Processing method for improving surface quality of TRIP steel

A processing method and technology of surface quality, applied in the processing field of improving the surface quality of TRIP steel, can solve problems such as the deterioration of coating performance of TRIP steel, and achieve the effects of improving surface quality, simple process and high industrial feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) According to weight percentage: C: 0.18%; Si: 0.3%; Mn: 1.56%; Al: 1.44%; Cr: 0.077%; P: 0.008%; S: 0.008%; To avoid the chemical composition of impurities, choose and match raw materials, use intermediate frequency vacuum induction furnace to smelt TRIP steel at 1500~1600℃, and then cast TRIP steel ingot into a steel plate with a thickness of 50mm; measure the steel plate A c1 is 790°C,A c3 It is 895°C.

[0038] (2) The TRIP steel plate is rolled to 4mm by using a two-roll reversing hot rolling mill. rolling to the target thickness;

[0039] (3) Roll the TRIP steel plate in step (2) to 1mm by using a four-roll irreversible cold rolling mill, the process parameters are: the reduction of each pass is 10-40%, and the target thickness is rolled to the target thickness after 10 passes;

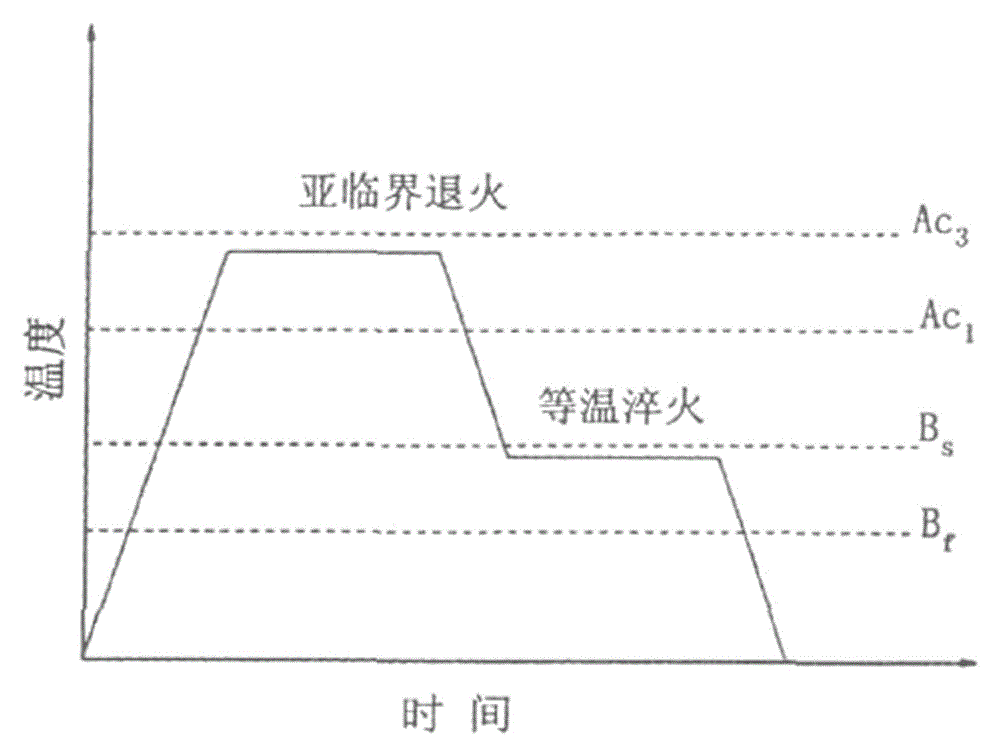

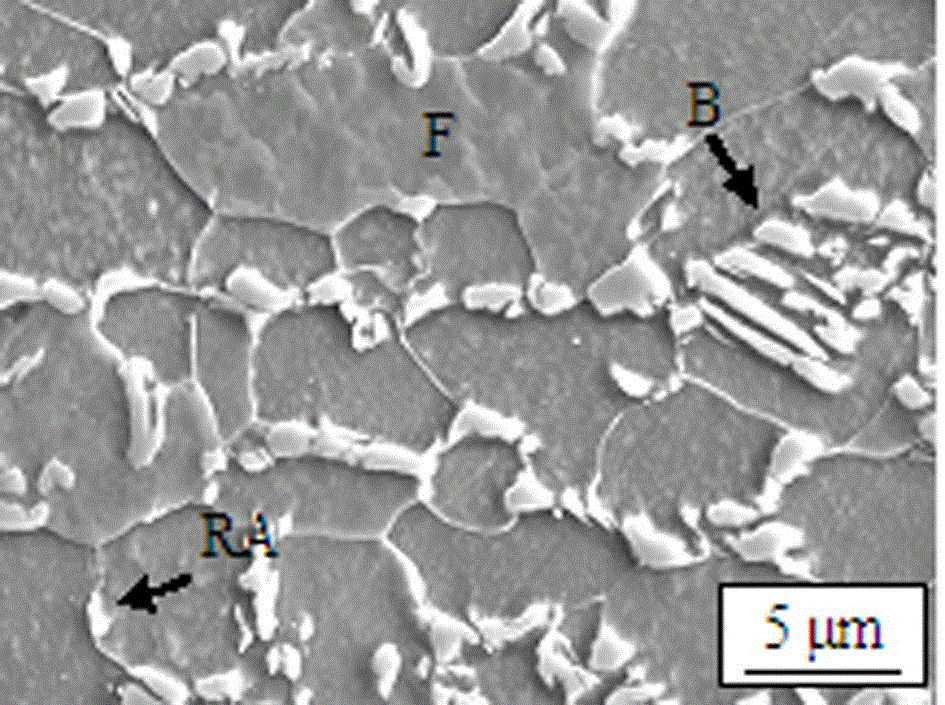

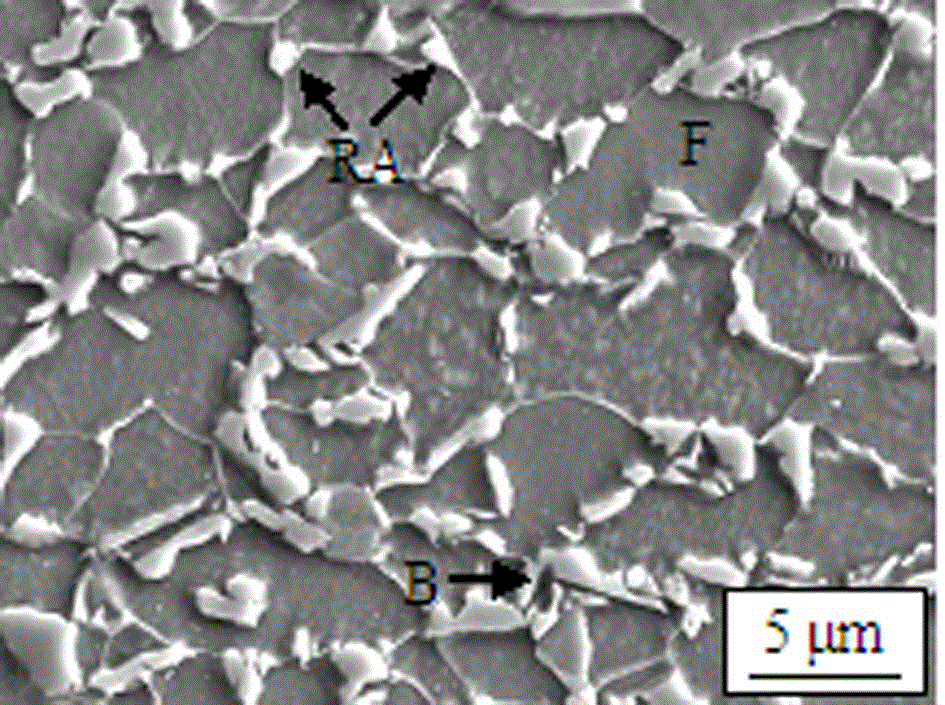

[0040] (4) Anneal the high-alumina TRIP steel plate in step (3) in a box-type heating furnace. The process parameters are: the annealing temperature is 920°C, and the holding time i...

Embodiment 2

[0044] (1) According to weight percentage: C: 0.18%; Si: 0.3%; Mn: 1.56%; Al: 1.44%; Cr: 0.077%; P: 0.008%; S: 0.008%; To avoid the chemical composition of impurities, choose and match raw materials, use intermediate frequency vacuum induction furnace to smelt TRIP steel at 1500~1600℃, and then cast TRIP steel ingot into a steel plate with a thickness of 50mm; measure the steel plate A c1 is 790°C, A c3 It is 895°C.

[0045] (2) Roll the TRIP steel plate to 4mm by using a two-roll reversing hot rolling mill. The process parameters are: the heating temperature is 1200°C, the final rolling temperature is 950°C, and the pass reduction is 10-50%. After 7 passes rolling to the target thickness;

[0046] (3) Roll the TRIP steel plate in step (2) to 1mm by using a four-roll irreversible cold rolling mill, the process parameters are: the reduction of each pass is 10-40%, and the target thickness is rolled to the target thickness after 10 passes;

[0047] (4) Anneal the high-alumi...

Embodiment 3

[0051] (1) According to weight percentage: C: 0.2%; Si: 0.2%; Mn: 1.6%; Al: 1.6%; Cr: 0.07%; P: 0.01%; S: 0.009%; To avoid the chemical composition of impurities, choose and match raw materials, use intermediate frequency vacuum induction furnace to smelt TRIP steel at 1500~1600℃, and then cast TRIP steel ingot into a steel plate with a thickness of 50mm; measure the steel plate A c1 at 800°C, A c3 It is 910°C.

[0052] (2) Roll the TRIP steel plate to 4mm by using a two-roll reversing hot rolling mill. The process parameters are: the heating temperature is 1200°C, the final rolling temperature is 950°C, and the pass reduction is 10-50%. After 7 passes rolling to the target thickness;

[0053] (3) Roll the TRIP steel plate in step (2) to 1mm by using a four-roll irreversible cold rolling mill, the process parameters are: the reduction of each pass is 10-40%, and the target thickness is rolled to the target thickness after 10 passes;

[0054] (4) Anneal the high-alumina TR...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Strong plastic product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com