Patents

Literature

80results about How to "High industrial feasibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for growing graphene film by using low-temperature chemical vapor deposition

ActiveCN103184425AReduce roughnessReduce nucleation densityPolycrystalline material growthFrom chemically reactive gasesGas phaseMaterials science

The invention relates to a method for preparing a graphene film in a low-temperature condition. The method at least comprises the following steps: (1), performing smooth treatment on a metal substrate; (2), performing doping of a chemical reagent on the surface of the metal substrate obtained in the step (1); (3), under a protective atmosphere, performing annealing treatment on the metal substrate obtained in the step (1); (4), contacting the metal substrate with a carbon source, and performing chemical vapor deposition in the low-temperature condition to obtain the graphene film; and optionally, after the step (4), performing step (5), stopping heating, cooling to the room temperature, and taking out the metal substrate with the graphene film thereon, wherein the chemical reagent is a precursor salt of metal. The method for growing the graphene film is low in growth temperature, low in cost, high in industrialized feasibility and wide in select range of the substrate, and can prepare the complete single-layer or multi-layer graphene film with high quality.

Owner:WUXI GRAPHENE FILM +1

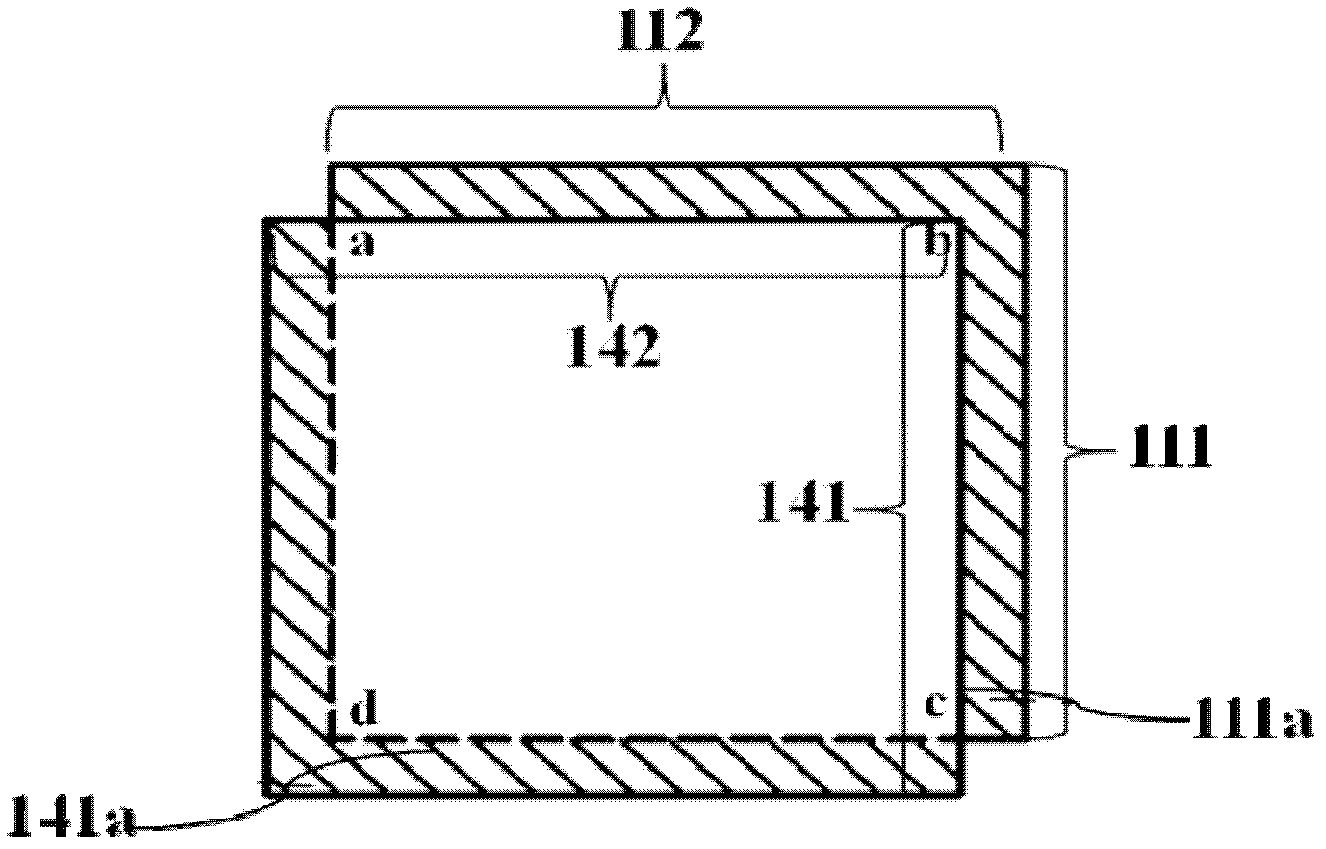

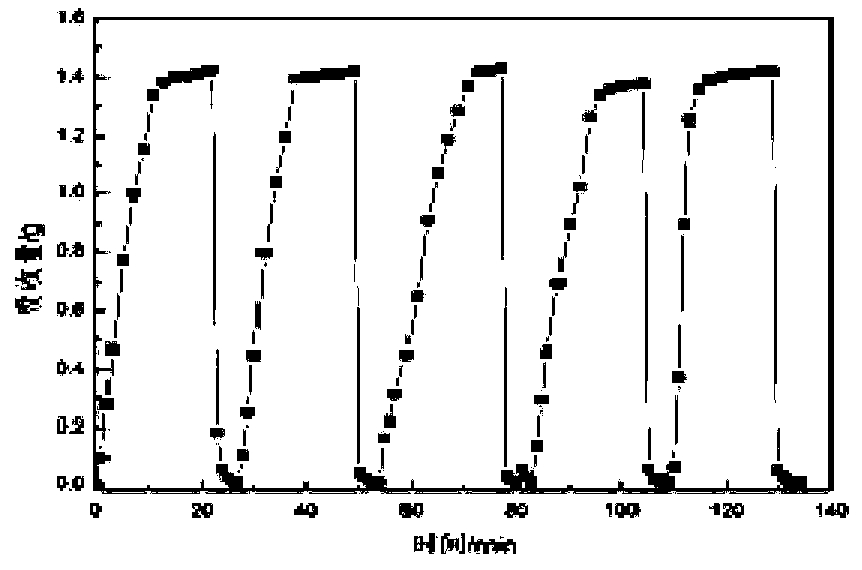

Electrochromism assembly provided with composite electrochromism materials

InactiveCN103135306AFast transmissionFast electrochromic responseNon-linear opticsElectronic transmissionOptoelectronics

The invention discloses an electrochromism assembly provided with composite electrochromism materials. The electrochromism assembly mainly comprises a first transparent substrate, a first transparent conducting layer, an electrochromism layer, a second transparent substrate, a second transparent conducting layer, an auxiliary electrochromism layer, and electrolyte. The electrochromism assembly quickens electronic transmission speed through mixing of metal doping materials, and further achieves the function of quick metachromatism.

Owner:ASIATREE TECH

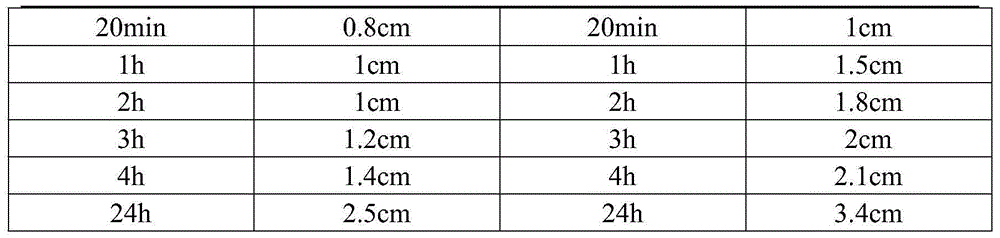

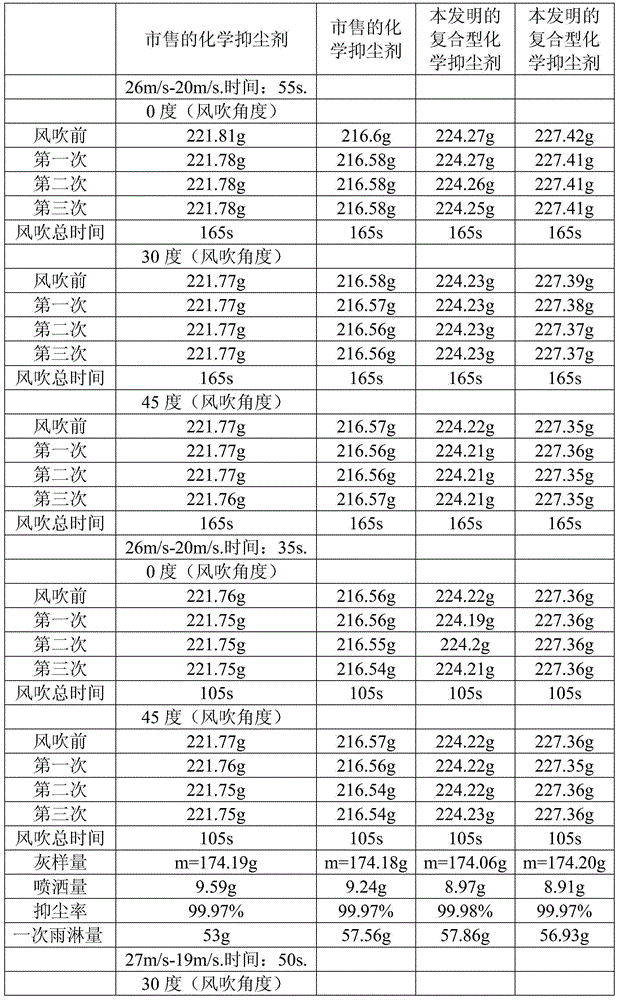

Compound type chemical dust suppressant and preparation method thereof

InactiveCN104694083AEconomical and Applicable HighGood application effectOther chemical processesPolyvinyl acetatePolyethylene glycol

The invention discloses a compound type chemical dust suppressant and a preparation method thereof. The compound type chemical dust suppressant disclosed by the invention comprises the following raw materials in percentage by weight: 5%-50% of polyethylene glycol 4000, 1%-20% of sodium sulfate, 2%-45% of polyvinyl acetate, 5%-55% of gelatin, 15%-70% of starch and 1%-10% of sodium polyacrylate. The compound type chemical dust suppressant disclosed by the invention has the advantages of high economic applicability, high practical applicability, environmental protection and good dust suppression effect. The raw materials for preparing the compound type chemical dust suppressant are low in cost, environment-friendly, non-poisonous and harmless to environments, and therefore, the compound type chemical dust suppressant has the effects of preventing dust pollution and protecting environments.

Owner:YUNNAN MINZU UNIV

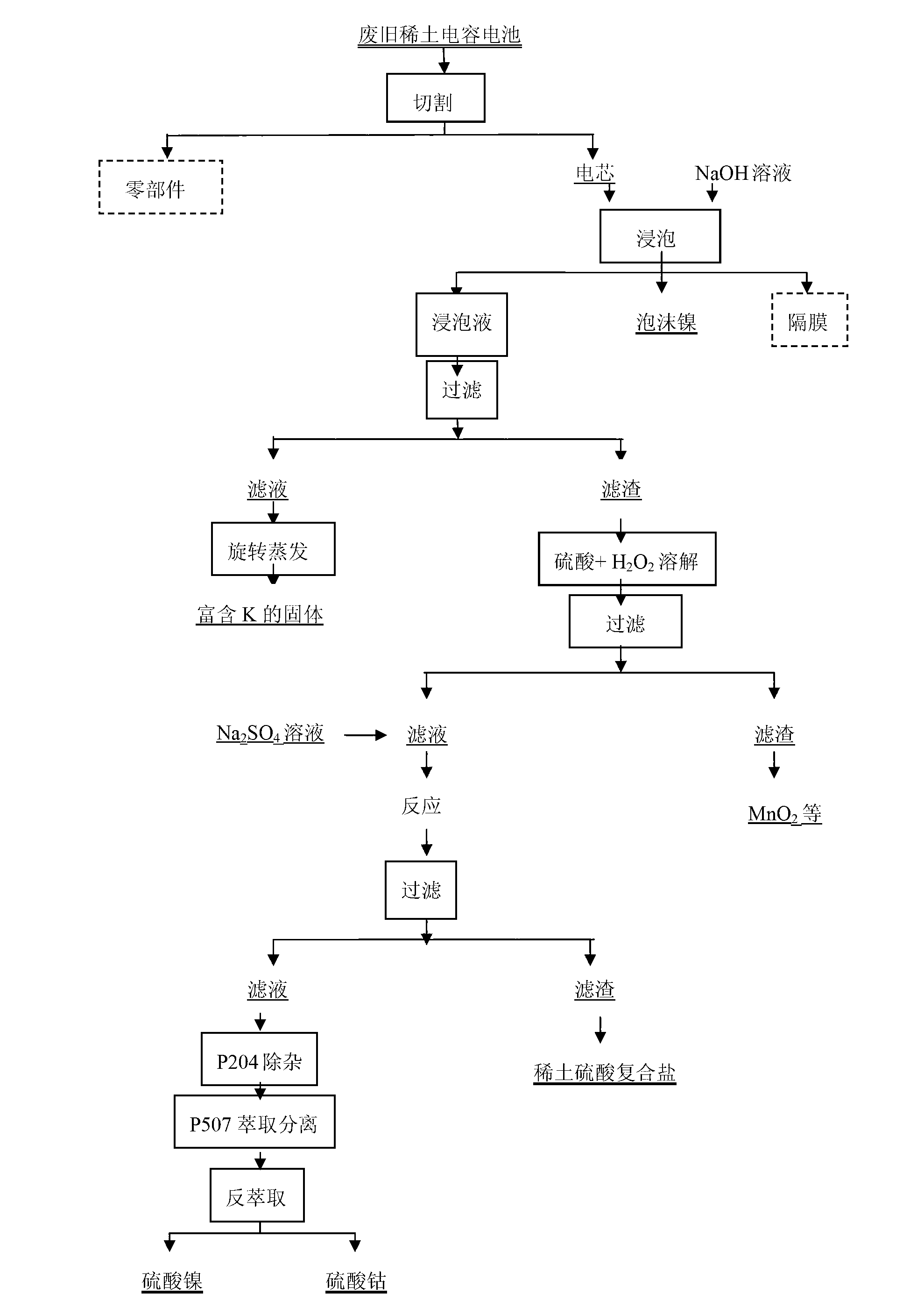

Integrated recovery method of waste and old rare earth capacitance battery

ActiveCN103233123AImplement step by stepAchieve recyclingProcess efficiency improvementCapacitanceRecovery method

The invention relates to an integrated recovery method of waste and old rare earth capacitance battery, which belongs to the colored metallurgy technology field of rare earth, nickel and other metal resources. The method comprises the following steps: cutting waste and old rare earth capacitance battery, separating electrical core and components; adding NaOH into electrical core for ultrasonic immersion, and then separating diaphragm and foamed nickel, and obtaining the soak solution; filtering, dissolving filter residues with sulfuric acid and H2O2; filtering, adding Na2SO4 into the filtrate for reaction; filtering the reaction solution, and the filter residue is a rare earth sulfuric acid composite salt, and obtaining battery grade nickel sulfate and cobalt sulphateby P204 edulcoration, P507 extraction separation and re-extraction. The invention realizes the grading recovery of battery spare and accessory parts and battery materials, and separation of battery spare and accessory parts and electrical core, and recycle of battery housing and pole, and separation and re-utilization of rare earth, nickel and cobalt, thereby establishing a base for dynamic reservations of rare earth, nickel and other rare resources with low cost and obvious economic benefit.

Owner:淄博国利新电源科技有限公司

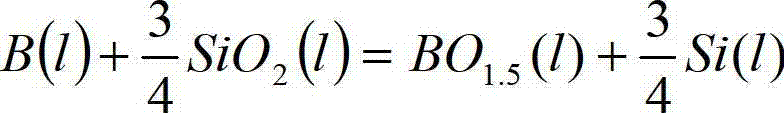

Method for removing boron and phosphorus impurity in industrial silicon by slagging refining

InactiveCN102951645AHigh partition coefficientGood removal effectSilicon compoundsMedium frequencyInductively coupled plasma

The invention discloses a method for removing the boron and phosphorus impurity in industrial silicon by slagging refining, and relates to the industrial silicon impurity removal technology. The method comprises the following steps of: 1) coating a compact SiC coating as an inner layer on the surface of a graphite crucible, and coating a Y2O3 coating on the SiC coating as an outer layer; 2) after slagging constituent is mixed, putting into a pre-processed graphite crucible; 3) opening a medium-frequency induction furnace for heating until slag charges are molten; 4) after the slag charges are molten, adding the industrial silicon into the molten slag charges, carrying out slagging refining, and reacting if power is lowered after the slag charges and silicon materials are totally molten; 5) inserting a venting pin into the molten liquid, and introducing Ar+H2O into the system to guarantee that the silicon and the slags are contacted; 6) pulling out the venting pin, and pouring the upper layer of silicon liquid of the molten liquid into a standing graphite module for cooling; 7) continuously adding silicon materials, and repeating steps 4) to 6); and 8) cutting impurity enrichment parts on the tail part and the head part of refined polysilicon, and measuring the content of residual parts of boron and phosphorus by ICP-MS (inductively coupled plasma-mass spectrum). The method has the advantages of simple technology and high industrial feasibility.

Owner:XIAMEN UNIV

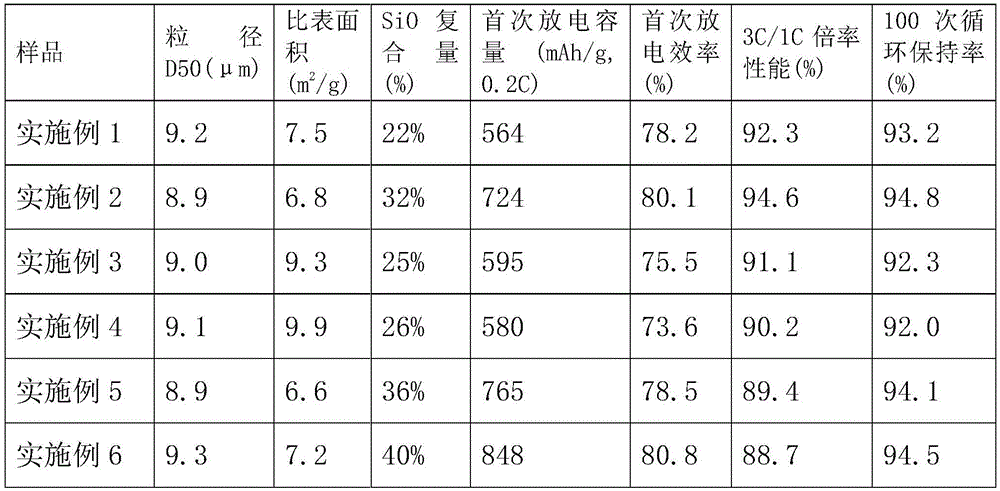

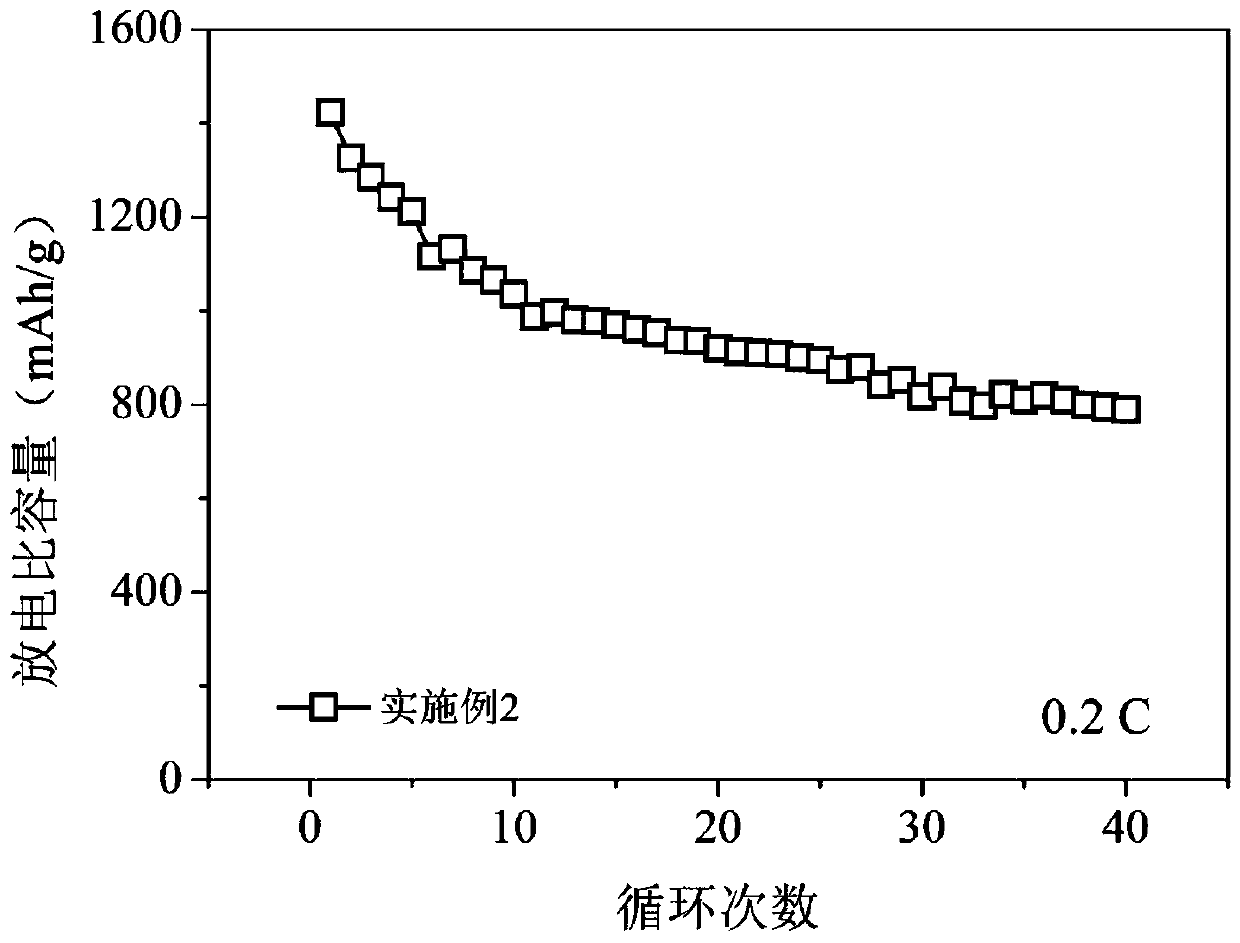

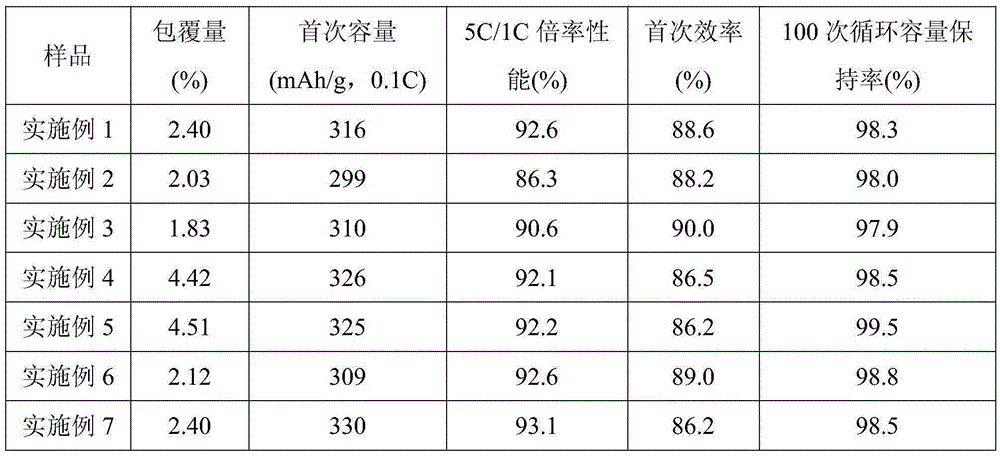

Preparation method of high capacity lithium ion battery hard carbon composite negative electrode material

ActiveCN106532009ASolve the defect of low reversible capacityMeet the requirements of charge and discharge performanceCell electrodesCarbon compositesElectrical battery

The invention relates to the technical field of lithium ion battery, and in particular to a preparation method of a high capacity lithium ion battery hard carbon composite negative electrode material. The method is characterized by comprising the steps of (1) mixing materials, (2) conducting the crosslinking polymerization reaction, (3) conducting the high temperature curing treatment, (4) pre-carbonizing, (5) carbonizing, and (6) cladding. In step (1), the organic polymers and crosslinking agent are pulverized, and is mixed with SiOx filler uniformly to acquire the mixture powder. Compared with the prior art, the method can solve the problem of low reversible capacity of the hard carbon negative electrode material currently available. The prepared high capacity lithium ion battery hard carbon composite negative electrode material has the advantages of being uniform in particle distribution, good in appearance, excellent in electrochemical properties and safety, having a good adaptability to the electrolyte and other additives, thus being capable of meeting the requirements of the charging and discharging properties of the negative electrode material imposed by the high capacity, high multiplying power lithium ion battery with excellent high and low temperature cycle operation performance.

Owner:SHANGHAI SHANSHAN TECH CO LTD

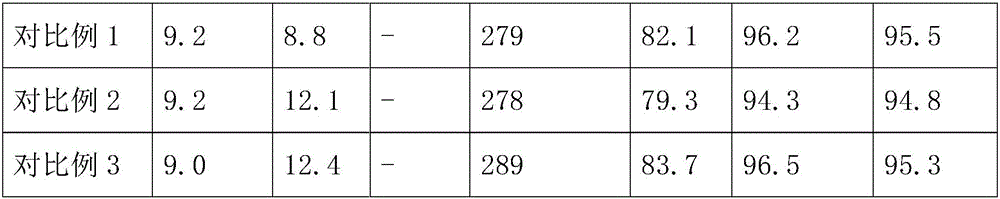

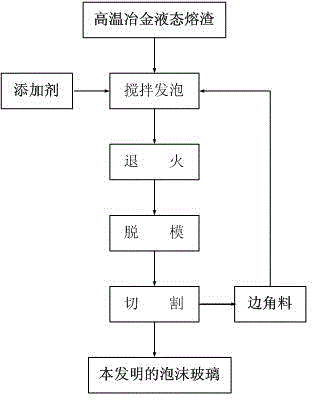

Method for preparing foam glass by virtue of high-temperature liquid-state metallurgical clinker

ActiveCN104891815AHigh industrial feasibilityReduce manufacturing costLiquid stateCompressive strength

The invention provides a method for preparing foam glass by virtue of high-temperature liquid-state metallurgical clinker. The method comprises the steps of with the high-temperature liquid-state metallurgical clinker discharged from a metallurgical smelting furnace as a direct raw material, carrying out foaming on the high-temperature liquid-state metallurgical clinker and an additive by virtue of waste heat of the clinker, and carrying out processes of annealing, demolding and cutting, so as to prepare the foam glass. According to the preparation method, the industrially discarded high-temperature liquid-state metallurgical clinker is directly used as the raw material, the sensible heat of the clinker is adequately utilized, the energy consumption of the whole production process is low, and secondary pollutants are not generated, so that the industrial feasibility is relatively high. Besides, the volume density of the prepared foam glass is 518.6kg.m<-3>-597.4kg.m<-3>, the average pore size is 3.75mm-4.84mm, the compressive strength is 9.4MPa-15.8MPa, and thus the foam glass is superior to common clinker foam glass at present.

Owner:NORTHEASTERN UNIV

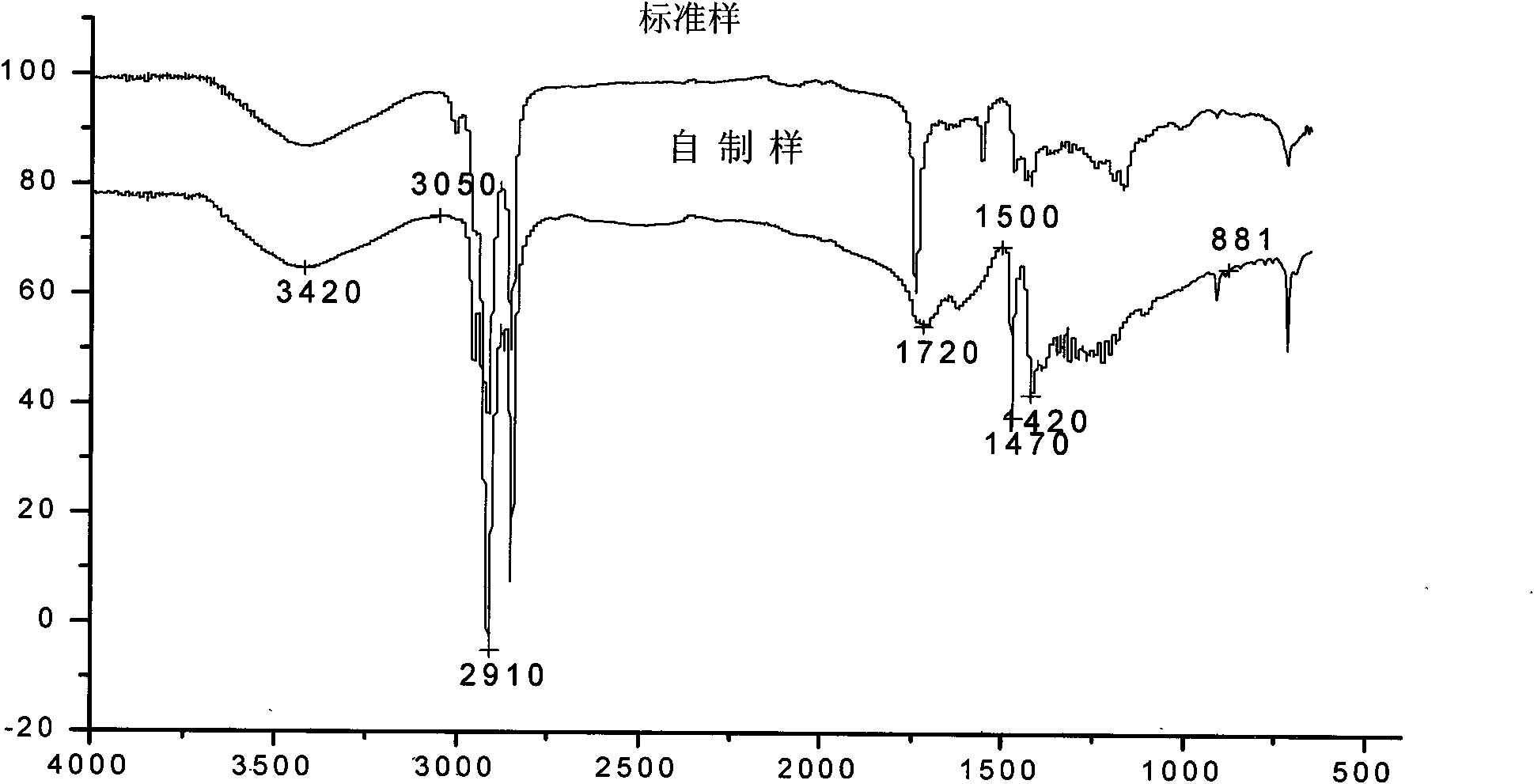

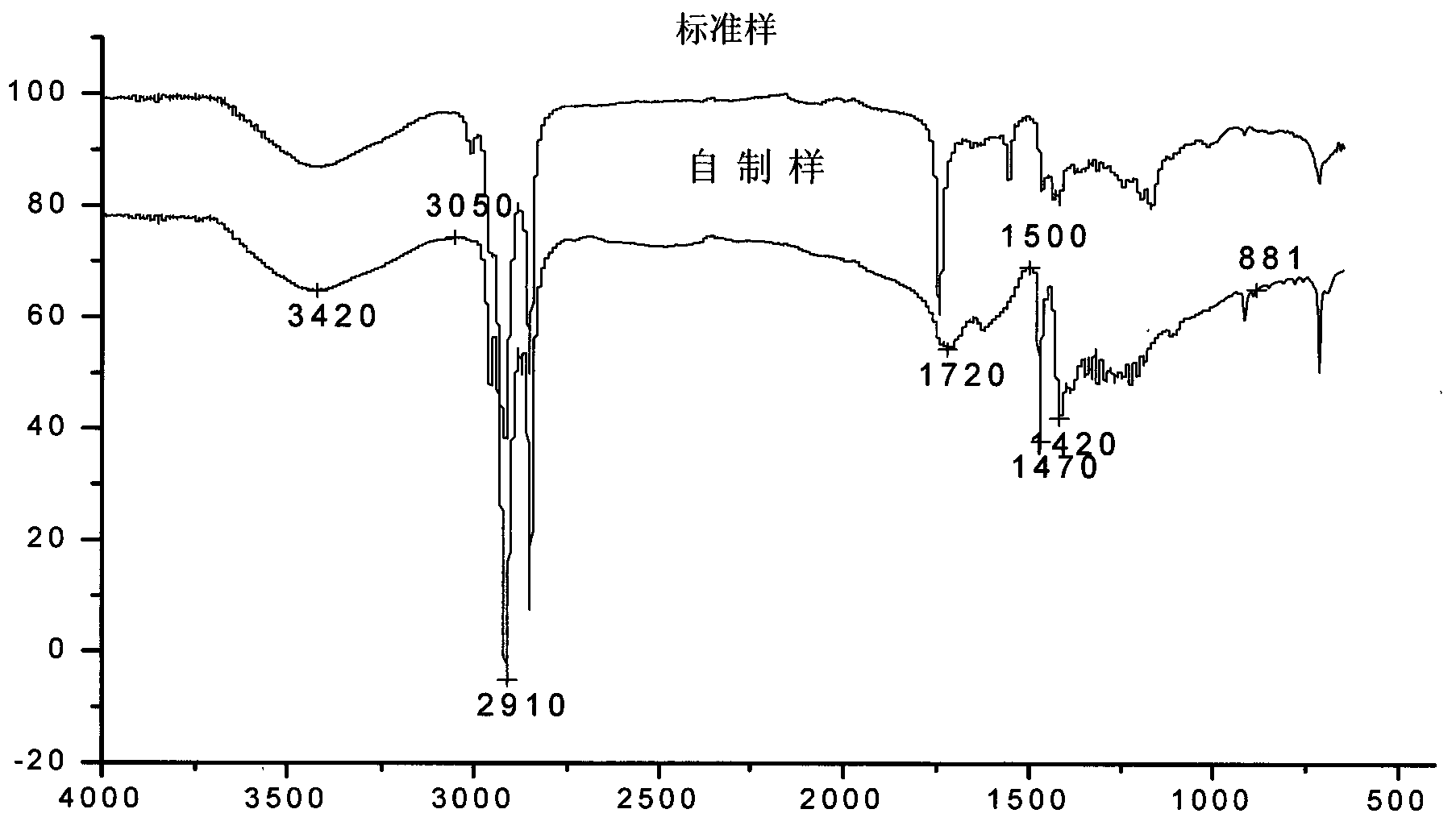

Method for directly synthesizing sucrose fatty acid ester by biodiesel and sucrose

InactiveCN101805381ALow costHigh industrial feasibilityEsterified saccharide compoundsSugar derivativesSucroseBiodiesel

The invention provides a method for directly synthesizing sucrose fatty acid ester by biodiesel and sucrose, in which a solvent-free method is adopted to synthesize the sucrose fatty acid ester under the protection of N2 and the barometric pressure of 1, and an isovolumetric immersion method is adopted to prepare a load-type solid base catalyst by immersion; then potassium stearate is added after the biodiesel is mixed with the sucrose, the mixture is reacted until the reaction system presents in a faint yellow emulsion, then the load-type solid base catalyst is added to continue to react, temperature is raised during stirring, N2 is introduced, methanol generated in the reaction process is removed when air in the reaction system is driven away, warming reaction is carried out under the protection of the N2, then the reaction system is cooled, the introduction of N2 is stopped, water is added to stop reaction, and the product is stirred for 10min at the temperature of 80 DEG C; and the crude product is processed to obtain the refined product of the sucrose fatty acid ester. After the crude product is purified by a solvent extraction method, the product purity is above 98%, the N2 can be reused, and the catalyst can be recycled.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

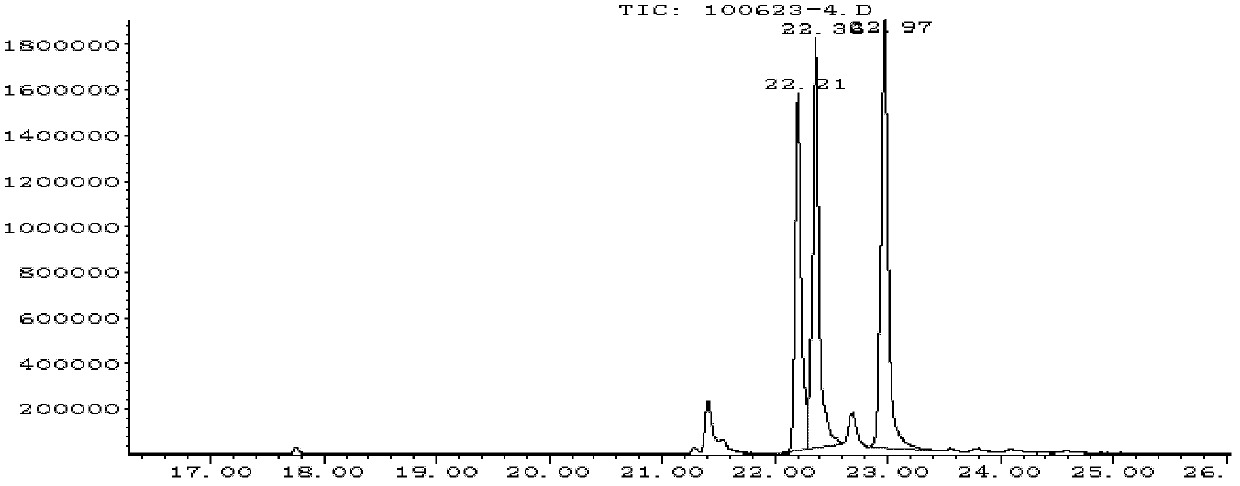

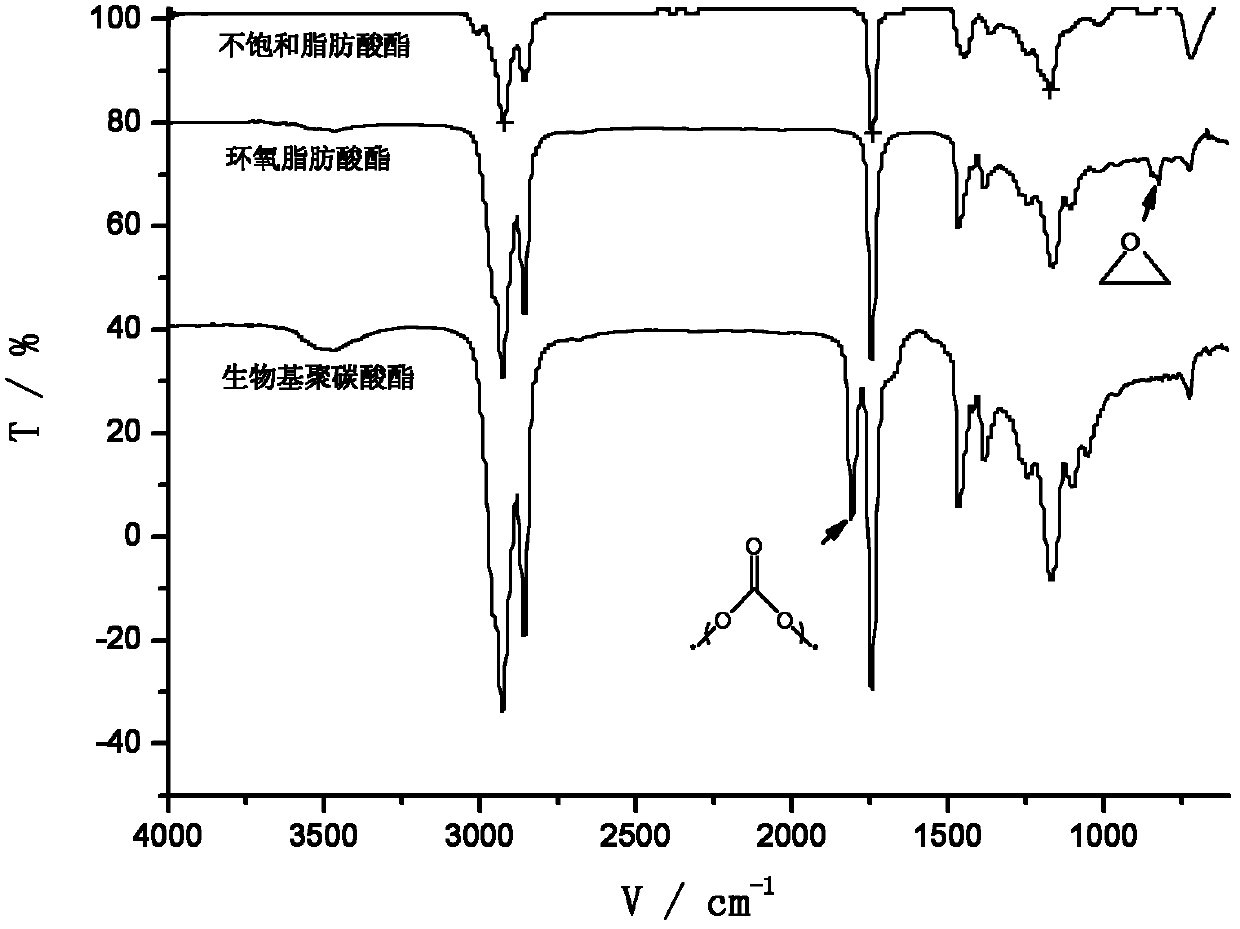

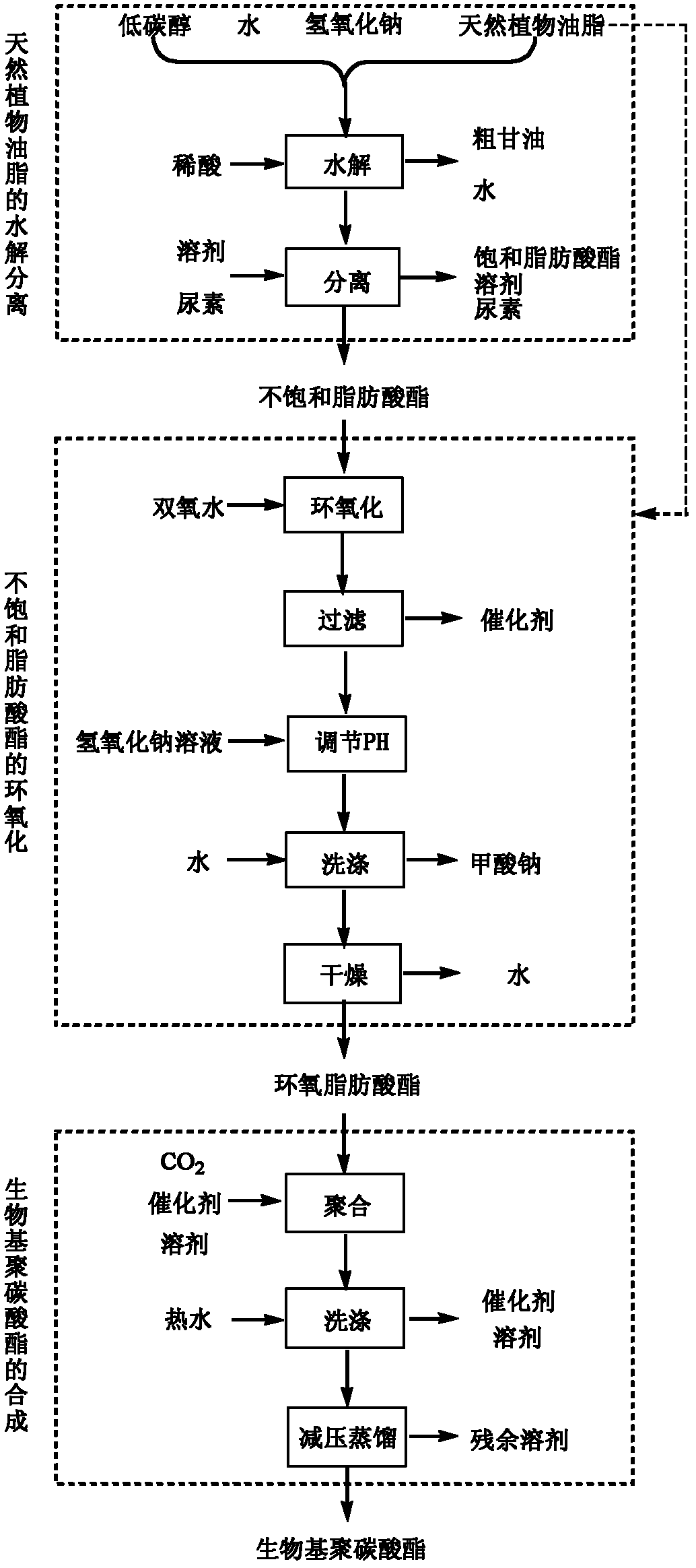

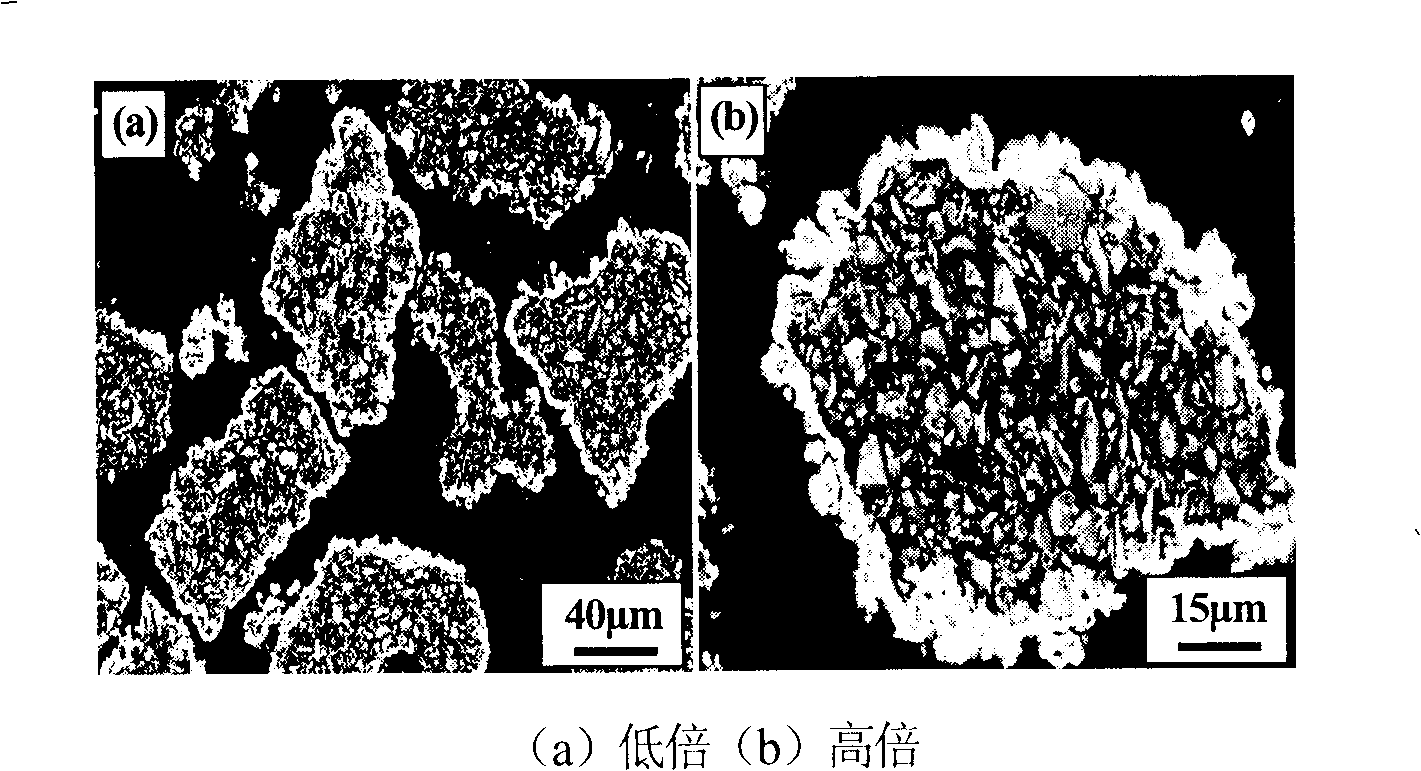

Biologic polycarbonate and preparation method thereof

InactiveCN102585192ALow costGood product performanceFatty acid esterificationFatty acids production/refiningPolycarbonateFatty acid ester

The invention provides a biologic polycarbonate and a preparation method thereof. The biologic polycarbonate is obtained by polymerizing biologic epoxy fatty acid ester serving as a raw material and CO2 gas, the yield is more than or equal to 70 percent, the number-average molecular weight is 11,000 to 30,000, and the molecular weight distribution is 1.10 to 1.74; and the biologic epoxy fatty acid ester is obtained by hydrolyzing, freezing and separating unsaturated fatty acid ester from natural vegetable fat and then performing epoxidation, or obtained by direct epoxidation of the natural vegetable fat. The renewable natural vegetable fat and the greenhouse gas CO2 are used as raw materials, so the method is environment-friendly, low in cost and simple and feasible in process operation, the solvent and the catalyst can be efficiently recycled, and the method is environment-friendly and suitable for industrialized production.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Preparation method of ginsenoside extract for beverage

The invention discloses a preparation method of a ginsenoside extract for a beverage. The preparation method aims to solve the technical problems that a current ginsenoside extract is prone to being turbid after being dissolved in water and is difficultly applied to addition in the beverage with a certain requirement for clarity. The preparation method comprises the approximate steps: ginsenosidein raw ginseng is subjected to liquid extraction firstly, and grease in ginsenoside extraction filtrate is removed through diatomite; then insoluble tiny impurities in the ginsenoside extraction filtrate are removed by filtering through a three-stage filtration system; and finally, spray drying is conducted, by combing the difference between the molecular weight of proteins and the molecular weight of the ginsenoside and ultrafiltration membrane separation, the unstable macromolecular proteins are separated, and thus the ginsenoside extract with high solution stability is obtained. A clarifiedsystem can be formed by the ginsenoside extract obtained through the preparation method and a solution, thus it is ensured that the obtained ginsenoside extract has the great solution stability, theapplication concentration of the ginsenoside in the beverage is greatly increased, and the stability of the ginsenoside in the beverage is greatly improved.

Owner:广东青云山药业有限公司

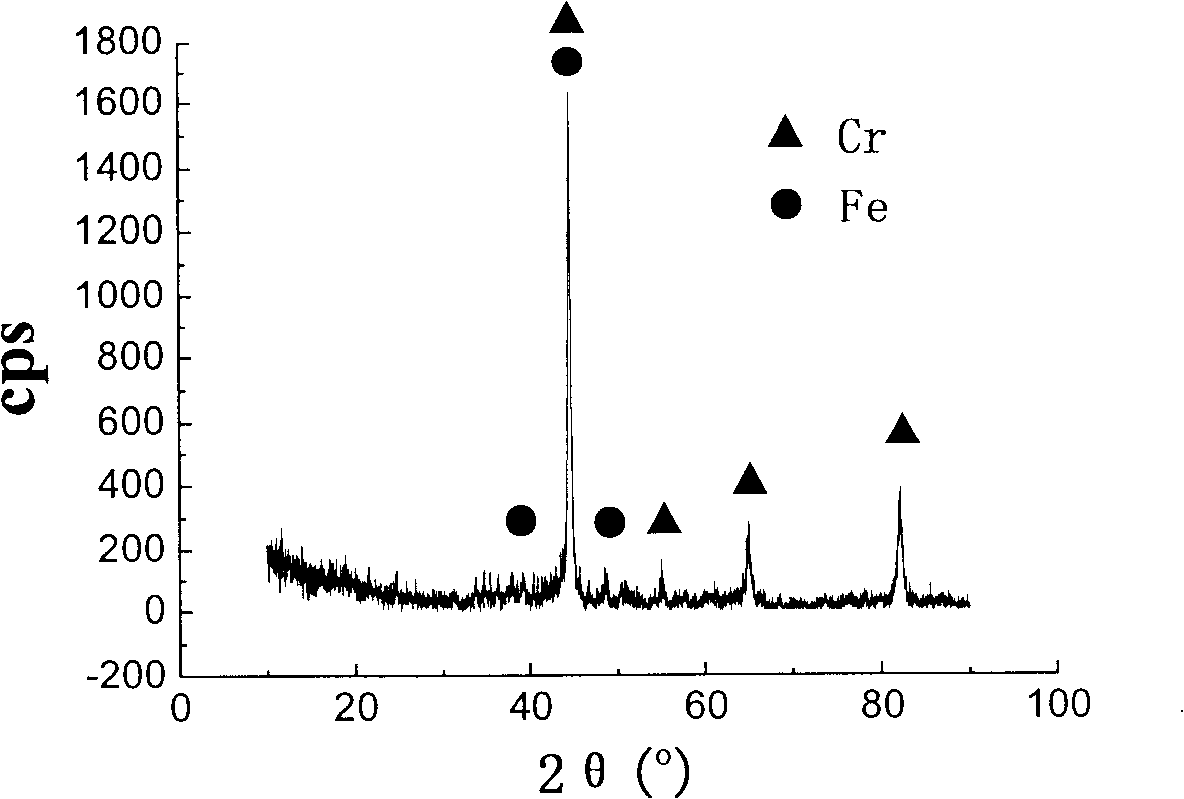

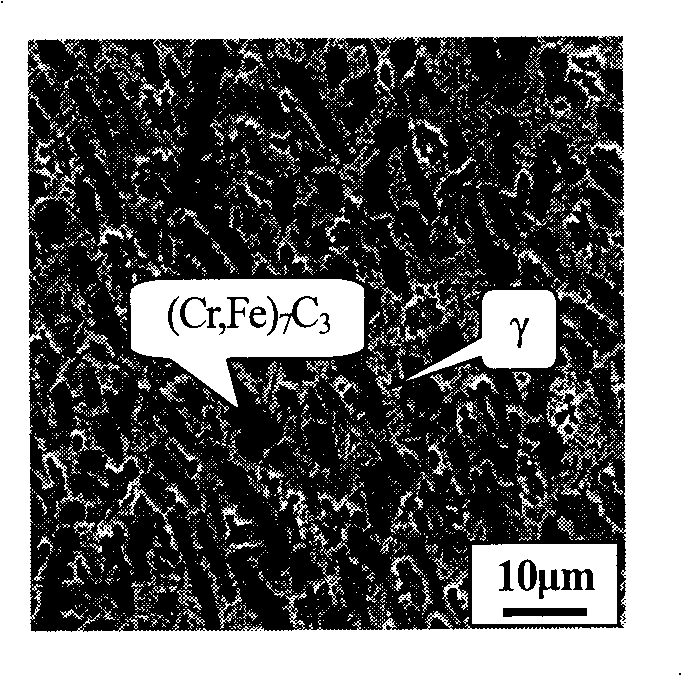

Synthetic reaction plasma cladding powder and preparation technique thereof

InactiveCN101255557AHigh bonding strengthAvoid easy separationMetallic material coating processesSucroseGranularity

The invention discloses a chromium-ferrum-carbon- tungsten-nickel synthetic reaction plasma cladding powder and the preparing process thereof. With sucrose as the precursor of carbon, by carbonizing under a specific temperature, a chromium-ferrum-carbon- tungsten-nickel plasma cladding composite power coated with carbon is formed. The process is as follows: mixing the raw materials powder(except the sucrose) in accordance with the granularity requirement in proportion, wet grinding, drying the mixed slump powder, carbonizing the mixture of the dried powder and the sucrose by step, and crushing and screening the carbonized block-like substance. The invention solves the problem that reaction components are separated in plasma cladding powder when preparing carbide metal composite coating by plasma cladding in current technology, besides, sucrose is the precursor of carbon, which has low carbonizing temperature, the produced carbon has high purity, the carbonizing process has low pollution, and the industrial feasibility is high.

Owner:WEIFANG UNIVERSITY

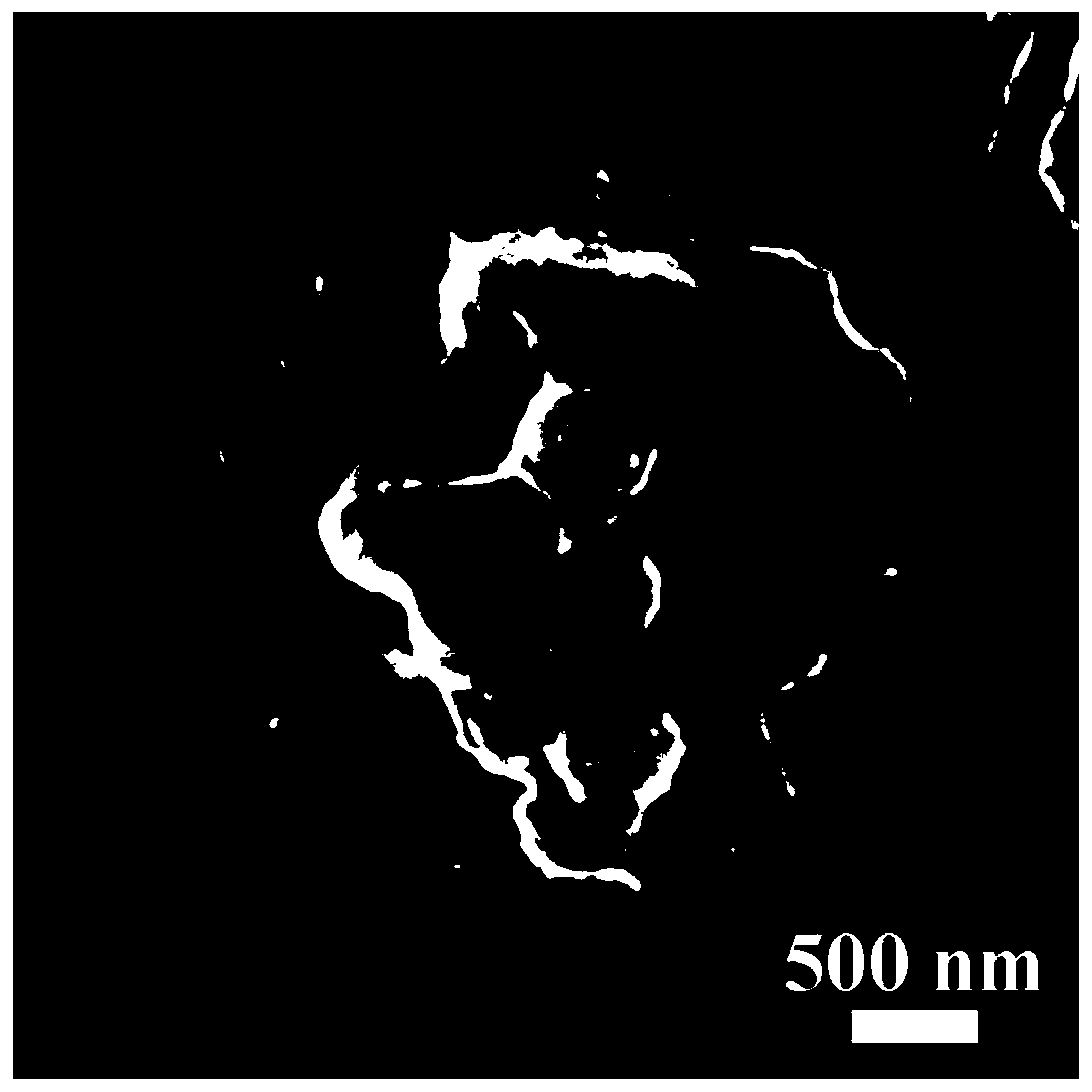

Preparation method of sodium-sulfur battery positive electrode material and application thereof

ActiveCN110504440AIncrease energy densityImprove conductivitySecondary cellsPositive electrodesSulfurTemplate based

The invention relates to a preparation method of a sodium-sulfur battery positive electrode material and application of the sodium-sulfur battery positive electrode material in a sodium-sulfur battery. The preparation method of the positive electrode material comprises the steps of preparing a sulfur-carrying material with a spherical three-dimensional porous structure by using a hard template-based pore forming technology and a spray drying technology granulation technology, and further preparing the composite positive electrode material with sulfur powder. The Ti3C2 / S composite positive electrode material has the characteristics of good conductivity, special two-dimensional layered structure, higher specific surface area and the like, is applied to the sodium-sulfur battery, and is beneficial to high-speed transmission of electrons, so that the battery performance is improved.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

Preparation method of modified lithium ion battery graphite cathode material

InactiveCN106495143ALow curing temperatureUniform viscosityCarbon compoundsCell electrodesPhenolLithium-ion battery

The invention discloses a preparation method of a modified lithium ion battery graphite cathode material. Graphite and asphalt are crushed and mixed to obtain asphalt coated graphite precursor powder after heat treatment, and the asphalt coated graphite precursor powder is subjected to high-temperature heat treatment, natural cooling and then classification under protection of N2 to obtain modified graphite A. Water-soluble thermosetting phenol resin is diluted and heated, the modified graphite A is added into the resin, and the modified graphite A and the resin are sufficiently stirred to obtain solution B. The solution B is filtered, dried, cured, carbonized and classified to obtain the modified lithium ion battery graphite cathode material. Raw materials are cheap and easy to get, the preparation method is simple in process, mild in condition, convenient in operation and high in safety, the prepared material is excellent and stable, and performance parameter range is wide and easily controlled. The material has an application prospect in the field of electronic products, power vehicles, solar and wind power generation and the like.

Owner:SHANGHAI SHANSHAN TECH CO LTD +1

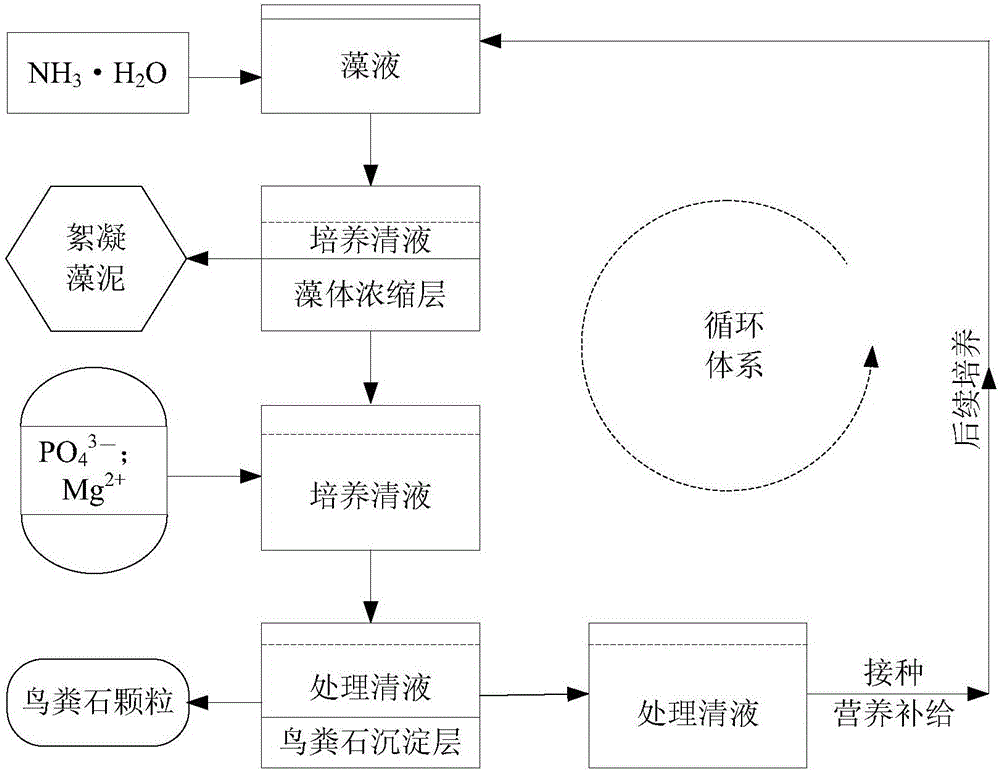

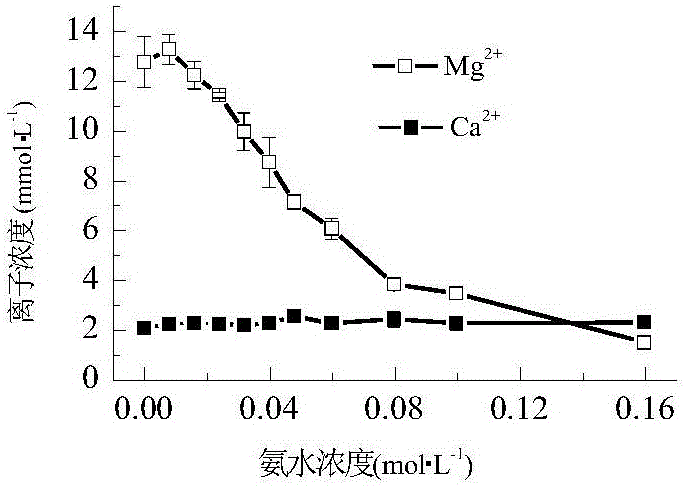

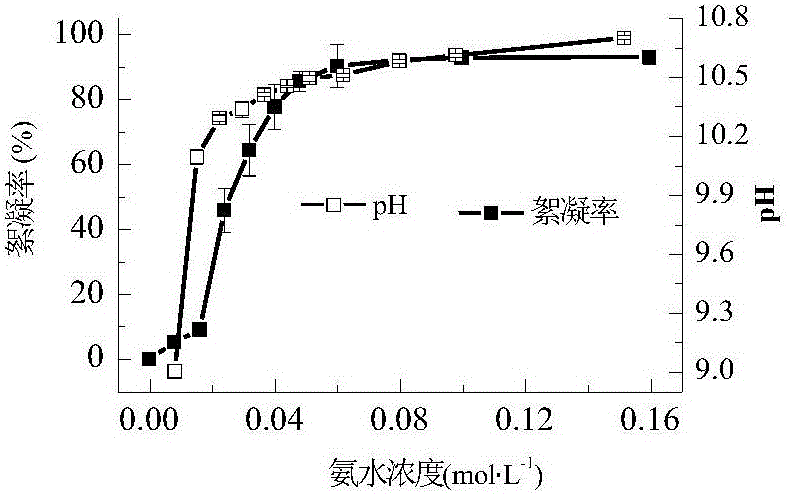

Microalgae cycling breeding technology

InactiveCN105018349AEfficient deaminationSolve recycling difficultiesUnicellular algaeBiomassNH3 compound

The invention discloses a microalgae cycling breeding technology. The technology comprises the steps of 1, adding ammonia to a culture solution where microalgae are cultured, so that flocculation of the microalgae is achieved by means of the ammonia; 2, separating microalgae floccules from the culture solution to obtain culture liquor, and then adding PO43- and Mg2+ to the culture liquor to enable NH4+ in the culture liquor to react with PO43- and Mg2+ to generate NH4MgPO4.6H2O sediment; 3, separating the NH4MgPO4.6H2O sediment from the culture liquor to obtain treating liquor, adding certain constituents to the treating liquor to form a new culture solution, and conducting cycling culture of the microalgae by means of the new culture solution; 4, repeating the steps 1, 2 and 3 in sequence to achieve cycling breeding of the microalgae. By the adoption of the method, cost is low, efficiency is high, and environment friendliness is realized. The technology is suitable for large-scale breeding of microalgae and harvesting of microalgae biomass.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

Lithium ion sieve doped with IIIA element as well as preparation method and application thereof

InactiveCN111001373ARaw materials are easy to getShort processOther chemical processesWater/sewage treatment by sorptionAir atmosphereThallium trifluoroacetate

The invention discloses a lithium ion sieve doped with an IIIA element as well as a preparation method and application thereof. The method comprises the following steps: mixing a manganese source anda lithium source, and uniformly grinding; adding a salt or elementary substance of the IIIA element, uniformly grinding, and then drying; carrying out dry grinding on the dried raw materials to obtainpowder, carrying out segmented roasting for 0.5-16 hours at 300-800 DEG C in an oxygen or air atmosphere, and cooling to obtain an ion sieve precursor; pickling the ion sieve precursor for 4-12 hours, filtering and drying to obtain the ion sieve; and the salt or elementary substance of the IIIA element is more than one of Na2B4O7.10H2O, boron powder, aluminum sulfate, aluminum hydroxide, galliumchloride, gallium nitrate, indium hydroxide or thallium trifluoroacetate. The 4h adsorption capacity of the ion sieve product prepared by the method is close to 20mg / g, and the acid pickling manganeseloss is reduced by one time compared with that of lambda-MnO2 serving as an ion sieve and is superior to the adsorption performance of the ion sieve prepared by taking LiMn2O4 as a precursor.

Owner:HUNAN BRUNP RECYCLING TECH +2

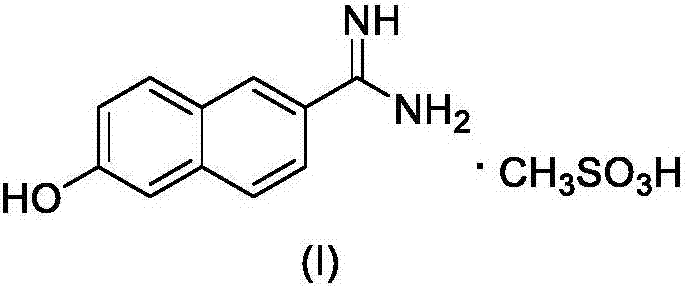

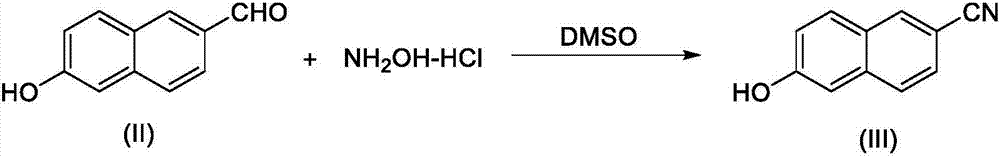

New 6-amidino-2-naphthol methanesulfonate synthesis method

ActiveCN103896809AReduce pollutionMild reaction conditionsSulfonic acids salts preparationSodium bicarbonateHydroxylamine Hydrochloride

The present invention relates to a new synthesis method for a nafamostat mesylate intermediate 6-amidino-2-naphthol methanesulfonate. According to the new method, 6-hydroxy-2-naphthaldehyde is adopted as a raw material, dimethyl sulfoxide is adopted as a reaction solvent, the dimethyl sulfoxide and hydroxylamine hydrochloride are subjected to an addition elimination reaction to obtain 6-cyano-2-naphthol, the 6-cyano-2-naphthol is subjected to a pinner reaction in a HCl / methanol solution to obtain 6-hydroxy-2-naphthalene imino methyl ester hydrochloride, ammonia gas is introduced to carry out an aminolysis reaction to obtain 6-amidino-2-naphthol, and the 6-amidino-2-naphthol sequentially reacts with sodium bicarbonate and methanesulfonic acid to convert into the 6-amidino-2-naphthol methanesulfonate. According to the present invention, in the new synthesis method, the 6-cyano-2-naphthol preparation in the first step adopts the completely-new method, the use of the highly toxic copper cyanide in the traditional method is avoided, the operations are simple, and the conditions are mild; and the second step adopts the improved pinner method, wherein the reaction of acetyl chloride and methanol is adopted to produce HCl to replace direct introduction of HCl gas into the reaction system, such that the improved method has strong operability and industrialization is easily achieved.

Owner:BEIJING LABWORLD BIO MEDICINE TECH

Recycling method for aluminum in aluminum alloy chemical milling waste liquid

InactiveCN108585008AShort production processEasy to makeNanotechnologyAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationNano structuringCentrifugation

The invention relates to a recycling method for aluminum in an aluminum alloy chemical milling waste liquid, and belongs to the technical fields of recovery and recycling of aluminum alloy alkaline chemical milling waste liquids. The method specially comprises the following steps: 1) performing separation treatment: performing centrifugation on the aluminum-containing alloy chemical milling wasteliquid, and removing a precipitate in the waste liquid; 2) under normal temperature and normal pressure, adding hydrogen peroxide into the precipitate-removed waste liquid, and performing a full reaction to obtain a reaction mixture; and 3) performing solid-liquid separation on the reaction mixture to obtain a AlOOH crystal filter cake and a filtrate; and washing the AlOOH crystal filter cake by using water, and performing drying to prepare nano AlOOH. The method provided by the invention has a short production process, small demand for equipment and a fast reaction speed; the recovery rate ofaluminum resources in the chemical milling waste liquid is up to 83%; the prepared product is the orthorhombic AlOOH with a particle size of 50-200 nm, and has a nano structure and the advantages ofa large specific surface area and high purity; and the method facilitates industrial production and applications of medicines, catalysts, adsorbents, ceramics and fireproof materials.

Owner:SHENYANG AEROSPACE UNIVERSITY

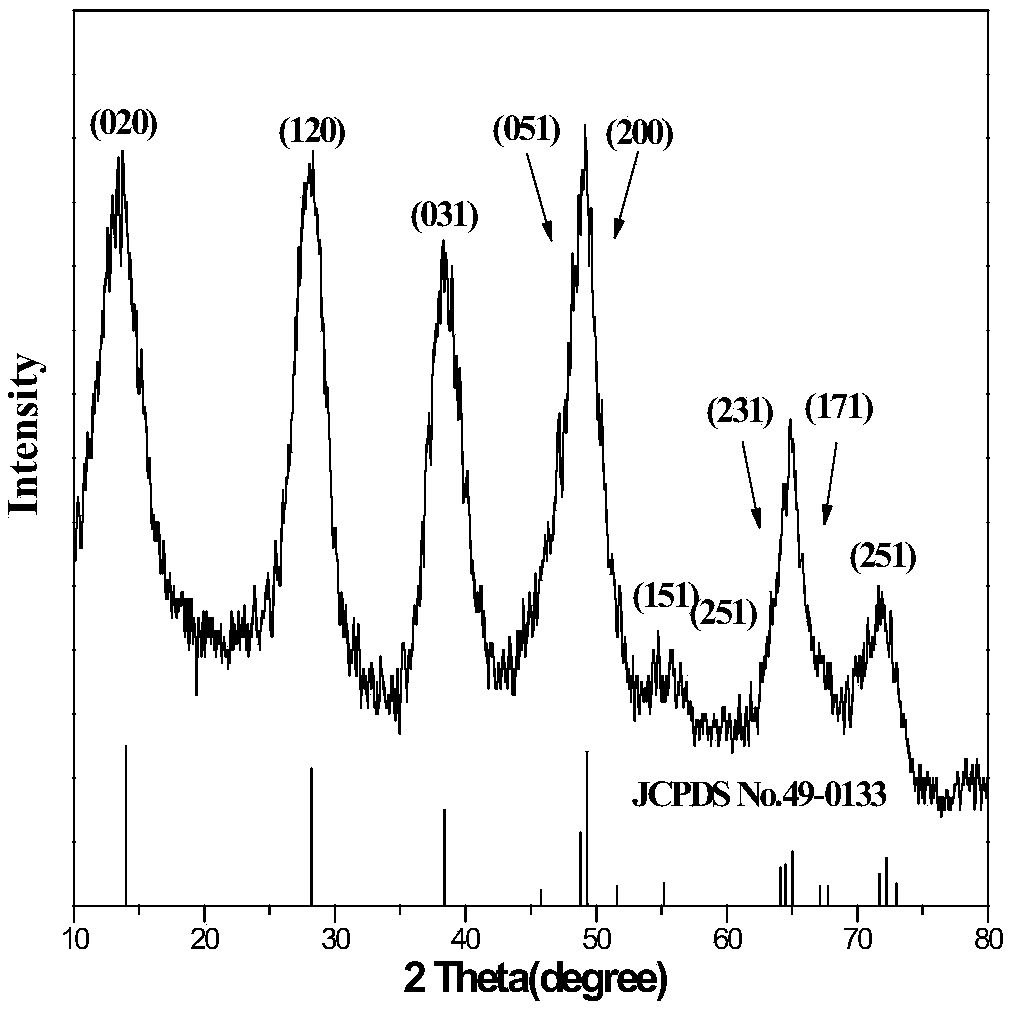

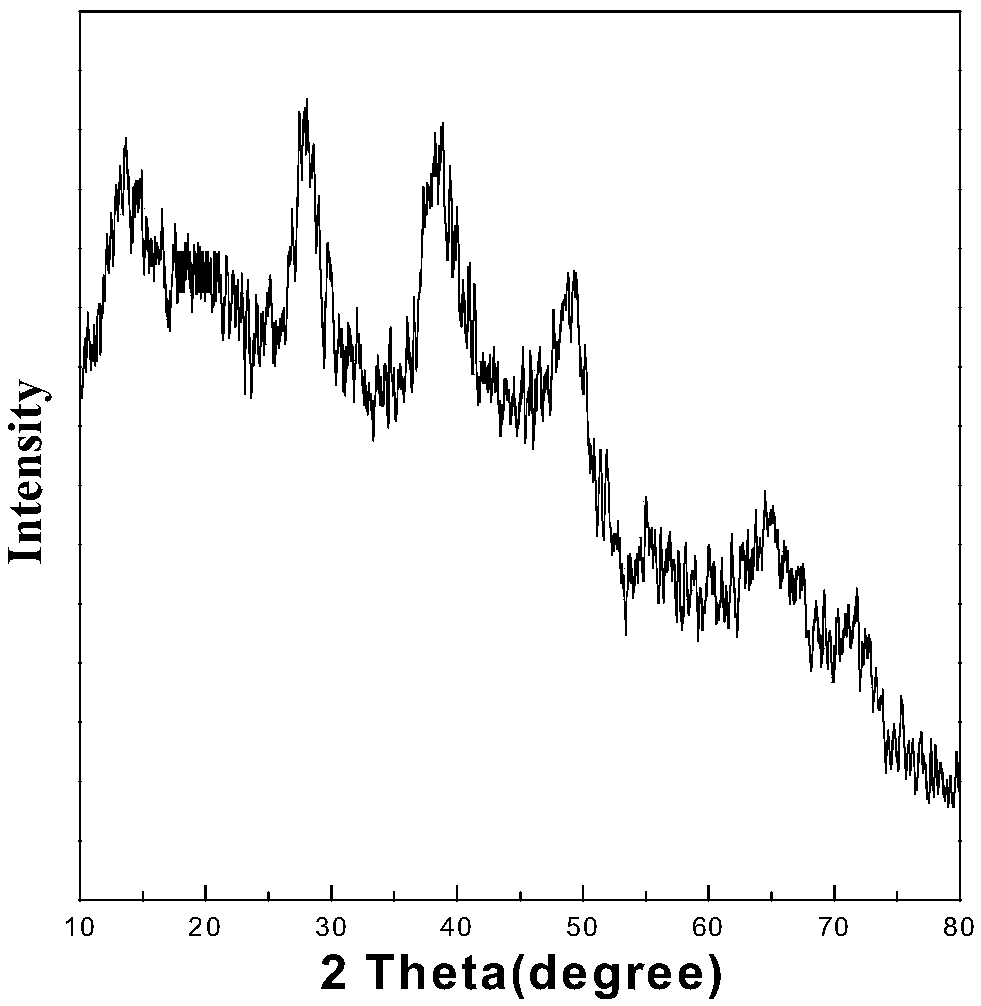

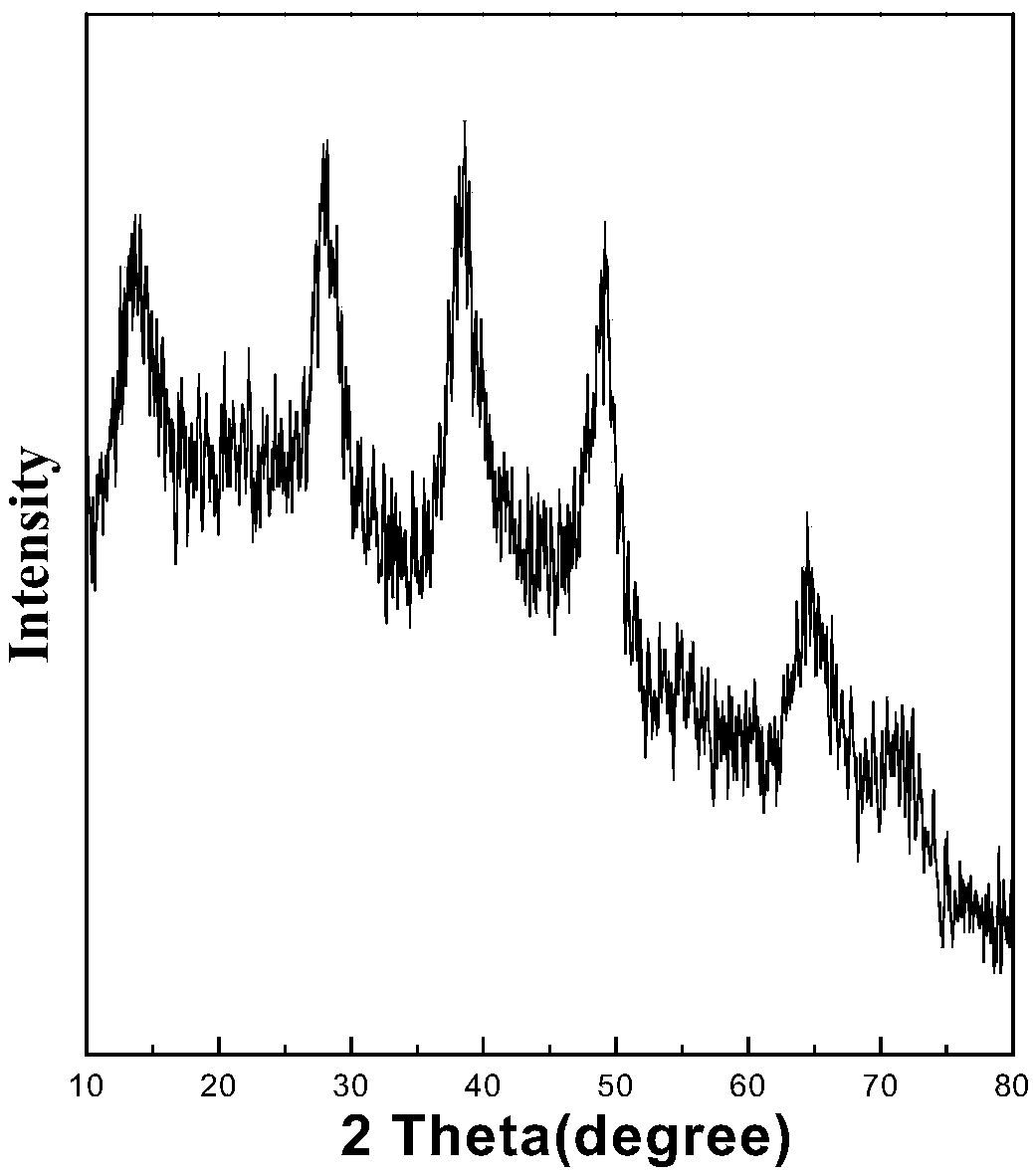

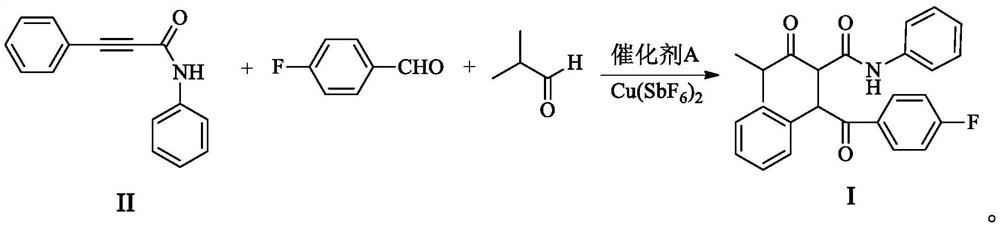

Method for synthesizing atorvastatin calcium intermediate by multi-component one-pot method

ActiveCN111909048AEmission reductionShort reaction stepsOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystAcyl group

The invention provides a method for synthesizing an atorvastatin calcium intermediate by a multi-component one-pot method, and particularly provides a one-pot method for synthesizing 4-(4-fluorophenyl)-2-(2methylpropionyl)-3-phenyl 4-oxo-N-phenyl butyramide. The preparation method is characterized in that N-phenyl phenylpropiolamide, 4-fluorobenzaldehyde and isobutyraldehyde are synthesized by a one-pot method under the action of Cu(SbF6)2 and a Pd-ligand catalyst to obtain a target compound. The one-pot method conforms to the characteristics of green chemistry and high atom economy, and emission of three wastes and pollution factors is remarkably reduced; the reaction steps are short, and the yield (about 80-87%) is obviously higher than that of the technical scheme of the existing multi-step synthesis method; raw materials are easily available; the process operation is simple; the EHS risk is low; and the industrialized feasibility is high.

Owner:ZHEJIANG HONGYUAN PHARMA

Monolithic VOCs catalytic combustion catalyst, and preparation method thereof

InactiveCN109701548AImprove stabilityImprove overall lifespanCatalyst activation/preparationIncinerator apparatusFiberAbsorption capacity

The invention provides a monolithic VOCs catalytic combustion catalyst, and a preparation method thereof. According to the preparation method, a high molecular fibrofelt is subjected to carbonizationprocessing at certain conditions so as to obtain a carbon fibrofelt, and activation pore-forming is carried out; introduction of active components into the activated fibrofelt through dipping is carried out, drying is carried out, and under inert gas protection, calcining processing at a certain temperature is carried out so as to obtain the monolithic VOCs catalytic combustion catalyst. The monolithic VOCs catalytic combustion catalyst is low in catalytic initial temperature, wide in working temperature range, high in catalytic activity, and long in service life. The preparation method is simple, convenient, and effective; operation is convenient; raw materials are widely available; the prepared monolithic VOCs catalytic combustion catalyst is stable in structure and excellent in heat conductivity; active component distribution is uniform; abundant pore structures are formed; specific absorption capacity on small molecular volatile organic compounds is achieved; a problem in the priorart that the activity of a conventional monolithic VOCs catalyst is poor is solved; preparation cost is low; product property is stable; and the preparation method is suitable for industrialized production.

Owner:BIOMINTEC ENVIRONMENT (SHANGHAI) CO LTD

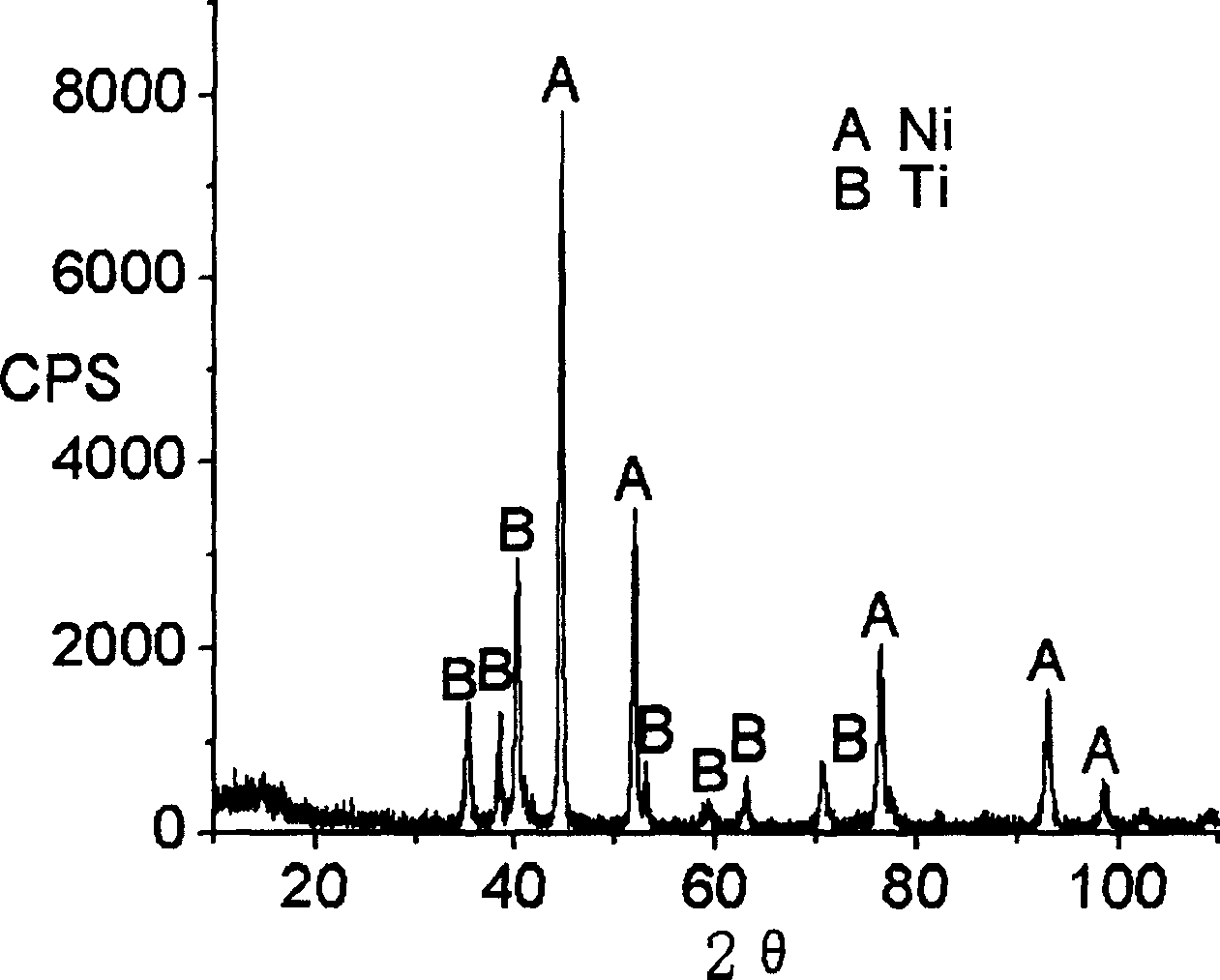

Titanium-nickel-carbon reacting spraying composite powder and preparation thereof

InactiveCN1288272CHigh bonding strengthAvoid easy separationMolten spray coatingSucroseSpray coating

The invention was involved in Ti-Ni-C alloys response spray coating complex powder and its preparation method, which belonged to the powder manufacturing craft of metal ceramic complex coating technology. Cane sugar was used as precursor of carbon and it was carbonized under definite temperature to form Ti-Ni-C alloys response spray coating complex powder, which was enclosed by material powder. The technology was: mixing the Ti and Ni power with mixture ratio ->wet grinding->drying the slurry ->carbonization step by step->breaking and screening. The method not only settled the separation of response component during the response spray powder but also the cane sugar was used as precursor of carbon so it had low carbonization temperature, high carbon purity, small pollution of process of carbonization and the high industrial feasibility. To select Ni as the metal base to reduce rather large grain TiC conglobation and increase the wear-resisting property of coating.

Owner:UNIV OF SCI & TECH BEIJING

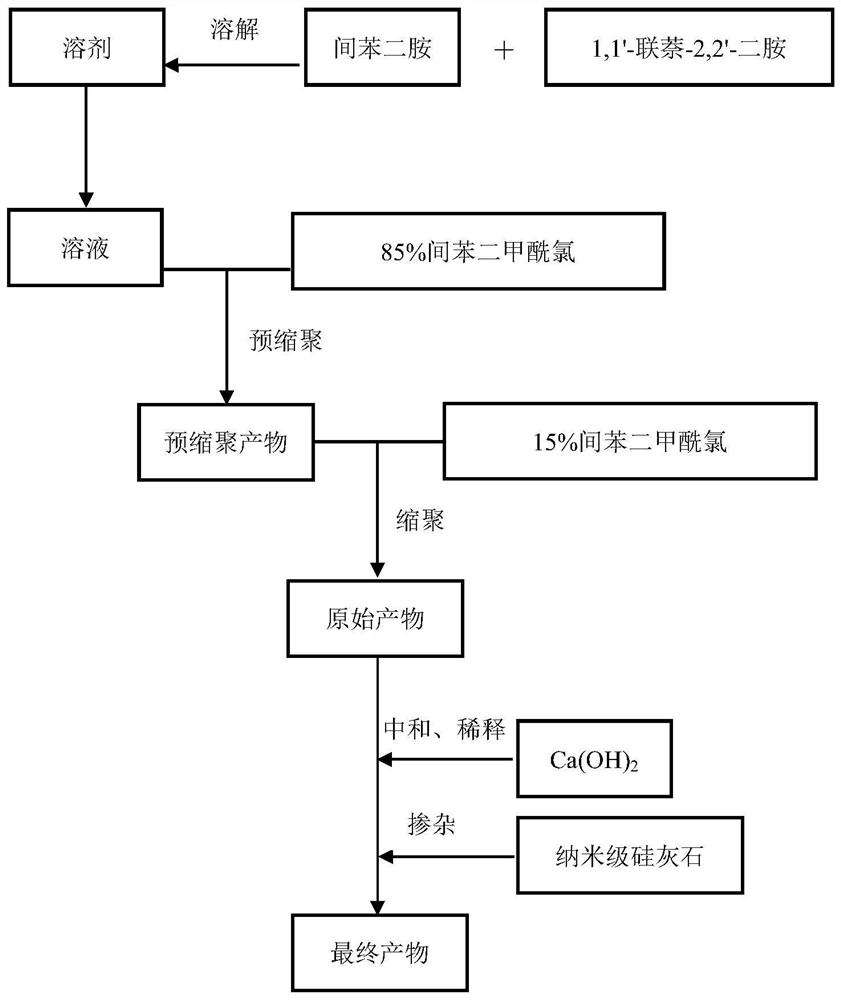

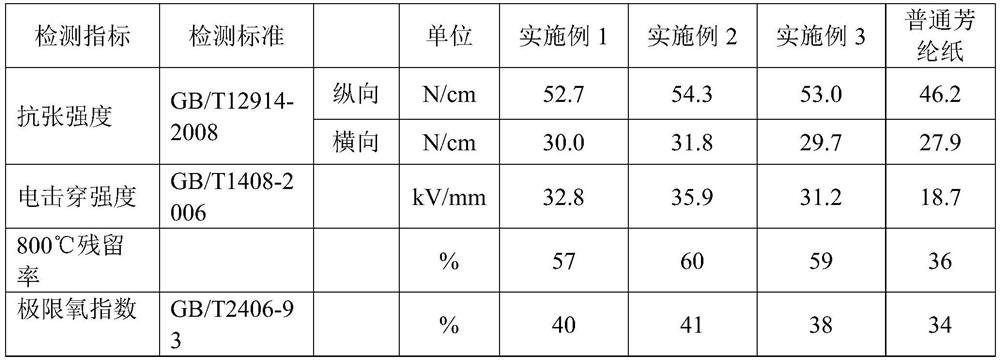

Meta-aramid resin for fibrid, fibrid, aramid paper and synthesis method

ActiveCN112812294AImprove solubilityHigh solid contentArtifical filament manufactureMonocomponent polyamides artificial filamentPolymer scienceAramid

The invention discloses meta-aramid resin for fibrid, the fibrid, aramid paper and a synthesis method. Under the protection of inert gas, a part of isophthaloyl dichloride is added in batches into a polar solvent dissolved with m-phenylenediamine and 1,1'-binaphthalene-2,2'-diamine, and carrying out pre-polycondensation; adding the rest isophthaloyl dichloride into a reaction system in batches, increasing a reaction temperature, and carrying out polycondensation; adding a neutralizer into the reaction system to obtain a reaction product; and adding nanoscale wollastonite into the reaction product, and conducting uniform dispersing to obtain the meta-aramid resin. According to the invention, a third monomer, namely 1,1'-binaphthalene-2,2'-diamine is introduced into an aramid fiber rigid chain system, so the viscosity of a final product system is reduced, and production efficiency is effectively improved. The nanoscale wollastonite is added into precipitation resin, so the insulating strength, the thermal stability and the mechanical strength of meta-aramid insulating paper can be improved, and the requirement for long-term safe and stable application in a high-electric-field environment can be met.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

White light polymer material, preparation method and applications thereof

InactiveCN105254855AGood film formingImprove thermal stabilityOrganic chemistrySolid-state devicesPolymer sciencePolymer

The present invention provides a polymer material having a structure represented by a general formula I, wherein x is more than 0 and is less than or equal to 0.995, y is more than or equal to 0.005 and is less than 1, x+y is equal to 1, n is an integer between 1-100, and R and R' are the same or different, and independently represent alkyl having a carbon atom number of 1-10. The polymer material has high stability and high luminous efficiency, and can improve the service life and the stability of the device; and due to the characteristic of the easy exciplex formation from the single polymer, various color group components in the polymer can be regulated to obtain the white light polymer material. The present invention further provides a white light device using the polymer material of the present invention. The formula I is defined in the specification.

Owner:JIANGSU HECHENG ADVANCED MATERIALS

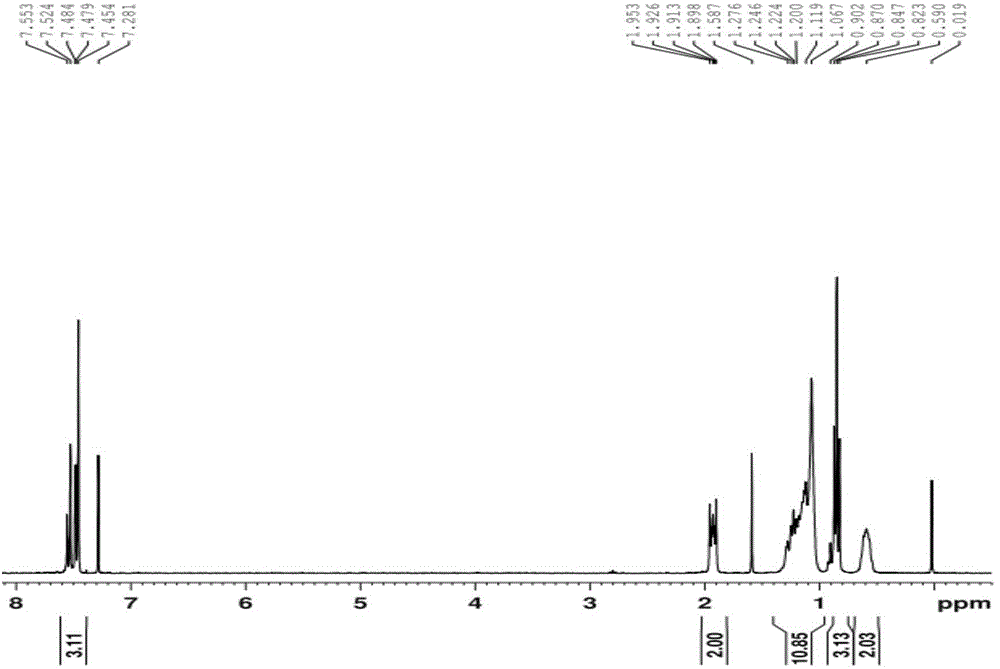

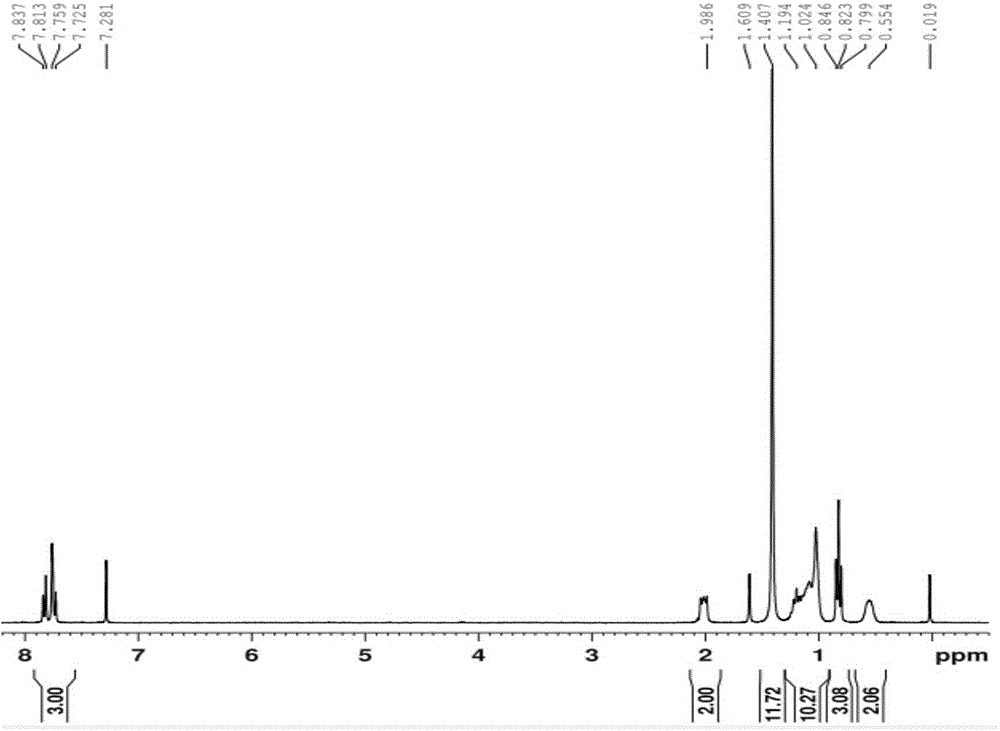

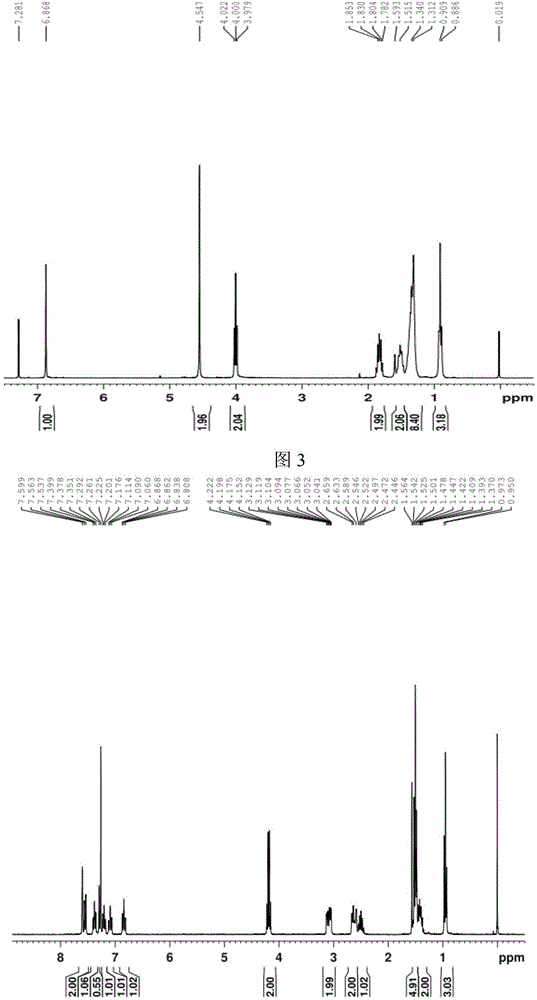

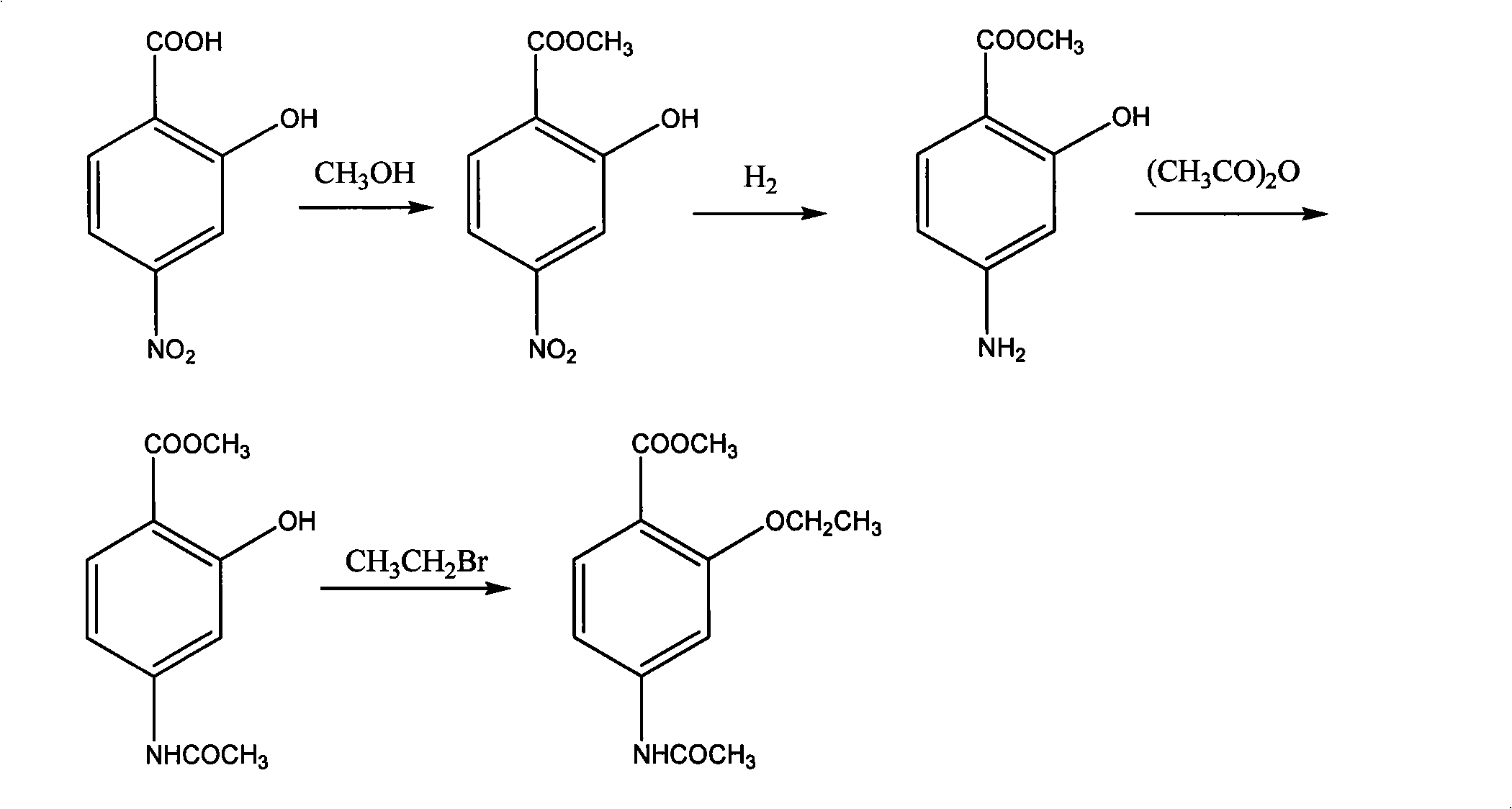

Preparation of 2-ethoxy-4-acetaminobenzoic acid methyl ester

InactiveCN101348444ALow priceRaw materials are easy to getOrganic compound preparationCarboxylic acid amides preparationIce waterPolymer science

A preparation method for 1.2-oxethyl-4-acetamido methyl benzoate comprises the following steps that 2-hydroxyl-4-nitrobenzoic acid is taken as a raw material, is dissolved in 4 to 5mol of methanol as calculated by raw material per mol and is added with 5 to 10g of catalyst; the mixture is heated and undergoes back flow; when reaction is carried out for 3 hours, the catalyst is filtered out; hydrogenation reduction of nitro is carried out under a pressure of 0.3MPa and at a temperature of 50 DEG C; the temperature is controlled between 25 and 35 DEG C; according to a proportion that 1mol acetic anhydride is dripped into every mol of the raw material, acetic anhydride is dripped and stirred at a temperature of between 40 and 50 DEG C for 40min; the mixture is cooled down to room temperature after solidifying; according to a proportion that 200 to 300ml of water is added in every mol of the raw material, water is added and stirred, and acetylated solid can be obtained after sucking filtration and drying; the acetylated solid product obtained from each mol of raw material is dissolved in 100ml of DMF, and 1mol of potassium carbonate and 1mol of CH3CH2Br are added and stirred at a temperature of between 50 and 60 DEG C for 3 hours; the reactants are poured with ice water so as to obtain a brown solid after filtration; normal hexane and toluene with the volume ratio equal to 1 to 1 are used to dissolve the brown solid; and after heated back flow and recrystallization, a silvery white 1.2-oxethyl-4-acetamido methyl benzoate solid can be obtained.

Owner:ZHEJIANG ESIGMA BIOTECH CO LTD

Method for conducting copper infiltration on 3D printed tungsten blank through tungsten powder fuse jet

ActiveCN112792352AImprove printing efficiencyReduce manufacturing costAdditive manufacturing apparatusTransportation and packaging3d printMolecular materials

The invention discloses a method for conducting copper infiltration on a 3D printed tungsten blank through tungsten powder fuse jetting, and relates to the technical field of 3D printing. The method comprises the steps of S1, raw material proportioning, S2, tungsten-based plastic wire manufacturing, S3, 3D printing, S4, high-temperature sintering, S5, copper infiltration, S6, heat treatment and S7, machining. Tungsten powder and a plastic-based material are mixed, a tungsten-based plastic wire is manufactured and is heated into a molten fluid through a wire feeder, jetting 3D printing is performed to obtain a designed tungsten blank, high-temperature sintering is performed on the tungsten blank, a plastic-based high-molecular material is removed, a porous tungsten blank is prepared, and copper infiltration is performed to obtain the required tungsten-copper part; according to the method, jetting 3D printing is adopted, the printing efficiency is relatively high, the printing equipment is simplified, and the printing cost is greatly reduced; the tungsten blank subjected to jetting printing is adopted, the method is close to a traditional tungsten powder pressing and sintering technology, the tungsten powder is not molten, and retained copper infiltration pores are uniform.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

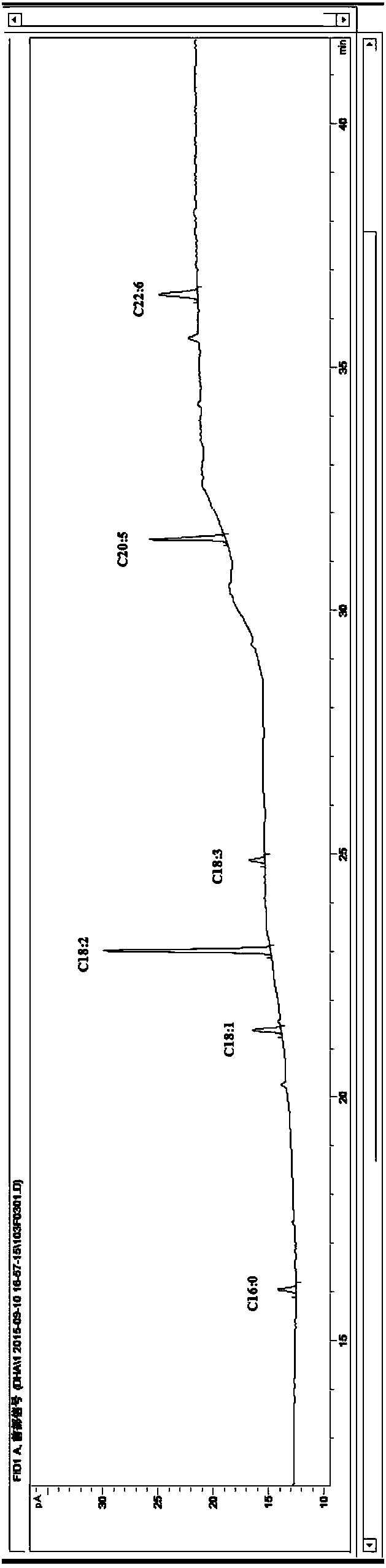

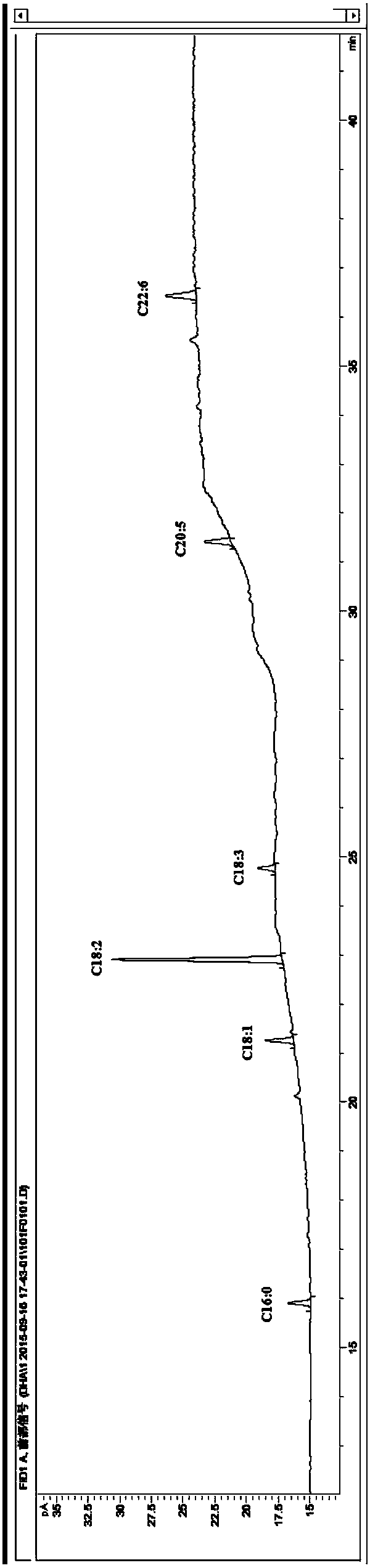

Preparation method of euphausia superba oil substitute

ActiveCN108265090AFully absorbedTake advantage ofImmobilised enzymesHydrolasesBiotechnologyEngineering

The invention discloses a preparation method of a euphausia superba oil substitute, and provides a method for preparing a fat composition containing phosphatide type DHA and phosphatide type EPA and afat composition prepared according to the method. Particularly, by accurate control over the ratio of DHA to EPA in reaction raw materials, the fat composition which contains the phosphatide type DHAand the phosphatide type EPA and is almost the same as natural euphausia superba oil is prepared.

Owner:COFCO GROUP +3

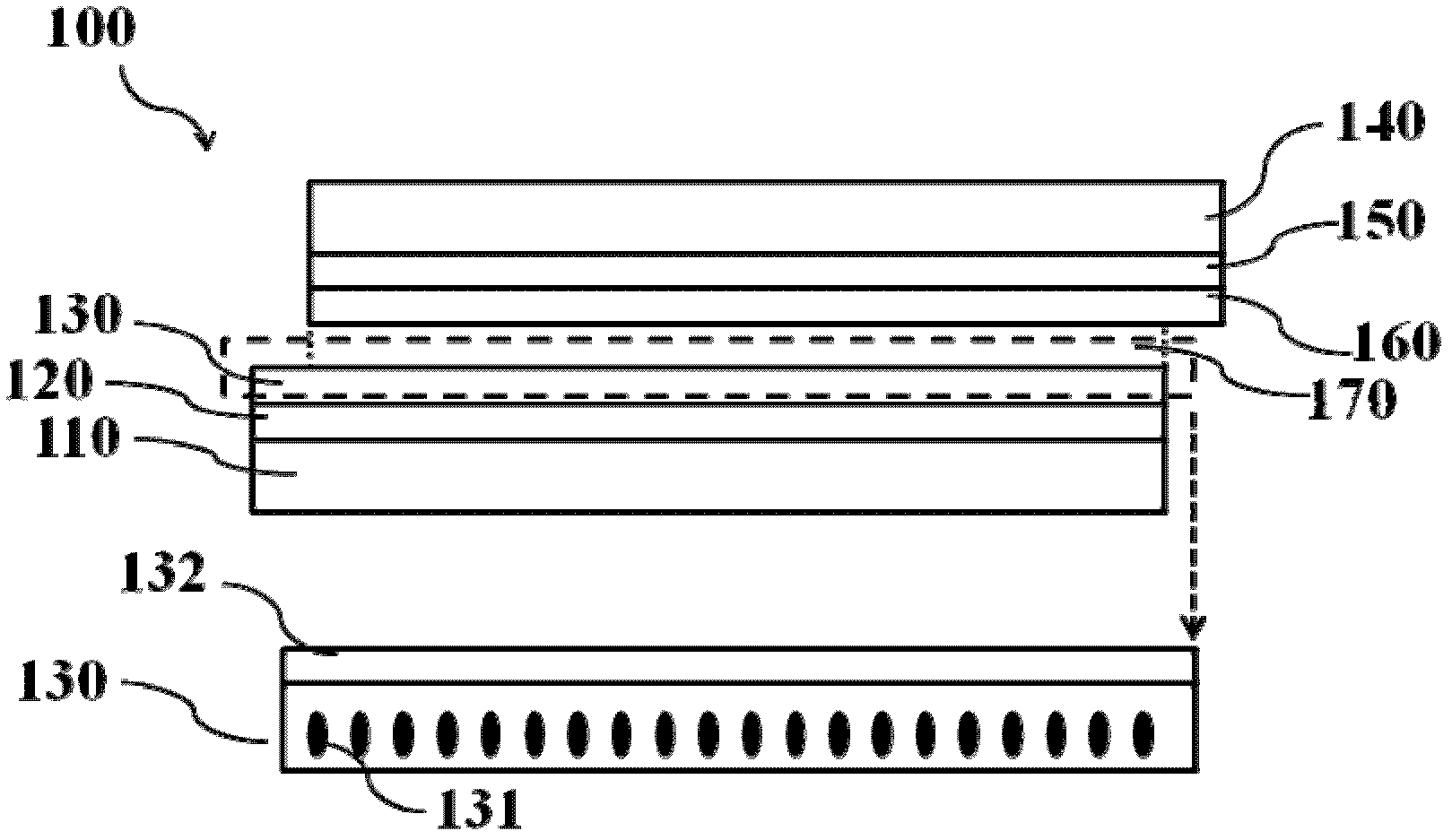

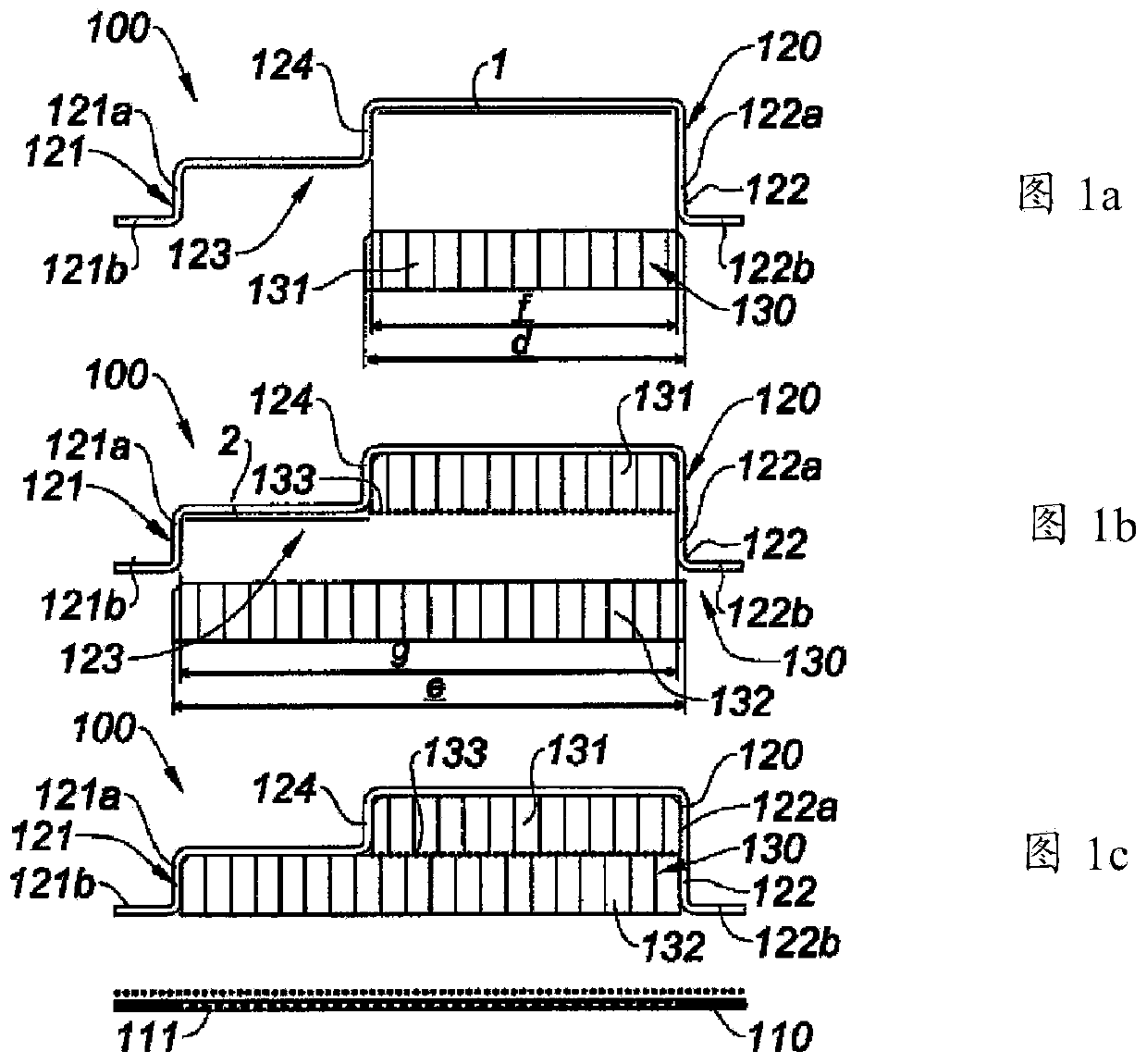

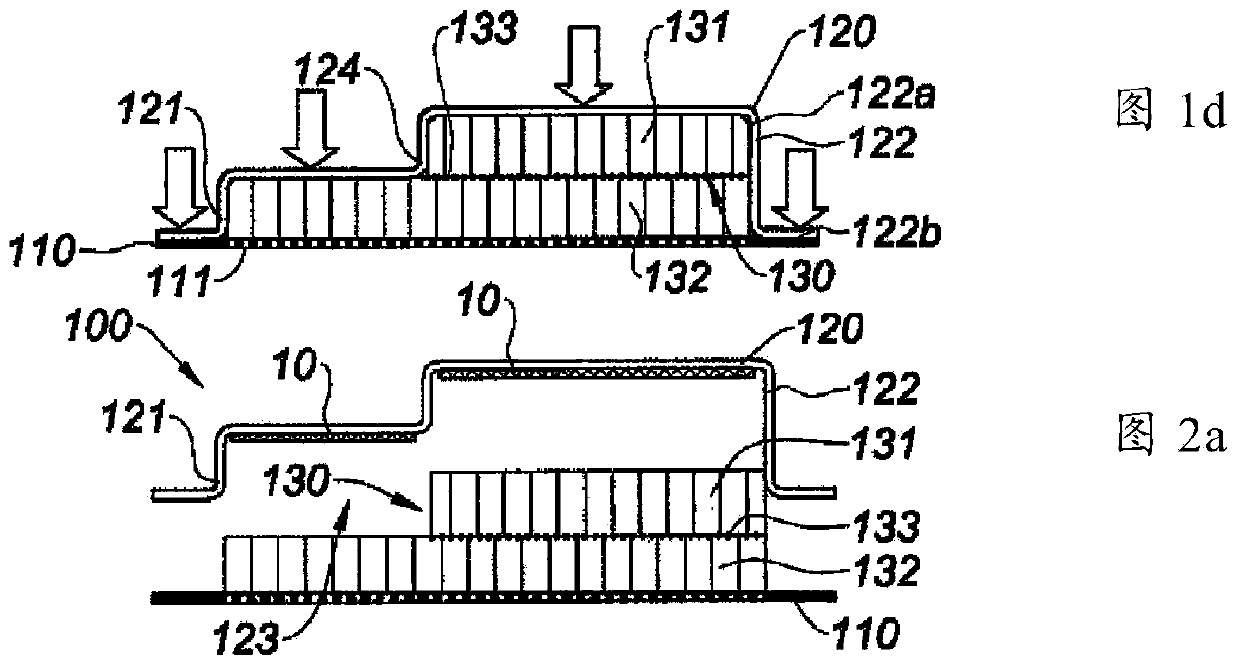

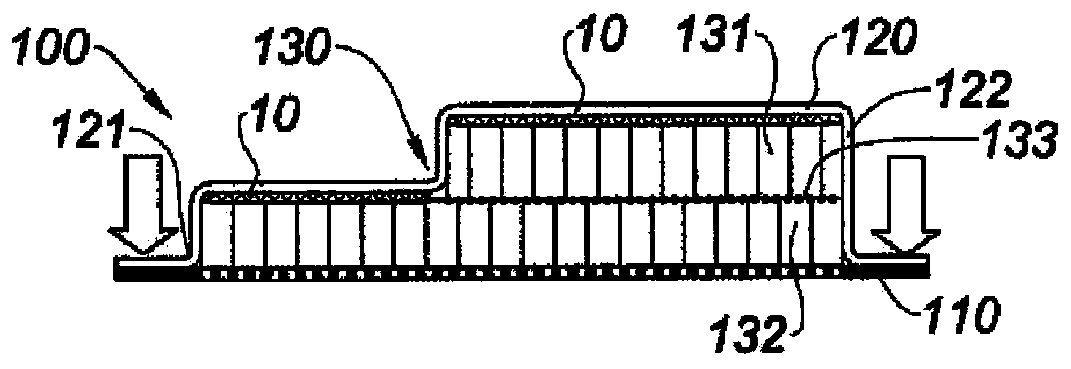

Structural acoustic attenuation panel

InactiveCN103858159AIncrease the effective acoustic surfaceReduce the failure rateSound producing devicesUltrasound attenuationMedicine

The invention relates to an acoustic attenuation panel (100) which includes the following main elements: a resistive skin (110) having acoustic holes; a solid skin (120); an acoustic structure (130) including a sound-absorbing material and arranged between the resistive skin (110) and the solid skin (120), characterised in that the solid skin (120) is structural and is configured in order to form at least one transverse spacer (121, 122) between the solid skin (120) and the resistive skin (110) of the acoustic attenuation panel (100).

Owner:AIRCELLE

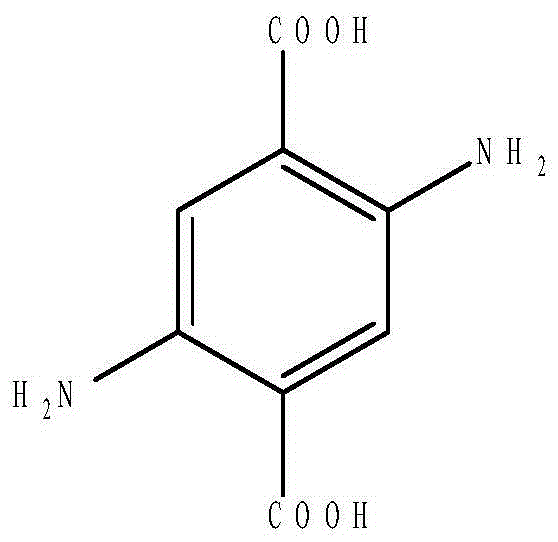

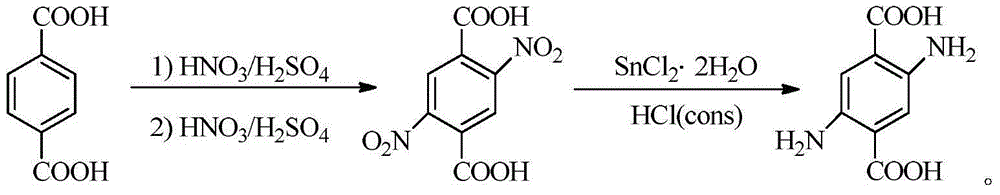

Preparation method of 2,5-diamino terephthalic acid

InactiveCN104693057AReduce pollutionSignificant technological progressOrganic compound preparationAmino-carboxyl compound preparationNitrationReaction step

The invention discloses a preparation method of 2,5-diamino terephthalic acid. The preparation method of 2,5-diamino terephthalic acid comprises a nitratlon reaction step of nitrifying terephthalic acid by using concentrated nitric acid in concentrated sulfuric acid to prepare 2,5-binitro terephthalic acid; and a reduction reaction step of reducing 2,5-binitro terephthalic acid in the presence of a reducing agent to prepare 2,5-diamino terephthalic acid. The preparation method of 2,5-diamino terephthalic acid is low-cost and easily available in raw material, easily controllable in reaction process parameters, simple to operate, high in yield, high in purity and high in industrial practicality.

Owner:SHANGHAI INST OF TECH

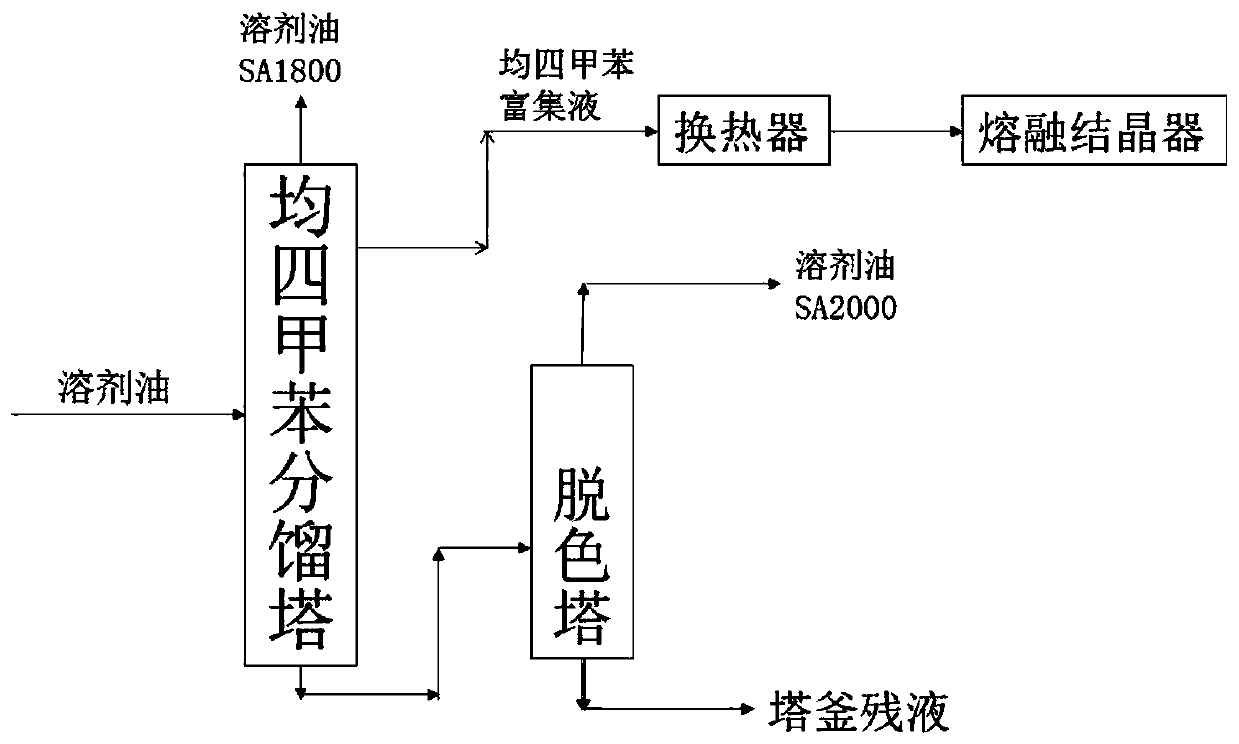

Method for decolorizing solvent oil and extracting durene

PendingCN111377793AImprove securityHigh industrial feasibilityDistillation purification/separationHydrocarbonsProcess engineeringSolvent

The invention provides a method for decolorizing solvent oil and extracting durene, which comprises the following steps of feeding a solvent oil raw material into a durene fractionating tower, extracting durene enrichment liquid from a side line, feeding the durene enrichment liquid into a multi-stage melting crystallizer for melting crystallization after passing through a heat exchanger, and refining to obtain durene, fractionating at the top of a durene fractionating tower to obtain solvent oil SA1800, sending the tower bottom liquid of the durene fractionating tower into a decolorizing tower, separating from the top of the decolorizing tower to obtain solvent oil SA2000, and sending the tower bottom residual liquid of the decolorizing tower into a coking system. According to the method,continuous rectification and melting crystallization are coupled, durene is purified from the solvent oil, the solvent oil is decolorized, heavy aromatics are further deeply processed from the solvent oil stage, and economic benefits are improved. The method is simple to operate, high in safety, low in energy consumption and high in industrial feasibility.

Owner:NORTH HUAJIN CHEM IND CO LTD

The synthetic method of nafamostat mesylate intermediate-6-amidino-2-naphthol mesylate

ActiveCN103896809BReduce pollutionMild reaction conditionsSulfonic acids salts preparationSodium bicarbonateHydroxylamine Hydrochloride

Owner:BEIJING LABWORLD BIO MEDICINE TECH

Ether-based guanidine salt ionic liquid for absorbing SO2 gas, preparation method and applications thereof

ActiveCN111171310AIncreased dispersionHigh charge distribution characteristicsOrganic compound preparationDispersed particle separationPhysical chemistryEther

The invention provides an ether-based guanidine salt ionic liquid for absorbing SO2 gas, a preparation method and applications thereof, wherein the cation of the ionic liquid is 1,1,3,3-tetramethylguanidine methoxypolyethylene glycol, and the anion of the ionic liquid is Br<->, Cl<-> or polyethylene glycol dicarboxylate ions. The ionic liquid disclosed by the invention has the advantages of high SO2 absorption rate, good regeneration performance and easiness in industrial application, and the preparation method of the ionic liquid is simple.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com