Method, apparatus and system for recognizing knob operation

A technology of rotary operation and knob, which is applied in the direction of measuring devices, program control in sequence/logic controllers, instruments, etc., can solve the problems of misoperation of installation and disassembly of rotary buttons, and achieve the effect of solving misoperation and reducing misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

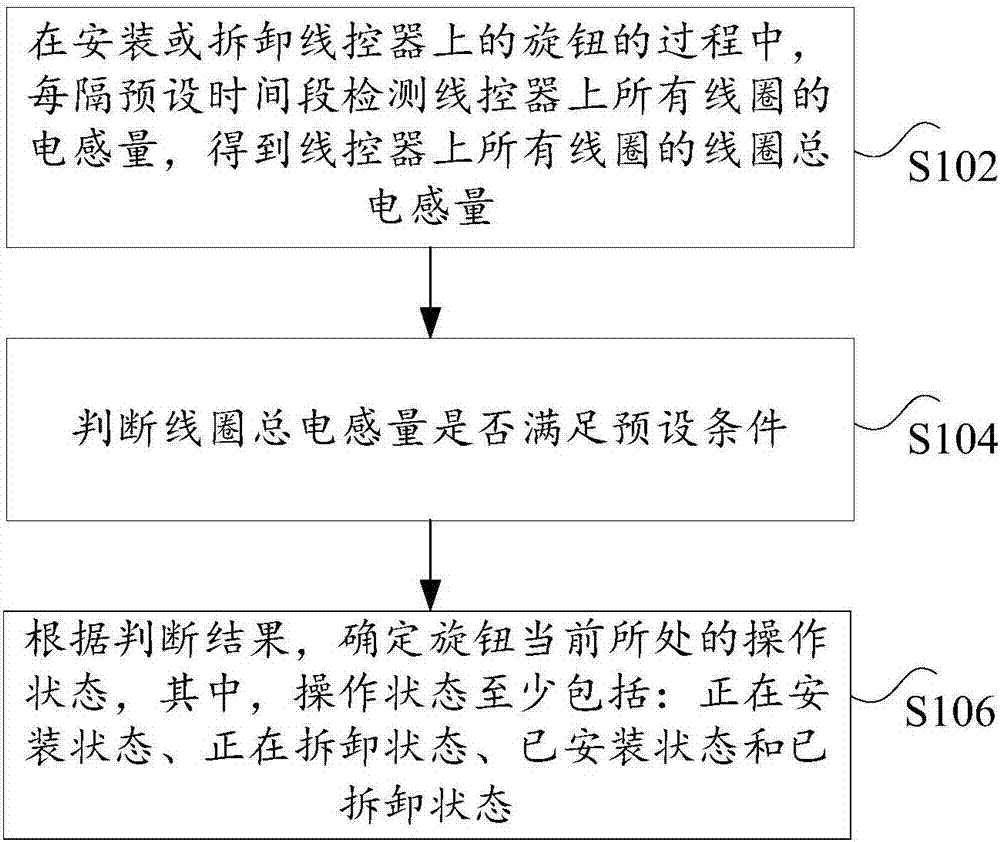

[0023] According to an embodiment of the present invention, there is provided an embodiment of a method for identifying the operation of a knob. It should be noted that the steps shown in the flowchart of the accompanying drawings can be executed in a computer system such as a set of computer-executable instructions, and, Although a logical sequence is shown in the flowchart, in some cases, the steps shown or described may be performed in a different order than here.

[0024] figure 1 It is a flowchart of a method for identifying the operation of a knob according to an embodiment of the present invention, such as figure 1 As shown, the method includes the following steps:

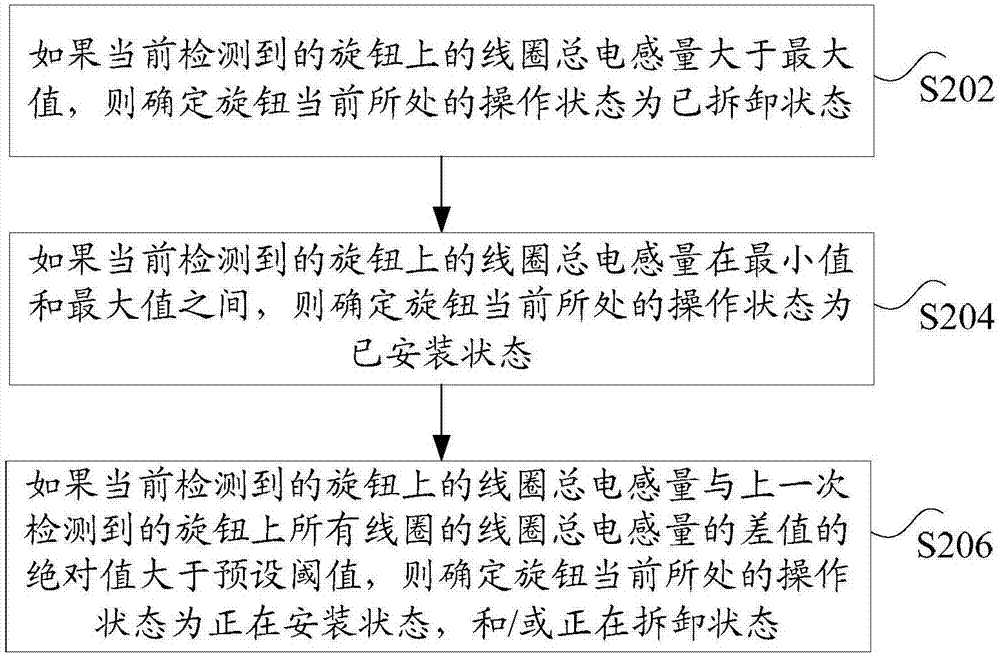

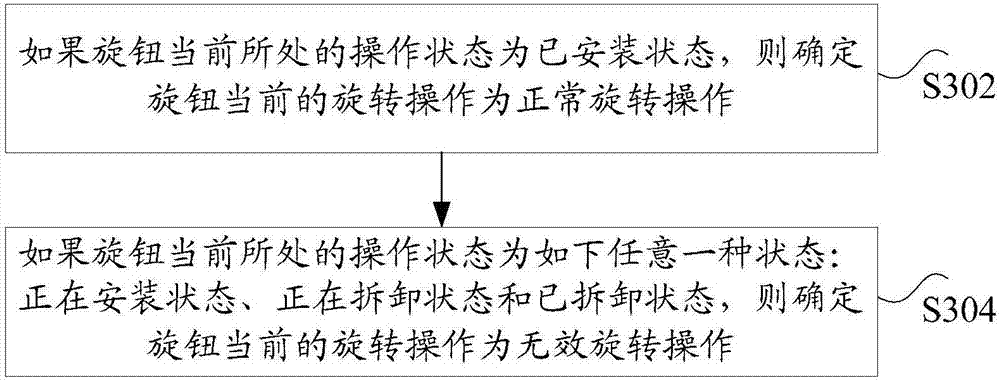

[0025] In step S102, in the process of installing or removing the knob on the wire controller, the inductances of all coils on the wire controller are detected every preset time period to obtain the total coil inductances of all coils on the wire controller.

[0026] Specifically, in the above steps, the installat...

Embodiment 2

[0090] According to an embodiment of the present invention, an embodiment of a device for identifying the operation of a knob is provided.

[0091] Figure 7 It is a schematic diagram of the structure of a device for identifying the operation of a knob according to an embodiment of the present invention, such as Figure 7 As shown, the device includes: an acquisition module 701, a first judgment module 703, and a first determination module 705.

[0092] The obtaining module 701 is used to detect the inductance of all coils on the wire controller every preset time period during the process of installing or removing the knob on the wire controller to obtain the total coil inductance of all coils on the wire controller.

[0093] Specifically, in the acquisition module 701, installation is to place the knob on the remote control panel; disassembly is to remove the knob from the remote control panel. The total inductance of the coil is the inductance of all induction coils on the knob. Th...

Embodiment 3

[0108] According to an embodiment of the present invention, an embodiment of a system for recognizing the operation of a knob is provided.

[0109] Figure 8 It is a schematic diagram of the system structure for identifying knob operation according to an embodiment of the present invention, such as Figure 8 As shown, the system includes: a wire controller 10, a processing unit 20, and a controller 30.

[0110] The wire controller 10 is used to detect the inductance of all coils on the wire controller every preset time period during the process of installing or removing the knob on the wire controller;

[0111] The processing unit 20, connected to the wire controller, is used to calculate the total inductance of all coils on the wire controller, and determine whether the total inductance of the coil meets the preset condition, and determine the current operating state of the knob according to the judgment result, where , The operating status includes at least: being installed, bein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com