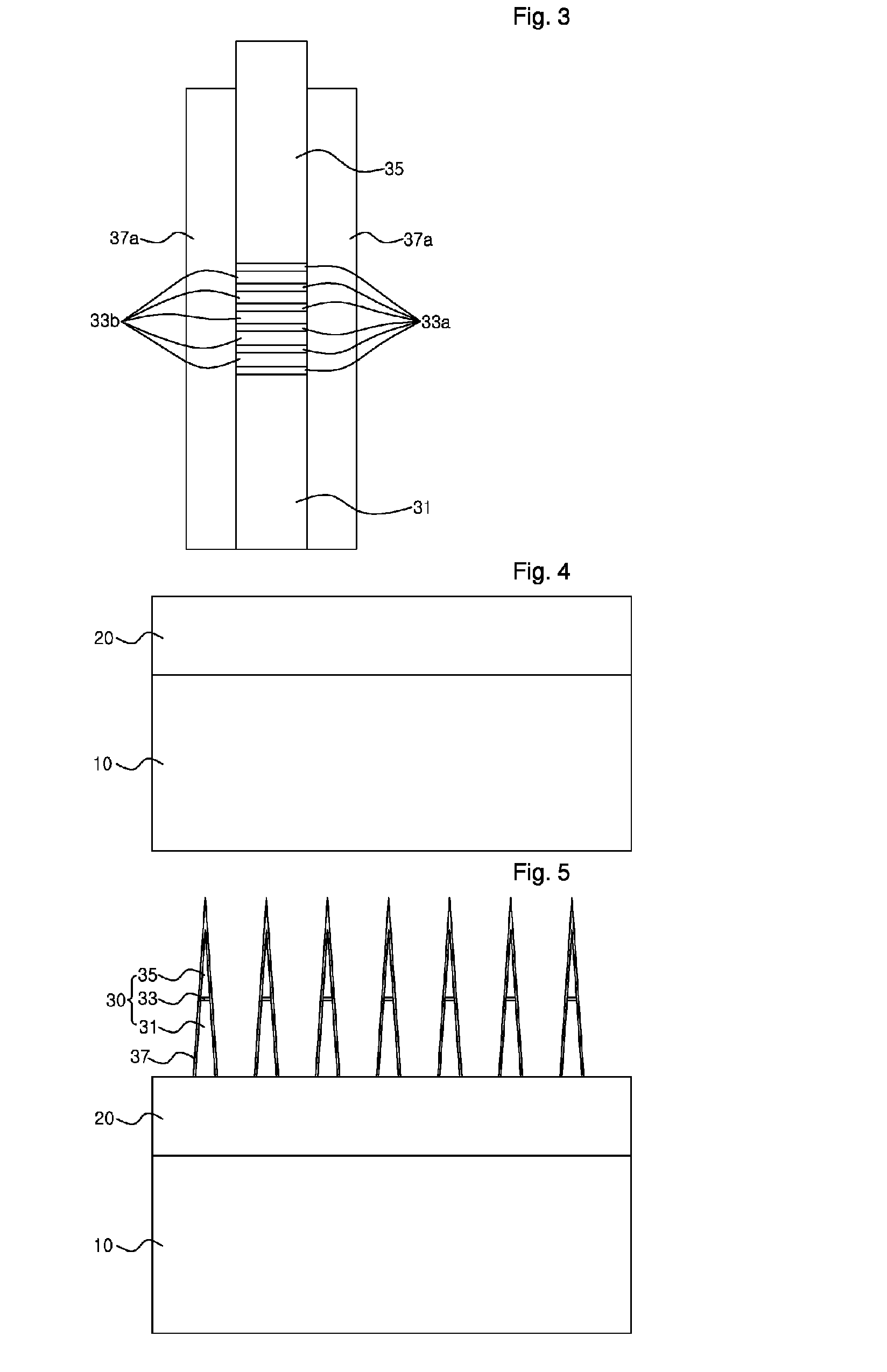

Nanostructure Having a Nitride-Based Quantum Well and Light Emitting Diode Employing the Same

ActiveUS20080157057A1Increase brightnessReduce impactNanostructure manufactureSemiconductor/solid-state device manufacturingQuantum efficiencyNanostructure

Disclosed are a nanostructure with an indium gallium nitride quantum well and a light emitting diode employing the same. The light emitting diode comprises a substrate, a transparent electrode and an array of nanostructures interposed between the substrate and the transparent electrode. Each of the nanostructures comprises a core nanorod, and a nano shell surrounding the core nanorod. The core nanorod is formed substantially perpendicularly to the substrate and includes a first nanorod of a first conductivity type, an (AlxInyGa1-x-y)N (where, 0≦x≦1, 0≦y≦1 and 0≦x+y≦1) quantum well, and a second nanorod of a second conductivity type, which are joined in a longitudinal direction. The nano shell is formed of a material with a bandgap greater than that of the quantum well, and surrounds at least the quantum well of the core nanorod. Meanwhile, the second nanorods are connected in common to the transparent electrode. Accordingly, with the nano shells, it is possible to provide a light emitting diode capable of improving external quantum efficiency by preventing non-radiative recombination on a surface of the (AlxInyGa1-x-y)N quantum well.

Owner:SEOUL VIOSYS CO LTD

Fabrication of nonpolar indium gallium nitride thin films, heterostructures and devices by metalorganic chemical vapor deposition

InactiveUS20070111488A1Quality improvementPolycrystalline material growthSemiconductor/solid-state device manufacturingGas phaseNear ultraviolet

A method for the fabrication of nonpolar indium gallium nitride (InGaN) films as well as nonpolar InGaN-containing device structures using metalorganic chemical vapor deposition (MOVCD). The method is used to fabricate nonpolar InGaN / GaN violet and near-ultraviolet light emitting diodes and laser diodes.

Owner:RGT UNIV OF CALIFORNIA +1

Methods of fabricating semiconductor structures or devices using layers of semiconductor material having selected or controlled lattice parameters

ActiveUS20110156212A1Semiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsSemiconductor structure

Methods of fabricating semiconductor devices or structures include bonding a layer of semiconductor material to another material at a temperature, and subsequently changing the temperature of the layer of semiconductor material. The another material may be selected to exhibit a coefficient of thermal expansion such that, as the temperature of the layer of semiconductor material is changed, a controlled and / or selected lattice parameter is imparted to or retained in the layer of semiconductor material. In some embodiments, the layer of semiconductor material may comprise a III-V type semiconductor material, such as, for example, indium gallium nitride. Novel intermediate structures are formed during such methods. Engineered substrates include a layer of semiconductor material having an average lattice parameter at room temperature proximate an average lattice parameter of the layer of semiconductor material previously attained at an elevated temperature.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

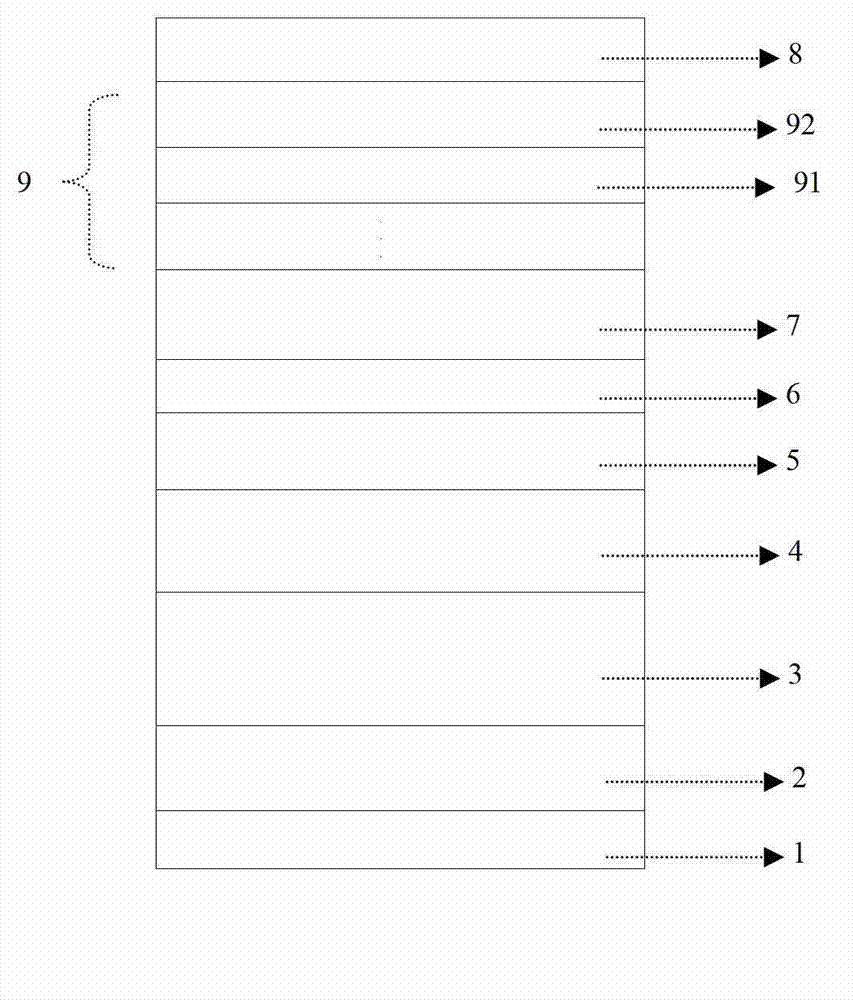

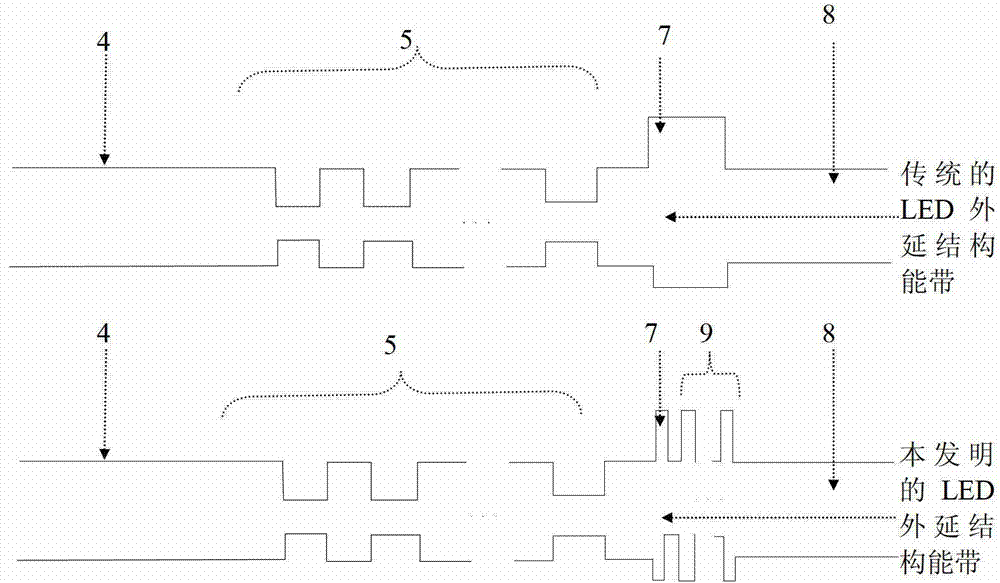

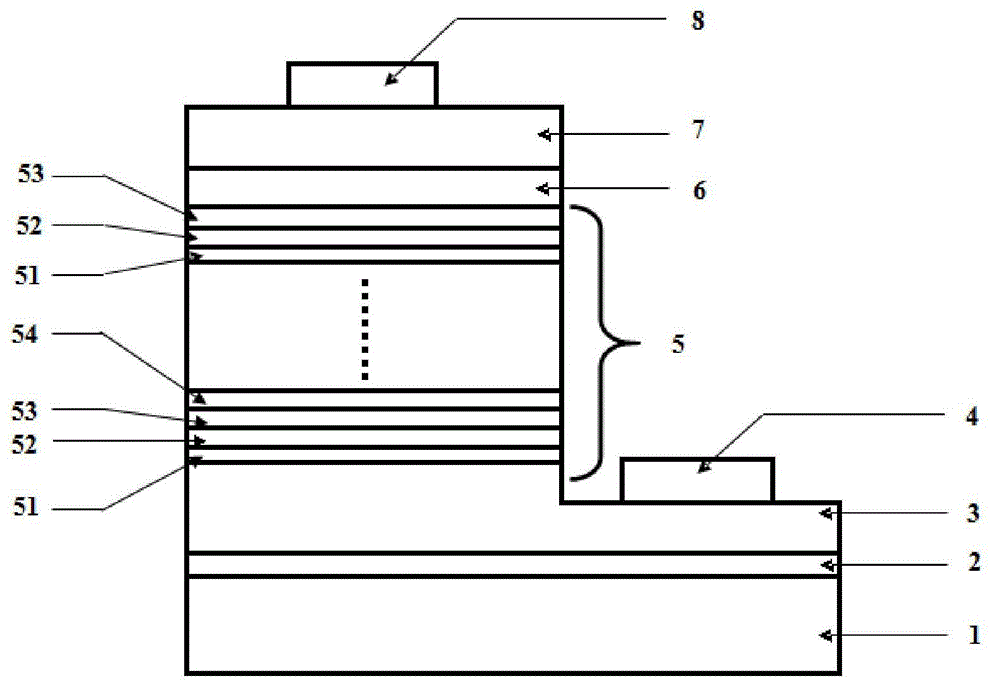

LED (Light Emitting Diode) epitaxial structure with P (Positive) type superlattice and preparation method thereof

ActiveCN103050592AStop SpillFacilitate horizontal expansionSemiconductor devicesPotential wellHigh density

The invention discloses an LED (Light Emitting Diode) epitaxial structure with a P (Positive) type superlattice and a preparation method thereof. The epitaxial structure comprises a substrate, wherein a GaN (Gallium Nitride) buffer layer, an undoped GaN layer, an n (negative) type GaN layer, a multi-quantum well luminous layer, a first P type GaN layer, a P type AlGaN (Aluminium Gallium Nitride) electronic blocking layer and a second P type GaN layer are sequentially arranged on the substrate from bottom to top, and the P type superlattice formed by a PInGaN (P type Indium Gallium Nitride) potential well layer and a PAlGaN potential barrier layer in a periodic interactive overlapping way is arranged between the P type AlGaN electronic blocking layer and the second P type GaN layer. The PInGaN potential well layer in the P type superlattice generates and constrains a great number of holes for the formation of a two-dimensional hole high-density state; the PAlGaN potential barrier layer hinders the escape of the holes; in such a way, the transverse spreading of the holes is improved, the electron overflow can be prevented, the hole injection efficiency is increased and the electron and hole recombination probability is improved; and therefore, the brightness of a chip can be improved by 5-10%.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

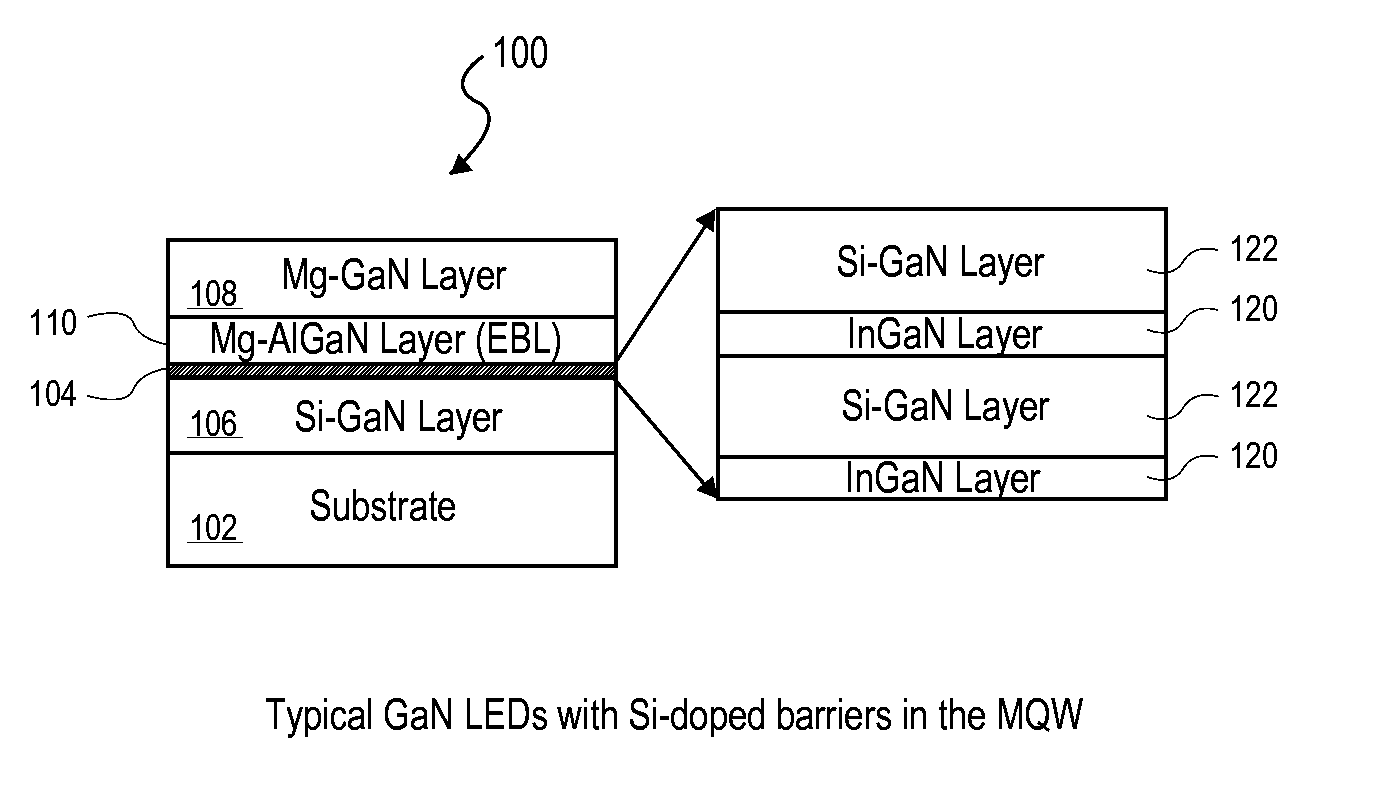

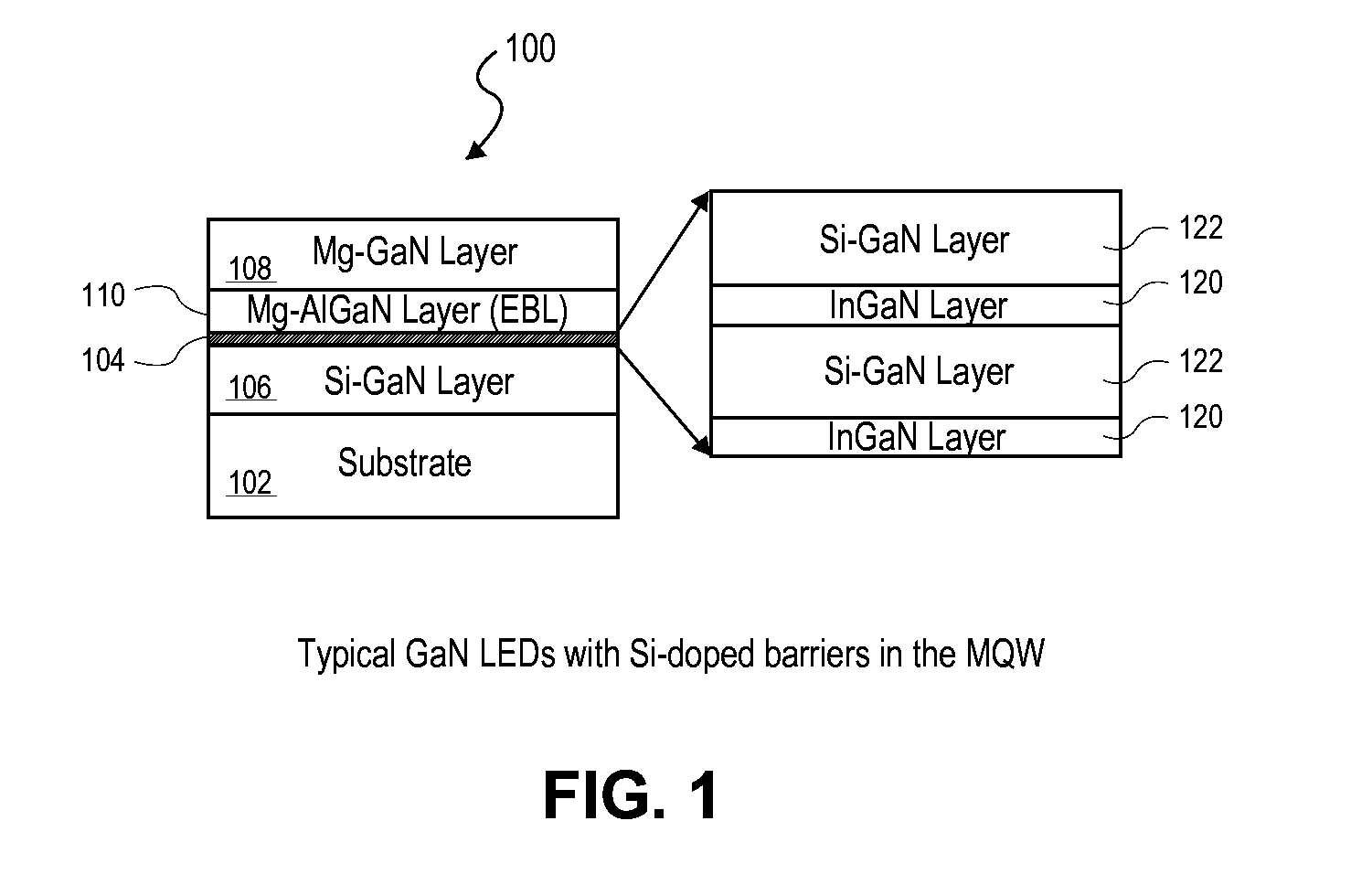

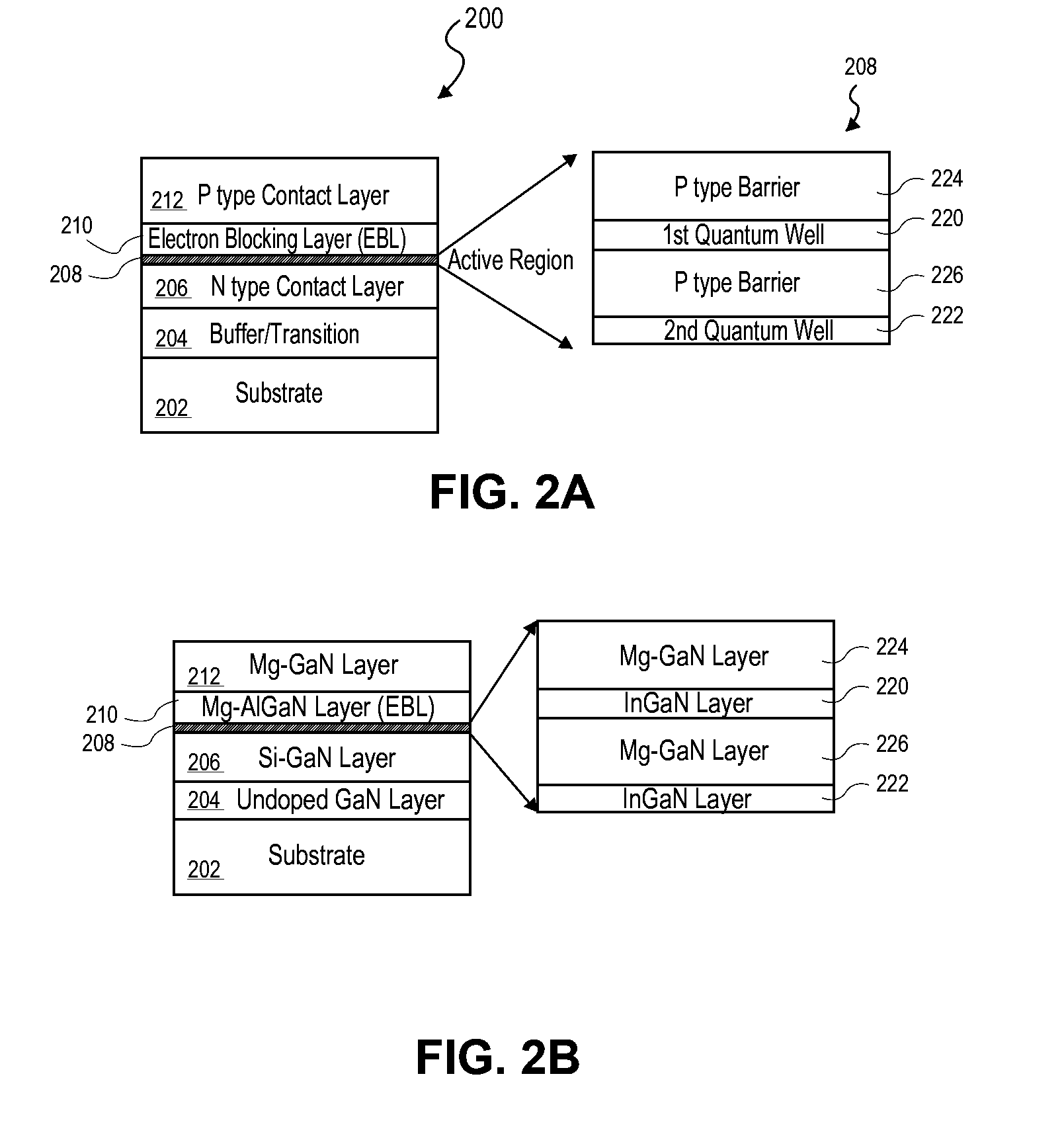

Light emitting diode with enhanced quantum efficiency and method of fabrication

InactiveUS20120235116A1Low costIncrease varietyPolycrystalline material growthConductive materialIndiumAlloy

One embodiment of a quantum well structure comprises an active region including active layers that comprise quantum wells and barrier layers wherein some or all of the active layers are p type doped. P type doping some or all of the active layers improves the quantum efficiency of III-V compound semiconductor light emitting diodes by locating the position of the P-N junction in the active region of the device thereby enabling the dominant radiative recombination to occur within the active region. In one embodiment, the quantum well structure is fabricated in a cluster tool having a hydride vapor phase epitaxial (HVPE) deposition chamber with a eutectic source alloy. In one embodiment, the indium gallium nitride (InGaN) layer and the magnesium doped gallium nitride (Mg—GaN) or magnesium doped aluminum gallium nitride (Mg—AlGaN) layer are grown in separate chambers by a cluster tool to avoid indium and magnesium cross contamination. Doping of group III-nitrides by hydride vapor phase epitaxy using group III-metal eutectics is also described. In one embodiment, a source is provided for HVPE deposition of a p-type or an n-type group III-nitride epitaxial film, the source including a liquid phase mechanical (eutectic) mixture with a group III species. In one embodiment, a method is provided for performing HVPE deposition of a p-type or an n-type group III-nitride epitaxial film, the method including using a liquid phase mechanical (eutectic) mixture with a group III species.

Owner:APPLIED MATERIALS INC

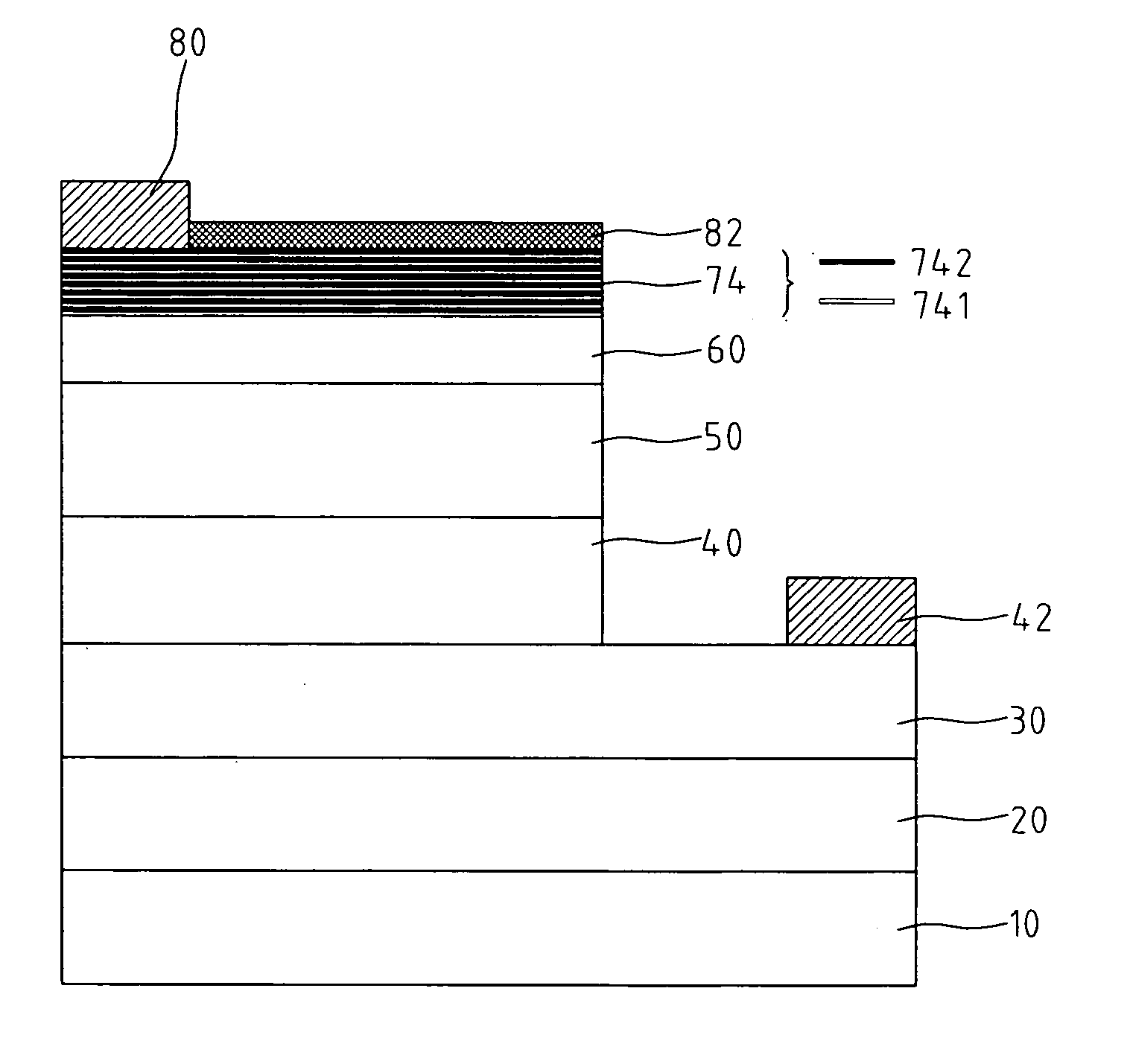

High-power gallium nitride based LED with novel structure

InactiveCN101740691AEffective mass is smallIncrease concentrationSemiconductor devicesIndiumGallium nitride

The invention relates to a gallium nitride based light-emitting diode, in particular to a high-power gallium nitride based light-emitting diode structure; the high-power gallium nitride based light-emitting diode comprises a substrate, an N-type gallium nitride layer arranged on the substrate, a AlGaN cavity barrier layer arranged on a high table top of the N-type gallium nitride layer, an asymmetrical multiple quantum well active layer arranged on the cavity barrier layer, a P-type gallium nitride layer arranged on the asymmetrical multiple quantum well active layer, a P+-InGaN conducting layer arranged on the P-type gallium nitride layer, and an indium titanium oxide electrode layer which is arranged on the P+-InGaN conducting layer from bottom to top; a silicon dioxide passivation layer is arranged on the top surface of the whole light-emitting diode and the side surface connected to the high and low table tops, an N electrode is arranged on the lower table top of the N-type gallium nitride layer, and a P-electrode is arranged in the middle of the indium titanium oxide electrode layer. The light-emitting diode structure can improve the injection efficiency of the cavity and improve the photoelectric conversion efficiency.

Owner:SUZHOU NANOJOIN PHOTONICS

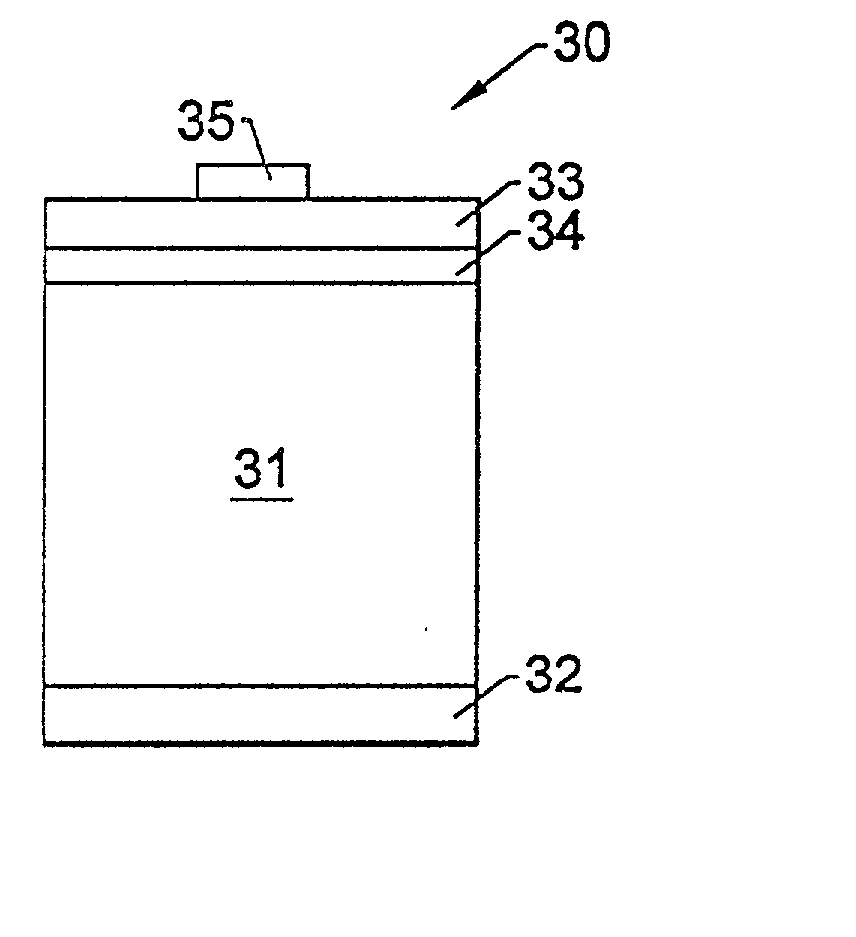

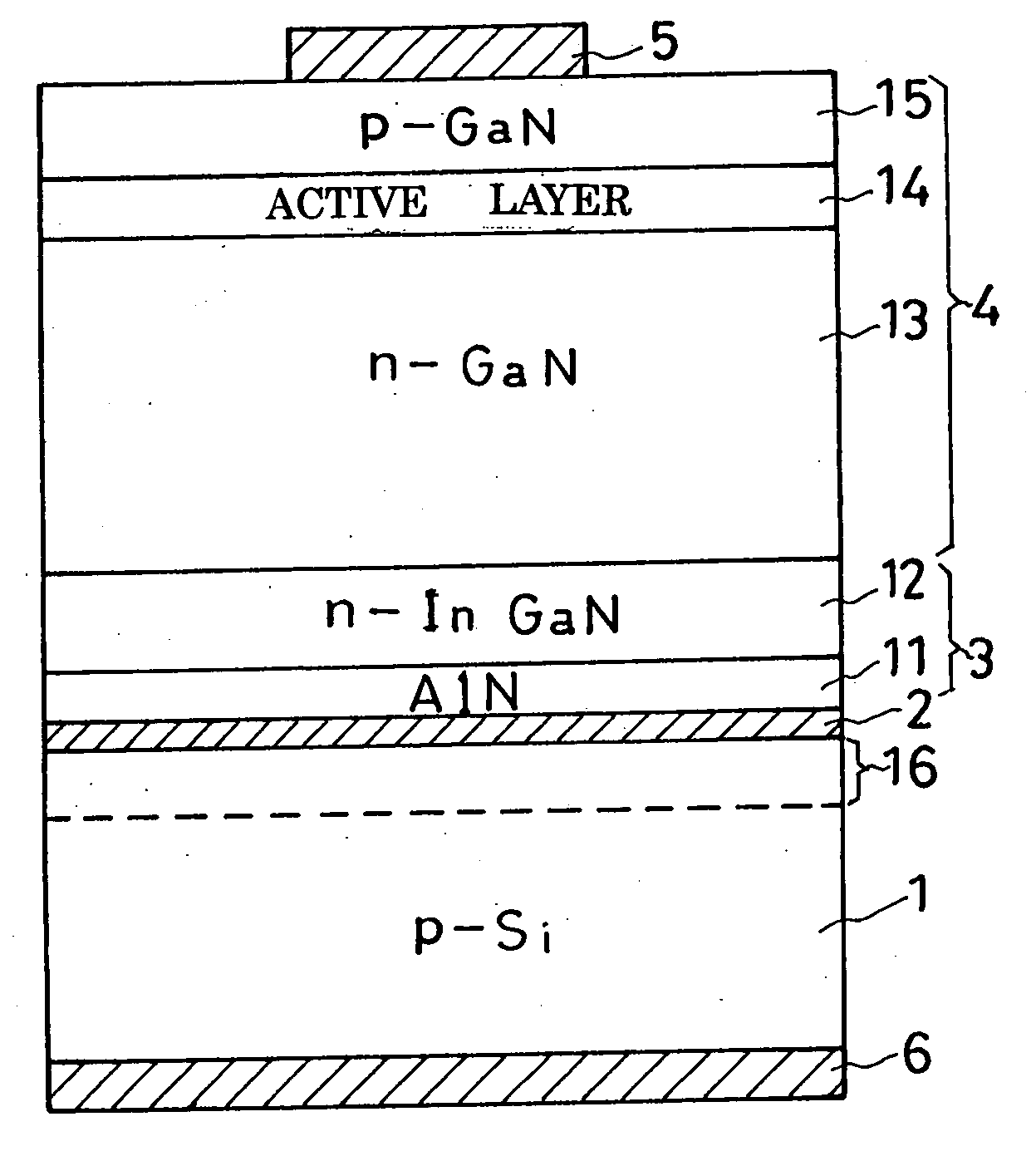

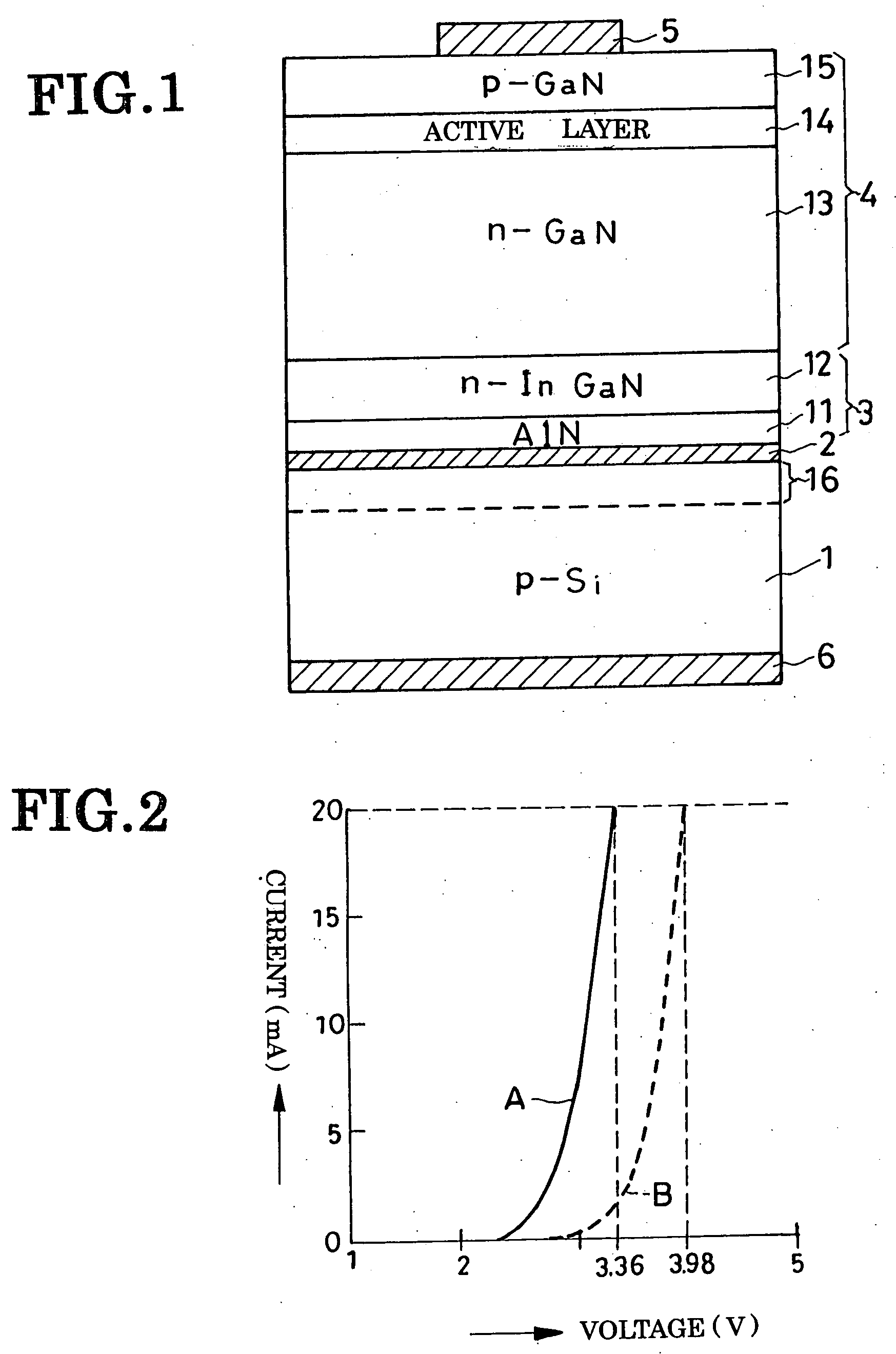

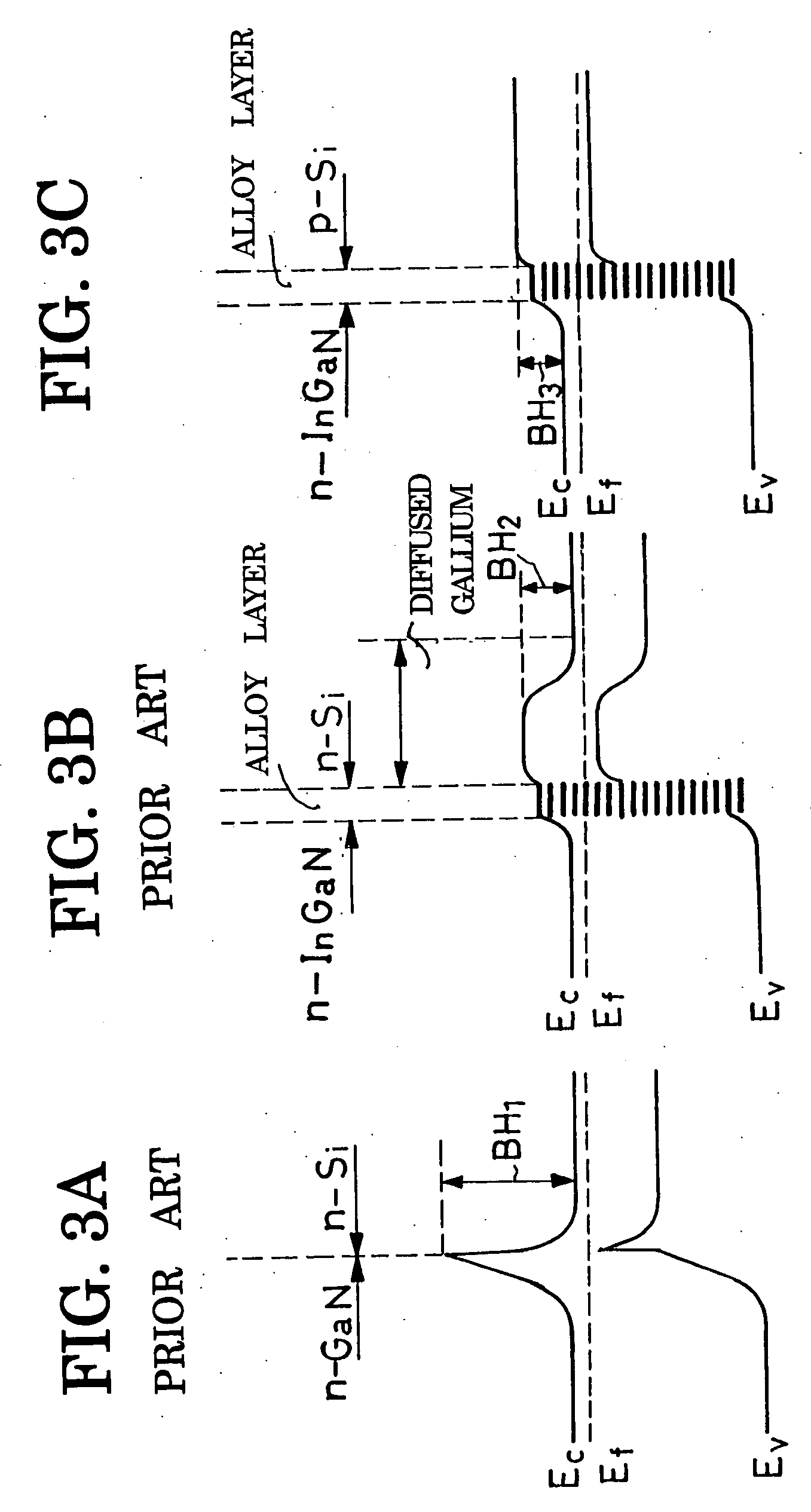

Nitride-based semiconductor device and method of fabrication

ActiveUS20060094145A1Minimize voltage dropLess voltageSemiconductor/solid-state device manufacturingSemiconductor devicesIndiumDevice material

A light-emitting diode is built on a silicon substrate doped with a p-type impurity to possess sufficient conductivity to provide a current path. The p-type silicon substrate has epitaxially grown thereon two superposed buffer layers of aluminum nitride and n-type indium gallium nitride. Further grown epitaxially on the buffer layers is the main semiconductor region of the LED which comprises a lower confining layer of n-type gallium nitride, an active layer for generating light, and an upper confining layer of p-type gallium nitride. In the course of the growth of the main semiconductor region there occurs a thermal diffusion of aluminum, gallium and indium from the buffer layers into the p-type silicon substrate, with the consequent creation of an alloy layer of the diffused metals. Representing p-type impurities in the p-type silicon substrate, these metals do not create a pn junction in the substrate which causes a forward voltage drop.

Owner:SANKEN ELECTRIC CO LTD

Cutting fluid for hard brittle material and uses thereof

ActiveCN101205498ANo pollution in the processFree from harmAdditivesBase-materialsMetal impuritiesWater soluble

The invention relates to a water-soluble cutting liquid used for processing hard brittle materials. The components of the invention by weight percentage are as follows: 70 to 100 percent of polyalkoxylated compound, 0 to 15 percent of extreme pressure resistant chelation anti-settling agent, 0 to 15 percent of dissolution promoter . The cutting liquid of the invention has the advantages of no pollution, low metal impurity content, high cutting sheet rate, and high finished product qualification rate and so on. The invention also relates to the application of the cutting liquid in the processing of monocrystalline silicon, polysilicon, germanium, gallium arsenide, quartz, Indium gallium nitride or precious stones.

Owner:LIAONING OXIRANCHEM INC +3

Methods of forming relaxed layers of semiconductor materials, semiconductor structures, devices and engineered substrates including same

ActiveUS20100176490A1Low viscosityReduce lattice strainSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsSemiconductor structure

Methods of fabricating relaxed layers of semiconductor materials include forming structures of a semiconductor material overlying a layer of a compliant material, and subsequently altering a viscosity of the compliant material to reduce strain within the semiconductor material. The compliant material may be reflowed during deposition of a second layer of semiconductor material. The compliant material may be selected so that, as the second layer of semiconductor material is deposited, a viscosity of the compliant material is altered imparting relaxation of the structures. In some embodiments, the layer of semiconductor material may comprise a III-V type semiconductor material, such as, for example, indium gallium nitride. Methods of fabricating semiconductor structures and devices are also disclosed. Novel intermediate structures are formed during such methods. Engineered substrates include a plurality of structures comprising a semiconductor material disposed on a layer of material exhibiting a changeable viscosity.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES +2

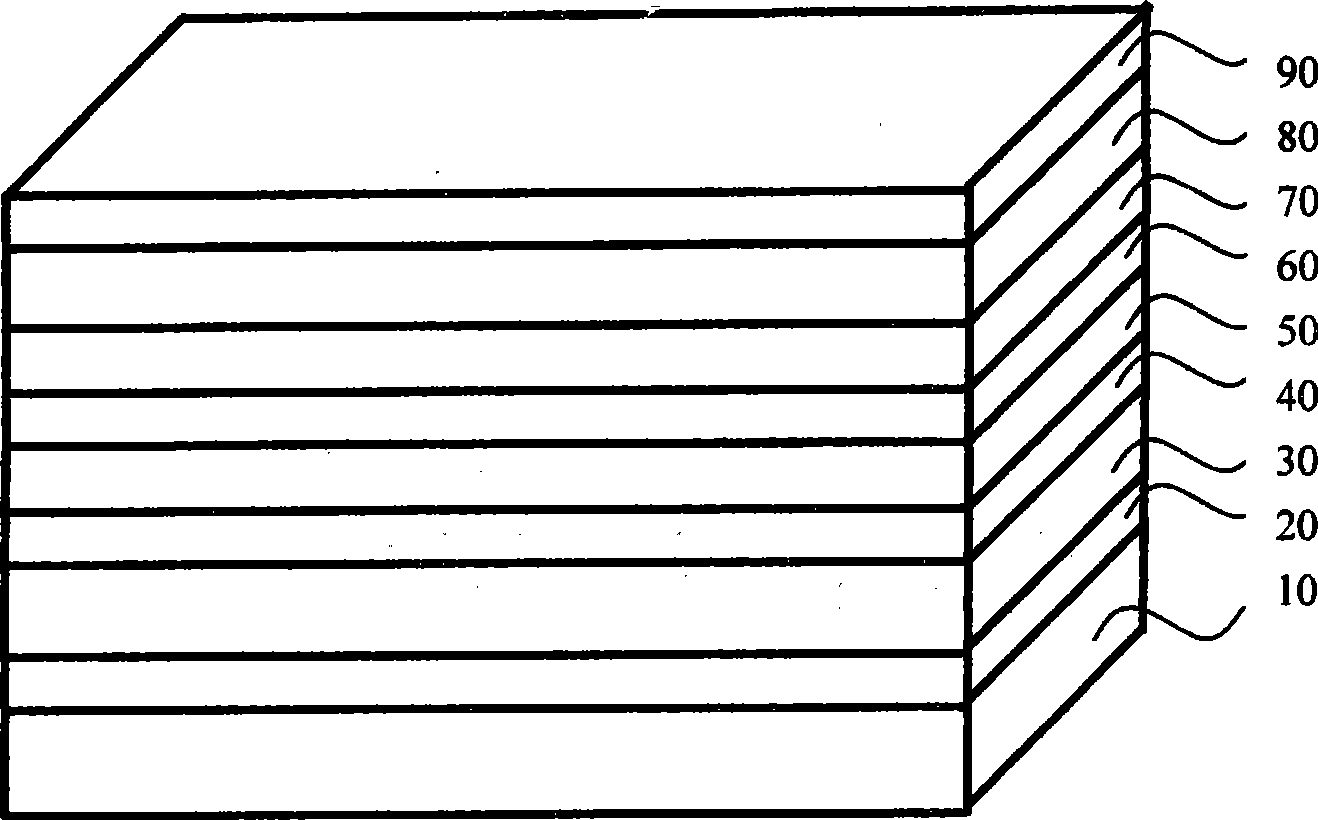

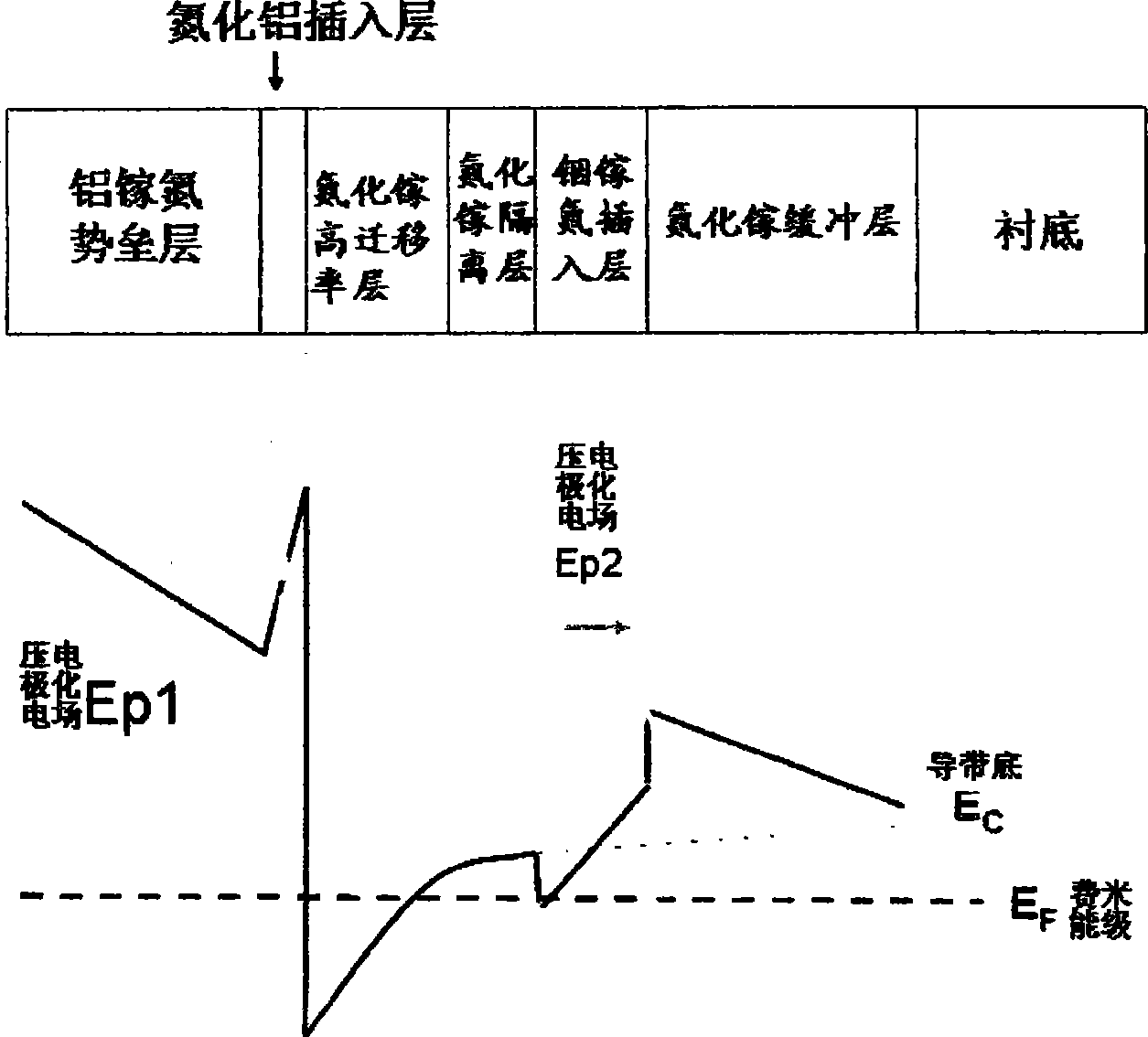

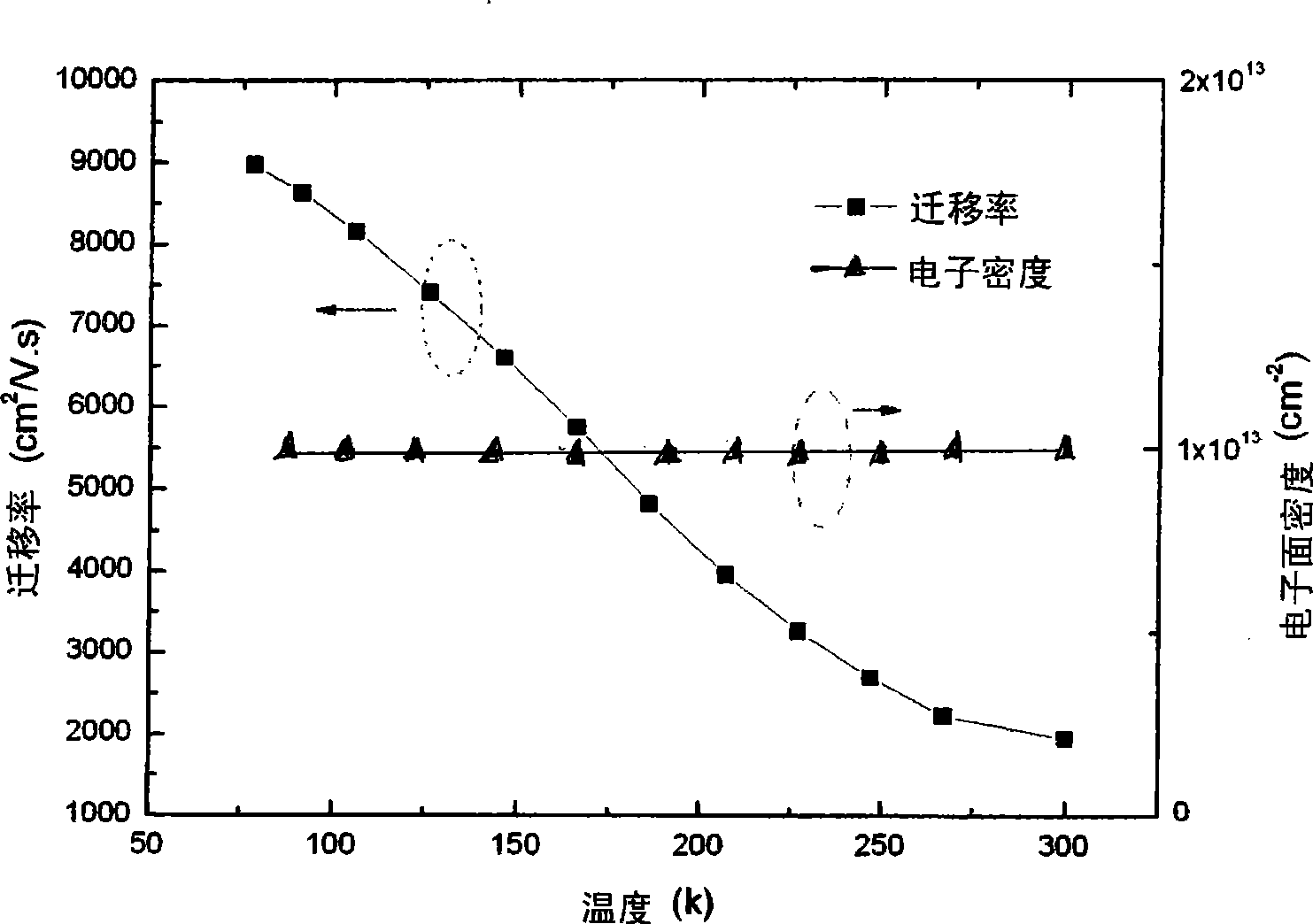

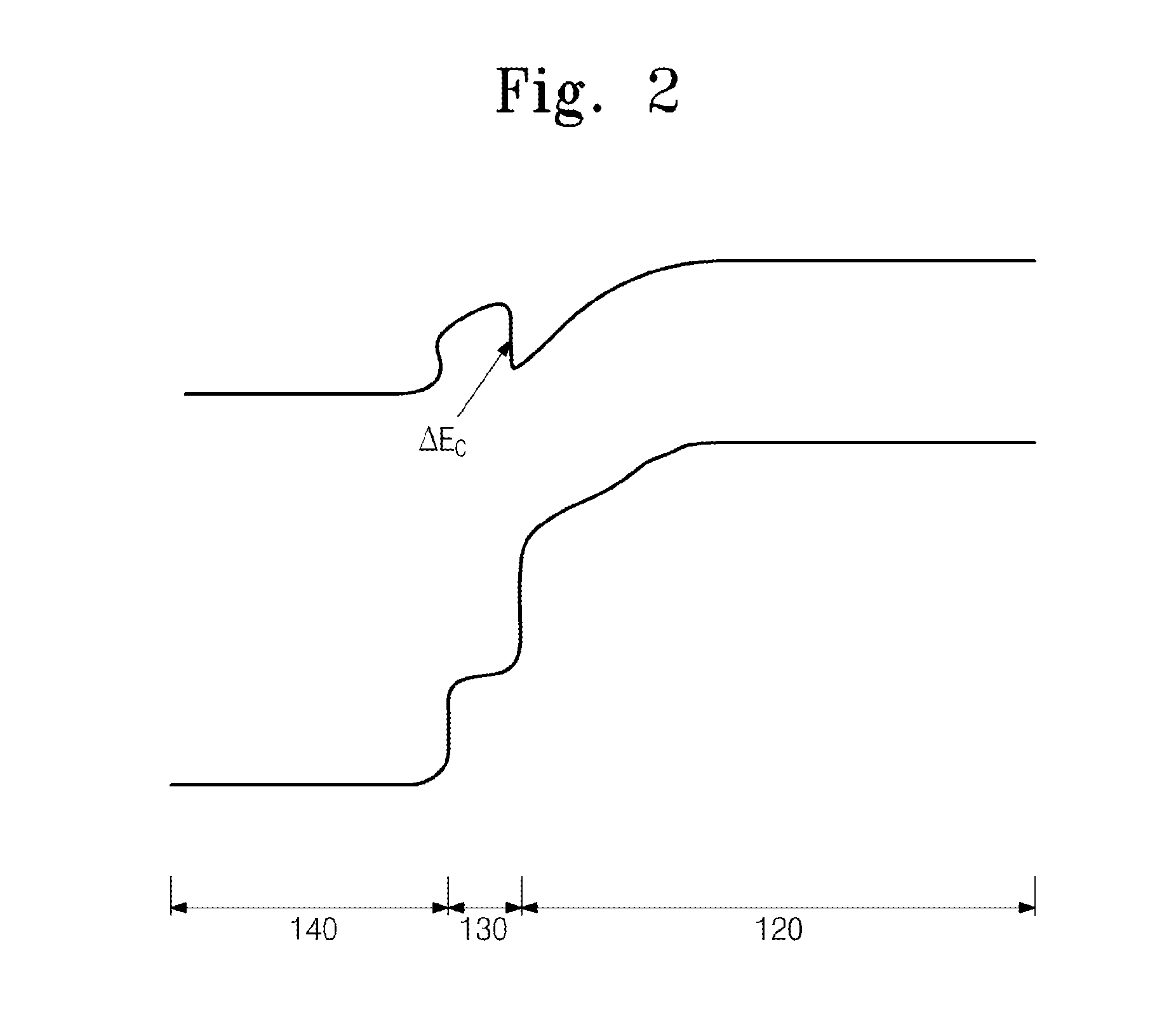

Gallium nitride based transistor structure with high electron mobility

InactiveCN101399284APrevent segregation and spreadHigh conduction band discontinuitySemiconductor devicesIndiumIsolation layer

A gallium nitride-based high electron mobility transistor structure comprises: a substrate; a low temperature nucleating layer is produced on the substrate; a gallium nitride-based high resistivity layer is produced on the low temperature nucleation layer; an indium gallium nitride insertion layer is produced on the gallium nitride-based high resistivity layer; a low temperature gallium nitride isolation layer is produced on the indium gallium nitride insertion layer; a high mobility gallium nitride layer is produced on the low temperature gallium nitride isolation layer; an aluminum nitride insertion layer is produced on the high mobility gallium nitride layer; an aluminium gallium nitride barrier layer is produced on the aluminum nitride insertion layer; a gallium nitride cap layer is produced on the aluminium gallium nitride barrier layer, and the gallium nitride cap layer effectively inhibit the current collapse effect.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

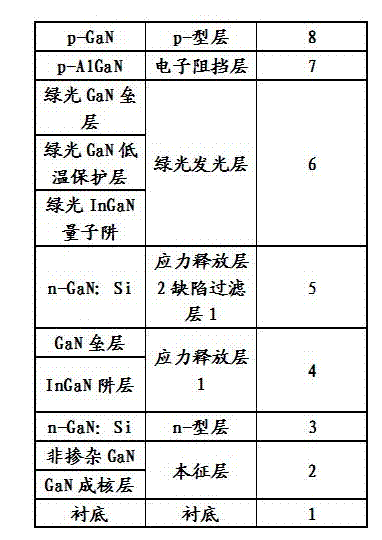

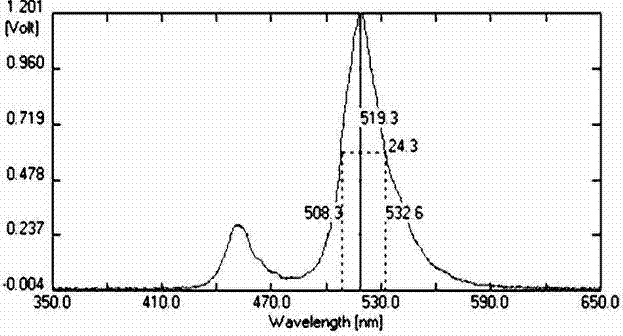

Green light emitting diode and manufacturing method thereof

InactiveCN102738333AImprove luminous efficiencyAvoid phase separationSemiconductor devicesQuantum efficiencyStress relieving

The invention discloses a green light emitting diode and a manufacturing method thereof. The green light emitting diode is characterized in that a low-temperature protective layer is introduced during epitaxial growth of an InGaN (Indium Gallium Nitride) / GaN (Gallium Nitride) quantum well; the quantum well structure changes from InGaN / GaN to an InGan / Gan low-temperature protective layer 1 / GaN structure; thereby protecting In in the InGaN / GaN, and avoiding damage to the In in high-temperature growth, and thus effectively avoiding phase separation of an In component in the InGaN, and improving the internal quantum efficiency; and in addition, two different stress relieving layers are located between an n-type layer and a green light emitting layer, and thus the stress of the green light emitting diode is decreased.

Owner:江苏汉莱科技有限公司

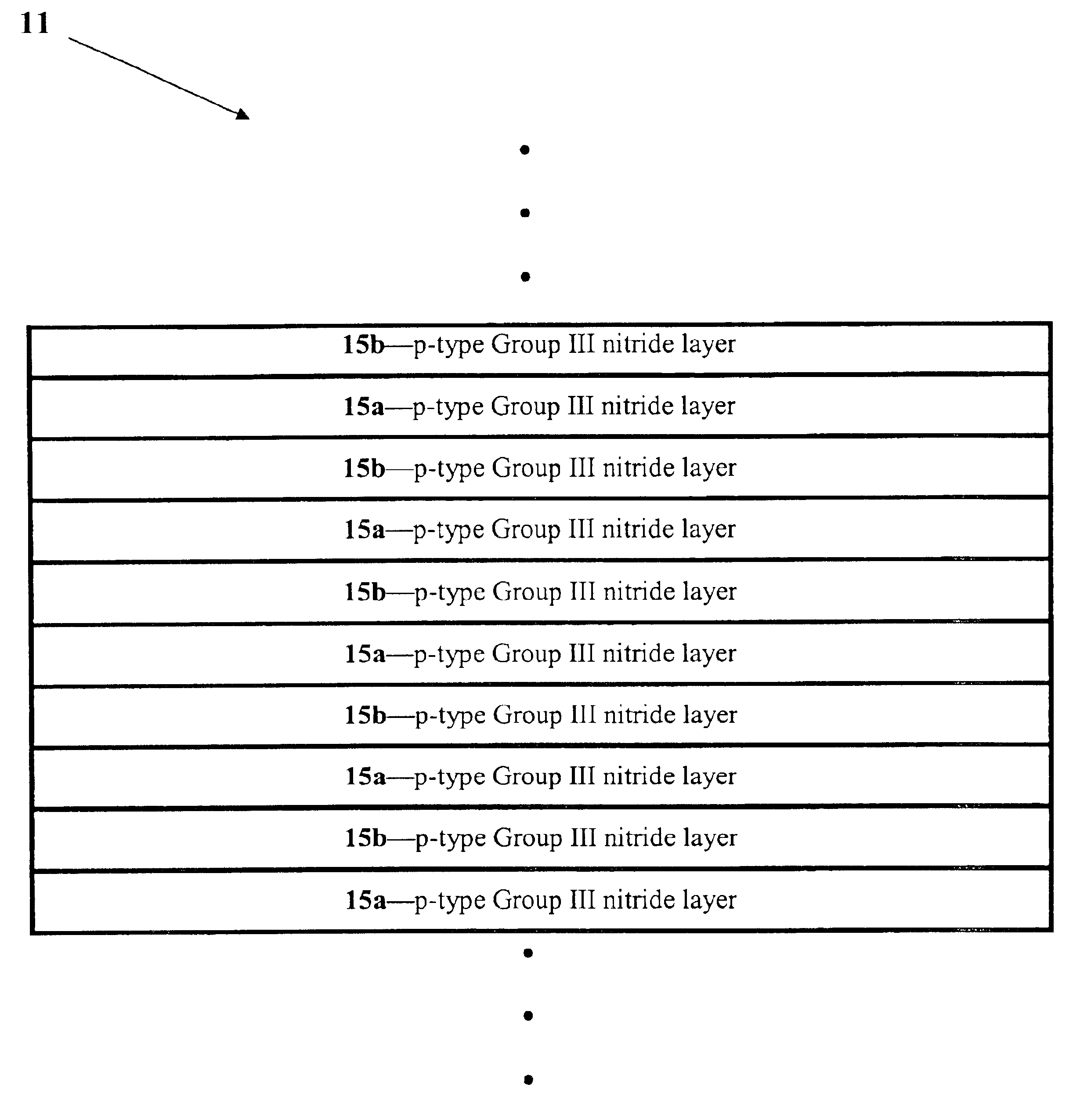

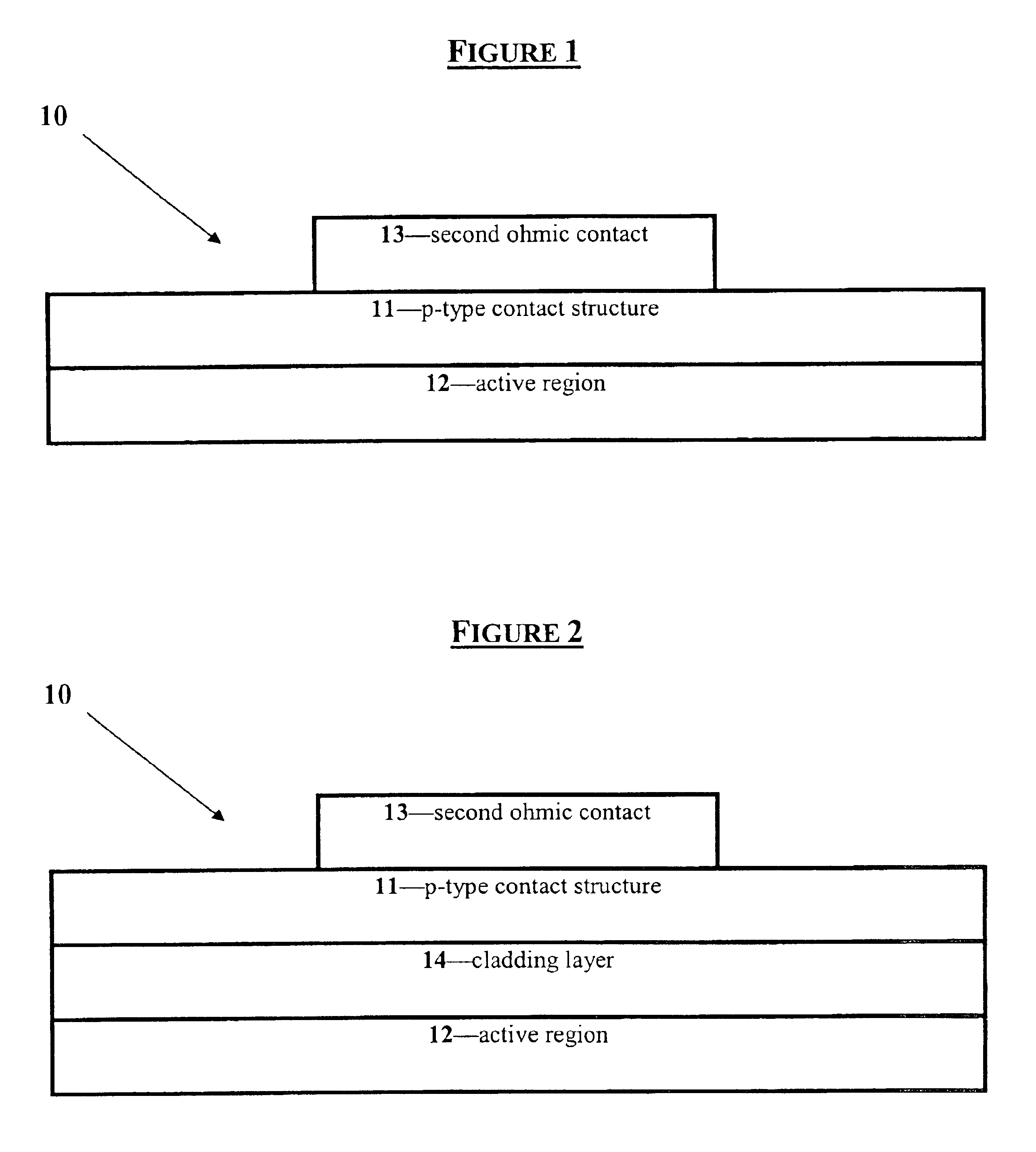

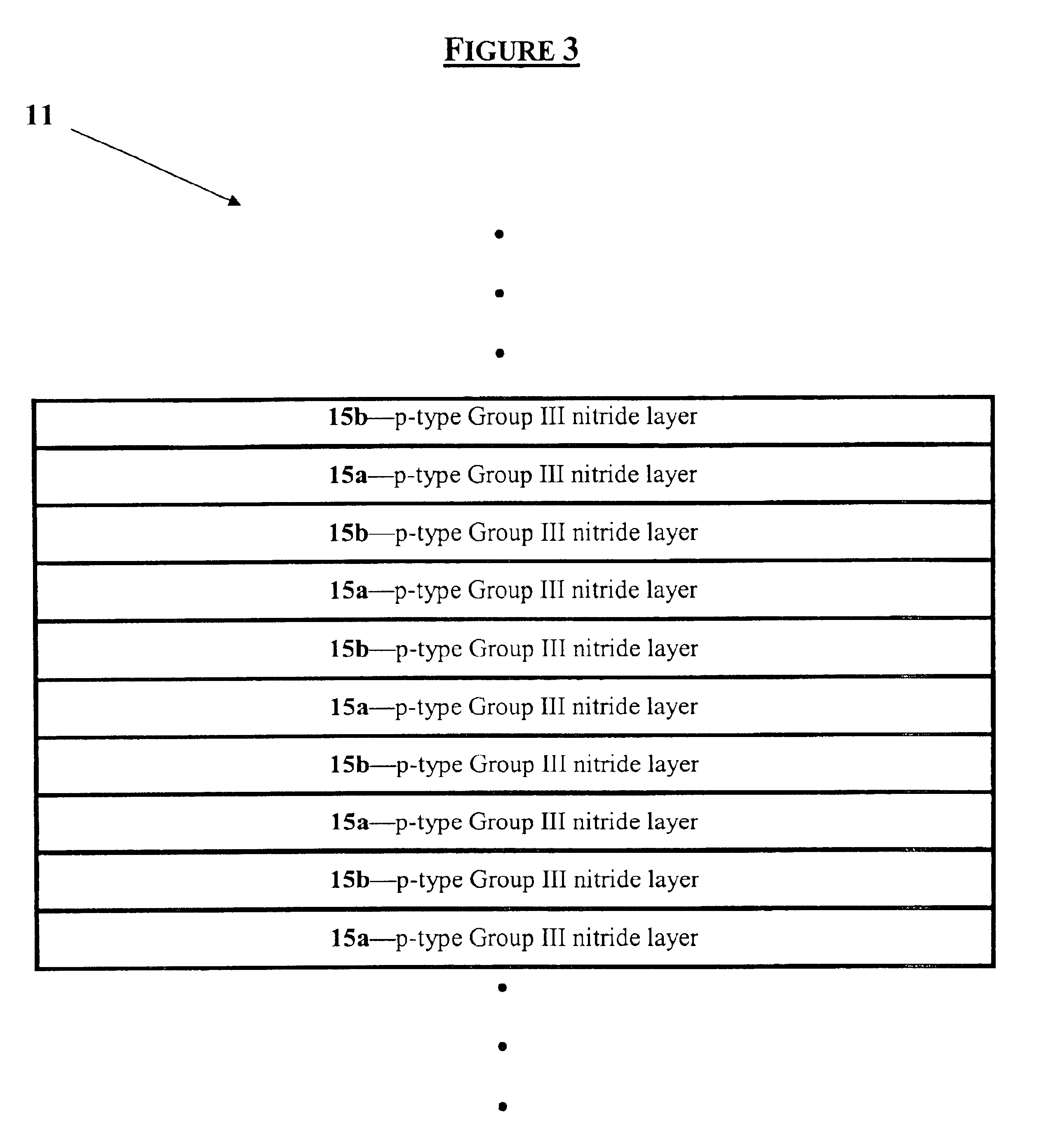

Group III nitride contact structures for light emitting devices

A superlattice contact structure for light emitting devices includes a plurality of contiguous p-type Group III nitride layers. The contact structure may be formed of p-type indium nitride, aluminum indium nitride, or indium gallium nitride. Also disclosed is a light emitting device that incorporates the disclosed contact structures.

Owner:CREELED INC

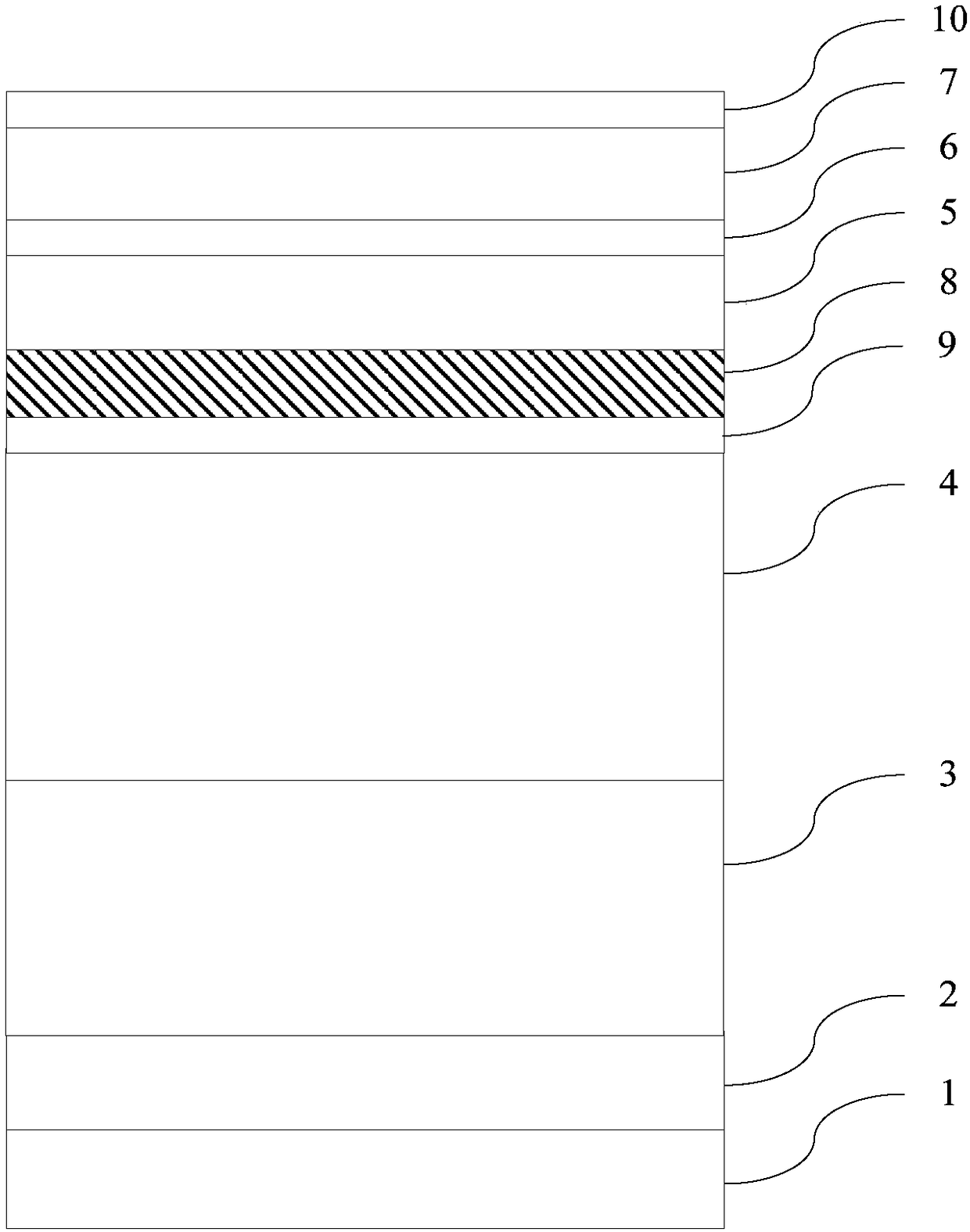

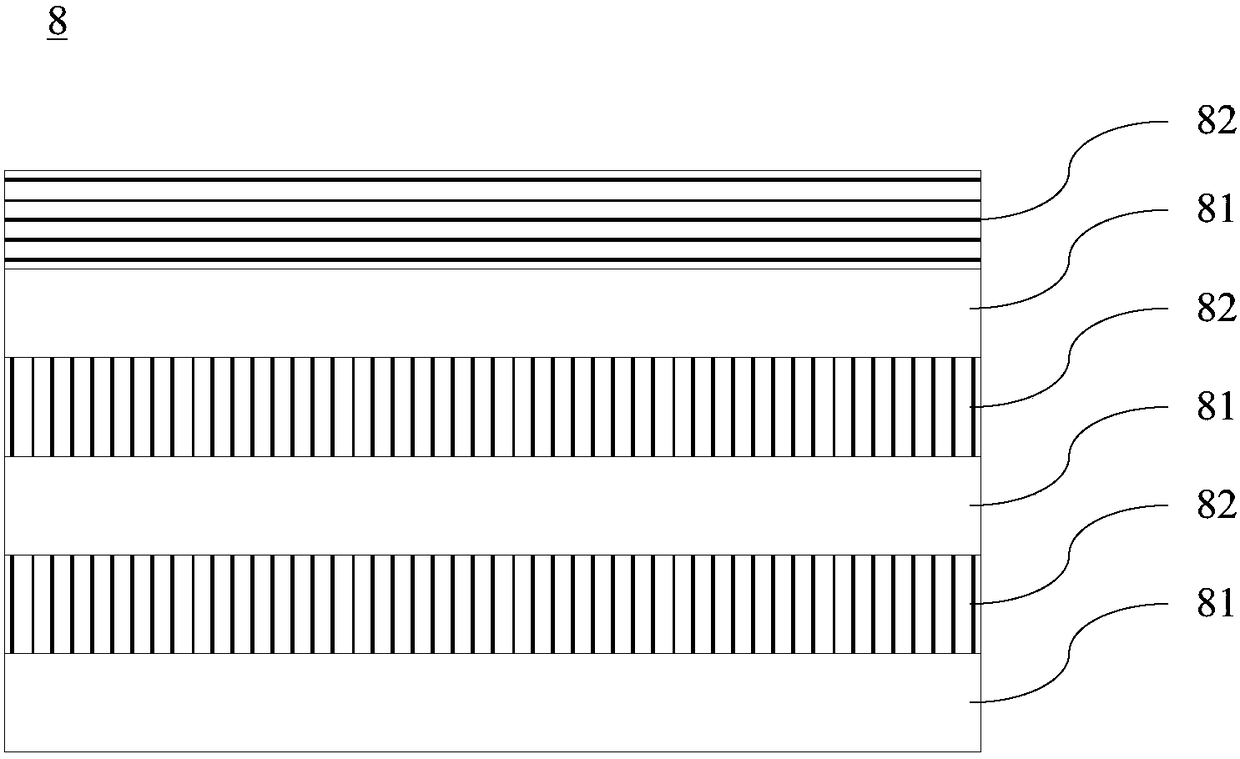

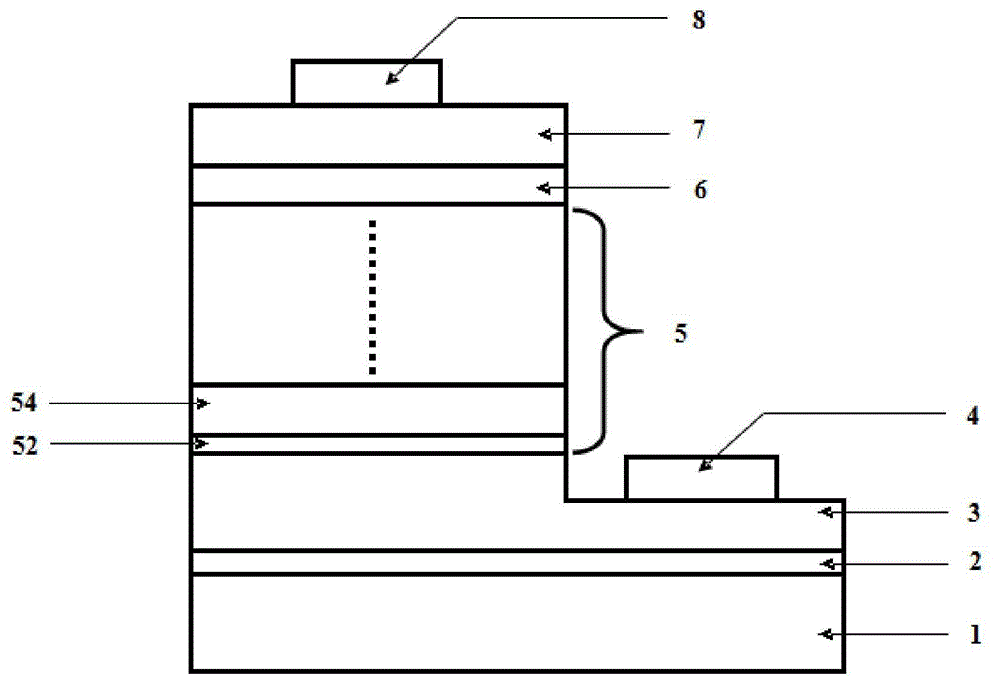

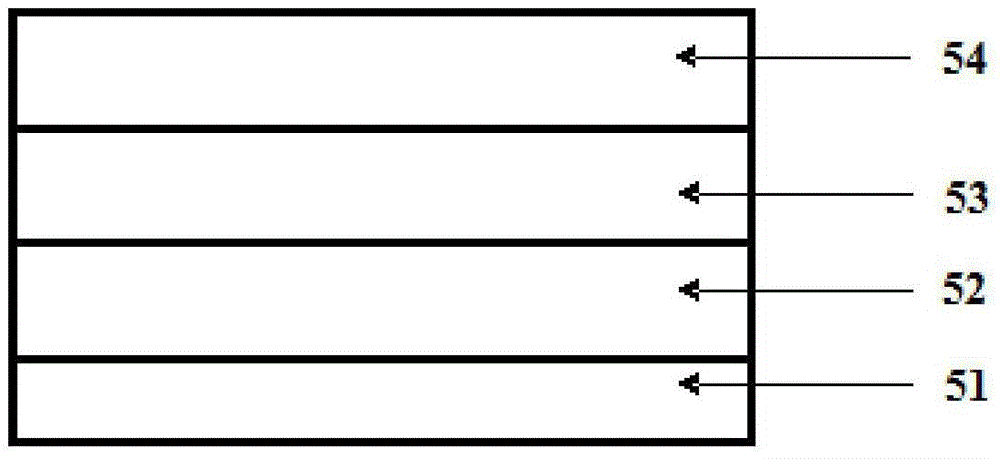

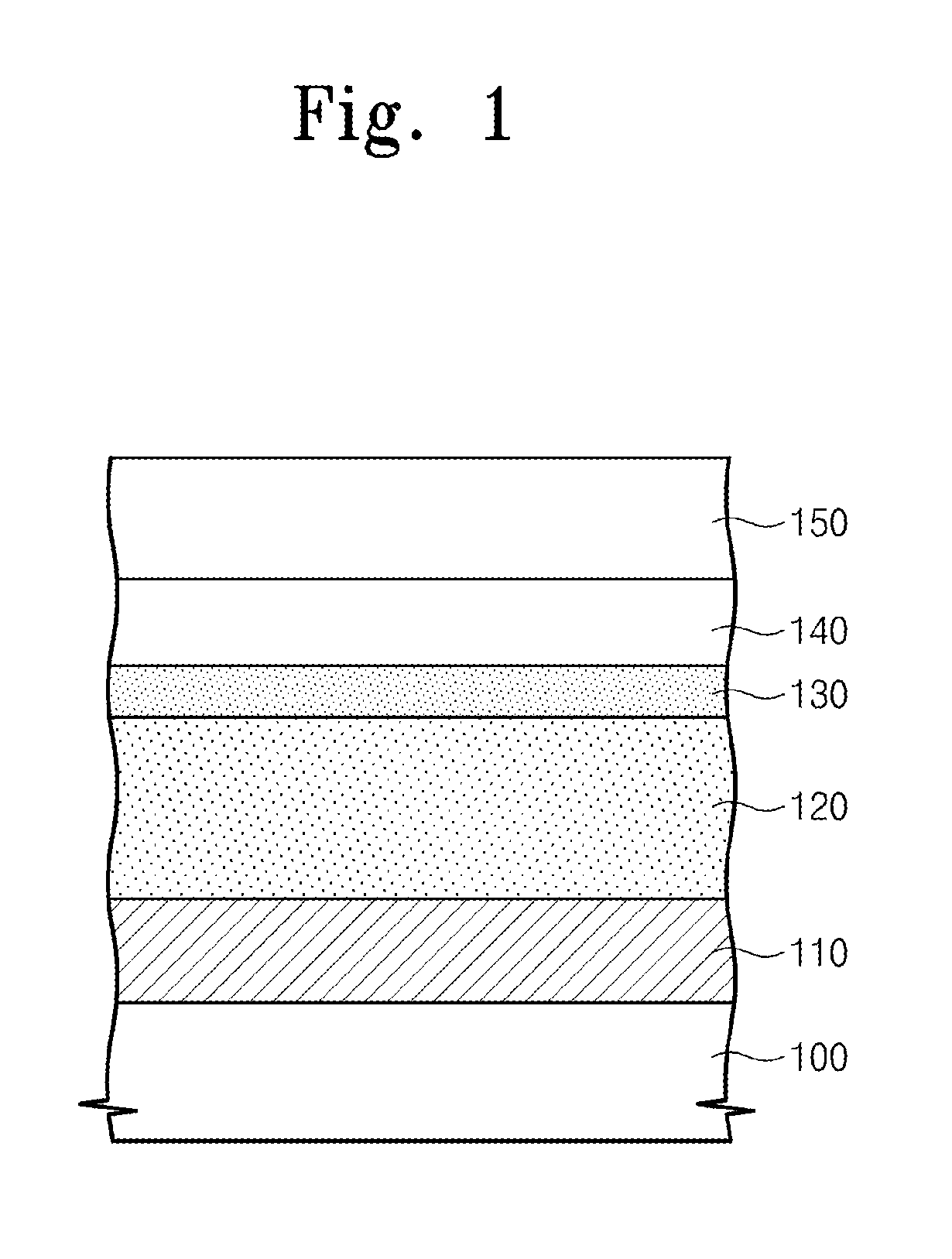

Light emitting diode epitaxial wafer and manufacturing method thereof

ActiveCN108091736AEffect of Luminous EfficiencyImprove luminous efficiencySemiconductor devicesDopantGallium nitride

The invention discloses a light emitting diode epitaxial wafer and a manufacturing method thereof, belonging to the technical field of semiconductors. The epitaxial wafer includes a substrate, a buffer layer, an undoped GaN layer, an N-type GaN layer, a second electron blocking layer, a multiple quantum well layer, a first electron blocking layer, and a P-type GaN layer. The electron blocking layer includes a plurality of first sub-layers and a plurality of second sub-layers that are alternately stacked. Each first sub-layer is an undoped indium gallium nitride layer, a second sub-layer of theplurality of second sub-layers closest to the multiple quantum well layer is a first aluminum gallium nitride layer, the first aluminum gallium nitride layer is an undoped aluminum gallium nitride layer, and each second sub-layer among the second sub-layers except the second sub-layer closest to the multiple quantum well layer is a second aluminum gallium nitride layer, the second aluminum gallium nitride layer is a P-type doped aluminum gallium nitride layer, and the doping concentration of a P-type dopant in each second aluminum gallium nitride layer is smaller than the doping concentrationof a P-type dopant in the GaN layer. The luminous efficiency can be improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

Gallium nitride base light-emitting diode with composite potential barrier

ActiveCN103151435AReduce the built-in electric fieldEliminate mismatchSemiconductor devicesPotential wellIndium

The invention discloses a gallium nitride base light-emitting diode with a composite potential barrier. The gallium nitride base light-emitting diode comprises a sapphire substrate, a buffering layer, an n-type gallium nitride epitaxial layer, a multiple quantum well active area, a p-type algan epitaxial layer and a p-type gallium nitride epitaxial layer, wherein the sapphire substrate, the buffering layer, the n-type gallium nitride epitaxial layer, the multiple quantum well active area, the p-type algan epitaxial layer and the p-type gallium nitride epitaxial layer are arranged sequentially from bottom to top. A p-type metal electrode is arranged on the upper surface of the p-type gallium nitride epitaxial layer. An n-type electrode is arranged on a lower platform surface of the n-type gallium nitride epitaxial layer. The multiple quantum well active area comprises 5-20 indium gallium nitride potential well layers which are arranged at intervals from bottom to top. A first kind composite potential barrier layer is arranged between every two indium gallium nitride potential barrier layers. A second kind composite potential well layer is arranged on the upper surface of an indium gallium nitride potential well layer at the top layer. According to the composite potential barrier, at the contact position of an aluminum, gallium and indium nitride layer and an InGaN potential well layer, a built-in electric field which is produced due to a polarization effect can be decreased through adjustment of aluminum (Al) and indium (In). On a contact interface between an AlInGaN layer and a GaN layer, a ratio between the Al and the In is adjusted to be 0.83:0.17, and lattices of the Al and the In are enabled to be matched.

Owner:SOUTHEAST UNIV

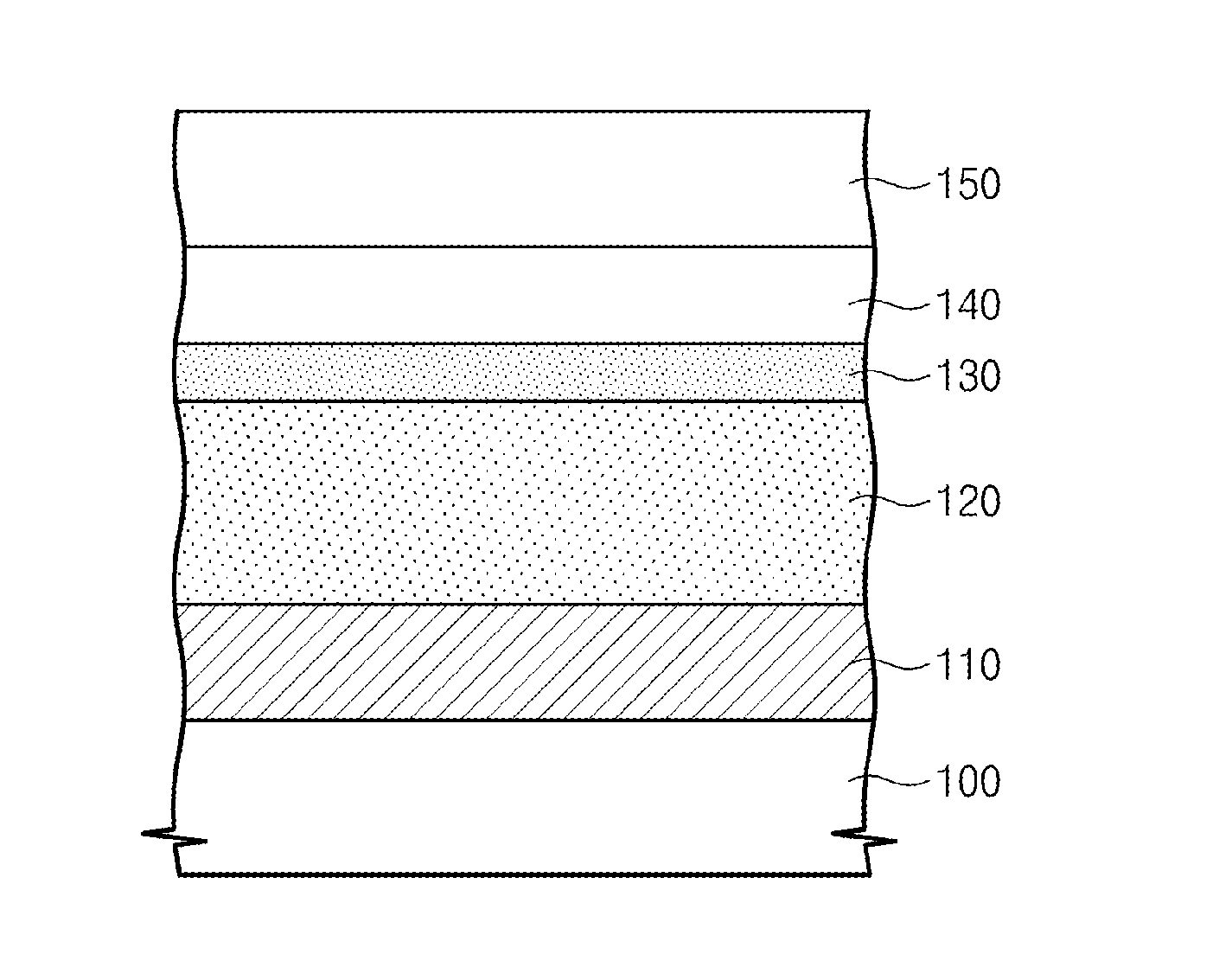

Solar cell and method of fabricating the same

InactiveUS20100319777A1Easy to makeImprove efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingSolar cellMetal electrodes

A solar cell and method of fabricating the same are provided. The solar cell includes a metal electrode layer, an optical absorption layer, a buffer layer, and a transparent electrode layer. The metal electrode layer is disposed on a substrate. The optical absorption layer is disposed on the metal electrode layer. The buffer layer is disposed on the optical absorption layer and includes an indium gallium nitride (InxGa1-xN). The transparent electrode layer is disposed on the buffer layer.

Owner:ELECTRONICS & TELECOMM RES INST

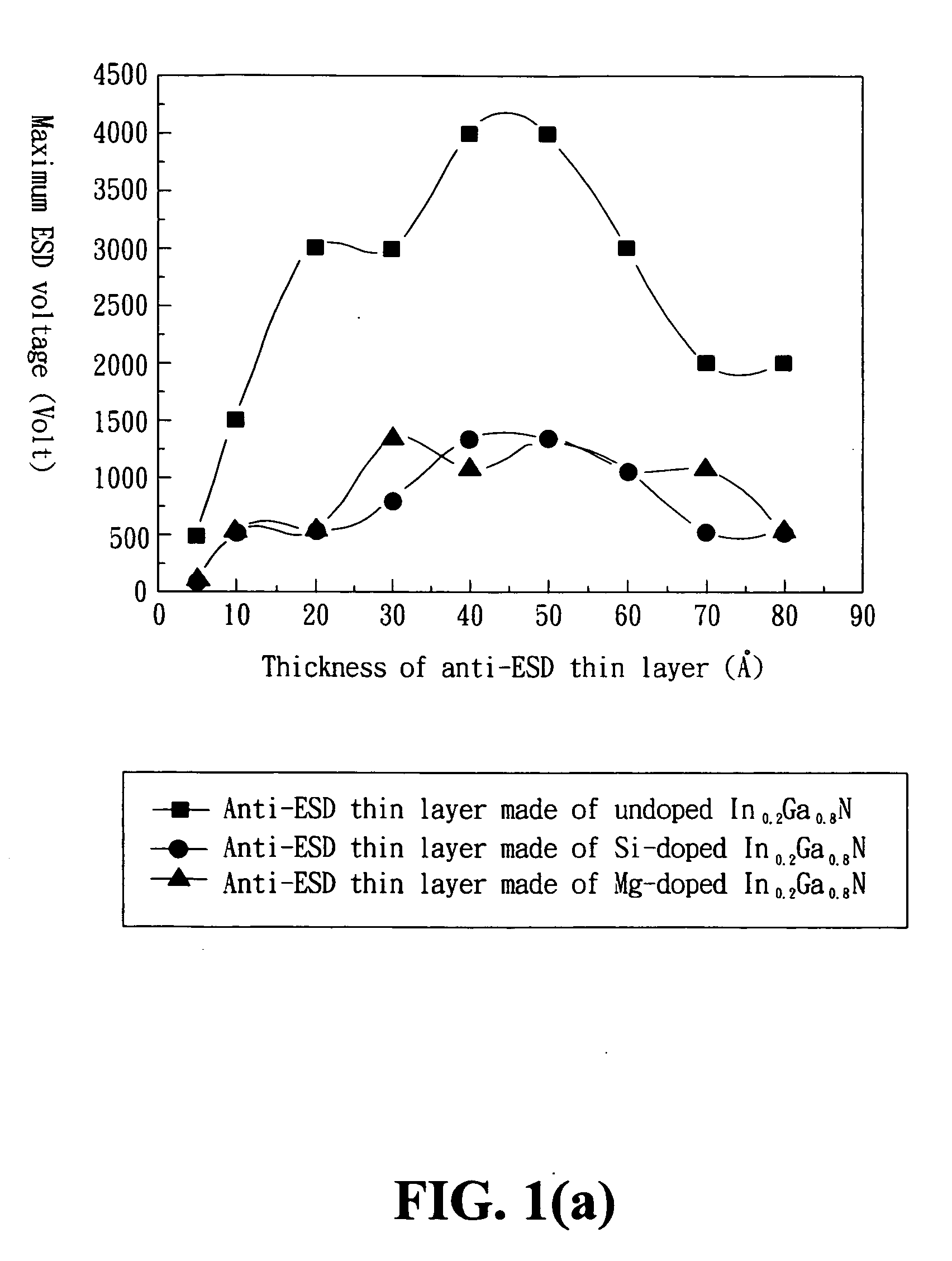

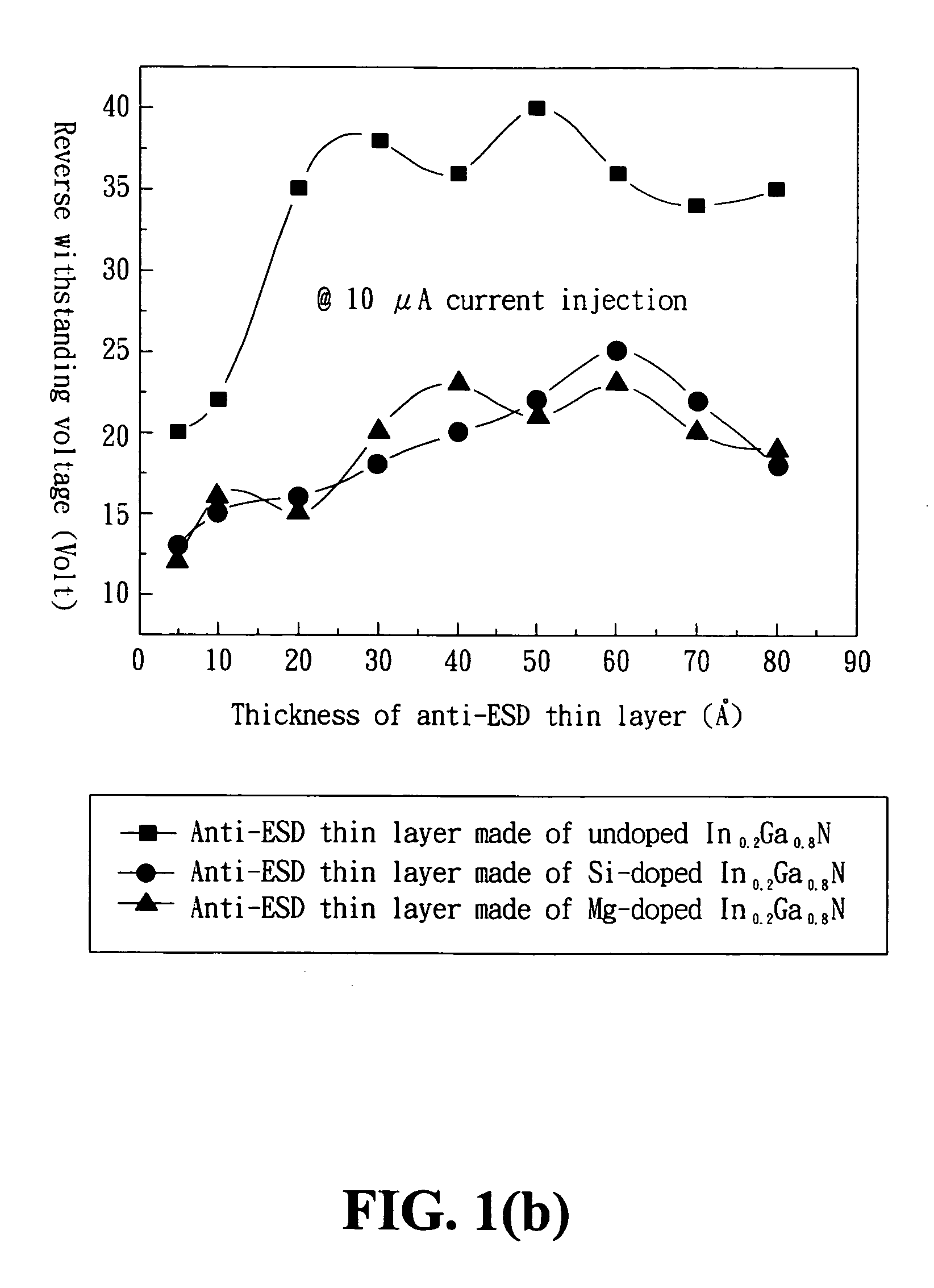

Gallium-nitride based light-emitting diodes structure with high reverse withstanding voltage and anti-ESD capability

InactiveUS20060076574A1High resistivityHigh voltageSolid-state devicesSemiconductor devicesIndiumThin layer

An epitaxial structure for GaN-based LEDs to achieve better reverse withstanding voltage and anti-ESD capability is provided herein. The epitaxial structure has an additional anti-ESD thin layer as the topmost layer, which is made of undoped indium-gallium-nitrides (InGaN) or low-band-gap (Eg<3.4 eV), undoped aluminum-indium-gallium-nitrides (AlInGaN). The anti-ESD thin layer could also have a superlattice structure formed by interleaving at least an undoped InGaN thin layer and at least a low-band-gap, undoped AlInGaN thin layer. This anti-ESD thin layer greatly improves the GaN-based LEDs' reverse withstanding voltage and resistivity to ESD, which in turn extends the GaN-based LEDs' operation life significantly.

Owner:FORMOSA EPITAXY INCORPORATION

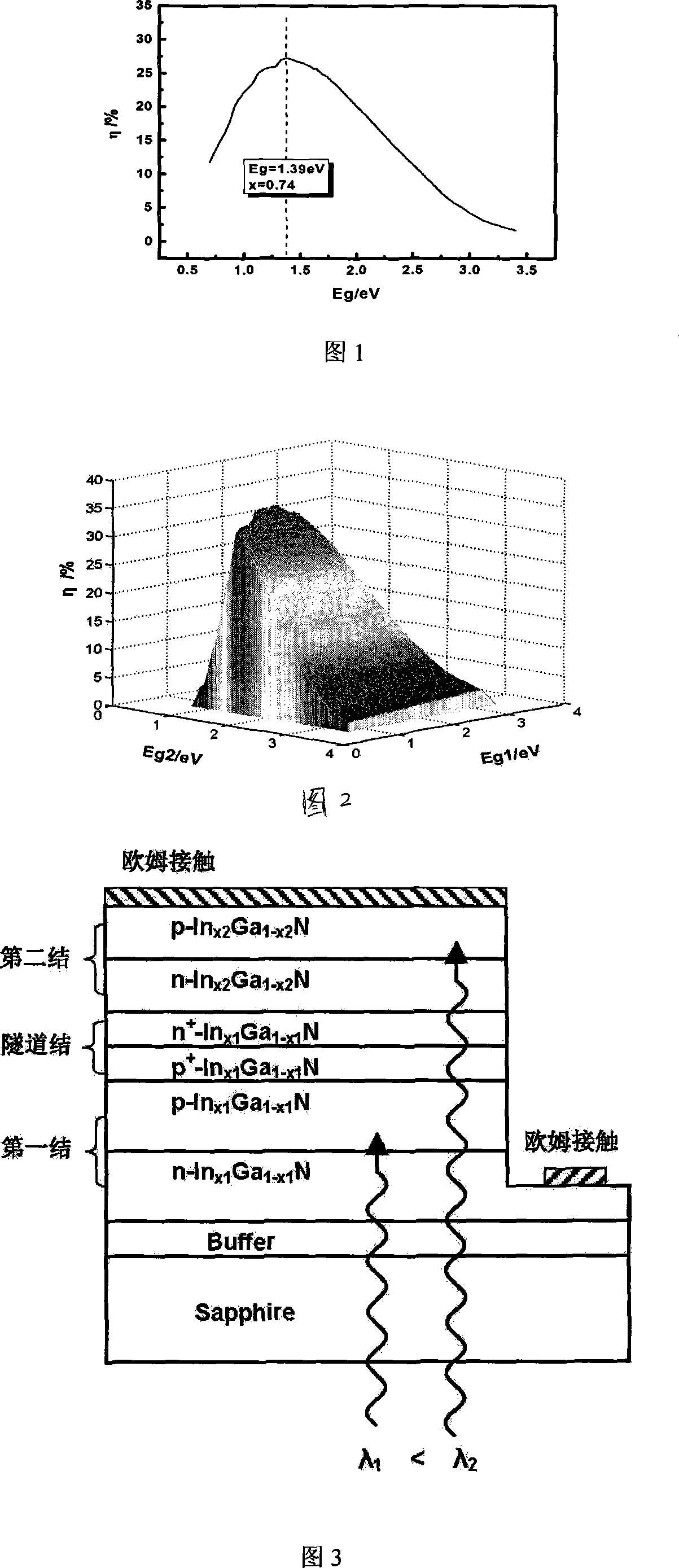

Setup method for indium-gallium-nitride p-n node type multi-node solar battery structure

InactiveCN101101933AImprove conversion efficiencyPhotovoltaic energy generationSemiconductor devicesEngineeringSolar battery

The invention is concerned with a setting method of structure to multi-junction solar battery in type of InGaN p-n. It takes current-pressure equation, relation formula between InxGa1-xN energy gap and In composing and correlative parameters of InxGa1-xN of solar battery in type of InGaN p-n to count the largest transition efficiency of InGaN multi-junction (solo-junction) solar battery and the best energy gap of junction material to get the said transition efficiency and corresponding value of In composing. Take InxGa1-xN with those different In composing as junction material and connect them with tunnel kink in series. Set metal conduct pole on the first junction n (or p)-Inx1Ga1-x1N and the last I junction p (or n)-InxiGa1-xiN, and cover film to reduce reflection on incidence surface.

Owner:NANJING UNIV

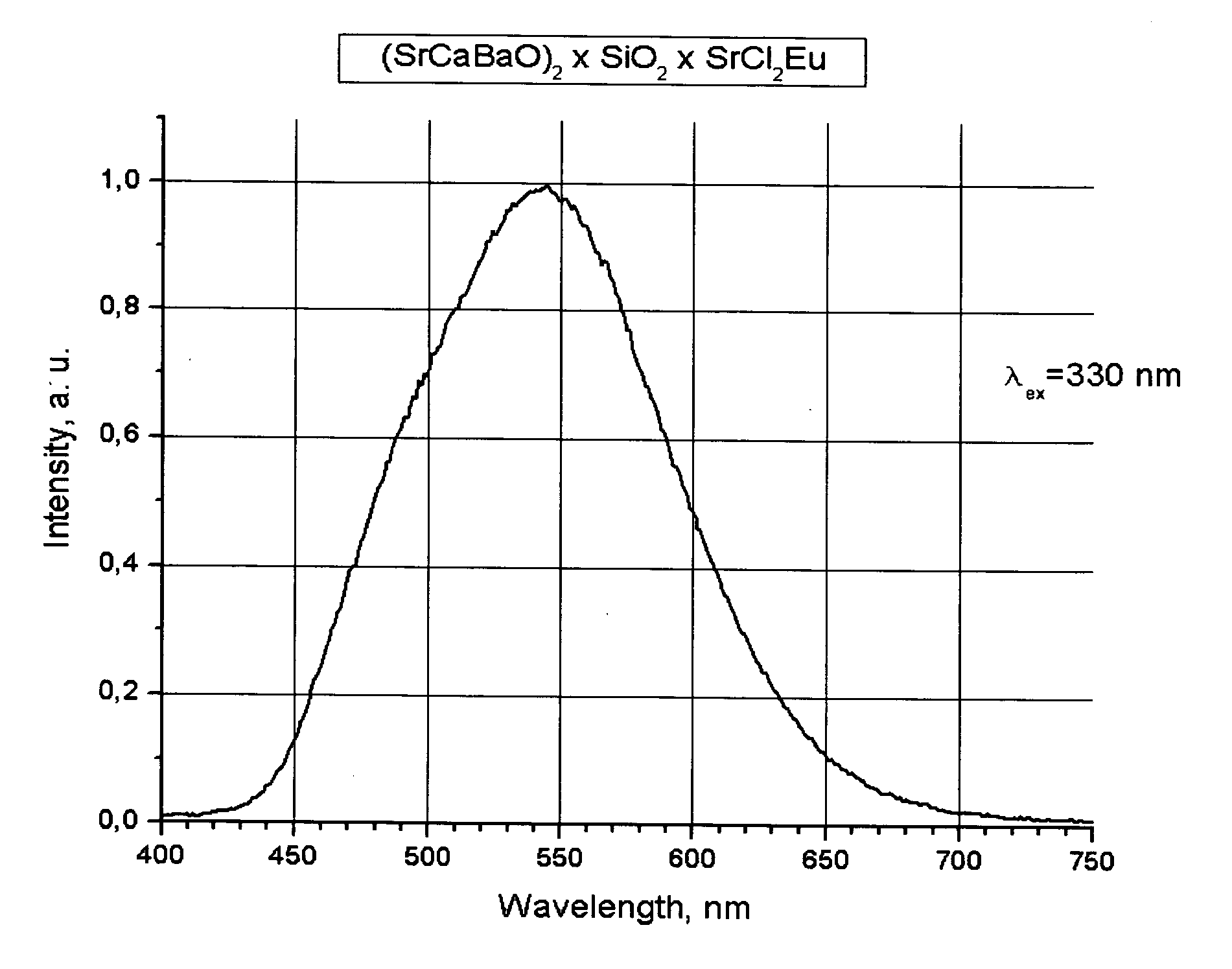

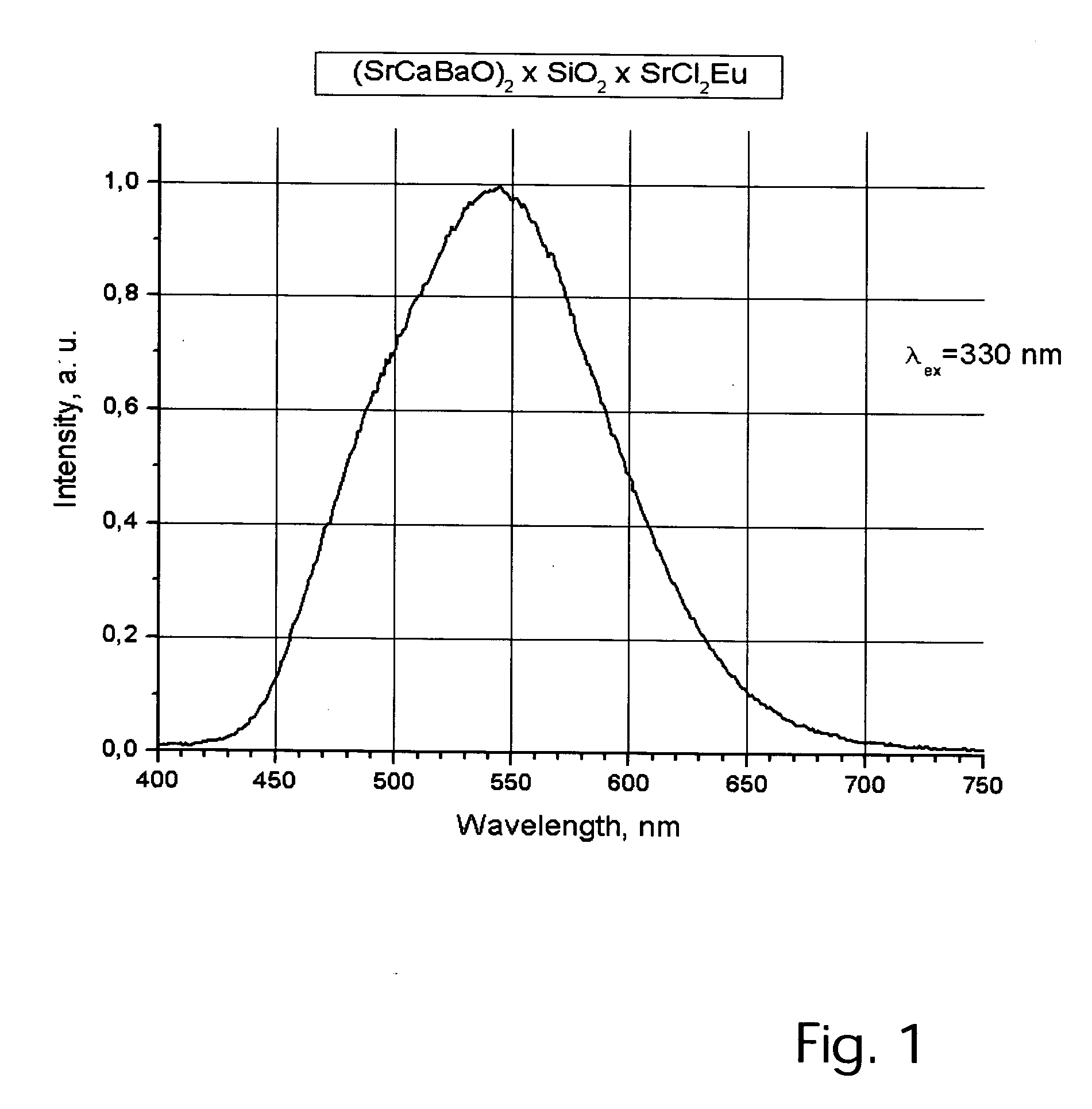

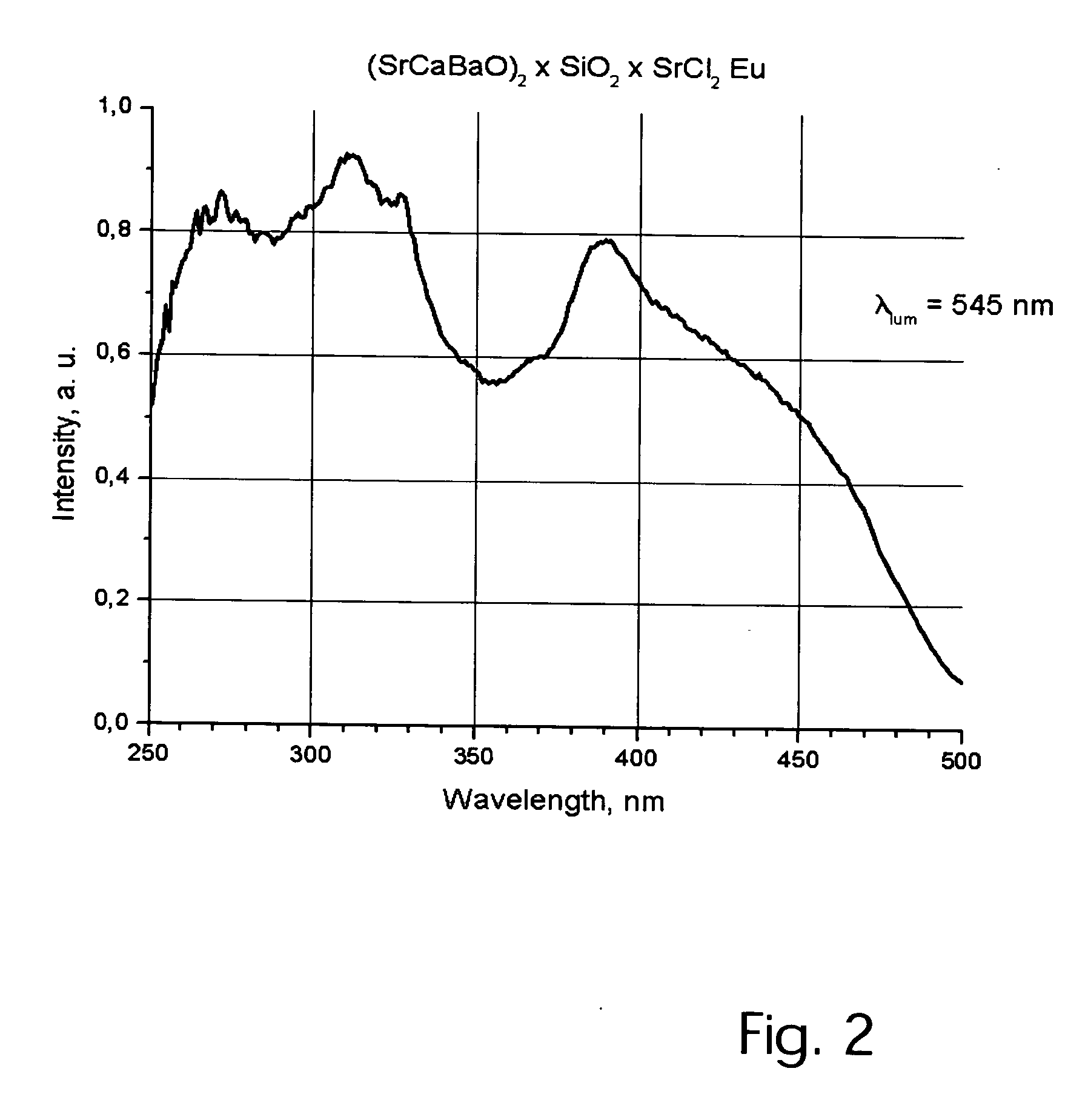

Light emitting halogen-silicate photophosphor compositions and systems

InactiveUS20070145879A1Improve performanceDischarge tube luminescnet screensLamp detailsDevice materialHigh energy

New high-performance, highly tunable photophosphors are presented. These photophosphor's pump spectra and emission spectra are both manipulated via variances in the formulation of compounds taught herein. In addition, new combinations of semiconductor devices in conjunction with these optically active materials are described. In particular, light emitting semiconductors fashioned as diodes from indium gallium nitride construction are combined with these photophosphors. High-energy short wavelength light mixes with the longer wavelengths light emitted by the halogen-silicate photophosphor to produce a broad spectrum perceived by human observers as “white light”.

Owner:ACOL TECH

Iii-nitride light-emitting diode and method of producing the same

ActiveUS20120025232A1Improve performanceMaintain good propertiesSemiconductor/solid-state device manufacturingSemiconductor devicesOhmic contactLight-emitting diode

Embodiments of the present invention provides III-nitride light-emitting diodes, which primarily include a first electrode, a n-type gallium nitride (GaN) nanorod array consisted of one or more n-type GaN nanorods ohmic contacting with the first electrode, one or more indium gallium nitride (InGaN) nanodisks disposed on each of the n-type GaN nanorods, a p-type GaN nanorod array consisted of one or more p-type GaN nanorods, where one p-type GaN nanorod is disposed on top of the one ore more InGaN nanodisks disposed on each of the n-type GaN nanorods, and a second electrode ohmic contacts with the p-type GaN nanorod array.

Owner:NATIONAL TSING HUA UNIVERSITY

Fabrication of nonpolar indium gallium nitride thin films, heterostructures and devices by metalorganic chemical vapor deposition

InactiveUS7504274B2Polycrystalline material growthSemiconductor/solid-state device manufacturingGas phaseChemical vapor deposition

A method for the fabrication of nonpolar indium gallium nitride (InGaN) films as well as nonpolar InGaN-containing device structures using metalorganic chemical vapor deposition (MOVCD). The method is used to fabricate nonpolar InGaN / GaN violet and near-ultraviolet light emitting diodes and laser diodes.

Owner:RGT UNIV OF CALIFORNIA +1

Nanostructure having a nitride-based quantum well and light emitting diode employing the same

ActiveUS8330173B2Increase brightnessReduce impactNanostructure manufactureSemiconductor/solid-state device manufacturingQuantum efficiencyNanostructure

Disclosed are a nanostructure with an indium gallium nitride quantum well and a light emitting diode employing the same. The light emitting diode comprises a substrate, a transparent electrode and an array of nanostructures interposed between the substrate and the transparent electrode. Each of the nanostructures comprises a core nanorod, and a nano shell surrounding the core nanorod. The core nanorod is formed substantially perpendicularly to the substrate and includes a first nanorod of a first conductivity type, an (AlxInyGa1-x-y)N (where, 0≦x<1, 0≦y≦1 and 0≦x+y≦1) quantum well, and a second nanorod of a second conductivity type, which are joined in a longitudinal direction. The nano shell is formed of a material with a bandgap greater than that of the quantum well, and surrounds at least the quantum well of the core nanorod. Meanwhile, the second nanorods are connected in common to the transparent electrode. Accordingly, with the nano shells, it is possible to provide a light emitting diode capable of improving external quantum efficiency by preventing non-radiative recombination on a surface of the (AlxInyGa1-x-y)N quantum well.

Owner:SEOUL VIOSYS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com