Method for directly synthesizing sucrose fatty acid ester by biodiesel and sucrose

A technology of sucrose fatty acid ester and biodiesel, which is applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problem that catalysts cannot be recycled, and achieves low industrial cost, wide source of raw materials, and stable reaction system. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

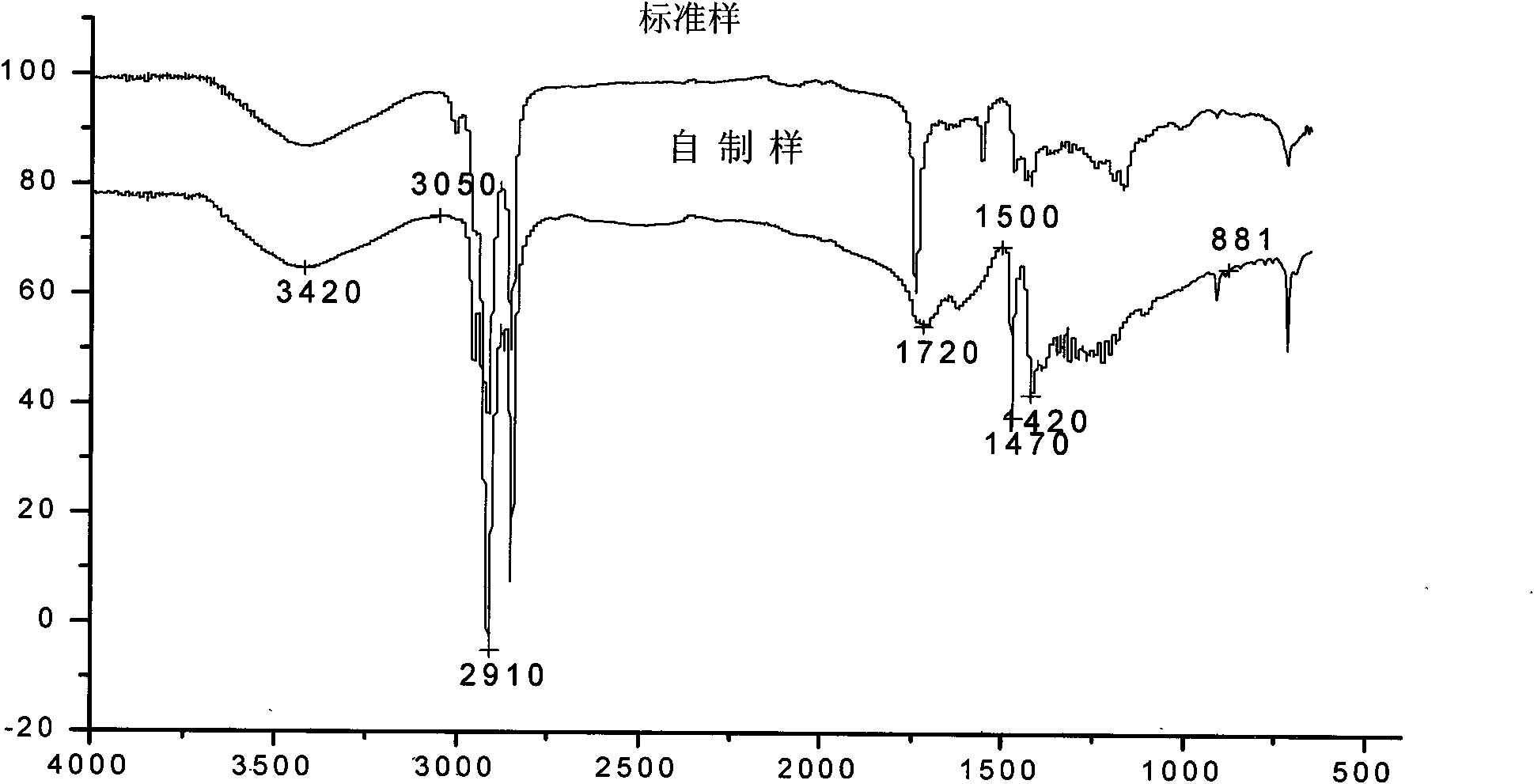

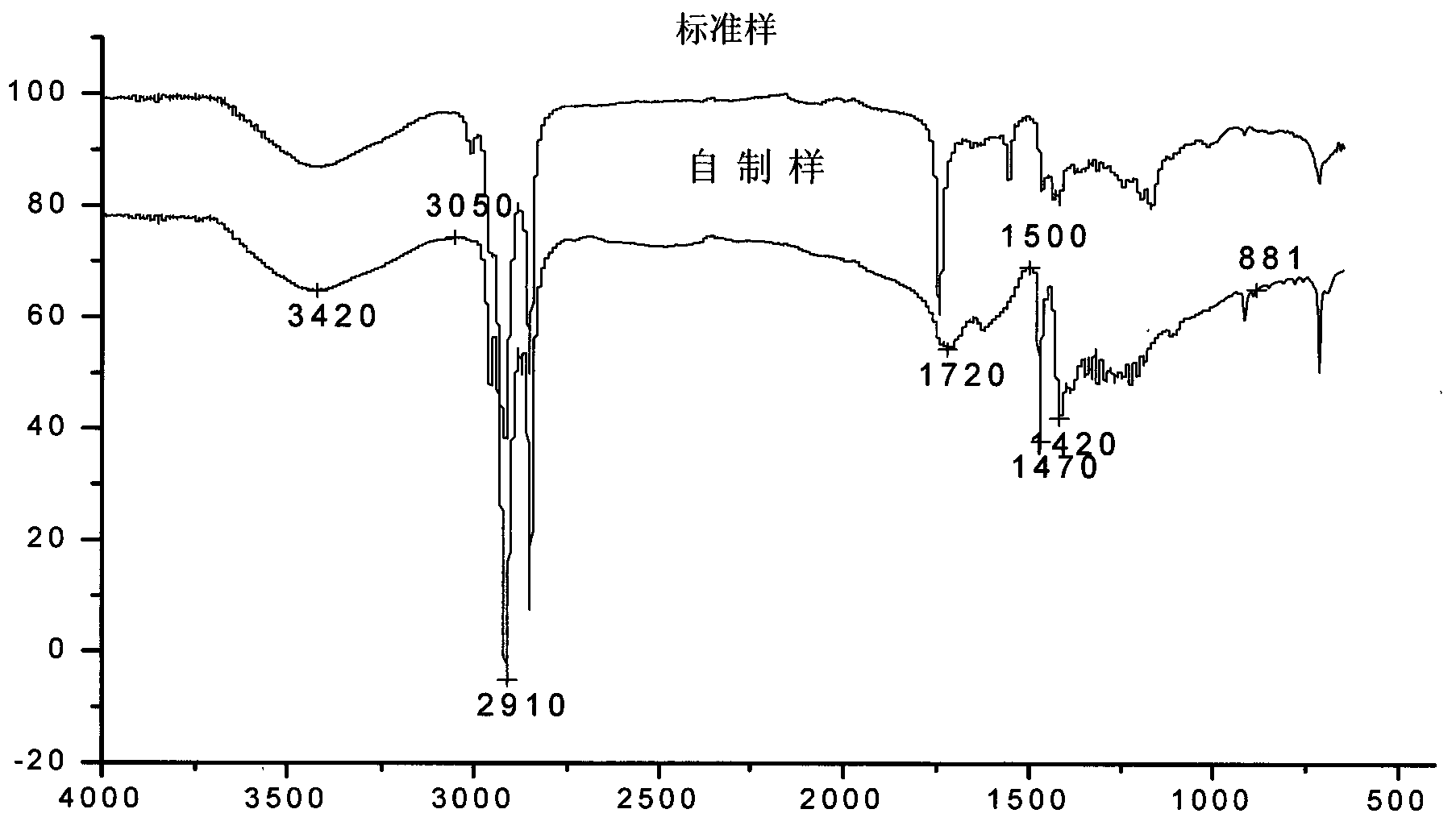

Image

Examples

Embodiment 1

[0037] (1) Preparation of supported solid base catalyst: Weigh the catalyst potassium carbonate and activated carbon carrier with a molar ratio of 1:25 and impregnate them for 24 hours by equal volume impregnation method, filter, dry the filter cake at 120°C for 2 hours, and calcinate at 450°C After 5h, obtain loaded solid base catalyst---K 2 O / C catalyst;

[0038] (2) Preparation of homogeneous system: after biodiesel and sucrose are mixed in the ratio of biodiesel by mass ratio: sucrose=1:1, add potassium stearate accounting for 15% of the total mass of the mixture, heat up while stirring, at 80 Stir at ℃ for 0.5h, until the reaction system is light yellow emulsion, add 3% of the total mass of the mixture of K 2 O / C catalyst, continue stirring for 0.5h;

[0039] (3) Preparation of sucrose fatty acid ester: heat up while stirring, and pass into N 2 , drive away the air in the reaction system and take away the methanol produced in the reaction, N 2 Raise the temperature to...

Embodiment 2

[0042] (1) Preparation of supported solid base catalyst: Weigh 1: 20 potassium carbonate and activated carbon carrier with molar ratio and impregnate for 24h by equal volume impregnation method, filter, dry the filter cake at 110°C for 3h, and calcined at 600°C for 3h, take out for use;

[0043] (2) Preparation of homogeneous system: after biodiesel and sucrose are mixed in the ratio of biodiesel by mass ratio: sucrose=2:1, add potassium stearate accounting for 10% of the total mass of the mixture, heat up while stirring, at 80 Stir at ℃ for 1.0h, until the reaction system is light yellow emulsion, add 2% of the total mass of the mixture of K 2 O / C catalyst, continue stirring for 0.5h;

[0044] (3) Preparation of sucrose fatty acid ester: heat up while stirring, and pass into N 2 , drive away the air in the reaction system, N 2 Raise the temperature to 130°C under protection, react for 3.5 hours, then cool down to below 100°C, stop feeding N 2 , add water to stop the react...

Embodiment 3

[0047] (1) Preparation of supported solid base catalyst: the K recovered in Example 1 2 The O / C catalyst was washed twice with deionized water and ethyl acetate respectively, dried at 110°C, and set aside;

[0048] (2) Preparation of homogeneous system: after biodiesel and sucrose are mixed in the ratio of biodiesel by mass ratio: sucrose=2:1, add potassium stearate accounting for 5% of the total mass of the mixture, heat up while stirring, at 80 Stir at 0.5 h for 0.5 h until the reaction system is light yellow emulsion, add the K recovered in Example 1 accounting for 3% of the total mass of the mixture 2 O / C catalyst, continue stirring for 0.5h;

[0049] (3) Preparation of sucrose fatty acid ester: heat up while stirring, and pass into N 2 , drive away the air in the reaction system, N 2 Raise the temperature to 135°C under protection, react for 3 hours, then cool down to below 100°C, stop feeding N 2 , add water to stop the reaction, stir at 80°C for 10min;

[0050] (4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com