Meta-aramid resin for fibrid, fibrid, aramid paper and synthesis method

A technology for fibrids and synthesis methods, which is applied in the fields of fibrids, aramid paper and synthesis, and meta-aramid resins for fibrids, and can solve the problems of fibrid insulation performance, thermal stability and mechanical strength. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

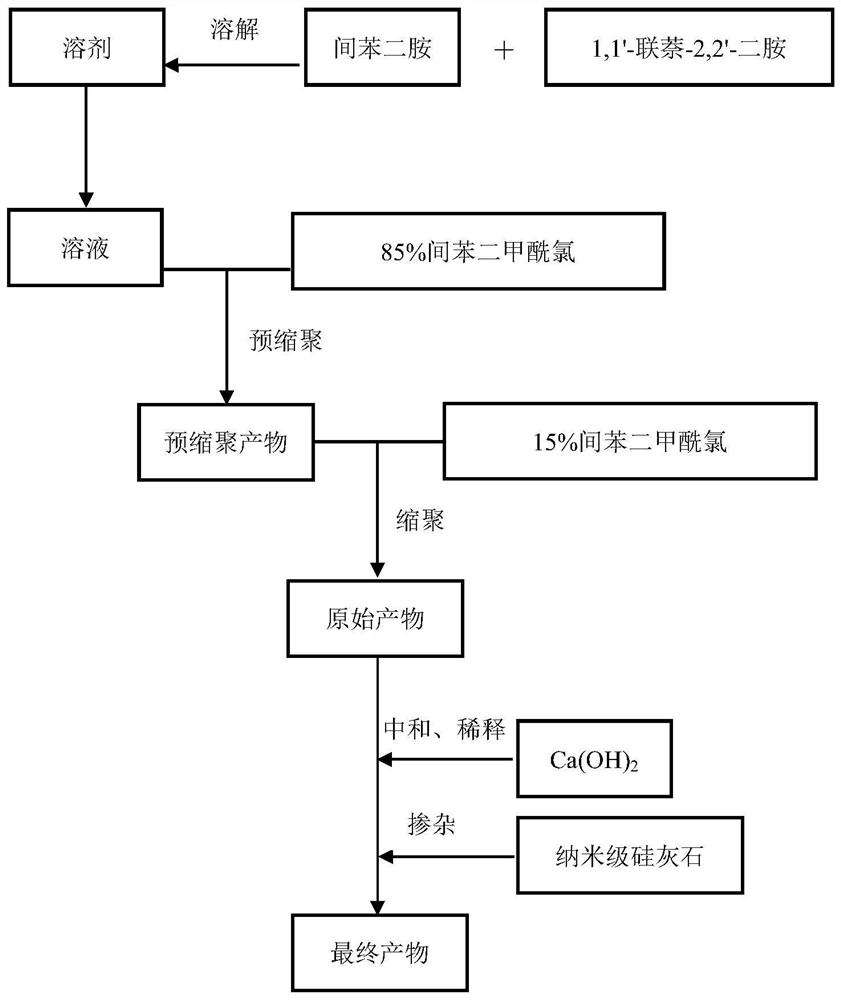

[0029] The present invention uses isophthaloyl dichloride and m-phenylenediamine as the main raw materials, and 1,1'-binaphthyl-2,2'-diamine as the third monomer, through precondensation, polycondensation, neutralization and nanoscale Wollastonite doping steps to synthesize meta-aramid resin for fibrids. Such as figure 1 , the synthetic method of meta-aramid fiber resin for fibridation of a specific embodiment of the present invention, comprises the following steps:

[0030] a. Precondensation: Under the environment of dry nitrogen protection, dissolve m-phenylenediamine in a polar solvent at room temperature, the concentration of m-phenylenediamine is 0.6-0.7mol / L, and then add a certain amount of 1,1 Stir the '-binaphthyl-2,2'-diamine until it is completely dissolved to a concentration of 0.1 to 0.2 mol / L, and cool the solution to -9°C to -3°C. Add isophthaloyl chloride in an amount of 75-90% of m-phenylenediamine in batches, control the reaction temperature below 30°C, an...

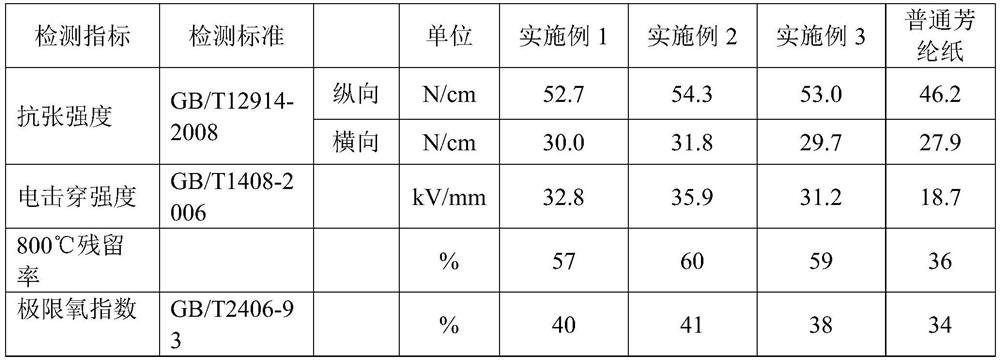

Embodiment 1

[0036] The synthetic method of meta-aramid fiber resin for the precipitated fiber of the present embodiment comprises the following steps:

[0037] a. Precondensation: Under the environment of dry nitrogen protection, dissolve m-phenylenediamine in N,N-dimethylacetamide (DMAC) at room temperature, so that the concentration of m-phenylenediamine is 0.6mol / L, After stirring until it is completely dissolved, add a certain amount of 1,1'-binaphthyl-2,2'-diamine and stir until it is completely dissolved, so that the concentration is 0.1mol / L, and the solution is cooled to -9°C. Add isophthaloyl chloride in an amount of 85% m-phenylenediamine in batches, control the reaction temperature below 30°C, and react for 1.5 hours;

[0038] b. Polycondensation: add isophthaloyl chloride with an addition amount of 15% m-phenylenediamine in batches to the system in step a, stir rapidly, the reaction system gels, control the reaction temperature at 45°C to 55°C, and the reaction time is 1h ; ...

Embodiment 2

[0043] The synthetic method of meta-aramid fiber resin for the precipitated fiber of the present embodiment comprises the following steps:

[0044] a. Precondensation: Under the environment of dry nitrogen protection, dissolve m-phenylenediamine in N,N-dimethylacetamide (DMAC) at room temperature, so that the concentration of m-phenylenediamine is 0.7mol / L, After stirring until it is completely dissolved, add a certain amount of 1,1'-binaphthyl-2,2'-diamine and stir until it is completely dissolved, so that the concentration is 0.2mol / L, and the solution is cooled to -3°C. Add isophthaloyl chloride in an amount of 85% m-phenylenediamine in batches, control the reaction temperature below 30°C, and react for 2 hours;

[0045]b. Polycondensation: add isophthaloyl chloride with an addition amount of 15% m-phenylenediamine in batches to the system of step a, stir rapidly, the reaction system gels, control the reaction temperature at 45°C to 55°C, and the reaction time is 1.5 h;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com