Neutral silicone weather resistant glue formula and technique for preparing the same

A silicone weather-resistant adhesive, neutral technology, applied in the direction of adhesives, etc., can solve the problems of unavoidable storage period of alcohol-based adhesives, influence, high hydroxyl content, etc., to achieve the effect of improving storage period, slowing down the viscosity peak, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

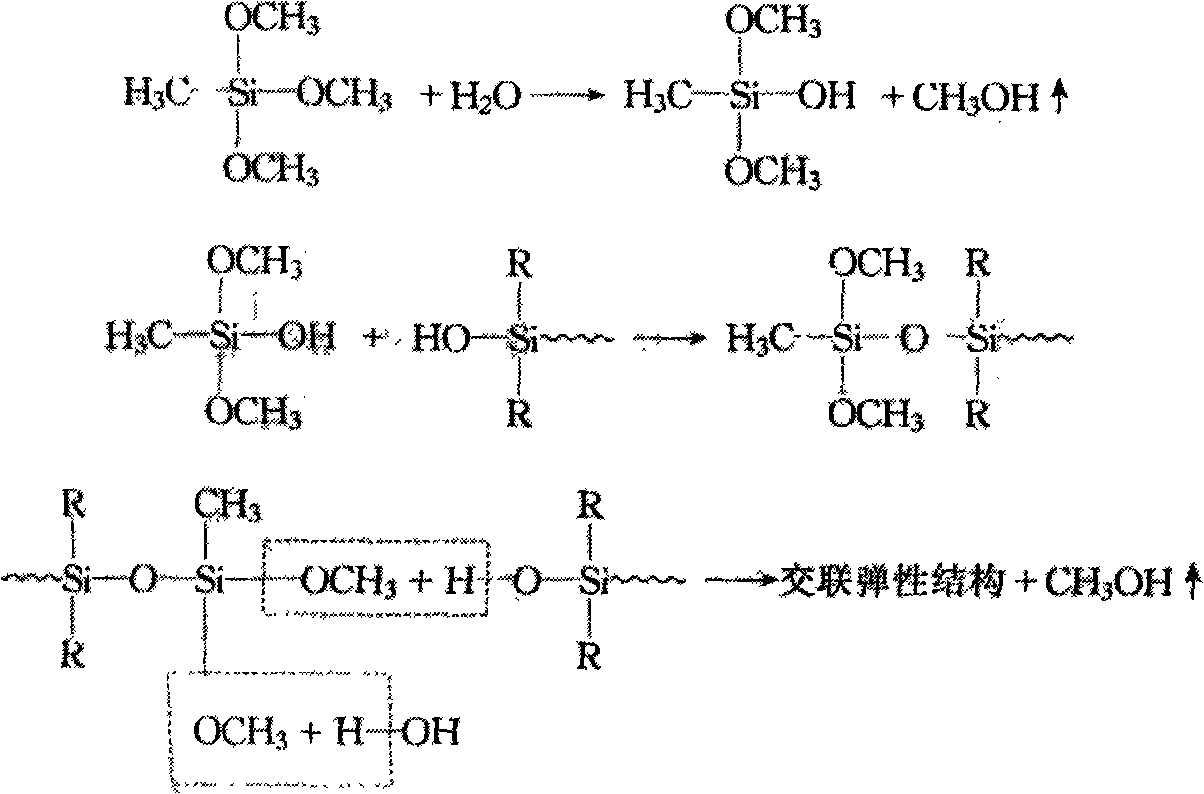

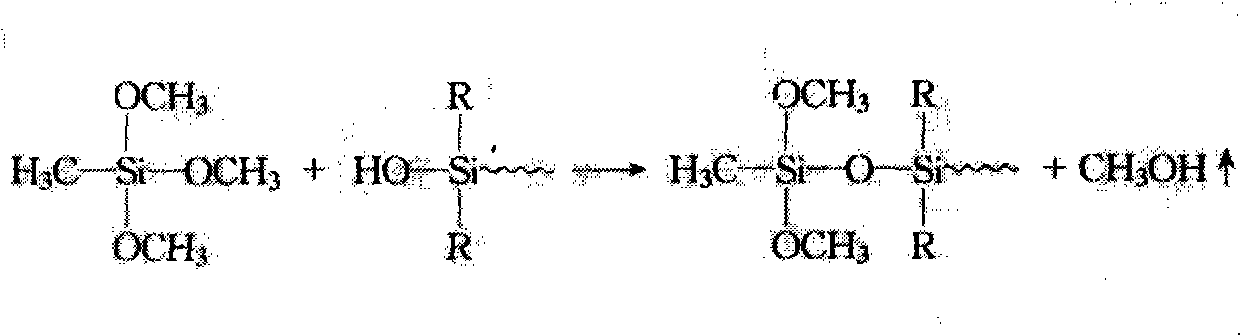

Method used

Image

Examples

Embodiment 1

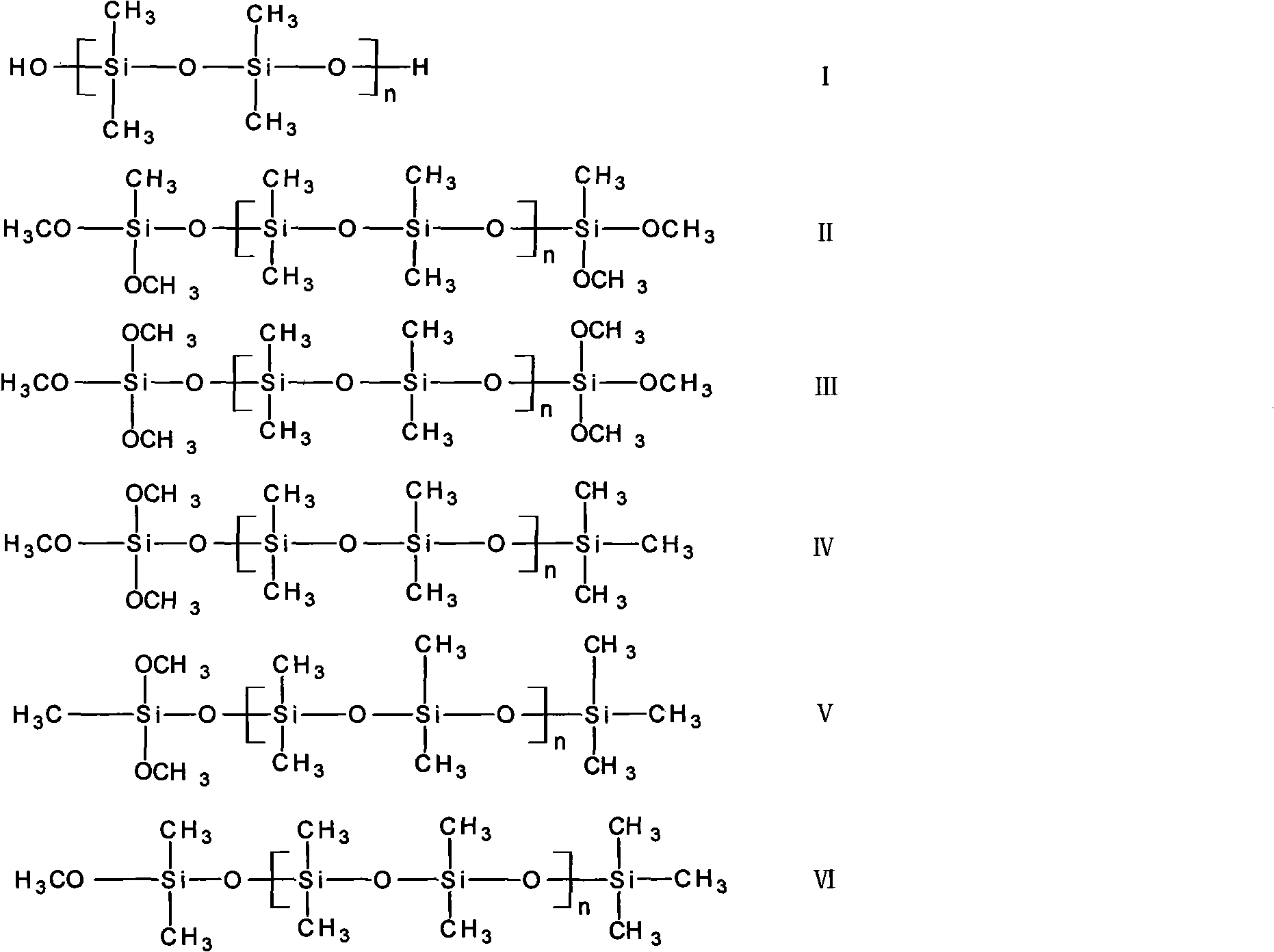

[0046] Example 1: 100 parts of α, ω-dihydroxy polydimethylsiloxane (I) and 100 parts of light activated calcium carbonate were added to a vacuum kneader, the temperature was controlled at 120° C., and the vacuum degree was 0.098 MPa. Mix and dehydrate for 3 hours, then three-roll grinding to make base rubber; then move the base into a high-speed disperser, and mix 8 parts of methyltrimethoxysilane and 2 parts of γ-aminopropyltriethoxysilane at room temperature , 1 part of γ-(2,3-glycidoxy) propyltrimethoxysilane, 3 parts of titanium diisopropoxy diacetoacetate and dimethylmethoxysiloxy terminated poly Add 10 parts of dimethylsiloxane (V) into the high-speed disperser in batches, and stir with the gum base in vacuum. The vacuum degree is -0.098MPa, the rotation speed is 500rpm, and the stirring time is 60 minutes.

Embodiment 2

[0047]Example 2: 50 parts of α, ω-dihydroxypolydimethylsiloxane (I) and 50 parts of α, ω-methyldimethoxysiloxy-blocked polydimethylsiloxane (II) 100 parts as the base polymer, and 100 parts of light active calcium carbonate were added to the vacuum kneader, the temperature was controlled at 120 ° C, the vacuum degree was 0.098 MPa, blended and dehydrated for 3 hours to make base rubber, and then moved into a high-speed mixer; At room temperature, mix 5 parts of methyltrimethoxysilane, 2 parts of γ-aminopropyltriethoxysilane, 1 part of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, Add 3 parts of titanium isopropoxy bisacetoacetate and 10 parts of dimethylmethoxysiloxy-terminated polydimethylsiloxane (V) into the high-speed dispersing machine in batches, and evacuate with the base glue Stir. The vacuum degree is -0.098MPa, the rotation speed is 500rpm, and the stirring time is 60 minutes.

Embodiment 3

[0048] Example 3: The method is the same as in Example 2, and the base polymer is α, ω-methyldimethoxysiloxy-terminated polydimethylsiloxane or (II) 50 parts, α, ω-trimethoxy 50 parts of siloxy-terminated polydimethylsiloxane (III).

[0049] The following is a comparison of the contamination, storage life and physical properties of Examples 1-3.

[0050] Table 1 Comparison of physical performance parameters

[0051]

[0052] Note 1: See Table 2 (Contamination Test Results) for specific test results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com