Patents

Literature

192results about How to "Reduce absorption loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

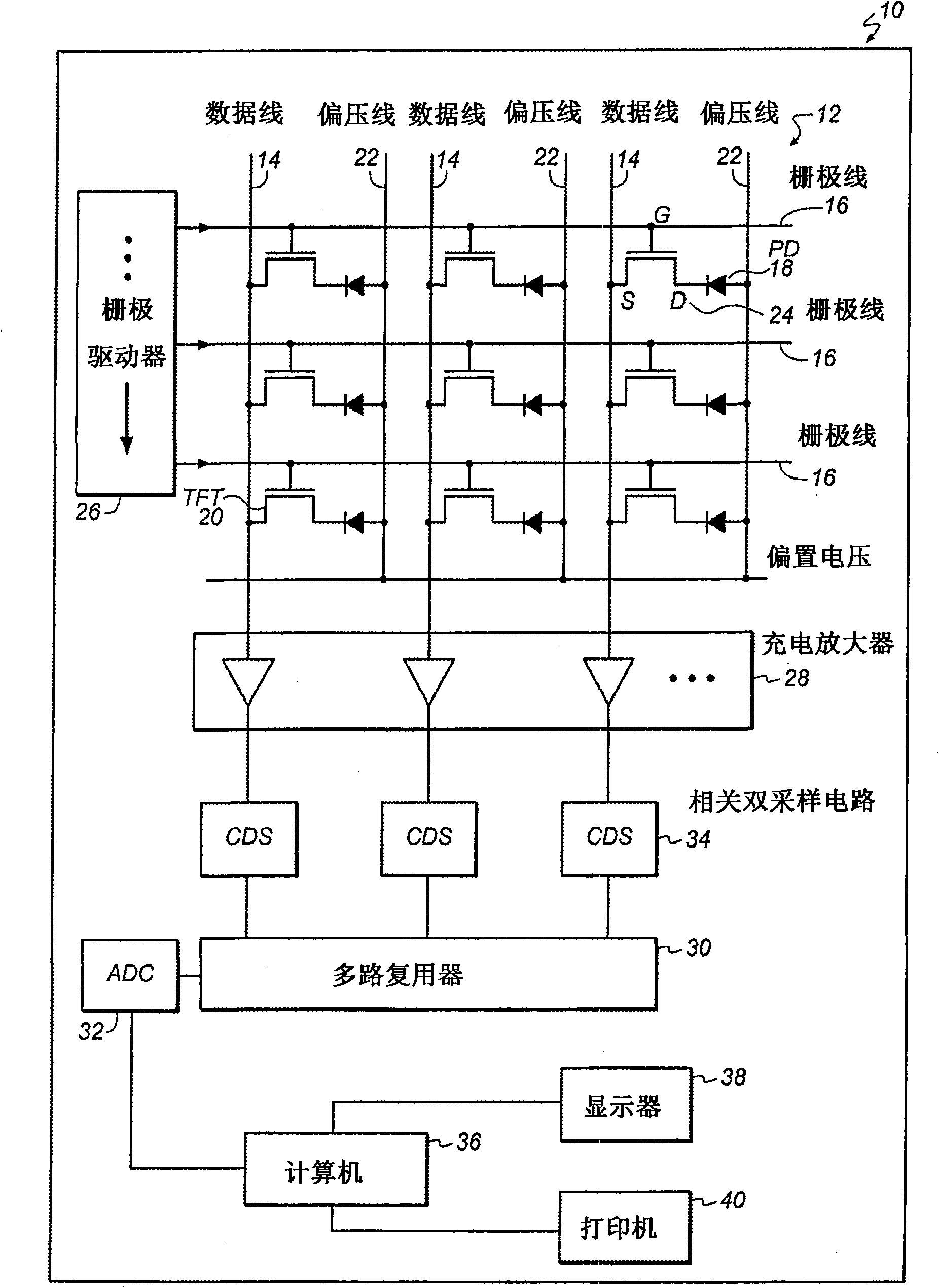

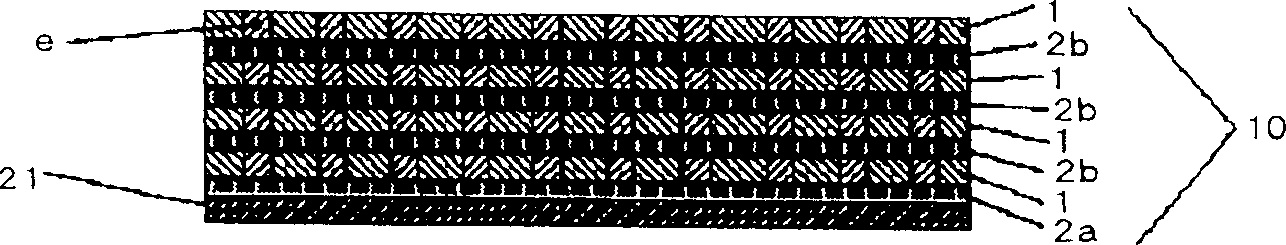

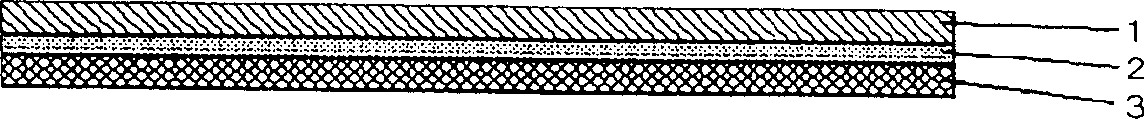

Dual-screen digital radiographic imaging detector array

ActiveCN101561505ADetection speedHigh mechanical strengthTelevision system detailsX-ray/infra-red processesSoft x rayPhosphor

A radiographic imaging device has a first scintillating phosphor screen having a first thickness and a second scintillating phosphor screen having a second thickness. A transparent substrate is disposed between the first and second screens. An imaging array formed on a side of the substrate includes multiple photosensors and an array of readout elements.

Owner:CARESTREAM HEALTH INC

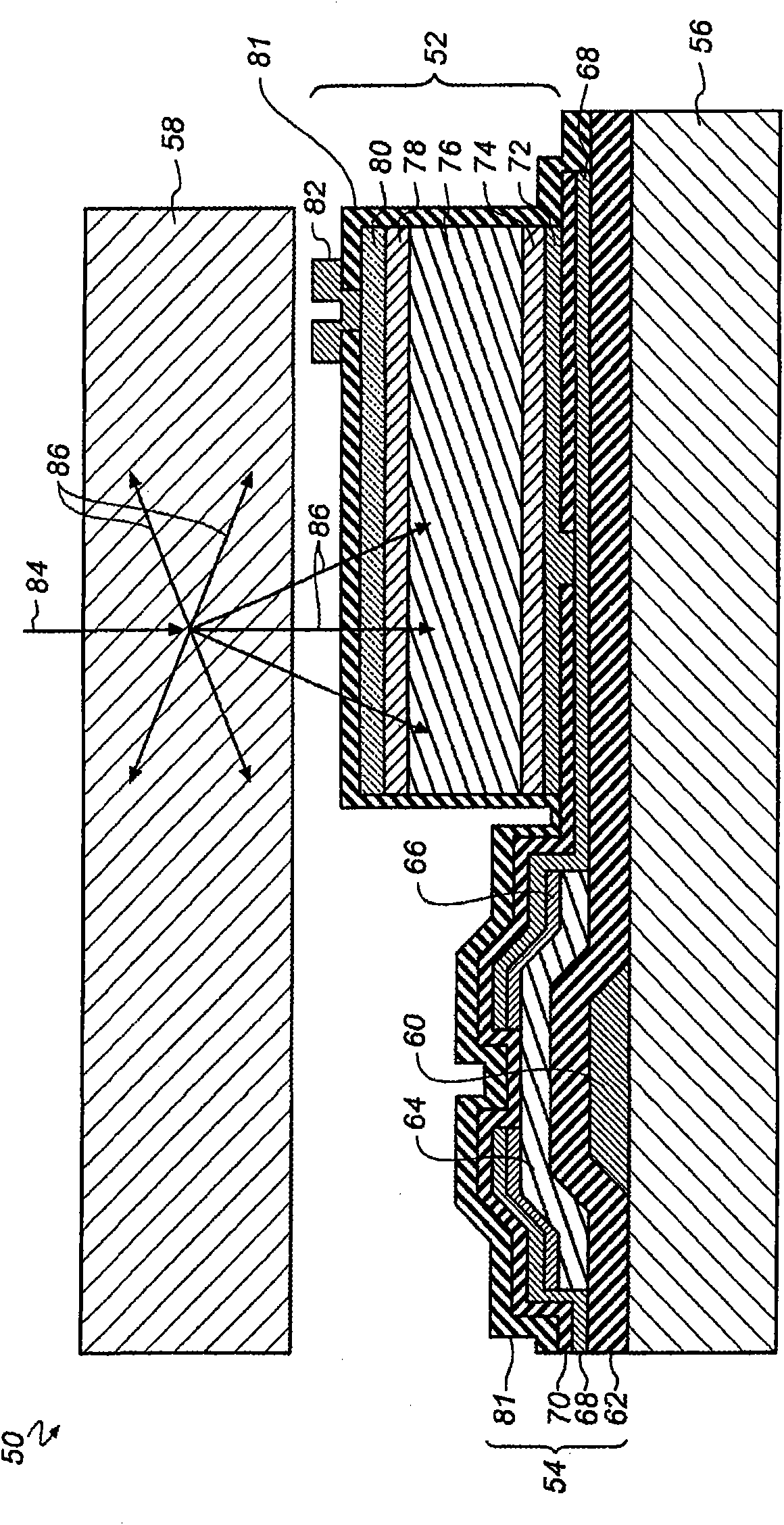

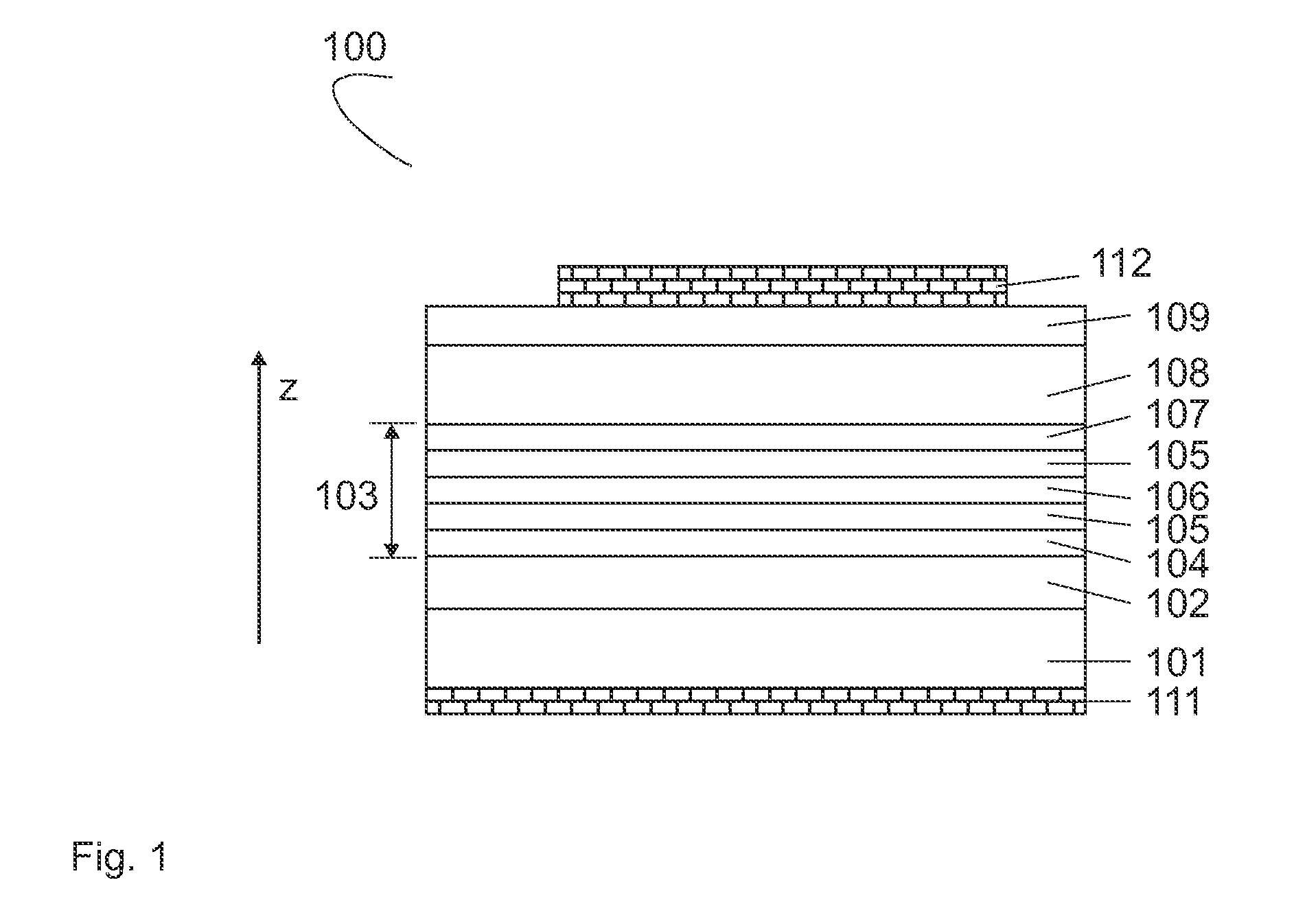

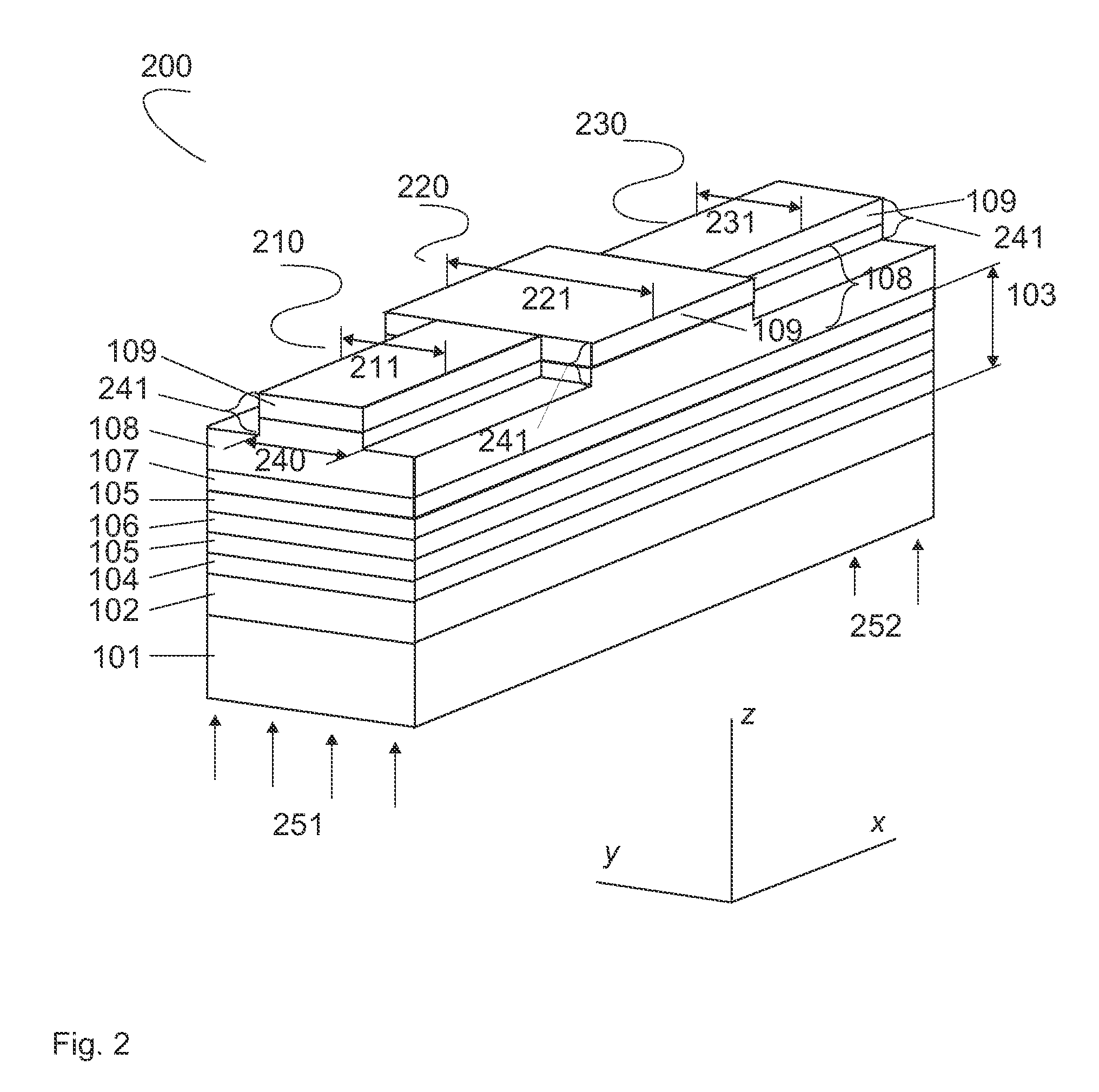

High-Power Optoelectronic Device with Improved Beam Quality Incorporating A Lateral Mode Filtering Section

InactiveUS20070223549A1Simplified method of fabricatingLeakage losses is still relatively largeOptical wave guidanceLaser detailsLight beamWaveguide

An optoelectronic device includes a planar active element, a vertical waveguide surrounding the active element in the vertical direction, and a lateral waveguide comprising at least one active section and at least one filter section following each other in the longitudinal direction. At least part of the active element within the active section generates optical gain in response to above-threshold pumping. The broad lateral waveguide in the active section can localize multiple lateral optical modes. In the filter section, no lateral confinement is provided for the lateral optical modes. The device further comprises means to ensure low absorption loss in the filter section and, therefore, ensure high efficiency. In one embodiment low absorption loss is achieved by pumping of at least part of the active element within the filter section. In another embodiment, the active element has small overlap with the vertical optical modes.

Owner:INNOLUME

Silicon solar battery antireflective thin film

InactiveCN101022135AImprove surface passivation effectReduce light absorption lossSemiconductor devicesRefractive indexCompound (substance)

This invention discloses an anti-reflection film of silicon solar cell used in solar cells by depositing a rich silicon SiN film on the positive surface of a silicon chip and a SiN film with ideal match on the rich silicon SiN film, in which, and the film content closing to the Si chip surface is high and the surface pasivation effect is better than the SiN film approaching to the idea match, the surface composition speed is more than one time less than the normal matched SiN film, and the rich Si film is thin and only absorbs 20%-30% short waves with the wavelength about 300nm and does not absorb long-middle lightwaves and other composition approaches to ideal chemical match.

Owner:JIANGSU AIDE SOLAR ENERGY TECH CO LTD

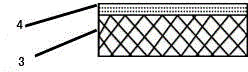

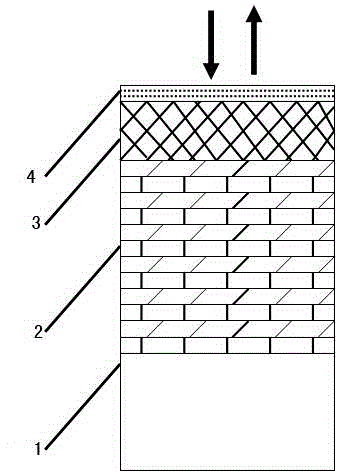

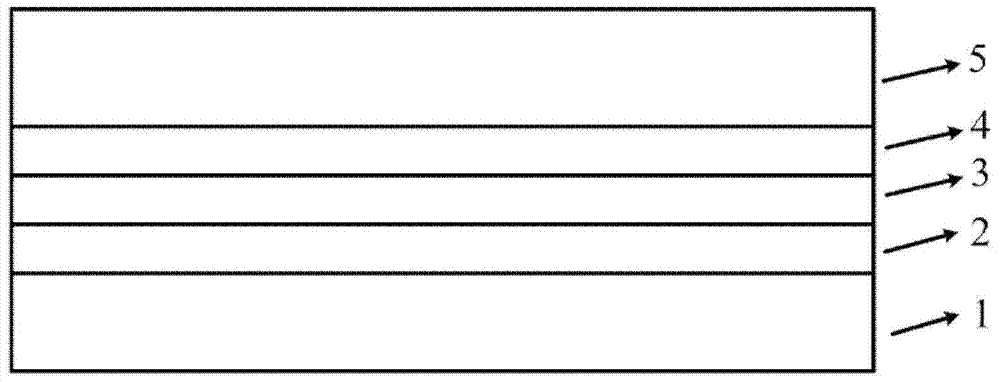

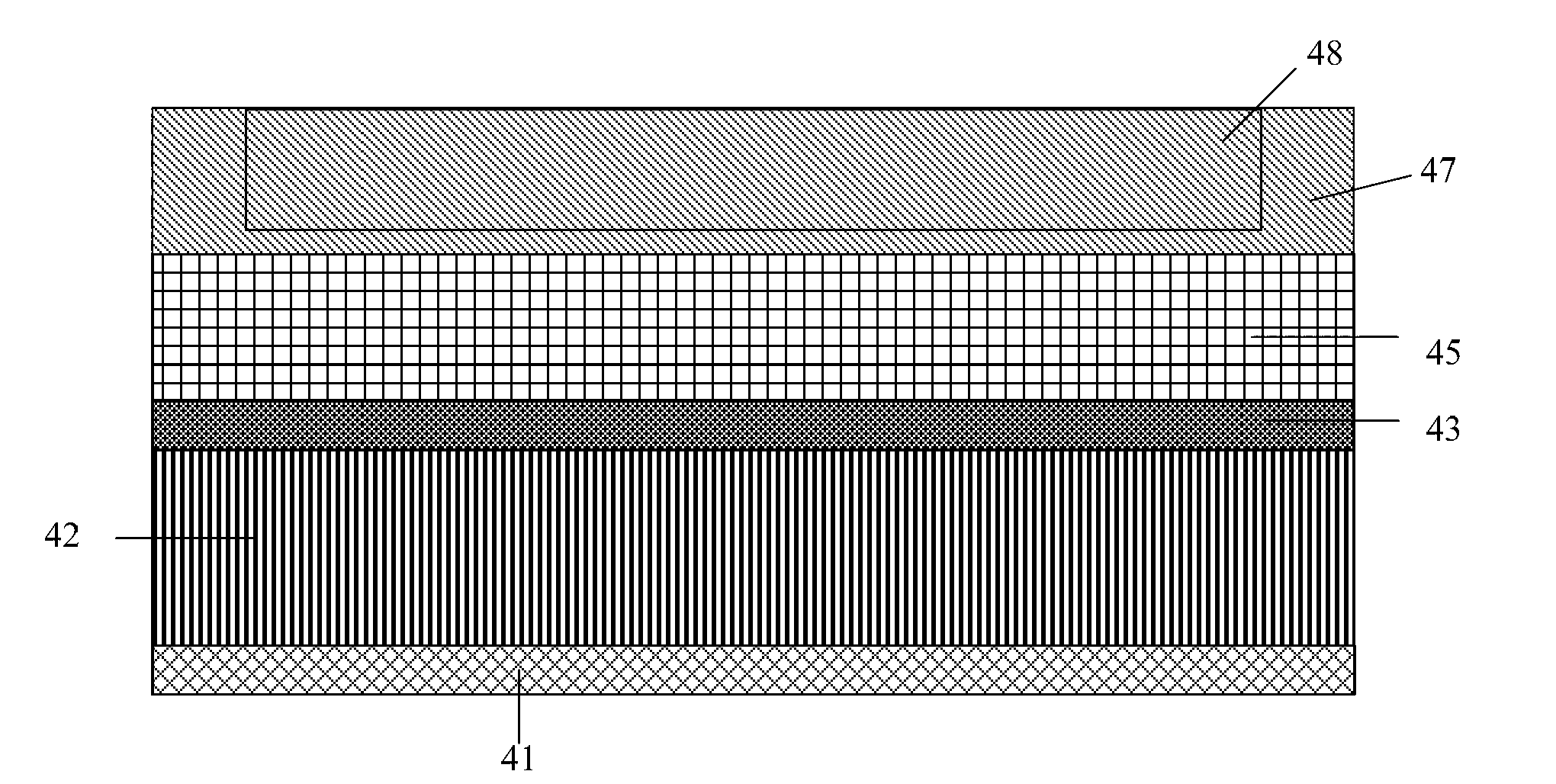

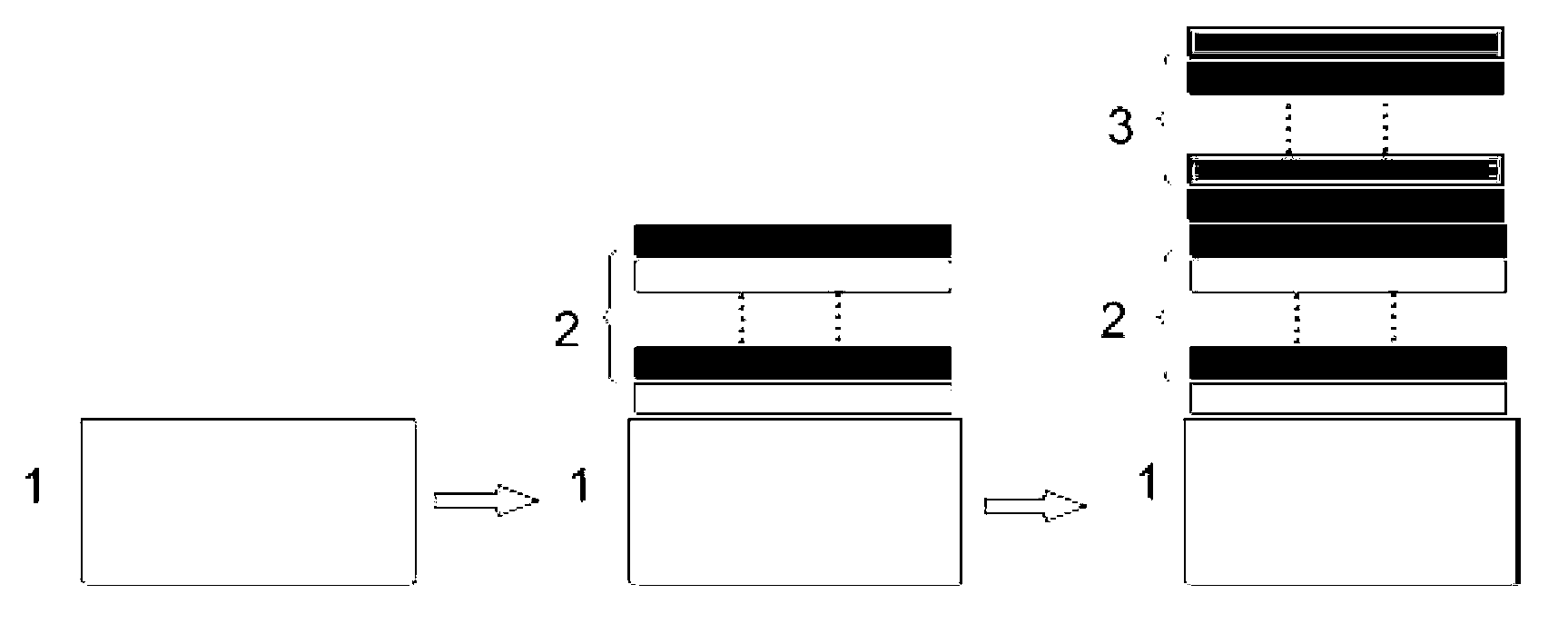

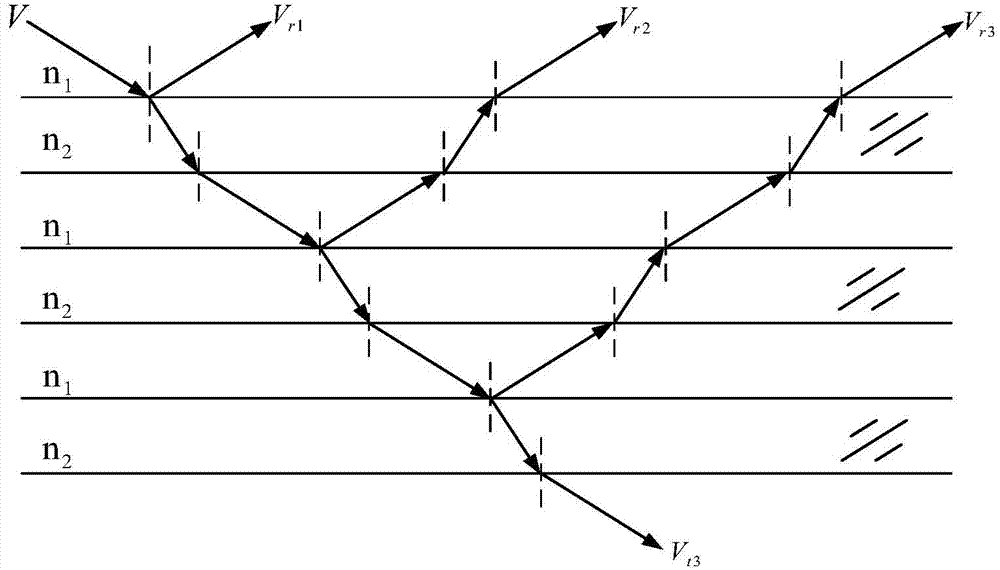

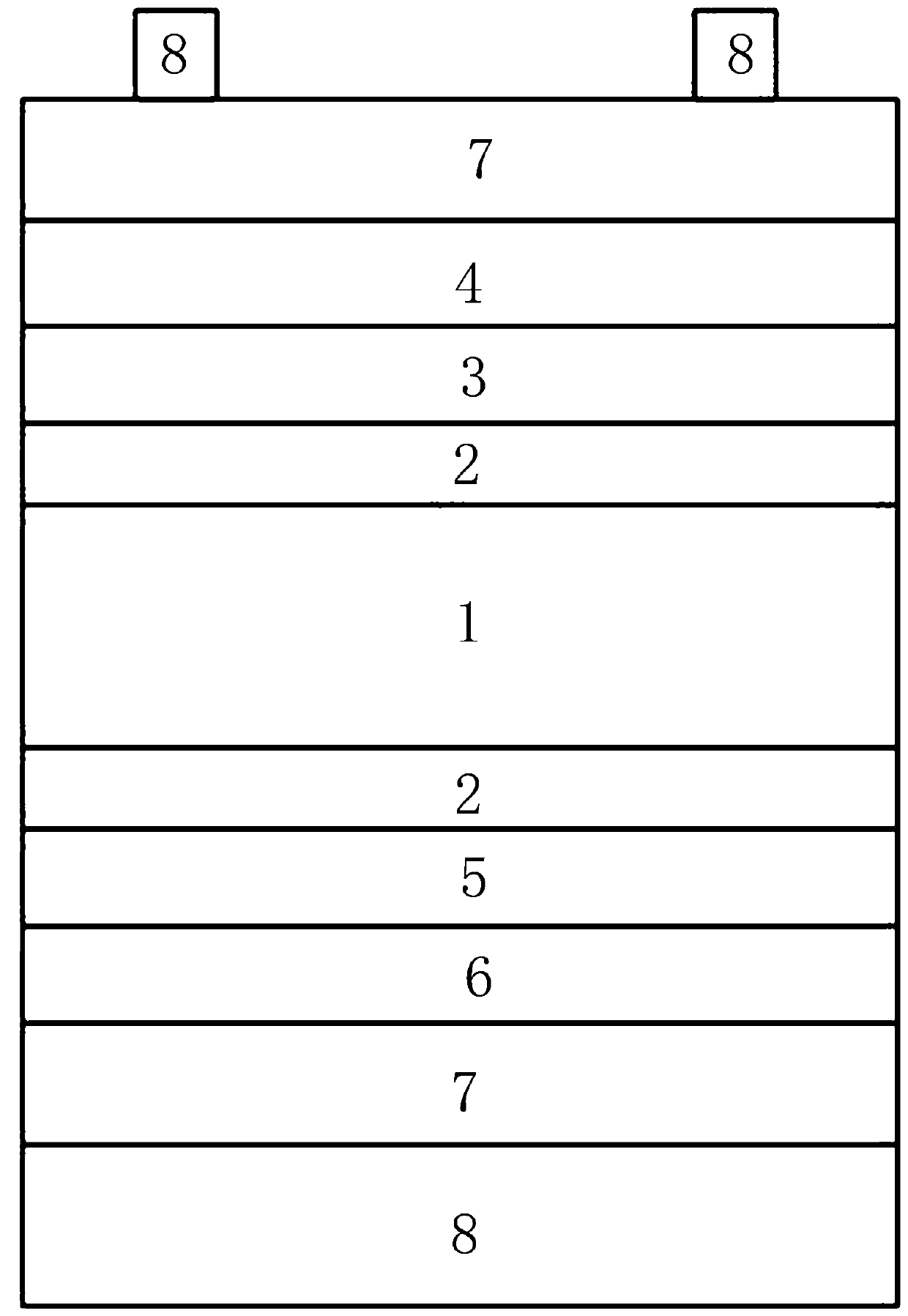

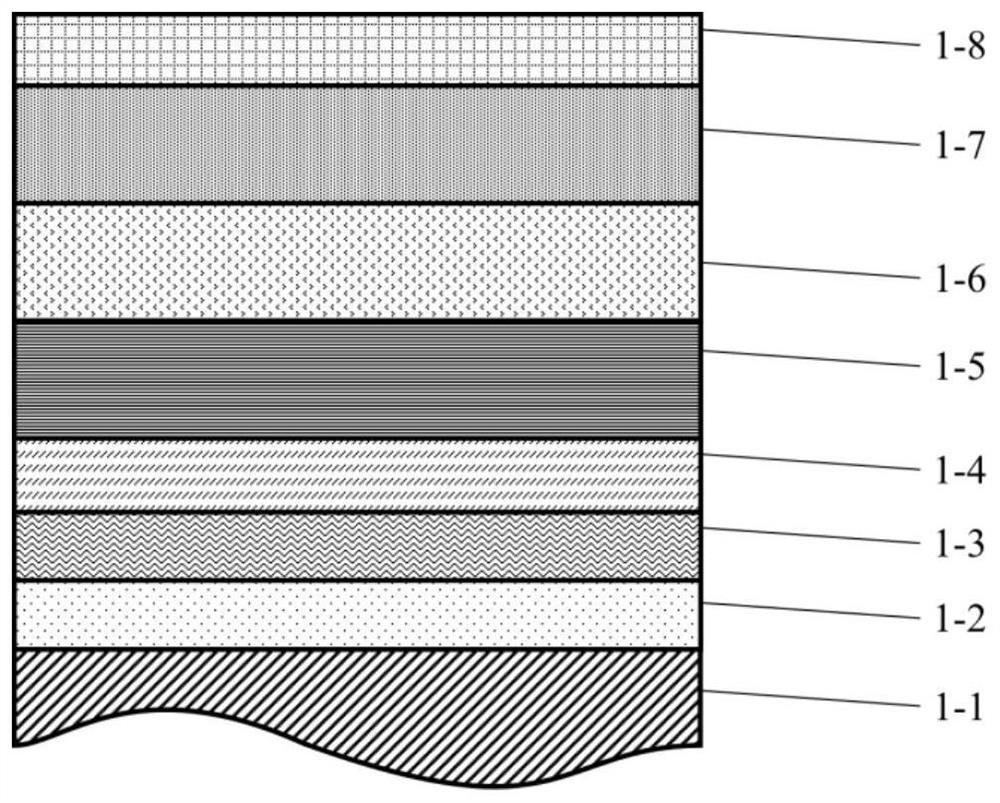

Two-dimensional stratified material based practical saturable absorber and production method thereof

InactiveCN104218443AWide wavelength rangeReduce absorption lossActive medium materialActive medium shape and constructionMode-lockingWavelength

The invention relates to a two-dimensional stratified material based practical saturable absorber and a production method thereof, and belongs to the field of saturable absorbers of lasers. The two-dimensional stratified material based practical saturable absorber comprises a substrate, a high-reflection layer, a saturable absorption layer and a functional layer. One end face of the functional layer is connected with the saturable absorption layer, one end face of the saturable absorption layer is connected with the high-reflection layer, and one end face of the high-reflection layer is connected with the substrate. By the two-dimensional stratified material based practical saturable absorber and the production method thereof, application of the lasers, such as Q-switching, mode locking and optical signal processing, is realized. By the high-reflection layer formed by composite materials, absorption loss is reduced and reflection rate is increased, and optimal material combinations can be found in terms of different wave lengths.

Owner:鲍小志

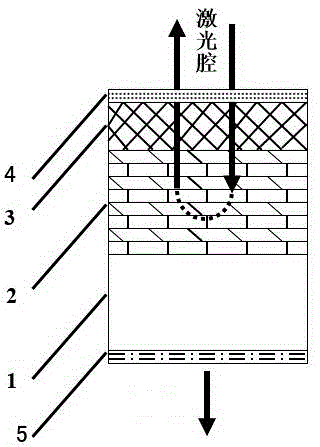

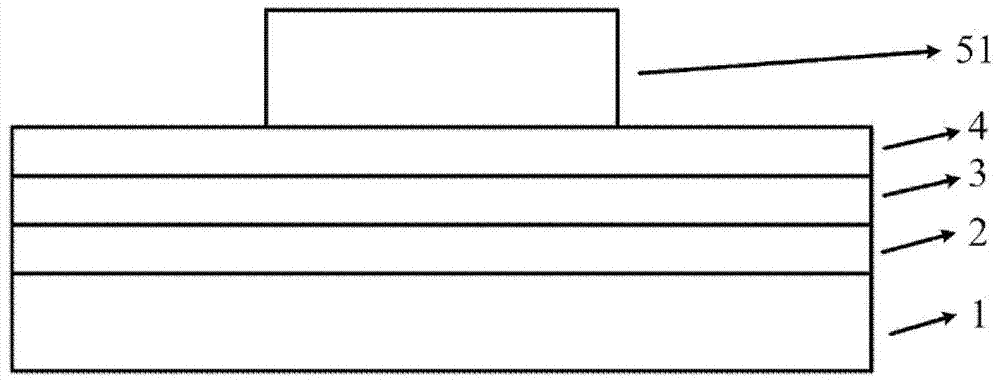

Practical saturable absorption device based on black phosphorus

InactiveCN104466646AWide wavelength rangeFlexible adjustment of modulation depthLaser detailsSemiconductor lasersMode-lockingBlack phosphorus

The invention relates to a practical saturable absorption device based on black phosphorus and belongs to the field of saturable absorption devices of laser devices. The practical saturable absorption device based on the black phosphorus is formed by combining four layers of materials or mutual combining three layers of the four layers of materials or combining the four layers of materials combined mutually and functional insertion layers added on the upper portion and the lower portion of the four layers of materials at will or combining the saturable absorption layers and any one layer of materials or combining the saturable absorption layers, and each saturable absorption layer comprises at least one of a black phosphorus film, black phosphorus nano lamella particles, black phosphorus ramifications and functionalization black phosphorus. According to the practical saturable absorption device based on the black phosphorus, the application of Q regulation and mode locking of the laser device, optical signal processing and the like is achieved, and more importantly, the effect that the modulation depth can be flexibly regulated by giving play to the property of the black phosphorus is achieved.

Owner:鲍小志

Rare-earth uniformly-doped fiber perform core rod and preparation method thereof

ActiveCN102992613AImprove homogeneityHigh Refractive Profile FlatnessGlass shaping apparatusGlass fibre productsFiberRare earth ions

The invention relates to a rare-earth uniformly-doped fiber perform core rod and a preparation method thereof. The core rod adopts silicon dioxide used as a matrix and is at least doped with a rare earth ion and a co-doping ion, wherein the doping concentration of the rare earth element is calculated in the oxide form; the concentration of the doped rare earth oxide is 0.05-0.5mol%; the co-doping ion is at least one of Al and P elements; the co-doping agent concentration is calculated in the oxide form; and the concentration of the co-doping agent oxide is 0.4-10mol%. The core rod is prepared by adopting a powder forming-sintering method. The core rod disclosed by the invention has the advantages that the fiber core has high doping uniformity in the axial direction and the radial direction; the refractive index profile of the fiber core has high flatness; the numerical aperture (NA) of the fiber core is accurate and adjustable; and the optical fiber has high slope efficiency. Based on the rare earth doped core rod, various rare-earth doped optical fibers with different structures can be manufactured by using a core rod through the external cladding technology, i.e., the manufacturing requirements of rare earth doped optical fibers with different structures such as single cladding single mode, double cladding single mode, polarization-maintaining double cladding, large-mode field area air hole double cladding and the like are satisfied.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

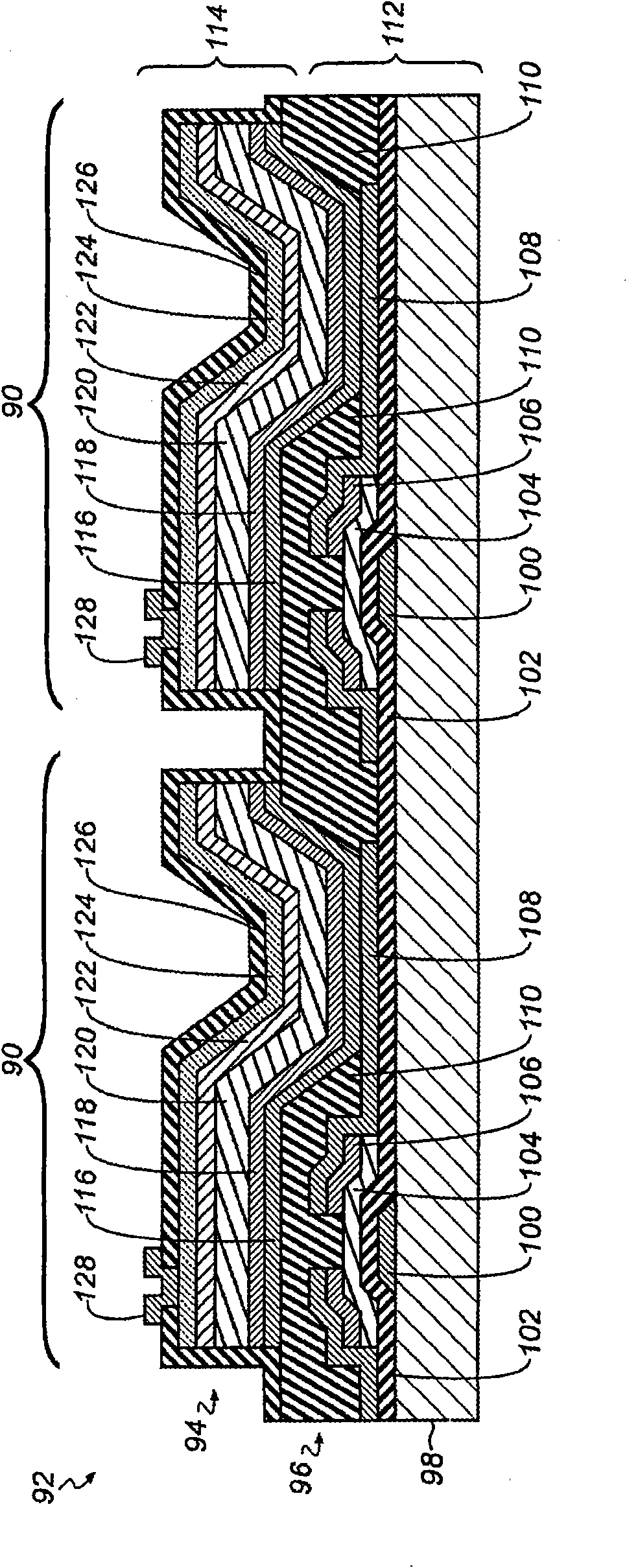

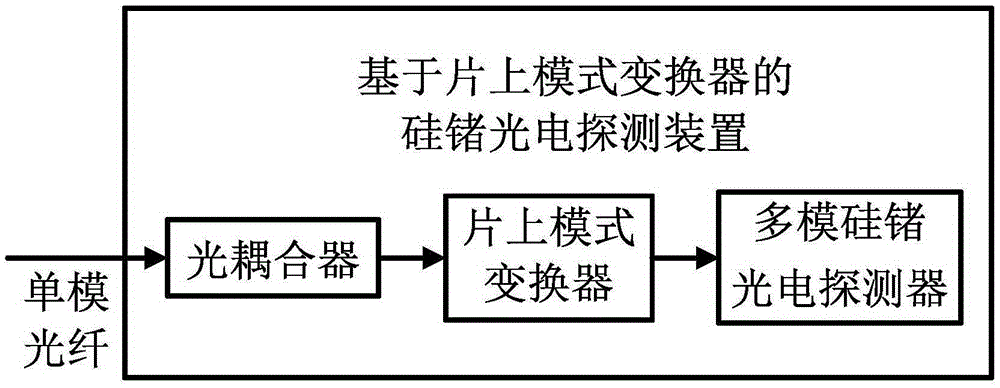

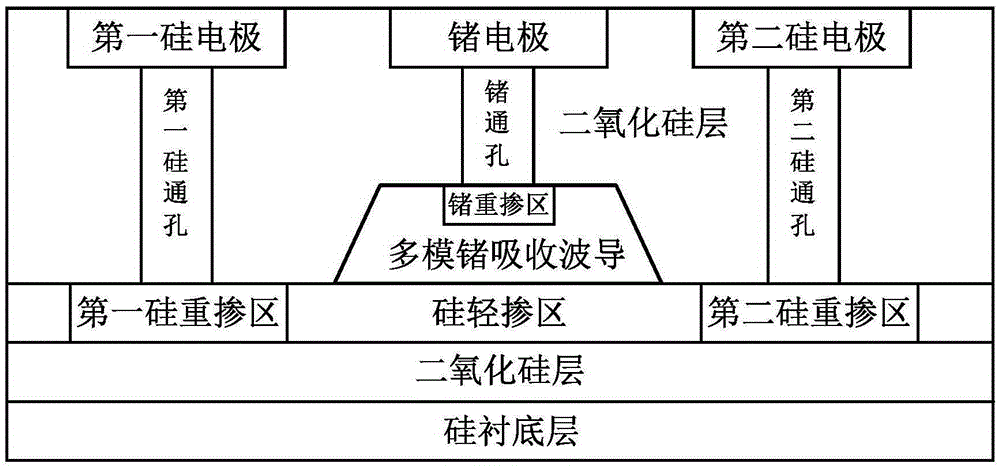

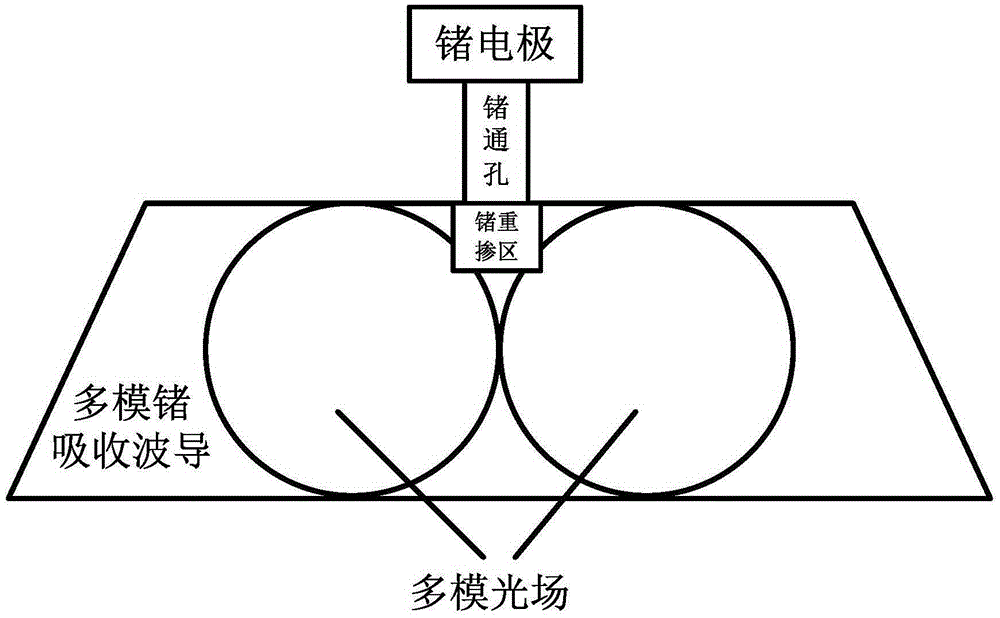

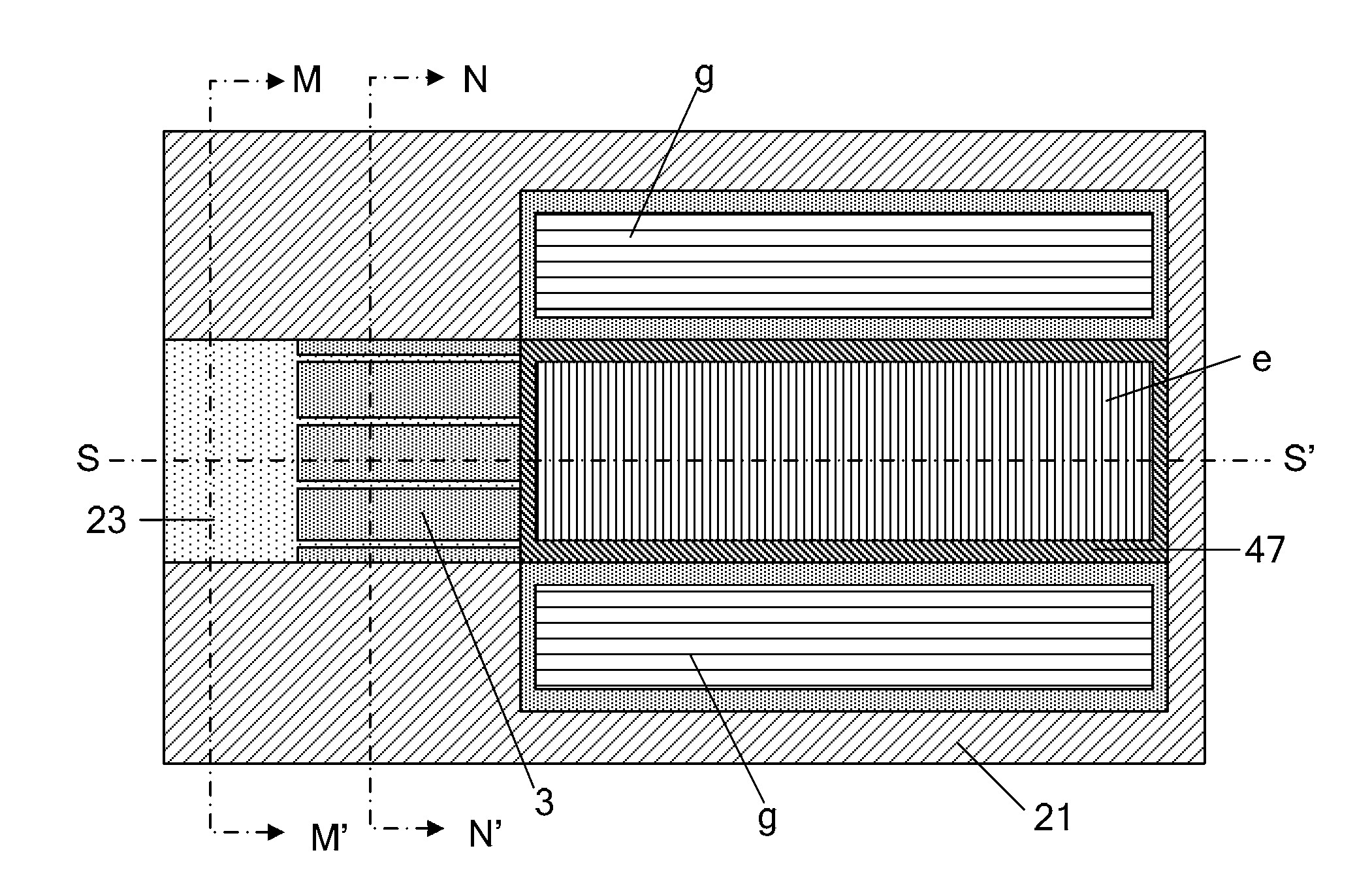

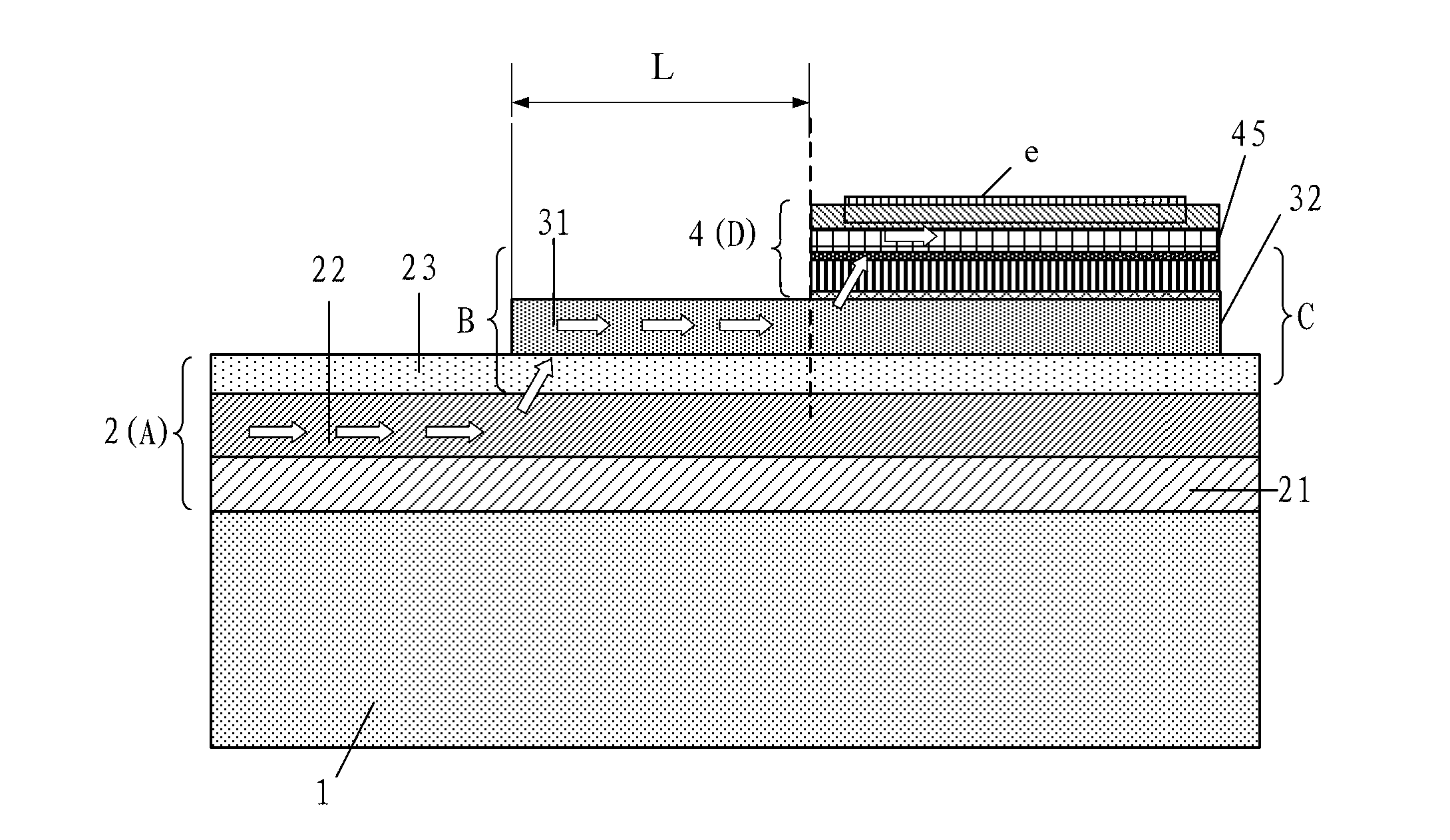

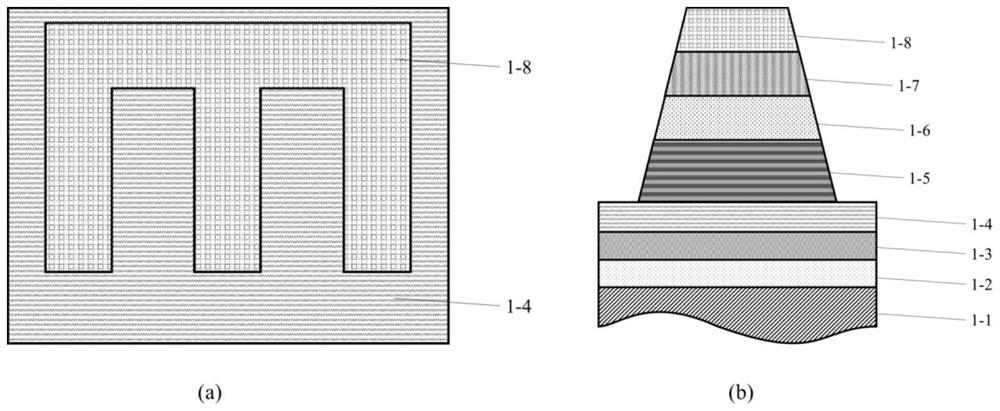

On-chip mode converter based silicon-germanium photoelectric detection apparatus

ActiveCN105405911AImprove responsivenessReduce absorption lossRadiation controlled devicesSemiconductor devicesCouplingResponsivity

The invention discloses an on-chip mode converter based silicon-germanium photoelectric detection apparatus, and relates to the field of an optical communication device. The silicon-germanium photoelectric detection apparatus comprises an insulating substrate, an optical coupler, an on-chip mode converter and a multi-mode silicon-germanium photoelectric detector; the optical coupler, the on-chip mode converter and the multi-mode silicon-germanium photoelectric detector are connected in sequence, and are all fixed on silicon wafers of the insulating substrate; the incident fundamental mode optical signal is transmitted to the optical coupler through single-mode fiber; the fundamental mode optical signal after being subjected to the coupling by the optical coupler enters the on-chip mode converter; the on-chip mode converter converts the fundamental mode optical signal into a multi-mode optical filed; the multi-mode optical field enters the multi-mode silicon-germanium photoelectric detector; and the multi-mode silicon-germanium photoelectric detector converts the multi-mode optical field into an electric signal. A germanium heavily-doped region in the silicon-germanium photoelectric detection apparatus is positioned in a region with relatively weak optical strength distribution in the multi-mode optical field; the absorption loss of the germanium heavily-doped region and germanium through holes on the optical field is obviously reduced, and the responsivity of the silicon-germanium photoelectric detection apparatus can be effectively improved.

Owner:WUHAN POST & TELECOMM RES INST CO LTD

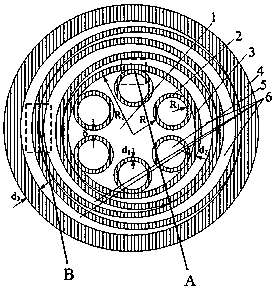

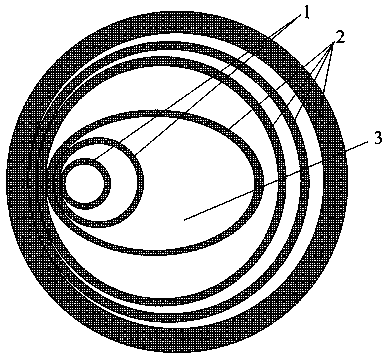

Microstructured hollow-core optical fiber

ActiveCN108181684AHigh damage thresholdReduce absorption lossOptical waveguide light guideMicrostructured optical fibrePhotonicsBroadband

The present invention provides a microstructured hollow-core optical fiber. The optical fiber comprises first type medium circular tubes, second type medium circular tubes, and a third type medium circular tube; the first type medium tubes are nested in the second type medium circular tubes and are periodically distributed along the circumference of the second type medium circular tubes; intervalsbetween the outer walls of the adjacent first type medium circular tubes are greater than 0; the second type medium circular tubes are nested in the third type medium circular tube; and the first type medium circular tubes, the second type medium circular tubes and the third type medium circular tube are connected with one another in a tangent or intersecting manner. According to the microstructured hollow-core optical fiber of the invention, confinement loss can be lowered by simply increasing the number of the second type medium circular tubes, so that a difficulty that the confinement lossof a negative-curvature anti-resonant hollow-core optical fiber cannot be reduced by simply adopting a means of increasing annular layers which assists in reducing the confinement loss of a hollow-core photonic band gap optical fiber can be eliminated. According to the optical fiber provided by the invention, too many nodes will not be introduced into the cross section of the optical fiber, and anew scheme and idea can be provided for the design and manufacture of a broadband low-loss hollow-core optical fiber.

Owner:JIANGXI NORMAL UNIV

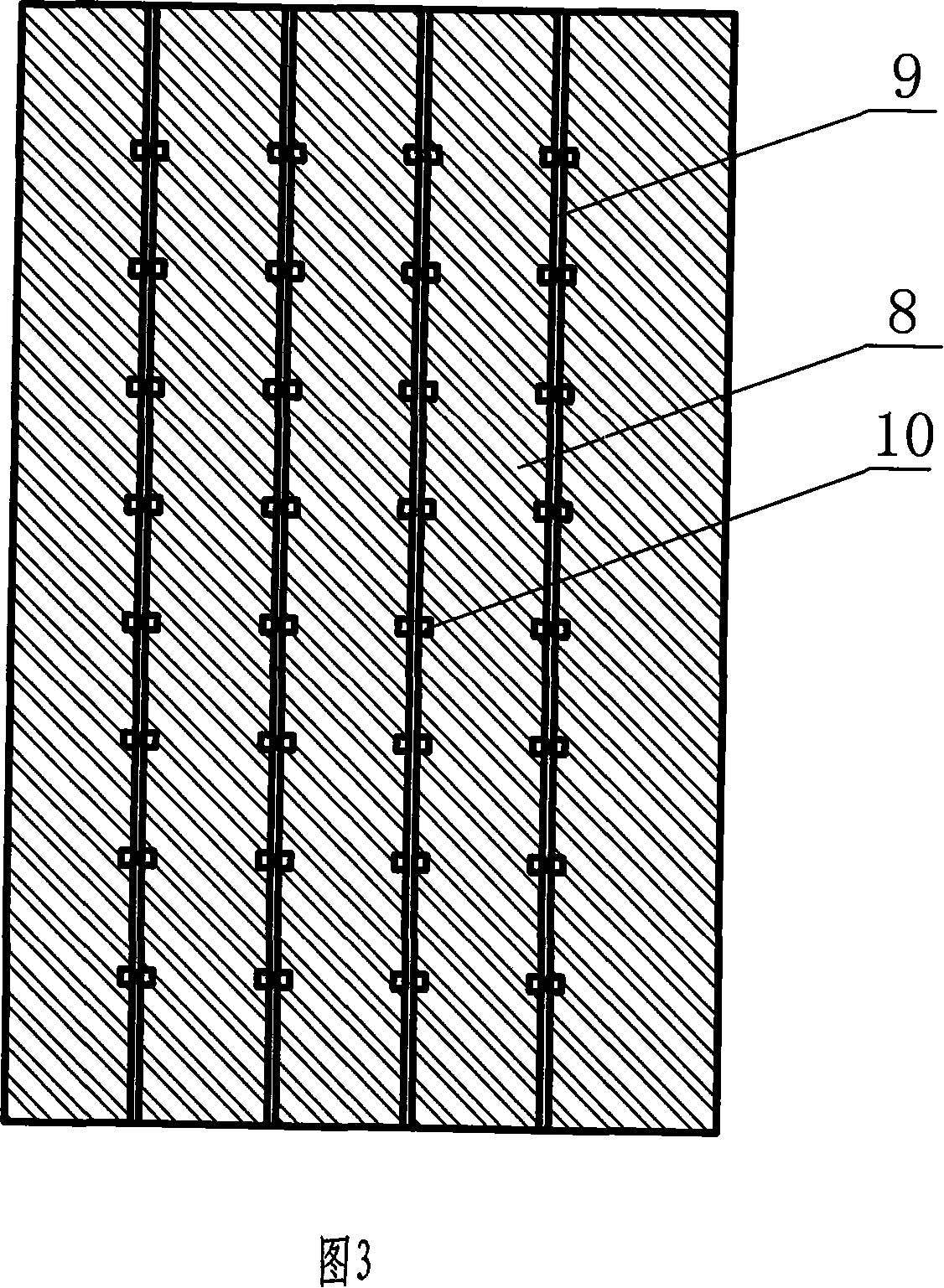

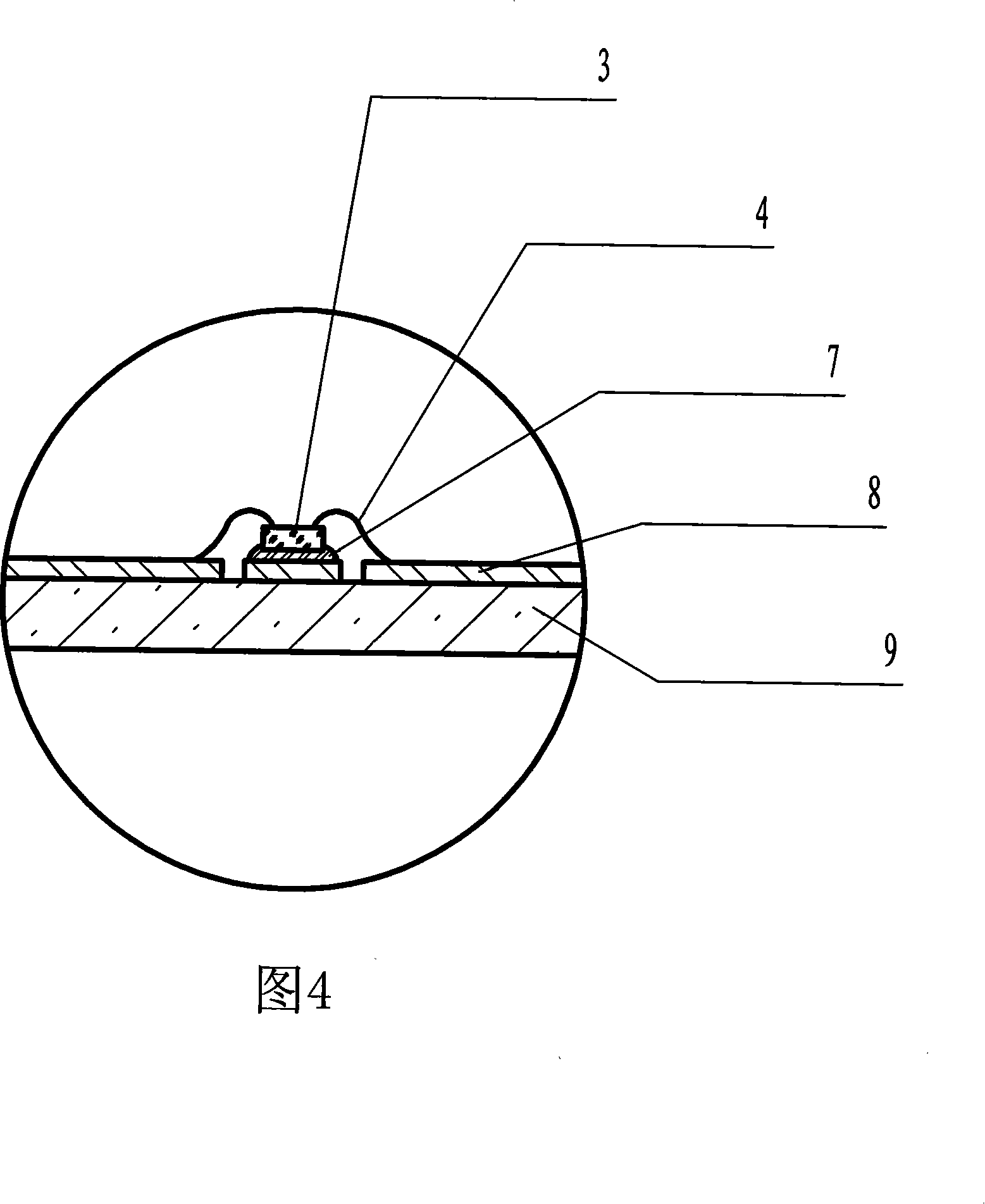

White light LED area lighting source module package method

ActiveCN101137255AAvoid Increased Cooling CostsLow calorific valuePlanar light sourcesElectrical apparatusLuminous intensityColloid

The invention discloses a packaging method for white light LED surface light source module, which insists of processing steps such as making circuit boards, fixing crystal, bonding, packaging basic bond line and so on. The invention adopts steps: distributing multiparticulate miniwatt LED chips on a circuit board and packaging integrally to form a high power LED light source, dispersing the heat source, reducing heat productivity on a unit area, reducing heat dispersion requirement standard. Adopting white colloid as solid crystal glue can improve more than 70% of back face emergent light utilance. The basic bond line packaging makes microcosmic light source points distribute uniformly on a bigger area, reduce luminous intensity on a unit area. The light flux on a unit area of traditional LED light source is more than 100 lm / cm<2> generally, while light flux on a unit area of the invention is less than 51 lm / cm<2> generally, thereby glaring is overcame.

Owner:SHIJIAZHUANG EMPOLDER SHENTONG MACHINE ELECTRIC EMPOLDER

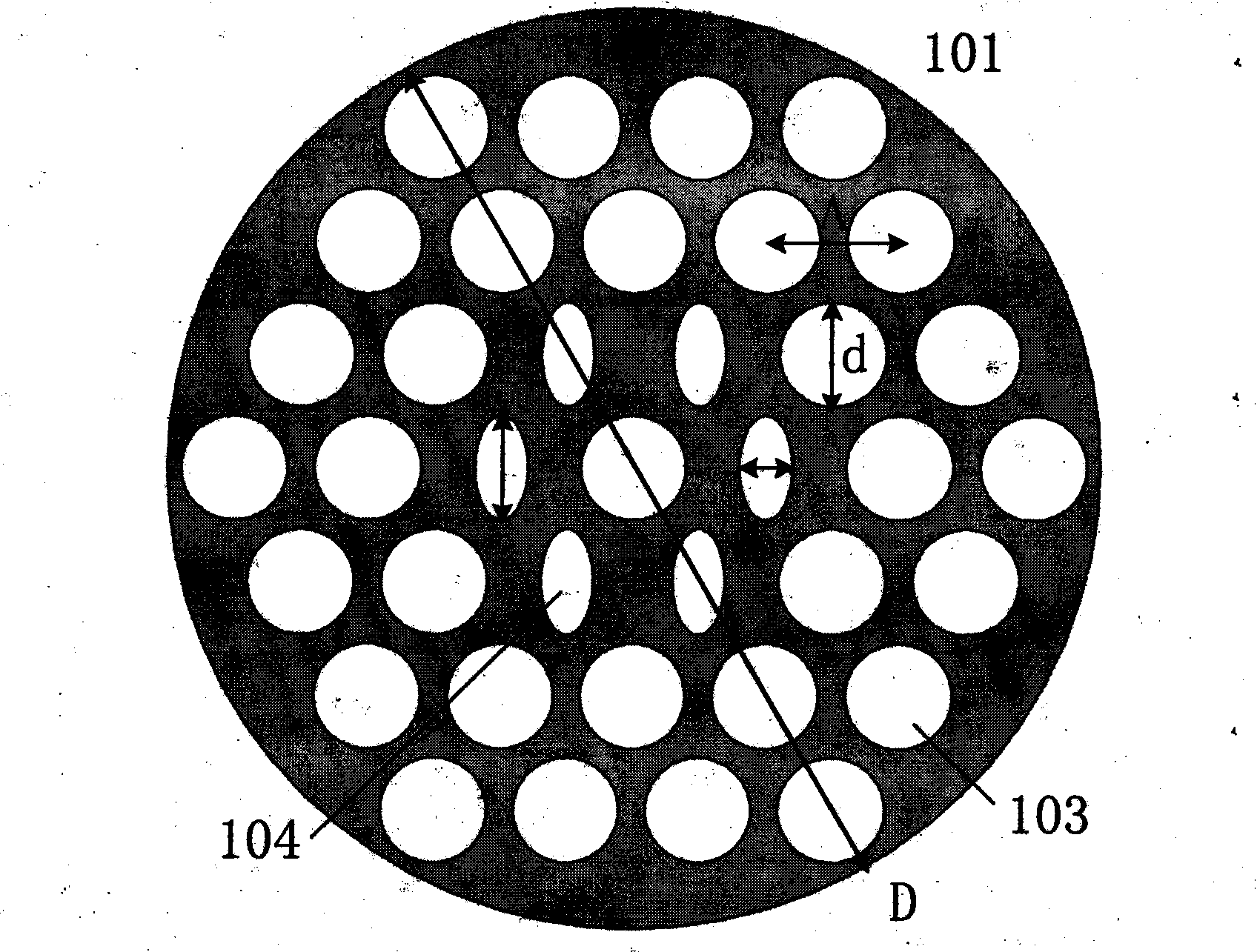

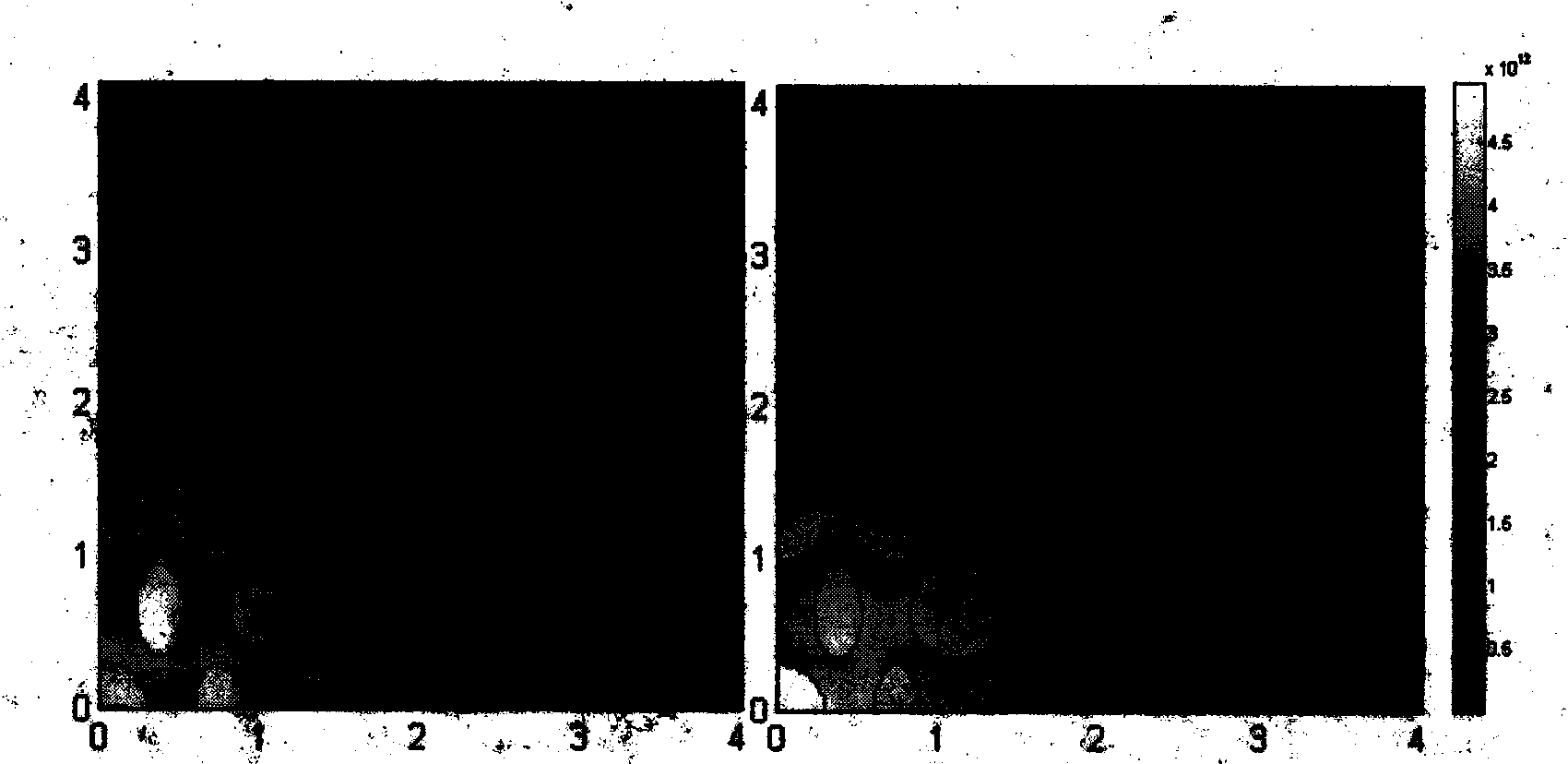

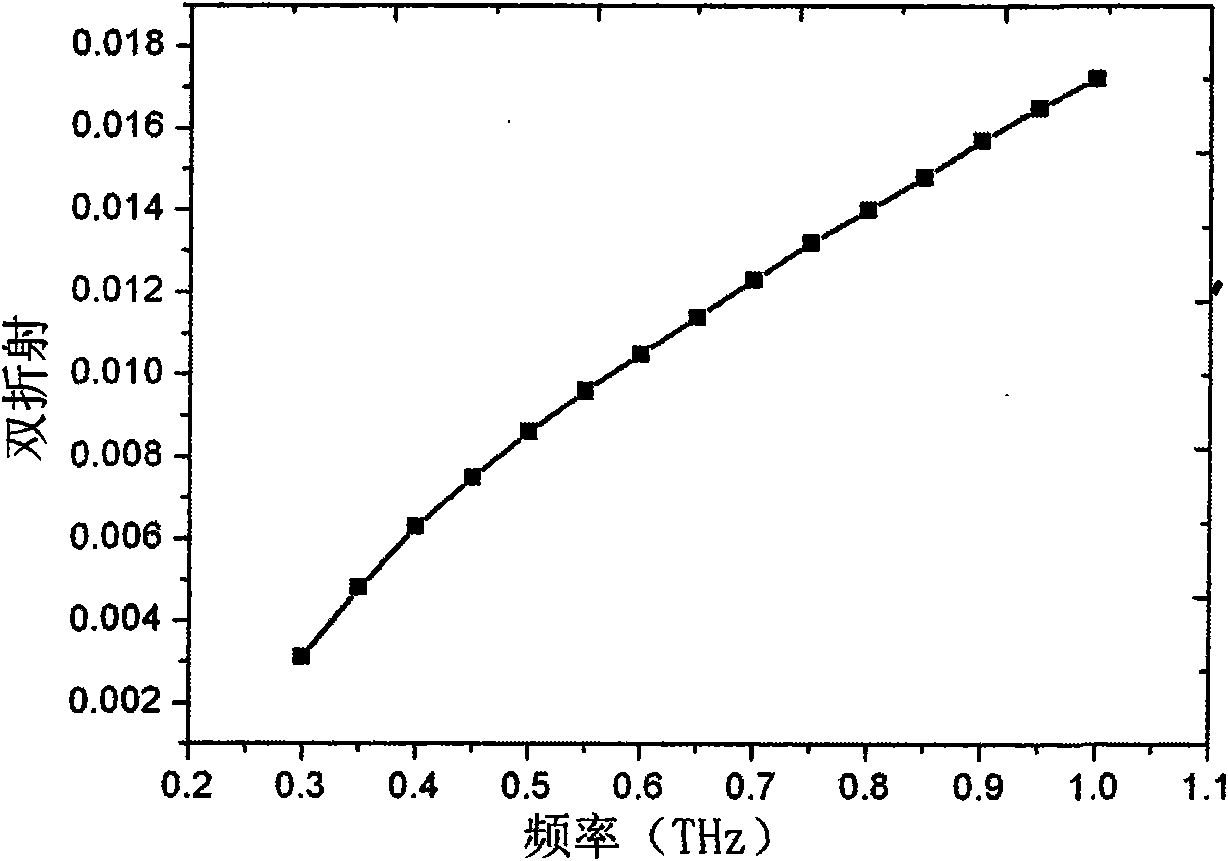

High-birefringence sub-wavelength porous T-Hz optical fiber

InactiveCN101788695AReduce transmission lossHigh birefringenceCladded optical fibreOptical waveguide light guideEllipseWave band

The invention relates to the technical field of T-Hz waveguide and provides a high-birefringence sub-wavelength porous T-Hz optical fiber. An ellipse ventage structure of which the size is much smaller than the wave length is added in an optical fiber core of the high-birefringence sub-wavelength porous T-Hz optical fiber; and the invention has the sub-wavelength mode bound capability while the high birefringence is provided at the T-Hz wave band, and also has high-birefringence property in the wider T-Hz bandwidth. The high-birefringence sub-wavelength porous T-Hz optical fiber can be used for the manufacturing of a sub-wavelength size T-Hz device, thereby being applied in the fields of sensing and detection and communication of T-Hz.

Owner:BEIHANG UNIV

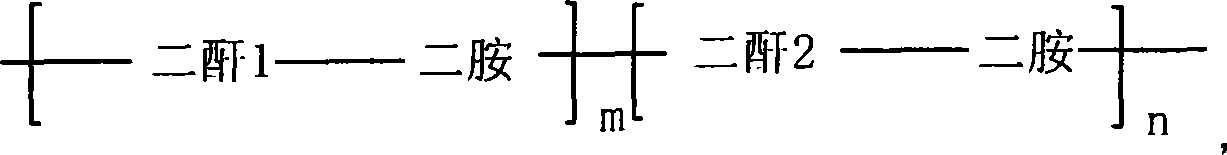

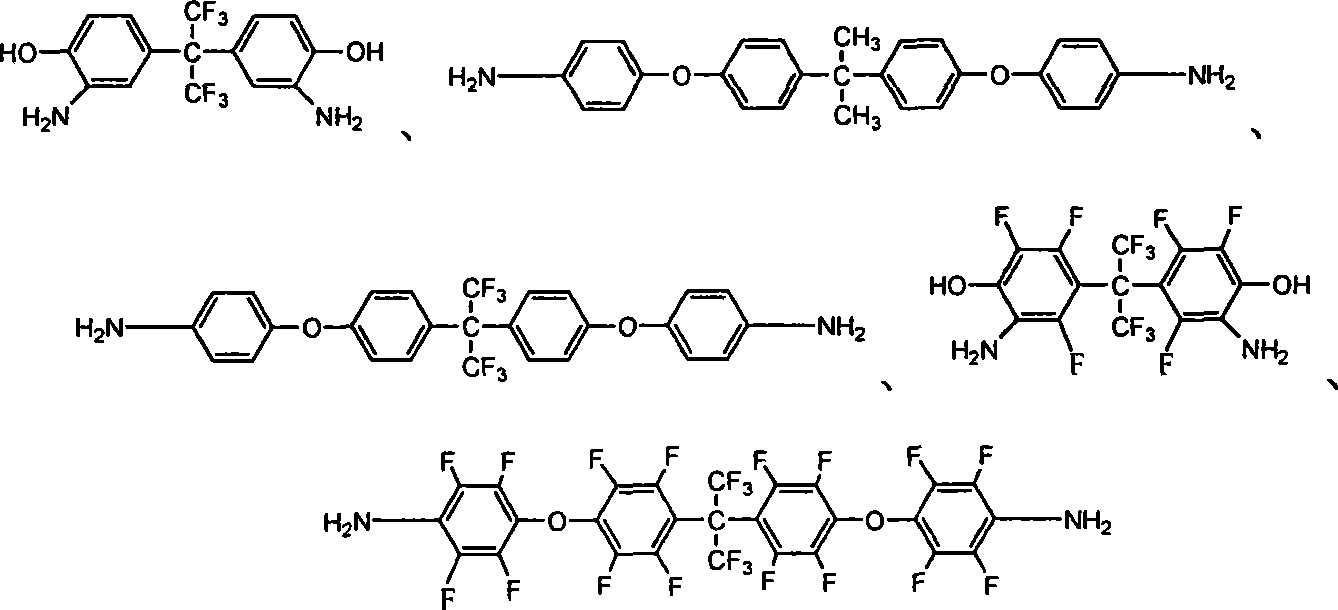

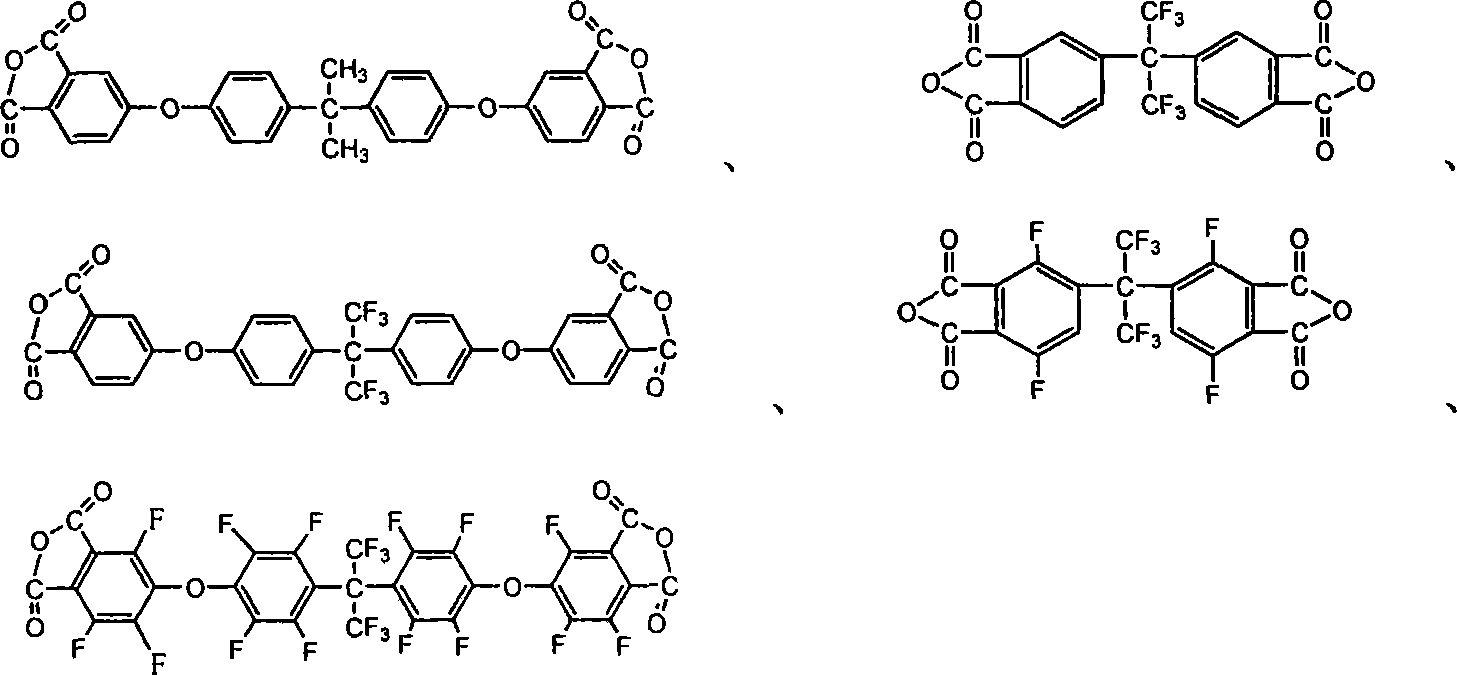

Fluorine-contained polyimide optical waveguide material and method for producing the same

InactiveCN101246222AImprove solubilityEasy to processOptical waveguide light guideRefractive indexOptical communication

The invention provides a fluorine-containing polyimide optical waveguide material and the preparing method thereof relating to the integrating polymer material preparing method in optical device, which can be applied in waveguide optics device, the material is obtained from condensation and copolymerization of three monomers, that is the fluorine-containing polyimide is condensed and copolymerized from two diamine monomers and one dianlydride monomer or from two diamine monomers and one dianlydride monomer, after purification, the fluorine-containing polyimide n-methyl-2-pyrrolidone solution is obtained, and is then dropped on center of clean substrate for spin coating to form film, and desiccation and curing. The glass transition temperature of the material is above 200 DEG C, in the field of optical communication on 1550nm the optical loss is less than 0.6dB / cm, the refractive index on 1550nm is 1.5-1.6.

Owner:SOUTHEAST UNIV

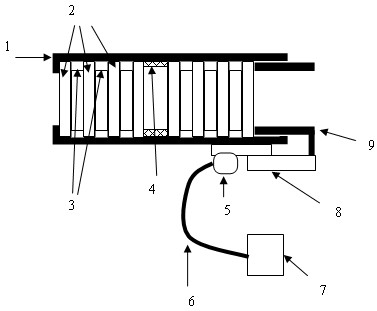

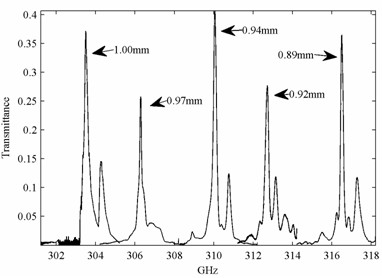

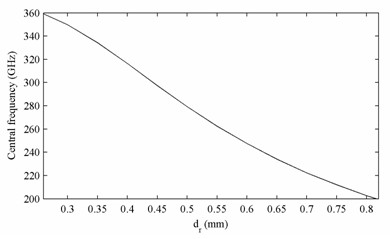

Terahertz wave adjustable narrow band filter based on silicon-based photonic crystal structure

InactiveCN102324907ALow costEasy to manufactureMultiple-port networksHigh resistanceBand-pass filter

The invention discloses a terahertz wave adjustable narrow band filter based on a silicon-based photonic crystal structure. The filter comprises a filter metal shell, uniform high-resistance silicon wafers, annular gaskets, a spring piece, a driving motor, a lead, a motor driving controller, a translation table and a hollow push post, wherein one end of the filter metal shell is provided with a vertical edgefold inwardly; a plurality of groups of uniform high-resistance silicon wafers and annular gaskets are uniformly arranged at intervals in the filter metal shell, then the spring piece is arranged in the filter metal shell, and the same quantity of groups of uniform high-resistance silicon wafers and annular gaskets are arranged at intervals in the filter metal shell again; the hollow push post is sleeved in the other end of the filter metal shell; the outer end of the hollow push post is fixed on the translation table; a translation table base is fixed with the metal shell; the translation table is driven to shift by using the driving motor; and the motor driving controller is used for controlling the driving motor through the lead. The terahertz wave adjustable narrow band filter has the advantages of simple structure, low cost, extremely narrow filtering bandwidth, small loss, wide frequency adjustable range, high modulating speed and high performance.

Owner:CHINA JILIANG UNIV

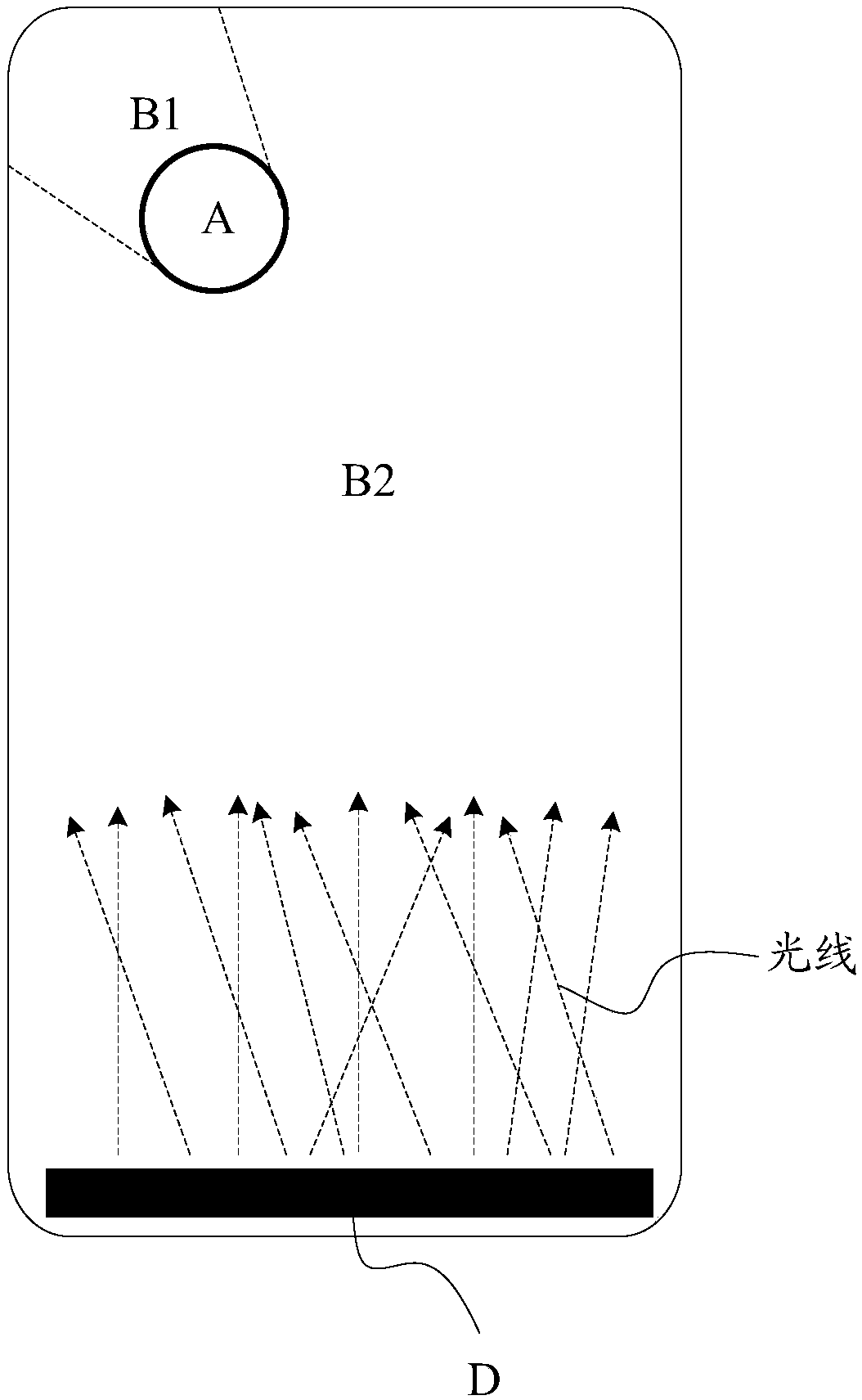

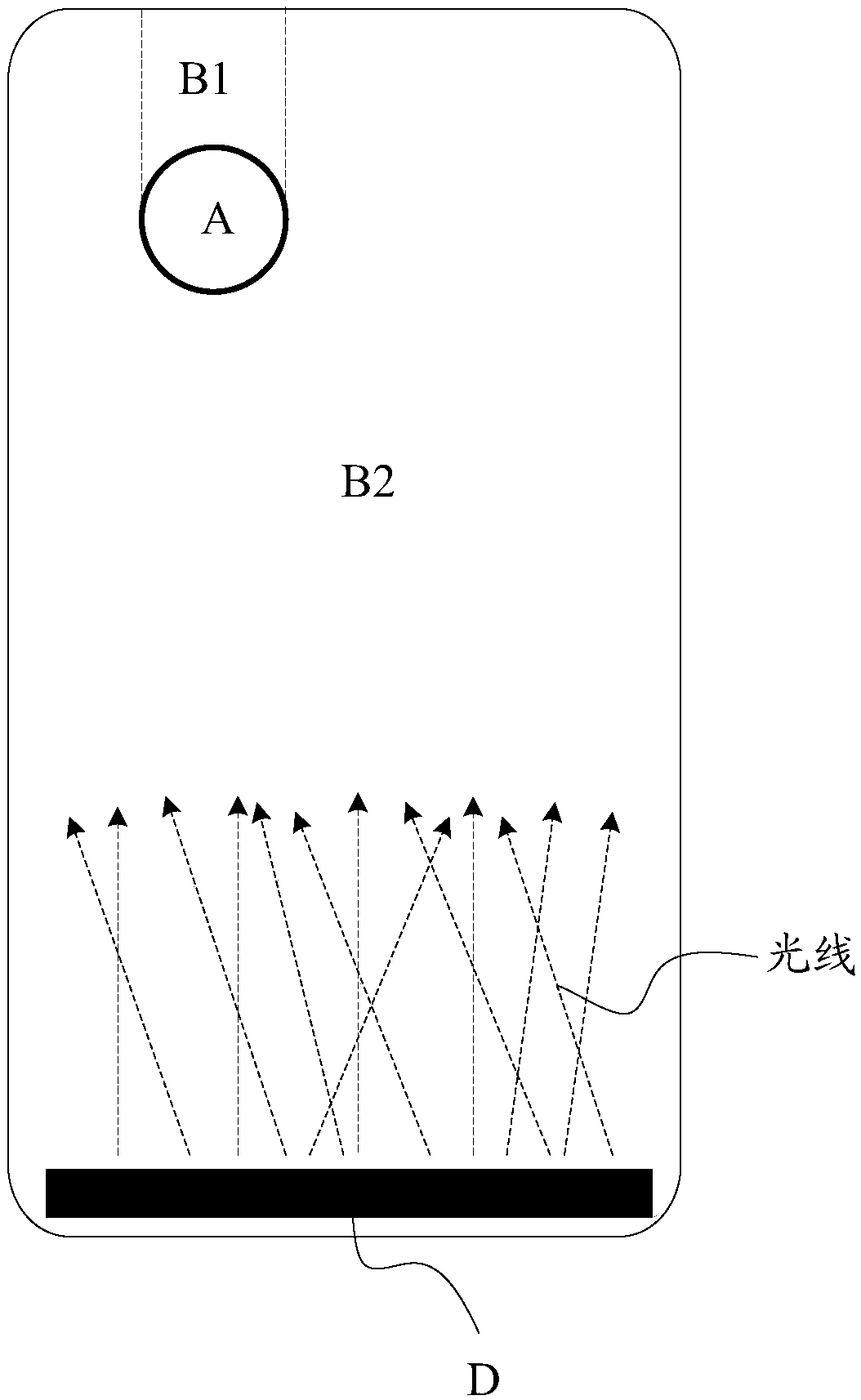

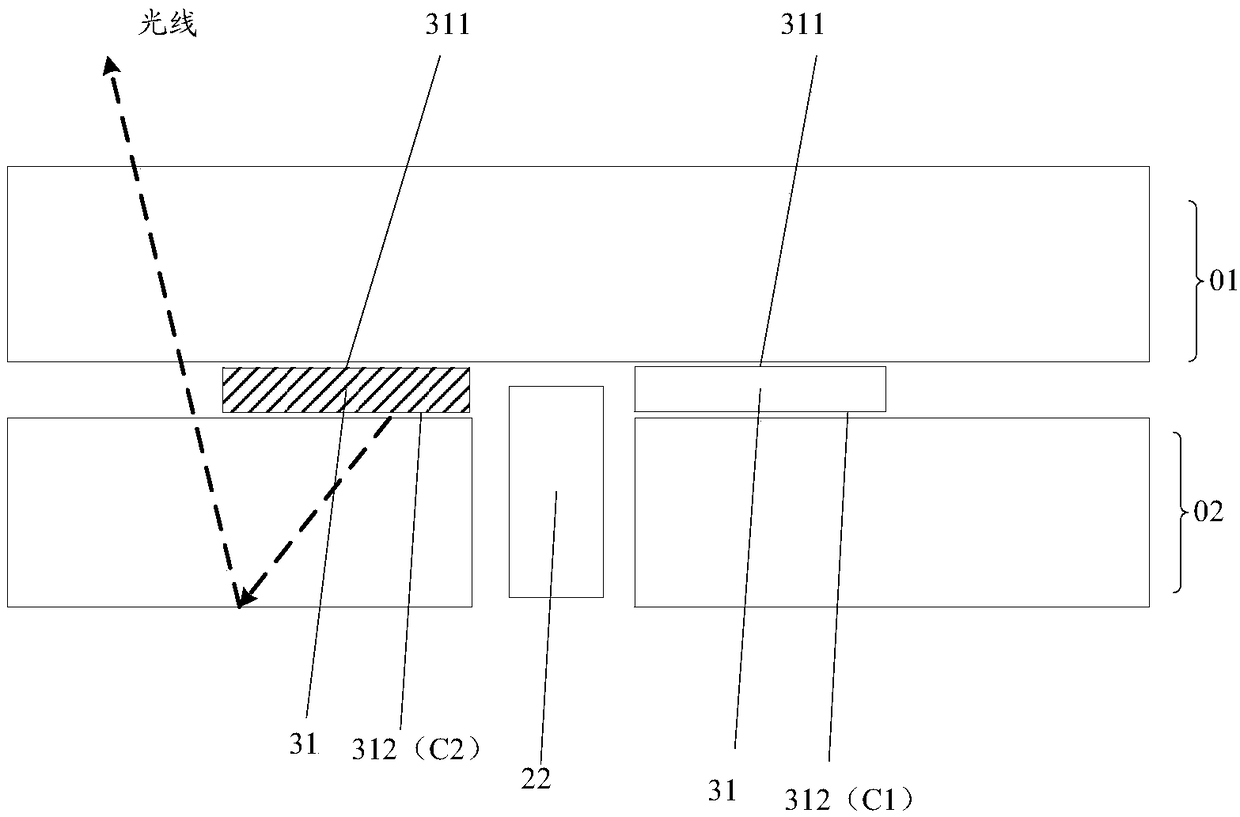

Display device

ActiveCN108826103AImprove the exit rateReduce absorption lossIdentification meansReflectorsMasking tapeDisplay device

The invention provides a display device. The display device comprises a display panel and a backlight module opposite to the display panel, wherein the backlight module comprises a lateral light source; the backlight module is provided with a through hole, which penetrates through the backlight module and are used for mounting functional modules. The display device also comprises a first masking tape which is arranged around the through hole and on the light-emitting surface of the backlight module for fixing the display panel and the backlight module; the first masking tape comprises a blackfirst surface adhered to the display panel, and a second surface adhered to the backlight module, wherein the second surface comprises a black first area and a white second area, the first area is arranged on the side of the through hole which is close to the lateral light source, and the second area is arranged on the side of the through hole which is away from the lateral light source.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

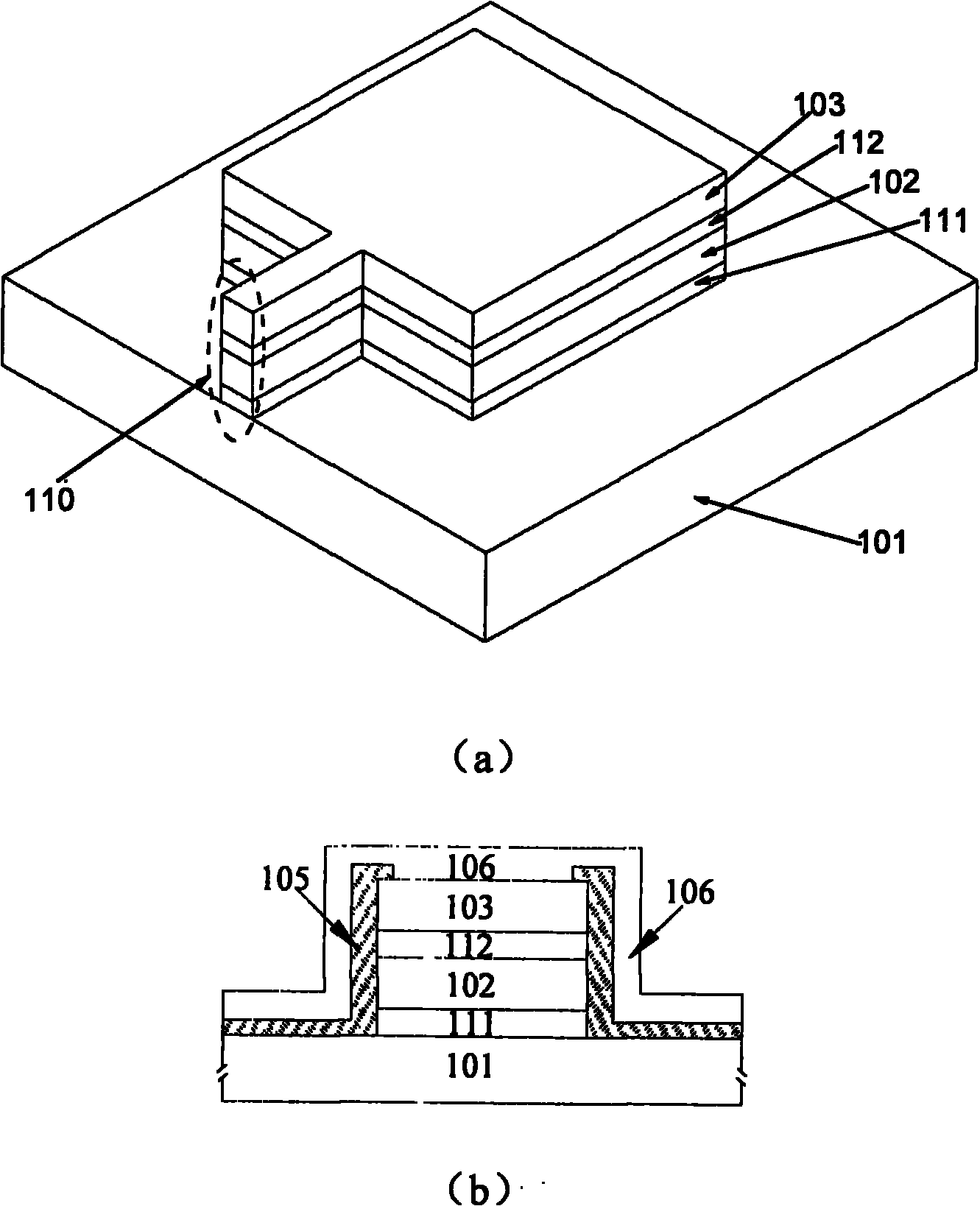

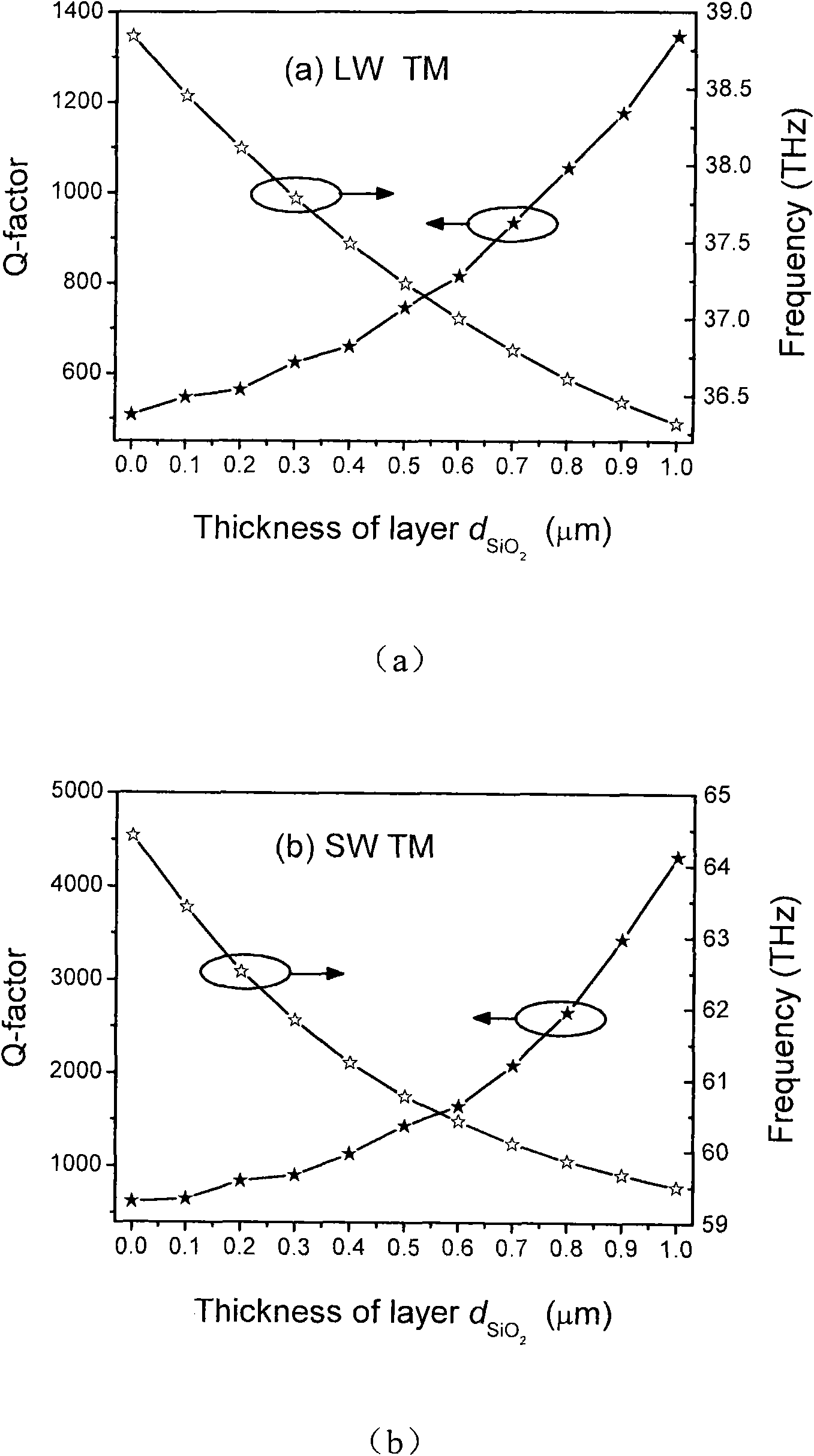

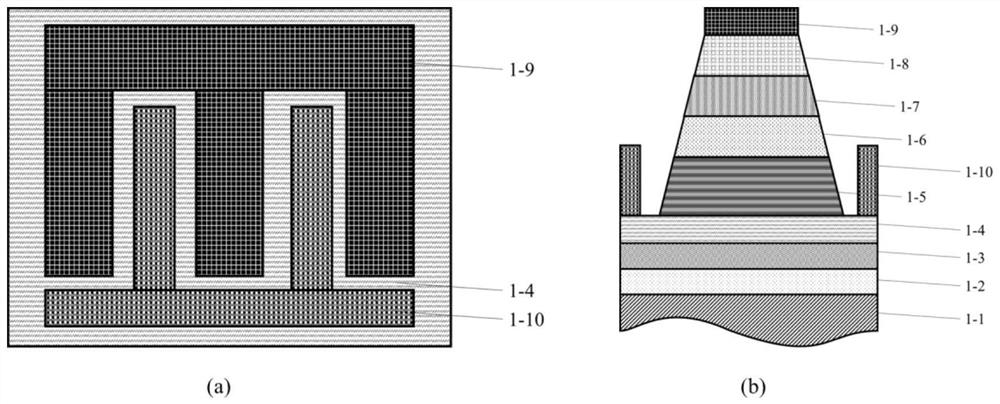

Quantum cascade laser regular polygonal microcavity laser and manufacturing method thereof

InactiveCN101867147ASimple structureSimple preparation processLaser detailsLaser optical resonator constructionLower limitOhmic contact

The invention discloses a quantum cascade laser regular polygonal microcavity laser, comprising a substrate of a quantum cascade epitaxial layer, a lower limiting layer positioned on the substrate, an active area / an injecting area positioned on the lower limiting layer; an upper limiting layer arranged on the active area / an injecting area, and an upper wrapping layer containing an ohmic contact layer, wherein the side walls of the lower limiting layer, the active area / the injecting area, the upper limiting layer and the upper wrapping layer are wrapped by an insulating layer which is wrapped by a front electrode layer. The invention discloses a manufacturing method of the quantum cascade laser regular polygonal microcavity laser simultaneously. The invention uses a SiO2 insulating layer and a Ti / Ag / Au electrode layer to wrap the etched side wall of the quantum cascade laser regular polygonal microcavity laser, thus enhancing the limitation for the light field in a microcavity, and improving the quality factor of the mode in the microcavity; and the laser has simple structure and convenient manufacturing technique.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

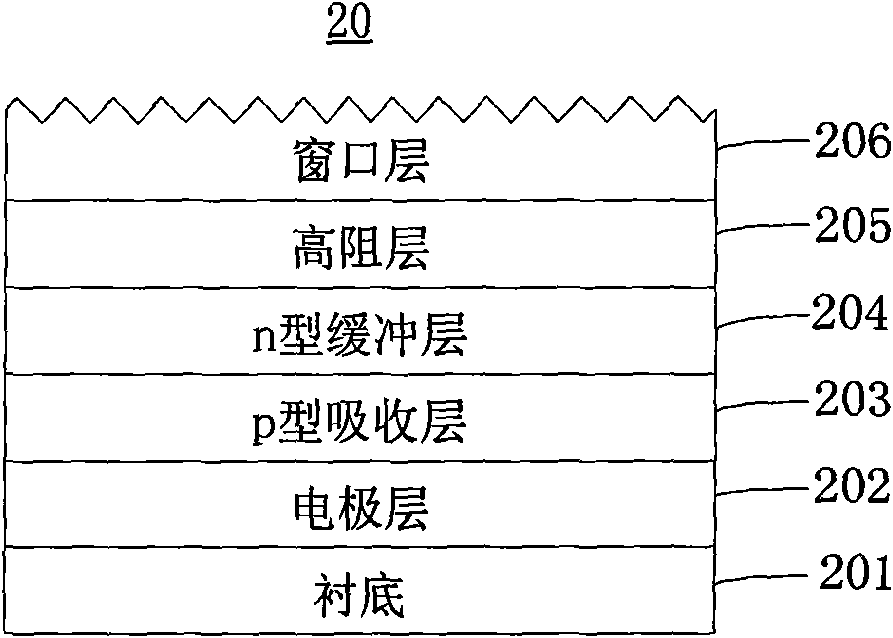

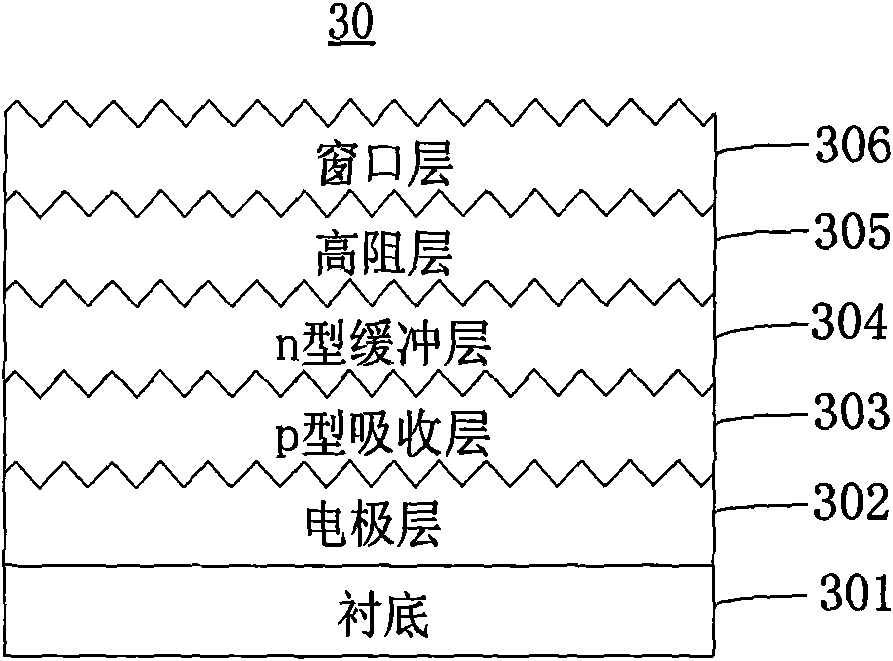

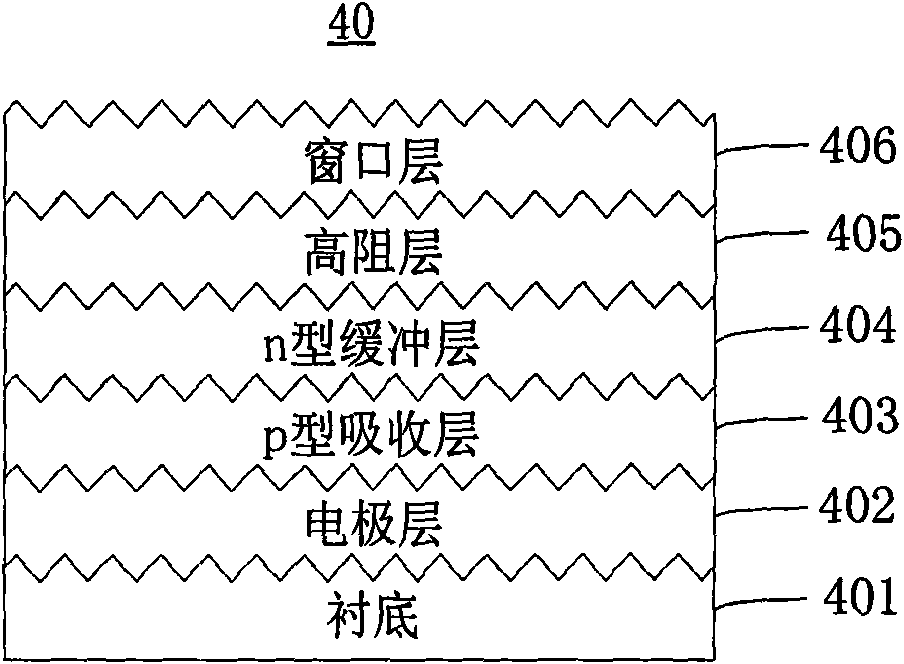

Thin-film photovoltaic cell and manufacturing method thereof

ActiveCN101944541AImprove effective light utilizationIncrease the optical pathFinal product manufacturePhotovoltaic energy generationHigh resistanceTrapping

The invention relates to a thin-film photovoltaic cell and a manufacturing method thereof. The thin-film photovoltaic cell comprises a lining, an electrode layer, a p-type absorption layer, an n-type buffer layer, a high-resistance layer and a window layer, which are sequentially arranged in an overlapping way from the bottom up. The window layer is a near infrared waveband low-absorption high-conductivity ZnO-based transparent conductive window layer. The thin-film photovoltaic cell is in a light trapping structure. The manufacturing method of the thin-film photovoltaic cell comprises the steps of: providing a lining; depositing an electrode layer; depositing a p-type absorption layer; depositing an n-type buffer layer; depositing a high-resistance layer; depositing a near infrared low-absorption ZnO-based window layer; and forming a light trapping structure. The thin-film photovoltaic cell has the absorption layer of small thickness and has higher effective light utilization ratio.

Owner:珠海中科先进技术研究院有限公司

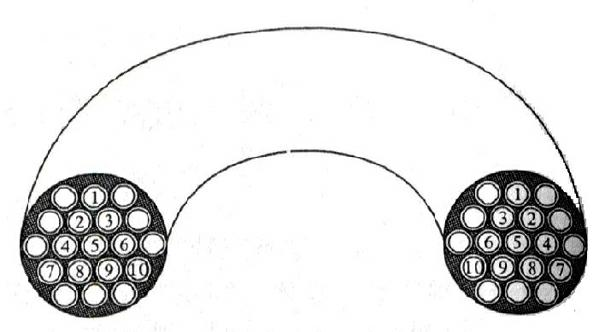

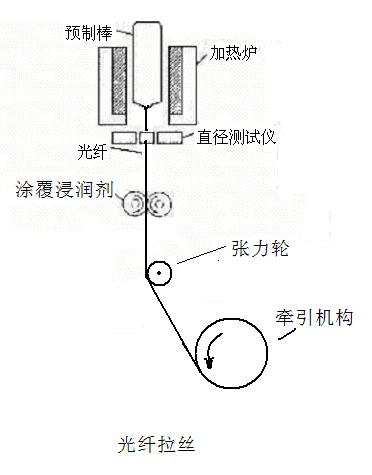

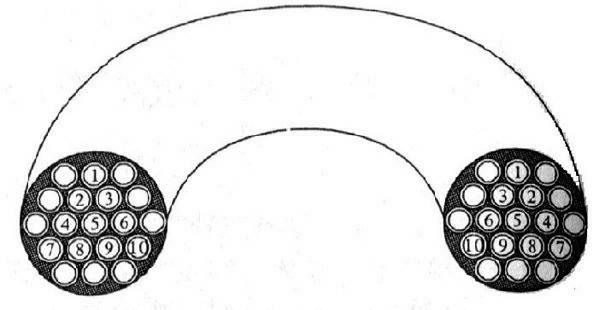

Manufacturing method of quartz optical fiber image bundle

ActiveCN102520479AReduce absorption lossGuaranteed transmission qualityGlass making apparatusBundled fibre light guideSkin structureQuartz

The invention relates to a manufacturing method of a quartz optical fiber image bundle. A quartz perform with a core skin structure is drawn into a quartz optical fiber filament, wherein the filament diameter of the quartz optical fiber filament is less than 50 microns; during the wire drawing process, a glass fiber impregnating compound is coated on the optical fiber filament, so that the optical fiber filament is protected; and a sliding filament trolling method is utilized to carry out processing on the drawn quartz optical fiber filament to manufacture a quartz optical fiber image bundle.

Owner:NANJING CHUNHUI SCI & TECH IND

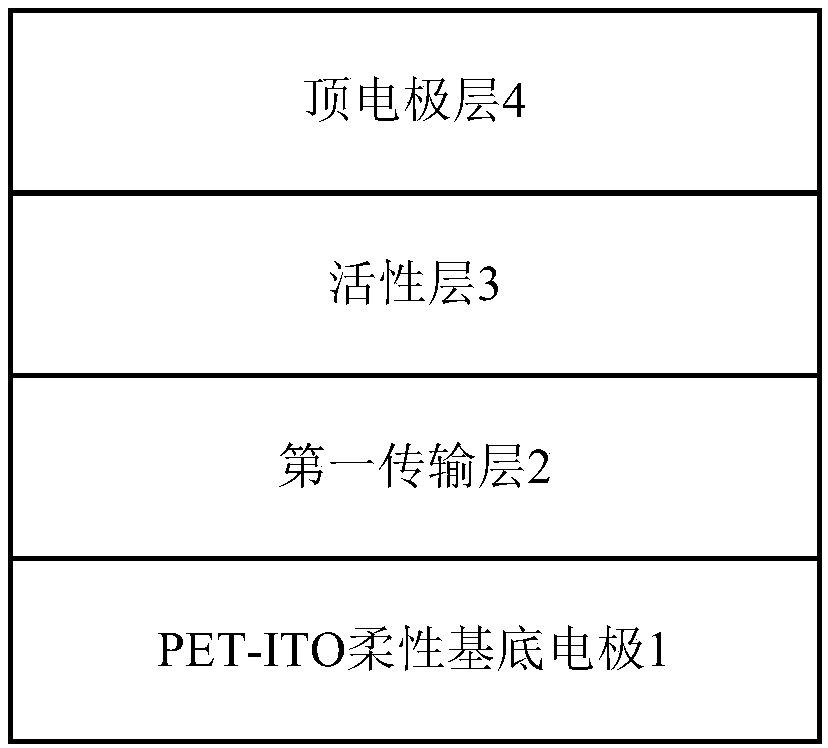

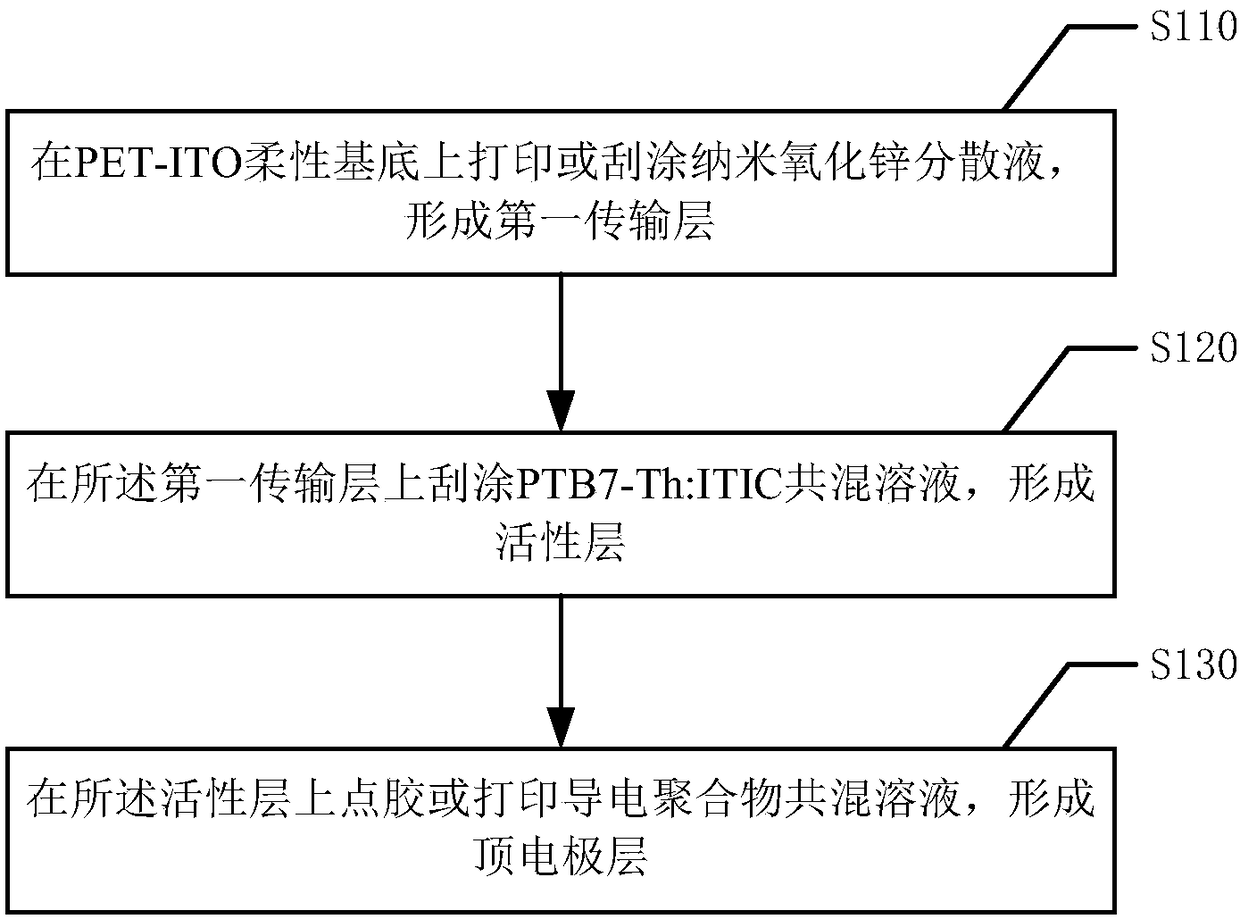

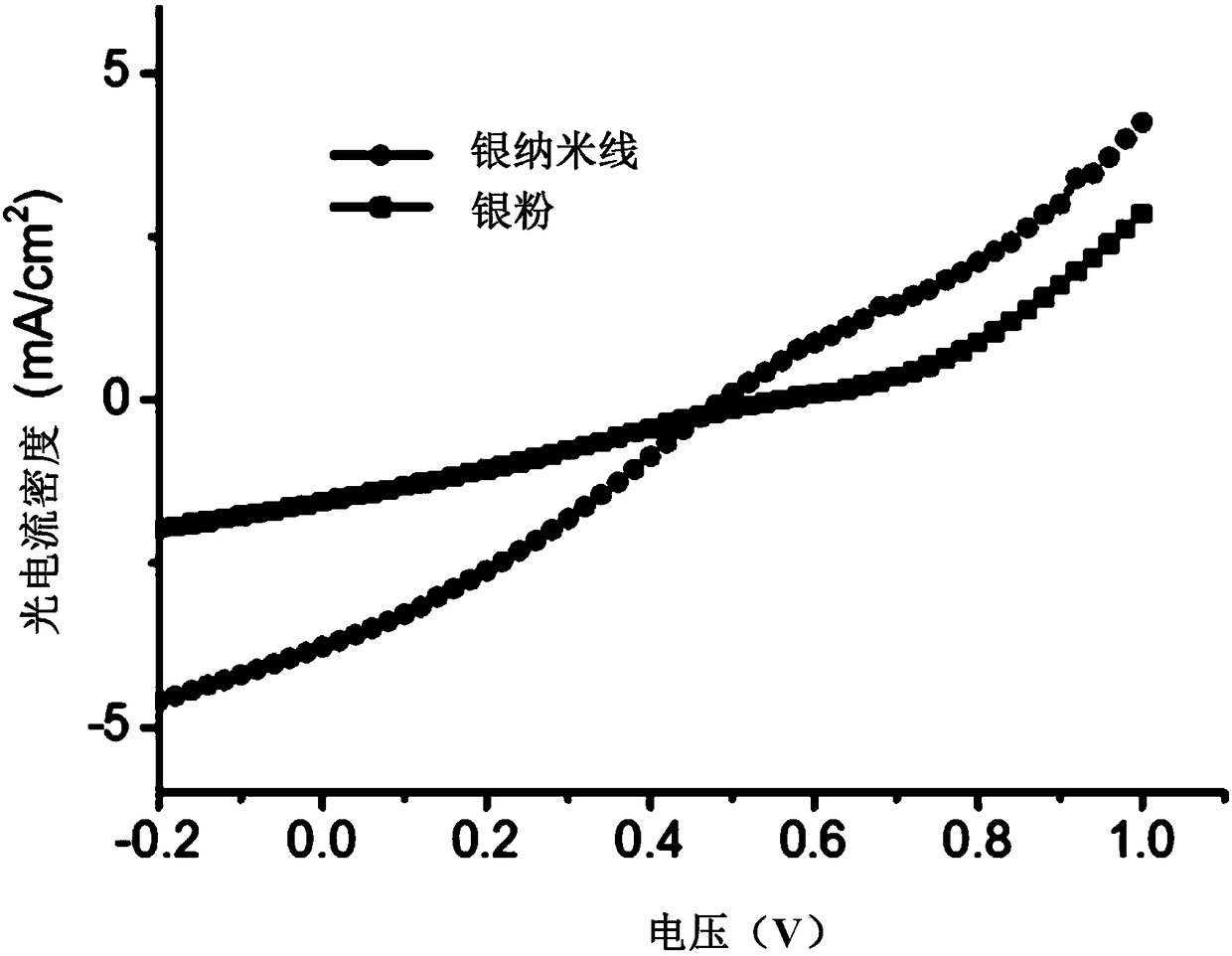

Flexible organic solar cell and full-printing preparation method thereof

InactiveCN108550697AReduce absorption lossAvoid damageMaterial nanotechnologyDuplicating/marking methodsOrganic solar cellSilver electrode

The invention relates to the field of solar cells, and particularly provides a flexible organic solar cell and a full-printing preparation method thereof. The silver conductive ink is printed on a flexible substrate to form a comb-shaped silver electrode. Meanwhile, a high-conductivity transmission layer is used, so that the absorption loss of the light is reduced. The dependence of a battery device on an ITO electrode is reduced. A conductive polymer blended solution is dispensed or printed on an active layer, and then a top electrode layer of hole transmission and electrode blending is formed. Or, the silver conductive ink is printed on a second transmission layer and then a comb-shaped silver electrode is formed. The damage of the solvent to the thin film of the active layer is reduced.The yield of the flexible organic solar cell is improved.

Owner:SHANGHAI MI FANG ELECTRONICS LTD

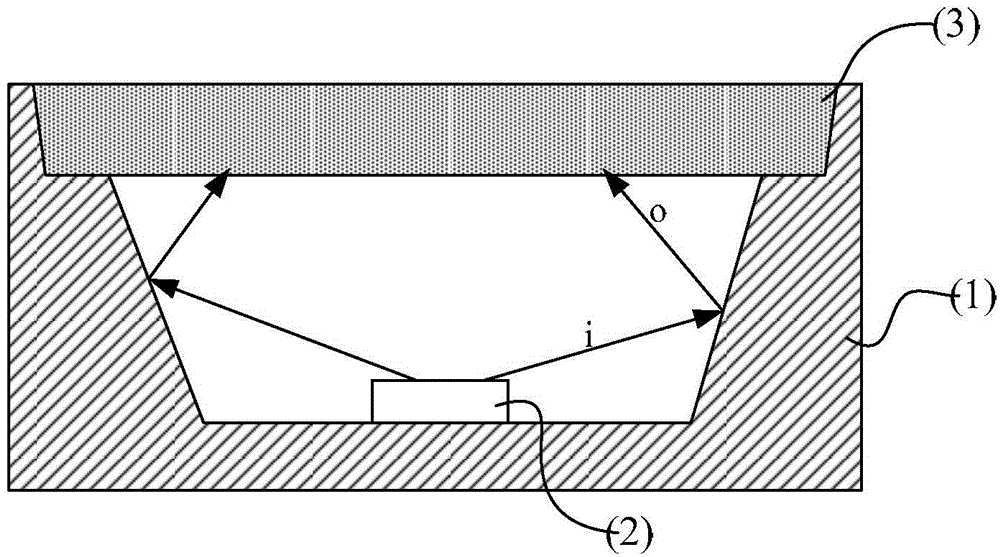

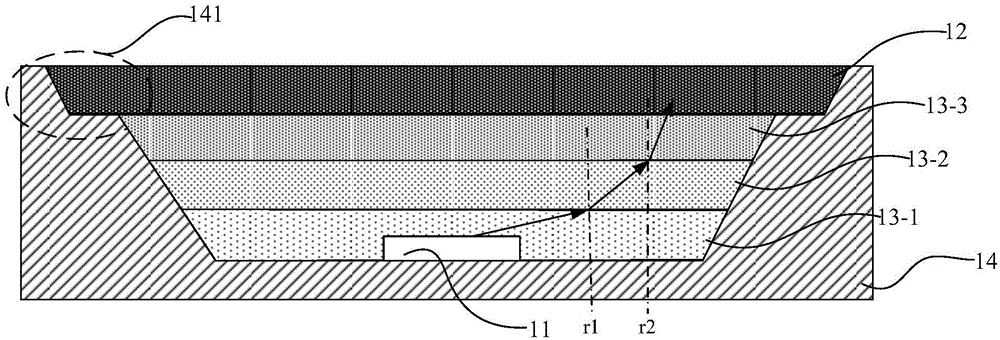

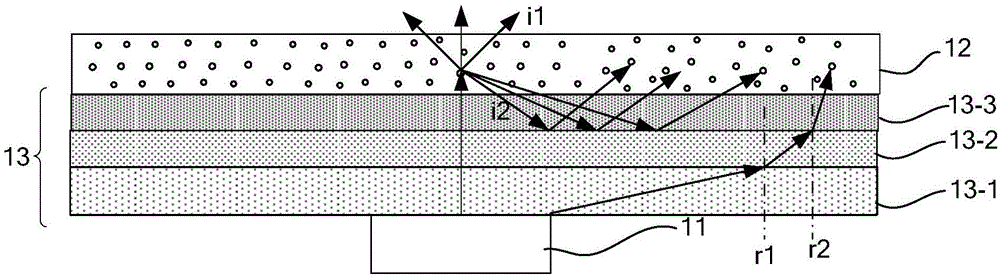

Quantum dot light-emitting component, backlight module and display device

ActiveCN106299075AImprove light extraction efficiencyAvoid enteringNon-linear opticsSemiconductor devicesQuantum dotDisplay device

An embodiment of the invention provides a quantum dot light-emitting component, a backlight module and a display device, relates to the field of photoelectric devices, and can reduce back scattering light loss and improve light-emitting efficiency of the quantum dot light-emitting component. The quantum dot light-emitting component comprises a support frame, an excitation light source, a refraction layer and a quantum dot layer, wherein the support frame is in a groove shape; the excitation light source is arranged at the bottom of a groove in the support frame, and is used for emitting excitation light; the refraction layer is arranged in the light output direction of the excitation light source, and the refraction layer is made of a light transmitting material; the propagation direction of the excitation light emitted by the excitation light source deflects to the center normal direction of a light output plane of the excitation light source after the excitation light passes through the refraction layer; the quantum dot layer is arranged on the refraction layer, and the quantum dot layer emits light when excited by the excitation light; and the excitation light source, the refraction layer and the quantum dot layer as well as the support frame are packaged together to form an integrated enclosed structure. The embodiment of the invention is used for manufacturing the quantum dot light-emitting component.

Owner:HISENSE VISUAL TECH CO LTD

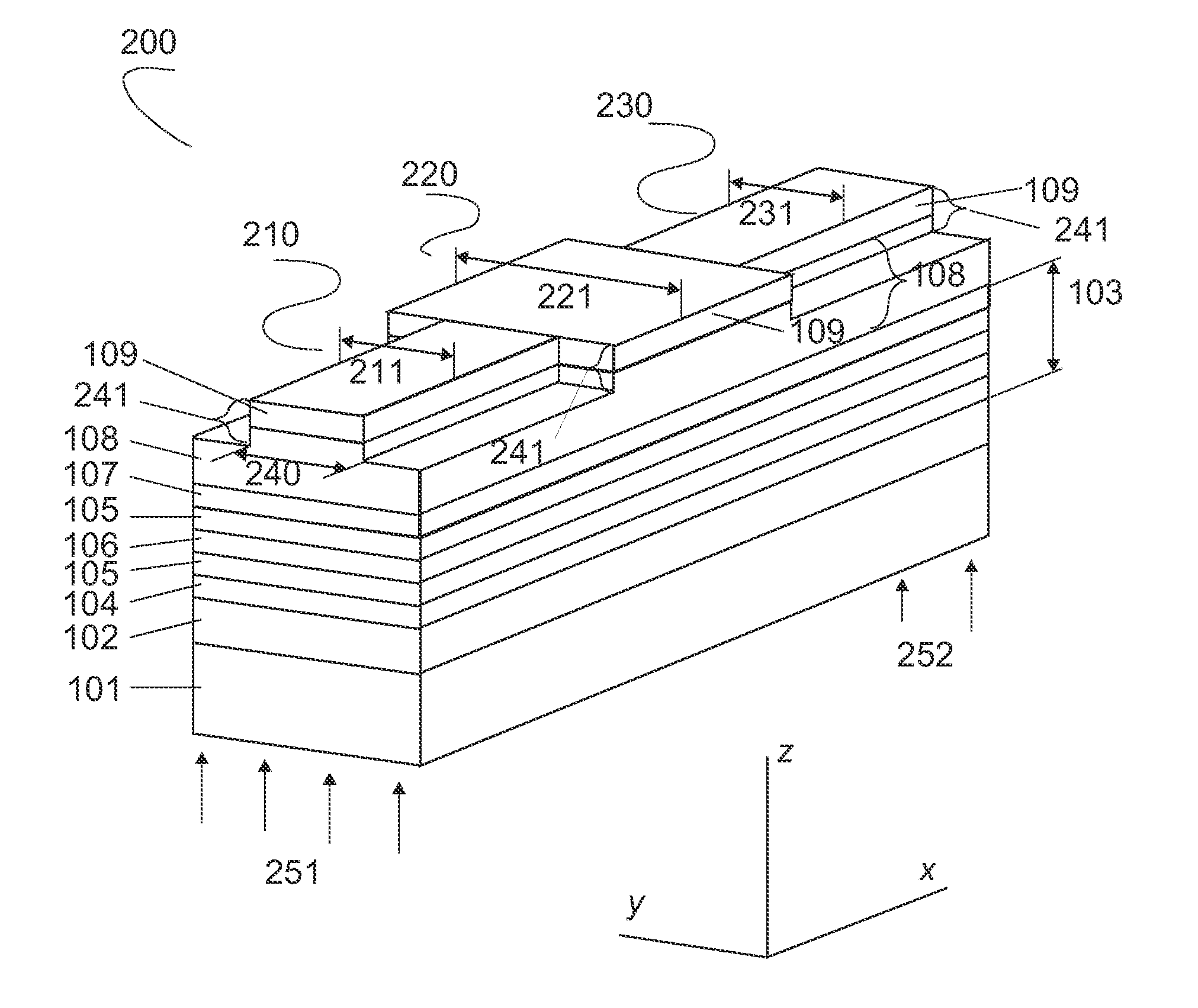

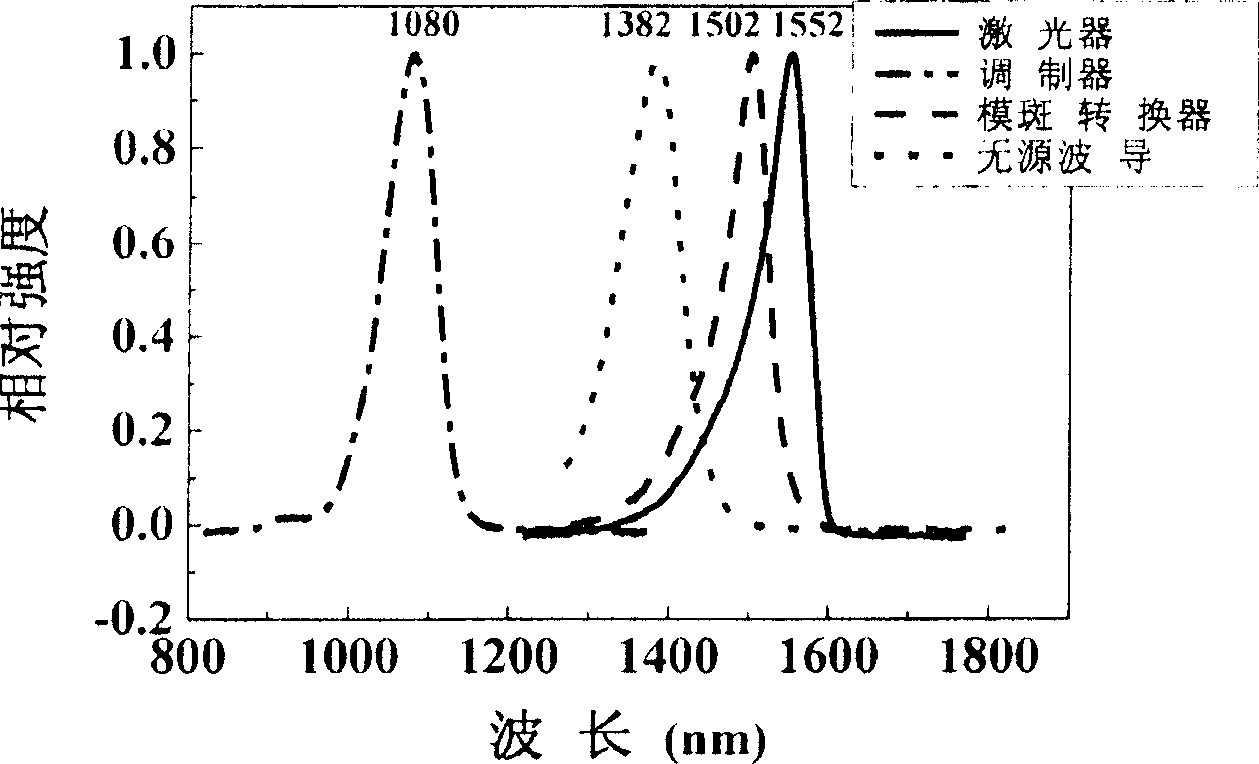

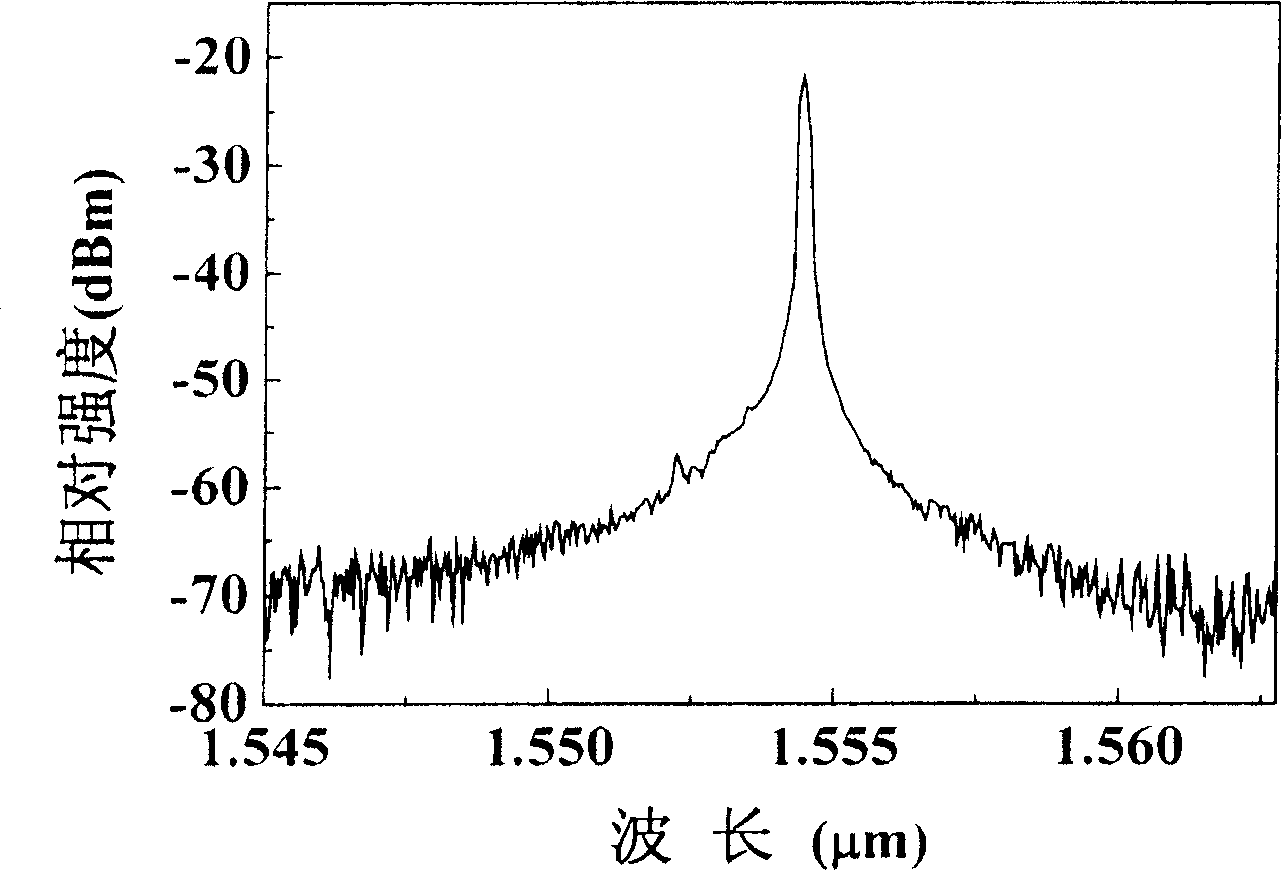

Integration method for electric absorption modulation laser and modular spot converter

InactiveCN1909309AReduce the number of growthHas an effectLaser detailsSemiconductor lasersPhosphate ionSilicon dioxide

The invention relates to an integration method of electric adsorption modulation laser and mode speckle converter, which comprises: growing n-type indium phosphate buffer layer on the substrate; corroding the upper 1.1Q layer on the chip, to grow buffer layer; growing silica dioxide protective layer on the whole chip, and corroding the silica dioxide protective layer at two ends of mode speckle converter; pouring low-energy phosphate ion; growing the silica dioxide protective layer again; heating, keeping warm, anneal on the chip; corroding silica dioxide protective layer; using relative light etching plate to mask the laser and modulator, to form the upper ridge and lower ridge on the converter; growing p-type indium phosphate and indium gallium arsenic phosphate etching stop layer; etching ridge pilot structure; depositing medlin at two sides of laser and modulator; opening the electrode windows of laser and modulator; etching the electrode images on the laser and modulator to splash the P electrode and remove the P electrode; extending the substrate, and splashing n electrode; slicing the sample to form tubular chip.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

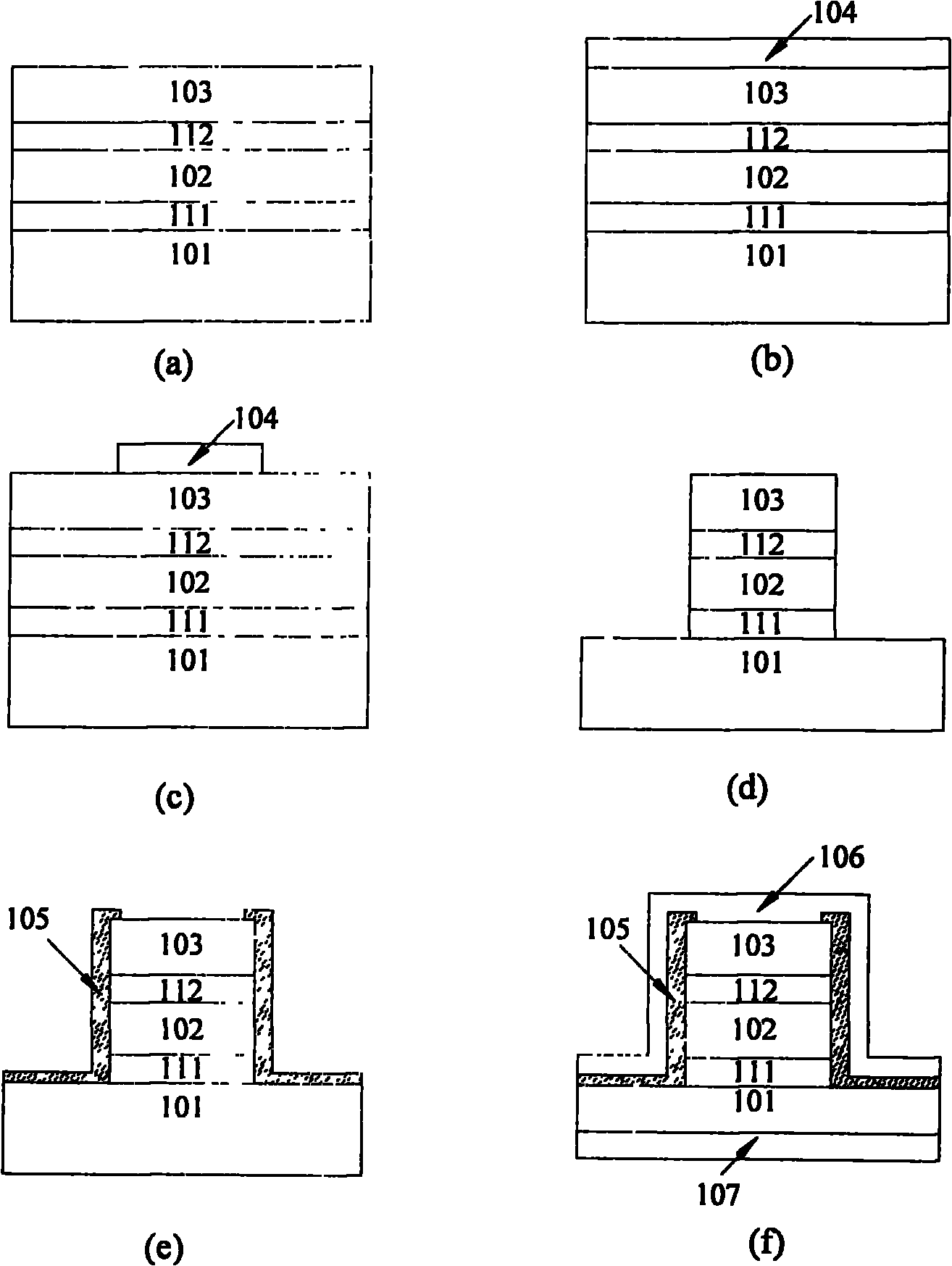

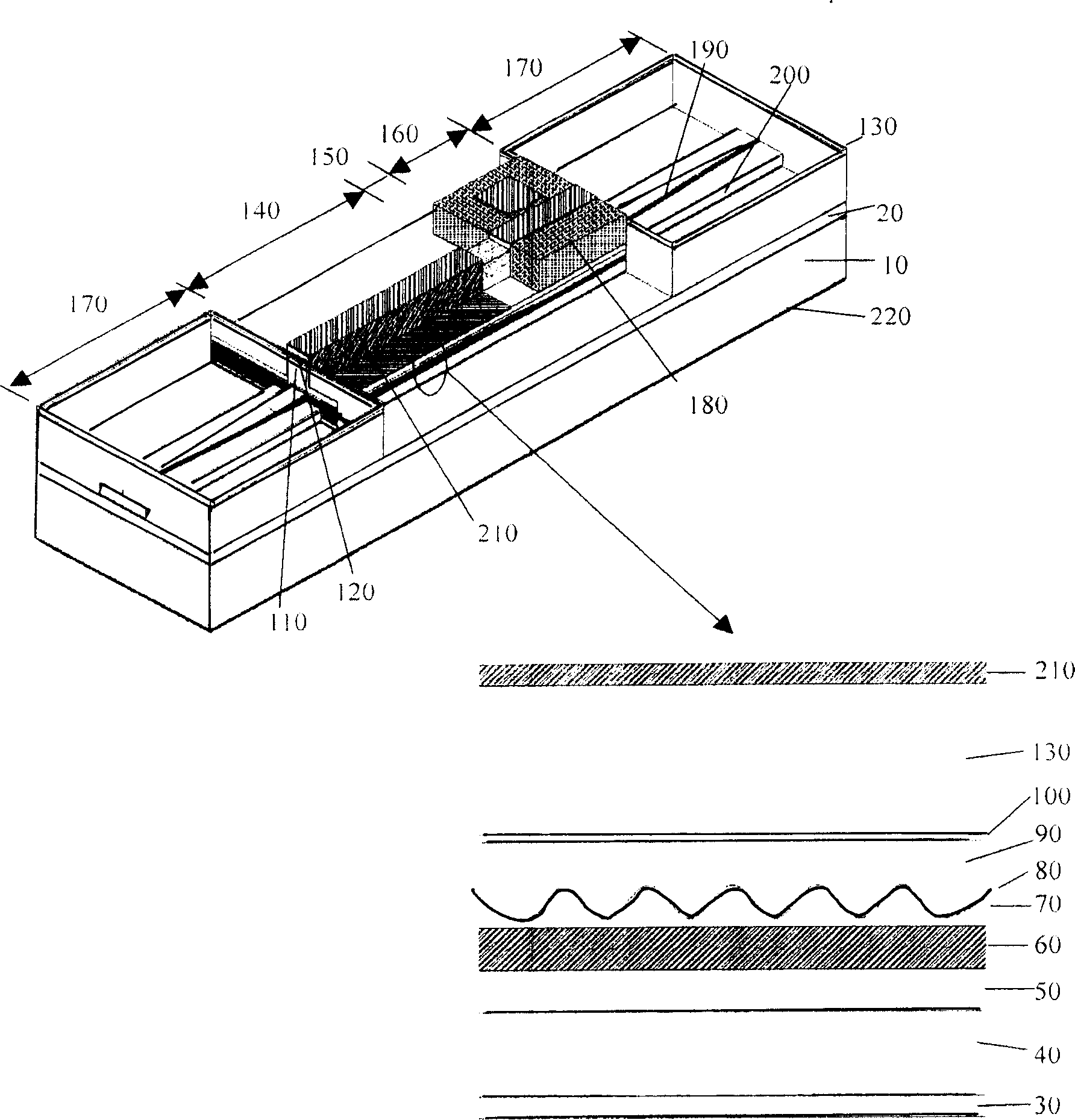

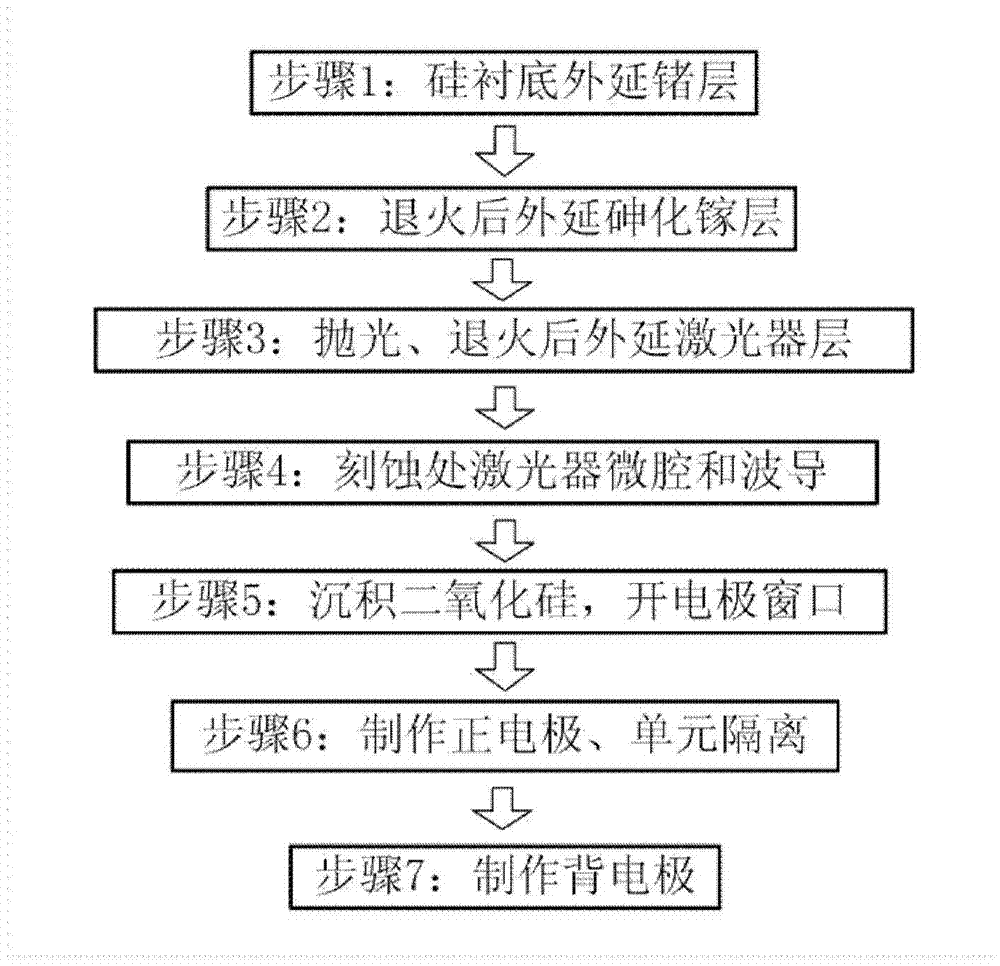

Method for manufacturing silicon substrate microcavity laser device

ActiveCN103579902AQuality improvementReduce absorption lossLaser detailsLaser optical resonator constructionEtchingUltra-high vacuum

The invention discloses a method for manufacturing a silicon substrate microcavity laser device. The method for manufacturing the silicon substrate microcavity laser device comprises the steps that a germanium layer is formed on the front face of a silicon substrate in an extension mode by adopting an ultra-high vacuum chemical vapor deposition method; the silicon substrate with the epitaxial germanium layer is put in an MOCVD reaction chamber, and a low-temperature nucleary gallium arsenide layer and a high-temperature gallium arsenide layer are grown in sequence respectively; a laser device structure is formed in an extension mode after surface polishing is carried out on the high-temperature gallium arsenide layer; a mocrocavitie and an output waveguide are formed on the laser device structure in a drying etching mode; a silicon dioxide layer is deposited after the mocrocavitie and the output waveguide are formed, and an electrode window is formed in the upper portion of the microcavity; positive electrodes are manufactured on the silicon dioxide layer and the upper surface of the electrode window, and electrode isolation is carried out; a back electrode is manufactured on the back face of the silicon substrate, and the manufacturing of the device is completed. According to the method for manufacturing the silicon substrate microcavity laser device, high-quality III-V group layers are achieved by combining the ultra-high vacuum chemical vapor phase epitaxy and MOCVD, and the cleanness and leveling of the surface are achieved by polishing and cleaning. The smooth side wall of the microcavity is achieved through drying etching and wet etching, and the losses of the laser device are reduced.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Photodiode and manufacturing method thereof

ActiveCN102916071AReduce energy lossReduced scattering lossSemiconductor devicesIncident wavePhotodiode

The embodiment of the invention discloses a photodiode and a manufacturing method thereof, relating to the field of opto-electrical technology, wherein the photodiode is capable of reducing the energy loss. The photodiode comprises a substrate positioned on a bottom layer, a lower cladding layer boss covering the substrate, an incident wave core guiding layer covering the lower cladding layer boss, an upper cladding layer covering the incident wave core guiding layer, an optical matching layer positioned above the upper cladding layer and an avalanche photodiode positioned above the middle part of the back end of the optical matching layer, wherein the width of the lower cladding layer boss at the tail end in the incident wave direction is wider than that of the beginning end in the incident wave direction, both sides of the lower cladding layer boss at the tail end in the incident wave direction are parallel, and both sides of the lower cladding layer boss at the beginning end in the incident wave direction are parallel; and the optical matching layer comprises an optical matching layer front end and an optical matching layer back end, wherein the optical matching layer front end comprises at least one air seam extended along the incident wave direction, and the optical matching layer front end is divided into characteristic units partitioned by the air seams. The embodiment of the invention is applied to manufacturing the photodiode.

Owner:HUAWEI TECH CO LTD +1

Low-loss deep-ultraviolet multilayer film production method

InactiveCN103018798AImprove compactnessImprove surface roughnessVacuum evaporation coatingSputtering coatingScattering lossEvaporation

The invention relates to a low-loss deep-ultraviolet multilayer film production method, belongs to the application field of the deep-ultraviolet optical technology, and aims at solving the problems of the deep-ultraviolet optical film in the prior art that an optical film system is large in absorption loss by adopting a total oxide film layer and is large in scattering loss by adopting a total fluoride film layer. The low-loss deep-ultraviolet multilayer film production method includes the following steps: 1 an optical substrate needing film plating is subjected to ultrasonic cleaning, slow pulling and dewatering and N2 drying; 2 an oxide film layer stack is prepared on the optical substrate obtained in the step 1 by aid of the ion assisted electron beam evaporation technology according to a film system structure of the film design; and 3 a fluoride film layer stack is prepared on the oxide film layer stack by aid of the thermal evaporation process. The low-loss deep-ultraviolet multilayer film production method overcomes shortcomings of the loose interior structure and large surface roughness of films in a total fluoride multilayer film system and the shortcoming of large absorption loss of a total oxide multilayer film system caused by acting of middle-and-outer-layer oxide films and laser.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

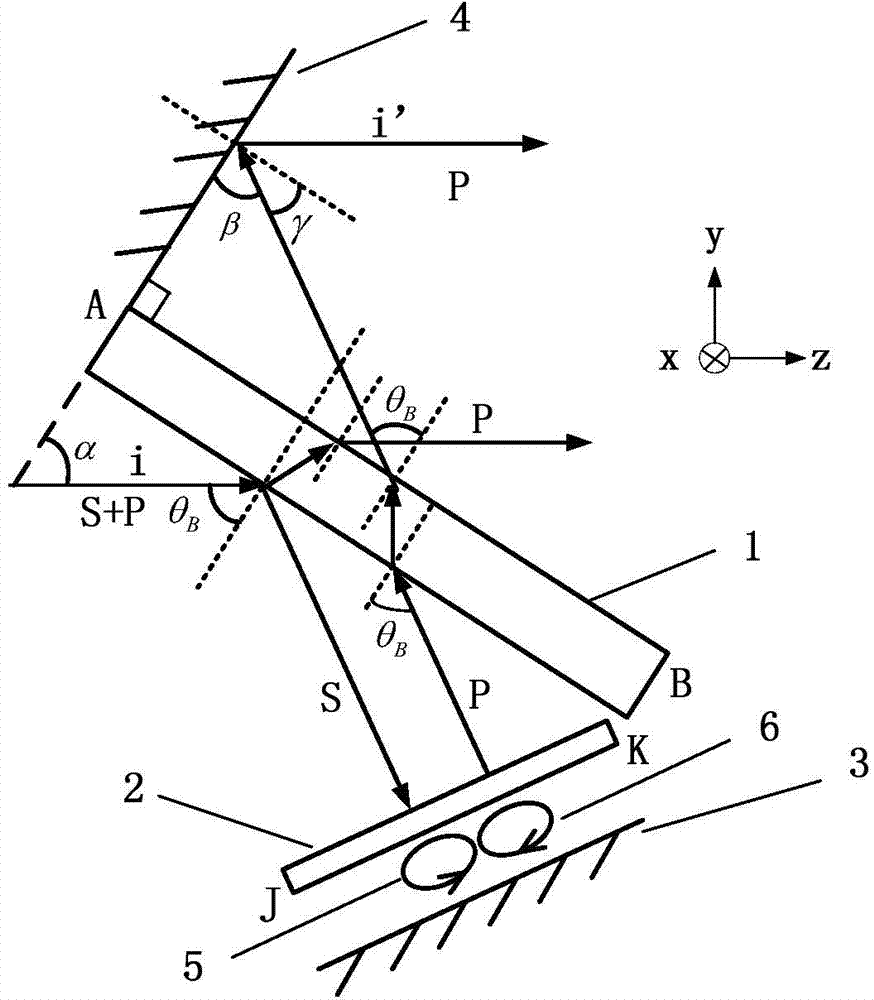

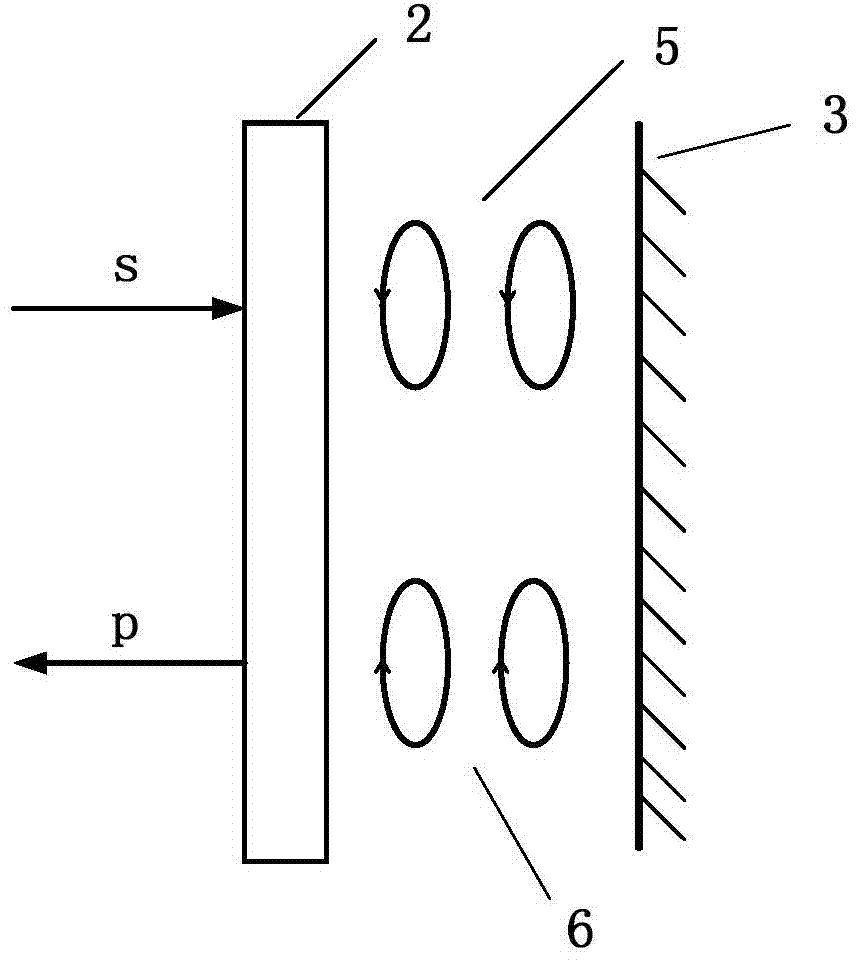

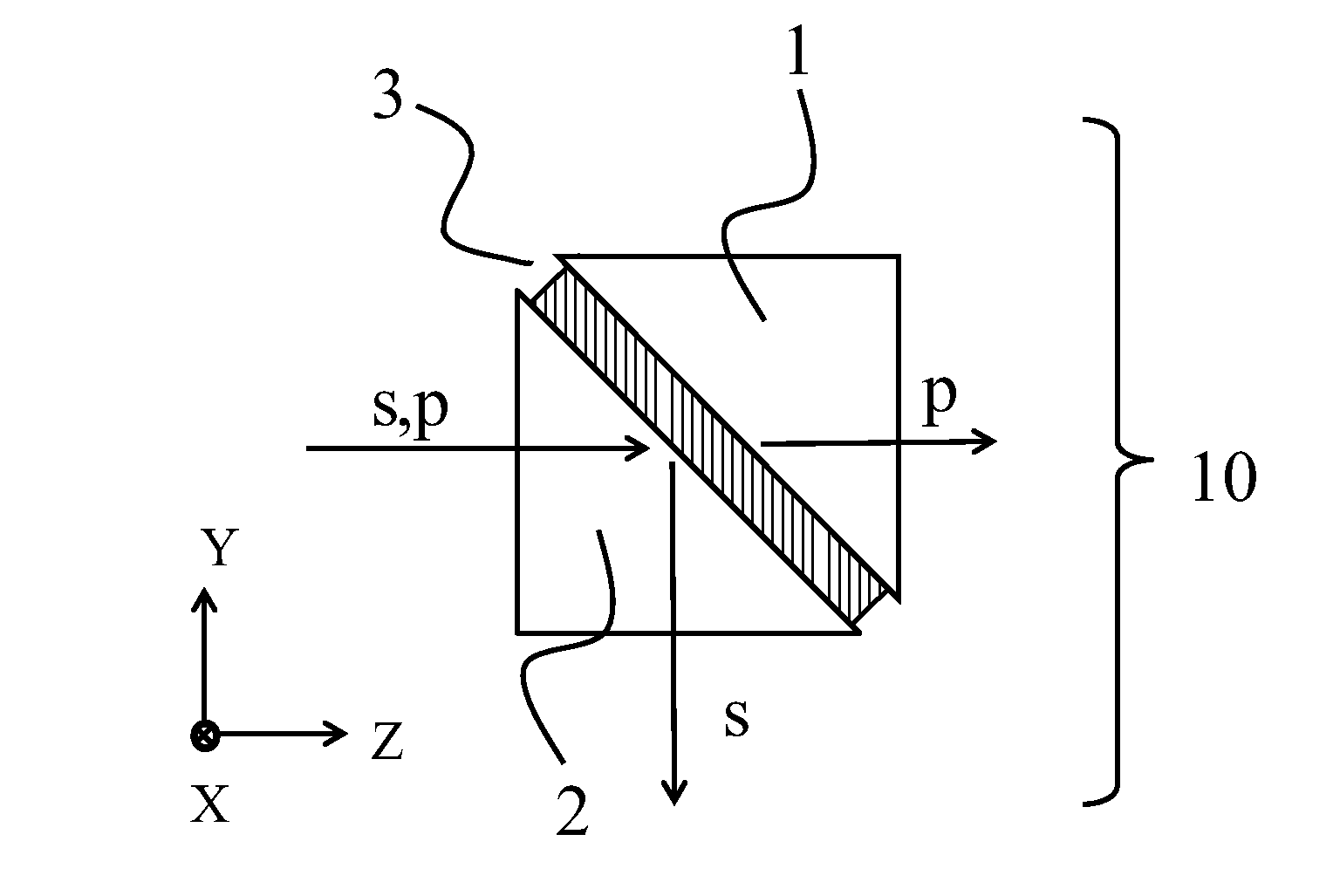

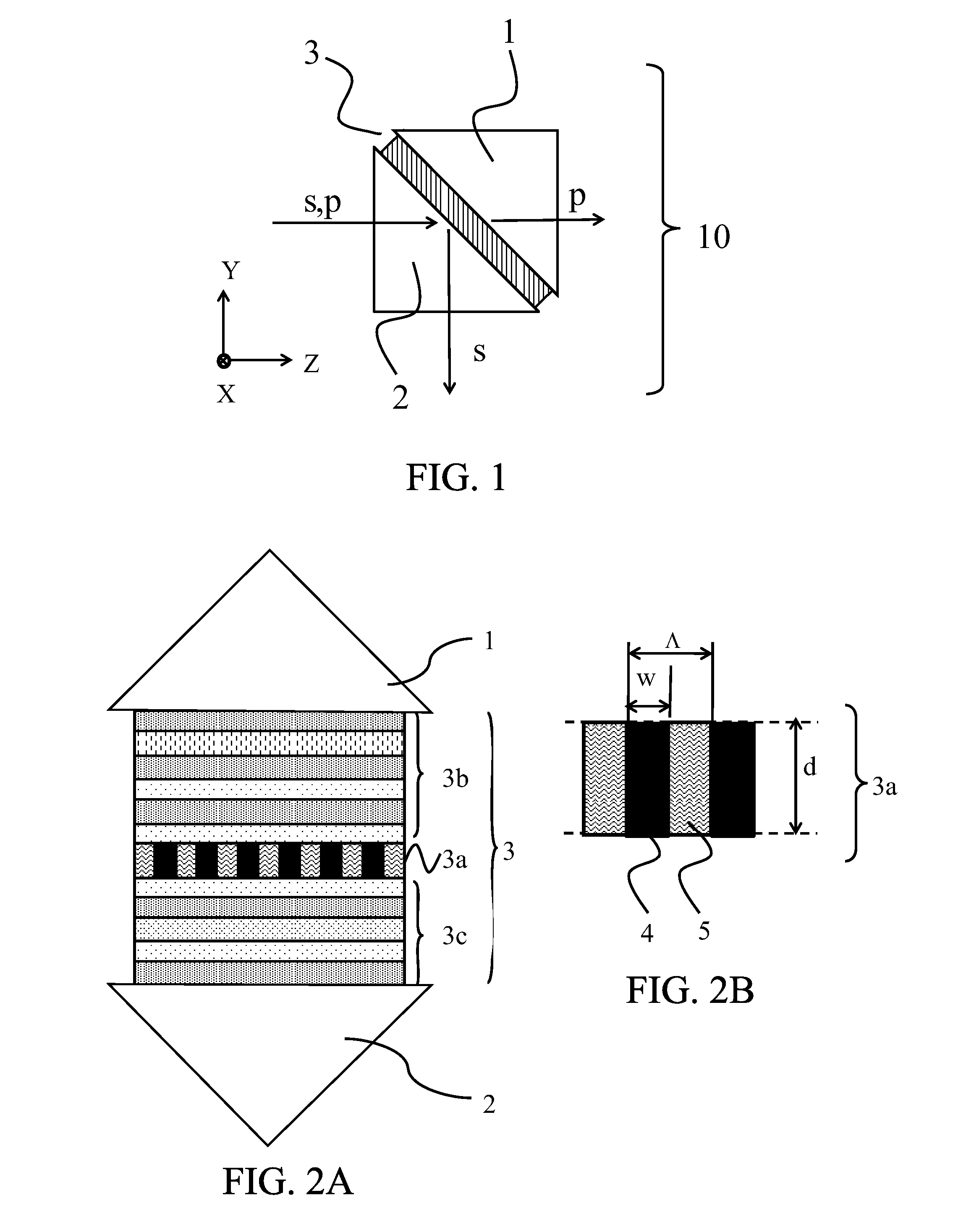

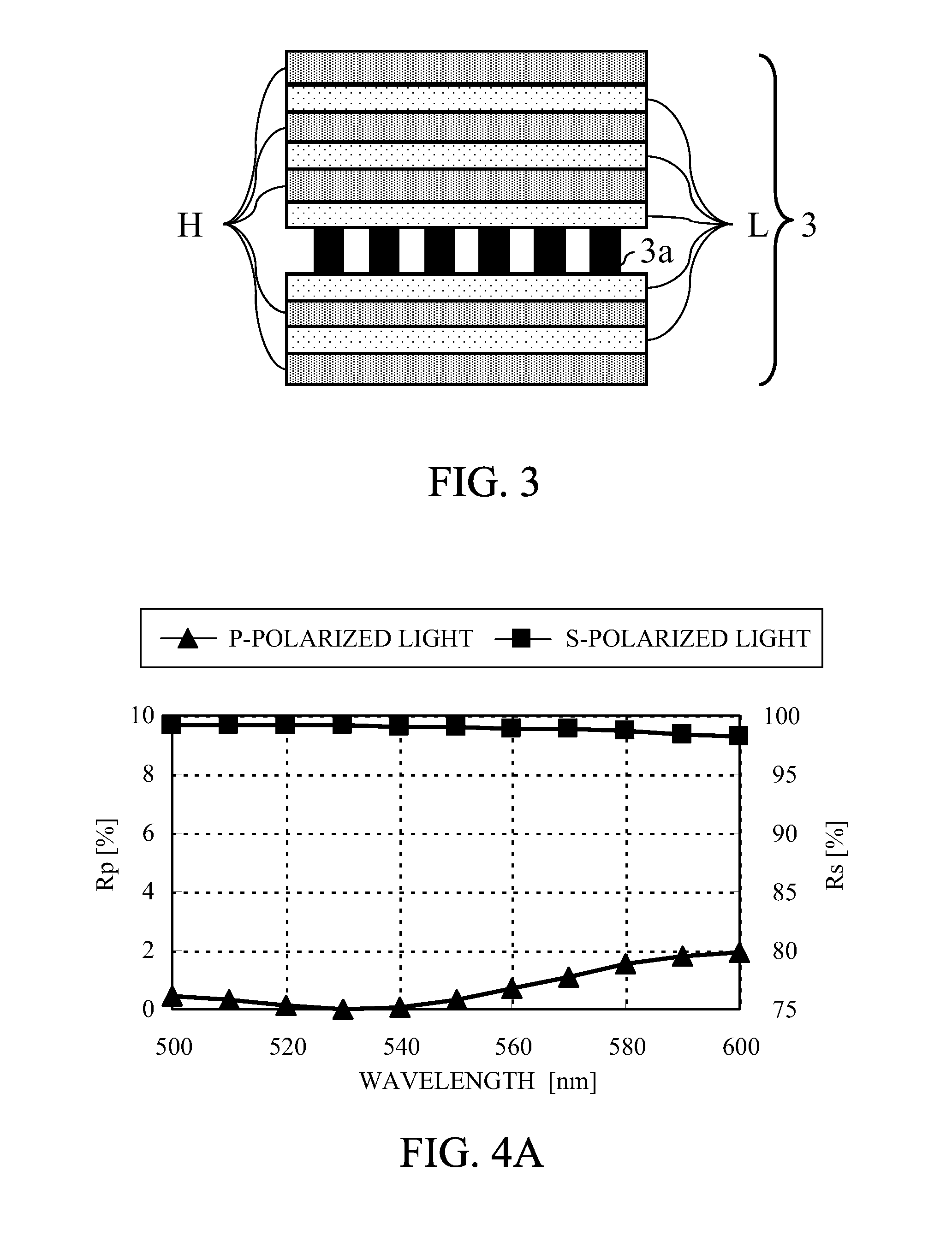

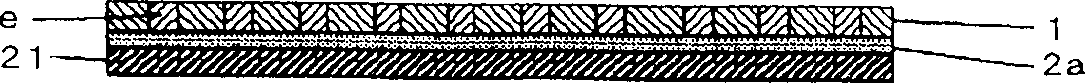

Efficient polarization purifying device

ActiveCN103487945AHigh degree of polarizationIncreased Polarization PurityNon-linear opticsOptical elementsOptical axisHigh energy

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

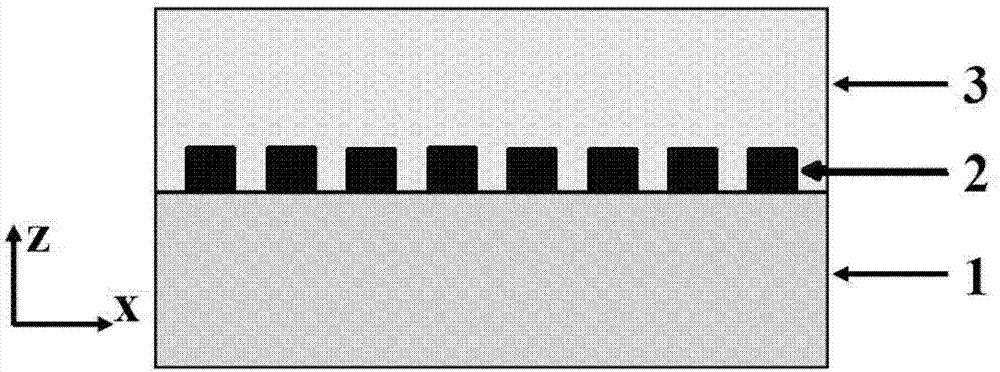

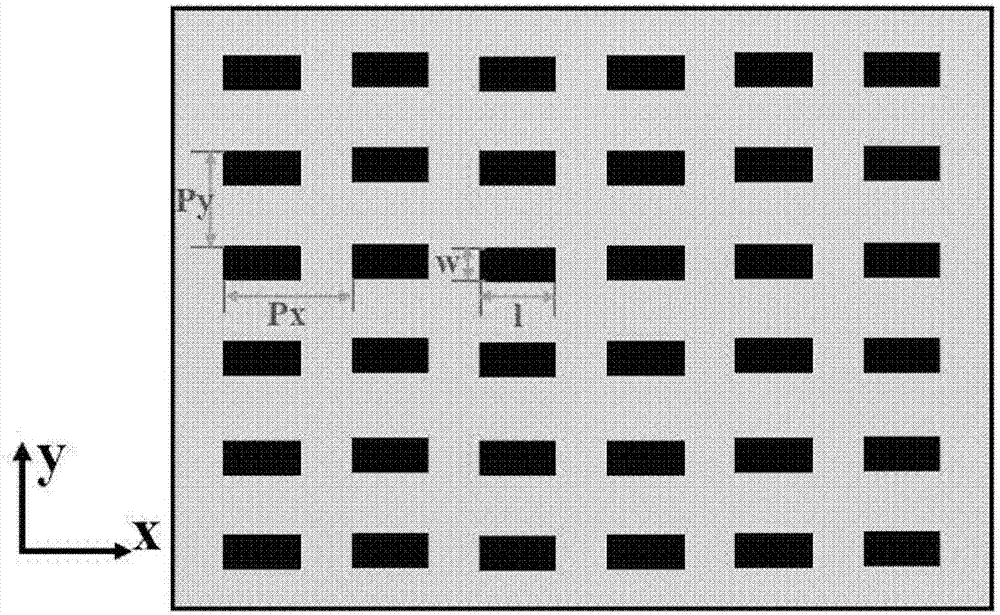

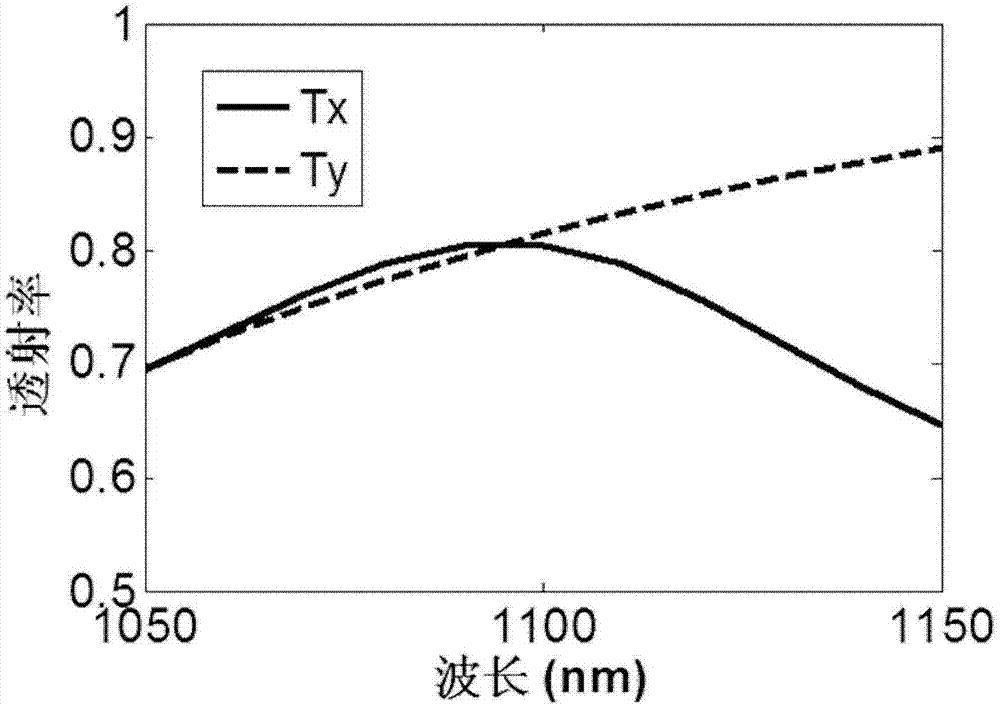

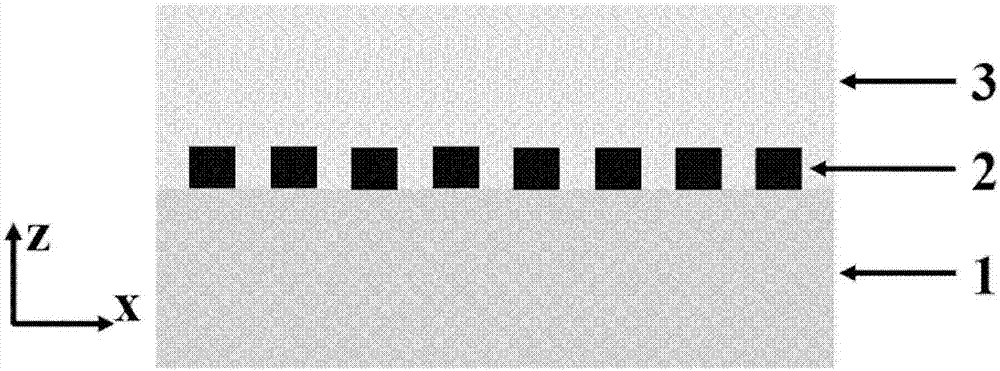

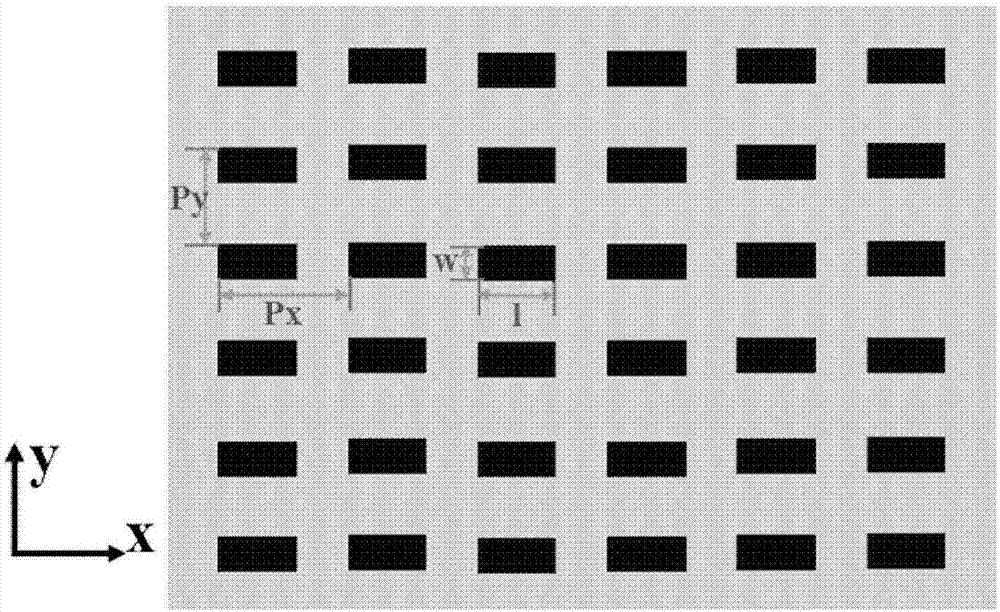

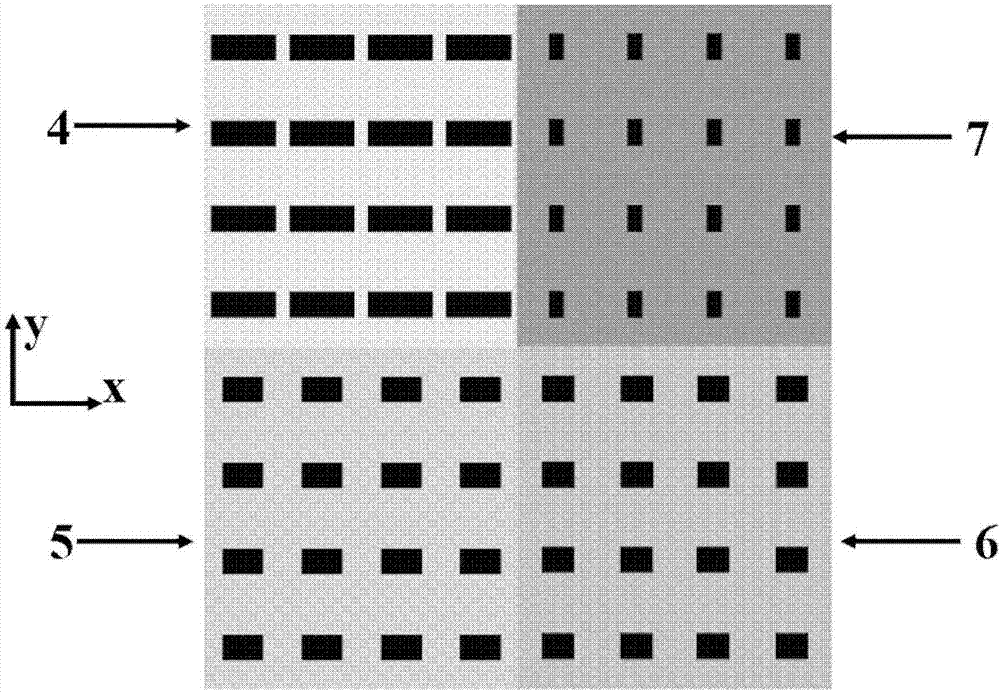

Metal metamaterial wave plate

InactiveCN107238885AReduce reflection lossReduce absorption lossPolarising elementsResonant cavityMetal particle

The invention provides a metal metamaterial wave plate. The metal metamaterial wave plate comprises a medium substrate, a metal metamaterial layer and a medium wrapping layer, wherein the metal metamaterial layer is arranged on the medium substrate and comprises metal particles periodically arrayed; the medium wrapping layer is arranged on the metal metamaterial layer and used for providing impedance matching; the metal particles periodically arrayed are distributed in a rectangular array; each metal particle of the metal particles periodically arrayed comprises at least one pair of smooth plane side walls in parallel, and a Fabry-Perot resonant cavity is formed between adjacent metal particles in the direction perpendicular to the smooth plane side walls. The metal metamaterial wave plate has the advantages that the conversion efficiency is high, the working wave band is wide, integration is easy and preparation is easy.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Novel fully passivated contact crystalline silicon solar cell and preparation method thereof

InactiveCN110112226AImprove conductivityHigh optical transmittanceFinal product manufacturePhotovoltaic energy generationOptical propertyNanocrystalline silicon

The invention discloses a novel fully passivated contact crystalline silicon solar cell and a preparation method thereof. The novel fully passivated contact crystalline silicon solar cell comprises acrystalline silicon layer, an ultra-thin silicon oxide passivation layer is arranged on the two sides, a mixed phase silicon oxide / nanocrystalline silicon layer is arranged on the front surface, an intrinsic hydrogenated amorphous silicon layer and a p-type hydrogenated amorphous silicon layer are arranged on the reverse surafce, and an ITO layer and an Ag electrode are arranged outside the two sides. The mp-SiOx / nc-Si is applied to replace the poly-Si layer in the SiOx / poly-Si passivation contact structure of the TOPCon cell to act as the front passivation contact of the cell, and the intrinsic hydrogenated amorphous silicon (a-Si: H (i)) and the doped a-Si: H stack layer are used as the reverse passivation contact and the fully passivated contact crystalline silicon solar cell is designed and prepared so that the electrical and optical properties of the front surface of the passivated contact crystalline silicon solar cell can be enhanced.

Owner:ZHEJIANG NORMAL UNIVERSITY

Spatial beam phase regulation device

ActiveCN107390299ARealize phase controlReduce reflection lossOptical elementsResonant cavityResonance

The invention provides a spatial beam phase regulation device. The spatial beam phase regulation device is characterized in that a Fabry Perot resonant cavity is utilized to realize phase regulation of any degree between 0 to 360 DEG for the incident light; a dielectric substrate and a dielectric coating layer are utilized to provide protection and impedance match for a phase regulation layer; and different resonant cavity width in a periodicity array is used to generate different phase time-delay for the transmitted light to realize spatial beam phase regulation. The spatial beam phase regulation device utilizes Fabry Perot resonance in the thick metal meta-material particle periodicity array to realize phase regulation of the spatial beam, and has the advantages of large phase regulation range, high work efficiency, wide suitable wave band and simple device structure which is easy to prepare.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

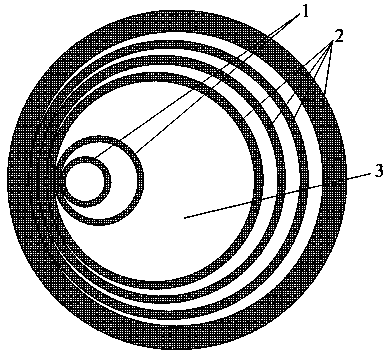

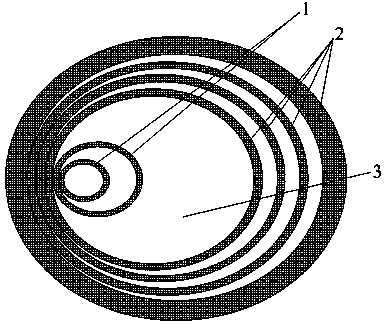

Hollow optical fiber with multiple resonance layers

ActiveCN109212662AHigh damage thresholdReduce manufacturing difficultyOptical fibre with multilayer core/claddingFiberRefractive index

The invention provides a hollow optical fiber with multiple resonance layers. The hollow optical fiber with multiple resonance layers comprises a high-refractive index cladding region and a low-refractive index fiber core region, wherein the cladding region is composed of a negative curvature boundary region and a positive curvature boundary region, the positive curvature boundary region coats thenegative curvature boundary region, a medium tube of the negative curvature boundary region is a first type medium tube, and the medium tube of the positive curvature boundary region is a second typemedium tube; and a region surrounded by an external wall of an outermost layer medium tube of the first type medium tubes and an inner wall of an innermost layer medium tube of the second type mediumtubes is a fiber core region. In the hollow optical fiber with multiple resonance layers provided by the invention, optical fiber modes are mainly distributed in air holes, thus, material absorptionloss of the optical fiber can be reduced effectively, a damage threshold value of the optical fiber can be improved, distance between an optical fiber node and the fiber core can be adjusted by increase of radius size of the medium tube in the negative curvature boundary cladding region, and by increase of the distance, coupling between a fiber core mode and a node mode can be reduced.

Owner:JIANGXI NORMAL UNIV

Polarization beam splitting element and image projection apparatus

InactiveUS20120249969A1Reduce absorption lossSufficient reflectanceProjectorsPolarising elementsRefractive indexDielectric

The polarization beam splitting element splits an entering beam according to polarization directions. The element includes, in order from a beam entrance side, an entrance side multi-layered film layer constituted by laminated multiple dielectric films, and a one-dimensional grating structure having a grating period smaller than a wavelength of the entering beam and formed of a metal. When a medium existing on the beam entrance side further than the entrance side multi-layered film layer is referred to as an entrance medium, the multiple dielectric films constituting the entrance side multi-layered film layer include at least one dielectric film having a higher refractive index than that of the entrance medium and at least one dielectric film having a lower refractive index than that of the entrance medium.

Owner:CANON KK

Light diffusion plate, optical unit and liquid crystal display

InactiveCN1366191AReduce the amount of solutionIncrease brightnessDiffusing elementsPolarising elementsLiquid-crystal displayDisplay device

A light diffusing plate, which can anisotropically scatter linearly polarized light and has excellent diffusion properties in the scattering direction, and is suitable for improving the clarity and brightness of liquid crystal displays. The light diffusing plate includes a birefringent film and microdomains in a birefringent film having birefringence characteristics different from those of a birefringent film and existing in a dispersed state, the birefringent film comprising a birefringent stretched film, and the microdomains comprising a positive uniaxial liquid crystal polymer, wherein the microdomains are in The length in the direction of the stretching axis is longer than the length in the direction perpendicular to the stretching axis, and the liquid crystal polymer is aligned in the direction perpendicular to the stretching axis of the birefringent stretched film.

Owner:NITTO DENKO CORP

Deep ultraviolet micro-LED with high electro-optical conversion rate and inverted structure and preparation method of deep ultraviolet micro-LED

ActiveCN112542533AReduce absorption lossReduce reflectionFinal product manufactureSemiconductor devicesElectro-opticsOhmic contact

The invention discloses a high-reflectivity deep ultraviolet micro-LED with an inverted structure and a preparation method of the deep ultraviolet micro-LED. P-type ohmic contact metal is etched, thereserved P-type ohmic contact metal is a two-dimensional array composed of a plurality of small pattern units arranged periodically, a micro-grid P-type ohmic contact electrode is formed, Al metal isdeposited on the micro-grid P-type ohmic contact electrode, a reflecting layer is formed to cover a micro-mesa, the Al metal is completely embedded into a gap of the micro-grid P-type ohmic contact electrode, and the inclination angle of the side wall of the micro-mesa is adjusted between 30 degrees and 90 degrees. According to the invention, the micro-grid P-type ohmic contact electrode is adopted, the absorption loss of ultraviolet light in the LED structure is reduced, and the reflection of the ultraviolet light at the electrode is enhanced by the Al metal, so that most of emergent light isemitted from the back surface of the inverted structure, and the light extraction efficiency of the ultraviolet light in the UV LED is greatly improved; and the deep ultraviolet micro-LED is high inflexibility, is compatible with in-plane and vertical-structure inverted micro-LEDs, mini-LEDs and the like, facilitates the improvement of the performance of a device, and achieves the batch production.

Owner:PEKING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com