Invisible self-adjustable general probe for automobile

A self-adjusting, automotive technology, applied to vehicle components, vehicle safety arrangements, bumpers, etc., can solve problems such as reversing collision accidents, difficulty in grasping the reversing distance, and increased difficulty in operation, so as to ensure versatility and smooth outer surface Neat and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings.

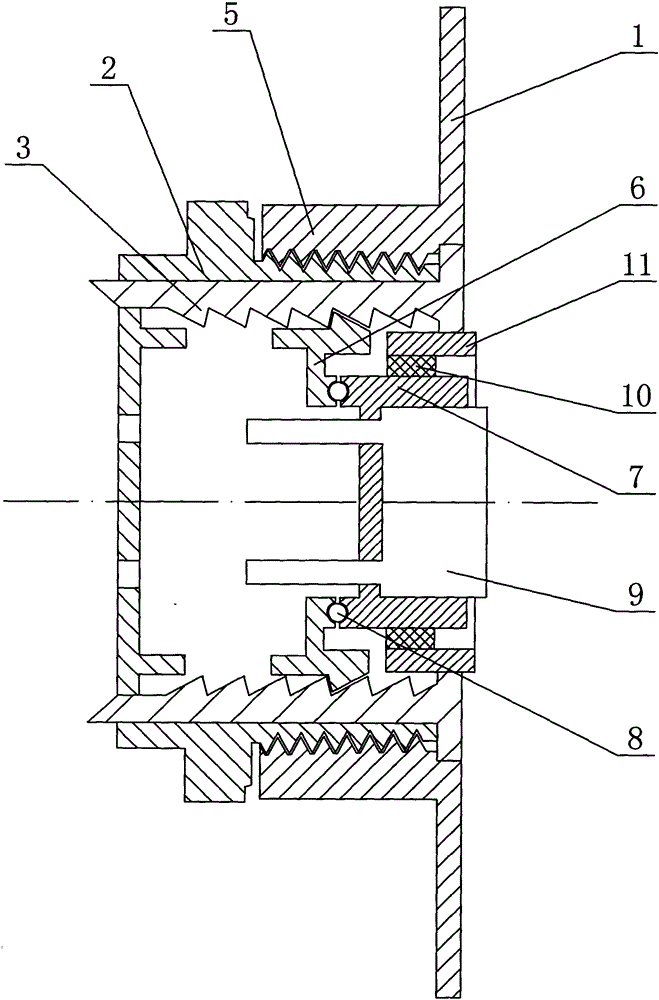

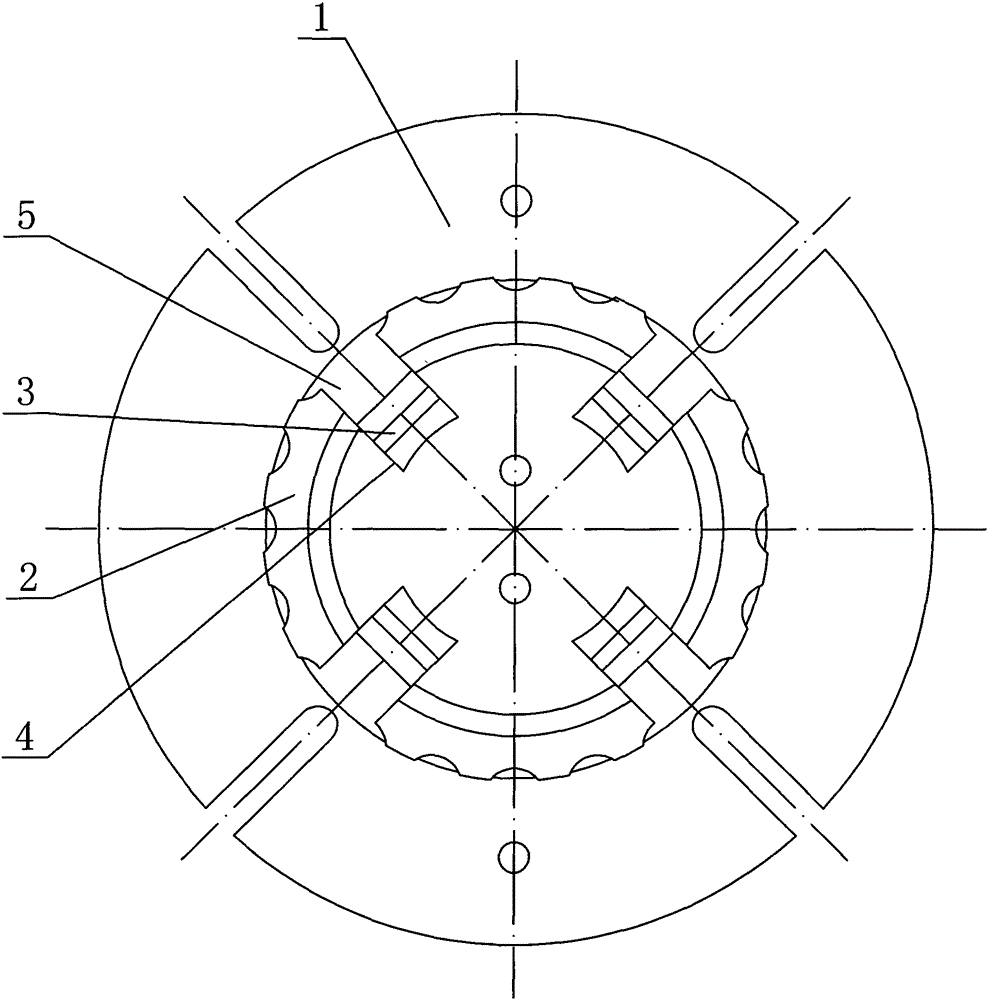

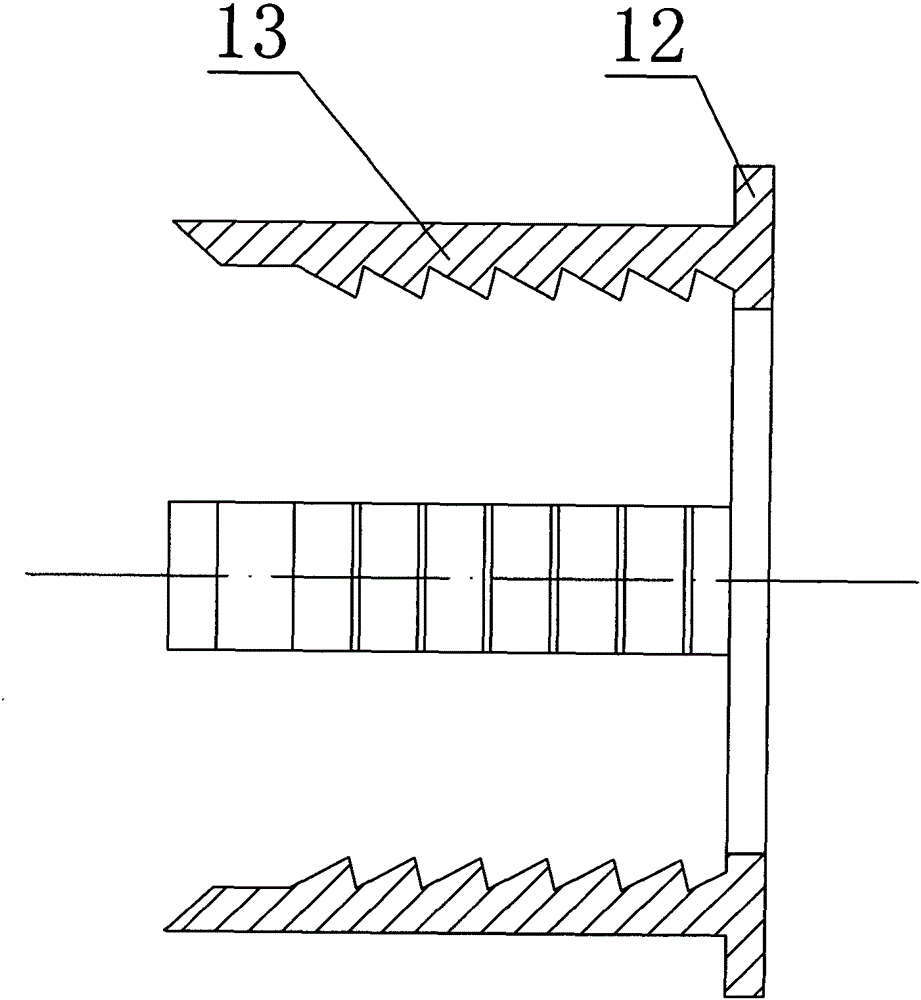

[0023] Such as figure 1 , figure 2 , image 3 As shown, a kind of stealth self-adjusting type automobile universal probe comprises a bumper 1, a housing 2, a coil 3, a telescopic frame 6, a probe 9, a probe bracket 7, a protective case 11 and a connecting ring 10, and the bumper 1 Mounting holes for probes 9 are arranged on the bumper 1. A connection block 5 is fixed on the inner side of the bumper 1. The casing 2 is screwed to the connection block 5. The casing 2 is a cylindrical casing 2, and the cylindrical casing 2 Threads are provided on the outer circumference of the cylinder wall, and the shell 2 is connected to the connecting block 5 through threads. Four grooves 4 are arranged on the cylinder wall axially, and the four grooves 4 are evenly distributed along the circumference of the cylinder wall of the shell 2. A coil 3 is arranged between the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com