Patents

Literature

202 results about "POTASSIUM STEARATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium Stearate has the form of a white, crystalline powder. It is soluble in hot water and alcohol. It is derived from Stearic Acid—a byproduct of vegetable oil through the saponification process. Potassium Stearate is primarily used as a cleansing agent and emulsifier.

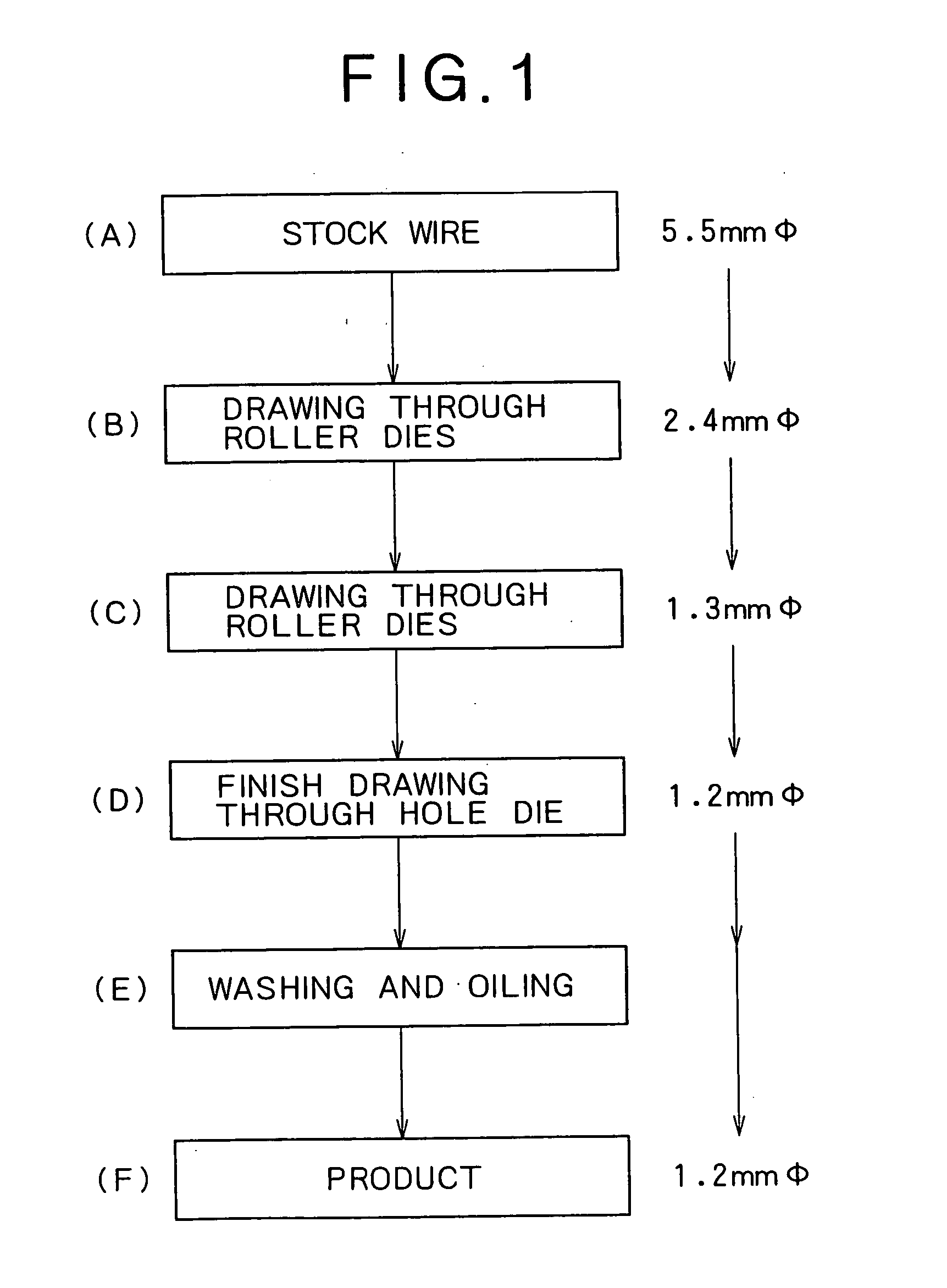

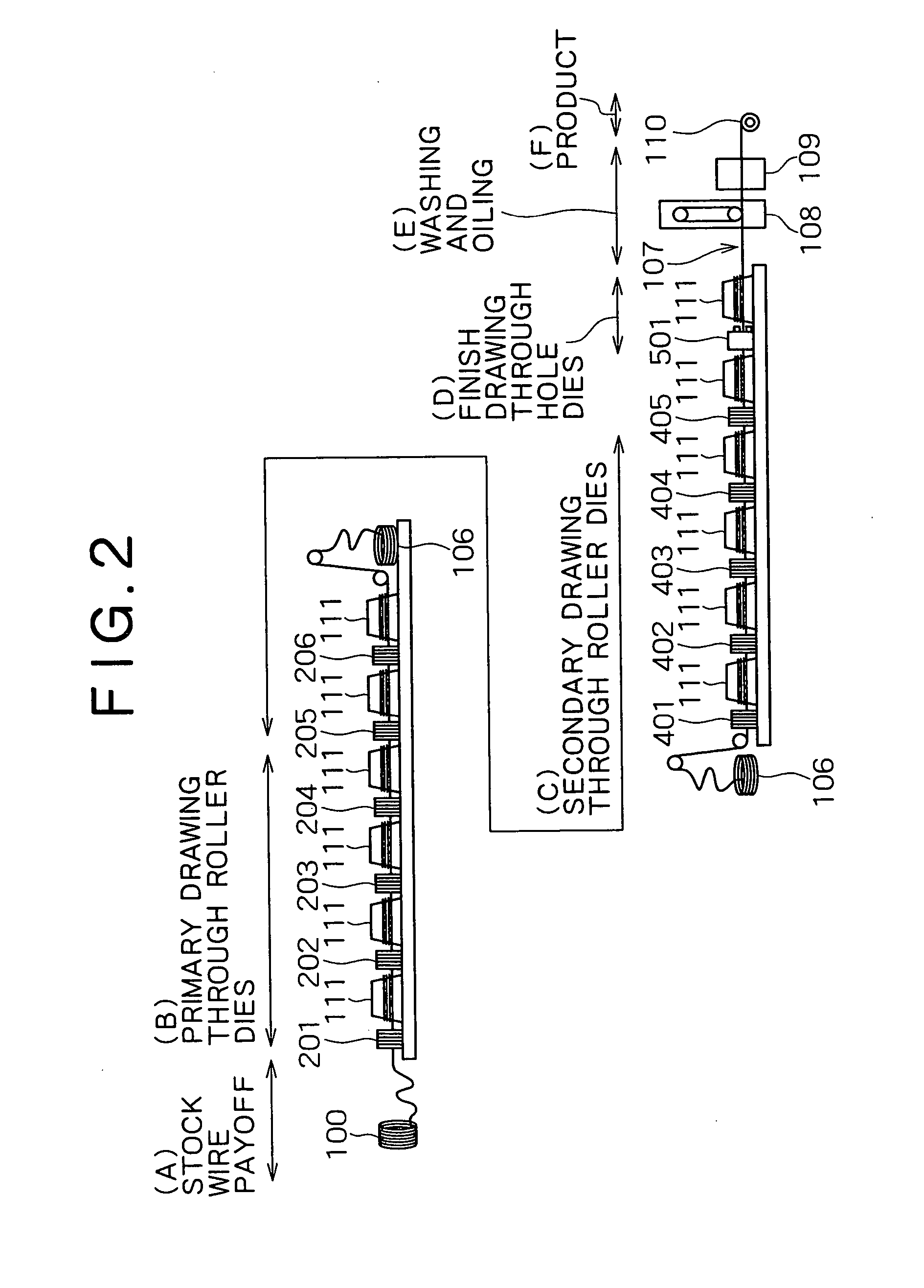

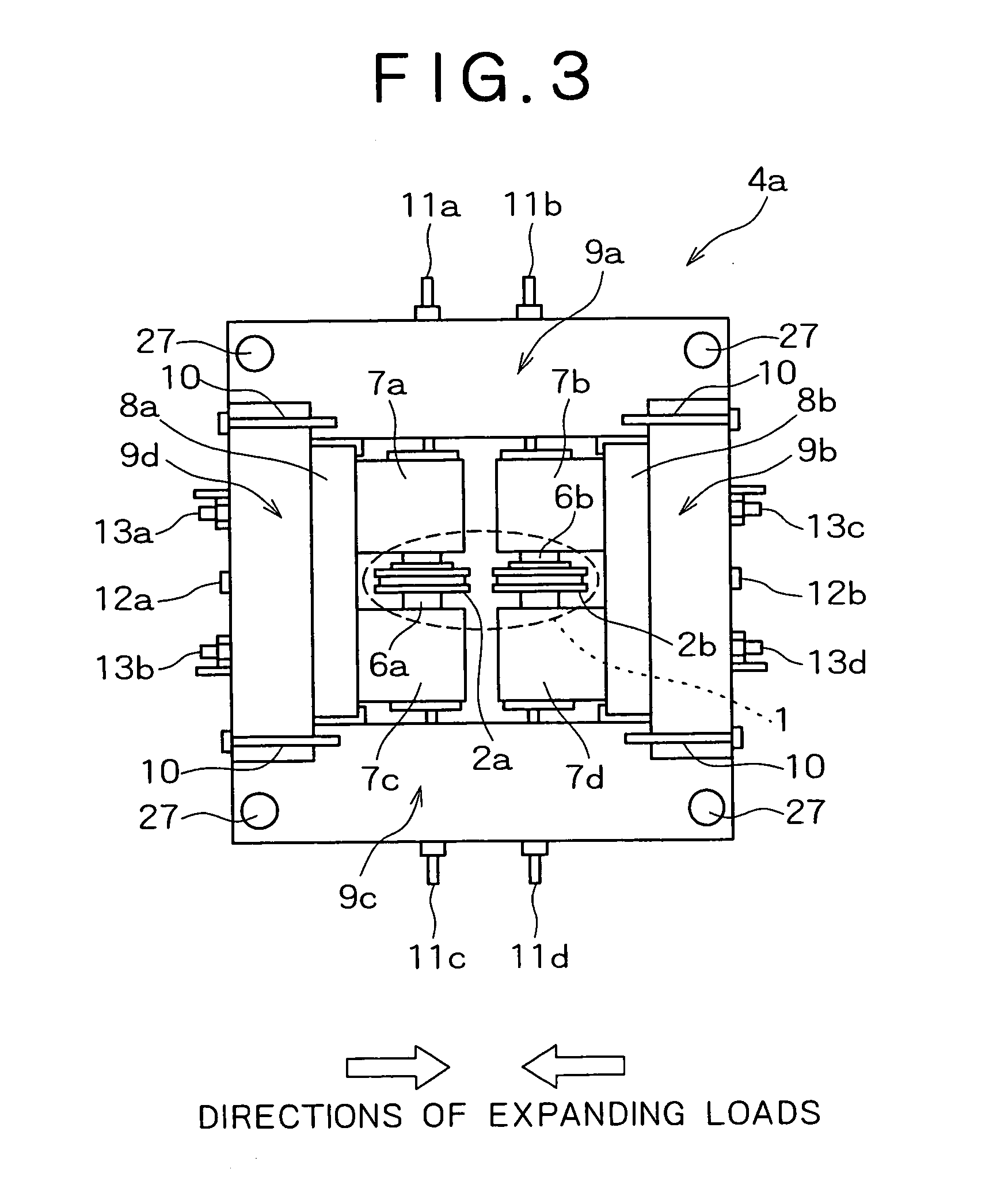

Method of producing solid wire for welding

ActiveUS20050045699A1Uniform applicationEfficient weldingDrawing diesArc welding apparatusCopper platingSodium stearate

A method for efficient production of a welding solid wire free of copper plating. The method consists of drawing by means of roller dies with the help of a dry solid lubricant for drawing which is at least either of sodium stearate or potassium stearate, removing the lubricant from the wire surface by means of a washing device, and applying a lubricant for wire feeding to the surface of the drawn wire by means of an oiling device. High-speed drawing by means of roller dies makes a stock wire into a welding solid wire having the diameter of the finished wire or nearly finished wire. The drawing step is followed by the washing step and the lubricant applying step, which are all accomplished in-line.

Owner:KOBE STEEL LTD

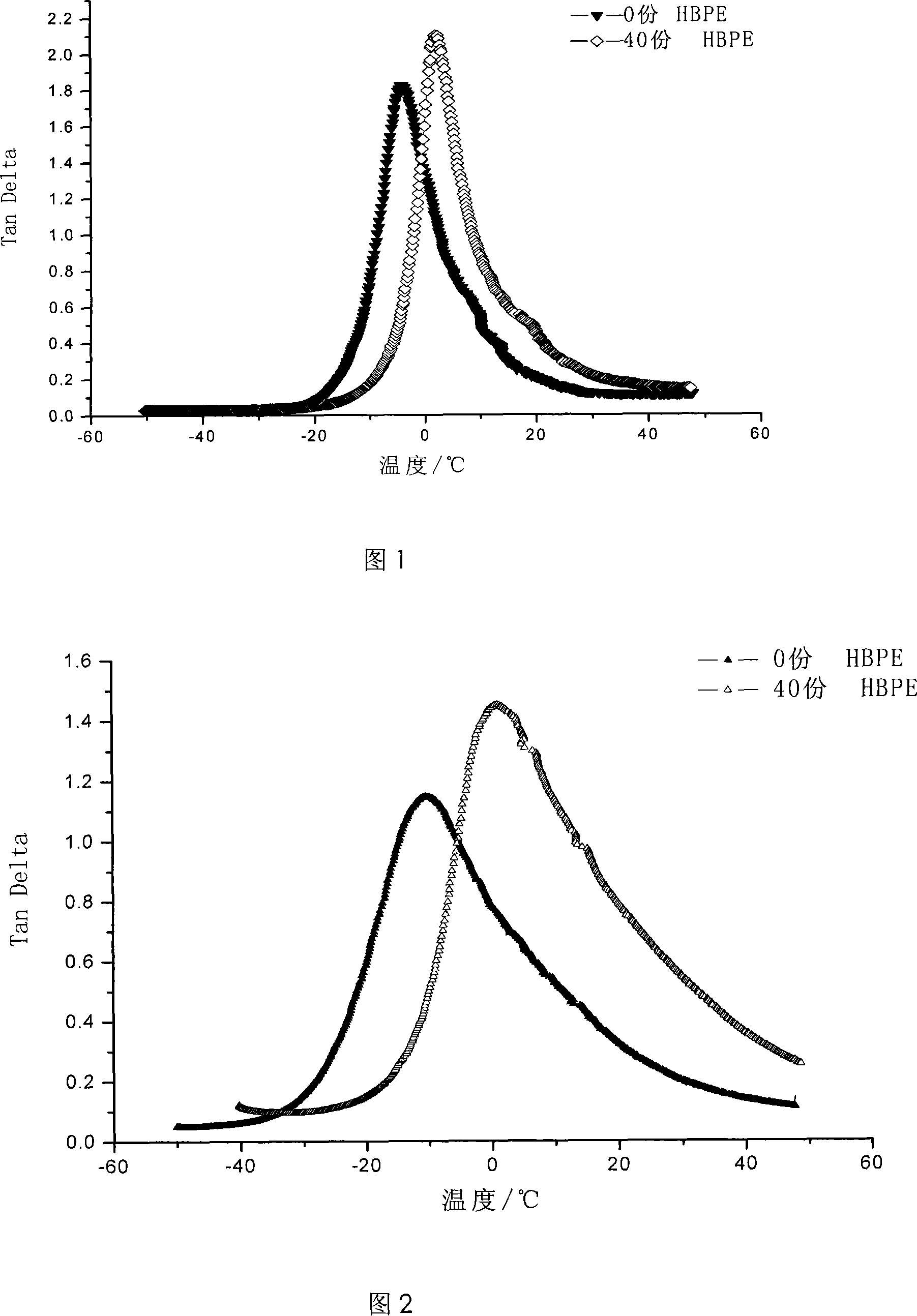

Preparation of high-damping rubber containing hindered phenol terminated hyper branched polymer

The invention belongs to the field of functional polymer materials. Aiming at the defect that the small organic molecules are easy to be moved and are easy to low the mechanical properties of a rubber, a hyperbranched polymer promoter capable of effectively enhancing the damping capacity of the rubber is designed. The invention is calcualted in mass percentage: 100 shares of raw rubbers, 10 to 40 shares of terminated hyperbranched polymers of hindered phenol, 0.5 to 1 share of potassium stearates, 3 to 5 shares of stearic acids, 5 to 8 shares of zinc oxides, 1 to 2 shares of sulfurs and 20 to 30 shares of carbon blacks are selected and the raw materials are mixed with each other uniformly on an open mill; the mixtures are subject to the packing mixing for 8 to 12 times; the mixtures are driven to rest for 10 to 16 hours with ventilation and the vulcanization time of the mixtures is tested on a rotor-free curometer at a temperature ranging from 150 DEG C to 170 DEG C; the curing time is recorded after the vulcanization curve flattens out; then the vulcanization is carried out utilizing a platten curometer, the temperature is set to range from 150 DEG C to 170 DEG C corresponding to the rotor-free curometer and the pressure is 15MPa and the strips are taken out. The invention can enhance the damping capacity of the rubber, overcome the defect of a small organic molecular promoter without lowering the mechanical properties of the rubber and maintain the stable performances for a long time.

Owner:BEIJING UNIV OF CHEM TECH

Rubber framework grease seal for automobile gear box and manufacturing method thereof

InactiveCN101319082APrevent leakageSolve the problem of oil leakageEngine sealsDomestic articlesSodium stearateSulfur

The invention provides a rubber framework oil seal used for a gear box of an automobile and a manufacturing method thereof. The rubber framework oil seal comprises the following compositions in weight portion: 100 portions of activated chlorine type acrylate adhesive AR840, 0.5 to 1 portion of a vulcanizing activator stearic acid, 1.5 to 2 portions of a process additive TM-80, 2 to 3 portions of a vulcanizing agent sodium stearate, 0.5 to 0.6 portion of an accelerating agent sulfur and potassium stearate, 1 to 2 portions of an age inhibitor 445, 1 to 2 portions of MB, 4 to 6 portions of a strengthening agent carbon soot and 22 to 28 portions of a siliceous reinforcing agent. The rubber framework oil seal has the characteristics of stable size of hypoid gear oil of the gear box, oil resistance, anti-aging property, and sealing reliability, etc.

Owner:青岛茂林橡胶制品有限公司

Acrylic ester rubber and preparation method thereof

InactiveCN101633768AImprove the defect of sticky rollerReasonable ratioSodium stearatePolymer science

The invention provides acrylic ester rubber and a preparation method thereof. The acrylic ester rubber is characterized by comprising the following components by weight: 70-90 portions of tri-acrylate rubber AR840, 10-30 portions of butyronitrile rubber NBR, 55-75 portions of fast extruding carbon black N550, 1-2 portions of anti-aging agent RD, 1-2 portions of anti-aging agent MB, 0.5-1 portion of anti-scorching agent CTP, 3-5 portions of dioctyl phthalate DOP, 1-2 portions of dispersant rhine powder-42, 0.3-0.5 portion of common sulphur, 0.2-0.4 portion of tetramethyl thiuram disulfide TMTD, 3.5-4.0 portions of sodium stearate and 0.3-0.5 portion of potassium stearate. The sticking phenomenon is reduced and the elasticity, extensile intensity and low temperature resistance of the acrylic ester rubber are improved.

Owner:QINGDAO HILYWILL ADVANCED MATERIALS TECH

High-quality water-based paint for wicker products

ActiveCN105969015AImprove temperature resistanceImprove wear resistanceAnti-corrosive paintsWater basedPolyethylene glycol

The invention discloses a high-quality water-based paint for wicker products. The high-quality water-based paint is prepared from the following materials: acrylic emulsion, ethylene glycol monobutyl ether, polyethylene glycol monomethyl ether, urea-formaldehyde resin, polyethylene glycol, potassium stearate, epoxidized soybean oil, calcium pyrophosphate, modified kaolin, modified alkyd resin, hexakis (methoxymethyl) melamine, carbomer, sodium coconut oil acyl methyl taurine and deionized water. The high-quality water-based paint is good in bonding property with the wicker products and rapid in self-dryness; the strength is improved by 30% or more, the characteristics of corrosion prevention and dampness prevention are obviously improved, and the scratch resistance and the high-temperature after-tack resistance are improved; and furthermore, the high-quality water-based paint is environment-friendly and free from environmental pollution.

Owner:安徽亮发家居有限公司

Rubber formula and preparation method thereof

The invention discloses a rubber formula and a preparation method thereof. The rubber formula comprises the following raw materials in part by weight: 10-90 parts of acrylic rubber, 10-90 parts of nitrile rubber, 2-6 parts of zinc oxide, 0.5-3 parts of stearic acid, 0.5-3 parts of p-phenylenediamine antioxidant, 30-65 parts of high wear resistant carbon black, 20-75 parts of semi-reinforcing carbon black, 0.2-1 part of sulfur, 0.2-0.8 part of accelerant, 0.5-2 parts of potassium stearate and 1.5-4 parts of sodium stearate, wherein the sum of parts by weight of the acrylic rubber and the nitrile rubber is 100. The preparation method comprises the steps as follows: rolling crude rubber, mixing the rubber and adding a vulcanization system. The rubber prepared by the rubber formula has the advantages of good overall performance and higher mechanical property, oil resistance, high temperature resistance and the like, and is low in cost and suitable for producing an oil resistant sealing element product resistant to the high temperature of 150 DEG C, such as an automobile transmission oil seal gasket; and the preparation method is simple and cannot cause the phenomenon of roll banding or roll release.

Owner:芜湖禾田汽车工业有限公司

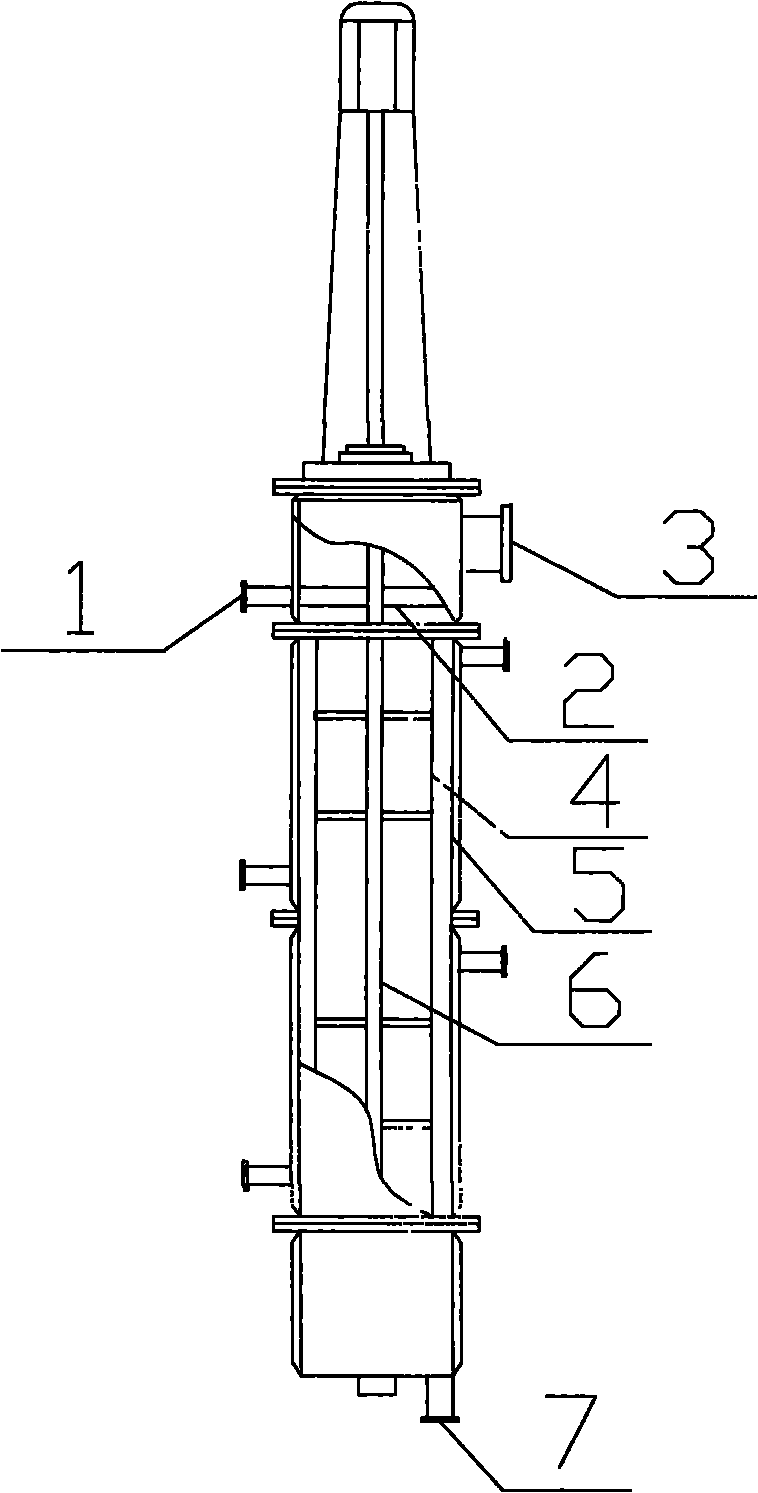

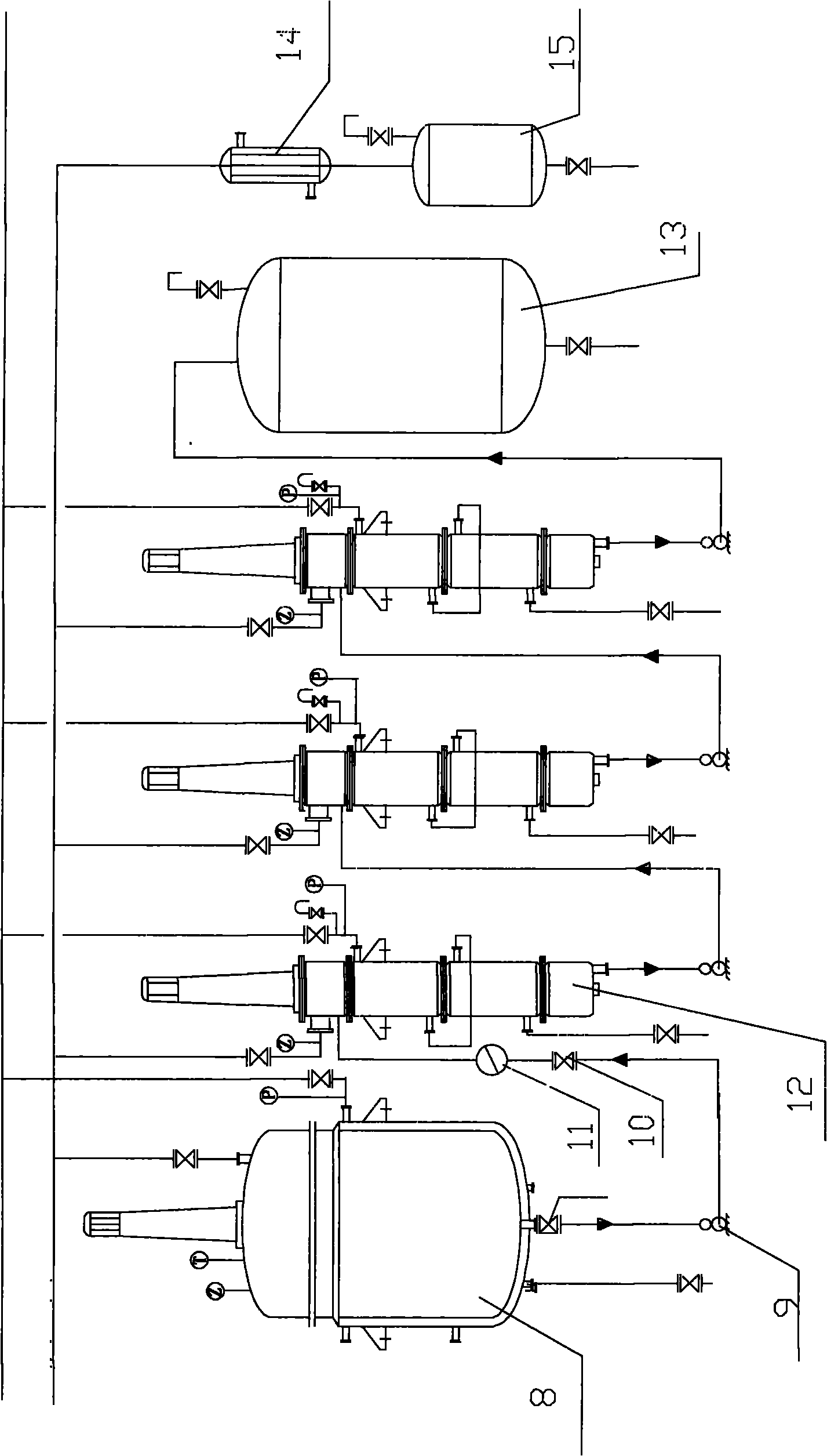

Process for synthesizing sucrose polyester by using rotating film transesterification flow reactor

InactiveCN102093438AIncrease contact areaSimple interfaceEsterified saccharide compoundsSugar derivativesResource utilizationPOTASSIUM STEARATE

The invention discloses a process for synthesizing sucrose polyester, particularly a process for synthesizing sucrose polyester by using a rotating film transesterification flow reactor. The process comprises the following steps: methyl oleate, sucrose powder, potassium stearate and potassium carbonate are added into a mixing kettle, and heated while stirring; the materials enter the rotating film transesterification flow reactor to react; the crude fatty acid sucrose polyester product obtained after the reaction enters a product storage tank, and the reaction product methanol enters a methanol receiver after being cooled by a condenser; and the crude product in the product storage tank is neutralized with acetic acid, washed and dried to obtain the sucrose polyester product. The low-boiling-point substances generated in the process provided by the invention are quickly removed out of the reaction system, thereby being beneficial to the generation of the product, greatly increasing the reaction speed and enhancing the product quality. The process can be used for continuous-feeding production, is beneficial to large-scale production, enhances the production efficiency, has the advantages of high yield and simple process, lowers the production cost and raises the resource utilization ratio.

Owner:ADANA FOOD TECH LIUZHOU

Modified oilproof aging-resistant polyvinyl chloride cable sheath material

ActiveCN103540065AImprove performanceHigh strengthPlastic/resin/waxes insulatorsInsulated cablesLow-density polyethyleneElastomer

The invention relates to a cable material, and in particular relates to a modified oilproof aging-resistant polyvinyl chloride cable sheath material which is prepared from the following raw materials in parts by weight: 24 to 28 parts of SG-1 polyvinyl chloride, 20 to 24 parts of POE (Polyolefin Elastomer), 5 to 8 parts of low-density polyethylene, 6 to 9 parts of antimonous oxide, 2 to 3 parts of Ca-Zn stabilizing agent, 2 to 3 parts of nylon fiber, 8 to 10 parts of coumarone, 2 to 3 parts of potassium stearate, 3 to 4 parts of polyethylene wax, 18 to 20 parts of dioctyl phthalate, 3 to 5 parts of zinc oxide, 1 to 2 parts of accelerant M, 0.5 to 1.0 part of bis(isooctylmercaptoacetate) dioctyldilauryltin, 12 to 15 parts of attapulgite, 12 to 15 parts of nano silicon dioxide and 14 to 16 parts of auxiliary agent. The prepared cable sheath material is high in strength and good in flexibility, and has the performances of high-temperature aging resistance, oil osmosis resistance and chemical solvent resistance by combining the advantages of SG-1 polyvinyl chloride, the POE, the low-density polyethylene and the other raw materials. Thus, the prepared cable sheath material can be widely used for preparing various cable sheath insulating materials, thereby having broad market demand prospect.

Owner:东莞市龙之翼实业有限公司

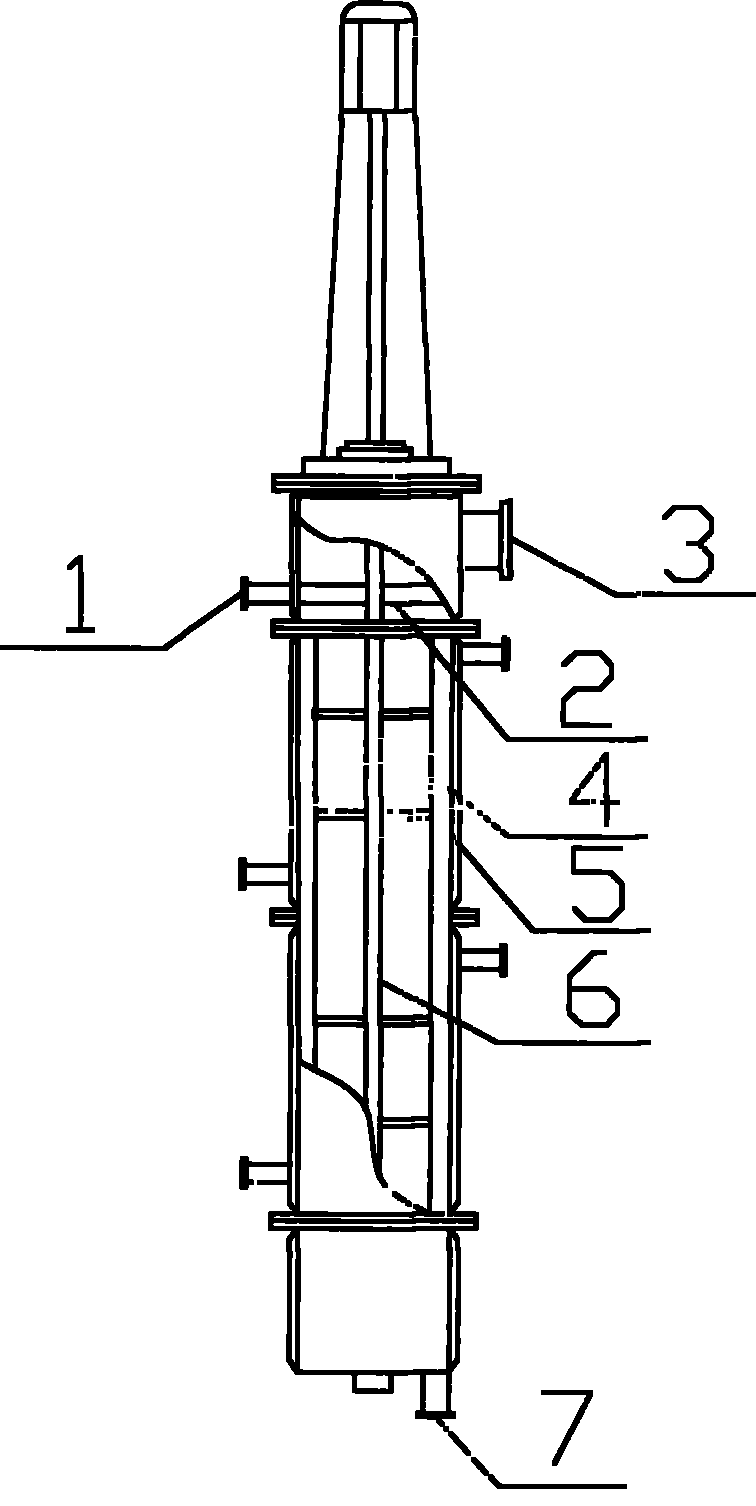

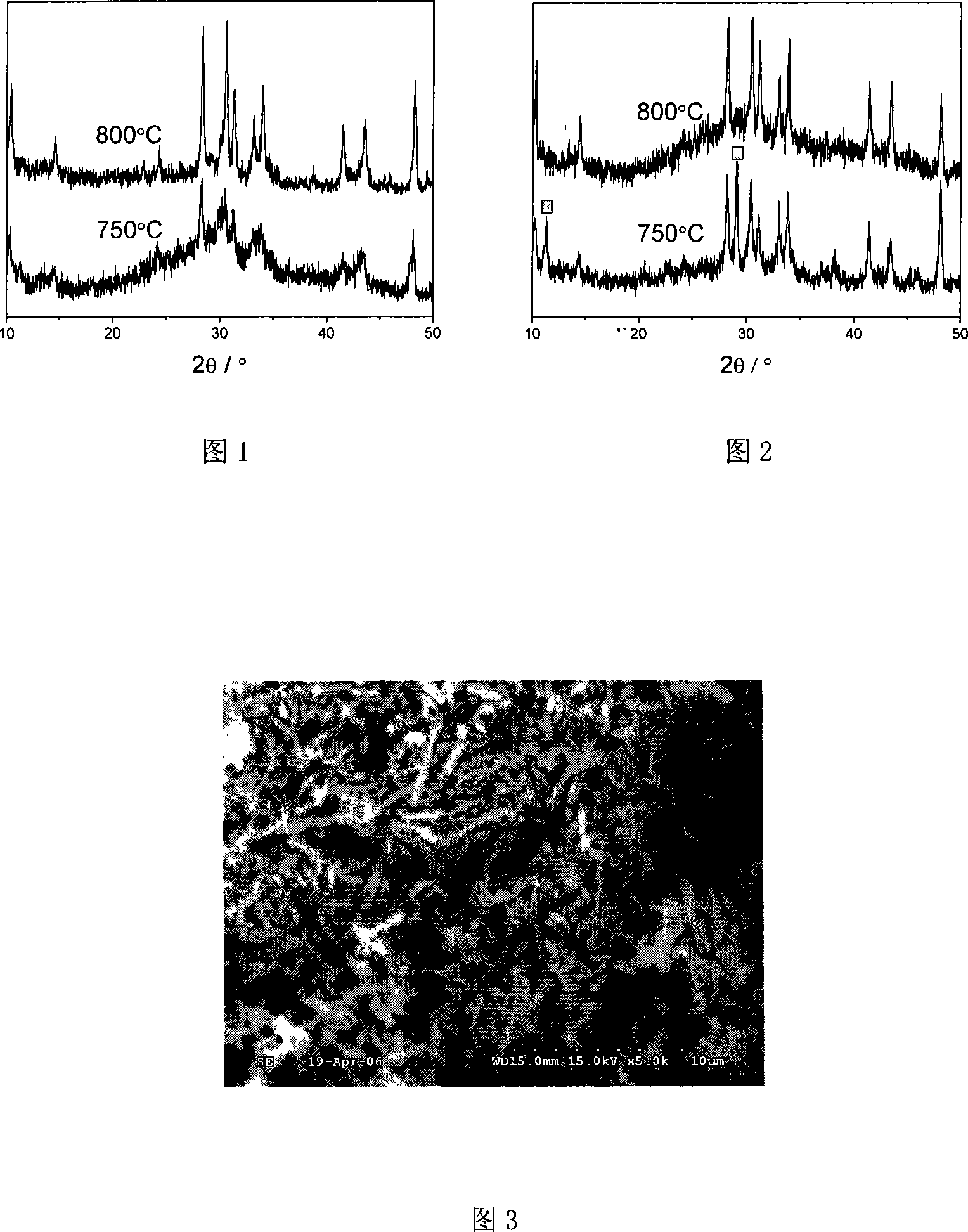

Method for fast preparing lamellate potassium titanate

InactiveCN101214997AShorten heating and stirring timeShort manufacturing timeTitanium compoundsMaterials preparationCombustion

The invention discloses a process for fast preparing layered potassium titanate salt, belonging to the technical field of nanometer material preparation. The step 1 of the method is molten mixing, selecting reactant of potassium stearate and butyl titanate potassium titanium mole ratio of which is 1:2, adding butyl titanate into molten potassium stearate to blend and the heating and stirring time is 0.5 hour, step 2 is electric furnace combustion, placing the mixture obtained in step 1 into a bunsen beaker, displaying the bunsen beaker on the electric furnace to combust for 2 hours to the burning point, step 3 is sintering, sufficiently abrading the burned product of the electric furnace in step 2, placing in a muffle furnace and heating to 750-800 DEG C at the warming-up speed of 15 DEG C / min and then sintering to obtain layered potassium titanate salt K2Ti4O9. The method not only simplifies the reacting process, shortens the reacting time, but also secures the purity of the product.

Owner:BEIJING JIAOTONG UNIV

Preparation method of rubber asphalt waterproof coating

InactiveCN105062282AImprove adhesionGood acid and alkali resistanceUnspecified rubber coatingsAnti-corrosive paintsSodium BentonitePolymer science

The invention discloses a preparation method of a rubber asphalt waterproof coating. The preparation method comprises the following steps: performing thin-passing plastication of polyurethane rubber and acrylate rubber at first; then adding coconut diethanolamide, sodium lignin sulfonate, sulfonated succinate and lecithin; mixing and discharging; feeding into a shearing machine; adding ethylene-propylene-diene monomer while shearing to obtain a rubber emulsion; heating 10# petroleum asphalt for dehydration; adding the heated and dehydrated 10# petroleum asphalt into a 4-octylphenol polyoxyethylene ether, sodium lauryl diphenyl ether disulfonate, potassium stearate, polyvinyl alcohol and water mixed solution; stirring to obtain an asphalt emulsion; finally, mixing the obtain rubber emulsion and asphalt emulsion with acrylic resin, ethylene glycol ethyl ether, chlorinated polyethylene, silicon carbide whiskers, bentonite, hydroxyl silicone oil, an ethylene-vinyl acetate copolymer, a plasticizer, a foam killer and a pigment; stirring at 40-50 DEG C; leaving to cool to obtain the rubber asphalt waterproof coating. The rubber asphalt waterproof coating is high in tensile strength, good in high-temperature resistance and excellent in low-temperature flexibility.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

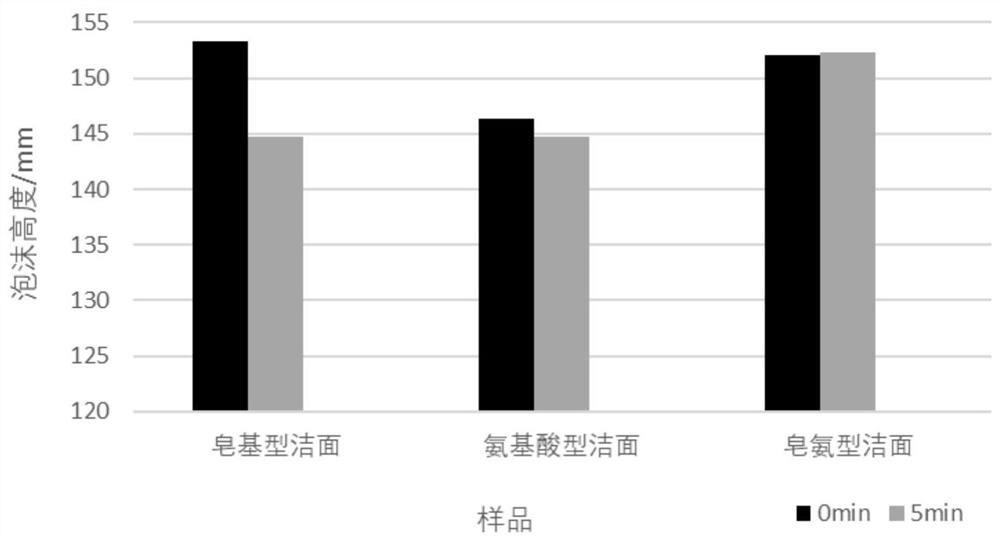

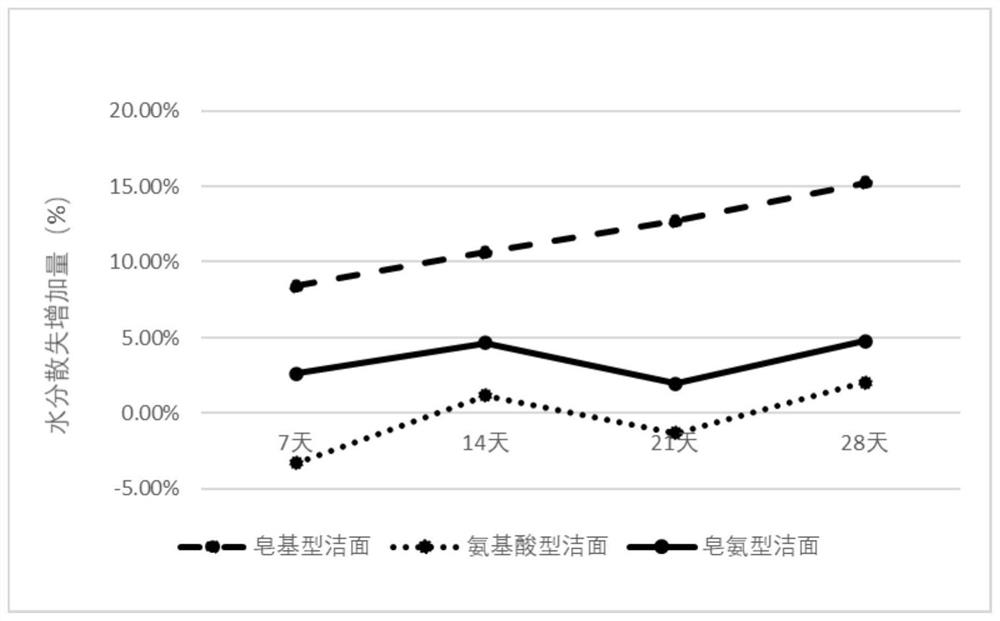

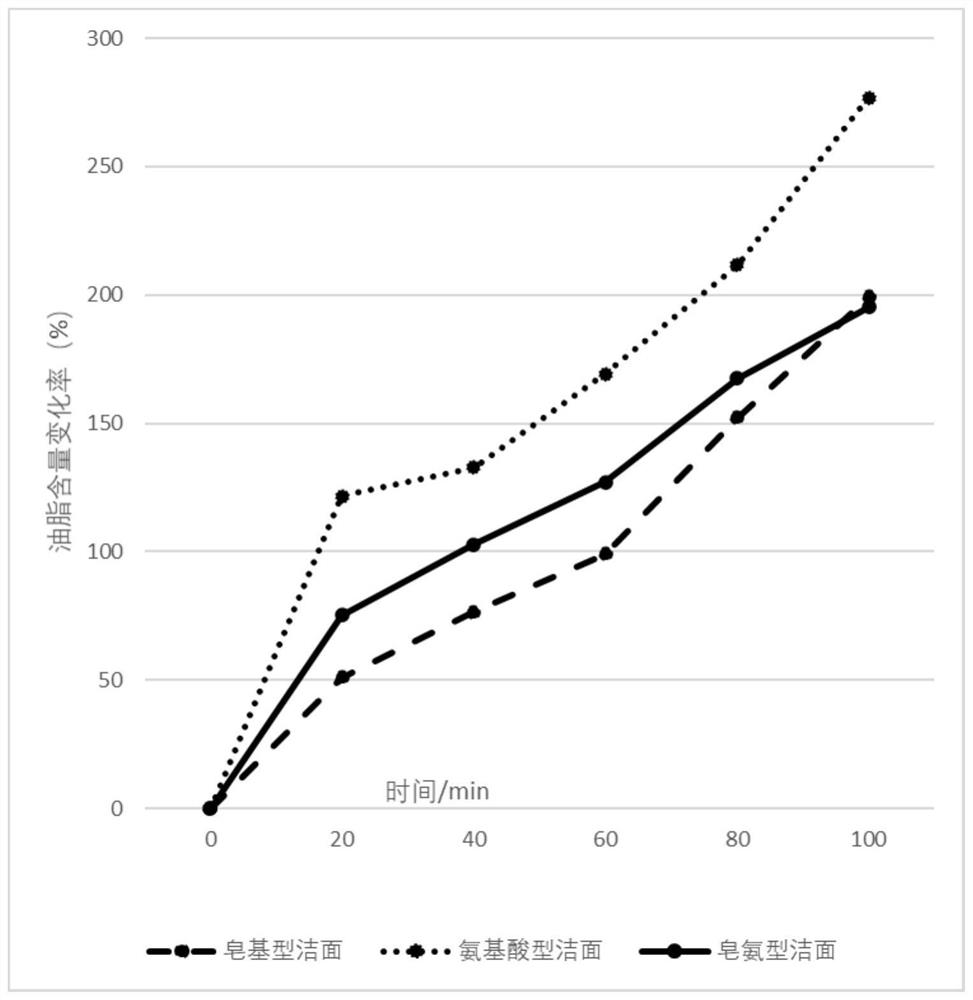

Soap ammonia type facial cleansing product and preparation method thereof

ActiveCN111631974AFine foamLess irritatingCosmetic preparationsToilet preparationsSodium acetatePOTASSIUM STEARATE

The invention relates to a soap ammonia type facial cleansing product and a preparation method thereof. The product comprises an amino acid surfactant, a soap-based surfactant, an auxiliary surfactant, an auxiliary agent and a solvent, wherein the amino acid surfactant is at least one selected from potassium cocoyl glycinate, sodium cocoyl glycinate, sodium lauroyl sarcosine, TEA-cocoyl alaninate,sodium cocoyl glutamate, TEA-lauroyl glutamate, sodium lauroyl glutamate and sodium palmitoleyl glutamate; the soap-based surfactant is at least one selected from potassium cocoate, potassium laurate, potassium myristate, potassium palmitate and potassium stearate; and the auxiliary surfactant is at least one selected from sodium lauroamphoacetate, lauryl hydroxyl sulphobetaine, cocamidopropyl betaine, lauryl glucoside, decyl glucoside, cocamidopropyl betaine, cocamide, dodecyl dimethyl betaine and palm kernelamide. The cleaning agent has the characteristics of low irritation, high cleaning efficiency, rich foam and good use feeling.

Owner:HUNAN YUJIA COSMETICS MFG CO LTD

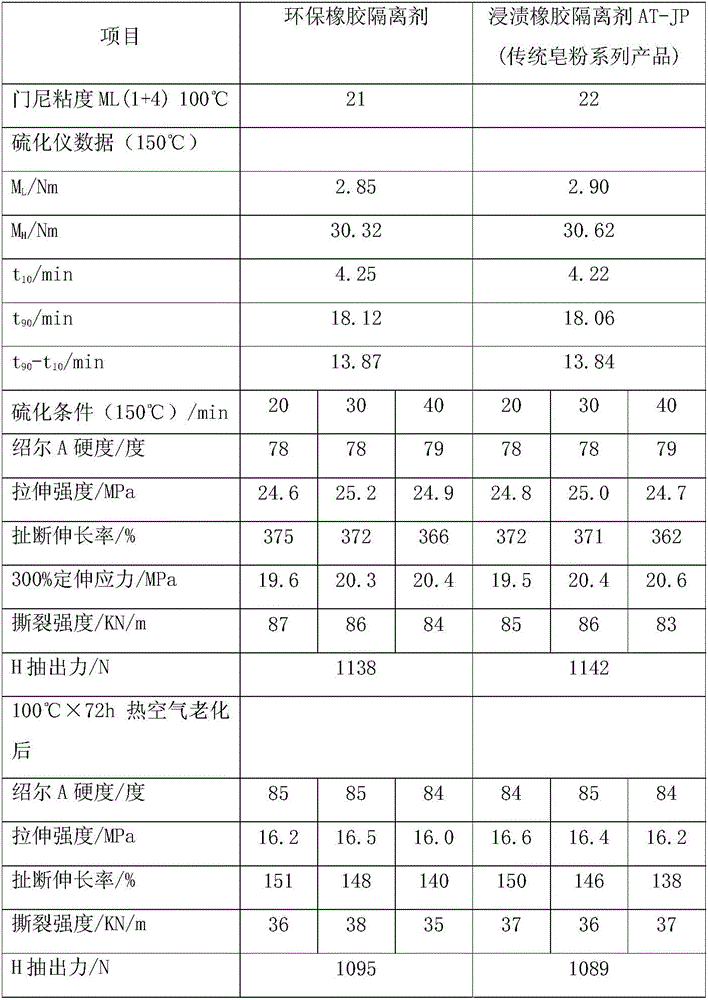

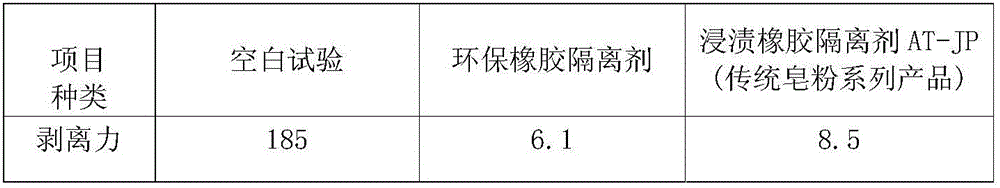

Environment-friendly rubber isolation agent

The invention discloses an environment-friendly rubber isolation agent. The isolation agent comprises the following components in parts by weight: 24-36 parts of polyoxyethylene sorbitan monooleate, 2-4 parts of waterborne polyamide wax, 30-38 parts of calcium stearate, 18-30 parts of hydrated silicon dioxide, 8-14 parts of potassium stearate, 2-5 parts of silicone oil defoaming agents and 2-6 parts of sodium carboxymethylcellulose. The isolation agent is excellent in compatibility, long in actual effect and low in addition amount, and is green and environmentally friendly; the preparation process of the environment-friendly rubber isolation agent is simple and feasible; the cost is low.

Owner:JIANGSU KAOU CHEM

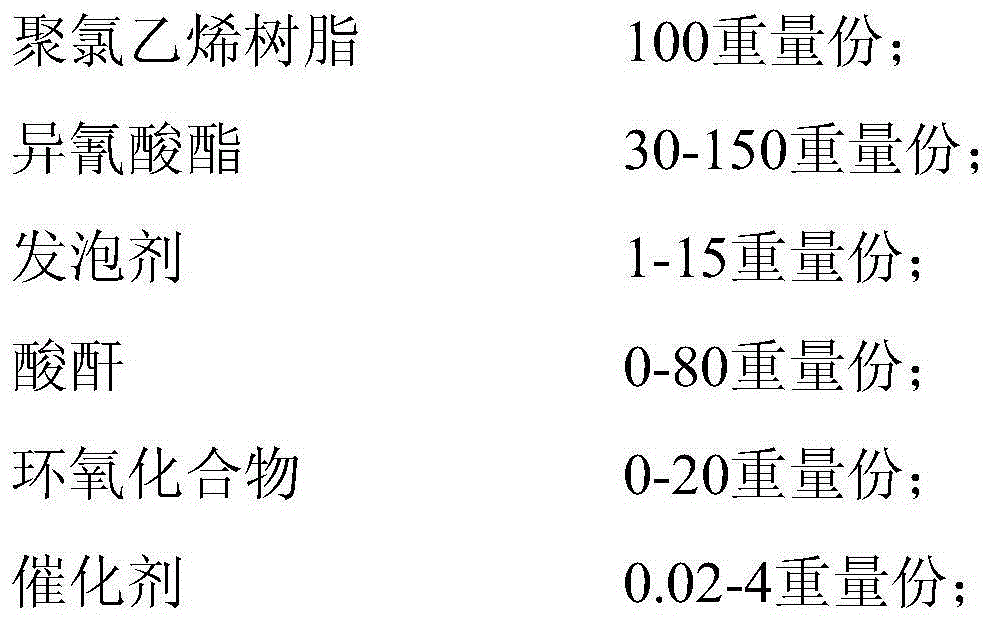

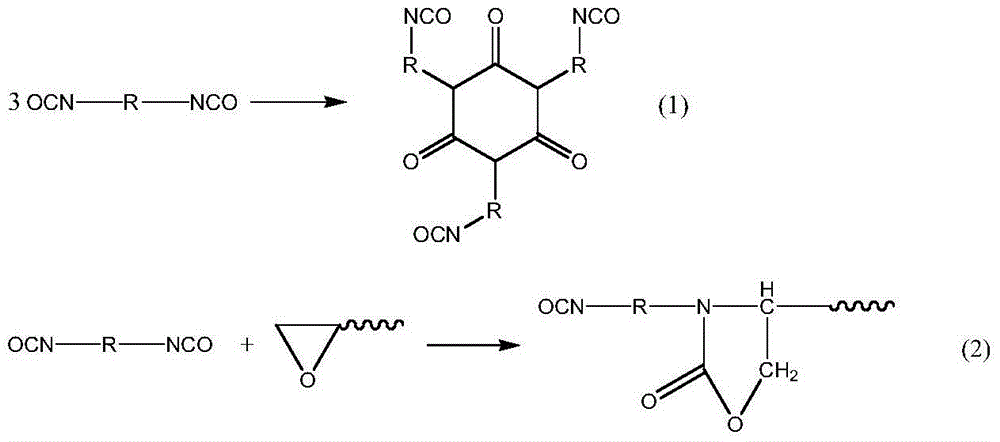

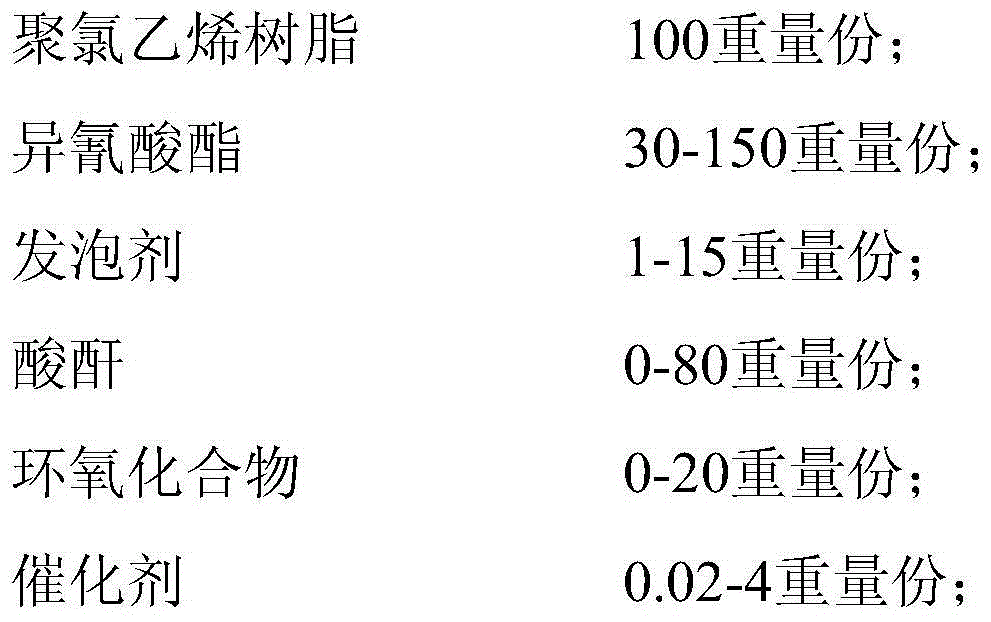

Crosslinking polyvinyl chloride foam and preparation method thereof

The invention discloses crosslinking polyvinyl chloride foam and a preparation method thereof, and belongs to the technical field of foamed materials. The problem of long time consumption of preparation of a crosslinking polyvinyl chloride foamed material in the prior art is solved, so that the quality and heat-resistant performance of the foamed material can be improved. The crosslinking polyvinyl chloride foam comprises the components in parts by weight: 100 parts of PVC resins, 30-150 parts of isocyanate, 1-15 parts of foaming agents, 0-80 parts of anhydride, 0-20 parts of epoxy compounds and 0.02-4 parts of catalysts, wherein the catalyst is one or more of N',N'',N'''-tri(dimethyl aminopropyl) symmetrical hexahydro-triazine, N-(alpha-ethoxyl) dimethylenimine, indole, sodium caprylate, isocaprylic acid, potassium oleate and potassium stearate. The foamed material is high in quality and heat-resistant performance, and high in production efficiency.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Acrylic rubber composite

InactiveCN102002202ALow costGood physical and mechanical propertiesFlexible pipesPolymer scienceSodium stearate

The invention relates to an acrylic rubber composite which comprises the following components: acrylic rubber, semi-reinforced furnace black N774, silica powder 750, di adipate, cyclohexyl N-phthalimidyl sulfide, stearic acid, organic alkyl phosphate, 4,4-diphenylamine antiager Naugard 445, potassium stearate SK-1, sodium stearate SN-1 and sulfur. In the composite of the invention, due to addition of the silica powder 750, the formula cost is reduced, the physical and mechanical properties of the materials are improved and the volume resistivity of the acrylic rubber is changed. Compared with the traditional products, the difference is obvious, the tensile strength is 12.0MPa, the volume resistivity is 1*107 omega.cm which is 1*105 omega.cm higher than that of the traditional product, and the service life of the cooled tube of an automatic gearbox is prolonged. The acrylic rubber composite can preferably meet the anti-resistance performance, thermostability performance and hot oil resisting performance of rubber tubes.

Owner:TIANJIN PENGYI GRP CO LTD

Renewable super-hydrophobic coating

InactiveCN102453425AEasy to makeSimple manufacturing methodPolyether coatingsAcetic acidCalcium hydroxide

The invention discloses a renewable super-hydrophobic coating, which consists of a binder, a filler, a mixed solvent and a surfactant. The binder is made of poly(furfuryl alcohol), the filler is made of calcium hydroxide, the mixed solvent consists of acetone and ethyl acetate, and the surfactant is a mixture of potassium stearate, water and ethanol. The coating has a special function of becoming super-hydrophobic once again by virtue of surface regeneration after surface failure.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

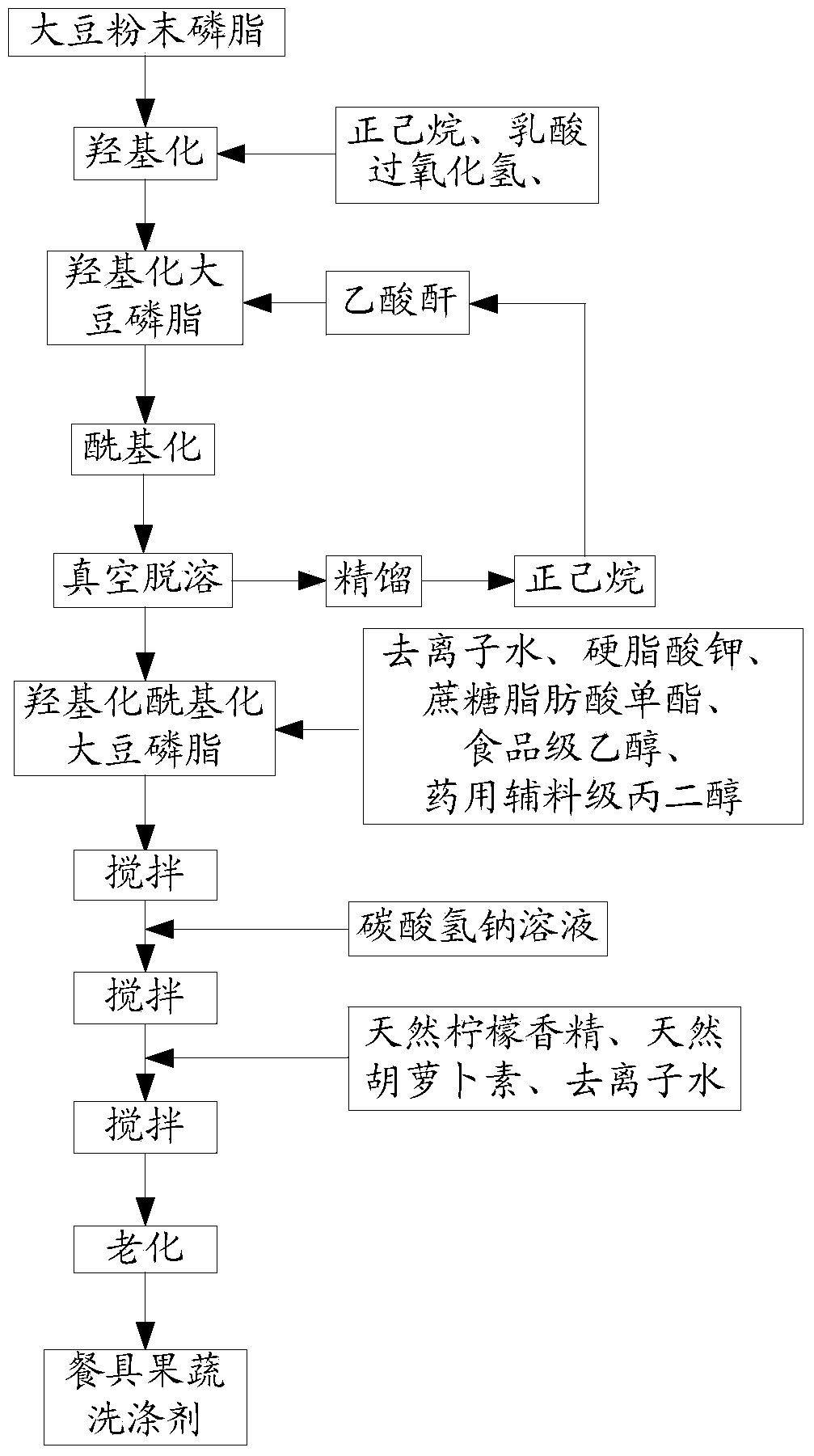

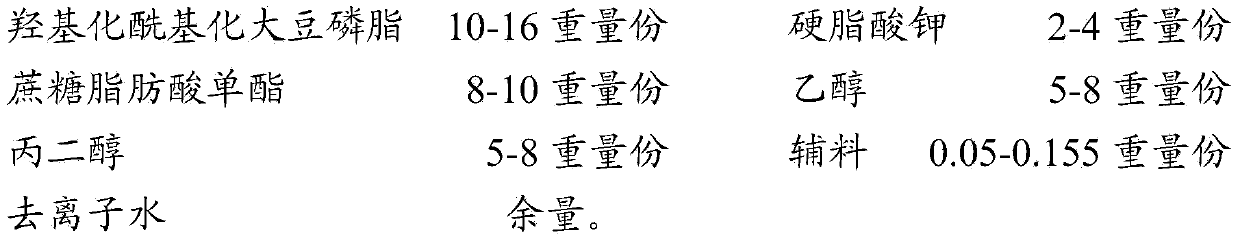

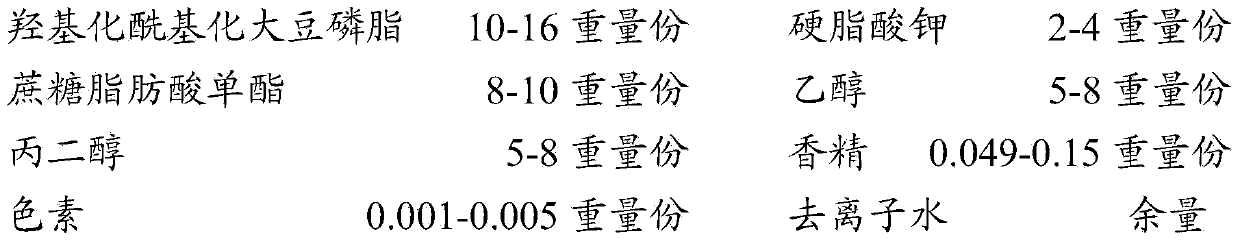

Detergent for tableware, fruits and vegetables and preparation method thereof

ActiveCN103627540ASave waterGood low temperature stabilityAmpholytes/electroneutral surface-active compoundsDetergent compounding agentsPesticide residueWater resources

The invention provides a detergent for tableware, fruits and vegetables and a preparation method thereof. The detergent is prepared from the following raw materials in parts by weight: 10 to 16 parts of hydroxylated acylated granulesten, 2 to 4 parts of potassium stearate, 8 to 10 parts of cane sugar fat acid monoester, 10 to 16 parts of a viscosity regulator, 0.05 to 0.155 part of auxiliary materials and the balance of deionized water, wherein the hydroxylated acylated granulesten is obtained by hydroxylating and acylating granulesten powder. The detergent for tableware, fruits and vegetables is environment-friendly, has decontaminating and pesticide residue removing functions and can reduce irritation to hands; moreover, the detergent can be washed away with little water, thereby being favorable for saving water resources.

Owner:SANHE HOPEFULL BIOTECH +1

Method for directly synthesizing sucrose fatty acid ester by biodiesel and sucrose

InactiveCN101805381ALow costHigh industrial feasibilityEsterified saccharide compoundsSugar derivativesSucroseBiodiesel

The invention provides a method for directly synthesizing sucrose fatty acid ester by biodiesel and sucrose, in which a solvent-free method is adopted to synthesize the sucrose fatty acid ester under the protection of N2 and the barometric pressure of 1, and an isovolumetric immersion method is adopted to prepare a load-type solid base catalyst by immersion; then potassium stearate is added after the biodiesel is mixed with the sucrose, the mixture is reacted until the reaction system presents in a faint yellow emulsion, then the load-type solid base catalyst is added to continue to react, temperature is raised during stirring, N2 is introduced, methanol generated in the reaction process is removed when air in the reaction system is driven away, warming reaction is carried out under the protection of the N2, then the reaction system is cooled, the introduction of N2 is stopped, water is added to stop reaction, and the product is stirred for 10min at the temperature of 80 DEG C; and the crude product is processed to obtain the refined product of the sucrose fatty acid ester. After the crude product is purified by a solvent extraction method, the product purity is above 98%, the N2 can be reused, and the catalyst can be recycled.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Preparation method for sucrose fatty acid ester

ActiveCN106083944ALow degree of substitutionImprove performanceEsterified saccharide compoundsSugar derivativesSucroseDistillation

The invention provides a preparation method for sucrose fatty acid ester. The preparation method comprises the following steps: A) subjecting sucrose and alkyl stearate to a reflux reaction in a solvent mixture in the presence of potassium carbonate and potassium stearate so as to obtain a product mixture, wherein the solvent mixture is composed of dimethyl sulfoxide and dichloromethane in a volume ratio of 1: (3-8); B) adding a saturated sodium chloride solution into the product mixture, adjusting a pH value to 6.6 to 7.2, adding an extractant for extraction, carrying out liquid separation and taking an organic phase; and C) subjecting the organic phase to pressure-reduced concentration and carrying out drying by distillation so as to obtain sucrose fatty acid ester. The preparation method belongs to the technical field of chemical engineering, is simple in operation steps, optimizes a reaction system and reaction conditions, reduces the usage amount of dimethyl sulfoxide, decreases production of by-products, and improves product yield and purity; and the prepared sucrose fatty acid ester has low degree of substitution and excellent performance.

Owner:GUANGZHOU CARDLO BIOCHEM TECH

Surface-treated calcium carbonate and paste resin composition containing same

InactiveUS20120035312A1Good storage stabilityLow viscosityCalcium/strontium/barium carbonatesInksStearic acidPOTASSIUM STEARATE

The invention provides a surface-treated calcium carbonate that when incorporated into a paste resin, can impart low viscosity and high thixotropy and offers excellent storage stability, and paste resin compositions containing the same. The surface-treated calcium carbonate is a calcium carbonate surface-treated with a surface treatment agent containing a sodium salt or potassium salt of a fatty acid, wherein the total content of a sodium salt and a potassium salt of lauric acid, a sodium salt and a potassium salt of palmitic acid and a sodium salt and a potassium salt of stearic acid in the surface treatment agent is 80% by weight or more, the content of the sodium salt and potassium salt of lauric acid is within the range of 30% to 60% by weight, the content of a sodium salt and a potassium salt of an unsaturated fatty acid in the surface treatment agent is 5% by weight or less, and the BET specific surface area is 10 m2 / g or more.

Owner:SHIRAISHI KOGYO KAISHA LTD

Fertilizer for grape vine

InactiveCN105801312ARich in nutrientsIncrease profitAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphateMonopotassium phosphate

The invention discloses a fertilizer for a grape vine. The fertilizer is prepared from the following raw materials in parts by weight: 45-55 parts of calcium magnesium phosphate, 30-40 parts of a biogas waste fertilizer, 50-60 parts of fermentative manioc waste, 15-20 parts of black soybean straw powder, 4-6 parts of soyabean extraction, 6-10 parts of a soil conditioner, 3-4 parts of monopotassium phosphate, 5-6 parts of ammonium molybdate, 2-4 parts of potassium stearate, 5-6 parts of propylene glycol, 6-8 parts of ascorbic acid, 10-15 parts of talcum powder, 4-6 parts of hawthorn fruit powder, 2-4 parts of tangerine powder, 1-3 parts of sodium borate, 1-2 parts of zinc acetate, 3-4 parts of radix sophorae flavescentis, 6-10 parts of potato powder and 1-2 parts of monoammonium phosphate. The organic fertilizer is comprehensive in nutrients, reasonable in raw material ratio, high in fertilizer utilization rate; nitrogen, phosphorus and potassium in the fertilizer are suitable for growth of the grape vine; the effectiveness of various elements can be fully developed; organic matters and microelements required for plant growth are also added; the yield and the quality of grapes can be improved on a large scale; the fertilizer is low in cost; and the grown grapes are large in size, fresh, sweet and delicious.

Owner:HEFEI XUANDA AGRI TECH DEV CO LTD

Bottom material modifier used for aquaculture

InactiveCN105314691AAvoid Exceeding MetricsEffective control quantityClimate change adaptationWater/sewage treatmentPotassiumAquatic product

The invention relates to a bottom material modifier used for aquaculture. The bottom material modifier comprises a main raw material, an auxiliary material, and a carrier; the main raw material comprises potassium monopersulfate and sodium sulfate; the auxiliary material comprises one randomly selected from magnesium stearate, polyvinylpyrrolidone, potassium stearate, and microcrystalline cellulose; and the carrier comprises sodium sulfate. More specifically the main raw material comprises 4 to 20 parts of potassium monopersulfate and 79 to 95 parts of sodium sulfate; and bottom material modifier comprises 0.1 to 1 part of the auxiliary material. The raw materials above are directly pressed into tablets with a diameter ranging from 4 to 12mm; and the bottom material modifier is used for aquaculture to improve water body environment. The production cost of the bottom material modifier is not high; and the bottom material modifier is convenient to use, and is suitable to be popularized in related technological fields.

Owner:TIANJIN RONG LEE BIOTECH DEV CO LTD

Modified polyethylene insulating material for wire harness of communication equipment

ActiveCN103554616AImprove performanceHigh strengthPlastic/resin/waxes insulatorsCellulose acetatePolystyrene

The invention relates to an insulating material for a wire harness, and specifically relates to a modified polyethylene insulating material for a wire harness of communication equipment. The material comprises the following raw materials in parts by weight: 24-28 parts of medium density polyethylene, 12-16 parts of metallocene linear low density polyethylene, 5-9 parts of polyphenylene sulfide, 5-6 parts of cellulose acetate, 16-19 parts of polystyrene, 2-3 parts of an antioxidant 1010, 5-6 parts of hydrogenated rosin, 3-4 parts of coumarone, 30-34 parts of tributyl citrate, 1-3 parts of potassium stearate, 5-10 parts of aluminum nitride, 3-4 parts of zinc borate, 12-15 parts of zinc pyrophosphate, 23-26 parts of carbon black N330 and 14-16 parts of an assistant. The insulating material combines the advantages of the raw materials such as medium density polyethylene and polystyrene and enhances the performance of conventional polystyrene blending materials; and the prepared material is high in strength, impact-resistant, good in toughness, good in electric insulation, chemical-corrosion-resistant, ageing-resistant and long in service life, can be widely applied to manufacture of insulating sheathes, terminals, bandage materials and the like of wire harnesses at all parts of the communication equipment, and is wide in market requirement prospect.

Owner:合肥得润电子器件有限公司

High-elasticity durable automobile rubber shock absorbing material

InactiveCN109161042AStrong heat resistanceImprove wear resistanceEpoxy resin coatingsWear resistantAntioxidant

The invention discloses a high-elasticity durable automobile rubber shock absorbing material. The high-elasticity durable automobile rubber shock absorbing material comprises a shock absorbing material body and a wear-resistant coating which coats the outer side of the shock absorbing material body; the shock absorbing material body is prepared from the following raw materials in parts by weight:20 to 30 parts of EPDM, 20 to 25 parts of butyl rubber, 10 to 15 parts of butadiene rubber, 4 to 7 parts of talcum powder, 2 to 5 parts of a toughening agent, 2 to 4 parts of an antioxidant, 1 to 4 parts of an anti-aging agent, 1 to 3 parts of a coupling agent, 3 to 9 parts of epoxidized soybean oil, 3 to 6 parts of a maleic anhydride compatilizer, 3 to 7 parts of paraffin, 5 to 8 parts of nano-barium sulphate, 2 to 5 parts of modified nano silicon nitride, 1 to 3 parts of potassium stearate, 2 to 5 parts of an accelerant, 2 to 4 parts of a coupling agent, 1 to 2 parts of zinc borate and 3 to7 parts of sulphur. According to the high-elasticity durable automobile rubber shock absorbing material, the wear resistance and the durability of a shock absorbing piece are greatly improved by the wear-resistant coating on the outer side of the shock absorbing material body.

Owner:ANHUI WEIWEI RUBBER PARTS GRP

High-strength waterproof concrete and preparation method thereof

InactiveCN104591775AAvoid corrosionImprove corrosion resistanceSolid waste managementCeramicwareFiberSlag

The invention discloses high-strength waterproof concrete. The high-strength waterproof concrete contains the following raw material components: cement, sea sand, pebbles, water, superfine slag powder, superfine nickel slag powder, superfine coal ash, diatomite, flue gas desulfurization gypsum, nano-calcium carbonate, granite powder, fiber, super absorbent resin, dipropyl glycol, potassium stearate, nano-magnesium oxide, an early strength agent, a retarder, a foaming agent, a foam stabilizer and a corrosion inhibitor. The high-strength waterproof concrete is high in strength and good in water tolerance. The invention further discloses a preparation method of the high-strength waterproof concrete. The preparation method has the beneficial effects that the raw materials are easily available, the operation is easy, and the stability of the obtained concrete is good.

Owner:无为县严桥双龙建材厂

Water-based metal detergent and preparation method thereof

The invention discloses a water-based metal detergent and a preparation method thereof. The detergent is prepared from potassium stearate, vegetable fiber powder, cocoanut fatty acid diethanolamide, disodium ethylene diamine tetraacetate, AEO9, polyepoxysuccinic acid, propylene glycol, cetanol polyoxyethylene ether, methylepichlorohydrin, branched secondary alcohol ethoxylate, urea peroxide, dodecylbenzene sulfonic acid, nonylphenol polyoxyethylene ether, diethylene glycol monobutyl ether, polyvinyl alcohol, nanometer TiO2, water lily extract product lignanoids, cactus root extract liquid, and the balance of deionized water. The pure plant extract water lily lignanoids are introduced to the preparation field of metal decontaminating agents, and the nanometer TiO2 is added, so the detergent has a substantial decontamination effect, can rapidly clean spots, oil stains and other pollutants on parts, and can prevent rusts of the parts to maintain the shining state of the parts for a long term.

Owner:BOHAI UNIV

Preparation of oily anti-blocking agent and application method

InactiveCN106518323AReduce dosageLow costLayered/coated fertilisersFertilizer mixturesNitro compoundAnticaking agent

Disclosed is an oily anti-blocking agent. The oily anti-blocking agent is prepared from, by mass, 40-60 wt% of palm oil, 20-40 wt% of oleic acid, 5-20 wt% of oleamide, 5-20 wt% of phosphate, and 2-10 wt% of potassium stearate; a preparation method of the oily anti-blocking agent comprises the steps of heating the raw materials to 80-110 DEG C, mixing and uniformly stirring the raw materials, and cooling the raw materials to an indoor temperature; an application method of the oily anti-blocking agent comprises the steps of heating the oily anti-blocking agent to 70-110 DEG C, dropping the oily anti-blocking agent to a compound fertilizer with the temperature of 50-60 DEG C after the oily anti-blocking agent is melted, fully wrapping the oily anti-blocking agent into particle surface of the fertilizer through a wrap machine, wherein 0.5-2.0 kg of the oily anti-blocking agent is added into per ton of the compound fertilizer. According to the preparation of oily anti-blocking agent and the application method, operation is simple, industrialized production is easy, use amount is small, and cost is low; meanwhile, the oily anti-blocking agent is easy to degrade, free of pollution, good in anti-blocking effect, and is capable of making an anti-blocking rate of granulous nitro-compound fertilizer reach 90% or above.

Owner:YANSHAN UNIV

Anti-cracking impermeable concrete, and preparation method thereof

The invention provides an anti-cracking impermeable concrete and a preparation method thereof. The anti-cracking impermeable concrete comprises following raw materials, by weight, 160 to 200 parts of cement, 15 to 20 parts of nickel slag micro powder, 10 to 12 parts of ultra-fine fly ash, 40 to 50 parts of sand, 8 to 14 parts of spathic iron, 2 to 4 parts of diatom mud, 4 to 5 parts of sodium sulfate, 2 to 4 parts of potassium chloride, 12 to 16 parts of calcium carbonate, 8 to 15 parts of blast furnace slag, 2 to 4 parts of aluminium hydroxide, 6 to 10 parts of dicalcium silicate, 5 to 8 parts of phenolic resin, 2 to 5 parts of dipropyl ethanediol, and 1 to 3 parts of potassium stearate. The anti-cracking impermeable concrete is capable of preventing generation of surface and internal cracks caused by non-structural reasons such as concrete temperature and drying shrinkage effectively, and possesses excellent impact resistance, impermeability, corrosion resistance, and rust resistance.

Owner:LIUZHOU LIANHAI TECH

Sunscreen composition

A cosmetic composition is provided including a water-insoluble UV-A sunscreen agent having a λmax at 330-380 nm, a water-insoluble UV-B sunscreen agent having a λmax between 280 and 320 nm, and a water-soluble sunscreen agent having a λmax between 280 and 400 nm, the water-soluble sunscreen agent being neutralized with metallic counter ions which in a first portion are sodium and in a second portion are potassium ions present in a respective molar ratio of 0.5:2 to 2:1, and a cosmetically acceptable carrier including from 0.2 to 4% of potassium stearate by weight of the composition.

Owner:CONOPCO INC D B A UNILEVER

Anti-corrosion natural rubber cable material

InactiveCN103554557AHeat resistantOil resistantInsulated cablesInsulated conductorsAdhesiveAcrylic rubber

The invention relates to a cable material, and particularly relates to an anti-corrosion natural rubber cable material. The cable material comprises the following raw materials in parts by weight: 40-45 parts of natural rubber, 20-24 parts of chloroprene rubber adhesive (CR121), 15-20 parts of poly-1-butene, 4-5 parts of magnesium oxide, 8-10 parts of acrylic rubber, 28-32 parts of white carbon black, 4-5 parts of coumarone, 4-5 parts of potassium stearate, 20-25 parts of nano-kaolin, 1-2 parts of sulphur, 10-15 parts of nano calcium carbonate, 1-2 parts of anti-aging agent 4010NA, 15-20 parts of diethylene glycol dibenzoate, 1-2 parts of accelerant tetramethylthiuramdisulfide (TMTD0, 1-2 parts of accelerant M, 1-2 parts of bi(dioctyl oxygen radical pyrophosphate) ethylene titanate, 33-36 parts of N330 carbon black and 4-5 parts of assistant. The cable material is combined with advantages of the raw materials such as the natural rubber, the chloroprene rubber adhesive, the acrylic rubber, the poly-1-butene and the like; the characteristics of the traditional natural rubber cable material are improved; the modified material has the advantages of heat resistance, oil resistance, chemical resistance, storage stability and the like, can meet the operating requirements of specific occasions, and is broad in application prospect.

Owner:安徽文峰电子科技集团有限公司

Stabilizing agent in urea peroxide storage process and preparation method of stabilizing agent

ActiveCN102617406AExtended shelf lifeEasy to use on siteUrea derivatives preparationOrganic compound preparationTri calcium phosphatePOTASSIUM STEARATE

The invention belongs to the technical field of a peroxide stabilizing agent and particularly relates to a stabilizing agent in a urea peroxide storage process and a preparation method of the stabilizing agent. The stabilizing agent in the urea peroxide storage process provided by the invention comprises the following material ingredients in parts by weight: 5 to 20 parts of water absorption agents, 5 to 15 parts of flow aids, 5 to 20 parts of heat resistance agents and 40 to 80 parts of solid active oxygen stabilizing agents, wherein the water absorption agents are one kind of materials of magnesium chloride, calcium chloride or sodium chloride or a mixture of the magnesium chloride, calcium chloride and sodium chloride, the flow aids are one kind of materials of magnesium carbonate, light magnesium carbonate, potassium stearate, microcrystalline cellulose, superfine silica powder or tricalcium phosphate or a mixture of magnesium carbonate, light magnesium carbonate, potassium stearate, microcrystalline cellulose, superfine silica powder and tricalcium phosphate, the heat resistance agents are one kind of materials of potassium sulfate, potassium chloride or potassium nitrate or a mixture of potassium sulfate, potassium chloride and potassium nitrate, and the solid active oxygen stabilizing agents are one kind of materials of sodium tripolyphosphate, sodium fluoride, sodium borate and sodium silicate or a mixture of sodium tripolyphosphate, sodium fluoride, sodium borate and sodium silicate. Products provided by the invention have a long quality guarantee period, the bag expansion is avoided, the agglomeration is avoided, the in-site use is convenient, the product flowability is good, and the application range is wide.

Owner:石家庄卫科生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com