3D interval woven fabric

A 3D technology for woven fabrics, applied in the field of woven fabrics, can solve problems such as inability to beat weft normally, misalignment in the horizontal direction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

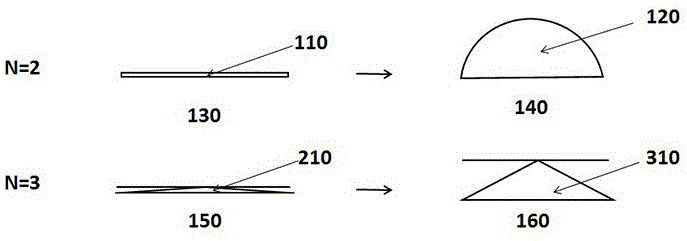

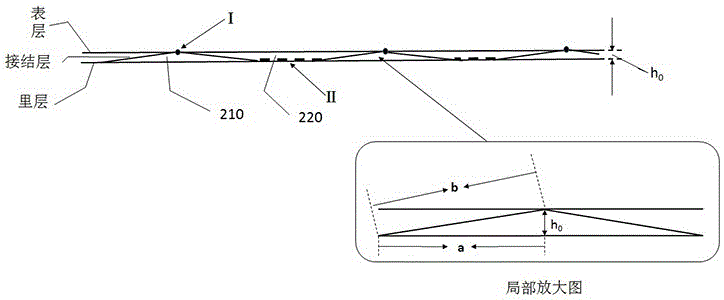

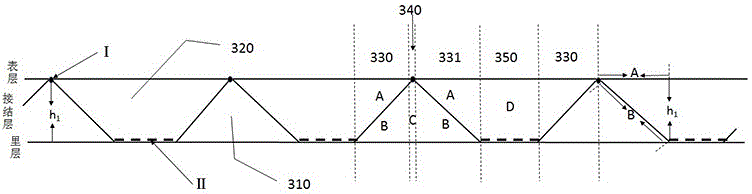

[0032] In order to illustrate the present invention in detail, the specific application of the scheme of the present invention on down-proof fabrics for down jackets will be described below in conjunction with the accompanying drawings and examples. It should be noted that the specific embodiments described here are only used to explain the present invention, including but not limited to this example.

[0033] The characteristic of the 3D structure woven fabric is that it is a one-time weaving of a self-contained hollow structure without additional sewing. These hollow structures can be directly filled with cashmere, saving the cumbersome process of sewing threads connecting two layers of fabrics and solving the problem of sewing The needle hole is easy to run down. At the same time, the three-dimensional hollow fabric can still maintain the flatness of the inner and outer fabrics after the hollow is filled with down, which solves the long-standing problem that the appearance o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com