Grinding aid for slag cement

A technology of slag cement and grinding aid, applied in the field of building materials, can solve the problems of low strength of slag cement and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] According to the weight ratio, heat one-third of the 66.5% deionized water to 70°C, add 1% hydroxypropyl methylcellulose to it, and keep stirring to disperse, and then add the remaining amount of cold water Wherein, cooling and stirring continuously until the solution is transparent. Then add 10% triethanolamine, 15% glycerol, 2% sodium hexametaphosphate, 3% anhydrous sodium acetate and 2.5% sodium dodecylbenzenesulfonate in sequence, stir for half an hour Get grinding aids.

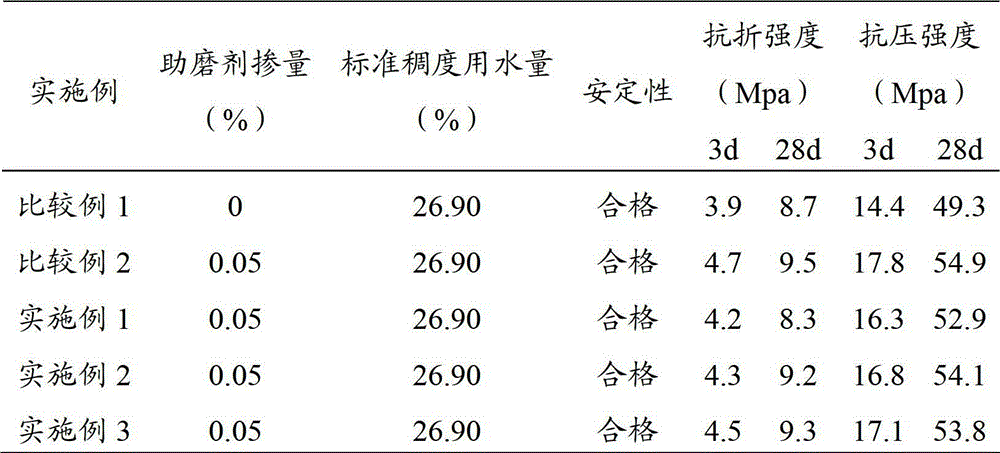

[0053] The grinding aid that the present invention will obtain is in Carry out the experiment in the small mill of standard experiment, test its performance, the material ratio of cement is: the clinker of 46.0wt%, the gypsum of 4.0wt% and the slag of 50.0%, experimental result is as shown in table 1, and table 1 is the present invention The performance test results of the grinding aids obtained in Examples and Comparative Examples.

Embodiment 2

[0055] According to the weight ratio, heat one-third of the deionized water with a weight ratio of 57% to 70°C, add 2% hydroxypropyl methylcellulose to it, and keep stirring to disperse, and then add the remaining amount of cold water Wherein, cooling and stirring continuously until the solution is transparent. Then add 12% diethanolamine, 20% propylene glycol, 3% sodium hexametaphosphate, 1% anhydrous sodium acetate and 5% sodium dodecylbenzenesulfonate in sequence, and stir for half an hour to obtain Grinding aid.

[0056] The grinding aid that the present invention will obtain is in Carry out the experiment in the small mill of standard experiment, test its performance, the material ratio of cement is: the clinker of 46.0wt%, the gypsum of 4.0wt% and the slag of 50.0%, experimental result is as shown in table 1, and table 1 is the present invention The performance test results of the grinding aids obtained in Examples and Comparative Examples.

Embodiment 3

[0058] According to the weight ratio, heat one-third of the deionized water with a weight ratio of 68% to 70°C, add 2% hydroxypropyl methylcellulose to it, and keep stirring to disperse, and then add the remaining amount of cold water Wherein, cooling and stirring continuously until the solution is transparent. Then add 8% triisopropanolamine, 10% ethylene glycol, 5% sodium hexametaphosphate, 5% anhydrous sodium acetate and 2% sodium dodecylbenzenesulfonate successively, stir Grinding aid was obtained after half an hour.

[0059] The grinding aid that the present invention will obtain is in Carry out the experiment in the small mill of standard experiment, test its performance, the material ratio of cement is: the clinker of 46.0wt%, the gypsum of 4.0wt% and the slag of 50.0%, experimental result is as shown in table 1, and table 1 is the present invention The performance test results of the grinding aids obtained in Examples and Comparative Examples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com