Integration method for electric absorption modulation laser and modular spot converter

A mode-spot converter and electro-absorption modulation technology, which is applied to lasers, laser components, semiconductor lasers, etc., to achieve high internal quantum efficiency, reduce growth times, and reduce device costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

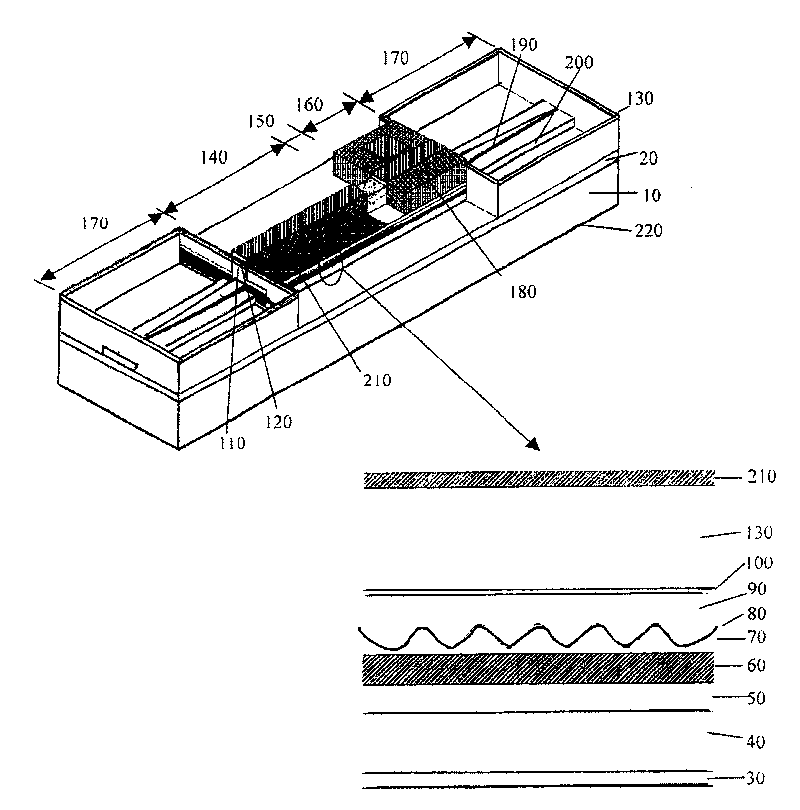

[0098] see again figure 1 As shown, the present invention relates to an integrated method of an electroabsorption modulated laser and a mode spot converter, comprising the following manufacturing steps:

[0099] (1) The 2-inch n-InP substrate undergoes strict decontamination (heating and boiling with ethanol, trichlorethylene, acetone, and ethanol in sequence) → pickling (soaking in concentrated sulfuric acid for 1 to 2 minutes) → water washing (rinsing with deionized water More than 50 times) → after drying treatment, put it into the growth chamber, the growth temperature is 655°C, the growth pressure is 22mbar, and the graphite boat rotates at 75-80 rpm. Growth rate 0.4~0.7nm / s;

[0100] (2) On the n-type indium phosphide substrate (100) epitaxially grow n-type indium phosphide buffer layer (0.5μm thick), lower waveguide layer (thickness 50nm, bandgap wavelength 1.1μm), 0.2μm phosphide Indium space layer, thin 1.1Q layer (30nm);

[0101] (3) Using PECVD technology to grow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com