Paperboard laminating slitting device

A technology for laminating and cardboard, applied in lamination devices, layered products, lamination auxiliary operations, etc., can solve the problems of uneven tearing, low efficiency and high labor cost, and achieve the effect of flushing lamination incisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

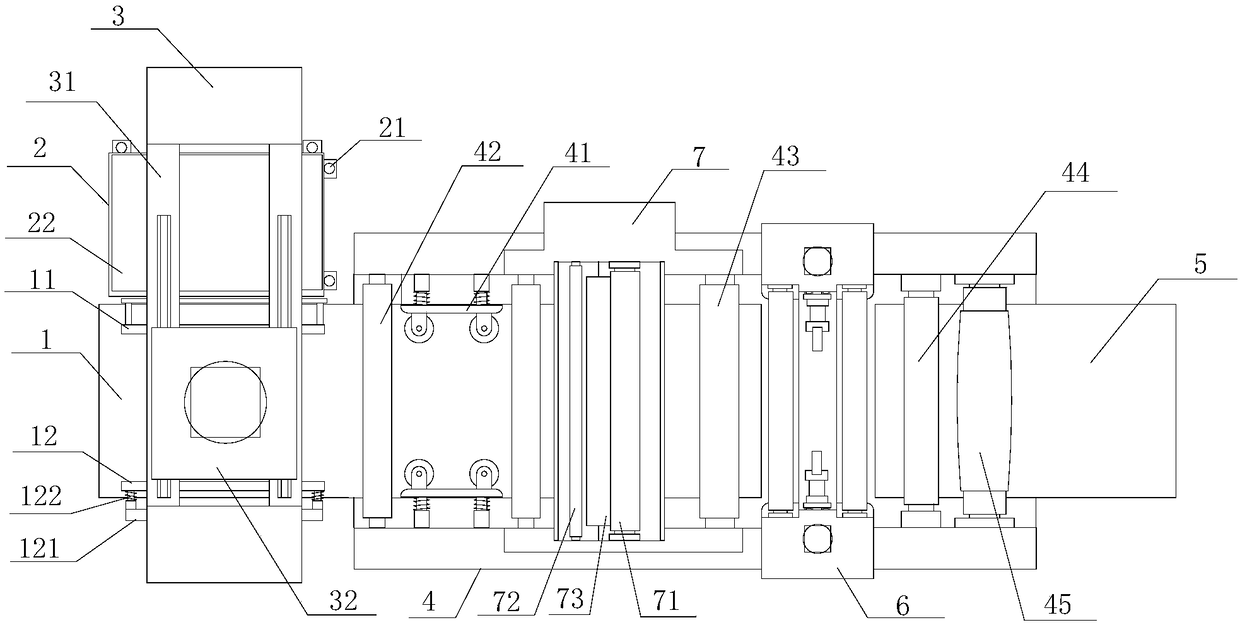

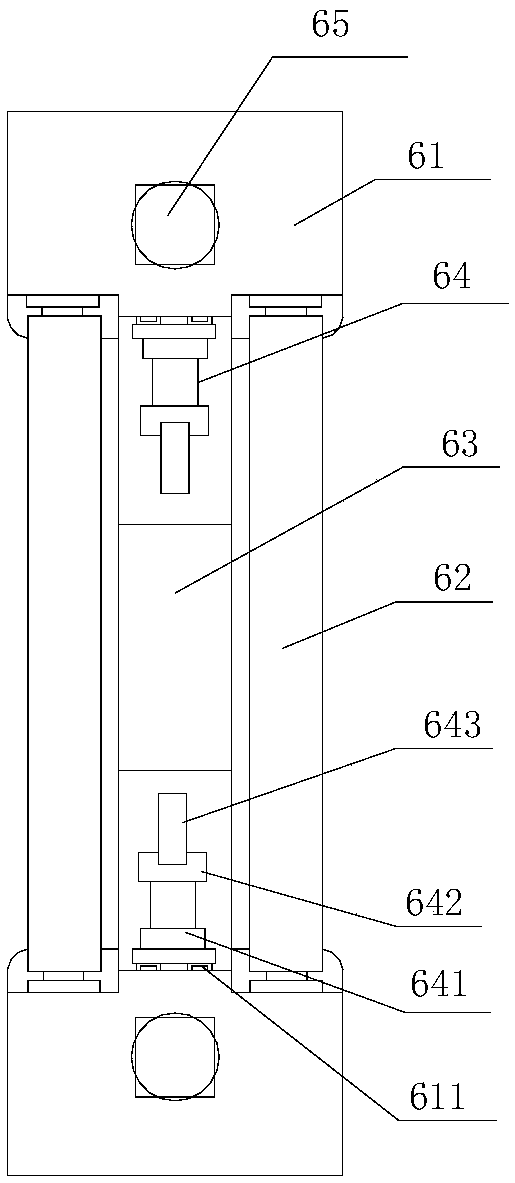

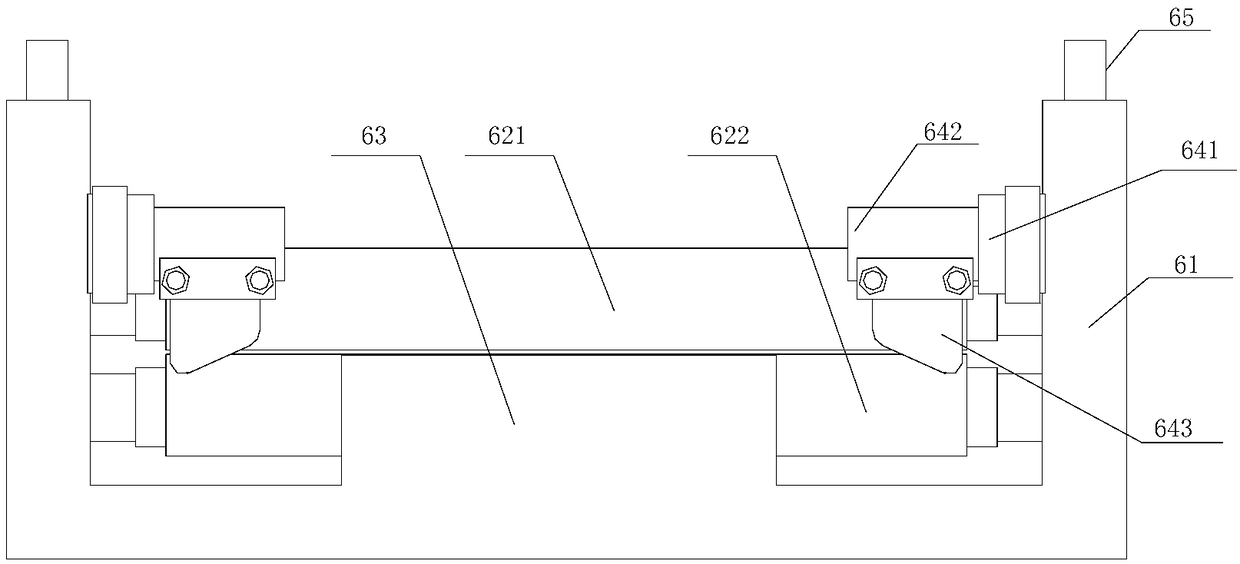

[0017] refer to Figure 1 to Figure 4 , a cardboard coating cutting device of the present invention, comprising a first conveyor belt mechanism 1, a material storage mechanism 2, a mechanical claw conveying mechanism 3, a frame 4, a second conveyor belt mechanism 5, a cutting mechanism 6 and a film coating mechanism 7, The mechanical claw conveying mechanism 3 spans the first conveyor belt mechanism 1 and the material storage mechanism 2, and the mechanical claw conveying mechanism 3 is provided with a feeding sucker mechanism, and the two ends of the frame 4 are respectively provided with a first conveyor belt mechanism 1 and the second conveyor belt mechanism 5, a coating mechanism 7 is arranged between the first conveyor belt mechanism 1 and the second conveyor belt mechanism 5, and the introduction roller assembly 42, the coating mechanism 7, and the lead-out roller assembly 42 are sequentially arranged on the frame 4 Roller assembly 43, slitting mechanism 6, auxiliary pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com