GaN-based LED integrated chip with multiple light-emitting sub areas

A technology of integrated chips and photons, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of PN junction short circuit, easy disconnection of interconnection lines, complicated process, etc., to prevent breaking, avoid small round corner bending, Enhance the effect of side wall reflections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

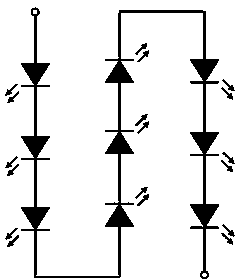

[0022] For front-mount LED chips that emit light from the p-GaN layer, the implementation steps are as follows:

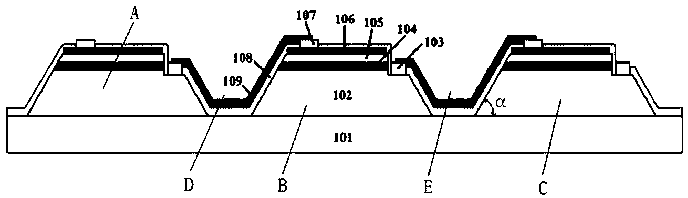

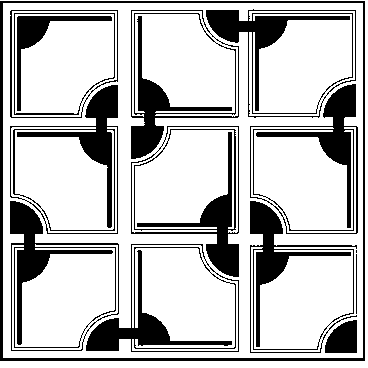

[0023] Step 1, take an LED epitaxial wafer, the specific structure includes a substrate 101, an epitaxially grown n-GaN layer 102, a quantum well active region 104, and a p-GaN layer 105, and form side walls by photolithography and dry etching The isolation trench is inclined at a large angle, the depth of the trench reaches the insulating substrate, and the included angle α between the side wall of the trench and the plane of the substrate is 30-80°. For the specific method, please refer to the content disclosed in the Chinese patent application with application number 201210492636.3.

[0024] In step 2, photolithography and dry etching are used to etch n-GaN steps in each light-emitting sub-region.

[0025] In step 3, a layer of ITO is evaporated on the entire chip as the current spreading layer 106, and then corresponding patterns are obtained by photolithograp...

Embodiment 2

[0034] For flip-chip LED chips that emit light from the substrate, the implementation steps are as follows:

[0035] Step 1, take an LED epitaxial wafer, the specific structure includes a substrate 101, an epitaxially grown n-GaN layer 102, a quantum well active region 104, and a p-GaN layer 105, and form side walls by photolithography and dry etching The isolation trench is inclined at a large angle, and the depth of the trench reaches the insulating substrate. Concrete method is identical with embodiment 1.

[0036] In step 2, photolithography and dry etching are used to etch n-GaN steps in each light-emitting sub-region.

[0037] In step 3, a reflective current spreading layer 106 is prepared on the surface of the p-GaN layer by photolithography, metal evaporation and Lift-off process, and the current spreading layer is also a mirror.

[0038] Step 4, deposit a layer of SiO on the whole wafer 2 As the insulating protective layer 108, part of SiO is etched by photolithogr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com