Patents

Literature

1170results about How to "Increase the amount added" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

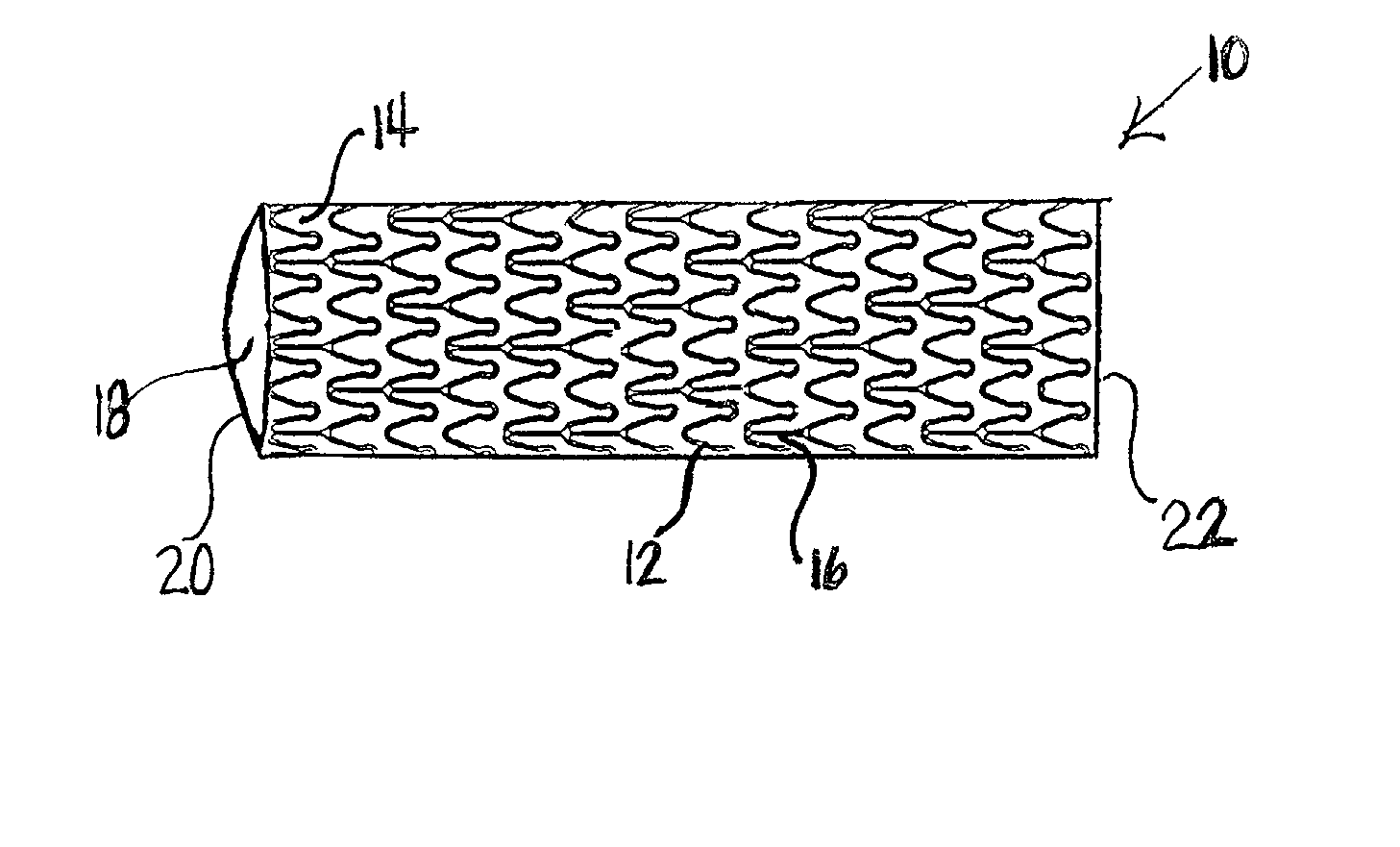

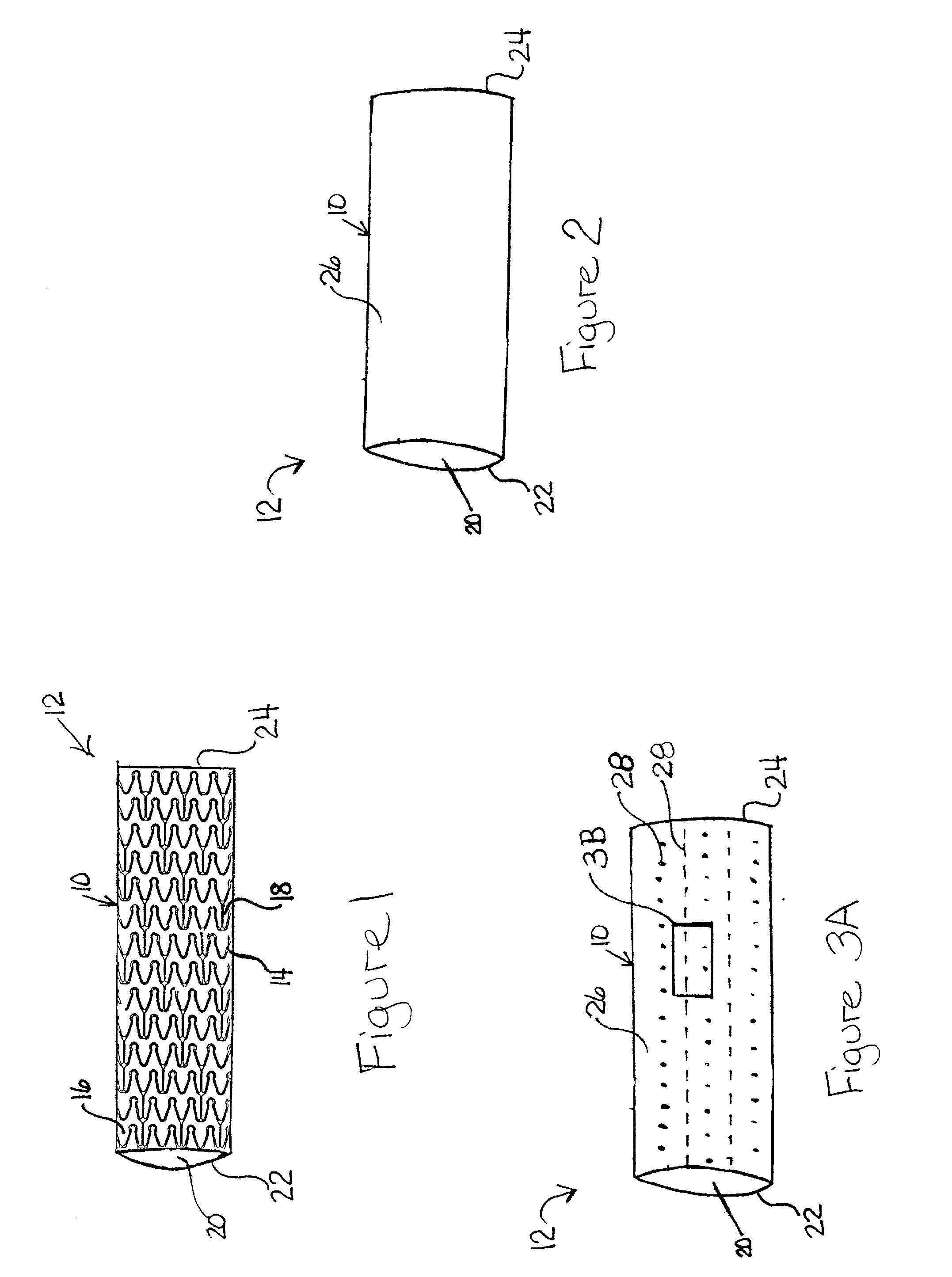

Methods of forming a coating for a prosthesis

InactiveUS6503556B2Increase the amount addedIncrease the number ofRadiation applicationsGlovesProsthesisImplanted device

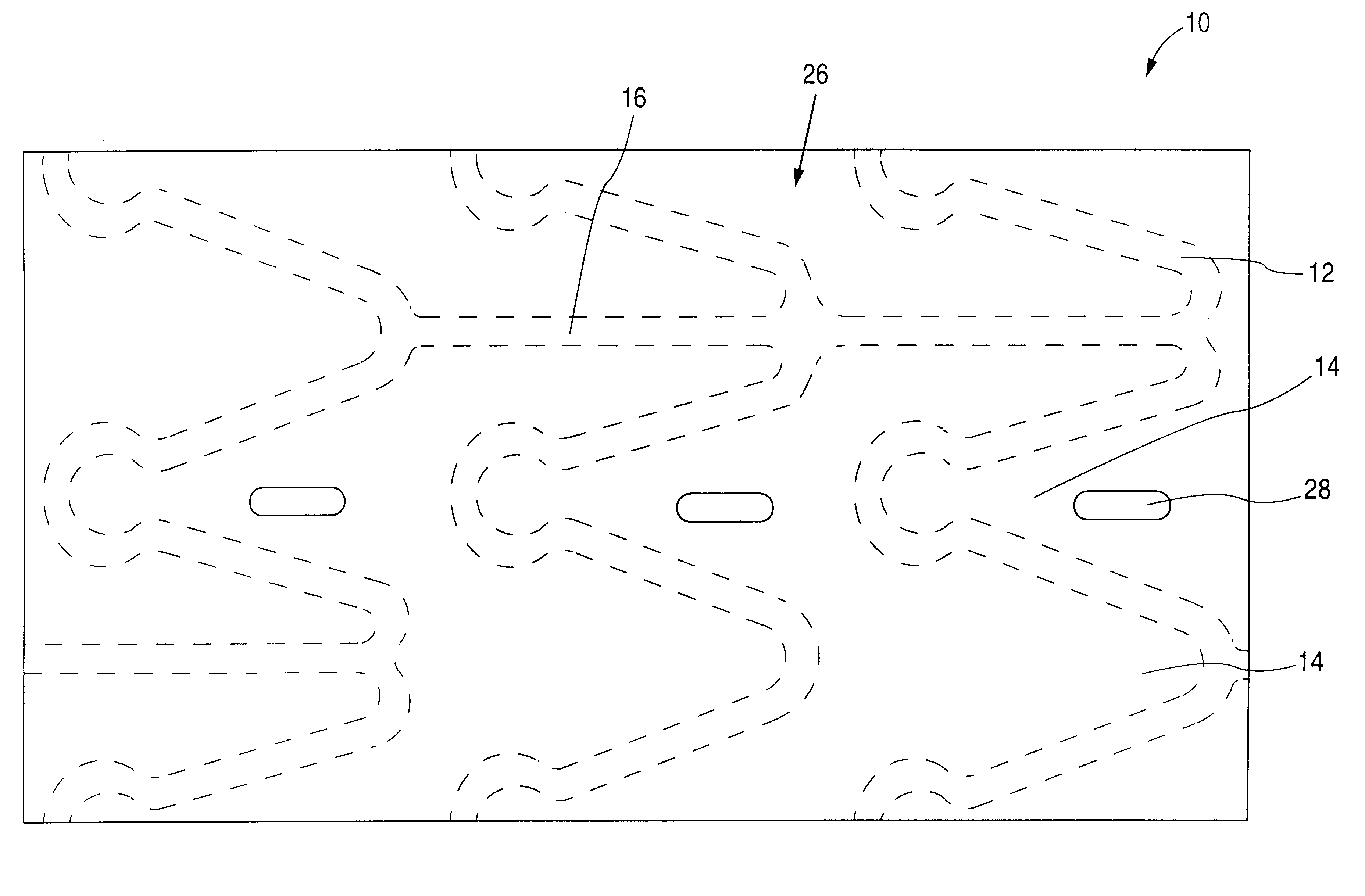

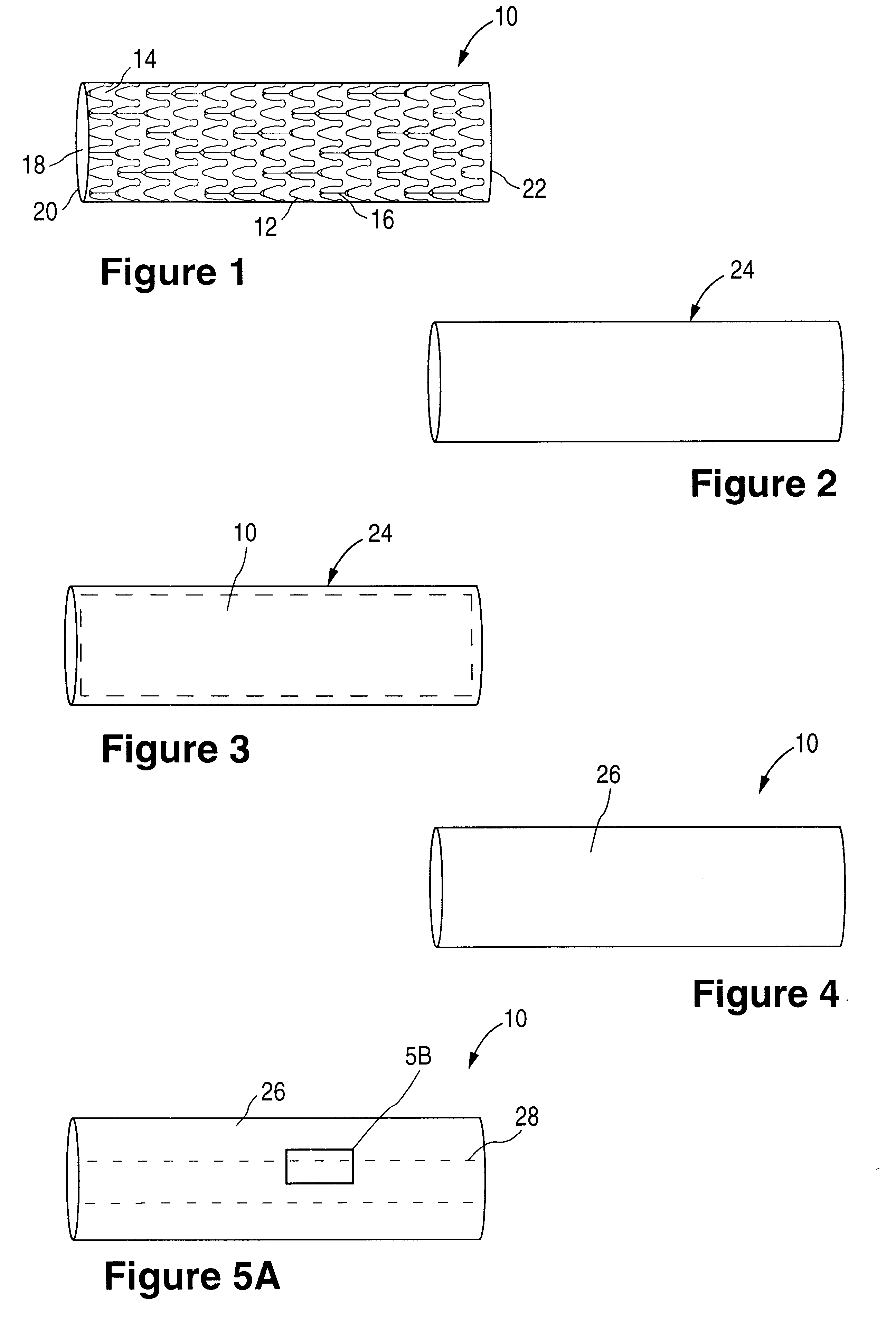

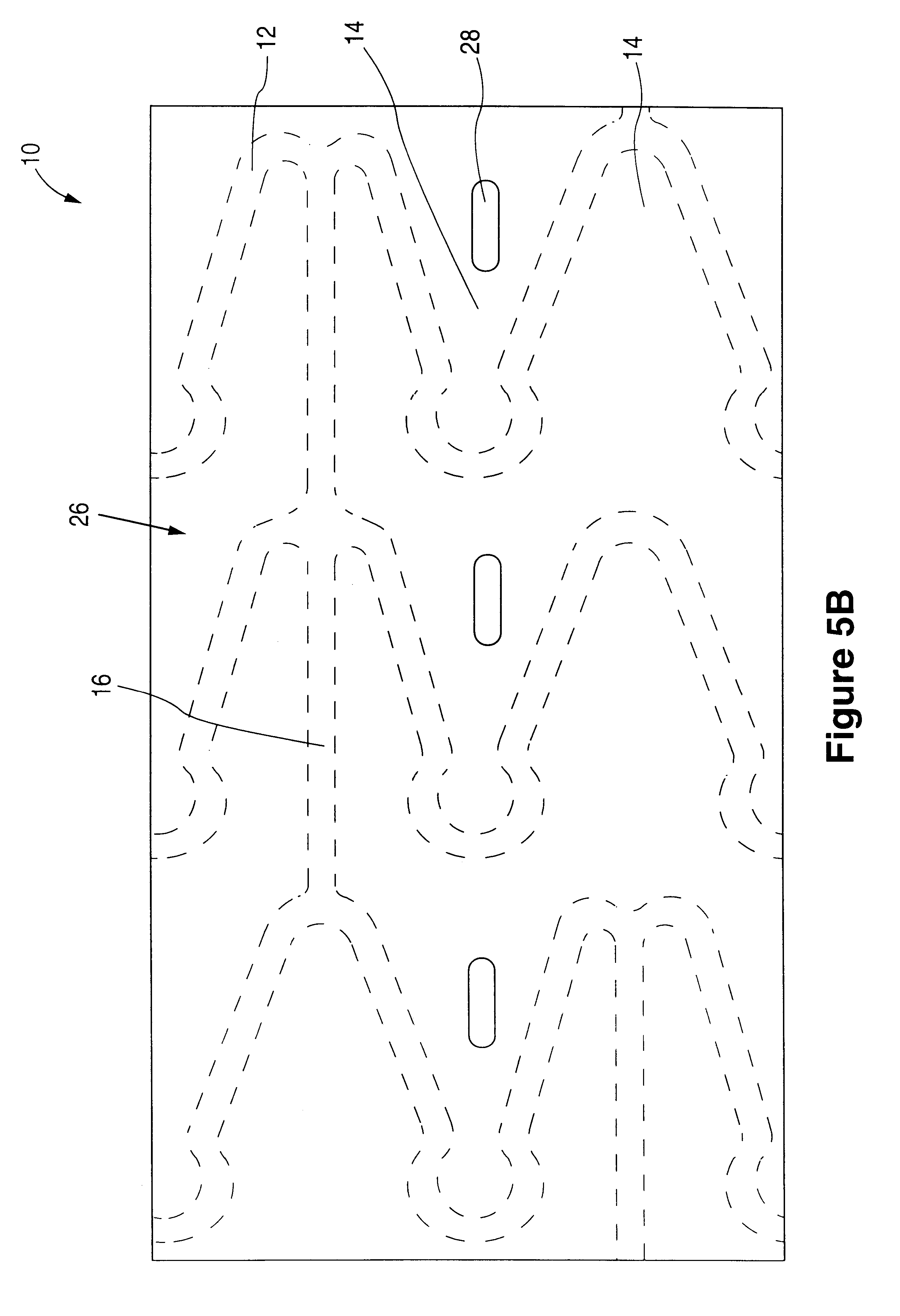

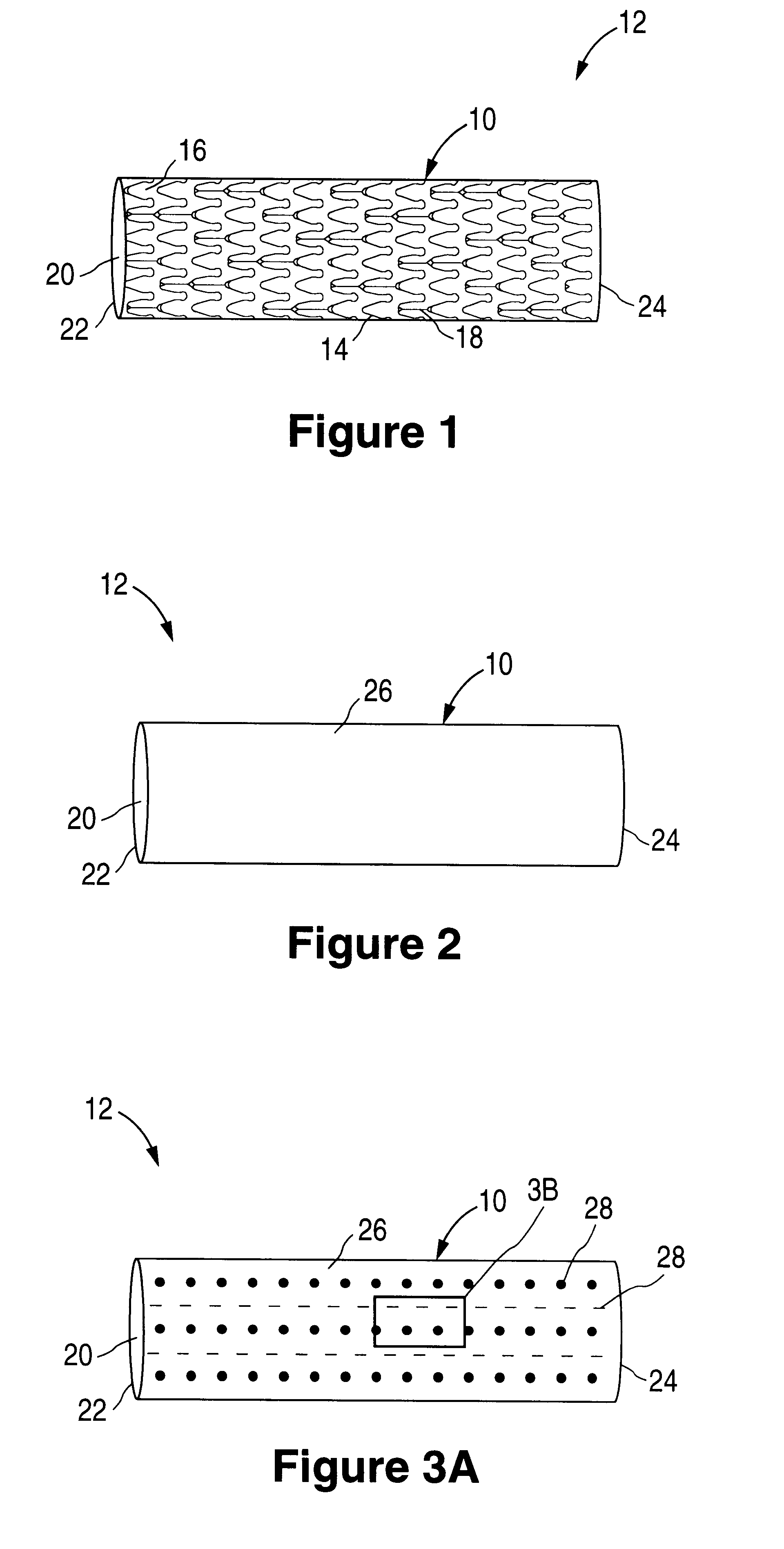

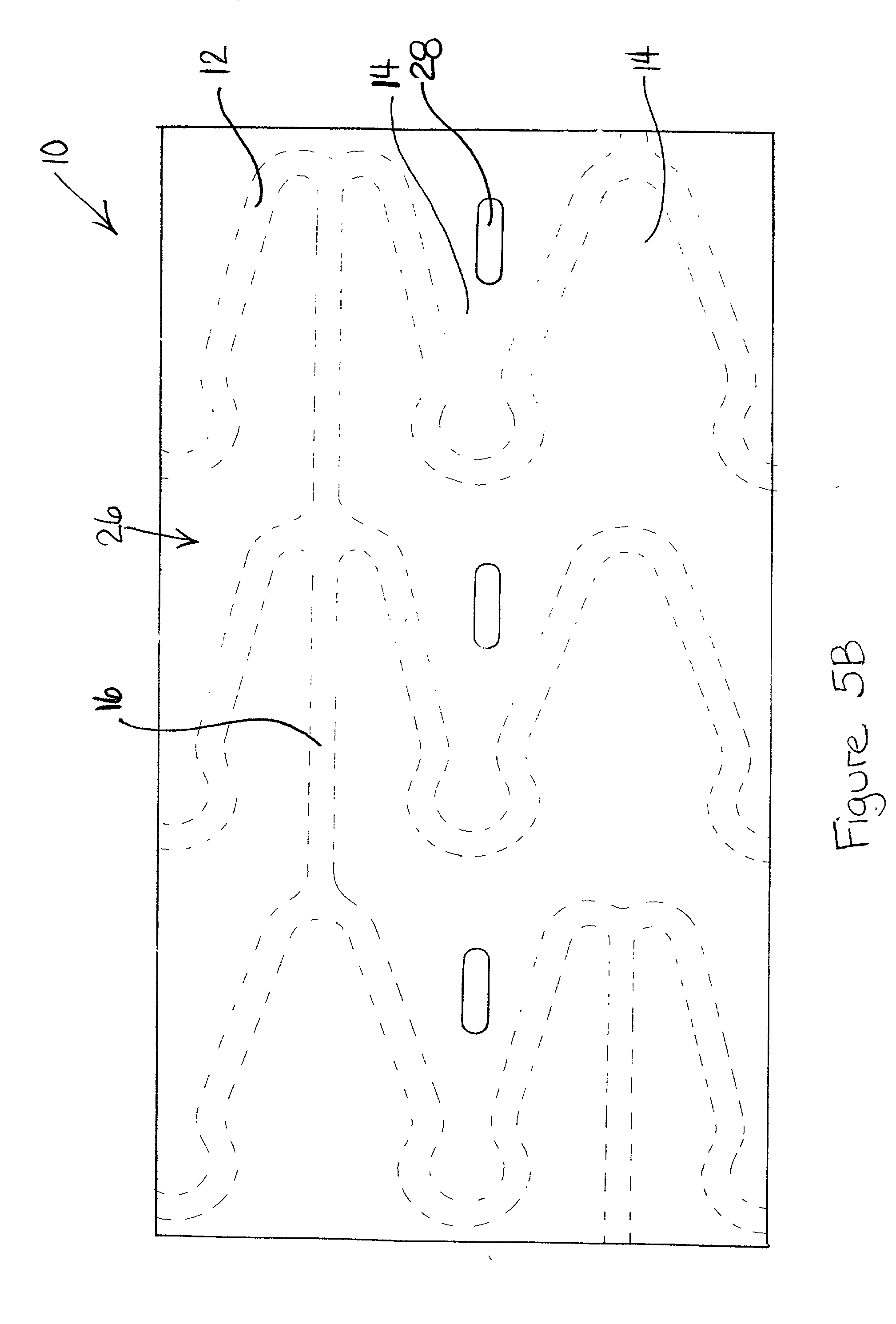

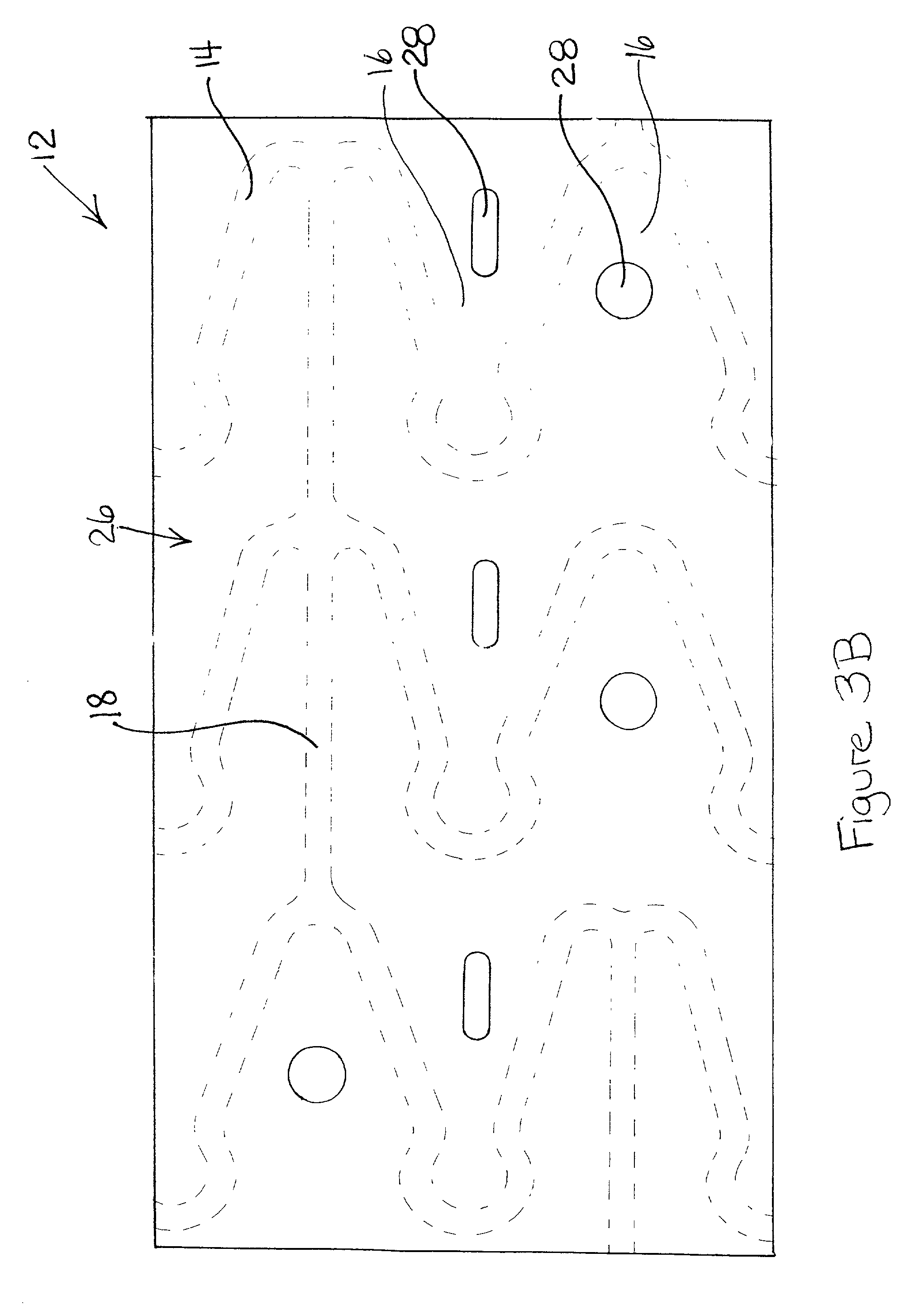

Methods of forming a coating onto an implantable device or endoluminal prosthesis, such as a stent, are provided. The coating may be used for the delivery of an active ingredient. The coating may have a selected pattern of interstices for allowing a fluid to seep through the coating in the direction of the pattern created.

Owner:ABBOTT CARDIOVASCULAR

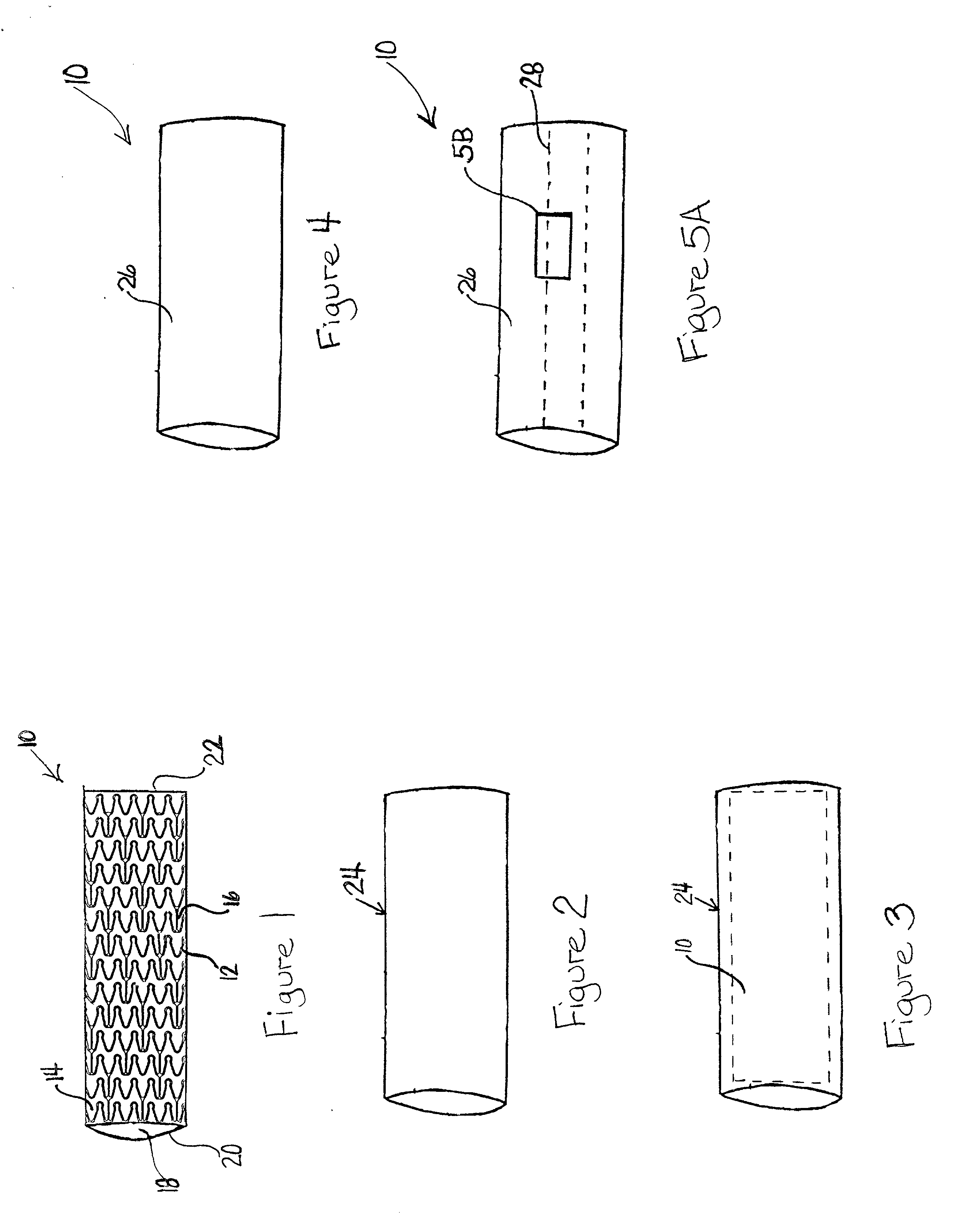

Sheath for a prosthesis and methods of forming the same

InactiveUS6540776B2Increase the amount addedIncrease the number ofStentsPharmaceutical containersProsthesisImplanted device

Owner:ABBOTT CARDIOVASCULAR

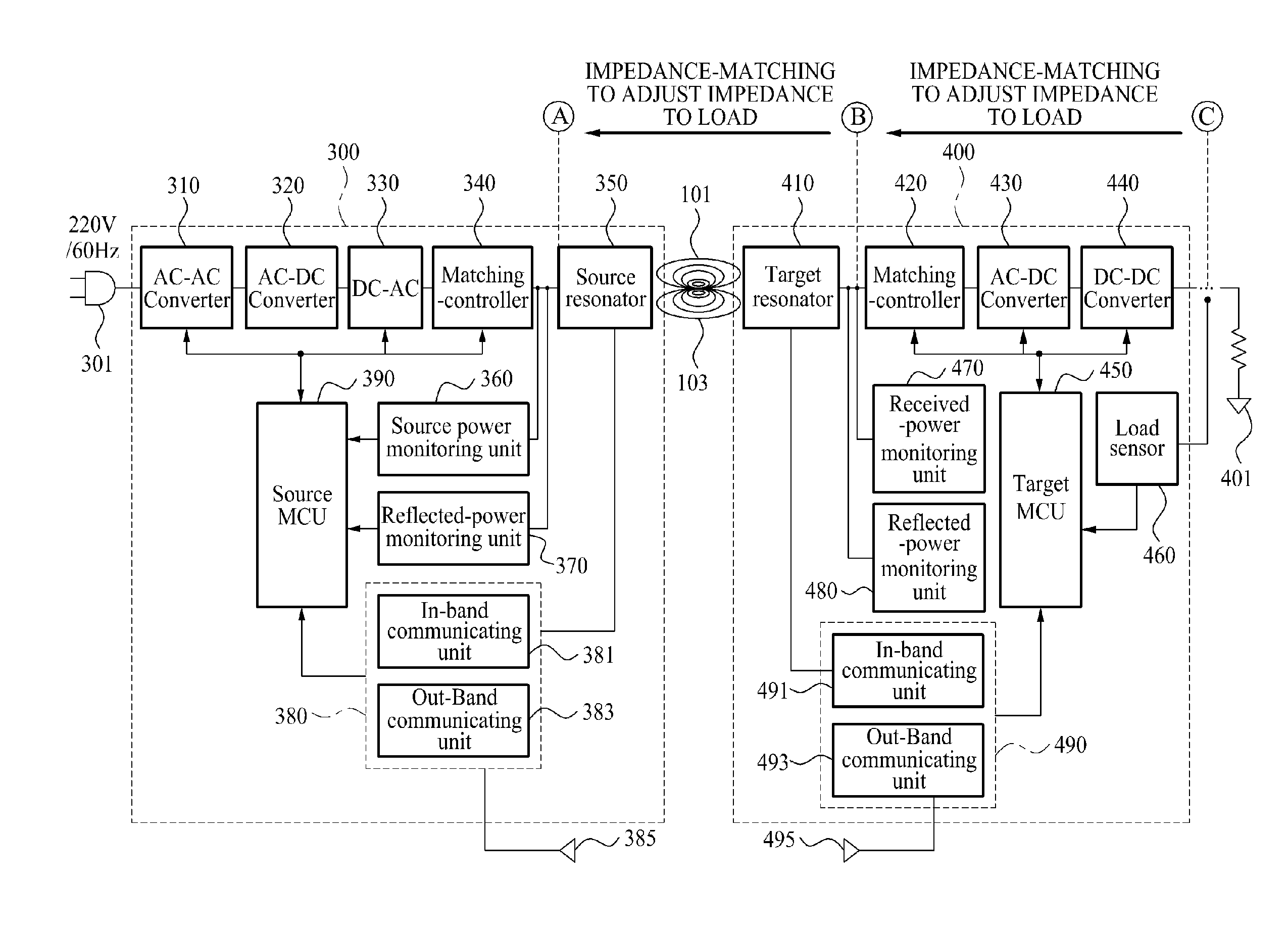

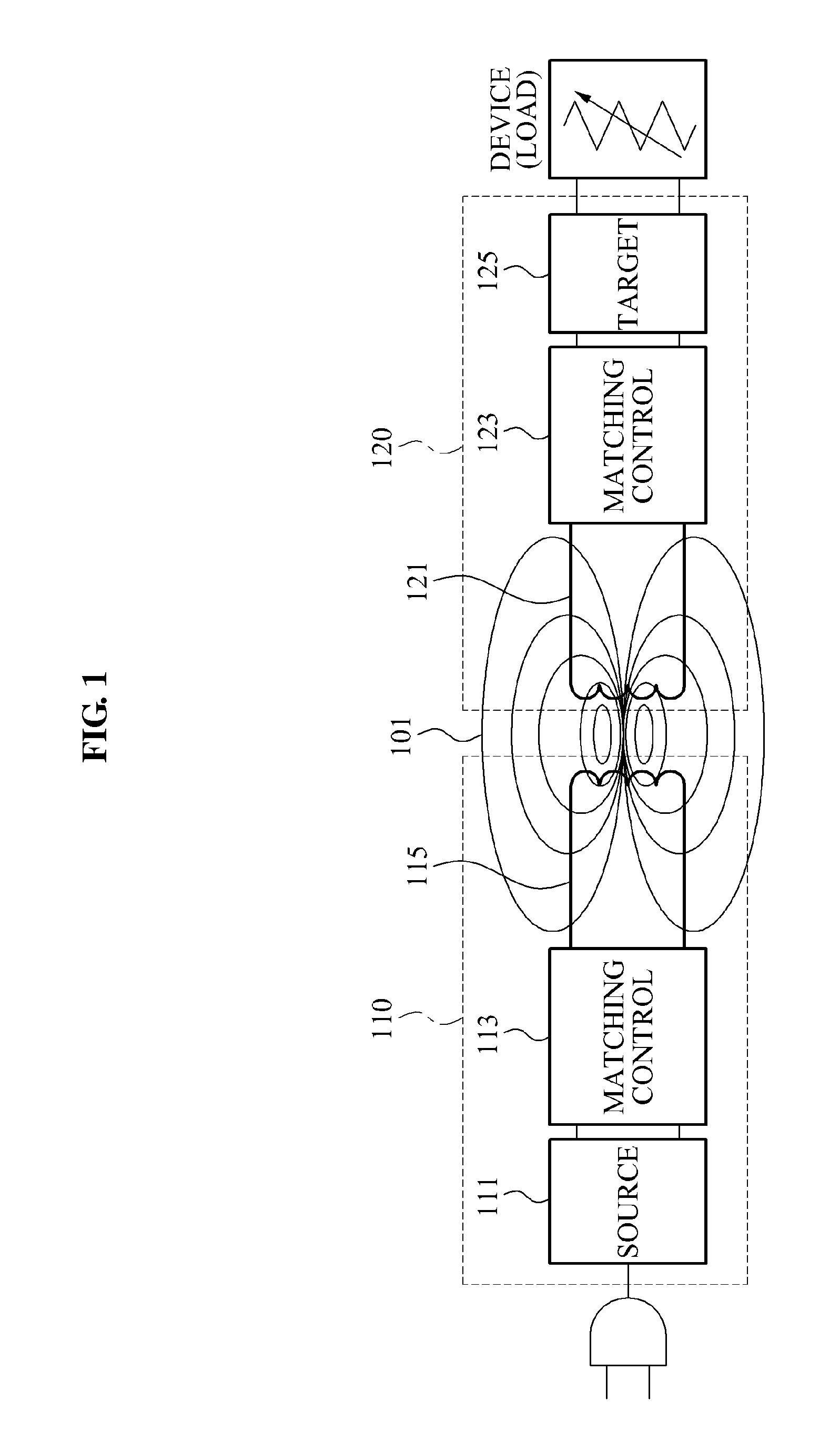

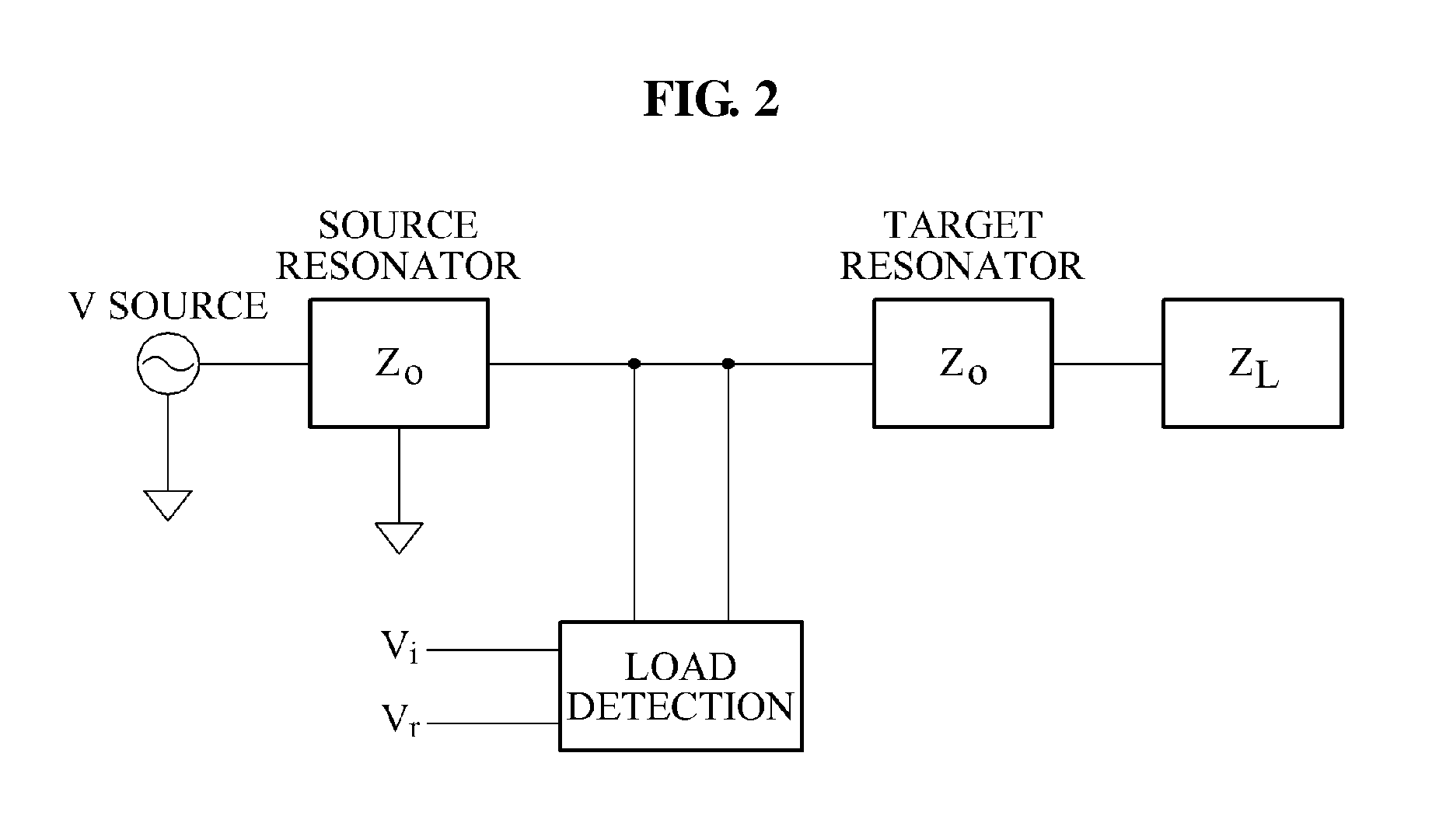

Apparatus and method of matching in a source-target structure

InactiveUS20110266880A1Reduce the amount presentIncrease the amount addedMultiple-port networksElectromagnetic wave systemCouplingResonance

Provided is a source-target structure matching controlling apparatus and method that may perform matching control of a source-target structure while resonance power is transmitted and received through the source-target structure. The source-target structure matching controlling apparatus may include a target resonator to receive, from a resonance power transmitter, the resonance power through a magnetic-coupling, and a rectifier to rectify the resonance power to generate a DC voltage, and provide the DC voltage to a load. The source-target structure matching controlling apparatus may detect an impedance of the load and a variance in the impedance, and may transmit, to the resonance power transmitter, information associated with the variance in the impedance of the load.

Owner:SAMSUNG ELECTRONICS CO LTD

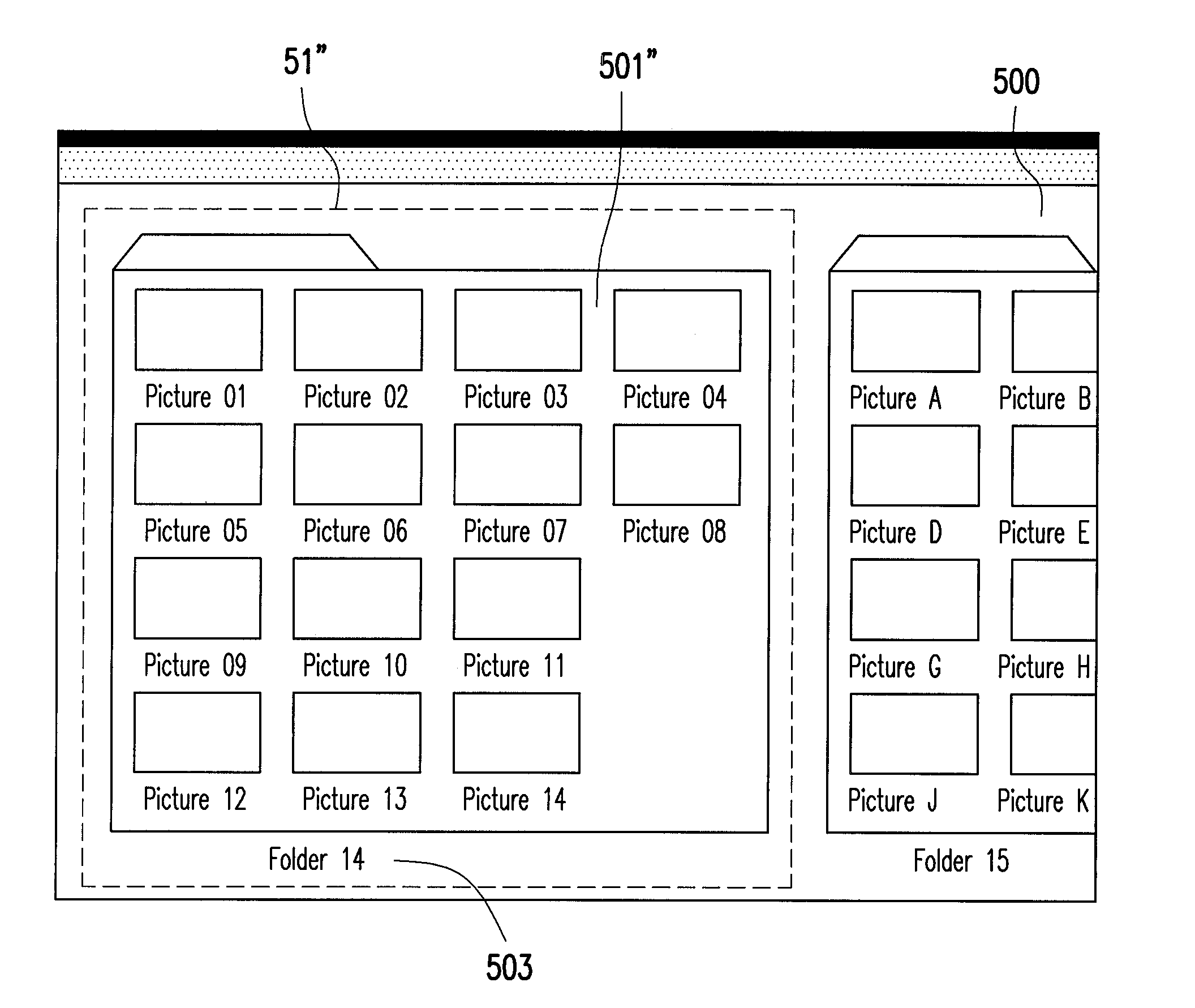

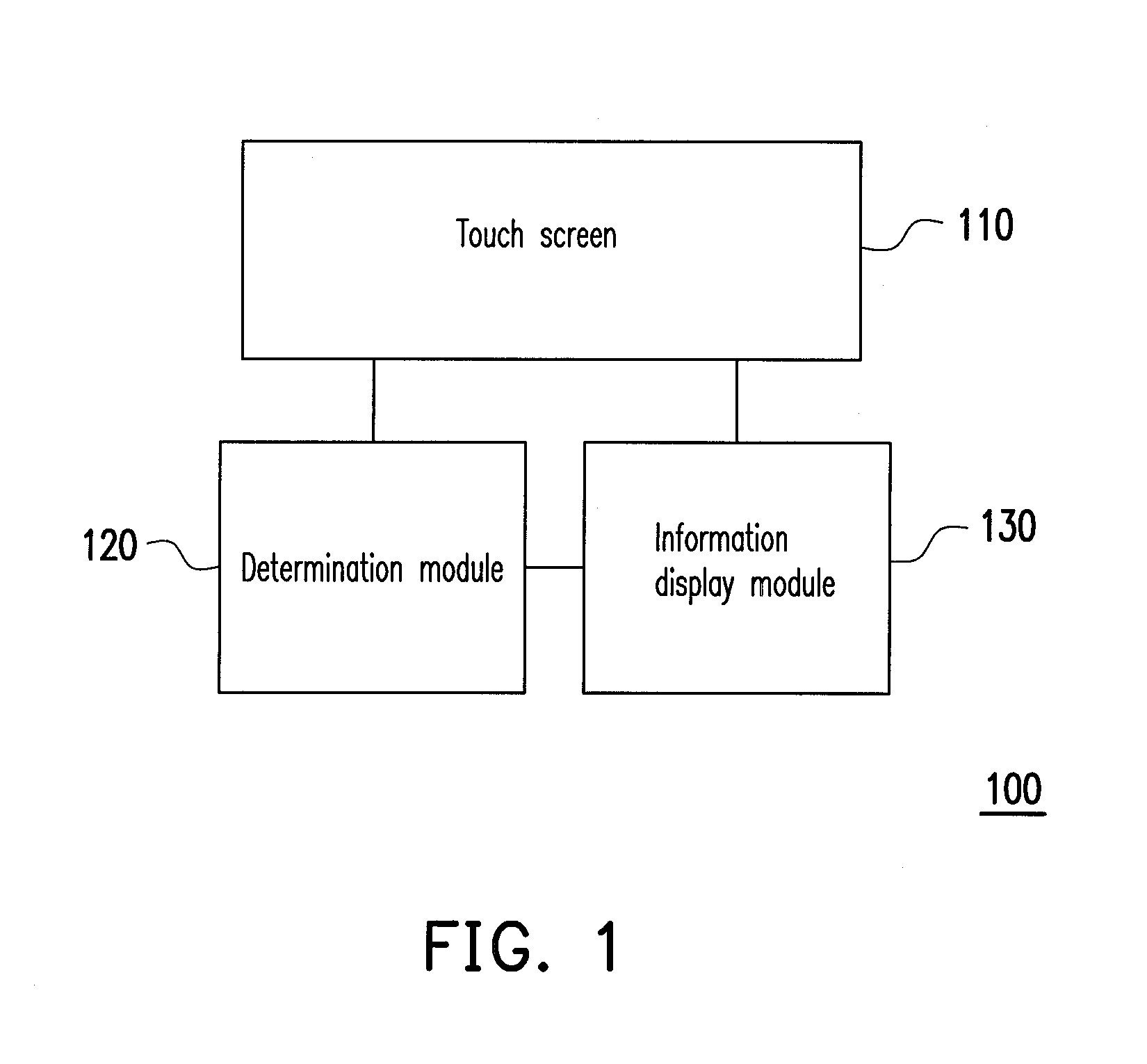

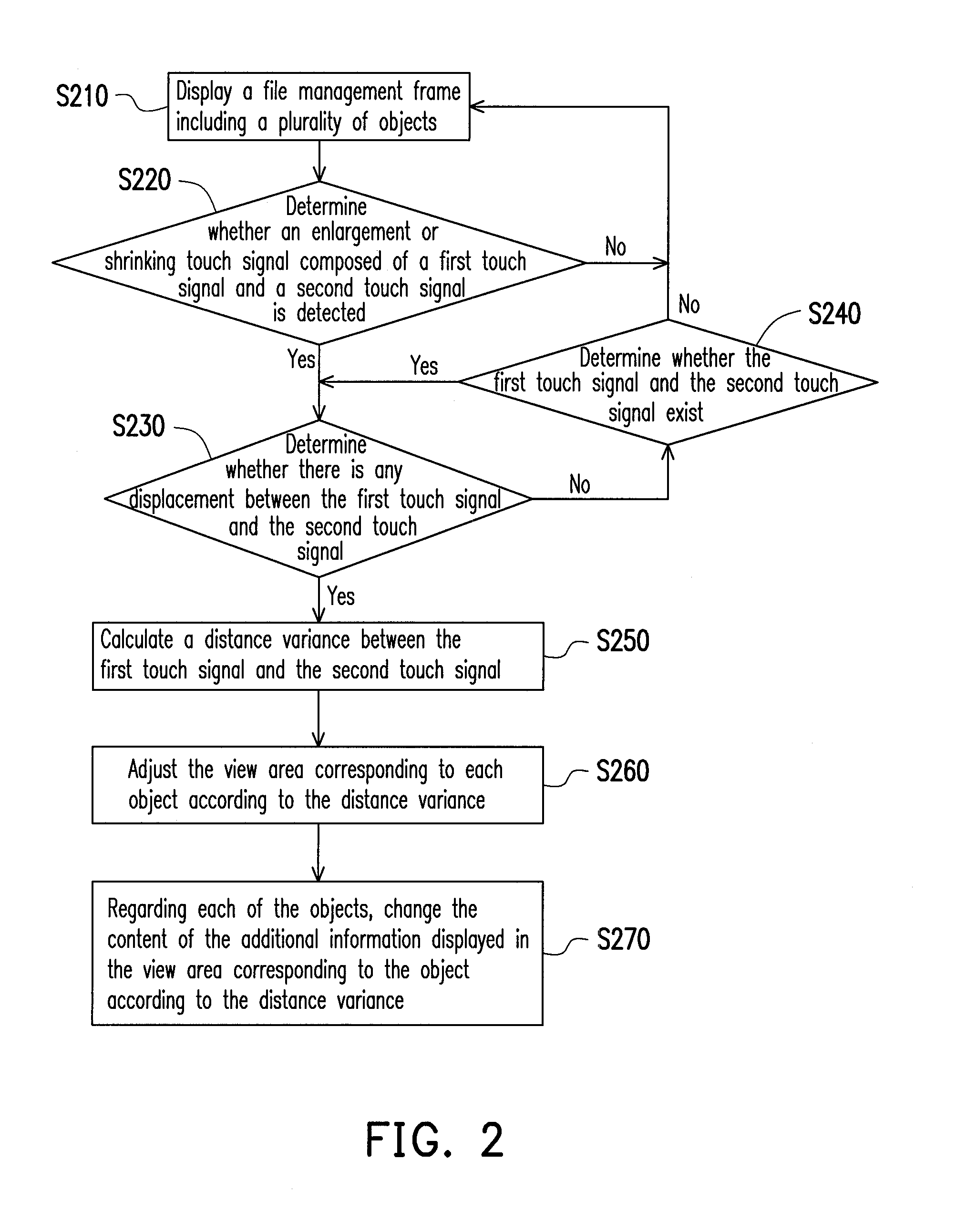

Electronic device and information display method thereof

InactiveUS20120192110A1Conveniently obtainIncrease volumeInput/output processes for data processingPresent methodOn-screen display

An electronic device and an information display method thereof are provided. The electronic device has a screen and is configured to receive signals from a touch input / output interface. The screen displays a file management frame including a plurality of objects, wherein each of the objects is corresponding to a view area within the file management frame and has additional information and / or a preview icon. In the present method, an enlargement or shrinking touch signal is detected via the touch input / output interface. The view area corresponding to each of the objects is adjusted according to the enlargement or shrinking touch signal. Regarding each of the objects, the content of the additional information to be displayed in the view area corresponding to the object is changed according to the enlargement or shrinking touch signal.

Owner:COMPAL ELECTRONICS INC

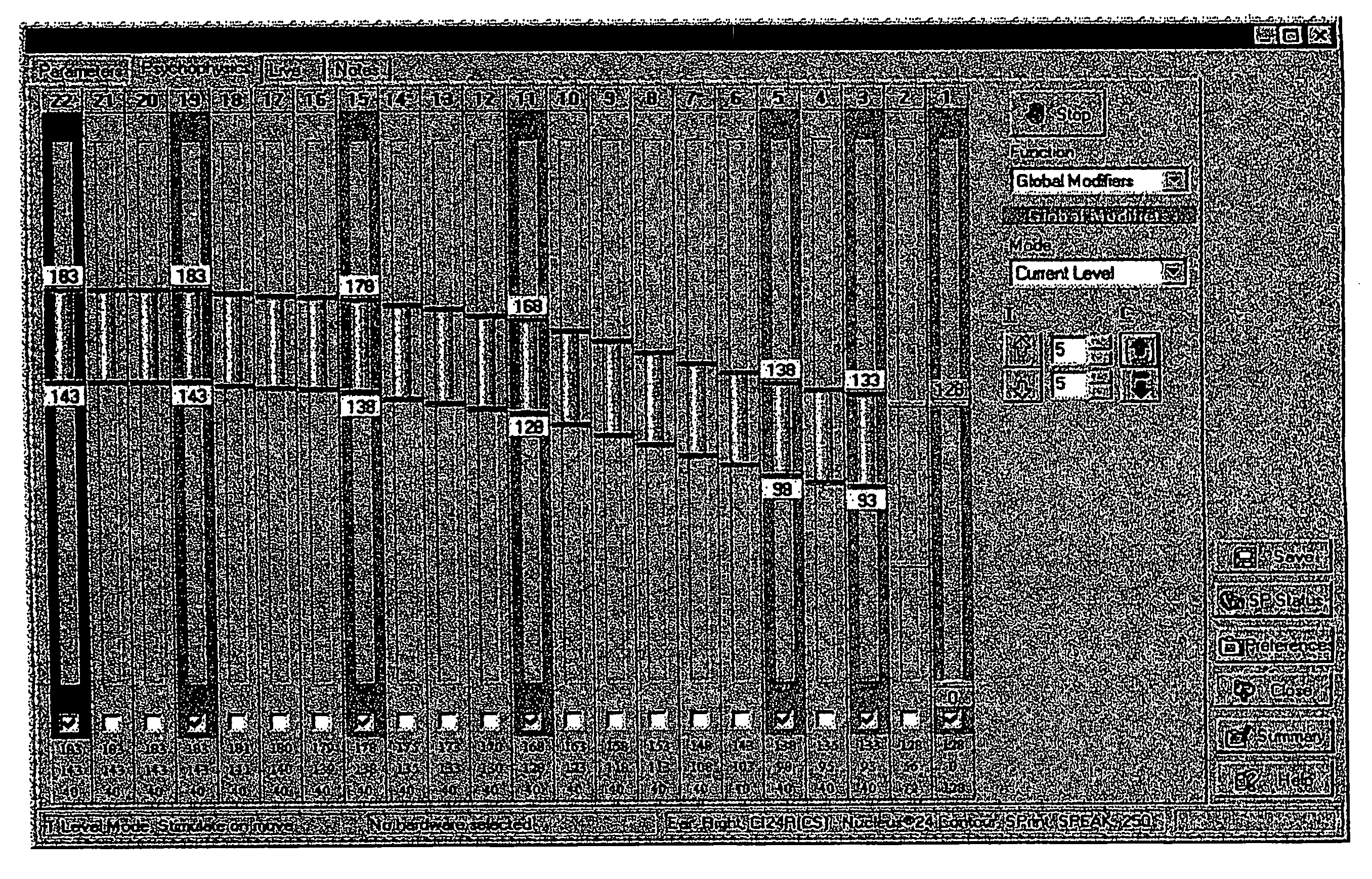

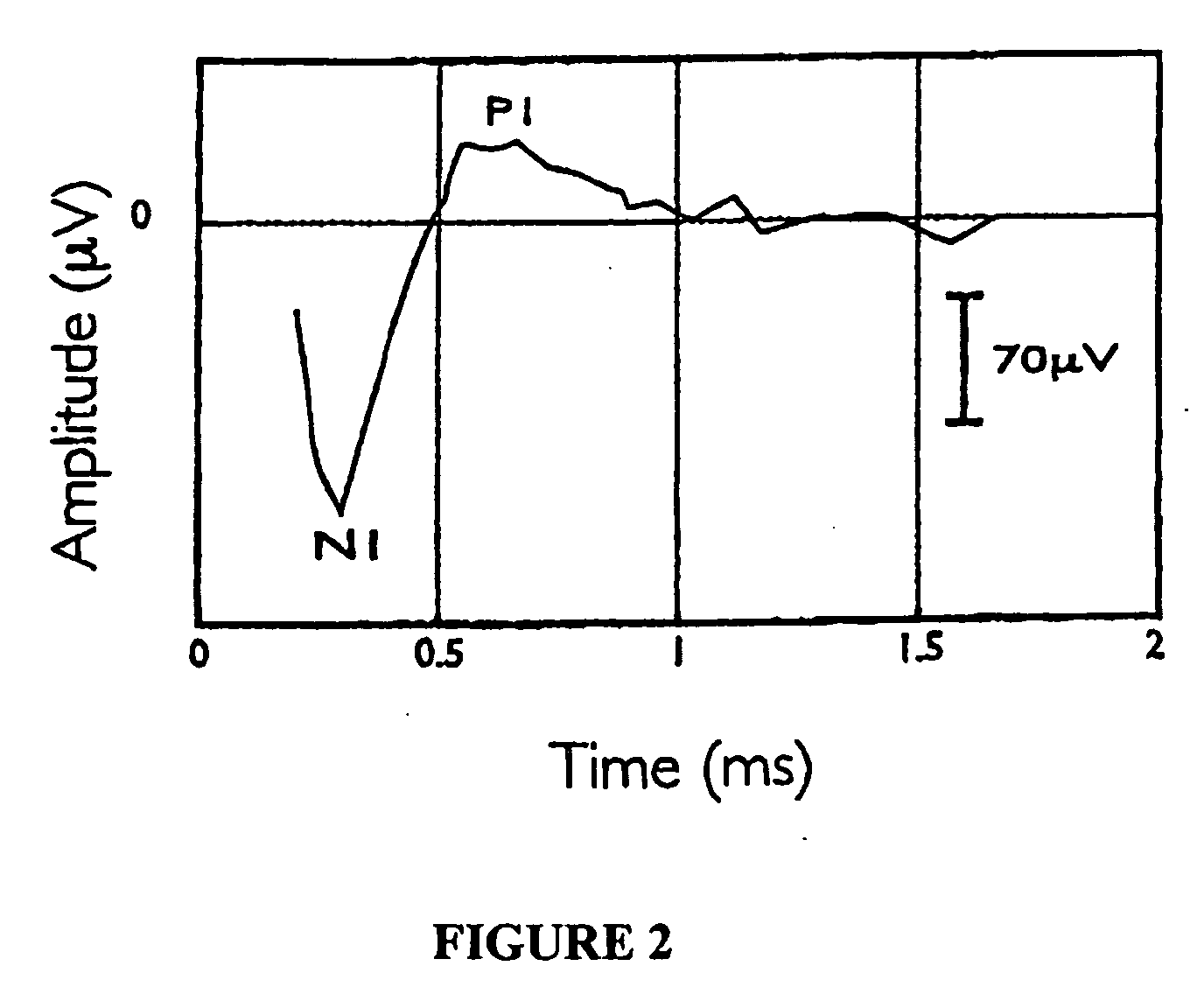

Parametric fitting of a cochlear implant

ActiveUS20060235332A1Reduce the amount requiredMore recipient friendlyElectrotherapyDiagnostic recording/measuringPower flowEngineering

A method of fitting an auditory stimulation system to a recipient the system having a plurality of channels, and the method including the steps of establishing an initial current level profile representative of a current level setting spanning across at least some of the plurality of channels and adjusting parameters of the initial current level profile in the presence of a stimulation signal. There is further included a programming apparatus adapted to be interfaced with the auditory stimulation system to allow manipulation of threshold (T) and comfort (C) levels of the system. The apparatus includes a graphical display means adapted to display a graphical representation of the current profile of the channel array and means for adjusting a current level setting of the current pmfile of the array.

Owner:COCHLEAR LIMITED

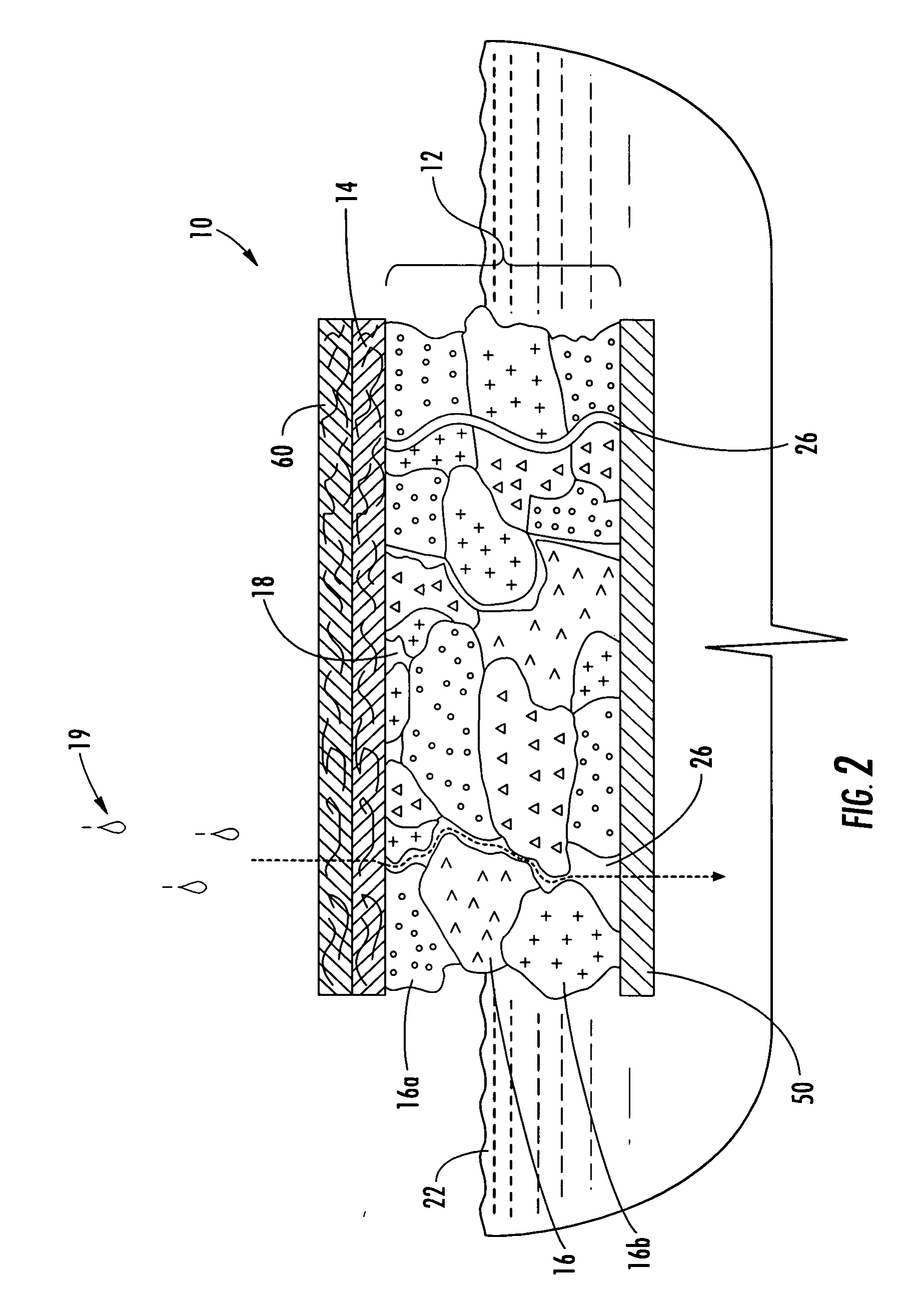

Methods of forming a coating for a prosthesis

InactiveUS20020122877A1Increase the amount addedIncrease the number ofRadiation applicationsGlovesProsthesisImplanted device

Methods of forming a coating onto an implantable device or endoluminal prosthesis, such as a stent, are provided. The coating may be used for the delivery of an active ingredient. The coating may have a selected pattern of interstices for allowing a fluid to seep through the coating in the direction of the pattern created.

Owner:ABBOTT CARDIOVASCULAR

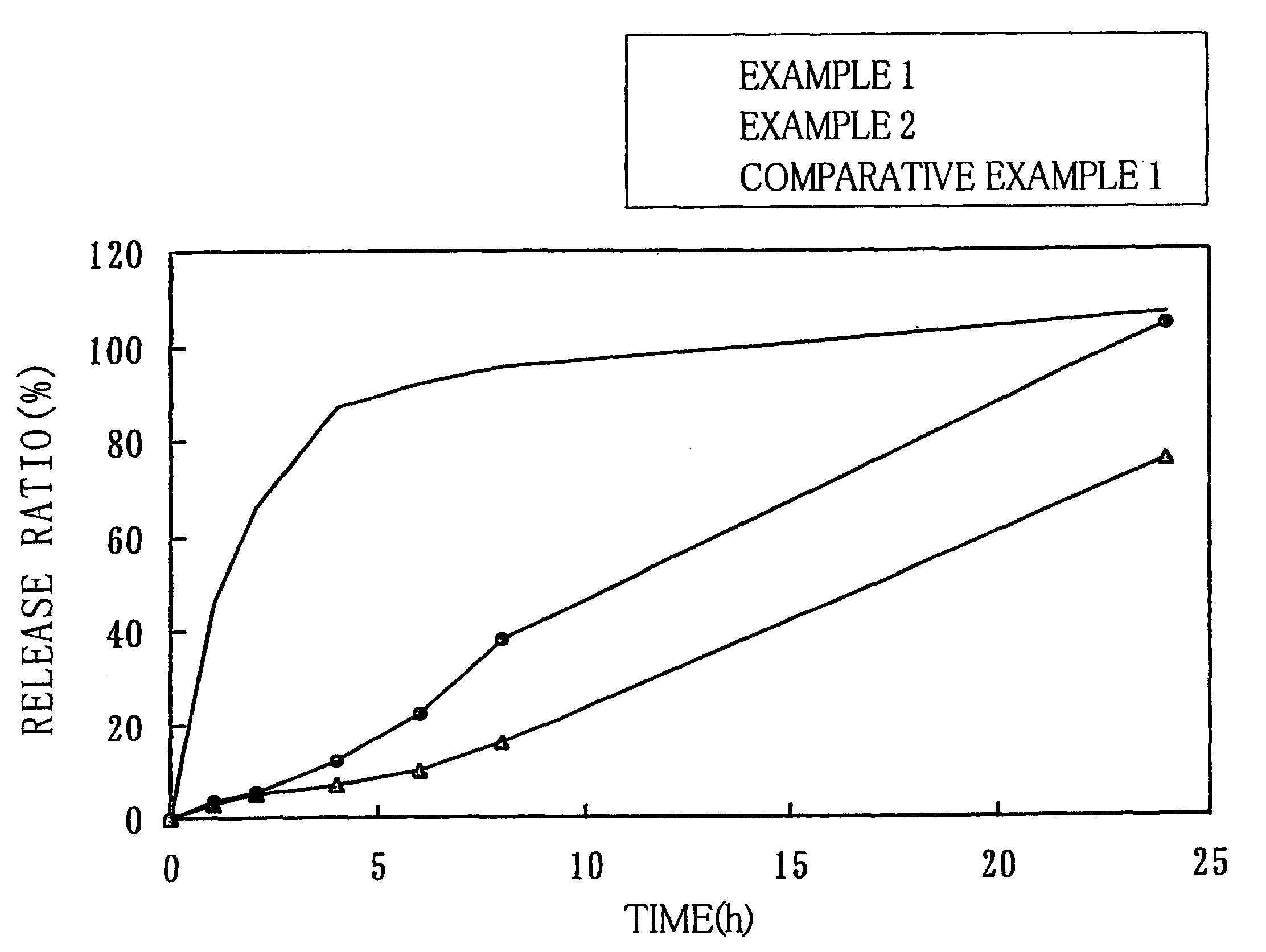

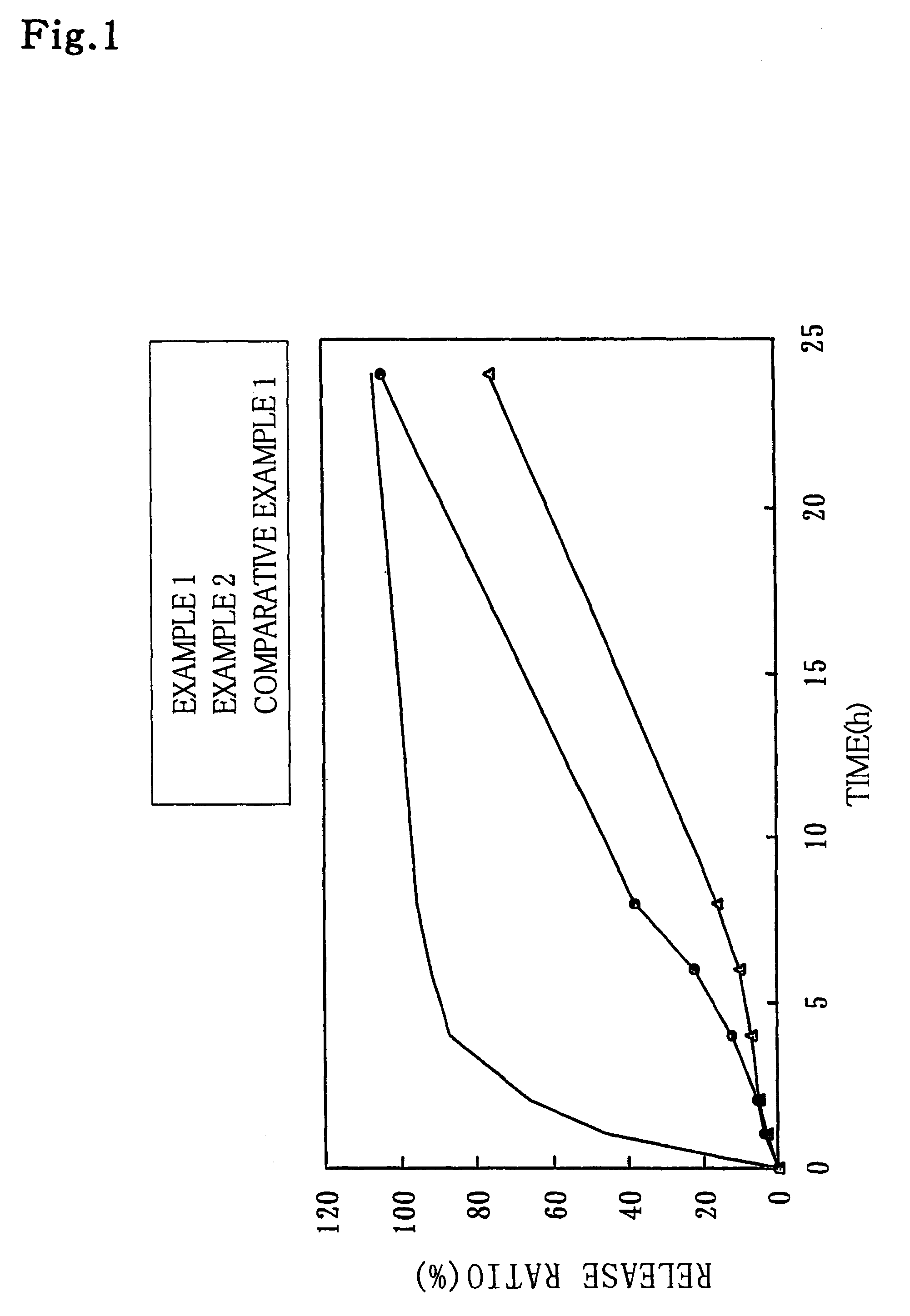

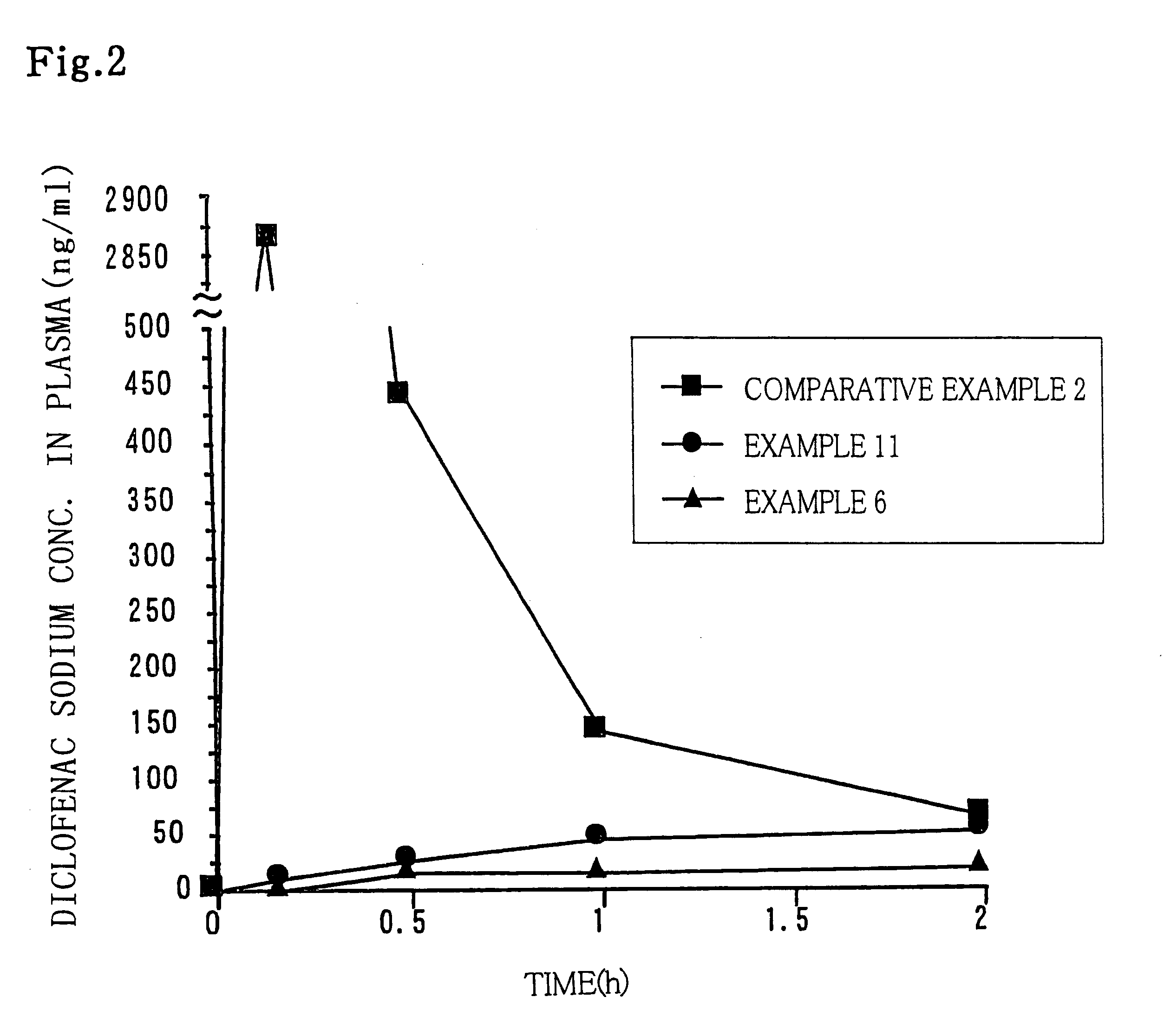

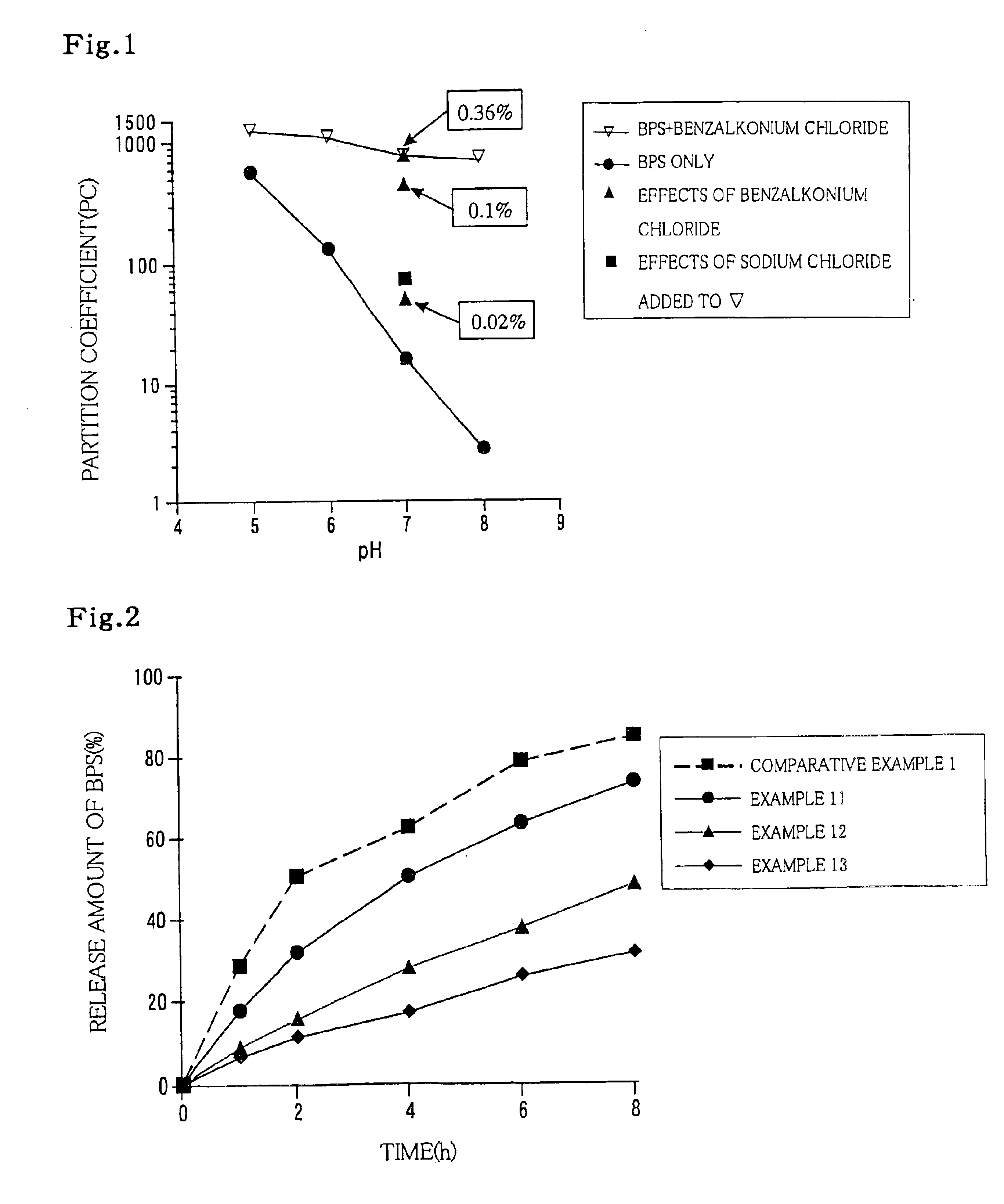

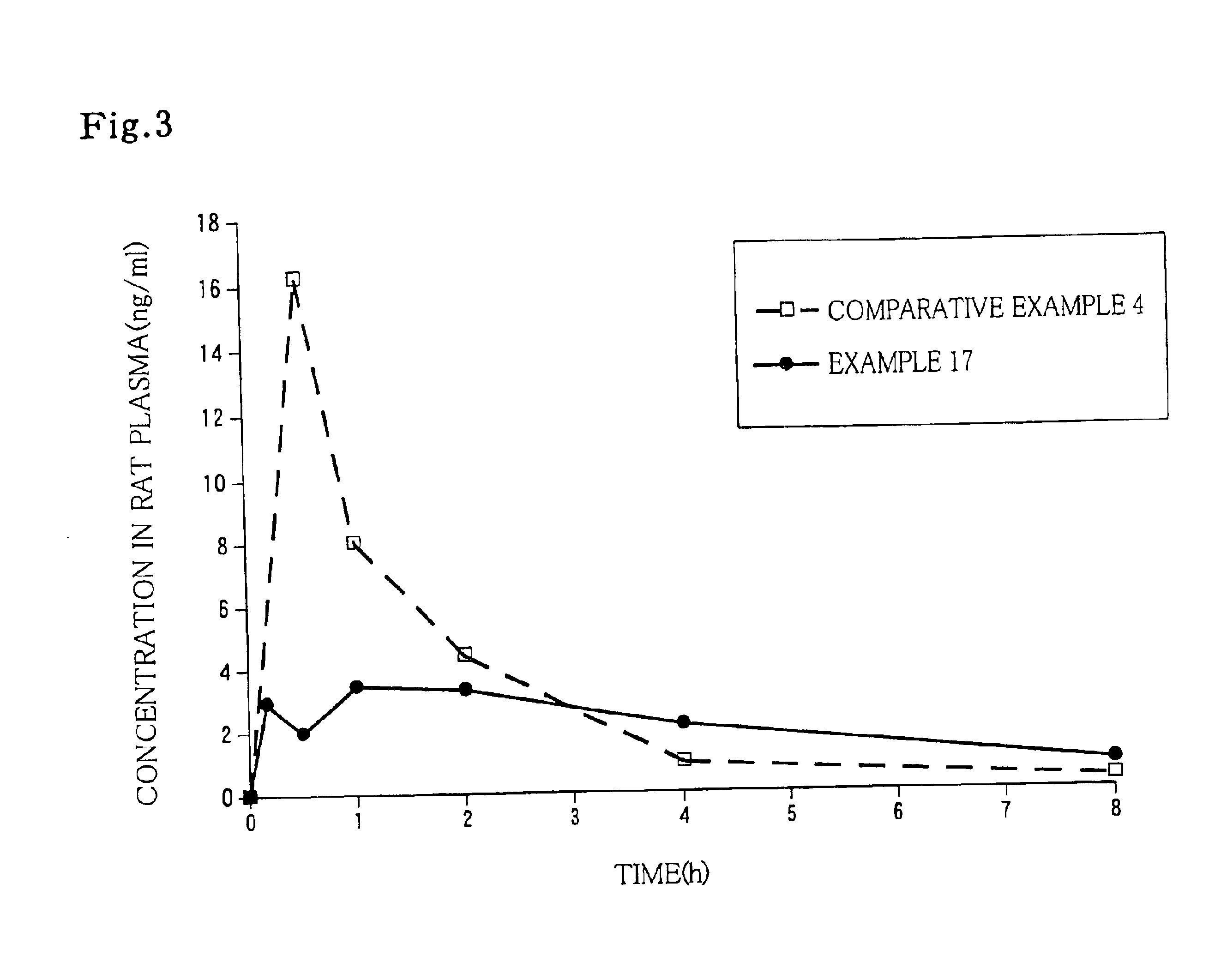

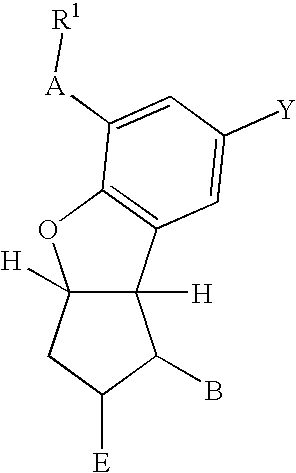

Sustained release medicinal compositions

InactiveUS6328979B1Improve hydrophobicityGood sustained release effectElcosanoid active ingredientsAerosol deliverySolubilityAcid derivative

The present invention relates to sustained-release pharmaceutical compositions for ionic pharmaceutically active substances (excluding ionic prostanoic acid derivatives) containing ionic compounds having opposite charges to those of the active substances and increasing hydrophobicity of the active substances. More specifically, the invention relates to sustained-release pharmaceutical compositions comprising the ionic pharmaceutically active substances and the ionic compounds having opposite charges to those of the active substances and increasing hydrophobicity of the active substances that contain hydrophobic groups in the molecule thereof. The pharmaceutical composition of the invention can exhibit excellent sustained release effect of the active substance, irrespective of water solubility possessed by the ionic pharmaceutically active substances.

Owner:ASTELLAS PHARMA INC

Quick-disintegrating tablet in buccal cavity and manufacturing method thereof

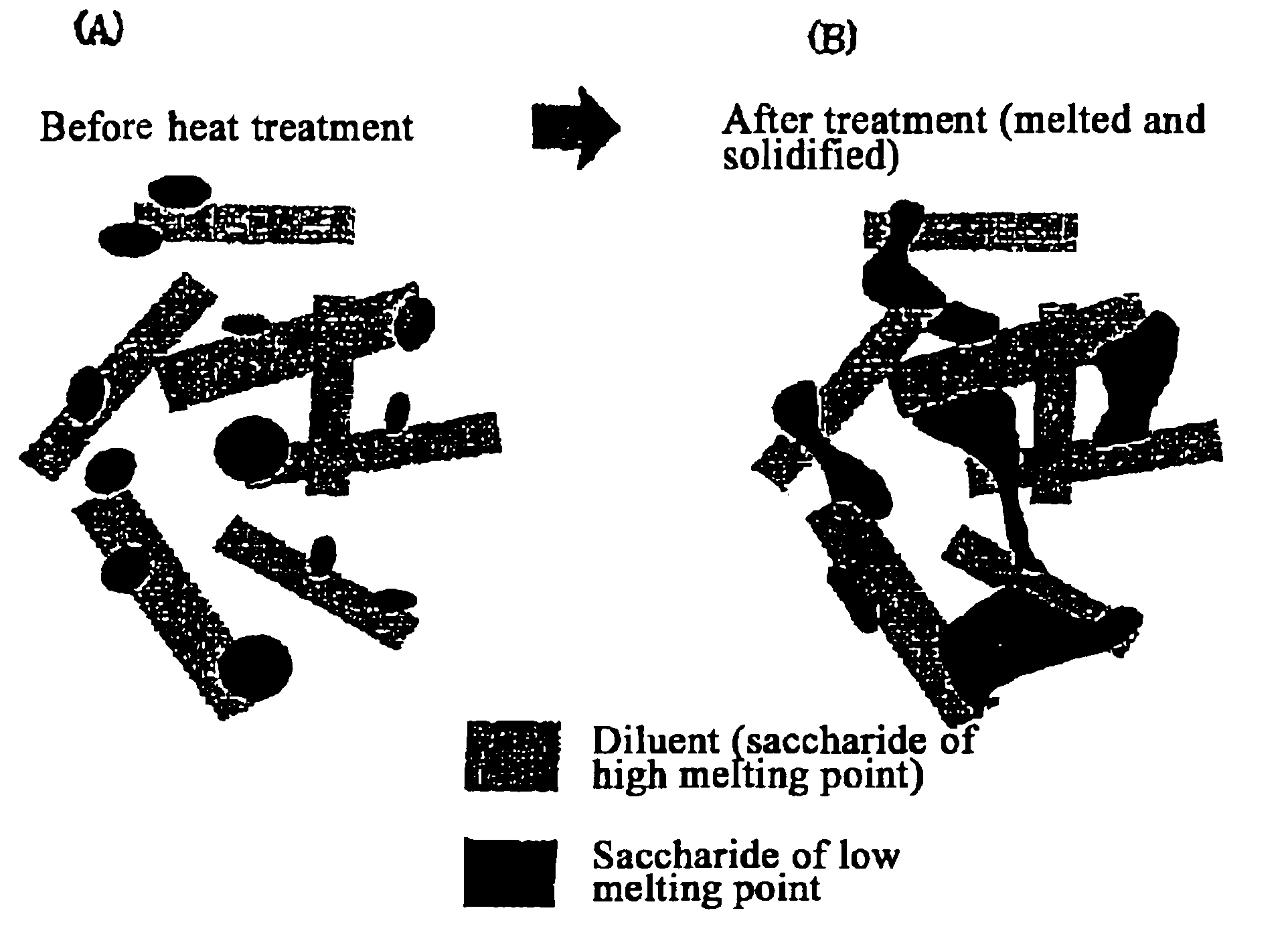

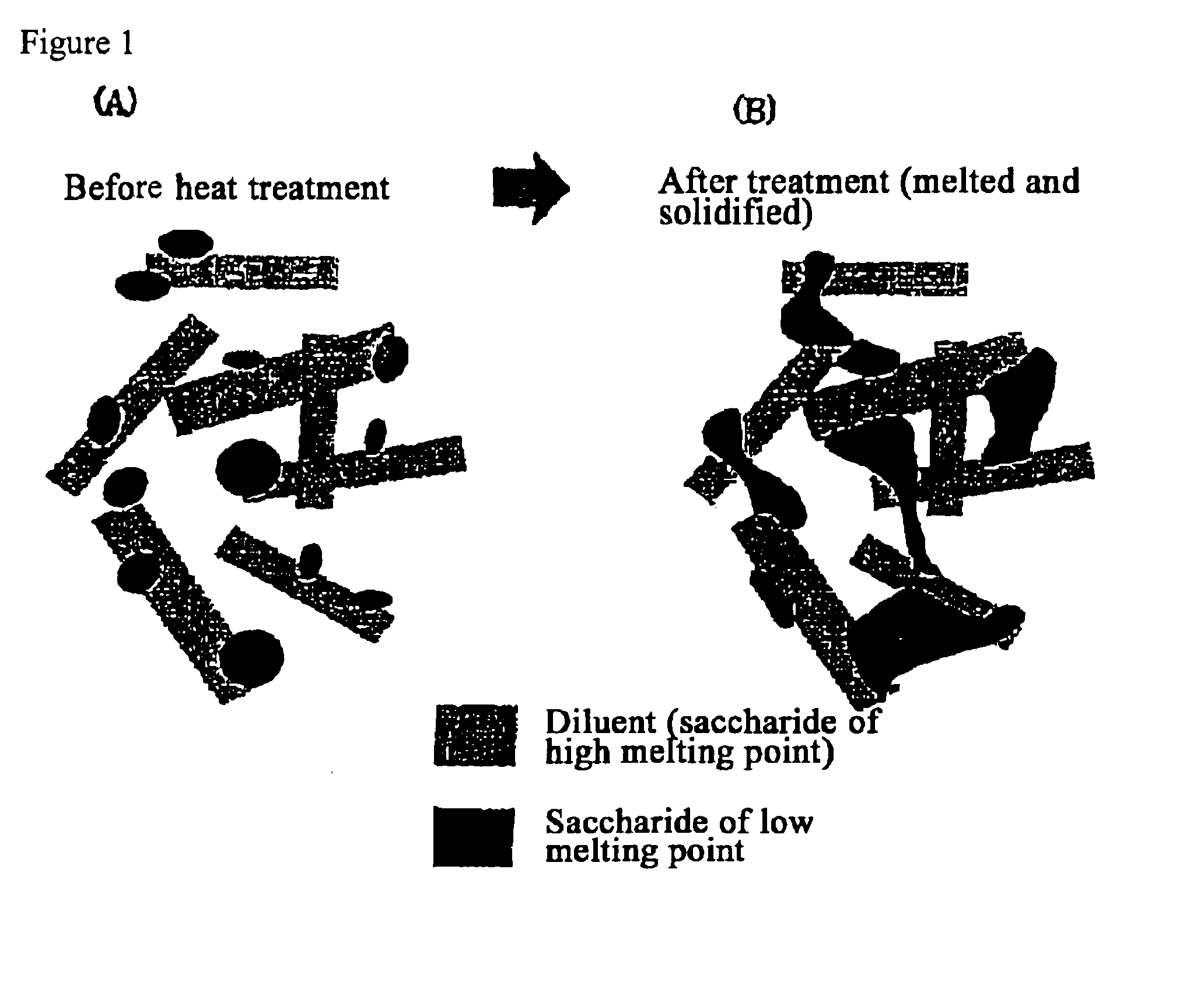

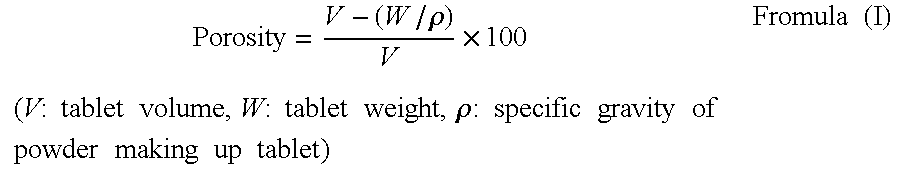

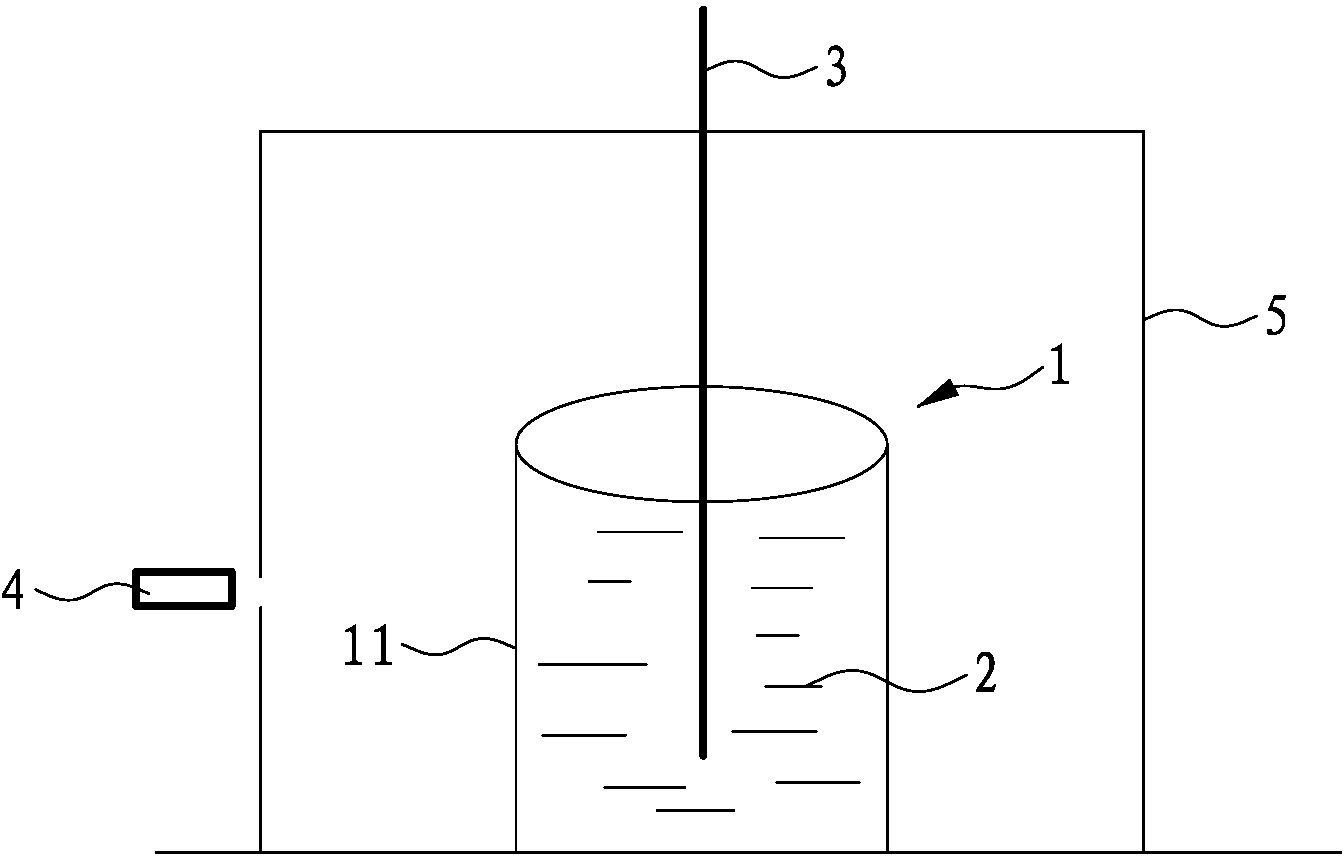

InactiveUS6872405B2Improves friabilityHigh strengthPharmaceutical non-active ingredientsDrageesPharmaceutical SubstancesOrganic chemistry

The present invention relates to a quick-disintegrating tablet in the buccal cavity comprising a drug, a diluent, and a saccharide with a relatively lower melting point than the drug and the diluent, which is obtained by uniformly mixing the saccharide with a low melting point in the tablet so that a bridge will be formed between said drug and / or said diluent particles by the product of melting and then solidification of this saccharide with a low melting point. Moreover, the present invention relates to a method of manufacturing a quick-disintegrating tablet in the buccal cavity comprising a drug, a diluent and a saccharide with a relatively lower melting point than the drug and the diluent, which comprises (a) the process whereby tablet starting materials including a drug, a diluent, and a saccharide with a relatively lower melting point than the drug and the diluent are molded under the low pressure necessary for retaining the shape of a tablet, (b) the process whereby the molded product obtained in process (a) is heated to at least the temperature at which this saccharide with a low melting point will melt, and (c) the process whereby the molded product obtained in process (b) is cooled to at least the temperature at which the molten saccharide with a low melting point solidifies. The present invention presents a quick-disintegrating tablet in the buccal cavity that can be used for practical purposes in that it has almost the same properties as conventional oral pharmaceutical tablets, that is, it has sufficient tablet strength that it can be used with automatic unit dosing machines, and it is produced by conventional tableting machines, and a manufacturing method thereof. Moreover, the present invention presents a quick-disintegrating tablet in the buccal cavity which, in comparison to conventional quick-disintegrating tablets in the buccal cavity, has increased tablet strength and an improved friability without prolonging the disintegration time in the buccal cavity, and a manufacturing method thereof.

Owner:ASTELLAS PHARMA INC

Graphene-containing insulated radiating composition and preparation and application thereof

ActiveCN103804942AHigh thermal conductivityImprove mechanical propertiesCoatingsPigment treatment with organosilicon compoundsHeat conductingGraphene

The invention discloses a graphene-containing insulated radiating composition and preparation and application thereof. The composition comprises the components of silica-coating graphene, insulated heat-conducting filler, a surface treating agent, and a function additive. The preparation method comprises the following steps of: hydrolyzing ethyl silicate on the graphene surface by the sol-gel method to obtain graphene coated with a silica film on the surface; adding the surface treating agent to a mixture of the insulated heat-conducting filler and modified graphene; uniformly agitating; then adding the function additive; and uniformly dispersing to obtain the insulated radiating composition. The composition has the advantages that the graphene is processed by insulating and coating, and the insulated heat-conducting filler and additive of other forms are coordinately added, thus the composition shows high radiating improvement effect in the plastic cement and coating fields; and the composition can be widely applied to a heating element and a radiating facility of various electronic products and electrical equipment, and can greatly improve the radiating effect as well as prolong the service life of devices.

Owner:XIAMEN KNANO GRAPHENE TECH CORP

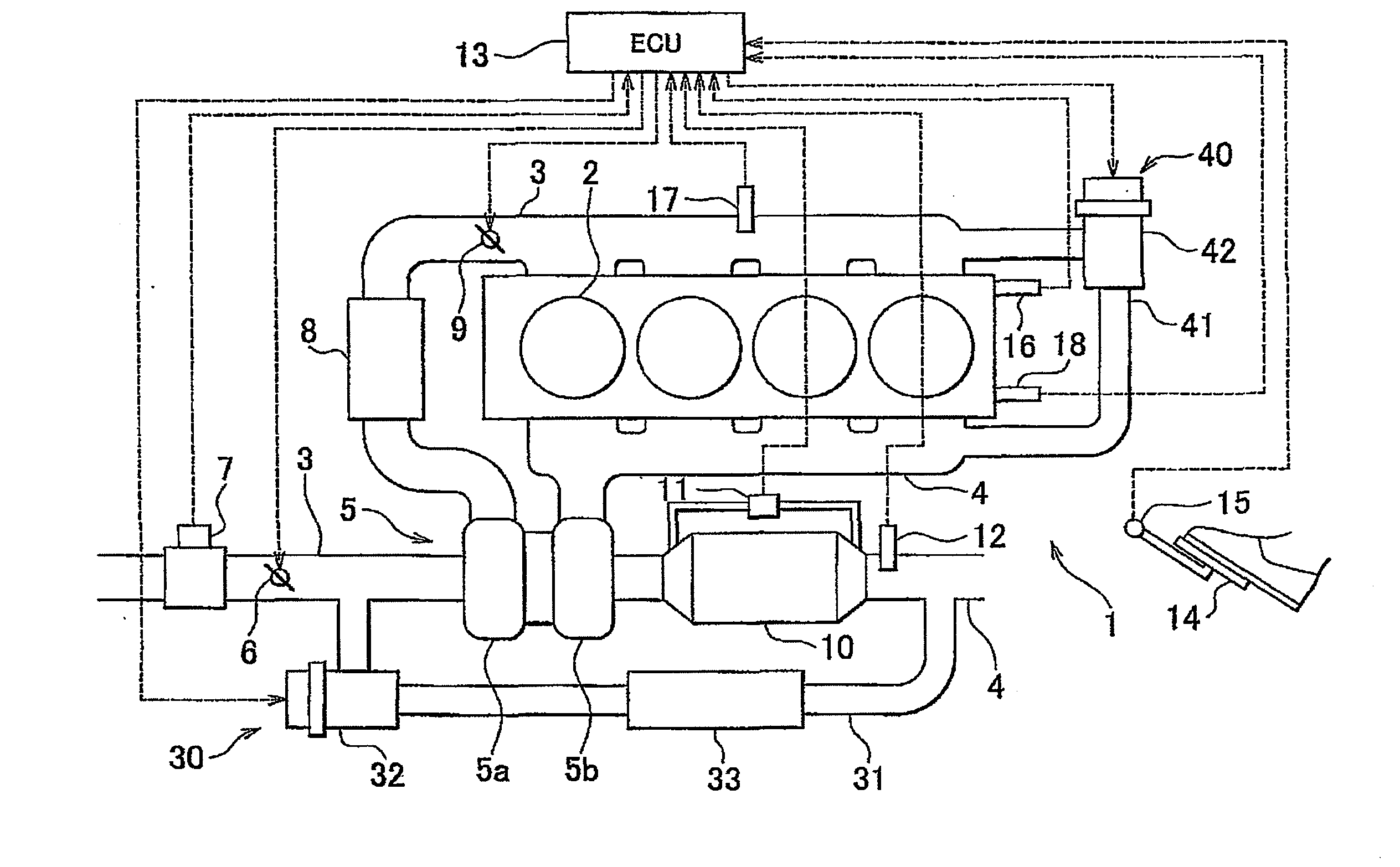

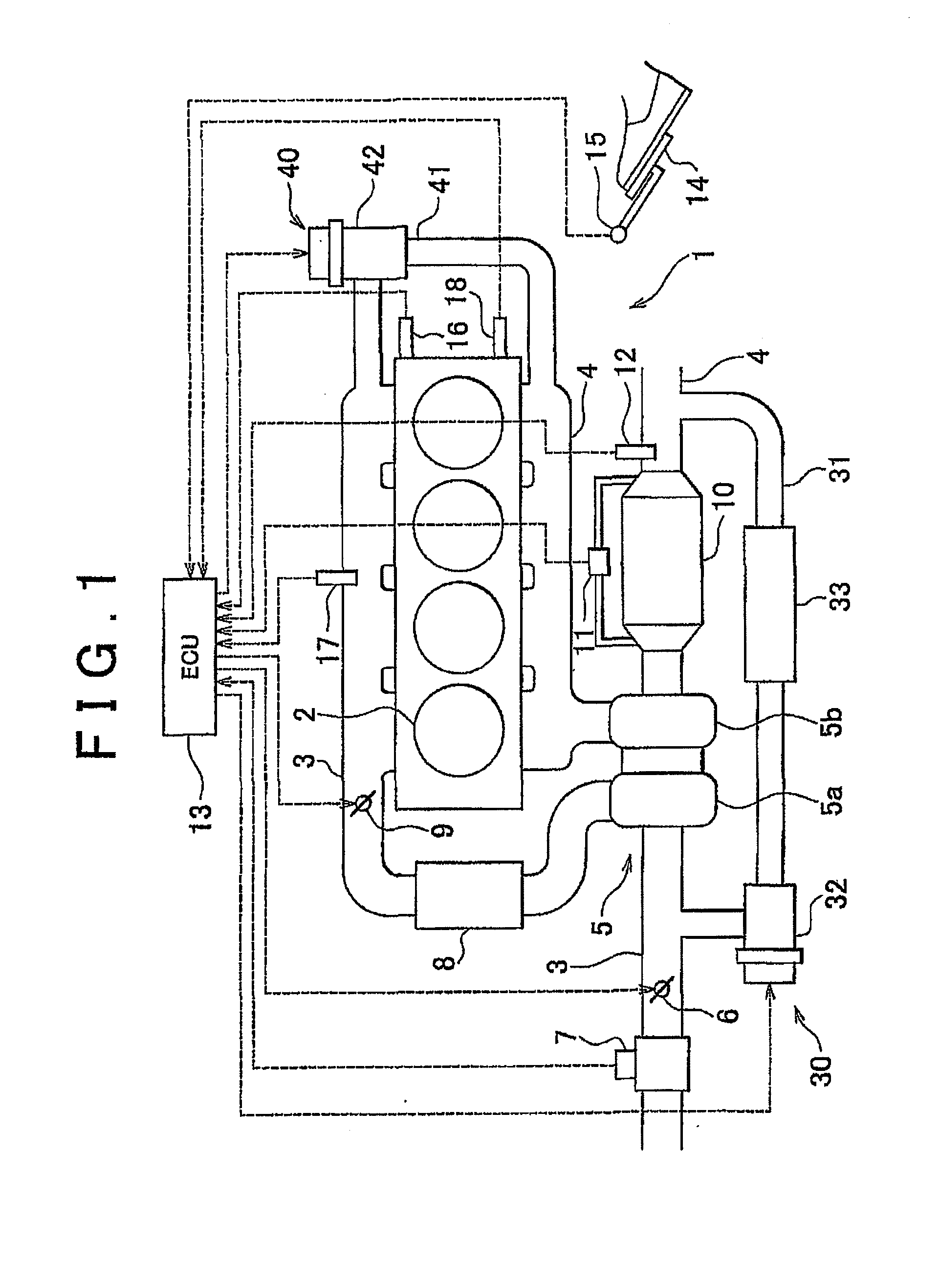

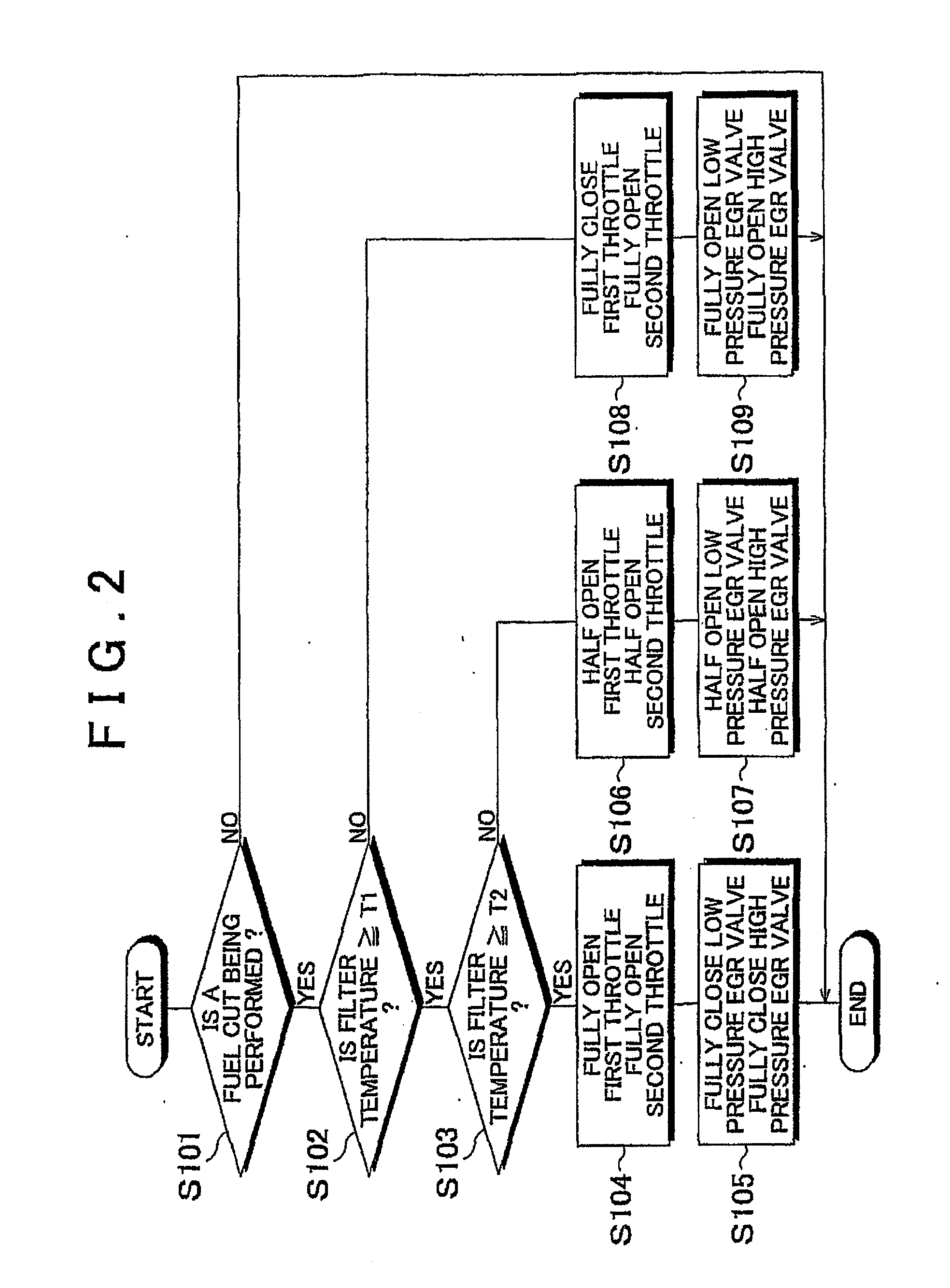

Exhaust Gas Recirculation Apparatus of an Internal Combustion Engine and Control Method Thereof

InactiveUS20080295514A1Reduce the amount requiredReduce the amount of solutionElectrical controlNon-fuel substance addition to fuelExternal combustion engineTurbocharger

An exhaust gas recirculation apparatus of an internal combustion engine includes a turbocharger provided with a turbine in an exhaust passage and a compressor in an intake passage, a low pressure EGR passage which connects the exhaust passage downstream of the turbine with the intake passage upstream of the compressor, a high pressure EGR passage which connects the exhaust passage upstream of the turbine with the intake passage downstream of the compressor; an exhaust gas control catalyst provided in the exhaust passage downstream of the turbine and upstream of the low pressure EGR passage; and EGR gas amount changing means for simultaneously changing amounts of EGR gas flowing through the low pressure EGR passage and the high pressure EGR passage such that a temperature of the exhaust gas control catalyst is within a target range.

Owner:TOYOTA JIDOSHA KK

Sustained release pharmaceutical compositions

InactiveUS6919372B1Improve hydrophobicityGood sustained release effectBiocideAerosol deliverySolubilityAcid derivative

The present invention relates to sustained-release pharmaceutical compositions for ionic pharmaceutically active substances containing ionic compounds having opposite charges to those of ionic prostanoic acid derivatives and increasing hydrophobicity of the active substances. More specifically, the invention relates to sustained-release pharmaceutical compositions comprising the ionic prostanoic acid derivatives and the ionic compounds having opposite charges to those of the prostanoic acid derivatives and increasing hydrophobicity of these derivatives that contain hydrophobic groups in the molecule thereof.The pharmaceutical composition of the invention can exhibit excellent sustained release effect of the ionic prostanoic acid derivatives, irrespective of water solubility possessed by the ionic prostanoic acid derivatives.

Owner:TORAY IND INC +1

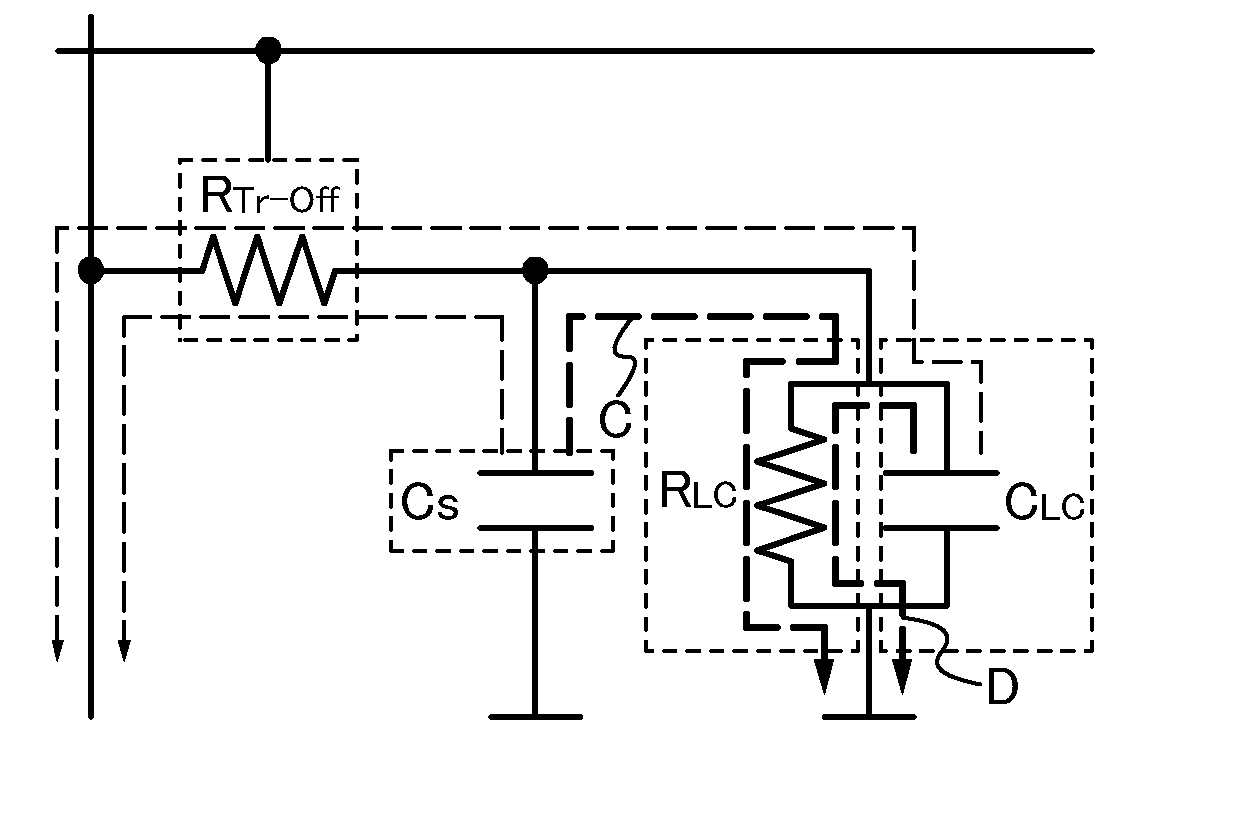

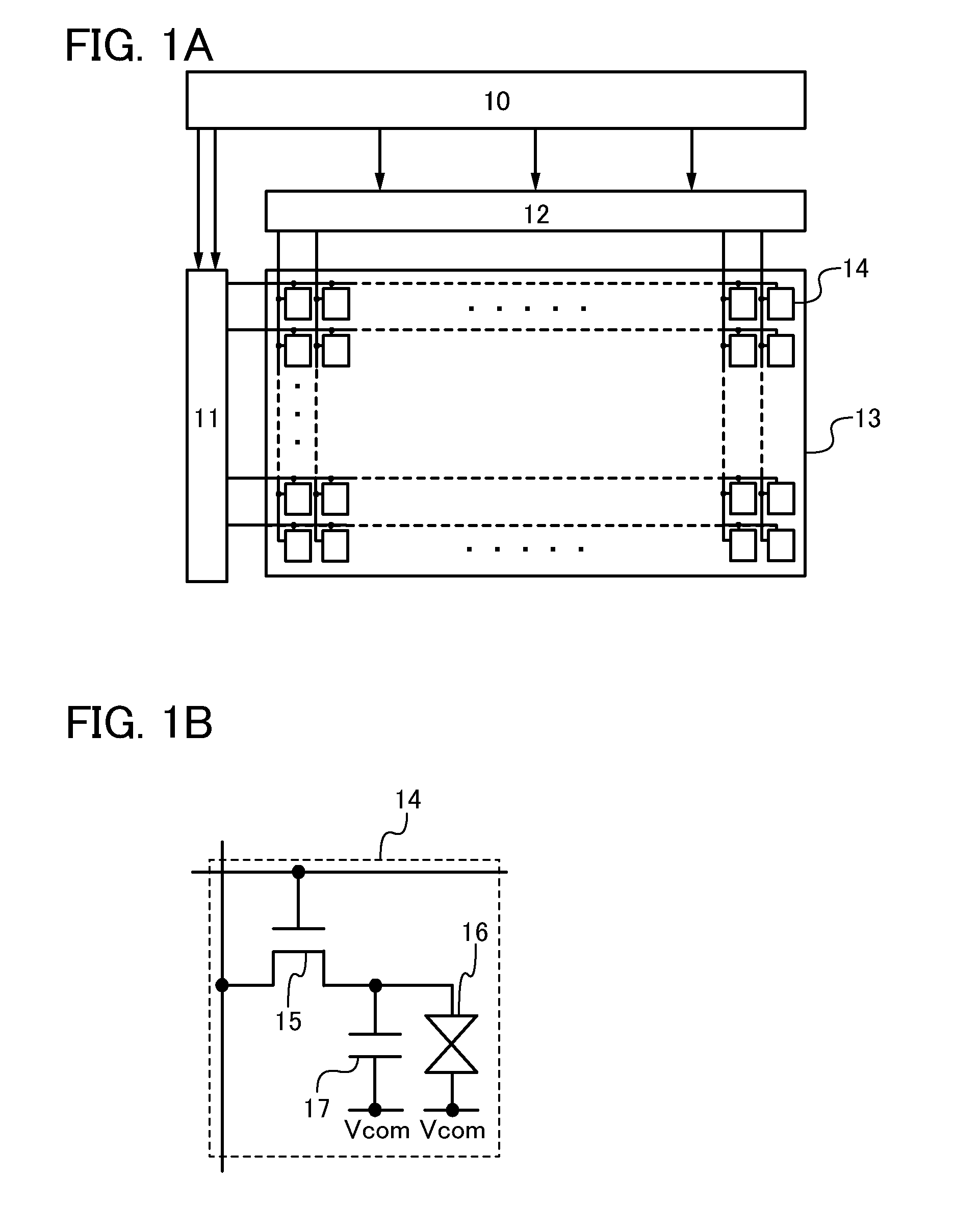

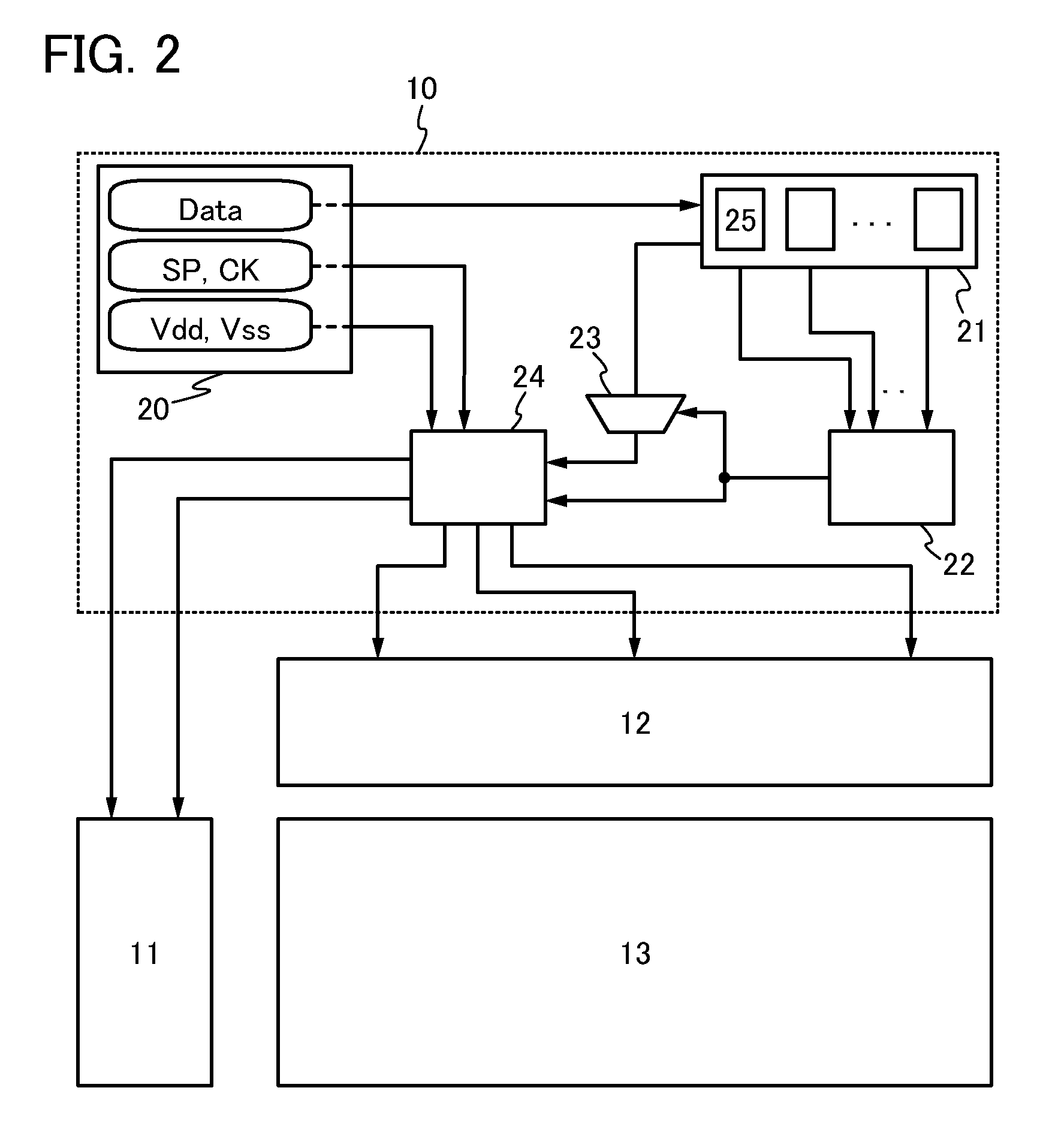

Liquid crystal display device and electronic device

ActiveUS20110149185A1Reduce leakageReduce power consumptionTransistorStatic indicating devicesLiquid-crystal displayRoom temperature

To reduce power consumption and suppress display degradation of a liquid crystal display device. To suppress display degradation due to an external factor such as temperature. A transistor whose channel formation region is formed using an oxide semiconductor layer is used for a transistor provided in each pixel. Note that with the use of a high-purity oxide semiconductor layer, off-state current of the transistor at a room temperature can be 10 aA / μm or less and off-state current at 85° C. can be 100 aA / μm or less. Consequently, power consumption of a liquid crystal display device can be reduced and display degradation can be suppressed. Further, as described above, off-state current of the transistor at a temperature as high as 85° C. can be 100 aA / μm or less. Thus, display degradation of a liquid crystal display device due to an external factor such as temperature can be suppressed.

Owner:SEMICON ENERGY LAB CO LTD

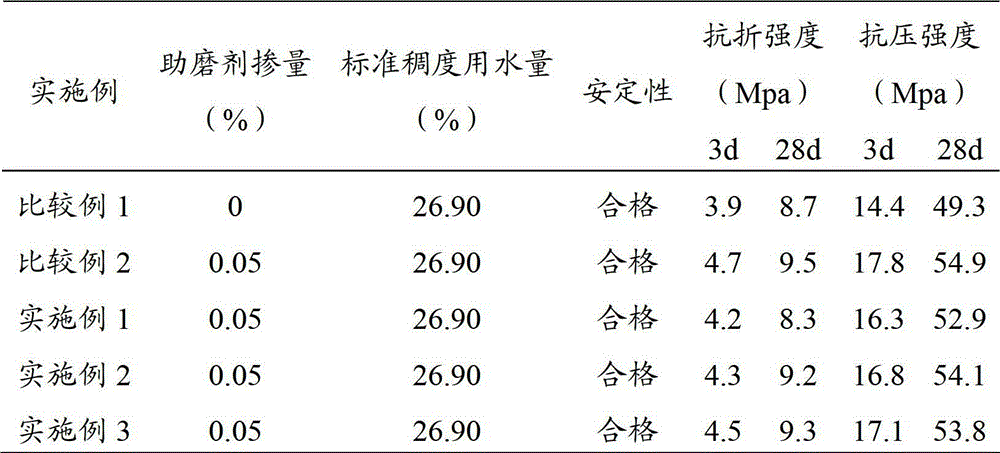

Grinding aid for slag cement

The invention provides a grinding aid for slag cement. The grinding aid provided by the invention comprises the following components by weight percent: 5-20wt% of alcohol amine compound, 0.1-5wt% of hydroxypropyl methyl cellulose, 5-30wt% of polyhydric alcohol compound, 0.5-10wt% of sodium hexametaphosphate, 1-10wt% of soluble sulfate, 1-8wt% of sodium dodecyl benzene sulfonate and the balance of water. In the grinding agent provided by the invention, the hydroxypropyl methyl cellulose is beneficial for stimulating the activity of the slag, forming stable hydrous products in the reaction process, improving the property of the cement, improving the strength of the cement and improving the stability of the liquid grinding aid at the same time. Experimental result shows that the grinding aid is capable of increasing the breaking strength of the cement to 9.5MPa and increasing the compressive strength to about 55MPa.

Owner:SHANDONG HONGYI TECH +1

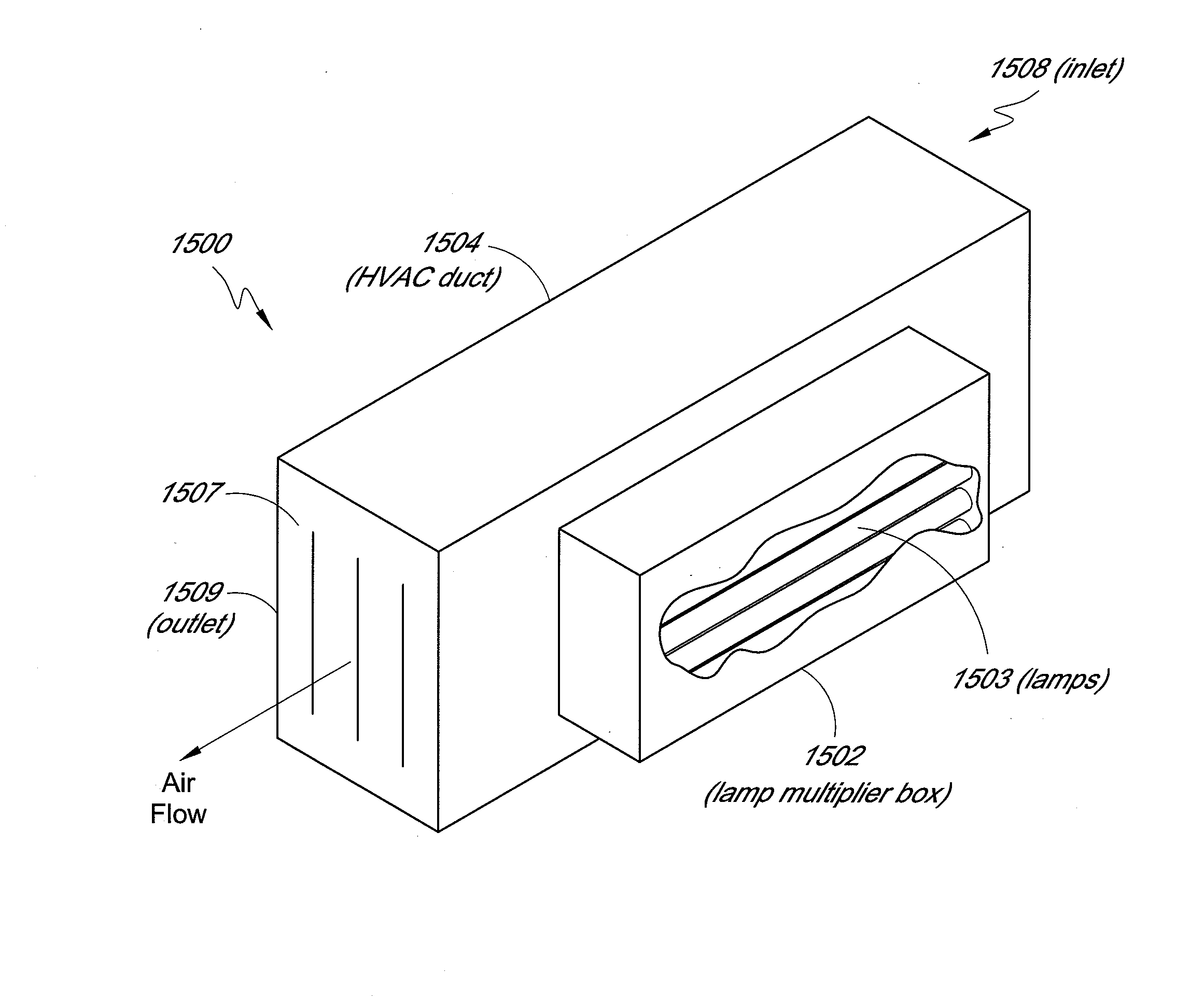

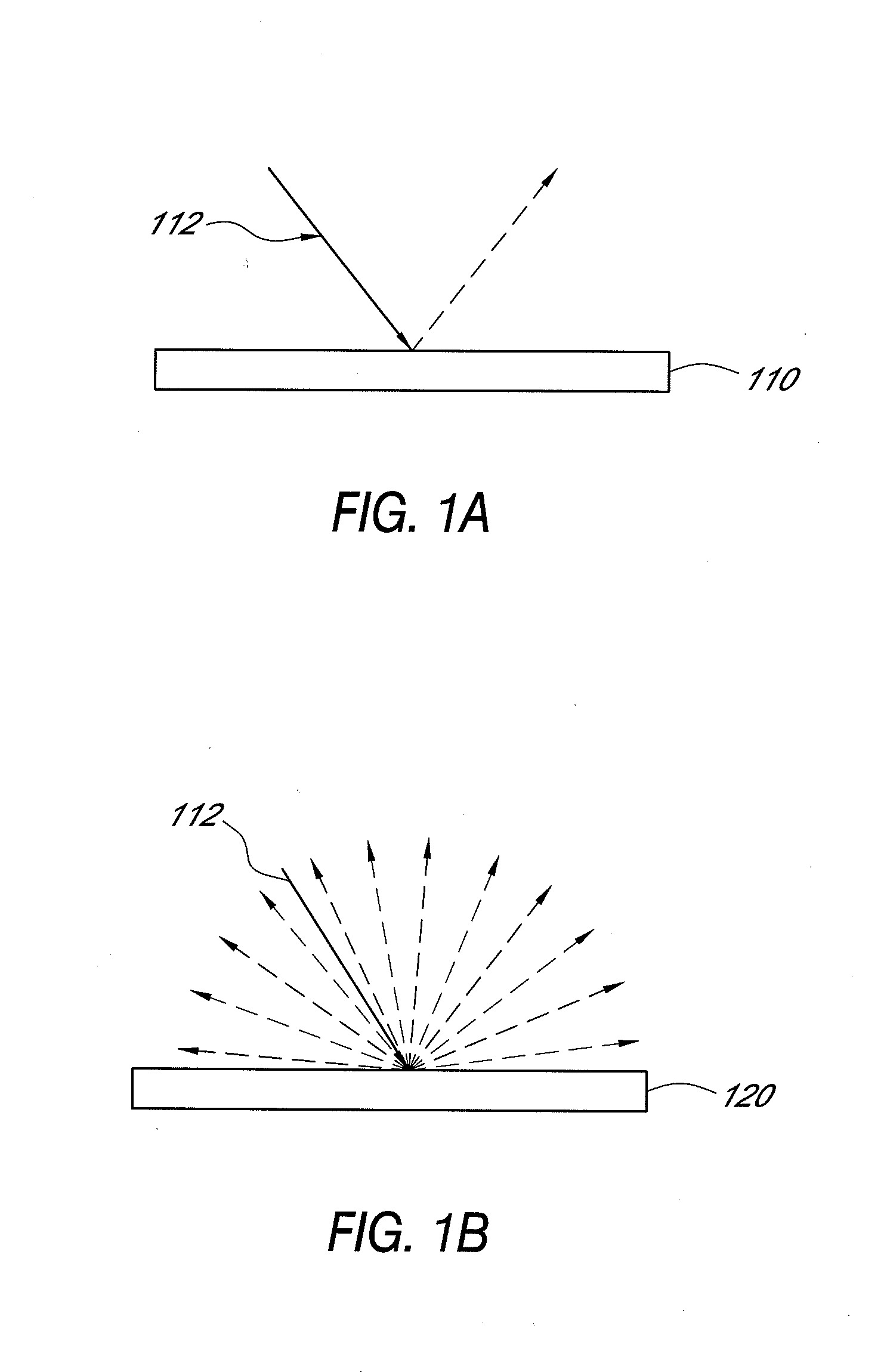

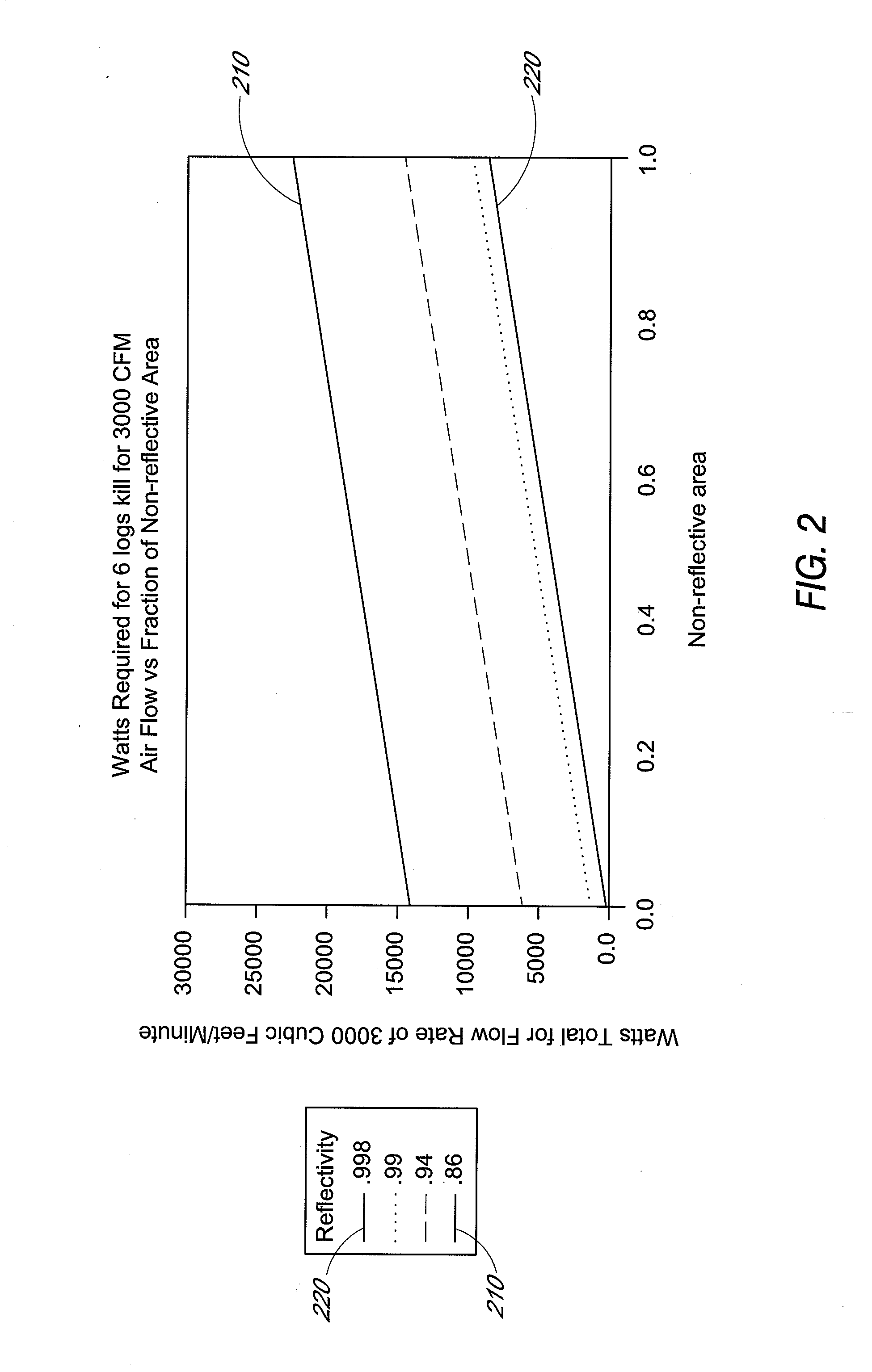

UV flux multiplication system for sterilizing air, medical devices and other materials

ActiveUS20080152548A1Reduced Power RequirementsReduce in quantityMechanical apparatusMaterial analysis using wave/particle radiationUltraviolet lightsOptoelectronics

An ultraviolet flux multiplying air sterilization chamber comprises inner surfaces having a diffuse reflective behavior. The sterilization chamber includes an inlet aperture and an outlet aperture for air to flow through said chamber and a light source emitting an ultraviolet light. Due to the reflectivity of the inner surfaces of the chamber, a flux of the ultraviolet light is multiplied by reflecting multiple times from the inner surfaces of the chamber. The inlet and outlet apertures are advantageously configured to reduce the amount of light that escapes from the chamber and increase the amount of photons available in the chamber. In an exemplary embodiment, perforated end panels having diffuse, reflective interior surfaces may be provided over at least a portion of the inlet and outlet apertures.

Owner:NOVATRON

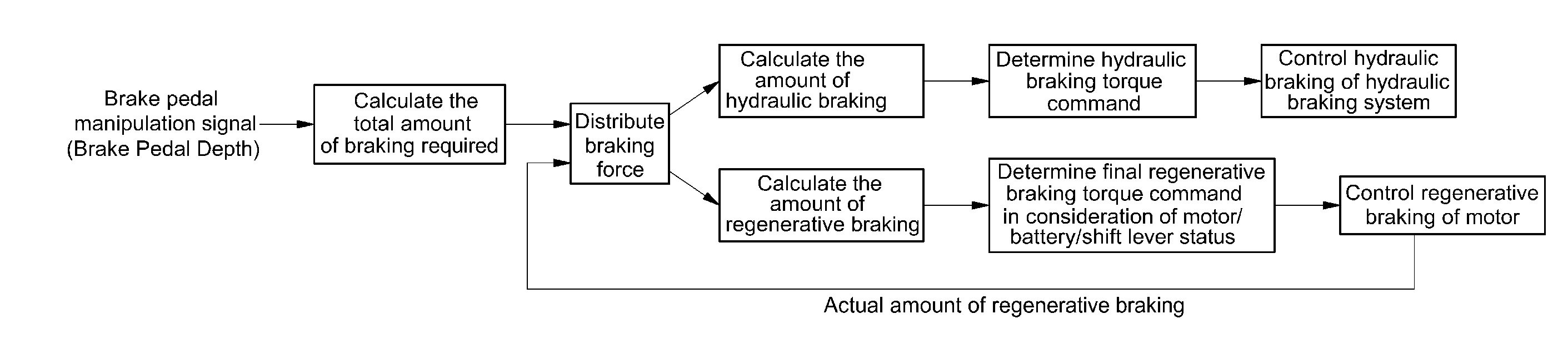

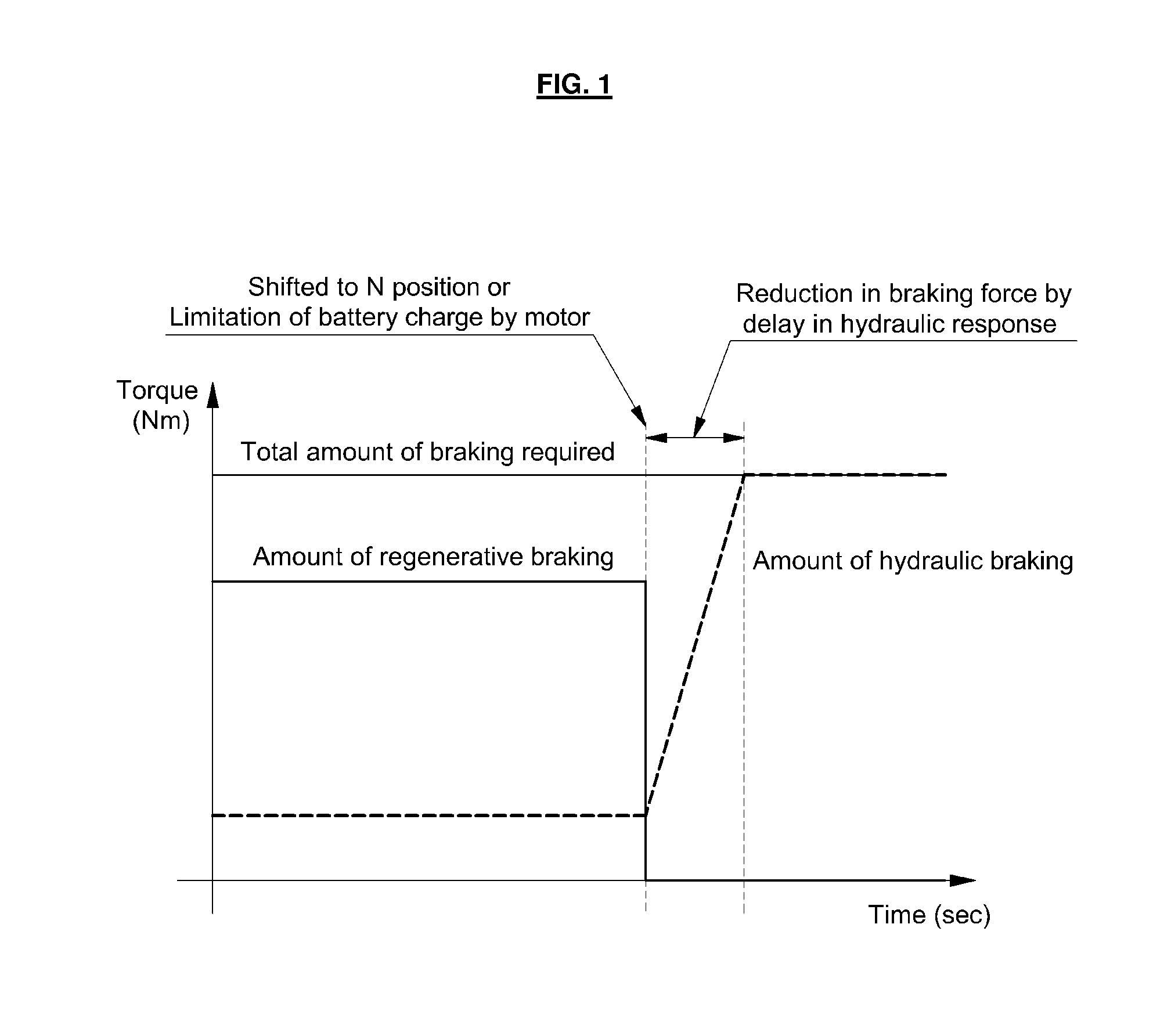

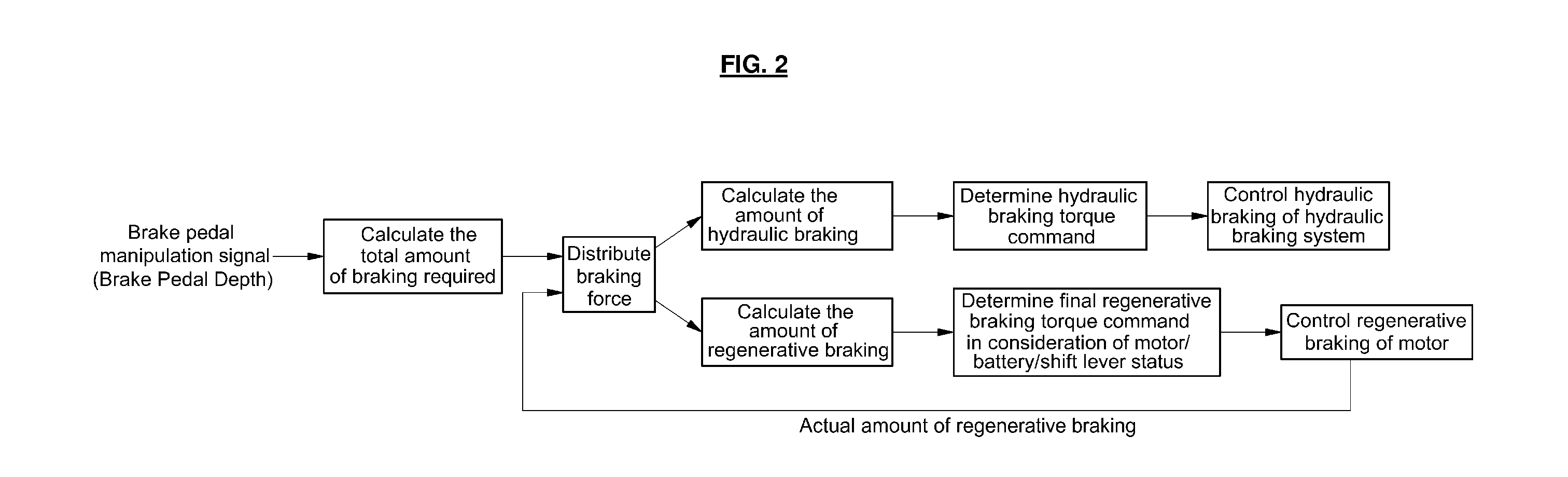

Braking control method for electric vehicle

InactiveUS20120056470A1Reduces regenerative braking capacityReduce amountBraking element arrangementsBraking action transmissionRegenerative brakeElectric vehicle

The present invention features braking control methods for an electric vehicle. Such methods include identifying a vehicle operational condition occurring during regenerative braking that reduces regenerative braking capacity; linearly reducing the amount of regenerative braking of a motor of the electric vehicle after identifying such a vehicle operational condition; and at the same time, increasing the amount of hydraulic braking of a hydraulic braking system to compensate for the reducing of the amount of regenerative braking. Such operational conditions include when the temperature of a motor or battery is increased above a predetermined level during regenerative braking or when the shift lever is shifted to Neutral (N) position by a driver during regenerative braking.

Owner:HYUNDAI MOTOR CO LTD

Ligands That Enhance Endogenous Compounds

InactiveUS20070298041A1Increase the amount addedHigh activityVirusesImmunoglobulins against cytokines/lymphokines/interferonsHalf-lifeReactive site

The invention relates to ligands that comprise a moiety (e.g., a dAb) that has a binding site with binding specificity for an endogenous target compound but do not substantially inhibit the activity of said endogenous target compound. Preferably, the ligand does not bind to the active site of an endogenous target compound. The invention relates to the use of such a ligand for the manufacture of a medicament for increasing the half-life, bioavailability, activity or amount of an endogenous target compound to which the ligand binds.

Owner:DORMANTIS LTD

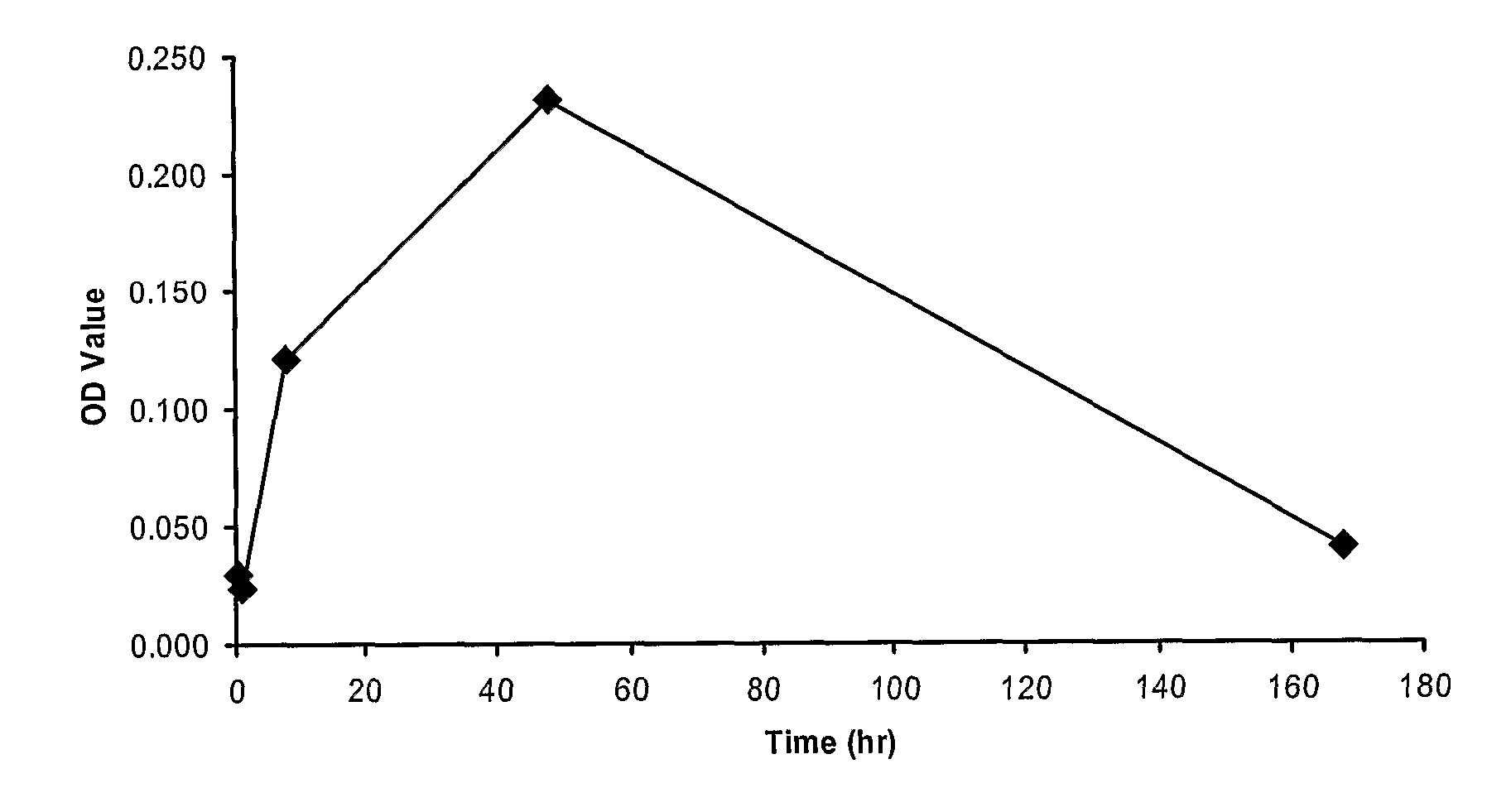

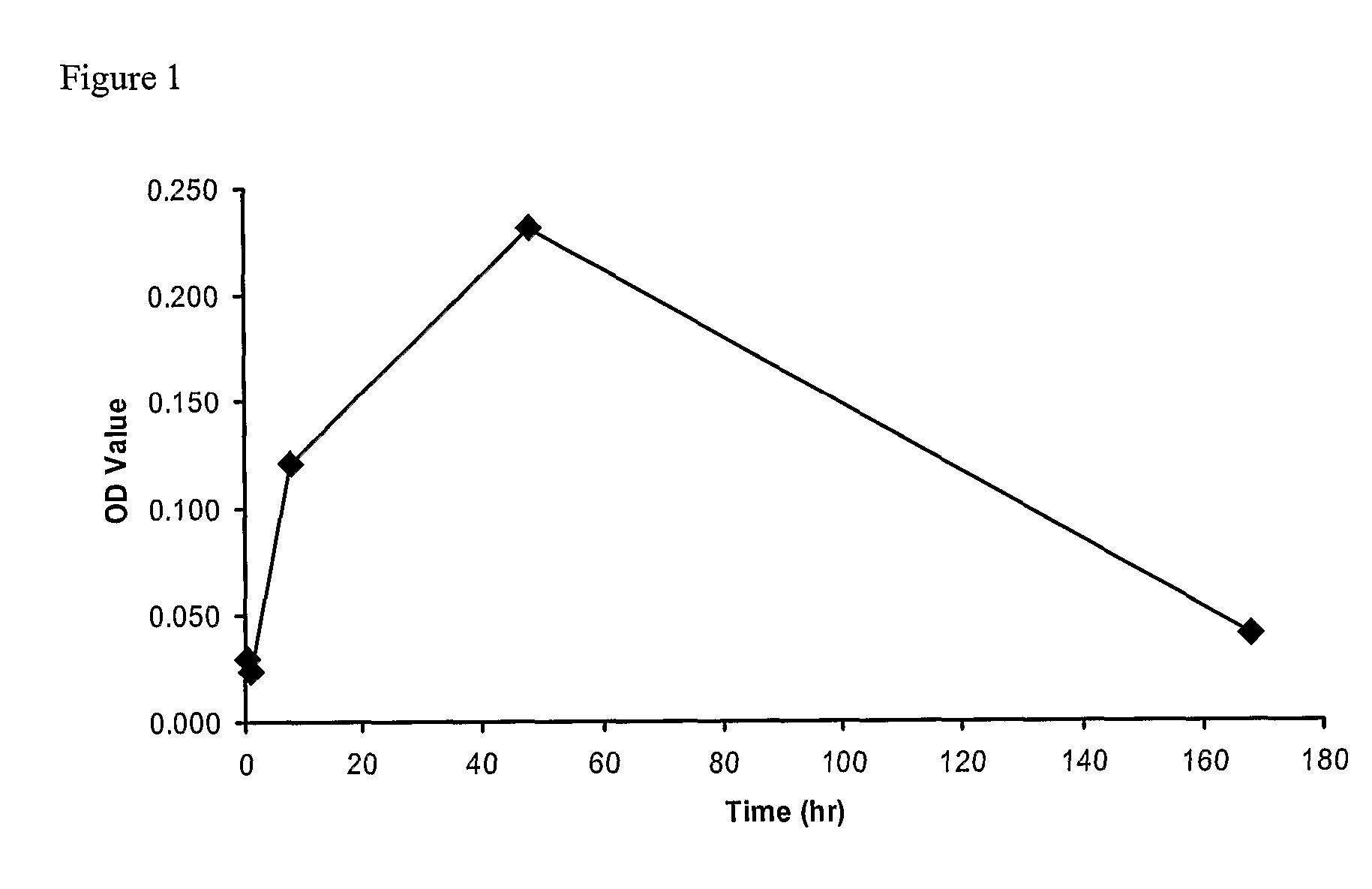

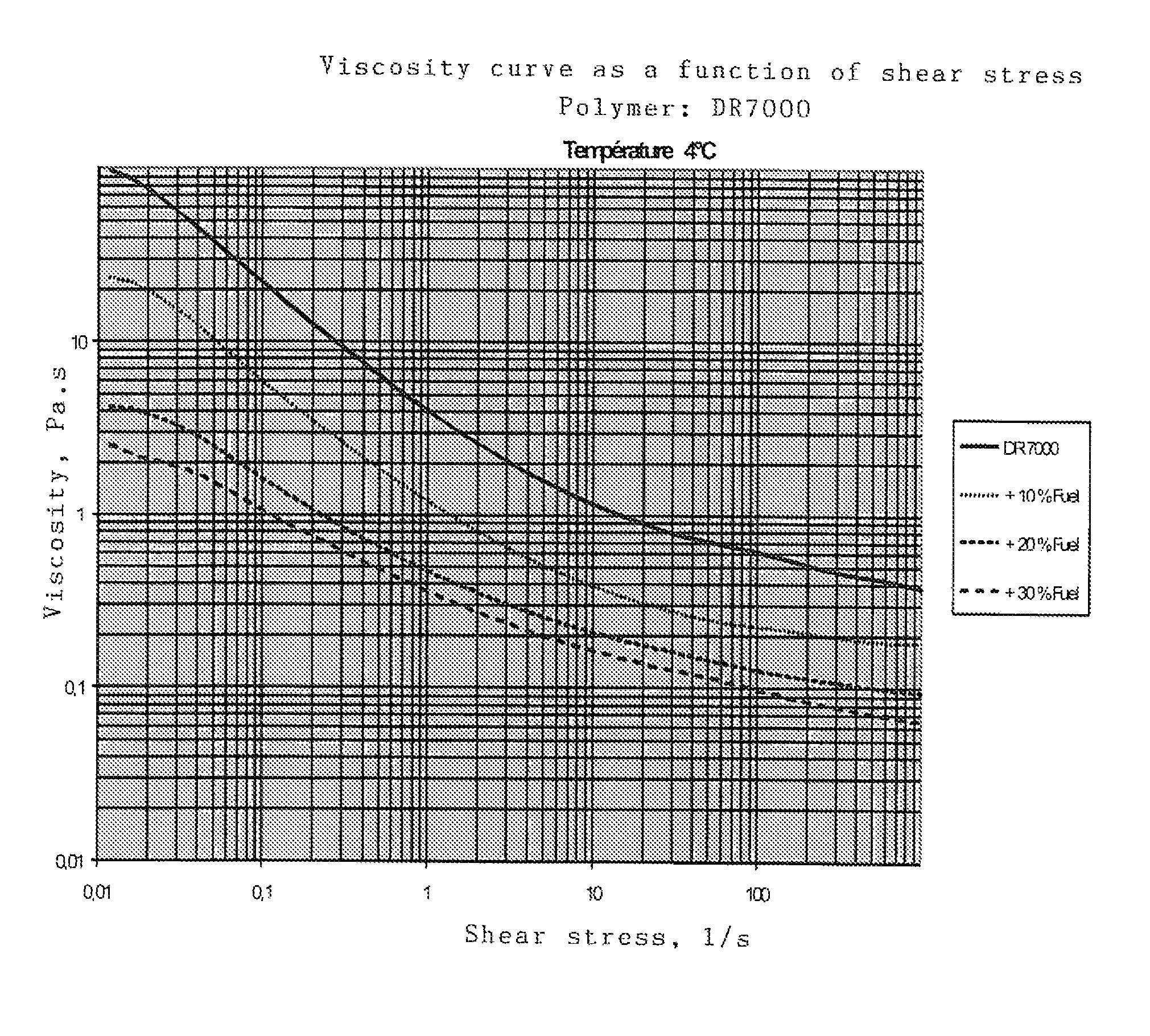

Process for increasing the transport flow rate of oil from producing wells

InactiveUS8517104B2Low viscosityIncrease injection rateFluid removalPipeline systemsEmulsionPipeline transport

A process for increasing, on an existing installation, the amount of water-soluble polymer in an emulsion injected into pipelines transporting oil produced at offshore oil wells, includes before injection, diluting the emulsion with fuel oil found on the platform or Floating Production Storage & Offloading unit (FPSO).

Owner:S P C M SA

Flame-retarding polymer foam material and preparation method thereof

ActiveCN102127269AIncrease the amount addedAddition changeLaminationLamination apparatusPolymer sciencePolystyrene

The invention discloses a flame-retarding polymer foam material which is characterized by comprising polymer foam plastic, wherein the surface of the polymer foam plastic is provided with an organic flame retardant layer; and the organic flame retardant layer is formed by attaching a molten organic flame retardant to the surface of the polymer foam plastic through a spraying, coating or soaking way. The invention also discloses a preparation method of the flame-retarding polymer foam material. In the invention, a flame-retarding variety which is effective to the polymer foam plastic, in particular to extrusion foamed polystyrene foam plastic, is selected from numerous flame retardants, and the polymer foam product with excellent flame-retarding property is prepared by adopting a simple and feasible method. Through the invention, an effective method for increasing the addition amount of the flame retardant is obtained on the premise of not influencing the foaming property of the foam products and not reducing the strength and the insulation and thermal preservation property of foams, and different flame-retarding requirements can be met by flexibly changing the attaching amount of the flame retardant.

Owner:连云港传奇阻燃科技有限公司

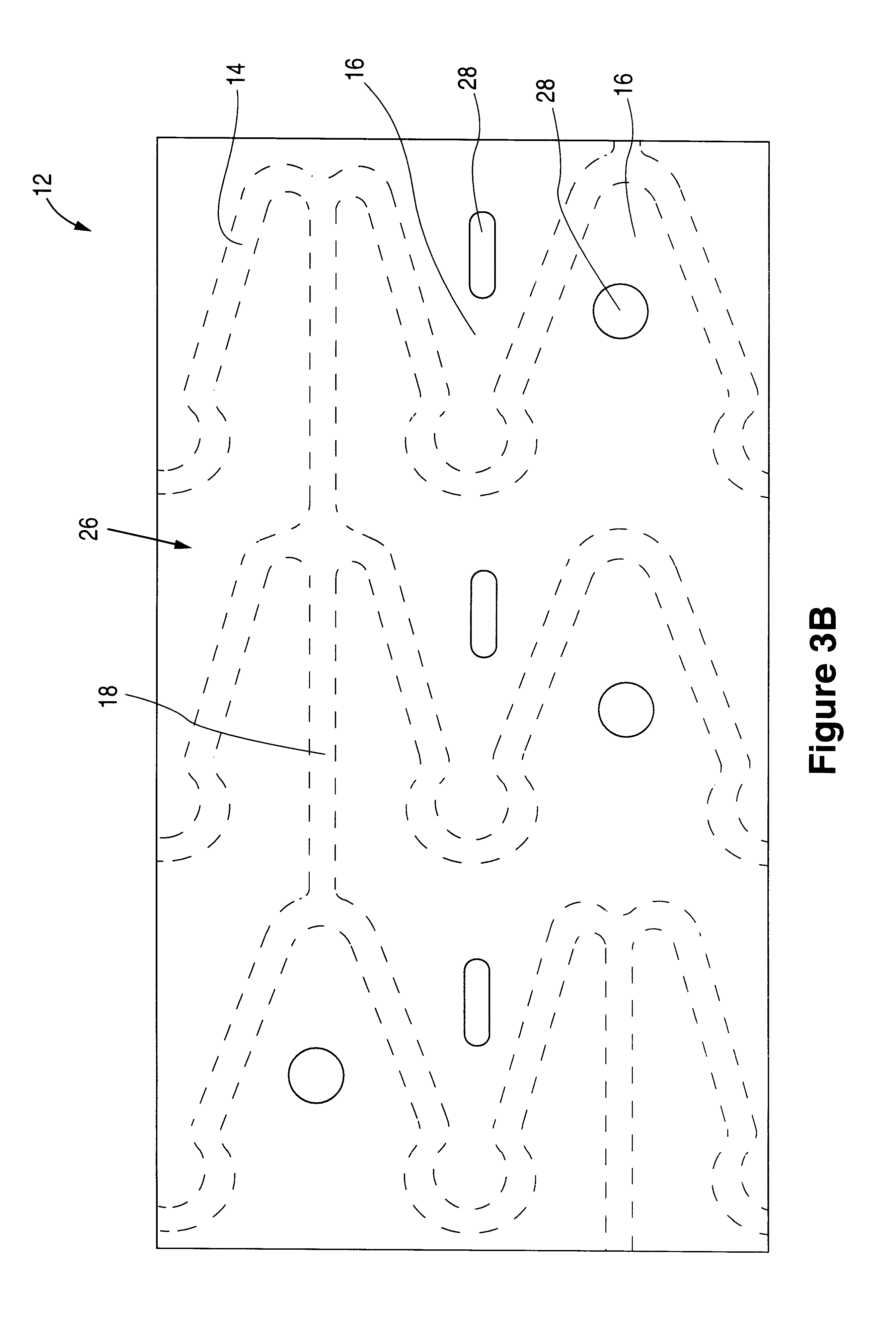

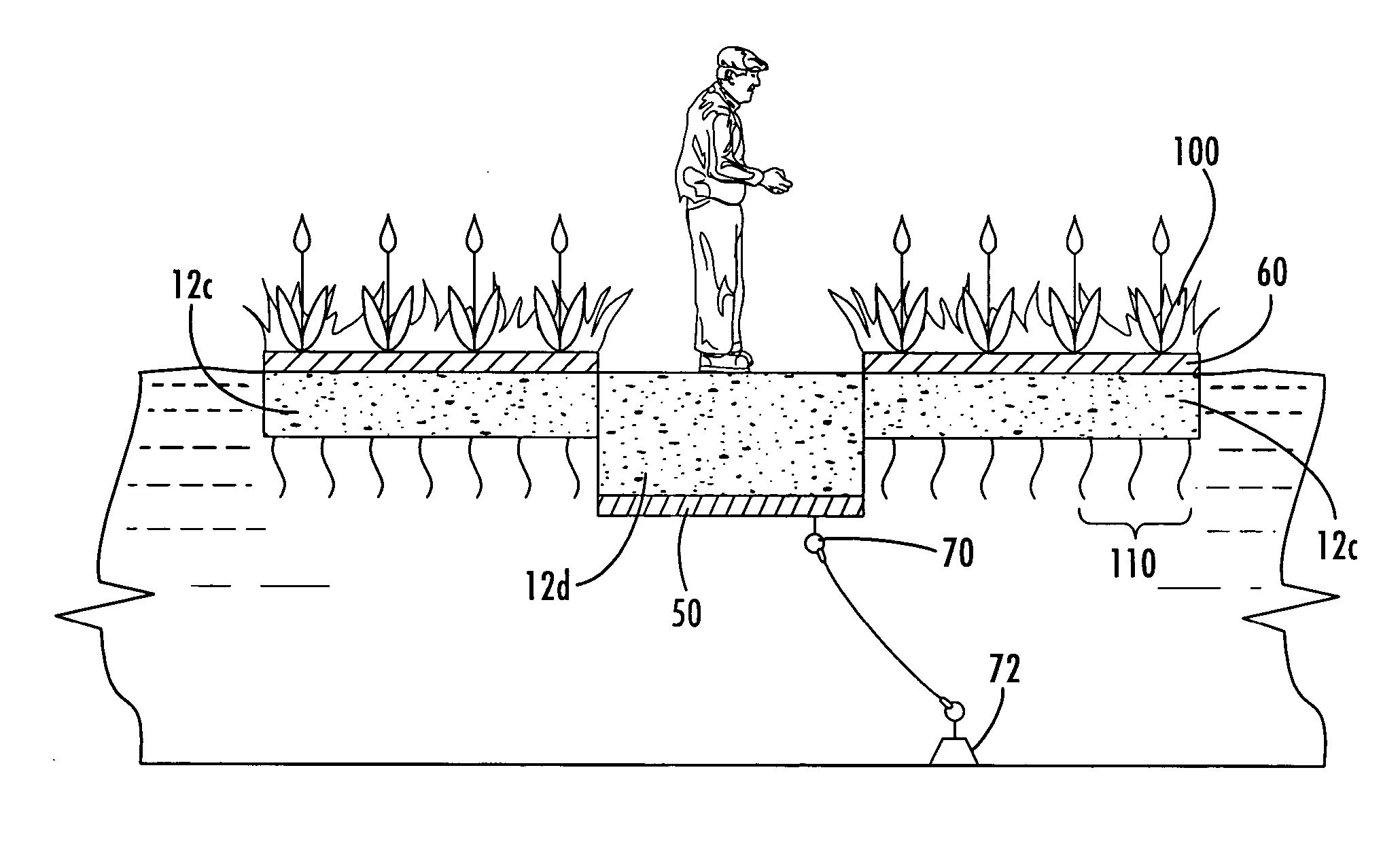

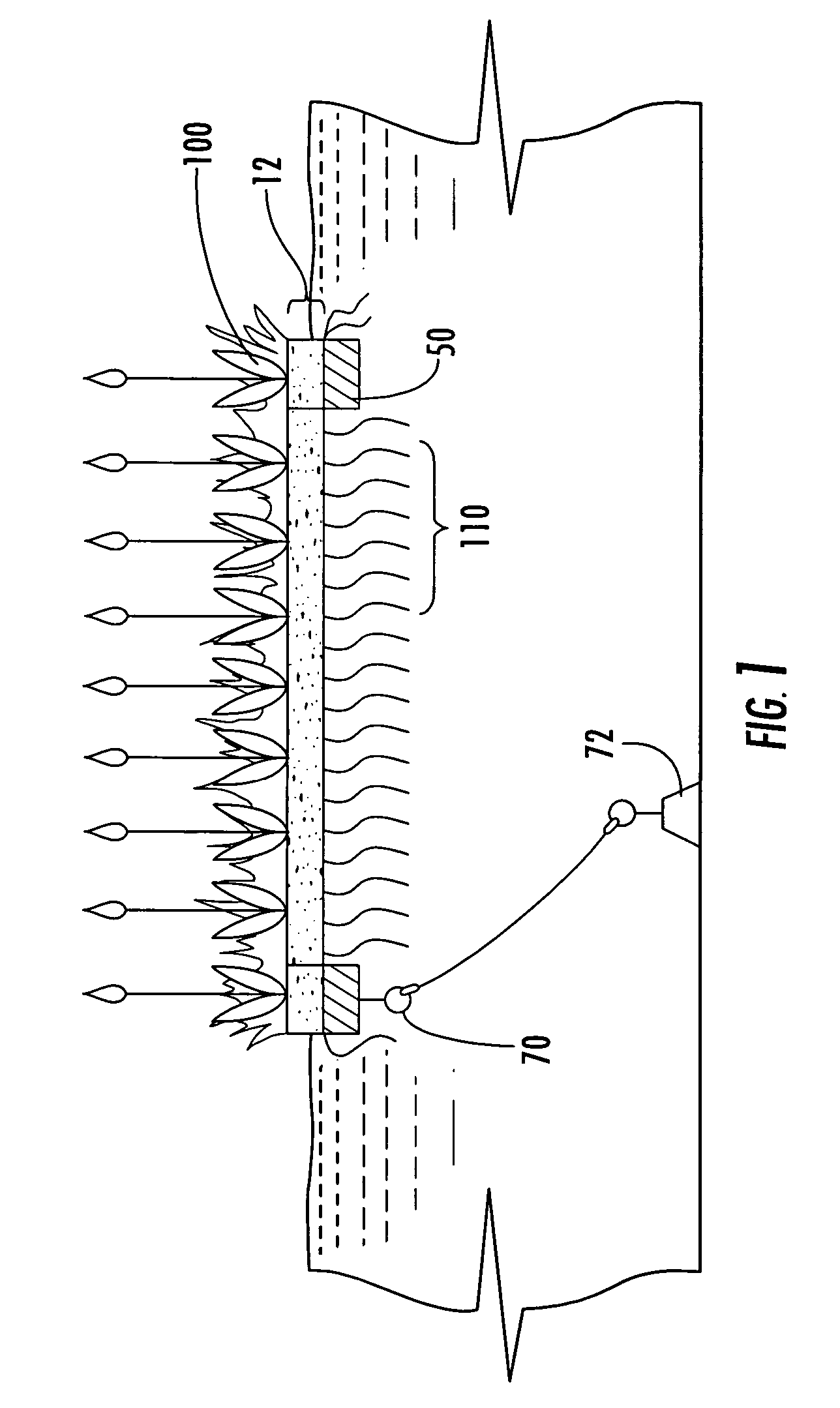

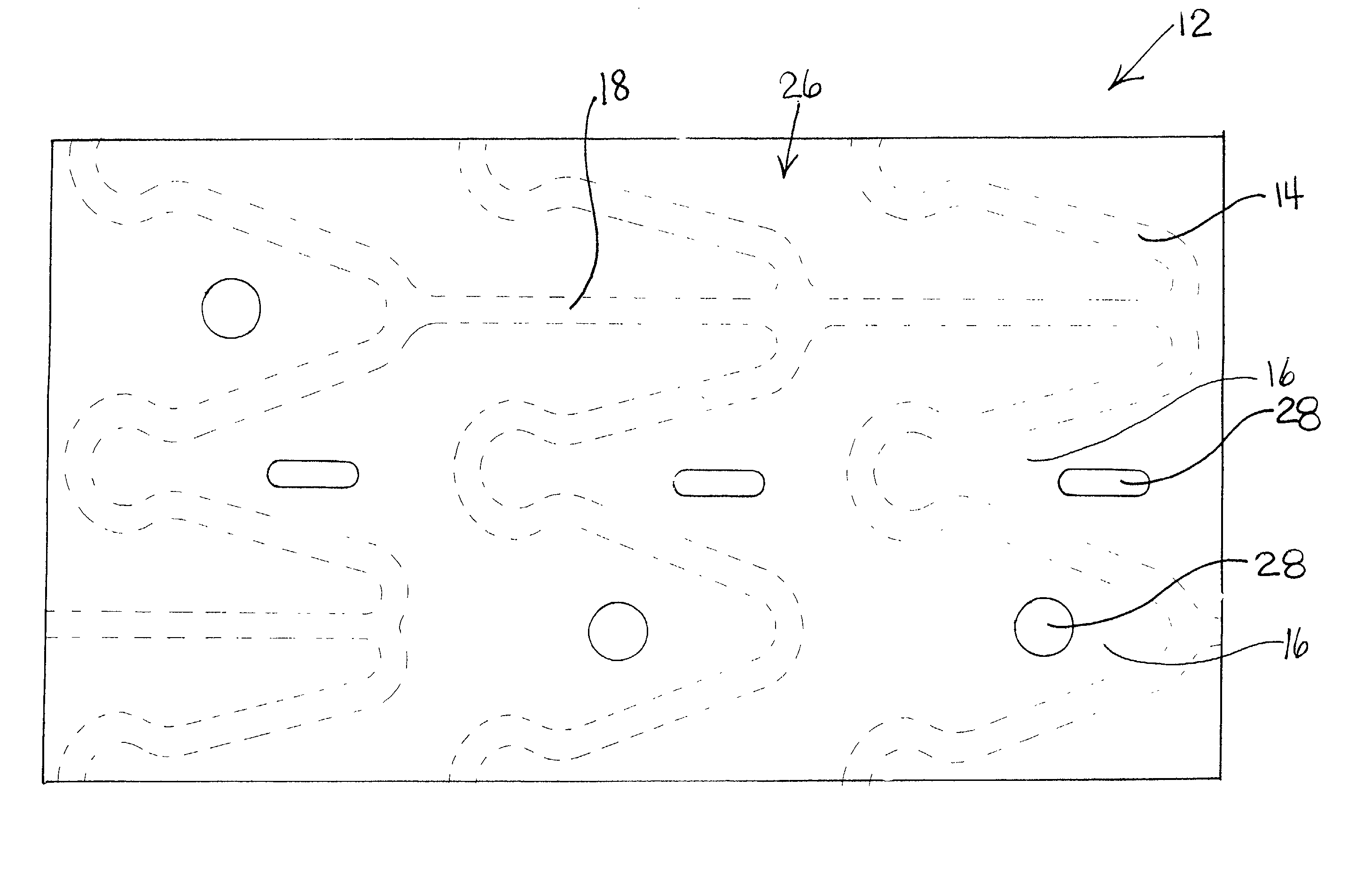

Floating wetland structures for use in water remediation

InactiveUS20060243659A1Increase the amount addedAvoid submersionWater cleaningSeparation devicesVegetationEngineering

Floating wetland structures of the invention are generally formed from one or more floatation panels made of a plurality of polymeric foam particles arranged in a piled laminate structure. The foam particles are arranged within the piled laminate structure so as to define void pathways between at least a portion of said foam particles. The void pathways within the piled laminate structure are of sufficient size and quantity to allow rainwater to flow through and of such an orientation to allow for the roots of vegetation to easily penetrate the structure.

Owner:3R FOAM

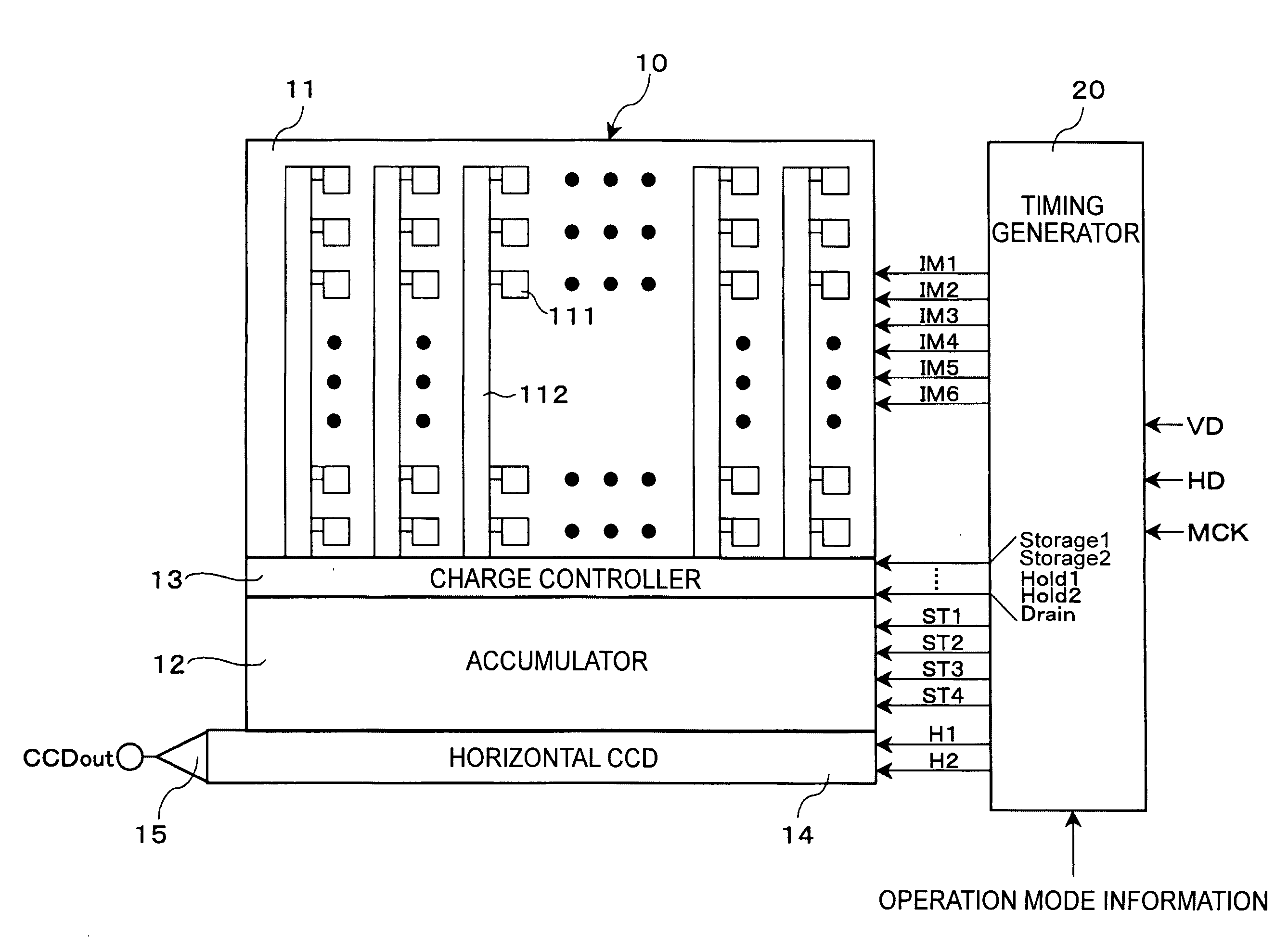

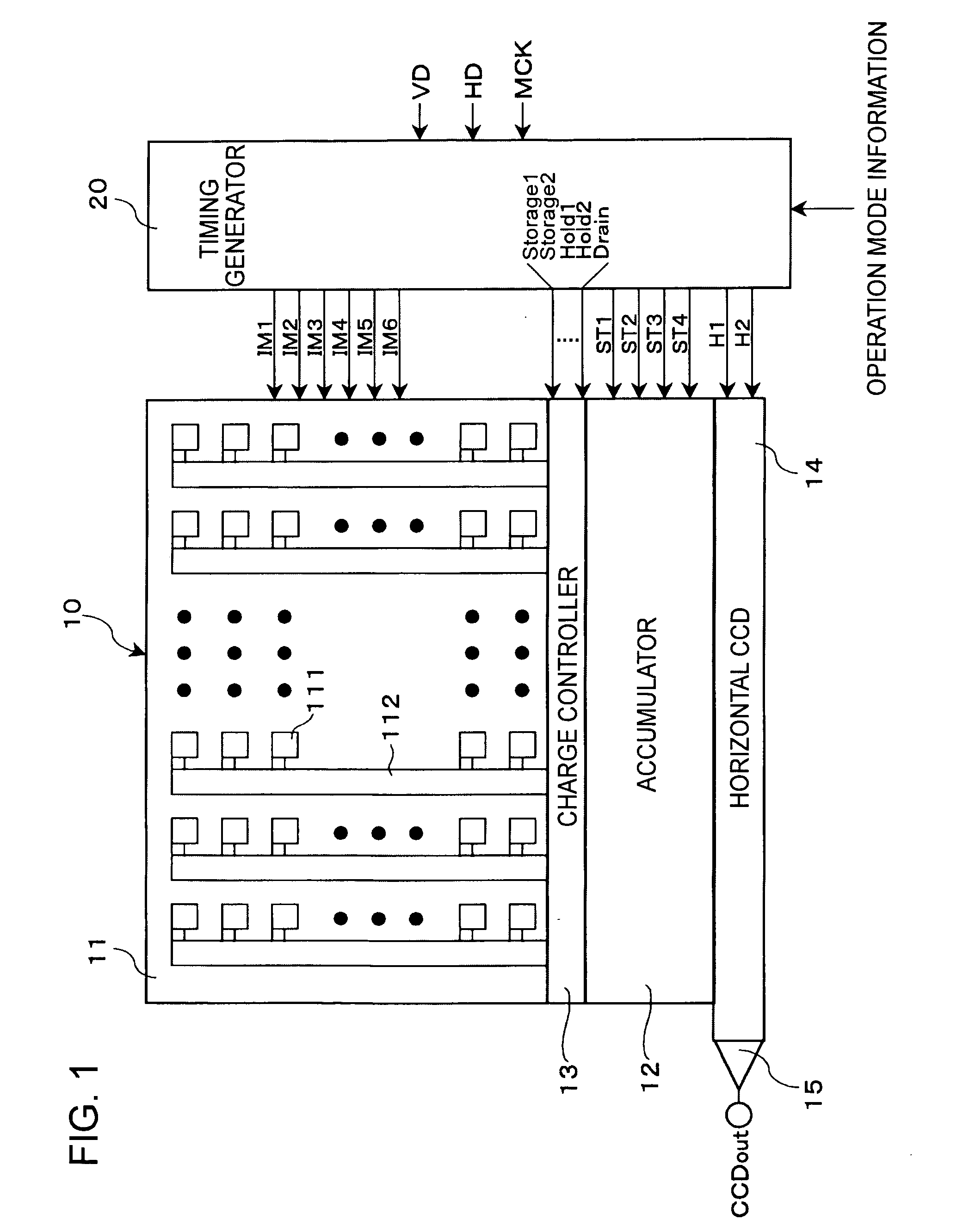

Solid-state imaging device, method for driving solid-state imaging device, and image apparatus

InactiveUS20060092304A1Improve balanceReduce horizontal driving frequencyTelevision system detailsTelevision system scanning detailsCharge controlOperation mode

A solid-state imaging device includes an imaging unit, a charge control unit, and a horizontal transfer unit. The imaging unit includes a plurality of pixels arranged into a matrix for performing photoelectric conversion, and a plurality of vertical transfer units arranged in columns for vertically transferring signal charges of the plurality of pixels on a column-by-column basis. In a predetermined operation mode, a predetermined number of columns greater than one are used as a unit, and the charge control unit stops transferring charges from a vertical transfer unit in a predetermined column of the predetermined number of columns, and adds the signal charges transferred from the vertical transfer units in the two or more remaining columns of the predetermined number of columns to output the added signal charges. The horizontal transfer unit horizontally transfers the signal charges output from the charge control unit.

Owner:SONY CORP

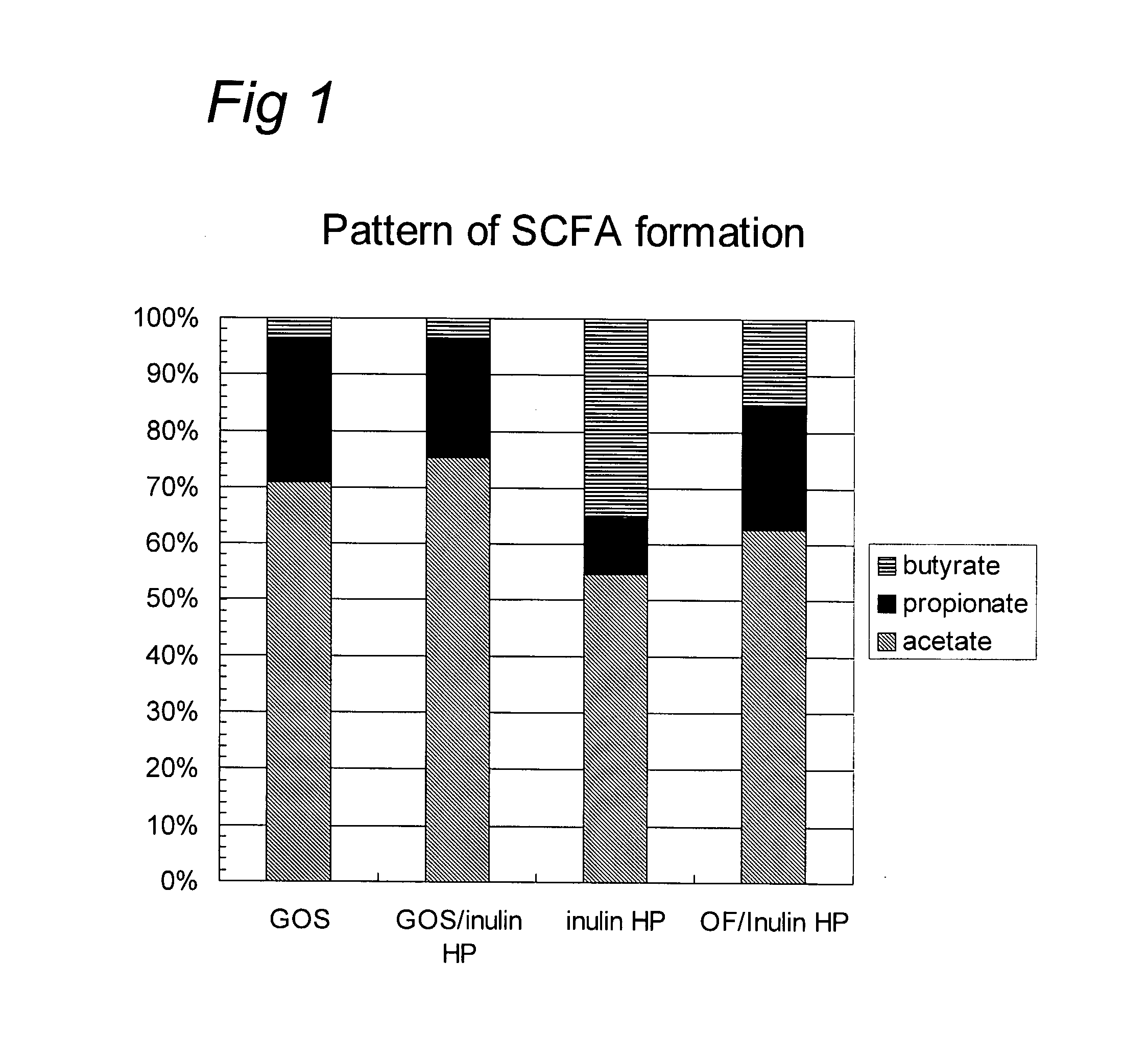

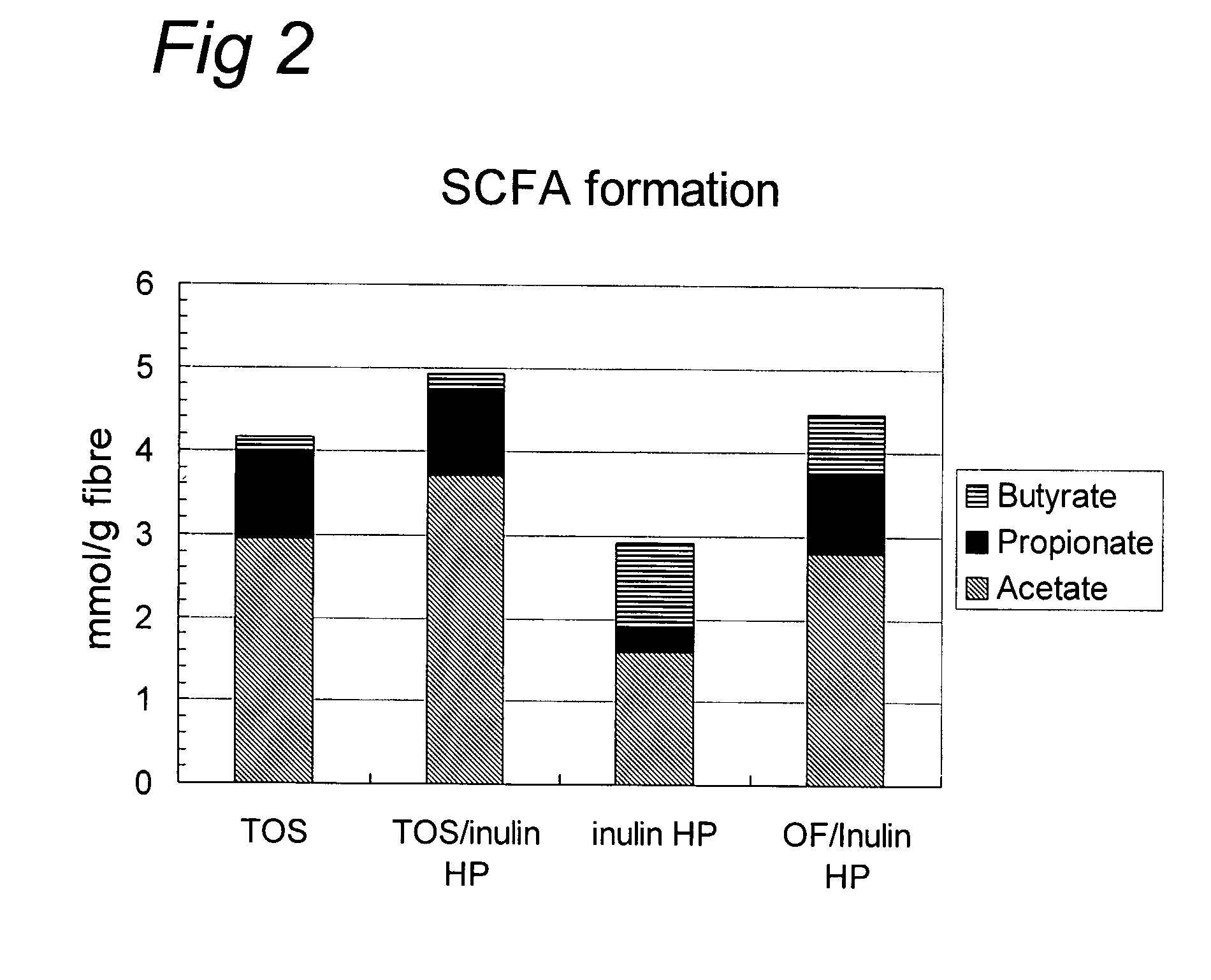

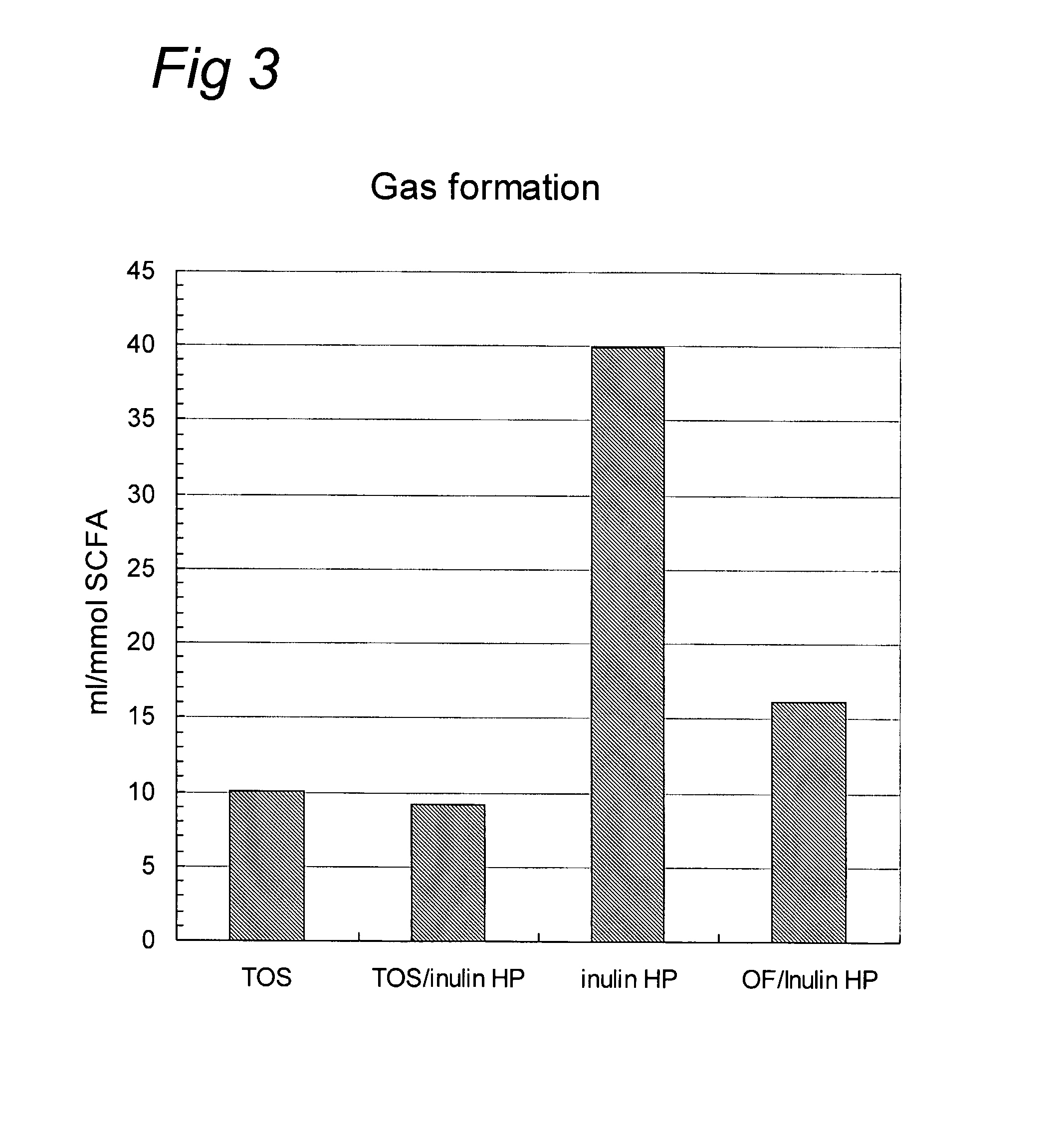

Synergism of gos and polyfructose

InactiveUS20100069320A1Increase the amount addedDecrease in faecal pHBiocideHydrocarbon active ingredientsPolyfructoseMedicine

The present invention relates to the filed of prebiotics. Provided are uses for compositions comprising synergistically effective amounts of polyfructose and galactooligosaccharides (GOS).

Owner:NUTRICIA

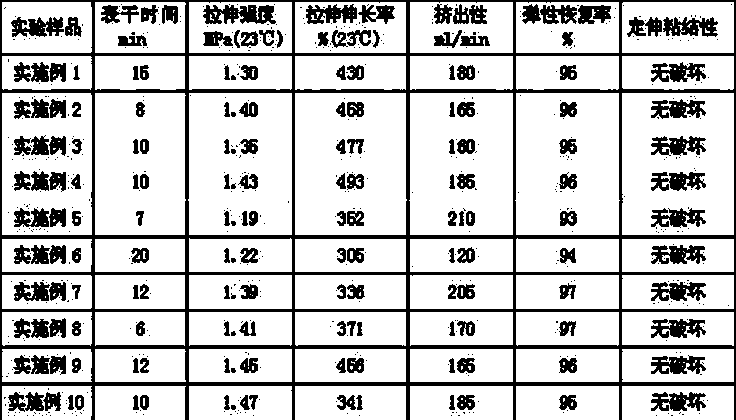

Neutral silicone weather resistant glue formula and technique for preparing the same

The invention relates to a weather resistant glue, especially a neutral silicone weather resistant glue formula and a technique for preparing the same. The formula includes the following components: basic polymer, plasticizer, stuffing, cross linker, anchoring agent and catalyst, which are prepared as follow: basic polymer: 10-100 parts; plasticizer 1-50 parts; stuffing 1-150 parts; cross linker 0.5-10 parts; anchoring agent 0.5-10 parts; catalyst 0.001-15 parts. The neutral silicone weather resistant glue produced by the invention has the advantages of pollution-free, improved product storage time, adjusted modulus, reduced viscosity peak, easy production without tin catalyst or the like.

Owner:深圳市百丽春粘胶实业有限公司

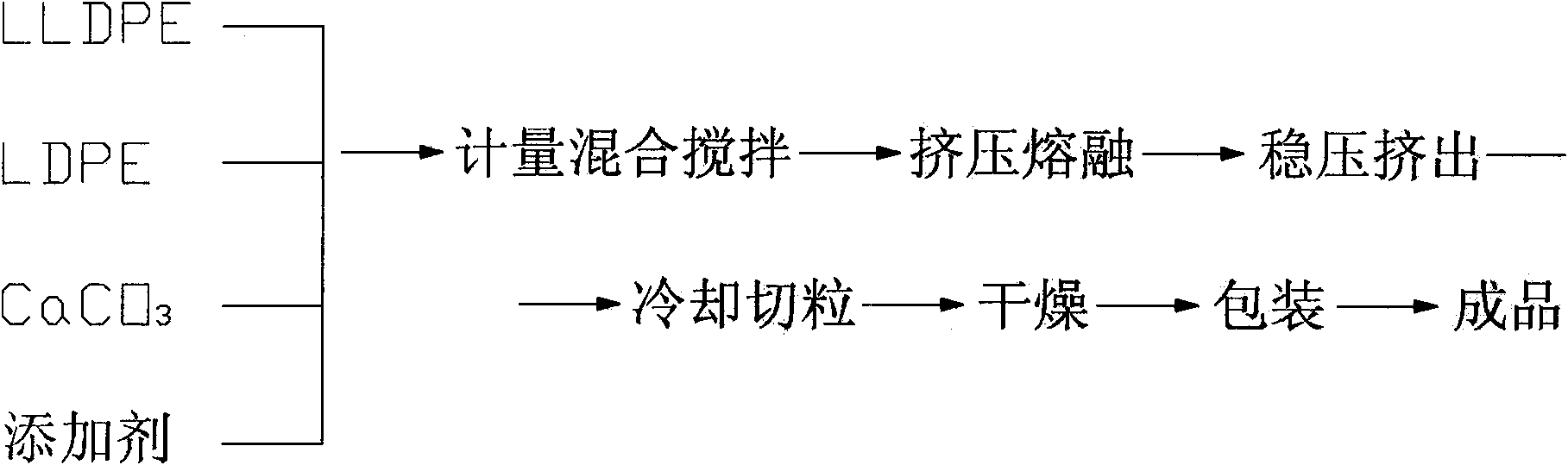

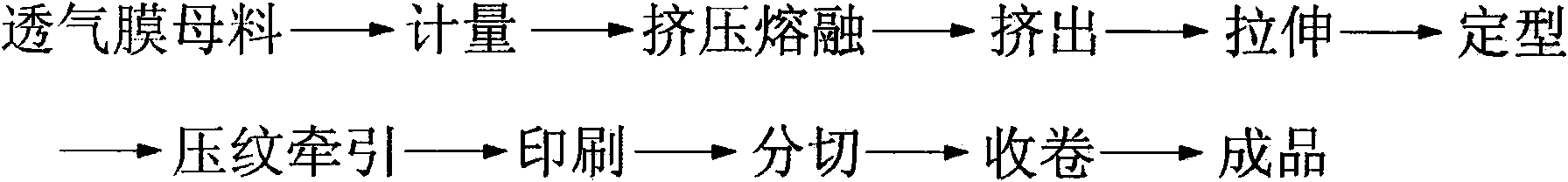

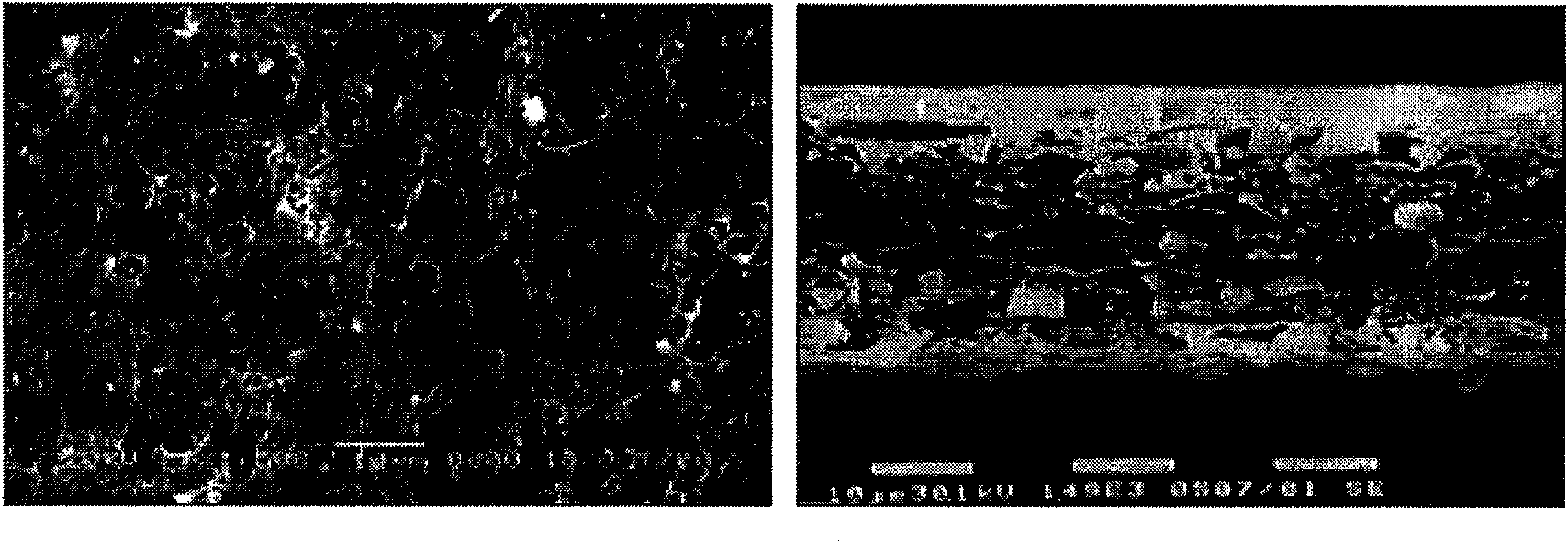

Ultrathin high porosity film and preparation method thereof

The invention discloses an ultrathin high porosity film and a preparation method thereof. The film comprises the following components by weight percent: 40-50% of : PE(LLDPE / LDPE), 45-55% of calcium carbonate and 3-5% of modified additives (plastic additive and film forming additive). The preparation method of the invention comprises the following steps: (1) breathable film master batch process flow and (2) breathable film process flow. The product of the invention can replace imported products, thus reducing the production cost of the breathable film, improving the current dilemma of foreignmonopoly, filling the domestic blank to develop and produce the breathable film material with independent intellectual property rights and having practical and great economic benefit and social benefit.

Owner:ZHEJIANG YUEHAN TECH BREATHABLE MATERIAL

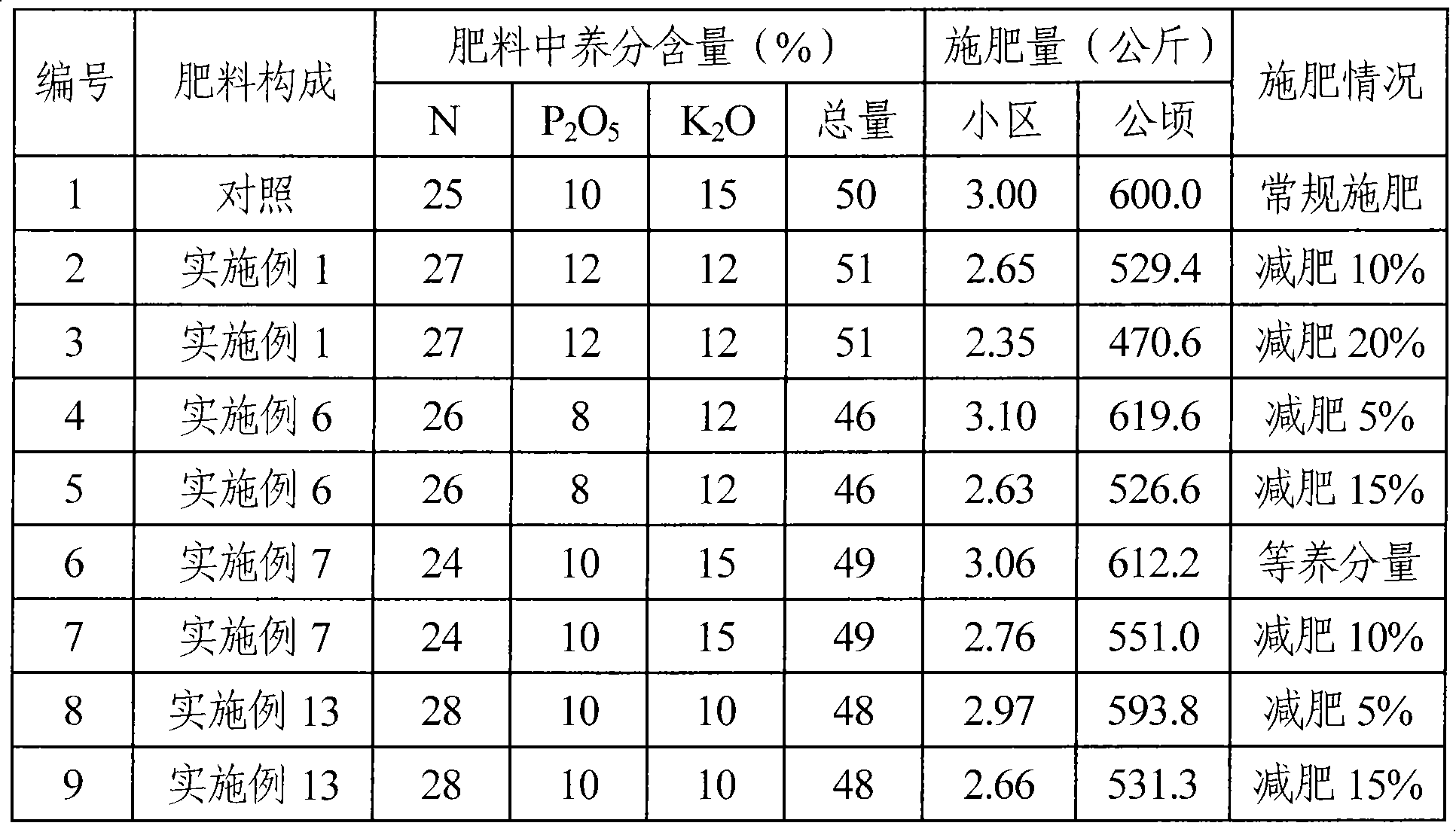

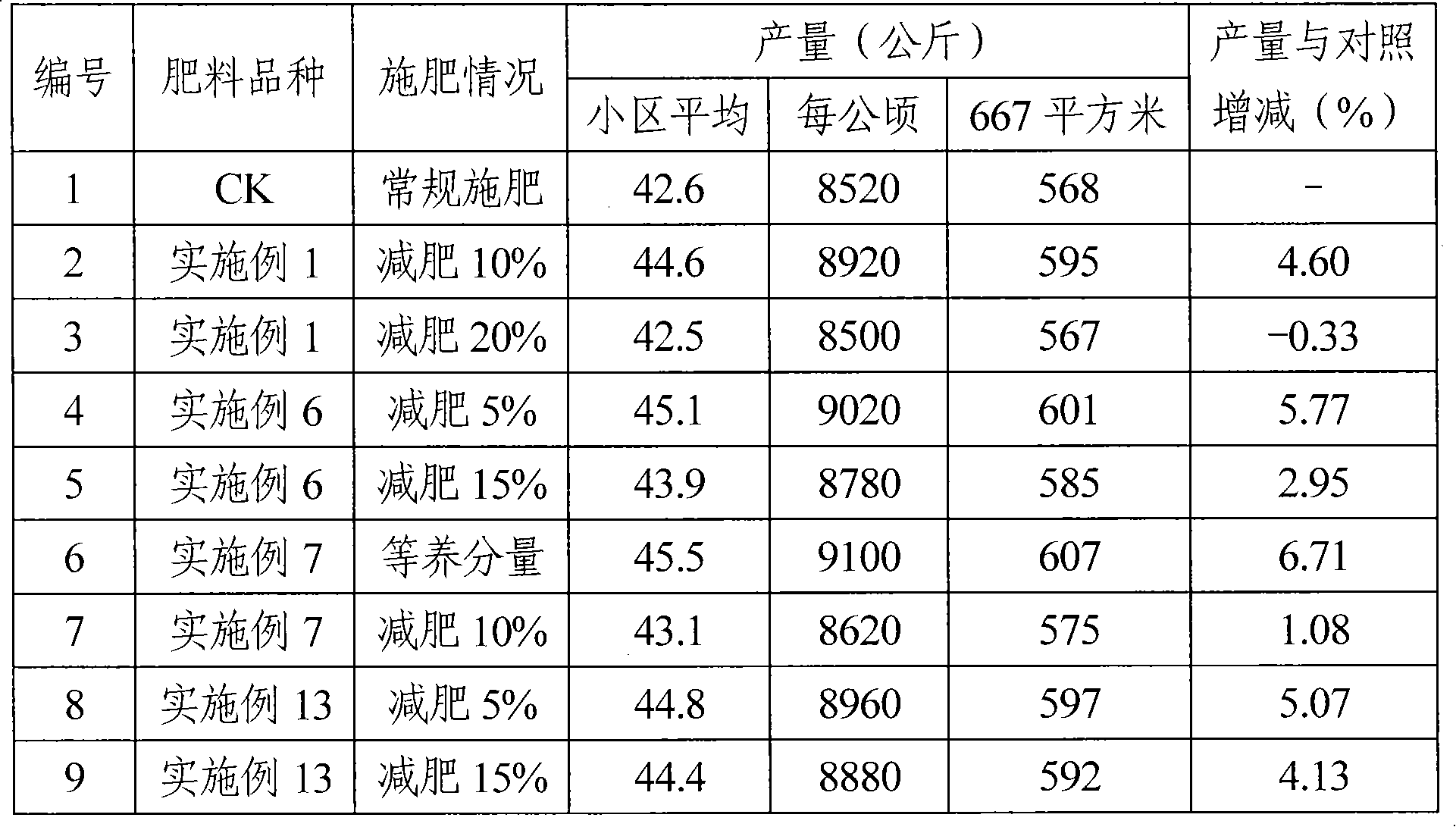

Long-acting slow-release corn special blending fertilizer and preparation method thereof

InactiveCN101618987ANo pollution in the processSimple processFertilizer mixturesPhosphorus utilizationNitrification inhibitors

The invention relates to a soil fertilizer technique, in particular to a long-acting slow-release corn special blending fertilizer and a preparation method thereof to solve the problems that the nitrogen and phosphorus utilization rate of the fertilizer is low, the after manuring in the corn growth period consumes a large amount of time and labor and the like. The blending fertilizer comprises the following components in percentage by weight: 45 to 58 percent of nitrogen fertilizer, 16 to 25 percent of phosphate fertilizer, 16 to 25 percent of potassium fertilizer, and 4 to 14 percent of nitrogen phosphorus fertilizer synergist; and nutritive substances of the blending fertilizer comprise the following components in percentage by weight: 24 to 28 percent of pure nitrogen, 8 to 12 percent of diphosphorus pentanitride, and 10 to 15 percent of potassium oxide. The preparation method comprises the following steps: adding the granular nitrogen fertilizer, phosphate fertilizer, potassium fertilizer and the nitrogen phosphorus fertilizer synergist into a mixing and stirring machine according to the weight ratio, mixing and stirring the materials evenly to obtain the long-acting slow-release corn special blending fertilizer, and performing sub-package to obtain the finished product; or selecting a urease inhibitor, a nitrification inhibitor and a phosphate fertilizer synergist to granulate by mixing so as to obtain the granular nitrogen phosphorus fertilizer synergist, and then blending the granular nitrogen phosphorus fertilizer synergist with the granular nitrogen fertilizer, phosphate fertilizer and potassium fertilizer to obtain the finished product. The long-acting slow-release corn special blending fertilizer and the preparation method have simple process and easy implementation, are suitable for one-step basal application without after manuring for corn production in the Northeast, and reduce the usage amount by 10 to 20 percent without reducing the yield.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

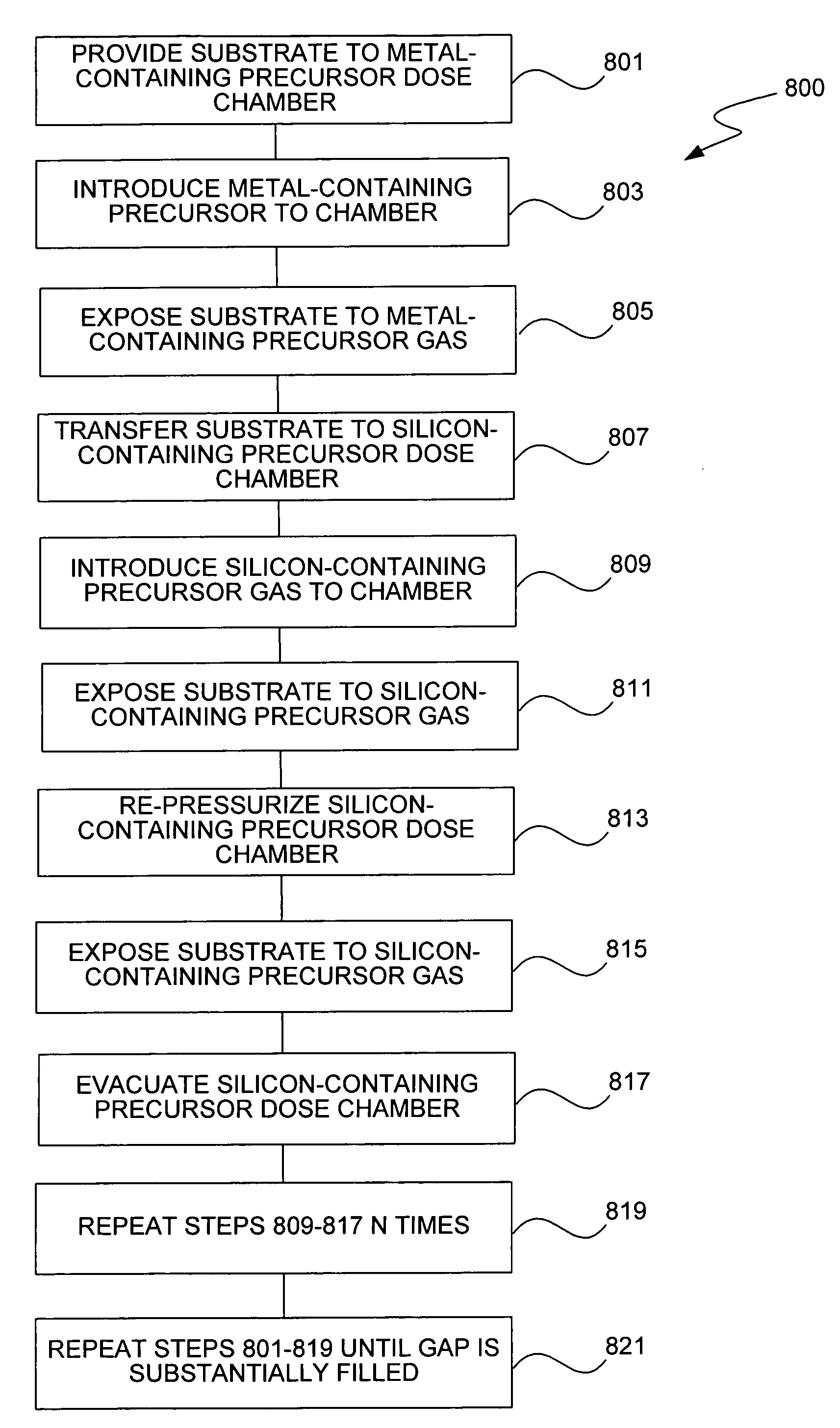

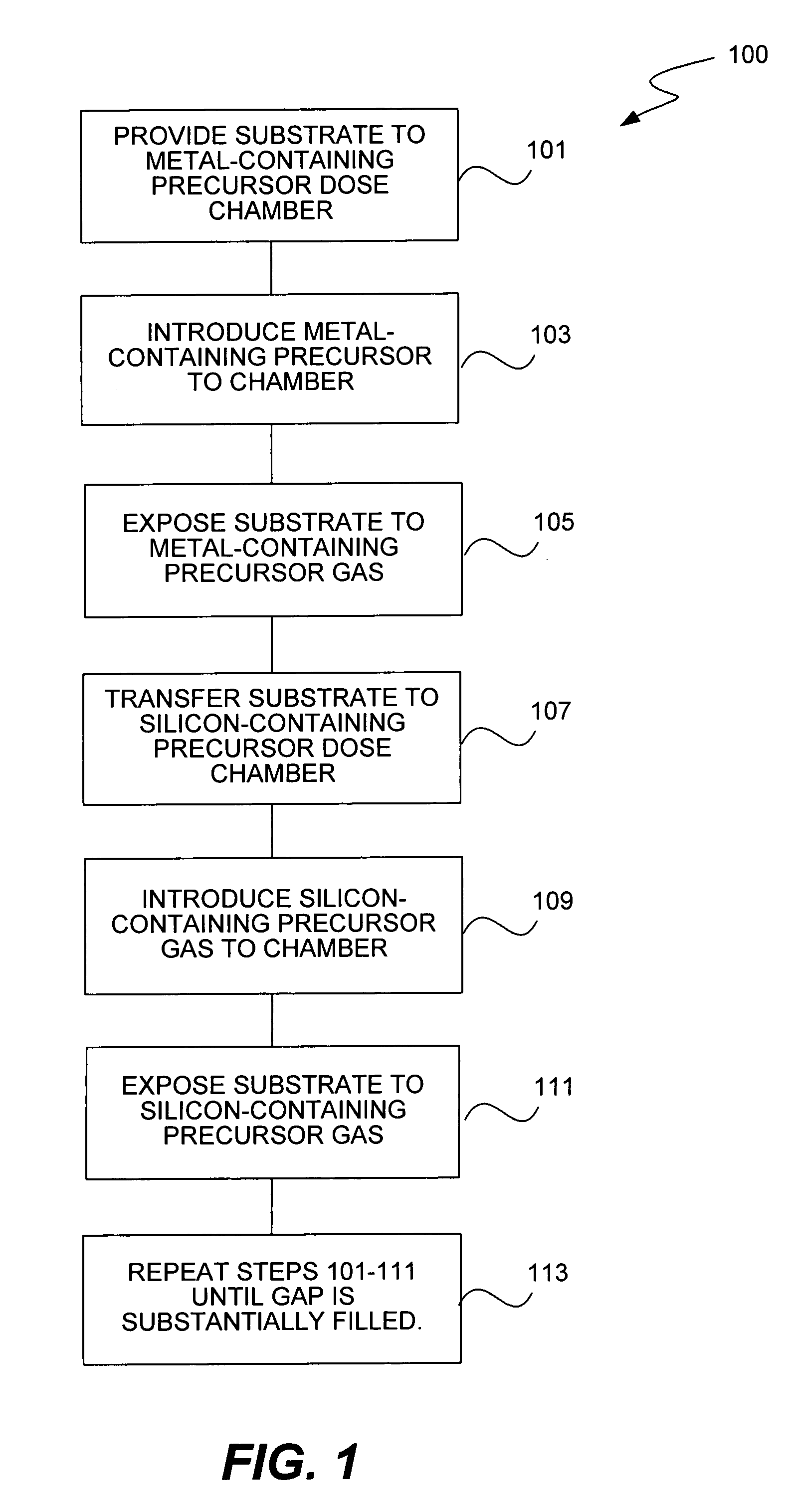

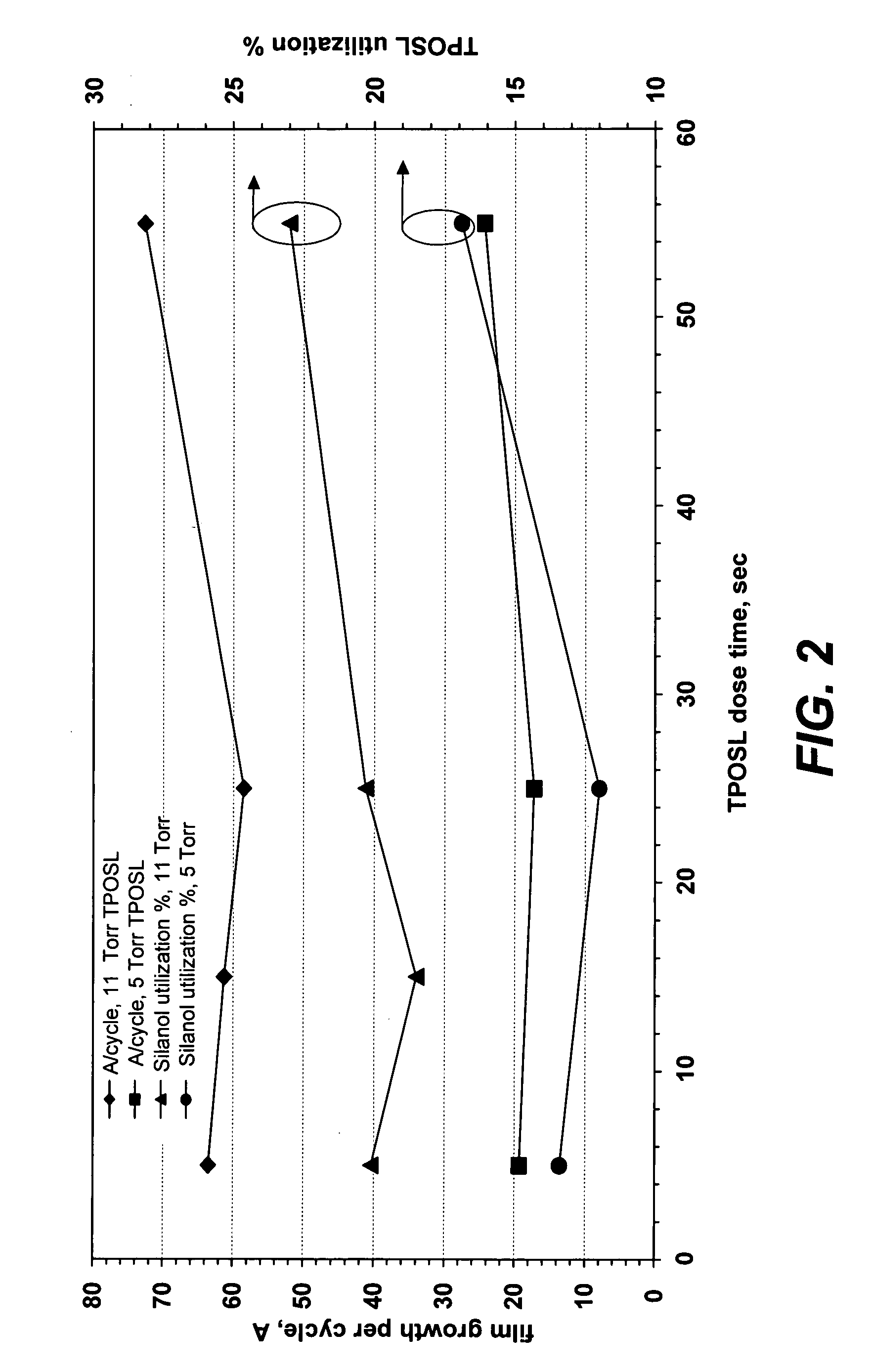

Optimal operation of conformal silica deposition reactors

ActiveUS7135418B1Reduce the amount requiredIncrease the amount addedSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon dioxideSilicon

Methods of forming conformal films that reduce the amount of metal-containing precursor and / or silicon containing precursor materials required are described. The methods increase the amount of film grown following each dose of metal-containing and / or silicon-containing precursors. The methods may involve introducing multiple doses of the silicon-containing precursor for each dose of the metal-containing precursor and / or re-pressurizing the process chamber during exposure to a dose of the silicon-containing precursor. The methods of the present invention are particularly suitable for use in RVD processes.

Owner:NOVELLUS SYSTEMS

Lyophilized platelet rich plasma for the use in wound healing (chronic or acute) and bone or tissue grafts or repair

InactiveUS20050191286A1Simple compositionPrevent flow awayBiocidePeptide/protein ingredientsWhite blood cellAntibiotic Y

This invention relates to an improved Lyophilized platelet rich plasma used to make a platelet gel wound healant, and methods of preparation and use thereof for healing wounds are disclosed. The improved wound healant comprises therapeutically effective amounts of activated growth factors, platelet ghost, plasma (know as the plasma back bone), white blood cells with optional none, one or more additional anti-oxidant such as vitamin A and / or C and / or E, and / or none one or more antibiotics and / or GHK-Cu (produced by ProCyte Inc.)

Owner:WALKER MACKIE J JR

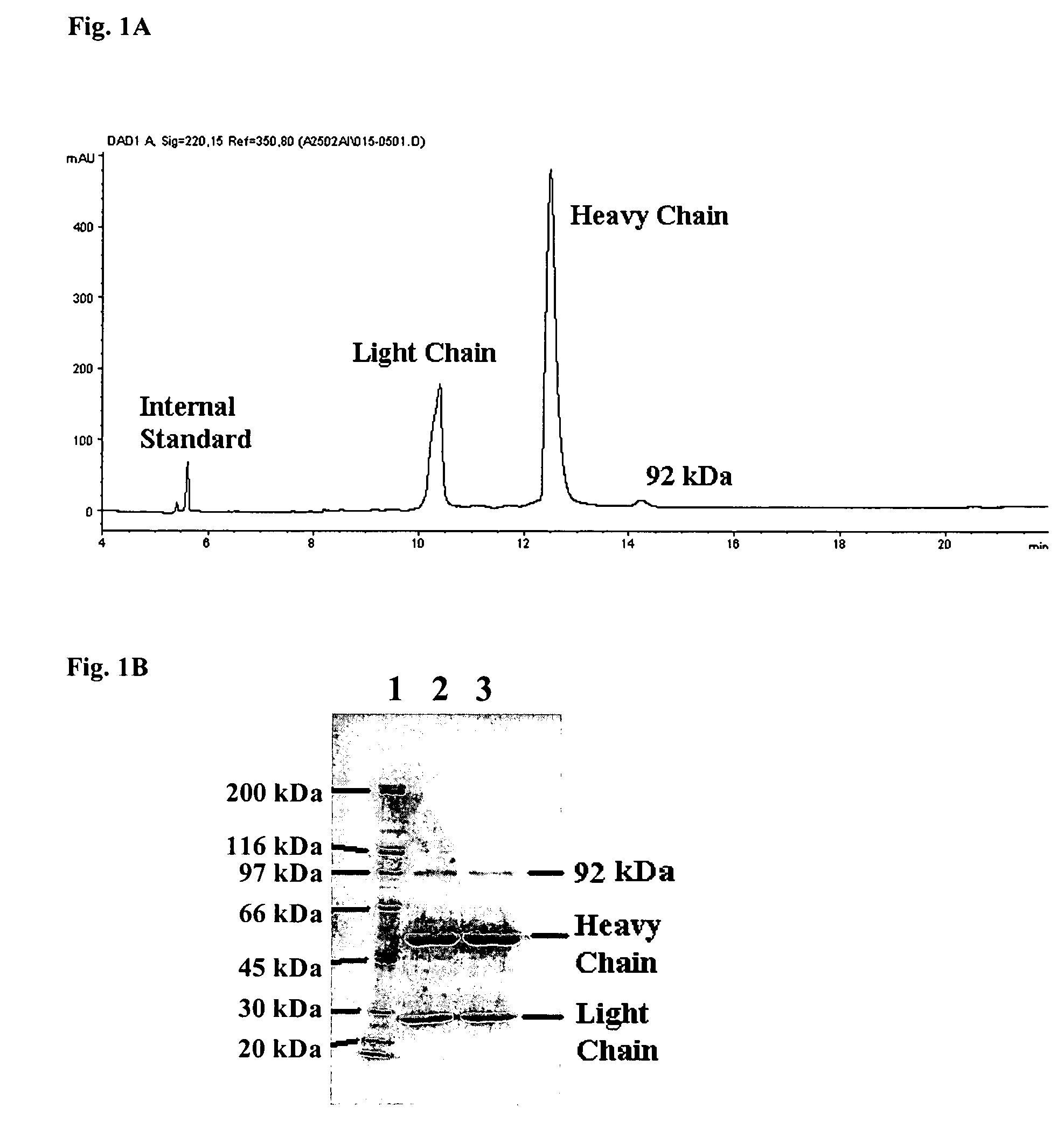

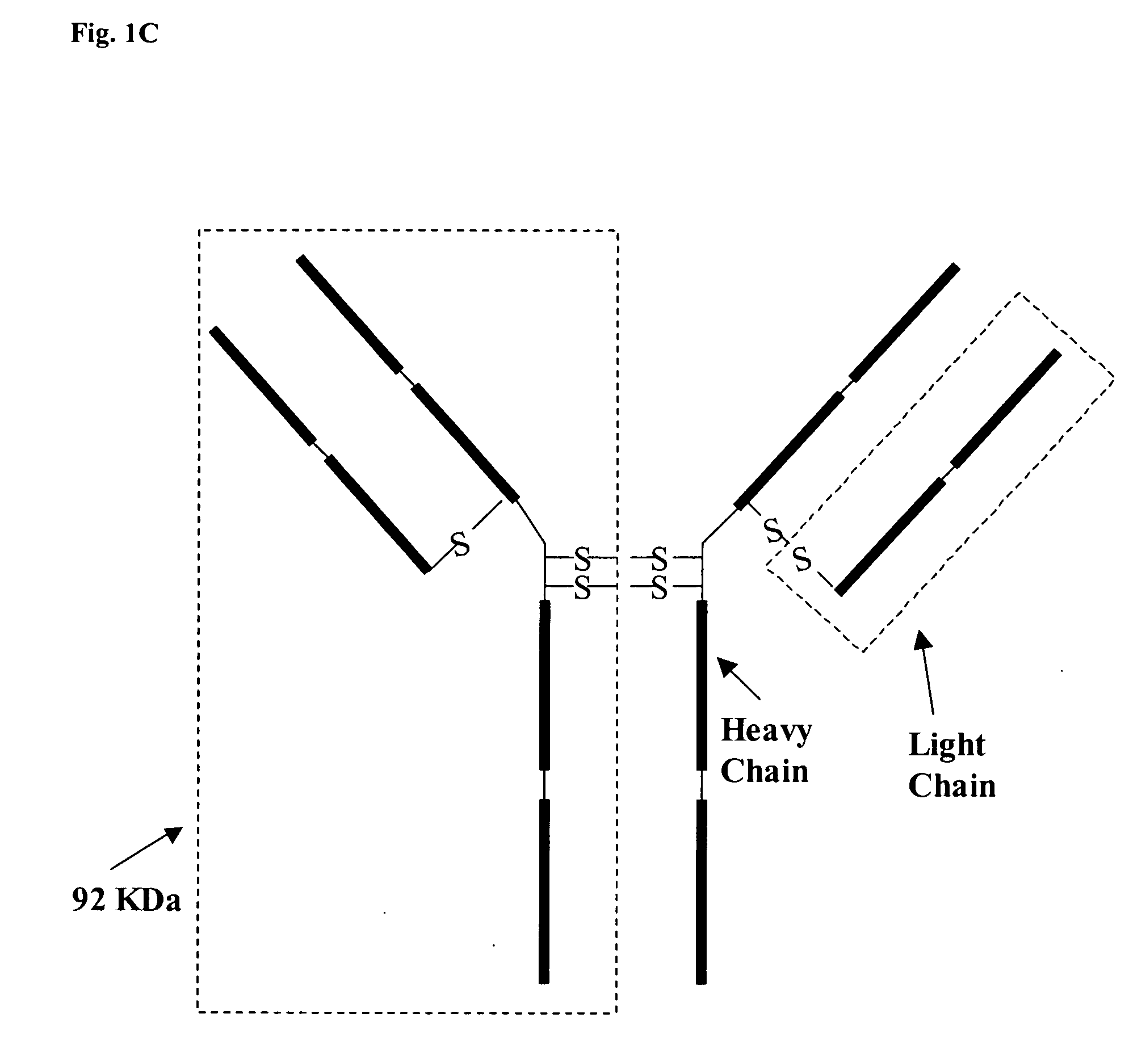

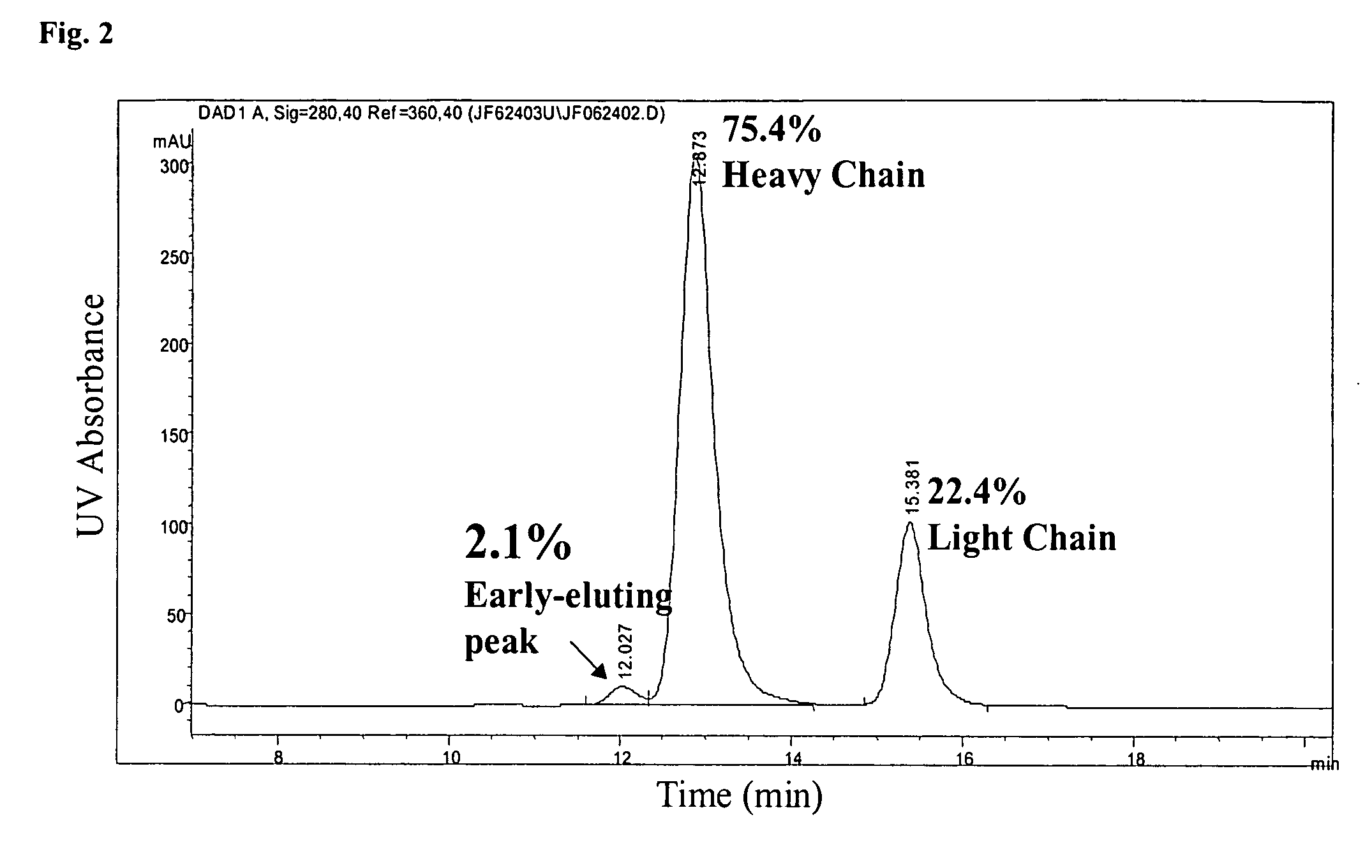

Macromolecules comprising a thioether cross-link

ActiveUS20060216284A1Reduce the amount of solutionIncrease the amount addedImmunoglobulins against cell receptors/antigens/surface-determinantsAntibody ingredientsCross-linkAntigen

The present invention provides macromolecules comprising at least one thioether cross-link. A thioether cross-link comprising a single thioether bond between two residues of a macromolecule. The macromolecules of the invention can display enhanced stability, pharmaceutical properties and functional properties. In particular, the invention provides an isolated antibodies comprising at least one thioether cross-link that specifically bind to particular antigens. The present invention also provides a composition comprising a macromolecule substantially free of a denaturing reagent, wherein the macromolecule comprises at least one thioether cross-link. In addition, the present invention provides a method for producing the macromolecules and compositions of the invention.

Owner:MEDIMMUNE LLC

Method for preparing electrothermal film by graphene aqueous slurry

ActiveCN105898906APrevent volatilizationImprove conductivityHeating element materialsOrganic solventAcrylic resin

The invention discloses a method for preparing an electrothermal film by graphene aqueous slurry. The method comprises the steps of: (1) adding deionized water and an amine compound to solid acrylic resin to obtain water-soluble acrylic resin; (2) adding graphene and an auxiliary agent to the water-soluble acrylic resin, and dispersing and mixing the water-soluble acrylic resin to obtain a homogeneous dispersion liquid; (3) adding a binder to the homogeneous dispersion liquid, and stirring and mixing the homogeneous dispersion liquid to obtain the graphene aqueous slurry; and (4) coating a film-forming carrier with the graphene aqueous slurry to form a graphene conducting layer and drying the graphene conducting layer to obtain the electrothermal film. The electrothermal film with excellent thermal conductivity and electrical conductivity can be prepared with the aqueous slurry; no organic solvent is added in the preparation process; the problem of VOC emission does not exist; and the method is safe and environment-friendly. Compared with other technologies that require special modification of filler, the preparation method is simple; coupling treatment is not carried out on an exothermic material by adoption of a coupling agent; the existing production technology can be simplified; and the production cost is reduced.

Owner:DEYANG CARBONENE TECH

Sheath for a prosthesis and methods of forming the same

InactiveUS20020123788A1Increase the amount addedIncrease the number ofStentsPharmaceutical containersMedicineProsthesis

An implantable device or endoluminal prosthesis, such as a stent, having a sheath and a method of forming the sheath are provided. The sheath may be used for the delivery of an active ingredient. The sheath may have a selected pattern of interstices for allowing a fluid to seep through the sheath in the direction of the pattern created.

Owner:ABBOTT CARDIOVASCULAR

Method for preparing silicone sealant

ActiveCN103642452AIncrease the amount addedImprove stabilityNon-macromolecular adhesive additivesOther chemical processesPolymer sciencePtru catalyst

The invention discloses a method for preparing silicone sealant. The method comprises the following steps: adding alpha,omega-dyhydroxy polydimethylsiloxane, filler and dimethyl silicon oil into a vacuum kneading machine, vacuuming, heating and mixing for 2-5 hours; stopping heating, introducing nitrogen to change the vacuum state, adding a silane coupling agent, mixing for 0.5-1 hour at the vacuum degree of -0.06 to -0.1Mpa, introducing nitrogen to change the vacuum state; sealing and cooling to room temperature, subsequently transferring into a stirring machine, adding a cross-linking agent, a thickening agent and a catalyst, vacuuming, and uniformly stirring and mixing so as to obtain the silicone sealant. According to a product of the silicone sealant, the addition amount of the filler is increased, the product stability and the surface smoothness are improved, the thixotropy and the deep curing are also improved, the curing homogeneity is good, the tensile strength, the elasticity and the cohesiveness are greatly improved, expensive white carbon black can be replaced, the filling amount is large, the curing time is short, the construction efficiency is improved, the process is simple and feasible, the production cost is low, and good economic benefits and social benefits are achieved.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com