Patents

Literature

44results about How to "Improve the exit rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

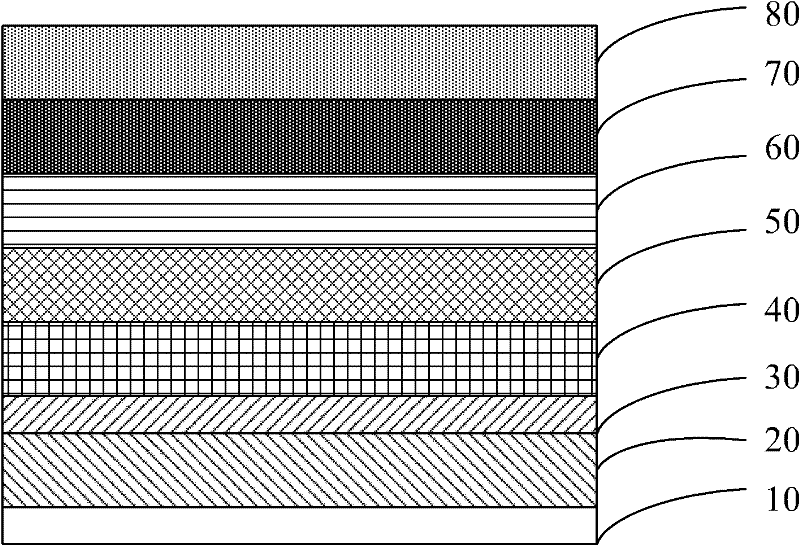

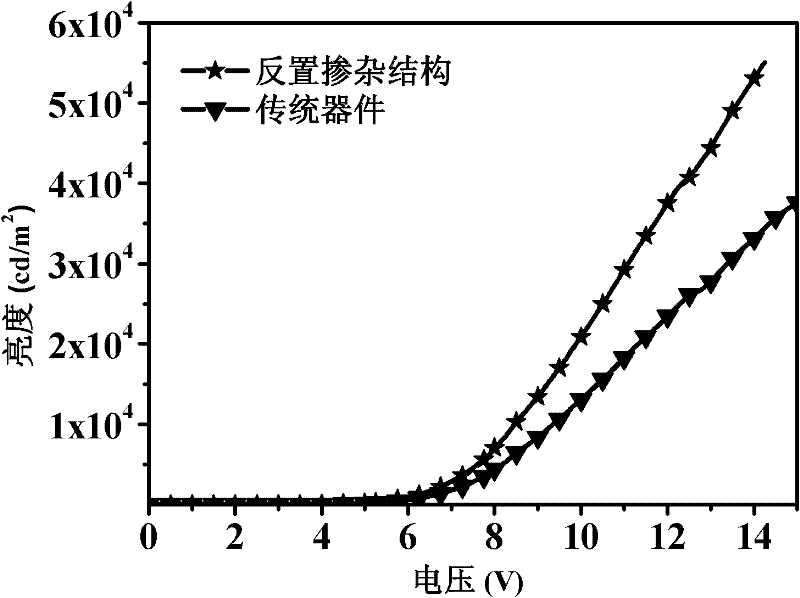

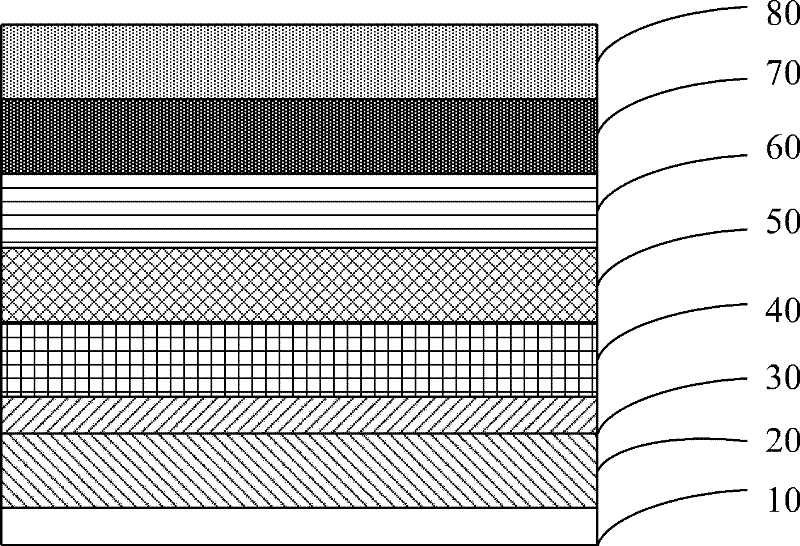

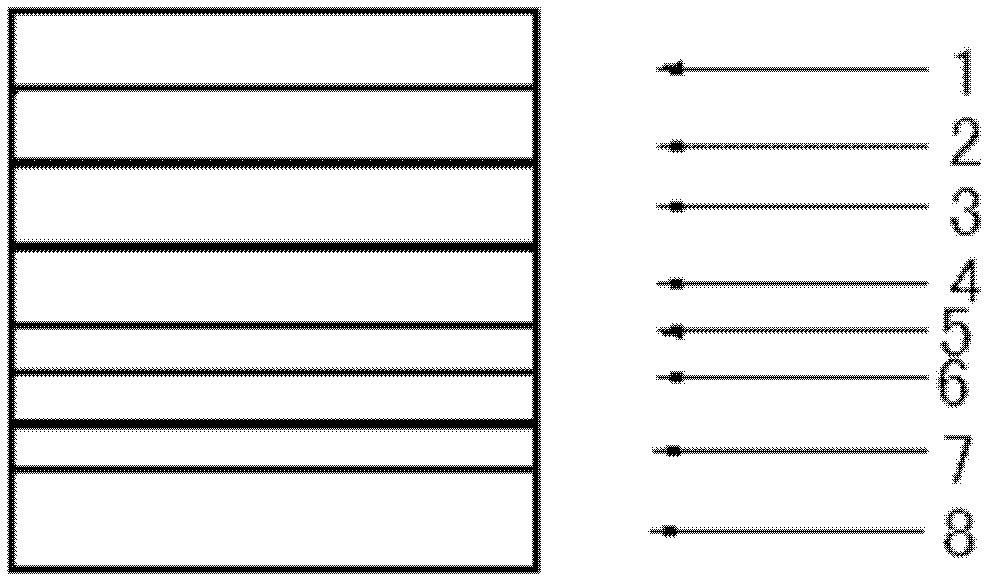

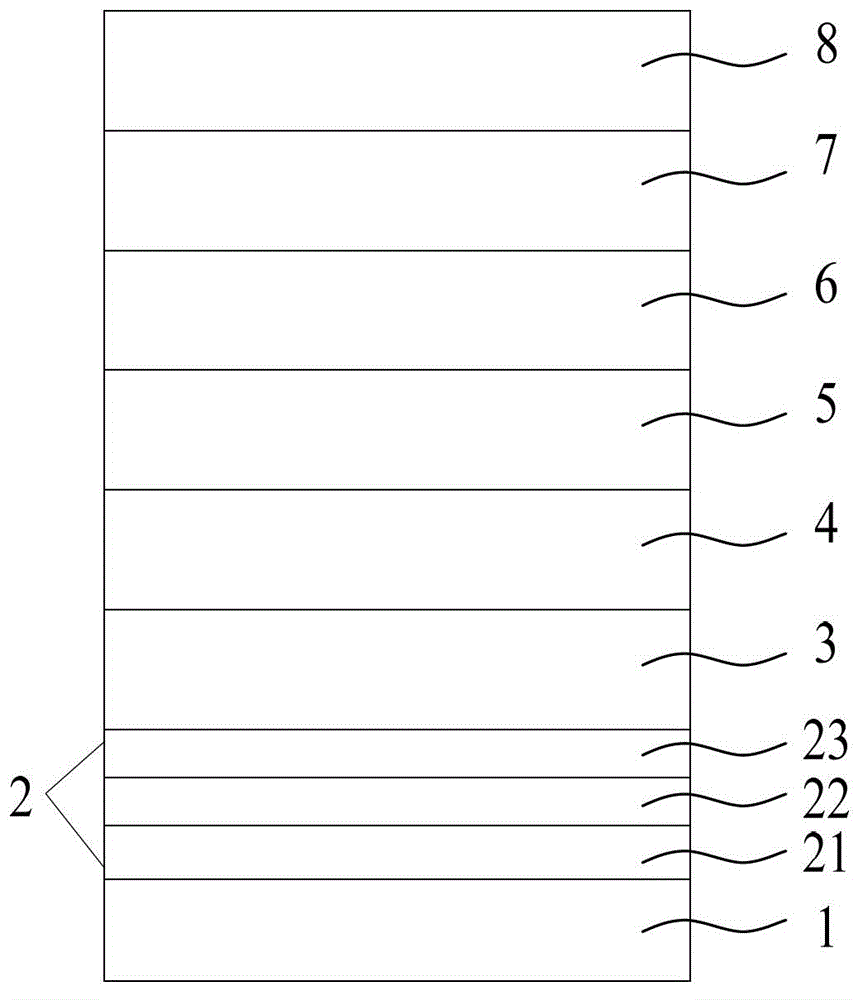

Organic electroluminescent device

ActiveCN102694125AImprove the exit rateReduced luminescence lossSolid-state devicesSemiconductor/solid-state device manufacturingRefractive indexOrganic electroluminescence

An organic electroluminescent device comprises a reflecting layer, a glass substrate, a conductive film, a metal cathode, an n-doped electron transport layer, a p-n doped luminescent layer, a p-doped hole transport layer and a metal anode which are orderly stacked together. The organic electroluminescent device is a top-emitting device of an inverse structure; lights are emitted from the top of the device, and the glass substrate equipped with the conductive film acts as a backlight surface, thus the problems of light absorption by the substrate and light emission from the substrate are well solved. In addition, the inverse structure enables the refractive index of materials to be arranged from small to big based on the direction of emitted light, and total reflection will not occur for the light at the moment, thus reducing light emission loss caused by total reflection and improving light exitance.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

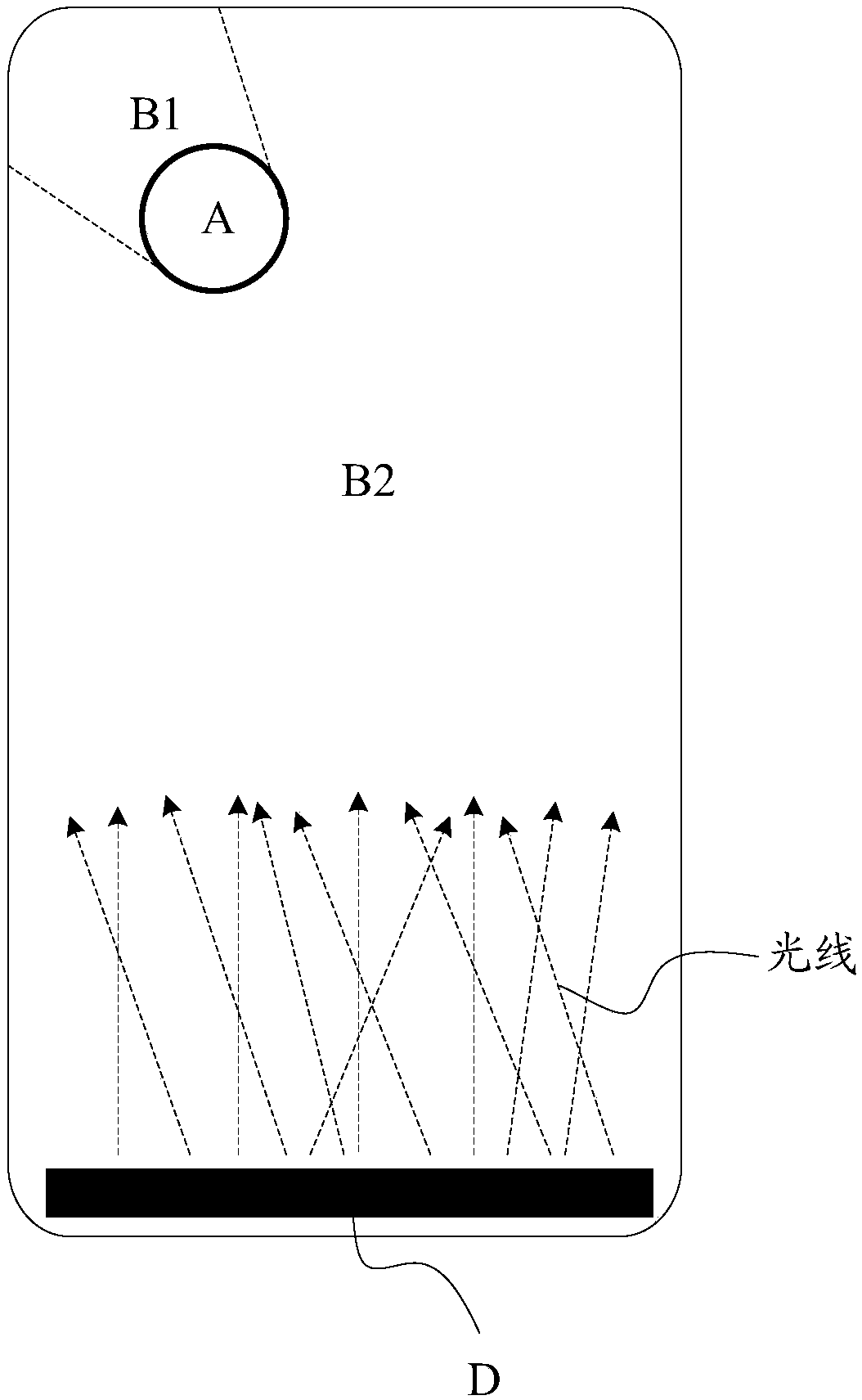

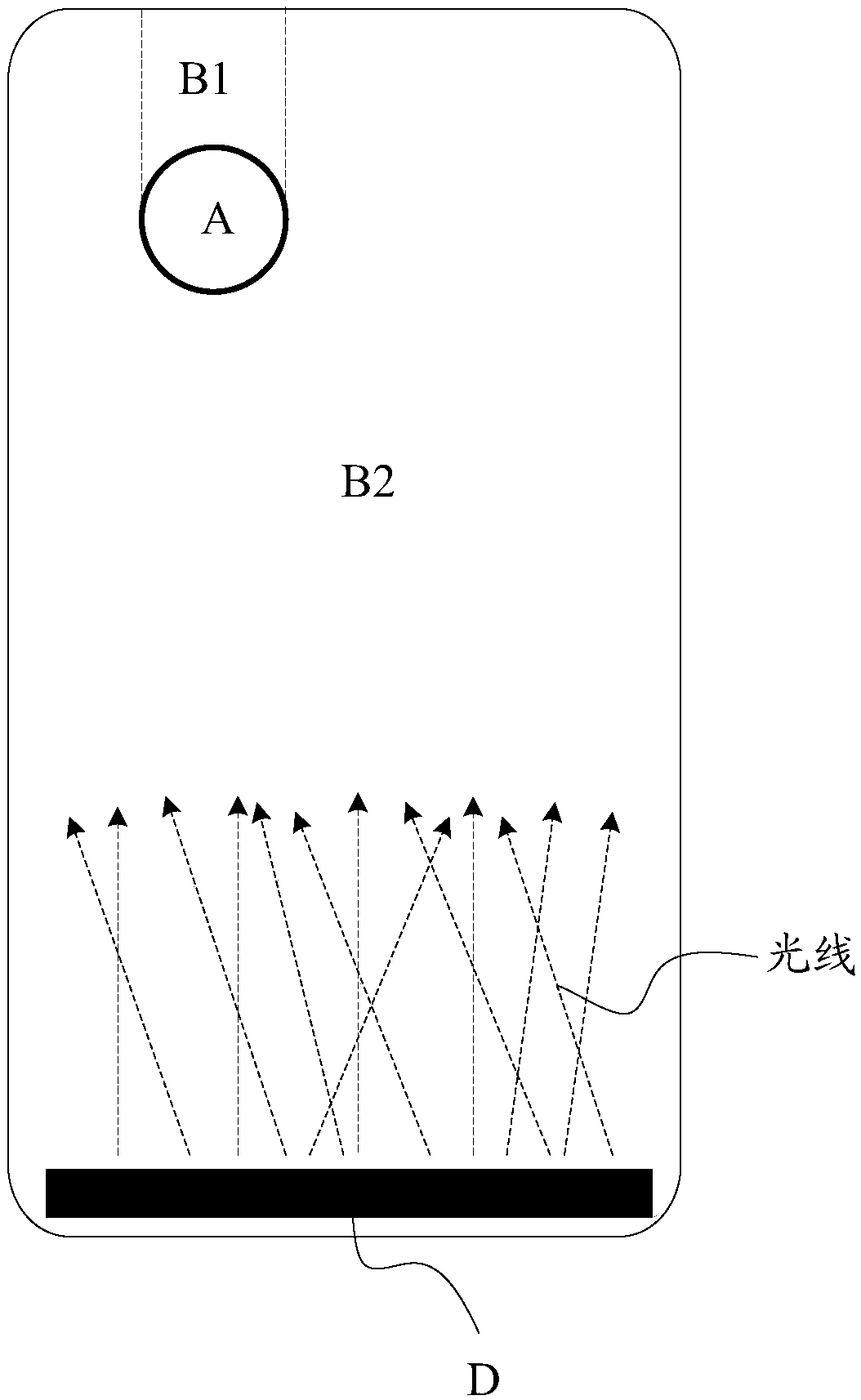

Display device

ActiveCN108826103AImprove the exit rateReduce absorption lossIdentification meansReflectorsMasking tapeDisplay device

The invention provides a display device. The display device comprises a display panel and a backlight module opposite to the display panel, wherein the backlight module comprises a lateral light source; the backlight module is provided with a through hole, which penetrates through the backlight module and are used for mounting functional modules. The display device also comprises a first masking tape which is arranged around the through hole and on the light-emitting surface of the backlight module for fixing the display panel and the backlight module; the first masking tape comprises a blackfirst surface adhered to the display panel, and a second surface adhered to the backlight module, wherein the second surface comprises a black first area and a white second area, the first area is arranged on the side of the through hole which is close to the lateral light source, and the second area is arranged on the side of the through hole which is away from the lateral light source.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

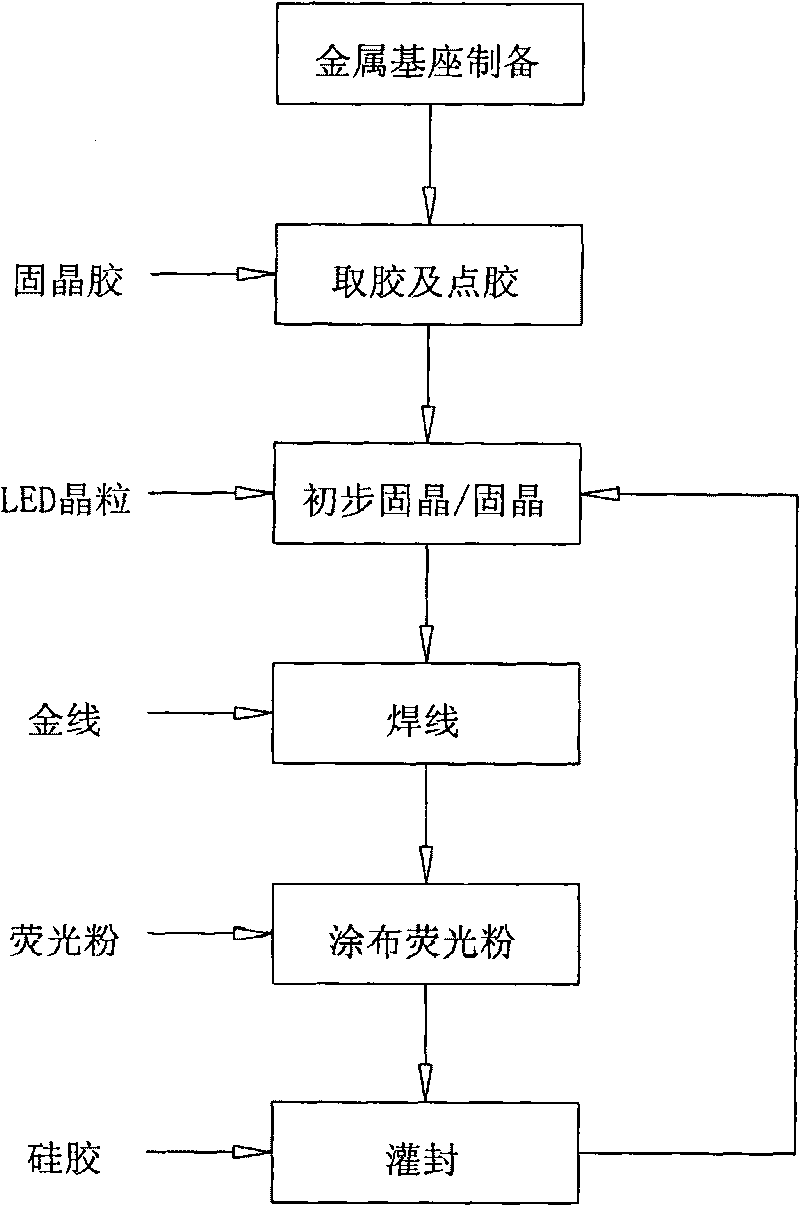

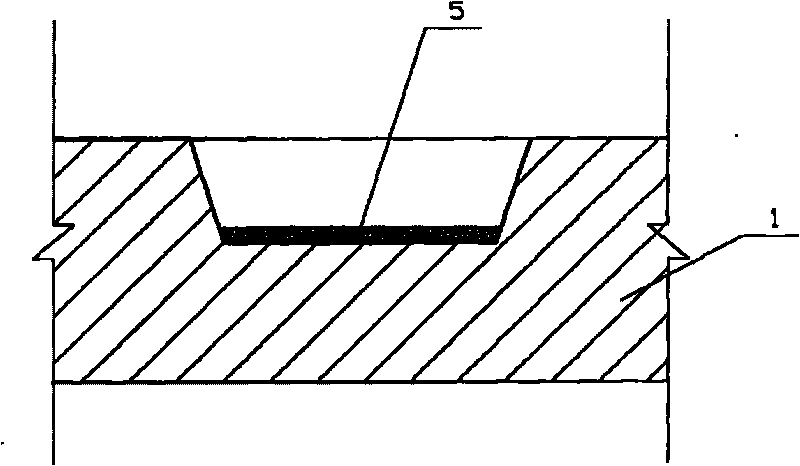

Novel LED die bonding method

The invention relates to a novel LED die bonding method which comprises the steps: firstly, coating a thin layer of die bonding glue on a bottom die bonding surface of a LED crystal particle fixing concave pit with a reflection layer on a metal base; after completion, placing the LED crystal particles at a base die bonding surface dispensed with die bonding glue, compacting and completing primary die bonding, then welding gold thread, coating fluorescent powder, and finally encapsulating by silica gel so as to wholly wrap LED crystal particles in the silica gel, thus completing final die bonding. The traditional LED carry out die bonding by the die bonding glue, while in the invention, only a thin layer of die bonding glue is coated for playing a role of primary die bonding, and finally the die bonding protection is carried out by encapsulating the silica gel. The method does not influence LED solid luminescence, and the light emitted from the periphery thereof is reflected out by the fixing concave pit, thus improving light extraction efficiency.

Owner:SUZHOU ZHONGZE OPTOELECTRONICS TECH

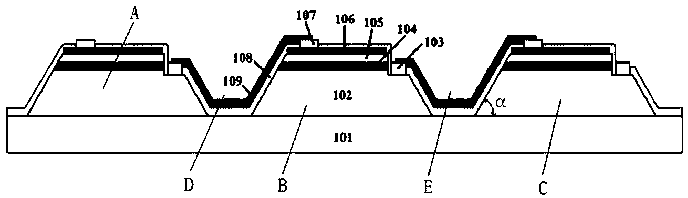

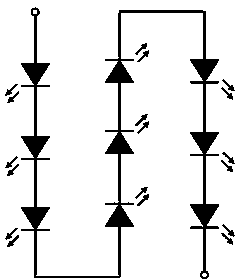

GaN-based LED integrated chip with multiple light-emitting sub areas

InactiveCN103730479AReduce the probability of breaking the circuitImprove reliabilitySolid-state devicesSemiconductor devicesReflection lossQuantum well

The invention discloses a GaN-based LED integrated chip with multiple light-emitting sub areas, and belongs to the technical field of LED chip structures. The GaN-based LED integrated chip with the multiple light-emitting sub areas comprises a substrate, an n-GaN layer, a quantum well active area, a p-GaN layer, a current spreading layer, a P electrode and at least two light-emitting sub areas. Grooves which are mutually isolated are formed between adjacent light-emitting sub areas, and the bottoms of the grooves are placed on the surface of the substrate. According to the GaN-based LED integrated chip with the multiple light-emitting sub areas, the open circuit probability is lowered to the maximum degree when an interconnecting wire stretches across the grooves, the emergent probability of internal total reflected light of the chip can be improved, internal reflection loss is reduced, and therefore light extraction efficiency is improved.

Owner:南京大学扬州光电研究院

Backlight source structure and working method thereof

InactiveCN102072436AReduce light lossImprove the exit rateMechanical apparatusLight guides for lighting systemsLong wavelengthSource structure

The invention discloses a backlight source structure and a working method thereof. Emergent blue light can be mixed with long-wavelength yellow light obtained by the transformation of the blue light in the excitation of fluorescent powder to obtain required white light by adopting a rational fluorescent powder proportion and distributing fluorescent powder dots on a light guide plate according to proper rules. Compared with the conventional method in which white-light light emitting diodes (LED) form a light source, the method is convenient to operate, reduces the cost of the light source, reduces optical loss, increases the exitance of the light, can further reduce the power of a backlight source and has great significance in energy saving popularization.

Owner:SUN YAT SEN UNIV

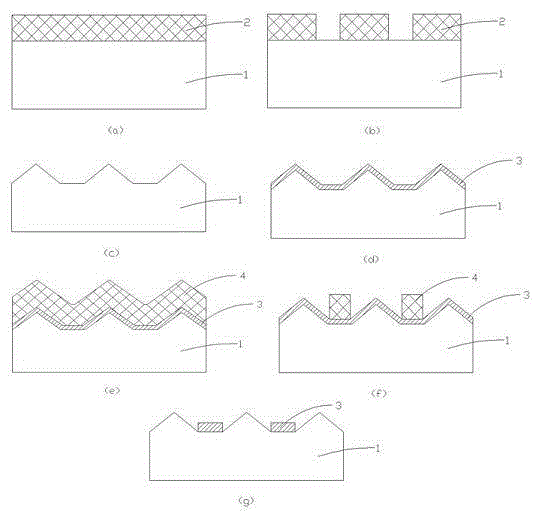

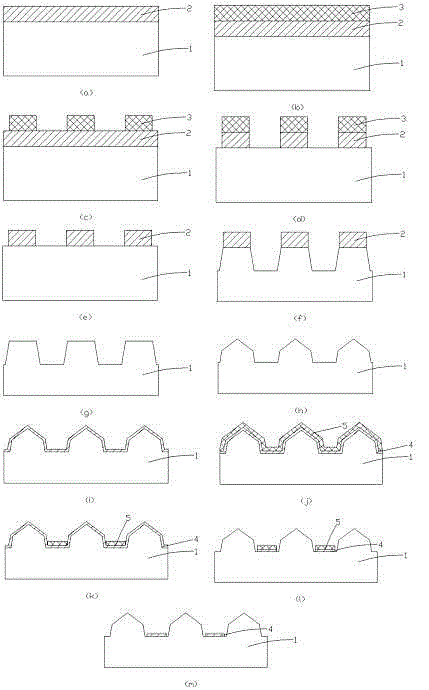

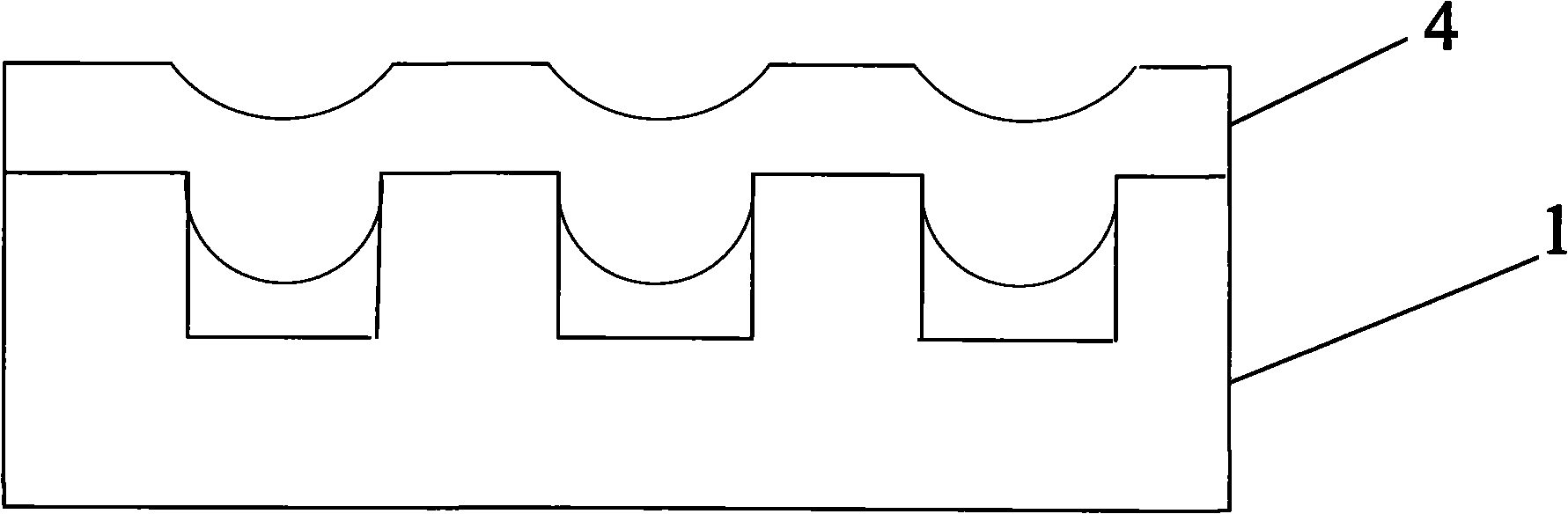

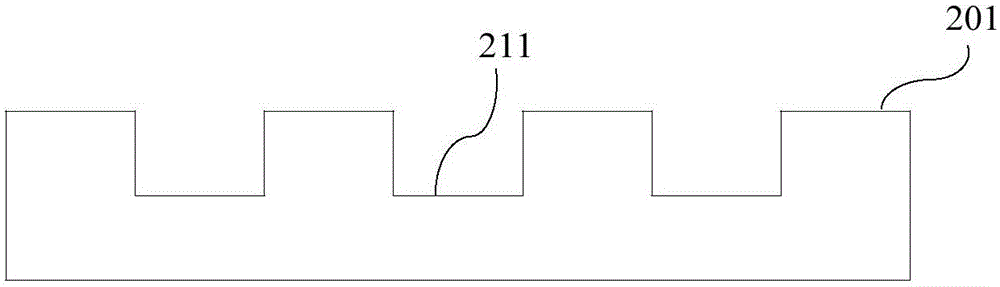

Producing method for graphical sapphire substrate

The invention discloses a producing method for a graphical sapphire substrate. A flat substrate is provided; a mask layer is formed on the surface; a graphical mask layer is produced on the surface of the mask layer by utilizing a photolithography; a graph is formed on the surface of the substrate by adopting a wet process corrosion or dry process etching technology by utilizing the graphical mask layer; the mask layer is removed; an insulating medium film is formed on the surface of the graphical substrate; the insulating medium film in the clearance of the graphical substrate is protected by utilizing the photolithography; the insulating medium film out of the photolithography protection is removed by adopting the wet process corrosion or dry process etching technology. According to the invention, epitaxy cannot grow on the surface of the insulating medium film; the epitaxial growth in the vertical direction is avoided; lateral epitaxial growth is increased; the dislocation density in a glowing area is reduced; the insulating medium film with certain film thickness is adopted to fill the clearance of the graphical substrate; the depth of the clearance is reduced; epitaxial growth cycle is reduced.

Owner:SHENZHEN DESUN PHOTOELECTRICITY

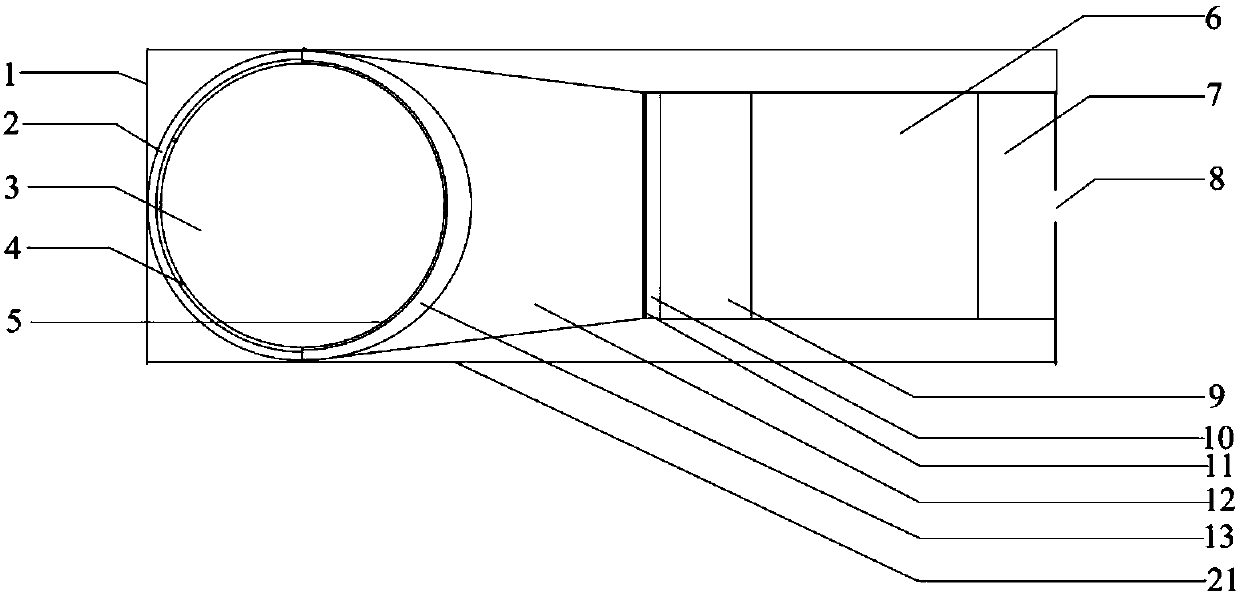

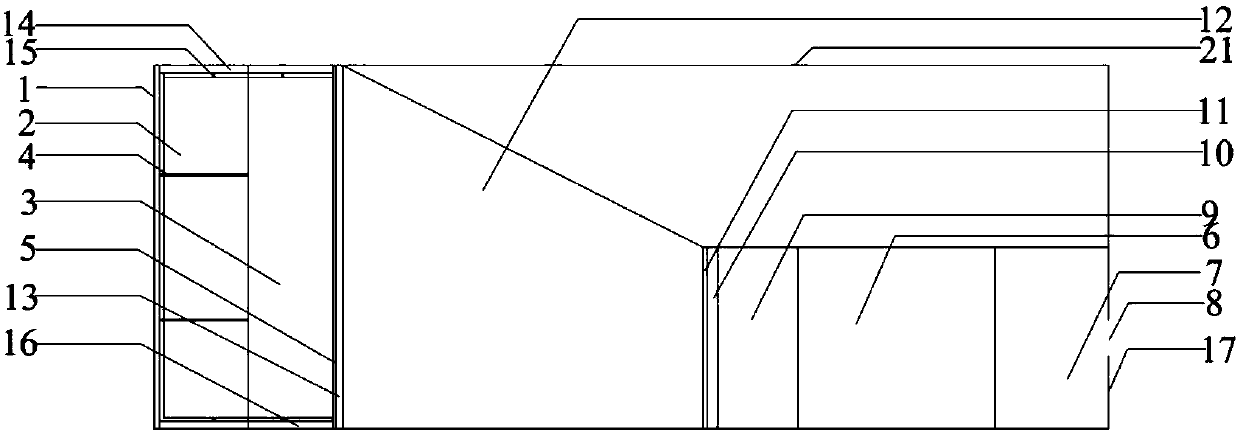

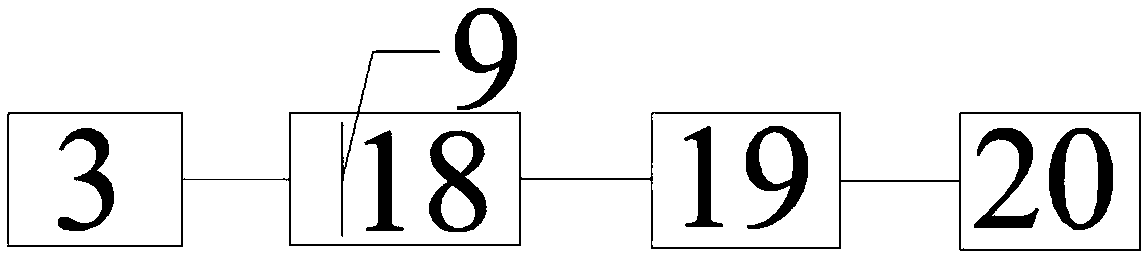

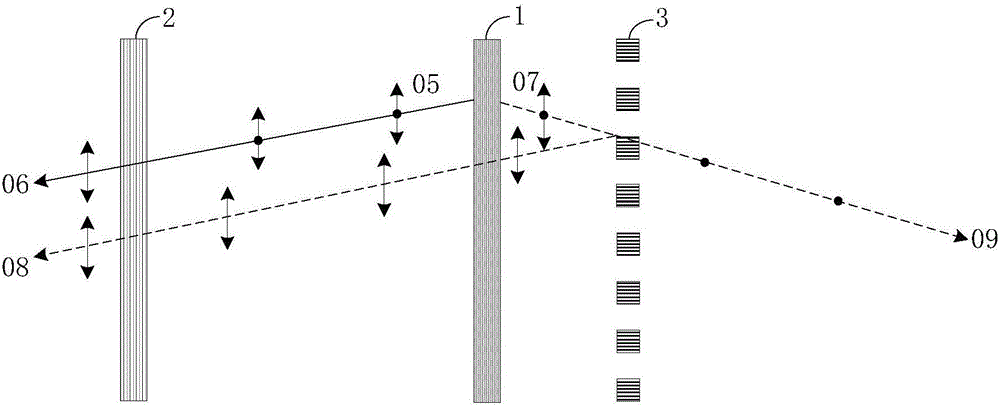

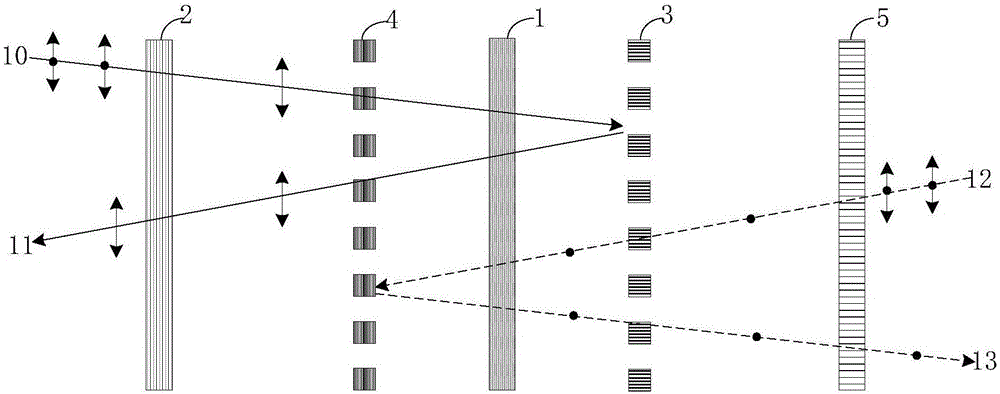

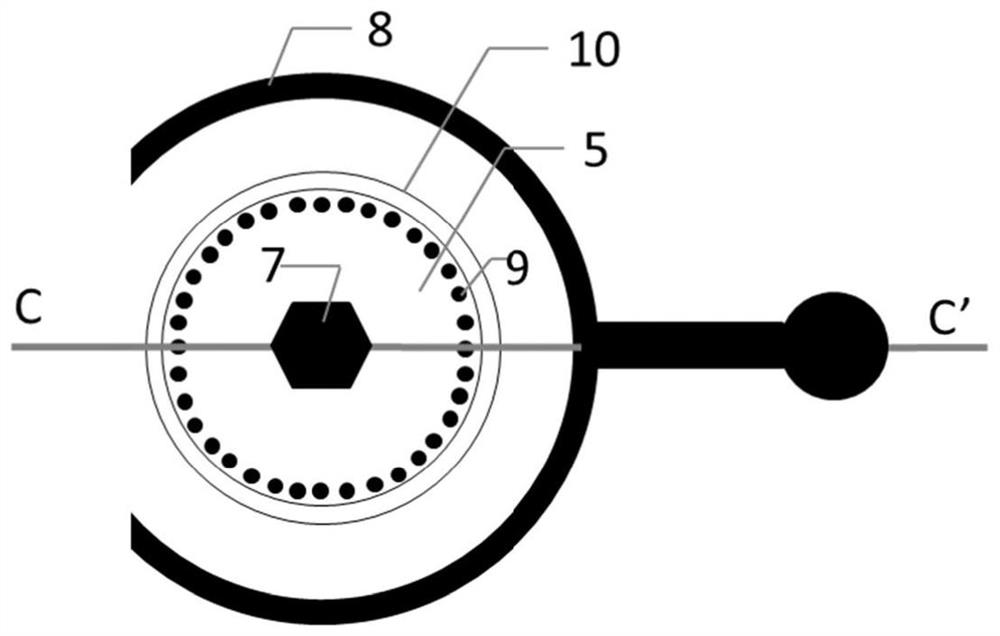

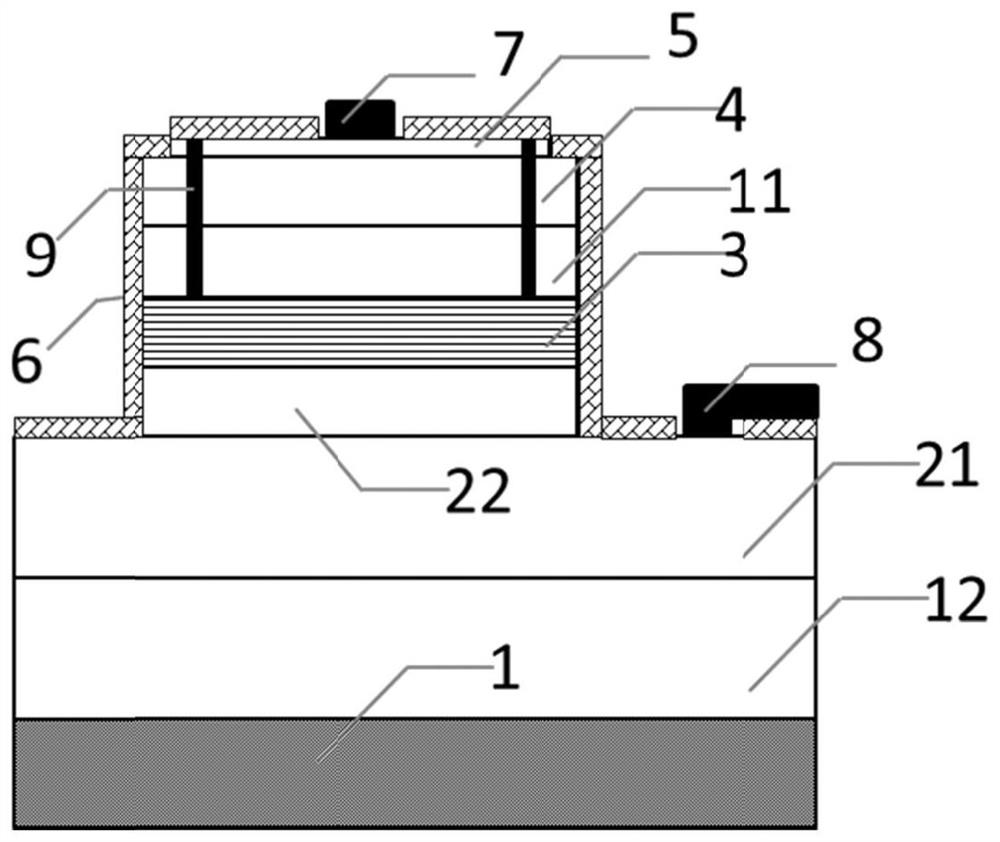

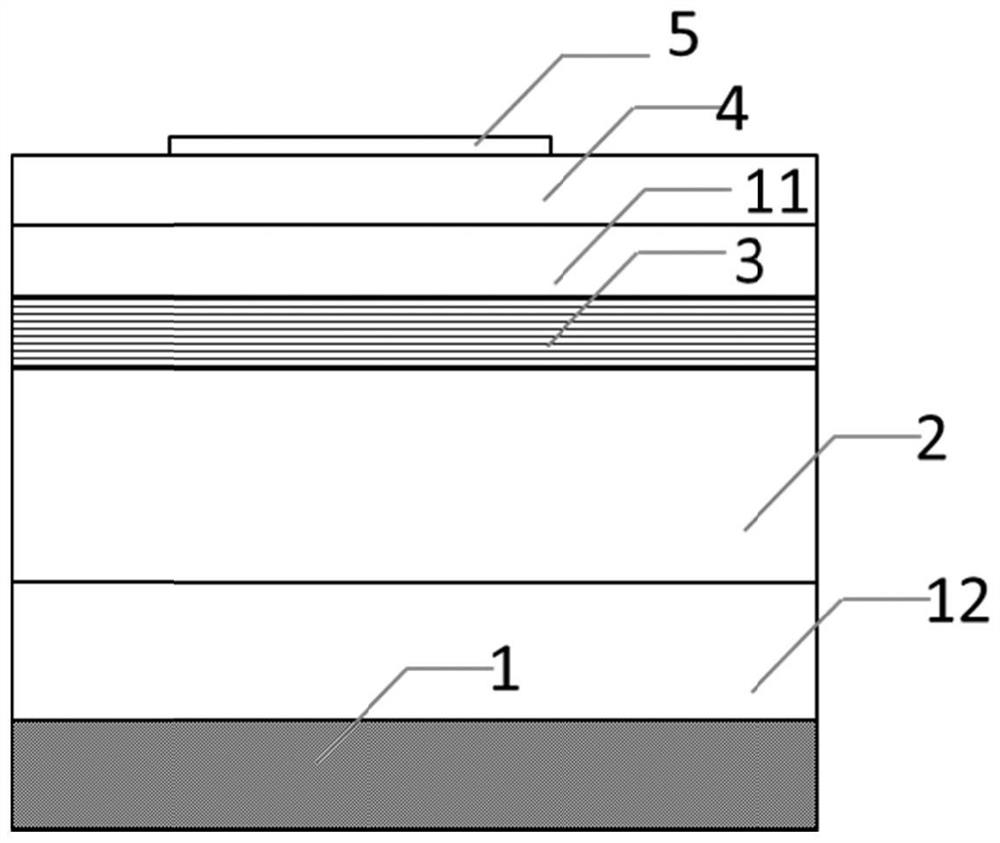

Novel scintillation detector with high photon transmission efficiency

InactiveCN107688193AImprove collection effectIncrease effective countX/gamma/cosmic radiation measurmentOptical pathlengthIonizing radiation

The invention discloses a novel scintillation detector with high photon transmission efficiency. The novel scintillation detector has the principle that when rays enters a crystal, secondary electronsare generated near the surface of the incidence end of the crystal (3), and fluorescence is generated; a part of fluorescence photons can be absorbed and consumed by the crystal and can escape to a position outside the crystal. The light path is reduced in a lateral window opening emitting mode; the photon collection is more facilitated. The escaped photon returns into the crystal (3) through thereflection by a reflecting layer; the generated photons pass through an antireflection film (5), a coupling agent (11), an optical glass convex lens (13) and a light guide cavity (12) to enter an optical cathode (9) of an electronics system (22) for generating photoelectrons; the photoelectrons are amplified and shaped by the subsequent electronic element to from a pulse signal; the event is finally recorded as a radiation event.

Owner:JILIN UNIV

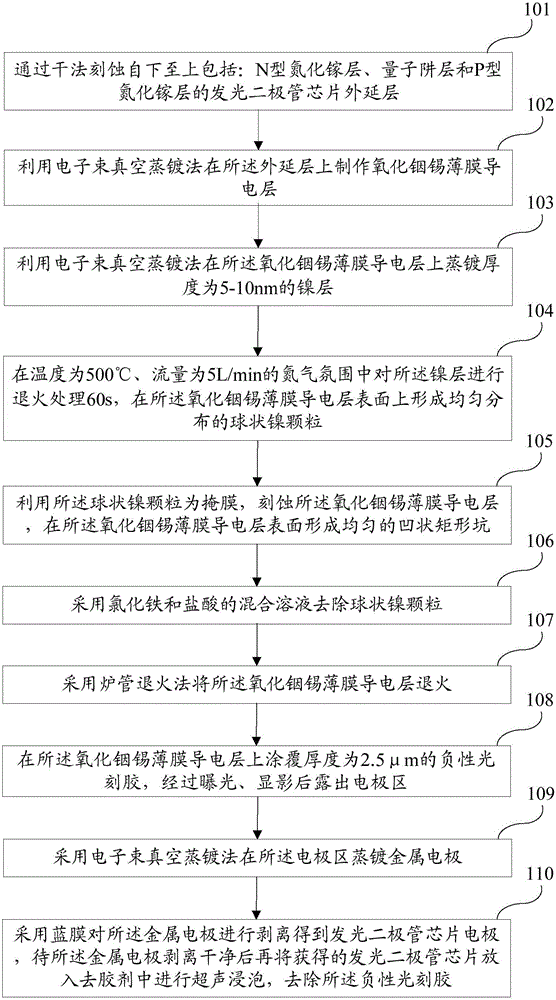

LED chip electrode and fabrication method thereof

ActiveCN105118905AImprove the exit rateImprove luminous efficiencySemiconductor devicesIndiumIndium tin oxide

The invention discloses a fabrication method of an LED chip electrode. The fabrication method includes the following steps that: dry etching is performed on an epitaxial layer, an N type GaN layer is exposed; an indium tin oxide film conductive layer is fabricated; a chromium layer is formed through evaporation; a nickel layer is formed through evaporation; annealing treatment is performed on the nickel layer under a nitrogen atmosphere, so that the nickel layer can form uniformly-distributed spherical nickel particles on the surface of the chromium layer; with the spherical nickel particles adopted as an etching mask, the chromium layer is etched, so that nanoscale recessed rectangular pits can be formed on the surface of the chromium layer through etching; the spherical nickel particles are removed through corrosion; an aluminized layer, a titanium layer, a platinum layer and a gold layer are formed sequentially through evaporation; and glue is removed through peeling, and as a result, the LED chip electrode can be obtained. The invention also discloses an LED chip electrode; the LED chip electrode includes a chromium layer, an aluminum layer, an evaporation aluminum, a titanium layer, a platinum layer and a gold layer which are distributed sequentially from bottom to top; and nanoscale recessed rectangular pits can be formed on the surface of the chromium layer through etching. According to the LED chip electrode and the fabrication method thereof of the invention, the nanoscale lumpy structures can be formed on the surface of the chromium layer, so that the exitance of light on the surface of the chromium layer can be increased; light that is reflected into the chip by the aluminum layer and is further reflected out can be increased, and therefore, the luminous efficiency of an LED can be obviously improved.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

Double-sided electroluminescent display panel and display device

ActiveCN106024848AIncrease contrastImprove low contrastSolid-state devicesSemiconductor/solid-state device manufacturingContrast ratioElectroluminescent display

The invention discloses a double-sided electroluminescent display panel and a display device. The display panel comprises a first absorption polarization structure arranged on a first light-emitting face of a transparent EL structure, and a first reflection polarization structure arranged on a second light-emitting face of an EL structure, wherein the homology axis of the first absorption polarization structure and the homology axis of the first reflection polarization structure are perpendicular to each other, the first absorption polarization structure is used for absorbing light of a first wave component and transmitting light of a second wave component, and the first reflection polarization structure is used for transmitting light of the first wave component and reflecting light of the second wave component. Through the common effect of the first absorption polarization structure and the first reflection polarization structure, the intensity of environment light can be weakened when the high emission ratio of self-illumination is ensured, the contrast ratio of the double-sided display panel is increased, the influences of environment light on the double-sided display panel are reduced, and the problem that an existing double-sided display panel is low in contrast ratio due to the transparent EL structure is solved.

Owner:BOE TECH GRP CO LTD +1

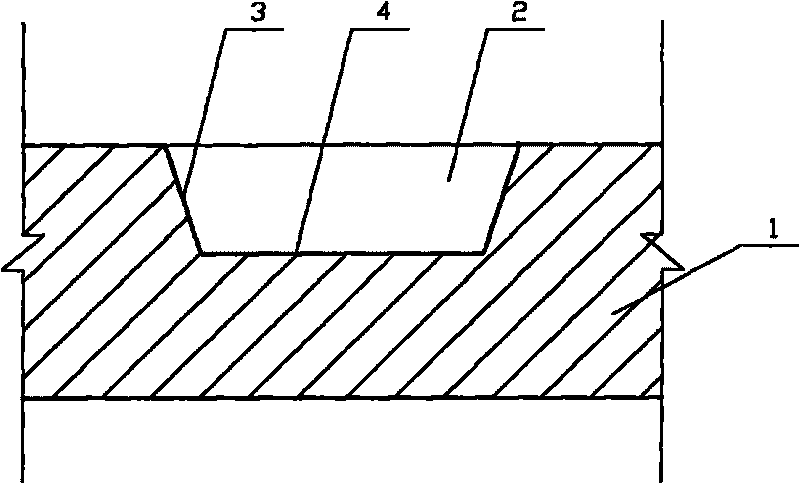

High-performance glass encapsulation method of light emitting diode

The invention discloses a method for encapsulating a light emitting diode by using a glass lens cavity with high extracting rate and light beam collimation. The method comprises the following steps of: step 1, preparing a glass lens of a sealed light emitting diode chip on a glass wafer; step 2, coating fluorescent powder: evenly coating a fluorescent powder layer on the periphery of the light emitting diode chip or coating fluorescent powder on the glass inner wall; and step 3, filling silica gel in a gap between the light emitting diode chip and a glass ball cavity, splicing with the silicon wafer carried with the light emitting diode chip through a glass encapsulating body so that the light emitting diode chip is located in a cavity at the back side of the glass encapsulating body. The invention can realize white light emitting diode with even light intensity and has high emission rate of light rays; the encapsulation glass lens realizes the collimation of the light beam; the encapsulating reliability is very good; and the effective working time of the light emitting device is greatly prolonged.

Owner:SOUTHEAST UNIV

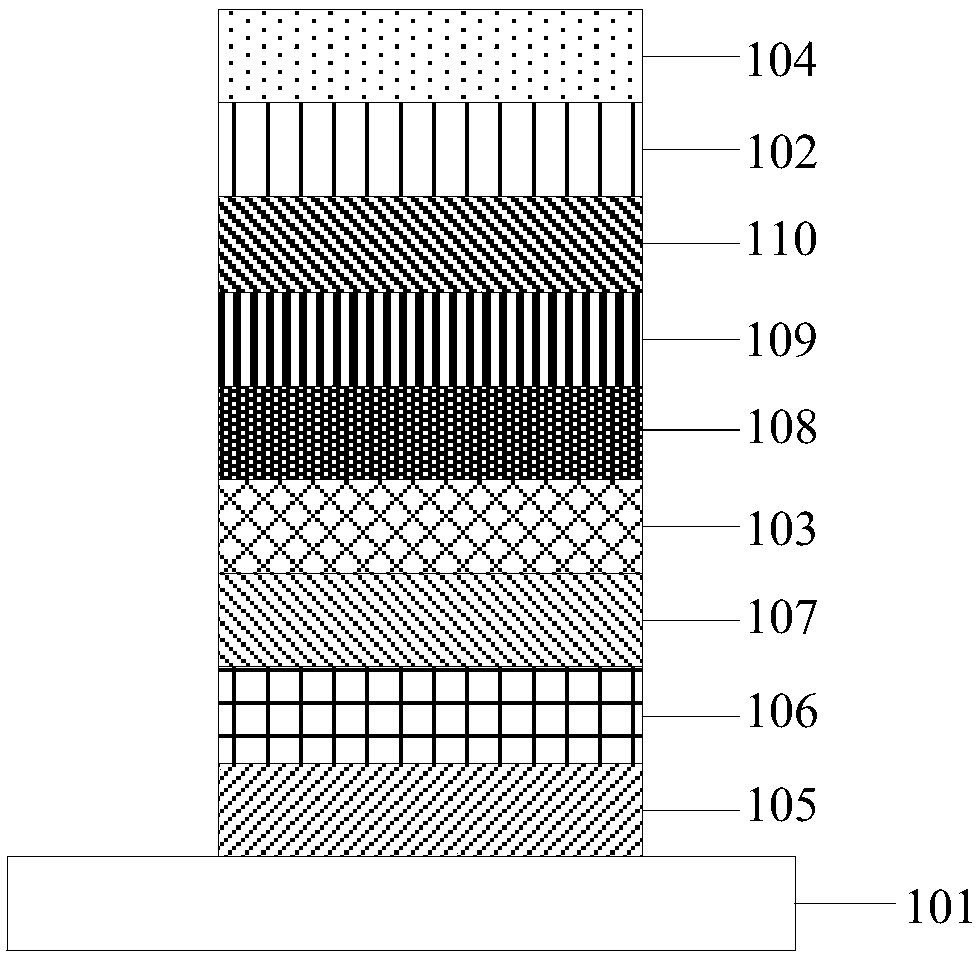

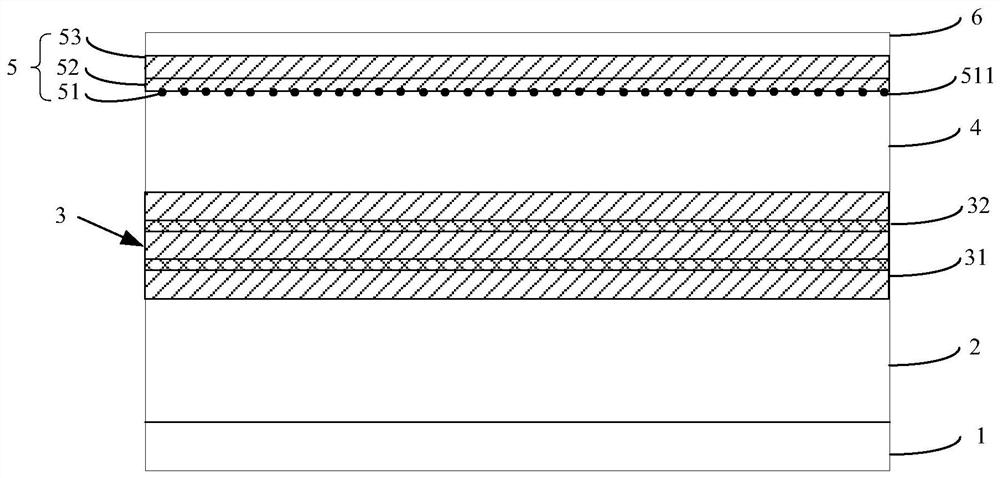

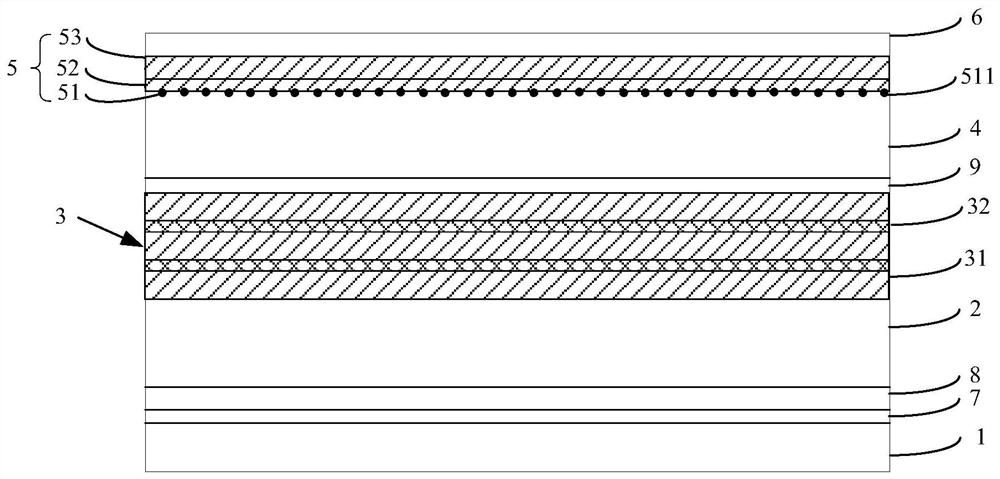

LED, manufacturing method thereof and display device

InactiveCN108565349ADoes not increase drive voltage differenceIncrease brightnessSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceRefractive index

The invention discloses a LED, a manufacturing method thereof and a display device. The LED comprises: a first electrode, a second electrode, a light-emitting layer between the first electrode and thesecond electrode, and a light extraction layer on a side of the second electrode away from the light-emitting layer; wherein the light extraction layer comprises a photoresponsive material. Since thecis-structure of the photoresponsive material can be easily converted into a trans-structure under ambient light conditions and the refractive index of the trans-structure of the photoresponsive material is greater than the refractive index of the cis-structure, the refractive index of the photoresponsive material increases under the effect of ambient light so that the refractive index of the light extraction layer containing the photoresponsive material may also increase. Thus, more light can be refracted from the LED, which effectively increases the light emission rate. Therefore, when theLED is used in outdoor high light environment, the brightness of the display device can be enhanced without increasing the driving voltage difference of the LED, and the standby time is not affected.

Owner:BOE TECH GRP CO LTD +1

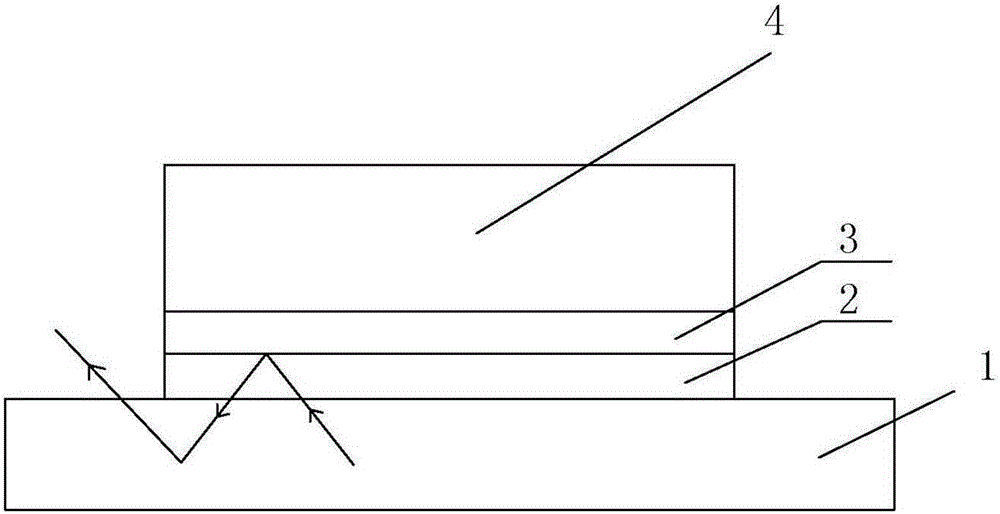

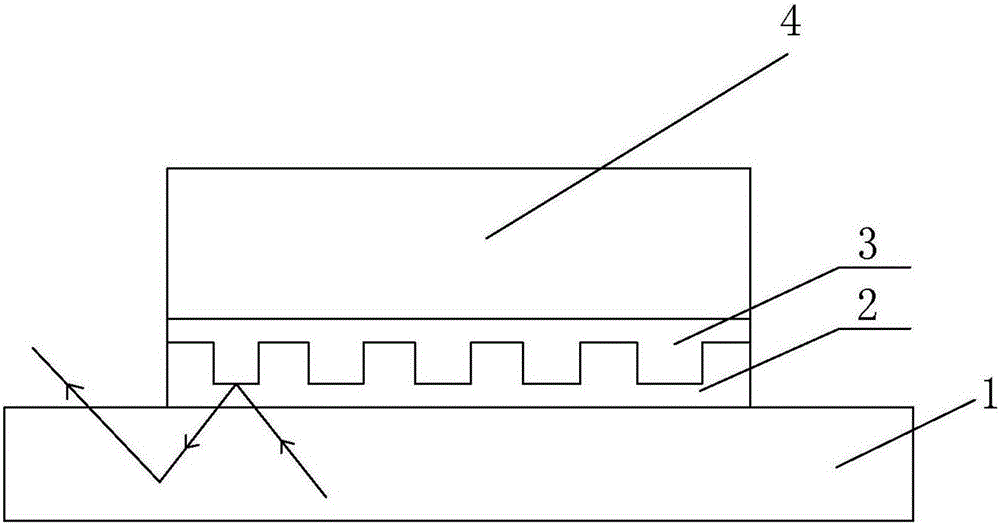

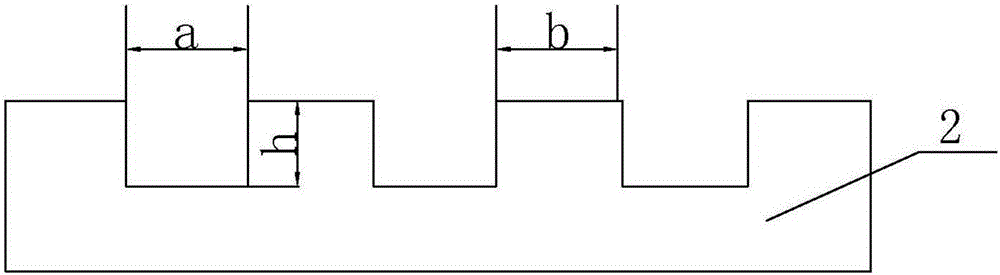

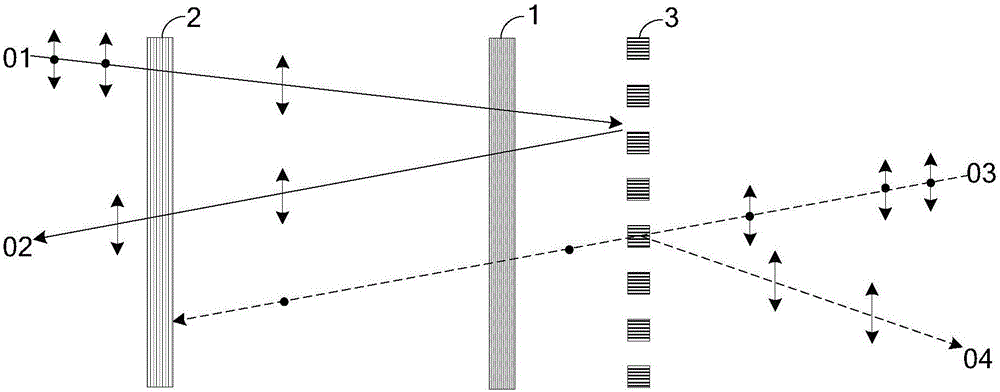

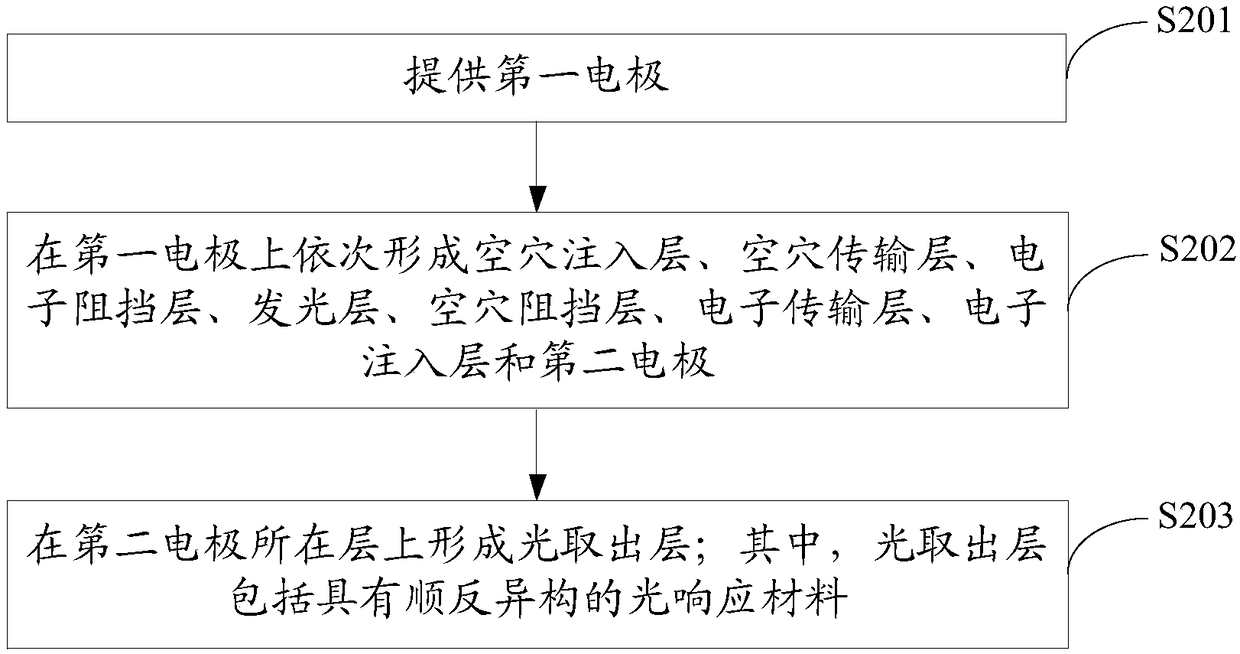

Top-emitting organic electroluminescence device and manufacturing method thereof

InactiveCN103137890AImprove the exit rateImprove anti-reflection effectSolid-state devicesSemiconductor/solid-state device manufacturingHole injection layerOptoelectronics

The invention discloses a top-emitting organic electroluminescence device and a manufacturing method thereof. The top-emitting organic electroluminescence device comprises a substrate, a positive electrode, a hole injection layer, a hole transmission layer, a luminescent layer, an electron transmission layer, an electron injection layer and a negative electrode, wherein a titanium dioxide antireflection film is formed on the negative electrode. The manufacturing method of the top-emitting organic electroluminescence device comprises a procedure that the titanium dioxide antireflection film is formed on the negative electrode. Compared with a top-emitting organic electroluminescence device in the prior art, the top-emitting organic electroluminescence device has the advantages that the light emitting rate is high, and luminous efficiency is greatly improved.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

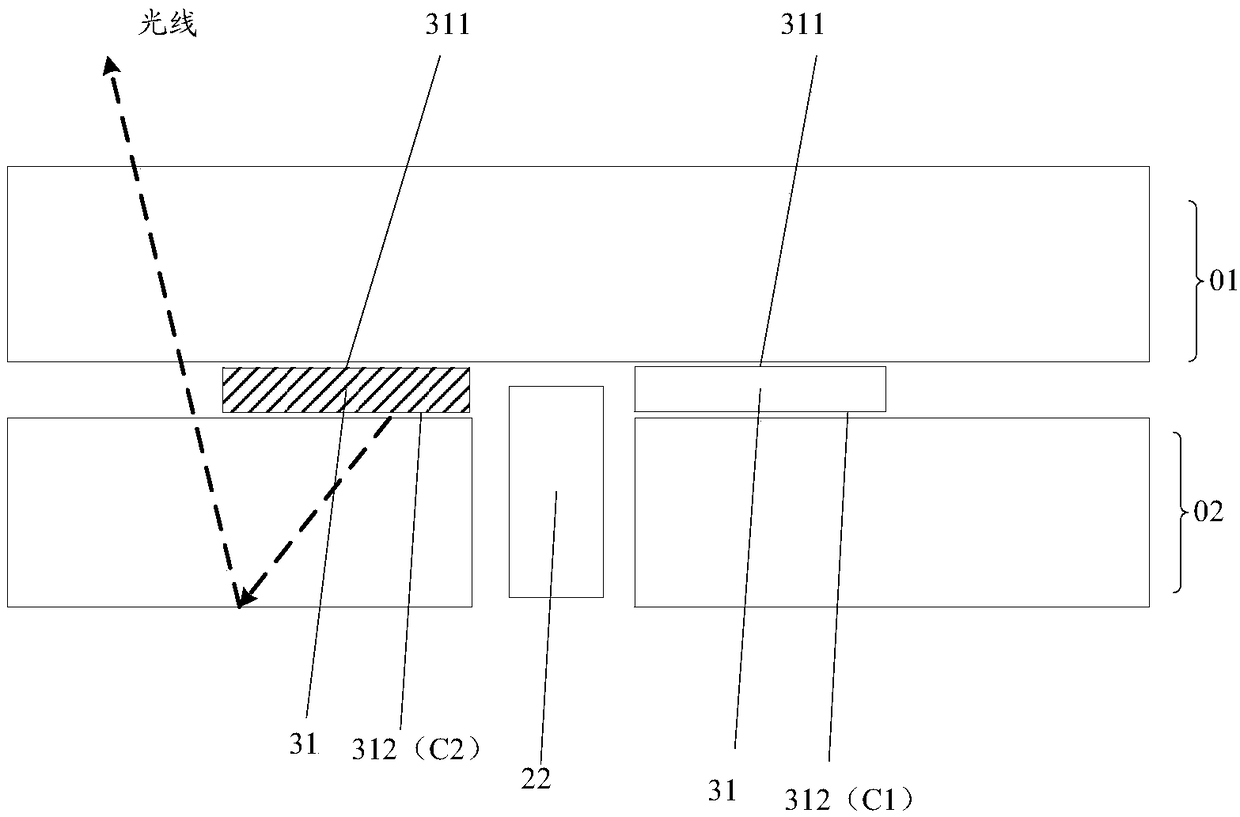

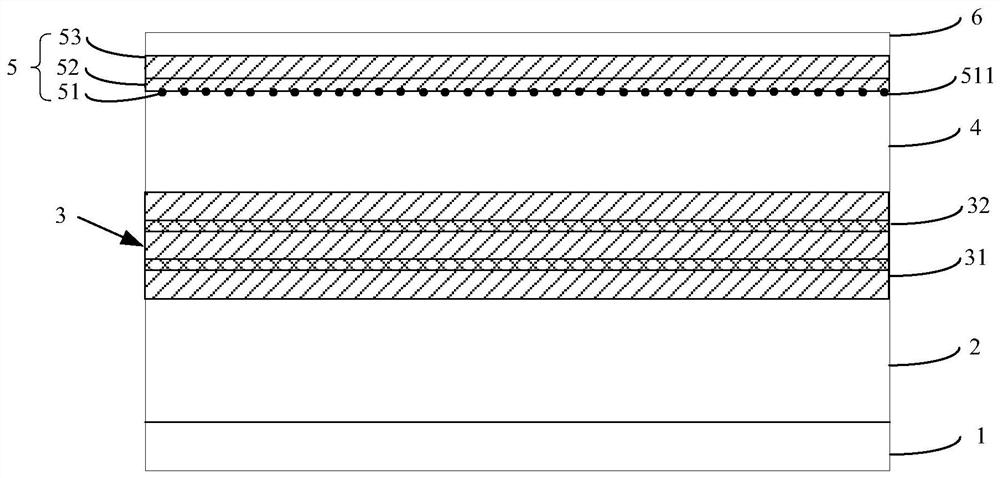

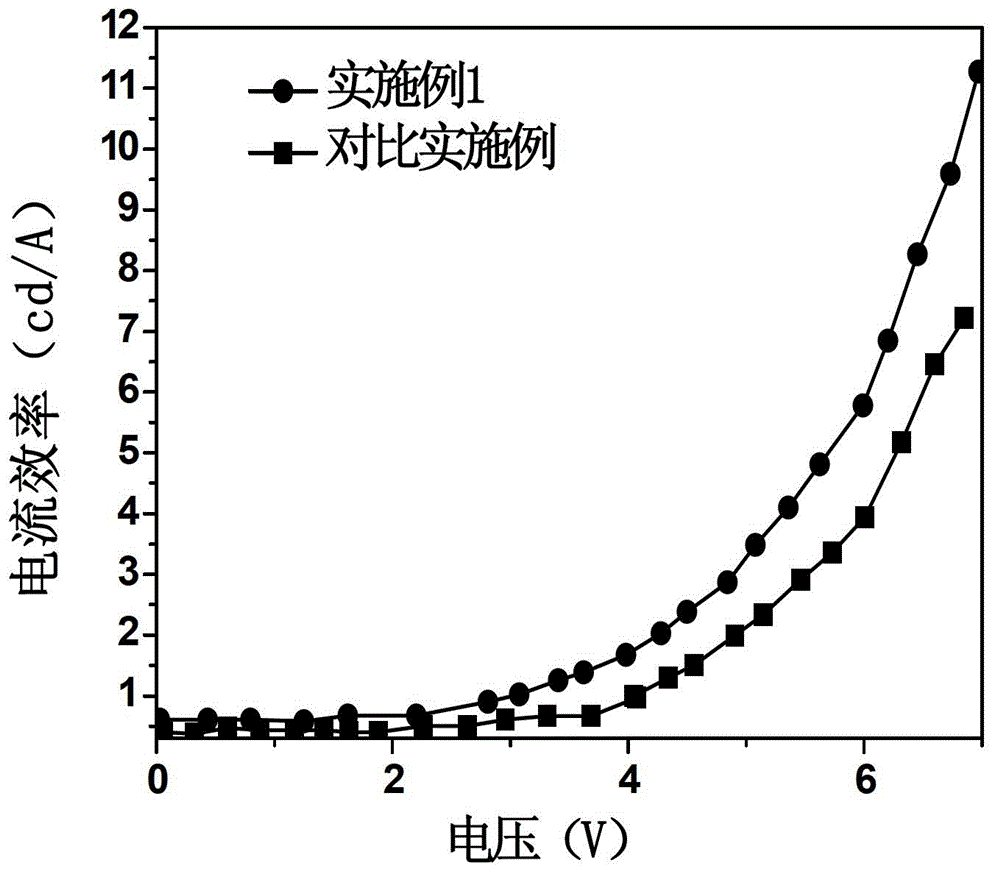

Light guide structure, OLED (Organic Light-Emitting Diode) display component and display device

InactiveCN103698839AImprove the exit rateImprove the display effectSolid-state devicesOptical light guidesLight guideMedia layer

The invention relates to the field of display technology, in particular to a light guide structure, an OLED (Organic Light-Emitting Diode) display component and a display device. The light guide structure comprises a first medium layer and a second medium layer which have different dielectric constants; metal nanoparticles for enhancing the light guide effect are arranged between the interfaces of the first medium layer and the second medium layer. The light guide structure, the OLED display component and the display device which are provided by the invention have the advantage that because the metal nanoparticles are arranged between the two light guide layers, the luminous exitance can be increased to the max.

Owner:BOE TECH GRP CO LTD

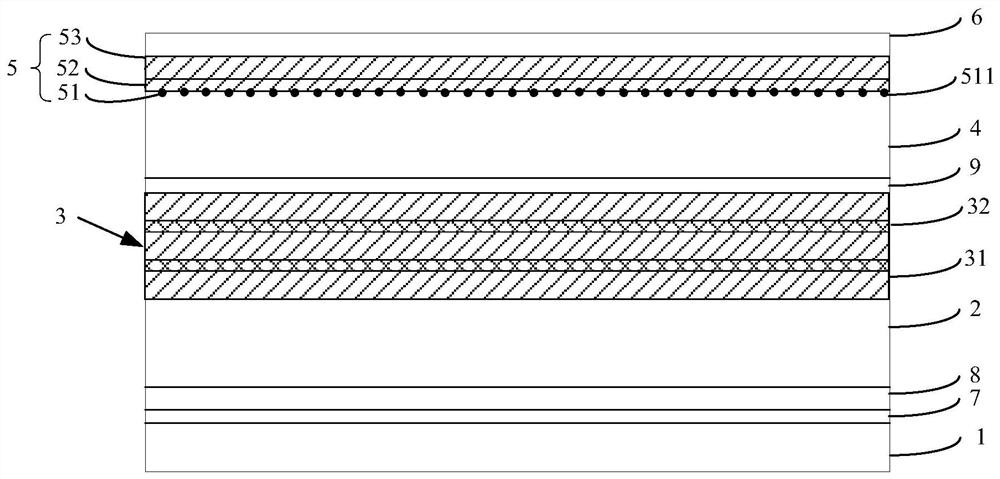

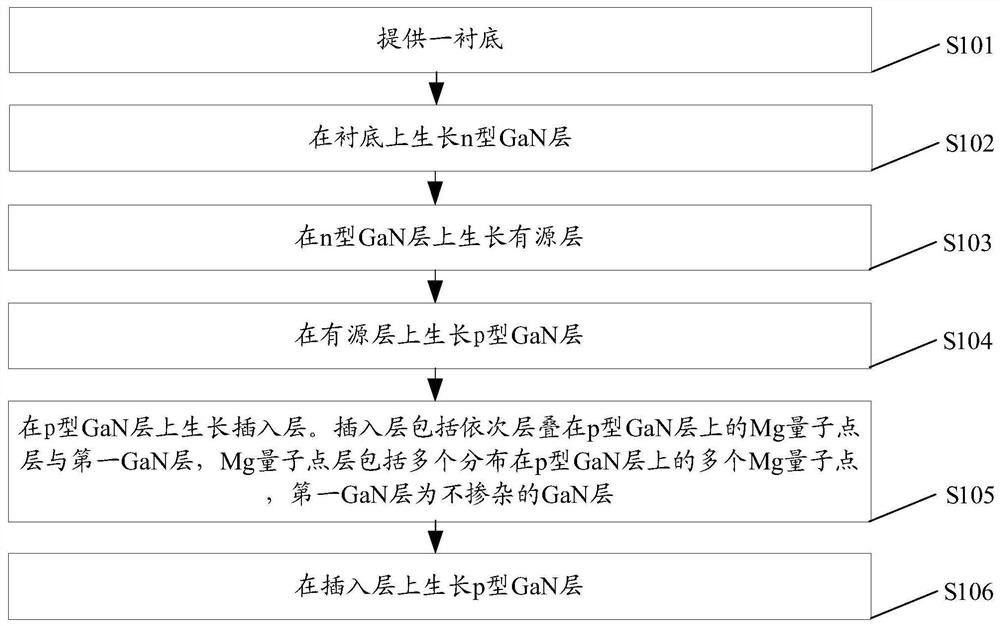

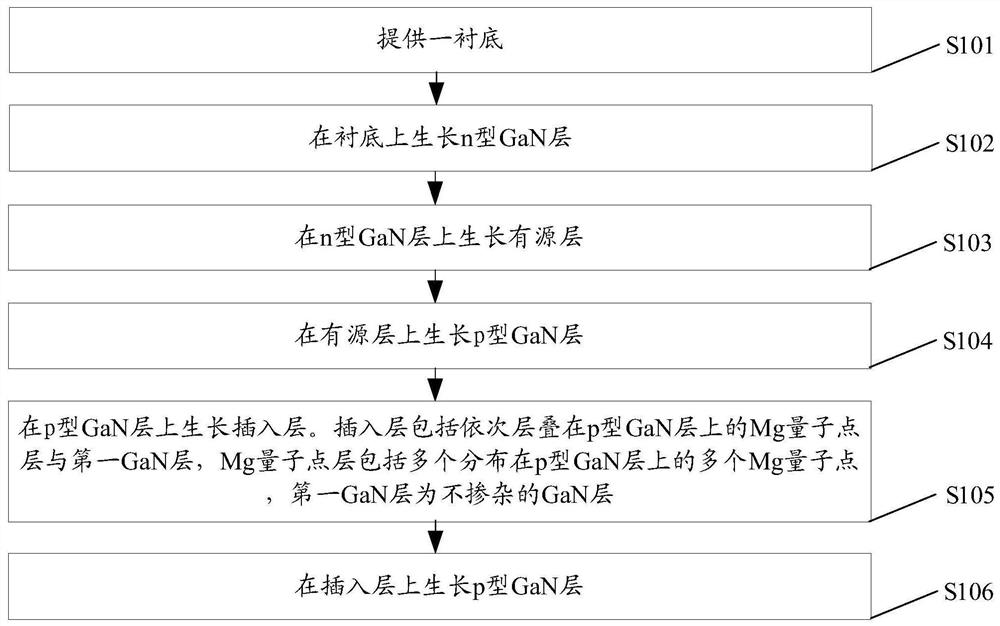

Light-emitting diode epitaxial wafer and preparation method thereof

ActiveCN112186081AImprove the exit rateQuality assuranceSemiconductor devicesQuantum dotDiffuse reflection

The invention provides a light-emitting diode epitaxial wafer and a preparation method thereof, and belongs to the technical field of light emitting diodes. An insertion layer is added between a p-type GaN layer and a p-type contact layer, and the insertion layer comprises an Mg quantum dot layer and a first GaN layer which are sequentially stacked on the p-type GaN layer. The Mg quantum dot layercomprises a plurality of Mg quantum dots distributed on the p-type GaN layer, the interfaces between the plurality of Mg quantum dots and the p-type GaN layer and between the plurality of Mg quantumdots and the first GaN layer are rough, diffuse reflection of light rays at the interface of the p-type GaN layer can be increased, total reflection of the light rays possibly occurring at the interface of the p-type GaN layer is reduced, and therefore the light emitting rate is improved. The first GaN layer can cover the rough surface of the Mg quantum dot layer, and the quality of the p-type contact layer growing on the first GaN layer is ensured. The light extraction rate of the finally obtained light-emitting diode epitaxial wafer can be improved.

Owner:HC SEMITEK SUZHOU

Transparent conducting layer manufacturing method for increasing light emitting diode chip brightness

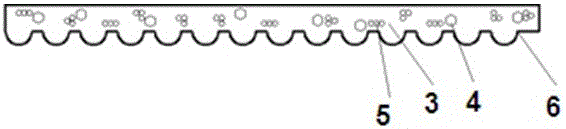

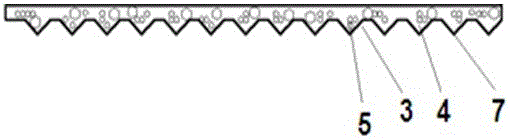

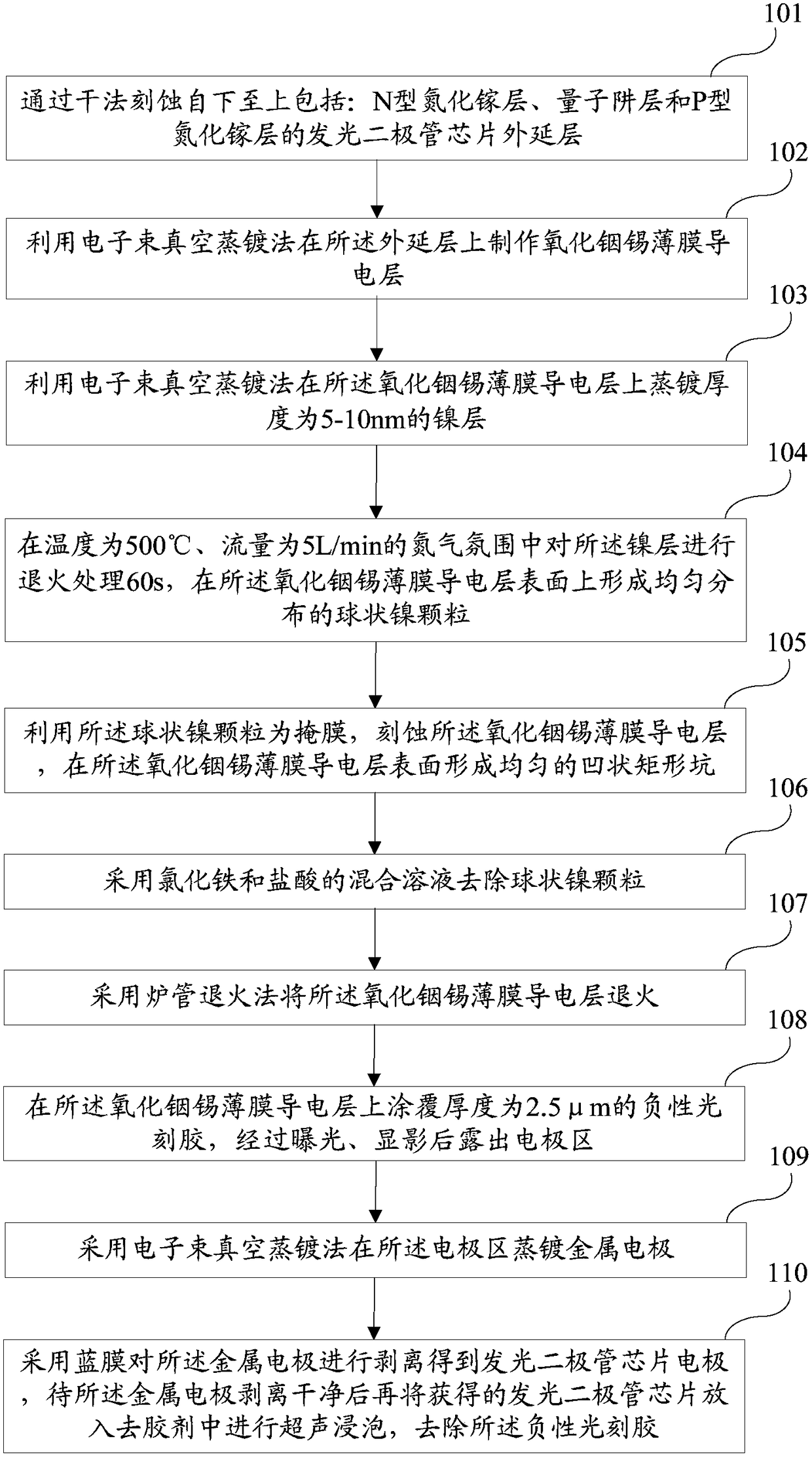

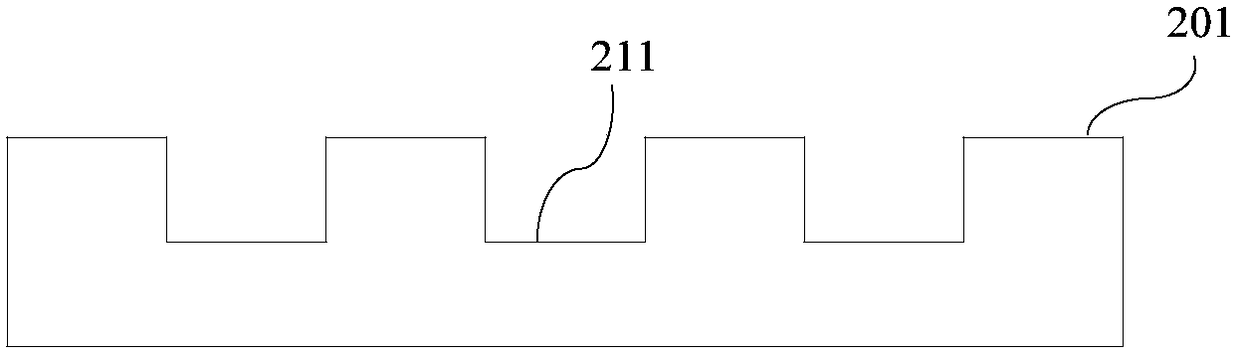

ActiveCN105789403AImprove luminous efficiencyImprove the exit rateSemiconductor devicesIndiumEvaporation

The invention discloses a transparent conducting layer manufacturing method for increasing light emitting diode chip brightness. The method comprises following steps: etching a light emitting diode chip epitaxial layer through a dry method preparing a tin indium oxide film conducting layer on the epitaxial layer; preparing a nickel layer with thickness from 5 to 10 nm on the tin indium oxide film conducting layer by a vapor plating method; performing annealing to the nickel layer; forming uniformly distributed spherical nickel particles on the tin indium oxide film conducting layer surface; etching the tin indium oxide film conducting layer with the spherical nickel particles as a mask layer to form uniform concave rectangular pits on the tin indium oxide film conducting layer surface; removing the spherical nickel particles; coating the tin indium oxide film conducting layer with negative photoresist and exposing electrode zones after exposure and development; preparing metal electrodes at the electrode zones by means of the vacuum electron beam evaporation method; peeling the metal electrodes to obtain light emitting diode chip electrodes and removing the negative photoresist. By means of the method, the brightness of light diode chip is increased.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

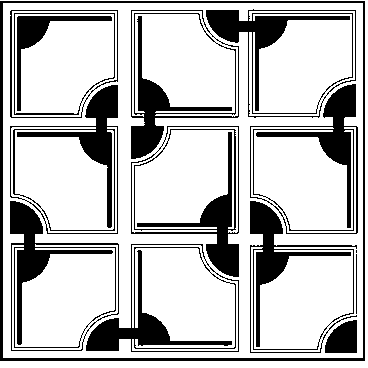

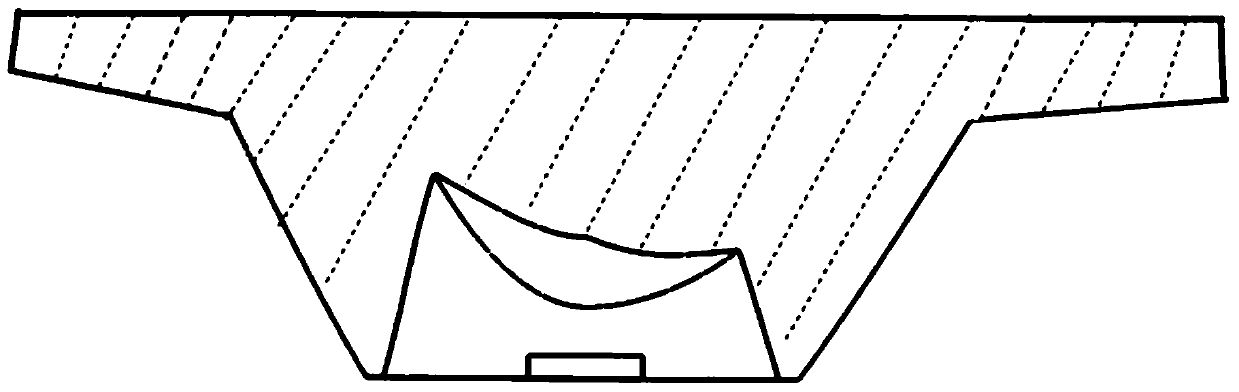

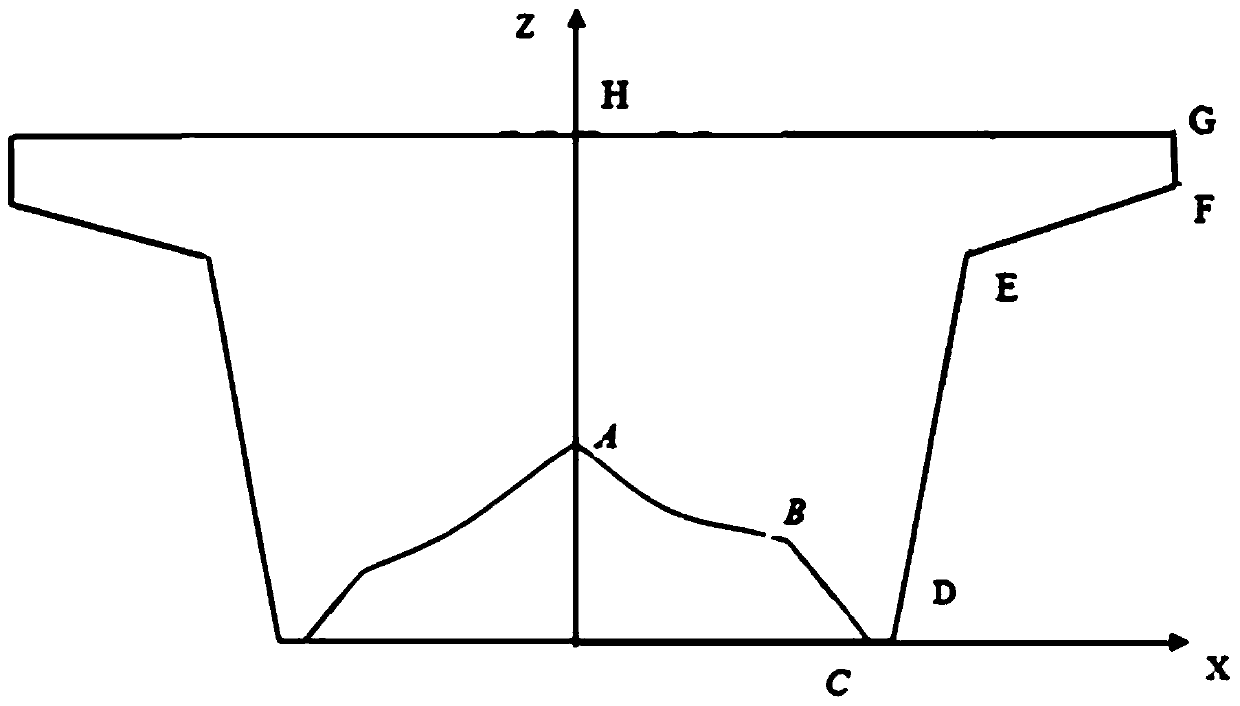

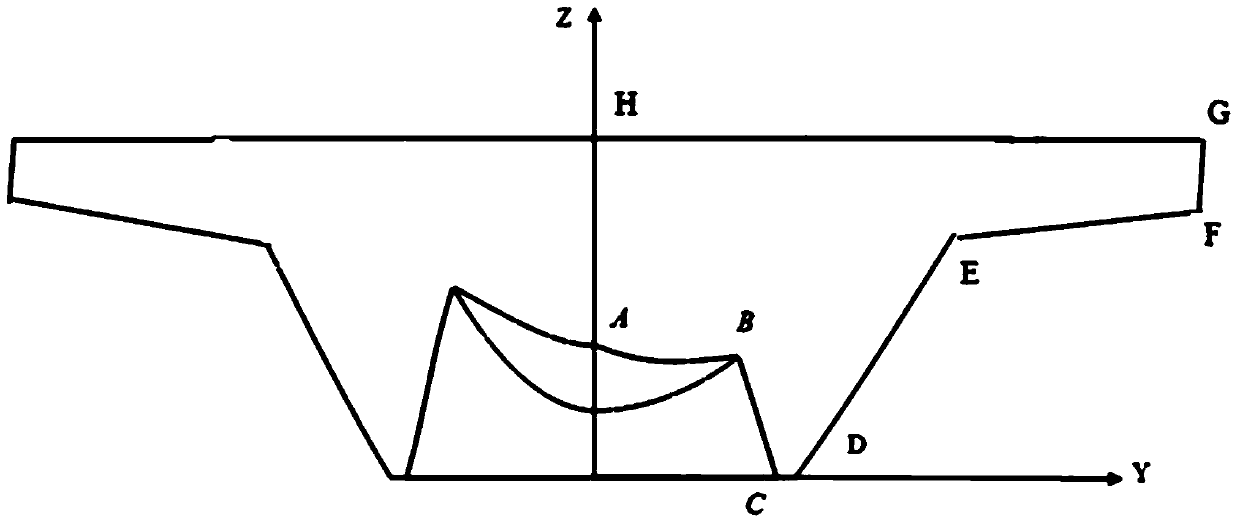

LED graphic optimized packaging substrate, LED packaging member and manufacture method thereof

InactiveCN104752586AImprove light extraction efficiencyIncrease the probability of exitSemiconductor devicesLed packagingEngineering

The invention discloses an LED graphic optimized packaging substrate provided with inverted conical groove patterns. The radius of the bottoms of the inverted conical grooves ranges from 0.3 to 1mm, the incline angle of the inverted conical grooves ranges from 45 to 75 degrees, and the distance between the centers of the inverted conical grooves ranges from 0.5 to 1mm; a silver layer is planted on the horizontal surface and the surfaces of the inverted conical grooves of the packaging substrate. The invention further discloses an LED packaging member with the graphic optimized packaging substrate and a manufacture method thereof. Compared with the prior art, the substrate has the advantages that the direct emitting opportunity is provided for fully reflected light, and the light emitting efficiency is improved by 13.5% around.

Owner:SOUTH CHINA UNIV OF TECH

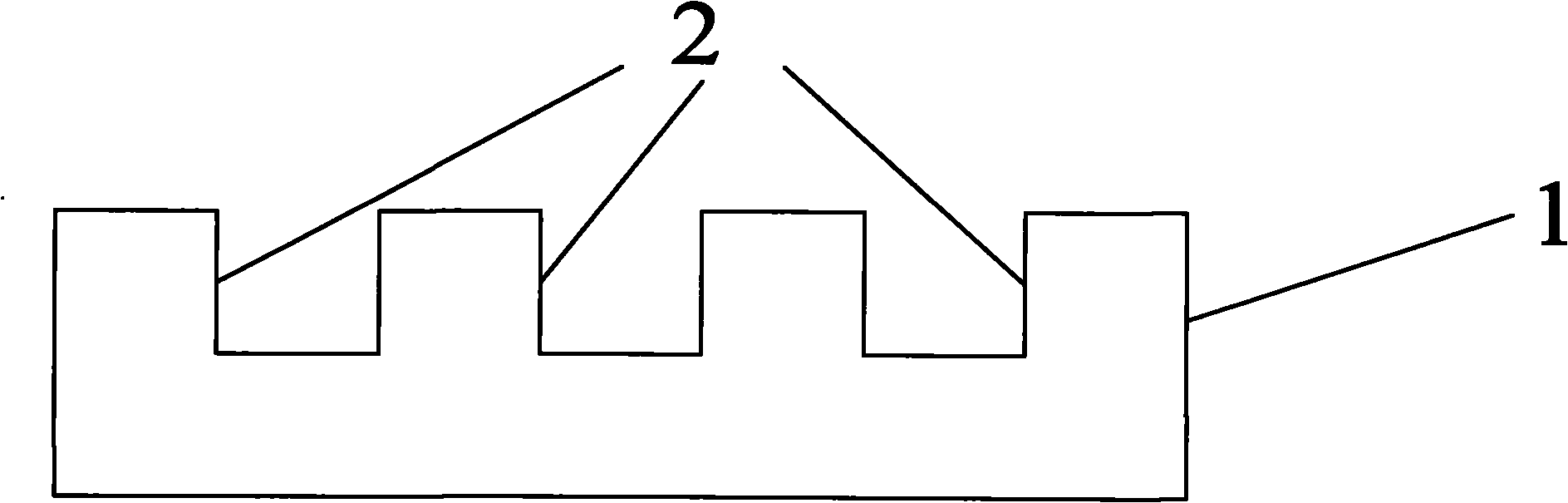

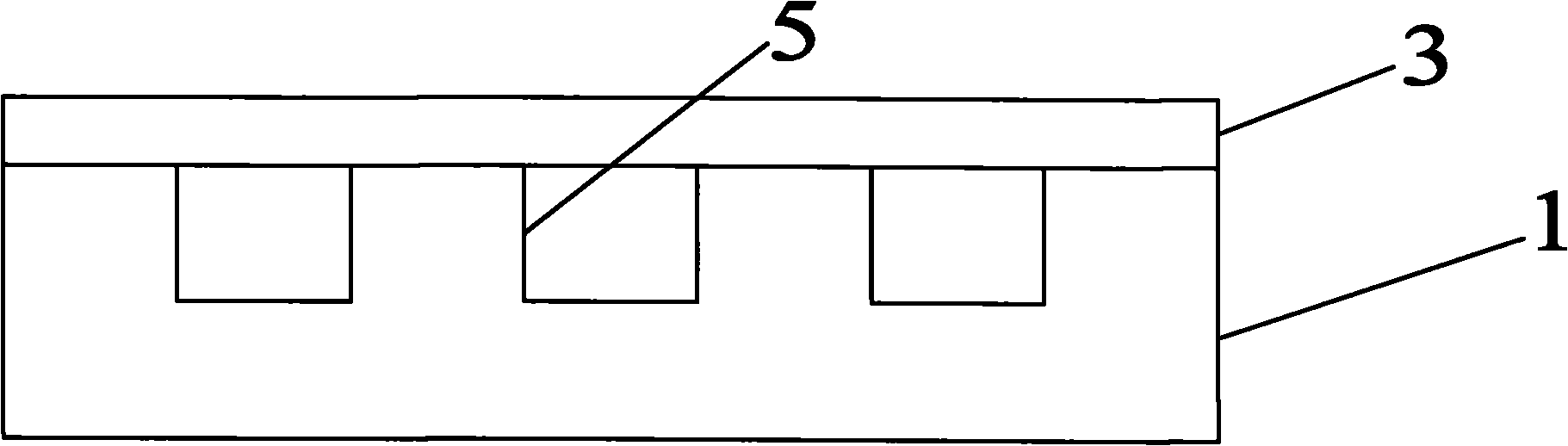

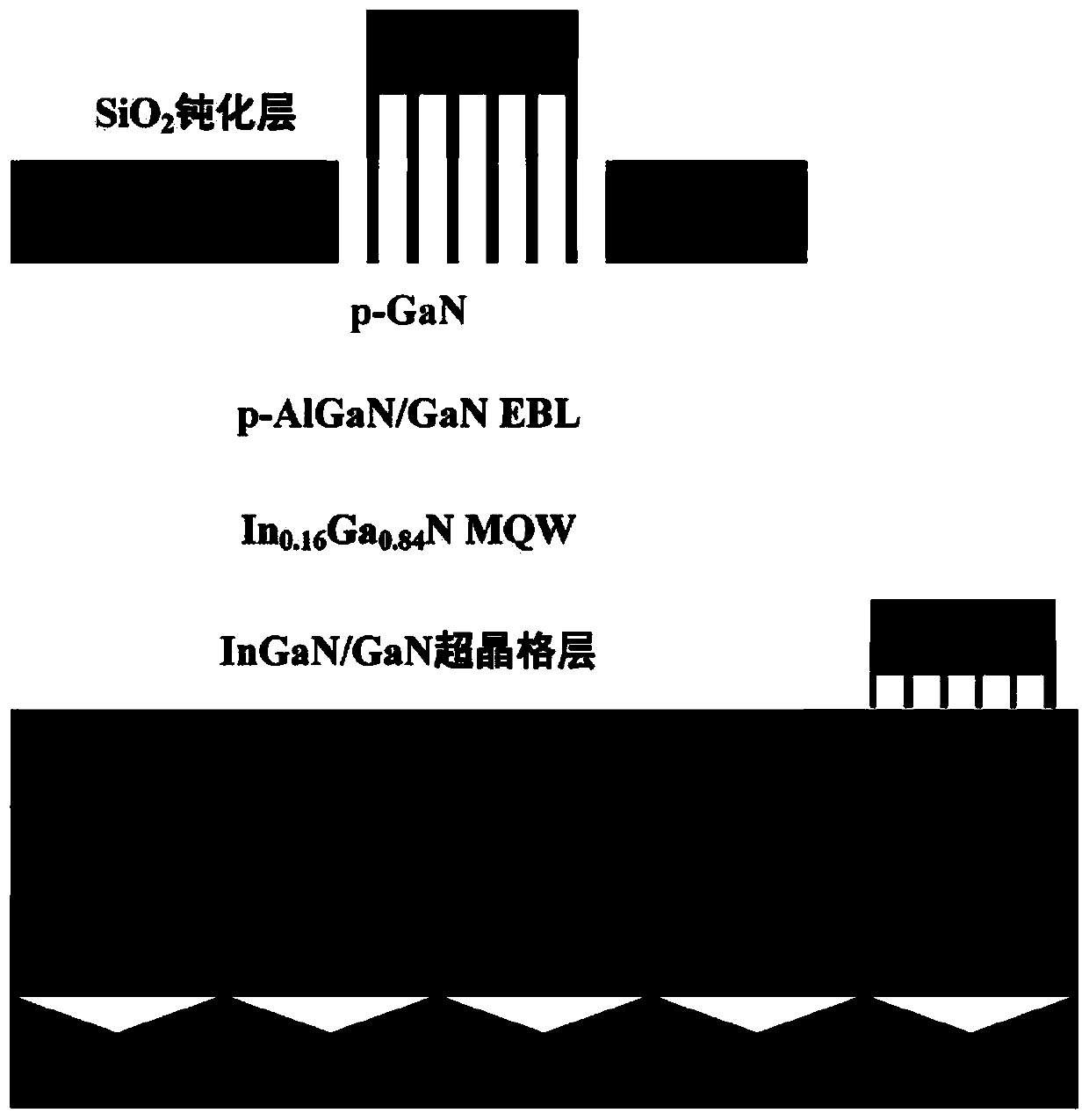

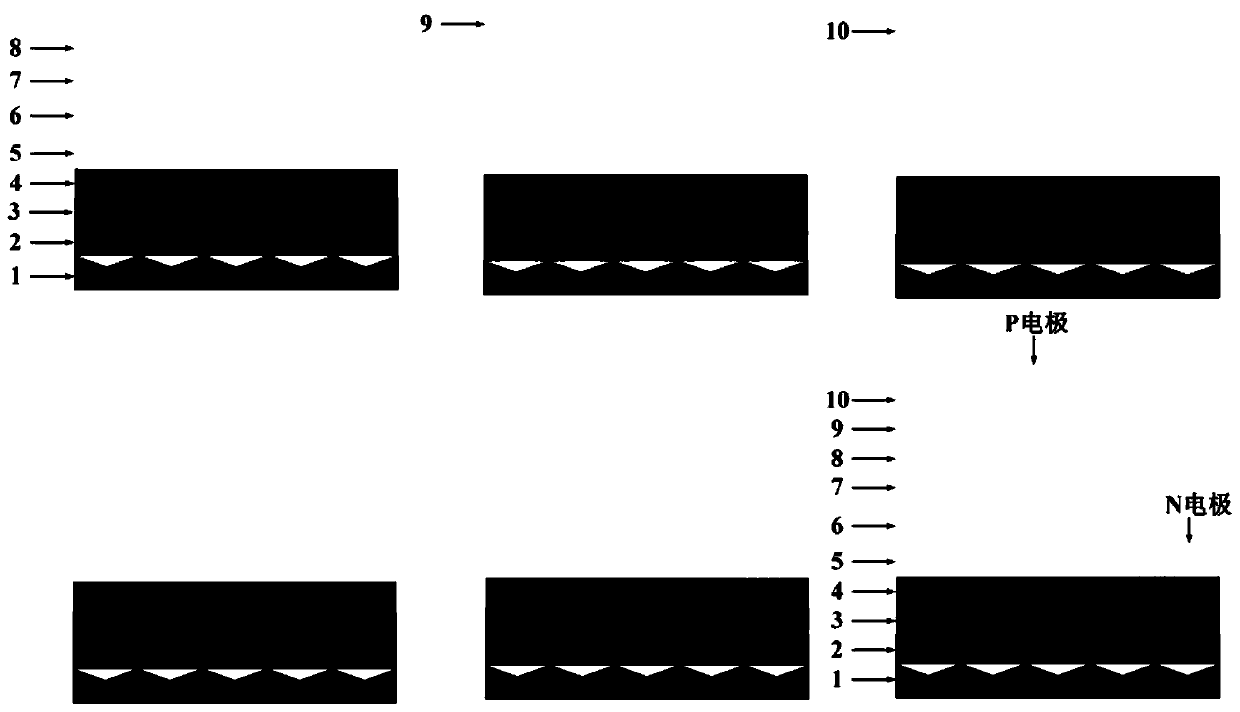

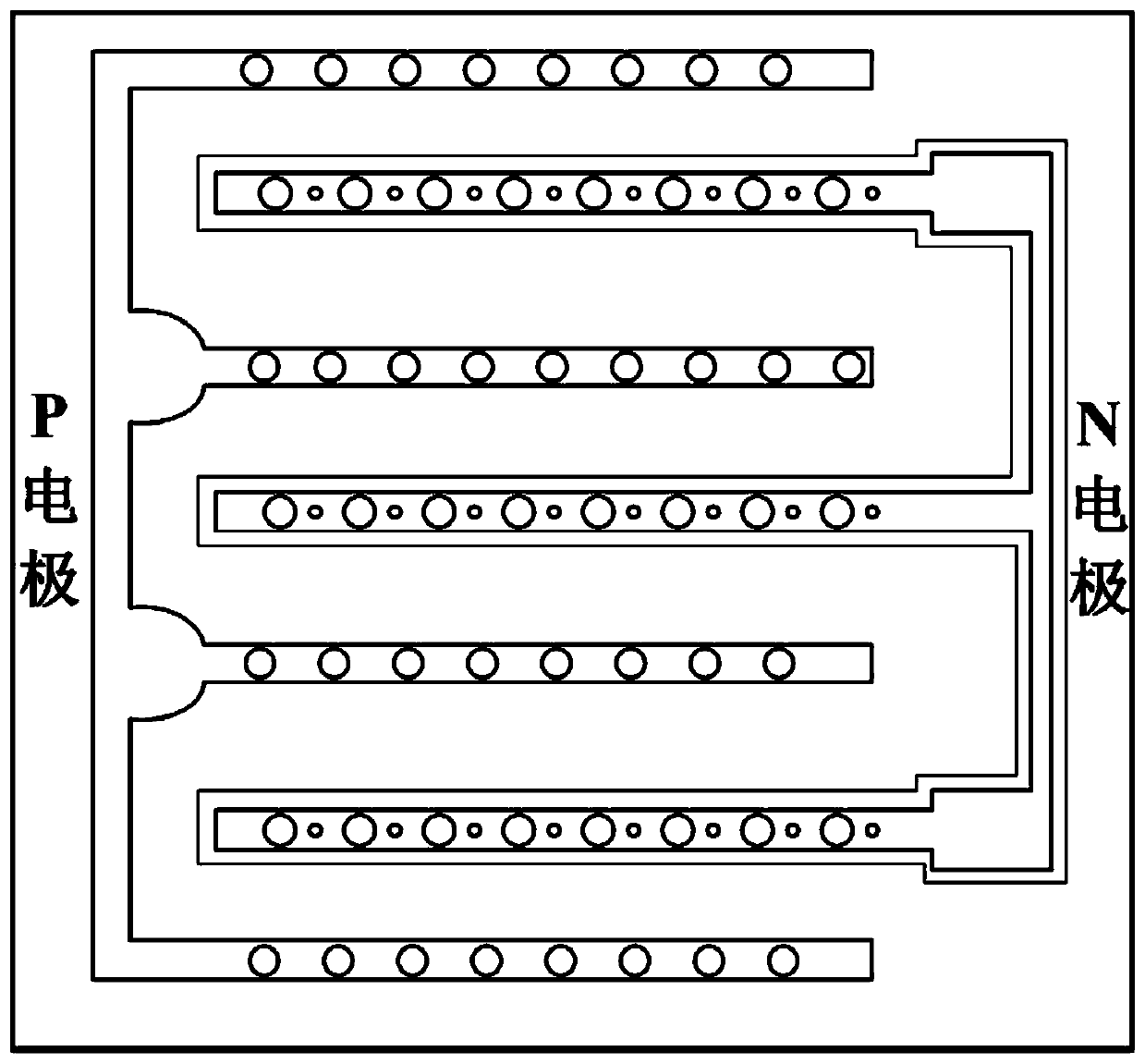

Gan-based light-emitting diode with nanoscale silicon dioxide grating passivation layer and its processing method

ActiveCN108461593BImprove the exit rateBreak the total reflection interfaceSemiconductor devicesGratingNucleation

The invention discloses a GaN-based LED (Light Emitting Diode) having a nano-sized SiO2 grating passivation layer, and a processing method thereof. The GaN-based LED comprises a substrate and an epitaxial layer, wherein the epitaxial layer comprises an AIN nucleation layer, a GaN buffer layer, an n-type GaN layer, an InGaN / GaN superlattice layer, an In0.16Ga0.84N multiple quantum well layer, a p-AlGaN / GaN electronic blocking layer and a p-type GaN layer; a part of the epitaxial layer is etched to the n-type GaN layer, an un-etched part of the epitaxial layer forms a comb-shaped raised structure, the etched part of the epitaxial layer forms a comb-shaped groove structure matched with the comb-shaped raised structure; the p-type GaN layer is provided with an IOT layer, a SiO2 passivation layer and a P electrode thereon, the exposed n-type GaN layer after etching is provided with an N electrode, the SiO2 passivation layer is deposited between the N electrode and the n-type GaN layer, theSiO2 passivation layer is deposited on a sidewall of the raised structure; the ITO layer and the SiO2 passivation layer have graphical through-hole structures of which shapes are evenly distributed along the P electrode or the N electrode. The GaN-based LED of the invention has the beneficial effects that: the surface of the LED is protected, generation of a leakage current is limited, at the sametime, a current is expanded, current gathering is reduced, and luminous efficiency is improved.

Owner:JIANGXI ZHAO CHI SEMICON CO LTD

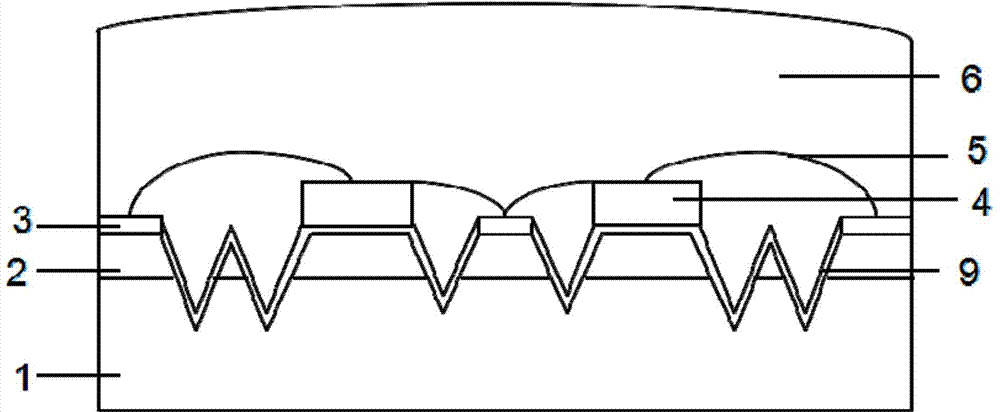

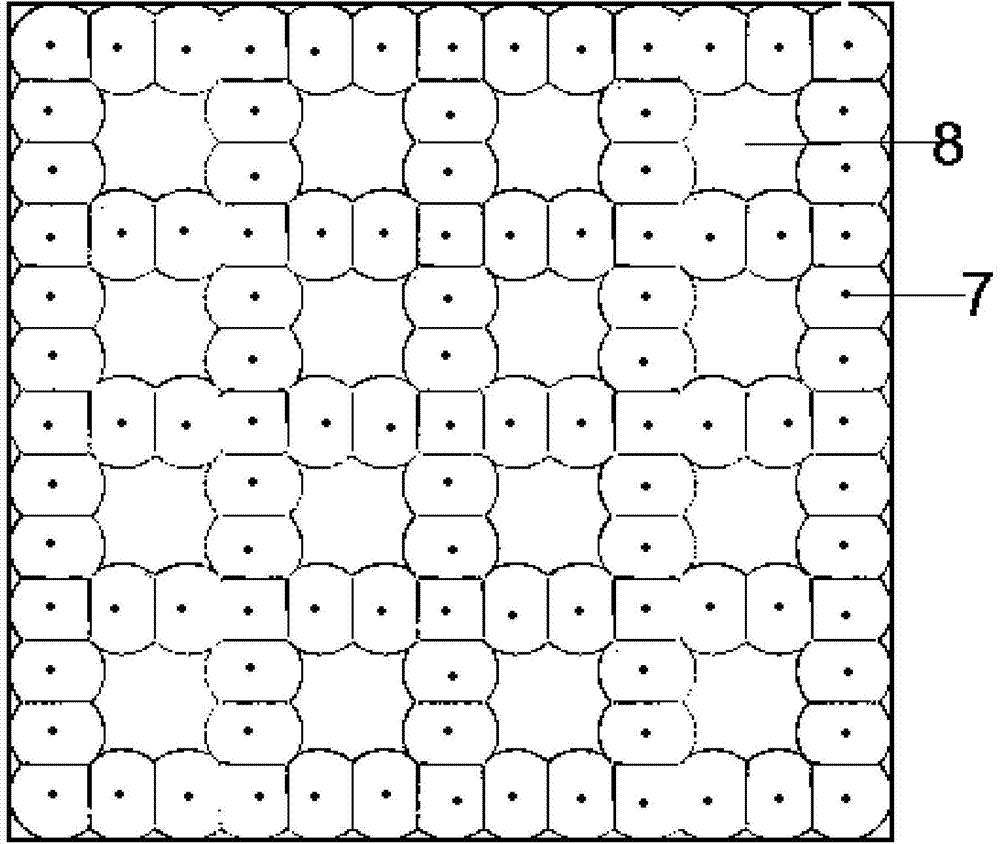

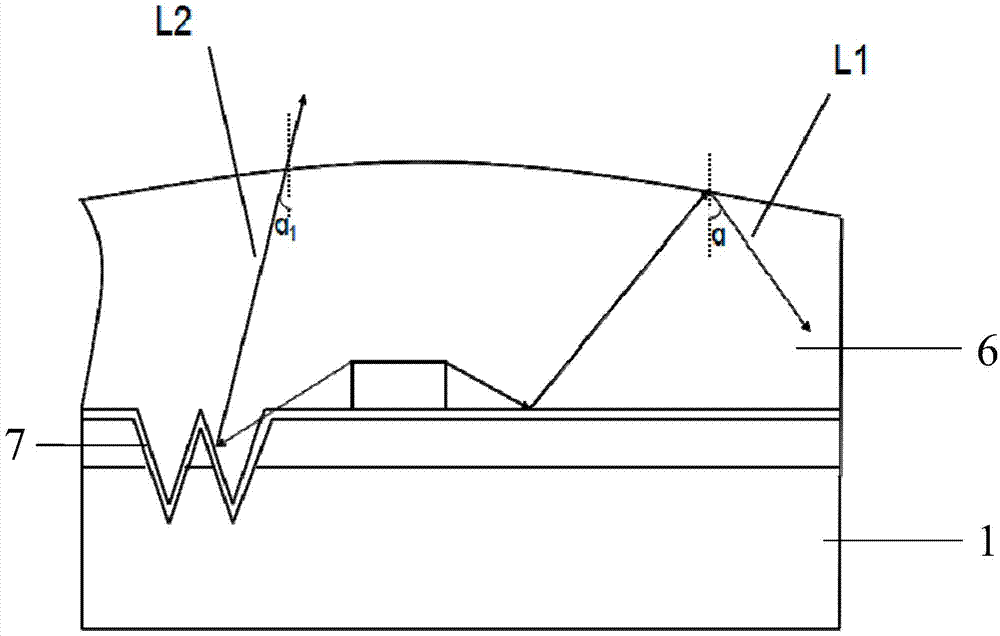

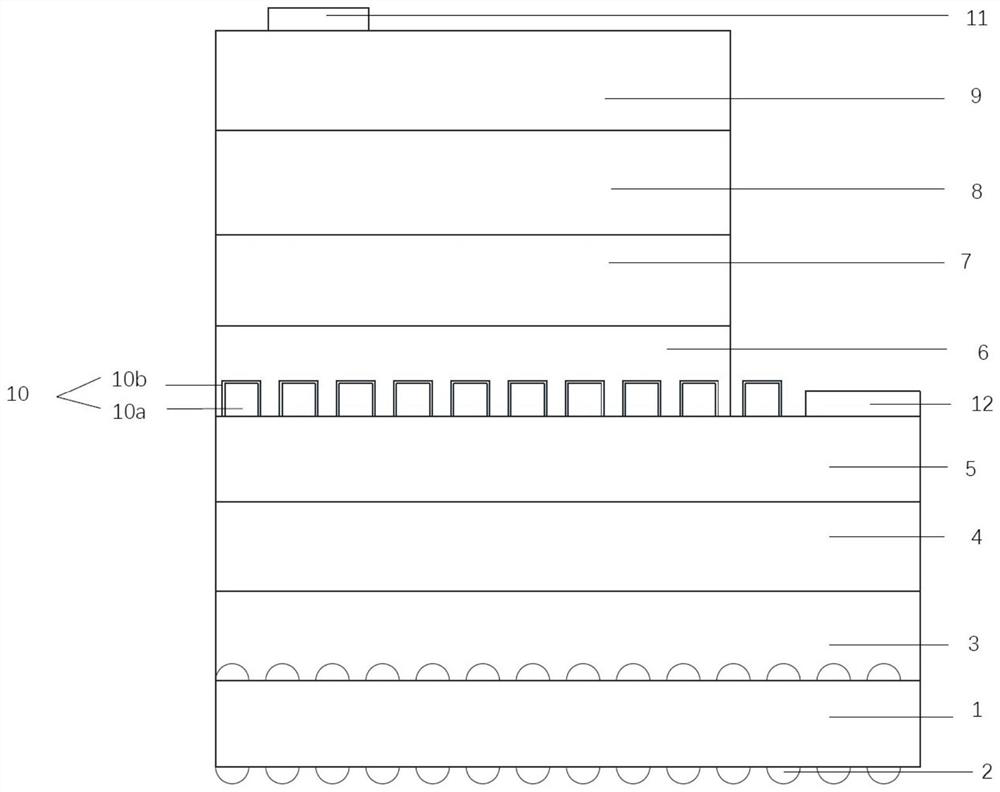

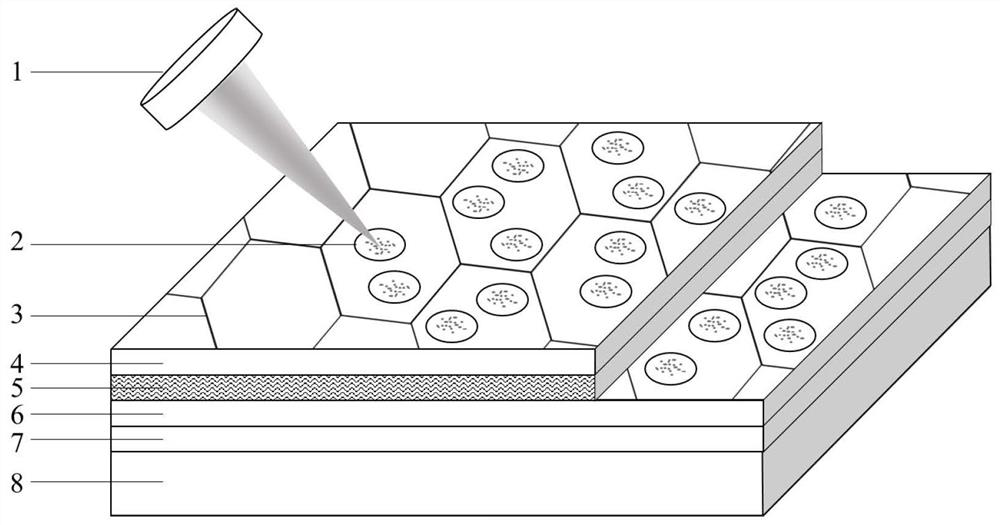

Deep ultraviolet LED with high external quantum efficiency and production method thereof

ActiveCN113054064AImprove the exit rateImprove extraction efficiencySemiconductor devicesQuantum efficiencyUltraviolet

The invention relates to a deep ultraviolet LED with high external quantum efficiency and a production method thereof. The deep ultraviolet LED comprises a patterned sapphire substrate, the upper surface and the lower surface of the patterned sapphire substrate are respectively provided with a micro-dome-shaped structure arranged in a regular hexagonal array shape, the upper surface of the patterned sapphire substrate is provided with an epitaxial lamination layer, the epitaxial lamination layer is provided with an mesa step exposing an n-AlGaN layer, and a nano-particle array of an Al-SiO2 core-shell structure is arranged on the side, close to the multiple quantum wells in the epitaxial laminated layer, of the surface of the n-AlGaN layer. By using the micro-dome type patterned sapphire substrate which is symmetrical up and down, the light emitting probability can be improved, the light extraction efficiency can be increased, the defect density of the AlGaN epitaxial layer can be reduced, the non-radiative recombination can be decreased, and the internal quantum efficiency can be improved; and the nano-particle array resonates with photons emitted by an LED through the local surface plasmon resonance effect of Al nanoparticles so that the field intensity near a quantum well is enhanced, and the internal quantum efficiency is improved.

Owner:SOUTH CHINA NORMAL UNIVERSITY

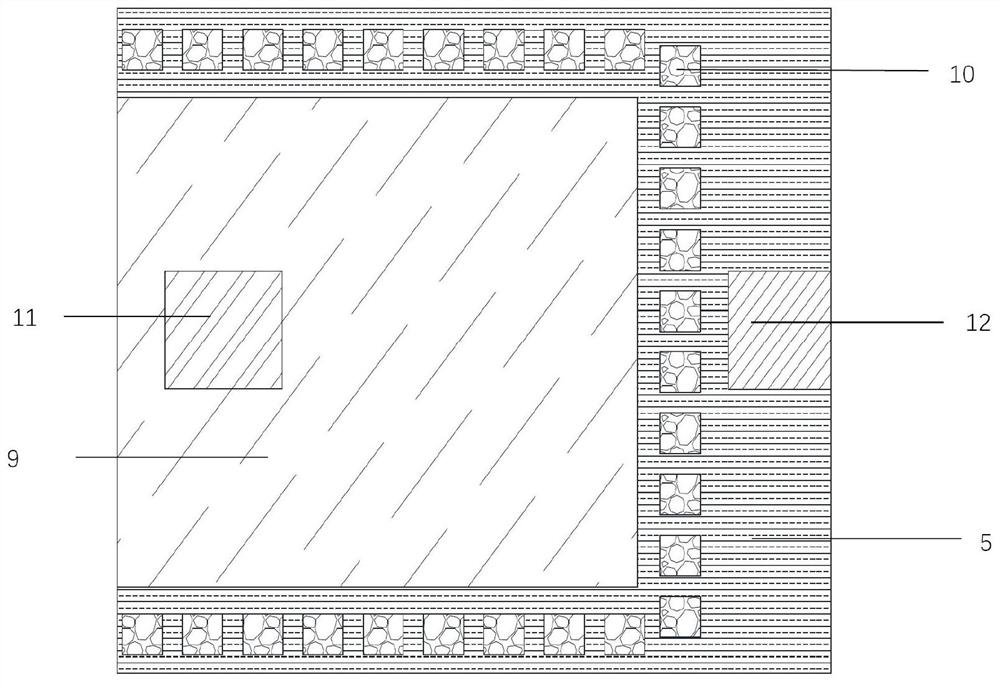

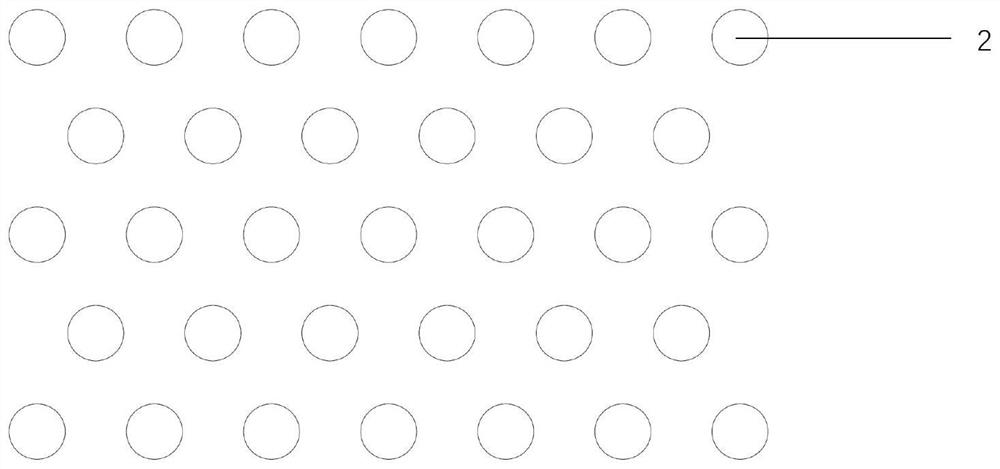

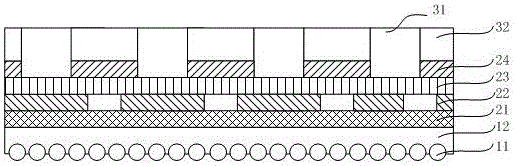

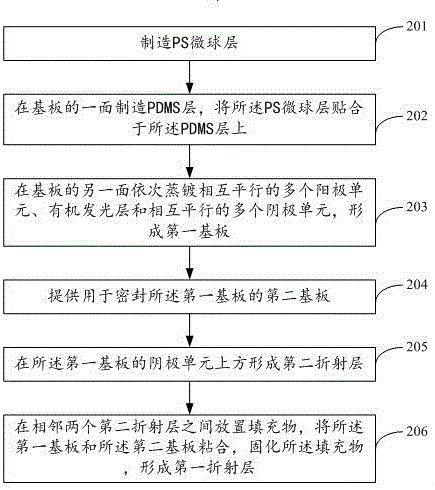

Organic electroluminescent displayer and manufacturing method thereof

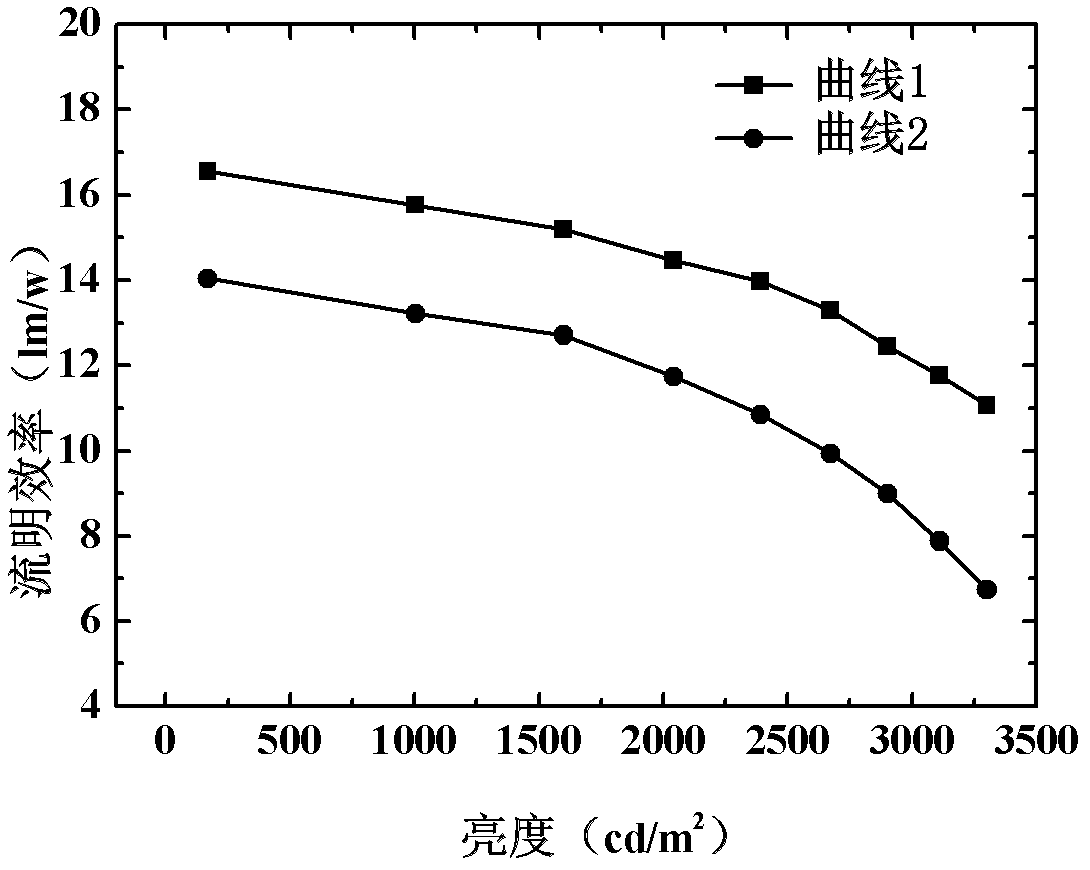

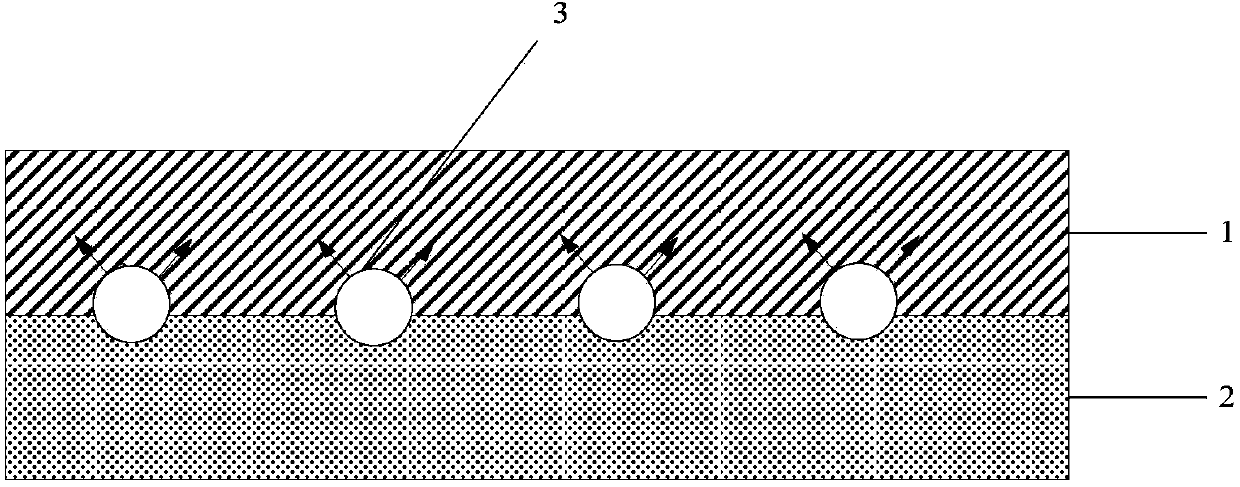

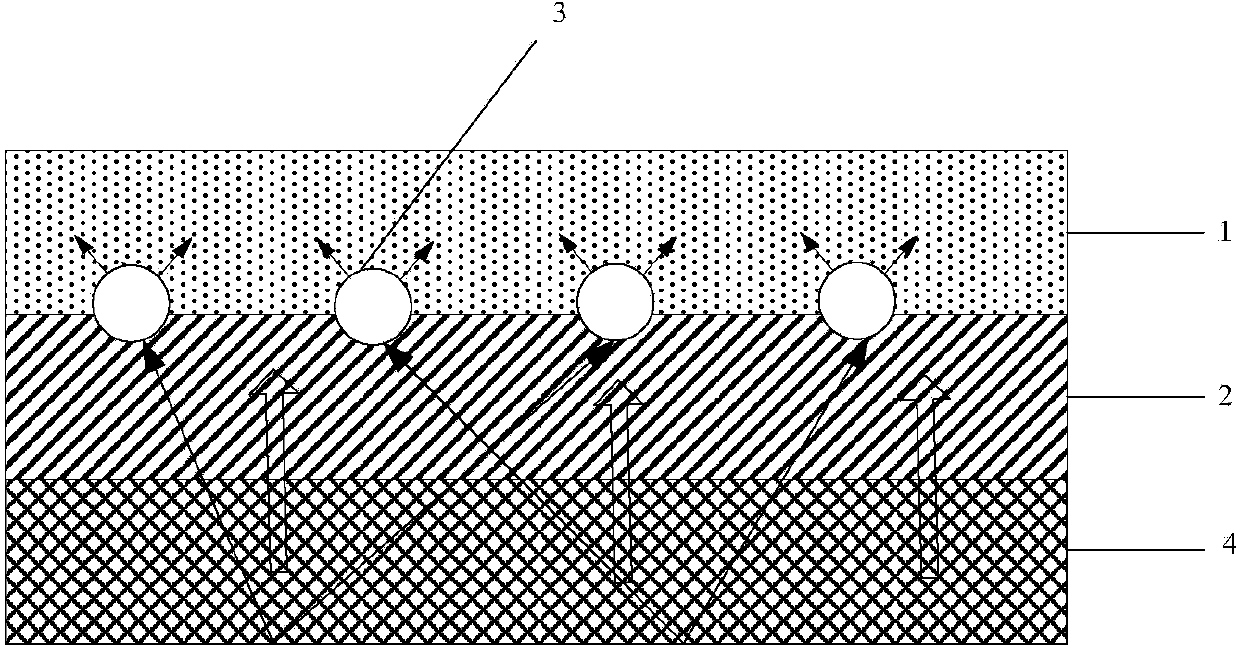

InactiveCN105655381AImprove the exit rateReduce reflectionSolid-state devicesSemiconductor/solid-state device manufacturingMicrosphereRefractive index

The invention discloses an organic electroluminescent displayer and a manufacturing method thereof and belongs to the technical field of displayer manufacturing. The organic electroluminescent displayer comprises a PS microsphere layer embedded in one side of a PDMS layer; a substrate, a plurality of parallel positive electrode units, an organic light emitting layer and a plurality of parallel negative electrode units are sequentially arranged on the other side of the PDMS layer; the positive electrode units and the negative electrode units are parallel and staggered; the organic light emitting layer is provided with a first refraction layer, the negative electrode units are provided with second refraction layers, and the refractive index of the first refraction layer is larger than that of the second first refraction layers. By means of the organic electroluminescent displayer and the manufacturing method thereof, light emitting efficiency of the organic electroluminescent displayer can be improved, double-side light emission is achieved, and color mixing between pixels is prevented.

Owner:王金

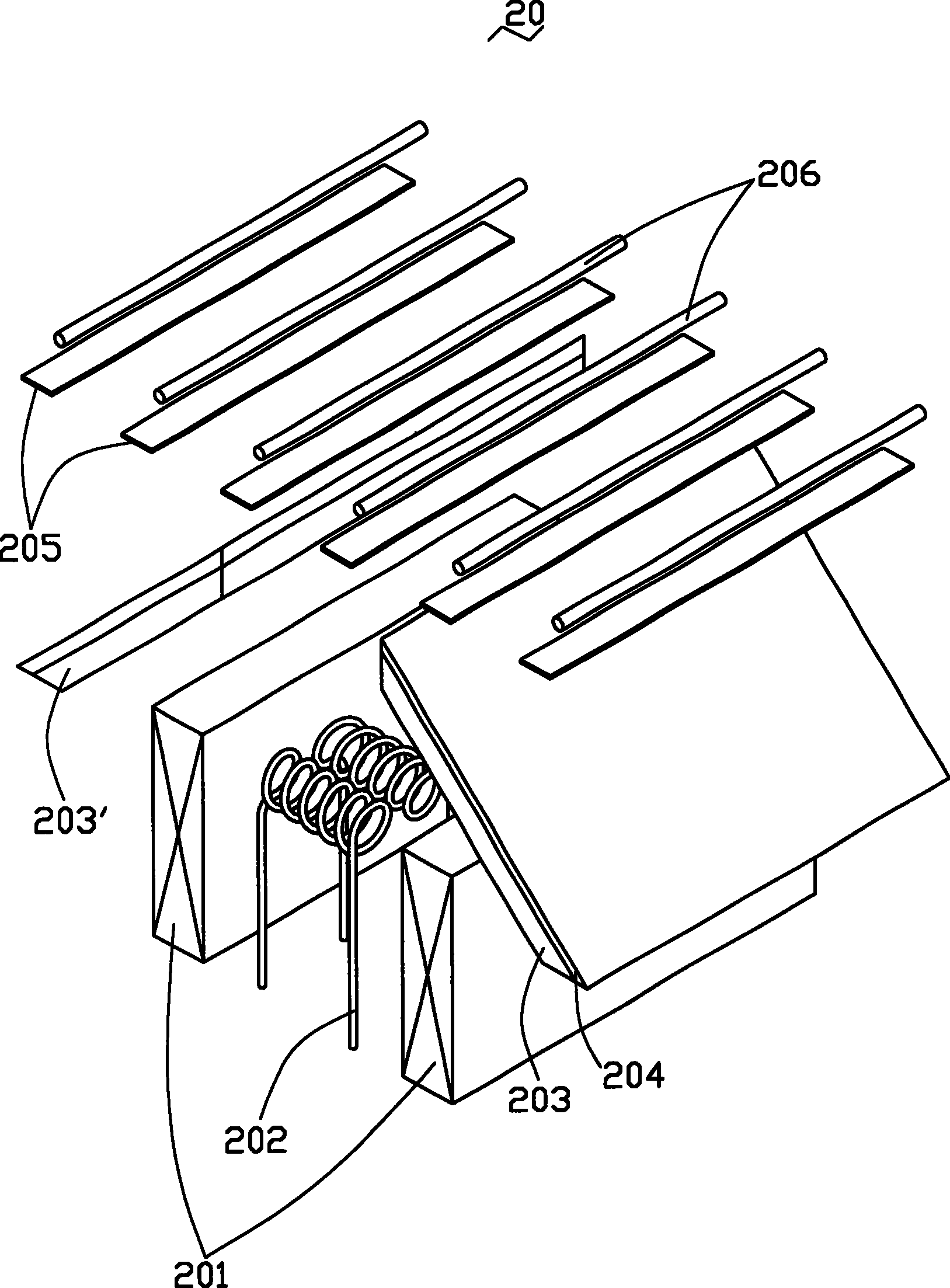

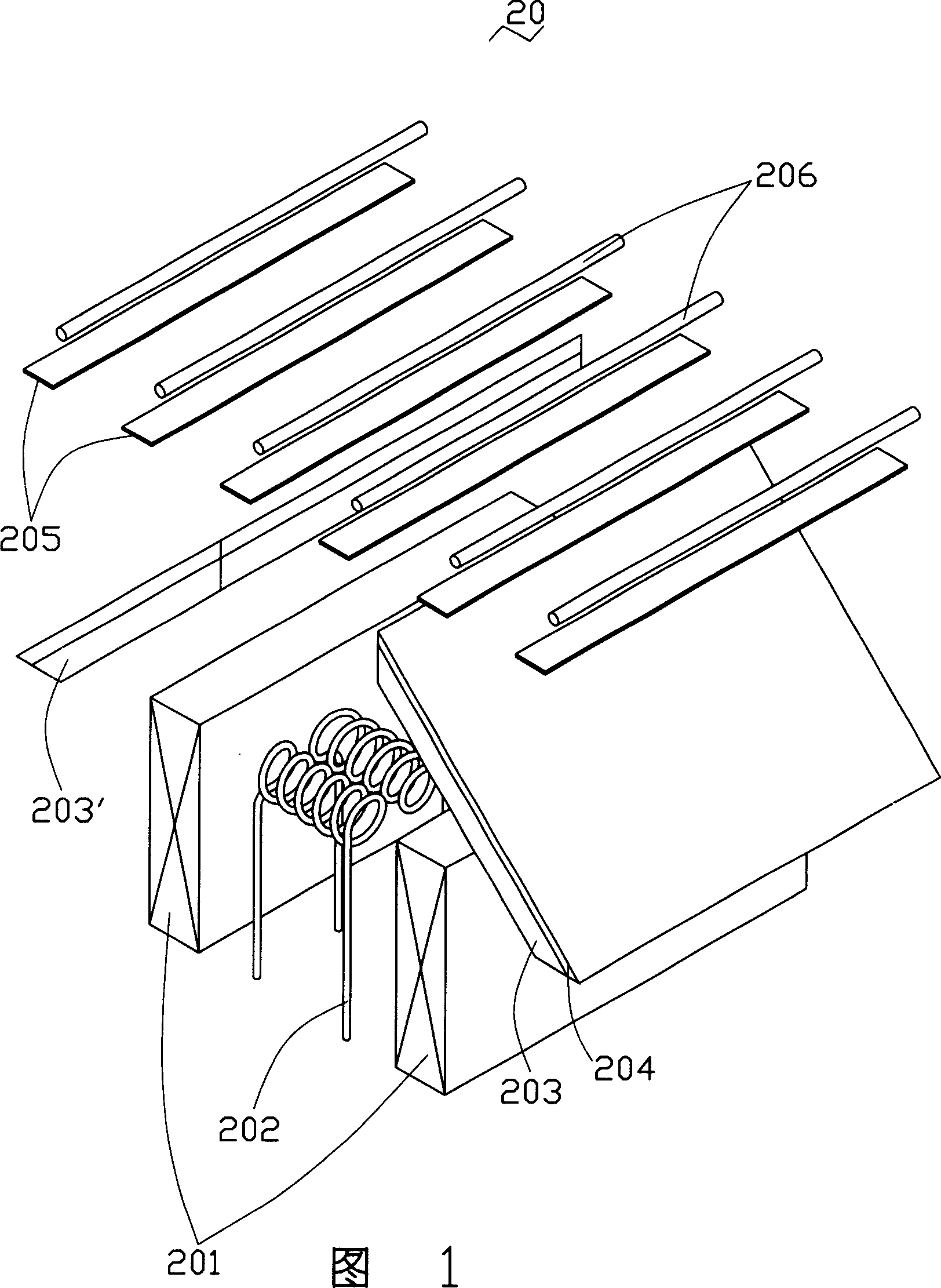

Electron source and surface light source employing same

InactiveCN1929070BImprove the exit rateHigh inert gas ionization rateGas plasma lampsElectric discharge tubesElectron sourceAtomic physics

This invention relates to one electron source, which comprises the following parts: one magnetic coil; multiple lamp wires on coils to heating the lamp wires to send electrons; cathode set by two inclination to form one hollow chamber with one first opening and one second open relative to first larger than first open; the magnetic coil and wires locate on second open; the said multiple lamp wiressend electron from first open.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

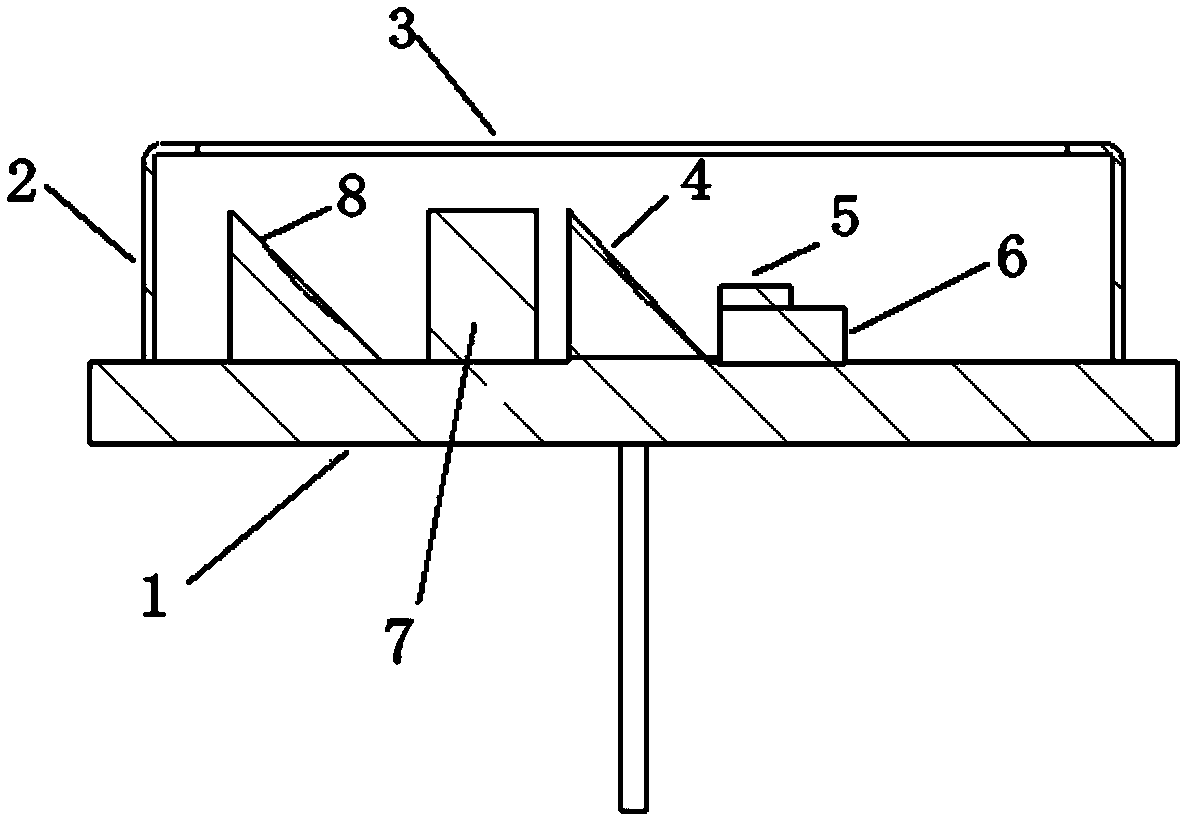

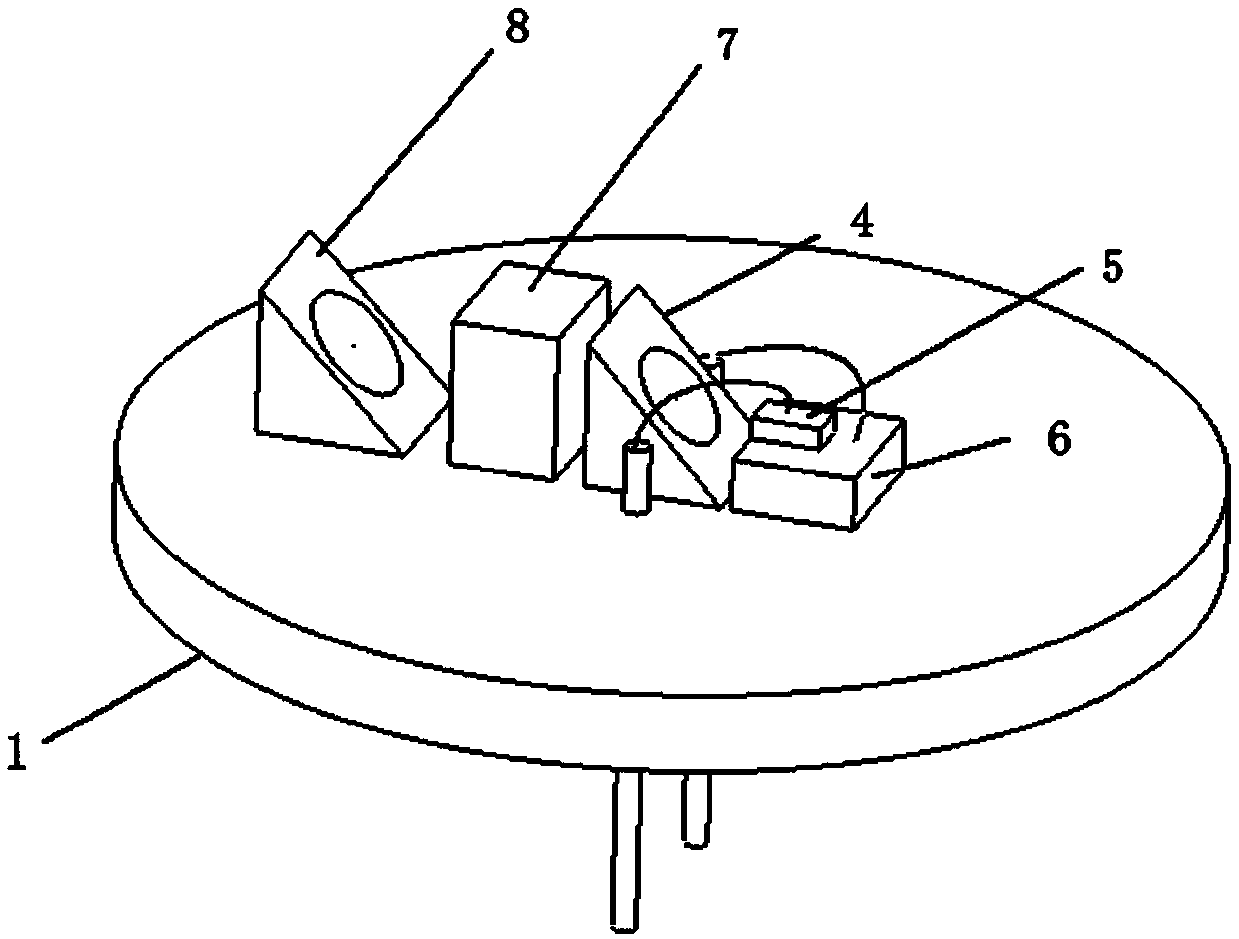

Self-indicating patch semiconductor laser and packaging method thereof

InactiveCN111224314AReduce oxidationExtended service lifeLaser detailsSemiconductor lasersLight reflectionEngineering

The invention relates to a self-indicating patch semiconductor laser and a packaging method thereof. The self-indicating patch semiconductor laser comprises a tube socket and a tube cap arranged on the tube socket, and in a space formed by the tube socket and the tube cap, a COS, a 45-degree right-angle semi-reflection table, a crystal and a 45-degree right-angle total reflection table are sequentially arranged on the tube socket along an optical path; two 45-degree reflective modules are arranged on the tube socket; the first 45-degree light reflection module (45-degree right-angle half-reflection table) reflects 50% of laser, so that a light path is changed by 90 degrees, the laser is emitted in a direction vertical to the tube socket, 50% of laser can also pass through the lens, a crystal is arranged on the light path, a 808nm laser is pumped into a 1064nm laser, then the 532nm laser green laser is generated through a frequency doubling crystal, and after the green laser passes through a second 45-degree reflection module (45-degree right-angle total reflection table), the light path is changed by 90 degrees and is emitted out perpendicular to the tube base.

Owner:潍坊华光光电子有限公司

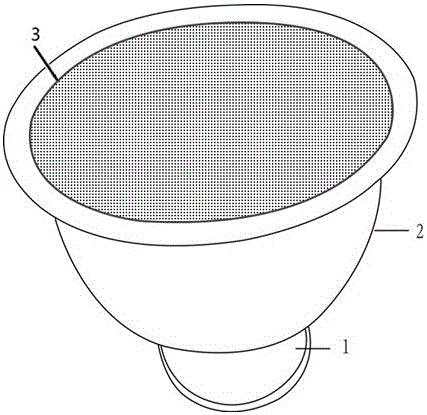

Plastic optical reflector for downlight with microlens array on surface

ActiveCN103775977BIncrease diffuse reflectanceIncrease heightLighting device detailsSemiconductor devices for light sourcesOptical reflectionLight energy

The invention discloses a plastic optical reflecting cover for a tube lamp with an lenticular array on the surface. The plastic optical reflecting cover comprises a lamp assembling port and a light distribution cover, wherein the lamp assembling port is fixed on the bottom end of the light distribution cover, the lenticular array structure is arranged in the light distribution cover, the lenticular array structure is a semispherical structure, a prism structure, a pyramid structure, a rectangular lens structure, a pyramidal structure, a semi-cylindrical structure, a semi-elliptical structure and a parabolic curve structure; the lenticular array structure is distributed in a triangular form, a regular hexagonal form, a rectangular form, a radiative form, a circular form and an elliptical form. By adopting the plastic optical reflecting cover, no optical dead corner exists, the light energy utilization rate is increased, and a purpose for increasing the light emitting efficiency and light emitting uniformity can be realized.

Owner:BEIJING UNIV OF CHEM TECH

Method for making transparent conductive layer for improving brightness of light-emitting diode chip

ActiveCN105789403BImprove luminous efficiencyImprove the exit rateSemiconductor devicesIndiumEvaporation

The invention discloses a transparent conducting layer manufacturing method for increasing light emitting diode chip brightness. The method comprises following steps: etching a light emitting diode chip epitaxial layer through a dry method preparing a tin indium oxide film conducting layer on the epitaxial layer; preparing a nickel layer with thickness from 5 to 10 nm on the tin indium oxide film conducting layer by a vapor plating method; performing annealing to the nickel layer; forming uniformly distributed spherical nickel particles on the tin indium oxide film conducting layer surface; etching the tin indium oxide film conducting layer with the spherical nickel particles as a mask layer to form uniform concave rectangular pits on the tin indium oxide film conducting layer surface; removing the spherical nickel particles; coating the tin indium oxide film conducting layer with negative photoresist and exposing electrode zones after exposure and development; preparing metal electrodes at the electrode zones by means of the vacuum electron beam evaporation method; peeling the metal electrodes to obtain light emitting diode chip electrodes and removing the negative photoresist. By means of the method, the brightness of light diode chip is increased.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

A plane lens and an illumination lens device based on the plane lens

InactiveCN105423235BNot easy to get dirtyNot easy to wearSemiconductor devices for light sourcesRefractorsSurface smoothnessSurface flatness

The invention discloses a plane lens and an illuminating lens device based on the plane lens. The plane lens comprises a transparent lens body. The transparent lens body is provided with a bottom face, a total-reflection face and an emergence face. The bottom face is provided with an incidence groove used for containing a light source and faces towards the interior of the transparent lens body. The side wall of the incidence groove serves as an incidence face. According to the improvement of the technical scheme, the incidence face comprises a small-angle incidence face body and a large-angle incidence face body; a transition curved face is arranged between the total-reflection face and the emergence face; the total-reflection face comprises a first total-reflection face body and a second total-reflection face body. The illuminating lens device comprises one or more plane lens. The plane lens and the illuminating lens device based on the plane lens have the advantages, which cannot be achieved by existing products, that the surface smoothness is good, cleaning is convenient, and the light-pervious efficiency is high.

Owner:江西天同光电有限公司

Organic electroluminescent device and preparation method

InactiveCN104009175AEliminate reflectionsReduce the refractive index differenceSolid-state devicesSemiconductor/solid-state device manufacturingMolecular orbital energyRefractive index

The invention discloses an organic electroluminescent device which comprises a glass substrate, an anode layer, a hole injection layer, a hole transport layer, a luminescent layer, an electron transport layer, an electron injection layer and a cathode which are successively laminated. The anode layer is composed of a hafnium-containing compound layer, a conductive single metal layer and a praseodymium oxide layer which are successively laminated. The hafnium-containing compound has high refractive index and high light transmittance, thus reducing refractive index difference between an anode and the glass substrate, avoiding total reflection and effectively enhancing light extraction efficiency. The conductive single metal plays a role in electric conduction, thus raising carrier transmission efficiency, reducing interior energy consumption of the device and making energy to be used more in light extraction. The highest occupied molecular orbital energy of the praseodymium oxide is high, thus guaranteeing hole injection. The invention also discloses a preparation method of the organic electroluminescent device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Light-emitting diode epitaxial wafer and preparation method thereof

ActiveCN112186081BImprove the exit rateQuality assuranceSemiconductor devicesQuantum dotDiffuse reflection

The disclosure provides a light-emitting diode epitaxial wafer and a preparation method thereof, belonging to the technical field of light-emitting diodes. An insertion layer is added between the p-type GaN layer and the p-type contact layer, and the insertion layer includes a Mg quantum dot layer and a first GaN layer sequentially stacked on the p-type GaN layer. The Mg quantum dot layer includes a plurality of Mg quantum dots distributed on the p-type GaN layer. The interface between the multiple Mg quantum dots and the p-type GaN layer and the first GaN layer will be relatively rough, which can increase the light transmission rate in the p-type GaN layer. The diffuse reflection at the interface of the GaN layer reduces the total reflection of light that may occur at the interface of the p-type GaN layer, thereby increasing the light output rate. The first GaN layer can cover the relatively rough surface of the Mg quantum dot layer to ensure the quality of the p-type contact layer grown on the first GaN layer. The light extraction rate of the finally obtained light emitting diode epitaxial wafer can be improved.

Owner:HC SEMITEK SUZHOU

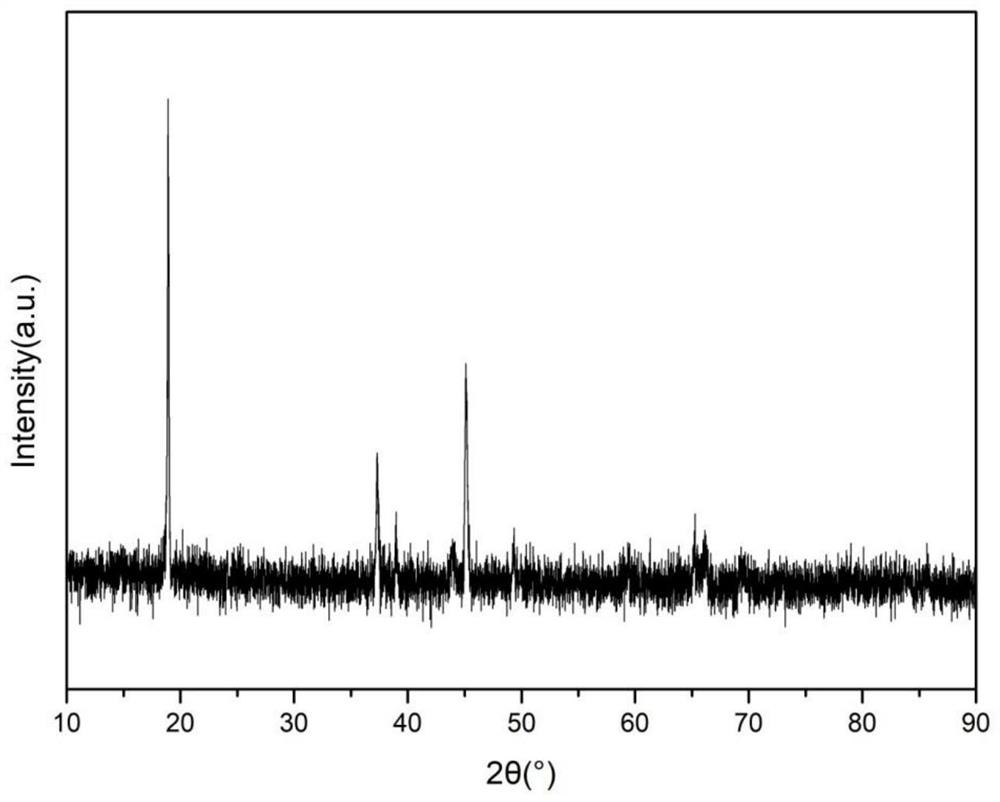

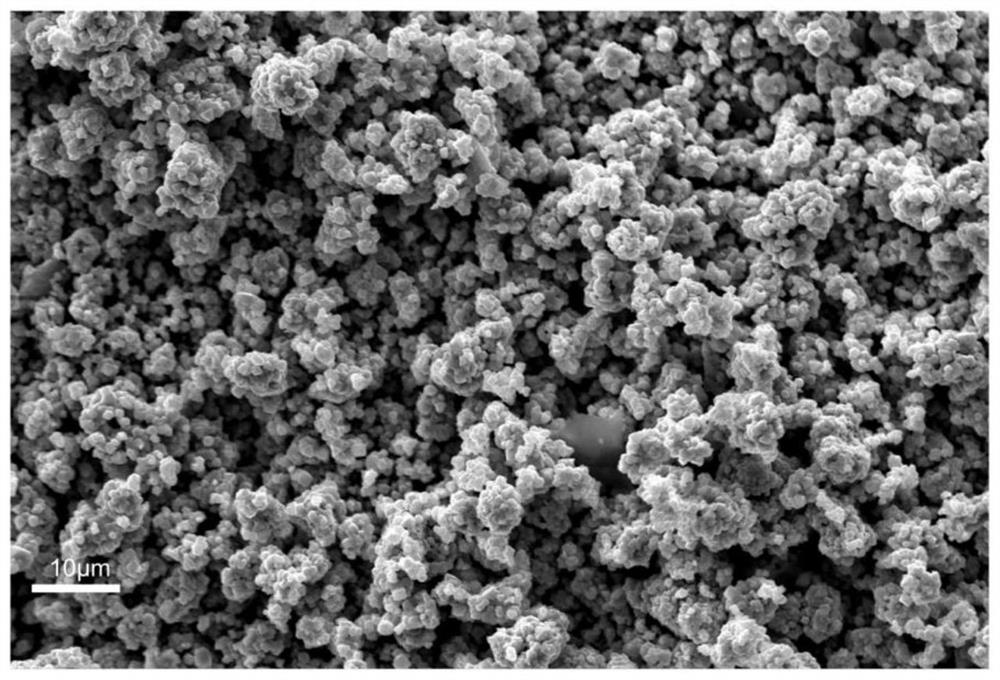

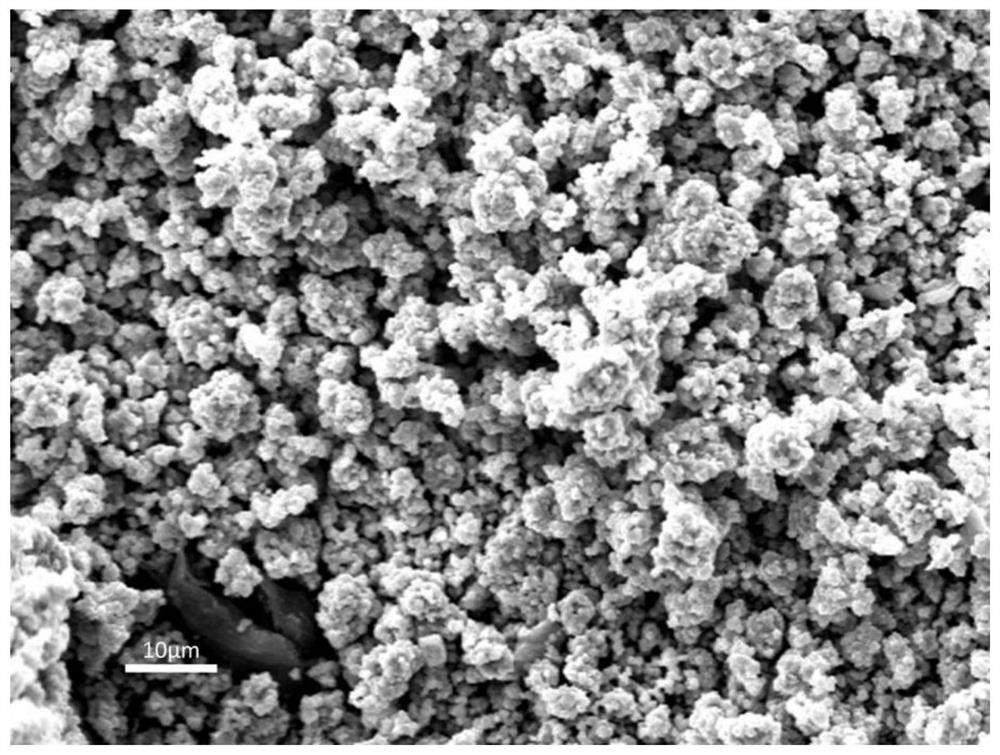

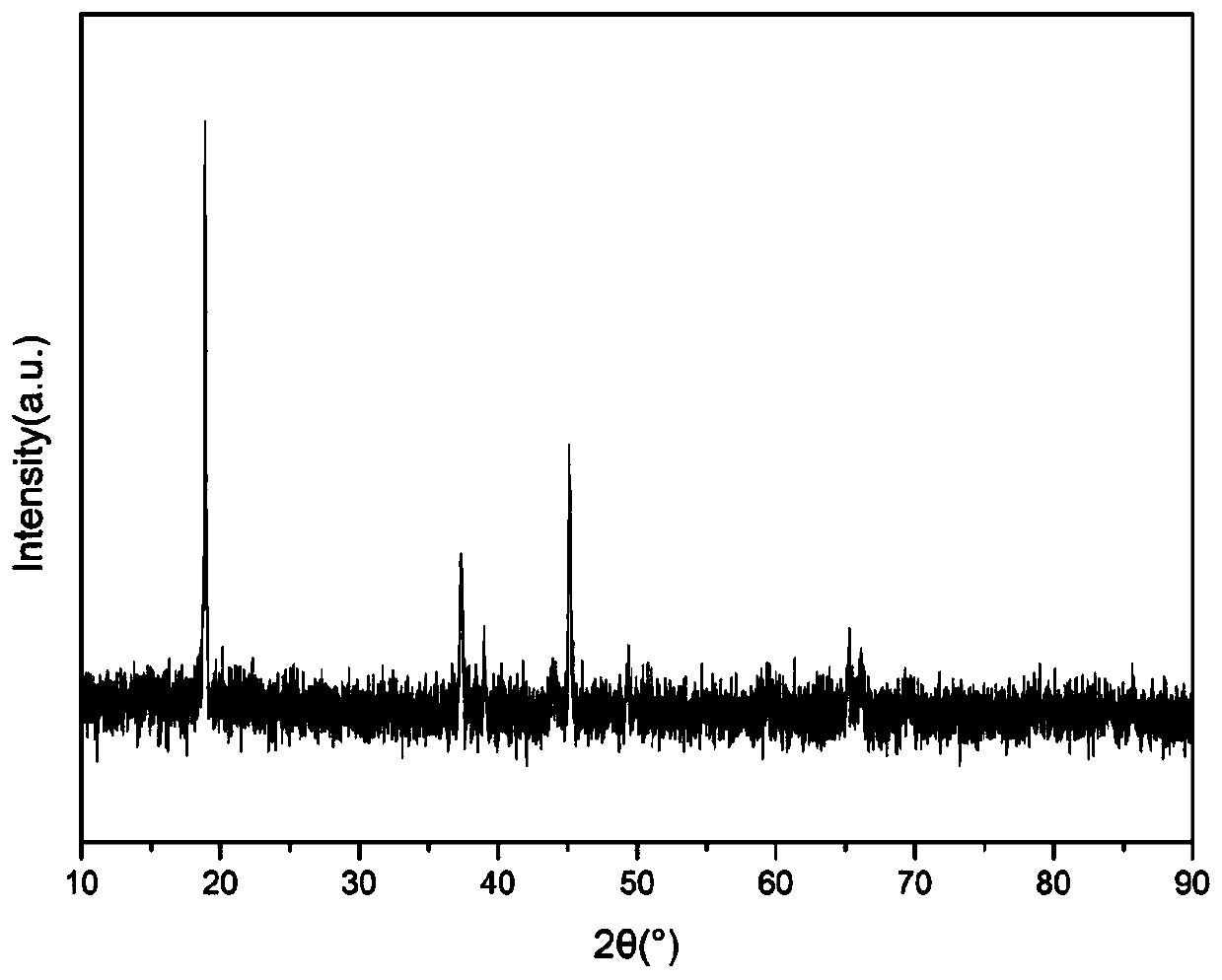

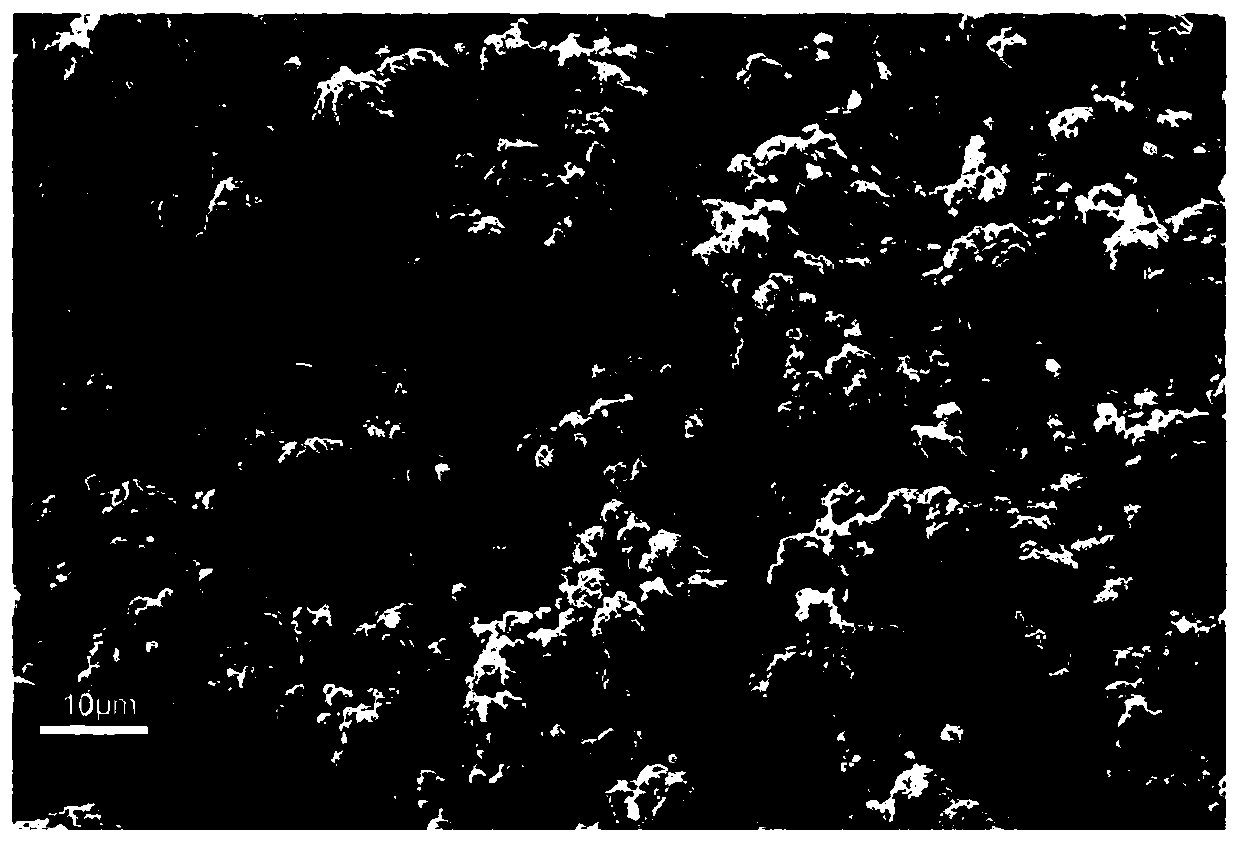

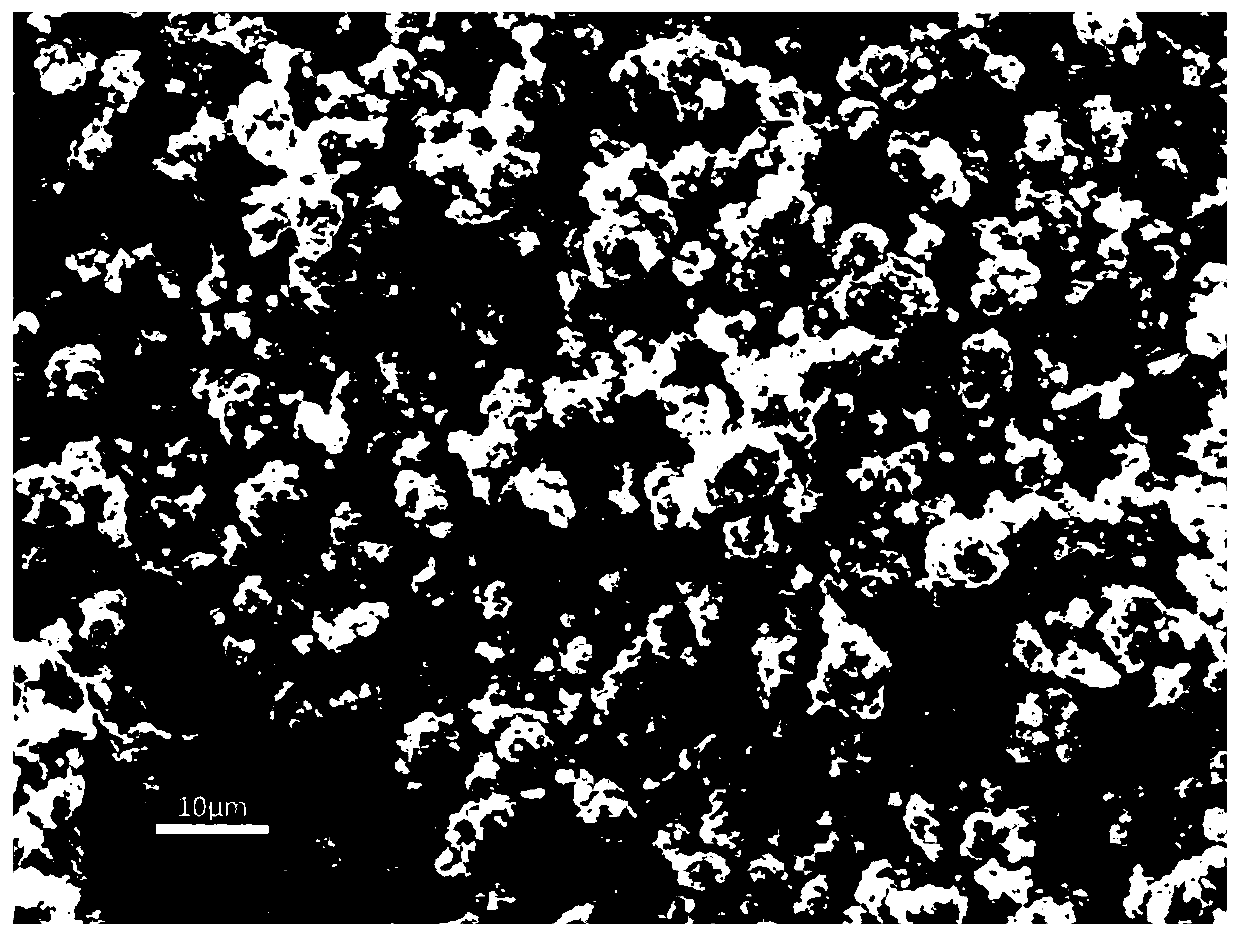

A kind of preparation method and application of hierarchical structure cathode material for lithium ion battery

ActiveCN110380041BEasy to embedImprove mechanical propertiesSecondary cellsPositive electrodesElectrical batteryMolten salt

The invention belongs to the technical field of lithium ion batteries, and in particular relates to a hierarchical structure positive electrode material for lithium ion batteries and a preparation method thereof. The chemical formula of the hierarchical structure positive electrode material is specifically LiNi x co y Al 1‑x‑y o z Cl 2‑z ; 0.1≤x≤0.9, 0.1≤y≤0.9, 1.5≤z≤1.95, made by water mixing, molten salt mixing, sintering and crushing, by adding Cl element to replace the O element in the original NCA material, forming a different Compared with the NCA-like positive electrode of the traditional NCA material, the hierarchical structure positive electrode material has a regular and uniform microscopic morphology and has three characteristics of high potential, high specific energy, and high rate output.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

Micron forward-installed LED device for inhibiting SRH non-radiative recombination and preparation method and application of micron forward-installed LED device

PendingCN114744090AImprove external quantum efficiencyImprove the exit rateSemiconductor devicesQuantum efficiencySemiconductor materials

According to the micron normally-installed LED device for inhibiting SRH non-radiative recombination and the preparation method and application of the micron normally-installed LED device, a micron hole array is prepared on a micro-size device, an N-type material is injected, the effect of the micron hole array is to form a circle of high-resistance area on the edge of a P-type semiconductor material transmission layer, and therefore current is limited to be expanded to an area with many side wall defects on the edge of the device. And when the carriers are diffused to the edge, SRH recombination can be caused due to the existence of etching defects, so that the SRH recombination of the carriers can be fundamentally reduced, and the external quantum efficiency is improved.

Owner:SOUTH CHINA UNIV OF TECH

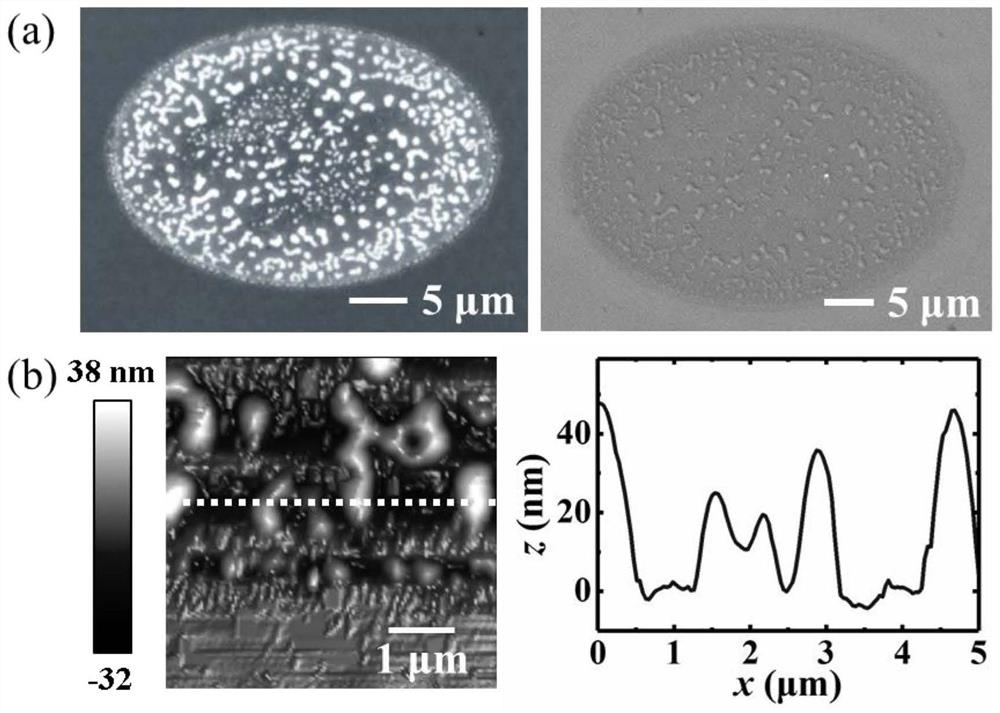

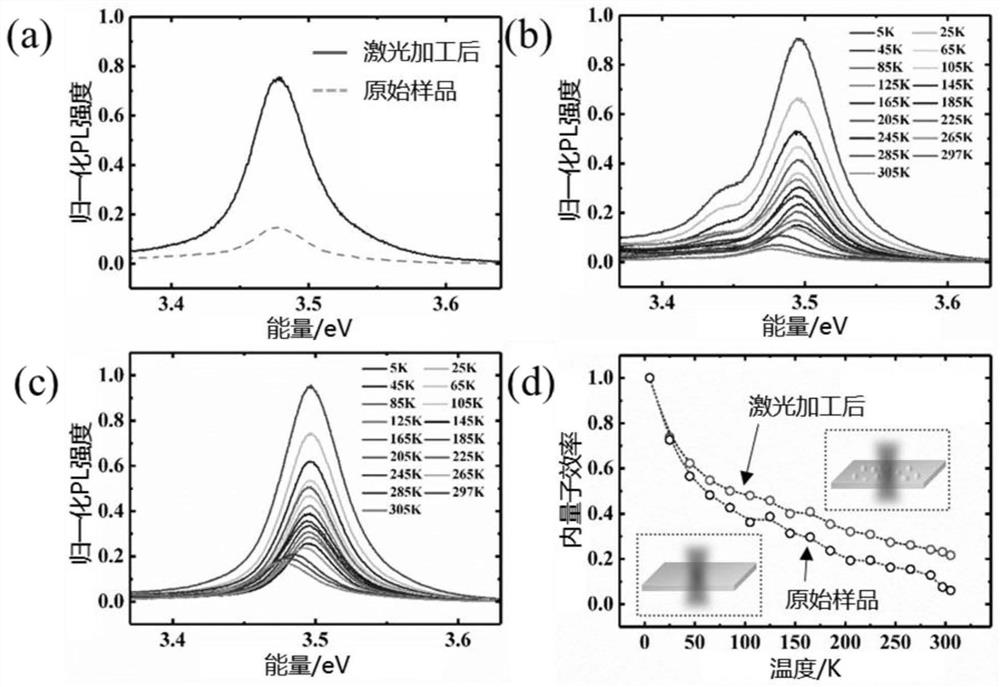

Method for enhancing internal quantum efficiency of ultraviolet LED through femtosecond laser

ActiveCN113161231AHigh transparencyDoes not affect any selective processingMaterial nanotechnologySemiconductor/solid-state device manufacturingPhotoluminescenceFemto second laser

The invention relates to a method for enhancing the internal quantum efficiency of an ultraviolet LED through femtosecond laser, which belongs to the technical field of semiconductor optoelectronic devices. According to the method, the femtosecond laser beam is used for processing on the surface of the GaN-based LED, the Ga nano-particles are obtained through single-point ablation in an oblique incidence mode, and the GaN-based LED internal quantum efficiency in the ultraviolet band is improved based on surface plasmon excimer excitation regulation and control. The method is simple and easy to implement, single-pulse processing is carried out through oblique incidence of femtosecond laser under the condition that new metal impurities are not introduced, and the material is induced to generate coulomb explosion phase change by utilizing the high peak density of the femtosecond laser and the high-temperature decomposition characteristic of the GaN material, so that the metal Ga nano-particles are formed, and large-area efficient processing can be achieved; and finally, the photoluminescence (PL) intensity and the internal quantum efficiency of the ultraviolet band are effectively enhanced, and the method can be widely applied to the fields of medical sterilization, secret communication and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for preparing hierarchical structure positive pole material for lithium ion battery and application

ActiveCN110380041AEasy to embedImprove mechanical propertiesSecondary cellsPositive electrodesPhysical chemistryMolten salt

The invention belongs to the technical field of a lithium ion battery and particularly relates to a hierarchical structure positive pole material for the lithium ion battery and a method for preparingthe hierarchical structure positive pole material for the lithium ion battery. A chemical formula of the hierarchical structure positive pole material is specifically LiNixCoyAl1-x-yOzCl2-z, whereinthe x is not smaller than 0.1 and is not greater than 0.9, the y is not smaller than 0.1 and is not greater than 0.9, the z is not smaller than 1.5 and is not greater than 1.95, the hierarchical structure positive pole material is prepared through water mixing, molten salt mixing, sintering and pulverization, by replacing O elements in an original NCA material by adding Cl elements, an NCA-type positive pole different from a conventional NCA material is formed, and the hierarchical positive pole material has the regular uniform microscopic morphology and further has high potential, high specific energy and high magnification output.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com