Multi-stage under-pressure sealing pressure measuring device and method for ultra-long spongy coal seam drilling

A pressure measuring device, a soft technology, used in safety devices, sealing/isolation, measurement, etc., can solve problems such as collapse, bending, measurement, and inability to conduct coal seam gas pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0037] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

[0038] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

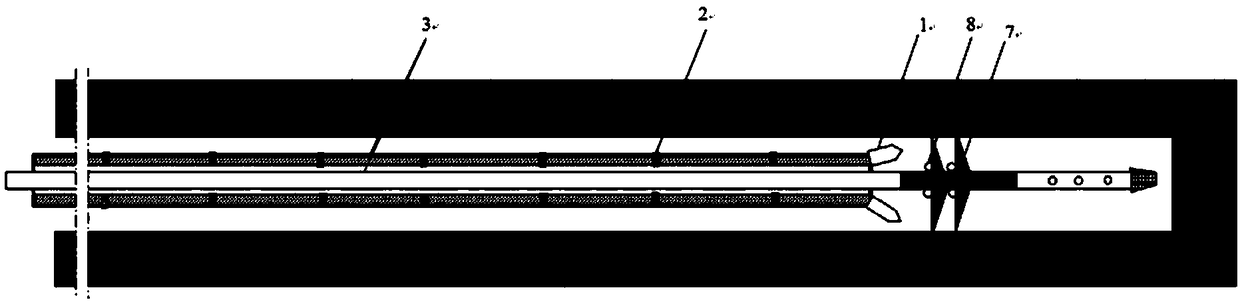

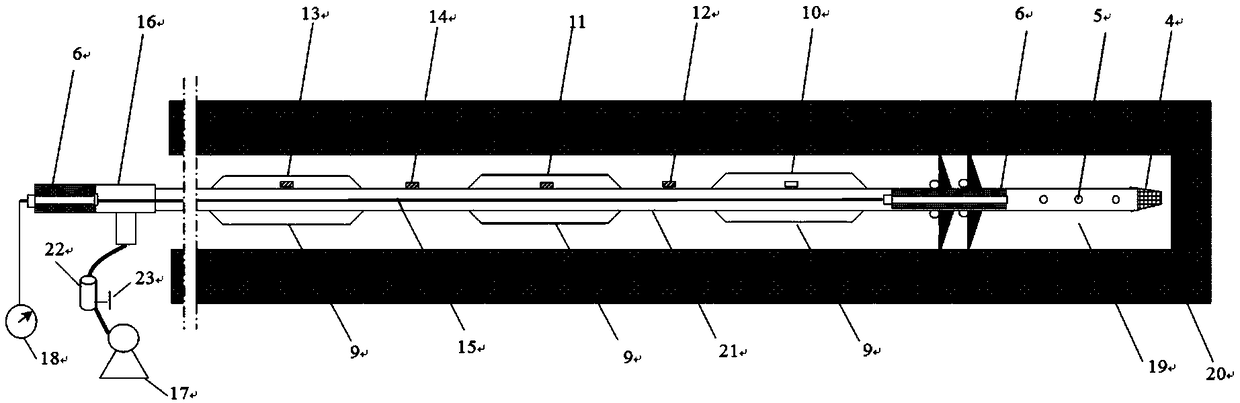

[0039] Such as Figure 1-2 As shown, a kind of ultra-long soft coal seam drilling multi-stage belt pressure sealing pressure measuring device of the present invention, it comprises pressure measuring device 3 main bodies;

[0040] The pressure measuring device 3 includes a galvanized pipe 21, a gas pipeline 15, a grouting pump 17 and a pressure gauge 18; the top of the galvanized pipe 21 is provided with an air intake head 4; the body of the galvanized pipe 21 is provided with a plurality of expansion capsules at intervals 9. An opening 10 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com