A welding process and structural parts

A technology of welding process and structural parts, which is applied to the structural connection of printed circuits, electrical components, printed circuit components, etc., can solve the problems of reducing mechanical stress of solder joints, circuit board breaks, etc., to reduce mechanical stress and reduce mechanical stress. The effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

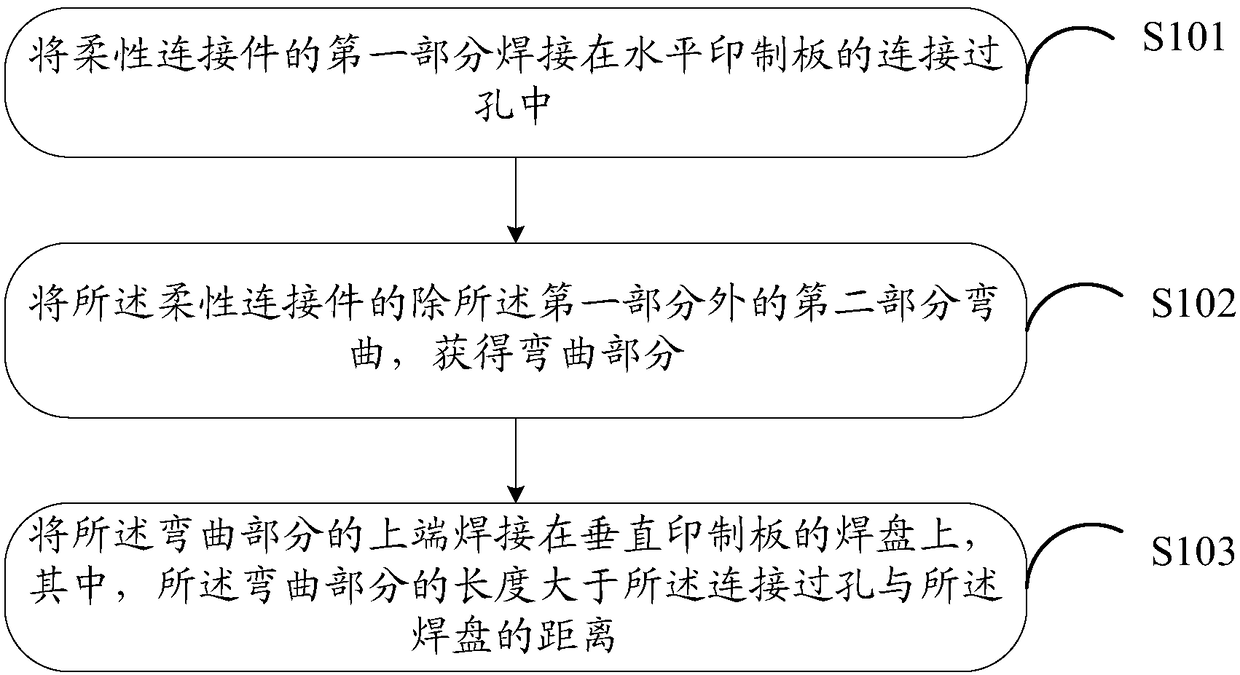

[0059] Please refer to figure 1 , is a flow chart of a welding process provided in Embodiment 1 of the present application, and the welding process includes:

[0060] S101: Welding the first part of the flexible connector into the connection via hole of the horizontal printed board;

[0061] S102: Bending a second part of the flexible connector except the first part to obtain a bent part;

[0062] S103: Solder the upper end of the bent portion on the pad of the vertical printed board, wherein the length of the bent portion is greater than the distance between the connection via hole and the pad.

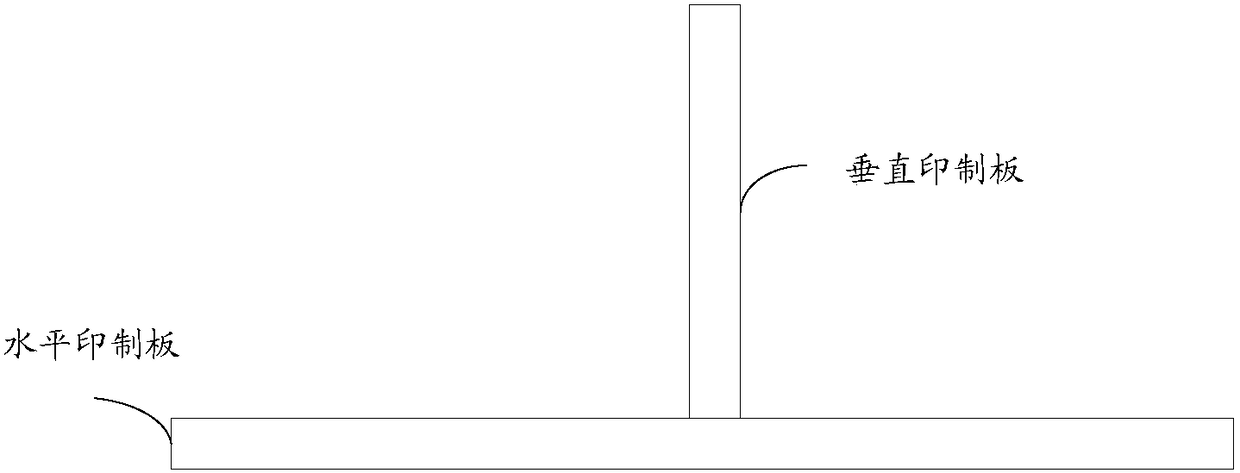

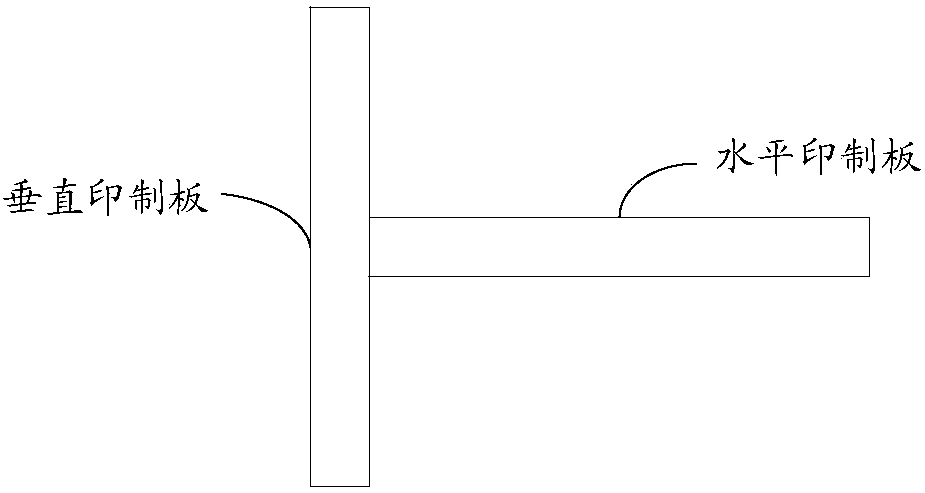

[0063] In the specific implementation process, the welding process can be specifically applied to the production of circuit boards in notebook computers or smart phones, and can also be applied to other electronic devices with printed boards in an orthogonal position relationship, such as Figure 2A and Figure 2B As shown, here, examples are not given one by one.

[0064] In the...

Embodiment 2

[0085] Based on the same inventive concept as Embodiment 1 of this application, please refer to Figure 7 , is a schematic diagram of a structural member provided in Embodiment 2 of the present application, and the structural member includes:

[0086] The horizontal printed board 10 has a via hole;

[0087] a vertical printed board 20 with pads;

[0088] A flexible connector 30 has a first end and a second end;

[0089] Wherein, the first end is pierced and welded in the via hole, the second end is welded on the pad, and the flexible connector is curved, and the length of the flexible connector is longer than the The distance between the via hole and the pad.

[0090] In the second embodiment of the present application, the first end is L-shaped.

[0091] In the second embodiment of the present application, the second end is arched, and the uppermost end of the arch is welded on the pad.

[0092] In the second embodiment of the present application, the flexible material i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com