Patents

Literature

167 results about "Austempering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

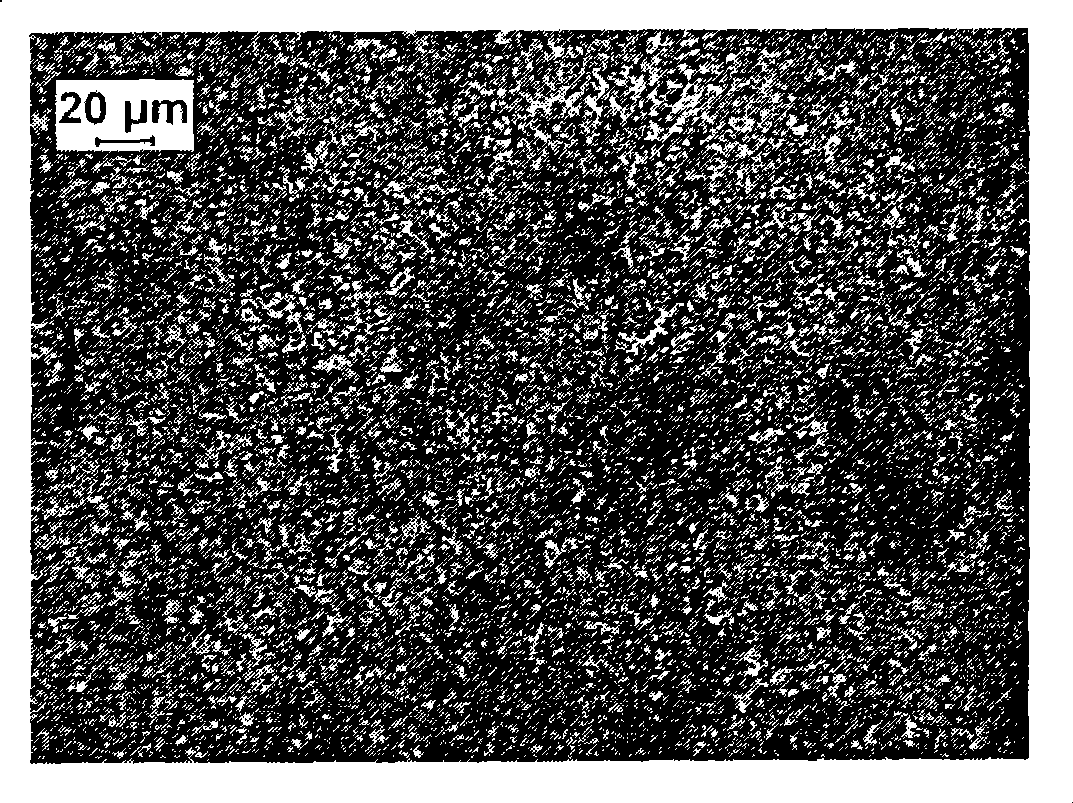

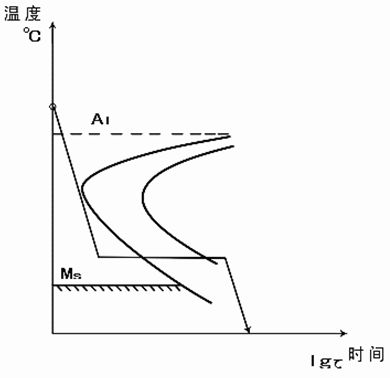

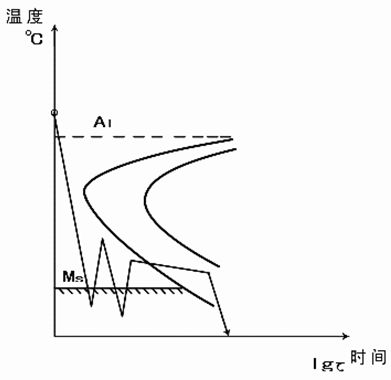

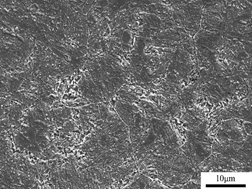

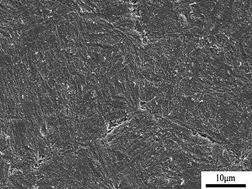

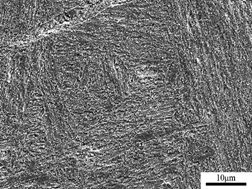

Austempering is heat treatment that is applied to ferrous metals, most notably steel and ductile iron. In steel it produces a bainite microstructure whereas in cast irons it produces a structure of acicular ferrite and high carbon, stabilized austenite known as ausferrite. It is primarily used to improve mechanical properties or reduce / eliminate distortion. Austempering is defined by both the process and the resultant microstructure. Typical austempering process parameters applied to an unsuitable material will not result in the formation of bainite or ausferrite and thus the final product will not be called austempered. Both microstructures may also be produced via other methods. For example, they may be produced as-cast or air cooled with the proper alloy content. These materials are also not referred to as austempered.

Heat treatment method of steel belt for packages and steel belt for packages

ActiveCN101363078AGuaranteed plasticityExtend the time of austemperingFurnace typesProcess efficiency improvementTowerWater cooling

The invention relates to a heat treatment method of a steel strip for packaging, comprising the following steps: a) the steel trip is heated to the austenitizing temperature; b) isothermal quenching is carried out in molten lead; c) the lead is scraped off in a carbon tower; and d) the strip is cooled by water. The heat treatment method is characterized in that the temperature range of the isothermal quenching in the step b) is 355-365 DEG C and the isothermal quenching time is 21-28s. The invention further discloses a steel strip for packaging obtained by the heat treatment method. The components of the steel strip (by weight percentages) are as follows: 0.29-0.35% of C, 0.15-0.35% of Si, 1.20-1.55% of Mn, not more than 0.030% of P, not more than 0.030% of S and Fe. The heat treatment method solves the problems that tensile strength of the existing steel strips for packaging can not exceed 1250MPa, the elongation after fracture is less than 6%, and the two-phase region quenching profile of a sheet is poor.

Owner:上海宝钢新材料技术有限公司

High-boron low-carbon abrasion resistant cast steel and heat treatment method thereof

InactiveCN101260501ARich sourcesReduce manufacturing costProcess efficiency improvementElectric furnaceChemical compositionRoom temperature

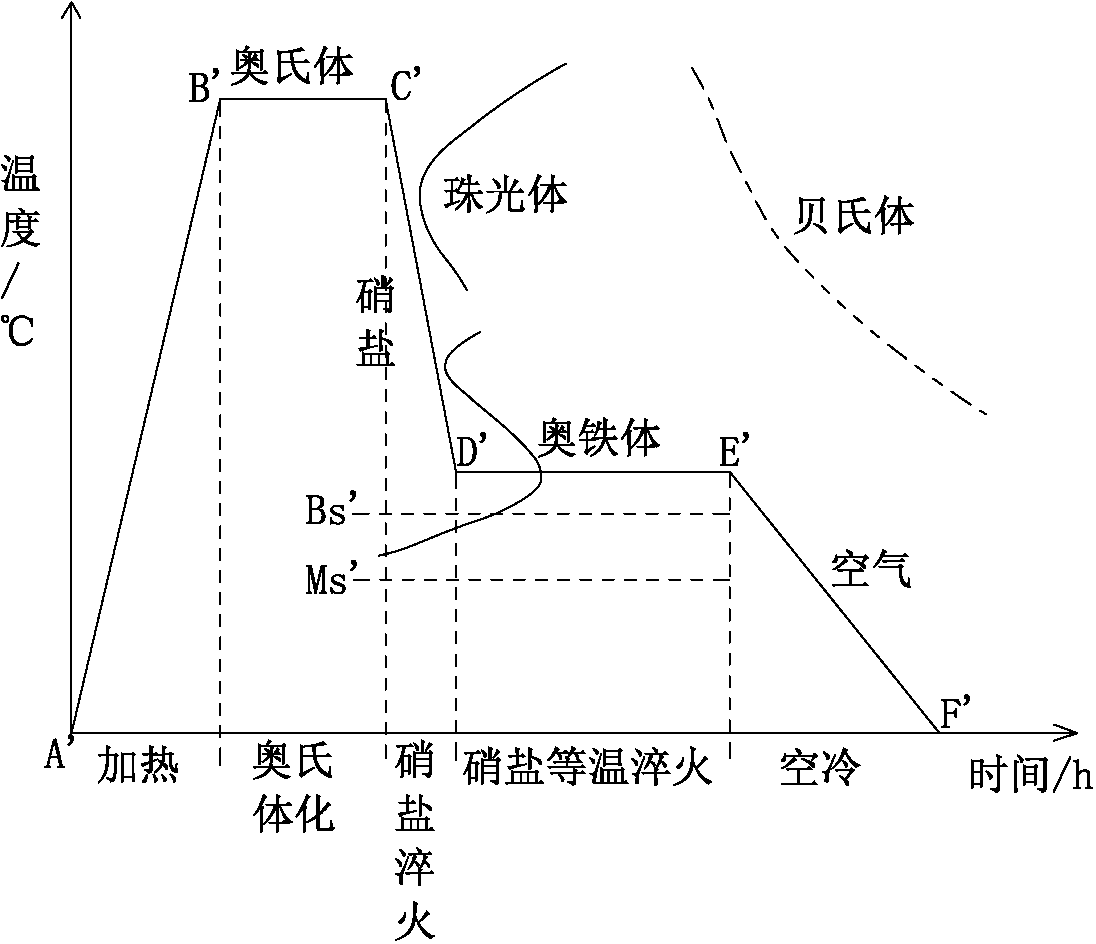

The invention relates to high-boron low-carbon wearproof cast steel and a heat treatment method thereof, which belongs to the steel material technical field. The cast steel comprises the following chemical compositions in percentage by weight (wt percent): 0.15 to 0.30 percent of C, 1.5 to 2.5 percent of B, 2.6 to 3.0 percent of Si, 1.4 to 1.8 percent of Cr, 0.5 to 0.8 percent of Mn, 0.05 to 0.12 percent of Ce, 0.03 to 0.15 percent of V, 0.03 to 0.15 percent of Ti, less than 0.05 percent of P, less than 0.05 percent of S, the balance being Fe, the content of v and Ti is more than 0.01 and less than 0.25. In the invention, a casting is kept between 880 DEG C and 920 DEG C for 1h to 3h, treated by isothermal quench in an isothermal salt bath furnace with the temperature between 250 DEG C and 300 DEG C, is kept for 2h to 4h and later cooled in the air to room temperature, thereby obtaining the high-boron low-carbon wearproof cast steel. Compared with the prior art, the cast steel and the technology of the invention have the advantages of good plasticity and toughness, high wear resistance , low cost, etc.

Owner:BEIJING UNIV OF TECH

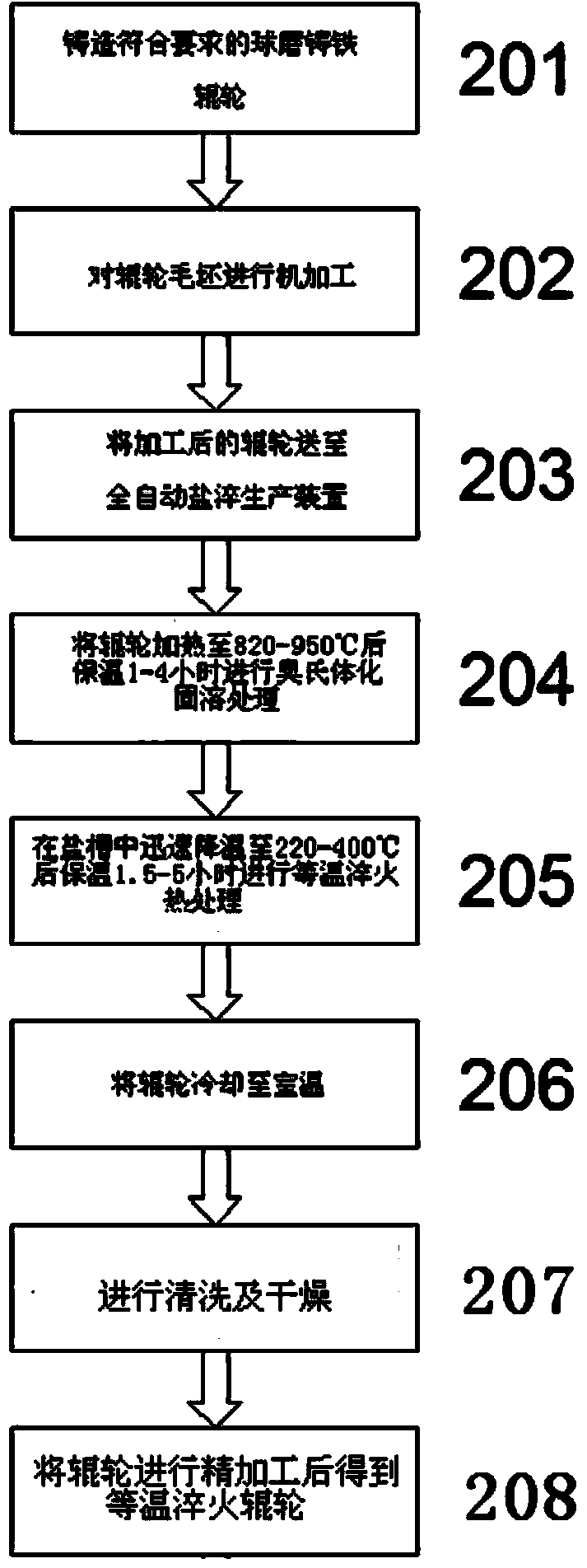

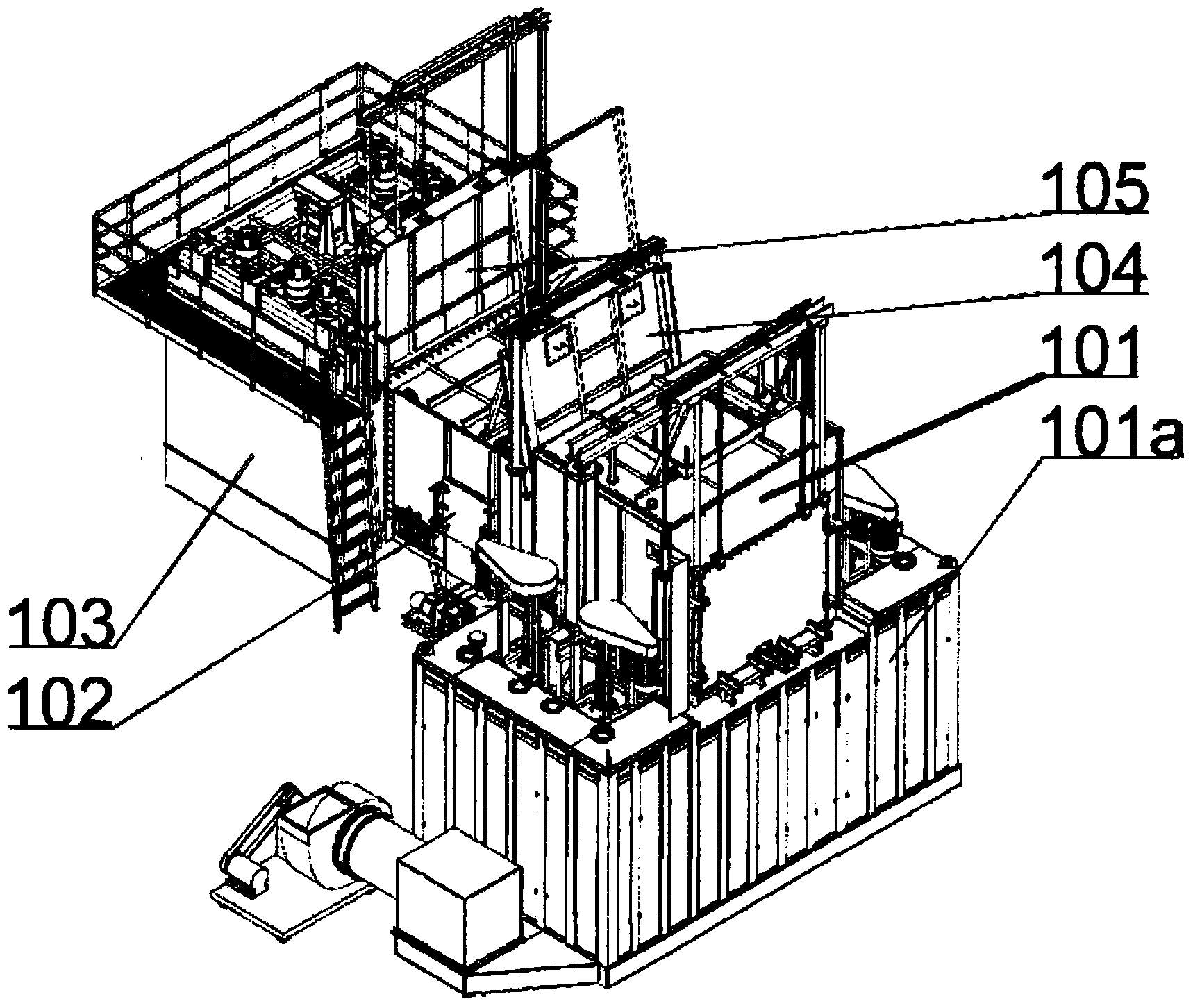

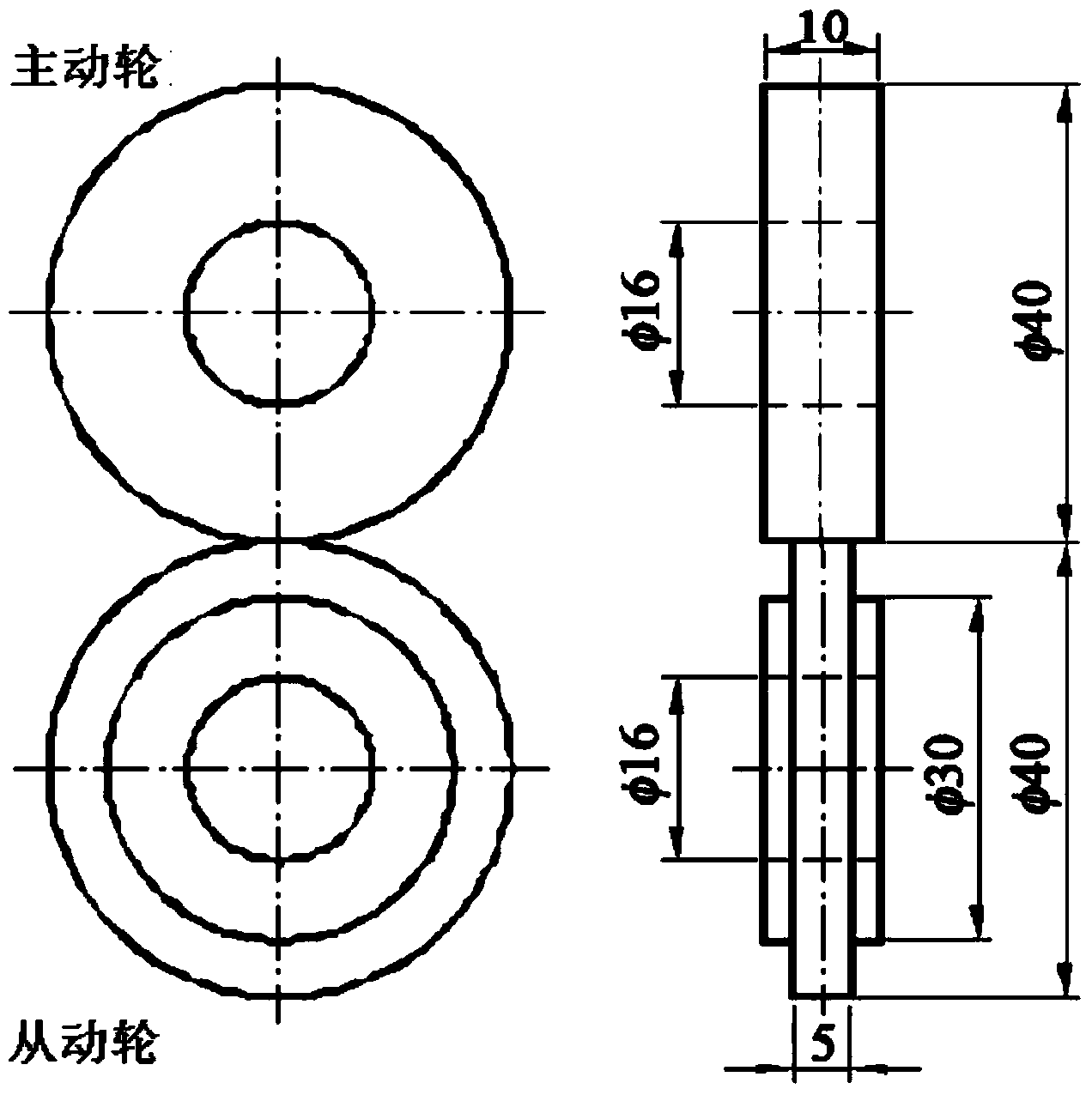

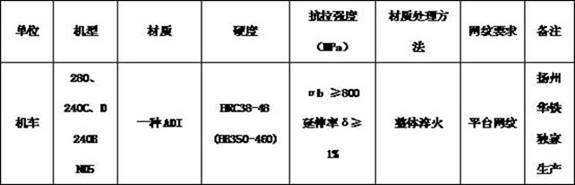

Isothermal quenching nodular cast iron roller for push-pull vehicle on heat treatment production line and production method thereof

ActiveCN103834854AHigh material strengthHigh elongationFurnace typesHeat treatment furnacesSurface oxidationPush pull

The invention discloses an isothermal quenching nodular cast iron roller for a push-pull vehicle on a heat treatment production line and a production method thereof. The nodular cast iron roller at least comprises Fe and also comprises the following elements in percentage by mass: 3.20-4.0 percent of carbon, 2.10-2.90 percent of silicon, 0.3-0.65 percent of manganese, less than or equal to 0.1 percent of phosphorus and less than or equal to 0.1 percent of sulfur. The nodular cast iron roller is made of isothermal quenching nodular cast iron, adopts a casting mode and isothermal quenching heat treatment and has high graphite self-lubricating performance, and a hardened layer can be generated in the operating process. Because the roller adopts the casting mode, the complex shape can be cast to be close to the final size, and the roller is subjected to heat treatment in an airtight environment with atmosphere protection after one-step finish machining only, so that surface oxidation and decarbonization are avoided. Then, the roller is transferred into a quenching tank with a speed-regulating stirring and water supply device for performing isothermal quenching heat treatment in an atmosphere protection environment, and acicular ferrite and high-carbon austenite metallographic structures are obtained.

Owner:上海宝华威热处理设备有限公司

Process for manufacturing bimetal compound casting liner plate

The invention puts cold material in the lower part of casting section, then pours medium carbon low-alloy bainite abrasion resistant liquid metal in to liner; pours high carbon low-alloy bainite abrasion resistant liquid into work layer to cast liner plate; cleaning casting element and quenching at constant temperature, to form the work surface as high-rigid high carbon low-alloy bainite abrasion resistant layer, liner as high-flexibility medim carbon low-alloy bainite abrasion resistant steel. The invention has low cost and long service life.

Owner:郭继伟

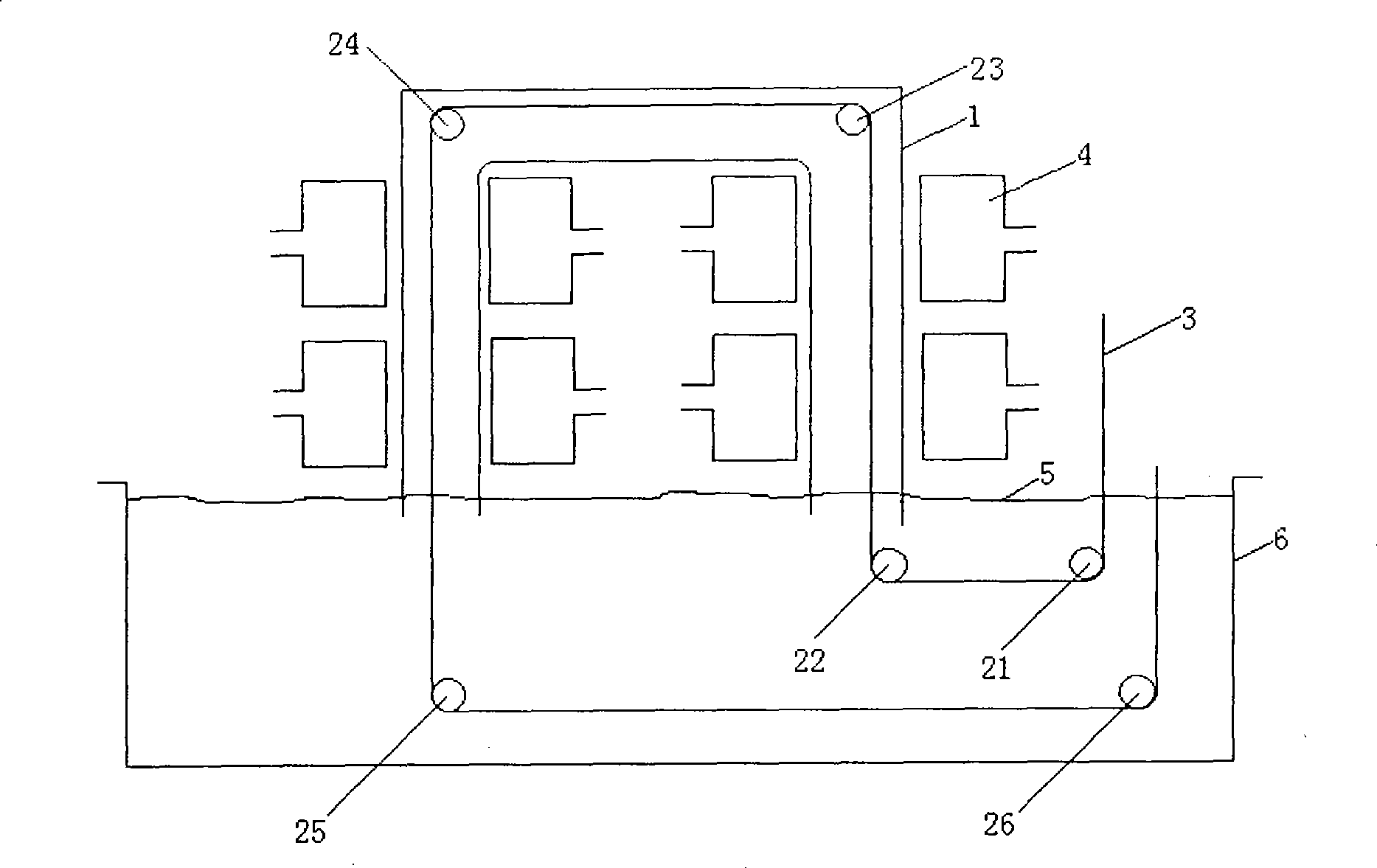

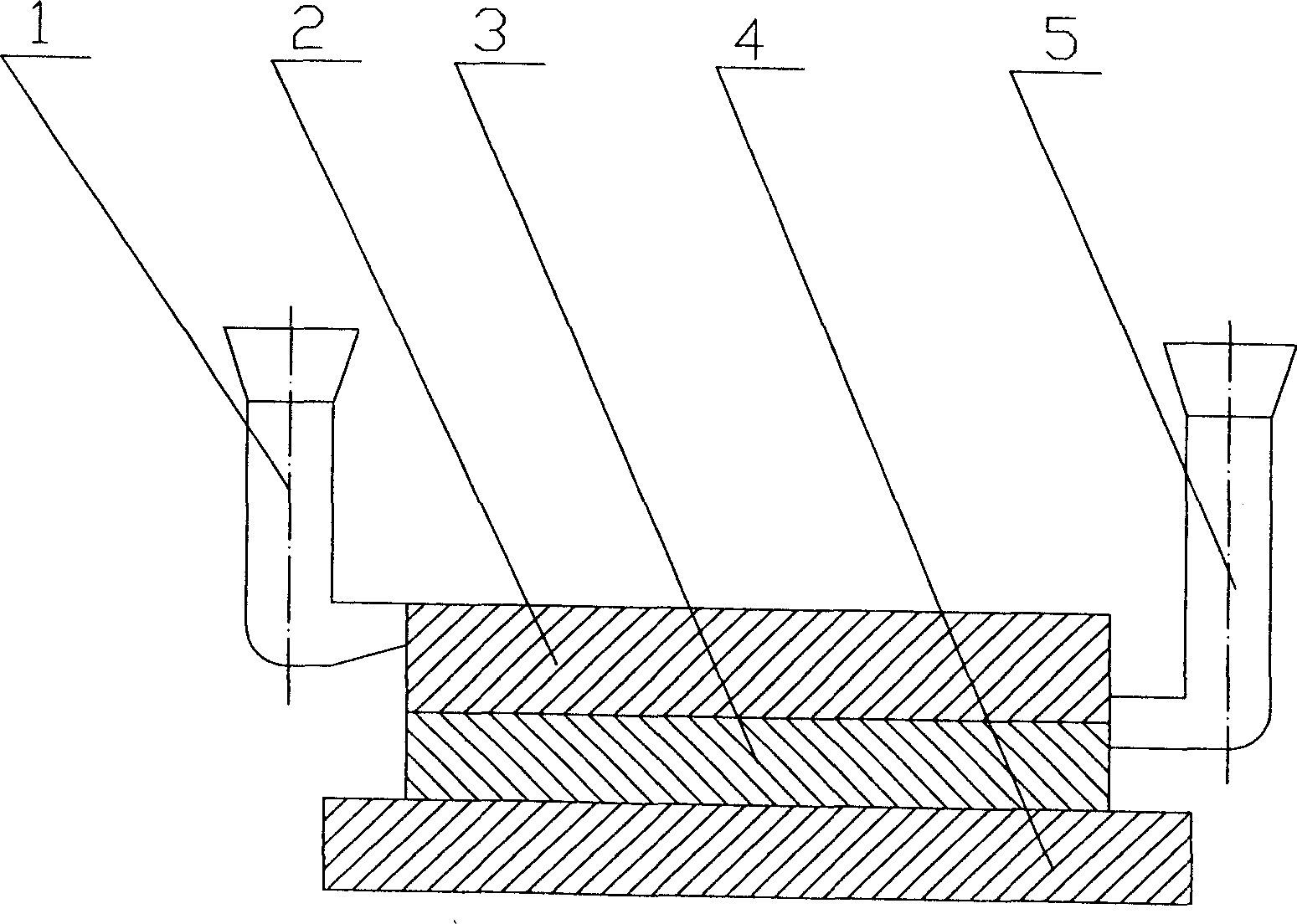

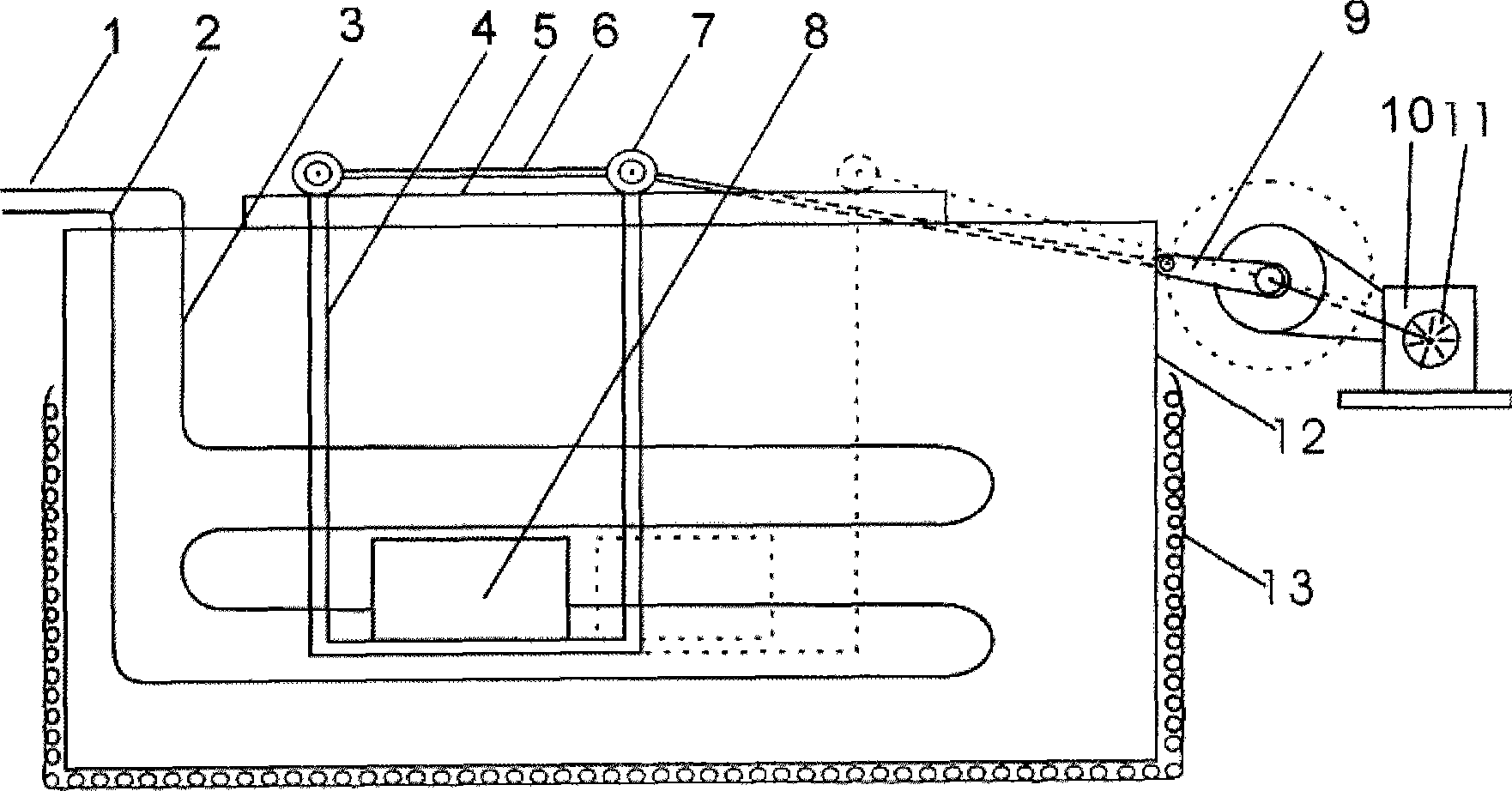

Stirring inner water cooling isothermal quench salt bath

InactiveCN101487078AImprove hardenabilityAccelerate heat dissipation and coolingQuenching agentsQuenching devicesAustemperingReciprocating motion

The invention discloses a stirring inner water cooling austempering salt bath. The two sides above the salt bath are provided with orbits and a movable rack with rolling wheels which are arranged in the orbits, a work rest in the bath body is fixedly connected with the movable rack, and a work rest bearing the work pieces or work piece hurdles moves back and forth driven by a swinging mechanism through the movable rack to stir the salt bath, thus leading to the rapid heat dissipation and cooling of high temperature austenitizing work pieces and uniform temperature of the salt bath; and the inner walls on the two sides near the bath are provided with snake-shaped cooling pipes by which the bath is communicated with a cooling pool, and then circulating cooling water is pumped in the bath to strengthen the function of heat dissipation and cooling of the salt bath and cause the bath to rapidly return to the set austempering temperature. The churning inner water cooling austempering salt bath has the advantages of simple structure, convenient operation, less energy losses and stable salt bath temperature and the salt bath is applicable to small serial production and mass mechanized production. The salt bath can harden ADI pieces with the thickness being 80mm, thus avoiding the problems of not hardening matrix and residual ferrite (pearlite), so the salt bath is suitable for producing high-quality products.

Owner:WUHAN TEXTILE UNIV

Method for producing transformation induced plasticity (TRIP) seamless tube

InactiveCN102407245AAustempering achievedReduce contentFurnace typesHeat treatment furnacesAustemperingChemical composition

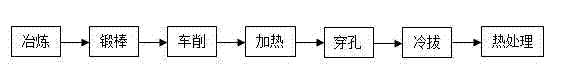

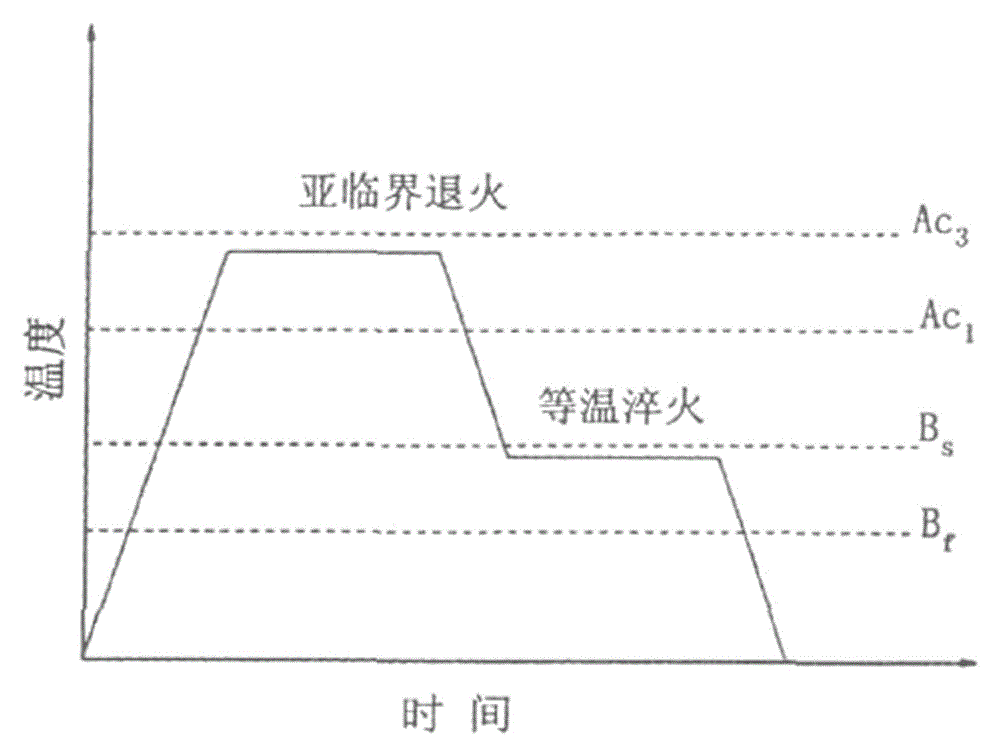

The invention belongs to the field of preparation of steel tubes, and in particular relates to a method for producing a transformation induced plasticity (TRIP) seamless tube. The method comprises the following steps that: a smelted ingot is forged into a rod, turned, heated, punched and subjected to cold drawing to obtain a seamless cold drawing steel tube, and the seamless cold drawing steel tube is placed in a resistor furnace for critical region isothermal annealing for 180-1200 seconds at the temperature of 780-850 DEG C, and then is rapidly placed in a salt bath furnace for bainite region isothermal annealing for 120-1800 seconds at the temperature of 380-470 DEG C so as to obtain the TRIP seamless tube. According to the technical scheme in the invention, the chemical components of common low carbon steel can be used for producing the TRIP seamless tube with good comprehensive mechanical properties, high yield strength up to 580MPa, high tensile strength up to 763MPa and high product of strength and elongation up to 22029MPa.%. The method is easy to realize in industrialized production, has the advantages of relatively stable process and relatively low cost, and is suitable for producing TRIP seamless steel tubes with different chemical components and sizes.

Owner:NORTHEASTERN UNIV LIAONING

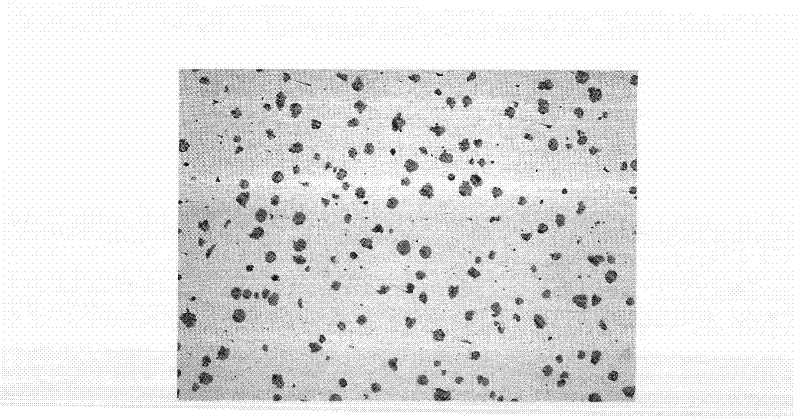

Carbide-containing ductile iron and its making method

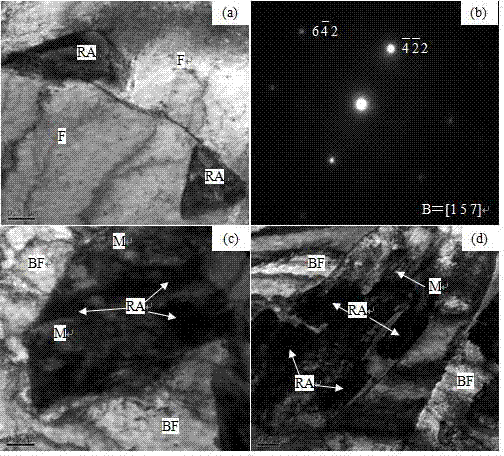

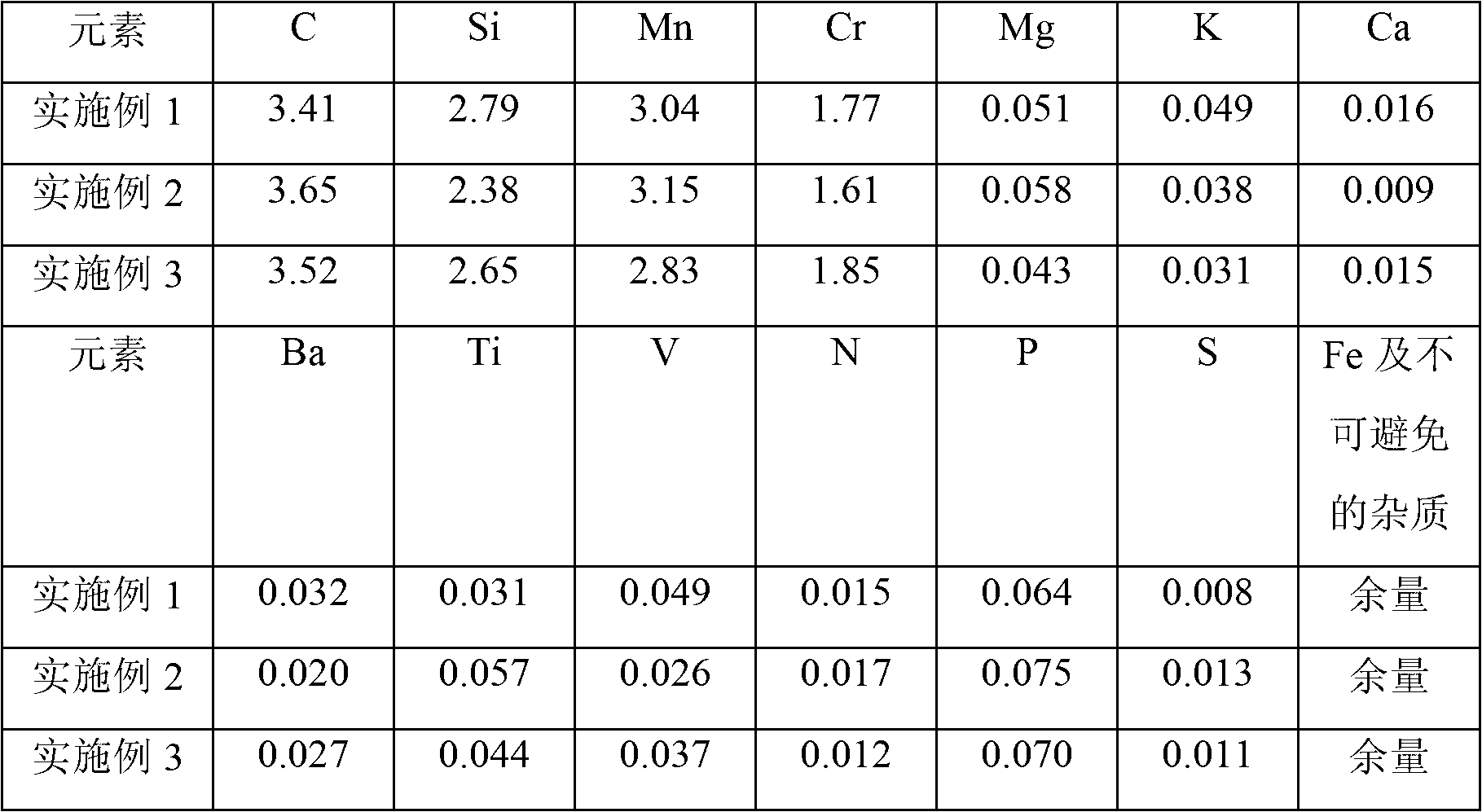

The invention discloses a carbide-containing ductile iron and its making method. The carbide-containing ductile iron comprises the following components, by mass, 3.40-3.65% of C, 2.35-2.80% of Si, 2.80-3.15% of Mn, 1.60-1.85% of Cr, 0.04-0.06% of Mg, 0.03-0.05% of K, 0.008-0.016% of Ca, 0.018-0.035% of Ba, 0.03-0.06% of Ti, 0.025-0.050% of V, 0.012-0.018% of N, 0.10% or less of P, 0.02% or less of S, and the balance Fe and inevitable impurities. The carbide-containing ductile iron can be obtained through melting in an electric furnace or a cupola furnace, cast forming and isothermal quenching, and has the advantages of excellent performances, low cost, application popularization, and good effects.

Owner:BEIJING UNIV OF TECH

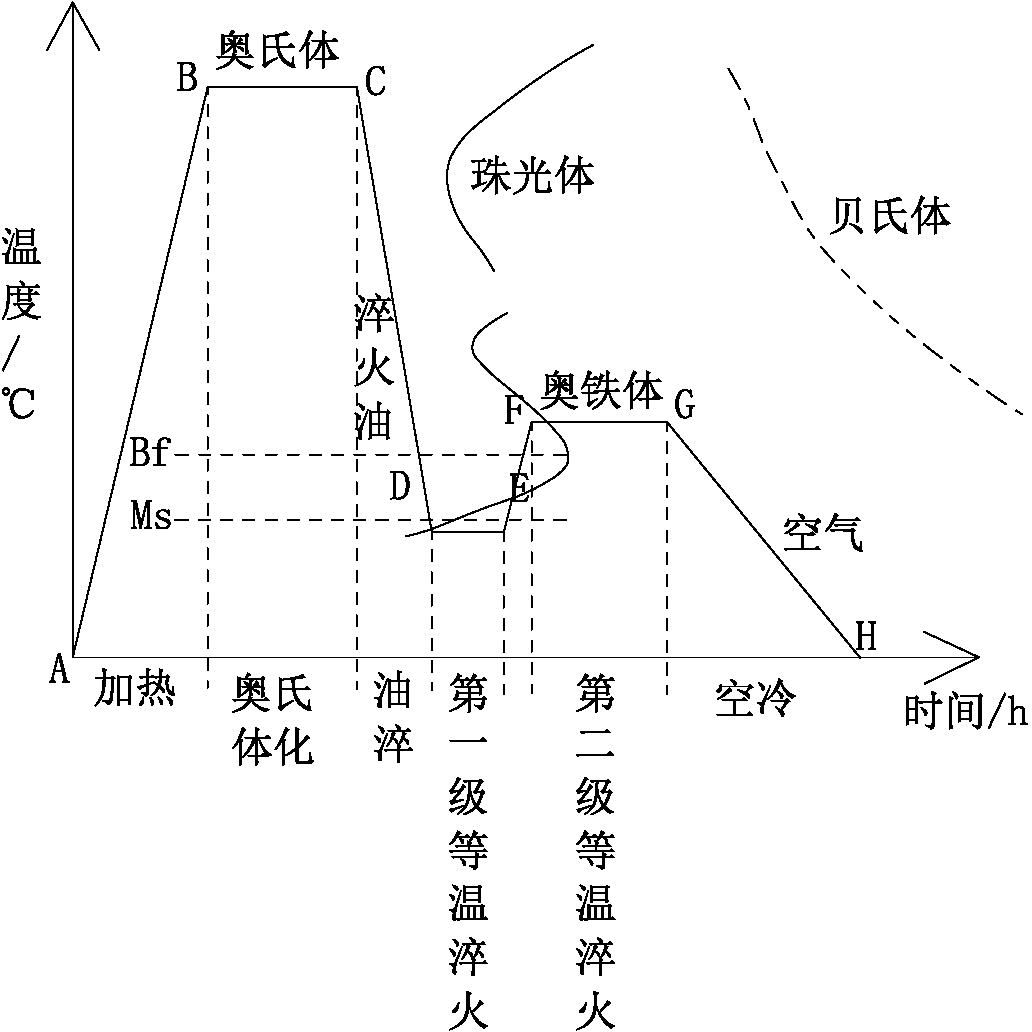

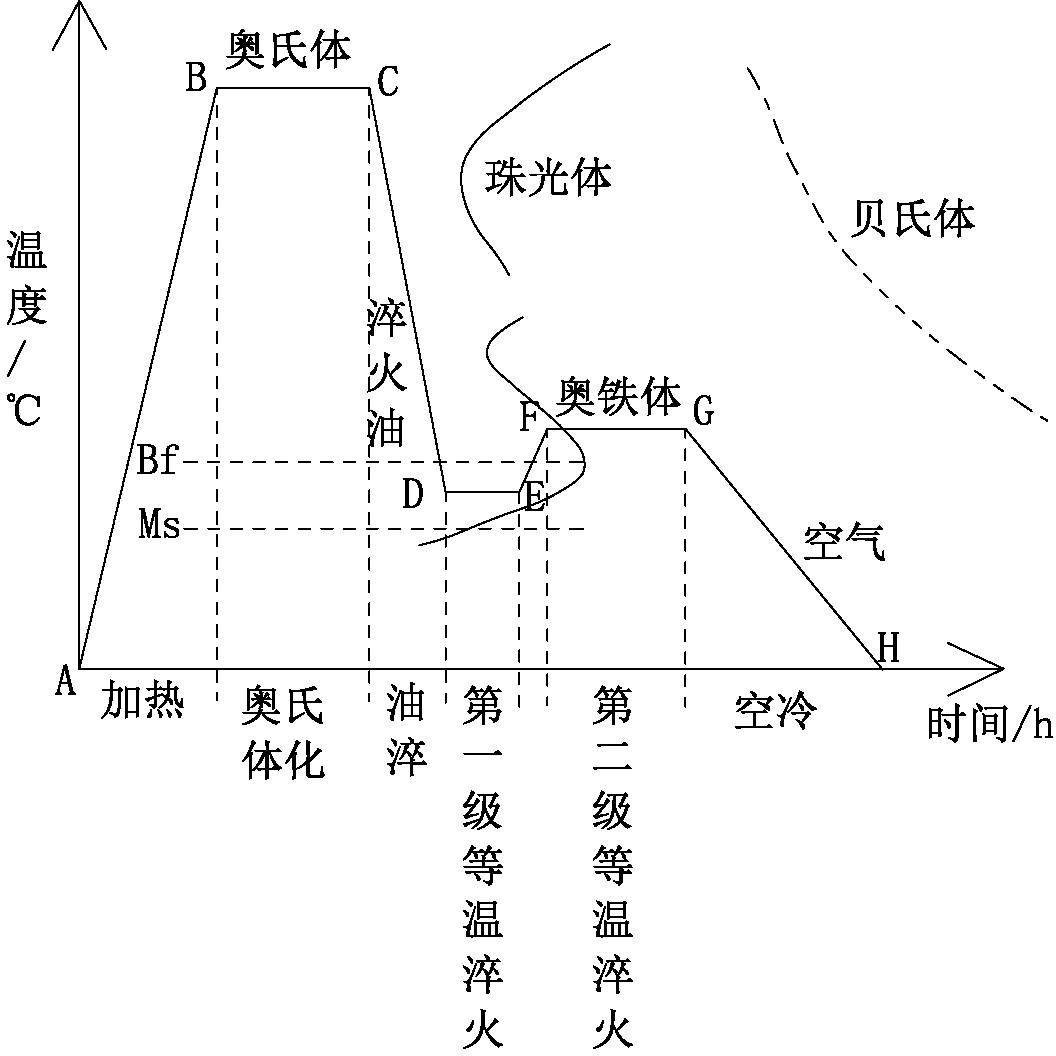

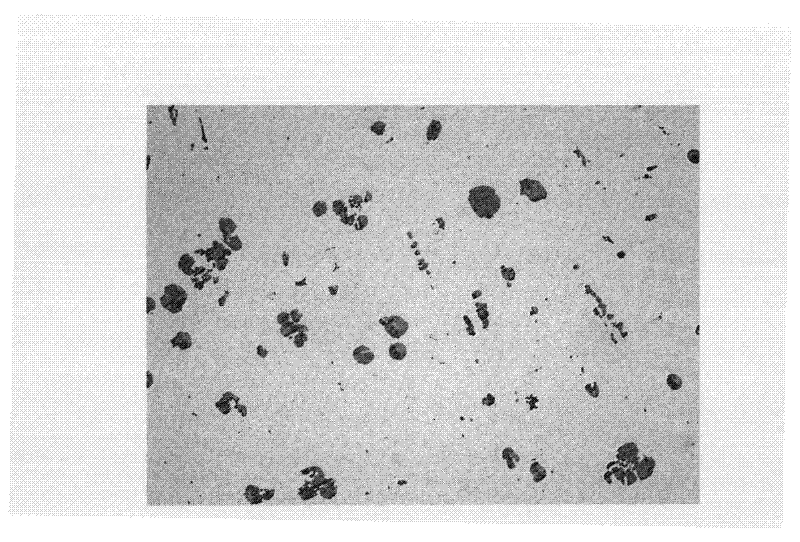

Carbide-carrying austempered ductile iron and quenching technology thereof

The invention relates to a carbide-carrying austempered ductile iron and a quenching technology thereof. Cr and B are added to an Mn-Si alloy, the carbide amount is properly increased, and inoculating deterioration treatment is carried out by using RE-B, so the carbide becomes a fine uniformly-distributed agglomerate to improve the hardness, the abrasion resistance, the hardenability and the toughness; and the addition of Sn and the increase of the Si amount are carried out to improve the potential of a matrix electrode, and the added Sn and the increased Si form a surface passivating film together with Cr to improve the corrosion resistance. The quenching technology of the carbide-carrying austempered ductile iron is step austempering and is characterized in that an austempered workpiece undergoes first-step austempering by using grading quenching oil to avoid the generation of pearlite, and then second-step austempering is carried out at a proper temperature in an air isothermal furnace to obtain a proper amount of fine lower bainite, increase the amount of tempered martensite, and improve the hardness and the abrasion resistance, so the carbide-carrying austempered ductile iron having the advantages of high strength and hardness, appropriate toughness, strong abrasion and corrosion resistances, good processing properties, easy precision guarantee and low cost is obtained.

Owner:高州创建铸造有限公司

Austempering ductile iron (ADI) supercharged diesel engine six-cylinder crankshaft and production method

Owner:长春怀林机械工程材料科技有限公司

Method for producing wheel made of austempered ductile iron (ADI) material

ActiveCN102560228AReduce running noiseFurnace typesHeat treatment furnacesAustemperingMetallic materials

The invention discloses a method for producing a wheel made of an austempered ductile iron (ADI) material, and relates to metal materials, in particular to an ADI rail transit wheel and a production method thereof. The method comprises the following steps of: pouring an ADI wheel casting blank, performing rough machining on the wheel casting blank, performing isothermal quenching, performing shot blasting, and performing finish machining. Surface strengthening can be realized through shot blasting, and the problem that the wear resistance and noise of a cast steel wheel and a rolled steel wheel cannot meet the service requirements at present is solved.

Owner:扬州华铁机电集团有限公司

Austempered ductile iron and quenching technology thereof

The invention provides an austempered ductile iron adjusting chemical component. The chemical component uses Mn and Si as a base to substitute Mo and Ni, and contains a plurality of elements comprising Cu, B, Nb and Cr to realize low and micro alloying, so the respective effects of all elements are fully performed, the interactive effect promotion is realized, the hardenability is increased, the alloy consumption is reduced, and the cost is reduced. The invention also provides a new austempered ductile iron quenching technology matched with the austempered ductile iron. The technology is a step austempering technology using step quenching oil and an air isothermal furnace. The heat treatment of a workpiece through the technology realizes crystal grain refinement, good hardenability, high strength and toughness, low hardness (HB190-240) before the step austempering treatment, and good processing performances; and the obtained processed austempered ductile iron has a high hardness (HRC35-56) and extremely less oxidation and deformation, so the precision is guaranteed, and finishing treatments comprising grinding and the like are not needed. Compared with traditional nitrate bath austempering technologies, the austempered ductile iron quenching technology has the advantages of low cost, no generation of large amounts of harmful substances comprising nitrite or the like, low pollution and safety.

Owner:高州创建铸造有限公司

Isothermal quench bainitic ductile cast iron and use thereof

The invention relates to an austempering bainite spheroidal graphite cast iron and application thereof. The compositions by weight percent of the austempering bainite spheroidal graphite cast iron are 3.50 to 3.8 percent of carbon, 2.2 to 2.7 percent of silicon, 0.2 to 0.5 percent of manganese, less than or equal to 0.07 percent of phosphor, less than or equal to 0.03 percent of sulfur, 0.03 to 0.06 percent of magnesium, 0.01 to 0.04 percent of rhenium, 0.45 to 0.75 percent of copper, and the balance being iron. The austempering bainite spheroidal graphite cast iron is used as a fitting part of a pump or a fitting part of a pulling machine. The austempering bainite spheroidal graphite cast iron has the advantages that: firstly, the austempering bainite spheroidal graphite cast iron has superior comprehensive performance, is easy to manufacture and has low cost; secondly, the austempering bainite spheroidal graphite cast iron has long service life, low manufacturing cost, superior corrosion resistance and abrasion resistance, and good strength, plasticity and toughness; and thirdly, the industrial production of the austempering bainite spheroidal graphite cast iron on pump products, particularly the application of the austempering bainite spheroidal graphite cast iron on marine pump products and mine pump products and the application of the austempering bainite spheroidal graphite cast iron as the fitting part of the pulling machine effectively improve the product performance in the two industries and can bring about significant economic benefit.

Owner:朱志文

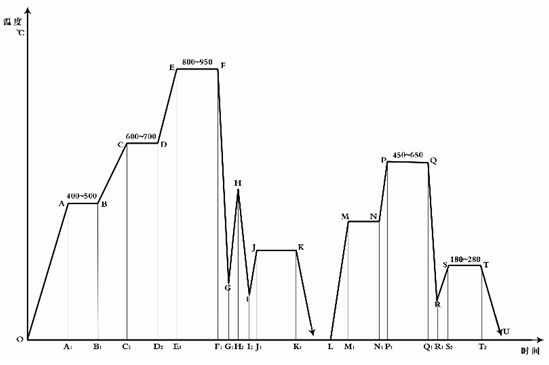

Steel isothermal quenching-tempering cooling technology

ActiveCN102605145AReduce labor intensitySolve hardenability problemsHeat treatment process controlUltimate tensile strengthTreatment quality

The invention relates to a steel isothermal quenching-tempering cooling technology in which the 'difficulty coefficient of heat treatment' is defined with innovative thought, the 'bainite transformation isothermal quenching cooling manner' is redefined and the 'traditional unique cooling manner' is subverted, so that the traditional steel hardenability theory is overturned, a brand new steel harednability theory is established, and the steel hardenability is greatly improved. After austenitizing, the steel is not cooled completely in water, the energy difference between the surface of the steel and the water is increased through temperature returning so that water cooling speed is improved again and the steel harednability is improved; temperature is returned again, waste heat is used forisothermality; mid-high temperature tempering is carried out, incomplete water cooling is adopted for preventing a secondary temper brittleness, and secondary bainite quenching and self tempering treatment are carried out through temperature returning by utilizing waste heat. The technical effect of the steel isothermal quenching-tempering cooling technology is as follows: a large amount of energy and resources are saved, heat treatment cost is lowered, the environment is protected, the labor intensity of a labor is relieved, the heat treatment quality is improved, the problem of hardenability of toughness heat treatment of a large workpiece at the position of 1 / 2T is solved, the processes are combined, and energy is saved and emission is reduced.

Owner:王长文

Steel pipe reducing machine or sizing machine ductile iron roll and preparation method thereof

ActiveCN102268588AReduce the content of nickel alloy componentsGuaranteed uptimeFurnace typesHeat treatment furnacesQuenchingPrecious metal

The invention discloses a steel pipe reducing mill or sizing mill nodular cast iron roller and a preparation method thereof. According to the invention, better mechanical properties than the conventional heat treated nodular cast iron roller are obtained by adopting a reasonable component ratio and a nickel free scheme, reducing component compositions of other alloy contents in the nodular cast iron roller and carrying out isothermal quenching by adopting a two-step method, so that the strength and the toughness of the nodular cast iron roller are greatly increased; the wear resistance of thenodular cast iron roller achieves the level of the traditional high-nickel sizing and reducing the alloy nodular cast iron roller through laboratory experiments and installation use; and the actual needs of production are met. The use and consumption of precious metals are reduced and the costs of manufacture and use are minimized.

Owner:SHANDONG PROVINCE SIFANG TECHN DEV

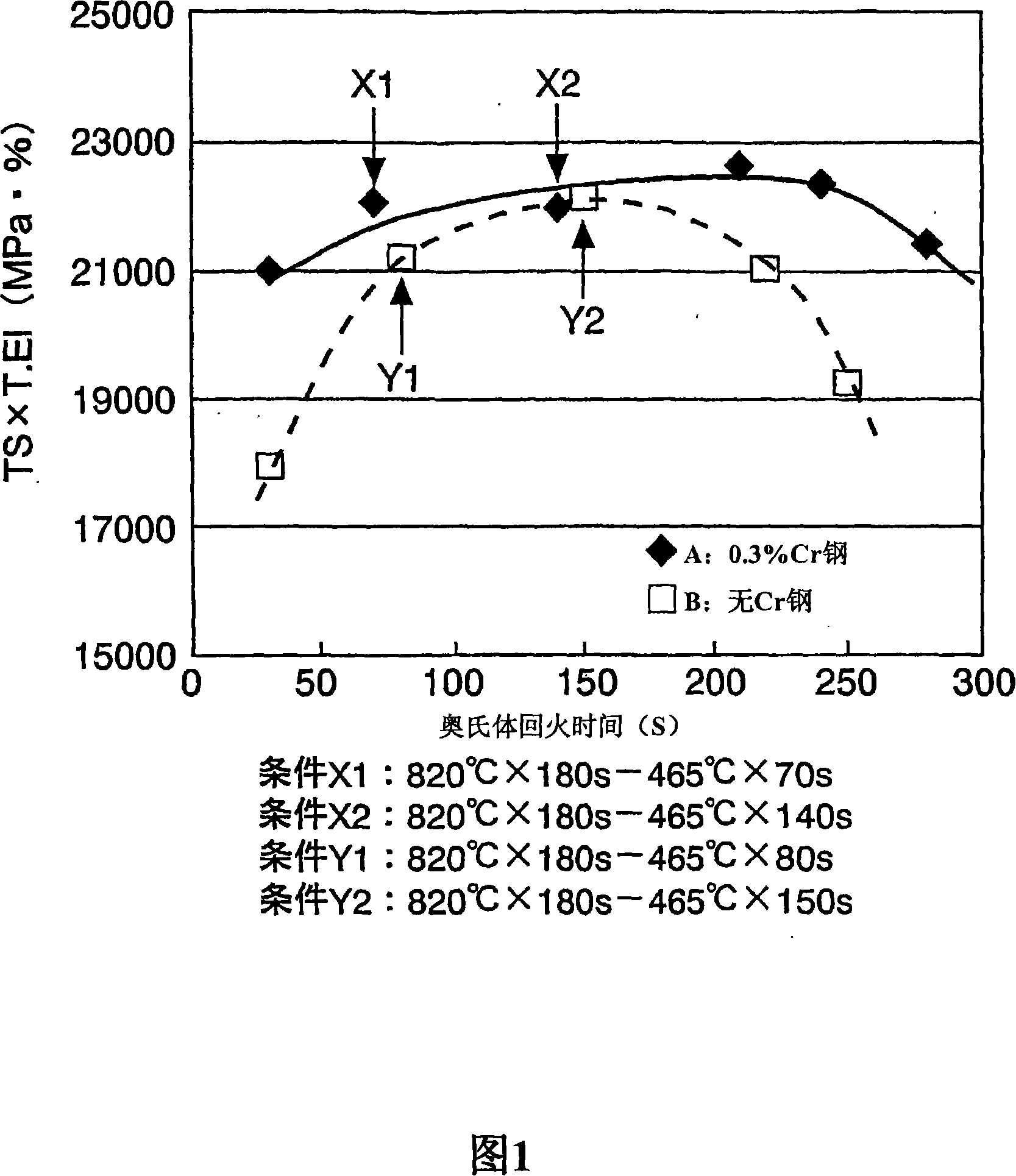

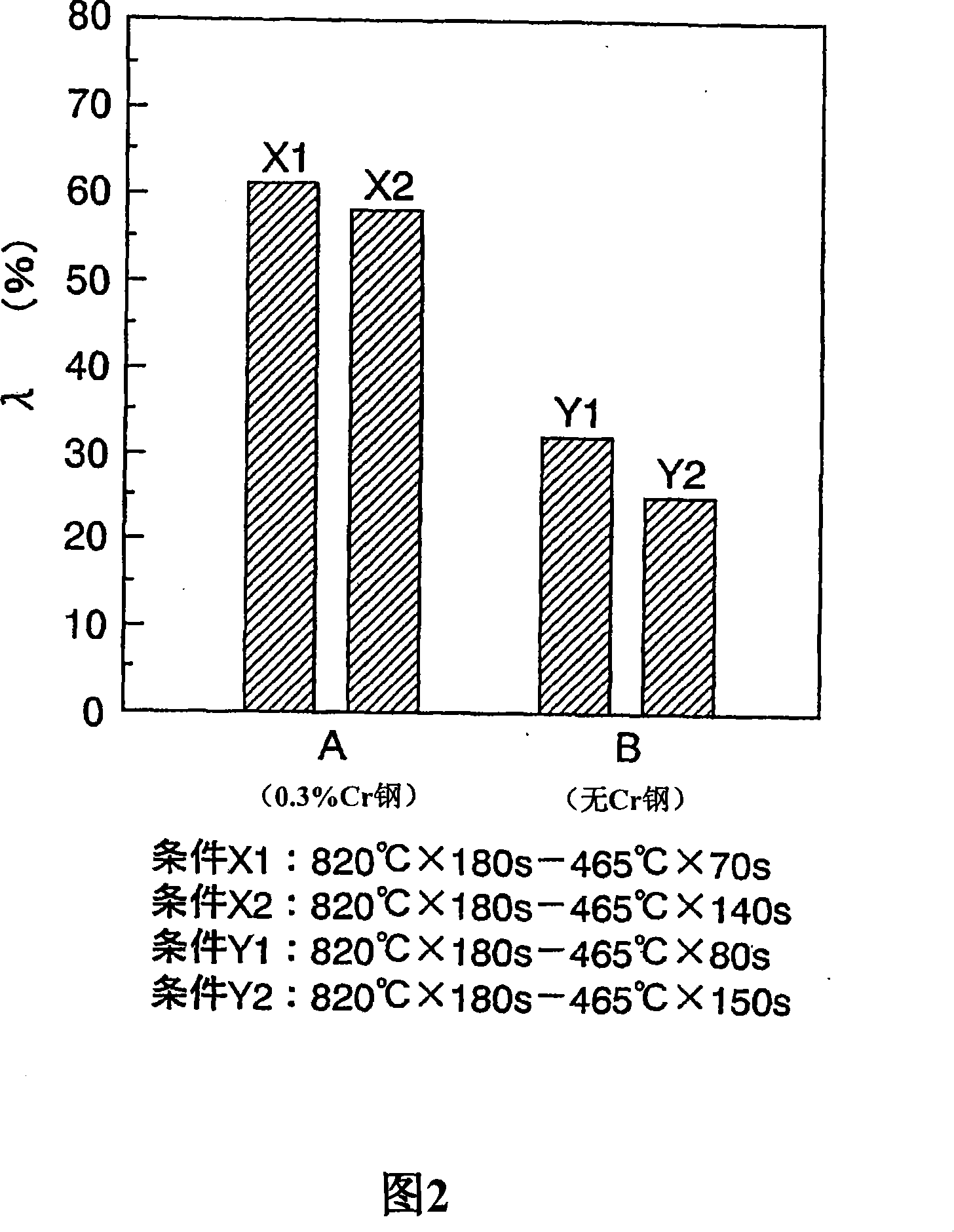

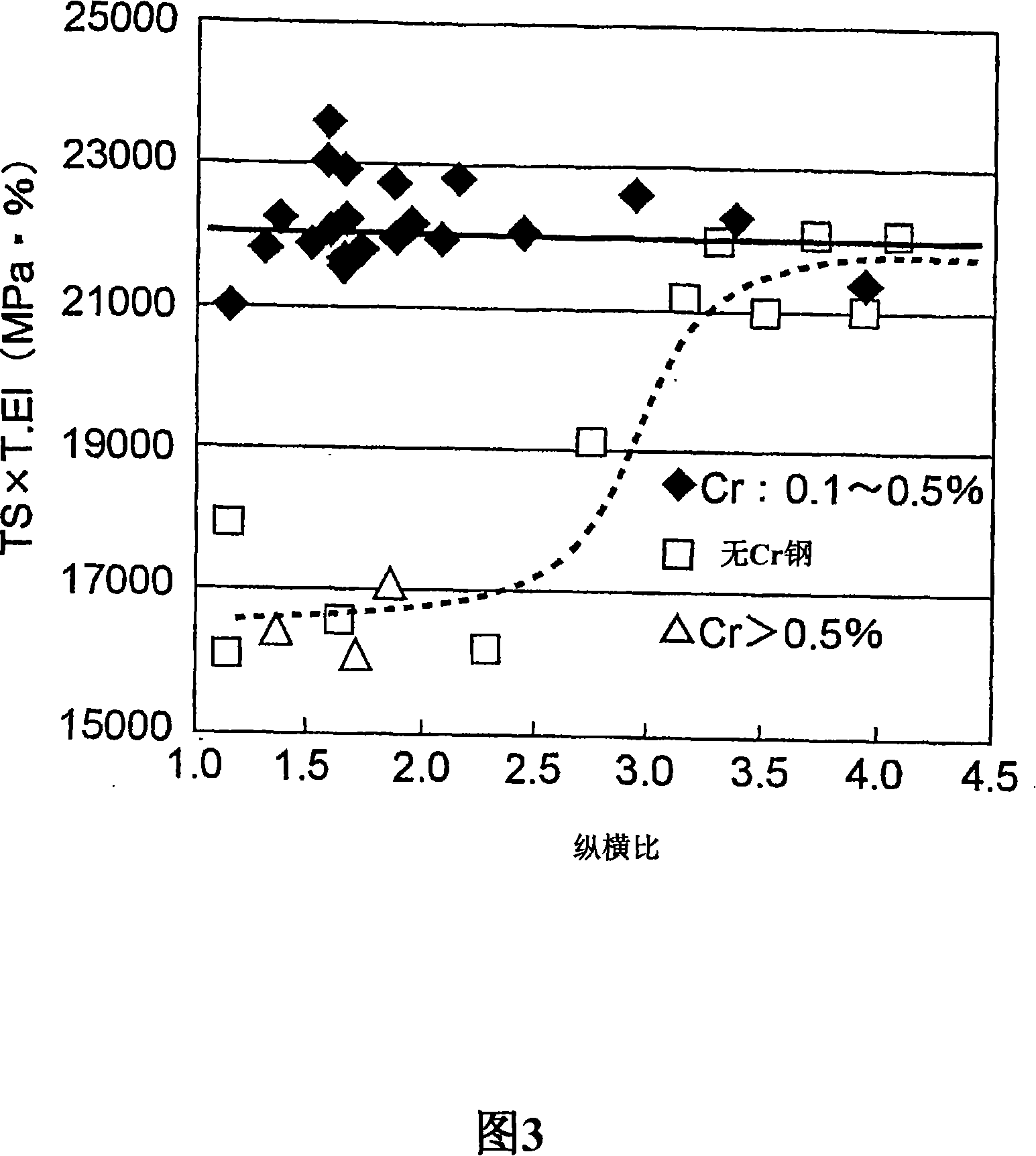

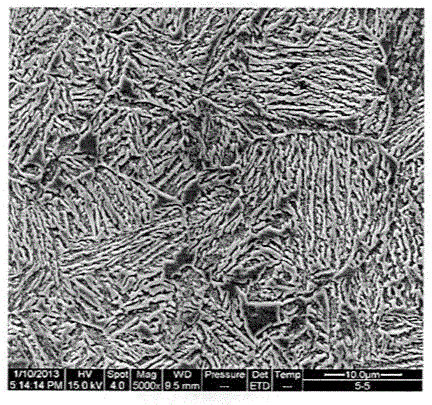

High-strength steel sheet plated with zinc by hot dipping with excellent formability and process for producing the same

A high-strength steel sheet plated with zinc by hot dipping which has excellent processability. It can be produced using a production line which includes zinc plating by hot dipping and in which a sufficient austempering time after annealing is not secured, without necessitating a special structural control as a pretreatment. The high-strength steel sheet plated with zinc by hot dipping contains 0.05-0.3 mass% carbon, up to 1.4 mass% (including 0 mass%) silicon, 0.08-3 mass% manganese, 0.003-0.1 mass% phosphorus, up to 0.07 mass% sulfur, 0.1-2.5 mass% aluminum, 0.1-0.5 mass% chromium, and up to 0.007 mass% nitrogen, provided that silicon + aluminum = 0.5 mass%, with the remainder consisting of iron and unavoidable impurities. The steel sheet has a volume content of residual austenite of 3% or higher, and residual austenite grains have an average aspect ratio of 2.5 or lower.

Owner:JFE STEEL CORP

Boron-containing high-silicon bainite wear-resistant corrosion-resistant alloy and manufacturing method thereof

The invention relates to a boron-containing high-silicon bainite wear-resistant corrosion-resistant alloy and a manufacturing method thereof. The alloy comprises the following chemical components in percentage by weight: 0.3-0.6% of C, 1.6-2.6% of Si, 0.6-1.0% of Mn, 0.6-4.0% of Cr, 0.3-0.5% of Mo, 0.3-0.5% of Ni, 0.3-0.5% of Cu, 0.1-0.3% of Ti, 0.05-0.1% of B, 0.05-0.15% of Ce, 0.05-0.15% of Nb, less than 0.04% of P, less than 0.04% of S and the balance of Fe. The manufacturing method comprises the following steps: carrying out electric-furnace smelting, carrying out secondary aluminum insertion deoxidization, putting on the bottom of a casting ladle to form a casting, austenizing the casting at 850-950 DEG C, keeping the temperature for some time, putting in a salt bath at 200-260 DEG C to carry out primary isothermal quenching, keeping the temperature for 5-10 minutes, carrying out secondary isothermal quenching in a salt bath at 260-400 DEG C, keeping the temperature for 0.5-4 hours, and cooling in air to obtain the wear-resistant corrosion-resistant alloy of which the austenite-bainite base is distributed with boride. The alloy is low in preparation cost and suitable for marine silt erosion and corrosion environments, has favorable comprehensive properties of toughness, wear resistance and corrosion resistance, and can be used for dredger cutter teeth, slurry pipelines, centrifugal-pump impellers, blades and the like.

Owner:CHANGXING DETIAN ENG MACHINERY

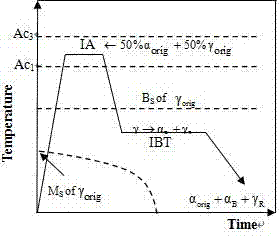

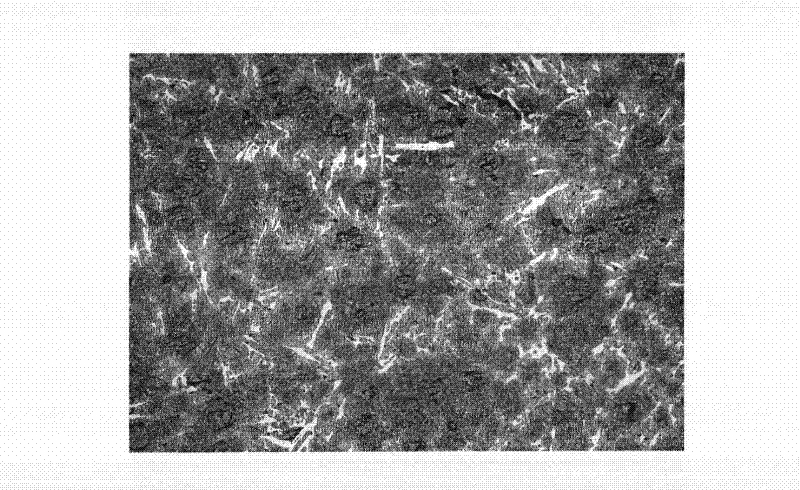

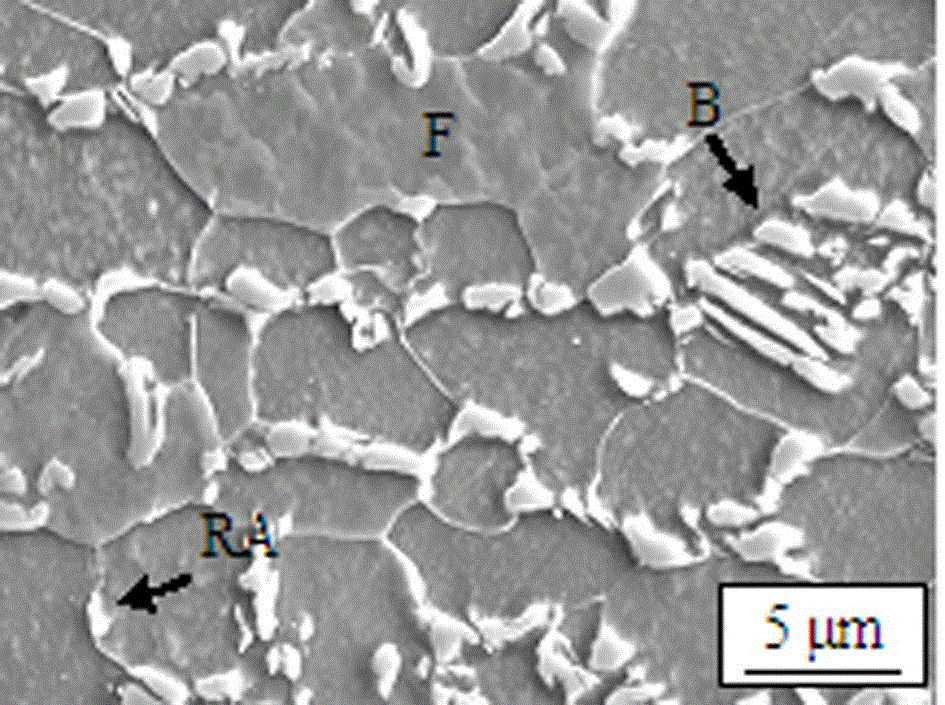

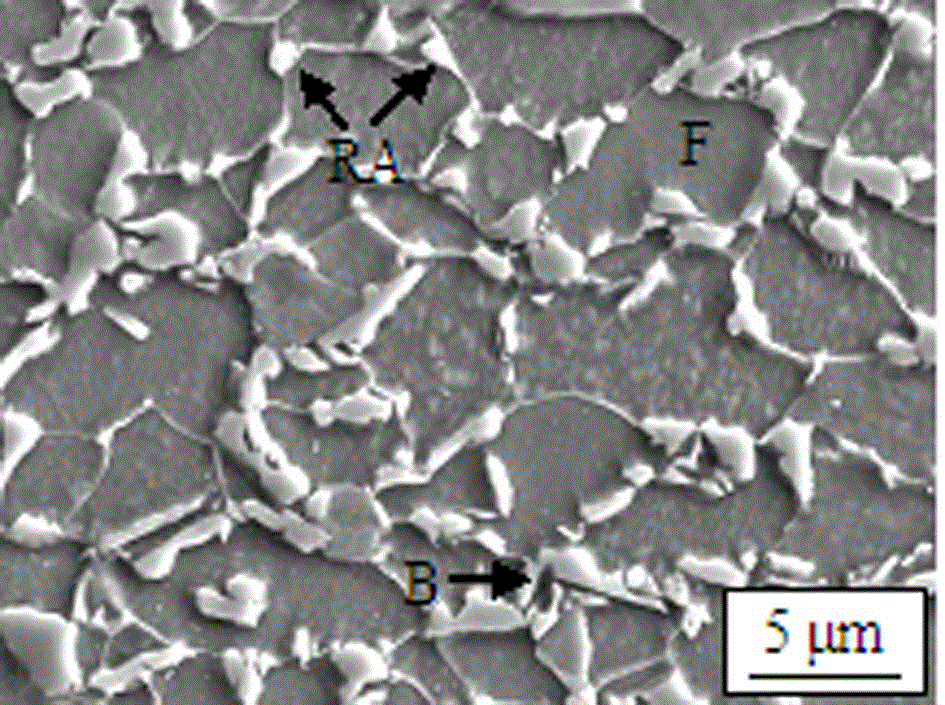

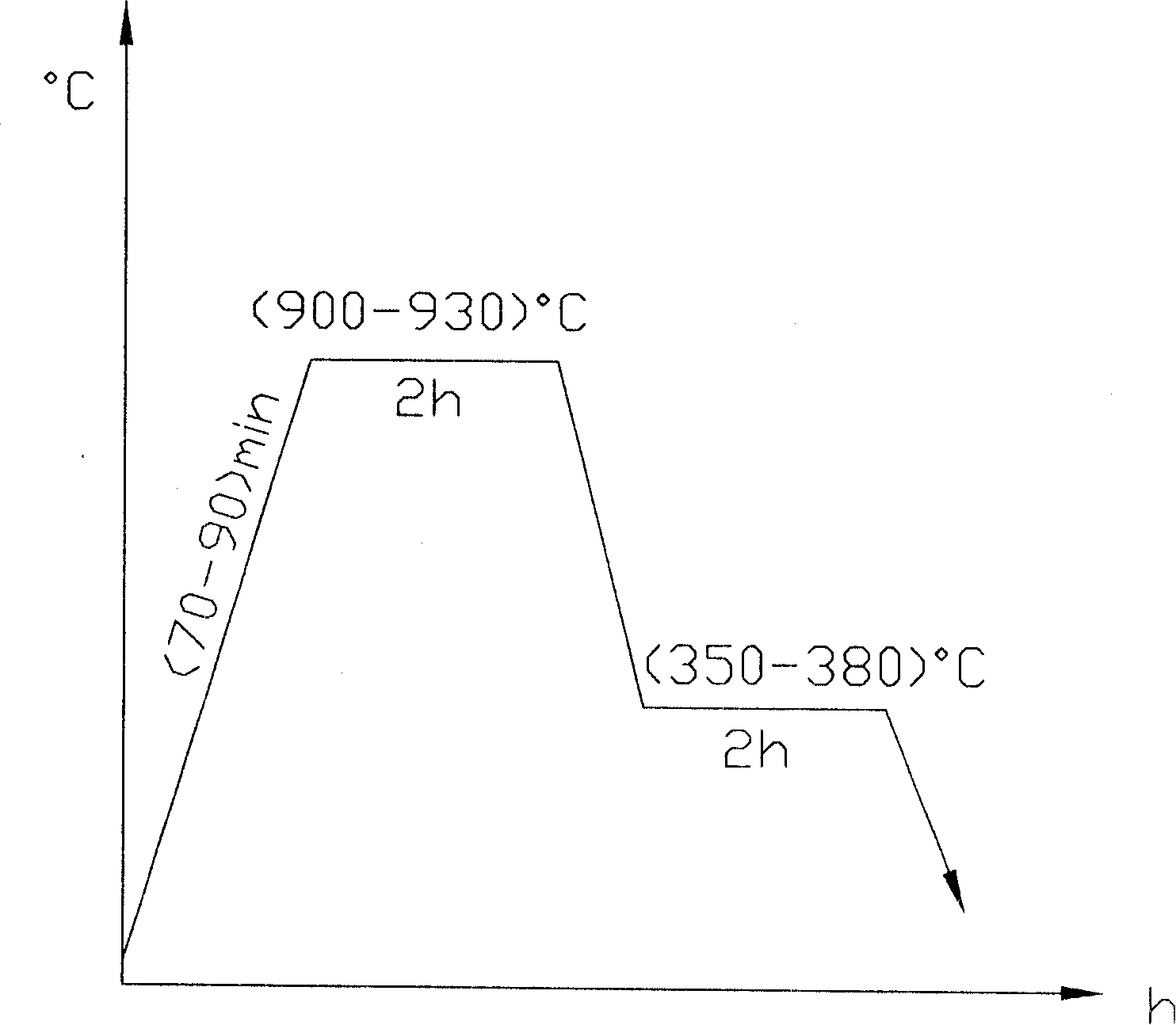

Preparation technology for nodular cast iron with TRIP (transformation-induced plasticity) effect

The invention relates to a preparation technology for nodular cast iron with a TRIP (transformation-induced plasticity) effect. The preparation technology can be used for producing a nodular cast iron part, of which the strength of extension is greater than 700MPa, the elongation is 8%, and the product of strength and elongation is greater than 6000MPa%. The cast tissue is a complex phase tissue of ferrite base, bainite, retained austenite, a bit of martensite and graphite, soft ferrite base endows the whole cast with good ductility, hard bainite, distributed in the ferrite base in a complex intertwining manner, serves as a skeleton so as to improve the strength of the cast, a bit of martensite is the hardest phase in the tissue and plays a role in improving the strength of the cast, furthermore, a bit of retained austenite not only improves the ductility of the cast, but also can produce a TRIP effect at room temperature. Therefore, the nodular cast iron with the TRIP effect has better comprehensive property than common isothermal quenching nodular cast iron, improves both the ductility and strength of the cast, and has higher product of strength and elongation.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method for wear-resistant alloy steel

The invention discloses a preparation method for wear-resistant alloy steel. The wear-resistant alloy steel contains the following components by weight percent: 0.4 to 0.6 percent of C; 1.0 to 1.2 percent of B; 1.8 to 2.2 percent of Si; 2.4 to 2.8 percent of Cr; 1.3 to 1.5 percent of Mn; 0.08 to 0.12 percent of Ce; 0.2 to 0.3 percent of V; 0.03 to 0.15 percent of Ti; 0.005 to 0.01 percent of N; 0 to 0.05 percent of P; 0 to 0.05 percent of S; and Fe in balancing amount. The preparation method comprises the following steps: melting molten steel, adjusting the components before a furnace to be qualified, and heating to 1580 to 1600 DEG C; adding aluminum for de-oxygenation, wherein the quantity of the added aluminum is 0.15 to 0.30 percent that of the molten steel, and discharging; conducting combined modification on the molten steel with cerium-based tombar thite, ferrotitanium and ferrovanadium; casting the molten steel into casts after the modification; after austenitizing for 2 to 4 hours under the condition of 960 to 980 DEG C, conducting isothermal quenching on the casts directly in an isothermal salt bath furnace of which the temperature ranges from 310 to 330 DEG C; insulating for 2 to 4 h; and conducting air cooling on the casts to ensure that the temperature of the casts is the same as the room temperature.

Owner:TANGSHAN DONGFANG HUASHENG GOOD WEAR RESISTING HIGH TECH

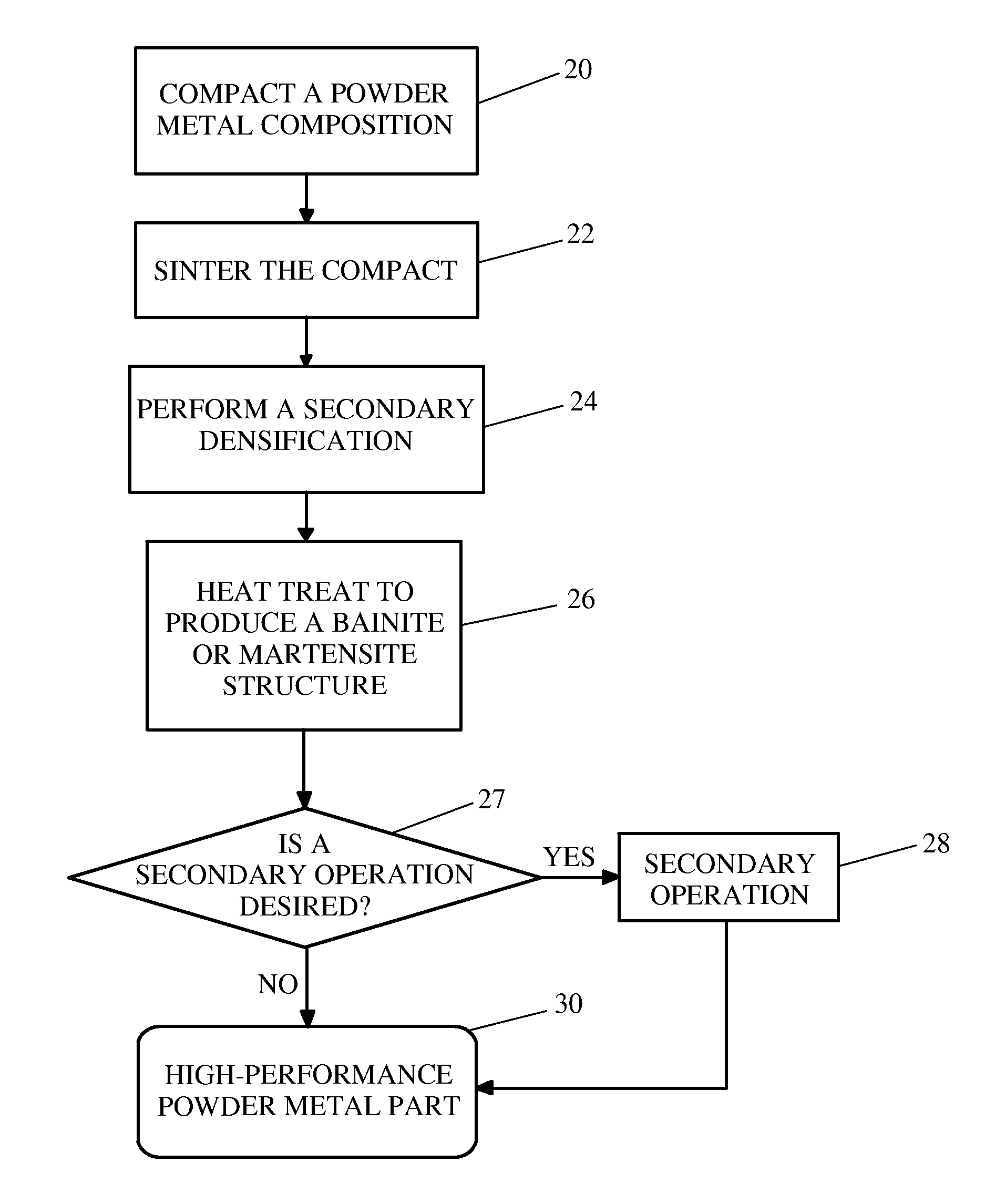

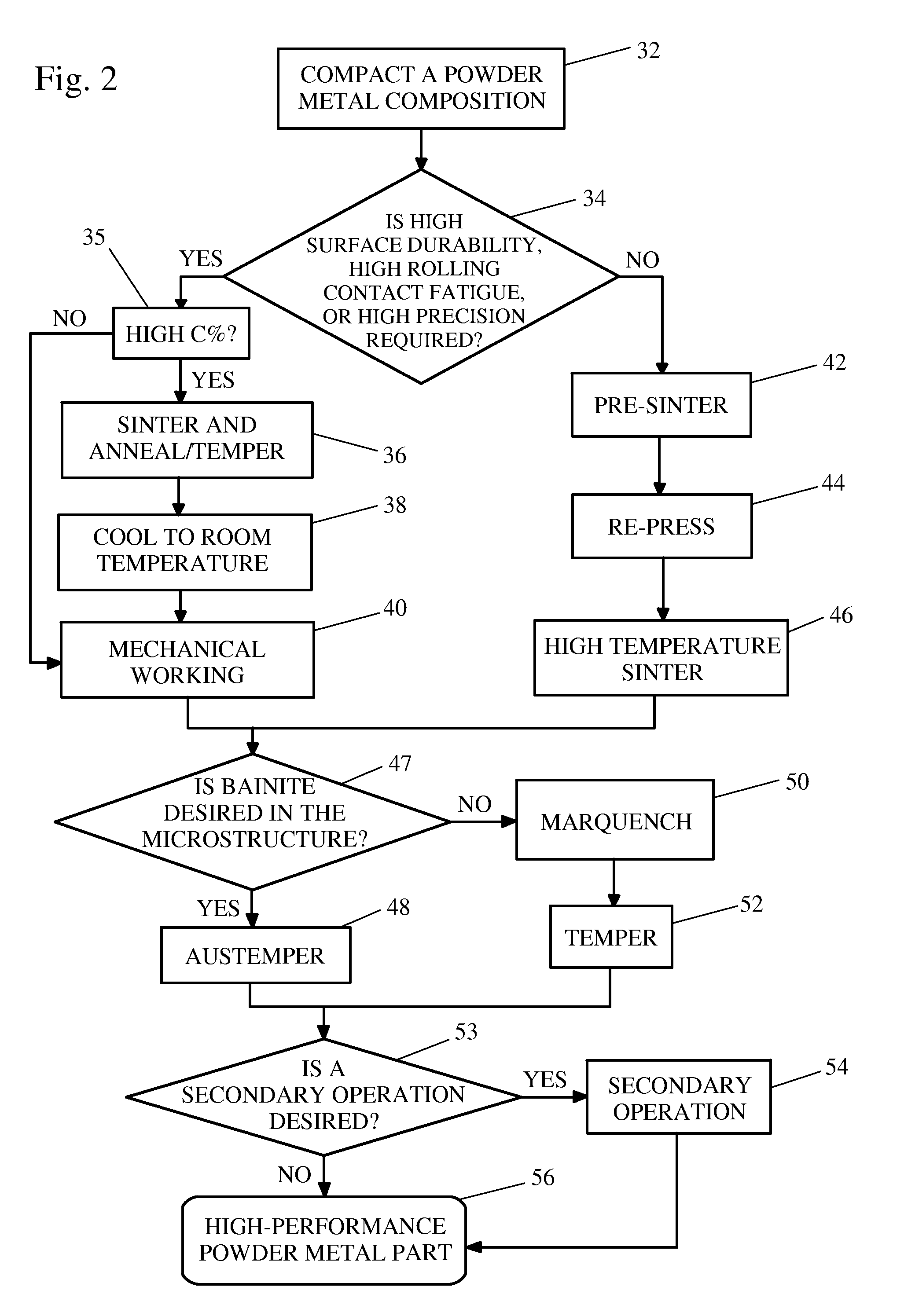

Austempering/marquenching powder metal parts

InactiveUS20060182648A1High densityImprove performanceTransportation and packagingMetal-working apparatusHeat treatedParticulate material

A powder metal part is made by compaction at room temperature or an elevated temperature followed by sintering, a secondary densification, heat treating, and optional secondary operations. The particulate materials preferably include iron, 0-2.0 wt % copper, 0.15-0.9 wt % carbon, 0.5-2.0 wt % molybdenum, 0.5-4.5 wt % nickel, 0-4.0 wt % chromium, and 0-1.5 wt % silicon. At least one secondary densification is applied to the part after compaction and pre-sinter / sinters steps to achieve medium to high density. The secondary densification is part of a double-press double-sinter (DPDS) or is a mechanical working depending on the application requirements. The powder metal is heat treated by austempering or marquenching followed by tempering. A unique composite microstructure is achieved from austempering by controlling the powder chemistry and the holding time at an elevated temperature. The combination of a secondary densification and austempering or marquenching produces a high performance powder metal part for demanding applications.

Owner:BORGWARNER INC

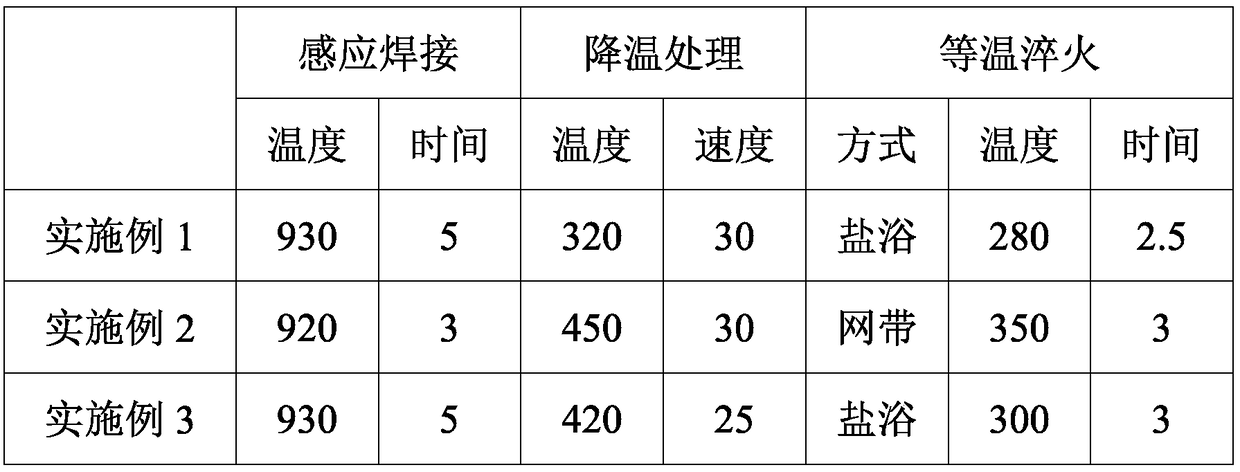

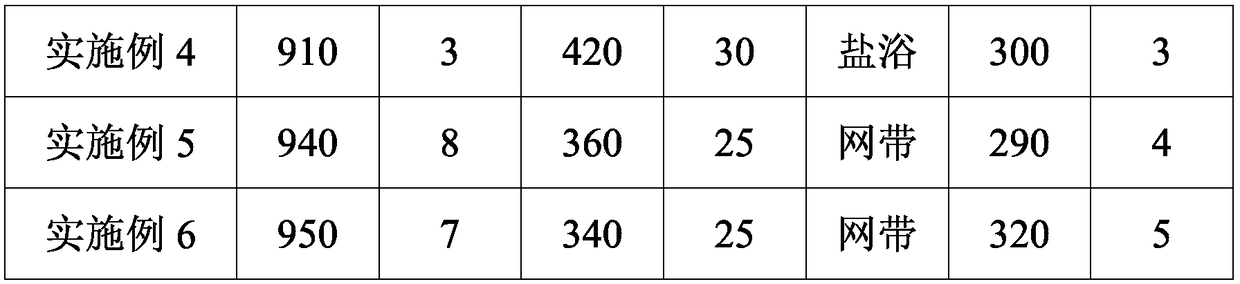

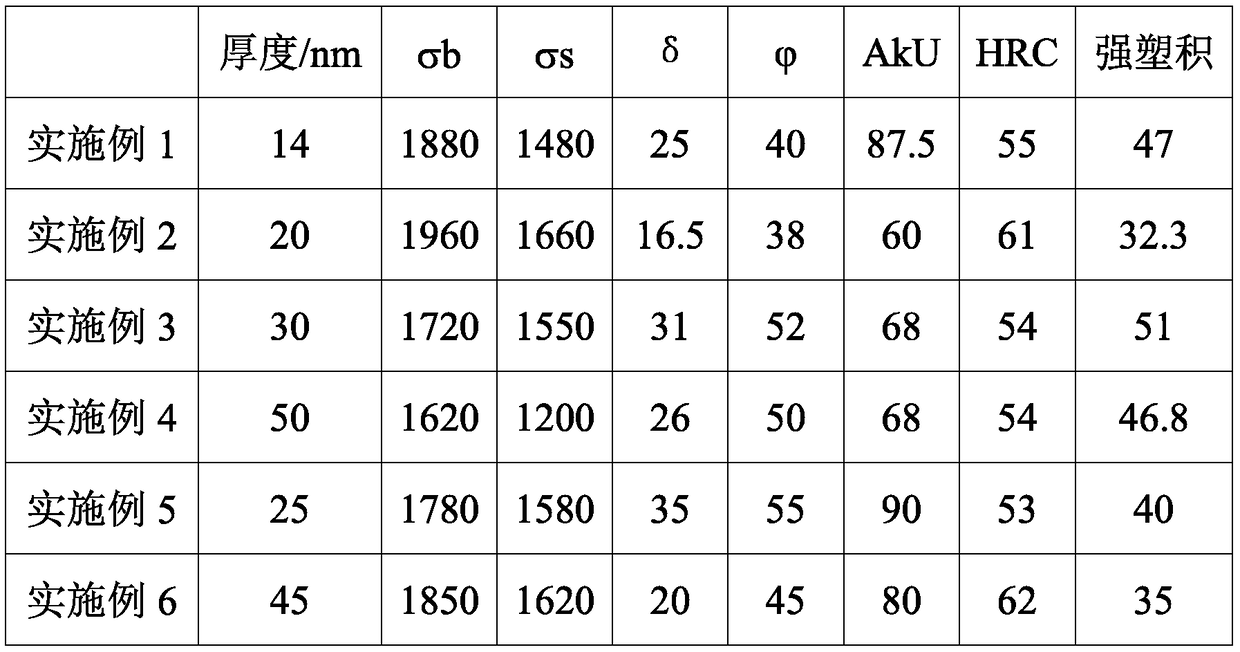

High performance cutting pick and manufacturing method thereof

InactiveCN108977631AOptimize chemical compositionHigh hardnessFurnace typesHeat treatment furnacesRaw materialMicrostructure

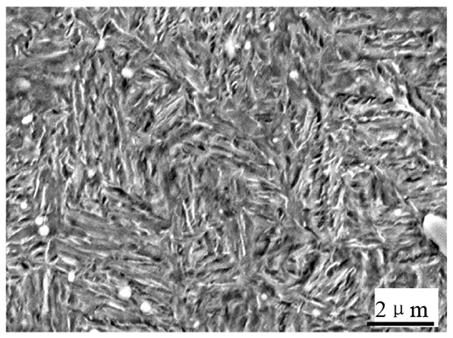

The invention provides a high performance cutting pick and a manufacturing method thereof, the high performance cutting pick comprises a tooth tip and a tooth body. The tooth body is high-strength, high-toughness and high-wear-resistance steel. The chemical components are as following by weight percent, 0.30 to 0.40 of C, 2.30 to 2.50 of Si, 2.20 to 2. 60 of Mn, 0.80 to 1.50 of Cr, 0.35 to 0.45 ofMo, 0.01 to 0.1 of Re, 0.02 to 0.04 of Nb, less than 0.01 of S, less than 0.01 of P, and the rest of Fe. After raw materials are refined and cast to obtain steel ingots or subjected to continuous casting to obtain continuous casting billets, after being rolled into round steel, cutting and annealing are conducted, and finally a cutting pick body is obtained by cold forging. The tooth tip is prepared from cemented carbide and welded to the tooth body by medium frequency induction heating. After cooling, austempering treatment is conducted, and finally discharging and air-cooling to room temperature are conducted. The finally obtained tooth body has tensile strength sigma b of 1700 to 2000MPa, yield strength sigma s of 1100 to 1520MPa, elongation delta of 16 to 35%, section shrinkage phi of45 to 55%, impact work Aku of 55 to 90 J, hardness HRC of 53 to 62, and strong plastic product of 32 to 51 GPa.%. The microstructure of the tooth body is a nano-carbide-free bainite-martensitic multiphase organization, and the thickness of a substructure slat is 10 to 50 nm.

Owner:鄂尔多斯市神东天隆矿山机械有限责任公司 +1

Nano bainite hot work die steel and preparation method thereof

PendingCN111893391AImprove irregular shapesImprove its distributionFurnace typesHeat treatment furnacesAustemperingTempering

The invention discloses nano bainite hot work die steel, and belongs to the technical field of die steel. The nano bainite hot work die steel comprises the following components of, in percentage by mass, 0.32-0.45 of C, 0.80-1.5 of Si, 0.20-0.50 of Mn, 4.75-5.05 of Cr, 1.10-1.75 of Mo, 0.8-1.00 of V, less than 0.02 of P, less than 0.01 of S, the balance Fe and inevitable impurities, and the structure of the hot work die steel is nano bainite. In addition, the invention further discloses a preparation method of the nano bainite hot work die steel. The nano bainite hot work die steel has the beneficial effects that 1, irregular shapes of carbide and distribution of carbide in a forged structure are improved through quenching and tempering pretreatment; 2, the content of Si element is high, precipitation of carbide in the isothermal quenching process is inhibited, and it is ensured that the nano bainite structure is obtained; 3, the unnotched impact energy of a secondary tempering sampleof the nano bainite hot work die steel is not lower than 500 J, the tensile strength is not lower than 1900 MPa, and the hardness is not lower than 52 HRC; and 4, the preparation process flow is simple and practicable, industrial production is facilitated, and the preparation efficiency is high.

Owner:YANSHAN UNIV

Processing method for improving surface quality of TRIP steel

InactiveCN105063311AImprove the shortcoming of narrow annealing process windowImprove surface qualityChemical compositionTRIP steel

The invention provides a processing method for improving surface quality of TRIP steel, comprising the following steps: (1) preparing the TRIP steel from the following raw materials by weight percent: 0.10-0.25% of C, 1.0-4.0% of Mn, less than or equal to 0.5% of Si, 1.0-5.0% of Al, less than or equal to 0.1% of Cr, less than or equal to 0.01% of P, less than or equal to 0.01% of S, and the balance of Fe and inevitable impurities by virtue of smelting, and cogging the TRIP steel into a steel plate; (2) rolling the steel plate to the thickness of 4mm; (3) rolling the steel plate to the thickness of 1mm; (4) annealing the steel plate; and (5) performing isothermal quenching on the high aluminum TRIP steel plate obtained in the step (4). According to the scheme in the invention, by setting the annealing temperature of the high aluminum TRIP steel plate to be above Ac3 and below the liquidus temperature, the defect that the heat treatment temperature of conventional TRIP steel only can be limited between Ac1-Ac3, so as to cause a narrower annealing process window can be improved.

Owner:NORTHEASTERN UNIV

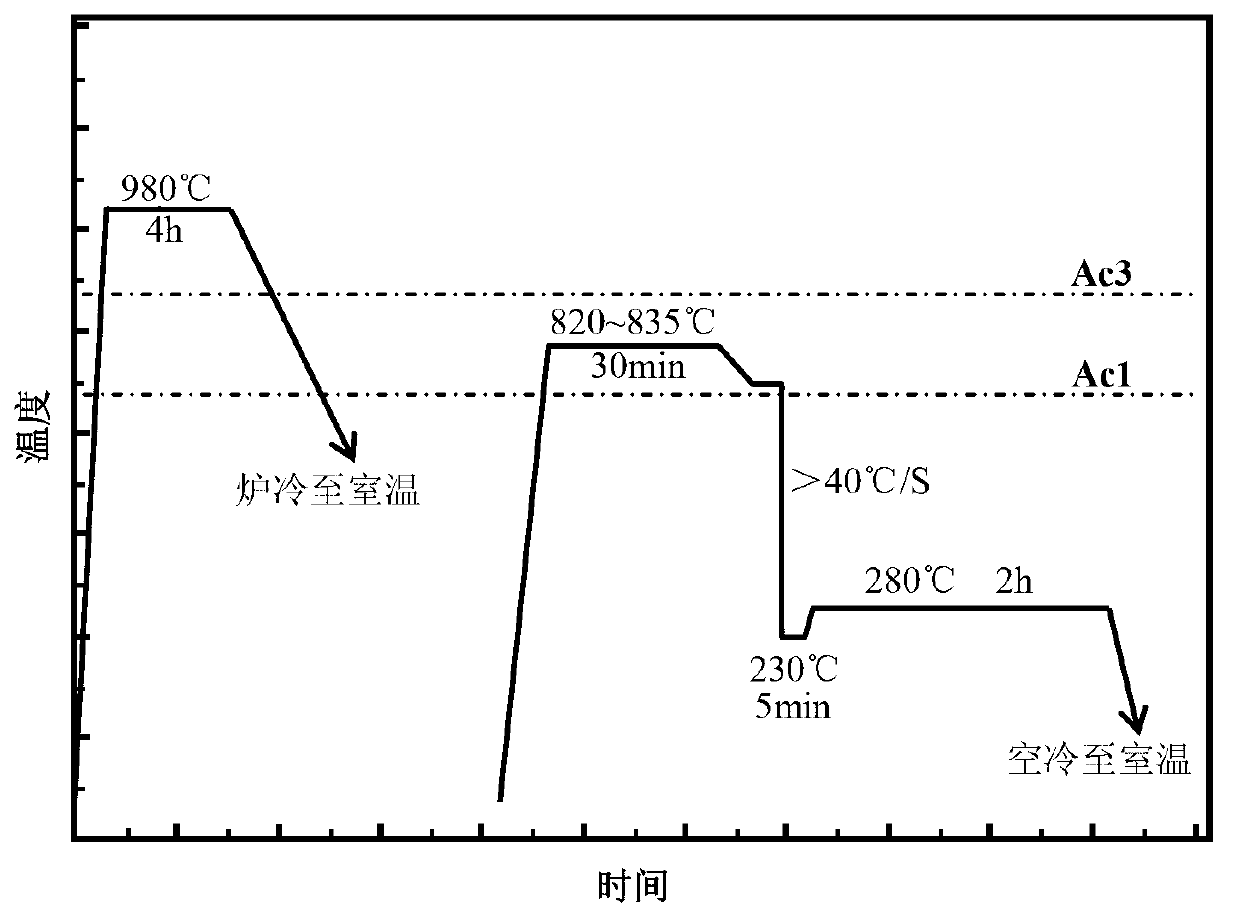

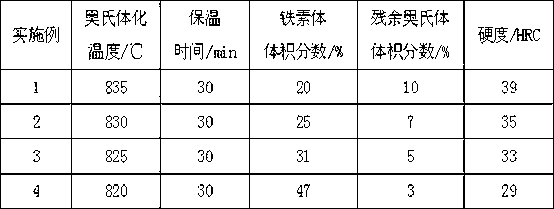

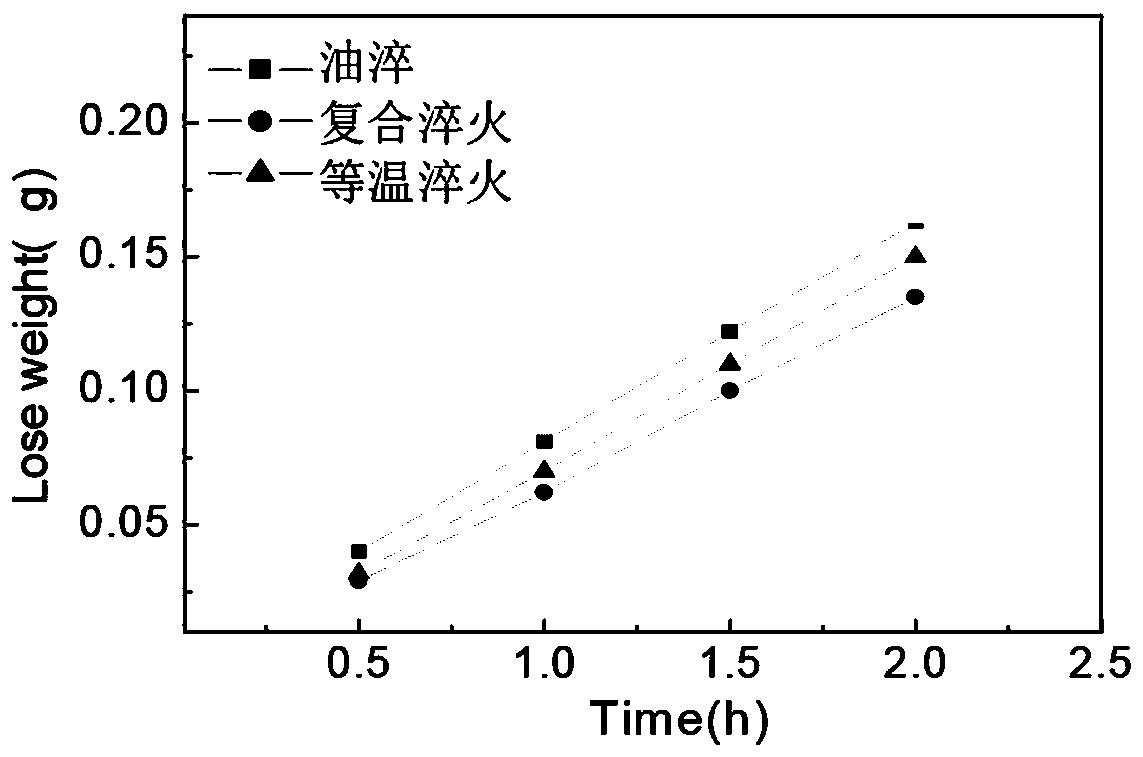

Method for optimized quenching process for obtaining 8Cr4Mo4V steel

The invention relates to a method for an optimized quenching process for obtaining 8Cr4Mo4V steel. The method comprises the following steps of (1) determining a heating solution process; (2) determining the time point of the highest hardness of isothermal hardening; (3) carrying out composite quenching treatment on the basis of the step (2); (4) selecting an optimized composite quenching process sample; and (5) carrying out tempering treatment on the optimized composite quenching process sample obtained in the step (4) at 510-550 DEG C for 1.8-2.5 h for 3-4 times, and obtaining the 8Cr4Mo4V steel subjected to final optimized heat treatment. The method has the advantages of scientificity, feasibility, simplicity in operation and the remarkable effect, and a space for improving the performance of the 8Cr4Mo4V steel is enlarged.

Owner:SHENYANG POLYTECHNIC UNIV

Austempered ductile iron, method for producing this and component compri

ActiveUS20100006189A1Easy to combineImprove ductilitySoil-shifting machines/dredgersFurnace typesAustemperingHigh intensity

Austempered ductile iron (ADI) for components requiring high strength and / or ductility, which has a silicon content of 3.35 weight-% to 4.60 weight-%, and which is obtainable by performing an ADI-heat treatment using an austenitization temperature of at least 910° C.

Owner:INDEXATOR GROUP

Alloy steel for braking caliper and preparation method thereof

InactiveCN102409259AHigh hardnessImprove wear resistanceFurnace typesHeat treatment furnacesIntermediate frequencyManganese

The invention relates to alloy steel for a braking caliper and a preparation method thereof. The alloy steel comprises the following components by weight percent: 0.32-0.34% of C, 0.24-0.31% of Si, 0.63-0.67% of Mn, 0.001% of P, 0.008% of S, 0.19-0.22% of Cr, 0.04-0.05% of Ni, 0.006-0.009% of Mo, 0.027-0.028% of Co, 0.0001% of V, 0.01-0.02% of Al, 0.125-0.13% of W, 0.0001% of Ti, 0.002% of B, 0.002-0.005% of Nb and the balance of Fe. According to the invention, the alloy steel is smelted in an intermediate frequency induction furnace; the normalizing and isothermal quenching are carried out on the alloy steel; a large amount of pearly-lustre substrates are obtained through the normalizing process; and the austenite of the alloy steel is converted into a lower bainite structure through theisothermal quenching; therefore, the hardness, wear-resisting property and surface heat-resistant performance of the alloy are greatly improved.

Owner:宁波精磊汽车零部件有限公司

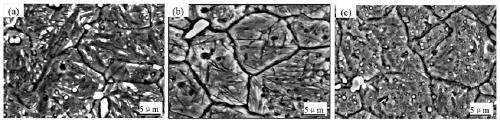

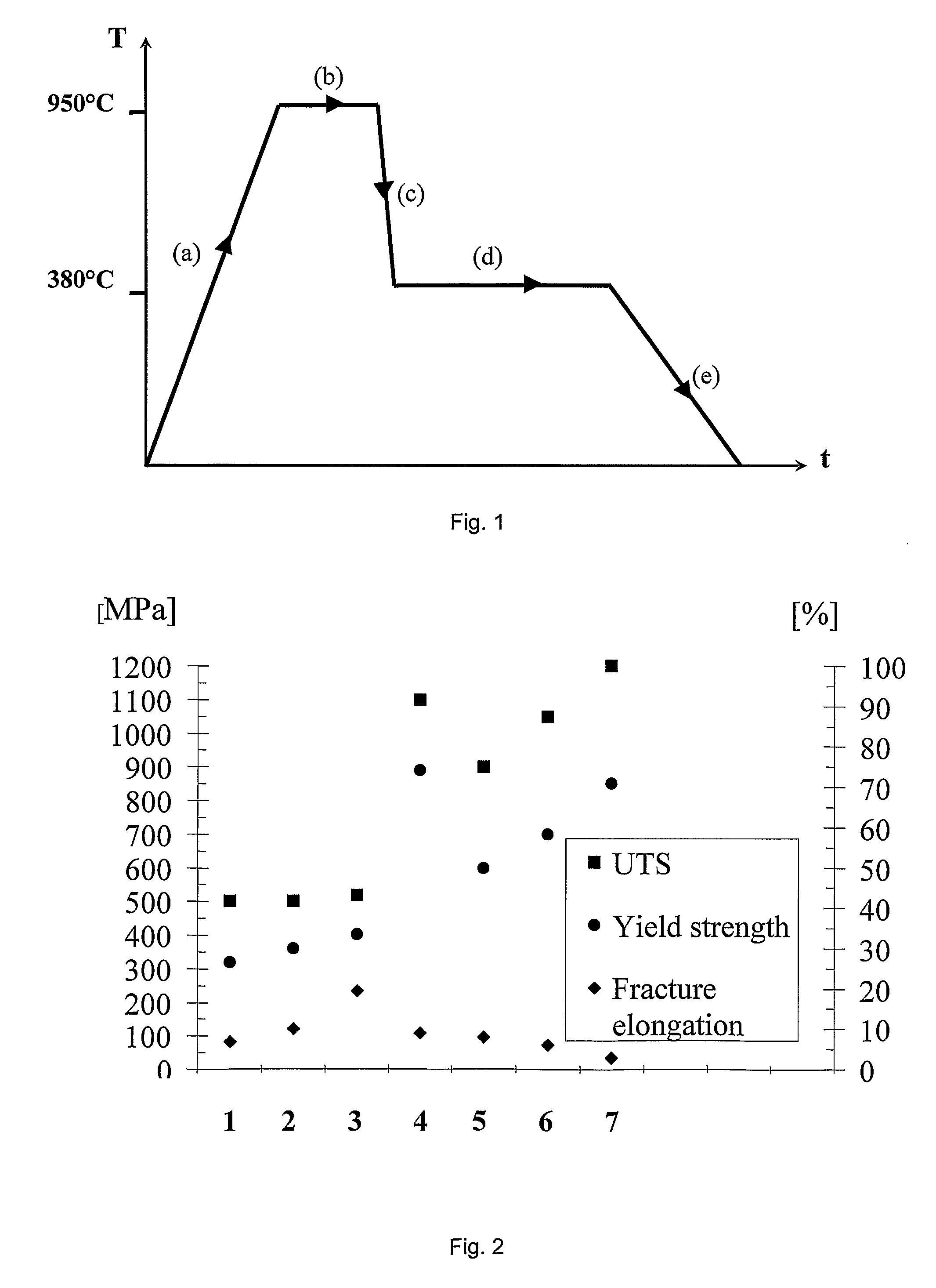

Isothermal hardening bainite thin wall cylinder cover

InactiveCN101195893AExtended service lifeReduce consumptionCylinder headsCylindersAustemperingHeat conservation

The invention relates to an isothermal quenching bainite thin wall cylinder liner. The isothermal quenching bainite technology comprises the following steps: the temperature of a high bainite transformation region is 350 to 450 DEG C, and the isothermal quenching is operated at 350 to 380 DEG C. A cylinder liner after being roughly machined is arranged in a vertical pit furnace, the temperature of the cylinder liner is elevated to 900 to 930 DEG C, the cylinder liner is insulated for two hours, then cooled to 350 to 380 DEG C, and delivered to a salt bath furnace to be insulated for two hours. The isothermal quenching bainite cylinder liner material comprises the following elements according to the content percentage: 2.8 to 3.0 percent of C, 1.7 to 2.1 percent of Si, 0.6 to 0.9 percent of Mn, 0 to 0.15 percent of P, 0.35 to 0.5 percent of Mo, 0.6 to 1.2 percent of Cu, 0.2 to 0.4 percent of Ni, 0.25 to 0.45 percent of Cr, and 91 to 92.5 percent of Fe.

Owner:韦星野

Isothermal quenching nodular cast iron as well as preparation method and application thereof

InactiveCN110952031ASolve the deformationSolve problems such as substandard performanceFoundry mouldsProcess efficiency improvementAustemperingDuctile iron

The invention relates to isothermal quenching nodular cast iron as well as a preparation method and application thereof. The isothermal quenching nodular cast iron is prepared from the following components of, in percentage by weight, 3.60%-3.75% of C, 2.30%-2.50% of Si, 0.20%-0.40% of Mn, less than or equal to 0.06% of P, less than or equal to 0.03% of S, 0.70%-0.80% of Cu, 0.10%-0.20% of Mo, 0.03%-0.06% of Mg, and the balance Fe; and the preparation method of the isothermal quenching nodular cast iron comprises the following steps that (1) nodulizing inoculation is conducted on molten iron by adopting a pouring nodulizing method, pouring is conducted after the inoculation is completed, and after pouring is completed and cooling is conducted, the nodular cast iron is obtained; and (2) thenodular cast iron obtained in the step (1) is sequentially subjected to preheating, austenitizing and salt bath quenching, and the isothermal quenching nodular cast iron is obtained after the salt bath quenching is completed. According to the isothermal quenching nodular cast iron as well as the preparation method and the application thereof, the problems that the performance of an axle housing does not reach the standard and the like when the isothermal quenching nodular cast iron material is used for integrated manufacturing are solved, and efficient utilization of the isothermal quenchingnodular cast iron in the integrated axle housing is achieved.

Owner:CHINA FIRST AUTOMOBILE +1

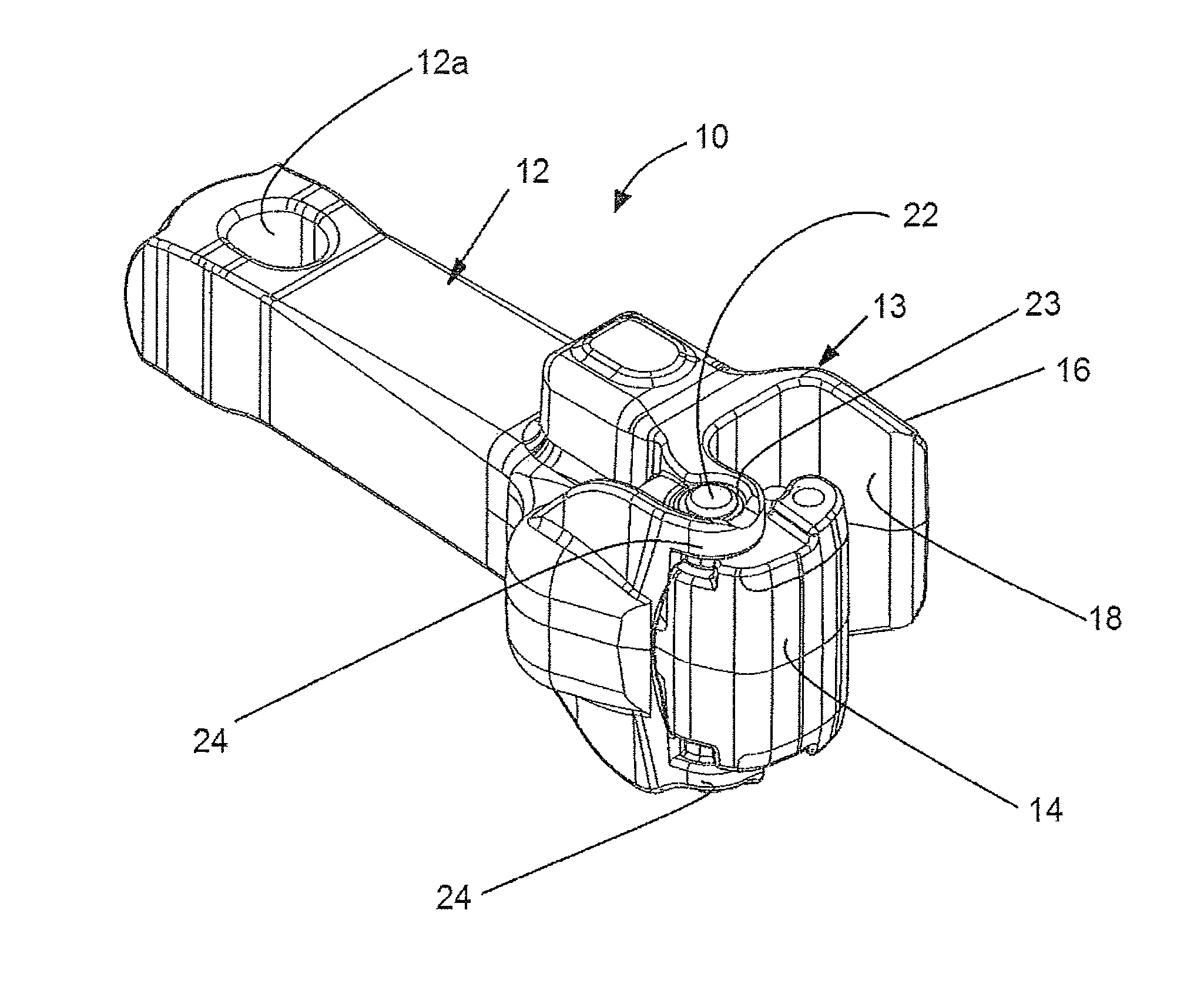

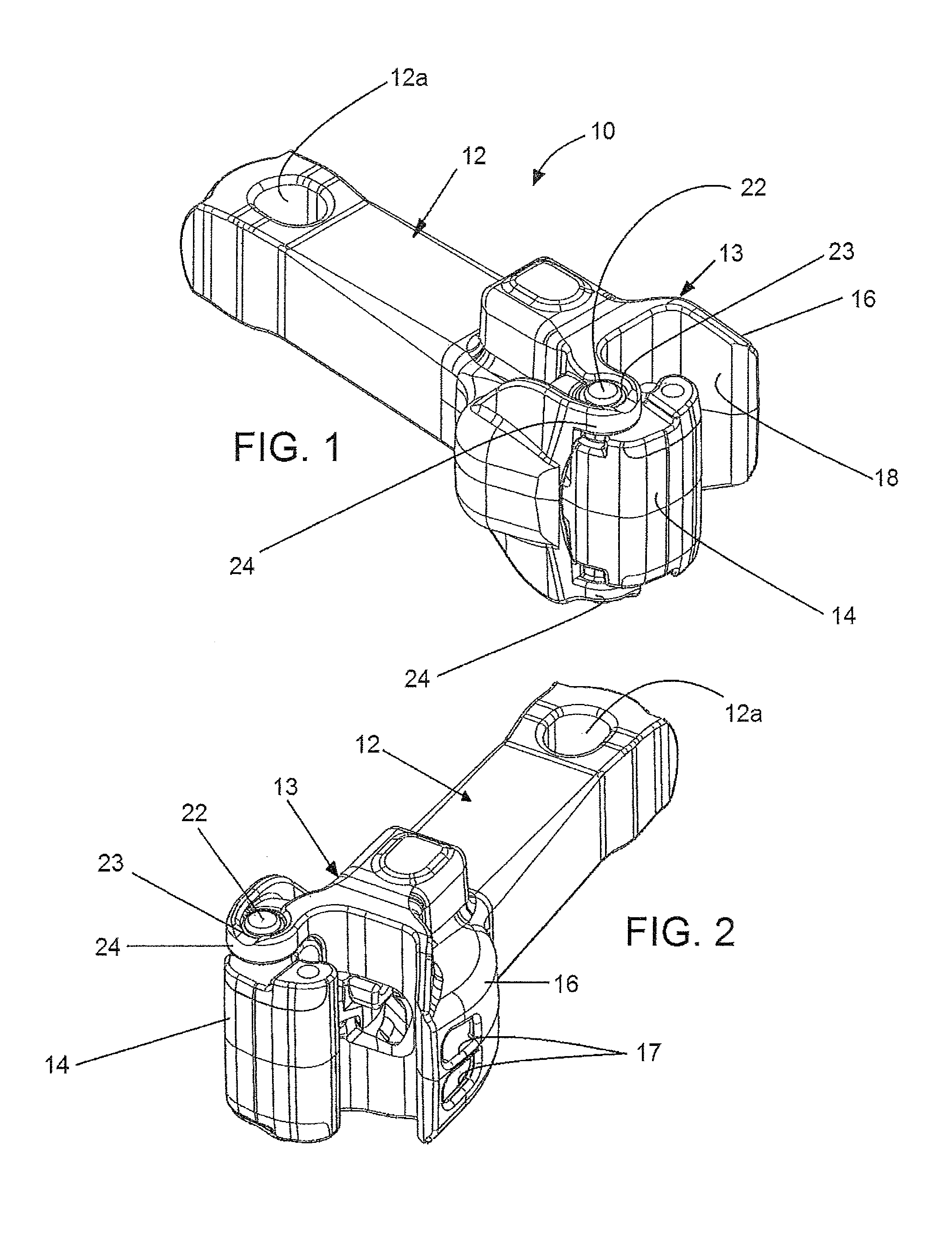

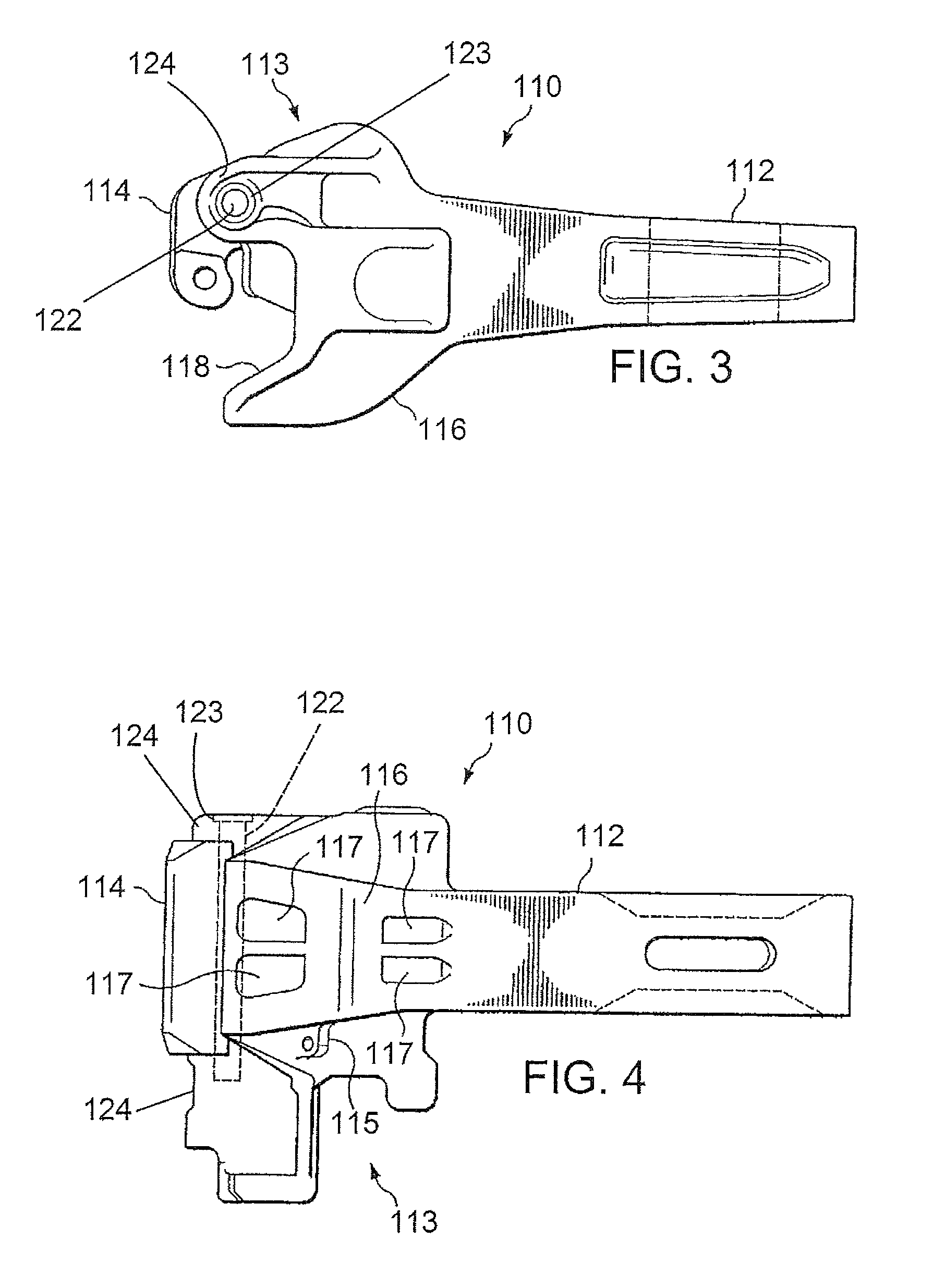

Lightweight coupler

ActiveUS9038836B1Eliminates and reduces of disadvantageEliminates and reduces of and problemRailway coupling accessoriesAustemperingVolumetric Mass Density

The coupler system of a railway car truck is constructed such that basic overall appearance may be maintained, but the actual material of which it is constructed is changed. According to one embodiment, the coupler is constructed from cast austempered ductile iron; whereas cast iron has a density, 0.26 lbs / in^3, which is approximately 8% less than steel, 0.283 lbs / in^3, thereby allowing for a reduction in weight over steel. A suitable austempering process is used to produce the austempered metal coupler and components thereof. A second benefit of embodiments of the present invention provides for a more efficient use of materials, meaning less metal is used to make the same final shape, as a way of reducing the coupler weight. Both factures combined allow for a lighter weight coupler, while utilizing the standard designs. Alternate coupler configurations are disclosed for further reducing coupler weight.

Owner:PENNSY CORP

Method Of Making An Austempered Ductile Iron Article

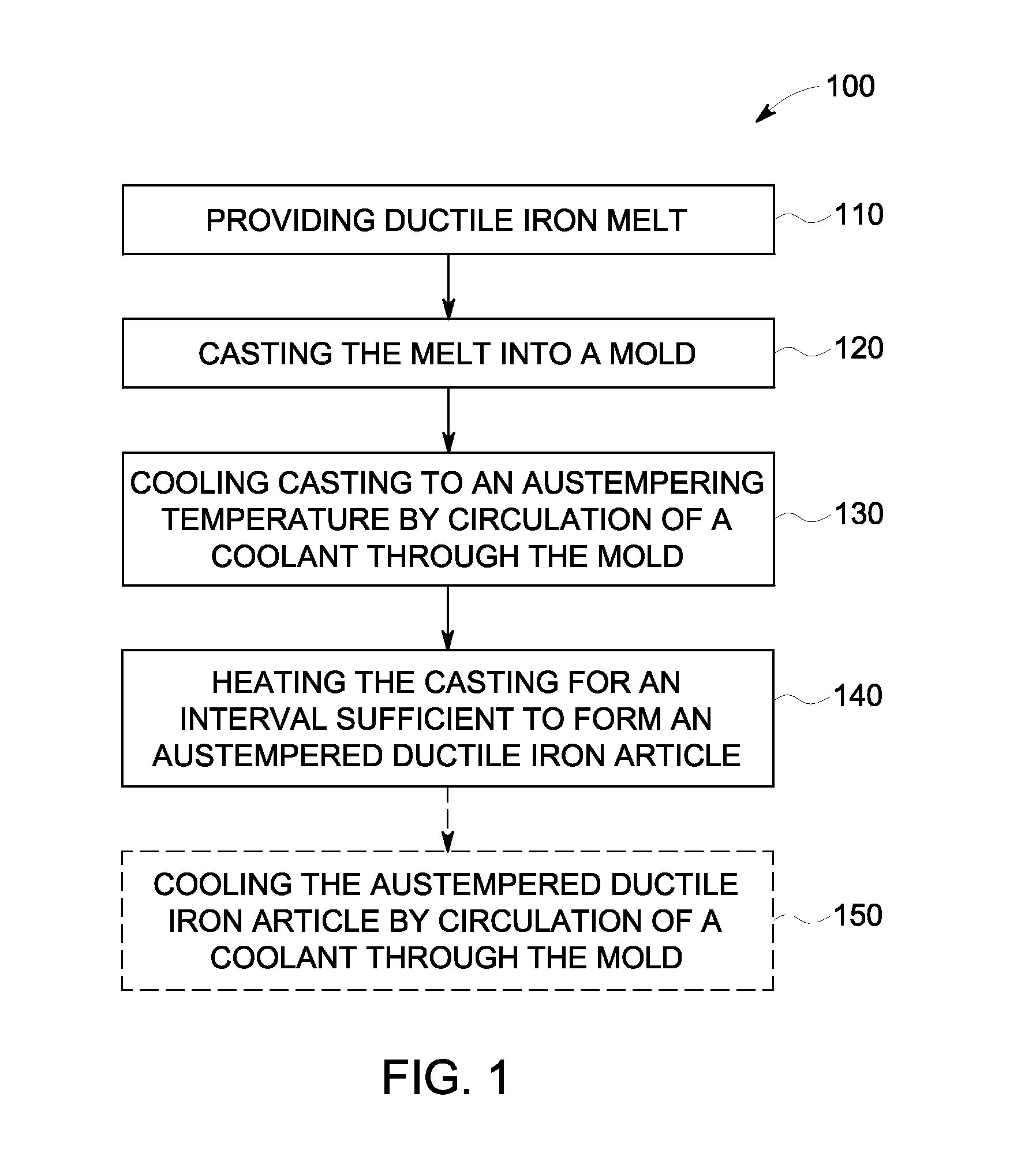

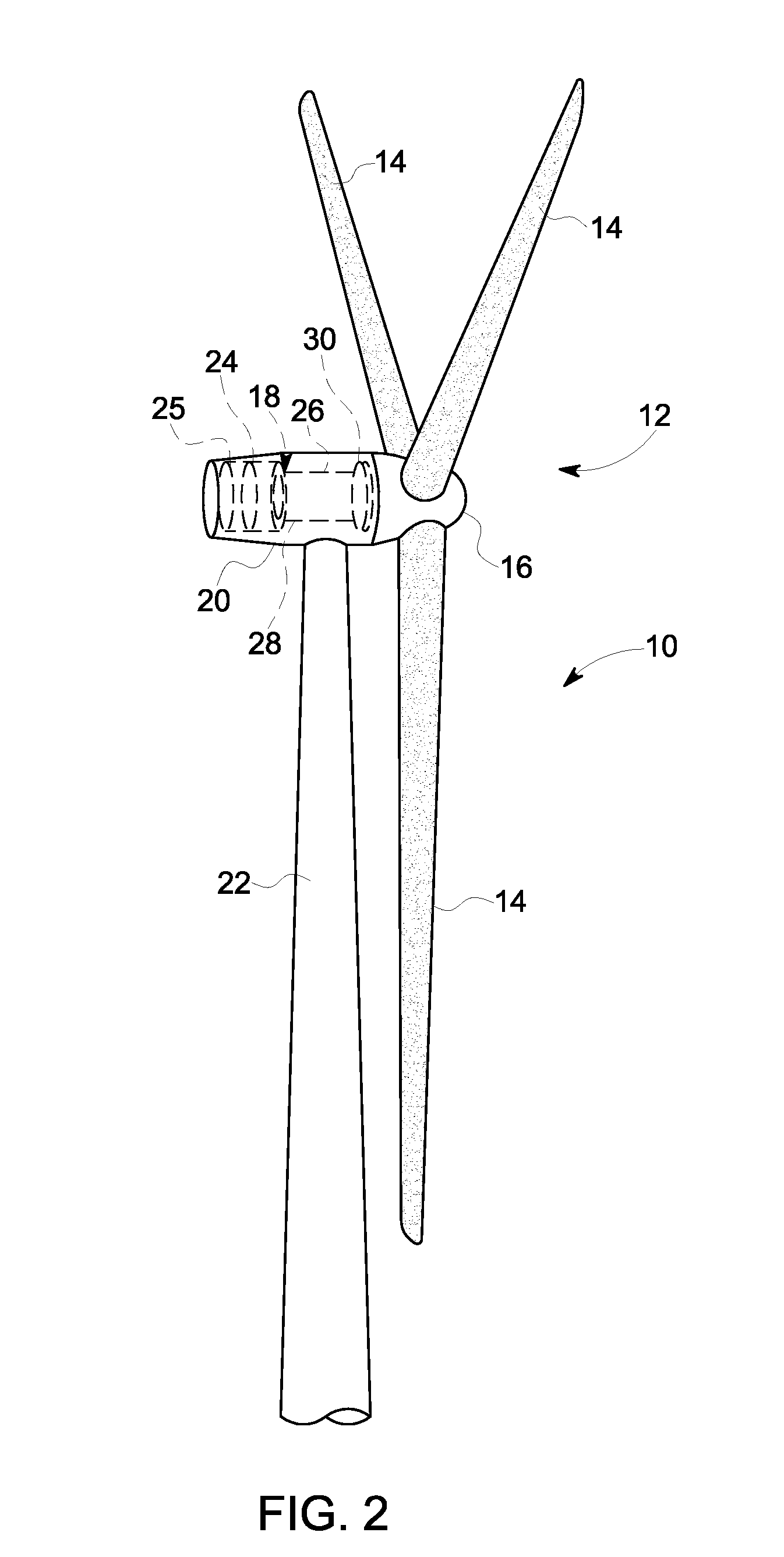

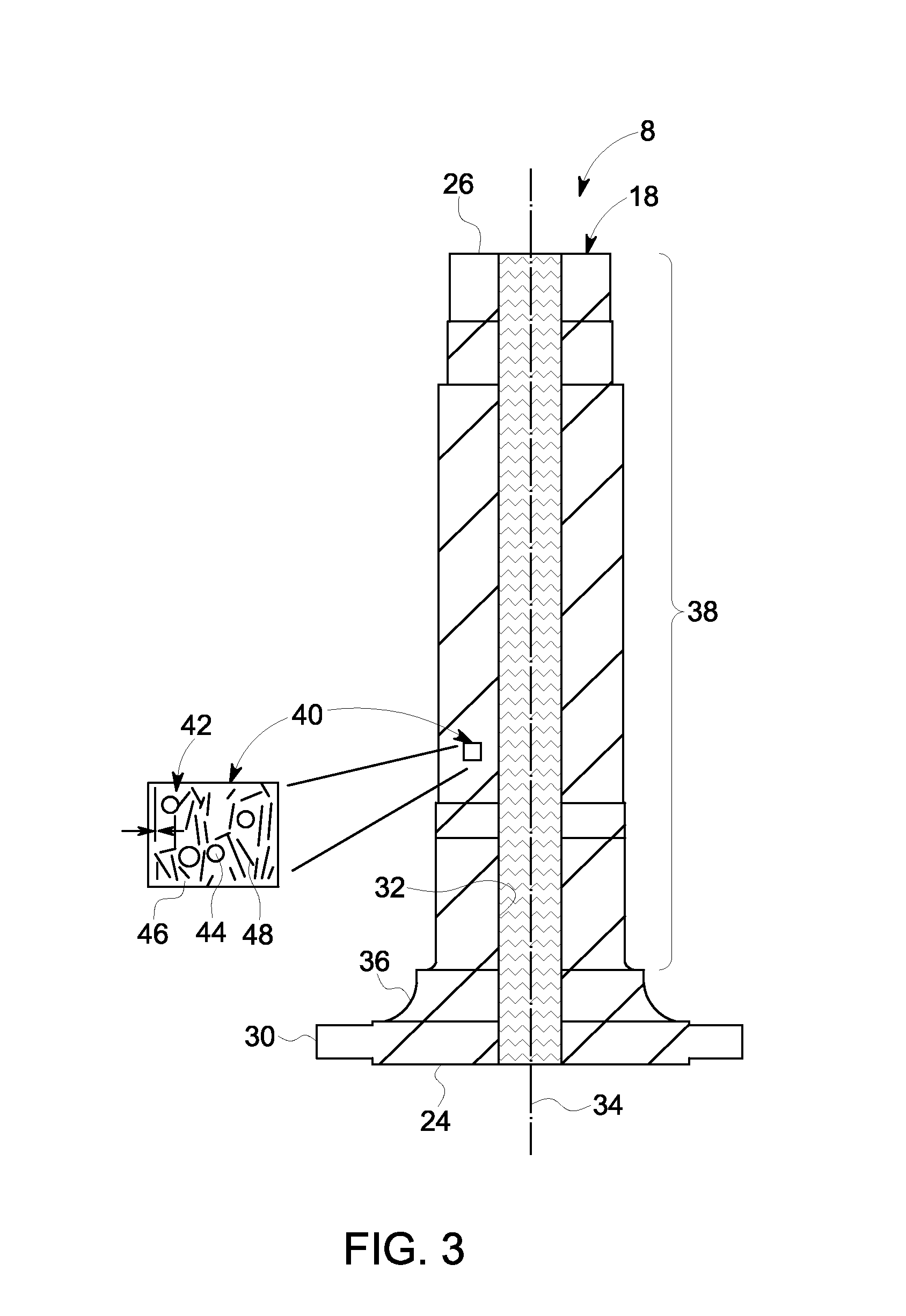

A method of making an austempered ductile iron article is disclosed. The method includes providing a melt of a ductile iron alloy composition. The method also includes casting the melt into a mold to form a casting. The method further includes cooling the casting to an austempering temperature by circulating a coolant through the mold; wherein cooling comprises solidifying the melt and forming a ductile iron article. Still further, the method includes heating the casting to maintain the austempering temperature for an interval sufficient to form an austempered ductile iron article that comprises a microstructure comprising ausferrite.

Owner:GENERAL ELECTRIC CO

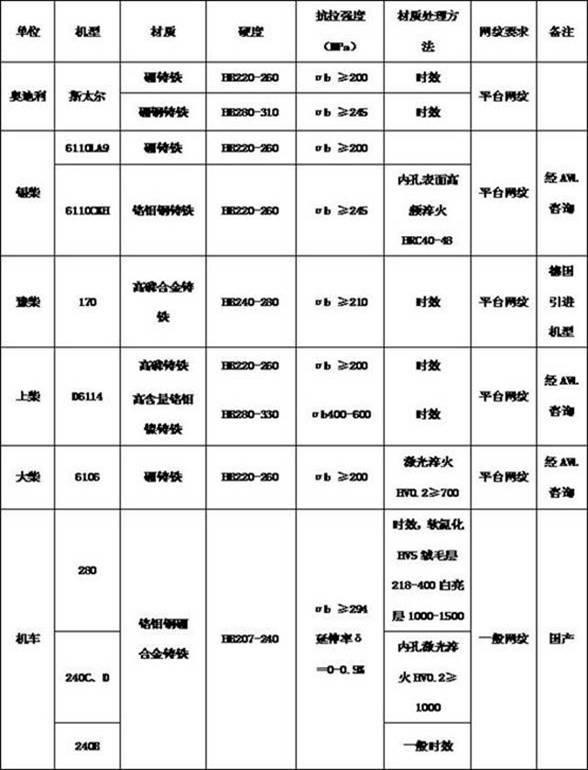

Method for producing austempered ductile iron (ADI) cylinder sleeve

The invention discloses a method for producing an austempered ductile iron (ADI) cylinder sleeve, belongs to metal materials, and in particular relates to the technical field of production processes for ADI supercharged engine cylinder sleeves. The method comprises the steps of casting an ADI cylinder sleeve casting blank, finely machining the cylinder sleeve casting blank, performing isothermal quenching treatment and shot blasting treatment and machining platform reticulate patterns. The method solves the problem that the fatigue property and the abrasion resistance of the conventional service materials such as boron cast iron, boron-copper cast iron, chromium-molybdenum-copper cast iron, high-phosphorus alloy cast iron, high-phosphorus cast iron, high-content chromium-molybdenum-nickel cast iron and chromium-molybdenum-copper-boron alloy cast iron cannot meet the service requirements of high strength engines.

Owner:扬州华铁机电集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com