Patents

Literature

288results about How to "Guaranteed flush" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

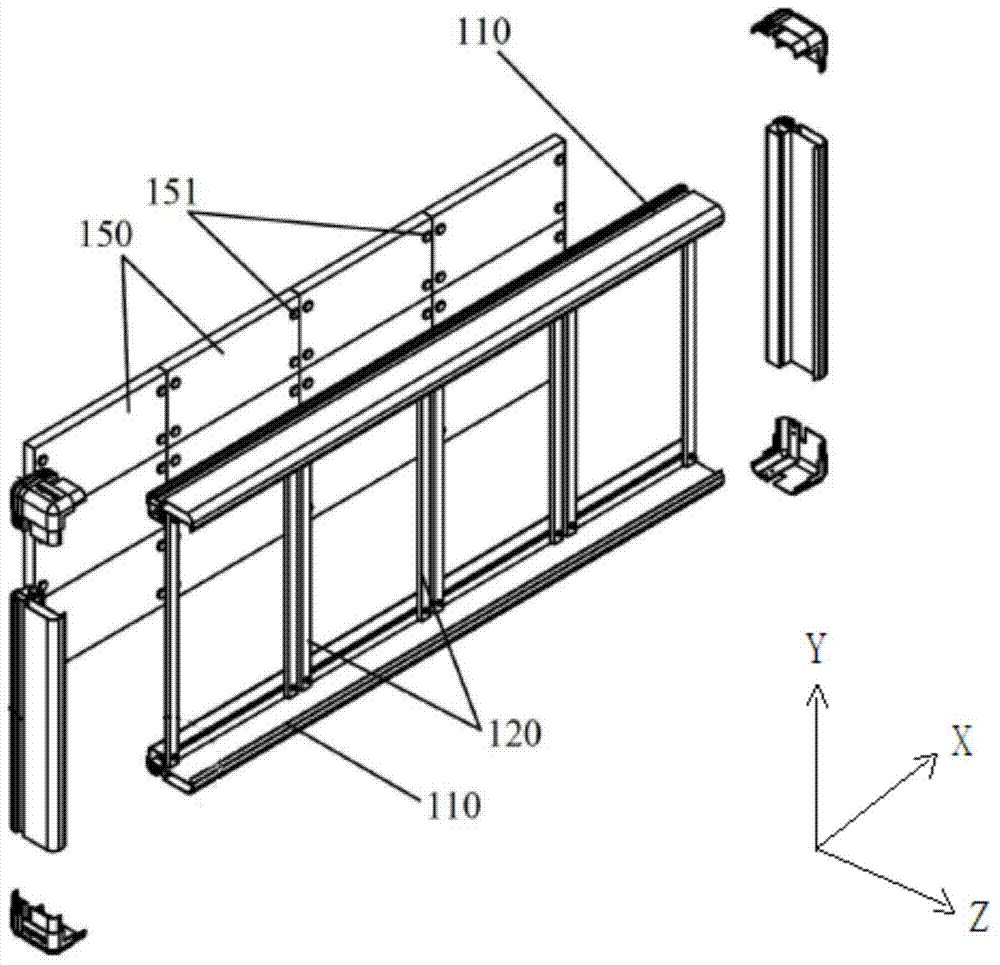

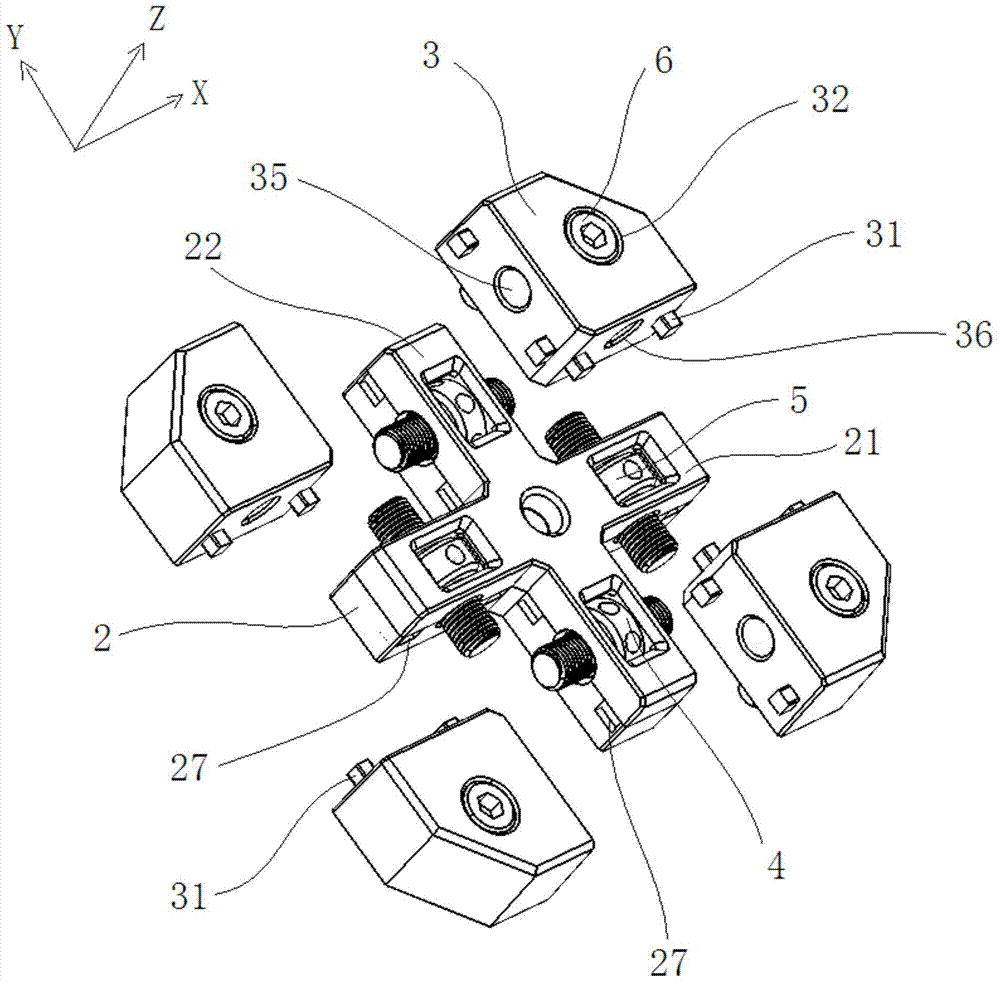

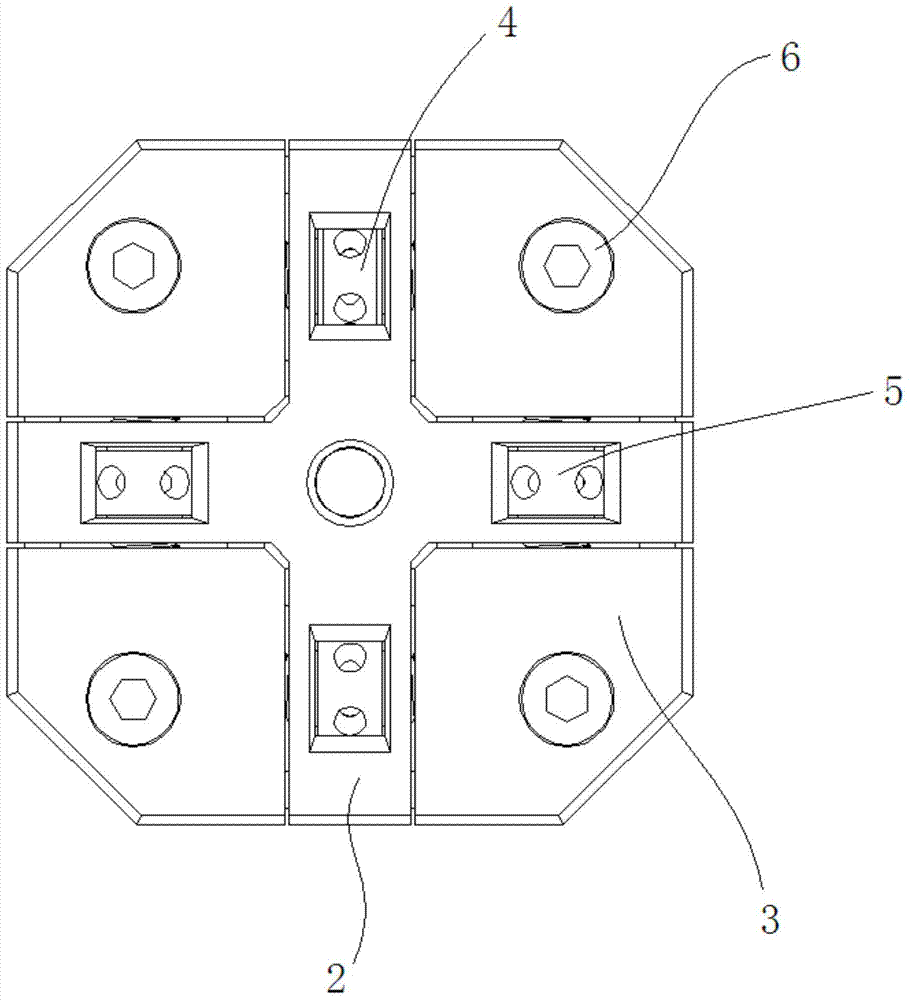

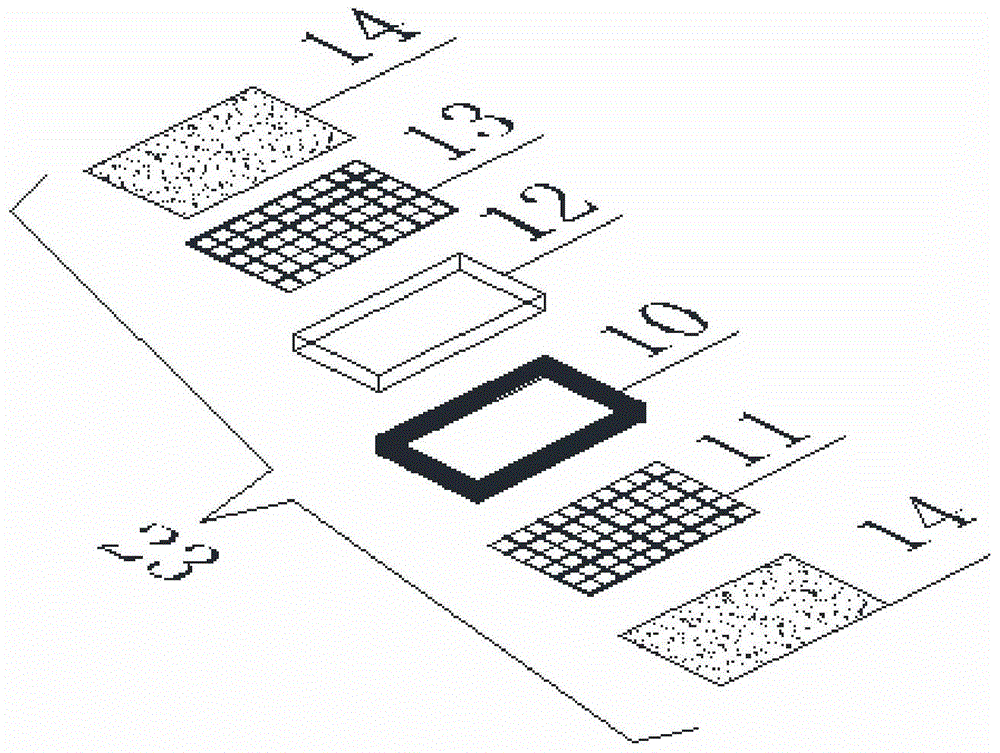

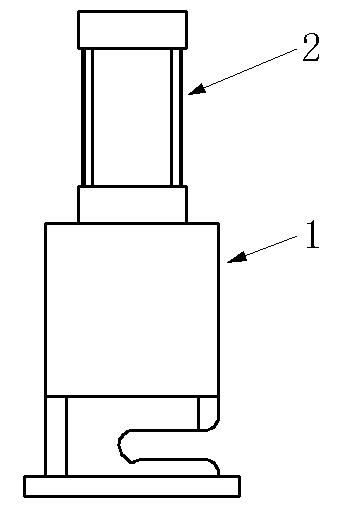

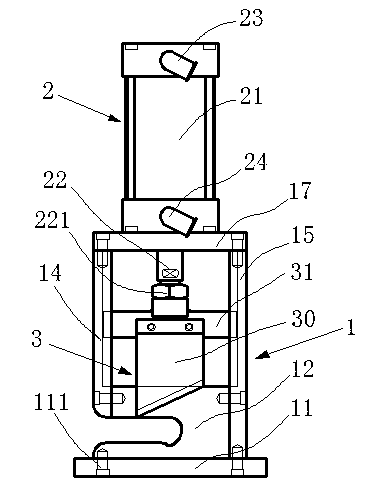

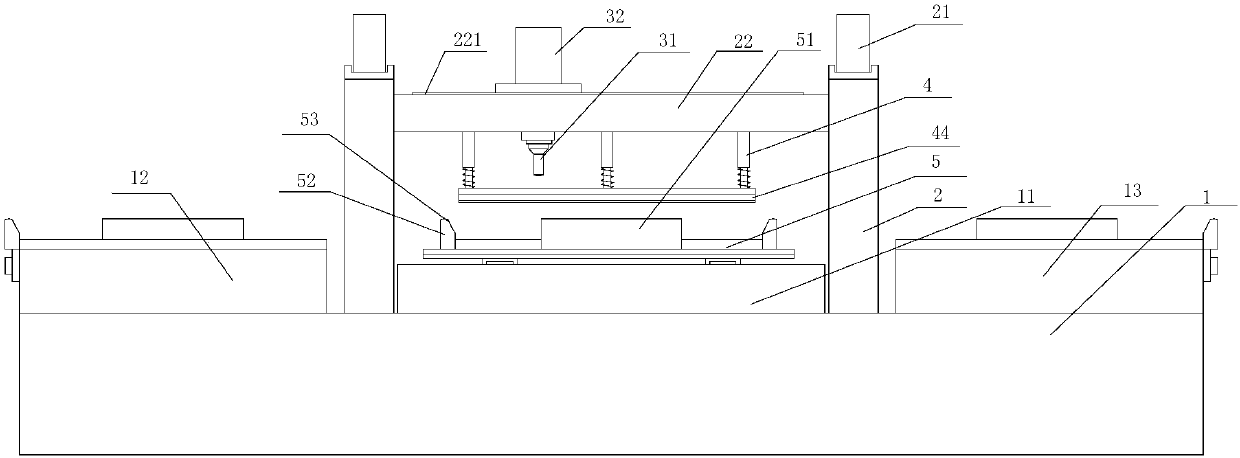

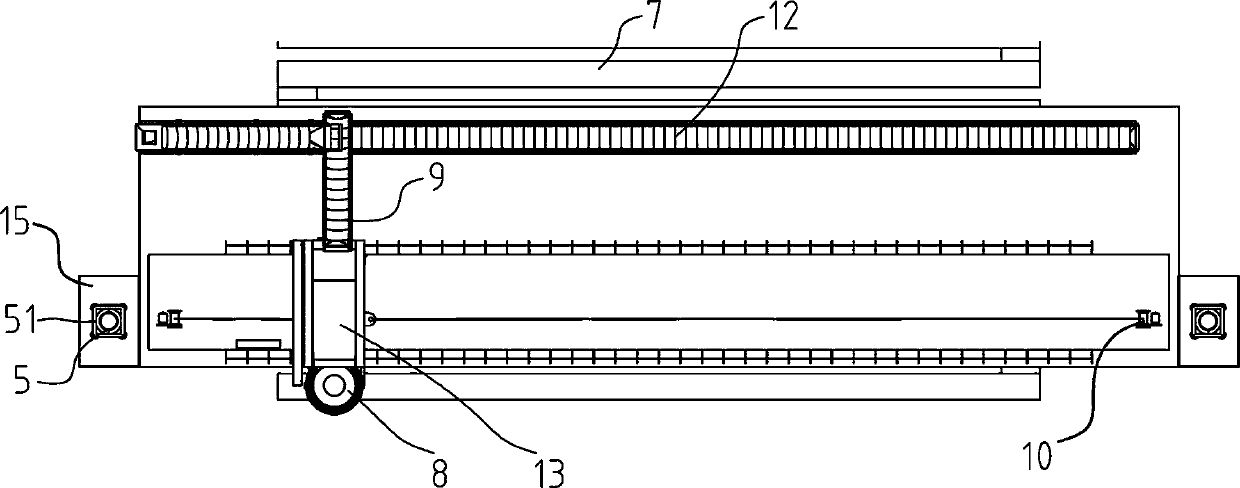

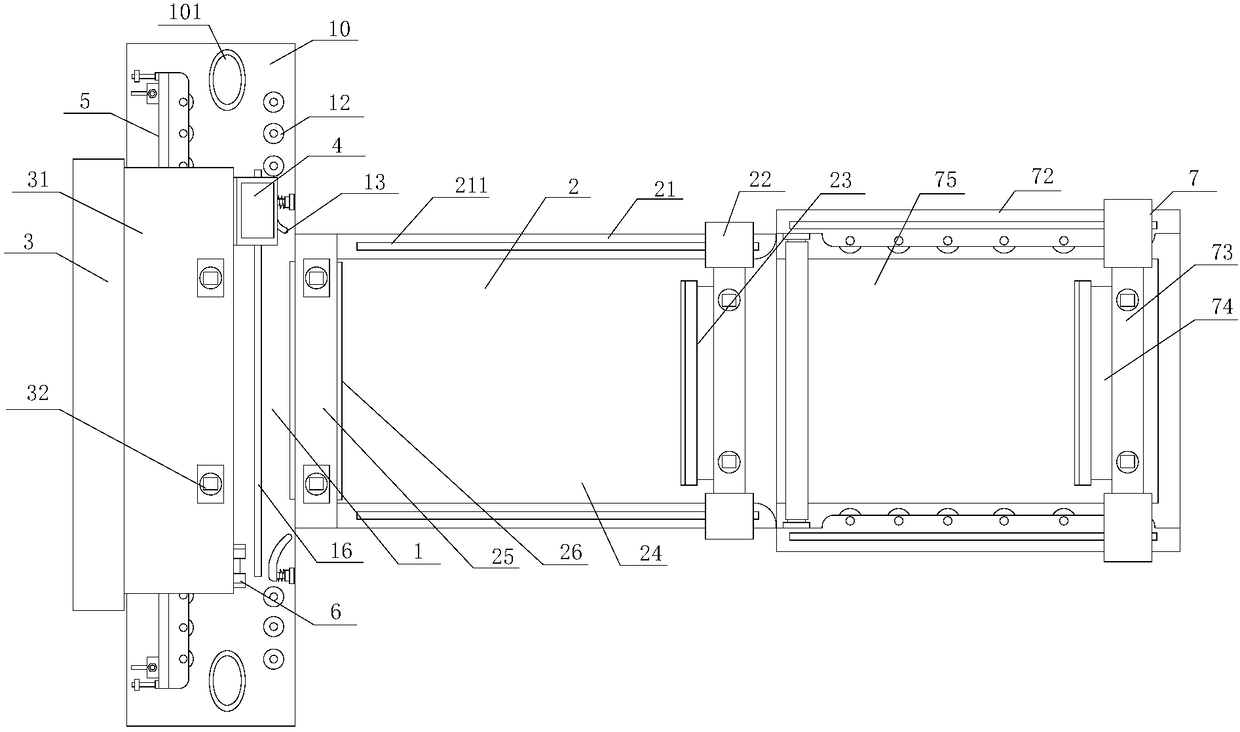

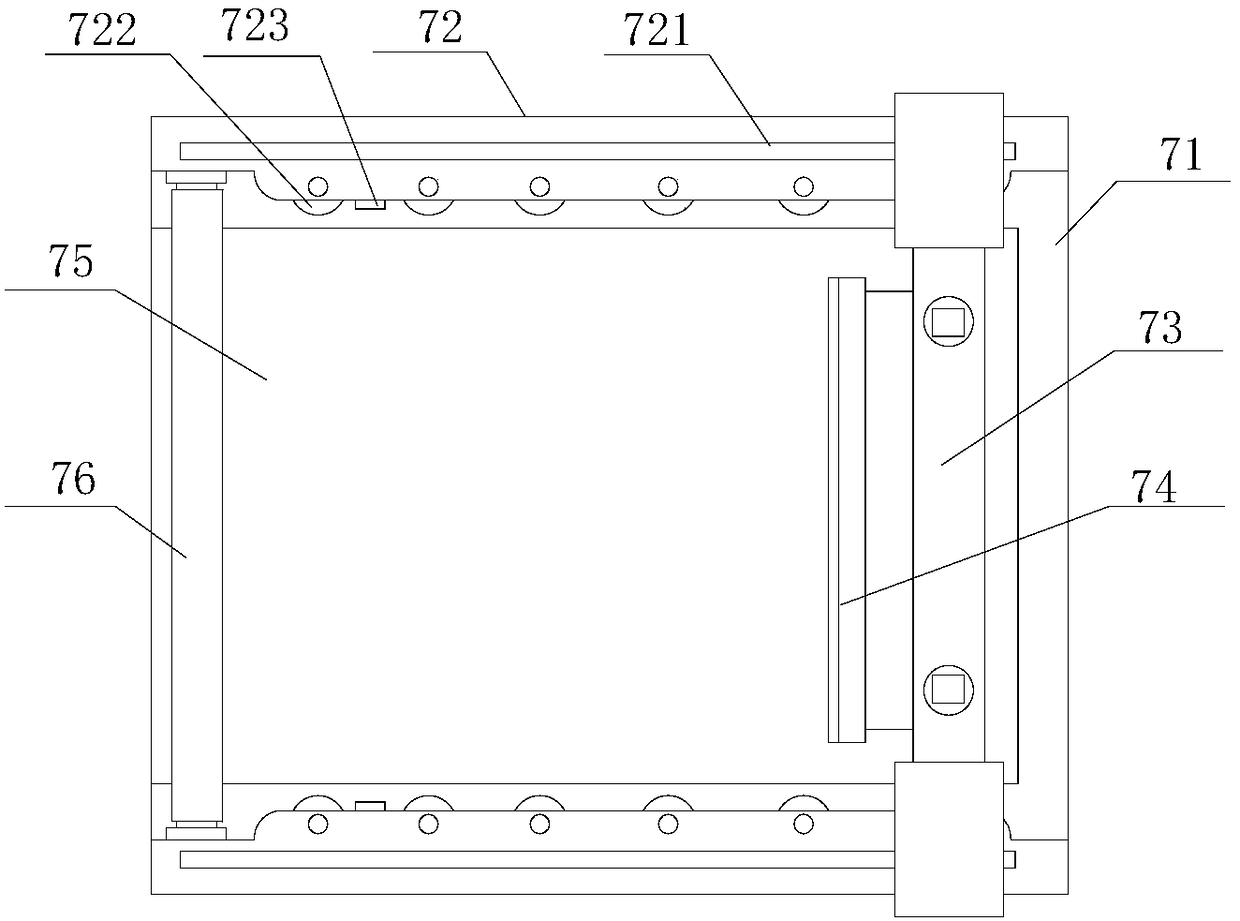

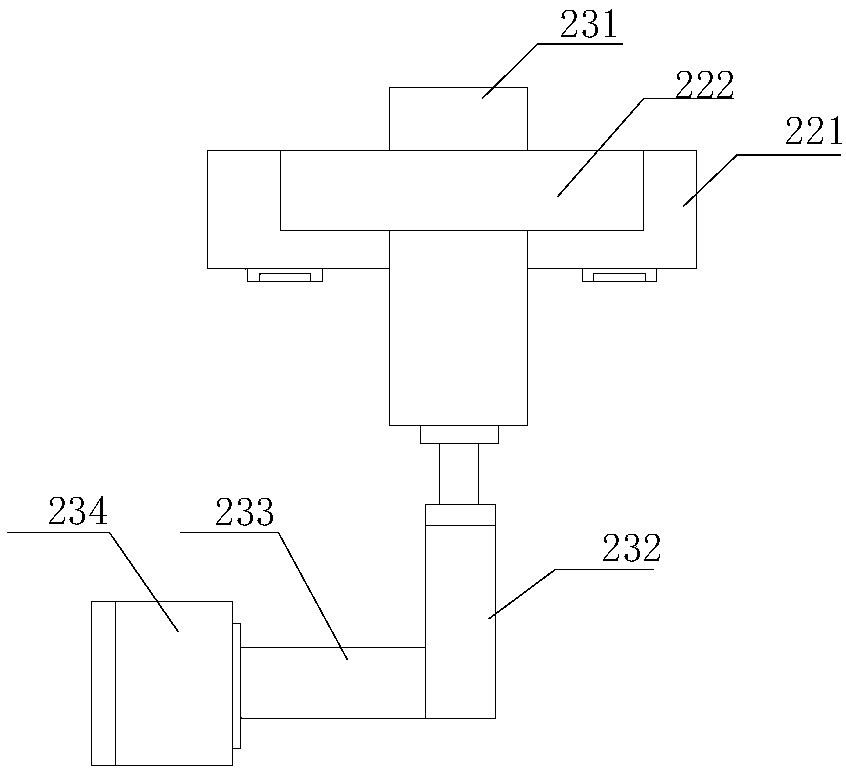

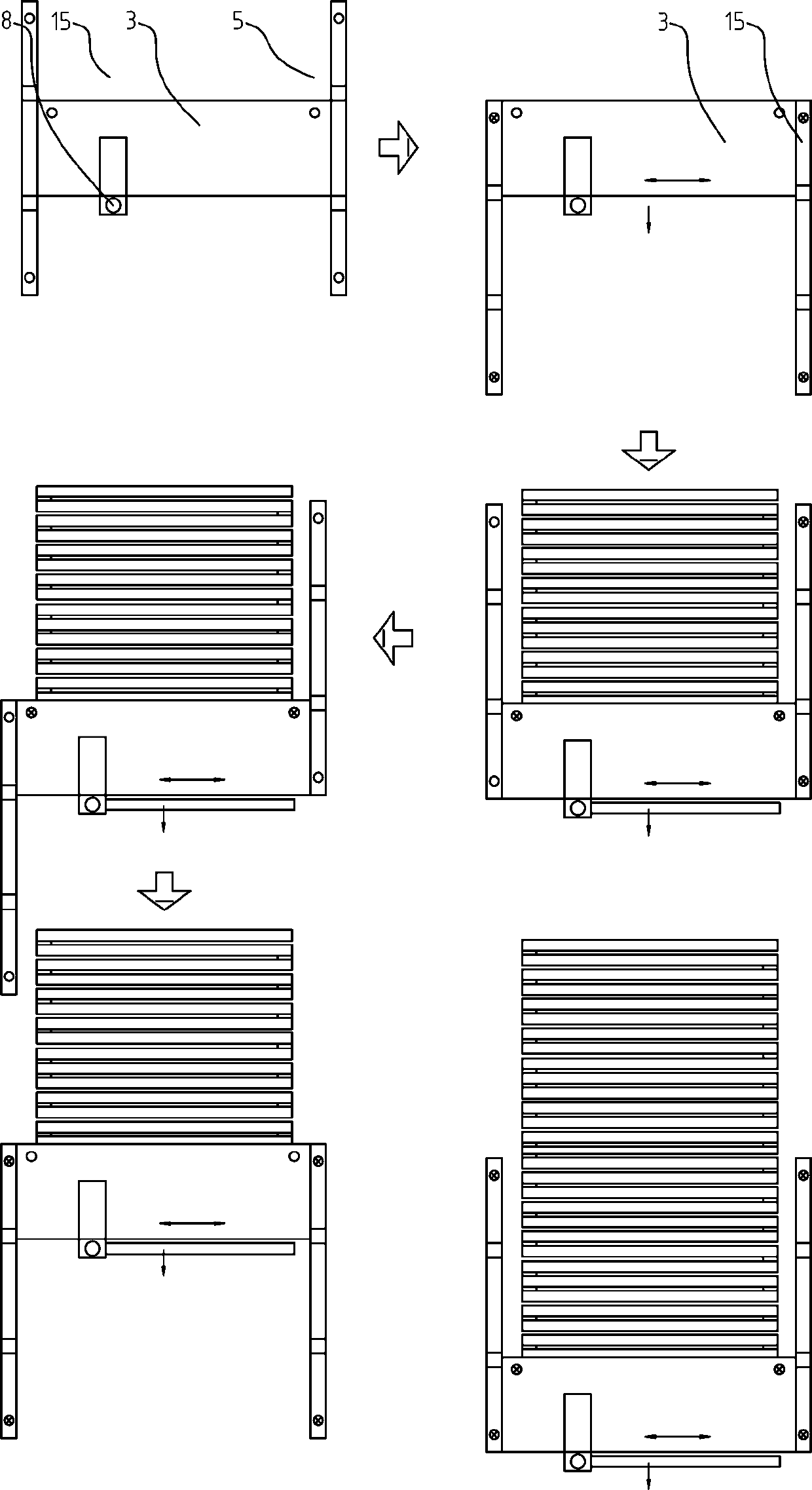

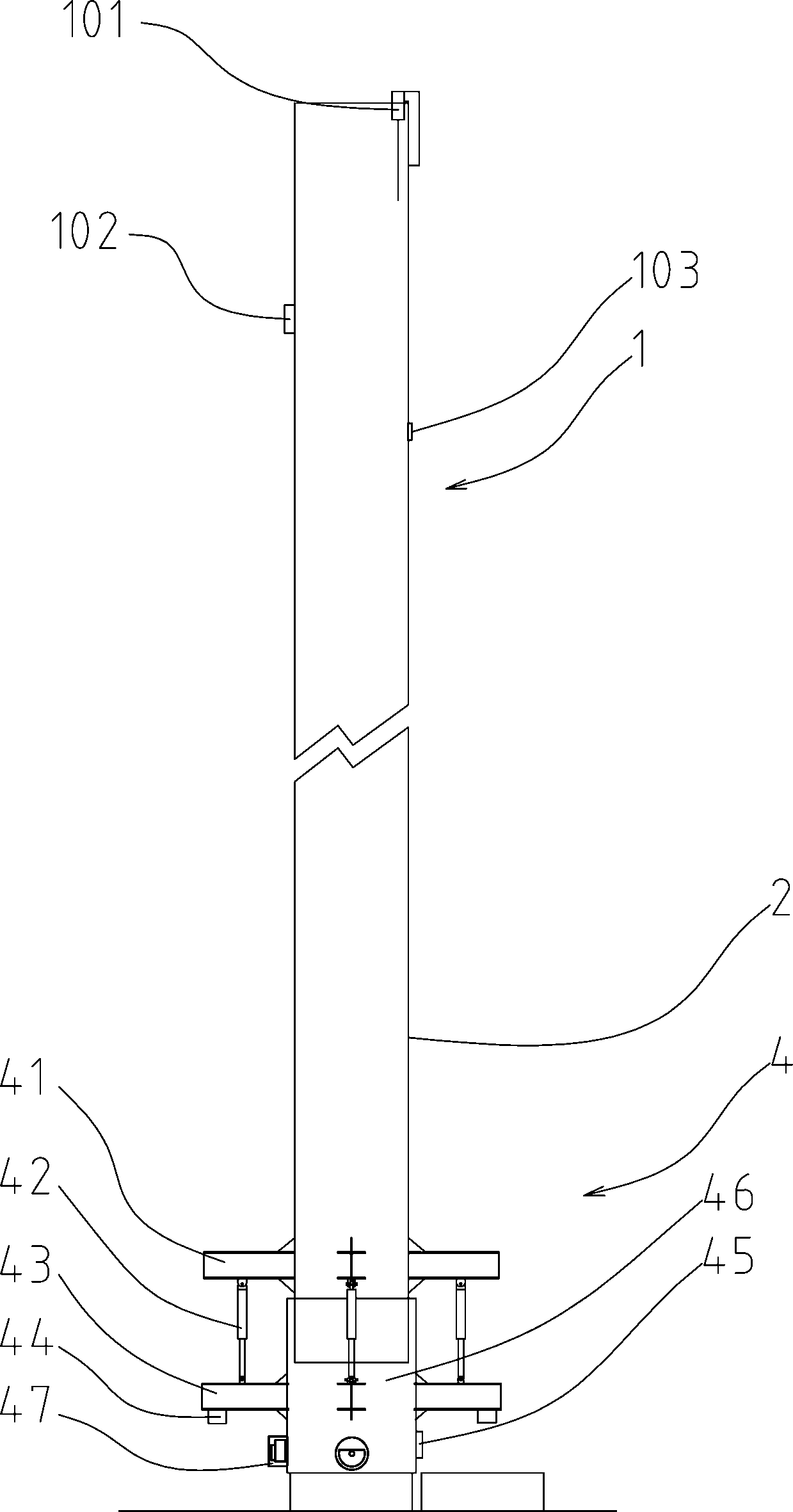

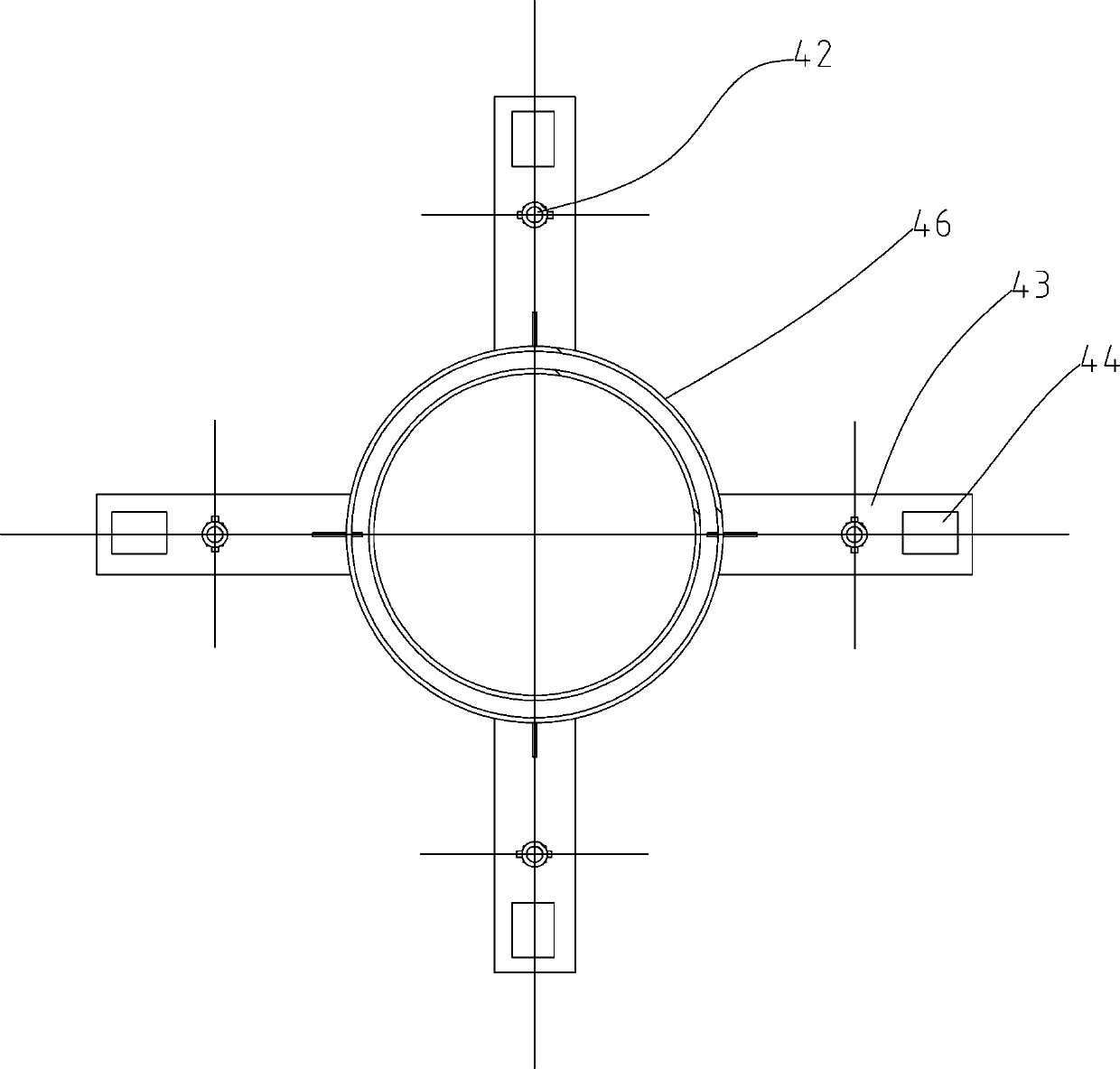

LED module installing mechanism

ActiveCN104723074AEasy to adjustSave adjustment timeCasings/cabinets/drawers detailsPrintingLED displayEngineering

The invention discloses an LED module installing mechanism. The LED module installing mechanism comprises a fixed rack (2), a gap adjusting mechanism on the fixed rack (2), and at least two moving blocks (3) movably connected with the fixed rack (2). LED modules (100) are arranged on the moving blocks (3). The two ends of the gap adjusting mechanism are connected with the moving blocks (3) respectively. By adjusting the moving block (3) on the two sides to move away or get close to each other, a gap between the LED modules (100) arranged on the moving blocks (3) is adjusted. The invention belongs to the technical field of LED modules and LED display screens. According to the LED module installing mechanism, the technical problems in the prior art that the method for adjusting the planar gap between the LED modules is complex and unstable, and the adjustment on the planeness which is perpendicular to the planar direction of the LED modules is unable to achieve are solved. The LED module installing mechanism is particularly applicable to adjusting the planeness perpendicular to the direction of the LED modules and the planar gap between the LED modules, the adjusting operation is simple, and the adjusting effect is stable.

Owner:GLUX VISUAL EFFECTS TECH (SHENZHEN) CO LTD

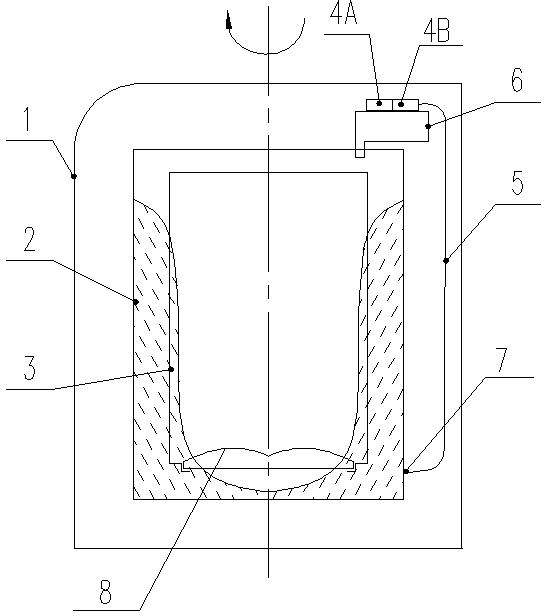

Sterilizing, disinfecting and mildew-proof barrel-cleaning washing machine and barrel-cleaning control method thereof

InactiveCN102628205AAvoid depositionEnsure normal dischargeOther washing machinesControl devices for washing apparatusImpellerInlet valve

The invention discloses a sterilizing, disinfecting and mildew-proof barrel-cleaning washing machine which comprises a shell, wherein an external water-storing barrel and an internal washing barrel are arranged in the shell; a water inlet box, a draining valve, a clutch, a program controller and a power supply part are arranged in the shell; a water inlet valve is arranged on the water inlet box; an ozone generating device is mounted on the water inlet box; an air outlet end of the ozone generating device is communicated with the bottom of a side wall of the external barrel through an ozone pipeline; the ozone generating device is connected with the program controller and the power supply part; and the draining valve and the clutch are respectively arranged and are respectively controlled by the program controller. The invention also discloses a barrel-cleaning control method of the washing machine. The sterilizing, disinfecting and mildew-proof barrel-cleaning washing machine is simple in structure and convenient in use; the internal barrel, the external barrel, the space between the internal and external barrels and the space under an impeller are cleaned and are sterilized and disinfected by using ozone; when water is discharged, the impeller is started to rotate positively and negatively by the washing machine so as to prevent line scraps and dirt in water from depositing at the bottom of the external barrel and internal barrel and on the impeller; the discharging of the line scraps and dirt is ensured; and the barrel-cleaning function is achieved.

Owner:HENAN XINFEI ELECTRICAL EQUIP

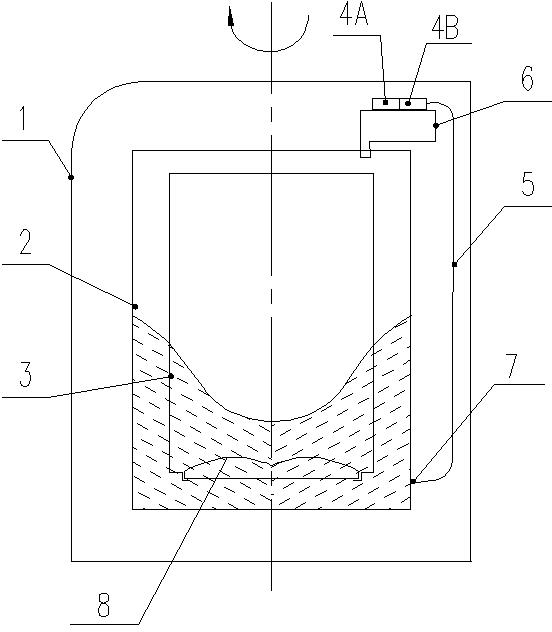

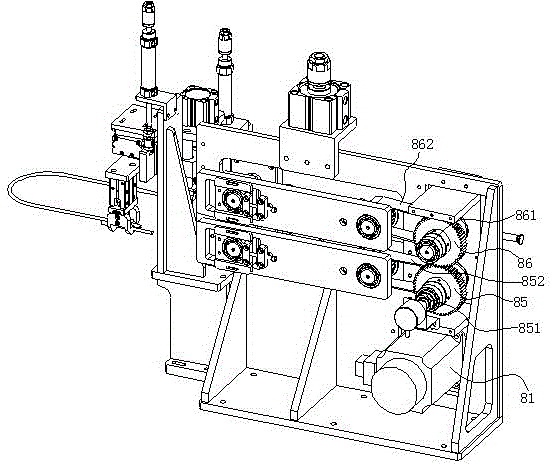

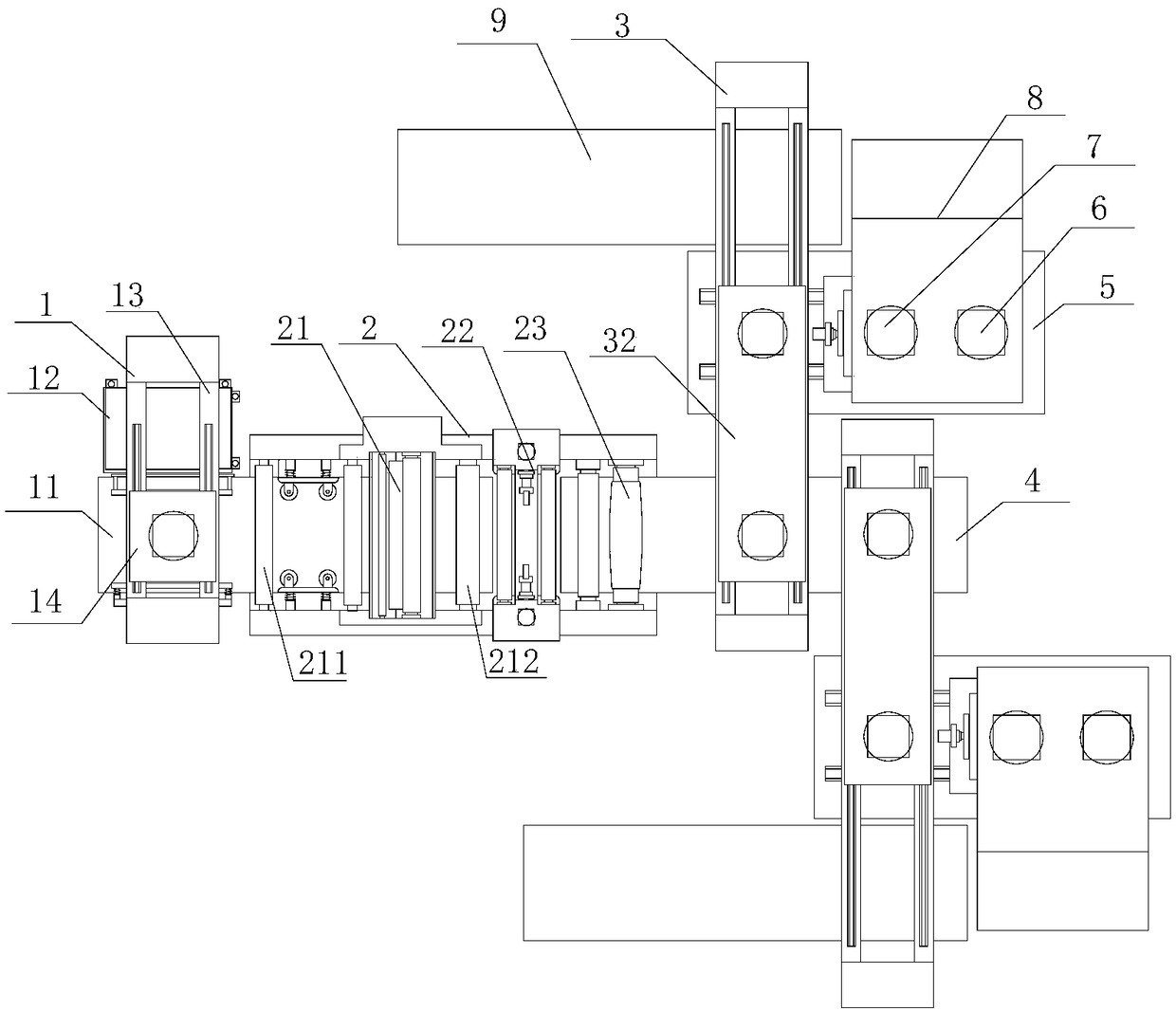

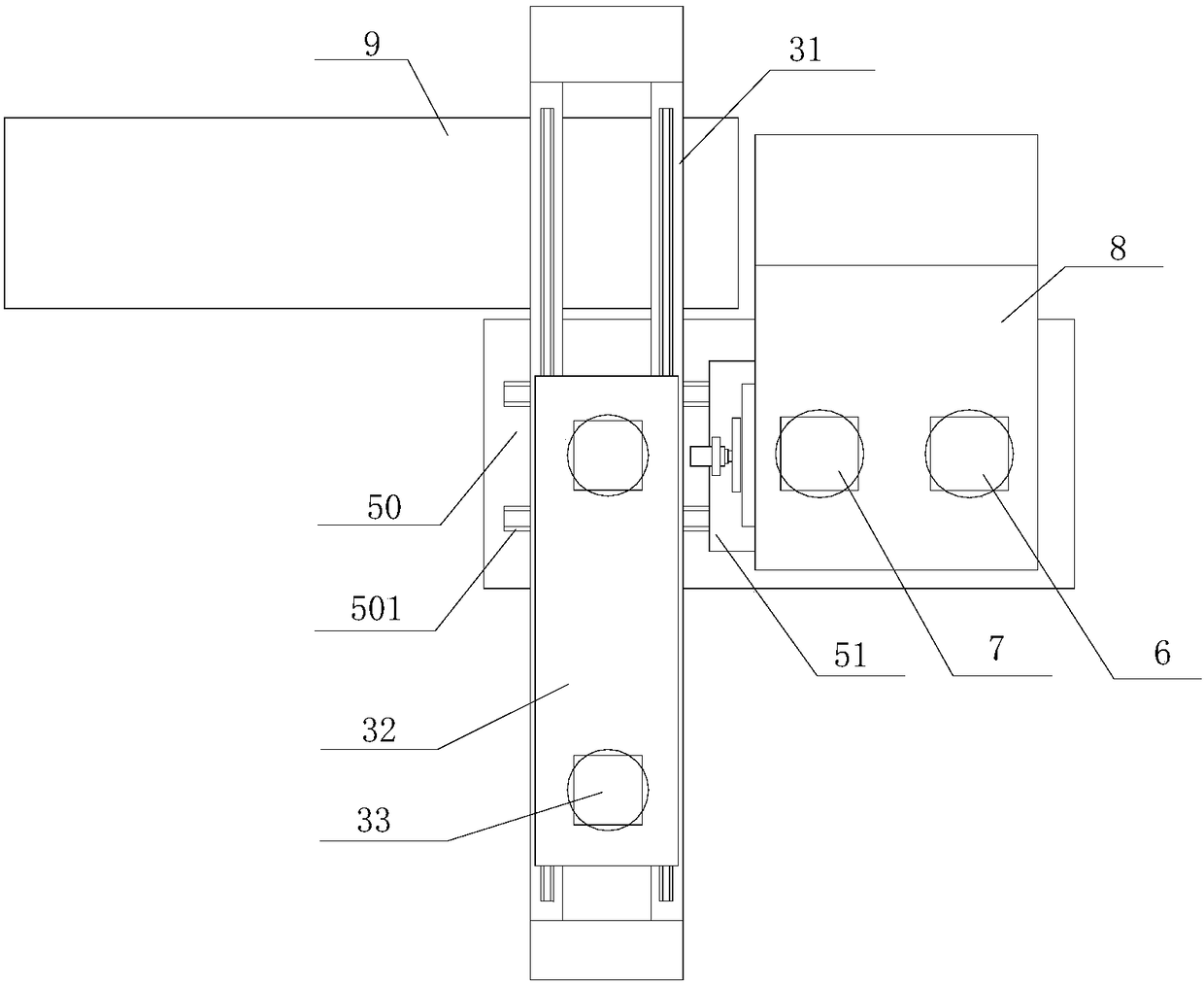

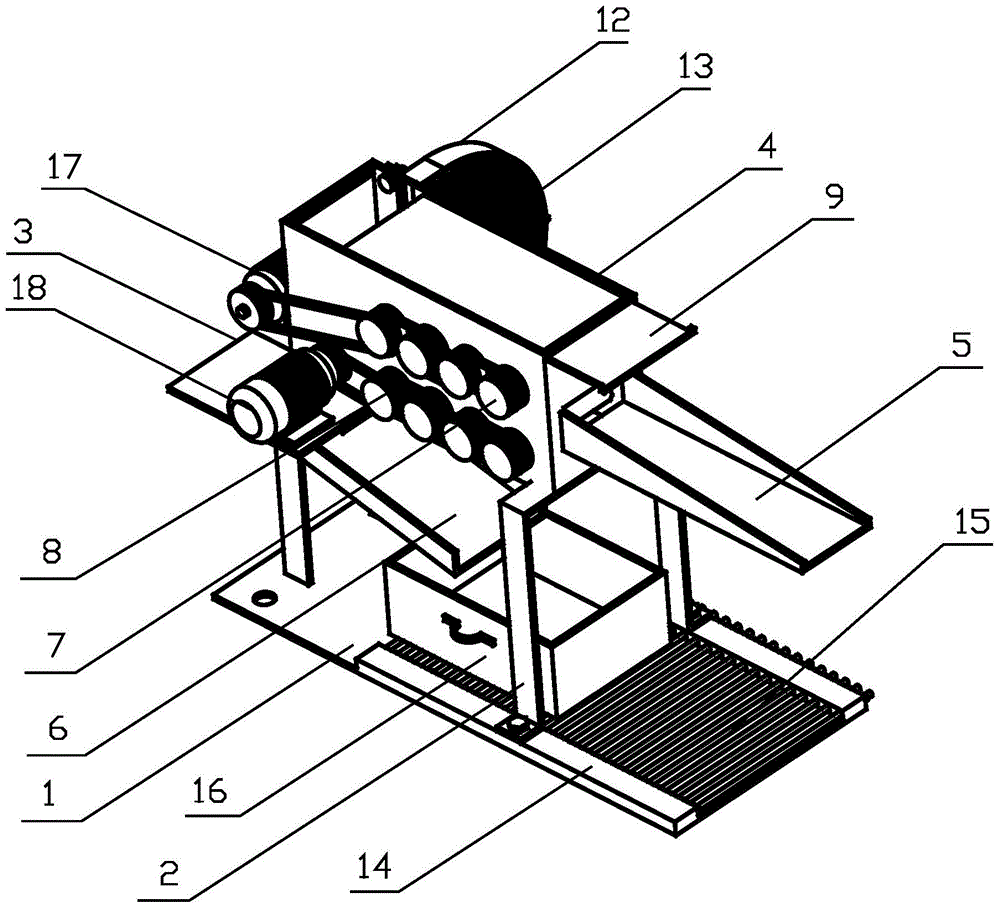

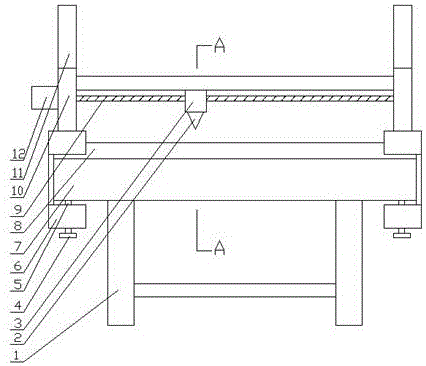

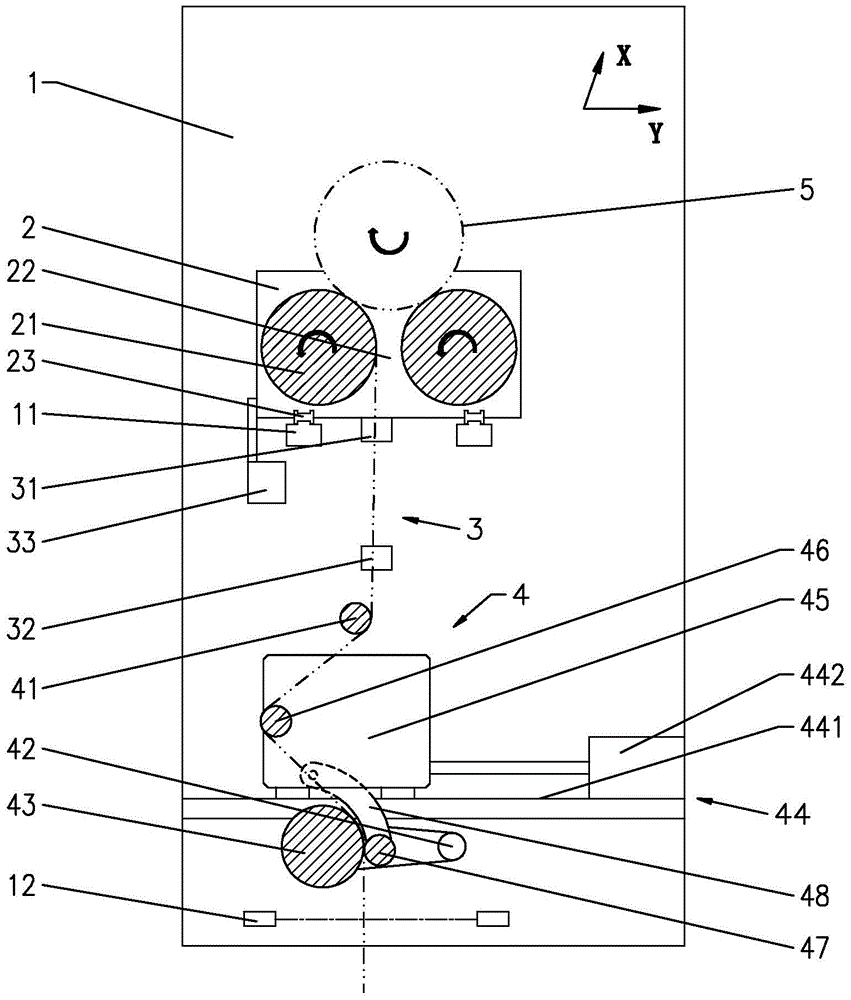

Wire bending device

The invention discloses a wire bending device. The wire bending device comprises a frame; a first belt conveying component; a vertical plate; a second belt conveying component opposite to a first conveying belt up and down and bonded with the first conveying belt to form a wire feeding mechanism for clamping and conveying wires; a driving component; a wire bending component including a first air jaw cylinder, two first clamping jaws mounted at a free end of the first air jaw cylinder, a rotating cylinder for driving the first air jaw cylinder to swing between a position on the outer side of the tail end of the wire feeding mechanism and a position far from the tail end of the wire feeding mechanism, and a first lifting cylinder for driving a cylinder body of the rotating cylinder to move in the height direction of the frame; a wire clamping component; and a cutting component. In the wire bending device, the wire bending process is automatically finished, so that the wire bending efficiency is improved; and meanwhile, the wires are cut after being bent to possibly guarantee levelness of two ends of the wires.

Owner:DONGGUAN SENJIA MACHINERY

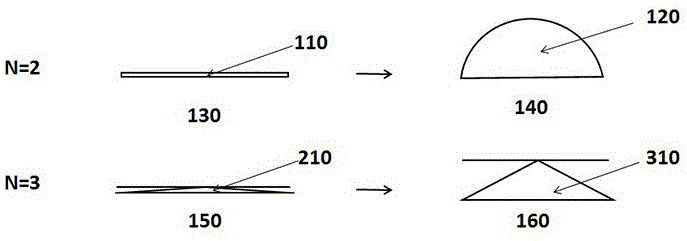

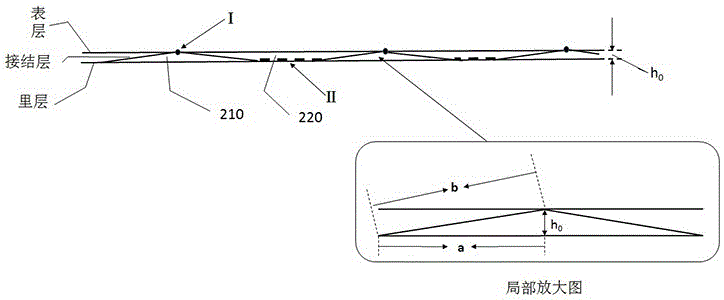

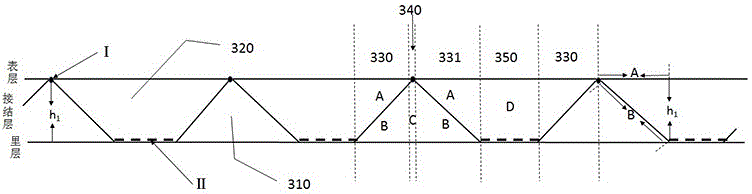

3D interval woven fabric

InactiveCN106012237AAvoid delivery problemsAvoid the problem of not being able to beat up the weft normallyWoven fabricsShrinkage rateBiomedical engineering

The invention discloses 3D interval woven fabric. The 3D interval woven fabric is obtained through conversion of multi-layer hollow fabric on a loom by means of the warp shrinkage rate difference, and the finished product is of a three-dimensional hollow structure. The 3D interval woven fabric can be woven in the non-transformed common loom. The 3D interval woven fabric with the certain thickness and the hollow structure can be used in the three-dimensional fields of reinforcing materials and woven fabric and woven garment materials with fillers.

Owner:谢强

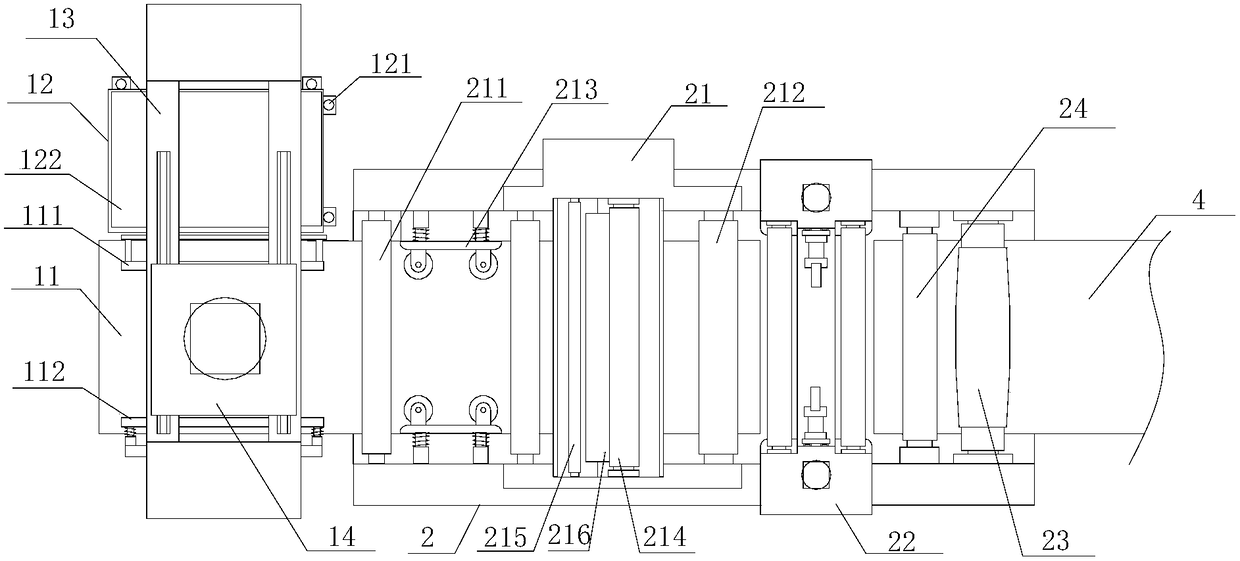

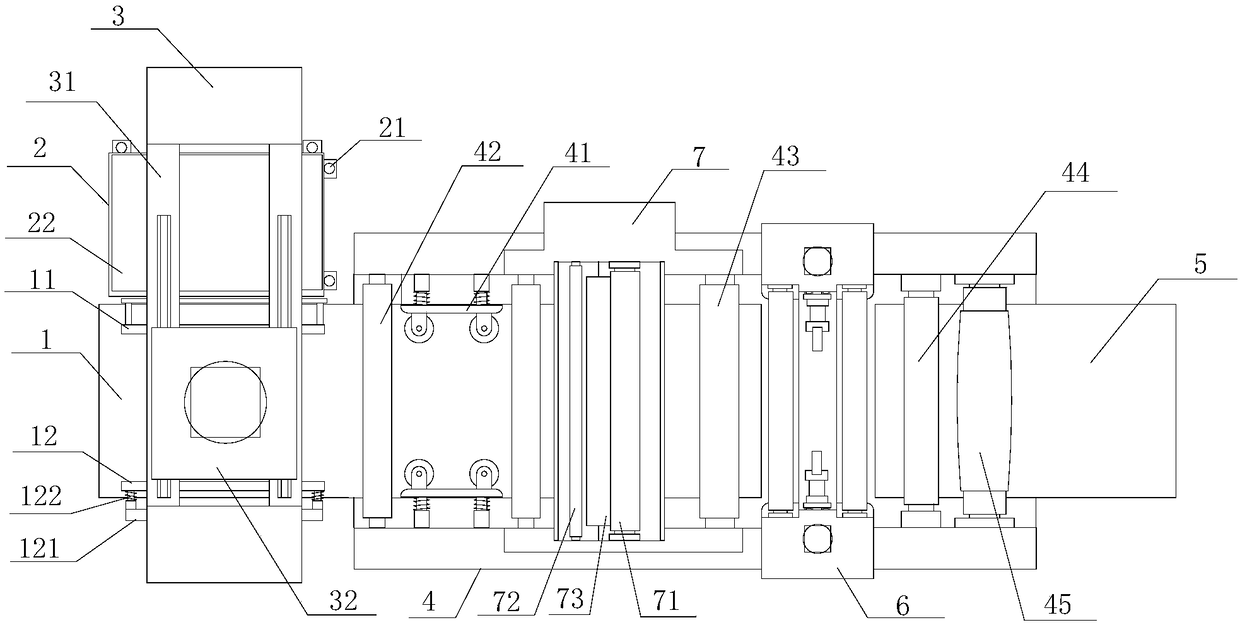

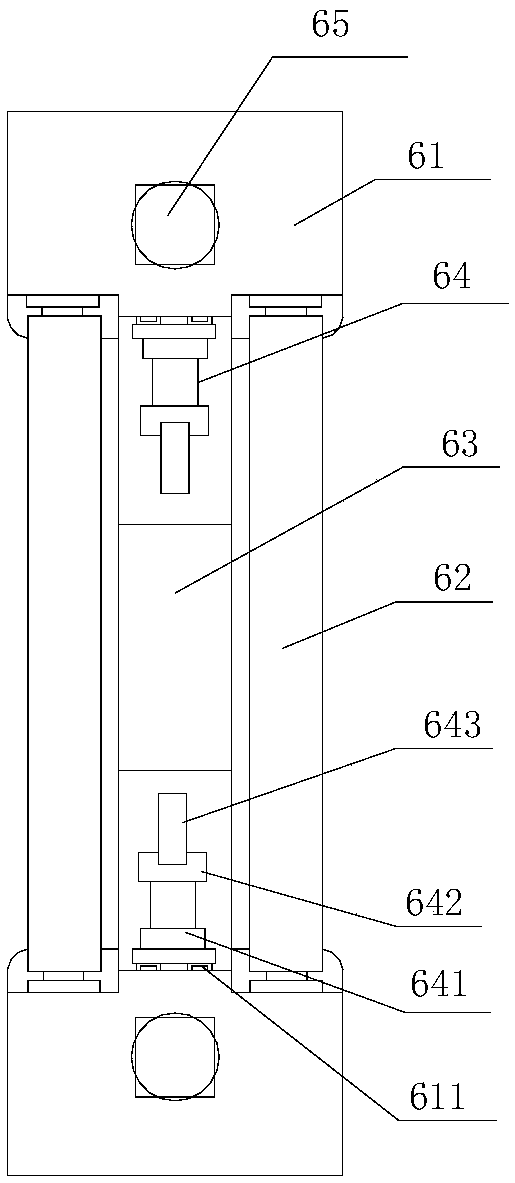

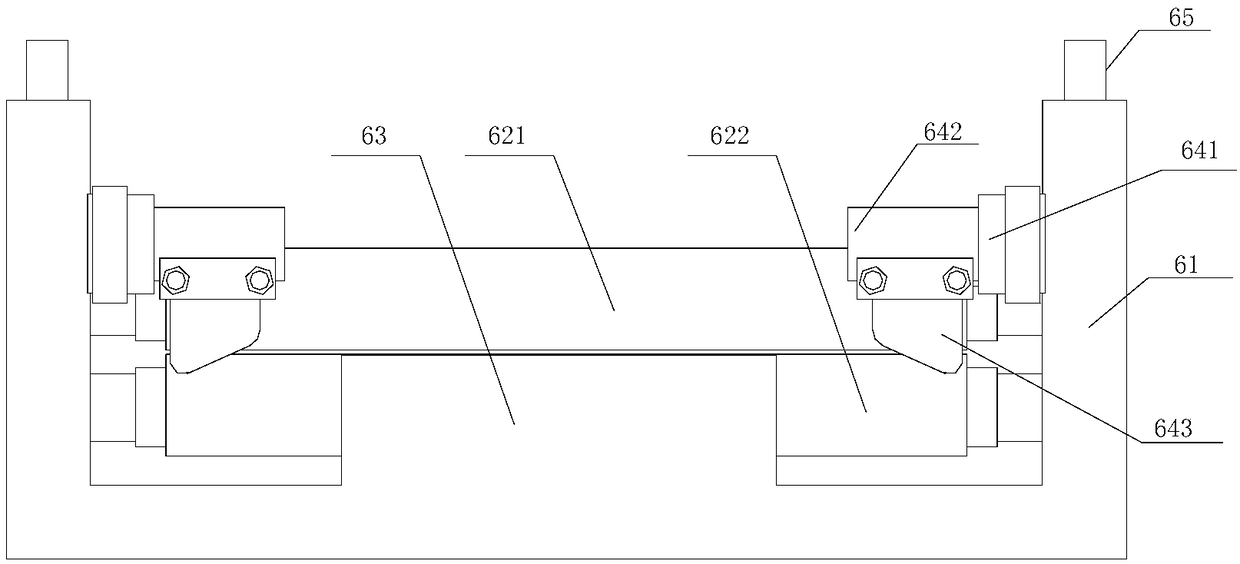

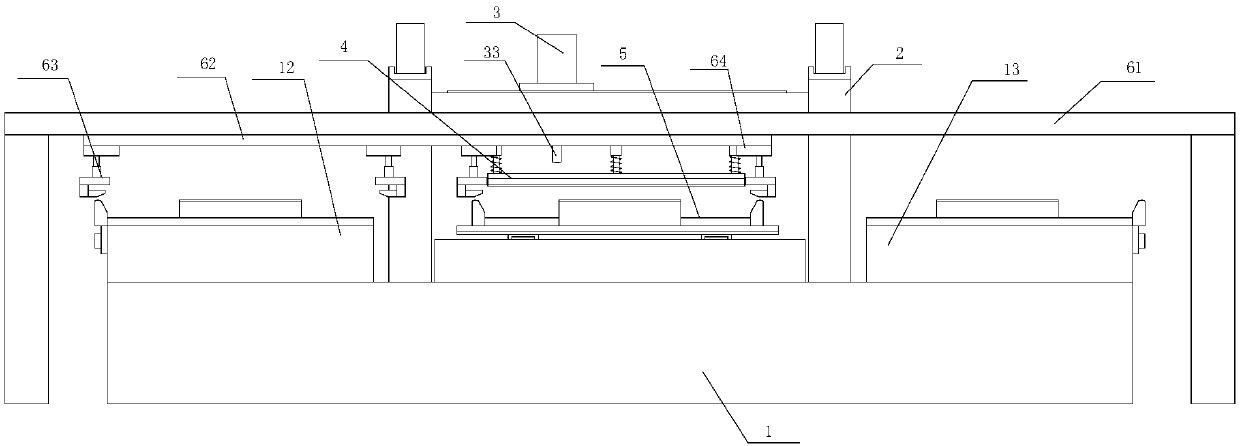

Film-coated paperboard die-cutting production device

PendingCN108215319ASnap offGuaranteed flushLamination ancillary operationsPaper-makingCardboardFilm-coated tablet

The invention discloses a film-coated paperboard die-cutting production device, which comprises a paperboard feeding mechanism, a film coating and slitting mechanism, a first mechanical gripper conveying mechanism, a film-coated paperboard conveyor belt mechanism, a die-cutting and feeding carriage mechanism, an indentation mechanism, a die-cutting mechanism, an installation frame and a discharging conveyor belt mechanism. A first conveyor belt mechanism is arranged on the paperboard feeding mechanism; a film coating mechanism, a slitting mechanism and a film breaking roller assembly are sequentially arranged on the film coating and slitting mechanism; the slitting mechanism is located between the first conveyor belt mechanism and the film-coated paperboard conveyor belt mechanism; a carrier lower die assembly is arranged on the die-cutting and feeding carriage mechanism, and sequentially passes through the lower parts of the die-cutting mechanism and the indentation mechanism; and theconveyor belt mechanism and a mechanical gripper are cooperated for feeding, a notch is firstly cut on a film-coating connecting part after film coating, a film breaking roller is utilized for forming a cutting pressure from two ends of the notch to the interior, the film-coating connecting part is quickly pulled apart, and the film-coated paperboard is sequentially subjected to die-cutting and indentation, so that the production efficiency can be improved.

Owner:嘉兴市鸿业包装有限公司

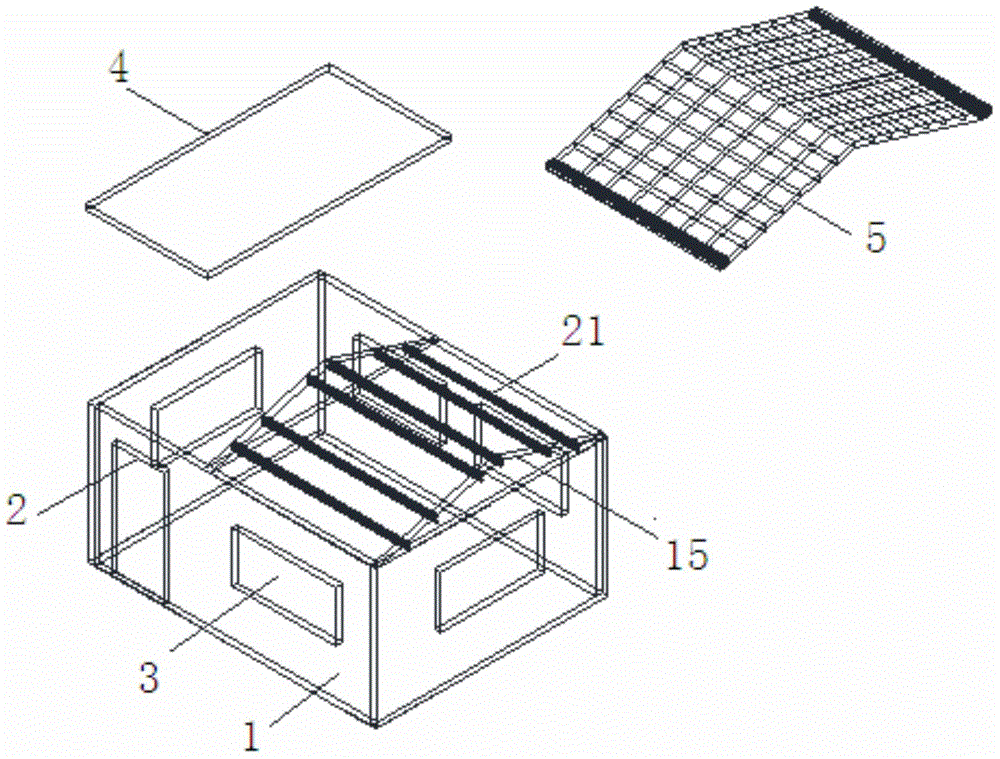

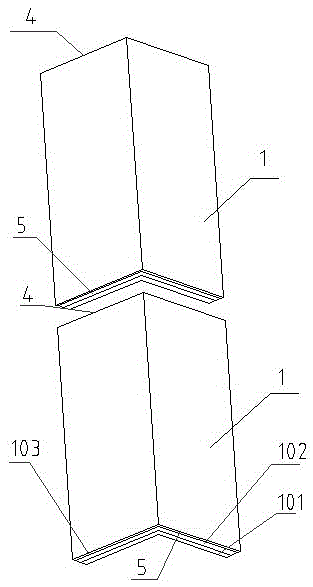

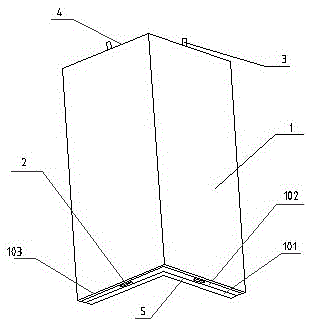

Novel house capable of being fast disassembled and assembled and assembling method thereof

ActiveCN104389349AEasy to operateSimple processBuilding material handlingBeam angleAssembly disassembly

The invention discloses a novel house capable of being fast disassembled and assembled and an assembling method thereof. The novel house comprises a wall. The lower portion of the wall is connected with ground ring beam angle iron. The upper portion of the wall is connected with top ring beam angle iron. One side of the top ring beam angle iron is connected with a flat roof. A waterproof layer is disposed on the flat roof. The upper portion of one side of the top ring beam angle iron is connected with a house frame. An inclined roof is disposed on the house frame. A waterproof layer covers the inclined roof. The wall, the flat roof and the inclined roof are formed by a plurality of wall module units which are connected in a threaded manner. The ground ring beam angle iron and the top ring beam angle iron are of an angle iron structure. The wall module units are connected with the ground ring beam angle iron and the top ring beam angle iron through threads. The wall module units are spliced to form a door opening and window openings. The wall module units above and below the door opening and the window openings are respectively connected with the wall module units on the outer sides of the door opening and the window openings through angle fixing angle iron in a threaded and matched manner. The novel house is convenient to assemble and disassemble, fast in construction and recyclable.

Owner:SHANDONG SHUANGDELI CONSTR TECH

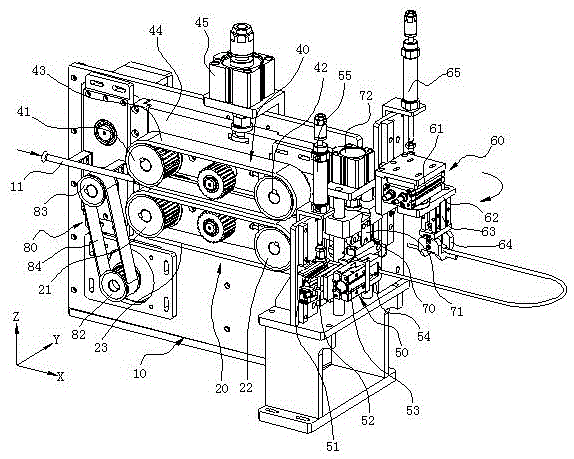

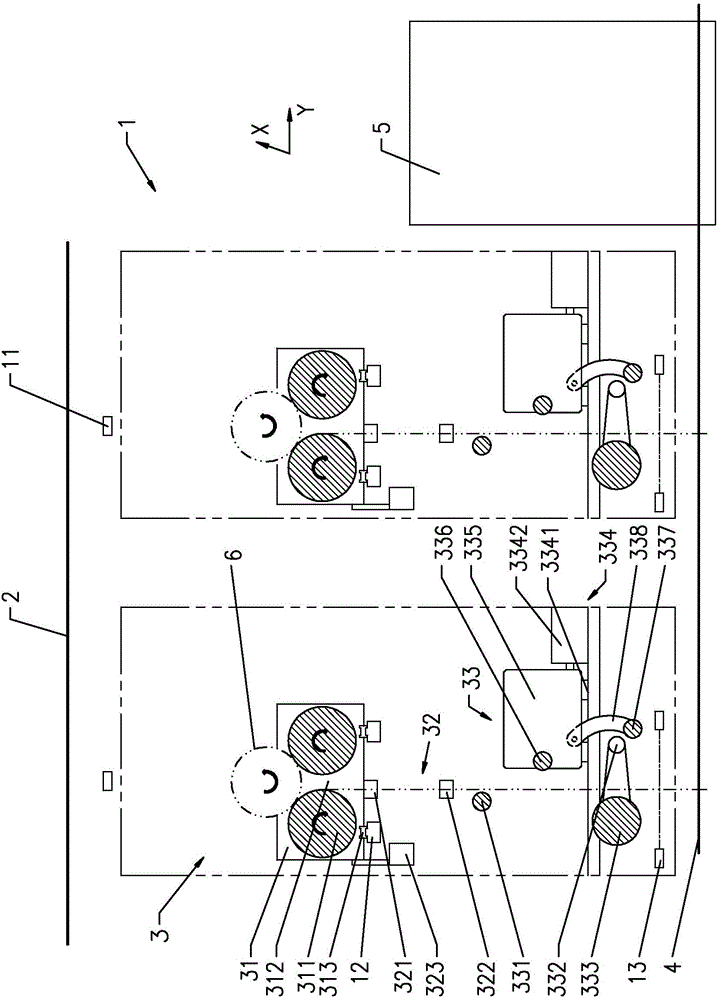

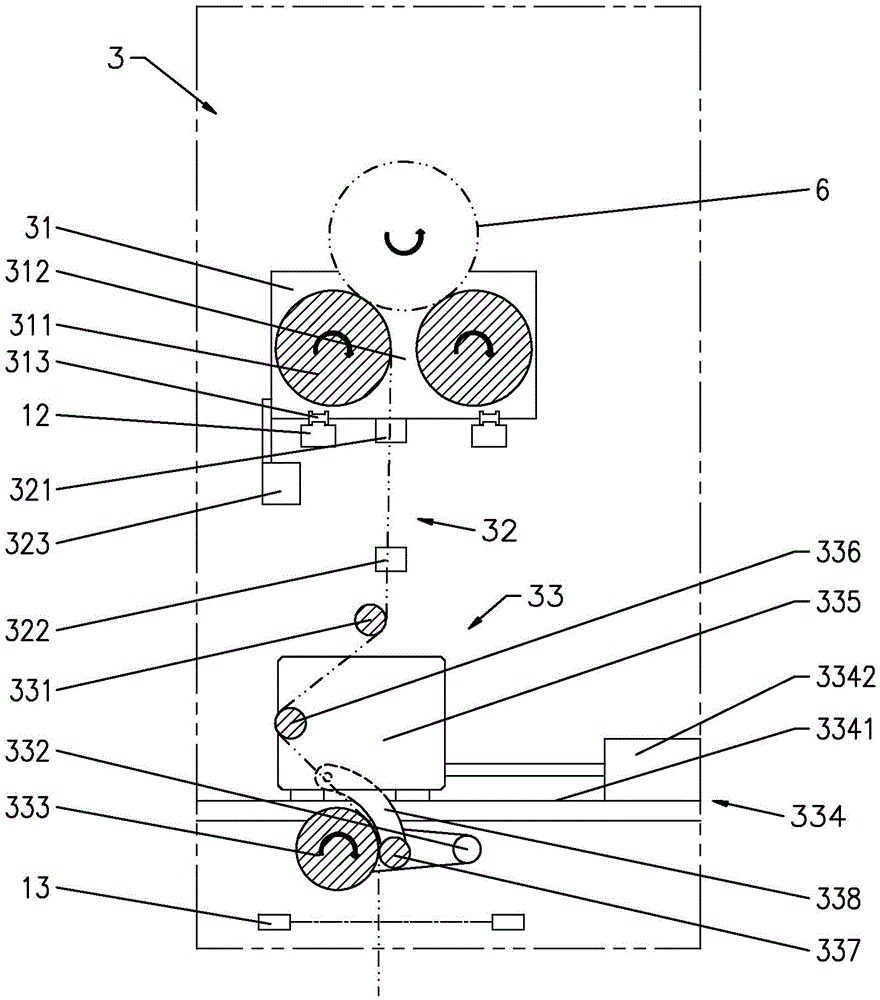

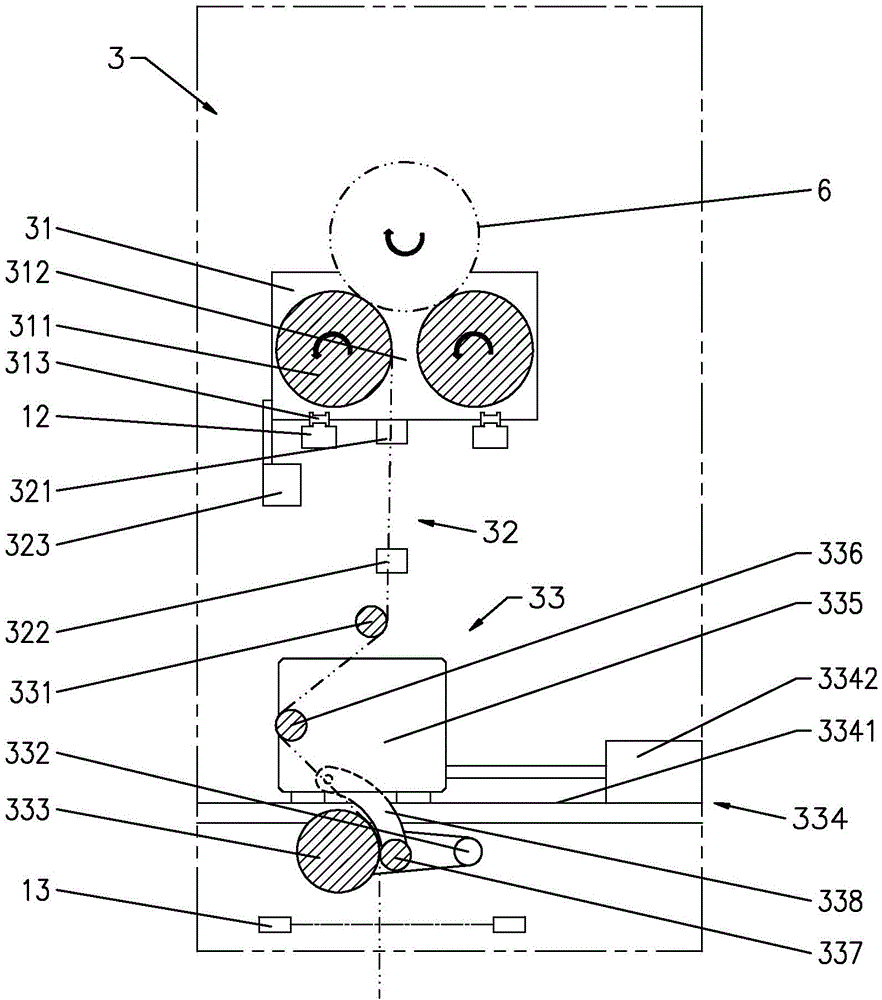

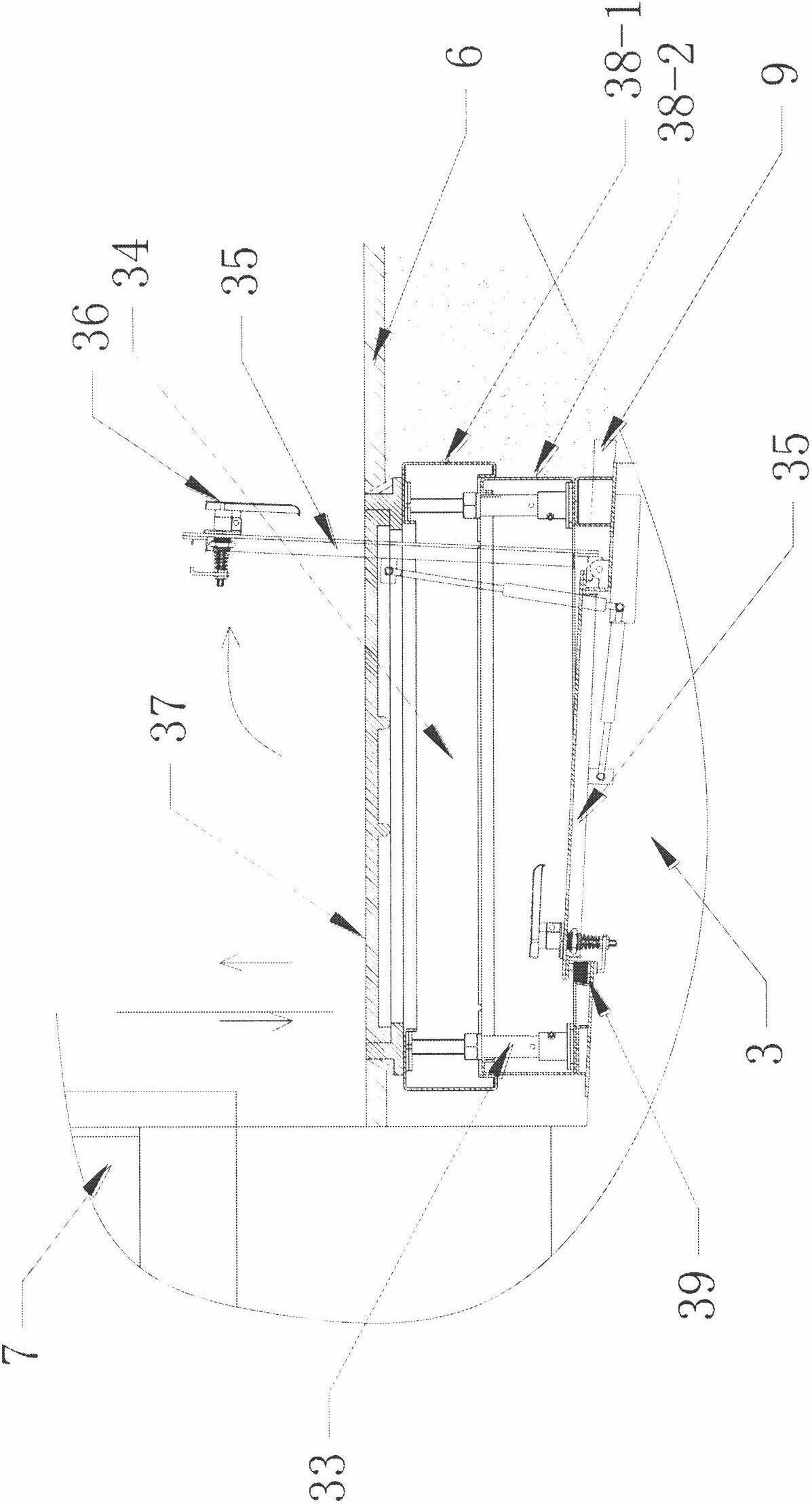

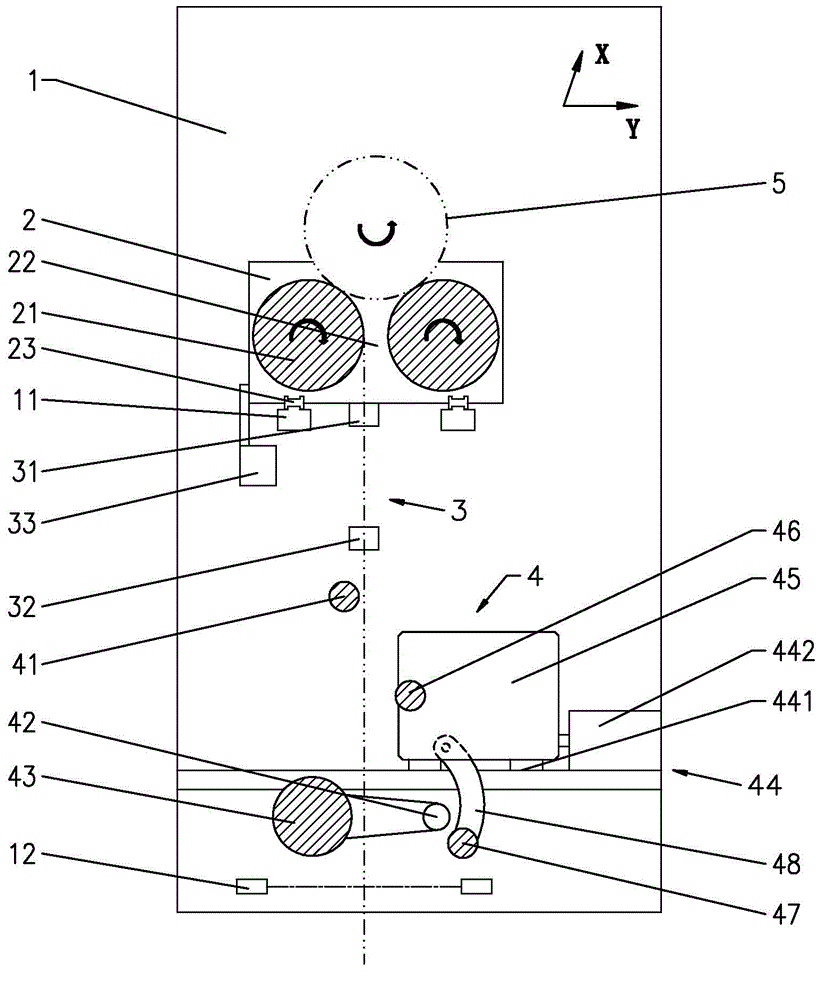

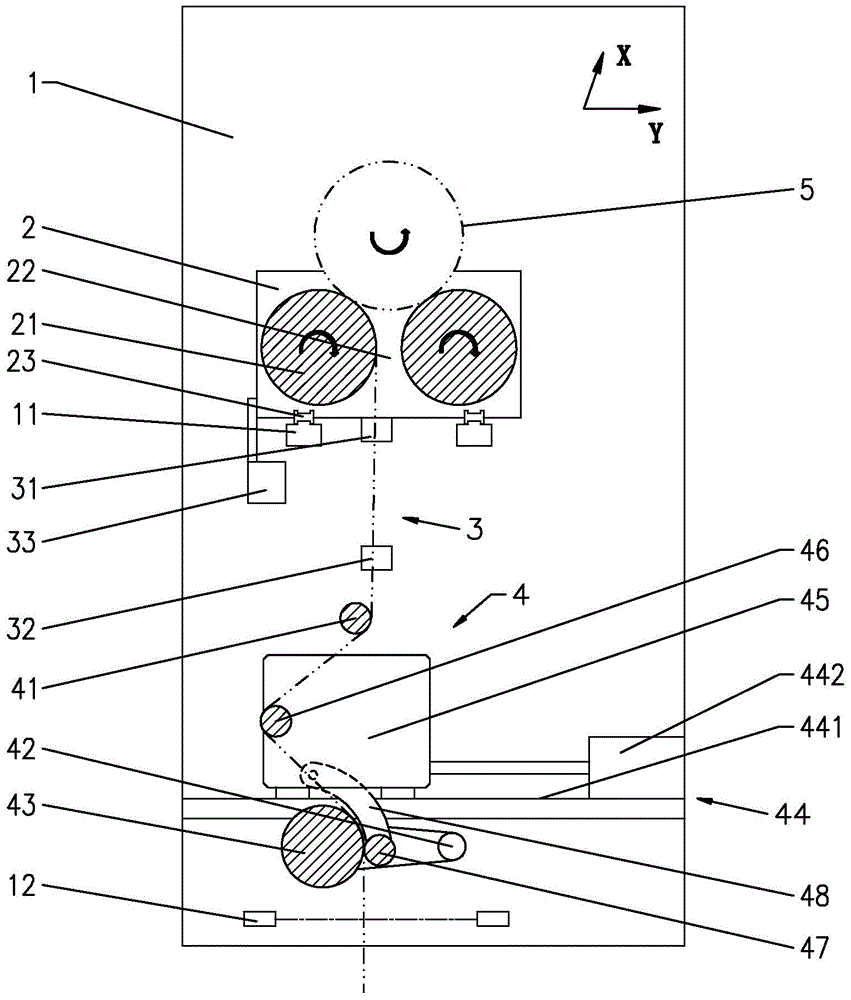

Flexible material processing and production equipment

The invention discloses flexible material processing and production equipment, which comprises a machine frame, wherein the machine frame is provided with a material input mechanism, a plurality of discharging and collection mechanisms, a material output mechanism and processing equipment, wherein each discharging and collection mechanism comprises two power rolls and a tension mechanism, each tension mechanism comprises at least one fixing roll, a traction roll, a second movement frame, at least one movement roll and a press roll, each traction roll is driven by a second power device, each second movement frame is driven by a Y-axis movement mechanism, and each movement roll and each fixing roll are vertically staggered. The flexible material processing and production equipment has the advantages that the structure is compact, and the space is saved; a material coil can be conveniently and rapidly charged; the flexible material is discharged and collected according to requirements, and a plurality of coils of flexible material can be flexibly and quickly replaced according to requirements.

Owner:GOERTEK INC

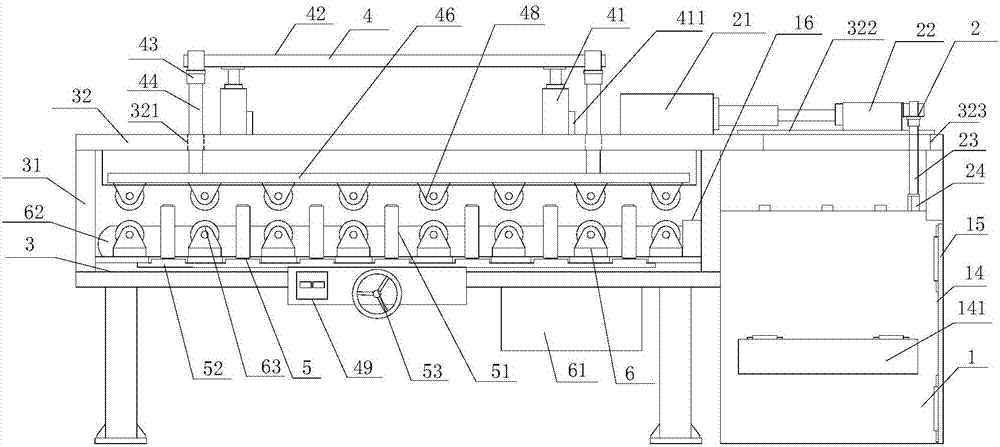

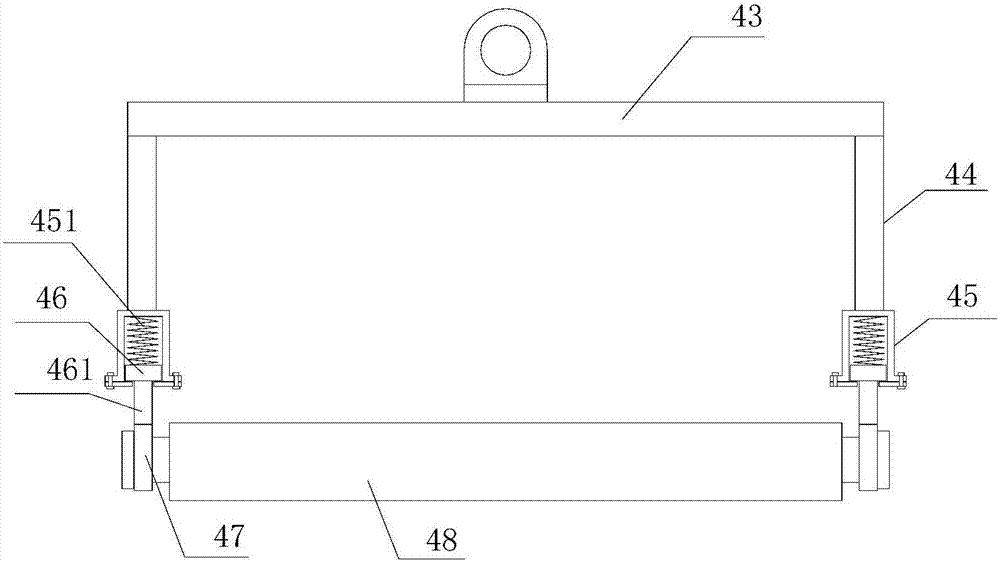

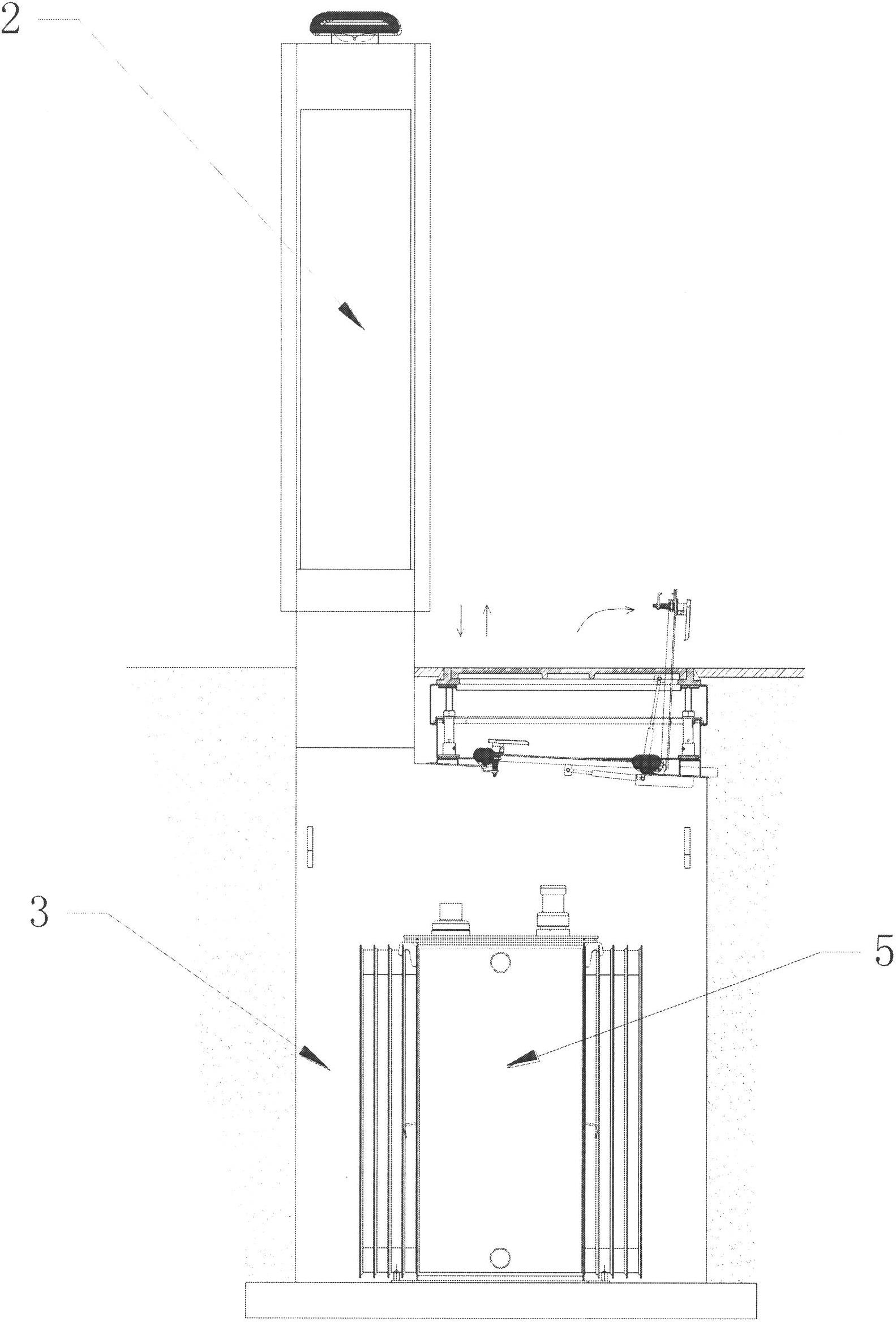

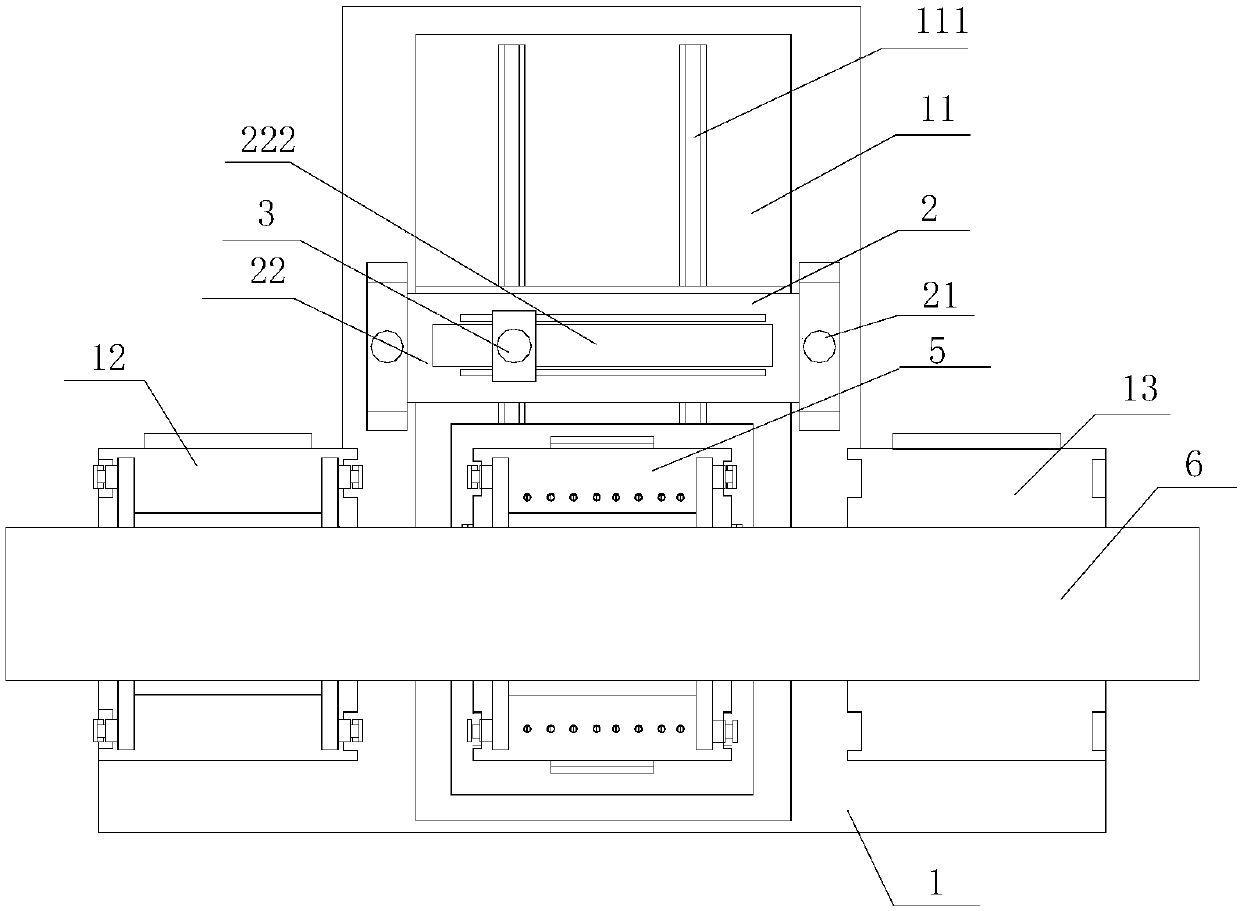

Panel feeding device

The invention provides a panel feeding device. The panel feeding device comprises a lifting and sheet distribution device, a pushing device, a rack, a pressing device, guide devices and a conveying device; a lifting mechanism is arranged inside the lifting and sheet distribution device and provided with a storage platform; the conveying device is installed on the rack and provided with a plurality of conveying roller assemblies; the rack is further provided with the pressing device; the pressing device is provided with a connection rod support; a mounting frame is installed below the connection rod support and internally provided with a plurality of pressure roller assemblies; the pressure roller assemblies are matched with the conveying roller assemblies; the guide devices are arranged on the two sides of the rack and provided with a plurality of guide roller assemblies; single sheet conveying of panels is achieved through the lifting and sheet distribution device, then the conveying device and the pressing device are matched to achieve conveying operation of the panels, a buffer spring adopted in the pressing device is used for enhancing the feeding stability, the automation degree is high, and the production efficiency is improved effectively.

Owner:王维东

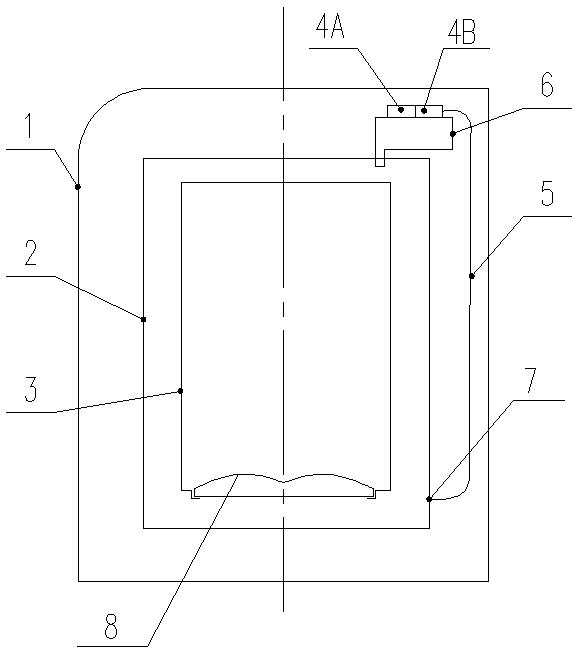

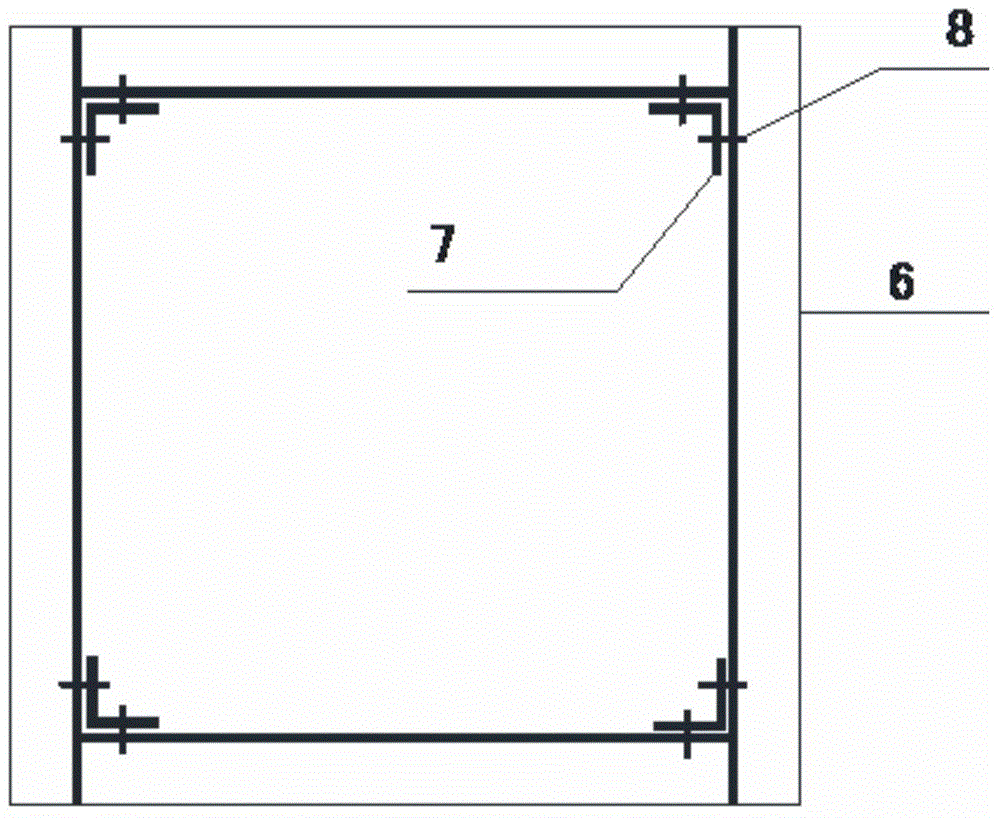

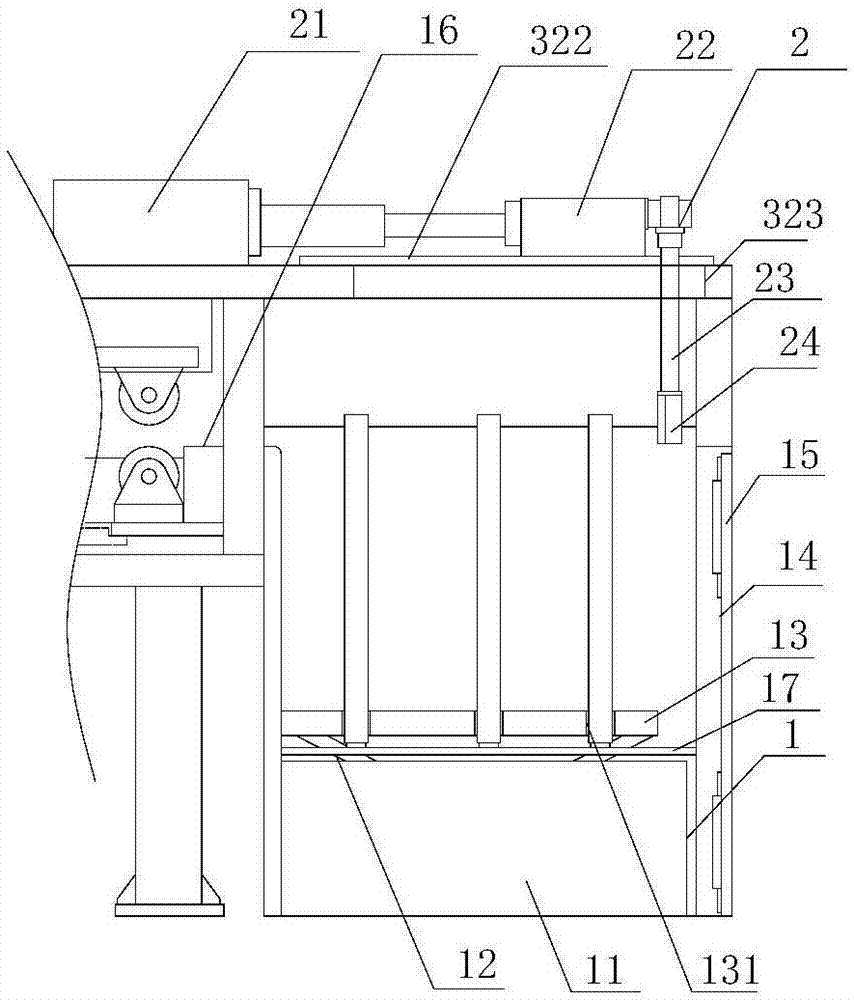

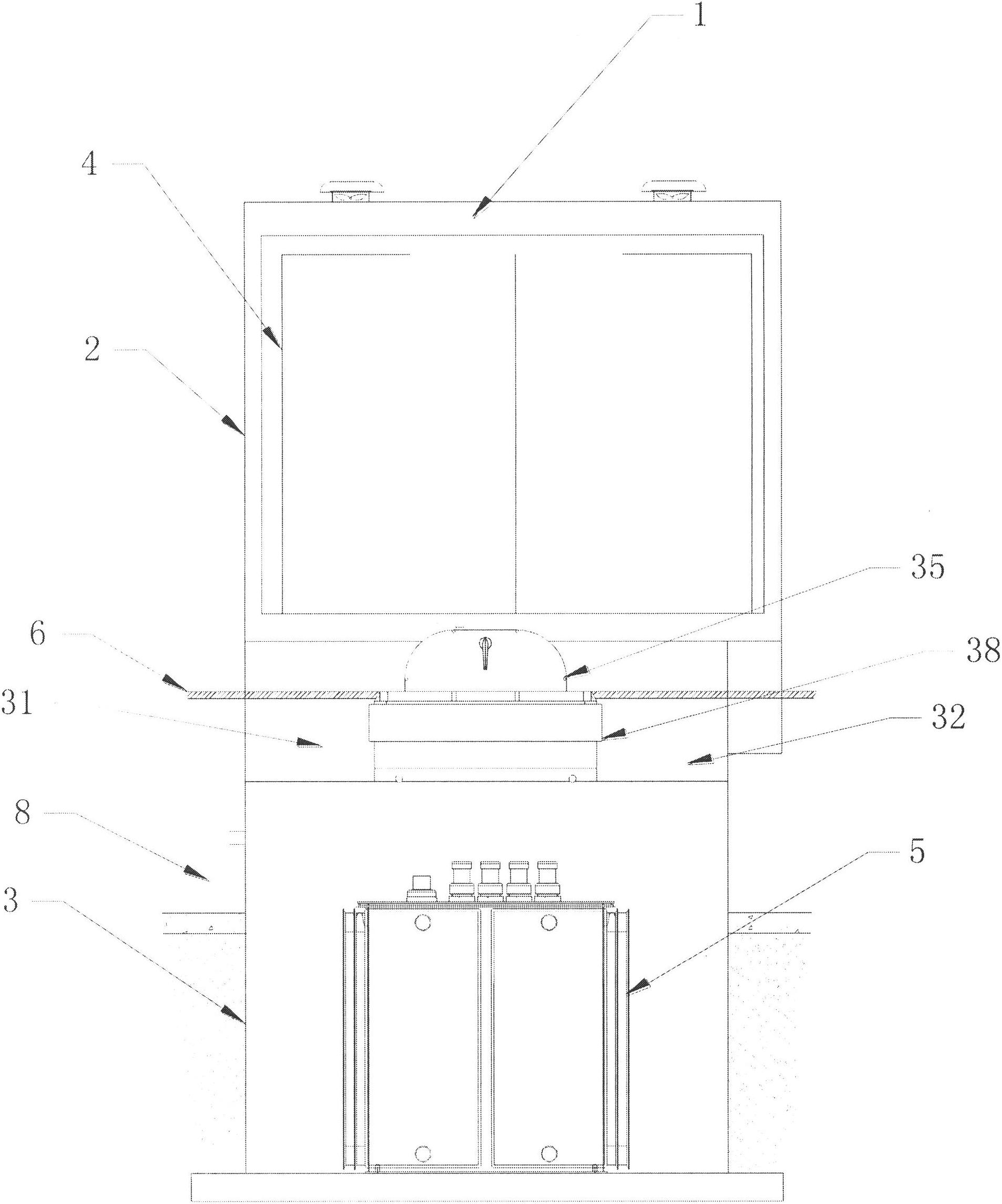

Lower box body structure of half-buried box-type substation

InactiveCN102646936AGuaranteed flushEnsure safetySubstation/switching arrangement detailsEnclosed substationsTransformerGround plane

The invention provides a lower box body structure of a half-buried box-type substation. The lower part of the lower box body structure is a transformer room, a neck port for being connected with an upper box body upwardly extends from one side of the top of the lower box body structure, and the rest part of the lower box body structure is an upper surface; the upper surface is provided with an upper surface opening, the size of the upper surface opening is enough for the access of a transformer, and an upper surface cover plate is arranged on the upper surface opening; the upper surface cover plate is provided with an operating hole which is used for the access of people, and an operating door is arranged on the operating hole; a lower box body is arranged under the ground surface, the upper part of the neck of the lower box body is higher than the ground surface, and the lower part of the lower box body is lower than the ground surface; an outer frame is arranged at the periphery of the operating door, the outer frame comprises an upper frame and a lower frame, and a lifting adjustment device for adjusting the relative distance from the upper frame to the lower frame is arranged in the outer frame; the upper frame is provided with a ground surface cover plate, and the ground surface cover plate is level with the ground surface; and an empty well is formed between the ground surface cover plate and the upper surface cover plate. According to the lower box body structure of the half-buried box-type substation, the ground surface cover plate is ensured to be level with the ground plane, and thus, the safety of pedestrians and vehicles and the overall appearance are ensured; and meanwhile, a safeguard measure is provided for operating personnel accessing the operating hole.

Owner:钱子坚

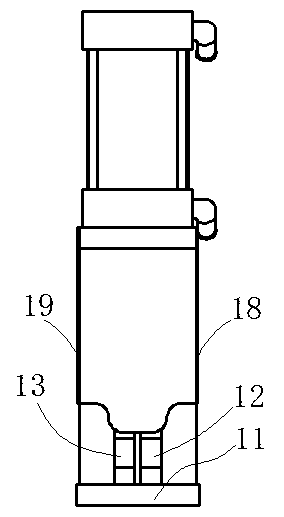

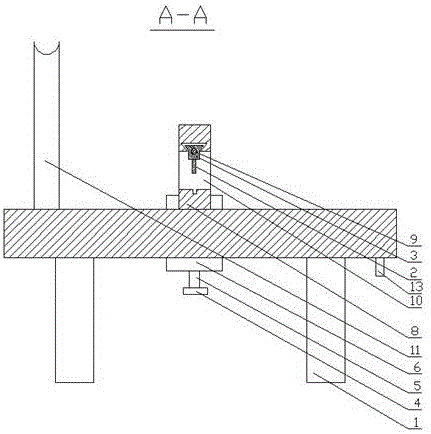

Nylon tube feeder and using method thereof

InactiveCN102794783AMeet the requirementsGuaranteed stabilityMetal working apparatusEngineeringPiston rod

The invention discloses a nylon tube feeder and a using method thereof, and belongs to enginery. The nylon tube feeder mainly comprises a feeder framework, a motive power air cylinder, a nylon tube cutter component, an auxiliary calibrated scale assembly for measuring the cutting length and a pneumatic control device for implementing cutting operation; the feeder framework is a metal support structure of the device; the motive power air cylinder for providing cutting motive power is fixed on the upper part of the feeder framework; a nylon tube cutter is installed on the lower part of the motive power air cylinder; the motive power air cylinder provides cutting motive power for the nylon tube cutter; a left fixed block and a right fixed block which are fixed on the base at the bottom of the feeder framework form a containing space, and the containing space is provided with a matched clearance for containing the vertical cutting motion of a cutter body of the nylon tube cutter; the motive power air cylinder comprises an air cylinder body and a piston rod; the nylon tube cutter comprises the cutter body and a sliding block; and the nylon tube cutter and the piston rod are fixedly connected. The nylon tube feeder is small in volume and simple in structure, and when the nylon tube is cut, the cutting quality is ensured because of the extrusion effect of the nylon tube cutter.

Owner:CHANGCHUN CHINAUST AUTOMOBILE PARTS

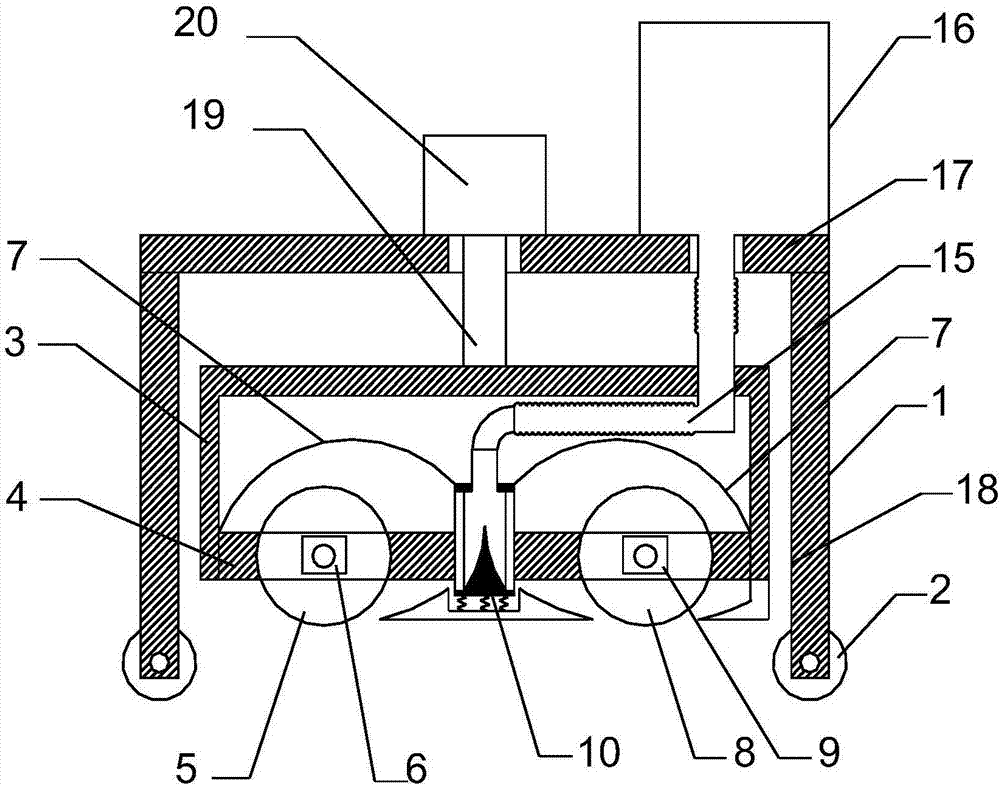

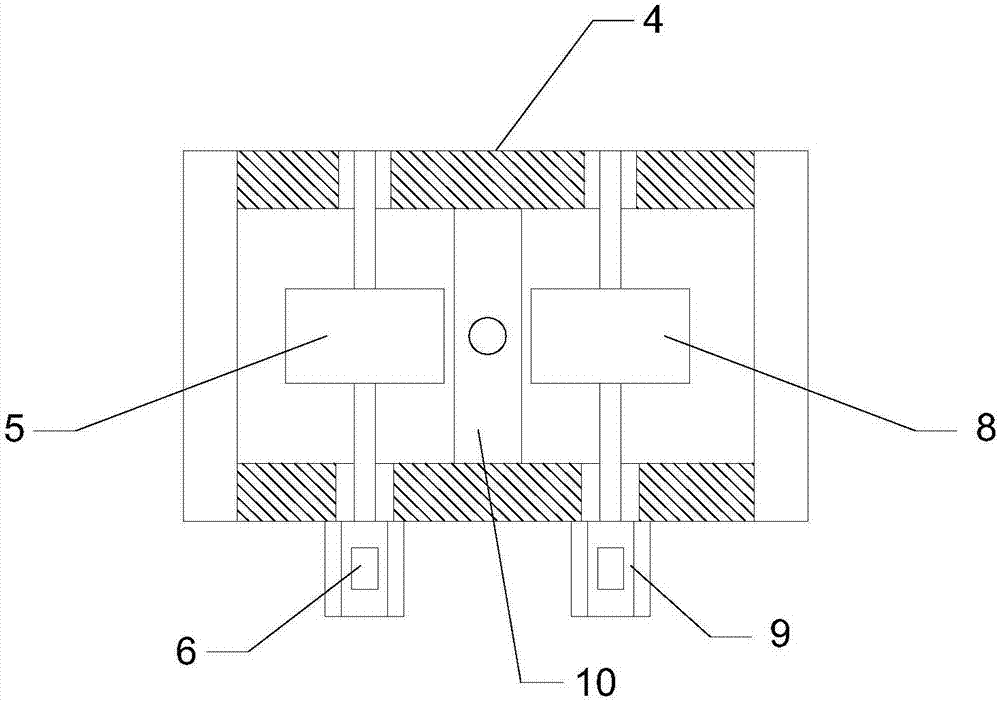

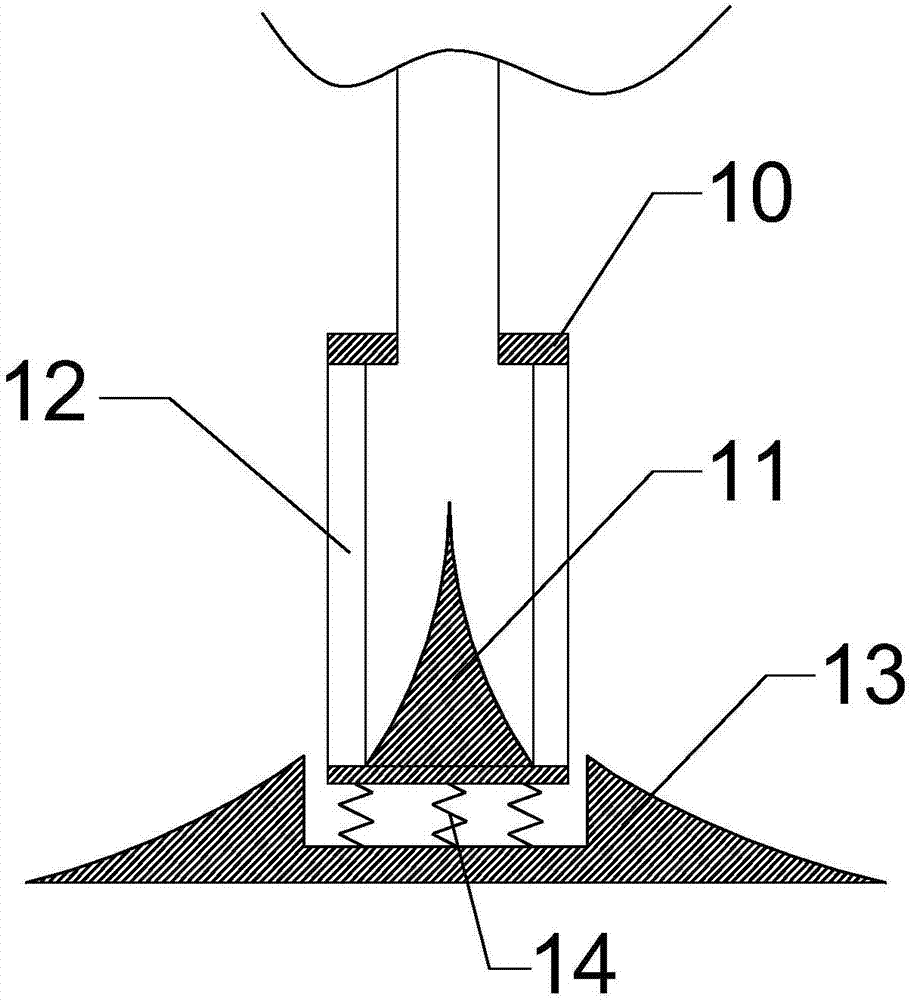

High-efficiency ground slotting device

PendingCN107386082AImprove work efficiencyEasy to collectBuilding constructionsRoads maintainenceLine tubingSlag

The invention discloses a high-efficiency ground slotting device. The device comprises a vehicle body; rolling wheels are arranged at the bottom of the vehicle body; a mobile rack is arranged in the vehicle body, the lower part of the mobile rack is fixedly connected with a crossbeam plate, and the right side of the crossbeam plate is in rotating connection with a grinding wheel; and a dust sucking cylinder is arranged between the grinding wheel and a slotting blade group. Slotting blades connected in an interlaced manner are arranged to crush concrete, so concrete slag can be conveniently collected; an industrial dust suction machine, a dust sucking cylinder and an outer guiding block are arranged to fully suck the concrete slag; and the grinding wheel is arranged to polish the inner wall of a groove body to make the slag fully crushed and sucked and guarantee the parallel and level of edges of the groove body, so a pipeline can be conveniently directly laid, the groove body can be molded once, and the slotting working efficiency is improved.

Owner:ZHENGZHOU UNIV

Chemical scrubbing method of the flat-plate film

InactiveCN101116797AEasy to cleanGuaranteed flushSemi-permeable membranesAutomatic controlControl system

The present invention relates to a chemical washing technology for diaphragm, which is applicable to the washing process of plate diaphragm in plate diaphragm biologic reactor; the present invention can detect through the operation pressure in the running process of the plate diaphragm; when the pressure is more than certain degree, an automatic control system can adjust the aeration quantity of the plate diaphragm, meanwhile, a washing liquid is added into the plate diaphragm through a medicine adding system, after for a while, the washing liquid is discharged from the plate diaphragm, the described steps is repeated by once at least; the washing chemical agent added in the present invention can effectively wash the inside of the plate diaphragm, the control on the staying time can assure the medicine to penetrate from the inside to the outside of the diaphragm in order to wash a diaphragm hole and the outside of the diaphragm; a continuous aeration process can assure the air to flush on the external surface of the diaphragm to remove a pollutant outside the washed diaphragm in time, a repetitive washing process can avoid the incomplete washing effect from the first washing process, and improve the effectiveness of diaphragm washing; the invention has the advantages of an easy operation, a high automatic degree and so forth.

Owner:TORAY FIBER RES INST(CHINA) CO LTD +1

Paperboard laminating slitting device

PendingCN108146054ASnap offGuaranteed flushLamination ancillary operationsLaminationPaperboardEngineering

The invention discloses a paperboard laminating slitting device. The paperboard laminating slitting device comprises a first conveying belt mechanism, a material storage mechanism, a mechanical arm conveying mechanism, a rack, a second conveying belt mechanism, a slitting mechanism and a laminating mechanism, wherein the mechanical arm conveying mechanism stretches across the first conveying beltmechanism and the material storage mechanism, a feeding suction cup mechanism is arranged on the mechanical arm conveying mechanism, the laminating mechanism is arranged between the first conveying belt mechanism and the second conveying belt mechanism, the rack is provided with an importing roller assembly, the laminating mechanism, an exporting roller assembly, the slitting mechanism, an auxiliary pressing roller assembly and a film-breaking roller assembly in sequence, a hot press roller mechanism is arranged on the laminating mechanism, and the slitting mechanism is symmetrically providedwith film cutter assemblies. The conveying belt mechanisms cooperate with mechanical arms for feeding, after laminating, a cut is firstly cut from the junction of laminated film, different pressures of all portions of film-breaking rollers and panels are utilized to form shear pressure from the two ends of the cut to the inner portion, the junction of the laminated film is quickly pulled broken, and it is guaranteed that the cut of the laminated film is neat and even.

Owner:嘉兴市鸿业包装有限公司

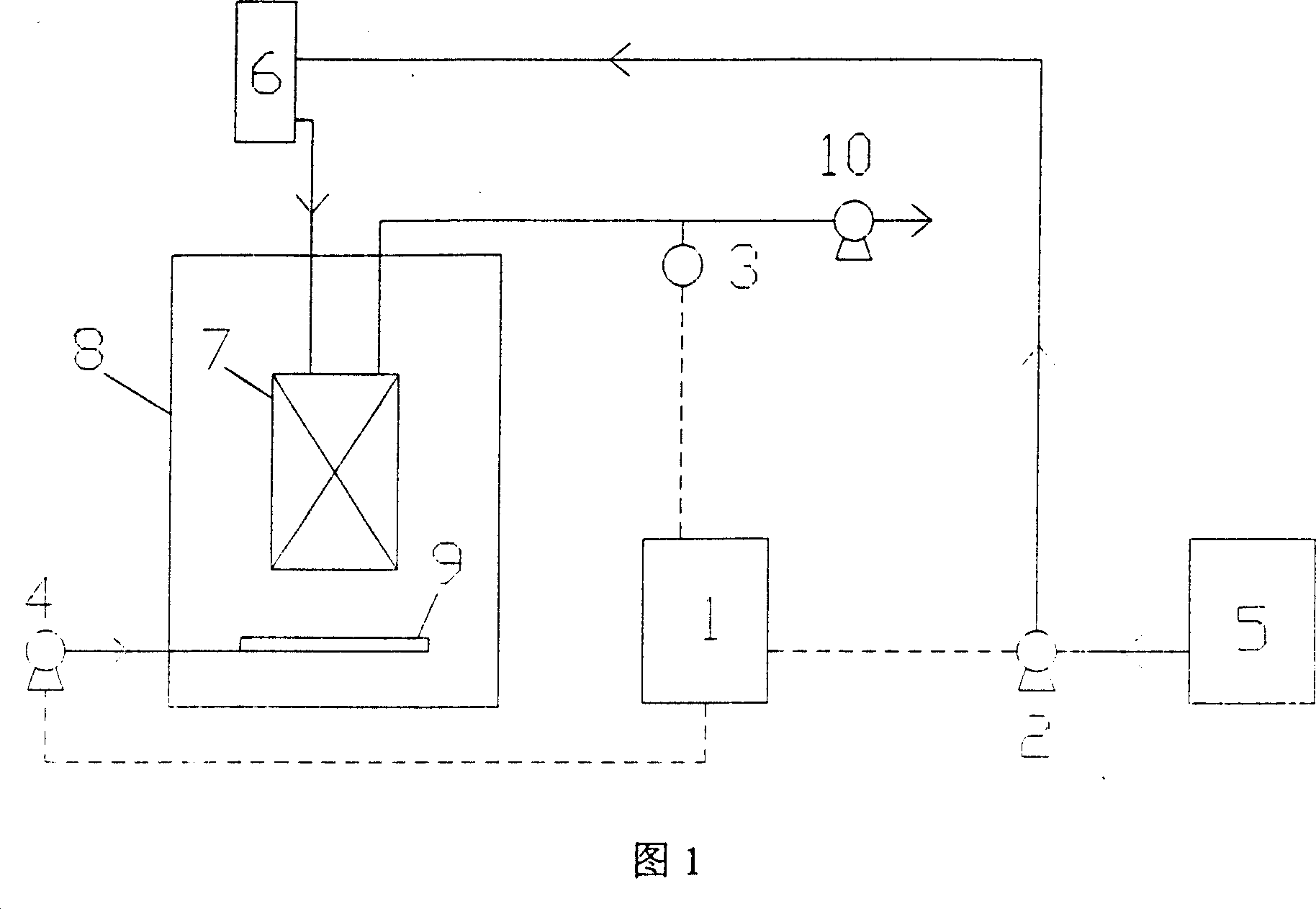

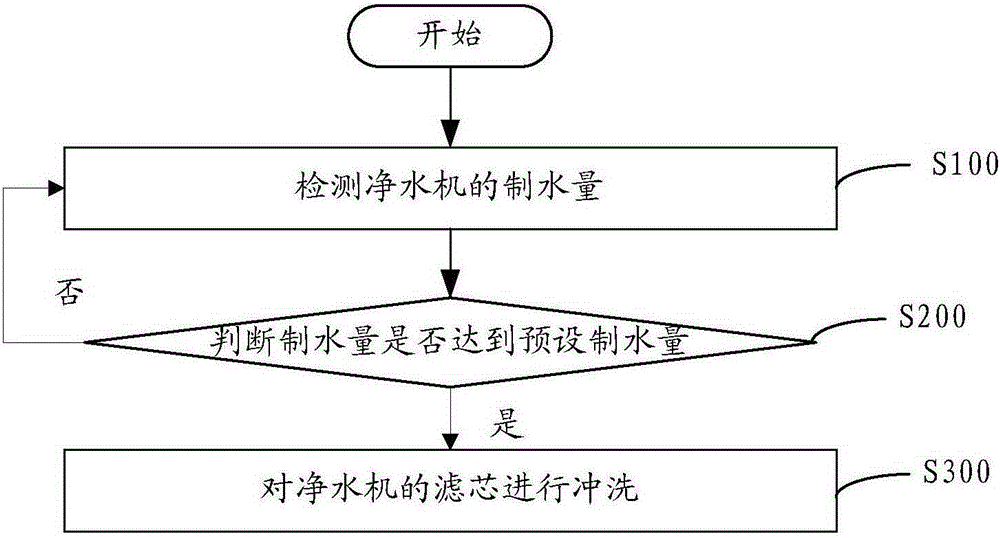

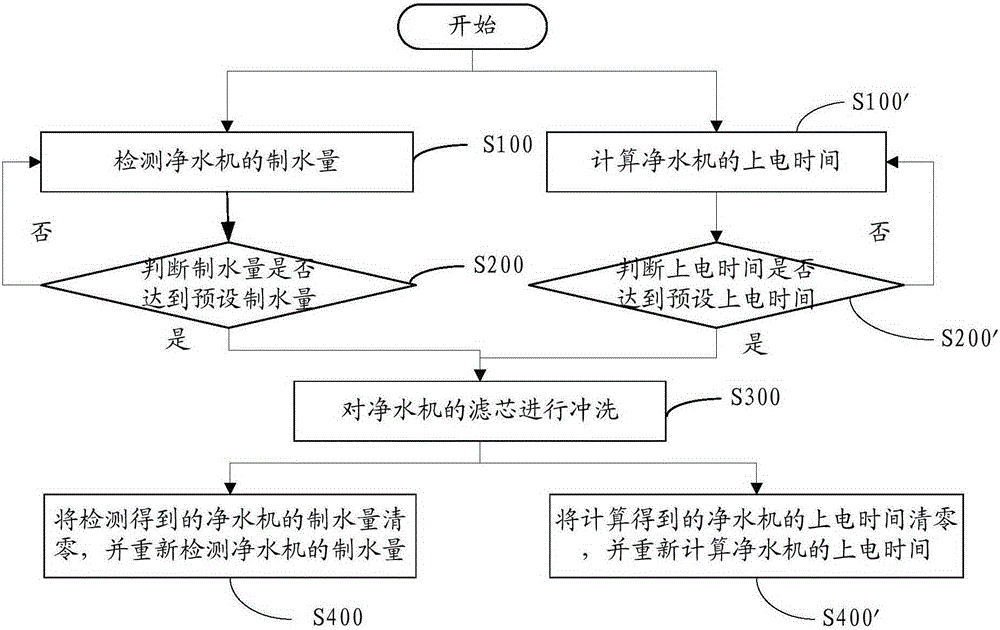

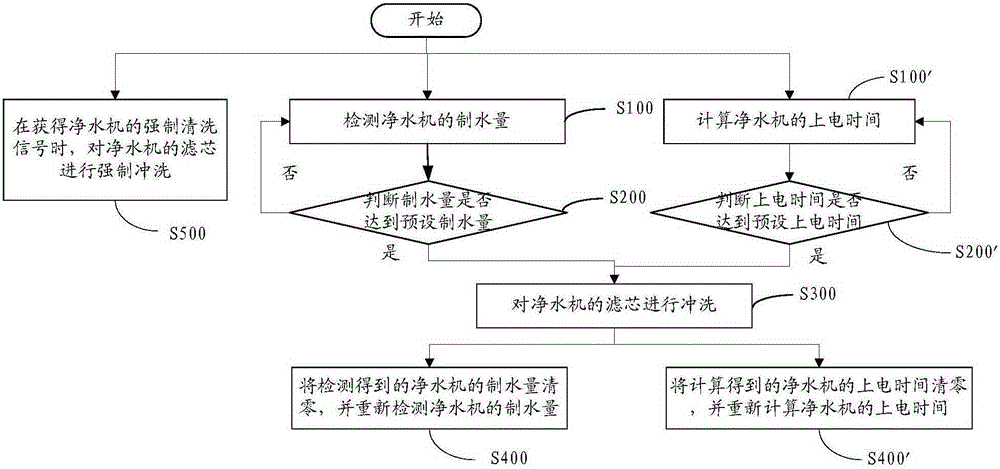

Flushing method of water purifier and water purifier

InactiveCN105327542AGuaranteed flushGuaranteed timelinessWater/sewage treatmentStationary filtering element filtersWater productionEngineering

The invention provides a flushing method of a water purifier and the water purifier. The method includes the steps of detecting the water production amount of the water purifier, judging whether the water production amount reaches the preset water production amount or not, flushing a filter element of the water purifier if the water production amount reaches the preset water production amount, and repeatedly detecting the water production amount of the water purifier if the water production amount does not reach the preset water production amount. According to the flushing method, the filter element of the water purifier is flushed according to the water production amount of the water purifier in the actual use process, pollution sources can not be left on the filter element, it is ensured that the filter element of the water purifier can be flushed in time, and therefore the service life of the filter element is prolonged.

Owner:GREE ELECTRIC APPLIANCES INC

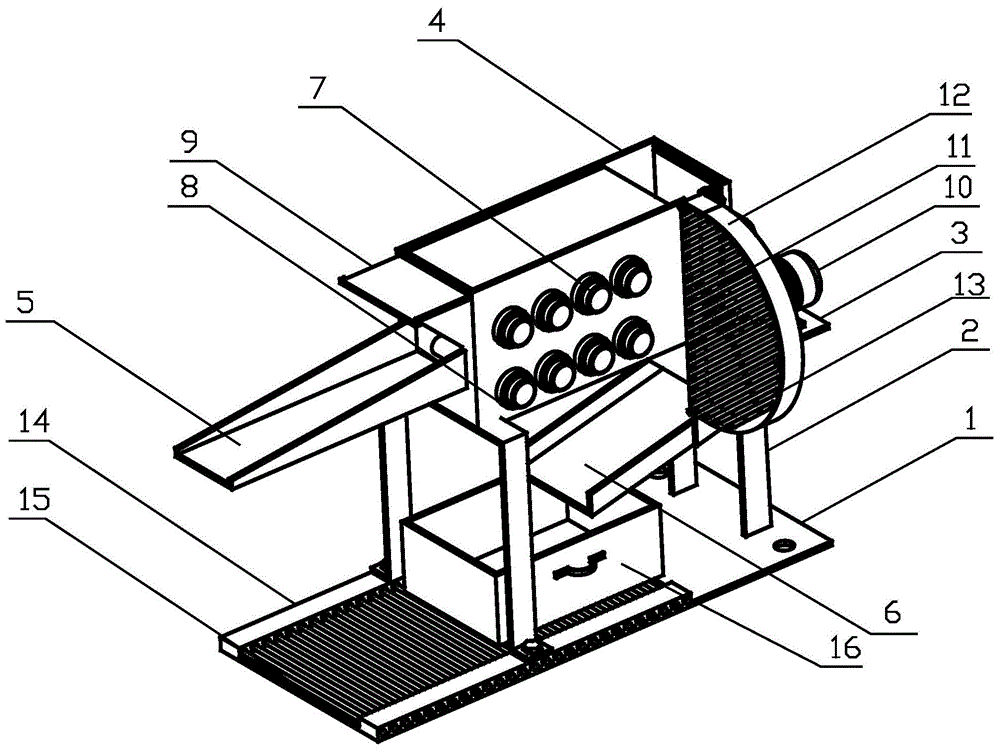

Chinese herbal medicine slicing machine

The invention relates to Chinese herbal medicine processing equipment, in particular to a Chinese herbal medicine slicing machine. The Chinese herbal medicine slicing machine comprises a supporting body, a box body, a feeding structure, a slicing mechanism, a discharging mechanism and a power transferring mechanism. A supporting frame is arranged on a base. A case is fixed to the supporting frame. An upper shifting roller set, a bottom shifting roller set, a slicing table (not marked in the figure), and a cutting feed port are arranged in the case. A feed hopper is arranged on one side of the outside of the case. A discharge hopper is arranged below the slicing table of the case. A platform is arranged on the other side of the case. A first motor, a second motor and a third motor are arranged on the platform. The discharge hopper is arranged below a receiving box. The Chinese herbal medicine slicing machine has the beneficial effects that cut openings of Chinese herbal medicine are flush, and the slicing speed is high; the shifting roller sets are used for feeding, and the slice thicknesses are uniform; the distance between the shifting roller sets can be adjusted, and thus the application range is wide; and elastic shaft sleeves are arranged on the shifting rollers, so that the herbal medicine is protected against crushing damage, and the slicing operation is safe.

Owner:裴佩

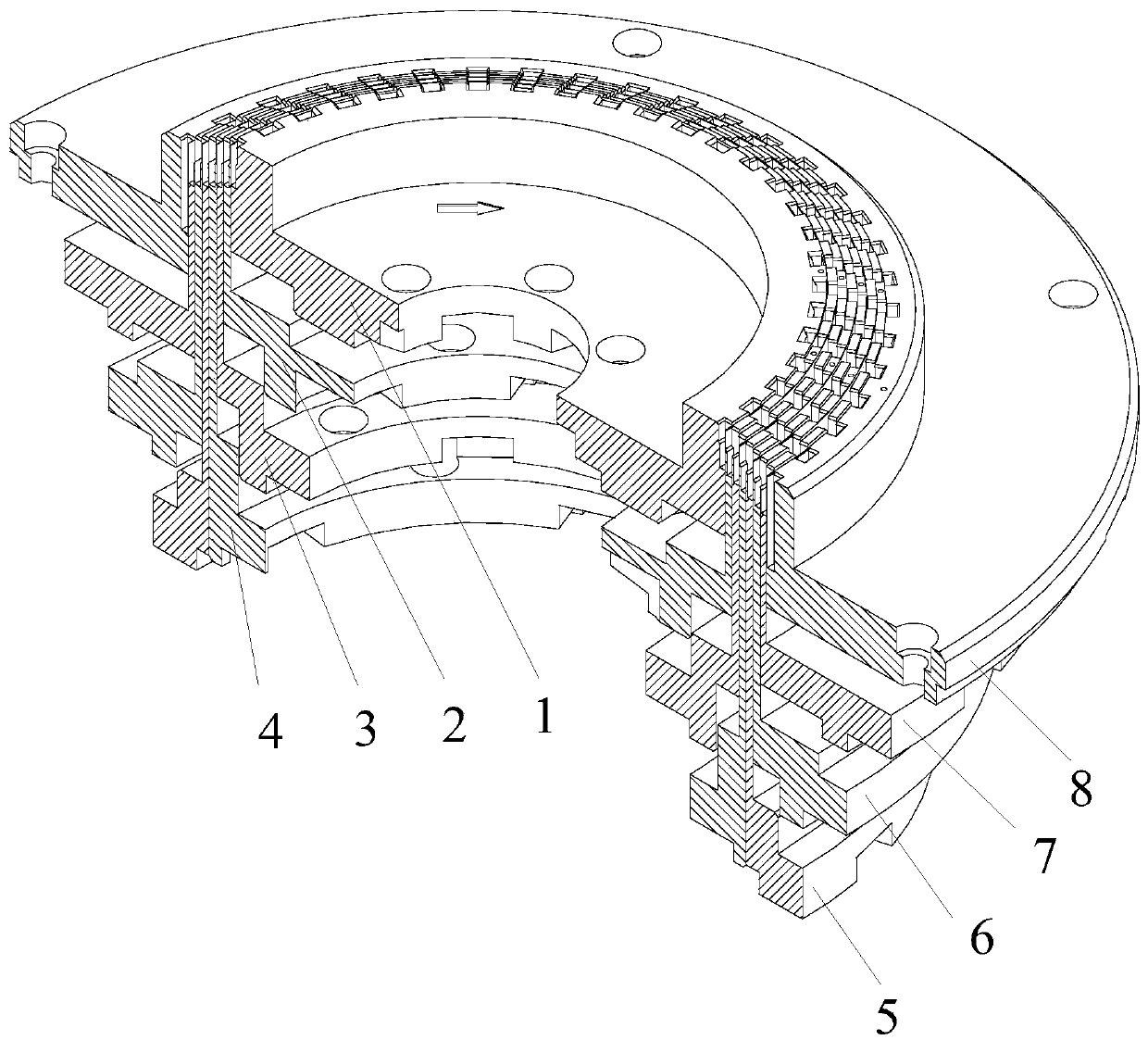

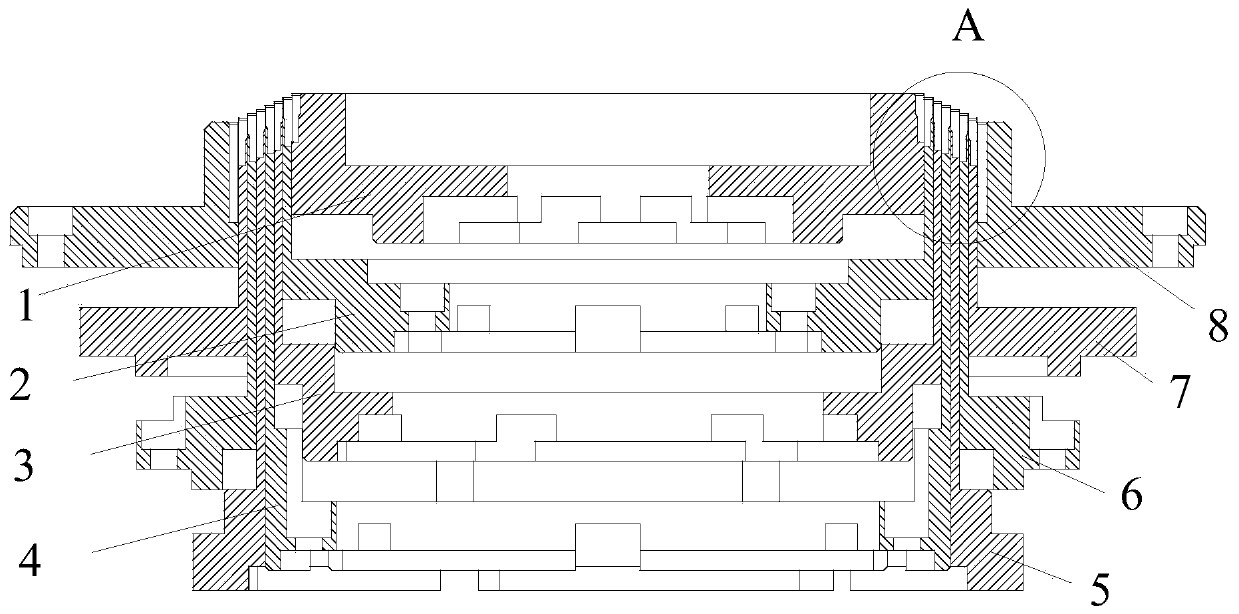

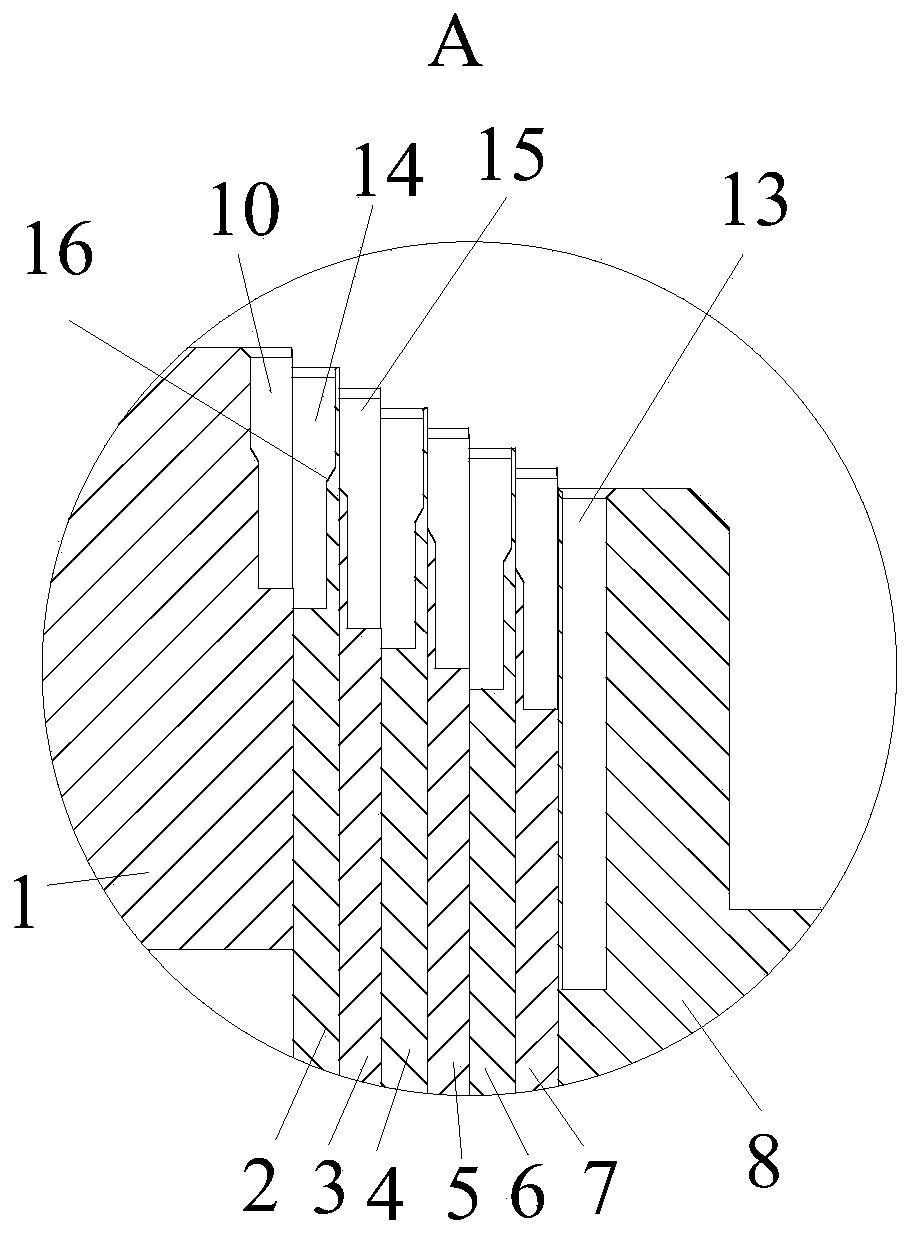

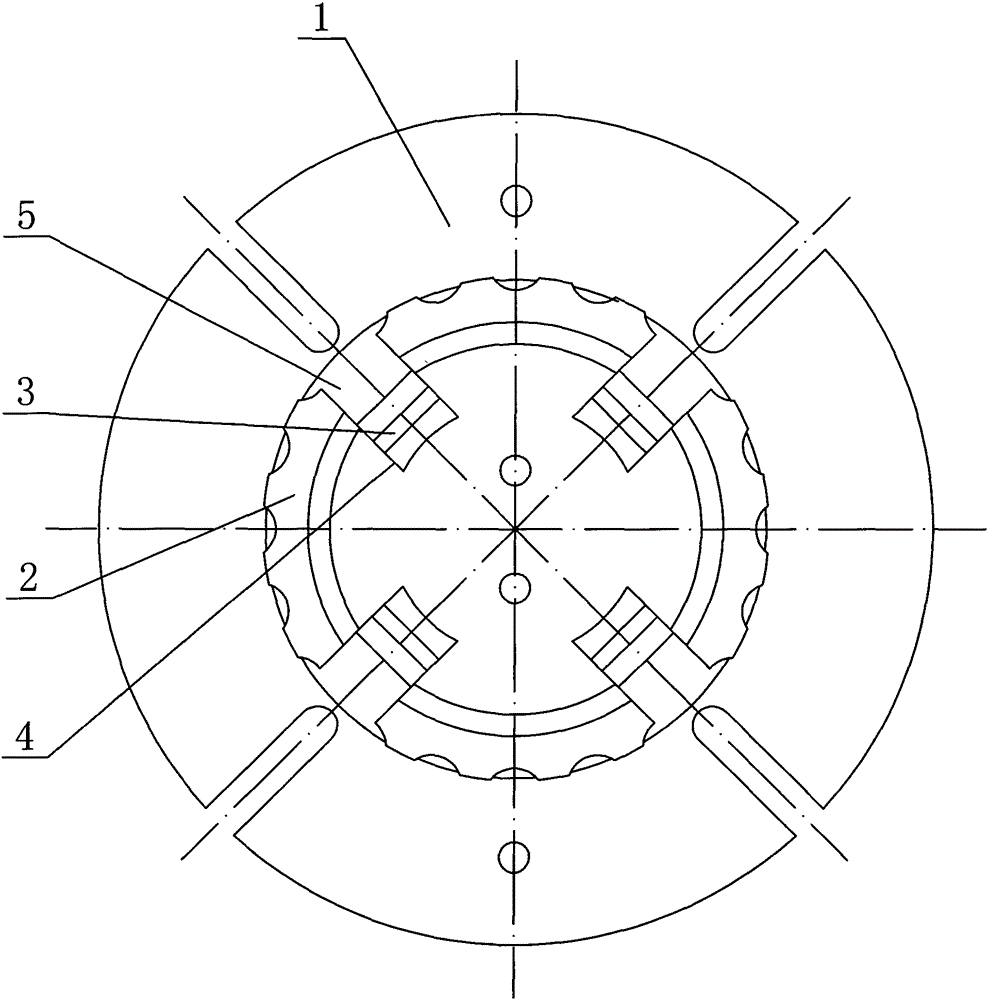

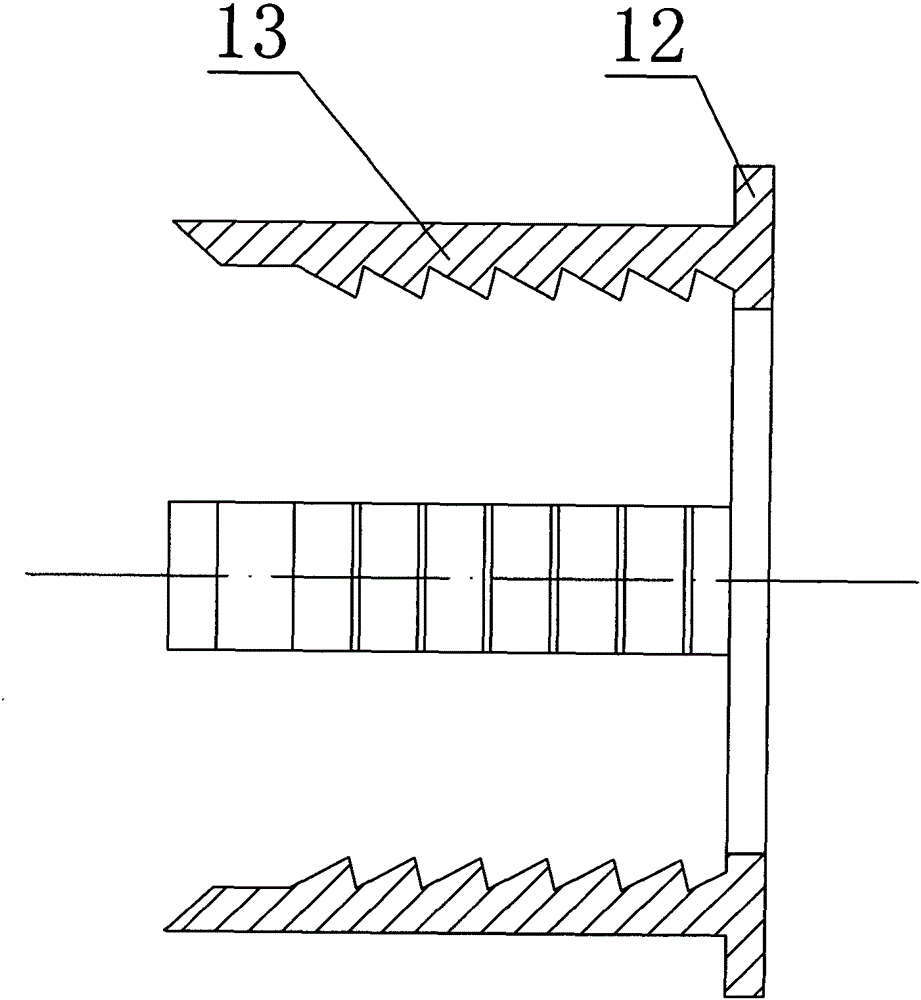

Device for twisting end of stator of flat wire motor

ActiveCN110729858AReduce in quantityReduce process steps and reduce manufacturing costsManufacturing dynamo-electric machinesElectric machineControl theory

The invention discloses a device for twisting the end of a stator of a flat wire motor. The device comprises an even number of molds which are sequentially nested in the radial direction. Multiple inner slots are formed in the upper end face of a working ring of an inner mold in the circumferential direction, wherein the outer sides of one part of the inner slots are opened to form first-class inner slots, and the outer sides of the other part of the inner slots are closed to form second-class inner slots. Multiple outer slots are formed in the upper end face of a working ring of an outer moldin the circumferential direction, wherein the inner sides of one part of the outer slots are opened to form first-class outer slots, and the inner sides of the other part of the outer slots are closed to form second-class outer slots. Multiple middle slots are formed in the upper end face of a working ring of each middle mold in the circumferential direction, wherein the inner sides of one part of the middle slots are opened to form first-class middle slots, and the outer sides of the other part of the middle slots are closed to form second-class middle slots. The upper end faces of the working rings of all the molds are distributed in a gradually-reduced step shape from inside to outside. The device has the advantages that the process steps are reduced and the cost is saved.

Owner:HEFEI JUYI POWER SYST CO LTD

Hanging tag perforating device automatic loading and unloading

PendingCN107696150AGuaranteed flushRealize automatic loading and unloadingMetal working apparatusPunchingRobot hand

The invention provides a hanging tag perforating device automatic loading and unloading. The hanging tag perforating device comprises a rack, a lifting driving mechanism, a punching and perforating mechanism, a compressing mechanism, a loading die seat and a feeding device, a workbench is arranged on the rack, longitudinal guide rails are arranged on the workbench, the loading die seat is movablymounted on the longitudinal guide rail, a feeding guide rail is arranged on the feeding device, a feeding sliding seat is mounted on the feeding guide rail, a first manipulator component and a secondmanipulator component are arranged below the feeding sliding seat, a lifting frame is arranged on the lifting driving mechanism, a transverse guide rail is arranged on the lifting frame, an auxiliarysliding seat is arranged on the punching and perforating mechanism and matched with the transverse guide rail, a perforating component is mounted on the auxiliary sliding seat, and the compressing mechanism is arranged below the lifting frame. Automatic loading and unloading can be realized through manipulators on the feeding sliding seat, and notches can be ensured to be flush through guiding andcompressing of a compressing plate.

Owner:HAIYAN HUAGANG PRINTING CO LTD

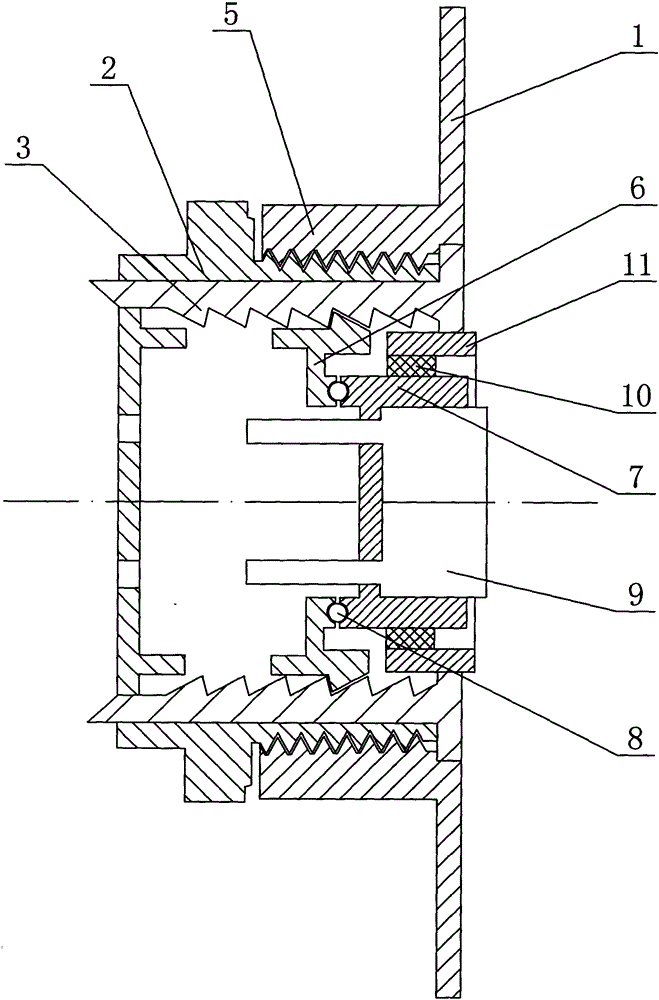

Invisible self-adjustable general probe for automobile

The invention relates to an invisible self-adjustable general probe for an automobile. A probe mounting hole is formed in a bumper; connecting blocks are fixed on the inner side face of the bumper; a casing is in threaded connection with the connecting block; the casing is a cylindrical casing; threads are arranged on the outer circumference of the cylindrical wall of the cylindrical casing; the casing and the connecting blocks are connected through threads; grooves are formed in the axial direction of the cylindrical wall; a helical coil is arranged between each connecting block and the bottom of the corresponding groove; each helical coil is connected with an expansion bracket through the threads; the front end of the expansion bracket is connected with a probe bracket through a universal ball; a probe is arranged in the probe bracket; a protective casing is arranged outside the probe bracket; the probe bracket and the protective casing are connected by a connecting ring. After the invisible self-adjustable general probe disclosed by the invention is arranged on the automobile bumper, the invisible self-adjustable general probe can be flush with the plane of the bumper, so that the appearance of the automobile can be kept attractive; the size of outer diameter of the probe can be regulated according to the aperture size of the probe mounting hole in the bumper, so that the generality of the probe is guaranteed; the probe is retractable and is adjustable in angle; the distance and the angle which can be detected by the probe can be adjusted.

Owner:深圳卓安坤达智能科技有限公司

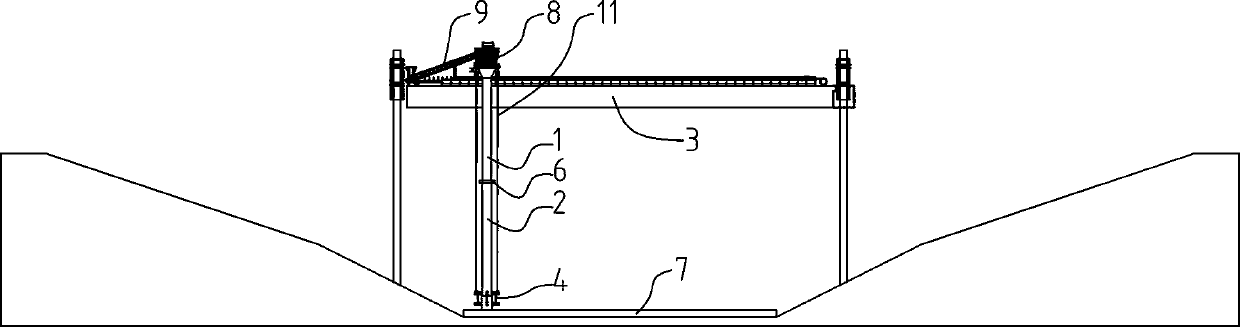

Floating-type underwater gravel base bed continuous leveling ship

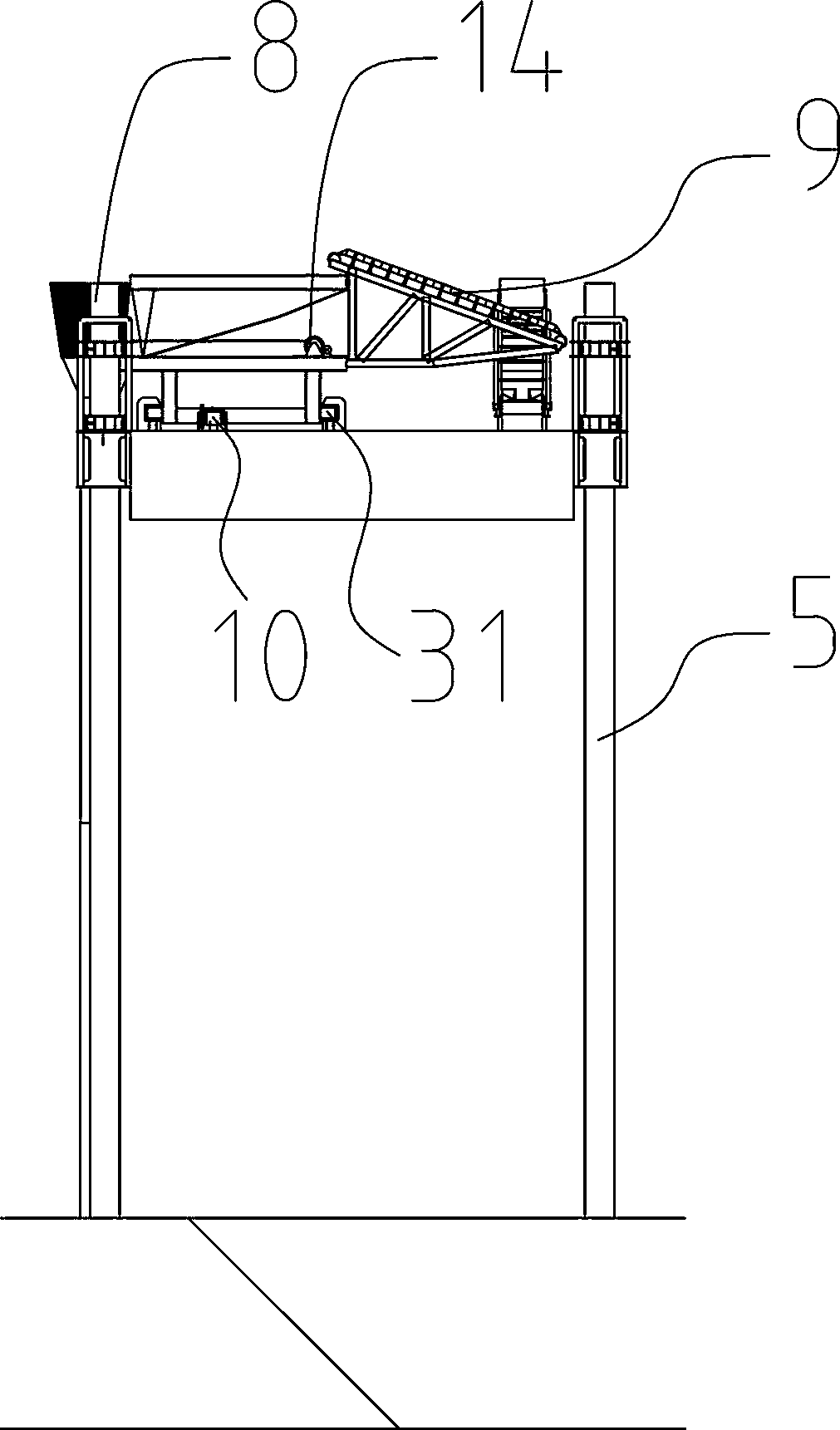

PendingCN109898514AAdjustable lengthPrecise thickness controlWaterborne vesselsFoundation engineeringSternBuilding construction

The invention provides a floating-type underwater gravel base bed continuous leveling ship, which comprises a hull. Lifting positioning piles are arranged at a bow and a stern of the hull and slidablyconnected with the hull; a conveying trolley is further arranged and driven by a driving device to slide in the length direction of the hull, an articulated chute is arranged on the conveying trolley, a material feeding opening is formed in the top end of the articulated chute, and the bottom end of the articulated chute is close to the water bottom; and one or more conveying belts for supplyingmaterials to the conveying trolley are further arranged. By adopting the scheme that the positioning piles and the hull are slidably connected in the horizontal direction, after riprapping construction is completed in an area, precisely guided continuous moving can be achieved by moving the positioning piles and the hull in a reciprocating mode, thus the situation that the hull needs to be re-positioned every time when the hull is moved is avoided, and high-precision and continuous Z-shaped riprapping paving construction is achieved through the articulated chute.

Owner:CCCC SECOND HARBOR ENG

Automatic feeding paperboard cutting device

PendingCN108146015AGuaranteed flushEasy to operateBox making operationsPaper-makingPaperboardEngineering

The invention discloses an automatic feeding paperboard cutting device. The automatic feeding paperboard cutting device comprises a rack, a supplying mechanism, an installation supporting base, a cutting mechanism, an adjustable guiding mechanism, a discharging mechanism and a feeding device. One side of the rack is provided with the supplying mechanism, and the feeding device coordinates with thesupplying mechanism. The feeding device is internally provided with a lifting feeding platform. A second pushing mechanism is arranged above the lifting feeding platform. The cutting mechanism is provided with a third walking base and a cutting knife assembly. The adjustable guiding mechanism is arranged on one side of the rack. The rack is provided with a first through groove. The first throughgroove is movably provided with the discharging mechanism. The discharging mechanism is symmetrically provided with two second pushing blocks. The feeding device carries out feeding, a pushing block mechanism controls paperboards to move so that feeding and discharging of cutting can be achieved, a compressing mechanism is used for compressing the paperboards, it is guaranteed that cutting openings are flush, operation is easy, the production efficiency can be improved, and safety problems are avoided.

Owner:长兴天誉包装股份有限公司

Cloth cutting-off device for textiles

The invention relates to the textile field, in particular to a cloth cutting-off device for textiles. By means of the cloth cutting-off device for the textiles, cloth can be automatically cut off, it is guaranteed that cutting edges of the cloth are flush, the cloth cutting-off speed is high, and therefore the production efficiency of textile enterprises is improved. The cloth cutting-off device for the textiles comprises a workbench which is of a cuboid structure; the two sides of the workbench are each provided with a sliding trough which is of a U-shaped structure, and the side edges of the workbench are half-wrapped by the sliding troughs; a frame is arranged on the upper surfaces of the sliding troughs, a sliding block is hung on the frame through a dovetail structure, and a cutter is inlaid on the lower surface of the sliding block and is of a double-edge structure; the end face of the frame is provided with a servo motor which is connected with a first screw rod, the first screw rod penetrates through the sliding block and is in threaded connection with the sliding block, a cushion block is arranged on the portion, corresponding to the cutter, of the upper surface of the workbench, and the upper surface of the cushion block is provided with a groove structure. The cloth cutting-off device for the textiles is high in use efficiency, low in use cost and suitable for cutting of cloth.

Owner:SUZHOU COMFORT TEXTILE NEW MATERIALS TECH CO LTD

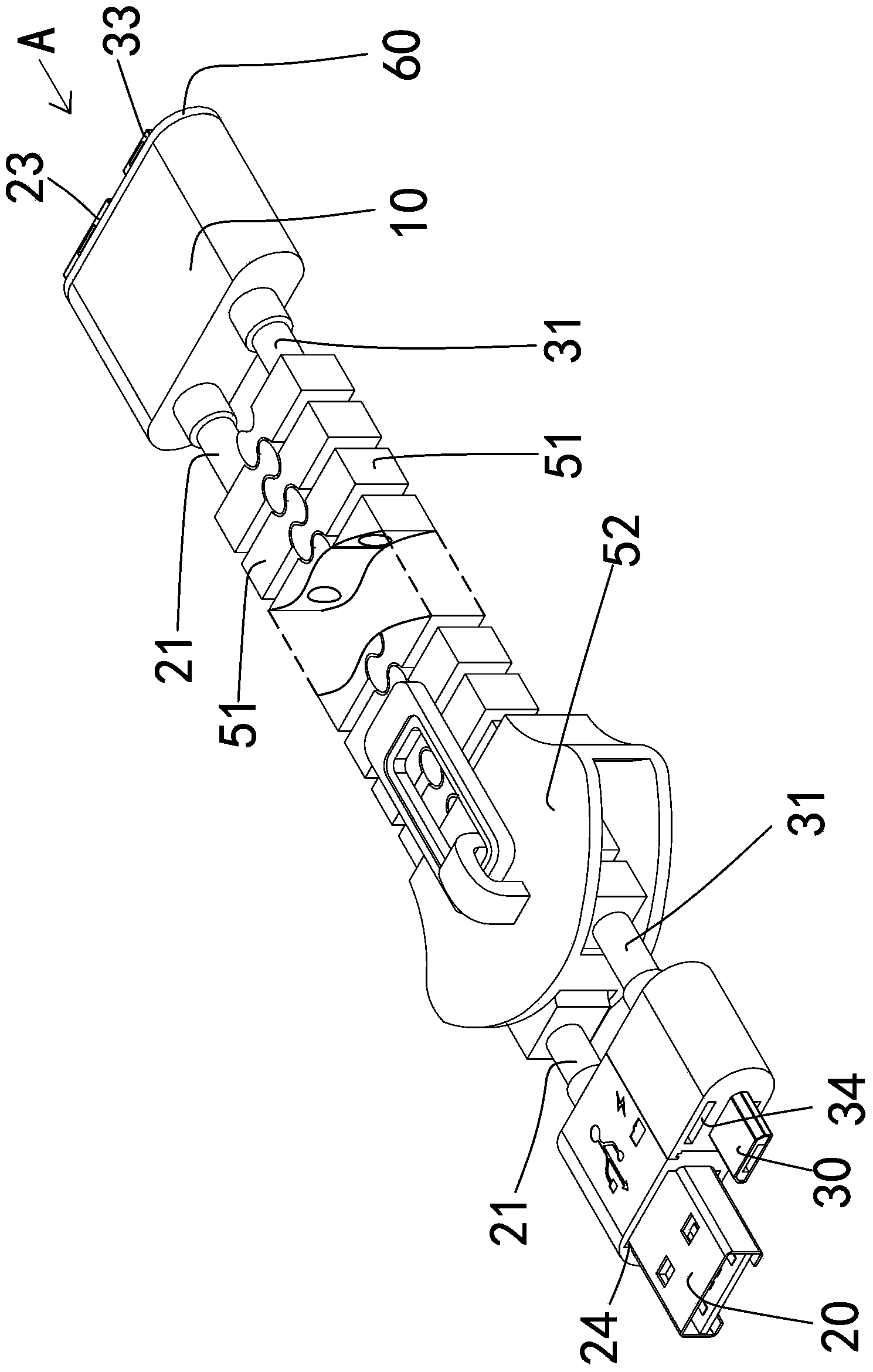

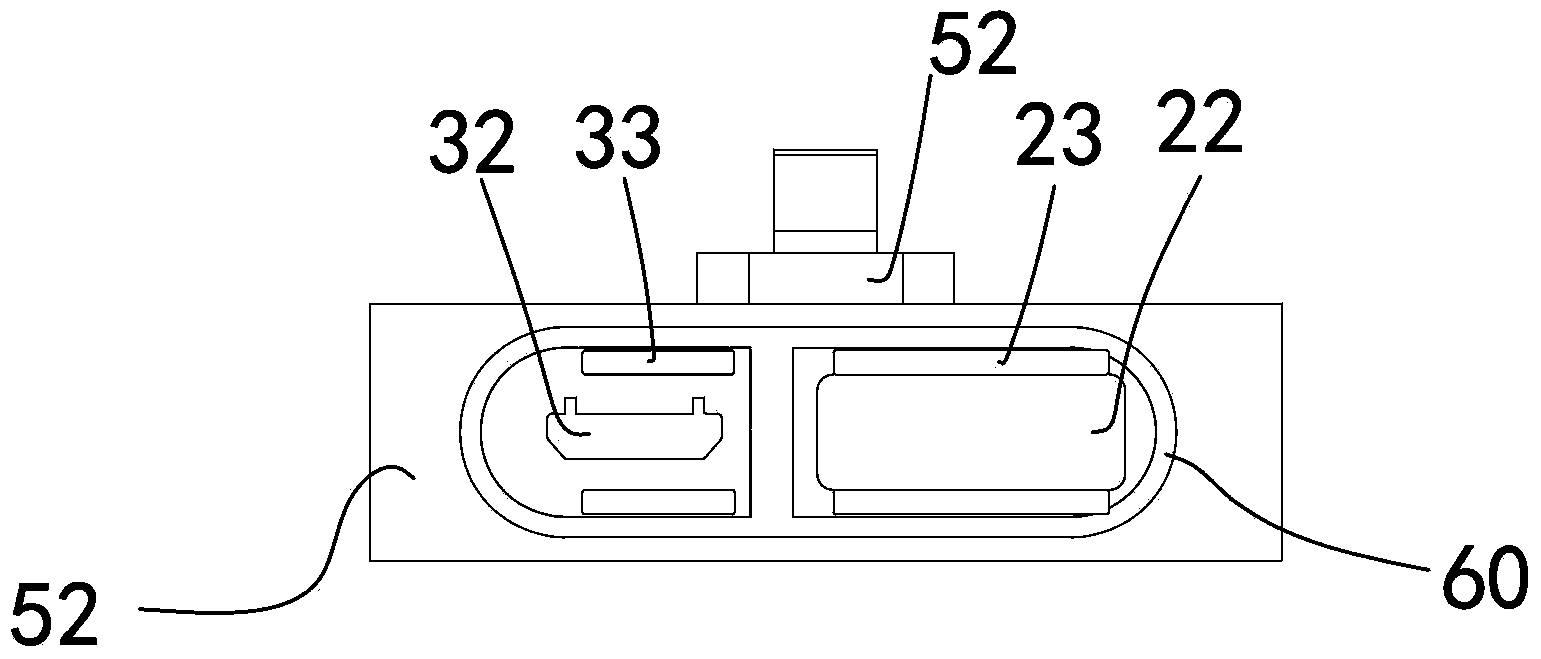

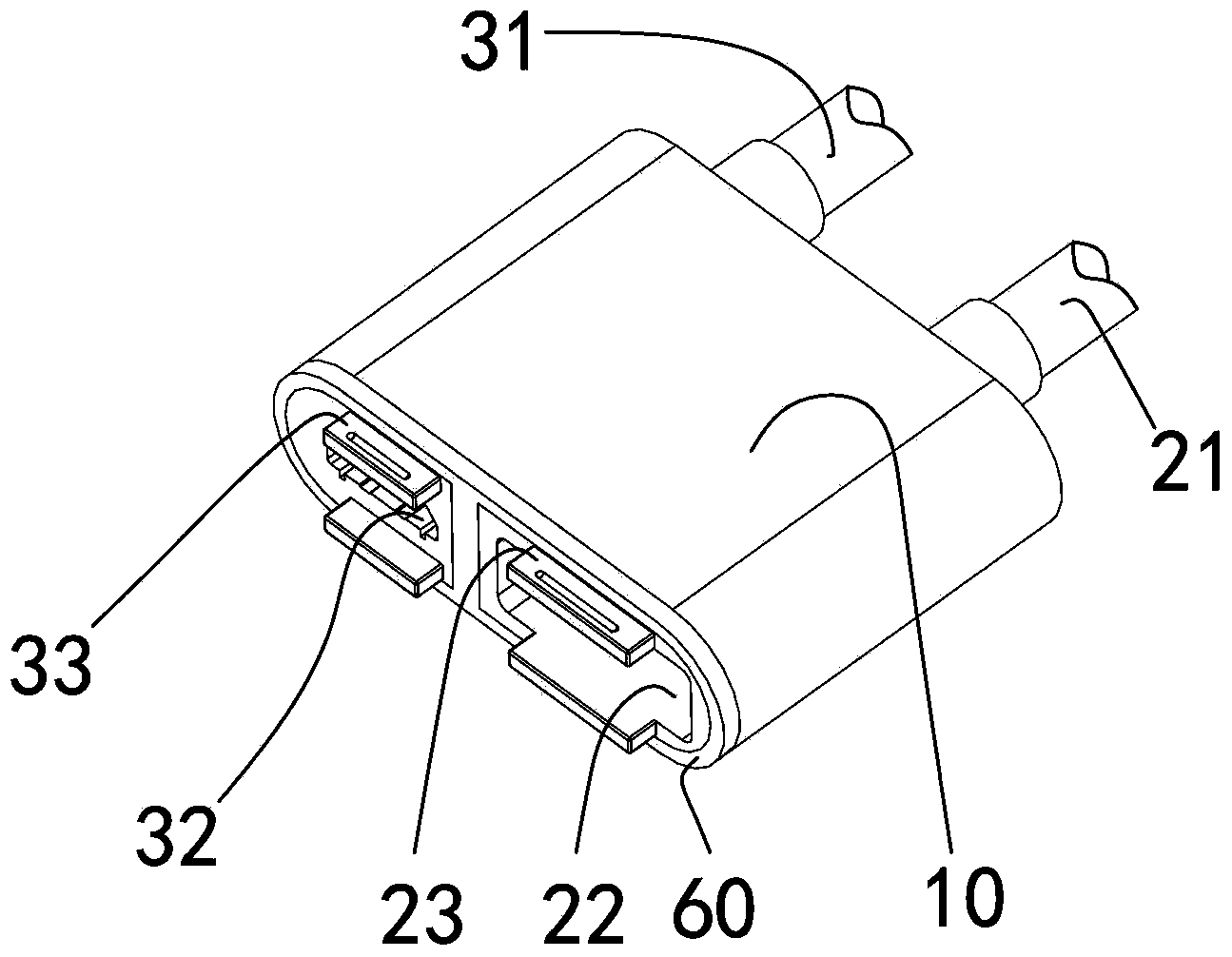

USB (universal serial bus) device

InactiveCN103455465AAvoid water short circuitRealize data connectionCouplings bases/casesElectric digital data processingData connectionElectronic communication

The invention relates to the field of electronic communication, and discloses a USB (universal serial bus) device, which comprises an OTG (on-the-go) controller, a first plug, a second plug and a switchover device; the OTG controller is used for being externally connected with two piece of externally connected equipment to perform data interchange; the first plug is used for being plugged with the first externally connected equipment; the second plug is used for being plugged with the second externally connected equipment; the OTG controller is respectively communicated with the first and second plugs; the switchover device is used for controlling the communicating state of the first and second plugs and performing data processing by the OTG controller. The USB device can realize the data connection between mobile equipment or connection between a computer and the mobile equipment or be used as a power supply line for charging the mobile equipment or a battery by changing the work state of the switchover device, so the universality and portability of the USB device is improved.

Owner:COMBO STUDIO

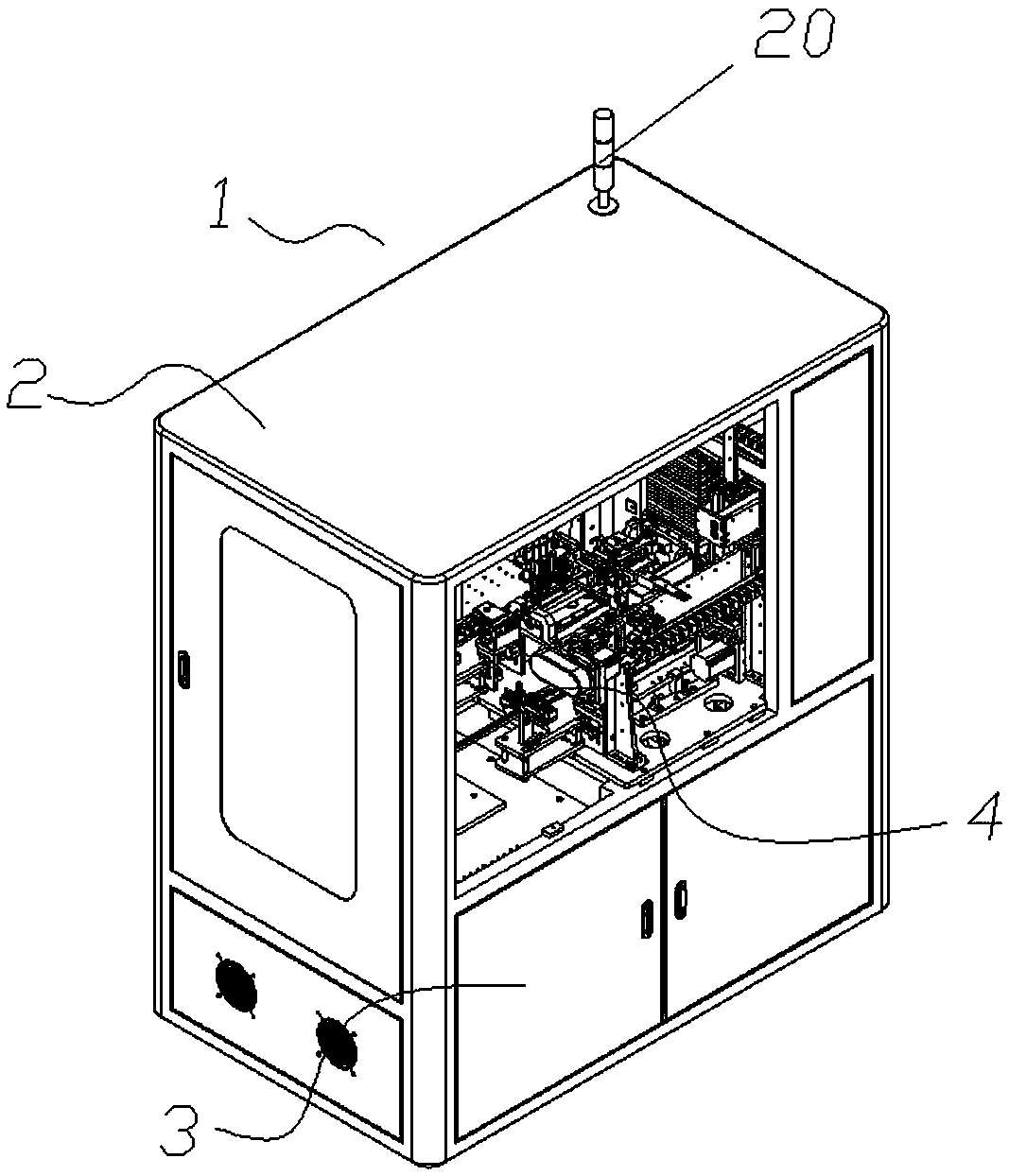

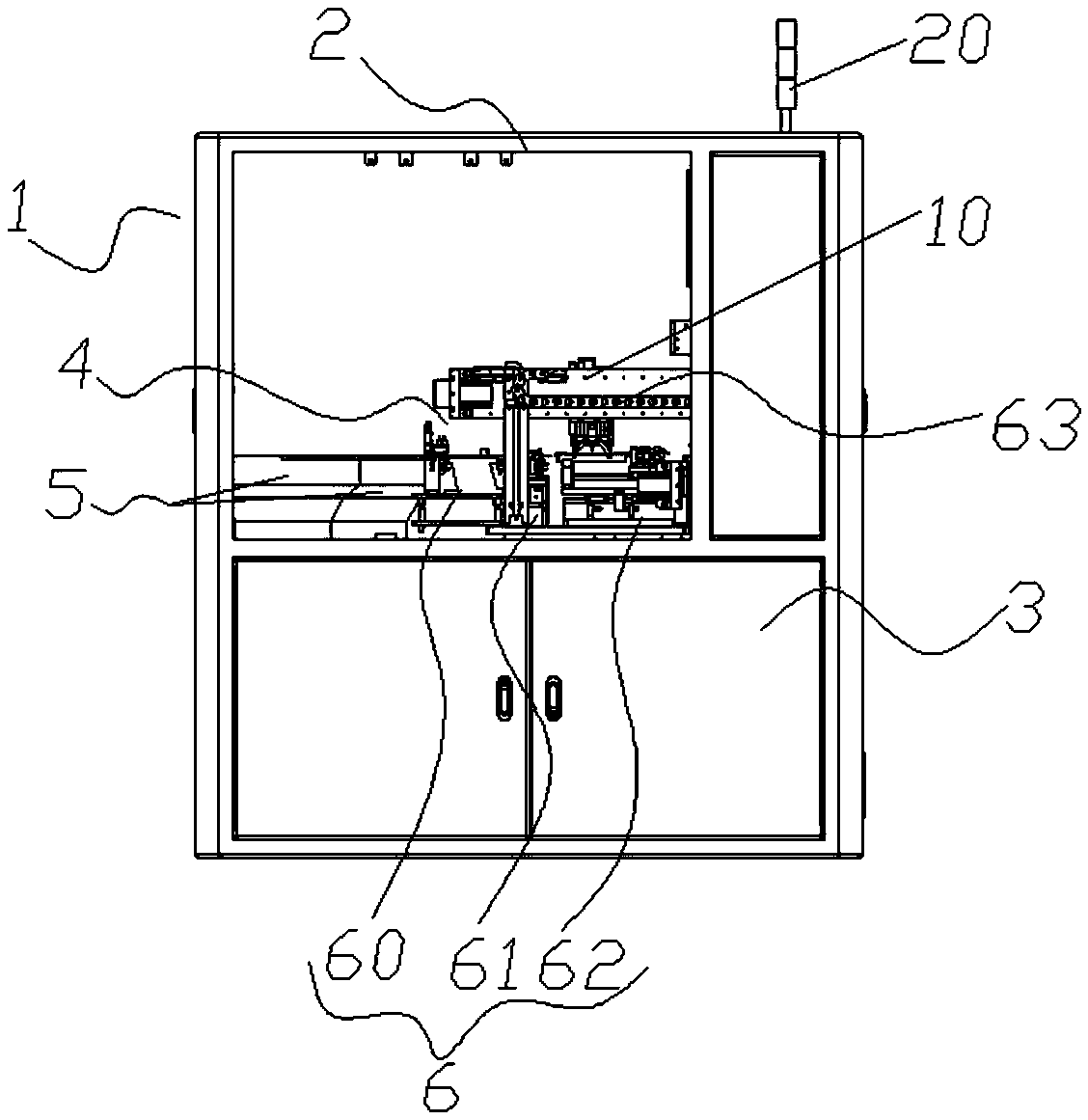

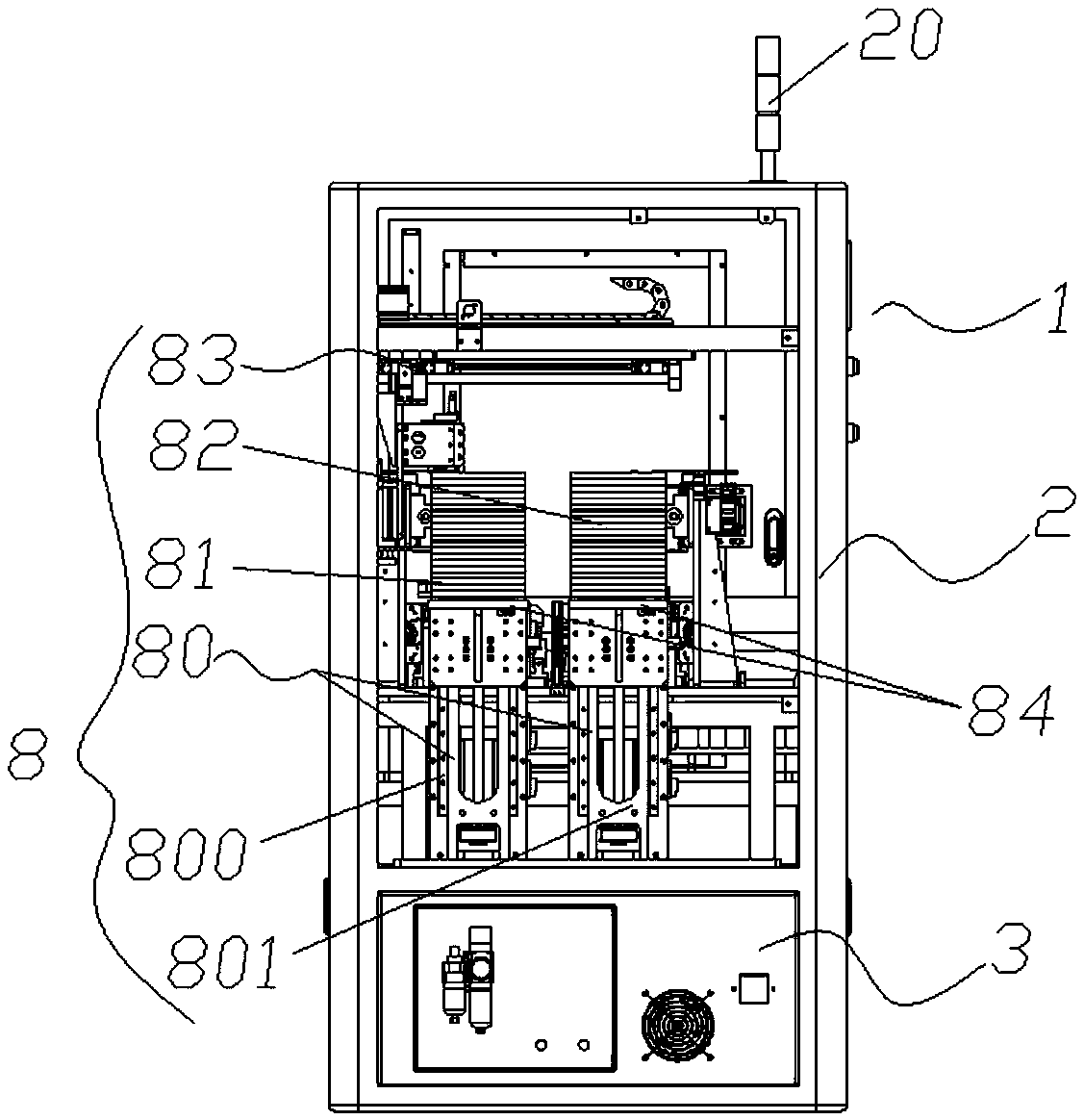

Automatic bead stringing equipment and automatic bead stringing method of stainless steel watchband parts

PendingCN109531138AImprove production and processing efficiencyImprove subsequent grinding qualityAssembly machinesAutomatic processingManipulator

The invention discloses automatic bead stringing equipment of stainless steel watchband parts. The automatic bead stringing equipment comprises a machine frame, a control cabinet and two groups of processing stations; each of the two processing stations comprises a sequencing vibration disc, a rapid positioning threading device, a placing device and a feeding and discharging device, wherein each of the sequencing vibration disc, the rapid positioning threading device, the placing device and the feeding and discharging device is provided with a detection sensor; and each rapid positioning threading device comprises a feeding mechanism, a material clamping mechanism, a silk yarn placing mechanism, a carrying mechanical arm and a fixing support, wherein the carrying mechanical arm is arrangedon the fixing support. The invention further discloses an automatic bead stringing method. According to the equipment and the method, two processing stations are arranged, the production processing efficiency is improved, full automatic processing such as automatic feeding, stringing, positioning and discharging of a processing part and a silk yarn can be realized through the sequencing vibrationdiscs, the rapid positioning threading devices, the placing devices and the feeding and discharging devices, the labor intensity and the cost are reduced, the production efficiency is improved, the stringing quality is guaranteed, and the subsequent grinding quality is improved.

Owner:盈利时表业(东莞)有限公司

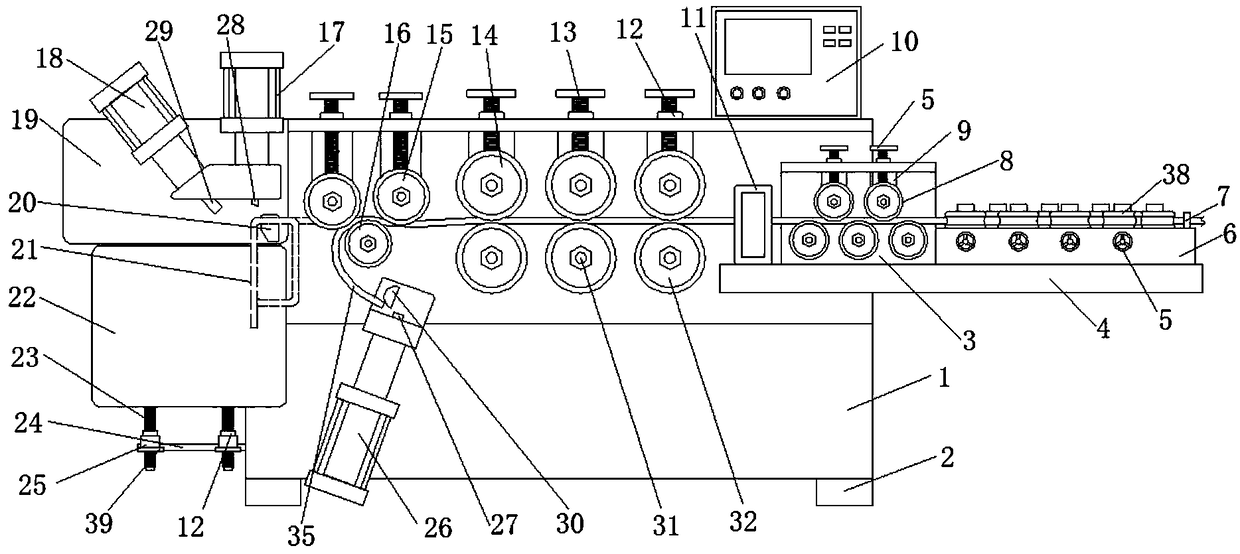

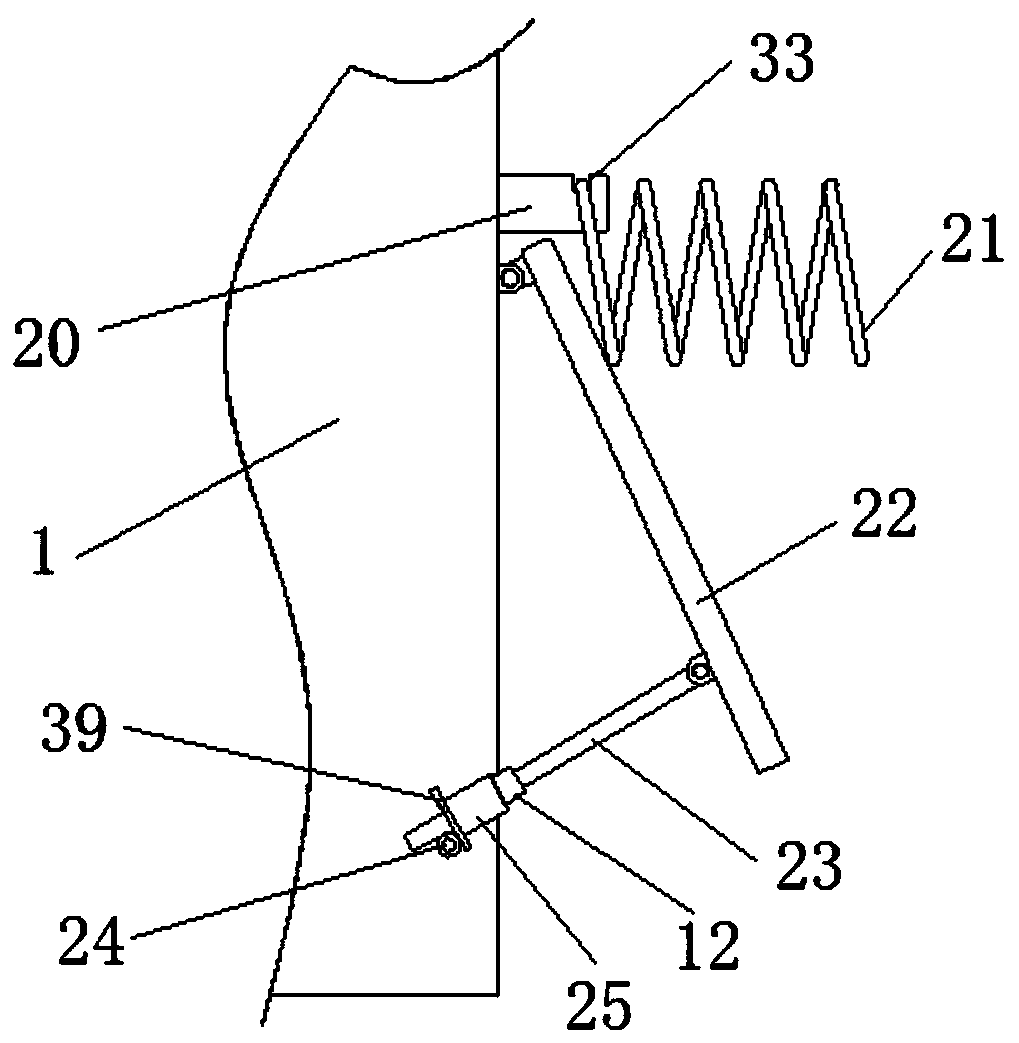

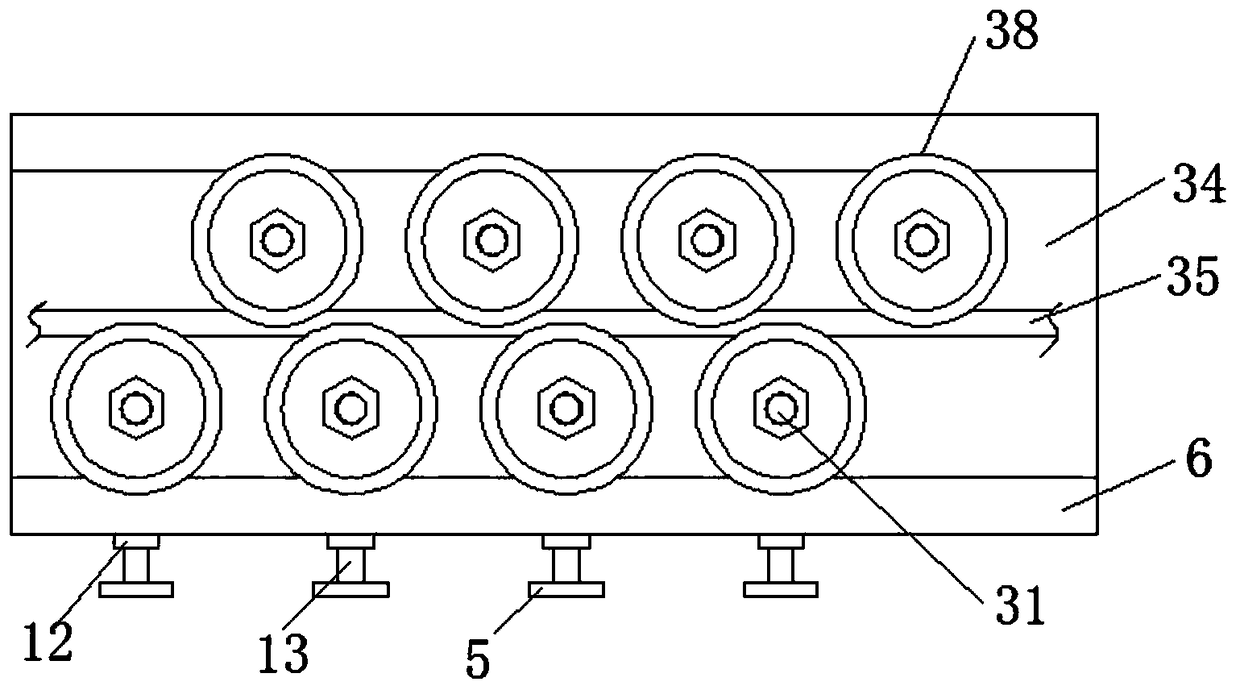

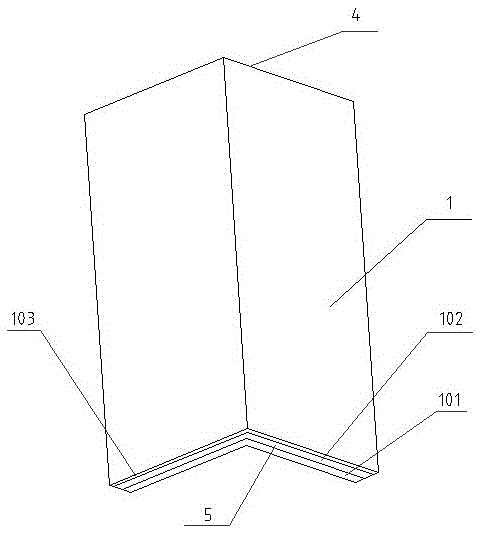

Dual-purpose prestress spiral bar winding machining device

ActiveCN109500303ATo achieve the purpose of straighteningAdjustable tightnessMetal working apparatusHydraulic cylinderWinding machine

The invention discloses a dual-purpose prestress spiral bar winding machining device. The dual-purpose prestress spiral bar winding machining device comprises a winding main machine and a control mainmachine, a fixing plate is further fixedly arranged at the end portion of the front end of the winding main machine, a second cutting-off hydraulic cylinder and a right-angle forming hydraulic cylinder are fixedly arranged on the fixing plate correspondingly, the second cutting-off hydraulic cylinder and the right-angle forming hydraulic cylinder are connected with the control main machine through signal lines, moreover, the output shaft of the second cutting-off hydraulic cylinder is vertically downwards and is fixedly provided with a second cutting-off knife, the output shaft of the right-angle forming hydraulic cylinder is obliquely downwards and is fixedly provided with an impact head, moreover, a guide block is further fixedly arranged on the fixing plate, a supporting plate which isobliquely arranged is further distributed below the fixing plate, moreover, the upper end of the supporting plate is hinged to the side wall of the winding main machine, the back face of the lower end of the supporting plate is fixedly supported on the side wall of the winding main machine, and is provided with an inclination angle adjusting mechanism. According to the dual-purpose prestress spiral bar winding machining device, the problem that a conventional pre-stress spiral bar winding machine cannot achieve the function of simultaneously machining a square spiral bar and a circular spiralbar through the same winding machine is solved.

Owner:安徽伟豪预应力设备有限公司

PCF board fixing device and installing method

InactiveCN105544996AQuick placementGuaranteed verticalityBuilding material handlingConstruction engineeringEconomic benefits

The invention relates to the technical field of building construction, in particular to a PCF board fixing device. The PCF board fixing device comprises a PCF board and further comprises a positioning hole formed in the upper installing end face of the PCF board and a positioning shaft arranged on the lower installing end face of the PCF board. The positioning hole and the positioning shaft are arranged in a matched mode. Due to the fact that the PCF board is provided with the positioning hole and the positioning shaft, the problem that the PCF board is difficult to place is effectively solved, the problem that the PCF board needs to be adjusted for the second time, and accordingly construction progress and building quality are affected is also solved, the PCF board can be fast and conveniently positioned and fixed, construction progress is substantially accelerated, lots of time and manpower are saved, there are large influences on increase of economic benefits, meanwhile, building quality is improved, and safety of a building is guaranteed.

Owner:CHENGDU SIXTH CONSTR ENG

Material collection and discharging mechanism

ActiveCN104310087ARealize continuous feedingDatum edge flushWebs handlingEngineeringMechanical engineering

The invention discloses a material collection and discharging mechanism, which comprises a machine frame, wherein a first movement frame is arranged above the machine frame, and is provided with two power rolls, the two power rolls are driven by a first power device, a material collection and discharging gap is formed between the two power rolls, a correction mechanism is arranged between the first movement frame and the machine frame, a tension mechanism is arranged under the machine frame, and comprises at least one fixing roll and a traction roll, the traction roll is driven by a second driving device, a second movement frame is arranged on the machine frame, is driven by a Y-axis movement mechanism, and is provided with at least one movement roll, the movement roll and the fixing roll are vertically staggered, and the second movement frame is also provided with a press roll. The material collection and discharging mechanism has the advantages that the flexible material can be discharged from a material coil and can be collected onto the material coil; the structure is simple, and the cost is low.

Owner:GOERTEK INC

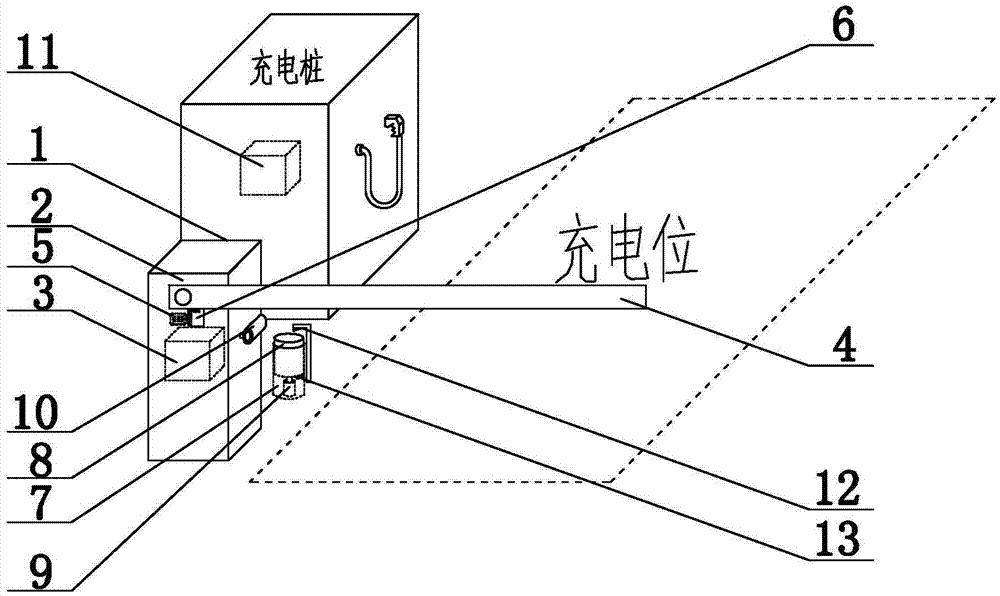

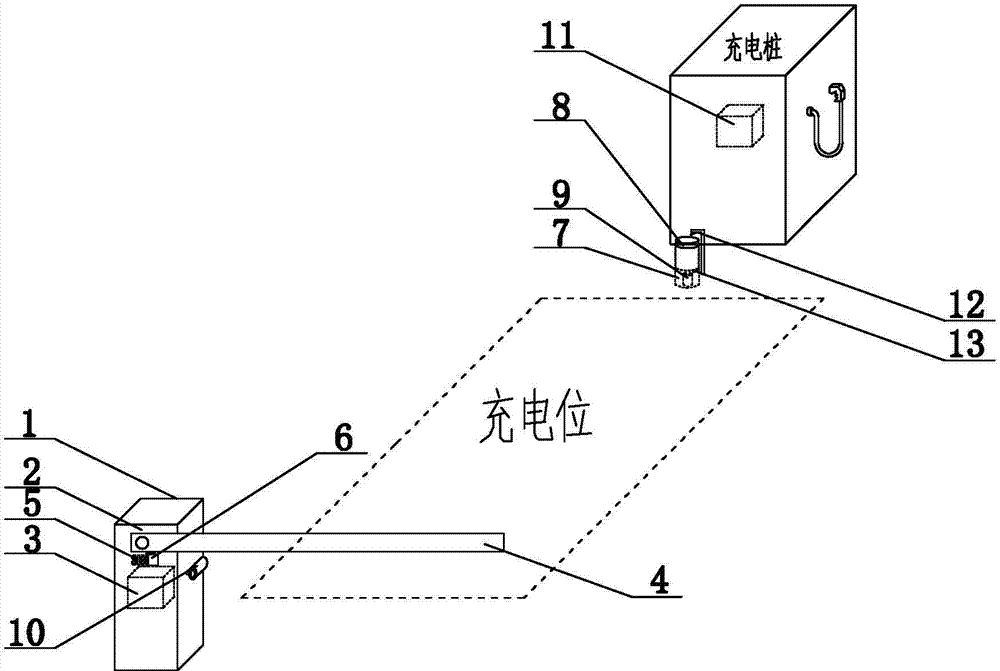

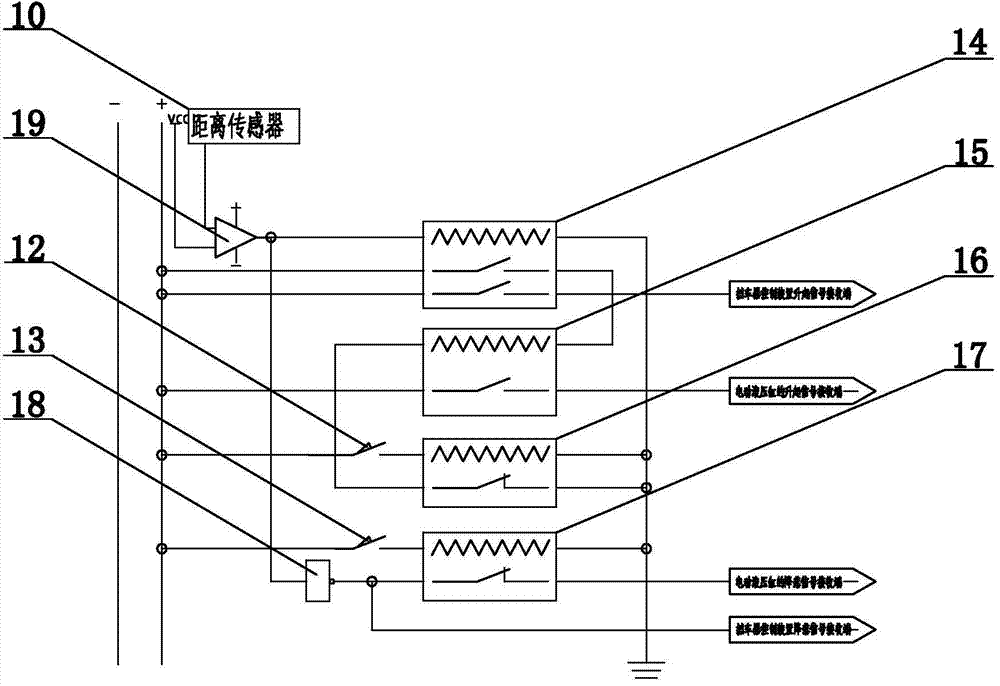

Collision preventing system for smart vehicle entering and leaving charging area

ActiveCN104851319ASlow down the riseRise enoughAnti-collision systemsHydraulic cylinderElectric machinery

The invention provides a collision preventing system for a smart vehicle entering and leaving a charging area and belongs to the field of collision preventing systems for the smart vehicle entering and leaving the charging area. The system includes a vehicle blocking device provided with a box body, a control device and a blocking bar. A motor is arranged in the box body. The motor cooperates with the blocking bar through a gear box. A side of the vehicle blocking device is provided with a hole. A protection post is arranged in the hole. The protection post is connected to the bottom of the hole through an electric hydraulic cylinder. A detection device is arranged on the box body. The output terminal of the detection device is connected to the controller. The output terminal of the controller is connected to a rise control end and a descent control end of the electric hydraulic cylinder and a signal receiving end of the control device of the vehicle blocking device. Therefore, the electric vehicle is prevented from knocking down a charging pole effectively.

Owner:国网山东桓台县供电公司 +1

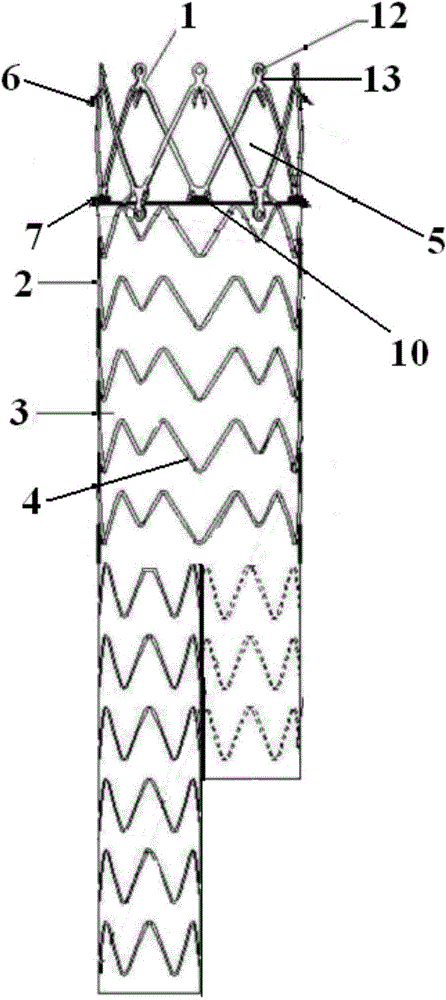

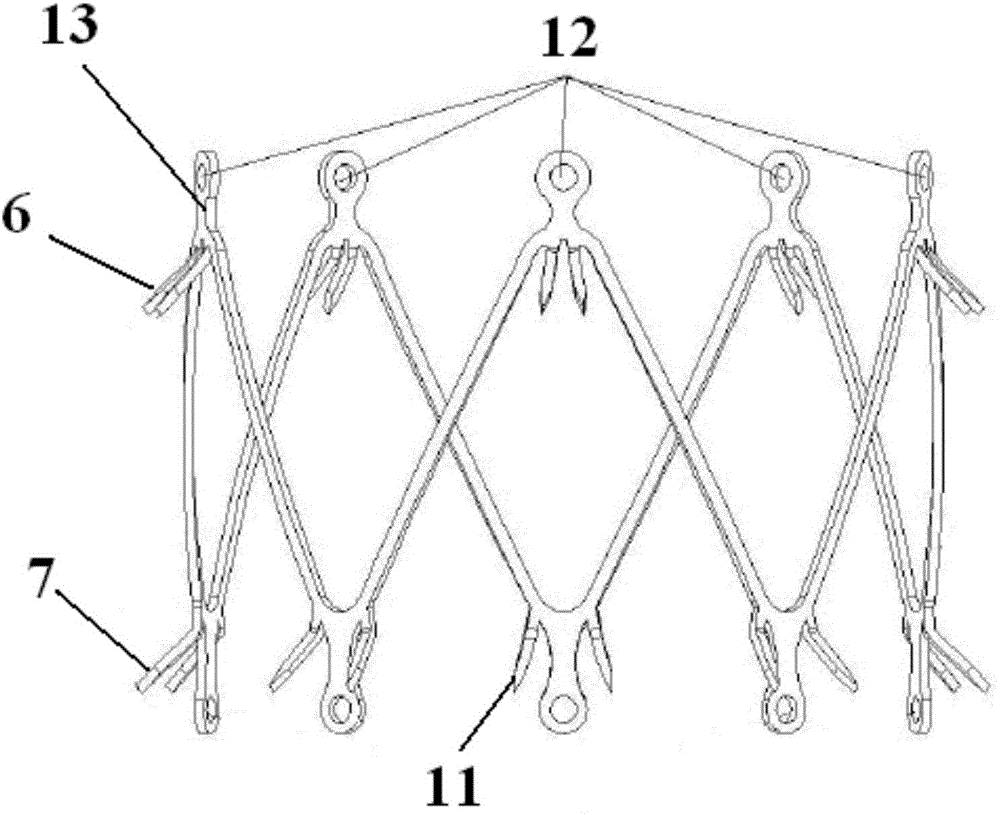

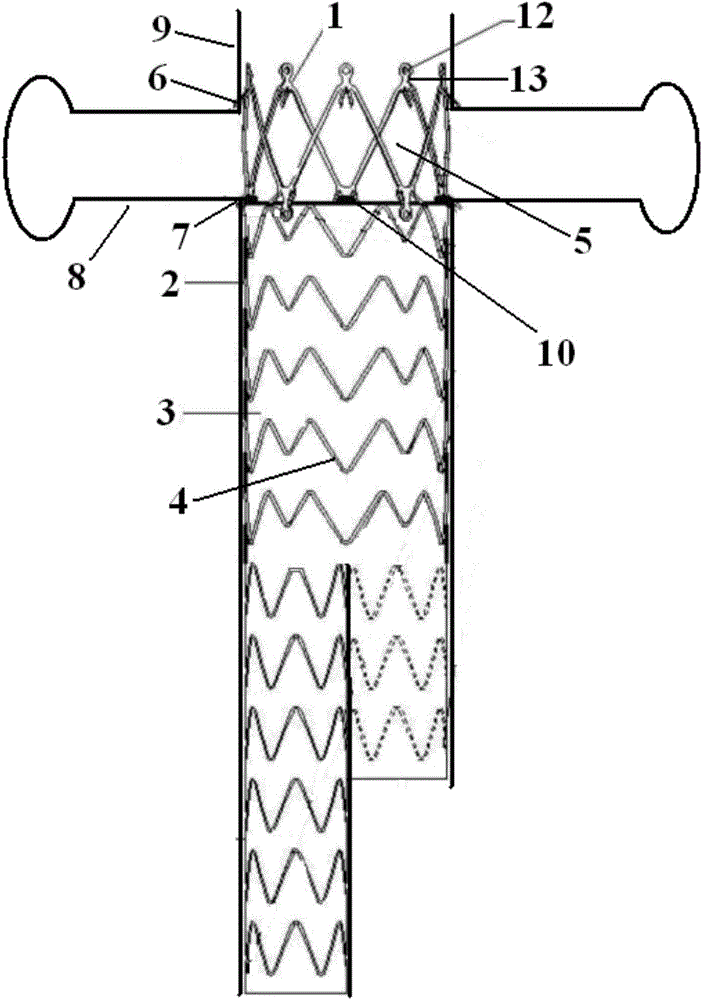

Aorta abdominalis covered stent

The invention discloses an aorta abdominalis covered stent. The aorta abdominalis covered stent comprises a covered stent and a bare stent, wherein the covered stent is of a cylindrical structure, comprises a covered fluid passageway and is used for being matched with the inner wall of an aorta abdominalis and suitable for expanding the aorta abdominalis. The bare stent is in a wavy shape and connected with the top end of the covered stent, and comprises crest structures away from the covered stent and trough structures close to the covered stent, and a fluid passageway is formed between each crest and the corresponding trough. The aorta abdominalis covered stent further comprises upper anti-disengagement fixing structures arranged on the crest structures and lower anti-disengagement fixing structures arranged on the trough structures, wherein the upper anti-disengagement fixing structures are used for being fixed to the portions, above a renal artery, of the aorta abdominalis, the lower anti-disengagement fixing structures are used for being fixed to the portions, below the renal artery, of the aorta abdominalis, and therefore the whole aorta abdominalis covered stent can be fixed into the aorta abdominalis.

Owner:BEIJING PERCUTEK THERAPEUTICS CO LTD

Underwater gravel foundation bed laying device and method

PendingCN110004933APrecise thickness controlAdjustable lengthFoundation engineeringMarine site engineeringSternConveyor belt

The invention provides an underwater gravel foundation bed laying device and method. The underwater gravel foundation bed laying device comprises a hull, wherein a transportation trolley is arranged on the hull, the transportation trolley is driven by a driving device to slide in the length direction of the hull, a sliding tube is arranged on the transportation trolley, a material conveying port is formed in the top end of the sliding tube, and the bottom end of the sliding tube is close to the bottom of the water. The underwater gravel foundation bed laying device is further provided with atleast one conveyor belt for feeding the transportation trolley; buoyancy tank sliding rails are arranged at the positions of a ship bow and a stern of the hull, the buoyancy tank sliding rails are slidably connected with the hull, and positioning columns which can be lifted and lowered are arranged on the two buoyancy tank sliding rails and the hull; and the buoyancy tank sliding rails are of a folded structure. By adopting a scheme in which two foldable buoyancy tank sliding rails and the hull are alternately positioned through the positioning columns and relatively slid, after the riprap construction in an area is completed, the reciprocating movement of the positioning columns and the hull can achieve precise guided continuous movement, the condition that the hull is positioned every time the hull is moved is avoided, and high-precision continuous Z-shaped riprap paving construction is achieved through the sliding tube.

Owner:CCCC SECOND HARBOR ENG

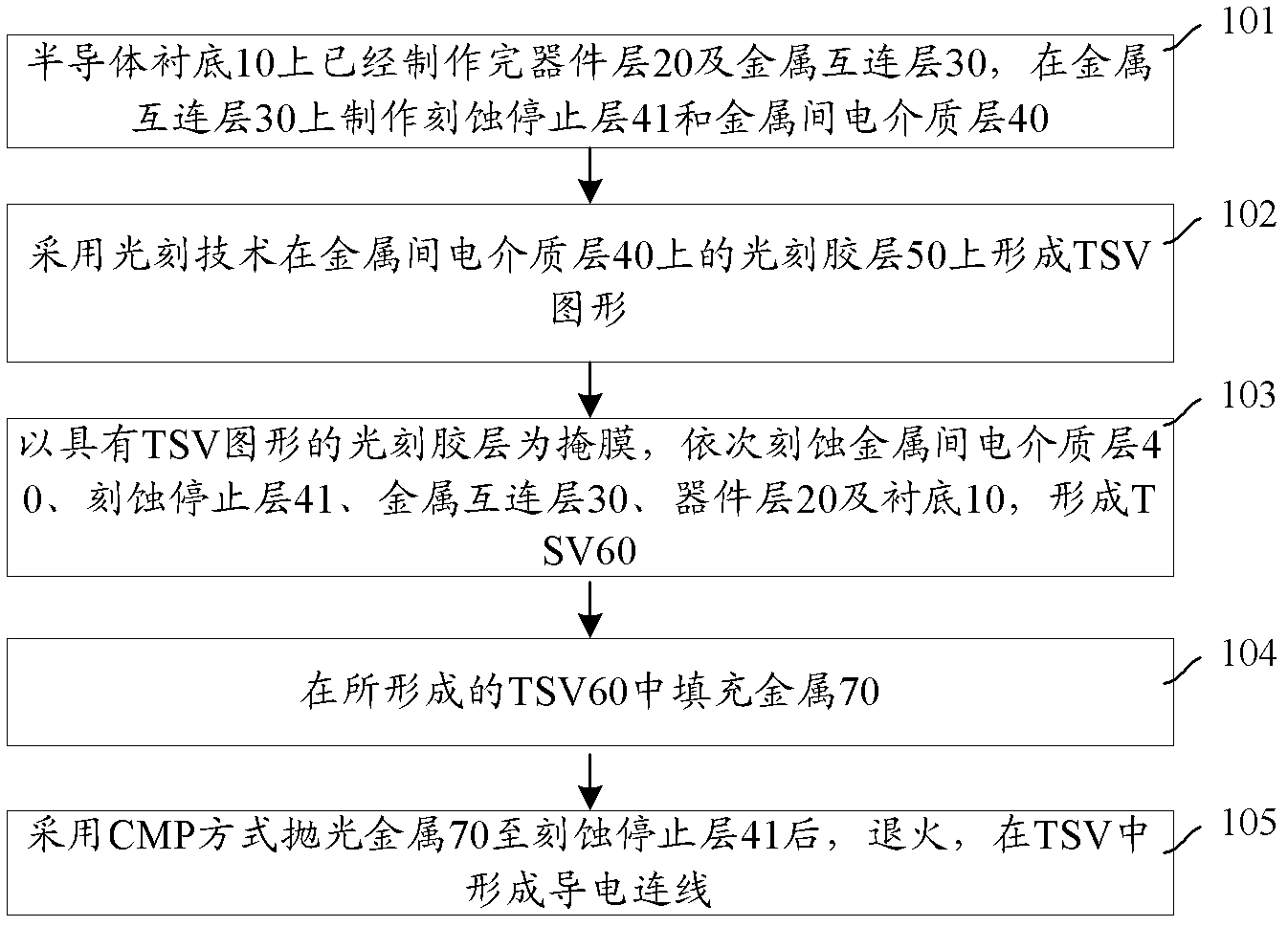

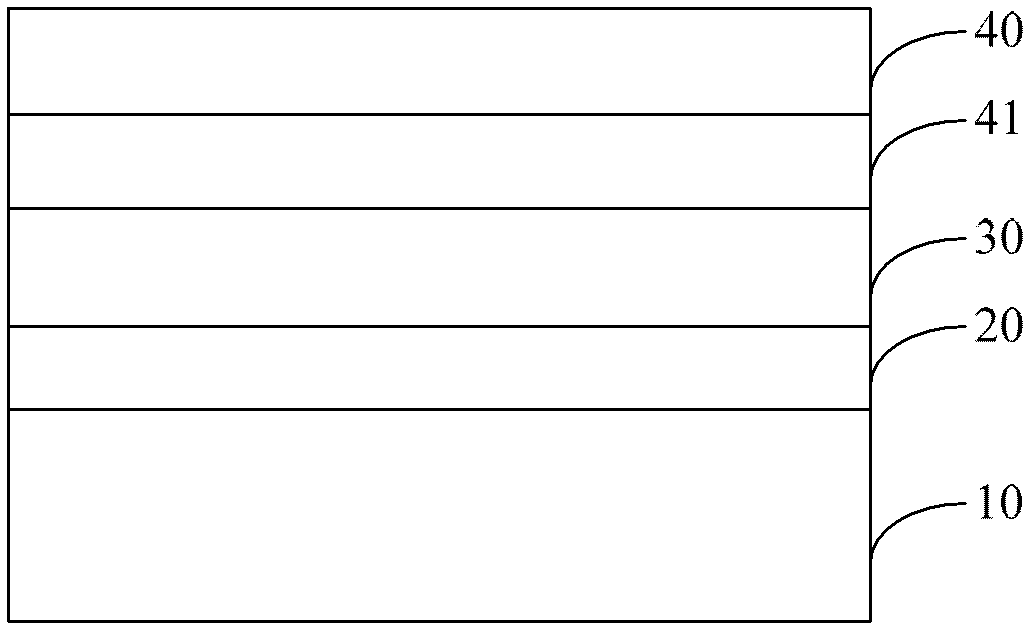

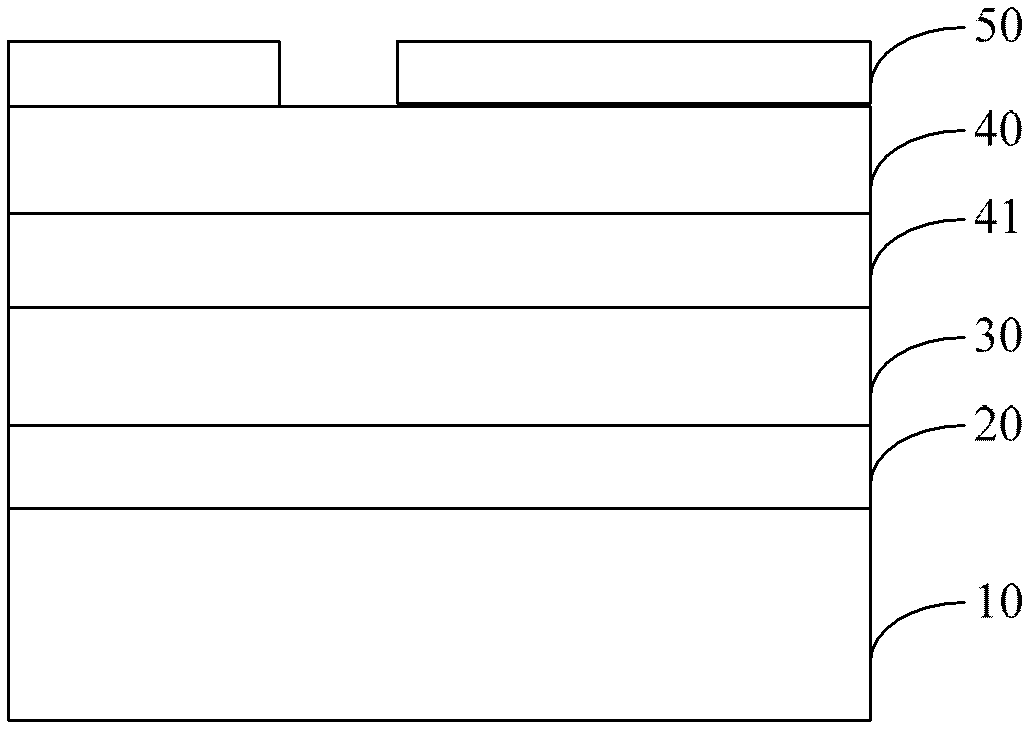

Through silicon via manufacturing method

ActiveCN103151298AGuaranteed flushImprove yieldSemiconductor/solid-state device manufacturingSemiconductorMaterials science

The invention discloses a through silicon via (TSV, Through Silicon Via) manufacturing method. The method provides a new TSV corrugated metal pipe (CMP) technology. After convex metal is formed according to the prior art to manufacturing the TSV, a polishing step is added, the convex metal in the TSV is polished into a flushed surface and an etch stop layer is removed, so that conductive wires manufactured by the TSV are flushed with the surface, and the semiconductor device yield is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com