Patents

Literature

140results about How to "Low hydroxyl content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intermediate film for laminated glass and laminated glass

ActiveCN103140450AImprove sound insulationLow hydroxyl contentWindowsAntiglare equipmentPlasticizerPolyvinyl alcohol

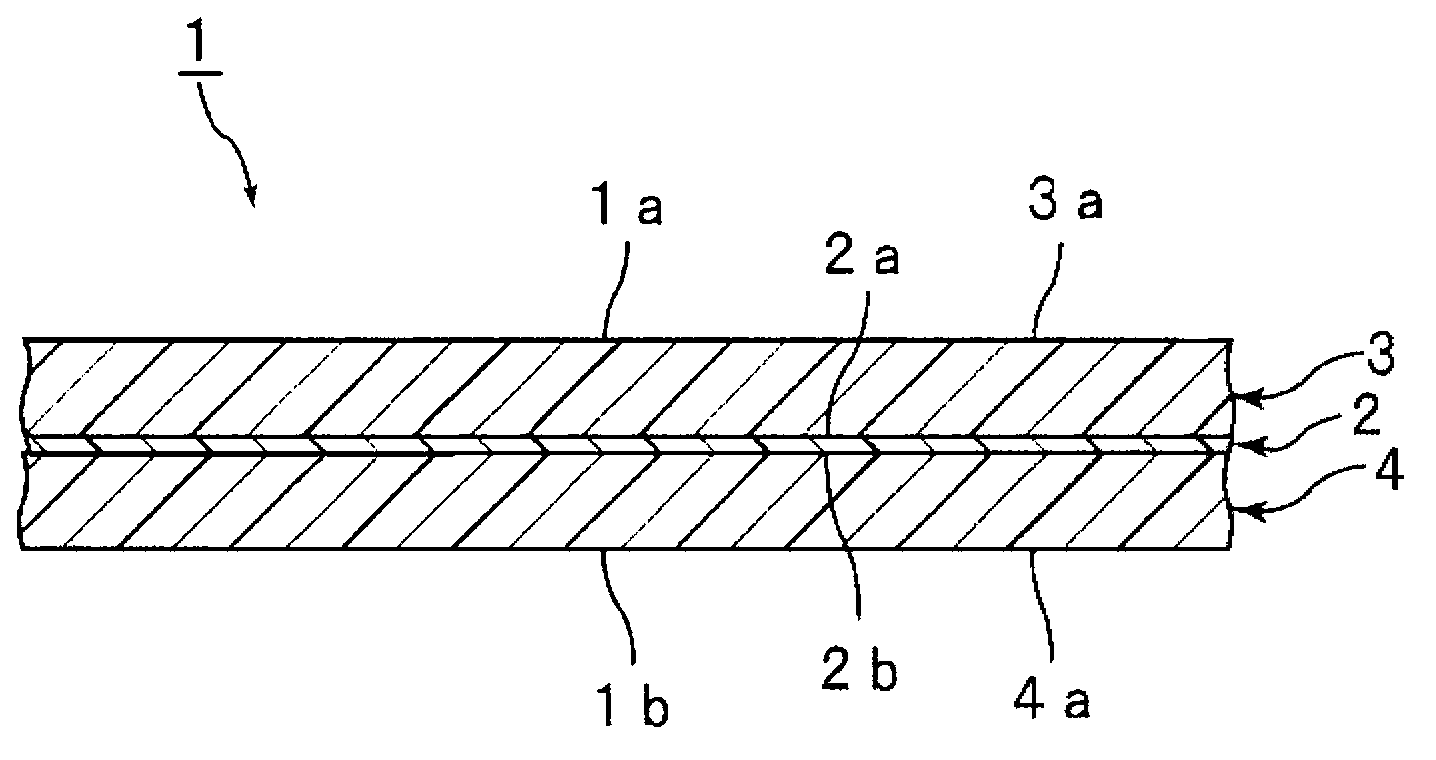

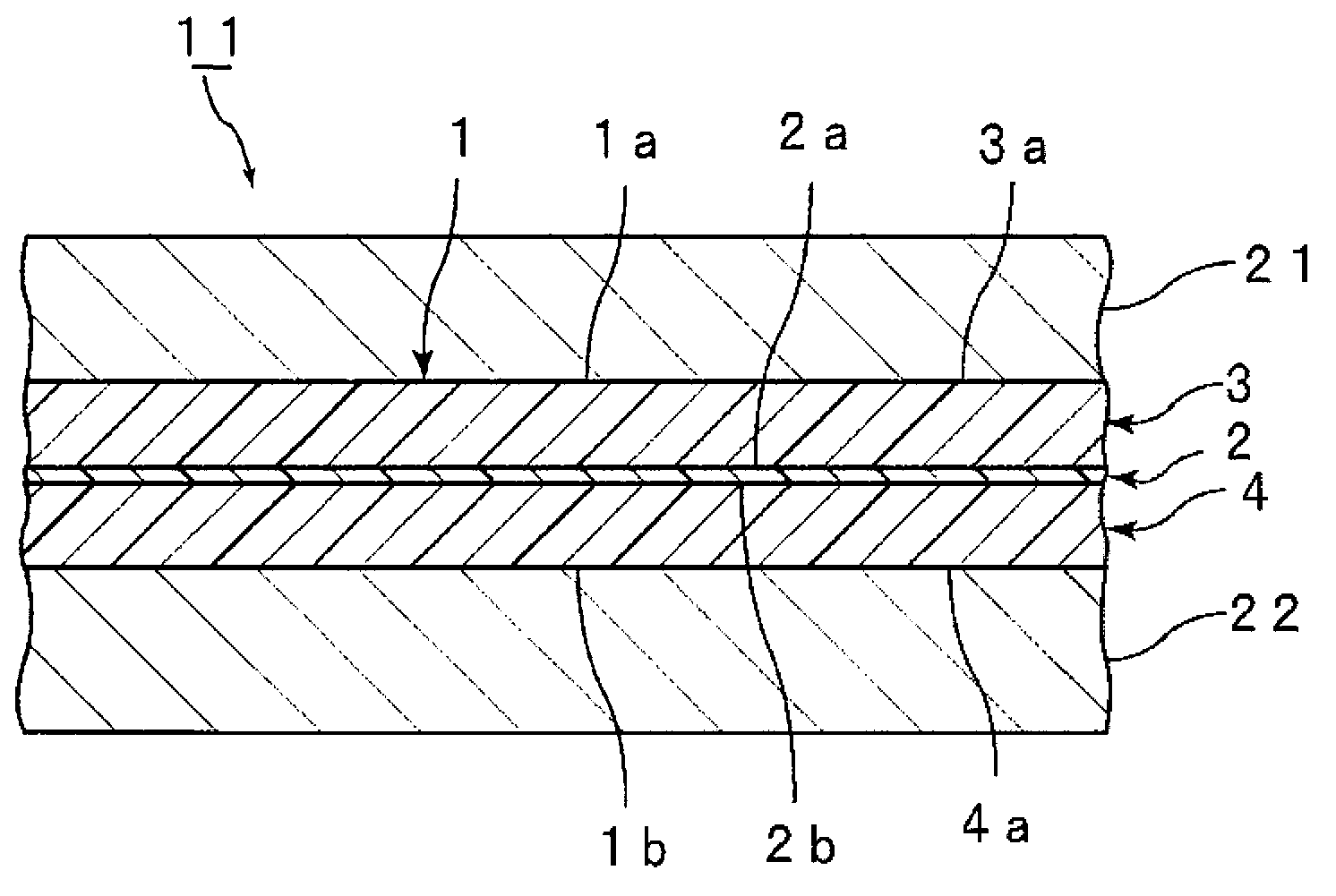

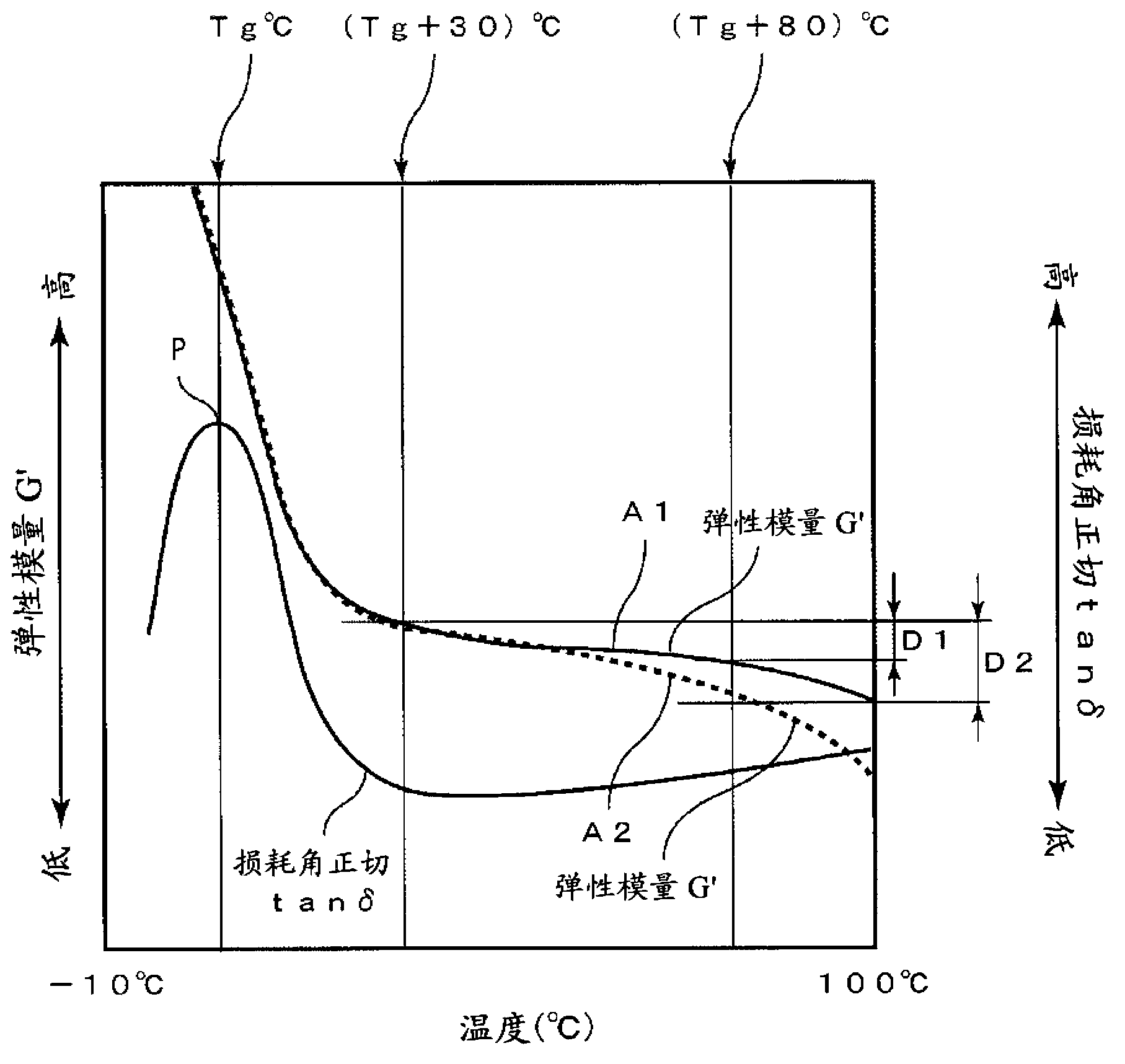

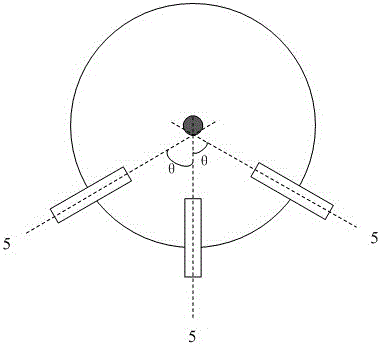

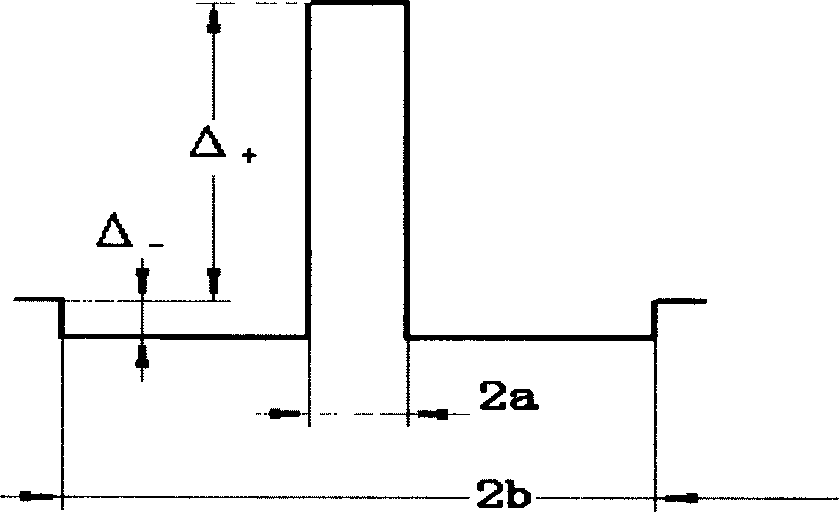

The present invention aims to provide an intermediate film for laminated glass which, in the case of being used for constituting a laminated glass, enables to improve the sound-insulating property in a high frequency range of the obtained laminated glass over a wide range of temperature. The intermediate film for laminated glass of the present invention 1 has a structure that a first layer 2, a second layer 3, and a third layer 4 are laminated in this order, each of the first, second, and third layers 2, 3, and 4 contains a polyvinyl acetal resin and a plasticizer, the hydroxy group content in the polyvinyl acetal resin contained in the first layer 2 is lower than each of the hydroxy group contents in the polyvinyl acetal resins contained in the second and third layers 3 and 4, and the ratio (T1 / (T2+T3)) of the thickness (T1) of the first layer 2 to the total thickness (T2+T3); of the second and third layers 3 and 4 is 0.14 or lower.

Owner:SEKISUI CHEM CO LTD

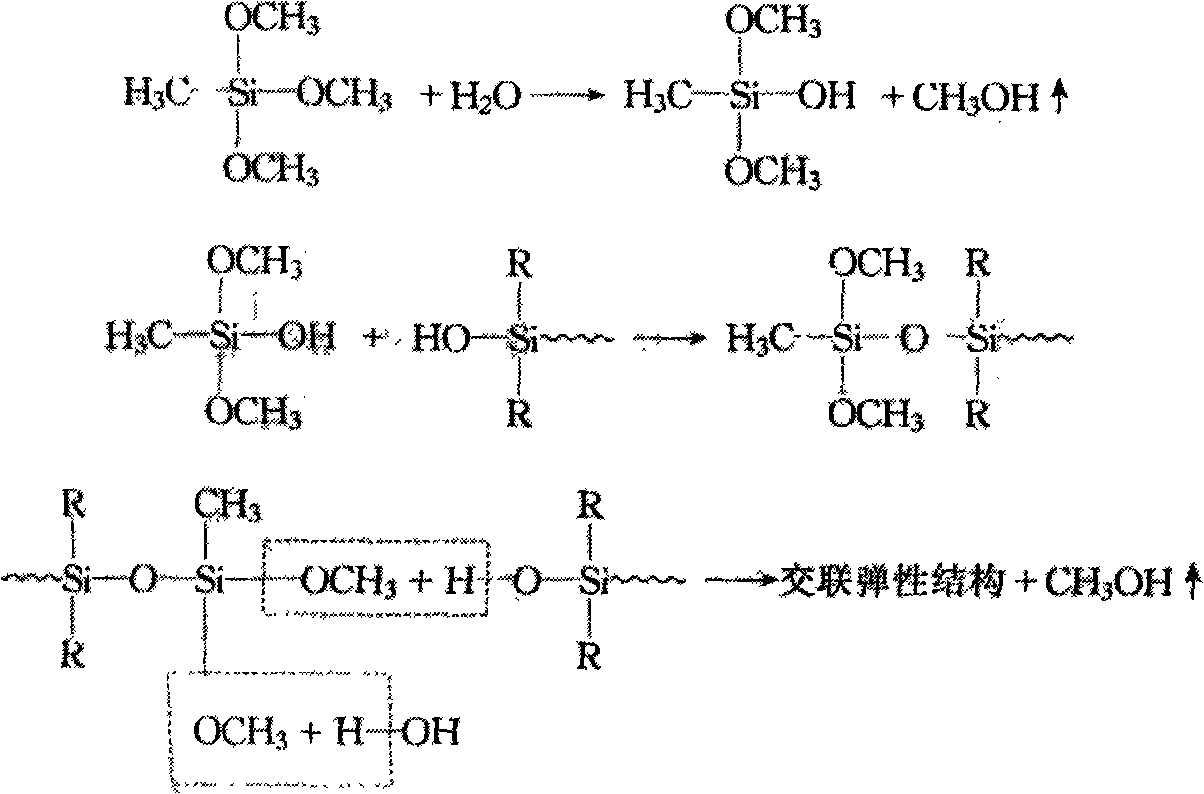

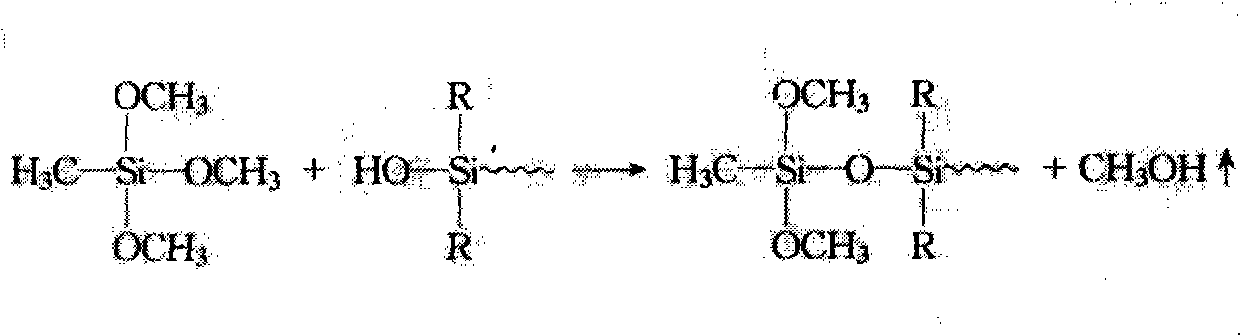

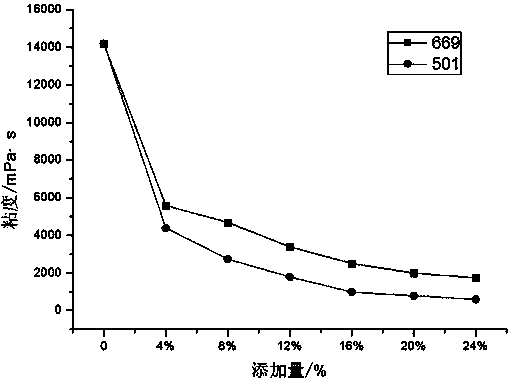

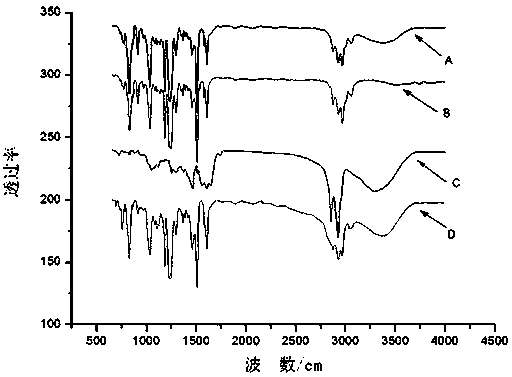

Neutral silicone weather resistant glue formula and technique for preparing the same

The invention relates to a weather resistant glue, especially a neutral silicone weather resistant glue formula and a technique for preparing the same. The formula includes the following components: basic polymer, plasticizer, stuffing, cross linker, anchoring agent and catalyst, which are prepared as follow: basic polymer: 10-100 parts; plasticizer 1-50 parts; stuffing 1-150 parts; cross linker 0.5-10 parts; anchoring agent 0.5-10 parts; catalyst 0.001-15 parts. The neutral silicone weather resistant glue produced by the invention has the advantages of pollution-free, improved product storage time, adjusted modulus, reduced viscosity peak, easy production without tin catalyst or the like.

Owner:深圳市百丽春粘胶实业有限公司

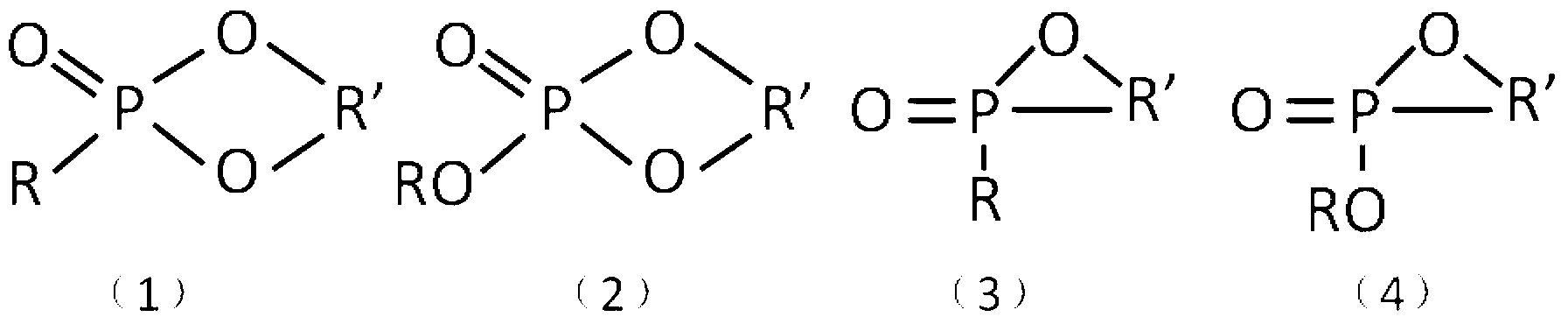

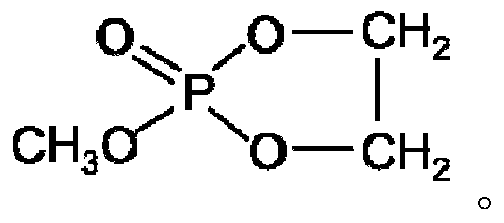

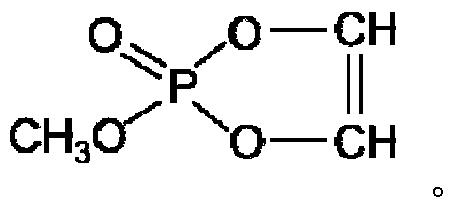

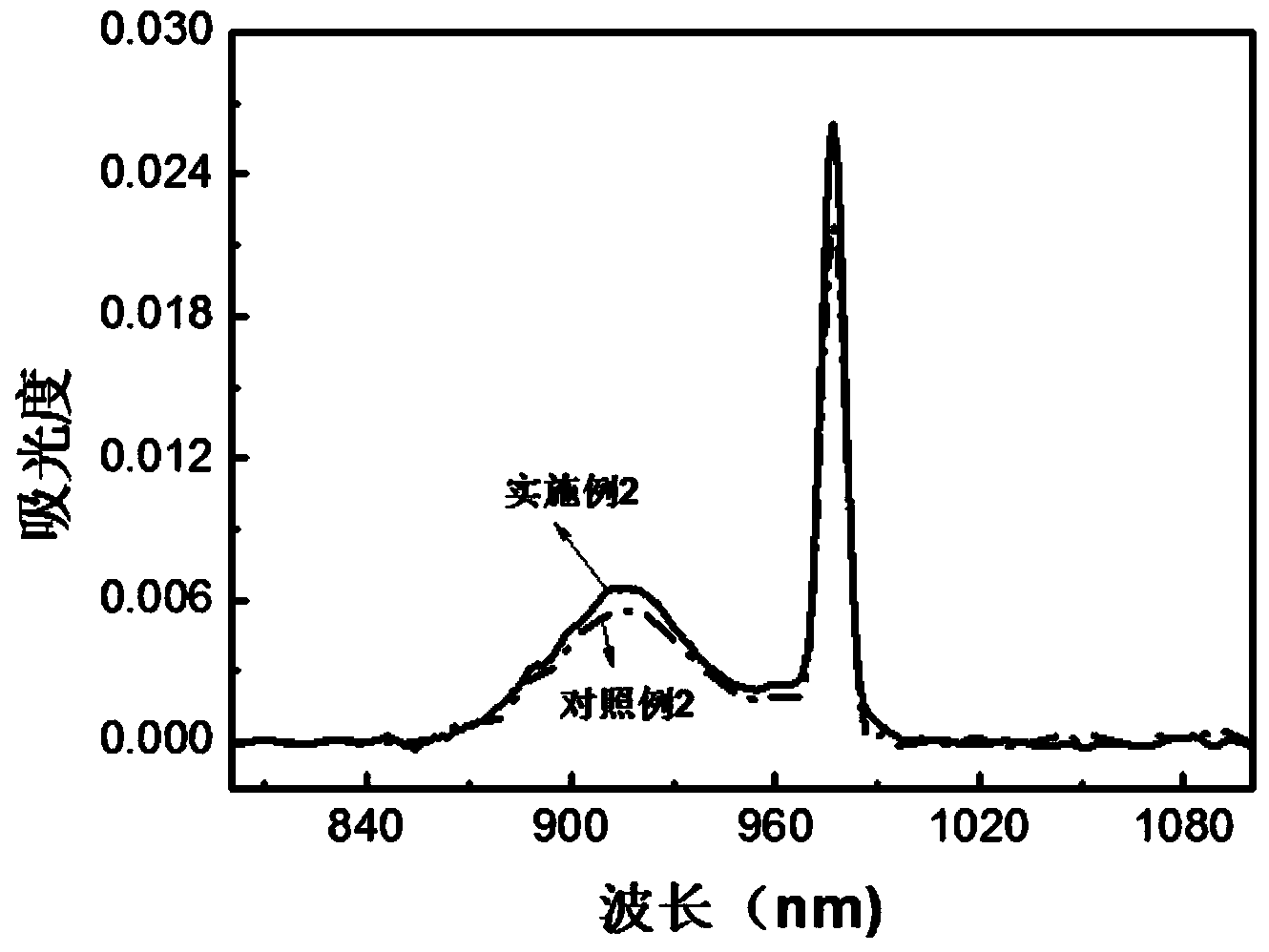

Lithium titanate battery and lithium titanate battery electrolyte

The invention discloses electrolyte for a lithium titanate battery. The electrolyte comprises a solvent, a solute and an additive, wherein the additive contains cyclic phosphate with the structural formula (1), (2), (3) or (4), R represents for a hydrocarbyl group of C1 to C6, a ketone group of C2 to C6, an ether group of C2 to C6 or a halogen element, and R' represents for a saturated hydrocarbyl group of the C2 to te C6 or unsaturated hydrocarbyl group of the C2 to the C6. In addition, the invention also discloses a lithium titanate battery.

Owner:NINGDE AMPEREX TECH

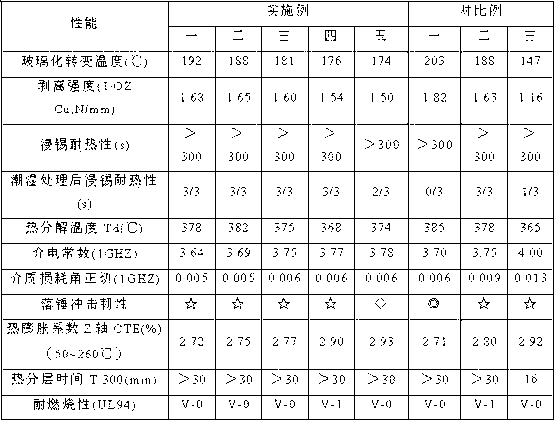

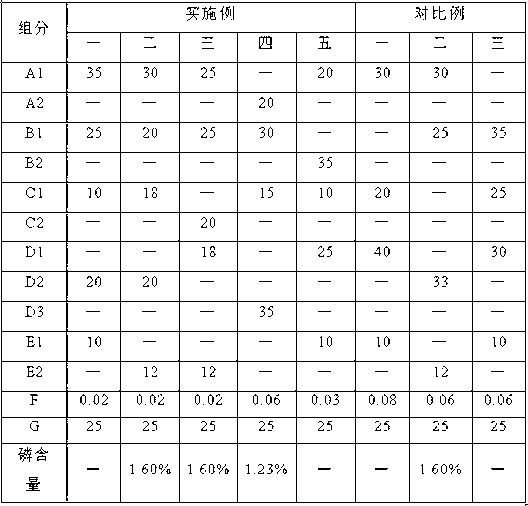

Resin composition for high-frequency high-speed substrate as well as prepreg and laminated board made of resin composition

ActiveCN103265810ALow dielectric loss tangentImprove heat resistanceSynthetic resin layered productsMetal layered productsPolymer scienceHigh density

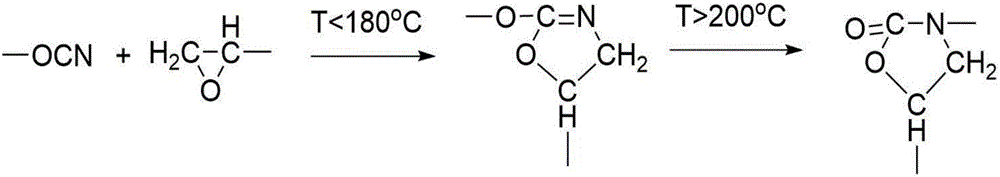

The invention discloses a resin composition for a high-frequency high-speed substrate. Measured according to solid weights, the resin composition comprises the following components: 10-50 parts of cyanate ester resin (a), 10-40 parts of anhydride compounds (b), 5-50 parts of benzoxazine resin (c), 5-50 parts of epoxy resin (d), 5-50 parts of flame retardant (e), 0-5 parts of curing accelerator (f) and 0-80 parts of inorganic filler (g). The resin composition disclosed by the invention has high moisture and heat resistance, high glass transition temperature as well as lower dielectric constant and dielectric loss tangent value, and can be well applied to the fields such as high-frequency, high-speed and high-density interconnection and the like; and a laminated board made of the resin composition has excellent moisture and heat resistance and good bonding power.

Owner:SHENGYI TECH SUZHOU

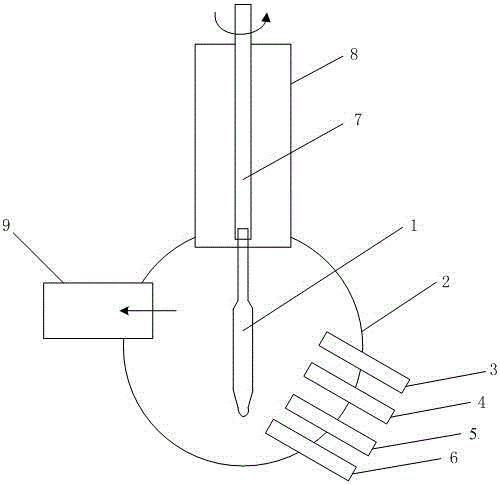

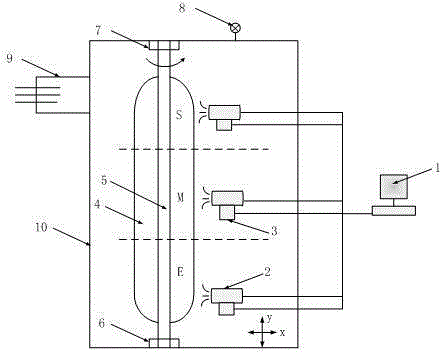

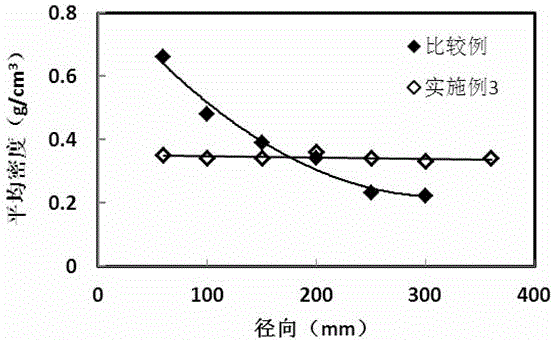

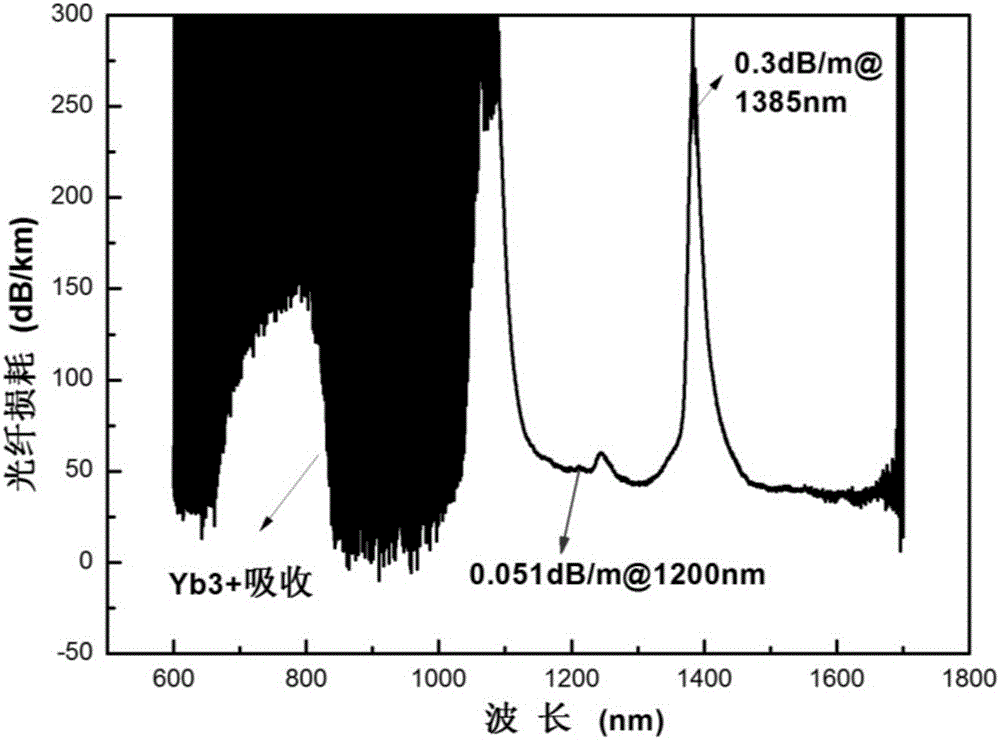

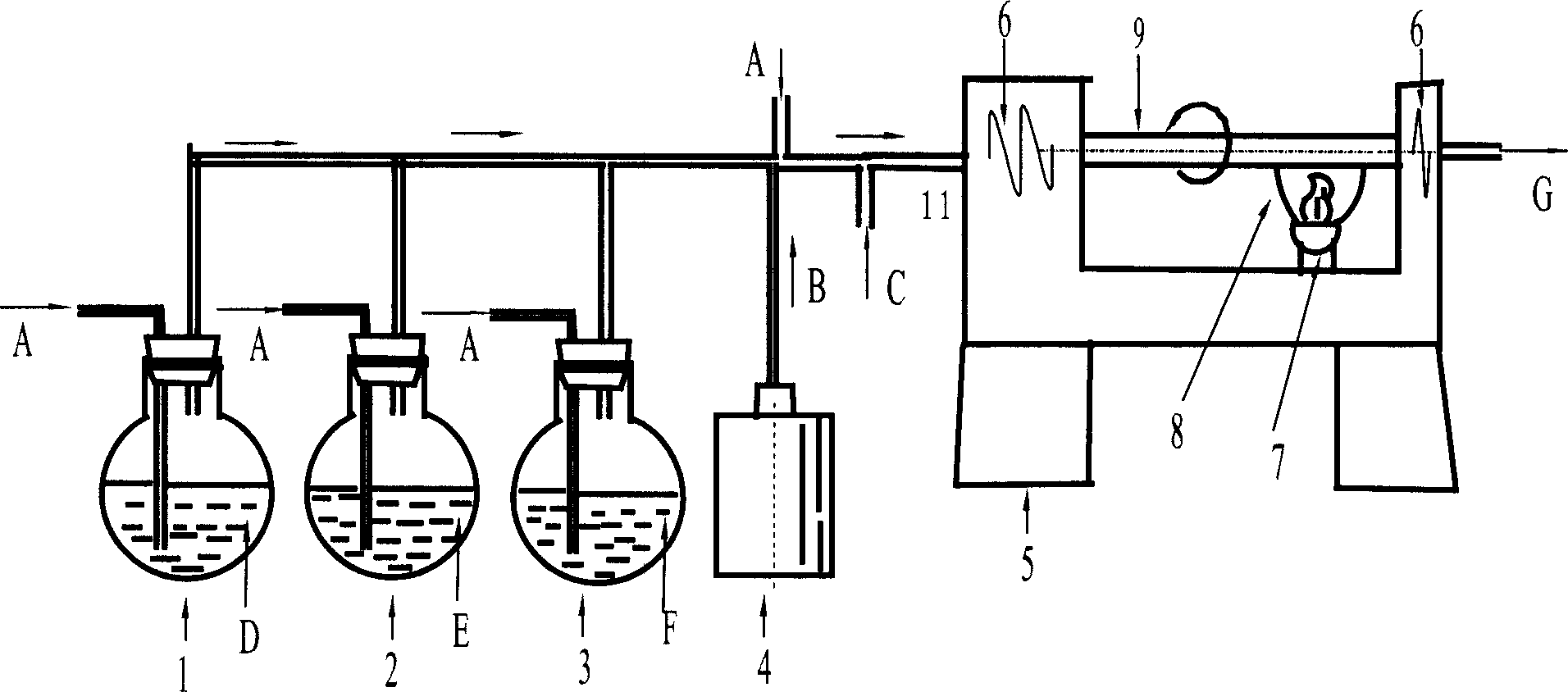

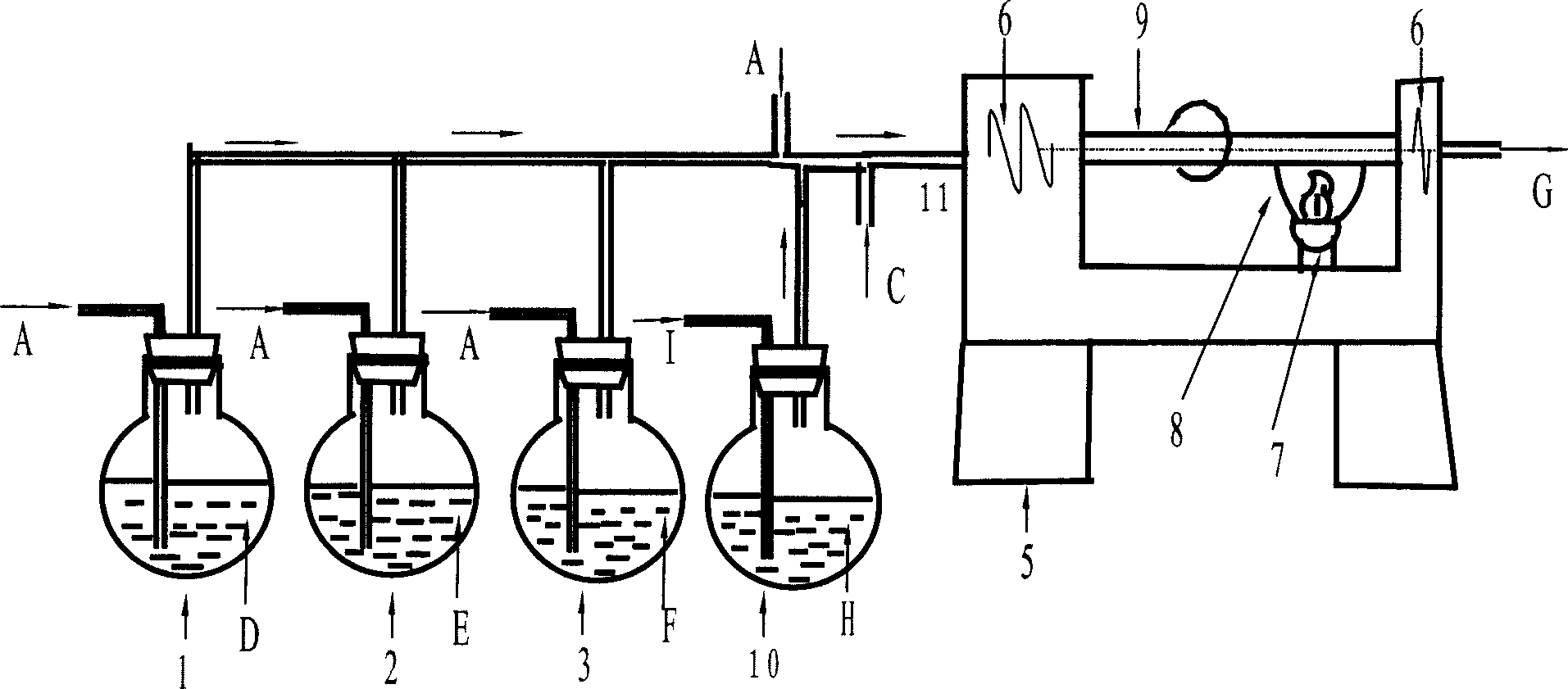

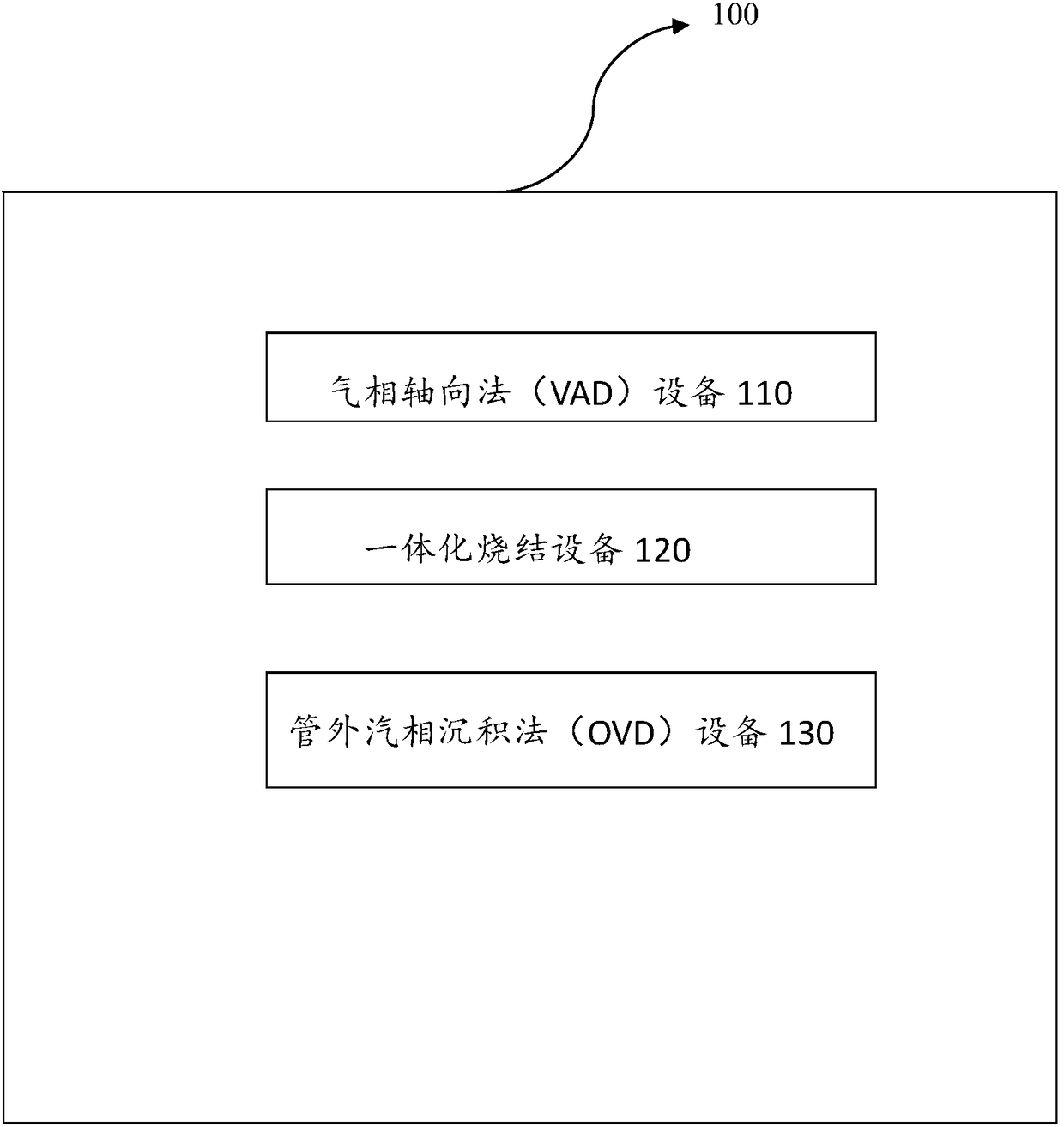

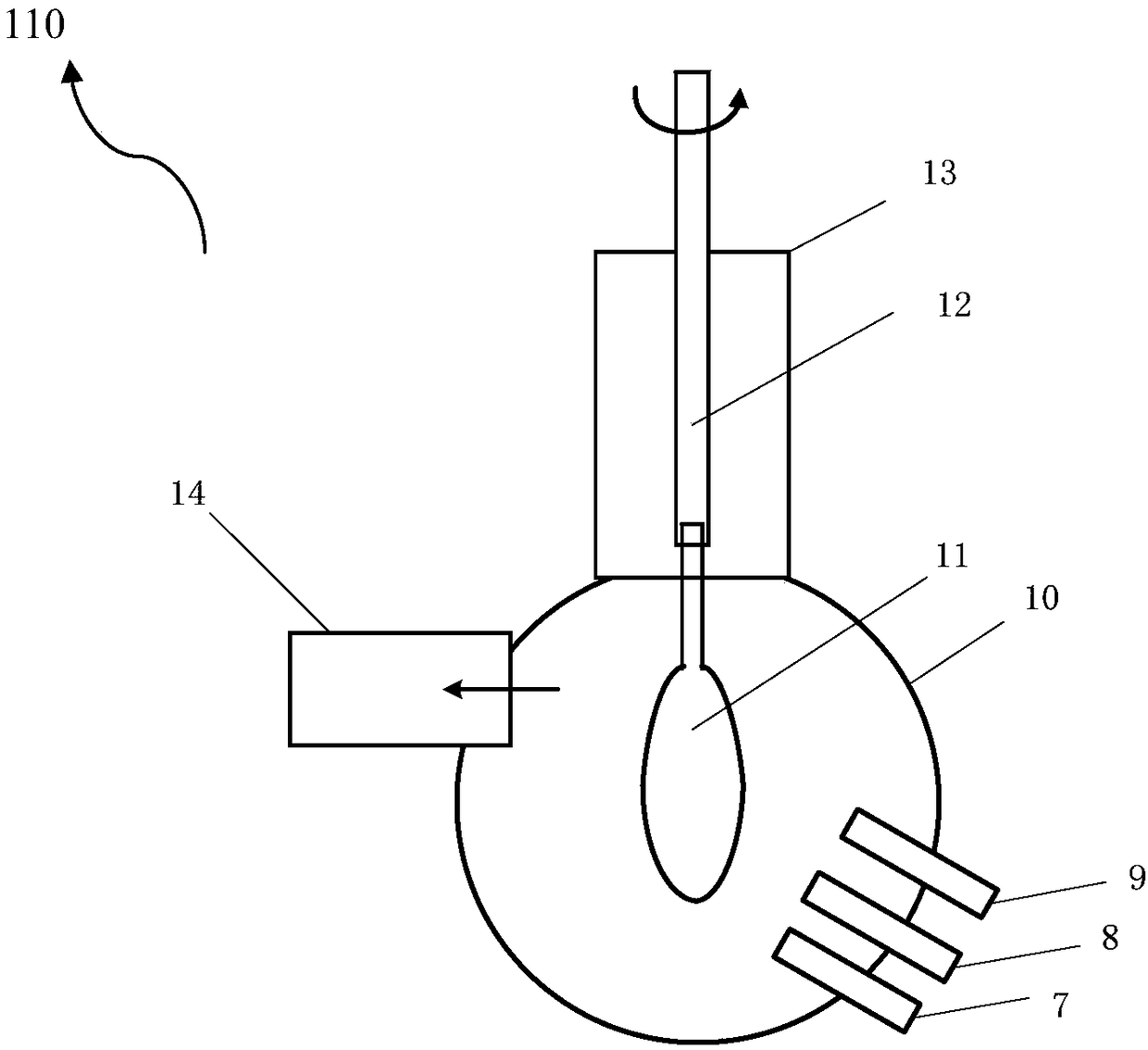

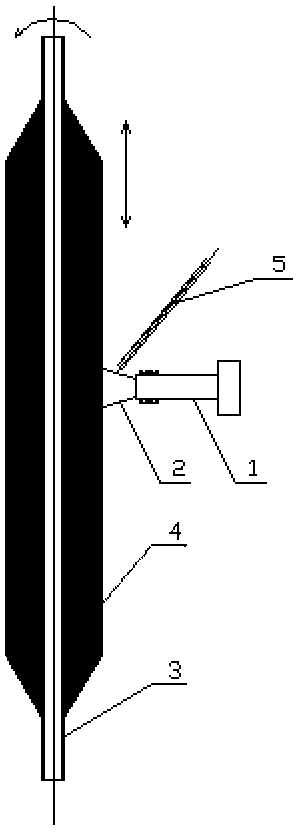

Method and equipment for preparing ultralow-loss optical fiber perform with fluorine-doped pure silicon core cladding

ActiveCN106007355AThe sintering process is simpleLow hydroxyl contentGlass deposition burnersGraphitePlastic optical fiber

The invention discloses a method and equipment for preparing an ultralow-loss optical fiber perform with a fluorine-doped pure silicon core cladding, and relates to a method for preparing the ultralow-loss optical fiber perform with the fluorine-doped pure silicon core cladding by doping fluorine in the cladding through powder obtained according to a vapor deposition method. The equipment comprises a target bar, a deposition chamber, an outer-cladding blow lamp, a middle-cladding blow lamp, an auxiliary blow lamp, a core layer blow lamp, a suspension rod, an exhaust pipe, an upper deposition cavity and a graphite heating resistance furnace. The upper deposition cavity is formed in the upper portion of the deposition chamber. The suspension rod is mounted in the upper deposition cavity, is provided with a hook and is connected with a lifting mechanism. The target bar is hung on the hook of the suspension rod connected with the lifting mechanism. The outer-cladding blow lamp, the middle-cladding blow lamp, the auxiliary blow lamp and the core layer blow lamp are mounted on one side of the lower portion of the disposition chamber sequentially. A graphite sintering furnace comprises a quartz suspension rod, a sealing component, a cover plate, a quartz furnace core tube, a graphite furnace core tube, a gas pipeline, a target bar, a powder body, a graphite heating body and a gas quality and flow controller.

Owner:ZHONGTIAN TECH ADVANCED MATERIALS CO LTD +1

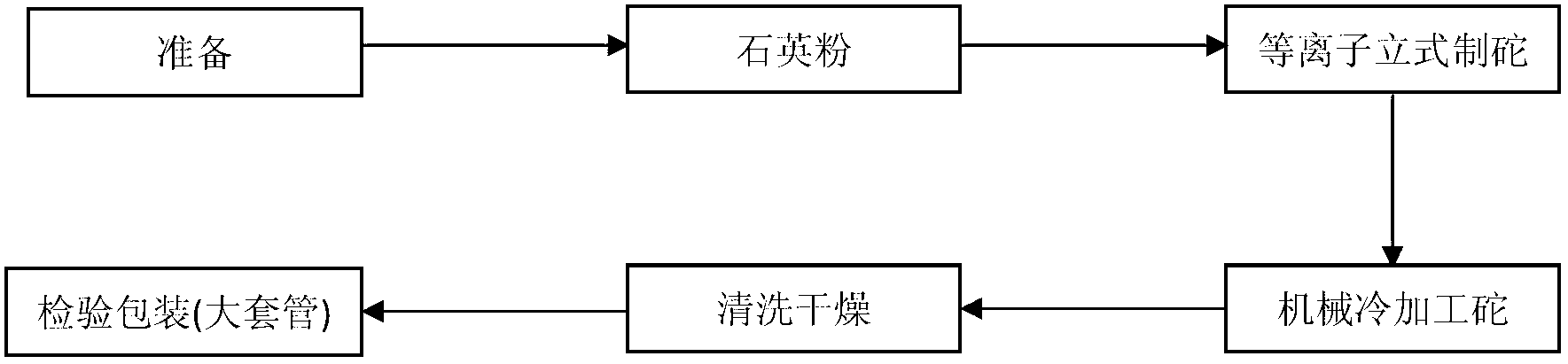

Preparing method of high purity quartz sleeve for large-size optical fiber preform

ActiveCN105330140AAvoid it happening againNo pollution in the processGlass shaping apparatusGlass productionAcid washingOxygen

The invention relates to a preparing method of a high purity quartz sleeve for a large-size optical fiber preform. The method comprises the steps of firstly, clamping a target rod or tube subjected to acid washing and drying on upper and lower chucks of an upright deposition device; adopting an upright sectional vapor deposition method, and introducing siloxane, oxygen, natural gas or methane or hydrogen gas, nitrogen gas as a raw material into a blowtorch, wherein after igniting, high temperature flame reacts to generate silicon dioxide powder with the particle size between 5-200nm, the powder is attached to the surface of the target rod or tube and finally achieves the set target rod size; then placing the silicon dioxide powder rod obtained by depositing into a graphite resistance furnace with the temperature being 1200-1600 DEG C, and introducing Cl2 and He with a flow ratio being (1-5) to (1-20) for vitrification sintering, thus obtaining a quartz sleeve preformed unit; performing mechanical cold machining on the quartz sleeve preformed unit to obtain the quartz sleeve; then adopting a weak base solution to wash, then repeatedly washing with deionized water, soaking with acid and finally washing with the deionized water and drying.

Owner:ZHONGTIAN TECH ADVANCED MATERIALS CO LTD +1

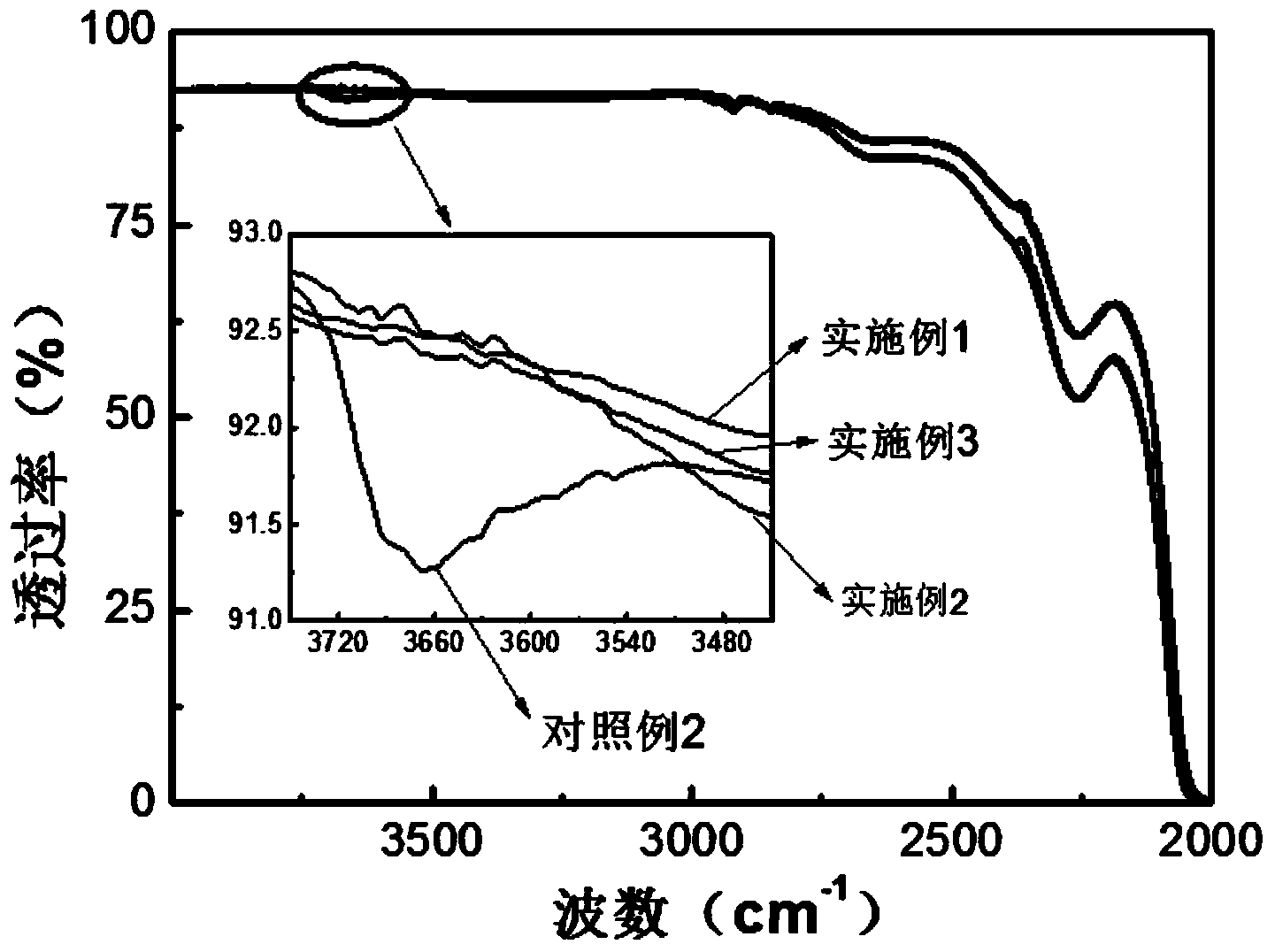

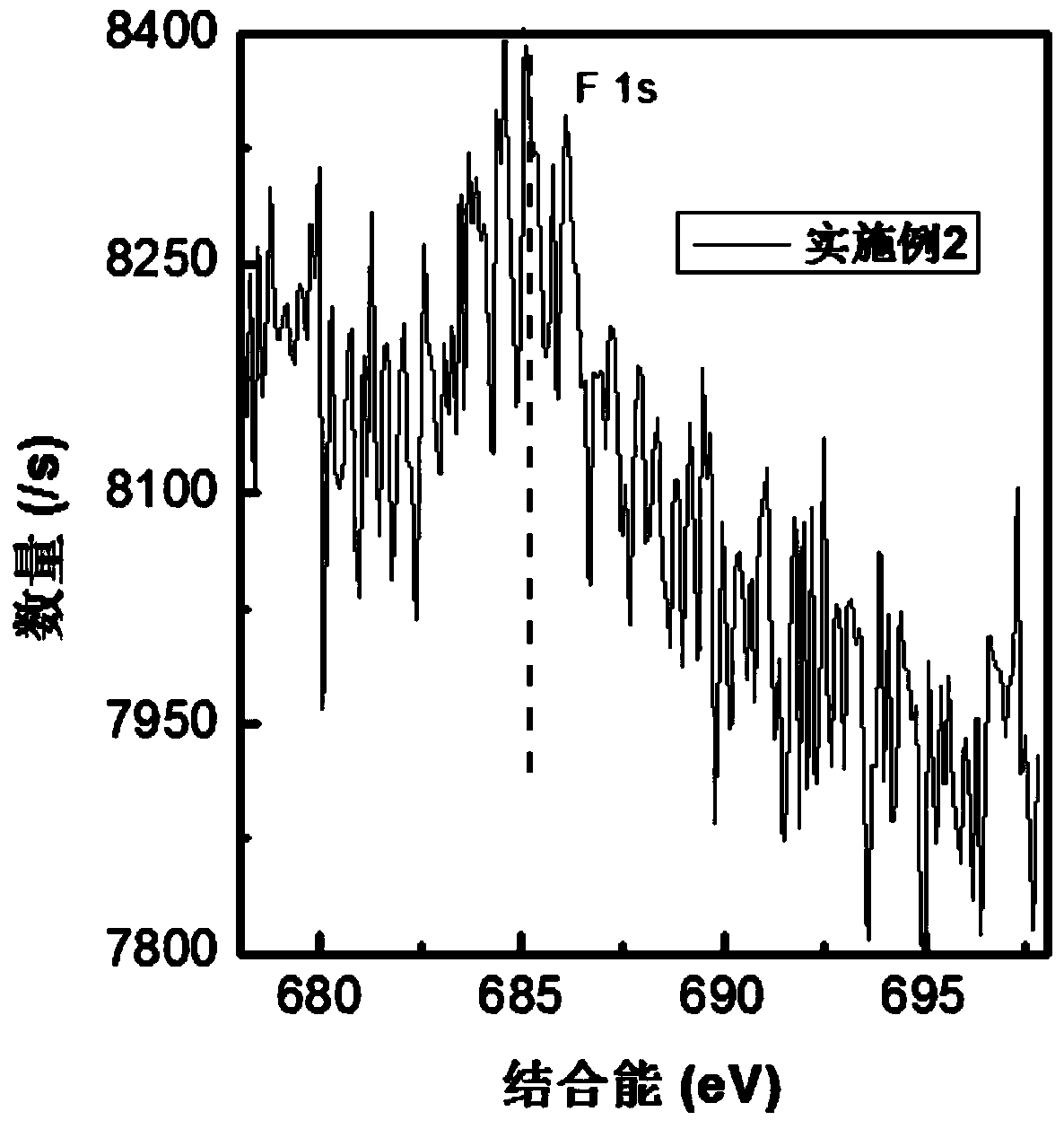

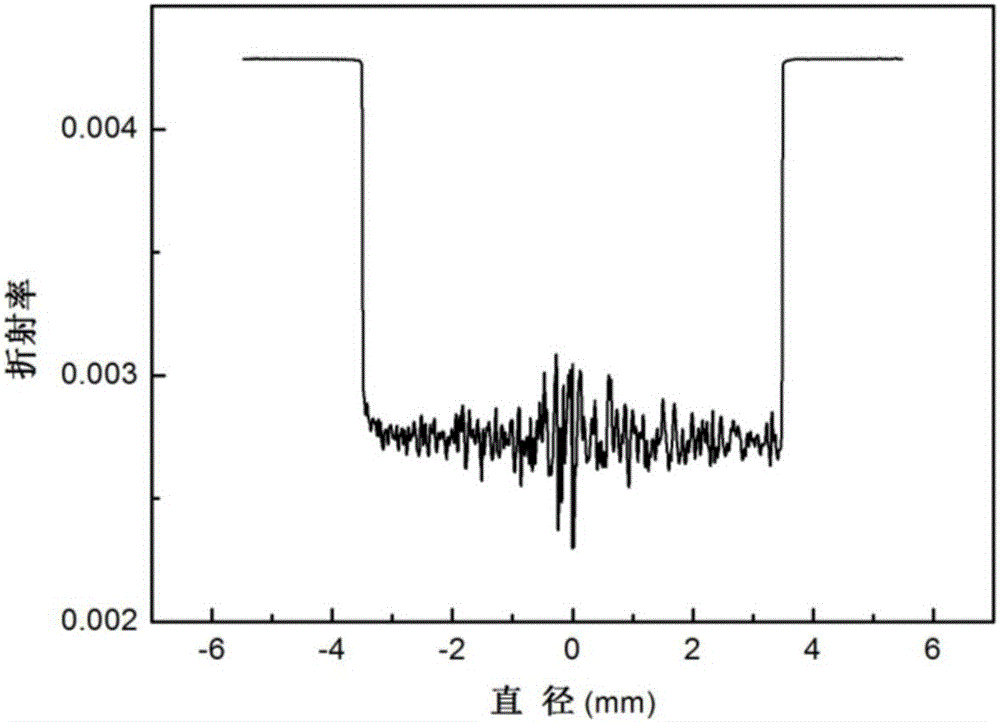

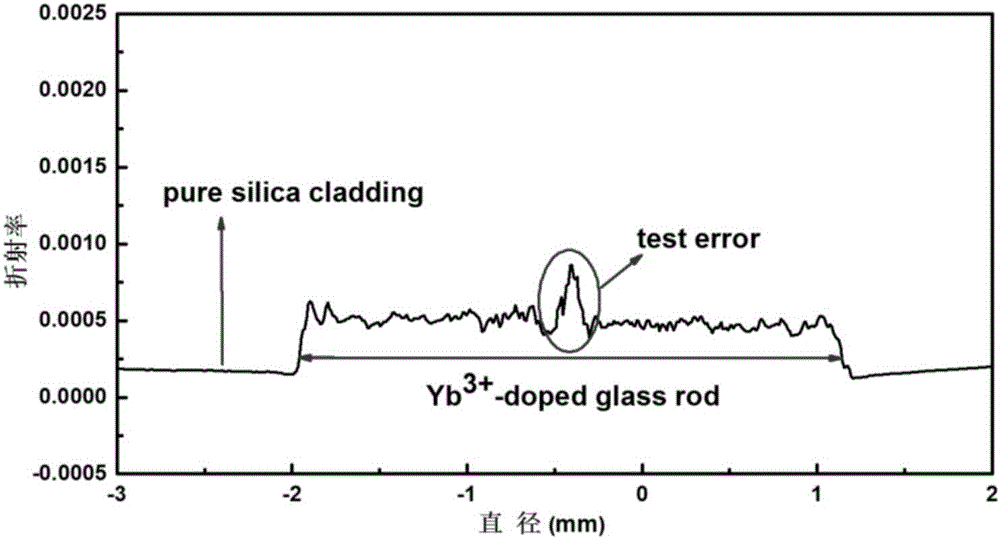

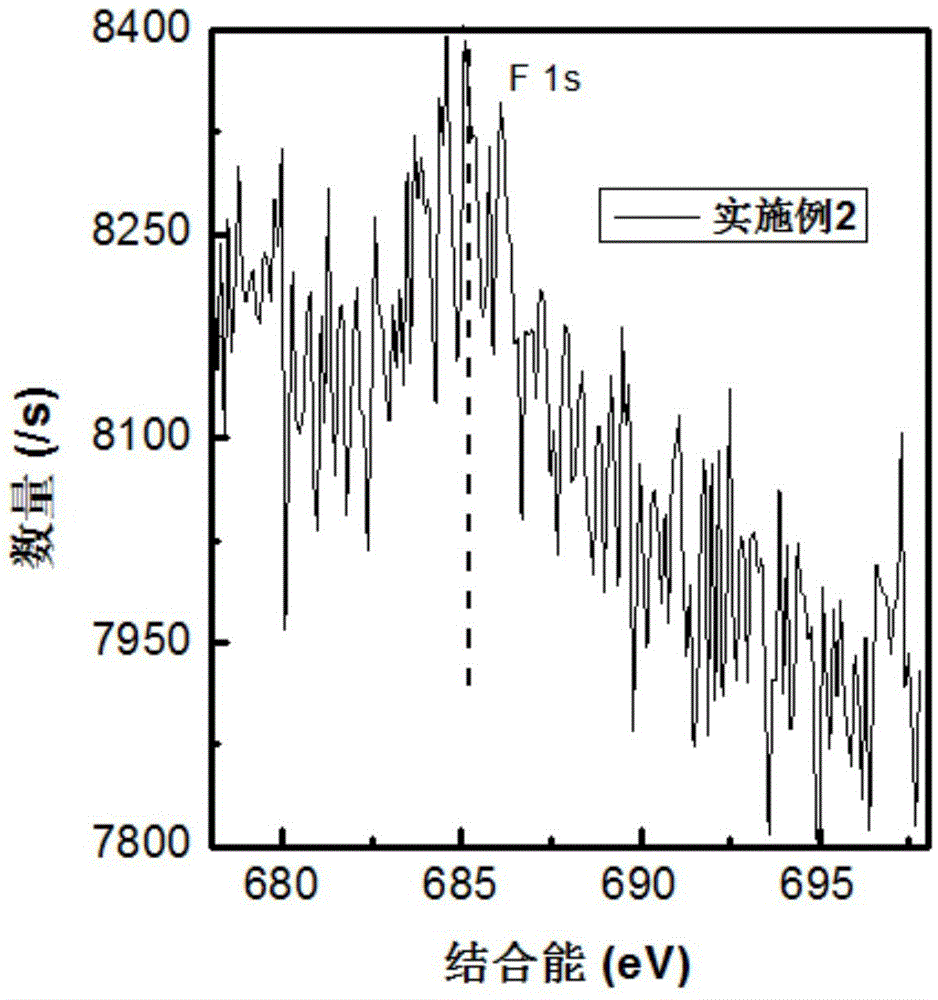

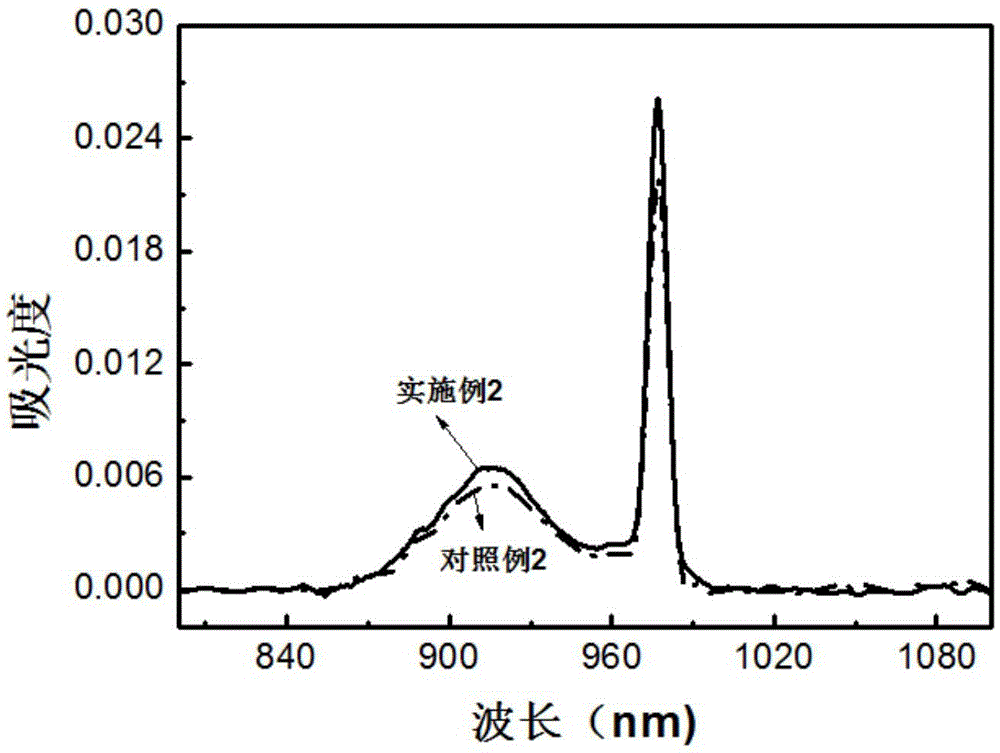

Preparation method for fluorine-containing low-refractivity Yb<3+>-doped quartz glass

The invention relates to a preparation method for fluorine-containing low-refractivity Yb<3+>-doped quartz glass. The method comprises the steps: starting from a solution, preparing evenly doped silicon oxide powder by using a sol-gel method; and carrying out decarbonization and dehydroxylation treatment on the powder, and finally sintering into glass. By applying the method, F<-> can be effectively introduced, and the rare earth-doped quartz glass with high uniformity, low hydroxyl content and the refractivity almost identical to that of the pure quartz glass can be obtained. The method can be applied to preparation of a high-brightness large-mode-field quartz optical fiber mandril.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Method for producing low-hydroxy-group squartz glass tube

InactiveCN1850679ASimple processEasy to operateGlass drawing apparatusGlass forming apparatusImpurityHydroxylation

The invention is a method for producing a low-hydroxyl quartz glass tube, characterized in that it selects 60-220 mesh high-purity quartz powder containing SiO2 >=99.90%, and impurities less than 30ppm, and dopes colorizing agent in 0.1-1.0% of the weight of the high-purity quartz powder, where the colorizing agent selects at least one of the divanadium triphosphate and cobalt oxide, mixed uniformly and dried; it adds the processed raw materials into a continuous melting quartz furnace and melts them, opens the gas outlet at the furnace mouth and discharges gas impurities, feeding the melted raw materials into a drawer for making tube drawing forming and draws them into blue quartz glass tubes; feeds the blue quartz glass tubes into a de-hydroxylation furnace for de-hydroxylation and obtaining the finished products. The hydroxyl content of the blue quartz glass tubes is generally lower than 1ppm and the products have good quality, and can be applied to special industries; and the process of the invention can implement continuous quartz glass tube production, having high productivity.

Owner:单军成

Preparation method of low-mass Yb3+ doped silica fiber preform mandrel

ActiveCN106007352AEasy to dopeLow hydroxyl contentGlass making apparatusSilica fiberRefractive index

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

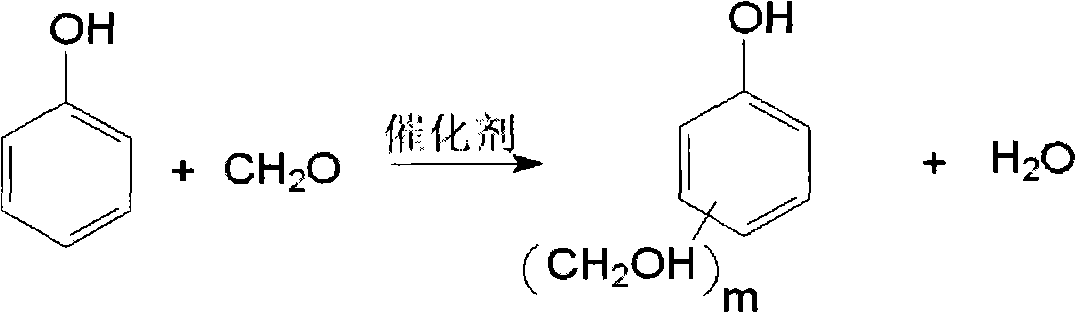

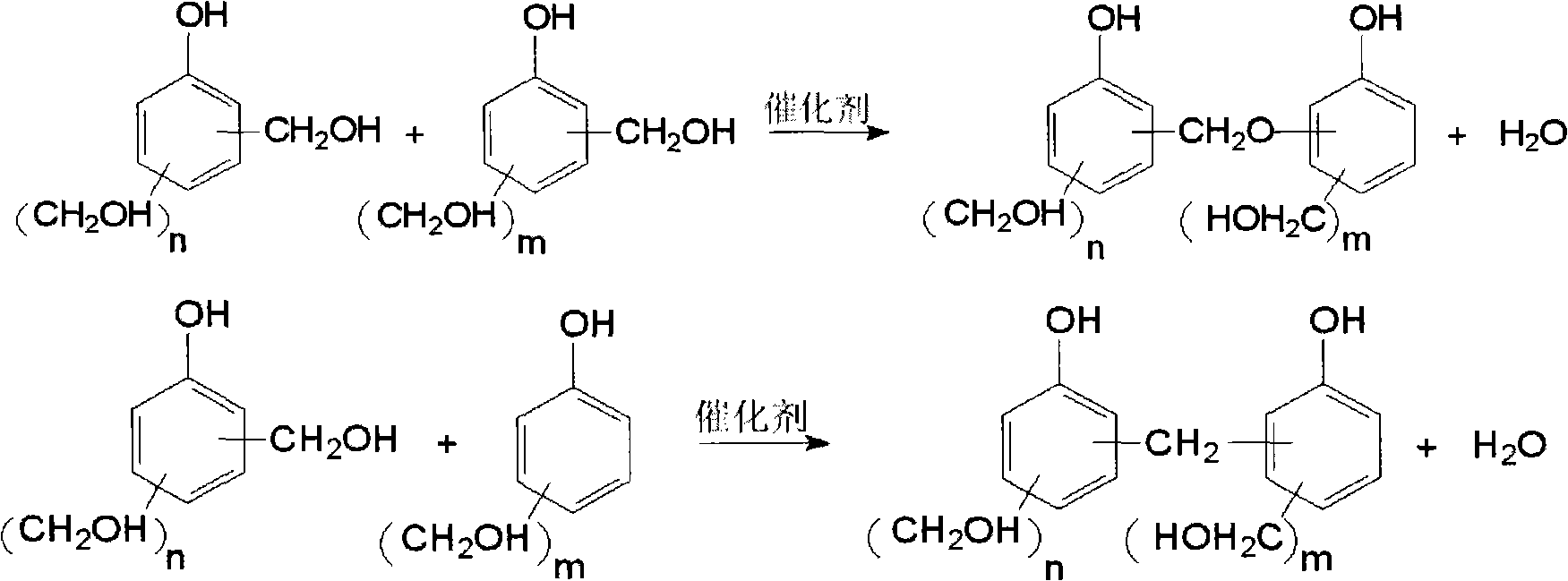

Preparation method for phenolic resin

The invention provides a preparation method for phenolic resin, which comprises the following steps: carrying out reaction on phenol, formaldehyde and organic compound containing amino and organic phosphorus compound under the condition of a basic catalyst to obtain the phenolic resin, wherein the organic phosphorus compound contains phosphorous and oxygen double bond, phosphorous and oxygen bond or hydroxyl. In the invention, the organic compound containing amino and the organic phosphorus compound are taken as modifiers to modify the phenolic resin; and nitrogenous groups and phosphoric groups are directly introduced in the structure of the phenolic resin and have the synergism inflaming retarding function so as to obtain the phenolic resin with excellent fire resistance. At the same time, the organic compound containing amino and the organic phosphorus compound enable the hydroxy content of the phenolic resin to be reduced and enable the hygroscopicity resistance of the phenolic resin to be improved.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

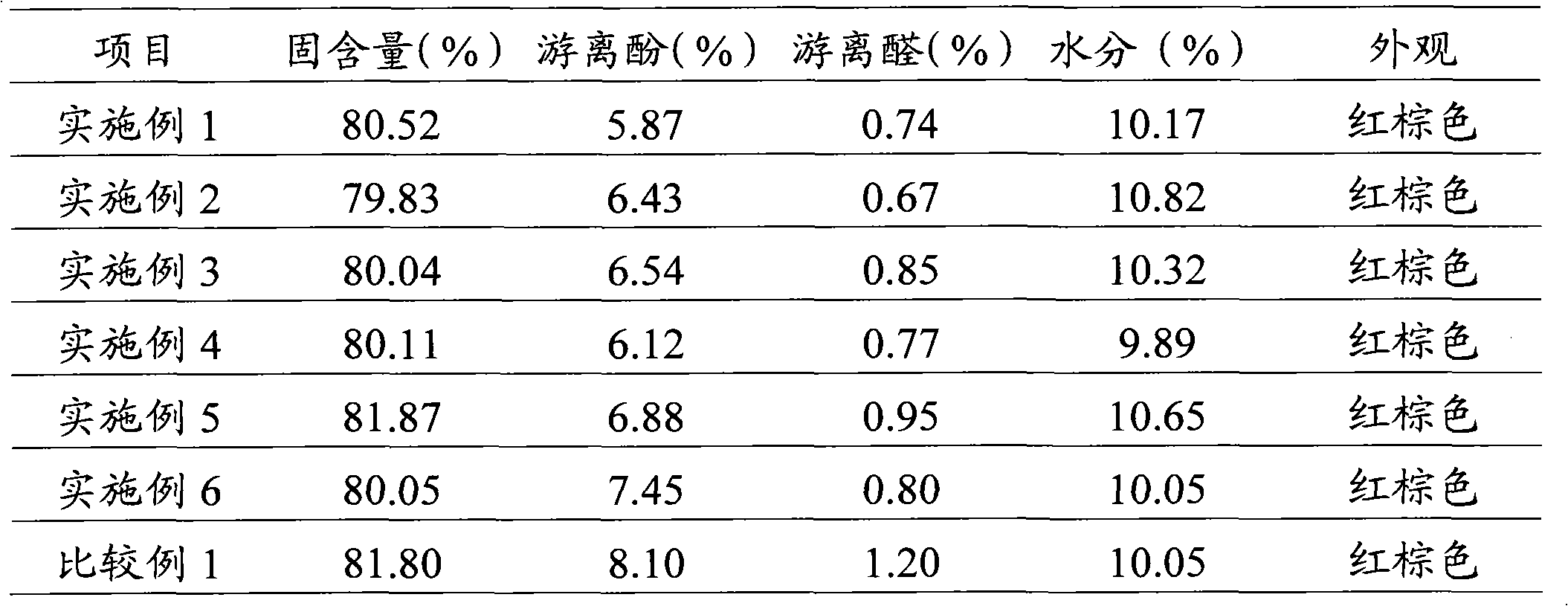

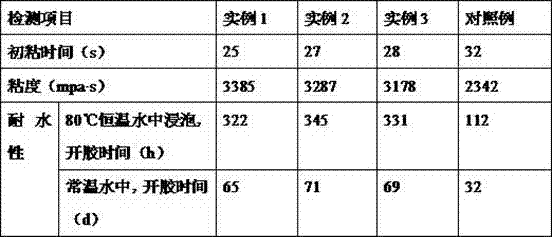

Paper-tube adhesive and preparation method thereof

InactiveCN107286873AImprove water resistanceLow hydroxyl contentMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesPotassium persulfateMethylrhenium trioxide

The invention relates to paper-tube adhesive and a preparation method thereof, which belongs to the technical field of adhesive. The paper-tube adhesive is prepared by mixing emulsion, oxidized lignin, potassium persulfate, ethylene glycol, kaolin powder, aluminum phosphate and water, heating, stirring to facilitate the reaction, cooling to room temperature, continuously stirring, and loading. The emulsion is prepared by heating and mixing water and polyvinyl alcohol, then cooling, adding emulsifier, plasticizer, defoaming agent and the like, continuously adding an initiator, heating, and stirring to facilitate the reaction; and the oxidized lignin is prepared by filtering papermaking black solution, heating and stirring filtrate and a sulfuric acid solution to facilitate the reaction, filtering, mixing filter residues and a sodium hydroxide solution, adding sodium periodate and methyltrioxorhenium, stirring to facilitate the reaction, finally standing, filtering and washing. The paper-tube adhesive is good in water resistance and capable of meeting the production requirement.

Owner:常州明华运输有限公司

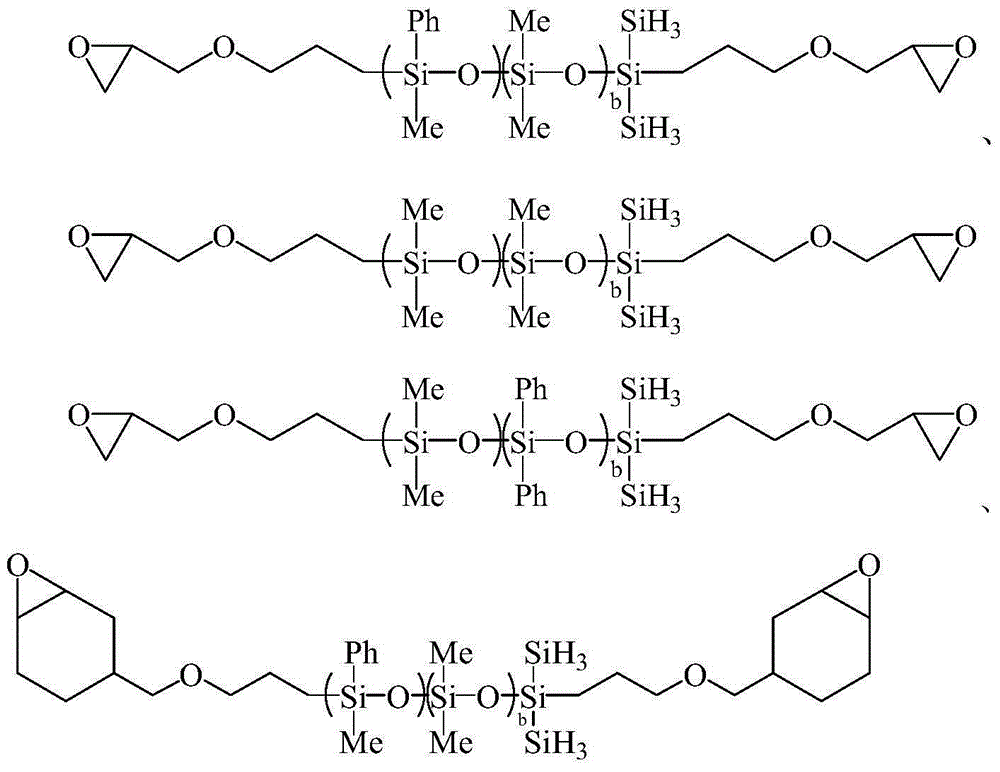

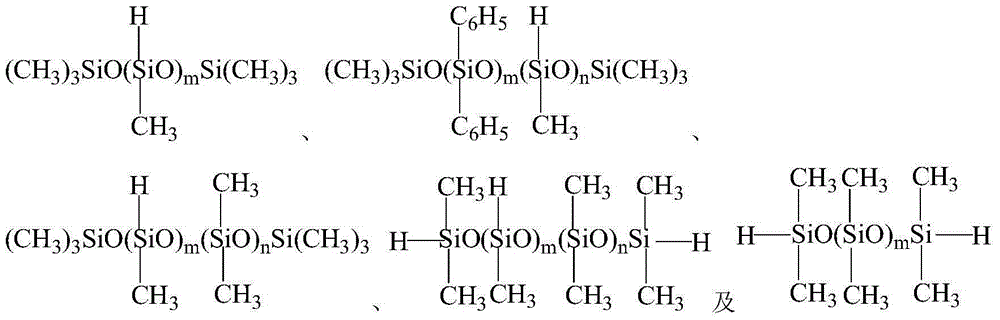

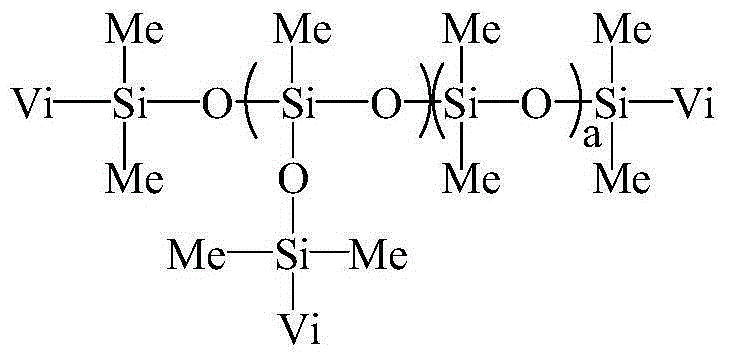

Organosilicon composite material and preparation method thereof

The invention discloses an organosilicon composite material and a preparation method thereof. The composite material is prepared from alkylene-containing polysiloxane, hydrogen-containing polysiloxane, epoxide group polysiloxane, a heat-conduction filling material, a hydrosilation catalyst, a reaction inhibitor and the like through mixing and curing. The prepared organosilicon composite material has the characteristics of low content of volatile compounds, resistance to high and low temperature, high heat conduction, light weight, high strength, good cementability, electrical insulating properties, etc., can meet development demands of functional assemblies for large power, microminiaturization, lightweight and high reliability, and is applicable as a badly-needed high-performance heat-conducting insulating material in military fields like aviation, spaceflight and weapons and in fields related to people's livelihood, e.g., an LED illumination system and an electronic circuit integration system.

Owner:HUNAN BOOM NEW MATERIALS

Method for producing low-hydroxyl-group quartz glass tube

InactiveCN1850680ASimple processEasy to operateGlass drawing apparatusGlass forming apparatusCopper nitrateImpurity

The invention is a method for producing a low-hydroxyl quartz glass tube, characterized in that it selects 60-220 mesh high-purity quartz powder containing SiO2 >=99.90%, and impurities less than 30ppm, and dopes colorizing agent in 0.1-1.0% of the weight of the high-purity quartz powder, where the colorizing agent selects at least one of the copper nitrate, magnesia and cerium oxide, mixed uniformly and dried; it adds the processed raw materials into a continuous melting quartz furnace and melts them, opens the gas outlet at the furnace mouth and discharges gas impurities, feeding the melted raw materials into a drawer for making tube drawing forming and draws them into wine quartz glass tubes; feeds the wine quartz glass tubes into a de-hydroxylation furnace for de- hydroxylation and obtaining the finished products-red quartz glass tubes. The hydroxyl content of the red quartz glass tubes is generally lower than 1ppm and the products have good quality, and can be applied to special industries; and the process of the invention can implement continuous quartz glass tube production, having high productivity.

Owner:单军成

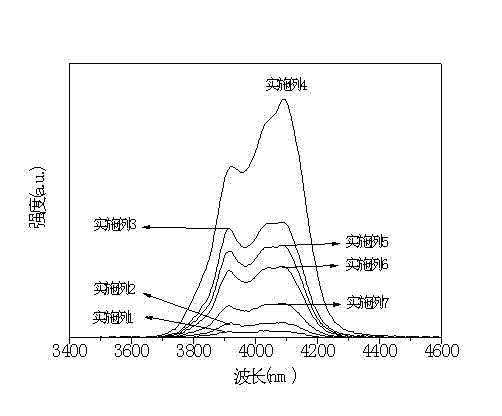

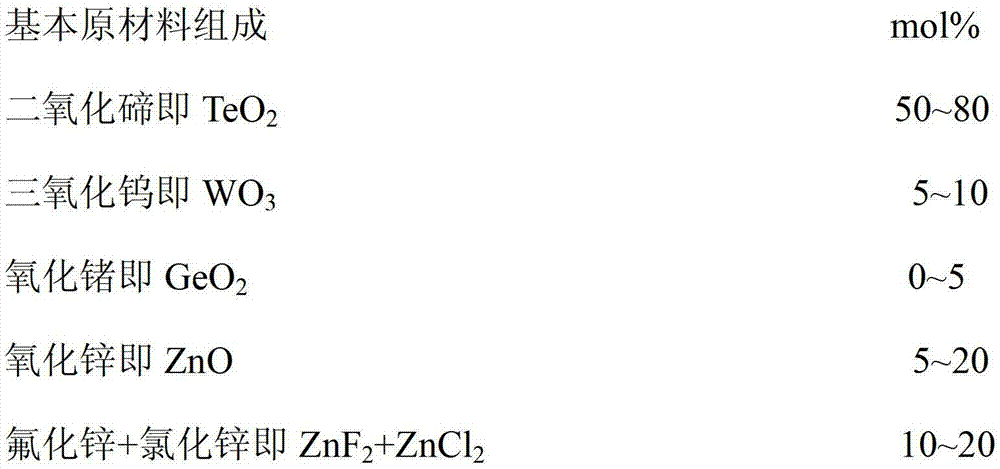

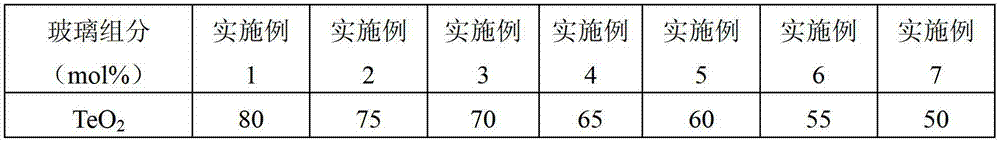

Method for preparing oxygen fluorine chlorine tellurate glass with intermediate infrared fluorescence output at 4 mu m

The invention relates to the technical field of intermediate infrared rare earth doped luminescent glass application, and aims at solving the technical problem of providing a method for preparing oxygen fluorine chlorine tellurate glass with intermediate infrared fluorescence output at 4 mu m. The glass is good in glass forming property, high in infrared light transmission rate, good in luminescence property and beneficial to output of fluorescence and laser of 4 mu m. The oxygen fluorine chlorine tellurate glass prepared by using a fusion method is tellurate glass which contains zinc fluoride and zinc chloride, and due to the appropriate amount of contains zinc fluoride and zinc chloride, the hydroxyl content and the phonon energy in the system are greatly reduced, so that the forming capability of the glass is effectively improved, the doping amount of rare earth ions is increased, and the fluorescence service lives of the rare earth ions are prolonged. By adopting the doping amount of the external doping rare earth ions, namely, Ho<3+> and Yb<3+>, the pumping efficiency of 980nm is greatly improved, and tests show that the oxygen fluorine chlorine tellurate glass has remarkable fluorescence output at 4 mu m.

Owner:CHINA ELECTRONICS TECH GRP NO 23 RES INST

Method for producing low water peak fiber

ActiveCN1569704AExcellent anti-hydrogen decay propertiesReduction factorGlass deposition burnersOptical light guidesAttenuation coefficientGas phase

The invention relates to a method for producing low water peak fiber by improved chemical gas phase deposition (MCVD) method, wherein the single-mode optical fiber has an attenuation coefficient <0.320 dB / km at the position of 1310nm, the monohydric peak attenuation coefficient is less than 0.310dB / km.

Owner:FENGHUO COMM SCI & TECH CO LTD

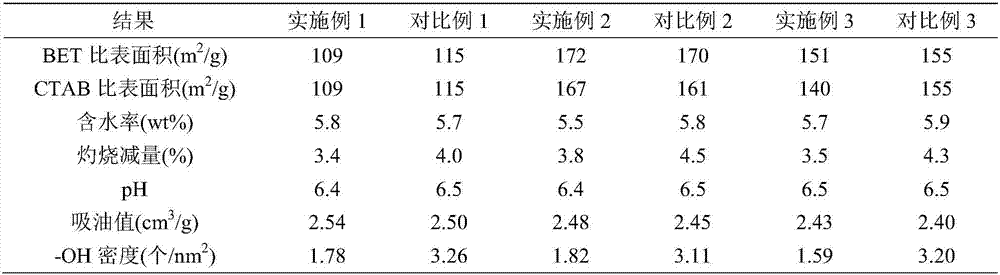

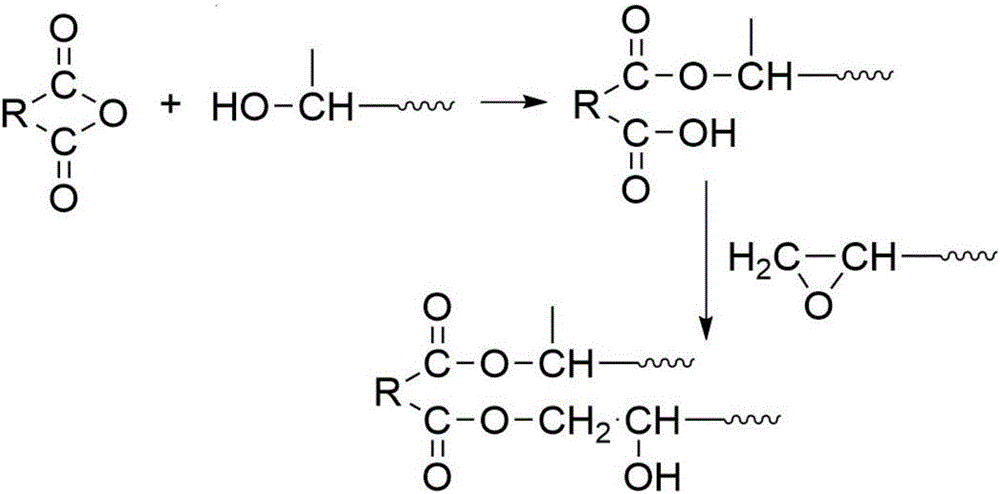

Low hydroxyl content white carbon black and preparation method thereof

The invention relates to a low hydroxyl content white carbon black and a preparation method of the low hydroxyl content white carbon black. The preparation method comprises the following steps: 1) preparing a reaction base solution with the pH of 7.0-10.5 at the temperature of 65-99 DEG C; 2) adding concentrated sulfuric acid and a sodium silicate solution to conduct a precipitation reaction, wherein the temperature of the precipitation reaction and the temperature of the reaction base solution are the same, keeping the pH of a system to 7.0-10.5 constant; 3) regulating the pH and post-processing to obtain the white carbon black. The white carbon black is low in hydroxyl content, the density of hydroxyl is less than 3 / nm<2>, the white carbon black is excellent in dispersity, the white carbon black is taken as a reinforcing agent to prepare a rubber, the excellent reinforcing effect is shown, the vulcanizing rate is increased, the vulcanizing time of the rubber material is shortened, and the processing performances and the mechanical property of a rubber compound are improved.

Owner:WUXI HENGCHENG SILICON IND CO LTD

Elastic fluorocarbon paint and formula thereof

The invention relates to a formula of elastic fluorocarbon paint. The formula comprises the following ingredients: 40-50% of fluorocarbon resin, 15-20% of elastic resin, 0.3-0.5% of a wetting agent, 0.3-0.5% of a dispersant, 0.5-1% of a leveling agent, 15-20% of aluminium powder, 0.1-0.2% of an antifoaming agent, 0.1-0.5% of an anti-settling agent, 0-0.5% of a drier and 15-20% of a solvent. Long straight chain and low branched chain of a high-molecular elastic cross-linking agent react with a fluorine-containing polymer to form a highly-straight-chain and low-branched-chain polymer, the structure of which is jagged. The ultimate embodiment of properties is reflected in appropriate surface strength, excellent elasticity, telescopic springback function, high tensile strength and fracture resistance, low surface polarity and strong resistance to soiling and weatherability.

Owner:上海奥泽涂料有限公司

Adhesive used for high-heat resistance leadless low-dielectric copper-clad plate and preparation method thereof

InactiveCN106381113AImprove performanceImprove heat resistanceNon-macromolecular adhesive additivesVinyl aromatic copolymer adhesivesAdhesiveSilanes

The invention relates to an adhesive used for a high-heat resistance leadless low-dielectric copper-clad plate and a preparation method thereof. The adhesive comprises the following components in parts by weight: 15-70 parts of low dielectric epoxy resin, 15-40 parts of modified polymerized acid anhydride, 5-40 parts of a cyanate esters curing agent, 2-40 parts of an active esters curing agent, 10-50 parts of a bromine-containing fire retardant, 0.05-1.000 parts of silane, 0.001-0.1 parts of a metals curing accelerator, 0.001-0.1 parts of an amines promoter, 0.005-0.1 parts of an imidazoles promoter, 10-60 parts of an inorganic filling material, and 1-8 parts of a flexibilizer. Compared with the prior art, the copper-clad plate has the advantages of high heat resistance, low water absorption, low dielectric loss and excellent resistance to heat and humidity.

Owner:NANYA NEW MATERIAL TECH CO LTD

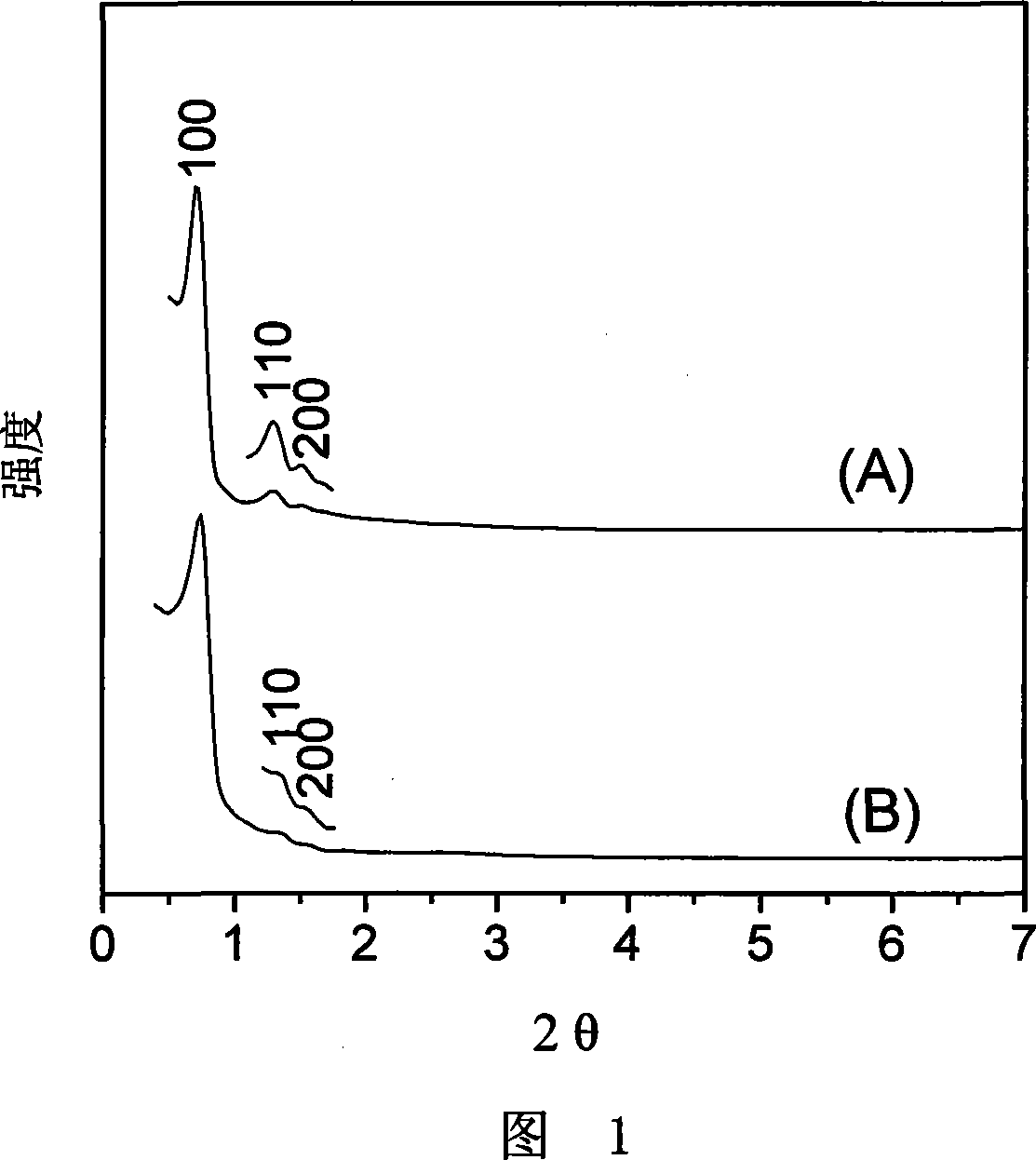

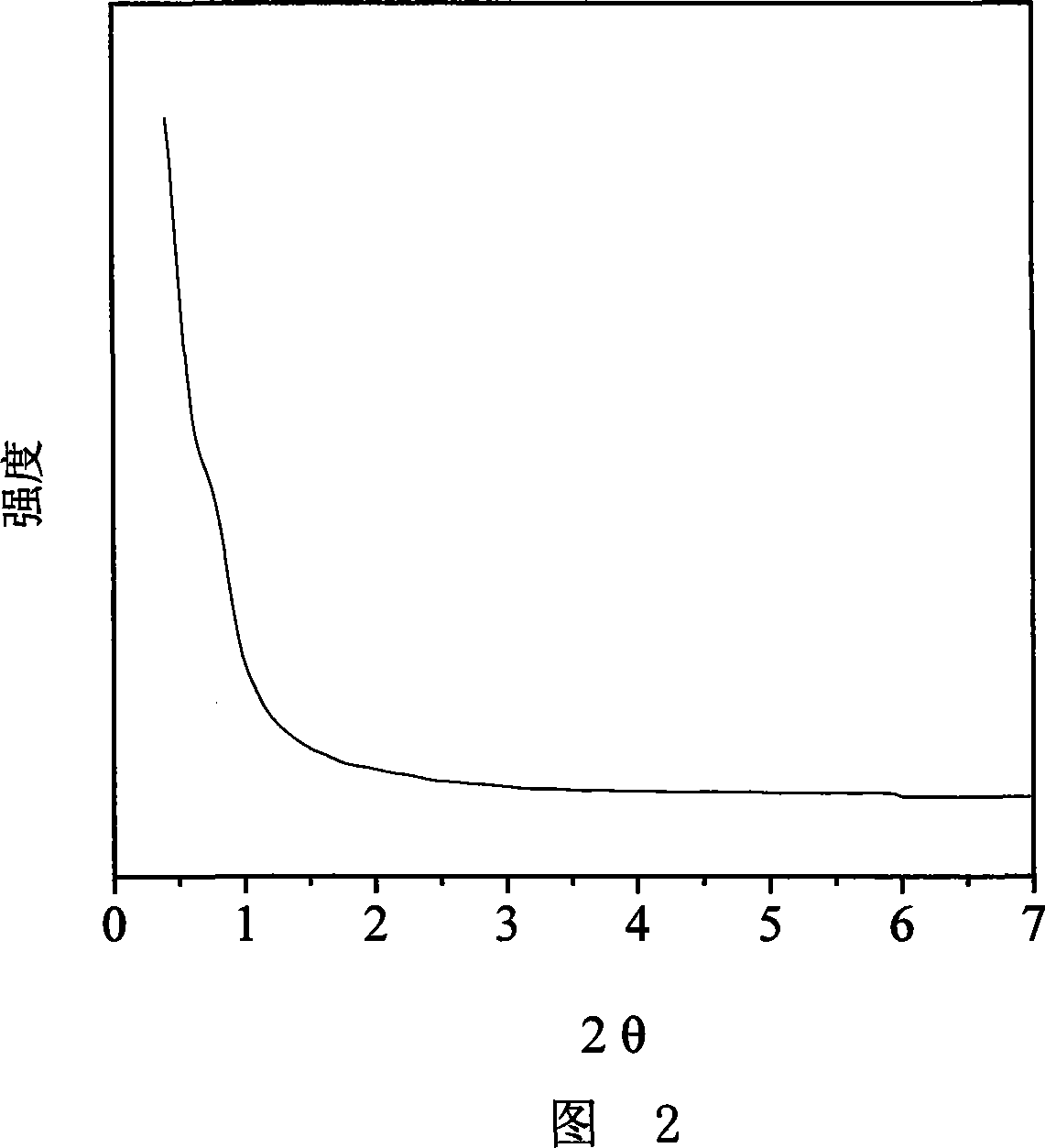

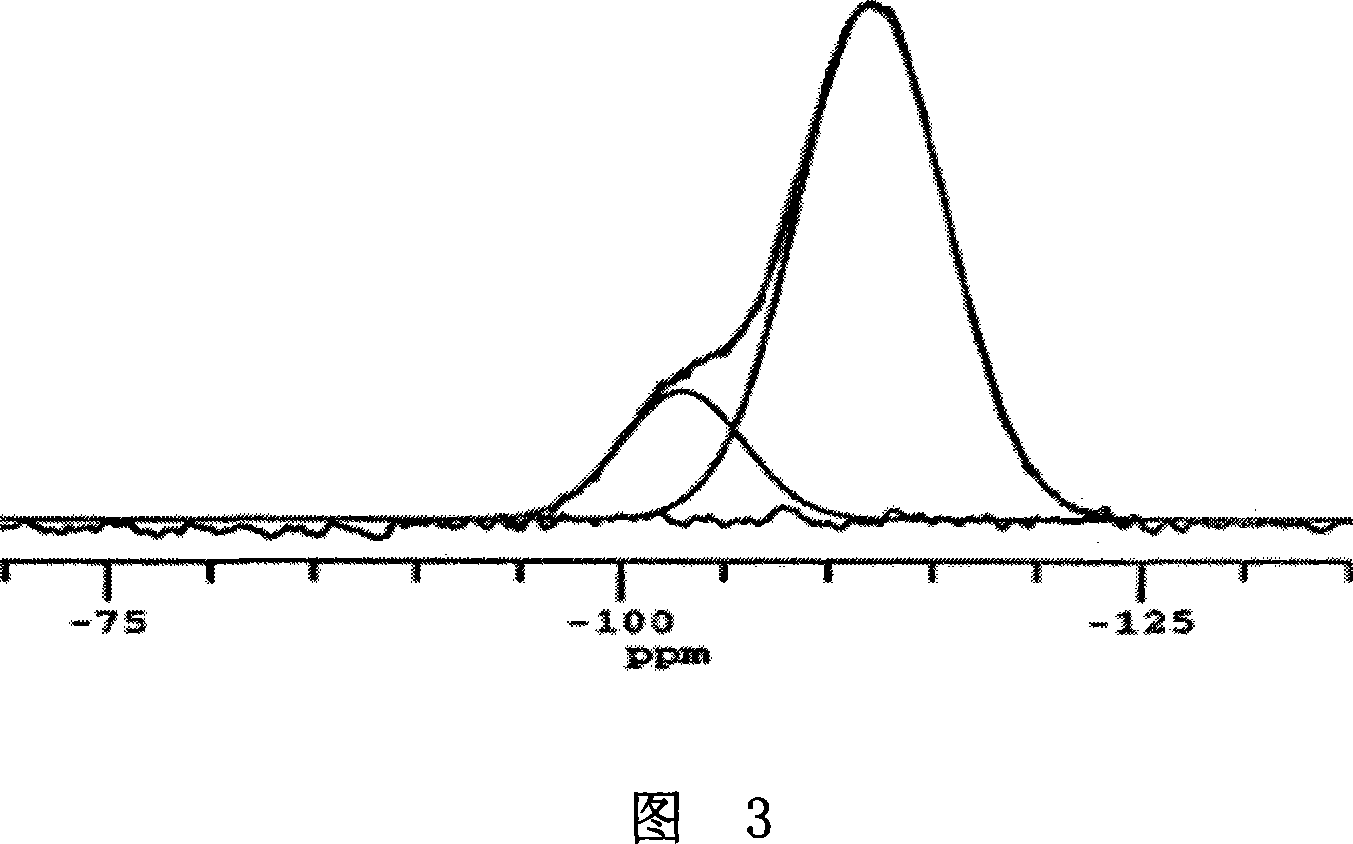

Method of preparing ordered mesoporous molecular sieve with high hydrothermal stability

InactiveCN101054182AAvoid toxicityLow hydroxyl contentCrystalline aluminosilicate zeolitesMolecular-sieve compoundsMolecular sieveHydrogen

The invention relates to a method for preparing ordered media-hole molecular screen with high hydro-thermal stability, which belongs to the technical field of inorganic chemistry and catalysis chemistry. And the processing contains preparing template agent and raw powder and removing template agent. During the template agent preparation, the mixture of small molecular quaternary ammonium salt and the carbon and hydrogen surface active agent is used as the template agent and the template agent solution is adjusted to PH<1 with HCl. During the raw powder preparation process, silica source is added in the template agent solution, stirred to produce sol and hydro-thermal crystallization for 24-120 hours at the temperature 100-220 degree which can be carried out in two steps. And during the template agent removal process, the raw powder is calcined in 400-700 degree. The invention uses the small molecular quaternary ammonium salt instead of F / C surface active agent as the mixed template agent, which avoids the toxicity of F-contained surface active agent and produces ordered media-hole molecular screen. The product has good hydro-thermal stability because the silica-contained substances in the skeleton of the product are highly condensed.

Owner:JILIN UNIV

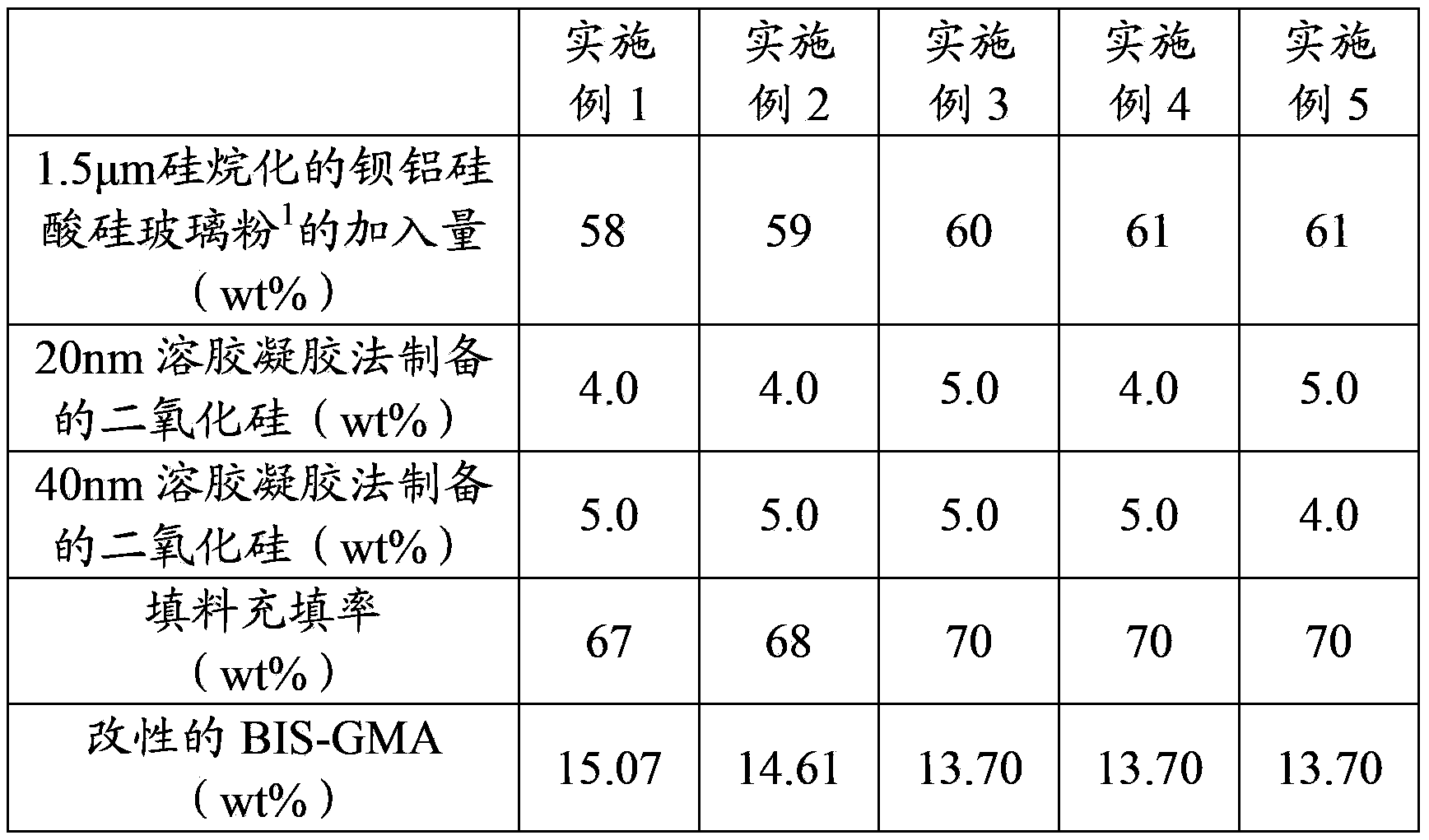

Dual curing crown nuclear resin for dentistry and preparation method thereof

InactiveCN103356391AMake up for the defect of poor infiltrationLow hydroxyl contentImpression capsDentistry preparationsFilling rateDual curing

The invention relates to dual curing crown nuclear resin for dentistry and a preparation method thereof. The dual curing crown nuclear resin comprises the following components in percentage by weight: 50-80 wt% of structured packing, 4.0-5.0 wt% of chemical curing initiator, 0.5-1.0 wt% of photocuring initiator, and the balance of two or more polymerizable acrylic monomers, wherein the mean grain size of the structured packing is 0.02-10 microns; and the structured packing contains the particles of which the volume fraction is less than 50% and the mean grain size is greater than 1.5 microns. The resin displays low cure volume shrinkage, high packing filling rate and high strength, so that the performance of the resin is greatly improved.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

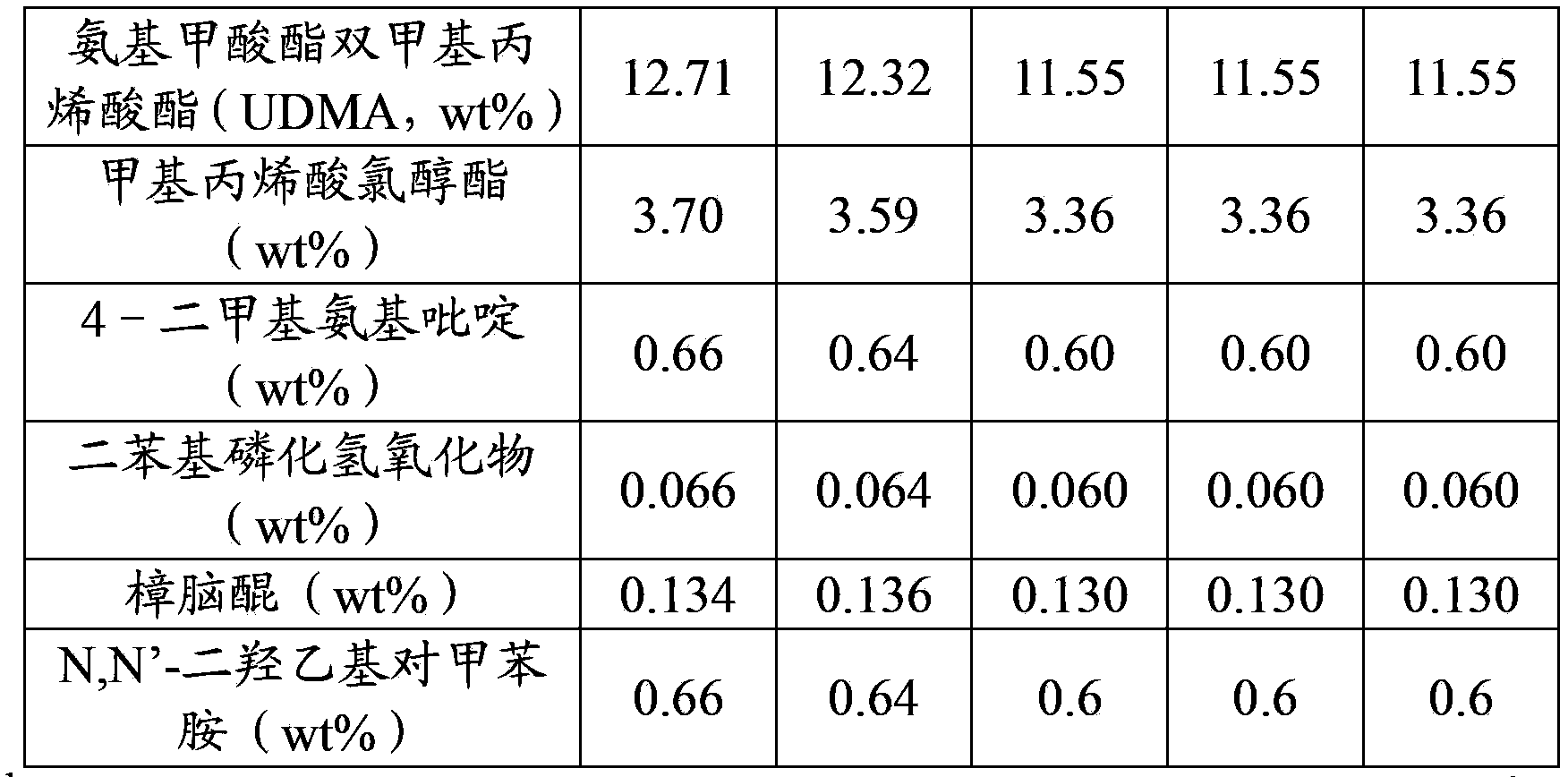

Optical fiber preform and manufacture method thereof

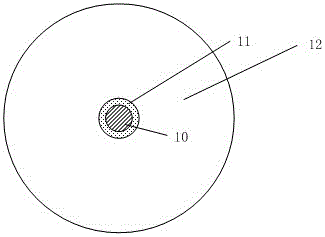

PendingCN109081575ALow hydroxyl contentPrecise control of fluorine dopingGlass making apparatusFiberZero-dispersion wavelength

The invention provides a manufacture method of an optical fiber preform, comprising the steps: providing a core layer, and precipitating a first inner coating layer and a second inner coating layer sequentially on the surface of the core layer; soaking the core layer with the first and second inner coating layers in a heating zone in suspended manner, and carrying out dehydroxylation and vitrification sintering to form a quartz glass rod; forming an outer coating layer on the surface of the quartz glass rod to obtain the optical fiber preform. The optical fiber preform herein has large size and good fluorine-doping control precision for a recessed layer, has bending performance under small radius R of < / =5 mm, has low fiber attenuation and good color dispersion, has zero-color-dispersion wavelength of < / =1320 nm and low hydroxy content, and meets the indicator of ITU-TG657B3 and higher.

Owner:ZHONGTIAN TECH ADVANCED MATERIALS CO LTD +1

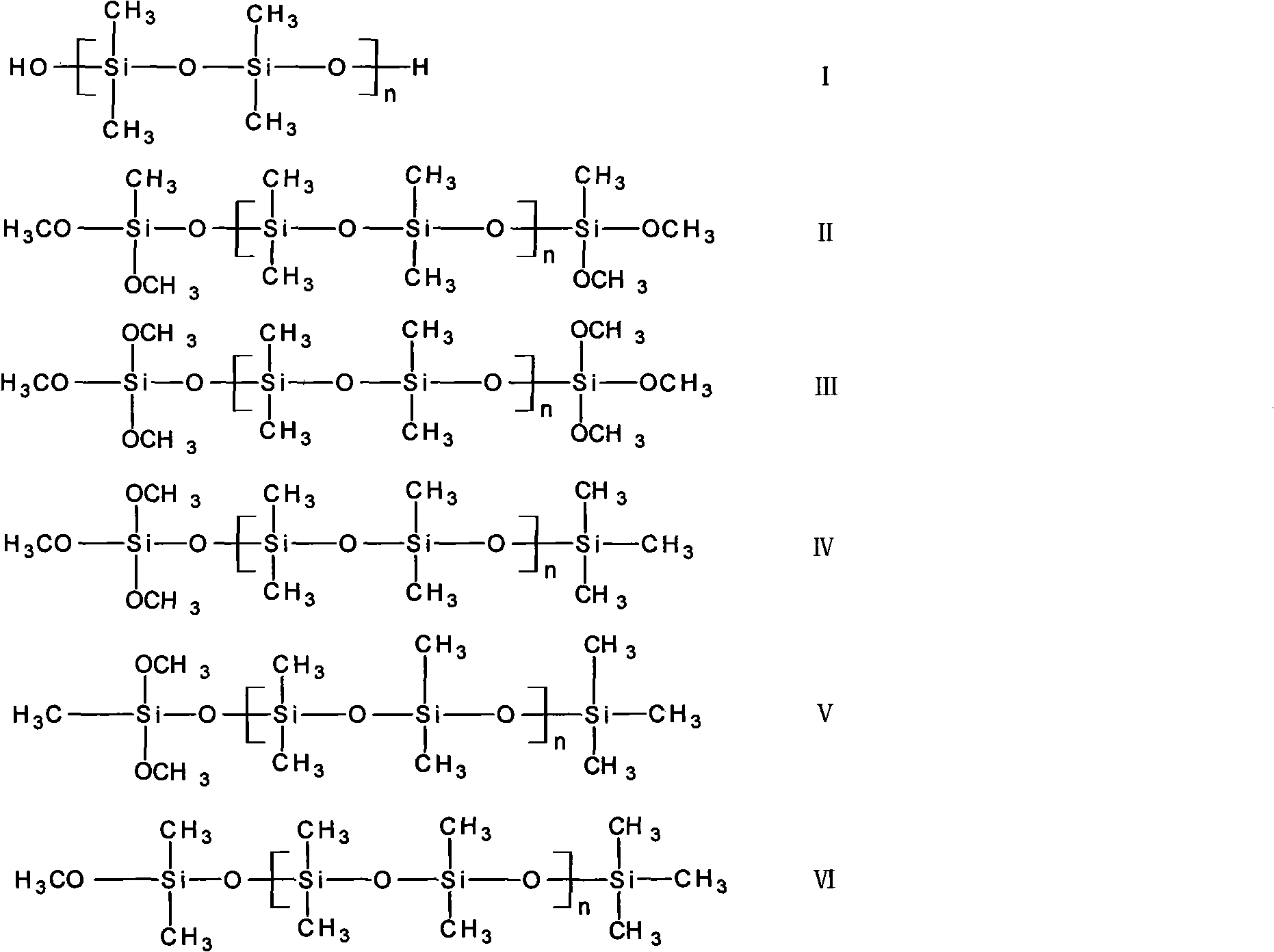

Preparation method of dimethicone and application thereof

The invention relates to a preparation method of an organosilicone product, more specifically to a preparation method of dimethicone with low hydroxyl content and application thereof. The method comprises the following steps: adding methylsiloxane, hexamethylsiloxane and an acid catalyst into a reaction kettle, stirring and heating to 70-75 DEG C under vacuum condition to carry out a reaction; standing for layering after the reaction, and releasing the reacted acid catalyst from the bottom valve of the reaction kettle; adding 15% of a sodium carbonate aqueous solution into the reaction kettle and stirring, and adjusting pH to 7-8 to obtain a neutral upper-layer oil crude product; standing and removing water, removing low-boiling-point substances from the oil crude product, cooling and filtering so as to obtain dimethicone. The dimethicone prepared by the above method has high conversion rate and low hydroxyl content. The product quality is stable, and production efficiency is high.

Owner:JIANGMEN SHENGPENG CHEM IND CO LTD

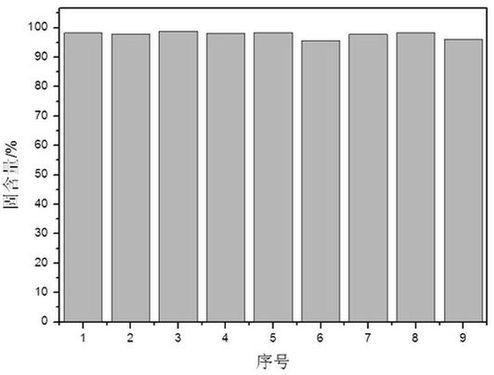

Solvent-free epoxy heavy-duty anticorrosive coating and preparation method thereof

InactiveCN110157293AReduce pollutionExcellent chemical stabilityAnti-corrosive paintsEpoxy resin coatingsEpoxyOrganic solvent

The invention relates to the field of anticorrosive coatings, in particular to a solvent-free epoxy heavy-duty anticorrosive coating and a preparation method thereof. The solvent-free epoxy heavy-dutyanticorrosive coating comprises a component A and a component B; the component A comprises 100 parts of a solvent-free epoxy resin, 8-16 parts of a active diluent, 70-115 parts of a pigment and filler, 1.5-2.6 parts of a coupling agent, 1.5-2.6 parts of a dispersing agent, and 0.8-1.3 parts of a thixotropic agent; and the component B is a curing agent, and the mass ratio of the component B to theliquid epoxy resin in the component A is (1.5:1)-(3.5:1). The solid content of the heavy-duty anticorrosive coating is 98% or more, and the coating is an environment-friendly coating; the coating contains only a very small amount of a volatile organic solvent, so that only a small amount of shrinkage cavities and pinholes are formed after the coating is cured, and the compactness of the coating effectively increases the barrier properties and permeability resistance of an anticorrosive coating layer.

Owner:HENAN UNIV OF URBAN CONSTR

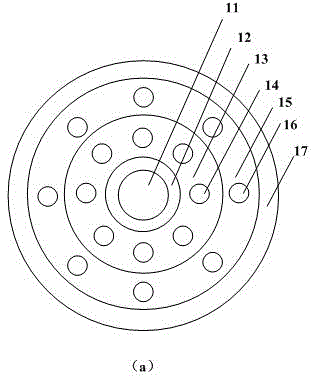

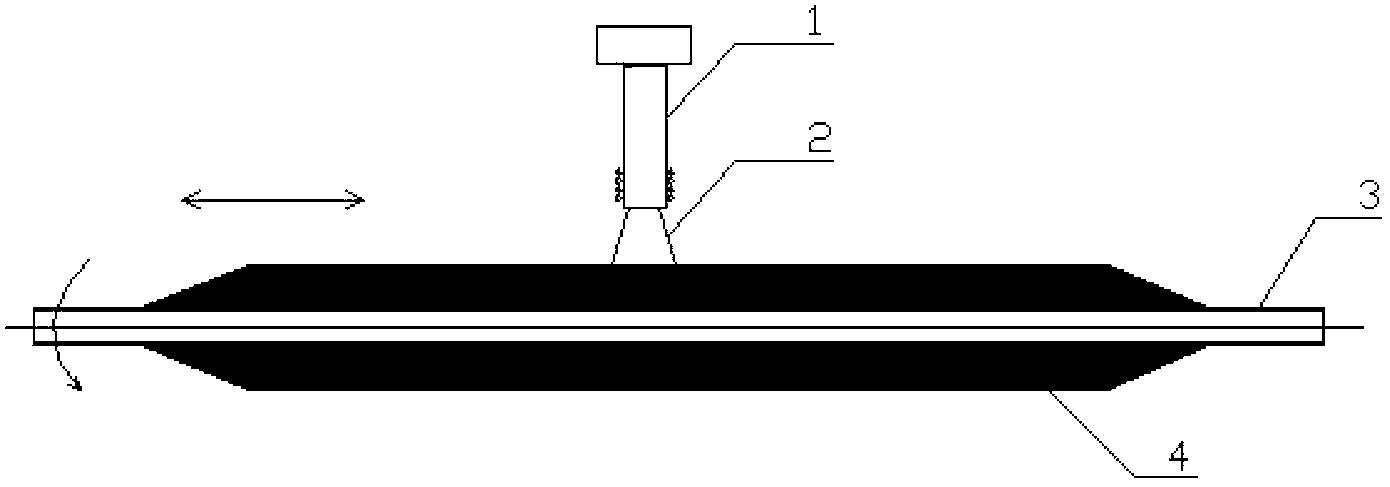

Preparation method of low-hydroxyl large-diameter large-length quartz piece

InactiveCN103224319ALow hydroxyl contentHigh purityGlass shaping apparatusGlass deposition burnersTemperature resistanceVertical axis

The invention relates to a preparation method of a quartz product, and especially relates to a preparation method of a low-hydroxyl large-diameter large-length quartz piece. According to the invention, the piece is prepared with a plasma vertical solid-phase external deposition method. One or a plurality of plasma torches can be configured. During a smelting process, the plasma torch is maintained unmoved, or is subjected to translational motions up and down on a vertical axis. The smelting temperature which is quartz piece surface temperature is 1800-2500 DEG C. Quartz sand is delivered in from a blanking pipe at a plasma torch upper port or by plasma device central airflow. A central base pipe or base rod is fixed on a glass machine tool, and simultaneously rotates when performing translational movements up or down on the vertical axis. Along with the relative movements of the plasma flame and the central base pipe or base rod, the quartz sand is deposed and molten layer by layer, such that a hollow quartz blank piece or a solid quartz blank piece is formed. With the plasma vertical solid-phase external deposition novel method, the prepared quartz piece has the characteristics high purity, low hydroxyl content, high softening point, high strength, high temperature resistance, and uniform diameter.

Owner:久智光电子材料科技有限公司

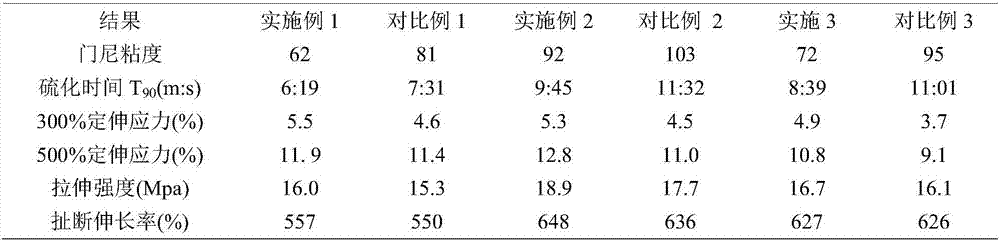

Modified precipitated silicon dioxide and preparation method for modified precipitated silicon dioxide

The invention provides a modified precipitated silicon dioxide and a preparation method for the modified precipitated silicon dioxide and relates to the technical field of silicon dioxide preparation.The preparation method for the modified precipitated silicon dioxide comprises the following steps: adding a cationic surface active agent into a sodium silicate solution and rising temperature, thereby acquiring a solution A; adding sodium sulfate into the solution A for precipitation reaction; using a sulfuric acid solution for regulating pH in the reaction process; ageing after the ending of reaction, thereby acquiring the modified precipitated silicon dioxide. According to the invention, the cationic surface active agent is added into the sodium silicate solution, positive charges are carried by the cationic surface active agent after dissolving in water, and then negative charges on the precipitated silicon dioxide surface interact with the positive charges on the surface of the cationic surface active agent, so that a cladding modification effect can be achieved, the stability and dispersity of the precipitated silicon dioxide grains can be promoted and the compatibility of themodified precipitated silicon dioxide and the rubber matrix can be obviously promoted.

Owner:重庆市黔永硅业有限公司

Preparation method of moistureproof starch glue

InactiveCN108342172ALow water absorptionImprove moisture resistanceProtein adhesivesGlue/gelatin preparationMoisture resistanceAbsorption effect

The invention relates to the technical field of adhesive preparation, in particular to a preparation method of moistureproof starch glue. The preparation method comprises the following steps: preparing alkalization liquid from soybeans as a raw material, putting the alkalization liquid in a centrifugal machine for centrifugal separation to obtain a supernatant liquid, acidizing the supernatant liquid with diluted hydrochloric acid to obtain a lower protein precipitation, adding a half of the protein precipitation in a sodium hydroxide solution to obtain a hot alkaline degradable protein fluid,treating the other half of protein precipitation to obtain soybean protein powder subjected to acid heat treatment, mixing the hot alkaline degradable protein fluid with the soybean protein powder subjected to acid heat treatment, and performing mixed heating on the mixture and a starch grafted styrene-acrylic emulsion to obtain the moistureproof starch glue. Styrene-acrylic latex is grafted on starch, so that a water absorption effect of a hydroxide radical on the starch can be shielded, and the moisture resistance of the starch glue is improved; and alkali modification of soy protein underrelatively high sodium hydroxide solution concentration is conducted, and part of soy protein is hydrolysed, so that the surface tension of an adhesive emulsion is reduced, the contact angle is increased, the moisture resistance effect is achieved, and the application prospect is wide.

Owner:常州五荣化工有限公司

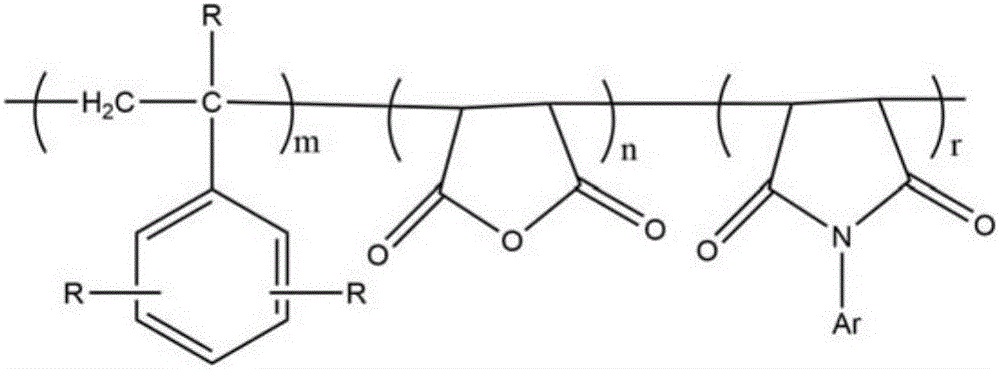

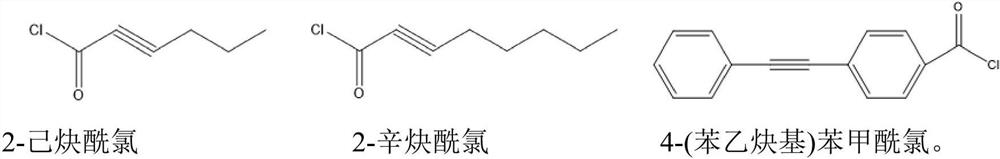

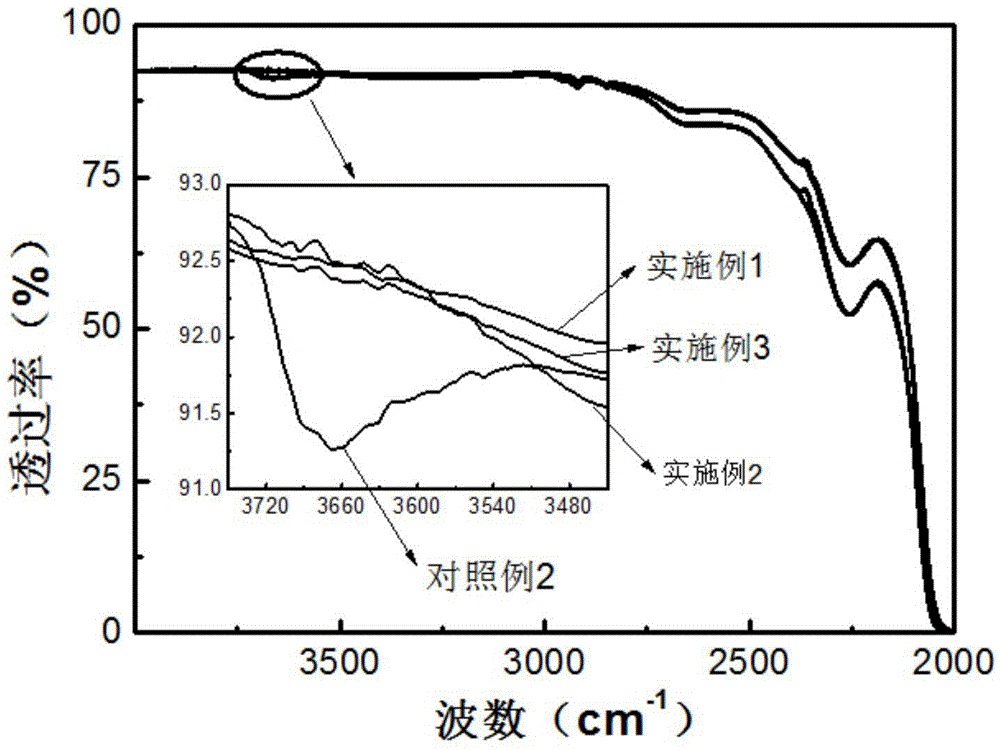

Modified lignin as well as preparation method and application thereof in rubber composite material

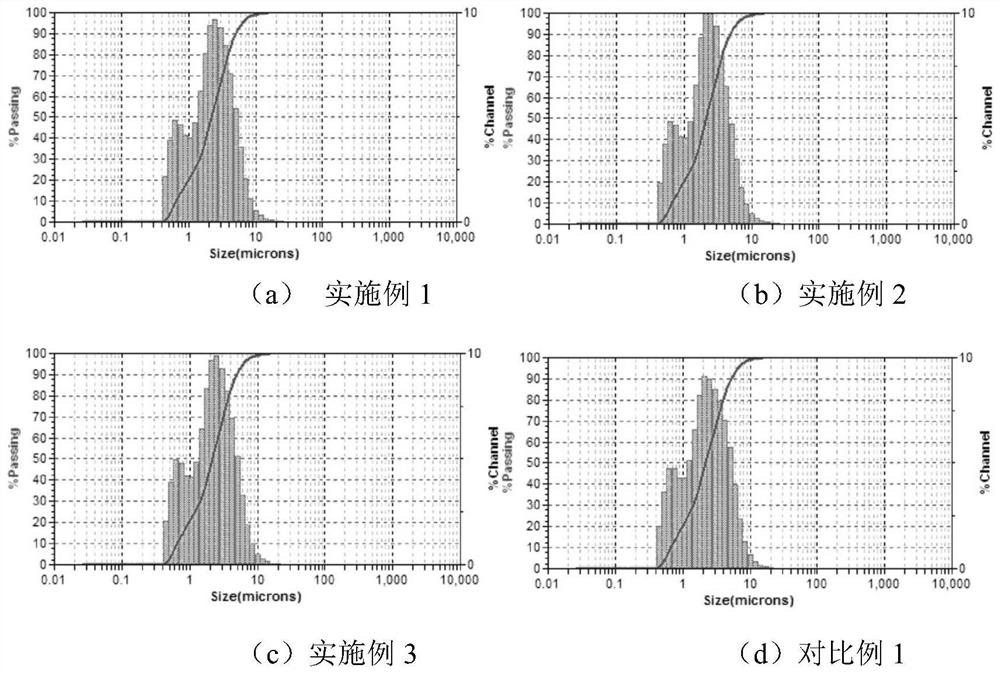

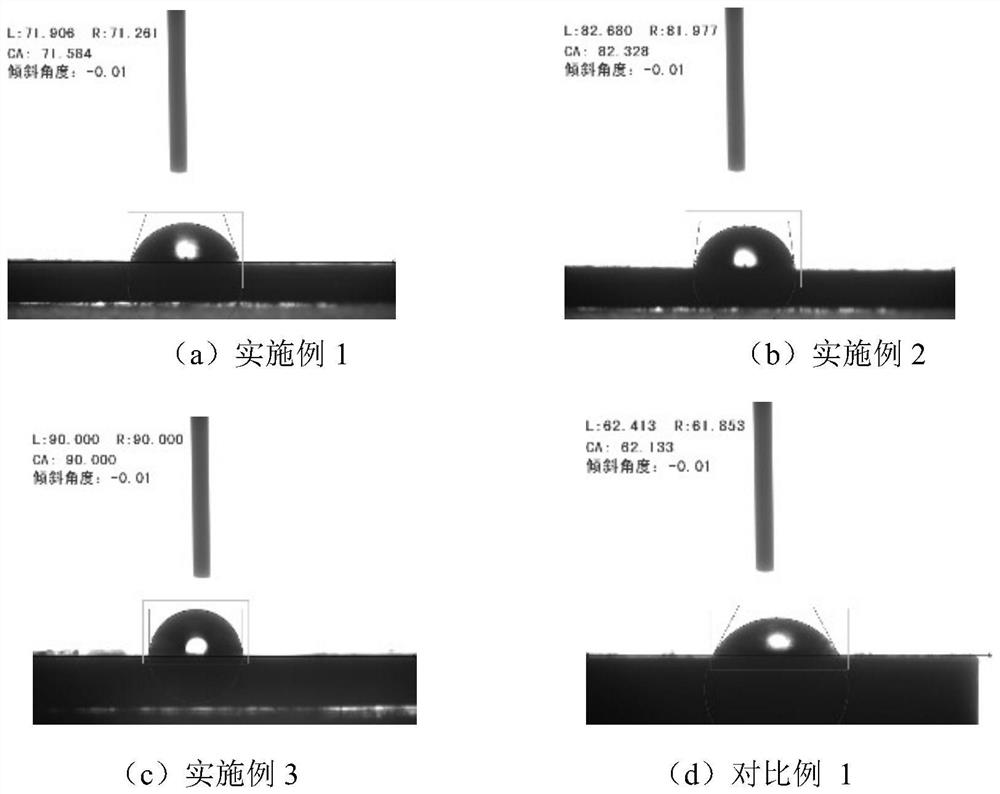

ActiveCN112831059ADecrease molecular polarityInhibition of self-aggregation tendencyNatural rubberPolymer chemistry

The invention discloses modified lignin, a preparation method thereof and application of the modified lignin in a rubber composite material. Lignin and alkynyl compounds react in an organic solvent to obtain a reaction solution containing the modified lignin. The modified lignin has the following advantages: (1) the structure of the alkynylation reagent contains an acyl chloride functional group, and the acyl chloride functional group is easily subjected to esterification reaction with an alcoholic hydroxyl group and a phenolic hydroxyl group in lignin molecules to generate the modified lignin grafted with an unsaturated alkynyl functional group; (2) through alkynylation modification, the content of hydroxyl in lignin molecules is reduced, the molecular polarity is reduced, the self-aggregation tendency of lignin caused by hydrogen bonds is inhibited, lignin powder with relatively low particle size is obtained through grinding, the compatibility and affinity of lignin and non-polar natural rubber are improved, and the dispersion of the lignin in a natural rubber matrix is promoted.

Owner:NANJING UNIV OF TECH +1

Preparation method of fluorine-containing low refractive index yb3+ doped quartz glass

The invention relates to a preparation method for fluorine-containing low-refractivity Yb<3+>-doped quartz glass. The method comprises the steps: starting from a solution, preparing evenly doped silicon oxide powder by using a sol-gel method; and carrying out decarbonization and dehydroxylation treatment on the powder, and finally sintering into glass. By applying the method, F<-> can be effectively introduced, and the rare earth-doped quartz glass with high uniformity, low hydroxyl content and the refractivity almost identical to that of the pure quartz glass can be obtained. The method can be applied to preparation of a high-brightness large-mode-field quartz optical fiber mandril.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

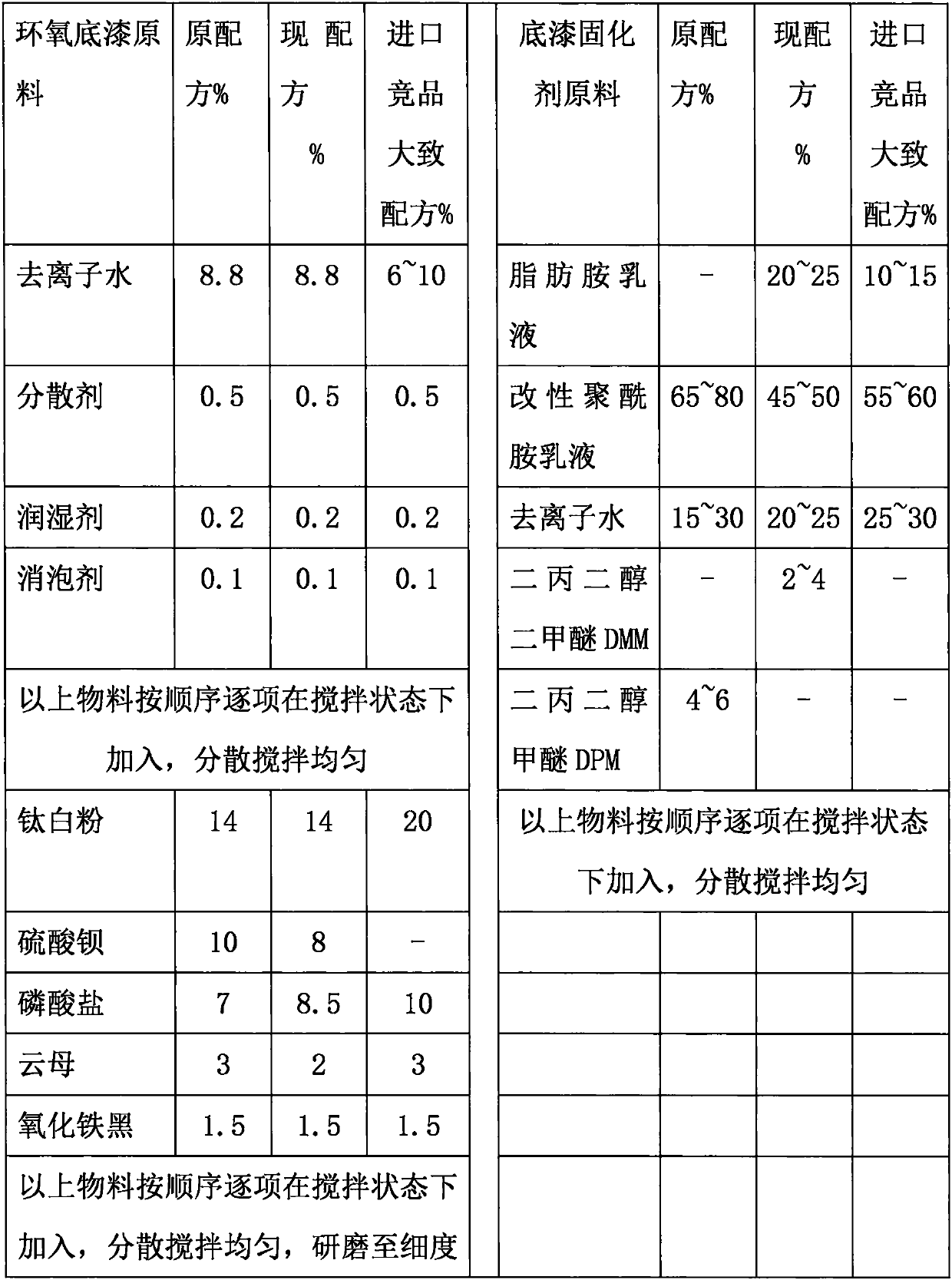

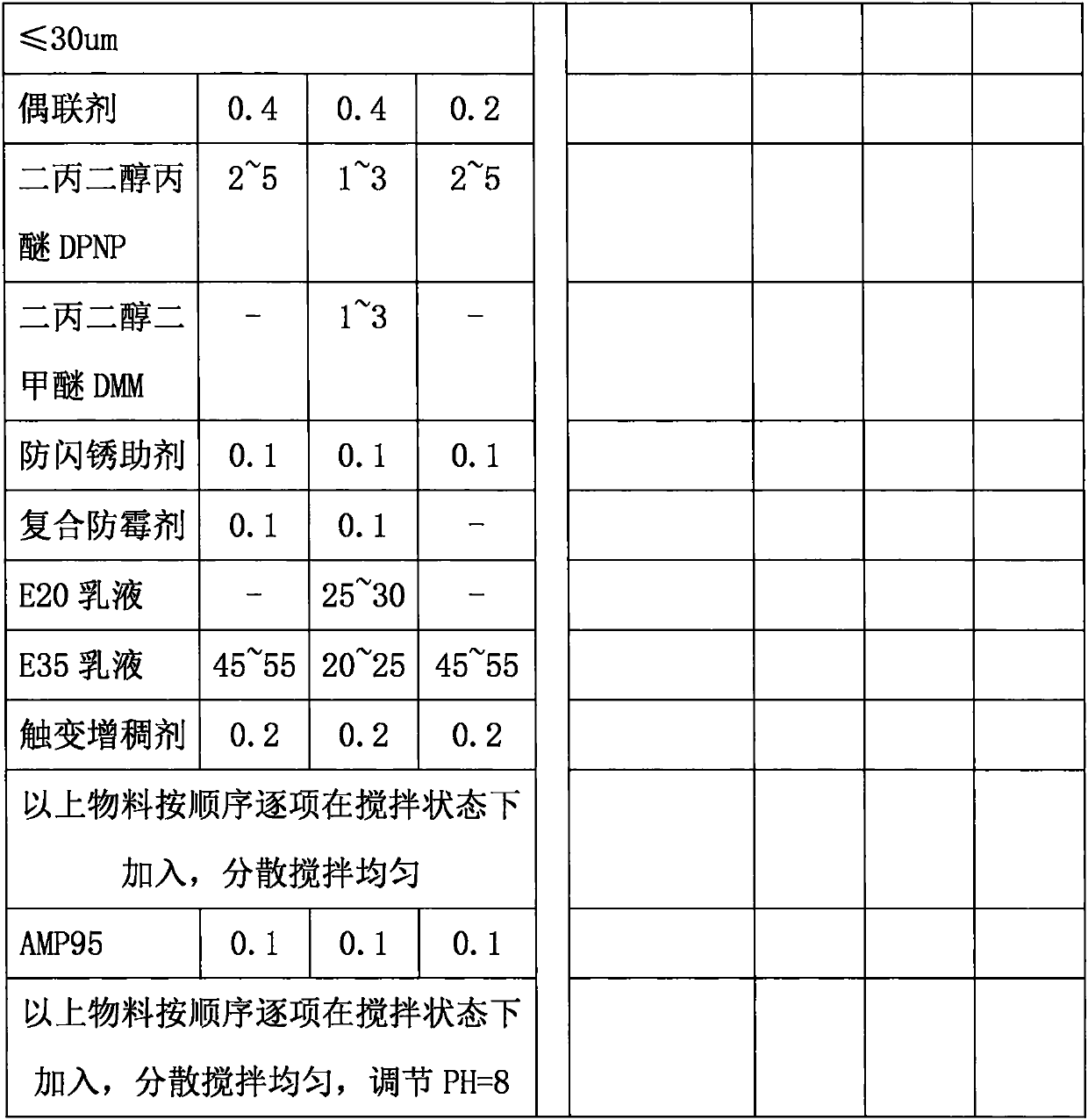

Special two-component water-based paint for buses and coating process of two-component water-based paint

InactiveCN110551437ALow VOCImprove film formationPretreated surfacesAnti-corrosive paintsWater basedEpoxy

The invention provides special two-component water-based paint for buses. The special two-component water-based paint comprises a two-component water-based epoxy primer, two-component water-based intermediate paint and two-component water-based finishing paint. While maintaining the original physical and chemical properties without reducing, compared with traditional solvent-based bus paint, the use of organic solvents can be significantly decreased, and VOC is lowered; compared with existing water-based bus paint on the market, the flash drying time can be shortened, the production pace is speeded up, and the more efficient coating efficiency can be obtained.

Owner:上海时佳涂料有限公司

Modified coconut shell and natural rubber composite cable sheath material

InactiveCN104194239ALow hydroxyl contentImprove hydrophobicityRubber insulatorsInsulated cablesFiberVulcanization

The invention discloses a modified coconut shell and natural rubber composite cable sheath material which is characterized by comprising the following raw materials in parts by weight: 100 parts of natural rubber, 8-10 parts of maleic anhydride, 30-40 parts of coconut shell fiber, 15-20 parts of kieselguhr, 5-10 parts of nylon PA, 10-15 parts of calcined clay, 30-40 parts of white carbon black, 20-30 parts of carbon black, 20-40 parts of attapulgite, 4-4.5 parts of zinc oxide, 1.5-2 parts of sulfur, 1-2 parts of vulcanization accelerant N-cyclohexyl-2-benzothiazole sulfonamide, 3-4 parts of bi(3-triethoxy silylation propyl) tetrasulfide and 1.5-2 parts of stearic acid, wherein the particle size of the coconut shell fiber is 20-30mm. The modified coconut shell and natural rubber composite cable sheath material is good in physical and mechanical properties and relatively excellent in thermo-oxidative aging resistance, ozone resistance and ultraviolet resistance.

Owner:ANHUI LAND GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com