A slitting and conveying device for a laminating machine

A technology of conveying device and laminating machine, which is applied in the directions of transportation and packaging, layered products, thin material processing, etc. It can solve the problems of low production efficiency, uneven tearing, adhesion, etc., and achieve thorough cooling and flat film incision. neat, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

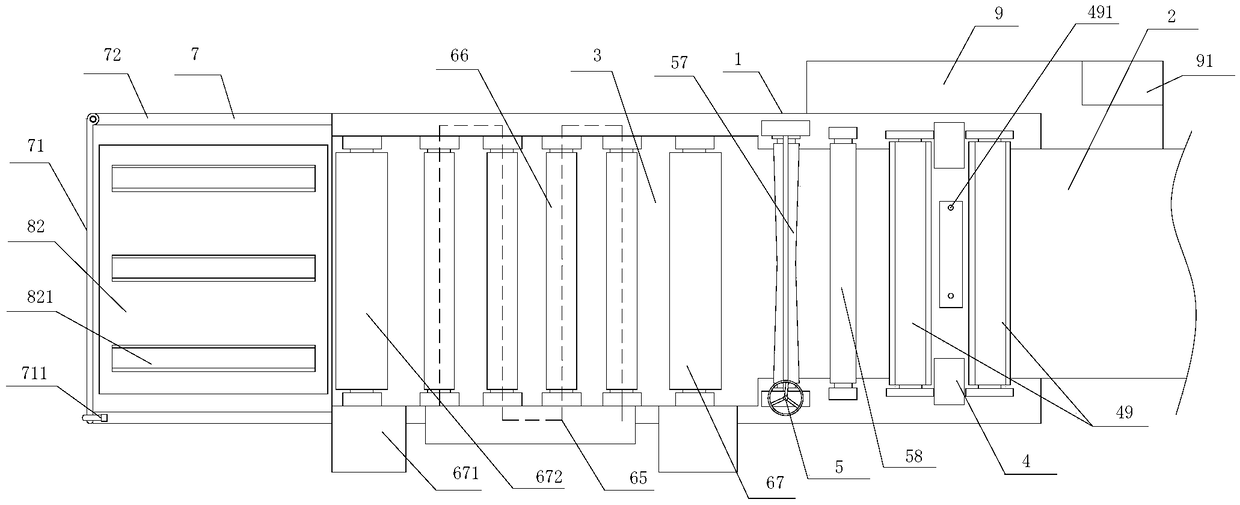

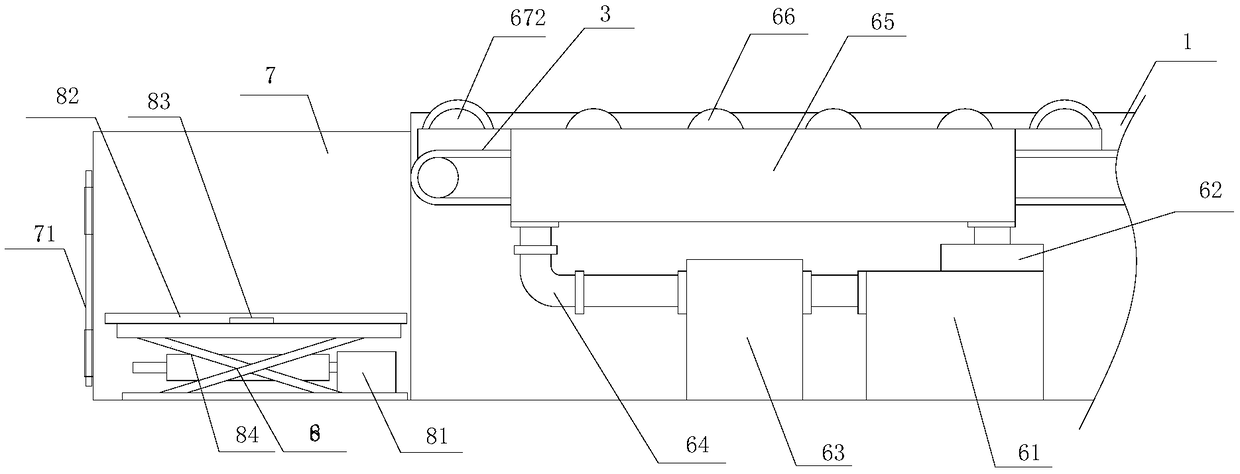

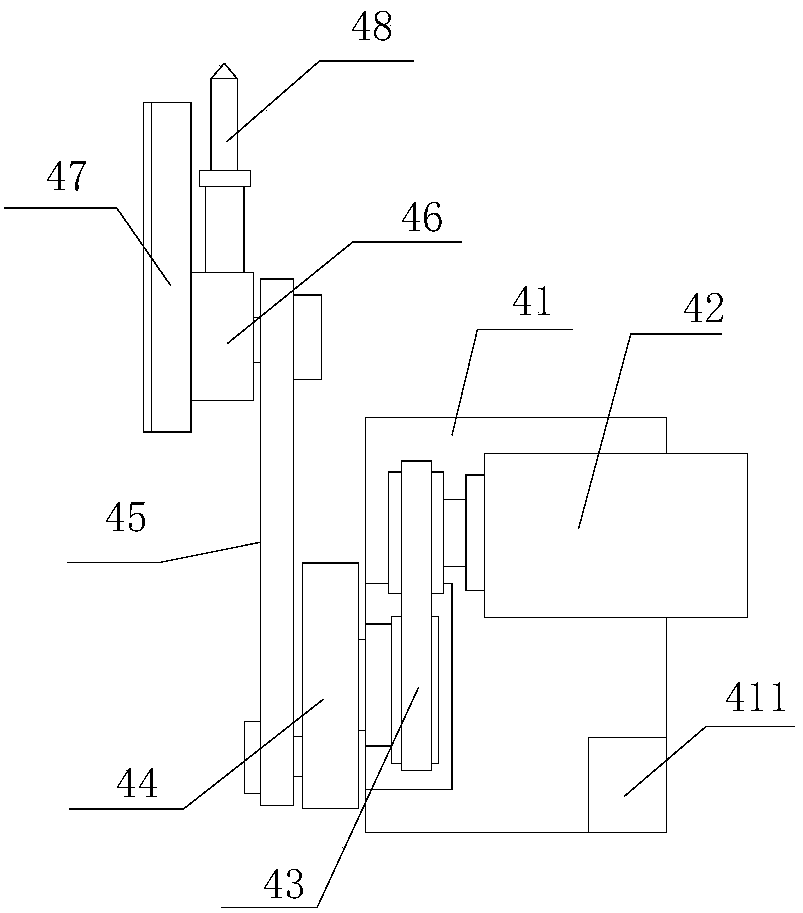

[0015] refer to Figure 1 to Figure 4A slitting and conveying device for a laminating machine in the present invention includes a frame 1, a first conveyor belt mechanism 2, a second conveyor belt mechanism 3, a slitting device 4, a slitting roller assembly 5, a cooling circulation device 6, a feeding box 7, Lifting platform device 8 and servo control box 9, described frame 1 is provided with first conveyor belt mechanism 2, second conveyor belt mechanism 3, is provided with cutting device between described first conveyor belt mechanism 2, second conveyor belt mechanism 3 4. The first conveying roller assembly 49 is provided on both sides of the cutting device 4, and several cooling roller assemblies 66 and two second conveying roller assemblies 67 are arranged on the cooling circulation device 6. The cooling roller assembly 66 is evenly distributed between the two second conveying roller assemblies 67, the slitting roller assembly 5 is provided with a slitting pressing roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com