Patents

Literature

149 results about "Thermal crystallization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

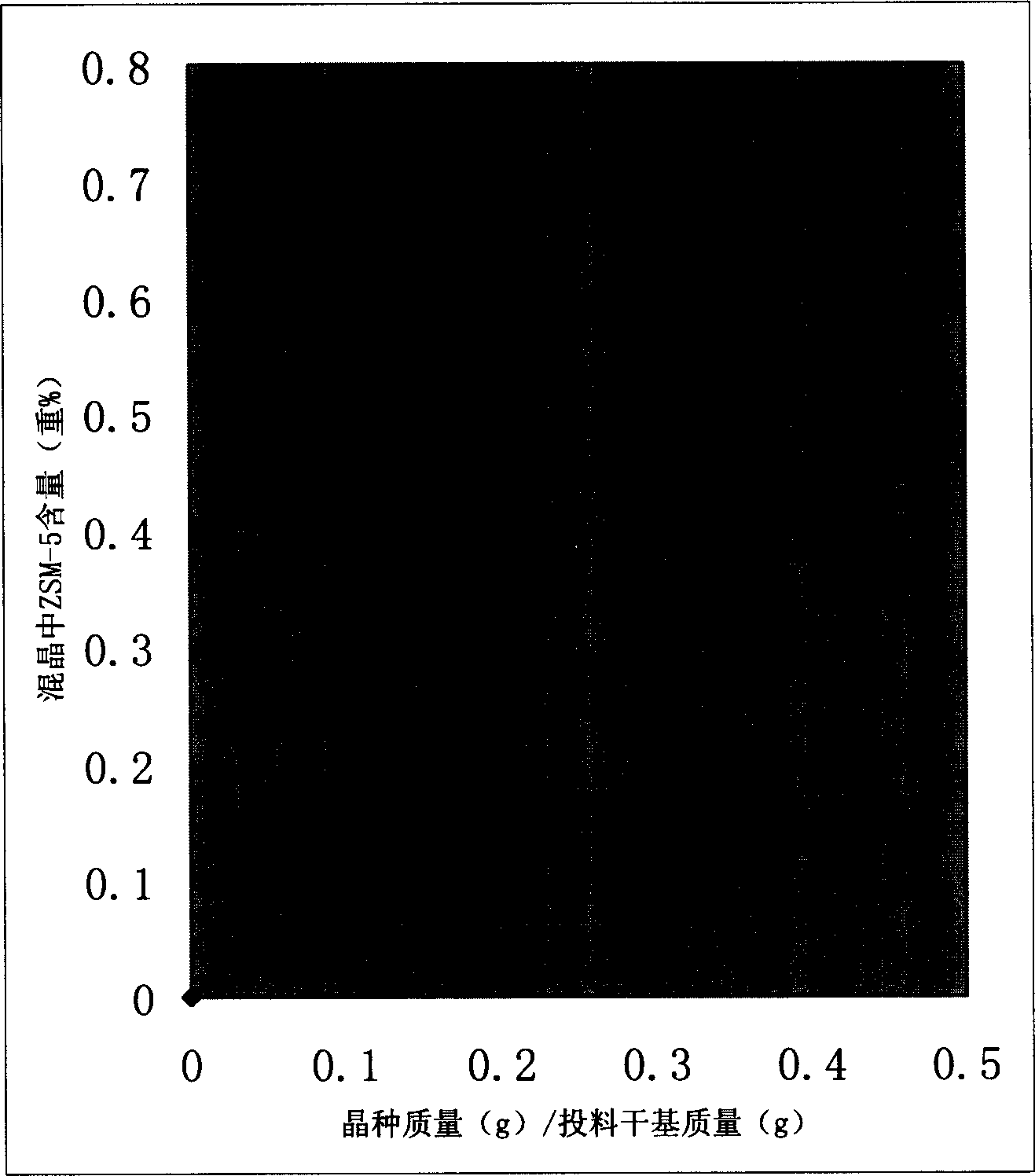

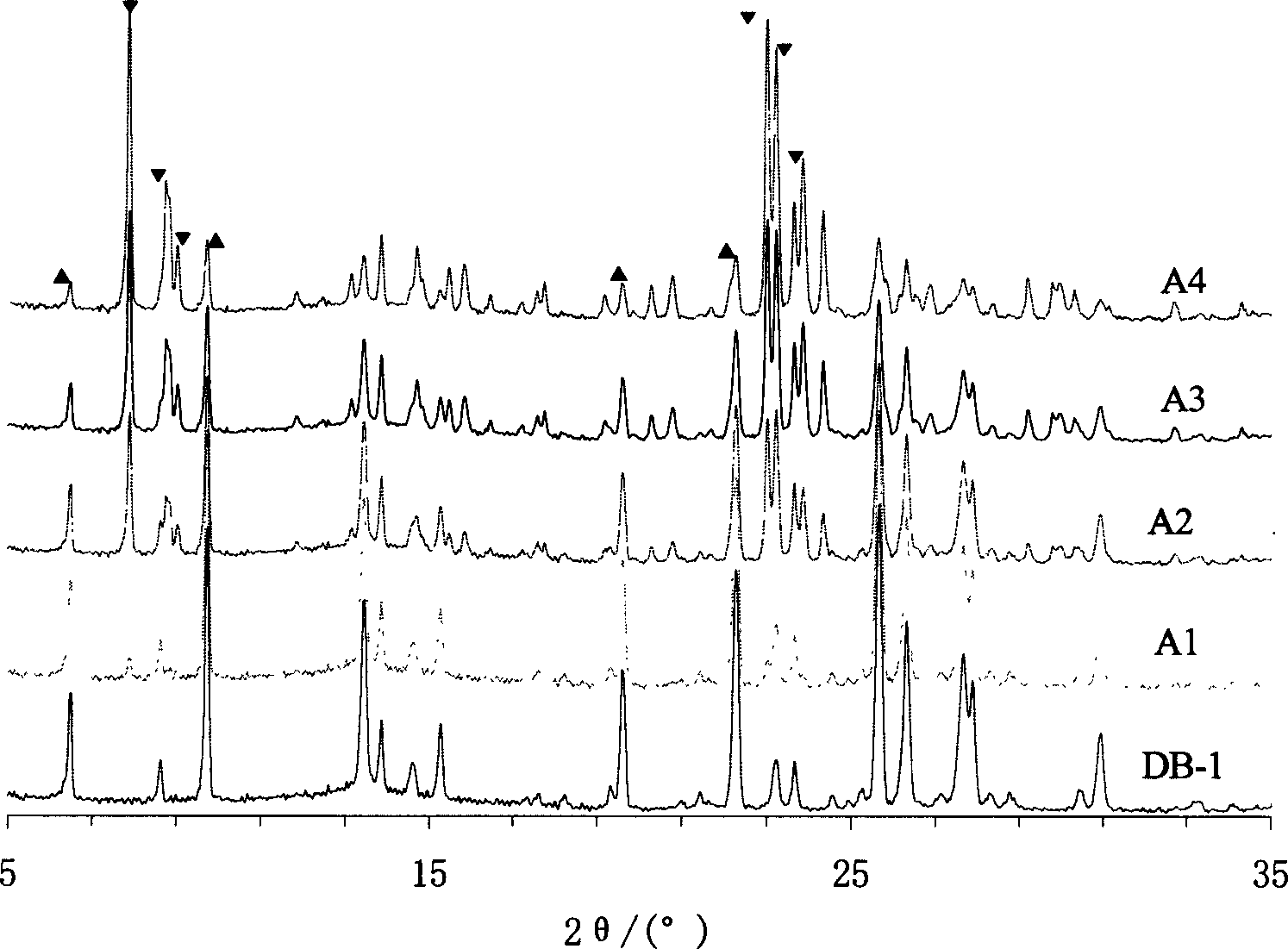

Synthetic method for ZSM-5/mordenite mixed crystal material

InactiveCN1565970ALower synthesis costEasy to adjustMolecular sieve catalystsMordenite aluminosilicate zeoliteMordeniteThermal crystallization

The invention discloses a synthetic method for ZSM-5 / mordenite mixed crystal material, wherein ZSM-5 molecular sieve is charged into the synthesized reaction mixture of mordenite as seed crystal, and said material is prepared through water thermal crystallization. The invention realizes low making cost and more ideal catalyzing performance.

Owner:CHINA PETROLEUM & CHEM CORP +2

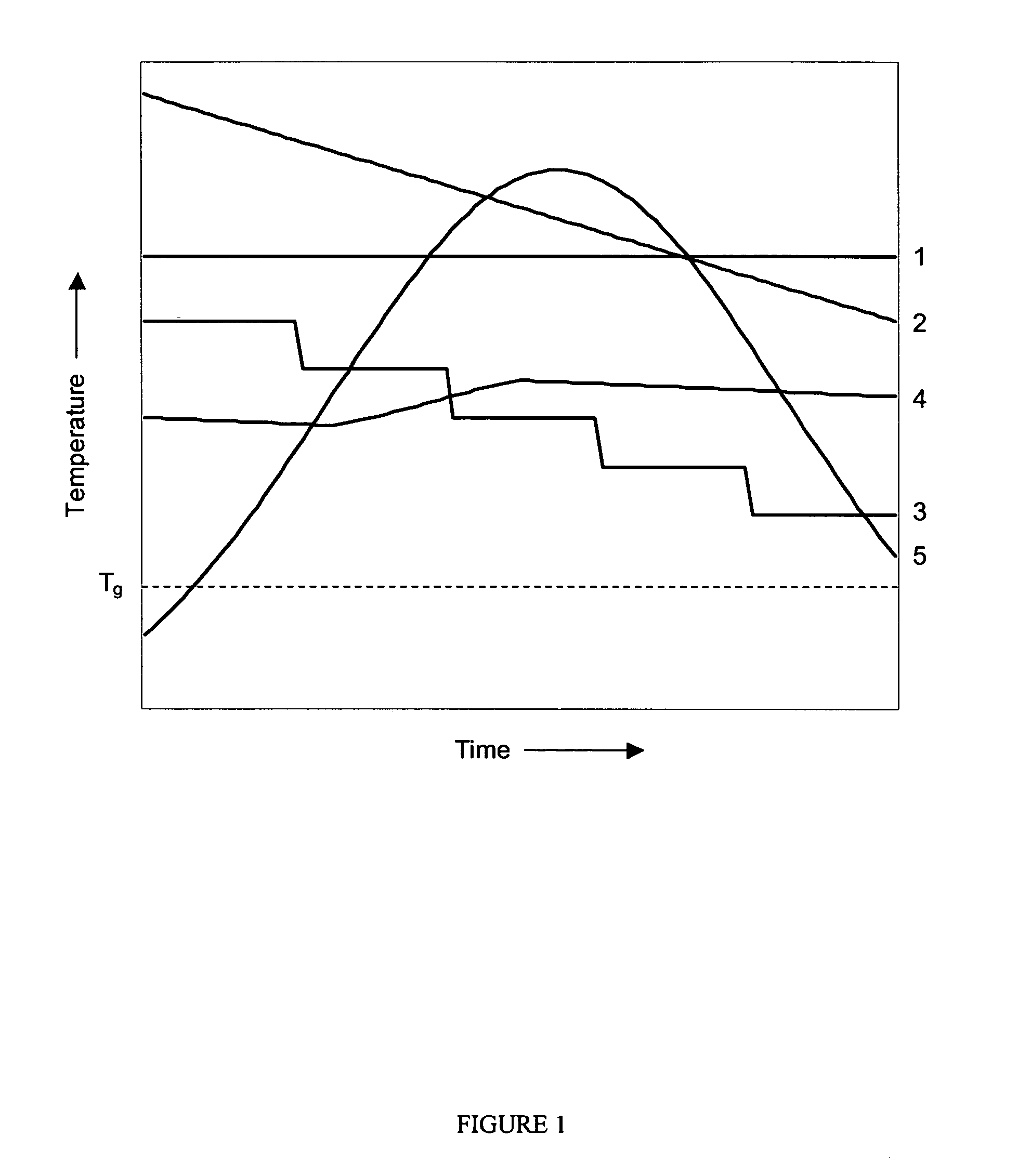

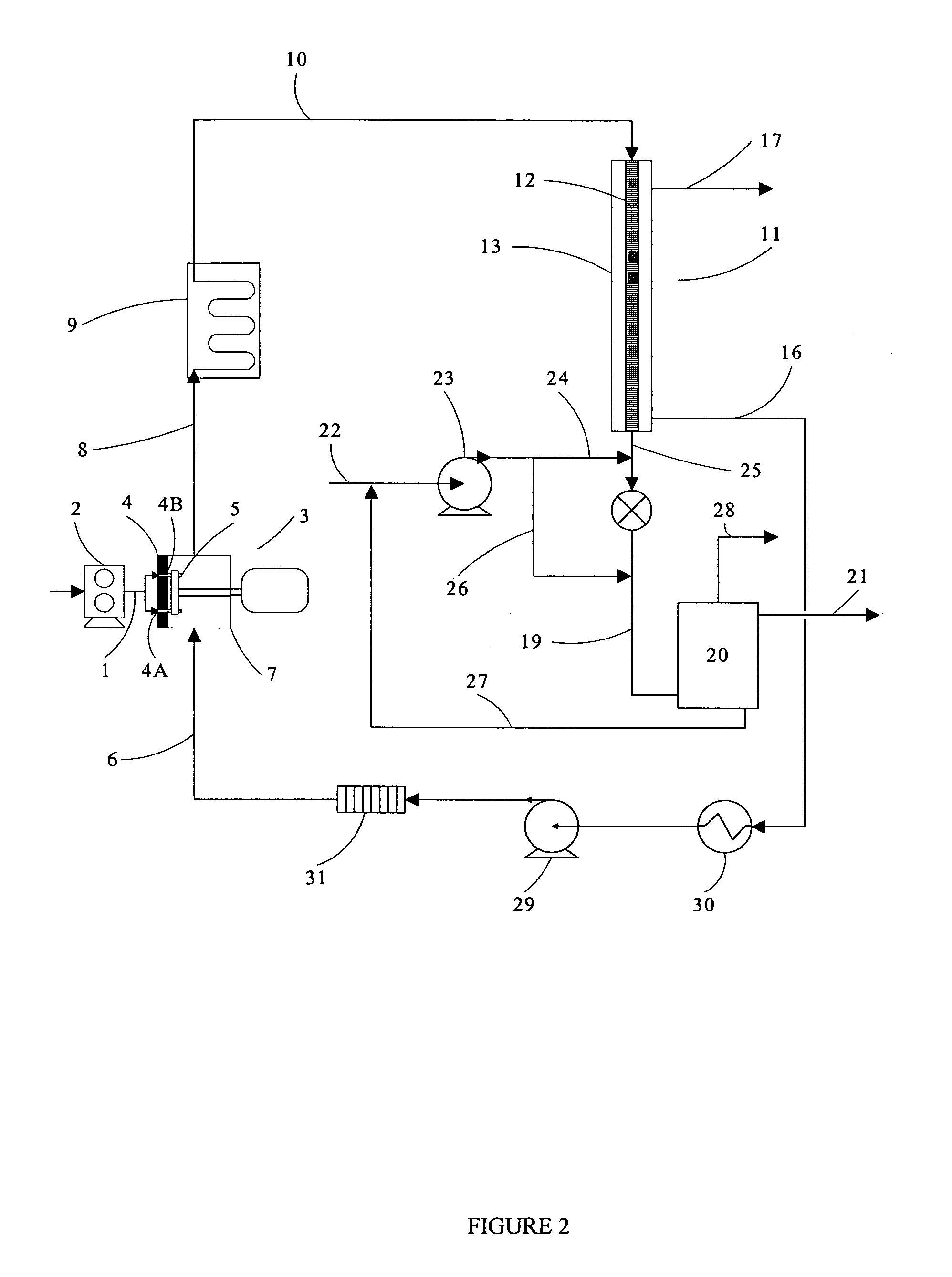

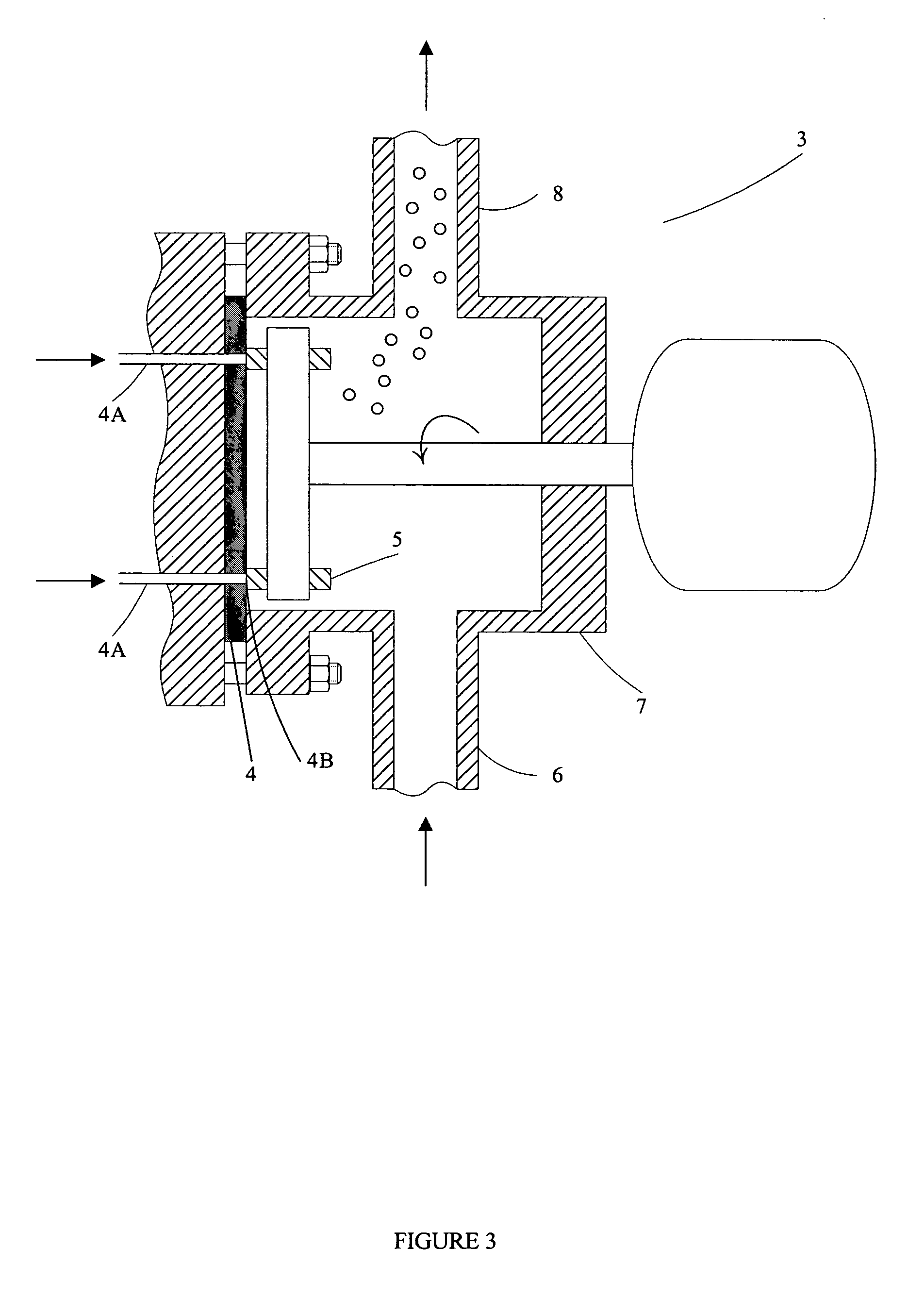

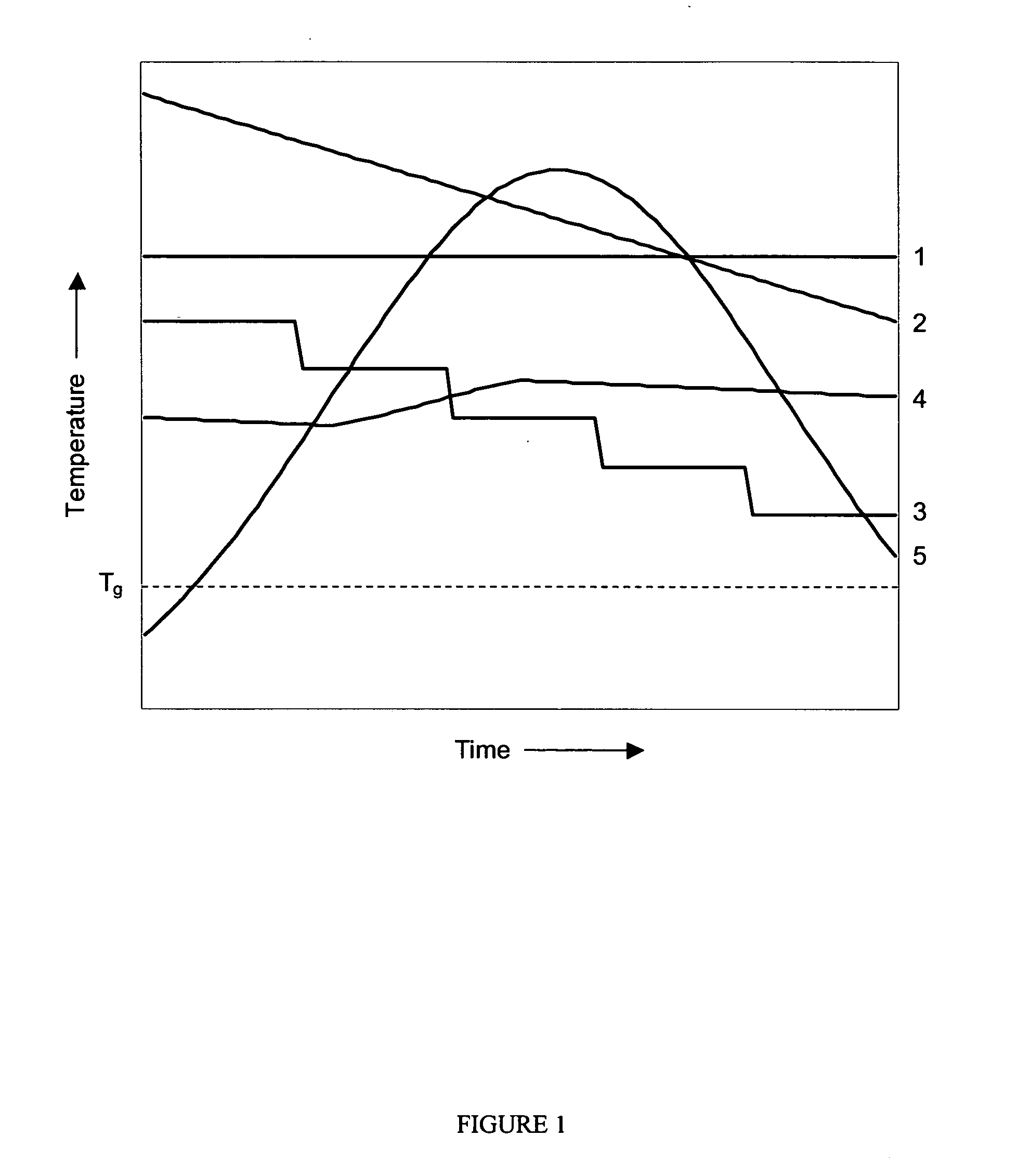

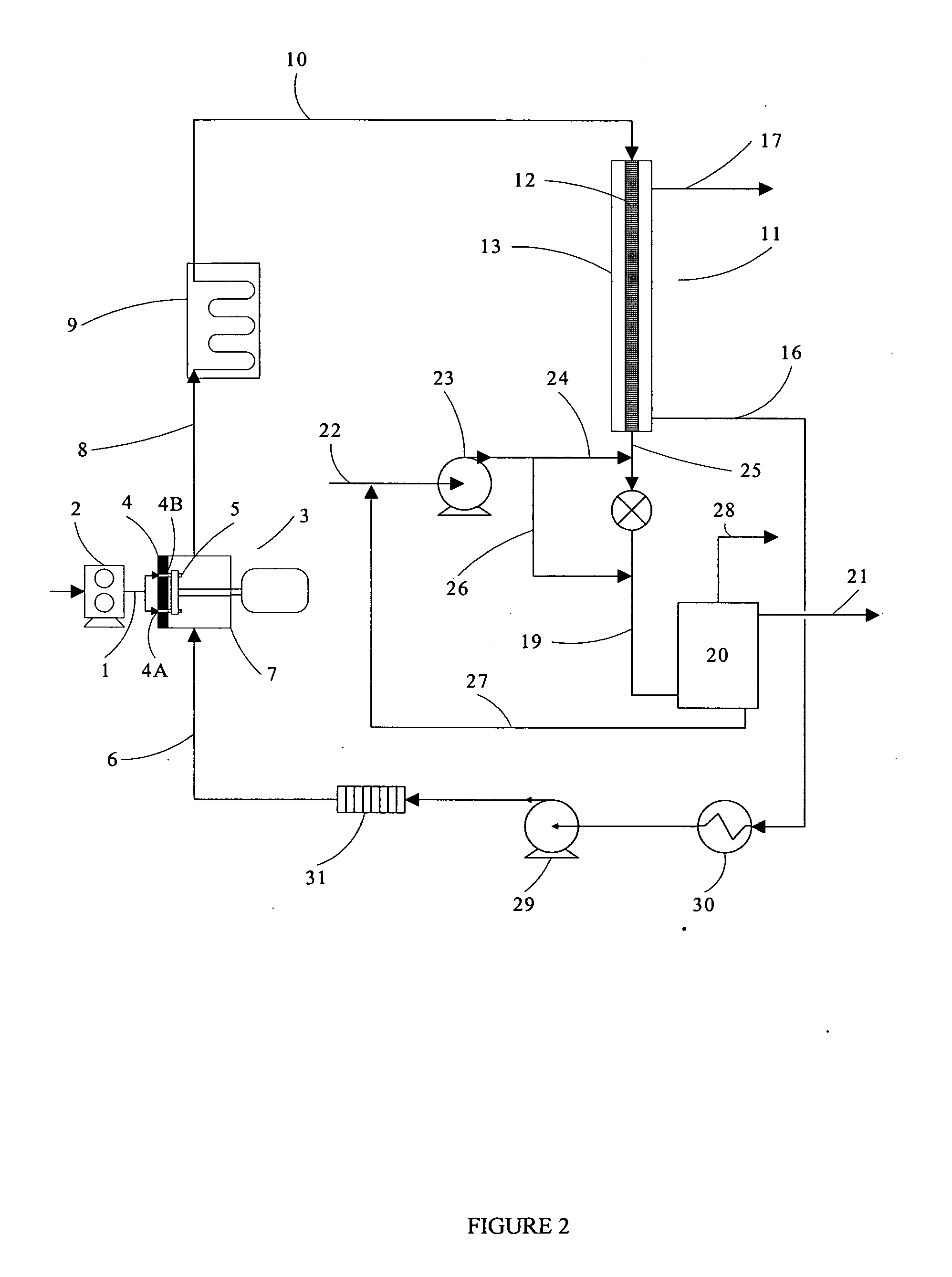

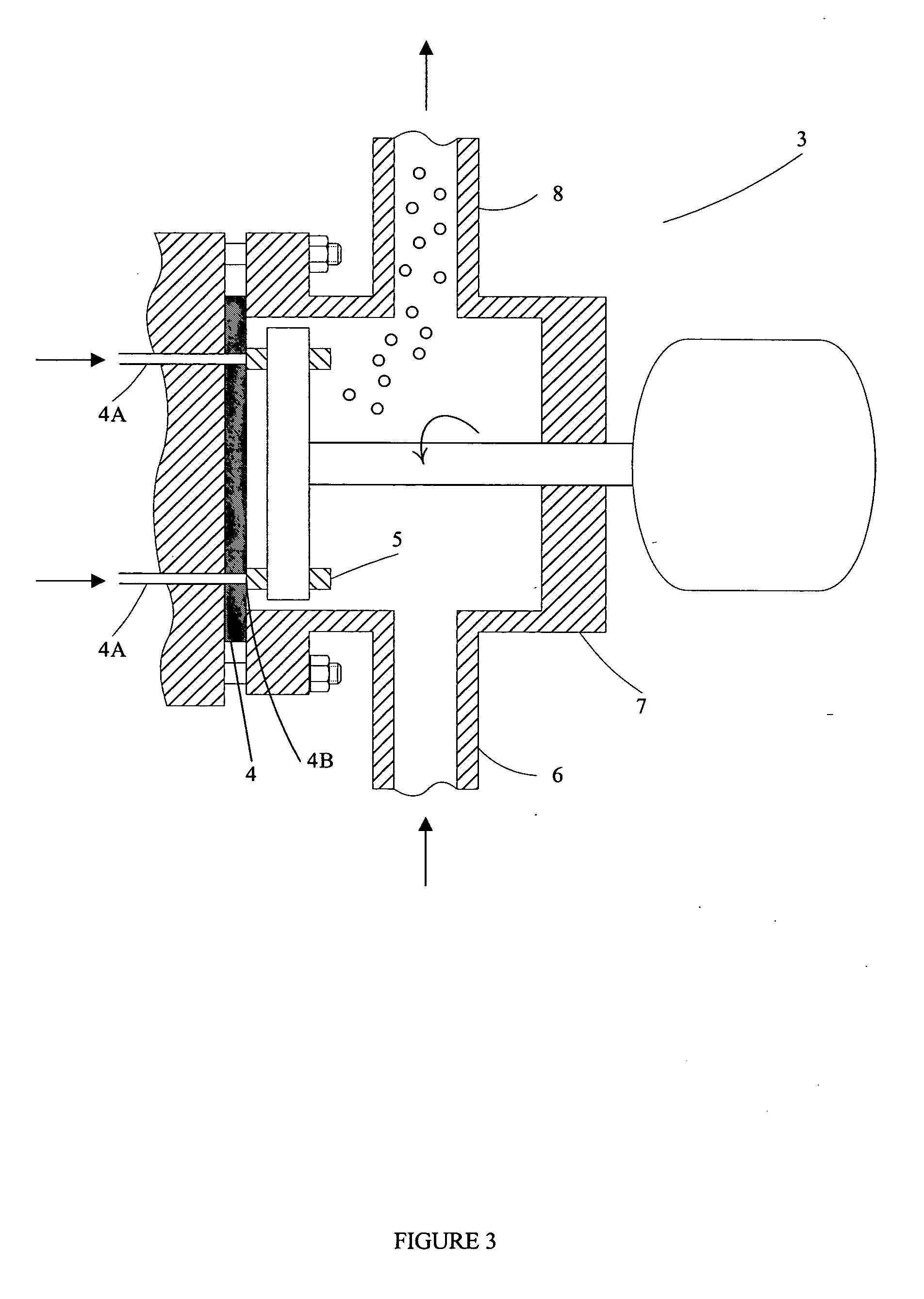

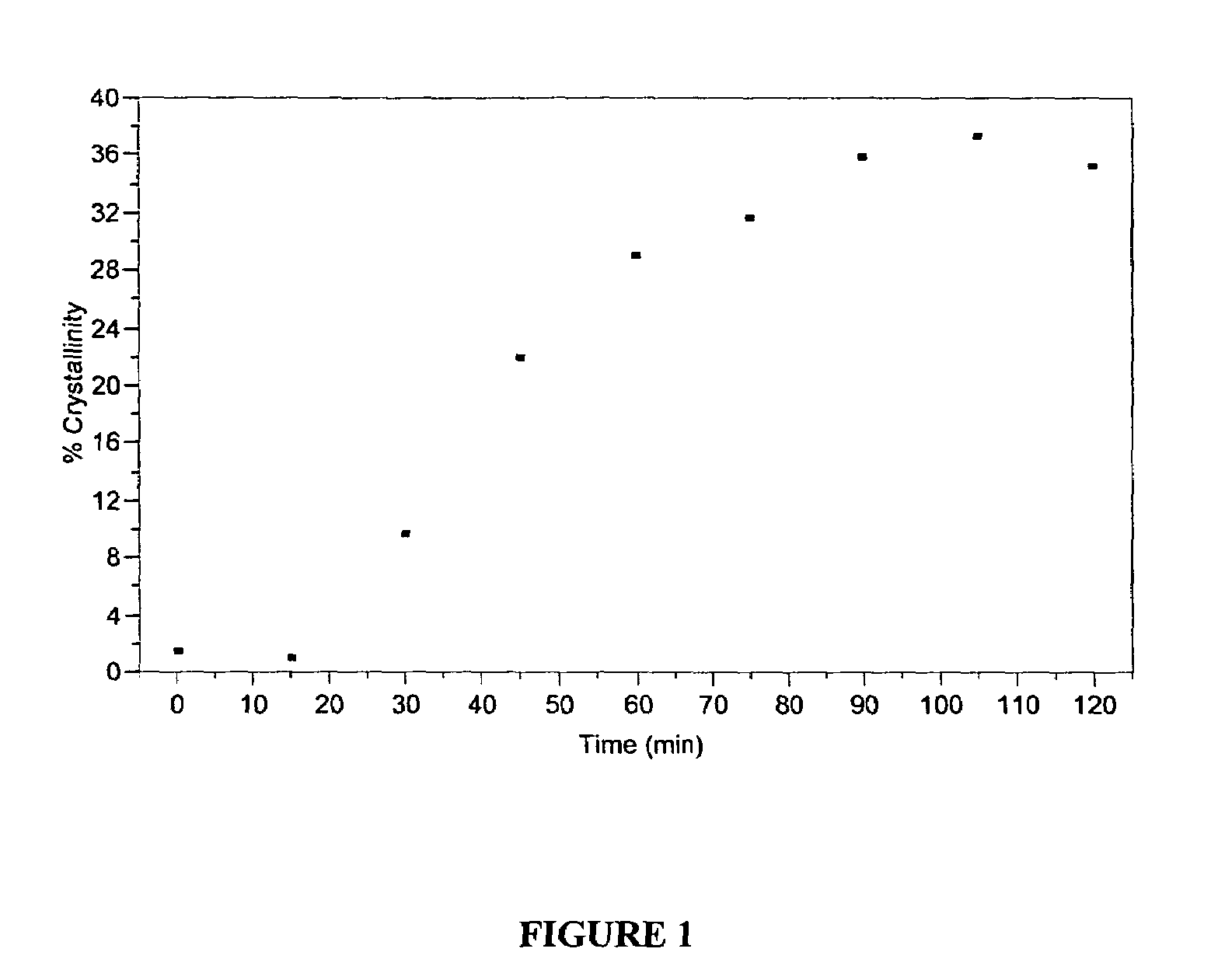

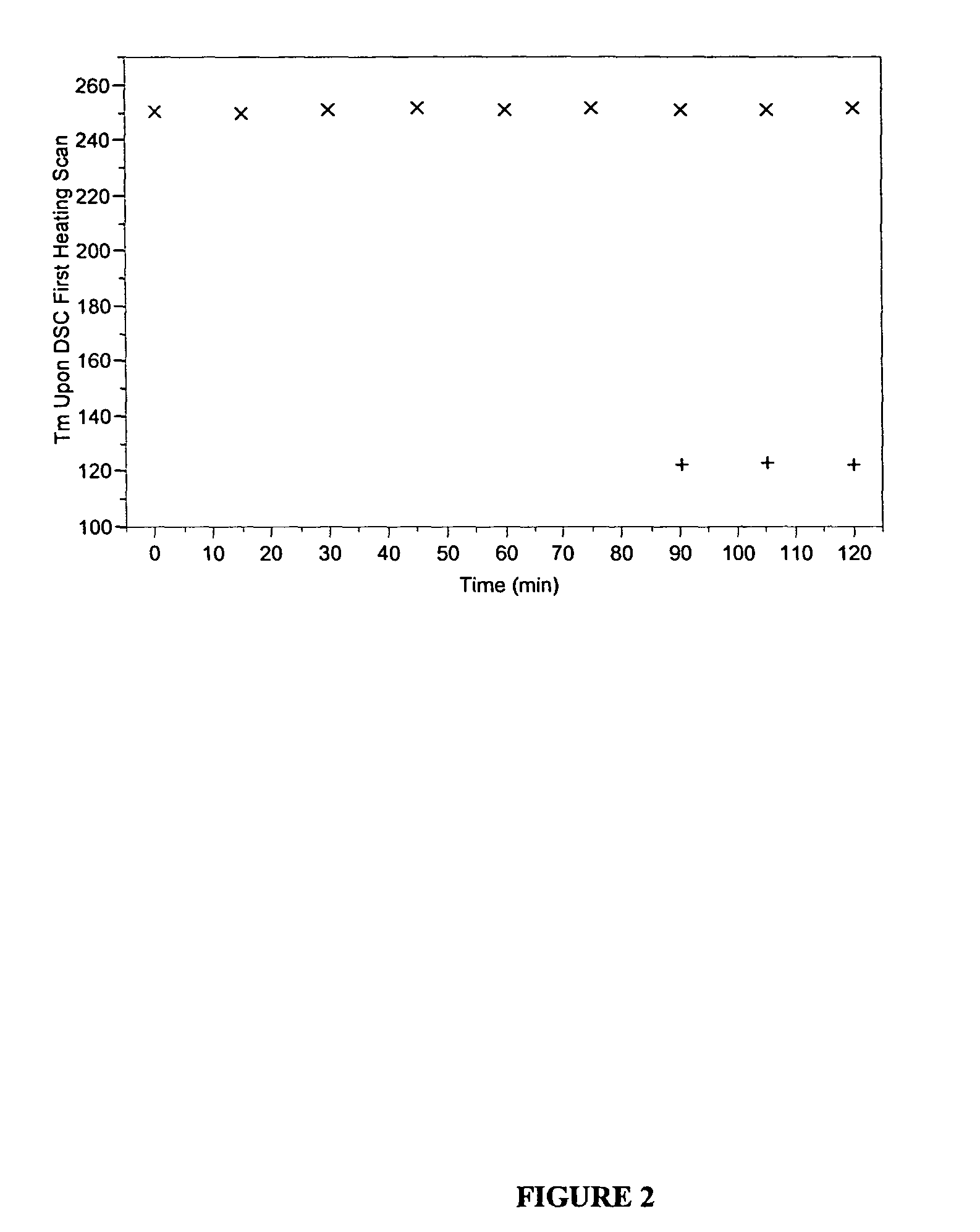

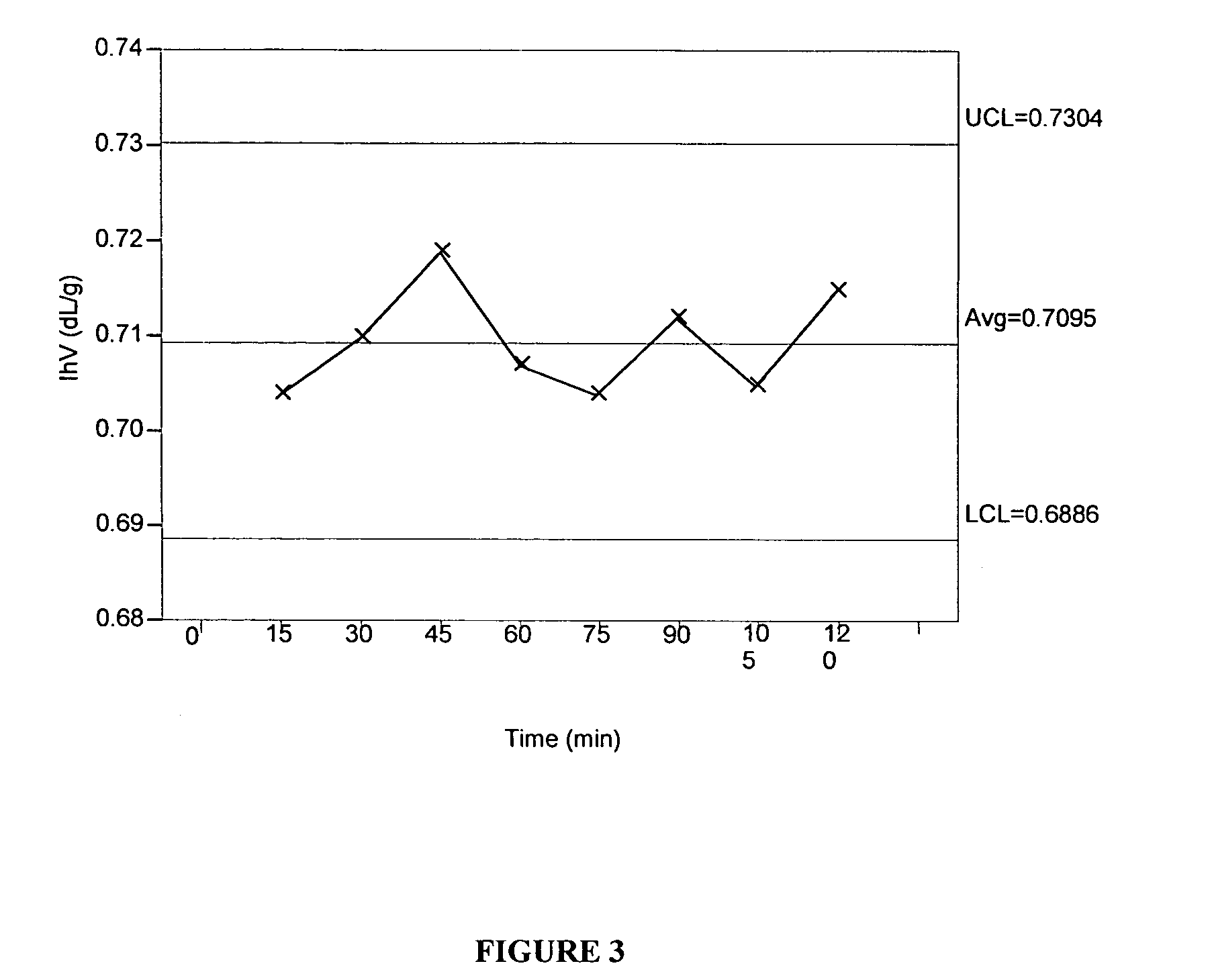

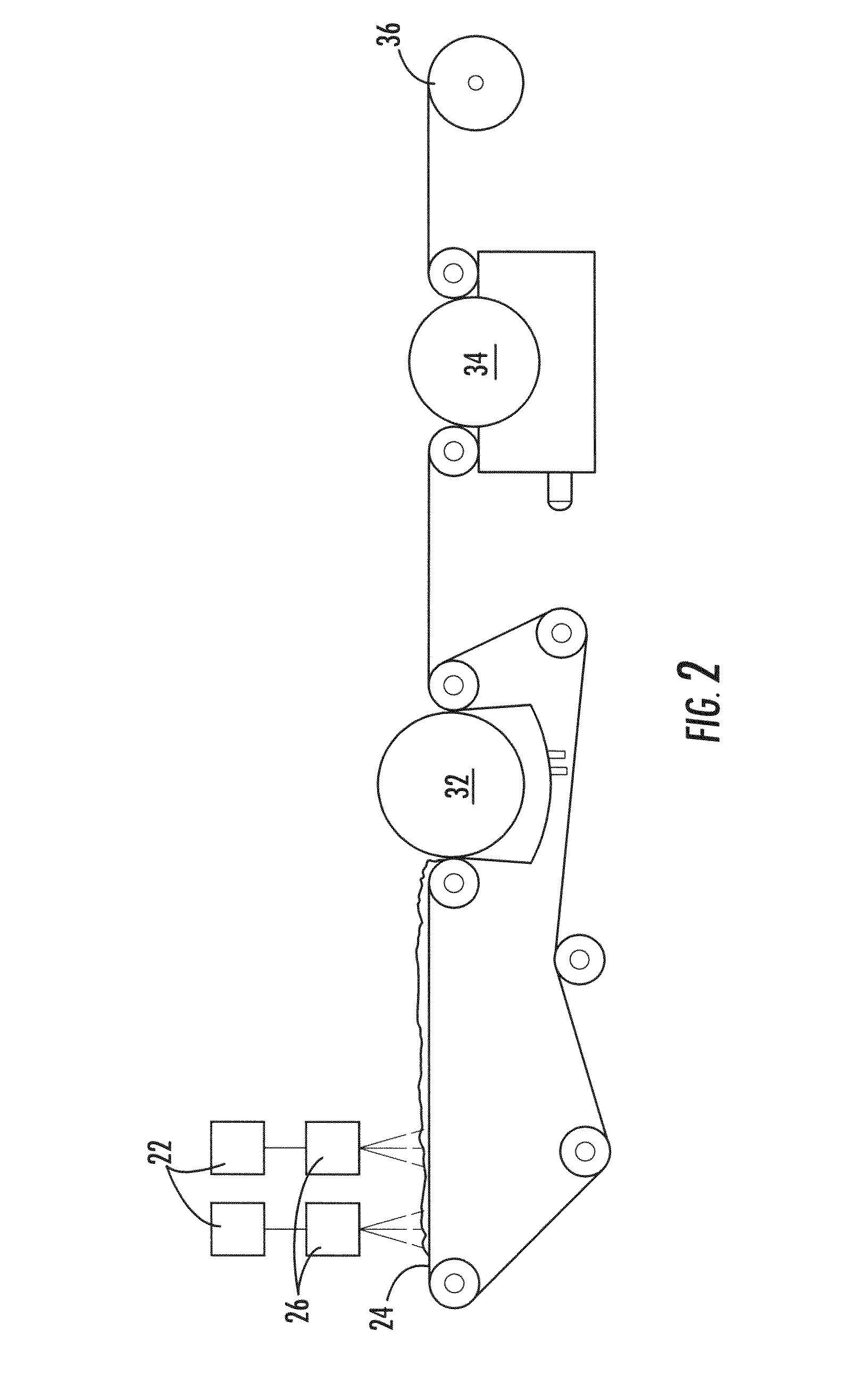

Thermal crystallization of a molten polyester polymer in a fluid

InactiveUS7192545B2Reduce molecular weightEnergy efficiencyDrying gas arrangementsCeramic shaping apparatusPolyesterLiquid medium

A process for crystallizing a polyester polymer by introducing a molten polyester polymer, such as a polyethylene terephthalate polymer, into a liquid medium at a liquid medium temperature greater than the Tg of the polyester polymer, such as at a temperature ranging from 100° C. to 190° C., and allowing the molten polyester polymer to reside in the liquid medium for a time sufficient to crystallize the polymer under a pressure equal to or greater than the vapor pressure of the liquid medium. A process flow, underwater cutting process, crystallization in a pipe, and a separator are also described.

Owner:ALPEK POLYESTER SA DE CV

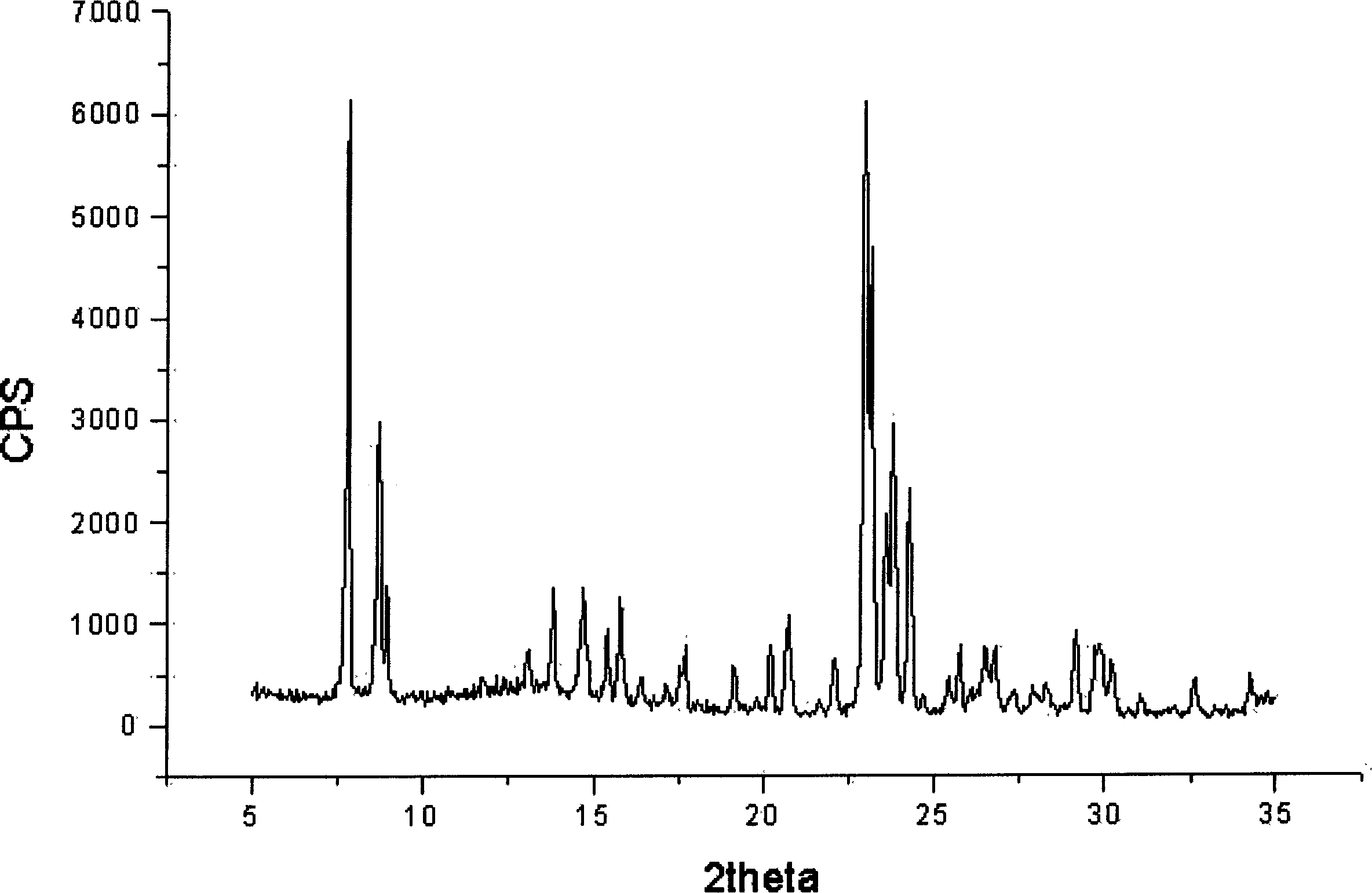

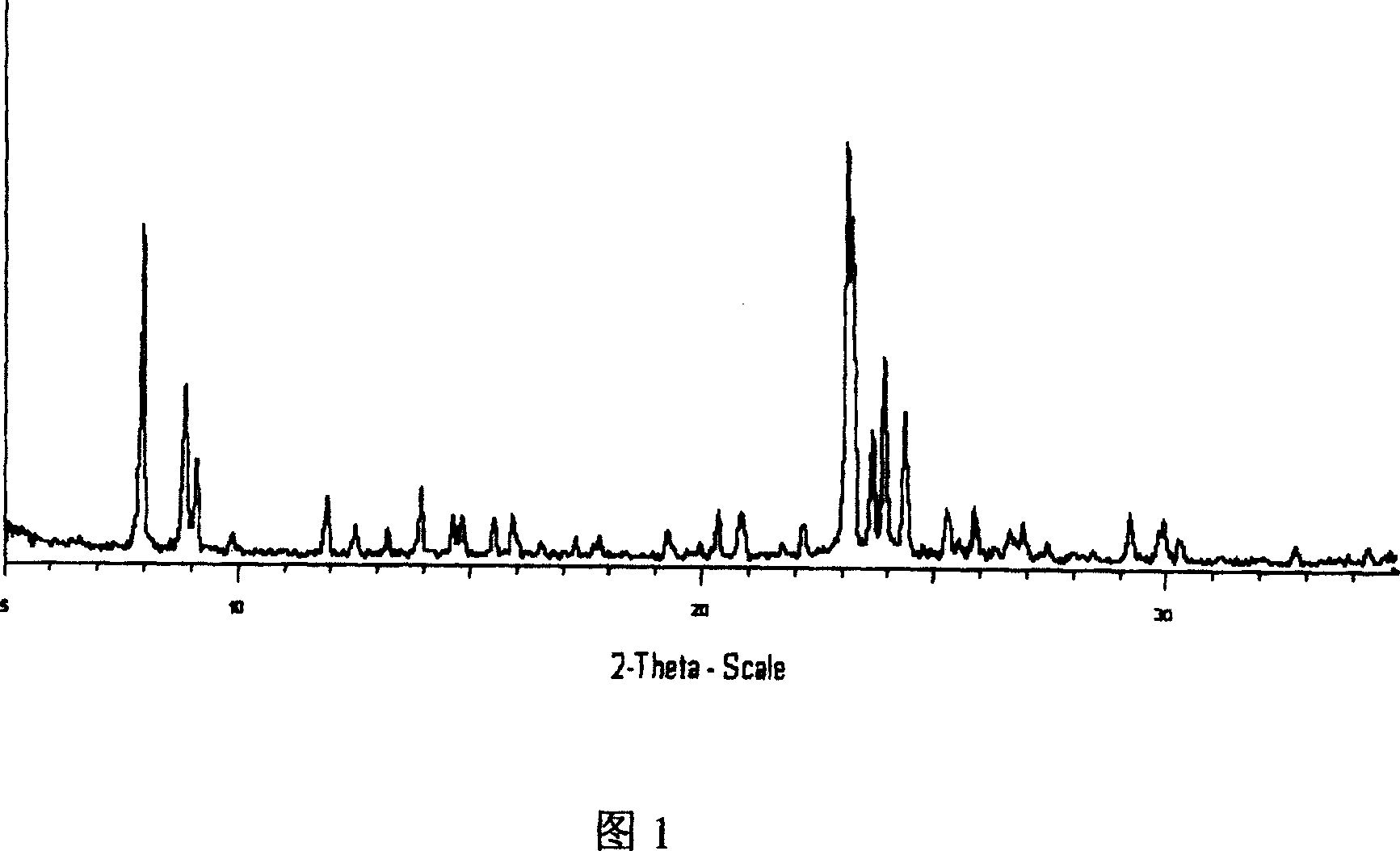

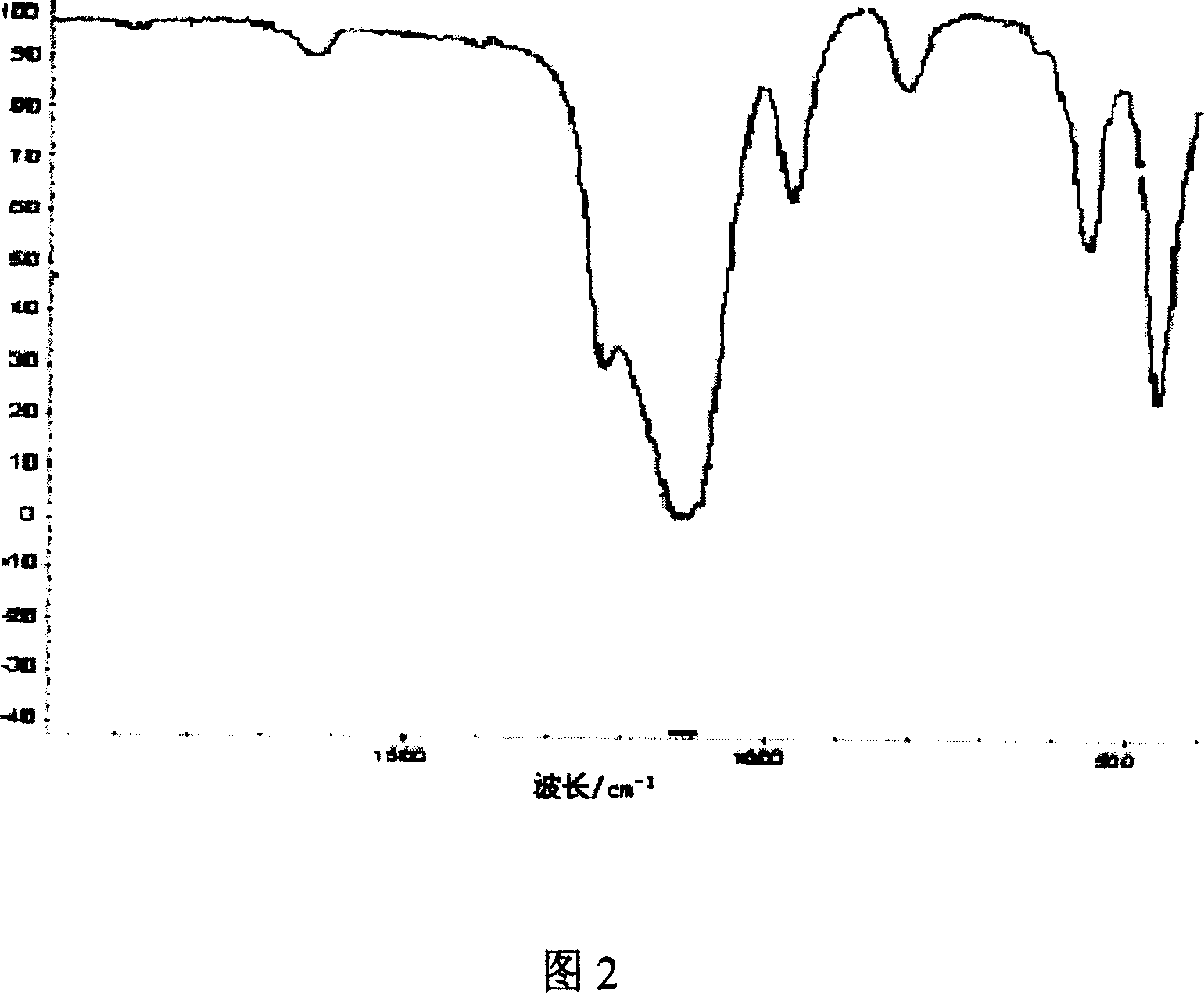

Synthesis method of fine grain ZSM-5 zeolite molecular sieve with high silicon aluminium ratio

InactiveCN1699173AUniform particle sizeHigh ratio of silicon to aluminumPentasil aluminosilicate zeoliteSynthesis methodsSurface-active agents

The invention relates to a synthesis method of fine grain ZSM-5 zeolite molecular sieve with high silicon aluminium ratio, which comprises using a surface active agent, charging it into acidified aluminium salt solution, then slowly dropping alkaline solution formed from sodium silicate, template agent and seed crystal into aluminium saline solution, the overall composition of the obtained reaction mixture being Na2O:Al2O3:SiO2:H2O=1.5-4.0:1:20-280:500-2000 by mol ratio, then subjecting the reaction mixture to thermal crystallization through the conventional method.

Owner:DALIAN LIGONG QIWANGDA CHEM TECH

Thermal crystallization of polyester pellets in liquid

InactiveUS20050065318A1Improve heat transfer rateEnergy efficiencyCrystallization separationSolid sorbent liquid separationPolyesterLiquid medium

A process for thermally crystallizing a polyester polymer by introducing pellets into a liquid medium having a temperature of at least 140° C. within a liquid medium zone and crystallizing the submerged pellets at or above the vapor pressure of the liquid medium without increasing the molecular weight of the pellets, and while the pressure on at least a portion of the pellets is equal to or greater than the vapor pressure of the liquid medium, separating at least a portion of said pellets and at least a portion of the liquid medium from each other. The crystallization is desirably conducted in the liquid medium zone without mechanically induced agitation. Optionally, the pellets are formed by an underfluid pelletizer. There is also provided a process for thermally crystallizing solid pellets in a pipe by directing a flow of solid pellets in a liquid medium through a pipe having an aspect ratio L / D of at least 50:1, wherein the solid pellets are crystallized in the pipe at a liquid medium temperature greater than the Tg of the polyester polymer.

Owner:ALPEK POLYESTER SA DE CV

Thermal crystallization of a molten polyester polymer in a fluid

ActiveUS20050154183A1Energy efficiencyImprove heat transfer rateDrying gas arrangementsChemical/physical/physico-chemical stationary reactorsThermal crystallizationPolyester

A process for crystallizing a polyester polymer by introducing a molten polyester polymer, such as a polyethylene terephthalate polymer, into a liquid medium at a liquid medium temperature greater than the Tg of the polyester polymer, such as at a temperature ranging from 100° C. to 190° C., and allowing the molten polyester polymer to reside in the liquid medium for a time sufficient to crystallize the polymer under a pressure equal to or greater than the vapor pressure of the liquid medium. A process flow, underwater cutting process, crystallization in a pipe, and a separator are also described.

Owner:ALPEK POLYESTER SA DE CV

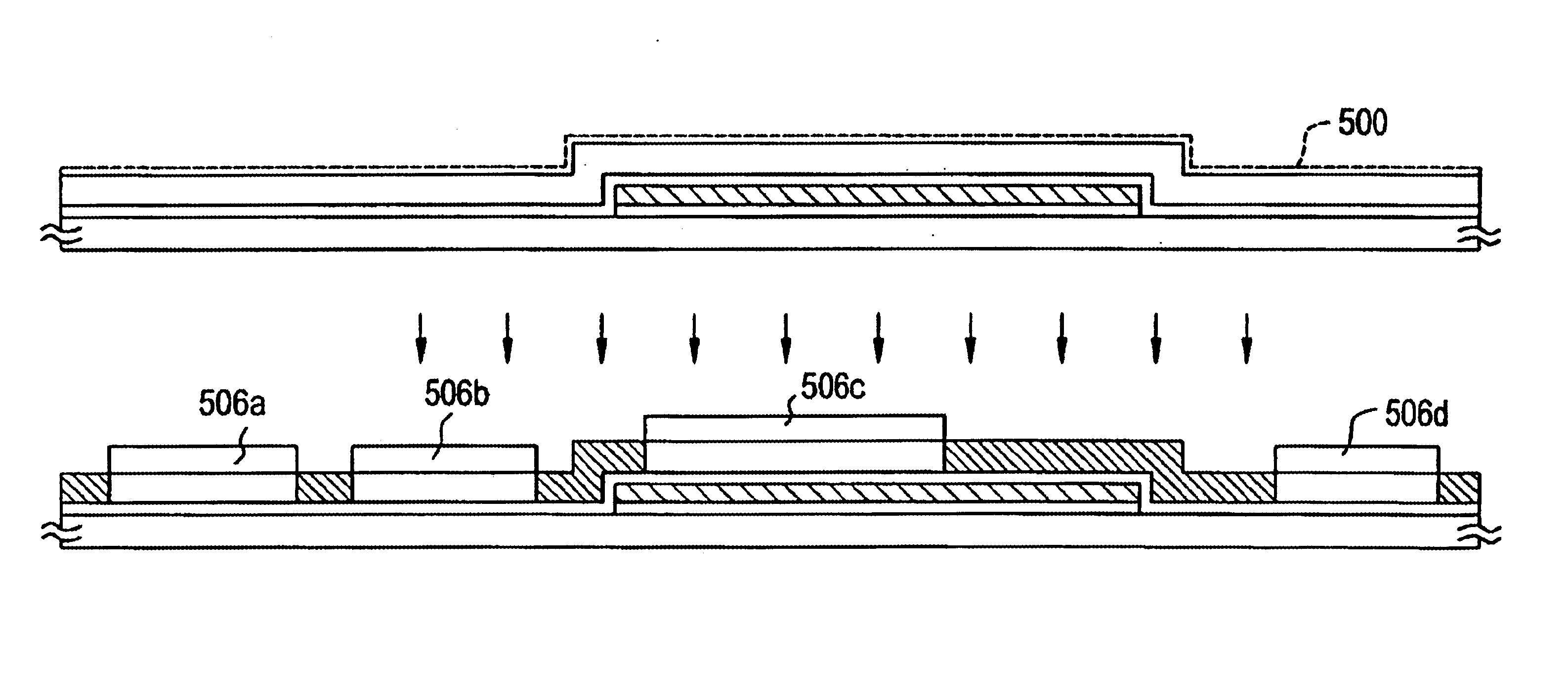

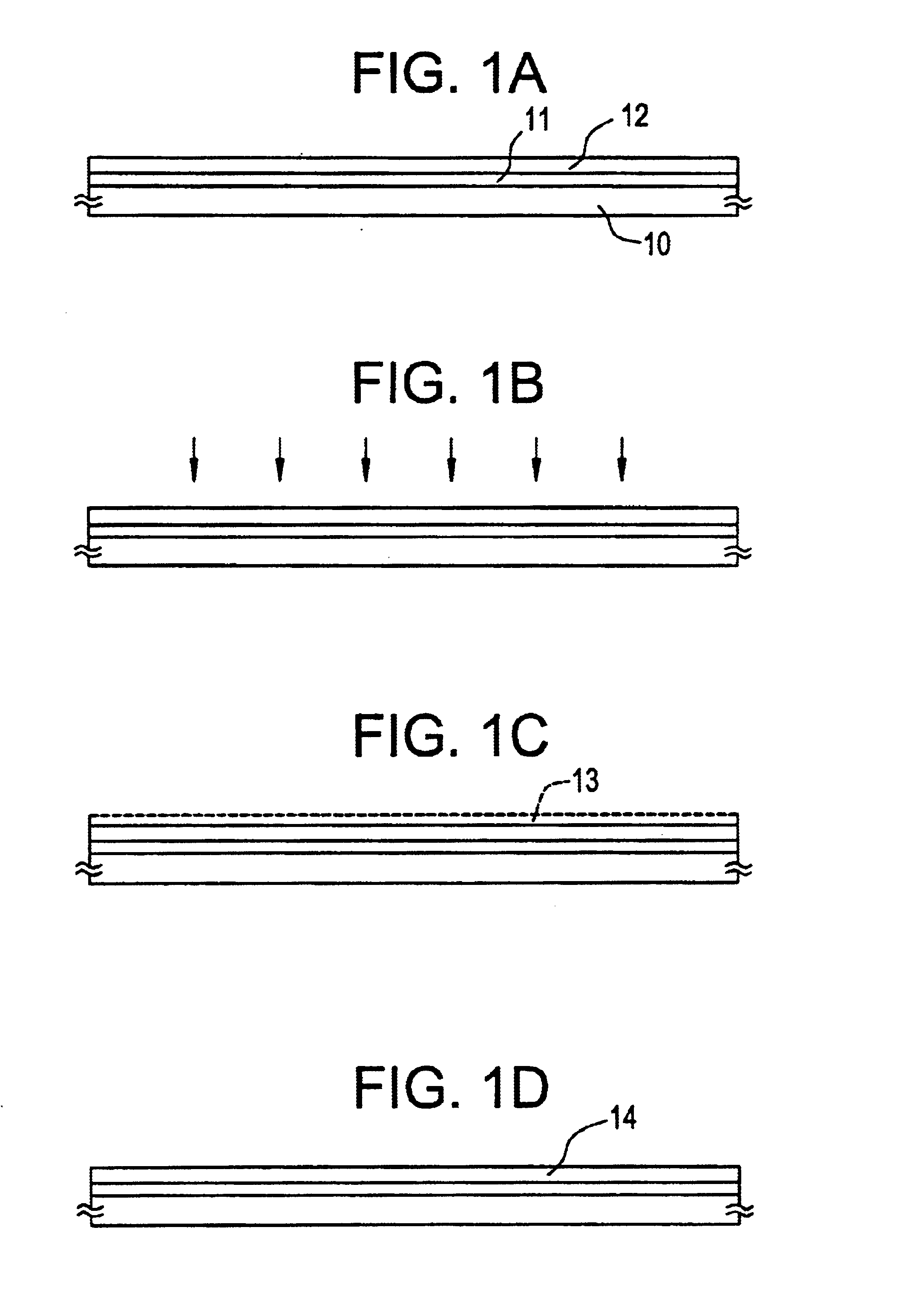

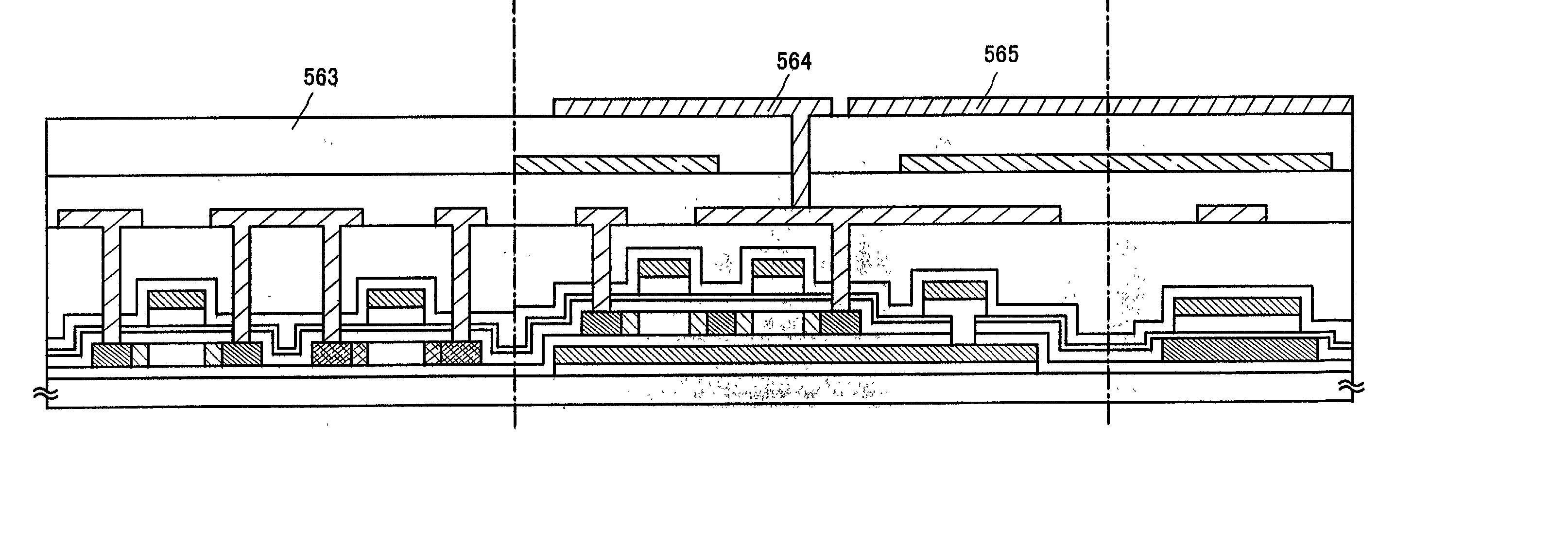

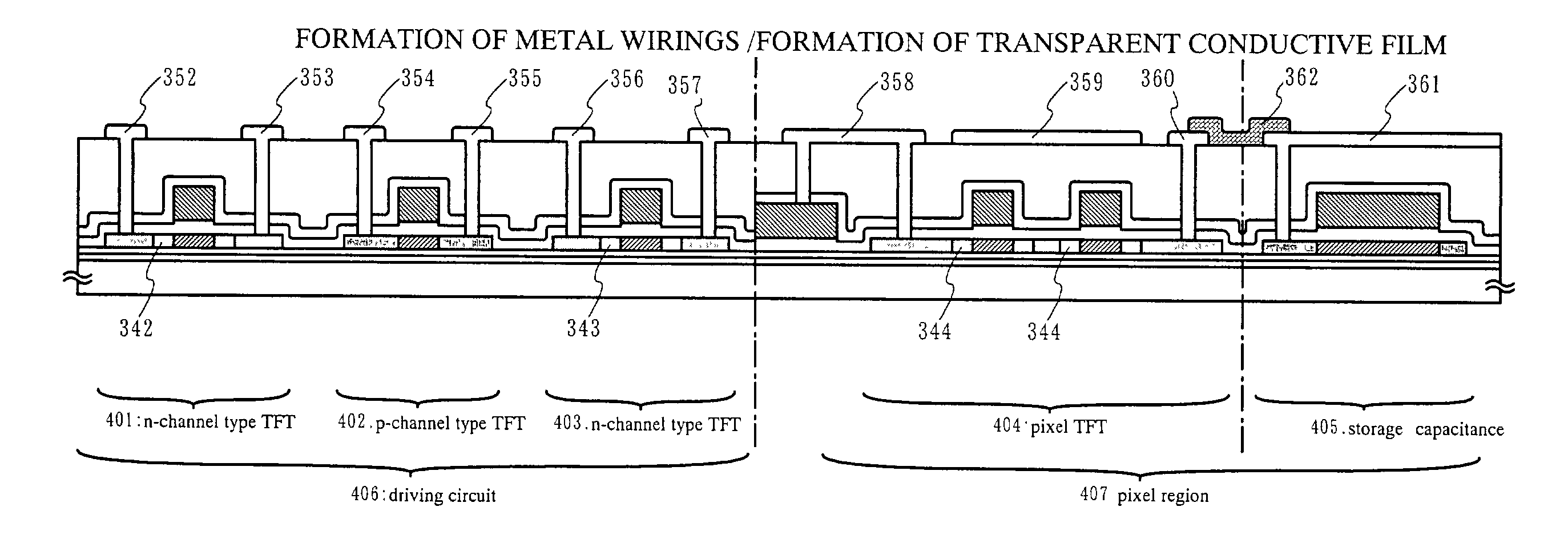

Method of manufacturing a semiconductor device having a crystallized semiconductor film

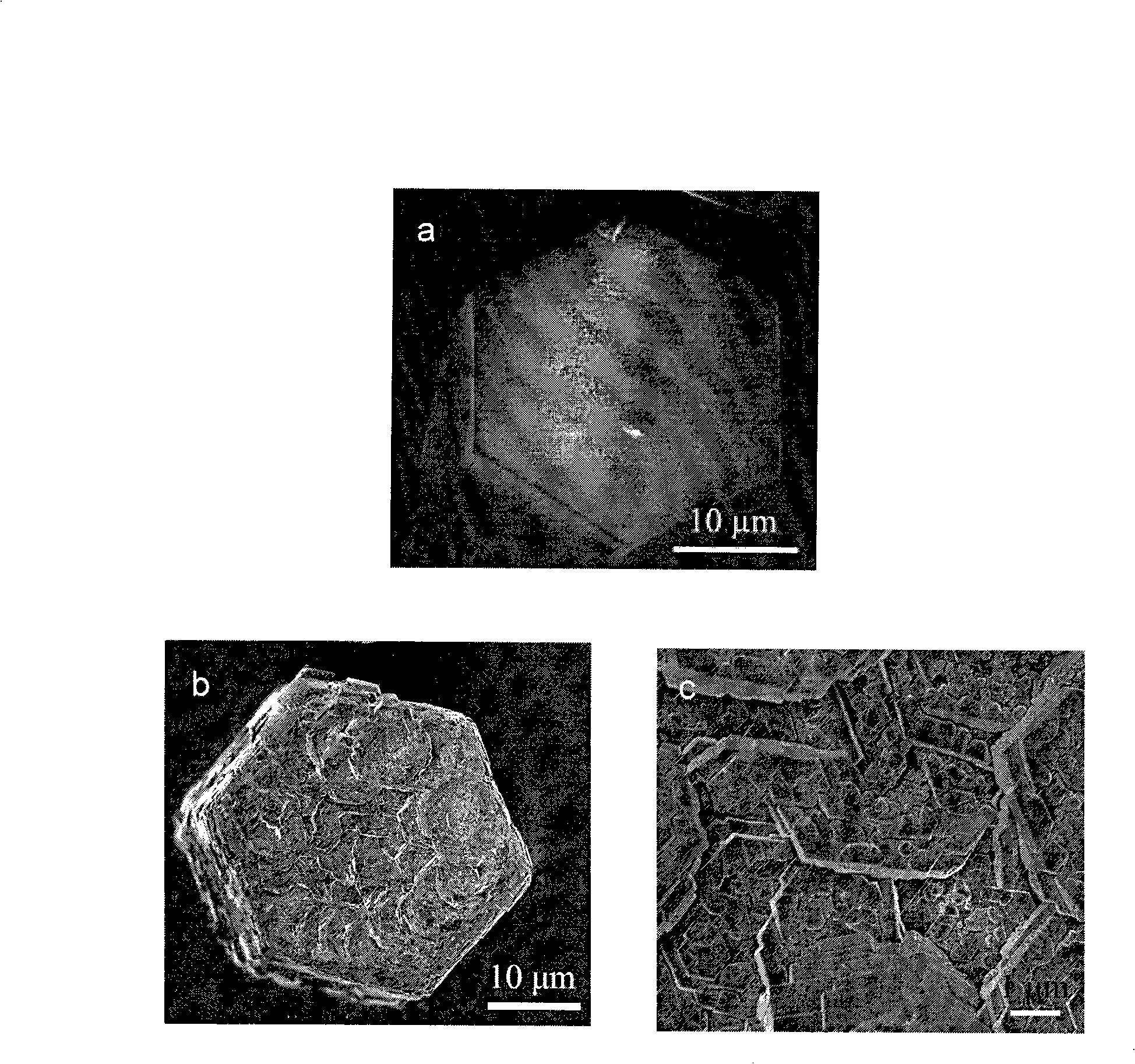

InactiveUS6830994B2High densityChemical potential of the semiconductor film is increasedTransistorSolid-state devicesAtmospheric airNitrogen

The number of grains in active regions of devices can be made uniform by making the grains of crystalline semiconductor films, obtained by thermal crystallization using a metal element, smaller. The present invention is characterized in that a semiconductor film is exposed within an atmosphere in which a gas, having as its main constituent one or a plurality of members from the group consisting of inert gas elements, nitrogen, and ammonia, is processed into a plasma, and then thermal crystallization using a metal element is performed. The concentration of crystal nuclei1 generated is thus increased, making the grain size smaller, by performing these processes. Heat treatment may also be performed, of course, after exposing the semiconductor film, to which the metal element is added, to an atmosphere in which a gas, having as its main constituent one or a plurality of members from the group consisting of inert gas elements, nitrogen, and ammonia, is processed into a plasma.

Owner:SEMICON ENERGY LAB CO LTD

Thermal crystallization of polyester pellets in liquid

InactiveUS7329723B2High molecular weightCrystallization separationSolid sorbent liquid separationPolyesterLiquid medium

A process for thermally crystallizing a polyester polymer by introducing pellets into a liquid medium having a temperature of at least 140° C. within a liquid medium zone and crystallizing the submerged pellets at or above the vapor pressure of the liquid medium without increasing the molecular weight of the pellets, and while the pressure on at least a portion of the pellets is equal to or greater than the vapor pressure of the liquid medium, separating at least a portion of said pellets and at least a portion of the liquid medium from each other. The crystallization is desirably conducted in the liquid medium zone without mechanically induced agitation. Optionally, the pellets are formed by an underfluid pelletizer. There is also provided a process for thermally crystallizing solid pellets in a pipe by directing a flow of solid pellets in a liquid medium through a pipe having an aspect ratio L / D of at least 50:1, wherein the solid pellets are crystallized in the pipe at a liquid medium temperature greater than the Tg of the polyester polymer.

Owner:ALPEK POLYESTER SA DE CV

Method of manufacturing a semiconductor device

InactiveUS20020155706A1High densityChemical potential of the semiconductor film is increasedTransistorSolid-state devicesAtmospheric airNitrogen

The number of grains in active regions of devices can be made uniform by making the grains of crystalline semiconductor films, obtained by thermal crystallization using a metal element, smaller. The present invention is characterized in that a semiconductor film is exposed within an atmosphere in which a gas, having as its main constituent one or a plurality of members from the group consisting of inert gas elements, nitrogen, and ammonia, is processed into a plasma, and then thermal crystallization using a metal element is performed. The concentration of crystal nuclei1 generated is thus increased, making the grain size smaller, by performing these processes. Heat treatment may also be performed, of course, after exposing the semiconductor film, to which the metal element is added, to an atmosphere in which a gas, having as its main constituent one or a plurality of members from the group consisting of inert gas elements, nitrogen, and ammonia, is processed into a plasma.

Owner:SEMICON ENERGY LAB CO LTD

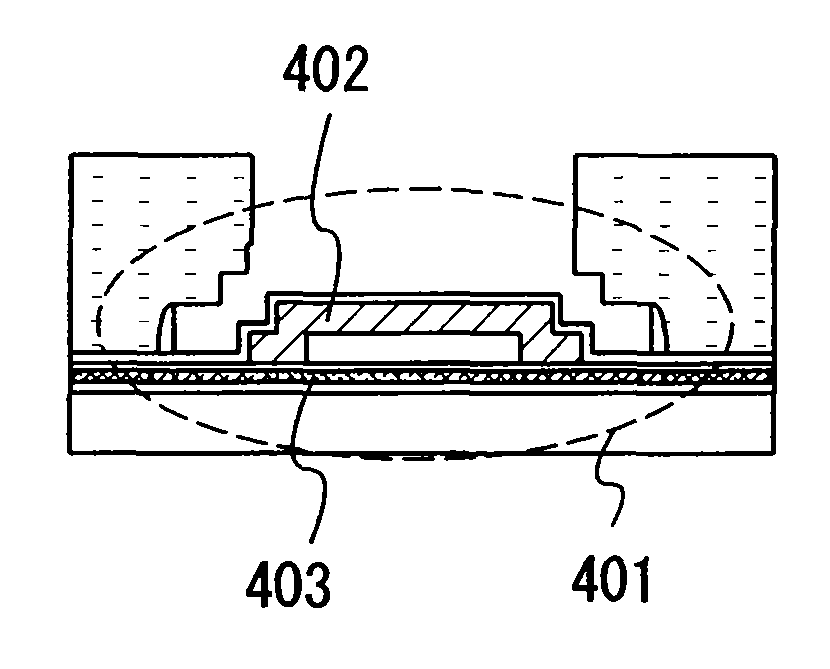

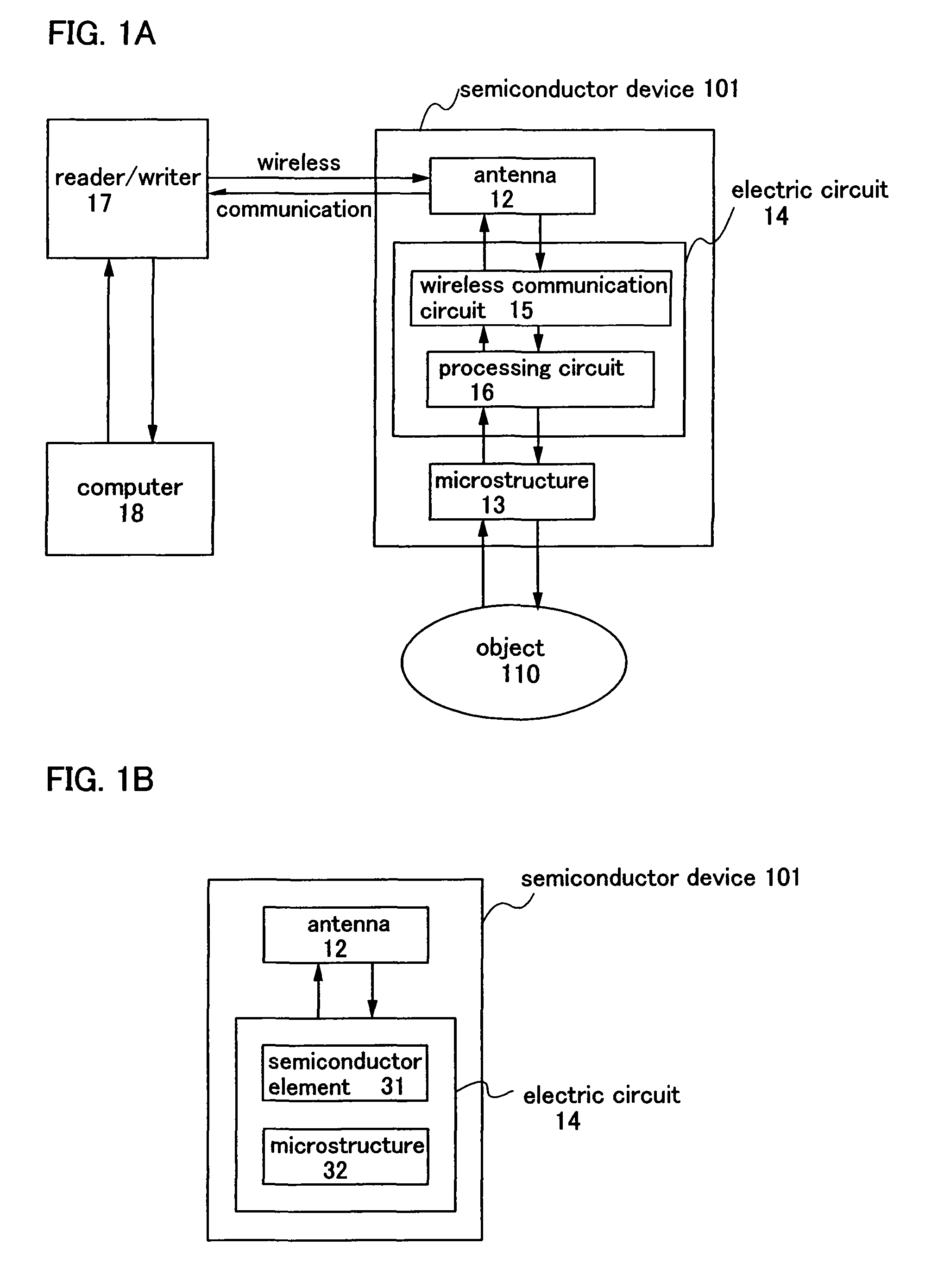

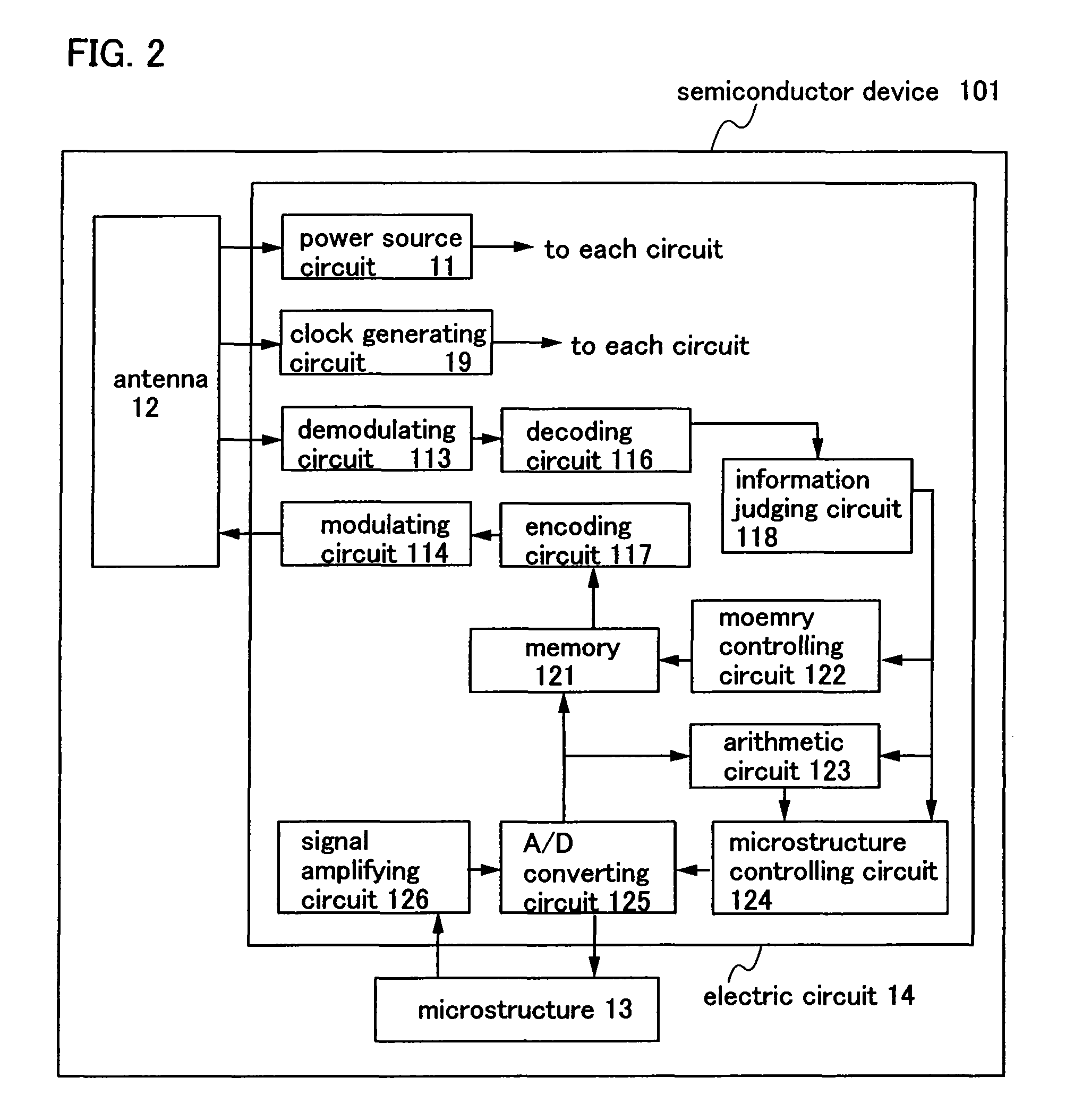

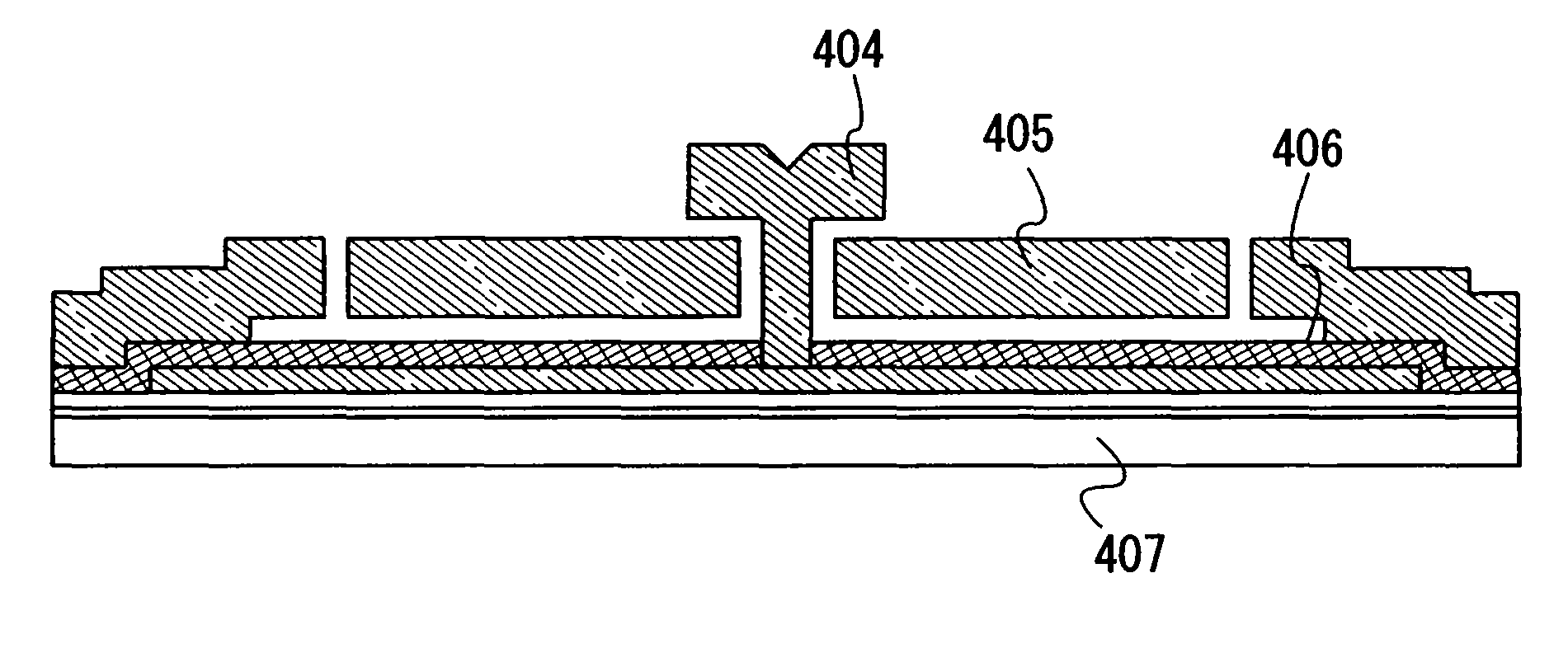

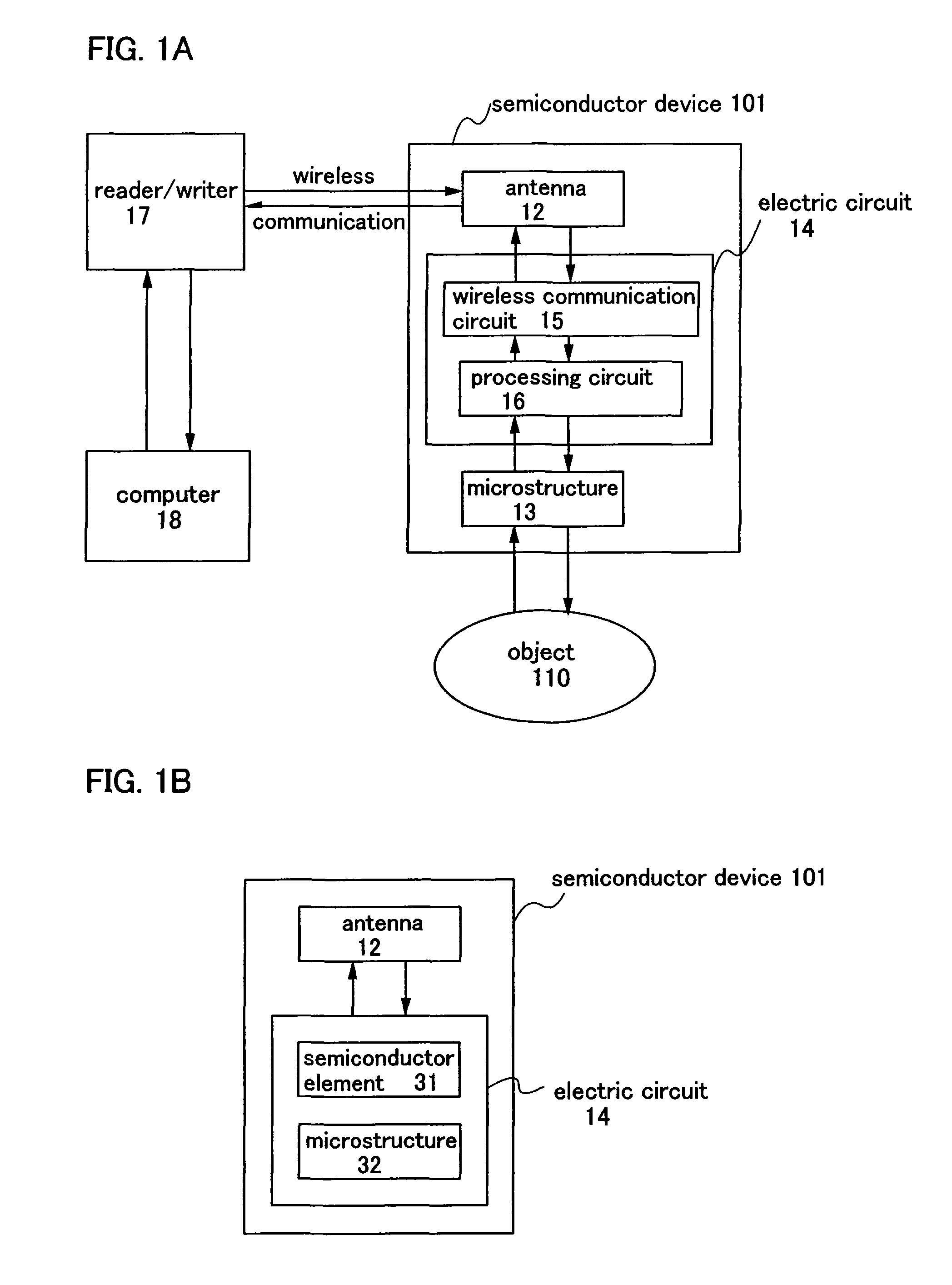

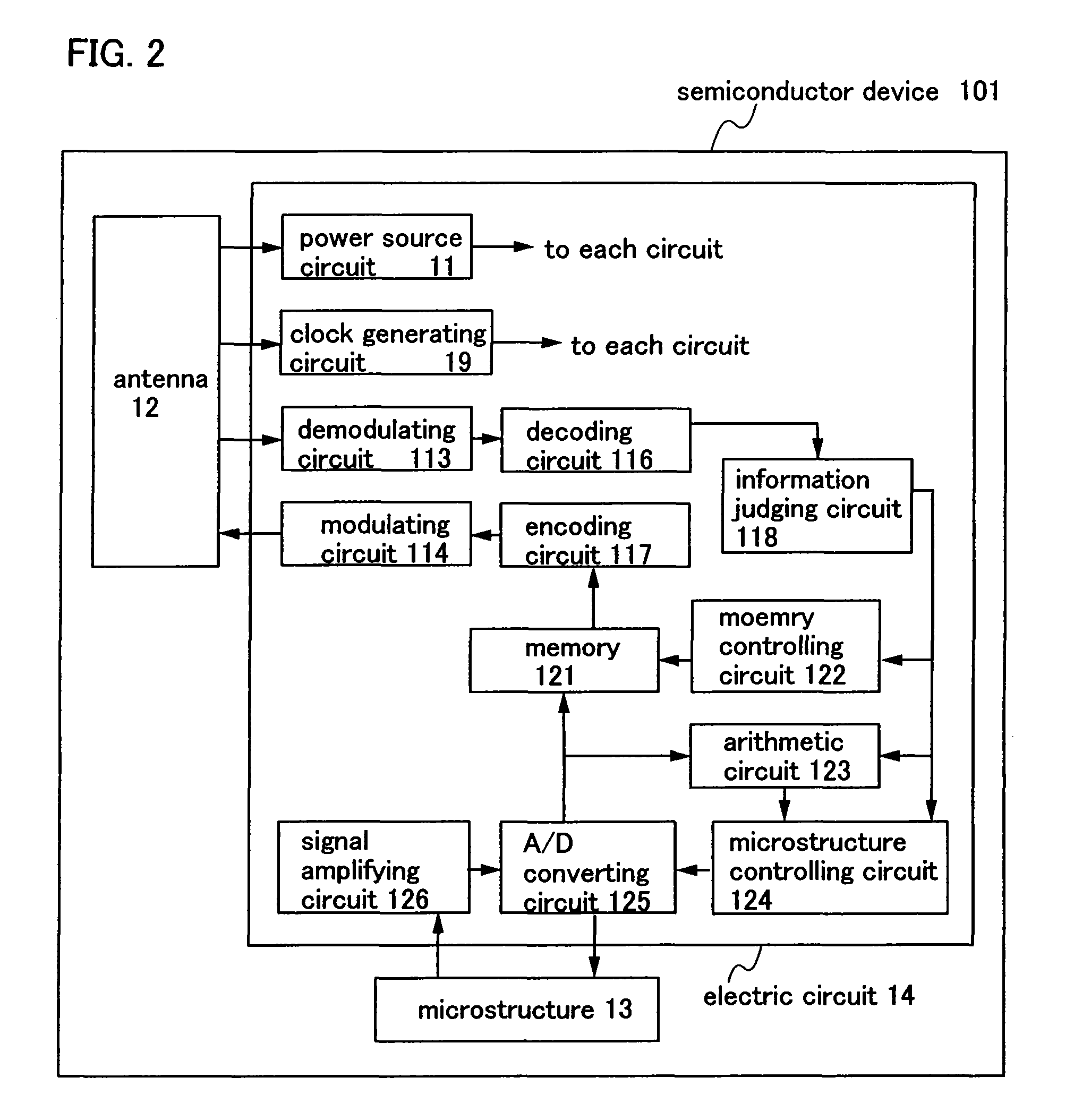

Semiconductor device and manufacturing method thereof

InactiveUS7642612B2Reduce stepsLow pour pointSemiconductor/solid-state device detailsSolid-state devicesLaser crystallizationCommunication circuits

It has been difficult to manufacture a semiconductor device equipped with a microstructure having a space, an electric circuit for controlling the microstructure, and the like over one substrate.In a semiconductor device, a microstructure and an electric circuit for controlling the microstructure can be provided over one substrate by manufacturing the microstructure in such a way that a structural layer having polycrystalline silicon obtained by laser crystallization or thermal crystallization using a metal element is formed and processed at low temperature. As the electric circuit, a wireless communication circuit for carrying out wireless communication with an antenna is given.

Owner:SEMICON ENERGY LAB CO LTD

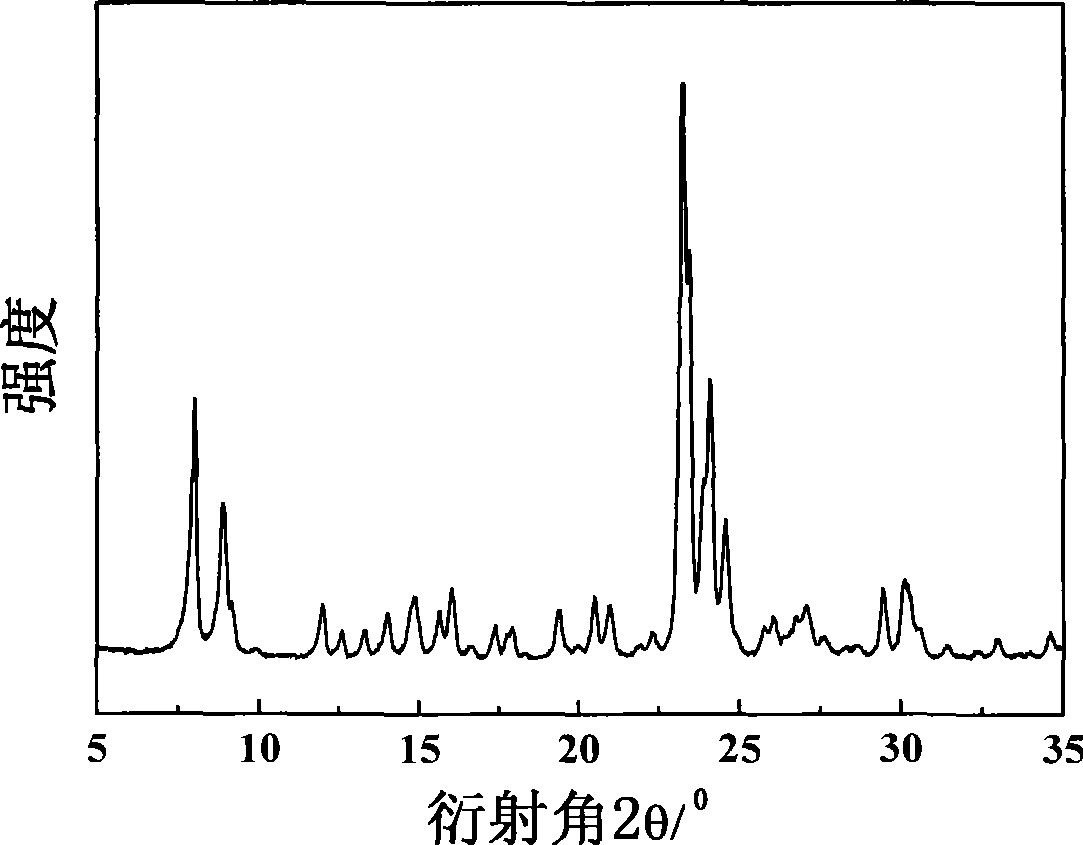

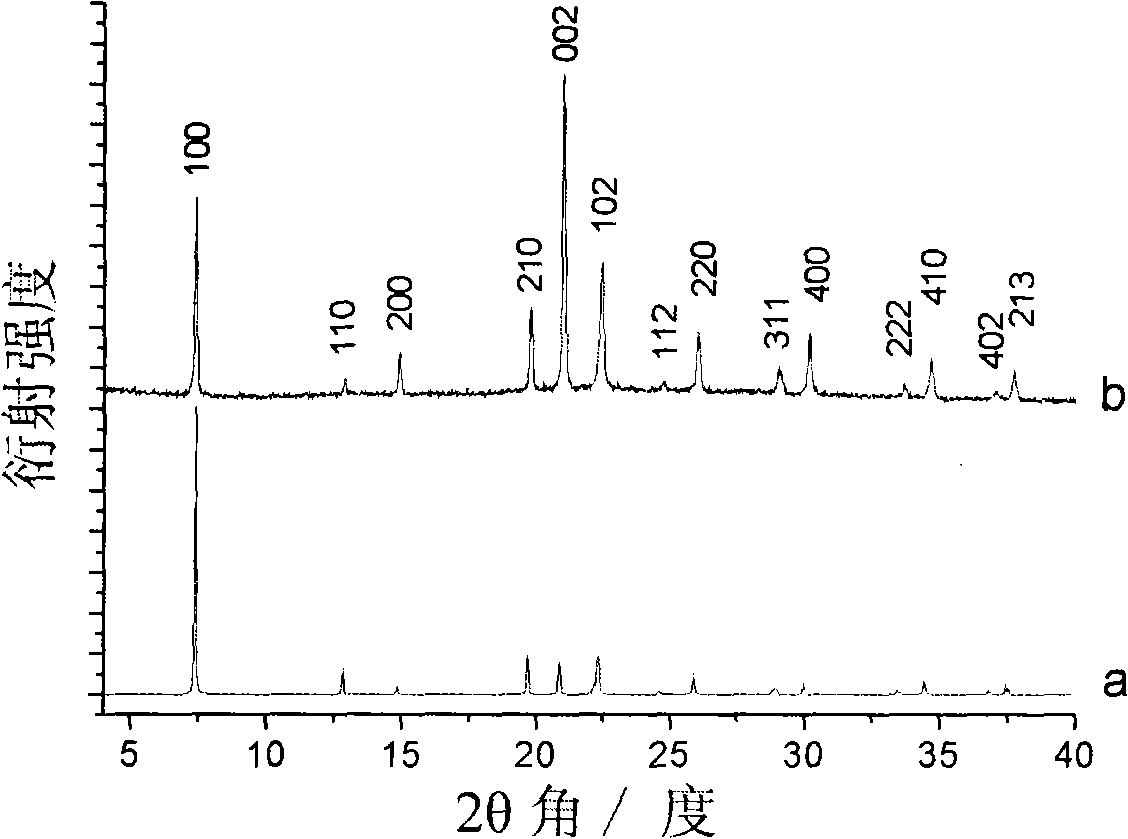

Method for synthesizing silicon aluminum orthophosphate molecular sieve using white bole

InactiveCN101176851AGood hydrothermal stabilityHigh reactivityMolecular sieve catalystsMolecular-sieve and base-exchange phosphatesALUMINUM PHOSPHATEWhite Bole

The invention relates to a method of molecular sieve catalyst synthesis using the kaolin for the synthesis of silicon aluminum phosphate molecular sieve, belonging to the technical field of the preparation of the catalyst materials. The invention is characterized in utilizing the low-cost kaolin as materials. Through (1) roasting the kaolin in the high temperature to gain the crystal aluminum sources and silicon sources; (2) mixing the kaolin with the phosphorus sources and the template agent with the deionized water, processing hydro-thermal crystallization, and roasting and activating the products after washing and drying, the catalyst of the silicon aluminum phosphate molecular sieve can be gained. The structure of the silicon aluminum phosphate molecular sieve is CHA or the intergrowth of CHA and AEI. The invention has the advantages of smaller or lamellar structure molecular sieve gains of the prepared catalyst, which can be used for the process of making olefin from the oxygenic compounds like the limited diffuse alcohol ether to gain the good activity of reaction and the product selectivity, and further the directly application of the catalyst carried by the kaolin micro sphere into fluidized bed reactor.

Owner:CHINA NAT CHEM ENG GRP CORP LTD +1

Semiconductor device and manufacturing method thereof

InactiveUS20060284183A1Reduce manufacturing costIncrease freedomSemiconductor/solid-state device detailsSolid-state devicesDevice materialLaser crystallization

It has been difficult to manufacture a semiconductor device equipped with a microstructure having a space, an electric circuit for controlling the microstructure, and the like over one substrate. In a semiconductor device, a microstructure and an electric circuit for controlling the microstructure can be provided over one substrate by manufacturing the microstructure in such a way that a structural layer having polycrystalline silicon obtained by laser crystallization or thermal crystallization using a metal element is formed and processed at low temperature. As the electric circuit, a wireless communication circuit for carrying out wireless communication with an antenna is given.

Owner:SEMICON ENERGY LAB CO LTD

Process for synthesizing ZSM-5 molecular sieve

InactiveCN1504410ALow costAvoid the disadvantages of difficult stirring and poor mass and heat transferPentasil aluminosilicate zeoliteSlurrySolid content

The invention provides a process for synthesizing ZSM-5, characterized in that, diatomaceous soil is used as a silicon source, and total or part of aluminum source to be mixed with other aluminum source, NaOH and water, 0-10 wt.% molecular sieve is added in as seed crystal to prepare slurry of reaction mixture, performing water thermal crystallization in normal condition. The process can reduce gelatification, increase solid content and reduce the cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesizing boron-containing molecular sieve

The invention relates to a method for synthesizing a boron-containing molecular sieve, namely a method for synthesizing a B-ZSM-5 molecular sieve, which belongs to the technical field of inorganic chemical synthesis. The method is characterized in that cheap cyclic molecular amine and hexamethylene imine (HMI) or piperidine (PI) or a mixture thereof is taken as an organic alkali template agent, and a directing agent is prepared by the synthesis process of the directing agent; substances such as a silicon source, a boron source, a sodium source and the like are adopted; the mol mixture ratio of SiO2 in the silicon source to the organic alkali template agent to B2O3 in the boron source to Na2O in the sodium source to H2O is equal to 1: (0.5-2): (0.005-0.1): (0-0.15): (10-40), and a mixture solution is prepared; and then a certain amount of the directing agent is added into the solution, and then the boron-containing molecular sieve (B-ZSM-5) is obtained through hydro-thermal crystallization and processes such as filtration, washing, drying, baking and the like.

Owner:SHANGHAI UNIV

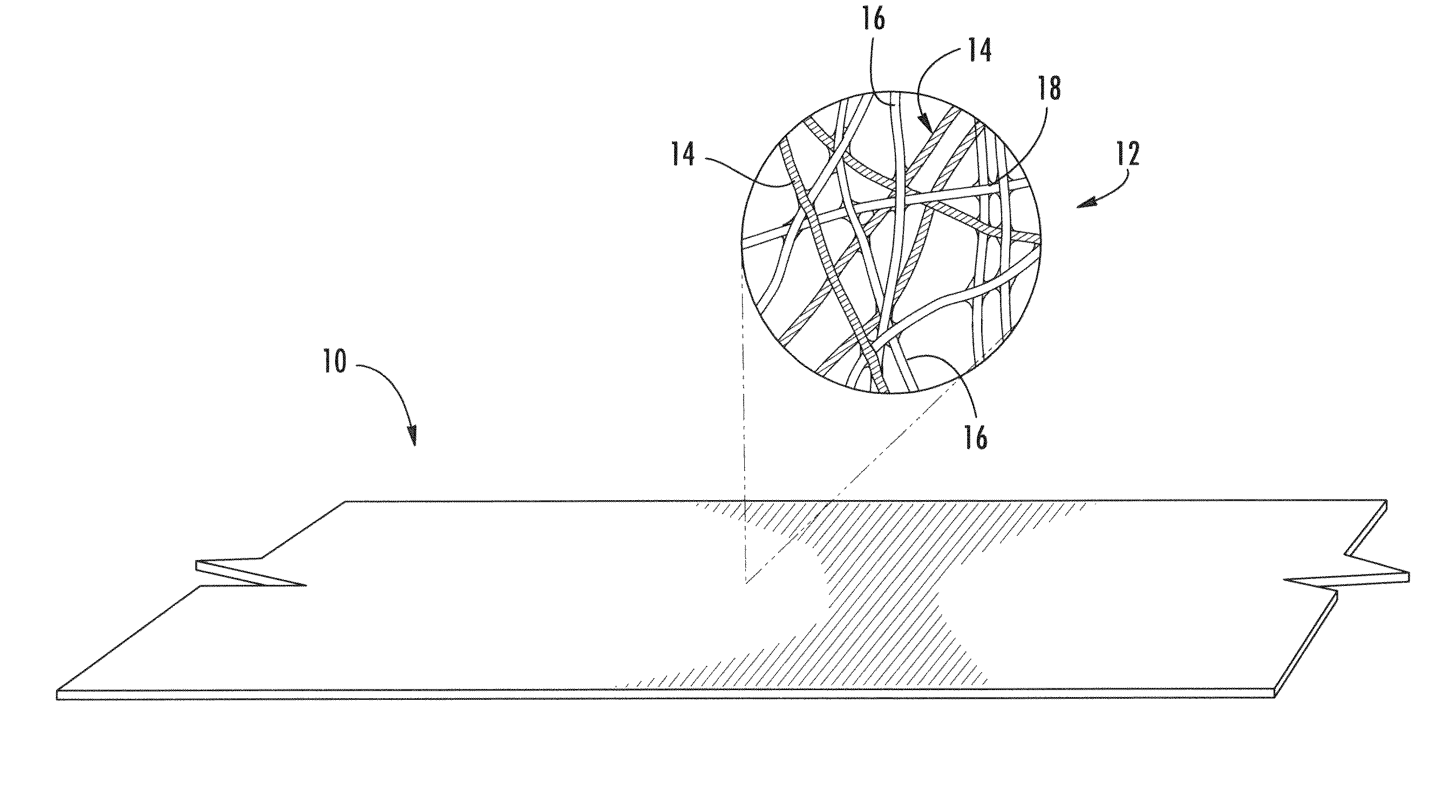

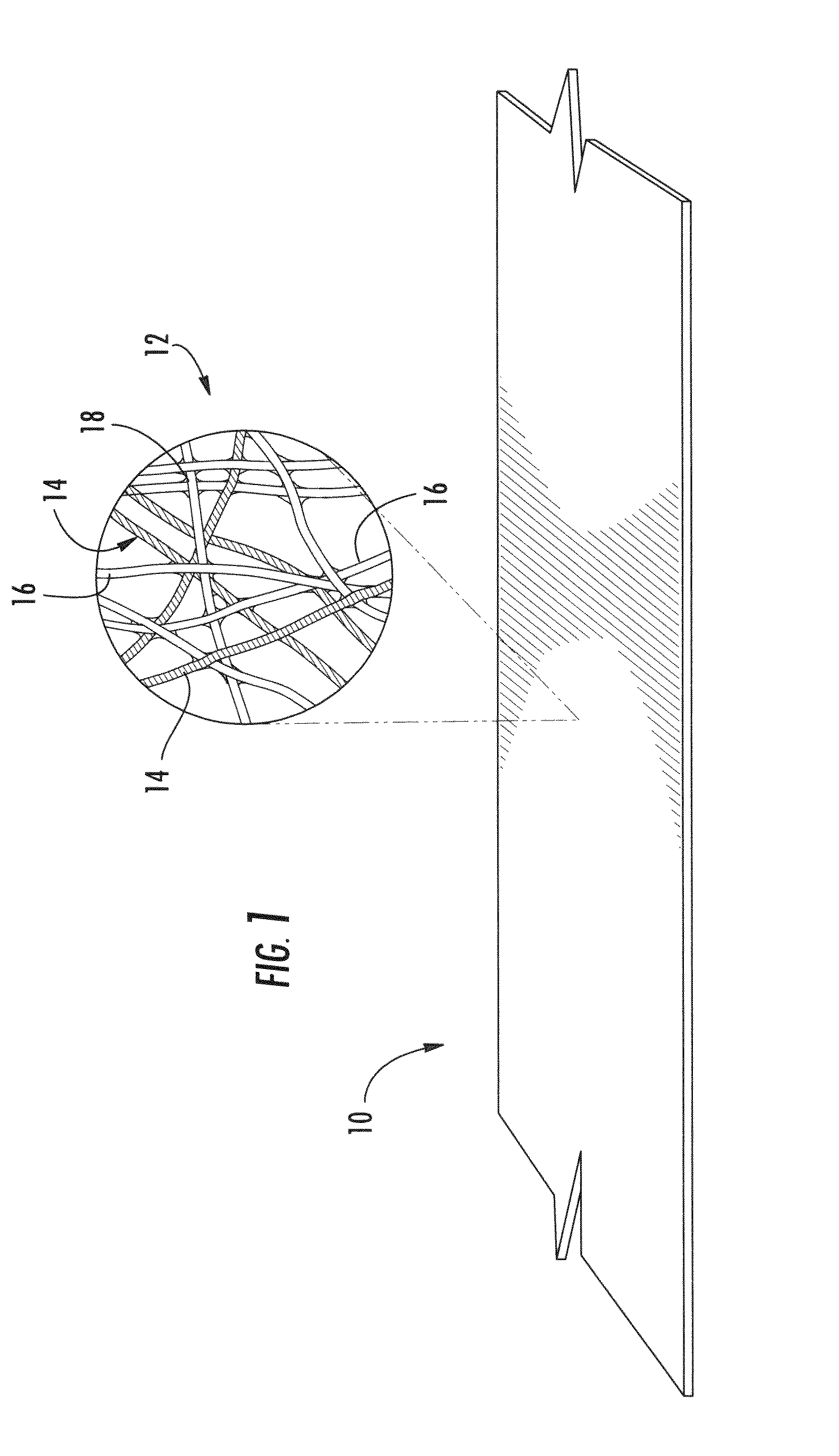

Area bonded nonwoven fabric from single polymer system

A nonwoven fabric is provided having a plurality of semi-crystalline filaments that are thermally bonded to each other and are formed of the same polymer and exhibit substantially the same melting temperature. The fabric is produced by melt spinning an amorphous crystallizable polymer to form two components having different levels of crystallinity. During spinning, a first component of the polymer is exposed to conditions that result in stress-induced crystallization such that the first polymer component is in a semi-crystalline state and serves as the matrix or strength component of the fabric. The second polymer component is not subjected to stress induced crystallization and thus remains in a substantially amorphous state which bonds well at relatively low temperatures. In a bonding step, the fabric is heated to soften and fuse the binder component. Under these conditions, the binder component undergoes thermal crystallization so that in the final product, both polymer components are semi-crystalline.

Owner:FIBERWEB LLC

Method for preparing double-catalysis center molecular sieve nucleocapsid material with hydrothermal/solvent-thermal system

InactiveCN101314135ALower catalyst costsImprove reaction efficiencyMolecular sieve catalystsMolecular-sieve and base-exchange compoundsAlkaneMolecular sieve

The invention belongs to a preparation technology of a molecular sieve core-shell material, in particular relating to a method for preparing the molecular sieve core-shell material with a double catalytic center by utilizing a water-thermal / solvent-thermal epitaxial growth method. The molecular sieve core-shell material prepared by the method can be respectively doped with different transition metal ions in two parts of a core and a shell according to the catalytic need so as to provide different catalytic centers. The method comprises the following steps that: a method of two-step synthesis is adopted, a molecular sieve crystal doped with transition metal ions A is prepared first, then is added into is a sol system of a molecular sieve crystal doped with transition metal ions B and is subject to water-thermal / solvent-thermal crystallization, and a micropore composite material provided with the double catalytic center can be produced by removing a template under high temperature. The molecular sieve core-shell material can be widely applied in the catalytic field through adjusting and changing the kind of doped metals, and is more suitable for being applied in fields of heterocatalytic reactions needing two-step catalysis, terminal group oxidation reactions of alkane, and structure reforming of long-chain alkane.

Owner:JILIN UNIV

Synthesis method of titanium-containing molecular sieve

InactiveCN100344375CReduce manufacturing costGood repeatabilityMolecular sieve catalystsCrystalline aluminosilicate zeolitesMolecular sieveInorganic Chemical

The invention relates the method for synthesizing titanium molecular screen, belonging to inorganic chemical synthesized technique field. The method comprises the following steps: using silica gel or silicasol as silicon source, using organic titanium acid ester as titanium source, using hexamethylene diamine or piperidine or the mixture of them as organic form agent, synthesizing the guiding agent, preparing reaction liquid, carrying out thermal crystallization, then filtering, washing, drying, calcining, and getting the TS-1 molecular screen. The method has the advantages of low cost, good repeatability and low pollution emission.

Owner:EAST CHINA NORMAL UNIV

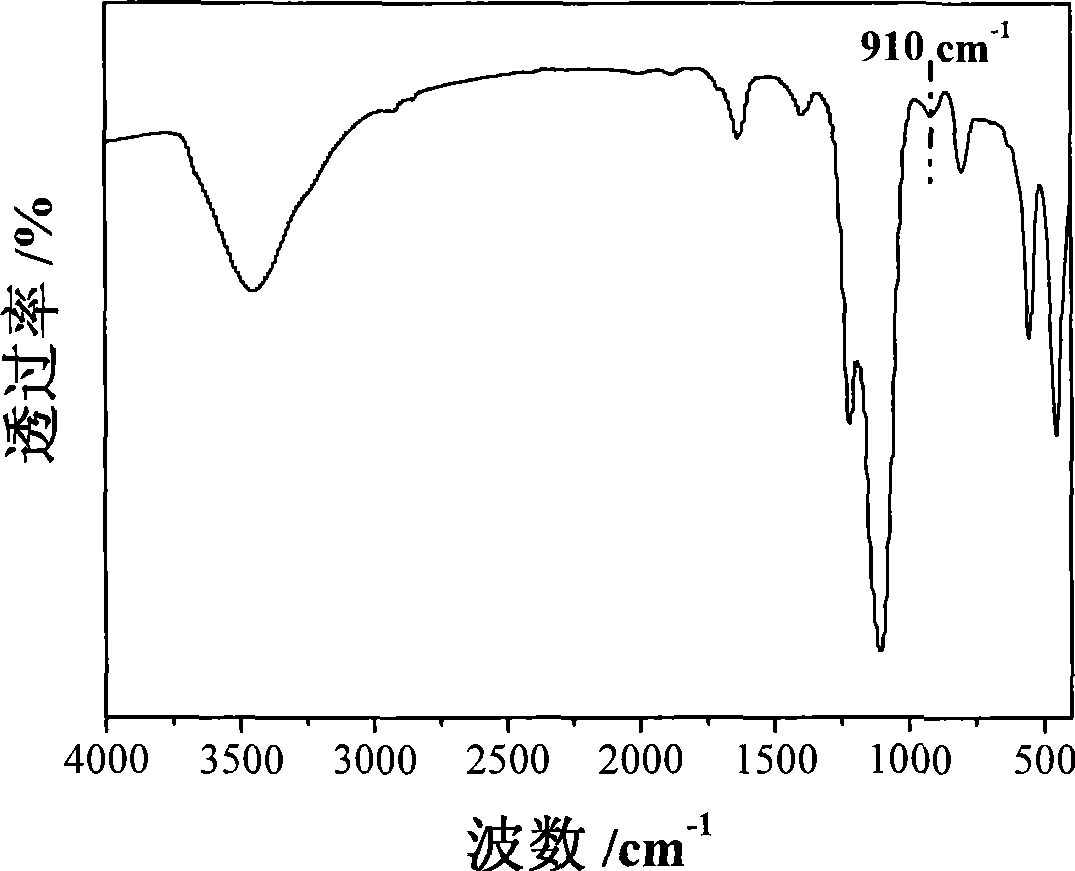

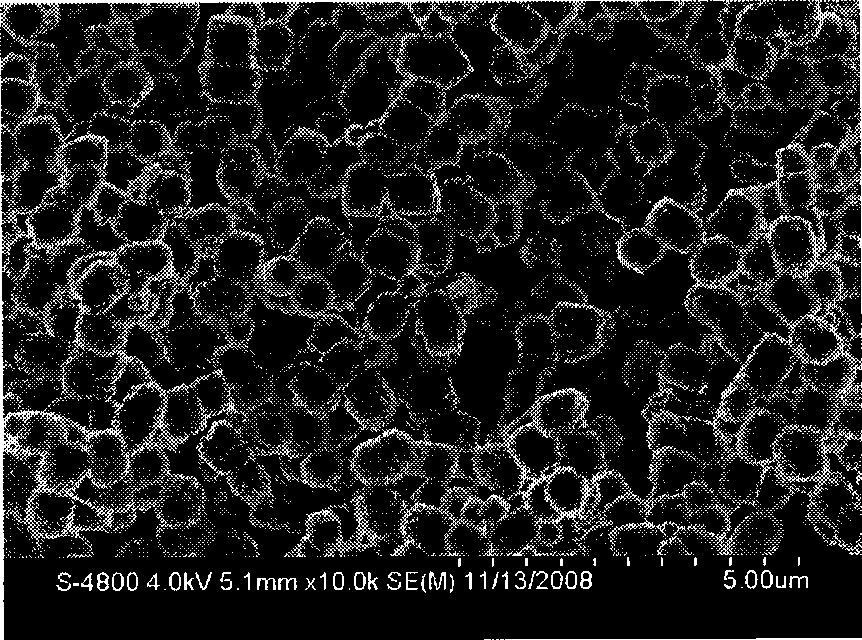

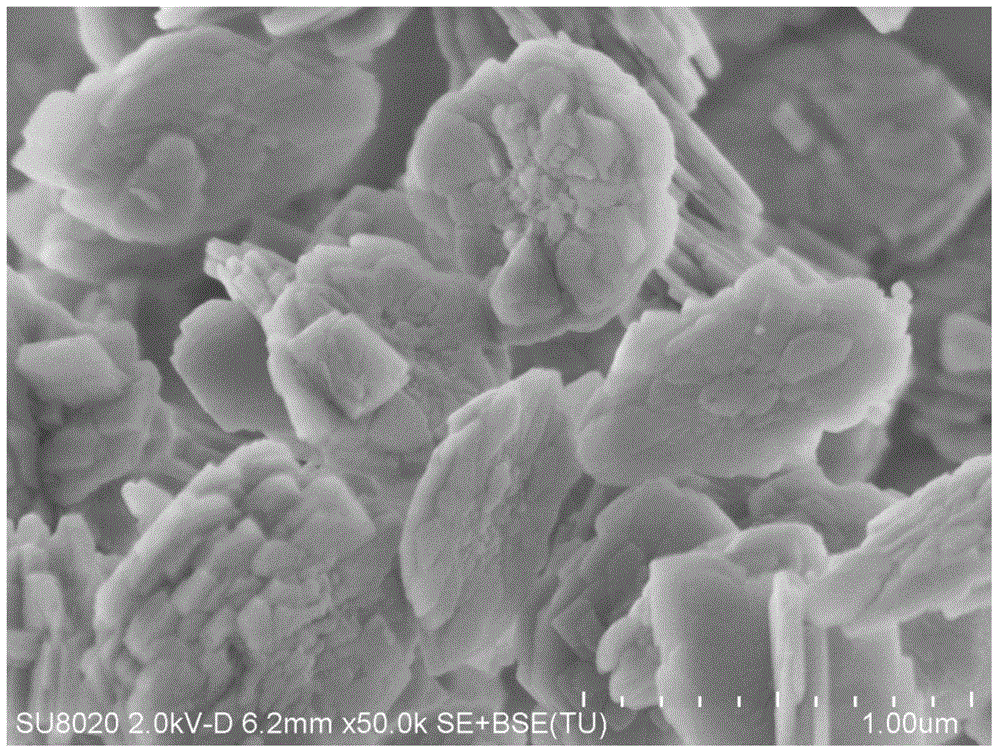

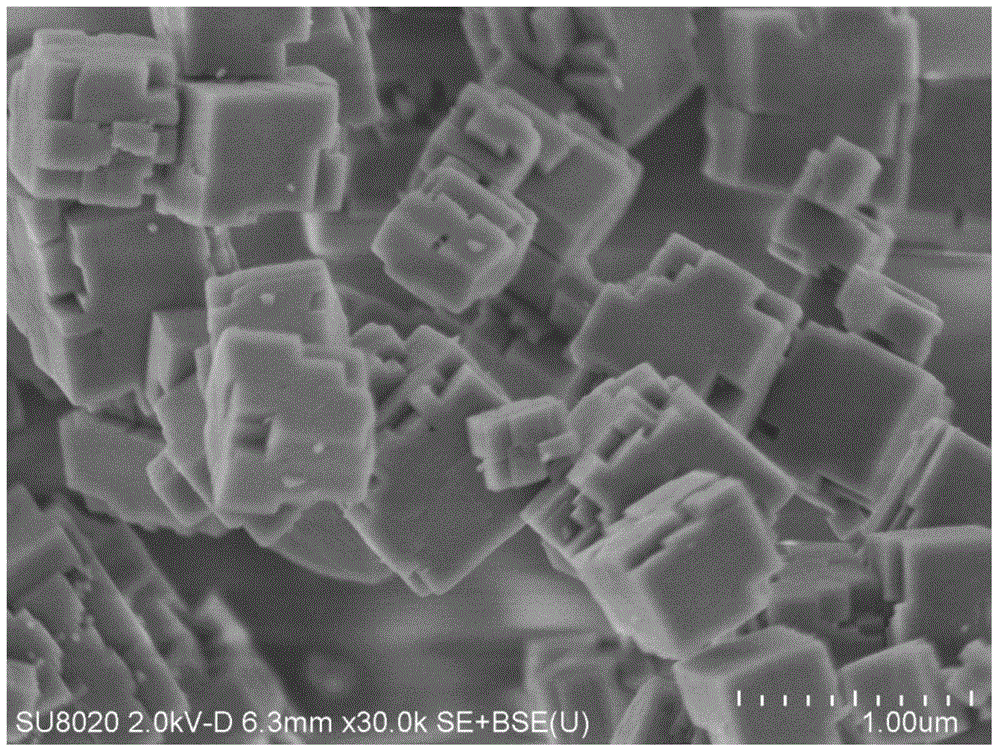

Synthetic method of flaky nano-SAPO-34 molecular sieve

ActiveCN105585022ASuitable for large-scale industrial productionHigh yieldMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveSeed crystal

The application relates to a method for preparing a flaky nano-SAPO-34 molecular sieve. The method is characterized by comprising the following steps: adding a specific organic additive into gel obtained by mixing of an aluminium source, a phosphorus source, a silicon source, a template and water, uniformly stirring, adding the mixture into a nano-SAPO-34 molecular sieve as seed crystal, and carrying out thermal crystallization to prepare the product. The SAPO-34 molecular sieve prepared by the above method shows excellent performance in a methanol-to-olefin reaction.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

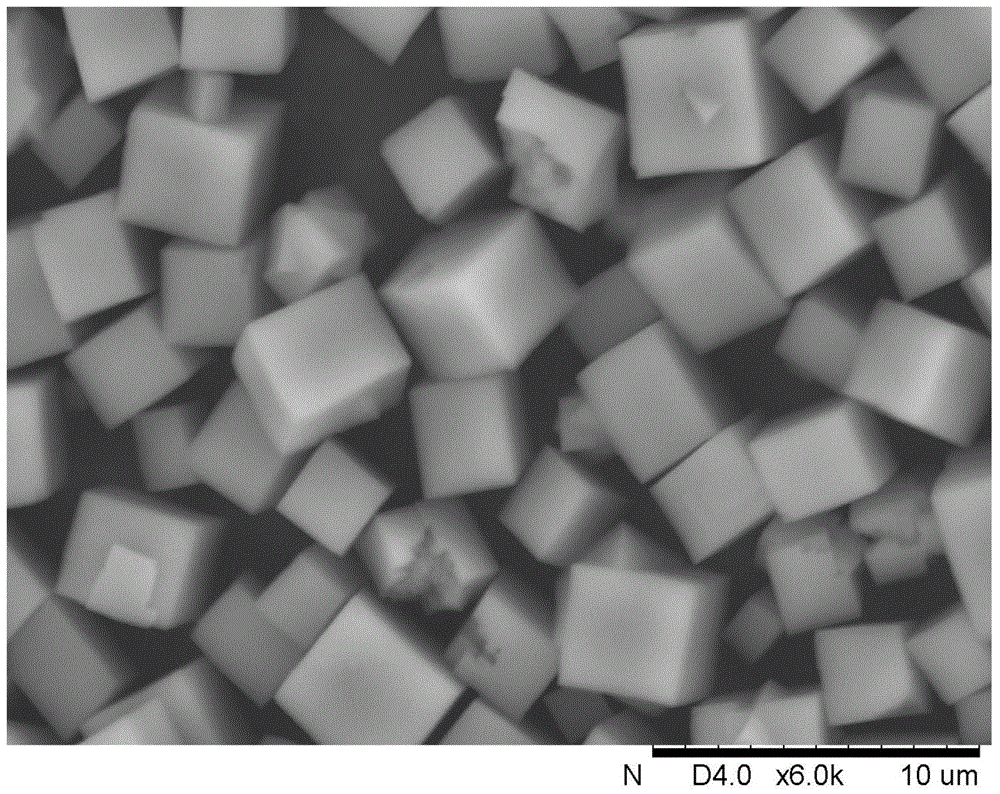

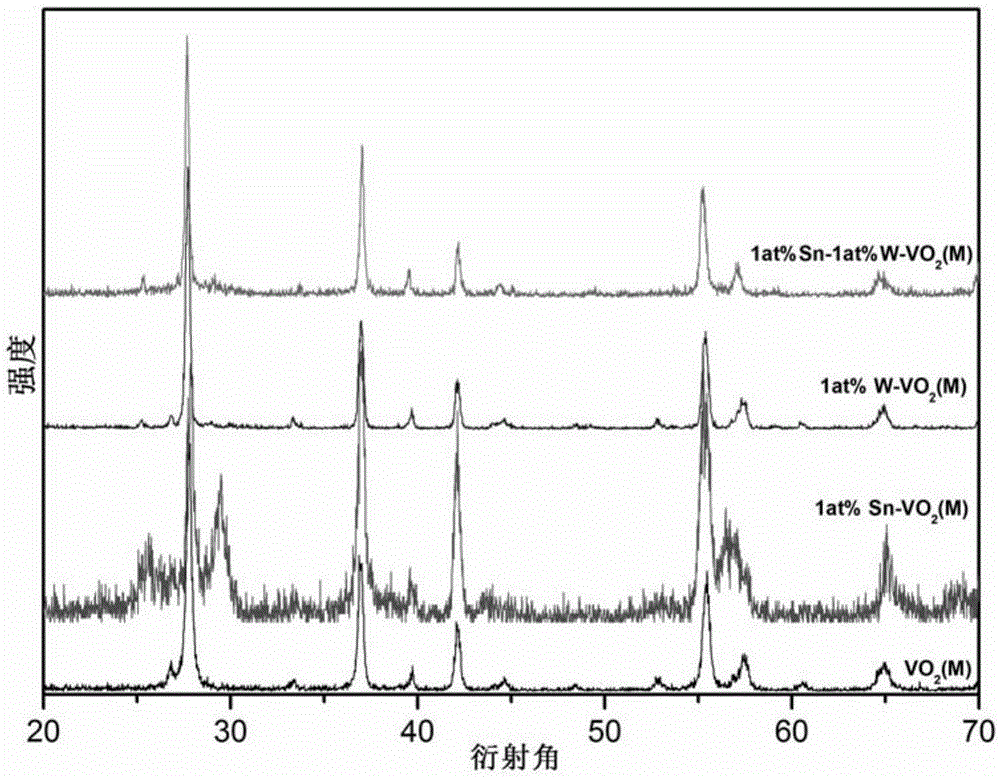

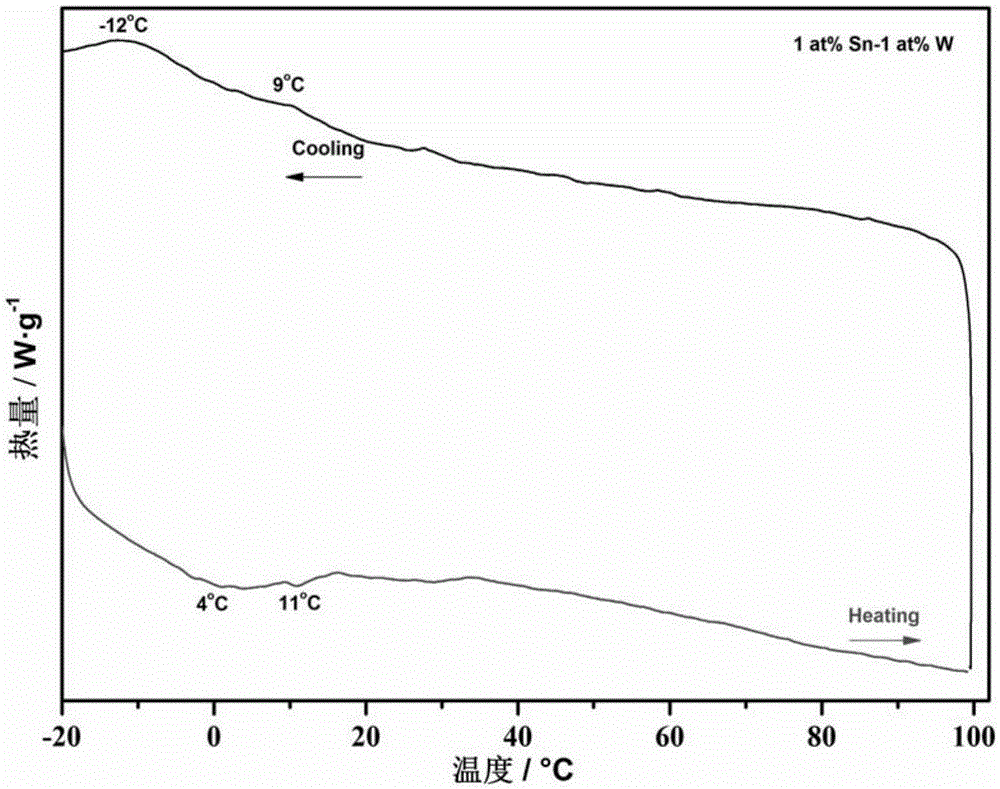

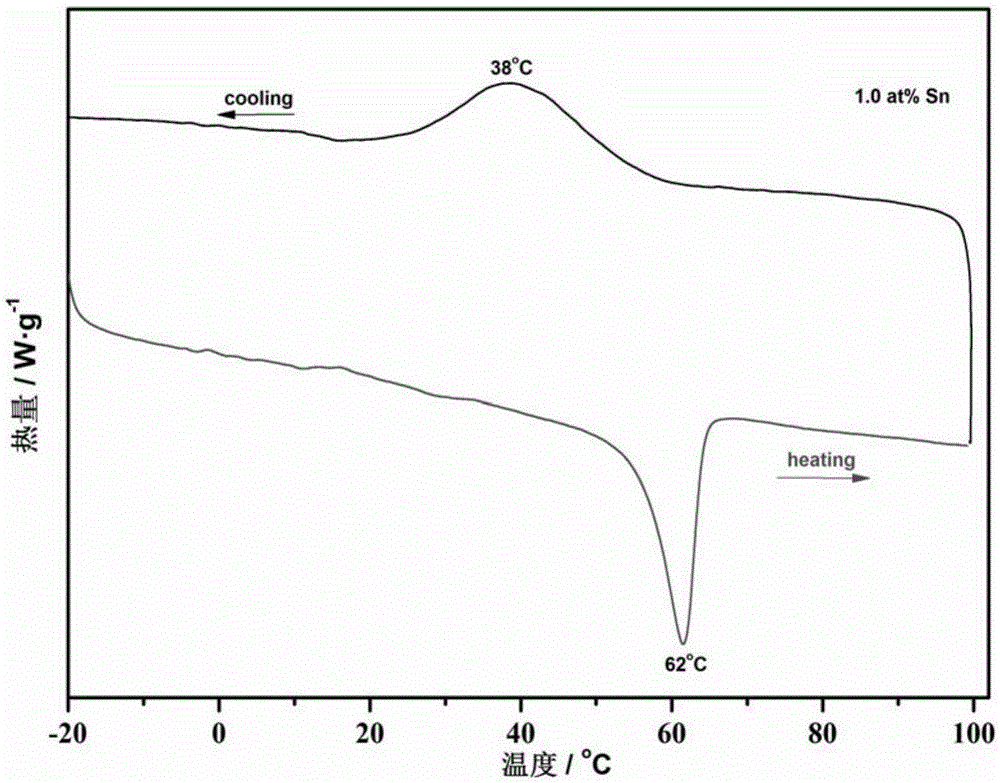

Tin-tungsten co-doped vanadium dioxide powder and preparation method thereof

InactiveCN105271408AGuaranteed purityLower phase transition temperatureTungsten oxides/hydroxidesVanadium oxidesVanadium dioxideCentrifugation

The invention provides a preparation method of tin-tungsten co-doped vanadium dioxide powder. The preparation method includes the steps that firstly, soluble vandic salt is dissolved and then reacts with precipitant to obtain a vanadium-sediment-containing intermediate, centrifugation, washing and diffusion are conducted, and vanadium-containing dispersion liquid is obtained; secondly, a tungsten source, a tin source, a needed oxidizing agent and a needed reducing agent are added to the dispersion liquid and evenly stirred, and the mixture is transferred into a hydrothermal kettle; the hydrothermal kettle is arranged at the temperature of 200-300 DEG C for a hydrothermal reaction for 6-72 h; after the hydrothermal reaction is completed, the product is centrifuged, washed and dried, and then the tin-tungsten co-doped vanadium dioxide powder is obtained. The preparation process is simple, cost is low, reproducibility is good, the controllable degree is high, the co-doped vanadium dioxide powder is directly prepared through a one-step hydrothermal method, and heat treatment or crystallization is not needed. The phase-transition temperature of VO2(M / R) nano-powder can be regulated through tin-tungsten co-doping.

Owner:UNIV OF SCI & TECH BEIJING

Synthesis method of fine grain ZSM-5 zeolite molecular sieve with high silicon aluminium ratio

InactiveCN100364890CUniform particle sizeHigh ratio of silicon to aluminumMolecular sieve catalystsPentasil aluminosilicate zeoliteSynthesis methodsSurface-active agents

The invention relates to a synthesis method of fine grain ZSM-5 zeolite molecular sieve with high silicon aluminium ratio, which comprises using a surface active agent, charging it into acidified aluminium salt solution, then slowly dropping alkaline solution formed from sodium silicate, template agent and seed crystal into aluminium saline solution, the overall composition of the obtained reaction mixture being Na2O:Al2O3:SiO2:H2O=1.5-4.0:1:20-280:500-2000 by mol ratio, then subjecting the reaction mixture to thermal crystallization through the conventional method.

Owner:DALIAN LIGONG QIWANGDA CHEM TECH

Method for synthesizing high-silicon mordenite in the absence of amine

InactiveCN1843915AIncrease productionLow priceMordenite aluminosilicate zeoliteMordenitePolytetrafluoroethylene

The invention discloses a method for preparing high silica mordenite without amine. The method employs silicon, alumina and deionized water as raw amaterial, and employs polyatomic alcohol as addictive; proceeds thermal crystallization in steeless autoclave interlined with politef, the crystallization temperature is 120-200 Deg. C and time is 12-240 hours; sucts, washes and dried the mixture got after crystallization and gets high silia mordenite with molar proportion of SiO2 / Al2O3 is 15-30:1. The invention employs pentaerythrite which is cheap, abundant and environment-friendly to replace the organic amine which is dear and environment-pollutant, and uses no inorganic acid or alkali corrosive to device. The pentaerythrite is helpful for generation of high silica mordenite and for reducing crystallization time. The invention is characterized by low production cost, high output, simple process and environment-friendly.

Owner:ZHEJIANG UNIV

Synthesis method of titanium-containing molecular sieve

InactiveCN1806918AReduce manufacturing costGood repeatabilityMolecular sieve catalystsCrystalline aluminosilicate zeolitesMolecular sieveInorganic Chemical

The invention relates the method for synthesizing titanium molecular screen, belonging to inorganic chemical synthesized technique field. The method comprises the following steps: using silica gel or silicasol as silicon source, using organic titanium acid ester as titanium source, using hexamethylene diamine or piperidine or the mixture of them as organic form agent, synthesizing the guiding agent, preparing reaction liquid, carrying out thermal crystallization, then filtering, washing, drying, calcining, and getting the TS-1 molecular screen. The method has the advantages of low cost, good repeatability and low pollution emission.

Owner:EAST CHINA NORMAL UNIV

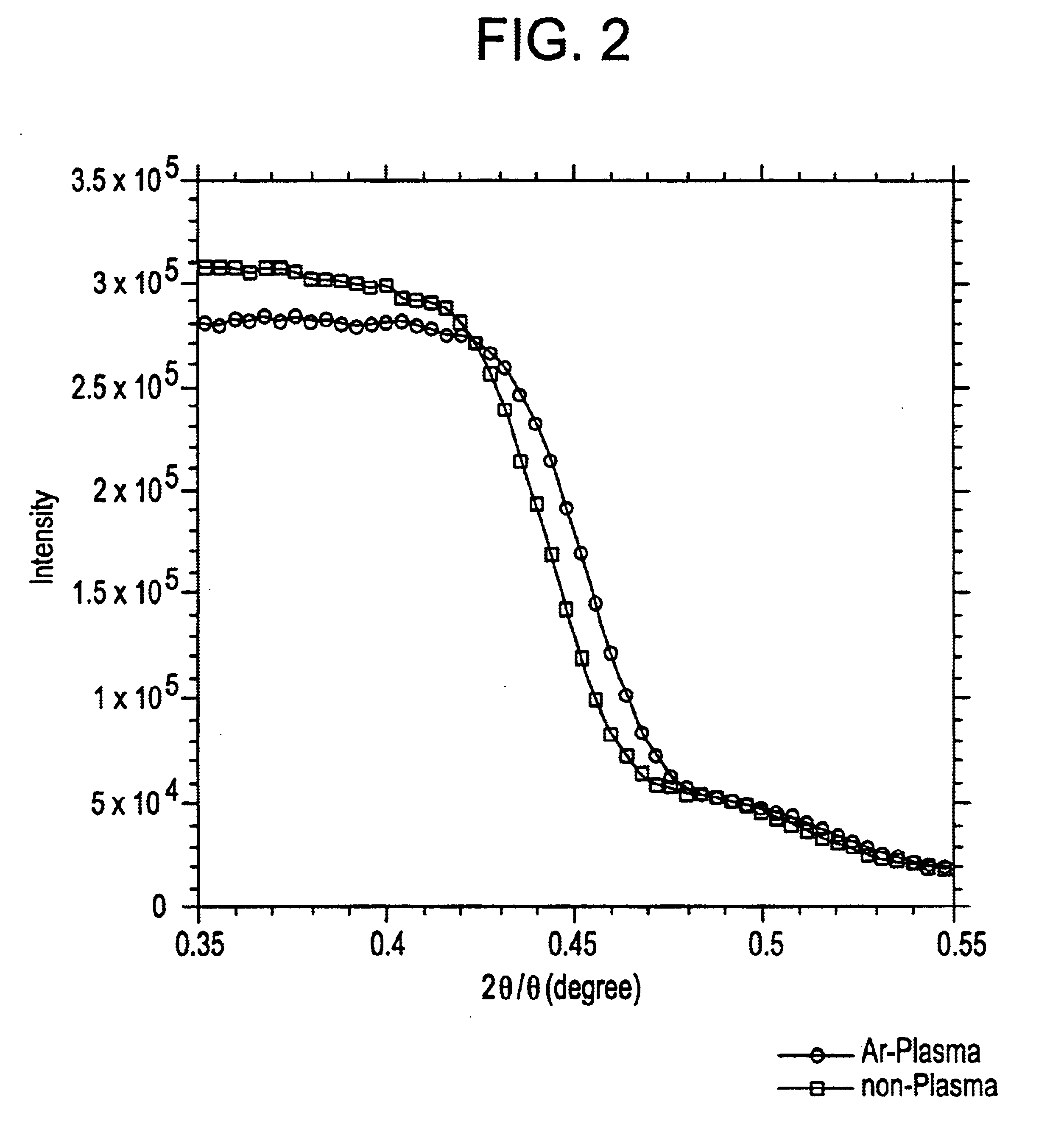

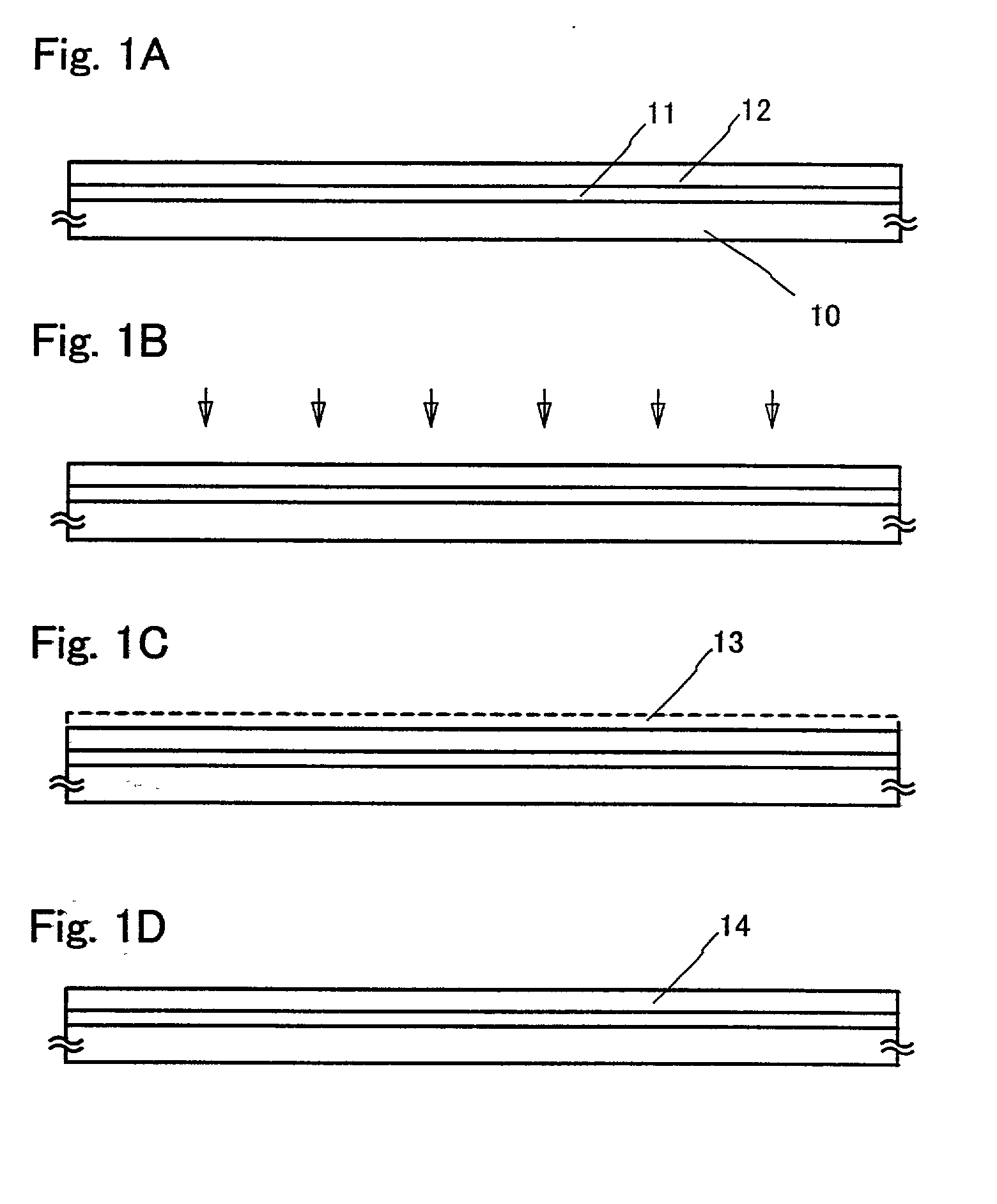

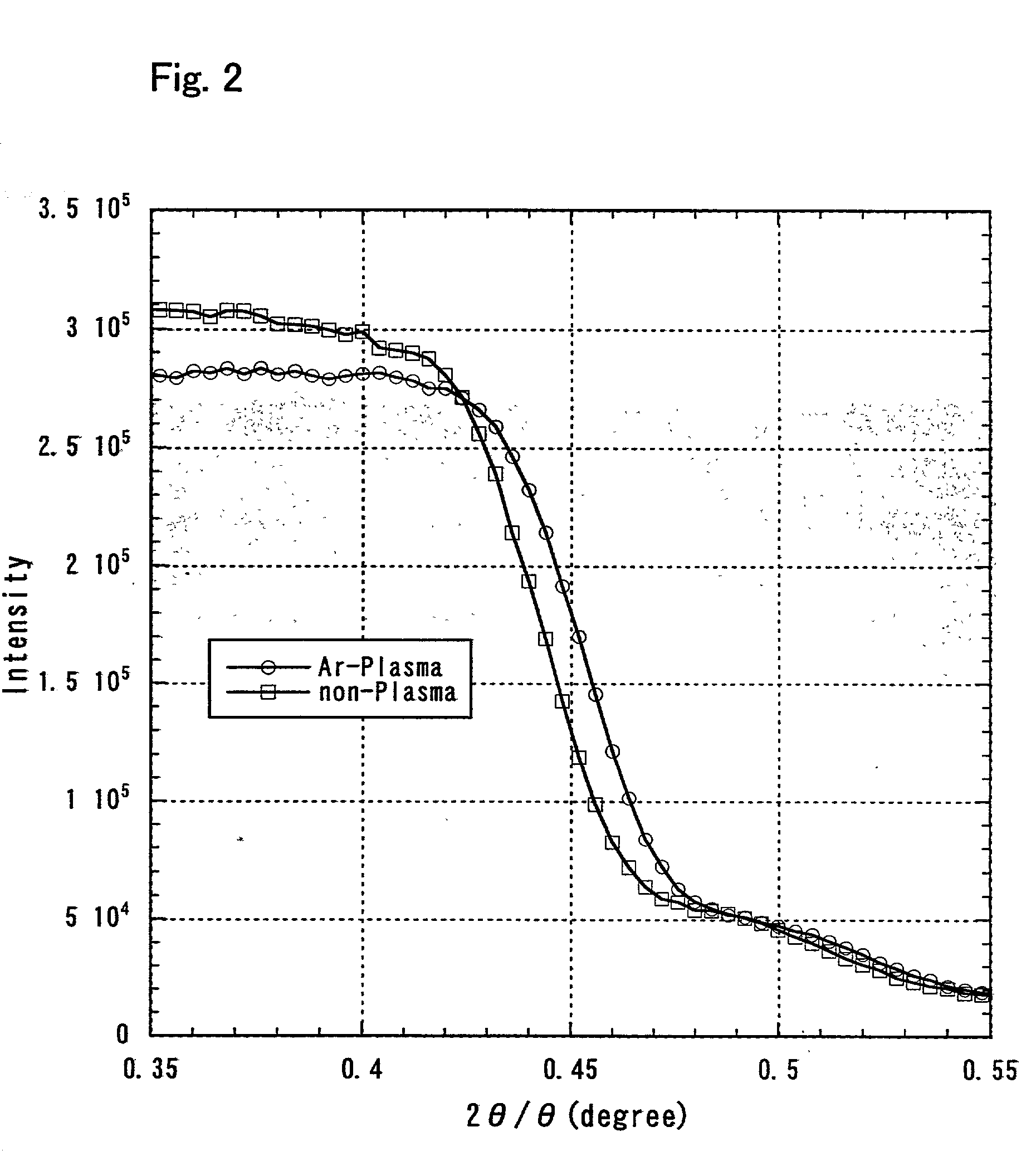

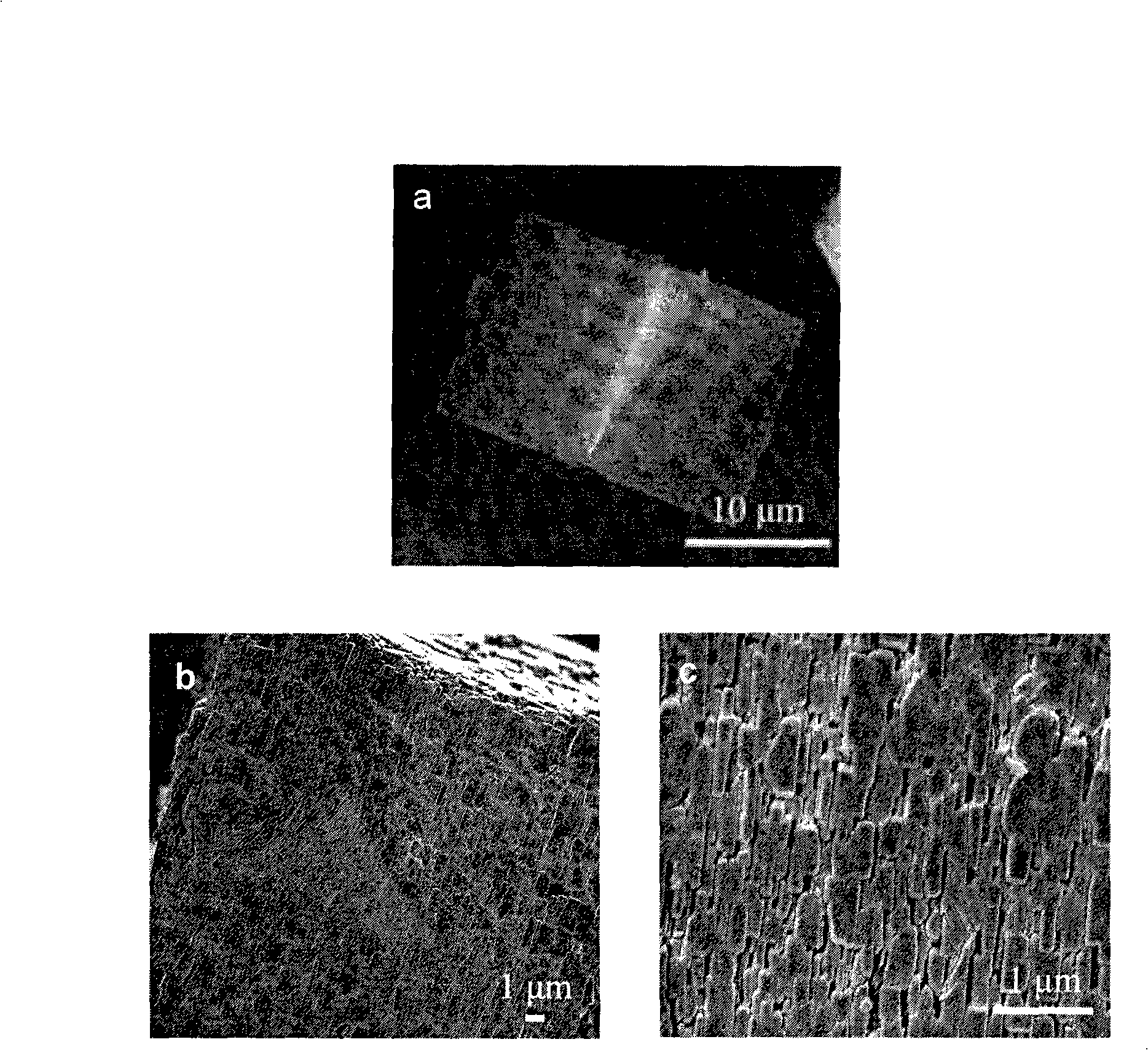

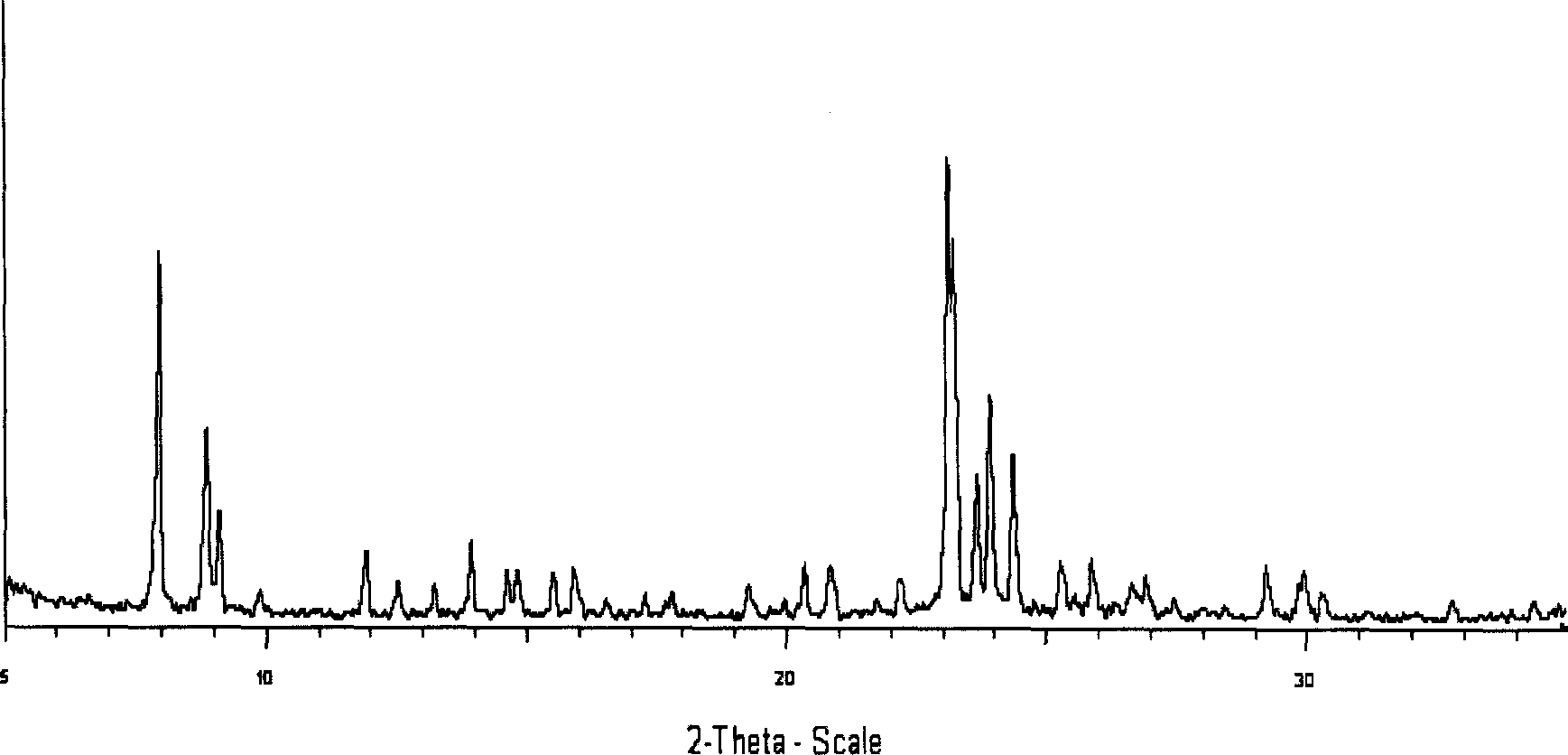

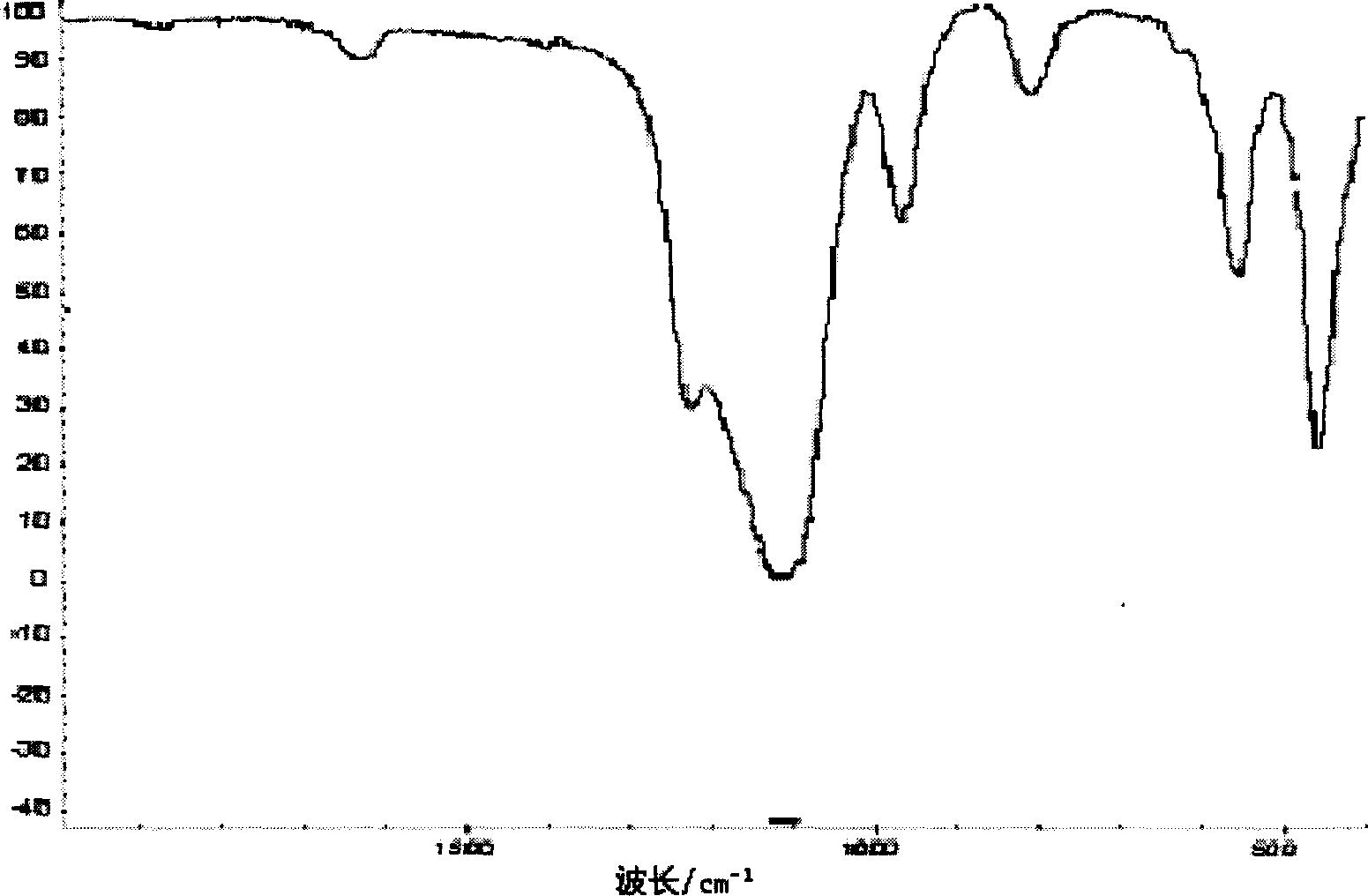

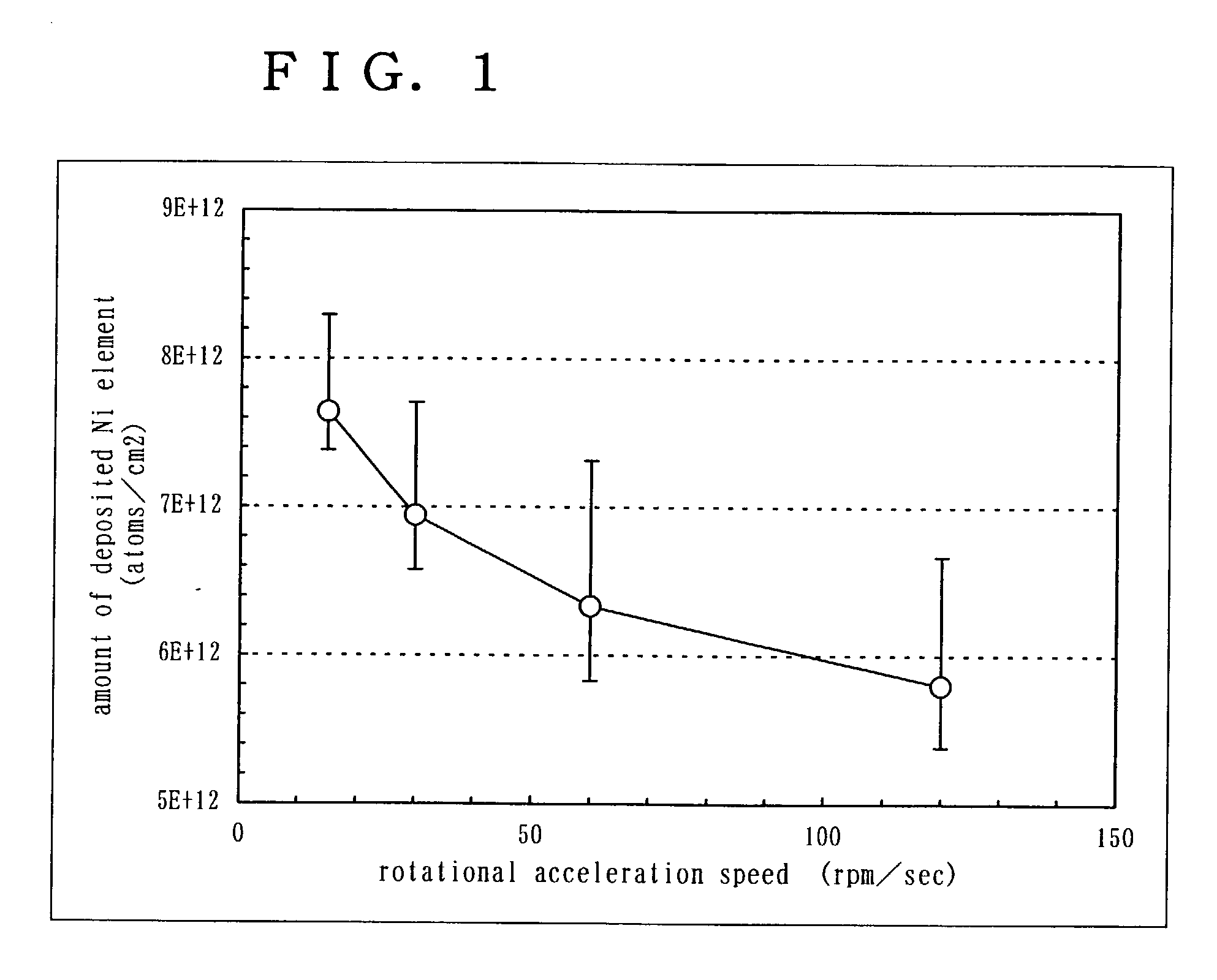

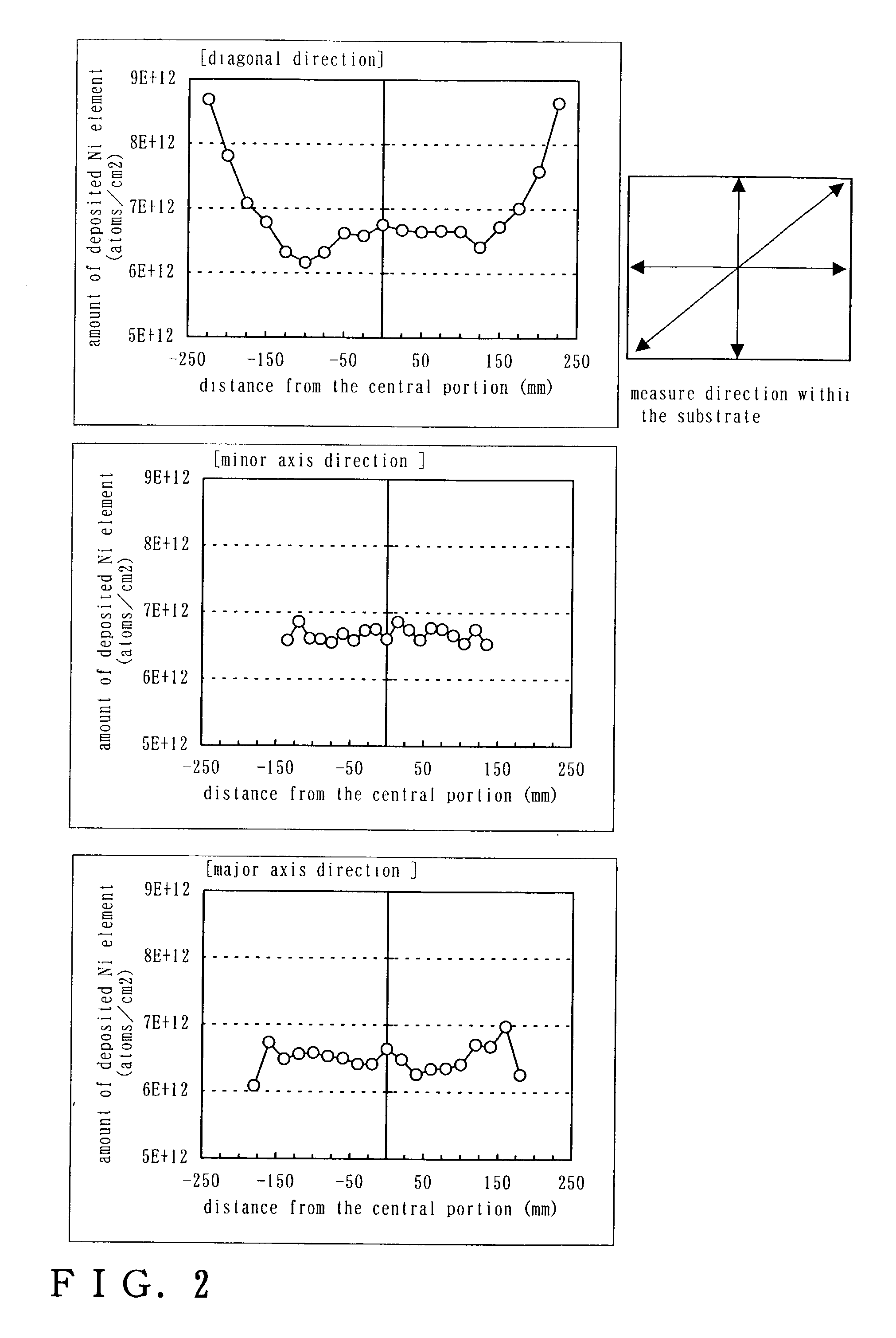

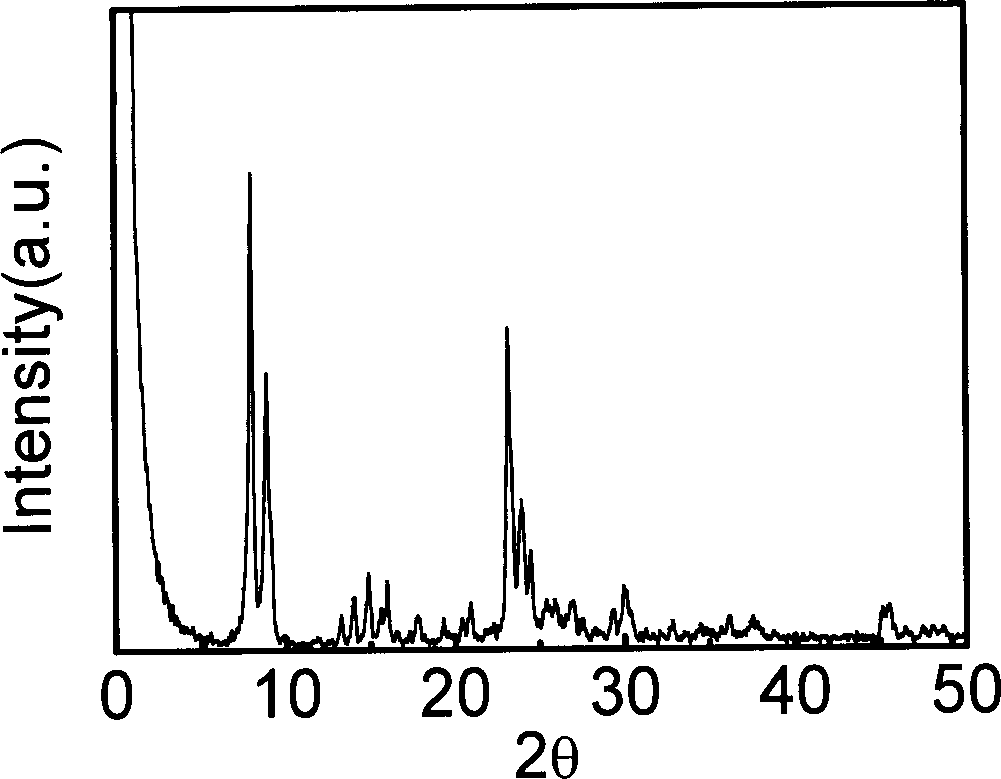

Crystalline semiconductor film, method of manufacturing the same, and semiconductor device

A spin addition method for catalyst elements is simple and very important technique, because the minimum amount of a catalyst element necessary for crystallization can be easily added by controlling the catalyst element concentration within a catalyst element solution, but there is a problem in that uniformity in the amount of added catalyst element within a substrate is poor. The non-uniformity in the amount of added catalyst element within the substrate is thought to influence fluctuation in crystallinity of a crystalline semiconductor film that has undergone thermal crystallization, and exert a bad influence on the electrical characteristics of TFTs finally structured by the crystalline semiconductor film. The present invention solves this problem with the aforementioned conventional technique. If the spin rotational acceleration speed is set low during a period moving from a dripping of the catalyst element solution process to a high velocity spin drying process in a catalyst element spin addition step, then it becomes clear that the non-uniformity of the amount of added catalyst element within the substrate is improved. The above stated problems are therefore solved by applying a spin addition process with a low spin rotational acceleration to a method of manufacturing a crystalline semiconductor film.

Owner:SEMICON ENERGY LAB CO LTD

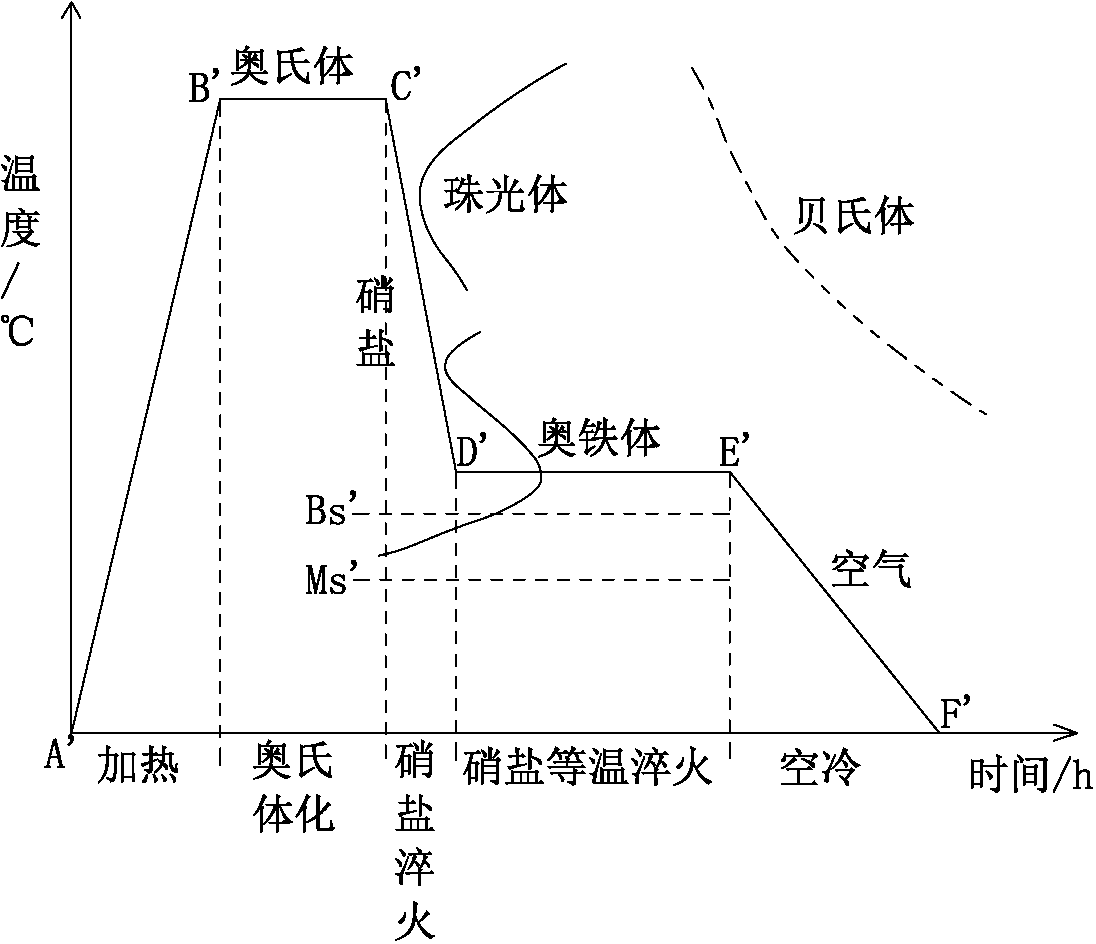

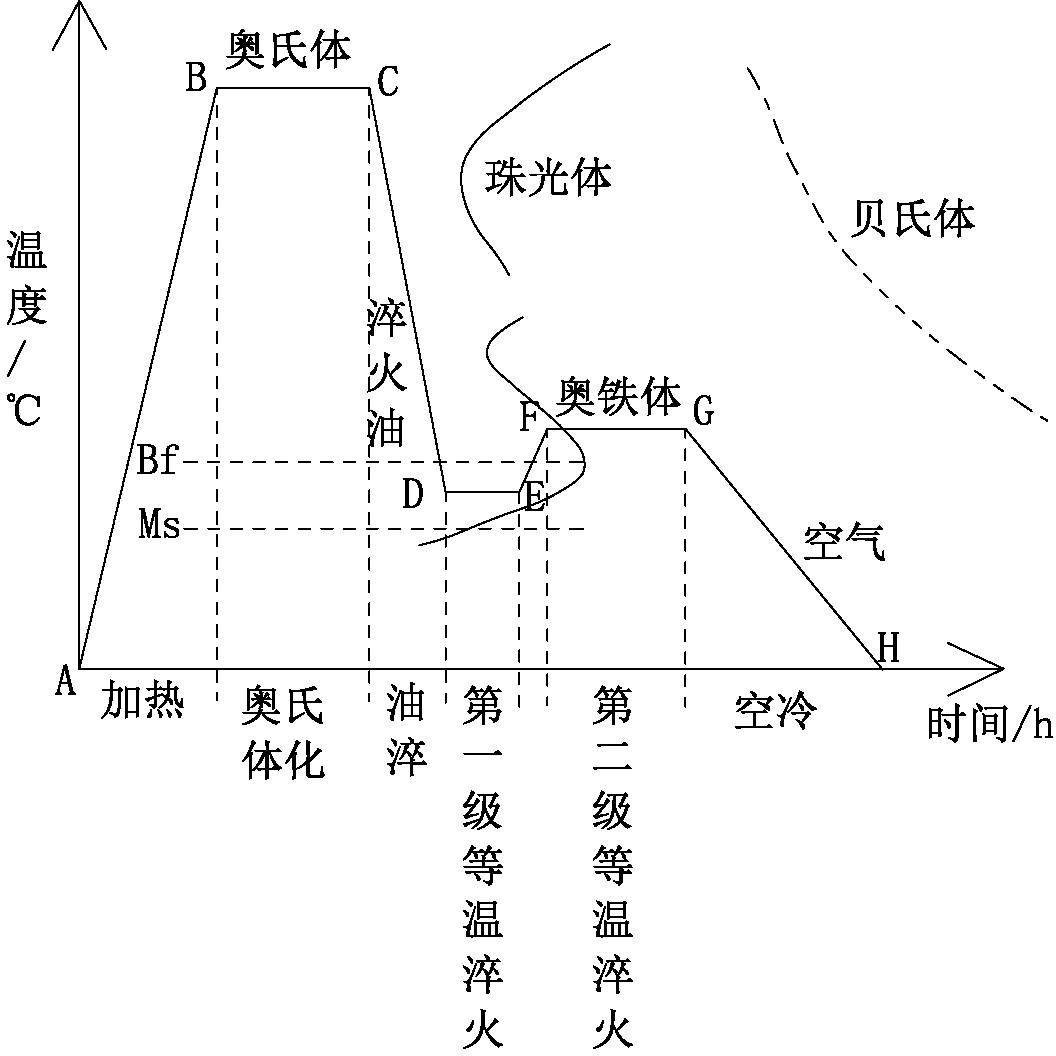

Austempered ductile iron and quenching technology thereof

The invention provides an austempered ductile iron adjusting chemical component. The chemical component uses Mn and Si as a base to substitute Mo and Ni, and contains a plurality of elements comprising Cu, B, Nb and Cr to realize low and micro alloying, so the respective effects of all elements are fully performed, the interactive effect promotion is realized, the hardenability is increased, the alloy consumption is reduced, and the cost is reduced. The invention also provides a new austempered ductile iron quenching technology matched with the austempered ductile iron. The technology is a step austempering technology using step quenching oil and an air isothermal furnace. The heat treatment of a workpiece through the technology realizes crystal grain refinement, good hardenability, high strength and toughness, low hardness (HB190-240) before the step austempering treatment, and good processing performances; and the obtained processed austempered ductile iron has a high hardness (HRC35-56) and extremely less oxidation and deformation, so the precision is guaranteed, and finishing treatments comprising grinding and the like are not needed. Compared with traditional nitrate bath austempering technologies, the austempered ductile iron quenching technology has the advantages of low cost, no generation of large amounts of harmful substances comprising nitrite or the like, low pollution and safety.

Owner:高州创建铸造有限公司

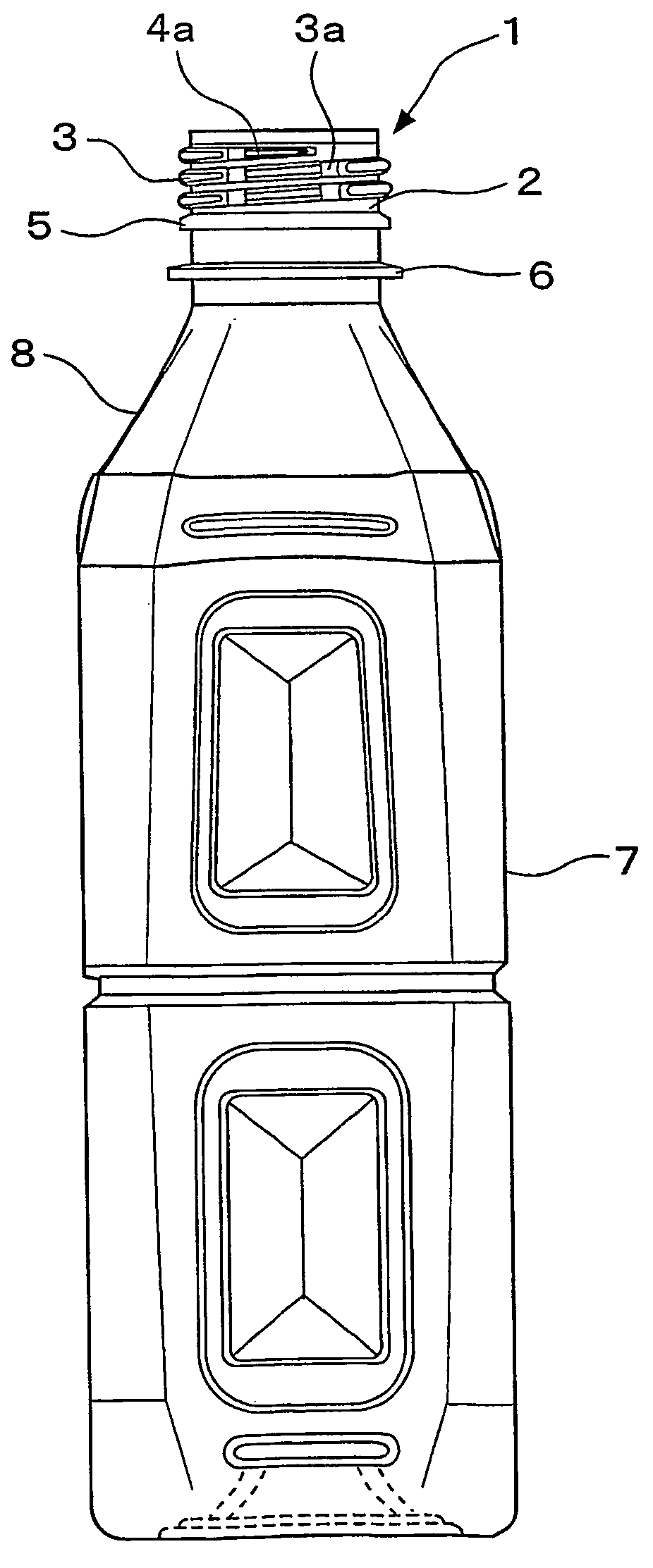

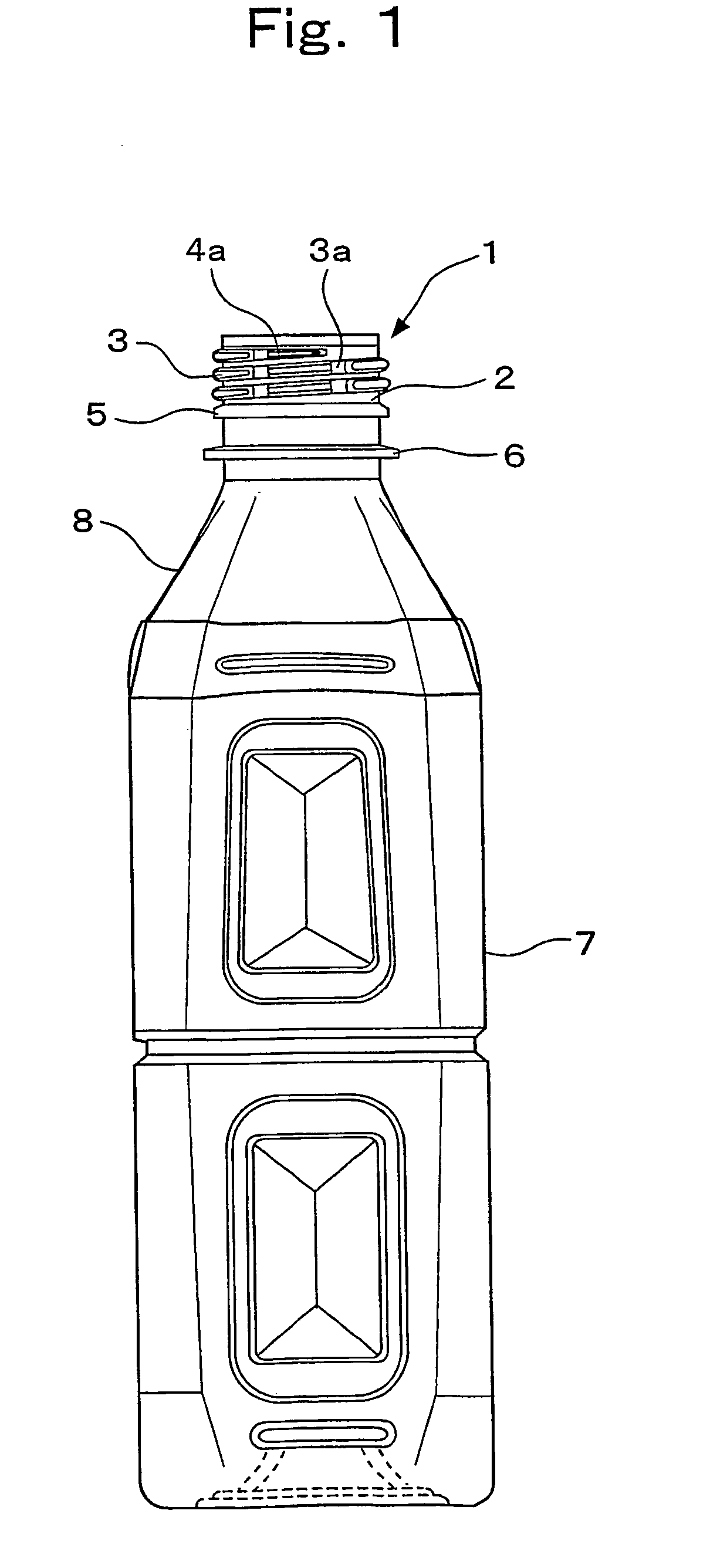

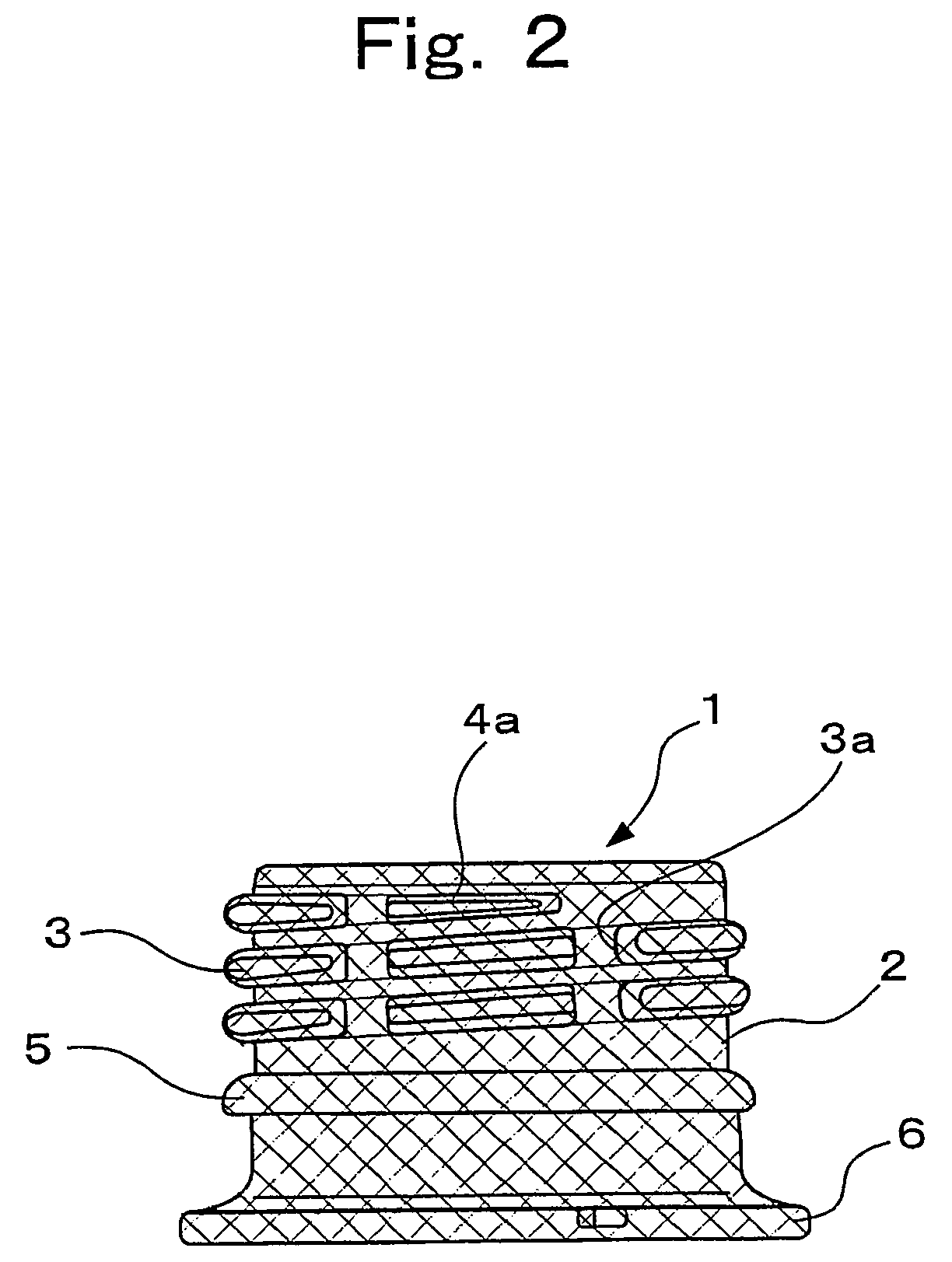

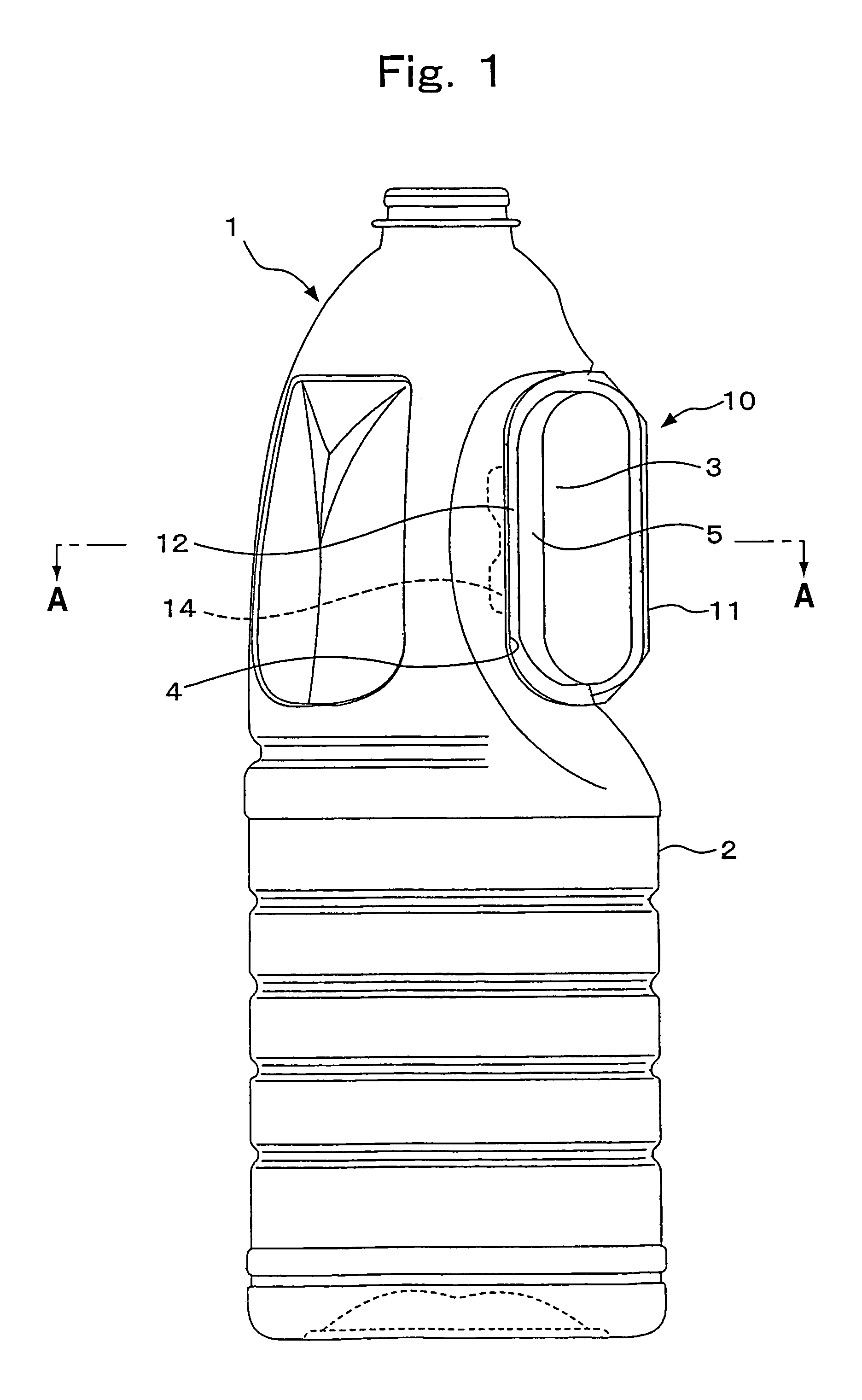

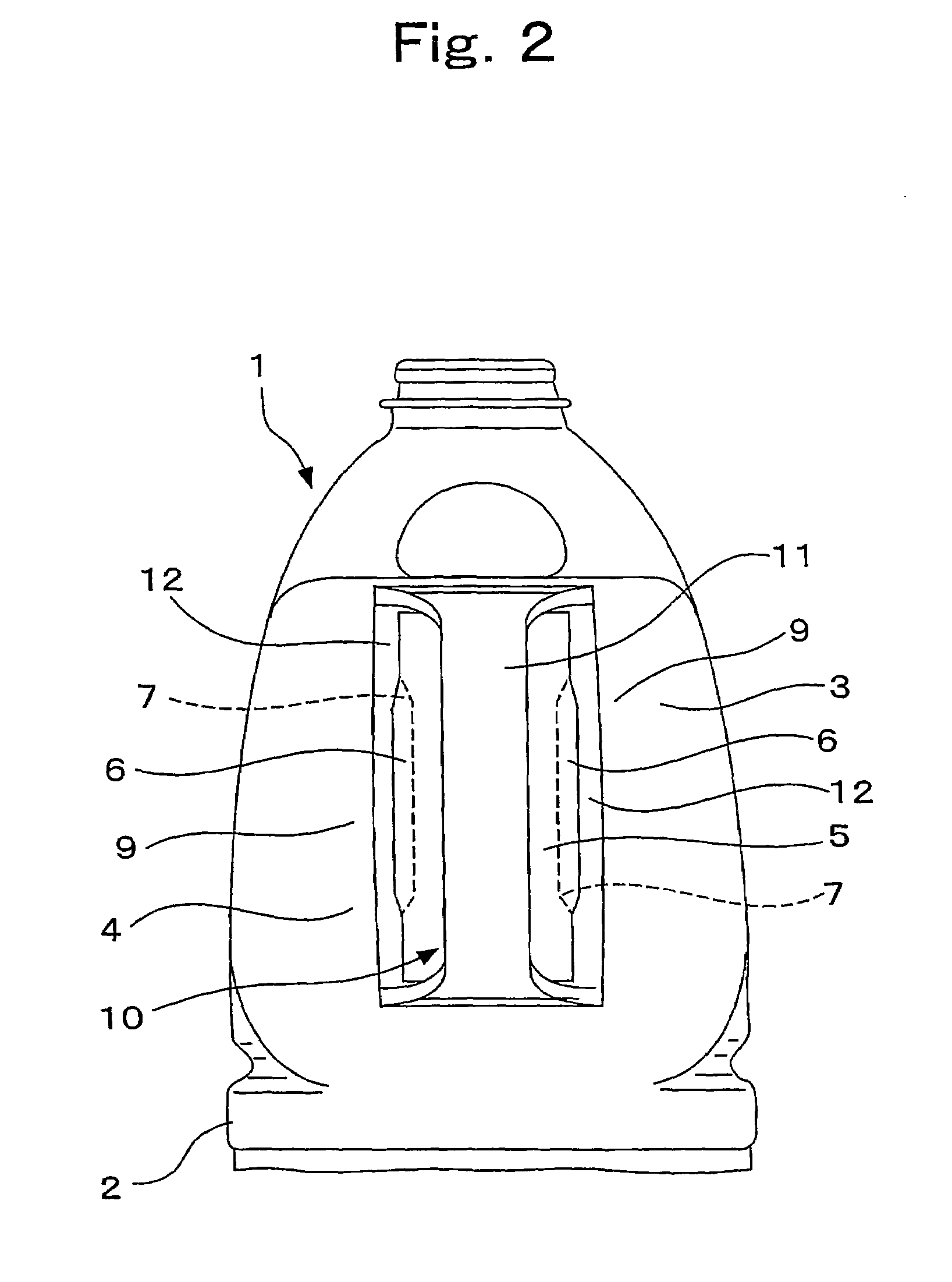

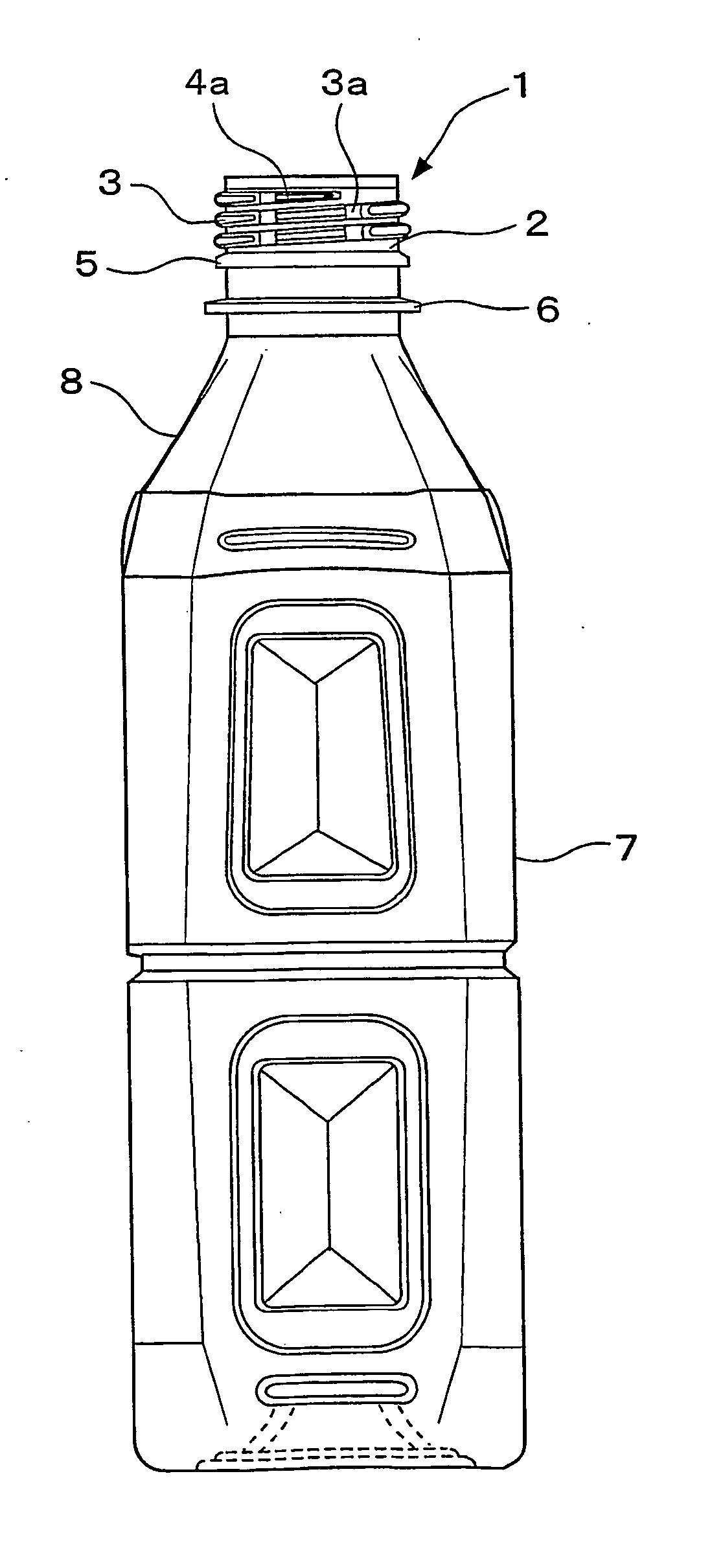

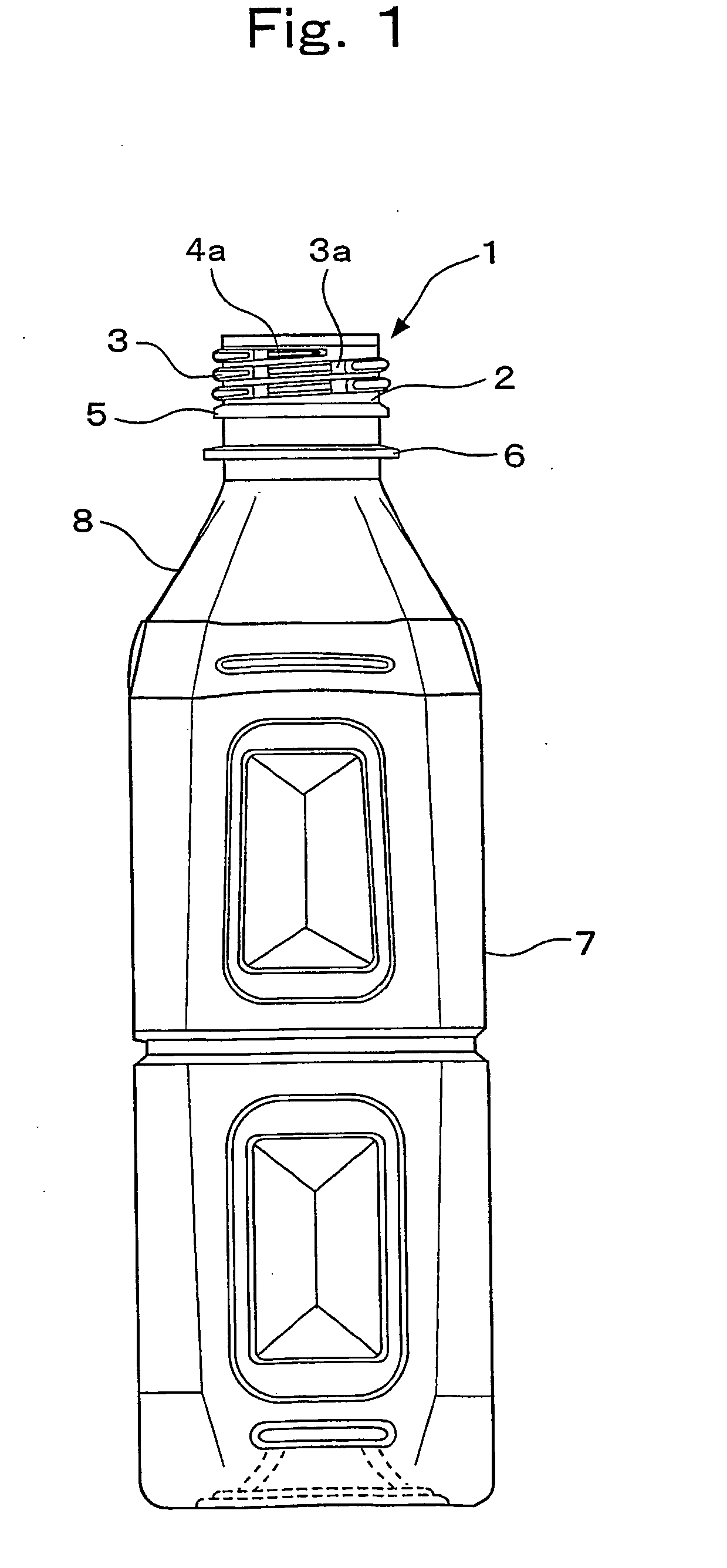

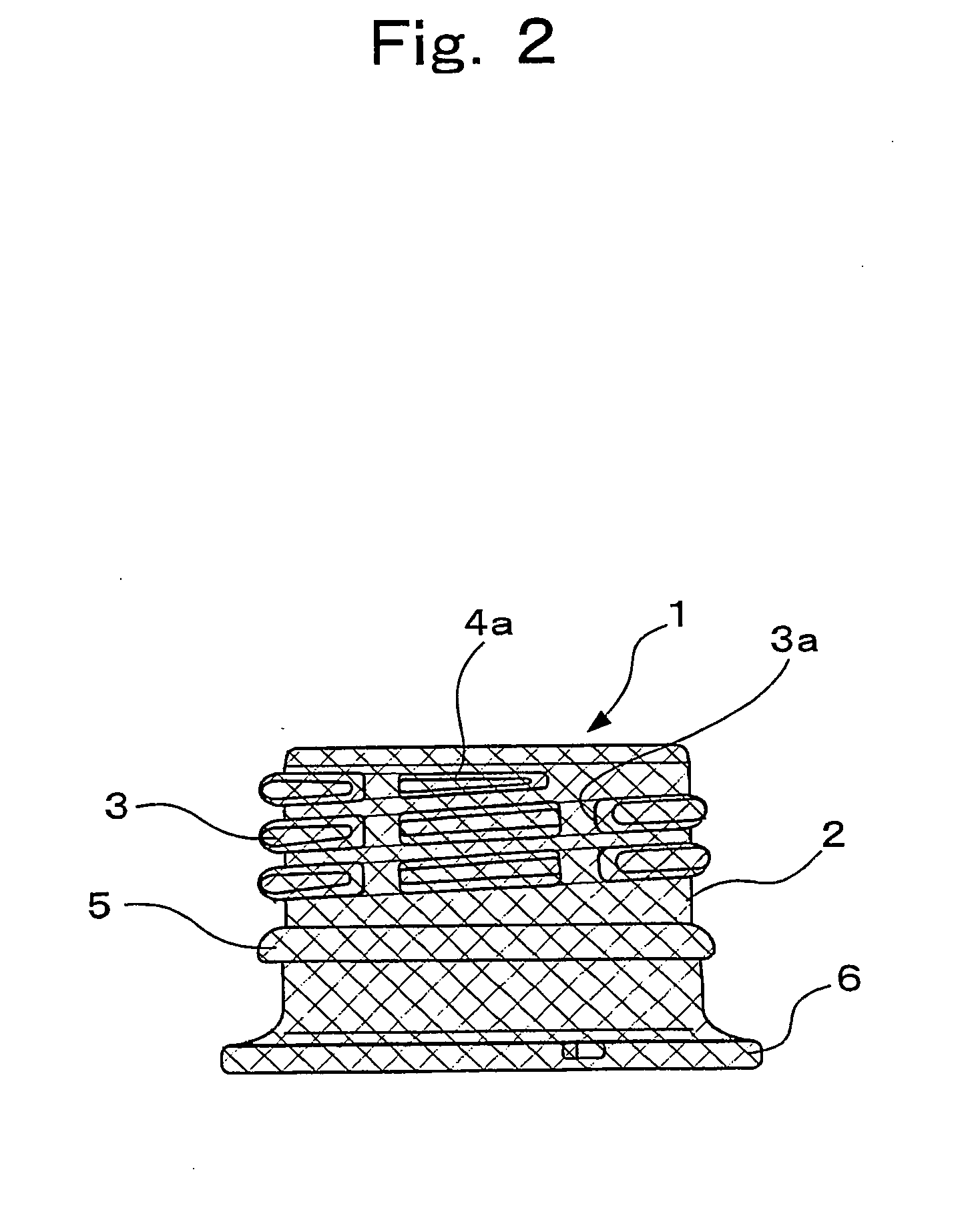

Neck of synthetic resin bottle

Owner:YOSHINO KOGYOSHO CO LTD

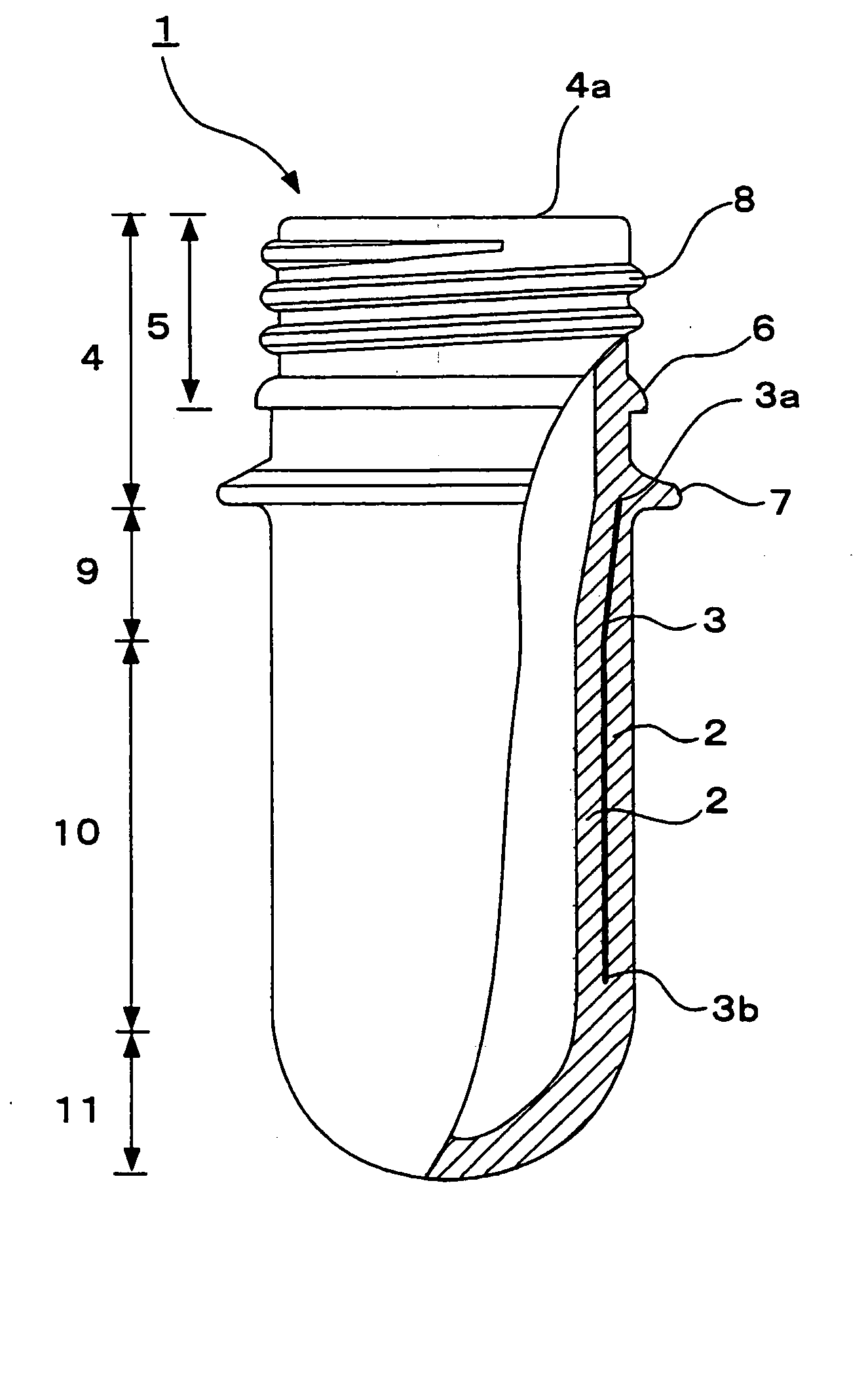

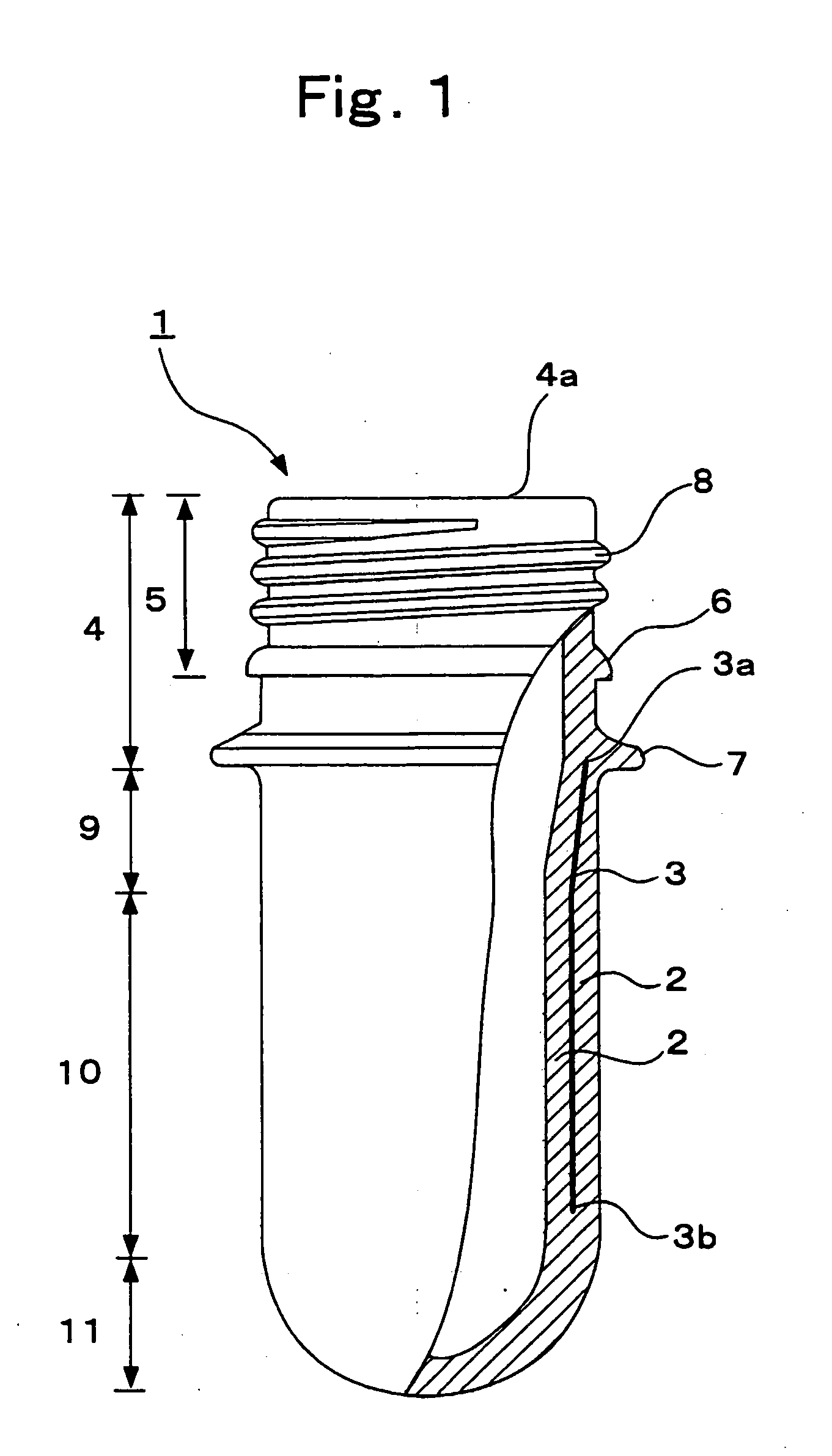

Biaxially oriented, blown-molded bottles and preform thereof

The purpose of this invention is to set the position of the gas barrier layer in such a manner as to solve the problem of decreased accuracy of neck molding dimensions created by the thermal crystallization and the problem of interlaminar separation in the bottom, both of which are associated with the provision of the gas barrier layer. Problems should be solved without being affected by the displacement of the gas barrier layer, which may take place during the co-injection operation of the PET resin layers and the gas barrier layer. A biaxially drawn, blow-molded bottle and its preform comprise at least a layer of a gas barrier material 3 laminated inside the PET resin layers 2, a functional portion 5 having a screw thread 8 raised spirally in the upper portion of neck 4 and also having a stop ring 6 disposed under the screw thread 8, and a neck ring 7 disposed at the lower end of the neck 4. In these preform and bottle, the leading edge 3a of the gas barrier layer 3 is positioned at a half height of the neck ring 7 where the most advanced front of the leading edge 3a neither reaches a half height of the stop ring 6 nor extends to the functional portion 5. It is intended here that the neck 4 would not be affected by the shrinking deformation caused by the existence of the gas barrier layer 3 in the functional portion 5 of the neck 4, which is treated for thermal crystallization.

Owner:YOSHINO KOGYOSHO CO LTD

Synthetic resin bottle with a handle

A synthetic resin bottle with a handle of this invention comprises a biaxially drawn and blow-molded PET bottle and a handle, an injection-molded product of the same PET resin, which is fitted firmly to the bottle as an insert. The up-and-down property of the surfaces of the handle inserts, which come in contact with the PET bottle, is adjusted in response to the softening and drawing state of the PET preform that is deformed and molded into the bottle. This adjustment causes the friction resistance to be reduced between the handle inserts and the blow-molded PET bottle. The finely textured up-and-down pattern can be easily formed through the tests and adjustments by the surface treatment inside the mold cavity used for the injection molding of the handle. Thus, the optimum surface properties can be obtained in response to the bottle sizes and the handle shapes. Therefore, this invention requires no separate process, such as thermal crystallization. Bottles, which fully get around the handle inserts, have high fitting strength but no abrasion, can be provided at a low cost.

Owner:YOSHINO KOGYOSHO CO LTD

Mouth tube portion of synthetic resin bottle body

The gas-venting groove or grooves are formed, while leaving a part of the thread ridge (3) up to a certain height, as the vertical degassing paths in the thread ridge carved on the outer surface of the round neck wall and the entire neck is whitened by the thermal crystallization. This thermal crystallization is conducted under the condition that the neck is prevented from undesired deformation caused by uneven resin flow state. Thus, the object of this invention is to provide a highly safe neck that can be used widely in the field of heat-resistant containers, pressure-tight containers, and heat-resistant and pressure-tight containers.

Owner:YOSHINO KOGYOSHO CO LTD

Multi-stage porous titanium-silicon zeolite preparation method and its uses in catalytic oxidation

InactiveCN1807244AEliminate mass transfer limitationsImprove catalytic performanceMolecular sieve catalystsCrystalline aluminosilicate zeolitesMolecular sieveCatalytic oxidation

The preparation method for titanium-silicon zeolite with multilevel holes comprises: 1) preparing the ordered meso-hole carbon material template agent; 2) leading all the silicon source, titanium source and said template agent into the hole channel in template agent with stage dipping; 3) taking water-thermal crystallization treatment to the obtained mixture; 4) removing the carbon material and agent. This invention has better catalysis performance than traditional molecular sieve, and fits to oil and fine chemical industry.

Owner:DALIAN UNIV OF TECH

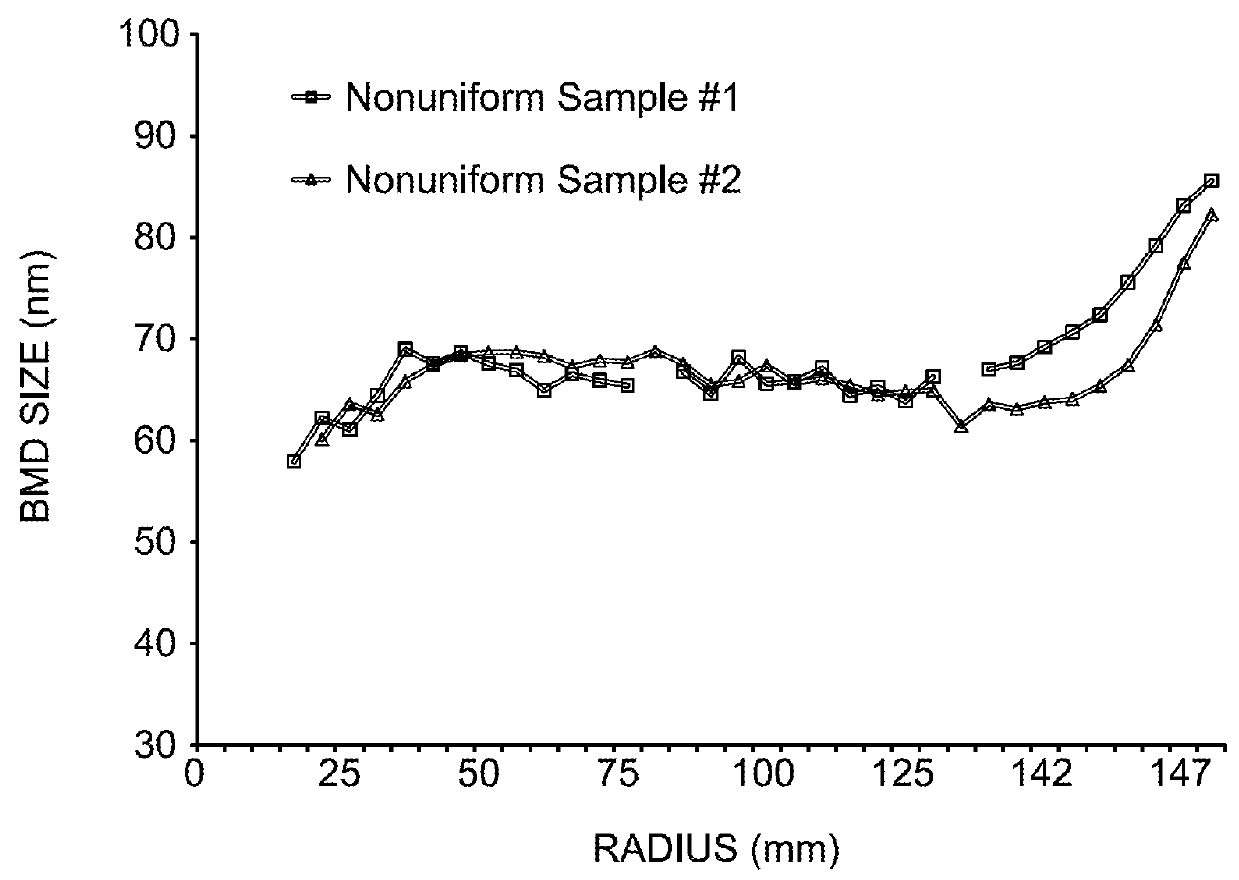

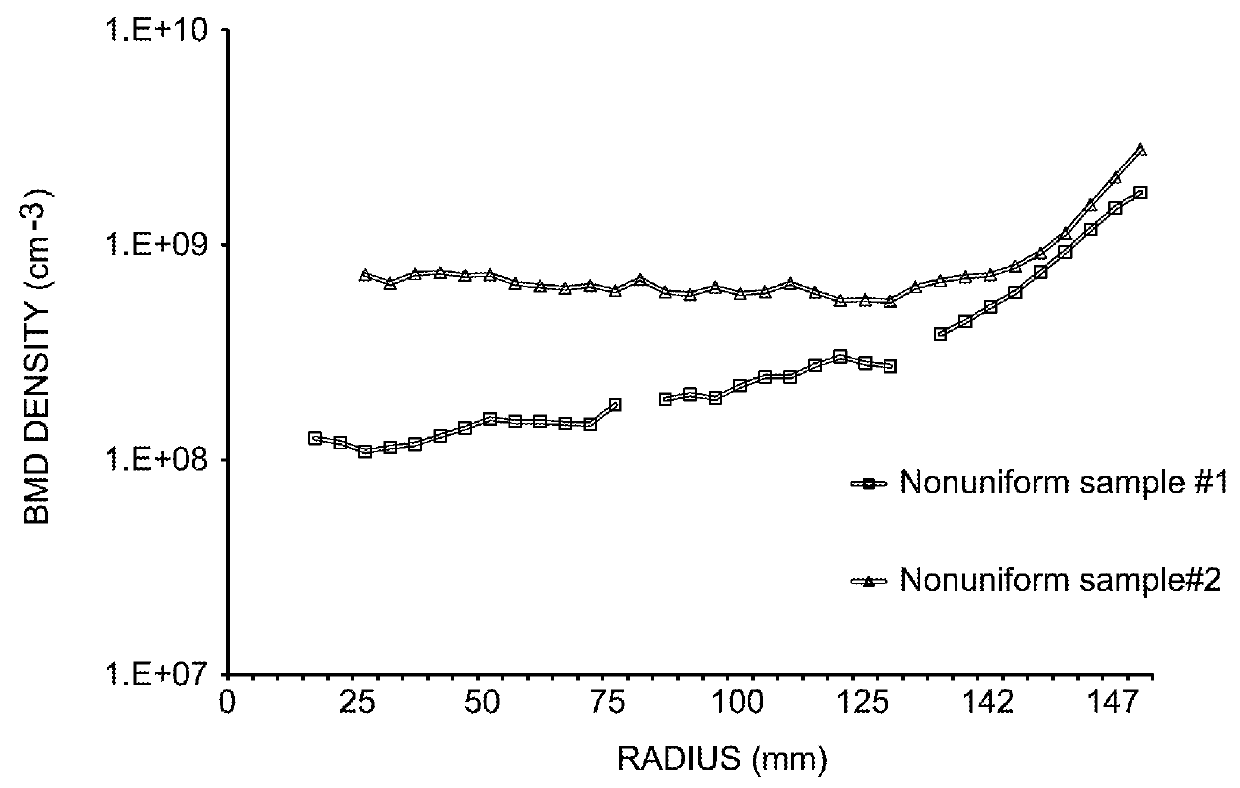

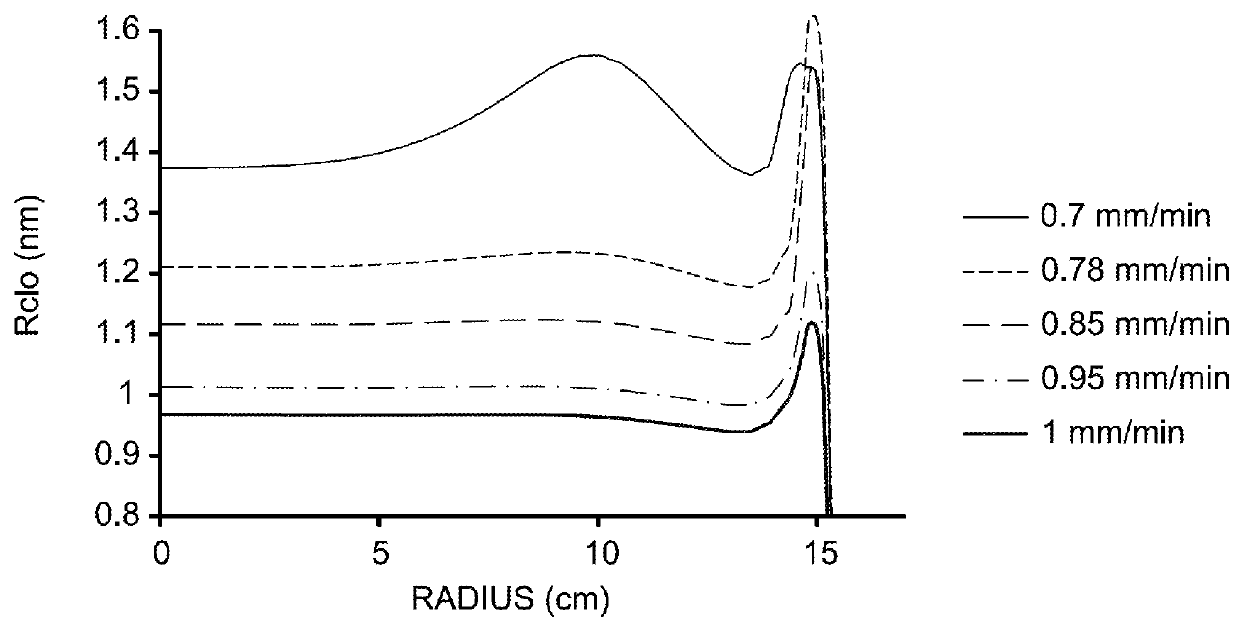

Nitrogen doped and vacancy dominated silicon ingot and thermally treated wafer formed therefrom having radially uniformly distributed oxygen precipitation density and size

ActiveUS20160032491A1Increase in radial bulk micro defect sizeImprove defect densityPolycrystalline material growthAfter-treatment detailsWaferingDensity distribution

Nitrogen-doped CZ silicon crystal ingots and wafers sliced therefrom are disclosed that provide for post epitaxial thermally treated wafers having oxygen precipitate density and size that are substantially uniformly distributed radially and exhibit the lack of a significant edge effect. Methods for producing such CZ silicon crystal ingots are also provided by controlling the pull rate from molten silicon, the temperature gradient and the nitrogen concentration. Methods for simulating the radial bulk micro defect size distribution, radial bulk micro defect density distribution and oxygen precipitation density distribution of post epitaxial thermally treated wafers sliced from nitrogen-doped CZ silicon crystals are also provided.

Owner:GLOBALWAFERS CO LTD

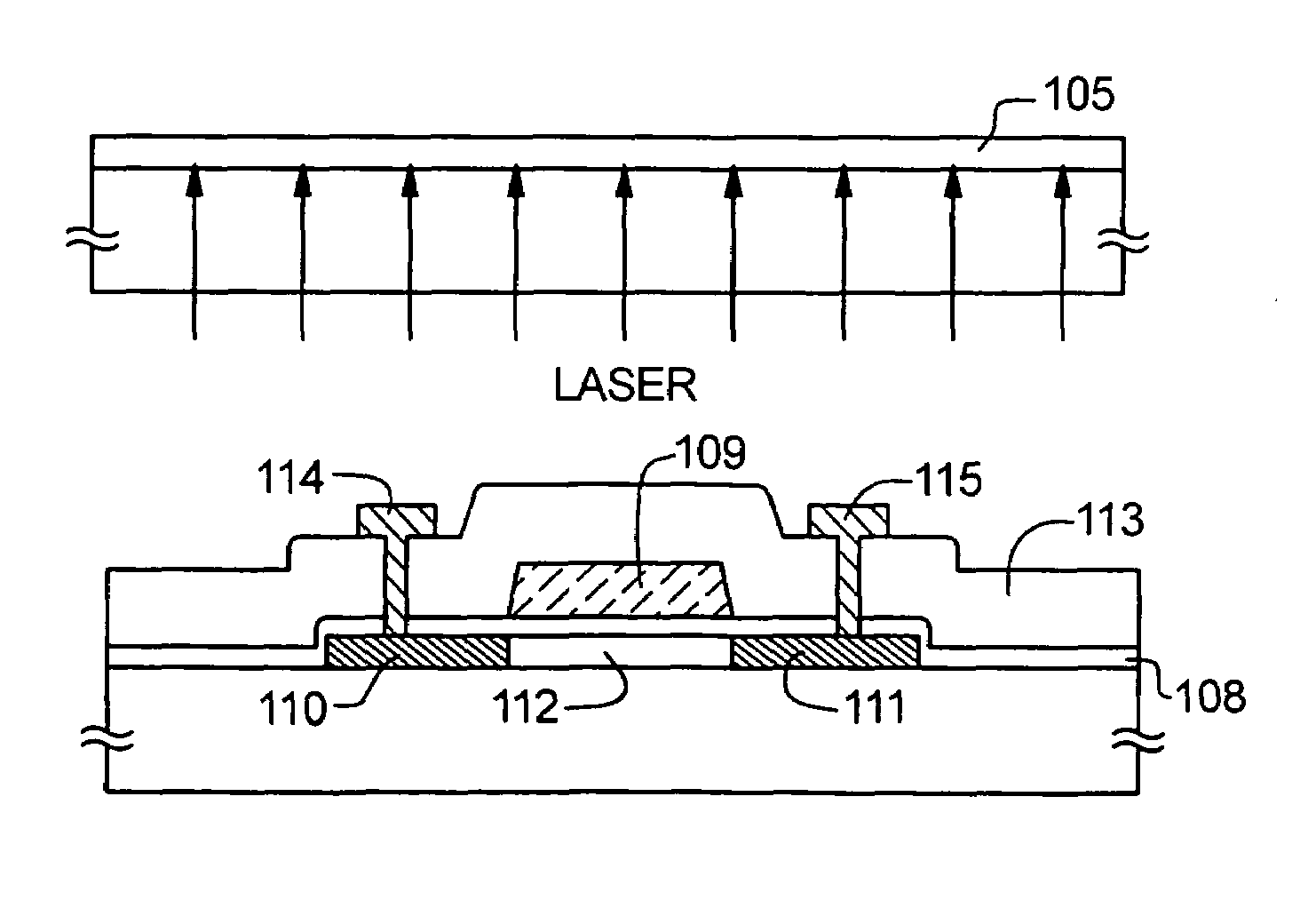

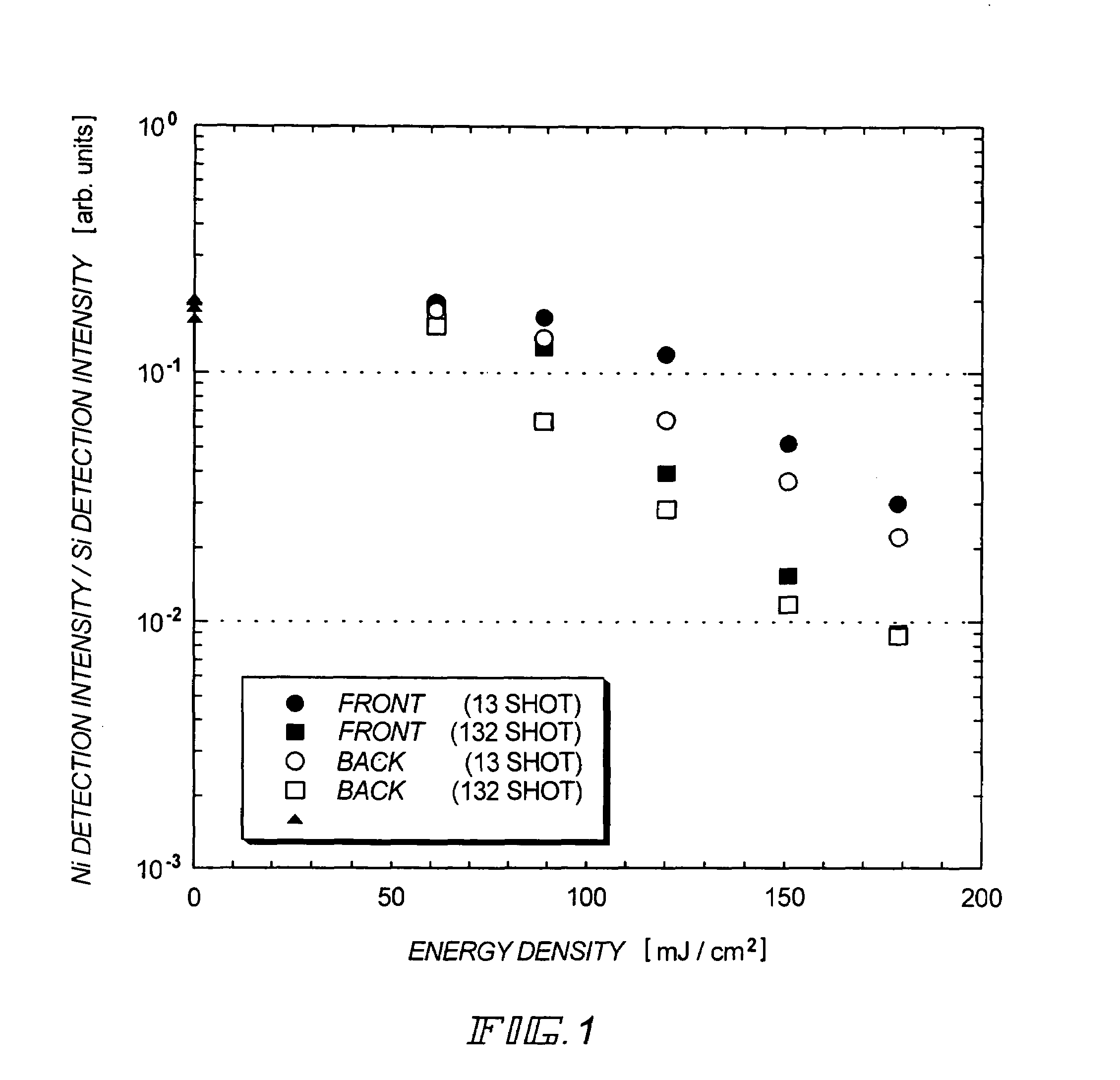

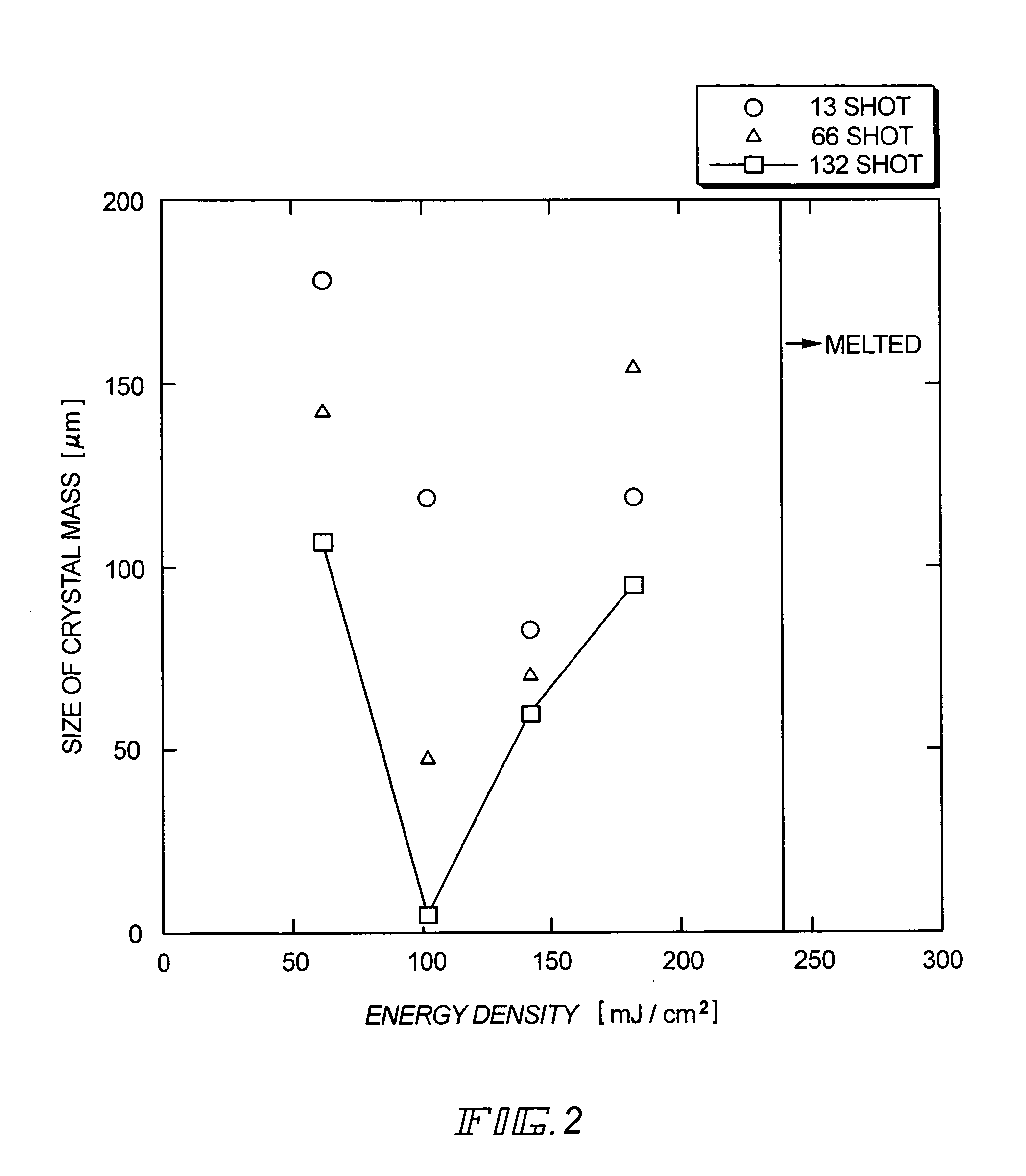

Semiconductor device and method of manufacturing the same

InactiveUS7211476B2Increase currentReduce volatilityTransistorLaser detailsAmorphous siliconLaser light

The sizes of crystal masses are made to be a uniform in a crystalline silicon film obtained by a thermal crystallization method in which a metal element is used. An amorphous silicon film to be crystallized is doped with a metal element that accelerates crystallization, and then irradiated with laser light (with an energy which is not large enough to melt the film and which is large enough to allow the metal element to diffuse in the solid silicon film) from the back side of a light-transmissive substrate. Thereafter, heat treatment is performed to obtain a crystalline silicon film. Thus crystal masses in the crystalline silicon film can have a uniform size and the problem of fluctuation between TFTs can be solved.

Owner:SEMICON ENERGY LAB CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com