High-power gallium nitride based LED with novel structure

A gallium nitride-based, high-power technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems that restrict photoelectric conversion efficiency, and achieve the effects of small effective mass, high concentration, and increased overlap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

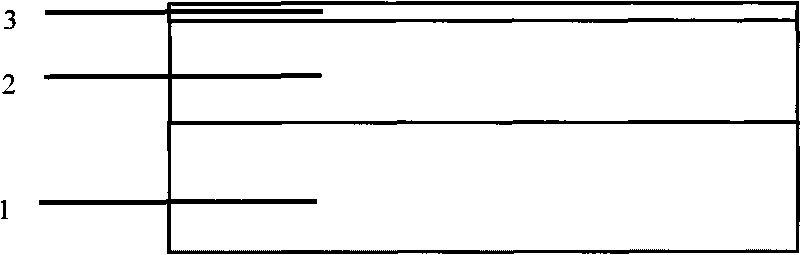

[0033] Step 1: epitaxially grow n-GaN layer 2 and AlGaN layer 3 on substrate 1 in sequence (refer to figure 1 );

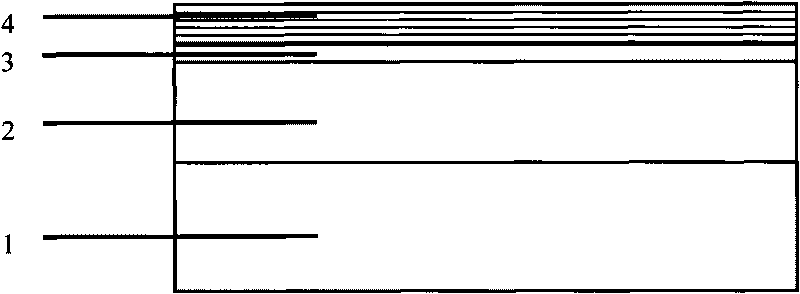

[0034] Step 2: growing the active layer 4 above the AlGaN layer 3, wherein the well width in the active region is controlled by adjusting the growth time, so that the well width gradually decreases from 3nm to 2nm from bottom to top (refer to figure 2 );

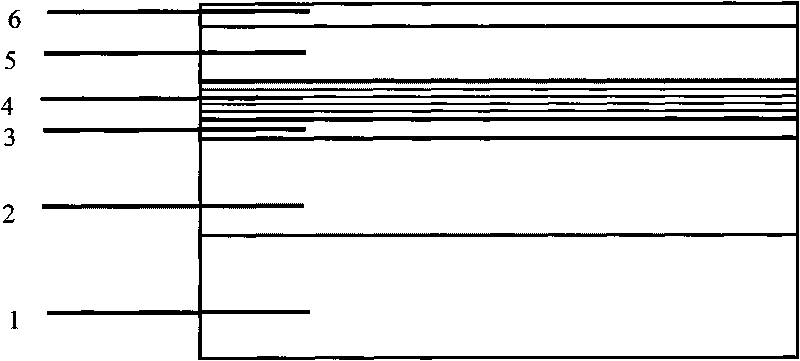

[0035] Step 3: On the active layer 4, grow p-GaN layer 5 and p+ -InGaN conductive layer 6 (refer to image 3 );

[0036] Step 4: In p + -On the InGaN layer 6, a masking layer 7 is deposited by PECVD; the material of the masking layer is SiO 2 (refer to Figure 4 );

[0037] Step 5: Coat photoresist on masking layer 7, use the method for photolithography and wet etching, carve strip-shaped n-GaN electrode region 8 on masking layer 7 (refer to Figure 5 );

[0038] Step 6: remove remain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com