Patents

Literature

43results about How to "Sowing realized" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

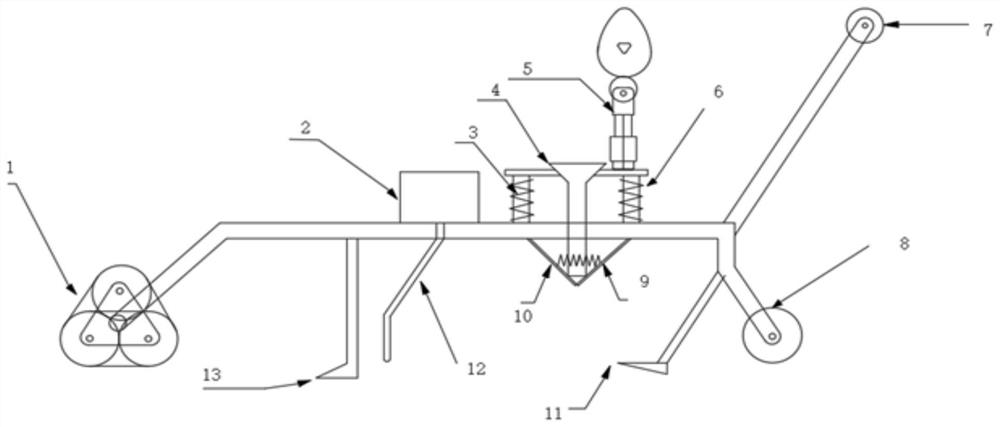

Device for tomato planting

InactiveCN108934277AStable deliveryAvoid accumulationSowingSeed coating/dressingEngineeringSilica gel

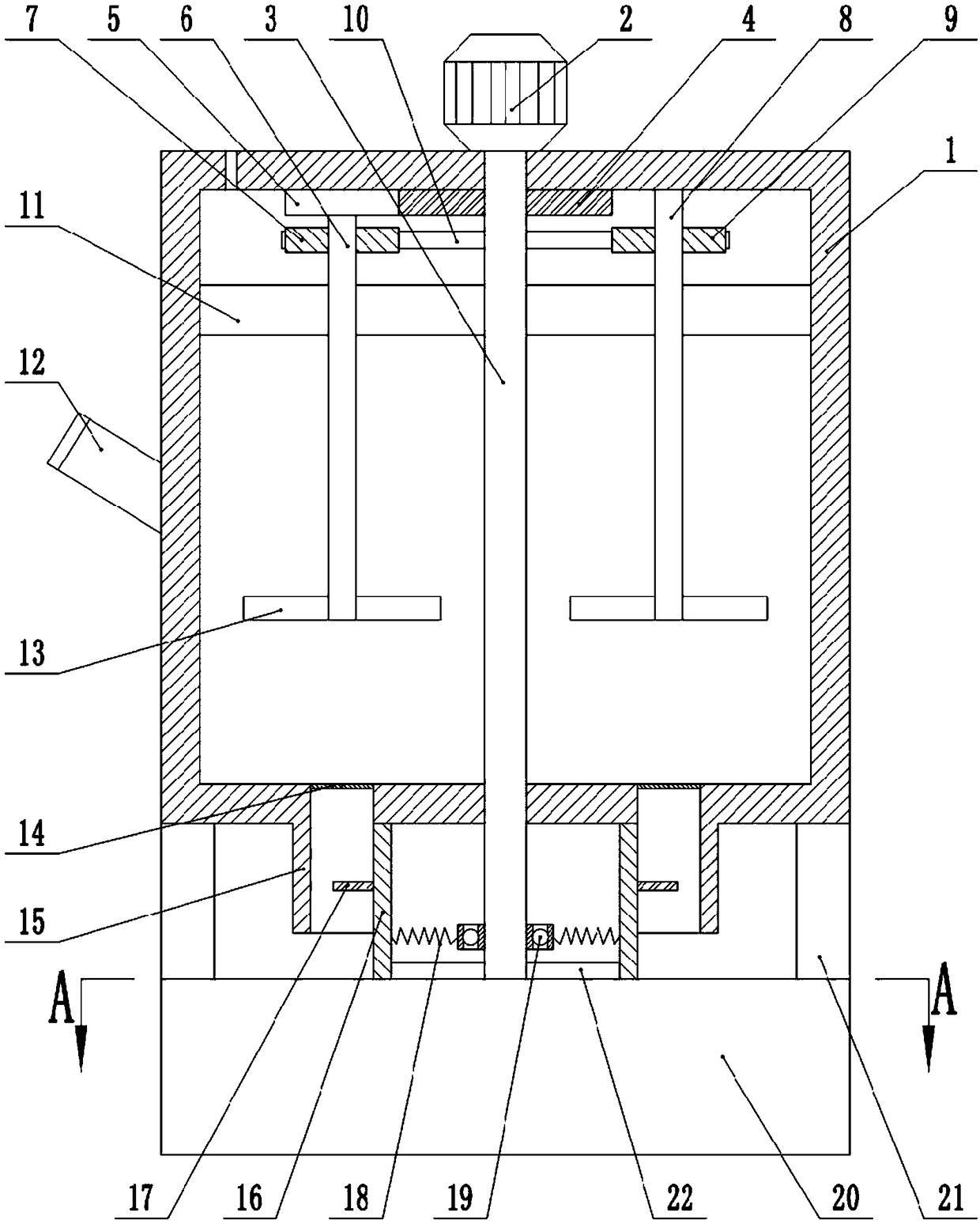

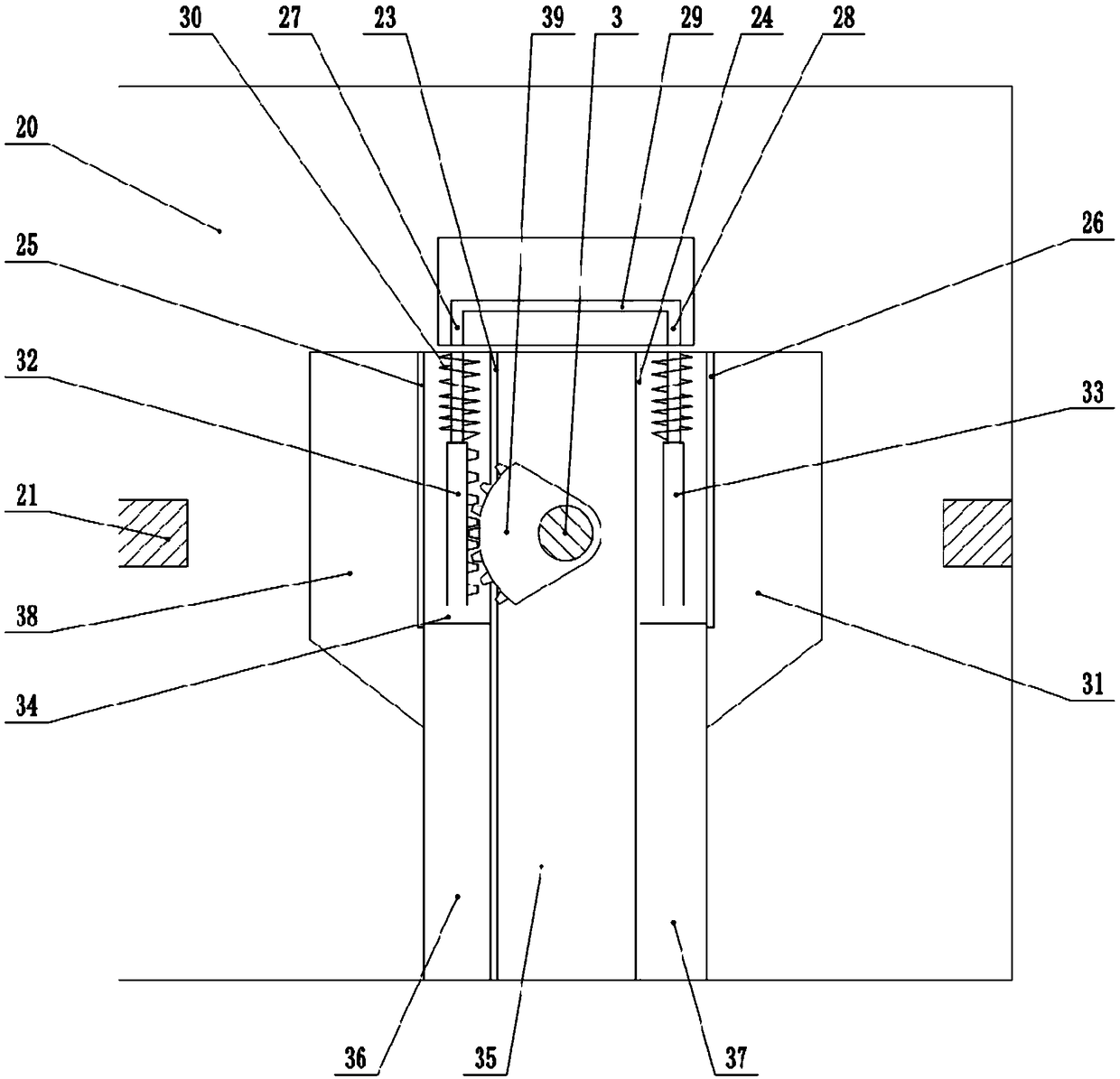

The invention belongs to the technical field of general agricultural machinery for sowing or fertilizing and particularly discloses a device for tomato planting. The device comprises a base and a mixing drum. The mixing drum is fixed to the base. An extrusion part is arranged in the mixing drum. The mixing drum is provided with a driving mechanism. The extrusion part is driven by the driving mechanism. A stirring mechanism is arranged in the mixing drum. The driving mechanism drives the stirring mechanism. The side wall of the mixing drum is provided with a feeding port for feeding nutrient soil, tomato seeds and dry silica gel particles. The lower end of the mixing drum is provided with a discharge port. The lower end of the discharge port is connected to an extrusion mechanism for extruding and cutting the materials to obtain particles. The extrusion mechanism is driven by the driving mechanism. The base is provided with a catapult mechanism. The catapult mechanism comprises a sowingtank below the discharge port. A pushing plate for pushing materials is slidably connected to the interior of the sowing tank and is driven by the driving mechanism. The device solves the problem that the existing tomato sowing method has complicated processes and needs peasant bending work.

Owner:贵州省福轩实业发展有限公司

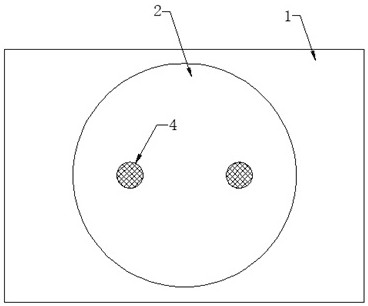

Sowing device for crop seeds

InactiveCN106508209ASowing realizedSow evenlySeed depositing seeder partsBroadcast seedersRotational axisEngineering

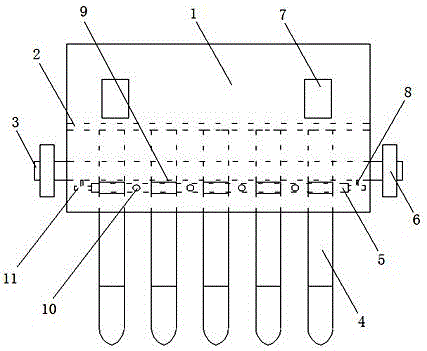

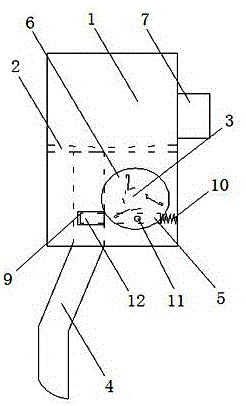

The invention discloses a sowing device for crop seeds. The sowing device comprises a seed box, a blanking board, a rotating shaft, blanking pipes, an adjusting plate and transmission wheels. The sowing device is characterized in that mounting blocks are arranged on the outer wall of the seed box, the blanking plate is arranged in the seed box, both ends of the rotating shaft penetrate the seed box, and shift levers are arranged at both ends of the rotating shaft in the seed box; the adjusting plate is arranged on the inner wall of the seed box by springs, the adjusting rods are arranged on both sides of the adjusting plate, baffles are arranged on the adjusting plate, and the transmission wheels are arranged at both ends of the rotating shaft. When sowing is needed, the transmission wheels drive the rotating shaft to rotate, the shift levers on the rotating shaft shift the adjusting rods to move the adjusting plate, the baffles exit from connecting grooves, the seeds are sown into soil through the blanking pipes, and sowing of the crop seeds is realized; multiple shift levers are arranged on the rotating shaft, so that the crop seeds are sown more uniformly, waste of the seeds is reduced, and the work efficiency is improved.

Owner:陶胜

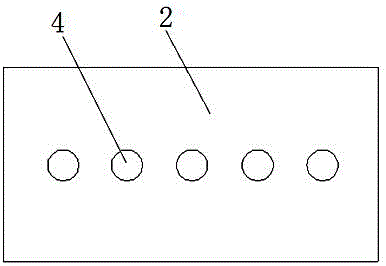

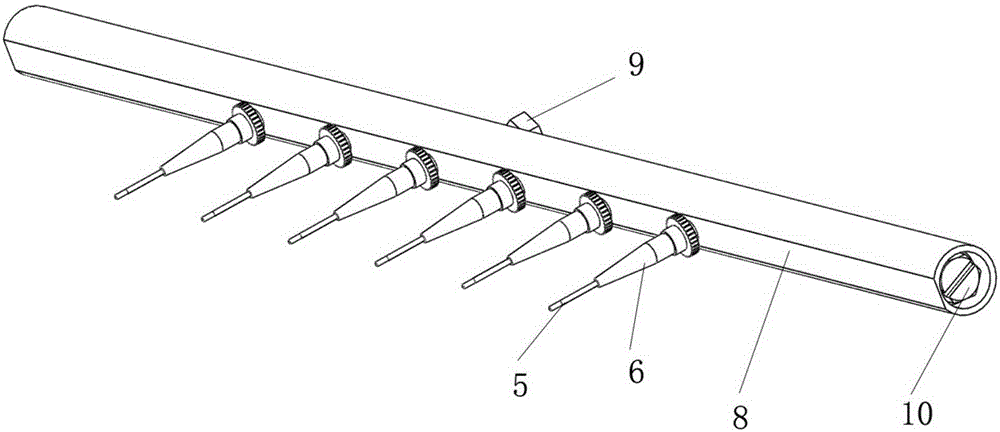

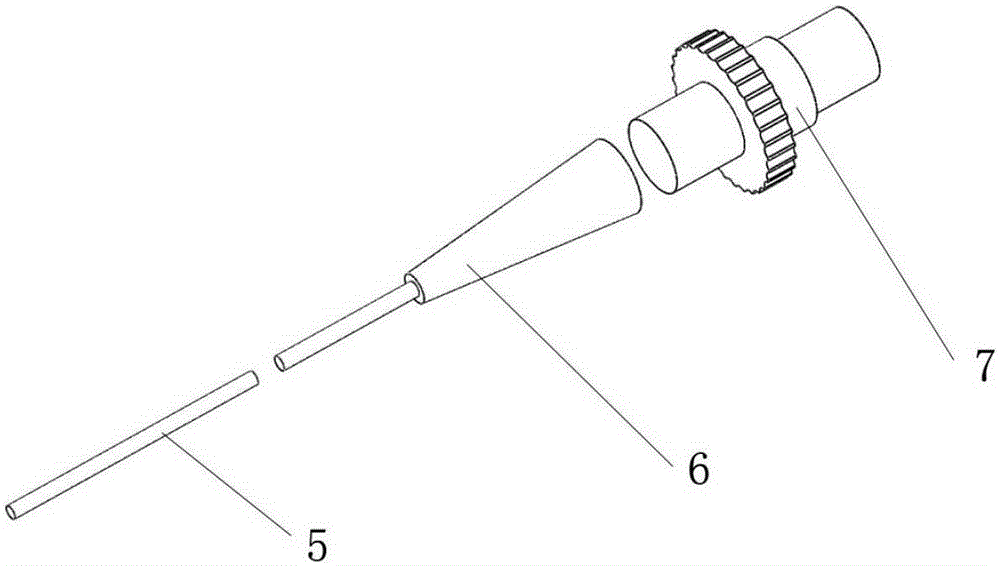

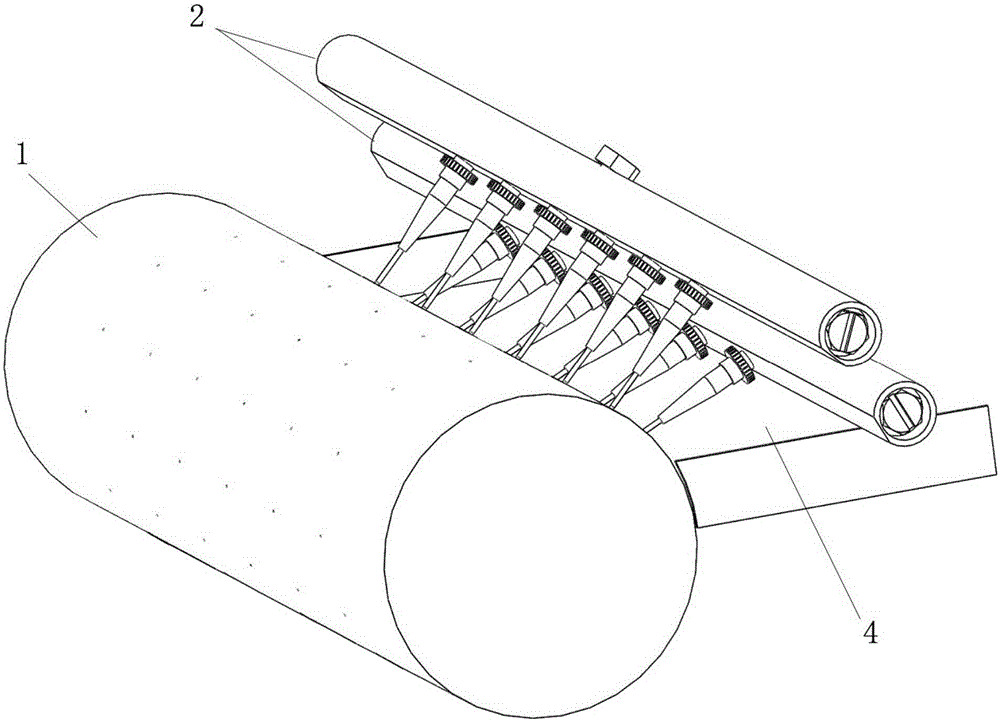

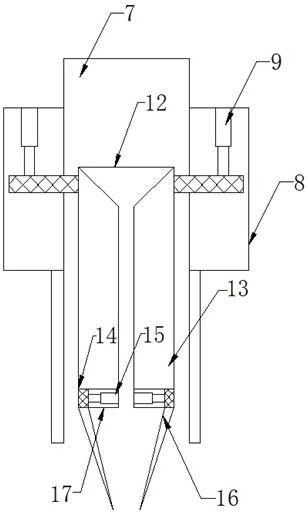

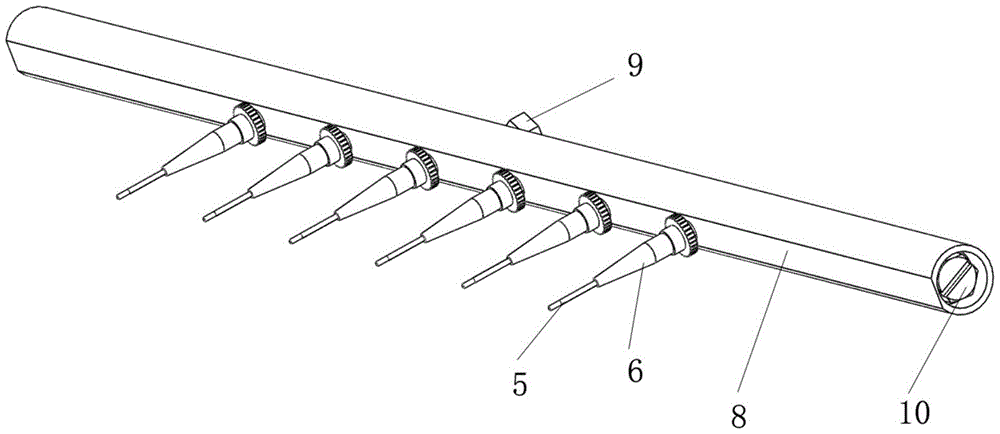

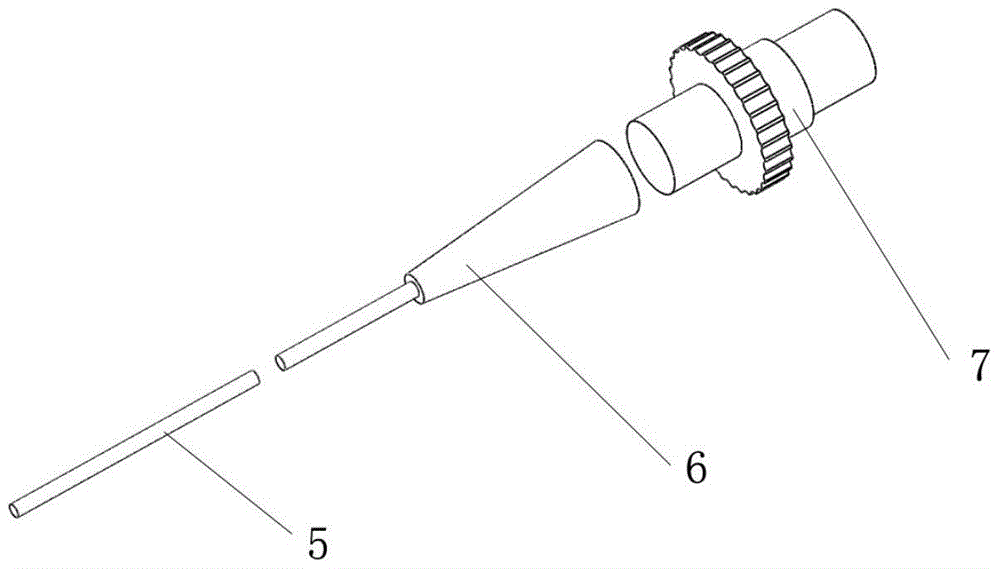

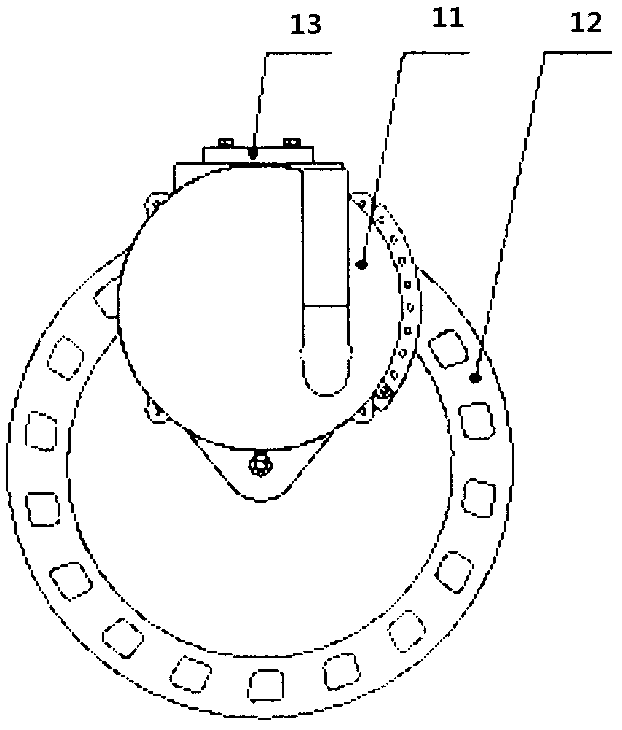

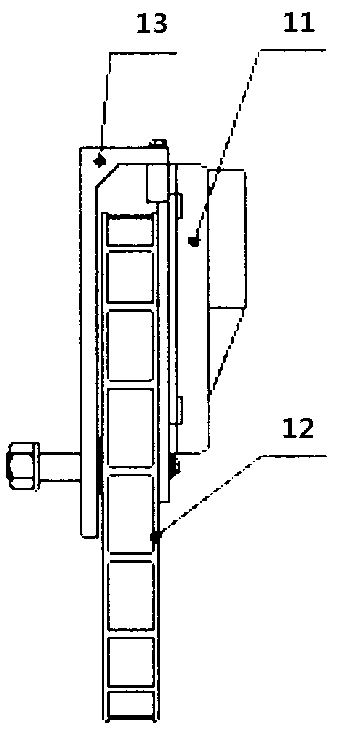

Scraping and touching air flow type seed removing device of seeding machine

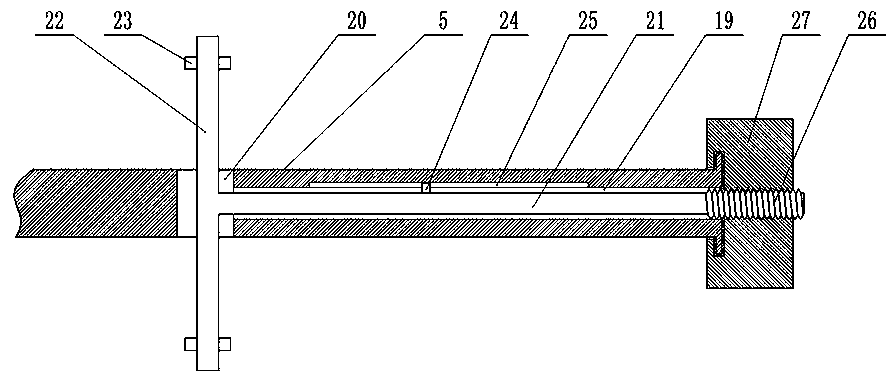

ActiveCN105210517ALow removal rateSowing realizedSeed depositing seeder partsEngineeringScrew thread

The invention discloses a scraping and touching air flow type seed removing device of a seeding machine. The seed removing device is arranged on a roller body of the seeding unit and comprises at least one set of seed removing pipes which are externally connected with an air supply system. Each seed removing pipe comprises a seed removing pipe body, air needles, thread rotary needle heads, seed pulling needles and a quick plug connector, wherein the thread rotary needle heads are distributed on one side of the cylindrical face of the seed removing pipe body, the quick plug connector is arranged on the other side of the cylindrical face of the seed removing pipe body, each thread rotary needle head corresponds to one air needle and one seed pulling needle, each thread rotary needle head, the corresponding air needle and the corresponding seed pulling needle are sequentially connected, and the quick plug connector is externally connected with the air supply system. According to the seed removing device, pneumatic power seed removing and mechanical power seed removing are combined, the seed removing effect is good, small round seeds and smell flat seeds can be removed so that the seeding unit can be used for sowing small flowering cabbage round seeds and the like and can also be suitable for sowing small tomato flat seeds and the like, single seeds can be precisely sown, and the seeding qualified rate is increased.

Owner:SOUTH CHINA AGRI UNIV

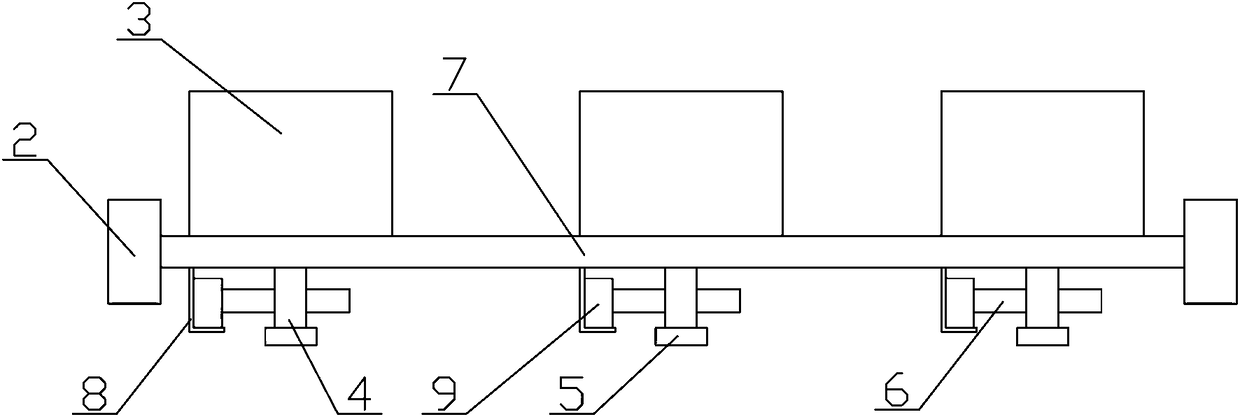

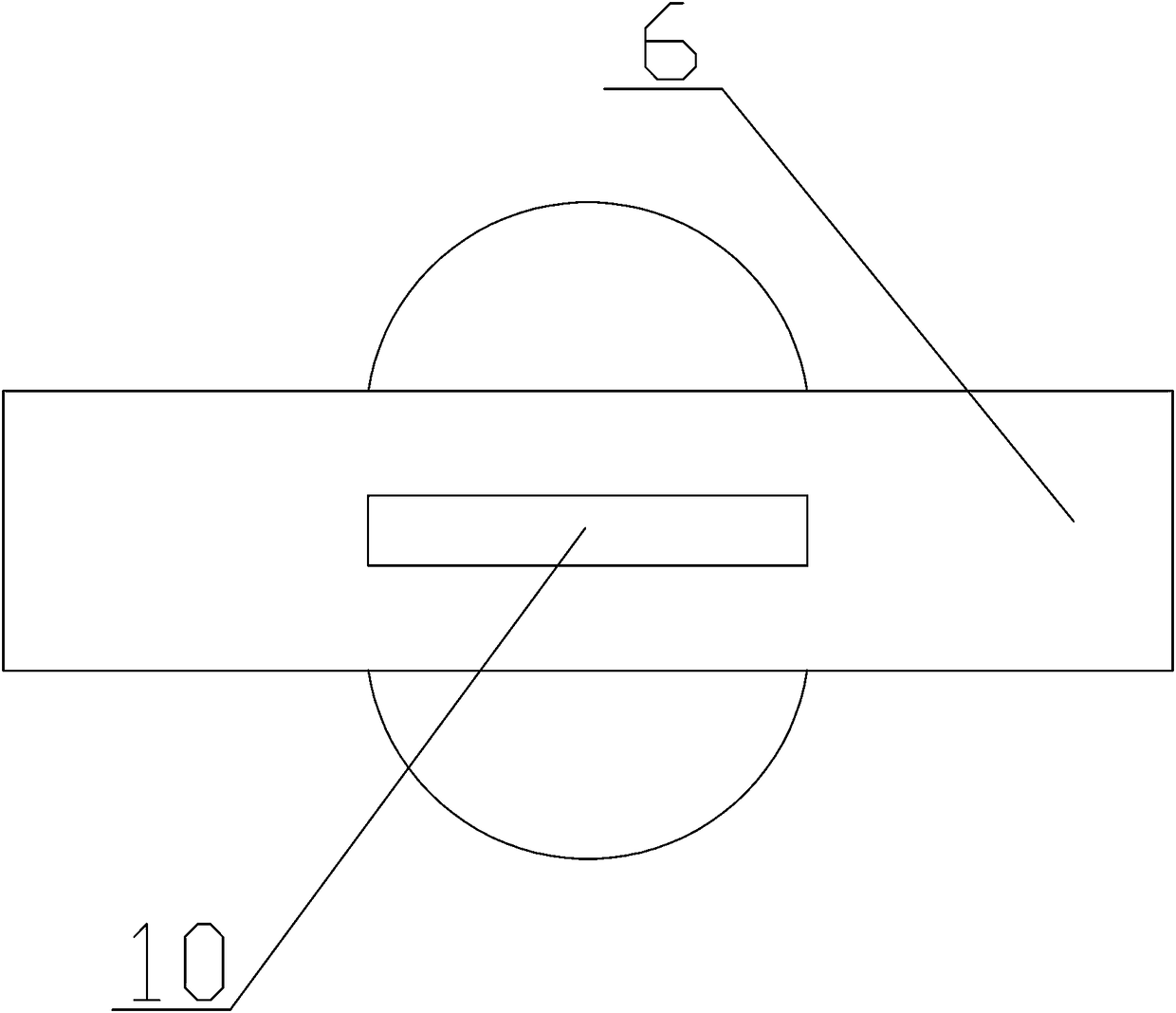

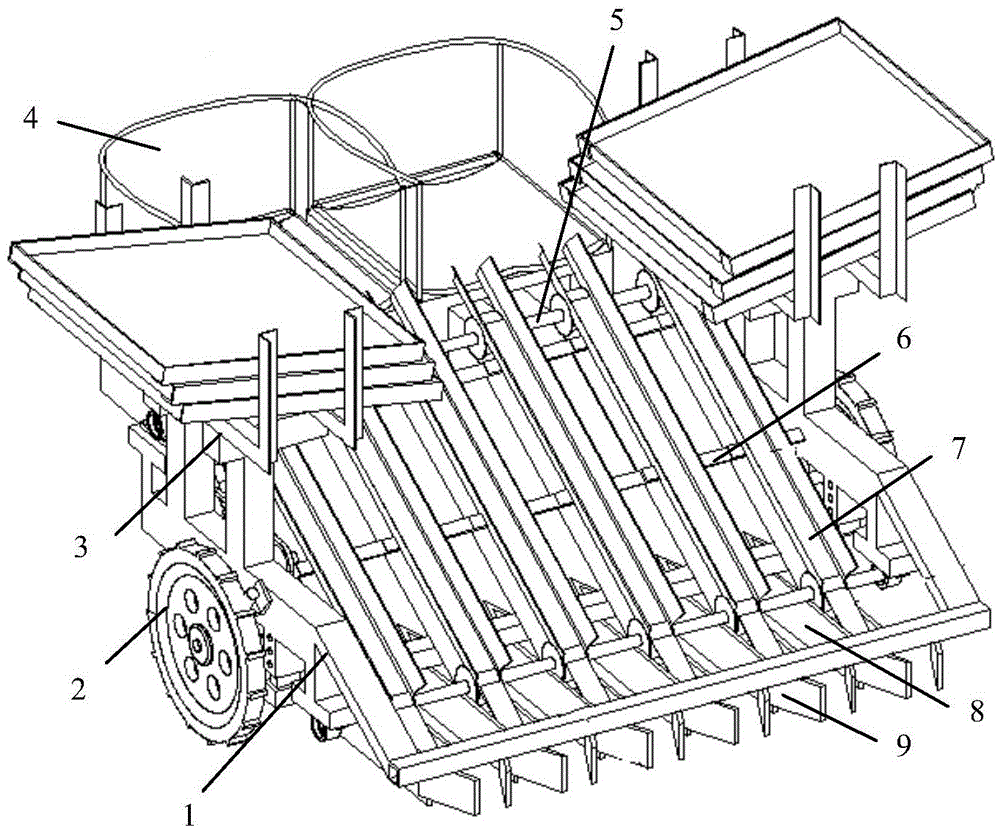

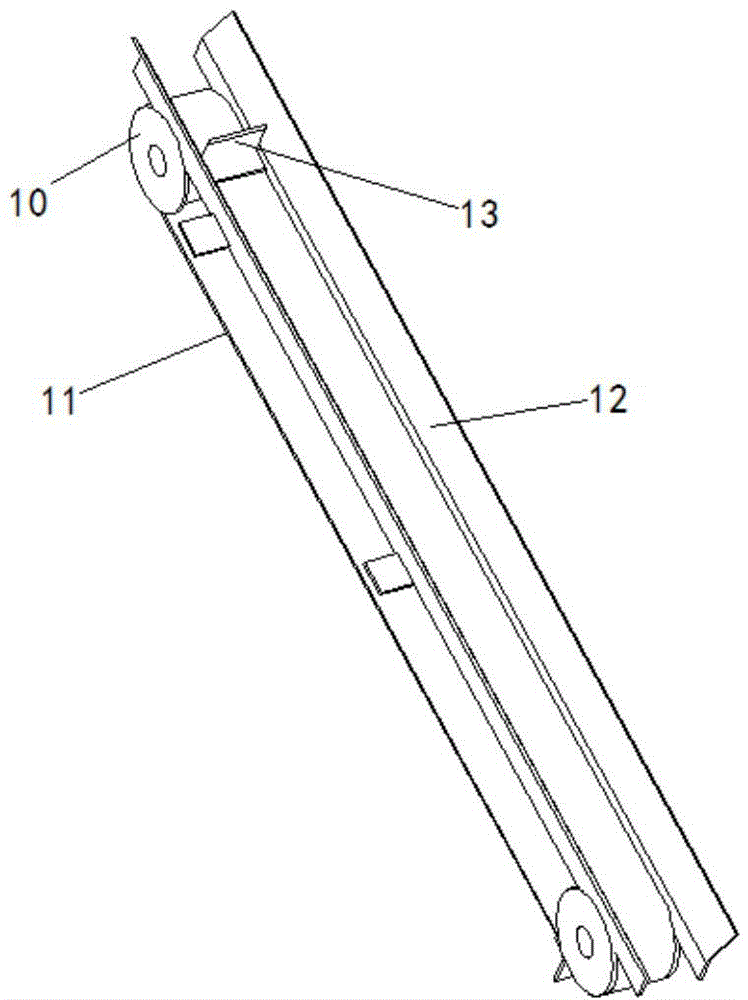

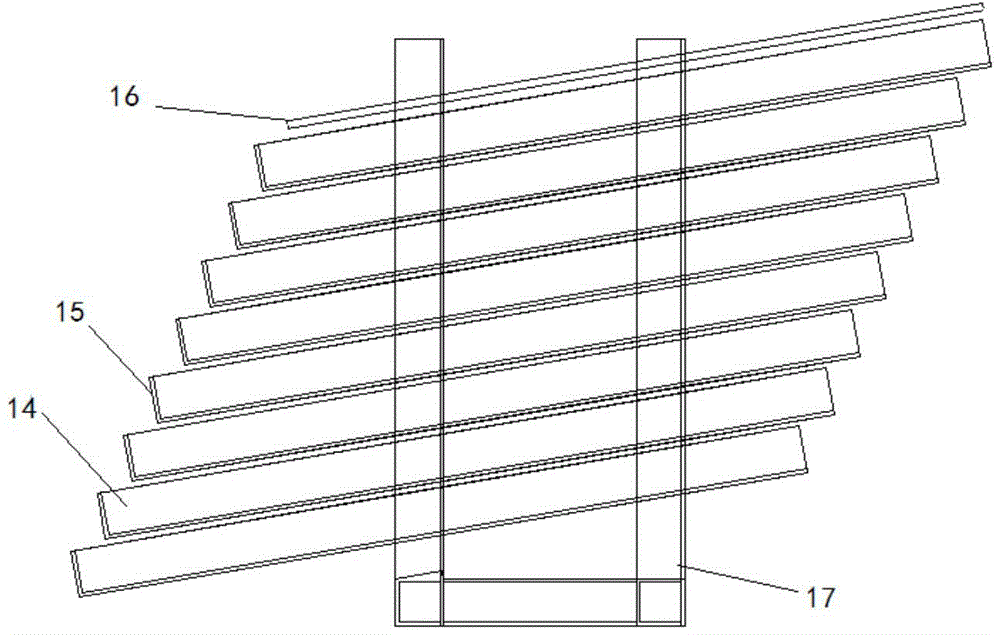

Semi-automatic garlic sower

InactiveCN104025776ASowing realizedSeed depositing seeder partsBroadcast seedersSemi automaticEngineering

The invention relates to a semi-automatic garlic sower which comprises a hanging mechanism, a garlic seed box feeding mechanism, a seed carrying table, a ditcher, a covering device, a land wheel mechanism, a transmission mechanism and a stander, wherein the garlic seed box feeding mechanism adopts an inclined conveying belt and comprises a synchronous belt, an upper belt wheel, a lower belt wheel, belt wheel shafts and a garlic seed box holding device; land wheels drive the synchronous belt to rotate through the transmission mechanism; multiple layers of seed carrying plates are arranged on the seed carrying table in an inclination manner; seed ditches are formed by the ditcher; along with the rotation of the synchronous belt, a garlic seed box is downwards conveyed along the garlic seed box holding mechanism and is finally steadily put into a seed ditch along a flow guide plate of the ditcher; the garlic seed box is covered with soil through the covering device behind. The semi-automatic garlic sower can realize mechanical sowing with 'root down and tip up' and 'straight planting' of garlic, and single garlic seed sowing is changed into strip sowing, so that the sowing efficiency is improved; furthermore, sowing requirements on different plant spacing and rows can be met according to seed hole distances on the garlic seed boxes and mounting distances of the belt wheels.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

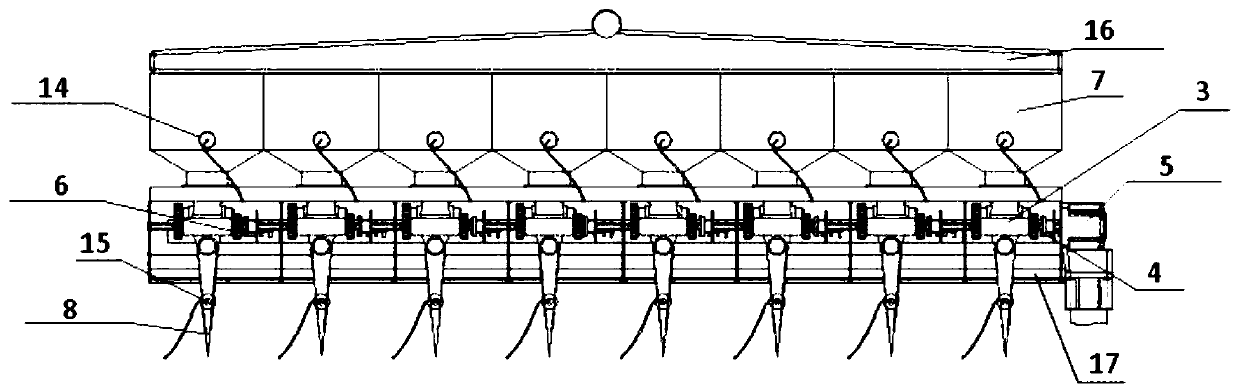

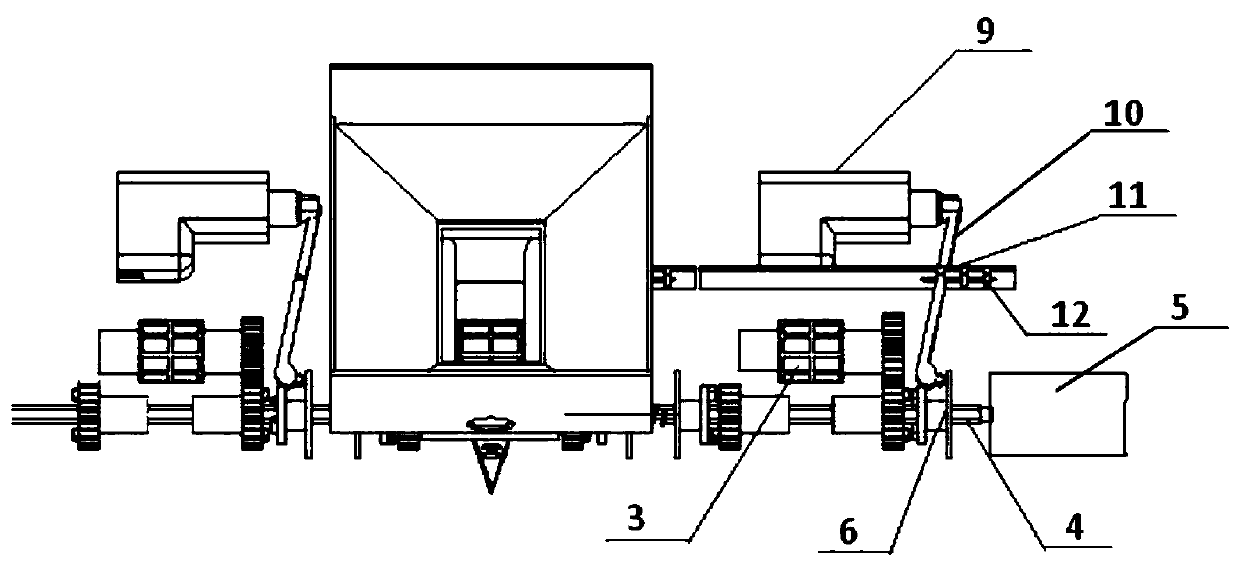

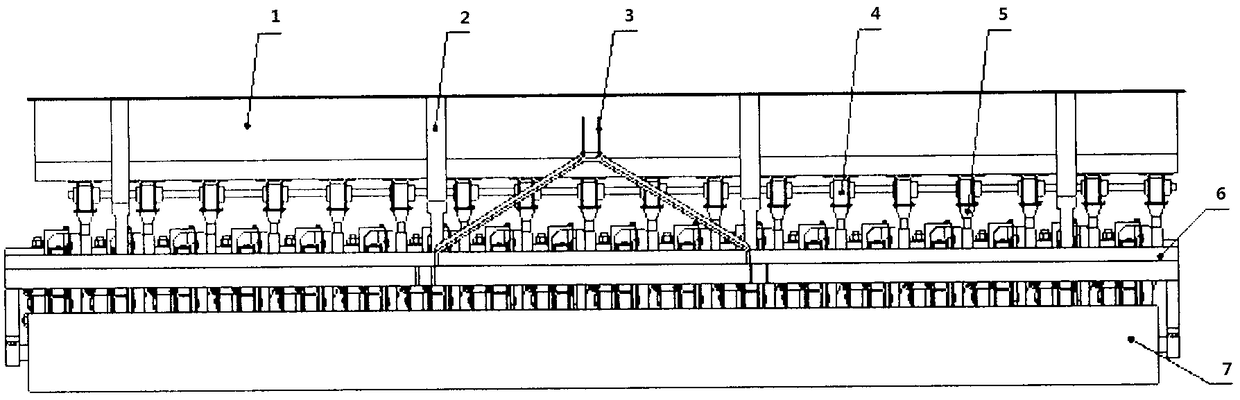

Direct rice seeding machine and planting method for color rice pattern plantation

The invention discloses a direct rice seeding machine and a planting method for color rice pattern plantation. The planting method comprises the following steps: 1, measuring data: measuring the area,length and width data of a land plot; 2, making a pattern: designing a pattern plane graph and a construction grid chart according to the area, length and width data of the land plot; and 3, seedingrice: determining the seeding time of rice with various leaf colors according to the growth cycles of the rice with different leaf colors, determining the seeding positions of the rice with differentleaf colors according to the construction grid chart, and performing seeding by using direct rice seeding. Seeds of the rice with different leaf colors can be arranged in different seed boxes of everyseeding assembly in order o realize the seeding of the seeds of the rice with different leaf colors, so the seeding efficiency and the seeding precision of the color rice pattern are improved.

Owner:CHENGDU ACAD OF AGRI & FORESTRY SCI +1

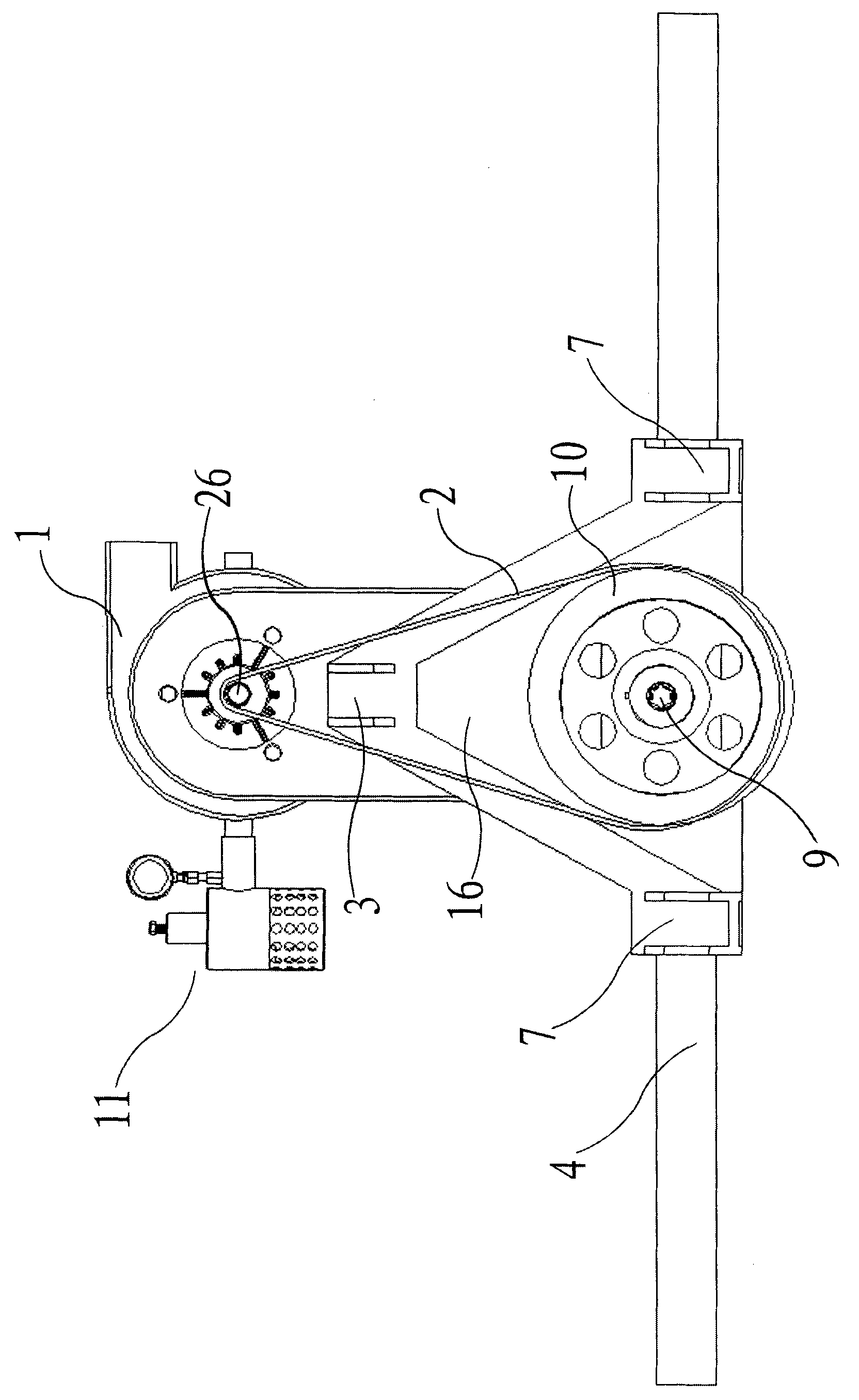

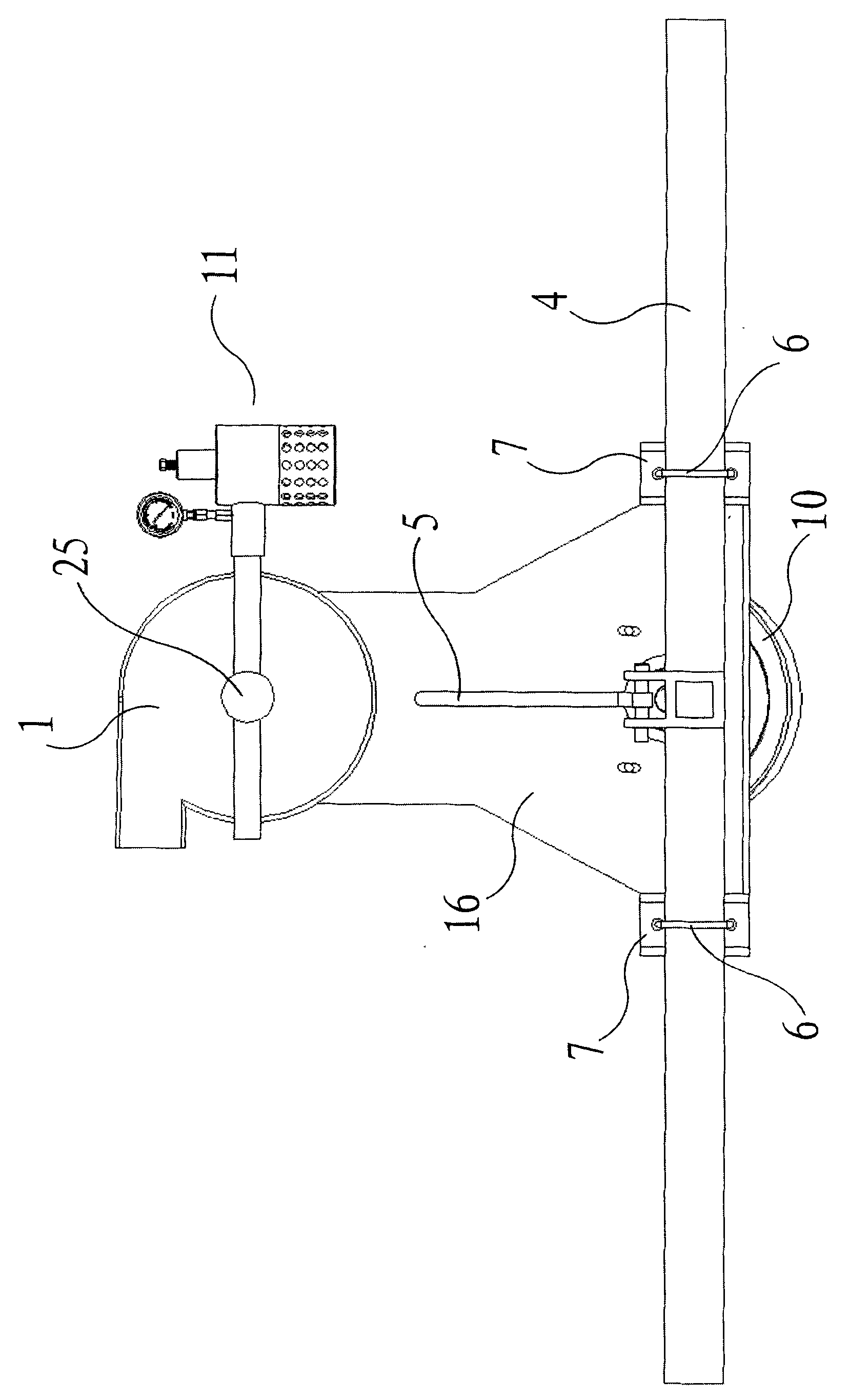

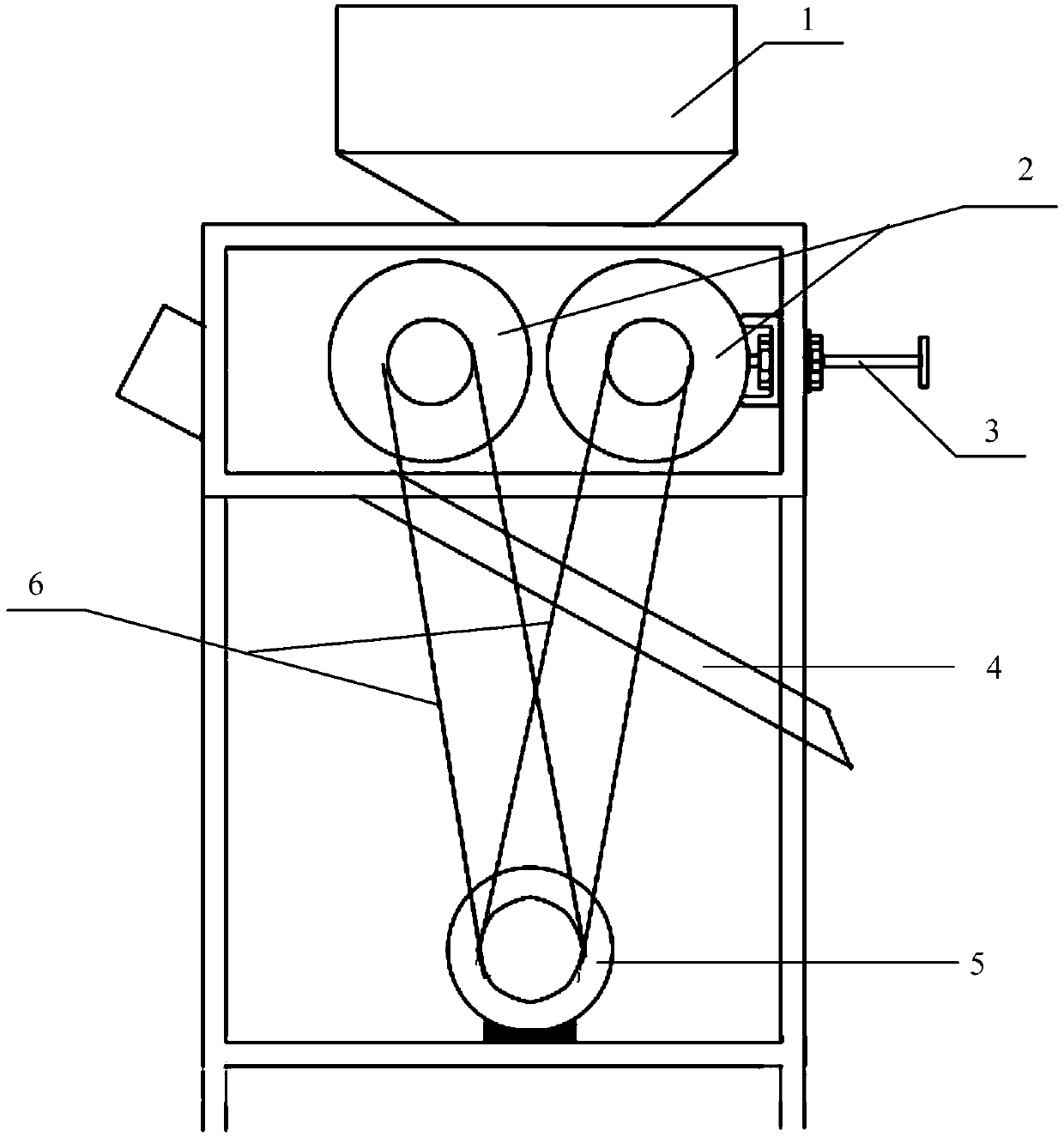

Fan assembly of air-aspiration type planting machine

ActiveCN103650713AImprove stabilityReduced sliding wearSeed depositing seeder partsRegular seed deposition machinesPulp and paper industryInert

The invention discloses a fan assembly of an air-aspiration type planting machine. A fan wheel (26) in a fan (1) is connected with a wheel (10) in a unidirectional automatic clutch device through a ribbed belt (2) in a transmission manner; one end of a negative pressure suction hole (25) in the fan (1) is connected with a negative pressure stabilizer (11), and the other end of the negative pressure suction hole (25) is connected with a planter of the planting machine. By the adoption of the ribbed belt (2), the fan assembly of the air-aspiration type planting machine can change the speed in position at a time; furthermore, the ribbed belt (2) is difficult to slip, so that the transmission efficiency is improved; due to the additional arrangement of the unidirectional automatic clutch device, when a tractor is deaccelerated rapidly during working, the fan can still continuously run under the action of the inert, so that the slip abrasion of the belt is alleviated, and the stability of instant air pressure of the fan is improved; the negative pressure stabilizer (11) is designed in order to realize the stable and high-efficiency planting, so that the fan can be greatly improved during running.

Owner:任丘市沃田农机有限公司

Non-tillage precision seeder

InactiveCN105210512AAvoid churnIncrease organic matterAgriculture gas emission reductionSeed depositing seeder partsSeederTraction frame

A non-tillage precision seeder comprises a machine frame, a traction frame, a furrowing and fertilization mechanism, a power drive mechanism, a non-tillage stubble cleaning mechanism, single seeding bodies, an earthing and compacting mechanism, seed discharging devices, a profiling mechanism, a seed fertilizer box and markers. The non-tillage precision seeder is reasonable in structure and reliable in performance, operation line spacing, operation depth, row spacing, seeding quantity and fertilizing amount can be conveniently adjusted within a larger range, stubble cutting, furrowing, fertilization and seeding can be directly performed in wheat stubble field which is not turned over, fertilization and seeding can be also performed after corn stubble field is subjected to straw turnover, and furrowing and fertilization, stubble cutting and soil loosening, furrowing and seeding, earthing, compaction and other working procedures are completed at a time. In addition, by the adoption of a non-tillage mode, water and soil loss can be prevented, drought and waterlogging resistance can be achieved, organic matter of soil can be increased, a soil structure can be improved, a large amount of working time and seed resources can be further saved, the yield can be increased, and the like. Thus, the non-tillage precision seeder is wide in application range and can meet the agricultural technology requirements of various regions.

Owner:SHANDONG CHANGLIN PAIKE MACHINERY CO LTD

Seeder and seeding device

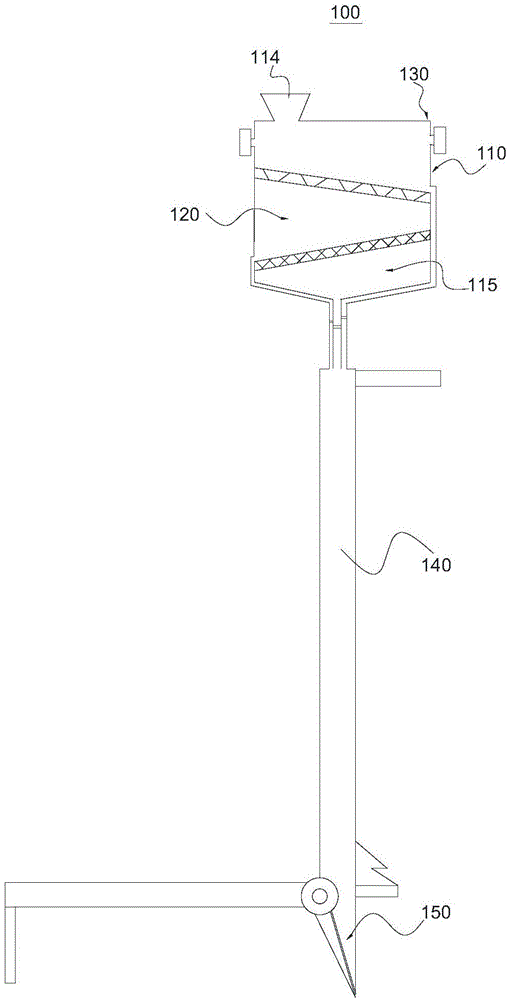

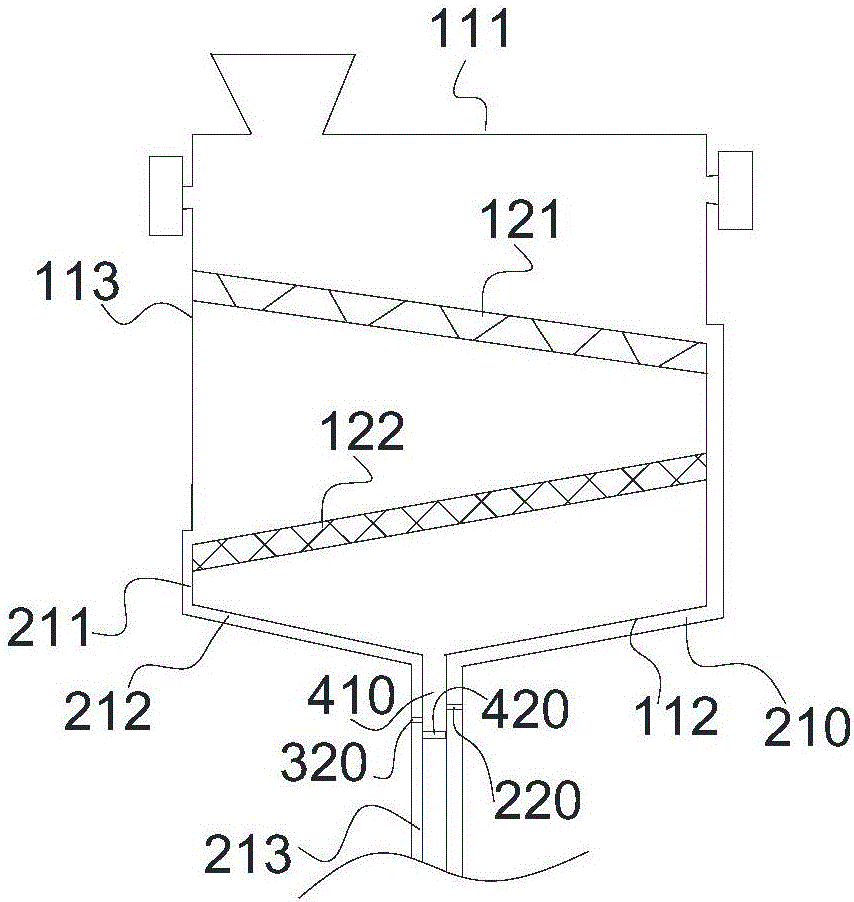

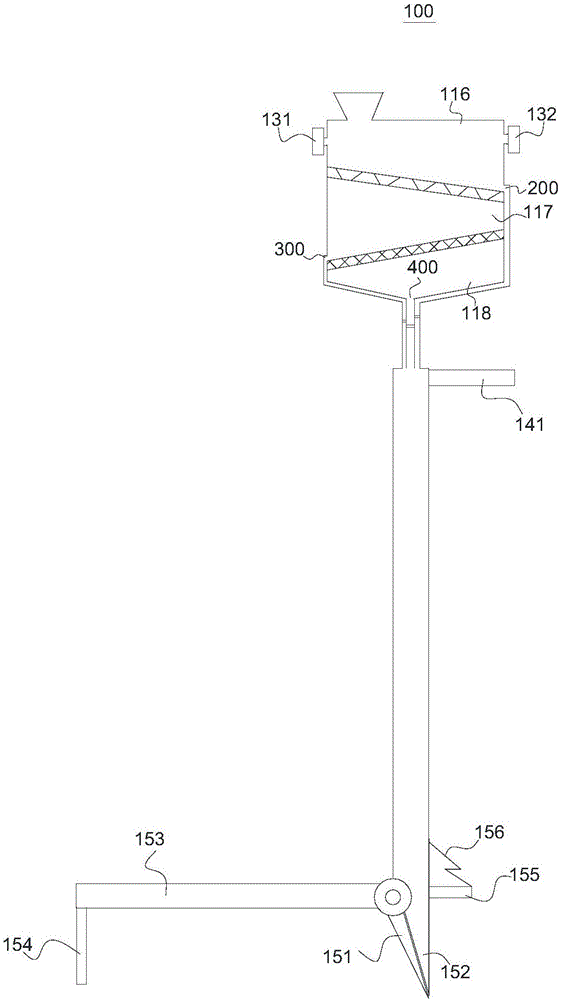

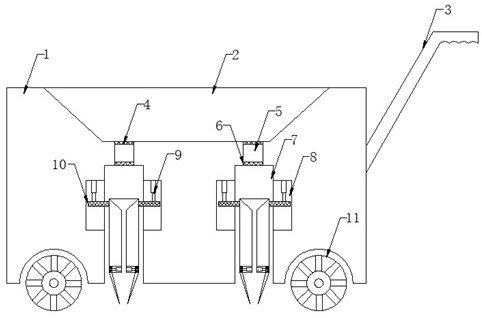

The invention relates to the technical field of agricultural machinery and provides a seeder and a seeding device. The seeder comprises a shell body, a feeding part and a discharging part, a first-grade sieve plate, a second-grade sieve plate, an air blower and a dust collection device, a seeding pipe and a dibbling nozzle, wherein the feeding part and the discharging part are arranged in the shell body; the shell body is internally provided with a feeding chamber, a first sieving chamber and a second sieving chamber; the discharging part is provided with a first discharging hole, a second discharging hole and a third discharging hole which are communicated with the feeding chamber, the first sieving chamber and the second sieving chamber in sequence; the first-grade sieve plate and the second-grade sieve plate are obliquely arranged in the shell body; the air blower and the dust collection device are located in the feeding chamber; the seeding pipe is selectively communicated with the first discharging hole, the second discharging hole and the third discharging hole; the dibbling nozzle is arranged at an outlet end of the seeding pipe and comprises a fixed shovel and a movable shovel which are movably connected. According to the seeder provided by the invention, seed impurity removal, sieving and selective seeding can be realized at the same time. The seeding device comprises the seeder and a sprinkler connected with the seeder; the seeding device has diversified functions and a scientific design.

Owner:JILIN ACAD OF AGRI SCI

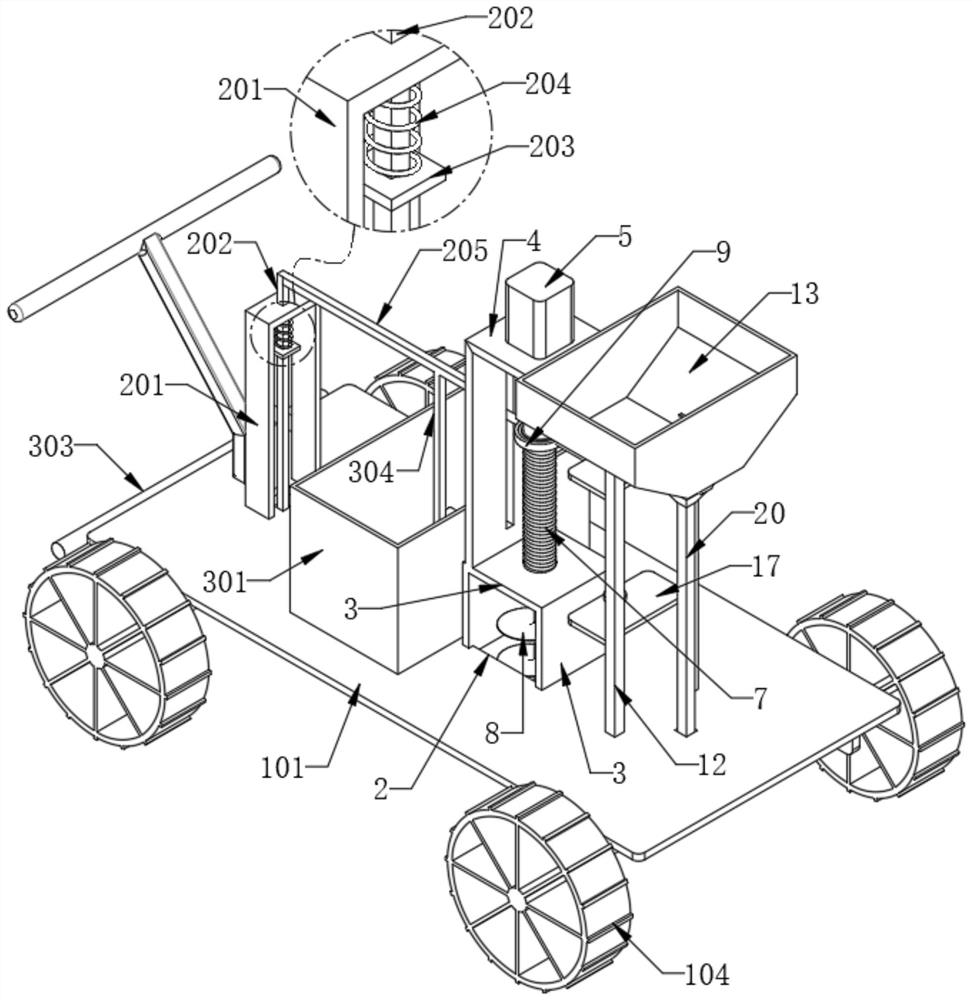

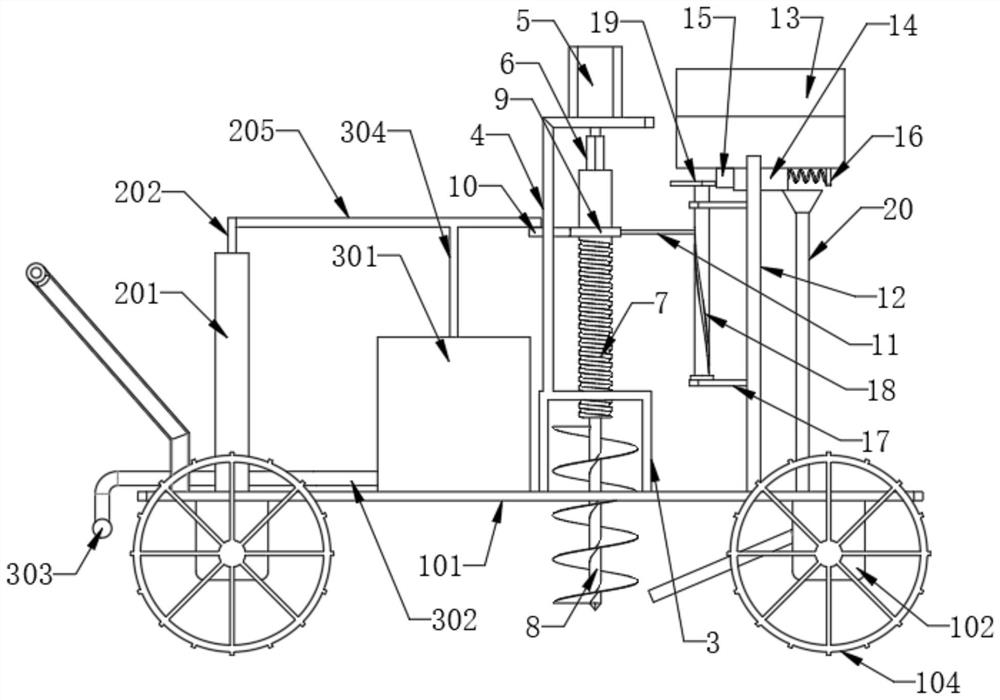

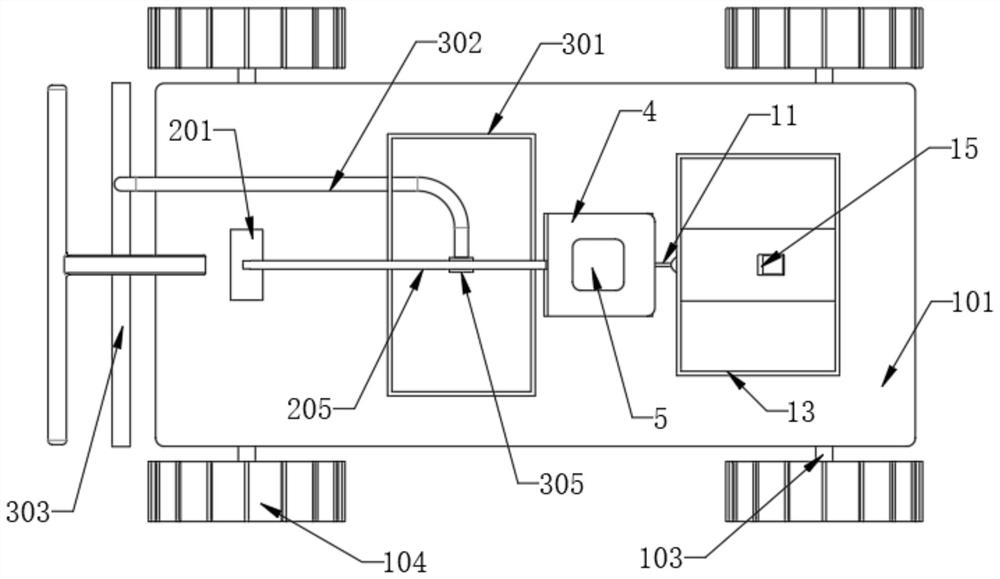

Punching and sowing integrated machine for tea planting

InactiveCN112056040ASowing is effectiveSowing realizedPlantingFurrow making/coveringHydraulic cylinderAgricultural engineering

The invention discloses a punching and sowing integrated machine for tea planting, which comprises a box body. A plurality of first grooves are formed in the bottom end of the box body at equal intervals, second grooves are formed in the groove walls of the two sides of each first groove, electric hydraulic cylinders are fixedly installed at the top ends of the two second grooves, connecting blocks are connected to the output ends of the two electric hydraulic cylinders, and one sides of the two connecting blocks are fixedly connected with the two sides of a punching cylinder correspondingly.According to the punching and sowing integrated machine for tea planting, the connecting blocks installed on the two sides of the punching cylinder are pushed through the electric hydraulic cylinders,the ground is effectively punched through the punching cylinder, and therefore tea seeds are sown. Sliding blocks are pushed to move through electric telescopic rods, the punching diameter is effectively controlled, and through installed limiting barrels, the quantity of the tea seeds put into the holes is effectively controlled, resource waste caused by excessive putting of the tea seeds is prevented, and the situation that the germination rate of the tea seeds is affected due to putting of too few tea seeds is avoided.

Owner:新沂经济开发区建设发展有限公司

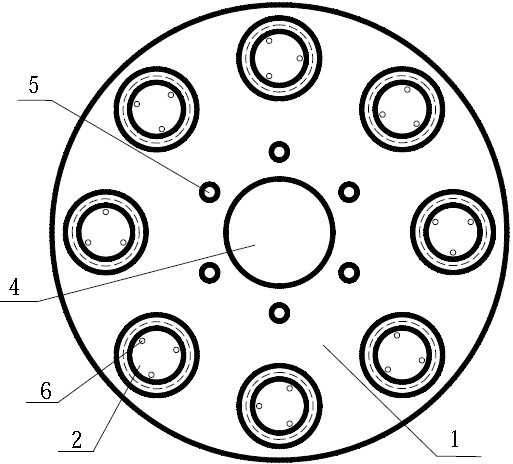

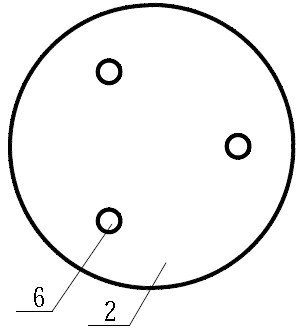

Seed suction disk with rapid transforming holes and seeder

ActiveCN102365914AEasy to replaceTo achieve the purpose of fixing the detachable seed suction pieceSeed depositing seeder partsRegular seed deposition machinesSeederEngineering

Belonging to the field of agricultural technologies, the invention aims to overcome disadvantages in prior art and provide a seed suction disk with rapid transforming holes able to realize convenient and rapid transformation into different sizes as well as a seeder. The seed suction disc comprises a disk body and a plurality of seed suction holes. The disk body is equipped with several detachableseed suction sheets on one side close to a seed filling chamber, and the other side of the disk body is embed with positioning disks corresponding to the detachable seed suction sheets in position and quantity. Each positioning disk is a magnetic ring provided with a through hole in the center and made of a permanent magnetic material, and the size of the through hole is smaller than sizes of thedetachable seed suction sheets. The detachable seed suction sheets are made of a magnetic induction material at least the external surfaces, and are adsorbed on the surfaces of the magnetic rings. The seed suction holes are positioned on the detachable seed suction sheets, and at least one seed suction hole is disposed within the through hole of a magnetic ring. The seed suction disk of the invention has a simple structure, and can transform the seed suction holes into different sizes and shapes rapidly and conveniently so as to adapt to sowing of different crops.

Owner:SOUTH CHINA AGRI UNIV

Rotary tillage ridging sowing and fertilization all-in-one machine

PendingCN108934244APrevent splashSowing realizedSpadesPloughsCombustion chamberAgricultural engineering

The invention relates to the field of agriculture, in particular to a rotary tillage ridging sowing and fertilization all-in-one machine. The machine comprises a construction chamber, a loading mechanism, a stirring mechanism, a suction fan, a driving mechanism, an abutting mechanism, a lifting mechanism and a material filter mechanism; a rotating shaft is rotationally connected into a support plate, the rotating shaft rotates and then drives a protrusion on a rotary table to rotate, the purpose that the protrusion pushes a sliding block is further achieved, and then the purpose that a supportcolumn extrudes a protective door is achieved; a second spring retracts, finally the protective door is opened, seeds flow into a material receiving barrel from a seed outlet and flow out of a protection cover finally, seed splashing is avoided, and sowing is achieved; the rotating shaft rotates to drive a protrusion on the other rotary table, and then a jacking pillar rises; a first spring stretches, and then fertilizer in a material barrel can flow into a connecting pipe from a material opening and finally flow into the protection cover; the phenomenon that the effect of the fertilizer is lowered is avoided.

Owner:王金玉

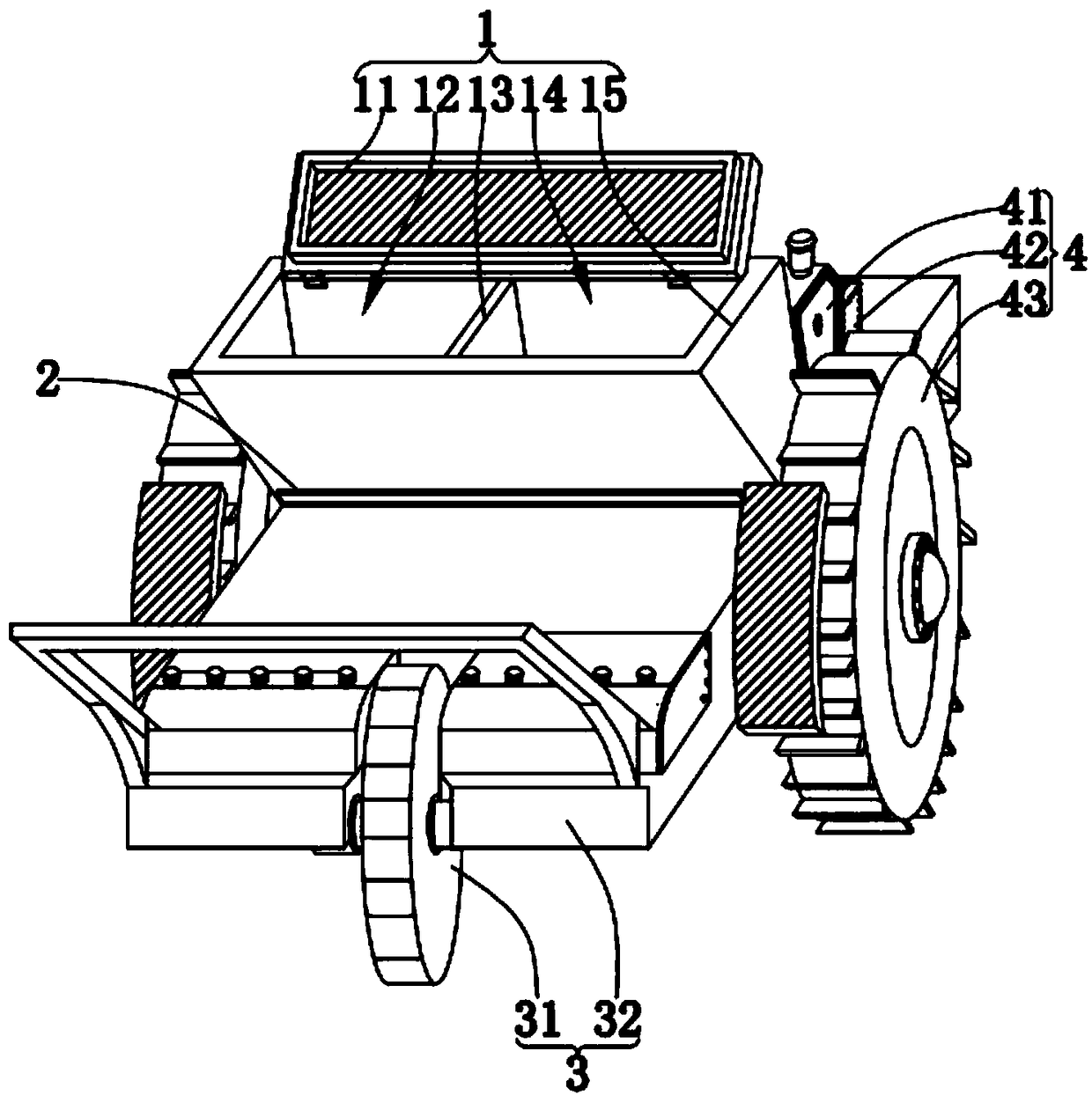

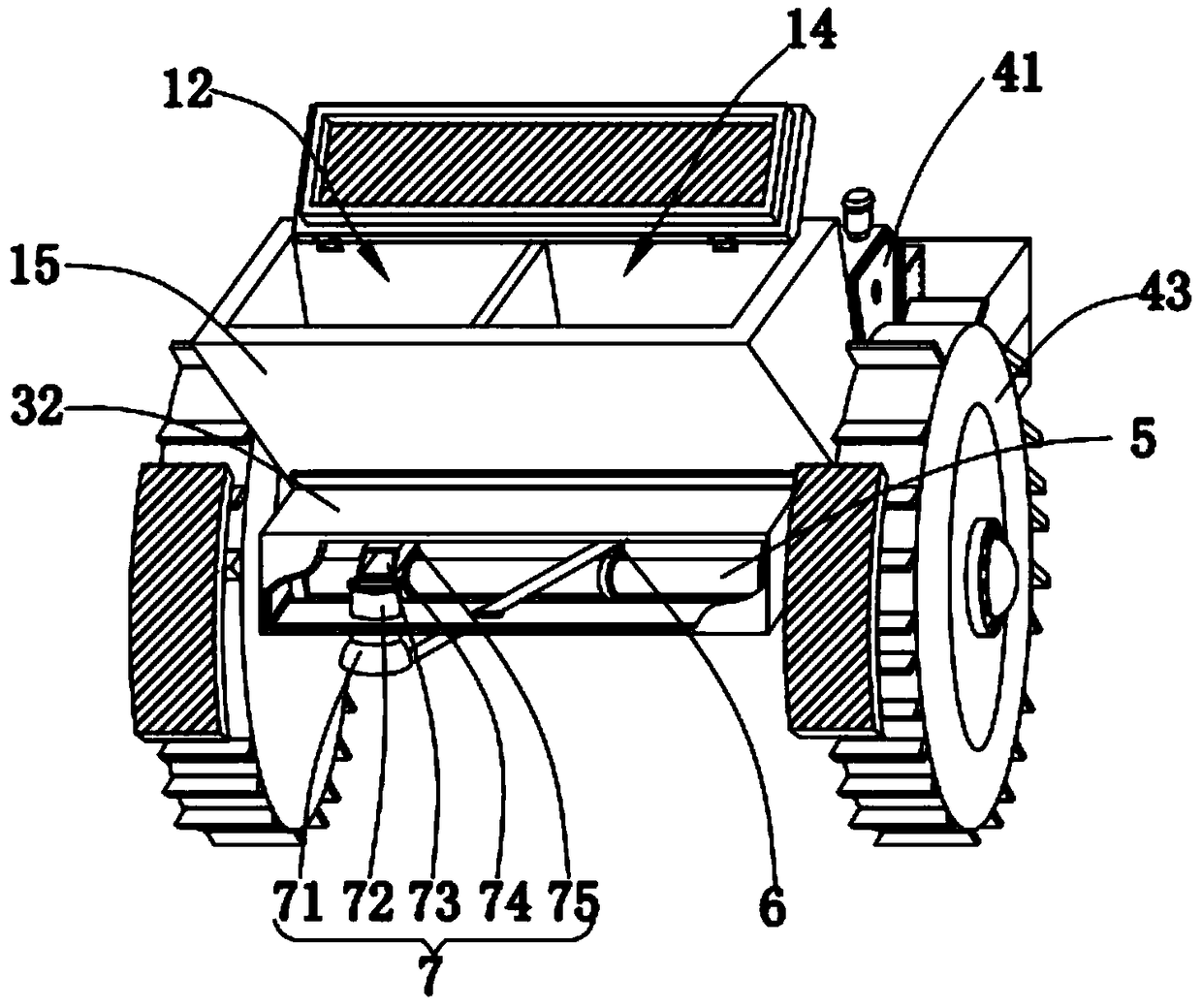

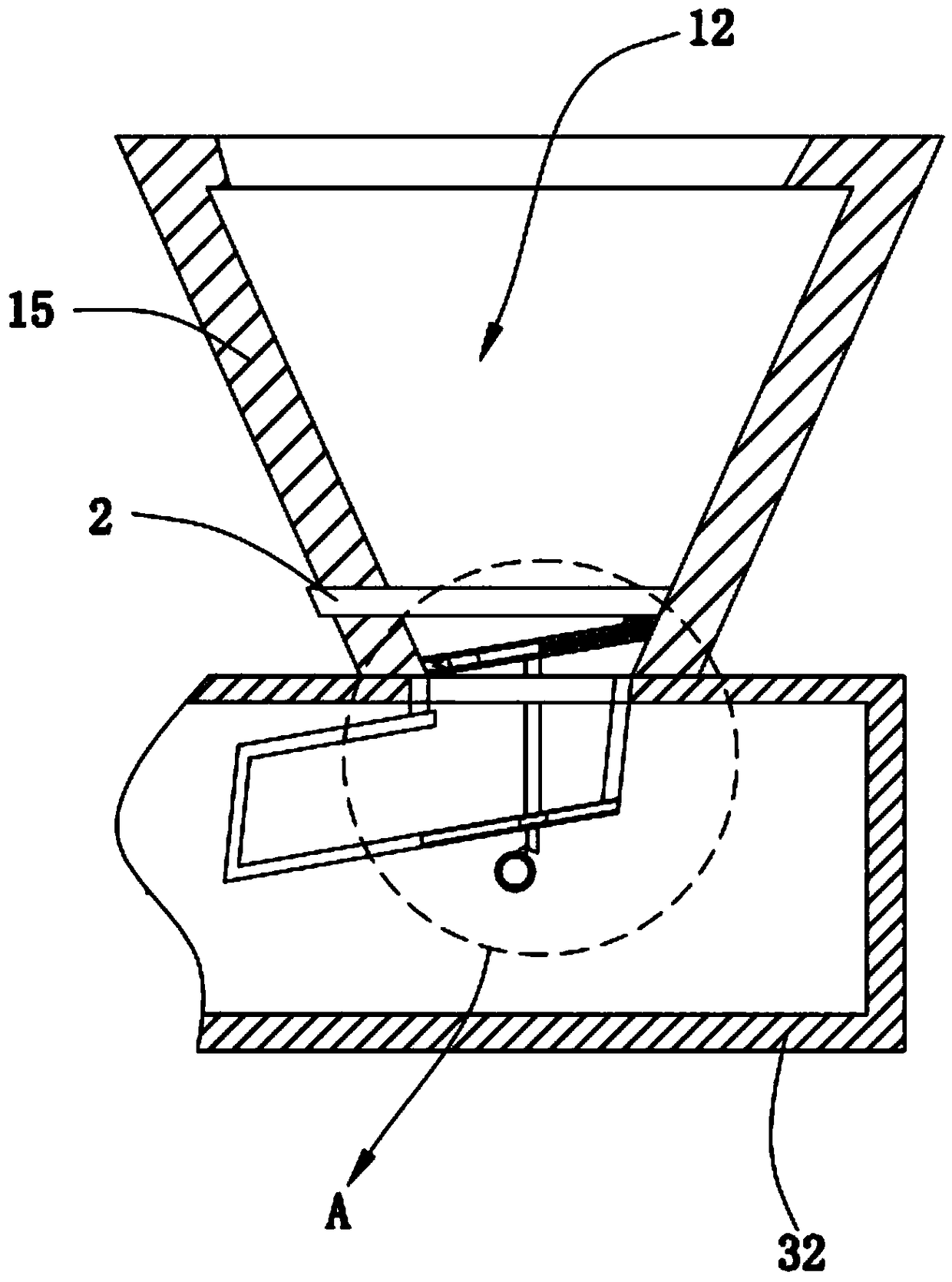

Rice spreading and planting device

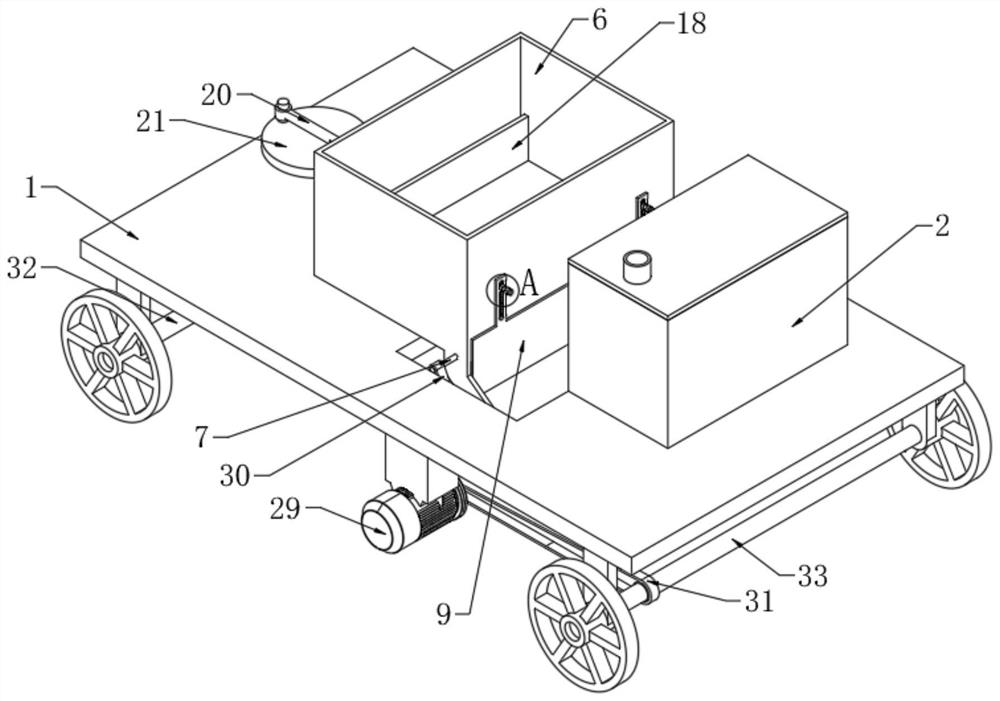

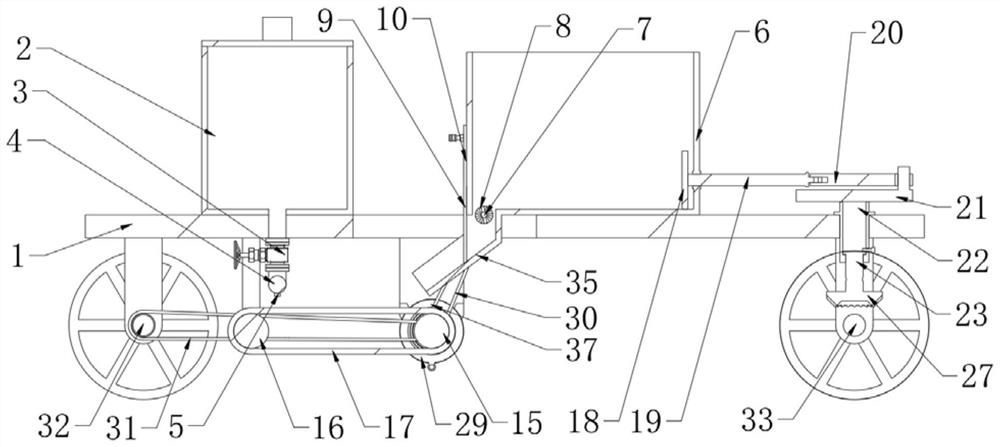

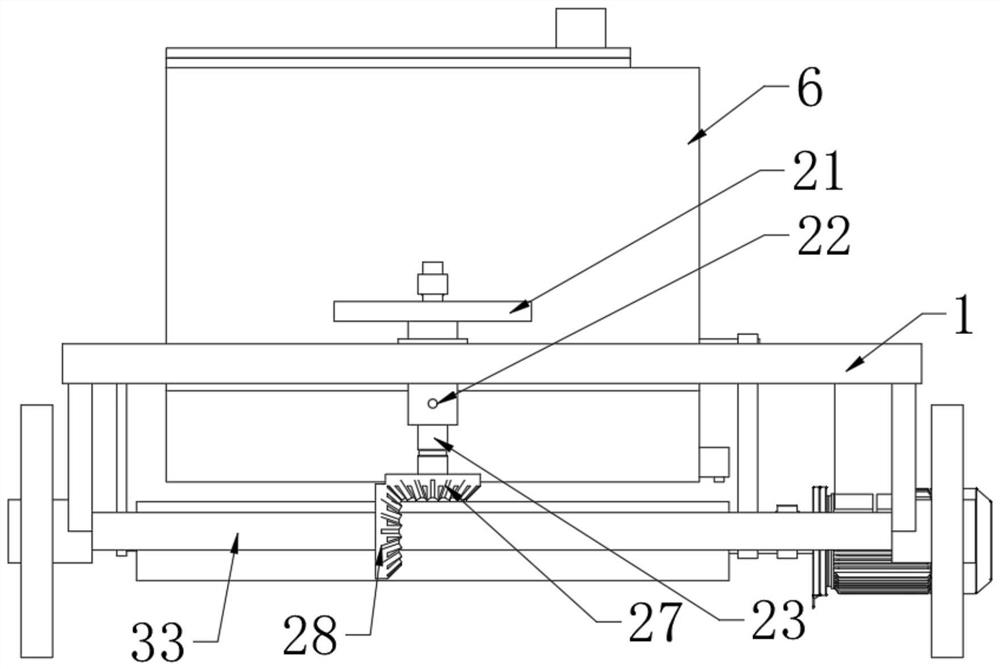

PendingCN111771481AThe equipment is compactLow manufacturing costSeed depositing seeder partsBroadcast seedersAgricultural engineeringSowing

The invention discloses a rice spreading and planting device. The rice spreading and planting device comprises a movable frame, a water spraying unit, a storage unit, a conveying unit, a material pushing reciprocating unit and a power unit. The water spraying unit and the storage unit are both installed on the movable frame; the storage unit comprises a turnover mechanism; the conveying unit is installed at the bottom of the movable frame; the feeding end of the conveying unit is located below the discharging end of the storage unit, and the discharging end of the conveying unit is located below the water outlet end of the water spraying unit; the material pushing reciprocating unit is installed on the movable frame and is in transmission through a second wheel shaft of the movable frame;the power unit is installed at the bottom of the movable frame; and the power output end of the power unit is connected with the power input ends of the conveying unit, the turnover mechanism and themovable frame. During sowing, seeds in the storage unit slide onto the conveying unit, the water spraying unit humidifies the seeds and forwards conveys the seeds to enable the seeds to fall into a sowing field, and when the number of the seeds in the storage unit is smaller than a preset value, the material pushing reciprocating unit moves to push the seeds to a discharging port of the storage unit.

Owner:卓志杰

Chinese medicinal plant sowing device

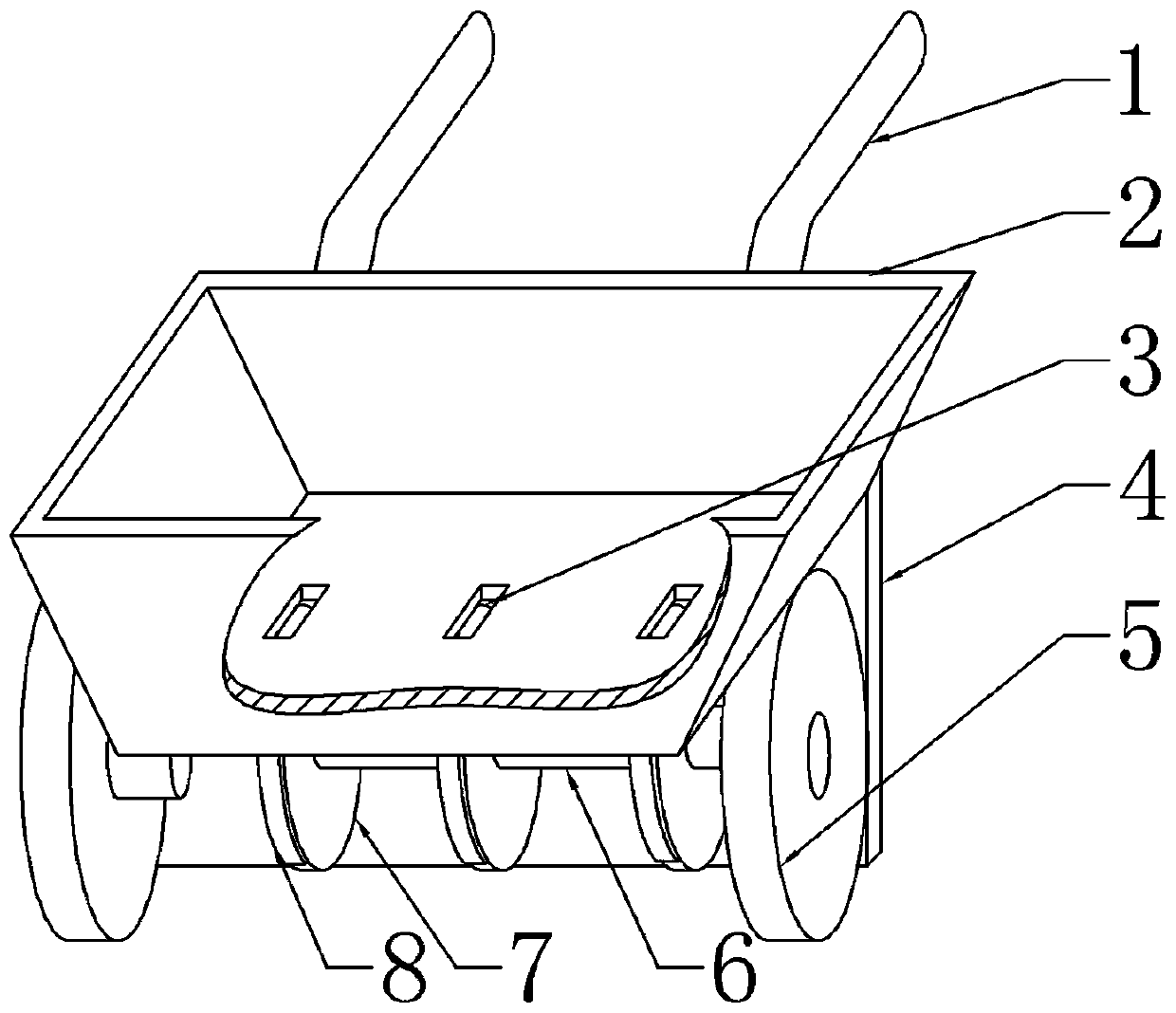

InactiveCN107624312AReduce labor intensitySowing realizedSeed depositing seeder partsBroadcast seedersEngineeringChinese drug

The invention discloses a Chinese medicinal plant sowing device in the field of sowing devices. The Chinese medicinal plant sowing device comprises a material storage hopper and pushing rollers rotatingly connected to two sides of a discharge hopper, the two pushing rollers are synchronously connected to a first-grade stepping motor, multiple through slots for leaking seeds are arranged at the bottom of the material storage hopper side by side at intervals, circular sowing trays are arranged below the through slots, the lower edges of the through slots contact with the sowing trays, the sowingtrays are vertically arranged, the sowing trays are connected through rotation shafts, the rotation shafts are connected to a two-stage stepping motor, and the side walls of the sowing trays are uniformly provided with multiple seed tanks for storing seeds. The sowing device is driven by the first-grade stepping motor. Under gravity, the sowing trays are used for realizing transfer of Chinese medicinal plant seeds from the discharge hopper to the planting holes so that the sowing process is finished.

Owner:遵义百草谷药业有限公司

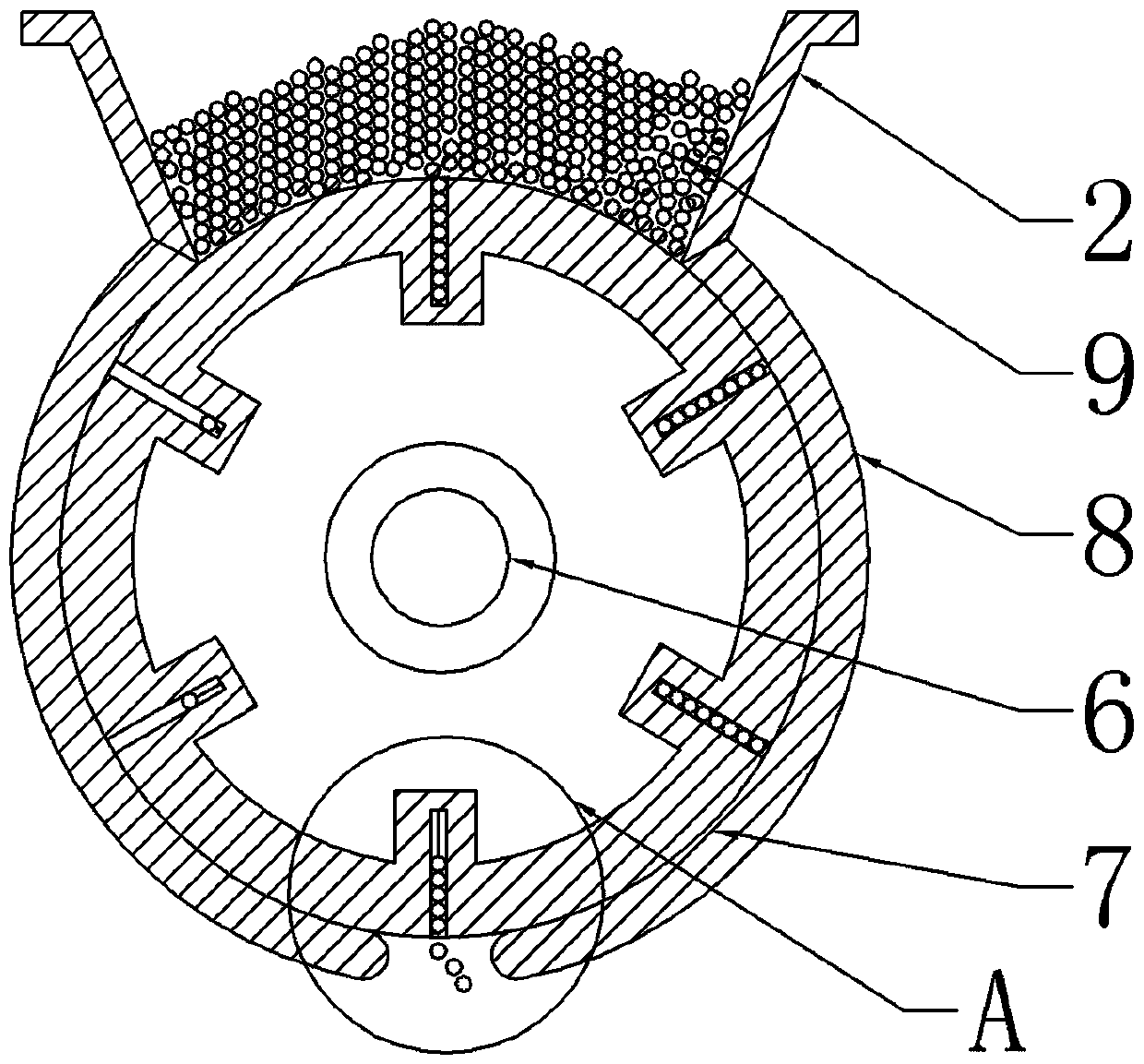

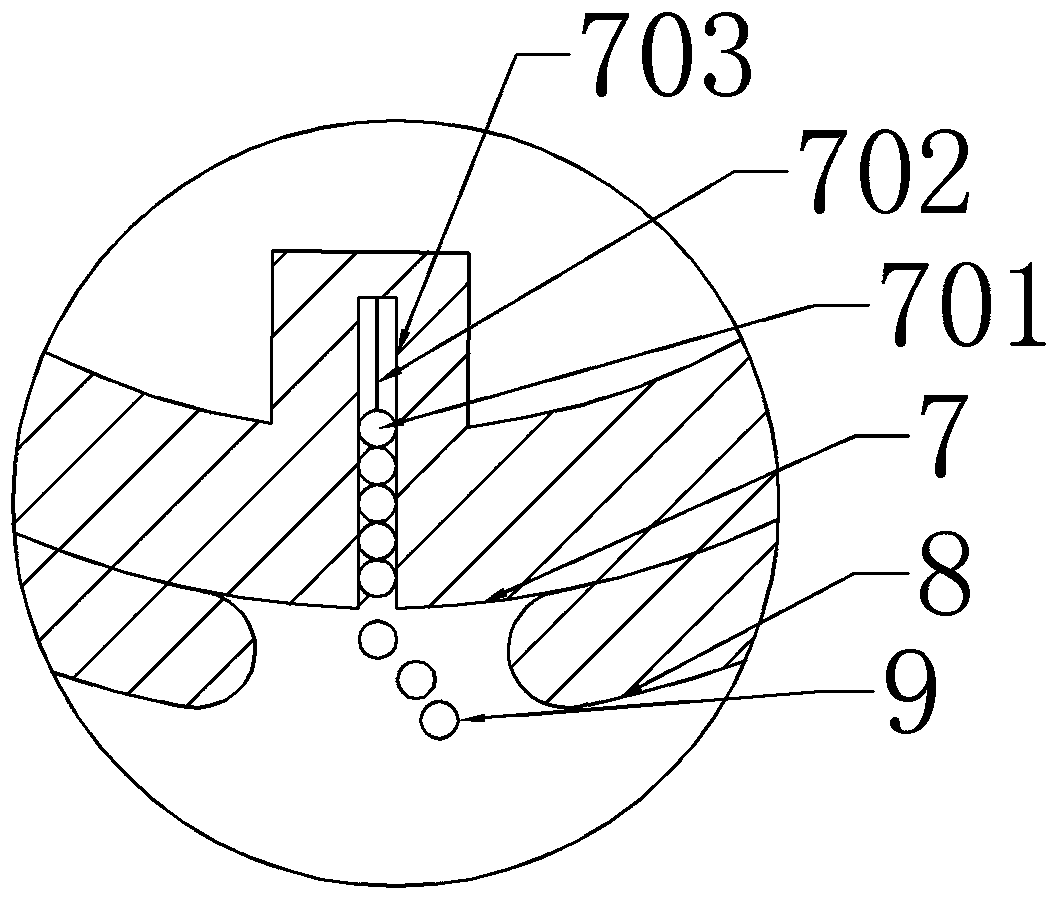

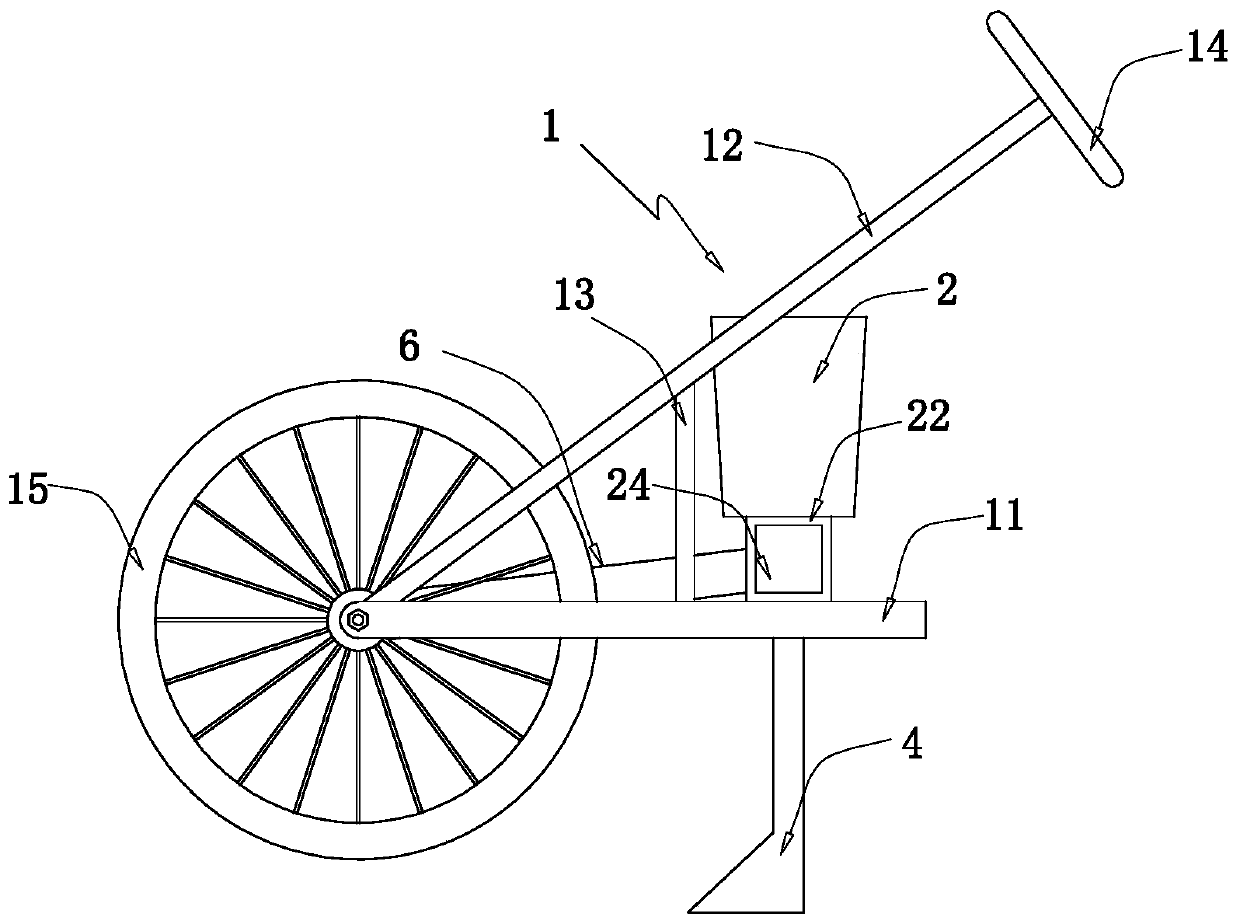

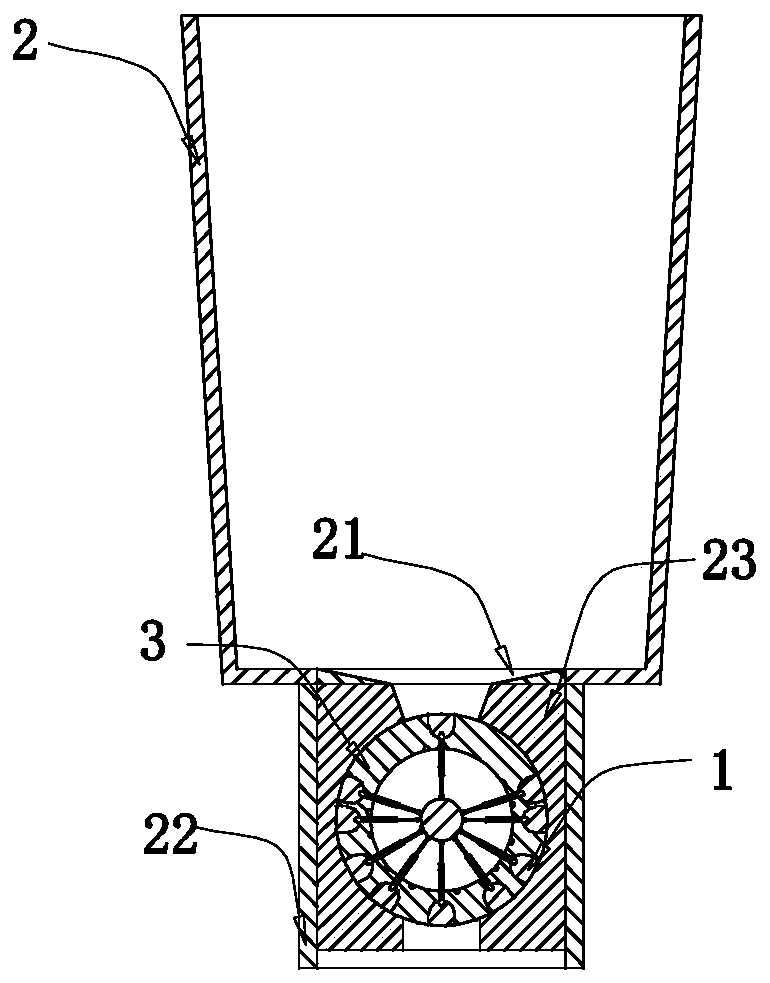

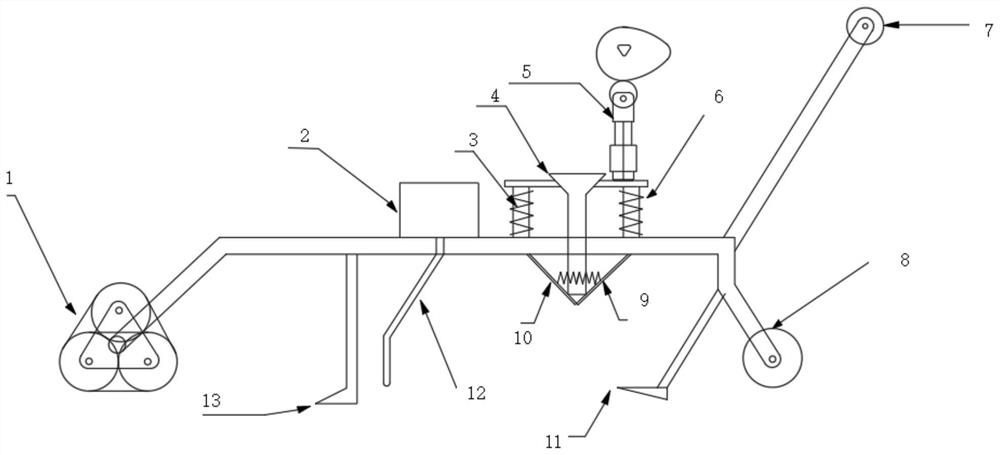

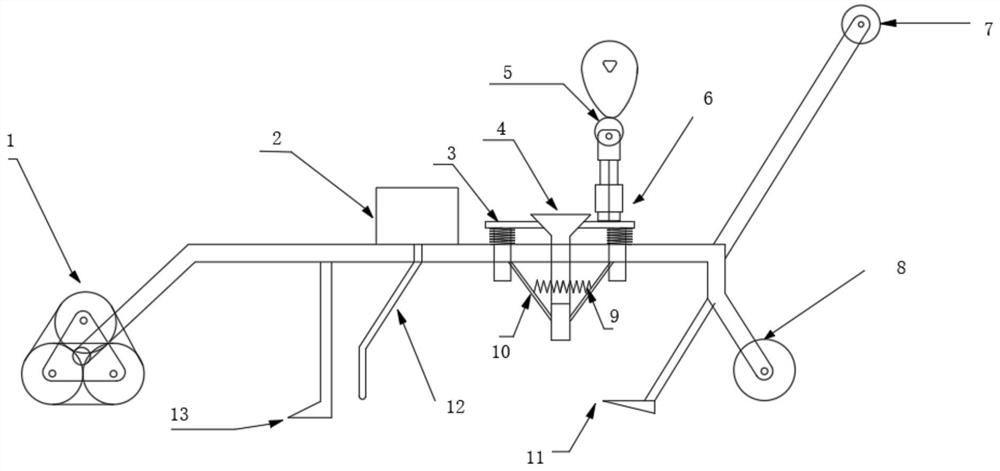

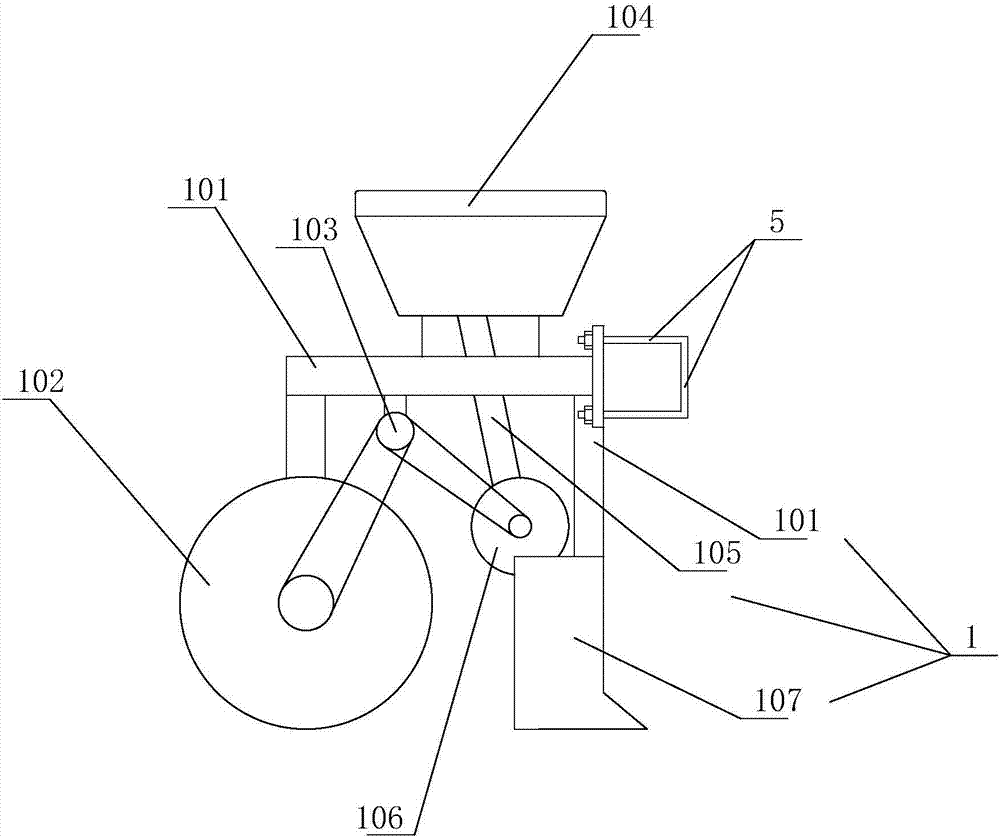

Peanut seeding and topdressing device

PendingCN110521351ASowing realizedTopdressing realizationPlantingFertiliser distributersEngineeringFertilizer

The invention discloses a peanut seeding and topdressing device. The peanut seeding and topdressing device is used for planting and fertilizer applying to mountain peanuts and intercropping peanuts. The peanut seeding and topdressing device comprises a rack and a seed box arranged on the rack, and further comprises a front walking wheel, a seed taking unit and a coulter, wherein the front walkingwheel is arranged on the front side of the rack; the seed taking unit is arranged below the seed box and comprises a shell, a supporting body, a seed taking disc, multiple seed taking grooves and a drive mechanism, wherein the shell is arranged between the rack and the seed box, the supporting body is arranged in the shell, the seed taking disc is rotatably arranged inside the supporting body, theseed taking grooves are formed in the outer round wall of the seed taking disc, and the drive mechanism is arranged between the seed taking disc and the front walking wheel; the coulter is arranged below the rack, an installing rod is fixed to the rack and slidingly connected with the coulter, and a locking structure is arranged between the installing rod and the coulter; an opening in the top ofthe installing rod is communicated with an outlet in the bottom of the supporting body. Through the device, peanuts can be seeded, and seeding distance can be adjusted; the device is suitable for seeding the peanuts, and further can realize topdressing. During topdressing, chemical fertilizer can be directly placed into the seed box.

Owner:BIOTECH RES CENT SHANDONG ACADEMY OF AGRI SCI

Seeder capable of quantitatively seeding

InactiveCN112534998ASowing realizedEasy accessDibble seedersSeed depositing seeder partsSeederAgricultural engineering

The invention discloses a seeder capable of quantitatively seeding. The seeder comprises a seeder body, a sealing mechanism, a limiting mechanism, a pull rod, a first spring, a first limiting column,a second limiting column, a connecting rod, a shaft sleeve, a drill bit, a power mechanism, a quantitative mechanism, a quantitative sleeve, a metering box, material receiving grooves, material leaking holes, a first limiting groove and a second limiting groove. The seeder has the beneficial effects that the proper metering box is selected according to the size of seeds, then the quantitative sleeve is rotated according to the specific seeding quantity requirement, so that the material leaking holes with the required quantity correspond to the material receiving grooves in the metering box, seeds are quantified, the pull rod is loosened, and the first spring drives the first limiting column to reset, so that the metering box is limited; and then the shaft sleeve is screwed towards the seeder body, the shaft sleeve abuts against the connecting rod to move towards the metering box, so that the second limiting column limits the metering box, the connecting rod drives the metering box to rotate by 180 degrees under the action of the power mechanism, the seeds are poured into the drill bit, and seeding of the seeds is achieved.

Owner:湖南景康生物科技有限公司

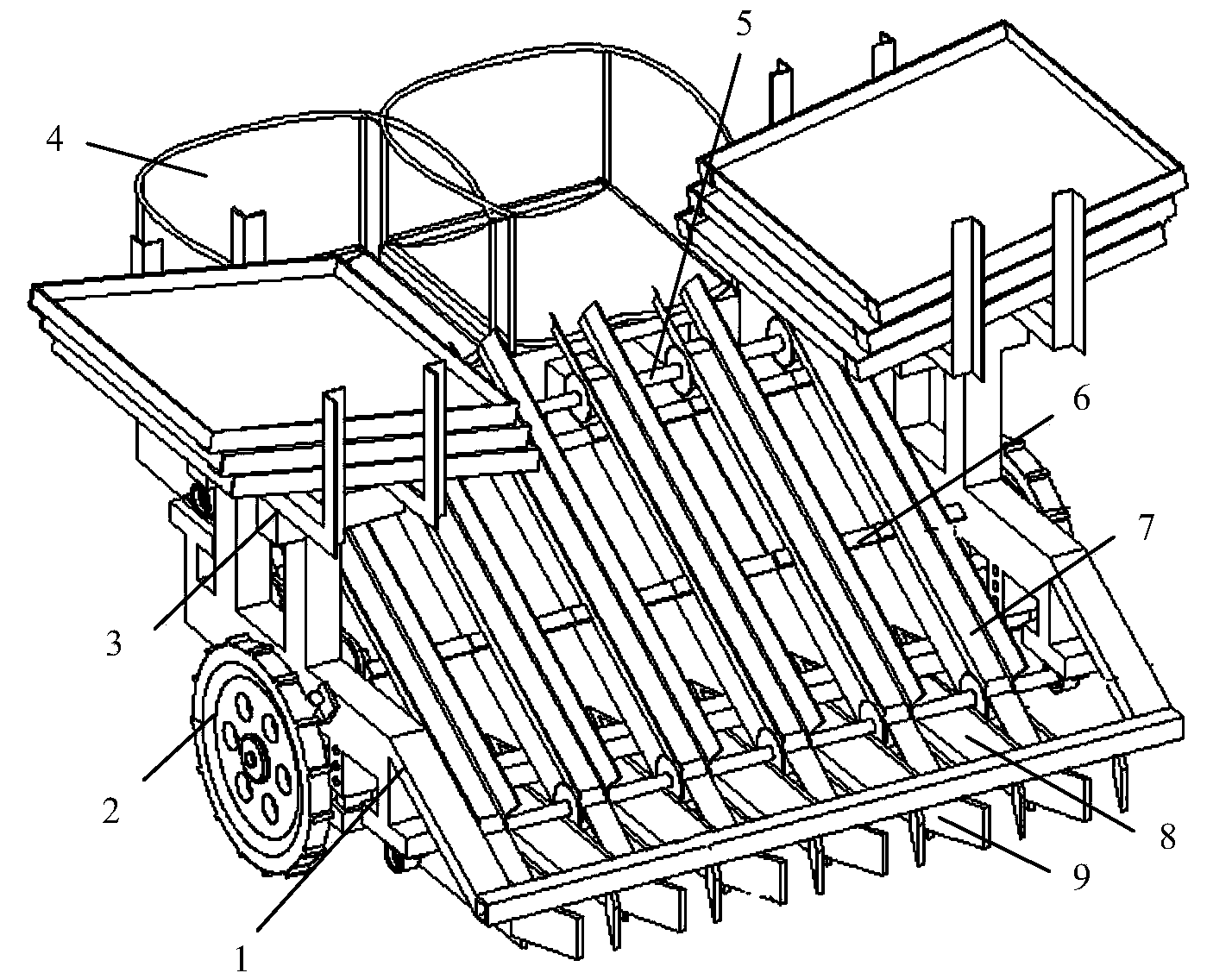

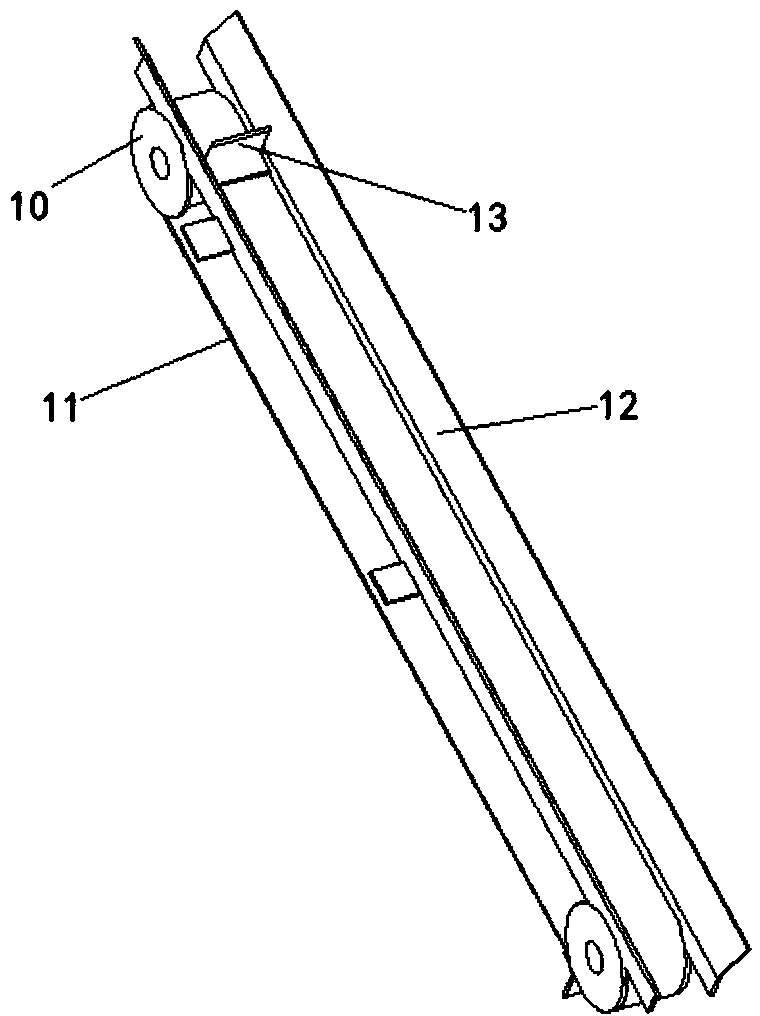

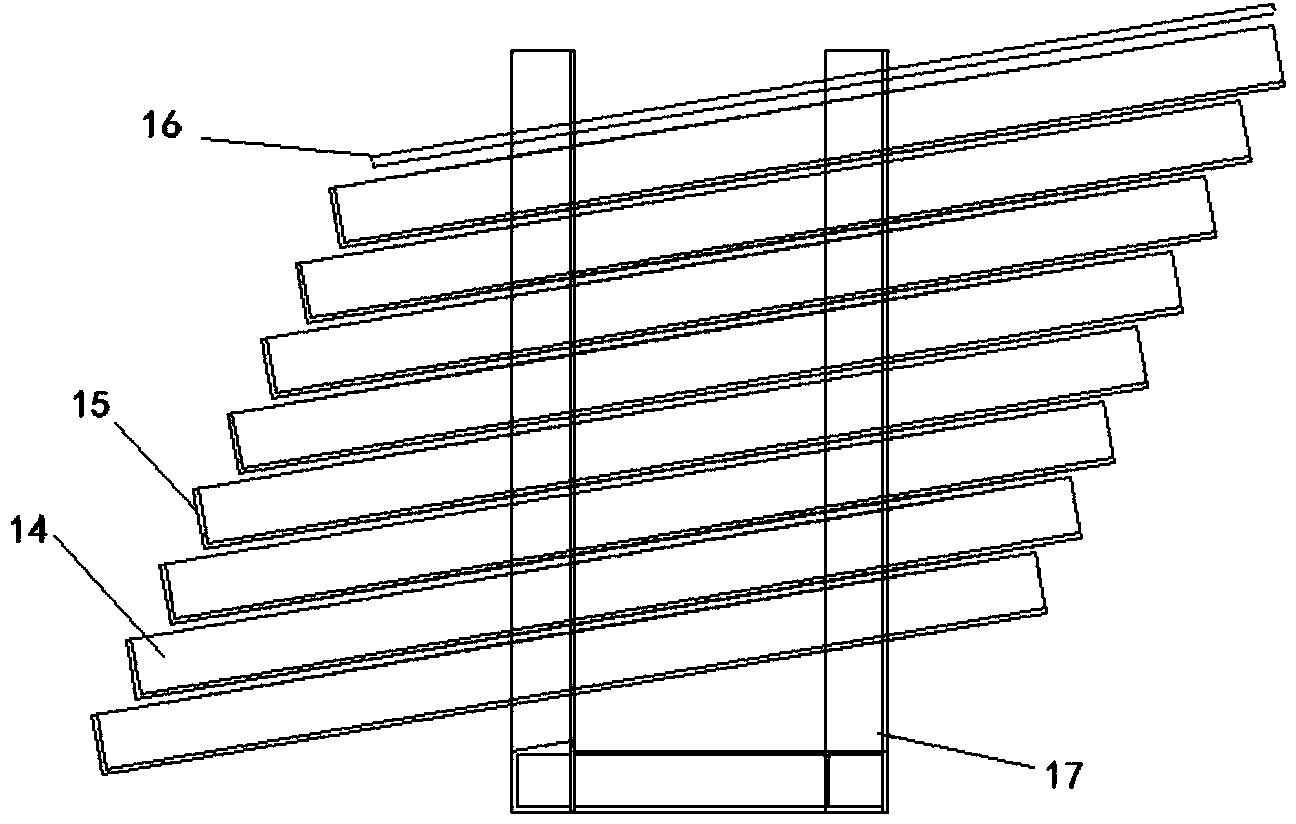

Semi-automatic garlic seeder

InactiveCN104025776BSowing realizedSeed depositing seeder partsBroadcast seedersSemi automaticEngineering

The invention relates to a semi-automatic garlic sower which comprises a hanging mechanism, a garlic seed box feeding mechanism, a seed carrying table, a ditcher, a covering device, a land wheel mechanism, a transmission mechanism and a stander, wherein the garlic seed box feeding mechanism adopts an inclined conveying belt and comprises a synchronous belt, an upper belt wheel, a lower belt wheel, belt wheel shafts and a garlic seed box holding device; land wheels drive the synchronous belt to rotate through the transmission mechanism; multiple layers of seed carrying plates are arranged on the seed carrying table in an inclination manner; seed ditches are formed by the ditcher; along with the rotation of the synchronous belt, a garlic seed box is downwards conveyed along the garlic seed box holding mechanism and is finally steadily put into a seed ditch along a flow guide plate of the ditcher; the garlic seed box is covered with soil through the covering device behind. The semi-automatic garlic sower can realize mechanical sowing with 'root down and tip up' and 'straight planting' of garlic, and single garlic seed sowing is changed into strip sowing, so that the sowing efficiency is improved; furthermore, sowing requirements on different plant spacing and rows can be met according to seed hole distances on the garlic seed boxes and mounting distances of the belt wheels.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Automatic seeder

PendingCN111406480ARealize fully automatic seeding functionFlexible sowingPlantingDibble seedersSeederDrive shaft

The invention discloses an automatic seeder, which comprises a rack, a travel mechanism, a sowing mechanism and a clutch separation mechanism, wherein the travel mechanism, the sowing mechanism and the clutch separation mechanism are arranged on the rack; the sowing mechanism comprises multiple groups of sowing parts connected through a drive shaft; each sowing part comprises a seed distributing mechanism and a clutch plate arranged in a sowing bin; each clutch plate is meshed with the corresponding seed distributing mechanism through a gear; the end part of the drive shaft is connected with an output shaft of a sowing motor; the clutch separation mechanism comprises multiple groups of clutch separation parts corresponding to the sowing parts; each clutch separation part comprises a screwmotor arranged on the rack; the output shaft of each screw motor is in contact with the corresponding clutch plate through a toggle lever; the rack is also provided with a vehicle speed sensor connected with a sowing controller; the sowing controller controls starting and stopping of a sowing operation through driving the sowing motor and the screw motors to act. According to the automatic seeder,multiple sowing parts can independently work, so that starting and stopping of the seeder and automatic sowing are achieved through the sowing mechanism and the clutch separation mechanism.

Owner:西安鸣士机电开发有限公司

An automatic corn seeding device

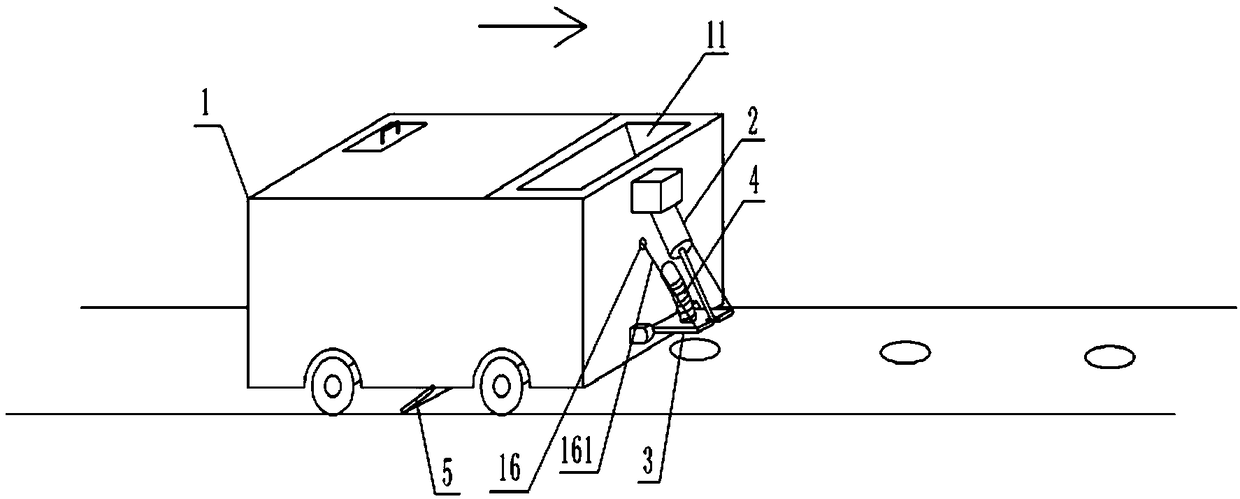

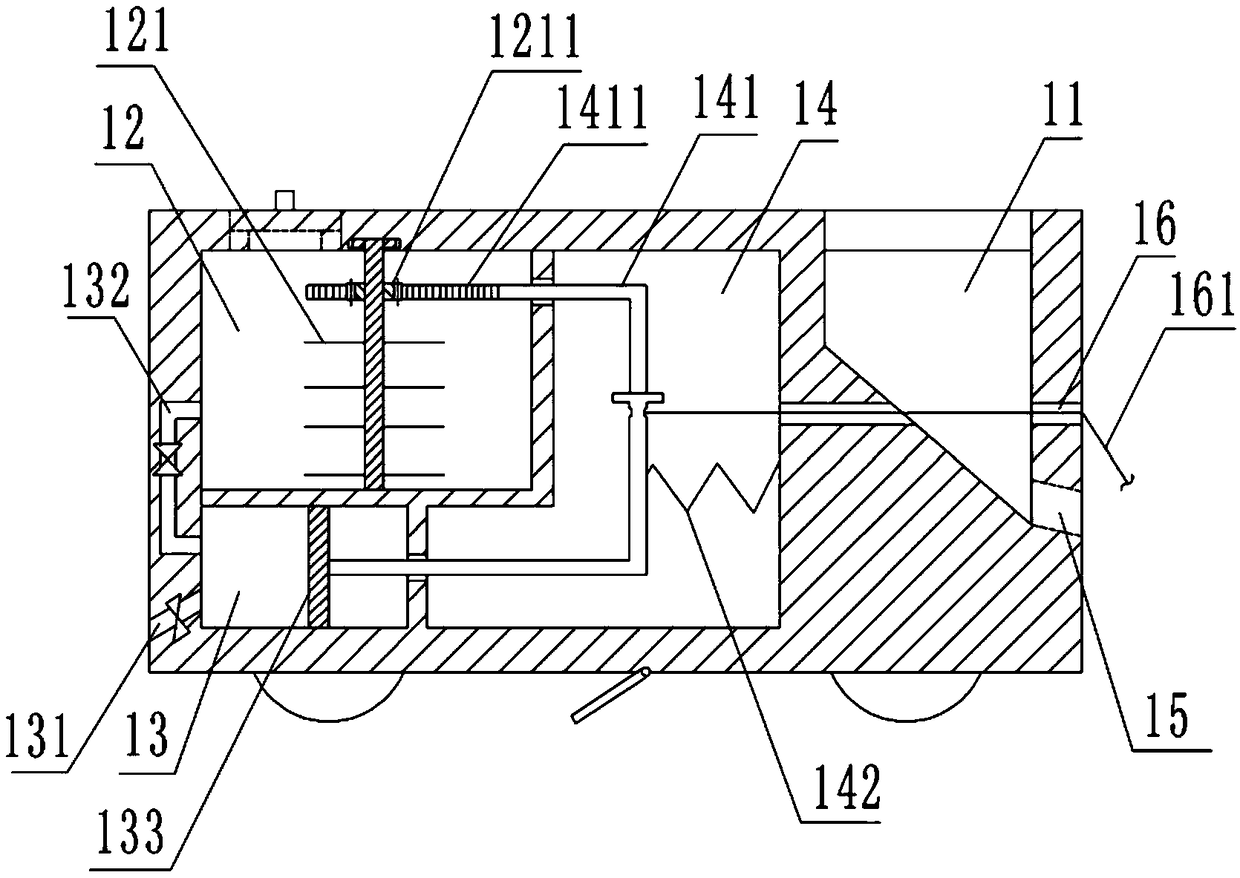

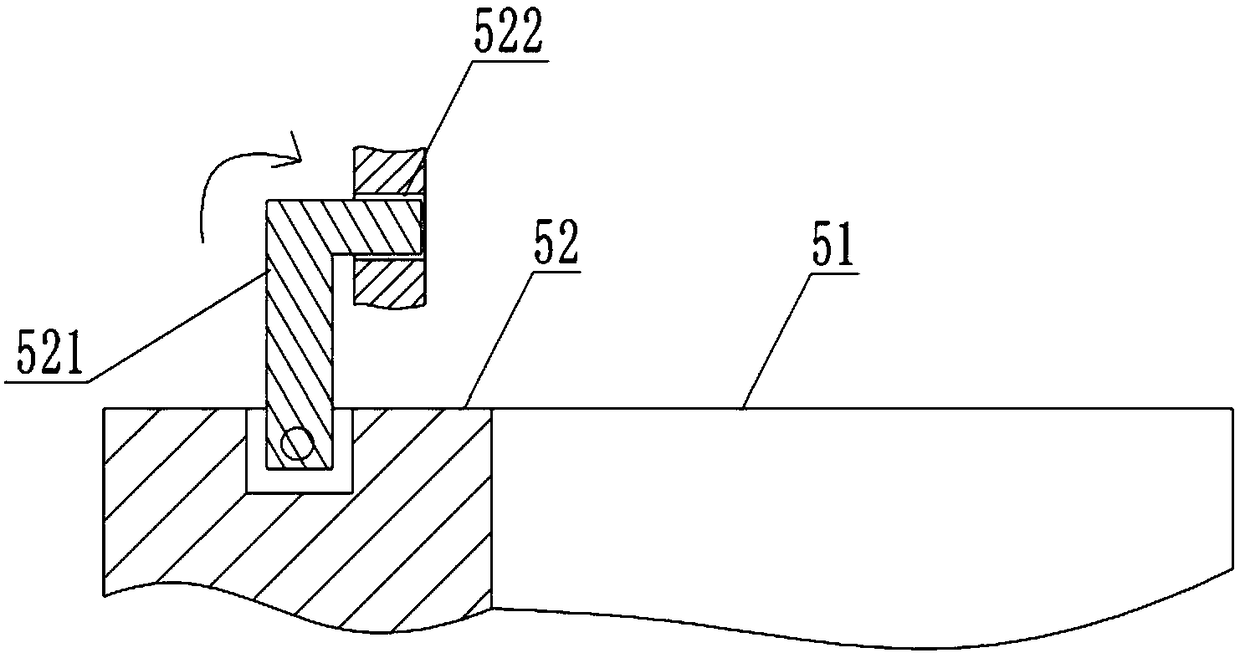

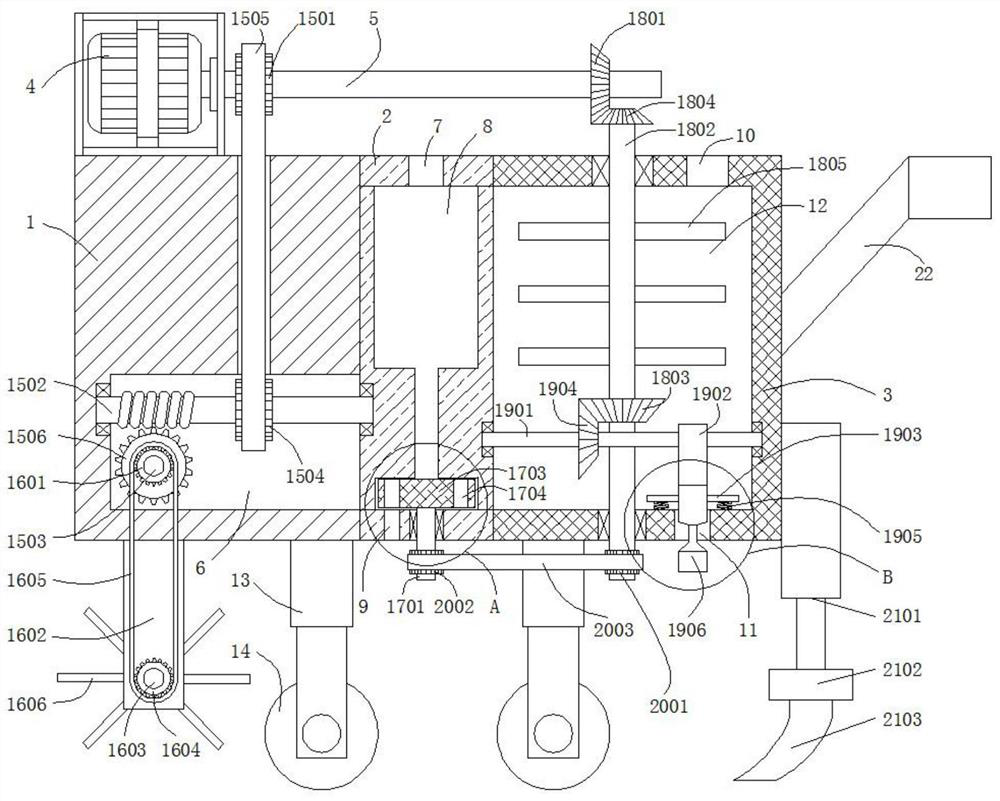

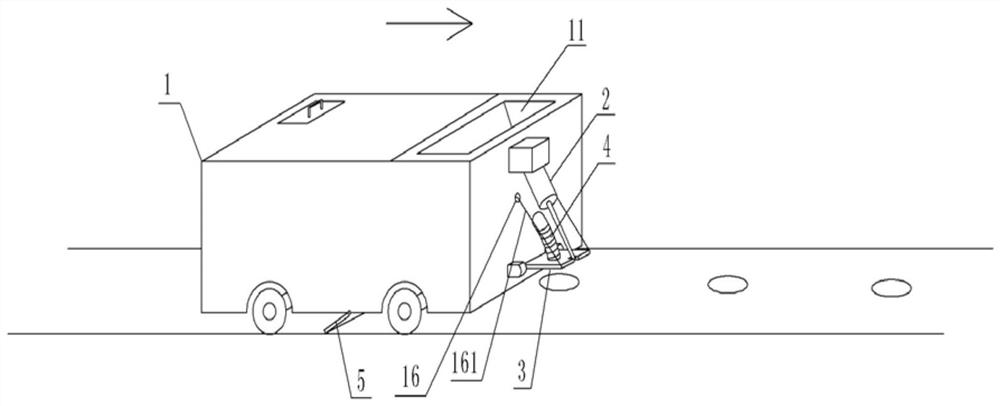

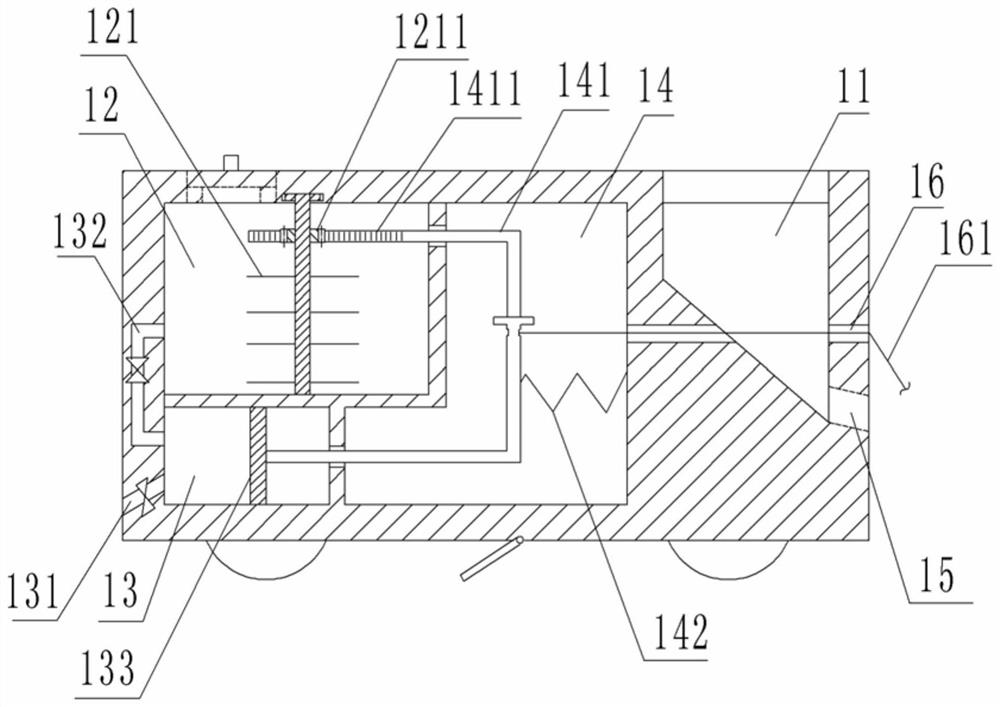

ActiveCN112616371BNot easy to rolloverSowing realizedPlantingSeed depositing seeder partsSeederAgricultural science

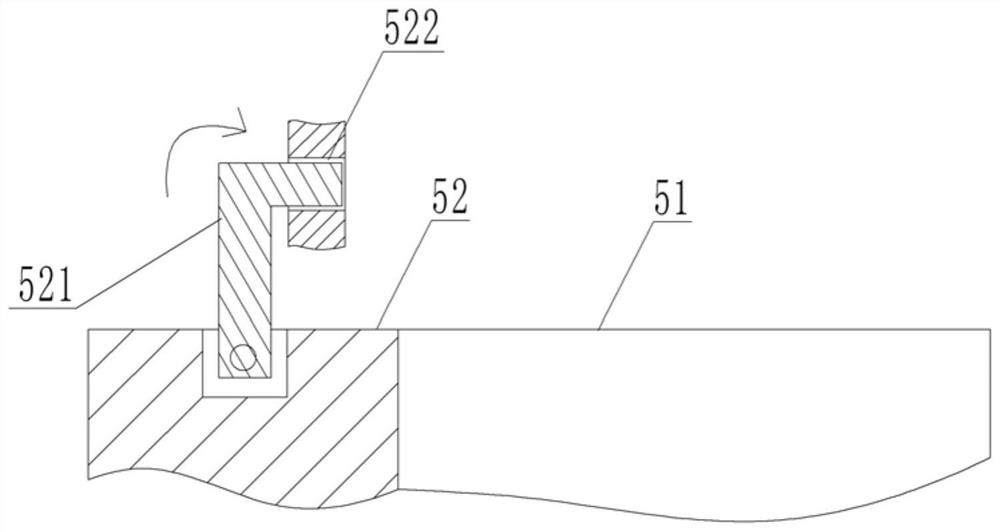

The invention belongs to the technical field of sowing devices, and relates to an automatic corn sowing device, which includes a car body, a crawler drive device, a fertilization device, a ditching device, an automatic sowing device and a soil-covering suppression device; the crawler drive device is driven by double crawlers and has strong adhesion The ditching device can easily plan the soil; the fertilizer guide pipe of the fertilization device is connected to the container to guide the fertilizer into the trench dug, and the amount of fertilization can be controlled by controlling the diameter of the conduit entrance. The automatic seeding device enables the seed box to move up and down under the action of the spring through the cam member, so that the seeder performs periodic and intermittent sowing. The covering soil compacting device is used to collect the soil discharged by the opener, and fill the soil back into the trench, and compact the soil after sowing and filling with the compacting wheel. The invention has small overall size, light weight, portability, simple structure, low manufacturing cost, is suitable for mass production, effectively solves the problem of corn sowing in small plots of land, and has great market prospects.

Owner:DALIAN UNIV OF TECH

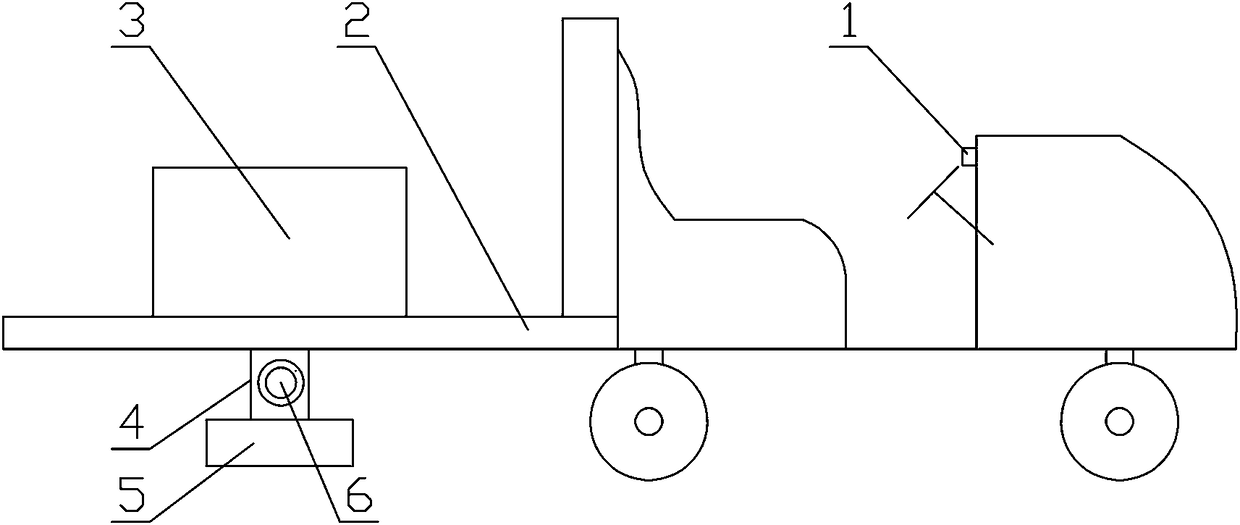

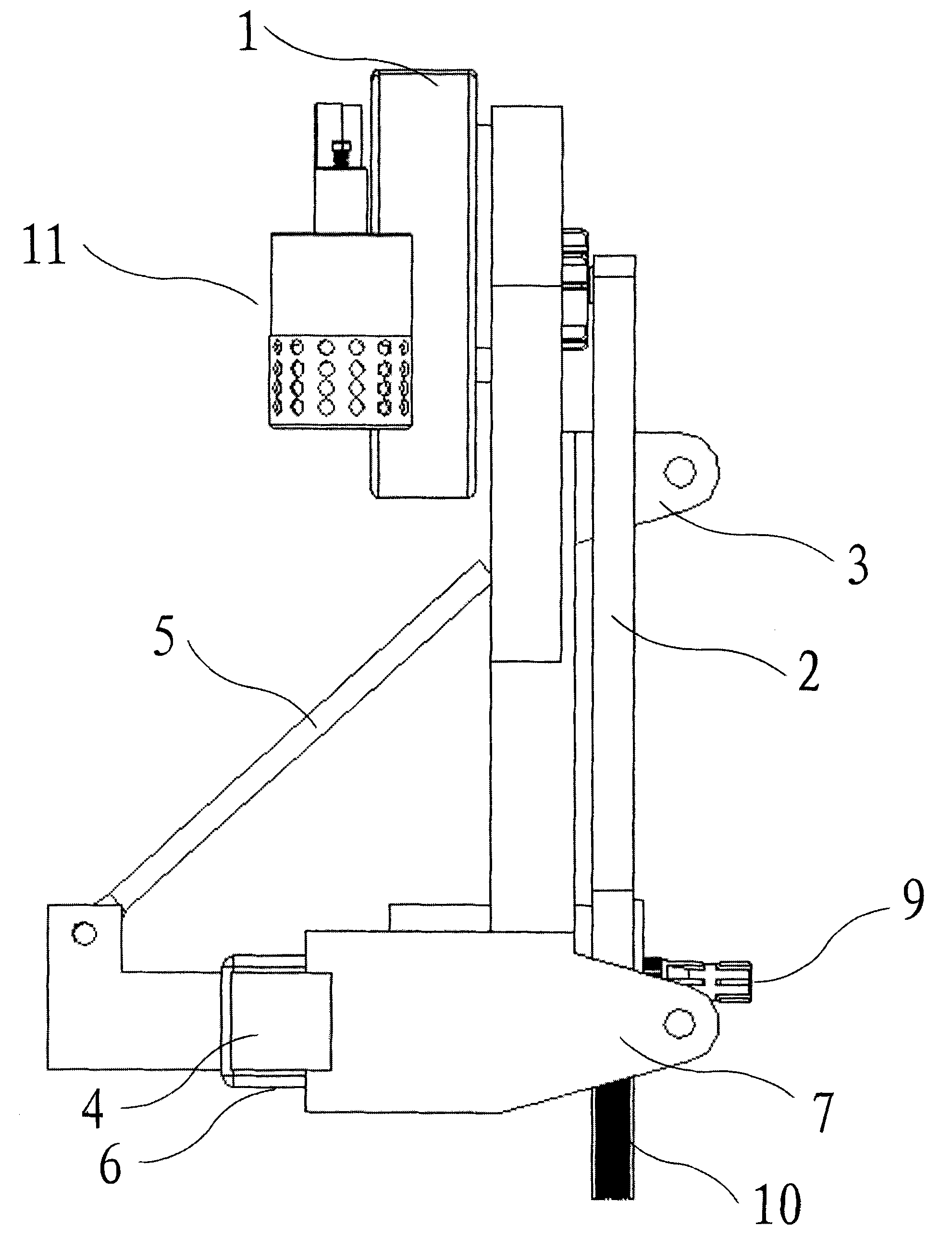

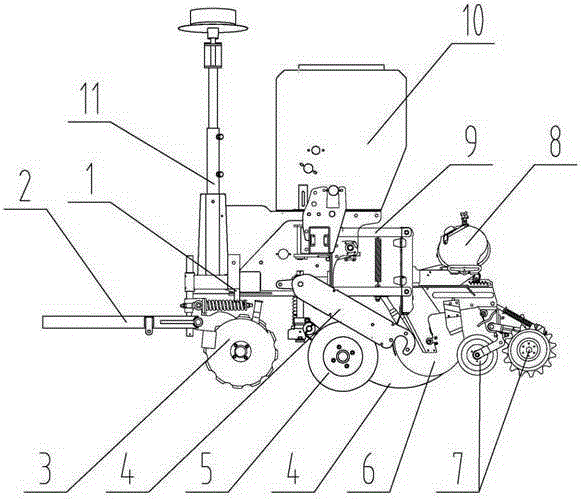

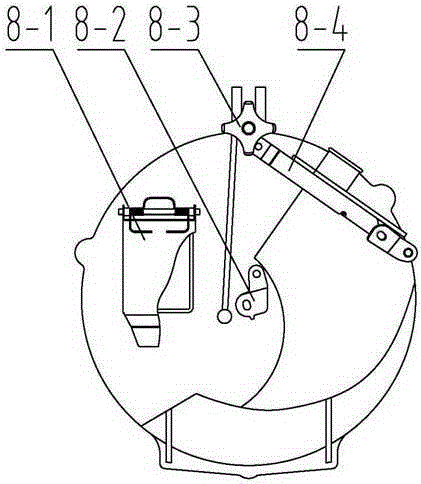

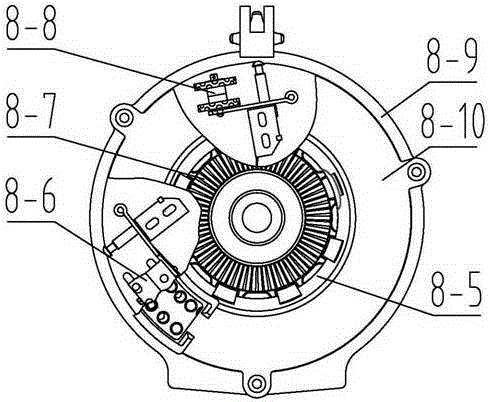

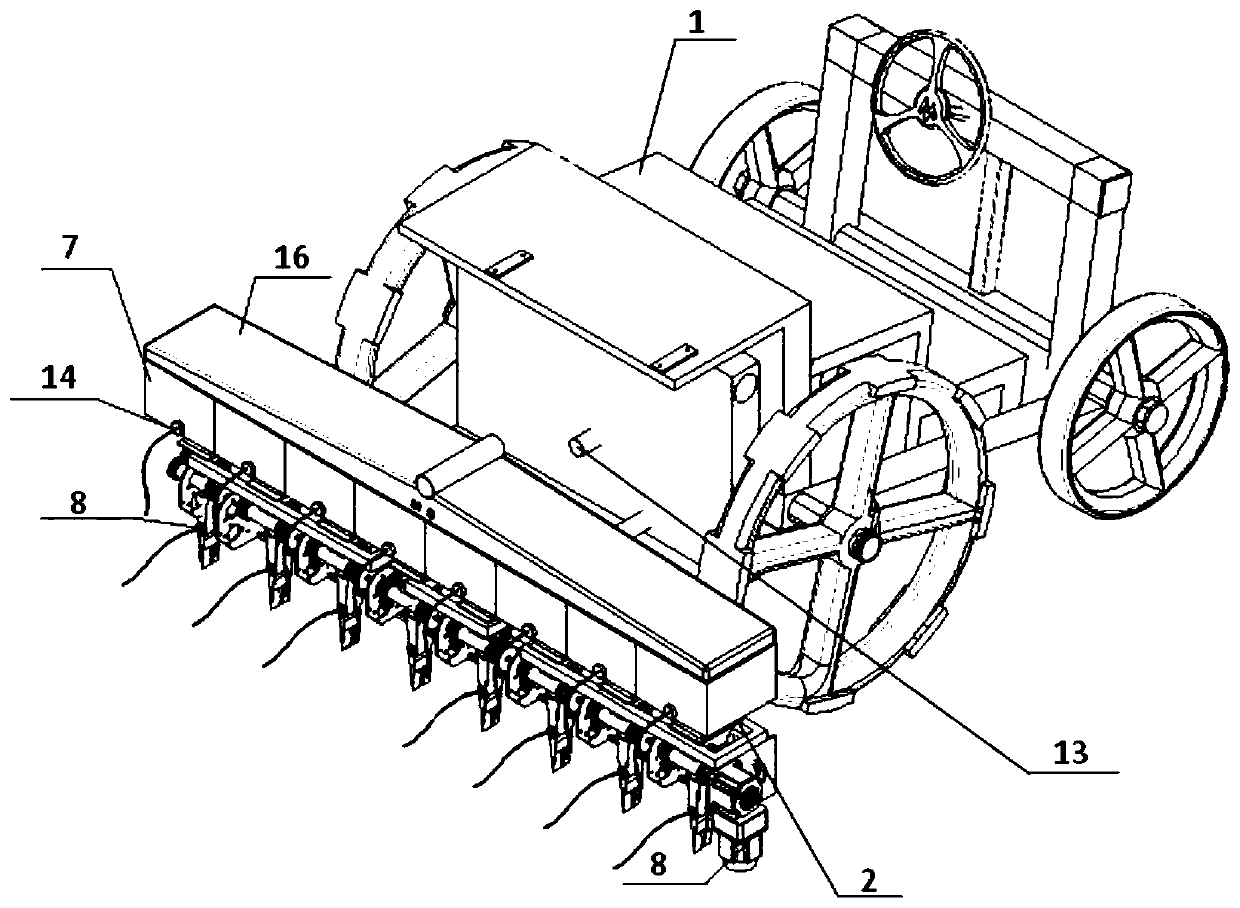

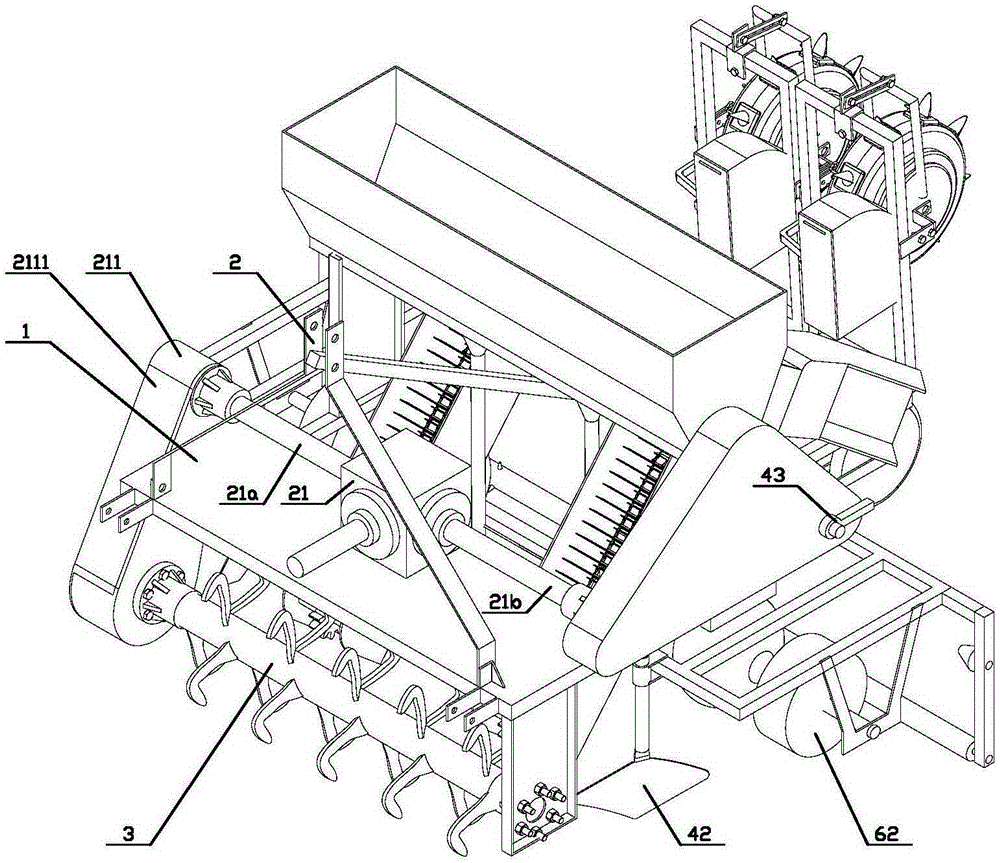

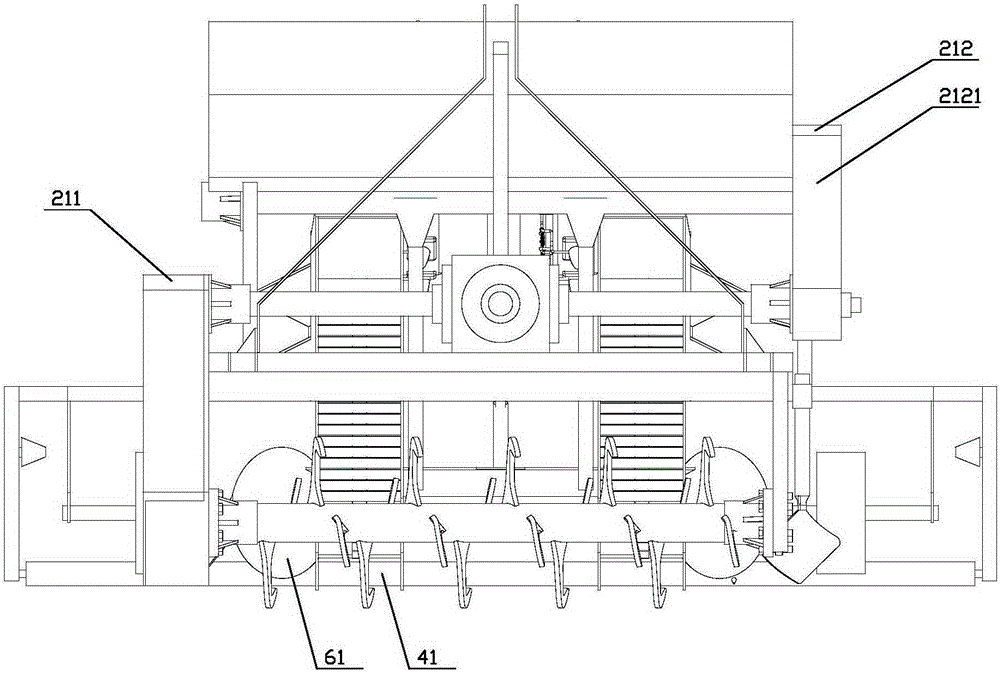

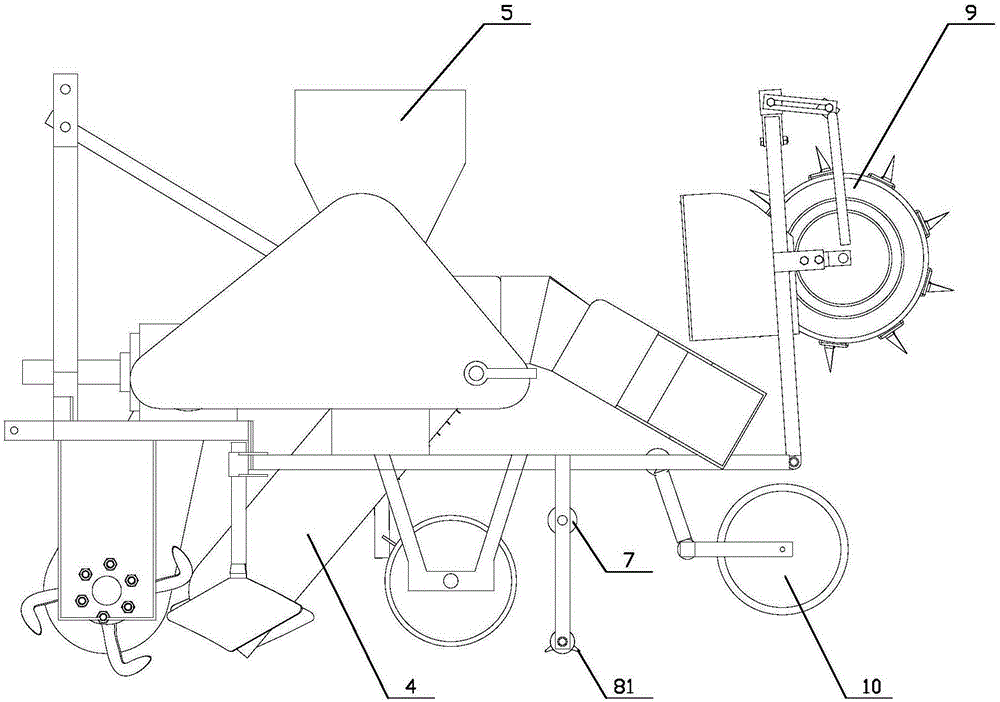

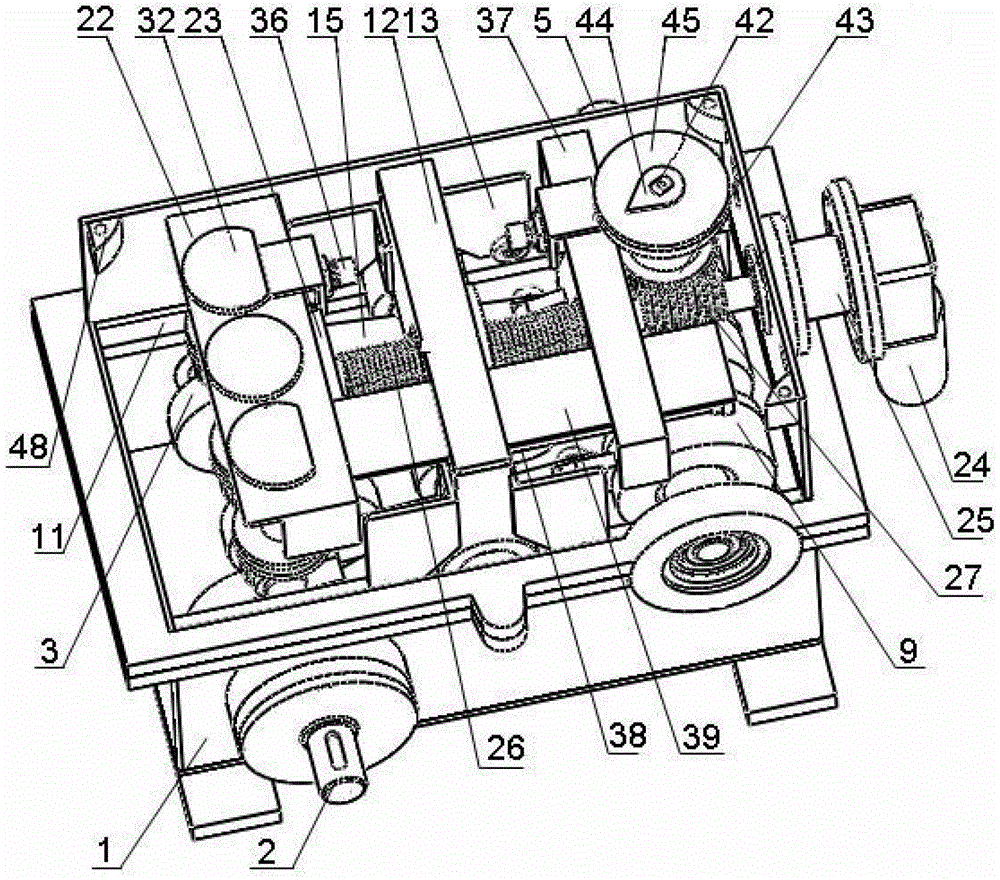

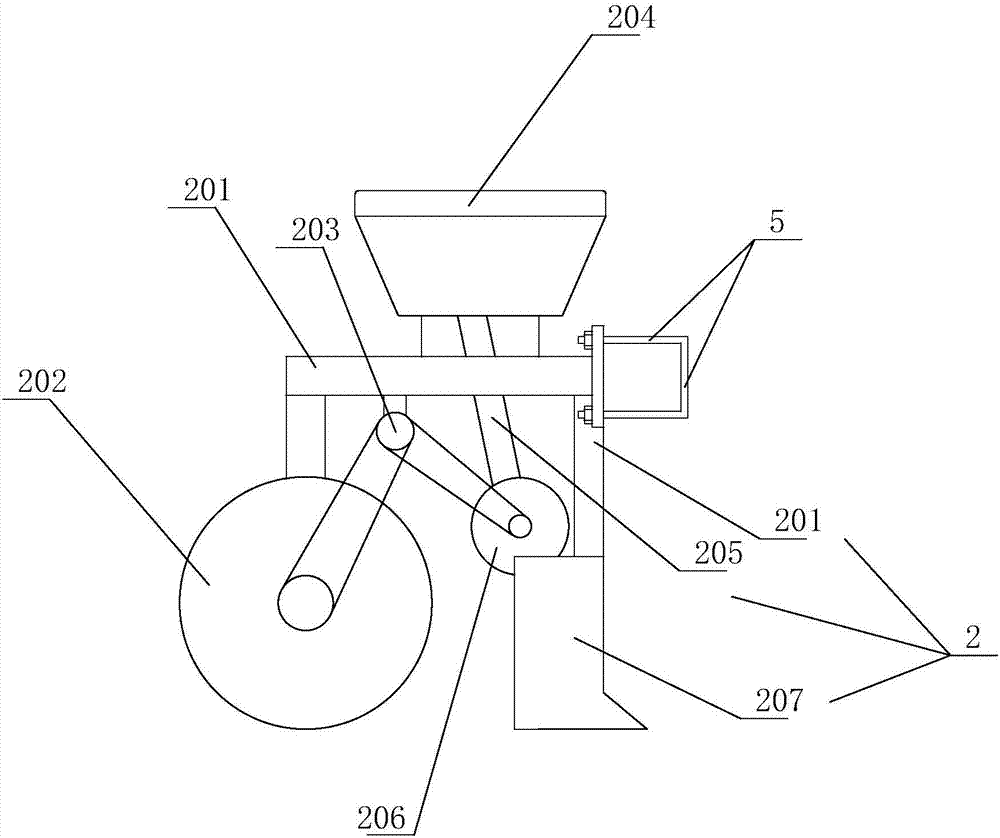

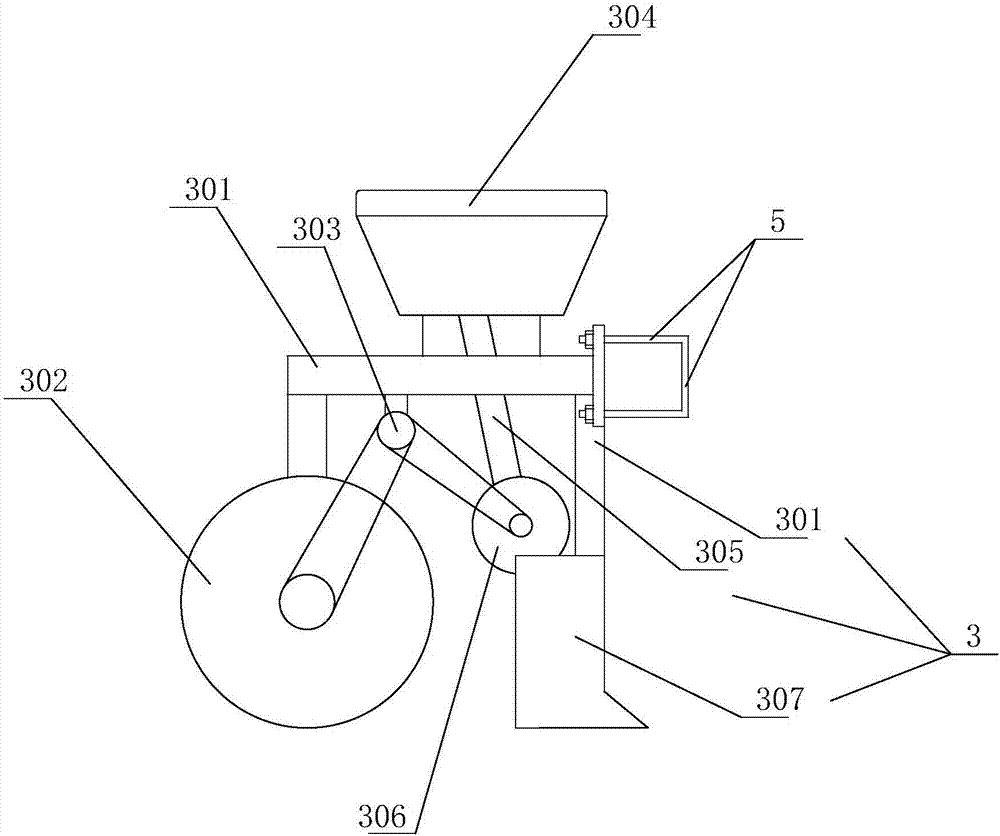

Multifunctional sowing machine

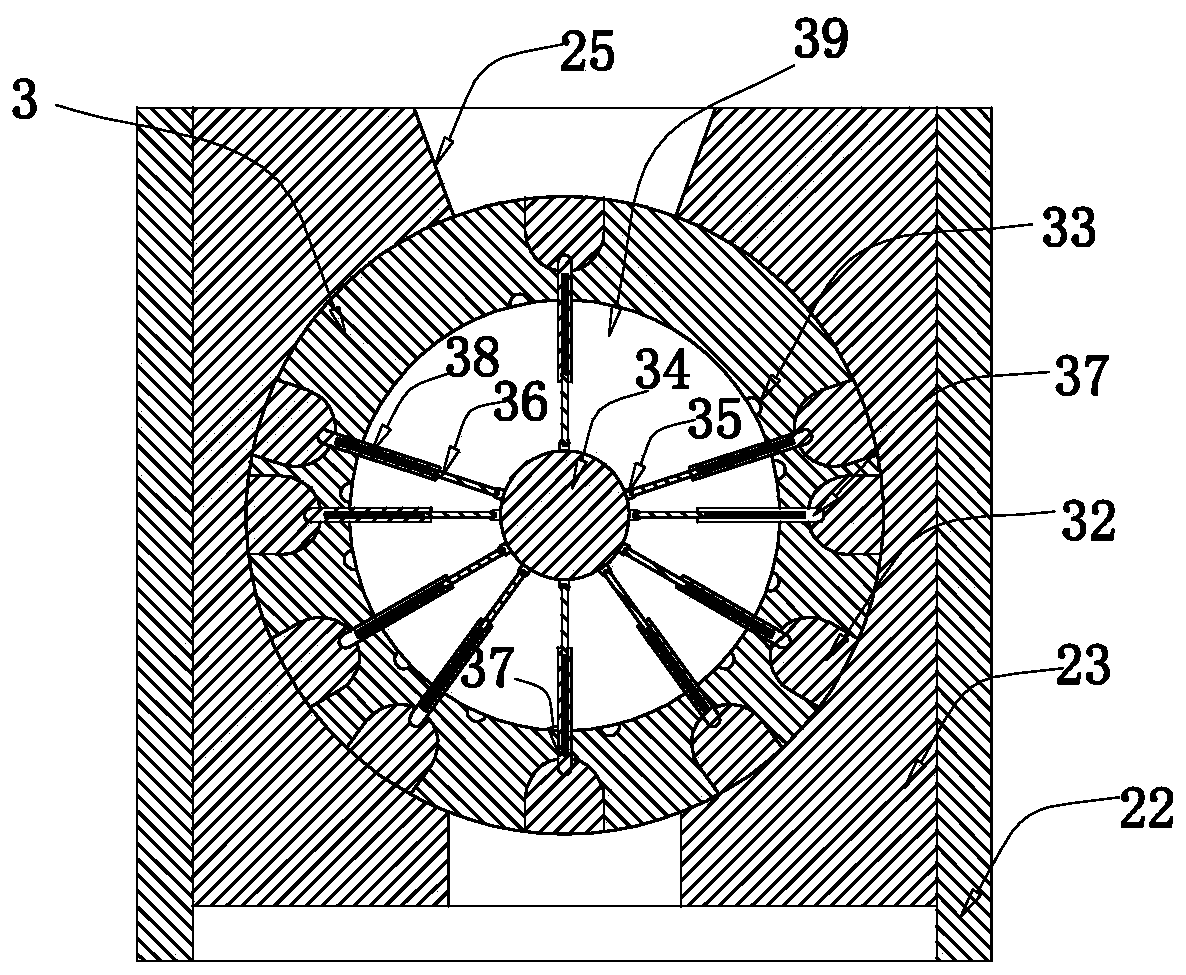

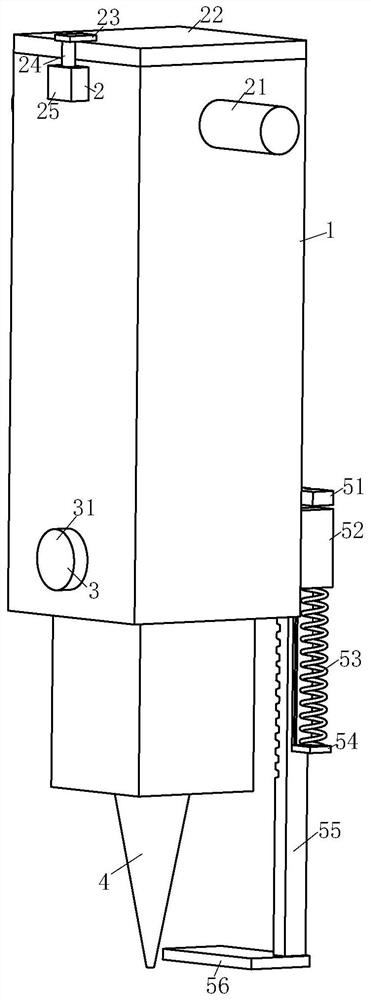

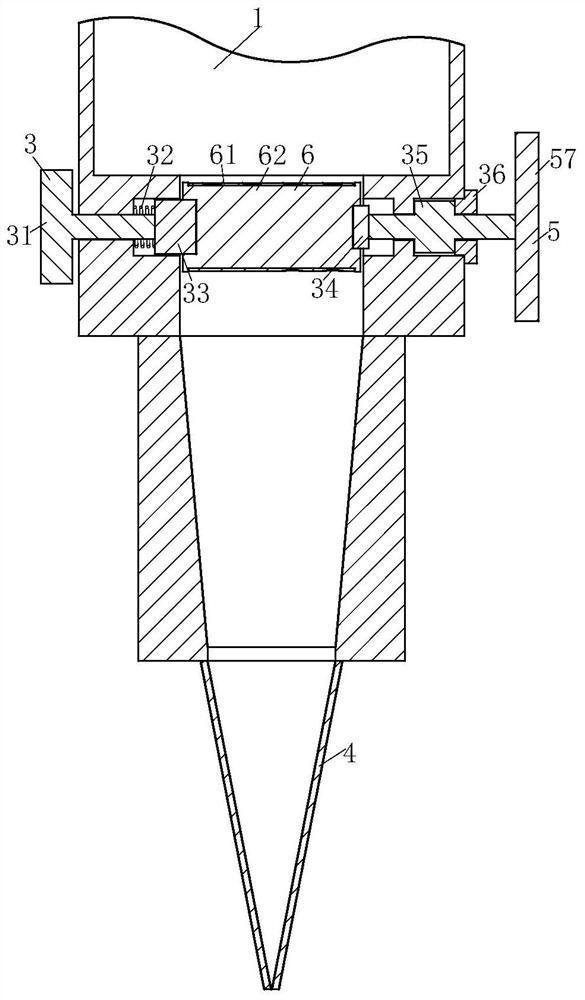

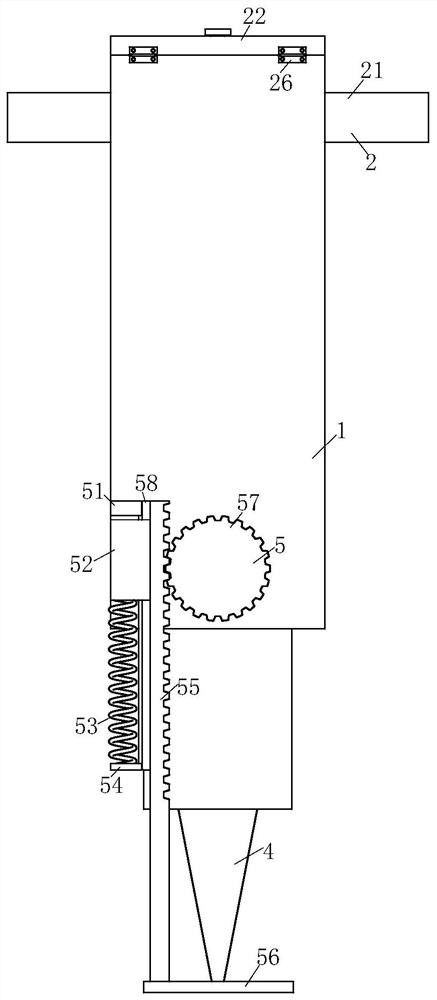

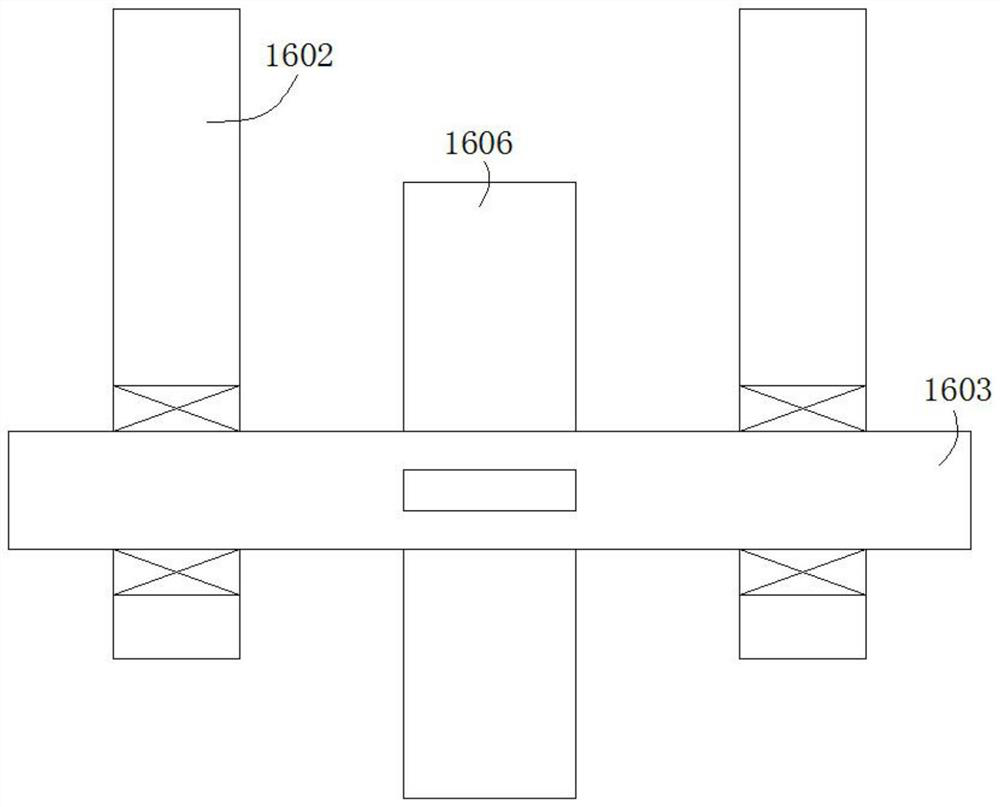

The invention belongs to the field of agricultural machines, and particularly relates to a multifunctional sowing machine. The multifunctional sowing machine comprises a machine frame 1 and a suspension device 2. The multifunctional sowing machine is characterized in that the suspension device 2 is arranged at the front end of the machine frame 1; the suspension device 2 comprises a gearbox 21, a first transmission gear 211 and a second transmission gear 212, and the second transmission gear 212 is connected with a soil feeding device 4 and a fertilization device 5; a film hanging rack 7 and a hole puncher 8 are arranged on the back of a shaping device 6; a hole sowing device 9 is arranged on the back of the machine frame 1 and comprises a hole sowing machine 91 and a hole sowing machine frame 92; a limiting wheel 10 is further arranged on the back of the machine frame 1. According to the multifunctional sowing machine, a soil shovel capable of adjusting the opening and closing angle is arranged on the lower portion of the soil feeding device to balance soil pressure on the front portion and the back portion of the soil feeding device; by the adoption of the mode that a soil scraping plate is additionally arranged on the shaping device, neatness of the sowing faces is guaranteed; the hole puncher is arranged behind the film hanging rack, so that follow-up workloads are reduced; various crops can be sown through the precision hole sowing machine with seeds of various specifications being compatible, and the multifunctional sowing machine is of great significance to improving the crop planting efficiency.

Owner:DINGXI SANNIU AGRI MACHINERY MFG

Surface soil shallow layer repairing device and land resource planting and recycling equipment

InactiveCN114451089AEasy to activate biological activityTo achieve the purpose of adding automationSpadesSoil lifting machinesChemical treatmentLand resources

The invention relates to the technical field of polluted soil treatment, in particular to an earth surface soil shallow layer repairing device and land resource planting and recycling equipment. According to the technical scheme, the device comprises a bearing plate trailer and a square containing window formed in the plate trailer, a U-shaped supporting frame fixed to the bearing plate trailer is arranged on the upper side of the square containing window, an L-shaped supporting plate is fixed to the upper side of the U-shaped supporting frame, and a motor is fixed to the upper side of the L-shaped supporting plate; and an output shaft of the motor penetrates through the top of the L-shaped supporting plate and is fixedly connected with a linkage edge rod, a matching screw column connected with the linkage edge rod in a sleeving mode is in threaded connection with the upper portion of the U-shaped supporting frame, a spiral drilling rod located on the inner side of the square containing window is fixed to the lower end of the matching screw column, and a collecting hopper is jointly fixed to the upper side of the bearing plate trailer through a pair of fixing columns. According to the method, a biological treatment technology and a chemical treatment technology are integrated, multiple treatment methods are synchronously carried out, existing comprehensive treatment steps are simplified, the construction efficiency is greatly improved, and application and popularization are facilitated.

Owner:闫蕊

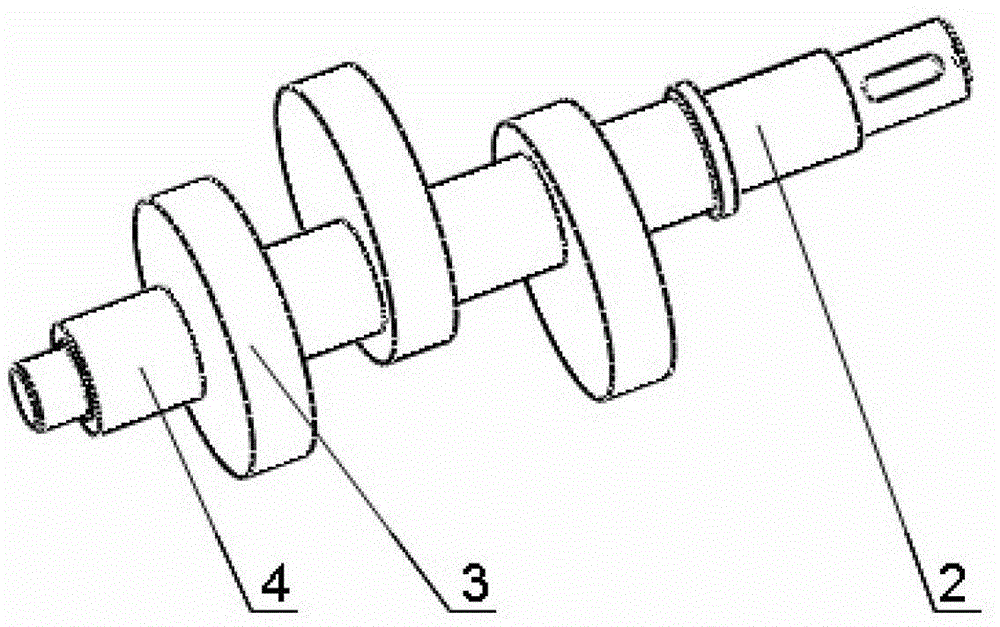

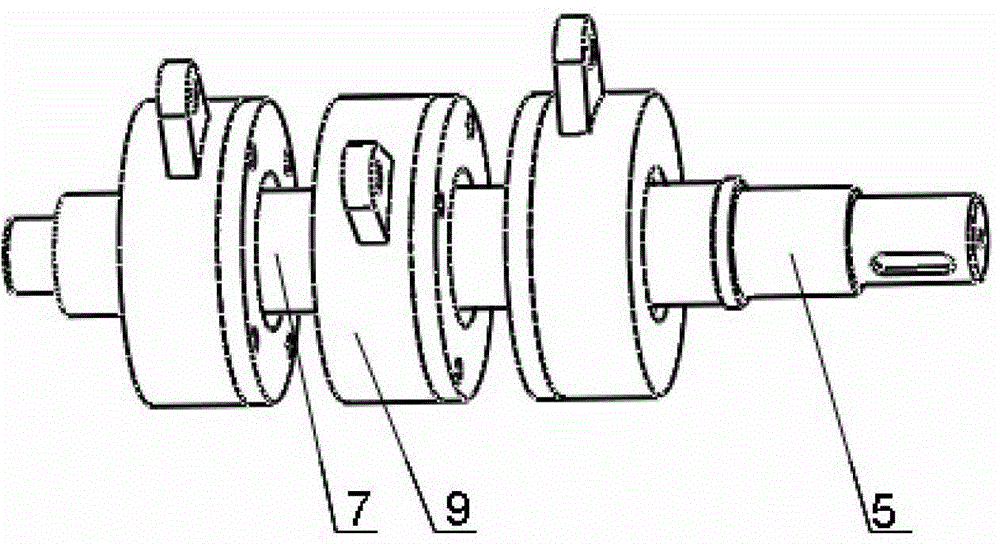

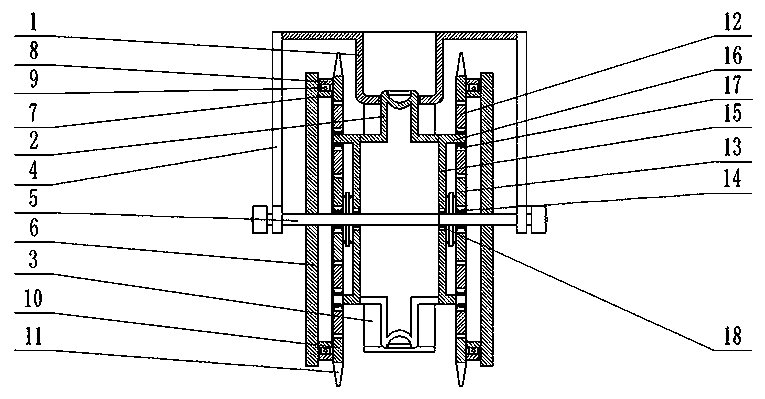

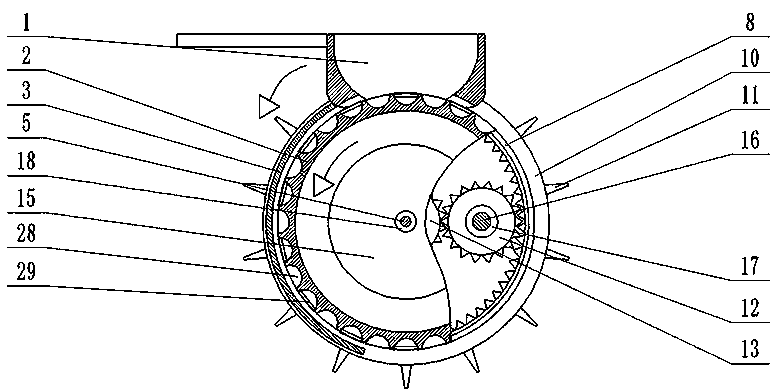

Electric-control mechanical stepless row spacing regulator for seeder

InactiveCN103190229BAchieve continuous rotationGuaranteed normal transmissionSeed depositing seeder partsFertiliser equipmentsSeederEngineering

The invention relates to an electric-control mechanical stepless row spacing regulator for a seeder. The electric-control mechanical stepless row spacing regulator comprises a tank body, and a power input device, a power output device, a transmission device, a regulating device, a plurality of sets of oscillating bar reset devices, a limiting device, a displacement detection device and a row spacing indicating device which are arranged in the tank body. The row spacing regulator is characterized in that the power input device comprises an input shaft, a spacer sleeve I and a plurality of cams spaced at a certain angle, two guide racks are arranged in the middle of two ends of a regulating rack, the lower end of the regulating rack is provided with oscillating shafts equal to the cams, roller oscillating bars penetrate the oscillating shafts at intervals, one end with a roller of each roller oscillating bar is pressed on the corresponding cam by the corresponding oscillating rod reset device, the other end of each roller oscillating bar is hinged with a clutch housing, a screw worm of the regulating device horizontally penetrates the regulating rack, one end, close to the worm, of the regulating device extends out of the tank body to be connected with a gear motor shaft, and a micro sliding block displacement sensor probe of the displacement detection device is fixed on the regulating rack. The electric-control mechanical stepless row spacing regulator for the seeder can be used for performing stepless regulation on row spacing so as to achieve variable seeding.

Owner:SHANDONG UNIV OF TECH

Potato seeder

InactiveCN110583180ASowing realizedEasy to adjust the distance between plantsPotato plantersSeederGear wheel

The invention discloses a potato seeder. The potato seeder includes a seed box and a socket-type seed separating plate, and the socket-type seed separating plate is arranged to be aligned with the lower opening end of the seed box; the potato seeder is characterized in that the portion, corresponding to the lower opening end, of the seed box is connected with a seed guard plate, a set of tooth rings is symmetrically arranged, stirring fingers are uniformly distributed at the top of each tooth ring, the tooth rings are meshed with the surrounding gears respectively, the set of surrounding gearsis symmetrically arranged, the surrounding gears are meshed with the center gears respectively, the center gears are arranged on rotary tables respectively, the opposite sides of the rotary tables are connected with the socket-type seed separating plate, counterbores are formed in the two ends of a central positioning shaft respectively, through holes are formed in the portions, at the bottom ends of the counterbores, of the central positioning shaft, the counterbores are communicated with the through holes respectively, guide rods are arranged inside the counterbores respectively, pressing rods are arranged inside the through holes respectively, the guide rods are vertically connected with the pressing rods respectively, contact feet are arranged at the two ends of each pressing rod andraised inside guide grooves, the end portions of the guide rods extend beyond the central positioning shaft and are provided with thread sections, and the guide rods are in threaded connection with rotary caps. The potato seeder has the advantages of a simple structure, convenient control and high working efficiency.

Owner:曹喜全

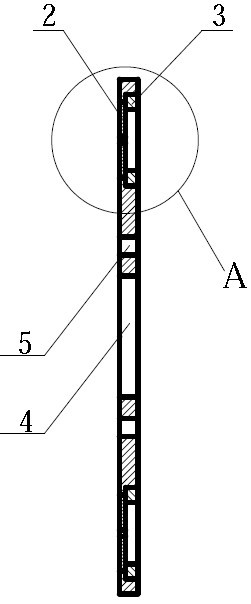

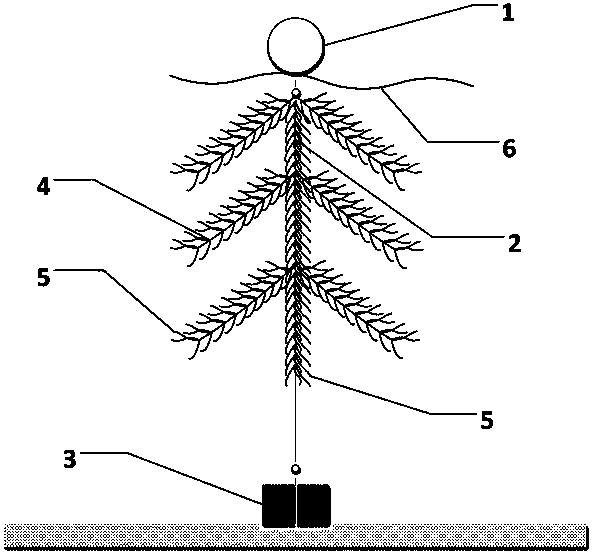

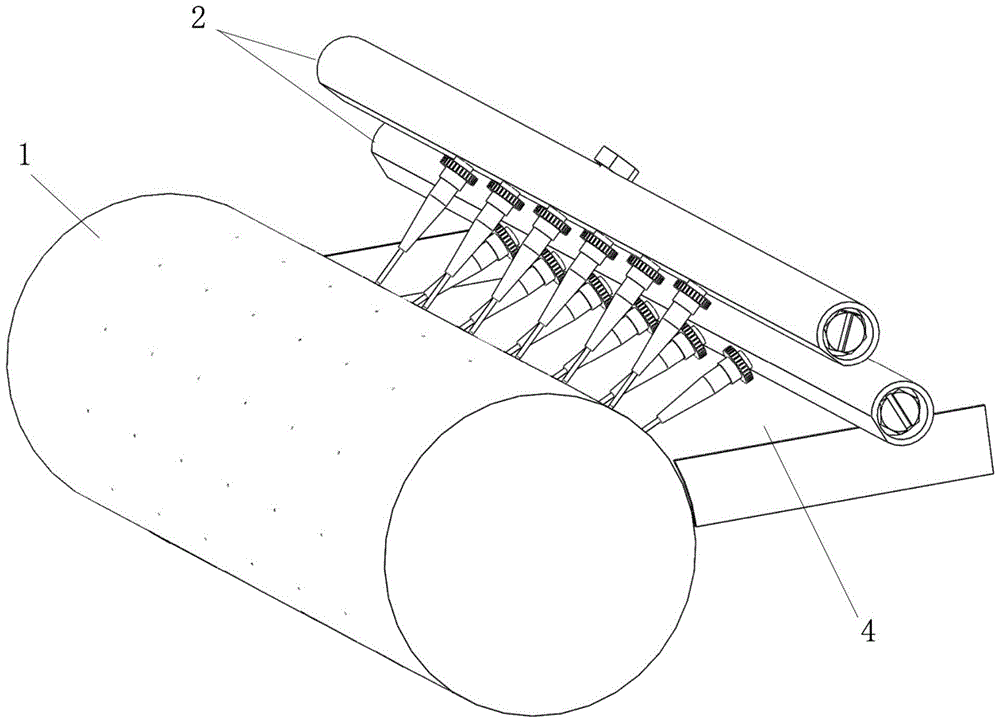

A method and device for naturally promoting maturation and sowing of subtidal eelgrass reproductive plants

ActiveCN105191780BLow costSowing realizedClimate change adaptationCultivating equipmentsSea grassRipening

The invention relates to a sea grass land restoration and reconstruction technology and particularly relates to a natural ripening accelerating and sowing method and device for a subtidal eelgrass reproductive plant. The method comprises the steps of clamping an eelgrass reproductive plant on a natural sea grass land onto a main rope and a side rope of a device, and then, putting the device for fixing the eelgrass reproductive plant into a proper natural sea area to carry out natural ripening accelerating and sowing on the eelgrass reproductive plant, wherein the device is sequentially provided with a floating ball, the main rope and a dropstone from top to bottom, the floating ball and the dropstone are respectively arranged at two ends of the main rope, and the main rope of which one end is provided with the floating ball is provided with the side rope along the length direction. By using the natural ripening accelerating and sowing method and device, an eelgrass seed can ripen and naturally drop, so that the collecting problem that the eelgrass seed does not ripen or the ripened seed drops is solved, and the sowing difficulty of seabed sea grass in a relatively deep subtidal water area is also overcome; by combining the simple, convenient and effective eelgrass sowing method, an eelgrass sea grass land in the relatively deep subtidal water area can be conveniently and rapidly restored or reconstructed; and meanwhile the device disclosed by the invention can be recycled, so that the cost can be reduced, and the used material cannot pollute the sea area.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

A method for using a water-retaining agent in drought-resistant sowing of peanuts, a sowing method and a system

ActiveCN105960882BSowing realizedPromote hydrationAgriculture tools and machinesLiquid seeding techniquesCrop cultivationAqueous solution

The invention discloses an application method of a water-retaining agent in peanut drought-resisting sowing, a sowing method and a system, and belongs to the technical field of crop cultivation. According to the method, a water-retaining agent water solution is pressed into peanuts with cracks in shells, then the shells of the peanuts are adhered with water-retaining agent powder, and then the treated peanuts are sown. According to the method, the utilization efficiency of the water-retaining agent is improved, the application amount of the water-retaining agent is reduced, and the water consumption demand for peanut seedling emergence and germination is ensured.

Owner:JIANGXI ACAD OF AGRI SCI

Fruit planting equipment

The invention relates to the technical field of agriculture, and in particular relates to fruit planting equipment. The fruit planting equipment comprises a planting trolley, wherein a seed holding cavity, a fertilizer water cavity, a fertilizing cavity and a pull rod cavity are formed in the planting trolley; a fertilizing pipe and a fertilizer feeding pipe communicate to the fertilizing cavity;a stirring rod is rotationally connected to the wall of the fertilizer water cavity, and a gear is fixed to the stirring rod; a piston is slidably connected in the fertilizing cavity; a pull rod is arranged in the pull rod cavity, and an elastic reset piece is arranged between the pull rod and the pull rod cavity; a rack is arranged at one end of the pull rod; the other end of the pull rod is fixedly connected to the piston; a hydraulic cylinder, a rotating plate and a discharge port are formed in the planting trolley; an elastic corrugated hose is detachably connected to the discharge port; adischarge hole is formed in the rotating plate; the output end of the hydraulic cylinder is hinged to the side, far away from the planting trolley, of the rotating plate; a pull rope is fixed to therotating plate, and the pull rope is fixed to the pull rod; and an earthing plate for earthing is arranged on the bottom surface of the planting trolley. The fruit planting equipment solves the problems in the prior art that earthing and fertilizer water watering cannot be carried out immediately after sowing and the fertilizer water can precipitate easily.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

A kind of integrated mechanical equipment for soil preparation and seeding for gardens

Owner:阜阳汇中芯自动化技术有限公司

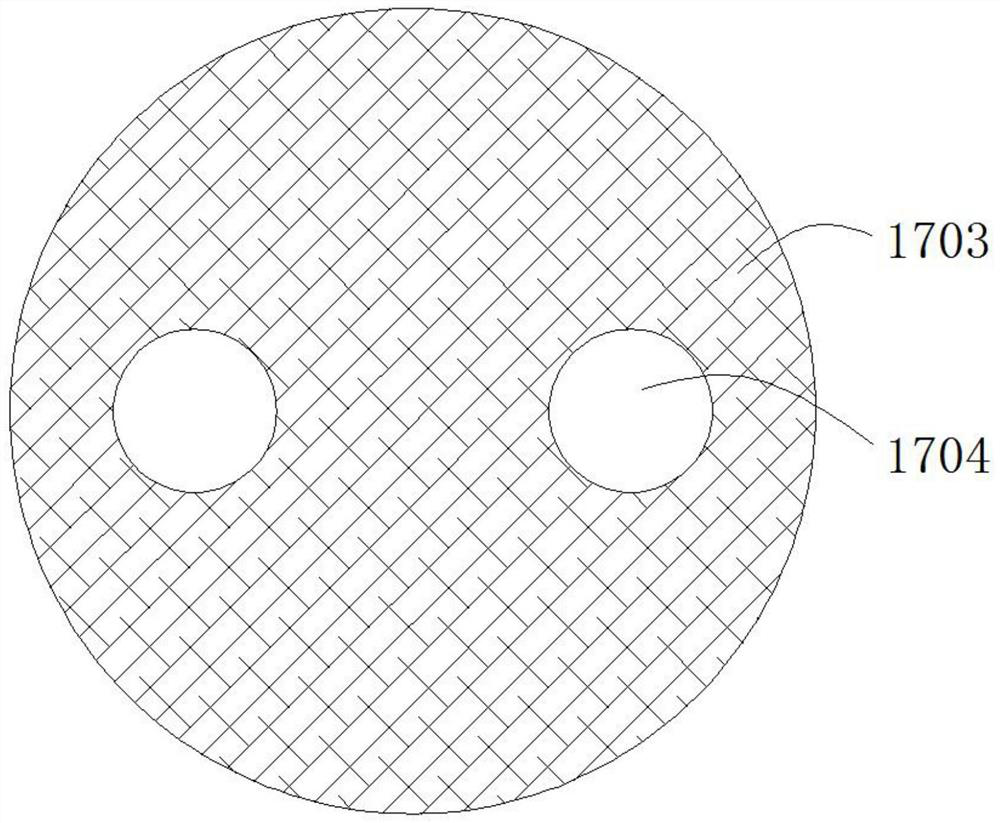

Seed cleaning device for scraping airflow seeder

The invention discloses a scraping and touching air flow type seed removing device of a seeding machine. The seed removing device is arranged on a roller body of the seeding unit and comprises at least one set of seed removing pipes which are externally connected with an air supply system. Each seed removing pipe comprises a seed removing pipe body, air needles, thread rotary needle heads, seed pulling needles and a quick plug connector, wherein the thread rotary needle heads are distributed on one side of the cylindrical face of the seed removing pipe body, the quick plug connector is arranged on the other side of the cylindrical face of the seed removing pipe body, each thread rotary needle head corresponds to one air needle and one seed pulling needle, each thread rotary needle head, the corresponding air needle and the corresponding seed pulling needle are sequentially connected, and the quick plug connector is externally connected with the air supply system. According to the seed removing device, pneumatic power seed removing and mechanical power seed removing are combined, the seed removing effect is good, small round seeds and smell flat seeds can be removed so that the seeding unit can be used for sowing small flowering cabbage round seeds and the like and can also be suitable for sowing small tomato flat seeds and the like, single seeds can be precisely sown, and the seeding qualified rate is increased.

Owner:SOUTH CHINA AGRI UNIV

Planting method for interplanting sesbania and wild soybean and matching fine-seeding fertilizing machine

PendingCN107155460AImprove the environmentEffective growth controlPlant protectionFertiliser and seeding apparatusSesbaniaAgricultural machinery

Owner:SHANDONG CROP GERMPLASM CENT

fruit planting equipment

ActiveCN108718619BSowing realizedEasy sowingPlantingTransportation and packagingHydraulic cylinderAgricultural science

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

Novel dry land precision hill-drop planter for rice

PendingCN109104946ASolve uneven sowingSolving the Seed Waste ProblemDibble seedersAgriculture gas emission reductionAgricultural engineeringAgricultural machinery

The invention provides a novel dry land precision hill-drop planter for rice, and belongs to the field of planter equipment, wherein the novel dry land precision hole-sowing machine is agricultural machinery equipment capable of performing precision sowing, and comprises a seed box, a rack, a seed box through shaft, a connecting frame, a seed metering device, a conveying pipe, a seed taking device, a transmission mechanism, a chain wheel chain, a wheel, a sowing disc, a foot pedal and a support frame. According to the present invention, the novel dry land precision hill-drop planter is the direct-sowing rice sowing machine capable of performing precision sowing, can sow rice seeds, can achieve precise seed taking and sowing, and can solve the problems of non-uniform sowing and waste of seeds due to the incapability of performing precision sowing of the existing planter so as to improve the mechanized level of agricultural production.

Owner:INST OF CROP SCI NINGXIA ACADEMY OF AGRI & FORESTRY SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com