Patents

Literature

65results about How to "Effective control quantity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

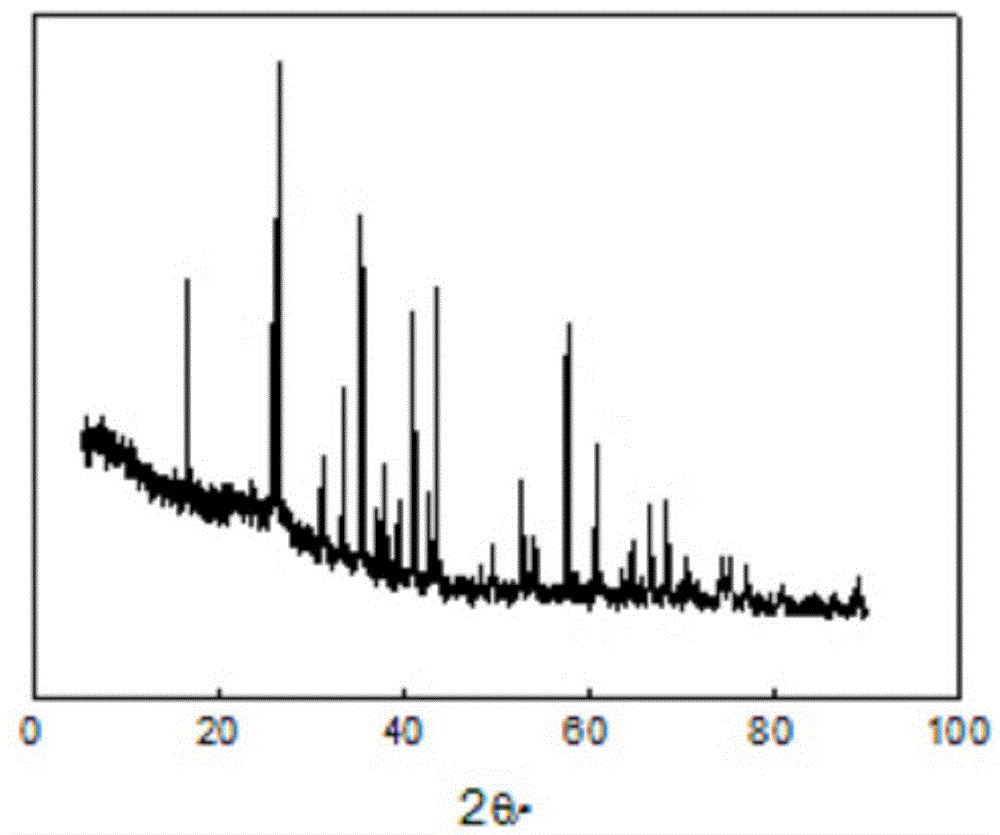

Method for producing steel plate of petroleum storage tank by using direct quenching process

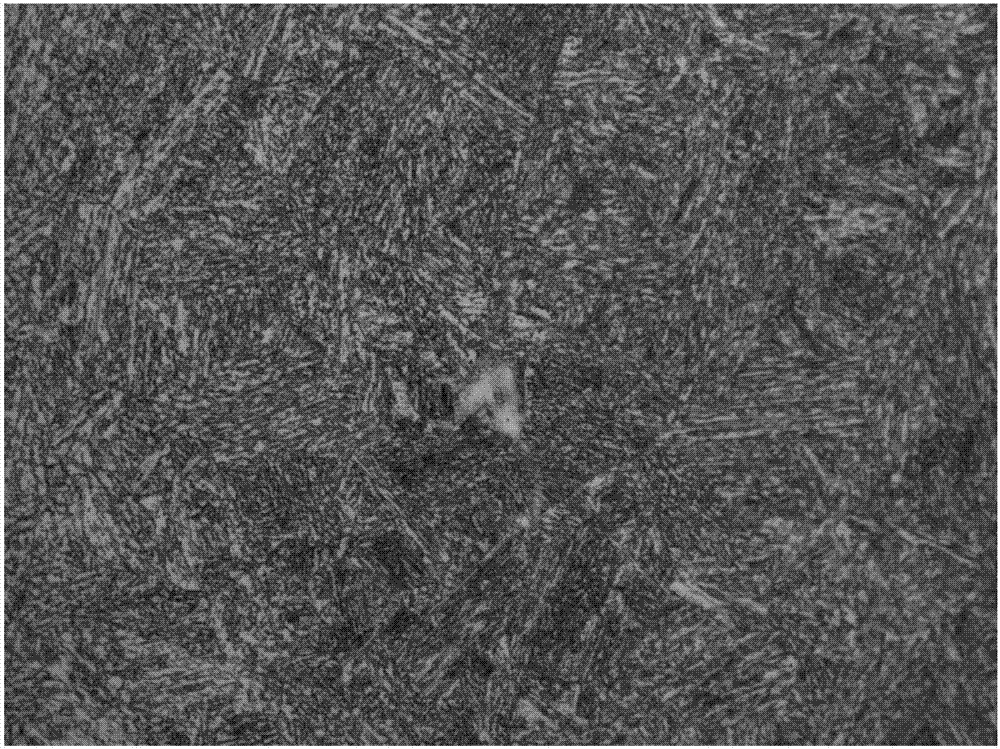

The invention discloses a method for producing a steel plate of a petroleum storage tank by using a direct quenching process. The invention provides a chemical composition of special petroleum storage tank steel and adopts a direct quenching process. The method comprises the following steps of: heating a steel blank to 1100 to 1280 DEG C, rolling into a steel plate in re-crystallization and non-recrystallization stages; carrying out on-line quenching operation under the conditions that the temperature of the steel plate is between 780 DEG C and 900 DEG C, the average cooling rate ranges from 25 DEG C / s to 60 DEG C / s, the cooling terminal temperature is less than or equal to 350 DEG C, and performing off-line tempering on the steel plate subjected to quenching. Compared with the conventional high-energy-consumption hardening process based on the combination of off-line tempering and tempering, the method provided by the invention has the advantages of short production flow and low energy consumption and the prepared steel plate has good general mechanical properties and high heat input welding property. The yield strength of the steel plate is more than 490 MPa and the tensile strength of the steel plate is more than 610 MPa. In case of high heat input welding (less than or equal to 400 KJ / cm), a welding heat affected zone maintains excellent low-temperature toughness, and the mean value of work done by impact at -20 DEG C is more than 50 J.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD +1

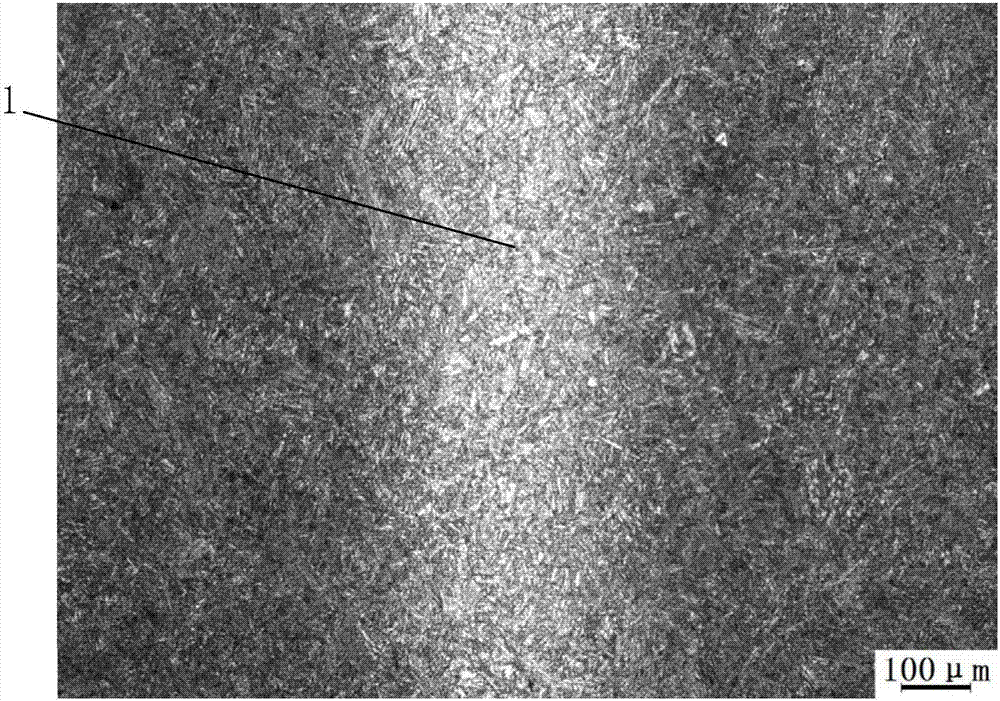

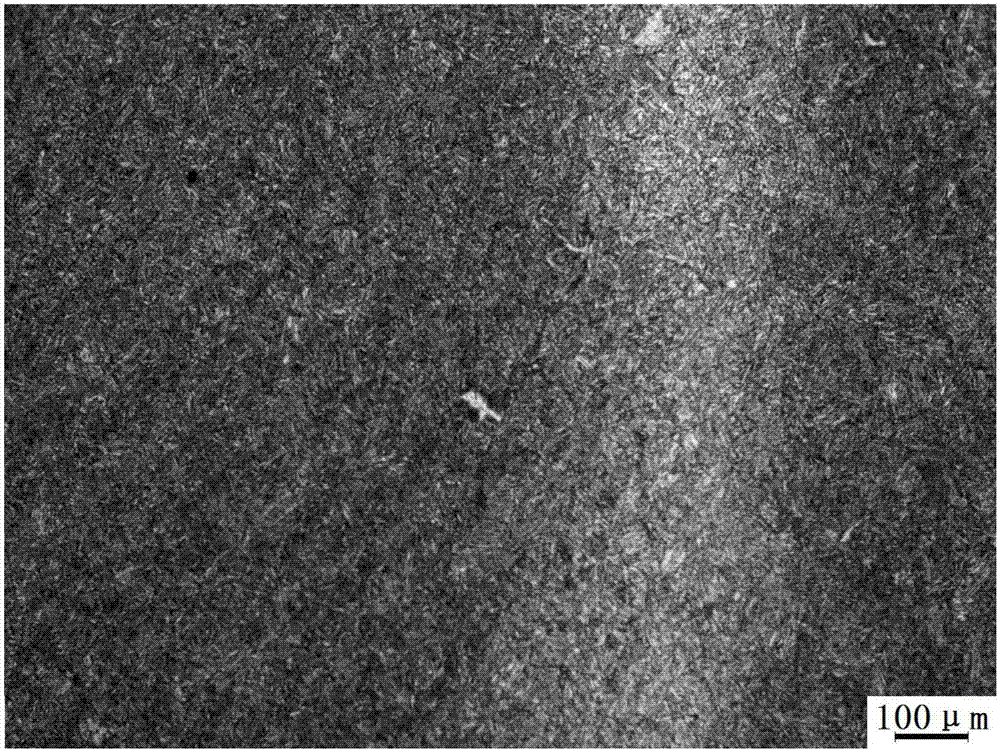

Technological method for controlling 'white block' tissues in bainite steel rail flash welding joint

The invention belongs to the technical field of steel rail welding, particularly discloses a technological method for controlling 'white block' tissues in a bainite steel rail flash welding joint and aims to solve the problems that 'white blocks' in microstructures of a flash welding joint welded by an existing bainite steel rail flash welding technology are large in number and size. According to the technological method, in the process that steel rail flash butt welding equipment is adopted to weld a bainite steel rail, the flashing and flattening stage, the pulsation stage, the accelerated burning stage, the upsetting stage and the pressure maintaining stage are controlled in sequence. The technological method is adopted to perform corresponding control in the bainite steel rail flash welding process, the number of 'white block' tissues near a weld joint can be lowered to the minimum, the sizes of the 'white block' tissues are reduced, the appearance of the steel rail is improved, therefore welding quality is stable, the mechanical property of the welding joint is guaranteed, the service performance of the bainite steel rail flash welding joint is improved, and safety of railway operation is guaranteed.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

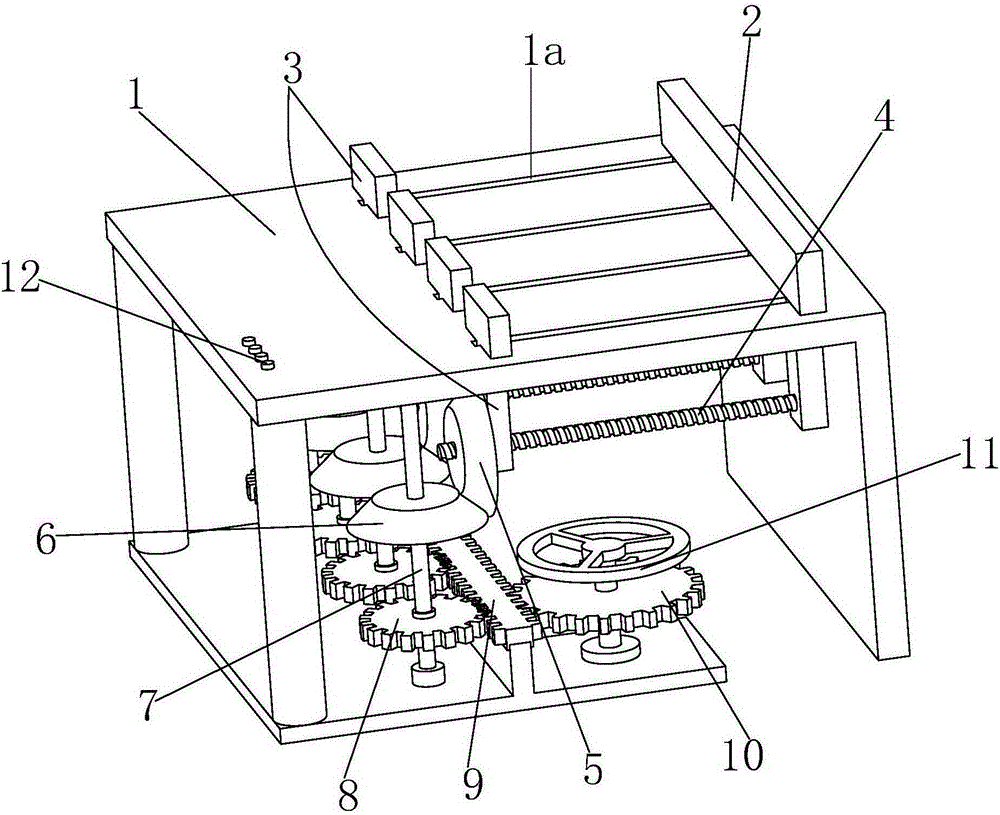

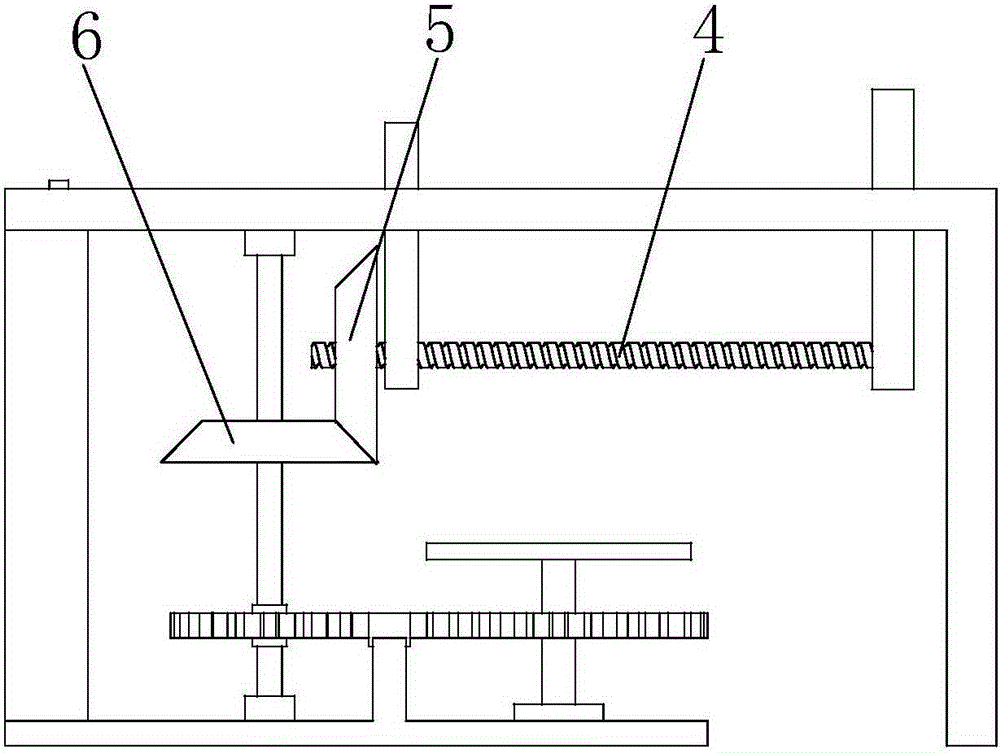

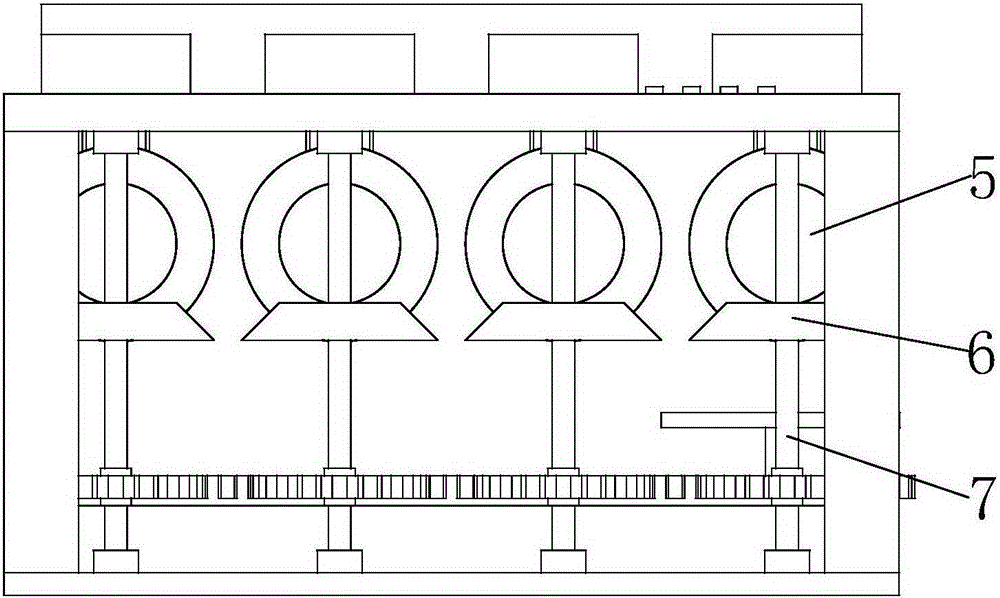

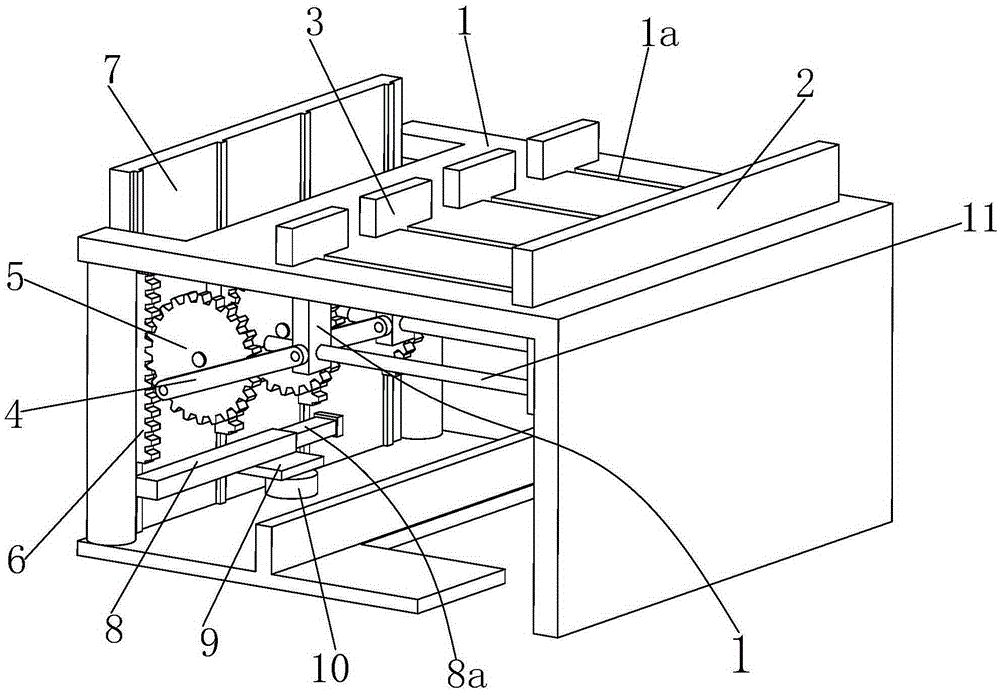

Fixture for milling end faces of workpieces in batches

InactiveCN105269356AEffective control quantityEasy to control the number of milling operationsPositioning apparatusMetal-working holdersBall screwOperation mode

The invention relates to a fixture for milling end faces of workpieces in batches. The fixture mainly comprises a workbench, wherein four sliding grooves are formed in the workbench in front and back; a positioning plate block is arranged at the right ends of the sliding grooves; clamping plates are mounted in the sliding grooves in a sliding manner; the lower ends of the clamping plates are connected with ball screws horizontally arranged; the left ends of the ball screws are connected with bevel gears I; the bevel gears I are meshed with bevel gears II; the bevel gears II are connected with rotating shafts; the lower parts of the rotating shafts are connected with clutch gears; the right ends of the clutch gears are meshed with a double-side rack mounted below the workbench in the manner of sliding front and back; the right end of the double side rack is meshed with a driving gear; and the driving gear is connected with a rotary table. The fixture provided by the invention not only has the function of quickly clamping multiple workpieces at one time in a convenient and rapid operation mode and a gear meshing transmission mode, but also can effectively control the number of clamped workpieces and further can indirectly realize the effects of controlling milling number of workpiecess and increasing the processing speed.

Owner:WUHU TAINENG ELECTRIC APPLIANCES

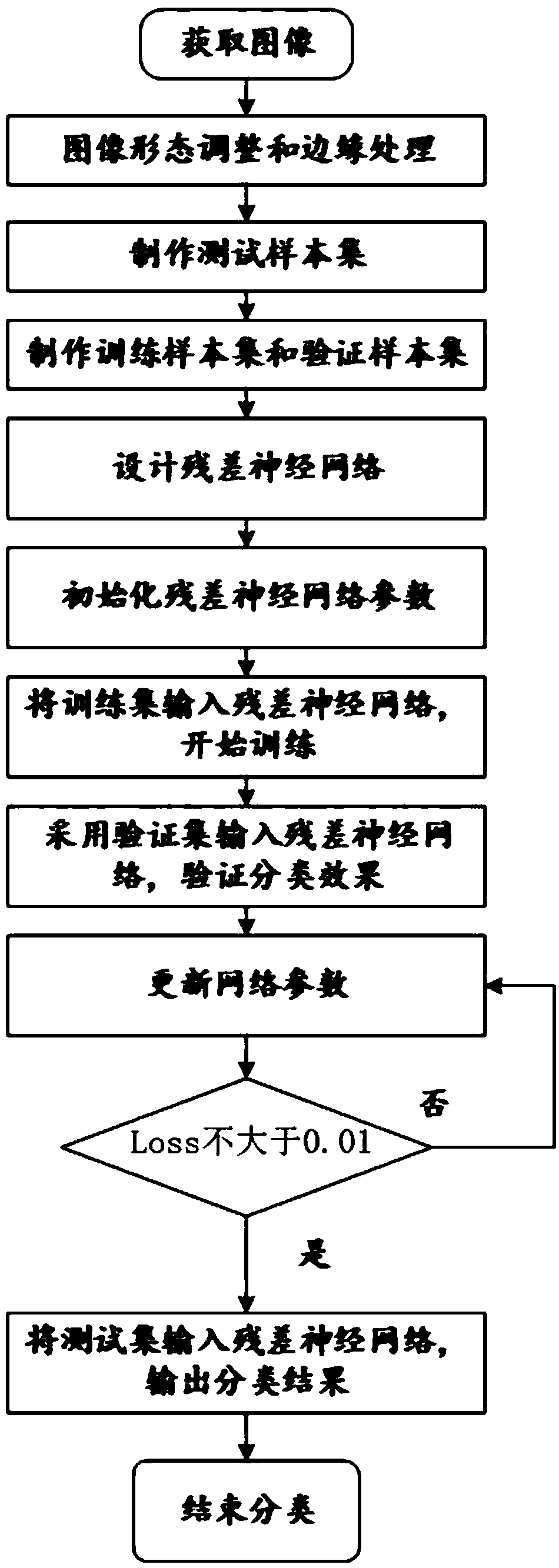

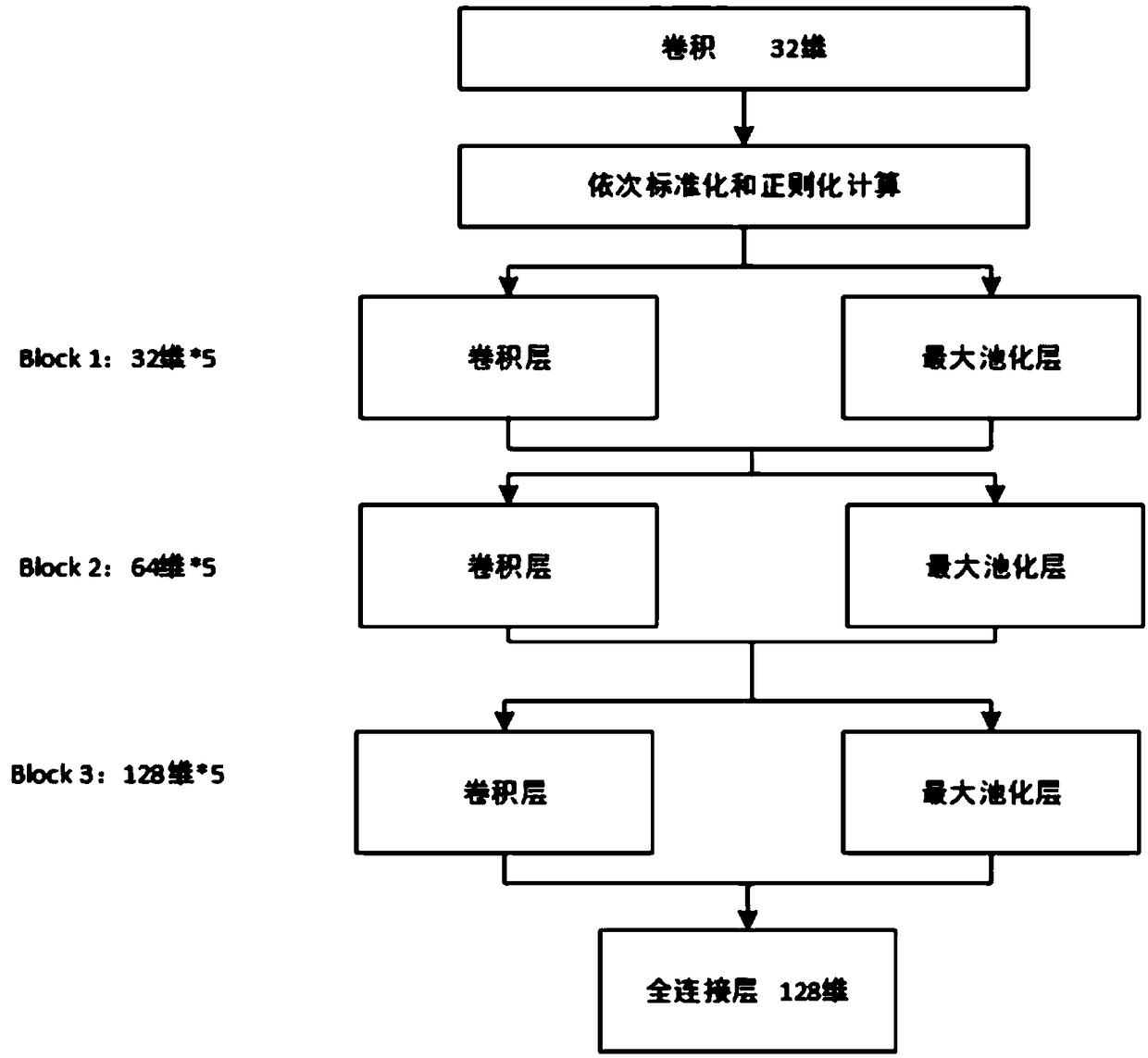

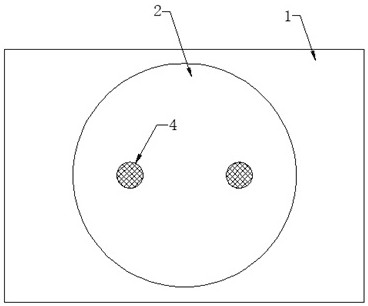

Photovoltaic cell appearance defect classification method based on multi-channel residual neural network

ActiveCN109376792AReduce training timeEffective control quantityCharacter and pattern recognitionClassification methodsResidual neural network

The invention relates to a photovoltaic cell appearance defect classification method based on a multi-channel residual neural network. The method classifies the photovoltaic cell appearance defects based on a depth learning algorithm of a multi-channel input residual neural network. Firstly, the acquired photovoltaic cell sheet appearance image is preprocessed. 20% of that target image are randomly selected as a t sample set, the remaining target images are manually sorted, label are added, the size of the target images is quantized and multi-channel information in the target images is extracted, so that the training sample sets with fixed scales are obtained respectively, and the sample sets are verified. The training set is inputted into the residual neural network, and the multidimensional output eigenvalue matrix of the image is obtained. According to the extracted multi-dimensional eigenvalue matrix, the verification set image features are loaded into softmax classifier for classification, and the classification results are compared with the labels, and the test data and multi-dimensional eigenvalue matrix are loaded into the classifier to obtain the final classification. Thisapplication has high accuracy and high speed.

Owner:HEBEI UNIV OF TECH

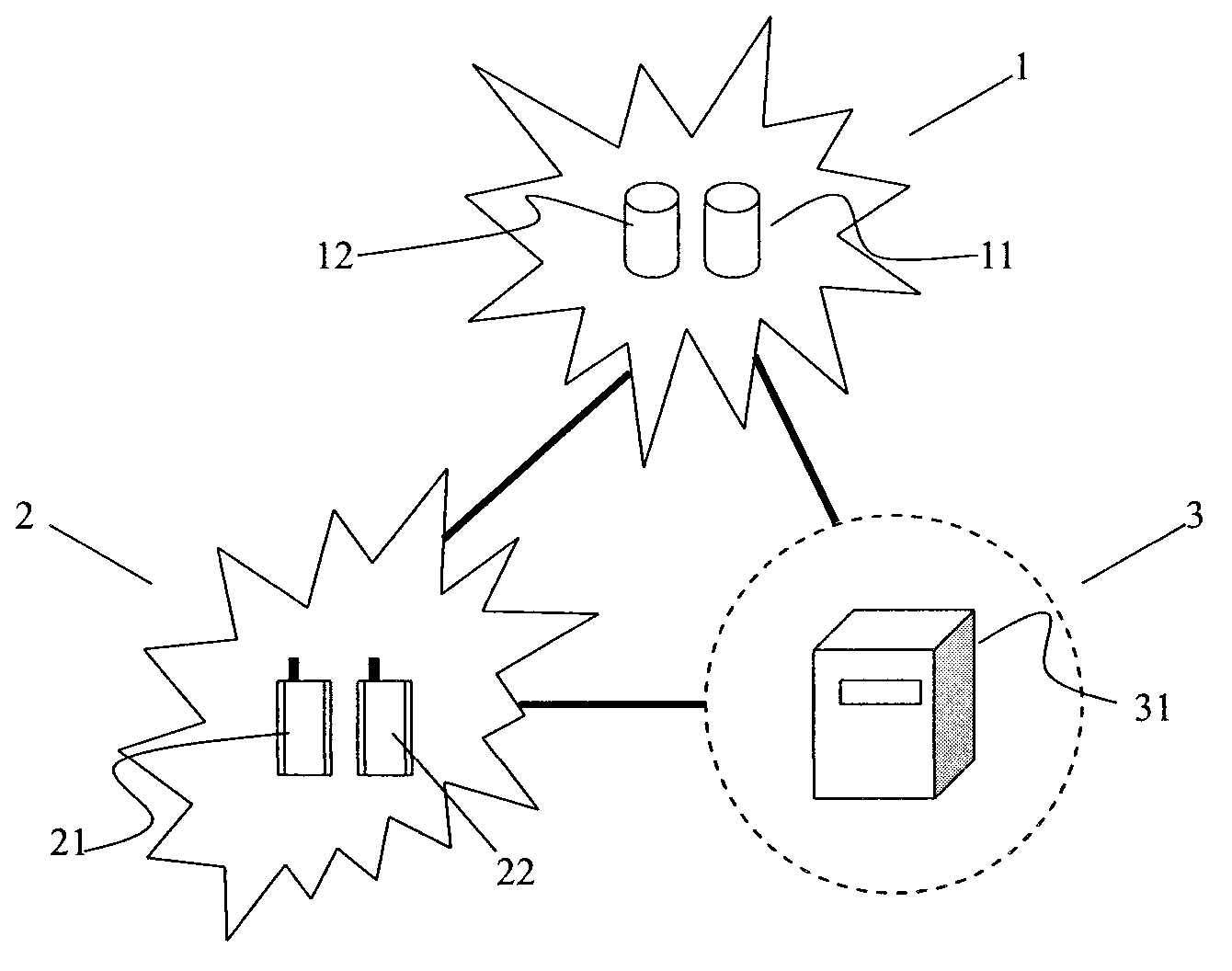

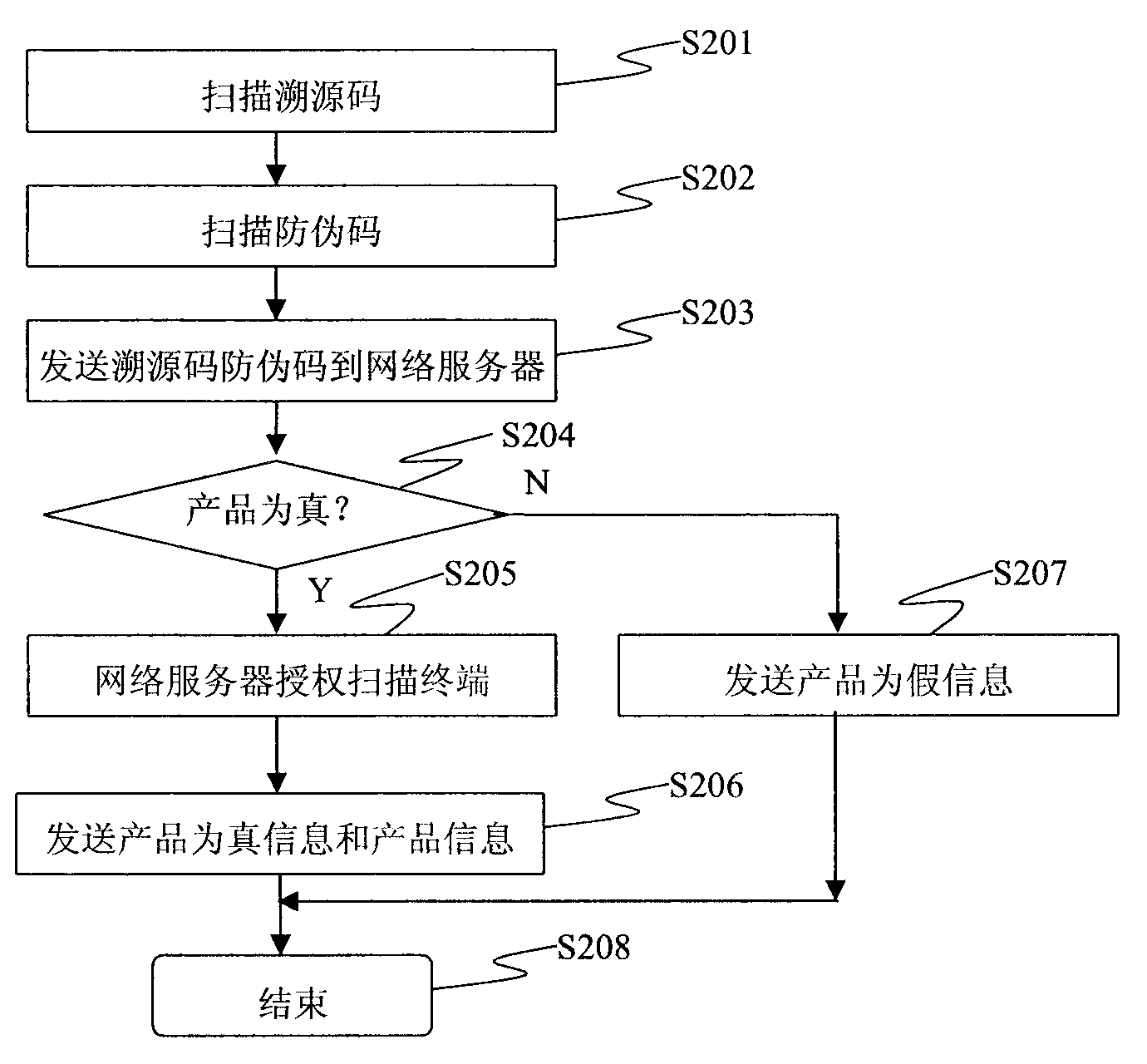

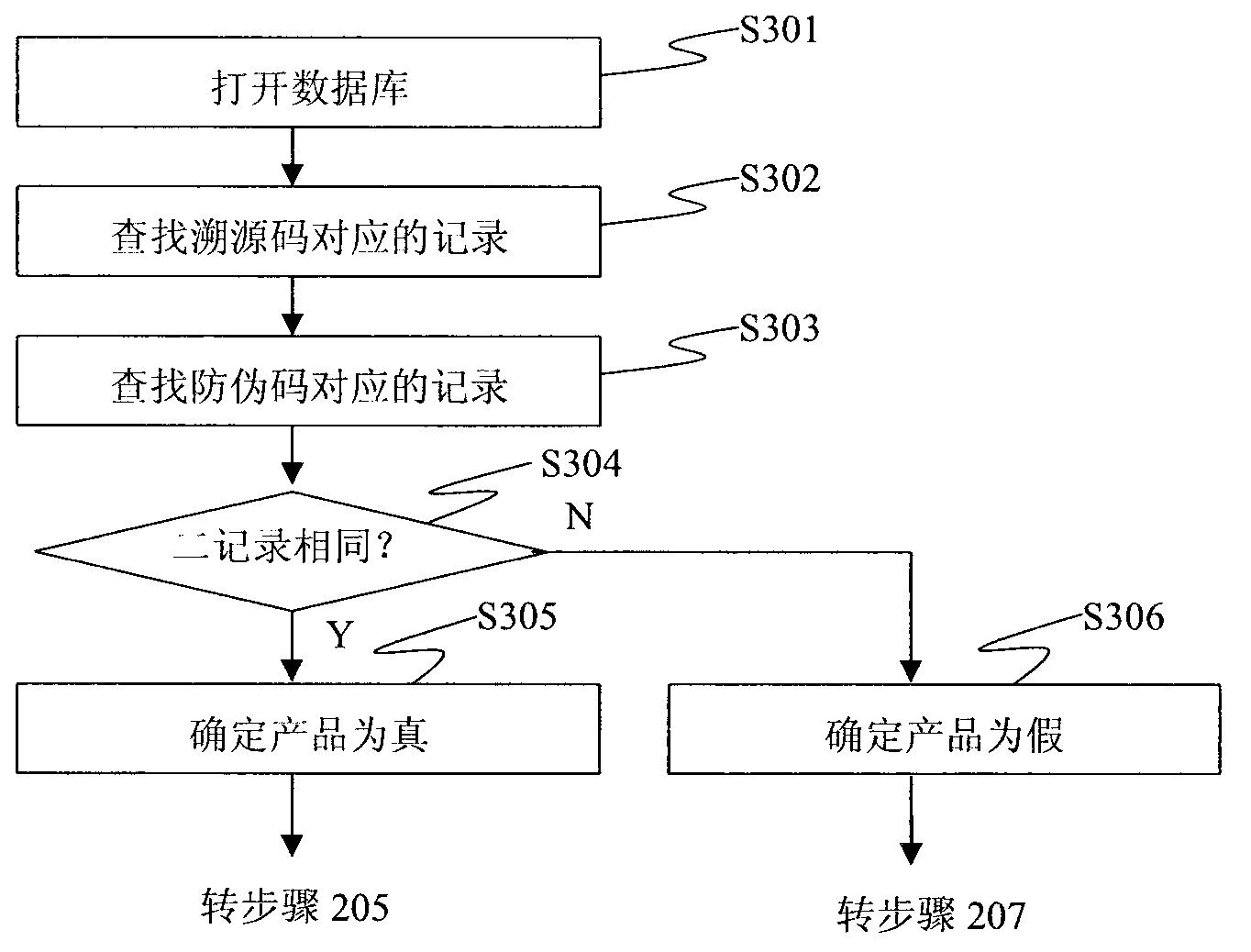

Method and system for verifying product authenticity

InactiveCN103077467AEffective control quantityControl quantityUser identity/authority verificationCommerceComputer terminalDependability

The invention discloses a method for verifying the product authenticity. The surface of a verified product is provided with a unique traceability code and a unique anti-counterfeiting code, and the traceability code and the anti-counterfeiting code have unique incidence relationship and one-to-one correspondence relationship. The method comprises the following steps of: a first mobile terminal scans the traceability code and the anti-counterfeiting code on the surface of the verified product, and sends the traceability code and the anti-counterfeiting code to a network server; the network server judges whether the verified product is true according to the traceability code and the anti-counterfeiting code; if so, the authorization to the first mobile terminal by the traceability code and the anti-counterfeiting code are set, and the information of which the judgment result is 'true' and the product information are sent to the first mobile terminal; and if not, the information of which the judgment result is 'false' is sent to the first mobile terminal. The invention also discloses a system for verifying the product authenticity. According to the above scheme, the first mobile terminal is authorized to improve the product authenticity authorization reliability.

Owner:王志刚

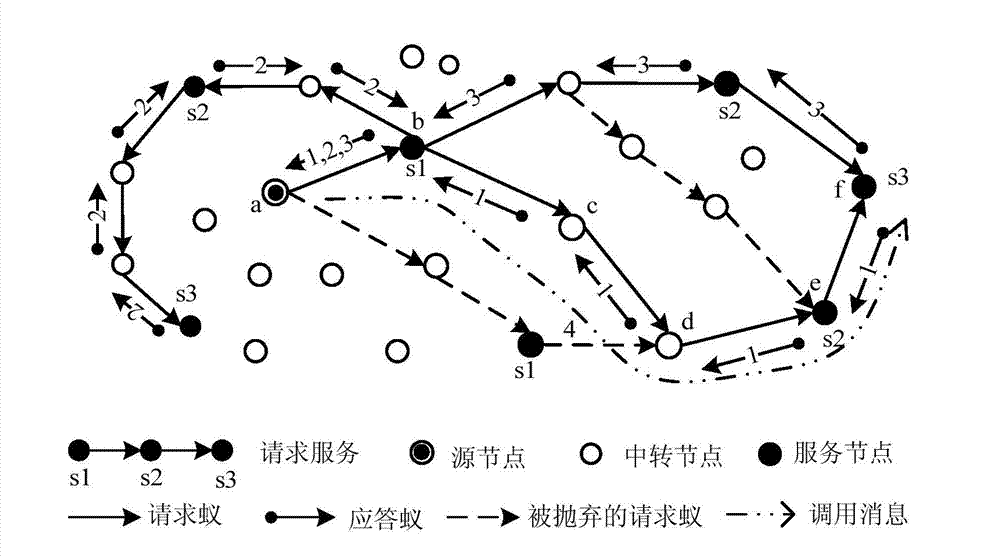

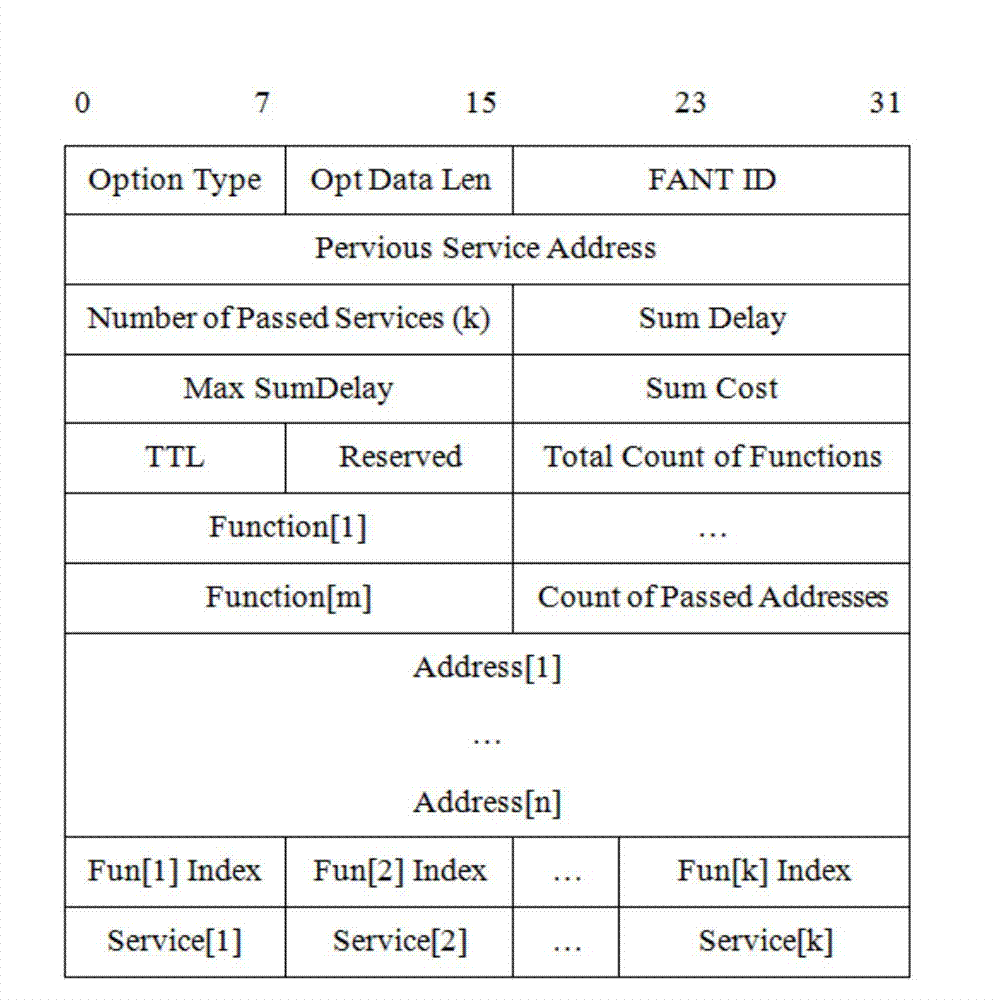

Ant colony algorithm-based distributed service composition method in mobile ad hoc network

ActiveCN104717238AReduce loadImprove efficiencyNetwork traffic/resource managementData switching networksComposite servicesDistributed services

The invention relates to an ant colony algorithm-based distributed service composition method in a mobile ad hoc network. The method comprises the following steps: 1, a service composition message is generated; 2, a service request message is processed; 3, a service response message is generated and spread; 4, optimal composite service is selected; and 5, composite service is called. If a service path happens to be cutoff, a step of adopting a local path repair method or a global path repair method for repairing the path is also provided. Compared with the prior art, historical service path information in the network is made full use of through the ant colony algorithm, a request message is sent directionally in a limited mode, the efficiency of message finding and the efficiency of composite service are improved, and message control load in the network is reduced.

Owner:SHANGHAI UNIVERSITY OF FINANCE AND ECONOMICS

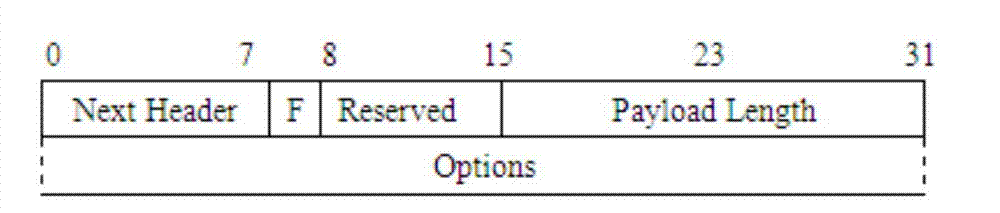

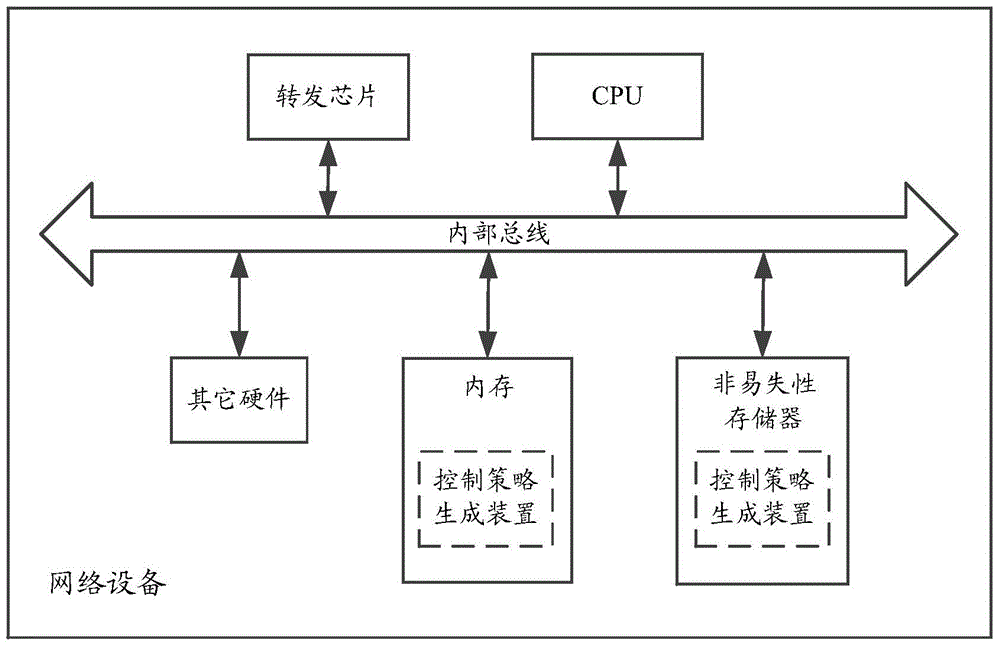

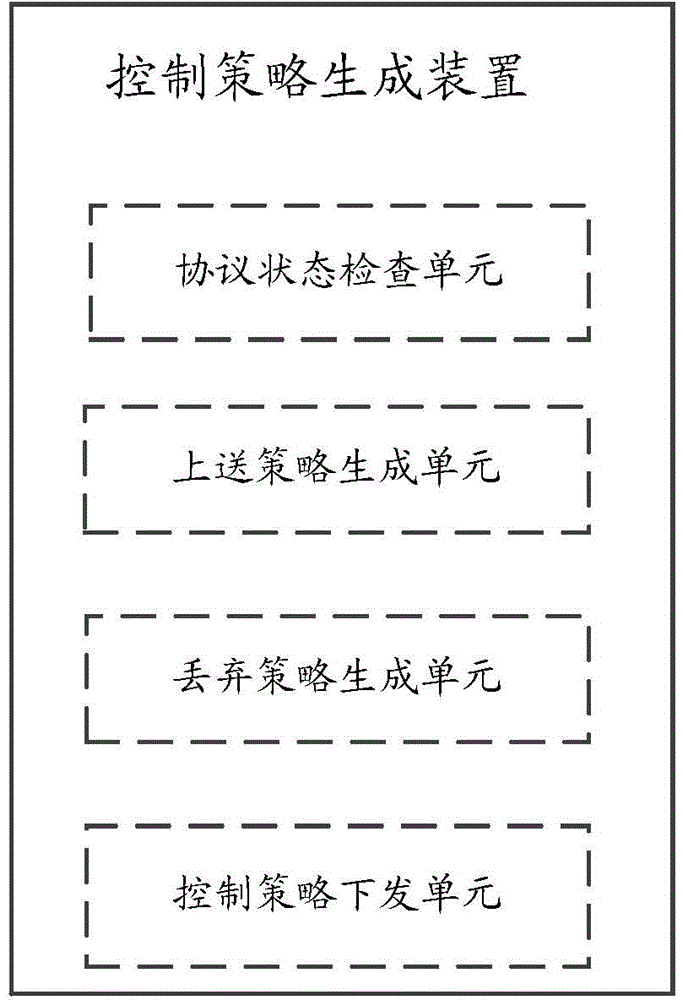

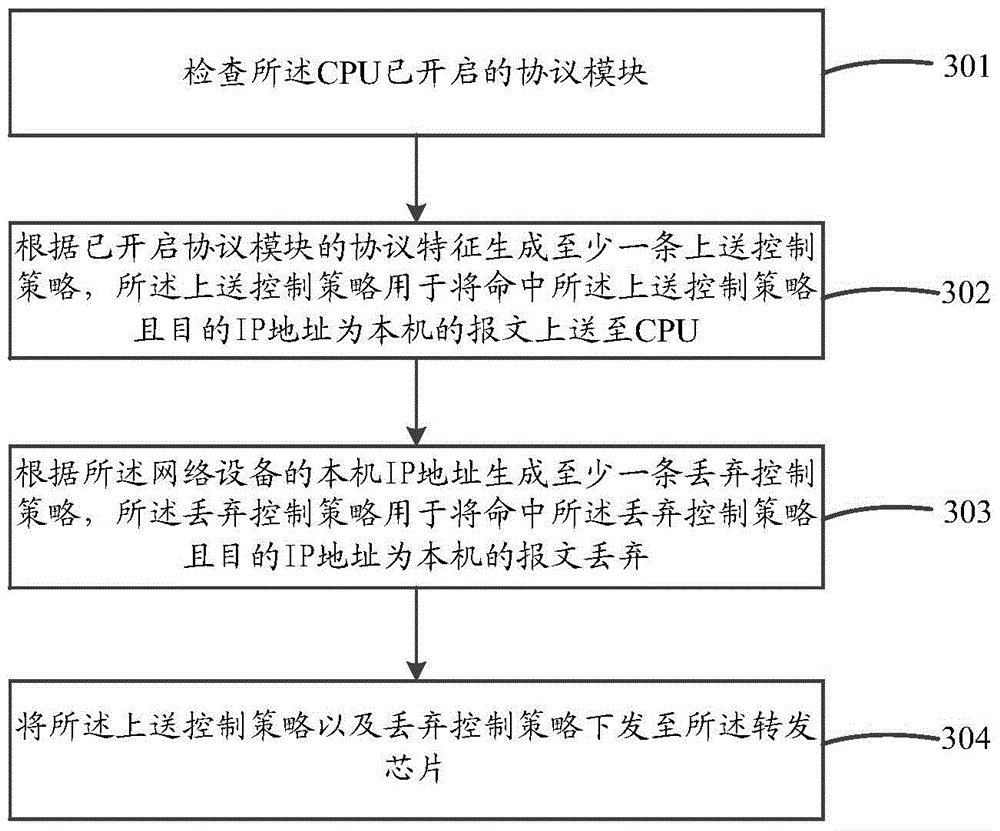

Control strategy generation method and apparatus

ActiveCN105337890AEffective control quantityAvoid unmanageable phenomenaData switching networksIp addressDistributed computing

The invention provides a control strategy generation method and an apparatus which are applied to network equipment including a forwarding chip and a central processor CPU. The method comprises the following steps of examining a protocol module started by the CPU; according to a protocol characteristic of the started protocol module, generating at least one up-supply control strategy, wherein the up-supply control strategy is used to make the forwarding chip send a message which hits the up-supply control strategy and whose objective IP address is a local host to the CPU; according to an IP address of the local host, generating at least one discarding control strategy, wherein the discarding control strategy is used to discard the message which hits the discarding control strategy; issuing the up-supply control strategy and the discarding control strategy to the forwarding chip. By using the method and the apparatus, a quantity of messages sent to the CPU can be effectively controlled; and phenomena that protocol interruption occurs and equipment can not be managed because that a protocol message or a management message which needs to be sent to the CPU for processing is discarded during a message attack are avoided.

Owner:HANGZHOU DPTECH TECH

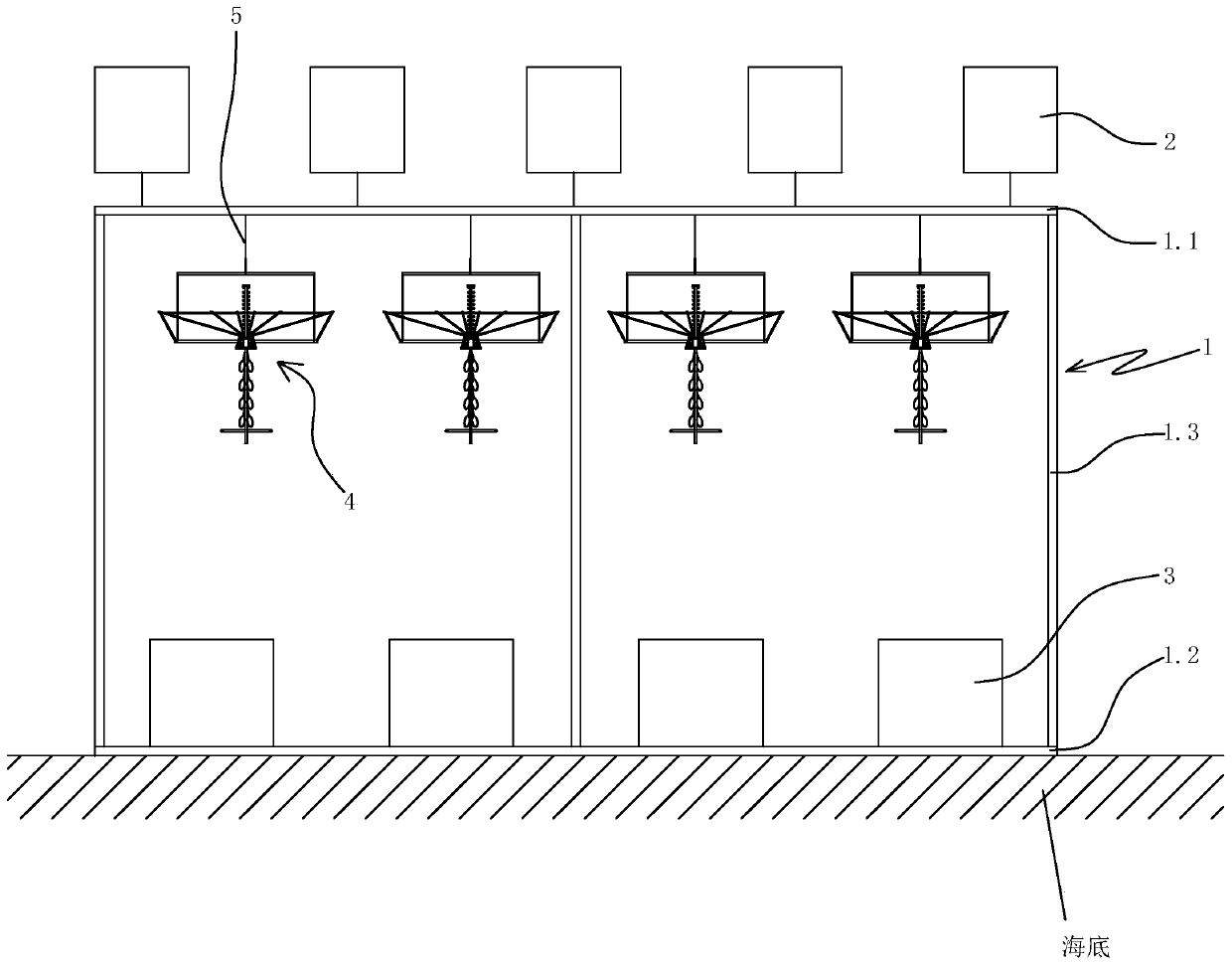

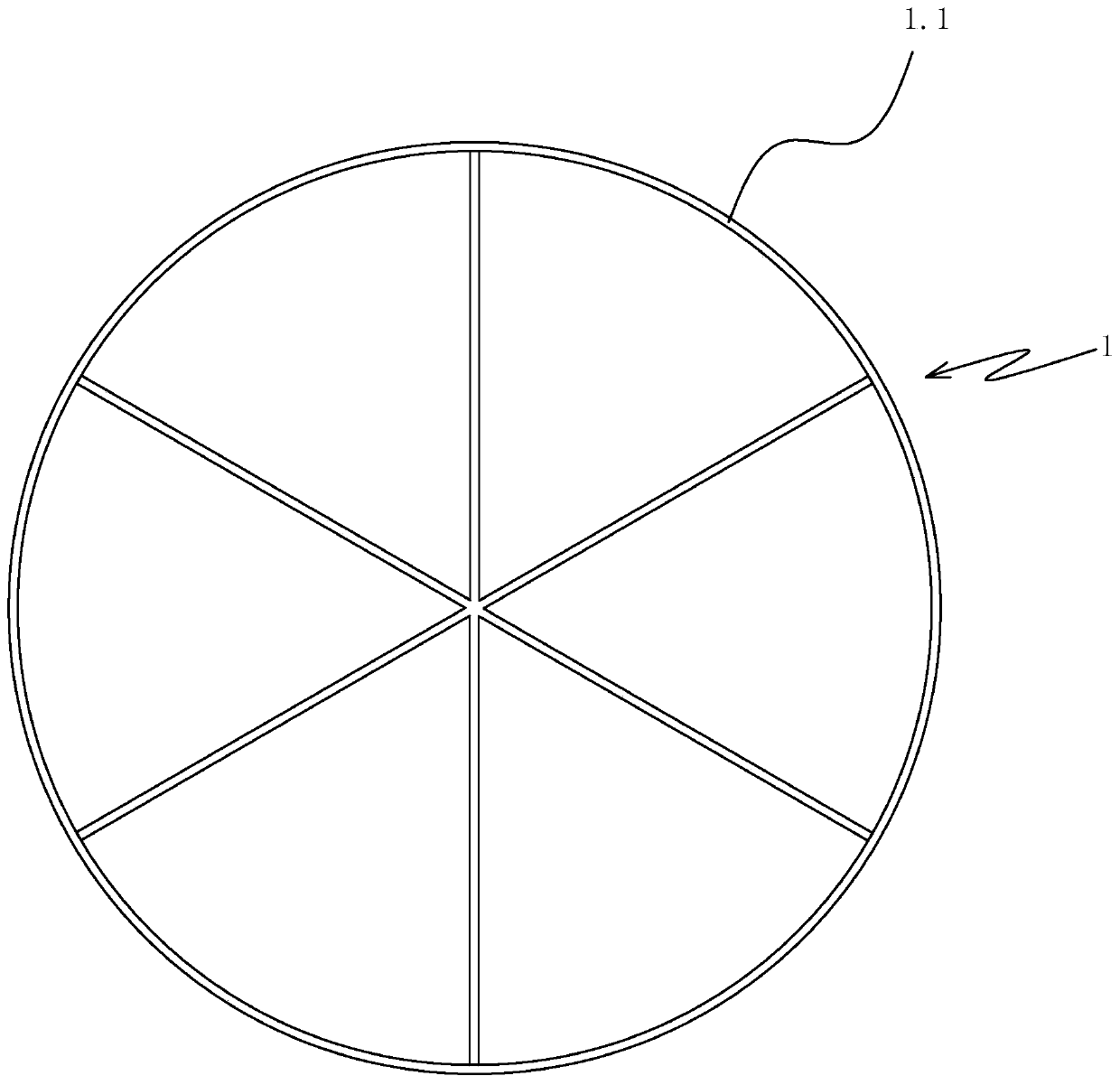

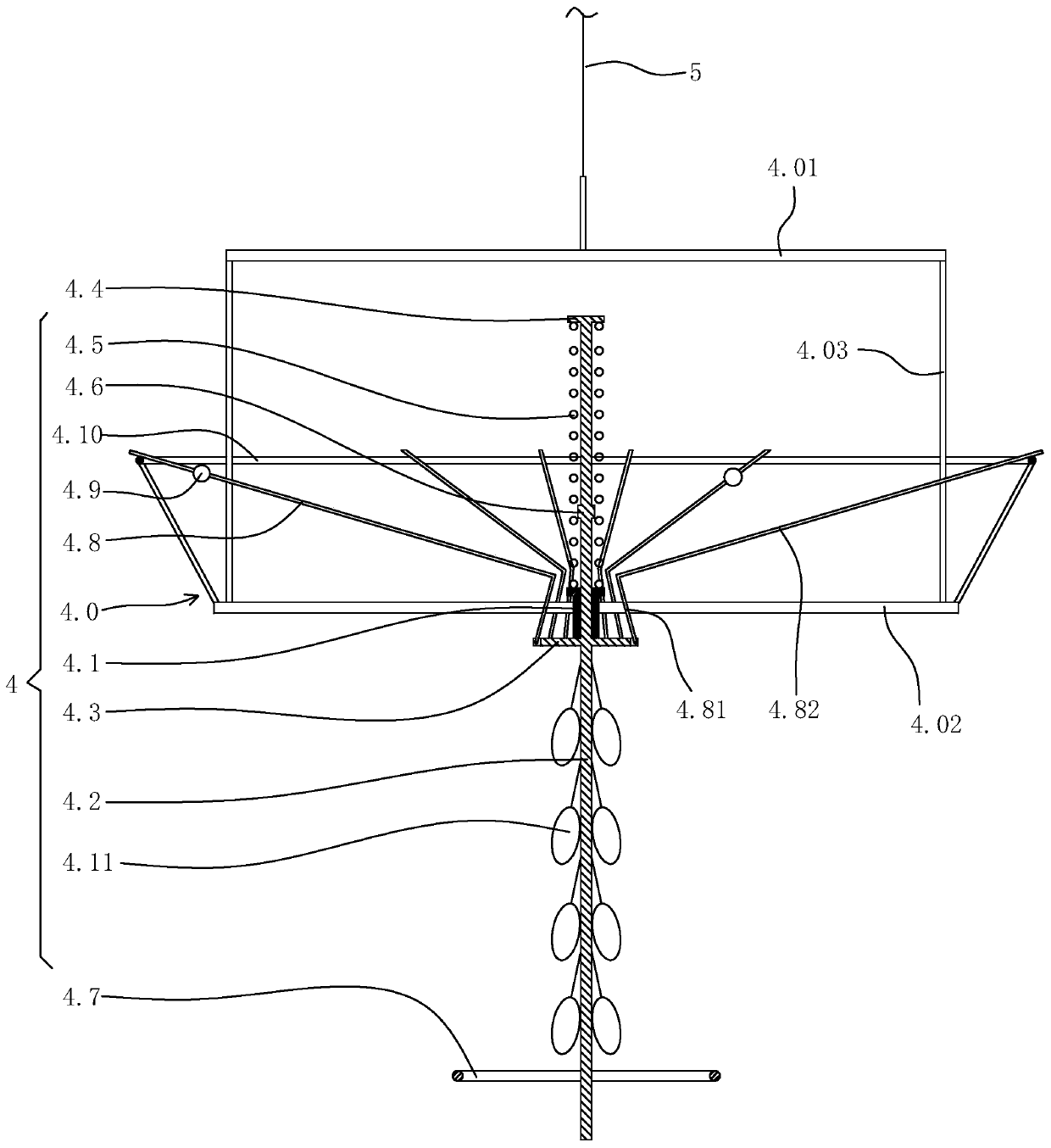

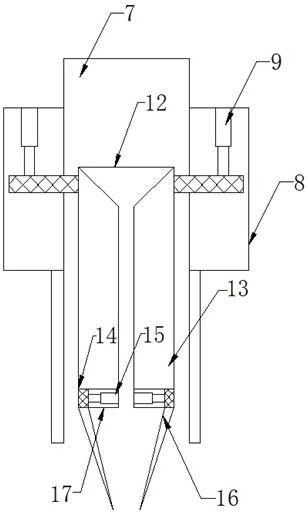

Inkfish egg attaching frame

ActiveCN110338109AEffective control quantityAvoid the problem of severely reduced hatchabilityClimate change adaptationPisciculture and aquariaBiologyEgg laying

The invention discloses an inkfish egg attaching frame, and aims at providing the inkfish egg attaching frame which can effectively control the number of each string of eggs of inkfish eggs, and effectively solve the problem that a large quantity of the inkfish eggs are stacked together, and the inkfish eggs surrounded in the middle suffer from development retardation or even rot and die. The inkfish egg attaching frame comprises a supporting framework and several inkfish egg laying mechanisms. The supporting framework comprises a bottom frame, a top frame and supporting rods connecting the bottom frame and the top frame, wherein the supporting framework sinks to the seabed and is supported on the seabed through the bottom frame. Each inkfish egg laying mechanism comprises a mounting frame, several induction bodies simulating the shapes of inkfish eggs, a vertical guide cover arranged on the mounting frame, a vertical guide rod slidably arranged in the vertical slide cover, an annularmounting plate which is arranged on the vertical guide rod and located below the vertical guide cover, and several interference stop rods uniformly distributed in the circumferential direction of thevertical guide rod; the mounting frame is suspended below the top frame through a connecting rope, so that the inkfish egg laying mechanisms are suspended below the top frame.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

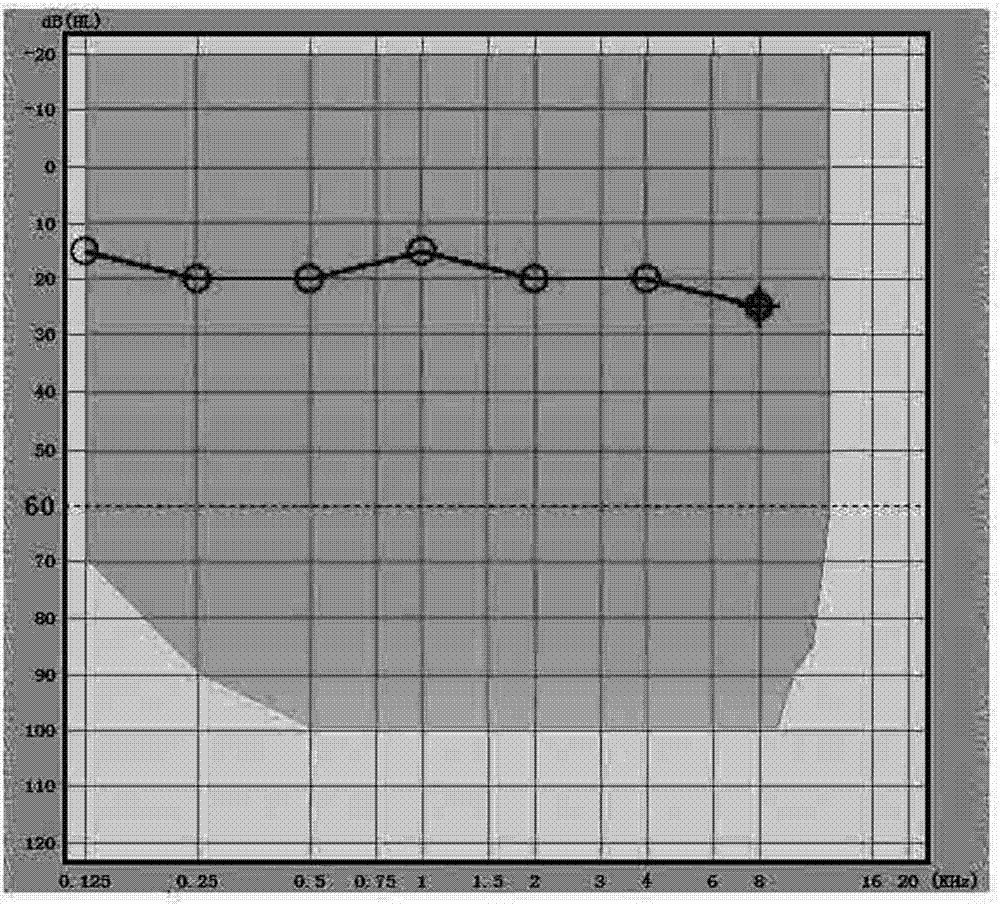

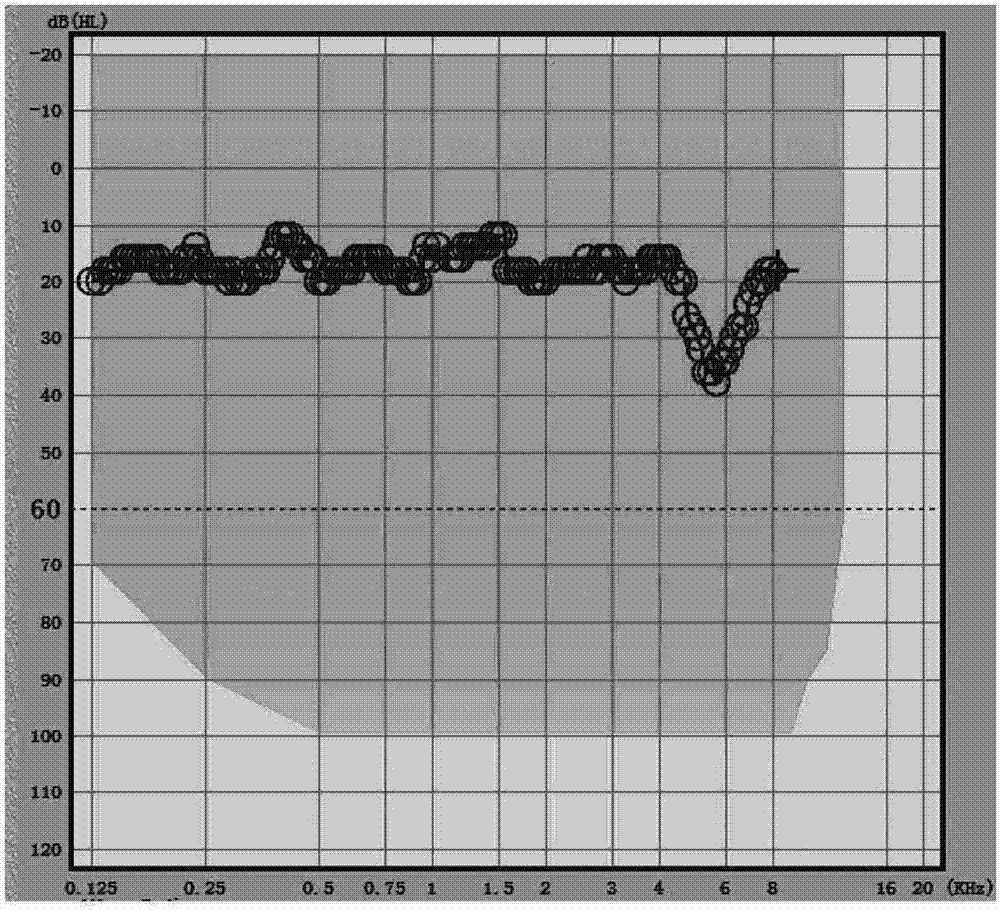

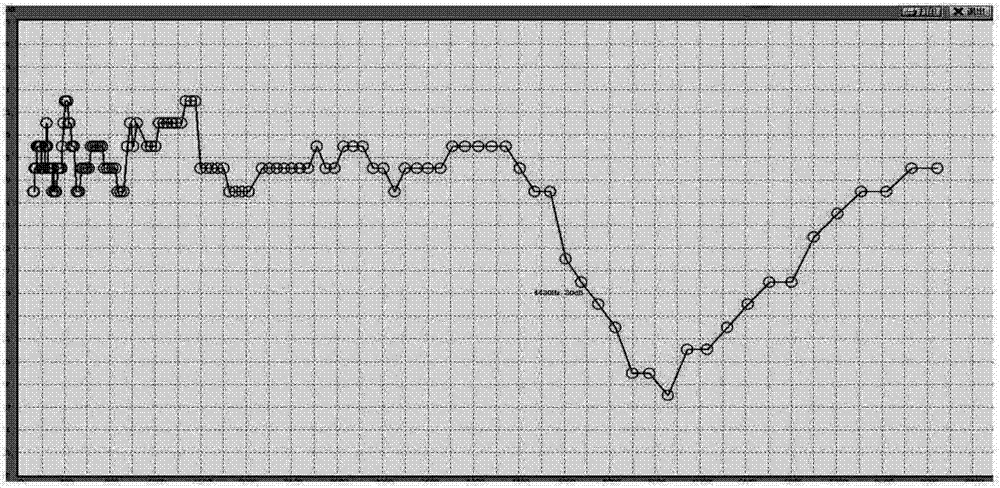

Hearing recognition sensitivity testing method

InactiveCN107049333AAvoid prolonged stimulationAvoid Threshold ErrorsAudiometeringSensorsTime historySensitivity testing

The invention discloses a hearing recognition sensitivity testing method. The method comprises the steps of a, setting testing parameters of a tested sound, wherein the testing parameters comprises a frequency value, a loudness value, stimulus time-history and stimulus interval time; b, determining a testing sequence of the tested sound; c, giving the tested sound, and conducting a test, wherein the frequency value is bigger than or equal to 1 Hz, the loudness value is bigger than equal to 1 dB, and the stimulus time-history is smaller than 1000 ms. In the hearing recognition sensitivity testing method, a digital technology is utilized to avoid inaccuracy of manual control operation, so that the tested sound is compared and tested on a lot of frequencies and loudness, a the situation that the stimulus time-history is too long can be avoided, the number of hair cells (bandwidth) participating in excitement is effectively controlled, a threshold value error caused when the stimulus of inner ear hair cells corresponding to a tested frequency point is too long is avoided, the frequency recognition ability, the loudness recognition ability and the time recognition ability of a testee are quickly detected, the accuracy of detection is improved, the obtained testing structure comprises a lot of detail information, and a more complete basis is provided for diagnosis of diseases.

Owner:FOSHAN BOZHI MEDICAL TECH CO LTD

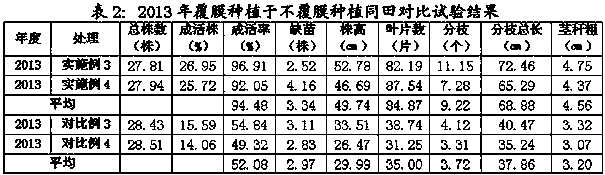

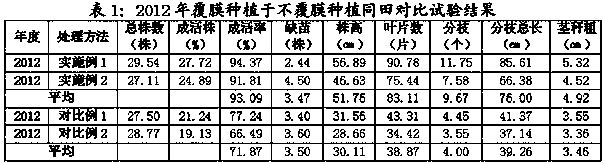

Tea seedling black film mulching cultivation method

InactiveCN103988702AIncreasing the thicknessImprove moisture conservation effectClimate change adaptationPlant protective coveringsBlow moldingSoil science

The invention discloses a tea seedling black film mulching cultivation method. The method comprises the steps that soil preparation is carried out in a conventional mode, and base fertilizer is applied sufficiently; earthing towards the center along fertilization furrows is carried out after fertilization to form planting ridges which are about 0.6 m wide and 0.10 m to 0.15 m high; the planting ridges of tea lines are covered with black mulching films flatly and tightly before tea seedlings are transplanted; black polyethylene blow molding agricultural films which are good in toughness, ageing resistant and good in shading effect are requested, the thickness of the films is 0.015 mm to 0.020 mm, the width is 0.8 m to 0.9 m, and the using amount of the mulching films is 5 to 6 kg in net weight per mu; tea seedling transplanting, seedling management, weeding, prevention and cure of diseases and pests and topdressing are carried out; the mulching films are recycled. The tea seedling black film mulching cultivation method can improve the survival rate of newly planted tea seedlings, tea gardens can be formed ahead of time for benefit acquiring, fertilizer and water can be utilized efficiently, weeds, the diseases and the insect pests can be controlled effectively, the investment of labor force and production management can be reduced, and production cost can be lowered.

Owner:贵州省现代农业发展研究所

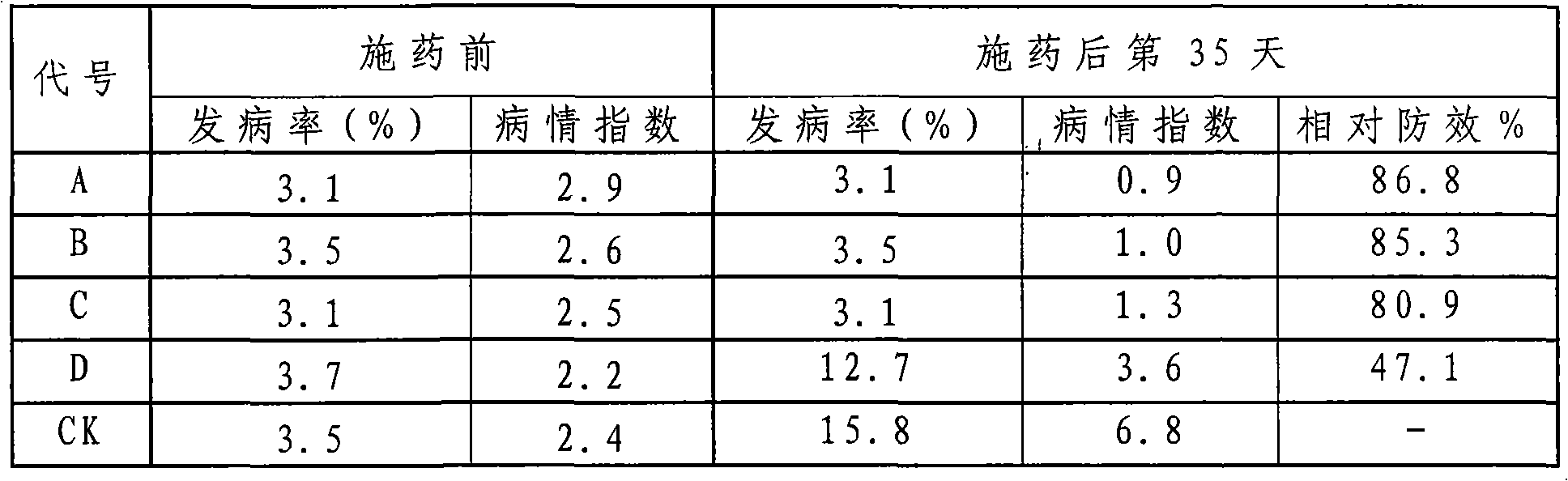

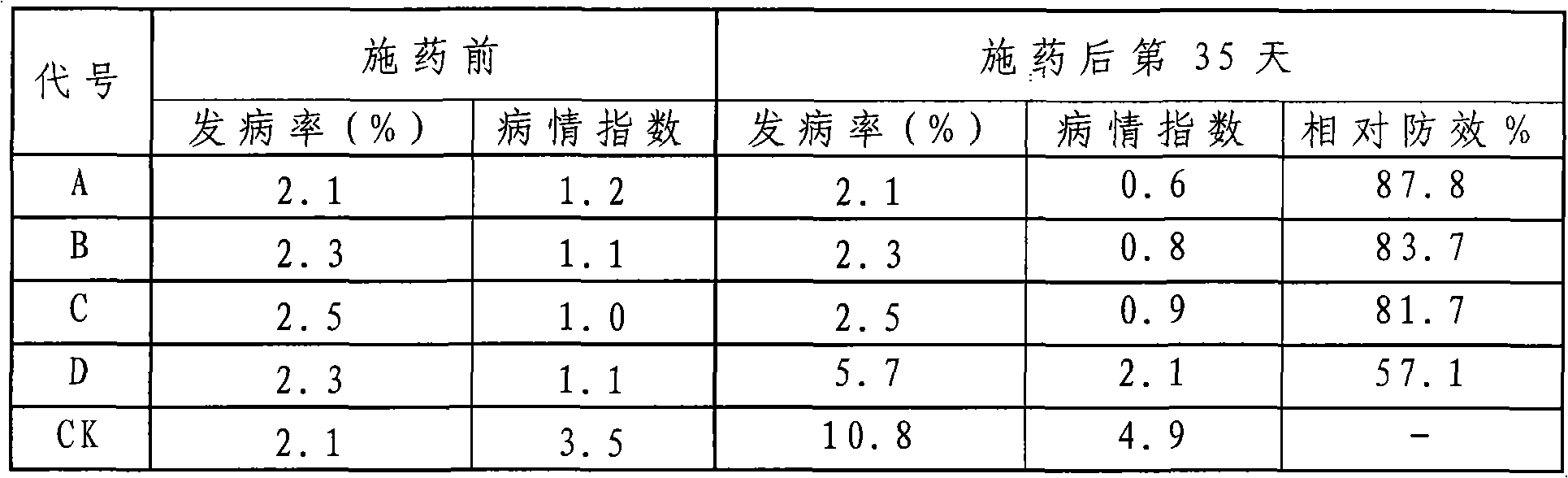

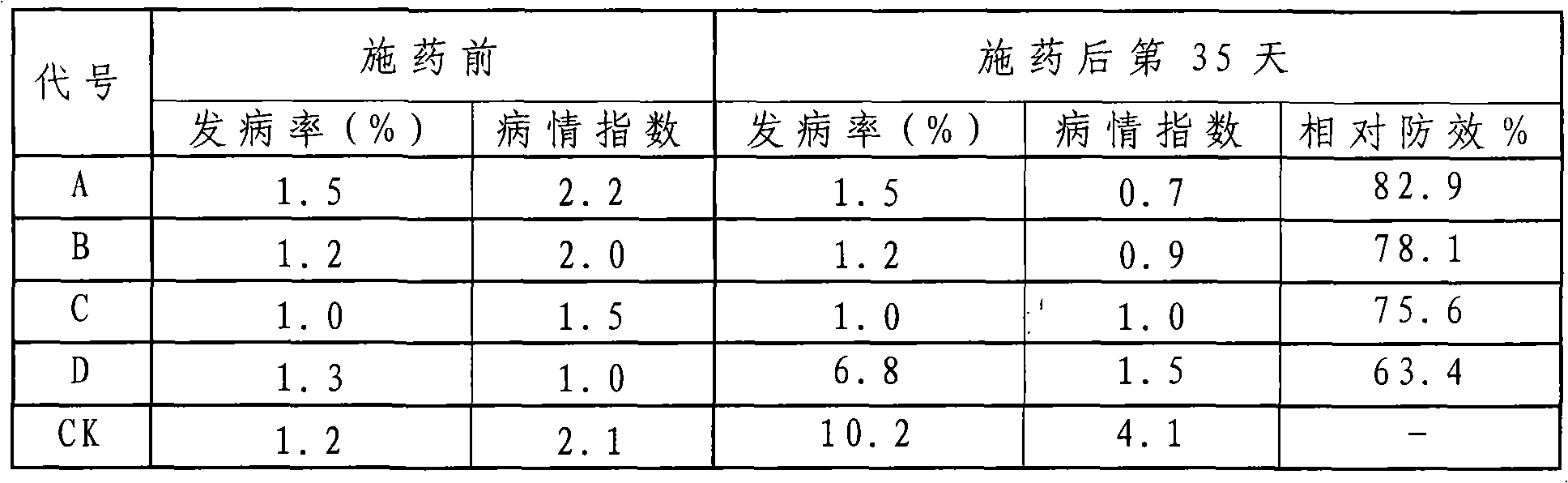

Anti-plant virus agent and preparation method and application thereof

InactiveCN101766187AImprove biological activityStrong insecticidal functionBiocidePlant growth regulatorsDiseaseMode of action

The invention discloses an anti-plant virus agent and a preparation method and application thereof. The anti-plant virus agent of the invention comprises the following components in parts by weight: 10-50 parts of jatropha curcas seed oil cake extract, 10-50 parts of alkaloid, 10-50 parts of fulvic acid salt, 5-50 parts of plant growth regulator, 10-60 parts of surfactant and 20-75 parts of solvent. The preparation method mainly comprises the following steps: respectively heating and dissolving the alkaloid, the plant growth regulator, the solvent, the jatropha curcas seed oil cake extract and the surfactant; adding, heating and dispersing the fulvic acid salt; and obtaining the anti-plant virus agent after cooling. The invention can solve the defects of single mode of action on the plant virus and low controlling effect of the current products. The product of the invention has the advantages of reduction of virus diseases transmitted by aphids, good therapeutic effect on plant virus diseases, obviously improvement of the disease-resisting capacity of plants, and good wettability, spreading property and permeability, low use cost and simple production processes.

Owner:罗波

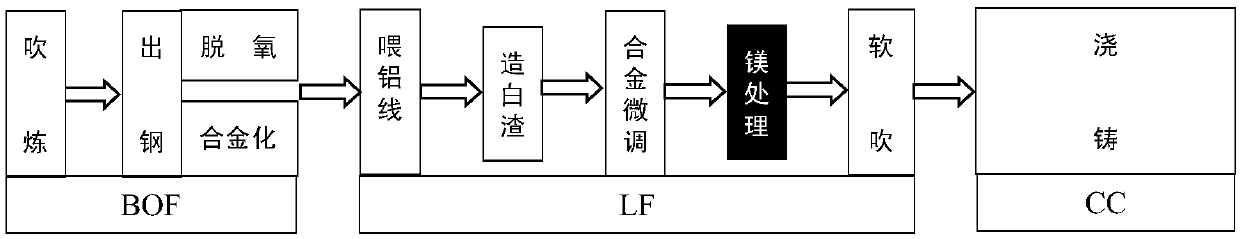

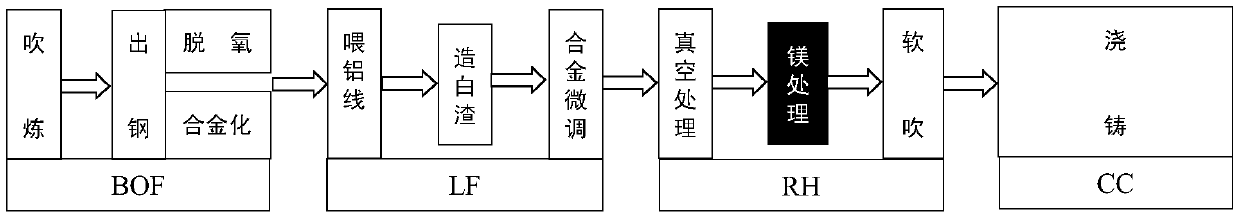

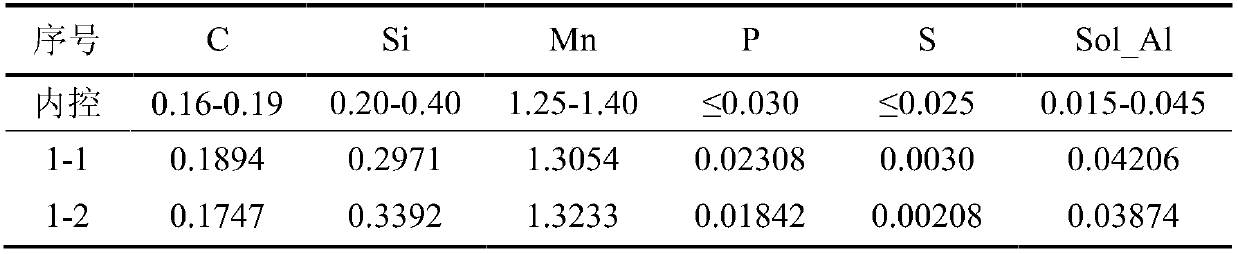

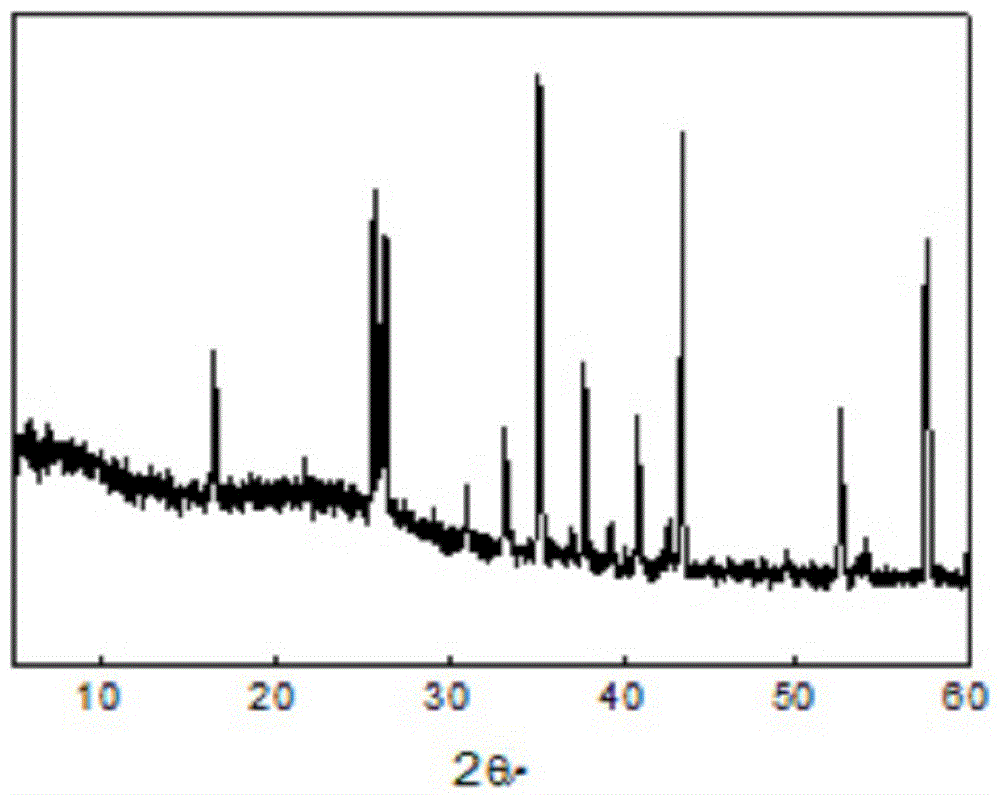

A kind of liquid magnesium treatment process for ship plate steel

A liquid magnesium treatment process for ship plate steel, which belongs to the field of clean steel smelting; the process is as follows: first, determine the station and timing of magnesium treatment: add Mg‑Al‑ after alloy fine-tuning in the LF process or after vacuum treatment in the RH process Fe alloy cored wire; secondly, according to the acid-soluble aluminum content of the steel type, on the premise of ensuring the magnesium treatment effect of Mg‑Al‑Fe alloy cored wire, coordinate the allocation of aluminum feeding amount and magnesium treatment wire feeding amount; then, carry out magnesium treatment Processing: In the LF or RH process, the cored wire feeding method is used to add Mg‑Al‑Fe alloy cored wire to the molten ship plate steel, and finally the finished molten steel is obtained. The ship plate rate deoxidized steel liquid magnesium treatment process of the present invention is used in the refining process of ship plate steel, and can control the cleanliness of the ship plate steel and the composition, quantity, particle size and distribution of inclusions in the steel; the method of the invention can improve the ship plate steel The cleanliness of plate steel and the control level of non-metallic inclusions can improve the mechanical properties and stability of ship plate steel.

Owner:NORTHEASTERN UNIV LIAONING

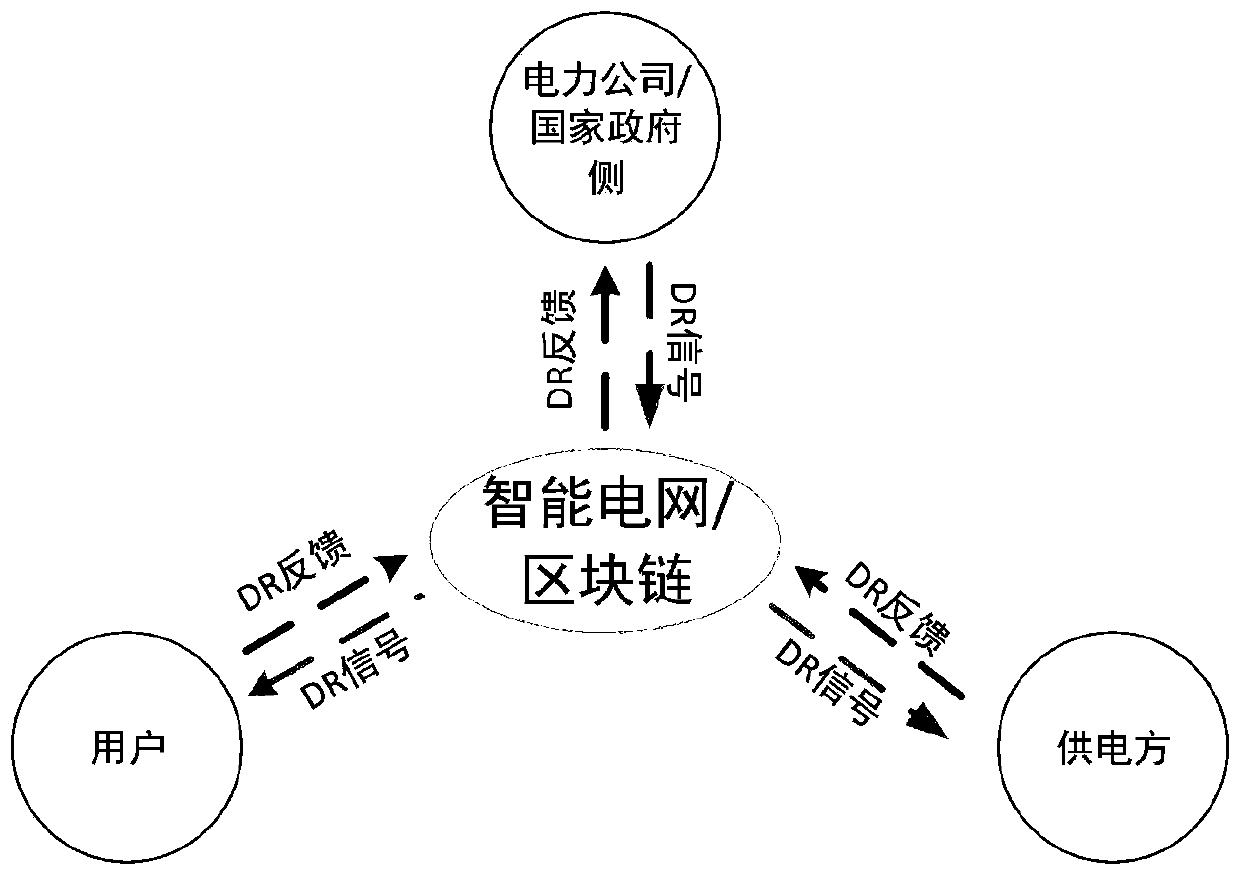

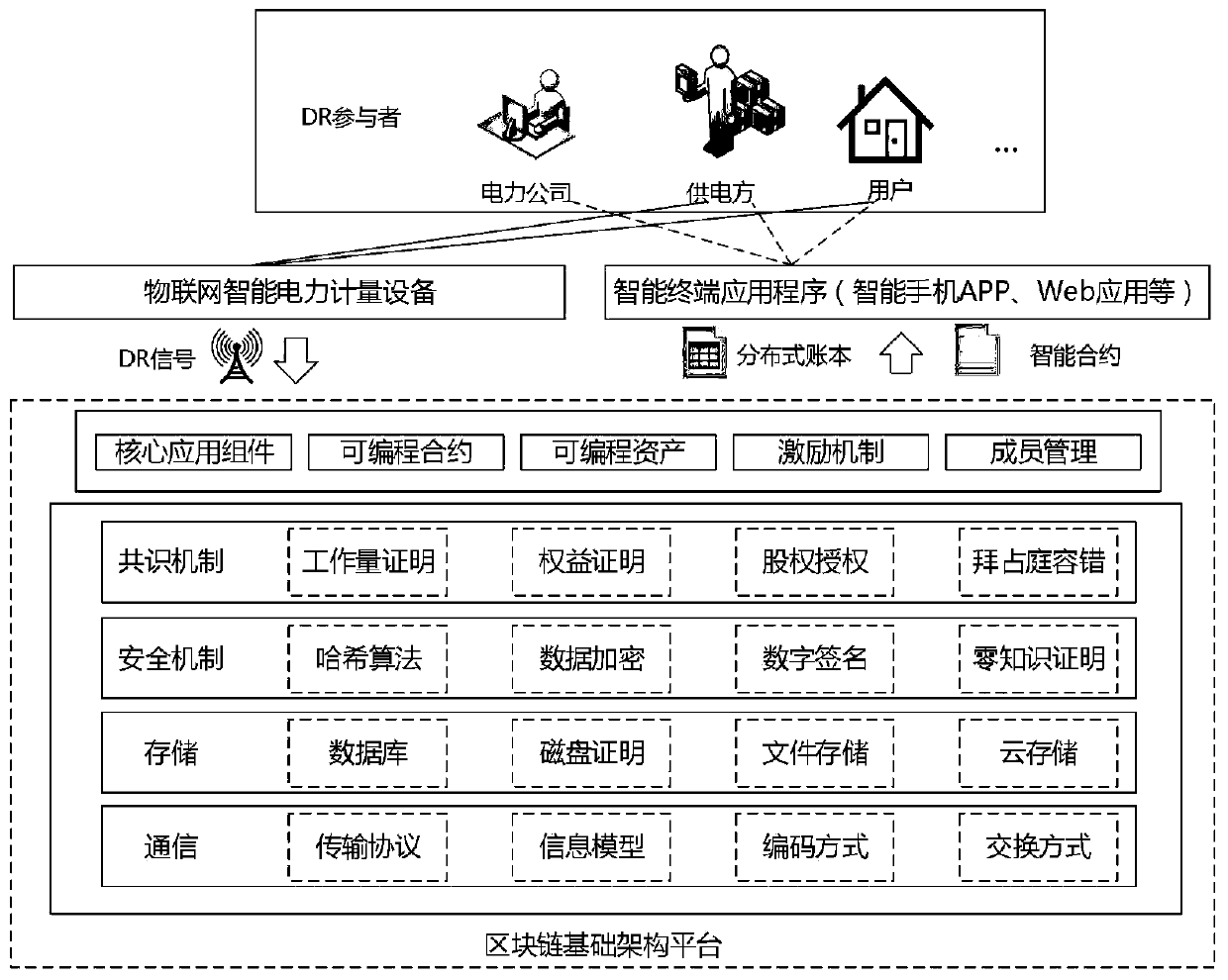

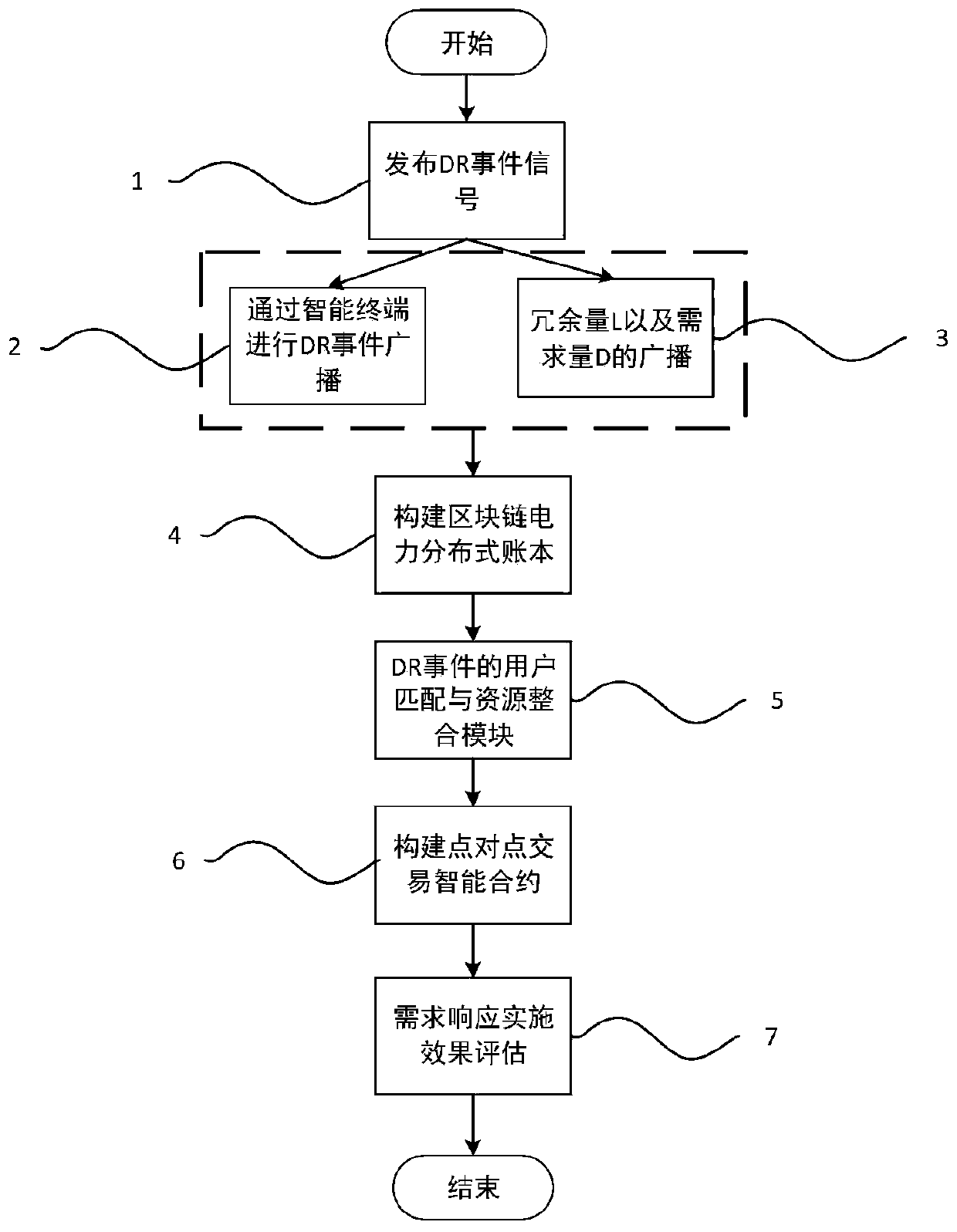

Control method of demand response management platform based on block chain technology

PendingCN111178682AImprove trustworthinessPreserve integrityResourcesInformation technology support systemIntegratorPower grid

The invention relates to a control method of a demand response management platform based on a block chain technology. The control method comprises the following steps: enabling a smart power grid to issue a DR event signal; broadcasting a DR event signal through the intelligent terminal; broadcasting redundancy and demand quantity; constructing a block chain electric power distributed account book; and performing user matching and resource integration of the DR event, and constructing a point-to-point transaction smart contract. The design is reasonable, the method is used for distributed management, control and DR verification in an intelligent power grid. Traceable and tamper-proof flexible transaction and nearly real-time DR verification are realized through the characteristics of the block chain. High reliability and decentralized operation are ensured; the whole demand response management platform is composed of a plurality of peer nodes including a power producer, a power company, a user, a load integrator, a supervision mechanism and the like, all stakeholders can carry out interaction coordination through an architecture platform based on a block chain, comprehensive and scattered energy demand and power generation cooperation are supported, and stable operation of a power grid is ensured.

Owner:STATE GRID TIANJIN ELECTRIC POWER +3

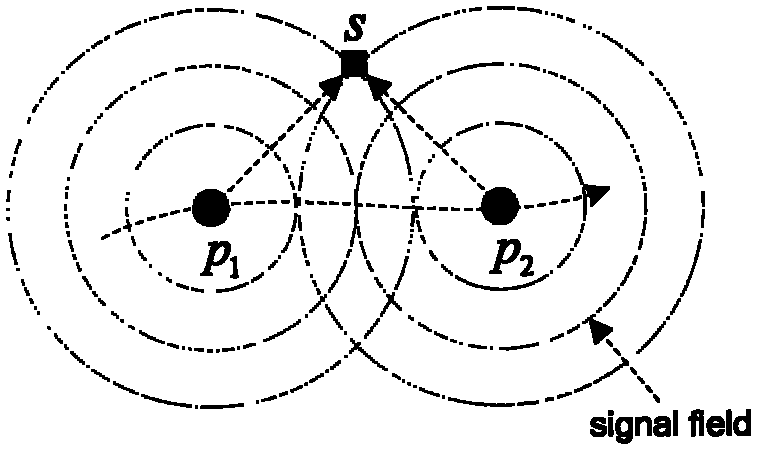

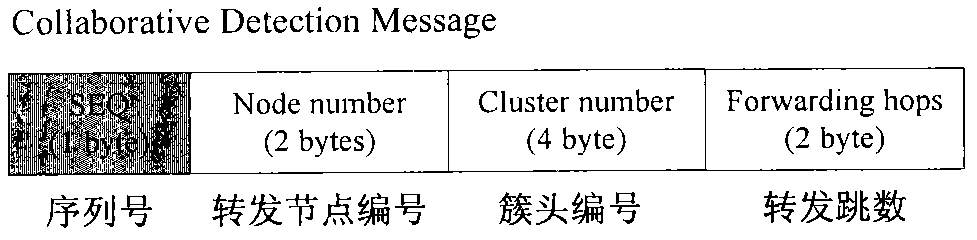

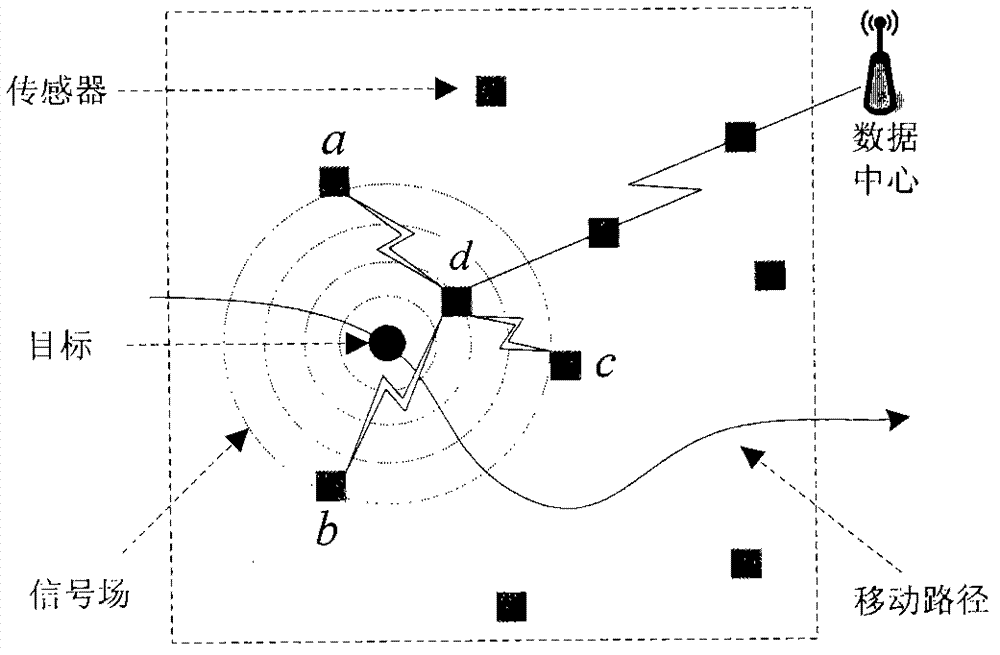

Correlation-based multi-sensor collaborative target detection method

InactiveCN102781032AEffective control quantityLower energy billsNetwork topologiesSensor nodeSearch and rescue

The invention discloses a correlation-based multi-sensor collaborative target detection method. The method is characterized by comprising the following steps that sensor nodes measure signals in a monitoring area independently; when the measured value of a certain sensor node exceeds a preset threshold, triggering to generate a dynamic detection cluster; member nodes in the cluster transmit a detection value sequence in a period of time to a cluster head node to form a detection matrix; and the cluster head node calculates the correlation measure among detection vectors in the detection matrix, and judges the existence of a target according to a calculation result. The target detection method provided by the invention is a measured value-based fusion detection method; a single sensor node does not need to perform local judgment; the influence on the judgment result caused by noises can be inhibited effectively; and the detection result has high accuracy. The method can be used in the aspects such as anti-intrusion alarm, people search and rescue under sudden disasters and traffic control in important places and areas.

Owner:NAVAL AERONAUTICAL & ASTRONAUTICAL UNIV PLA

Grass-growing cultivating mode of macadamia integrifolia orchard

InactiveCN108834714AImprove the effect of prevention and controlImprove planting efficiencyHops/wine cultivationTurf growingDiseasePest control

The invention discloses a grass-growing cultivating mode of a macadamia integrifolia orchard. The grass-growing cultivating mode comprises the following steps of constructing an orchard and performingplanting; performing fertilizing management; performing water management; performing leader branch cutting and performing trimming; performing extermination of diseases and insect pests; and performing grass growing in the orchard. According to the grass-growing cultivating mode disclosed by the invention, in accordance with the characteristics that in China, macadamia integrifolia is mainly planted in mountainous regions and hilly regions, and the row spacing between plants is large, orchard grass growing management is performed on the orchards; and besides, cultivation management of soil, water and fertilizers and the like is optimized, a macadamia integrifolia cultivating mode which is high in per mu yield, and can effectively exterminate diseases and insect pests, and take account ofprevention of soil erosion is provided, and the cultivating mode has important significance on accelerating the development of the macadamia integrifolia, enlarging the planting area and improving incomes of peasants.

Owner:SOUTH ASIAN TROPICAL AGRI SCI RES INST OF GUANGXI

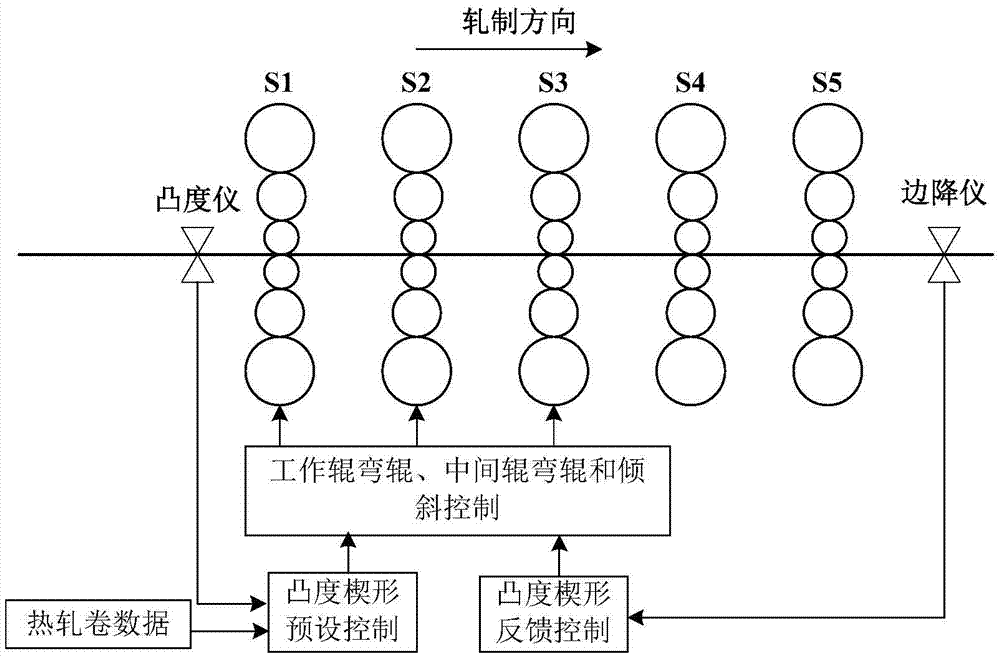

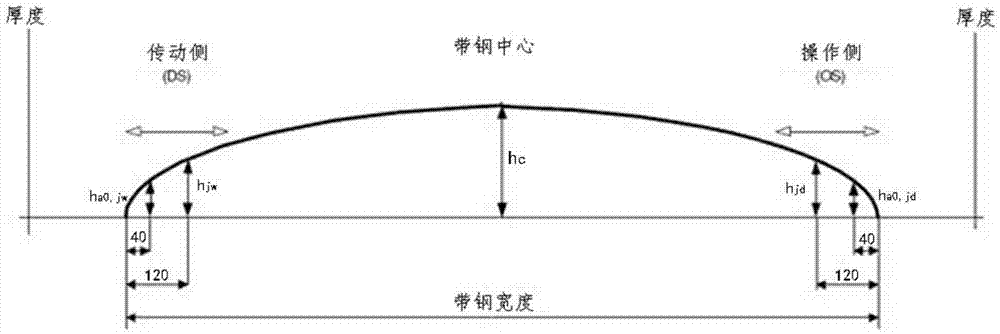

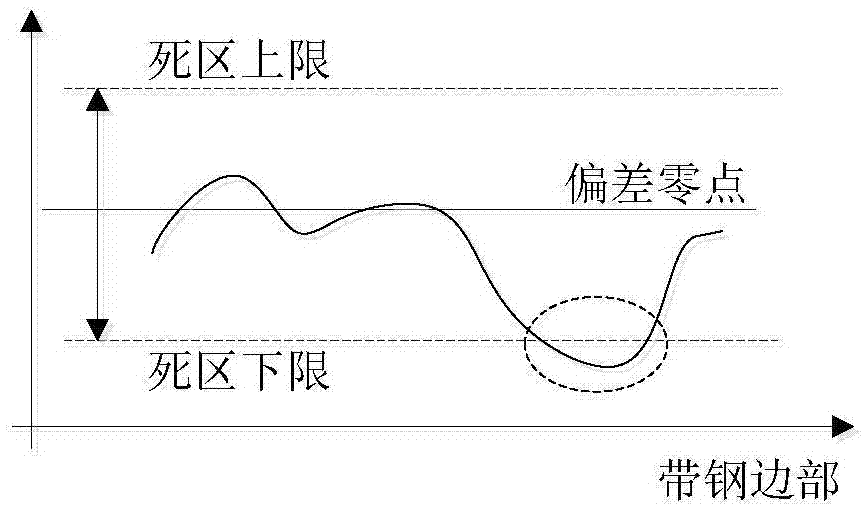

Cold-rolled silicon steel convexity and wedge shape dynamic setting control method

ActiveCN107127214AInhibit the impact of poor quality on the same boardSolve the problem of low control accuracy of transverse thickness uniformityRoll mill control devicesMetal rolling arrangementsLoop controlClosed loop

The invention relates to a cold-rolled silicon steel convexity and wedge shape dynamic setting control method. The method includes the steps that (1) a convexity and wedge shape preset control model is built; (2) the roller bending and pressing inclination of a rack S1 is adjusted; (3) the roller bending and pressing inclination of a second rack S2 and the roller bending and pressing inclination of a third rack S3 are adjusted; and (4) a convexity and wedge shape closed loop control model is built, wherein convexity and wedge shape closed loop control is achieved by adjusting the roller bending and pressing inclination of the rack S1 according to the convexity and wedge shape deviation actually measured by an outlet edge dropping instrument of a fifth rack S5, and please see the computational formula in the specification, wherein deltaF<w,1>=W<5m,a0>*K<ws,5>. According to the cold-rolled silicon steel convexity and wedge shape dynamic setting control method, convexity and wedge shape dynamic setting control over rolling mill inlet and outlet instrument detecting strip steel fracture surface measured data is used, and influences of the convexity and wedge shape deviation on the final intra-plate deviation quality are effectively restrained; and the outlet edge dropping instrument is used for cooperating with feedback control, the strip steel transverse thickness uniformity control accuracy in the cold-rolled silicon steel production process is improved, the lamination rate and the permeability of silicon steel products are accordingly improved, and the aim of improving the finished product quality and market competitiveness is achieved.

Owner:ANGANG STEEL CO LTD

Bottom material modifier used for aquaculture

InactiveCN105314691AAvoid Exceeding MetricsEffective control quantityClimate change adaptationWater/sewage treatmentPotassiumAquatic product

The invention relates to a bottom material modifier used for aquaculture. The bottom material modifier comprises a main raw material, an auxiliary material, and a carrier; the main raw material comprises potassium monopersulfate and sodium sulfate; the auxiliary material comprises one randomly selected from magnesium stearate, polyvinylpyrrolidone, potassium stearate, and microcrystalline cellulose; and the carrier comprises sodium sulfate. More specifically the main raw material comprises 4 to 20 parts of potassium monopersulfate and 79 to 95 parts of sodium sulfate; and bottom material modifier comprises 0.1 to 1 part of the auxiliary material. The raw materials above are directly pressed into tablets with a diameter ranging from 4 to 12mm; and the bottom material modifier is used for aquaculture to improve water body environment. The production cost of the bottom material modifier is not high; and the bottom material modifier is convenient to use, and is suitable to be popularized in related technological fields.

Owner:TIANJIN RONG LEE BIOTECH DEV CO LTD

Ecological method and application for controlling quantity of spirogyra biomass in lakes

InactiveCN104445628AReduce wasteAvoid chemical toxicityEnergy based wastewater treatmentBiological water/sewage treatmentTilapiaEconomic benefits

The invention discloses an ecological method and an application for controlling quantity of spirogyra biomass in lakes. The ecological method comprises the steps of: breading tilapias in lakes where submerged plants are grown; controlling the quantity of the tilapias to minimize influence of the tilapias on the submerged plants and effectively control spirogyra. The ecological method provided by the invention can prevent chemical toxicity brought by chemical method for controlling spirogyra and reduce manpower and property waste caused by manually catching sponge; and the harvested tilapias can bring a certain economic benefit; furthermore, the ecological method also can effectively control the quantity of pomacea canaliculata. As can be seen, the ecological method and application for controlling the quantity of the spirogyra biomass in lakes can be applied to maintaining the lake ecosystem, and is environment-friendly.

Owner:广州贝山水生态科技有限公司

Crataeguspinnatifida bunge alpha hydroxyl acid beverage and preparation method thereof

ActiveCN108065155AMake sure it's authenticEnsure naturalnessFood ingredient as colourFood preservationFruit juiceVitamin C

The invention discloses a preparation method of a crataeguspinnatifida bunge alpha hydroxyl acid beverage. The crataeguspinnatifida bunge alpha hydroxyl acid beverage comprises adding crataeguspinnatifida bunge oligosaccharide with a polymerization degree of 12-14 into crataeguspinnatifida bunge juice instead of saccharides, sweetening agent and preservative agent, performing low-temperature short-time sterilization at 65-75 DEG C for 5-10 minutes to obtain the crataeguspinnatifida bunge alpha hydroxyl acid beverage. The preparation method of the crataeguspinnatifida bunge alpha hydroxyl acidbeverage is simple in process and convenient to operate, can effectively protect activity of vitamin C to fully retain nutrition and flavor of crataeguspinnatifida bunge and effectively prolong the shelf life of the crataeguspinnatifida bunge alpha hydroxyl acid beverage. According to the prepared crataeguspinnatifida bunge alpha hydroxyl acid beverage, the raw materials of both juice and additives are from crataeguspinnatifida bunge, and both the content and the nutritional value are high, so that the crataeguspinnatifida bunge alpha hydroxyl acid beverage is rich in flavor and taste and wellachieves the functions of reducing blood pressure and fat, promoting digestion to eliminate stagnation, guiding qi, invigorating blood circulation, dissipating blood stasis and resisting radiation and aging as well as good healthcare effects of improving body immunity.

Owner:承德怡达食品股份有限公司

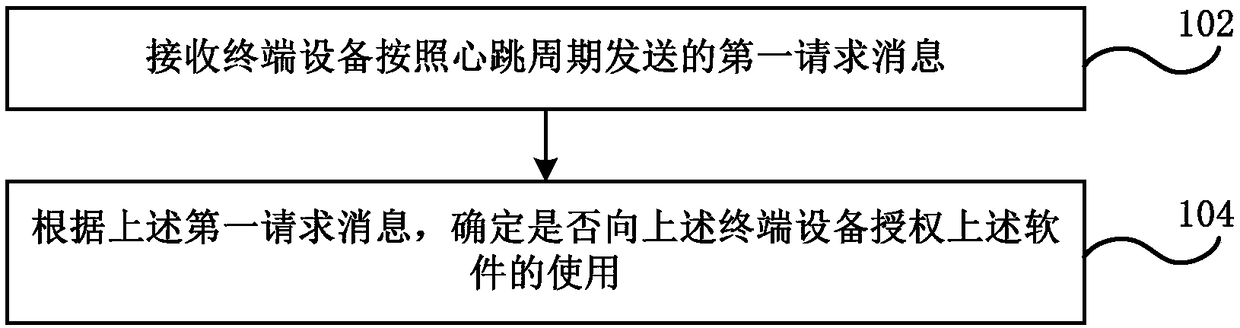

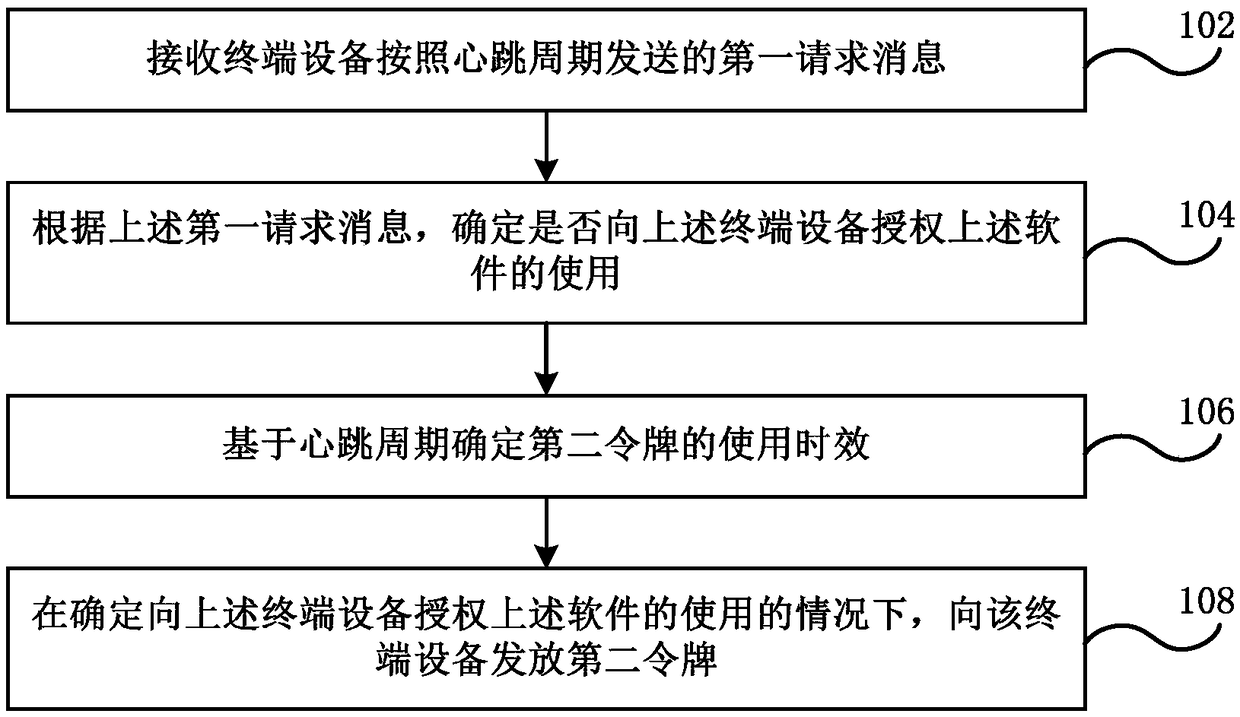

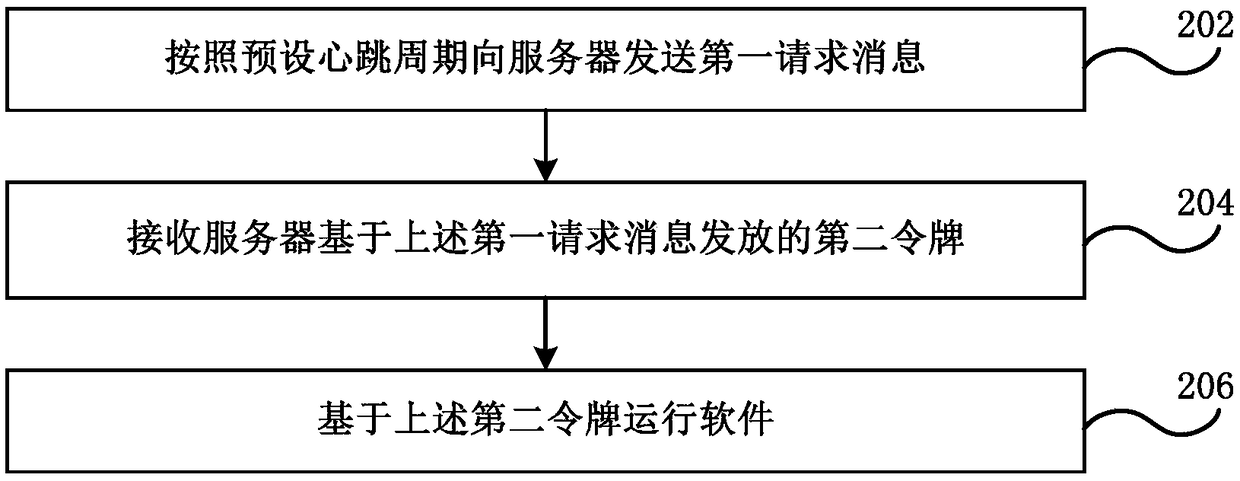

Software authorization processing and operation method and apparatus, and electronic device

ActiveCN108846263ARun effective controlControl quantityProgram/content distribution protectionAuthorizationVirtual machine

The embodiment of the invention discloses a software authorization processing and operation method and device, and an electronic device. The software authorization processing method comprises the following steps: receiving a first request message sent by a terminal device according to a heartbeat cycle, wherein the first request message comprises a first token for controlling operation of software, and user information; and determining whether the use of the software is authorized to the terminal device according to the first request message. According to the embodiment of the invention, the operation of the software on the terminal equipment can be effectively controlled and effectively control the quantity of the software simultaneously used by the same user information can be effectively controlled. The software authorization processing and operation method and device, and the electronic device can be applied to any terminal device, such as a computer, a virtual machine and the like.

Owner:BEIJING SENSETIME TECH DEV CO LTD

Method for killing limnoperna lacustris in long-distance raw water conveying pipe through hydrogen peroxide

InactiveCN103496770AEffective control quantityGood removal effectWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by oxidationTurbidityFresh water

The invention discloses a method for killing limnoperna lacustris in a long-distance raw water conveying pipe through hydrogen peroxide, and relates to a method for killing the limnoperna lacustris in a raw water conveying pipe. The method comprises the steps that the hydrogen peroxide is thrown in the long-distance raw water conveying pipe at the temperature of 20 DEG C to 30 DEG C for 4 to 14 days, and the concentration of the hydrogen peroxide in the raw water is controlled to be 1 to 10 mg / L. According to the method for killing the limnoperna lacustris in the long-distance raw water conveying pipe through the hydrogen peroxide, the hydrogen peroxide not only has the effect of killing the limnoperna lacustris, but also has the good pre-oxidation effect as pre-oxidant. The hydrogen peroxide has the good removing effect on turbidity, algae, bacteria and coilform groups, and the difficulty of the follow-up water processing technology is not increased. The method for killing the limnoperna lacustris in the long-distance raw water conveying pipe through the hydrogen peroxide can effectively control the amount of the limnoperna lacustris in raw water and in the pipe, and by means of the method, operation is safe and convenient, and the feasibility is high.

Owner:HARBIN INST OF TECH

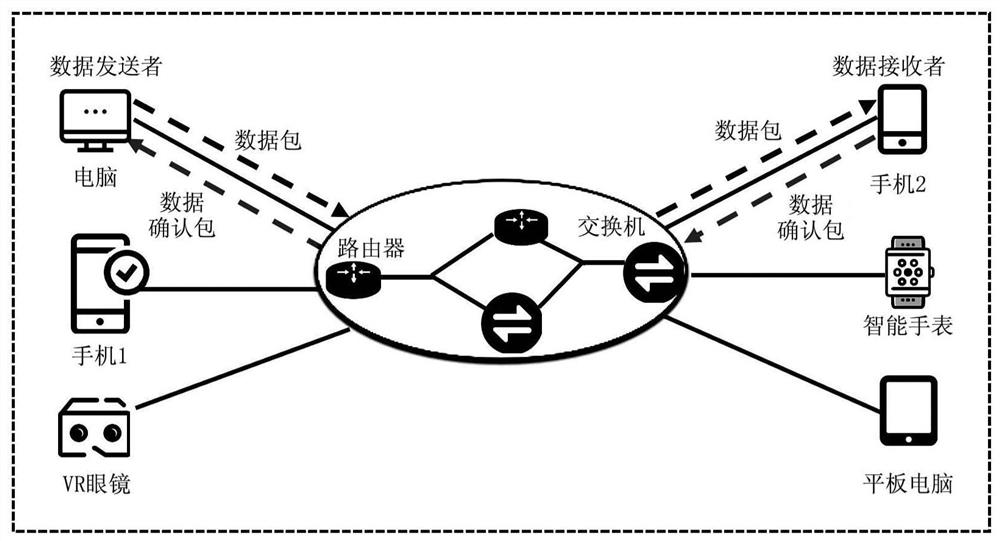

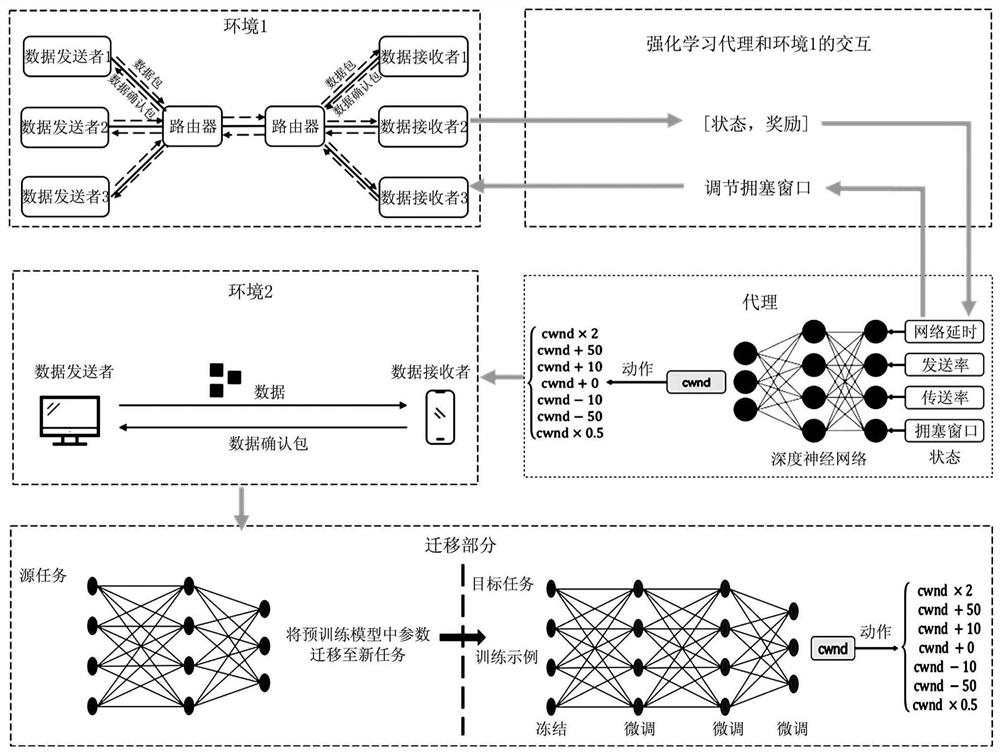

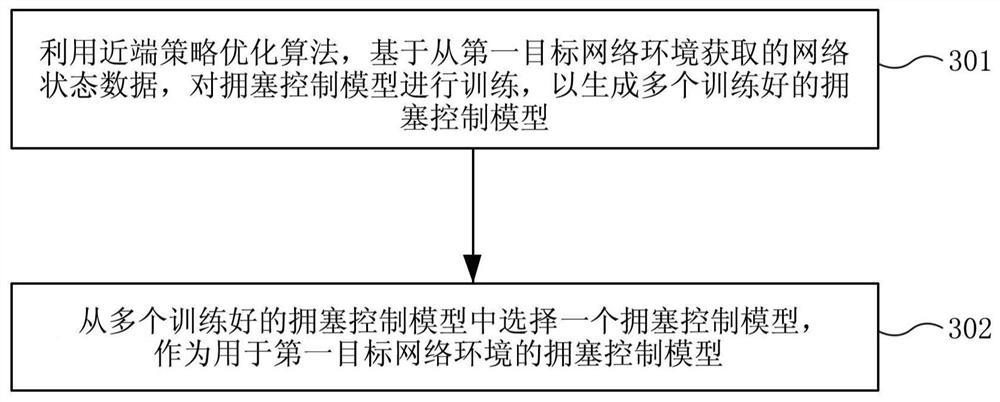

Training method and device of congestion control model and congestion control method and device

ActiveCN112770353AReduce lossEffective control quantityNetwork traffic/resource managementNeural architecturesCongestion windowSimulation

The invention relates to a training method and device of a congestion control model and a congestion control method and device. The training method comprises the following steps: training a congestion control model based on network state data acquired from a first target network environment by using a near-end strategy optimization algorithm to generate a plurality of trained congestion control models; selecting one congestion control model from the plurality of trained congestion control models as a congestion control model for a first target network environment, wherein the input of the congestion control model is the network state data, and the output of the congestion control model is a congestion window size adjusting action.

Owner:WUHAN UNIV +1

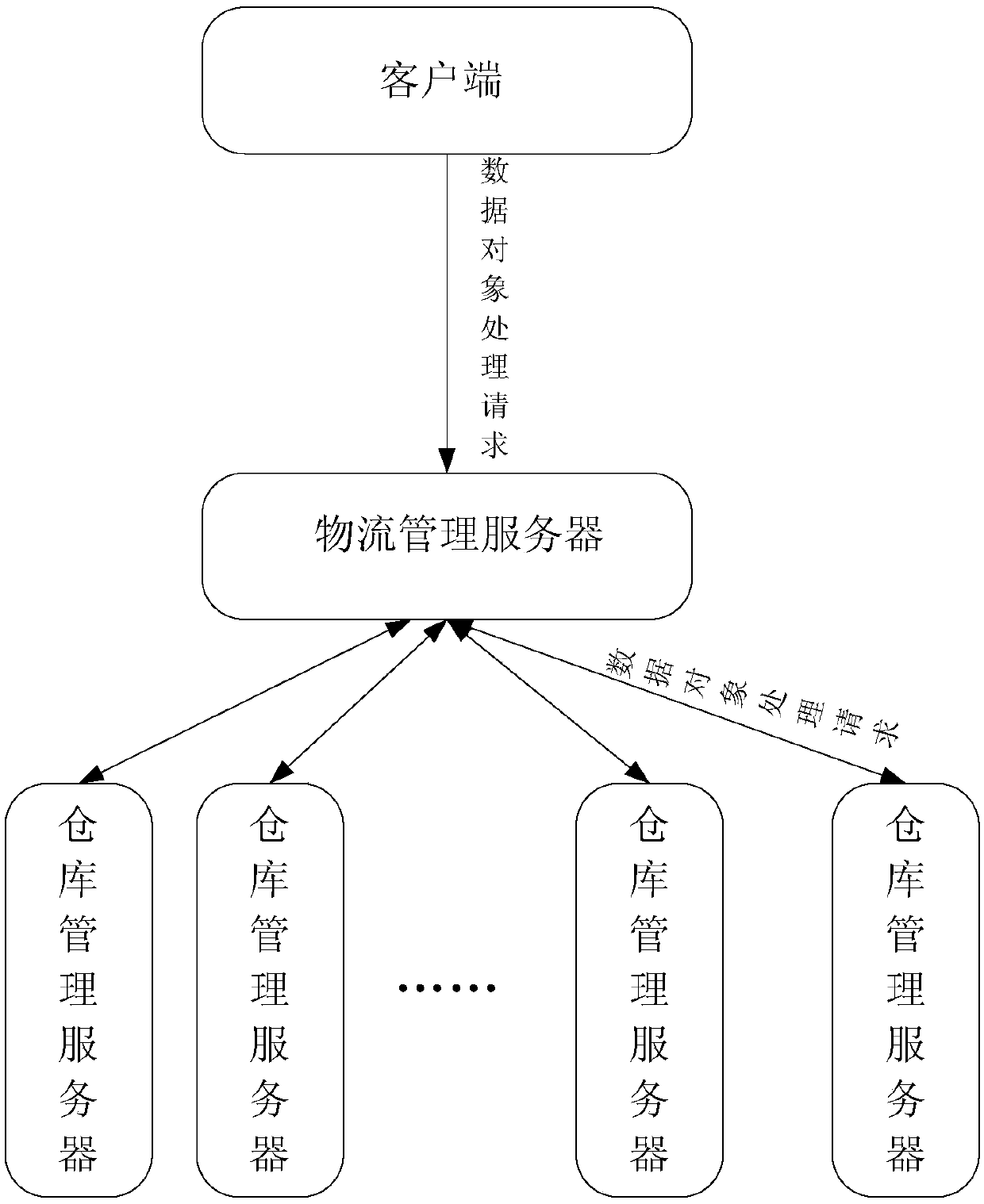

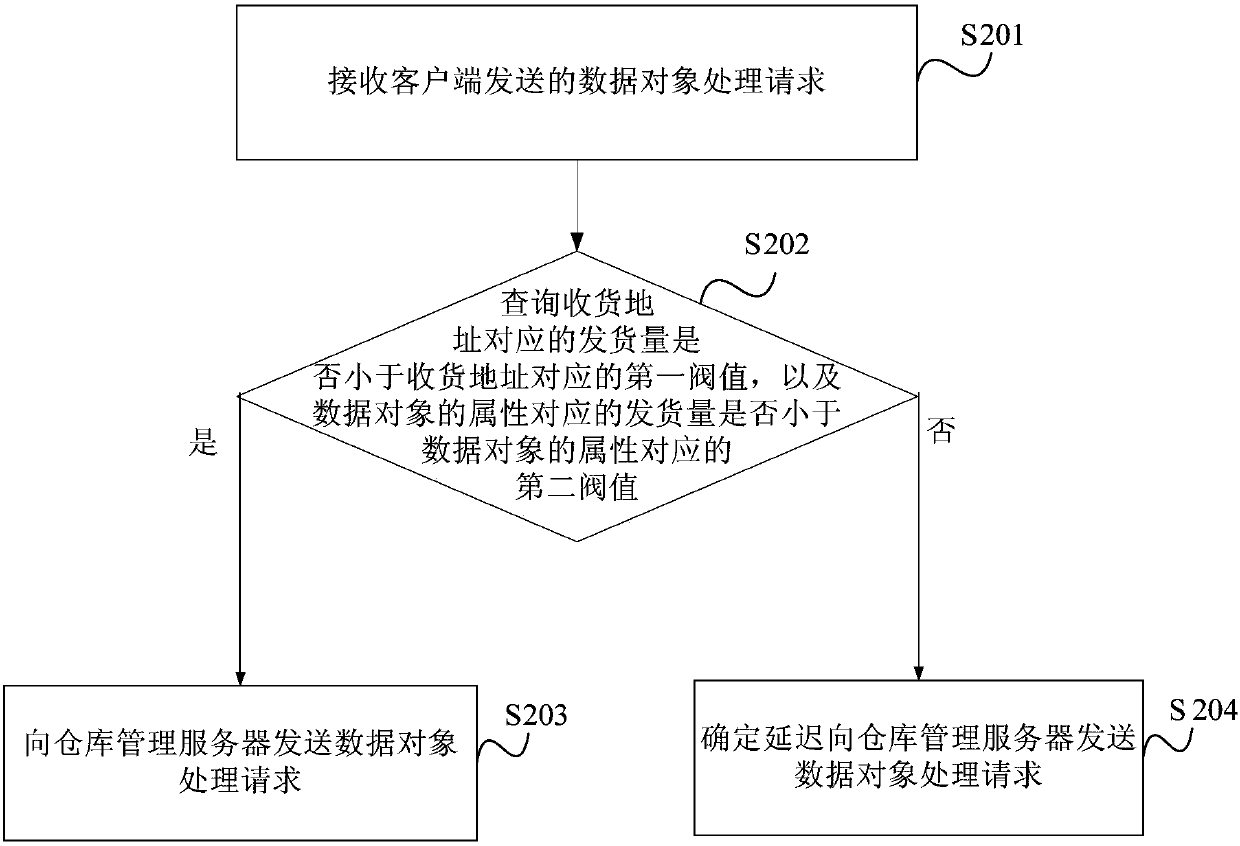

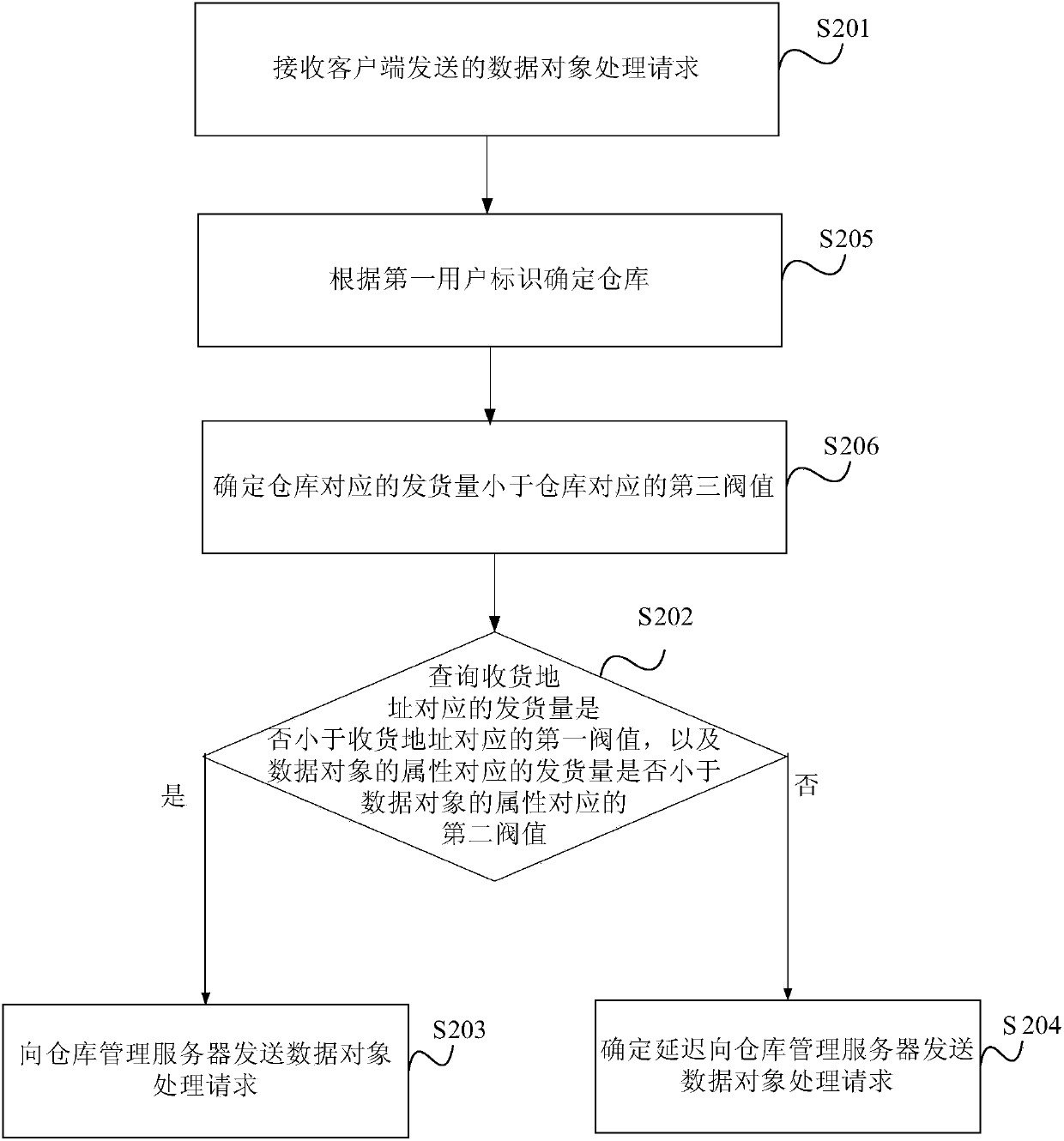

Data processing method and device

ActiveCN107808265AAvoid confusionAvoid delivery errors and other problemsBuying/selling/leasing transactionsLogisticsDatabaseData objects

The invention provides a data processing method and device. Whether a shipment corresponding to a receiving address is smaller than a first threshold value corresponding to the receiving address or not and whether a shipment corresponding to an attribute of a data object is smaller than a second threshold value corresponding to the attribute of the data object or not are inquired through receivinga data object processing request, which includes receiving address information related to the data object and the attribute information of the data object, sent by a client terminal. If the shipmentcorresponding to the receiving address is smaller than the first threshold value corresponding to the receiving address and the shipment corresponding to the attribute of the data object is smaller than the second threshold value corresponding to the attribute of the data object, the data object processing request is sent to a warehouse management server so as to enable warehouse workers to perform delivery treatment according to the data object processing request. Therefore, delivery efficiency of a warehouse is improved.

Owner:CAINIAO SMART LOGISTICS HLDG LTD

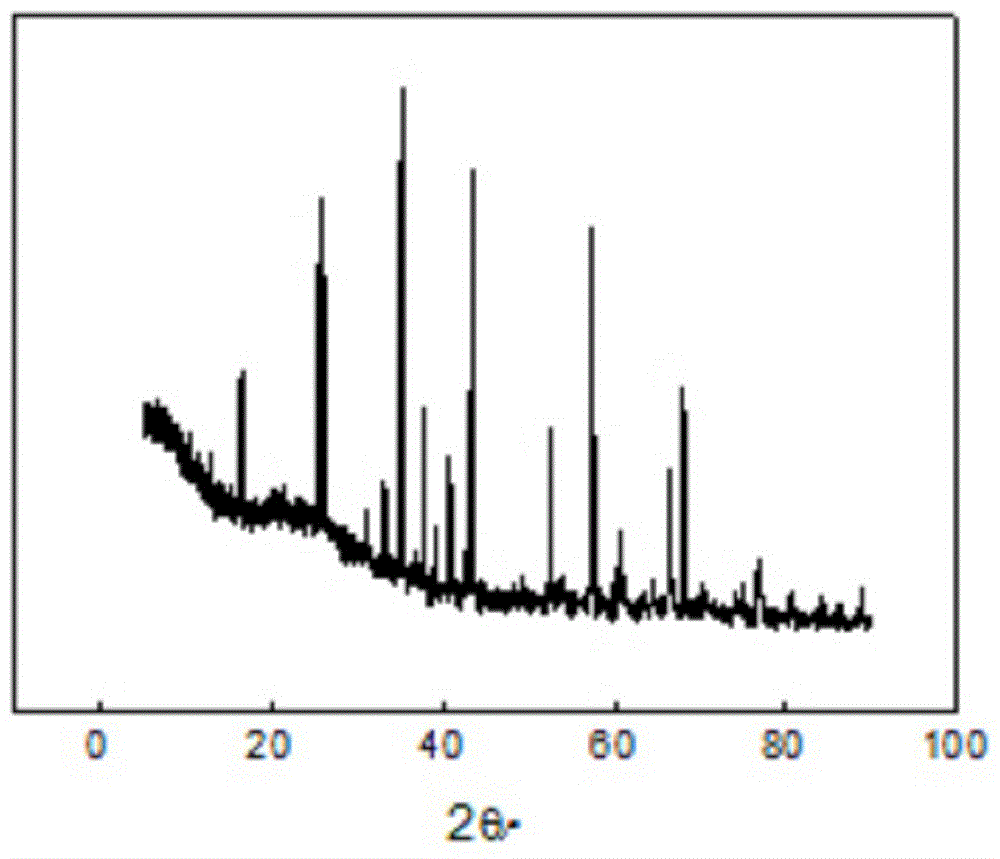

Porous mullite-corundum ceramics preparation method

The invention relates to a porous mullite-corundum ceramics preparation method. The method takes bauxitic clay and diatomite as raw materials, then employs steps of wet grinding, filtering, drying and stirring, and additionally adds a binder, a dispersant, a foam stabilizer and a foaming agent, and finally the product is molded, dried and sintered to obtain the porous mullite-corundum ceramics. The method has the characteristics of simple process, short production period, high efficiency, stable product quality, and low cost. The porous mullite-corundum ceramics material can be prepared according to the requirement, and has good industrial utilization prospect.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

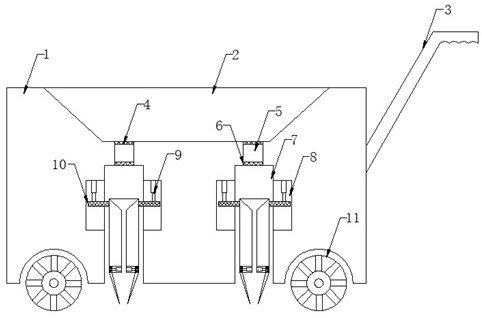

Punching and sowing integrated machine for tea planting

InactiveCN112056040ASowing is effectiveSowing realizedPlantingFurrow making/coveringHydraulic cylinderAgricultural engineering

The invention discloses a punching and sowing integrated machine for tea planting, which comprises a box body. A plurality of first grooves are formed in the bottom end of the box body at equal intervals, second grooves are formed in the groove walls of the two sides of each first groove, electric hydraulic cylinders are fixedly installed at the top ends of the two second grooves, connecting blocks are connected to the output ends of the two electric hydraulic cylinders, and one sides of the two connecting blocks are fixedly connected with the two sides of a punching cylinder correspondingly.According to the punching and sowing integrated machine for tea planting, the connecting blocks installed on the two sides of the punching cylinder are pushed through the electric hydraulic cylinders,the ground is effectively punched through the punching cylinder, and therefore tea seeds are sown. Sliding blocks are pushed to move through electric telescopic rods, the punching diameter is effectively controlled, and through installed limiting barrels, the quantity of the tea seeds put into the holes is effectively controlled, resource waste caused by excessive putting of the tea seeds is prevented, and the situation that the germination rate of the tea seeds is affected due to putting of too few tea seeds is avoided.

Owner:新沂经济开发区建设发展有限公司

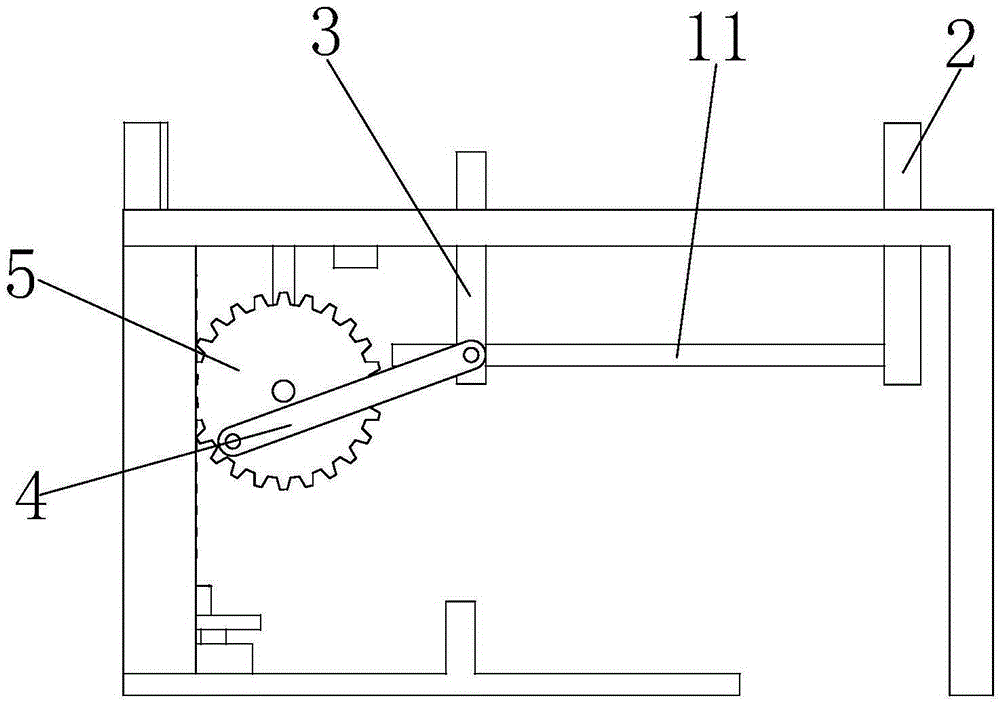

Controllable milling end face clamp for batches of workpieces

InactiveCN105269372AEasy to control the number of milling operationsEffective control quantityWork clamping meansPositioning apparatusGear wheelEngineering

The invention relates to a controllable milling end face clamp for batch of workpieces. The controllable milling end face clamp comprises a workbench, wherein four sliding grooves uniformly distributed in the workbench on the horizontal direction; a positioning plate is arranged at the right end of each sliding groove, and a clamping plate is mounted in each sliding groove in a sliding manner; the lower end of each clamping plate is articulated with a connecting rod, and a gear is arranged on the left side of each connecting rod; the left end of each connecting rod is articulated at the edge end of each gear, and the left side of each gear is meshed with a rack; a fixing plate for longitudinally mounting each rack in a sliding manner is arranged on the left side of each rack, and an adapter plate is arranged under each rack; a transiting extending end is mounted at the rear end in each adapter plate in a sliding manner, a push plate for fixedly mounting the adapter plate is arranged at the lower end of each adapter plate, and the lower end of the push plate is connected with an air cylinder. The controllable milling end face clamp can quickly clamp multiple workpieces in one time in a high automation way, and can also effectively control the quantity of the clamping workpieces through the fore-and-aft sliding of the transiting extending ends, therefore indirectly achieving the effects that the milling quantity of workpieces is conveniently controlled and the processing speed is increased.

Owner:WUHU TAINENG ELECTRIC APPLIANCES

Method for killing fresh water moule in raw water transportation pipeline by utilizing potassium permanganate

ActiveCN102205999BEasy to operateSolve problems that endanger the water delivery function of water pipelinesWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationFlocculationDisinfection by-product

The invention discloses a method for killing fresh water moule in a raw water transportation pipeline by utilizing potassium permanganate and relates to a method for killing the fresh water moule in the raw water transportation pipeline, solving the problems that the existing method for killing the fresh water moule in the raw water transportation pipeline is complicated in operation and is poor in feasibility, disinfection byproducts are generated by using a killing method in which a chloride-containing disinfector is used so as to threaten the safety of drinking water. The method comprises the step of continuously adding the potassium permanganate in the raw water transportation pipeline for 5-12 days, wherein the concentration of the potassium permanganate in each L of raw water is controlled to 1.2-1.5 mg, so that the fresh water moule in the raw water transportation pipeline is killed. The potassium permanganate can oxidize and kill the fresh water moule, the mortality of the fresh water moule is above 70%; and simultaneously, the potassium permanganate can remove fume in water and can exert a nuclear coagulation effect of manganese dioxide, thus the purposes of flocculation and precipitation are achieved in advance, and the difficulty of subsequently water treatment process is not increased. According to the invention, operation is simple, safe and stable, and no disinfection byproducts are generated, thus the method has an extremely high practicability.

Owner:HARBIN INST OF TECH

Ultrasonic preparation method for carotenoid geometrical isomer

ActiveCN101863810ATypes of Effective ControlEffective control quantityHydrocarbon purification/separationHydrocarbonsSolventChromatographic column

The invention discloses an ultrasonic preparation method for a carotenoid geometrical isomer, which comprises the following steps: (1) taking all-trans carotenoid and methylene chloride as a raw material and a solvent respectively so as to prepare solution; (2) putting the above solution into a container and using 20 khz probe-type pulse ultrasonic wave to process, wherein the processing procedure comprises the following steps: inserting the probe into undersurface of the solution for 1cm; keeping the height liquid level being within the range of 5-8cm to process for 5-20 minutes under the contions of 2-5s of pulse time, 50%-90% of duty cycle, -5-25 DEG G of temperature and 60.51-544.59 W / cm2 of sound intensity; and (3) using a C30 carotenoid chromatographic column to carry out routine chromatograph separation on product obtained by step (2) to obtain the carotenoid geometrical isomer; in addition, step (1) and step (2) are operated in the condition without sunlight. The carotenoid geometrical isomers with different types and quantities can be obtained effectively by the method.

Owner:ZHEJIANG UNIV

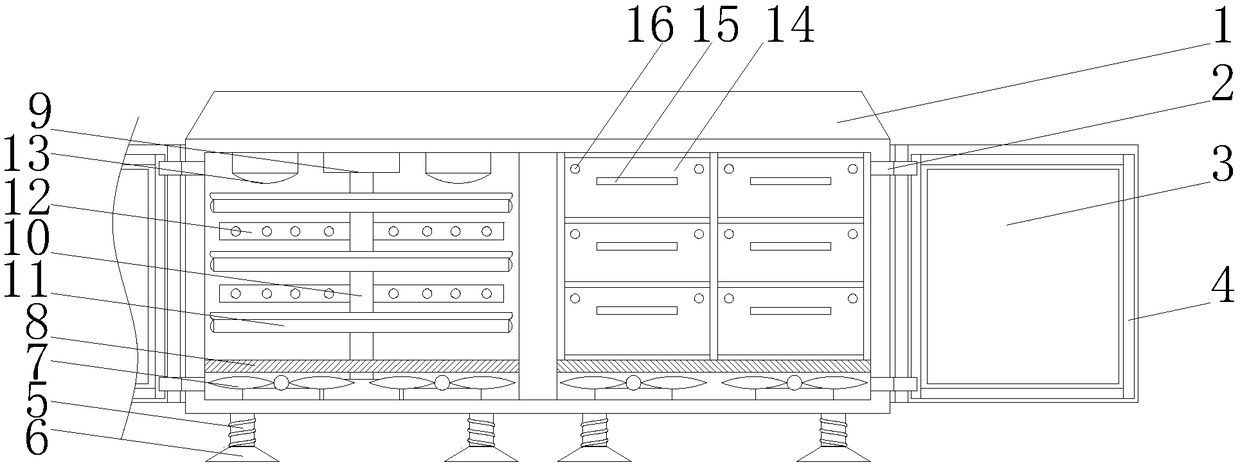

Medical article storage cabinet with automatic thermostat and sterilizer

InactiveCN108887902AGrowth inhibitionEffective control quantityChestsDressing tablesMicroorganismInsulation layer

The invention discloses a medical article storage cabinet with automatic constant temperature and sterilizer, comprises a cabinet body, one side wall of the cabinet body is rotatably connected with arotating shaft, one end of the rotating shaft is fixedly connected with a cabinet door, an inner wall of the cabinet door is fixedly connected with a seal, a spring rod is fixedly connected with a fixing seat at the bottom end of the spring rod of the cabinet body, a fan is fixedly connected with the bottom end of the cabinet body, and a heater positioned directly above the fan is fixedly connected with the inside of the cabinet body. The invention can effectively inhibit the growth of microorganisms by arranging an antibacterial layer of stainless steel, The ceramic insulation layer can effectively reduce the heat dissipation in the cabinet, thereby reducing the working time of the heater or the humidifier, saving energy and protecting the environment, and the ultraviolet sterilization lamp arranged at the same time can effectively control the quantity of microorganisms in the cabinet, thereby enhancing the practicability of the medical articles storage cabinet with the automatic constant temperature sterilizer.

Owner:芜湖碧水谣医疗设备科技有限公司

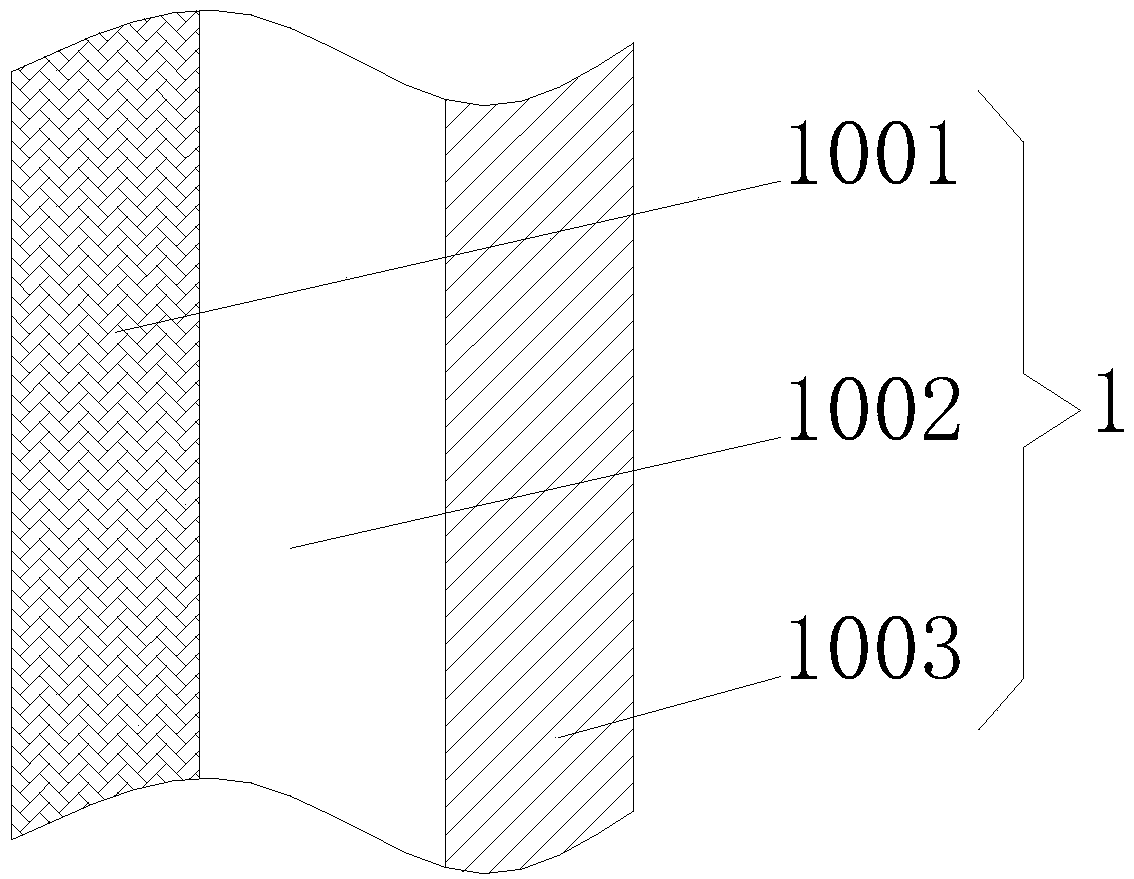

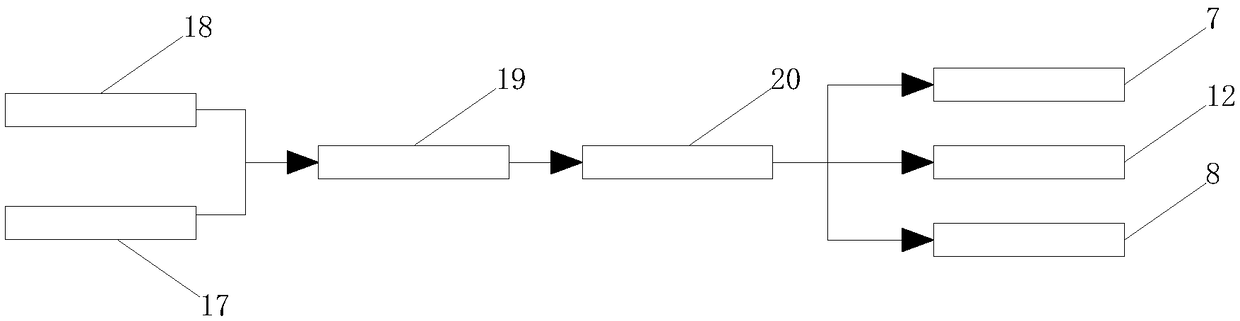

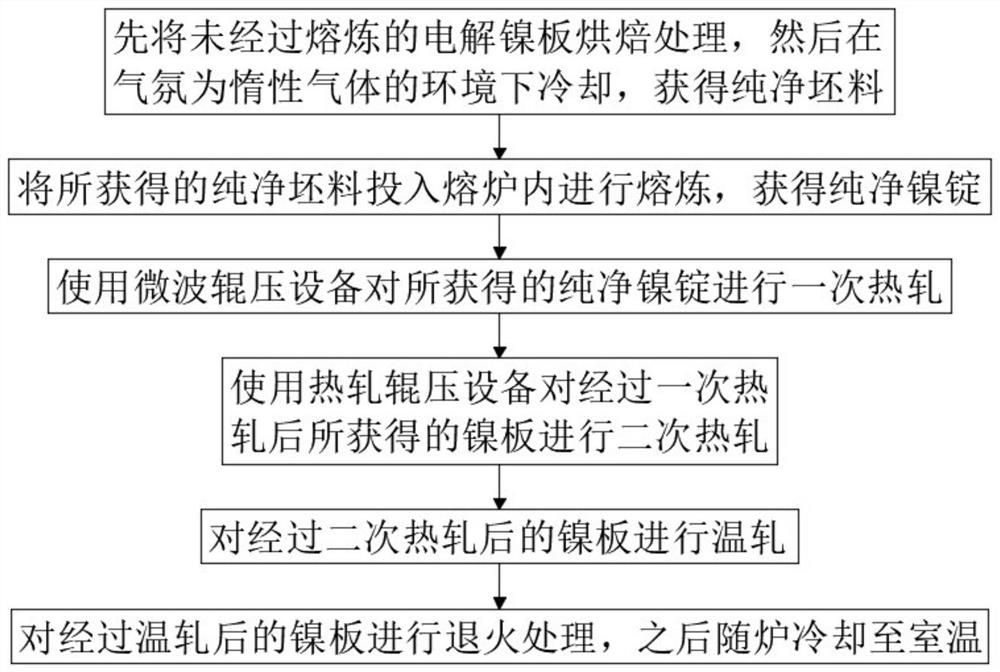

Nickel strip manufacturing process method capable of reducing generation of internal bubbles

InactiveCN112296119AImprove firmnessCompact structureMetal rolling arrangementsElectrolysisNonferrous metal

The invention discloses a nickel strip manufacturing process method capable of reducing generation of internal bubbles, and belongs to the technical field of non-ferrous metal material processing. Thenickel strip manufacturing process method comprises the following process flows: S1, firstly, an electrolytic nickel plate which is not smelted is baked, and then cooling is conducted in an atmosphere of inert gas to obtain a pure blank; S2, the obtained pure blank is put into a smelting furnace to be smelted, and a pure nickel ingot is obtained; and S3, primary hot rolling is conducted on the obtained pure nickel ingot by using microwave rolling equipment. According to the method, through the designed microwave rolling equipment, hot rolling equipment, primary hot rolling, secondary hot rolling, warm rolling and annealing processes, on the basis that the compactness of a nickel plate can be improved and the number of micropores and bubbles in the nickel plate and on the surface of the nickel plate can be effectively controlled, a large number of bubbles can be further eliminated, the micropore number can be reduced, and new microscopic cracks and bubbles cannot be generated, so thata metal nickel strip is more compact in structure, high in rolling precision and good in effect.

Owner:无锡腾达海川新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com