Compound type chemical dust suppressant and preparation method thereof

A composite dust suppressant technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of poor application effect, complicated preparation process, single dust suppressant, etc., and achieve environment-friendly dust suppression effect, preparation The effect of simple process and high industrial feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The composite chemical dust suppressant of the present invention is made up of the following raw materials by weight:

[0022] Polyethylene glycol 40005%, sodium sulfate 1%, polyvinyl acetate 2%, gelatin 11%, starch 70%, sodium polyacrylate 1%.

[0023] The concrete steps of the preparation method of the composite chemical dust suppressant of the present invention are as follows:

[0024] (1) Weigh the raw materials according to the proportion;

[0025] (2) After freeze-drying polyethylene glycol 4000 at an ultra-low temperature of -40°C to -30°C, pulverize it with a powerful pulverizer. Power on for 10 minutes, 5 minutes intermittently, repeat 3 times.

[0026] (3) adding all the weighed raw materials into the pulverizing mixer, starting the pulverization for 10 minutes, then intermittently for 5 minutes, and repeating this for 3 times to obtain the composite chemical dust suppressant of the present invention.

Embodiment 2

[0028] The composite chemical dust suppressant of the present invention is made up of the following raw materials by weight:

[0029] Polyethylene glycol 400045%, sodium sulfate 10%, polyvinyl acetate 10%, gelatin 5%, starch 15%, sodium polyacrylate 5%.

[0030] The concrete steps of the preparation method of the composite chemical dust suppressant of the present invention are as follows:

[0031] (1) Weigh the raw materials according to the proportion;

[0032] (2) After freeze-drying polyethylene glycol 4000 at an ultra-low temperature of -40°C to -30°C, pulverize it with a powerful pulverizer. Power on for 10 minutes, 5 minutes intermittently, repeat 3 times.

[0033] (3) adding all the weighed raw materials into the pulverizing mixer, starting the pulverization for 10 minutes, then intermittently for 5 minutes, and repeating this for 3 times to obtain the composite chemical dust suppressant of the present invention. 30s, repeating this for 3 times to obtain the composit...

Embodiment 3

[0035] The composite chemical dust suppressant of the present invention is made up of the following raw materials by weight:

[0036] Polyethylene glycol 400015%, sodium sulfate 10%, polyvinyl acetate 20%, gelatin 10%, starch 30%, sodium polyacrylate 5%.

[0037] The concrete steps of the preparation method of the composite chemical dust suppressant of the present invention are as follows:

[0038] (1) Weigh the raw materials according to the proportion;

[0039] (2) After freeze-drying polyethylene glycol 4000 at an ultra-low temperature of -40°C to -30°C, pulverize it with a powerful pulverizer. Power on for 10 minutes, 5 minutes intermittently, repeat 3 times.

[0040] (3) adding all the weighed raw materials into the pulverizing mixer, starting the pulverization for 10 minutes, then intermittently for 5 minutes, and repeating this for 3 times to obtain the composite chemical dust suppressant of the present invention.

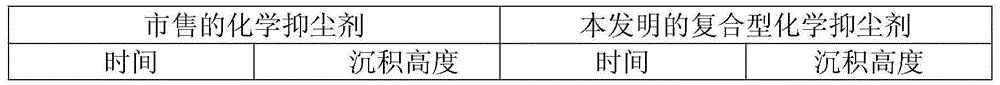

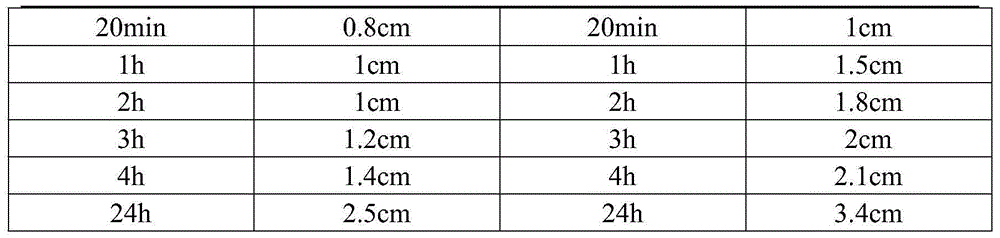

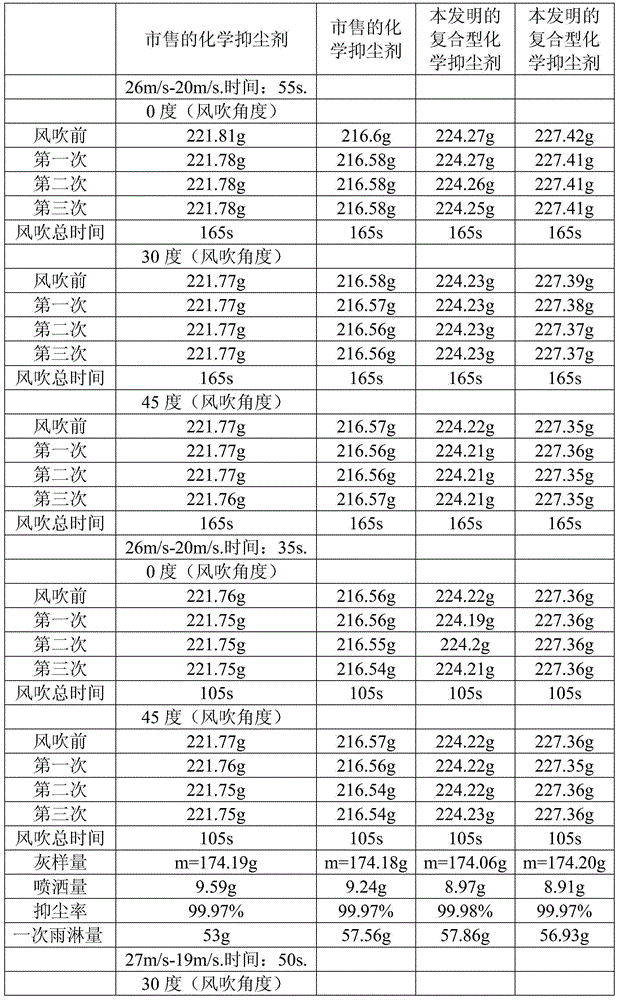

[0041] The commercially available chemical dust sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com